Patents

Literature

204 results about "Chemical grouting" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Chemical grouting is a pipe bedding, soil sealing and stabilization process. Chemical grouting permeates pore spaces in soil with grout that hardens into a sandstone-like mass.

Polyurethane chemical grouting material and production method

ActiveCN101220203AImprove featuresObvious effectPaving detailsMarine site engineeringPolyolChemical grouting

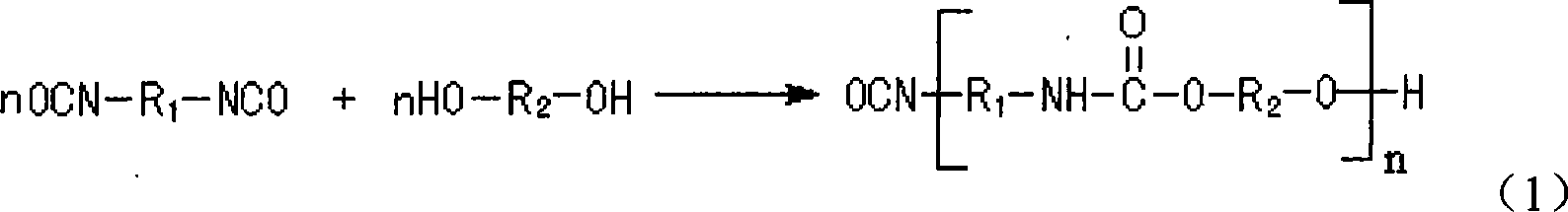

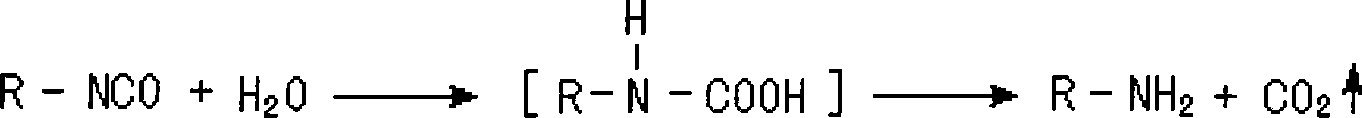

The invention provides a polyurethane chemical grouting material and a preparation method thereof. At first a hydroxyl-terminated polyurethane prepolymer is prepared: hydrophilic polyol or small molecular polyether and isocyanate are mixed and stirred at normal temperature, and heating and heat preservation processes, etc. are carried, and when -NCO percent is detected to be near zero by central control, the reaction is stopped, and the hydroxyl-terminated polyurethane prepolymer is prepared. Secondly, the hydrophilic polyurethane prepolymer is prepared: the macromolecular polyether and the hydroxyl-terminated polyurethane prepolymer prepared through the reaction are stirred and mixed evenly in a stirring reaction kettle which is provided with a condenser. At normal temperature, isocyanate is added into the kettle for stirring and heating and heat preservation processes, etc. are carried out; -NCO percent is detected, and the reaction is stopped when the -NCO percent is between 5.6 percent and 6.0 percent. Lastly the polyurethane grouting material is prepared: a diluting agent is added into the prepared polyurethane prepolymer, and the stirring process is started; foam stabilizer, polyurethane special catalyst and plasticizer are added into the prepolymer at the same time. The mono liquid grouting of the polyurethane chemical grouting material of the invention has simple construction, easy operation, and gel is nonpoisonous, and can be used for water shutoff of water supply lines, etc.

Owner:TIANJIN TIANDA TIANHAI NEW MATERIAL

Polyurethane grouting water plugging-reinforcing material, and preparation method and application method thereof

InactiveCN102702728AQuick responseQuick treatment of seepage waterUnderground chambersTunnel liningWater leakageChemical grouting

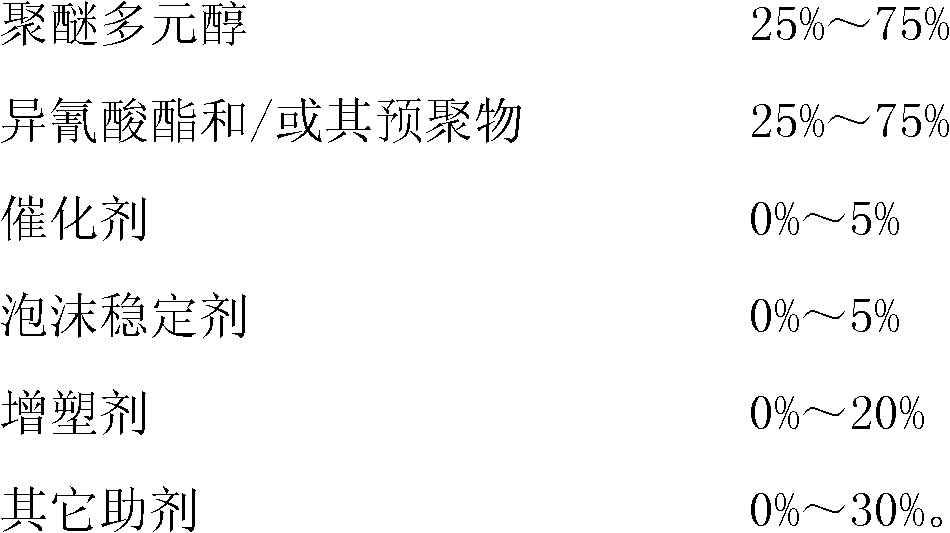

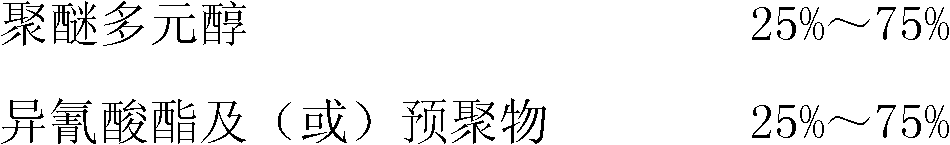

The invention discloses a polyurethane chemical grouting water plugging-reinforcing material which comprises a component A and a component B. The invention is characterized in that the component A is composed of polyether glycol and auxiliary materials, and the component B is composed of isocyanate and / or prepolymer thereof and auxiliary materials; and the auxiliary materials comprise catalyst, foam stabilizer and other assistants. The polyurethane chemical grouting water plugging-reinforcing material disclosed by the invention does not contain benzene, xylene, acetone and other solvents and does not influence the water quality after curing, and the solid content is 100%, thereby being environment-friendly and pollution-free; and when in use, the reaction speed of the double components is very high, the reaction starts after 20 seconds and basically finishes after 90 seconds, the reaction time is adjustable according to the engineering demands, and thus, the polyurethane chemical grouting water plugging-reinforcing material can effectively and quickly solve the problems of water leakage and water inflow of mines.

Owner:BEIJING ORIENTAL YUHONG WATERPROOF TECH CO LTD +2

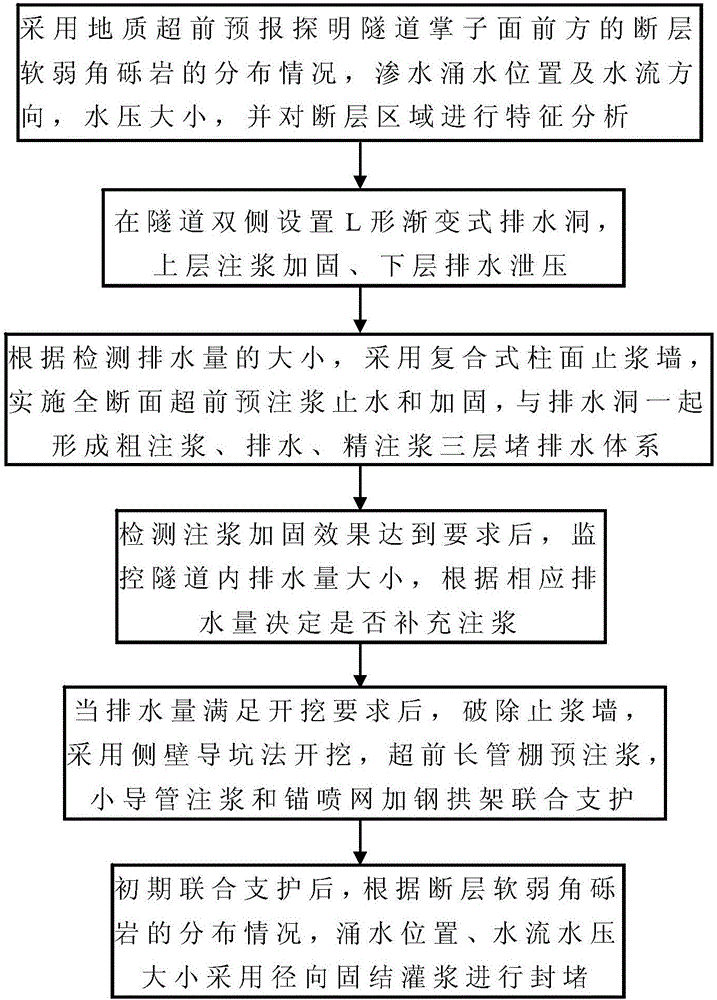

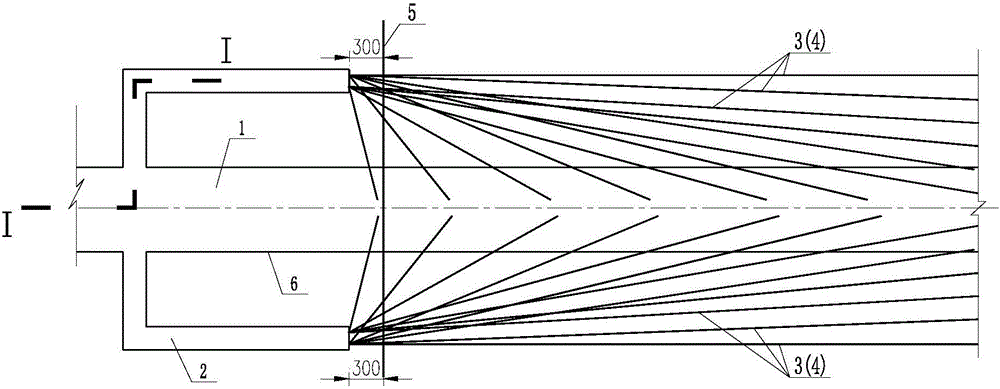

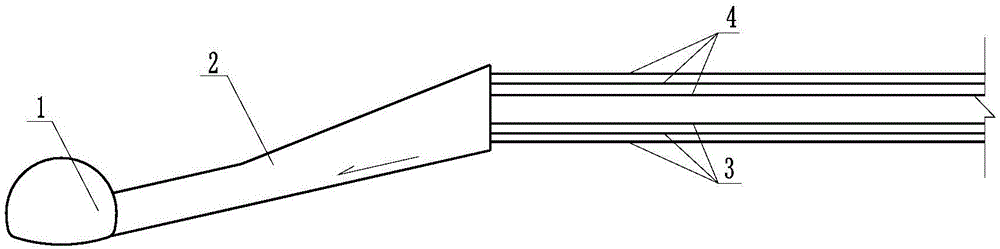

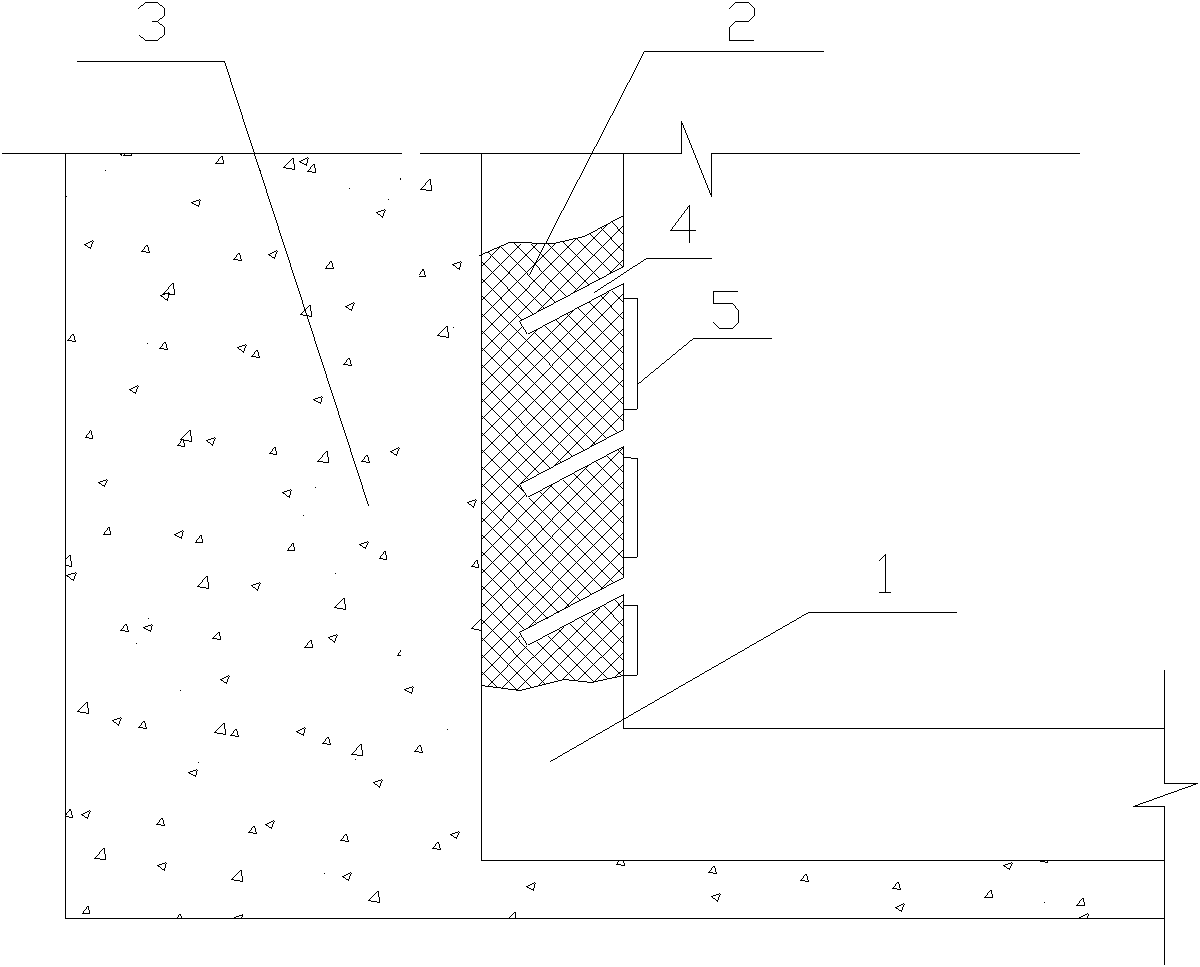

Construction method of high-tension water-rich extra-large-section weak breccia tunnel

The invention discloses a construction method of a high-tension water-rich extra-large-section weak breccia tunnel. The method includes the steps of exploring distribution of fault weak breccia in front of a tunnel face by an advanced geological forecast method; distributing L-shaped gradient drain holes in two inner sides of the tunnel, providing sector drain holes and grouting holes, and allowing upper grouting and lower drainage; providing a combined cylinder grout-stopping wall, and performing a full-face advanced chemical grouting consolidation; constructing an advanced long tube shed with a circumferential closed advanced tube shed guide wall having a foundation, distributing tapered quincunx examining drain holes to detect grouting effect, and finally excavating the tunnel. Through the use of the techniques such as three-layer stereoscopic grouting and drainage, and cement-water glass and epoxy resin sequential grouting, the problem that a high-tension water-rich surrounding rock area with loose weak breccia has ineffective grouting consolidation and non-obvious water plugging effect is solved.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

