Patents

Literature

251 results about "Silver ink" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Silver-containing inkjet ink

This invention pertains to inkjet ink comprising silver salt (silver ink), and an ink set comprising said silver ink and an ink with reducing agent to reduce the silver in the silver ink. The invention further pertains to an inkjet printing method for printing with the inventive ink set to create metallic silver images (or patterns). The printed silver patterns can be used, for example, in electronics and decorative applications.

Owner:EI DU PONT DE NEMOURS & CO

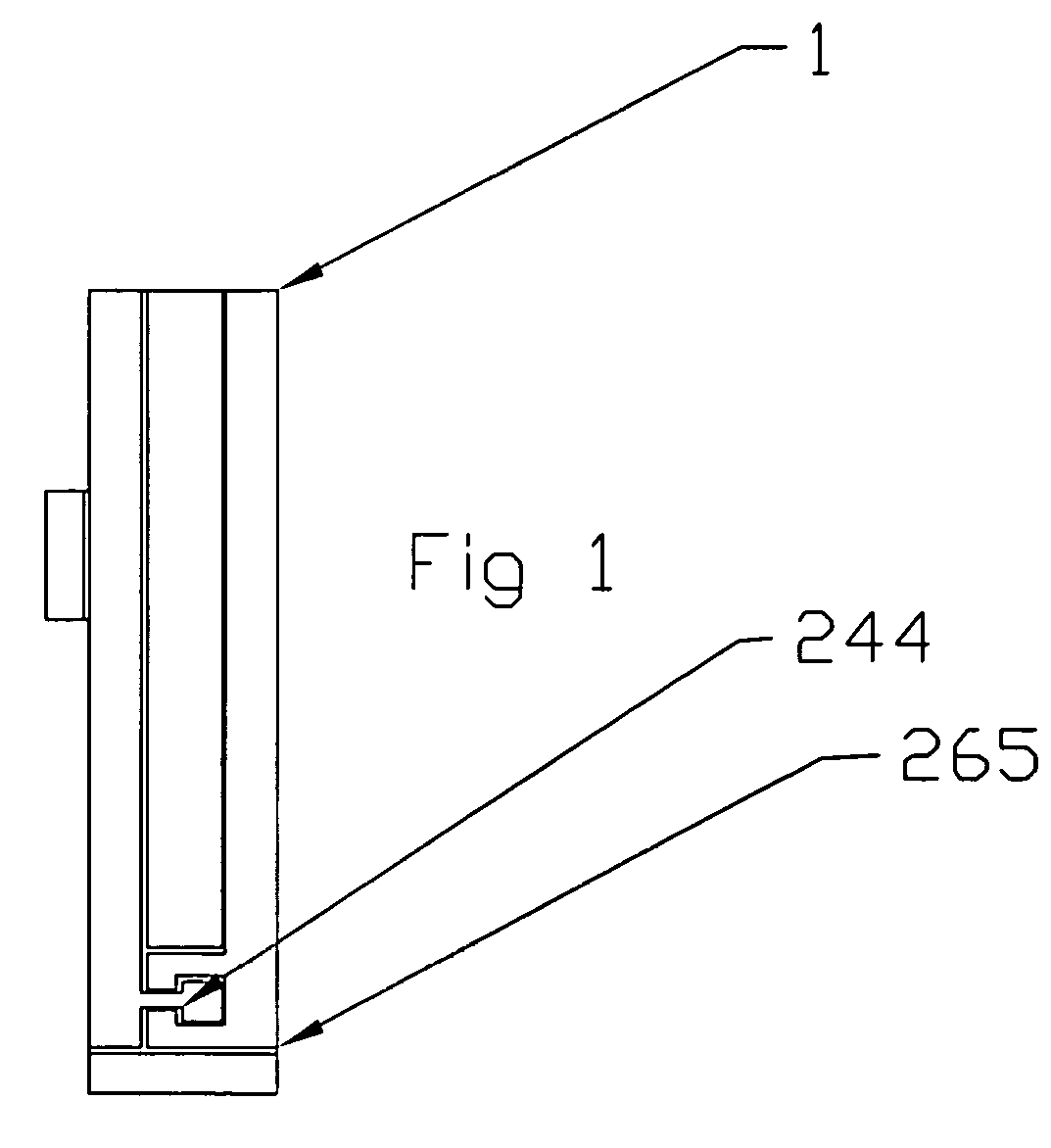

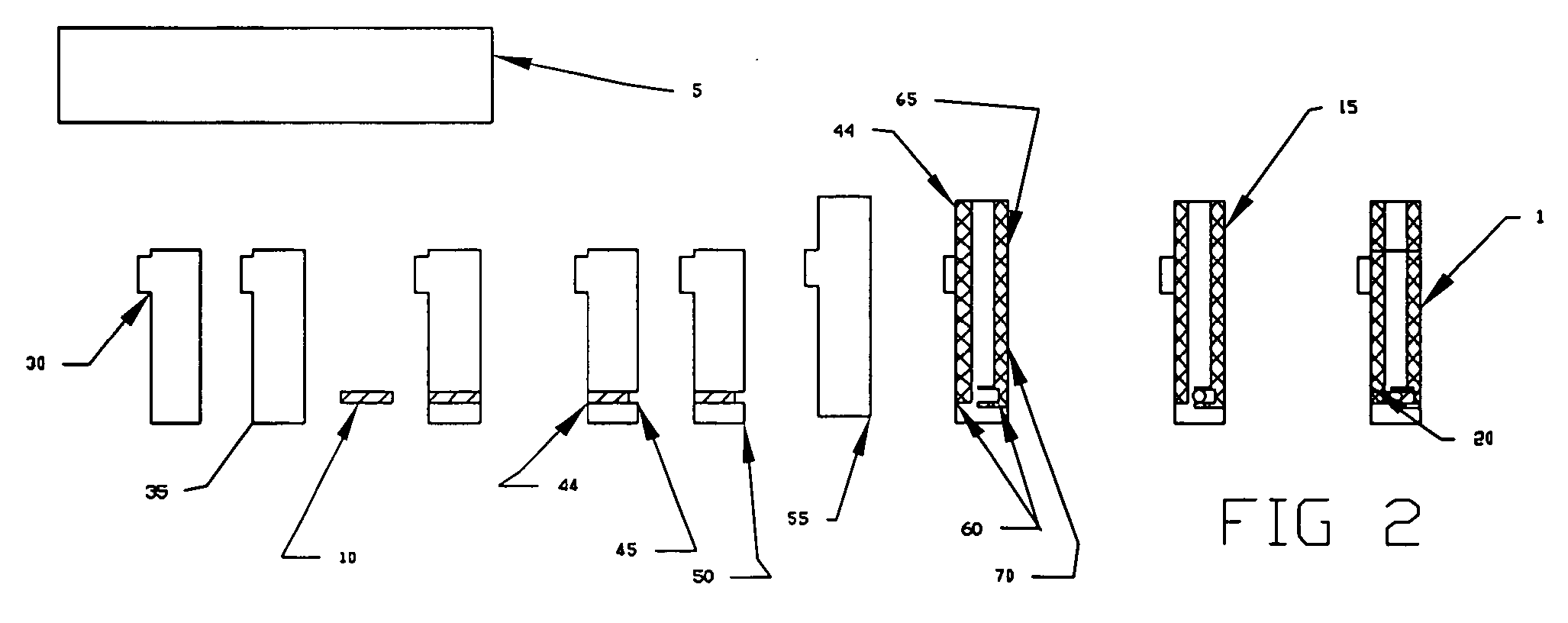

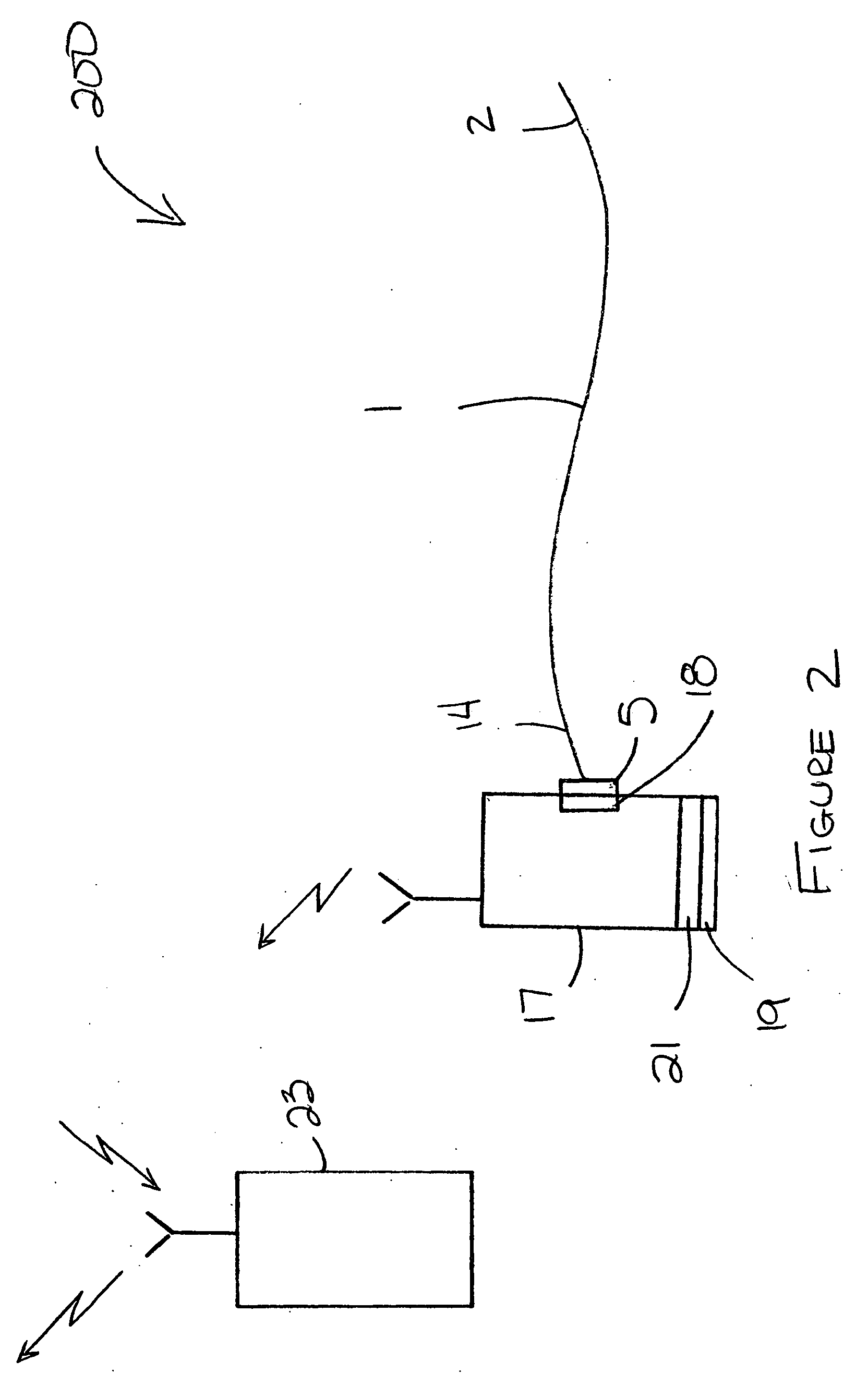

Strip electrode with conductive nano tube printing

InactiveUS20050186333A1Accurate electronic readoutMinimizing strip to strip variationImmobilised enzymesBioreactor/fermenter combinationsSilver inkCarbon nanotube

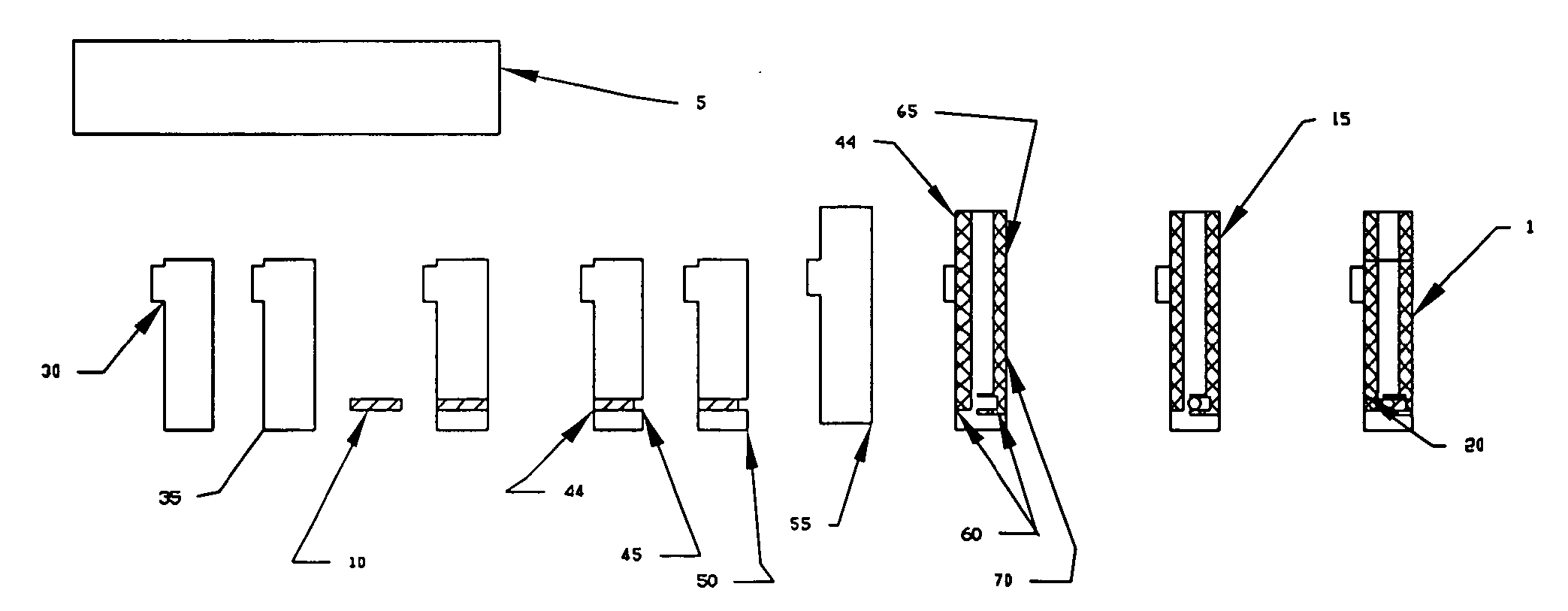

A sensor system that detects a current representative of a compound in a liquid mixture features a multi or three electrode strip adapted for releasable attachment to signal readout circuitry. The strip comprises an elongated support which is preferably flat adapted for releasable attachment to the readout circuitry; a first conductor and a second and a third conductor each extend along the support and comprise means for connection to the circuitry. The circuit is formed with single-walled or multi walled nanotubes conductive traces and may be formed from multiple layers or dispersions containing, carbon nanotubes, carbon nanotubes / antimony tin oxide, carbon nanotubes / platinum, or carbon nanotubes / silver or carbon nanotubes / silver-cloride. An active electrode formed from a separate conductive carbon nanotubes layer or suitable dispersion, positioned to contact the liquid mixture and the first conductor, comprises a deposit of an enzyme capable of catalyzing a reaction involving the compound and preferably an electron mediator, capable of transferring electrons between the enzyme-catalyzed reaction and the first conductor. A reference electrode also formed from a conductive carbon nanotube layer or suitable dispersion is positioned to contact the mixture and the second conductor. The system includes circuitry adapted to provide an electrical signal representative of the current which is formed from printing conductive inks made with nano size particles such as conductive carbon or carbon / platinum or carbon / silver, or carbon nanotubes / antimony tin oxide to form a conductive carbon nanotube layers. The multiple-electrode strip is manufactured, by then applying the enzyme and preferably the mediator onto the electrode. Alternatively the electrode can have a carbon nanotubes / antimony tin oxide, carbon nanotubes / platinum, or carbon nanotubes / silver or carbon nanotubes / silver-cloride surface and or a conductive carbon or silver ink surface connecting leg. The carbon nanotube solution is first coated and patterned into electro shapes and the conductive carbon nanotubes, carbon or silver ink can be attached by printing the ink to interface with the carbon nanotube electro surface. A platinum electrode test strip is also disclosed that is formed from either nano platinum distributed in the carbon nanotube layer or by application or incorporation of platinum to the carbon nanotube conductive ink.

