Stirring and filtering device for circulating pulp used in papermaking through glass fibers

A filter device and slurry technology, applied in the direction of filtration and separation, fixed filter elements, chemical instruments and methods, etc., can solve the problems affecting the quality and production efficiency of glass fiber filter paper, low service life of filter materials, poor filtration effect, etc. Achieve the effect of solving the problem of circulating fluid filtration, maximizing online cleaning and prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

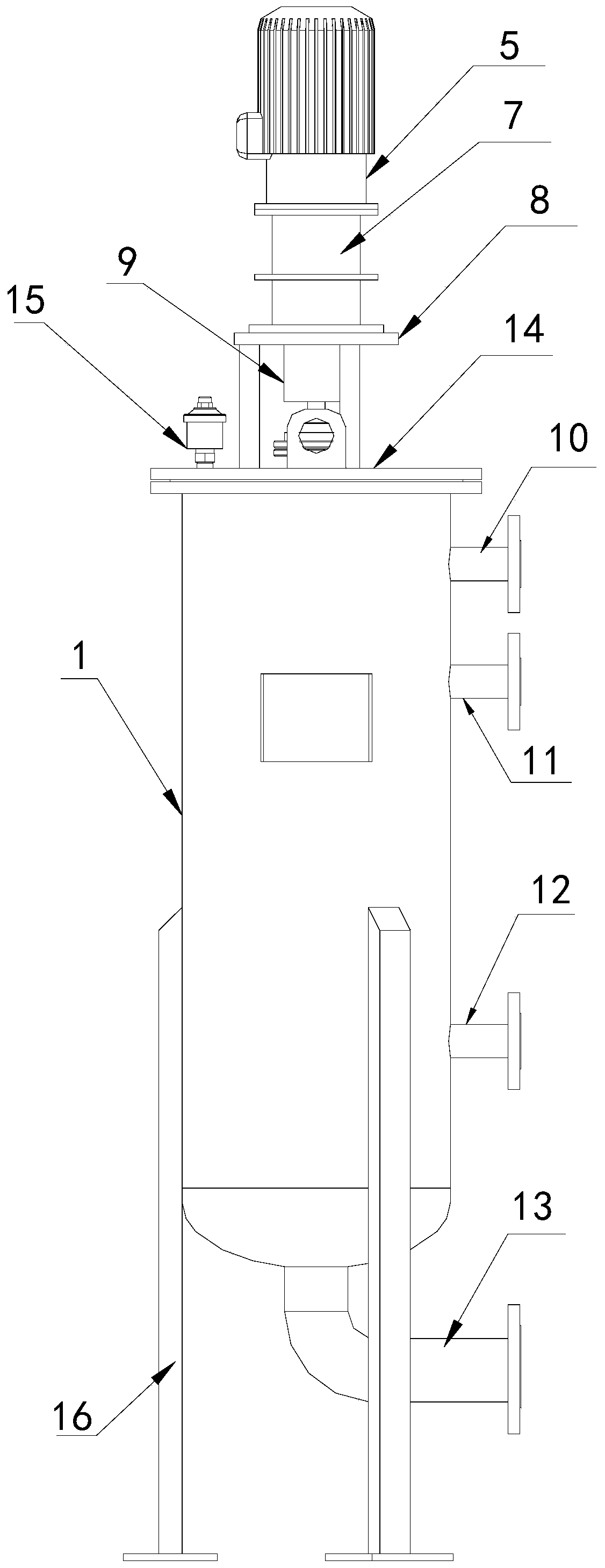

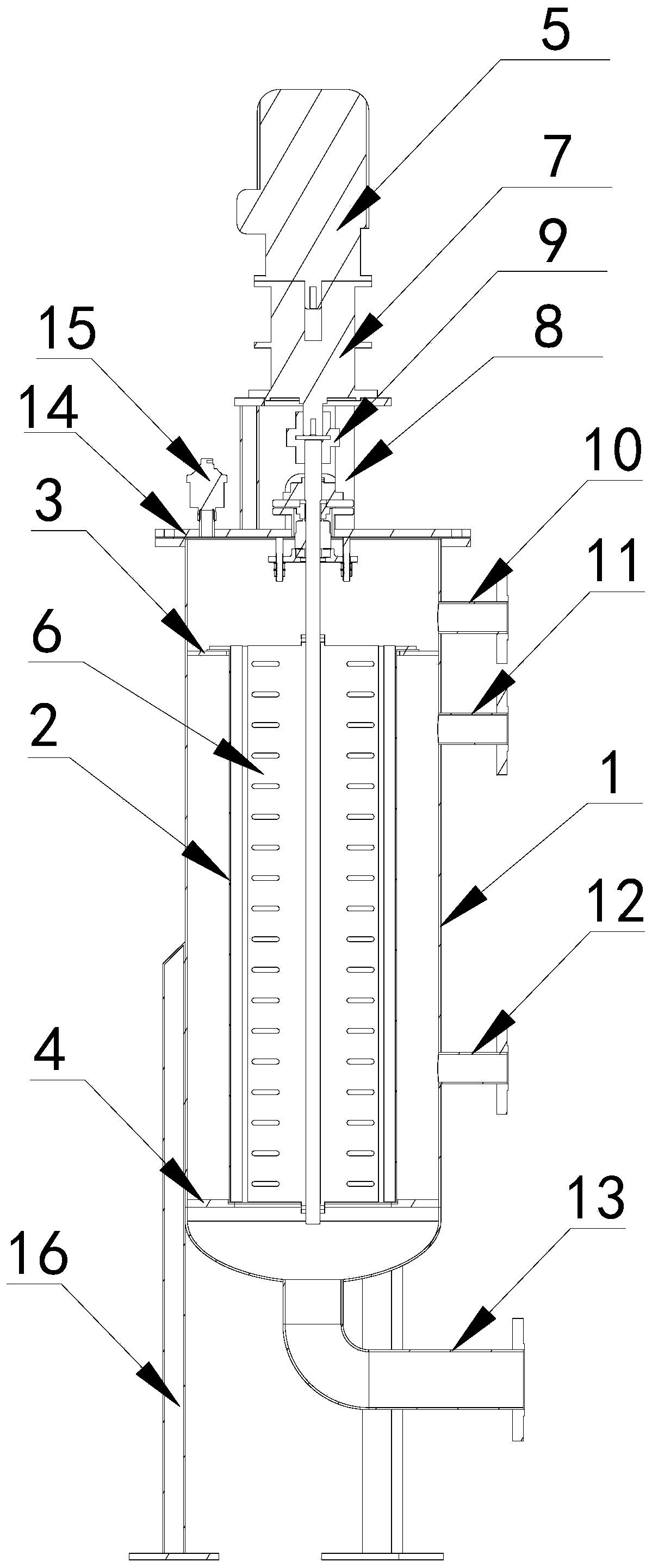

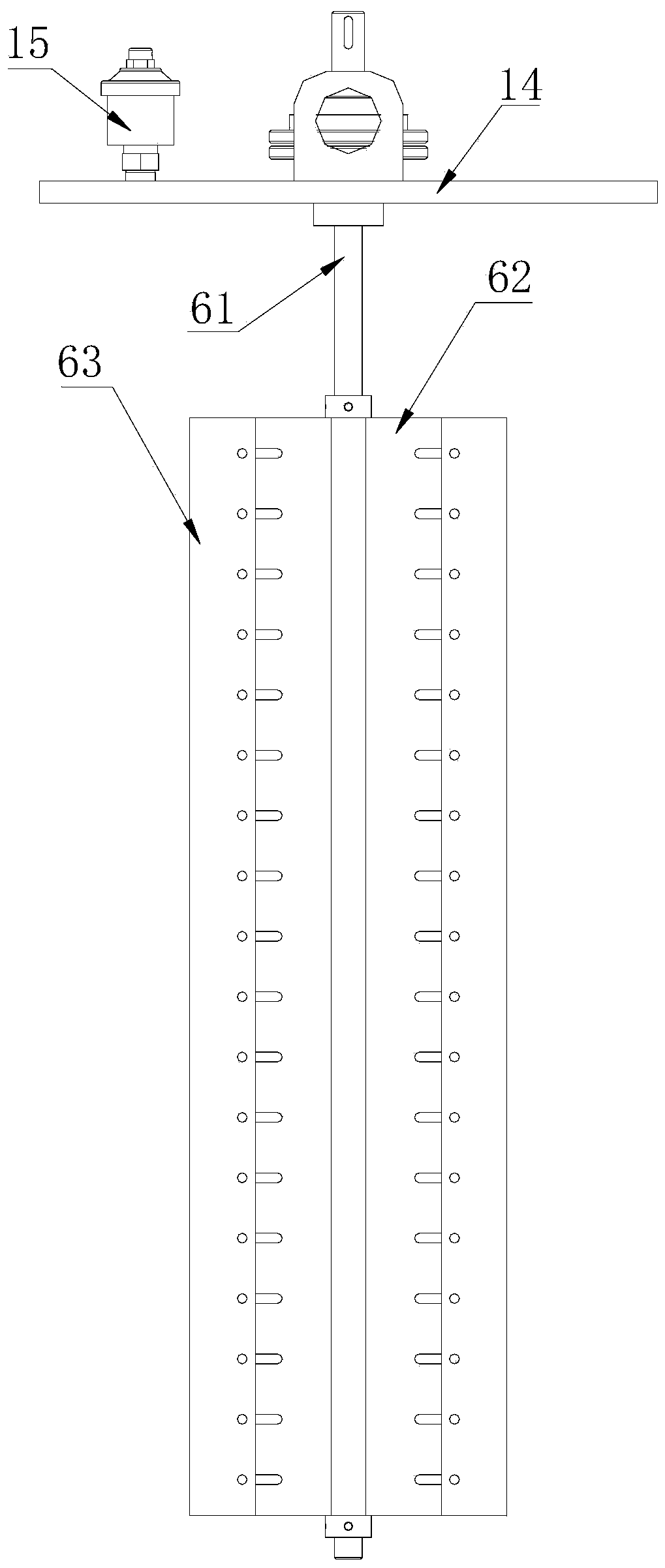

[0023] refer to figure 1 and figure 2 , is the stirring and filtering device of the present invention, which is mainly used in the filtration process of glass fiber papermaking circulating slurry, so that impurities such as glass fiber in the circulating slurry are filtered so that the effluent reaches the standard of recycling. Specifically, the stirring and filtering device includes a filter assembly for filtering the glass fiber circulating slurry and a stirring assembly for stirring the slurry and brushing the filter assembly. The filter assembly includes a filter tank 1 and a membrane filter element 2. The membrane filter core 2 is detachably arranged in the filter tank 1 and separates the filter tank 1 into an inner cavity and an outer cavity, which is convenient for regular replacement. Further, the upper part of the filter ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com