Patents

Literature

953results about How to "Reduce unit consumption" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

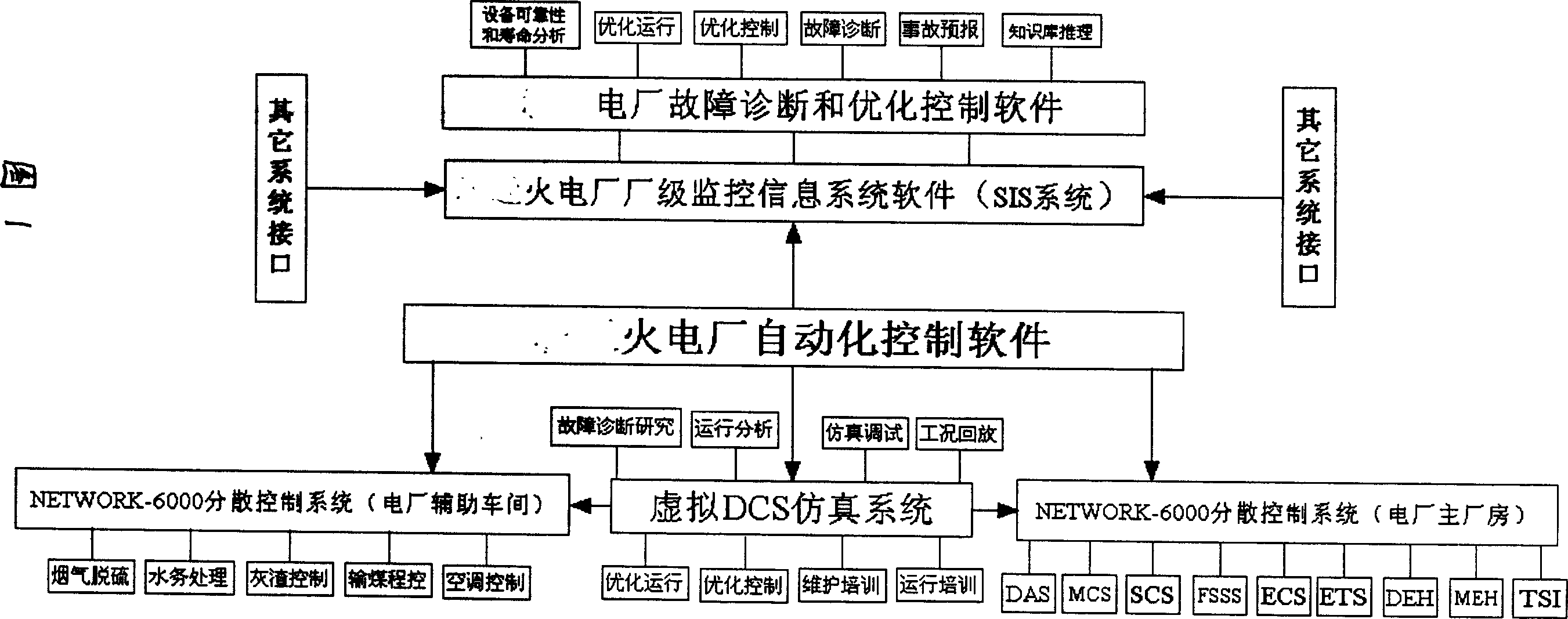

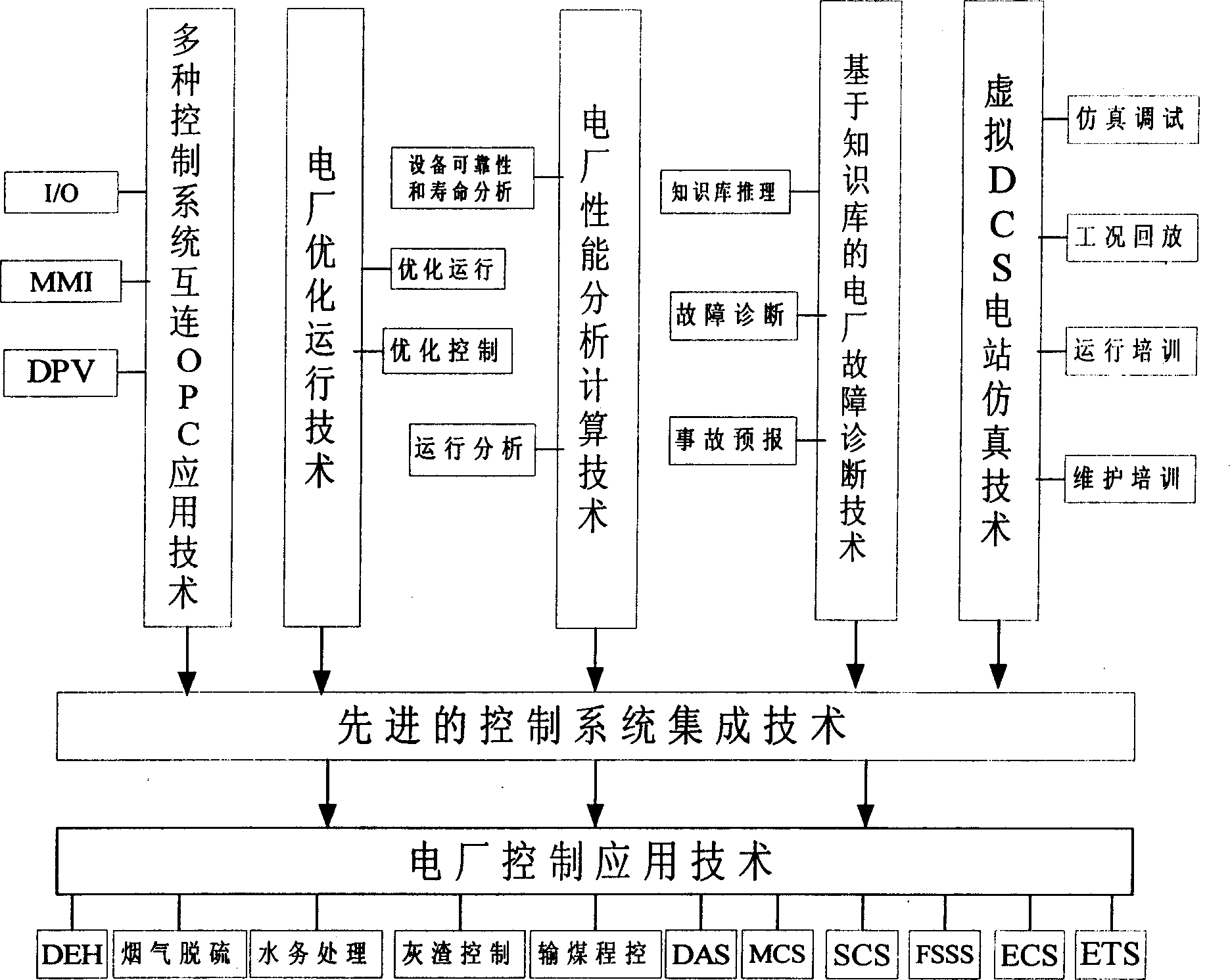

Automatic control system based on artificial intelligence for heat-engine plant

ActiveCN1694025ATake into account maturityGuaranteed growthComputer controlEnergy industryAutomatic controlPower station

The invention discloses a thermoelectric power station automatic control system based on artificial intelligence. It includes dispersible control system, virtual DCS simulation system, program controlling system, monitoring information system and malfunction diagnosing and optimizing controlling system; the dispersible control system is connected with the virtual DCS simulation system and program controlling system; the program controlling system process the operating parameters of every machine group transmitted by dispersible control system, and at the same time transmits data to monitoring information system to display, then transmits malfunction diagnosing and optimizing controlling system to have equipment state monitoring, malfunction diagnosing and forewarns. The invention gathers automatic control, optimizing operation, security monitoring and malfunction diagnosing and forecast. It can improves the automated management level of the thermoelectric power station operation, and enhances enterprises' benefit. It has great economic and applied value in the producing process automatic control of the thermoelectric power station.

Owner:南京科远智慧能源投资有限公司

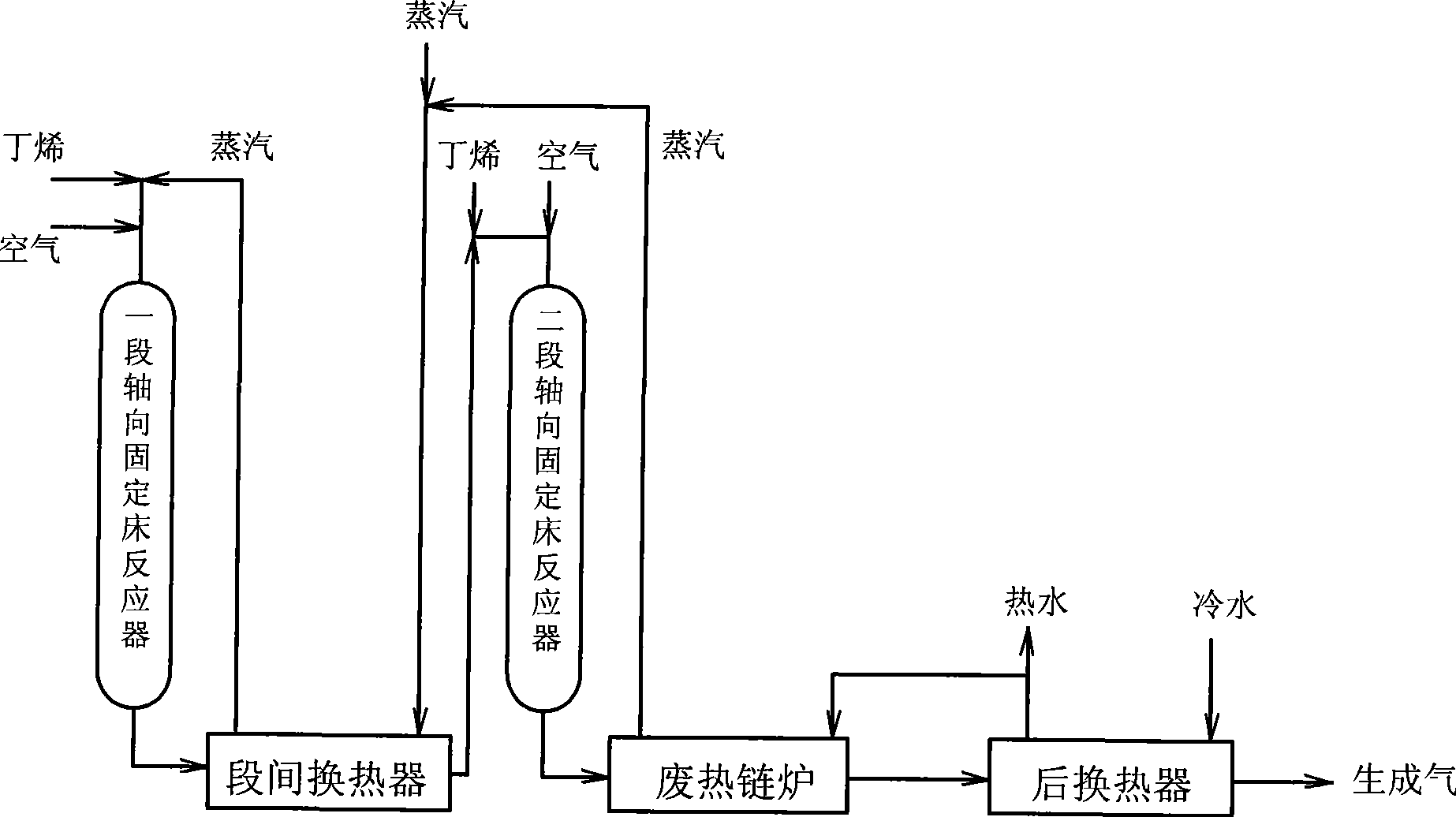

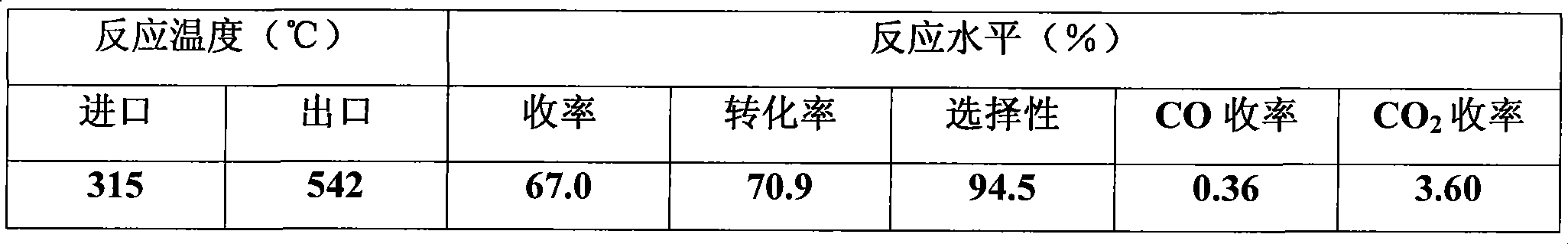

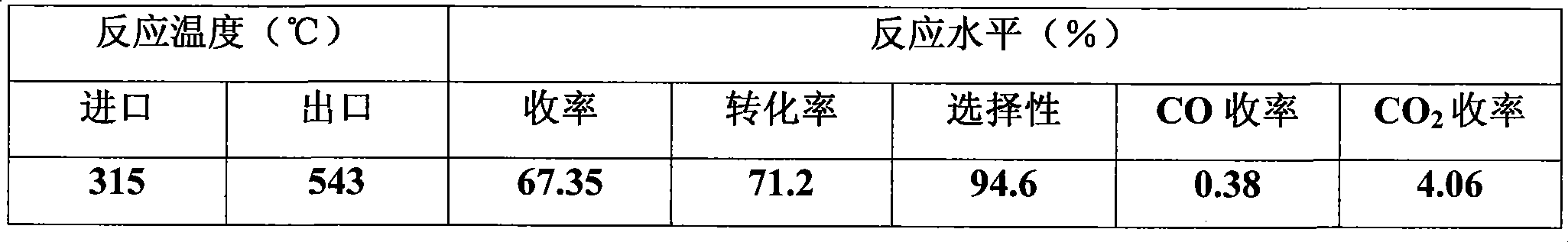

Method for preparing butadiene with butylene oxo-dehydrogenation of axially-located bed

ActiveCN101367702AIncrease productionReduce unit consumptionHydrocarbonsHydrocarbon preparationInlet temperatureFixed bed

The invention relates to a method of preparing butadience with a butylene oxydehydrogenation device in a fixed bed, which belongs to the chemical technical field. The butylene, air and water vapor give an oxydehydrogenation reaction in an axial fixed bed reactor and generate the butadience. The axial fixed bed reactor has two segments. Process equipment consists of a first segment of axial fixed bed reactor, an inter -segment heat exchanger, a second segment of axial fixed bed reactor, a waste heat boiler and a back heat exchanger in turn. The reactor is filled with iron-based catalyst. The ingredient of the water vapor of the first segment of reactor acts with the first segment via the inter-segment heat exchanger to generate gas in addition to exchanging heat and raising temperature and then is mixed with the ingredient butylene and the air of the first segment to achieve the inlet temperature of the first segment of reactor. The ingredient of the first segment enters to the first segment of reactor to react. After heat exchange and temperature reduction through the inter-segment heat exchanger, the gas generated in the first segment is mixed with the feed butylene of the second segment and the air to achieve the inlet temperature of the second segment of reactor and reacts in the second segment of reactor. The invention has the advantages of high yield coefficient, high selectivity and steam of low unit consumption. Heat energy can be used reasonably.

Owner:ZIBO QIXIANG TENGDA CHEM

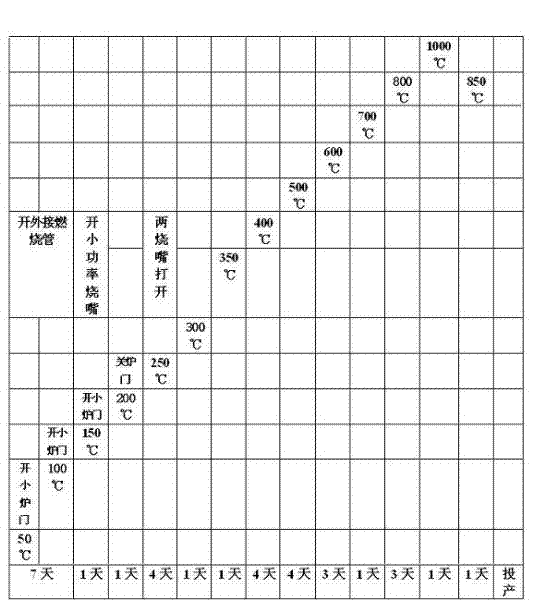

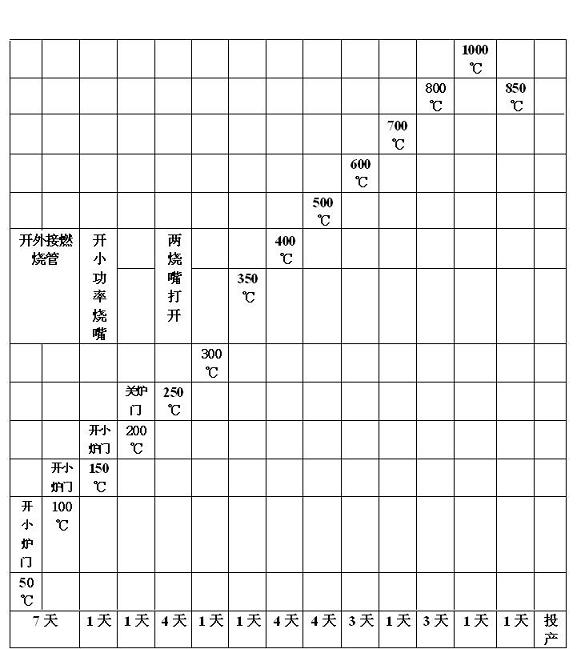

Production process for firing alumina foamed ceramic filter board in roller kiln

The invention relates to the field of the production of foamed ceramic filter boards, and aims to provide a production process for firing an alumina foamed ceramic filter board in a roller kiln. The process comprises the following steps of: weighing according to a formula, performing ball-milling and mixing uniformly to form slurry; cutting sponge, impregnating the sponge and sizing; drying, and guniting; and sintering in the lengthened roller kiln. According to the production process, the alumina foamed ceramic filter board is fired by utilizing the lengthened roller kiln, so the process is small in unit consumption, gas amount required by the roller kiln is little under the condition of producing the same quantity of the filter boards, the amount of discharged flue gas is also reduced greatly, and compared with the conventional technology, the production process has the advantages of energy conservation and environment friendliness; and the quality of the fired foamed ceramic filterboard is more stable.

