Deep-hole chemical grouting construction method applied to water leakage treatment of hydroelectric dam

A technology of chemical grouting and construction method, which is applied in water conservancy projects, sea area engineering, construction, etc. It can solve problems such as facility damage, failure to achieve reinforcement, concrete damage, etc., to save cost and investment, increase diffusion radius, and speed up The effect of project progress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

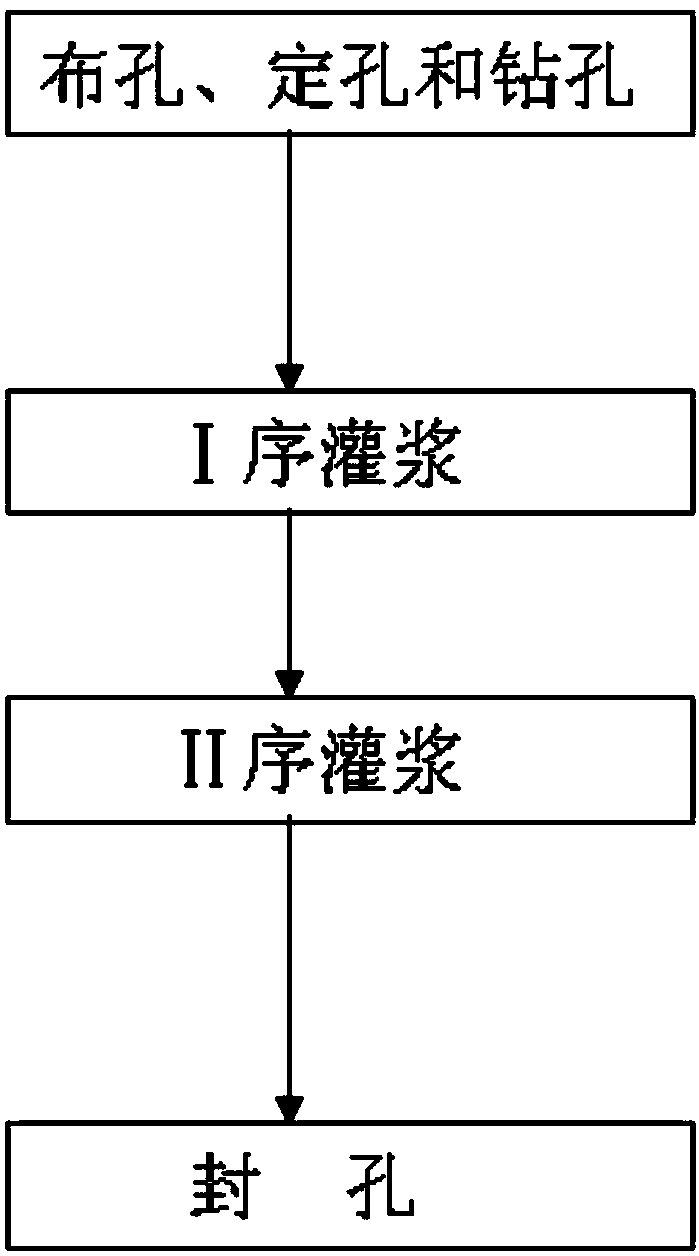

[0031] Such as figure 1 As shown, a deep hole chemical grouting construction method applied to hydropower dam leakage water treatment of the present invention comprises the following steps: (1) grouting holes are respectively arranged on the fracture surface of the concrete crack and on the concrete surface, Fixing and drilling holes; (2) Use polyurethane for first-order grouting to stop water, seal the leaking surface in front of the dam, and prevent water leakage in the reservoir area; (3) use epoxy resin for second-order grouting reinforcement; (4) ) to seal the hole.

[0032] In the above embodiment, in step (1), the following steps of cleaning after drilling are also included: first flush with high-pressure water until the backwater is clean; then use high-pressure air to remove the remaining water in the hole; completely remove the grouting hole Dust, small particles and other sundries in the hole, and no residual cleaning water in the grouting hole, and then carry out ...

