Patents

Literature

350 results about "Propyl acetate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

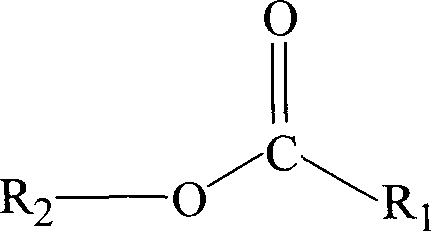

Propyl acetate, also known as propyl ethanoate, is a chemical compound used as a solvent and an example of an ester. This clear, colorless liquid is known by its characteristic odor of pears. Due to this fact, it is commonly used in fragrances and as a flavor additive. It is formed by the esterification of acetic acid and 1-propanol (known as a condensation reaction), often via Fischer–Speier esterification, with sulfuric acid as a catalyst and water produced as a byproduct.

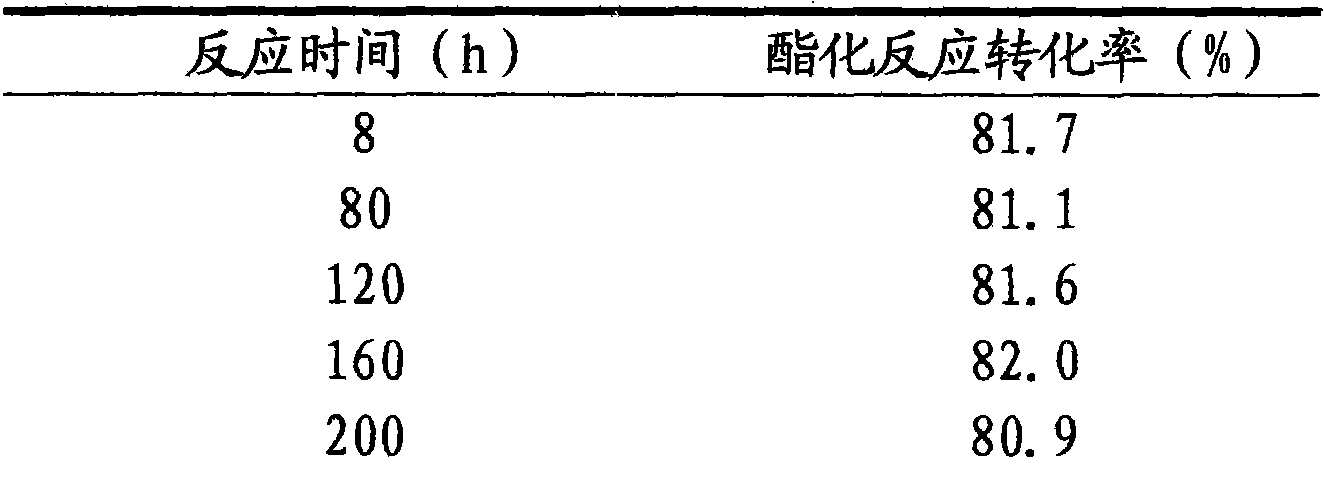

Hot stamping foil applied to overlapping hot stamping on gold stamping layer and preparation method of hot stamping foil

ActiveCN103465668AImprove trimming effectTransfer completelyDuplicating/marking methodsPolyurea/polyurethane coatingsHot stampingCellulose

The invention discloses a hot stamping foil applied to overlapping hot stamping on a gold stamping layer and a preparation method of the hot stamping foil. When overlapping hot stamping is carried out on an existing hot stamping foil, the defects that the transferring is incomplete, the hot stamping is not carried out on some portions due to omission, scumming is caused, powder falls off, and the edge of a hot stamping layer is not clear can happen. The hot stamping foil is composed of a base membrane layer, a release layer, a color coating layer, a vacuum aluminum coated layer and a gumming layer. The gumming layer is prepared by raw materials which comprise, by weight, 1-6 parts of chloroethylene-vinyl acetate resin, 1-10 parts of polyvinyl alcohol, 1-10 parts of acrylic ester, 1-5 parts of nitrocellulose, 1-5 parts of fumed silica, 20-70 parts of ethyl acetate, 10-50 parts of ethyl alcohol and 1-5 parts of propyl acetate. According to the hot stamping foil applied to the overlapping hot stamping on the gold stamping layer, the hot stamping foil has the good stamping performance and the good trimming performance, the overlapping hot stamping layer is complete in transferring, the edge is smooth and free of burrs, the adhesion is firm, the phenomena of dusting, powder falling and the like do not exist, the hot stamping effect is strong in third dimension, and the anti-fake performance is more outstanding.

Owner:云南玉溪东魅包装材料有限公司

Electrolyte for rechargeable battery

InactiveUS20060121356A1Large capacityImprove discharge performanceOrganic electrolyte cellsSecondary cellsPropionateAcetic acid

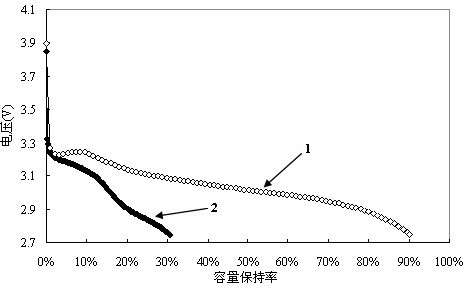

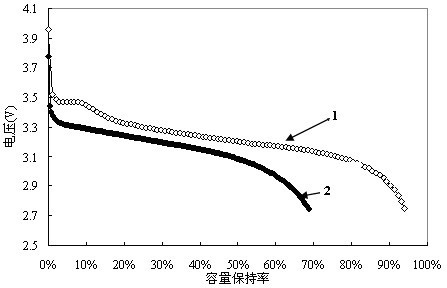

An electrolyte for a rechargeable battery includes 20-70% by volume of at least two cyclic carbonates selected from ethylene carbonate, propylene carbonate, vinylene carbonate or butylenes carbonate, 30-80% by volume of an ester selected from propyl propionate, propyl acetate, butyl acetate or a mixture thereof, and a lithium salt.

Owner:EXA ENERGY TECH +1

Printing ink

A print ink contains ester, alcohol solution of polyurethane resin, chloroacetate resin, pigment, propyl acetate, iso-proparol and ethyl acetate. Its advantages are high print effect, low poison and no damage to human body.

Owner:汕头市金平区五星油墨实业有限公司

Diesel oil pour point depressant composition, its preparation method and application

ActiveCN102517104AGood dispersionImprove low temperature fluidityLiquid carbonaceous fuelsFuel additivesWaxOrganic solvent

The invention discloses a diesel oil pour point depressant composition and its preparation method. The diesel oil pour point depressant composition, i.e. a diesel oil pour point depressant composition formed by mixing acetic ester organic solvents with a pour point depressant, comprises the following raw materials by mass percent: 0-20% of methyl acetate, 0-20% of ethyl acetate, 0-10% of propyl acetate, 0-30% of butyl acetate, and 20-80% of the pour point depressant. The preparation method consists of: mixing all the raw materials and then conducting stirring in water bath at a constant temperature of 50DEG C for 20min, and controlling the rotation speed at 150r / min, thus obtaining the diesel oil pour point depressant composition. Adding of the obtained diesel oil pour point depressant composition into commercially available 0# diesel oil can make the cold filter plugging point of the diesel oil reduced by 5-11DEG C and the condensation point reduced by 6-10DEG C. The diesel oil pour point depressant composition provided in the invention enhances the dispersion effect of pour point depressants on wax crystals, and improves the low temperature fluidity of diesel oil.

Owner:SHANGHAI INST OF TECH

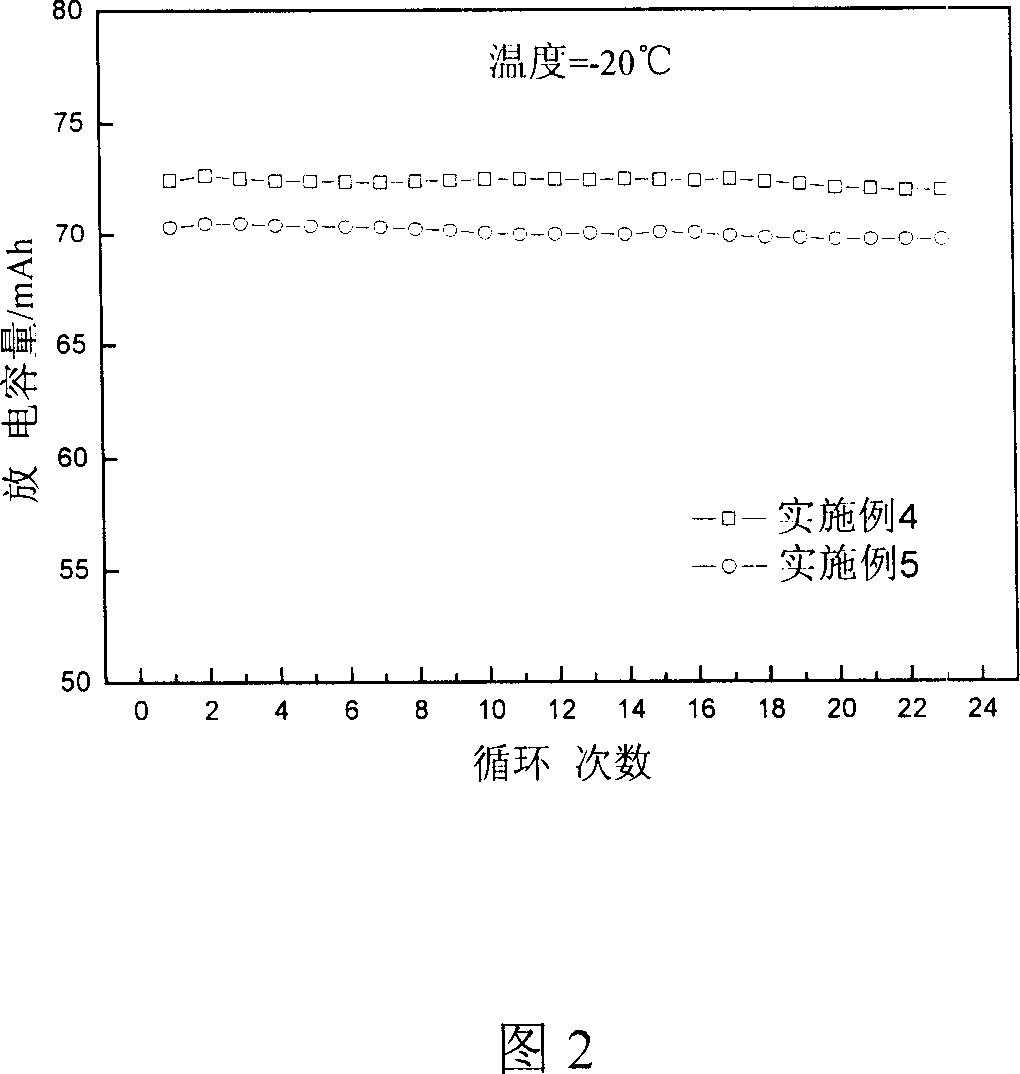

Electrolyte for high-power start-stop battery and power lithium battery

ActiveCN109713366ALower impedanceLong cycle lifeSecondary cells servicing/maintenanceHigh temperature storageMethyl carbonate

An electrolyte for a high-power start-stop battery comprises the following components, per 100 parts by weight, 14 to 20 parts of lithium salt, 70 to 85 parts of organic solvent, and 1 to 10 parts offunctional additives. The organic solvent comprises the following components, by weight accounting for the total weight of the electrolyte: 12 to 20 parts of ethylene carbonate EC, 5 to 11 parts of propylene carbonate PC, 10 to 20 parts of ethyl methyl carbonate EMC, 14 to 22 parts of propyl acetate PA, and 12 to 20 parts of propyl propionate PP. The lithium ion battery electrolyte of the invention can be reduced in electrical conductivity under a low-temperature condition, and improved in the low-temperature interface membrane impedance so as to be improved in the charging and discharging power characteristic at low temperature, further improves the high-temperature stability of the lithium salt and the interface membrane, is reduced in high-temperature side reaction, and improves the high-temperature storage and high-temperature cycle performance of the battery.

Owner:FENGFAN

Low-temperature hot stamping hot melt adhesive for alumite and preparation method thereof

ActiveCN103468174ALow softening temperatureReduce adhesionMonocarboxylic acid ester polymer adhesivesNon-macromolecular adhesive additivesHot stampingNitrocellulose

The invention provides low-temperature hot stamping hot melt adhesive for alumite and a preparation method of the low-temperature hot stamping hot melt adhesive. In the existing alumite rotary gold stamping process, heat transfer hot stamping temperatures are all within the range of 120 DEG C to 200 DEG C, if the temperature of a gold stamping plate is too high, energy consumption in the gold stamping process is increased, alumite hot stamping foil or printing materials can deform by being heated, and then hot stamping is inaccurate. The low-temperature hot stamping hot melt adhesive is prepared from the following raw materials, by weight, 1-6 parts of chloroethylene-vinyl acetate resin, 1-10 parts of terpene resin, 1-10 parts of acrylic ester, 1-5 parts of nitrocellulose, 1-5 parts of fumed silica, 20-70 parts of ethyl acetate, 10-50 parts of ethyl alcohol and 1-5 parts of propyl acetate. The low-temperature hot stamping hot melt adhesive is low in softening temperature and high in adhesive power, heat transfer hot stamping temperatures are within the range of 85 DEG C to 100 DEG C, energy consumption can be remarkably reduced, the problems that the gold stamping foil or the printing materials easily deform by being heated by high-temperature hot stamping, so that waste caused by inaccurate hot stamping is generated are solved.