Owner:HANGZHOU ZHONGYA NEW MATERIALS TECH

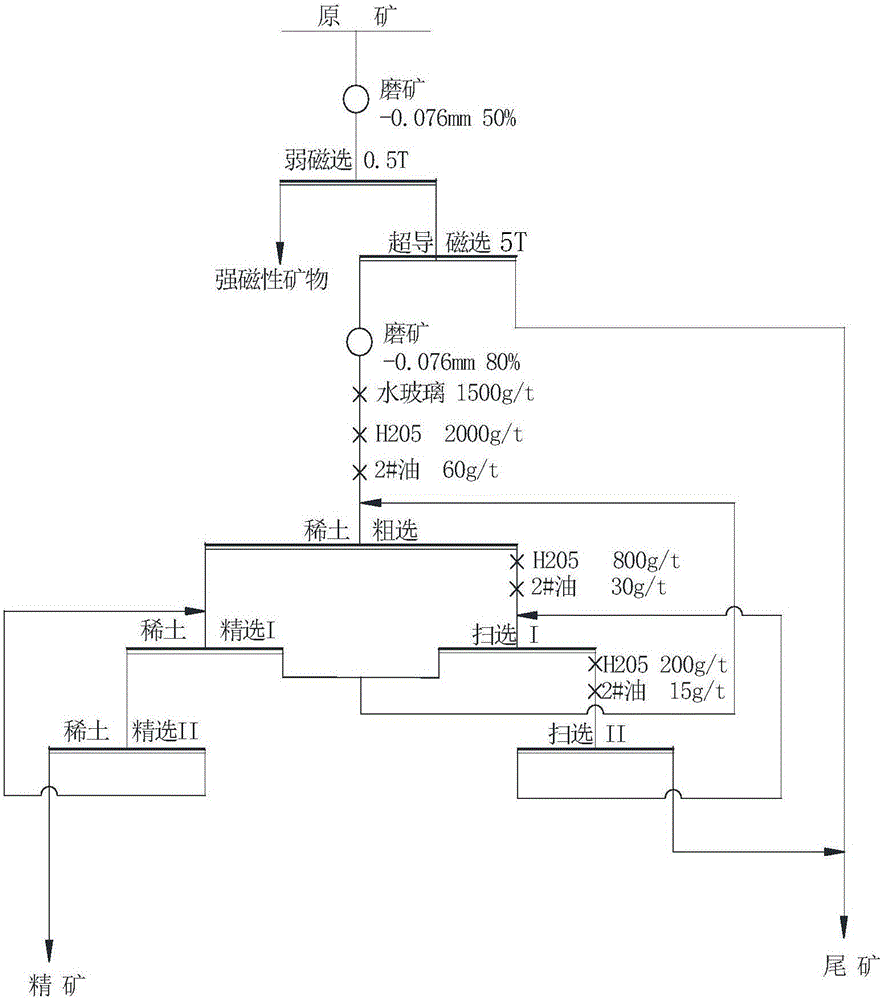

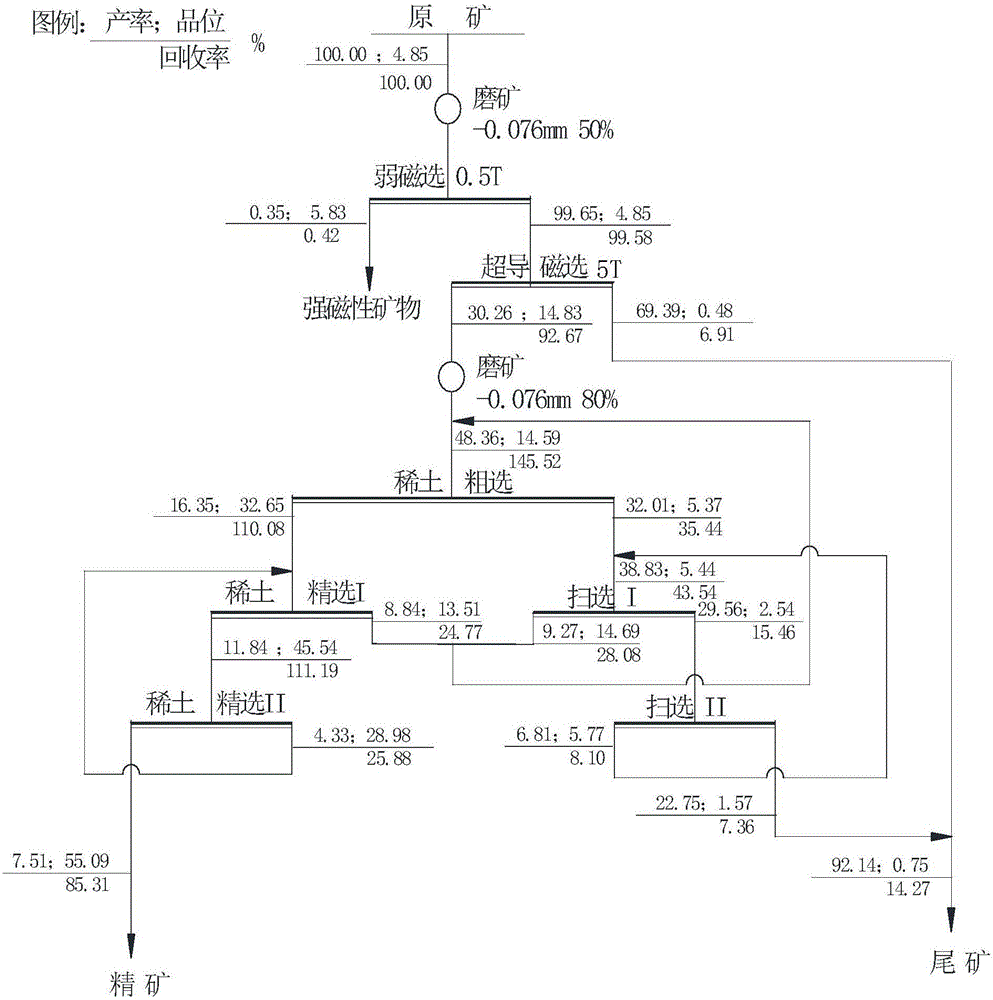

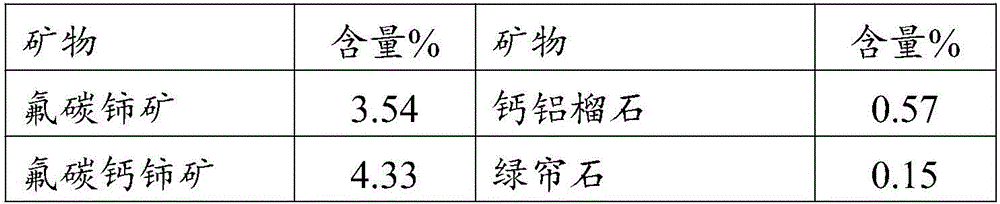

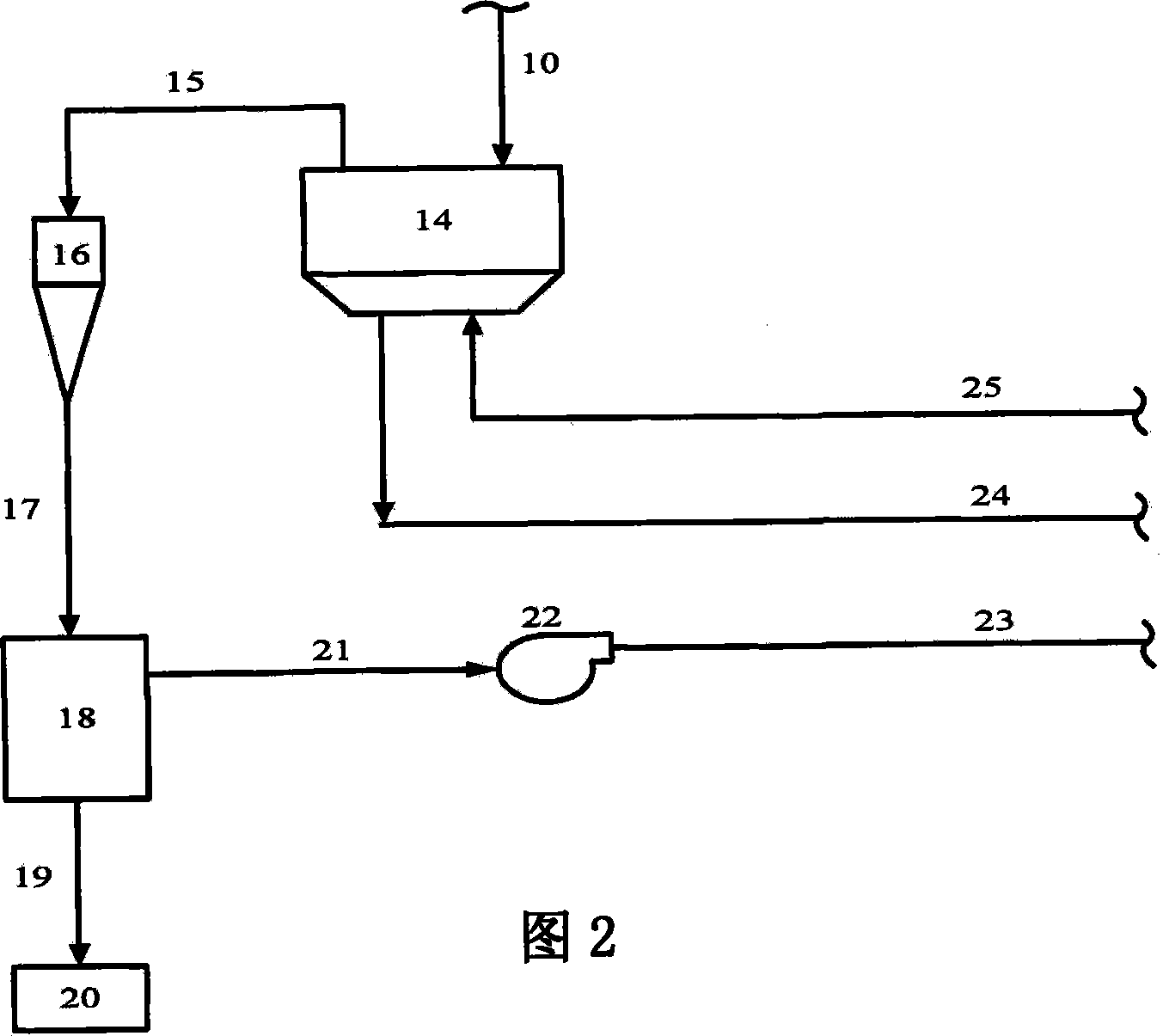

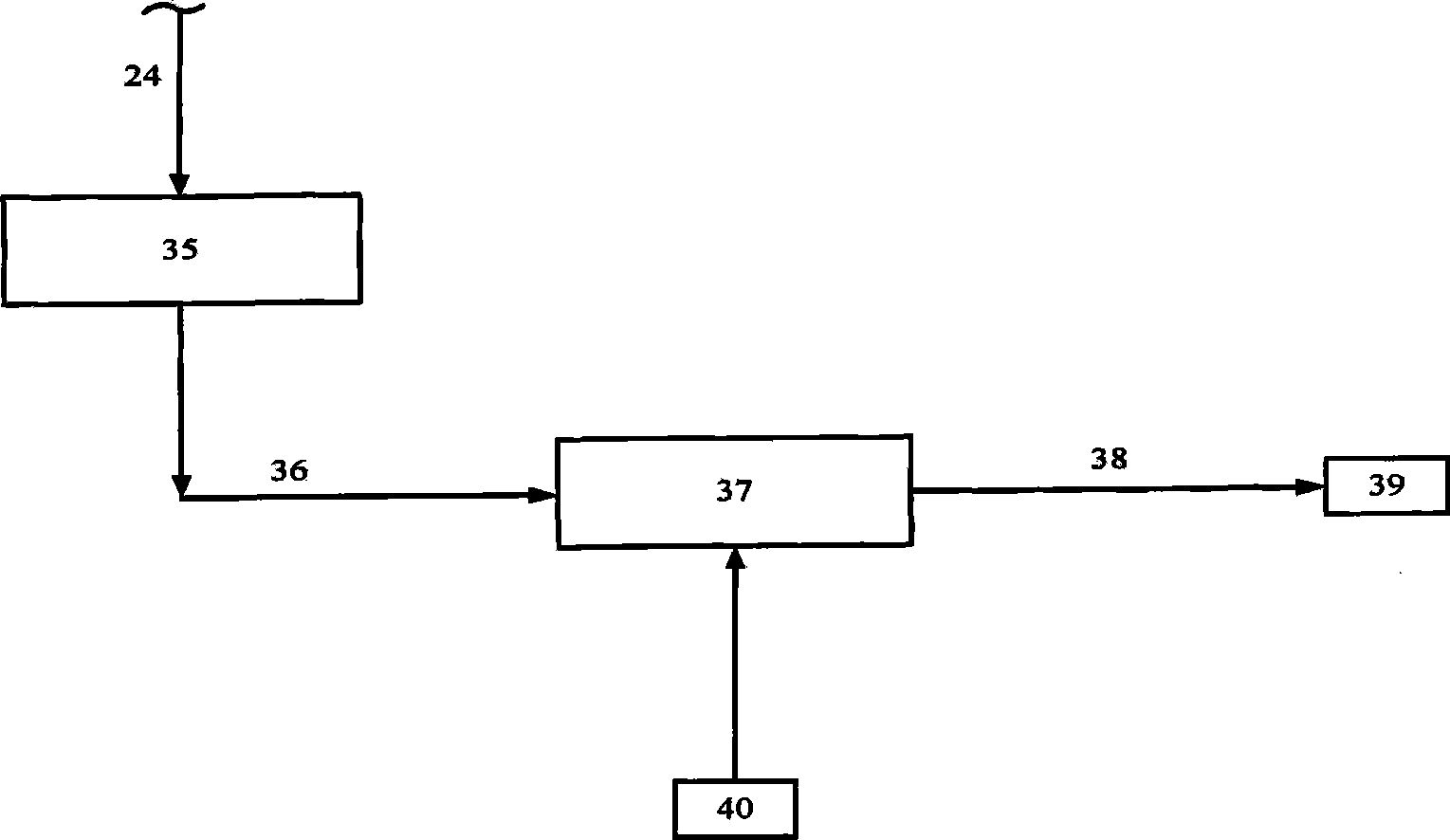

Beneficiation method of rare earth ore

ActiveCN106799300AReduce the amount requiredQuality assuranceWet separationRare earthUltimate tensile strength

The invention discloses a beneficiation method of rare earth ore. The beneficiation method comprises the steps that crude ore is subjected to crushing and ore grinding till the crude ore with the fineness being -0.076 mm accounting for 50% or above, low intensity magnetic separation is carried out to remove strongly magnetic minerals, then superconducting magnetic separation rougher flotation is carried out to obtain rare earth rough concentrates, the rare earth rough concentrates are ground till the rare earth rough concentrates with the fineness being -0.076 mm accounting for 80% or above, conventional flotation work is carried out, and final rare earth ore concentrates are obtained; conventional flotation work includes the processes of one-section rougher flotation, two-section concentration and two-section scavenging; according to low intensity magnetic separation, the magnetic field intensity ranges from 0.1 T to 0.5 T, and the magnetic field force is (3-15)*10<5>kA<2> / m<2>; and according to superconducting magnetic separation, the magnetic field intensity is larger than 0.5 T, and the magnetic field force is larger than 3*10<7>kA<2> / m<2>. According to the method, the high-grade rare earth rough concentrates can be obtained through superconducting magnetic separation, a large quantity of tailings can be thrown out, the grading efficiency is high, the two-section ball grinding ore feeding quantity is greatly reduced, grinding and selecting energy consumption is reduced, the rare earth grade of the obtained rare earth ore concentrates is improved, and the recovery rate is high.