Owner:DOUGLAS JOEL S MR

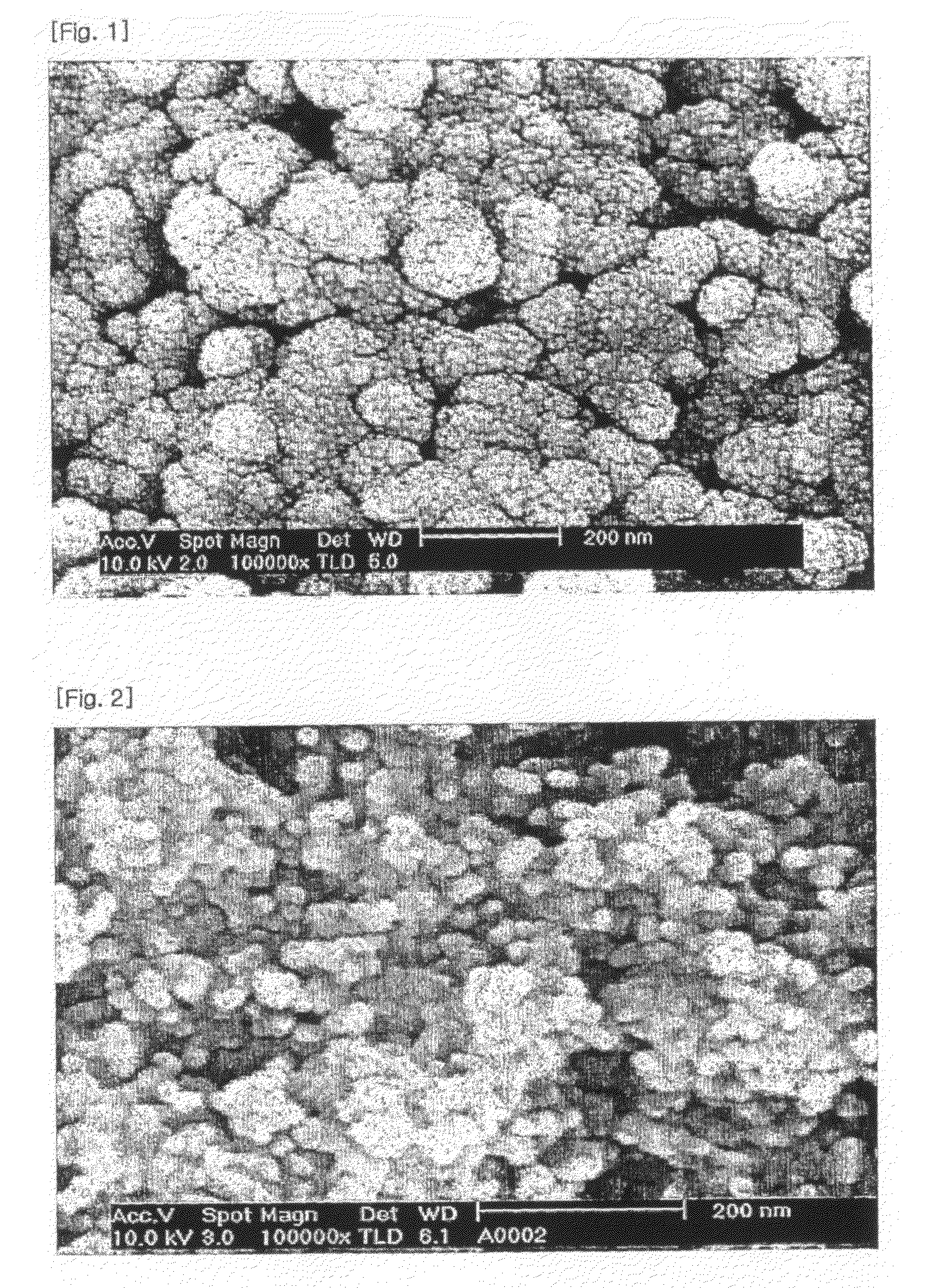

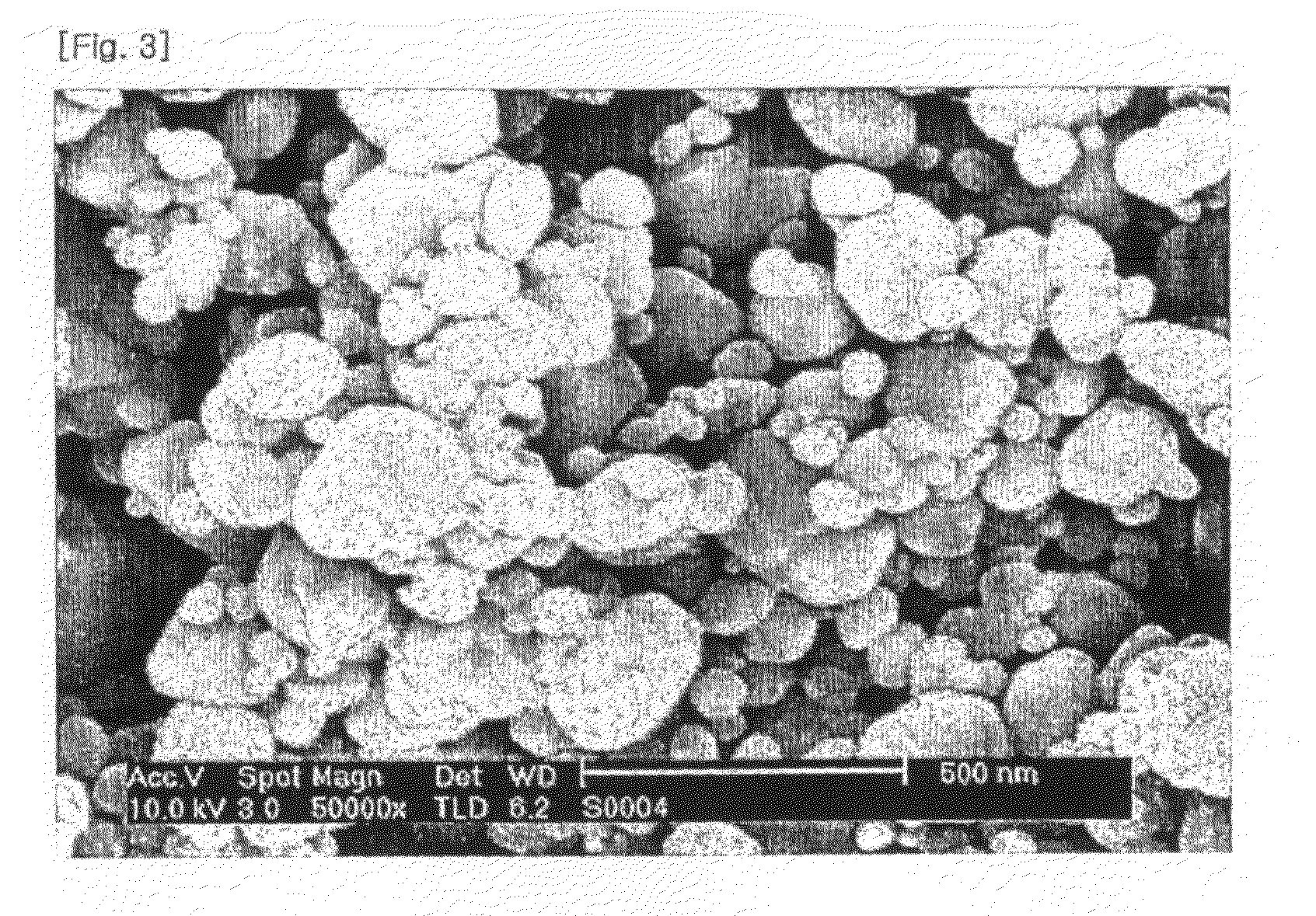

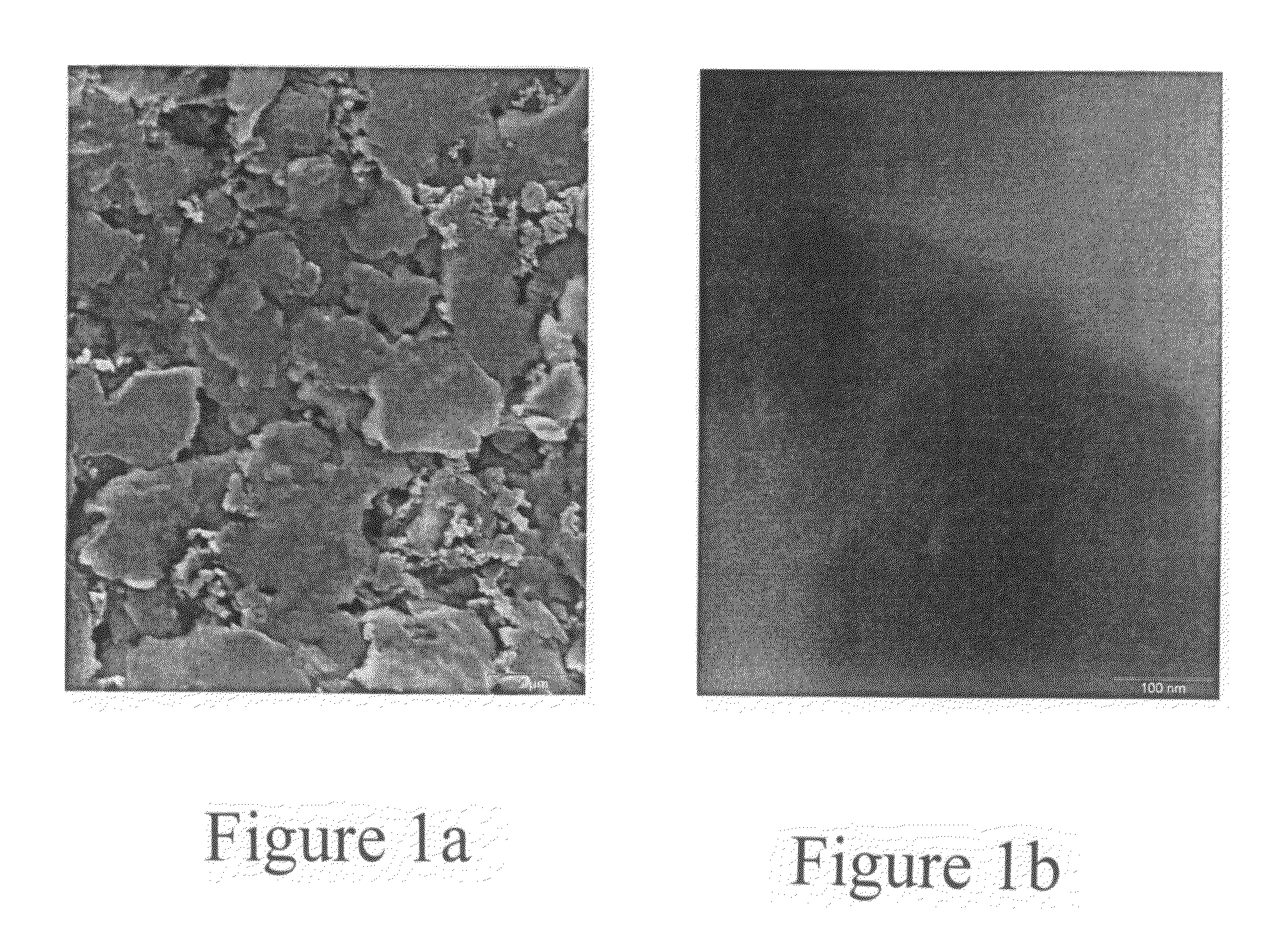

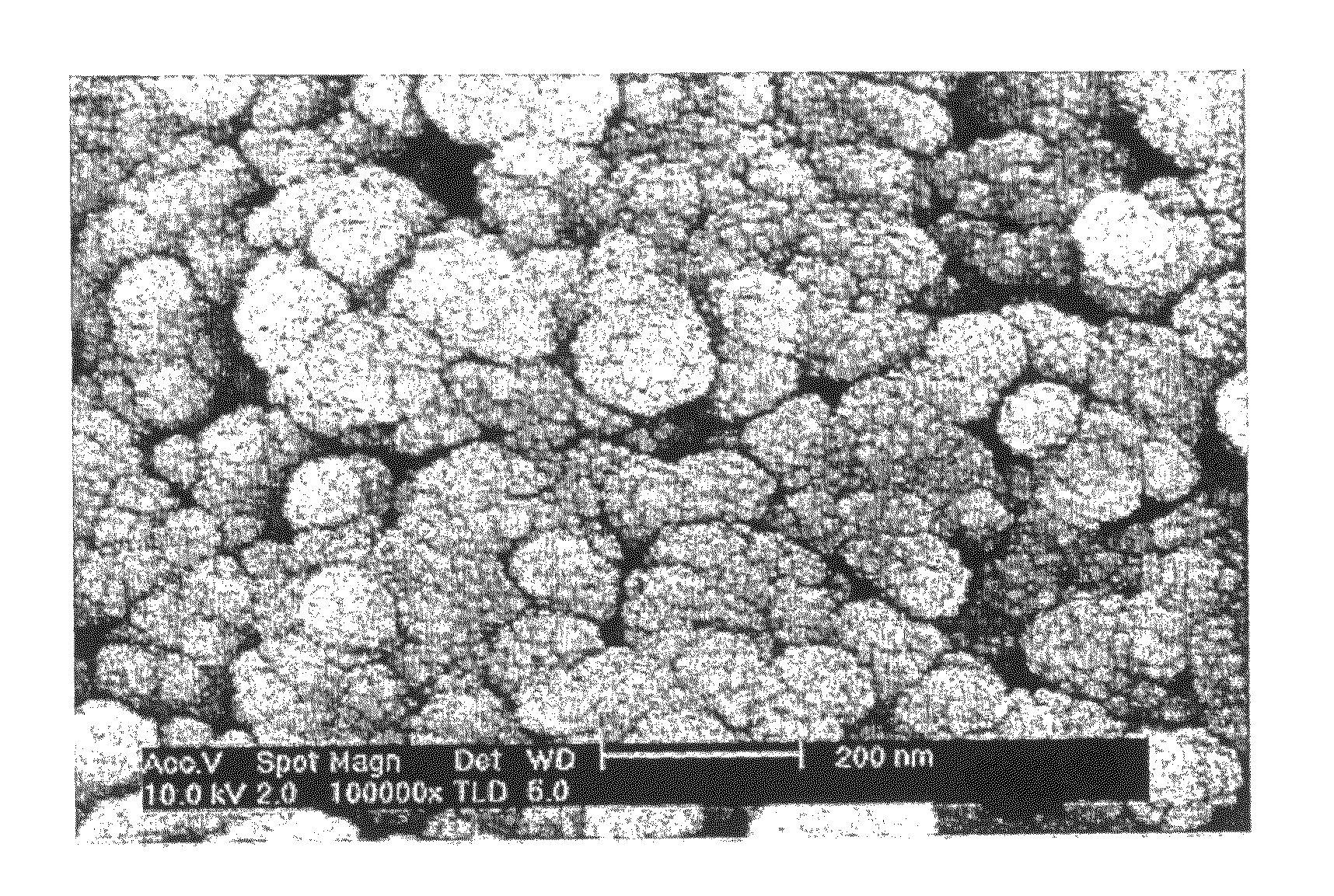

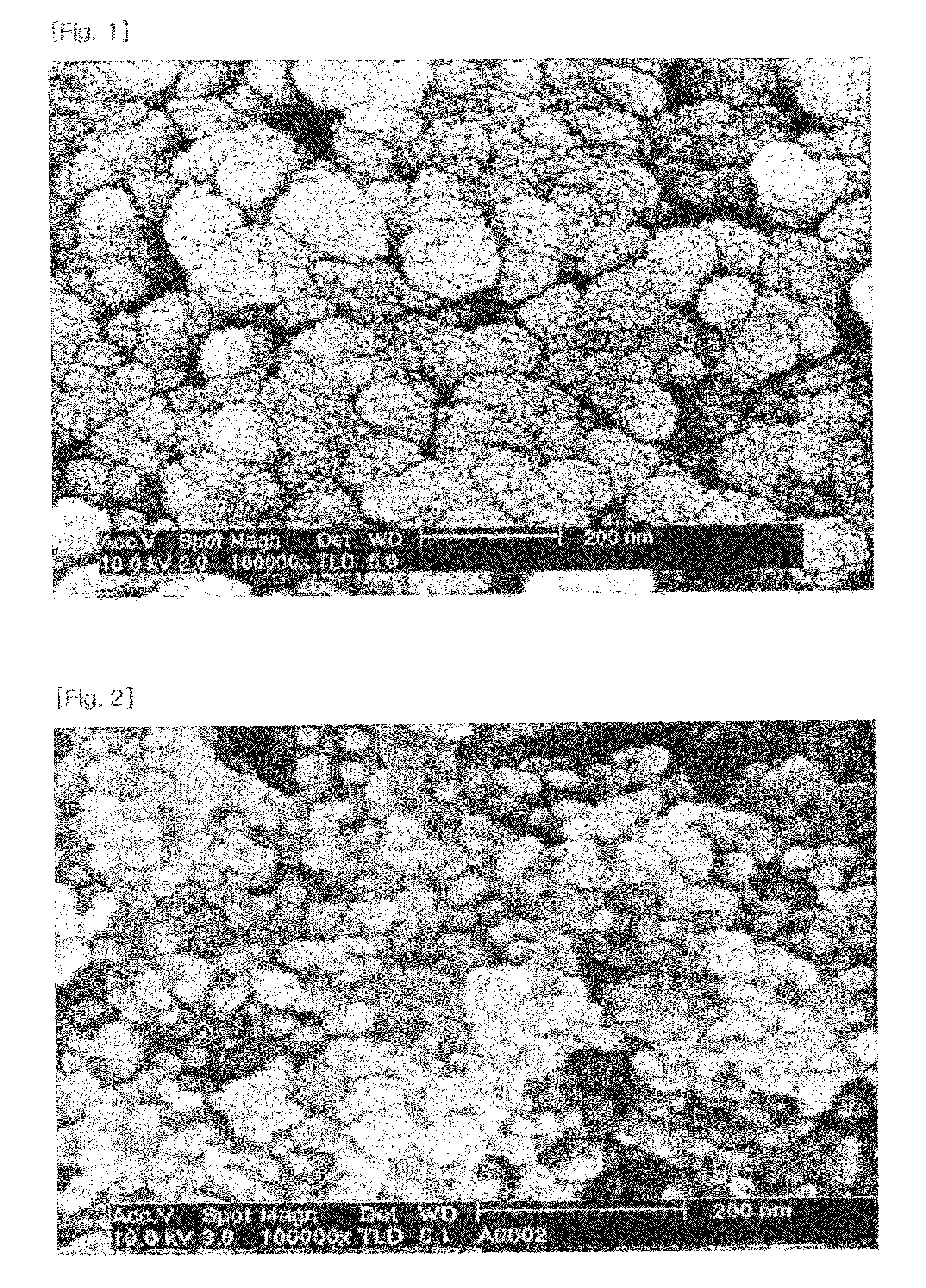

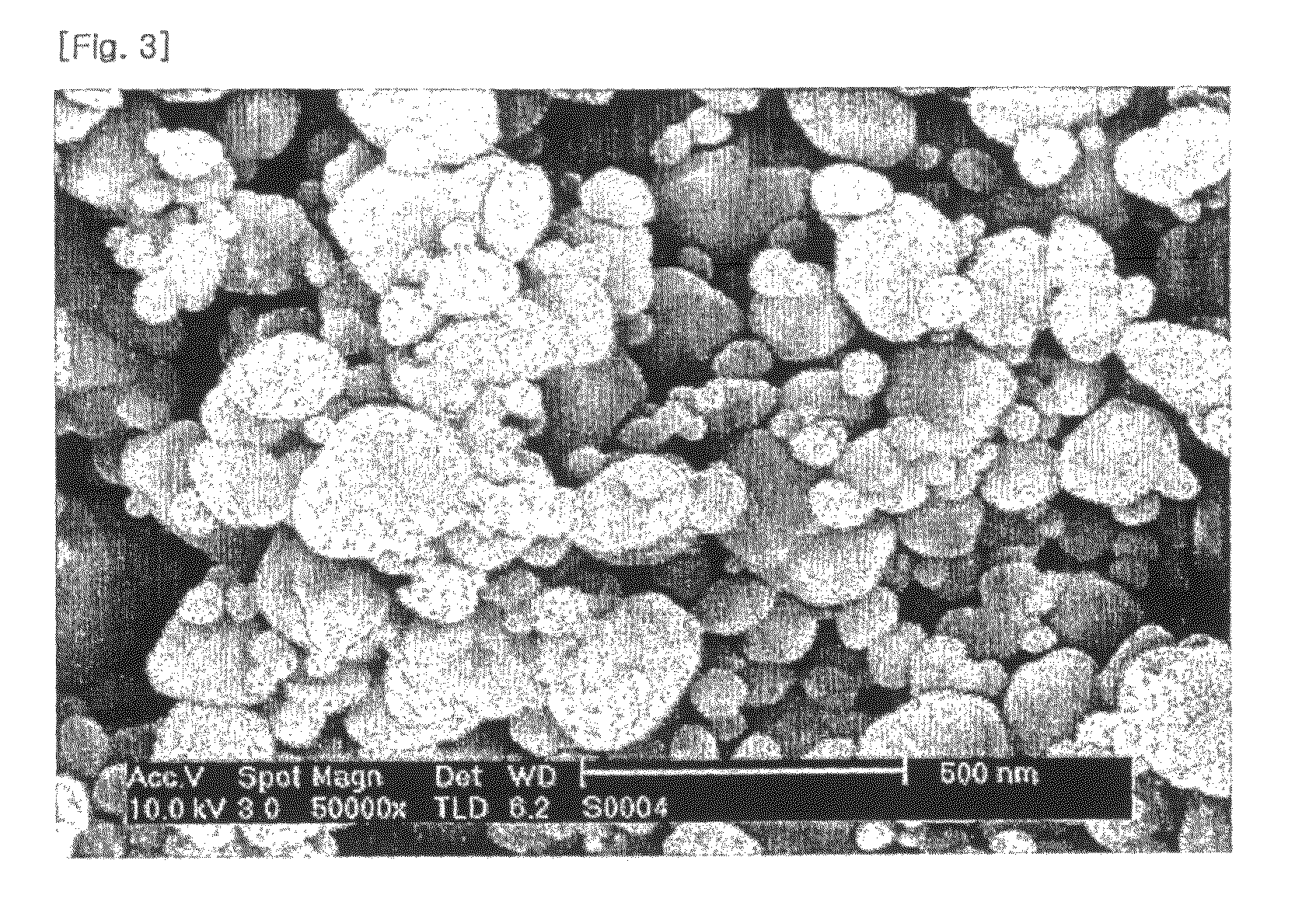

Process for preparation of silver nanoparticles, and the compositions of silver ink containing the same

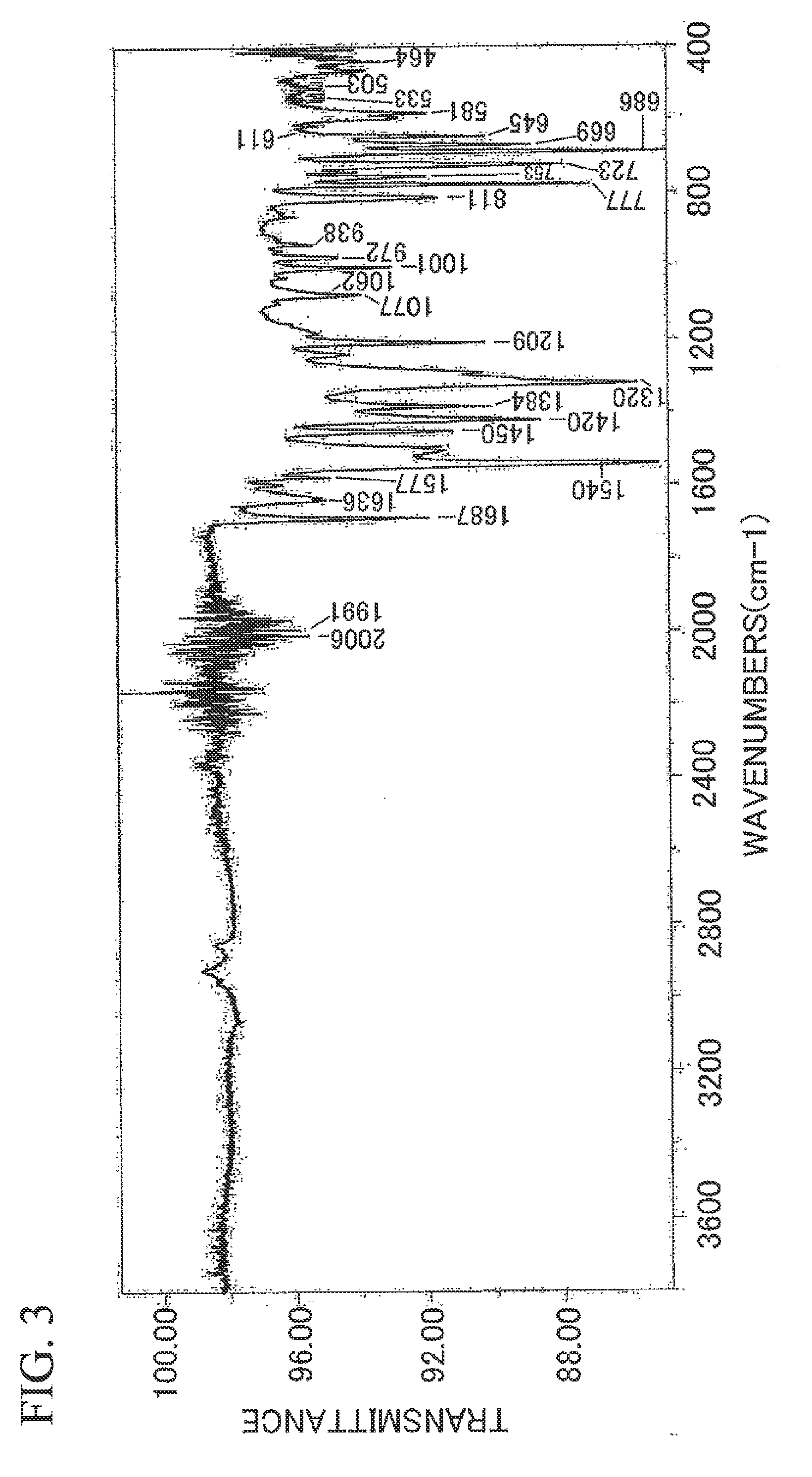

ActiveUS20100189901A1Small sizeGood physical propertiesMaterial nanotechnologyNanostructure manufactureSilver inkAmmonium carbamate

The present invention relates to a process for preparation of silver complex compound and the compositions of silver ink containing the same. The present invention includes a) preparing silver complex compound with special structure by reacting silver compound with at least one or two mixtures selected from ammonium carbamate compound, ammonium carbonate compound or ammonium bicarbonate compound and b) preparing silver nano particles by reacting the silver complex compound with reducer or reducing or pyrolyzing the silver complex compound by applying heat thereto. The preparing method according to the present invention can prepare the silver nano practical with various shapes through a simple preparation process, improve the selectivity of the size of the silver complex compound, fire the silver complex compound even when it is fired at a low temperature of 150° C. or less during a short time, provide the ink compositions capable of forming the coating or the fine pattern showing the high conductivity while facilitating the thickness control of the coating, and provide the ink compositions capable of being applied to the reflective film material, the electromagnetic wave shield, and the antimicrobial agent, etc.

