Patents

Literature

51results about How to "Solve turbidity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

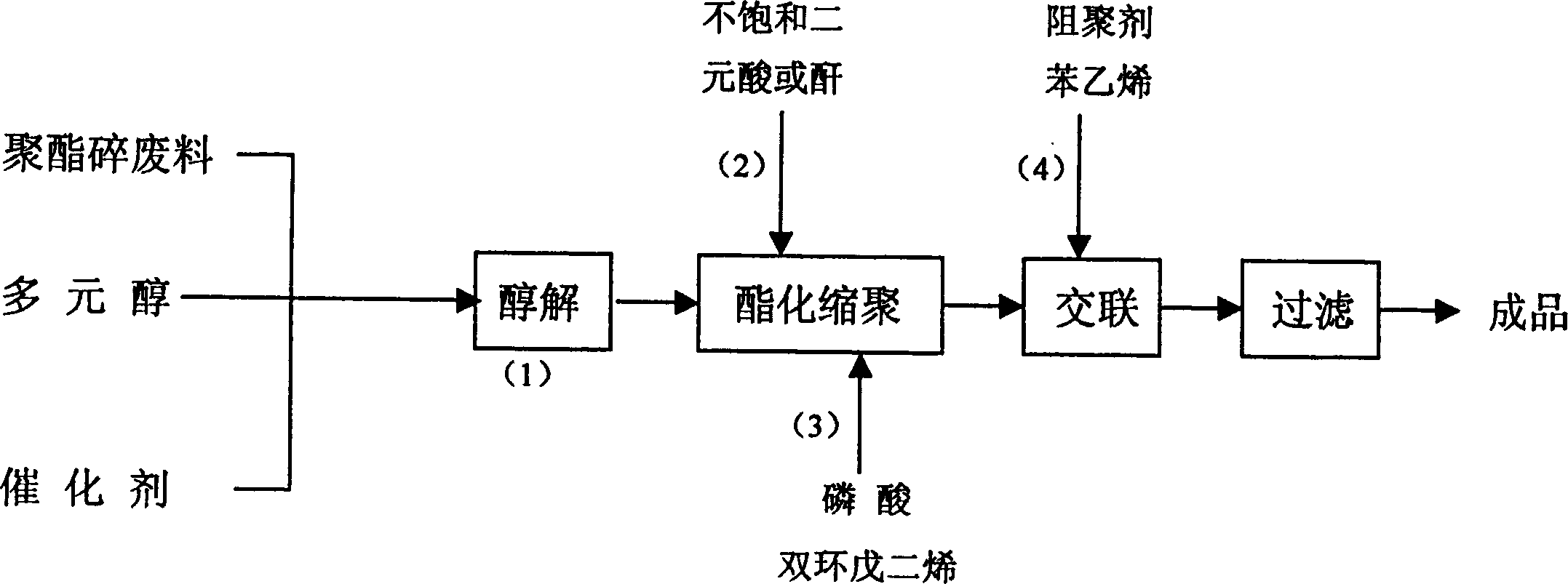

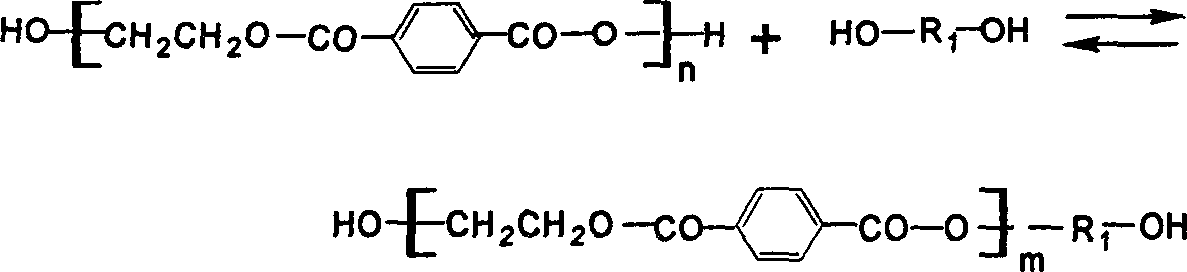

Synthesis of p-phenyl unsaturated polyester resin by using waste polyester material

The invention relates to a method for synthesizing unsaturated phenolic resin with various etherification waste, which includes the four steps: (1) etherification waste and polyhydric alcohol have alcohol sis and ester interchange with catalyst existing; (2)alcohol zed product and unsaturated binary acid or have etherification polycondensation; (3) use dicyclopentadiene (DCPD) to blocking modify in the later period of etherification polycondensation; (4) add into styrene solution for cross linking. The invention has plentiful sources of raw material, low price, decreased pollution and productive cost and energy saving, as well as eliminates the disadvantage of bad dissolubility in styrene .

Owner:HUACHANG POLYMER EAST CHINA UNIV OFSCI & TECH

Production method for edible vinegar

The invention relates to a method for producing table vinegar, which is to use water to fully moisten vinegar brewing raw materials, cook the raw materials, inoculate Daqu, Xiaoqu, bran koji, red koji and rice koji, and perform lactic fermentation, alcoholic fermentation, acetic fermentation, aging, heating aging, vinegar pouring and mixing to prepare table vinegar finished products. The invention applies the novel table vinegar brewing method through five types of koji, three types of fermentation and one type of aging. The brewed table vinegar has bright color and luster, transparent posture, rich koji flavor, tender and sour taste, coordinated five flavors and richer nutrition, and not only has the characteristics of spiced vinegar but also has the taste of mature vinegar.

Owner:吴德辉

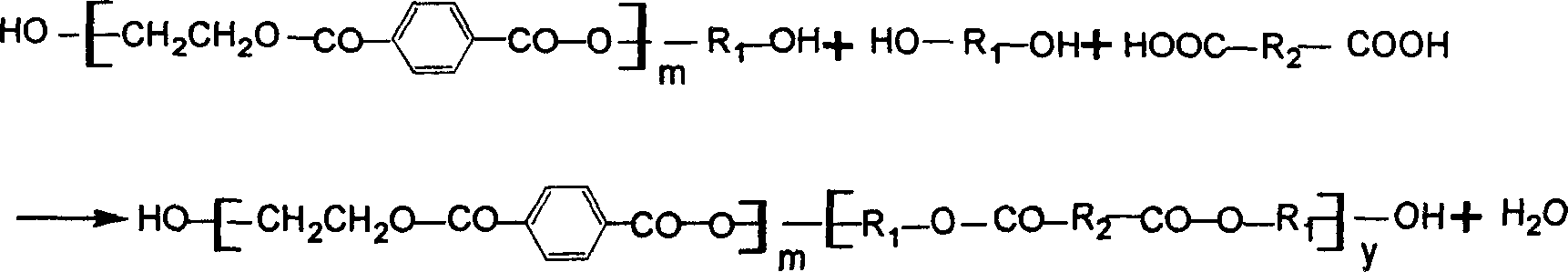

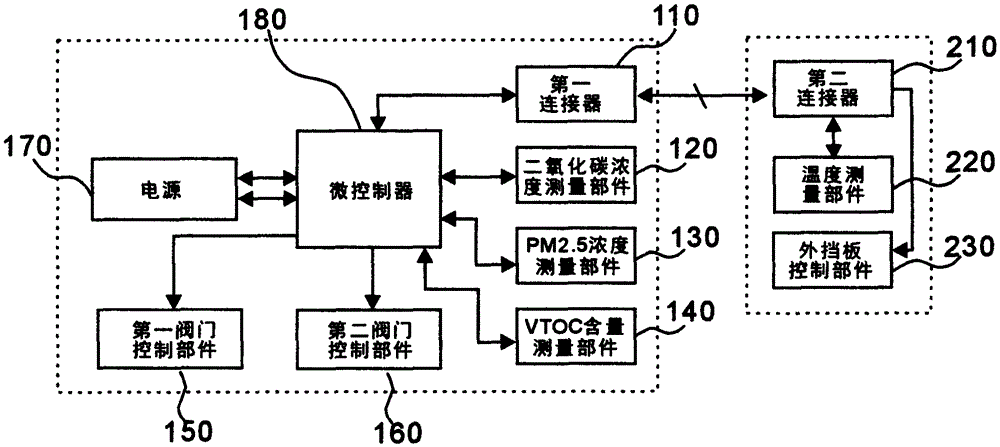

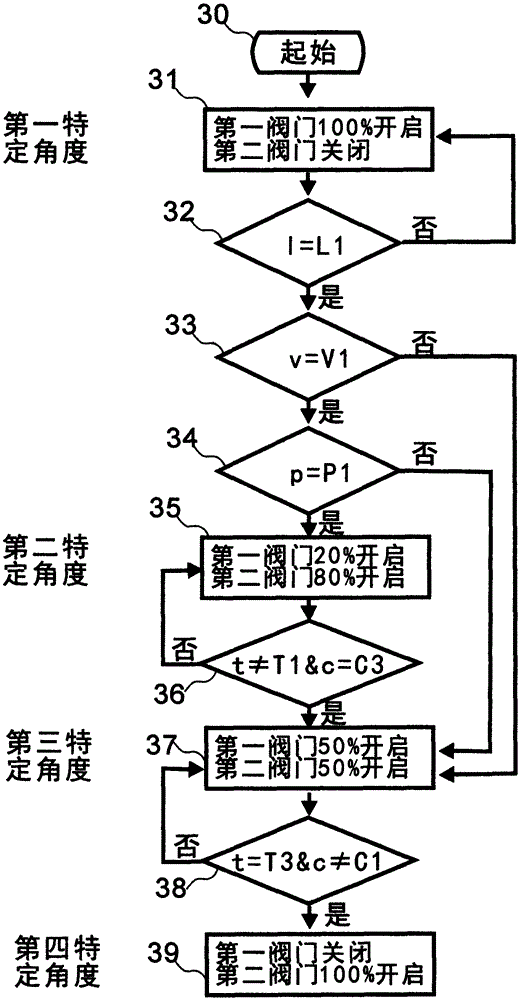

Air purification device

InactiveCN106016481AQuality improvementReduce use costMechanical apparatusSpace heating and ventilation safety systemsMicrocontrollerActivated carbon

An air purification device that can automatically control the ratio of mixed inhaled indoor air and outdoor air, the air purification device includes an air cleaner body and one or more ventilation duct components that can be installed in building walls, doors or windows The air purification device includes a microcontroller and a plurality of sensing and measuring components. According to the value fed back by the sensing components, the microcontroller controls the opening angles of the indoor air channel valve and the outdoor air channel valve to automatically control the mixing of indoor air and outdoor air. The proportion of outdoor air, under the action of the fan, the mixed air passes through the primary filter, HEPA high-efficiency filter, activated carbon adsorption filter, and sends fresh and pure air to the room. The present invention also includes a control method for automatically controlling the ratio of mixed inhaled indoor air and outdoor air.

Owner:王国伟

Method of preparing beer local flavor vinegar

InactiveCN101016509ATake advantage ofReduce pollutionVinegar preparationFood flavorAcetic acid bacteria

The invention discloses a preparing method of beer local flavor vinegar in brewing technical domain, which comprises the following steps: boiling waste beer; yeasting acetic acid mixed bacteria; clarifying; adding into clarificant; switching in scent yeast seed liquid in fermentation tank; proceeding flavor matter yeast; switching in acetic acid bacteria seed liquid; proceeding acetous fermentation; getting ripe fermented glutinour rice; adding into bentonite clay; stirring; stewing; depositing; fetching supernatant fluid; filtering with diatom earth filter; getting the clarifying beer local flavor vinegar. This invention resolves the problem of opacity and back-opacity, which can increase the scent composition of beer vinegar.