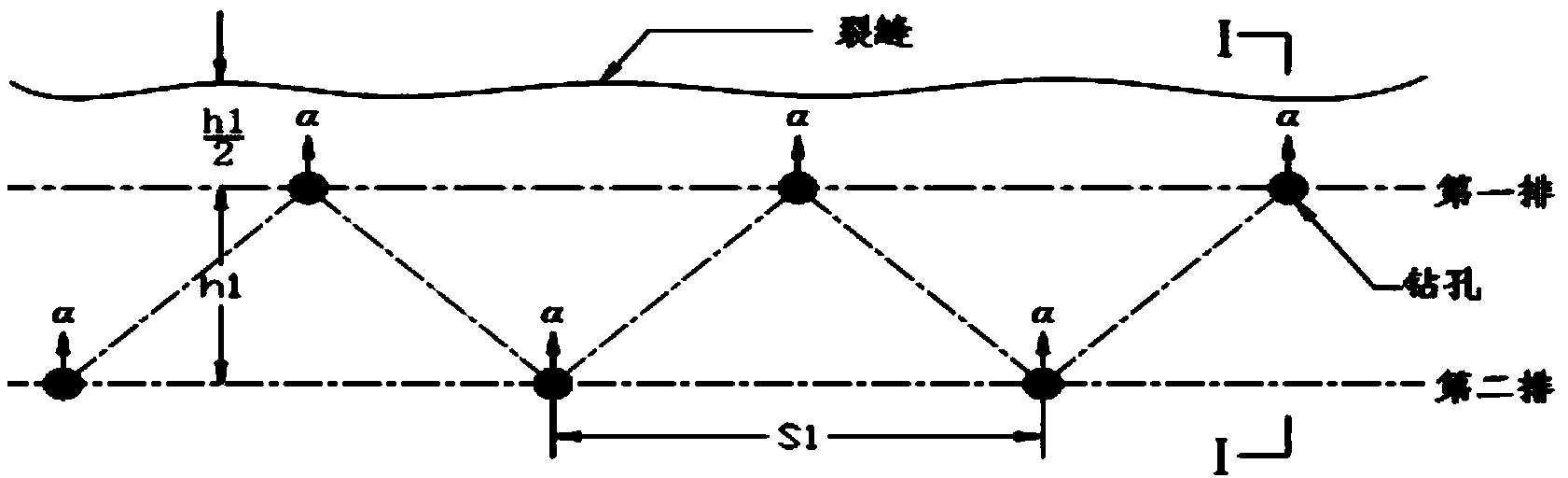

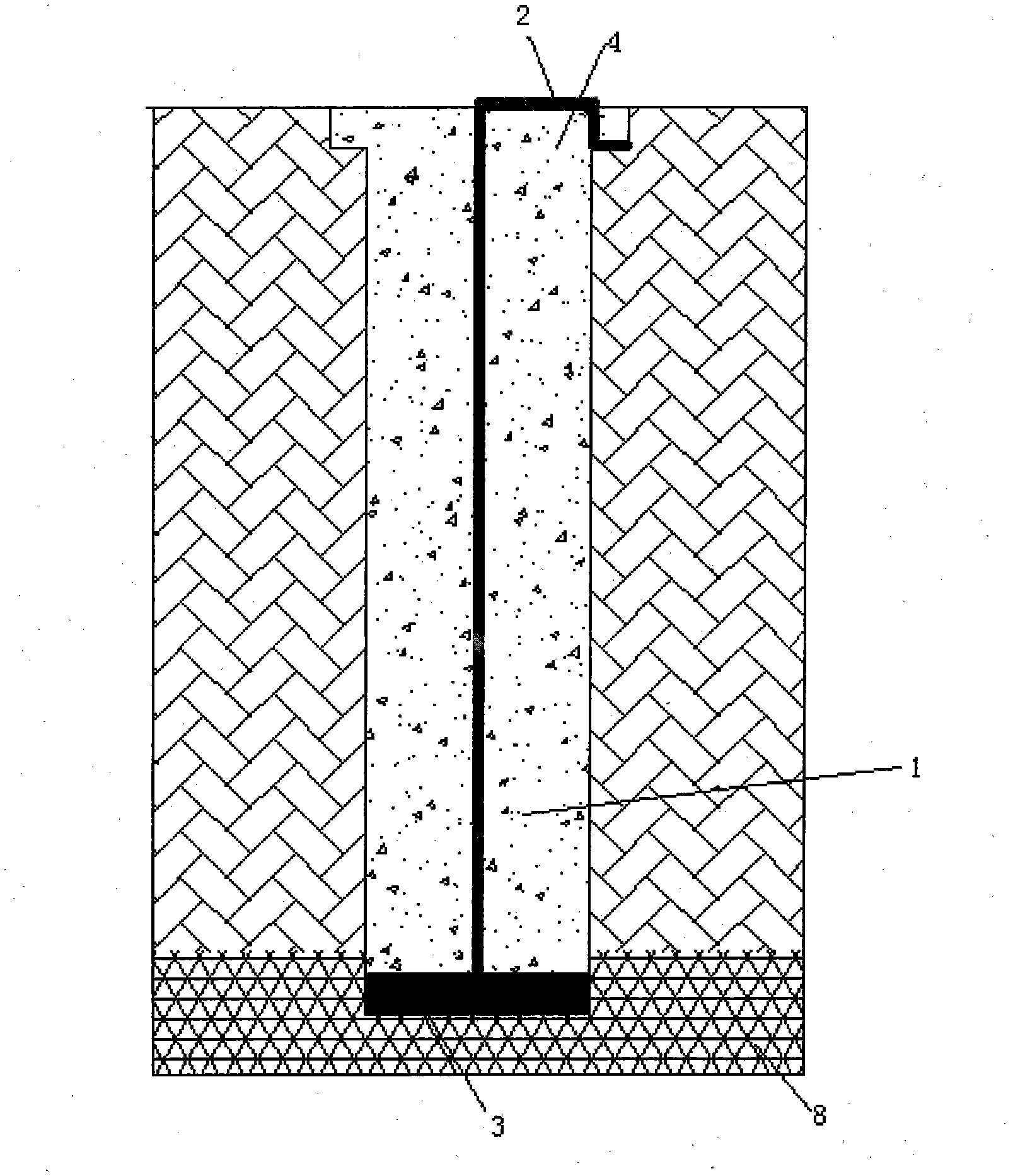

Method for sealing vertical cracks of basement concrete structures by using microbial grouting

ActiveCN102493494AEffective blockingReduce water seepageArtificial islandsUnderwater structuresBasementChemical grouting

The invention discloses a method for sealing vertical cracks of basement concrete structures by using microbial grouting, which seals the cracks by using a method of grouting into cracks on the inner sides of walls. In particular, the method comprises the steps of punching holes, cleaning the holes, sealing the surfaces of the cracks, preparing bacterium fluid and nutritive salt solution, grouting the bacterium fluid, grouting the nutritive salt solution, and sealing and plugging grouting holes. The bacterium fluid can induce calcium chloride to generate calcium carbonate sedimentary to effectively fill, seal and plug the cracks and the grouting holes. Water injection tests and observation after raining show that the original cracks are obviously reduced in water seepage.

Owner:SHANDONG JIANGU SPECIAL ENG LIMIT

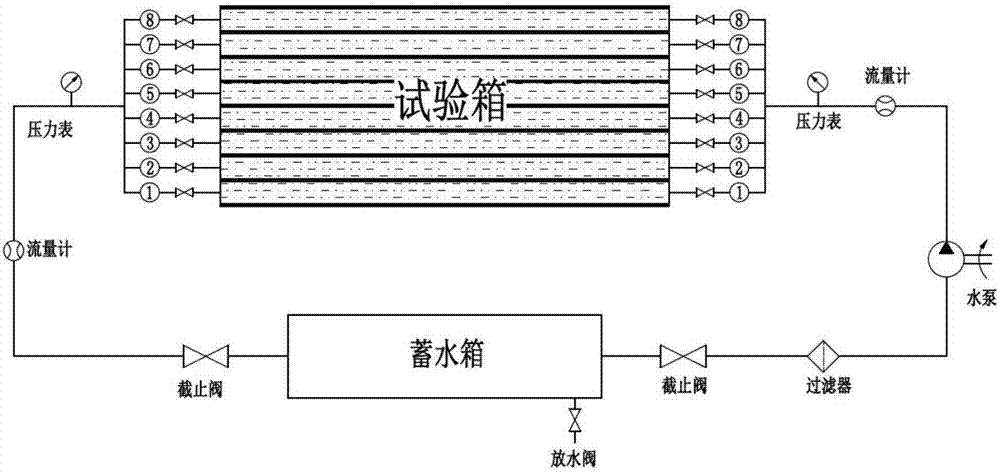

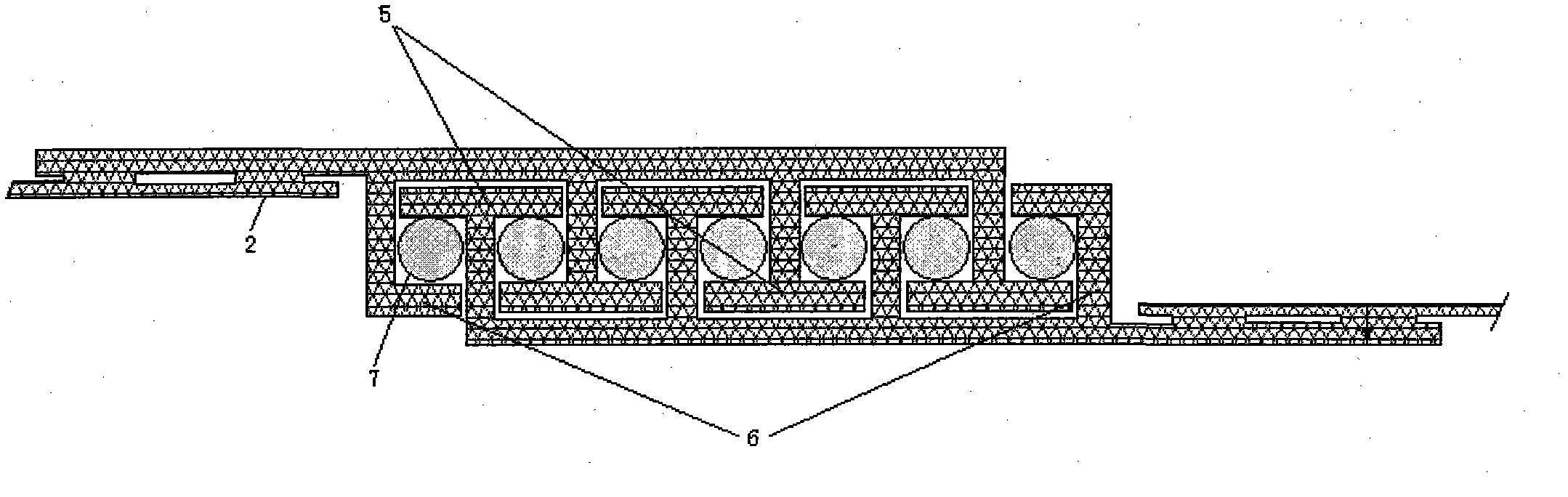

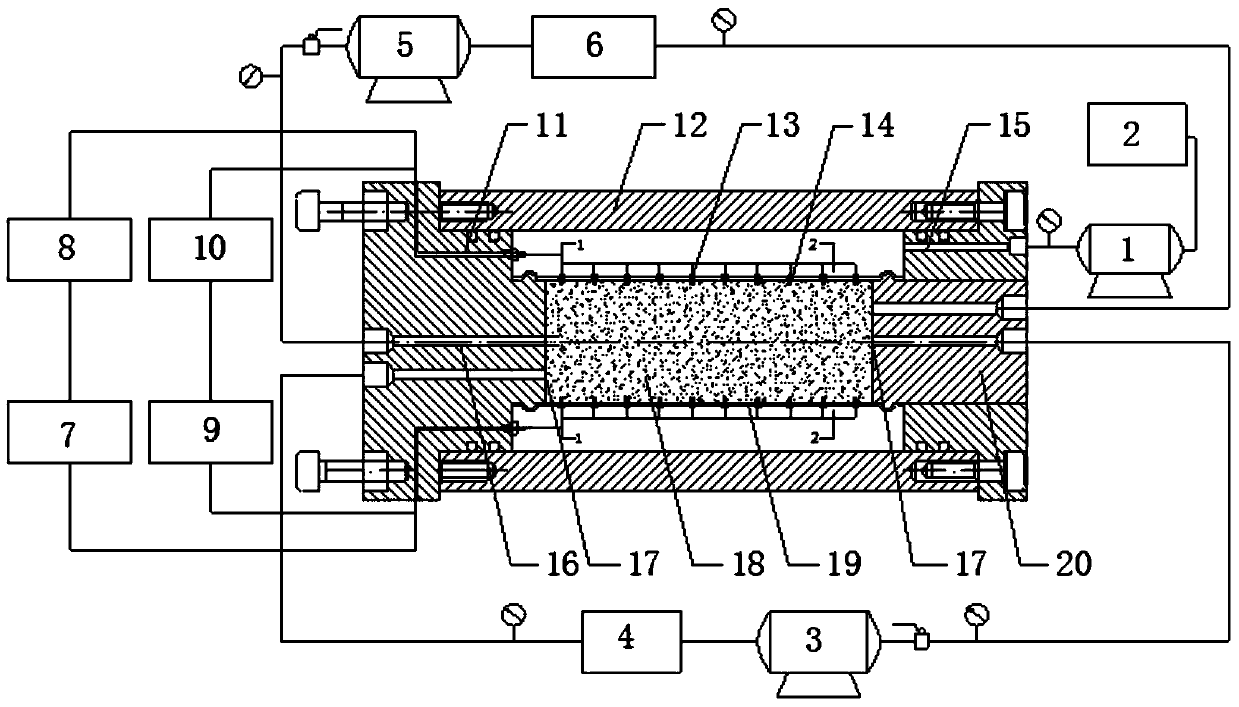

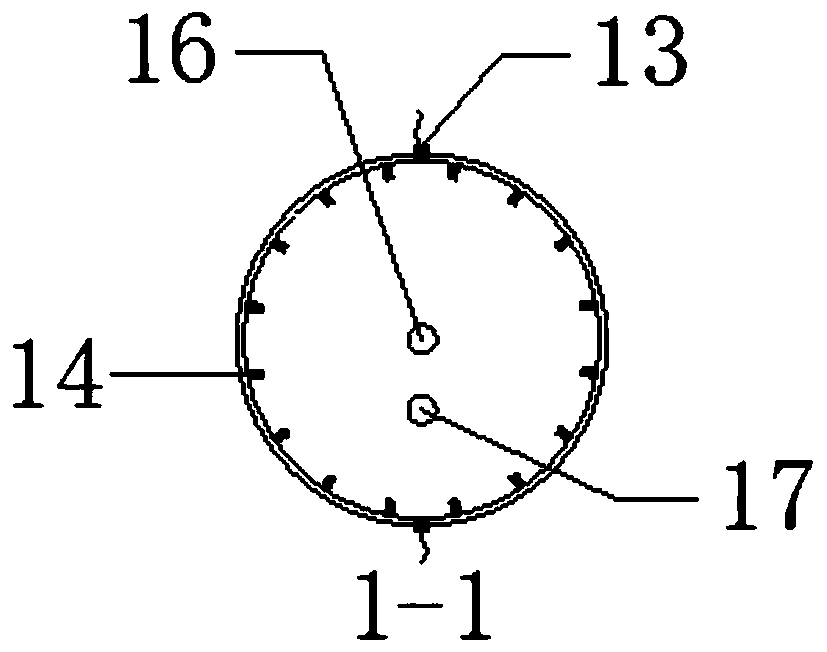

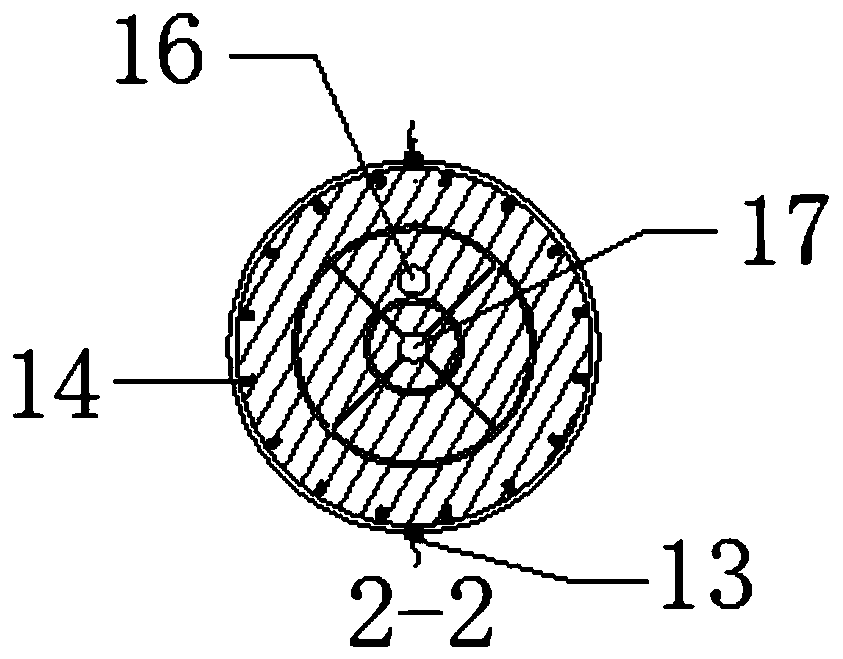

Dynamic water quicksand stratum reinforcement grouting diffusion rule visual simulation experimental device and method

ActiveCN107389898AImprove stabilityRecognizing and Revealing DiffusionEarth material testingCoal measuresSlurry

The invention discloses a dynamic water quicksand stratum reinforcement grouting diffusion rule visual simulation experimental device and method. The device comprises an experimental box, a hydraulic pressure control loading system, a vertical hydraulic loading mechanism and a lateral hydraulic loading mechanism, a double liquid chemical grouting system and a test system connected to a computer. The method adopts an engineering geomechanical experimental model with a coal measure stratum physical analog simulation material, a waterproof stratum and an aquifer of certain height filled in the experimental box, aquifer grouting and water-plugging reinforcement visual physical simulation test is carried out hermetically under the conditions of circulating dynamic water pressure and vertical and horizontal lateral stress to acquire or quantitatively describe and analyze the diffusion rule of double liquid chemical grout in the water-bearing sandstone layer or quicksand layer, thus realizing visual simulation experiment of the double liquid component chemical grouting and water-plugging process under a similar water burst or water inrush condition. The method can effectively recognize and reveal the slurry diffusion and consolidation characteristics under a mining dynamic water condition, determine rational grouting and water-plugging parameters, and evaluate the grouting effect.

Owner:XIAN UNIV OF SCI & TECH

Polymer-type water glass curing agent and application in water glass chemical grouting materials

InactiveCN101885591AResolution timeSolve the strength problemOther chemical processesBuilding constructionsSolubility(Hydroxyethyl)methacrylate

The invention relates to a polymer-type water glass curing agent with easily-controlled curing time and high toughness. The curing agent is mainly formed by polymerizing and copolymerizing double bonds-containing acids such as crylic acid, methacrylic acid and the like and double bonds-containing esters such as butyl methacrylate, vinyl acetate, hydroxy-ethyl methacrylate and the like by latex. The polymer-type water glass curing agent of the invention is a novel water-soluble water glass curing agent, which can control the curing time of the water-soluble grouting materials by controlling the content of carboxyl and ester group in a polymer. By using the curing agent, a water glass consolidating body has vey high compressive strength and toughness, synthetically overcomes the shortages of too fast curing time, high corrosiveness, low consolidating body strength and the like of an acid curing agent which is commonly used in the water glass grouting materials and the shortages of poor water solubility, slow curing time and the like of an organic ester curing agent, and can be widely applied in the field of anti-seepage stoppage engineering.

Owner:GUANGZHOU CHEM GROUTING CO LTD CAS

High flash point antiflaming type oil soluble polyurethane chemical grouting material

ActiveCN101649040AGuaranteed supplyGuaranteed timelinessUnderground chambersProtective foundationChemical groutingPlasticizer

The invention relates to a high flash point antiflaming type oil soluble polyurethane chemical grouting material, and aims to provide a chemical grouting material with high flash point (more than 100DEG C), flame retarding and good environmental protection property. The high flash point antiflaming type oil soluble polyurethane chemical grouting material is characterized by comprising the following materials by weight portion: 40-60 portions of isocyanate, 10-25 portions of polyether, 3-15 portions of plasticizer, 10-30 portions of high boiling point compound solvents, 10-20 portions of efficient fire retardants, 0.5-3 portions of foam stabilizers and 0.2-1 portion of catalyst. The invention can be used for the seepage-proofing and strengthening processing on palisades in the undergroundspace excavating process of a coal mine, a subway, a tunnel, and the like and the seepage-proofing processing and the like of a dam and other building foundations.