Owner:INKTEC CO LTD

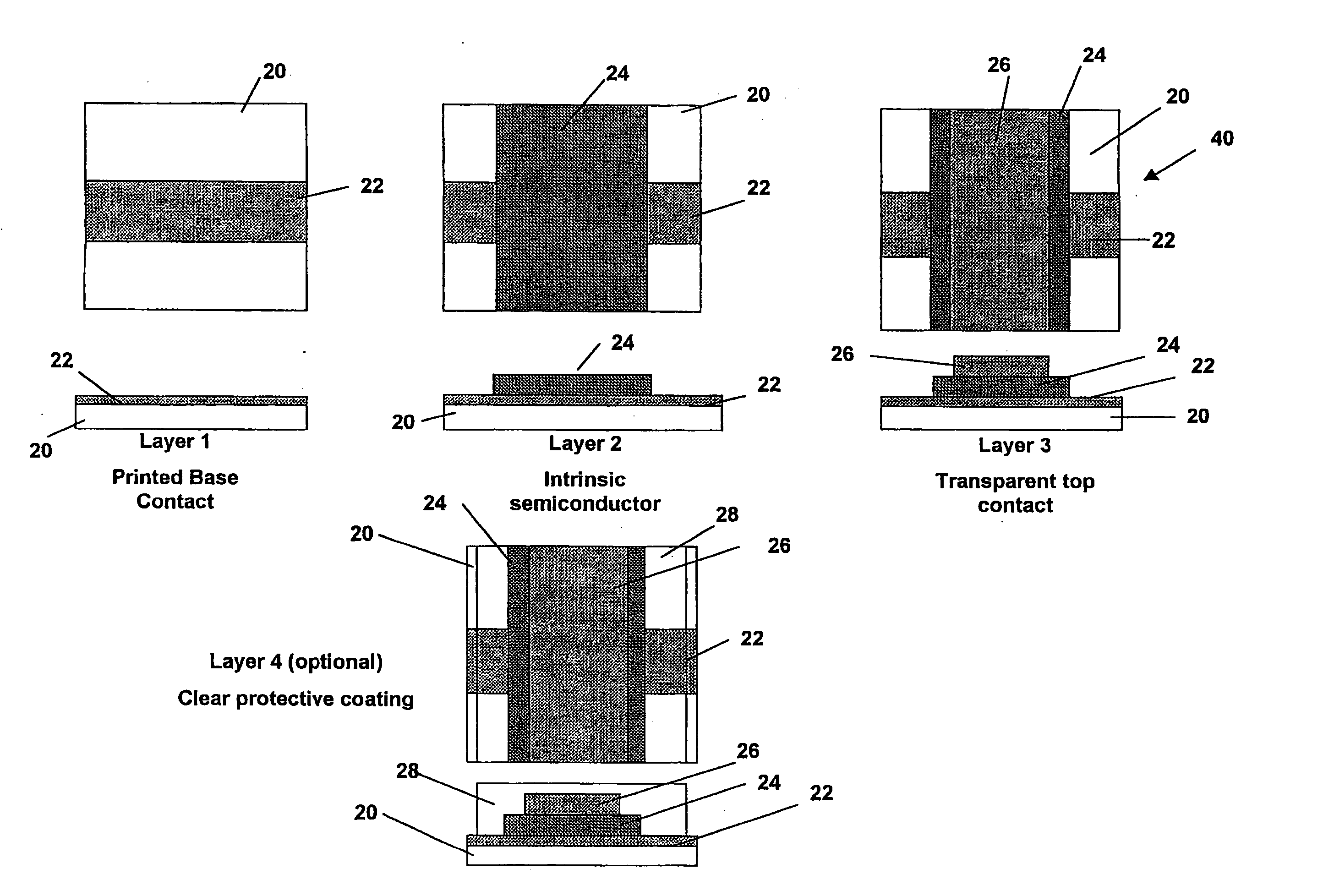

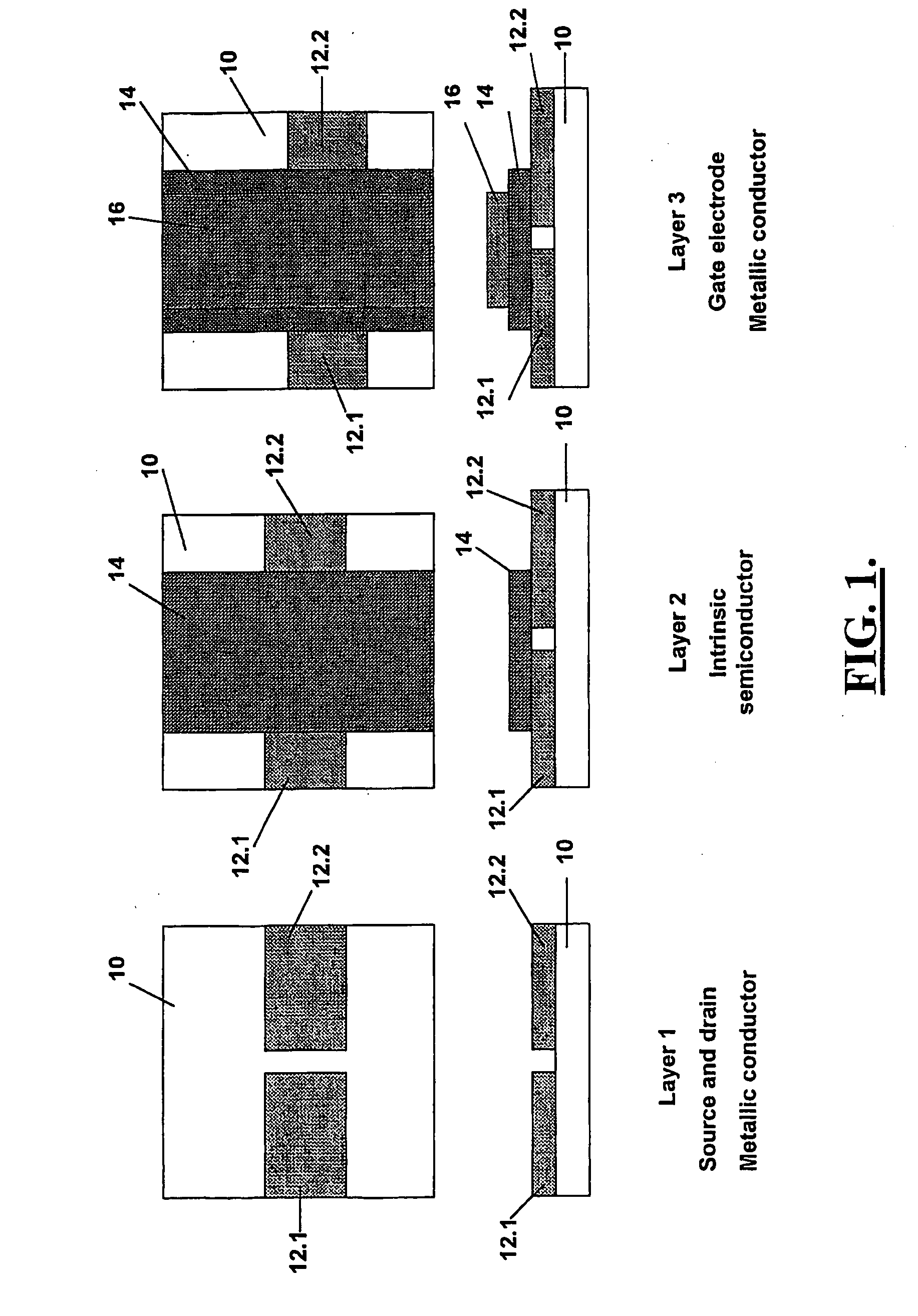

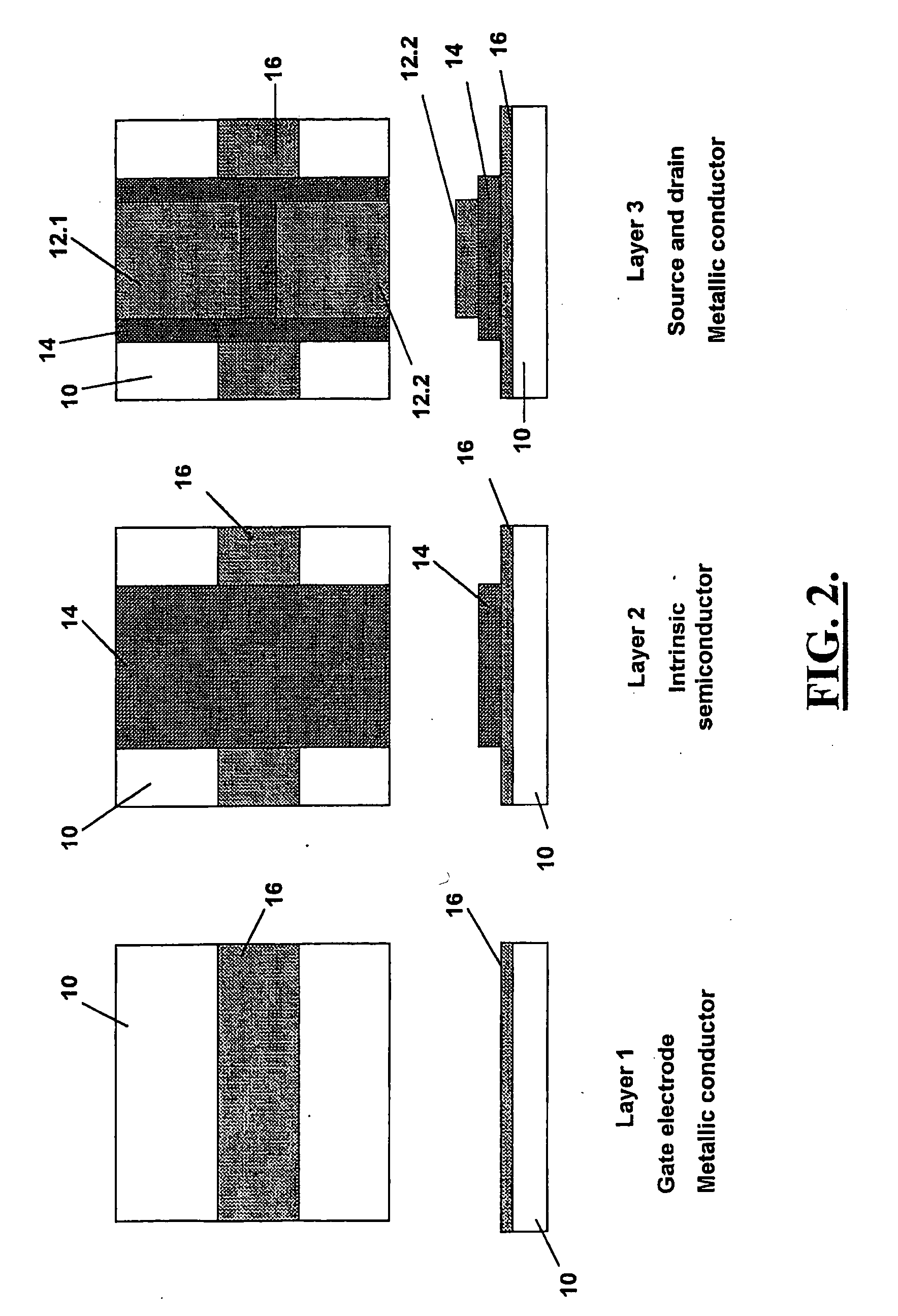

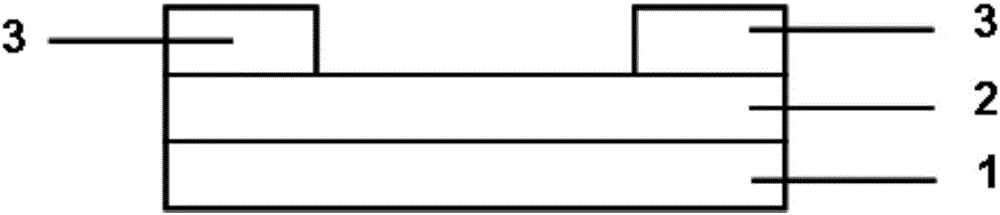

Thin film semiconductor device and method of manufacturing a thin film semiconductor device

A thin film semiconductor in the form of a metal semiconductor field effect transistor, includes a substrate 10 of paper sheet material and a number of thin film active inorganic layers that are deposited in layers on the substrate. The active layers are printed using an offset lithography printing process. A first active layer comprises source 12.1 and drain 12.2 conductors of colloidal silver ink, that are printed directly onto the paper substrate. A second active layer is an intrinsic semiconductor layer 14 of colloidal nanocrystalline silicon ink which is printed onto the first layer. A third active layer comprises a metallic conductor 16 of colloidal silver which is printed onto the second layer to form a gate electrode. This invention extends to other thin film semiconductors such as photovoltaic cells and to a method of manufacturing semiconductors.

Owner:PST SENSORS

High conductive water-based silver ink

Disclosed is a conductive composition which can be used to form an aqueous conductive ink with increased conductivity. The aqueous conductive composition contains conductive particles, preferably silver, an anionic wetting agent and a styrene-acrylic copolymer. The composition is highly conductive and requires reduced drying energy. In addition, it may be applied to low cost substrates by high speed printing processes.