Owner:QILU UNIV OF TECH

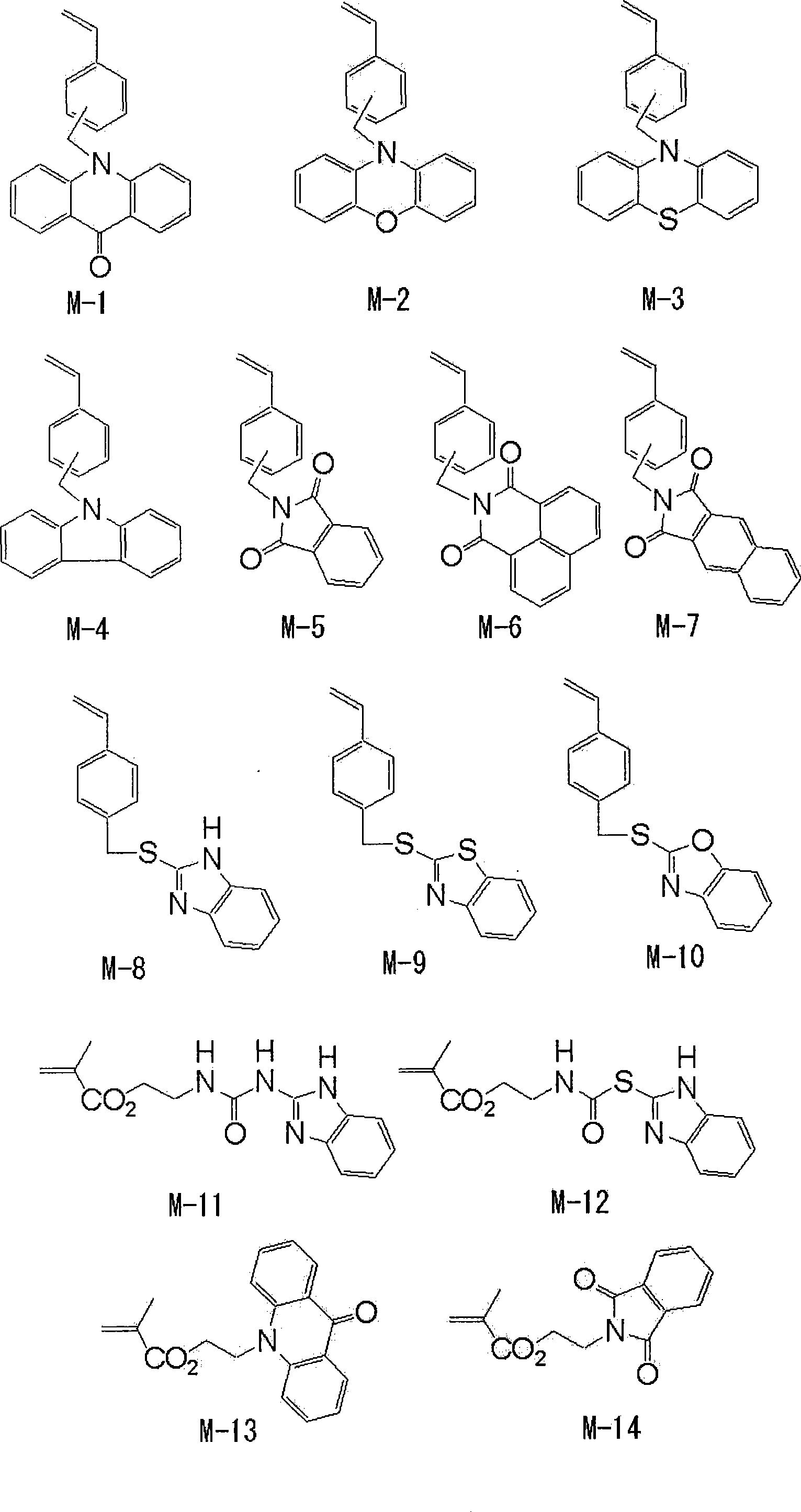

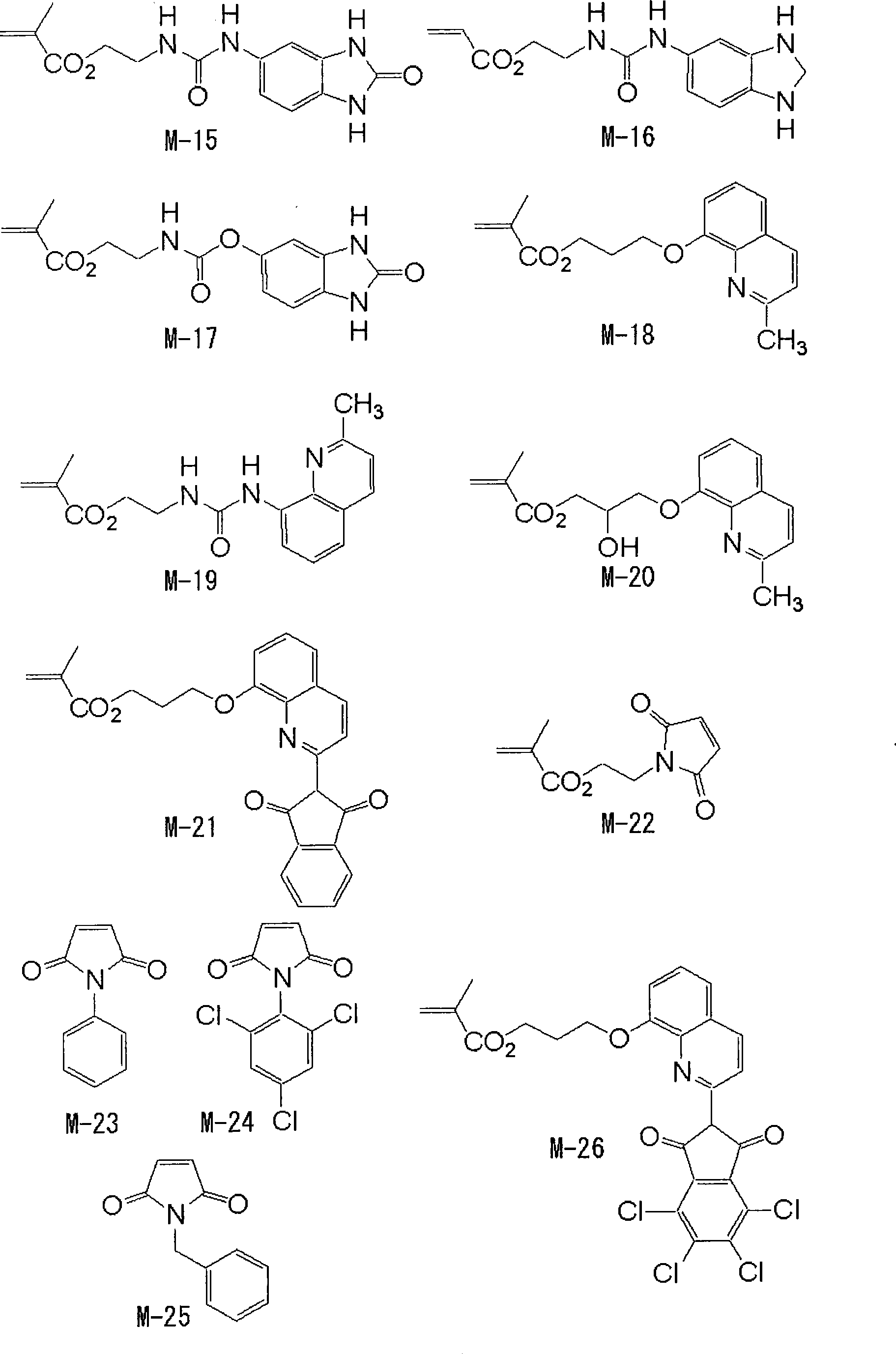

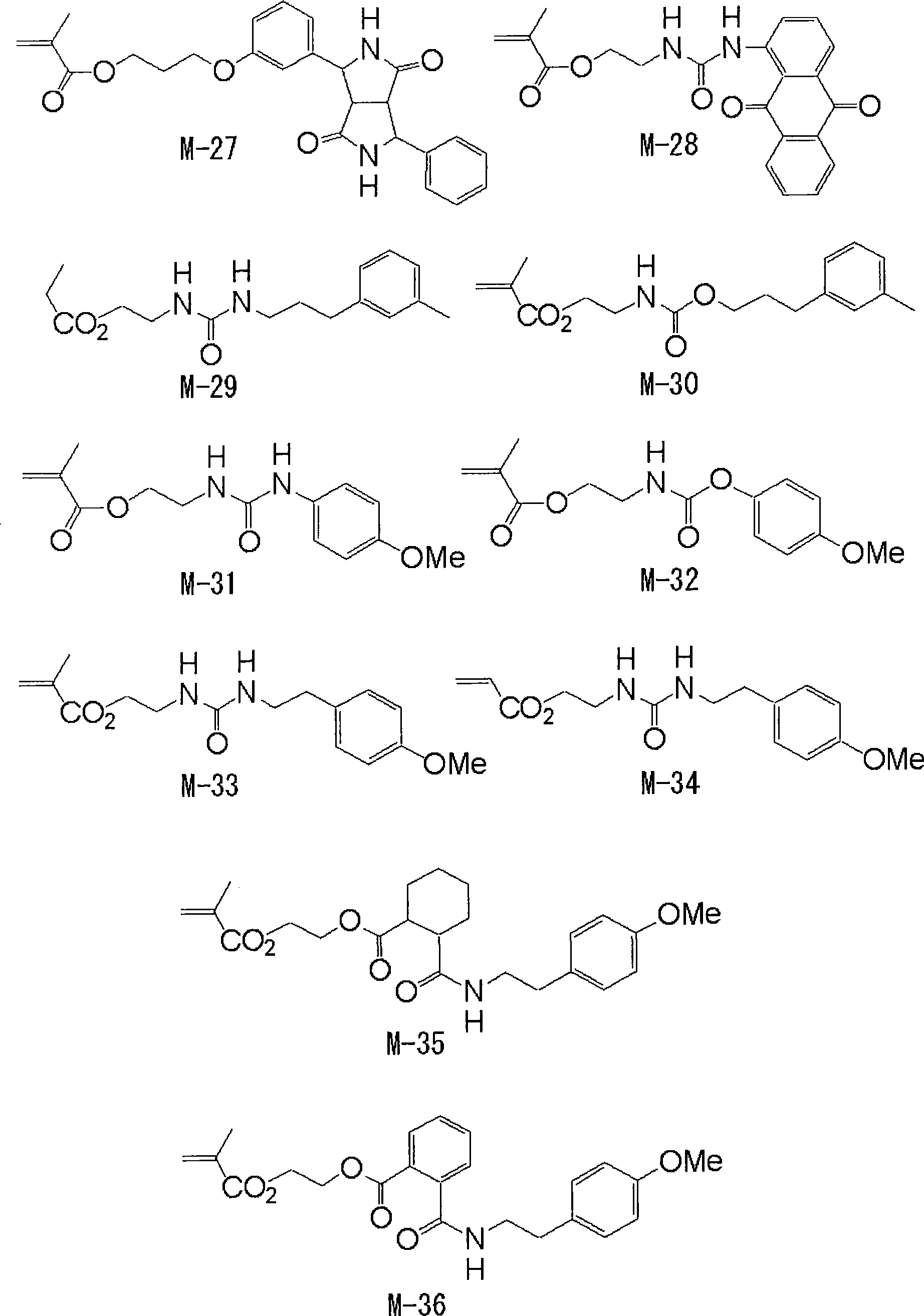

Processed pigment and pigment dispersion composition using the same, colored photosensitive composition

InactiveCN101445670AIncrease contrastLow color densityOptical filtersOrganic dyesPigment dispersionCopolymer

The present invention provides a processed pigment, a pigment dispersion composition and a photosensitive composition with good pigment dispersion and excellent developing performance even though thinning the pigment for obtaining a color filter with excellent color characteristics of contrast and the like. The processed pigment is made by covering a pigment using a block copolymer having pigment absorbability block and pigment non-absorbability block.

Owner:FUJIFILM CORP

Preparation method of whole wheat amino acid drink

InactiveCN102293436ARich flavor substancesGuaranteed full-bodied aromaFood preparationFiltrationWhole wheat

The invention discloses a preparation method of a wholewheat amino acid beverage, which, with barley and wheat as the raw materials, is produced with the processes of malt preparation, saccharification and mash filtration, clarification treatment and mouth irritation improvement. With abundant amino acid, the wholewheat amino acid beverage of the invention has pure mouthfeel, heavy fragrance and strong mouth irritation.

Owner:JIANGSU SHENHUA PHARMA

Processing process for special ginger garlic aromatic vinegar

The invention relates to a processing process for special ginger garlic aromatic vinegar, and belongs to the production processing field. The ginger garlic aromatic vinegar produced by the processing process not only retains flavor and physical and chemical quality of original vinegar but also fuses the original taste of ginger-garlic, so that the product has strong fermented vinegar fragrance and ginger garlic fragrance and is agreeable to taste with the mouthfeel being fragrant, sour, fresh and sweet, and at the same time, turbidity and precipitate of the ginger garlic aromatic vinegar / dumpling vinegar caused by colloid substances of the garlic and starch in the ginger.