Owner:江苏旌凯中科超导高技术有限公司

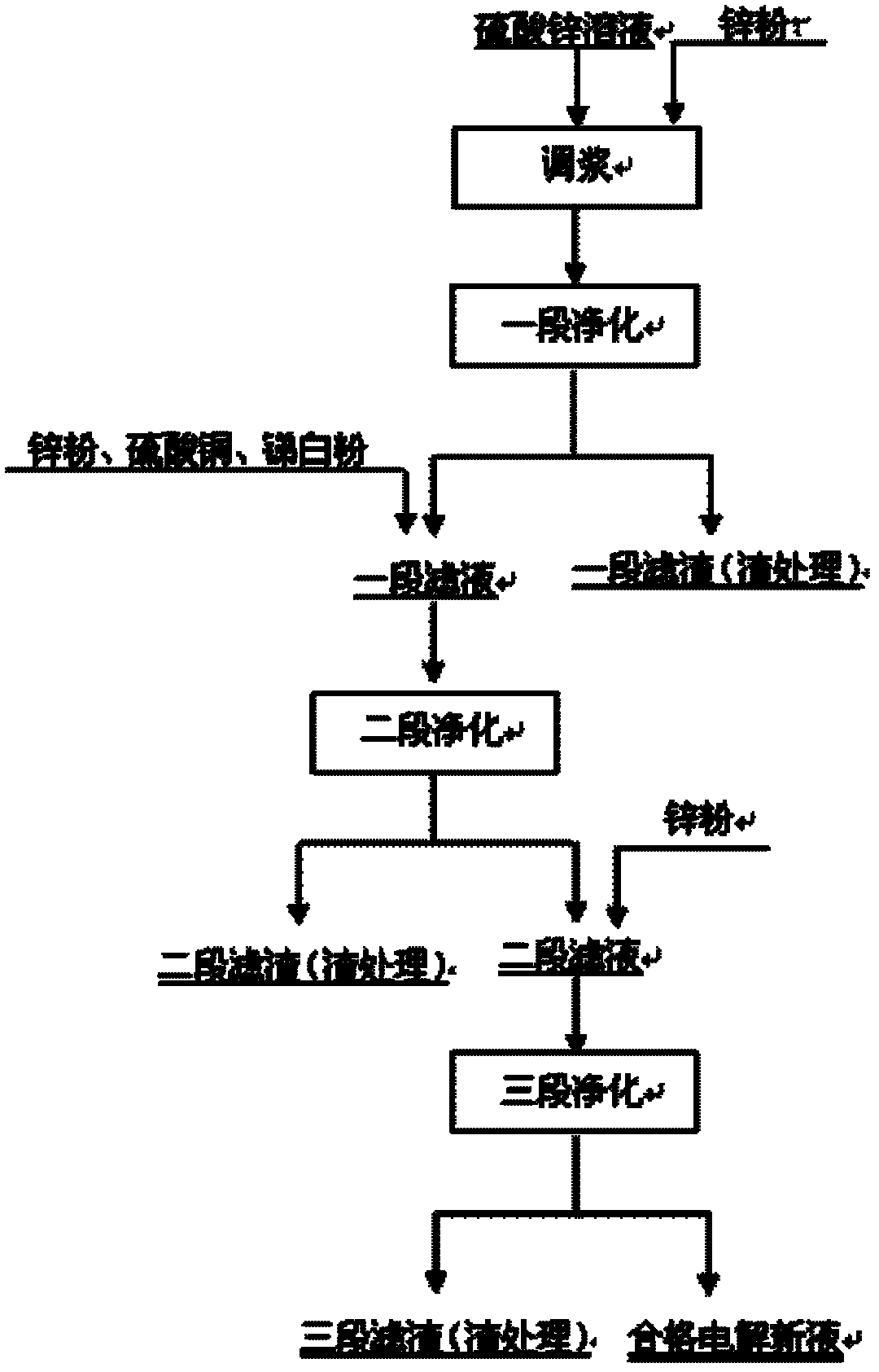

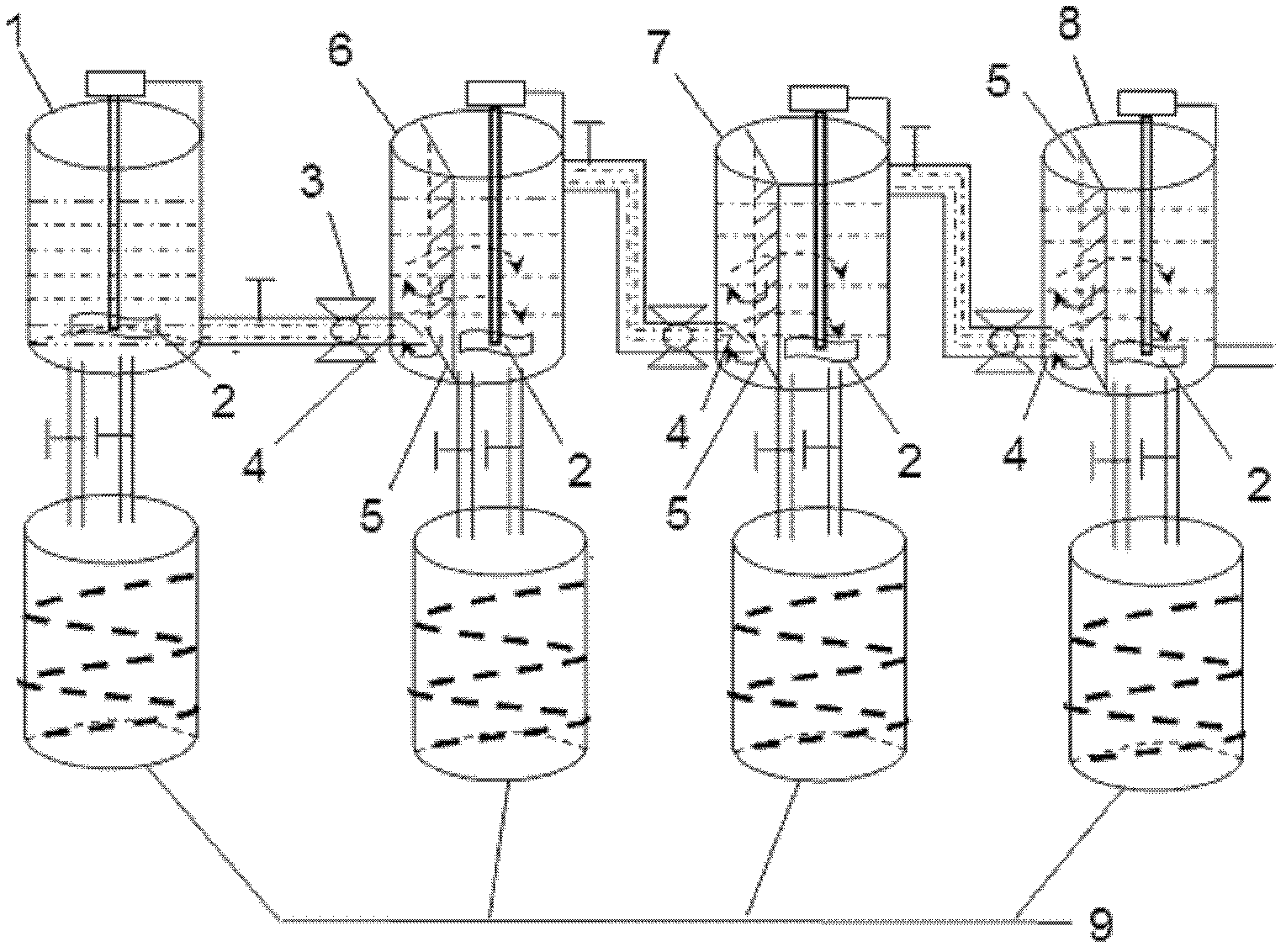

Method and device for purifying zinc sulfate solution based on action of cavitation effect

The invention relates to a method and a device for purifying a zinc sulfate solution based on action of a cavitation effect. The method comprises the following steps: adding zinc powder into a solution before purifying the zinc sulfate, and conveying the solution to a partition plate in a purifying container or forming cavitation effect bubbles through the periodic oscillation action of a vibration device for stripping impurities which are displaced out from the surface of the zinc powder, thereby keeping the reaction surface of the zinc powder exposed at any time, being capable of participating in displacement, purification and removal of the impurities and reducing the consumption amount of the zinc powder; and filtering the solution which passes through a 1-3 grade cavitation effect generation device for acting for 20-50 minutes, and obtaining filtrate which is a new qualified electrolysis solution and filter residue which is high-grade copper-cadmium slag or nickel-cobalt slag. When in purification and removal of cobalt and nickel, the zinc powder, copper sulfate and antimony white powder are further added into the purifying container, the energy consumption is low and the using quantity of the zinc powder is reduced from 100-200 times of the content in traditional displacement of the cobalt by using the zinc powder to 20-50 times of the content.

Owner:KUNMING METALLURGY INST

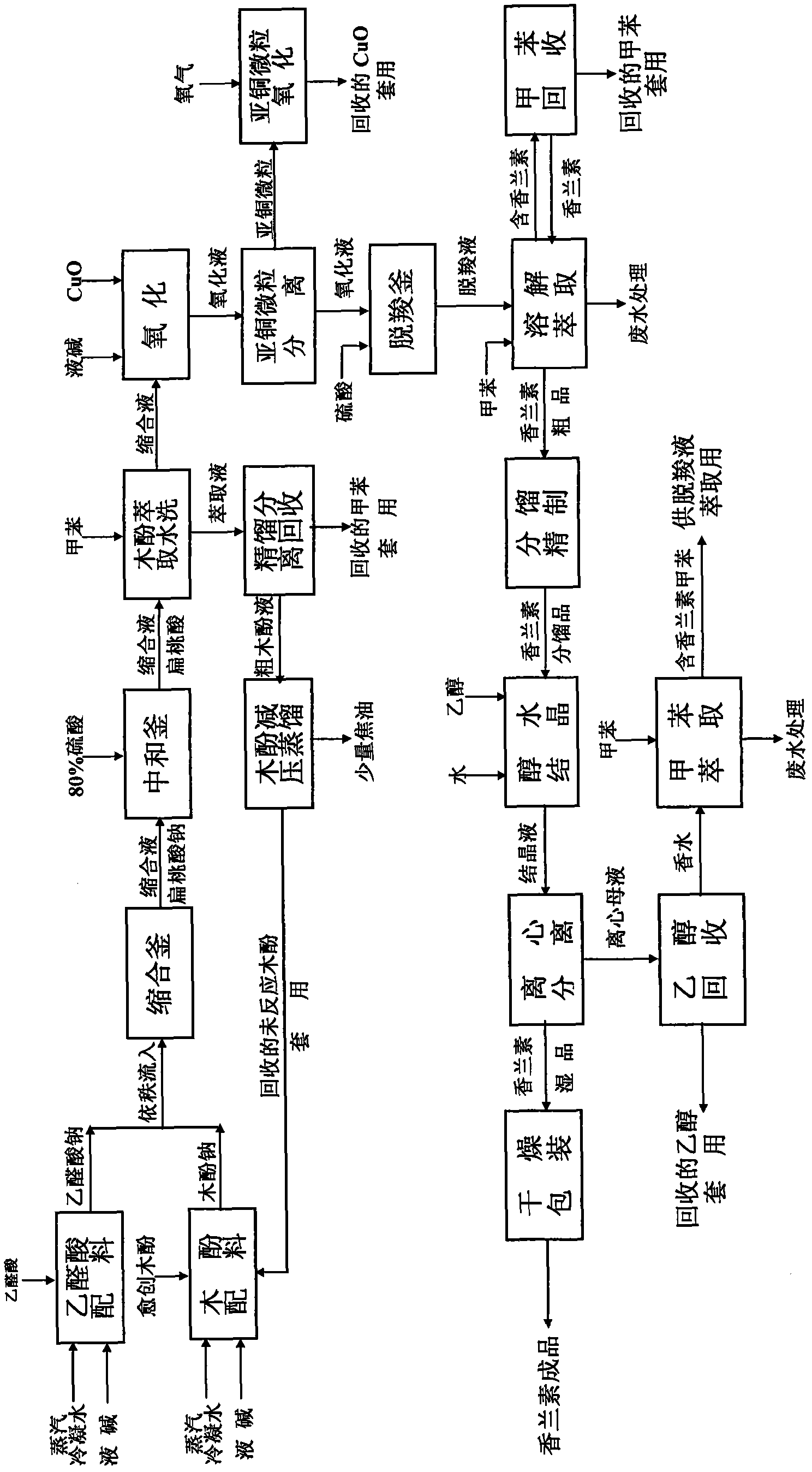

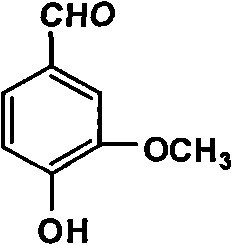

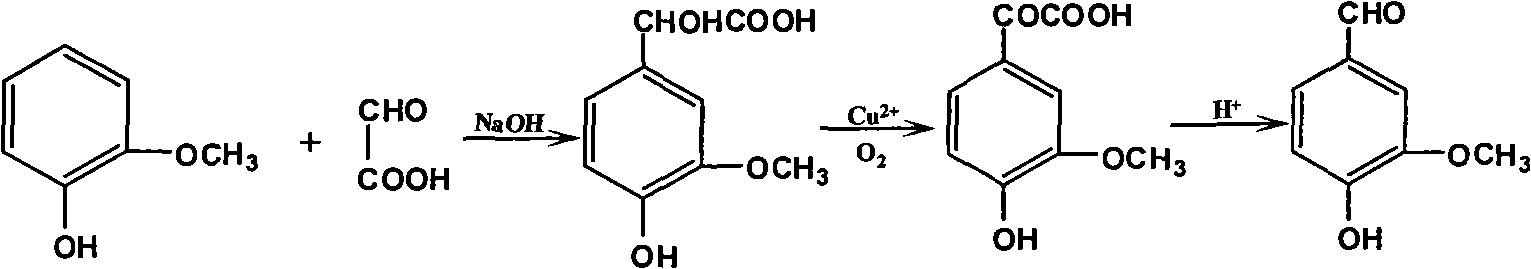

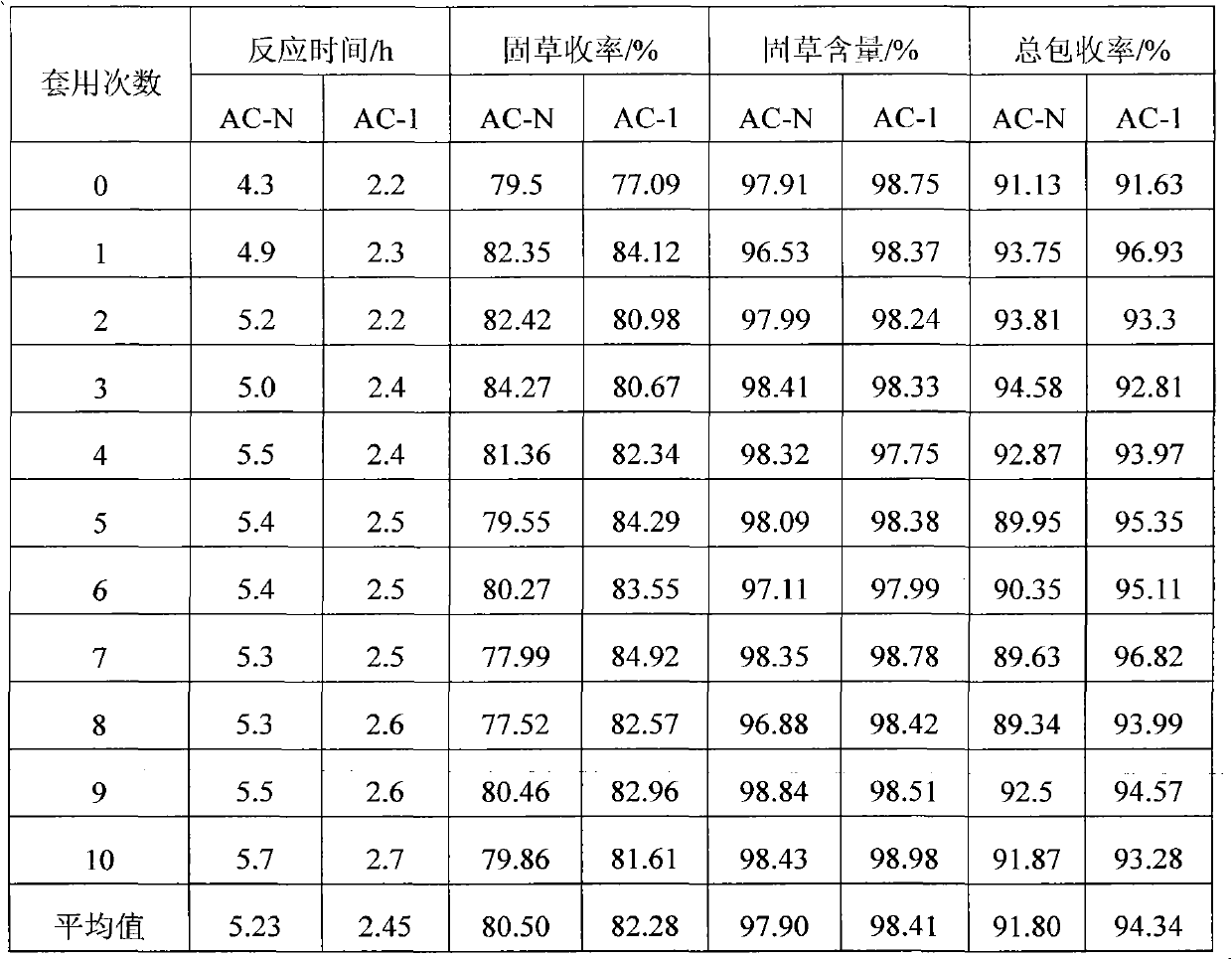

Productive technology of vanlillin by glyoxylic acid method

ActiveCN102010310AReduce organic contentReduce pollution sourcesOrganic compound preparationCarbonyl compound separation/purificationKetonic acidsFractionation

The invention discloses a productive technology of vanlillin by a glyoxylic acid method. The productive technology comprises a synthesis process, a fractionation process and a purification process, wherein the synthesis process comprises condensation treatment, oxidation treatment and decarboxylation treatment of methyl catechol and glyoxylic acid. The productive technology particularly comprisesthe following steps: respectively converting the methyl catechol and the glyoxylic acid into guaiacol sodium and sodium glyoxylate in a sodium hydroxide system; carrying out condensation treatment onthe guaiacol sodium and the sodium glyoxylate; after recovering the unreacted methyl catechol in a condensation liquid, carrying out oxidation treatment, namely carrying out catalytic oxidation on anethanol group in 4-hydroxy-3-methoxybenzene sodium glycolate by using copper oxide in the sodium hydroxide system to form a ketone group, thereby generating a corresponding ketonic acid compound; after separating red copper oxide particles from an oxidation liquid, carrying out decarboxylation treatment, namely using sulfuric acid to acidize the oxidation liquid, and simultaneously converting an acid group in the ketonic acid compound into carbon dioxide so as to generate 4-hydroxy-3- methoxybenzaldehyde; and carrying out the fractionation process and the purification process to obtain the vanlillin.

Owner:喜孚狮王龙香料(宁波)有限公司

Preparation method of 2,4-dichlorin phenoxyacetic acid

ActiveCN101062893AReduce the difficulty of operationReduce unit consumptionOrganic compound preparationCarboxylic compound preparationChlorophenolChemistry

The invention discloses a preparing method of weed killer 2, 4-dichlorobenzene oxide acetic acid, which comprises the following steps: (1) producing bi-chlorophenol sodium solution and sodium monochloracetate solution; (2) putting into bi-chlorophenol sodium solution in condensed still; heating to 90-110 deg. c; dropping sodium monochloracetate solution; reacting for 2-8h; connecting to oil-water separator in reacting period; refluxing; returning water phase to reactor; dividing out of oil phase; setting the mole ratio of bi-chlorophenol sodium and sodium monochloracetate at 1:0. 8-1. 2; disposing; getting the product. This invention possesses low cost, high receiving ratio and simple operation, which can realize self-control.

