Patents

Literature

654results about How to "Guarantee the construction progress" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

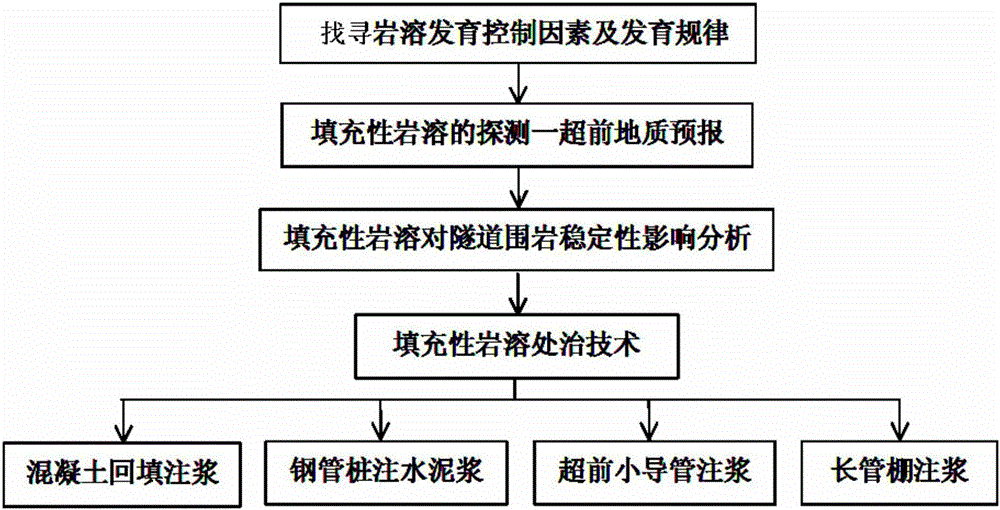

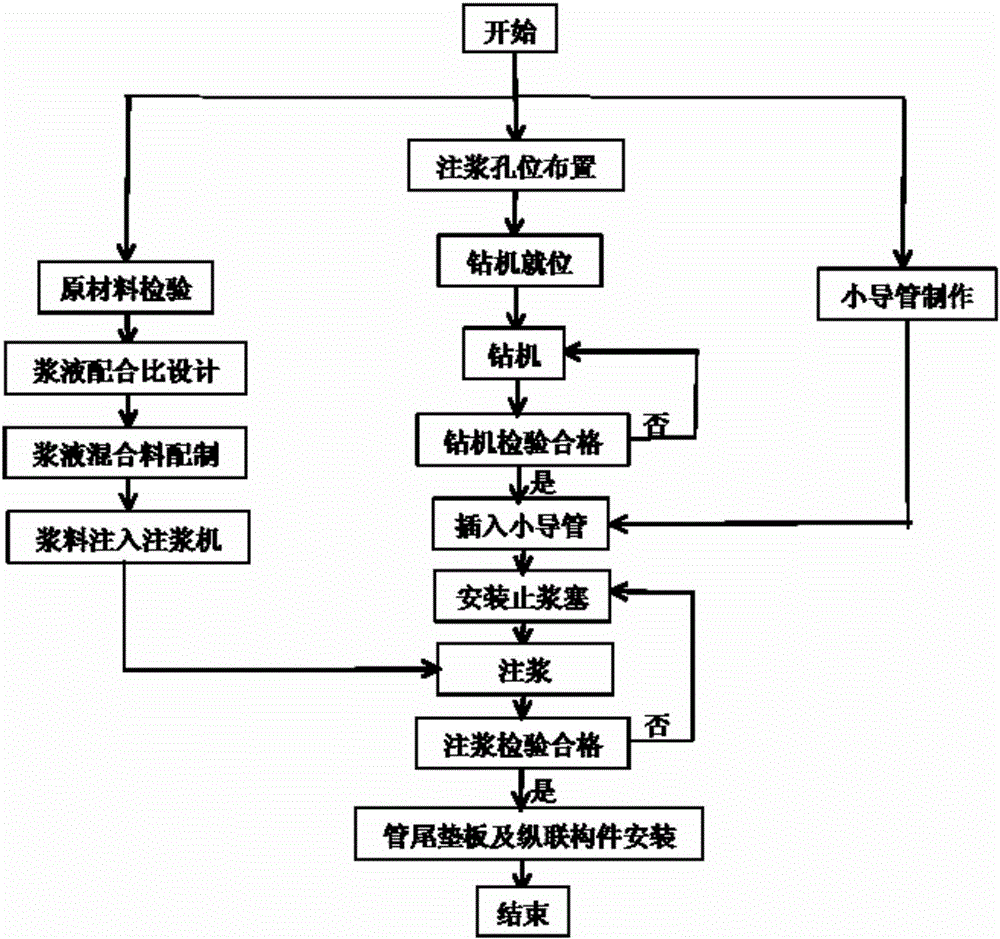

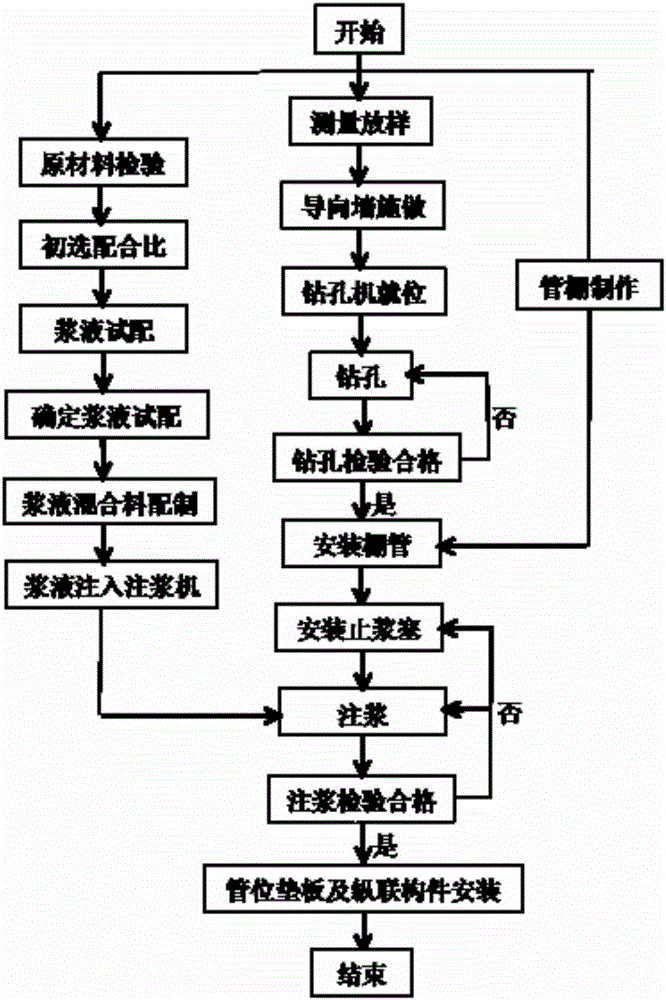

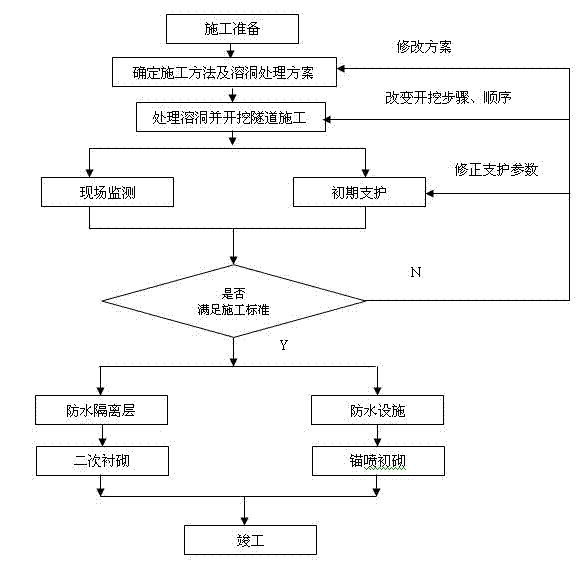

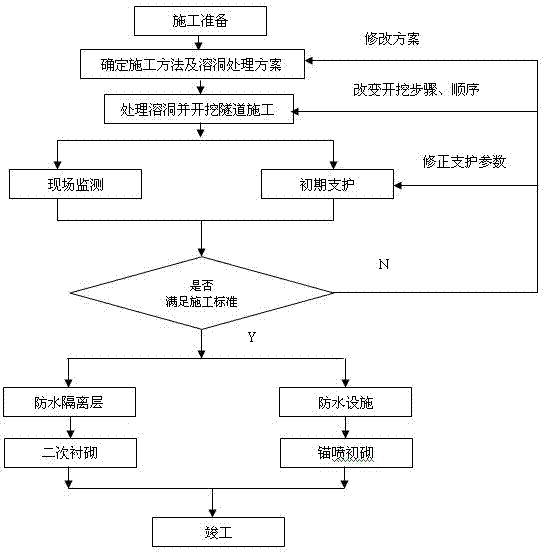

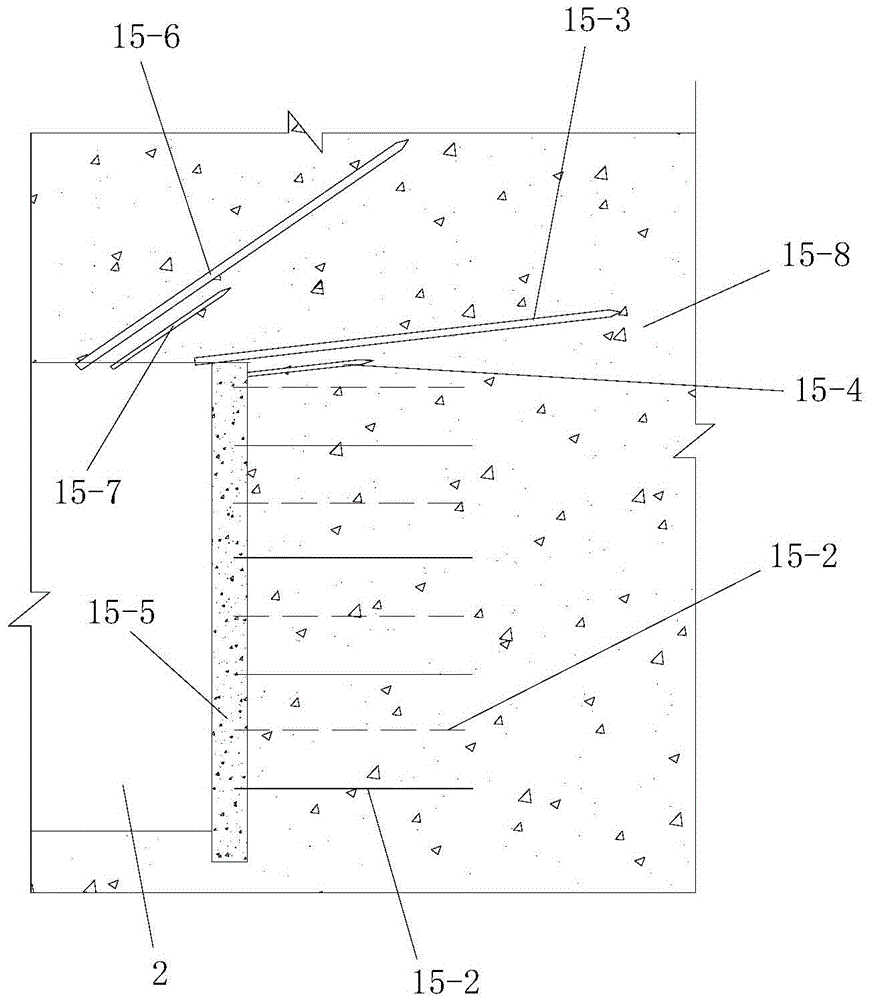

Construction treatment method of filling karst tunnel

InactiveCN106837353AReduce construction costsGrasp and implement in timeUnderground chambersTunnel liningRailway tunnelGeomorphology

The invention discloses a construction treatment method of a filling karst tunnel. The construction treatment method comprises the following steps that (a), a karst development control factor and a development principle are sought; (b), karst detecting is conducted for advance geology forecast; (c), analysis of influence of filling karst on stability of tunnel surrounding rocks is conducted; and (d), filling karst treatment is conducted. According to the construction treatment method of the filling karst tunnel, filling karst advance geology forecast, pre-reinforcement measures and the normal construction technical process of the tunnel are organically combined, and the safety risks of filling karst section tunnel construction are reduced or avoided by sufficiently using the means and methods such as advance geology forecast and pre-reinforcement. The construction treatment method is applied to tunnel filling karst construction of highways and railways, and meanwhile, the construction treatment method has imitative and referential significances on construction of the railways, the highways, municipal administrations and hydraulic tunnels (caves) with similar geological conditions.

Owner:CENT SOUTH UNIV +2

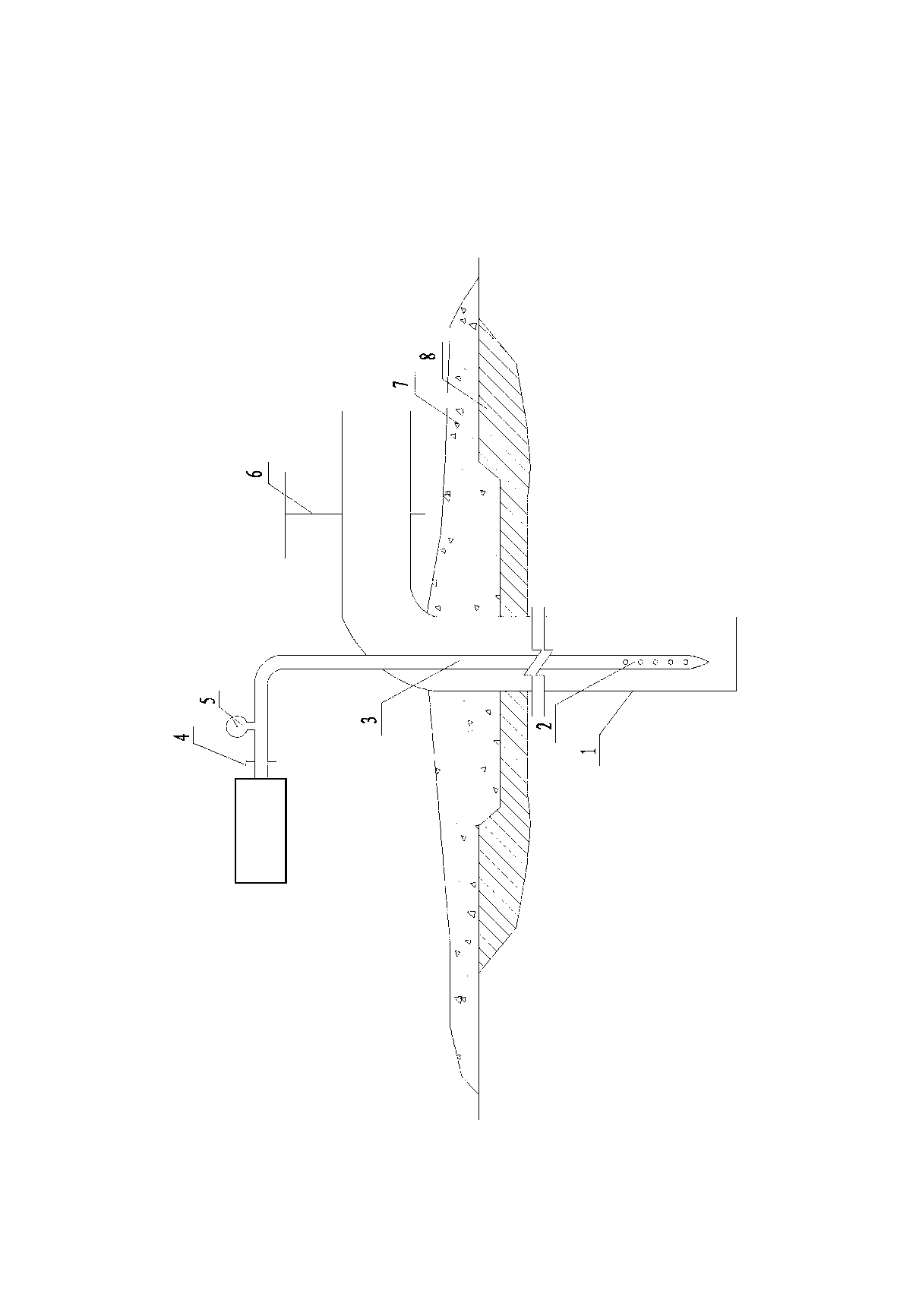

Construction technology for allowing tunnel to pass through ultra-large karst cave

ActiveCN102383806ADo not delay the construction periodQuality assuranceUnderground chambersFoundation engineeringShotcreteMesh reinforcement

The invention relates to a construction technology for allowing a tunnel to pass through a karst cave, and in particular relates to a construction technology for allowing a tunnel to pass through an ultra-large karst cave. The technology at least comprises the following steps of: 1) performing simple bridge treatment on the underground part of the karst cave; 2) performing primary support, namelyarranging a support wall at one side of the karst cave; 3) forming parallel guide holes; 4) performing bottom treatment; 5) treating the tunnel hole body at the inlet section of the karst cave; 6) filling C25 early strength sprayed concrete within 1 meter at the top of the support wall, and arranging phi 50 small grouting conduits with the lengths of 3 meters in the concrete, wherein the distancebetween the small conduits is 1.5 meters; 7) supporting the arch part and the side wall surrounding rock of the karst cave by adopting phi 22 cartridge anchor rods arranged in a plum blossom shape and at a distance of 150cm*150cm, hanging phi6 reinforcing meshes at a distance of 15cm*15cm, and spraying C25 early strength concrete with the thickness of 15 centimeters; 8) treating the accumulation of the karst cave; and 9) monitoring and measuring when the tunnel passes through the ultra-large karst cave. The construction technology for allowing the tunnel to pass through the ultra-large karst cave is simple in process, convenient for construction, low in cost, scientific, effective, energy-saving and environmentally-friendly.

Owner:CCCC SHEC DONGMENG ENG CO LTD

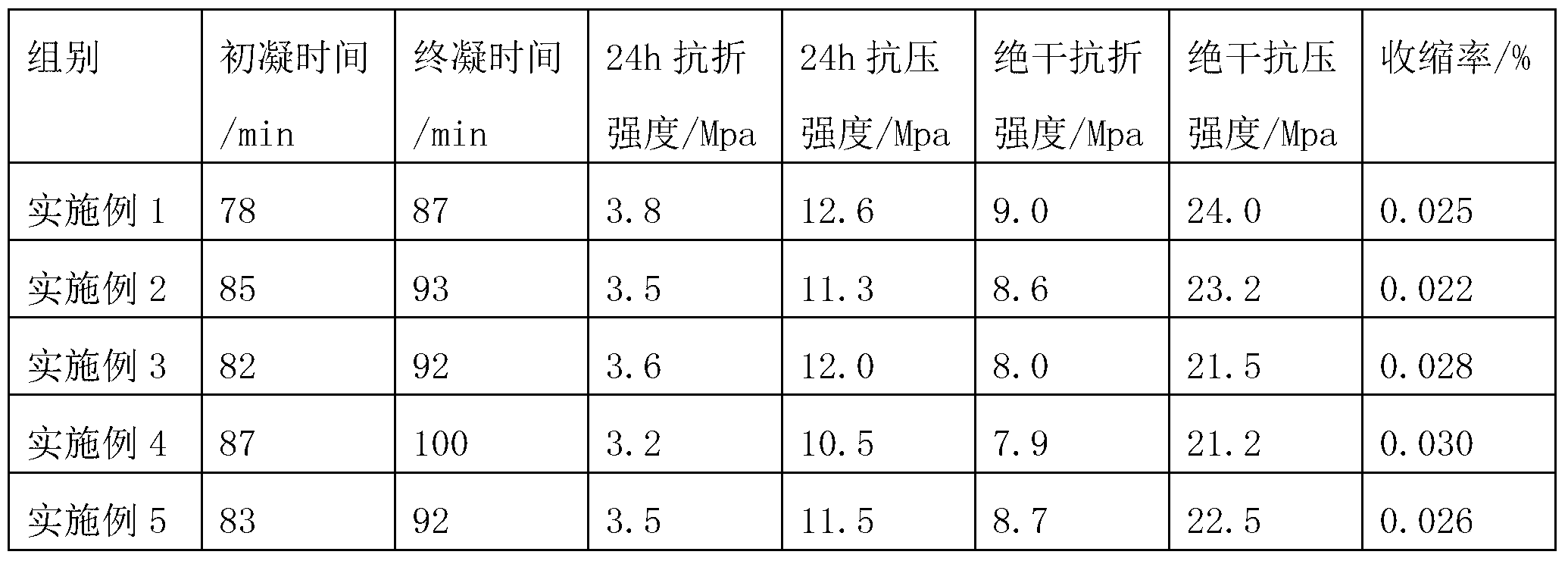

Alpha high-strength gypsum based self-leveling material prepared by adopting phosphogypsum and production process thereof

The invention relates to an alpha high-strength gypsum based self-leveling material prepared by adopting phosphogypsum and a production process thereof. The material comprises the following components in percentage by weight: 40-60% of alpha high-strength gypsum powder, 30-50% of aggregates, 1-4% of cement, 1-4% of fly ash, 2-4% of re-dispersible rubber powder, 0.1-0.3% of retarder, 0.2-0.75% of water reducing agent, 0.1-0.25% of water-retaining agent, 0.1-0.4% of air entraining agent and 0.05-0.15% of antifoaming agent. The production process comprises the steps of uniformly mixing the components and obtaining the alpha high-strength gypsum based self-leveling material. The alpha high-strength gypsum based self-leveling material disclosed by the invention has the advantages that the requirements of JC / T1023-2007 Gypsum based Self-leveling Mortar are met and the requirements on the 30min fluidity loss, the initial setting time, the final setting time, the breaking strength, the compressive strength and the shrinking rate are met.

Owner:WUHAN UNIV OF TECH

High-altitude long-span roofing pipe truss installation method

InactiveCN101666163AImprove construction qualityGuarantee the construction progressBuilding material handlingRebarReinforced concrete

The invention discloses a high-altitude long-span roofing pipe truss installation method which comprises the following steps: firstly, assembling pipe trusses on the ground, then arranging a construction platform beam at the high-altitude assembling pipe truss; adopting a movable tower crane to hoist the pipe trusses, and hoisting two sections of pipe trusses on an assembling bracket and a reinforced concrete stand column; finally, conducting high-altitude joint, assembly and welding on the pipe trusses; and after passing welding inspection, moving the assembling bracket to the next axis and conducting installation of the next pipe trusses. The high-altitude long-span roofing pipe truss installation method adopts ground segment assembly, movable tower crane hoisting and the high-altitude joint welding method, not only improves construction quality, guarantees construction process and safety, and simultaneously reduces construction cost.

