Patents

Literature

47results about How to "Meet the requirements of recycling" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

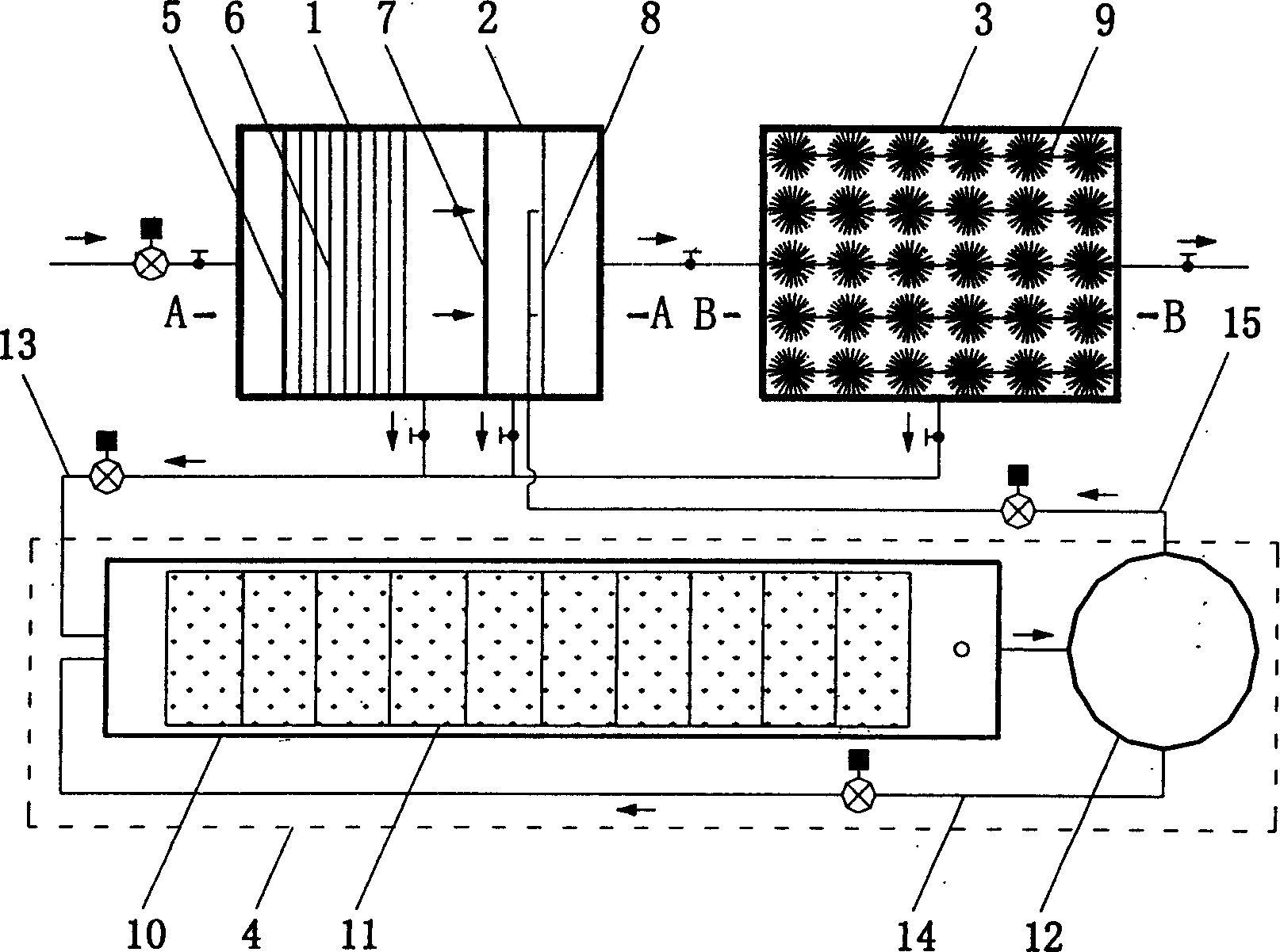

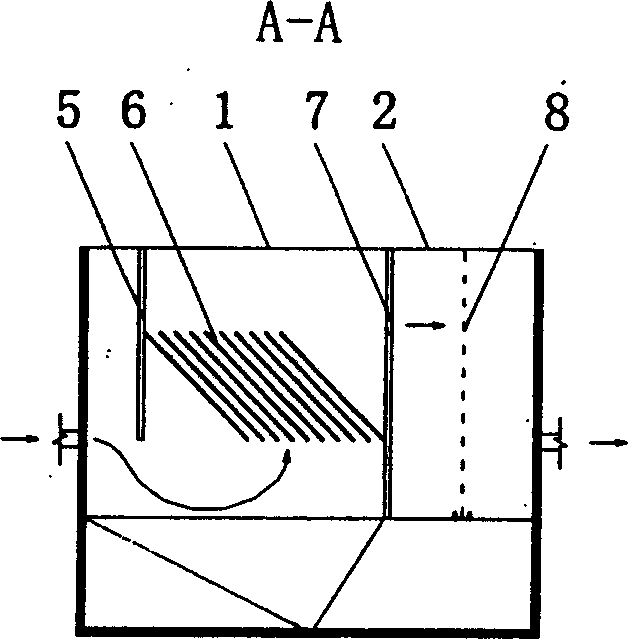

Polypropylene tail gas recovery device and recovery method

InactiveCN105004140AAchieve recyclingMeet the requirements of recyclingSolidificationLiquefactionRecovery methodSeparation technology

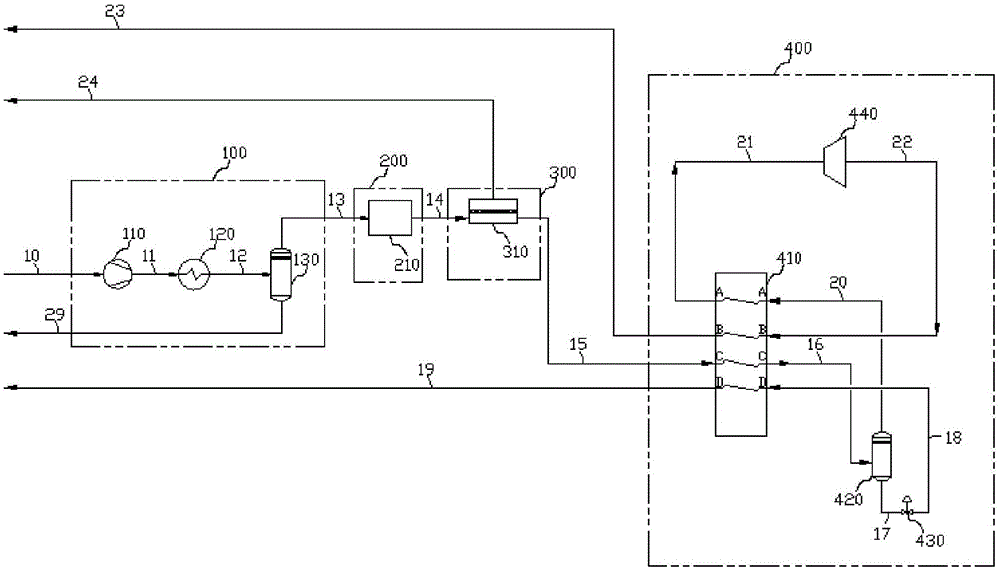

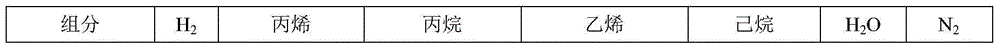

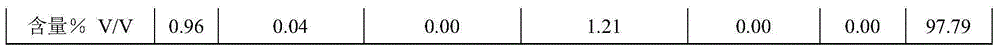

The invention discloses a polypropylene tail gas recovery device. The polypropylene tail gas recovery device comprises a compression unit, a drying unit, a membrane separation unit and a cryogenic separation unit, wherein the compression unit, the drying unit, the membrane separation unit and the cryogenic separation unit are connected in sequence. The compression unit comprises at least one compressor, a heat exchanger and a gas and liquid separator, wherein the compressors, the heat exchanger and the gas and liquid separator are connected in sequence. The drying unit comprises at least two adsorption towers which are connected in sequence, and drying agents are placed in the adsorption towers. The membrane separation unit comprises a membrane separator. The cryogenic separation unit comprises at least one high-efficiency multi-channel heat exchanger, at least one low-temperature gas and liquid separator, at least one gas expansion device and at least one liquid expansion device. According to a polypropylene tail gas recovery method adopting expansion refrigeration, propylene in polypropylene tail gas is liquefied to be recovered, and meanwhile nitrogen is purified to meet the requirement for nitrogen recycling; in combination with a membrane separation technology, hydrogen in the polypropylene tail gas is removed; the recovery rate of the propylene in the polypropylene tail gas reaches above 98%.

Owner:DALIAN EUROFILM IND

Apparatus for rapidly recovering energy source storage of electric automobile and operational method thereof

InactiveCN1557659ASo as not to damageAvoid damageElectric propulsion mountingElectric/fluid circuitElectricityElectric-vehicle battery

The present invention is one novel accumulator fast replacing device and operation method for electric automatic. Standard power source unit or combined power source unit and corresponding device are adopted for fast replacement of accumulator. At the same time, the method including user's buying only the use right of the accumulator, card consumption, electricity buying before running, recharging, establishing of charging station network, circulation of accumulator, supply of standard power source unit or combined power source unit by the accumulator producer and comprehensive recovering of waste accumulator is adopted. The present invention is suitable for various kinds of electric automobile.

Owner:于耀庆

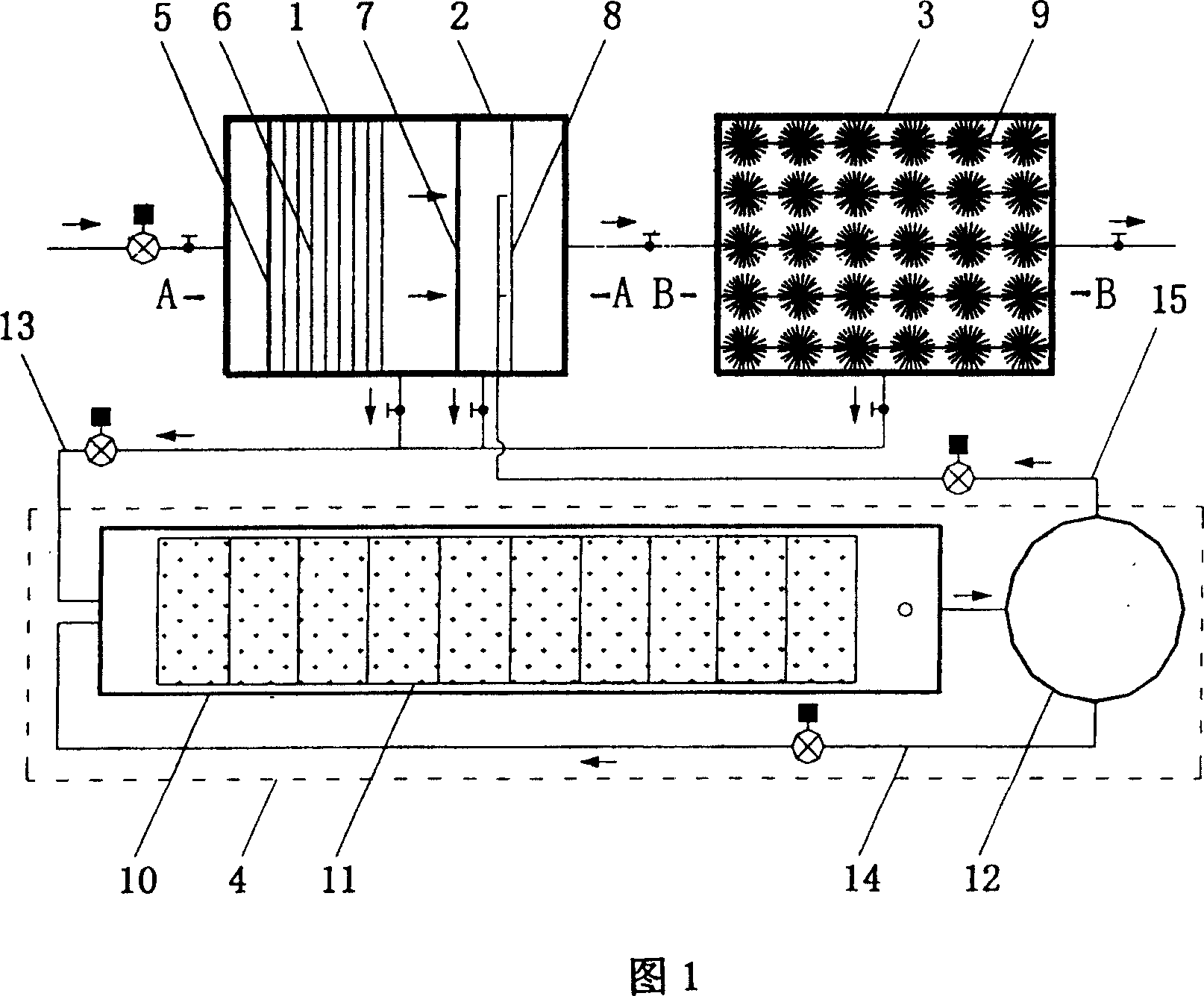

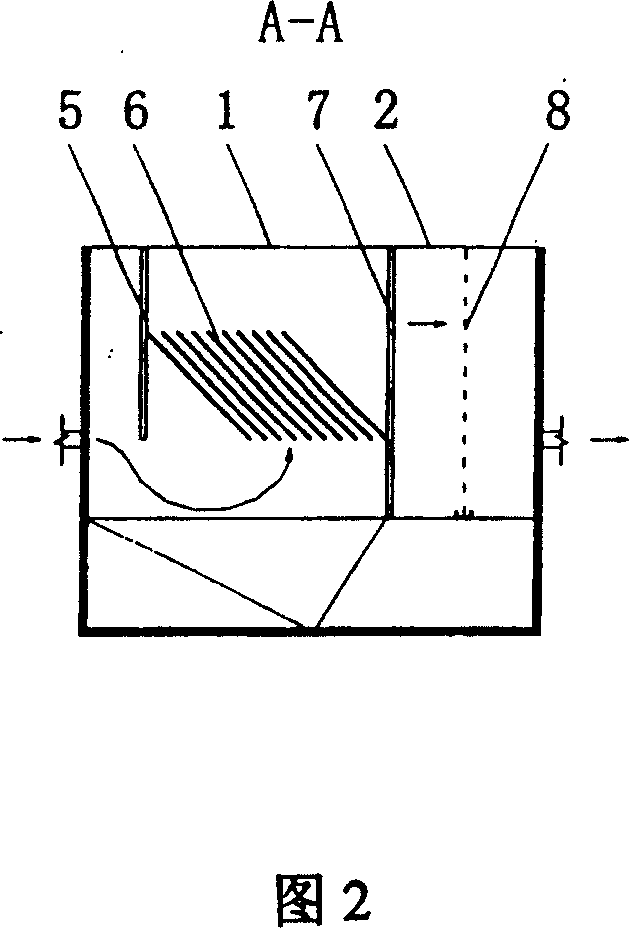

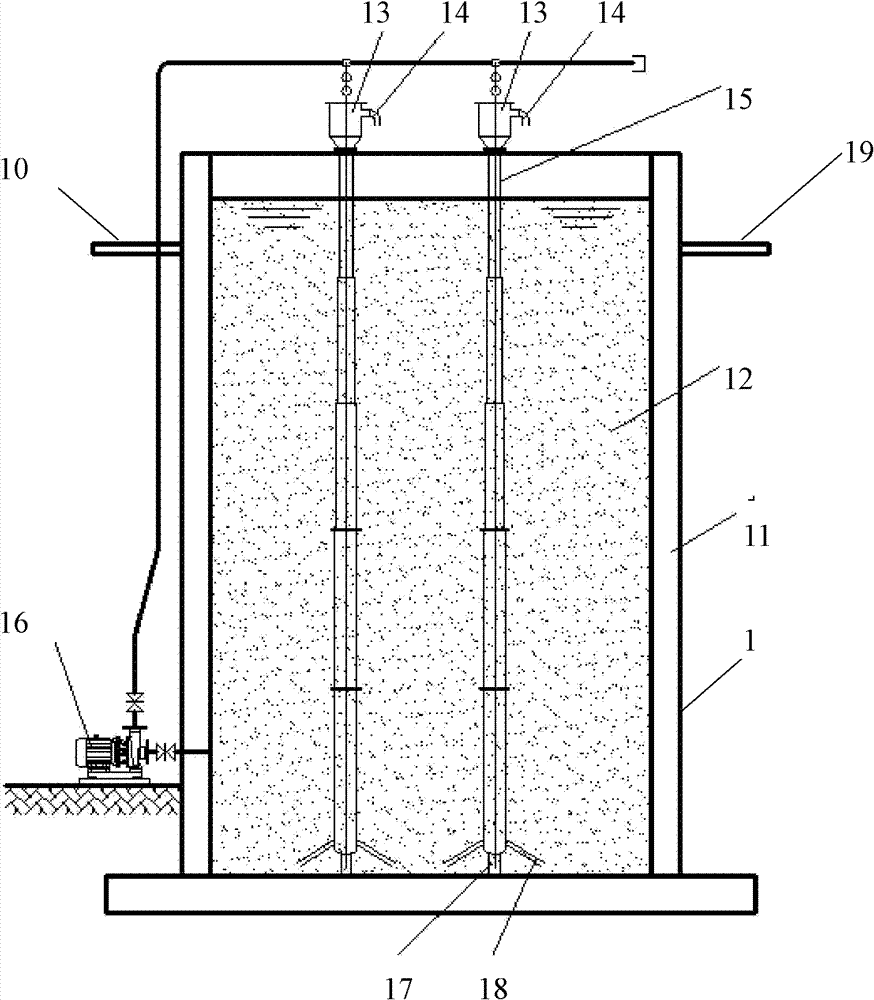

Comprehensive treating method and treating system for industrial aquatic cultivation sewage

InactiveCN1587121AEasy to manageRelieve pressureTreatment using aerobic processesMultistage water/sewage treatmentBiologySewage

The present invention discloses comprehensive treating method and system for industrial aquatic cultivation sewage. The sewage containing rich excrement, ammonia and other metabolic product as well as feed residue from the bottom of the industrial cultivation pond is treated successively through deposition of large grain excrement and feed residue in the inclined plate depositor, interception of other excrement and feed residue in the mechanical filter, and conversion of ammonia into nitrate with nitrifying bacteria in the biological filter. The treated sewage is returned to the cultivation pond circularly while the deposited, intercepted and flocculated matters are delivered to the plant filter with aquatic grass plant as medium. The mechanical filter is back flushed regularly.