Owner:SUN CHEM CORP

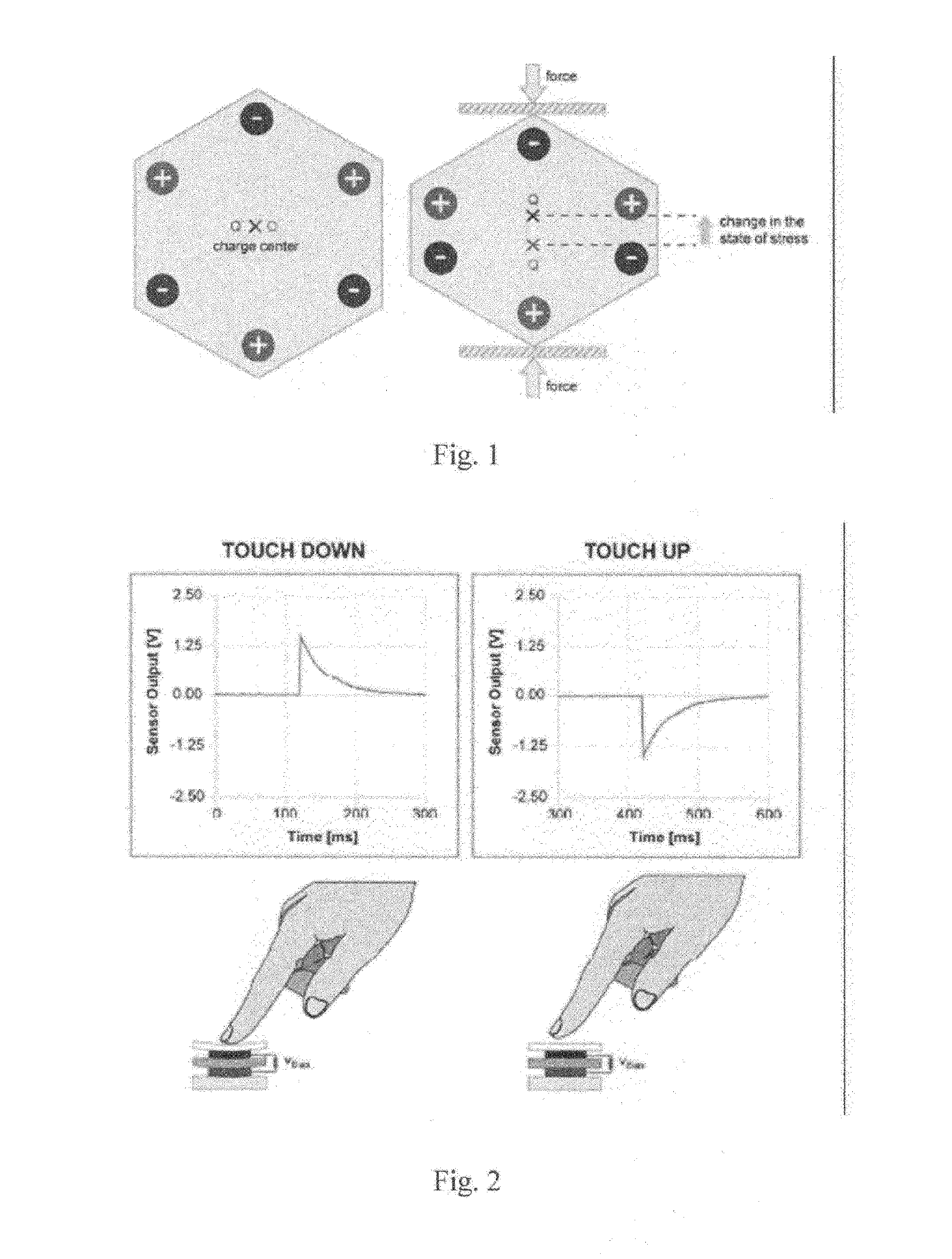

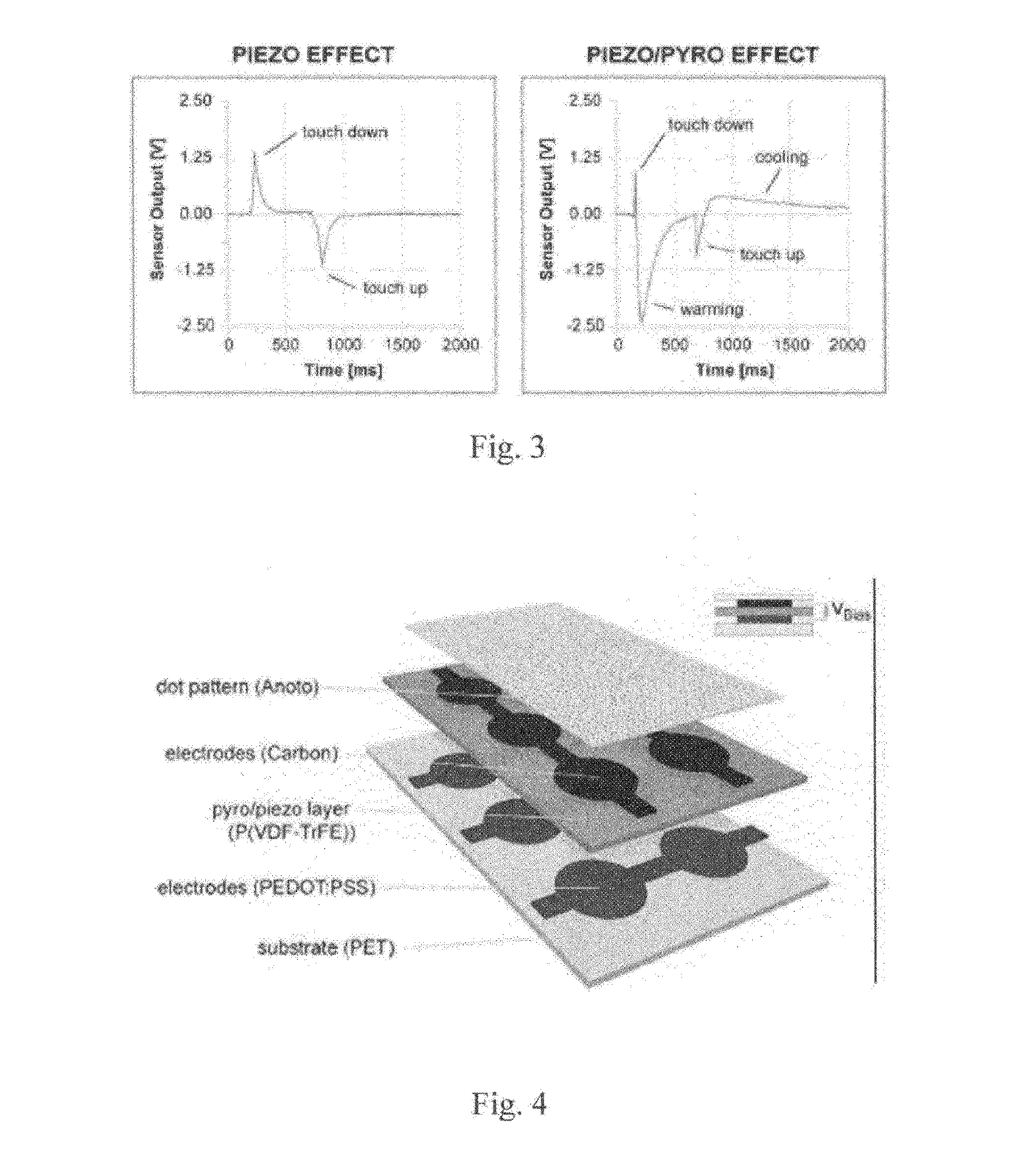

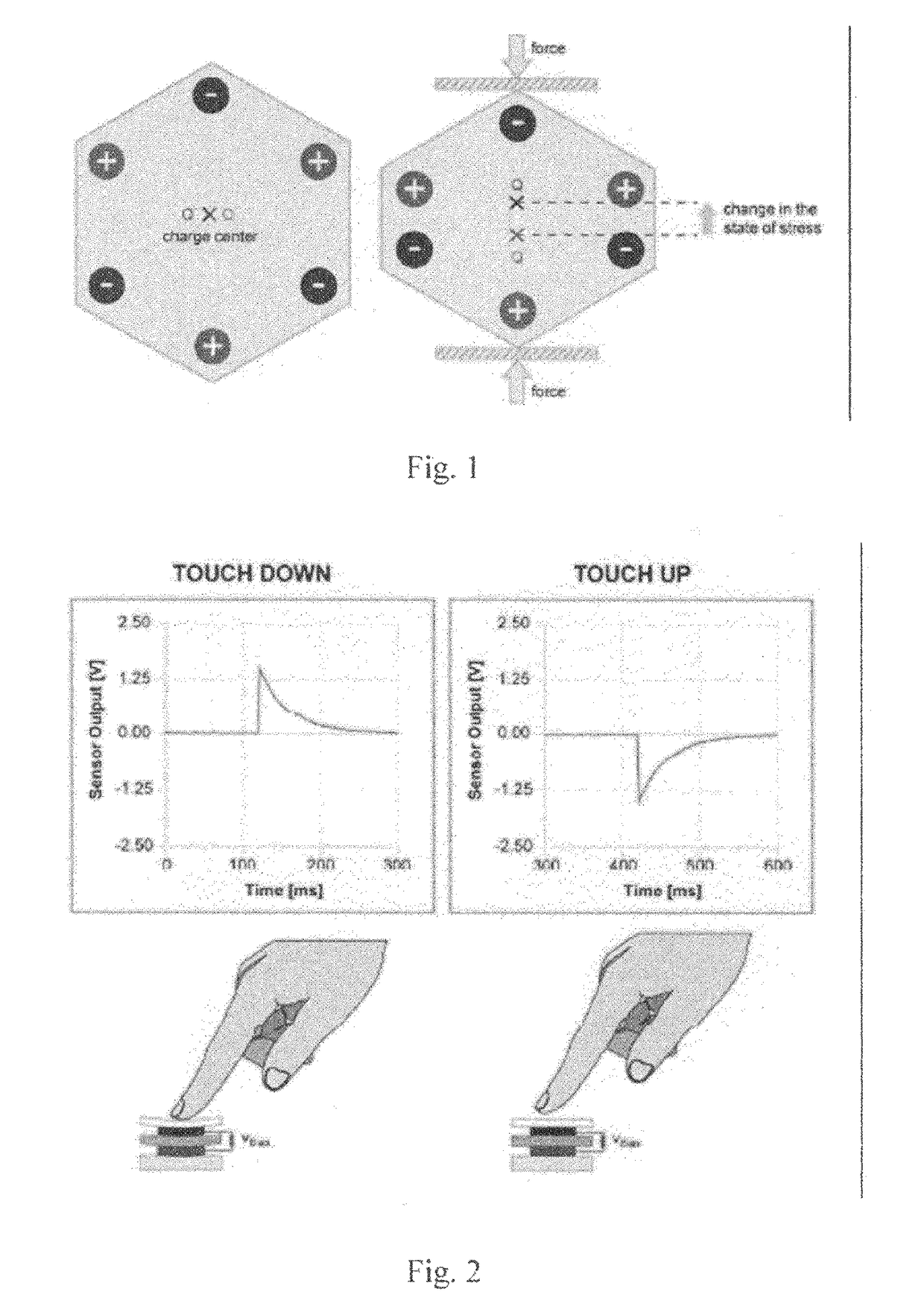

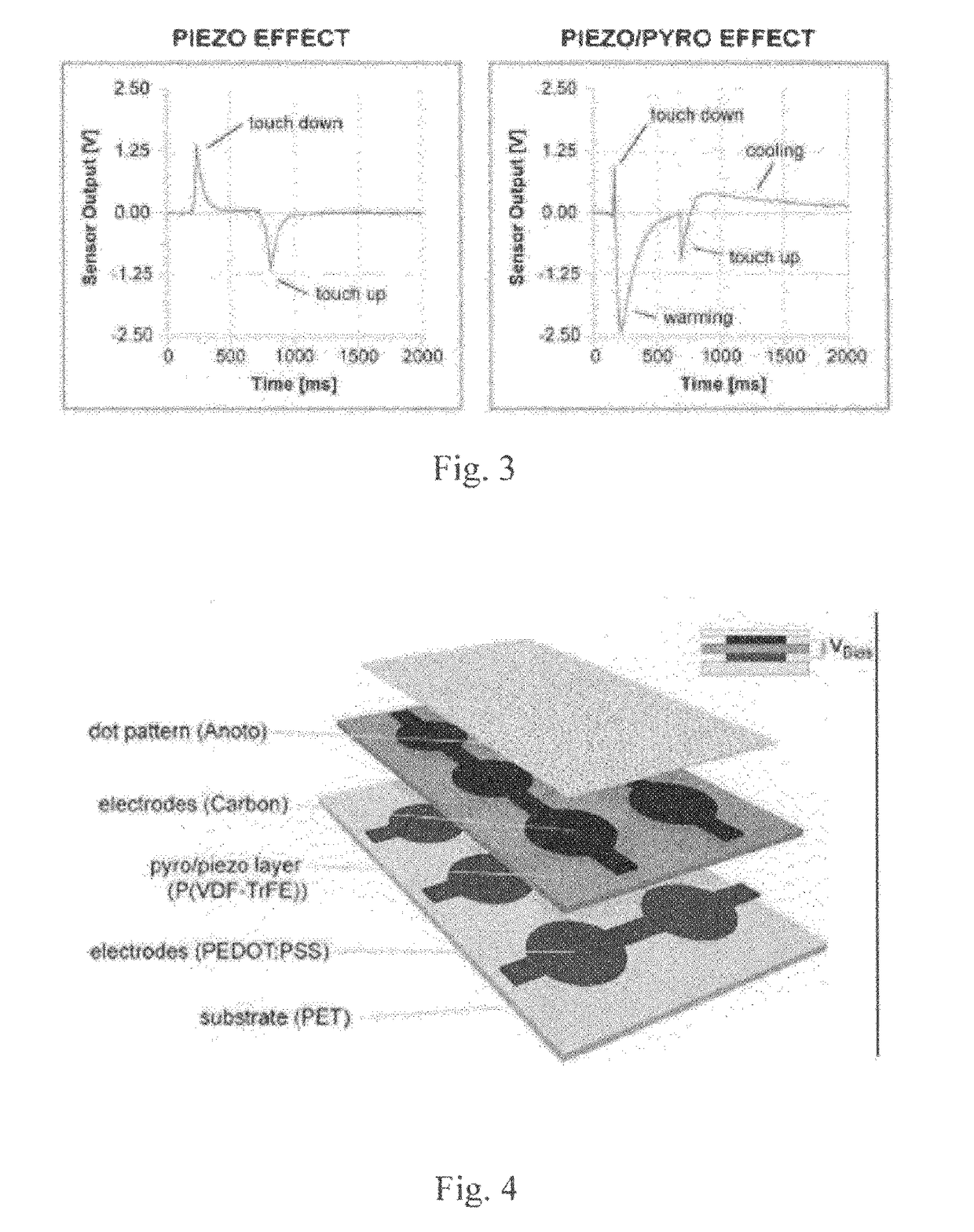

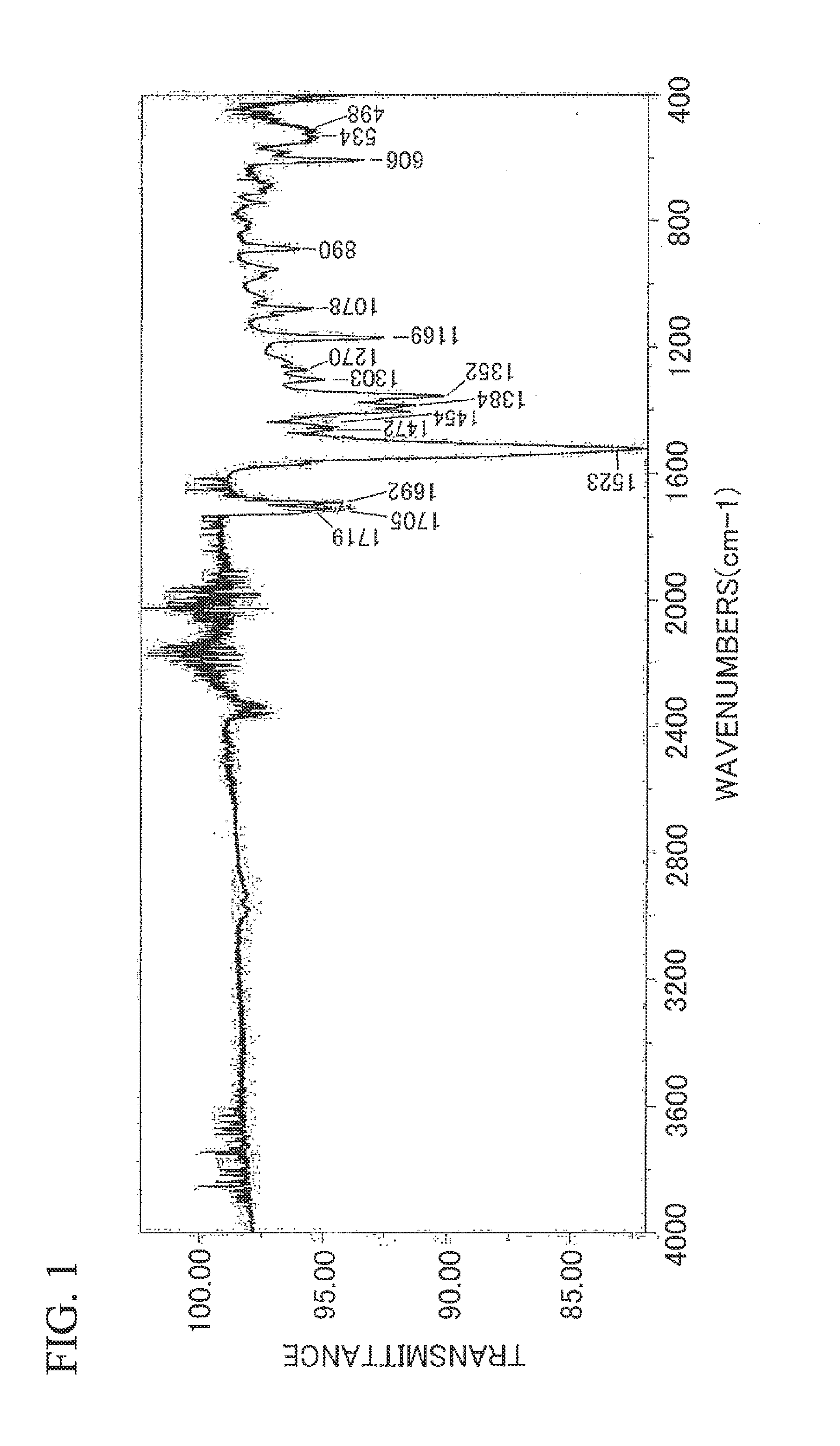

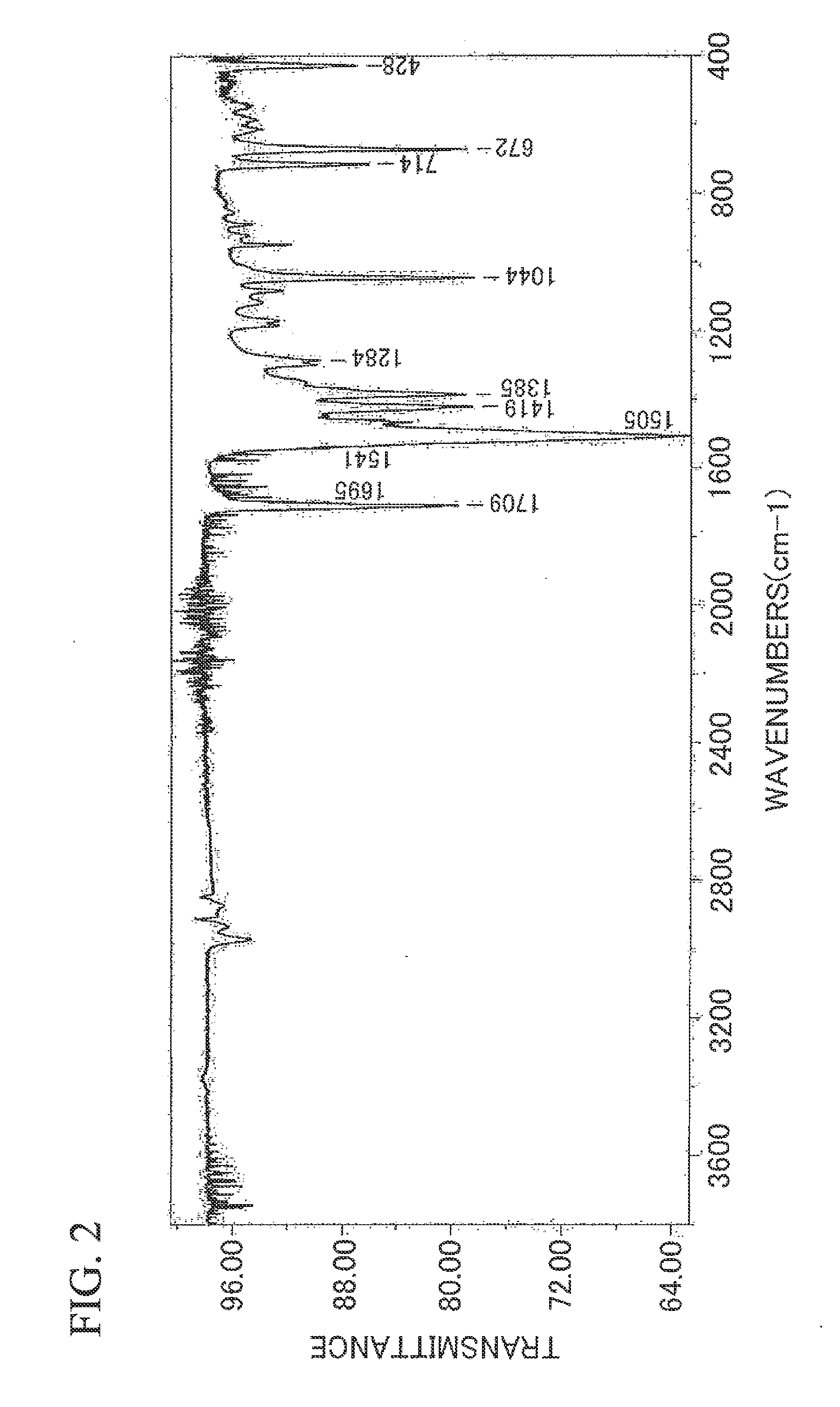

Printed piezoelectric pressure sensing foil

ActiveUS20150339001A1Digital data processing detailsInput/output processes for data processingSilver inkMicrocontroller

There is provided an sensing device, comprising: a substrate; a sensor ink printed onto the substrate; a conductive polymer ink printed onto the sensor ink; a conductive carbon paste formed on the polymer ink; and a conductive silver ink printed on the conductive carbon paste. There is also provided a sensing device for processing a signal generated by the input device, the sensing device comprising: an operational amplifier to amplify the signal; a filter to filter signal noise from the signal; an adder to apply an offset and attenuation to the signal; a microcontroller comprising an analogue to digital converter to convert the signal into a digital output signal.

Owner:JOANNEUM RES FORSCHUNGS GMBH

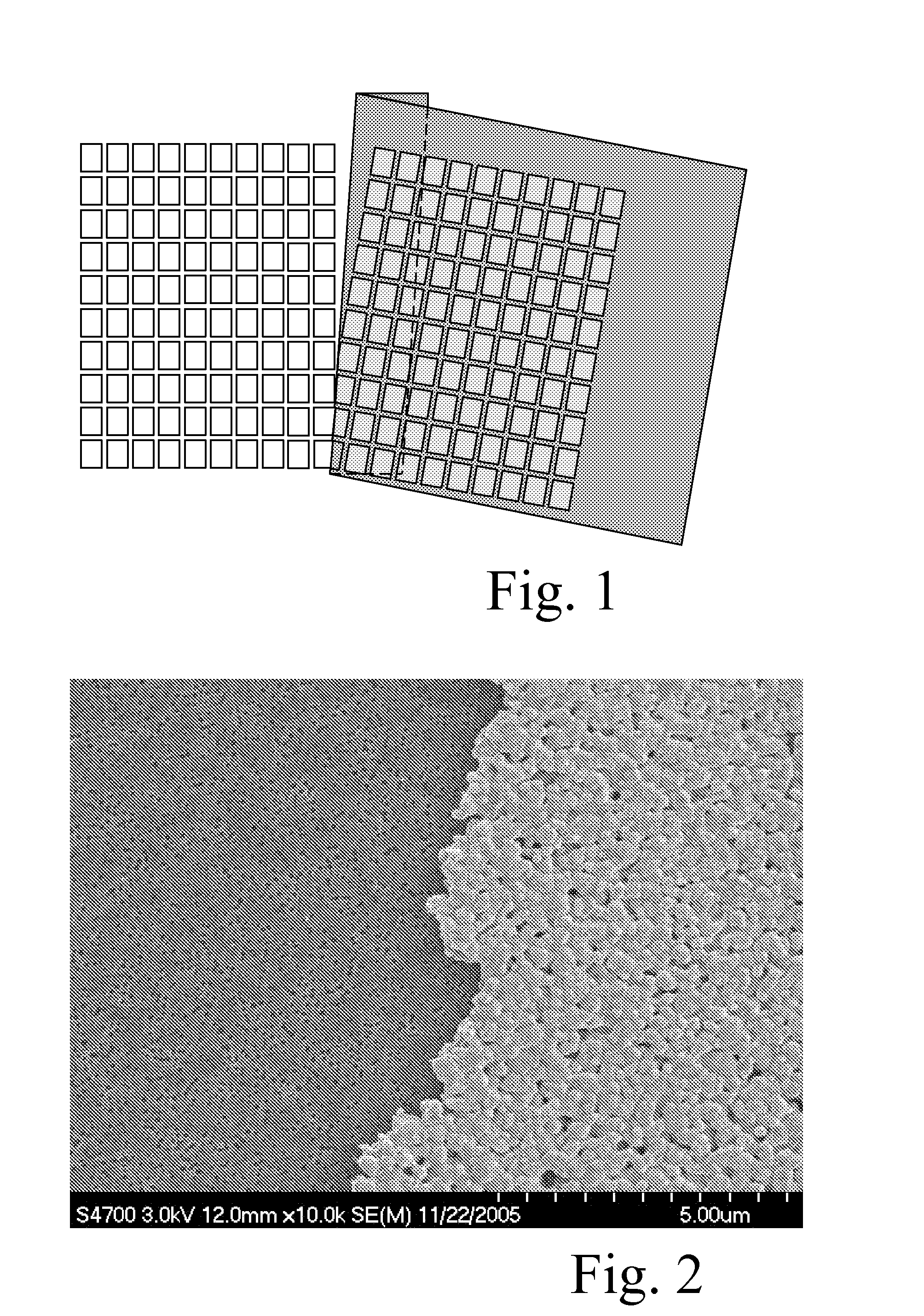

Carbon nanotubes-reinforced conductive silver ink

InactiveUS7763187B1Improve conductivityIncreased durabilityNon-metal conductorsPrinted circuit aspectsSilver inkSolvent

Conductive silver ink is reinforced using carbon nanotubes. Carbon nanomaterials are stabilized and uniformly dispersed in a solvent and mechanically mixed with conductive silver ink. The reinforcement material bridges the gap between separated silver flakes in the conductive silver ink. The carbon nanotubes reinforced conductive silver ink exhibits superior performance over unreinforced silver ink in its mechanical, electrical and thermal properties without significantly greater weight.

Owner:OCEANIT LAB

Printable flexible ammonia gas sensor and making method thereof

ActiveCN105866175AIncrease sensitivityLow costMaterial analysis by electric/magnetic meansSilver inkComposite film

The invention discloses a printable flexible ammonia gas sensor. The printable flexible ammonia gas sensor comprises a flexible substrate, an ammonia gas sensitive layer and interdigital electrodes, wherein the ammonia gas sensitive layer is a composite film formed by a conductive polymer and metal nano-wires, and covers the flexible substrate; and the interdigital electrodes are made of a conductive silver ink material, and are coated on the ammonia gas sensitive layer. The ammonia gas sensitive layer is made of a conductive polymer and metal nano-wire composite system, and a making method of the ammonia gas sensor adopts a low temperature solution technology, so the ammonia gas sensor made in the invention has the advantages of high sensitivity, fast response speed and good stability, and the making method has the advantages of simplicity, no requirement for the making area, suitableness for large-scale production, realization of simultaneous production of a plurality of devices on a same substrate, great improvement of the making efficiency, and reduction of the industrial production cost.

Owner:SHANGHAI JIAO TONG UNIV

Silver ink for forming electrodes

InactiveUS6517931B1Improve adhesionGood electrical propertiesFixed capacitor electrodesFixed capacitor dielectricSilver inkCeramic metal

The present invention provides an electrode ink composition and a method of using the same. The ink comprises a silver powder, a vehicle and an inhibitor. The silver powder is preferably free of palladium and gold and comprises particles having a maximum particle size of less than or equal to about 1 mum. The inhibitor comprises a powdered ceramic metal oxide composition comprising particles having a maximum particle size of less than or equal to about 0.9 mum.

Owner:FERRO CORP

Silver Ink Compositions Containing An Additive For Inkjet Printing

ActiveUS20080236444A1Improve adhesionDesired conductivityConductive materialInksSilver inkSilver particles

The present invention provides an aqueous ink containing ≧3% silver particles having much improved adhesion. It has been found that the adhesion can be improved by adding an aqueous cationic dispersion of a styrene / acrylate copolymer, PEI (polyethyleneimine), or arabinogalactan as an additive to the ink. The advantage of using one of these materials to improve the adhesion of the silver ink is the stability of the ink is maintained and the resistivity goal is met when printed onto the specified media. In other words, this invention provides a silver ink with great adhesion properties while still able to meet the <0.1 Ω / square resistivity requirement and remain stable for up to 4 weeks at 60° C. at accelerated oven aging conditions.

Owner:LEXMARK INT INC

Biological signal sensor on a body surface

An electrically conductive fiber and a coupled biomedical sensor are described. An electrically conductive core of the fiber includes a multiplicity of synthetic conductive filaments and an outer nonconductive fiber layer. The sensor area of the electrically conductive fiber is coated by thin film of silver ink and thin film of silver-silver chloride ink. The electrically conductive fiber's porous surface contacts the thin silver ink coating and the silver coating contacts the silver-chloride ink coating. A surface of the biomedical sensor is coated by a thick film of ionically conductive media, containing an electrolyte, in contact with the silver-chloride coating. The electrolyte diffuses into a porous structure of electrically conductive yarn.