Owner:POWERCHINA HUADONG ENG COPORATION LTD +1

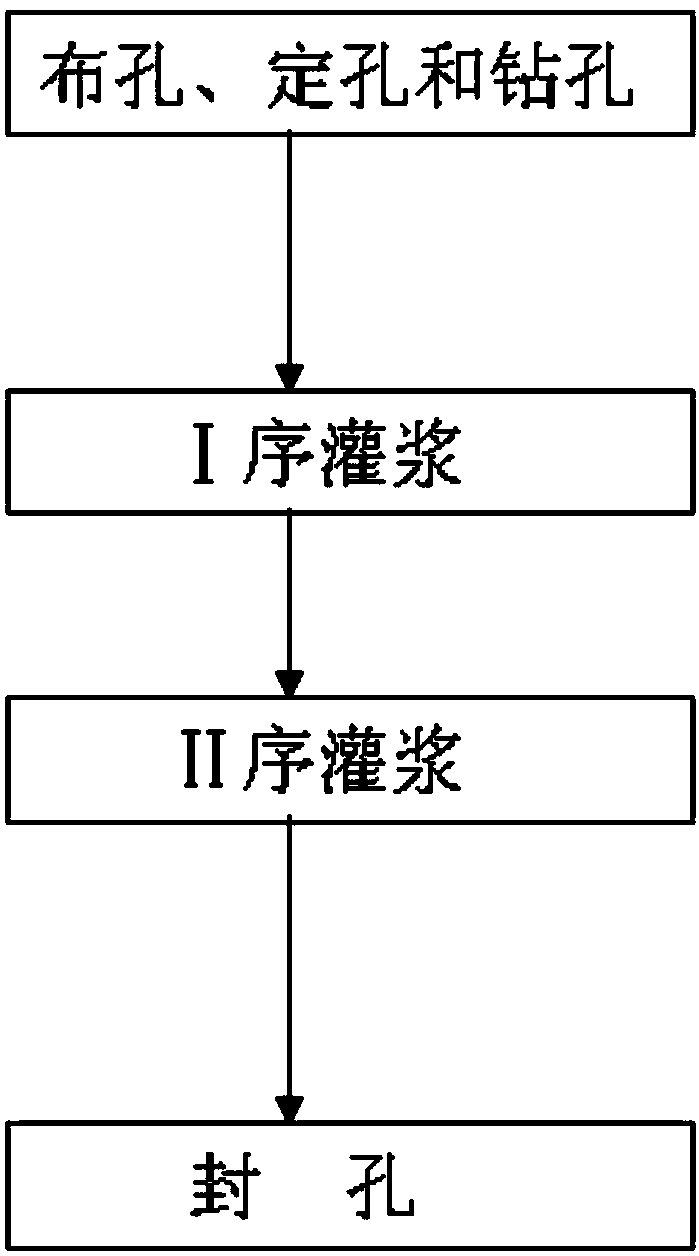

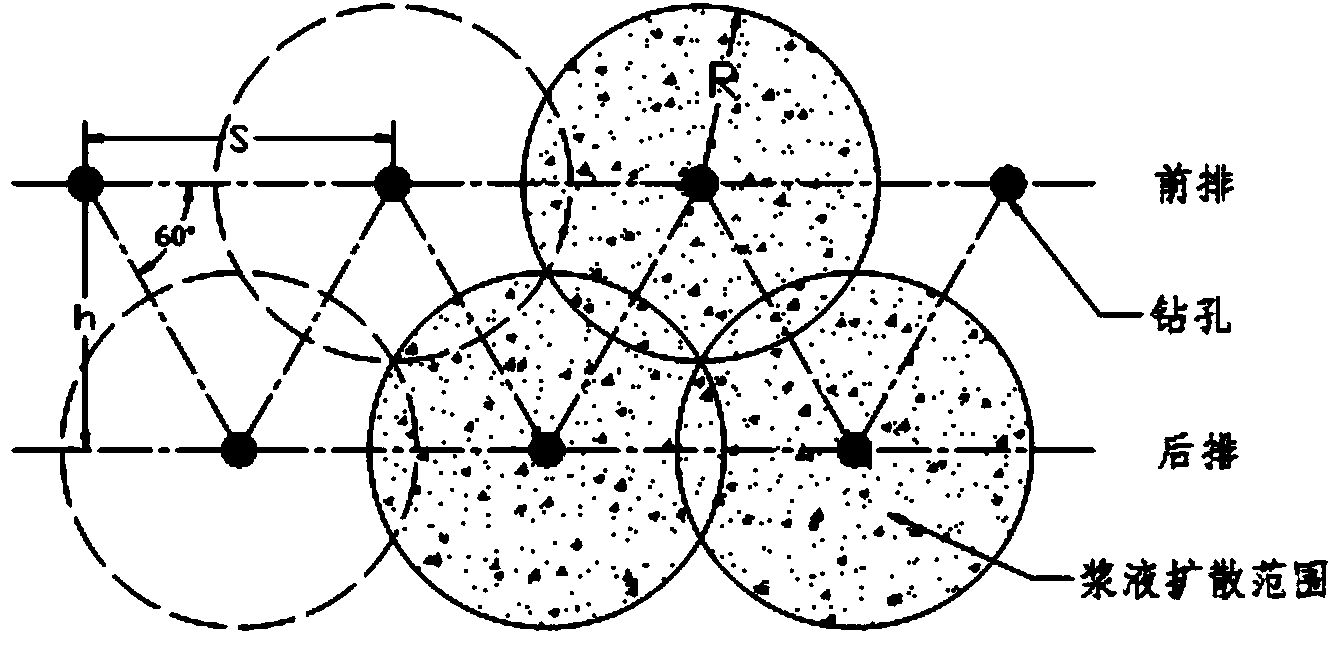

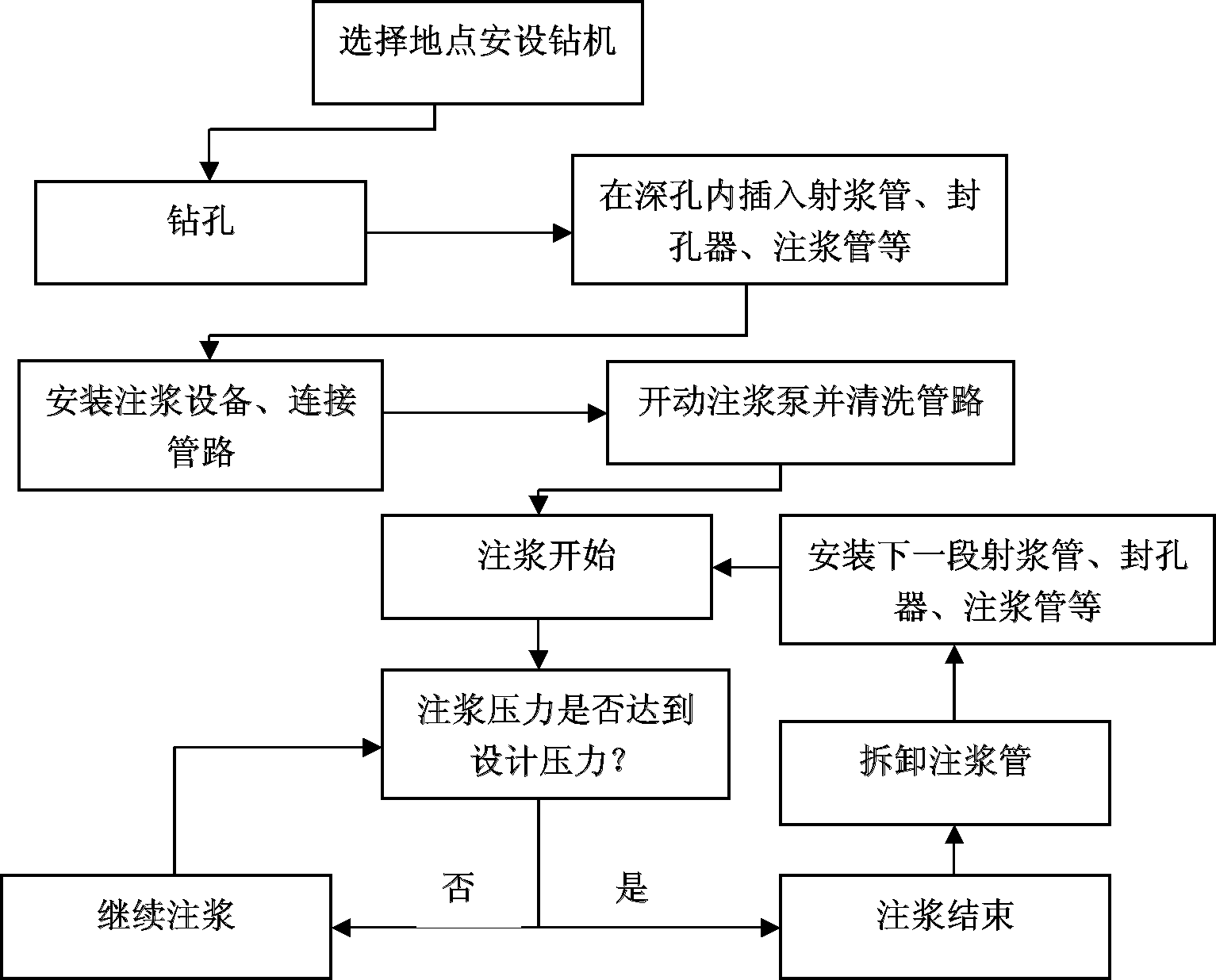

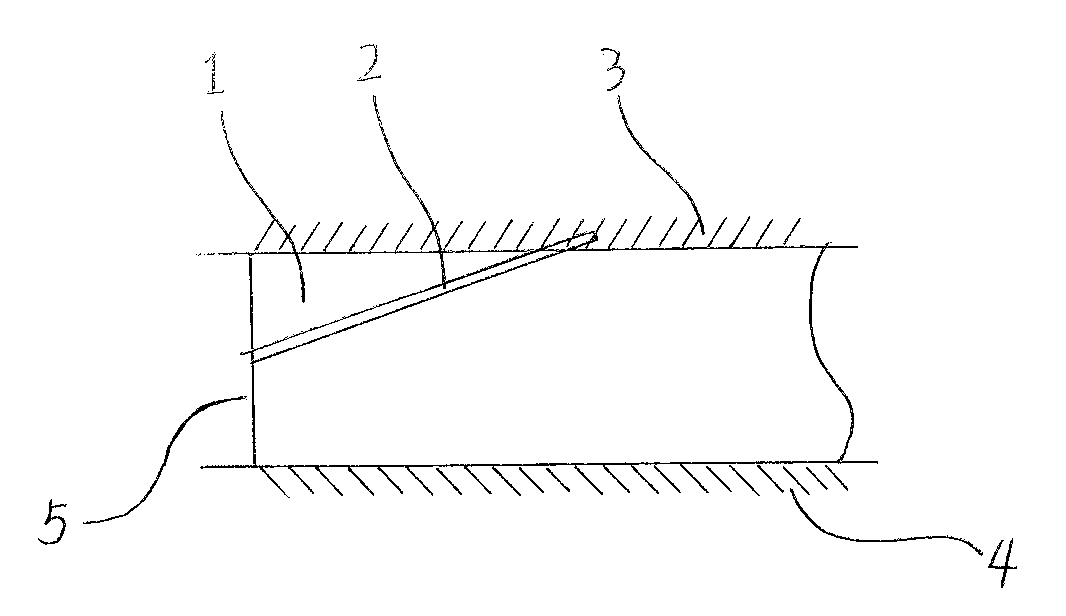

Deep-hole chemical grouting construction method applied to water leakage treatment of hydroelectric dam

InactiveCN103643657AReduce investmentShorten the effective diffusion radiusMarine site engineeringEpoxyWater leakage

The invention relates to the technical field of hydraulic engineering and in particular relates to a deep-hole chemical grouting construction method applied to water leakage treatment of a hydroelectric dam. The method comprises the following steps: (1) arranging, fixing and drilling grout holes in the concrete crack fracture surface and the concrete surface respectively; (2) performing primary grouting by polyurethane; (3) performing secondary grouting by epoxy resin; (4) sealing the holes. According to the method, the technologies of fixing the holes by a similar triangle principle, performing primary and secondary grouting by polyurethane and epoxy grouting materials, grouting in a high-voltage pulse manner, grouting in a high-flow manner and the like are innovatively used, so that the problem of water leakage of the hydroelectric dam is radically solved, the reinforcement effect is achieved, a full guarantee is provided for long-term safe and stable running of the dam, a large amount of materials are saved, the construction efficiency is improved, the project progress is accelerated, and the cost is greatly reduced. Therefore, the method is suitable for popularization and application in the field of water leakage treatment of related parts such as hydroelectric dam cracks and inter-dam cross joints.

Owner:CHINA HYDROPOWER ELEVENTH ENG BUREAU ZHENGZHOU CO LTD

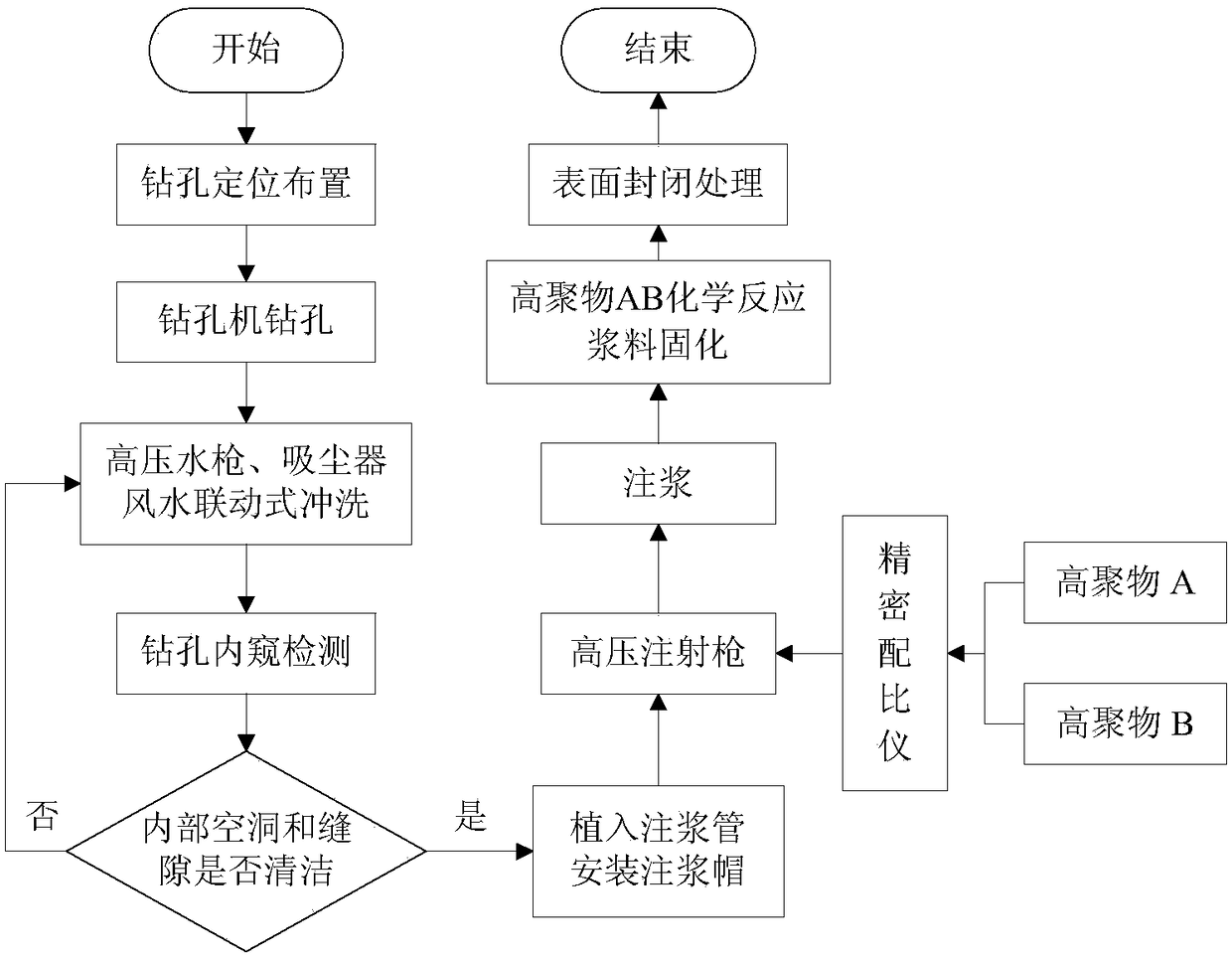

Construction process for plugging and consolidating concrete crack through chemical grouting

InactiveCN105239789ACrack works wellUniform thicknessBuilding repairsFoundation repairChemical groutingMaterials science

The invention relates to a construction process for plugging and consolidating a concrete crack through chemical grouting, which belongs to the technical field of concrete consolidation engineering and in particular relates to a concrete crack plugging and consolidating method. The construction process for plugging and consolidating the concrete crack through the chemical grouting comprises the following steps of the first step, opening a V-shaped groove, which is 20 mm wide at the upper part and at least 20mm deep, along the concrete crack; the second step, flushing the V-shaped groove; the third step, plugging the V-shaped groove; the fourth step, drilling a grouting hole; the fifth step, mounting a grouting head; the sixth step, performing grouting; and the seventh step, removing the grouting head. The construction process for plugging and consolidating the concrete crack through the chemical grouting, provided by the invention, is advantaged in that the grouting process is simple and convenient, the operation of the process is convenient, the crack is closely plugged without a gap, the plugged concrete crack is durable and fatigue-proof and not prone to crack again, the concrete crack plugging effect is good, the concrete surface is completely dry, leakage and moist are avoided, the thickness of a plugging and finishing coating on the surface of the crack is uniform, no missed brushing, no base exposure, no peeling, no swelling and no crack are achieved. And moreover, the process causes no pollution to the environment.