Owner:ZHEJIANG UNIV

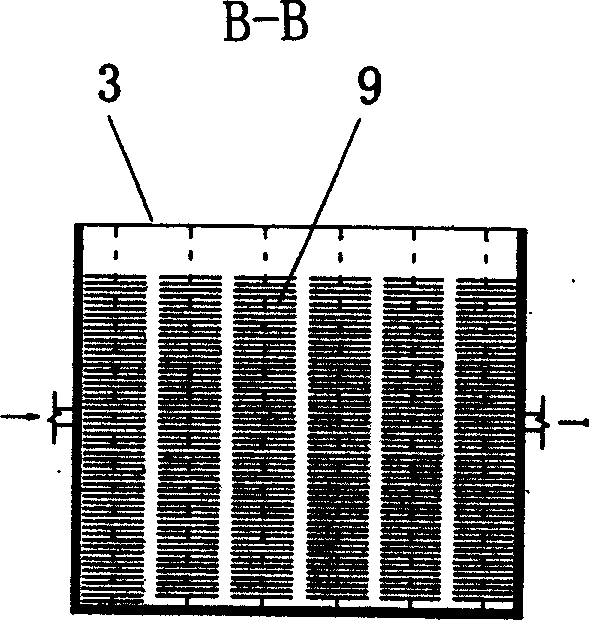

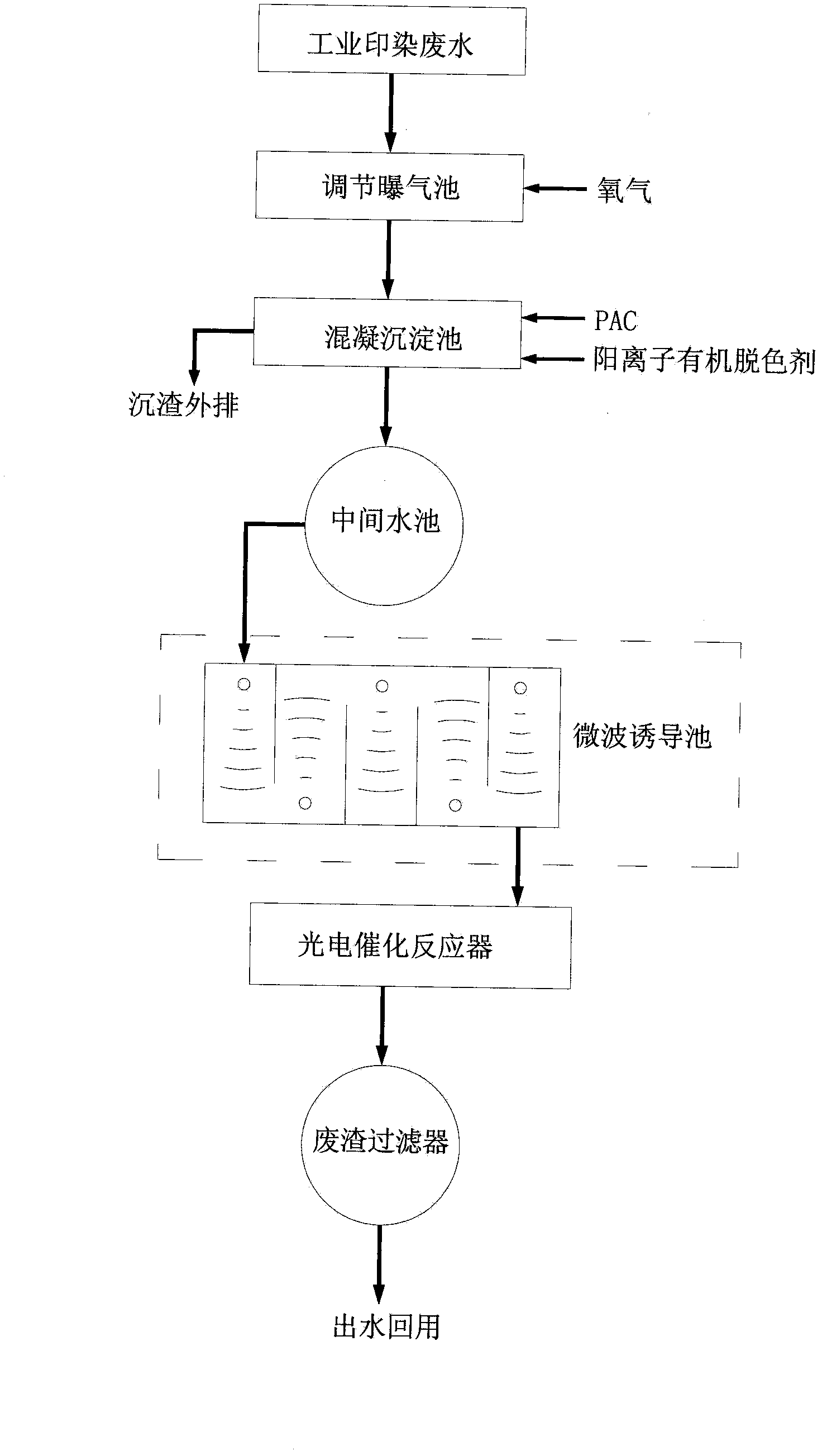

Process for treating printing and dyeing wastewater through combination method

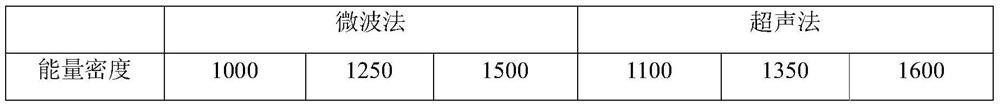

InactiveCN103570165AHigh removal rateGood decolorization effectWater/sewage treatment by irradiationMultistage water/sewage treatmentFiltrationWastewater

The invention relates to a process for treating printing and dyeing wastewater through a combination method. The process comprises a pretreatment process and a combined treatment process, wherein the pretreatment process comprises the following steps: regulating an aeration process and a neutralization, coagulation and precipitation process, performing pretreatment of aeration regulation and neutralization, coagulation and precipitation on wastewater, and performing combined treatment through microwave+photoelectrocatalysis+industrial waste residue filtration and adsorption. According to the process, degradation-resistant organic matters and other pollutants in the printing and dyeing wastewater can be effectively degraded, a wastewater treatment effect is improved, and the treated wastewater can basically meet the reutilization requirement. According to the process, related problems (particularly complex pollutant components, low biodegradability and high discoloring difficulty of the mixed printing and dyeing wastewater in a concentrated industrial park) for treatment of the printing and dyeing wastewater are effectively solved, a high-efficiency treatment process is provided, the treatment effect is stable, the production operating cost is low, and the operation is simple and convenient.

Owner:HUBEI CHUANDONG ENVIRONMENTAL ENERGY DEV CO LTD

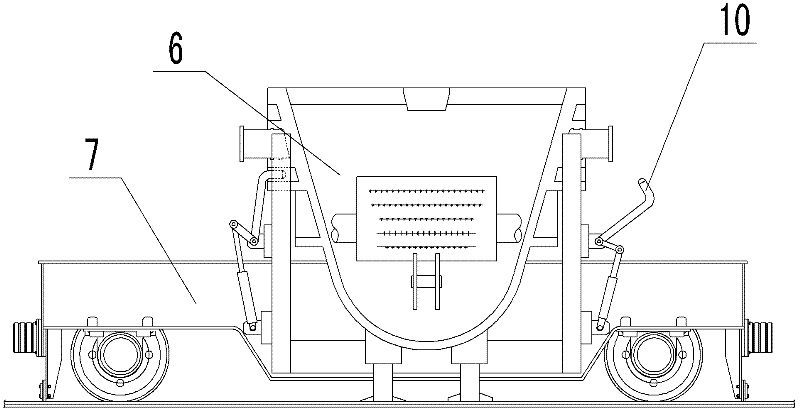

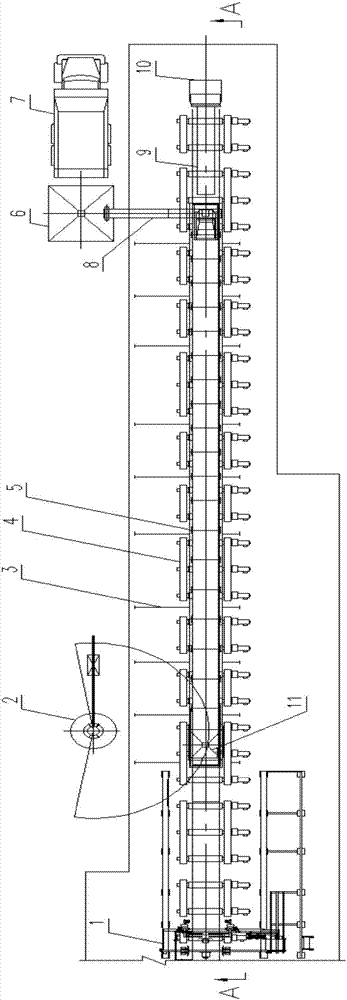

Slag water quenching method and device

InactiveCN102392084ATo achieve the purpose of safe recyclingMeet the requirements of recyclingRecycling and recovery technologiesProcess efficiency improvementGranularitySlag

The invention discloses a slag water quenching method and device, aiming at solving the problem of bad safety of slag water quenching treatment method in the prior art. According to the method, slag is distinguished and treated according to volume. The method comprises the following steps: putting slag to a processing station by a slag tipping unit, and turning on a pelletizer; cooling and crushing the slag with a stream of water by the pelletizer, and tipping the processed slag onto a grid sieve; letting the slag with large diameter enter in a slag collecting pit, crushing and recovering steel scrap, and letting the rest slag enter the slag collecting pool; letting the slag with small diameter enter in the slag collecting pool, and stirring and grabbing to a dripping slag bin. The device comprises the slag tipping unit, the pelletizer, the grid sieve, the slag collecting pit, the slag collecting pool, a turbid circulating water circulation system, and the dripping slag bin. The method and device disclosed herein have high safety, satisfy the requirements of steel-making, sintering and other processes for recycling slag with proper granularity, and are suitable for the field of steel-making technology.

Owner:HUATIAN ENG & TECH CORP MCC

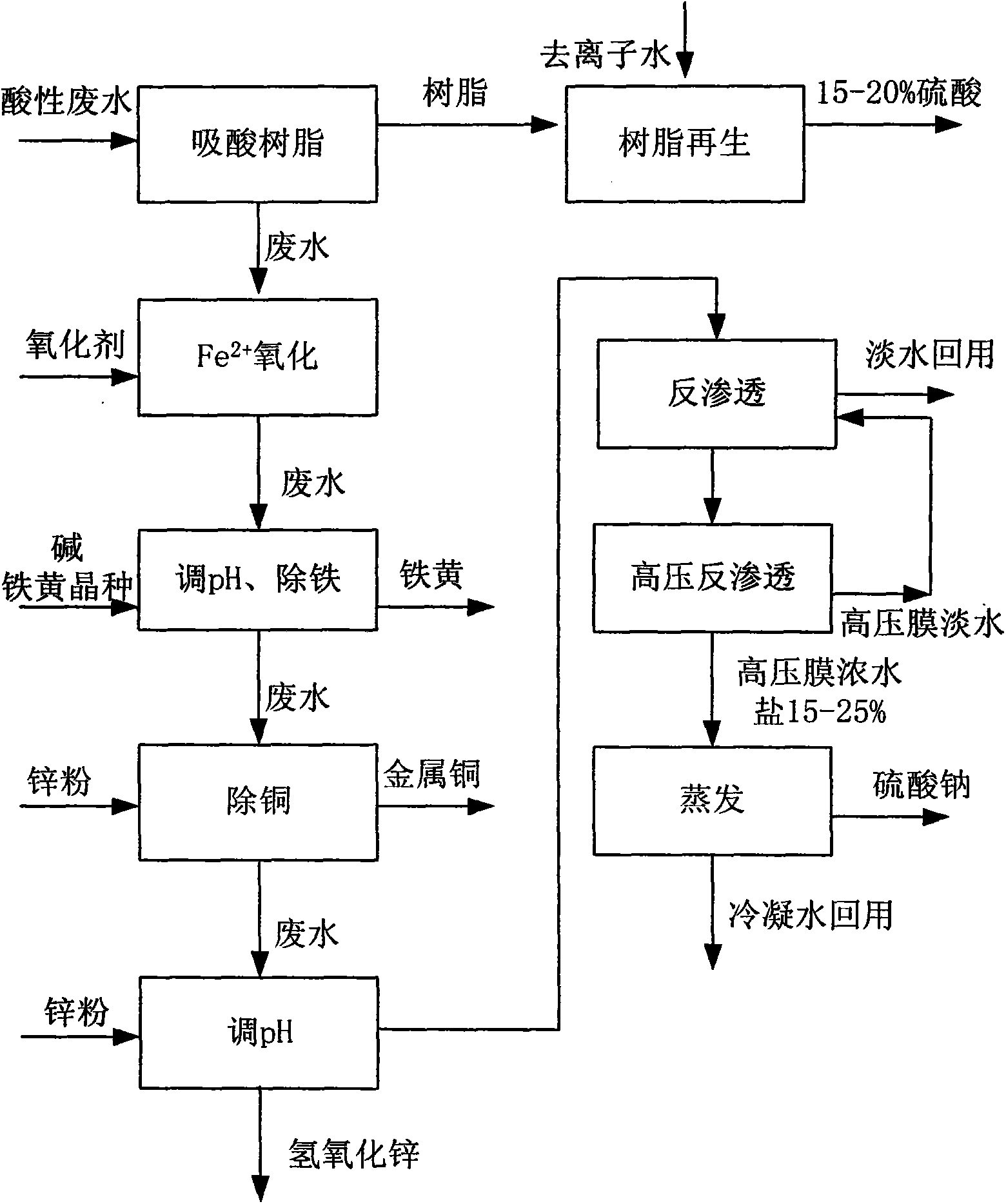

Method for recycling acid and heavy metal in gold smelting acid wastewater

InactiveCN104030510AEmission reductionOffsetting costsZinc oxides/hydroxidesMultistage water/sewage treatmentHeavy metalsCopper

The invention provides a method for recycling acid and heavy metal in gold smelting acid wastewater. The method comprises the steps of: adsorbing sulfuric acid in the acid wastewater by utilizing acid adsorption resins; adding oxidizing agents for oxidizing divalent iron in the wastewater into ferric ion; adding ferrite yellow seed crystals and rising the temperature for reacting; regulating a pH value to be 1.5-4.5; separating out the iron in the waste acid in a ferrite yellow form; adding zinc powder and replacing copper in the wastewater; regulating a pH value of the water subjected to copper separation to be 6.5-8.0; precipitating out zinc hydroxide; removing the wastewater of zinc and performing reverse osmosis membrane treatment; recycling the fresh water used in reverse osmosis in the production process; performing high pressure membrane treatment on dense water for reverse osmosis; evaporating the dense water subjected to the high pressure membrane treatment to obtain salt contents of sodium sulfate; performing reverse osmosis re-treatment on the fresh water subjected to high pressure membrane treatment; regenerating by using deionized water after the saturation of acid adsorption of the acid adsorption resins to obtain 15-20 percent of sulfuric acid.