Owner:LOBODZINSKI S SUAVE

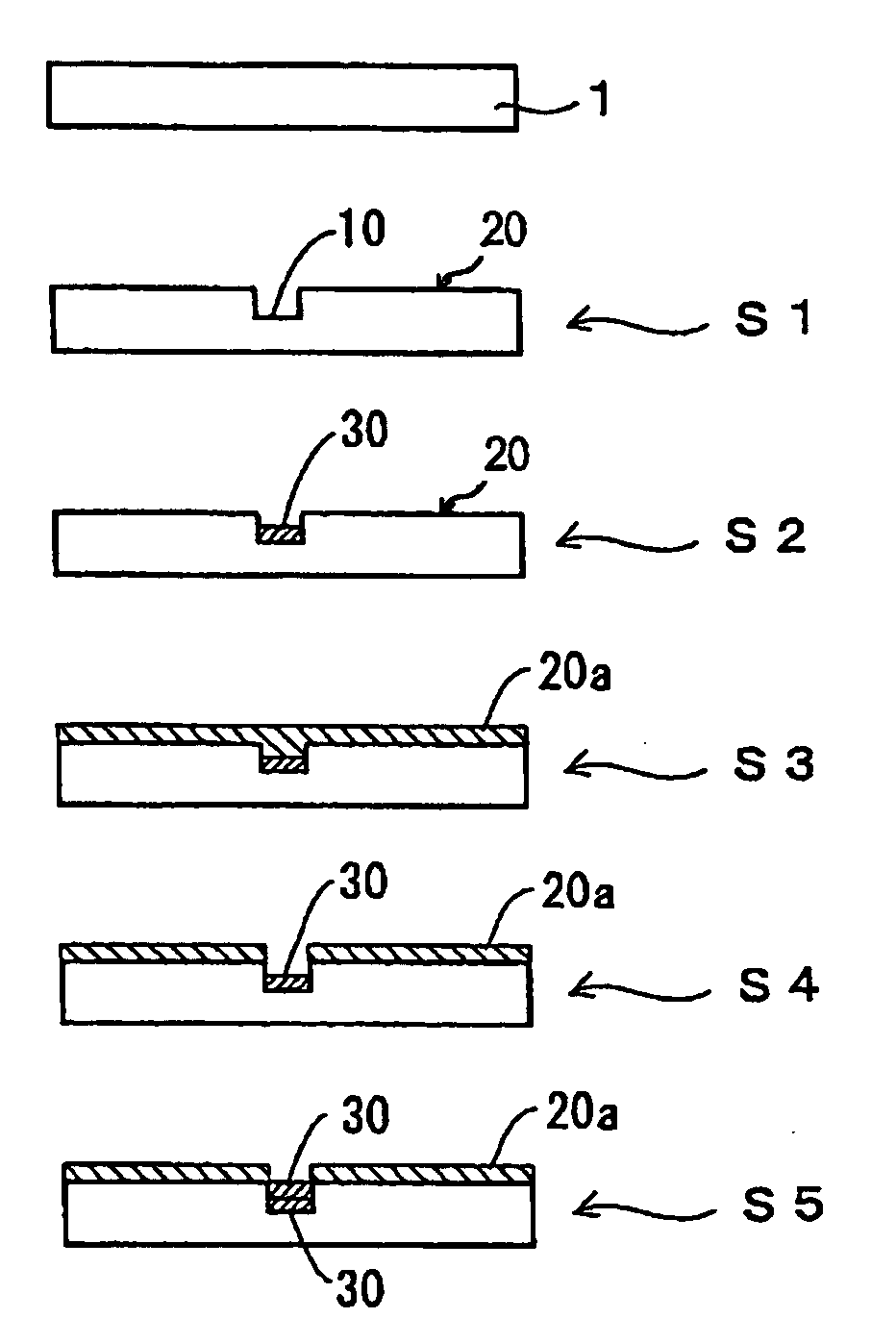

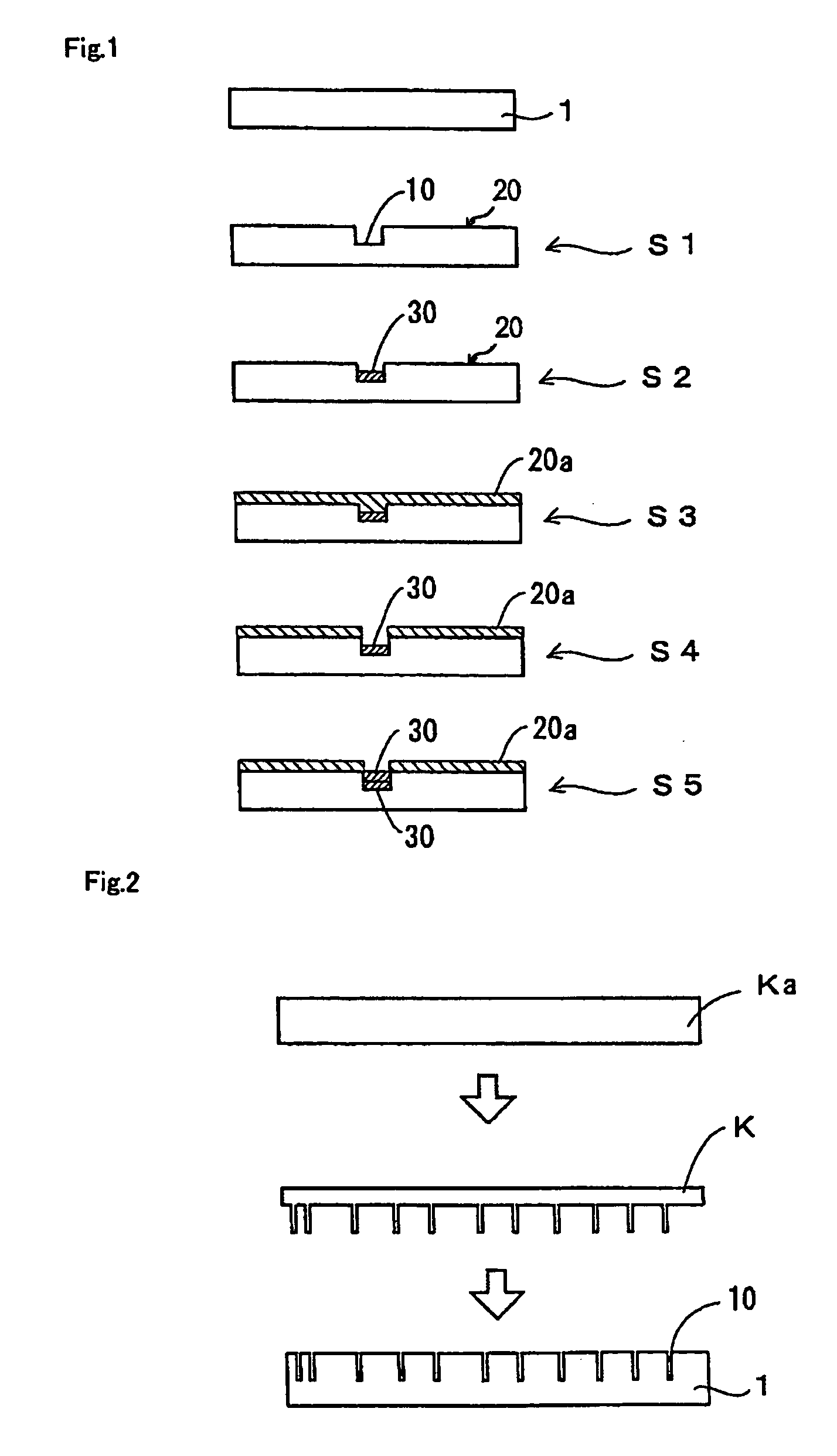

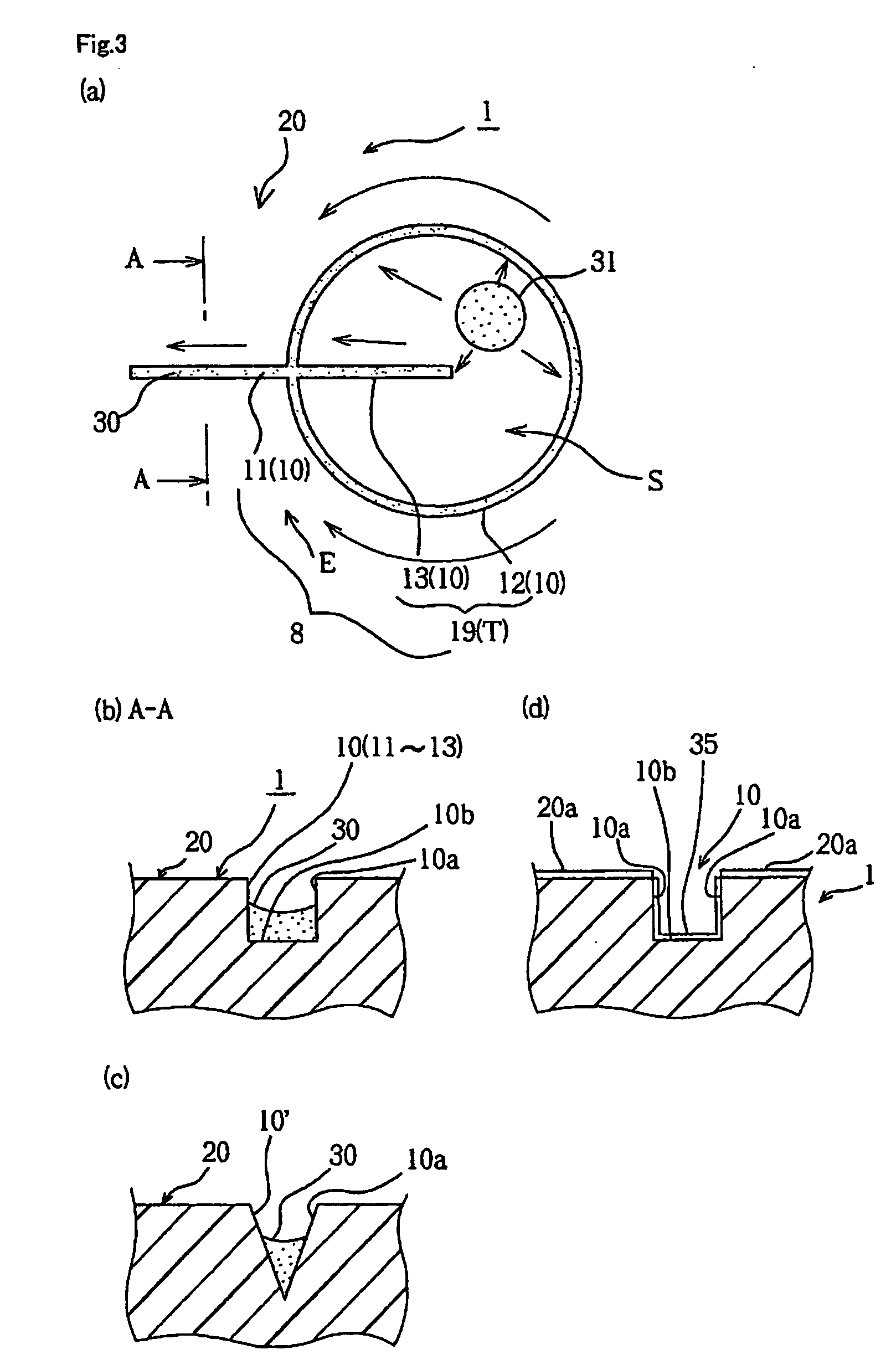

Wiring Circuit Board Producing Method and Wiring Circuit Board

InactiveUS20070220744A1Low costReduce consumption3D rigid printed circuitsPrinted circuit aspectsSilver inkHigh density

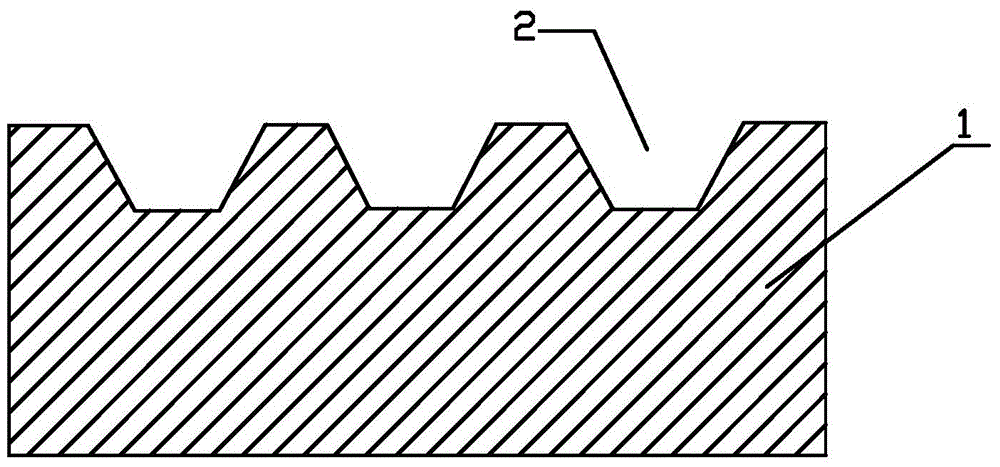

A wiring circuit board and a method of producing the same are provided in which a desired pattern of wiring is provided at higher density while permitting no overflow from the grooves of an electroless plating catalyst containing solution and an electric conductor forming liquid such as silver ink. The pattern of electric conductor is deposited by applying the electric conductor forming liquid into the grooves provided in a substrate and distributing the same along the grooves with the action of capillarity. The method starts with patterning the grooves in the surface of the substrate (S1), applying the electric conductor forming liquid into the grooves (S2), and coating the surface of the substrate with a layer of repellent liquid which is lower in the affinity with the electric conductor forming liquid (S3). This is followed by cleaning at least the grooves (S4) and then filling the grooves with the electric conductor forming liquid once again (S5). The electric conductor forming liquid applied into the grooves is then distributed throughout the grooves by the action of capillarity. When silver ink is used, the pattern of electric conductor is produced by repeating an action of applying and drying a number of times. Alternatively, the patter of electric conductor can be produced by an electroless plating technique or a combination of an electroless plating technique and an electro-plating technique for separating an electrical conductive material form the electric conductor forming liquid.

Owner:CLUSTER TECH

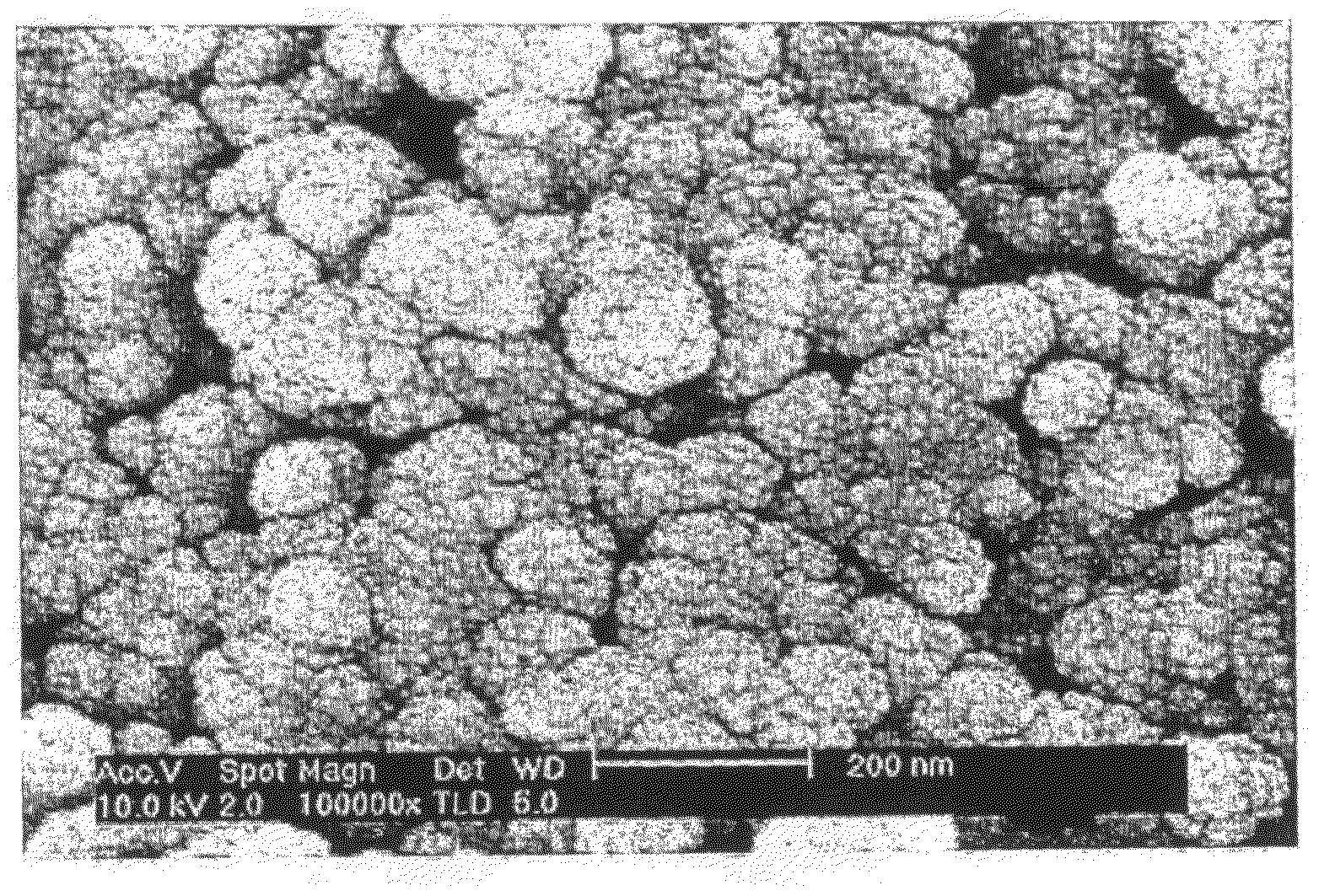

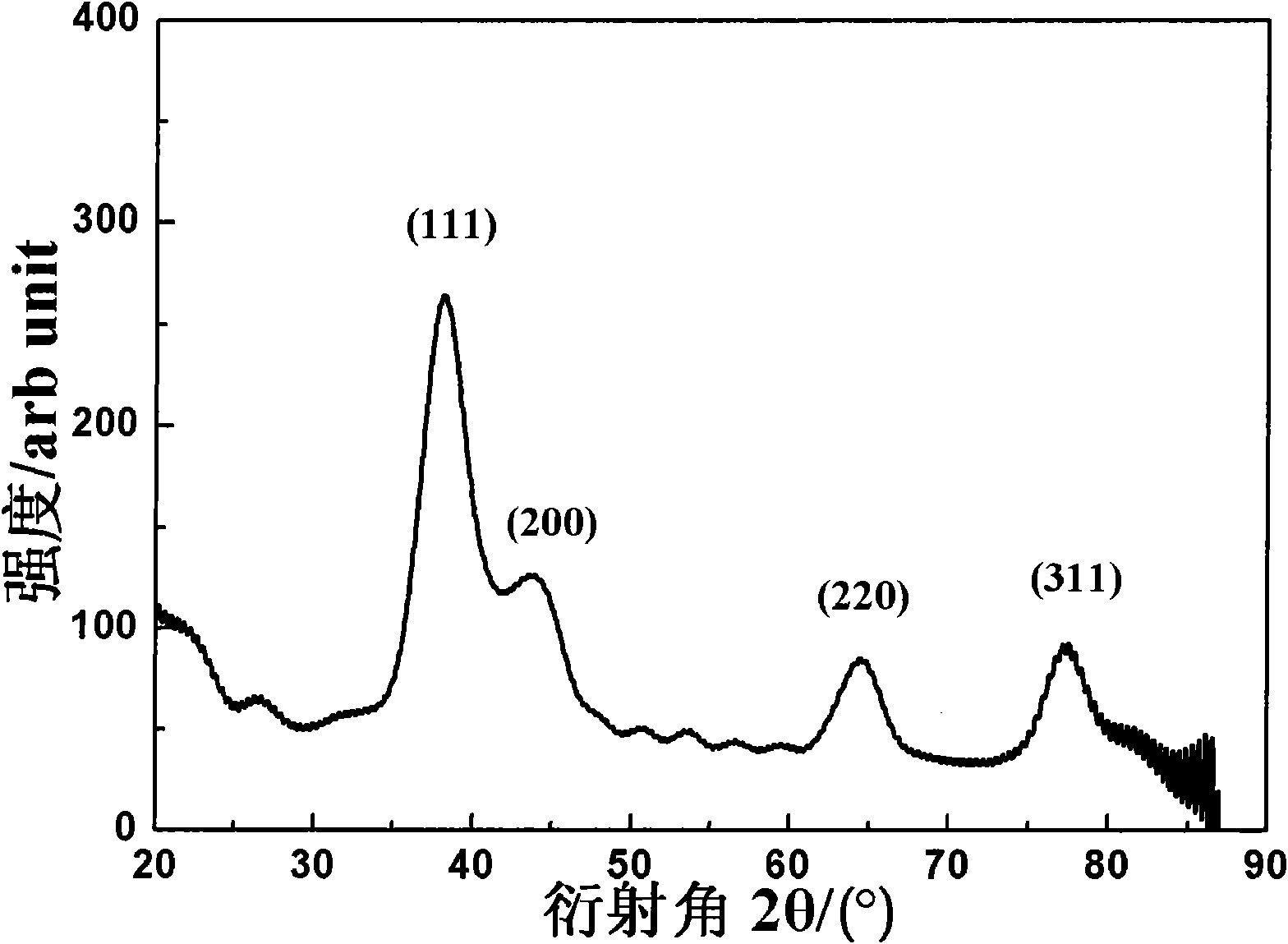

Process for preparation of silver nanoparticles, and the compositions of silver ink containing the same

ActiveUS8282860B2Small sizeGood physical propertiesMaterial nanotechnologyNanostructure manufactureSilver inkNanometre

The present invention relates to a process for preparation of silver nanoparticles and the compositions of silver ink containing the same. The present invention can prepare the silver nanoparticles with various shapes through a simple preparation process, improve the selectivity of the size of the silver nanoparticles, fire the silver nanoparticles even at a low temperature of 150° C. or less during a short time, provide the ink compositions capable of forming the coating or the fine pattern showing the high conductivity, and provide the ink compositions capable of being applied to the reflective film material, the electromagnetic wave shield, and the antimicrobial agent, etc.