Owner:赵涛

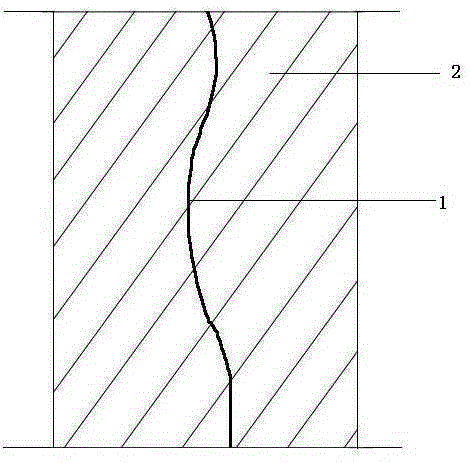

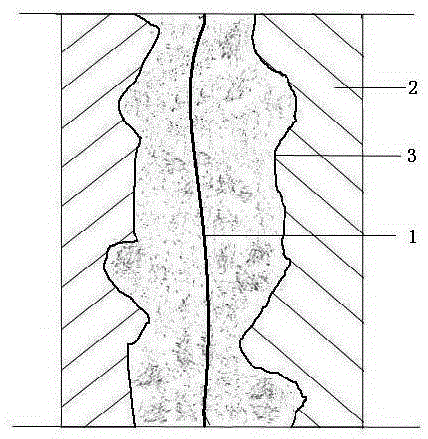

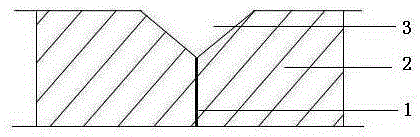

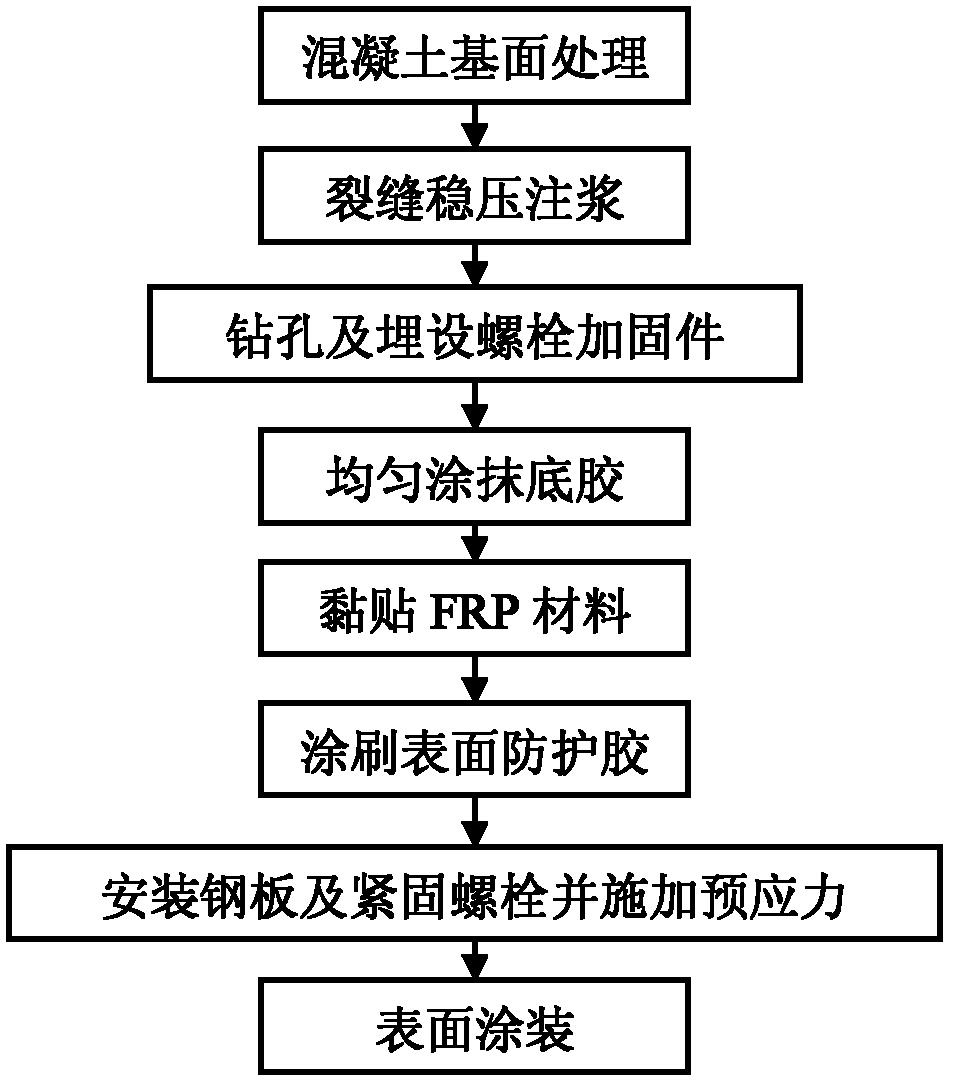

Reinforcement method for fiber reinforced composite plastic and concrete

InactiveCN102561412AImprove carrying capacityMaintenance and reinforcementArtificial islandsBuilding repairsSheet steelChemical grouting

The invention relates to a reinforcement method for fiber reinforced composite plastic and concrete, which includes: firstly performing crack grouting on the surface of concrete to be reinforced; secondly, drilling holes at set positions and embedding bolt reinforcing members according to the need of reinforcement; thirdly, applying base cement to the positions with FRP (fiber reinforced plastic) material and adhering the FRP material; fourthly, painting surface protection glue, mounting steel plates and fastening the bolts; and fifthly, performing surface coating. The fiber reinforced composite plastic and the concrete are technically integrated, optimized and modified according to respective characteristics of FRP and HB-FRP (hybrid bonded fiber reinforced plastic) technology and high (stable) pressure chemical grouting technology, so that the fiber reinforced composite plastic and the concrete have respective technical advantages, technical complementation and comprehensive improvement in reinforcing repair of defective components can be realized, material function utilization rate is increased greatly, the reinforcing effect is improved evidently, and the application range of the fiber reinforced composite plastic and the concrete can be widened greatly.

Owner:SHANDONG UNIV

Water seepage plugging construction method of shaft construction seams under high water head

ActiveCN103898873ASuccessful pluggingDoes not affect normal operationFoundation engineeringMarine site engineeringElastomerSlurry

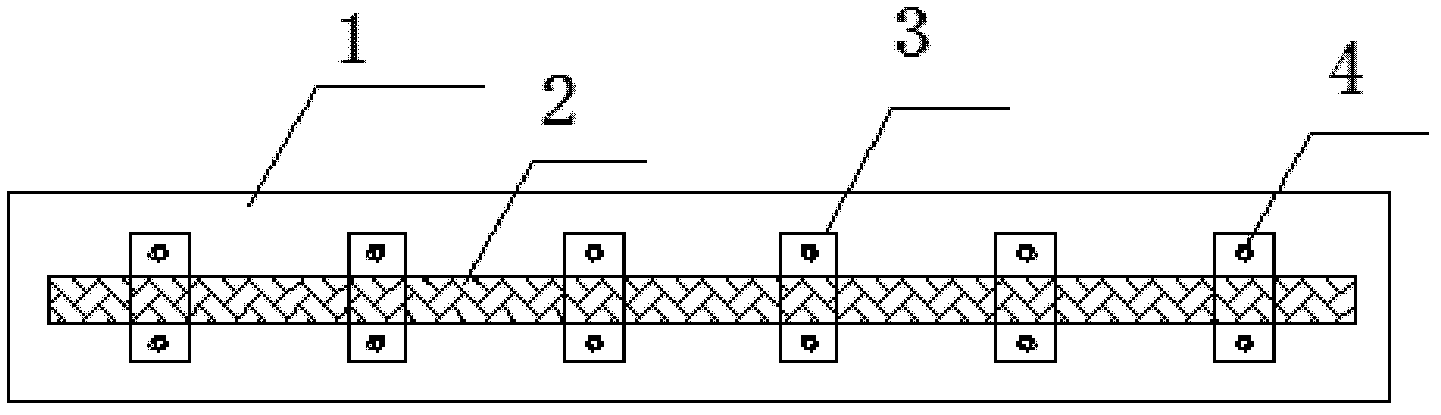

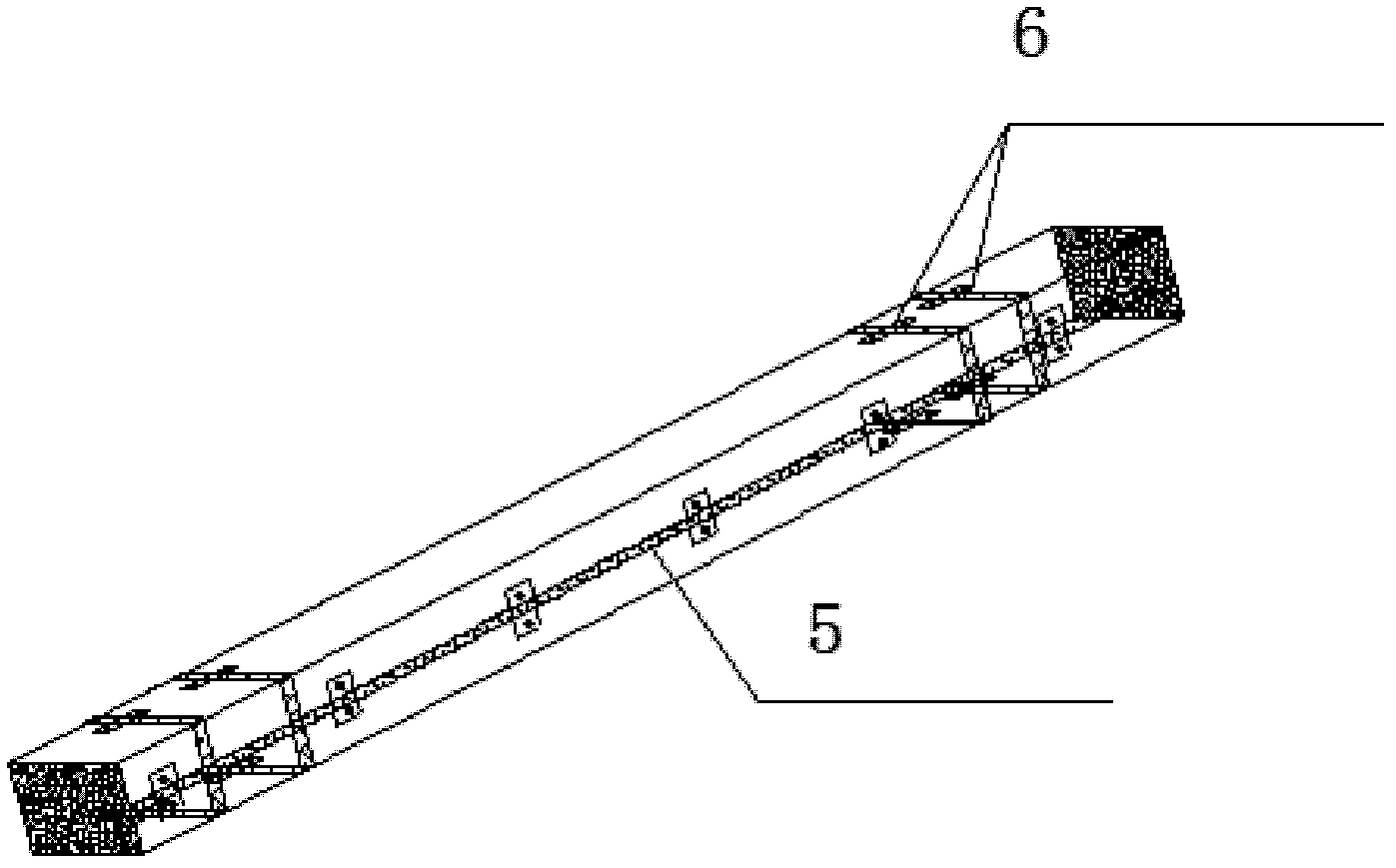

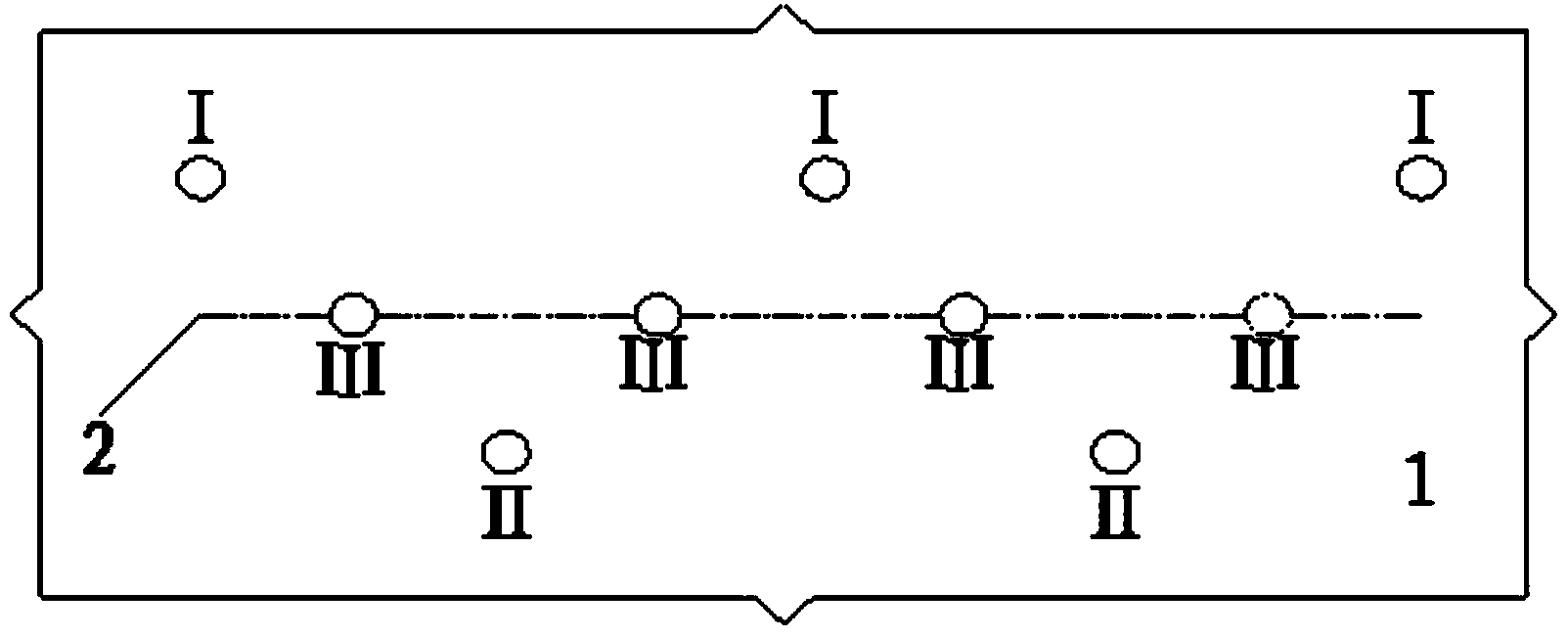

The invention discloses a water seepage plugging construction method of shaft construction seams under high water head. The water seepage plugging construction method includes that I-sequence grouting holes, II-sequence grouting holes and III-sequence grouting holes are arranged within a certain ranges of the seams, and water-soluble polyurethane chemical materials are injected into concrete cracks by the aid of a high-pressure grouting pump; when running into water in the concrete cracks, grout is rapidly dispersed, emulsified, expanded and solidified, so that all the cracks can be filled with solidified elastomers and water flow can be completely blocked out of a concrete structure; chemical grouting materials are filled into gaps between steel plates and wall surfaces on water seepage sides of the cracks, so that seamless integration of the steel plates and the wall surfaces can be guaranteed. Plugging construction on the water seepage side is free of affection of outside water level, normal operation of water conservancy rules is unaffected, and engineering benefits are improved; the water seepage plugging construction method has the advantages of safe construction, fast speed, reliable quality, low cost and the like.