Owner:CHINA METALLURGICAL CONSTR ENG GRP

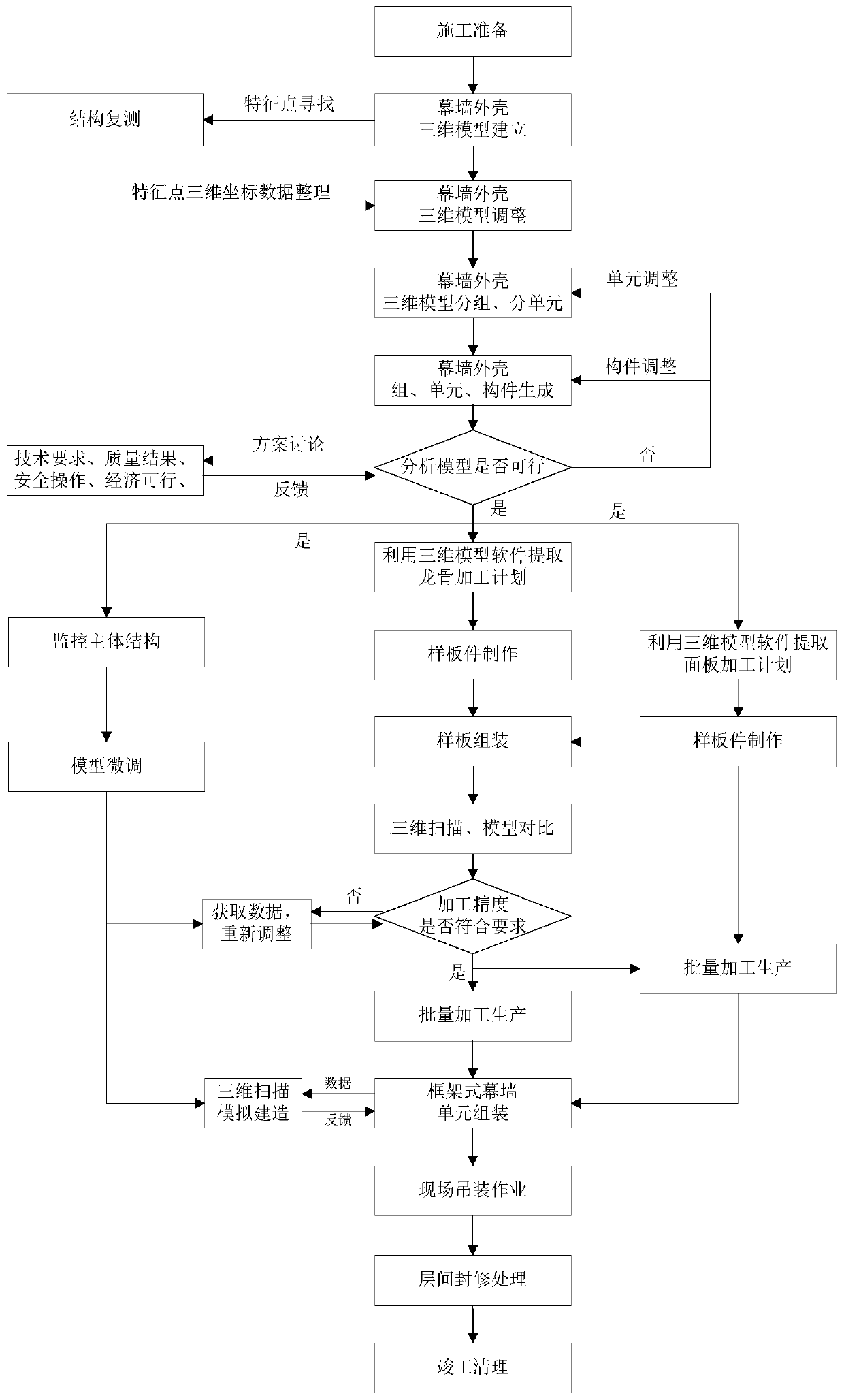

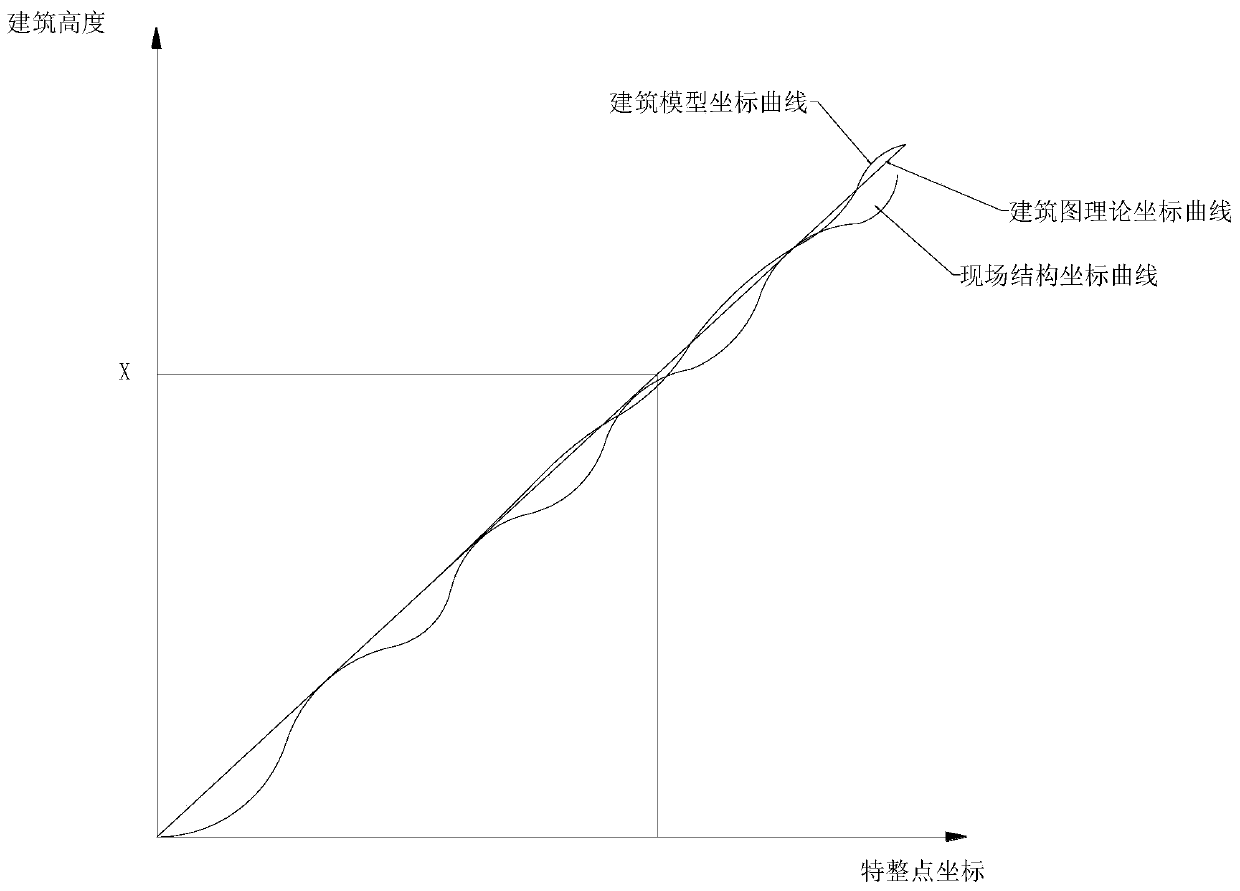

Frame-type curtain wall rapid assembly construction method and system based on BIM

InactiveCN110056106AFast and accurate generationSingle construction workWallsBuilding material handlingThree dimensional measurementHanging basket

The invention discloses a frame-type curtain wall rapid assembly construction method and system based on a BIM, and belongs to the field of curtain wall assembly construction. The to-be-solved technical problems are how to realize rapid assembly construction of a frame-type curtain wall and ensure the installation quality and performance of the curtain wall, according to the technical scheme, theframe-type curtain wall rapid assembly construction method includes the steps that three-dimensional model creation and adjustment of a curtain wall shell, curtain wall unit division, material component splitting and ordering are conducted through a BIM technology and a three-dimensional measurement technology, unit bodies of the frame-type curtain wall are assembled through centralized industrialprocessing, the processing quality of the frame-type curtain wall units is controlled by manufacturing standard parts, standard samples and using a three-dimensional scanning technology, site quick assembly construction of the frame-type curtain wall is completed through an integral hoisting technology, then treatment between layers is completed through a construction hanging basket or an elevating operating vehicle, and finally, rapid assembly construction operation of the frame-type curtain wall is realized. The invention further discloses the frame-type curtain wall rapid assembly construction system based on the BIM.

Owner:CHINA CONSTR EIGHTH ENG DIV

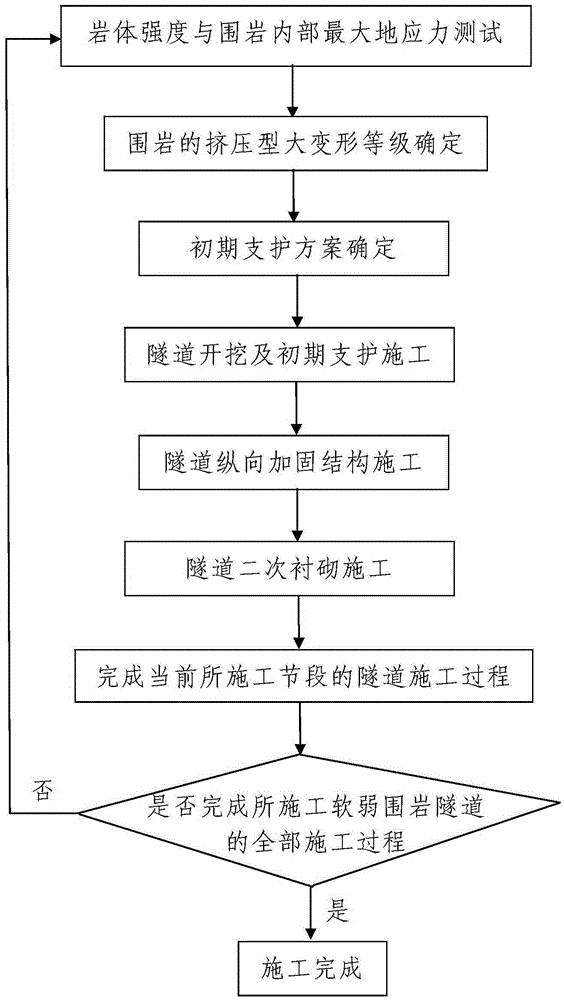

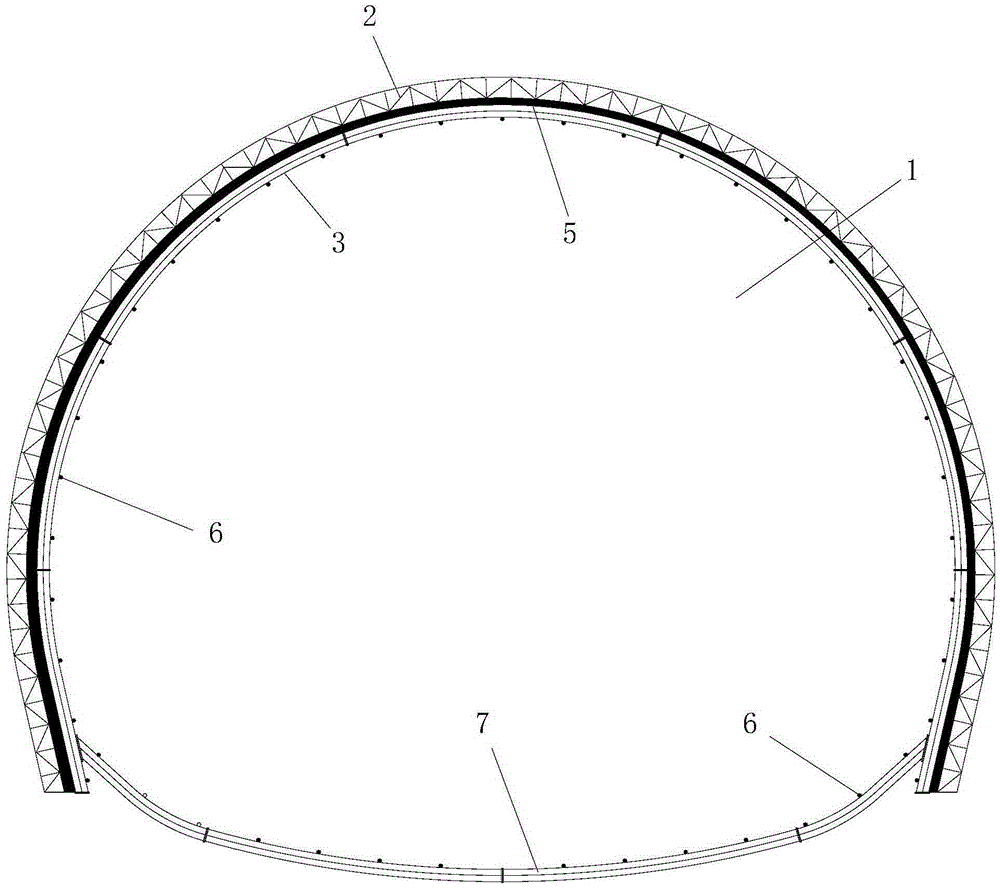

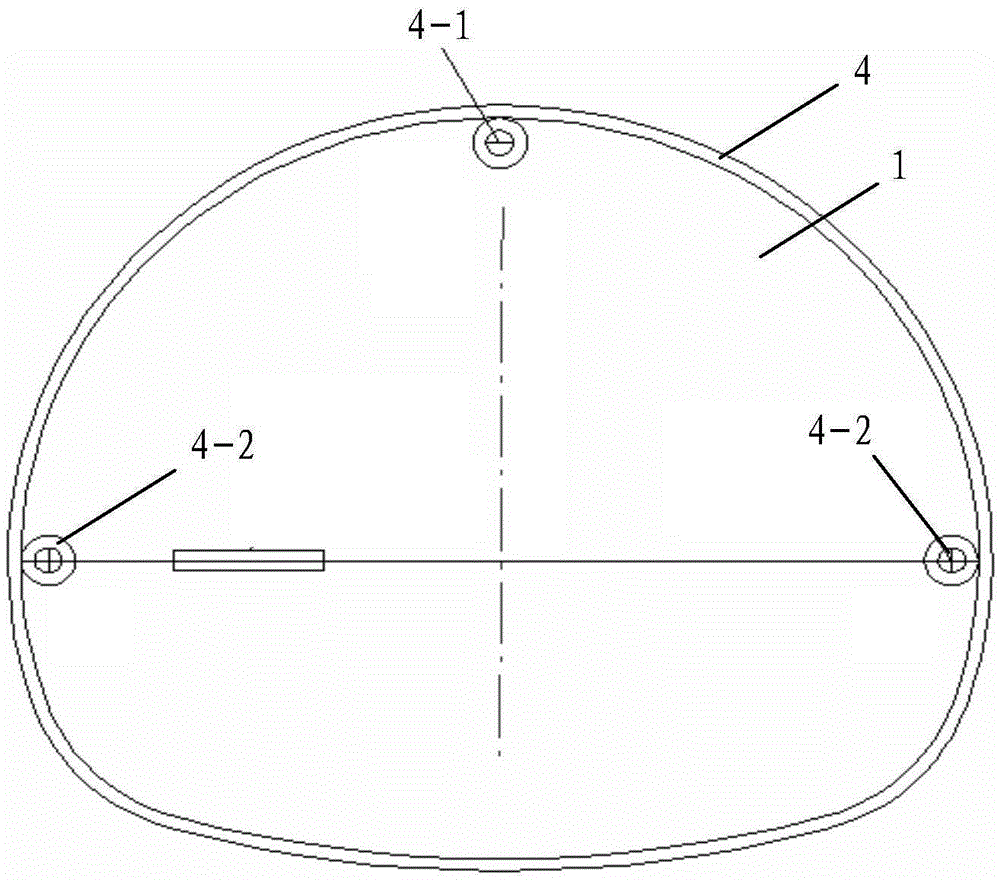

Large-deformation control construction method for high ground stress weak surrounding rock tunnel

ActiveCN105401947AThe method steps are simpleReasonable designUnderground chambersTunnel liningStructure of the EarthRock tunnel

The invention discloses a large-deformation control construction method for a high ground stress weak surrounding rock tunnel. A plurality of segments are arranged in the longitudinal extending direction of the tunnel from back to front to construct the constructed weak surrounding rock tunnel. The method comprises the steps that firstly, the rock strength and surrounding rock interior maximum ground stress test is carried out; secondly, the large extrusion deformation grade of the surrounding rock is determined; thirdly, a primary support scheme is determined; fourthly, tunnel excavation and primary support construction are carried out; fifthly, longitudinal tunnel strengthening structure construction is carried out; sixthly, tunnel secondary lining construction is carried out; seventhly, construction of the next segment is carried out according to the first step to the sixth step; and eighthly, the seventh step is repeated many times till the whole construction process of the constructed weak surrounding rock tunnel is finished. According to the method, the steps are simple, the design is reasonable, construction is convenient, and the using effect is good. The tunnel construction process of the high ground stress weak surrounding rock tunnel can be easily, conveniently and rapidly finished, the construction process is safe and reliable, and the large deformation of the weak rock can be effectively controlled.

Owner:CHINA RAILWAY 20 BUREAU GRP

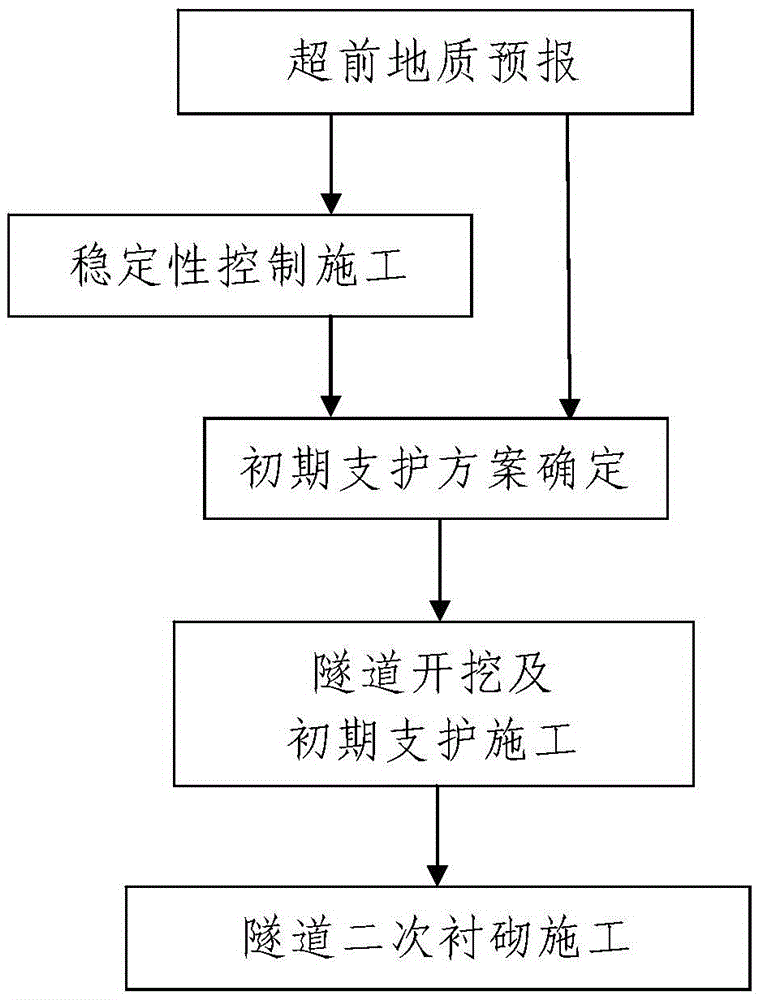

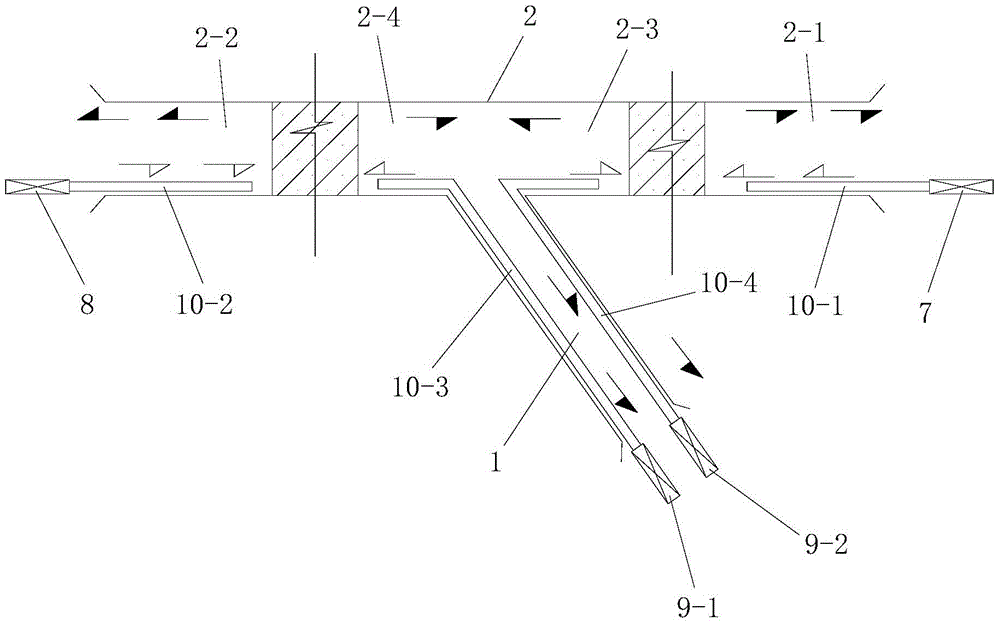

Water-rich weak surrounding rock long-and-big tunnel construction method

The invention discloses a water-rich weak surrounding rock long-and-big tunnel construction method. The method includes that a tunnel inclined shaft is arranged on one side of a main tunnel of a tunnel to be constructed, the main tunnel is divided into a tunnel entry section, a tunnel exit section and a middle connecting section connected between the tunnel entry section and the tunnel exit section, the middle connecting section is divided into an inclined shaft assisting construction entry section and an inclined shaft assisting construction exit section, and each of the tunnel entry section, the tunnel exit section, the inclined shaft assisting construction entry section and the inclined shaft assisting construction exit section is divided into multiple sections for construction. A construction method of each section includes: step 1, performing geological forecasting in advance, and when a debris flow formation exists ahead, entering a step 2, or else, entering a step 3; step 2, performing stability control construction; step 3, determining a primary supporting scheme; step 4, excavating the tunnel, and performing primary supporting construction; step 5, performing secondary lining construction on the tunnel. The water-rich weak surrounding rock long-big tunnel construction method is simple in step, reasonable in design, simple and convenient to construct, good in using effect, capable of meeting construction requirements of water-rich weak surrounding rock long-and-big tunnels, short in construction period and safe in construction process.

Owner:CHINA RAILWAY 20 BUREAU GRP

Direct local skirt border reversing construction for central island

InactiveCN1982546AReduce distortionEnsure safetyArtificial islandsBuilding constructionsSupporting systemPurlin

A job practice of which center island is done in sequence and partial skirts done inversely, comprising the following steps : set up exterior-protected construction, purlin and steel upright columns around the foundation ditch; dig on basin pattern for the first time to the depths to structural plane of purlin, earthwork are unified dig beneath the designed to the surrounding medium plate in the foundation ditch, pour the surrounding medium plate; dig for the second time with basin pattern downwards from the position of foundation ditch medium plate to the bottom of the designed foundation ditch, pour the center island plate; after the center island plate meets the maintenance time request of plate, construct in sequence to close the medium plate, setting fetching holes; then use medium plate for support system, construct criss-cross structural upper plate and plates in inverse zones. This construction method is convenient, save labor force and resources, improves the progress of the project, shorten the construction period.

Owner:SHANGHAI NO 7 CONSTR

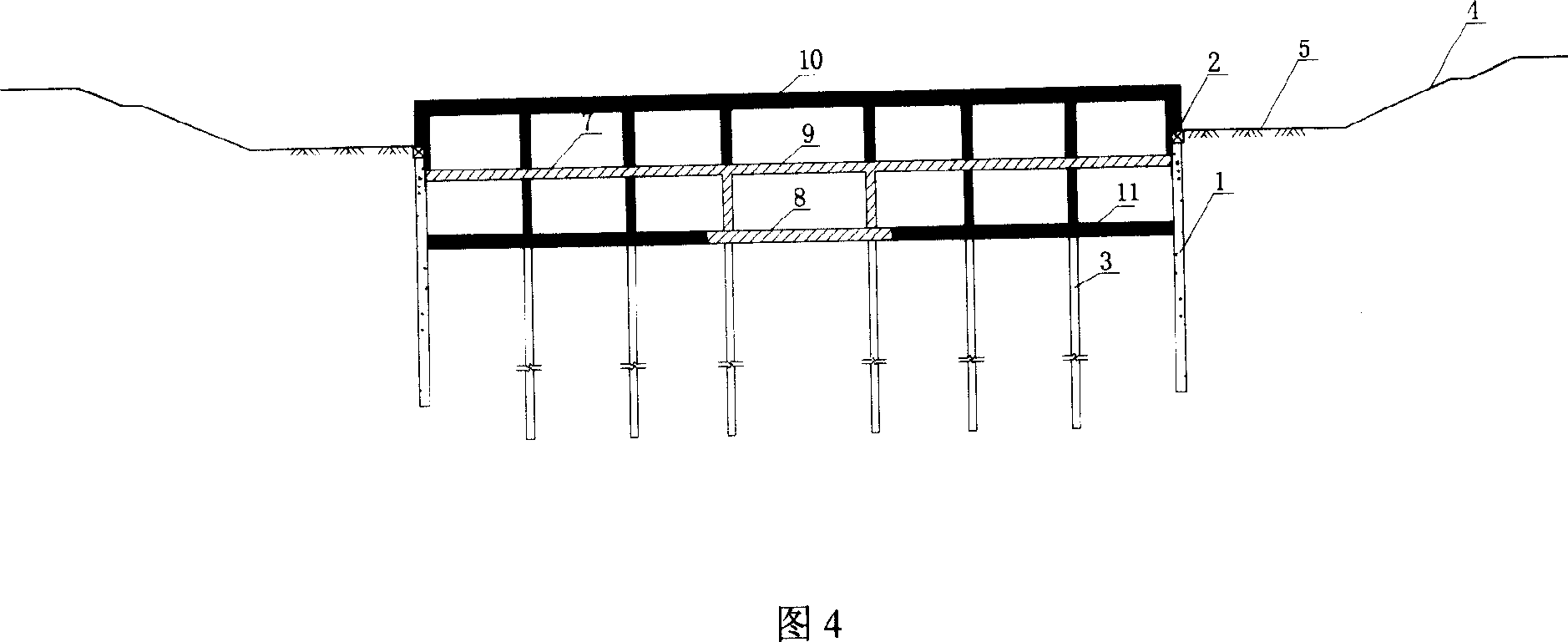

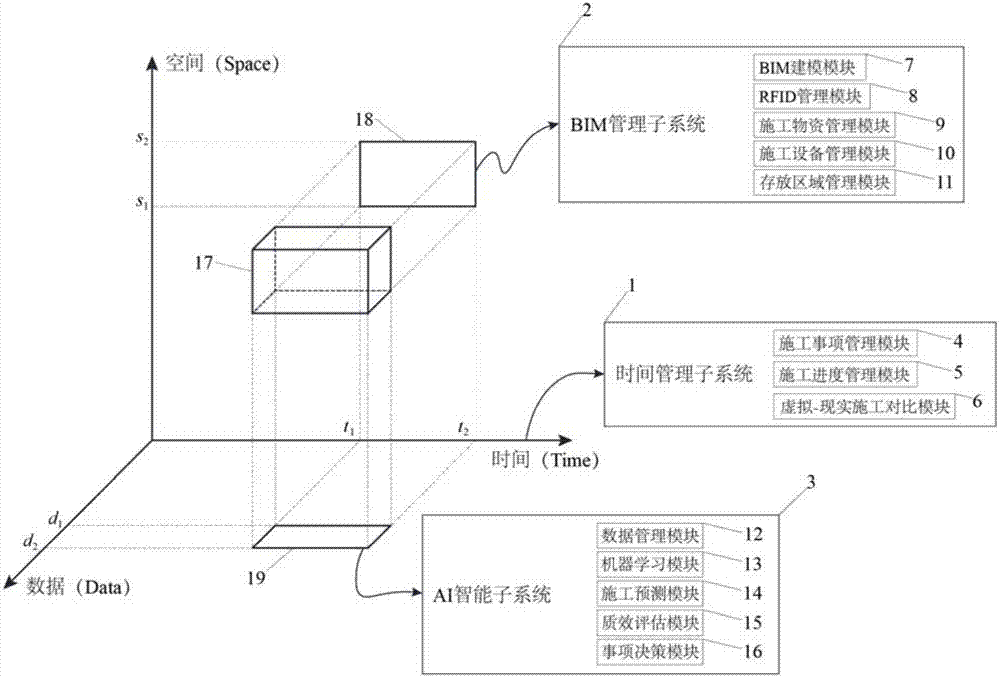

Intelligent large-scale shield tunnel management system based on BIM and AI

InactiveCN106897813AEasy to visualize managementEasy to monitorResourcesInformation repositoryState of art

The invention relates to an intelligent large-scale shield tunnel management system based on BIM and AI. The system comprises a time management subsystem used for regulating and managing the construction process and construction matters, a BIM management subsystem used for planning and managing the space position of materials and equipment and mobilisation & demobilisation, and an AI intelligent subsystem used for predicting resources needed by future construction and optimizing resource configuration in advance according to learning about known engineering. Compared with the prior art, the system is advantaged in that the time is the main line, the integral construction process is regulated and managed, and man-machine-material regulation is carried out; the space is the support, the BIM management subsystem is used for planning and managing the space position of the materials and the equipment and mobilisation & demobilisation; data is taken as the root, an engineering information database is managed and is taken as learning resources of the AI intelligent subsystem, an intelligentization level is improved continuously, the three are mutually independent and are associated through the data, visual management and monitoring on the tunnel shield construction process are facilitated, and construction experience references for subsequent engineering are facilitated.