Owner:INKTEC CO LTD

Printed piezoelectric pressure sensing foil

ActiveUS9612690B2Digital data processing detailsInput/output processes for data processingMicrocontrollerSilver ink

There is provided an sensing device, comprising: a substrate; a sensor ink printed onto the substrate; a conductive polymer ink printed onto the sensor ink; a conductive carbon paste formed on the polymer ink; and a conductive silver ink printed on the conductive carbon paste. There is also provided a sensing device for processing a signal generated by the input device, the sensing device comprising: an operational amplifier to amplify the signal; a filter to filter signal noise from the signal; an adder to apply an offset and attenuation to the signal; a microcontroller comprising an analog to digital converter to convert the signal into a digital output signal.

Owner:JOANNEUM RES FORSCHUNGS GMBH

Silver Ink Composition and Substrate

ActiveUS20130121872A1Superior glossinessSuperior specularityConductive materialInksAcetic acidSilver ink

There is provided with a silver ink composition which is formed by blending one or more kinds of silver β-ketocarboxylates selected from the group consisting of silver isobutyrylacetate, silver benzoylacetate, silver propionylacetate, silver acetoacetate, silver α-methylacetoacetate, and silver α-ethylacetoacetate, and an aliphatic primary or secondary amine having 1 to 10 carbon atoms, and a substrate with a surface on which a metallic silver layer which is formed by heating the silver ink composition is provided. According to the invention, it is possible to obtain a silver ink composition suitable for forming a metallic silver layer which has superior glossiness and specularity, and a substrate with a surface on which a metallic silver layer is formed using the silver ink composition.

Owner:TOPPAN EDGE INC

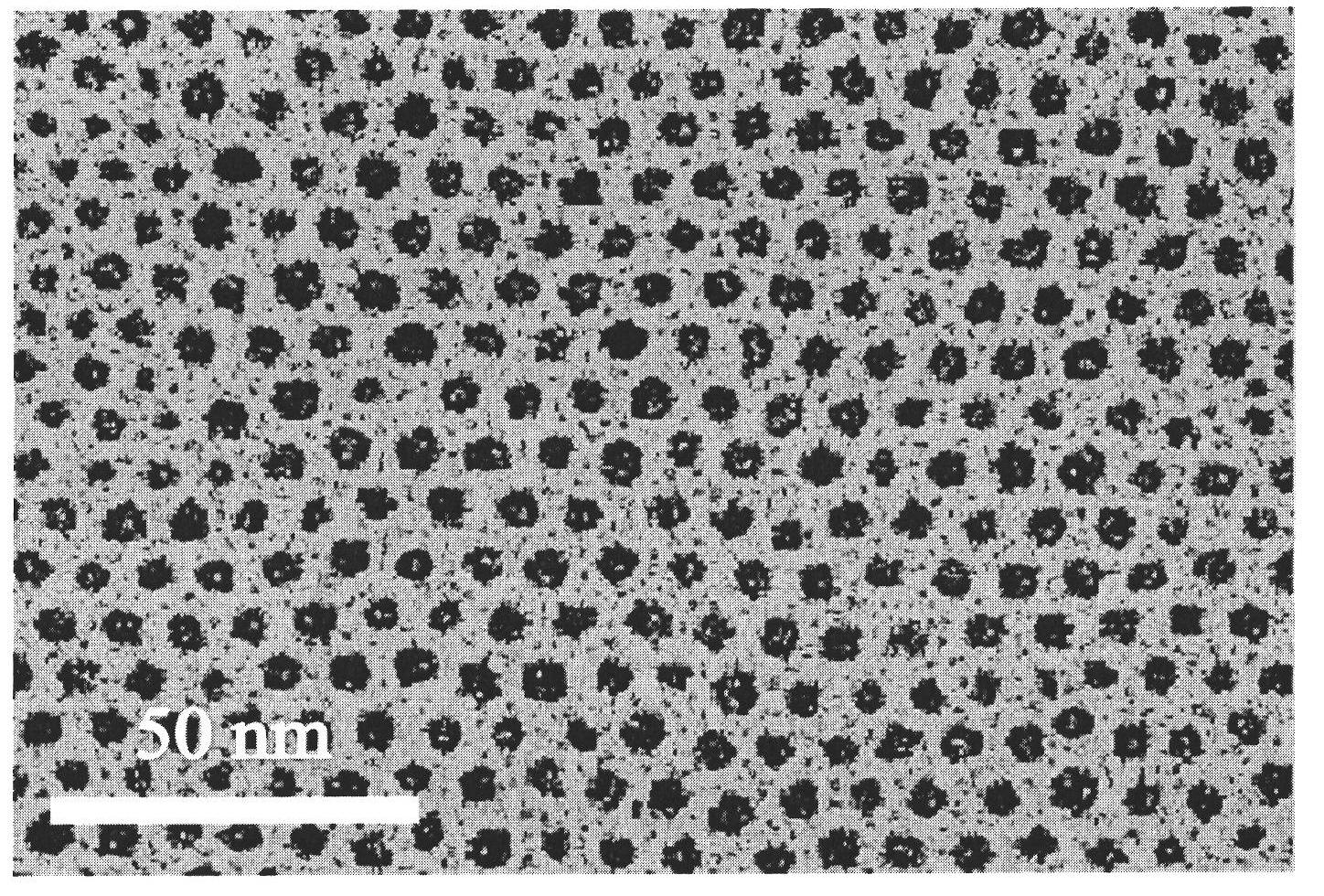

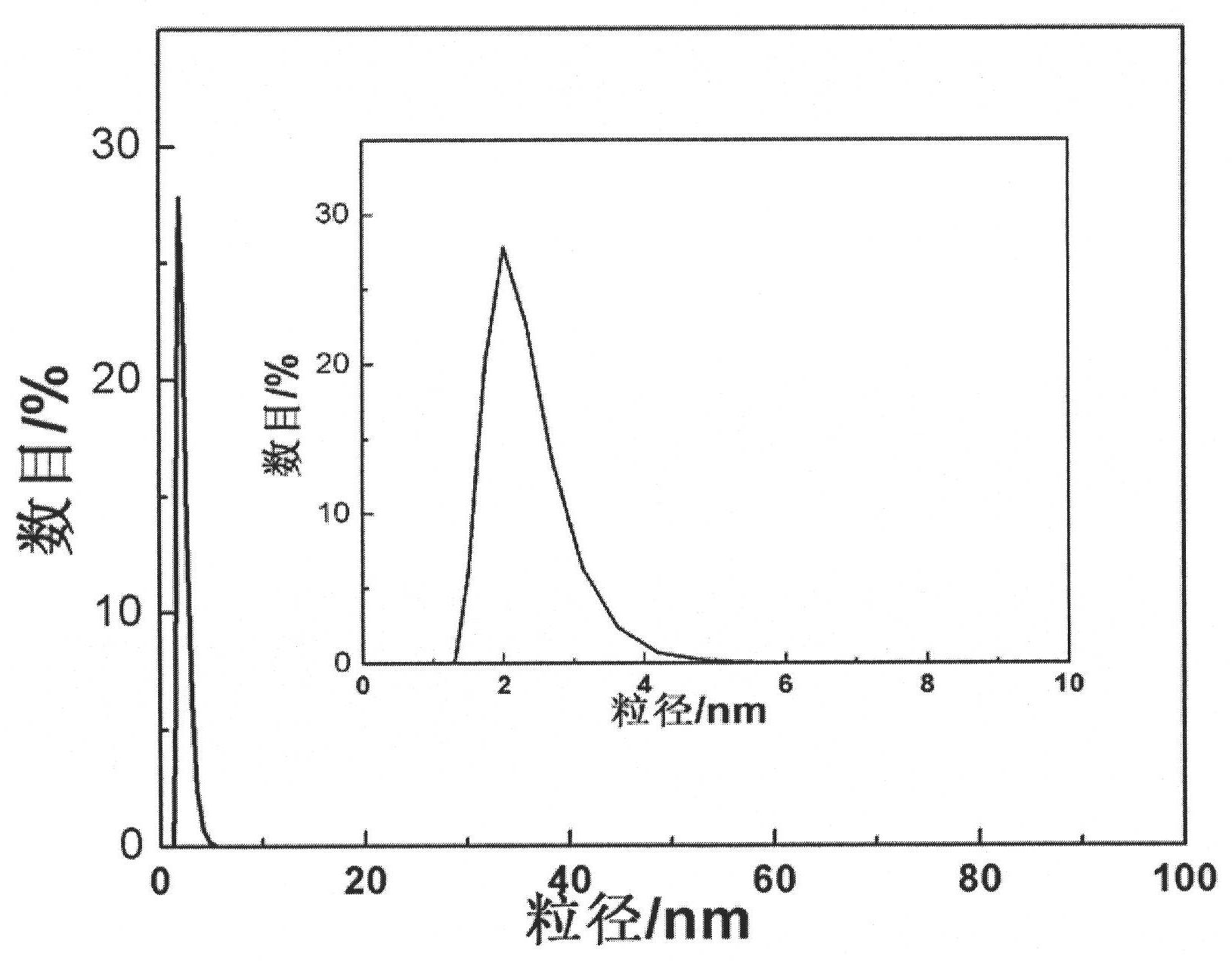

Method for preparing nano silver conductive ink

InactiveCN101870832ASimple processMild reaction conditionsInksMetallic pattern materialsSilver inkElectrolysis

The invention belongs to the field of nano technology and particularly relates to a method for preparing nano silver conductive ink. The method comprises the following steps: dissolving a silver salt and an organic protective agent in a solvent, adjusting the pH value of the solution to 9 to 10 with an alkaline complexing agent, and raising the temperature gradually to 30 to 100 DEG C till the reaction system is a transparent solution; and cooling the reaction system obtained by the previous step to room temperature, adding a reducer into the reaction system, and continuously stirring the reaction system for 20 to 30 minutes to obtain the nano silver conductive ink. The molar ratio of the organic protective agent to the silver salt is 0.01-3:1; each 0.01 mol of silver salt is dissolved in 5 to 50 milliliters of solvent; and the molar ratio of the reducer to the silver salt is 1-3:1. The nano silver prepared by the method has the advantages that: the particle size is less than 10 nanometers; the process is simple, the reaction conditions are mild and the reaction time is short; the raw materials are simple and the dose of the dispersant is small; the purity and concentration are high; and the conductive property is good. In addition, the preparation cost of the nano silver ink is low; no harmful waste is produced, so the requirements for 'green production' are met; and the nano silver ink can be widely used in fields of touch screens, electronic tags, thin film switches, flexible circuit boards, medical products, sensors, printing contact, radio frequency interference screening, electrolysis, multilayer circuit board hole filling and the like.

Owner:FUDAN UNIV

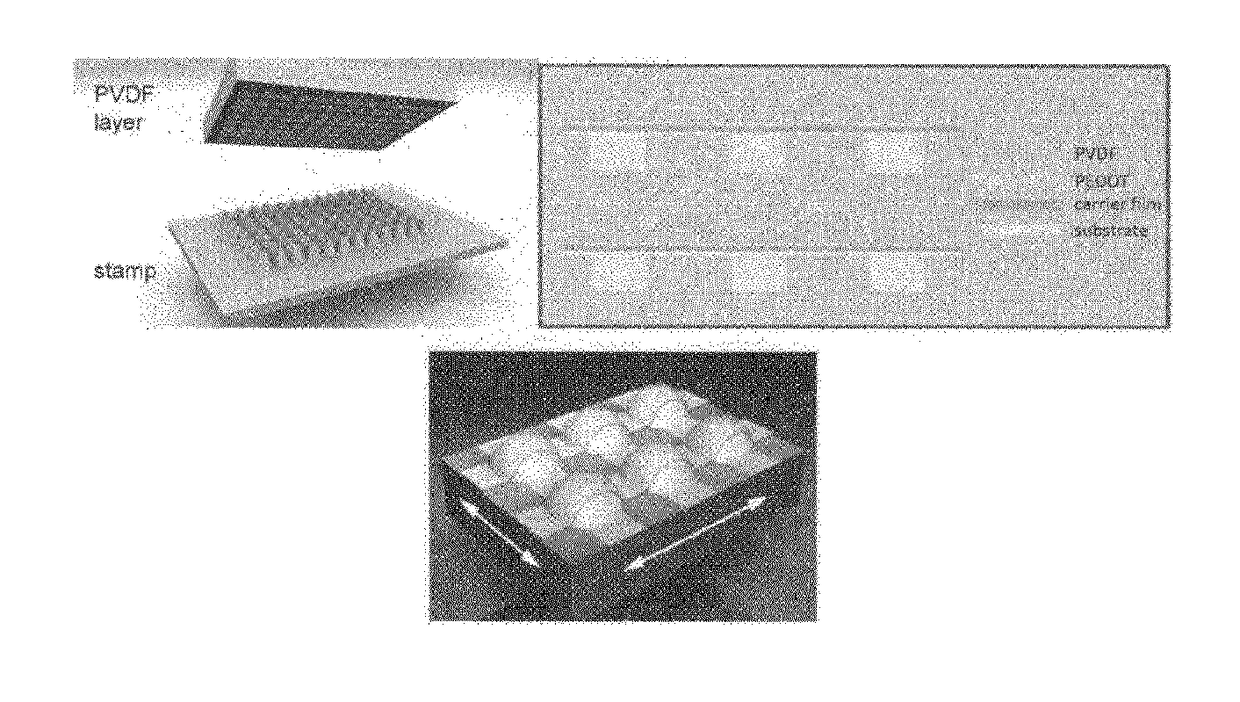

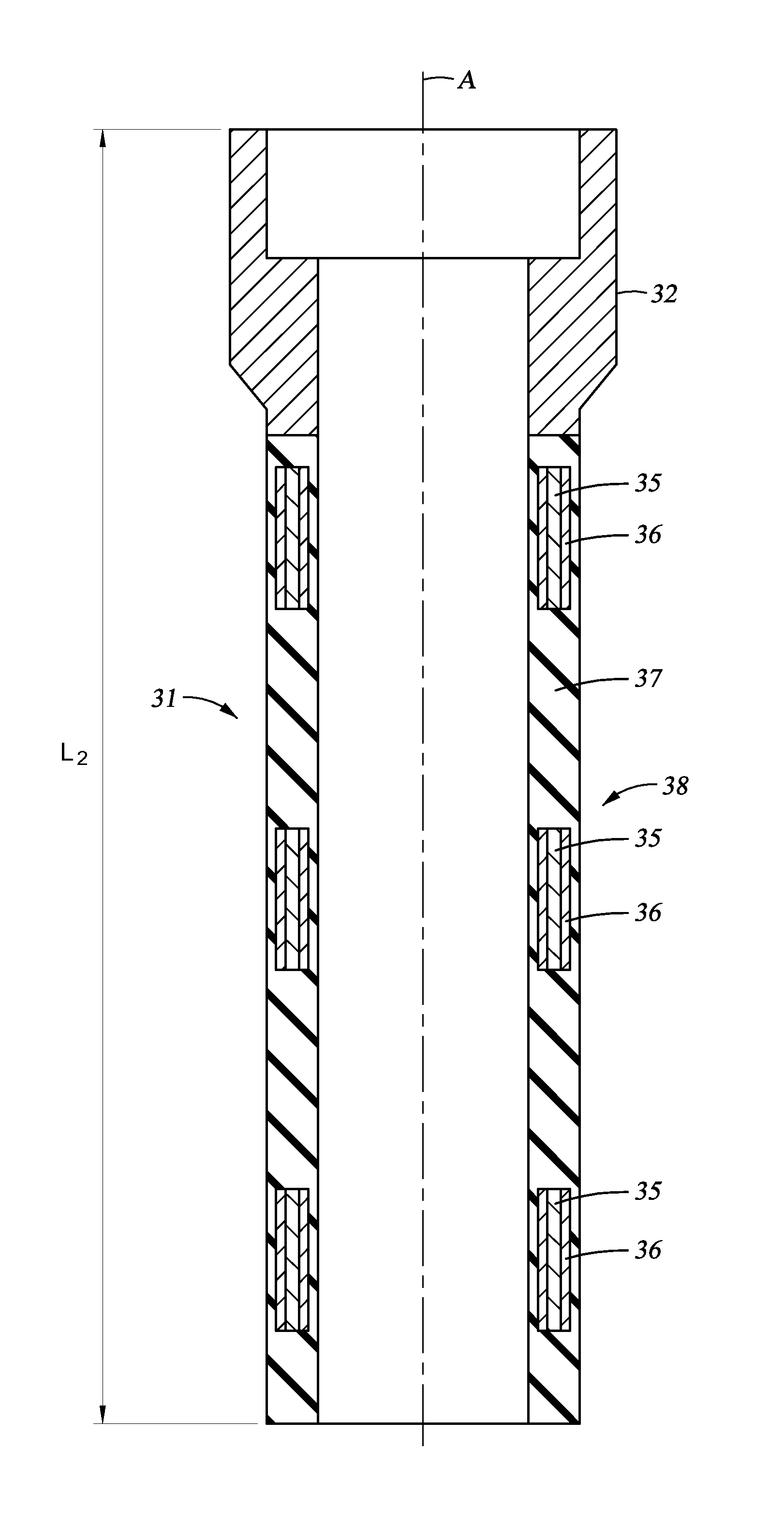

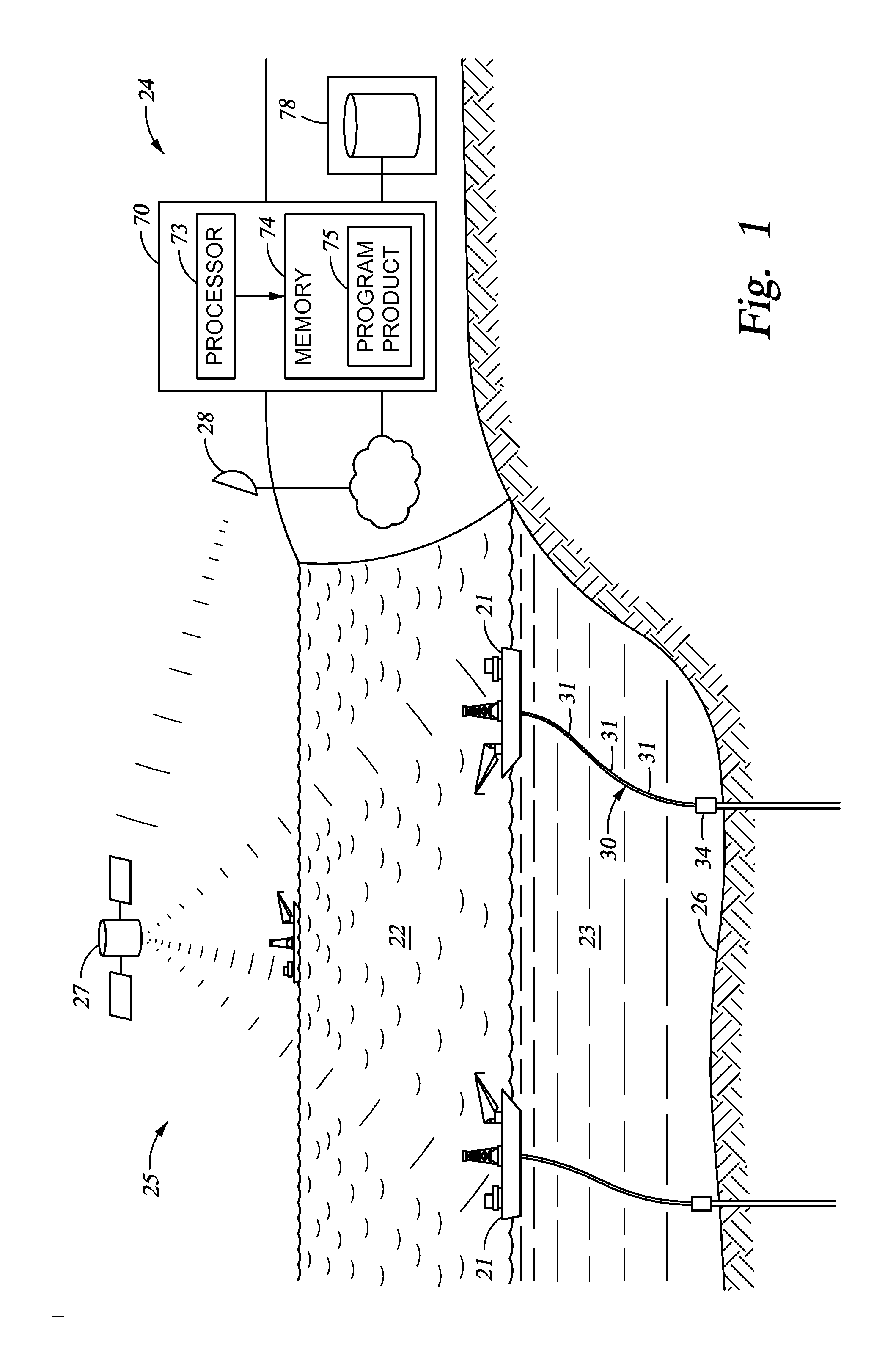

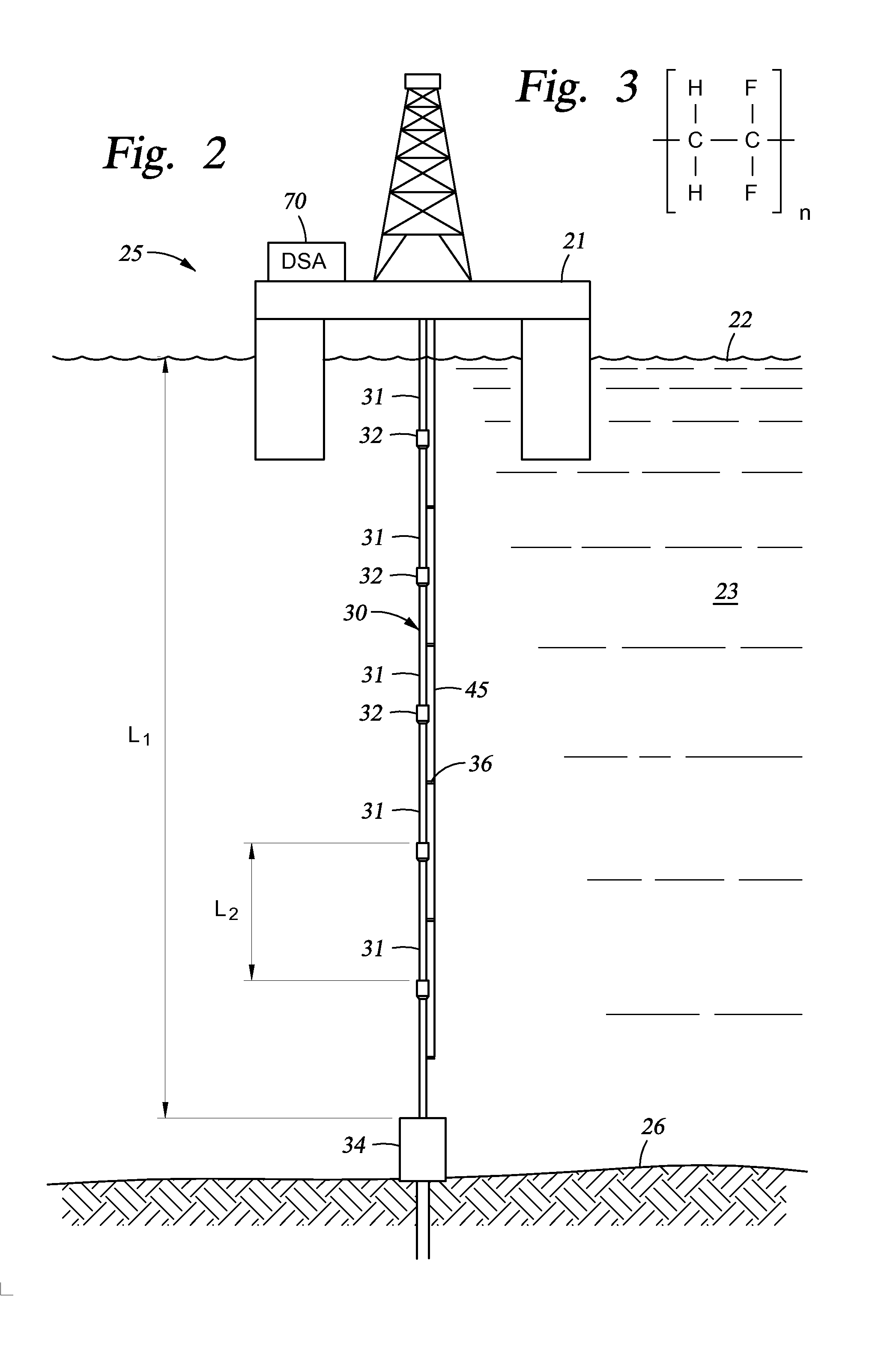

Marine composite riser for structrual health monitoring using piezoelectricity

InactiveUS20120031620A1Increase the areaEasy to detectDrilling rodsConstructionsSilver inkStructural health monitoring