Owner:ANHUI SHUIAN CONSTR GRP CO LTD

Composite grouting reinforcement anti-seepage treatment technology

ActiveCN102808427AShorten the setting timeControl the grouting processProtective foundationEpoxyChemical grouting

Owner:中国水利水电第七工程局成都水电建设工程有限公司

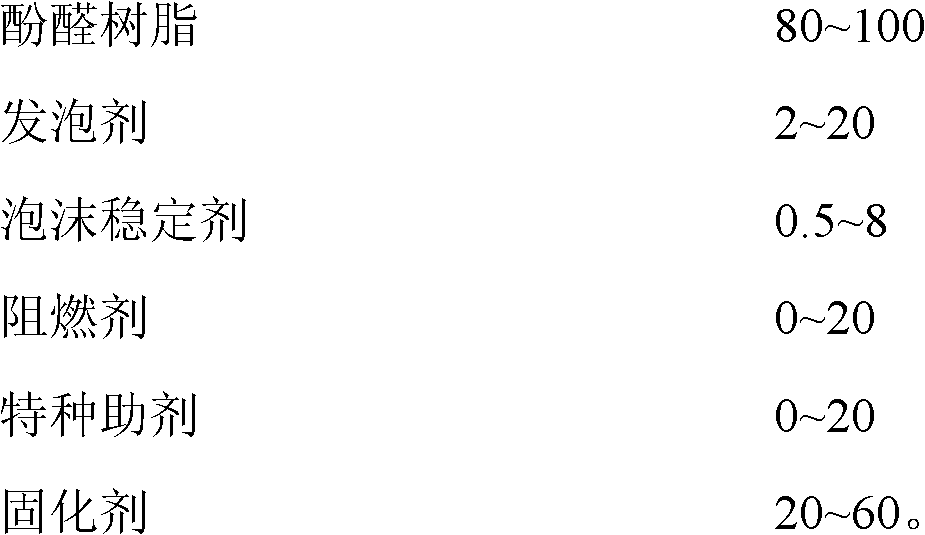

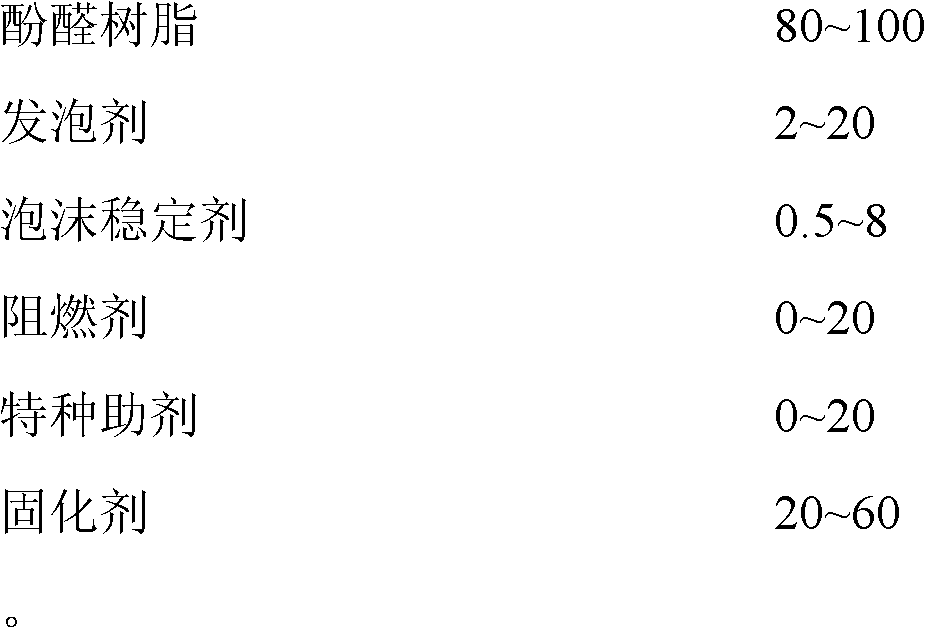

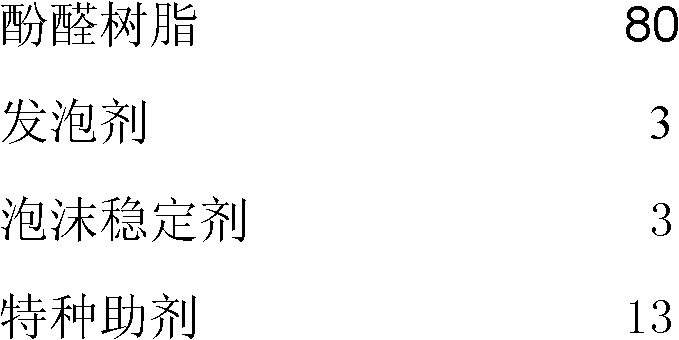

Chemical grouting filling seal material for coal mine, and preparation method and application method thereof

InactiveCN102702675AHigh foaming ratioNo pollution in the processUnderground chambersTunnel liningChemical groutingFoaming agent

The invention discloses a chemical grouting filling seal material for coal mine, which comprises a component A and a component B, wherein the component A comprises a main agent phenol formaldehyde resin and an assistant, and the assistant comprises one and / or mixture of a foaming agent, a foam stabilizer, a flame retardant, a special-type assistant and the like; the component B is a curing agent; and the component A and the component B are proportionally mixed to form the foam material. The chemical grouting filling seal material for coal mine can foam at room temperature, does not generate environment-polluting gas, has the advantages of high foaming ratio, high safety, no pollution, favorable flame retardancy, favorable antistatic property, simple production technique and easily controlled product quality, and is especially suitable for filling a coal mine.

Owner:BEIJING ORIENTAL YUHONG WATERPROOF TECH CO LTD +1

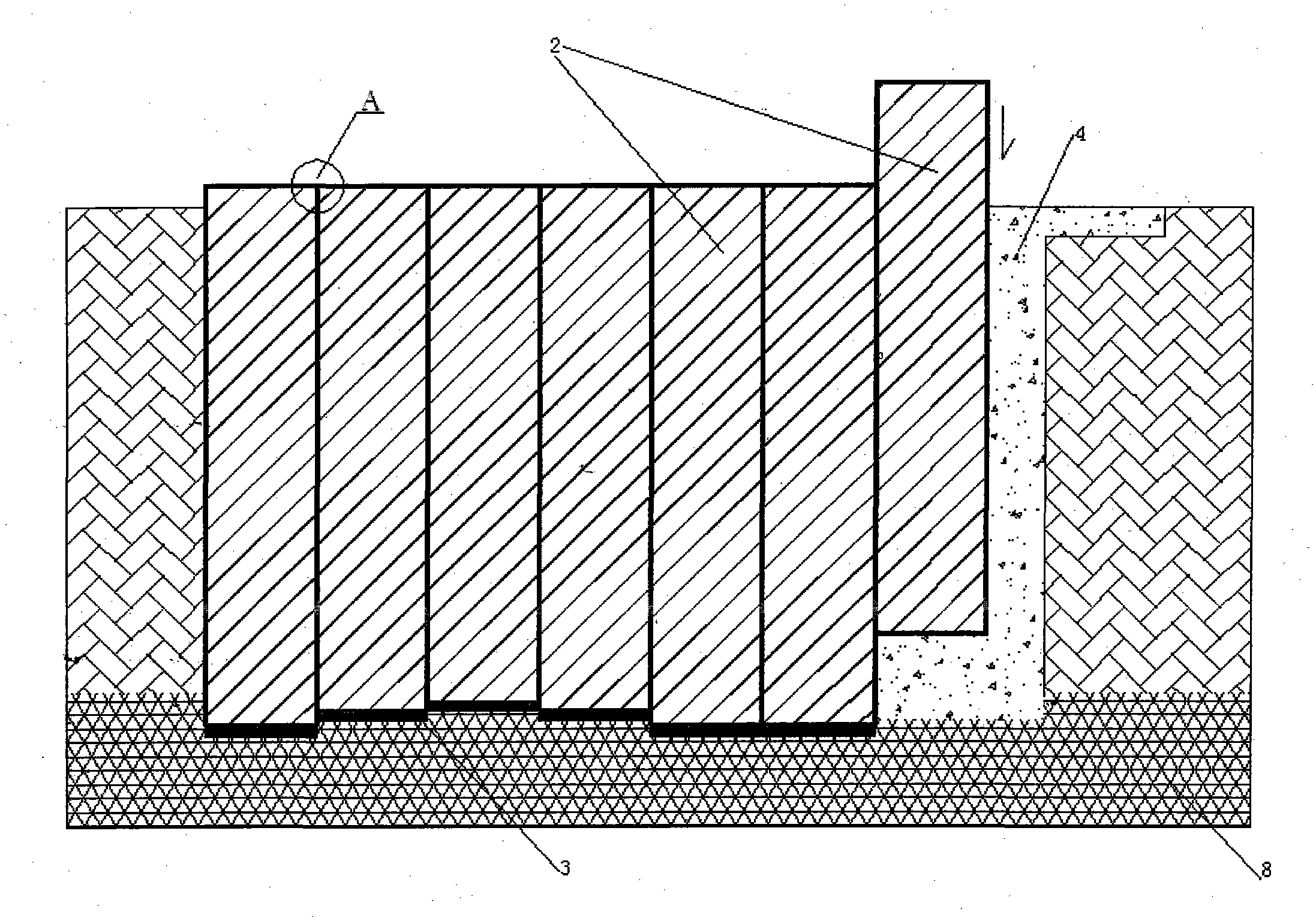

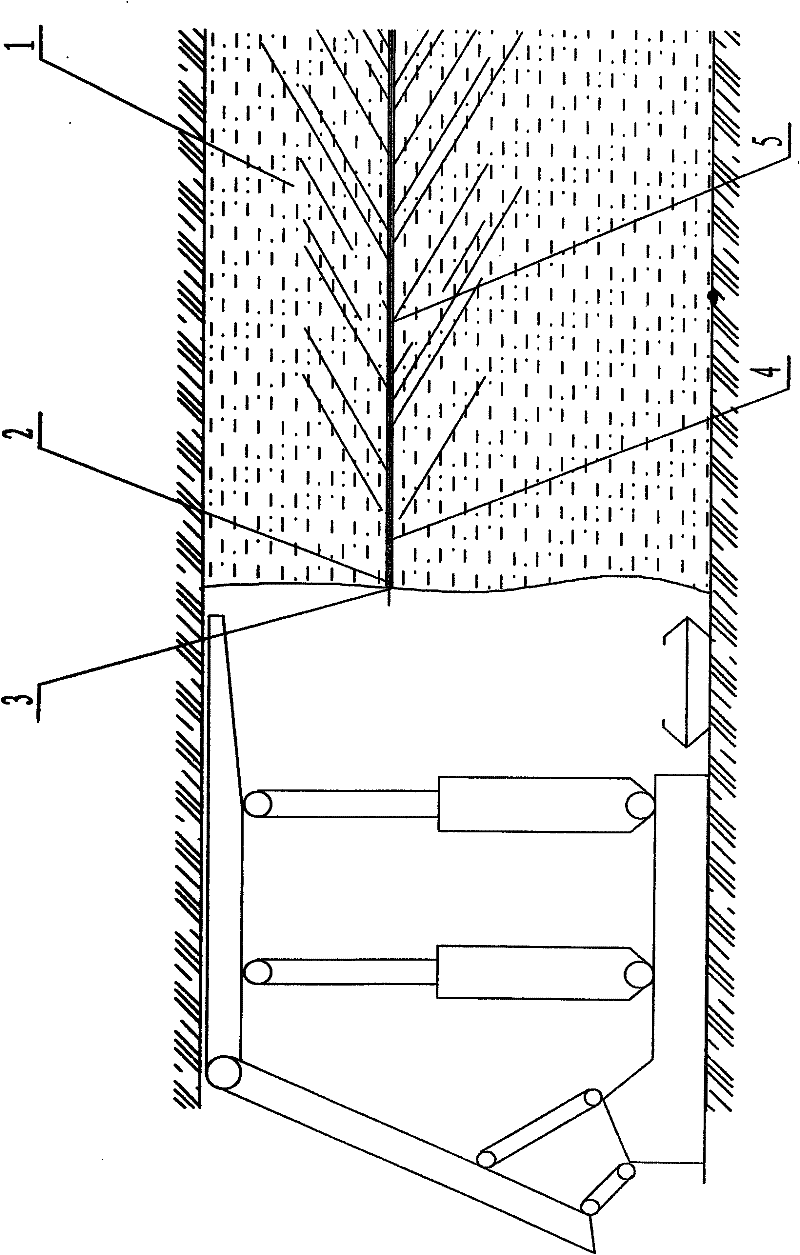

Method for installing vertical soft barrier system based on soil-stone foundation

InactiveCN102367672ADoes not affect the anti-seepage functionStop the spreadArtificial islandsProtective foundationGeomembraneChemical grouting

The invention discloses a method for installing a vertical soft barrier system based on a soil-stone foundation. The method comprises the following steps of: digging a ditch for installing the vertical soft barrier system; refilling anti-seepage slurry into the ditch to form a retaining wall protection layer; installing an HDPE (High-Density Polyethylene) geomembrane in the ditch by using a support tool to form an HDPE geomembrane wall; chemically grouting and sealing the bottom of the HDPE geomembrane wall to form a bottom sealing layer; and withdrawing the support tool to form the vertical soft barrier system. Due to the adoption of the method, an anti-seepage function is ensured, seepage at a joint is prevented, and isolated liquid is effectively prevented from being dispersed; the horizontal dispersion of pollutants can be prevented and blocked for a long time; a connecting lock piece has a reversely-rotatable HDPE structure of which the positive and negative surfaces can be replaced by each other, is provided with a plurality of sealing chambers, can be used for accommodating a plurality of sealing materials and joint seepage detection systems, and is easy to install and operate; an expansion water blocking gasket can expand after contacting water, so that liquid is prevented from flowing through a porous sealing device, and persistent sealing is ensured; and a large installation depth is realized.

Owner:BEIJING GEOENVIRON ENG & TECH

Method for leaking stoppage of external wall of underground structure

InactiveCN101864778AAvoid damageTo achieve the purpose of stopping waterProtective foundationChemical groutingWater flow

The invention discloses a method for leaking stoppage of an external wall of an underground structure, which comprises the following steps: (1) drilling the external wall of the underground structure; (2) embedding a grouting pipe; (3) grouting; and (4) cutting the grouting pipe, and repairing the hole. The method adopts a path opposite to the ground water seepage path, and the cement slurry is filled in the gap on the back of the wall, thereby realizing the purpose of stopping water. The active leaking stoppage outside the side wall of the underground structure is achieved through drilling the external wall of the underground structure, embedding the grouting pipe, filling the seepage crack with the cement slurry and blocking the water flow channel. Therefore, the method has a wide scope of application, and can be used for seepage treatment of cracks caused for different reasons. The construction is simple, the scope of one-time treatment is large, and the cost of the method is lower than the method of leaking stoppage through chemical grouting. Moreover, no grouting of crack slots is needed for leaking stoppage, thereby reducing the damage to the concrete appearance; and simultaneously, the effect of leaking stoppage is good, and no repeated leakage can occur. Therefore, the method can be widely applied in leaking stoppage of construction joints, expansion holes, settlement joints, temperature shrinkage cracks and other cracks.

Owner:GUANGDONG FOUND ENG GRP CO LTD

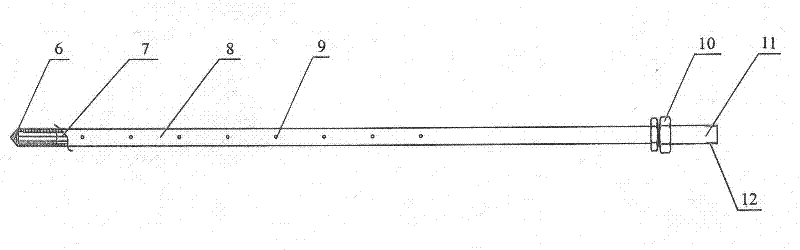

Method for reinforcing working surface of loose and soft coal bed by utilizing nonmetal grouting anchor cable

The invention discloses a method for reinforcing a working surface of a loose and soft coal bed by utilizing a nonmetal grouting anchor cable. The grouting anchor cable is made of a high-strength composite material carbon fiber / glass fiber. The reinforcement of the working surface of the loose and soft coal bed is realized through the processes of surveying and lofting, drilling holes in a coal body, manufacturing and arranging the grouting anchor cable, sealing an anchor cable hole, and grouting chemical grout in the hole and the like. As the grouting anchor cable is made of nonmetal materials, no sparks are generated when a coal-winning machine cuts, and the grouting anchor cable has the characteristics of flame retardancy, anti-static electricity, safety and reliability in use and hightensile strength, higher breaking force, light weight, and capability of being bent and coiled, and is higher than steel and convenient in transportation; and by utilizing the method, deep hole reinforcement and support on the working face can be carried out under the condition that the coal face can not be supported by using a metal anchor cable, the grouting support operation can be carried outon the working surface on site by combining a chemical grouting method, and the coal body of the working surface can be reinforced at the upper and lower tunnels of the working face by combining the chemical grouting in advance.

Owner:HEBEI TONGCHENG MINING TECH

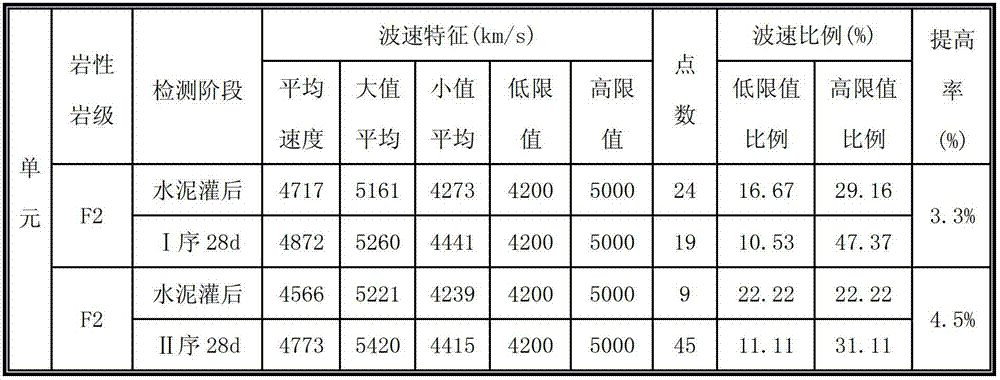

Water-rich loose and broken coal and rock mass grouting solidification experimental device and effect evaluation method

The invention provides a water-rich loose and broken coal and rock mass grouting solidification experimental device and an effect evaluation method. The water-rich loose and broken coal and rock massgrouting solidification experimental device comprises an experimental cavity formed in a steel structure kettle body, a circulating water pressure loading system communicating with a confining pressure loading system, a grouting system communicating with the confining pressure loading system, an ultrasonic testing system and an electrical resistivity tomography system, wherein the ultrasonic testing system and the electrical resistivity tomography system are connected to the experimental cavity; and the water pressure and chemical grout are input into the experimental cavity of a stratum model, thus the coal measure stratum wave speed, dynamic mechanical parameters and electrical resistivity information in the experimental cavity in the grouting process are monitored in real time through the ultrasonic testing system and the electrical resistivity tomography system, and the water-rich loose and broken coal and rock mass grouting reinforcing effect is evaluated. Multi-field physical evolution law simulation tests in the chemical grouting process in water-rich loose and broken coal and rock mass and the grouting effect are quantitatively evaluated, and the scientific basis is provided for loose and broken coal and rock mass grouting reinforcing parameter determination and effect test evaluation of underground engineering.