Owner:TONGJI UNIV

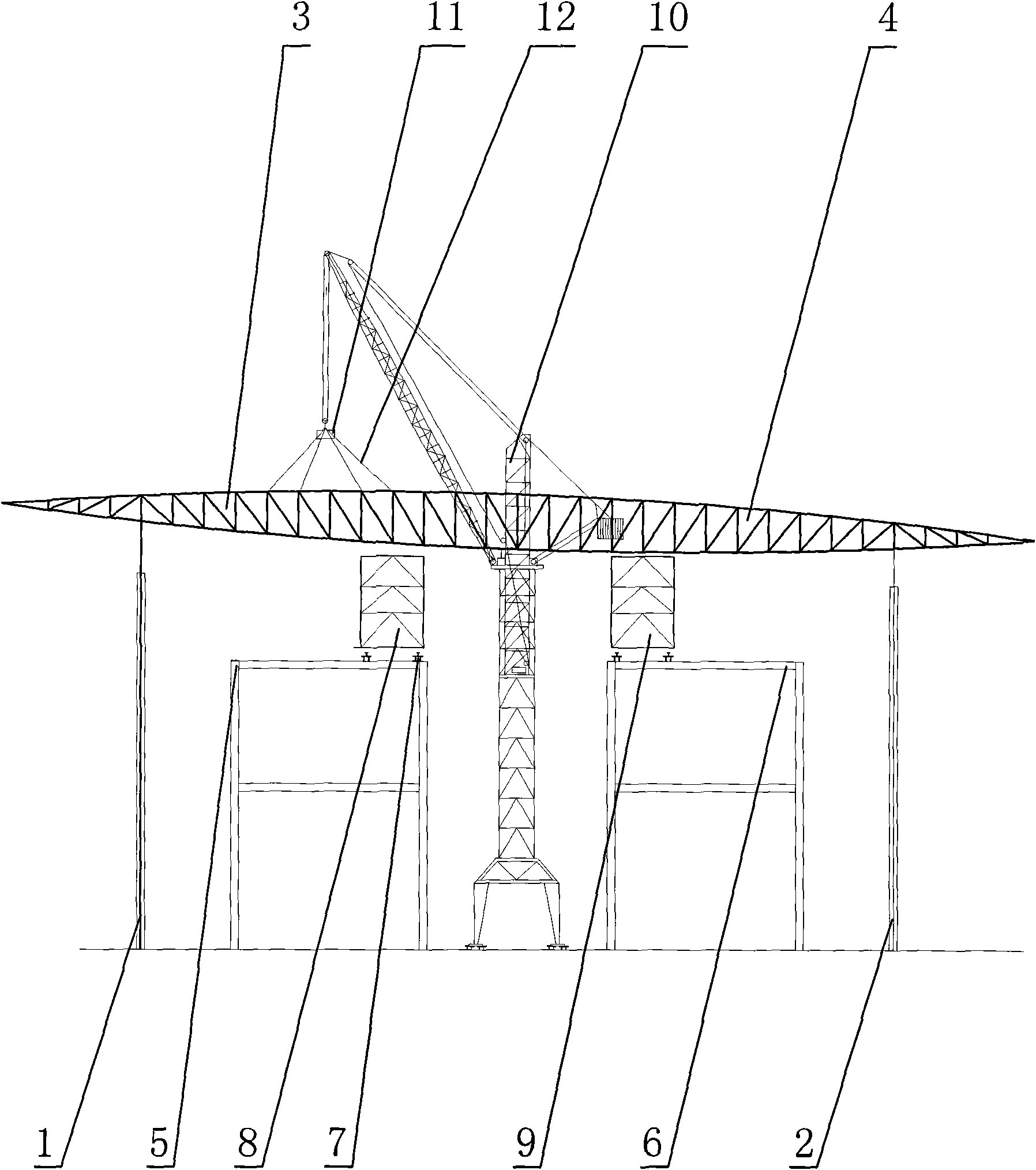

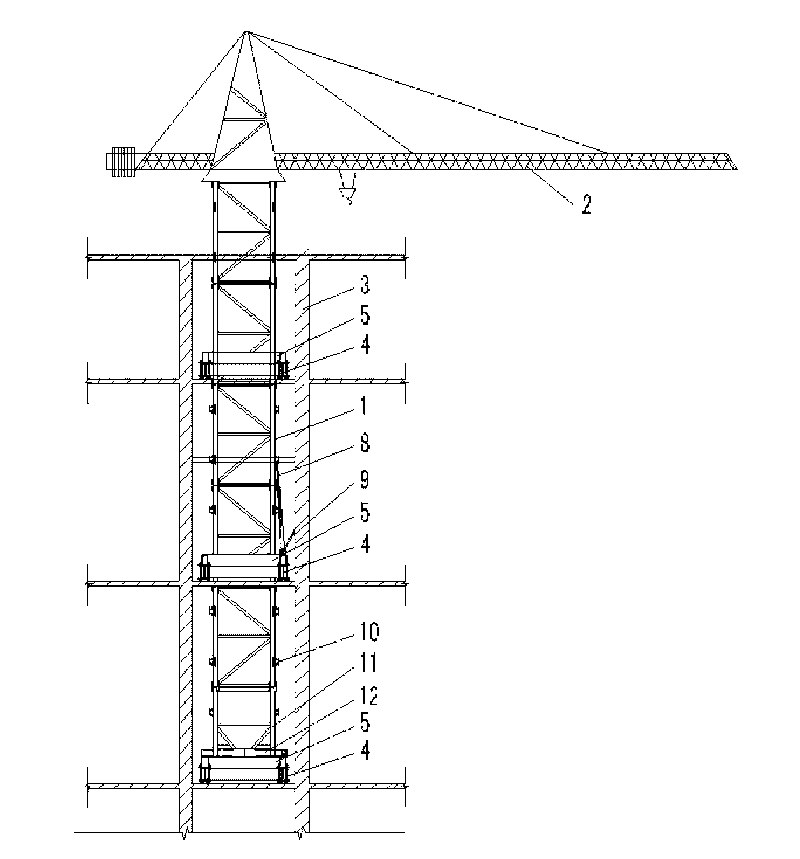

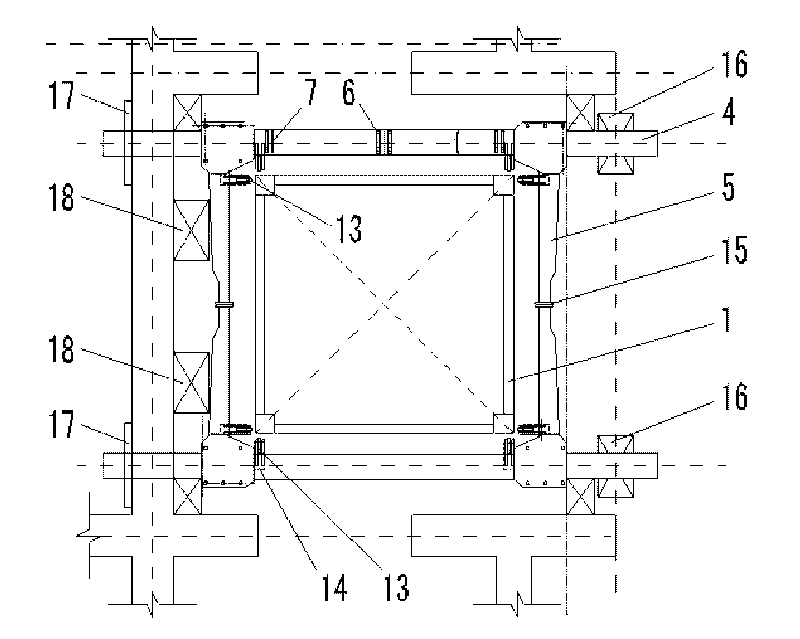

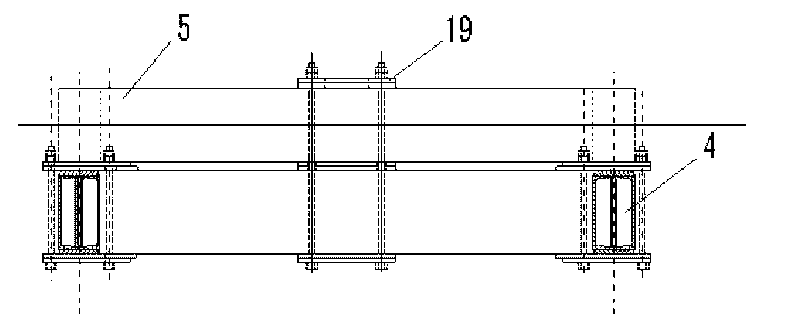

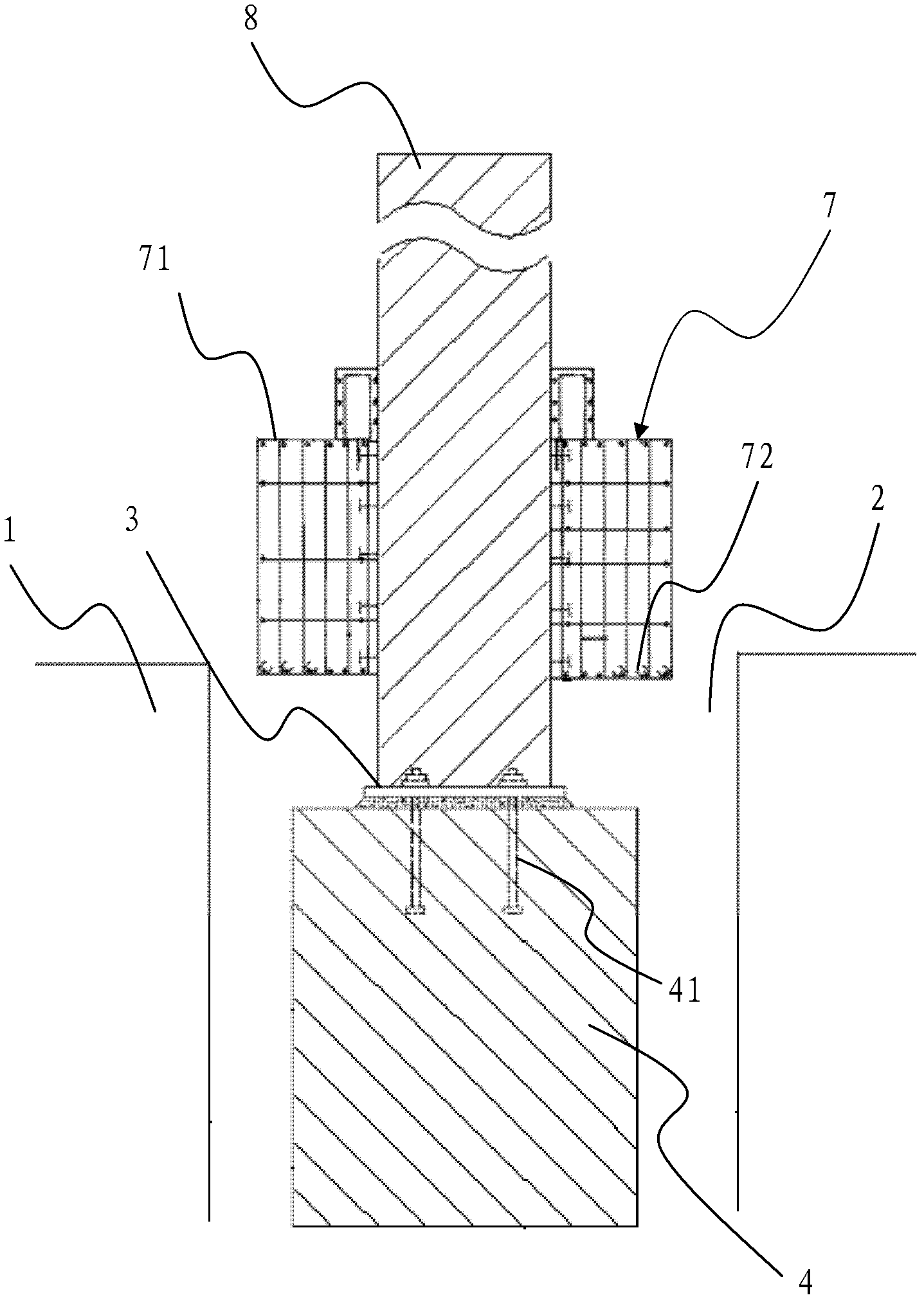

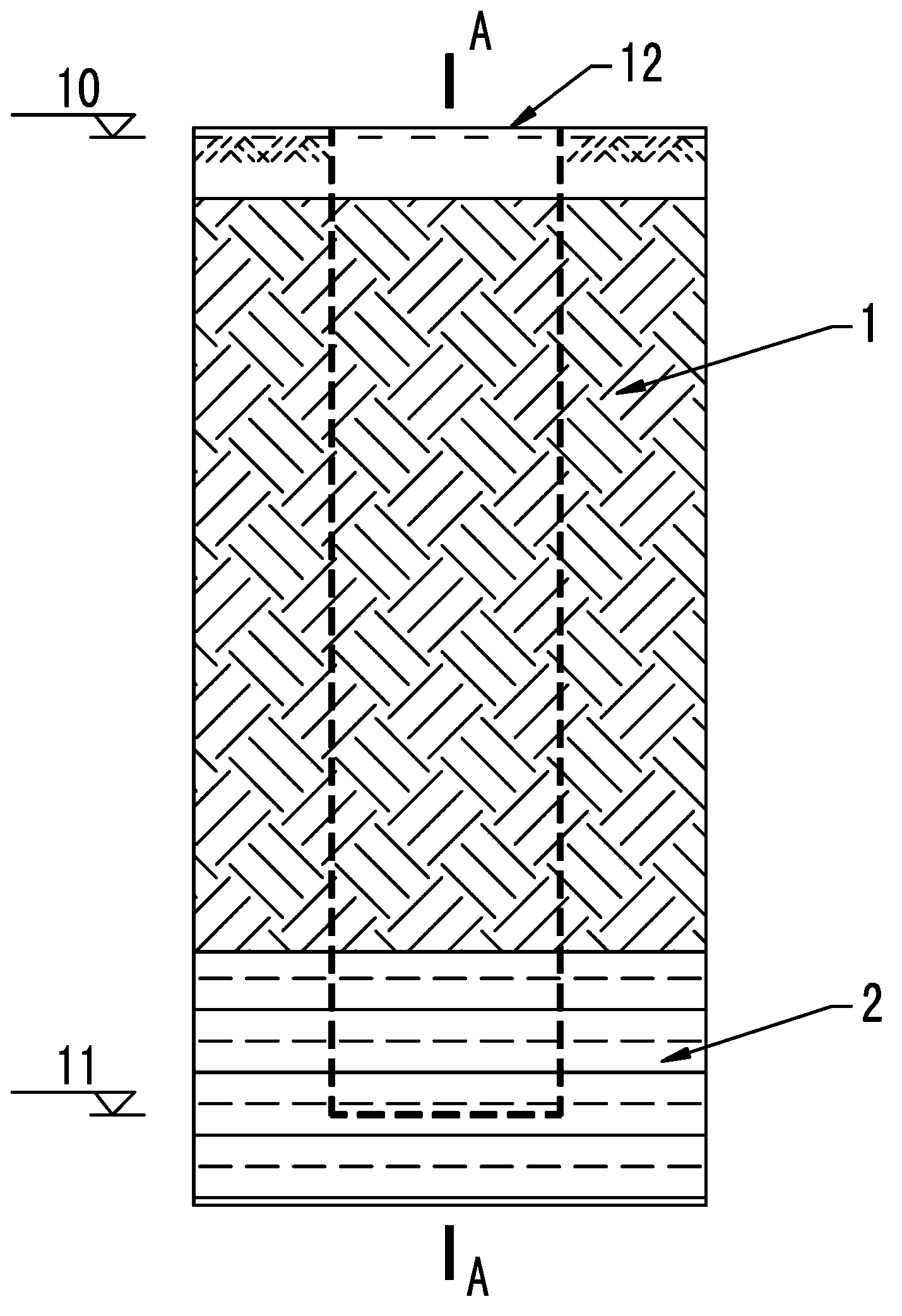

Self-climbing tower crane

InactiveCN101691191AHave vertical transportation requirementsMeet vertical transportation requirementsCranesSocial benefitsTower crane

The invention discloses a self-climbing tower crane, which comprises a tower body (1), a hoisting arm (2) and a climbing mechanism, wherein the climbing mechanism comprises a main stressed supporting steel beam (4) and a steel structure climbing attached frame (5); the steel structure climbing attached frame (5) is fixedly connected on the main stressed supporting steel beam (4) and is provided with a jacking cylinder (8) and a supporting steel beam (9); and a tower body supporting tread (10) is arranged on a tower body (1), and the bottom of the tower body (1) is provided with a climbing base section (11). The self-climbing tower crane can climb upward along a constructed structure by using the constructed building structure as a support, meet the requirements of superhigh-rise and out-of-code tall buildings on vertical transportation at the whole construction height, contribute to construction efficiency, construction period reduction, steel conservation and energy conservation and create obvious economic and social benefits.

Owner:CHINA CONSTR FOURTH ENG DIV

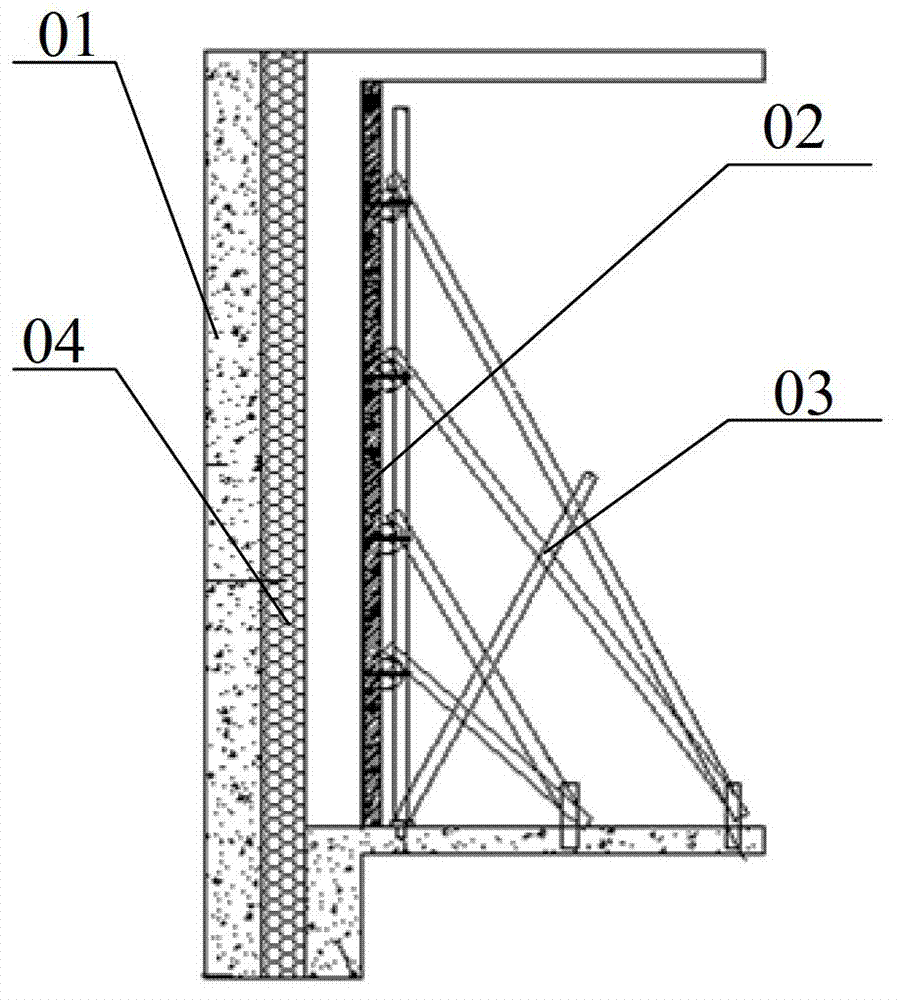

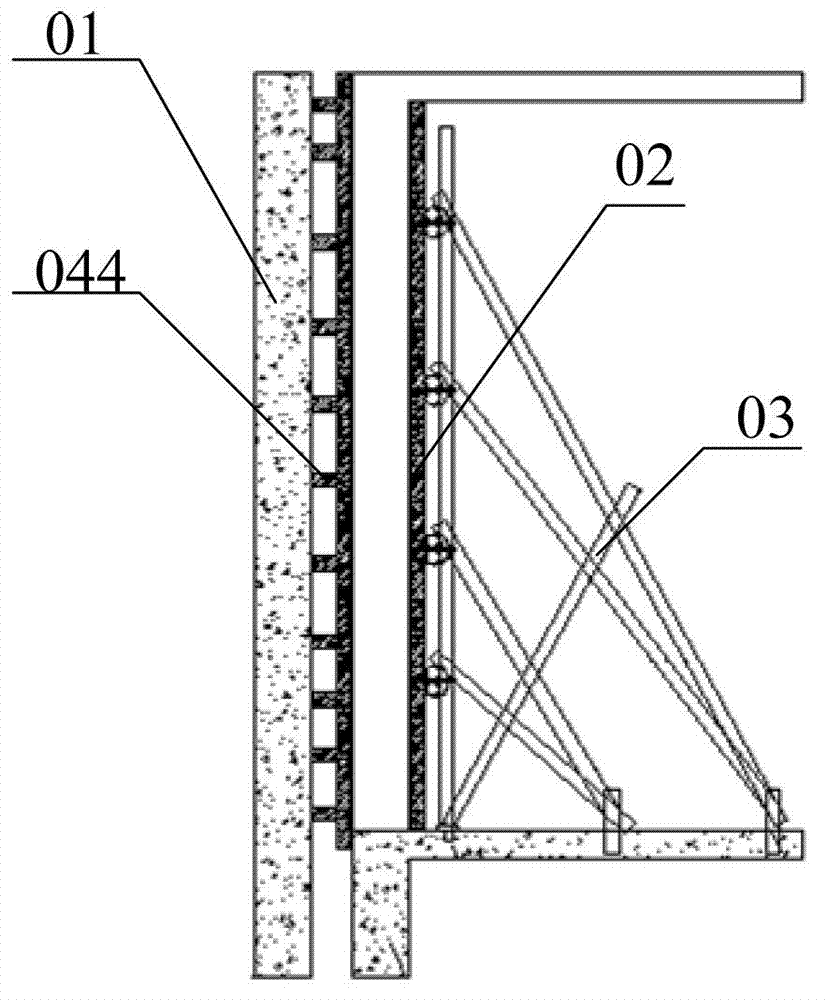

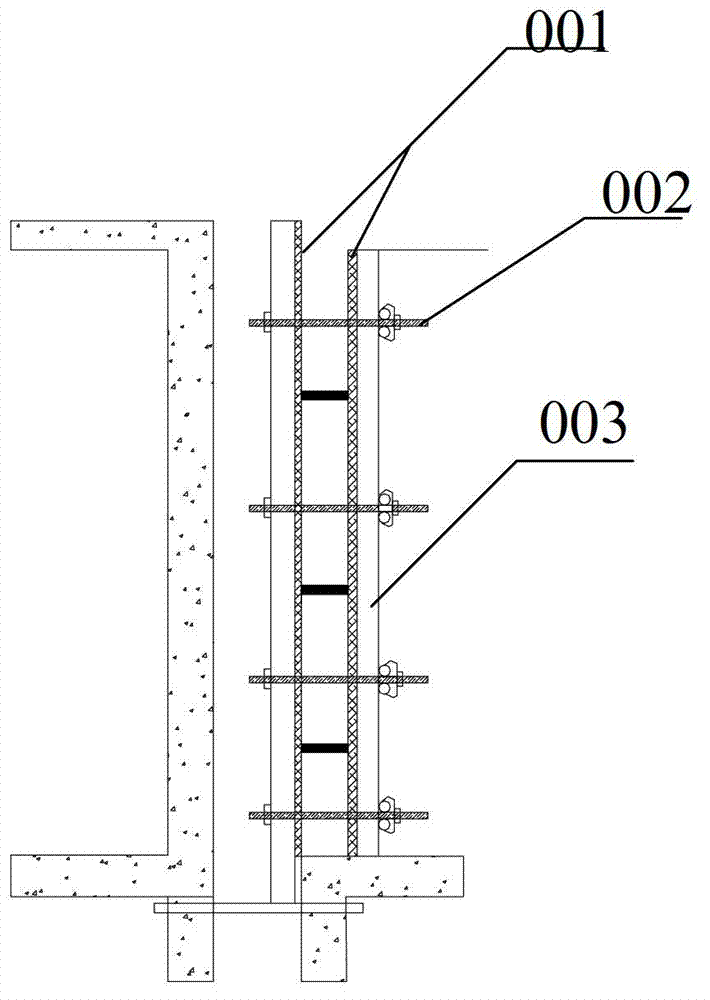

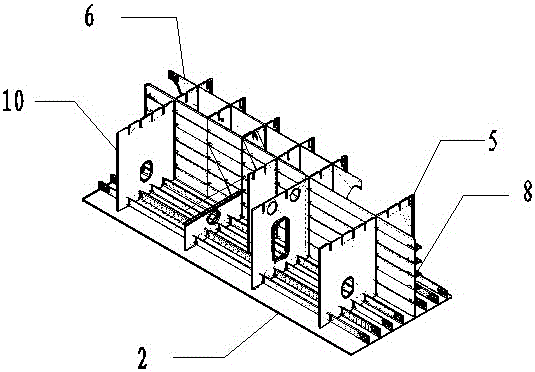

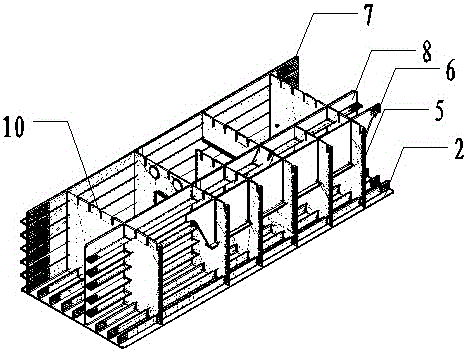

Formwork system of shear walls at two sides of extensible seam

InactiveCN103114717AShorten the construction periodGuarantee the construction progressForms/shuttering/falseworksExpansion jointSymmetric axis

The invention discloses a formwork system of shear walls at two sides of an extensible seam. The formwork system of the shear walls at the two sides of the extensible seam comprises two sets of wall body pouring formworks arranged symmetrically with the extensible seam as a symmetric axis, side face fastening steel tubes and end portion fastening steel tubes, wherein, the side face fastening steel tubes and the end portion fastening steel tubes are used for fixing the wall body pouring formworks. Each set of the wall body pouring formwork is respectively enclosed by an outer side formwork, an inner side formwork and an end portion formwork. A support block is respectively arranged between the outer side formwork and the inner side formwork in each set of the wall body pouring formwork and each outer side formwork and each inner side formwork are fastened through each transverse fastening steel tube, each side face fastening steel tube and a split bolt. Each end portion formwork is pressed on each outer side formwork and each inner side formwork through the end portion fastening steel tubes, bolt rods and match of end portion movable nuts on the bolt rods. According to the formwork system of the shear walls at the two sides of the extensible seam, the formworks at the two sides of the extensible seam can be erected by once in a narrow space, construction period is greatly shortened, engineering cost is reduced, and the formwork system is not limited by the size of the extensible seam and particularly applicable to the condition that the extensible seam is small.

