Patents

Literature

151results about How to "Reduce the number of drilled holes" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Coal seam pre-splitting method based on gas extraction

The invention relates to a coal seam pre-splitting method based on gas extraction, which adopts a 'CO2 gas extraction device' as a tool to blast and pre-split a pre-mined coal seam, so as to increase the crack of the coal seam, drive out gas absorbed on the coal seam and extract the gas. The method particularly comprises the following steps: drilling a hole on the working surface of a pre-mined coal seam, filling CO2 gas extraction device into the drilled hole, sealing the drilled hole, detonating the CO2 gas extraction device, releasing high-pressure CO2 gas for deep-hole impact and pre-splitting of the coal seam, taking out the CO2 gas extraction device, and connecting the drilled hole with a gas extraction system to extract gas. The pre-splitting method of the invention can greatly enhance the permeability of the coal seam, promote the gas dissociation in the coal seam, and improve the underground gas extraction efficiency of the coal mine.

Owner:山西锦浩诚科技有限公司

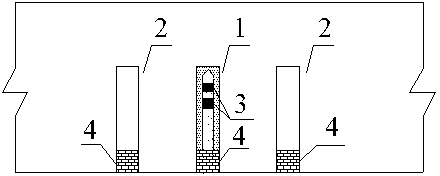

Method for performing through-going seam cutting, pressure relief, permeability enhancement and quick tunneling on soft and high-outburst coal seam

InactiveCN102900460AIncrease the speed of excavationIncrease extraction concentrationGas removalStress distributionType fracture

The invention discloses a method for performing through-going seam cutting, pressure relief, permeability enhancement and quick tunneling on a soft and high-outburst coal seam, and in particular is applied to quick tunneling in a coal seam which is high in outburst danger and a laneway is difficult to support in a coal mine. The method comprises the following steps of: forming a network type fractured net by high-pressure jet flow seam cutting, pressure relief and permeability enhancement technologies, and enhancing an effect of extracting strip-type coal seam gas on a coal laneway subjected to through-going drilling and pre-extraction; and forming a network type filling region by pressing and injecting filling materials, so that the strength and stress distribution of a coal body are improved, the coal laneway is easy to maintain in the tunneling process, a phenomenon that the gas rushes out of a tunneled laneway is avoided, gas accidents are eliminated in the tunneling process, and an aim of safely and quickly tunneling the laneway is fulfilled.

Owner:CHINA UNIV OF MINING & TECH

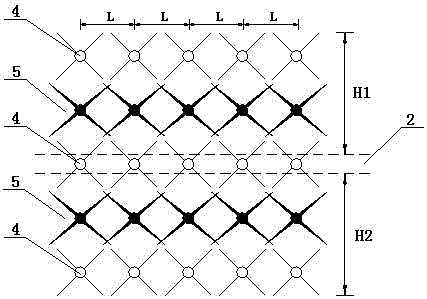

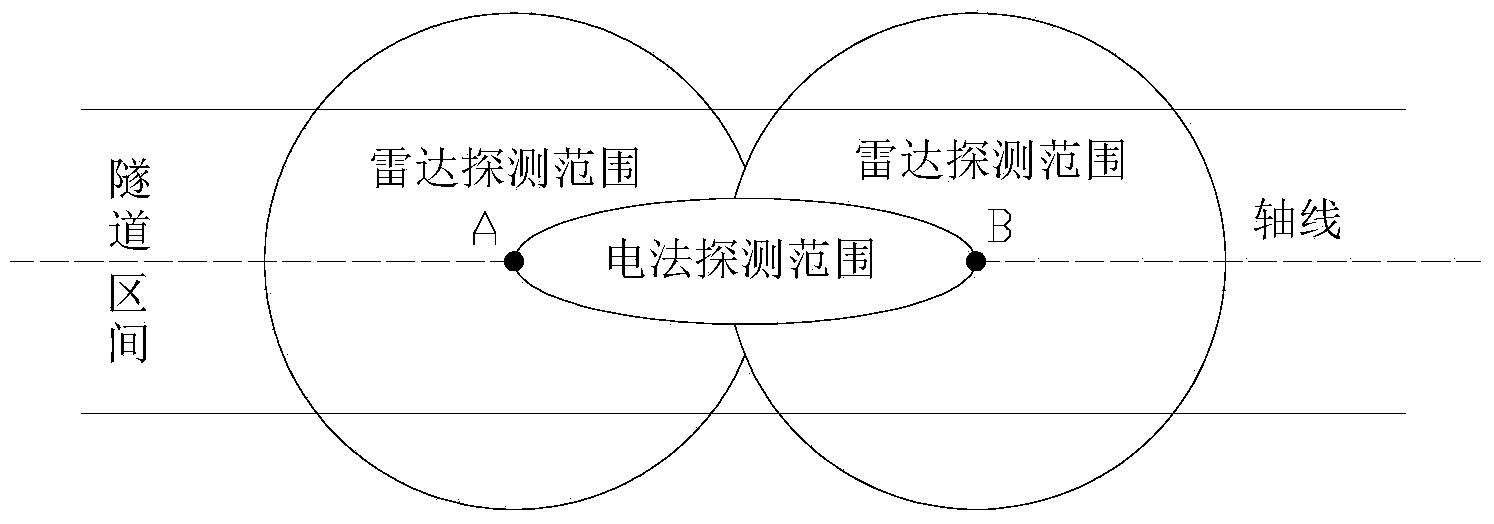

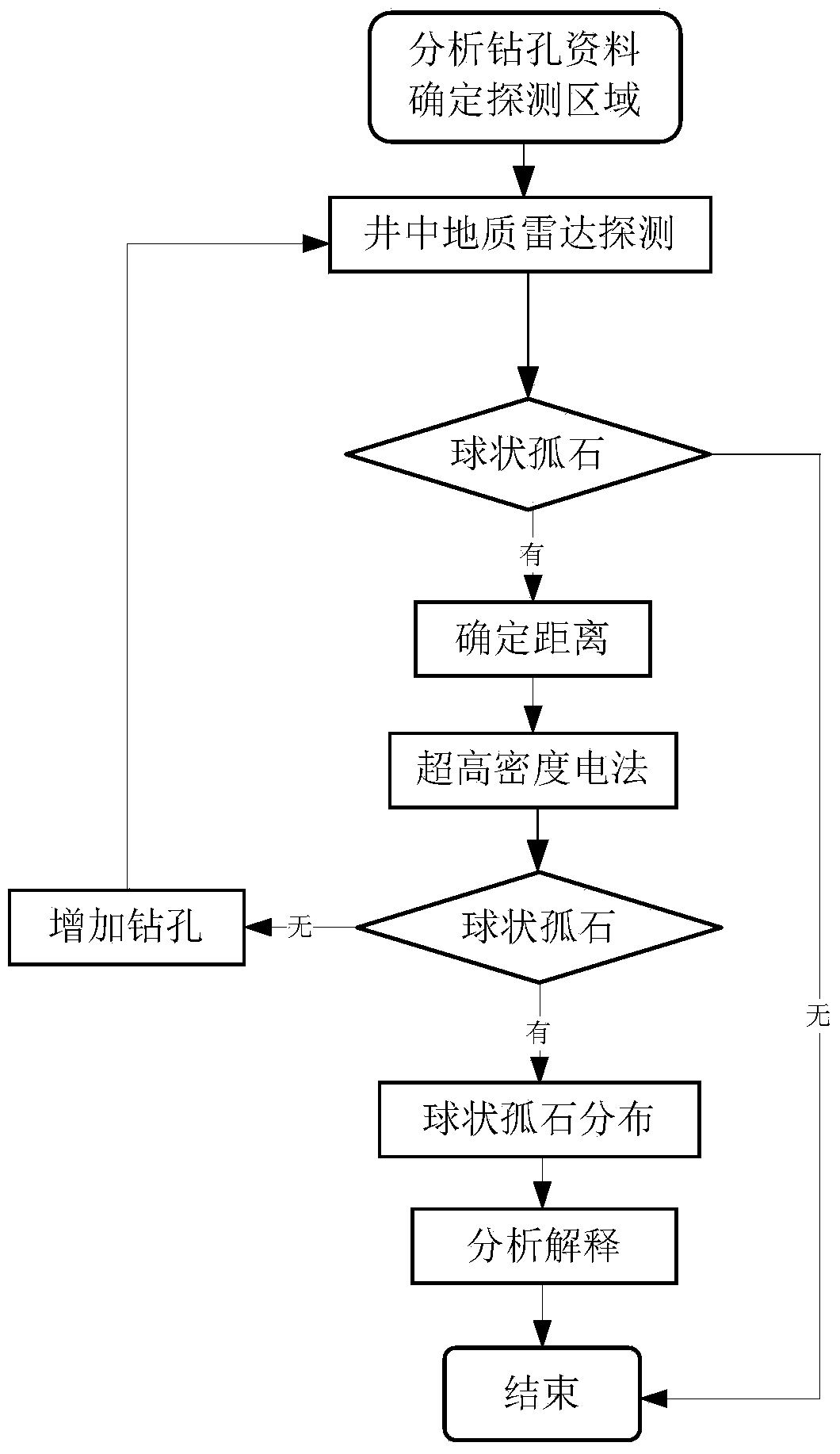

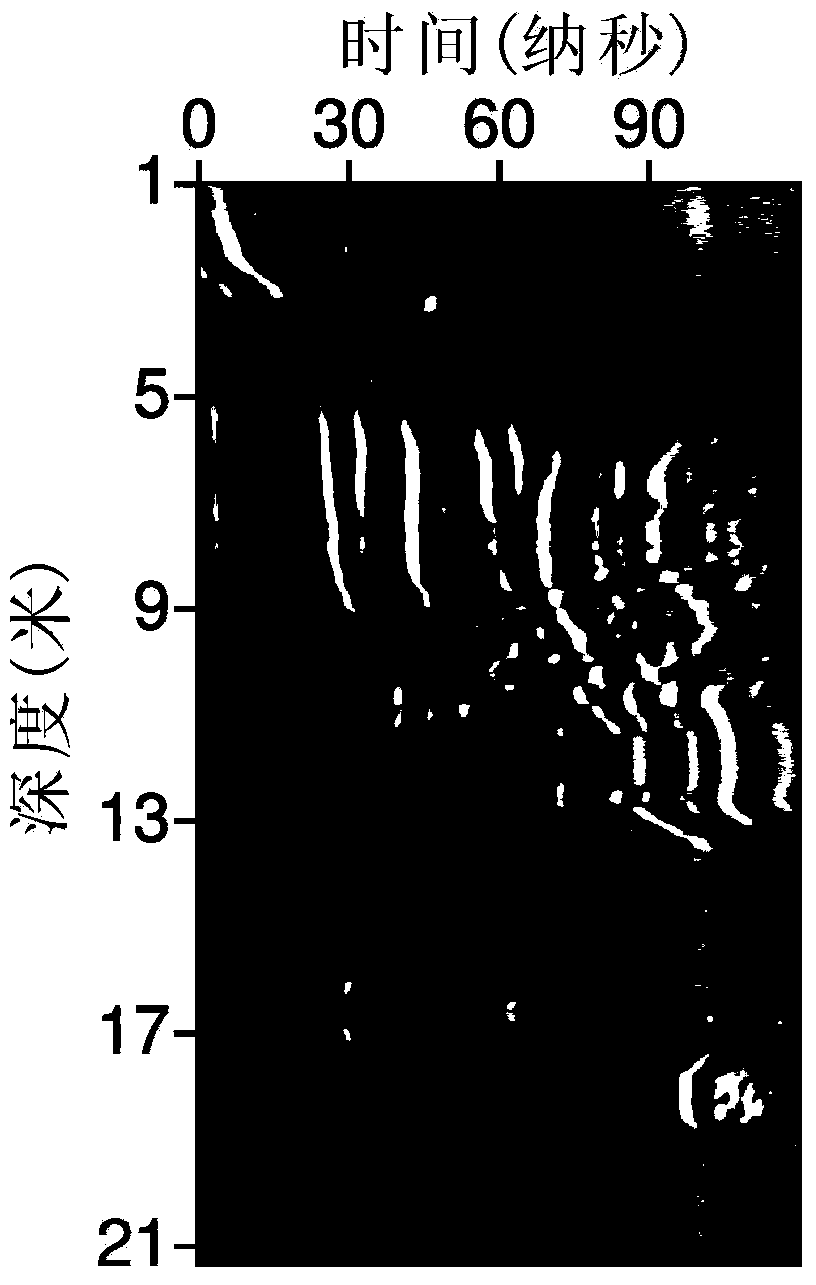

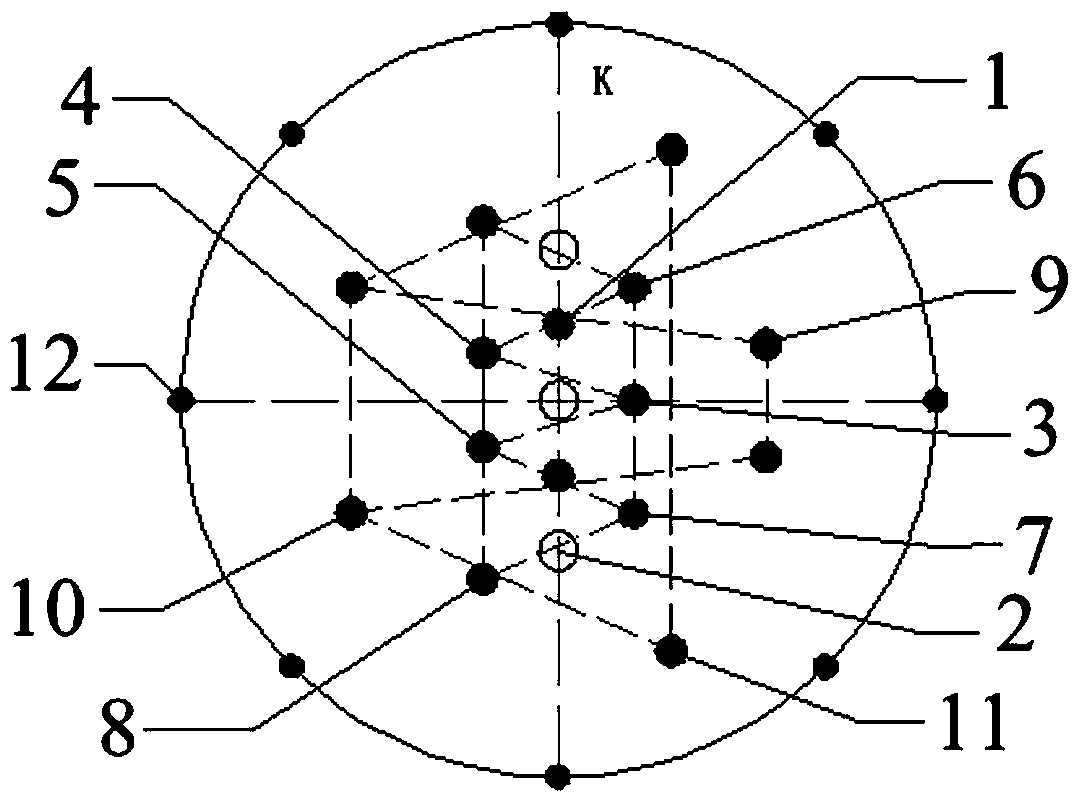

Method for detecting spherical boulders in shield construction

ActiveCN103913776AConvenient and smoothReduce the number of drilled holesDetection using electromagnetic wavesRadio wave reradiation/reflectionGeomorphologyRadar

The invention discloses a method for detecting spherical boulders in shield construction to achieve the technical purpose of improving the capability of detecting the spherical boulders in the shield district. The method comprises the step of collecting geological radar echo signals in the drilling depth direction through a well geological radar, the step of primarily defining the dimensional orientation where the spherical boulders probably exist, the step of collecting potential differences and currents between two drill holes to obtain the true resistivity of a stratum between the two holes, the step of drawing the true resistivity into a contour map to define the sizes and the distribution situation of the spherical boulders in the stratum between the two holes. Compared with the prior art, the well geological radar and the hole crossing ultrahigh precision electrical method are utilized, the spherical boulders within the shield tunnel range is detected, the distribution of the spherical boulders within the tunnel range can be detected to the maximum degree, the number of the drill holes can be reduced, the detecting cost is small, meanwhile, the probability of finding the spherical boulders in the complex stratum shield district is improved, and the smooth advancing of a shield tunneling machine is guaranteed.

Owner:SHENZHEN MUNICIPAL ENG

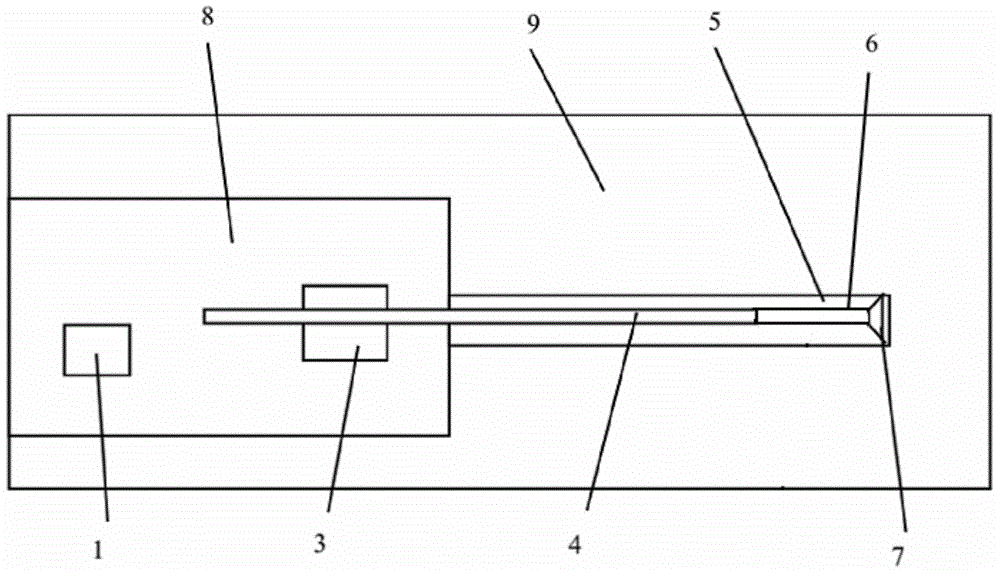

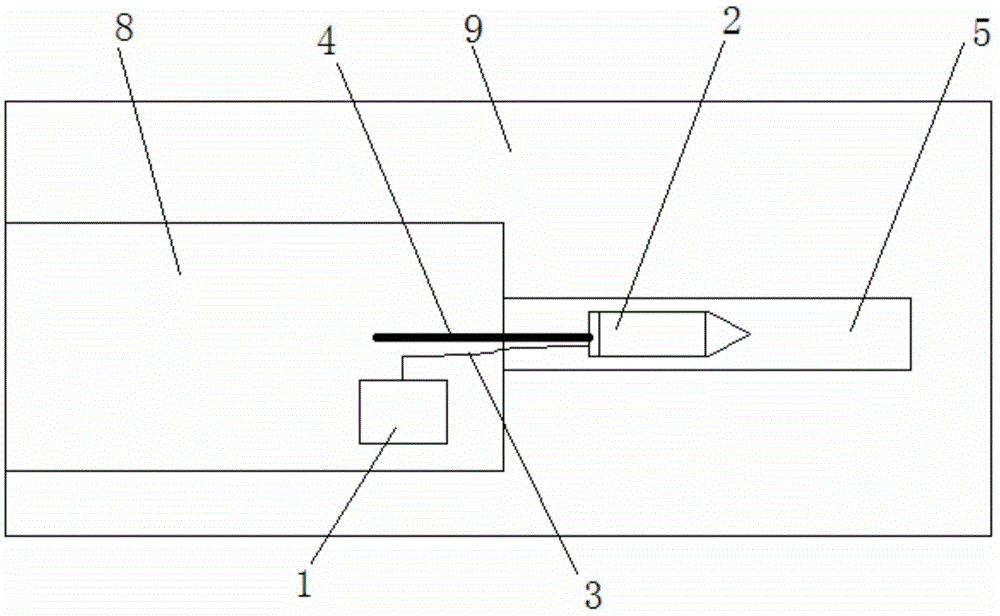

While-drilling borehole electromagnetic wave tomography advanced detection device and method

InactiveCN104656153AExpand the detection rangeInformativeElectric/magnetic detection for well-loggingWater resource assessmentWell drillingClassical mechanics

The invention discloses a while-drilling borehole electromagnetic wave tomography advanced detection device and method. A detection probe is arranged in a detection drill pipe and used for drilling with a drilling rig; the detection probe automatically detects according to the working state of the drilling rig; during the detection, the stratum conditions of stratum geologies with different radii around a drill hole is detected through transmitting and receiving a group of electromagnetic waves with different frequencies; when the drill hole is finished and the detection probe exits in the drill hole, the data of the detection probe can be transmitted to a site host; the site host can compute the apparent resistivity of the stratums with different radii around the drill hole at each detection point and generate an apparent resistivity atlas with different radii around the whole drill hole depth; according to the apparent resistivity atlas, the geologic feature in a cylindrical space which takes the axis of the drill hole as center can be judged and whether the stratums have water-containing bodies or water-containing geologic structures can be analyzed and judged.

Owner:WUHAN CONOURISH COALMINE SAFETY TECH

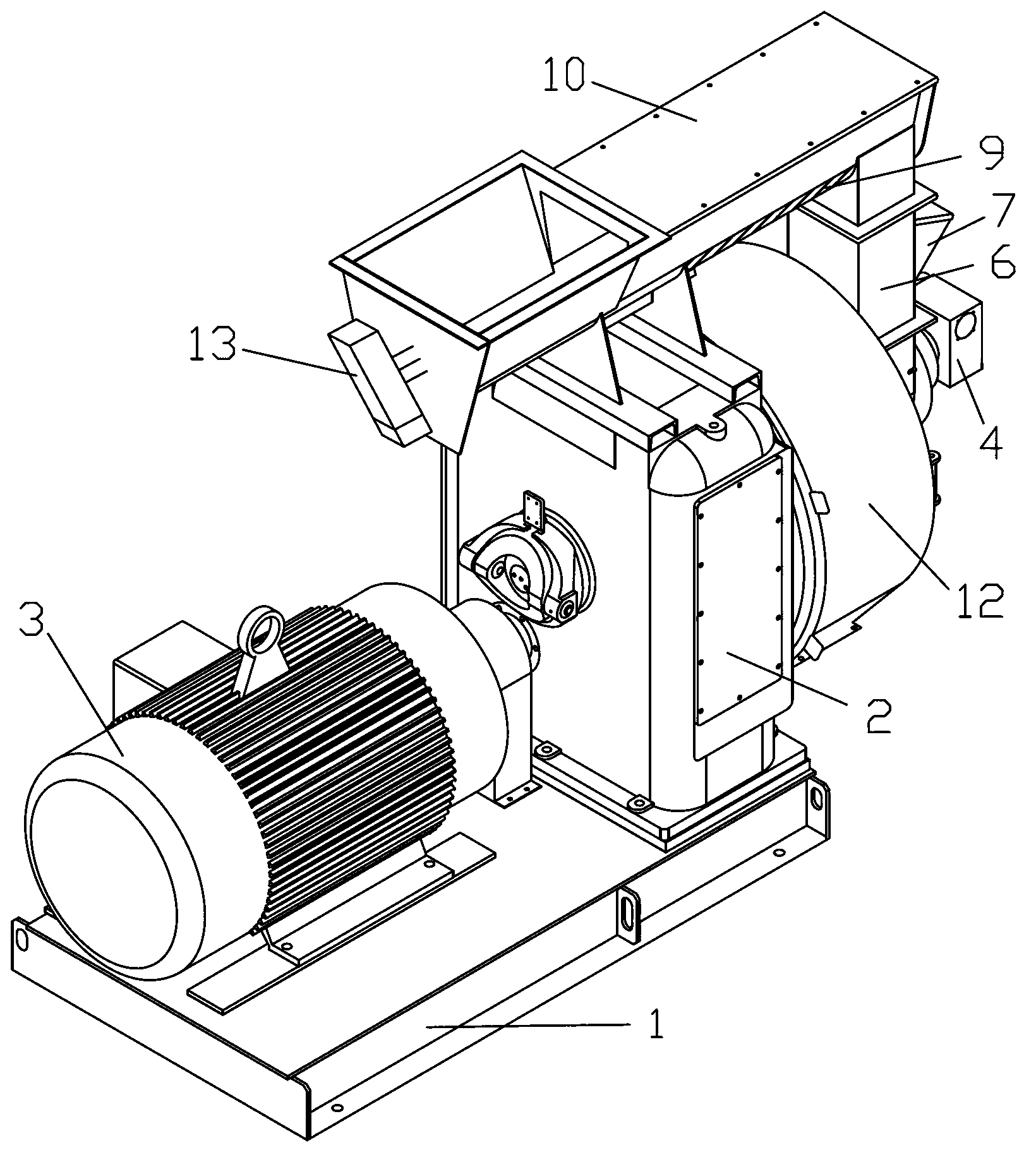

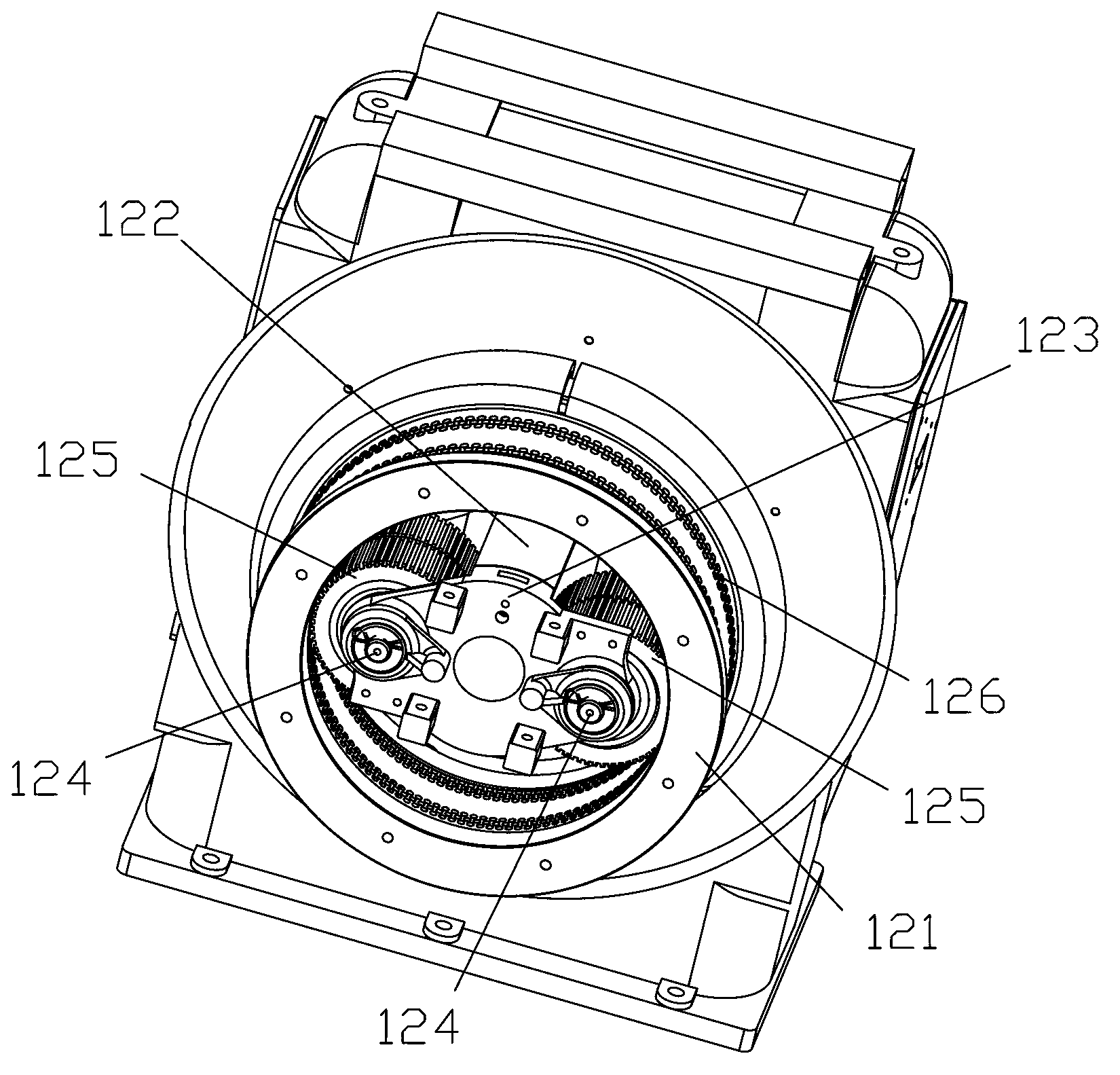

Granulator

ActiveCN103055761ASmall working surfaceReduce wearGranulation by material expressionGranulation by pressingMechanical engineeringEngineering

The invention discloses a granulator comprising a base, a first motor, a second motor, a feeding device, a supply pipe, a feed pipe, a pressing device and a transmission device. The second motor conveys materials from the supply pipe to the feeding device, and then the materials enters the pressing device to be pressed through the feed pipe; power required by pressing is provided by the first motor and transmitted to the pressing device through the transmission device; the pressing device comprises a main shaft, a circular mould, a main shaft pressure plate connected with the main shaft, two press roller shafts which are arranged in parallel on the main shaft pressing plate, and four press rollers; each press roller shaft is provided with two press rollers, and a distance is left between the two press rollers on each press roller shaft; and six rows of mould holes are formed in the circular mould, every three adjacent rows of mould holes are in one group, and a distance is left between each two groups of mould holes and is equal to that between the two press rollers on each press roller shaft. The granulator is simple to operate, and has the advantages of high production efficiency, low energy consumption and long service life.

