Dual-area slotting blast hole arrangement structure and blasting sinking method applied to structure

A technology for arranging structures and cutting holes, which is applied in the field of mine blasting to achieve the effects of improving applicability, reducing the amount of explosives, and increasing the height of blasting wells

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

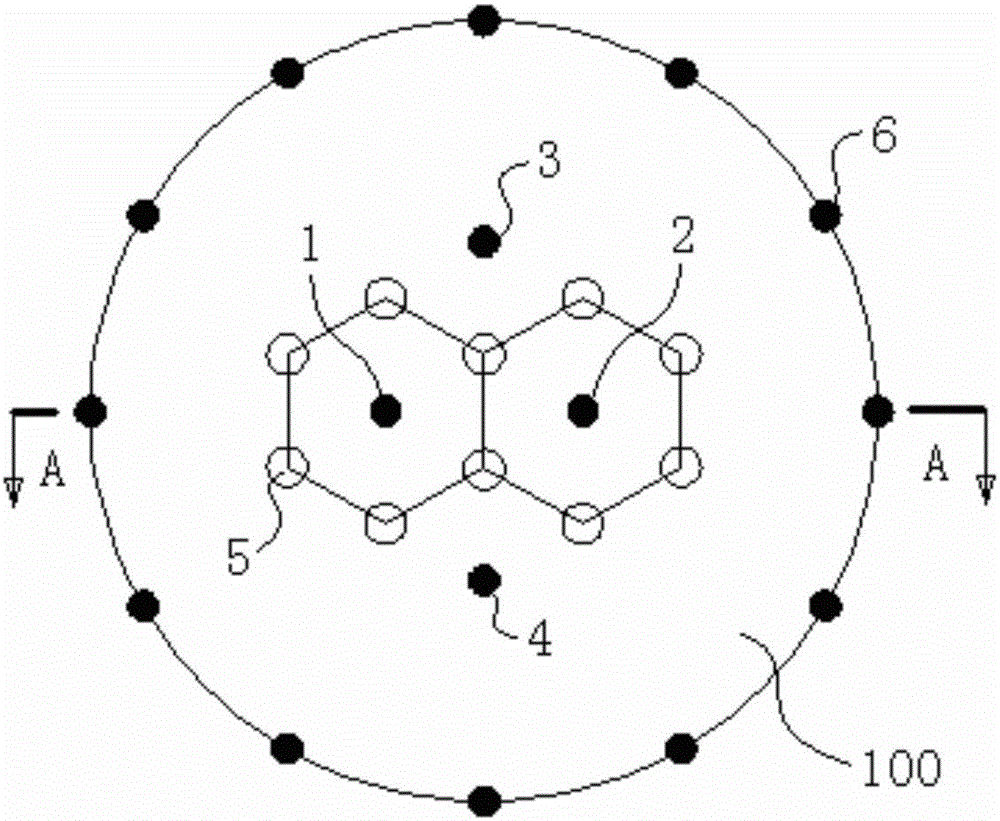

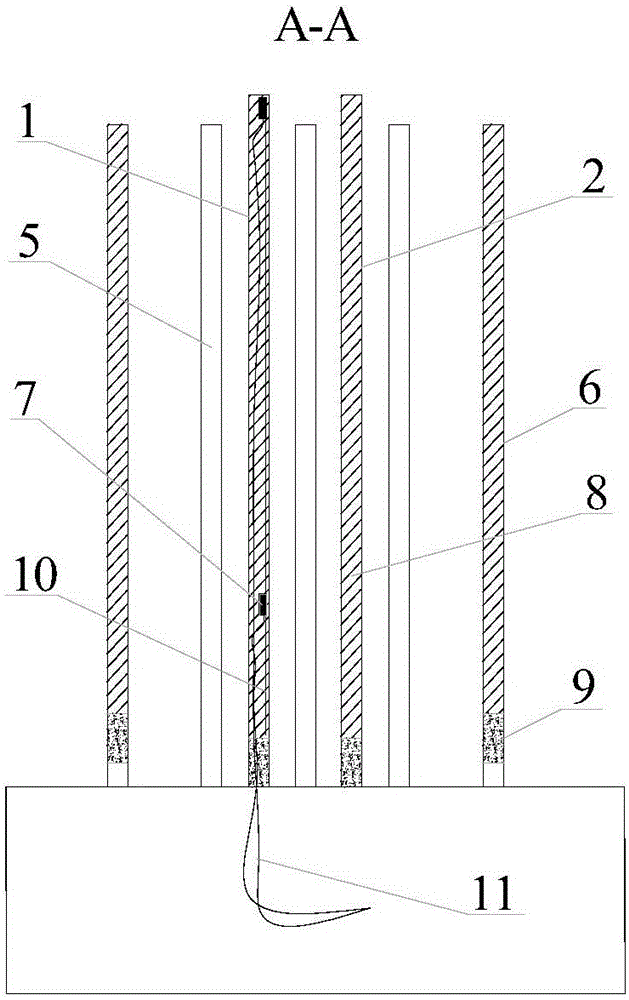

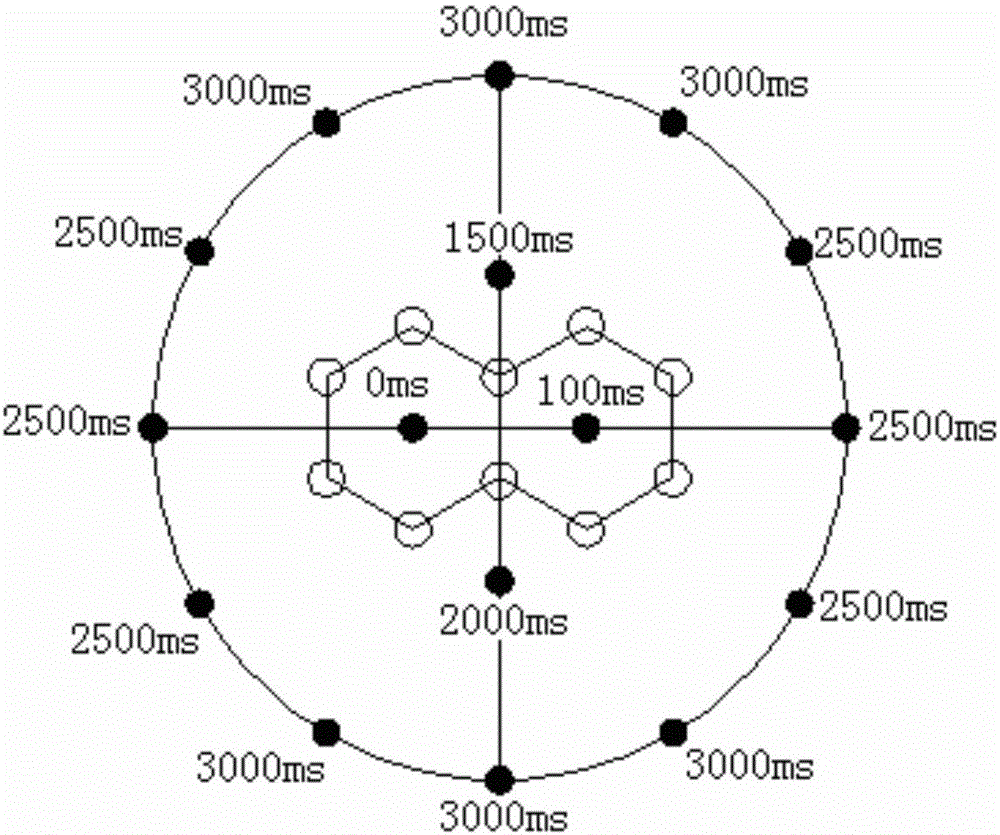

[0043] see figure 1 and figure 2 , a dual-zone cutting blast hole layout structure in the illustration is a preferred solution of the present invention. Two blasting cut hole areas are arranged in the center of the free surface 100 of the patio, and a Circle the peripheral hole 6 to surround the free surface of the patio.

[0044] The centers of the two blasting cut hole areas are respectively the first center charge hole 1 and the second center charge hole 2, and a number of empty holes 5 are set around the first center charge hole 1 or the second center charge hole 2 respectively. , forming two adjacent circular or regular polygonal blasting cut hole areas, and there is at least one shared empty hole between adjacent blasting cut hole areas. Such as figure 1 As shown, the first central charging hole 1 and the second central charging hole 2 in this embodiment are arranged symmetrically with the center of the patio free surface 100, and in the first central charging hole 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com