Owner:QINGDAO BOHAI CONSTR GROUP

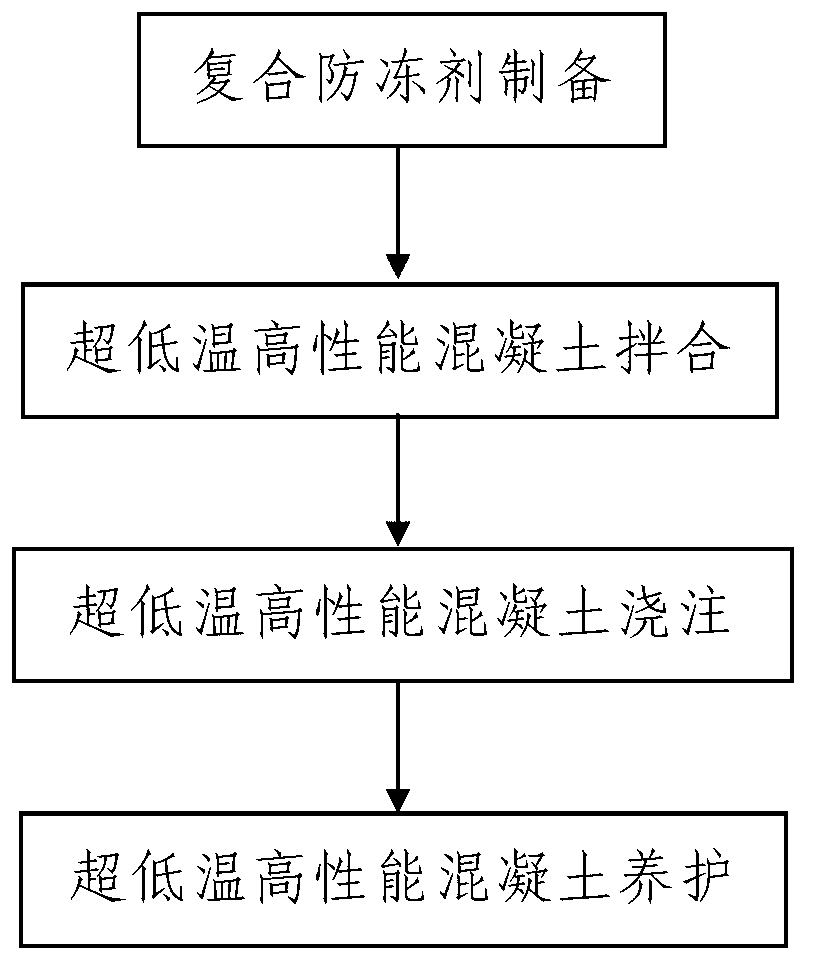

Construction technique for ultralow-temperature high-property concrete for railway construction in frigid areas

ActiveCN102797358AThe process steps are simpleEasy to operateBuilding material handlingCalcium formateSuperplasticizer

The invention discloses a construction technique for ultralow-temperature high-property concrete for railway construction in frigid areas. The construction technique comprises the steps as follows: A, mixing ultralow-temperature high-property concrete: gelled materials, sand, crushed stone, an efficient water reducing agent, compound antifreeze and water are evenly mixed to obtain the ultralow-temperature high-property concrete; the gelled materials are made by evenly mixing cement and mineral admixtures in the weight ratio of (88-78):(12-22); the weight ratio of the compound antifreeze to the mineral admixtures is (3-6):100; the compound antifreeze comprises 30 to 35 wt% of nitrate, 30 to 33 wt% of organic compound, 0.5 to 1wt% of calcium formate, and water as the rest; the nitrate is calcium nitrate or calcium nitrite; and the organic compound is methanol or alcohol; B, pouring the ultralow-temperature high-property concrete; and C, curing the ultralow-temperature high-property concrete. The construction technique has the advantages of reasonable design, simplicity in construction steps, convenience in operation, fast construction progress, low construction cost, and good structural quality of concrete used in construction.

Owner:CHINA RAILWAY 20 BUREAU GRP

Manufacturing method of double-anchor box type external node chord member

ActiveCN105729063ANo interferenceGuarantee the construction progressBridge structural detailsMachiningBuilding construction

The invention relates to a manufacturing method of a double-anchor box type external node chord member. The double-anchor box type external node chord member is manufactured according to the steps of S1) blanking, S2) machining, S3) flat plate drilling, S4) web receiving and machining, S5) plate unit assembly welding and S6) chord member assembly welding. As nodes are mounted out of anchor boxes connected with stay cables on the chord member to avoid from the connecting places between the anchor boxes and the stay cables, the anchor boxes cannot be interfered with the nodes, the installation of the stay cables of a bridge and the welding of node plates are not mutually interfered, and the construction progress of the bridge is guaranteed.

Owner:中铁山桥(南通)有限公司

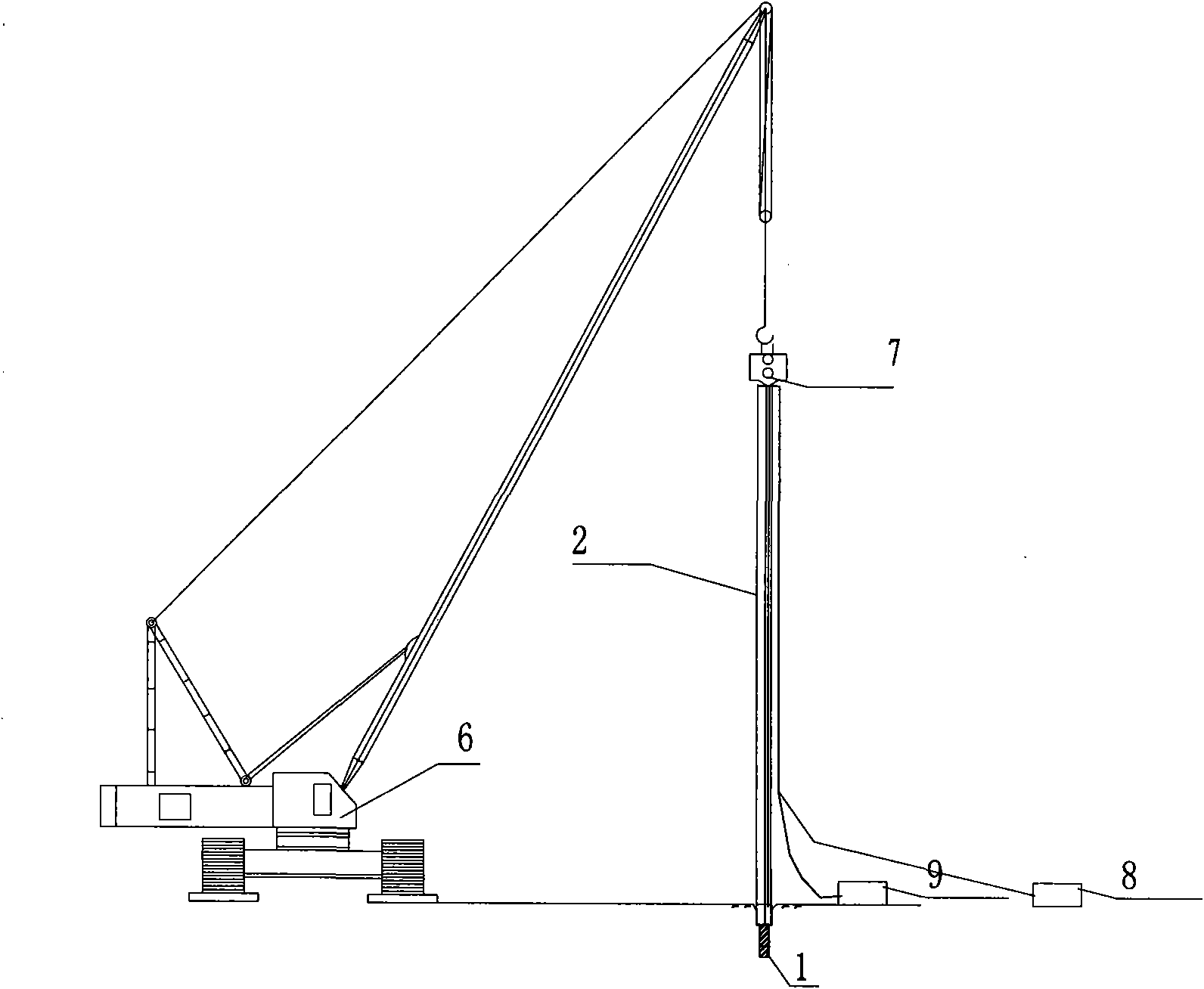

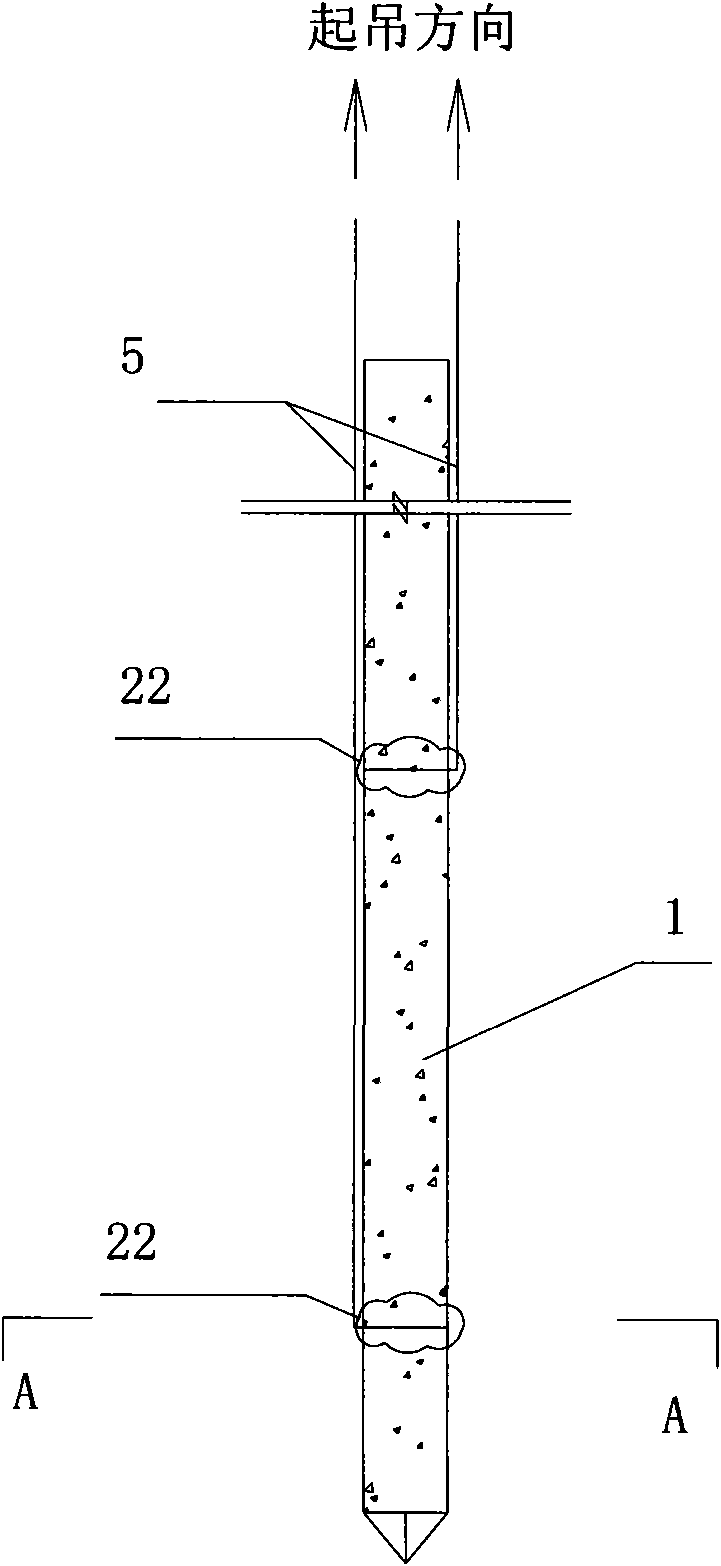

Pulling-out method of underground piles by sleeving, vibrating and punching

The invention relates to fundamental construction, in particular to a pulling-out method of underground piles. A pulling-out method of underground piles by sleeving, vibrating and punching is characterized by including the following steps: firstly, a sleeve is made, a long steel pipe is used as the sleeve, the external wall of the long steel pipe is provided with a water pipe and a ventilating pipe, one end head of the long steel pipe is in a sawtooth shape, and the internal wall of the long steel pipe is provided with a steel wire; secondly, the pile head position of an underground pile is determined, and soil is removed and backfilled; thirdly, a steel sleeve is vibrated and sunken, a caterpillar-band hoist is used for hanging a vibrating hammer to vibrate the sunken sleeve to enable the sleeve to sleeve the underground pile, and after the sleeve is positioned, the vibrating hammer is removed; fourthly, the pile is pulled out, after the sleeve sleeves the pile completely, the caterpillar-band hoist is used for contracting the steel wire to hoist; fifthly, the steel sleeve is pulled out by vibrating, the vibrating hammer is started up, and the caterpillar-band hoist is used for hoisting to pull out the steel sleeve with vibrating; and sixthly, a pile hole is levelly filled, and a disturbing area is processed. The invention can successfully pull out underground piles to remove the obstacle for construction.

Owner:SHANGHAI BAOYE GRP CORP

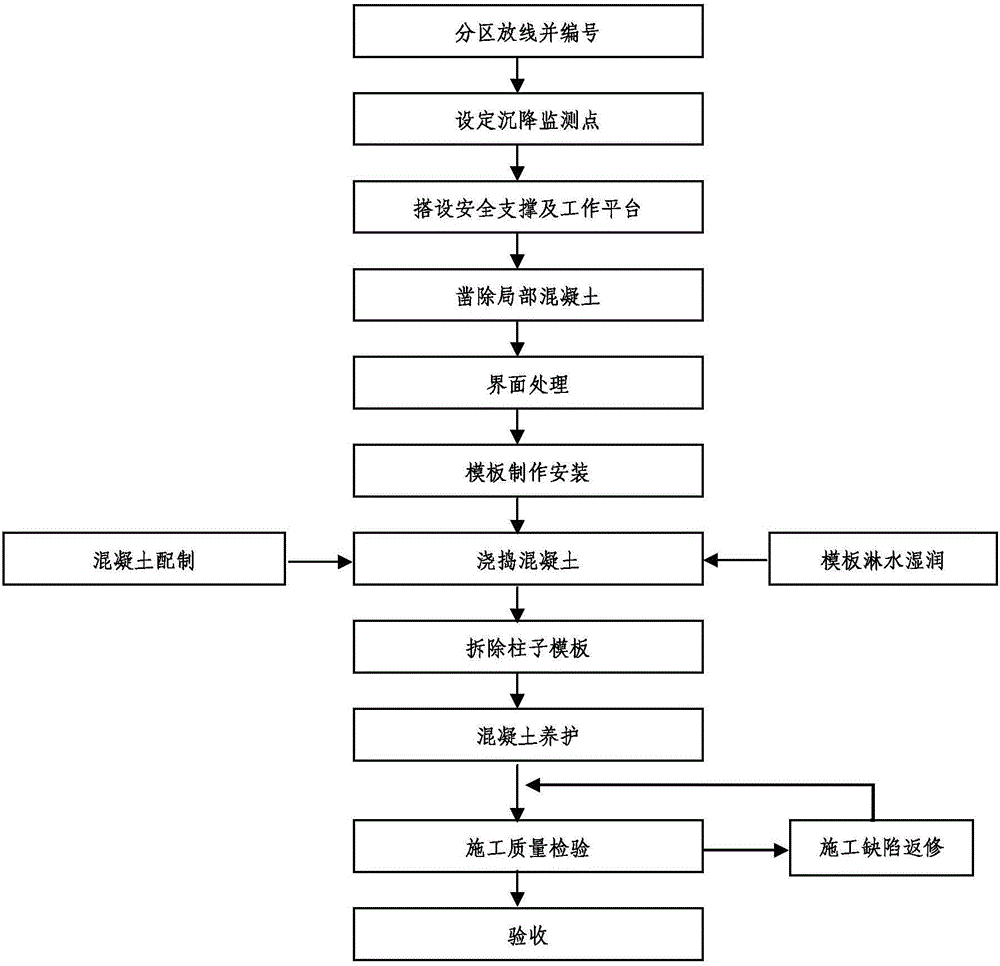

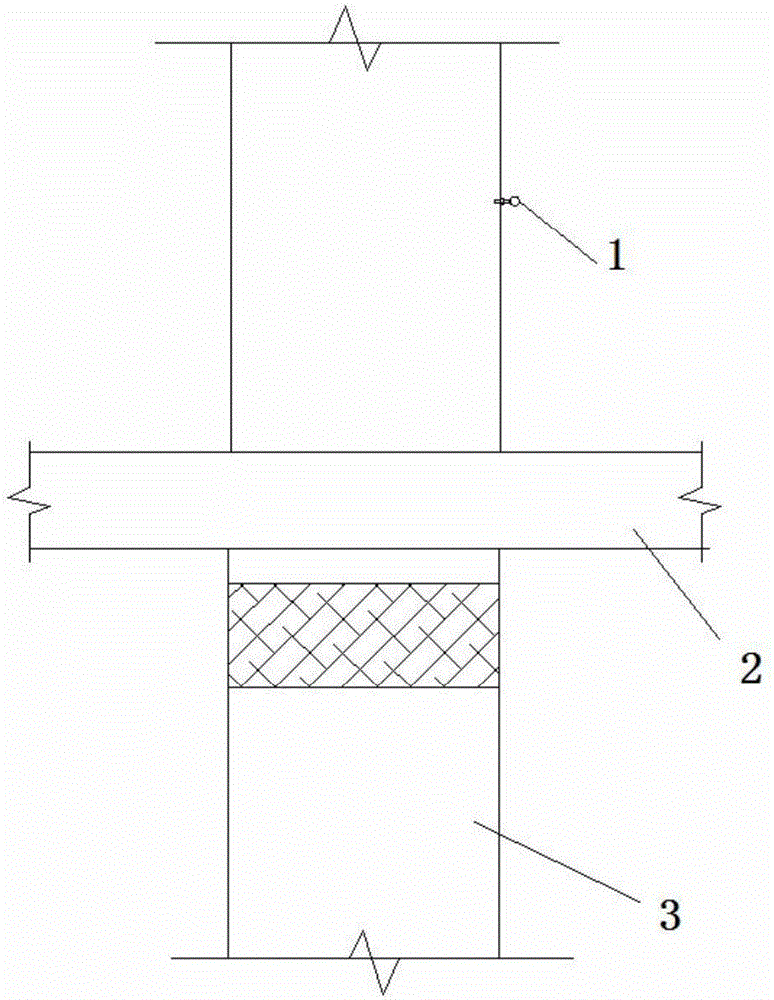

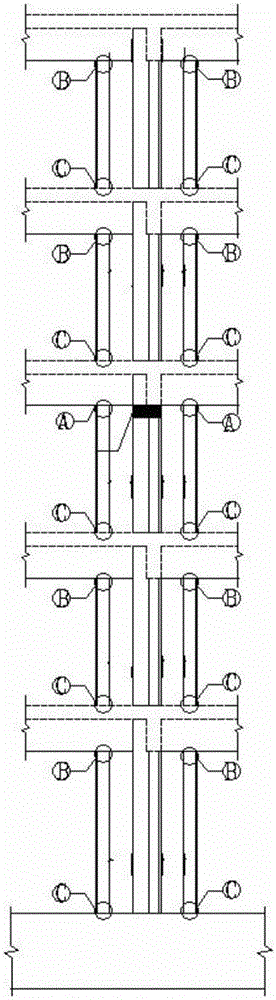

Construction method for partial replacement of concrete column

The invention relates to a construction method for partial replacement of a concrete column. The construction method comprises the following steps that construction is prepared, partition paying off and numbering are conducted, a settlement observation point is set, a temporary support system is erected, a safety support system and a workbench are erected, partial concrete of the column is chiseled away, interface processing is conducted, formwork mounting is conducted, concrete casting and tamping is conducted, formwork dismantling and concrete curing are conducted, and off-load support is dismantled. Displacement and settlement of an upper structure of a replacement region can be eliminated or reduced, concrete with low strength or serious defects is chiseled away, casting is conducted by adopting expansive concrete which is one strength grade higher than original replacement region concrete and good in the self-flow property. Compared with the prior art, the method has the advantages that construction is simple, quick, and easy to grasp, and construction comprehensive cost is low; the quality and construction progress can be guaranteed, and higher application and popularization value is achieved.