Owner:云南玉溪东魅包装材料有限公司

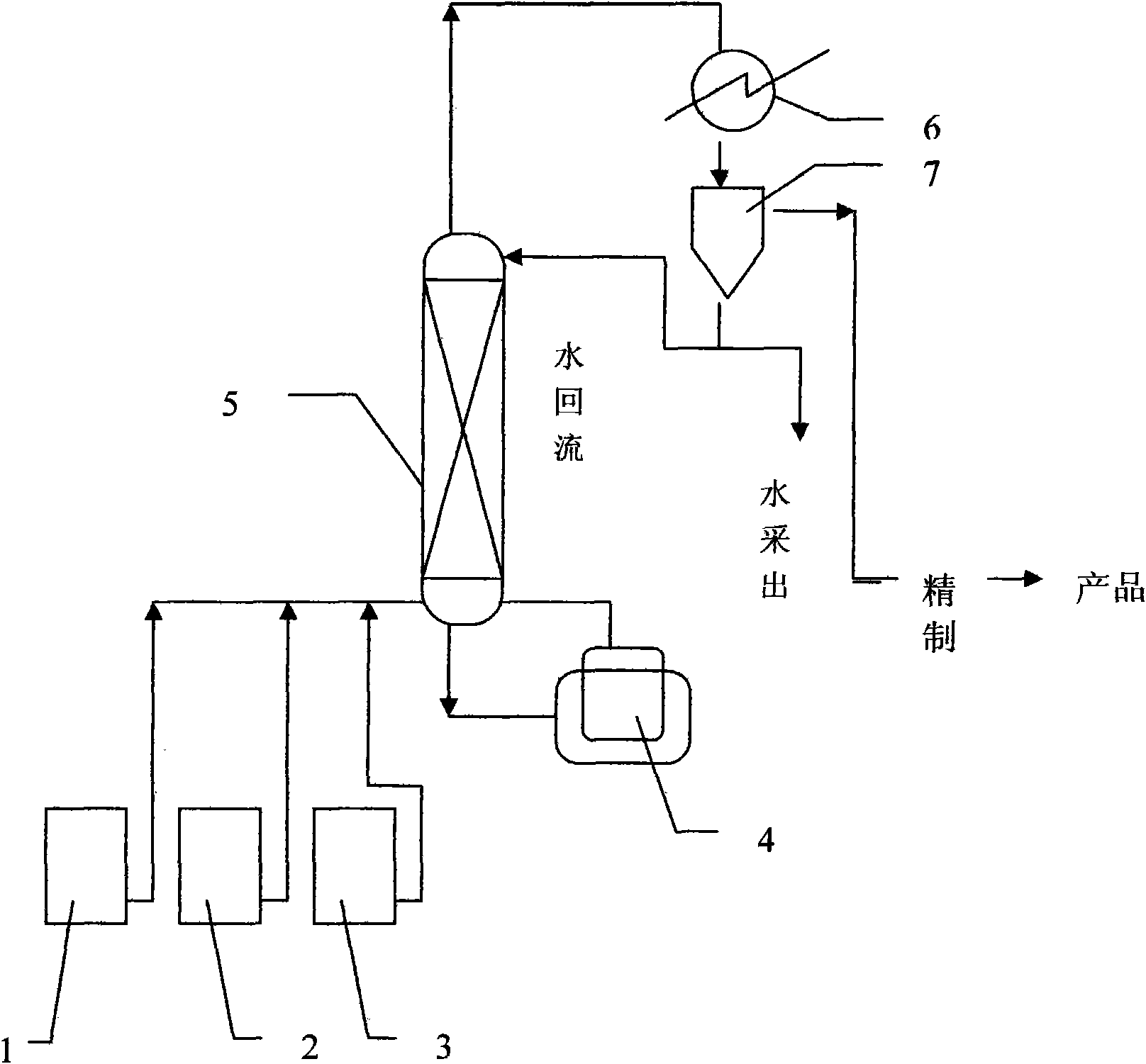

Method for preparing 1-Methoxy-2-propyl acetate by continuous esterification reaction

ActiveCN101337885ARealize industrial productionEmission reductionOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsAcetic acidFixed bed

The invention discloses a process for preparing propylene glycol methyl ether acetate by continuous esterification reaction, which adopts propylene glycol methyl ether and acetic acid as the raw materials. The process is characterized in that a solid acid catalyst is adopted to carry out two-section fixed bed continuous esterification reaction at the esterification temperature of 70 to 150 DEG C; water generated in the sterification reaction is removed by azeotropic distillation; and the result of the esterification reaction is rectified to remove and recover unreacted propylene glycol methyl ether and acetic acid to obtain propylene glycol methyl ether acetate. The method can achieve continuous production of propylene glycol methyl ether acetate, and has the advantages of simple operation manner, greatly improved production efficiency of propylene glycol methyl ether acetate, lowered production cost, reduced emission of solid contaminants and wastewater, and excellent large-scale industrial application value.

Owner:江苏德纳化学股份有限公司

Method for preparing azo dye with alkalescent arylamine serving as diazotization ingredient

ActiveCN103265820AReduce manufacturing costReduce pollutionMonoazo dyesDisperse dyePolyethylene glycol

The invention provides a method for preparing an azo dye with alkalescent arylamine serving as a diazotization ingredient. The method is characterized in that in a diazotization reaction, ethyl acetate, propyl acetate, butyl acetate, acetone, glycol dimethyl ether or polyethylene glycol 200 is used as a diazotization reaction solvent instead of concentrated sulfuric acid, fluoroboric acid or naphthalene disulfonic acid is used as a diazo salt stabilizer instead of concentrated sulfuric acid, a diazo salt is filtered and separated, filtrate is directly applied to a next diazotization reaction of the alkalescent arylamine, and the diazo salt is applied to a coupling reaction so as to synthesize disperse dyes. Compared with the traditional preparation methods, the method has the advantages that the dosage of the concentrated sulfuric acid can be reduced greatly during the diazotization reaction of the alkalescent arylamine, so that the production cost of the azo dye with the alkalescent arylamine serving as the diazotization ingredient is reduced greatly, the environmental pollution can be reduced from the source, the pollution retreatment of a production end is avoided, and thus, the method has broad application prospects.

Owner:DALIAN UNIV OF TECH

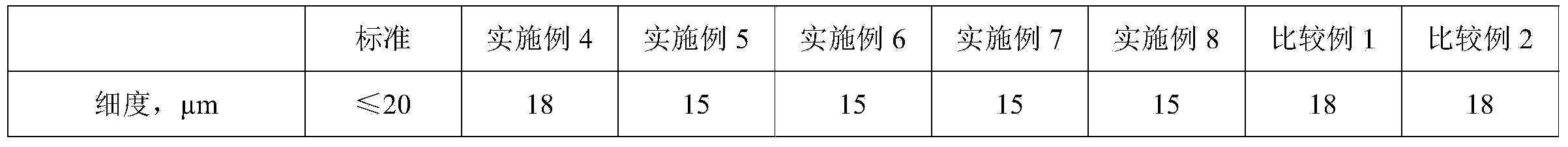

Ester-soluble polyurethane compound printing ink with high composite strength and preparation method thereof

The invention relates to compound printing ink, in particular to ester-soluble polyurethane compound printing ink and a preparation method thereof. The compound printing ink comprises the following components by weight percentage: 27 to 32 percent of modified polyurethane resin, 6 to 15 percent of vinyl chloride-vinyl acetate copolymer liquid, 8 to 33 percent of a pigment, 0.4 to 0.8 percent of a dispersing agent, 0.3 to 0.5 percent of wax powder, 0.2 to 0.8 percent of an antistatic agent, 0.2 to 0.5 percent of an anti-precipitating agent, 0.5 to 1.5 percent of an adhesive force reinforcing agent, 10 to 25 percent of propyl acetate, 5 to 15 percent of ethyl acetate, and 10 to 20 percent of butyl acetate. The compound ink prepared in the invention has the advantages as follows: the tinting strength is high; the color is bright; the transparency is high; the printing adaptability is high, so that the compound printing ink can be widely applied to high-low speed printing of plastic flexible packaging composite materials such as PET, NY and BOPP; the adhesive force to various plastic film base materials is great, and firmness is achieved; resistance to corrosion of acid, alkali and the like is high; hot adhesion phenomena are avoided; the water resistance is high; the temperature resistance is high, so that the compound printing ink can meet the processing requirements of follow-up processes such as boiling, high-temperature cooking, food refrigerating, and is high in storage stability.

Owner:BAUHINIA VARIEGATA INK ZHEJIANG

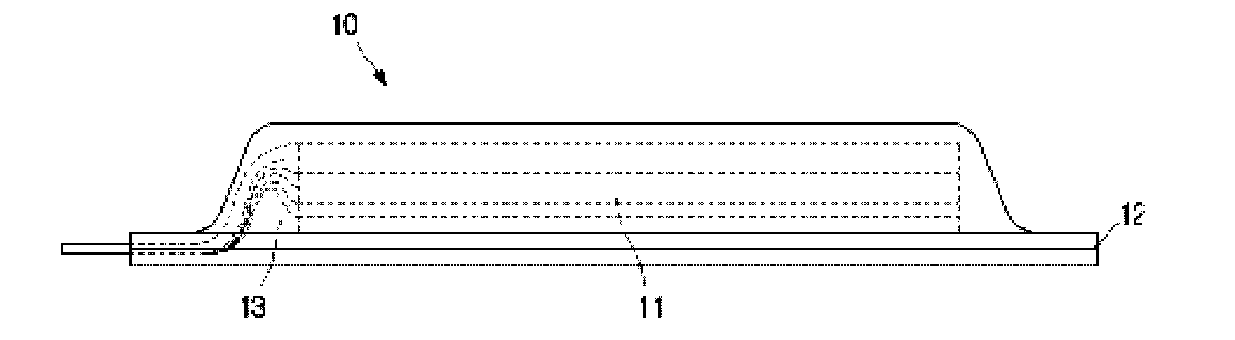

Pouch-Type Lithium Secondary Battery

ActiveUS20100279168A1Excellent high-rate discharging characteristicSolve the real problemCell electrodesFinal product manufactureHigh rateDissolution

A pouch-type lithium secondary battery includes an electrode assembly having an anode made of carbon material capable of occluding or emitting lithium ions, a cathode made of lithium-containing oxide, and a separator interposed between the cathode and the anode for electrical insulation therebetween; a pouch-type case made of sheet to provide a space receiving the electrode assembly; and a non-aqueous electrolyte injected into the electrode assembly. The non-aqueous electrolyte is a non-linear carbonate-based non-aqueous electrolyte including a lithium salt, (a) a cyclic carbonate compound, and (b) a linear ester compound selected from propionate-based compound, methyl butyrate, and propyl acetate, or their mixtures. During LiPF6 IM dissolution, the non-aqueous electrolyte has an ion conductivity of 9 mS / cm or above at about 23° C. This pouch-type lithium secondary battery ensures excellent high-rate discharging characteristics and solves swelling problems associated with a pouch-type lithium secondary battery.

Owner:LG ENERGY SOLUTION LTD

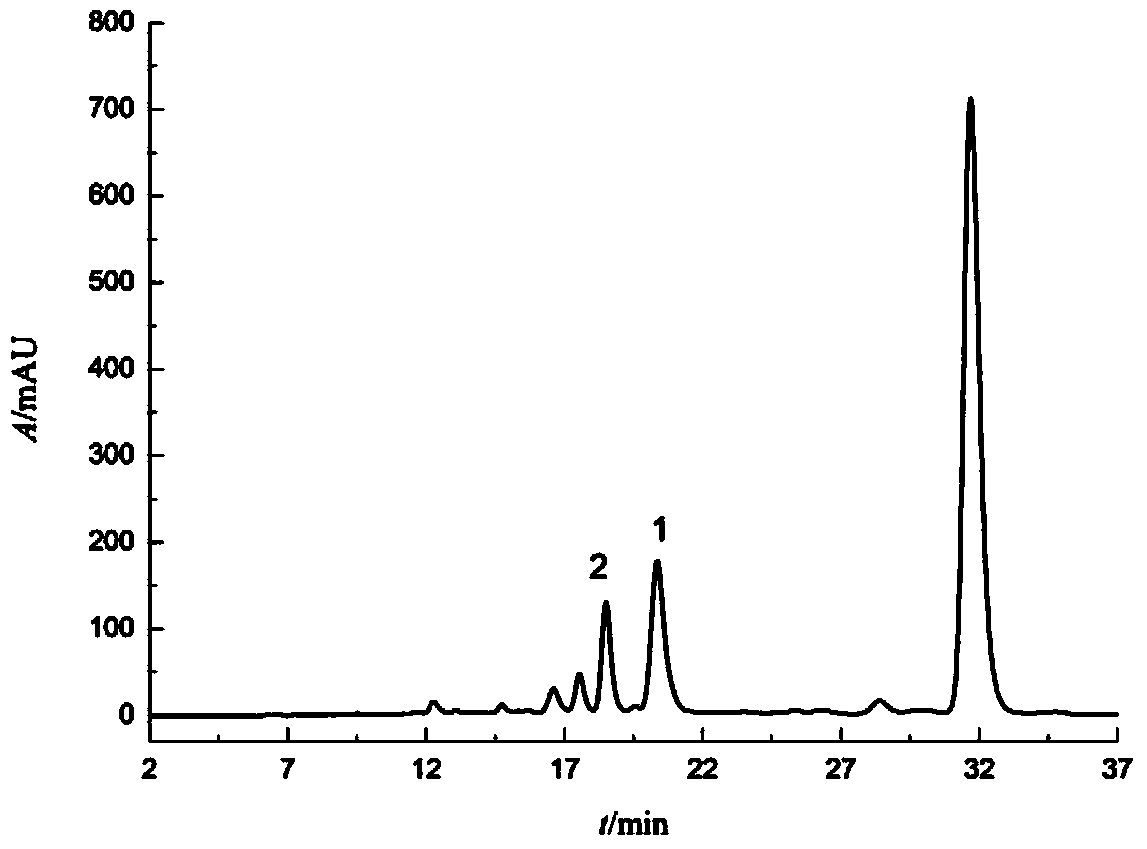

Method for preparing and purifying propyl acetate

InactiveCN1733685AOrganic compound preparationCarboxylic acid esters preparationAcetic acidPropyl acetate

The invention relates to a method for preparing and purifying propyl acetate, which comprises charging quantitative acetic acid, n-propanol (or isopropanol) and acidic homogeneous catalyst continuously into a pre-reactor, loading into esterification tower, obtaining crude ester on the top of the tower, loading the crude ester into a liquid-liquid rotating disc extraction tower, extracting and purifying with aqueous solution extracting agent of salts, recycling the extract phase and loading into rectifying tower for continuous distillation, thus obtaining n-propyl acetate or isopropyl acetate whose content is above 99.5% on the bottom of the tower.