Owner:XIAN UNIV OF SCI & TECH

Wall body structure seepage treatment method

InactiveCN108999421ASolve structural leakage problemsSolve the leakBuilding repairsSurface layerChemical grouting

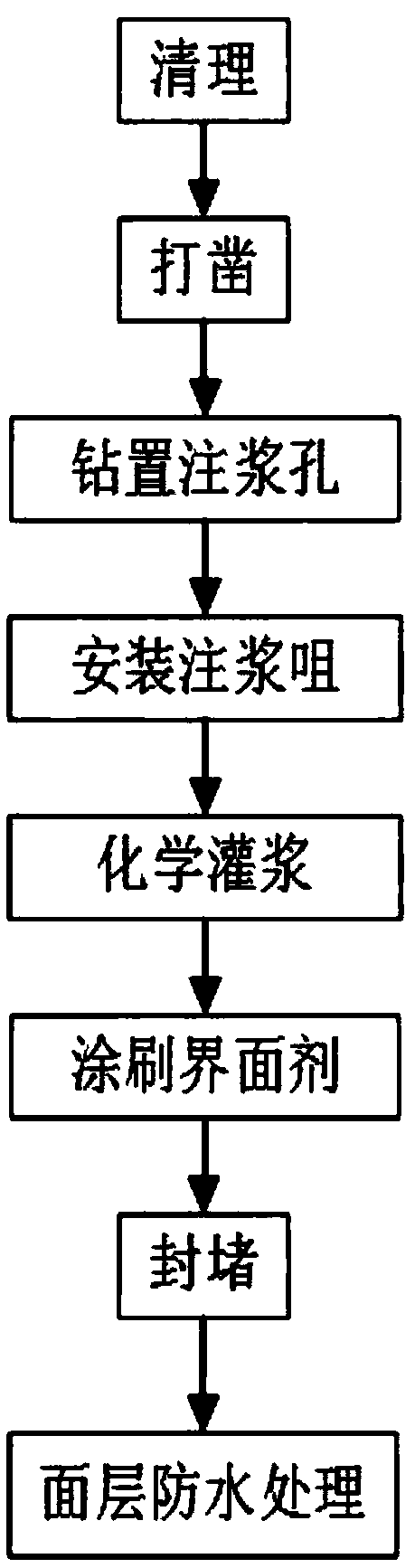

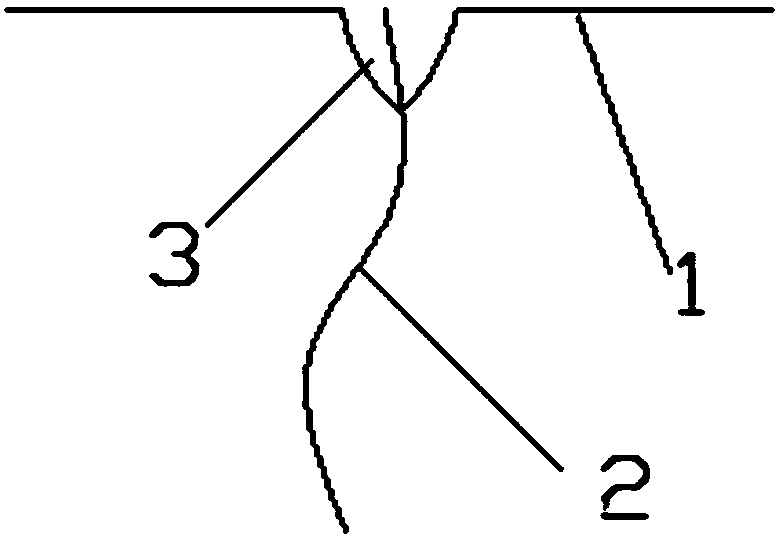

The invention discloses a wall body structure seepage treatment method, which comprises the steps of: cleaning, which is implemented by cleaning calcium carbonate and other residues on the base surface of a wall body structure to expose a seepage part; chiseling, which is implemented by chiseling on the periphery of the seepage part by taking the seepage part as a center point; slurry injection hole drilling, which is implemented by finding out a water flow direction of the seepage part, and drilling a slurry injection hole at an inclined angle of 45 degrees according to the water flow direction of the seepage part; slurry injection nozzle installation, which is implemented by installing a slurry injection waterstop syringe needle in the slurry injection hole according to the depth of theslurry injection hole; chemical grouting, which is implemented by carrying out grouting by means of a grouting machine according to the width of the seepage part; interface agent brushing, which is implemented by stirring an interface agent evenly, evenly brushing the interface agent on a structure groove surface layer; plugging, which is implemented by plugging the chiseled seepage part with a plugging material; and surface layer waterproofing treatment, which is implemented by brushing a surface layer of the plugged seepage part by using a capillary crystalline waterproof coating. The wall body structure seepage treatment method effectively solves the wall body structure seepage problem, has good waterproof effect and is durable.

Owner:广东碧通百年科技有限公司

Chemical grouting material for reinforcing loose and broken bedrock

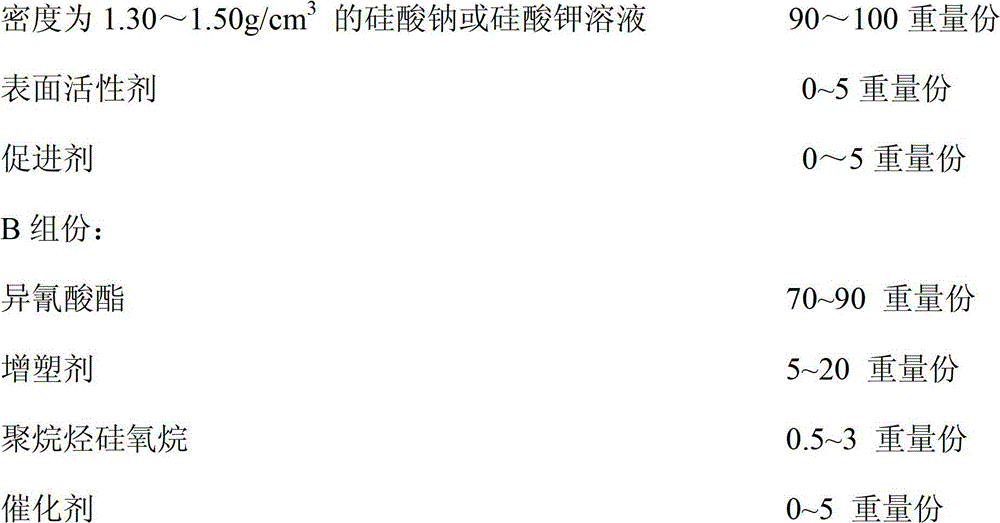

The invention relates to a chemical grouting material for reinforcing loose and broken bedrock. The invention provides a chemical grouting material for reinforcing the loose and broken bedrock, in order to improve the flash point, the burning point and the antistatic performance of the grouting material, reducing the temperature in polymerization reaction and lowering the cost. According to the technical scheme provided by the invention, the chemical grouting material for reinforcing the loose and broken bedrock comprises two components, including a component A and a component B; according to the formulas of the raw materials, the component A comprises 90 to 100 parts by weight of sodium silicate or potassium metasilicate solution, 0 to 5 parts by weight of surface active agent, and 0 to 5 parts by weight of accelerator; the component B comprises 70 to 90 parts by weight of isocyanate, 5 to 20 parts by weight of plasticizer, 0.5 to 3 parts by weight of polyalkane silicone, and 0 to 5 parts by weight of catalyst; the components A and B are uniformly mixed respectively; and in use, the components A and B are mixed according to the volume ratio of 1: 1. The chemical grouting material can be applied to quickly reinforcing the broken coal bed and rock bed and blocking water leakage.

Owner:HANGZHOU GUODIAN DAM SAFETY ENG

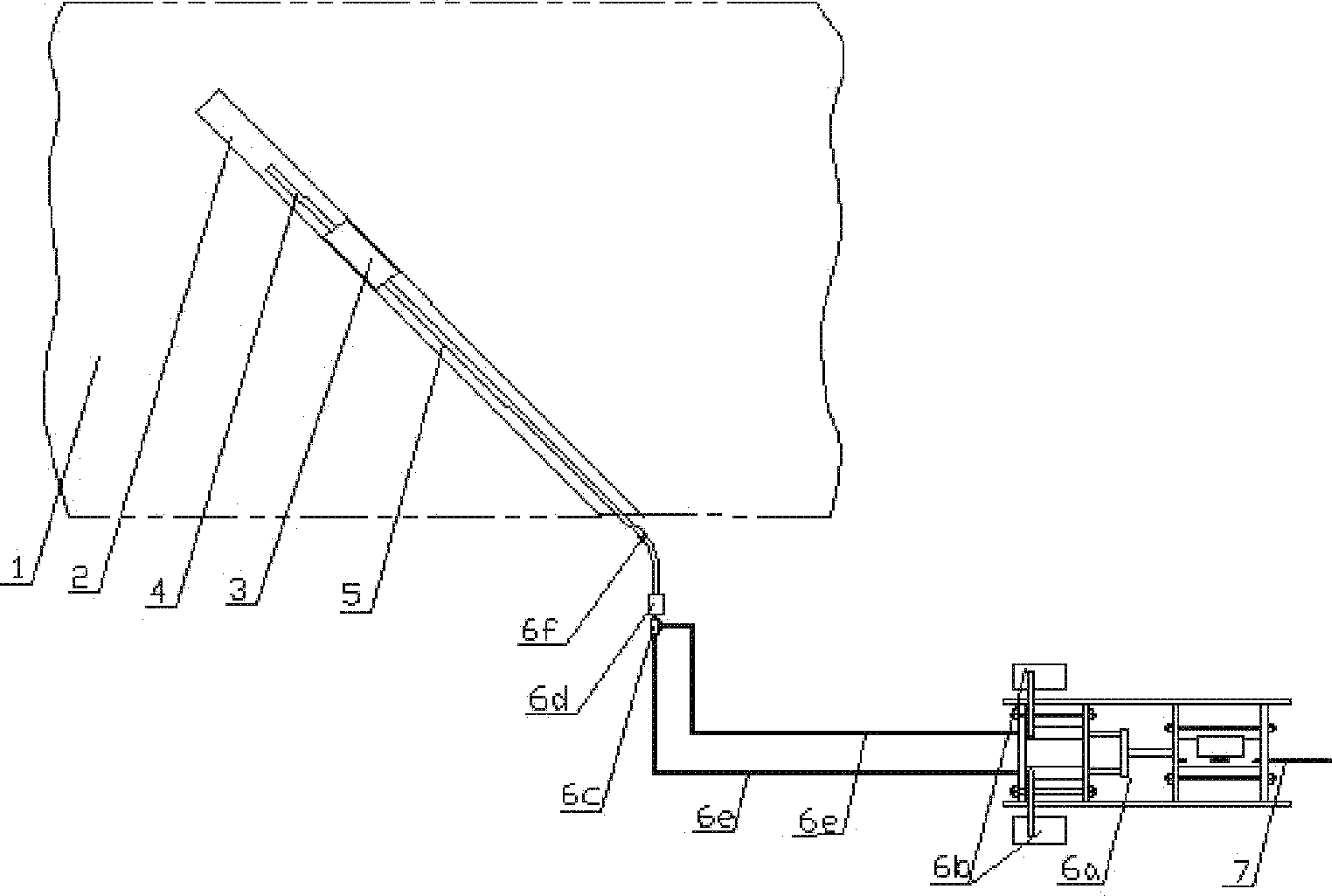

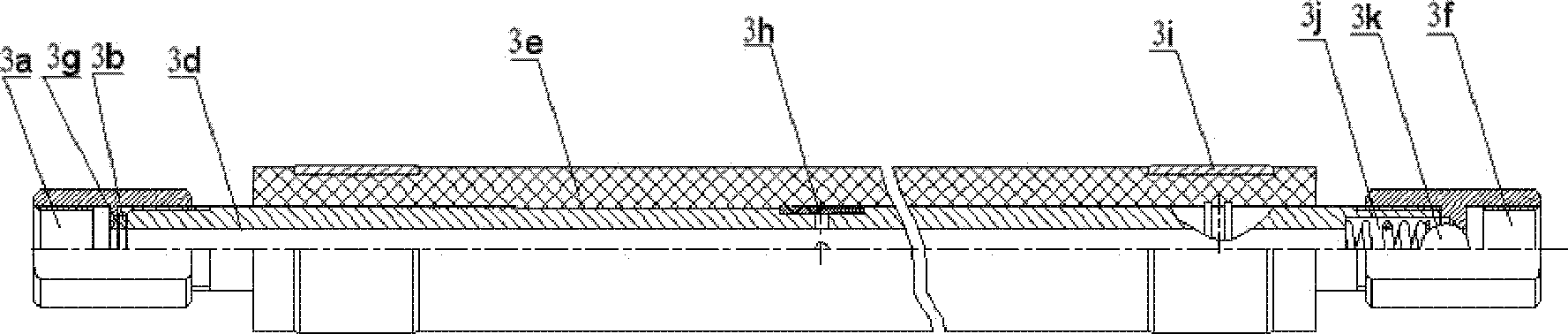

Grouting method and system of cracked coal rock mass

InactiveCN102635327AInhibit sheddingThe extraction process is smoothSealing/packingChemical groutingSlurry

The invention relates to the technical field of coal mine exploitation and discloses a grouting method and system of cracked coal rock mass. The grouting procedure is performed on the cracked coal rock mass of a back production gateway in front of a back production face, and the grouting method comprises the following steps: step 1. drilling a deep hole in the cracked coal rock mass by using a drill bit; step 2. inserting a hole packer connected with a slurry injection pipe and a grouting pipe in the deep hole, wherein the slurry injection pipe is connected with the front end of the hole packer, the grouting pipe is connected with the tail end of the hole packer, and the other end of the grouting pipe is connected with a chemical grouting machine; and step 3. sealing the hole and grouting section by section according to the depth of the deep hole, starting the chemical grouting machine to pressurize the hole packer to seal the hole, wherein a blocking piece is pushed away when a pressure value under which the blocking piece can be pushed away is reached, and then the slurry injection pipe grouts the deep hole. According to the invention, a hole is drilled in the cracked coal rock mass of the back production gateway in front of the back production face and grouting is performed section by section,the technique is simple, the low is low and the operation at the coal mining face is not affected.

Owner:TIANDI SCI & TECH CO LTD

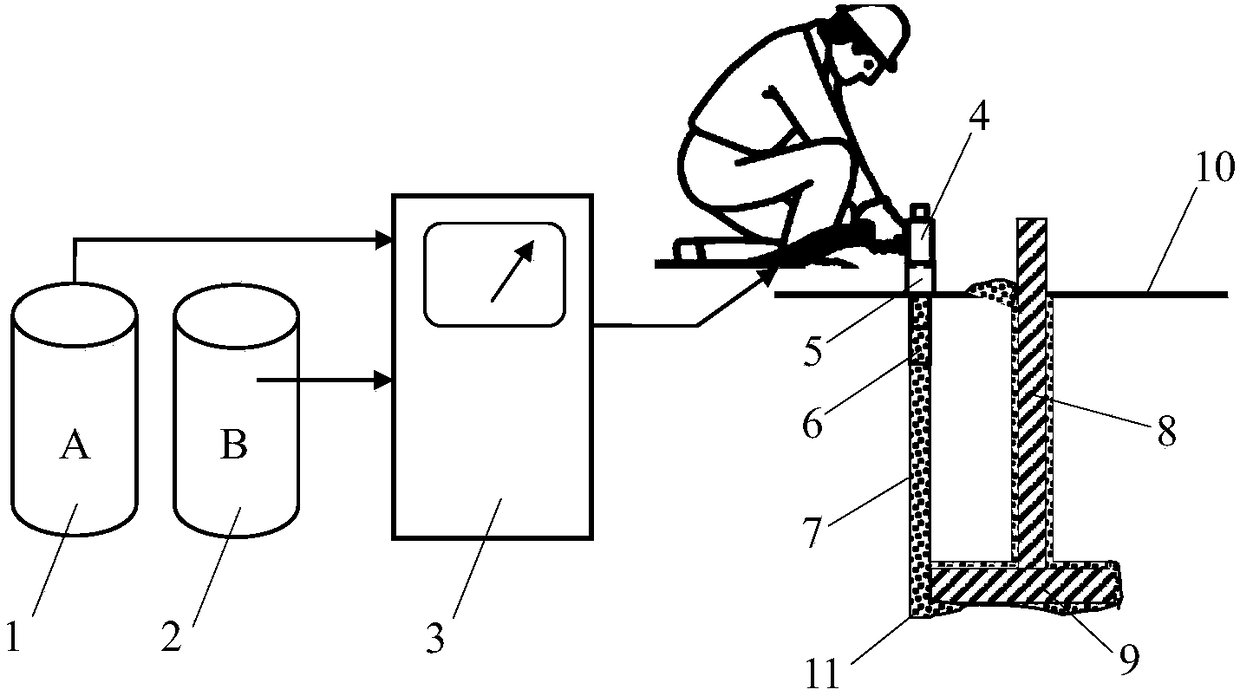

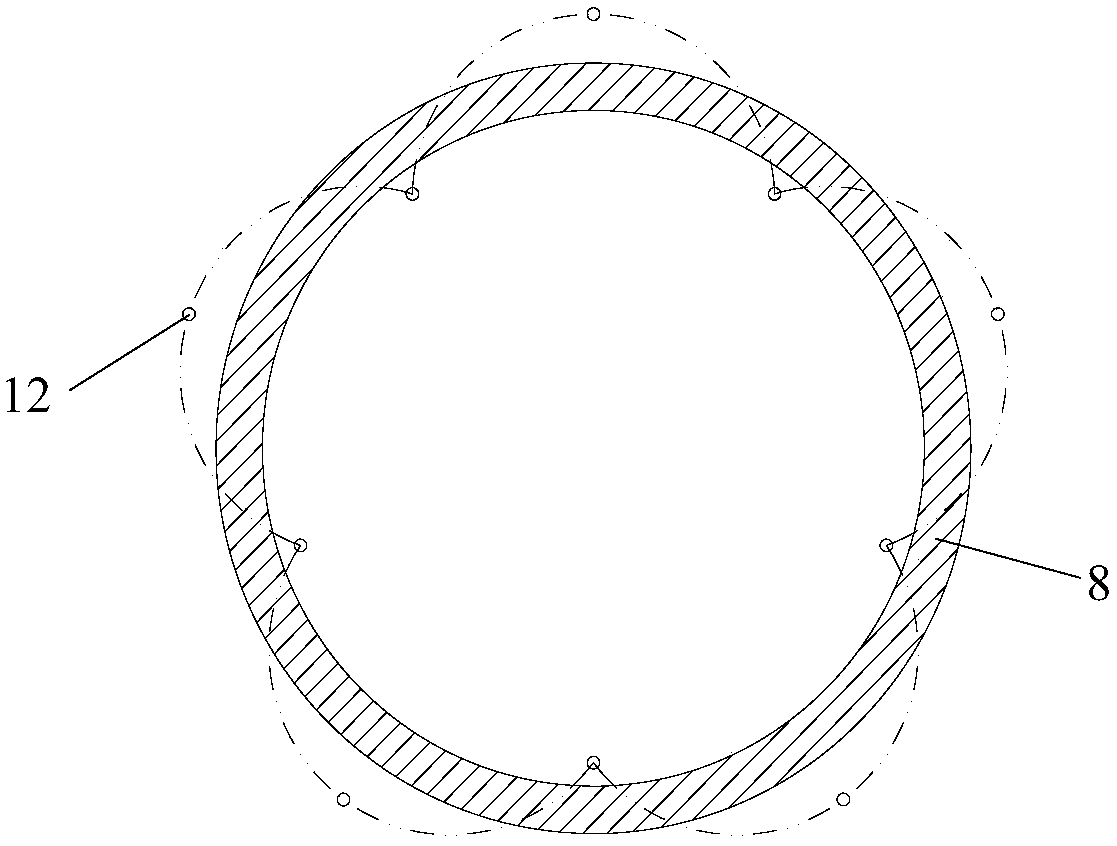

Draught fan foundation strengthening method

The invention provides a draught fan foundation strengthening method. The draught fan foundation strengthening method comprises the following steps that firstly, a plurality of grouting hole positionsare formed in the inner side and the outer side of a draught fan foundation ring at certain interval positions, a drilling machine is adopted for drilling the position below the lower bottom face ofa foundation ring bottom flange, and the drilling hole diameter meets the grouting slurry diameter requirement; secondly, drilling hole way cleaning is conducted; and thirdly, a high polymer materialA and a high polymer material B are prepared into high polymer polyurethane slurry according to the ratio to conduct high-pressure chemical grouting filling on a drilling hole way, the material A andthe material B are conveyed to the fracture plane gap position through the high pressure till fissure gaps are fully filled, the materials become solids from liquid after the chemical reaction, the size is slightly expanded, and the purposes of filling cavities and the gaps and extruding and discharging gap water are achieved. According to the draught fan foundation strengthening method, the project manufacturing cost is low, the construction period is short, strength is high, curing is fast, the construction effect is reliable, and rapid repairing and strengthening of the draught fan foundation can be achieved.