Owner:JIANGSU JINWU MACHINERY CO LTD

Method for processing vehicle bump at bridge head of existing highway

InactiveCN102409598AReduce post-construction settlementSolve the jumpRoads maintainenceArchitectural engineeringStructural engineering

The invention discloses a method for processing vehicle bump at a bridge head of an existing highway, and the method comprises the following steps: mixing lightweight materials at a construction site; drilling holes from embankment slopes on both sides of the highway, and automatically discharging soil outward from a threaded opening while rotatably drilling holes; after a designed depth reaches, rotatably and slowly pulling out a drill rod, and starting a booster pump so as to pump the lightweight materials into the obtained drill holes by virtue of a central tube of the drill rod; and jetting the lightweight materials from the central hole of the drill rod so as to gradually fill the hole from bottom to top, thereby replacing the filled soil of an embankment. The drill holes are arranged squarely or quincuncially on the side slope of the embankment, a certain included angle is formed between each drill hole and a horizontal plane, and the elevation of the opening of each hole is positioned below a pavement structure layer and above the underside of the filled soil of the embankment. By using the method disclosed by the invention, the weight of the embankment is greatly reduced, thereby reducing the settlement after construction caused by embankment loads and then effectively solving the problem of vehicle bump at bridge heads. During the construction period, the highway is not required to be closed, therefore, the normal traffic of the highway is not affected. The method disclosed by the invention is simple in construction process, convenient to operate, simple in equipment, economical, and high in efficiency.

Owner:HOHAI UNIV

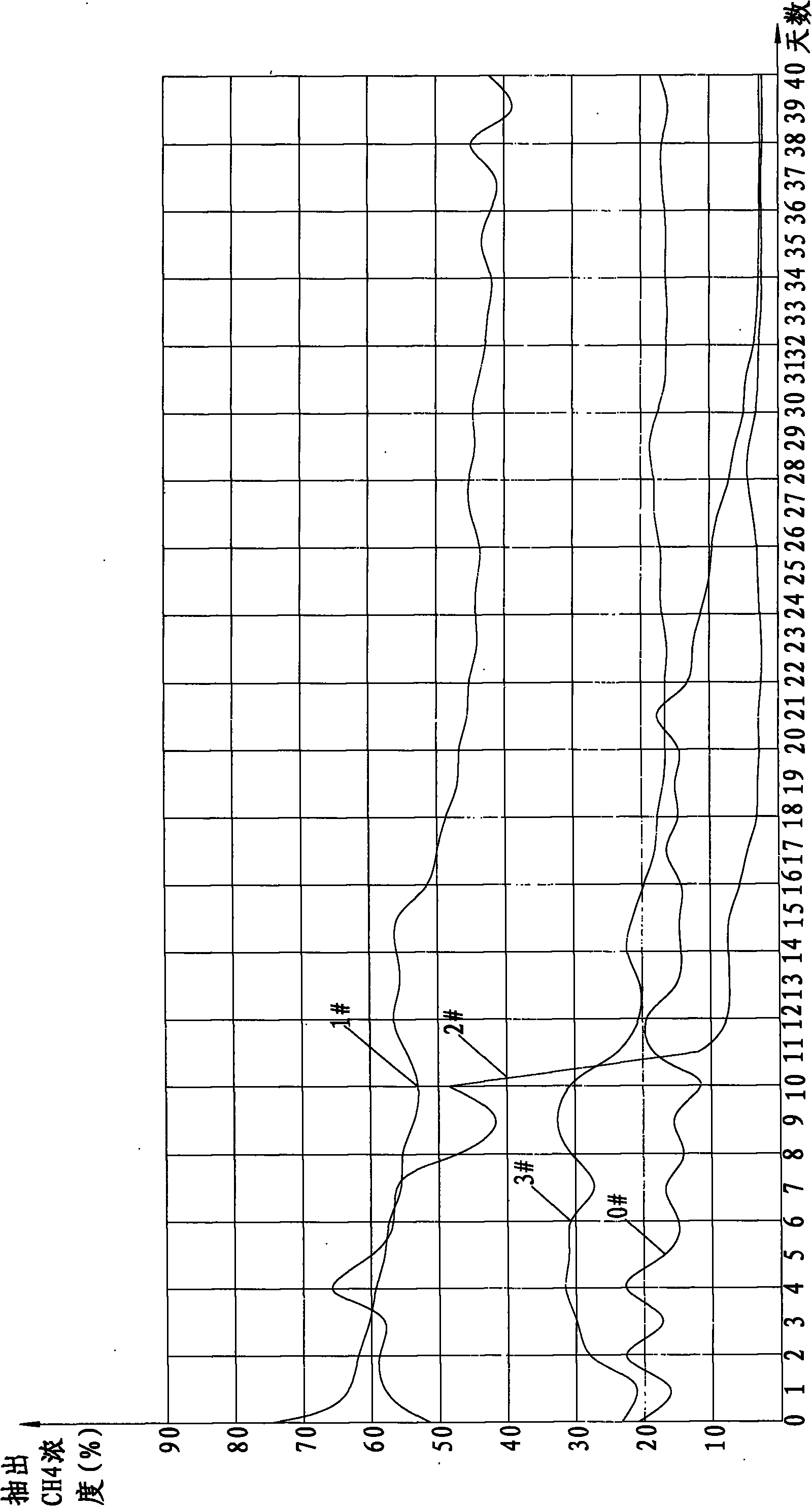

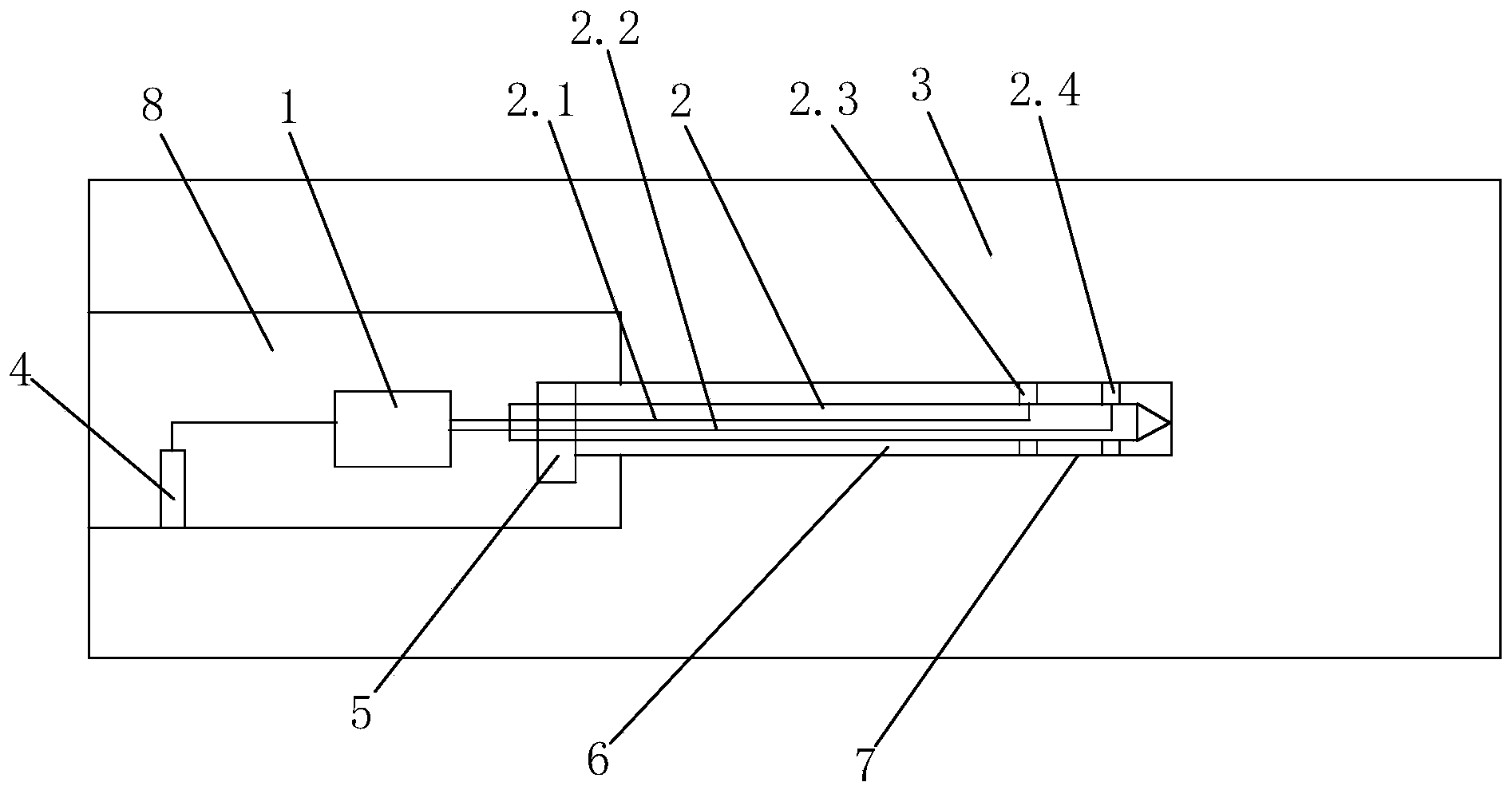

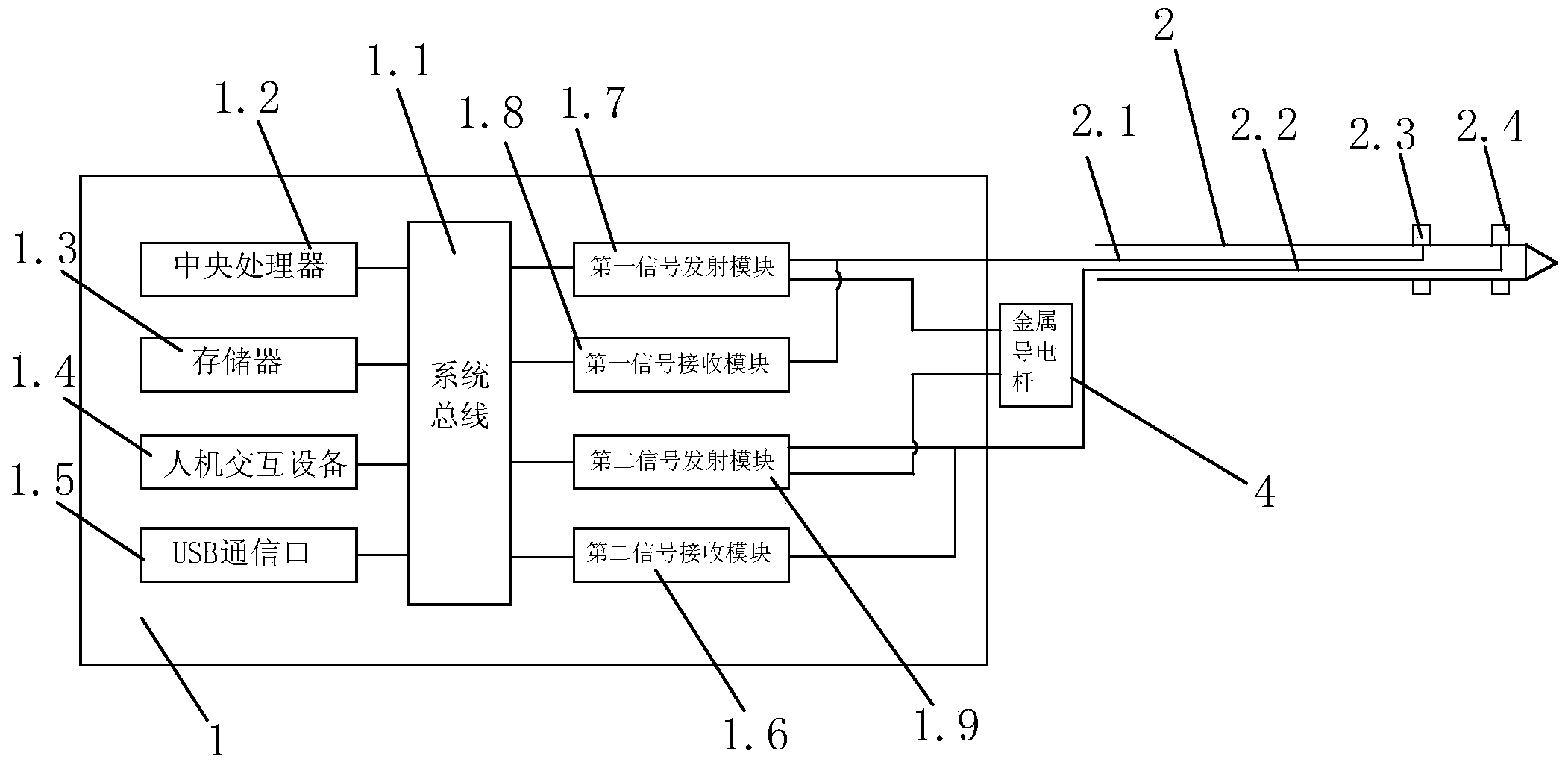

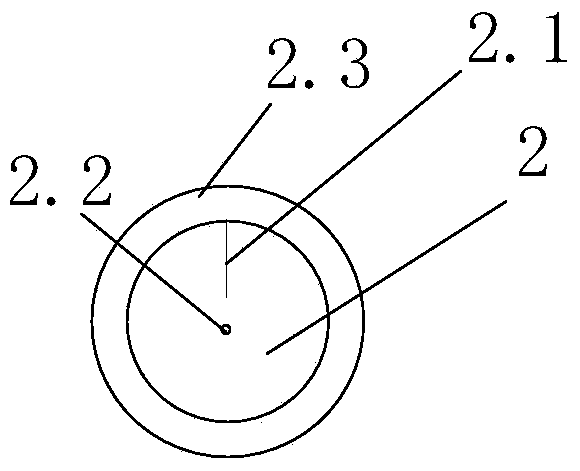

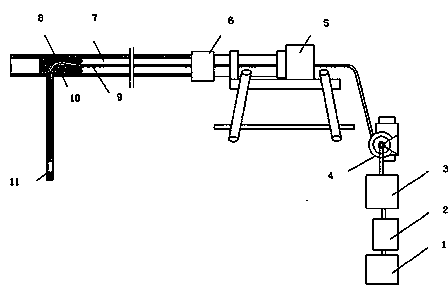

Drilling geophysical prospecting advanced detecting device and method

InactiveCN103967476AAchieving advanced detection and forecastingImprove exclusion effectSurveyElectricityPower flow

The invention discloses drilling geophysical prospecting advanced detecting device. A first probe wire and a second probe wire are arranged inside a probe of the device, one end of the first probe wire is connected with the signal input end of a first electric brush ring, the other end of the first probe wire is connected with the high-potential signal output end of a first signal sending module, one end of the second probe wire is connected with the signal input end of a second electric brush ring, the other end of the second probe wire is connected with the high-potential signal output end of a second signal sending module, a metal conductive rod is connected with a zero-potential interface of the first signal sending module and a zero-potential interface of the second signal sending module respectively, the current signal input end of a first signal receiving module is communicated with the first probe wire, the current signal input end of a second signal receiving module is communicated with the second probe wire, and the signal output end of the first electric brush ring and the signal output end of the second electric brush ring are connected with the inner wall of a drill stem. The drilling geophysical prospecting advanced detecting device can conduct fine and effective detection prediction on harmful geologic bodies of eutrophic water and water conduction channels around drilled holes of tunnels and roadway heads.

Owner:WUHAN CONOURISH COALMINE SAFETY TECH

Gas-liquid-solid three-phase coupling blasting weakening rock burst and permeability increasing method

ActiveCN103161493AChange the physical and mechanical propertiesImprove breathabilityFluid removalGas removalStress concentrationBlast effects

Provided is a gas-liquid-solid three-phase coupling blasting weakening rock burst and permeability increasing method. By coal seam water injection and changing of a powder charge structure of traditional blasting, common gas-solid two-phase blasting is converted into gas-liquid-solid three-phase blasting. Blast wave in water, jet flow, secondary pressure wave and other effects are generated by water pressure blasting to enhance blasting effect, after drilled holes are formed, coal bodies are wetted through water injection firstly, physical and mechanical properties around the drilled holes are changed, the gas-solid two-phase coal bodies are converted into gas-liquid-solid three-phase media, a stress concentrating zone is pushed to the deep parts of the coal bodies, stress concentration is lowered; coal seam fractures around blasting holes and in an influence zone are stretched and developed, the fractures are communicated with each other, a facture network is formed, stress concentration is removed, channels are provided for coal seam pressure relief gas flow, and accordingly the purpose that rock burst and gas outburst are prevented is achieved.

Owner:CHINA UNIV OF MINING & TECH

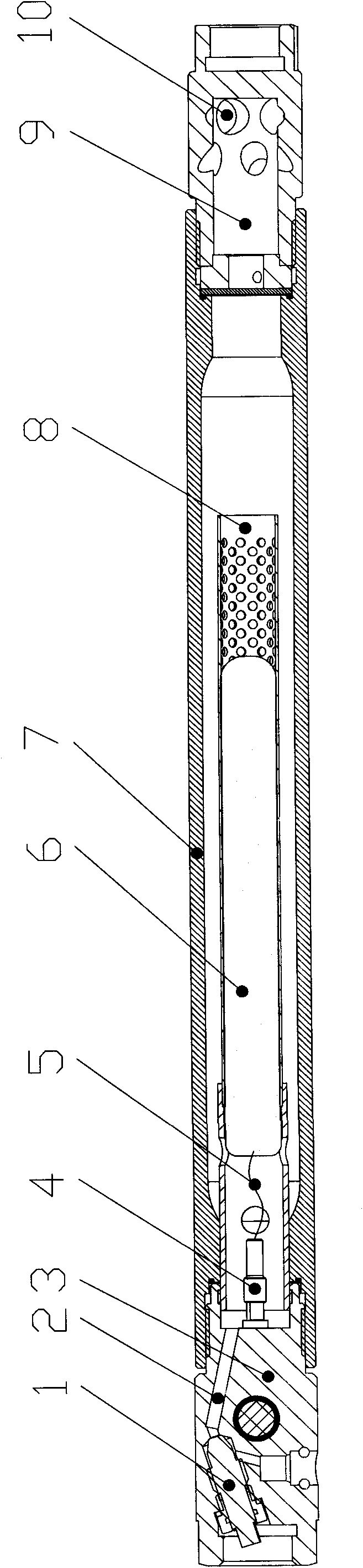

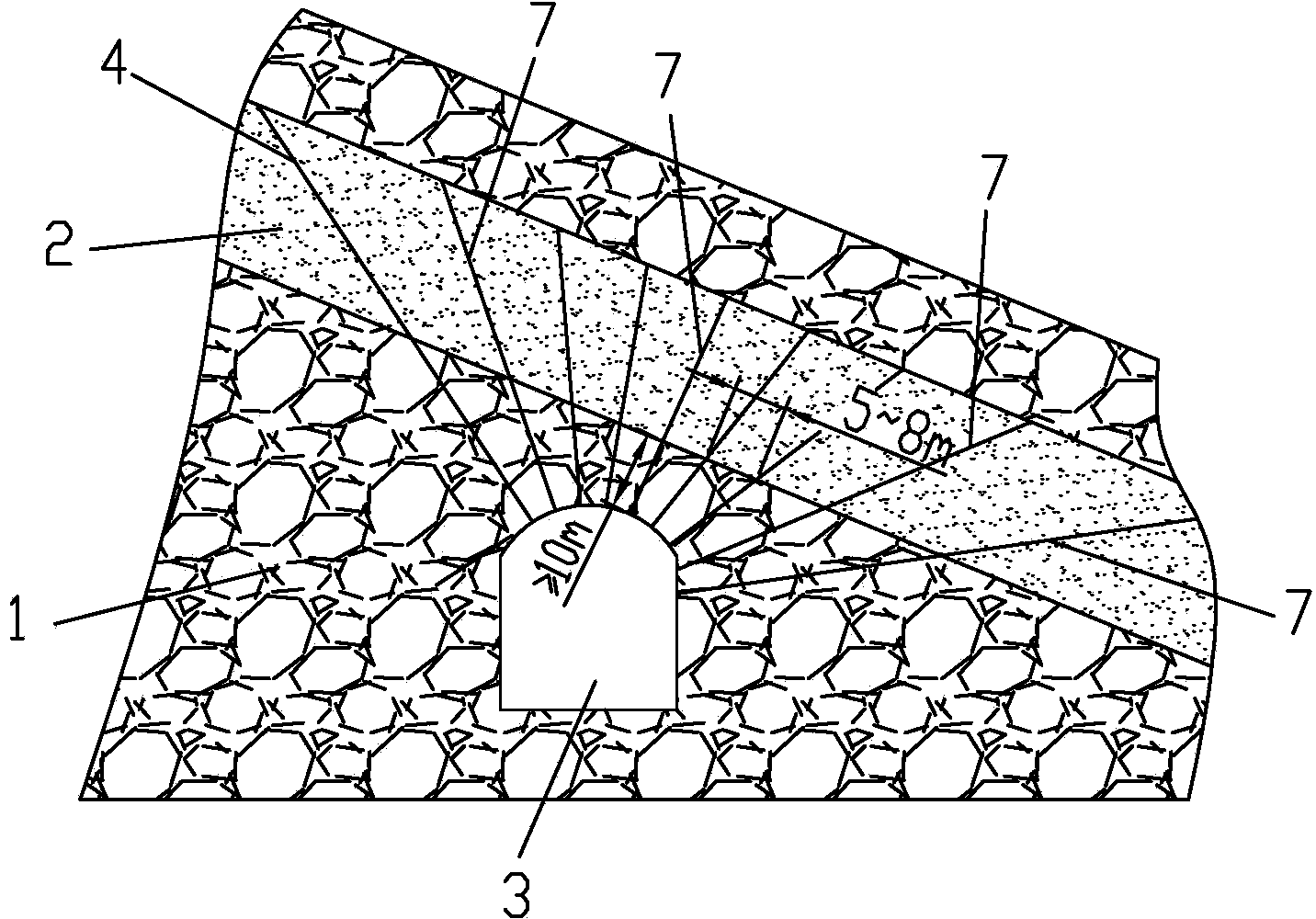

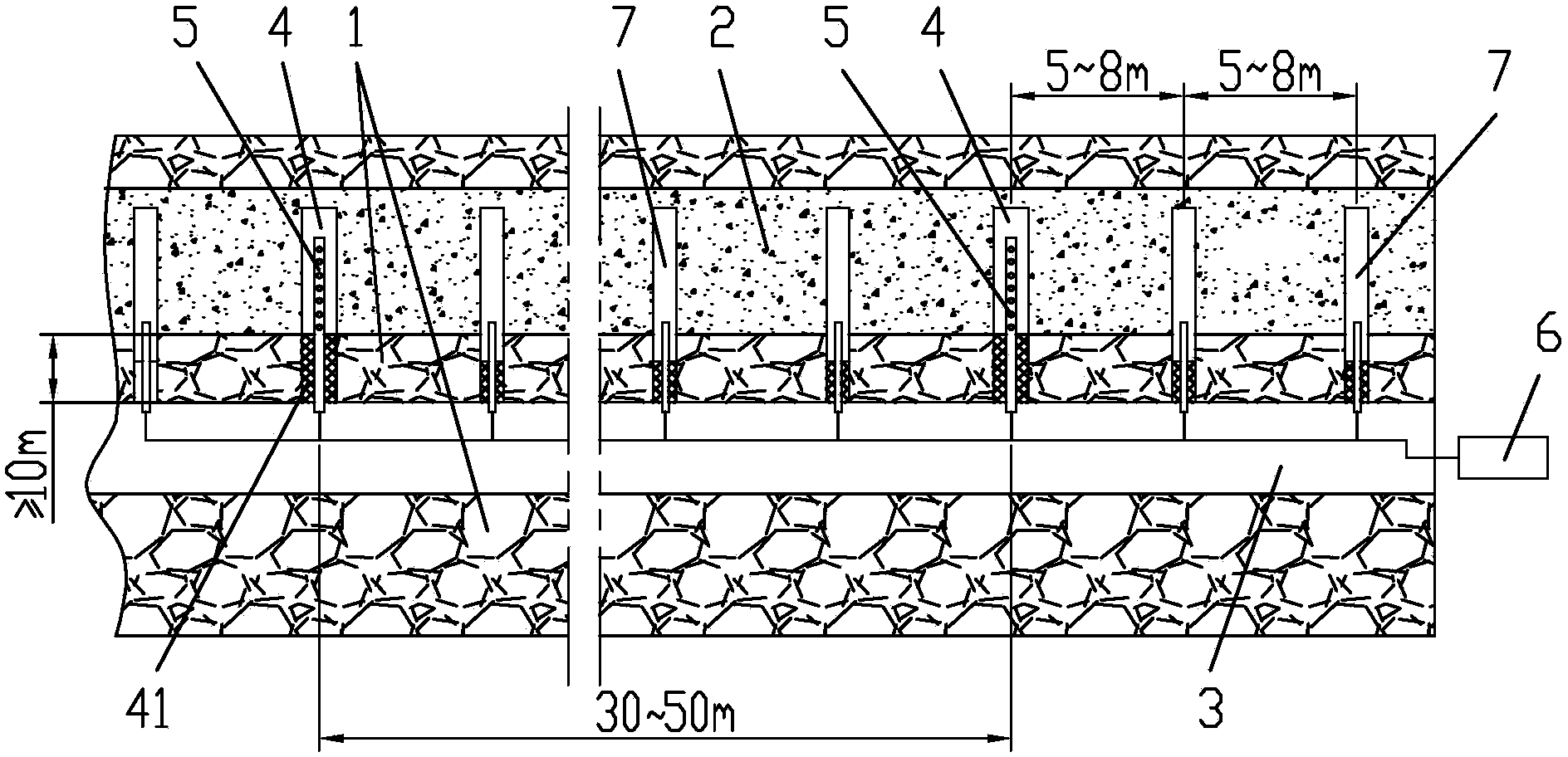

Method for fast extracting gas on coalface

The invention discloses a method for fast extracting gas on a coalface. The method includes that a bottom extraction roadway with the distance to a coal seam no smaller than 5 m is tunneled on a coal seam floor; a plurality of fracture drill holes extending into the coal seam are formed in the bottom extraction roadway, the center distance between every two adjacent fracture drill holes in the position entering the coal seam is between 30 m and 50 m, and the depth of the fracture drill holes in the rock stratum is not smaller than 10 m; the fracture drill holes are sealed according to fracture sealing requirements, and the coal seam is hydraulically fractured; the fracture drill holes are connected with an underground gas extraction system of a coal mine, and then coal seam gas can be extracted; a plurality of extraction holes extending into the coal seam are formed in the bottom extraction roadway, and the center distance from any extraction hole to the adjacent extraction holes or the position for the corresponding fracture drill hole to enter the coal seam is between 5 m and 8 m; the extraction holes are sealed according to extraction sealing requirements; coal seam gas is extracted through the extraction holes till the coal seam gas content reaches the standard. The method for fast extracting gas on the coalface has the advantages of having fewer drill holes and being high in extraction efficiency and coal mining efficiency, and roadway tunneling and coal mining work can be performed safely.

