Slag water quenching method and device

A steel slag and water quenching technology, which is applied in the field of steel slag water quenching and equipment, can solve the problems of slag tank opening, cracking and explosion of large-scale steel slag, and inability to effectively control the flow rate of steel slag, etc., and achieve high safety effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

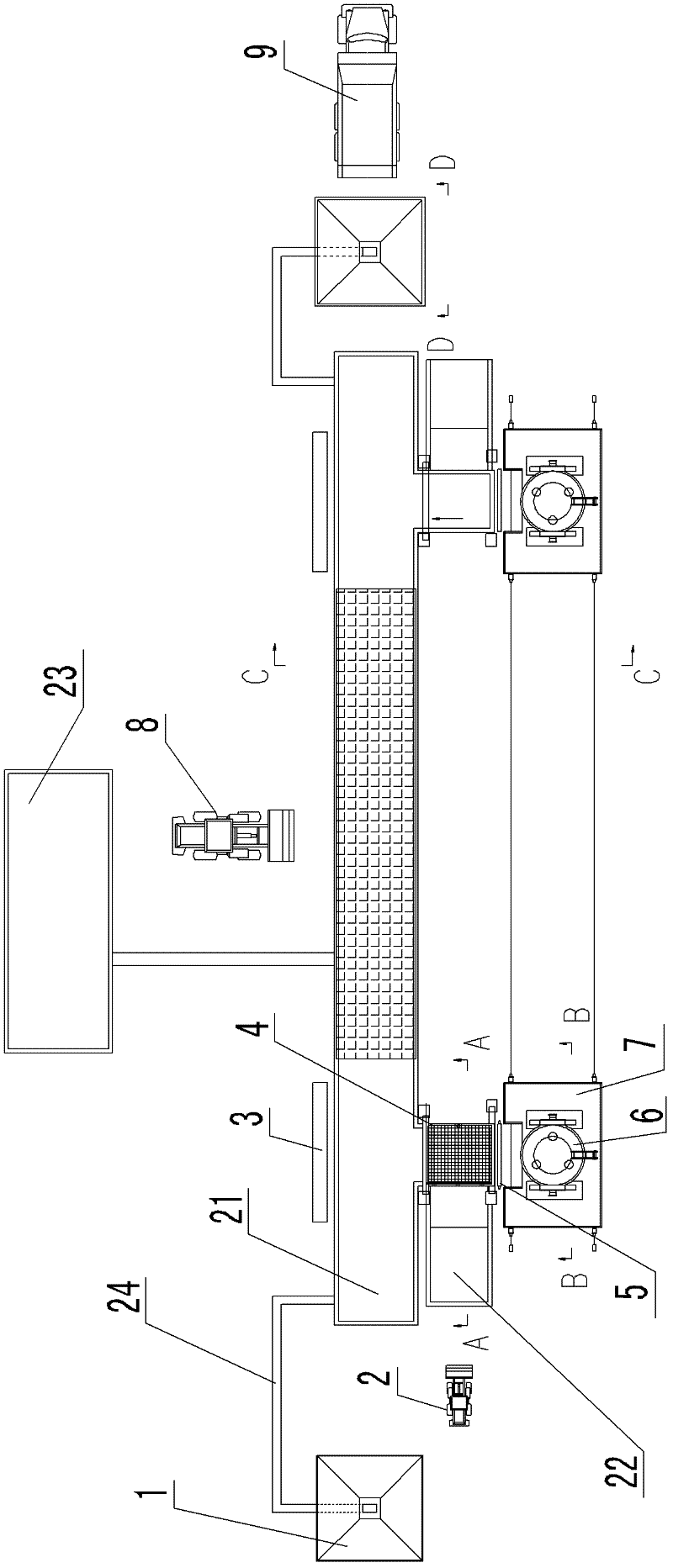

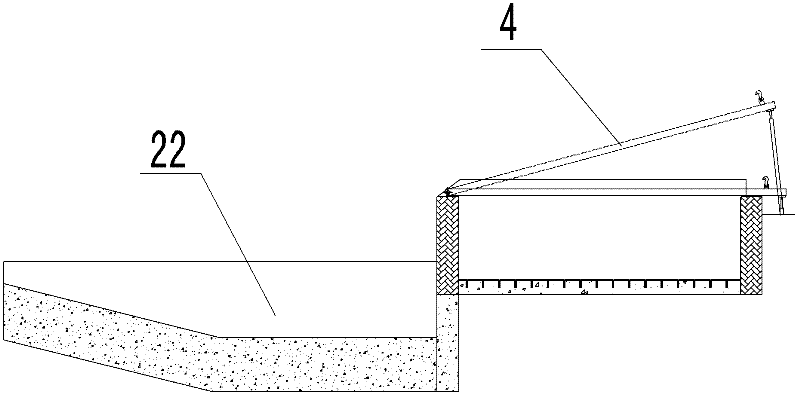

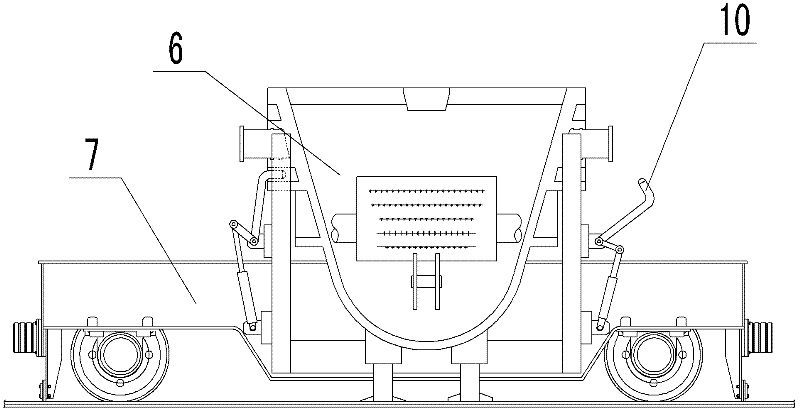

[0030] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

[0031] The steel slag water quenching method of the present invention distinguishes and processes the steel slag according to the volume, so as to achieve the purpose of safe recycling of the steel slag. The method comprises the steps of:

[0032] 1. The steel slag from the furnace is transported to the tank body of the slag tank tipping unit.

[0033] 2. The slag tank tipping unit moves along the track to the steel slag processing station to prepare for dumping steel slag; at the same time, open the steel slag granulator to prepare for granulation.

[0034] 3. The slag tank tipping unit dumps the steel slag in the tank to the grid sieve at a uniform speed.

[0035] 4. During the pouring process of steel slag, the granulator uses water flow to cool and break the steel slag, and the processed steel slag falls on the grid sieve.

[0036] 5. The steel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com