Owner:GUIYANG WEICHUNYUAN FOODS

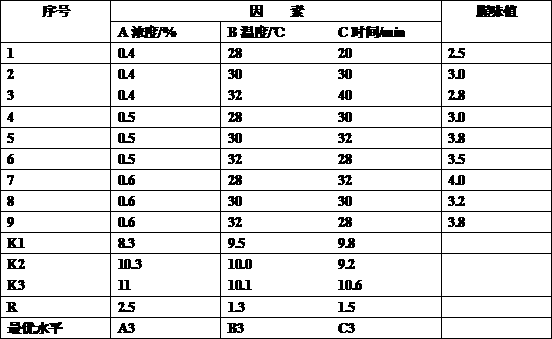

Preparation method for clear Huoshan dendrobium officinale beer

ActiveCN107354045AHigh clarityReduce turbidityBeer fermentationAlcoholic beverage preparationAqueous solutionFermentation

The invention provides a preparation method for clear Huoshan dendrobium officinale beer and belongs to the technical field of a clarifying method for dendrobium officinale beer. The preparation method for the clear Huoshan dendrobium officinale beer specifically comprises the following steps: preparing malt mash; using a lactic acid aqueous solution for ultrasonically digesting Huoshan dendrobium officinale; filtering, boiling, adding hops, cooling and then sealing for fermenting; adding a clarifying agent A, filtering, adding a clarifying agent B and uniformly mixing; and placing the Huoshan dendrobium officinale beer added with the clarifying agent B into an environment at 4+ / -1 DEG C, performing post-fermentation, filtering after the ending of the fermentation and removing the sediment in beer, thereby acquiring the clear Huoshan dendrobium officinale beer. The Huoshan dendrobium officinale beer prepared according to the invention is free from turbid phenomenon after long-term storage. The preparation method has ultrahigh marketing value and can create basis for putting the Huoshan dendrobium officinale beer into the market.

Owner:WEST ANHUI UNIV

Maturing agent for ripening distilled spirit

InactiveCN1696273ASolve the turbidity of wineEntrance mellowAlcoholic beverage preparationCalcium EDTAChemistry

A porous granular ageing agent for spirit is prepaired from silicate, magnesium complex, carbonate and Ca-contained stone powder. It features that the high-class ester of fatty acid in the spirit can be absorbed by the ageing agent particles under critical pressure, so improving the quality of spirit.

Owner:ZHONGLIN IND & TRADE TIANJIN CITY

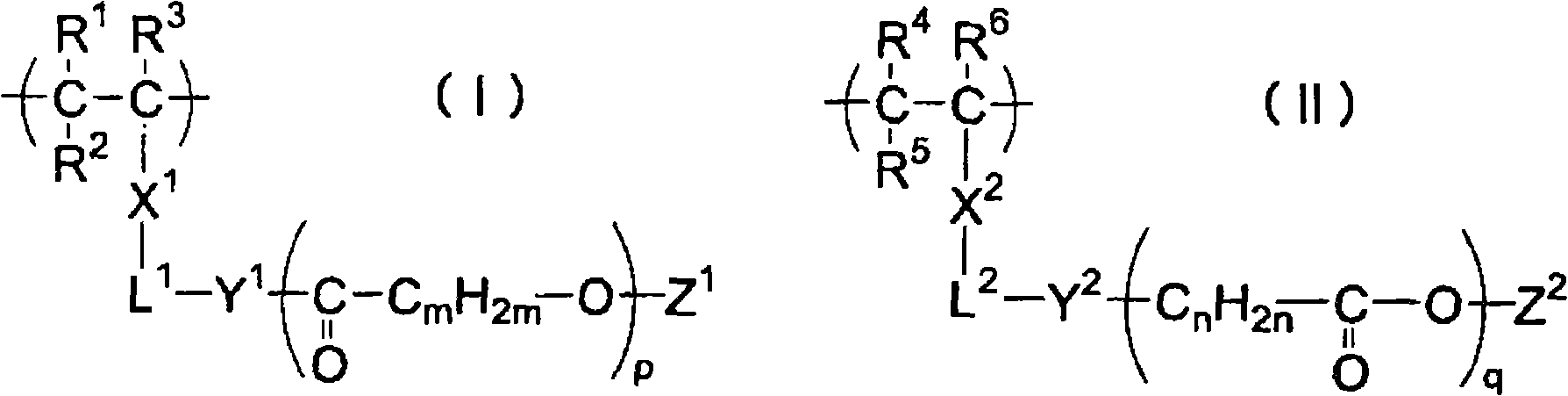

Pigment disperse combination, coloring photosensitive combination, color filter, liquid crystal display element and solid camera shooting element

ActiveCN101676338AEffectively unlockStrong electrostatic interactionTelevision system detailsOptical filtersPhotopigmentDouble bond

The present invention provides a pigment disperse combination, a coloring photosensitive combination, a color filter, a liquid crystal display element and a solid camera shooting element; the pigmentdisperse combination is capable of dispersing minute pigment in a manner of one particle, has an excellent disperse stability and may be formed coloring tunica with an excellent contrast grade; the coloring photosensitive combination contains the pigment disperse combination, has an excellent curing sensitivity, and may be formed high strength coloring curing membrane with an excellent contrast grade. The pigment disperse combination of the invention is characterized in that the pigment disperse combination contains (a) a high molecular compound, (b) a pigment and (c) an organic solvent, the high molecular compound contains at least one repetitive unit of repetitive units represented by formula (I) and formula (II), in the formula (I) and (II), R<1>-R<6> represent hydrogen atom and the like, X<1> and X<2> represent -CO- and the like, L<1> and L<2> represent two-valency organic linking groups and the like, Y<1> represents an oxygen atom and the like, Y<2> represents -C(=O)O- and the like, Z<1> and Z<2> represent groups containing a C-C double bond, m and n represent integers from 2 to 8, and p and q represent integers from 1 to 100.

Owner:FUJIFILM CORP

Method for producing vinegar

InactiveCN102373146ABright colorTransparentMicroorganism based processesVinegar preparationRed yeast riceAge method

The invention discloses a method for producing vinegar, comprising the following steps: 1, drenching raw materials for brewing vinegar in water completely, and boiling; 2, cooling the boiled materials, inoculating yeast for making hard liquor, chinese koji, bran koji, red yeast rice, and aspergillus oryzae, and carrying out lactic acid fermentation; 3, cooling, adding yeast, carrying out alcoholic fermentation, and carrying out acetic acid fermentation; 4, adding aged fermented grains, putting into a pot, adding aspergillus oryzae, and heating until aging; and 5, leaching vinegar, adjusting concentration, and carrying out disinfection to obtain a finished product. The vinegar aging method disclosed herein combines the protein decomposition fermentation process, high temperature aging, filtering leaching process and the like in soy sauce production based on traditional aging technology, solves the problem of raw material protein utilization rate in vinegar production, so as to solve the problem that vinegar turns turbidity because of protein deposition and increase the product quality of vinegar, and solves the quality problem that vinegar produced by solid state fermentation turns turbidity to make vinegar produced by solid state fermentation transparent. By adding aspergillus oryzae in the aging process, the content of amino acid in the produced vinegar is increased, and the nutrition and mouthfeel are enriched.

Owner:蒋先志

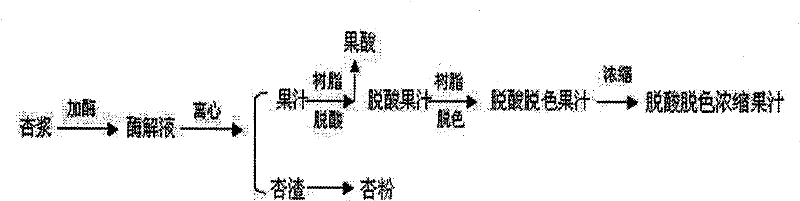

Method for producing concentrated apricot juice and natural fruit acid

InactiveCN102210447ASolve the problem of coloringSolve the problem of sour tasteFood preparationPectinaseCentrifugation

The invention relates to a method for producing natural fruit acid, concentrated apricot juice and apricot powder. Apricots are taken as a raw material. The invention relates to a process for producing the natural fruit acid, the concentrated apricot juice and the apricot powder. The process is characterized by comprising the following steps of: removing cores of the apricots, homogenating, adding pectinase and performing enzymolysis, extracting residue obtained after enzymolysis and centrifugation for the second time according to the conditions, removing the residue, mixing two supernatants and concentrating, allowing the concentrated supernatant to pass through a resin column, eluting by using water, concentrating solution obtained after elution to obtain the concentrated apricot juice, eluting by using 50 percent ethanol in which a small amount of ammonia water is added, concentrating eluent under reduced pressure at the temperature of between 60 and 70 DEG C, and drying to obtain the solid natural fruit acid.

Owner:JIANGNAN UNIV

Production method of honey purple potato food

InactiveCN103829186AFacilitated releaseIncrease nutritionFood preservationFood ingredient functionsBiotechnologyAmylase

The invention provides a production method of honey purple potato food, which belongs to the technical field of food processing. The production method comprises the following steps: cleaning, peeling and cutting purple potatoes, placing the cut purple potatoes in a composite colour fixative solution of ascorbic acid and sodium hydrogen sulphite, and carrying out cooking treatment at 80-95 DG C for passivating the activity of oxidase; adding beta-amylase and composite saccharifying enzyme into the pulped purple potatoes for enzymolysis, thereby promoting the release of active substances such as anthocyanin in cells; then adding acid proteinase for treating so as to avoid the problems of turbidity and secondary precipitation of the honey purple potato food during a storage process; and finally, blending the enzymolysis purple potato juice with honey, and concentrating in vacuum to obtain the honey purple potato food which is bright in colour and rich in nutrition.