Owner:广西建工第一建筑工程集团有限公司

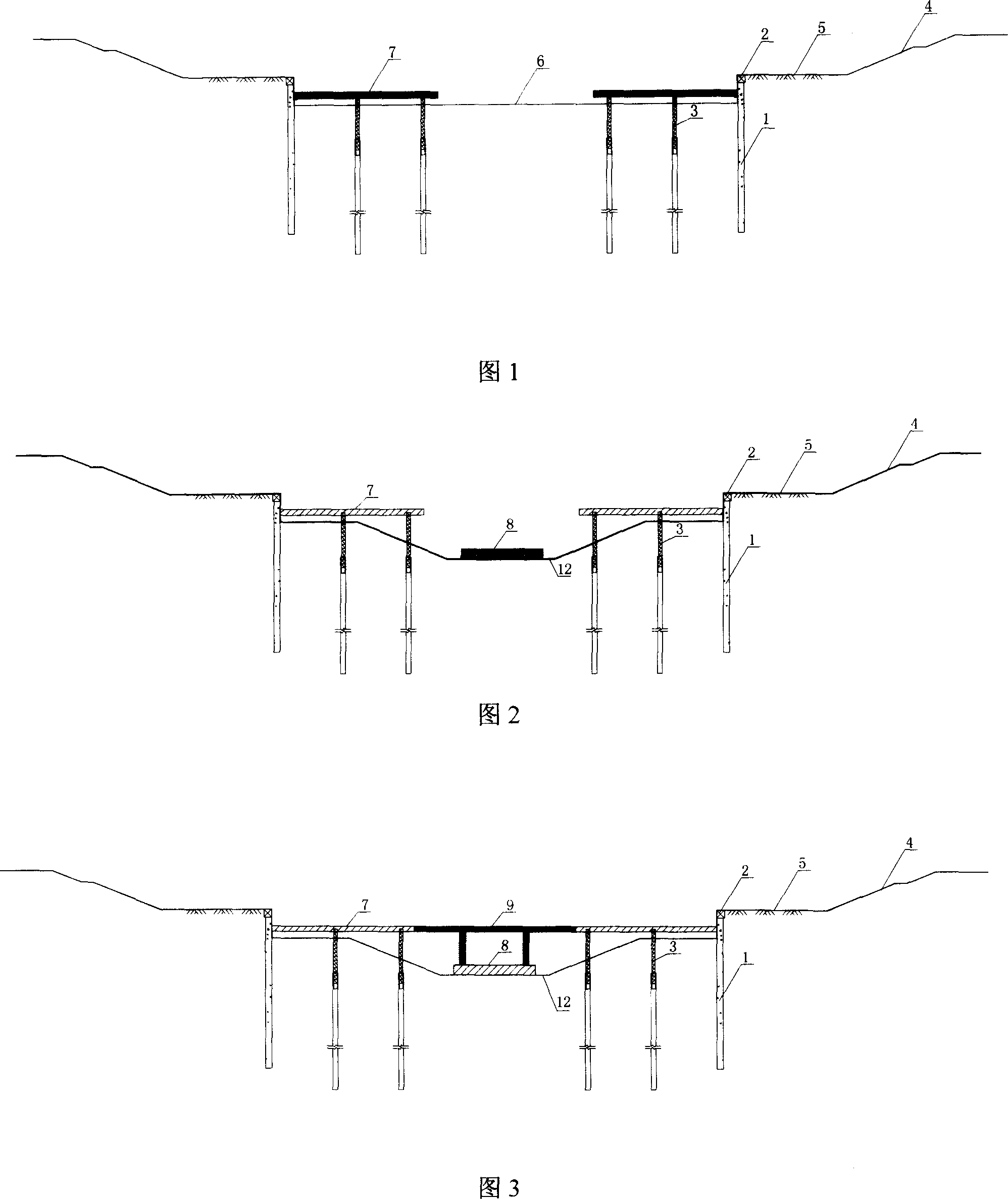

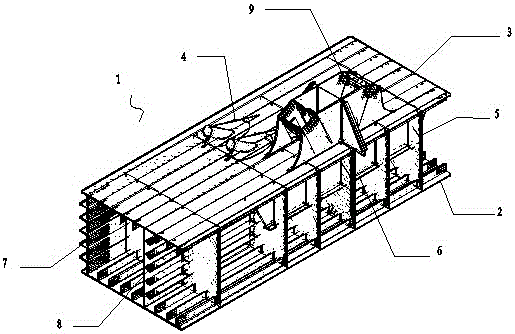

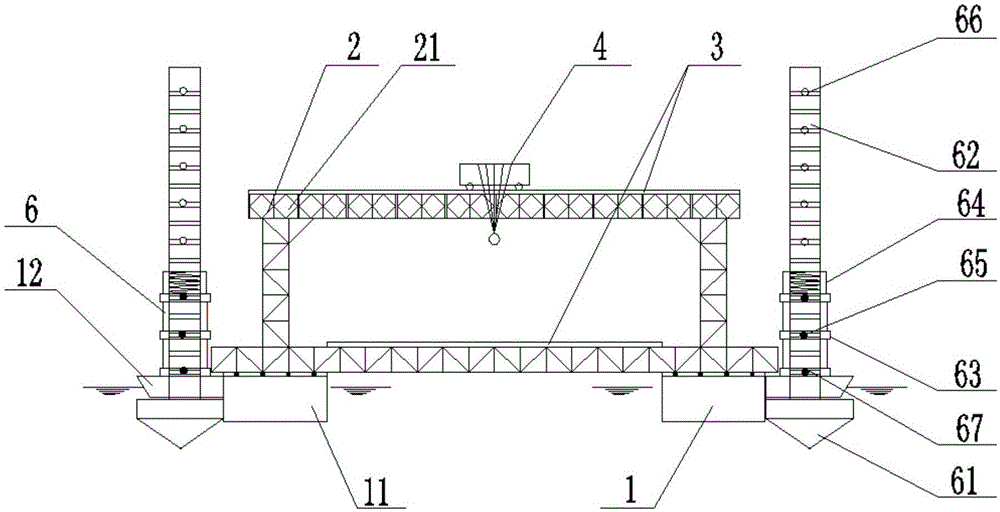

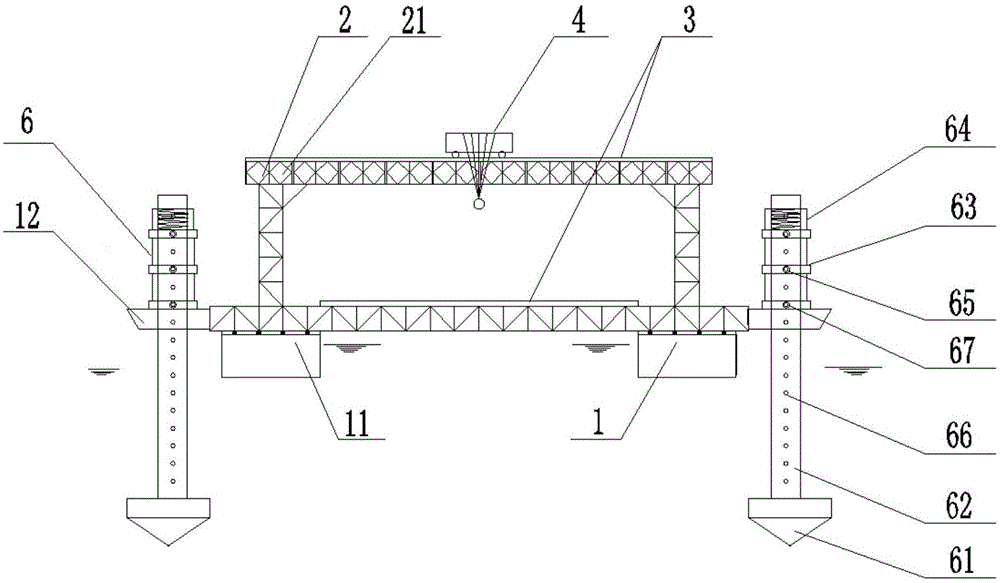

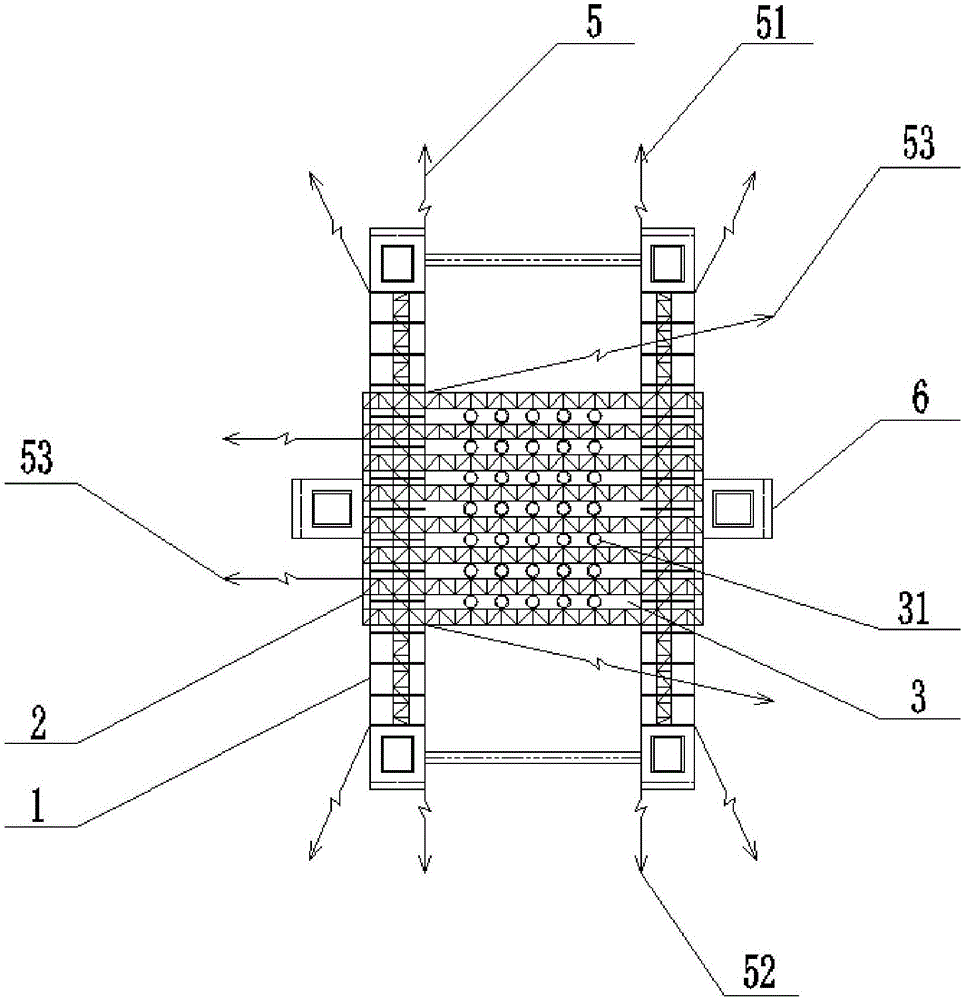

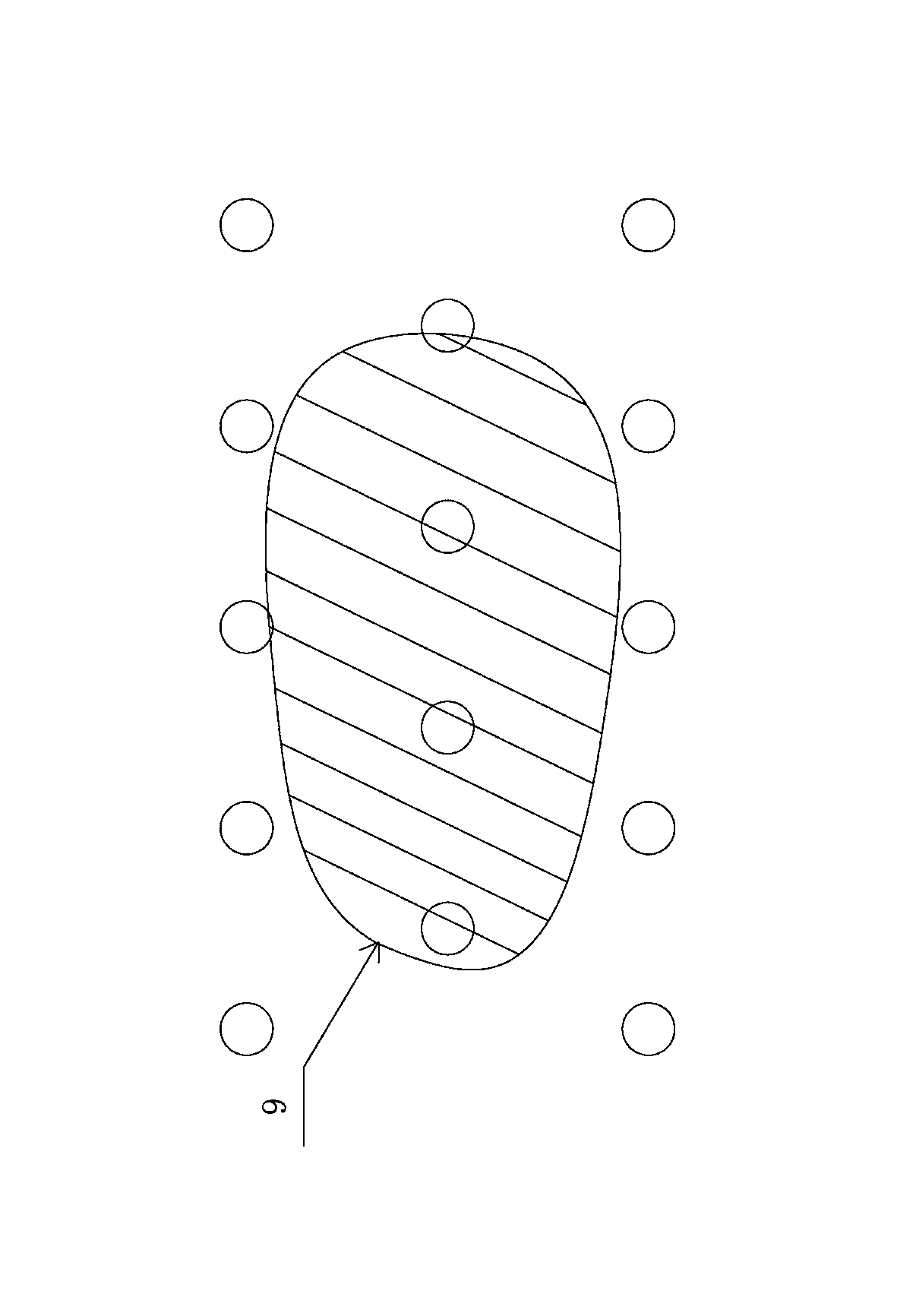

Movable construction platform for bridge foundation building

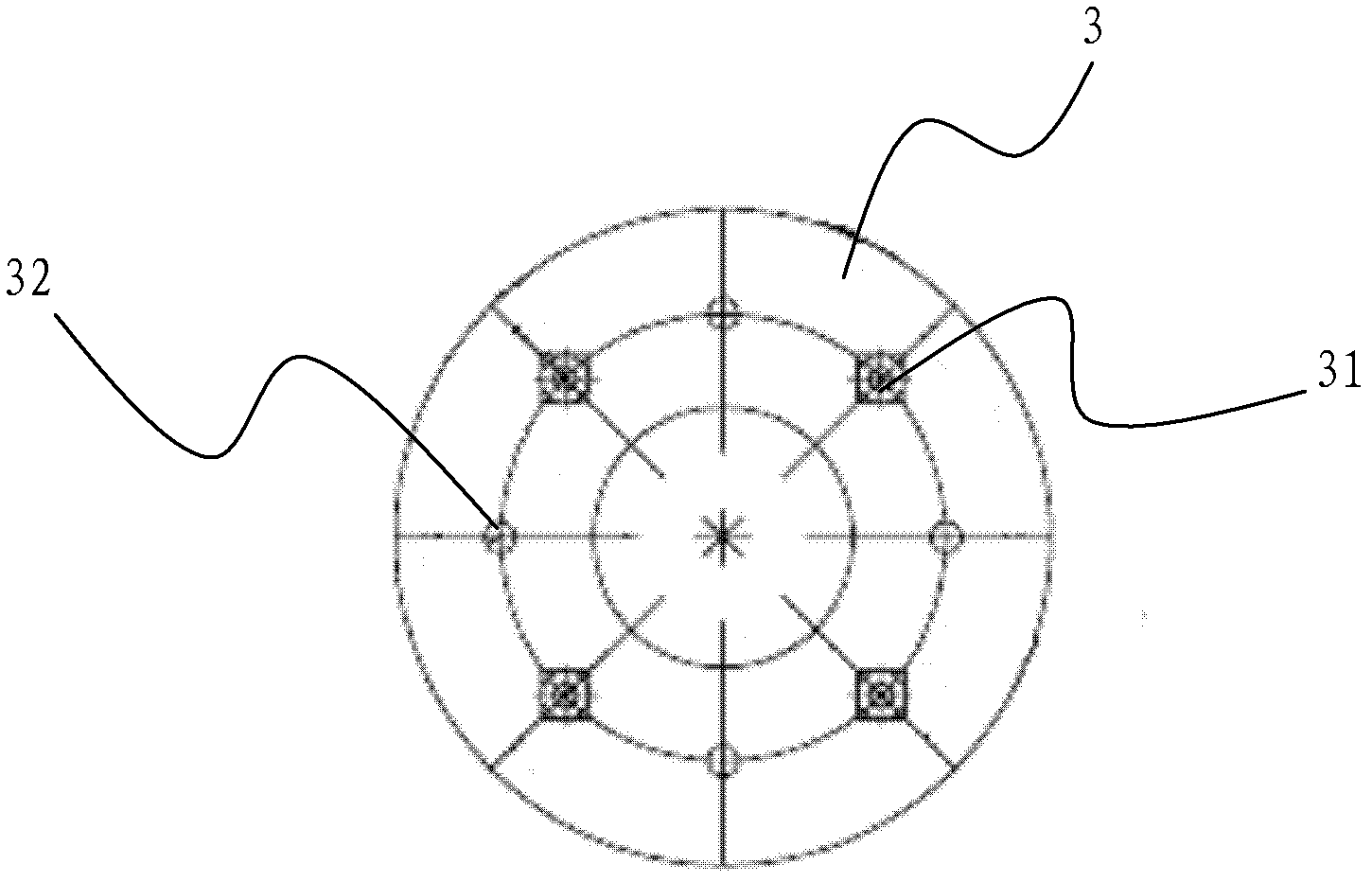

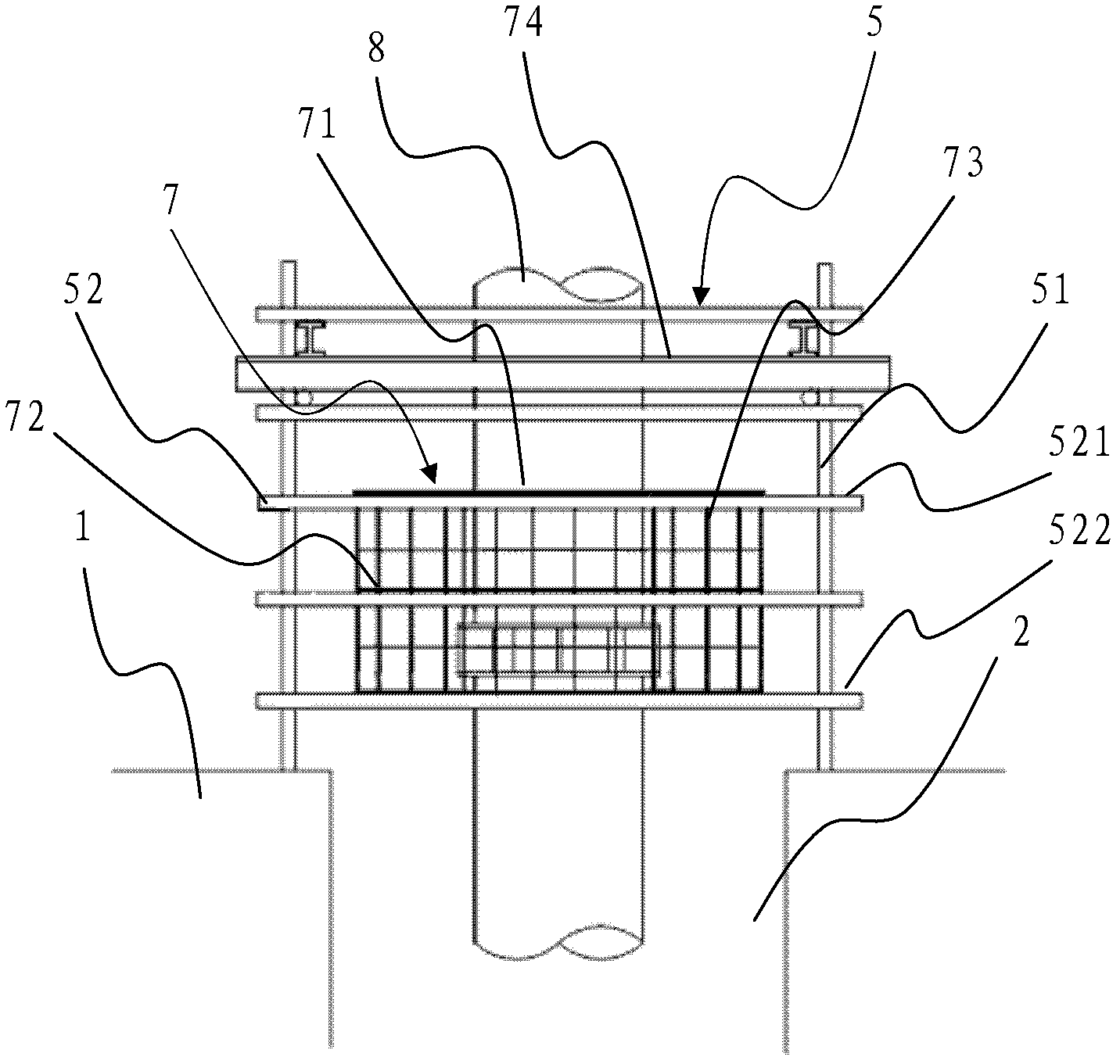

InactiveCN105088964AEasy to moveAdjustable shiftBridge erection/assemblyBulkheads/pilesBraced frameBody system

The invention provides a movable construction platform for bridge foundation building. The movable construction platform for bridge foundation building comprises floating bodies, horizontal support frameworks, horizontal backing plates, a lifting system, temporary fixing devices and support body systems; the horizontal support frameworks are laid on the upper surfaces of the floating bodies, the horizontal backing plates are laid on the upper surfaces of the horizontal support frameworks, filling pile holes formed according to bridge foundation building are formed in the horizontal backing plates, the lifting system is erected on the horizontal backing plates, and the support body systems are arranged on the peripheries of the floating bodies; each support body system comprises an anchor head, a support leg, support seats, hydraulic lifting equipment and bolt pins, wherein bolt pin holes longitudinally extending in a separated mode are formed in the support leg, through holes correspondingly communicated with the bolt pin holes are formed in the support seats, and the bolt pins are correspondingly inserted into the bolt pin holes and the through holes which are communicated with each other. The movable construction platform for bridge foundation building has the advantages that the platform can be steadily and firmly fixed on the construction water surface, cannot be shaken under the influences of tides or waves when construction is performed and is suitable for arrangement of various filling piles in bridge building; in addition, the size of the platform can be regulated, and construction is easy.

Owner:CHINA RAILWAY CONSTR BRIDGE ENG BUREAU GRP

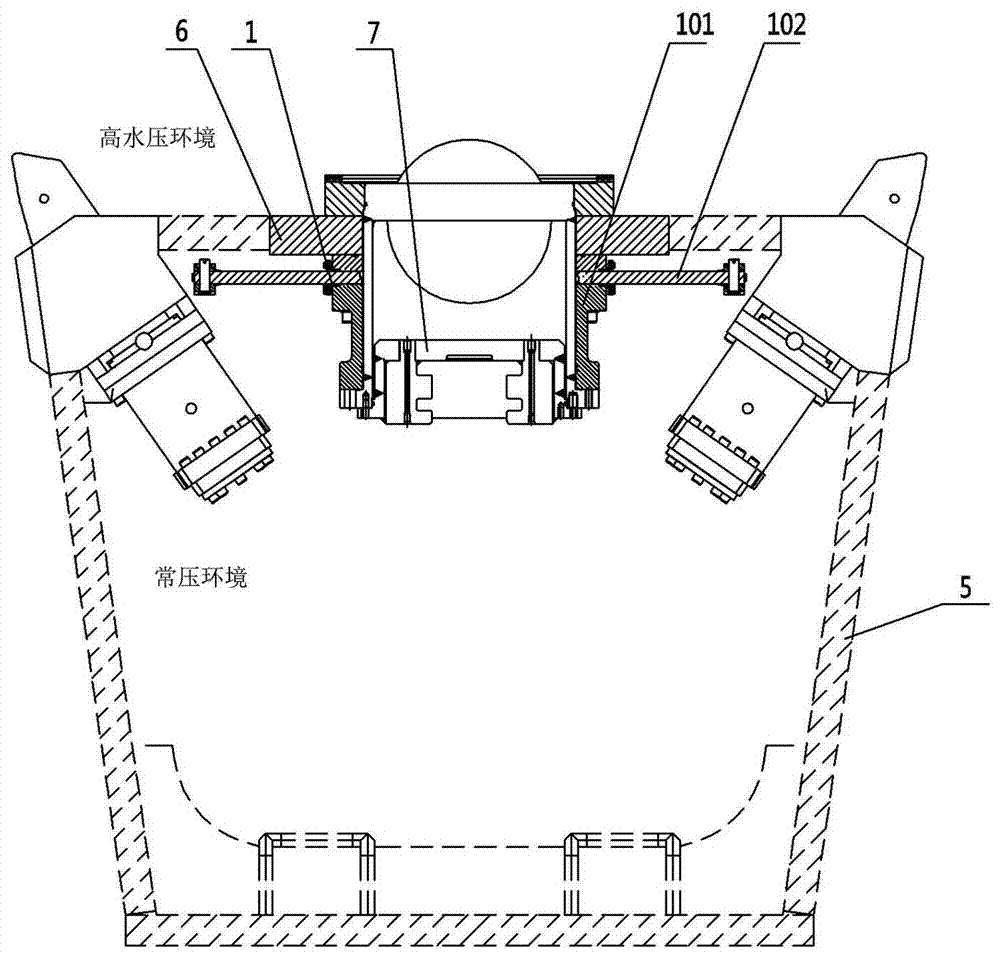

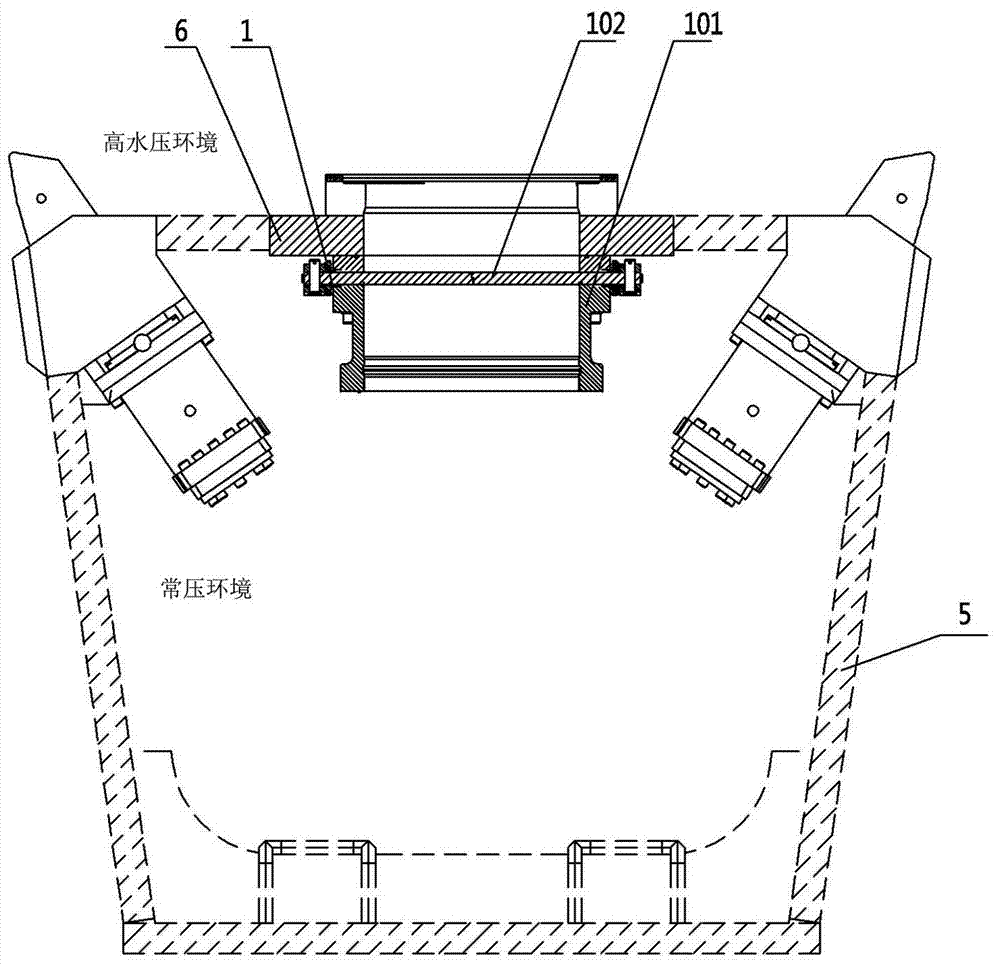

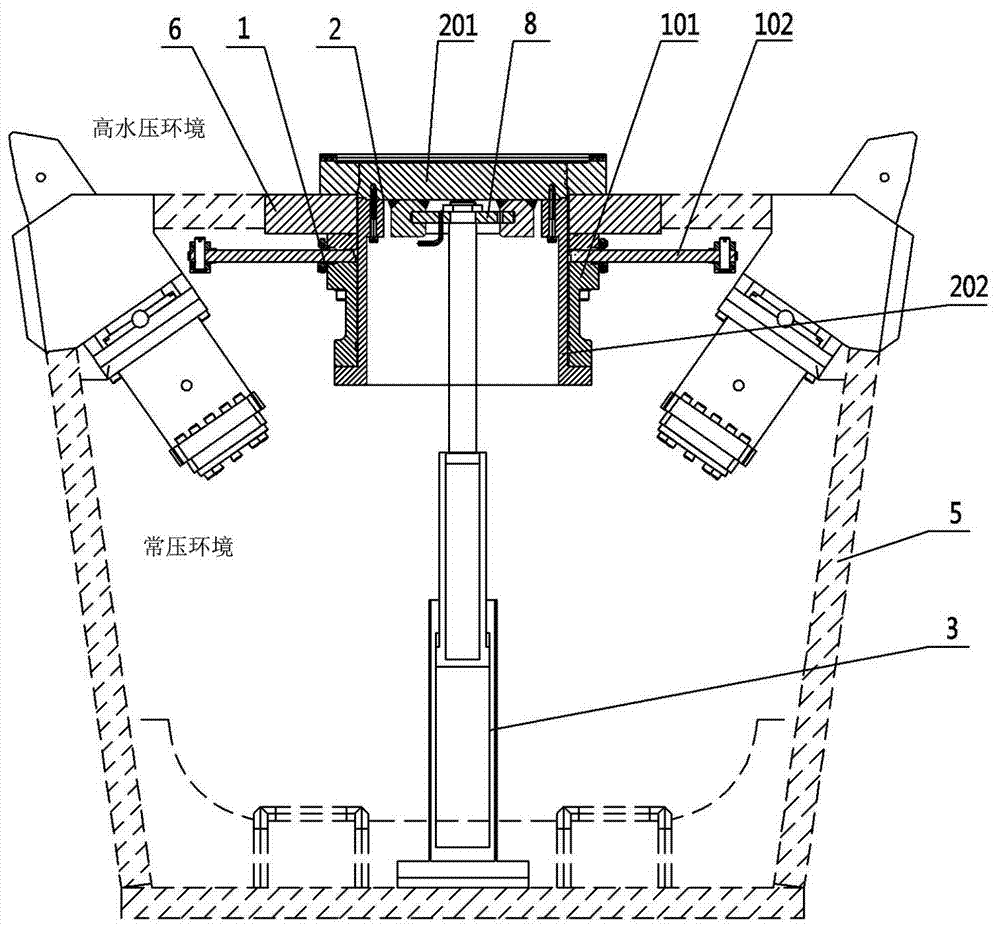

Sealed replacing tool and method of ordinary-pressure cutter replacement device of shield tunneling machine

The invention relates to the technical field of tunneling machines, in particular to a sealed replacing tool and method of an ordinary-pressure cutter replacement device of a shield tunneling machine. The sealed replacing tool of the ordinary-pressure cutter replacement device of the shield tunneling machine comprises a supporting oil cylinder, a seal barrel and a supporting seat. The seal barrel comprises a barrel front cover and a barrel back support. The barrel back support is connected into a cutter replacement supporting barrel of the ordinary-pressure cutter replacement device in a sleeved manner. A supporting oil cylinder is vertically arranged at the center of the lower end of the barrel front cover. The supporting oil cylinder and the barrel front cover are fixedly connected through an arranged supporting shoe clamping block. A supporting seat is of an annular supporting structure which is formed by splicing two semicircles. The bottom of the supporting seat can be fixedly connected with a welded seat through bolts. The sealed replacing tool and method of the ordinary-pressure cutter replacement device of the shield tunneling machine solves the problem that in the construction process in a high water pressure stratum, when seal of the ordinary-pressure cutter replacement device is ineffective and needs to be replaced, in the construction process, the practical function of the ordinary pressure cutter replacement device is guaranteed, and therefore the safety of ordinary pressure cutter replacement is guaranteed when the shield tunneling machine conducts construction in the high water pressure stratum.