A structural health monitoring system for a marine composite riser string is provided. Each riser pipe section includes a cylindrical form having an axis and also a carbon epoxy matrix. A sensor is associated with (e.g., embedded in) and substantially circumscribes the riser pipe section. The sensor includes a PolyVinyliDene Fluoride laminate and electrodes (e.g., conductive silver ink coating) so that the sensor generates electricity at the electrodes responsive to mechanical stresses and strains of the riser section, including vibrations. The system can also include a data acquisition system and digital signal analyzer to analyze signals responsive to the generated electricity at the electrodes of sensors and to provide health monitoring and damage detection for the marine riser pipe string, including impact damage and fatigue crack initiation. The system can further include a subsurface energy storage device and a plurality subsurface microelectromechanical devices coupled to the subsurface energy storage device.

Owner:VETCO GRAY

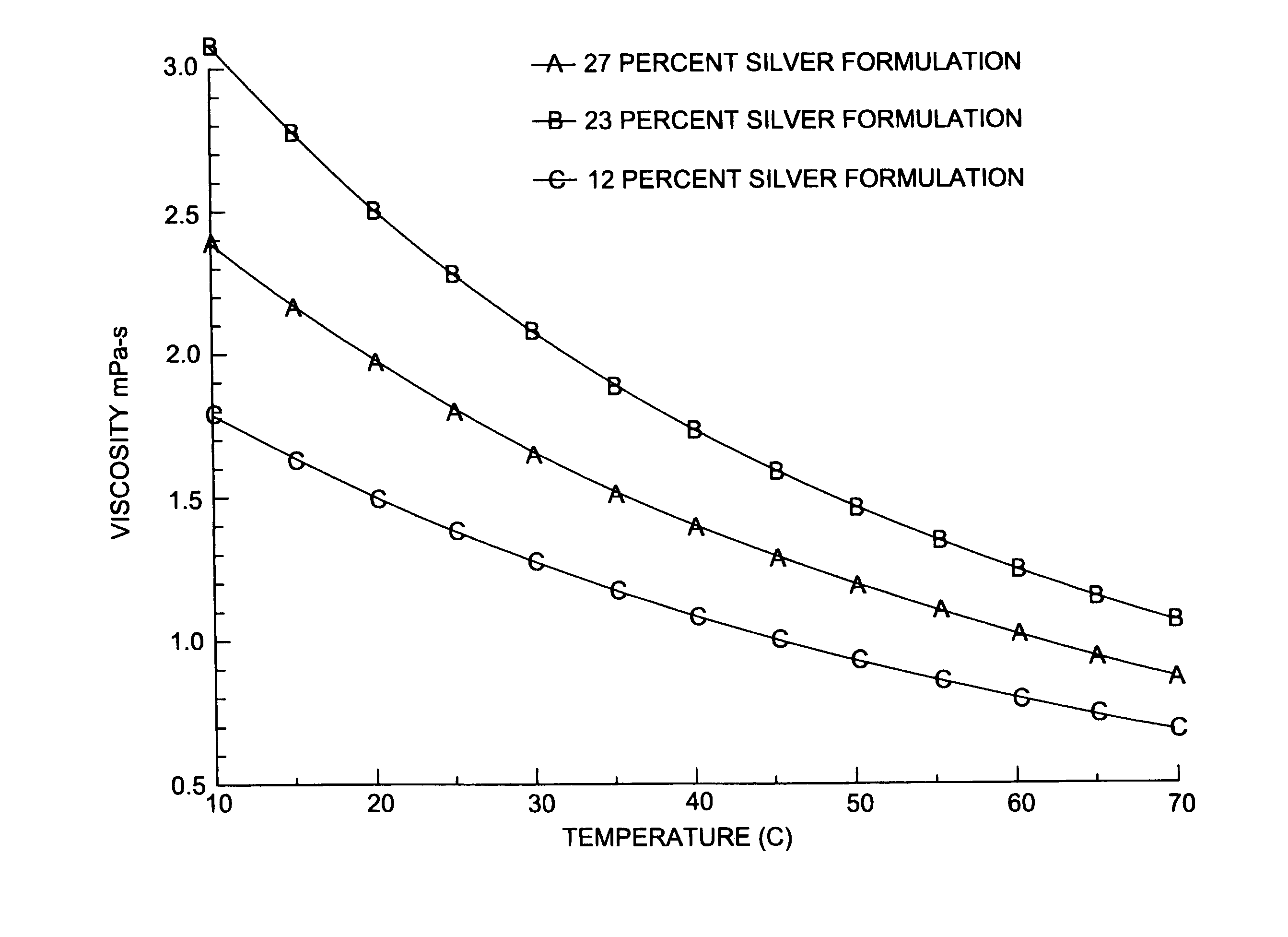

Thermal printing of silver ink

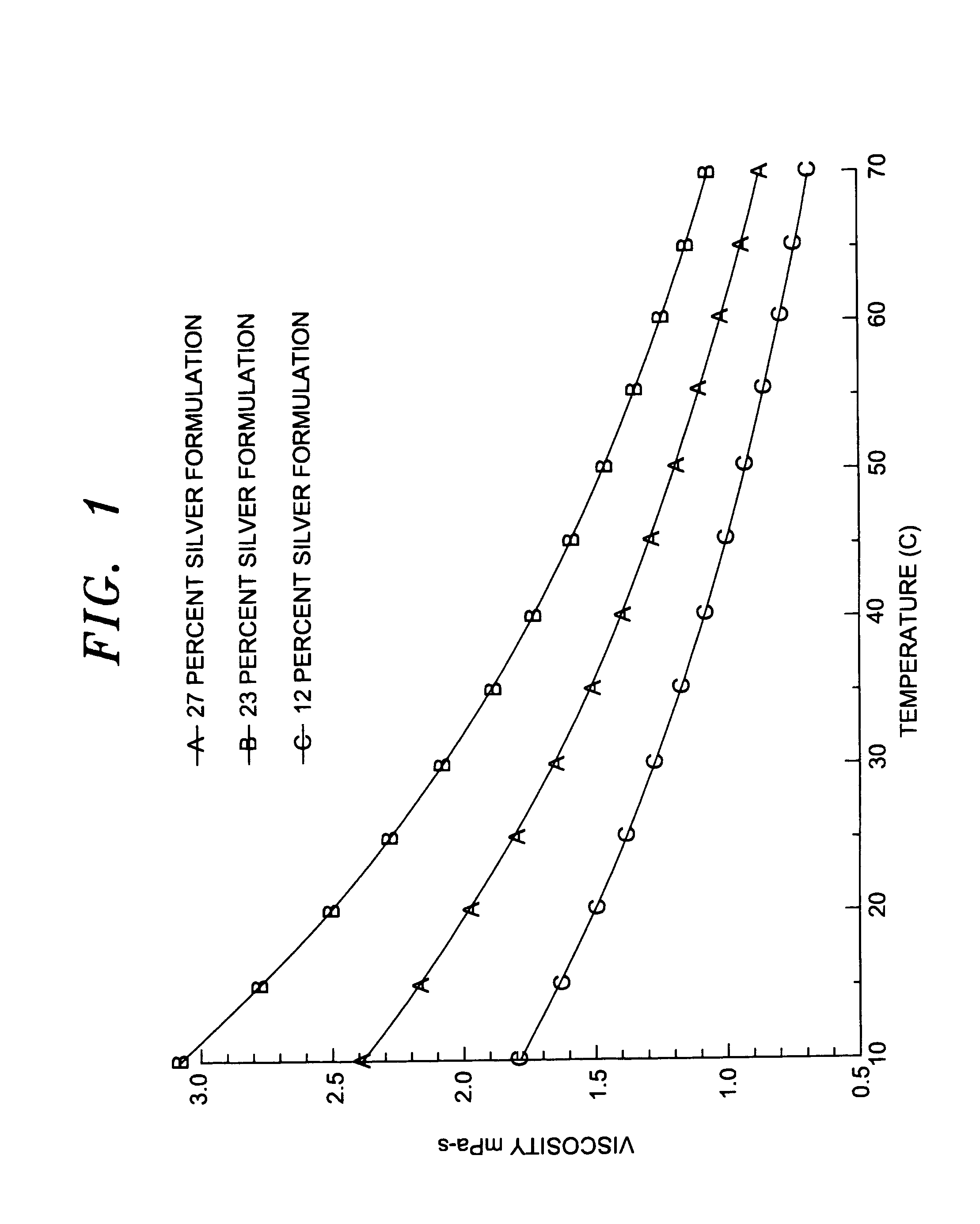

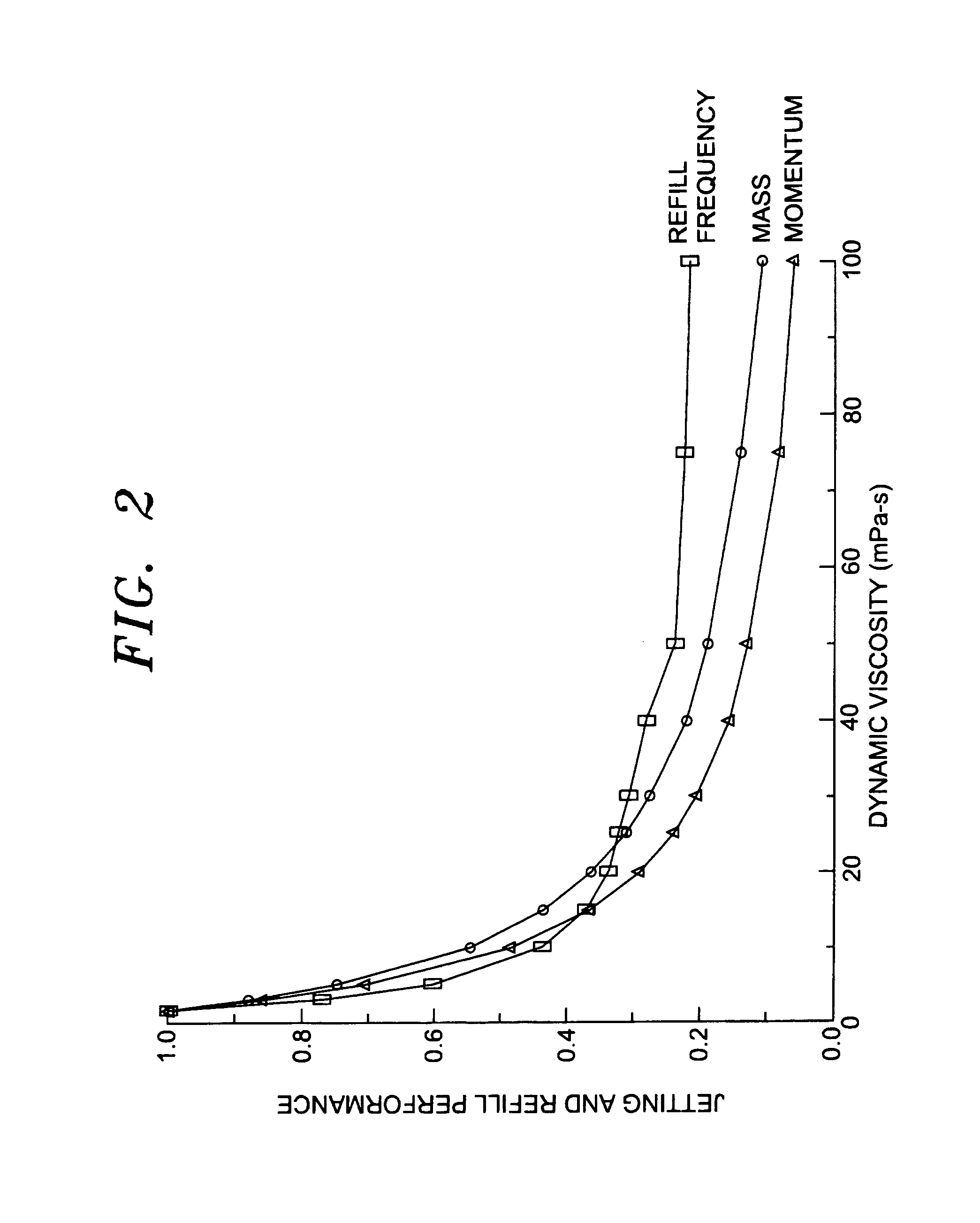

Aqueous inkjet inks having metal nanoparticles for printing of conductive patterns or for other reasons can be printed employing heat energy within the range of current printers. For optimum printing the energy delivered would be about 2.9×109 Joules / m3 or larger of volume of the heater stack, preferably not much larger so as to conserve energy. In embodiments the mole fraction of water in the ink would be greater than 0.9 computed with respect to only the liquid components of the ink and the ink would be heated by contact with the surface a heater heated to 1.5×1015 or more watts / m3 of volume of the heater stack. Embodiments of a silver ink will have greater than 12% silver and up to 27% silver by weight of the weight of the ink; the ink may have a viscosity of less than 3 Pa-s at 22 degrees C., preferably is less than 2.7 mPa-s; the ink may have a mole fraction of water greater than 0.87, preferably greater than 0.9, this mole fraction being computed with respect to all of the components of the ink.

Owner:LEXMARK INT INC

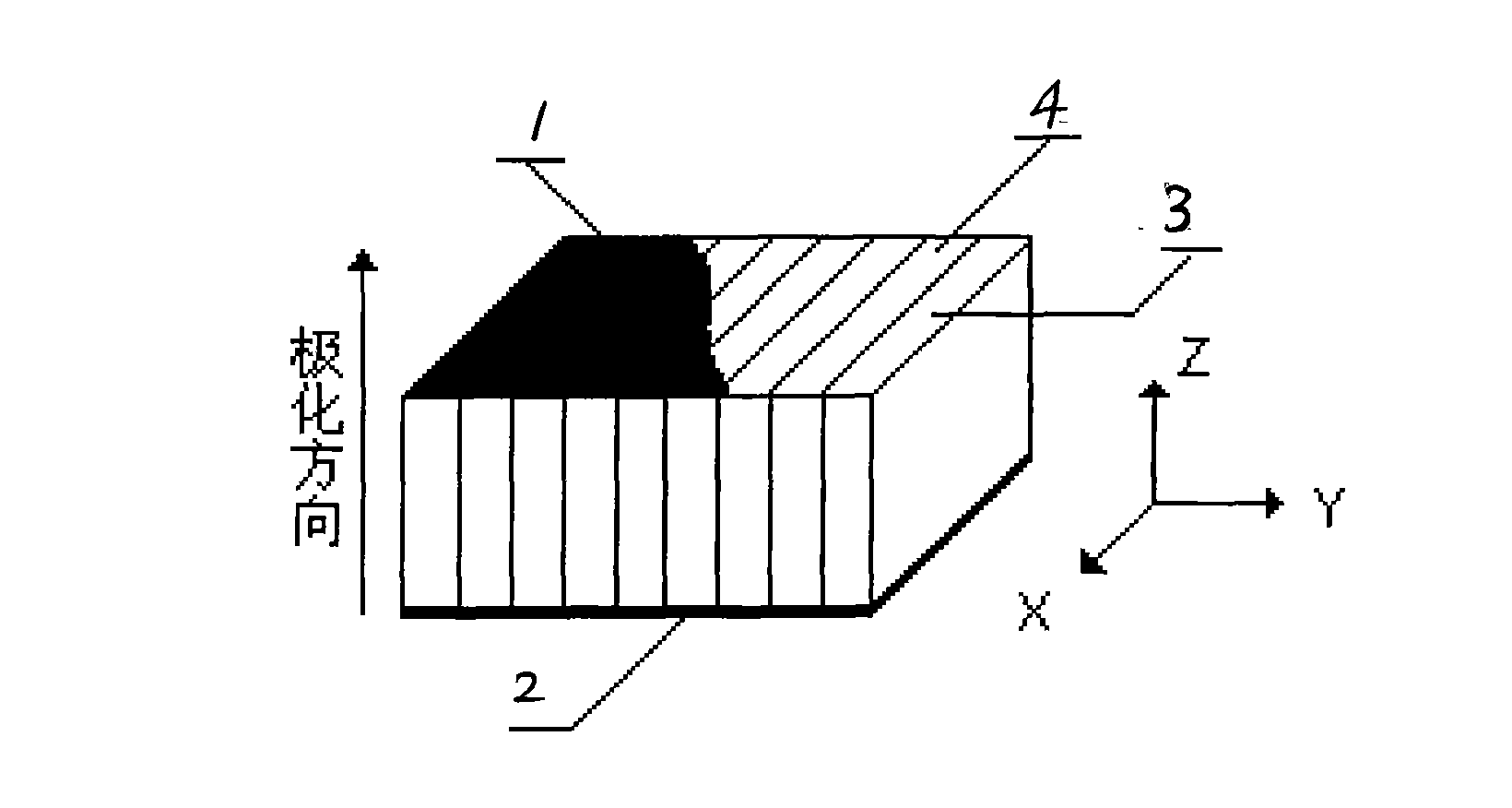

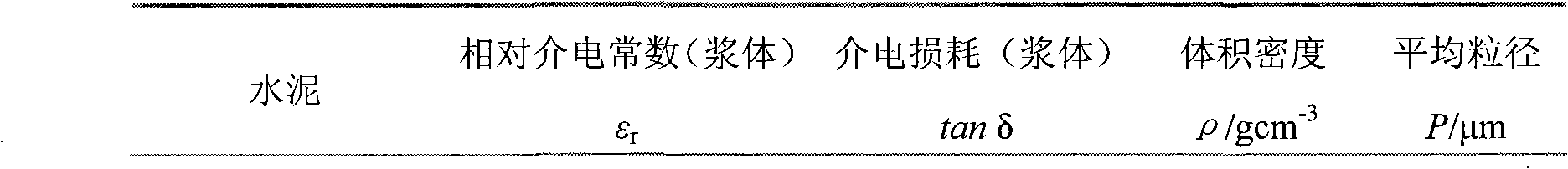

2-2 type cement base piezoelectric composite material

InactiveCN101538144AExcellent piezoelectric propertiesIncreased durabilitySilver inkPiezoelectric composite

The invention relates to a 2-2 type cement base piezoelectric composite material which belongs to an intelligent material in the civil engineering field. The composite material is manufactured by the following method: polarizing a cuboid piezoelectric ceramic block; using a slicer to sequentially cut out a series of piezoelectric ceramic pieces along the direction parallel to a piezoelectric ceramic polaxis and pouring cement according to a certain cement water ratio; after finishing the pouring, putting both a sample and a mould in a vacuum drying box for carrying out vacuum processing; putting the sample in a maintenance box for maintenance; and uniformly coating low-temperature conductive silver ink or plating an electrode on the two surfaces after two parallel surfaces are respectively sanded and polished so as to prepare the 2-2 type cement base piezoelectric composite material. The 2-2 type cement base piezoelectric composite material has the advantages of good piezoelectric performance and compatibility with concrete, integration of sensing and driving, good durability, simple preparation process, low cost, and the like.