Owner:NANJING FEIMA FOOD

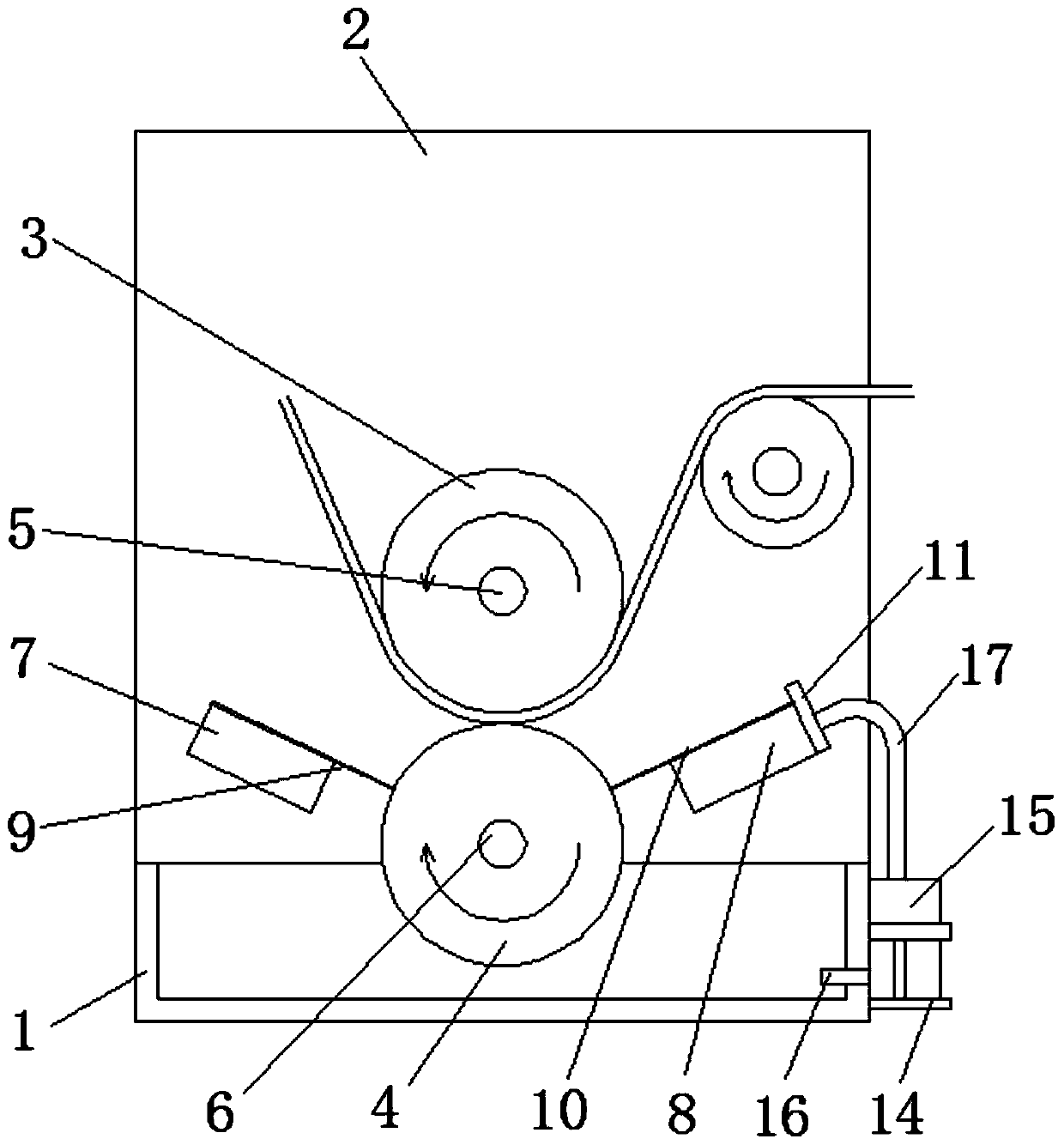

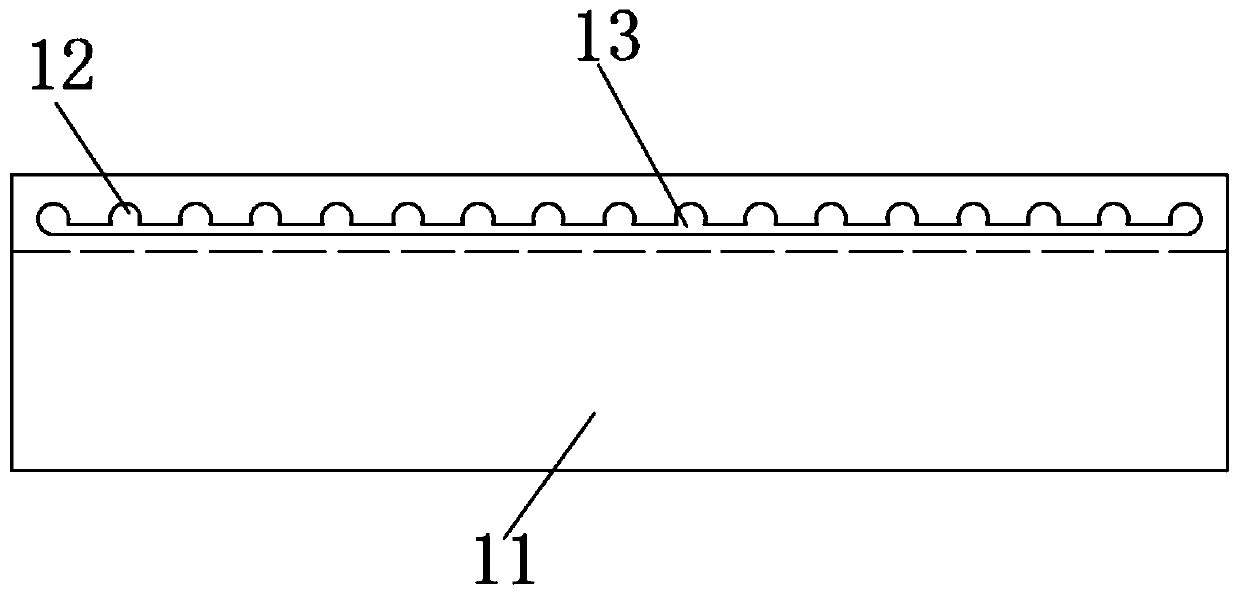

Aluminum-plastic film bubble-free gravure coating device and coating technology thereof

The invention discloses an aluminum-plastic film bubble-free gravure coating device. The device comprises a material box. A dandy roll and a gravure roll are arranged on the upper portion of the material box from top to bottom in sequence. A first fixing block is arranged on one side of the gravure roll. A second fixing block is arranged on the other side of the gravure roll, and the first fixingblock and the second fixing block are arranged symmetrically. The top of the first fixing block is provided with a first scraper used for scraping off excessive slurry in mesh holes of the surface ofthe gravure roll. The top of the second fixing block is provided with a second scraper used for filling the mesh holes of the surface of the gravure roll with slurry. The mesh holes of the surface ofthe gravure roll sequentially pass through the material box, the first scraper, the dandy roll and the second scraper in sequence while rotating. According to the aluminum-plastic film bubble-free gravure coating device, by arranging the second scraper and the flowing slurry on the scraper, the mesh holes in the gravure roll can be filled with the slurry before the gravure roll enters below the slurry liquid level inside the material box, the problem that bubbles are mixed into the slurry is effectively solved, the transfer coating slurry feeding amount is uniform, and no missing coating occurs.