Owner:CHINA RAILWAY ENGINEERING EQUIPMENT GROUP CO LTD

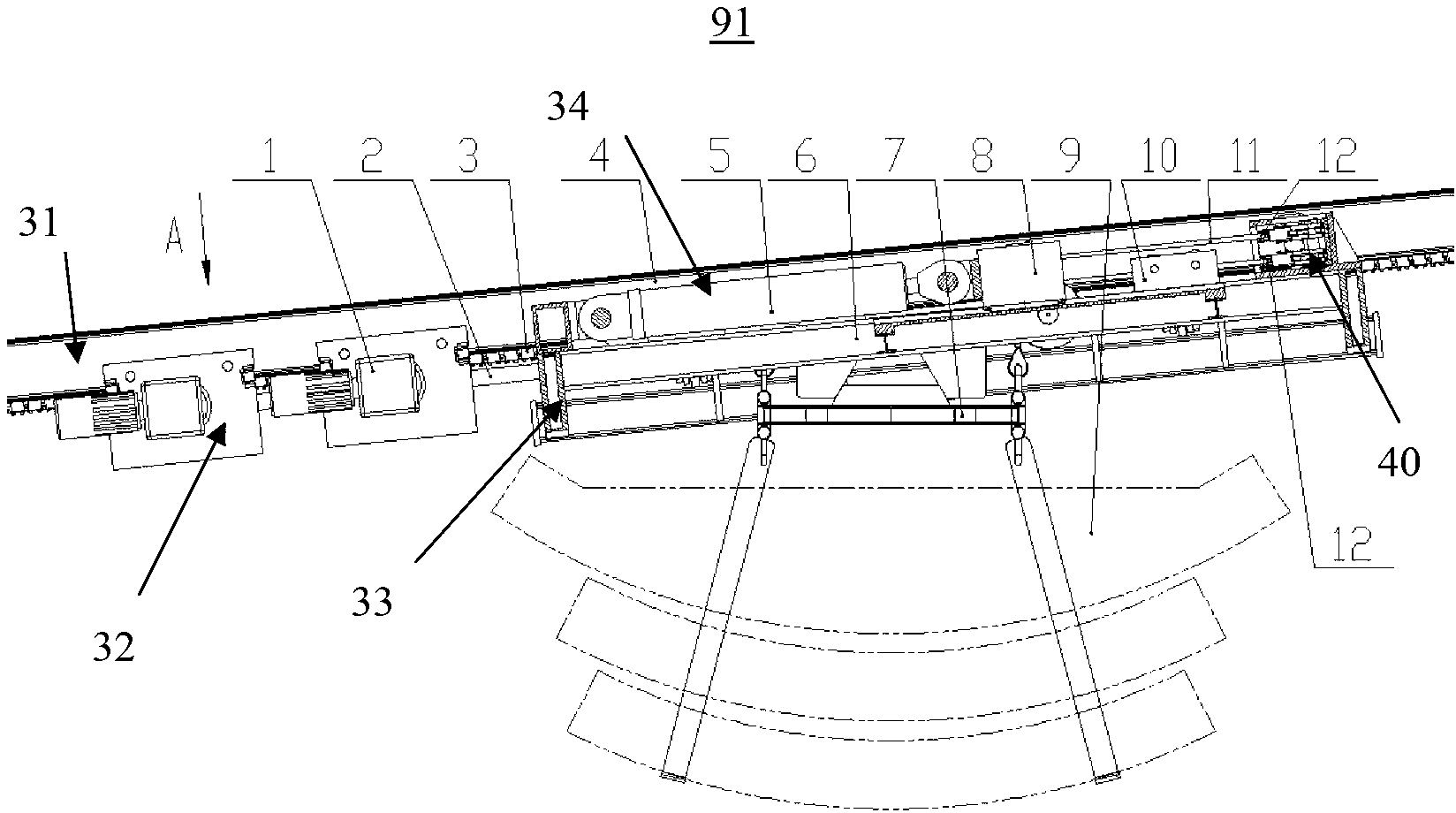

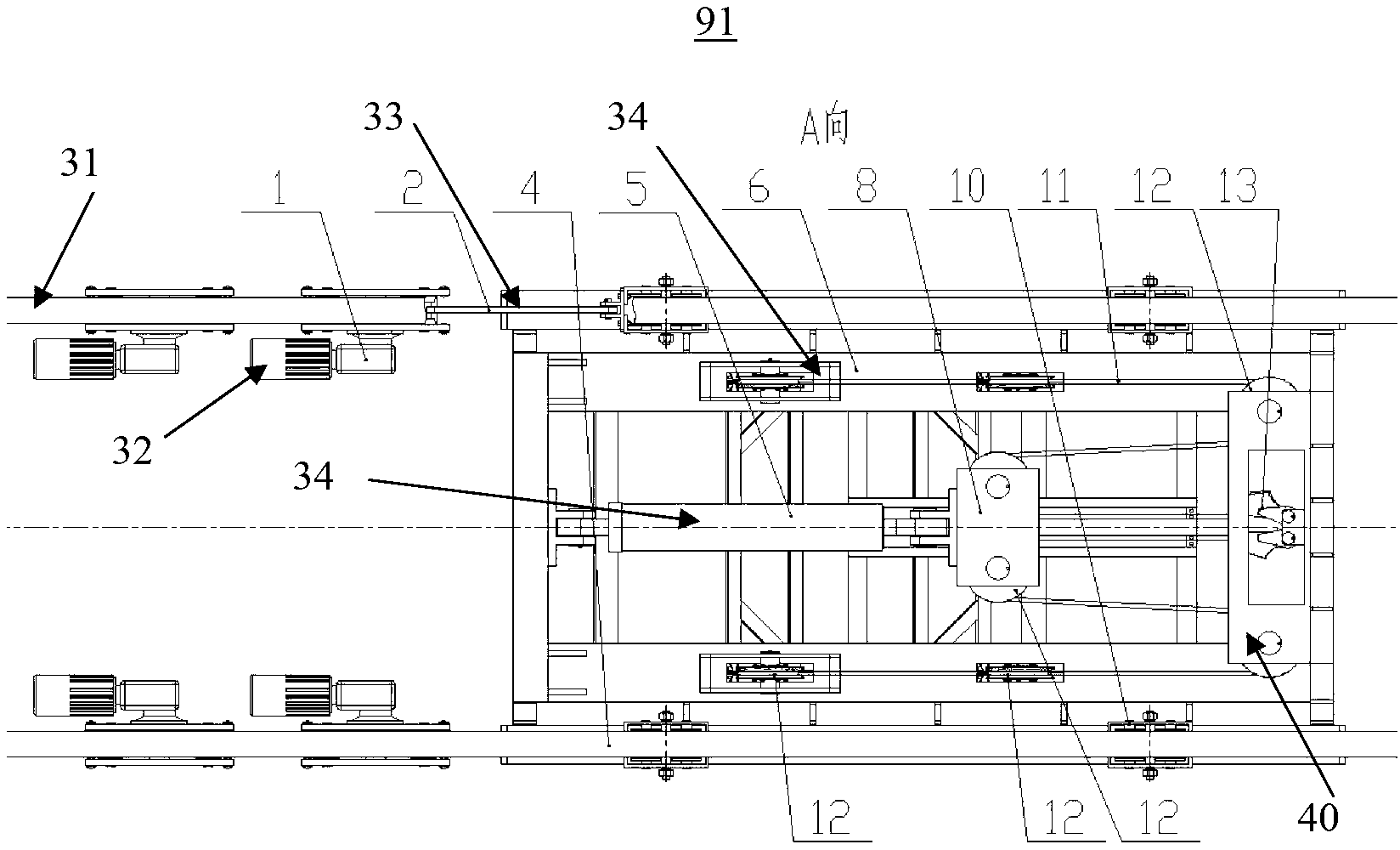

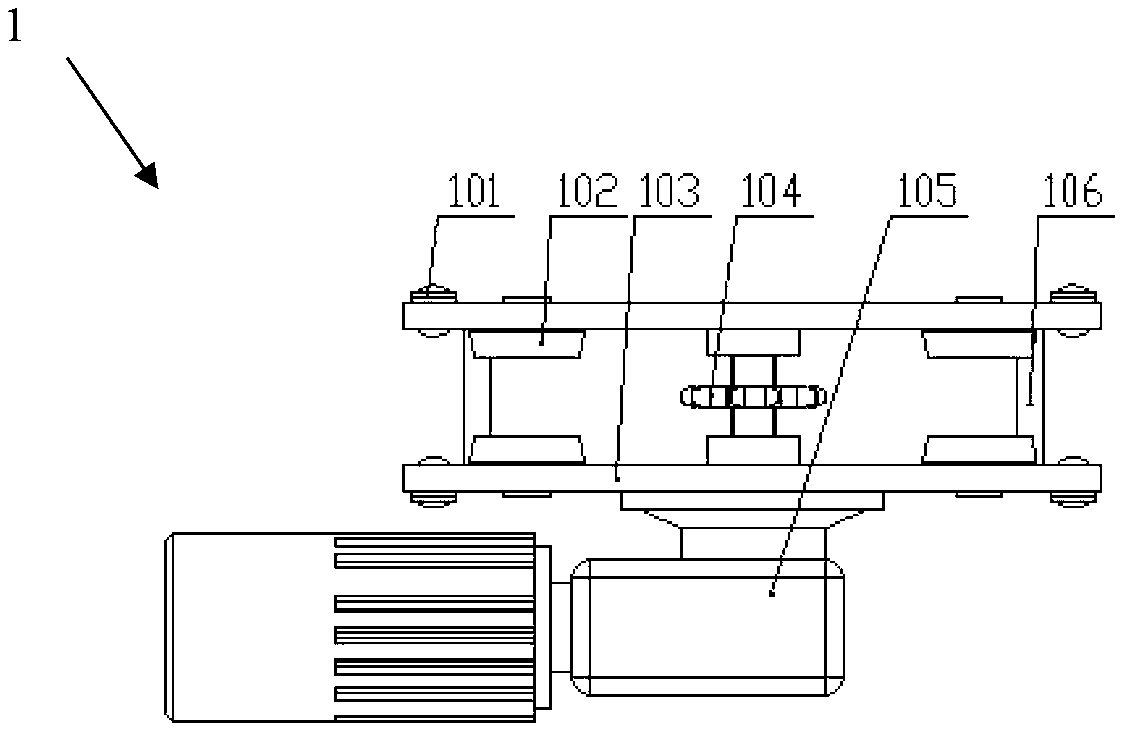

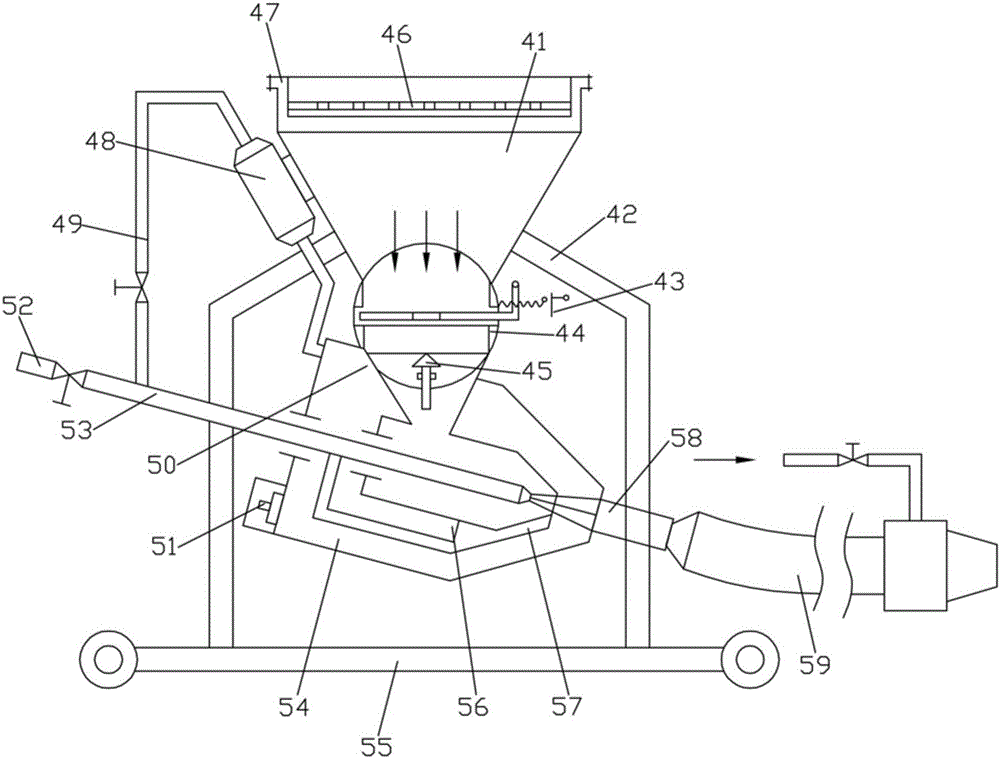

Material hoisting device for tunnel boring machine

ActiveCN103233752ASimple structureSmall footprintUnderground chambersTunnel liningTunnel boring machineEngineering

The invention relates to a material hoisting device for a tunnel boring machine. The material hoisting device for the tunnel boring machine comprises a guide rail mechanism, a power mechanism, a driven mechanism and a craning mechanism, wherein the guide rail mechanism comprises a guide rail and a first transmission part, the power mechanism comprises a power device and a connecting rod, the driven mechanism comprises a driven device and a driven machine frame, the craning mechanism comprises a balance frame, a hydraulic cylinder and a reverser. The reverser comprises a pulley wheel, a steel wire rope and a pulley wheel seat. Extension motion of the hydraulic cylinder is converted into lifting motion of the balance frame through the reversing of the steel wire rope and the pulley wheel, and accordingly material lifting is achieved. The power device and the first transmission part perform matched motion through the second transmission part to produce stable power, the stable power is acted on the driven mechanism through the connecting rod to enable the driven mechanism to drive the whole hoisting device to move together with the driven mechanism, and accordingly transportation of materials in the track direction is achieved. The material hoisting device for the tunnel boring machine has the advantages of being simple in structure, safe, reliable and high in efficiency, the problem that the materials and multiple tube pieces cannot be stably hoisted in a limited space at the same time is solved, and accordingly a construction schedule and the construction efficiency of the tunnel boring machine are guaranteed.

Owner:CHINA RAILWAY CONSTR HEAVY IND

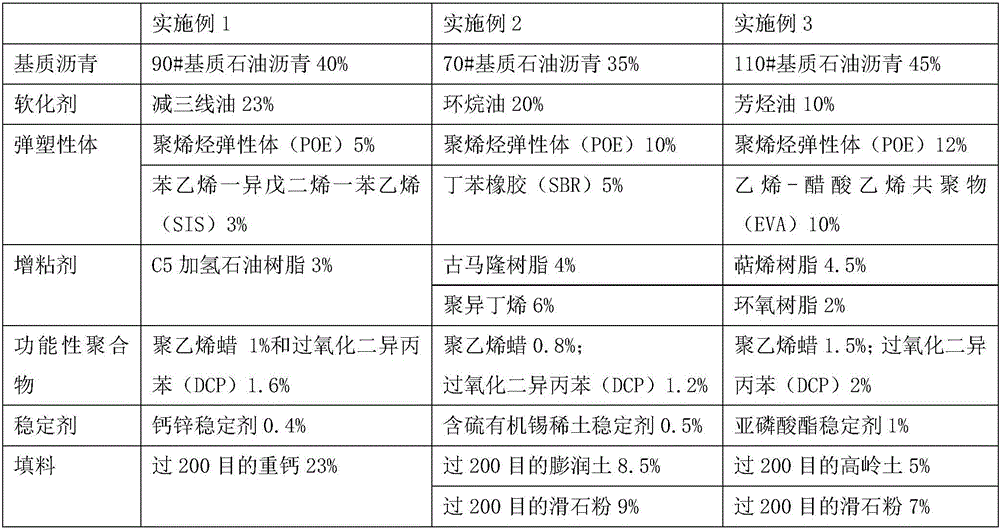

Non-cured rubber asphalt waterproof paint and preparation method thereof

InactiveCN106634602ANot affected by adhesive propertiesImprove thermal stabilityBituminous coatingsBituminous waterproofingPolymer science

The invention discloses a non-cured rubber asphalt waterproof paint and a preparation method thereof. The preparation method comprises the following steps: 1) weighing a matrix asphalt, a softener, an elastic plastic body, an adhesion agent, a functional polymer, a stabilizing agent and a filling material; 2)injecting the matrix asphalt to a reaction vessel, heating the materials, stirring the materials, adding the softener, and stirring the materials; 3) adding the obtained mixture and the elastic plastic body in a colloid grinder, growing the materials, opening the colloid grinder, grinding the materials, and continuously growing the materials; 4) adding an adhesion agent and a functional polymer, continuously stirring the materials; 5) adding a filling material and stirring the materials; and 6) adding a stabilizing agent, and stirring the material. The paint has high heat resistance, good construction property, good thermostability, chemical stability and anti-ultraviolet aging capability, bond property is not influenced due to extraneous environment, the paint has construction property for a wet basic layer, can increase the interfacial affinity interaction with the wet basic layer, and construction quality and progress can be effectively guaranteed, and the paint is environmentally friendly.

Owner:LOGISTICS UNIV OF CAPF

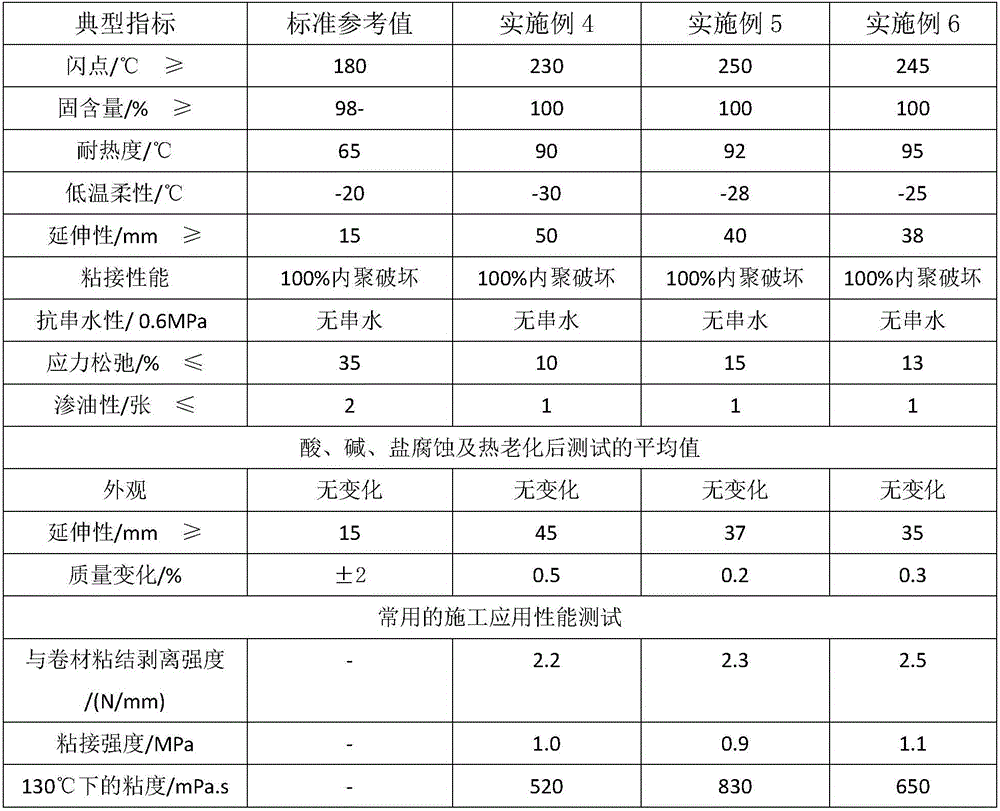

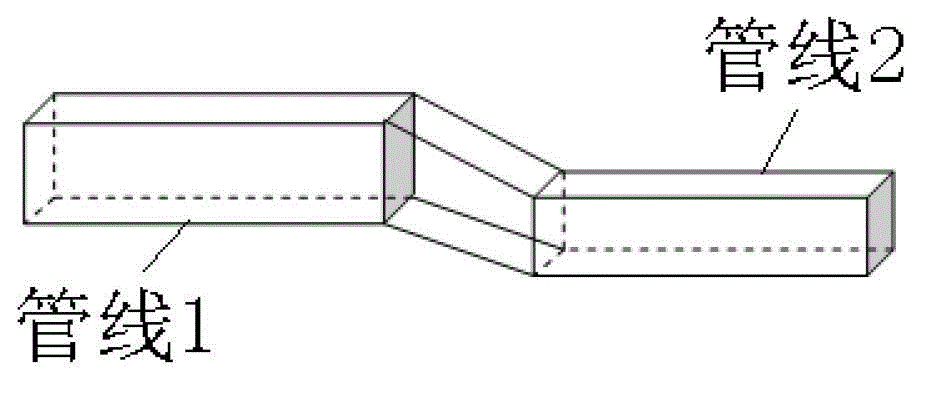

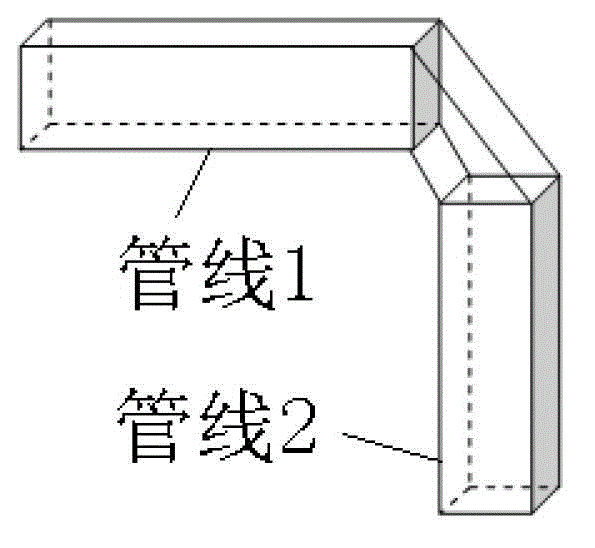

Underground integrated pipeline non-standard rectangular connector determination method based on BIM (Building Information Modeling)

InactiveCN102945294AQuick and automatic generationAccurate and automatic generationSpecial data processing applicationsEngineeringThree dimensional model

The invention discloses an underground integrated pipeline non-standard rectangular connector determination method based on BIM (Building Information Modeling), which is implemented according to the following steps: step 1, creating an underground integrated pipeline model based on the BIM, and reserving space for the non-standard rectangular connector; step 2, automatically obtaining the specifications of all pipelines; step 3, obtaining the spatial coordinates of the pipelines; step 4, determining two ports connected with the non-standard rectangular connector; step 5, calculating the spatial coordinates of two pipelines corresponding to four vertices of the ports; and step 6, determining four planes according to all vertices, so as to obtain a three-dimensional model of the non-standard rectangular connector connecting the two pipelines. Through adoption of the method of the invention, the rectangular connector is quickly, exactly and automatically generated in a BIM platform according to spatial positions of the two pipelines, which improves designing efficiency and quickens construction progress.