Owner:安可珍

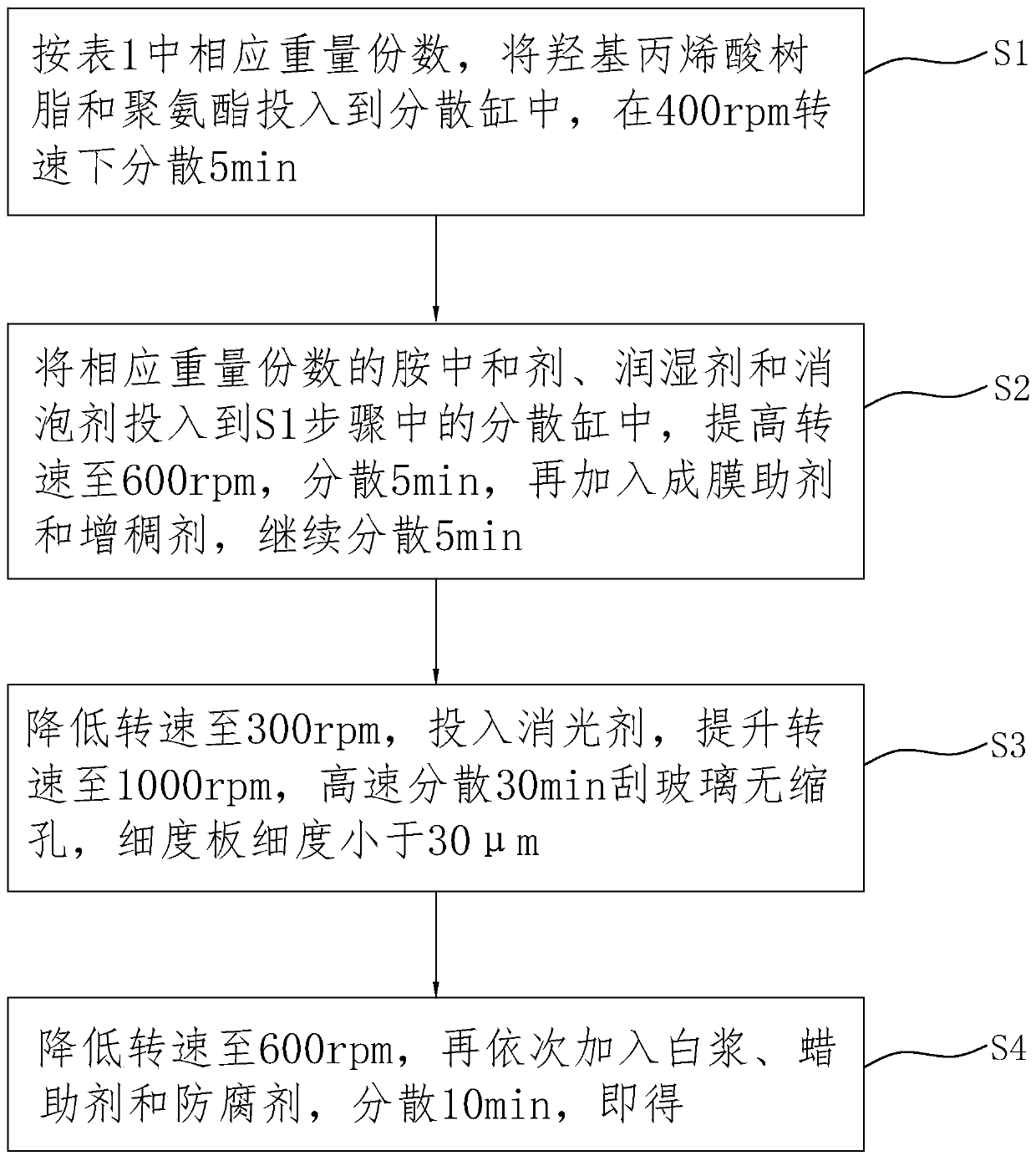

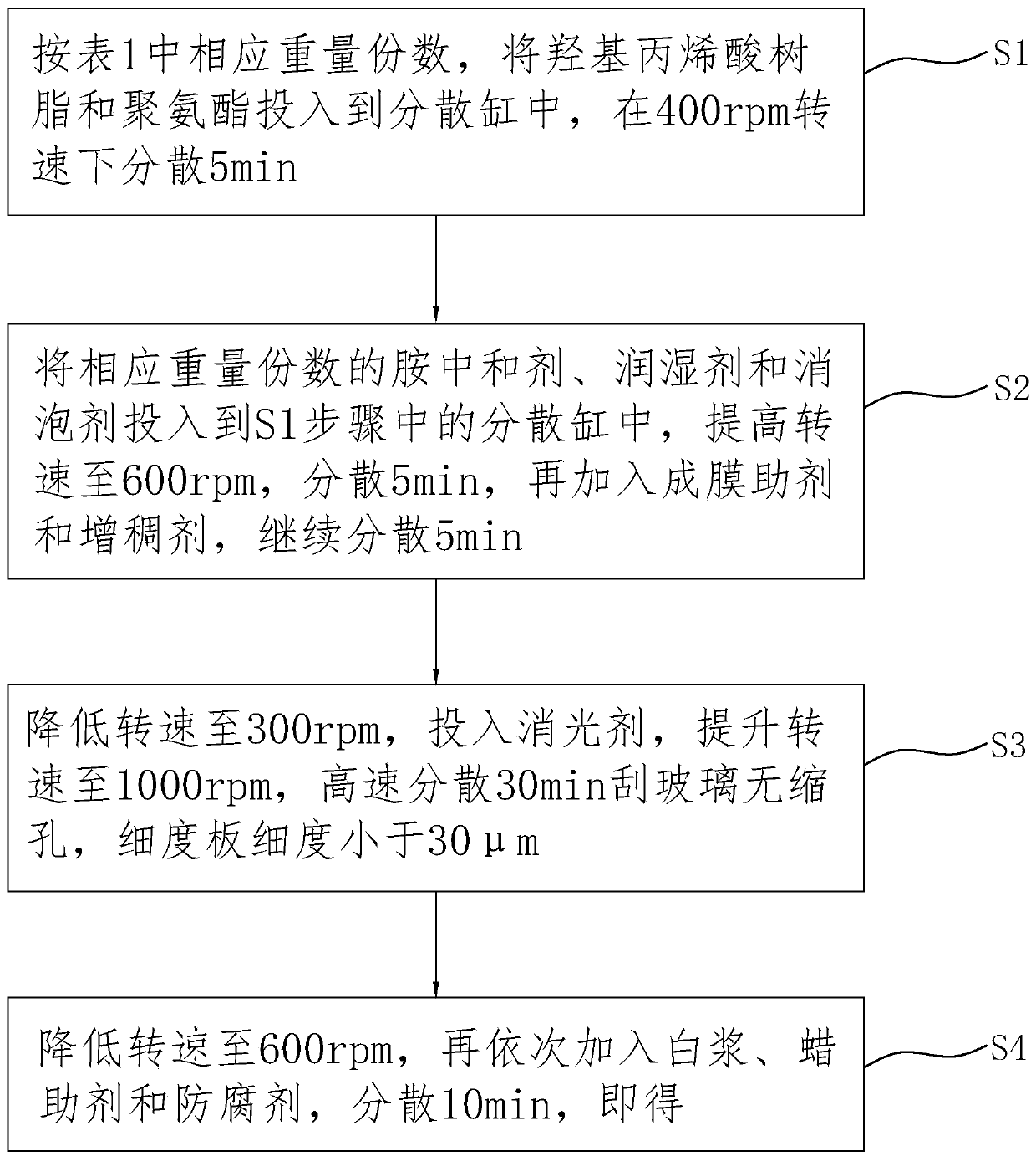

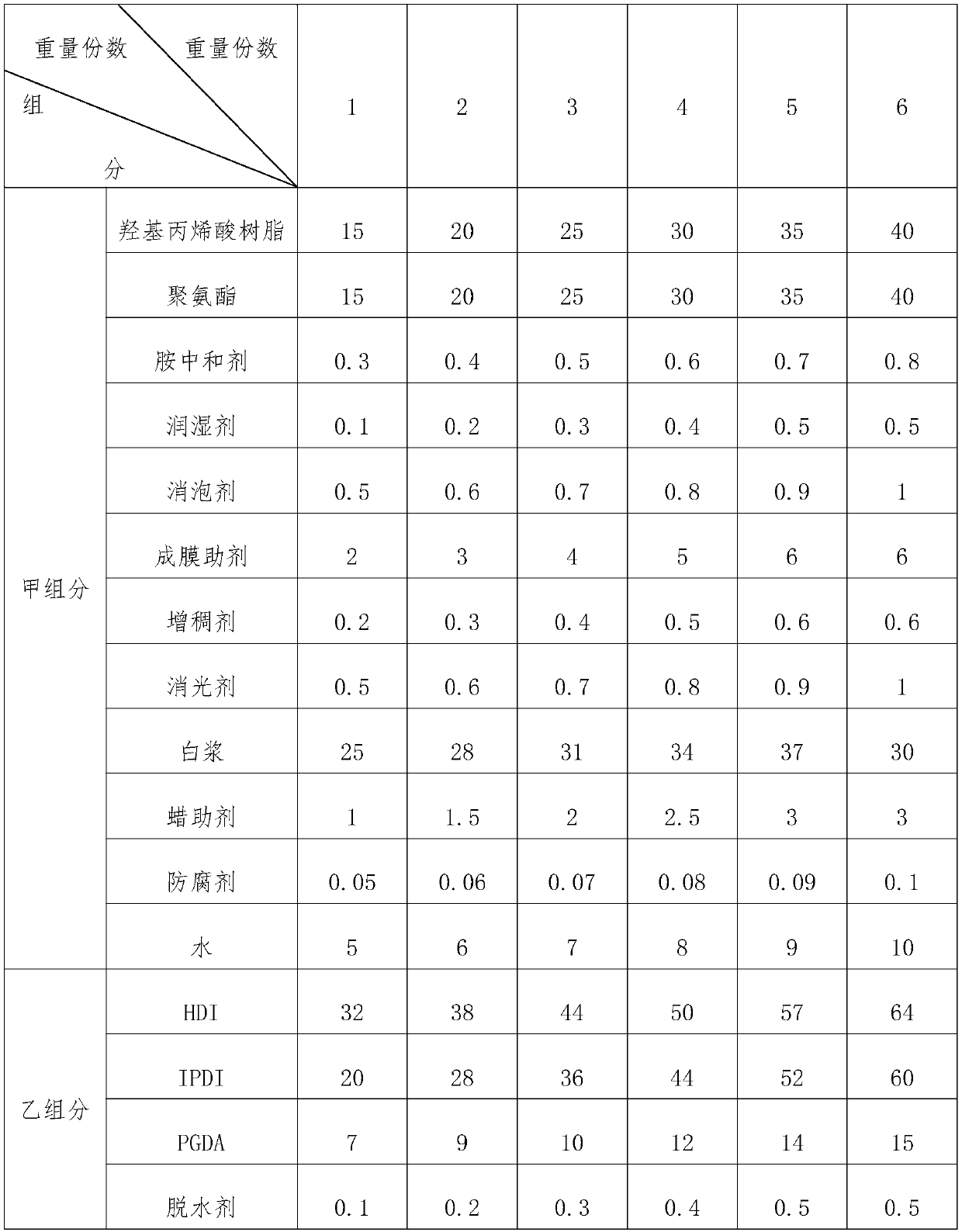

Water-based two-component matte white finish paint and preparation method thereof

InactiveCN111171696AExtend the usable timeLow usable timePolyurea/polyurethane coatingsFoaming agentAcrylic resin

The invention discloses water-based two-component matte white finish paint and a preparation method thereof, and relates to the technical field of water-based paint. The technical key points are as follows: the water-based two-component matte white finish paint comprises a component A and a component B. The component A comprises the following components in parts by weight: 15-40 parts of hydroxy acrylic resin; 15-40 parts of polyurethane; 0.3-0.8 parts of an amine neutralizer; 0.1-0.5 parts of a wetting agent; 0.5-1 parts of a de-foaming agent; 2-6 parts of a coalescing agent; 0.2-0.6 parts ofa thickening agent; 0.5-1 parts of a delustering agent; 25-30 parts of white pulp; 1-3 parts of a wax additive; 0.05-0.1 parts of a preservative; 5-10 parts of water; the component B is prepared fromthe following components in parts by weight: 32-64 parts of HDI; 20-60 parts of IPDI; 7-15 parts of PGDA; and 0.1-0.5 parts of a dehydrating agent. The water-based two-component matte white finish paint prepared by adopting the formula has the advantages of the long service life and recyclability.

Owner:SHANGHAI CHANGRUNFA PAINT

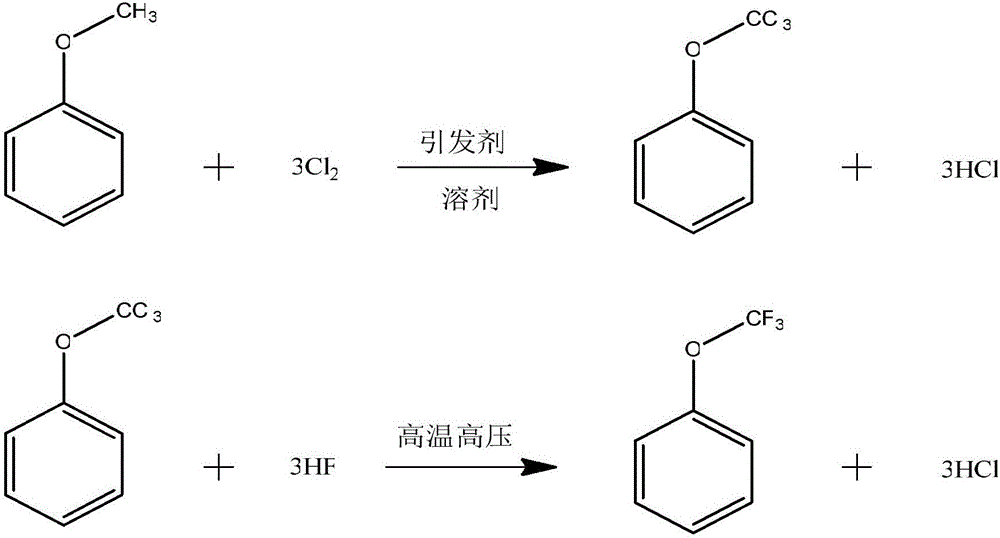

Production method of trifluoromethoxybenzene

ActiveCN106008175AHigh recovery purityHigh recovery rateOrganic chemistryOrganic compound preparationChemical reactionOil phase

The invention relates to a production method of an aromatic compound, in particular to a production method of trifluoromethoxybenzene. The production method includes chlorination reaction, fluoridation reaction and product separation and is characterized in that anisole is used as the initial raw material, the chlorination reaction uses aromatic hydrocarbon containing fluorine as the solvent, the solvent cannot be separated after the reaction, the fluoridation reaction of the solvent and HF is performed under proper conditions, the reaction products of the fluoridation reaction are subjected to washing and layering, the lower oil phase is subjected to rectification to obtain the trifluoromethoxybenzene, and the solvent is recycled. The purity of the obtained trifluoromethoxybenzene is larger than 99%, and the yield of the trifluoromethoxybenzene is larger than 95%. The chemical reaction formula is shown as follows.

Owner:SHANDONG DOCRIS CHEM

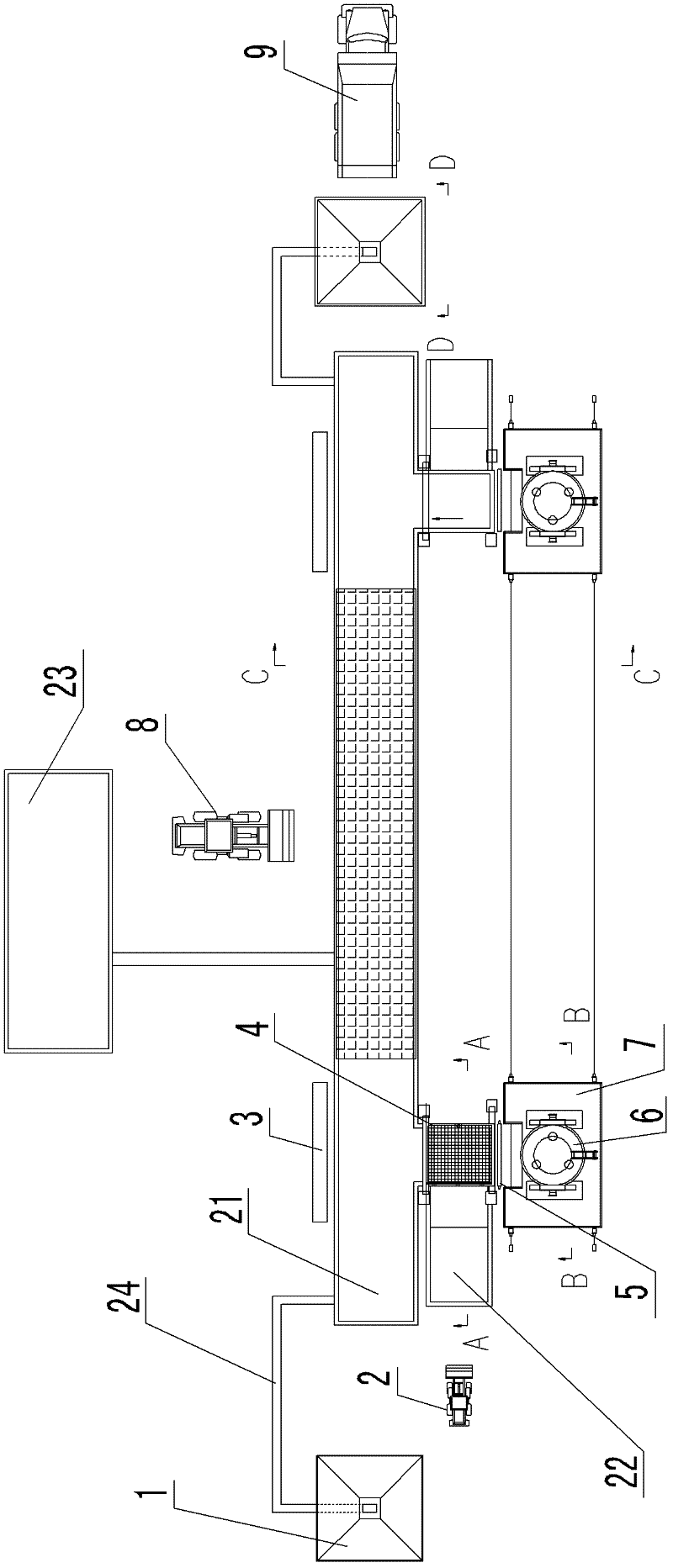

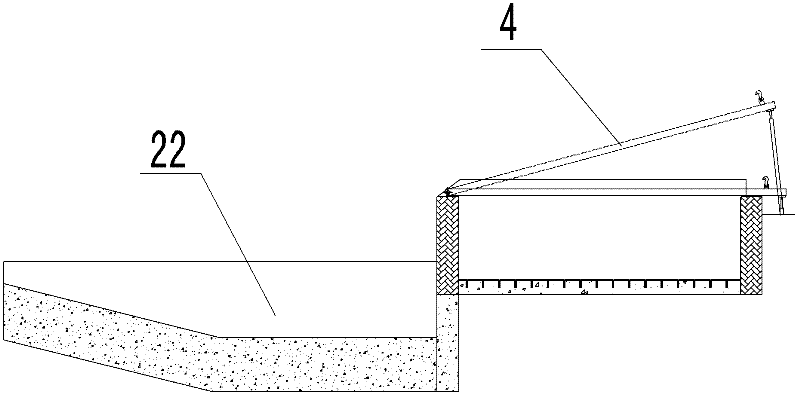

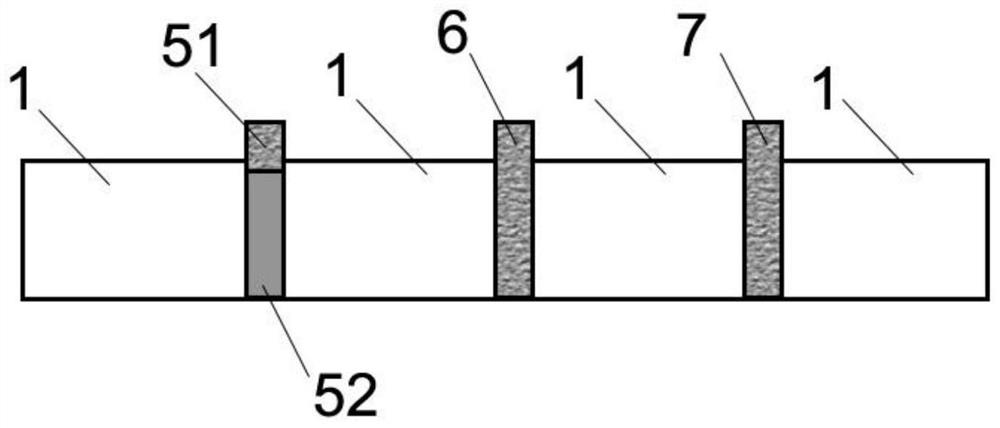

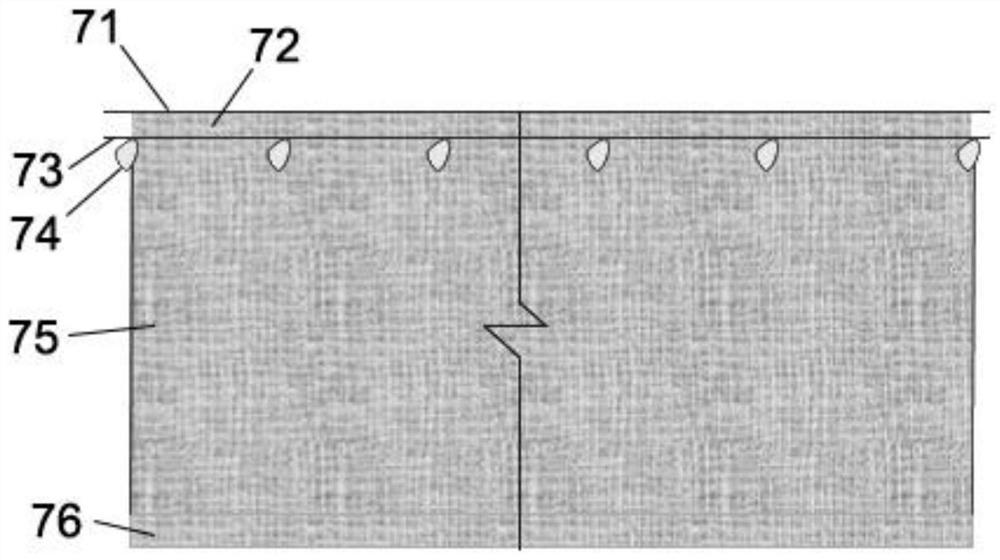

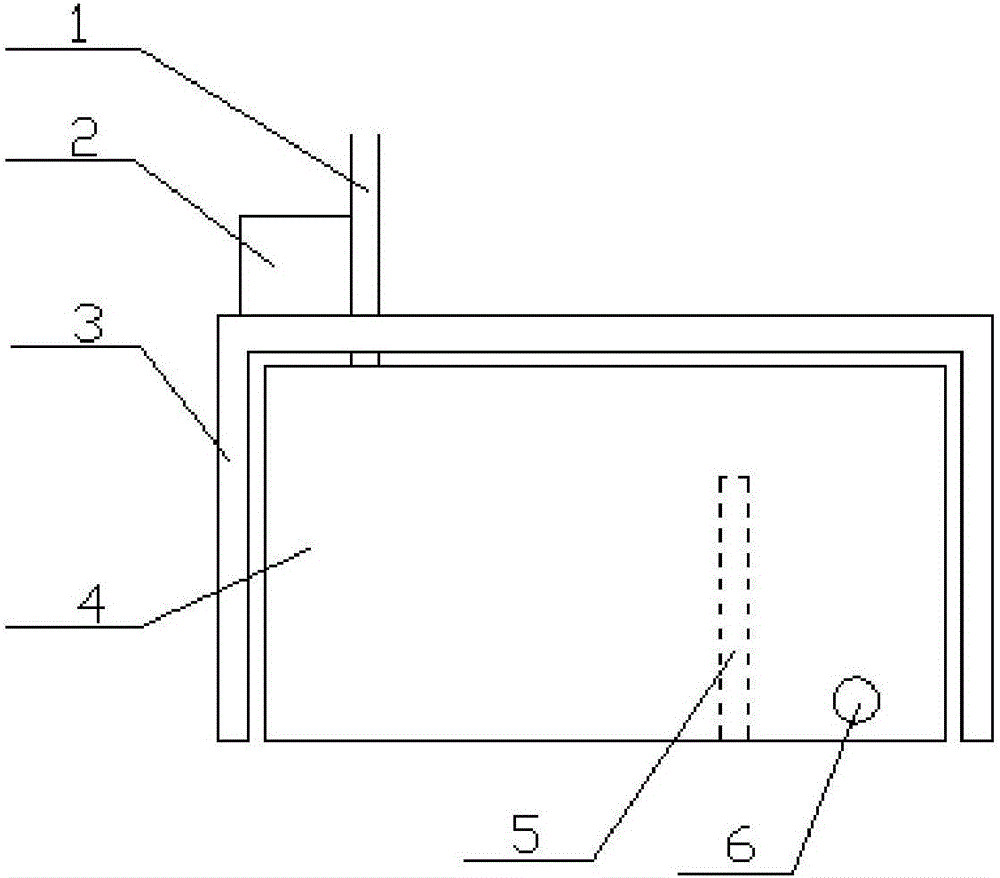

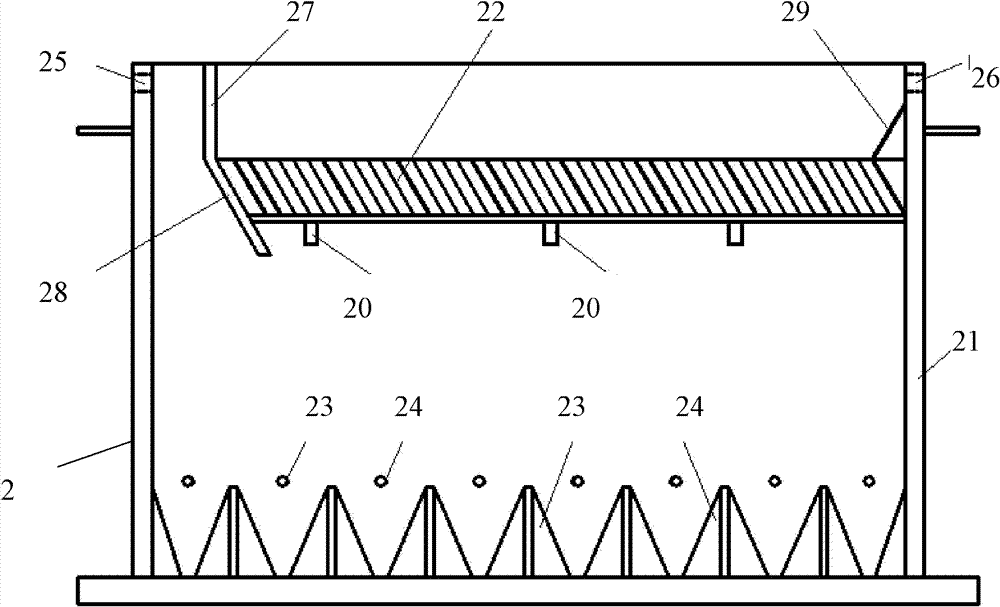

Freshwater aquaculture pond tail water treatment system

PendingCN111718073AFully purifiedMeet the requirements of recyclingWater contaminantsWaste water treatment from animal husbandryWater treatment systemWater source

The invention discloses a freshwater aquaculture pond tail water treatment system, belonging to the field of freshwater pond aquaculture. The tail water treatment system comprises a primary sedimentation tank 1 for receiving tail water, a nitrification / denitrification tank 2 and an aeration reoxygenation tank 3, wherein the nitrification / denitrification tank 2 is composed of a nitrification tank 21 and a denitrification tank 22, and the nitrification tank 21 is connected with the primary sedimentation tank 1 through an overflow dam 4; the denitrification tank 22 is connected with the aerationreoxygenation tank 3 through a second filter dam 5; and a third filter dam 211 is arranged between the nitrification tank 21 and the denitrification tank 22. With the system, purified water can reacha fishing standard and is even superior to an inflow water source, so cyclic utilization is realized.