Owner:LIYANG EXCELLENCE NEW MATERIAL TECH CO LTD

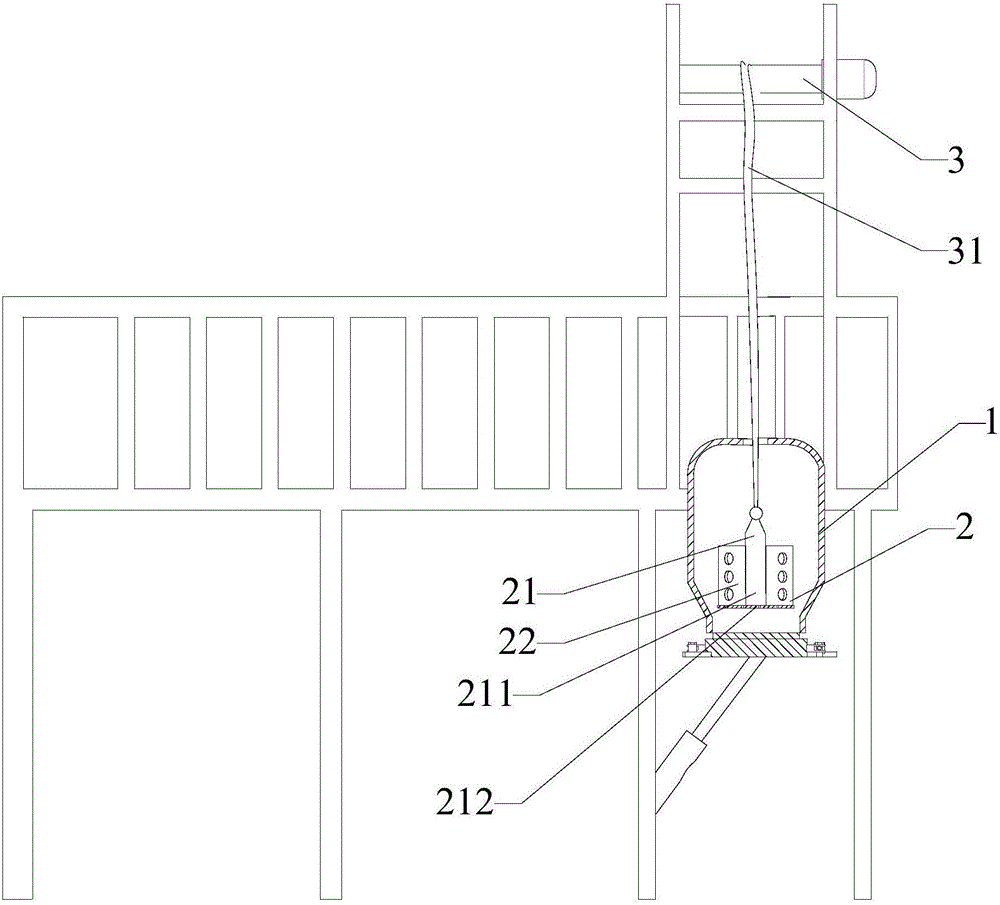

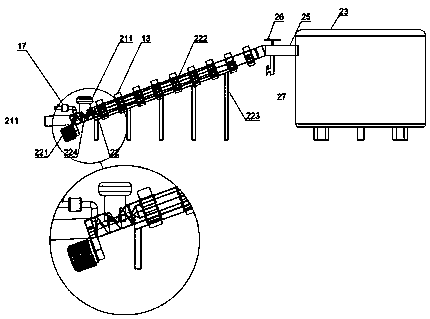

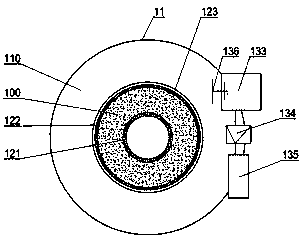

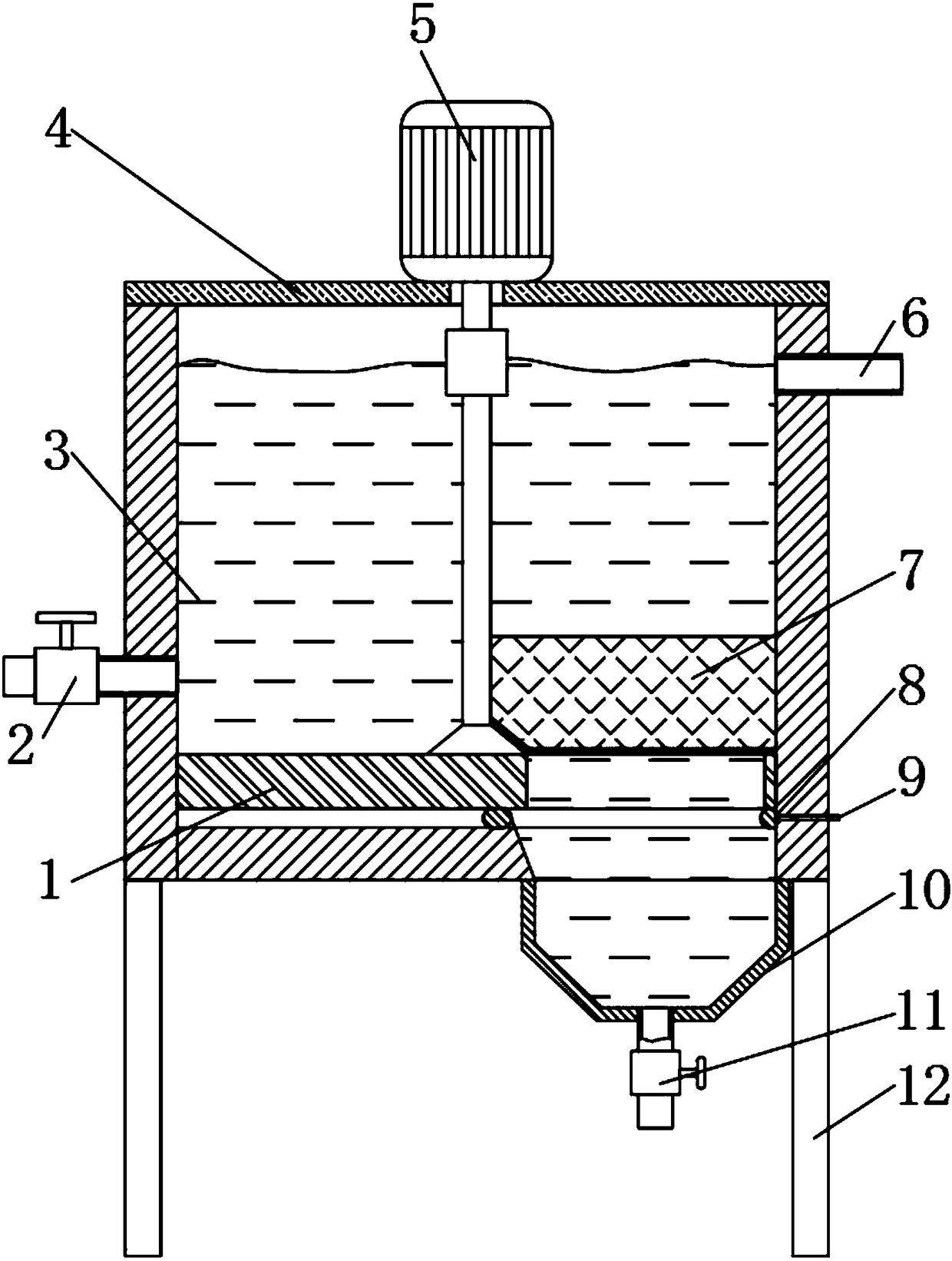

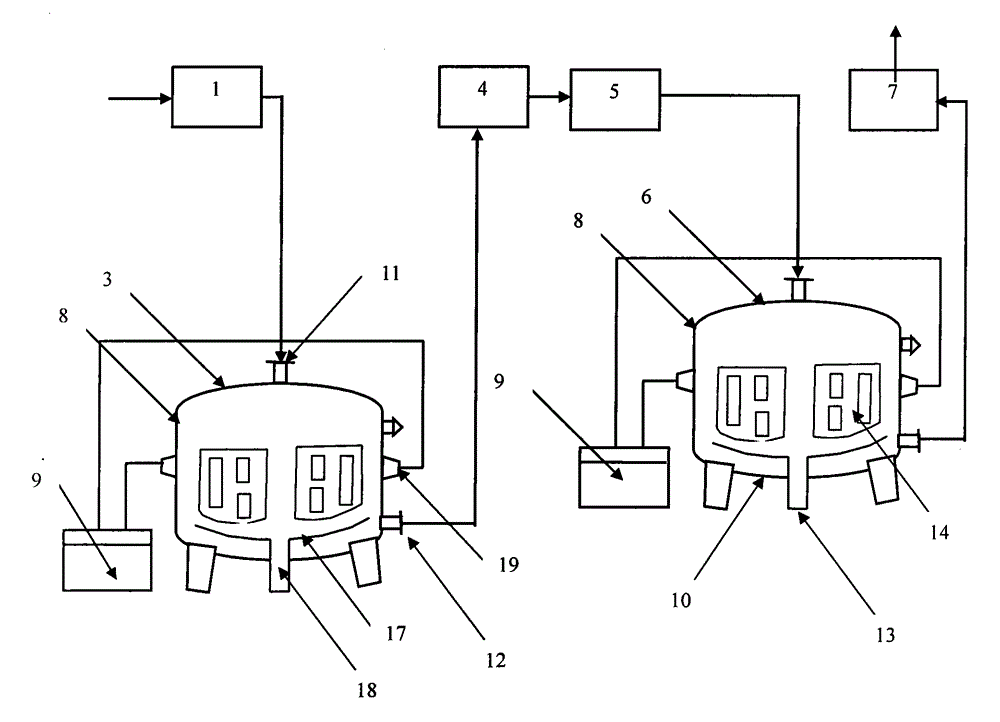

Extraction device

InactiveCN106334335ASolve turbidityEasy maintenanceGravity filtersSolid solvent extractionRaw materialWaste management

The invention relates to the technical field of extraction equipment, in particular to an extraction device. The extraction device comprises a tank, a filter basket and a lifting device. The tank is arranged on a support in a suspended mode, the bottom of the tank is provided with a filter basket inlet and outlet, and the filter basket inlet and outlet is provided with a sealing cover. The lifting device comprises a rope which is driven by a power mechanism and stretches and retracts in the vertical direction of the tank, and the rope penetrates through the tank and is connected with the filter basket. The extraction device has the advantages that raw materials of the extraction device are isolated in the filter basket, and thus solid-liquid separation after extraction is convenient; the filter basket of the extraction device penetrates through the filter basket inlet and outlet and exits from the lower end of the extraction device, and thus a large batch of raw materials can be efficiently and safely put into the filter basket or taken out of the filter basket; the extraction device can control the horizontal height of materials in the filter basket in the tank through the rope, so that whether the materials are steamed or cooked is controlled, and extraction efficiency is greatly improved.

Owner:FUZHOU RENLIANG BIOLOGICAL PROD CO LTD

Preparation technology for sodium chloride injection packaged in plastic bottles

InactiveCN105147603AImprove stabilityReduced Chances of ContaminationPharmaceutical containersPharmaceutical delivery mechanismScrapPolypropylene

The invention discloses a preparation technology for sodium chloride injection packaged in plastic bottles. The preparation technology includes the following measures that external force damage to bottle preforms and the bottles in the production process is reduced, and film scraps and fibers adhering to the insides and the outsides of bottle bodies are reduced; a filtering device is additionally arranged on a drain outlet of a sterilization cabinet, and accumulation of the film scraps in a sterilization pipeline and a heat exchanger is reduced; sterilization cabinet cleaning is enhanced, adhesion of yellowed film scraps after repeated high-temperature and high-heat treatment is reduced, the filtering device on the drain outlet of the sterilization cabinet is washed every day, and the sterilization cabinet is washed circularly with 2% NaOH solution each weak and carries out no-load sterilization once. After the measures are executed, the problem that liquid medicine in bottle bodies of the sodium chloride injection packaged in the polypropylene infusion bottles is turbid is solved, and the ratio of turbid liquid medicine in the bottle bodies is almost zero. By adjusting the formula, a new polypropylene material, a first-level recovered polypropylene granule material and thermoplastic elastomers are evenly mixed by the weight ratio of 1:1:1 and manufactured into hanging rings, the product quality is ensured while production cost is reduced, and the hanging rings will not break off.

Owner:GUANGXI YUYUAN PHARMA

Compound allantoin vitamin B6-E and ammoniation ethyl sulfate eye drops and preparation method thereof

ActiveCN102441001ASolve turbiditySolve easy discolorationSenses disorderPharmaceutical delivery mechanismVitamin b6Disodium Edetate

The invention discloses compound allantoin vitamin B6-E and ammoniation ethyl sulfate eye drops and a preparation method thereof. The compound allantoin vitamin B6-E and ammoniation ethyl sulfate eye drops are proportionally prepared from the main components of chondroitin sulfate, allantoin, taurine, vitamin B6 and vitamin E and the auxiliary materials of edetate disodium, boric acid, borax, polysorbate-80, benzalkonium chloride, natural borneol, ethanol and water for injection, and a preparation method is also provided. After the components of the compound allantoin vitamin B6-E and ammoniation ethyl sulfate eye drops and the eye drops which are prepared from the preparation method are applied, the medicine compatibility problem of five main components is solved, so the liquid medicine is clear, the contents of all the main medicines are stable, the aseptic and visible foreign matter inspection qualification rate of a product is ensured to be high, the cost is low, and the compound allantoin vitamin B6-E and ammoniation ethyl sulfate eye drops are worth being popularized in the industrial production field.

Owner:江西珍视明药业有限公司

Preparation process of plastic bottled dextrose injection

InactiveCN105193717AImprove stabilityReduced Chances of ContaminationOrganic active ingredientsPharmaceutical containersFiberBiochemical engineering

The invention discloses a preparation process of a plastic bottled dextrose injection. The following measures are taken: external force damage to bottle blanks and bottles in a production process is reduced, and adhesion of membrane scraps and fibers inside and outside the bottle bodies is reduced; (2) a filtering device is arranged on a water outlet of a sterilization cabinet, and the accumulation of the membrane scraps in a sterilization pipeline and a heat exchanger is reduced; (3) cleaning treatment of the sterilization cabinet is enhanced, the adhesion of the membrane scraps yellowed after repeated high-temperature heating is reduced, the filtering device on the water outlet of the sterilization cabinet is cleaned every day, and the sterilization cabinet is circularly cleaned with 2 percent NaOH solution and idle-load sterilization is performed once every week. After execution of the measures, the problem of presence of muddy liquid medicine in a polypropylene transfusion bottled dextrose injection bottle is solved, and the muddying probability of the liquid medicine in the bottle is almost zero. A formula is adjusted, and a novel polypropylene material, recycled first-level polypropylene particles and a thermoplastic elastomer are uniformly mixed according to a weight proportion 1:1:1 to make a hoisting ring, so that the production cost is lowered; meanwhile, the product quality is ensured, and the hoisting ring is prevented from being broken.

Owner:GUANGXI YUYUAN PHARMA

Preparation method for clarified locust bean gum

ActiveCN103947915AThe solution has good transparencySolve the problem of product turbidityFood preparationChemistryMagnesium

The invention relates to a preparation method for clarified locust beam gum, and belongs to the technical field of locust bean gum clarifying. The preparation method is characterized in that the clarifying process comprises the following steps: dissolving the locust bean gum powder (LBG) in water and adding magnesium chloride and potassium chloride to regulate the ions in solution and to increase the light transmission rate of the clarified locust bean gum; filtering, extracting, drying and crushing after adjusting the pH through alkalis and heating and insulating the solution to obtain the clarified locust bean gum (CLBG); sprinkling a dispersant to the clarified locust bean gum. The CLBG obtained by clarifying the LBG according to the technical process provided by the invention has the advantages that the solution has excellent transparency and the problem of product turbidity is solved; the diffusion type CLBG is also obtained by adding the dispersant to the CLBG, thereby increasing the diffusion of the CLBG in water, avoiding the agglomeration phenomena, and shortening the dissolving time.