Owner:SHANDONG WEIFANG RAINBOW CHEM

Catalyst for tert-butyl alcohol cleavage reaction and preparation method thereof

ActiveCN103611572AIncreased intermolecular attractionNot easy to fall offOrganic-compounds/hydrides/coordination-complexes catalystsHydrocarbon from oxygen organic compoundsChlorinated polyvinyl chloridePolystyrene

The invention provides a catalyst for tert-butyl alcohol cleavage reaction, which is prepared by the following steps: by using a melt granulation process, blending and melting polystyrene, chlorinated polyvinyl chloride, polytrifluorochloroethylene and polyvinylidene fluoride, and granulating; and carrying out sulfonation reaction on the granulation product in the fixed bed and sulfur trioxide to obtain the catalyst. When being used for tert-butyl alcohol cleavage reaction, the catalyst has the advantages of high selectivity for technique reaction, fewer side reactions and low shedding tendency of sulfo-group under high-temperature conditions. The invention also provides a preparation method of the catalyst.

Owner:南通灵润医用新材料有限公司

Preparation method for nitrogen-containing activated carbon catalyst

ActiveCN102553641AExcellent application lifeReduce unit consumptionOrganic-compounds/hydrides/coordination-complexes catalystsActivated carbonNitrogen

The invention discloses a preparation method for a nitrogen-containing activated carbon catalyst. The method comprises the following steps of: 1) pre-treating a carbonized material; 2) introducing a nitrogen-containing reagent, wherein the nitrogen-containing reagent is selected from carbamide, melamine or phenylamine, and the adding molar ratio of the carbonized material to the nitrogen-containing reagent is 1:(0.1 to 10); 3) activating in one step; and 4) refining. Compared with the traditional nitrogen-containing activated carbon catalyst, the catalyst prepared by the method has the advantages of high activity, long service life, high yield of reaction product, i.e., glyphosate when the catalyst is applied to the oxidization of N-phosphonomethyl aminodiacetic acid, and the like. The preparation method has the advantages of low pollution, safe and controllable process, short high-temperature activation period, low energy consumption, simple process, low cost and the like.

Owner:中国中化股份有限公司 +2

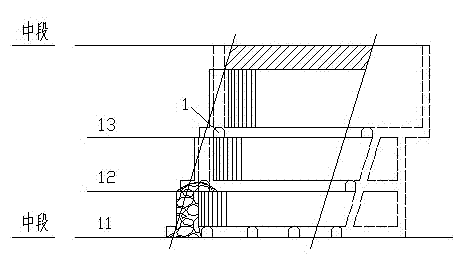

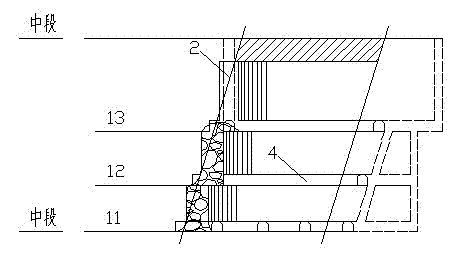

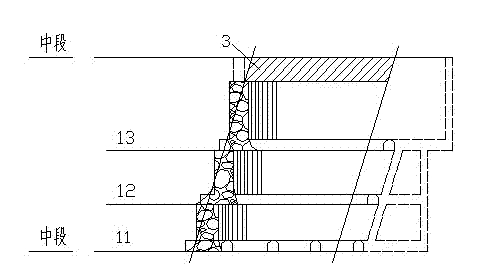

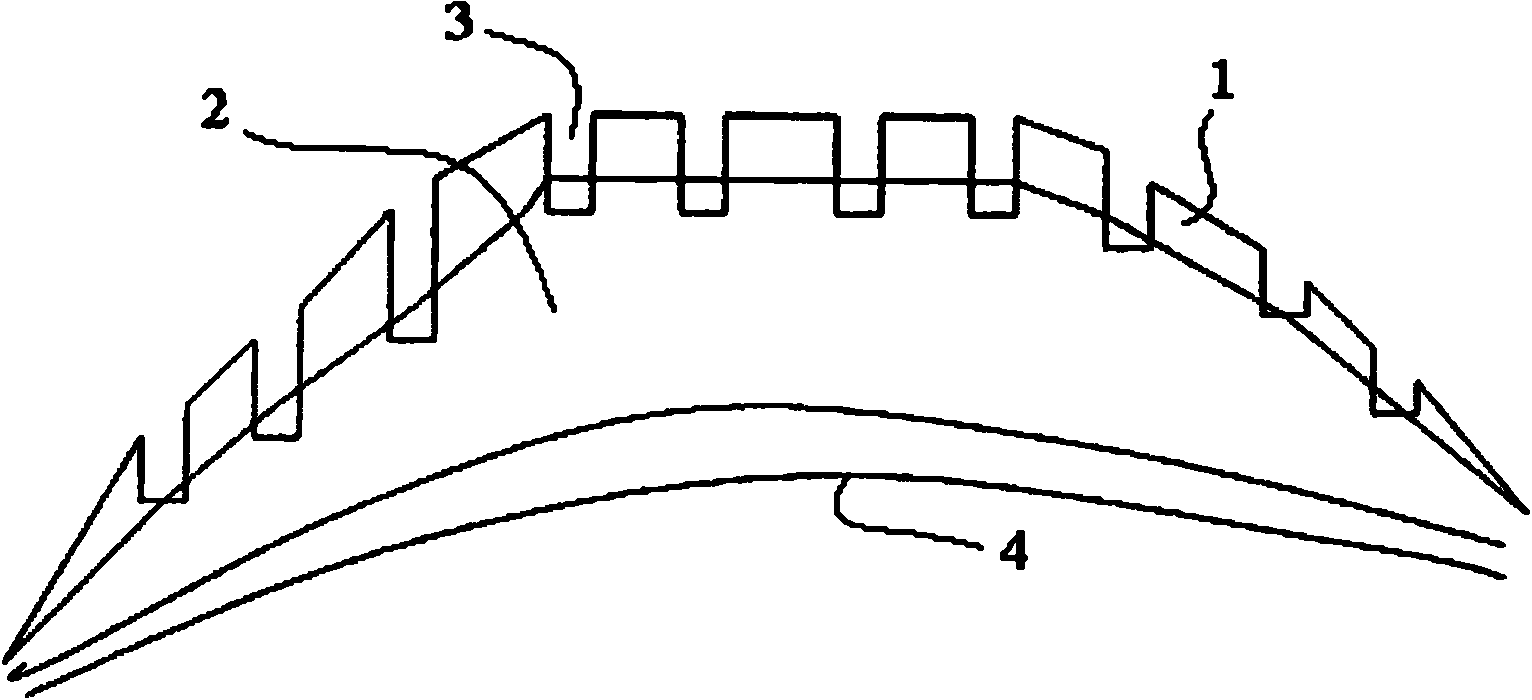

Overhand shrinkage spaced-loading split-blasting slot cutting method

ActiveCN103696769AQuality improvementControl chunk rateUnderground miningSurface miningTEX-explosiveMining engineering

The invention discloses an overhand shrinkage spaced-loading split-blasting slot cutting method, which aims at solving the problems that the ore discharging efficiency is low, the consumption of explosive is large, the rate of large ore blocks is high, the construction organization is complicated, a suspended roof is likely to form and the operation safety is poor in a traditional slot cutting process. The method comprises the following steps of step 1, determining geometric parameters of a cutting level; step 2, determining a position of a cutting open yard, to be specific, determining the parameter and height of a cross section, and selecting the position; step 3, determining rock drilling parameters in the slot cutting process, to be specific, determining the parameter of a resisting line, determining the hole-bottom distance parameter and determining side, hole and corner; step 4, forming a cutting slot; and step 5, discharging from the ore in a concentrating manner, wherein after the rearmost rows of blast holes in the uppermost layer of the cutting slot are exploded in an elementary error manner, ores falling into the cutting slot are concentratedly discharged through a first layer. By adopting the method for preserving the ores and finally discharging the ores concentratedly, the slot cutting can be safely and rapidly carried out for a chamber at the high quality.

Owner:NORTHWEST RES INST OF MINING & METALLURGY INST

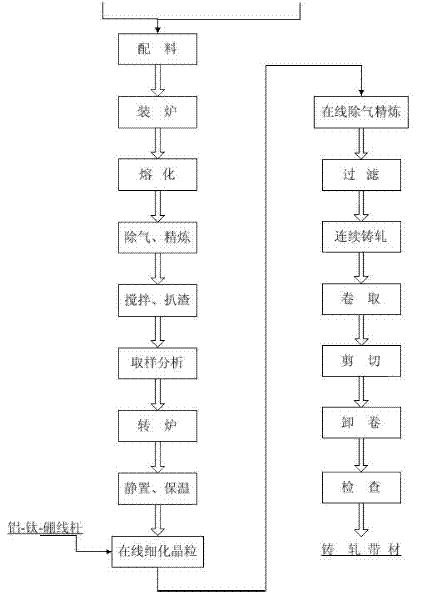

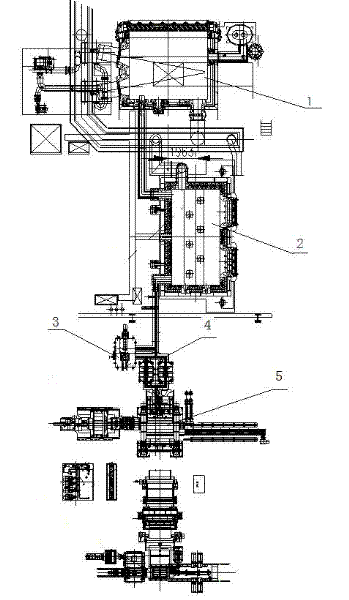

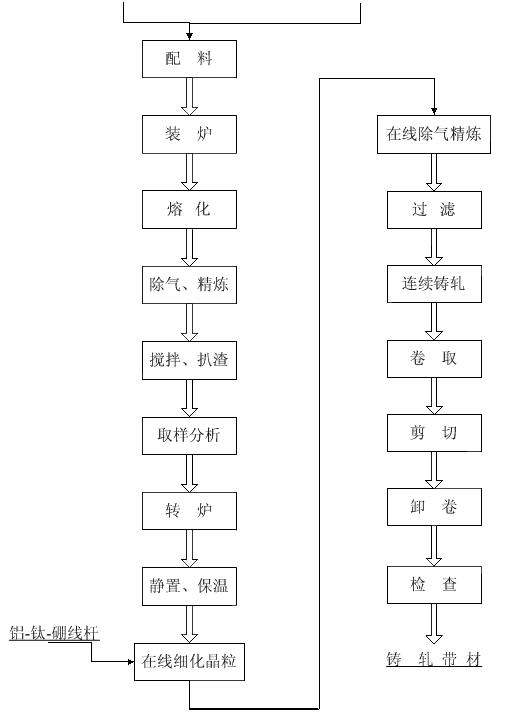

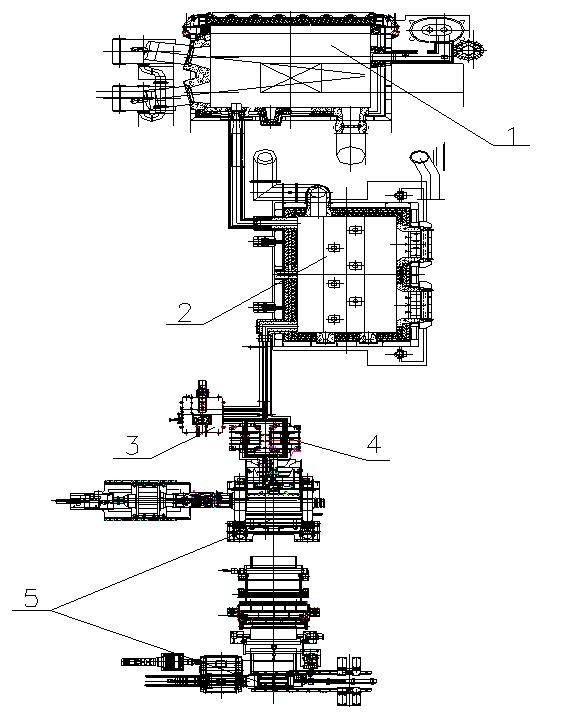

A continuous casting and rolling process for producing 5005 aluminum-plastic strip blanks

InactiveCN102266924AReduce burning lossReduce energy consumptionMetal rolling stand detailsMetal rolling arrangementsFoundryDual stage

The invention relates to the aluminum processing industry, in particular to a continuous casting and rolling process for producing 5005 aluminum-plastic strip blanks. The invention includes a holding furnace, an aluminum melting furnace, an on-line refining device, a two-stage filter item, and a continuous casting and rolling unit used in the production method. The process method includes the following steps: 1) batching step; 2) furnace loading step; 3 ) melting and stirring steps; 4) slag removal, sampling and analysis steps; 5) degassing refining, standing, heat preservation steps; 6) online melt processing steps; 7) continuous casting and rolling steps; 8) coiling and shearing steps ;9) Check the steps. The advantages of the method of the present invention: due to the use of 80% electrolytic aluminum liquid in the production process, the burning loss of aluminum is reduced to below 15‰, and the unit consumption of natural gas is reduced to below 80Nm3 / tAl, which is similar to the production of 3005 aluminum-plastic strips by using aluminum ingots for remelting Compared with the casting and rolling method of the billet, the burning loss and energy consumption of aluminum are reduced by 50%; the finished product rate reaches more than 99%. The invention discloses a continuous casting and rolling process for producing 5005 aluminum-plastic strip blanks, which is suitable for domestic and foreign aluminum and aluminum alloy casting industries.

Owner:GUIZHOU BRANCH CHINA ALUMINUM IND

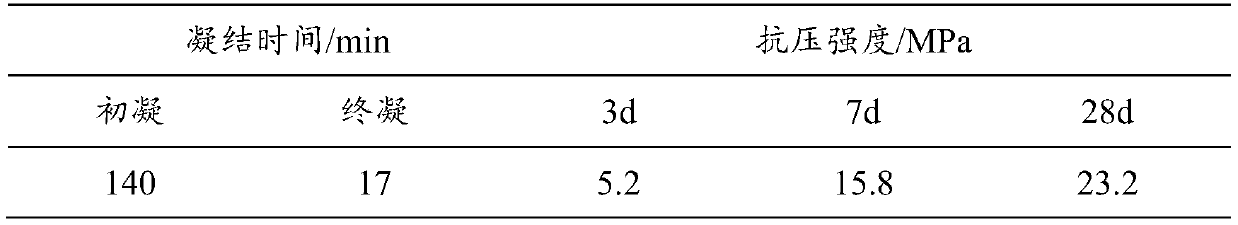

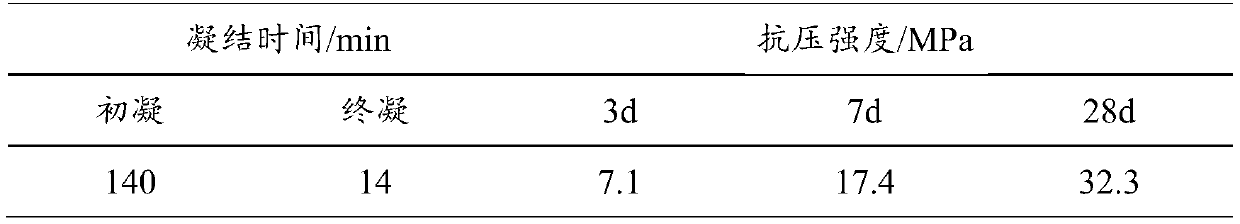

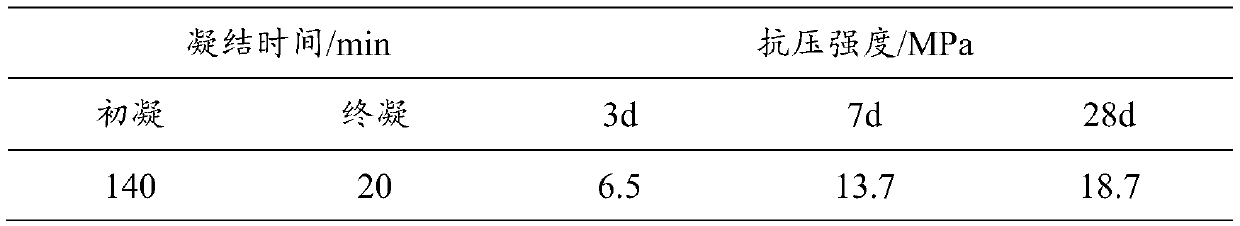

Preparation method of all solid waste and upper flow regime paste-like filling material

The invention relates to a preparation method of an all solid waste and upper flow regime paste-like filling material. Ferrosilicoaluminum-based solid wastes and calcium sulfate-based solid wastes, which are used as raw materials, are subjected to raw grinding, homogenization, firing and clinker grinding to produce a matrix material, and the matrix material is blended with filling aggregates, a fine-grained material, a regulator and wastewater to prepare the paste-like filling material. The method achieves the preparation of the paste-like filling material by recycling industrial solid wastes.The material is prepared from a liquid component A and a liquid component B, wherein the component A is composed of the matrix material and wastewater, and is a slurry formed by stirring and mixing,and the component B is composed of the filling aggregates, the fine-grained material, the regulator and the wastewater, and is a slurry formed by stirring and mixing. The paste-like filling material prepared from multiple solid wastes has excellent properties upper flow regime, early strength, fast hardness and low bleeding rate. The preparation method has the advantages of reasonable utilizationof the industrial wastes, great consumption of the industrial solid wastes, reduction of environmental impact, construction of the environment-friendly society, and easiness in preparation.