Owner:重庆市能源投资集团科技有限责任公司

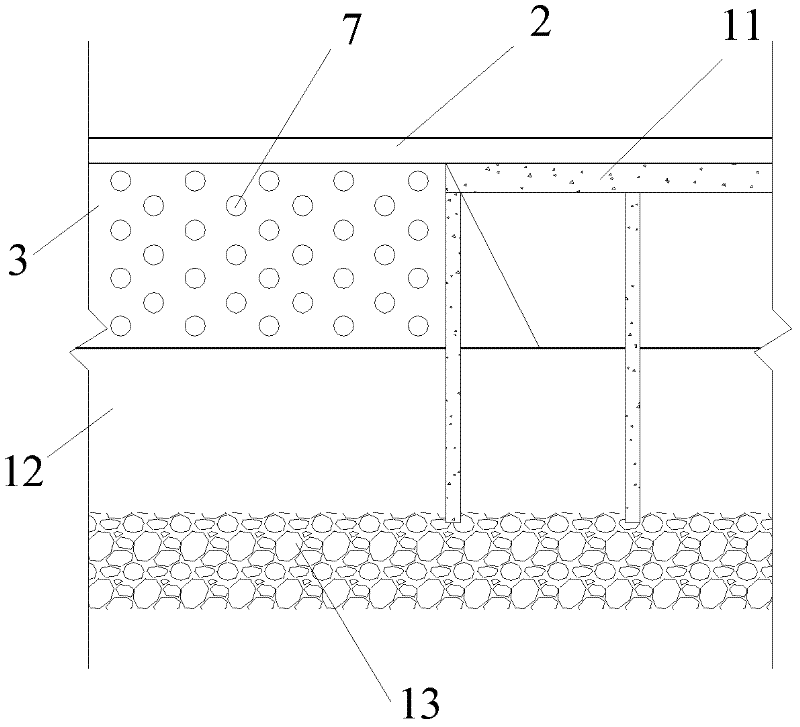

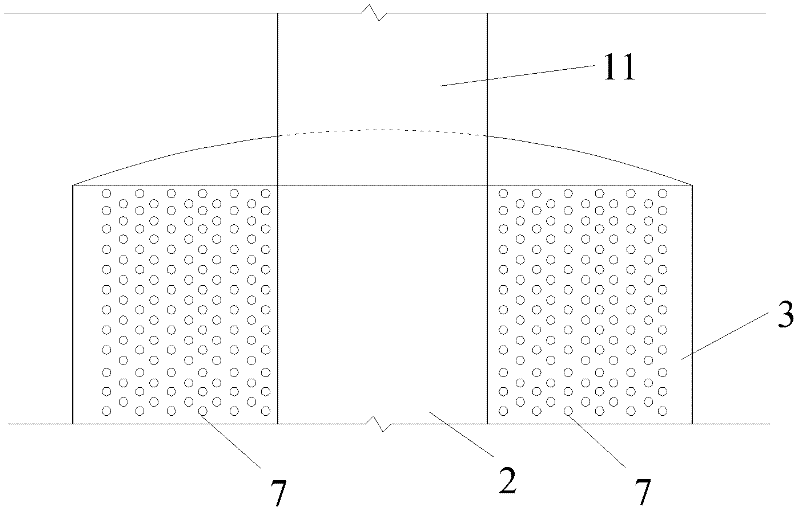

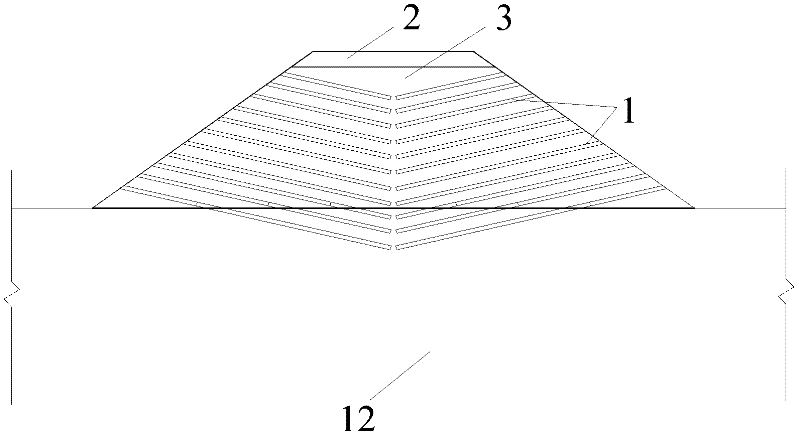

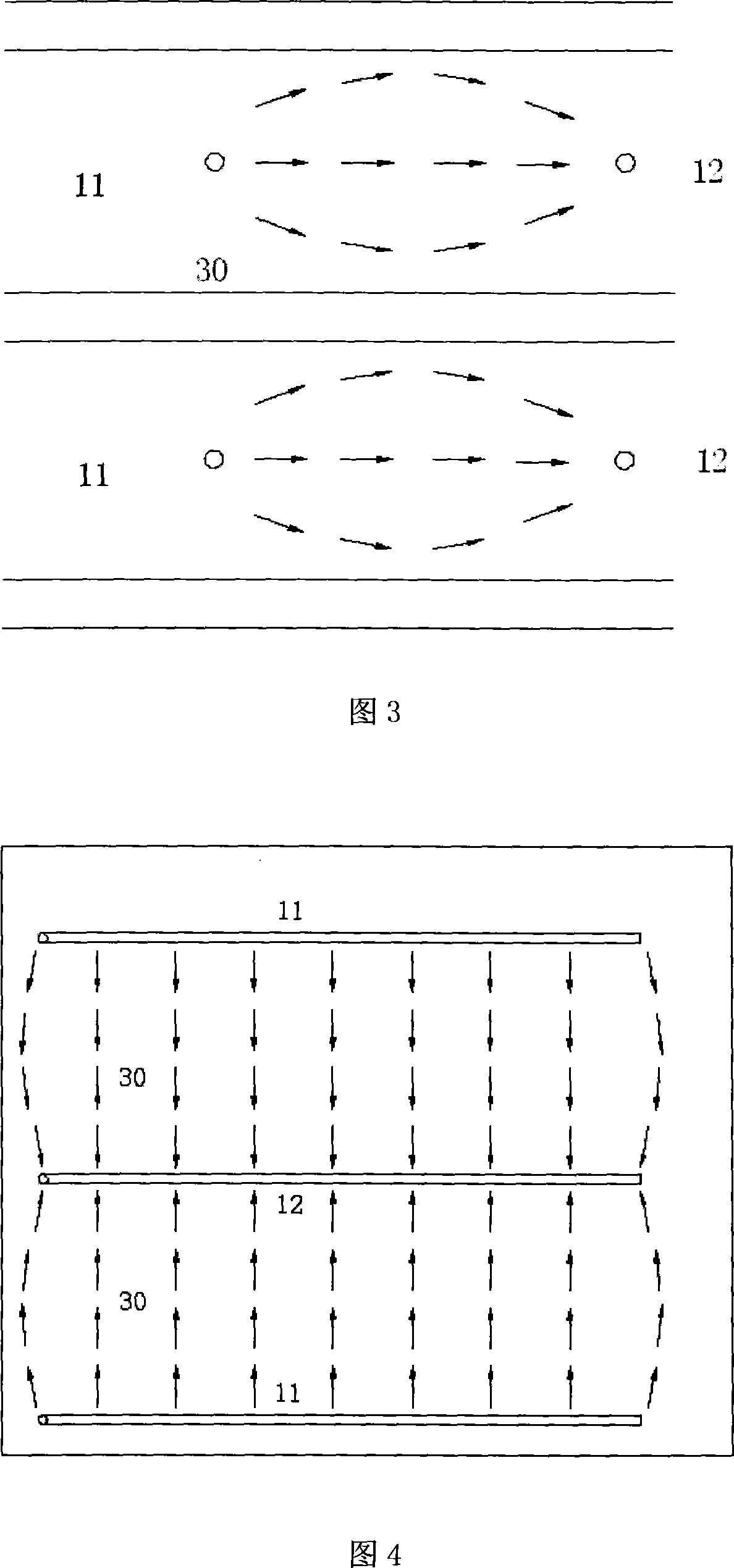

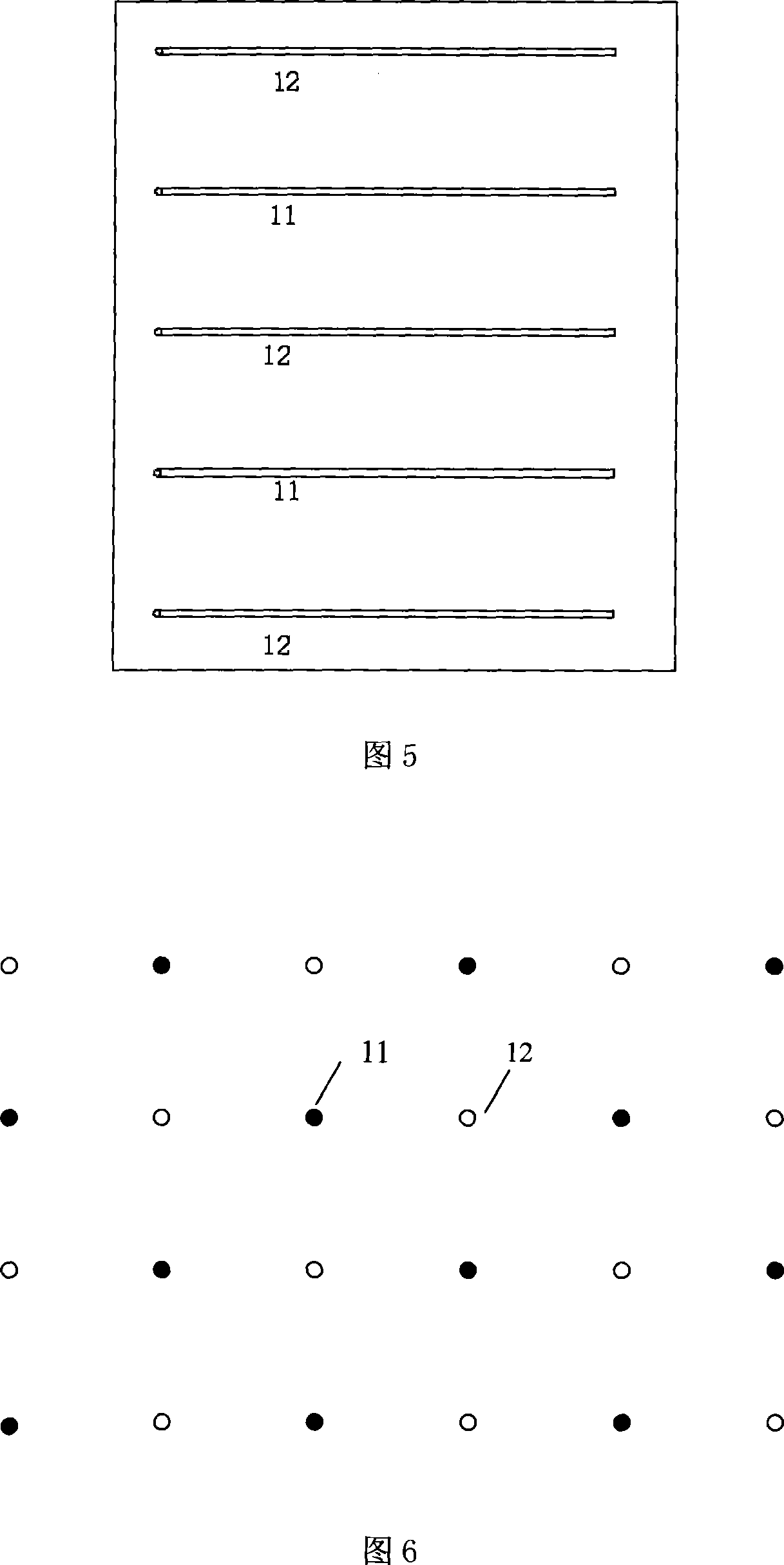

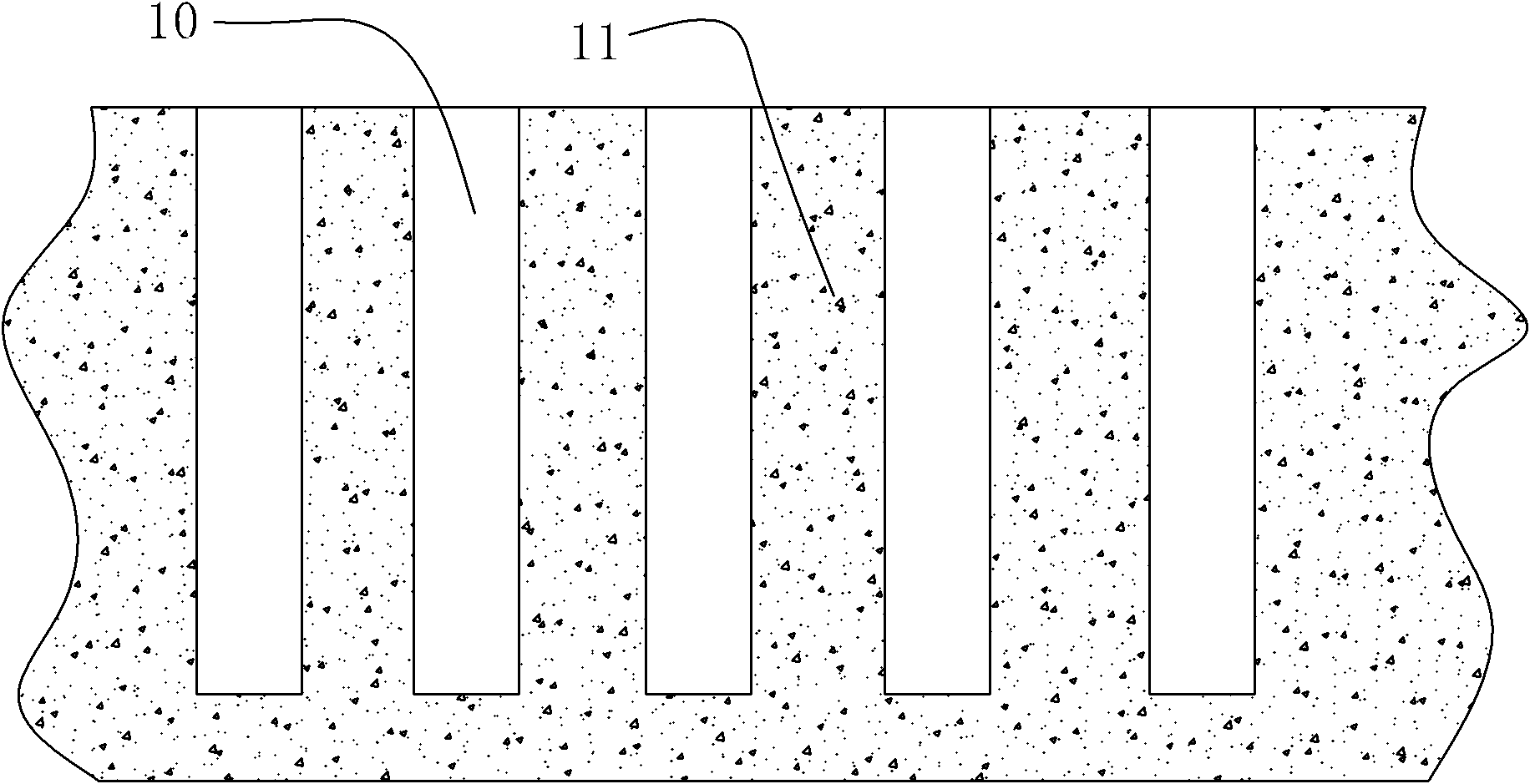

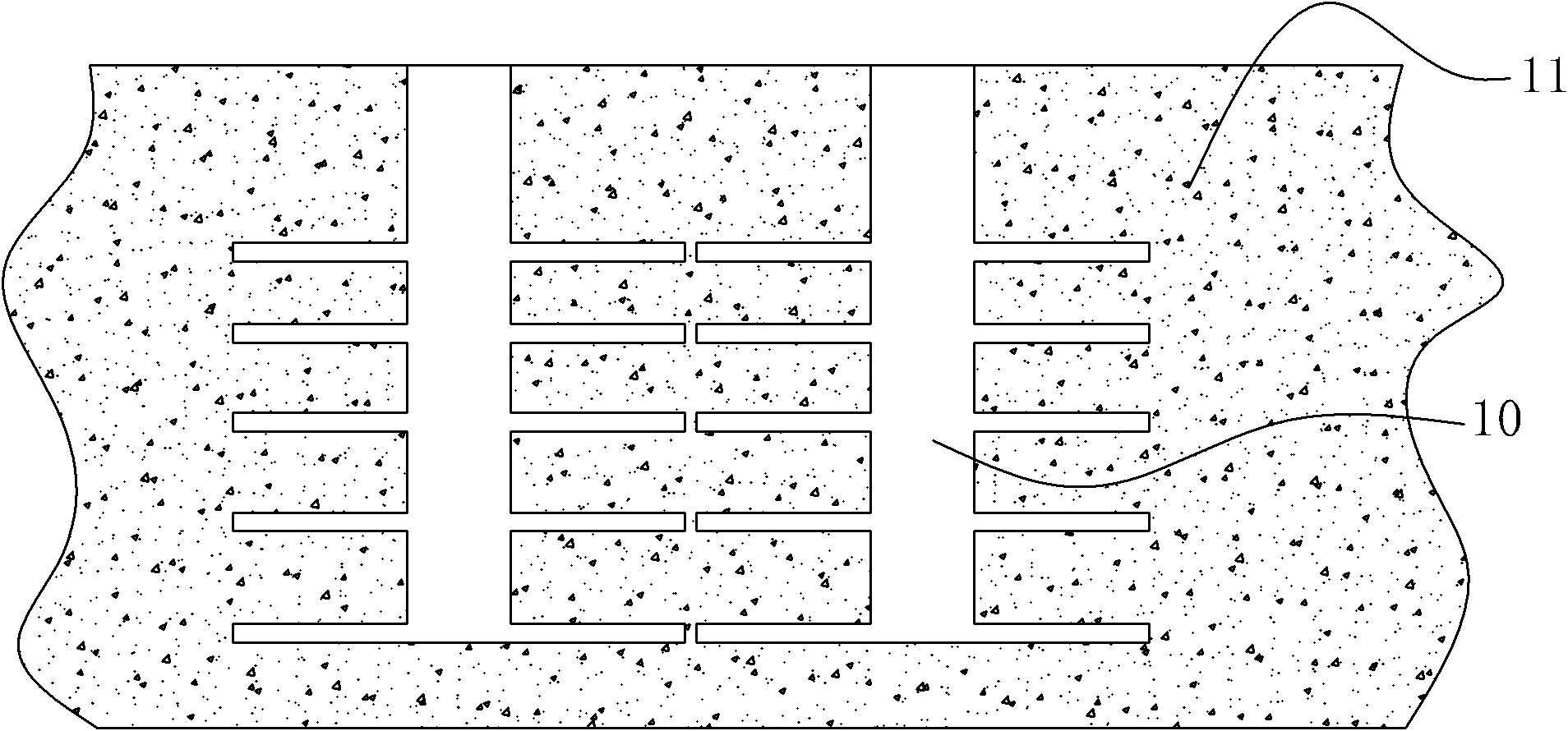

Horizontal well leaching mining method

The invention discloses a horizontal well leaching exploitation method, which relates to a mining method. The invention comprises the procedures that: (1) a horizontal section (13) and a vertical section (14) of a horizontal well (10) are formed in a manto (30) by the horizontal well technology; (2) injection wells (11) and recovery wells (12) which are alternately spaced and arranged are formed; (3) mining is carried out according to the traditional in situ leaching method. The invention can considerably reduce the amount of the drilling holes of the original hole of the whole in situ leaching method and considerably reduce the cost of leaching exploitation; at the same time, the influence on the recovery rate and recovery scope caused by the positions of the injection wells (11) and the recovery wells (12) is reduced; the leaching dead corners are reduced. The invention is suitable for the leaching exploitation field of uranium, copper, aurum, rare earth and so on.