Owner:TONGLIAO HUANGHELONG BIOENG

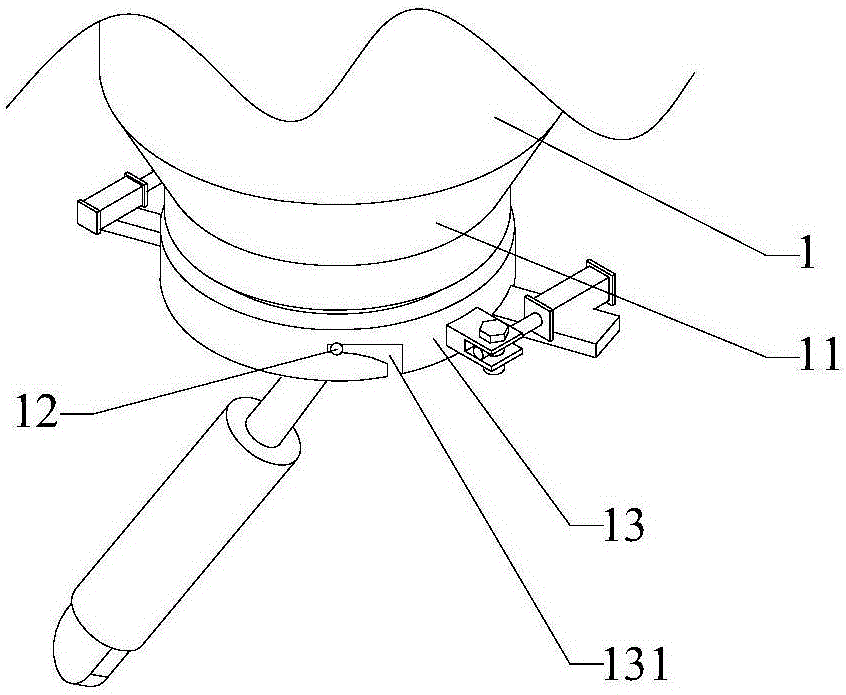

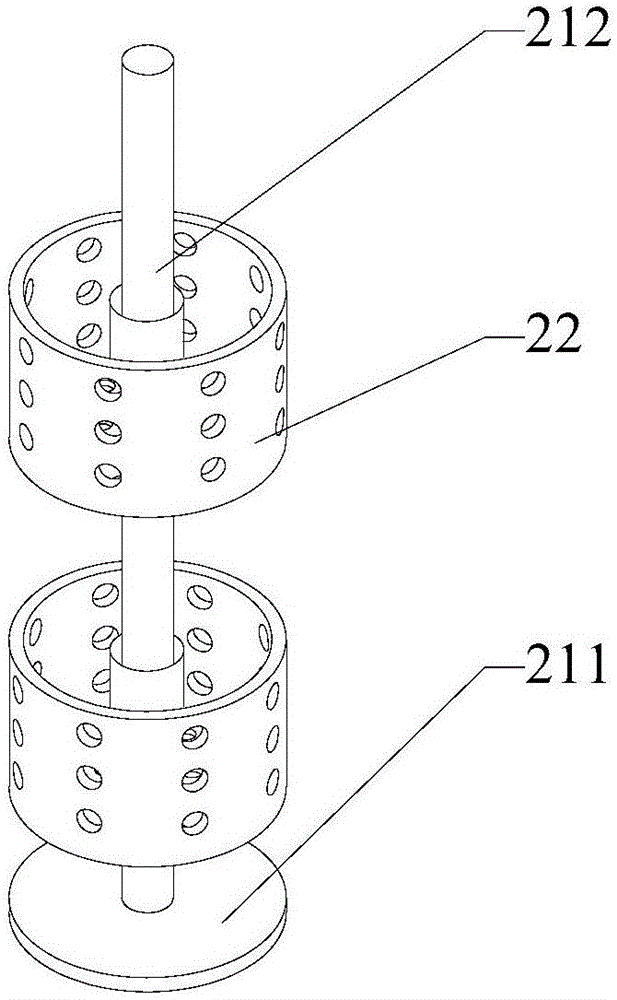

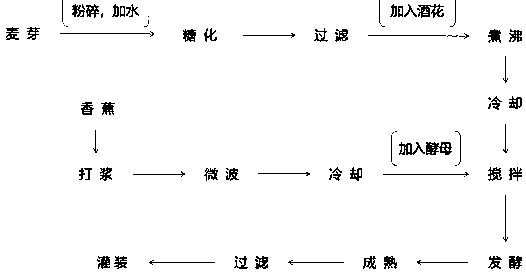

Method for preparing banana beer and beer prepared by method

The invention discloses a method for preparing the banana beer. The process of the method is simple, easy to run, and suitable for large-scale production. The method for preparing the banana beer comprises the steps of weighing and pulverizing malt, adding purified wat, preparing malt crude juice, saccharifying malt crude juice, filtering, and collecting supernatant clear juice to obtain malt clear juice, mixing that supernatant clear juice with the supernatant clear juice, and mixing the supernatant clear juice with the supernatant clear juice to obtain malt clear juice. the malt juice is added into the hops, evenly mixed, boiled, and cooled to the fermentation temperature; (2) removing head and tail and peeling the selected banana to obtain banana pulp; Carrying out coarse beating on banana pulp to obtain coarse banana pulp; The banana coarse pulp is transferred to a nitrogen positive pressure closed pipe microwave treatment device through an airtight pipe for microwave enzyme inactivation treatment, wherein the banana coarse pulp is heated while being stirred and conveyed by a spiral stirrer while being heated by microwave, and is conveyed forward while stirring to obtain the banana coarse pulp treated by microwave enzyme inactivation; 3) adding that banana crude pulp and the malt clear juice into the yeast and fermenting; (4) Mature, canned.

Owner:广西香蕉谷科技有限公司

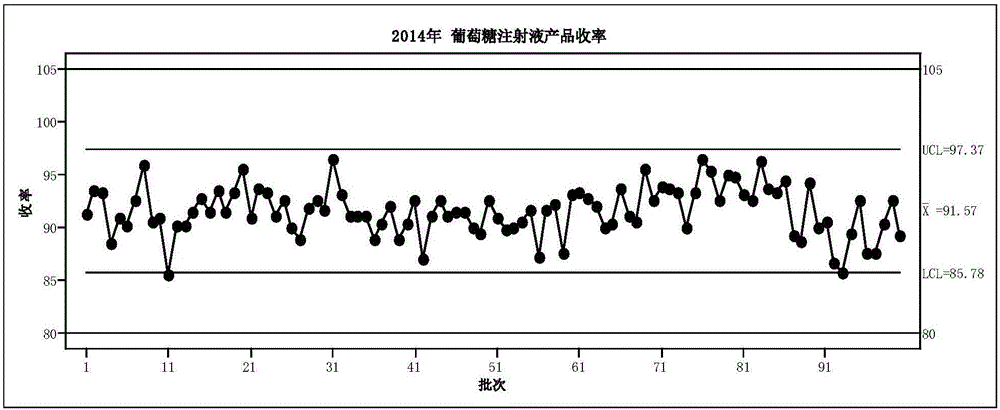

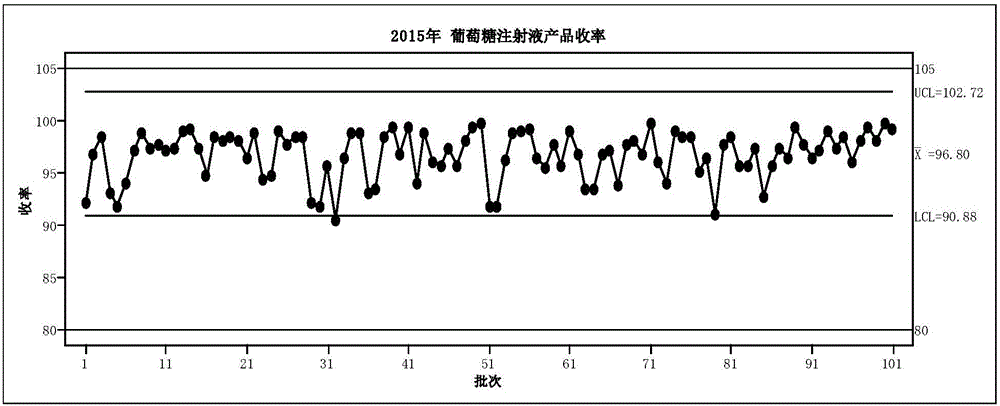

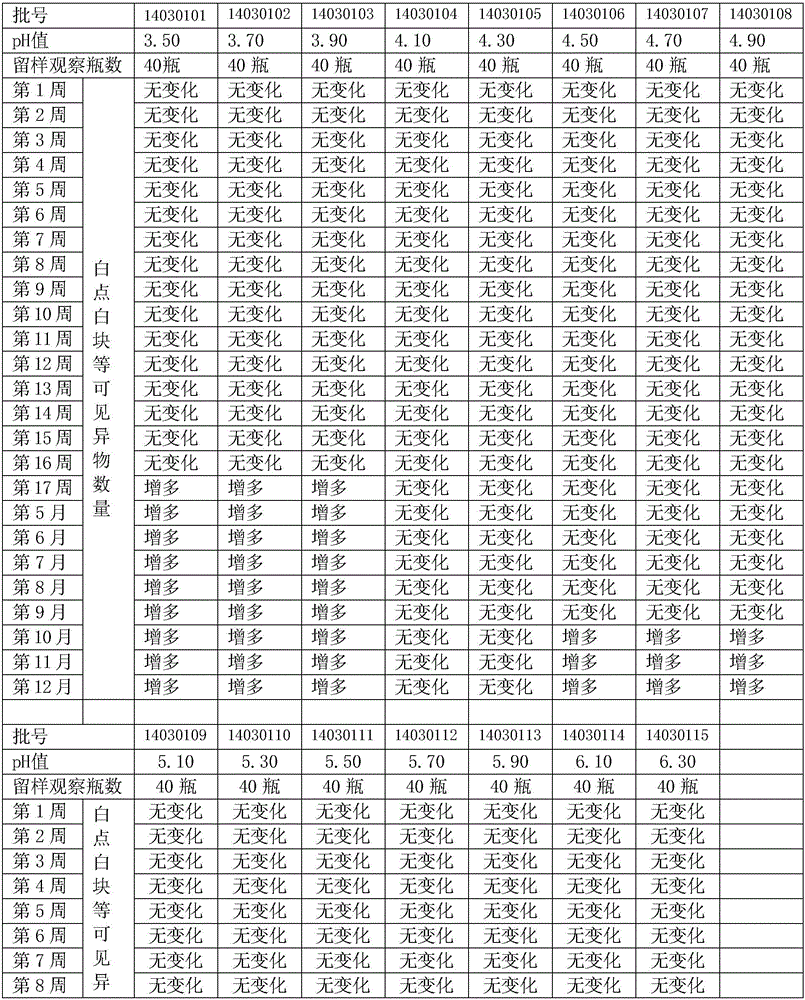

Production method of glucose injection

InactiveCN106265495AQuality improvementEfficient removalOrganic active ingredientsInorganic non-active ingredientsHigh concentrationActivated carbon

The invention discloses a production method of a glucose injection. By studying influences of the pH value on visible foreign matter of the glucose injection, it is shown that dextrin in glucose powder can be effectively pushed to be fully hydrolyzed by adding hydrochloric acid during high concentration preparation to control the pH value to range from 3.8 to 4.0, flocculation containing protein can be effectively adsorbed by activated carbon after dextrin is fully hydrolyzed, impurities in the glucose injection can be effectively removed, and therefore the glucose injection product is more transparent and clearer. During low concentration preparation, the pH value is controlled to range from 4.1 to 4.3, the visible foreign matter of the glucose injection is greatly reduced, and therefore the quality is more stable.