Owner:SHANGHAI PROJECT MANAGEMENT CO LTD

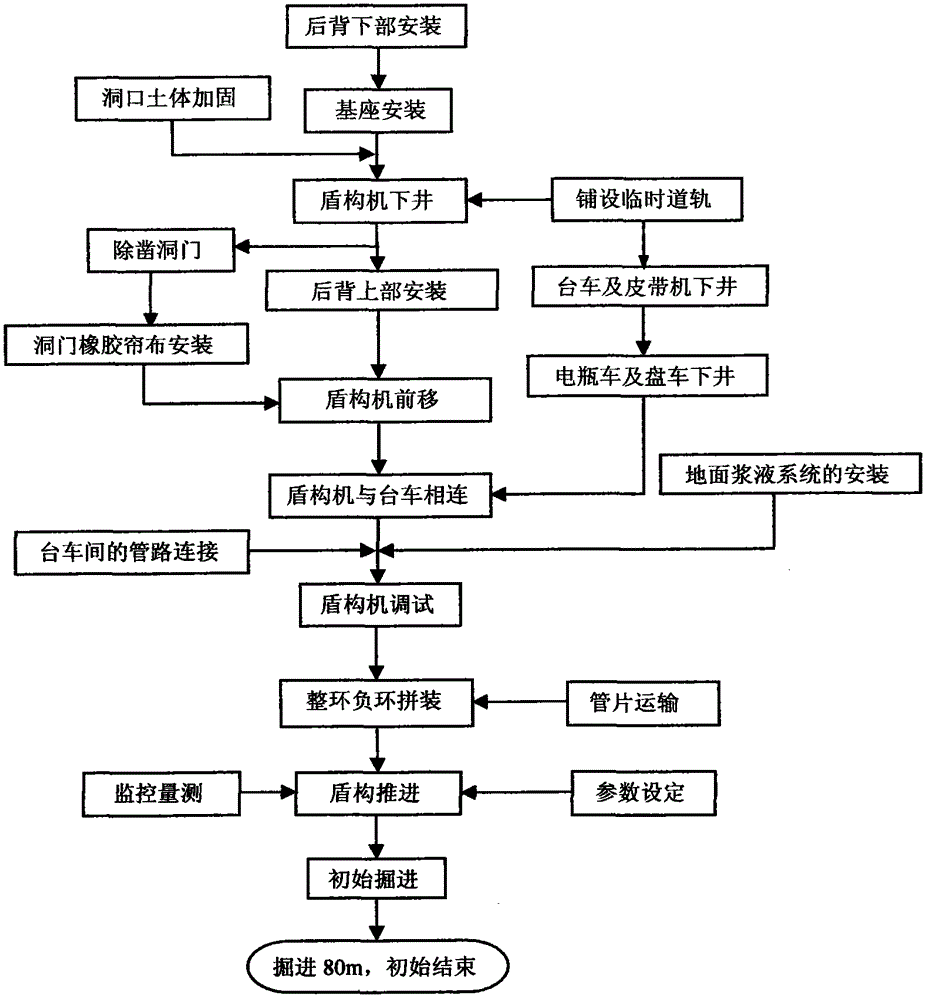

Small-radius shield curve launching construction technology on gravel clay layer

ActiveCN104912560AGuarantee the construction progressEnsure safetyUnderground chambersTunnel liningAttitude controlEngineering

A small-radius shield curve launching construction technology on a gravel clay layer relates to the technology of construction processes on a gravel clay layer, and comprises the following steps: 1, selecting a launching path; 2, reinforcing launching end stratum; 3, chiseling off a launching end portal; 4, mounting the launching end portal in a sealing manner; 5, mounting a launching base; 6, splicing partial segments; 7, mounting a reaction frame; and 8, controlling the shield curve launching posture. The small-radius shield curve launching construction technology is simple in process and reasonable in design, ensures continuous normal working of a shield, guarantees the launching quality and the tunnel construction progress and security and improves the economical benefits.

Owner:BEIJING NO 4 MUNICIPAL CONSTR ENG +1

Steel pipe column bearing table girder connection construction method

ActiveCN102505846AFast processingEnsure three-dimensional space positionBuilding material handlingRebarBuilding construction

The invention discloses a steel pipe column bearing table girder connection construction method. The method comprises the following steps of: paving a bottom plate cushioning layer; mounting a steel pipe column bottom plate in a bearing table foundation pit; building a bearing table ring girder reinforcing steel bar processing frame around the bearing table foundation pit; binding bearing table ring girder reinforcing steel bars on the bearing table ring girder reinforcing steel bar processing frame; setting a foundation beam supporting frame between a ring girder and a main girder connection; binding foundation girder reinforcing steel bars on a foundation girder supporting frame; hoisting a steel pipe column into each bearing table ring girder reinforcing steel bar and welding the steel pipe column on the steel pipe column bottom plate; and unloading the bearing table ring girder reinforcing steel bars and the foundation girder reinforcing steel bars as a whole. Due to the adoption of the steel pipe column bearing table girder connection construction method, the steel pipe column bearing table girder connection construction method which is convenient for construction is realized. The method has the advantages of convenience and quickness in construction, high construction speed, high quality and high stability.

Owner:CHINA CONSTR EIGHT ENG DIV CORP LTD

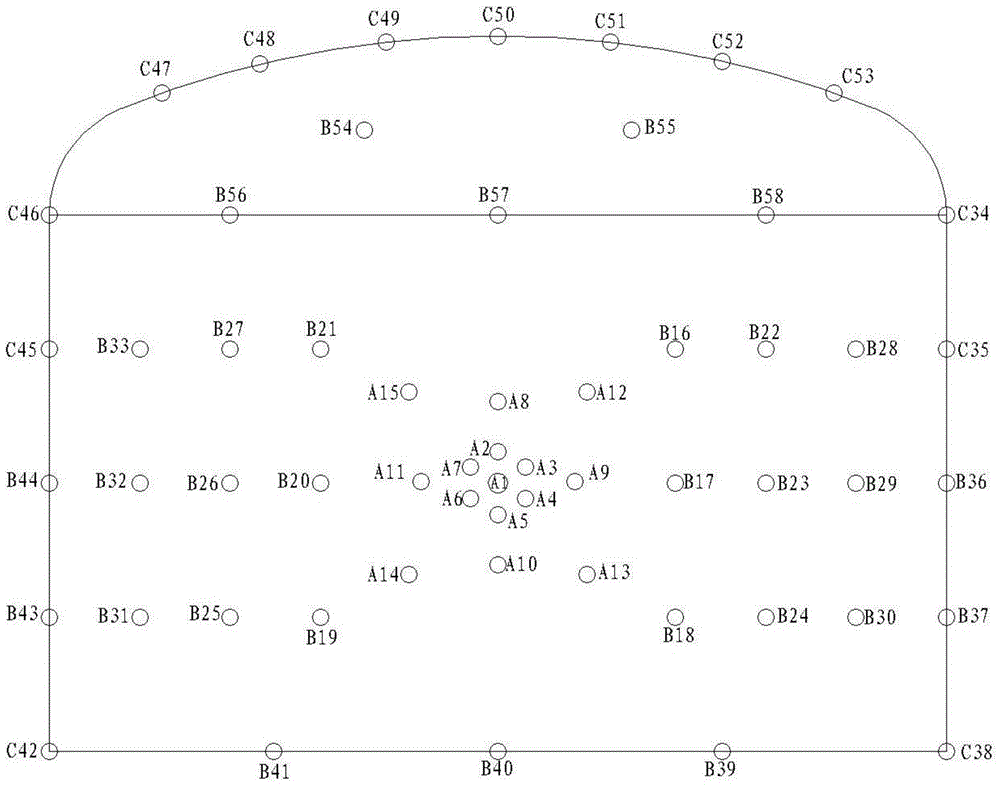

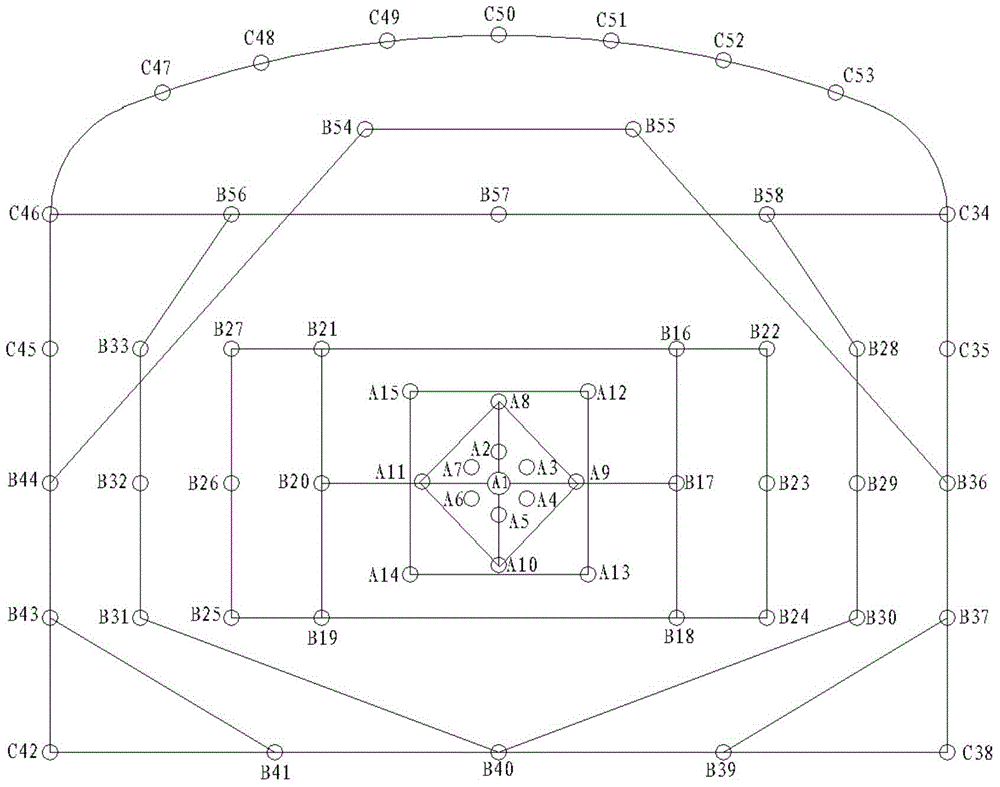

One-time-formed smooth blasting method for laneway

ActiveCN104613830AWeaken mutual clamping effectLarge compensation spaceBlastingDrill bitComputer science

The invention belongs to the technical field of laneway blasting, and particularly relates to a one-time-formed smooth blasting method for a laneway. The method comprises the steps of firstly tunneling into the rock stratum, then laying out breaking-in holes, brukup boreholes and periphery holes, and detonating in sequence after powder charging. According to the method, the rhombic and square combined arrangement mode is adopted, the mutual clamping action among rocks during blasting of all sections can be weakened effectively, regular underholes can be formed, and larger compensation space is provided for subsequent large-scale breaking. According to the method, drill bits of different specifications do not need to be prepared for rock drilling, the underholing process and the blasting network design are advanced, the clamping action among the periphery holes during blasting is lowered, and smooth blasting is achieved; no root is left on the bottom edge of the laneway, the secondary repair amount of the laneway is reduced, the safety and the stability of the laneway are improved greatly, the laneway is formed at a time, labor productivity is improved, and construction progress and construction quality are guaranteed.

Owner:招金矿业股份有限公司夏甸金矿 +1

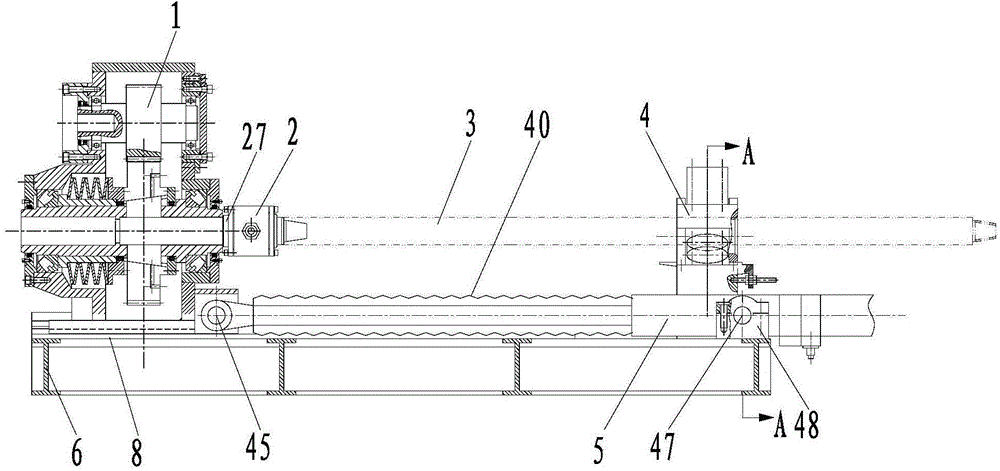

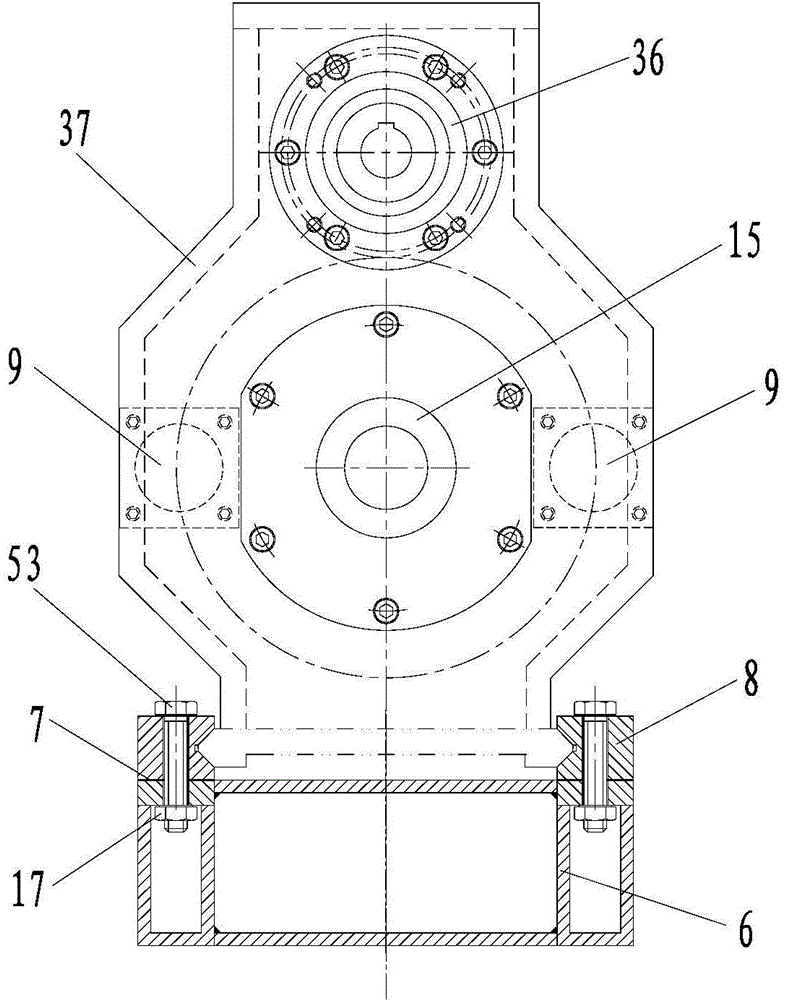

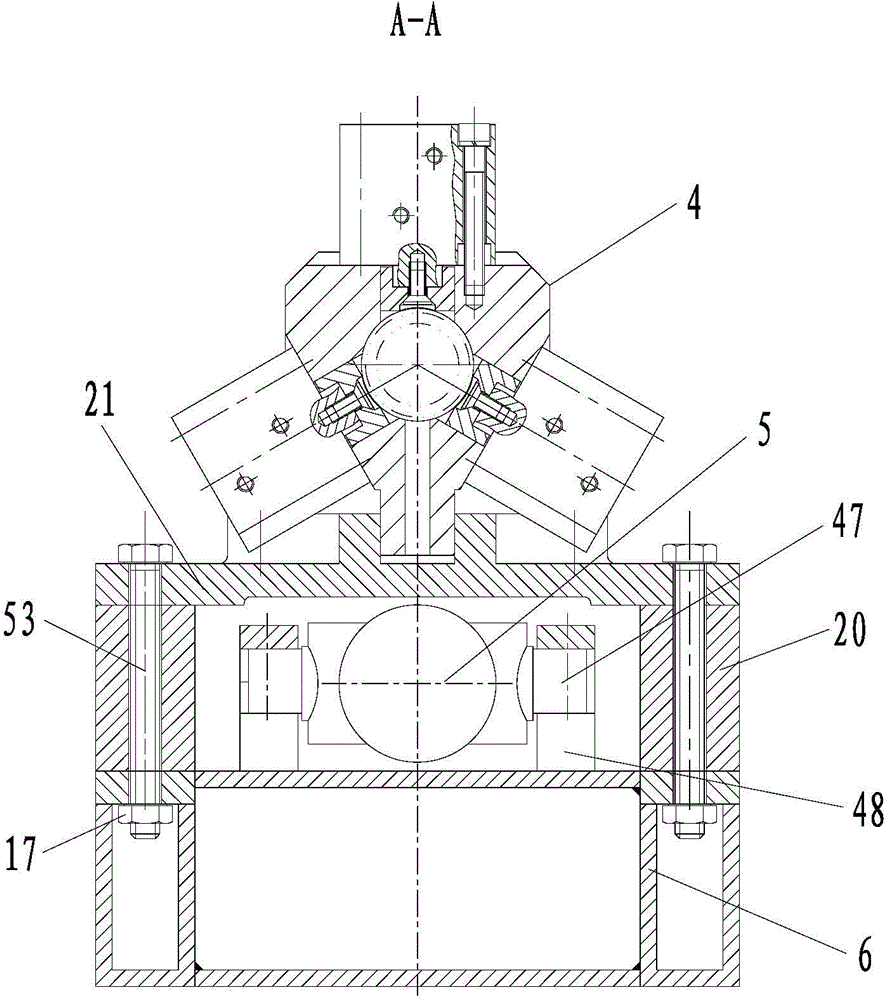

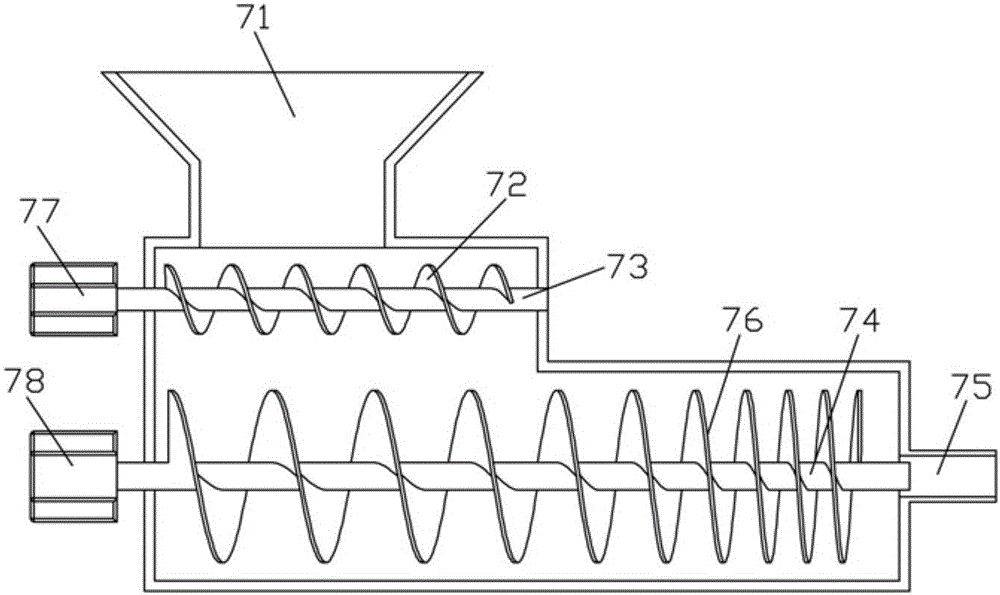

Light-type full-hydraulic drilling machine for underground drilling of coal mine

The invention discloses a light-type full-hydraulic drilling machine for underground drilling of a coal mine. The light-type full-hydraulic drilling machine comprises a stander, a drilling rod, a water braid, a guide rail, a propelling hydraulic cylinder, a hydraulic clamp and a drill power head, wherein the hydraulic clamp comprises a clamp base, a supporting seat, a clamping hydraulic cylinder and a clamp clamping tile; the water braid comprises a water braid shell, a water braid shaft, a water braid hollow shaft, two anti-abrasion ring, an isolating ring, a front end cover, a rear end cover and an anti-abrasion sealing ring; the drill power head comprises a speed reduction box body, a connection frame, a gear shaft, a hollow stepped shaft, a hydraulic motor, a spring mounting seat, a spring limiting seat, an end face check ring, a gear, a disk-type spring group, a power head clamping tile and a clamping hydraulic cylinder. The light-type full-hydraulic drilling machine is compact in structure, convenient and low in cost; the energy consumption is reduced, the power transmission efficiency is improved, and the clamping force on the drilling rod is stable and reliable; the service lives of the anti-abrasion sealing ring and the water braid shaft can be prolonged, the replacement trouble is reduced, the construction progress and safe production are guaranteed, vibration of the drilling machine is reduced, and the drilling rod is prevented from being broken.

Owner:XIAN UNIV OF SCI & TECH

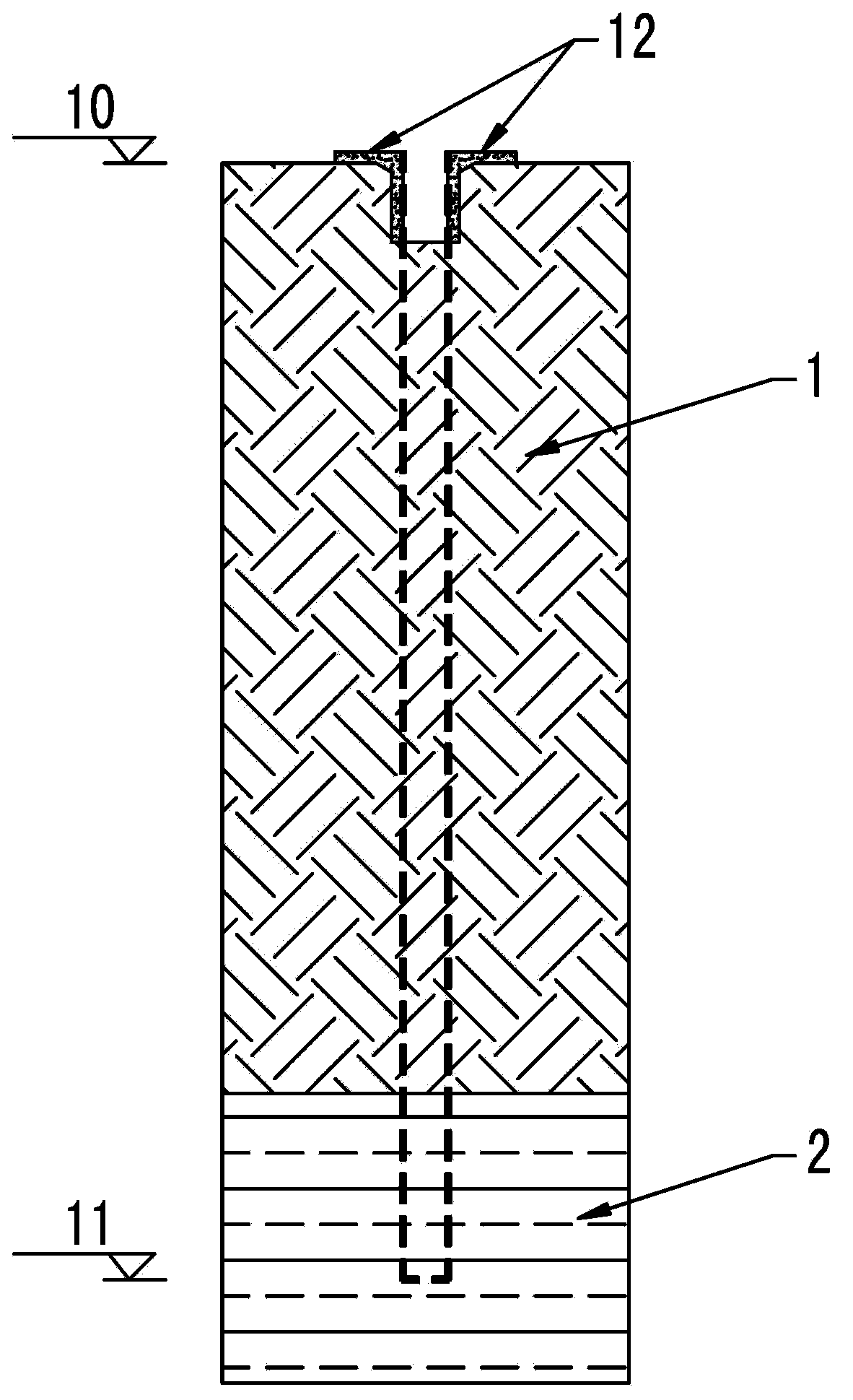

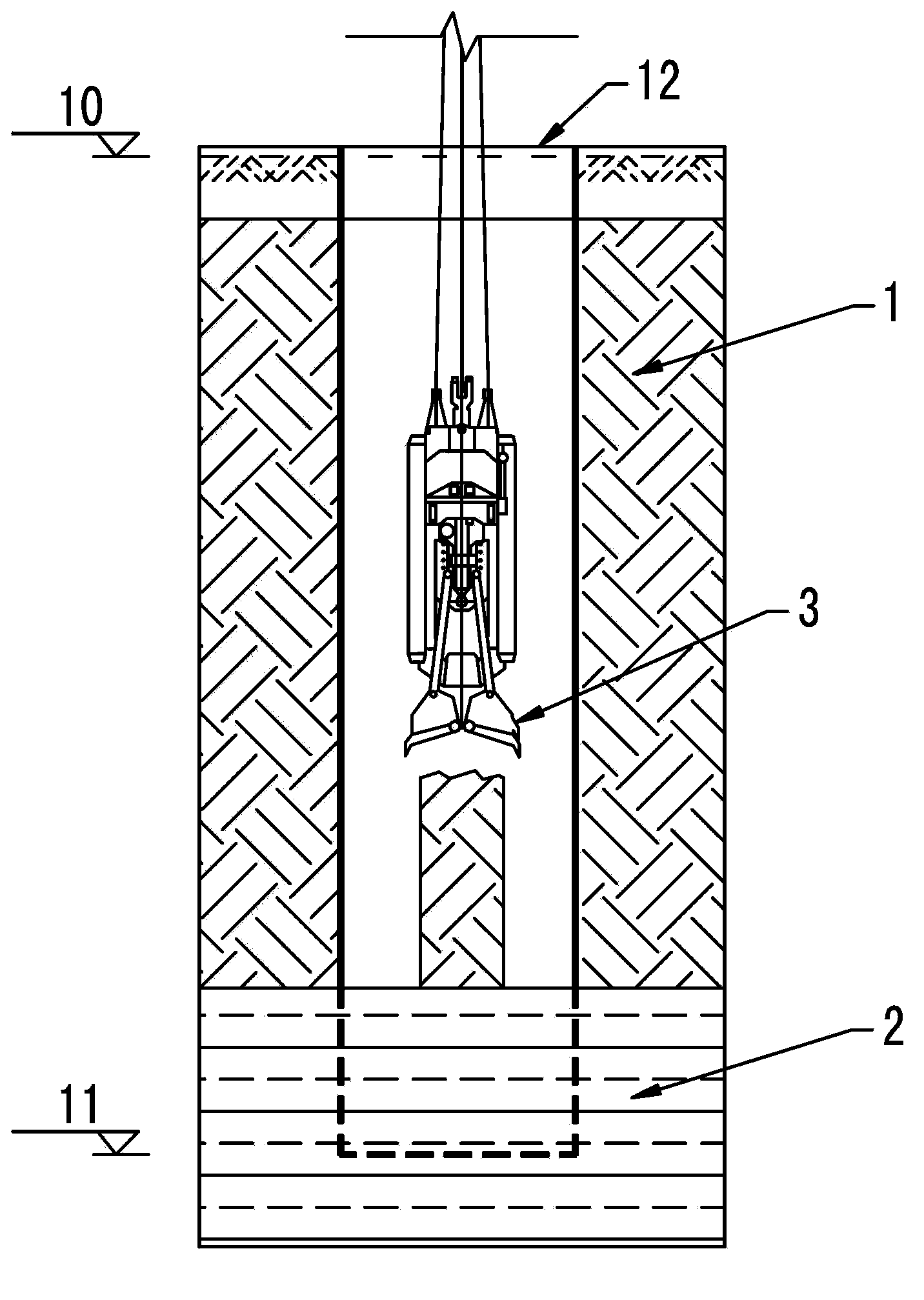

Grabbing, drilling and punching combined underground continuous wall grooving construction method

InactiveCN103774690AGuarantee the construction qualityGuarantee the construction progressArtificial islandsSoil-shifting machines/dredgersSlurry wallPunching

The invention provides an underground continuous wall grooving method under the soft soil and rock stratum combined geological conditions. The underground continuous wall grooving method comprises performing preparation work, wherein the preparation work comprises measurement and positioning, wall guide construction, division of groove sections of the underground continuous wall and slurry preparation; grabbing and digging the upper portion soft soil in the groove sections after slurry is injected into the groove sections and enabling the slurry to be added into groove holes along with unearthing; performing drilling and cutting on bottom hard rock stratums in the groove sections; breaking up the drilled hard rock stratums through a square hammer punching machine and performing groove repair; performing hole cleaning and hole cleaning acceptance by a slurry circulation method. According to the grabbing, drilling and punching combined underground continuous wall grooving construction method, grabbing, drilling and punching are combined with each other, grooving construction is performed on the different hardness of rock stratums through different constriction machines under the condition that the quality of the underground continuous wall grooving construction is ensured, and accordingly the construction capability of various common machines is fully utilized and the construction progress and quality of grooving is ensured; the influence on the surrounding environment of the punching grooving vibration can be effectively reduced; an expensive underground continuous wall groove milling machine does not need to be utilized and accordingly the construction cost can be effectively reduced.