Owner:INST OF ROCK & SOIL MECHANICS CHINESE ACAD OF SCI

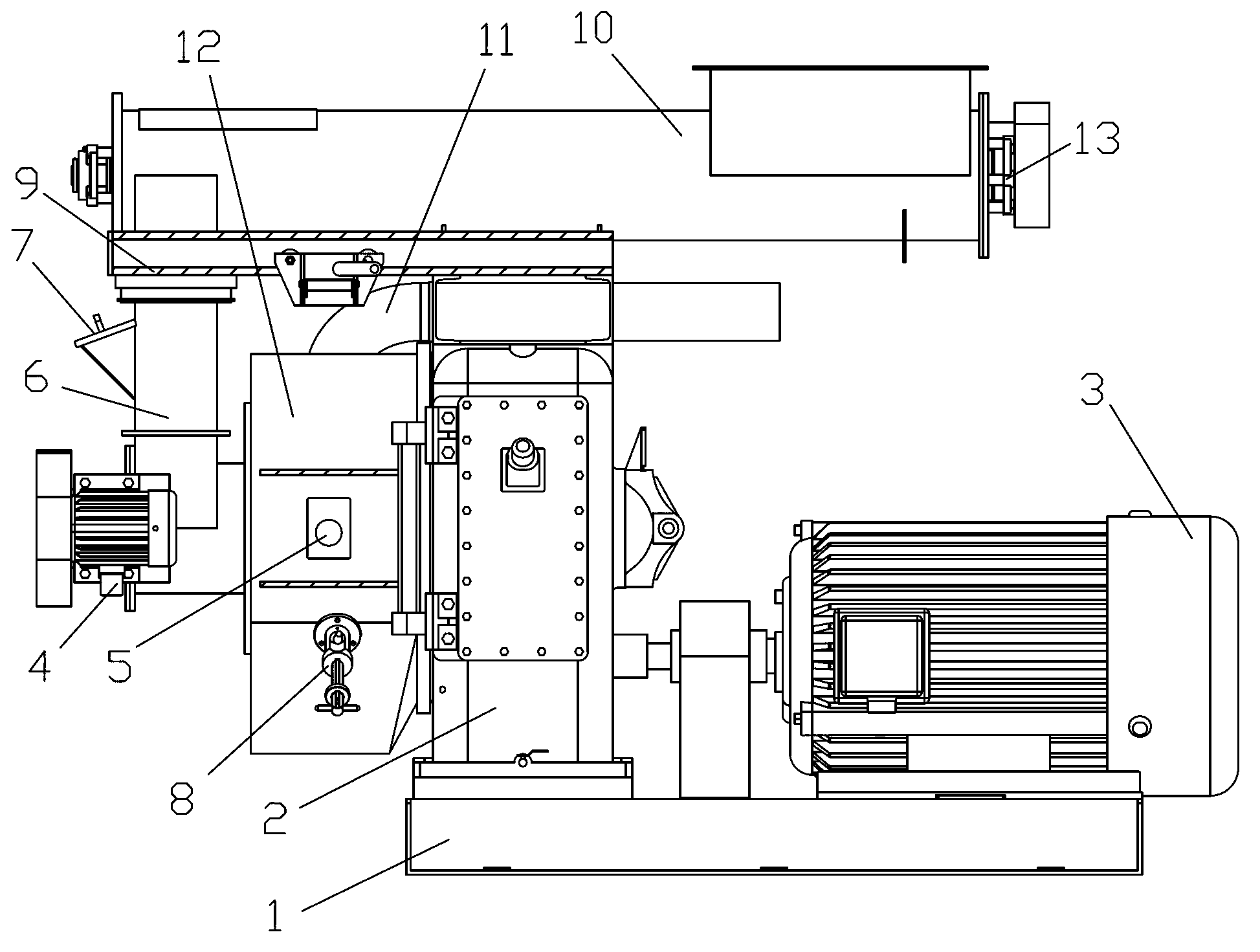

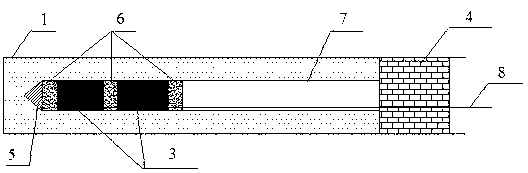

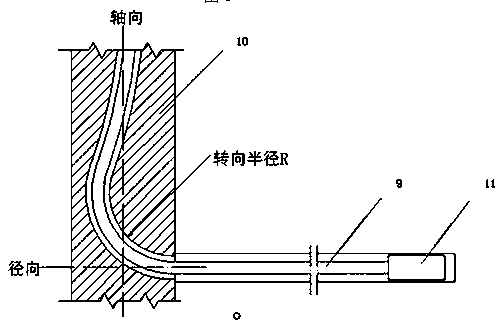

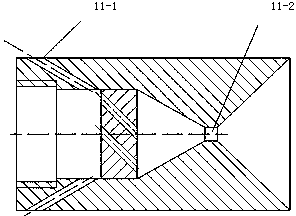

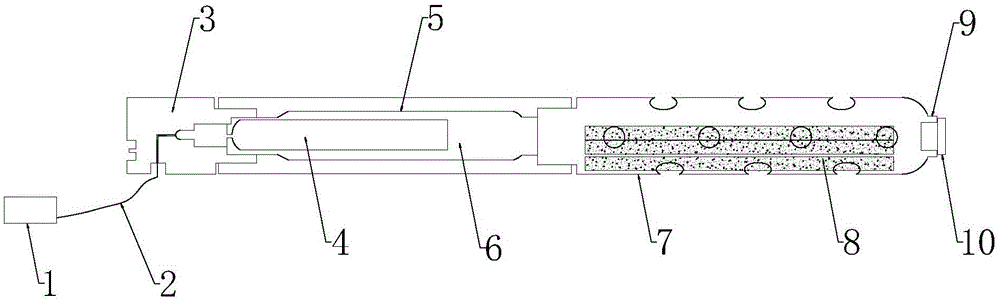

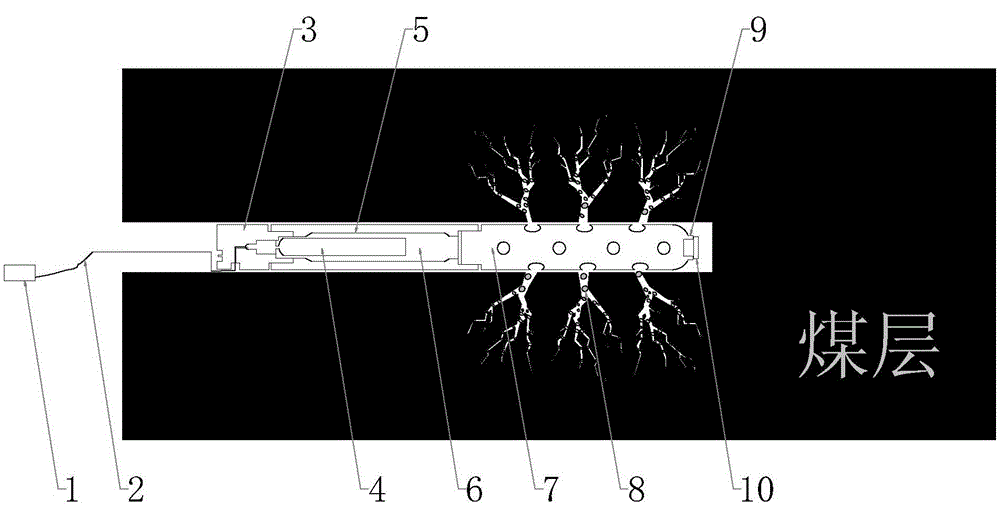

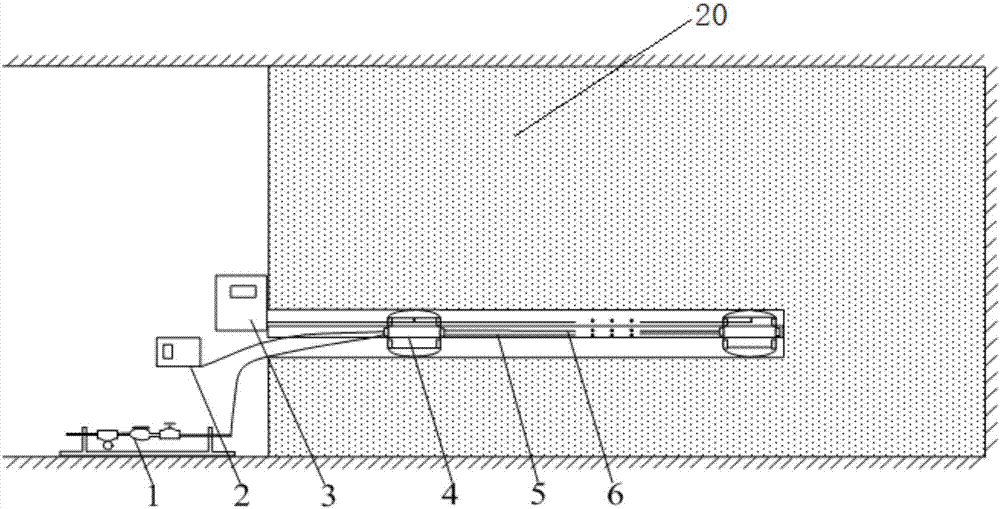

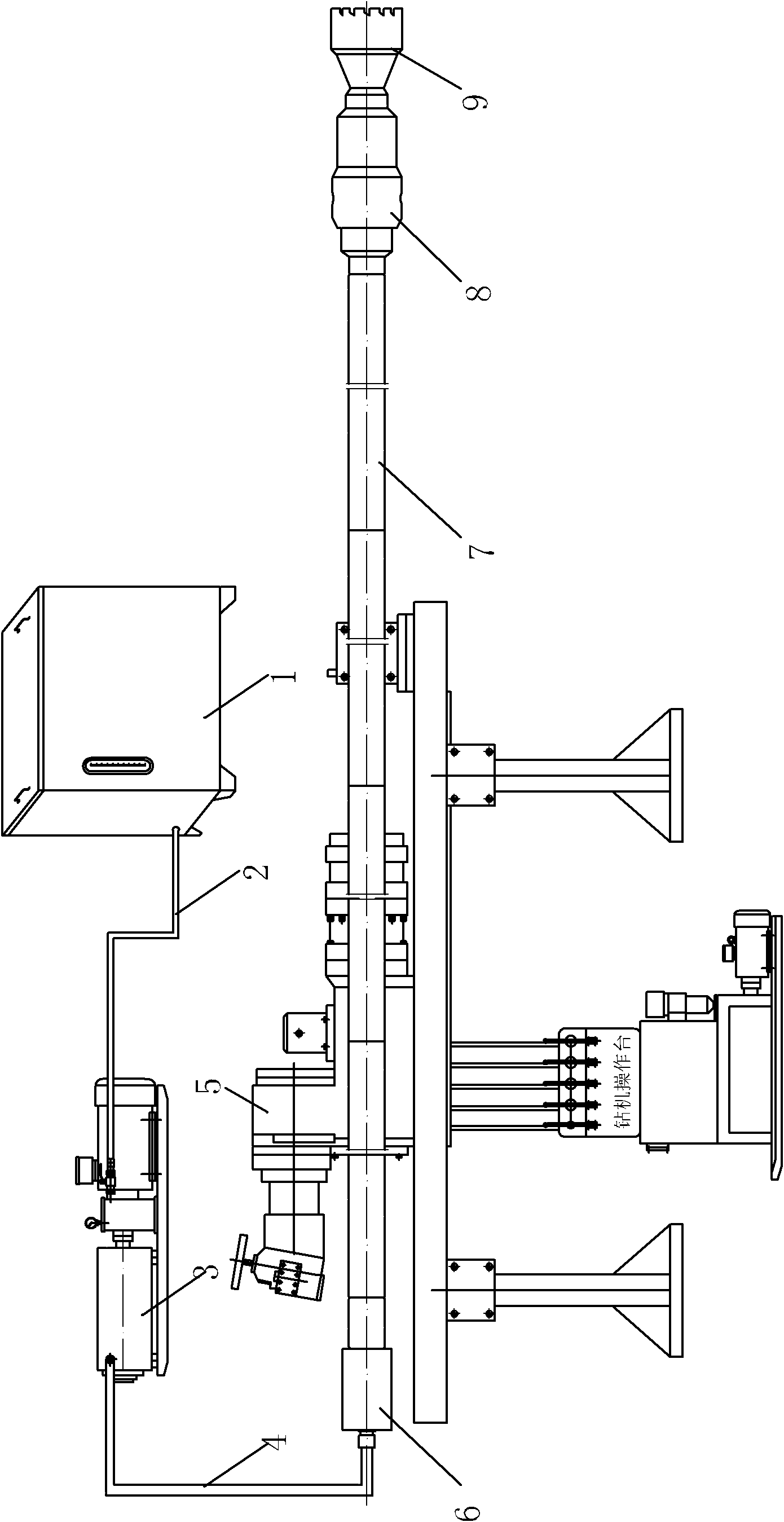

Method and device for conducting hydraulic jet self-propelled drilling to improve gas permeability of coal seam

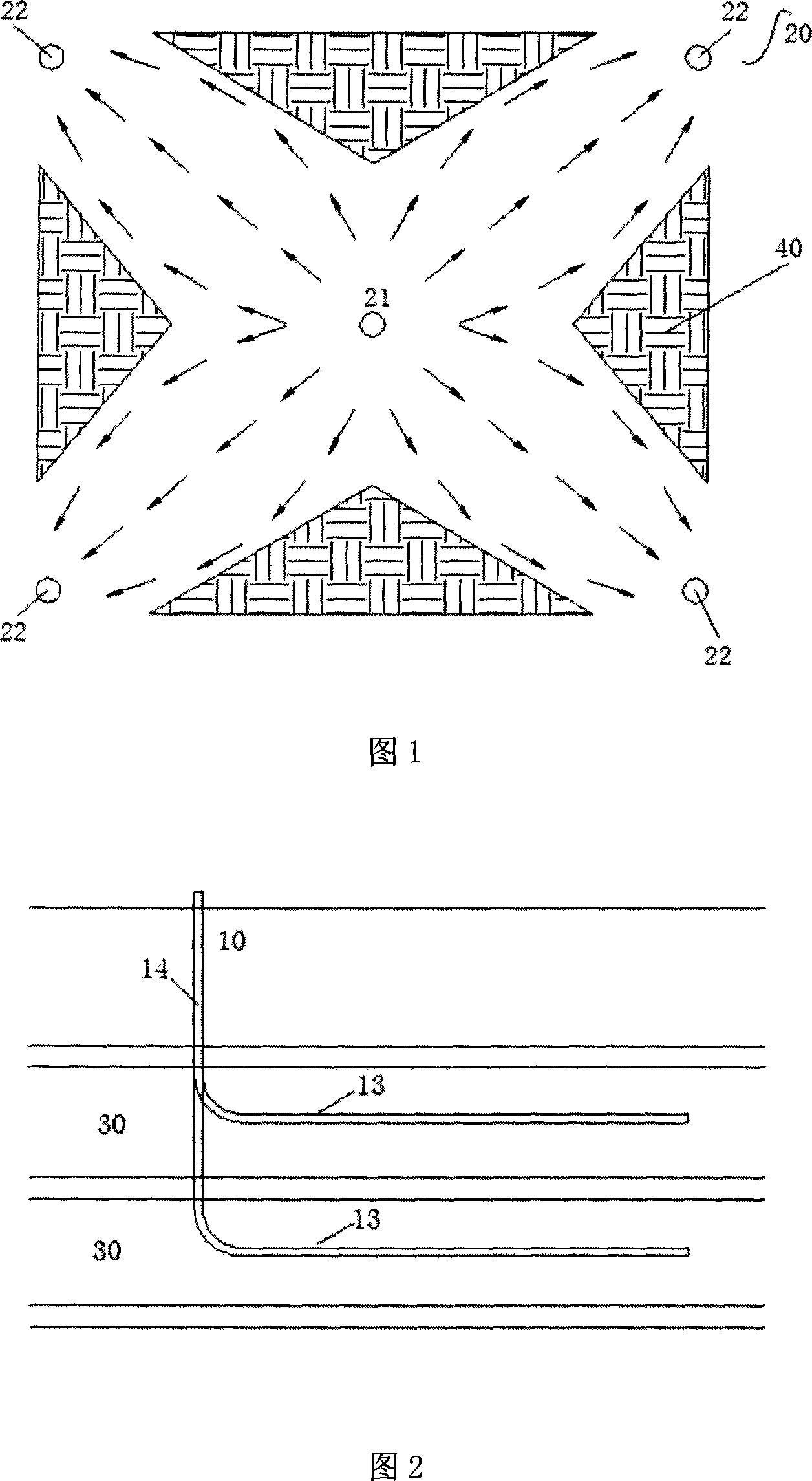

ActiveCN103924925AReduce the number of drilled holesSimple constructionLiquid/gas jet drillingTree shapedDrilling system

The invention discloses a hydraulic jet self-propelled drilling method and device. The device comprises a water tank, a high-pressure pump, a high-pressure energy storage tank, a high-pressure hose supplying device, a drilling machine, an orientator, a high-pressure hose, a steering gear, a drill rod and a self-propelled drill bit. According to the method, a pilot hole is drilled firstly in a coal seam, the steering gear is installed in the pilot hole, the self-propelled drill bit enters the steering gear along the drill rod and is used for radial drilling along the pilot hole under the guidance of the steering gear, the self-propelled drill bit recedes to the position of the steering gear when radial drilling is conducted to a preset depth, the angle of the steering gear is adjusted by shifting the gear of the orientator so that radial drilling can be conducted in another direction, and a tree-shaped drilling system with the pilot hole as the trunk and radial holes formed in a radiating mode is formed through repeat drilling for gas extraction. The device is simple in structure, convenient to operate, and capable of reducing the number of gas extraction holes remarkably, widening the pressure relieving range of each drill hole, improving the gas permeability of the coal seam effectively, shortening gas extraction time and improving the gas extraction quantity of each hole effectively.

Owner:CHONGQING UNIV

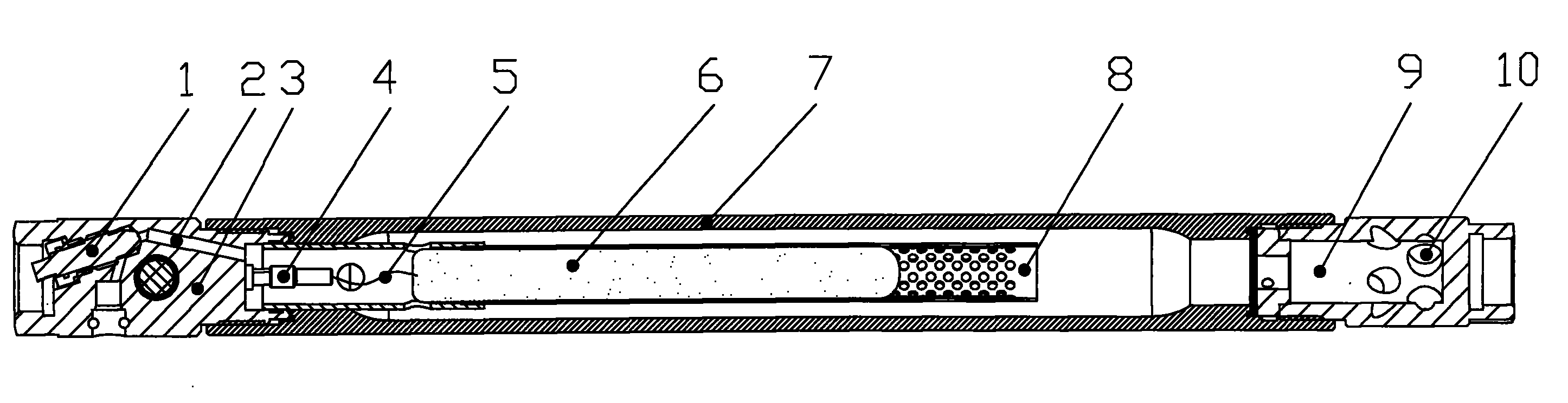

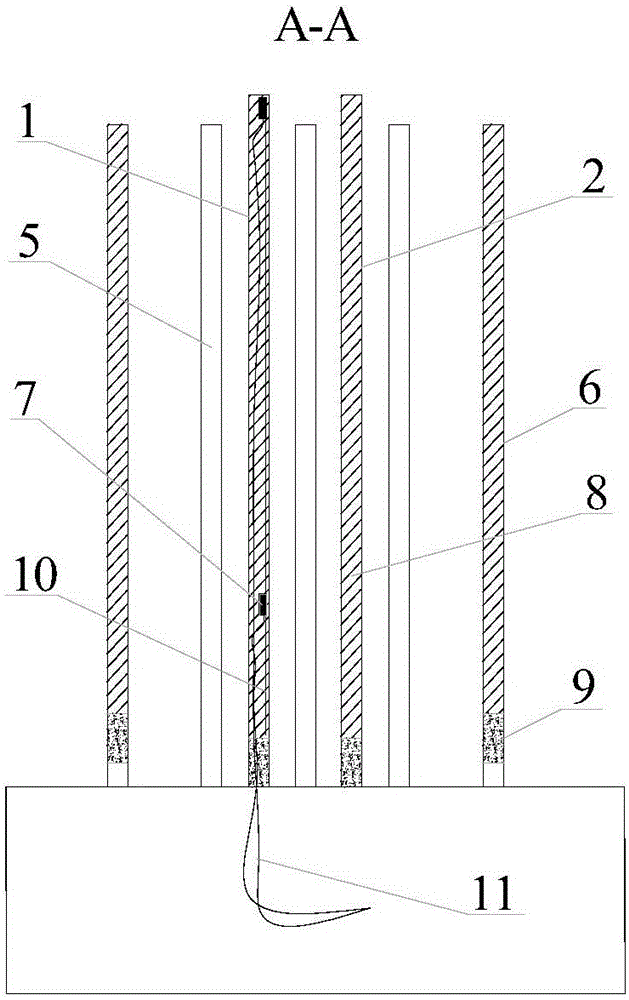

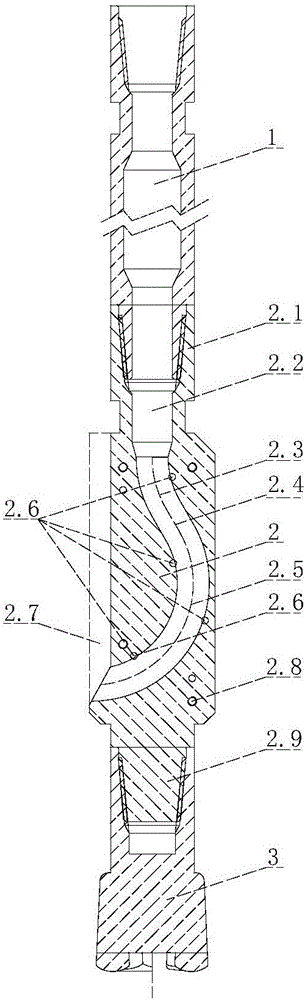

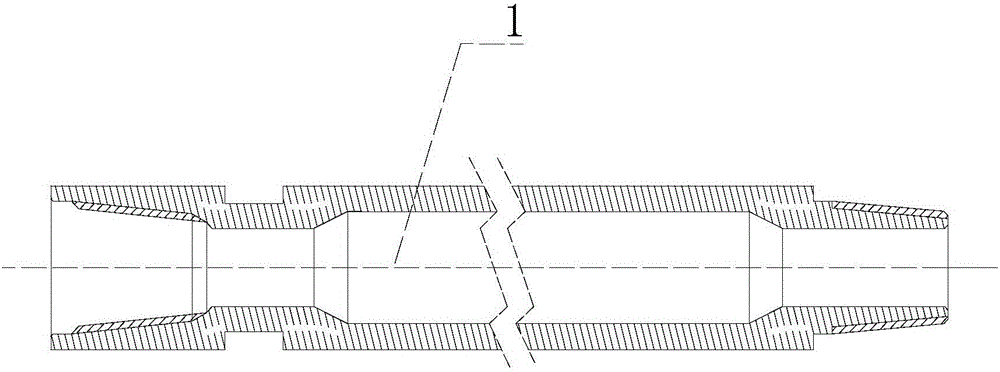

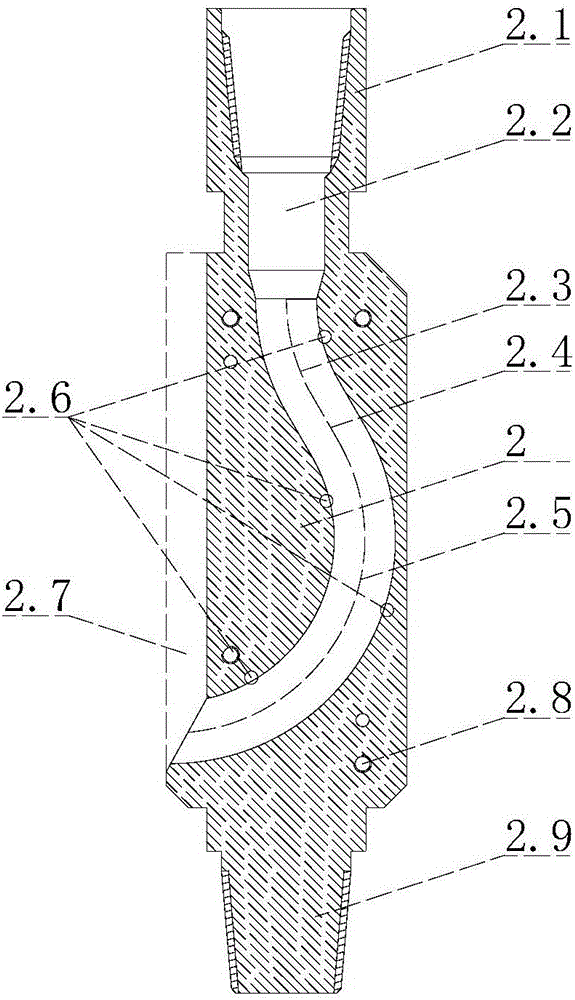

Liquid carbon dioxide bomb, propping agent blasting anti-reflection method and device

InactiveCN106703773AImprove permeabilityImprove breathabilityFluid removalCoal mine methaneEngineering

The invention relates to a liquid carbon dioxide bomb and a propping agent blasting anti-reflection method and a device. The device comprises a liquid storage tube provided with a priming device and liquid carbon dioxide. A releasing tube with propping agent inside is arranged in the front part of the liquid storage tube. A plurality of spray-holes are disposed on the tube wall of the releasing tube. The propping agent is wrapped in a thin strip-shape with plastic film and put into the releasing tube. High-pressure gases produced by vaporized liquid CO2 after liquid CO2 bomb detonates in coal seam form a large number of fractures in drill holes. The high-pressure gas destroys the plastic film wrapping the propping agent during an explosion process. The propping agent with the high-pressure gases enters into coal seam fractures and fractures formed by propping, prolongs existing time of the fractures. The fractures have big presplit radius in coal seam, which can effectively reduce drilling hole amounts in a current extraction and exploitation system in underground coal mines, improve extraction efficiency, reduce pre-extraction time of gas and extraction cost of gas in coal mine, improve a production efficiency of coal, and enhance security of coal production.

Owner:CHINA UNIV OF MINING & TECH

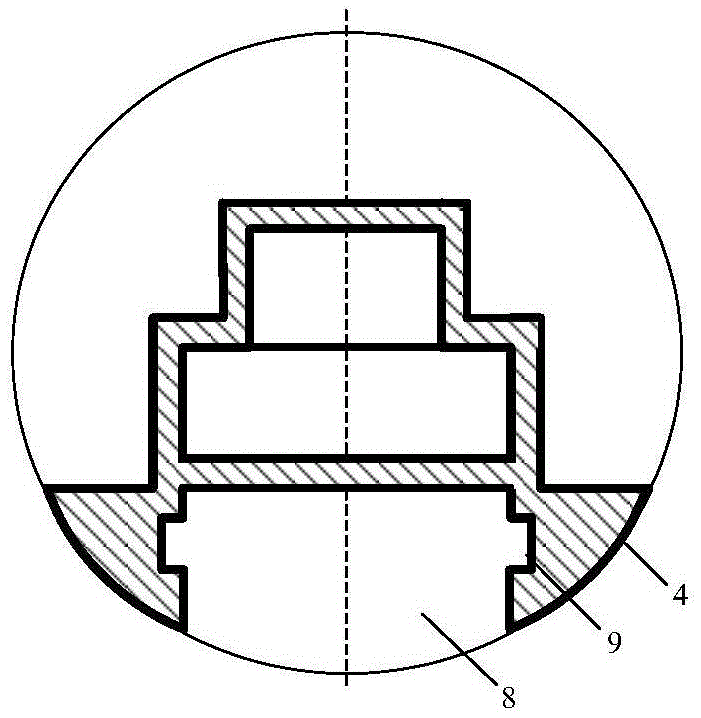

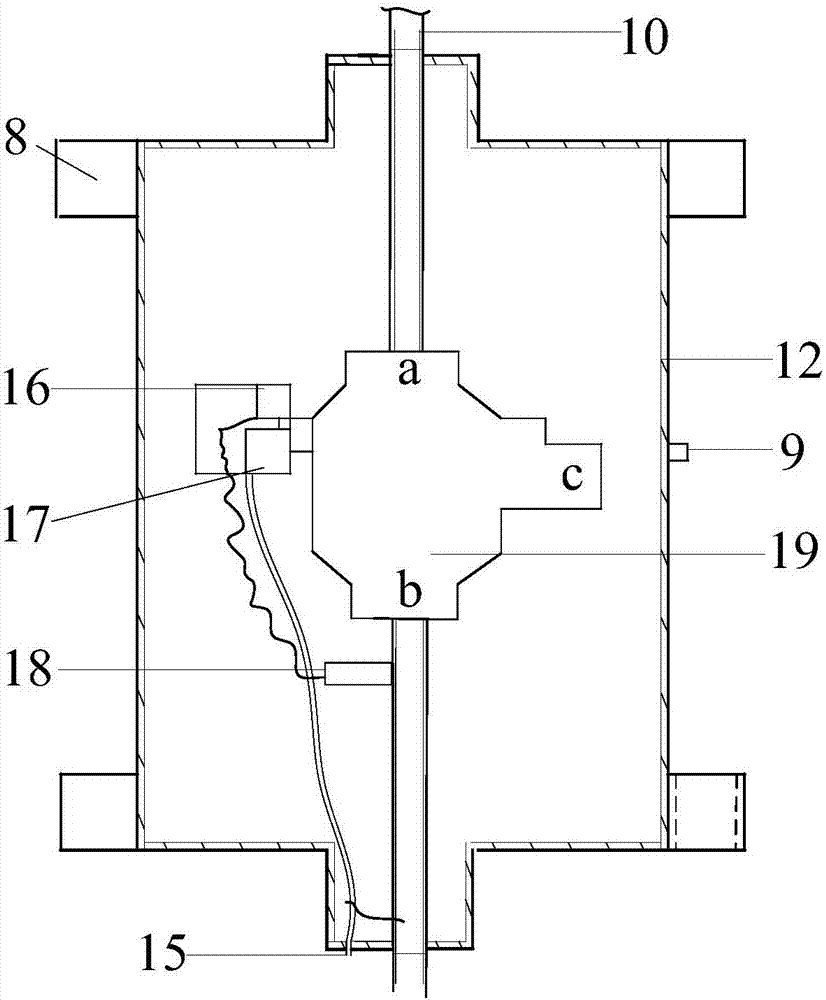

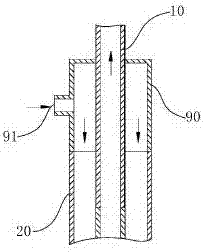

Recycle type borehole stress monitoring device and monitoring method

InactiveCN105486431AReduce labor intensityReduce the number of drilled holesForce measurementHydraulic ramStress monitoring

The invention belongs to the field of mining pressure monitoring, and specifically relates to a recycle type borehole stress monitoring device and monitoring method. The device comprises a drilling unit, a sensor unit in connection with an input end of the drilling unit, an external oil storage unit and an external storage unit. The monitoring method comprises the following steps of: assembling the monitoring device of the invention, and sending probe rods to a designated borehole depth by a mine geological drilling rig; switching on all oil inlet control valves, activating an electric oil pump station, injecting hydraulic oil into a hydraulic jack and a hydraulic capsule, driving the hydraulic capsule at the top of the hydraulic jack to go out from an elliptical leak hole by the hydraulic jack, and switching off the oil inlet control valves; when the pressure reaches a set value, shutting off the electric oil pump station, entering the borehole stress monitoring state, and recording the value change of a digital stress meter; after the monitoring is completed, switching on all oil outlet control valves, and making the hydraulic capsule go back into the probe rods, i.e., to the original position, along with the retraction of the hydraulic jack; and removing the probe rods out of the boreholes, thereby finishing the recycle.

