Processed pigment and pigment dispersion composition using the same, colored photosensitive composition

A technology for processing pigments and pigment dispersion, which is applied in the fields of processing pigments, pigment dispersion compositions using them, and colored photosensitive compositions, and can solve problems such as reduced alkali solubility, reduced sensitivity, and insufficient dispersant adsorption persistence. , to achieve the effect of inhibiting aggregation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0371] Hereinafter, the present invention will be described in more detail using examples, but the present invention is not limited to the following examples unless the gist of the present invention is exceeded. In addition, as long as there is no prior statement, "parts" are the standard of quality.

[0372]

[0373] (Synthesis of Specific Copolymer P-1)

[0374] Stir at a reaction temperature of 145°C for 60 minutes MMA 12.6g, MAA 2.7g, 2,6-diethyl-2,6-dimethyl-4-oxo-1-(1-ethoxyphenoxy)piperidine 70.6g and 150g of 1-methoxy-2-propanol. 113.4 g of MMA and 24.3 g of MAA were slowly added to the reaction mixture over 2.5 hours. Next, the temperature of the reaction mixture was maintained for 5 hours. The residual monomer was distilled off to obtain 135.6 g of an MMA-MAA copolymer.

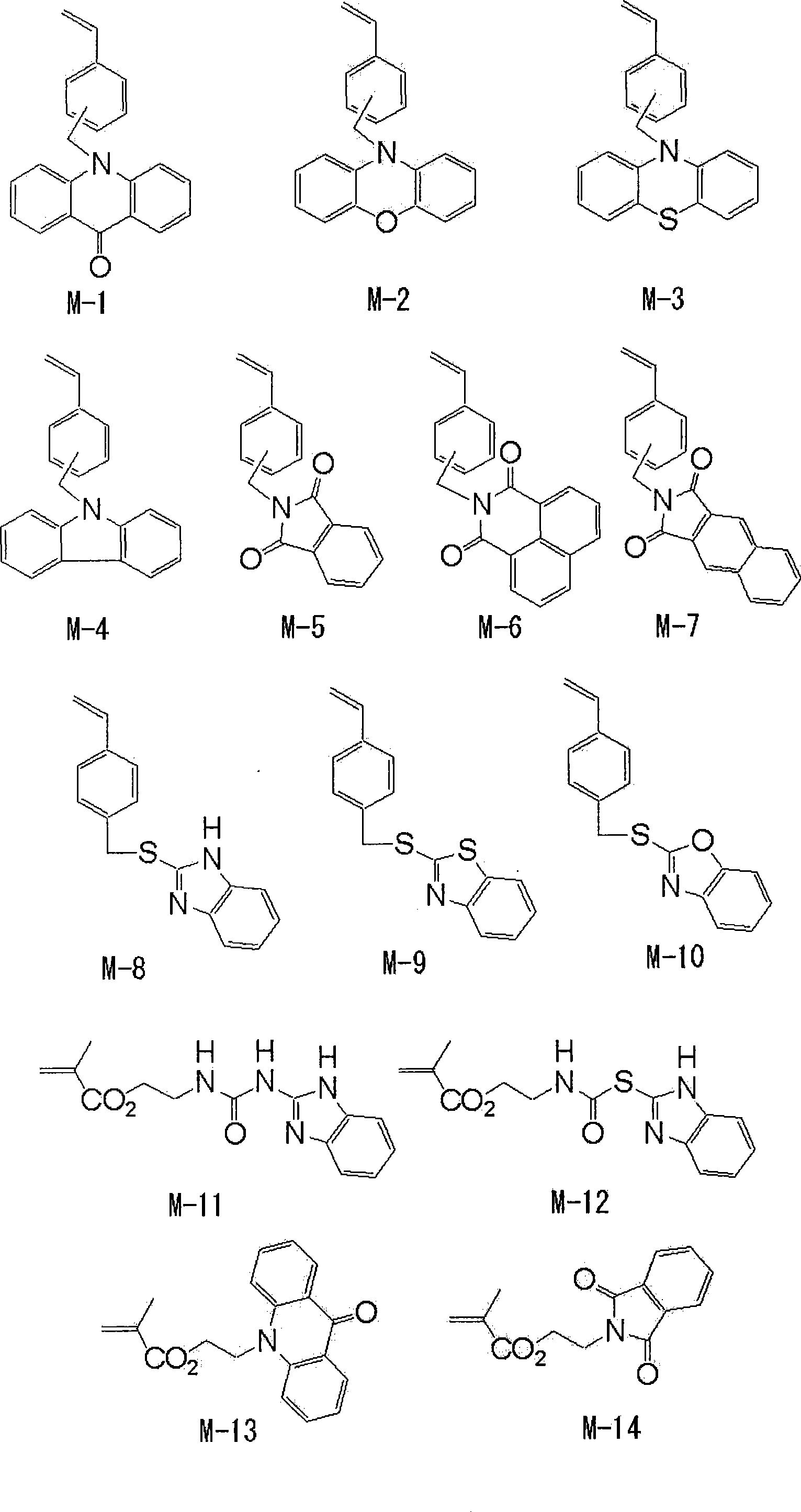

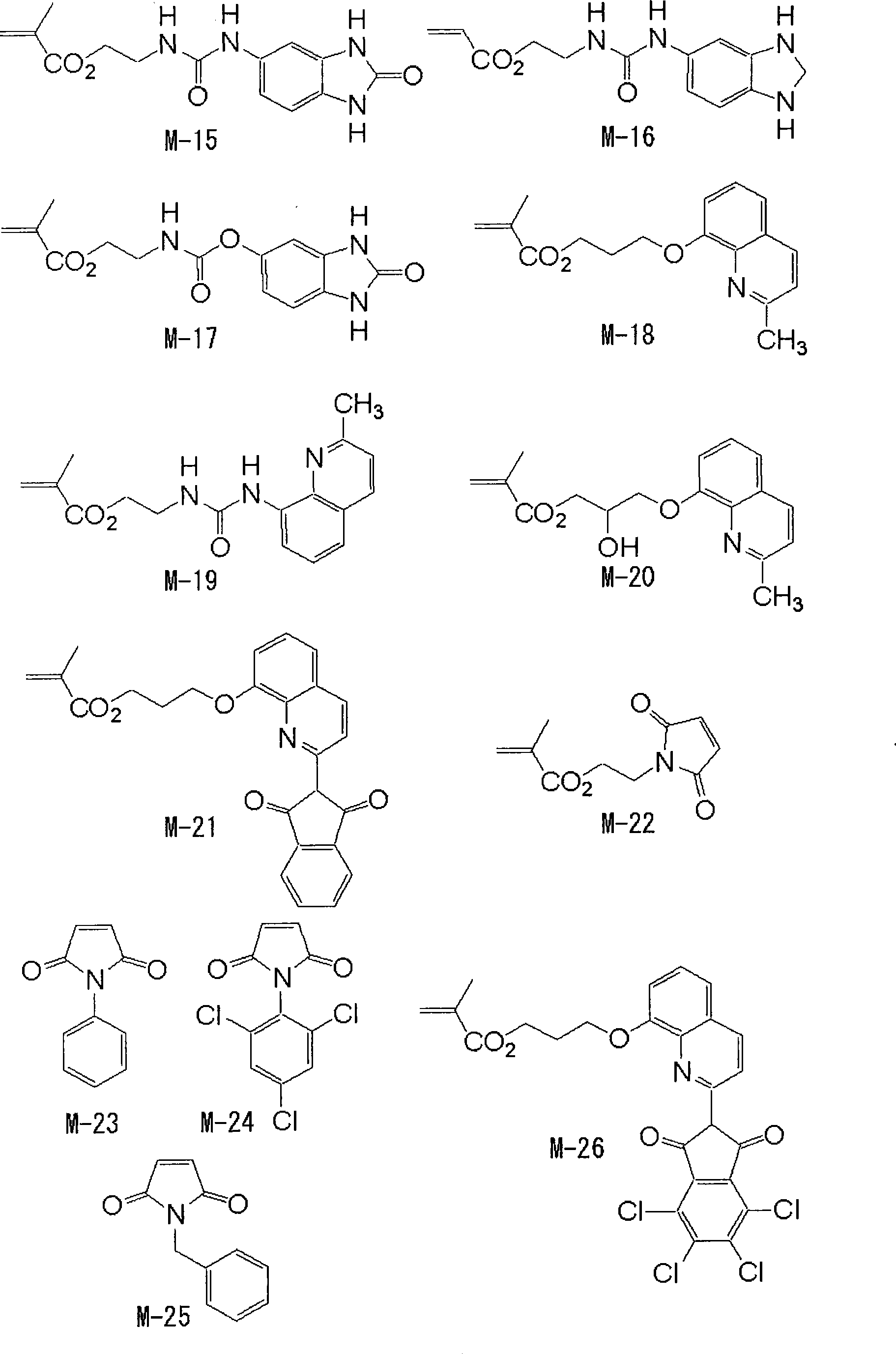

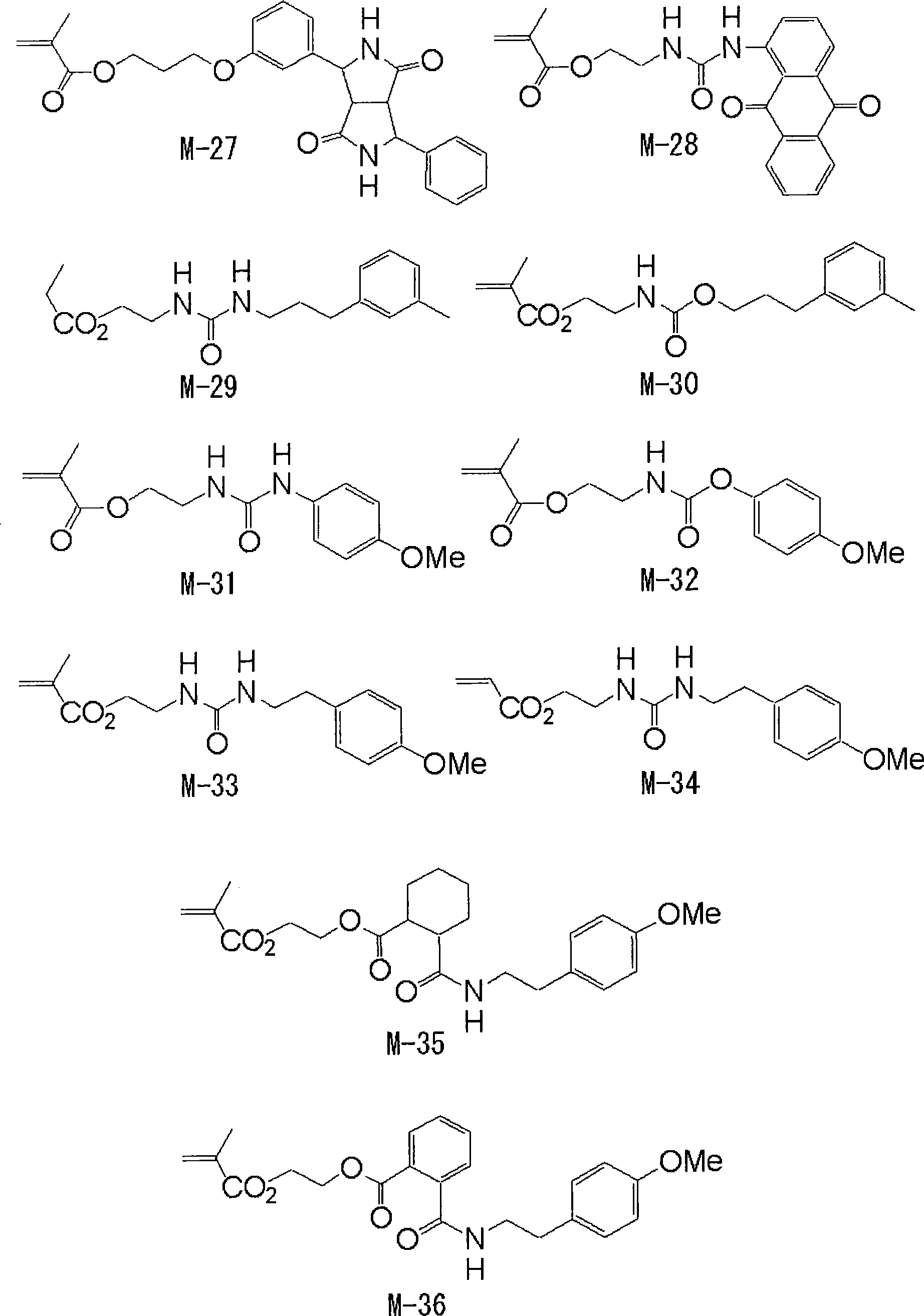

[0375]Together with 460g diethylene glycol ethyl ether acetate, at a reaction temperature of 145°C, heat and stir for 2 hours 27.0g MMA-MAA copolymer (the pigment non-absorptive block) and M-1...

Embodiment 2

[0434] [Example 2, Comparative Example 2]

[0435]

[0436] The components of the following composition (1) were mixed and stirred and mixed for 3 hours using a homogenizer at a rotation speed of 3,000 r.p.m. to prepare a mixed solution containing a pigment.

[0437] [composition (1)]

[0438] ・Processed pigments (pigments listed in Table 2) 95 parts

[0439] ・Derivative A (the following structure [Chemical 28]) 5 parts

[0440] Dispersant (30% 1-methoxy-2-propyl acetate solution of the dispersant listed in Table 8) (amount listed in Table 8)

[0441] 750 parts of 1-methoxy-2-propyl acetate

[0442] Next, the above-obtained mixed solution was further dispersed for 6 hours using a bead disperser DISPERMAT (manufactured by GETZMANN) with 0.3 mmφ zirconia beads, and thereafter, a high-pressure disperser NANO-3000-10 with a decompression mechanism was further used. (manufactured by Japan Ha-Yi (ビ-イ-イ-) Co., Ltd.), at 2,000kg / cm 3 Dispersion treatment is carried out at a flo...

Embodiment 3

[0473] [Example 3, Comparative Example 3]

[0474]

[0475] The components of the following composition (3) were mixed and stirred and mixed for 3 hours using a homogenizer at a rotation speed of 3,000 r.p.m. to prepare a mixed solution containing a pigment.

[0476] [Composition (3)]

[0477] ・Processed pigments (pigments listed in Table 10) 120 parts

[0478] Dispersant (30% 1-methoxy-2-propyl acetate solution of the dispersant recorded in Table 10) 250 parts

[0479] 750 parts of 1-methoxy-2-propyl acetate

[0480] Next, the above-obtained mixed solution was further dispersed for 6 hours using a bead disperser DISPERMAT (manufactured by GETZMANN) with 0.3 mmφ zirconia beads, and thereafter, a high-pressure disperser NANO-3000-10 with a decompression mechanism was further used. (manufactured by Japan Hayiyi Co., Ltd.), at 2,000kg / cm 3 Dispersion treatment is carried out at a flow rate of 500g / min under a certain pressure. This dispersion treatment was repeated 10 time...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com