Owner:SHANGHAI CONSTRUCTION GROUP

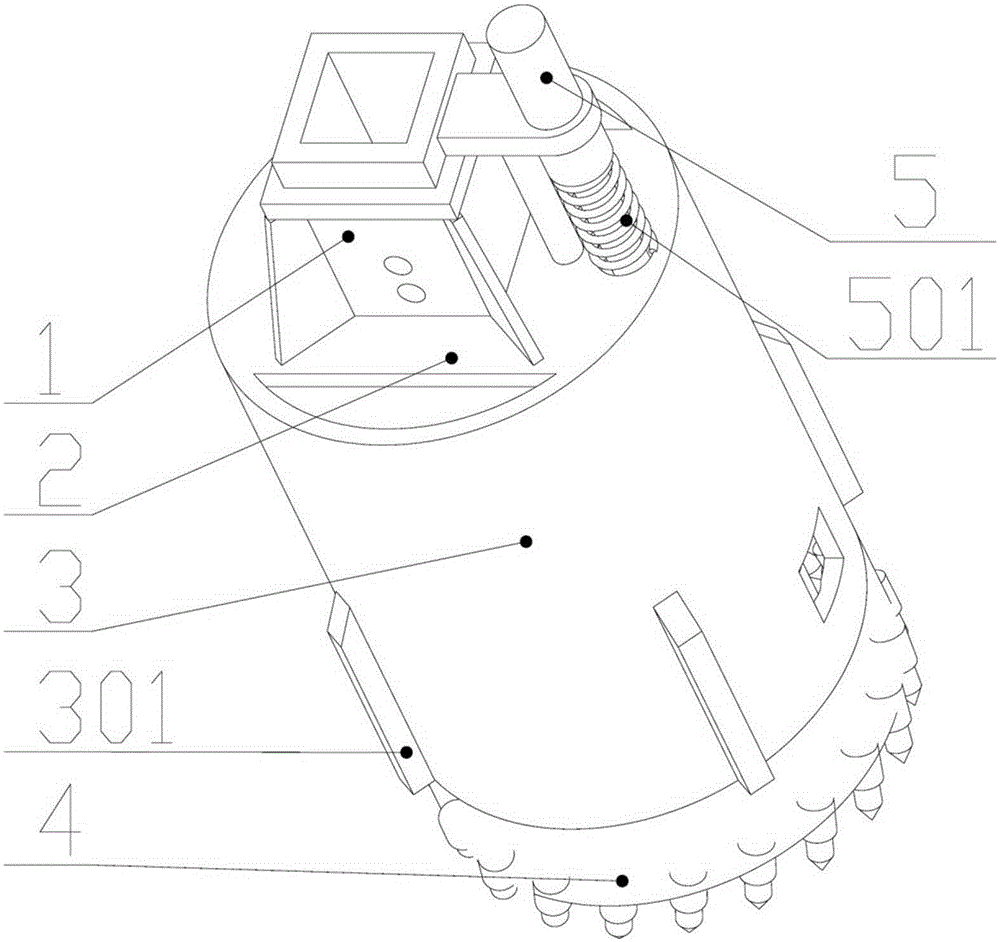

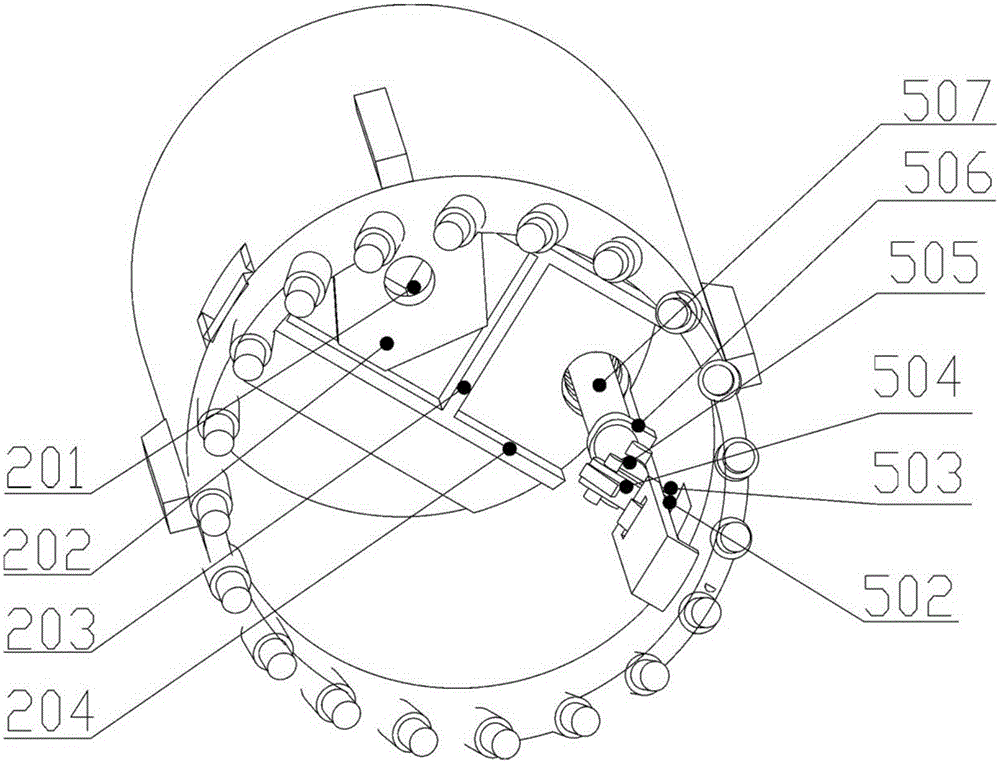

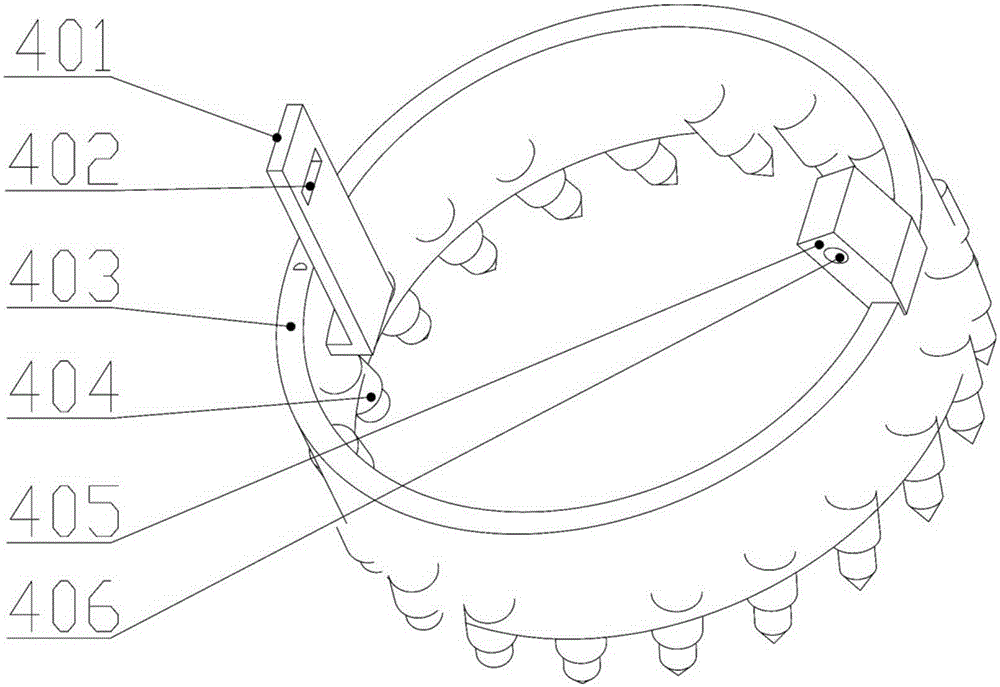

Rotary excavating drill bit

InactiveCN106481278AImprove construction efficiencyOvercome the shortcomings of being unable to continue constructionDrill bitsBorehole/well accessoriesHook plateDrill bit

The invention relates to a rotary excavating drill bit which comprises a drum, wherein a cover plate is arranged on an opening of the drum; a connecting square head is arranged on the outer surface of the cover plate; an opening device penetrates through the cover plate and is arranged in the drum; a drill bit component is moveably connected with the drum through a pin shaft; the drill bit component comprises an annular body; a plurality of cutting drills are arranged at the bottom edge of the annular body; inclined angles exist between the axes of the cutting drills and the axes of the annular body; a hook plate is arranged on the inner surface of the annular body; connecting lugs are symmetrically arranged on the inner surface on the other side of the annular body; a hook hole is formed in the hook plate; and the axle holes are formed in the connecting lugs. Due to the design, the rotary excavating drill bit is suitable for the drilling piling operation of the puddle and large gravel-containing soil foundation. The defect that the traditional flat-base and conical-base rotary excavating drill bits cannot continue construction if encountering with large gravels can be overcome, so that the construction efficiency of the rotary excavating drill bit can be greatly increased.

Owner:YICHANG CHAOYANG CONSTR ENG CO LTD

Quick construction method of tunnels traversing unfavorable geology

InactiveCN104100272ALess patchworkEasy to installUnderground chambersTunnel liningKarstGeological survey

The invention discloses a quick construction method of tunnels traversing unfavorable geology. The method includes the following steps: performing pre-construction karst survey and geological survey, and selecting an appropriate layered and partitioned excavation scheme for the sake of stability of excavation surrounding rock; adopting an advanced pipe roof or advanced grouting method and the like to perform advanced natural ground reinforcement; adopting a controlled blasting or presplitting blasting form and the like to perform tunnel blasting, excavating a main tunnel inwards along a tunnel portal, subjecting the main tunnel to supporting treatment, enhancing supporting intensity of a key part, and constructing an inverted arch so as to close an excavation face; and reinforcing a tunnel foundation. The construction scheme for tunnel portal engineering, the main tunnel, a first side tunnel and a second side tunnel needs to be optimized and determined according to geological conditions of the tunnels before construction, construction period is shortened to a certain extent, industrial modular processing and production of waterproof steel plates is adopted, mounting is facilitated, few joints exist, waterproof effect is good, and construction progress can be guaranteed.

Owner:CHINA ROAD & BRIDGE

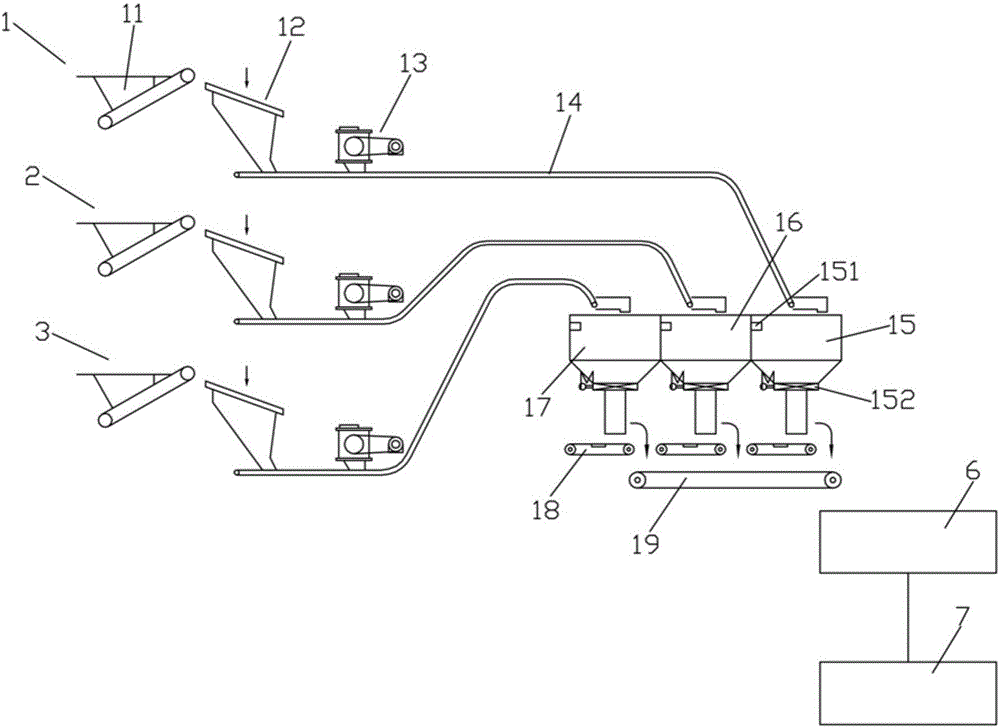

Concrete integral production system

ActiveCN105922438AStir wellAvoid slump lossDischarging apparatusMixing operation control apparatusMaterial supplyBelt machine

The invention discloses a concrete integral production system. The concrete integral production system comprises a dry material supply device, a concrete stirring device, a spiral extrusion conveying device and a control device; the dry material supply device, the concrete stirring device and the spiral extrusion conveying device are joined in sequence, wherein the dry material supply device includes a cement conveying line, a sand conveying line and a bubble conveying line; and cement, sand and bubble are pneumatically conveyed by the dry material supply device to enter a conveying belt machine, and are conveyed to the concrete stirring device by the conveying belt machine. Raw materials are conveyed by using a remote supply system, and are stirred by adding water in scene, so that dry concrete can be transported remotely or even preserved through sealing, the business scope of a concrete mixing plant is widened, the slump loss of concrete in the transportation process is prevented, and the construction while stirring is realized.

Owner:东莞市交港建材有限公司

Processing method for foundation pit piping

InactiveCN103061349AGuarantee the construction progressPrevent collapseFoundation engineeringSlurryBuilding construction

The invention relates to a processing method for foundation pit piping. The object of the processing method is to block water gushing channels and close big water gushing points through chemical grouts so as to prevent the under water below a foundation pit pouring into the foundation pit, and accordingly create conditions for a dry construction. The technical scheme of the processing method includes the steps of: a) distributing holes within a water gushing area; b) sequentially aligning and drilling the holes through a drill and timely pressing steel sleeves into the holes in the drilling process, wherein a water outlet valve is mounted at a water outlet of an elbow which is positioned at the upper end of the steel sleeve inside which grouting pipeline equipment is installed; c) after finishing the pressing of the steel sleeves, firstly blanketing the openings of the holes with clay, then covering the clay with concrete or mortar and sealing gaps with cotton and quick-drying cement; d) after the concrete strength is reached, closing the water outlet valves and using a grout pump to grout the water soluble polyurethane slurry into a hole enclosed by the steel sleeves through a grouting pipe and a shot grout porous pipe. The processing method for foundation pit piping is applicable to the pit construction process of high buildings.

Owner:ZHEJIANG HUADONG CONSTR ENG

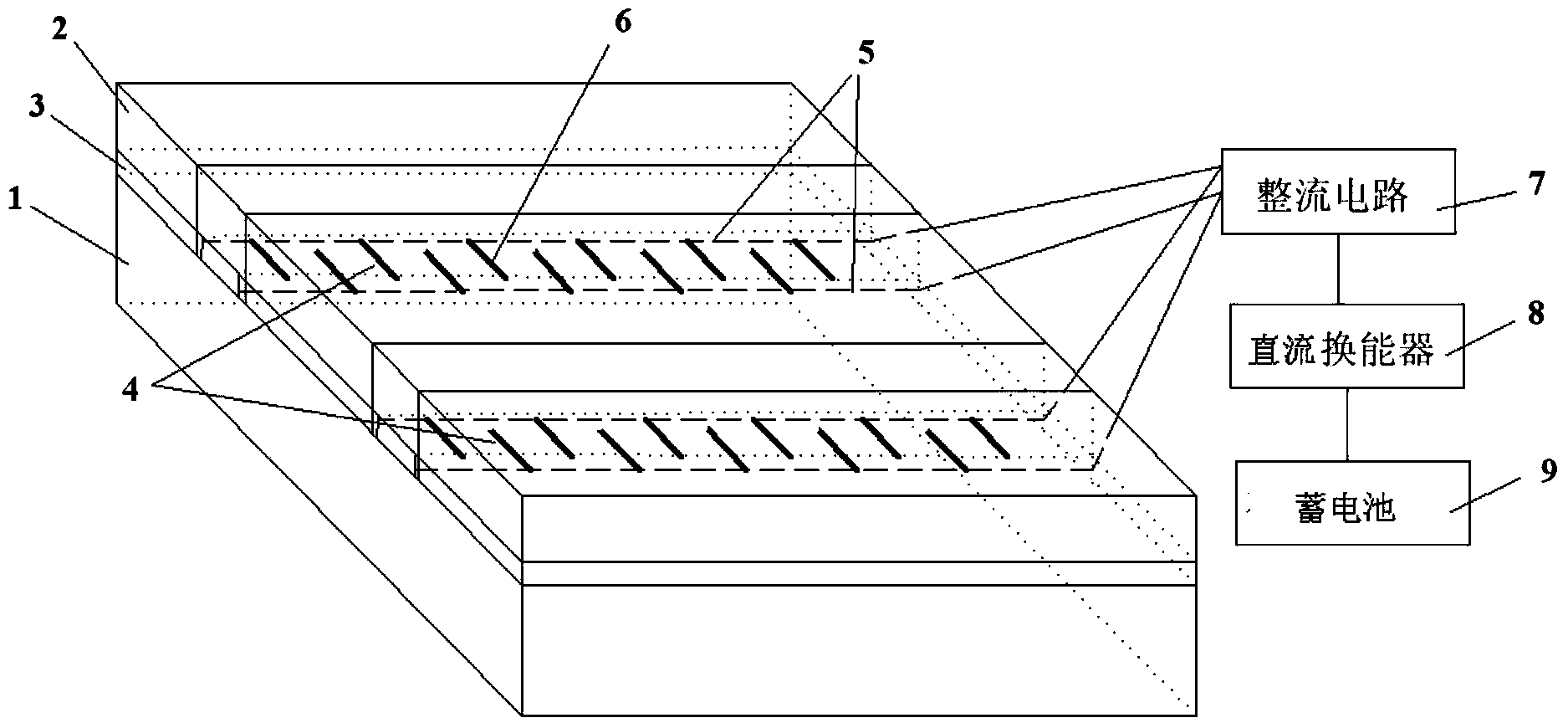

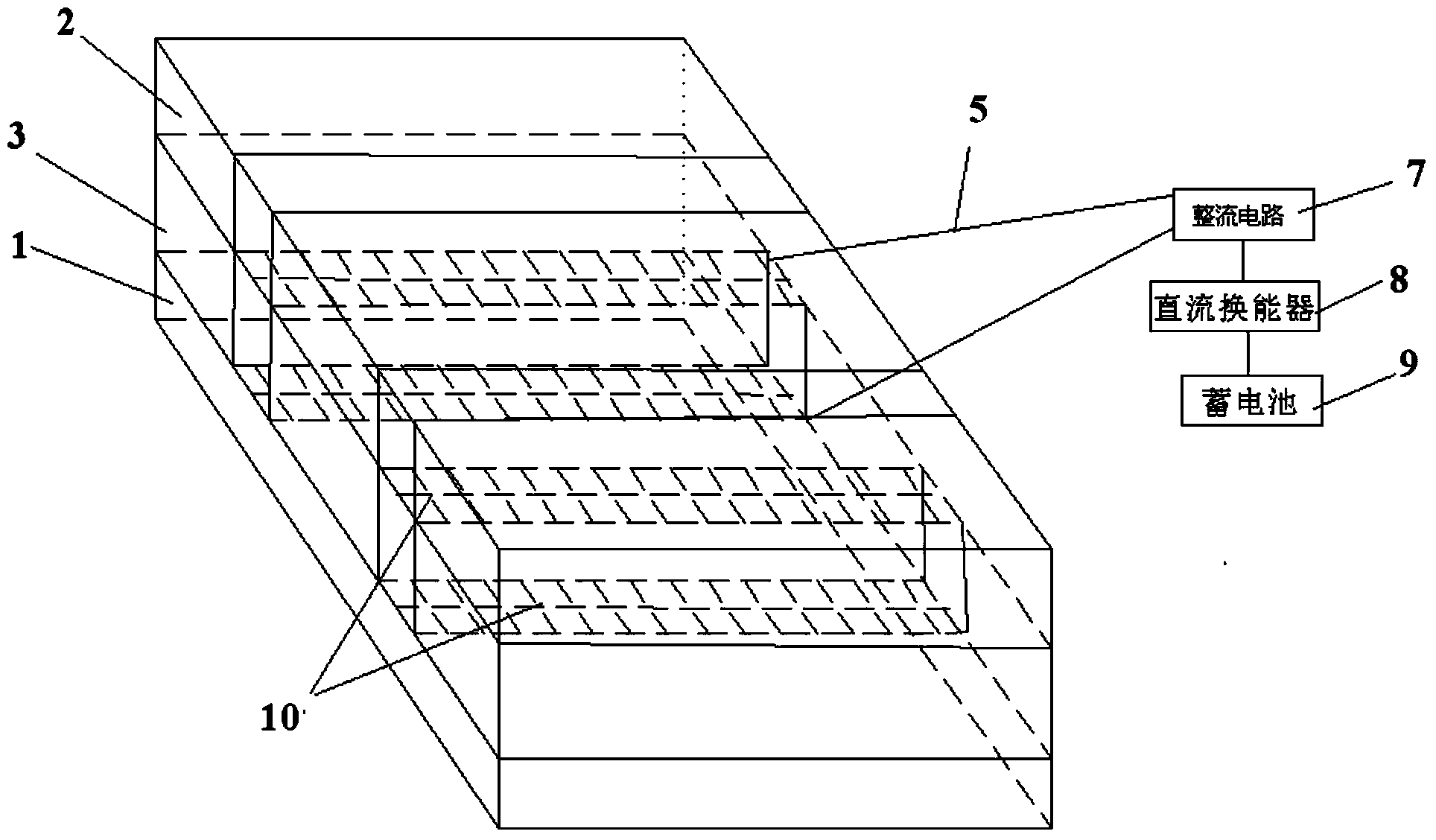

Piezoelectric asphalt concrete and power generation pavement structure thereof

ActiveCN103669151AImprove economyIncrease storage capacityIn situ pavingsTemporary pavingsElectricityConductive materials

The invention provides a piezoelectric asphalt concrete, which is composed of the following raw materials in parts by weight: 83 to 90 parts of aggregate, 4 to 6 parts of mineral powder, 2 to 4 parts of piezoelectric material, 1 to 2 parts of conductive material, and 3 to 5 parts of asphalt, wherein the total raw material part number is 100. The invention also provides two power generation pavement structures based on the piezoelectric asphalt concrete. The two power generation pavement structures utilize cooperation between the piezoelectric asphalt concrete and rod-shaped electrode or metal net electrode to achieve the electric energy collection. The piezoelectric asphalt concrete has a good economic property, and is suitable for being widely promoted and applied.

Owner:CHANGAN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com