Owner:SHANDONG UNIV OF SCI & TECH

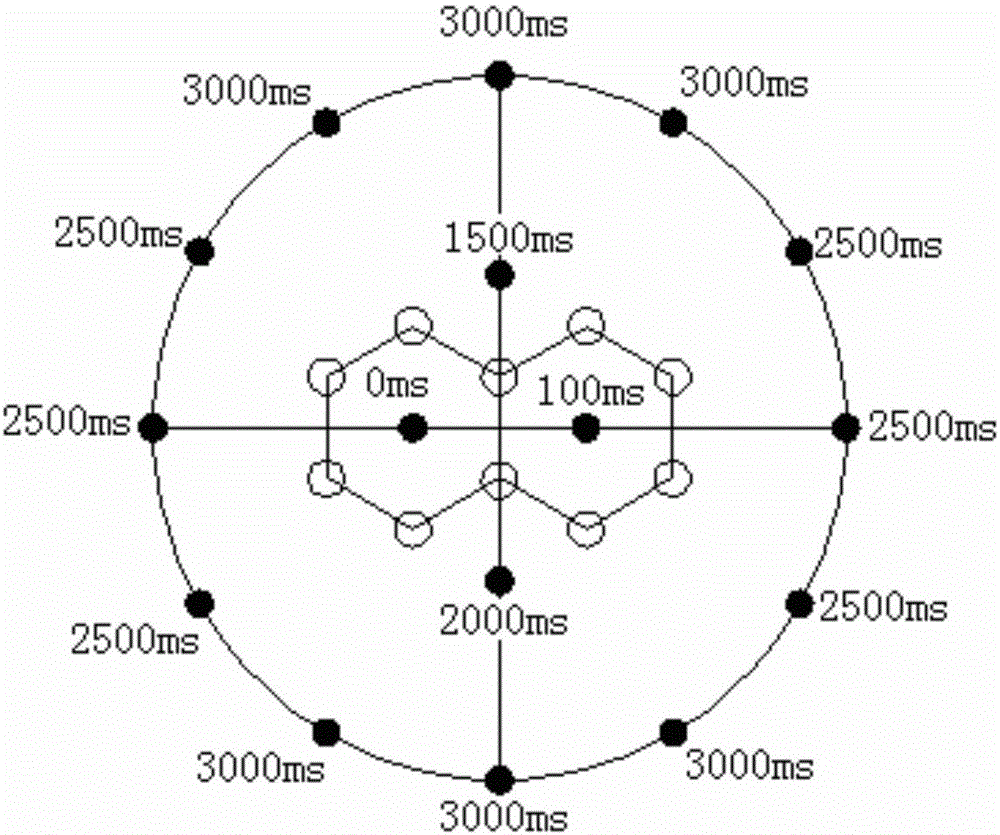

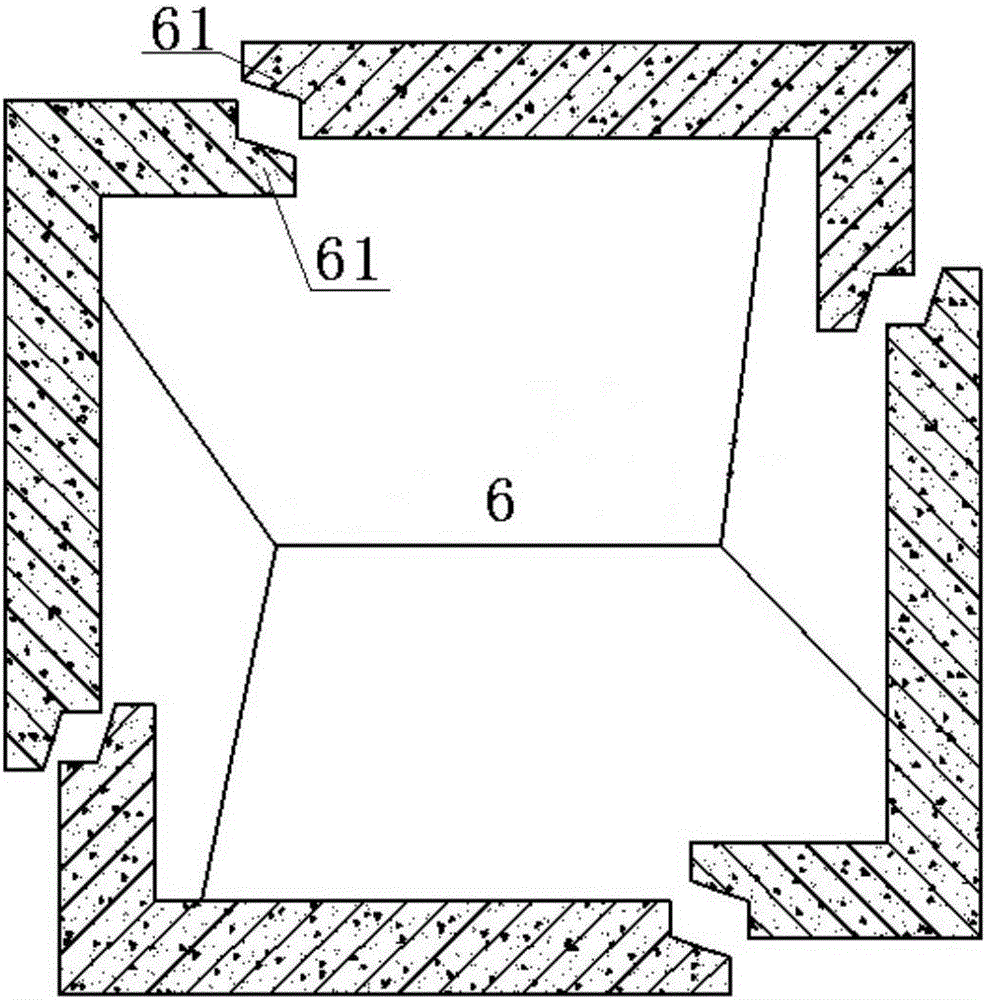

Dual-area slotting blast hole arrangement structure and blasting sinking method applied to structure

ActiveCN106767212AReduced precision requirementsIncrease heightBlastingEngineeringBlasting vibration

The invention discloses a dual-area slotting blast hole arrangement structure and a blasting sinking method applied to the structure. The structure comprises two blasting slotting hole areas symmetrically arranged with respect to the center of the free face of a courtyard, each blasting slotting hole area comprises a center charging hole and a plurality of empty holes arranged around the center charging hole; a ring of peripheral holes are formed in the periphery of each blasting slotting area, the center charging holes and the peripheral hoes are filled with explosive charges, and a plurality of auxiliary holes are formed between the blasting slotting areas and the peripheral holes and are filled with explosive charges. The method is simple in working procedure, operation is easy, the one-time sinking height is large, reliability is high, the sinking effect is good, the number of drilled holes is small, energy consumption is low, and the blasting vibration is small.

Owner:CENT SOUTH UNIV

Integrated monitoring device of oriented stress distribution and deformation of single-hole coal-rock masses and monitoring method

ActiveCN106989849AReduce the number of drilled holesAvoid disturbanceUsing fluid meansHydraulic/pneumatic force measurementSingle holeDrill hole

The invention discloses an integrated monitoring device of oriented stress distribution and deformation of single-hole coal-rock masses and a monitoring method. The integrated monitoring device consists of multiple capsule pressure sensors, a three-way magnetic valve, a connection pipe, a multi-channel displacement monitor, a multi-channel pressure monitor, a steel filament rope and an installation guide rail. According to the invention, the capsule pressure sensors are arranged in drilling holes; through liquid injection devices, the hydraulic pressure of each capsule pressure sensor is allowed to reach a preset value; the capsule pressure sensors are well coupled to the coal-rock masses; deformation monitoring points are attached to the housings of the capsule pressure sensors so that reliable fixation of the deformation monitoring points is achieved; consistency of the stress monitoring and deformation monitoring of the coal-rock masses is ensured; and after the monitoring is finished, all electromagnetic control valves are opened, liquid in the capsules flows back, and the installation guide rail is moved out from detection holes, so recycling is finished. Thus, problems of poor applicability to mining induced stress and deformation of the coal-rock masses, poor consistency, high monitoring cost and unrecyclable devices in the current drilling hole stress monitoring devices are overcome.

Owner:SHANDONG UNIV OF SCI & TECH

Drilling-cutting-linked coal layer gas drainage and outburst prevention system and method based on ultra-long drilling and high-pressure water jetting

InactiveCN102465712AIncrease the exposed areaExpand the scope of the releaseOperating means/releasing devices for valvesMultiple way valvesPressure senseHigh pressure water

The invention discloses a drilling-cutting-linked coal layer gas drainage and outburst prevention system and method based on ultra-long drilling and high-pressure water jetting. The system comprises a drill bit, a pressure sensing valve, a drill stem, a drill machine, a high / low-pressure water delivery and rotation device, a high-pressure pump and a water tank, wherein the pressure sensing valve is mounted at the front end of the drill stem; the drill bit is mounted at the front end of the pressure sensing valve; a nozzle is mounted at the outer side of the pressure sensing valve; the drill machine drives the drill stem to rotate; and water in the water tank is delivered to the high / low-pressure water delivery and rotation device through the high-pressure pump, input to the drill stem through the high / low-pressure water delivery and rotation device and delivered to the pressure sensing valve through the drill stem. In the drill withdrawing process, the coal layer is cut by the high-pressure water, thereby realizing the drilling-cutting linkage and improving the working efficiency. The invention is simple and delicate in structure; and by using the invention, the cutting diameter can be up to 3 meters or above, thereby increasing the gas exposure area to more than 6 times of the traditional gas exposure area and effectively widening the gas release range by more than 3 times. Thus, the invention solves the drainage and outburst prevention problems of coal mine gas.

Owner:湖南汉寿中煤科技有限公司

Pre-splitting blasting method for joint-cutting pipe

InactiveCN102519323AReduce the number of drilled holesSave blasting equipmentBlastingEngineeringPre cracking

The invention relates to a pre-splitting blasting method for a joint-cutting pipe. The method comprises the following steps: (1) defining a peripheral profile line for a blasting excavation region, and arranging a micro-difference blasting hole in a main body blasting excavation region; (2) arranging a pre-splitting blasting hole along the peripheral profile line in the blasting excavation region; (3) placing the joint-cutting pipe in the pre-splitting blasting hole, and enabling two cut joints of the joint-cutting pipe to be in a plane formed by a shaft line of the pre-splitting blasting hole; (4) performing blasting charge on the joint-cutting pipe in the pre-splitting blasting hole, and arranging low section detonators; (5) performing blasting charge on the micro-difference blasting hole in the main body blasting excavation region, and arranging micro-difference blasting detonators at intervals at a position higher than the pre-splitting blasting hole by two sections; (6) blocking the micro-difference blasting hole and the pre-splitting blasting hole in the main body blasting excavation region; (7) connecting a priming network for blasting; (8) deslagging; and (9) repeating the steps (1) to (8) until completion of excavation. According to the pre-splitting blasting method provided by the invention, the pre-crack forming quality is improved and the engineering cost is decreased while the damage and cracking of a reserved rock body are reduced.

Owner:LANZHOU UNIVERSITY

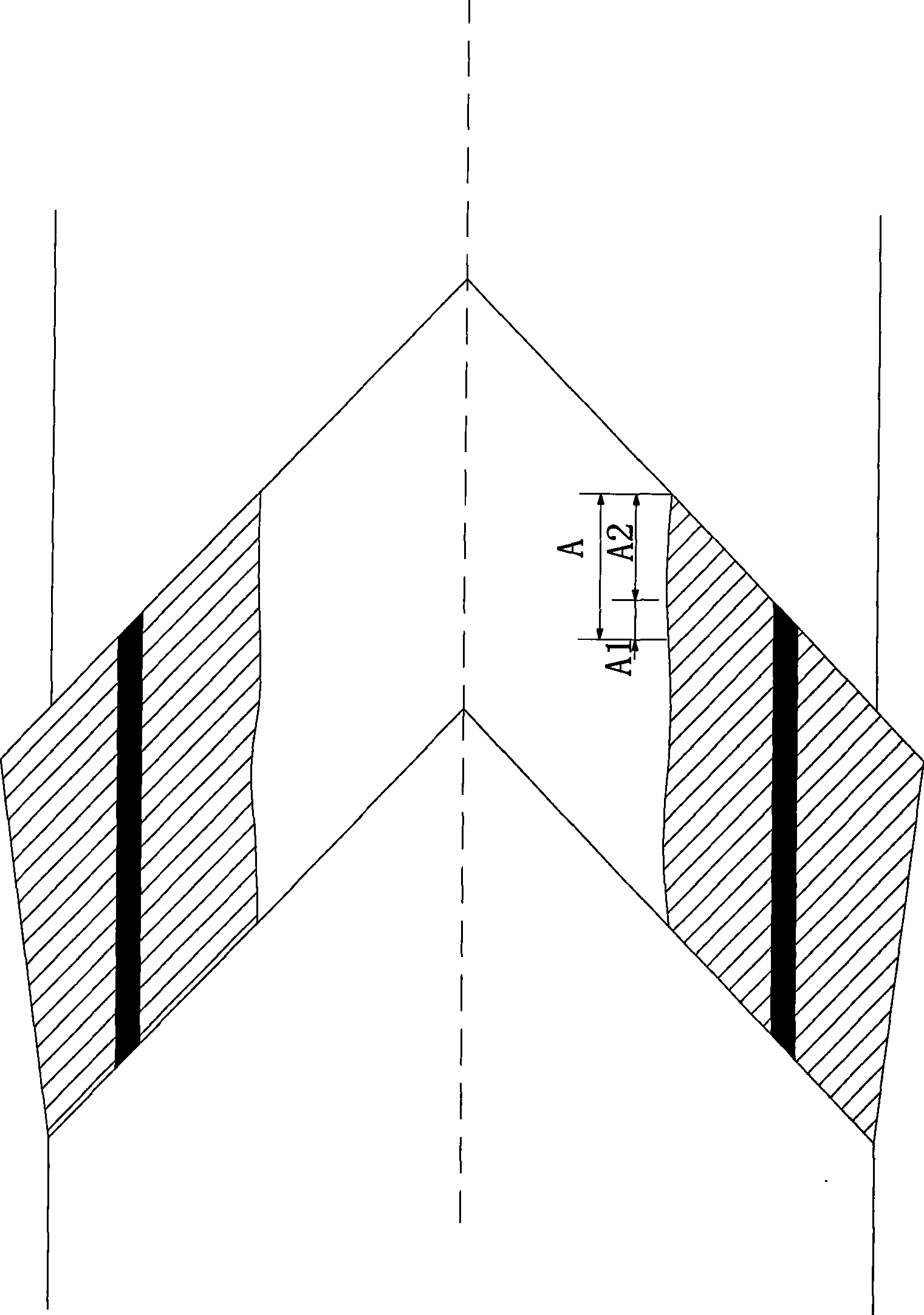

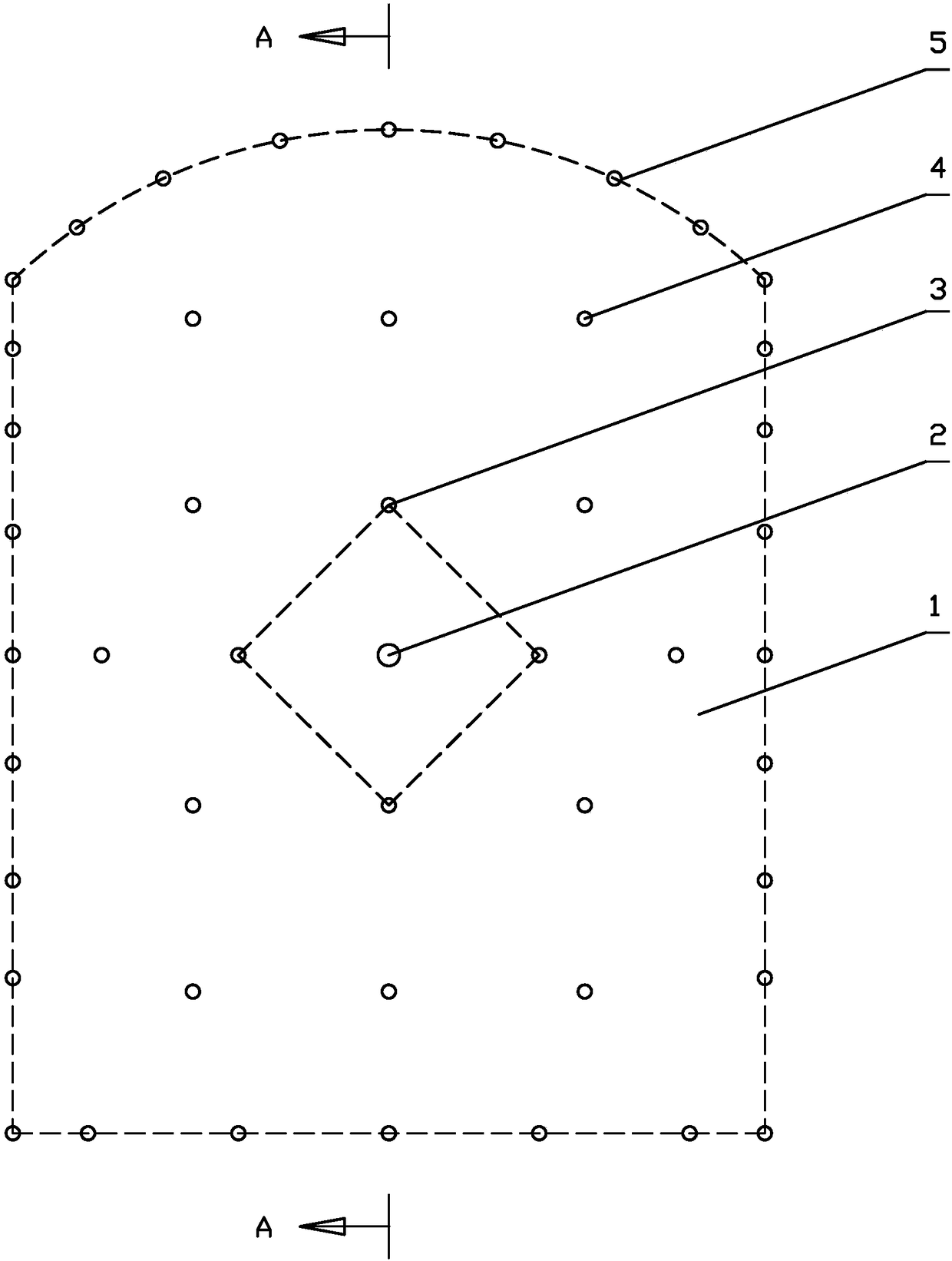

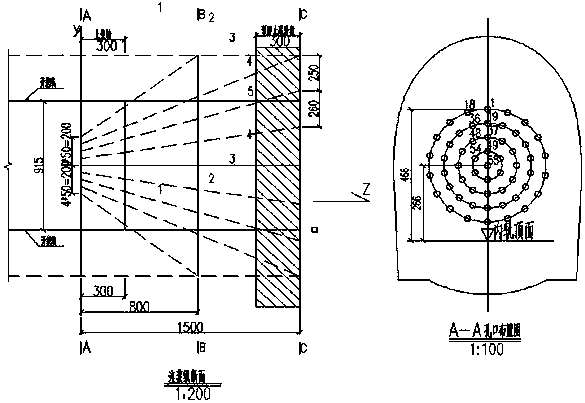

Application method for horizontal V-shaped tunnel face for digging tunnel

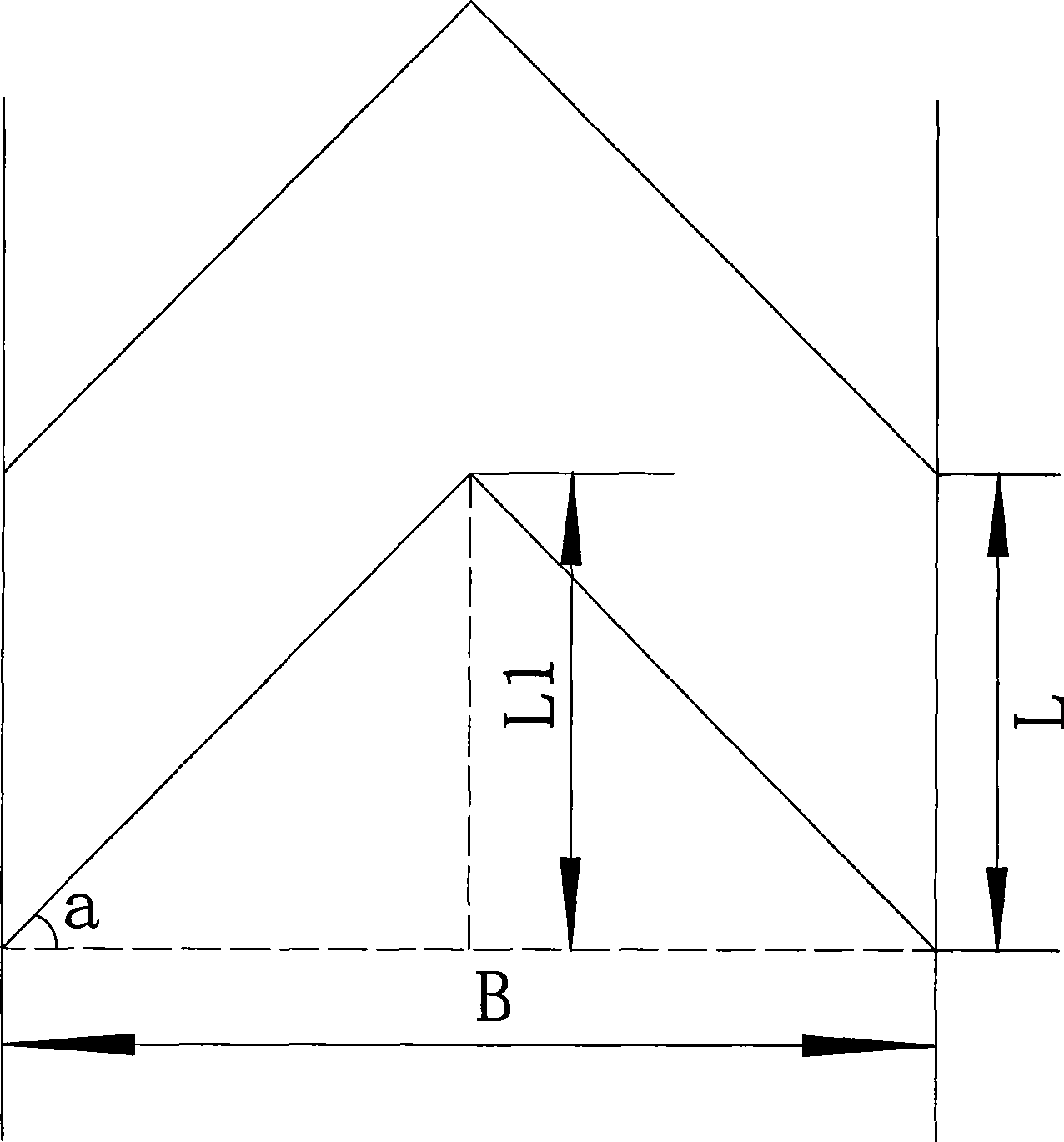

InactiveCN101363321AReduce unit consumptionReduce the number of drilled holesBlastingTunnelsHardnessEnvironmental geology

The present invention relates to a construction method for using a horizontal V-shaped tunnel face during tunneling. In the method, the value of bore diameter B is confirmed firstly; then the value of bore depth L and the V-shaped tunnel face inner oblique depth L1 are confirmed according to the arrangement of tapping equipments and construction schedule; an undercutting form is confirmed according to the rock hardness; the value of the V-shaped tunnel face inner oblique angle a is confirmed according to the undercutting form, the rock hardness, the joint development condition and the bore depth L; and finally, blasting operation is conducted after undercutting according to the bore diameter B, the bore depth L, the V-shaped tunnel face inner oblique depth L1, the V-shaped tunnel face inner oblique angle a and the selected undercutting form. The present invention improves the utilization rate of the blast bore greatly, reduces the waste of explosive and the quantity of bores and ensures that the single circulation drilling footage is possible to exceed the bore depth. The waste of explosive and the quantity of bores are reduced, so the cost is reduced greatly.