Owner:FRESHWATER FISHERIES RES CENT OF CHINESE ACAD OF FISHERY SCI

Purification system and purification method for treating VOCs-containing waste gas by using circulating fluidized bed.

PendingCN109107341AMeet the requirements of recyclingReduce dosageGas treatmentDispersed particle filtrationPurification methodsFluidized bed

The invention relates to the field of environmental engineering waste gas treatment, particularly to a purification system and a purification method for treating VOCs-containing waste gas by using a circulating fluidized bed. The purification system comprises a circulating fluidized bed type adsorption device, a regeneration device, a bag dust removal device, a fan and an incineration device, wherein one end of the circulating fluidized bed type adsorption device is connected to the regeneration device, the regeneration device is connected to the bag dust removal device, the bag dust removal device is connected to the fan, the other end of the circulating fluidized bed type adsorption device is connected to the bag dust removal device, and the bag dust removal device is connected to the fan. According to the present invention, the waste gas is converted into the fluid-state adsorbate carrying the organic matters after the waste gas contacts the adsorbate having adsorption ability, theadsorbate is captured and then is regenerated, the desorbed organic matters are subjected to harmless treatment by the incineration device, the desorbed and regenerated adsorbate is transported to thecirculating fluidized bed type adsorption device and is reused so as to meet the requirements of the recycling of the adsorbate; and the system and the method have characteristics of high VOCs removal rate, less adsorbate consumption and no emission of wastewater and other secondary pollutants, and are suitable for the treatment of high, medium and low concentration VOCs waste gas.

Owner:浙江中兵环保股份有限公司

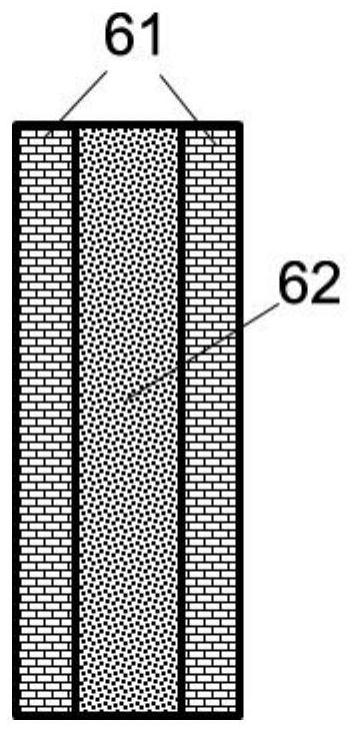

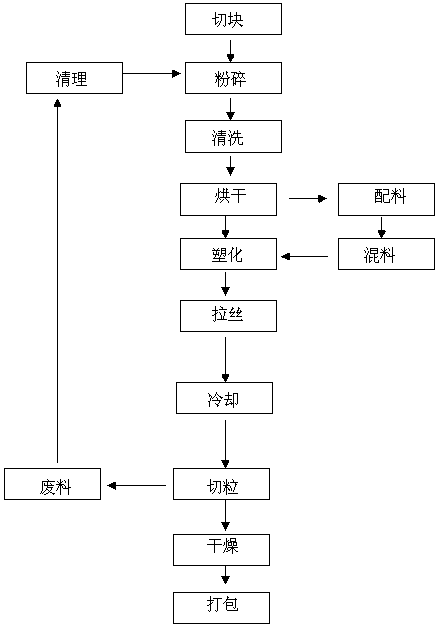

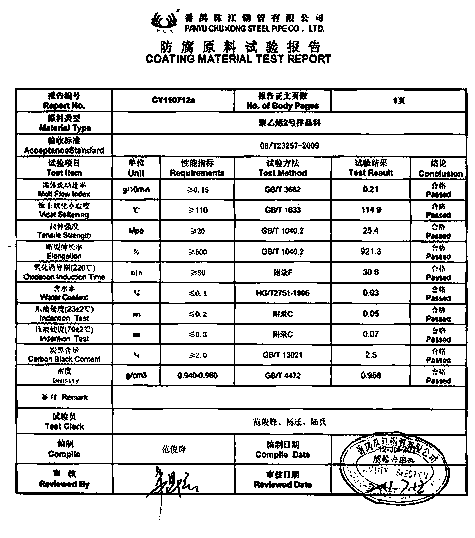

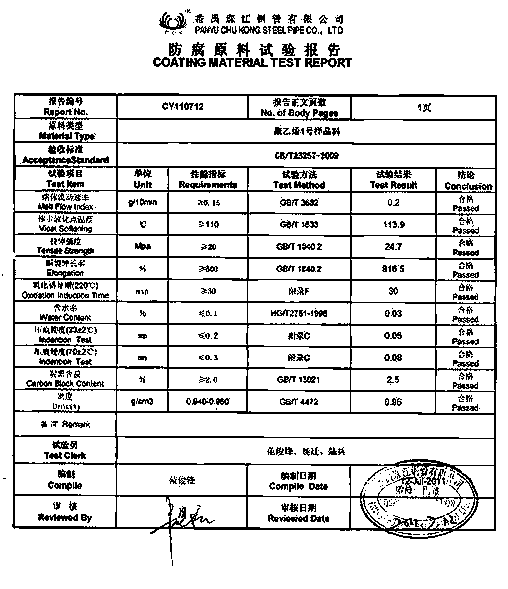

Method for recycling waste plastic for pipeline anticorrosion

ActiveCN103448159AImprove the mixing effectImprove plasticizing qualityPlastic recyclingSteel tubeEnvironmental resistance

The invention discloses a method for recycling waste plastic for pipeline anticorrosion, belonging to the technical field of high molecular materials applied to steel tube anticorrosion. The method is characterized by comprising the following steps: crushing; cleaning; re-proportioning anticorrosive 3PE (Poly Ethylene) waste plastic of a pipeline 3, namely the ratio of regenerating prilling materials: resin: an antioxygen: a processing agent=( is (80-70):(18-15):0.2:1.0. After prilling, the quality of the waste plastic satisfies the demand of technical standard (SY / T0413-2002) on the polyethylene anticorrosive layer of the buried steel pipeline, and the waste plastic can be reused to 3PE anticorrosion. The environmental pollution is eliminated and the environment problem is solved. The cost of raw materials for pipeline anticorrosion is saved, the utilization ratio of resources is improved, and the domestic blank is filled. The method belongs to circular economy, obtains good economic and social benefits, and has better popularization and application valves.

Owner:PANYU ZHUJIANG STEEL PIPE LIANYUNGANG

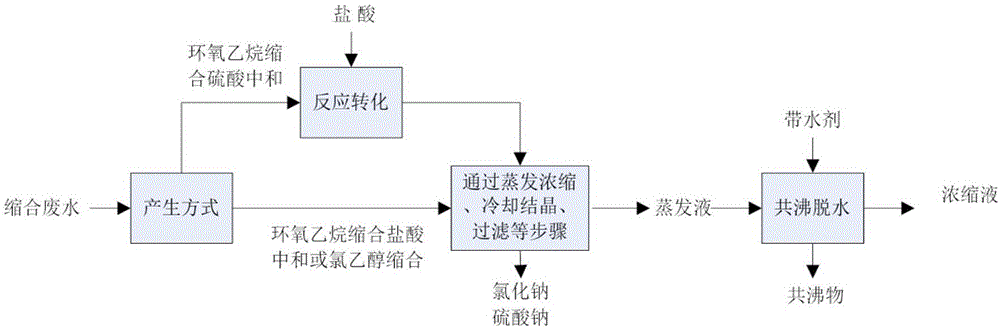

Treatment method of condensed wastewater generated in para-ester production process

ActiveCN107522339AEasy to handleNothing producedTreatment involving filtrationMultistage water/sewage treatmentFiltrationEvaporation

A treatment method of condensed wastewater generated in a para-ester production process is characterized in that the condensed wastewater contains ethylene chlorohydrin; and the treatment method comprises the following steps of: 1) performing evaporation, concentration, cooling crystallization and filtration on the condensed wastewater to form crystalloid salt and evaporated liquid, 2) adding a water-carrying agent into the evaporated liquid obtained in step 1), heating for azeotropic dehydration, and obtaining an azeotrope and concentrated liquid. The treatment method is concise in technical flow, simple to operate and low in cost, and no secondary pollutant is generated. The condensed wastewater in the para-ester production process can be treated more effectively; at the same time, an ethylene chlorohydrin product meeting recycling requirements is obtained; the wastewater treatment is achieved; and at the same time, resources are comprehensively utilized.

Owner:新乡市锦源化工有限公司 +1

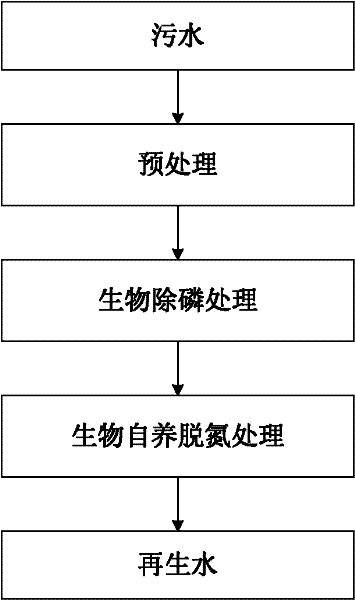

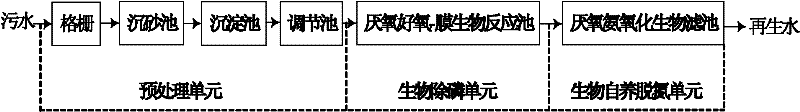

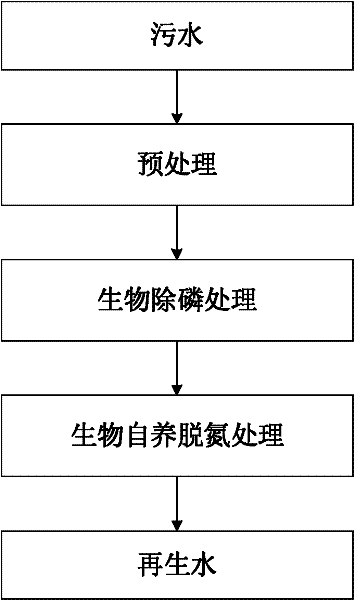

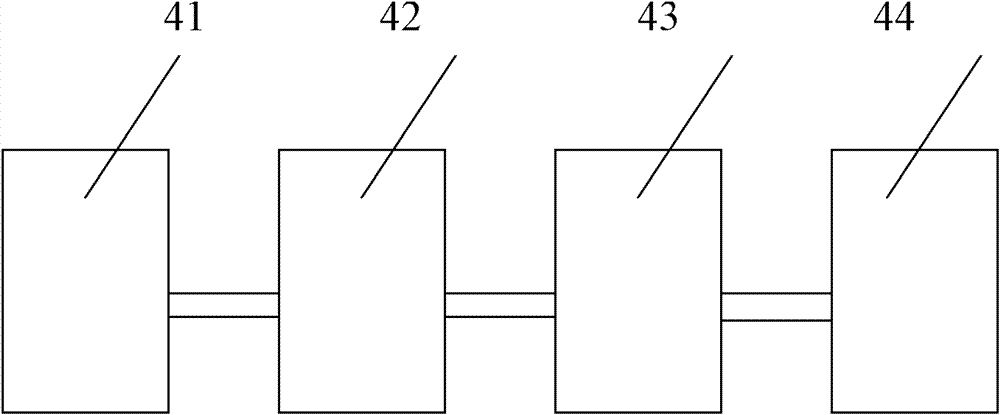

Method and System for Phosphorus and Nitrogen Removal in Sewage

InactiveCN102267783AShort hydraulic retention timeLow costMultistage water/sewage treatmentOxygenLarge particle

The invention discloses a method and system for removing phosphorus and nitrogen from sewage, belonging to the field of sewage treatment. The method includes: pretreatment: making the sewage enter the pretreatment unit for pretreatment, removing large suspended solids in the sewage, and adjusting the sewage from which the suspended solids have been removed; biological phosphorus removal treatment: making the effluent after the above pretreatment enter the Biological phosphorus removal and organic matter removal are carried out in the biological phosphorus removal unit; biological autotrophic denitrification treatment: the effluent after the above biological phosphorus removal treatment enters the biological autotrophic denitrification unit, and passes through the The autotrophic metabolism of anammox bacteria in the bioautotrophic denitrification unit removes nitrogen in sewage, and the effluent from the bioautotrophic denitrification unit is used as regenerated water for phosphorus and nitrogen removal. The method has short technological process, good phosphorus and nitrogen removal effects, and low cost.

Owner:BEIJING YIPU INT WATER AFFAIRS

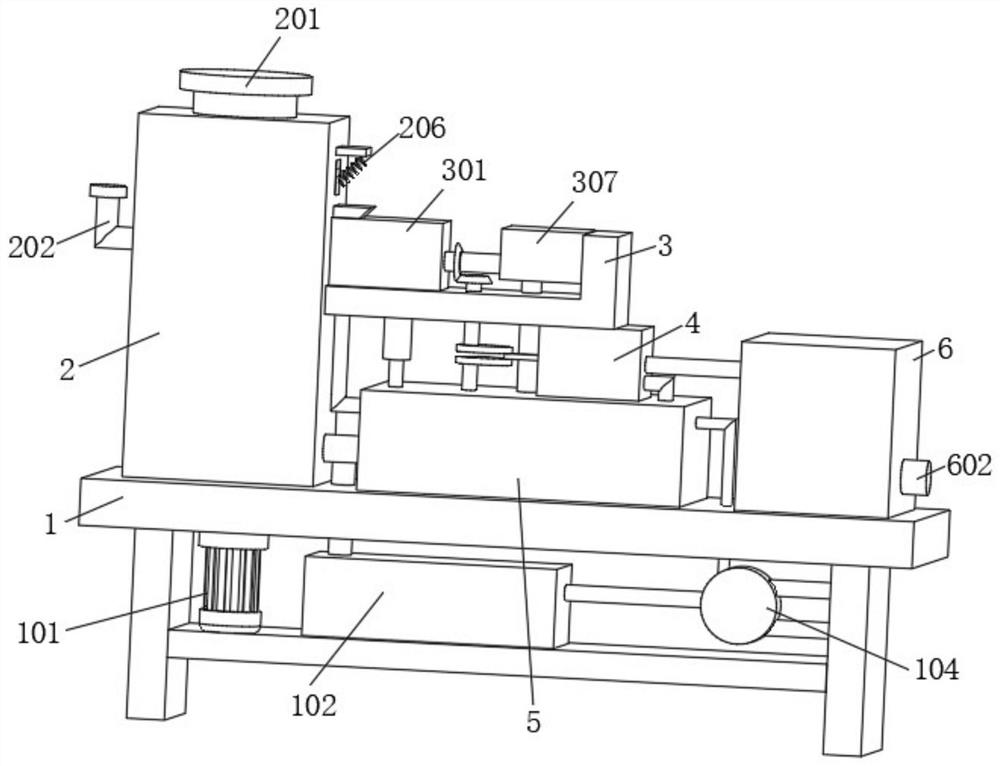

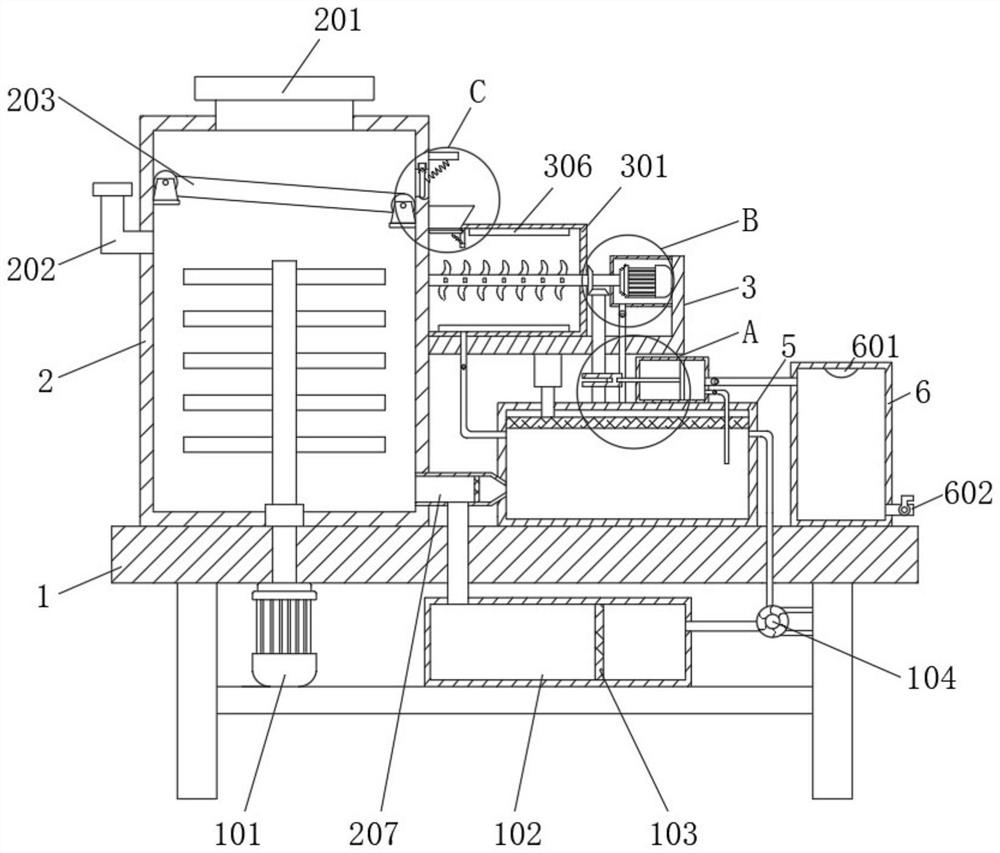

Recyclable sewage treatment device and treatment method

InactiveCN113072225AReduce buoyancyNot easy to precipitateWater/sewage treatment by irradiationSpecific water treatment objectivesSewageSewage treatment

The invention discloses a recyclable sewage treatment device and a treatment method, and belongs to the technical field of sewage treatment. The recyclable sewage treatment device comprises a supporting seat, a first treatment box and a second treatment box, the first treatment box and the second treatment box are both fixedly connected to the top of the supporting seat, and the recyclable sewage treatment device further comprises a supporting plate fixedly connected to the side wall of the first treatment box, a crushing box fixedly connected to the top of the supporting plate, and a heating plate fixedly connected to the inner wall of the crushing box and used for drying the garbage entering the crushing box for facilitating crushing of the garbage. Garbage in sewage can be dried and crushed after being screened, environmental pollution caused by direct discharge of the garbage is reduced, meanwhile, the garbage is dried, meanwhile, the sewage is heated, the buoyancy of the sewage is reduced, fine floccules which are not prone to sedimentation are rapidly settled, the cleaning effect is improved, and it is ensured that the treated sewage can meet the recycling requirement.