Owner:GUANGXI YUYUAN PHARMA

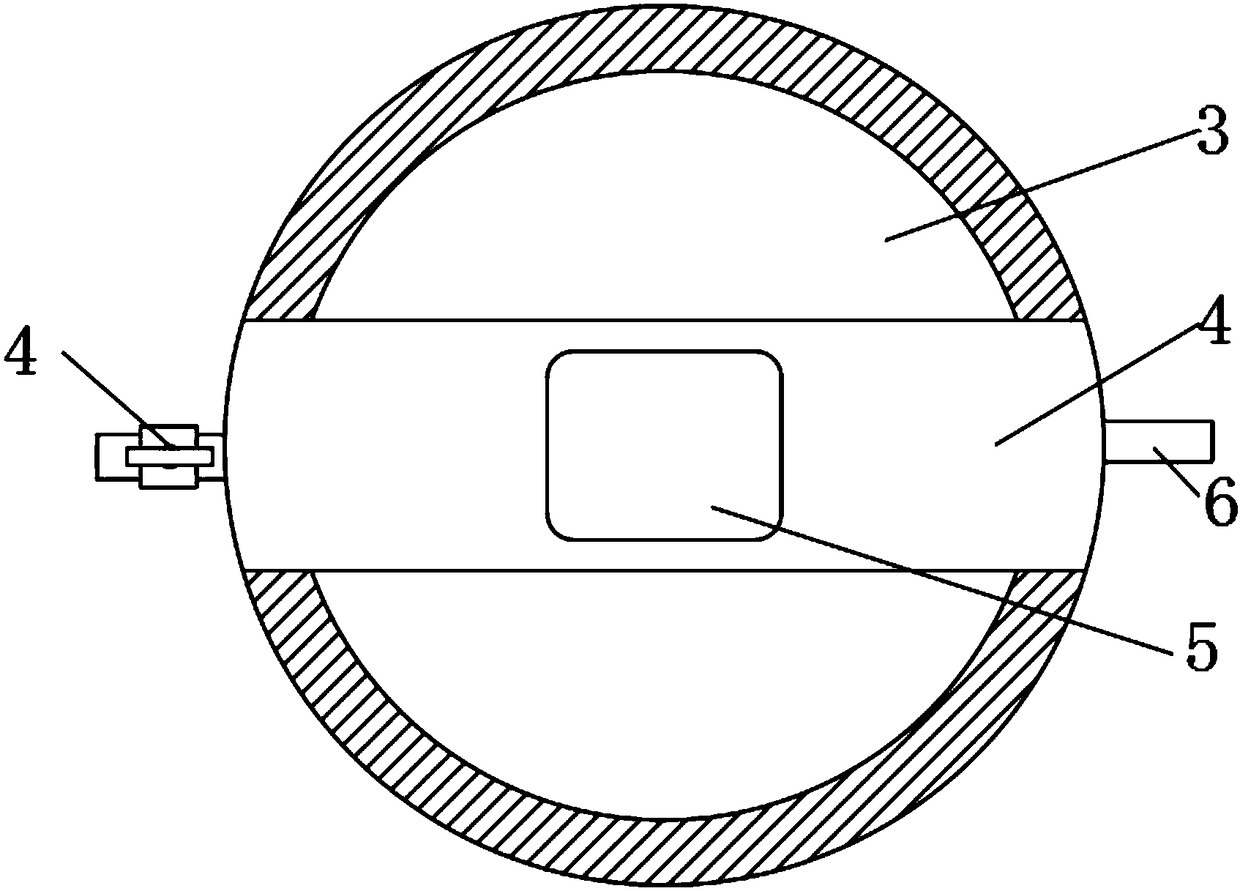

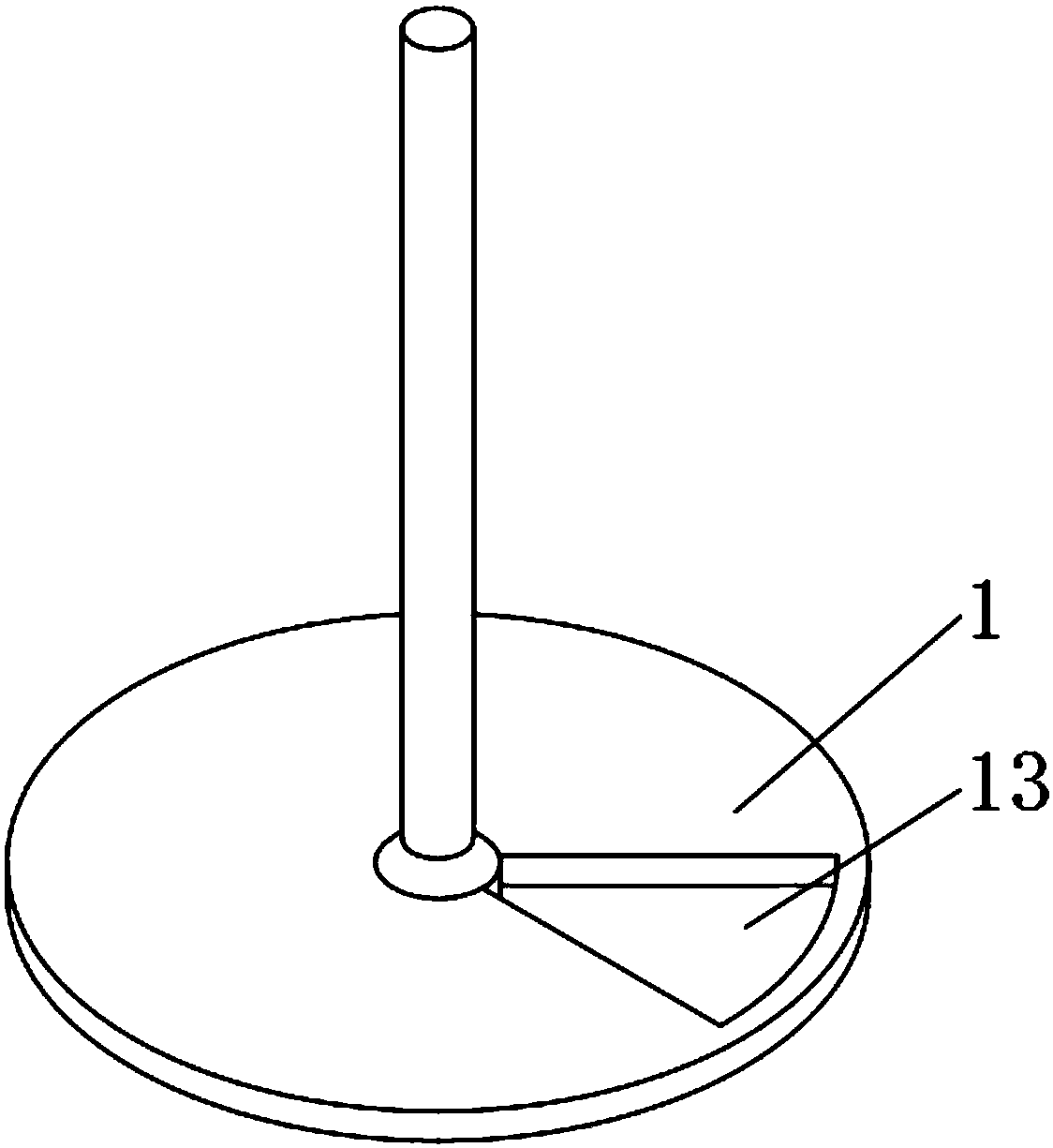

Novel water treatment rotary sedimentation bin for environmental protection

InactiveCN108295518ASolve turbiditySolve processingSettling tanks feed/dischargeSedimentation settling tanksCouplingEngineering

The invention discloses a novel water treatment rotary sedimentation bin for environmental protection. The novel water treatment rotary sedimentation bin for environmental protection comprises a sedimentation bin body, support legs are welded to the bottom of the sedimentation bin body, a support frame is arranged on the upper end face of the sedimentation bin body, a motor is placed on the upperportion of the support frame and is in transmission connection with a rotating disc located in the sedimentation bin body through a coupler, and the end face of the rotating disc is provided with a sewage drainage hole. According to the novel water treatment rotary sedimentation bin, the motor is erected at the upper portion of the sedimentation bin body through the support frame, then the motor is in transmission connection with the rotating disc, the rotating disc is provided with the sewage drainage hole, a scrape plate fitting the upper end face of the rotating disc is welded to the innerwall of the sedimentation bin body, a sediment collection bin is connected to the bottom of the sedimentation bin body, an airbag is connected between the sediment collection bin and the rotating discat the same time, in this way, the isolation between the sediment collection bin and the sedimentation bin body is achieved through the airbag, and the problem is effectively solved that turbid matter and sediments cannot be treated completely in the sediment treatment process.

Owner:郑州仟嘉安环保科技有限公司

Production method for preventing medicine liquor turbidity of glucose injection packaged in plastic bottle

InactiveCN105147601AImprove stabilityReduced Chances of ContaminationOrganic active ingredientsPharmaceutical containersFiberWater discharge

The invention discloses a production method for preventing medicine liquor turbidity of glucose injection packaged in a plastic bottle. The production method comprises the following steps that firstly, external force damage of a bottle blank and the bottle in the production process is reduced, and film scraps and fibers attached inside and outside a bottle body are reduced; secondly, a filtering device is additionally arranged at a water discharging port of a sterilization cabinet, and accumulation of the film scraps in a sterilization pipeline and a heat exchanger is reduced; thirdly, cleaning treatment of the sterilization cabinet is enhanced, attached film scraps becoming yellowish after multiple times of high temperature and large heat are reduced, the filtering device arranged at the water discharging port of the sterilization cabinet is cleaned every day, the sterilization cabinet is circularly cleaned through a 2% NaOH solution every week, and empty sterilization is carried out once every week. After the measures are taken, the problem of medicine liquor turbidity in the polypropylene infusion bottled glucose injection bottle body is solved, and the ratio of medicine liquor turbidity in the bottle body is almost zero.

Owner:GUANGXI YUYUAN PHARMA

Production method for preventing liquid medicine turbidity of plastic bottled dextrose injection

InactiveCN105125487AImprove stabilityReduced Chances of ContaminationOrganic active ingredientsPharmaceutical containersPolypropyleneScrap

The invention discloses a production method for preventing liquid medicine turbidity of a plastic bottled dextrose injection. The production method includes the following measures that firstly, external force damage caused in the production process of bottle embryos and bottles is reduced, and film scraps and fibers attached inside and outside bottle bodies are reduced; secondly, a sterilization cabinet draining opening filtering device is added, and accumulation of film scraps in a sterilization pipeline and a heat exchanger is reduced; thirdly, cleaning of the sterilization cabinet is strengthened, attachment of yellowed film scraps after multiple times of high-temperature heating is reduced, the sterilization cabinet draining opening filtering device is cleaned every day, a 2% NaOH solution is used for cyclically cleaning the sterilization cabinet every week, and no-load sterilization is conducted a time. After the measures are adopted, the problem of liquid medicine turbidity in the bottle bodies of the polypropylene infusion bottled dextrose injection is solved, and the probability of liquid medicine turbidity in the bottle bodies is almost zero. According to the production method, polypropylene new materials, recycled first-level polypropylene granule materials and thermoplastic elastomers are evenly mixed to manufacture a lifting ring according to the weight ratio of 2:2:1 through formula adjustment, the product quality is ensured while the production cost is reduced, and the lifting ring cannot be broken.

Owner:GUANGXI YUYUAN PHARMA

Preparation method of gelidium amansii and strawberry health-care vinegar

PendingCN111040923AGreat tasteReduce turbidityAlgae medical ingredientsVinegar preparationFragariaAlcohol content

The invention discloses a preparation method of gelidium amansii and strawberry health-care vinegar. The preparation method comprises the following ten steps: 1, pre-treatment of gelidium amansii; 2,treatment of strawberries; 3, adjustment of sugar degree; 4, adjustment of acidity; 5, sterilizing; 6, alcoholic fermentation; 7, adjustment of alcohol content; 8, acetic fermentation; 9, clarification treatment; and 10, filtering and bottling of clarified strawberry vinegar. The preparation method is used for preparing gelidium amansii and strawberry health-care vinegar.

Owner:YANTAI ENG & TECH COLLEGE YANTAI TECHNICIAN INST

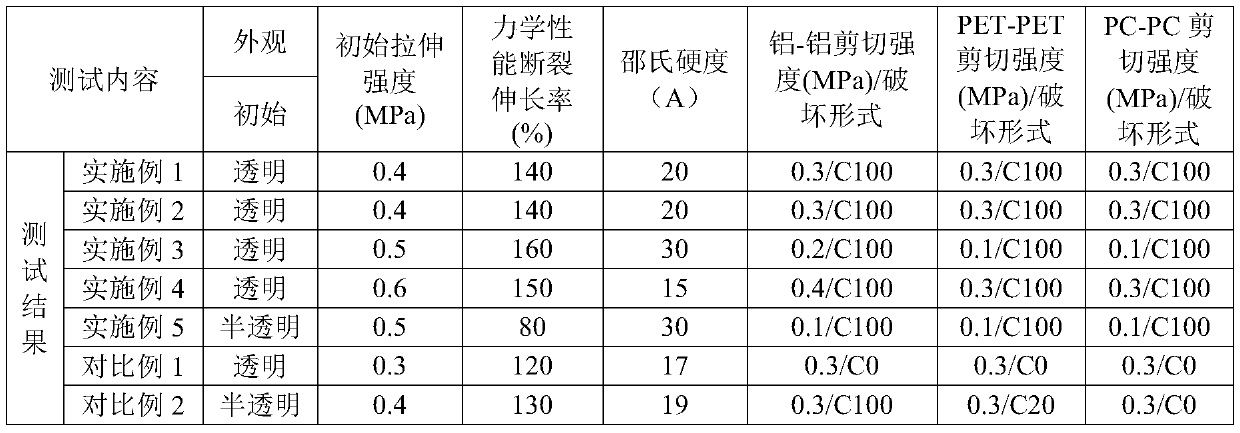

Bonding promoter for addition type silicone rubber as well as preparation method and application of bonding promoter

ActiveCN111484620AImprove compatibilityHigh transparencyMacromolecular adhesive additivesCyclohexanolCompatibilization

The invention provides a bonding promoter for addition type silicone rubber as well as a preparation method and an application of the bonding promoter. The preparation method comprises the following steps: reacting tetramethylcyclotetrasiloxane with a first mixture to obtain a first reaction product; mixing the first reaction product with 1-ethynyl-1-cyclohexanol to obtain a second mixture; and reacting the second mixture with allyl glycidyl ether to obtain the bonding promoter for addition type silicone rubber, wherein the first mixture comprises a complex of bis(trimethoxysilyl methyl)ethylene and platinum, and the platinum content of the complex is 1500-4500 ppm. By adopting bis(trimethoxysilyl methyl)ethylene as a raw material, the compatibility between the prepared bonding promoter and a system can be improved, the transparency can be improved, and meanwhile, due to introduction of alkoxy, the adhesion performance to a base material can be improved. The problem that in the prior art, addition type silicone rubber is turbid due to an adhesion promoter is solved, and the adhesive is suitable for the field with high light transmittance requirements.

Owner:TONSAN ADHESIVES INC

Production method for preventing turbidity of plastic-bottle sodium chloride injection

InactiveCN105287369AImprove stabilityReduced Chances of ContaminationMetabolism disorderPharmaceutical delivery mechanismFiberTurbidity

The invention discloses a production method for preventing turbidity of plastic-bottle sodium chloride injection. The production method includes 1) reducing damage caused by external force during production of bottle blanks and bottles and reducing membrane scraps and fiber attachments inside and outside bottle bodies; 2) increasing a sterilization cabinet drainage outlet filtering device to reduce accumulation of the membrane scraps in a sterilization pipeline and a heat exchanger; 3) strengthening sterilization cabinet washing treatment to reduce attachments of yellowing membrane scraps subjected to multi-time high temperature and high heat, wherein the sterilization cabinet drainage outlet filtering device is washed every day, and the sterilization cabinet is washed circularly by a 2% NaOH solution and is subjected to non-load sterilization once every week. According to the production method, the problem of turbidity of the sodium chloride injection in polypropylene infusion bottles is solved, and the turbidity rate of the sodium chloride injection in the bottle bodies is nearly zero.