Owner:SHANDONG UNIV

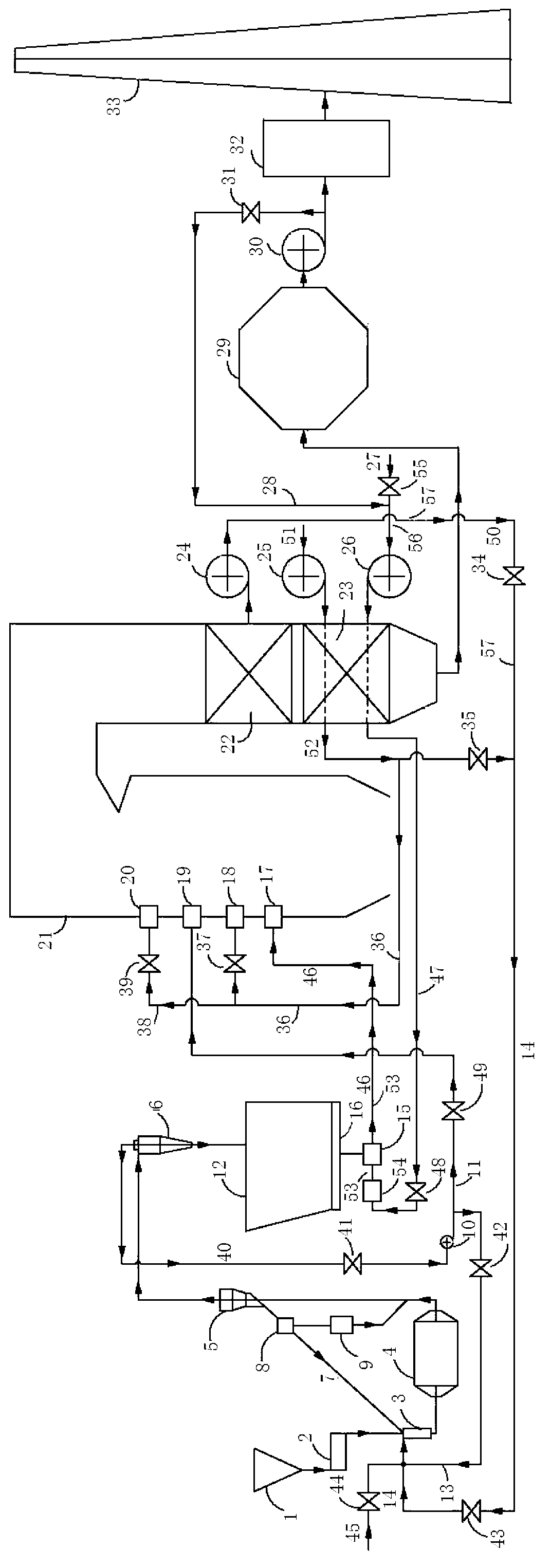

Storage-type super-low nitric oxide system in coal fired boiler coal mill

ActiveCN103216840ANot easy to explodeIncrease delivery temperatureLump/pulverulent fuel feeder/distributionLump/pulverulent fuel preparationPowder mixtureNitric oxide

The invention relates to a storage-type super-low nitric oxide system in a coal fired boiler coal mill. On the basis of the existing low-nitrogen burning technology, the superfine coal powder preparation technology and the smoke circulating technology are adopted. The smoke circulating technology adopts cold furnace smoke to be mixed with primary air to be supercharged by a primary fan, the heating and powder feeding technology of an air preheater and the hot air and high-temperature furnace smoke drying technology of the powder production system are adopted, i.e. superfine coal powder can be prepared, the hot furnace smoke enters a primary air large air bellow, the hot furnace smoke is mixed with superfine coal powder prepared by a superfine coal powder preparation device in a coal powder blender and supplied by a powder supply machine from a coal powder cabin to be heated, and the air-powder mixture is fed into a low-nitrogen burner through a primary air pipe. In the main burning area of the boiler, since the air content of the furnace smoke is little, a lower residual air coefficient can be realized, the emission of the nitric oxide can be reduced.

Owner:南京佛莱斯特环保科技有限公司

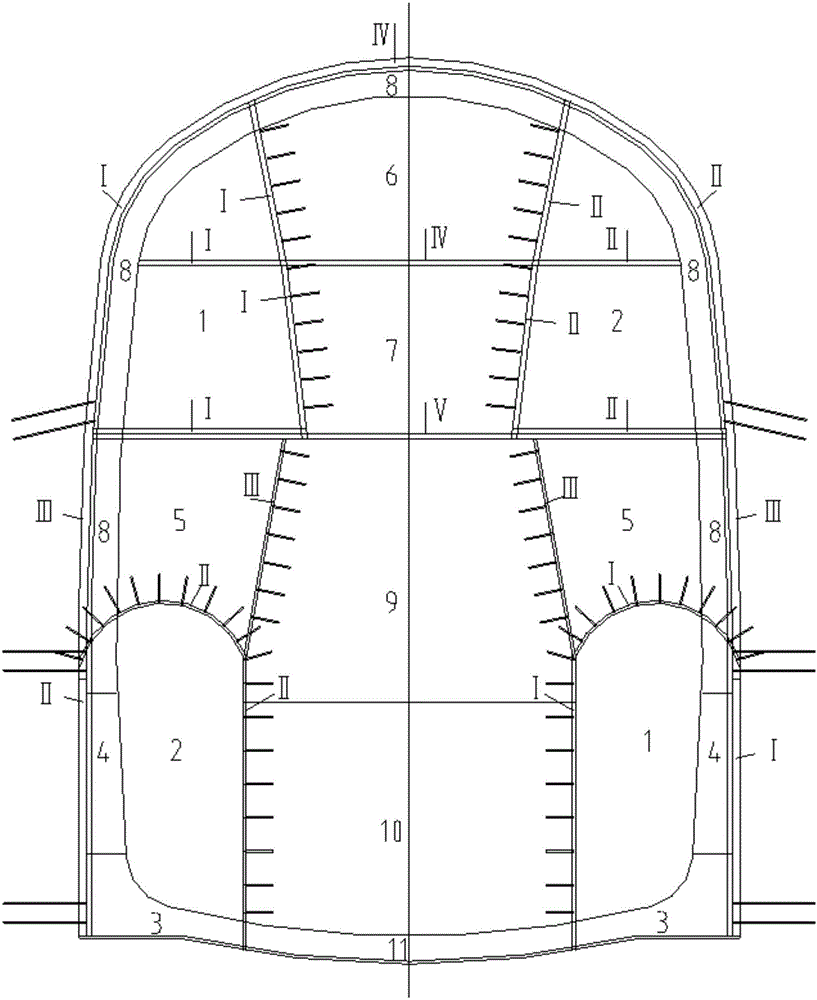

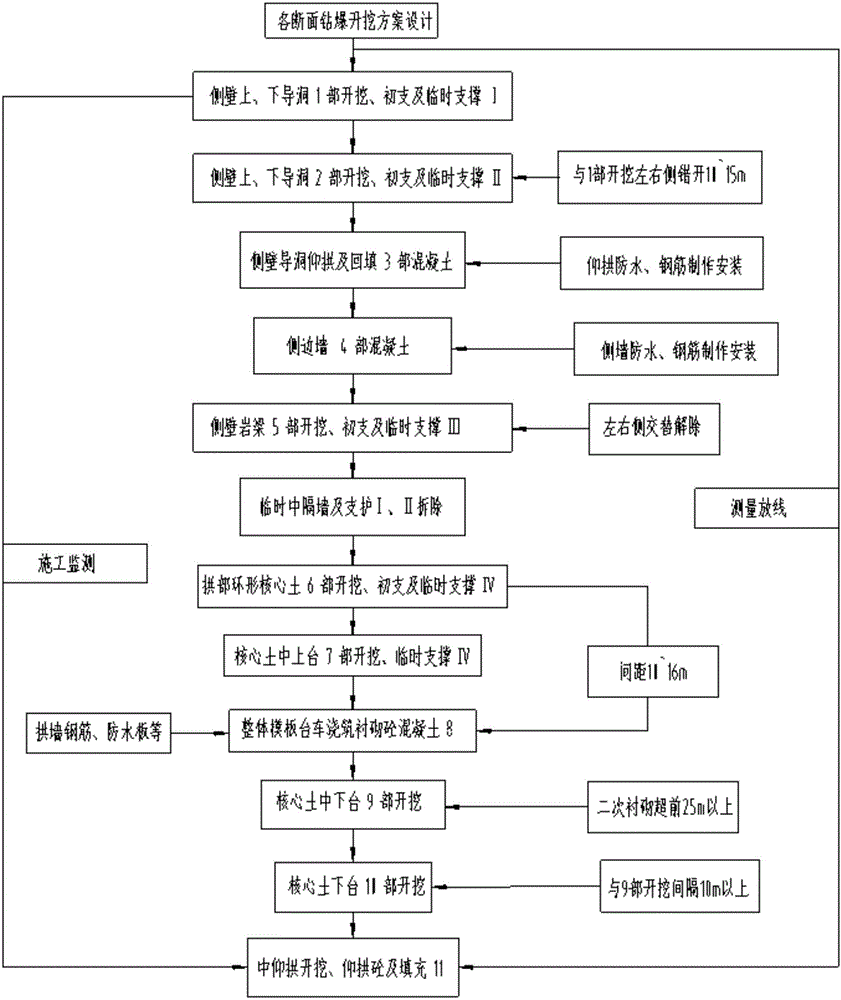

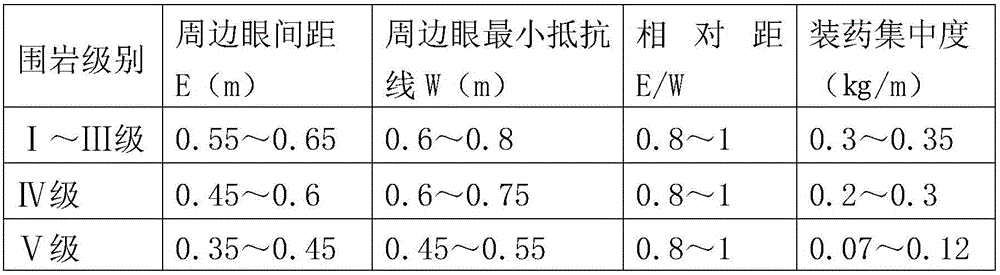

Construction method for excavating upper drift heading and lower drift heading in two side walls of ultra-large subsurface tunnel

InactiveCN106643361AReduce unit consumptionReduce the impactBlastingDrilling and blastingBuilding construction

The invention provides a construction method for excavating an upper drift heading and a lower drift heading in the two side walls of an ultra-large subsurface tunnel and belongs to the technical field of construction engineering. The method comprises the steps of drilling and blasting scheme design; construction requirements meeting of drilling and blasting design; blasting parameter selection; surveying and setting out; excavation of the upper pilot tunnel portion and the lower pilot tunnel portion of the two side walls; removal of reserved rock beam portions; excavation of an annular core soil portion of an arch portion; and excavation of core soil middle-upper steps, middle-lower steps and lower steps. Compared with a traditional two-side-wall drift heading method, according to the method, the way of excavating the upper drift heading and the lower drift heading at the same time is adopted, and the characteristics of the large-section tunnel can be fully utilized; a working face which can be excavated is increased; tunnel excavation conducted at the early stage is accelerated; and the construction period is effectively shortened. According to the method, reserved rock beams are utilized, so that horizontal support strength and global stability are effectively enhanced; horizontal convergence deformation and arch top settlement of the tunnel are decreased; and safety of buildings on the upper portion of the tunnel is guaranteed. According to the construction method, after the high side walls are constructed by means of the bottom of a lower pilot tunnel of the tunnel, backfilling is conducted, the height of a second lining construction section of the tunnel is reduced, and the construction problem of an ultra-large-section formwork trolley is solved.

Owner:CHINA CONSTR EIGHTH ENG DIV

Method for preparing aliphatic polycarbonate through continuous solution polymerization method

The invention provides a method for preparing aliphatic polycarbonate through a continuous solution polymerization method. The method comprises the following steps of a, injecting an epoxy monomer, carbon dioxide and catalyst into a circulation flow reactor through a continuous way, utilizing a circulation pump to provide power for the reaction materials, circularly returning partial reaction materials to the circulation flow reactor, driving one part of the reaction materials to leave the circulation flow reactor at a speed being identical to the feeding speed to enter a tubular reactor with a built-in static mixer; b, controlling the retention time of the pulp in the tubular reactor through the ratio of the pipe length and the flowing linear speed of the reaction materials, and gradually charging a solvent step by step through a plurality of feeding ports along the length of the tubular reactor; c, feeding an end sealing agent and a stabilizer through a feeding port on the tail end of the tubular reactor to carry out the in-situ chemical or physical modification; d, ensuring the reaction endpoint pulp which continuously flows out of a discharging end to enter a middle-pressure flash evaporator, carrying out the flash evaporation by utilizing the reaction pressure, removing the solvent, and returning the pulp to the tubular reactor after the pulp is condensed; and e, devolatilizing and drying the pulp to obtain a polymerization product.

Owner:BEIJING RISUN TECH CO LTD +1

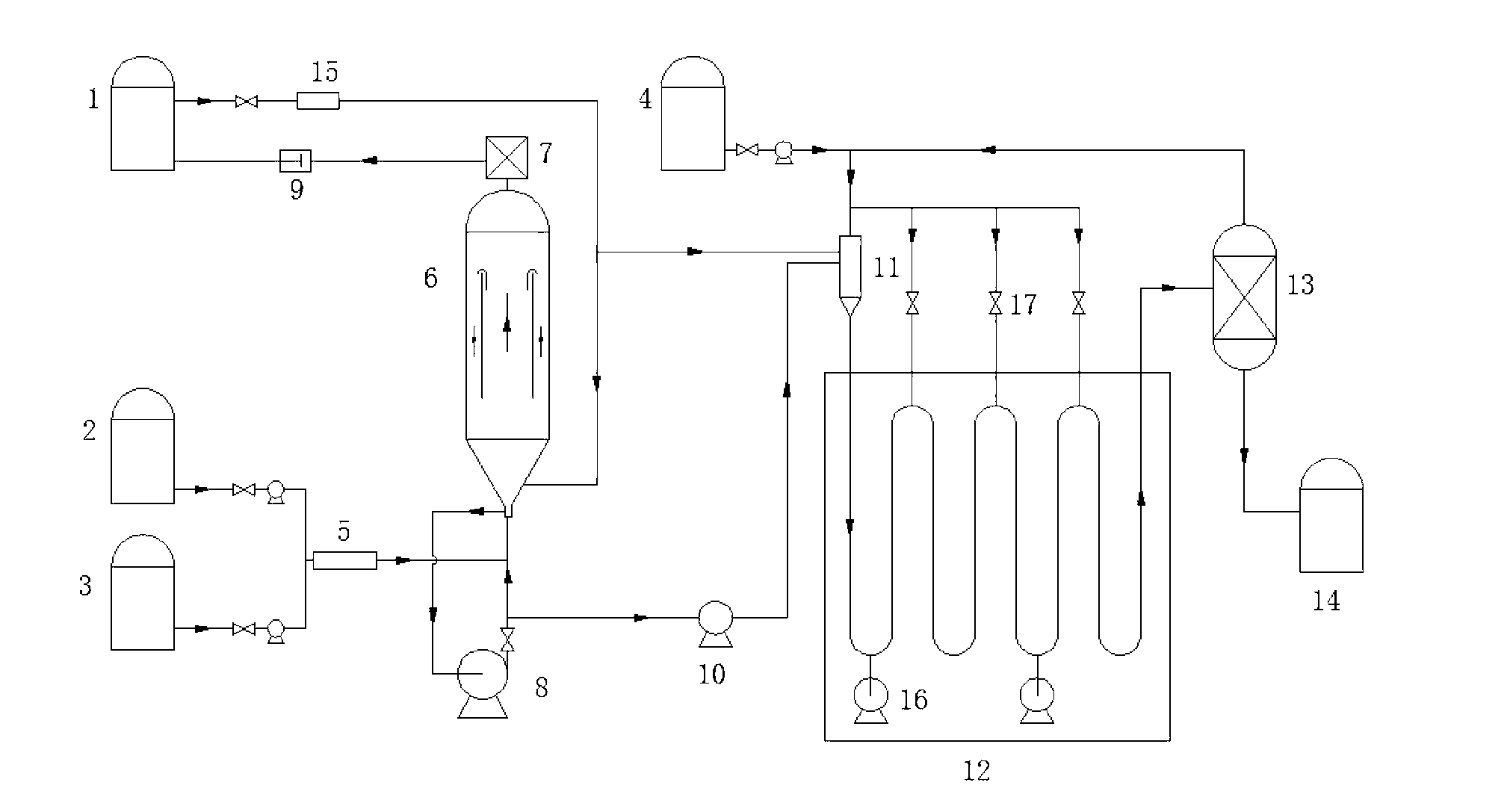

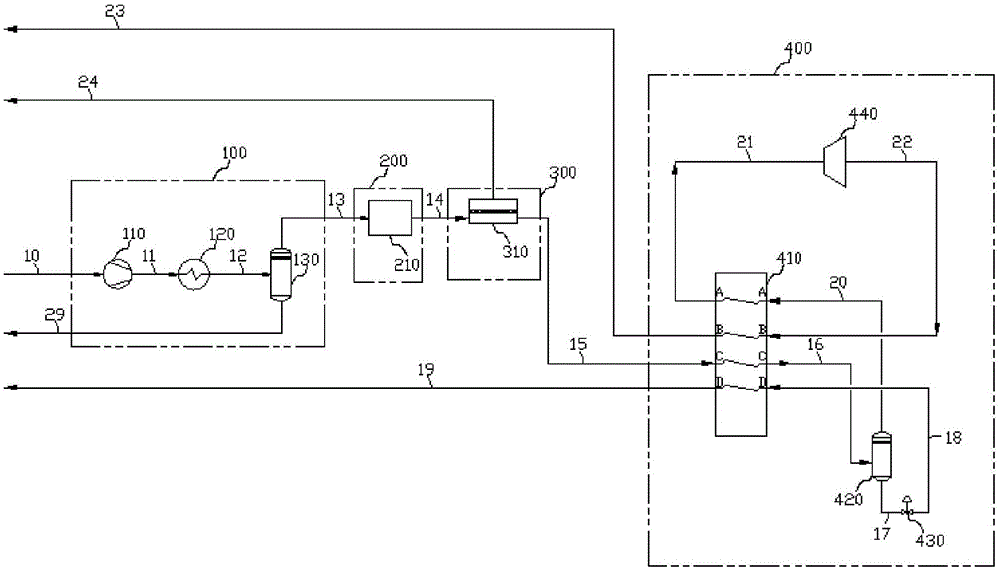

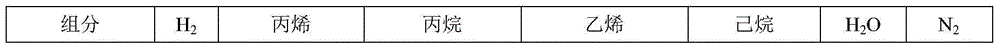

Polypropylene tail gas recovery device and recovery method

InactiveCN105004140AAchieve recyclingMeet the requirements of recyclingSolidificationLiquefactionRecovery methodSeparation technology

The invention discloses a polypropylene tail gas recovery device. The polypropylene tail gas recovery device comprises a compression unit, a drying unit, a membrane separation unit and a cryogenic separation unit, wherein the compression unit, the drying unit, the membrane separation unit and the cryogenic separation unit are connected in sequence. The compression unit comprises at least one compressor, a heat exchanger and a gas and liquid separator, wherein the compressors, the heat exchanger and the gas and liquid separator are connected in sequence. The drying unit comprises at least two adsorption towers which are connected in sequence, and drying agents are placed in the adsorption towers. The membrane separation unit comprises a membrane separator. The cryogenic separation unit comprises at least one high-efficiency multi-channel heat exchanger, at least one low-temperature gas and liquid separator, at least one gas expansion device and at least one liquid expansion device. According to a polypropylene tail gas recovery method adopting expansion refrigeration, propylene in polypropylene tail gas is liquefied to be recovered, and meanwhile nitrogen is purified to meet the requirement for nitrogen recycling; in combination with a membrane separation technology, hydrogen in the polypropylene tail gas is removed; the recovery rate of the propylene in the polypropylene tail gas reaches above 98%.