Owner:POWERCHINA HUADONG ENG COPORATION LTD

Chemical grouting material for coal-rock mass water shutoff and reinforcement and preparation method thereof

InactiveCN104498004AReduce the cost of water plugging and reinforcementRaw materials are cheap and easy to getDrilling compositionChemical synthesisChemical grouting

The invention belongs to the field of chemical synthesis, and particularly relates to a novel chemical grouting material for coal-rock mass water shutoff and reinforcement and a preparation method thereof. The chemical grouting material provided by the invention is prepared by mixing a component A and a component B at a volume ratio of 1:1, wherein the component A is prepared by proportionally mixing liquid sodium silicate, small-molecular alcohol and a catalyst; and the component B is prepared by proportionally mixing polyphenyl polymethylene polyisocyanate and a viscosity reducer. The chemical grouting material provided by the invention has the characteristics of low raw material cost, good permeability, fast curing, high adhesive force with a coal bed and high solidification strength; and particularly, the material does not foam in water, the water shutoff and reinforcement effects can be perfectly realized, the related raw materials are green and pollution-free, and the material does not contain volatile solvents or generate any poisonous gas and completely meets the requirements in use and environmental protection of coal mine water shutoff and reinforcement materials.

Owner:SHANDONG INOV NEW MATERIALS CO LTD

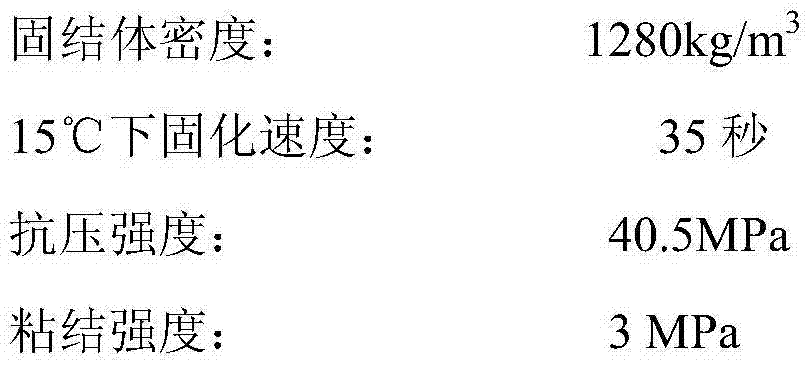

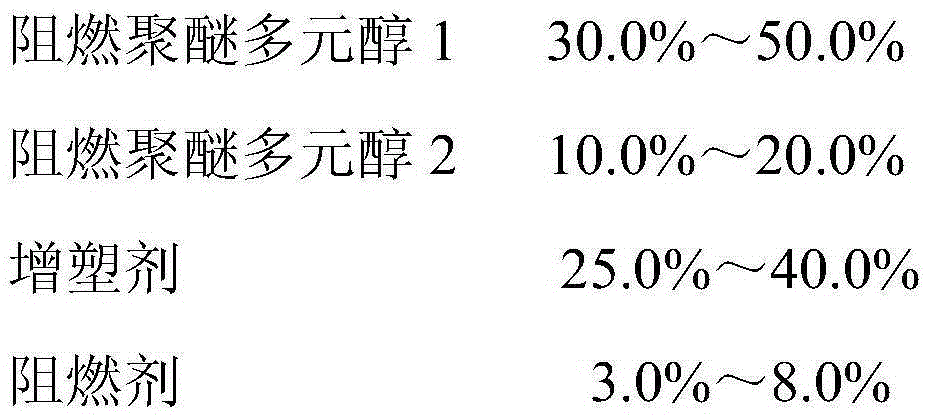

High-strength high-fire-retardant low-heat-release mining polyurethane grouting reinforcement material and preparation method and application thereof

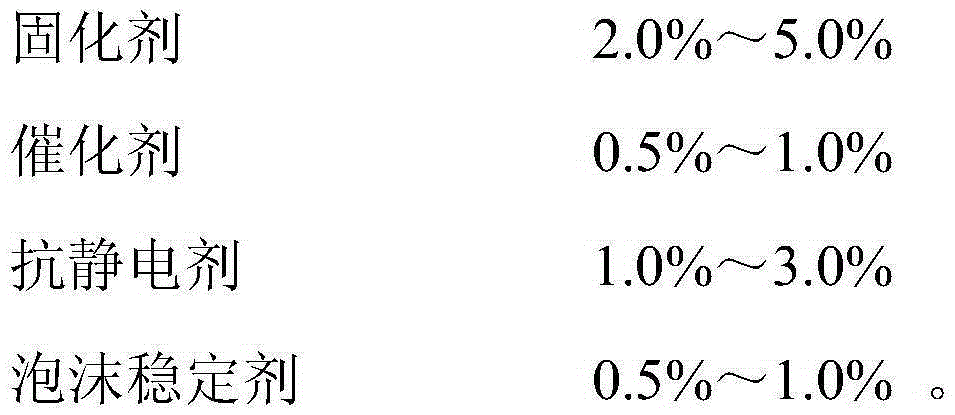

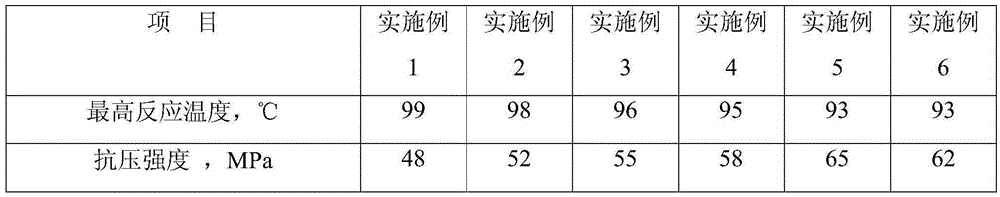

The invention belongs to the technical field of coal and rock chemical grouting reinforcement, and discloses a high-strength high-fire-retardant low-heat-release mining polyurethane grouting reinforcement material and a preparation method and application thereof. The material is obtained by matching a component I and a component II according to the volume ratio of one to one; the component I is prepared from, by weight, 70%-95% of isocyanate and 5%-30% of epoxy resin; the component II is prepared from, by weight, 30%-50% of flame retardant polyether polyol 1, 10%-20% of flame retardant polyether polyol 2, 25%-40% of plasticizers, 3%-8% of fire retardants, 2%-5% of curing agents, 0.5%-1% of catalyst, 1%-3% of antistatic agents and 0.5%-1% of foam stabilizer.

Owner:GUANGZHOU CHEM GROUTING CO LTD CAS

Method for preparing organic and inorganic hybridization modified polyurethane chemical grouting material

The invention discloses a method for preparing an organic and inorganic hybridization modified polyurethane chemical grouting material. The method adopts water-soluble end isocyanate-polyether prepolymer, special expandable phenol-formaldhyde resin and a surfactant to form a component A; and inosilicate liquor, an amine catalyst and an organic tin catalyst form a component B, and the component A and the component B are mixed and stirred uniformly. The chemical grouting material has the advantages of wide raw material sources, low cost, stable performance, appropriate viscosity, accurate gelation time control, low toxic chemical composition content, good flame retardant property, high adhesive strength, high stone forming rate, low permeability, high mechanical strength and good corrosion resistance and aging characteristic.

Owner:HEBEI TONGCHENG MINING TECH

Method and device for repairing concrete gap with chemical grout

ActiveCN101109231AEfficient constructionEasy constructionBuilding repairsLarge containersChemical groutingMaterials science

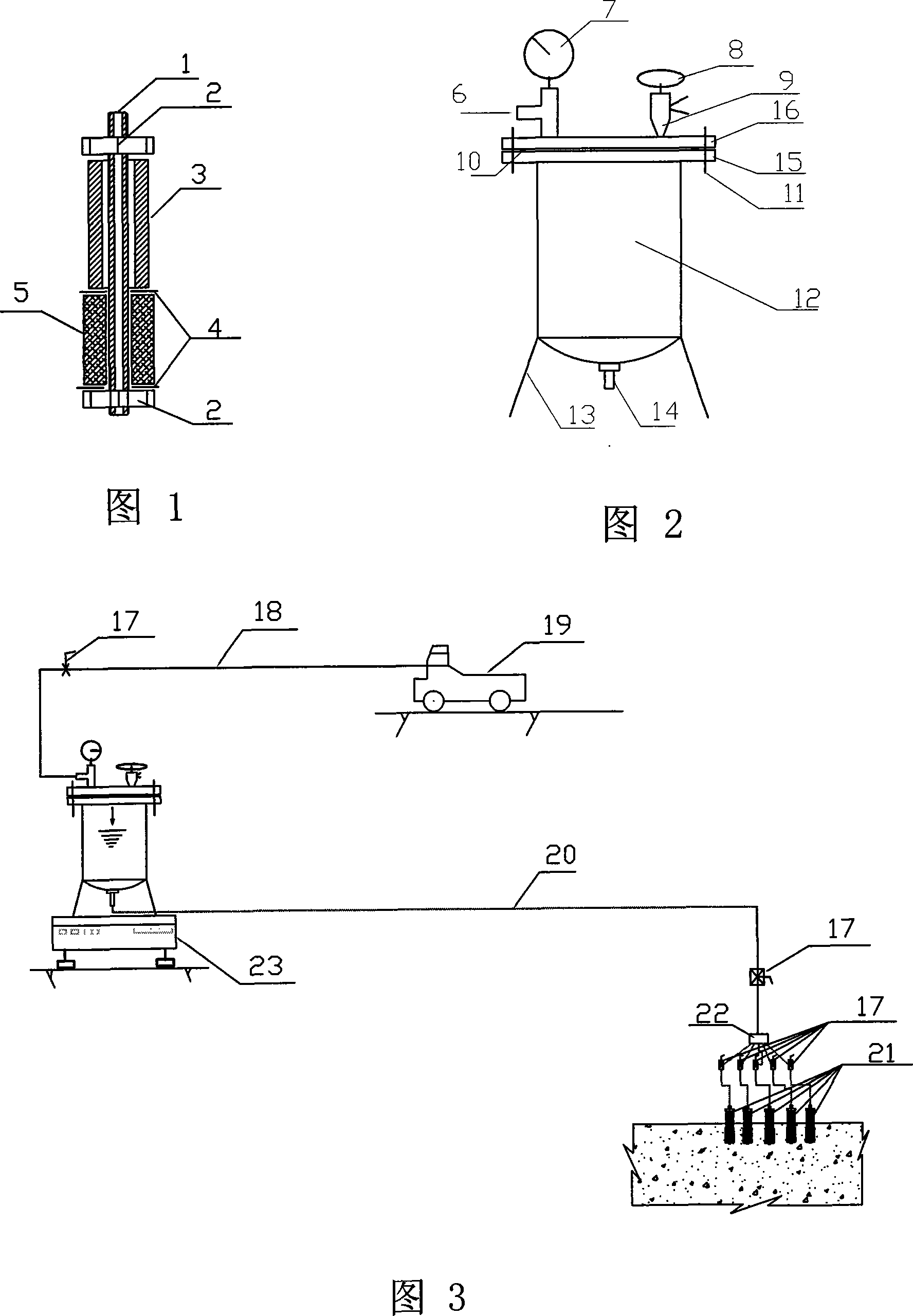

The invention relates to concrete, in particular to a mending method for concrete fissures of buildings and the devices used in the mending. The devices used comprises a grouting plug and a mortar-storage tank. The grouting plug is in such a form that an ejecting & pressing pipe is looped on the pipe wall at upper end of a mortar intaking pipe, a rubber plug is looped on the pipe wall at the lower end of the mortar intaking pipe, and the two ends of the mortar intaking pipe are looped with a press-tight nut respectively. The mortar-storage tank comprises a tank body and a tank cover. In the center at bottom of the tank body, a mortar-out opening is provided. The mortar-out opening is connected with a diverter through a mortar-out pipe. At the bottom of the tank body, a base is provided. The tank cover is in such a form that an end cover is fixed at top of the tank body, a cover plate is fastened on the end cover, an air inlet and a feed opening are provided on the tank cover. The grouting way comprises drilling hole, clamping the plug or burying the pipe, and configuring grouting devices, and grouting by a plurality of holes connected in parallel. The invention makes the construction for mending concrete fissures by chemical grouting more fine, simple, efficient, easier to operate, more accurate and faster.