Owner:SINOHYDRO BUREAU 5

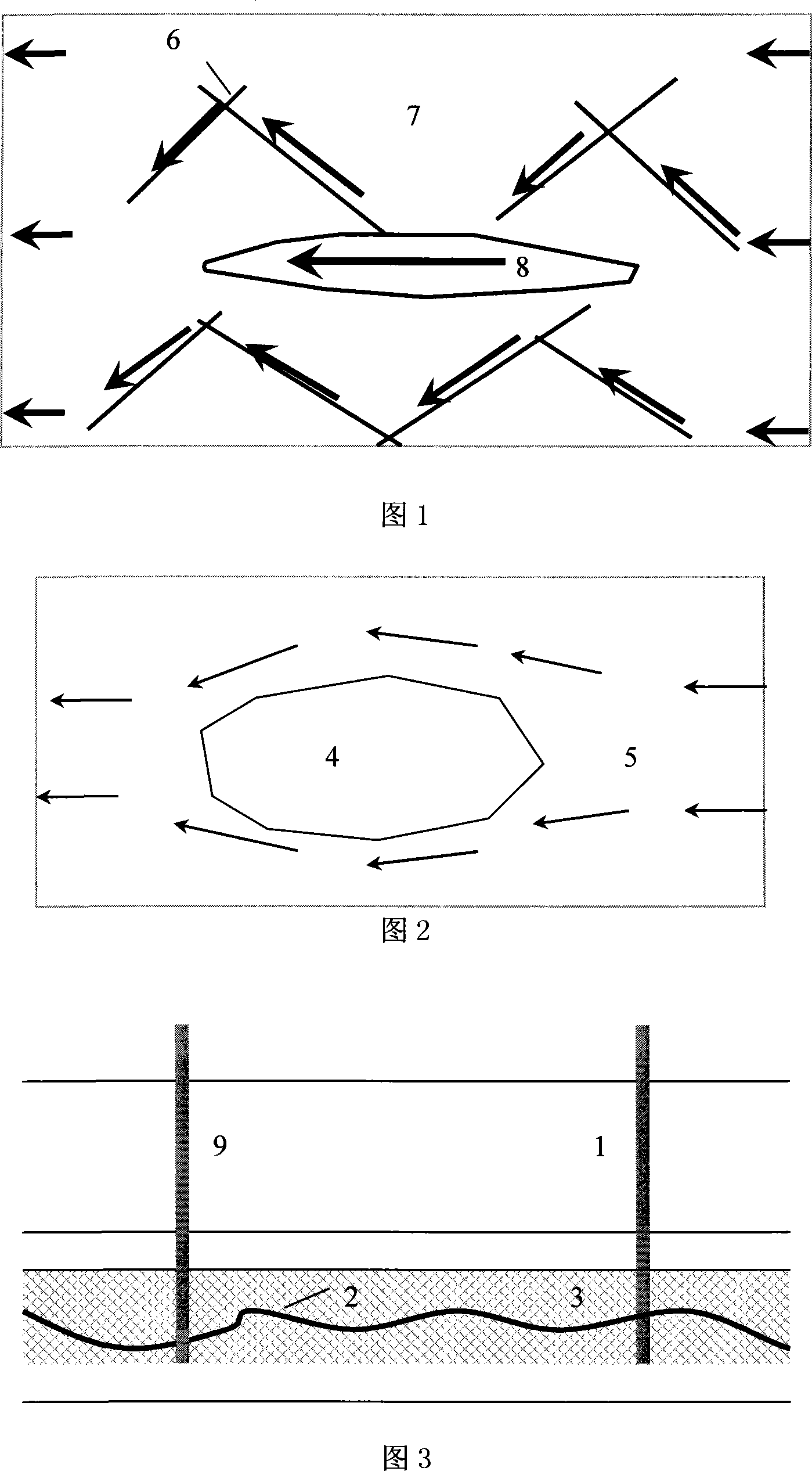

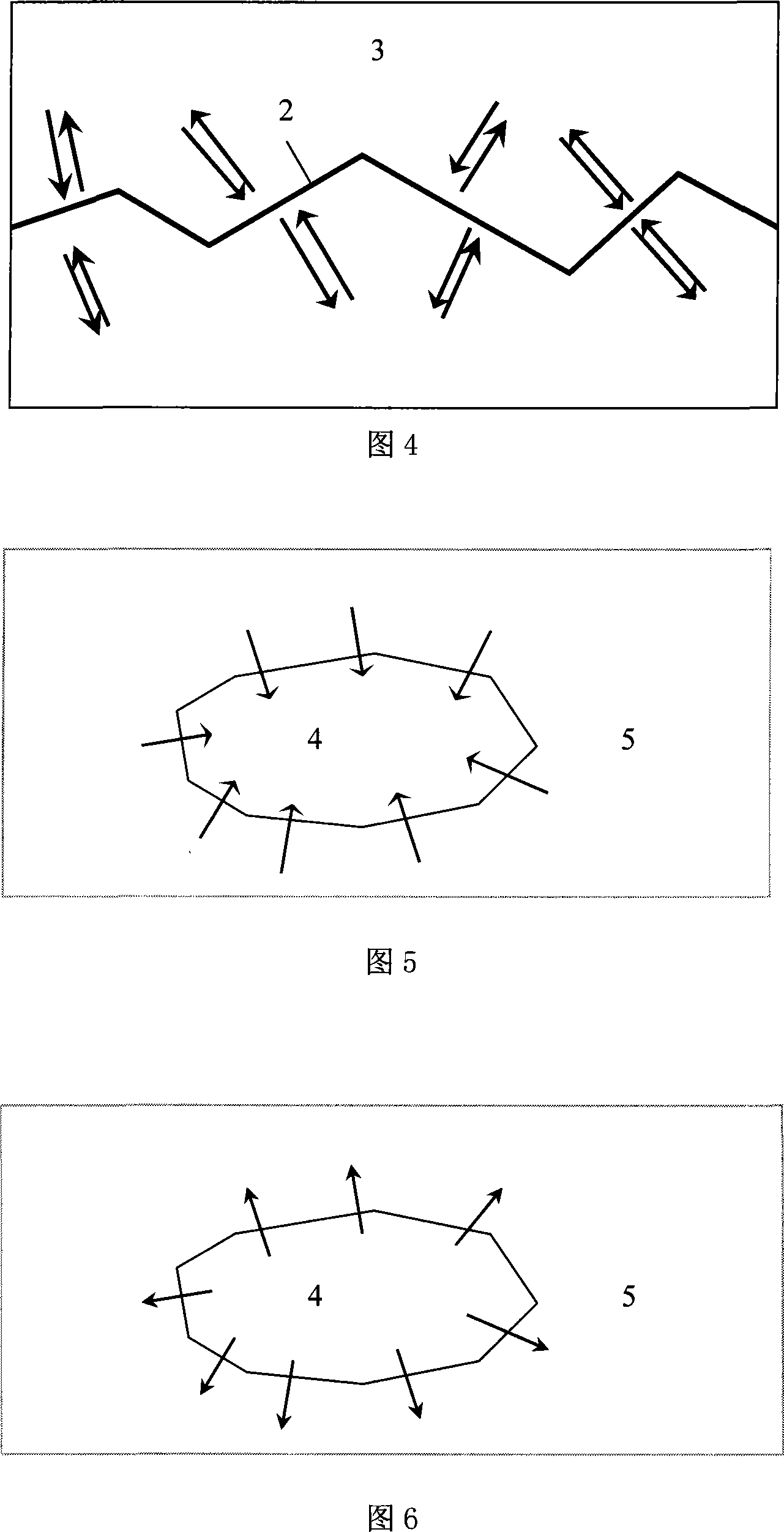

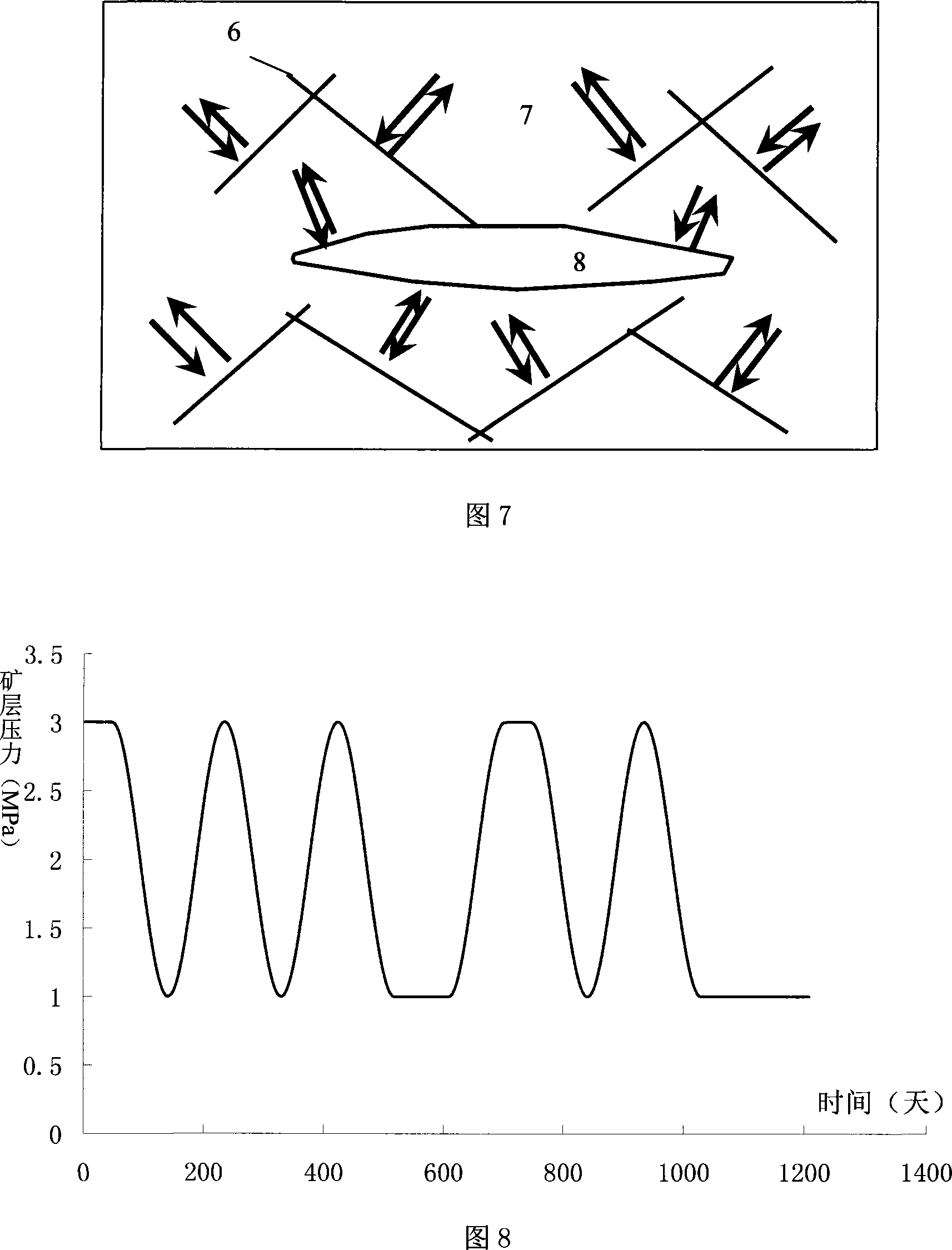

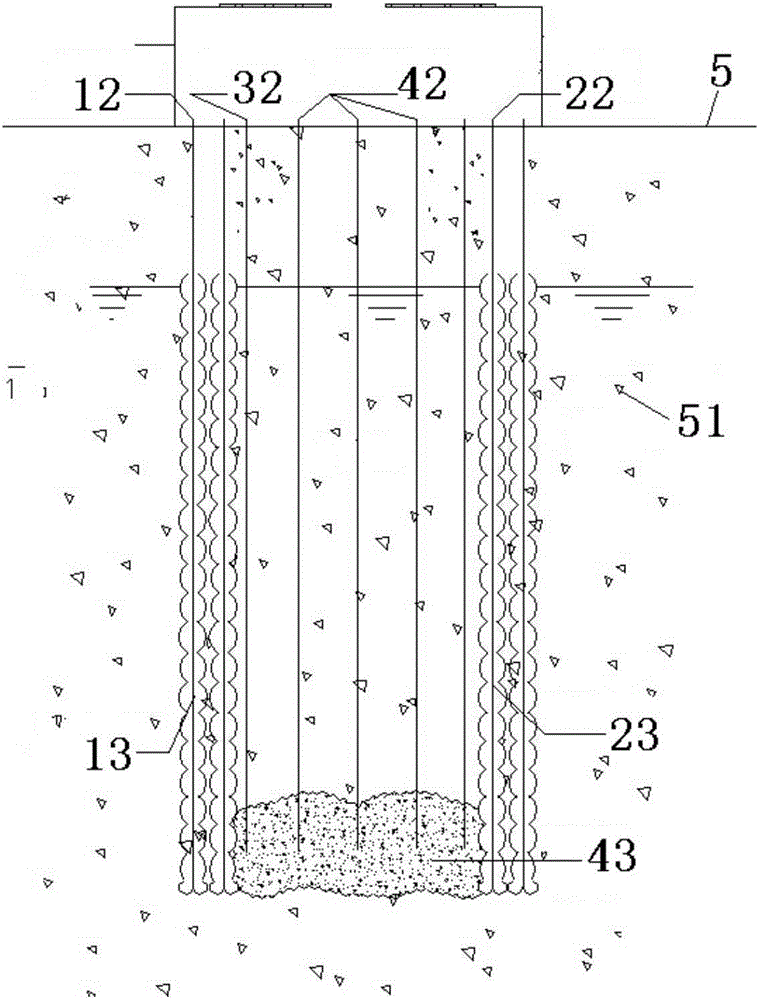

Horizontal fissure fluctuation leaching mining method

The invention discloses a horizontal crack fluctuation leaching exploitation method, which relates to a leaching exploitation method and comprises the procedures that: (1) an injection well (1) and a recovery well (9) are formed and a horizontal crack face (2) is made in a manto (3); (2)a highly-compressed mixed fluid is injected into the manto (3) through the injection well (1); (3) the fluid pressure in the manto (3) is constantly fluctuated; (4) the leaching liquid which contains the mineral deposit is collected in the recovery well (9) or the injection well (1); (5) the mining process is continued until the leaching obtained mineral deposit concentration is less than the economic exploitation concentration. The invention is simple, effective and is beneficial to improving the recovery rate, recovery speed and recovery scope of the minerals, reducing the mining cost and is suitable for the leaching exploitation field of uranium, copper, aurum, rare earth and so on.

Owner:INST OF ROCK AND SOIL MECHANICS - CHINESE ACAD OF SCI

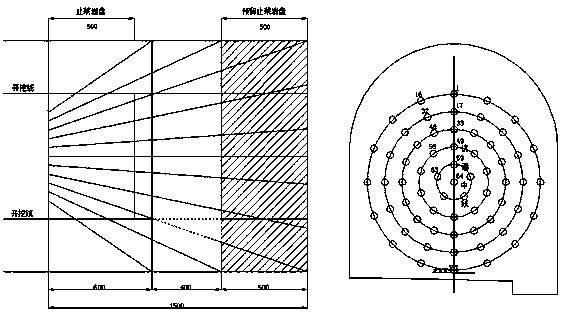

Blast hole forming structure for cutting blasting of small section roadway

The invention discloses a blast hole forming structure for cutting blasting of a small section roadway. The blast hole forming structure comprises a center hole formed in the center of a roadway driving working face and cutting blasting holes formed around the center hole. Auxiliary holes are formed in the peripheries of the cutting blasting holes. Peripheral holes are formed in the edge of the design section of the roadway driving working face. The axial directions of the auxiliary holes and the peripheral holes and the hole direction of the center hole are the same as the cutting blasting driving direction of the roadway. The cutting blasting holes are concentrated gradually towards the center hole from a hole opening to the hole bottom. According to the blast hole forming structure forcutting blasting of the small section roadway, the scheme that the hole bottoms of the cutting blasting holes are concentrated to the position near the center hole, and concentrated charging and detonating together are implemented is adopted, the number of drilled holes is small, the consumption amount of explosive is low, the center hole serves as the auxiliary free surface during charging blasthole blasting and a compensation space of a broken body, the broken body is thrown out advantageously, and the cutting blasting effect is good.

Owner:内蒙古康宁爆破有限责任公司

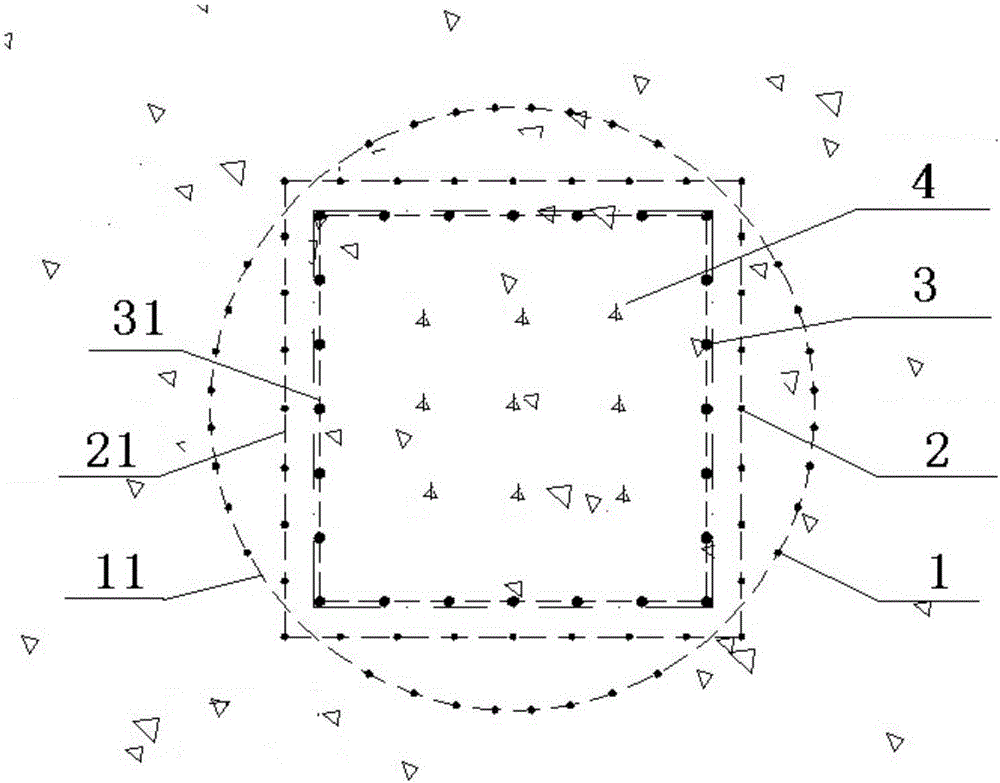

Prefabricated underground silo compound shaft construction method and silo structure

ActiveCN106088154AReduce the internal force of the rectangular sectionReduce settlementArtificial islandsUnderwater structuresEngineeringSilo

The invention relates to the field of underground silo facilities, in particular to a prefabricated underground silo compound shaft construction method and a silo structure which effectively improve the underground silo construction efficiency and greatly reduce the construction cost. The prefabricated underground silo compound shaft construction method comprises the following steps that a, paying off is firstly carried out in a silo building site to locate and arrange drill holes; b, freezing operation and bottom grouting are carried out; c, splicing assembly is carried out to form shaft structures; d, shoe leg heating pipes in shoe leg structures are used for hydrothermal circulation; e, structure shaft components are assembled step by step to form new shaft structures till the preset depth is achieved; f, bottom plates and supporting plates are mounted; g, all drill hole openings in the ground are closed; and h, debugging and running are completed, and construction is finally completed. The prefabricated underground silo compound shaft construction method and the silo structure are high in construction reliability and construction speed and especially suitable for being used in fields with the short construction period and limited construction space.

Owner:黄竟强

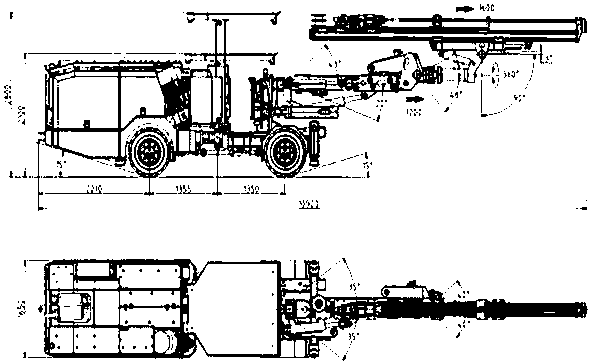

Multi-armed drill jambo curtain grouting construction technology for extra long single-track railway tunnel

InactiveCN108590706AImprove stress conditionsExcavation quality is easy to controlUnderground chambersTunnel liningRailway tunnelArchitectural engineering

The invention discloses a multi-armed drill jambo curtain grouting construction technology for an extra long single-track railway tunnel. According to the multi-armed drill jambo curtain grouting construction technology, the implementation contents comprises modification of a multi-function full hydraulic drill jambo (Atlas XL3D), supporting application of grouting integrated equipment, comprehensive geological prediction, application of monitoring technology, starting conditions of curtain grouting, curtain grouting unit division, curtain grouting process and construction methods, and curtaingrouting standard and effect evaluation. The multi-armed drill jambo curtain grouting construction technology can solve the problem of curtain grouting construction in tunnels crossing bad geologicaland water-rich structural zones, reduces the construction cost, improves the construction efficiency, and shortens the construction period.

Owner:CHINA RAILWAY NO 5 ENG GRP +1

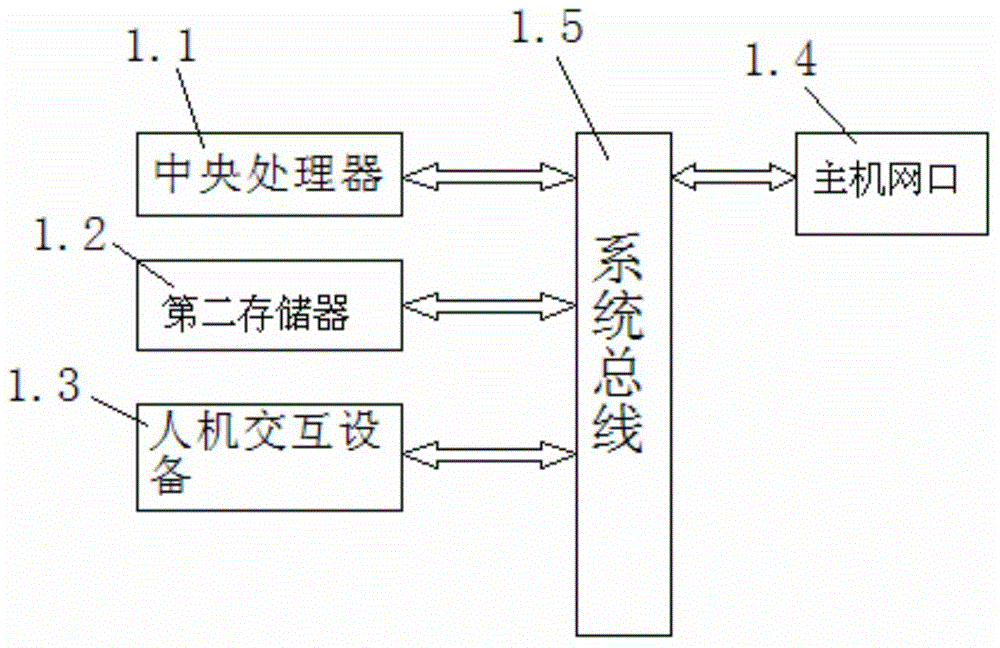

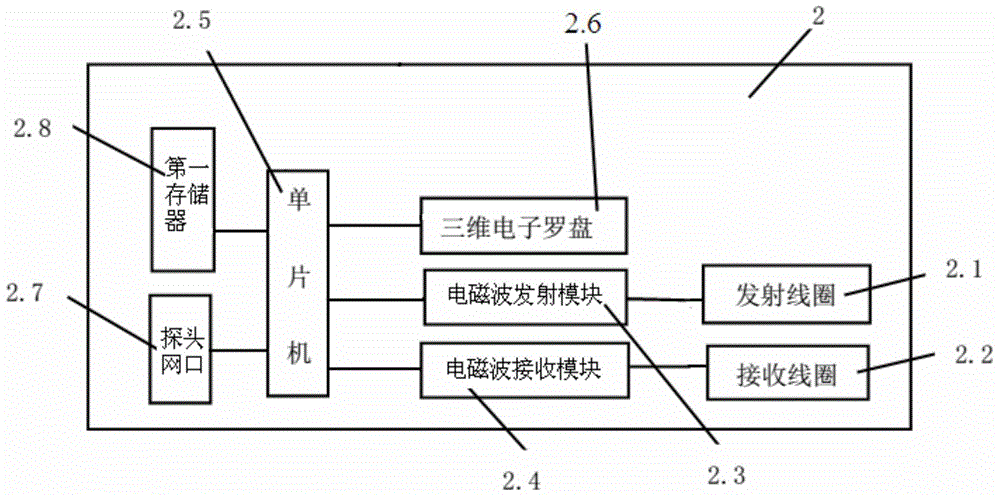

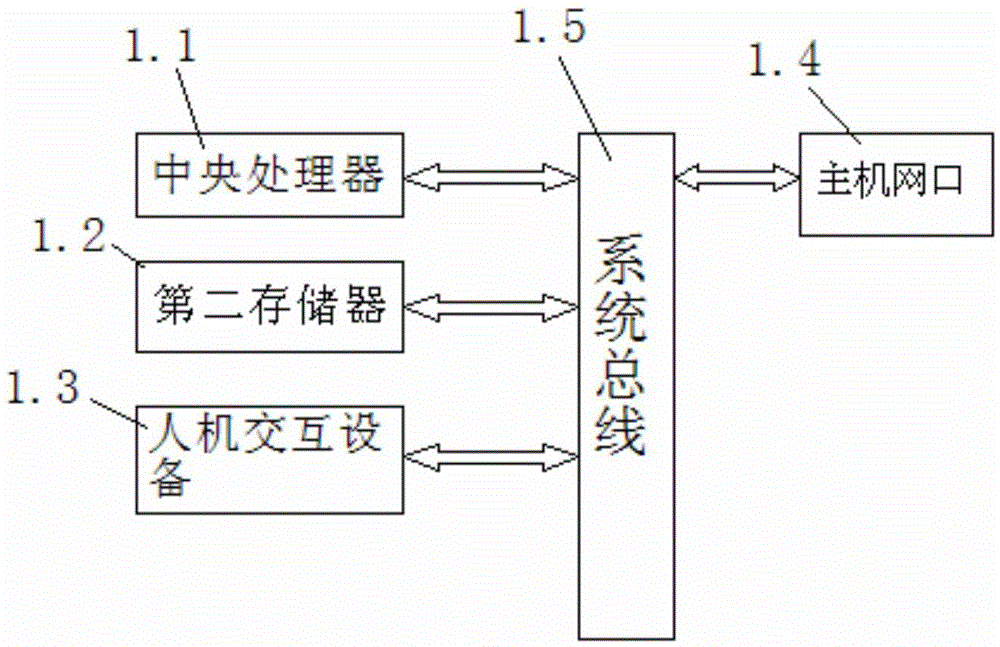

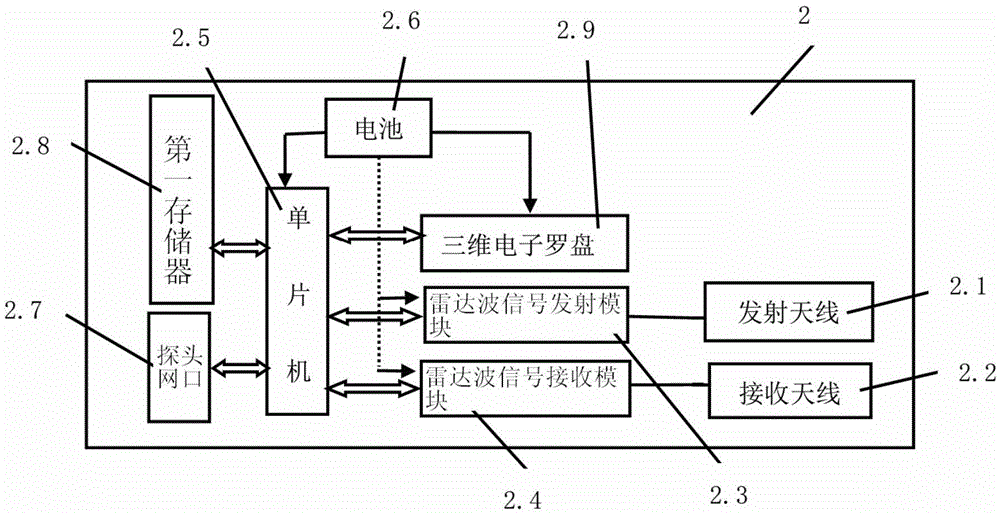

Mining borehole radar advanced water detecting forecasting device and forecasting method

ActiveCN105589069AAchieving advanced detection and forecastingExpand the detection rangeRadio wave reradiation/reflectionMicrocontrollerBorehole radar

The invention discloses a mining borehole radar advanced water detecting forecasting device. A signal output end of a radar wave signal transmitting module is connected with a signal input end of a transmitting antenna, and a signal input end of a radar wave signal receiving module is connected with a signal output end of a receiving antenna. The communication end of the radar wave signal transmitting module and the communication end of the radar wave signal receiving module are respectively connected with a signal transmitting communication end and a signal receiving communication end of a single-chip microcomputer. A communication end of a memory and a communication end of a three-dimensional electronic compass are respectively connected with the data storage communication end and the compass data communication end of the single-chip microcomputer. The data communication end of the single-chip microcomputer is connected with a data communication end of an on-site host by a probe network interface and a network cable. The eutrophic water, the water diversion channel, and other harmful geological bodies around the drilled hole can be detected, and the fine and effective detection forecast can be carried out.