Owner:GUANGXI YUYUAN PHARMA

Huoshan dendrobium officinale beer clarifying agent

ActiveCN107354046ANo turbidityGood clarificationBeer fermentationAlcoholic beverage preparationAlcoholBeta-Carotene

The invention provides a Huoshan dendrobium officinale beer clarifying agent, belonging to the technical field of dendrobium officinale beer clarifying agents. The Huoshan dendrobium officinale beer clarifying agent comprises a clarifying agent A and a clarifying agent B, wherein the clarifying agent A is added after yeast fermentation is completed, and the clarifying agent B is added after the mixture is filtered; the clarifying agent A comprises beta-carotene, sodium citrate and PVPP (Polyvinyl Pyrrolidone); and the clarifying agent B comprises a lotus leaf alcohol extract. By adopting the Huoshan dendrobium officinale beer clarifying agent, the problem that the non-biological stability is degraded as Huoshan dendrobium officinale is added in a Huoshan dendrobium officinale beer process is solved. The Huoshan dendrobium officinale beer clarifying agent provided by the invention is good in clarifying effect, is a natural extract, has a non-toxic effect and is harmless, and the Huoshan dendrobium officinale beer clarified with the clarifying agent is free of turbidity after long-term preservation.

Owner:WEST ANHUI UNIV

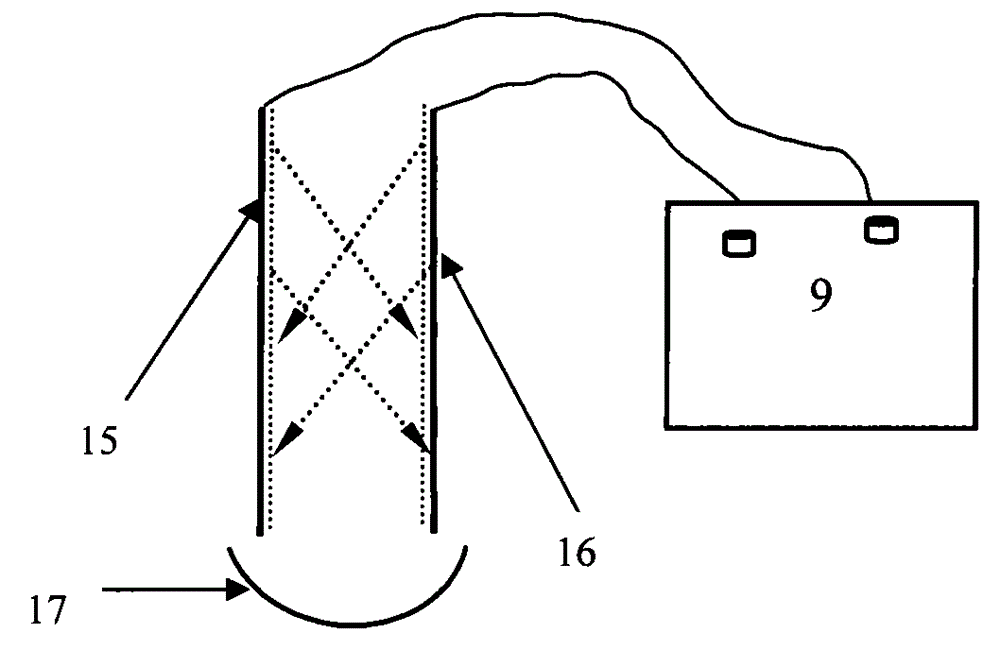

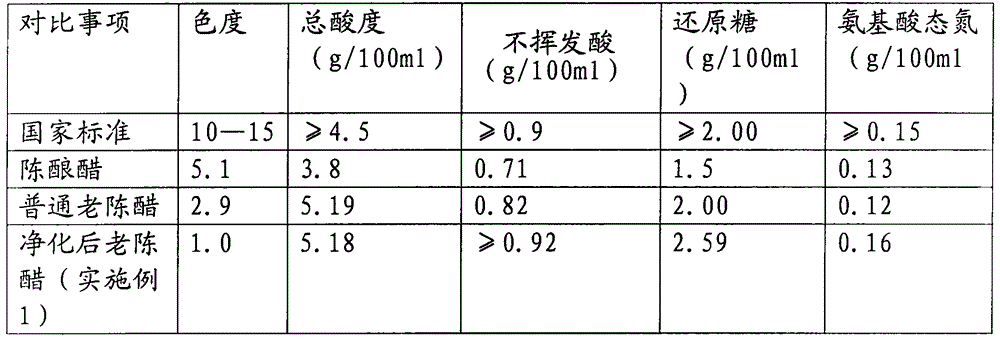

Purification process and purification device for super-mature vinegar

The invention relates to a purification process for super-mature vinegar. The purification process comprises the following steps: firstly, performing coarse filtration on the mature vinegar; secondly, performing oscillation gathering treatment, sterilization and aging treatment on the vinegar subjected to the coarse filtration for the first time; thirdly, performing oscillation gathering treatment and sterilization treatment for the second time, wherein a most key step is the oscillation gathering treatment, and a treatment mode is that voltage of not lower than 3,000 V is adopted for carrying out discharge on positive and negative electrode plates, and negative and positive ions generated by the positive and negative electrode plates in electrode space are utilized to adsorb sediments and microorganisms in the vinegar; in addition, oscillators connected to the positive and negative electrode plates are utilized to remove the sediments adhered to the positive and negative electrode plates and enable the sediments to drop into a sediment collecting tray, and the sediments are discharged through a residue discharge pipeline and a residue discharge hole. The process effectively solves serious turbidity and precipitation problems ubiquitous in super-mature vinegar and a problem of over-standard of mixed strains caused by easy microorganism propagation of the super-mature vinegar in the prior art.

Owner:山西太谷通宝醋业有限公司

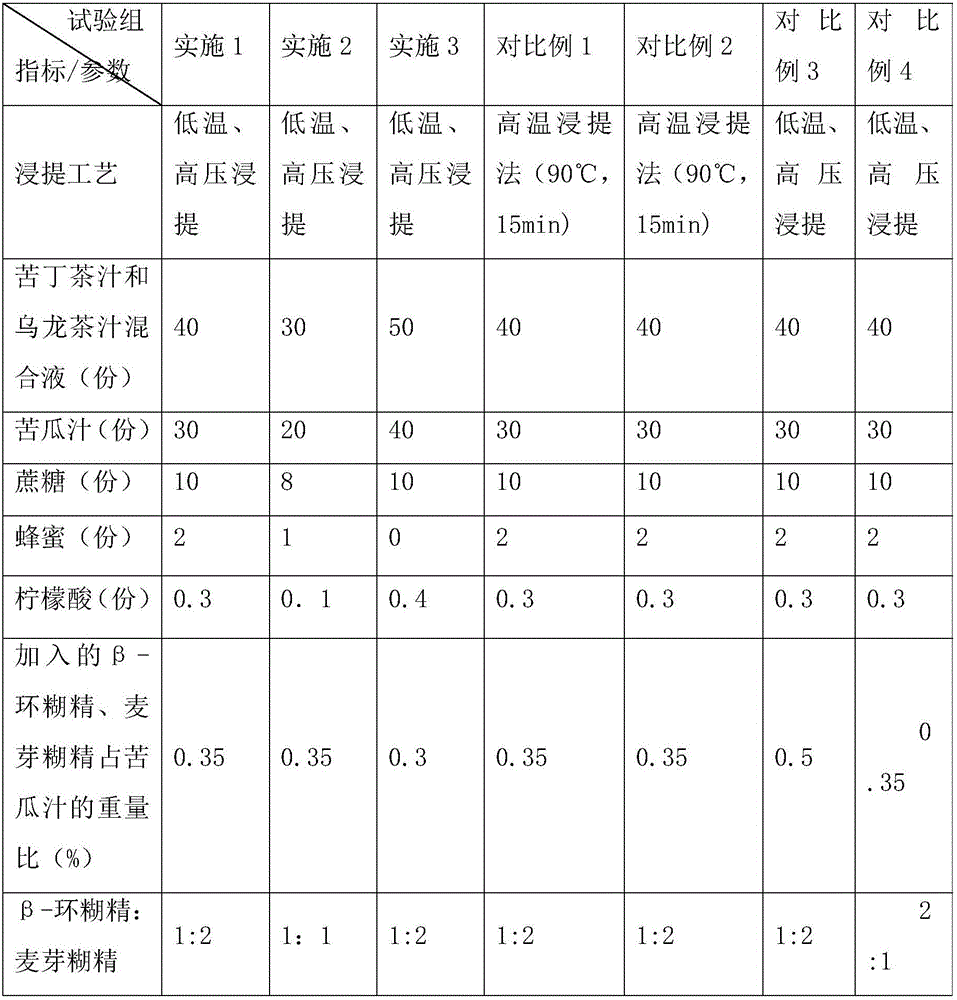

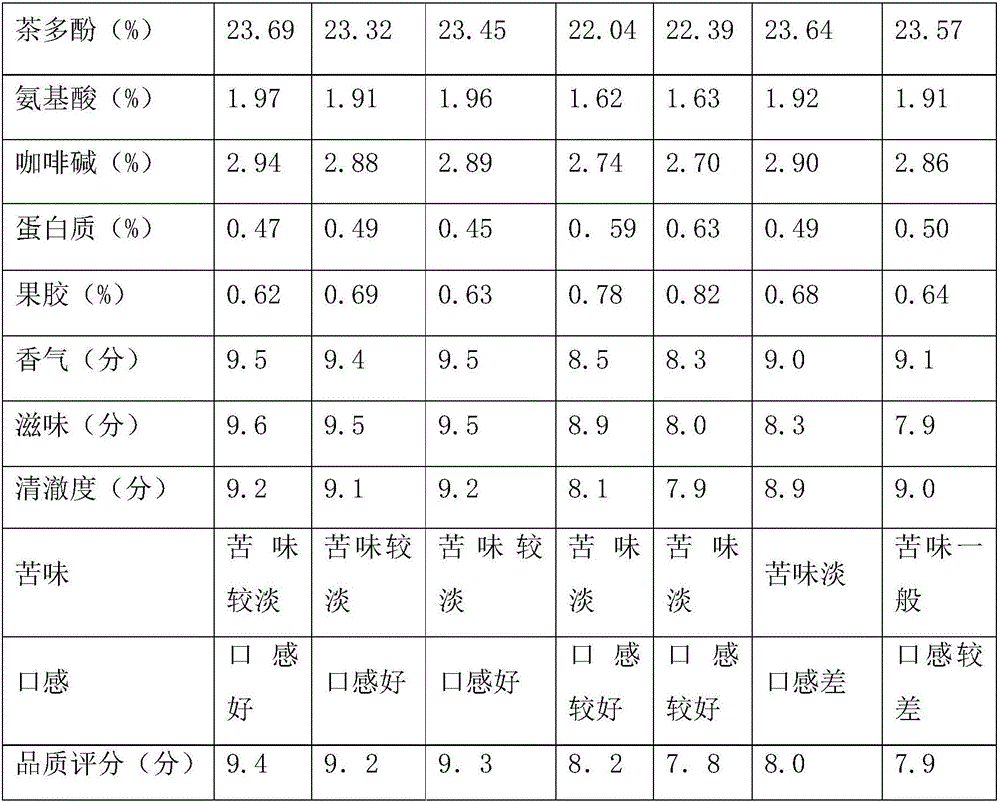

Preparation method of drink of leaf of Chinese holly

The invention belongs to the technical field of tea preparations and in particular discloses a preparation method of a drink of leaf of Chinese holly. The preparation method comprises the following steps: (1) preparation of juice of leaf of Chinese holly and oolong juice; (2) preparation of bitter melon juice; (3) blending: blending 30-50 parts of mixed liquor of the juice of leaf of Chinese holly and the oolong juice, 20-40 parts of bitter melon juice, 8-10 parts of sucrose, 1-3 parts of honey and 0.1-0.4 part of citric acid by weight, and then carrying out suction filtration again, thus obtaining mixed juice; (4) homogenization and degassing; and (5) canning, sterilization and cooling. The prepared drink of leaf of Chinese holly has better color, taste and fragrance and excellent quality.

Owner:正安县黔蕊茶业有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com