Owner:DALIAN EUROFILM IND

Cotton, wood and bamboo composite pulp phase-change microcapsule viscose and preparation method thereof

ActiveCN102839440AUniform particle sizeLittle impact on viscose quality and spinnabilityArtificial filaments from viscoseArtifical filament manufactureMethacrylate methylPolymer chemistry

The invention relates to cotton, wood and bamboo composite pulp phase-change microcapsule viscose and a preparation method thereof, belonging to the viscose field. The phase-change microcapsule comprises 80-250 parts of methyl methacrylate, 80-150 parts of phase change paraffin, 2.5-6 parts of an emulsifying agent, 0.5-1.5 parts of azo initiator, and 300-400 parts of deionized water. According to the invention, cotton, wood and bamboo composite pulp is used for preparing spun-viscose for producing the cotton, wood and bamboo composite pulp phase-change microcapsule viscose, and steps such as alkali steeping, aging, yellowing, dissolving and the like during the viscose production process are optimized. The microcapsule disclosed by the invention has a uniform grain size, is suitable for producing composite viscose and capable of remarkably improving the quality of the viscose and the spinnability with small influence; moreover, the prepared viscose not only has a natural moisturizing and ventilating effect of composite bamboo pulp fiber, but also has the function of accumulating heat and adjusting temperature.

Owner:CHENGDU GRACE FIBER

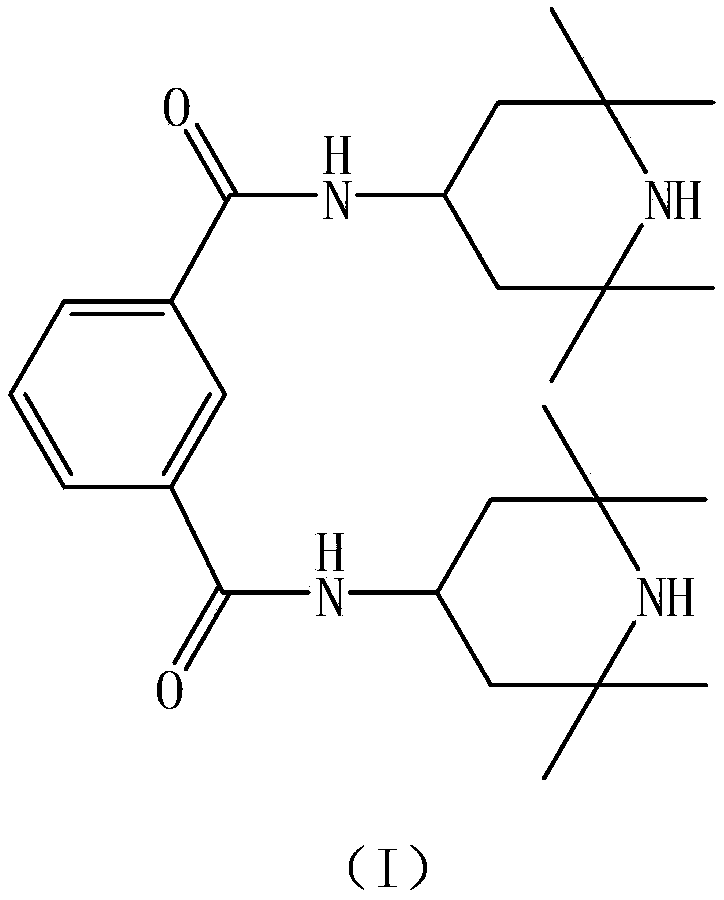

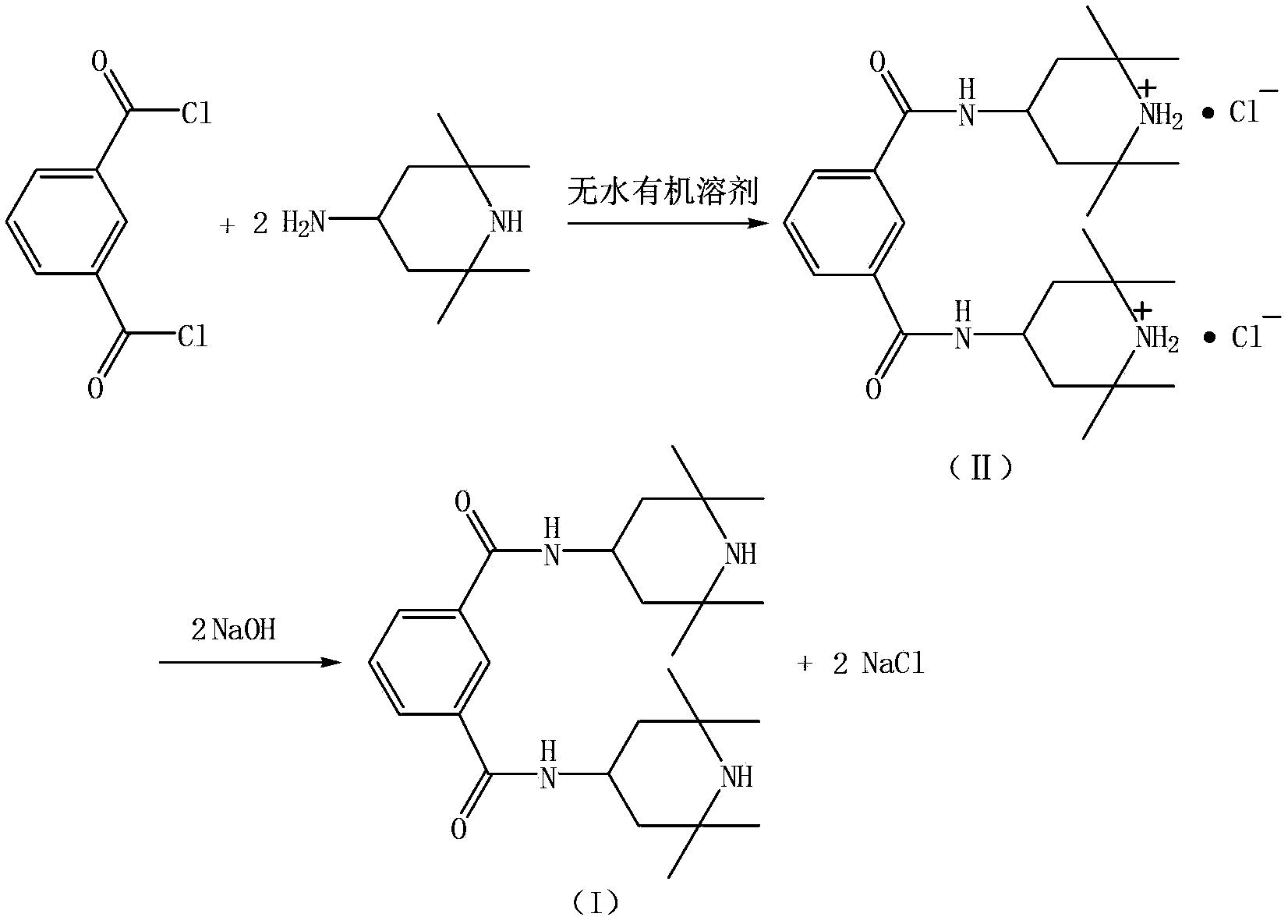

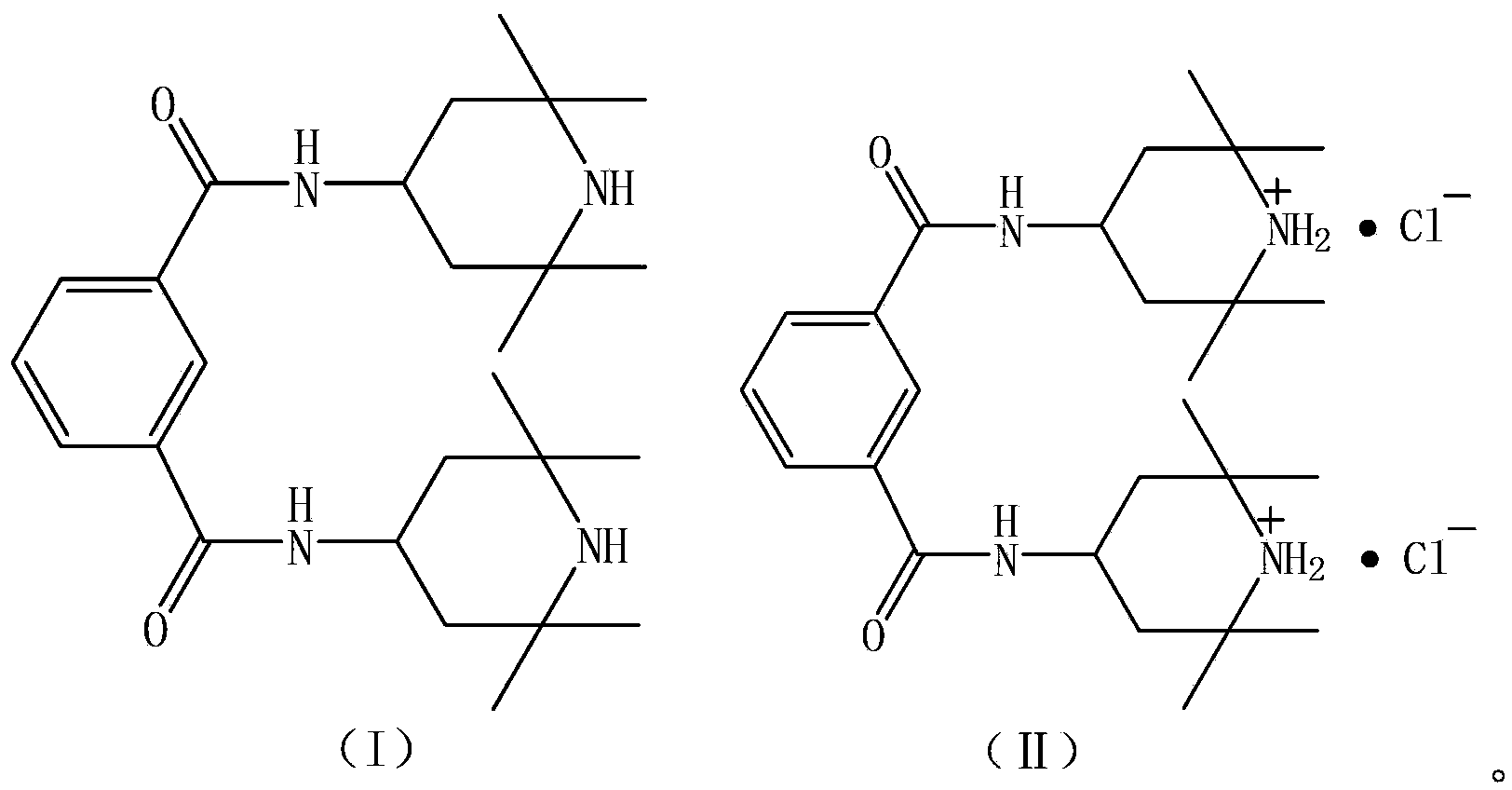

Preparation method of N, N'-bis(2, 2, 6, 6-tetramethyl-4-piperidyl)-1, 3-benzenedicarboxamide

The invention discloses a preparation method of N, N'-bis(2, 2, 6, 6-tetramethyl-4-piperidyl)-1, 3-benzenedicarboxamide which is represented by formula (I). The preparation method comprises following steps: (1) 2, 2, 6, 6-tetramethyl-4-aminopiperidine and m-phthalyl dichloride are taken as raw materials, and are reacted in an anhydrous organic solvent at a temperature of -5 to 25 DEG C until complete precipitation is realized, reaction liquid is filtered, and the filter cake is washed with the anhydrous organic solvent and dried so as to obtain an intermediate (II), wherein the anhydrous organic solvent is one selected from n-heptane, n-octane, petroleum ether, acetone or butanone; (2) at room temperature, the intermediate (II) is mixed uniformly with water, sodium hydroxide solution is added for neutralization, the mixture is filtered and washed with water so as to obtain a filter cake, and the filter cake is dried so as to obtain N, N'-bis(2, 2, 6, 6-tetramethyl-4-piperidyl)-1, 3-benzenedicarboxamide represented by formula (I). The preparation method possesses advantages of high product quality, simple operation technology, convenient operation process and high raw material utilization rate.

Owner:盘锦新秀新材料有限公司

Process for processing coal with low degree of metamorphism

InactiveCN101429463AGood environmental protectionEmission reductionSolid fuelsEngineeringAtmospheric pollution

The invention provides a technique for processing coal with low metamorphism degree, which comprises the steps of crushing and sieving pretreatment. The technique is as follows: raw coal particles are sent into a drier, and subjected to anoxybiotic hot gas drying under normal pressure, wherein the drying condition is controlled to 10 to 50 cubic meters of hot gas required for each 1 kilogram of the coal, and the temperature of the raw coal particles is controlled to between 210 and 250 DEG C; the raw coal particles are sent into a pyrolysis apparatus, and high-temperature oxygen-poor hot gas is injected according to the flow ratio of 5 to 50 cubic meters per kilogram of coal, wherein the temperature of the oxygen-poor hot gas entering into a pyrolyzing furnace is controlled to between 400 and 950 DEG C, and the oxygen content is controlled to less than 6 percent of the volume; and the coal is fully mixed with the hot gas and heated to a temperature of between 530 and 580 DEG C. The technique has the advantages that the sulfur content is reduced compared with that in the raw coal, so that atmospheric pollution is reduced; solid products produced by the technique have high environment-friendly characteristic; the discharge amount of nitrogen oxide is obviously reduced; and atmospheric pollution is reduced.

Owner:HUNAN HUAYIN ENERGY TECH

Zinc-aluminum-rare earth middle alloy and its use in hot galvanizing alloy production

The invention relates to a process for producing a hot dip galvanizing alloy and an interalloy thereof. The technical proposal comprises that the interalloy of zinc, aluminum and rare earth consists of the following components in mass percentage: 3 to 5 percent of Al, 6 to 10 percent of RE, and the balance being Zn. The method of producing the hot dip galvanizing alloy comprises the following steps: mixing the zinc, the aluminum and the rare earth according to the following weight ratio: 3 to 5 percent of the Al, 6 to 10 percent of the RE, and the balance being the Zn; melting the materials in an interalloy smelting furnace with smelting temperature of between 500 and 650 DEG C; stirring the materials evenly and casting the materials into the interalloy of the zinc, the aluminum and the rare earth; adding the solid zinc required for the production of the hot dip galvanizing alloy into the smelting furnace made from the hot dip galvanizing alloy to be melted into zinc liquid; adding a slag former to the zinc liquid, stirring the mixture and forming slag at a temperature of between 470 and 480 DEG C; removing the slag in the furnace; adding the alloy of the zinc, the aluminum and the rare earth required according to the mixture ratio of the produced hot dip galvanizing alloy to the zinc liquid; and stirring the mixture to obtain the hot dip galvanizing alloy. The process reduces the temperature for alloy smelting, shortens the smelting and stirring time, prolongs the service life of a core-type induction furnace and is advantageous to uniform the components of the hot dip galvanizing alloy, and has the advantages of low equipment cost and simple and convenient maintenance.

Owner:湖南株冶火炬新材料有限公司

Process for regenerating titanium-containing catalysts

InactiveUS7384882B2Improve usabilityReduce unit consumptionInorganic chemistryMolecular sieve catalystsTitaniumChemistry

The present invention discloses a process for regenerating titanium-containing catalysts, characterized in that a deactivated catalyst is treated in an acidic solution having a pH value of ≦3, and then dried and calcined. The process is simple in procedure and can make the catalytic activity, selectivity and stability of the regenerated catalyst be recovered to the level of its fresh catalyst.

Owner:CHINA PETROCHEMICAL CORP

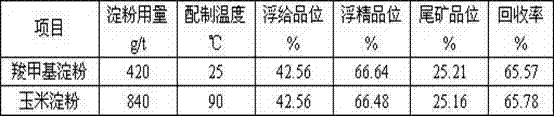

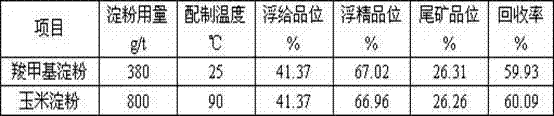

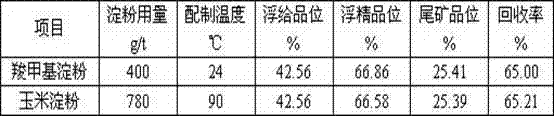

Carboxymethyl starch inhibitor for reverse flotation of hematite

InactiveCN103567078AReduce unit consumptionReduce consumptionFlotationCarboxymethyl starchProcess engineering

The invention provides a carboxymethyl starch inhibitor for reverse flotation of hematite. The carboxymethyl starch inhibitor is characterized in that water with the weight being 8 times to 10 times the weight of carboxymethyl starch and the carboxymethyl starch are sequentially added to a dispensing barrel at a room temperature, the water and the carboxymethyl starch are stirred for one hour, then, water is added for preparing a solution which is composed of, by weight, 1.5% to 3.0% of the carboxymethyl starch, and the carboxymethyl starch inhibitor is obtained. Compared with a frequently-used corn starch inhibitor, the carboxymethyl starch inhibitor has the advantages that the consumption of the carboxymethyl starch inhibitor is lowered by 44% to 50%, when the carboxymethyl starch inhibitor is prepared at the room temperature, the preparation process is simple, the energy consumption is reduced, the inhibiting effect is good, and the screening index is beneficially improved, and the carboxymethyl starch inhibitor is easy to store and not prone to deterioration when used at the room temperature.