Owner:NANJING HANERSI BIOLOGY TECHNOLOGY CO LTD

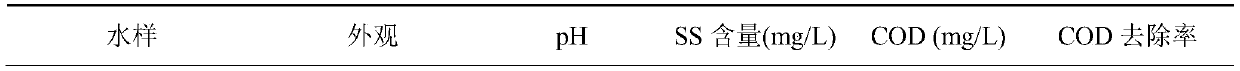

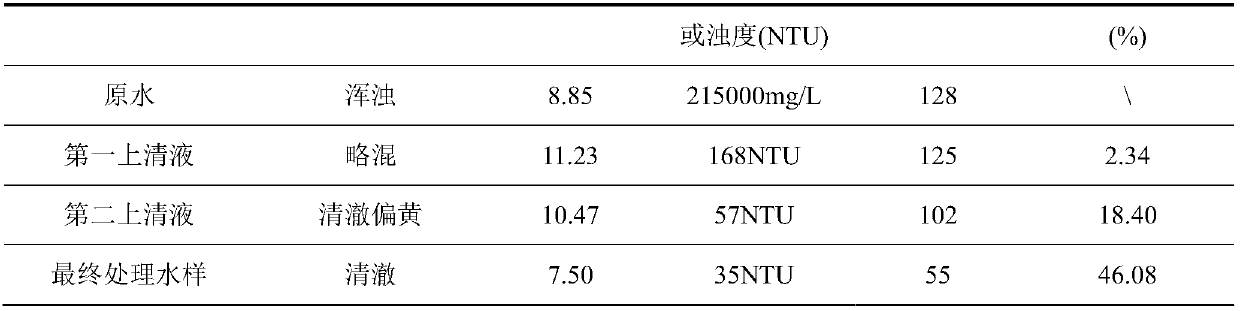

Method for treating and recycling fluorite beneficiation wastewater

InactiveCN109574263AMeet the requirements of recyclingSolve processingWaste water treatment from metallurgical processMultistage water/sewage treatmentSuspended particlesActivated carbon

The invention discloses a method for treating and recycling fluorite beneficiation wastewater. The method includes following steps: 1), adding lime into the fluorite beneficiation wastewater, sufficiently stirring, and coagulating and settling to obtain first supernate; 2), adding polyaluminum and polyacrylamide into the first supernate obtained in the step 1), stirring, and performing coagulationand sedimentation to obtain second supernate; 3), adjusting pH of the second supernate obtained in the step 2) to 6-8, adding activated carbon for adsorption, and removing the activated carbon afteradsorption is completed to obtain a final treatment water sample which can be recycled for a fluorite flotation system. The method is simple in operation; lime and polyaluminum are utilized to performcascaded coagulating and settling on suspended particles in the wastewater, and the activated carbon is utilized to selectively adsorb key impact factors in the wastewater, so that the wastewater after being treated by utilizing the method can be recycled for fluorite beneficiation, and efficient recycling of the fluorite beneficiation wastewater is realized.

Owner:HUNAN SHIZHUYUAN NON FERROUS METAL +1

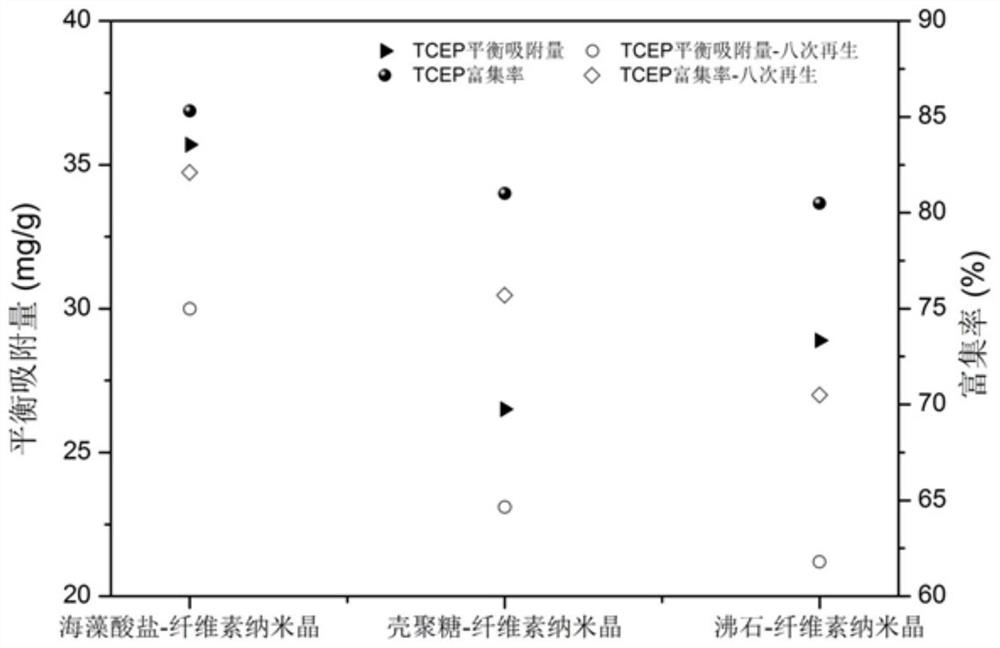

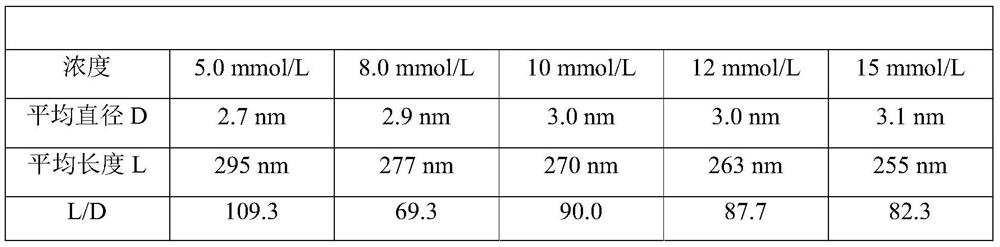

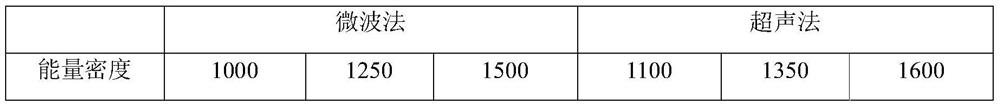

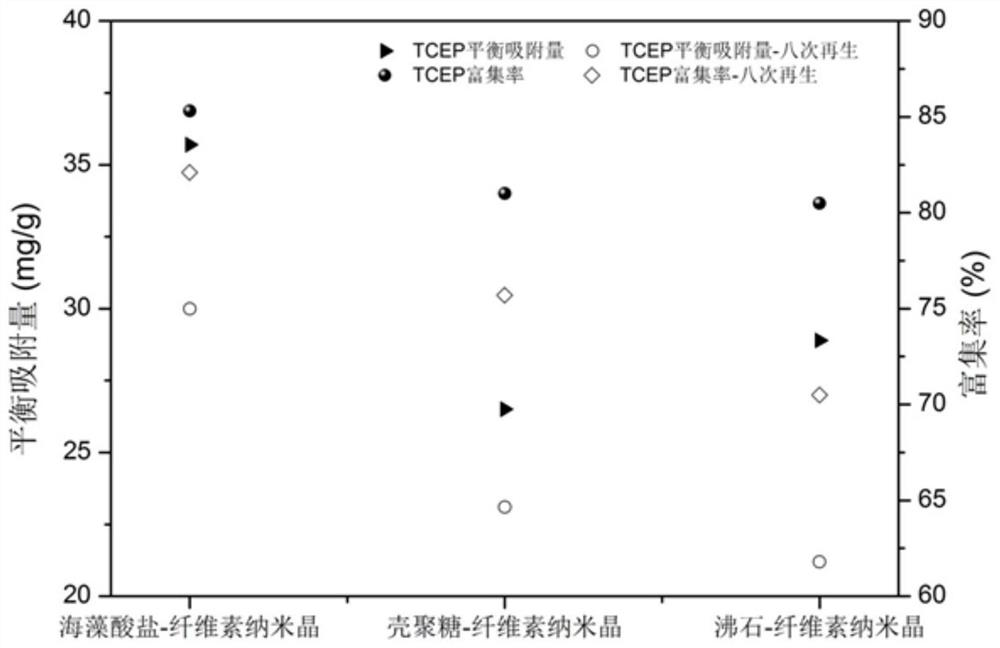

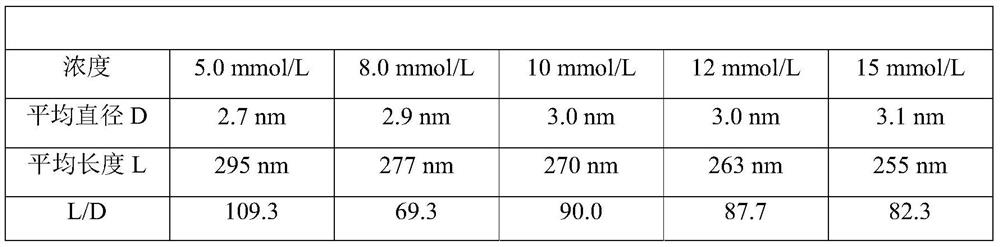

Cellulose nanocrystalline loaded sodium alginate adsorbent and application thereof to enrichment of organic phosphorus in wastewater

ActiveCN112495349AMeet the requirements of recyclingGuaranteed emission standardsSludge treatment by de-watering/drying/thickeningSludge treatment by oxidationSludgeResource recovery

The invention discloses a cellulose nanocrystalline loaded sodium alginate adsorbent and application thereof to enrichment of organic phosphorus in wastewater, and belongs to the technical field of environmental engineering. Papermaking deinking sludge is prepared into cellulose nanocrystals through a medicament conditioning-drying and crushing-chemical oxidation-microwave screening technology, and the cellulose nanocrystals are loaded on alginate under a weakly acidic condition, so that the cellulose nanocrystals have the capacity of enriching organic phosphorus in wastewater. By applying themethod, the content of organic phosphorus in the wastewater can be remarkably reduced, the total phosphorus of effluent is reduced, and up-to-standard discharge of sewage treatment is guaranteed; andthe enriched organophosphorus can be subjected to resource recovery of phosphorus in an incineration manner. Meanwhile, the papermaking deinking sludge is used for preparing high-added-value products, the application range of the papermaking deinking sludge is widened, and high feasibility is achieved.

Owner:JIANGNAN UNIV

Wastewater and reclaimed water recycling treatment system

InactiveCN110526501AEasy to handleMeet the requirements of recyclingSpecific water treatment objectivesTreatment involving filtrationActivated sludgeWater source

The invention discloses a wastewater and reclaimed water recycling treatment system. Sewage is firstly fed into an anoxic pond for anoxic hydrolysis, as the sewage has a high organic matter concentration, microorganisms are at an anoxic state at the moment, the microorganisms are facultative microorganisms, organic nitrogen in the sewage can be converted and decomposed into NH3-N by the microorganisms, and in addition, an organic carbon source is adopted as an electron donor to convert NH3-N and NO3-N into N2; secondly, the sewage is further fed into an aerobiotic pond from the anoxic pond, under appropriate conditions of dissolved oxygen and nutrition in the sewage, the microorganisms of the sewage are massively reproduced and inhabit on packing in the pond to form a biological membrane,organic matters can be adsorbed and degraded by the biological membrane when flowing through the packing along with the sewage, and thus the sewage can be purified; and finally, the sewage is fed intoa settling pond from the aerobiotic pond, peeled biological membranes and activated sludge can be removed, the precipitate effluent is fed into a sterilization pond, and a water source can be provided for later filtering. By adopting the set of the treatment system, living sewage can be well treated, and the living sewage can be further purified.

Owner:安徽金寨抽水蓄能有限公司 +2

Landscaping soil preparation method of mud cake obtained after muck is subjected to mud-sand separation

PendingCN113207615AMeet recyclingResolve disposal issuesGrowth substratesCulture mediaPhosphoric acidSoil science

The embodiment of the invention discloses a landscaping soil preparation method of the mud cake obtained after muck is subjected to mud-sand separation. The method comprises the following steps: carrying out crushing treatment on the mud cake obtained after mud-sand separation of the engineering muck by adopting a bucket crushing and screening machine to obtain particles with the particle size of less than 2 cm; metering a solid modifier by using a loader, carrying the solid modifier, putting the solid modifier into the crushed mud cake, adding phosphoric acid, and uniformly mixing by using a stirrer; and carrying the uniformly stirred crushed soil to a maintenance area for stacking and maintenance, and carrying out component detection on the mixture. The mud cake formed by mud-sand separation of engineering muck is improved into landscaping soil by adding the solid modifier, the steps of high-temperature heating and other extra energy consumption are not needed in the improvement process, the production process is simple, transportation is convenient, the requirement for landscaping soil can be met, and moreover, the landscaping soil meeting various environmental requirements can be obtained by adjusting the proportional components of the modifier.

Owner:CHINA CONSTR SCI & TECH CO LTD

Circulating water tank used for sesame cleaning

InactiveCN106108063AMeet the requirements of recyclingClimate change adaptationFood treatmentDepressed structureClean water

The invention discloses a circulating water tank used for sesame cleaning. The water tank comprises a frame, a tank body and a water pump. The tank body is arranged in the frame, the upper end face of the frame is located above the tank body, the water pump is arranged on the upper end face of the frame, the water pump is connected with a flow guide pipe, a partition board is disposed in the tank body, the internal space of the tank body is divided into a dirty water area and a clean water area, a pollution discharge port is formed in the bottom of the dirty water area, the flow guide pipe is arranged in the clean water area, and the bottom of the dirty water area and the bottom of the clean water area are both of a structure of which the two sides are indented to the middle. Water obtained after sesame cleaning or spin-drying can be recycled, dirt in water precipitates, and the water meets the recycling requirement.

Owner:天津市益民金星科技发展有限公司

A method for recovering waste lithium titanate battery

ActiveCN109065999AImprove leaching rateWeight increaseSolid waste disposalTransportation and packagingSlagSlurry

A method for recovering waste lithium titanate battery comprises the following steps: a, discharging; b, crushing and screening; c adding water to prepare slurry; d. adding hydrochloric acid to maintain the pH of the slurry at 0.5 to 1.5, temporarily stopping the addition of hydrochloric acid if the pH value of the slurry drops below 0.5 during the addition of hydrochloric acid, restarting the addition of hydrochloric acid after the pH value of the slurry rises above 1.5 during the reaction, and stopping the addition of hydrochloric acid when the pH value of the slurry rises less than 0.3 within 20 minutes; e filtering the slurry obtained in the step (d) to obtain filter residue containing titanium and carbon black; f, adding coke into the slag containing titanium and carbon black, introducing chlorine gas, returning the remaining solid slag to the step g, adding hydrogen peroxide to the solution containing the positive electrode active material powder obtained in the step e, filteringand removing iron, aluminum and titanium impurities, extracting and removing calcium and magnesium impurities, adding sodium carbonate to the remaining solution, and evaporating and concentrating after the reaction is complete. The method can separate high purity battery grade lithium titanate from waste lithium titanate battery.