Owner:SHANGHAI WUJING CHEM

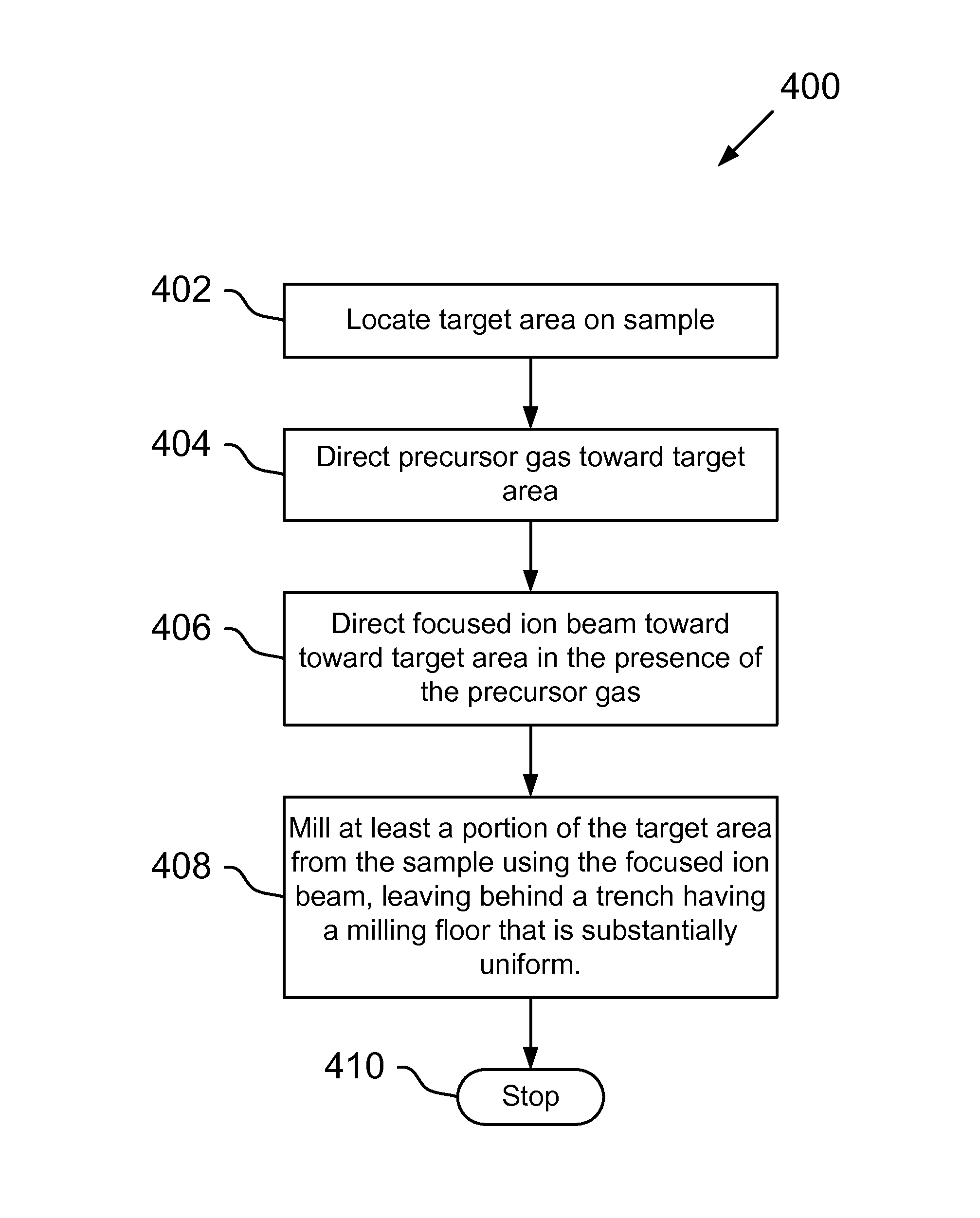

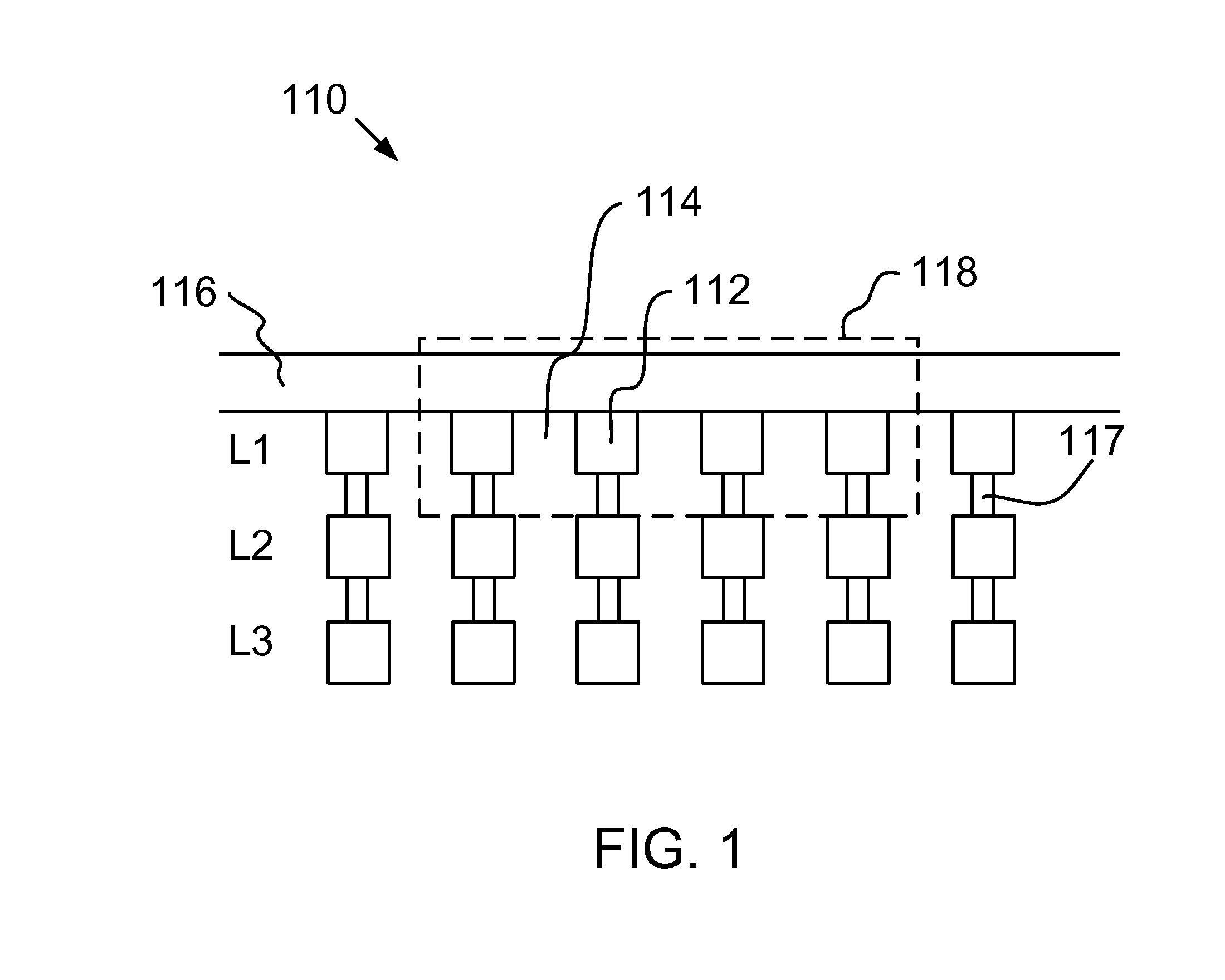

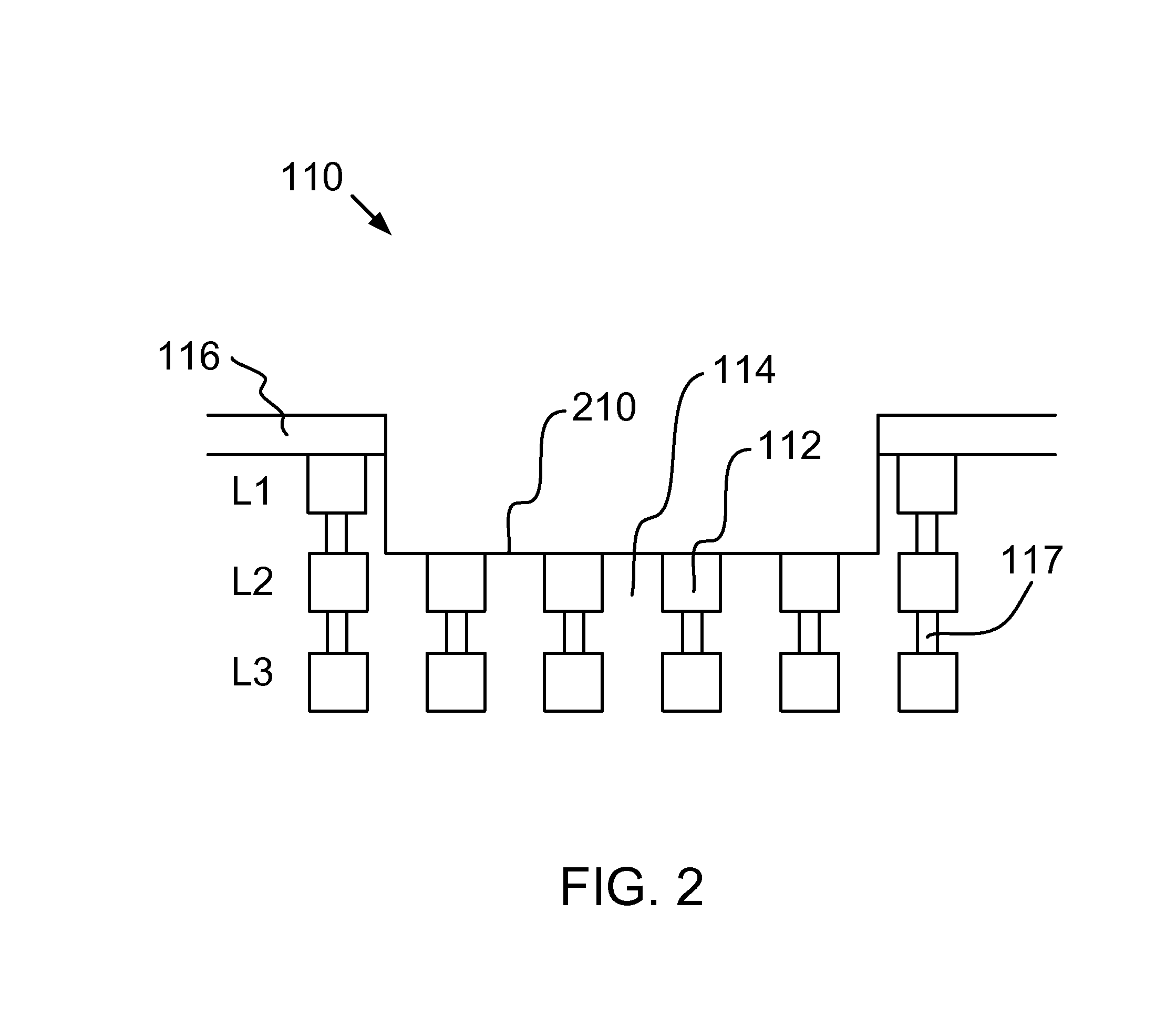

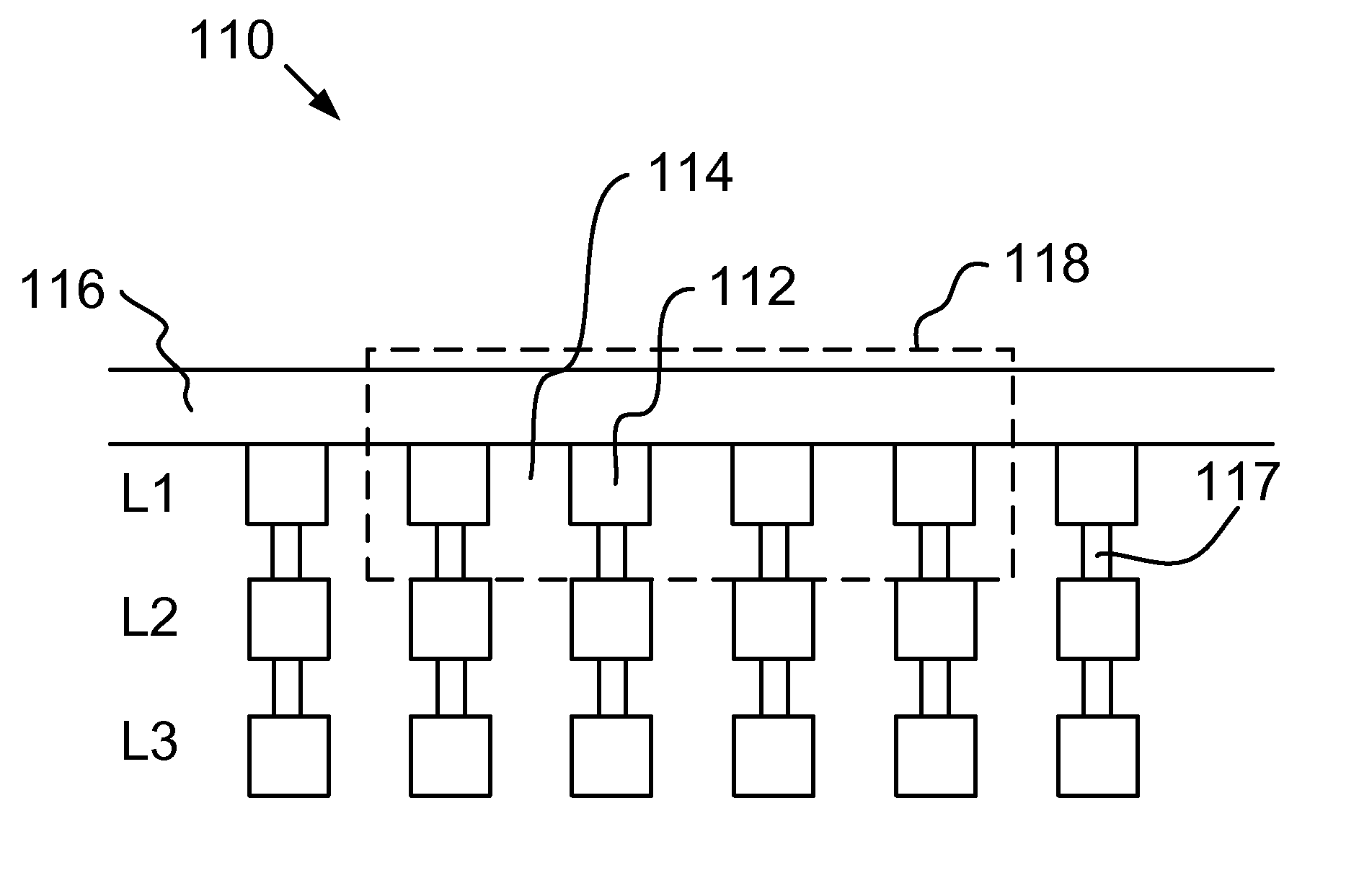

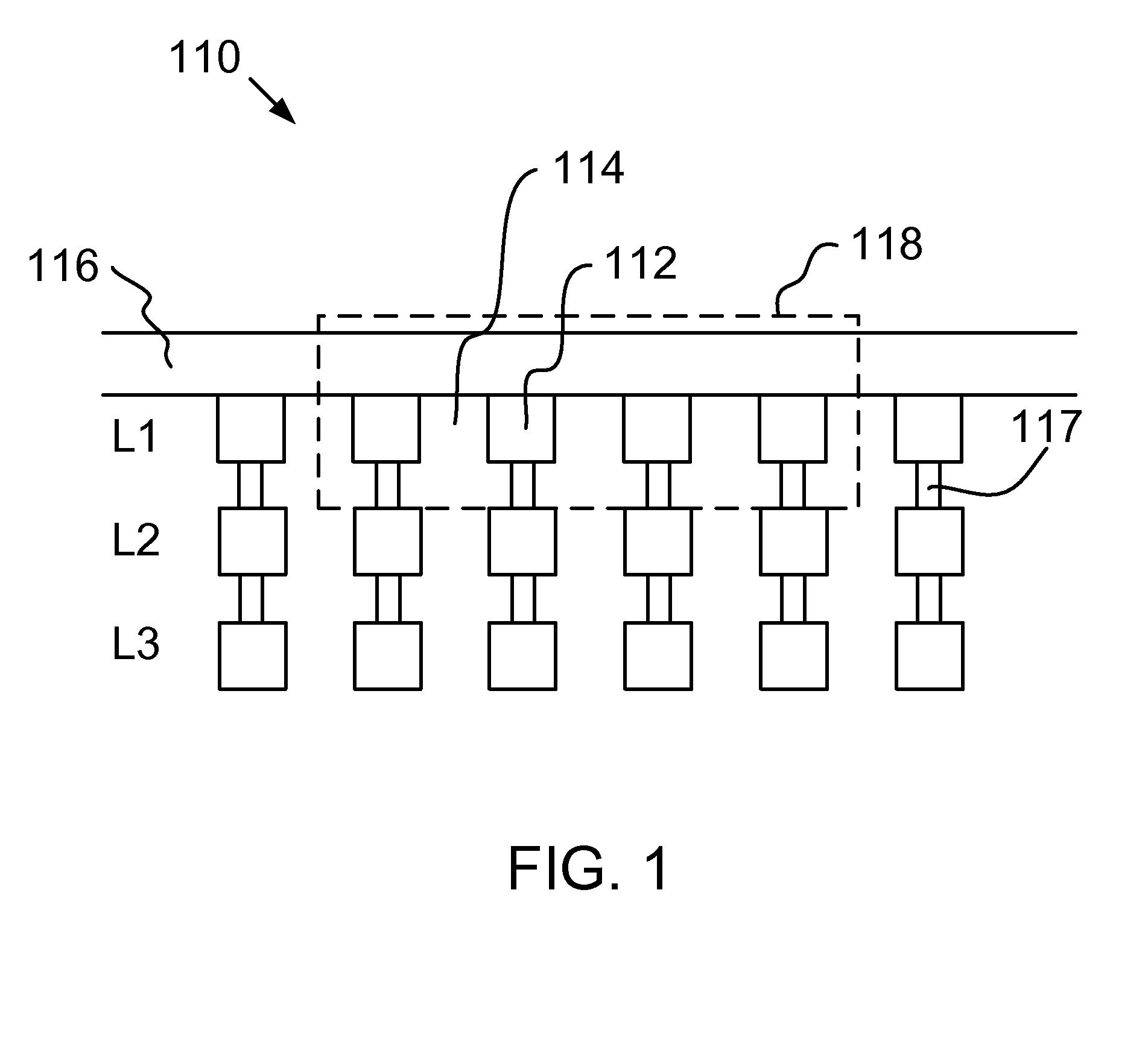

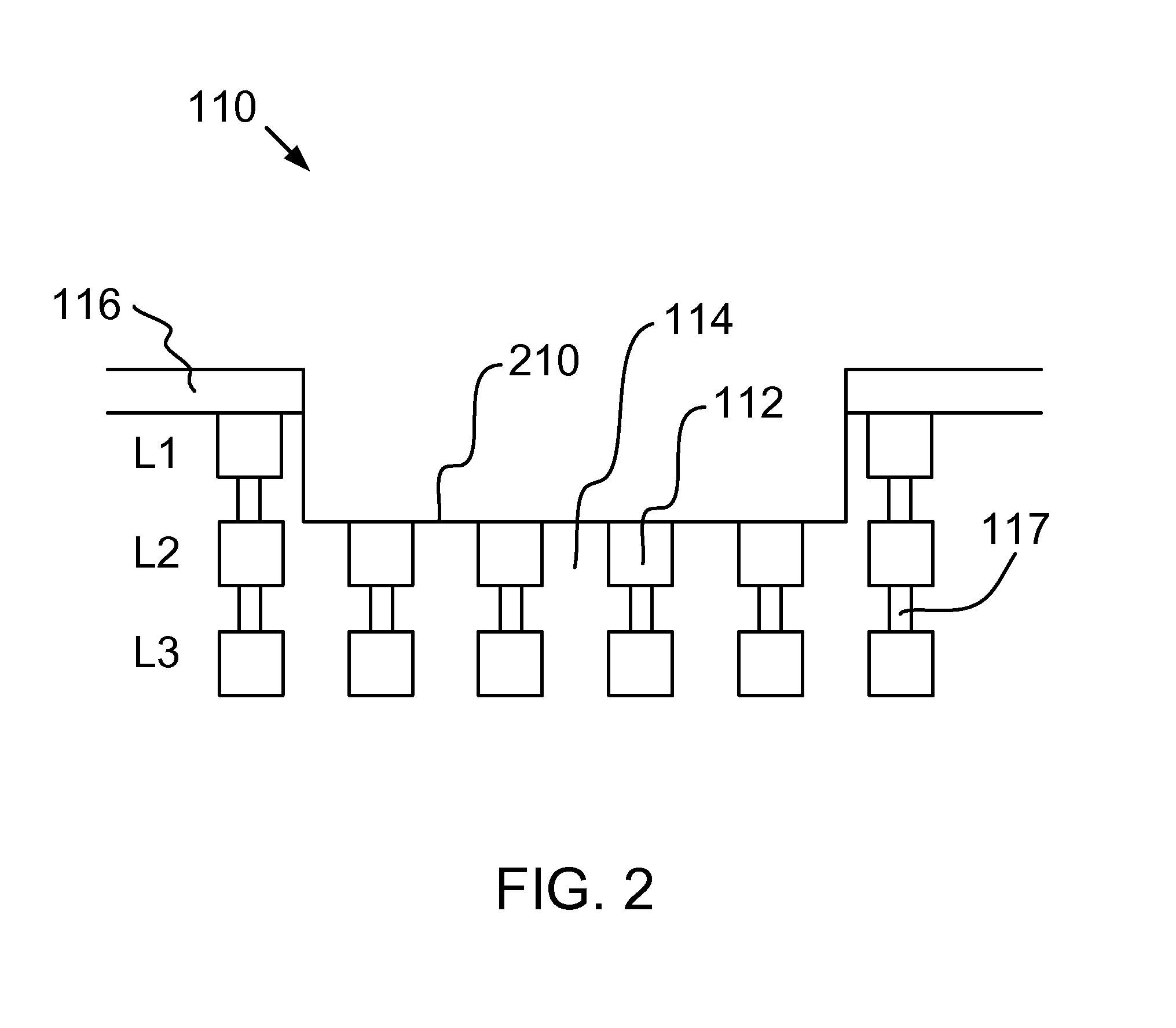

Precursor for planar deprocessing of semiconductor devices using a focused ion beam

ActiveUS9064811B2Easy to useElectric discharge tubesDecorative surface effectsMethyl methoxyacetateIon beam

A method and system for improved planar deprocessing of semiconductor devices using a focused ion beam system. The method comprises defining a target area to be removed, the target area including at least a portion of a mixed copper and dielectric layer of a semiconductor device; directing a precursor gas toward the target area; and directing a focused ion beam toward the target area in the presence of the precursor gas, thereby removing at least a portion of a first mixed copper and dielectric layer and producing a uniformly smooth floor in the milled target area. The precursor gas causes the focused ion beam to mill the copper at substantially the same rate as the dielectric. In a preferred embodiment, the precursor gas comprises methyl nitroacetate. In alternative embodiments, the precursor gas is methyl acetate, ethyl acetate, ethyl nitroacetate, propyl acetate, propyl nitroacetate, nitro ethyl acetate, methyl methoxyacetate, or methoxy acetylchloride.

Owner:FEI CO

Ultraviolet light curing coating and production thereof

InactiveCN1778850AImprove wear resistanceHigh hardnessPolyurea/polyurethane coatingsUltraviolet lightsKetone

A ultraviolet curing coating and its production are disclosed. The coating consists of filming substance, diluent and light initiating agent or assistants. The diluent is a organic solvent which comprises one of several from toluene, acetic ether, acetate butyrin, isobutyl acetate, propyl acetate, alcohol, n-butyl alcohol, ethylene ketone, dimethyl benzene, methyl isobutyl ketone, acetone, methyl ethyl ketone, ethanediol butyl ester and propylene butyl ester. It costs low, has better abrasive-resistance, hardness and adhesion.

Owner:BYD CO LTD

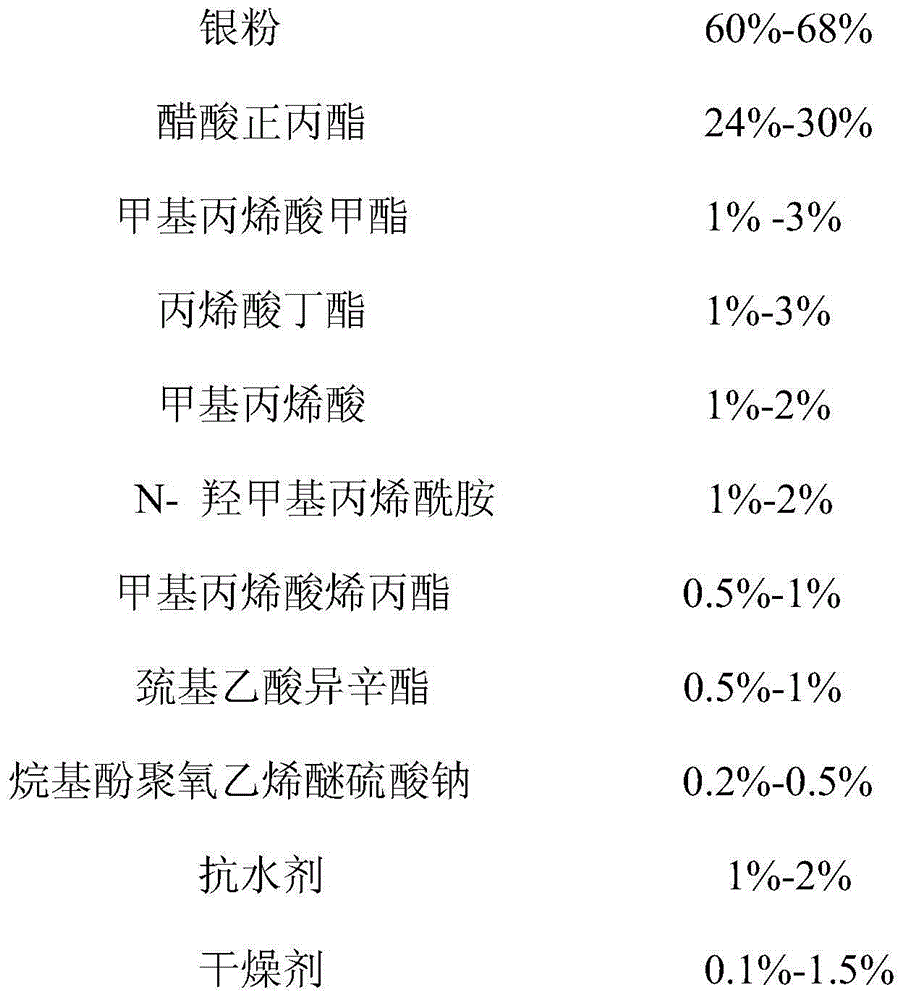

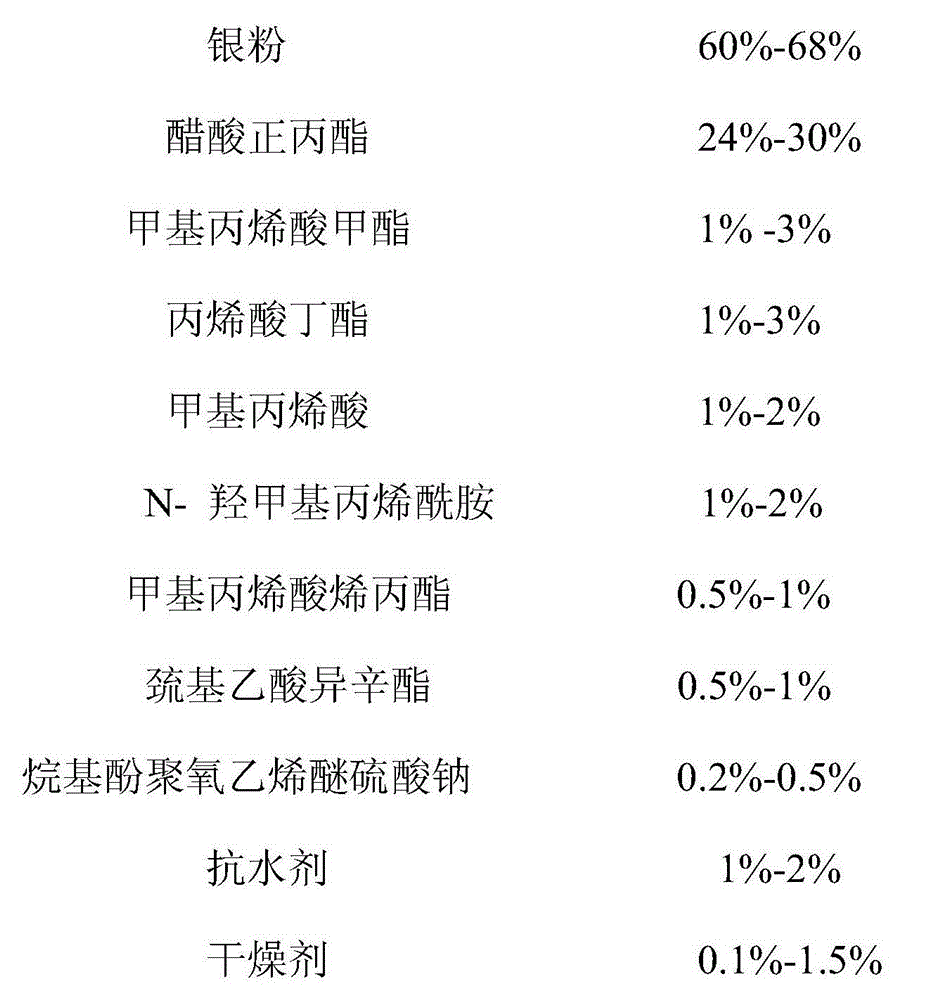

Silver ink with good metal printing effect and printing process using silver ink

ActiveCN104403407AGood metal effectImprove surface smoothnessInksOther printing apparatusCardboardSilver ink

The invention provides silver ink with a good metal printing effect and a printing process using the silver ink. The printing process comprises the steps that first, a coated surface of a white cardboard with a single side coated is coated with water-soluble varnish or UV (ultraviolet) varnish, images and texts are printed with well mixed gravure silver ink in a gravure manner, and finally, a layer of water-soluble varnish or UV varnish is printed on an image and text area with the gravure silver ink. The gravure silver ink is formed by blending the following materials in percentage by weight: 60-68% of silver powder, 