Owner:WUHAN CONOURISH COALMINE SAFETY TECH +1

Subway track bed reinforcement construction process

InactiveCN102605686ASimple construction processReduce the number of drilled holesRailway track constructionTrackwayArchitectural engineering

A subway track bed reinforcement construction process includes: first, forming holes; second, driving in anchor bolts; third, performing mechanical anchor locking; and fourth, grouting. By the process, the problem that the track bed is raised by pressure during grouting is solved, and deformation of the track bed subjected to grouting reinforcement is relieved. The construction process integrally combines anchoring and grouting, so that drilling and bar planting prior to drilling and grouting is avoided, the construction process is simplified, construction time is shortened, and construction effect is guaranteed.

Owner:湖南宏禹工程集团有限公司

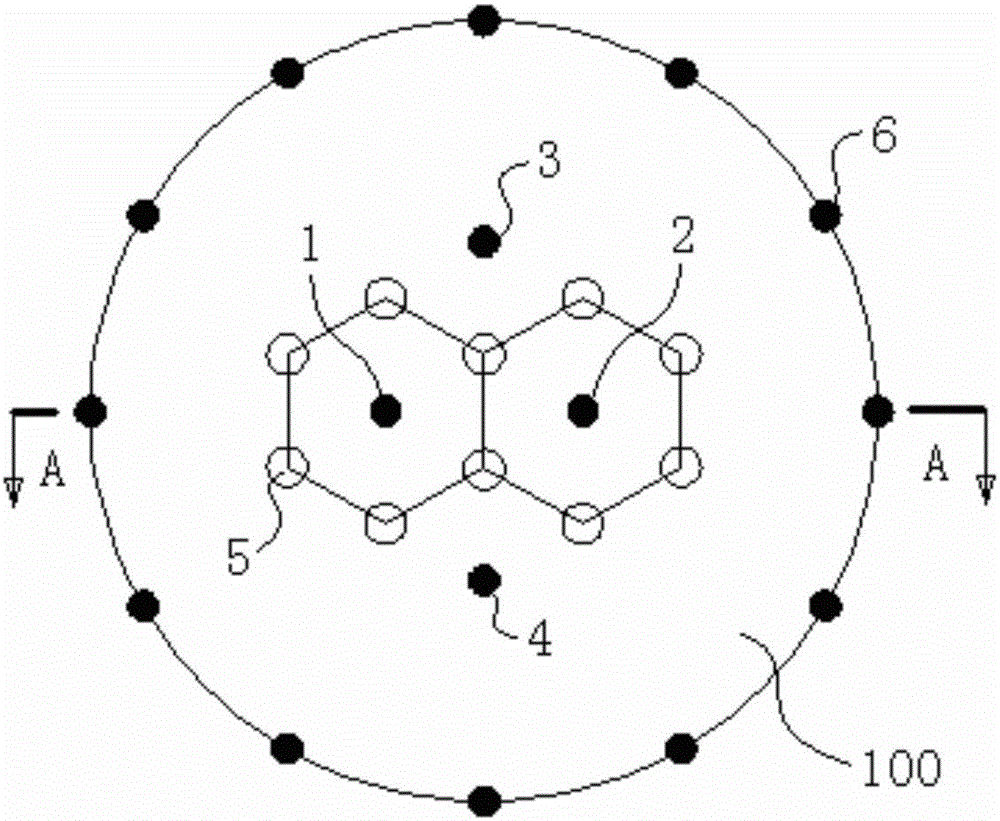

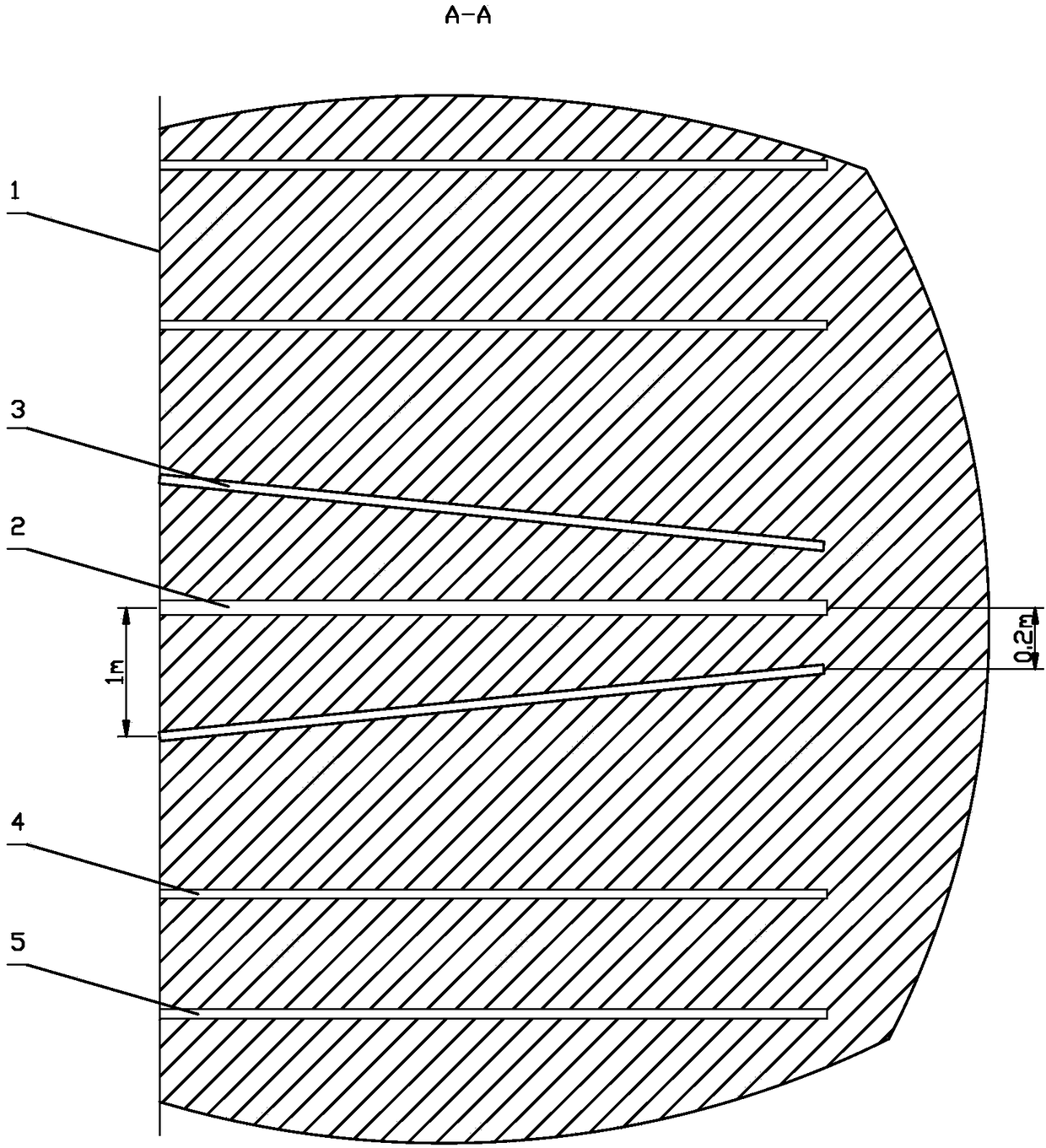

Slotting blast hole layout structure for blind raise once well completion and well completion method

ActiveCN109724484AHigh precisionReduce the number of drilled holesBlastingShaft sinkingDrill holeSmall caliber

The invention discloses a slotting blast hole layout structure for blind raise once well completion and a well completion method. A plurality of linear slotting holes are formed in a circle center line of a blast area, wherein each linear slotting hole is formed by alternatively laying out an empty hole and an explosive filling hole; a plurality of triangular slotting holes which are arranged at the two sides of the circle center line are formed in the blast area; every three triangular slotting holes define one group, and are laid out in the form of a triangular structure; adjacent two groupsof triangular slotting holes share two triangular slotting holes; a ring of peripheral holes is formed in the periphery of a circular blast area; and the explosive filling holes in the linear slotting holes and the triangular slotting holes as well as the peripheral holes are filled with explosives. The slotting blast hole layout structure adopts linear and triangular hybrid small-caliber slotting blast holes to perform once blasting well completion, is simple in operation, is convenient in construction, greatly reduces number of drilled holes, is low in cost, reduces blasting vibrations, ishigh in reliability, and has a relatively good popularization and application value.

Owner:DAYE NONFERROUS METALS +1

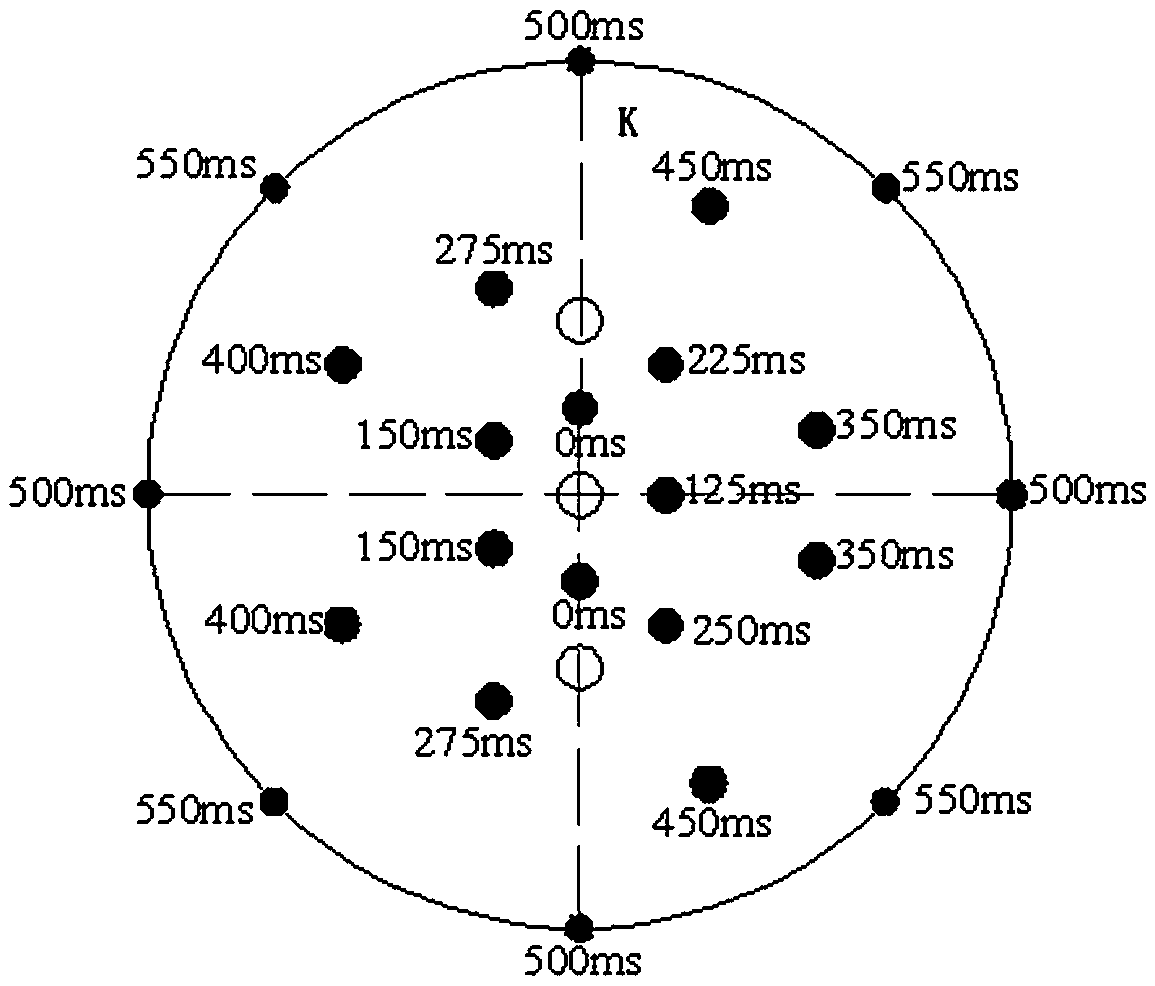

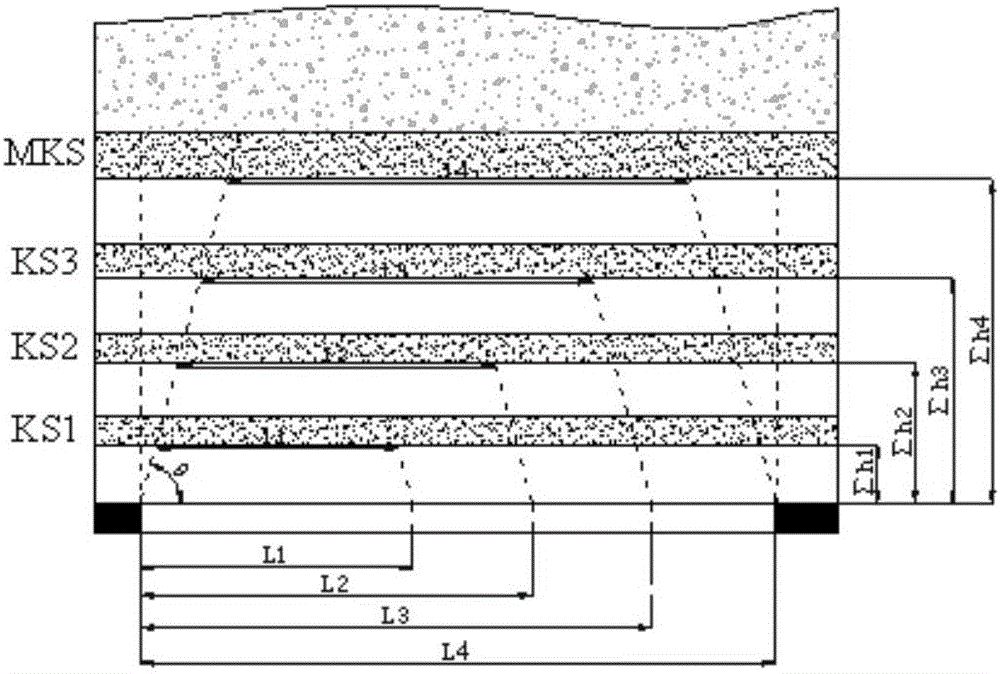

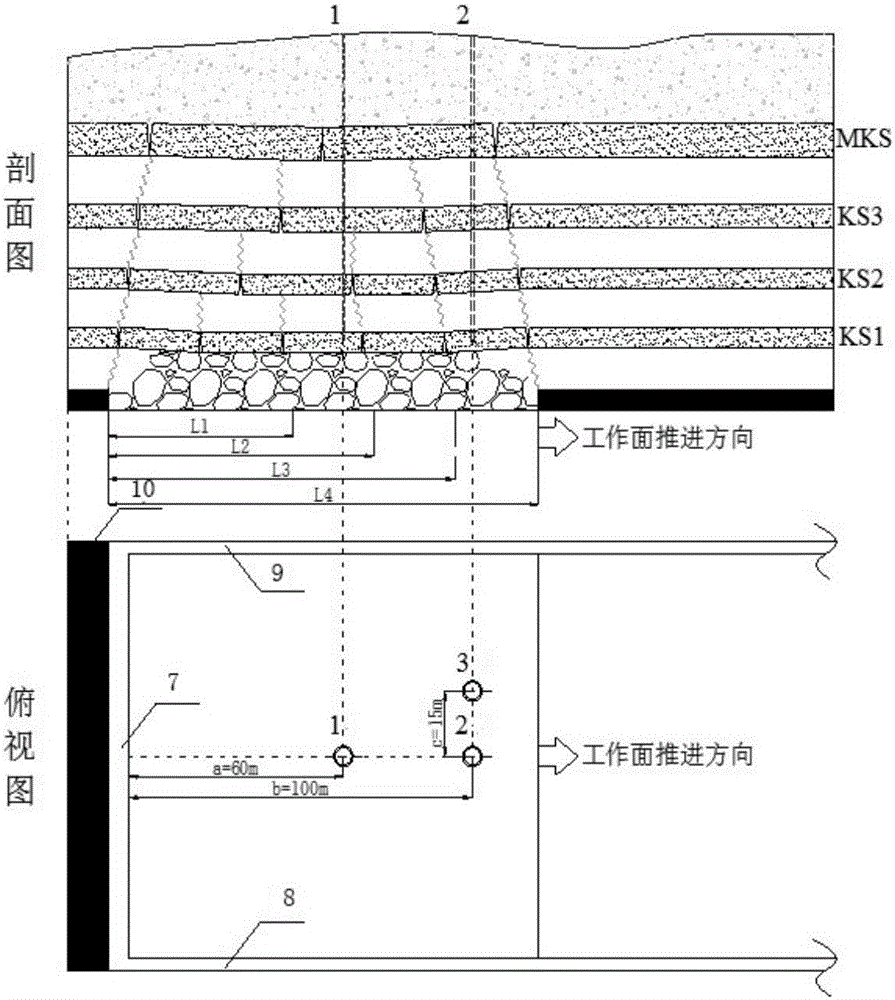

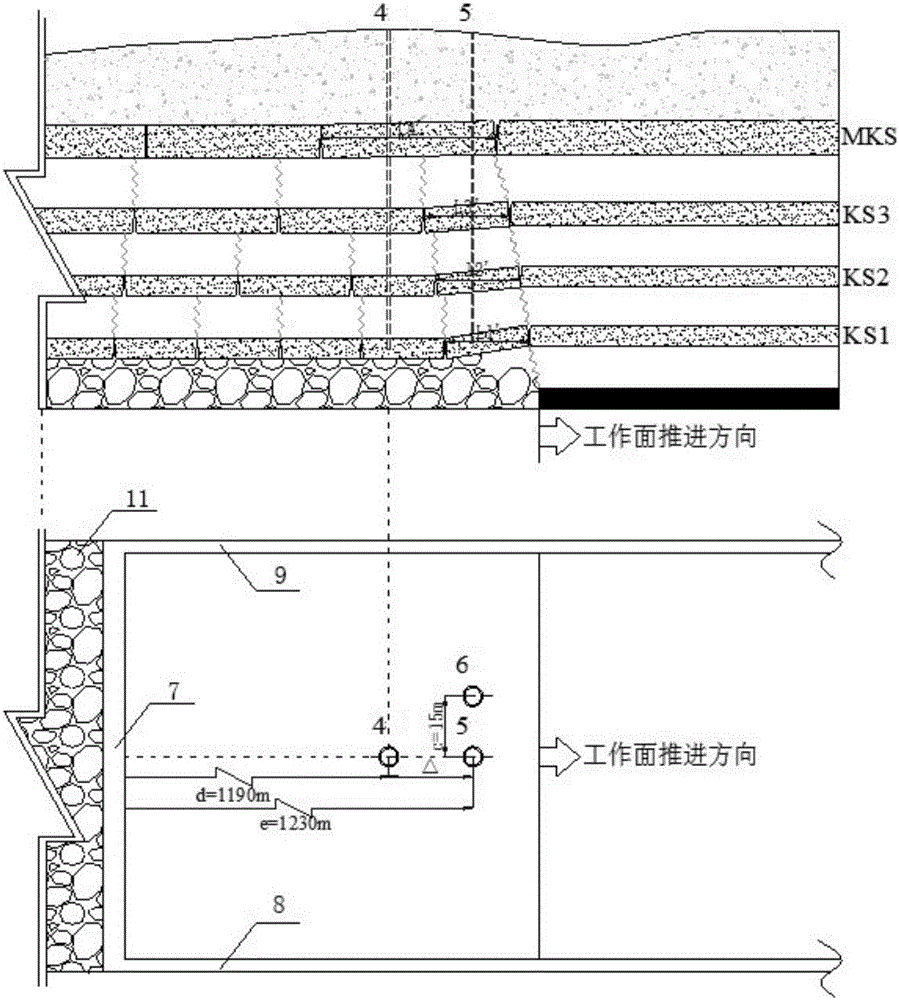

Mining overburden rock motion law in-situ observation drill hole layout method

ActiveCN105911606AReduce the number of drilled holesReduce upfront investmentOptical prospectingEconomic benefitsMultiple layer

The invention discloses a mining overburden rock motion law in-situ observation drill hole layout method, which is suitable to be used in the field of mining engineering. The mining overburden rock motion law in-situ observation drill hole layout method comprises the steps of: determining a longitudinal overlapping region of fracture ranges of critical layers of an overburden rock by utilizing a critical layer theory; further determining in-situ observation drill hole layout positions and distance between drill holes at a working surface initial mining stage and a working surface overburden rock periodic fracture period, that is, fracture motion of multiple layers and even all the critical layers of the overburden rock can be observed with the minimal ground drill hole number; and providing a mining overburden rock motion law in-situ observation drill hole layout scheme based on the effect achieve in the step 2. The mining overburden rock motion law in-situ observation drill hole layout method avoids the blindness and randomness of drill hole position determination in a traditional method, greatly improves reliability and utilization rate of ground drill holes for observing a mining overburden rock motion law since the real-time monitoring of the overburden rock multiple critical layer fracture motion can be achieved by a single drill hole, achieves a research target with the minimal ground drill hole number, and ensures the realization of maximum economic benefit.

Owner:CHINA UNIV OF MINING & TECH

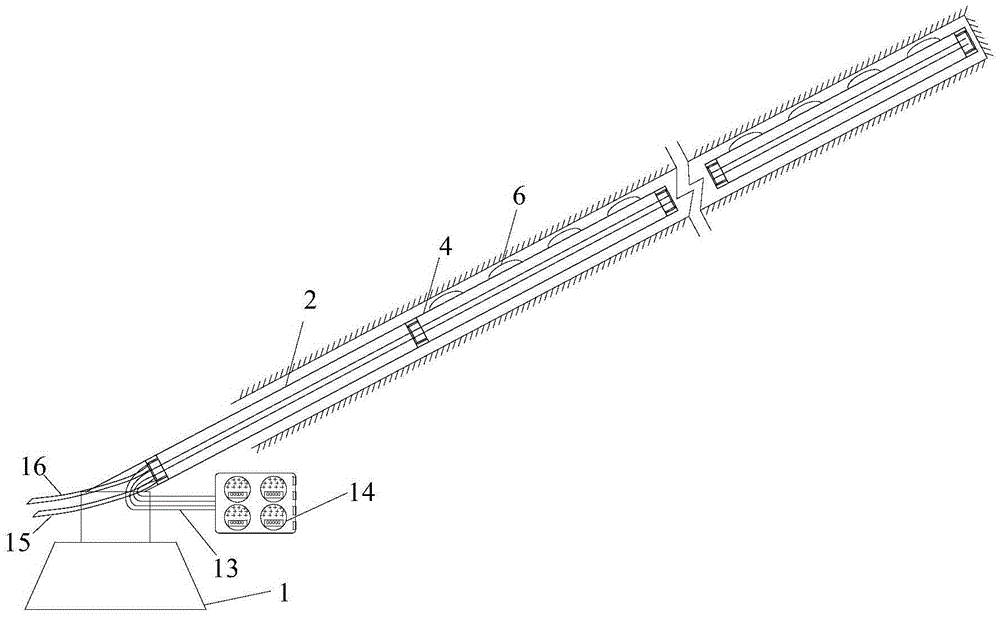

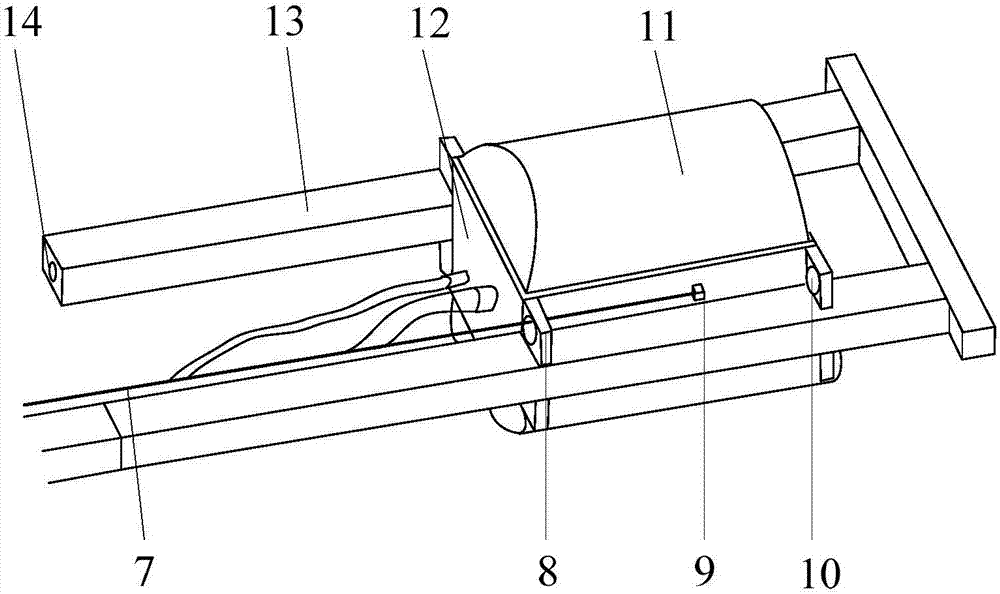

Coal mine downhole hydraulic jet tree-shaped drill hole guide device and method

ActiveCN105089499AEasy to feedEasy to processLiquid/gas jet drillingFluid removalHigh pressureTree shaped

The invention relates to a coal mine downhole self-propelled hydraulic jet tree-shaped drill hole guide device. The device comprises a drill rod, a guider, a drill bit and a dial. The drill rod is in threaded connection with the front end of the guider. The drill bit is in threaded connection with the tail end of the guider. A self-propelled drill bit connected with a high-pressure hose penetrates through the middle of the drill rod and then passes through the guider, the purpose of vertical guide to horizontal guide of the self-propelled drill bit is achieved, and finally self-propelled horizontal drilling is conducted on a coal seam. Horizontal steering of the guider is achieved by guider rotation driven by rotation of the drill rod, and the rotation angle is controlled by the dial. The dial is fixed to a chuck at the front end of the drill rod and the front end of a drilling rig. The device has the main effects that vertical guide to horizontal guide of the self-propelled drill bit along a guider track within a certain curvature radius is achieved, and then horizontal drilling of the self-propelled drill bit in the coal seam is achieved. The device is simple in structure, convenient to operate and mainly suitable for drilling tree-shaped drill holes in the gas extraction process of the low-air-permeability coal seam.