Owner:湖南金凯循环科技股份有限公司

Process for treating jet weaving wastewater

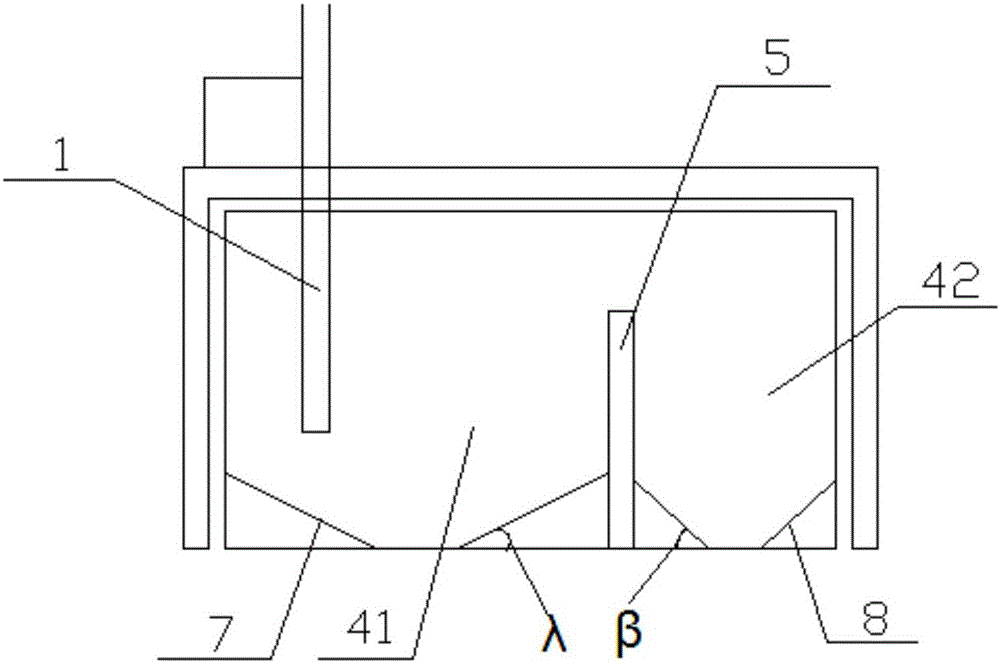

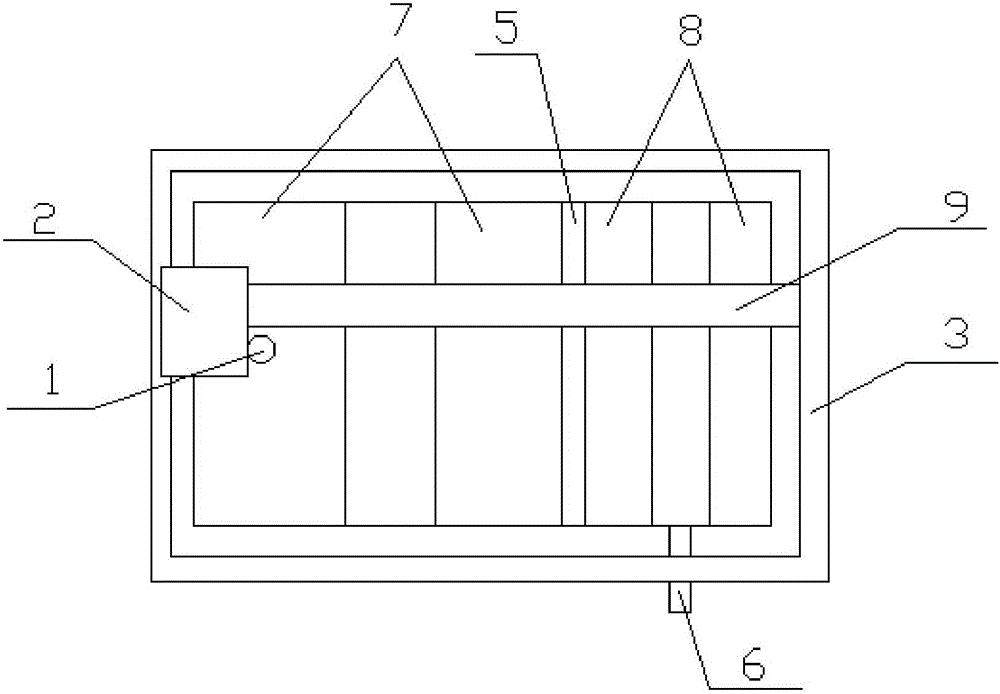

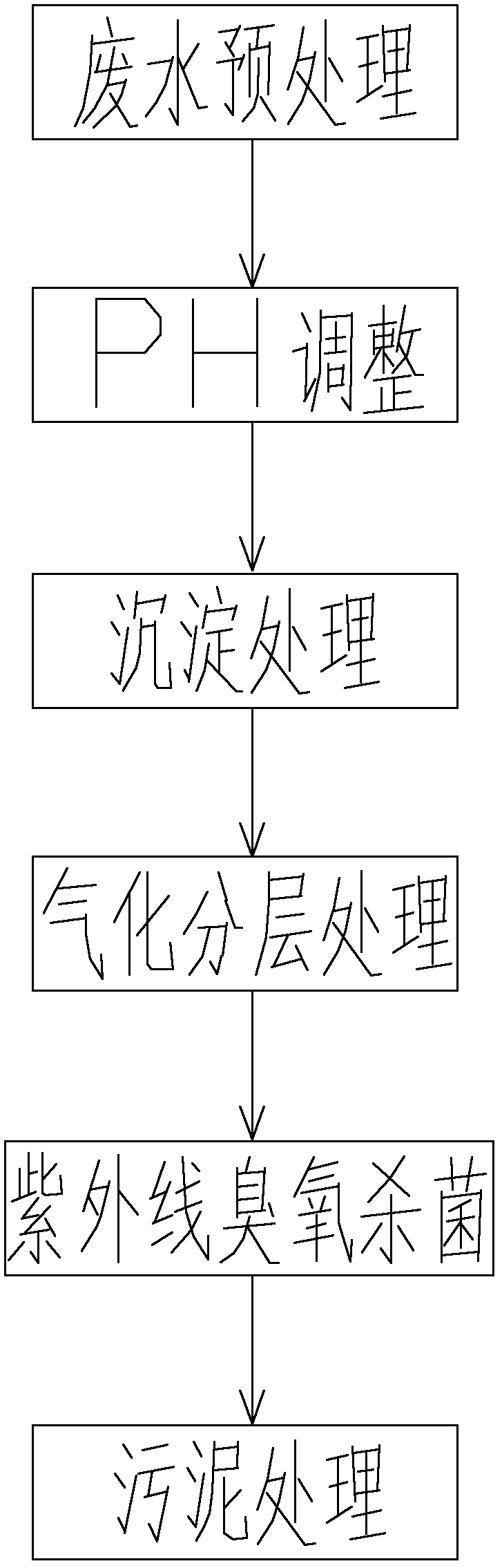

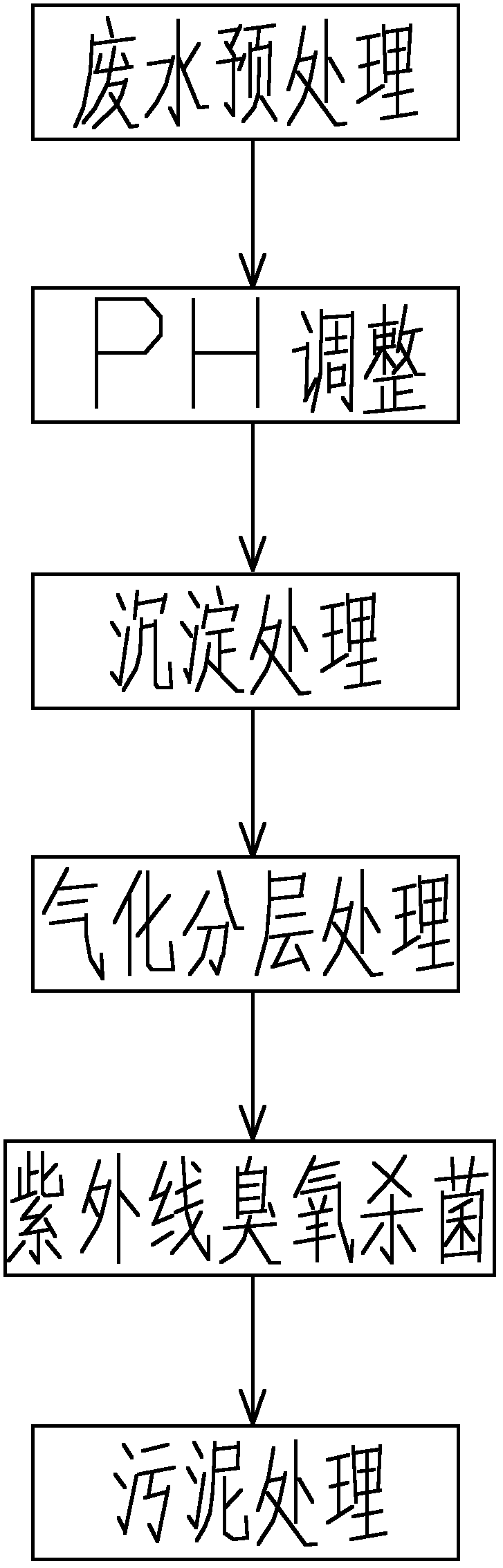

ActiveCN102503004AQuick removalMeet the requirements of recyclingWater/sewage treatment by irradiationMultistage water/sewage treatmentDiseaseChemical treatment

The invention discloses a process for treating jet weaving wastewater. The process sequentially comprises the following steps of: 1) pre-treating the wastewater; b) adjusting pH; c) treating precipitates; d) gasifying and layering; e) sterilizing by using ultraviolet rays and ozone; and f) treating sewage. Various treatment modes such as filtering, physical and chemical treatment, agent adding and coagulation, pressurization and floatation, water molecule refining, an UV / O3 light wave rapid disinfection and sterilization system and the like are adopted in the whole treatment process; water molecules and air are mixed and micronized according to a high-pressure floatation principle, and dirt and sundry particles in water can be subjected to floatation separation with raw water so as to form a floating layer state; sterilization is performed by using UV / O3 in a micronizing process so as to remove disease-causing germs and microorganisms from water quickly; and biochemical oxygen demand (BOD) content, chemical oxygen demand (COD) content and suspended solids in the wastewater are greatly reduced by secondary filtering, so the requirement of recycling the jet weaving wastewater can bemet.

Owner:浙江长兴艺柯纺织有限公司

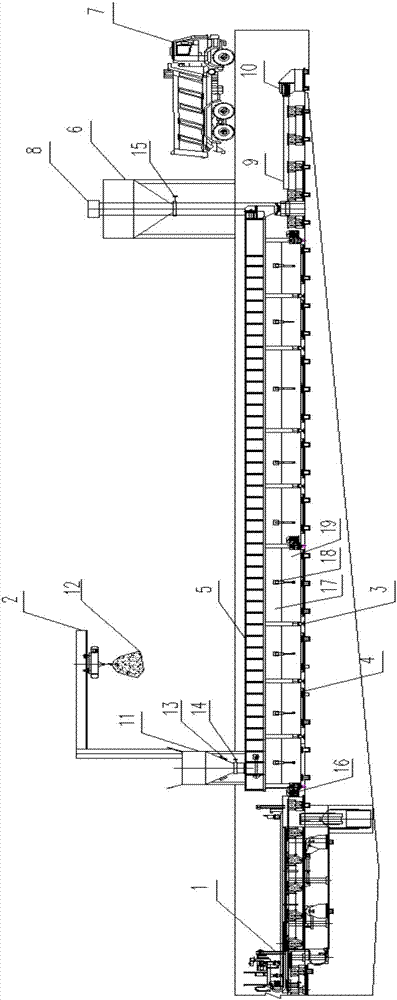

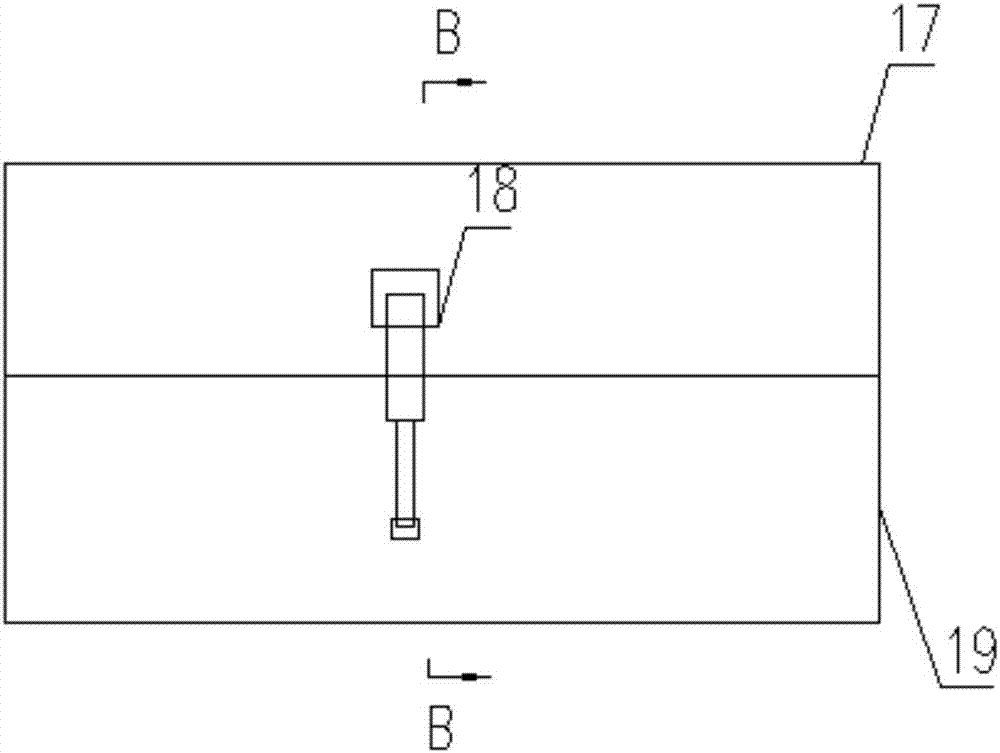

Device and method for drying scales by using slab continuous casting afterheat

InactiveCN107062860AMeet the requirements of recyclingDrying solid materials with heatDrying machines with progressive movementsEngineeringCantilever

The invention provides a device and a method for drying scales by using slab continuous casting afterheat. The device comprises a cantilever crane, a mobile sealing chain plate machine, a material receiving bin and a belt machine, wherein naturally aired wet scales are lifted to the material receiving bin by the cantilever crane; the mobile sealing chain plate machine is arranged above an after-cutting hot feeding roller way; the material receiving bin is positioned above the mobile sealing chain plate machine; after the material receiving bin is fully filled with materials, a first electric gate valve arranged at the lower part of the material receiving bin is started, and the wet scales are unloaded onto the mobile sealing chain plate machine and dried by using the slab afterheat; the belt machine extends from the mobile sealing chain plate machine to a finished product bin by a preset dip angle; the scales dried by the slab afterheat are conveyed into the finished product bin along the belt machine; and after the finished product bin is fully filled with the materials, a second electric gate valve is started, and the dried scales are transferred to a loading system of a metallurgy furnace by a transportation vehicle. The water content of the scales dried by radiation heat of a continuous-cast blank is lower than 1%; and the device is low in investment, low in operation cost and reasonable in process.