24-30% of n-propyl acetate, 1-3% of methyl methacylate, 1-3% of butyl acrylate, 1-2% of methacrylic acid, 1-2% of N-hydroxymethyl acrylamide, 0.5-1% of allyl methacrylate, 0.5-1% of isooctyl thioglycolate, 0.2-0.5% of alkylphenol ethoxylates sodium sulfate, 1-2% of water-resistant agents and 0.1-0.5% of drying agents. By means of the silver ink and the printing process, a metal ink layer has a refraction effect, the metal effect is more obvious and an optimal metal effect is achieved.

Owner:WUHAN HONGZHICAI PACKAGING PRINTING

Benzene-free alcohol-resistant PET (polyethylene terephthalate) thermoshrinkable film plastic printing ink and preparation method thereof

ActiveCN102702857AStrong alcohol resistanceSolve skin packaging problemsInksPolymer sciencePolyethylene terephthalate glycol

The invention relates to a benzene-free alcohol-resistant PET (polyethylene terephthalate) thermoshrinkable film plastic printing ink which is prepared from 50-75 wt% of solvent, 10-20 wt% of resin, 10-35 wt% of pigment and 1-5 wt% of assistant, wherein the solvent adopts a composite solvent, and is a mixture of ethyl acetate, n-propyl acetate, n-butyl acetate and butanone; the resin is a ternary vinyl chloride-vinyl acetate resin; the pigment adopts a synthetic pigment; and the assistant comprises gas-phase silicon dioxide as an anti-settling agent and polyethylene wax as a lubricating agent. The invention provides a special benzene-free plastic printing ink for a PET thermoshrinkable film. After the ink is matched with the PET thermoshrinkable film for printing, the printing product satisfies the requirement for environmental protection, is safe and nontoxic, can be recycled, has strong alcohol resistance, and well solves the problem of skin packaging in cleaning supplies, cosmetics and other alcohol-containing products.

Owner:STARLIGHT NEW CHEM MATERIALS

Precursor for Planar Deprocessing of Semiconductor Devices using a Focused Ion Beam

ActiveUS20140357088A1Uniform removalEasy to useElectric discharge tubesSemiconductor/solid-state device manufacturingMethyl methoxyacetateIon beam

A method and system for improved planar deprocessing of semiconductor devices using a focused ion beam system. The method comprises defining a target area to be removed, the target area including at least a portion of a mixed copper and dielectric layer of a semiconductor device; directing a precursor gas toward the target area; and directing a focused ion beam toward the target area in the presence of the precursor gas, thereby removing at least a portion of a first mixed copper and dielectric layer and producing a uniformly smooth floor in the milled target area. The precursor gas causes the focused ion beam to mill the copper at substantially the same rate as the dielectric. In a preferred embodiment, the precursor gas comprises methyl nitroacetate. In alternative embodiments, the precursor gas is methyl acetate, ethyl acetate, ethyl nitroacetate, propyl acetate, propyl nitroacetate, nitro ethyl acetate, methyl methoxyacetate, or methoxy acetylchloride.