Owner:ANSTEEL GRP MINING CO LTD

Process for producing gelatin by using acid method

InactiveCN102286252AReduce water consumptionReduce unit consumptionGlue/gelatin preparationFiltrationEvaporation

The invention discloses a process for producing gelatin by using an acid method. The process comprises the following steps of: selecting appropriate leather, and washing and mechanically degreasing the leather; soaking the leather into food-grade hydrochloric acid, washing the acid soaked raw material for at least two times, slowly performing neutralization reaction by using sodium hydroxide, extracting gelatin, adding a flocculating agent when the gelatin is treated, and performing flocculating settlement; and filtering the settled material through a cotton cake filter, performing ion exchange to remove metal ions and acid radical ions after the filtrate is obtained, performing membrane ultra-filtration concentration on the filtrate, performing three-effect evaporation and flash sterilization, extruding the gelatin, and thus obtaining a gelatin finished product. By the process, the whole production period is shortened, the quality of the product is improved, the water consumption during washing is reduced, and the unit consumption of the leather in production is reduced.

Owner:郭小棋

Waterless stemming and preparation method thereof

The invention relates to waterless stemming and a preparation method thereof. The waterless stemming is a fireproof, corrosion-resistant, washing-resistant and wear-resistant material for blocking an iron notch and filling iron notch gaps and cracks having various shapes. The waterless stemming has the advantages that 1, the waterless stemming does not yellow, does not produce black smoke, reduces benzpyrene content to a value less than 0.01% and has good filling performances, contractibility and sintering properties, 2, strength is high and stable blast furnace conditions are kept, 3, iron is produced stably, the iron notch can be opened easily, the pore is not broadened, melt iron flow and flow velocity can be effectively controlled, and strong slag resistance, erosion resistance and washing resistance are obtained, 4, the hearth is protected, crack is not produced in fast heating and high bonding strength of novel and old stemming is high, 5, opening performances are good and a boring process can be carried out easily by a tapping machine drill bit, 6, plasticity is good and clay gun operation and iron notch mud drum formation are convenient, and 7, a certain micro-expansion performance is obtained at a high temperature, gas permeability is good, strength is high and molten iron seepage caused by stemming contraction is avoided.

Owner:阜康市三工河乡樟兴新型耐火材料厂

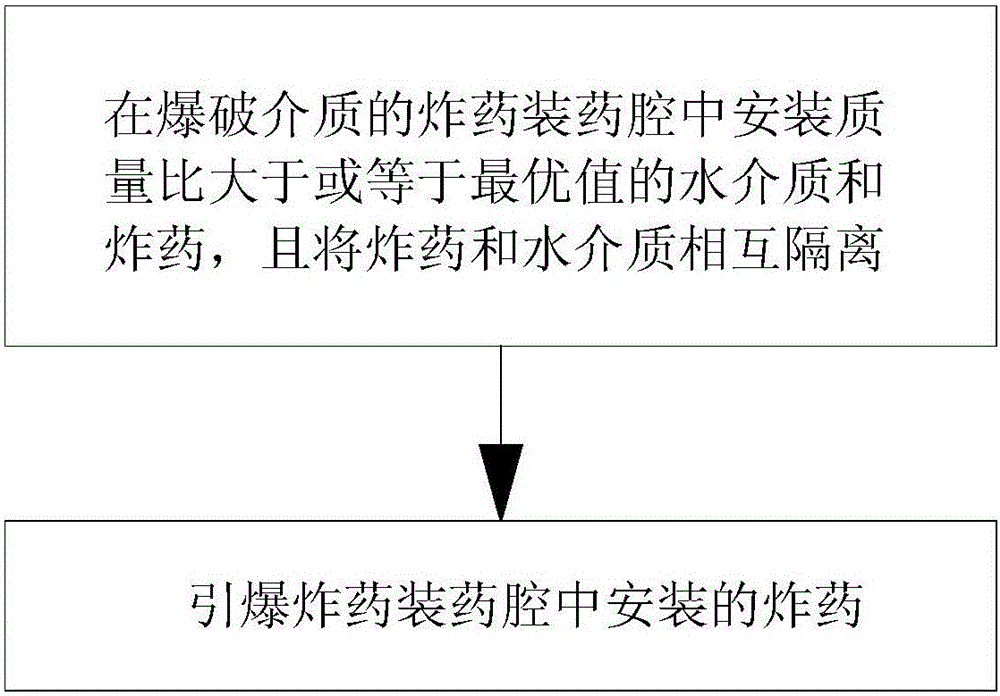

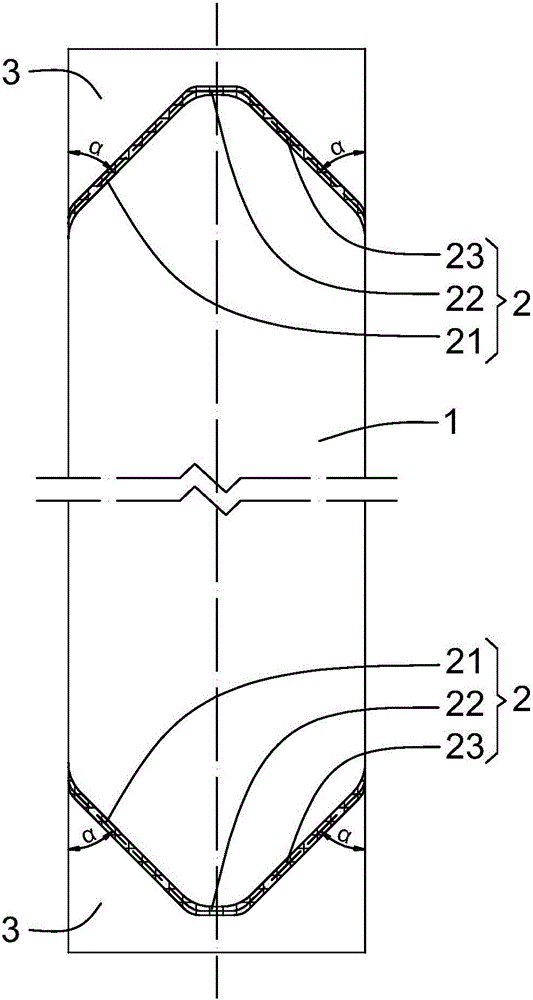

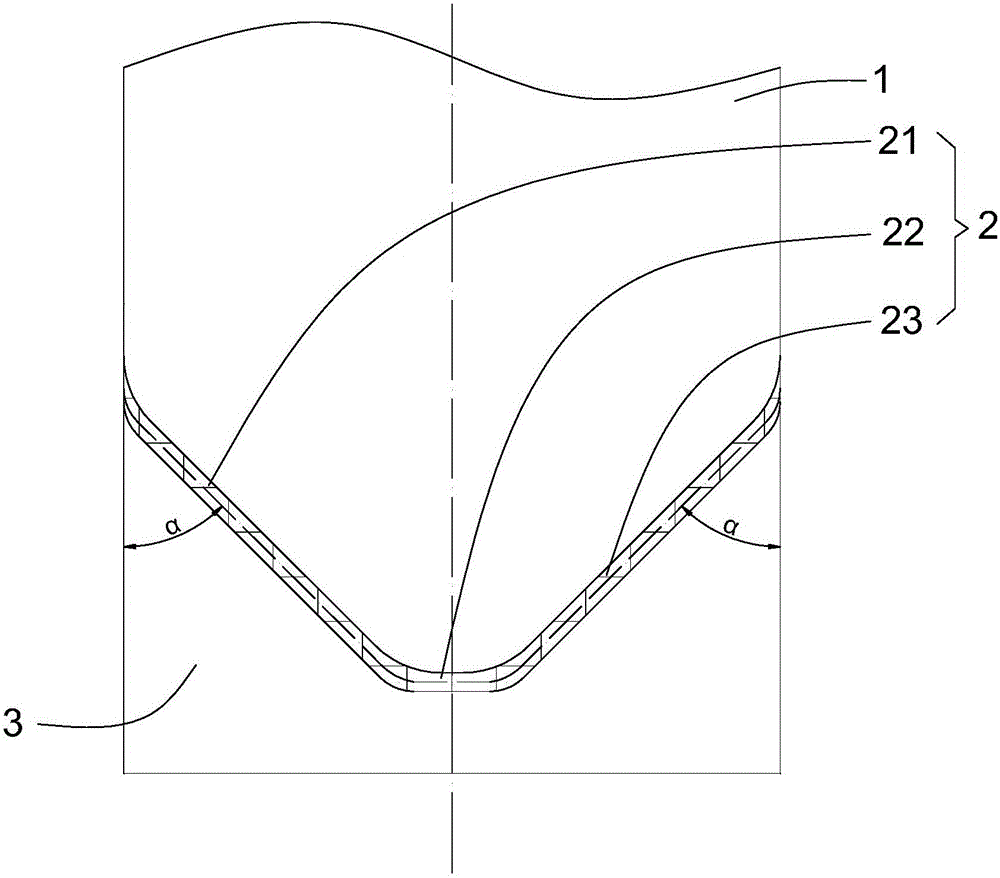

Aqueous medium energy transition blasting method and charging cavity

ActiveCN105674819ASolve the problem of insufficient effective utilization of energyAir Shock MitigationBlastingHydrogenMass ratio

The invention discloses an aqueous medium energy transition blasting method and charging cavity. The aqueous medium energy transition blasting method comprises the steps that firstly, an aqueous medium and explosives with the mass ratio larger than or equal to an optimal value are mounted in the explosive charging cavity of a blasting medium, and the explosives and the aqueous medium are isolated from each other; and then the explosives mounted in the explosive charging cavity are detonated. The aqueous medium and the explosives with the mass ratio larger than or equal to the optimal value M are mounted in the charging cavity, the explosives and the aqueous medium are isolated from each other, and the optimal value M is the ratio of explosion heat of the explosives adopted in the blasting process to heat energy released when water is synthesized by hydrogen and oxygen. The aqueous medium energy transition blasting method and charging cavity have the beneficial effects that the effective utilization rate of energy of the explosives can be increased, the blasting effect of the explosives on the blasting medium can be improved, blasting damage can be reduced, and blasting smoke is less.

Owner:秦健飞

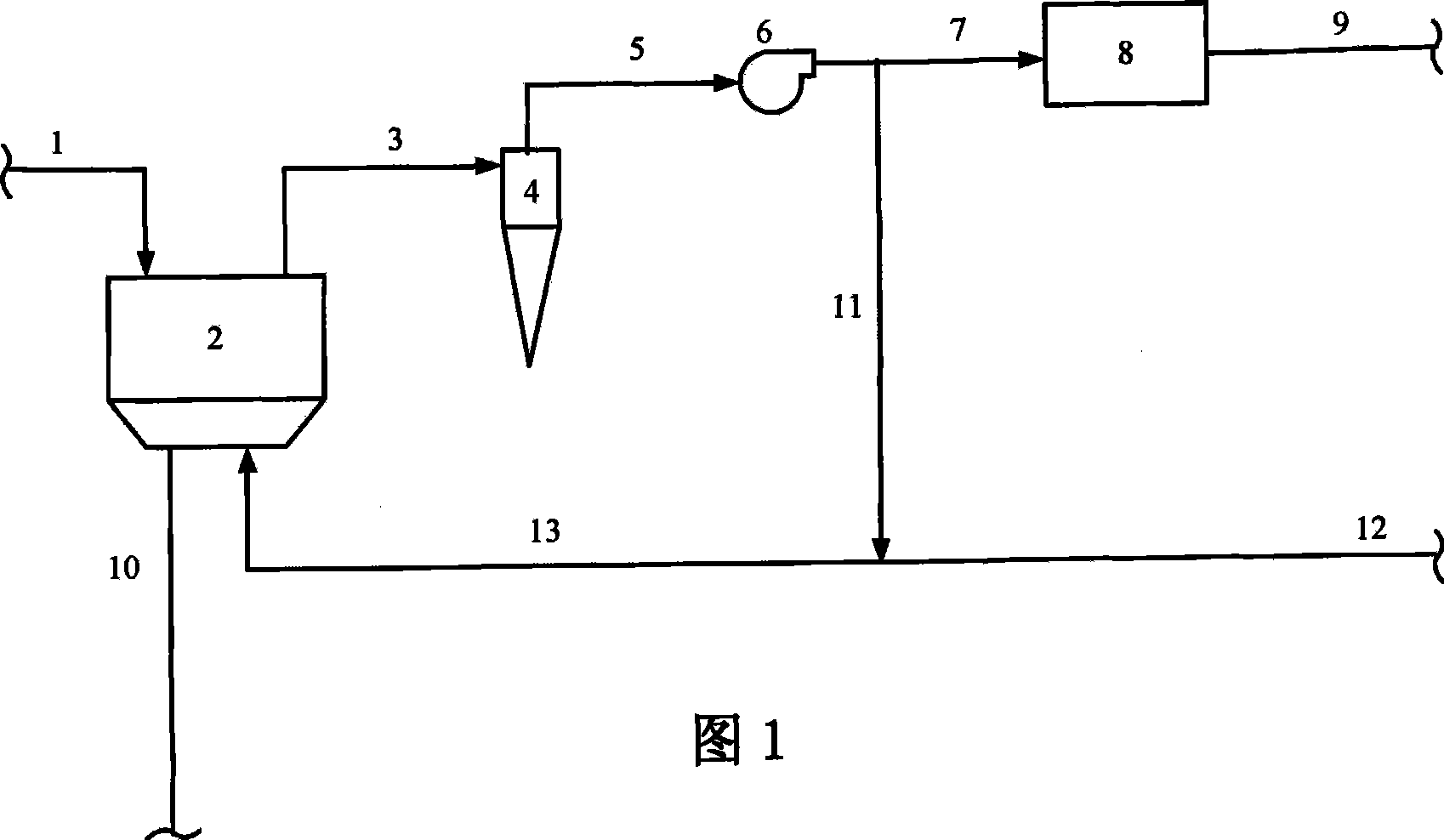

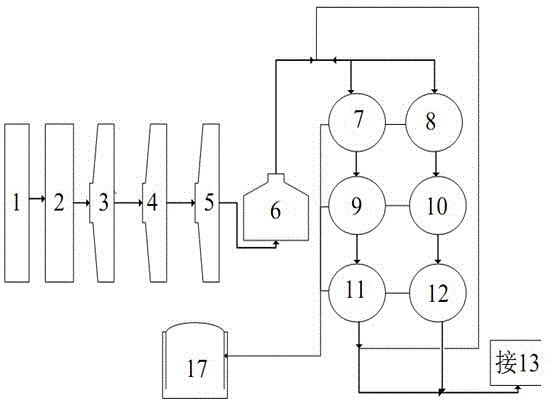

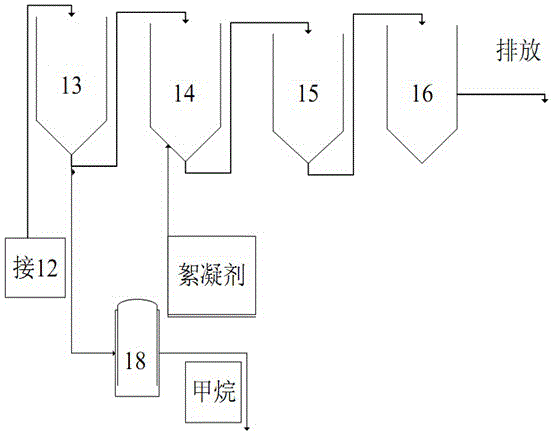

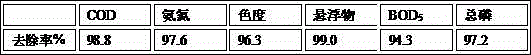

Industrial wastewater treatment system

ActiveCN104355504ASimple process conditionsLow costTreatment using aerobic processesWaste based fuelIndustrial waste waterSludge

The invention discloses an industrial wastewater treatment system, comprising a coarse screen, a fine screen, a regulating reservoir, a grit chamber, a primary settling tank, an anoxic pool, an anaerobic pool, an aerobic pool, a secondary sedimentation tank, a coagulating sedimentation tank, a filter tank, a disinfecting tank, an air storage tank and a sludge storage tank. Compared with the prior art, the treatment system has the advantages that the pollutant removal capacity is significantly improved, the COD removal rate can reach over 98%, the SS removal reach can reach over 99%, and the chroma removing rate can reach over 98%. The system reaction only relates to biochemical reaction; a composite flocculant prepared from aluminum residue and coal ashes is added at the treatment stage; and all by-products such as hydrogen sulfide and methane generated in the production process of the system are recycled.