Owner:HUATIAN ENG & TECH CORP MCC

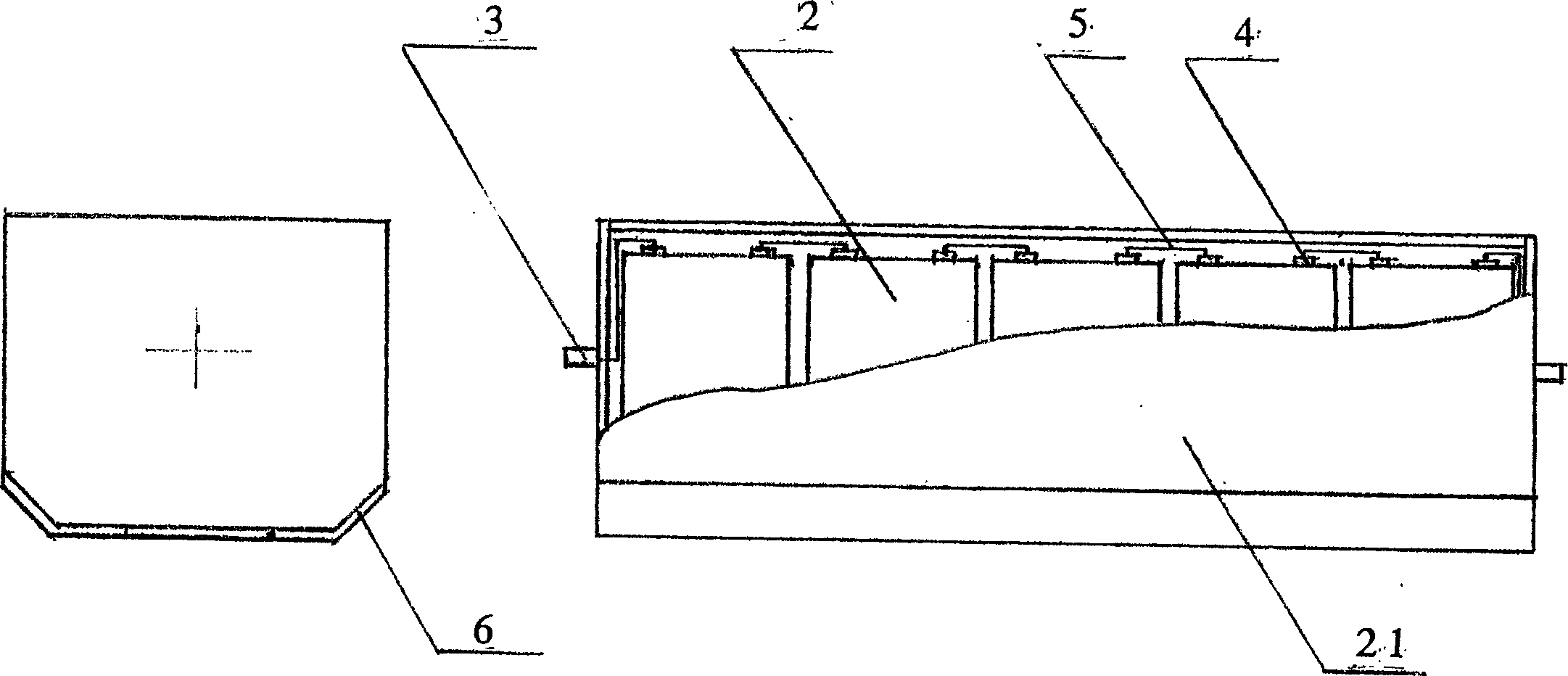

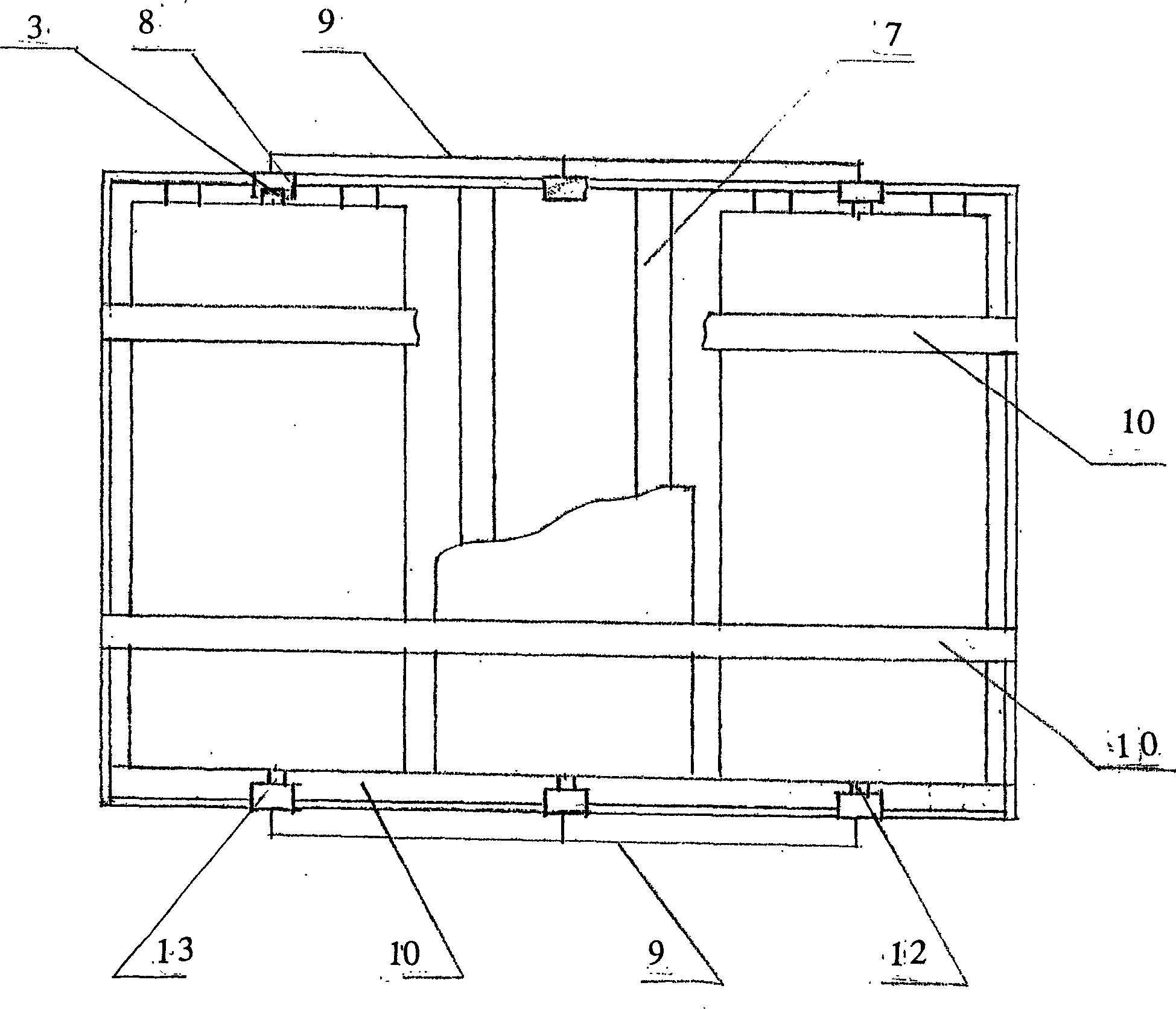

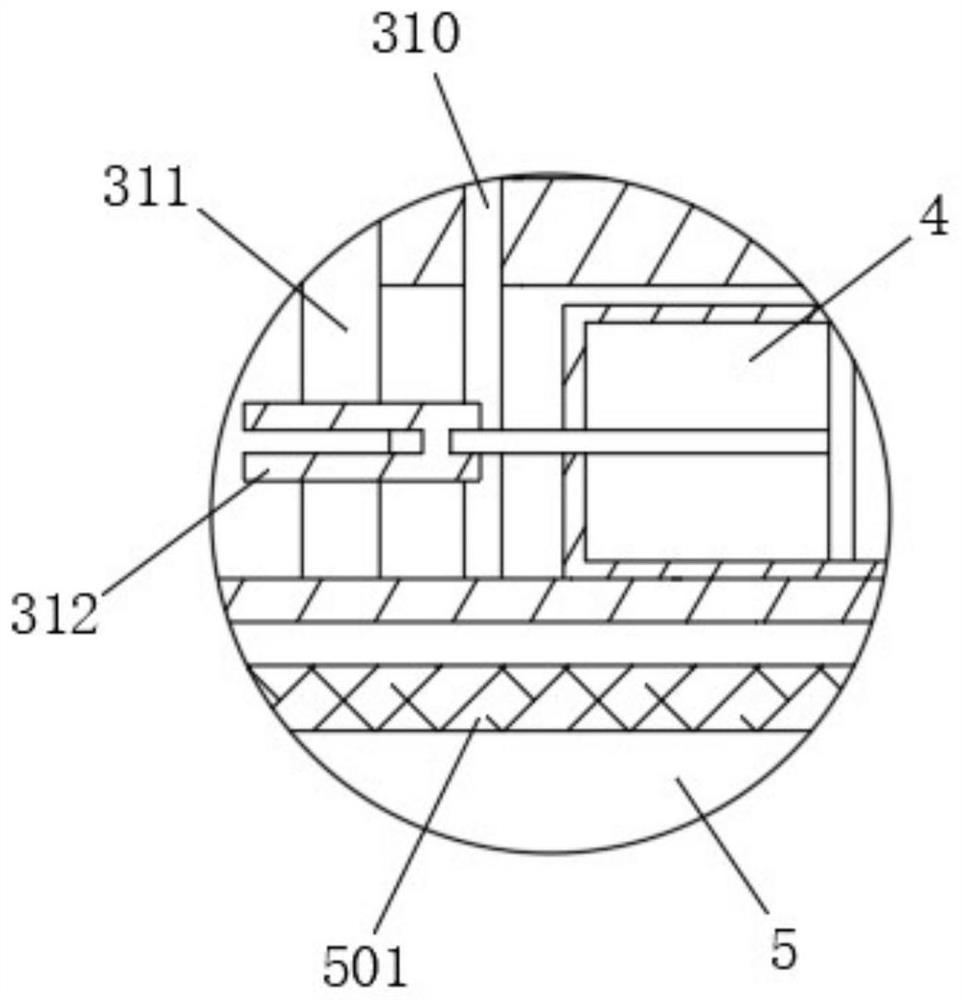

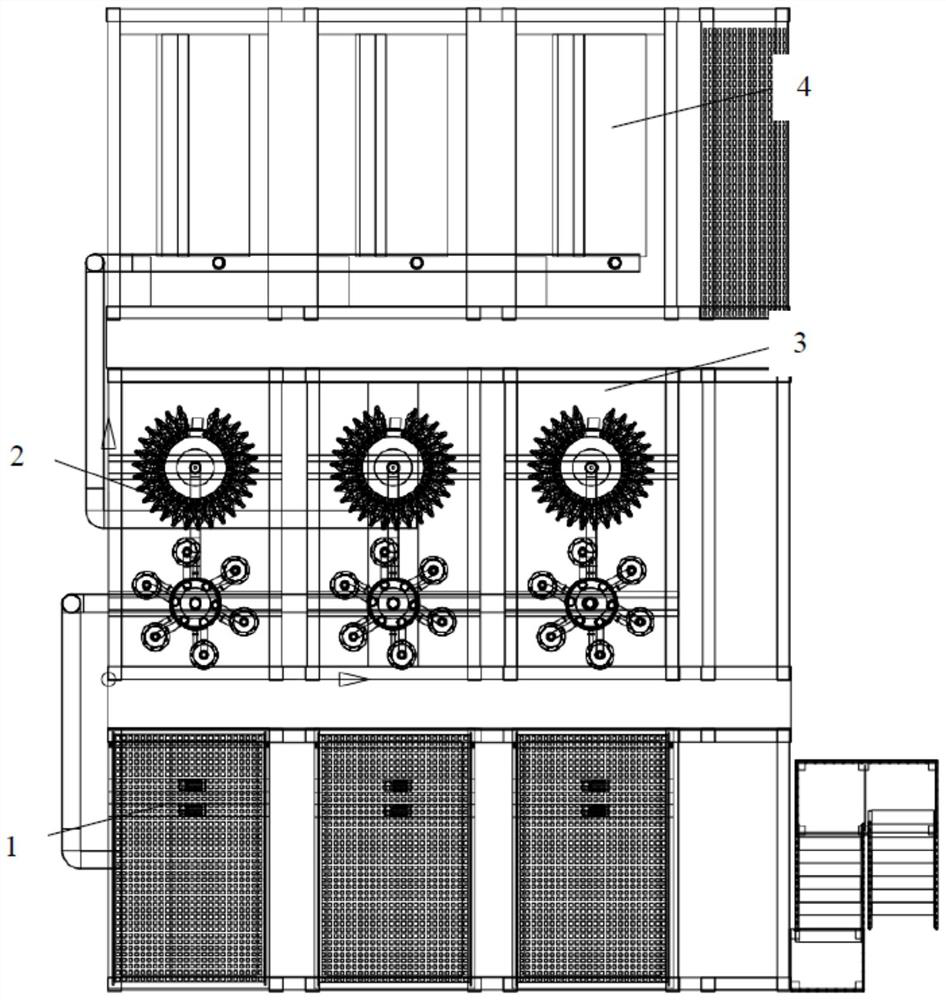

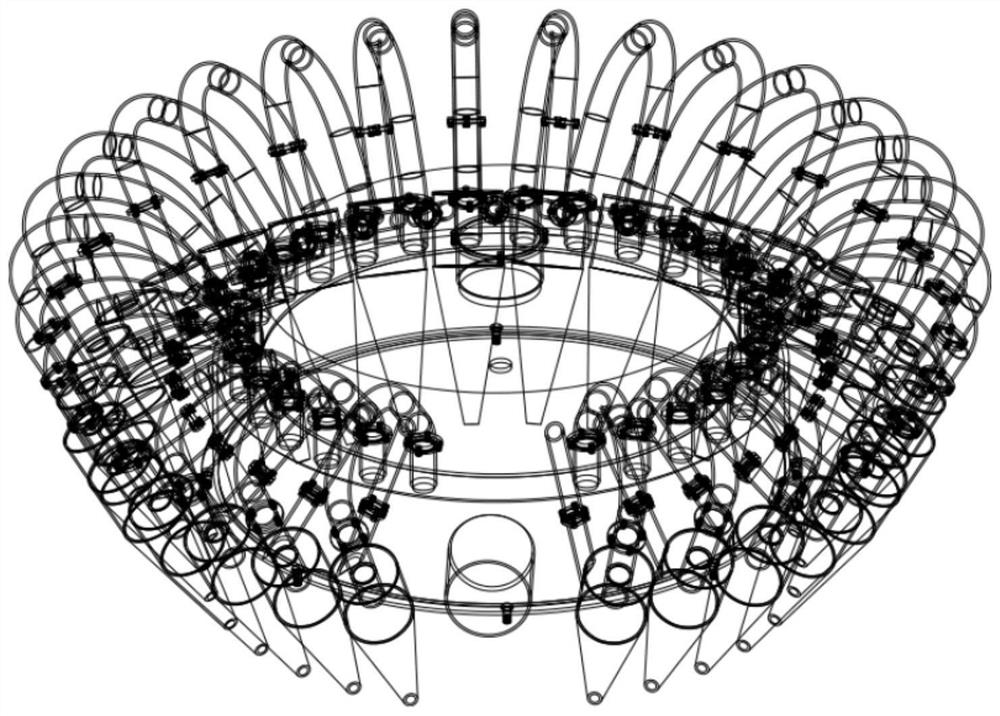

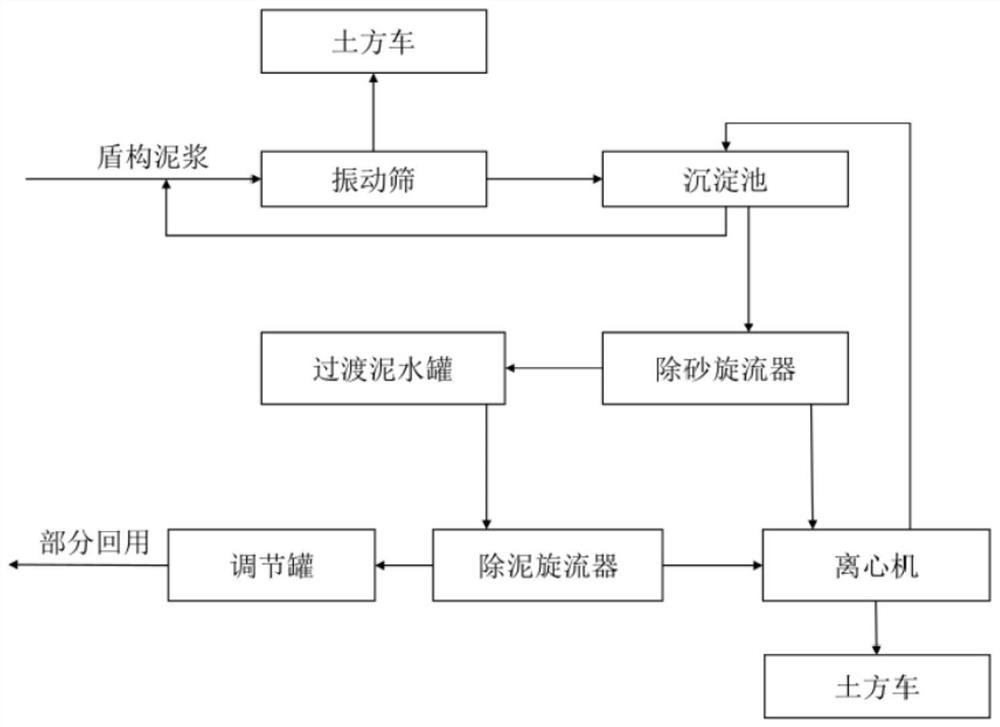

Integrated slurry-water separation system of shield tunneling machine

PendingCN112390485AEasy to handleMeet the requirements of recyclingSludge treatmentFiltration circuitsModular productSlurry

The invention discloses an integrated slurry-water separation system of a shield tunneling machine. The integrated slurry-water separation system comprises a vibrating screen system, a desanding cyclone, a desilting cyclone, a centrifugal separation system and a slurry adjusting system, and coarse particles are separated by adopting a three-layer vibrating screen. The cyclone separation system adopts two stages of cyclones for treatment, namely a cyclone desander and a desilter. The centrifugal separation system accelerates the settling velocity of solid-phase particles to realize solid-liquidseparation. The slurry conveying pump conveys the slurry adjusted by the slurry adjusting system to the shield tunneling machine. A treatment process flow of screening, desanding, desilting and centrifuging is adopted, soil cut by a shield can be effectively treated, slurry can be recycled, the mode of a slurry treatment system is mainly an integrated modular product, sealing treatment is carriedout, and waste water reaches the discharge standard.

Owner:BEIJING INSTITUTE OF PETROCHEMICAL TECHNOLOGY +1

Comprehensive treating method and treating system for industrial aquatic cultivation sewage

InactiveCN1303017CLower requirementEasy to manageTreatment using aerobic processesMultistage water/sewage treatmentNitrate saltsBiological filter

The present invention discloses comprehensive treating method and system for industrial aquatic cultivation sewage. The sewage containing rich excrement, ammonia and other metabolic product as well as feed residue from the bottom of the industrial cultivation pond is treated successively through deposition of large grain excrement and feed residue in the inclined plate depositor, interception of other excrement and feed residue in the mechanical filter, and conversion of ammonia into nitrate with nitrifying bacteria in the biological filter. The treated sewage is returned to the cultivation pond circularly while the deposited, intercepted and flocculated matters are delivered to the plant filter with aquatic grass plant as medium. The mechanical filter is back flushed regularly.

Owner:ZHEJIANG UNIV

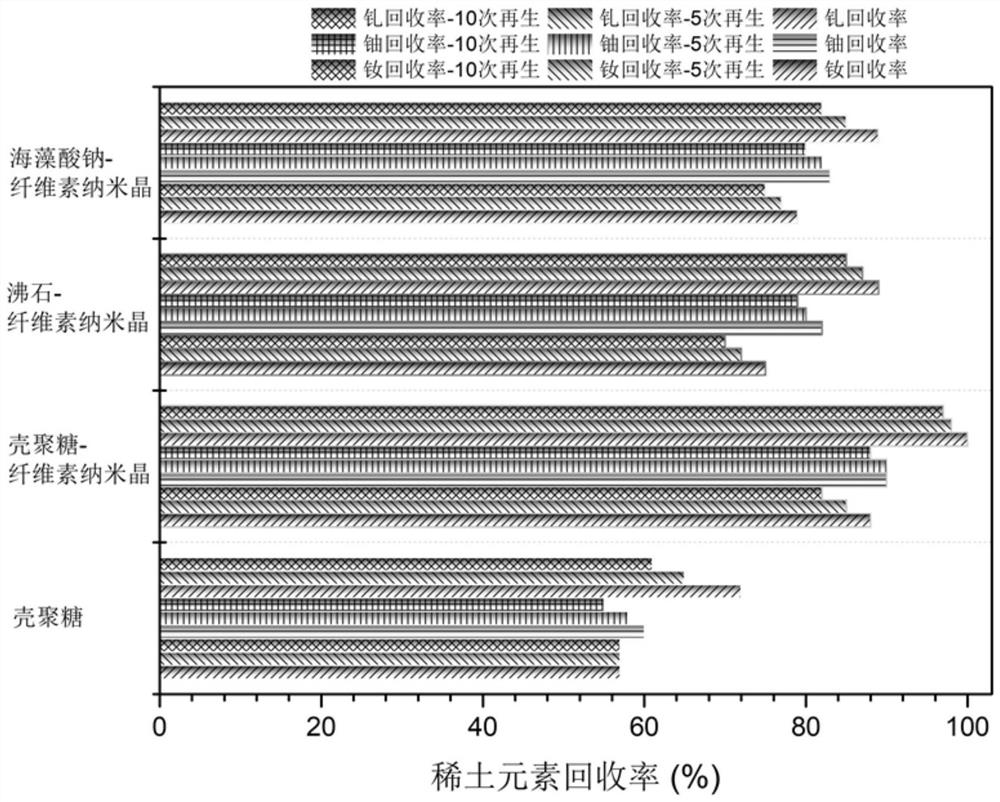

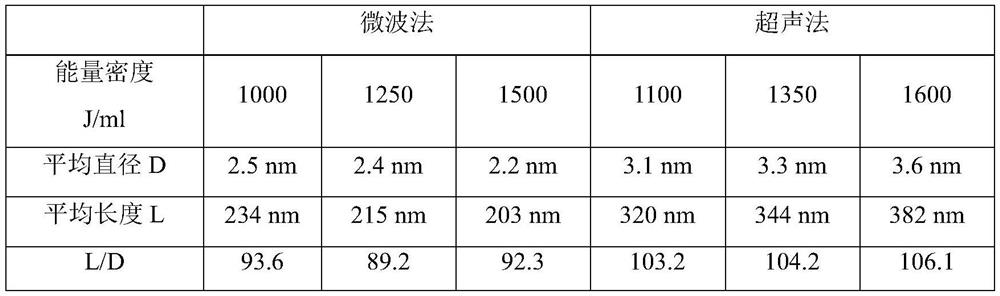

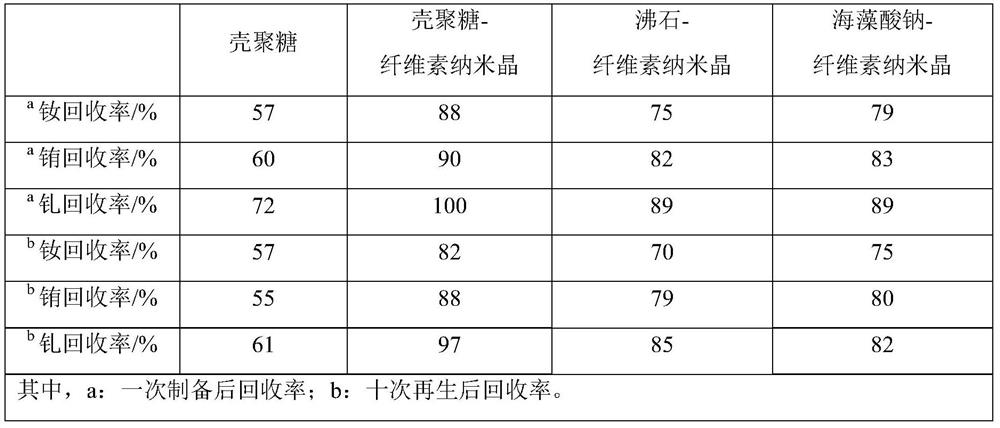

A cellulose nanocrystal-loaded chitosan adsorbent and its application in recycling rare earth elements from sewage

ActiveCN112516970BGuaranteed to meet discharge standardsReduce the impact of biological activityOther chemical processesProcess efficiency improvementSludgeSewage

The invention discloses a cellulose nanocrystal-loaded chitosan adsorbent and its application in recycling rare earth elements from sewage, belonging to the technical field of environmental engineering. The present invention prepares papermaking deinking sludge into cellulose nanocrystals through medicament conditioning-drying crushing-chemical oxidation-microwave sieving technology, and loads it on chitosan under weakly acidic conditions to make it suitable for recycling sewage. The effect of rare earth elements. Using this method can significantly reduce the impact of the presence of rare earth elements on the biological activity of sludge, and ensure that the sewage treatment meets the discharge standards; the obtained rare earth elements can be recycled for resource utilization after enrichment. At the same time, the preparation of high value-added products from papermaking deinking sludge broadens its application range and has high feasibility.

Owner:JIANGNAN UNIV

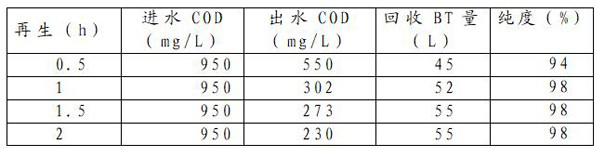

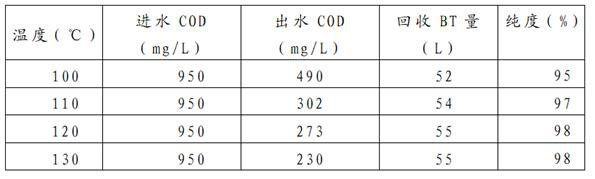

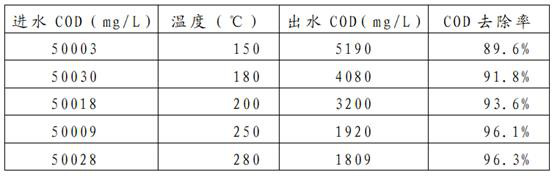

Process for deeply treating rubber accelerator DCBS mother liquor wastewater and recovering BT

PendingCN114409171AHigh purityReduce difficultySpecific water treatment objectivesWater contaminantsActivated carbonChemical oxygen demand

The invention belongs to the field of wastewater treatment, and particularly relates to a process for deeply treating rubber accelerator DCBS mother liquor wastewater and recycling BT. Comprising the following steps: 1) cooling rubber auxiliary DCBS mother liquor wastewater at-10 DEG C to remove a part of salt and organic matters; 2) carrying out catalytic oxidation to separate out most organic matters, and then reducing COD (Chemical Oxygen Demand) to 5000mg / L or below; 3) performing MVR evaporation concentration on the filtrate, and returning mother liquor to a raw water system for retreatment; the condensed water is adsorbed by activated carbon and returns to a production system for recycling; 4, the BT raw material can be recycled after the saturated activated carbon is subjected to steam backwashing. Four process schemes are effectively combined, the problem of water treatment in the past is solved, the treatment process is economical and feasible, and the environmental protection risk of an original treatment means is reduced.