Embodiment 2

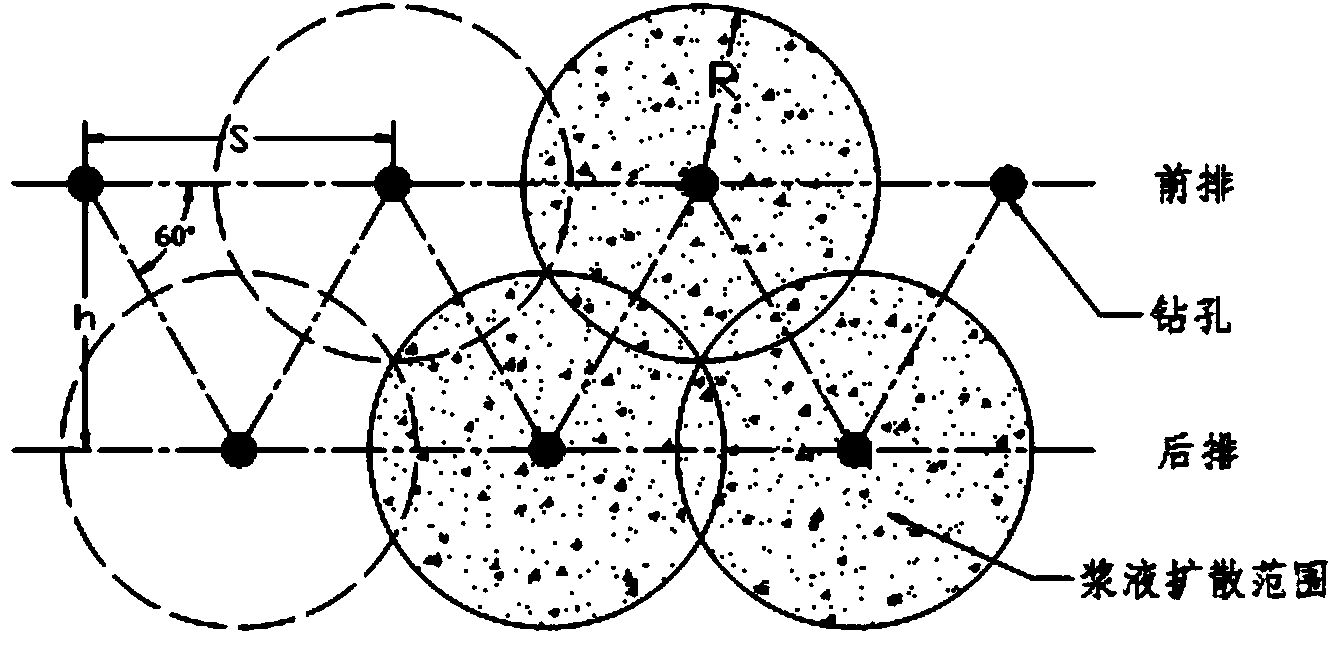

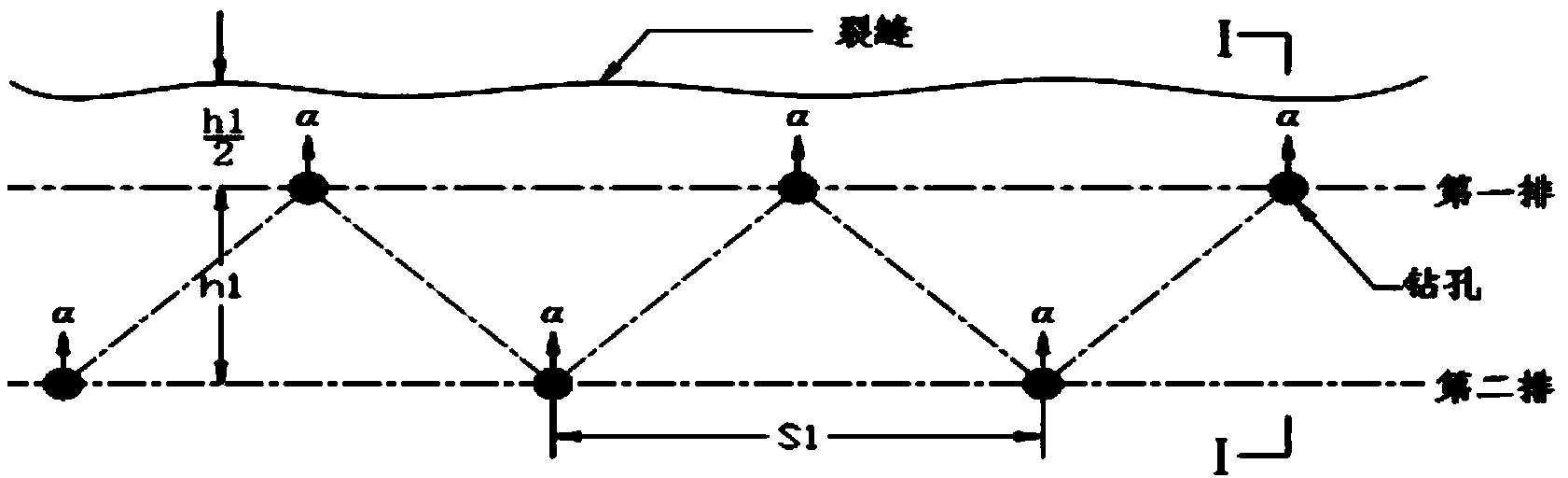

[0037] Such as Figure 1 to Figure 5 As shown, a kind of deep hole chemical grouting construction method applied to hydropower dam leakage water treatment of the present invention, the basic implementation steps are the same as embodiment 1, specifically, in order to avoid the ubiquitous string holes, In order to reduce material loss, reduce engineering investment, shorten construction period, and improve construction efficiency due to the phenomenon of waste holes, in step (1), use the principle of similar triangles to arrange holes, fix holes, and drill holes. Specifically: according to the effective diffusion radius R of chemical grouting grout in concrete cracks, in order to ensure that the chemical grout fills the crack surface compactly, determine the hole spacing S and row spacing h on the fracture surface of concrete cracks, and calculate according to the following formula:

[0038] S = 3 R - - ...

Embodiment 3

[0049] Such as Figure 1 to Figure 5 As shown, a kind of deep hole chemical grouting construction method applied to hydropower dam leakage water treatment of the present invention, the basic implementation steps are the same as embodiment 1 or embodiment 2, specifically:

[0050] In step (2), the grouting sequence from deep to shallow is used for hole-by-hole grouting; 72 hours after the grouting is completed, observe the water flow conditions of the adjacent epoxy resin grouting holes in the back row and the water leakage from the cracks in the corridor. If there is water leakage from the original water seepage joints in the corridor, then replenish polyurethane. If there is no water leakage from the original water seepage joints in the holes and in the corridor, proceed to step (3);

[0051] In step (3), the grouting step is as follows: firstly, a row of grouting holes at the bottom of the dam is used as the starting grouting point, and the grouting sequence is carried out r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com