Owner:FEI CO

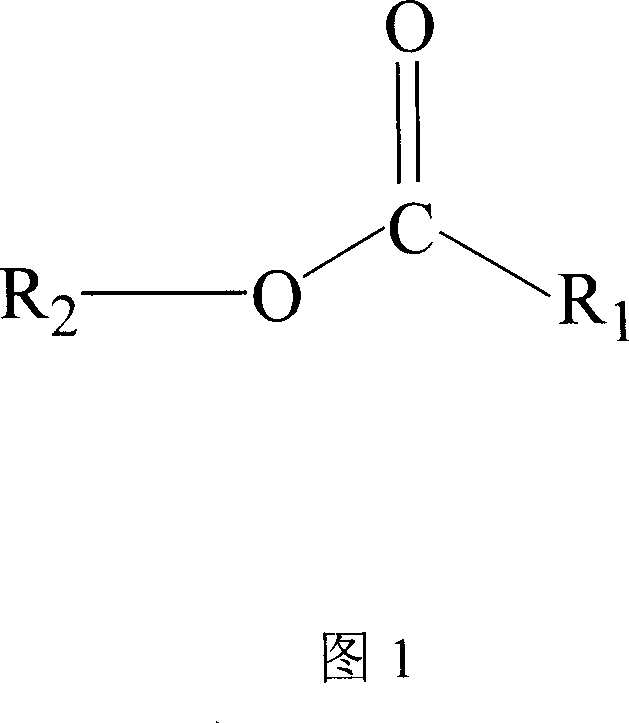

Lithium ion battery electrolyte and constitutive lithium ion battery

InactiveCN1976111AImprove ionic conductivityImprove low temperature performanceOrganic electrolyte cellsSecondary cellsAcetic acidOrganic solvent

An electrolyte of Li ion cell is prepared from non-aqueous organic solvent, Li salt and prolyl acetate compound. The propyl acetate compound used as cosolvent of electrolyte has low melting point and low viscosity so that low temperature performance of Li ion cell can be effectively improved.

Owner:SHANGHAI INST OF MICROSYSTEM & INFORMATION TECH CHINESE ACAD OF SCI

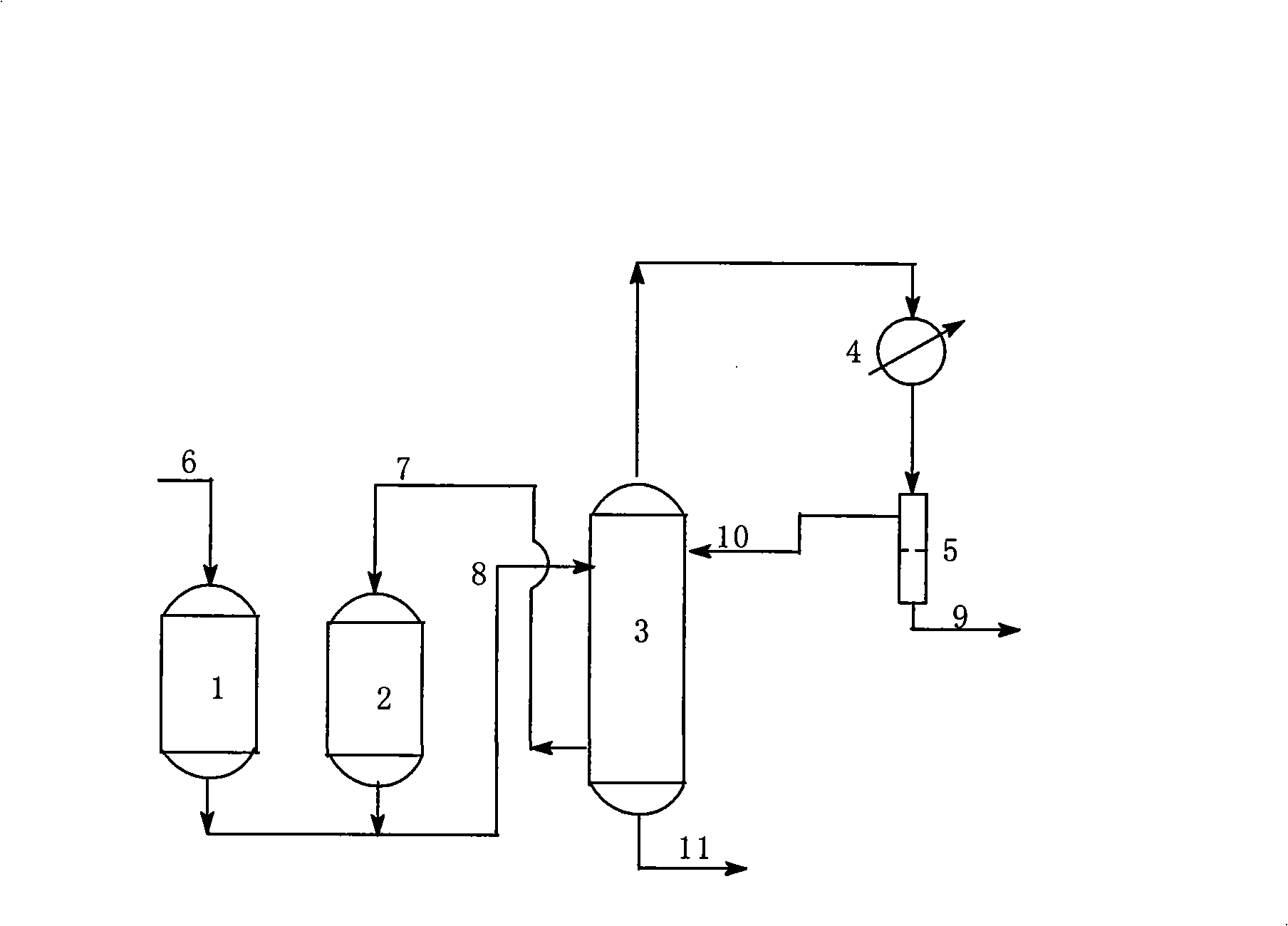

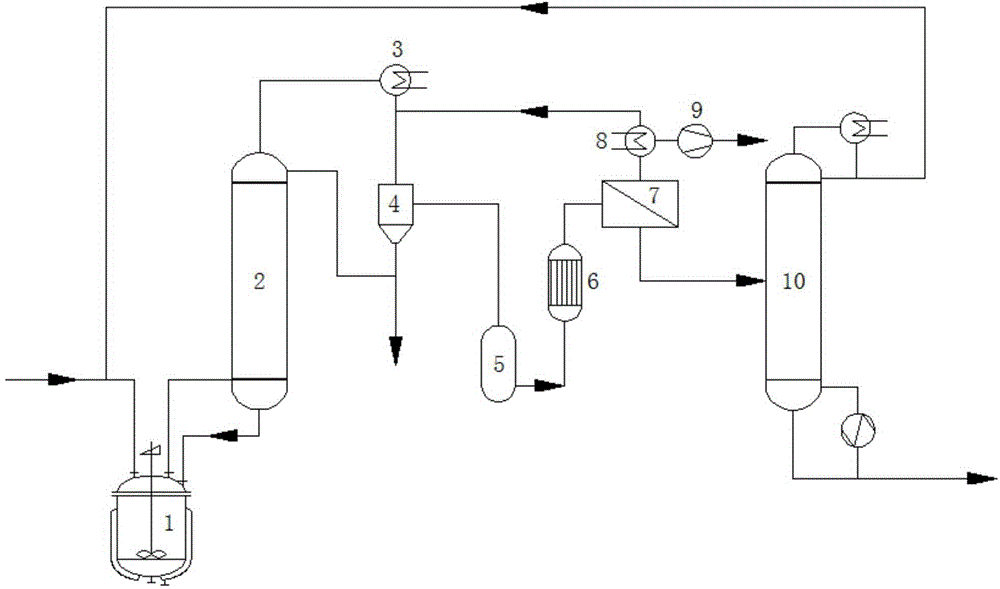

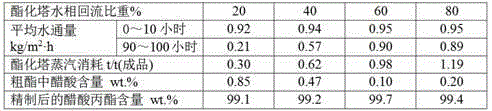

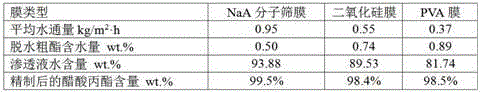

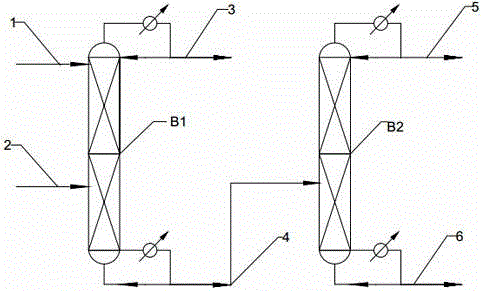

Refining method and device for n-propyl acetate esterification synthesis

ActiveCN104557529ASimple processImprove securityOrganic compound preparationCarboxylic acid esters separation/purificationN-Propyl alcoholEthylic acid

The invention relates to a refining method and device for n-propyl acetate esterification synthesis. The refining method comprises the following steps: feeding a crude product obtained in an n-propyl acetate reaction section into an esterification tower, performing preliminary separation on the n-propyl acetate in the esterification tower through a rectifying mode, and evaporating out raw ester consisting of the n-propyl acetate, water and part of n-propyl alcohol from the tower top of the esterification tower; after condensing the raw ester through a tower-top condenser, feeding the condensed raw ester into a tower-top layering machine for layering, refluxing a lower-layer water-phase part to an esterification tower, completely extracting and feeding an upper-layer organic phase into a pervaporation membrane separator to perform separation, so as to obtain dehydrated raw ester; enabling water and a little n-propyl acetate in a solution at a feed liquid side to penetrate through the pervaporation membrane in the form of steam, so as to obtain a penetrating fluid, and returning the penetrating fluid to tower-top layering machine of the esterification tower and discharging the layered penetrating fluid from the water phase; re-feeding the dehydrated raw ester into a refining tower to obtain a n-propyl acetate finished product. According to the refining method, the recovery rate is high, the process is simple, the safety coefficient is high, the feed liquid circulation volume is small, the operation energy consumption is low, and a third component is not added.

Owner:JIANGSU NINE HEAVEN HIGH TECH

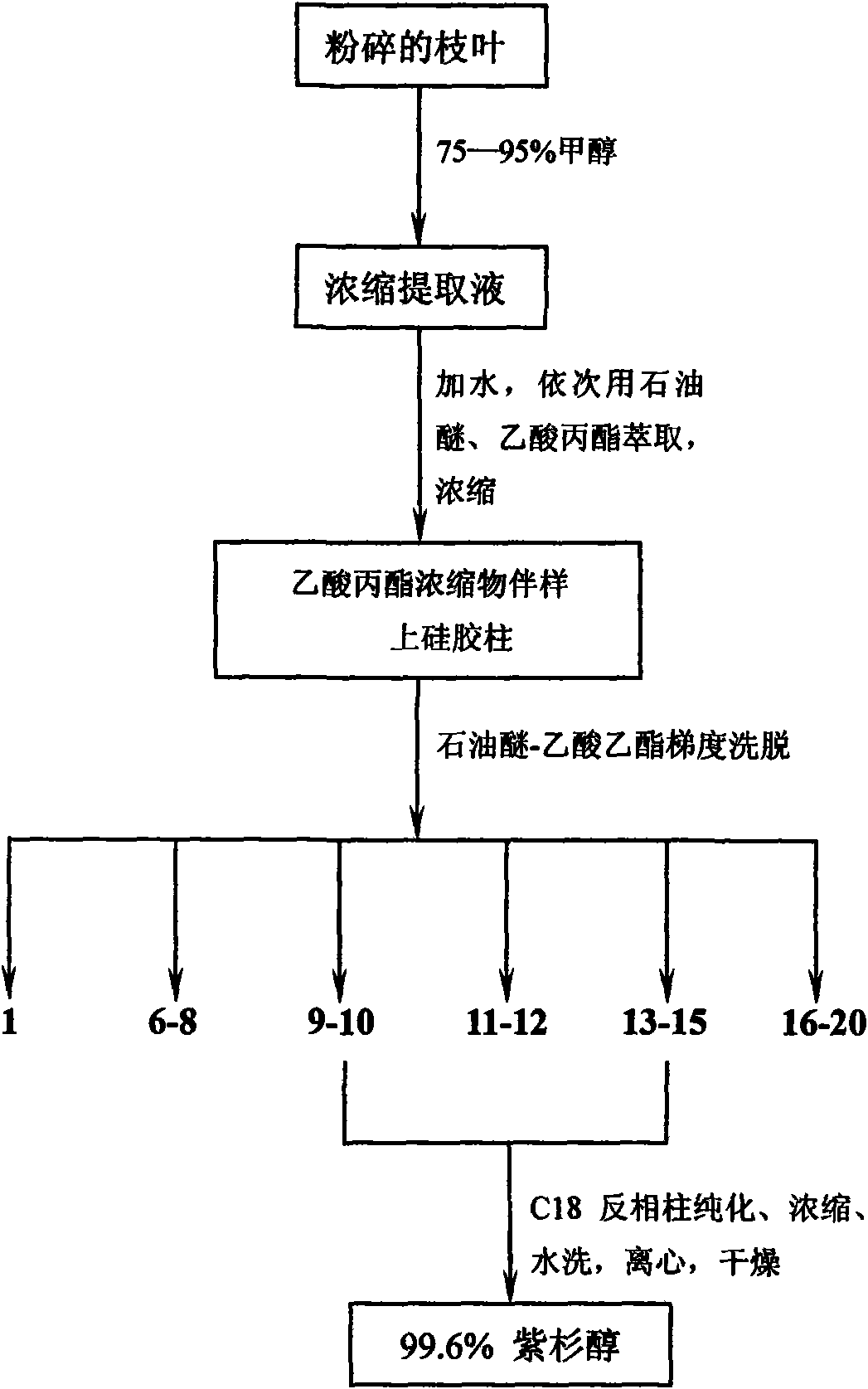

Extraction method of taxol from branches and leaves of artificially cultivated yew

InactiveCN101560197AProtect resourcesSimple processOrganic chemistryChromatographic separationNatural source

The invention relates to an extraction method of taxol from branches and leaves of artificially cultivated yew. A plurality of methods, such as planting of stocky yew, cultivating of tissue and semi-synthesis and total synthesis of taxol, have been developed home and abroad so as to obtain taxol raw material; however, the tissue cultivating method has low yield and high broth price; and the total synthesis has extremely low yield, worse therapeutic effect than natural-source taxol, and a high cost; thereby being difficult for commercial application. The invention uses branches and leaves of artificially cultivated taxus media, Yunnan taxus, southern taxus or northeastern taxus as raw materials; the raw materials are marinated by carbinol and extracted by petroleum oil and propyl acetate in sequence; and normal-pressure normal-phase silica gel column chromatography or reverse-phase high-pressure liquid chromatography is used to obtain high-purity taxol with a purity being higher than 99.6%. The preparation method has simple process, low cost, recyclable solvent and eluant; therefore, the method is applicable to industrial production and protects plant resource.

Owner:NORTHWEST A & F UNIV

Amitraz compositions

The present invention provides a stable composition which comprises a non-hydroxyl-group-containing solvent mixture comprising N,N-diethyl-m-toluamide and γ-hexalactone, optionally with dimethyl sulfoxide, eucalyptol and 1-methoxy-2-propyl acetate; and an effective amount of each of amitraz and at least one additional parasiticidal compound, such as R-28153. Said composition allows for high concentrations of a mixture of parasiticidal agents in a single application and is useful for treating and controlling parasiticidal infection and infestation in a homeothermic animal.