Owner:KEMAI CHEM

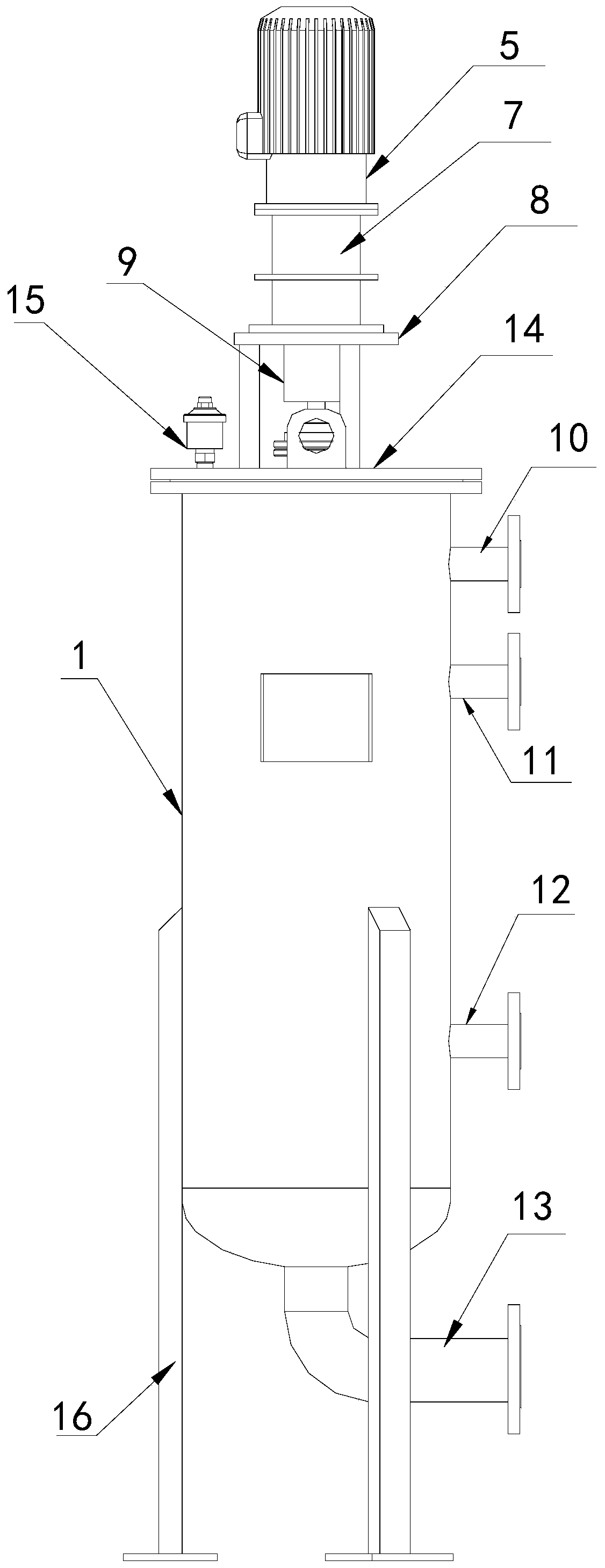

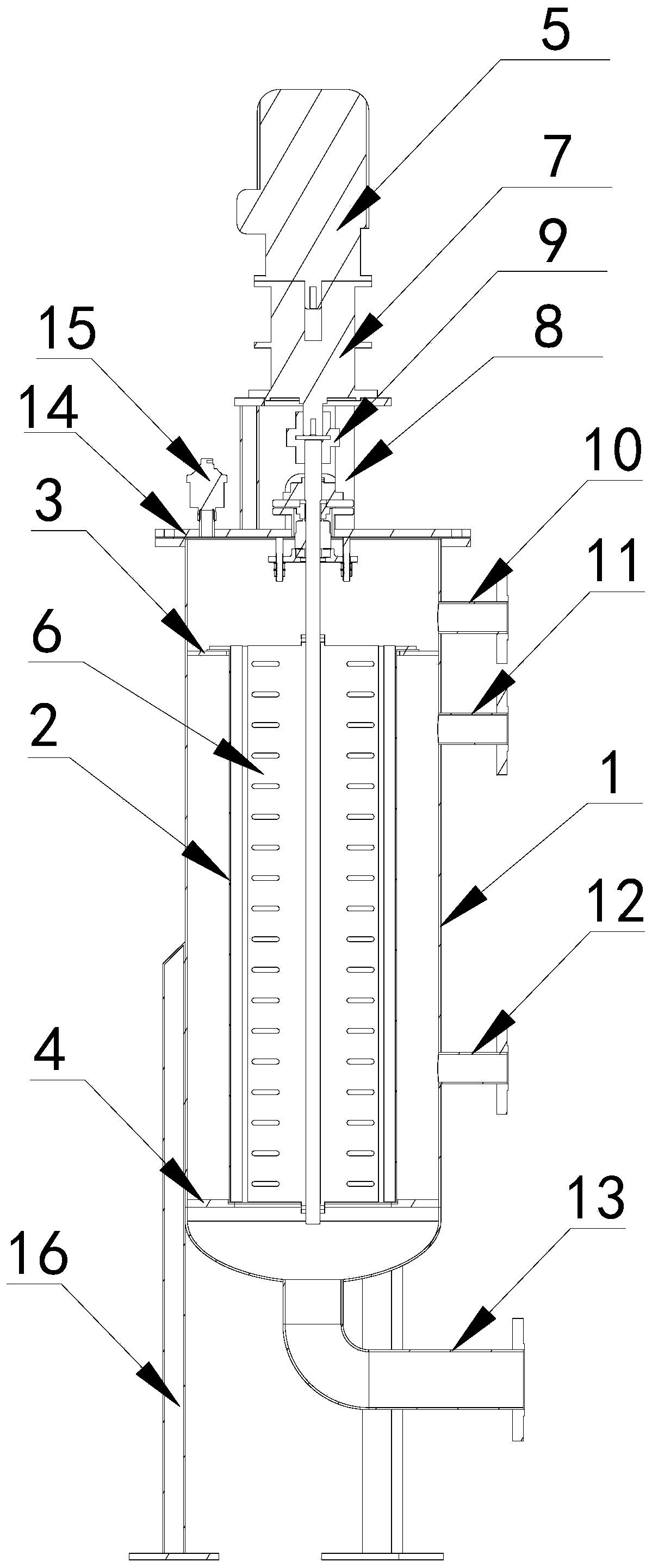

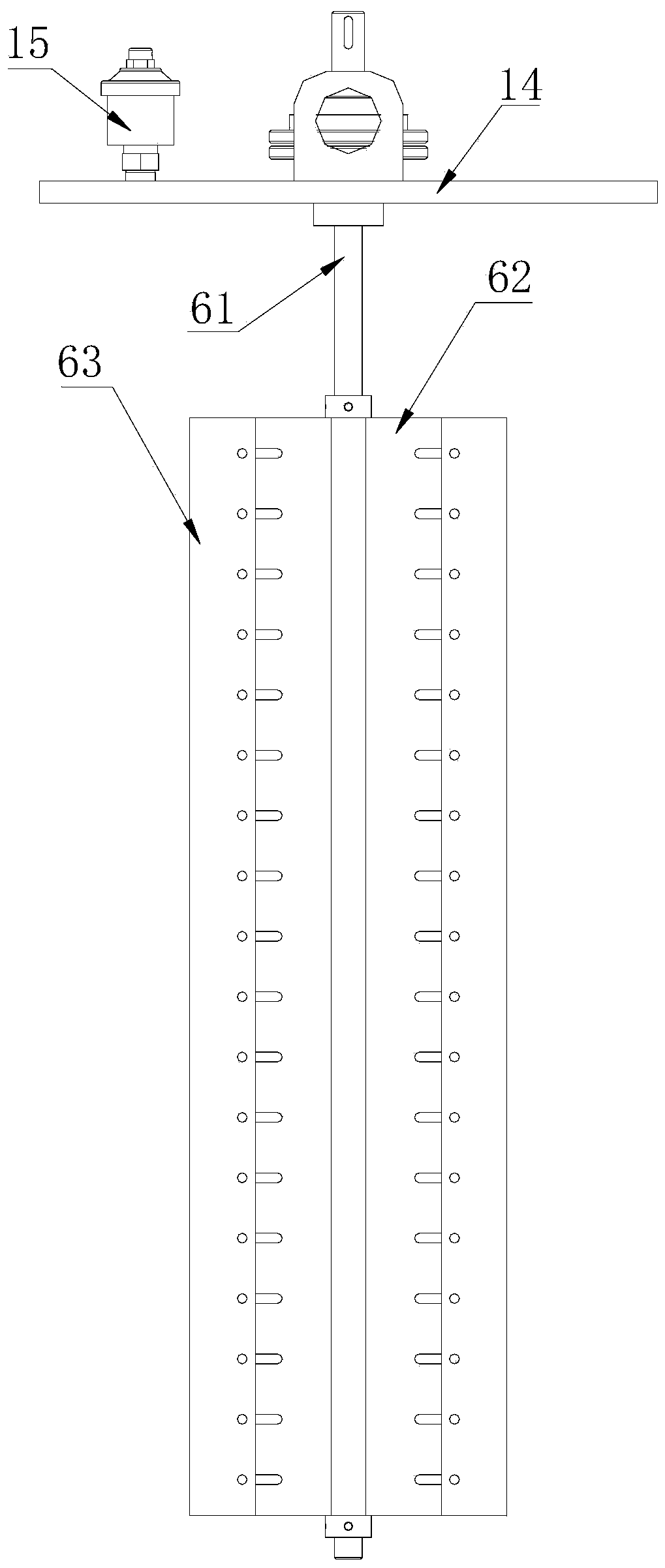

Stirring and filtering device for circulating pulp used in papermaking through glass fibers

PendingCN111013224AAvoid cloggingQuality improvementStationary filtering element filtersGlass fiberEngineering

The invention discloses a stirring and filtering device for circulating pulp used in papermaking through glass fibers, belonging to the technical field of glass fiber filter paper production equipment. The stirring and filtering device comprises a filtering assembly and a stirring assembly, wherein the filtering assembly comprises a filtering tank and a film filter element, and the film filter element is arranged in the filtering tank and divides the filtering tank into an inner cavity and an outer cavity; and the stirring assembly comprises a stirring motor and a transmission rotary brush; the stirring motor is fixedly arranged at the top of the filtering tank, the transmission rotary brush is arranged in the inner cavity, the outer edge of the transmission rotary brush is in contact withthe inner wall of the film filter element, a transmission shaft of the transmission rotary brush is in transmission connection with the stirring motor, and the stirring motor drives the transmissionshaft to rotate so as to enable the transmission rotary brush to rotate. According to the invention, residual glass fibers in circulating liquid can be prevented from blocking the filter element, impurities such as glass fibers in the circulating liquid can be effectively filtered, and effluent can meet the requirement of cyclic utilization, so the quality of the glass fiber filter paper is effectively improved, and environmental protection, energy conservation and low cost are achieved.

Owner:珠海菲伯过滤材料有限公司

A cellulose nanocrystal-loaded sodium alginate adsorbent and its application in enriching organic phosphorus in wastewater

ActiveCN112495349BGuaranteed emission standardsReduce contentSludge treatment by de-watering/drying/thickeningSludge treatment by oxidationSludgeWastewater

The invention discloses a cellulose nanocrystal-loaded sodium alginate adsorbent and its application for enriching organic phosphorus in waste water, belonging to the technical field of environmental engineering. The present invention prepares papermaking deinking sludge into cellulose nanocrystals through medicament conditioning-drying crushing-chemical oxidation-microwave sieving technology, and loads it on alginate under weakly acidic conditions to make it capable of enriching wastewater capacity of organic phosphorus. Using this method, the content of organic phosphorus in wastewater can be significantly reduced, the total phosphorus in effluent can be reduced, and the discharge of sewage treatment can be guaranteed. The enriched organic phosphorus can be recovered by means of incineration. At the same time, the preparation of high value-added products from papermaking deinking sludge broadens its application range and has high feasibility.

Owner:JIANGNAN UNIV

Device and method for advancement treatment of printing and dyeing wastewater

InactiveCN102329049BSmall particlesIncrease the areaMultistage water/sewage treatmentWaste water treatment from textile industryBiological activated carbonDyeing wastewater

The invention discloses a device for advancement treatment of printing and dyeing wastewater, aiming to solve the technical problems of water consumption, high cost and secondary pollution of the device and method for treating the printing and dyeing wastewater in the prior art. The device comprises a biological active-carbon water treatment device, the biological active-carbon water treatment device is connected with a biochemical settling pond which is connected with a reverse ore sand filter pool, and the reverse ore sand filter pool is connected with a clear water pool. The invention further discloses a method advancement treatment of the printing and dyeing wastewater. The printing and dyeing wastewater can be recycled for production after being subjected to the advanced treatment in the invention, so that zero emission is realized. The printing and dyeing wastewater treated by using the device and method disclosed by the invention not only can reach the requirement on recycling but also has the operation cost being 50% lower than the industrial water, and the operation cost is 0.5RMB per ton of water.

Owner:上海百峰环保工程有限公司

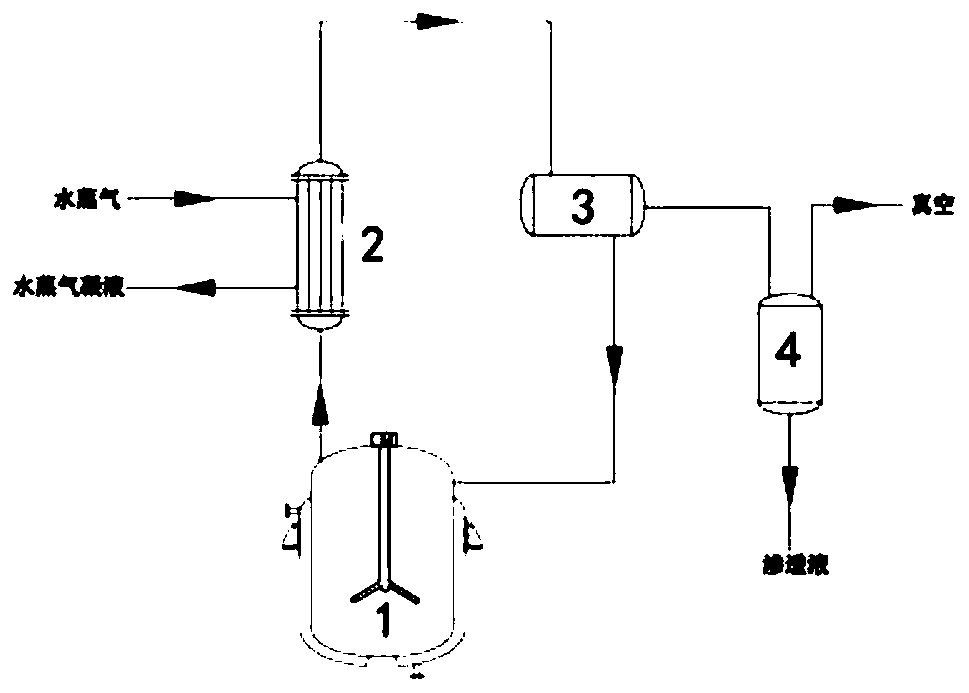

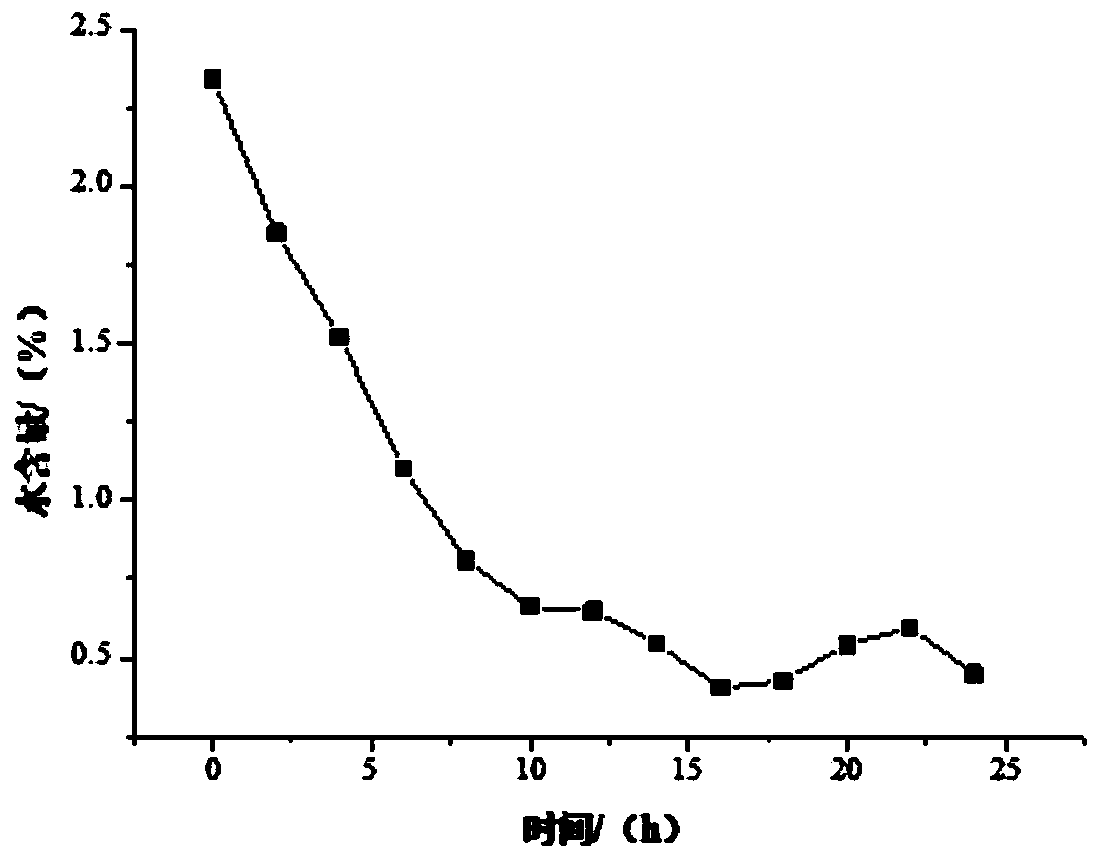

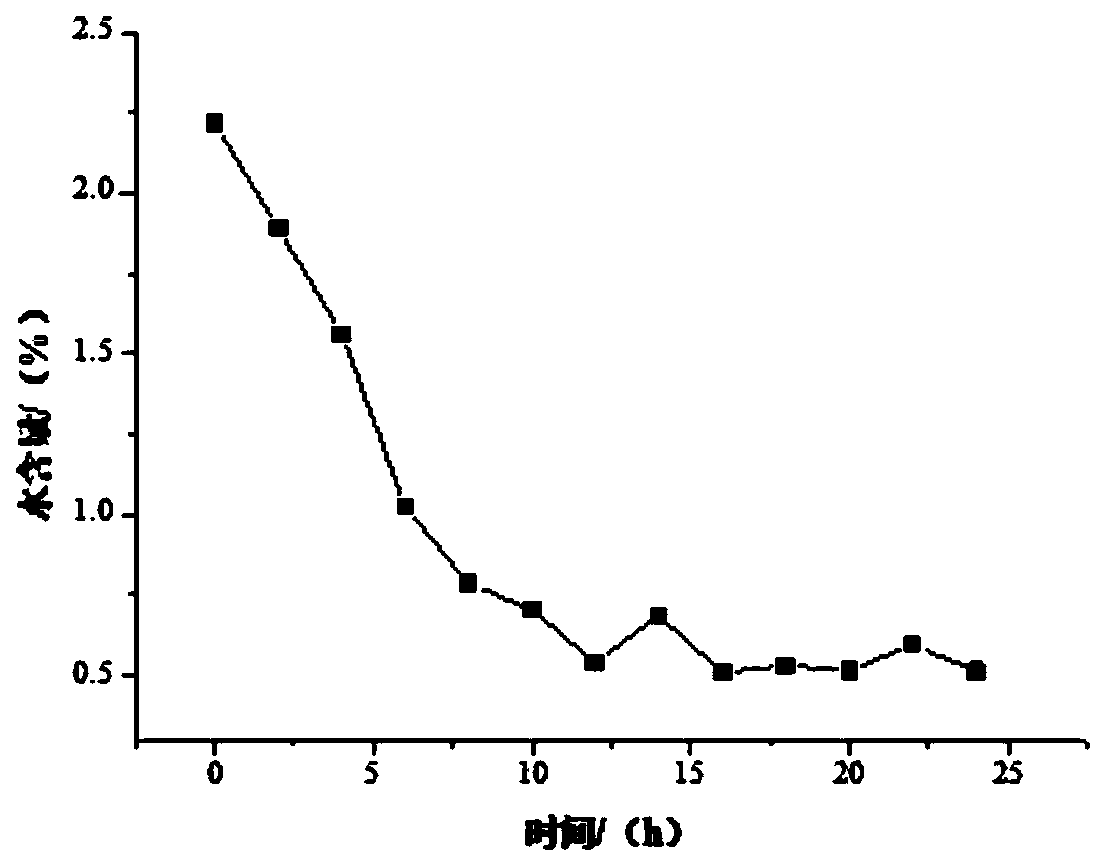

Method for synthesizing oxiracetam by adopting NaA type molecular film reactor

PendingCN111454190AReduce pollutionControl water contentOrganic chemistryChemical/physical/physico-chemical stationary reactorsSodium bicarbonateMembrane reactor

The invention discloses a method for synthesizing oxiracetam by adopting a NaA type molecular sieve membrane reactor. According to the method, the prepared NaA molecular sieve membrane is used to prepare oxiracetam through vapor permeation technology coupled with a cyclization reaction. The method specifically comprises the following steps of: adding absolute ethyl alcohol into a reaction flask, adding glycine hydrochloride and sodium bicarbonate in a stirring state, and heating to reflux; dropwise adding 4-chloro-3-hydroxybutyrate into the reaction liquid, continuing reflux stirring until thereflux is stable, placing the NaA type molecular sieve membrane reactor above the reaction liquid to be coupled with a cyclization reaction device and start vacuum for a reaction, and thereby obtaining a reaction product after the reaction is completed. According to the method, the energy consumption required by cyclization reaction and the requirements on reaction equipment are reduced, the yield of the product and the purity in the separation process are improved, the recycling of ethanol is realized, and the production cost is saved.

Owner:CNOOC TIANJIN CHEM RES & DESIGN INST +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com