Owner:广西华鸿明阳污水处理有限公司

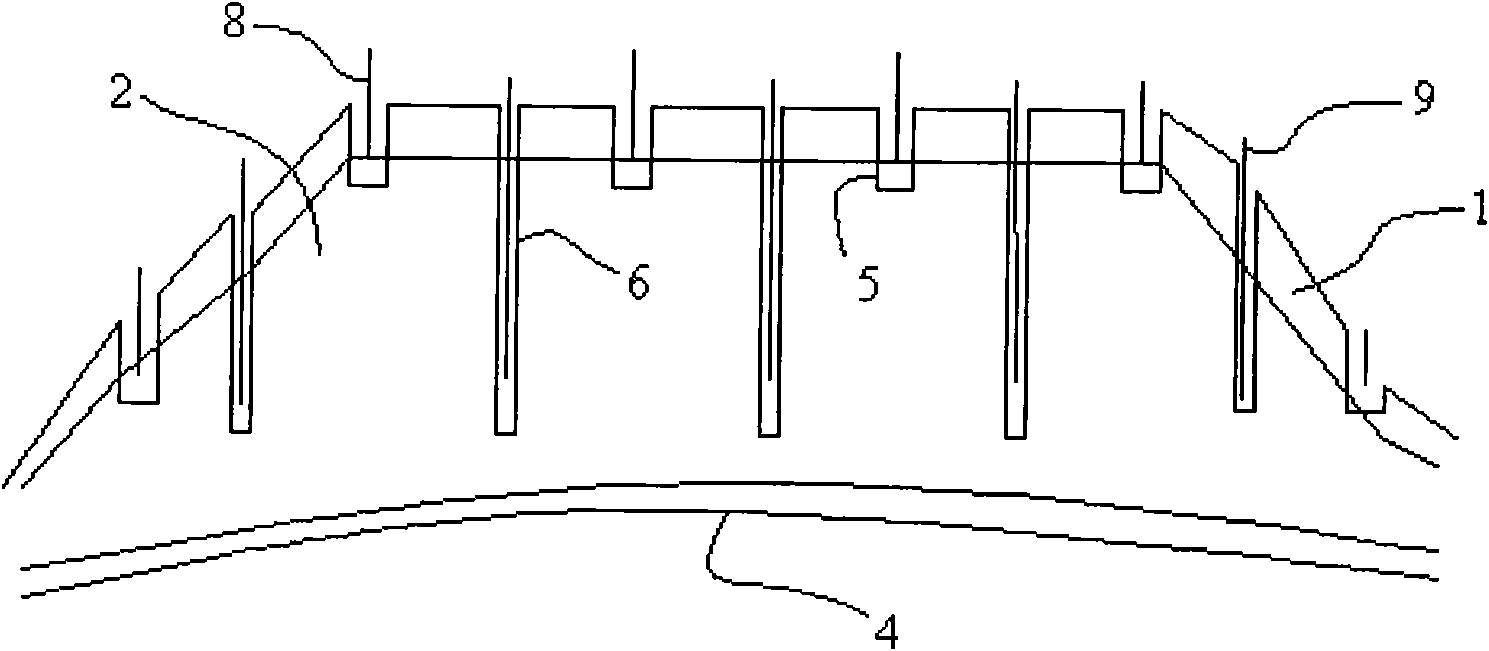

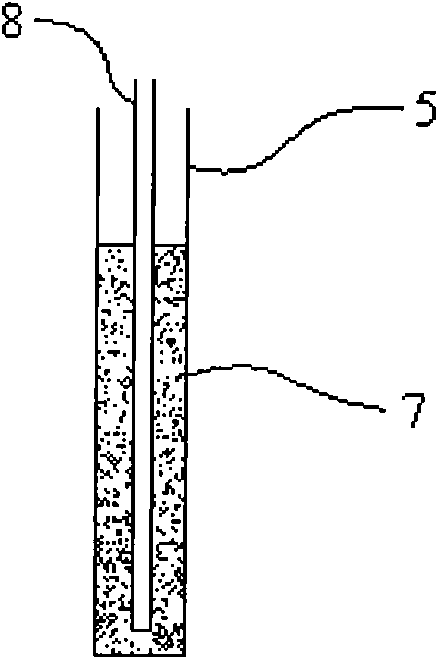

In situ leaching injection process

ActiveCN101915073AReduce wasteResidue reductionFluid removalProcess efficiency improvementRare earthIn situ leach

The invention discloses an ion adsorption rare-earth in situ leaching injection process, which is characterized by comprising the following steps of: setting an injection network with shallow injection wells and deep injection wells distributed at intervals according to mineral body space layout condition, mineral body thickness change condition, mineral soil permeability, project layout of a liquid receiving system and the like; and injecting the shallow injection wells and then injecting the deep injection wells in an injection process, and finally injecting top water to the shallow injection wells and the deep injection wells together. The in situ leaching injection process has the advantages of rare-earth leaching rate, high mother solution concentration, little mineral mother solution residue, low single leaching agent consumption, simple operation, wide application range and remarkable environment-friendly effect, meanwhile solves the problem of poor stability of a leaching dead zone and an injection process slope, and realizes controllability of flow direction, flow rate and injection strength of the leaching agent.

Owner:JIANGXI RARE EARTH & RARE METALS TUNGSTEN GRP HLDG CO LTD

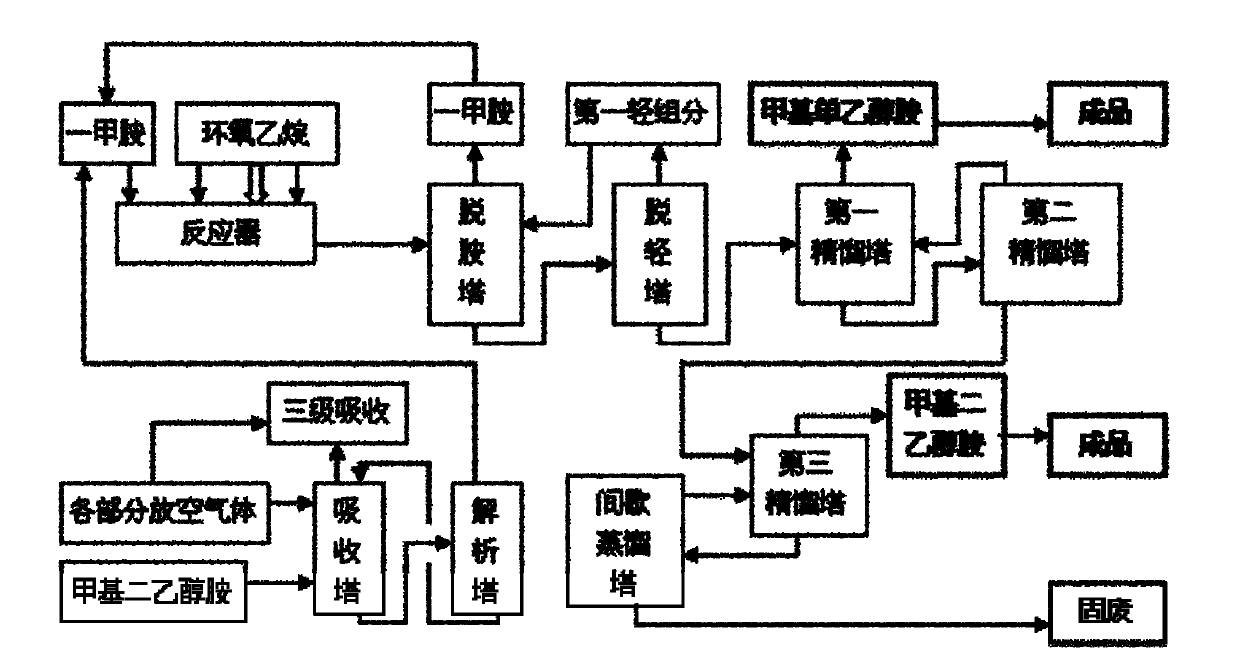

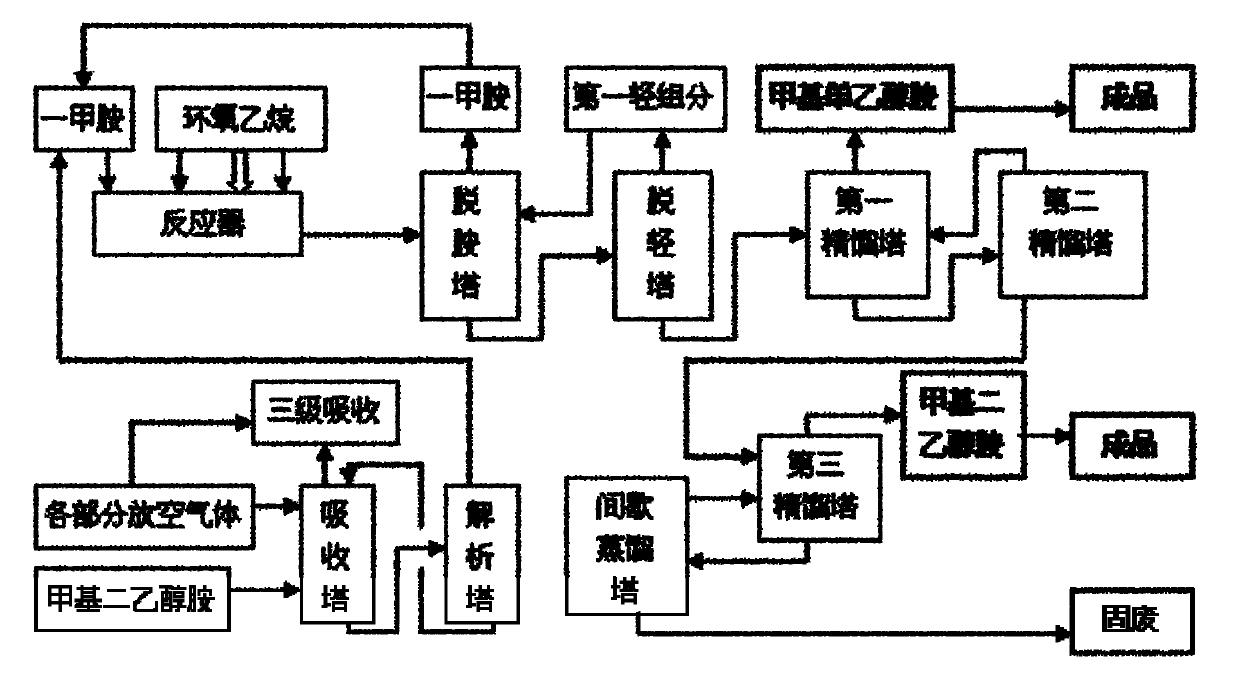

Method for producing alkyl alcohol amine

ActiveCN102557960ALess side effectsExpand the range of output ratio adjustmentOrganic compound preparationAmino compound preparationAlkyl transferAlcohol

The invention provides a method for producing alkyl alcohol amine. The method is characterized by comprising the following steps of: under an alkylation reaction condition, repeatedly contacting alkylene oxide with alkylamine in a reactor; and repeatedly reacting alkylene oxide with alkylamine. On one hand, the side reaction of the alkylene oxide is reduced, and the yield proportion adjusting ranges of alkyl mono-alkylol amine and alkyl di-alkylol amine are expanded; meanwhile, raw materials are not required to be mixed in advance, and the safety of production is improved; moreover, alkylene oxide enters segmentally in a multipoint way, so that reaction heat is segmentally released, and a reaction is more stable; and furthermore, the content of the mono-alkyl alkylol amine can be controlled, so that the mono-alkyl alkylol amine is not required to be taken as a circulating liquid, and the yield of the reaction is increased.

Owner:FEIXIANG NEW MATERIAL R & D SUZHOU INST

Continuous casting and rolling process for producing 3005 aluminum-plastic strip blank

The invention relates to the aluminum processing industry, in particular to a continuous casting and rolling process for producing a 3005 aluminum-plastic strip blank. In the process, an aluminum melting furnace, a heat preserving furnace, an online refining device, a two-stage filtering box, a continuous casting and rolling unit are used in the production method. The process method comprises the following steps of: 1) preparation; 2) feeding; 3) melting and stirring; 4) drossing and sampling for analysis; 5) degassing and refining, standing and heat preservation; 6) online melt treatment; 7) continuous casting and rolling; 8) reeling and cutting; and 9) checking. The continuous casting and rolling process in the invention has the advantages that an 80% electrolytic aluminum liquid is adopted in the production process, the burning loss of aluminum is reduced to be below 1.5%, and the unit consumption of gas is reduced to be below 80Nm<3> / tAl, thus both the burning loss of aluminum and the energy consumption are reduced by 50% as compared with a casting and rolling method which adopts aluminum ingot for remelting to produce the 3005 aluminum-plastic strip blank, and the production yield is up to over 99%. The continuous casting and rolling process method for producing a 3005 aluminum-plastic strip blank in the invention is applicable to the aluminum and aluminum alloy casting industry at home and abroad.

Owner:GUIZHOU BRANCH CHINA ALUMINUM IND

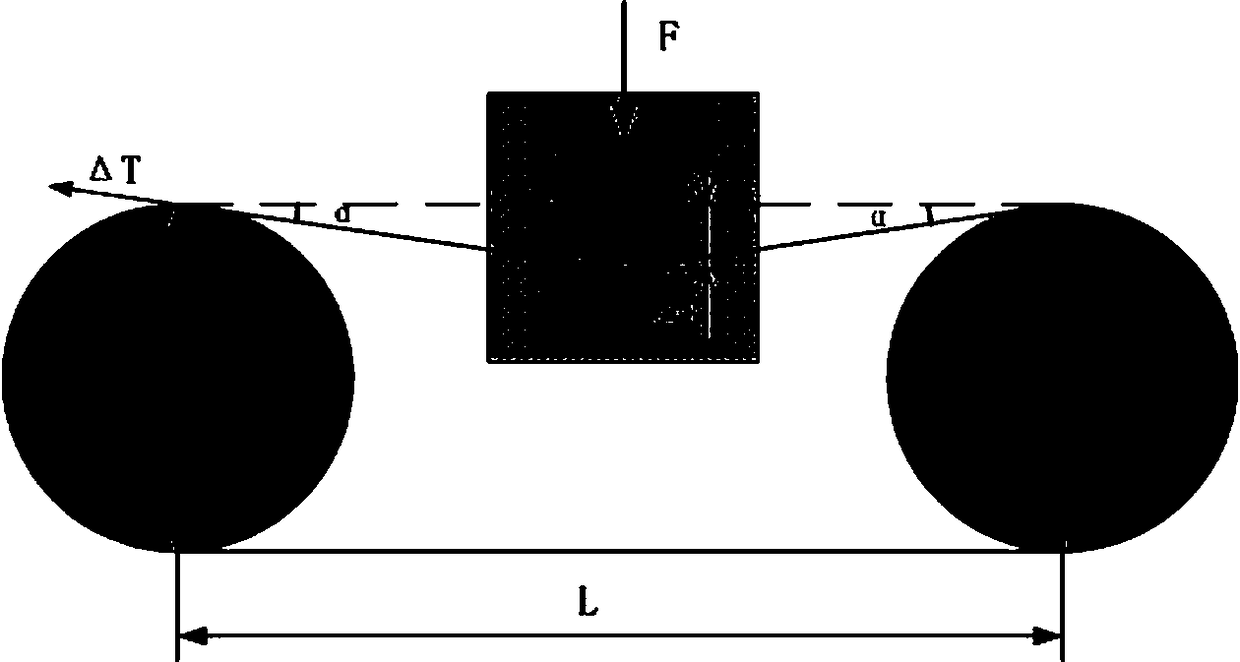

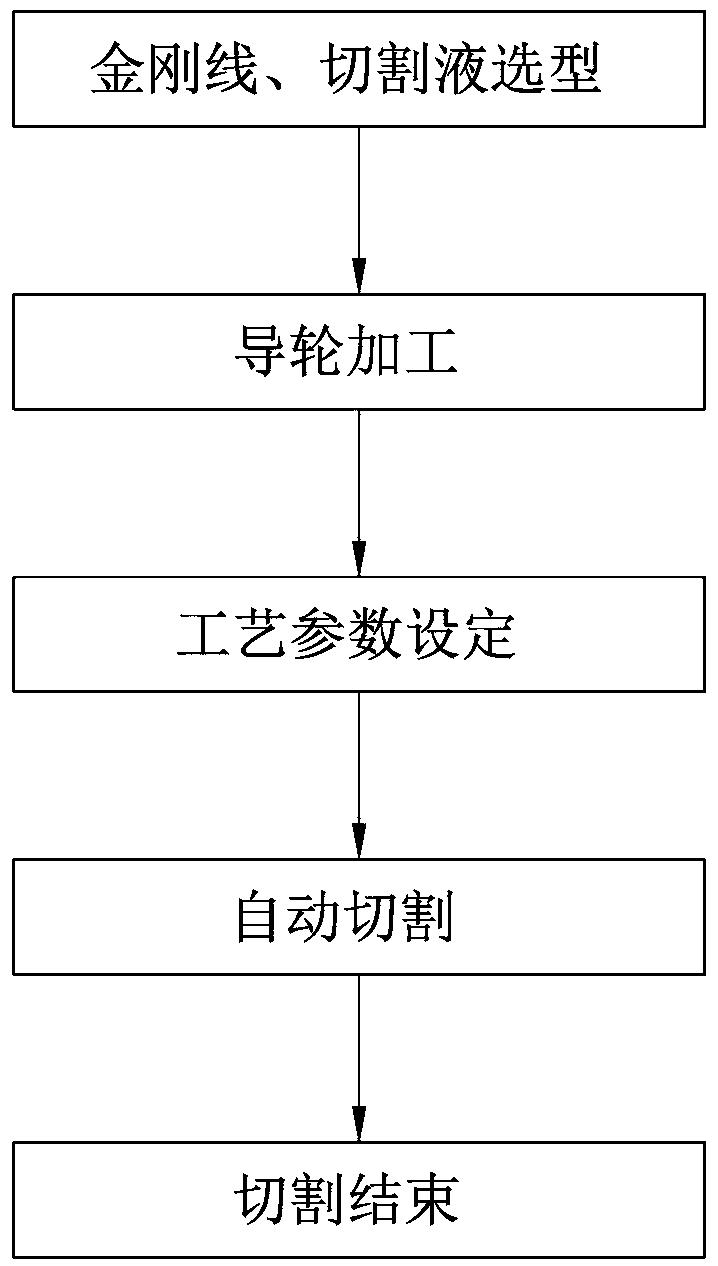

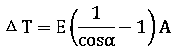

High-efficiency cutting method for crystalline silicon blocks

InactiveCN109304819AThe process takes a short timeIncrease slicing capacityFine working devicesMicrometerCrystalline silicon

The invention discloses a high-efficiency cutting method for crystalline silicon blocks in the field of solar energy application. The high-efficiency cutting method comprises the following steps of 1)diamond wire and cutting liquid selection, wherein a single-polycrystalline mixed sand electroplating diamond wire (the diamond wire diameter ranges from 50 micrometers to 70 micrometers is adopted,the cutting fluid is selected from a low COD coolant and pure water mixture; 2) guide wheel processing; 3) process parameter setting, wherein the diamond wire, the cutting fluid and a guide wheel arematched, after a cutting machine is assembled, the feeding speed of the working table is adjusted to be 800-3000micrometers per minute, the cutting fluid process flow is 110-180 KG / Min, the cutting liquid cooling temperature is 17-23 DEG C; 4) automatic cutting, wherein after the machine is started for warming up by 5-10 minutes, when it is known that the parameters are normal through spot check,automatic cutting starts; and 5) ending of cutting, wherein a rod is lifted to complete silicon block cutting. The high-efficiency cutting method effectively improves the cutting speed and the cuttingefficiency, improves the yield rate, reduces the cost of auxiliary materials like the diamond wire consumption, improves the slice profitability, and can be used for silicon wafer production.

Owner:YANGZHOU RONGDE NEW ENERGY TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com