Processing method for foundation pit piping

A treatment method and piping technology, applied in infrastructure engineering, construction, etc., can solve problems such as high long-term maintenance costs, high pumping costs, foundation pit collapse, etc., and achieve the effect of ensuring normal construction progress, short construction time, and preventing collapse

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

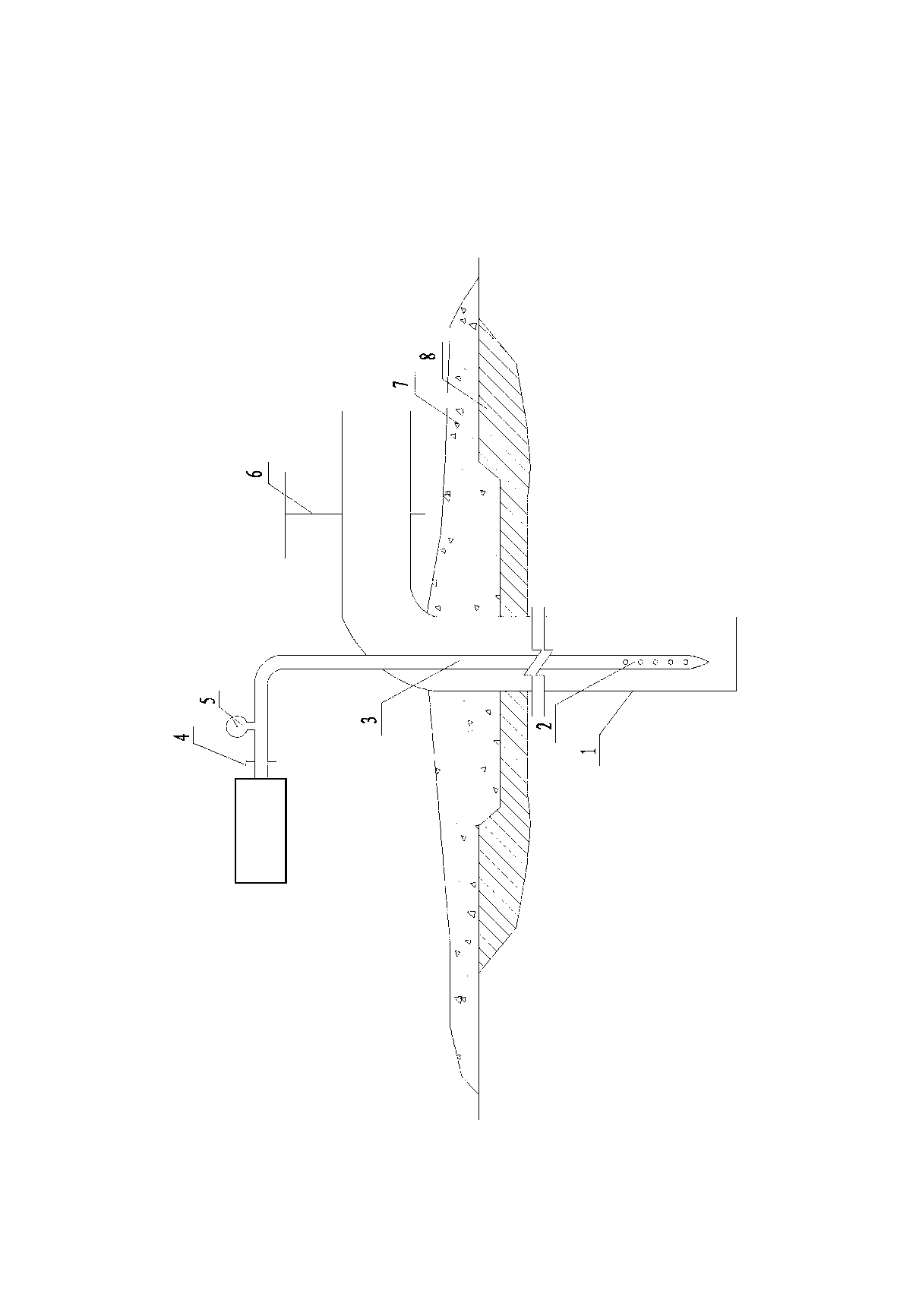

[0012] The construction method of the present embodiment comprises the following steps:

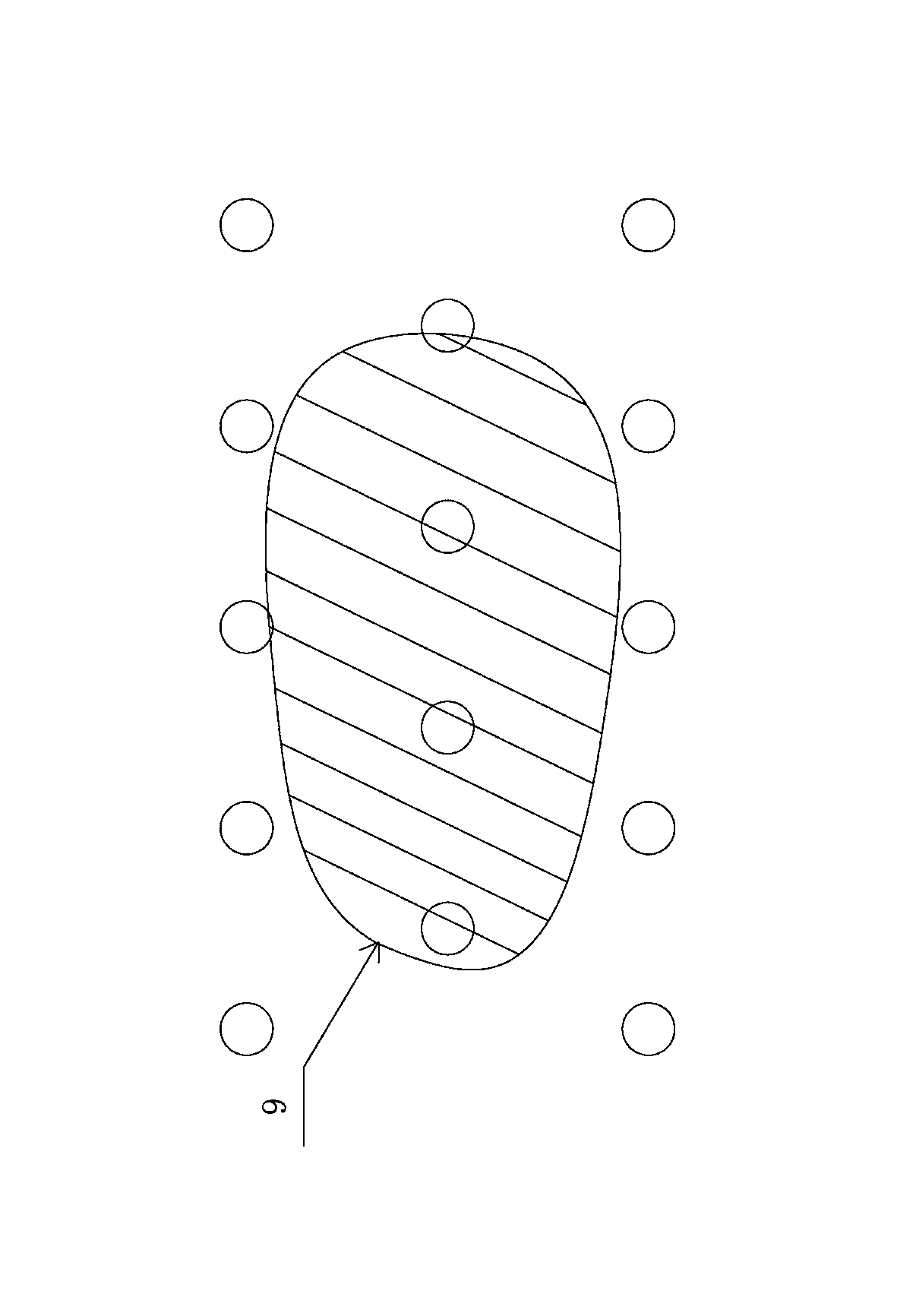

[0013] 1. See figure 2 According to the water gushing situation on site, holes are arranged inside and outside the water gushing surface range 9. The hole positions are mainly arranged in a plum blossom pattern, with a hole diameter of 110mm and a hole distance of 2m.

[0014] 2. Use a drilling rig to drill each hole position one by one. During the drilling process, the steel casing 1 should be followed up in time, and the steel casing should be lowered while drilling. In this case, the upper end of the steel casing is an elbow, and the outlet of the elbow is At the same time, install the grouting pipeline equipment in the steel casing 1, the grouting pipeline equipment includes a vertically arranged grouting pipe 3, and the lower end of the grouting pipe is connected to the grouting flower pipe 2 (pipe wall There are small holes on the top), the upper end of the grouting pipe protrudes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com