Owner:NIHON NOHYAKU CO LTD

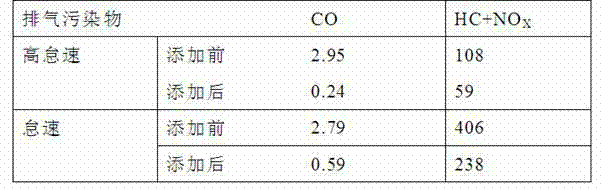

Automobile exhaust detergent and preparation method thereof

ActiveCN102408935AEffectively purify exhaust gasImprove protectionLiquid carbonaceous fuelsFuel additivesHigh carbonGlycerol

The invention relates to the technical field of automobile exhaust pollution control, especially an automobile exhaust detergent and a preparation method thereof. The automobile exhaust detergent is prepared by nitric acid propyl acetate, N, N-dimethylacetylamide, ethylene glycol monomethyl ether, diisopropyl ether, fatty alcohol, lauryl alcohol, high-carbon number fatty alcohol, multiple crude alcohol, glycerol palm kernel fatty acid ester and blackKwai acid glycerol according to a certain weight ratio. The invention has simple principle, easy preparation and low production cost, which can effectively purify exhaust gas discharged by vehicle and can help protect the environment; the pollution is reduced; the invention is suitable for wide promotion and application.

Owner:河北苏同兴盛新能源科技有限公司

Electrolyte of lithium ion battery

InactiveCN102593515AImproved high temperature inflationImprove low temperature performanceSecondary cellsElectrolytic agentOXALIC ACID DIHYDRATE

The invention belongs to the technical field of lithium ion batteries, particularly relates to electrolyte of the lithium ion batteries, and by weight, is composed of 13.5-18.5% of electrolyte, 66.5-78.5% of solvent and 8-15% of annexing agent. The solvent is composed of at least three of ethylene carbonate (EC), ethyl acetate (EA), propyl acetate (EP), dimethyl carbonate (DMC), methyl ethyl carbonate (EMC) and diethyl carbonate (DEC), the annexing agent is composed of at least three of vinylene carbonate (VC), 1,3 propane suhone (PS), difluoro oxalic acid lithium borate (LIODFB), propylene carbonate (PC), polyoxy diethyl ether and fluoro ethylene ester (FEC), and the electrolyte is lithium hexafluorophate (LiPF6). The electrolyte still has excellent performance at low temperature, and lithium ion batteries made of the electrolyte are excellent in low temperature discharge performance.

Owner:FULLYMAX BATTERY CO LTD

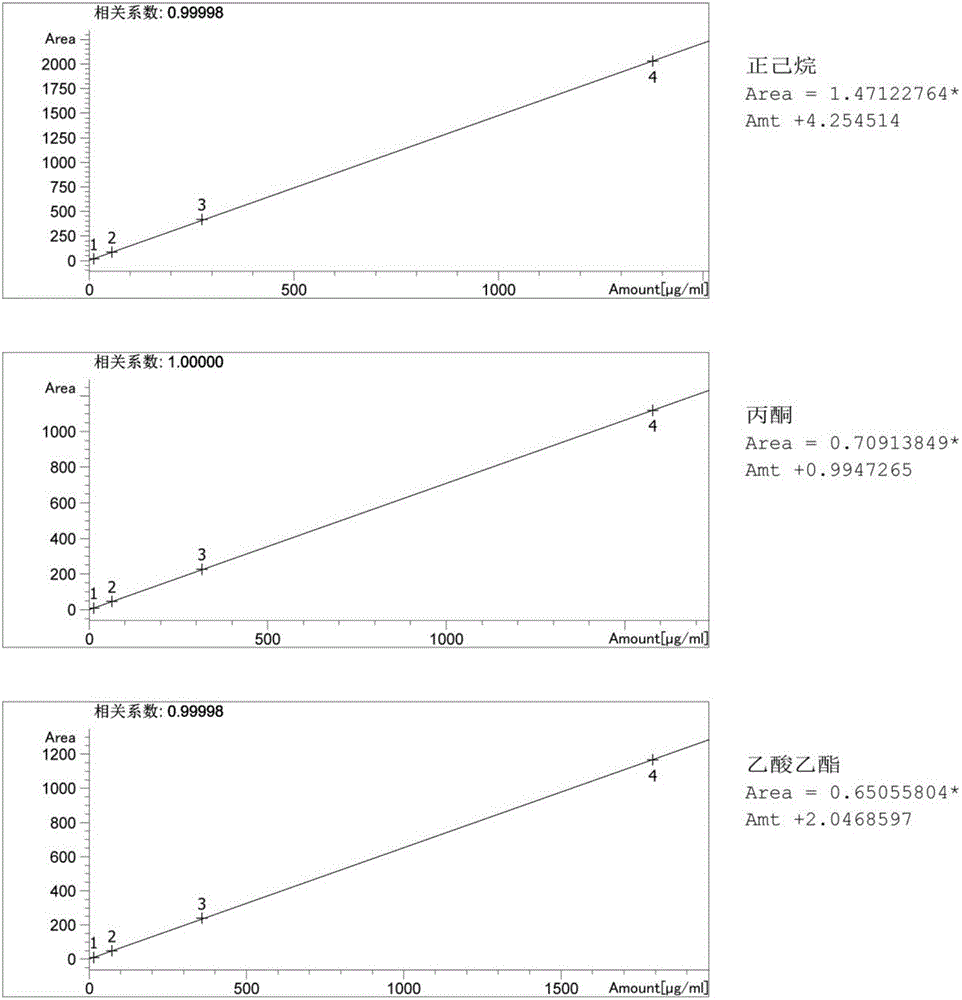

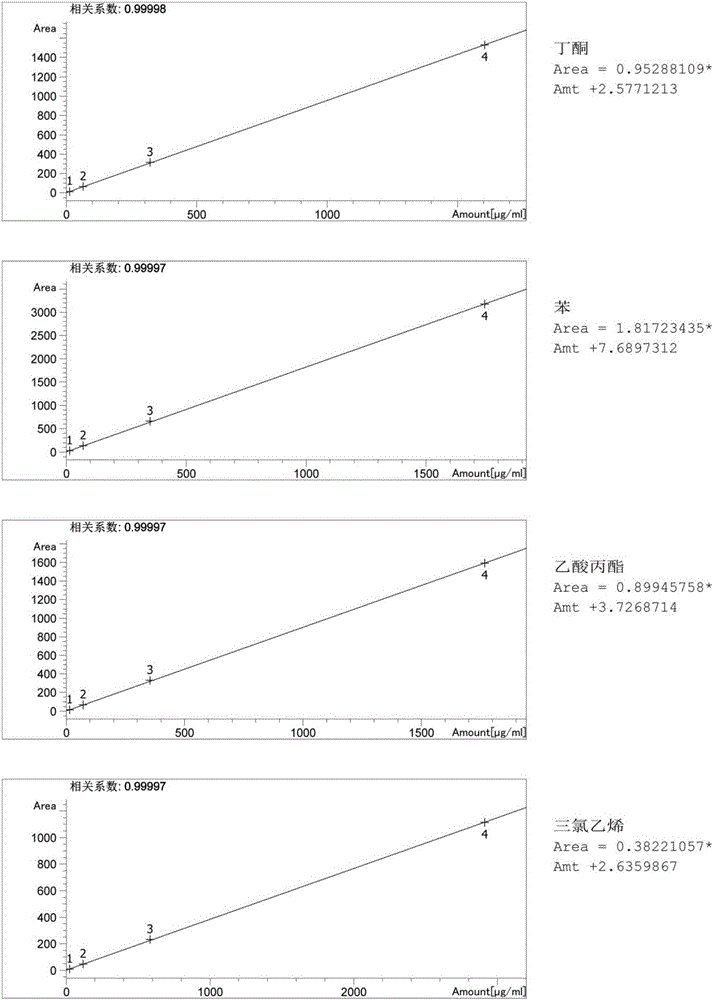

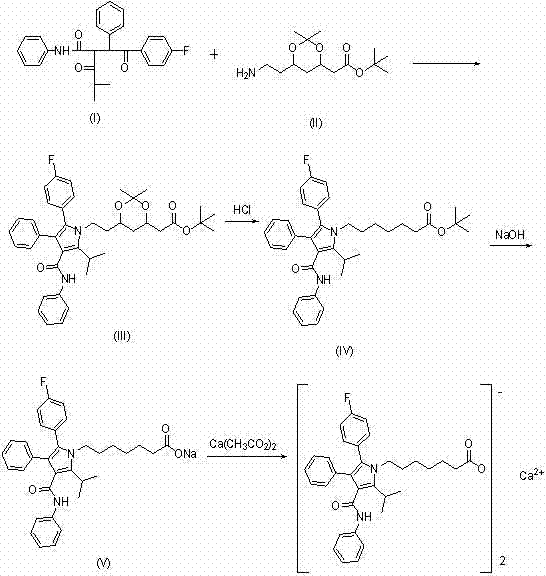

Gas chromatography method for organic mixture

InactiveCN106645453AAnalysis method is simpleAnalytical method is accurateComponent separationCyclohexanoneGas phase

The invention relates to the technical field of organic matter separation, in particular to a gas chromatography method for an organic mixture. The method includes: a to-be-tested sample is gasified in a gasifying chamber and carried into a chromatographic column by carrying gas, and various components in the sample are separated in the chromatographic column, flow out of the chromatographic column and enters a detector, wherein the chromatographic column is polarity capillary chromatographic column, the temperature of the chromatographic column rises in a programmed manner, the initial temperature of the chromatographic column is 40 DEG C, is kept for 4-5 minutes, and rises to 110 DEG C at the speed of 8-12 DEG C / minute, the temperature of the gasifying chamber is 200-220 DEGC, the temperature of a detecting chamber is 220-250 DEG C, the carrying gas is nitrogen, the flow of the carrying gas is 1.3-2mL / minute, and the split ratio of the carrying gas is (10-30):1. By the gas chromatography method, benzene, toluene, dimethylbenzene, ethylbenzene, styrene, trichloro-ethylene, n-hexane, acetone, butanone, cyclohexanone, ethyl acetate, propyl acetate and butyl acetate can be completely separated and accurately measured by one detection, and work efficiency is increased evidently.

Owner:青岛环湾检测评价股份有限公司

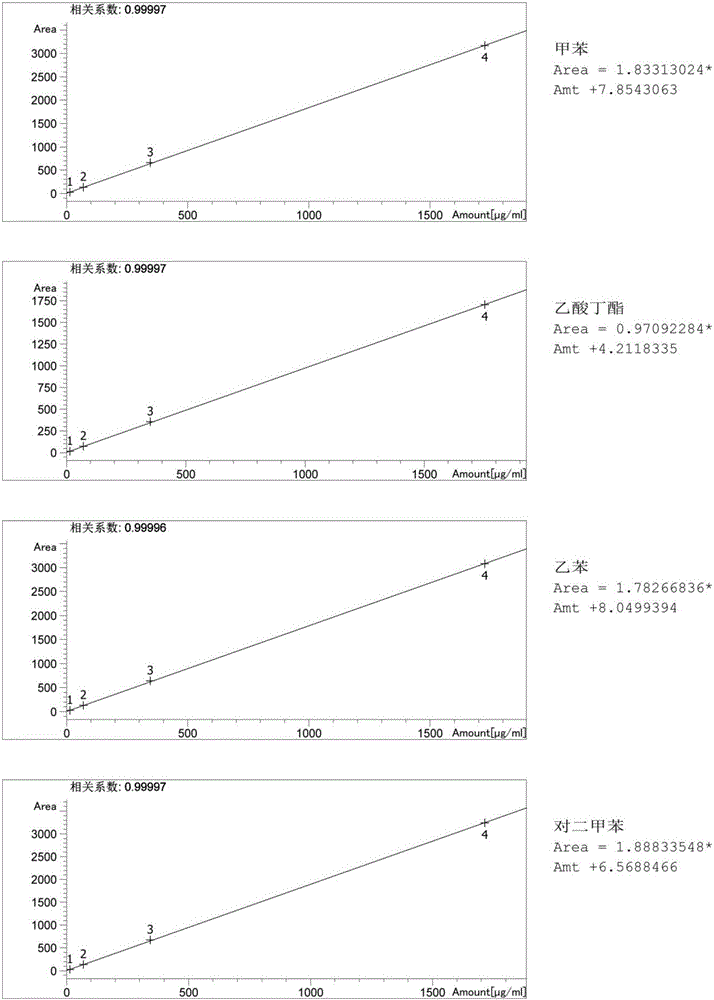

Method for preparing amorphous atorvastatin calcium

The invention provides a method for preparing amorphous atorvastatin calcium. The amorphous atorvastatin calcium is prepared by undergoing a four-step reaction. The method comprises the following steps of: continually performing acidolysis deprotection and an alkali hydrolysis reaction in the same boiler under the condition that methanol and tetrahydrofuran are taken as solvents; particularly extracting a generated calcium salt with propyl acetate or butyl acetate or ethyl acetate; adding acetone for dissolving; concentrating a part; and directly drying under reduced pressure to obtain amorphous atorvastatin calcium, wherein the total yield is more than or equal to 75 percent. Due to the adoption of the method, the reaction period is greatly shortened, the preparing period can be shortened by more than 30 hours, the production cost is lowered, environmental pollution is reduced, the product quality is improved, the process operating steps are simplified, industrial production is easy, operation is convenient, the synthesis yield is high, the raw material cost is low, the product quality is good, and the obtained atorvastatin calcium is amorphous.

Owner:JIANGXI FUSHINE PHARMA CO LTD

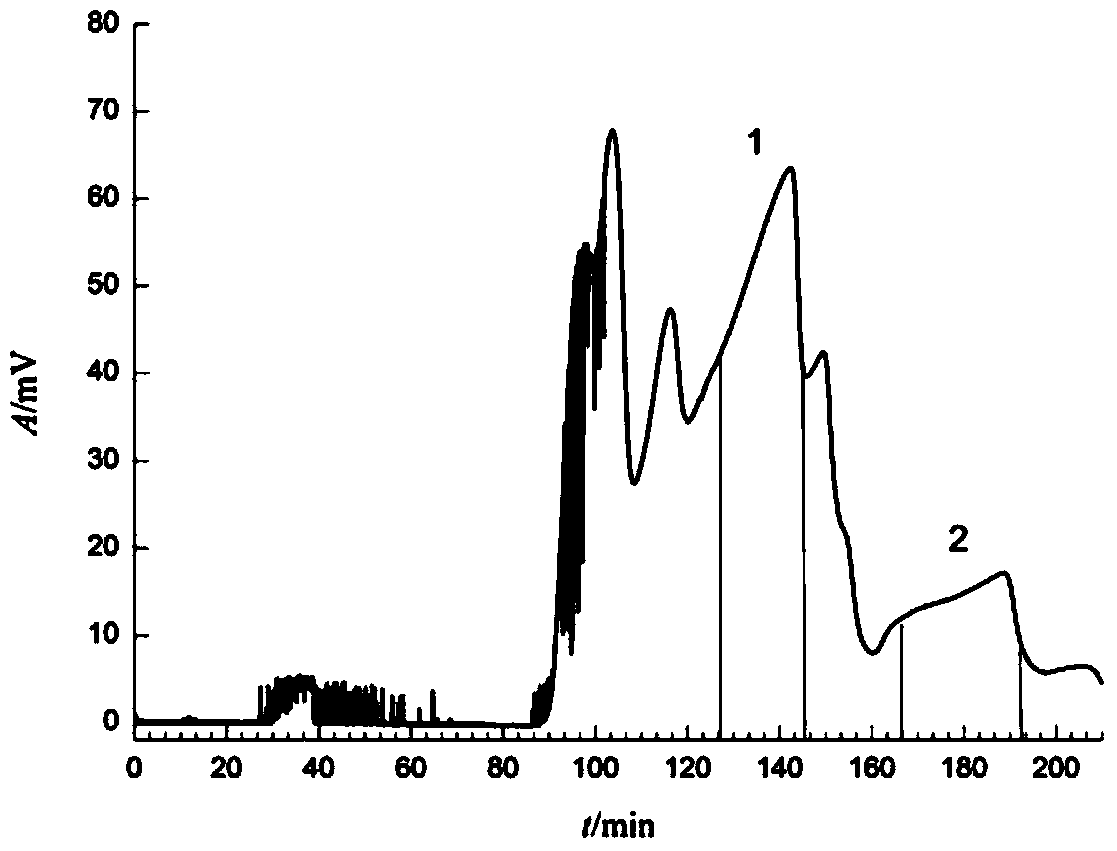

Method for preparing salvianolic acid B and rosmarinic acid by adopting high-speed counter-current chromatography separation and purification process

ActiveCN104031013ASimple and fast operationImprove efficiencyCarboxylic acid esters separation/purificationChromatographic separationSalvianolic acid B

The invention discloses a method for preparing salvianolic acid B and rosmarinic acid by adopting a high-speed counter-current chromatography separation and purification process. The method comprises the following steps: grinding salvia miltiorrhiza, performing ethanol extraction, enriching through macroporous adsorption resin to obtain a crude extract, and performing high-speed counter-current chromatography separation on the crude extract by a high-speed counter-current solvent system consisting of solvents A, B, C and D to prepare salvianolic acid B and rosmarinic acid respectively, wherein the volume ratio of the solvent A to the solvent B to the solvent C to the solvent D is (1-5) to (5-10) to (1-5) to (1-10); the solvent A is methanol, ethanol, n-hexane or iso-hexane; the solvent B is ethyl acetate, propyl acetate or n-butyl acetate; the solvent C is methanol, ethanol or acetone; the solvent D is water; an upper phase is a stationary phase; a lower phase is a mobile phase. According to the method, the salvianolic acid B and the rosmarinic acid are prepared by adopting the high-speed counter-current chromatography process, inreversible adsorption is not existent, and the sample loss is avoided; the method has the characteristics of having a good separation effect and being low in solvent consumption, pollution-free, efficient and quick.