Owner:SINOHYDRO BUREAU 7 CO LTD

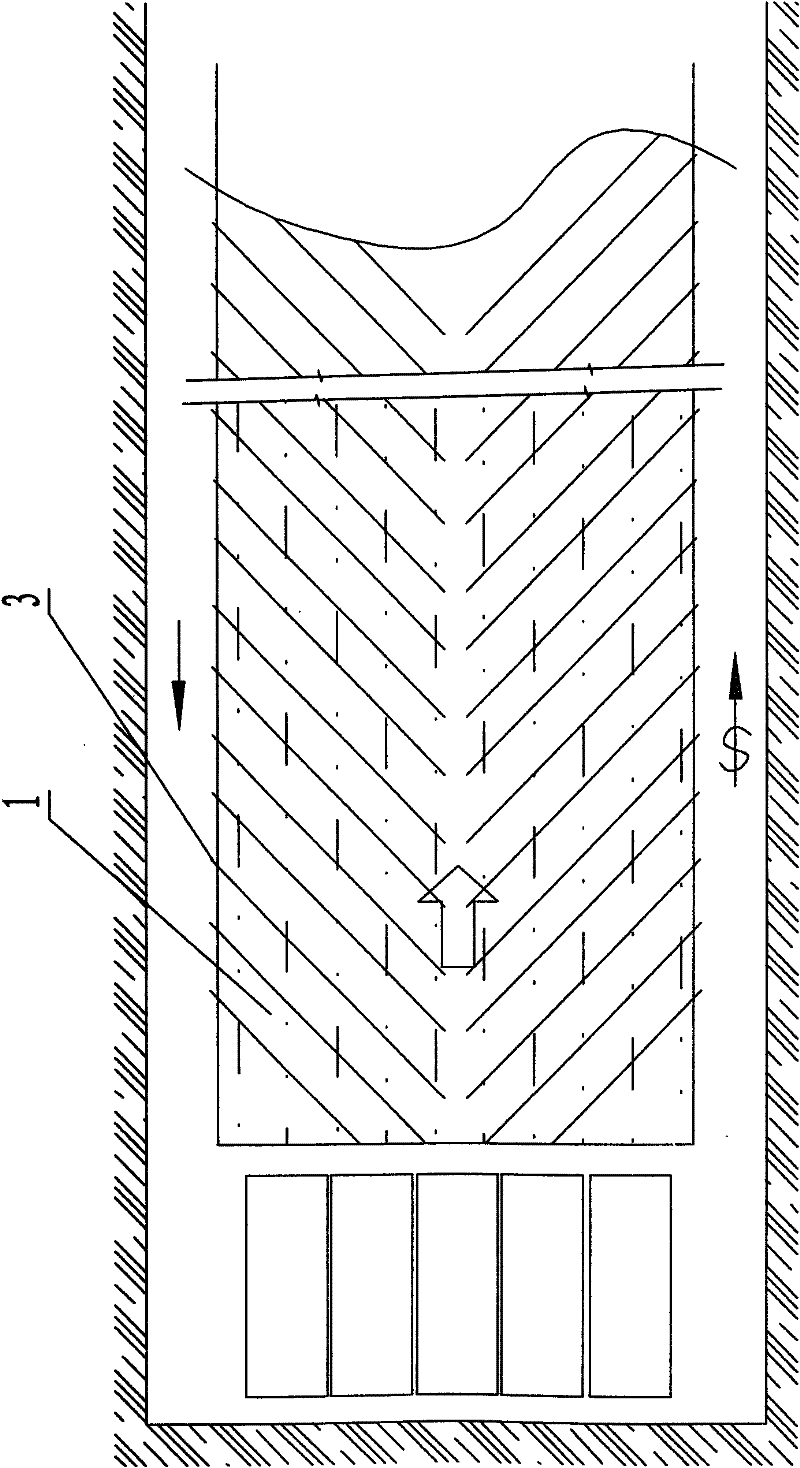

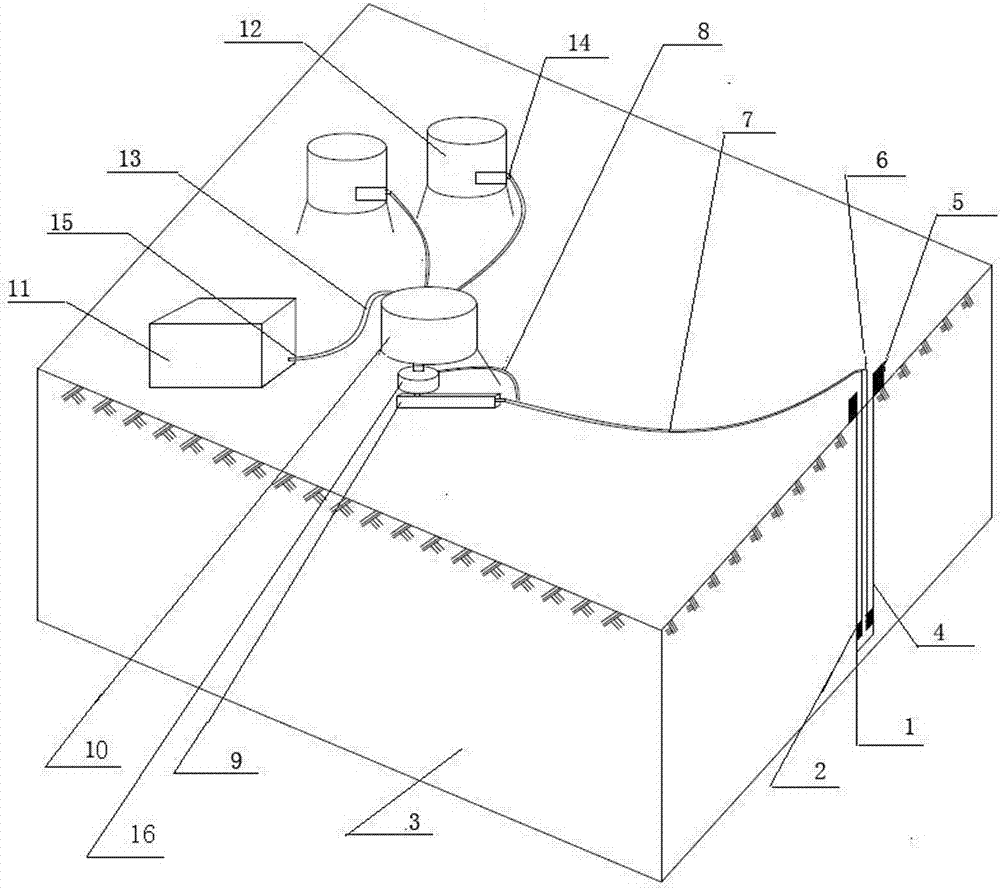

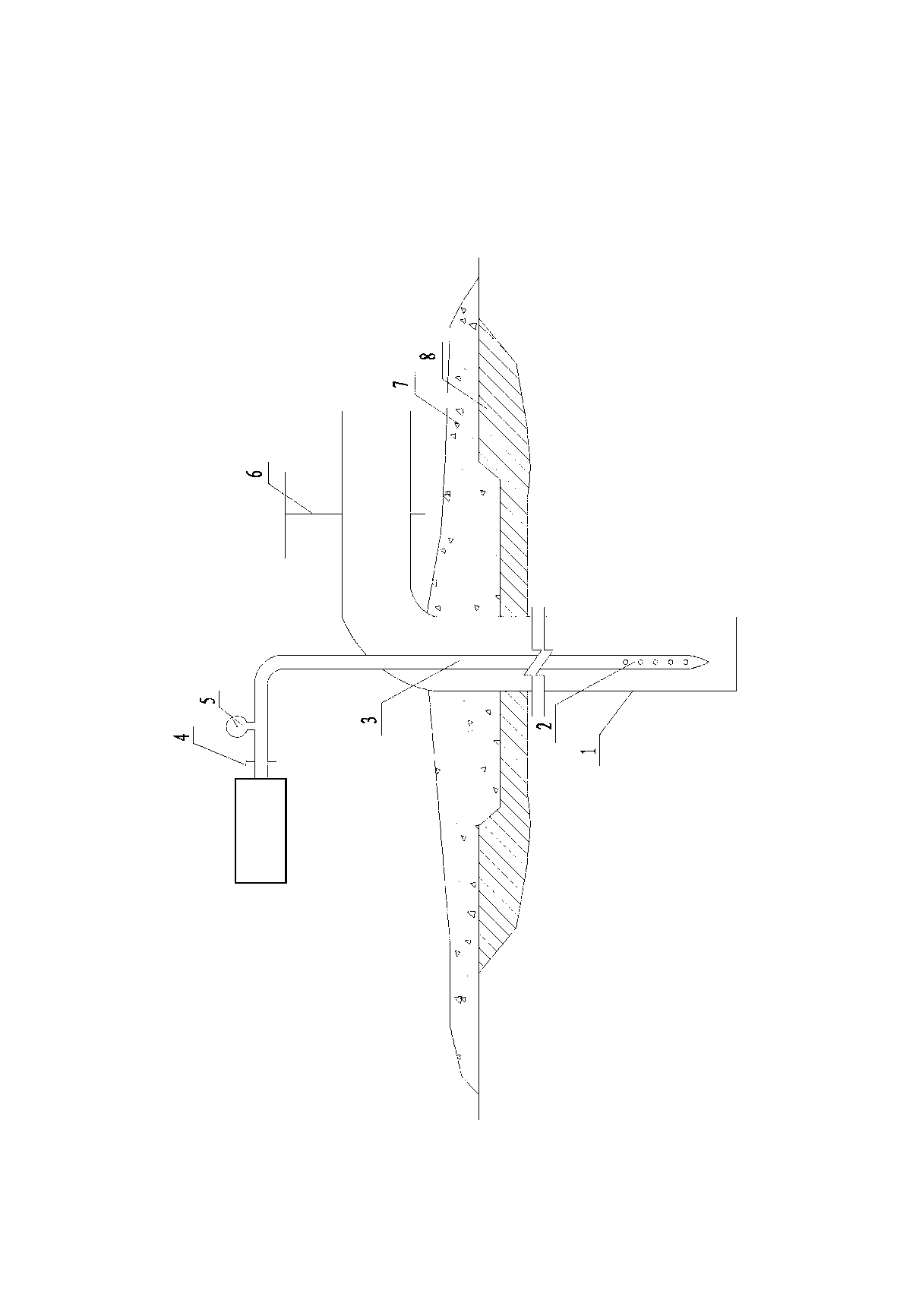

Device and construction method for conducting microorganism curing on silty and fine sand layer

The invention relates to a device and construction method for conducting microorganism grouting on a silty and fine sand layer. The device comprises a bacteria solution cultivating pot, a microorganism slurry stirrer and a mixed calcium source tank. The microorganism slurry stirrer is connected with the bacteria solution cultivating pot and the mixed calcium source tank through conveying pipelines correspondingly. A drilling machine drills into the bottom of the layer to be treated in the follow-pipe wall protection hole forming mode. A high-pressure slurry ejection pipe is arranged at the bottom of a wall protection sleeve. A gap between the wall protection sleeve and the high-pressure slurry ejection pipe is sealed through a slurry outlet section of the high-pressure slurry ejection pipe in a mold bag blocking mode. A high-pressure chemical grouting pump conducts pure compression type grouting construction on the microorganism slurry through a high-pressure grouting pipe and the high-pressure slurry ejection pipe. According to the device and the construction method, the slurry proportion is reasonable, the permeability in the silty and fine sand layer is good, diffusion is uniform, the maneuverability is high, the effect is reliable, cost is reduced, the device and the construction method can be widely applied to the field of foundation treatment of geotechnical engineering, the strength of a soil body is improved and the permeability of the soil body is reduced under the function of microorganism curing, and a new direction is provided for foundation treatment of the grouting technology based on the microorganism biochemistry mechanism.

Owner:CHINA INST OF WATER RESOURCES & HYDROPOWER RES +1

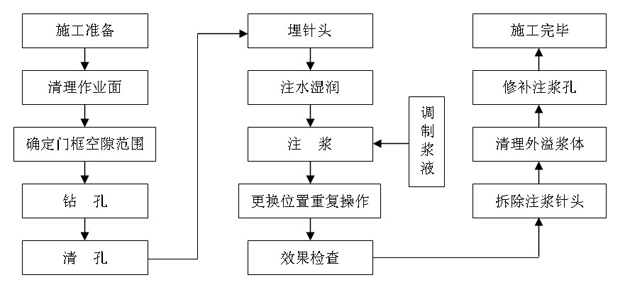

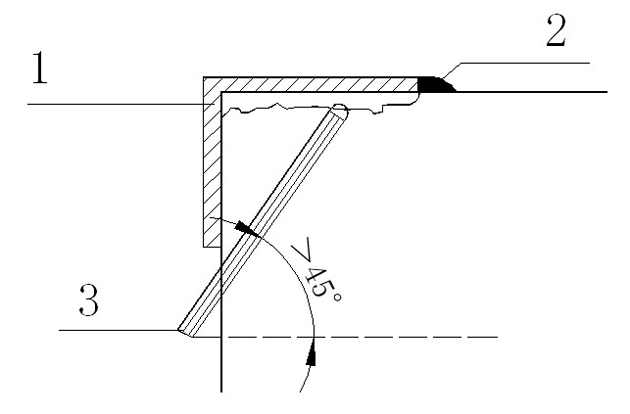

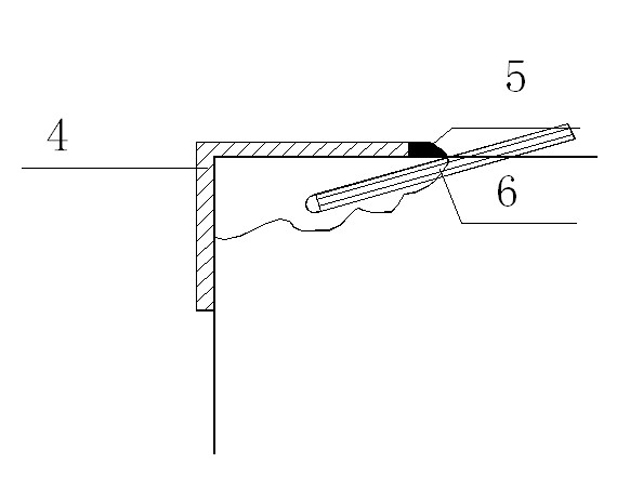

Method for grouting sealing of gap between steel door frame of protective sealed door and wall

The invention relates to a method for grouting sealing of a gap between a steel door frame of a protective sealed door and a wall, which belongs to the technical field of architectural construction. The method comprises the following construction steps of: 1) drilling and cleaning holes, namely drilling the holes on a concrete surface nearby the gap upwards or downwards by aiming at the direction of the gap, and cleaning dust in the holes after drilling; 2) embedding needle heads, namely embedding grouting needle heads through tool fastening; 3) grouting: a, mixing a water-soluble polyurethane chemical grouting material with an oil-soluble polyurethane chemical grouting material according to a weight proportion of 1:1 to prepare serous fluid; and b, starting grouting the serous fluid from a first needle head, immediately stopping the grouting when the serous fluid emerges from an adjacent needle head, continuously grouting the serous fluid from a second needle head, and performing the grouting forwards in turn; and 4) processing needle holes, namely after the serous fluid is coagulated, removing the grouting needle heads, and sealing the holes. The method has the advantages of simple process, convenient construction, reliable performance, corrosion resistance, no generation of mildews, high expansion efficiency, obvious construction effect and the like.

Owner:TIANJIN TIANYI CONSTR GRP

Processing method for foundation pit piping

InactiveCN103061349AGuarantee the construction progressPrevent collapseFoundation engineeringSlurryBuilding construction

The invention relates to a processing method for foundation pit piping. The object of the processing method is to block water gushing channels and close big water gushing points through chemical grouts so as to prevent the under water below a foundation pit pouring into the foundation pit, and accordingly create conditions for a dry construction. The technical scheme of the processing method includes the steps of: a) distributing holes within a water gushing area; b) sequentially aligning and drilling the holes through a drill and timely pressing steel sleeves into the holes in the drilling process, wherein a water outlet valve is mounted at a water outlet of an elbow which is positioned at the upper end of the steel sleeve inside which grouting pipeline equipment is installed; c) after finishing the pressing of the steel sleeves, firstly blanketing the openings of the holes with clay, then covering the clay with concrete or mortar and sealing gaps with cotton and quick-drying cement; d) after the concrete strength is reached, closing the water outlet valves and using a grout pump to grout the water soluble polyurethane slurry into a hole enclosed by the steel sleeves through a grouting pipe and a shot grout porous pipe. The processing method for foundation pit piping is applicable to the pit construction process of high buildings.

Owner:ZHEJIANG HUADONG CONSTR ENG

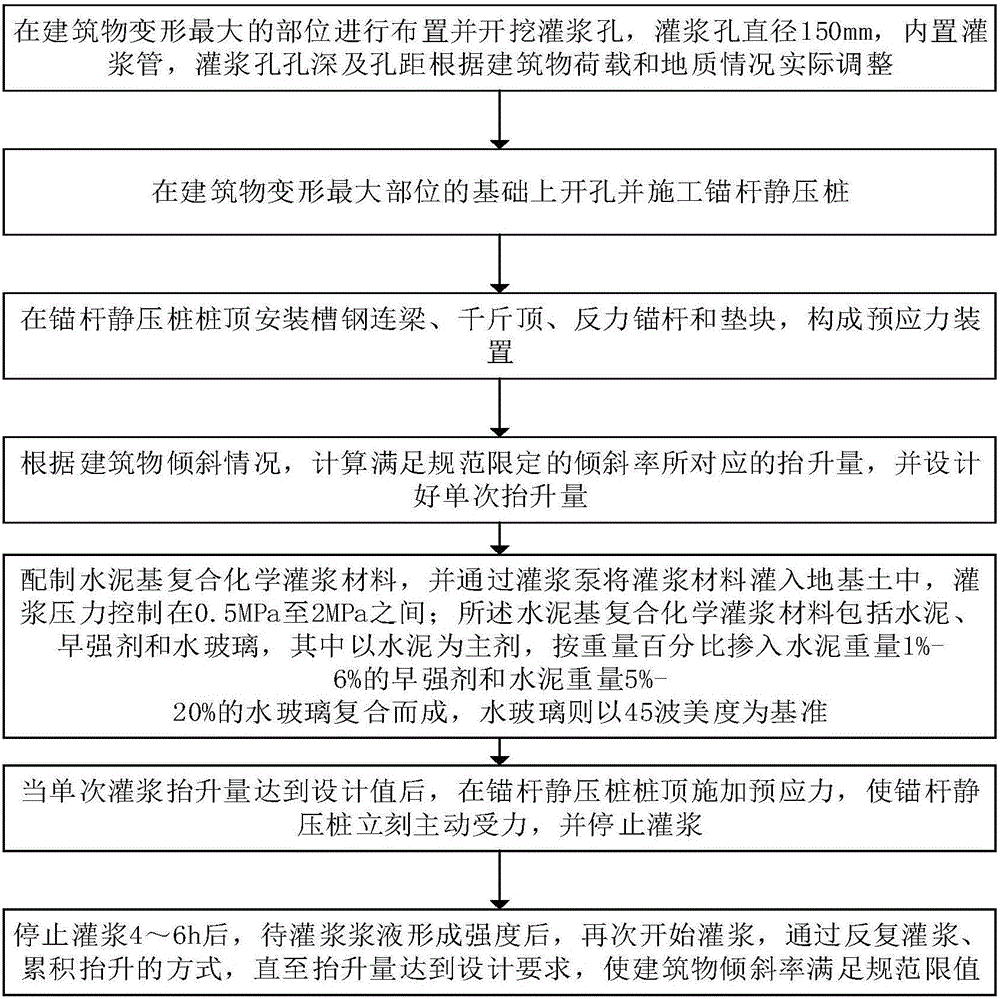

Grouting combined prestressed anchor rod static pressure pile rectification and reinforcement method

ActiveCN106522292ATo achieve the purpose of correctingShort curing timeFoundation engineeringChemical groutingPre stress

The invention discloses a grouting combined prestressed anchor rod static pressure pile rectification and reinforcement method. Firstly, the maximum settling position and the inclined direction of a building are determined; grouting holes are excavated; prestressed anchor rod static pressure piles are arranged; prestress devices are mounted on the static pressure piles; the building is connected with the static pressure piles through the prestress devices; then, cement base composite chemical grouting materials are mixed; the grouting materials are filled in a foundation through grouting pipes, and generate the excess pore pressure in the grouting holes to upwards deform soil of the foundation; the building is upwards hoisted under the effect of the excess pore pressure of the soil of the foundation; finally, proper prestress is applied to the static pressure piles, so that the building is suffered from upward support force to stop settling after grouting; and after grouting material induration forms strength, the next grouting operation can be performed. The rectification and reinforcement method has the advantages of simple operation, low risk, safety, reliability and capability of effectively slowing down dissipation of the excess pore pressure.

Owner:GUANGZHOU CHEM GROUTING CO LTD CAS

Spalling prevention method through full-length anchoring of rib with soft bolt

The invention discloses a spalling prevention method through full-length anchoring of a rib with a soft bolt. The spalling prevention method through the full-length anchoring of the rib with the soft bolt comprises the following steps in sequence: (1) utilizing a pneumatic column drilling machine to subject the inside of the coal wall to tiltingly drilling in the middle of a working face, drilling a hole between every two fully-mechanized coal mining supports, wherein the depth of the drill hole is 20-25m, the end of the drill hole is drilled to the inside of a coal seam roof to 1-2m; (2) after the drilling construction, utilizing a grouting pipe to bind a coir rope, utilizing the coir rope as the soft bolt and sending the coir rope to the end of the drill hole; (3) utilizing a pneumatic double-liquid chemical grouting pump to fill the drill hole with chemical pulp to perform full-length anchoring, and enabling the chemical pulp and the coir rope to solidify together to form a super-long bolt; (4) dismantling and moving away the pneumatic column drilling machine and the double-liquid chemical grouting pump; and (5) operating a coal mining machine to start to work to mine coal on a fully mechanized coal mining working face. The spalling prevention method through the full-length anchoring of the rib with the soft bolt has the advantages that the construction is simple, the rib spalling prevention effect is good, the cost is low, the quality of the coal is not affected and the like.

Owner:焦作煤业(集团)新乡能源有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com