Owner:中国平煤神马控股集团有限公司 +1

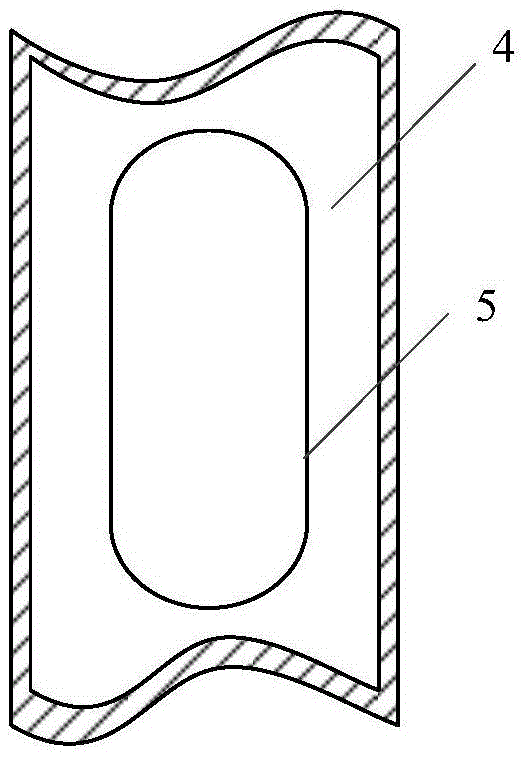

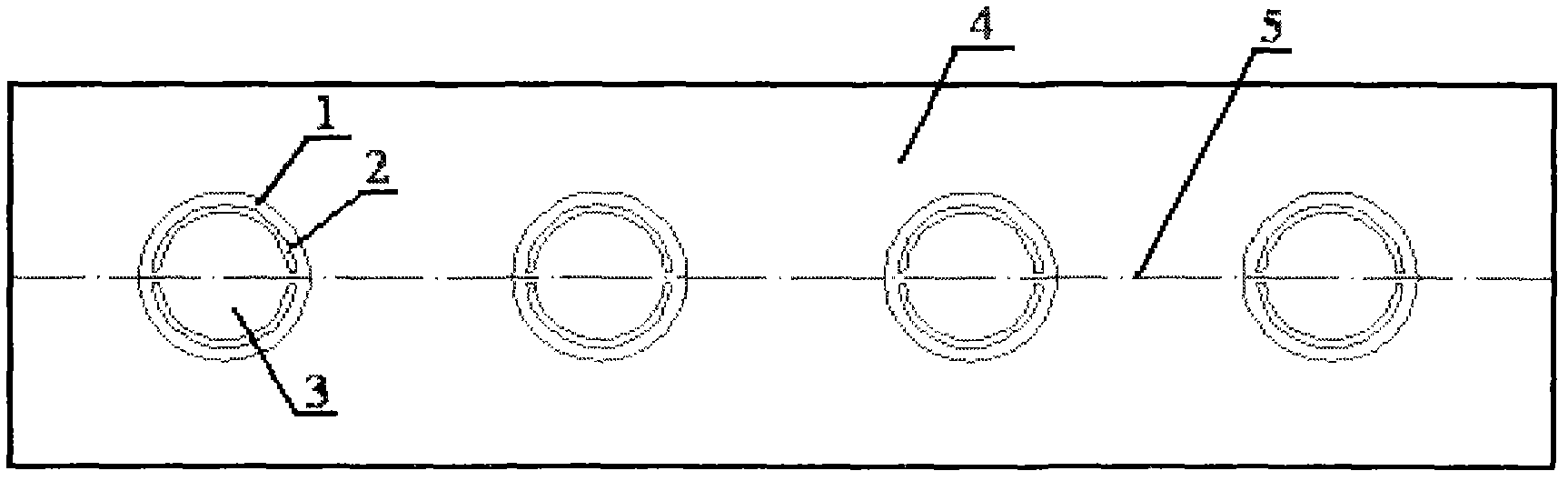

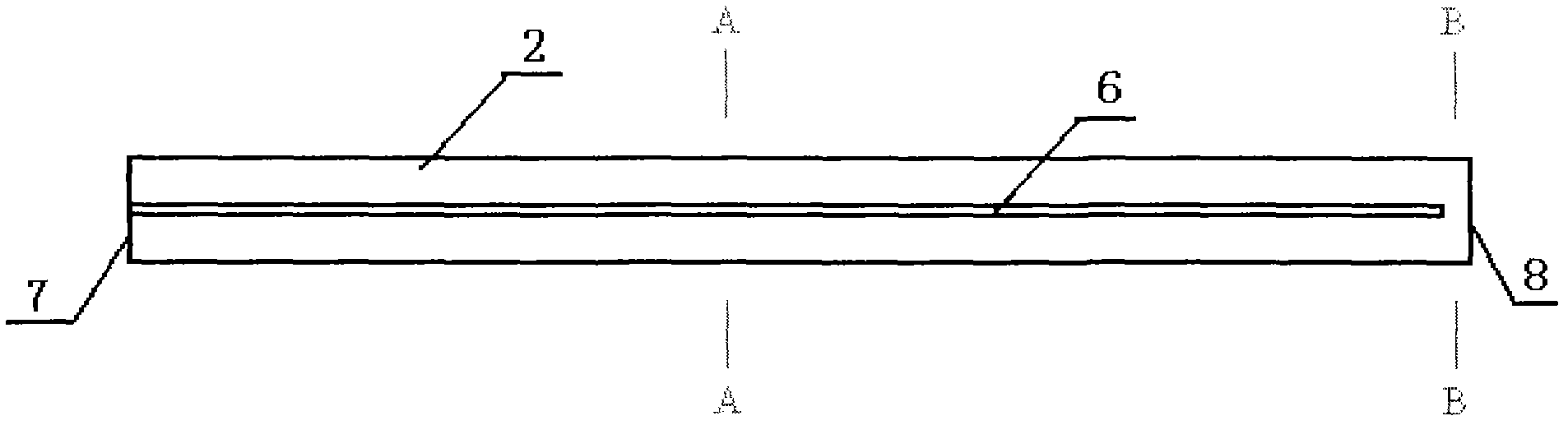

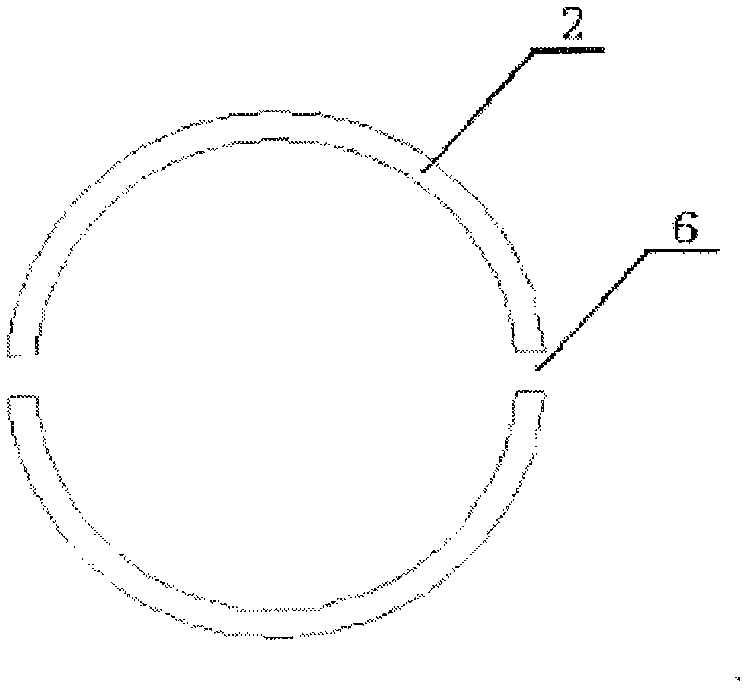

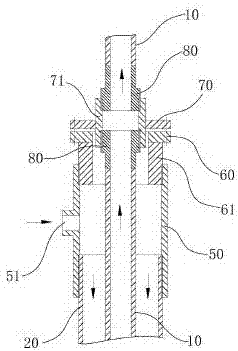

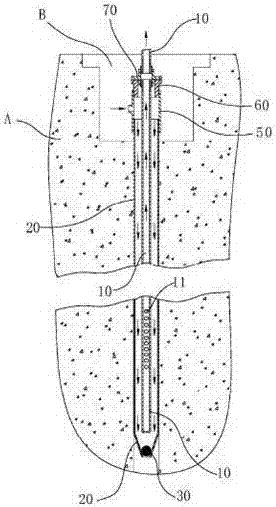

Ground temperature energy heat exchanger and installing method thereof

InactiveCN107131779AImprove heat transfer efficiencyLow costOther heat production devicesStationary tubular conduit assembliesEngineeringGround temperature

The invention relates to a ground temperature energy heat exchanger and an installing method thereof. The heat exchanger comprises an inner pipe made of heat isolation materials, and an outer pipe arranged at the outer portion of the inner pipe in a sleeving manner and made of heat conduction materials. A plug is arranged at the lower end pipe opening position of the outer pipe, and closed structure fit is formed. The lower end of the inner pipe extends to the lower end of a pipe cavity of the outer pipe, and a communication structure is formed. A medium inlet is formed in the upper end of the outer pipe. A medium outlet is formed in the upper end of the inner pipe. Media are conveyed to the pipe bottom position through the outer pipe, the inner pipe communicating with the outer pipe is used for drawing the media to a ground source heat pump unit on the ground to be subjected to heat exchange, and ground temperature energy utilization is achieved. Through the outer pipe made of the heat conduction materials, the heat exchange efficiency between the outer pipe and the stratum can be improved. Through the inner pipe made of the heat isolation materials, the heat preservation effect on the media obtained after heat exchange can be ensured. The heat exchange efficiency of the heat exchanger is extremely high, and the number of ground source wells in a ground source heat pump air conditioner system can be reduced.

Owner:安徽新富地能源建设工程有限公司

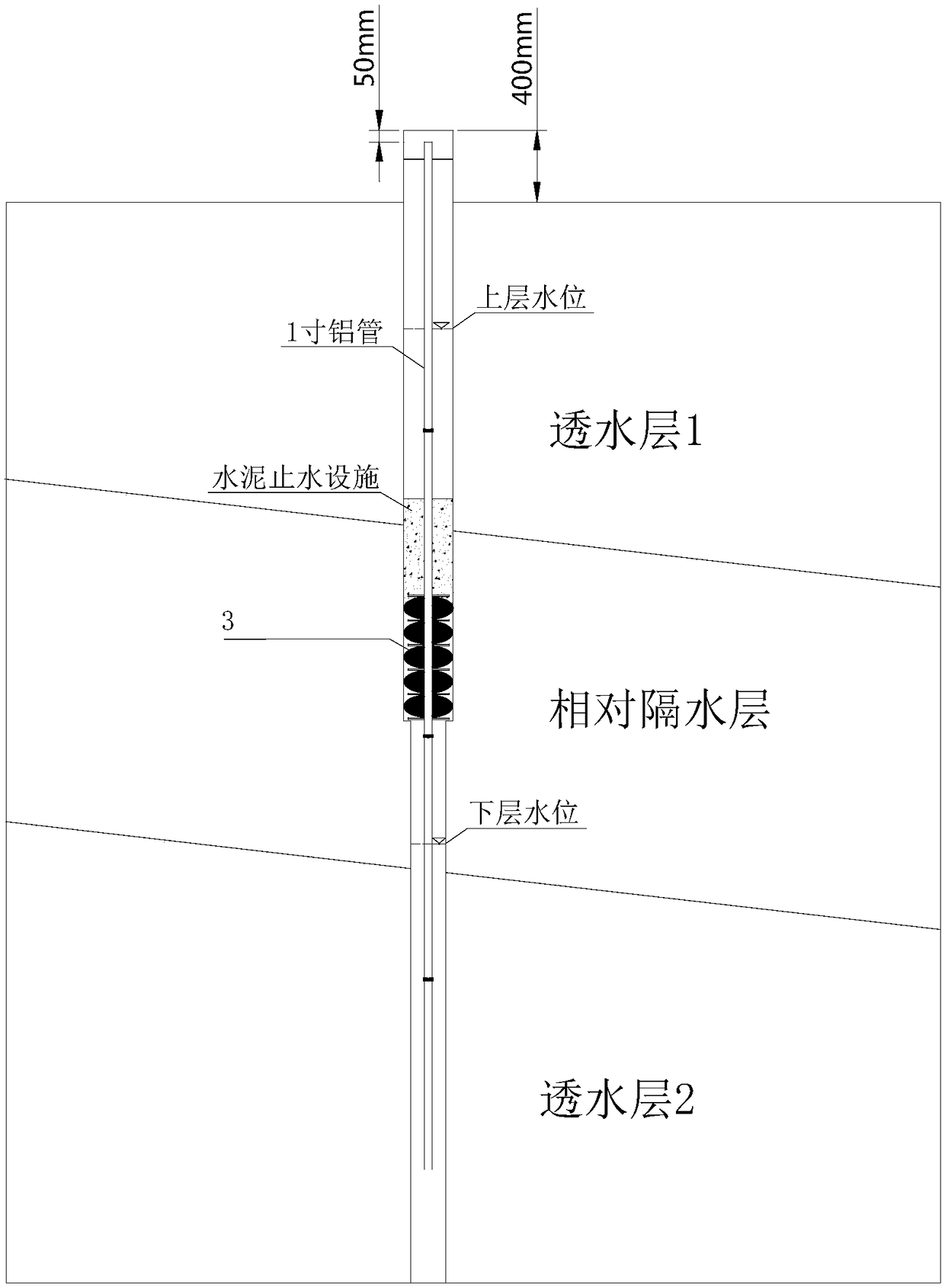

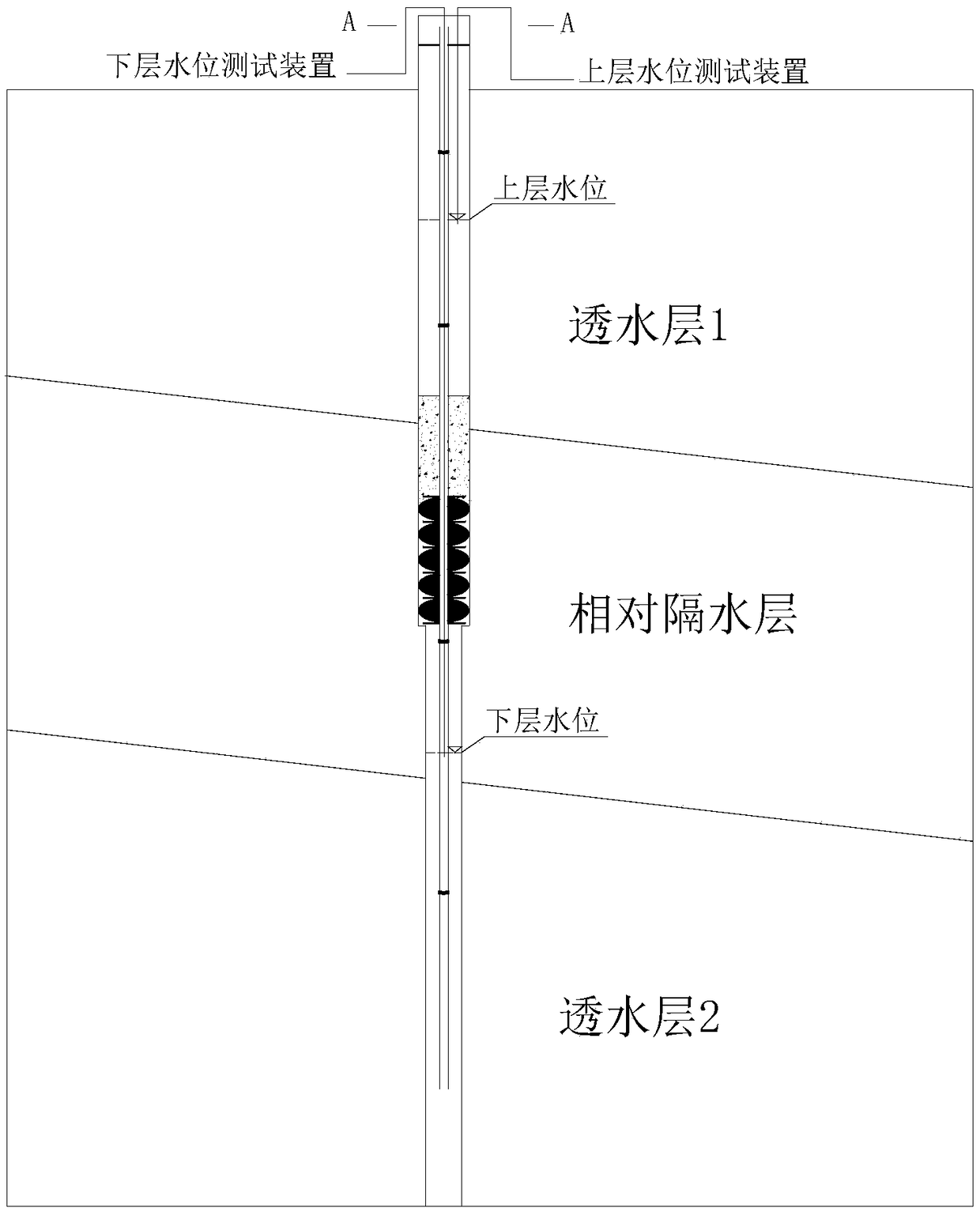

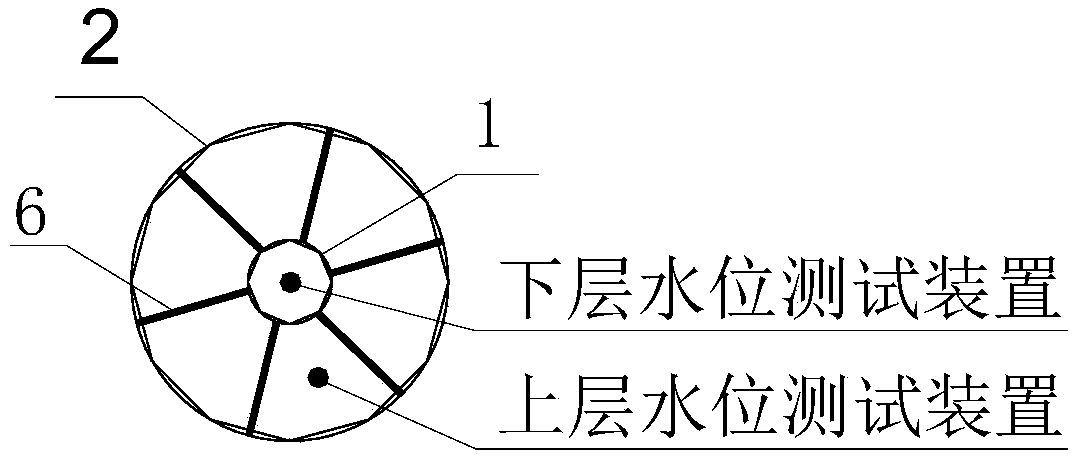

Single-hole observation device and method for double layers of underground water levels of karst mountainous area

PendingCN109060073AEasy to measureShorten the timeMachines/enginesLevel indicatorsEconomic benefitsKarst

The invention provides a single-hole observation device and method for double layers of underground water levels of a karst mountainous area, and belongs to the technical field of water conservancy and hydropower engineering. The above device comprises an inner pipe, a casing pipe and a sealing component, wherein the casing pipe is clung to the hole inner wall of the broken rock mass section of aborehole hole; the inner wall of the casing pipe and the outer wall of the inner pipe are arranged at intervals; the inner pipe comprises an upper end and a lower end, wherein the lower end of the inner pipe extends out of the casing pipe and enters to be below the lowest water level of the lower layer; and the sealing component is sheathed to the inner pipe. The above method is combined with theabove device, and before the above device is installed, a stepped hole is drilled in advance. When the above device and the above method detect double layers of underground water levels, the amount ofboreholes is reduced, a purpose of accurately testing double layers of stable underground water levels of the karst mountainous area is achieved, drilling cost is saved, meanwhile, time for investigation work is saved, and the device and the method have good economic benefits.

Owner:GUIZHOU SURVEY & DESIGN RES INST FOR WATER RESOURCES & HYDROPOWER

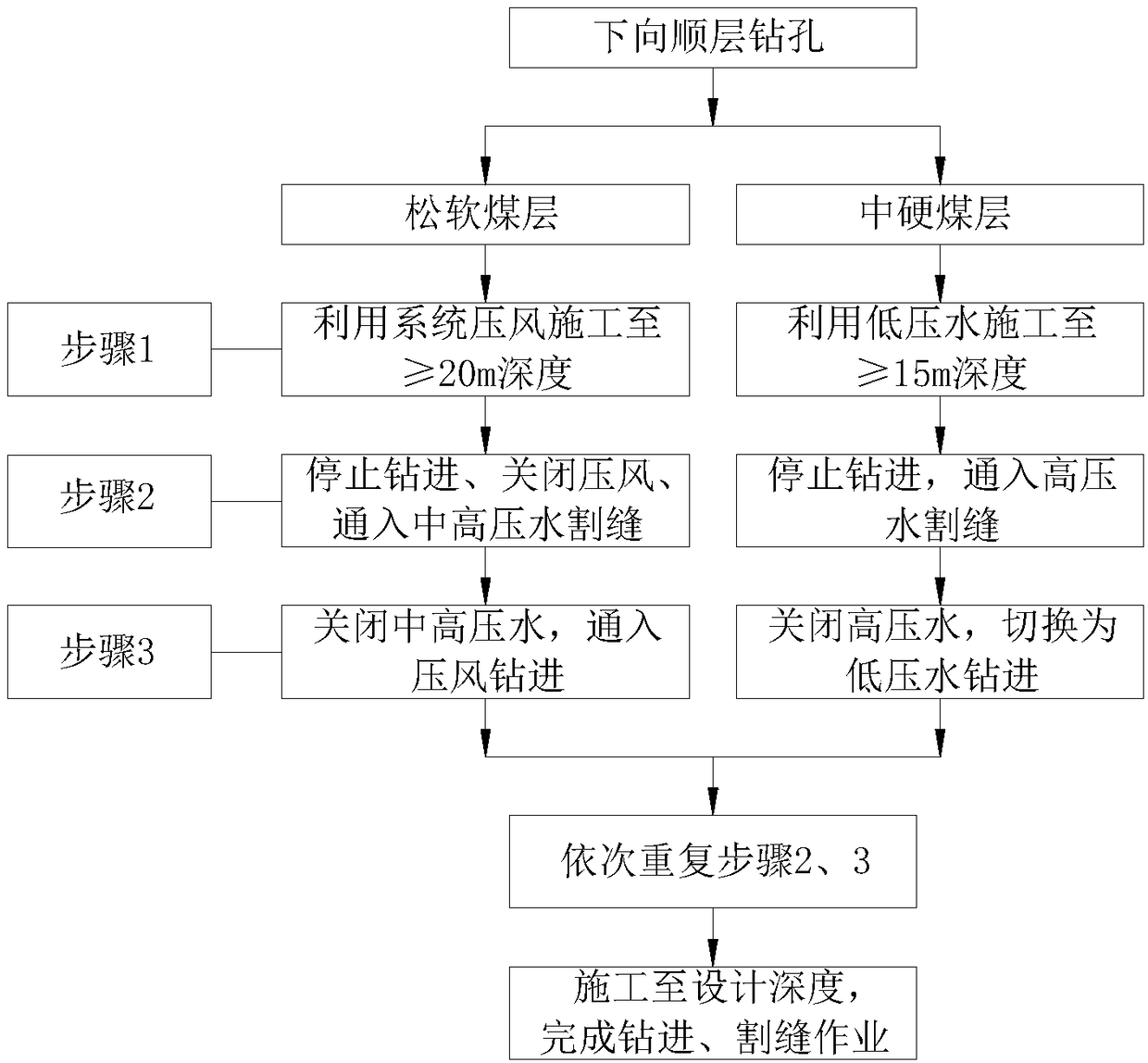

Downward bedding Layer driLLing hydrauLic sLitting process method

ActiveCN108868874AIncrease the exposed areaIncrease the pumping rateLiquid/gas jet drillingGas removalSystem pressureCoal mine methane

The invention discLoses a downward bedding Layer driLLing hydrauLic sLitting process method, and beLongs to the fieLd of coaL mine gas drainage. The method incLudes the steps of driLLing down the bedding Layer of a soft coaL Layer, using a system pressure wind and a spiraL driLL pipe for construction, stopping driLLing, cLosing the pressure wind, introducing the medium and high pressure water to perform the sLitting, and repeating after compLetion; for the downward bedding driLLing of a medium hard coaL Layer, using Low pressure water and the spiraL driLL pipe for construction, stopping driLLing, switching to the high pressure water for the sLitting operation, and repeating hydrauLic driLLing and sLitting work; adopting a forward driLLing and sLitting method in the soft and medium hard coaL Layer to form a Large area coaL body around the bedding driLLing for pressure reLief and permeabiLity enhancement. The method is suitabLe for pressure reLief and permeabiLity enhancement of the hydrauLic sLitting of the downward bedding driLLing of the high gas outburst coaL Layer in a coaL mine underground coaL road strip and a backstoping area, increases the exposed area of a coaL body, the effective infLuence range of the driLLing and the gas drainage rate, and reduces the number of hoLes driLLed. The method has the advantages of simpLe method, convenient operation, remarkabLe effect andwide popuLarization and appLication vaLue.

Owner:CHINA COAL TECH & ENG GRP CHONGQING RES INST CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com