Owner:ANHUI YONSENT PHARMA

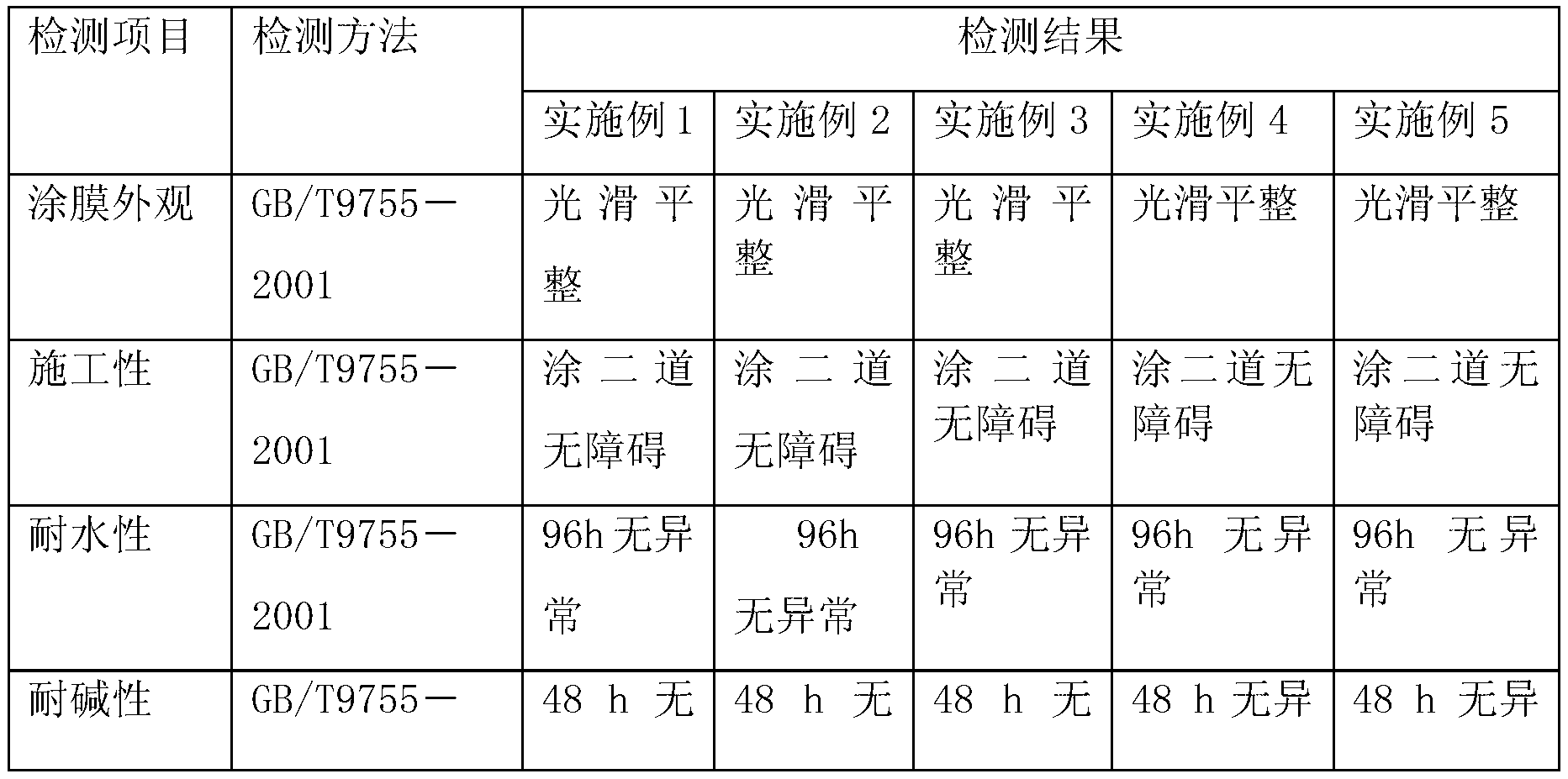

PVDF varnish, heat-insulation energy-saving fluorocarbon paint, and preparation methods thereof

InactiveCN103232772AGood weather resistanceIncreased durabilityReflecting/signal paintsPolymethyl methacrylateFluoropolymer

The invention provides a PVDF varnish, heat-insulation energy-saving fluorocarbon paint, and preparation methods thereof. The PVDF varnish comprises the components of, by weight, 30-40 parts of polyvinylidene fluoride (PVDF), 10-15 parts of polymethyl methacrylate, 7-15 parts of methoxy propyl acetate, 15-25 parts of isophorone, 15-25 parts of titanium dioxide, and 10-20 parts of xylene. The heat-insulation energy-saving fluorocarbon paint comprises the components of, by weight, 30-50 parts of PVDF, 25-40 parts of pigment and filler, 20-30 parts of isophorone, and 0.5-1 part of a dispersing agent. The invention provides the high-performance heat-insulation fluorocarbon paint with polyvinylidene fluoride (PVDF varnish) as a substrate and with a comprehensive heat insulation effect.

Owner:平耐新材料科技(山东)有限公司

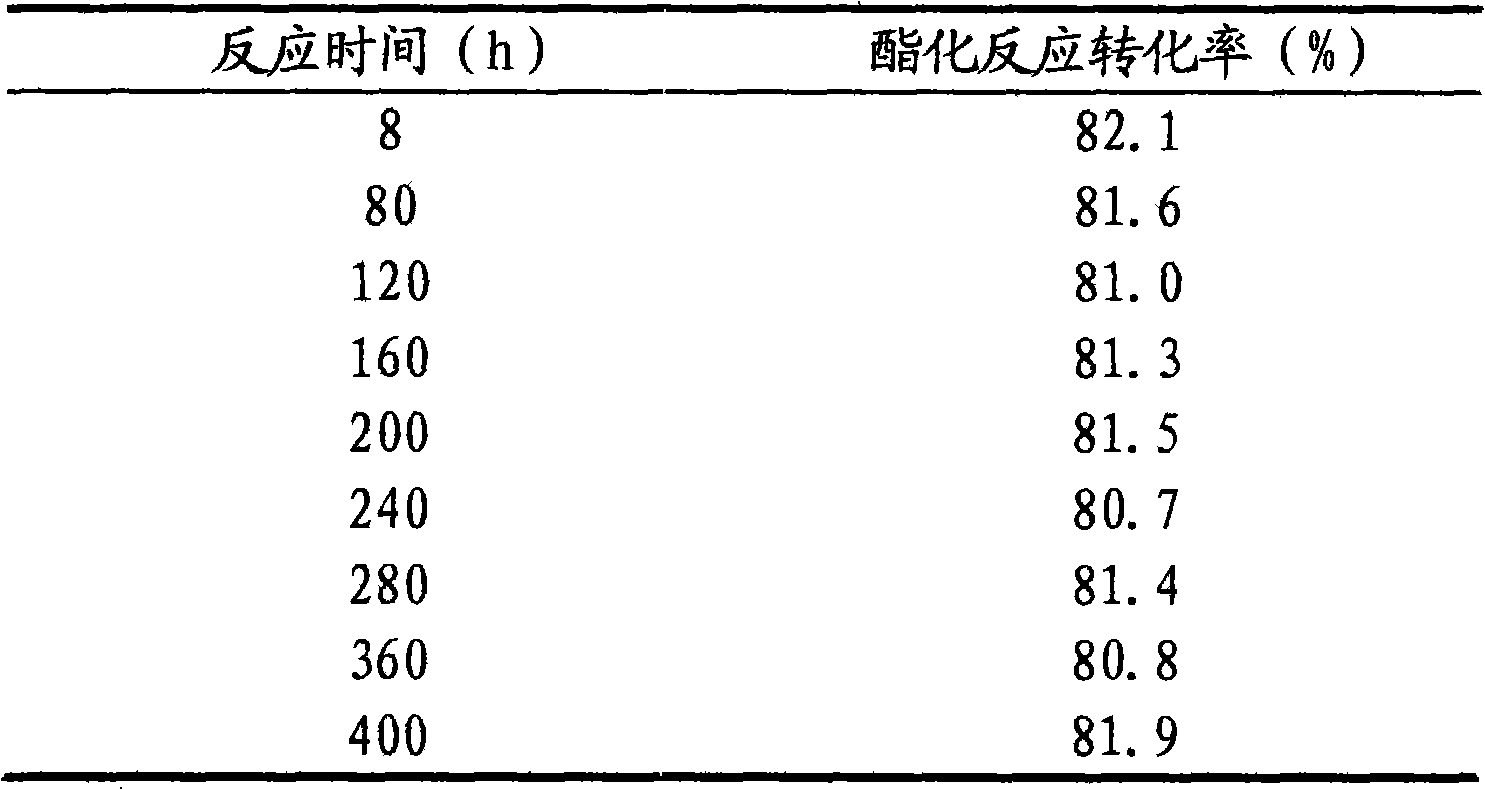

Method for reaction rectification coupling continuous preparation of and series acetate

ActiveCN1837183AReduce unit consumptionHigh selectivityOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsIsobutanolDistillation

The invention discloses a reaction-distillation coupling preparing acetic acid series ester method, which comprises the following steps: using glacial acetic acid and alcohol with lower five carbons (alcohol, optal,alcohol isopropylicum, butanol, isobutanol, amyl alcohol and isoamyl alcohol ) for raw material; adopting modified strong acidic phenylethene series basic ion exchange resin for accelerant; preparing by reaction-distillation coupling; getting acetic acid ethyl ester, propyl acetate, isopropyl acetate, butyl acetate, isobutyl acetate, amyl acetate and iso-amyl acetate; making glacial acetic acid and alcohol with lower five carbons to carry on esterification reaction by solid acid catalysis in trickle bed reactor; adding reaction product (acetic acid ethyl ester, propyl acetate, isopropyl acetate, butyl acetate, isobutyl acetate, amyl acetate and iso-amyl acetate), water and cycle still liquor in fractionating tower; getting acetic acid ethyl ester, propyl acetate, isopropyl acetate, butyl acetate, isobutyl acetate, amyl acetate and iso-amyl acetate by separating at the top of the tower. The conversion rate of alcohol with lower five carbons is more than 96%, the recovery ratio of acetic acid ethyl ester (propyl acetate, isopropyl acetate, butyl acetate, isobutyl acetate, amyl acetate and iso-amyl acetate) is more than 95%. The invention has high alcohol conversion rate, which simplifies the operation.

Owner:GUANGXI RES INST OF CHEM IND CO LTD

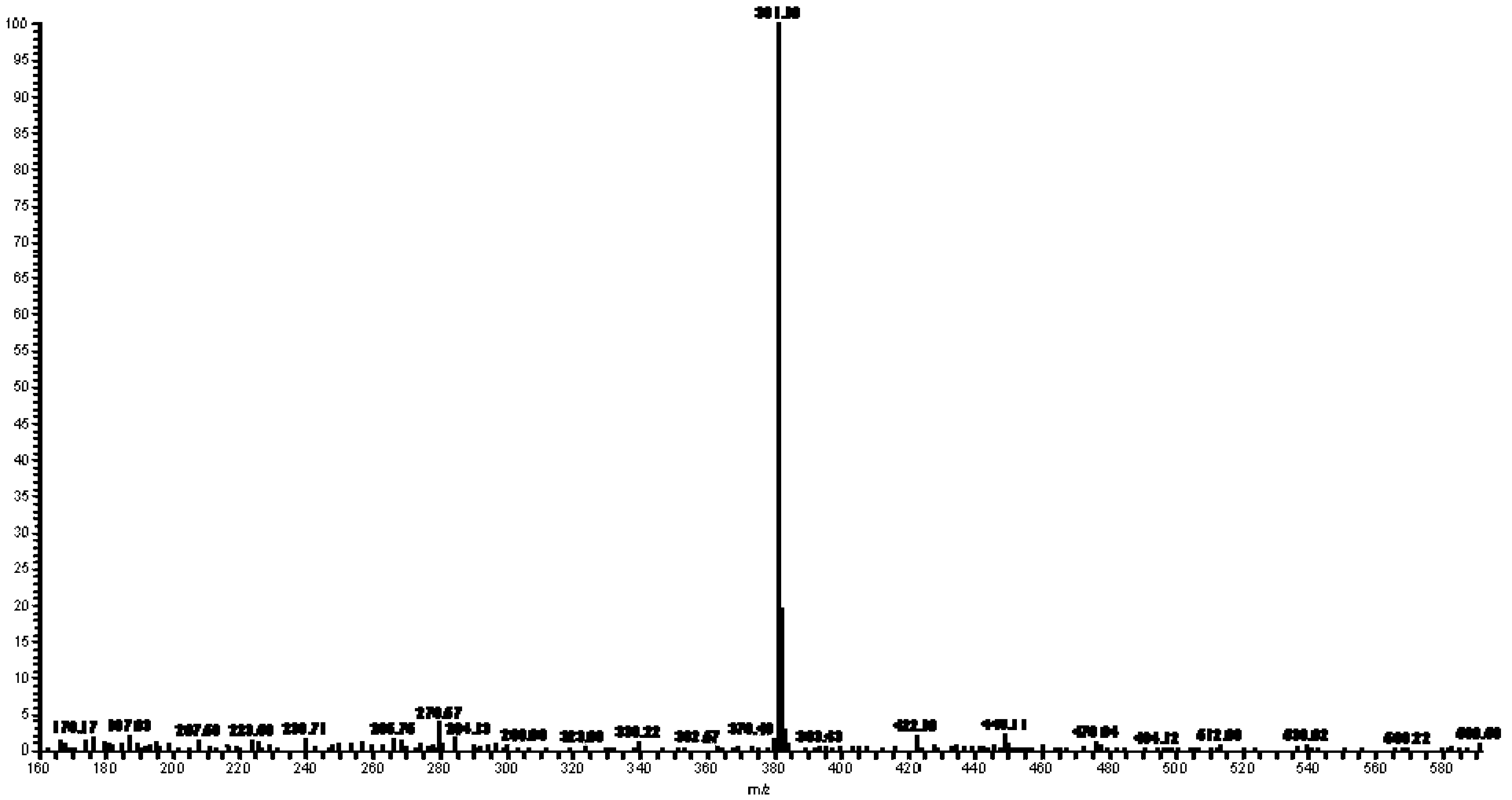

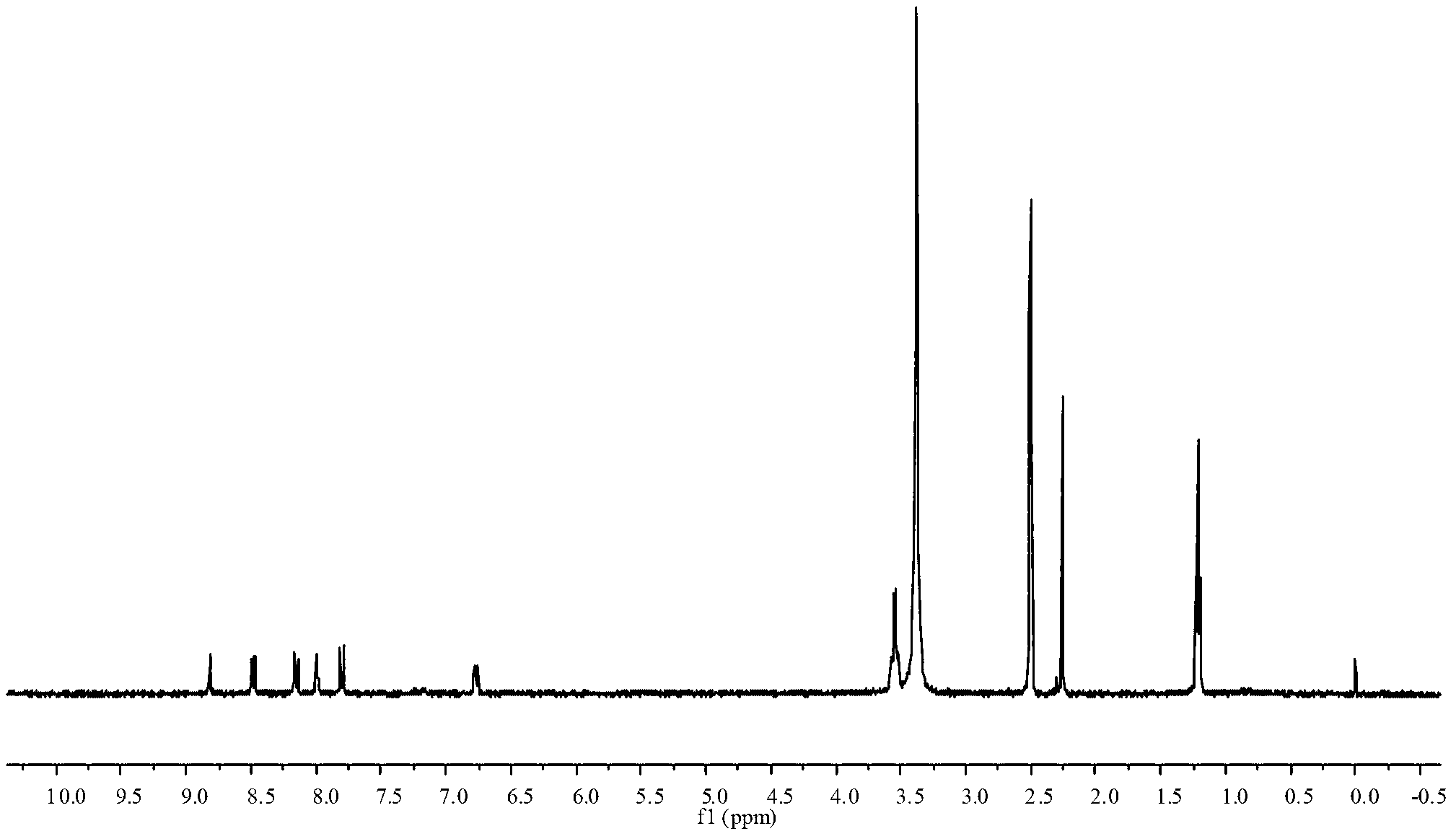

Continuous production method of propyl acetate

InactiveCN102001936ANon-volatileImprove solubilityOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsSolubilityRecyclable catalyst

The invention relates to a continuous production method of propyl acetate, and is characterized by comprising the following steps: adding ionic liquid dissolving inorganic compound of the Lewis acid into the glacial acetic acid and the normal propyl alcohol as the catalyst; heating the components in an esterification kettle for esterification reaction; adding the mixed raw material of the glacial acetic acid and the normal propyl alcohol with the same proportion into the esterification kettle continuously after the reaction begins to reflux; separating the propyl acetate generated in the reaction in an esterification tower, and sending the unreacted raw materials back to the esterification kettle from the bottom of the kettle to continue the reaction; steaming the water and part of the normal propyl alcohol from the tower top; after the cooling, refluxing one part of the steam to the tower top, and sending the other part of the steam to a stratifying device at the tower top; refluxing part of the aqueous phase at the lower layer to the esterification tower through a reflux ratio distributor, and recovering the other part of the aqueous phase; and sending the ester phase at the upper layer to the production purification stage for the further separation to obtain the propyl acetate product. The method of the invention has simple process, high esterification conversion rate, good product selectivity, recyclable catalyst, no device corrosion, environmental protection, simple synthesis method of the selected ionic liquid catalyst, and better solubility of the acid inorganic compound.

Owner:BEIJING INSTITUTE OF PETROCHEMICAL TECHNOLOGY

Baking printing ink transfer film and preparation method thereof

ActiveCN104476937AMeet environmental requirementsImprove clarityDuplicating/marking methodsInksEpoxyPolymer science

The invention relate to the technical field of transfer film preparation, in particular to a baking printing ink transfer film and a preparation method thereof. The baking printing ink transfer film sequentially comprises a base film layer, a release layer, a baking protection layer and a baking printing ink layer from top to bottom, wherein baking printing ink of the baking printing ink layer is prepared from the following components: 18%-20% of inorganic pigments, 0.5%-1% of a wetting agent, 40%-42% of polyester resin, 4%-5% of modified epoxy resin, 10%-13% of n-butyl ether amino resin, 3%-6% of benzol amino resin, 0.5%-1% of a flatting agent, 1.5%-2% of modified polyester resin, 4%-6% of closed polyisocyanate, 1%-2% of coupling agent, 2%-7% of normal propyl alcohol and 3%-10.5% of normal propyl acetate. The baking printing ink transfer film is prepared by sequentially coating the base film layer with a release material, a baking protection layer and a baking printing ink layer, and drying to obtain the baking printing ink transfer film. The baking printing ink transfer film can be directly transferred to tinplate or aluminum sheets, so as to solve defects that the printing definition of the tinplate and the aluminum sheets is poor, lots of materials are wasted, and the yield is low in the traditional process; the baking printing ink transfer film has the characteristics of high printing definition and material utilization rate, no waste and high yield.

Owner:DONGGUAN ZHUOYI PRINTING PROD

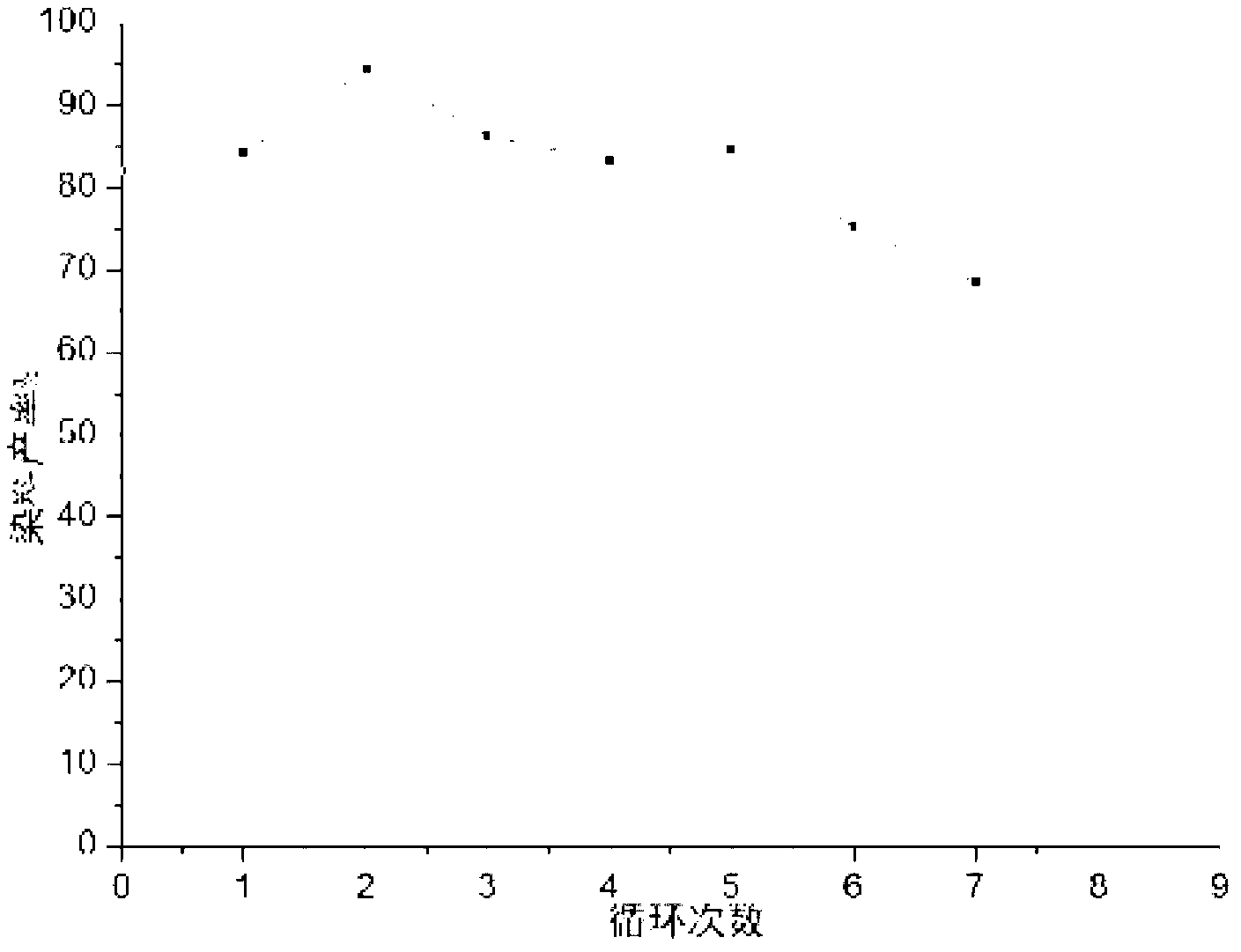

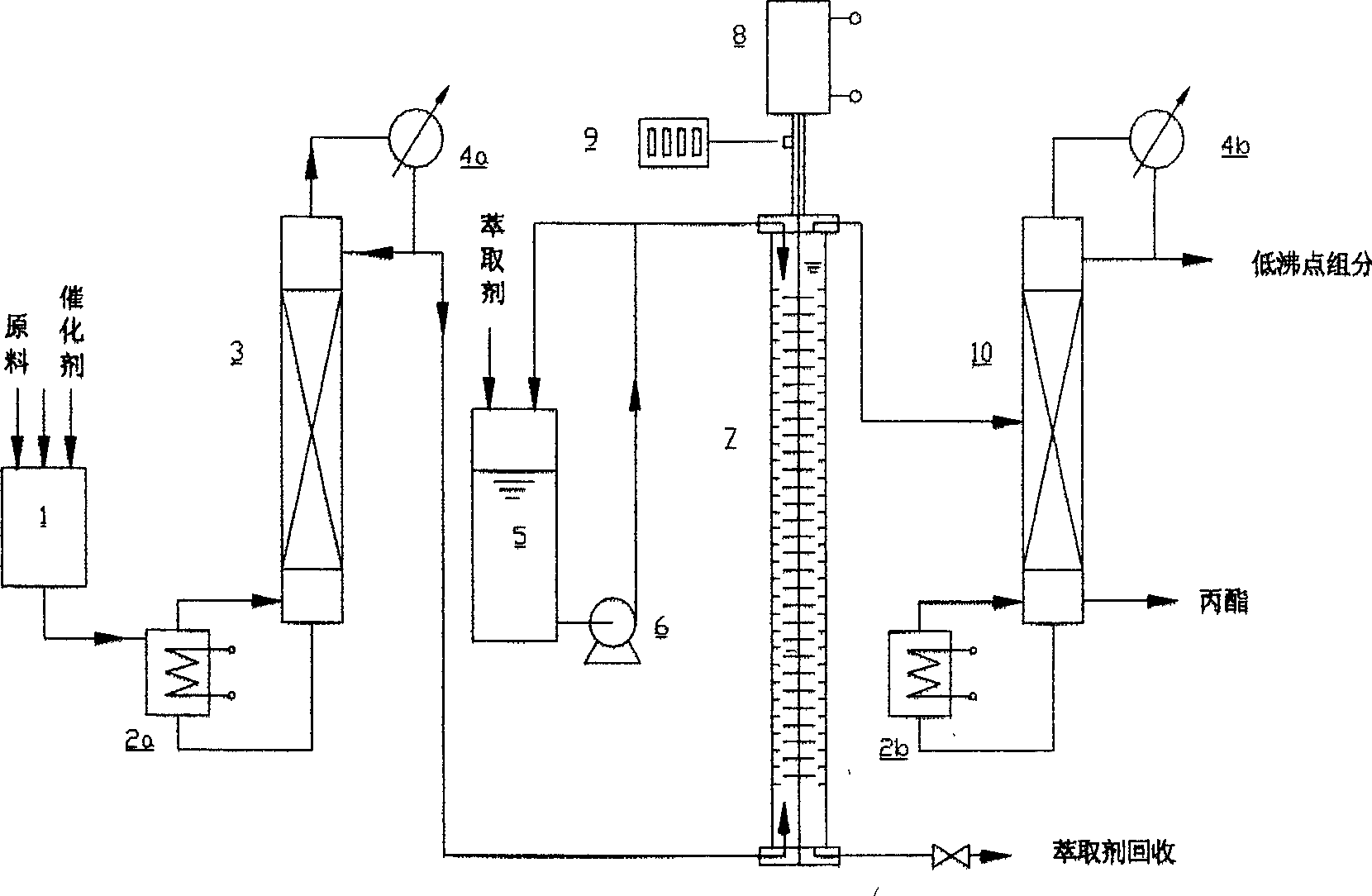

Method for separating ethanol-propyl acetate azeotrope through continuous extractive rectification

InactiveCN104610022AEnergy consumption advantagePurity advantageOrganic compound preparationCarboxylic acid esters preparationAcetic acidPropyl acetate

The invention relates to a method for separating ethanol-propyl acetate azeotrope through continuous extractive rectification. The extractive rectification often adopts a double-tower process flow, and comprises an extractive rectifying tower and a solvent recycling tower; in order to realize the production capacity of the extractive rectifying tower, not only a reasonable process flow and a reasonable tower structure are needed, but also a dosage ratio of a raw material to an extractant, a feeding position and many other factors are required. Aiming at an azeotropic system of the ethanol and the propyl acetate, a mixed solution of ethanediol and ionic liquid [Emim][BF4] and [Mpy][PF6] is used as the extractant, and finally the ethanol and the propyl acetate are separated.

Owner:UNIV OF JINAN

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com