Owner:UNIV OF JINAN

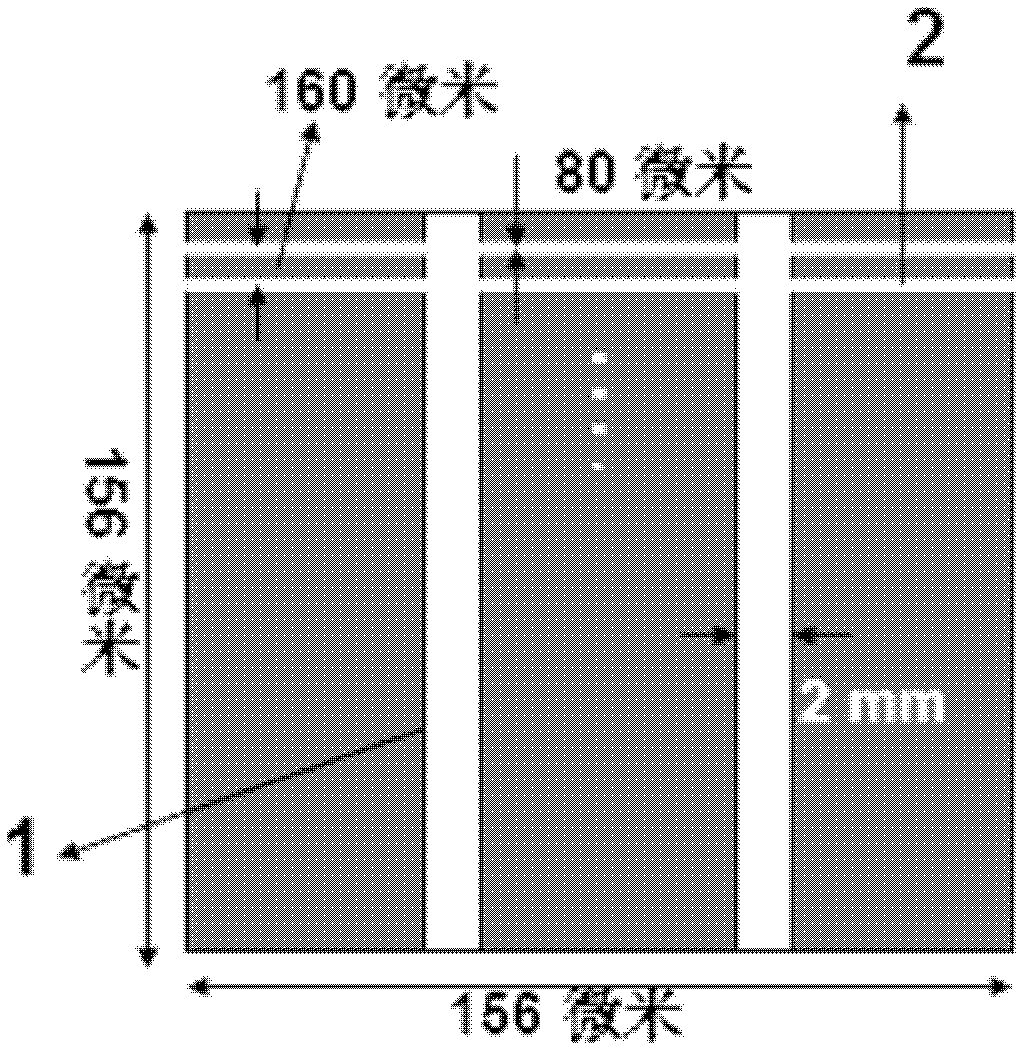

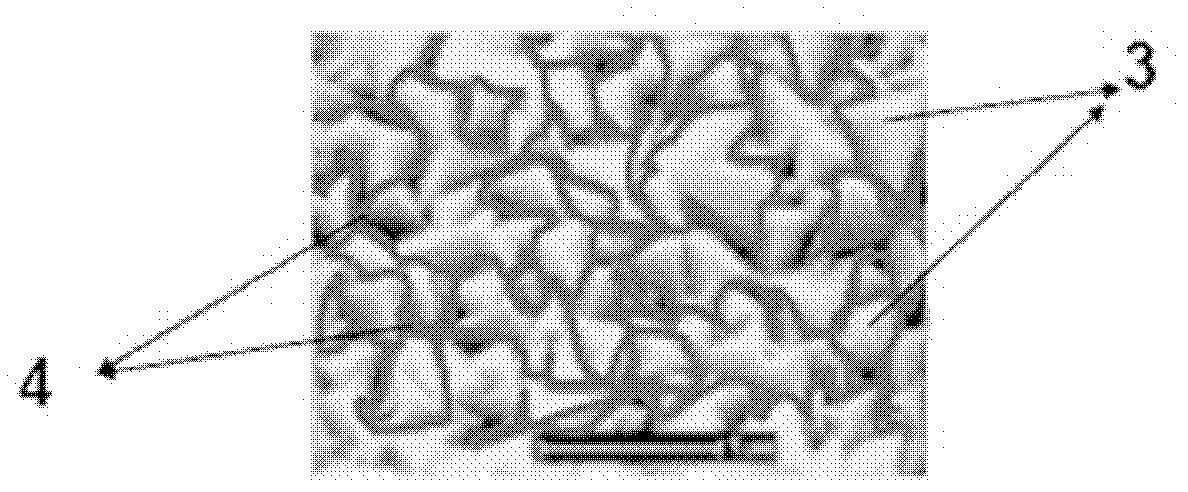

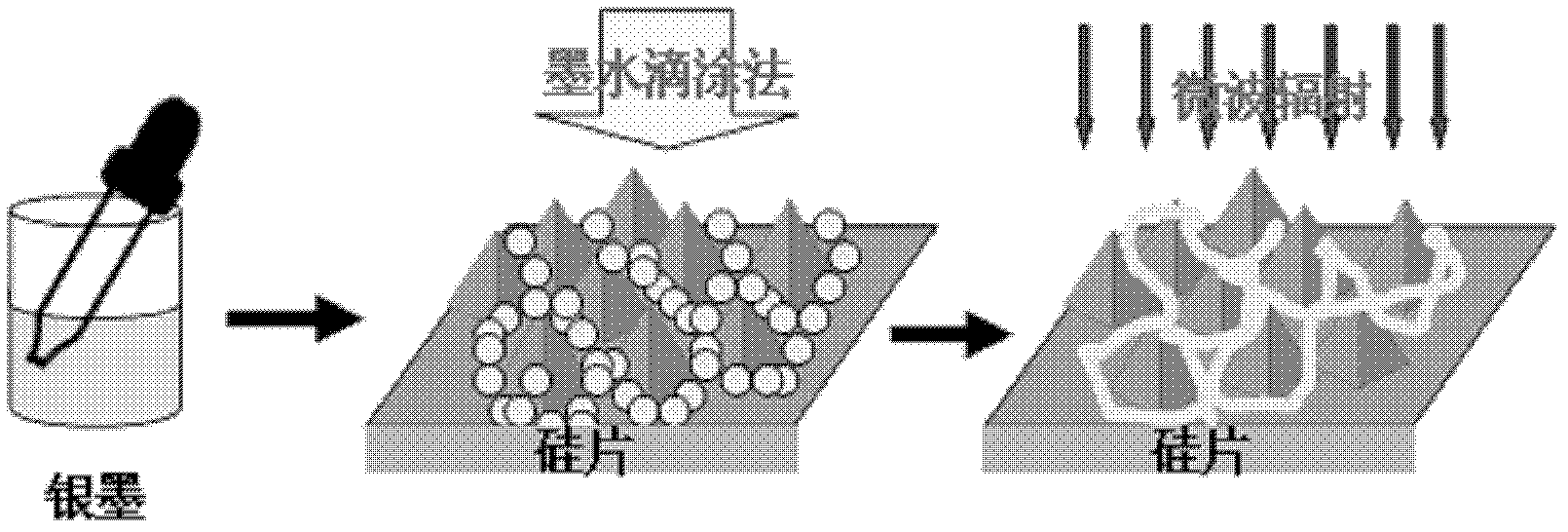

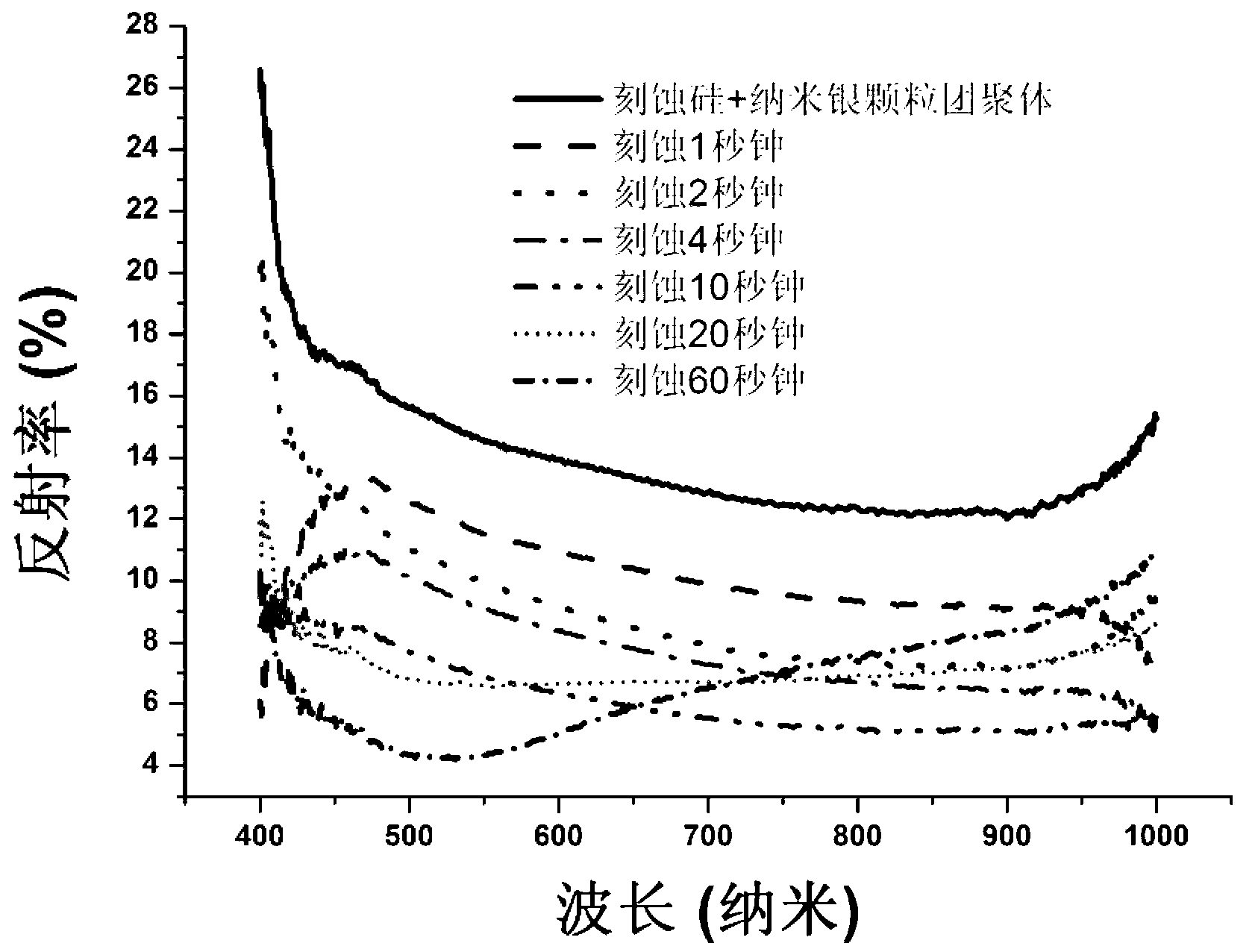

Method for preparing transparent electrode of crystalline silicon solar cell

ActiveCN102544223AReduced series resistanceReduce manufacturing costFinal product manufactureSemiconductor devicesSilver inkMetal nanowires

The invention relates to a method for preparing a transparent electrode of a crystalline silicon solar cell, which comprises the following steps: A, an electrode sample is prepared, wherein a silver ink solution is dripped to the surface of a silicon chip with a pyramidal textured structure, and a uniformly distributed nano silver particle aggregate structure is formed on the surface of the whole silicon chip by adopting a dripping and coating method; and B, the electrode sample is sintered, wherein the electrode sample is heated through the microwave radiation so as to allow the nano silver particles to mutually fuse, thereby forming mutually connected metal nano wire / rod network structure. The preparation method provided by the invention is simple and has a low cost. The transparent electrode prepared by the method comprises micropores and mutually connected metal nano wires. The transparent electrodes prepared by the invention are arranged at the bottom of the pyramidal textured surface of the crystalline silicon solar cell and mutually connected, has the advantages of lower light reflection rate, better conductibility, and excellent potential carrier collection efficiency, can serve as a perfect substituent for a traditional silver grid electrode, and can improve the conversion efficiency of the solar battery, with reduced manufacturing cost.

Owner:SOUTH CHINA NORMAL UNIVERSITY

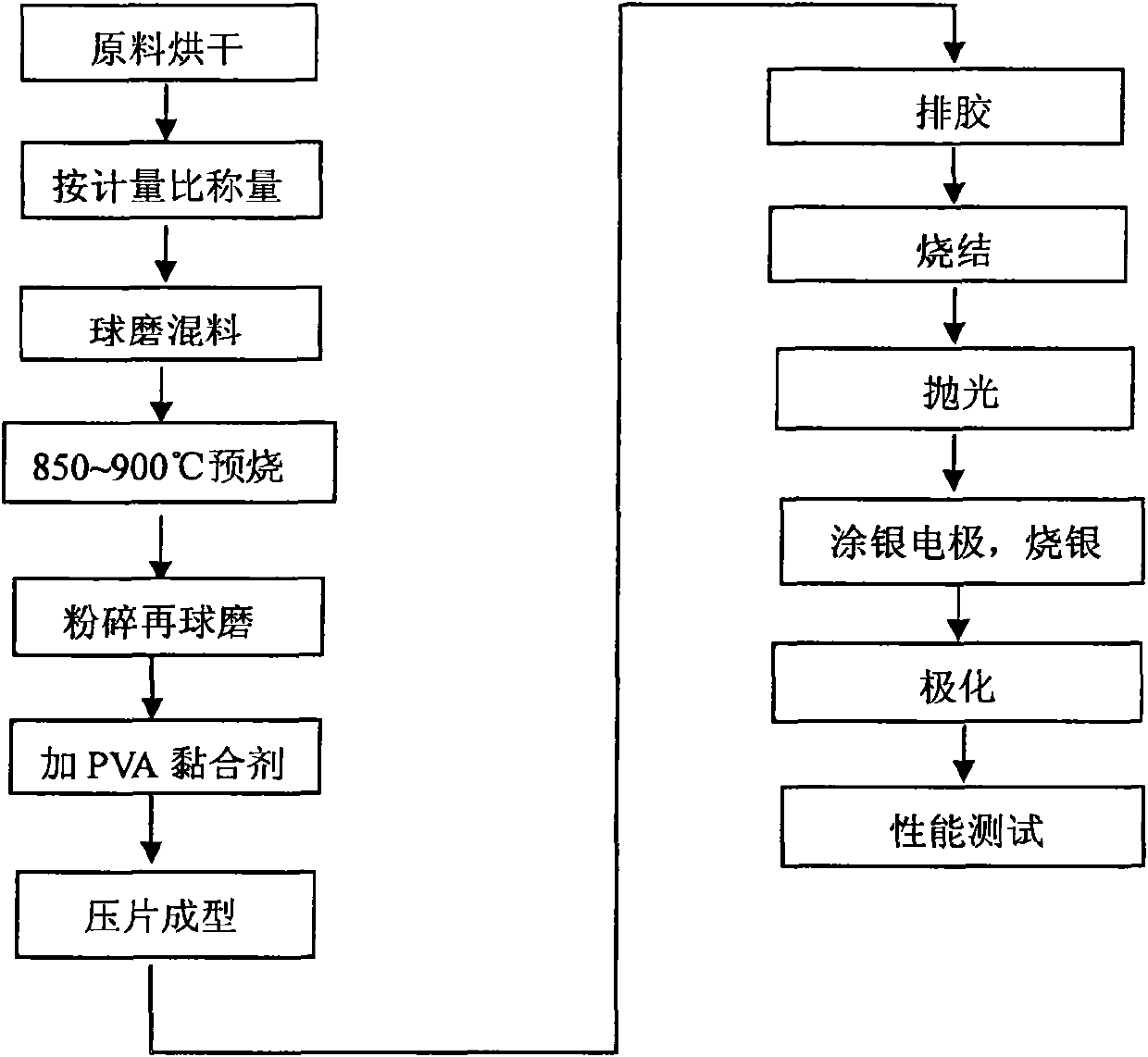

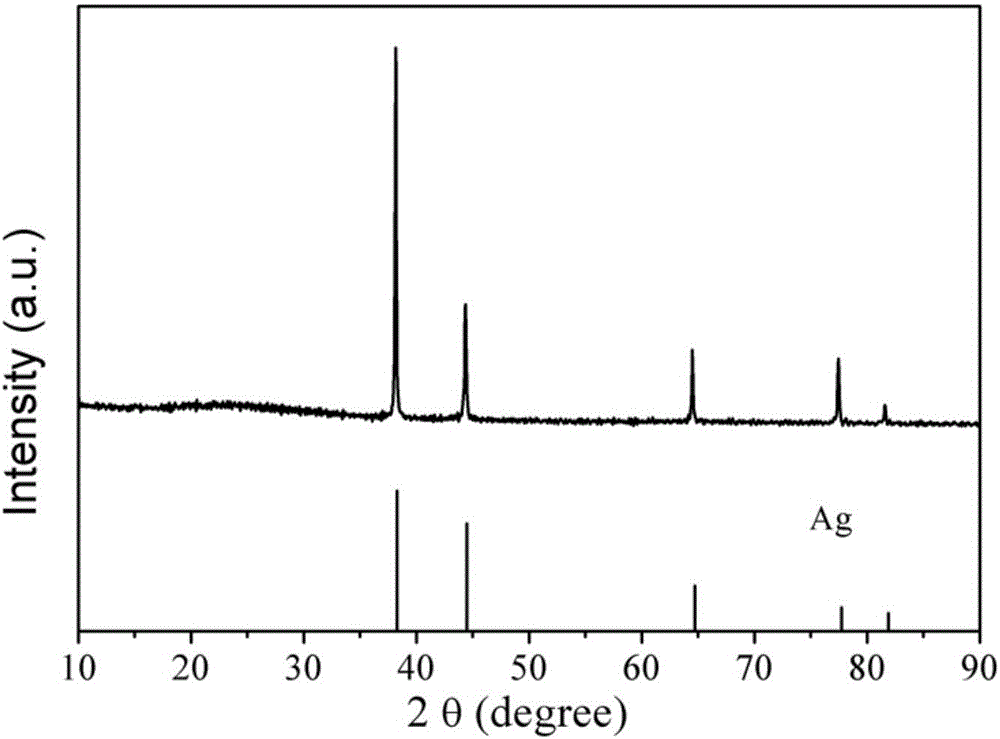

PPSMZT-doped piezoelectric ceramic, preparation method thereof and use thereof

InactiveCN101948309AImprove piezoelectric performanceLower sintering temperaturePiezoelectric/electrostrictive/magnetostrictive devicesSilver inkLithium

The invention discloses a PPSMZT-doped piezoelectric ceramic, a preparation method thereof and use thereof. The preparation method comprises the following steps: synthesizing a ternary Pb0.98Sr0.02(Mn1 / 3Sb2 / 3)x(Zr0.5Ti0.5)1-xO3(PSMZT) pre-burnt product; doping cobalt-niobium-bismuth-lithium-copper-nickel low-melting-point glass with the pre-burnt product according a stoichiometric ratio; granulating; tabletting; removing bonder; sintering; polishing; firing silver ink; and polarizing and thus obtaining the PPSMZT-doped piezoelectric ceramic. The method of the invention obviously reduce the sintering temperature of the ceramic and retaining the performance of the ceramic, is applicable to high-power piezoelectric material, and provides a raw material for manufacturing laminated piezoelectric ceramic elements.

Owner:JINAN UNIVERSITY

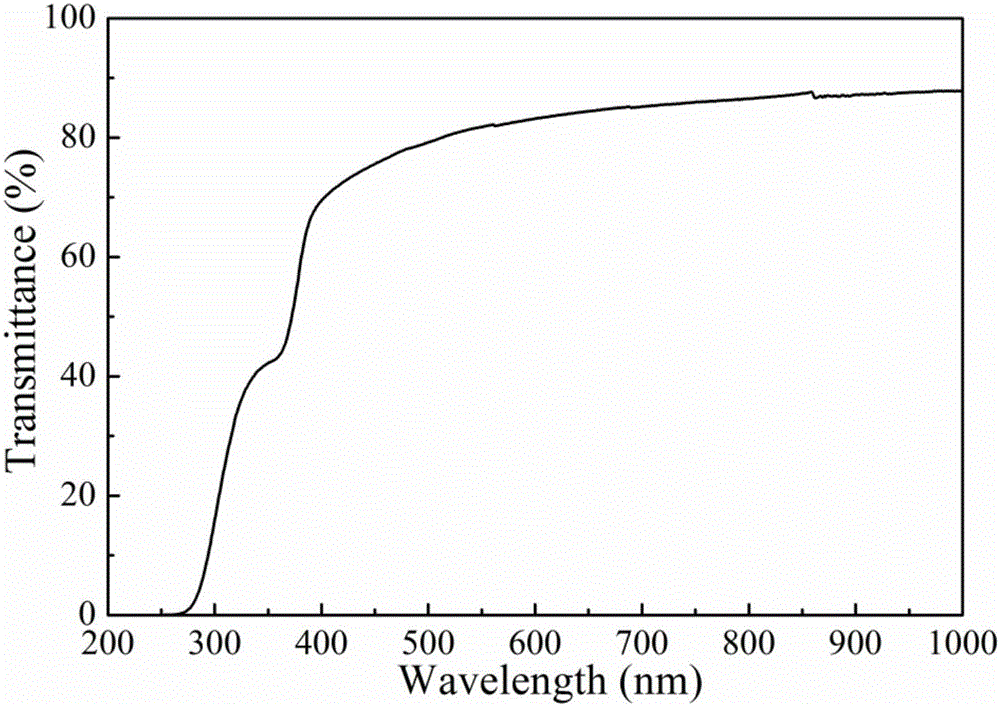

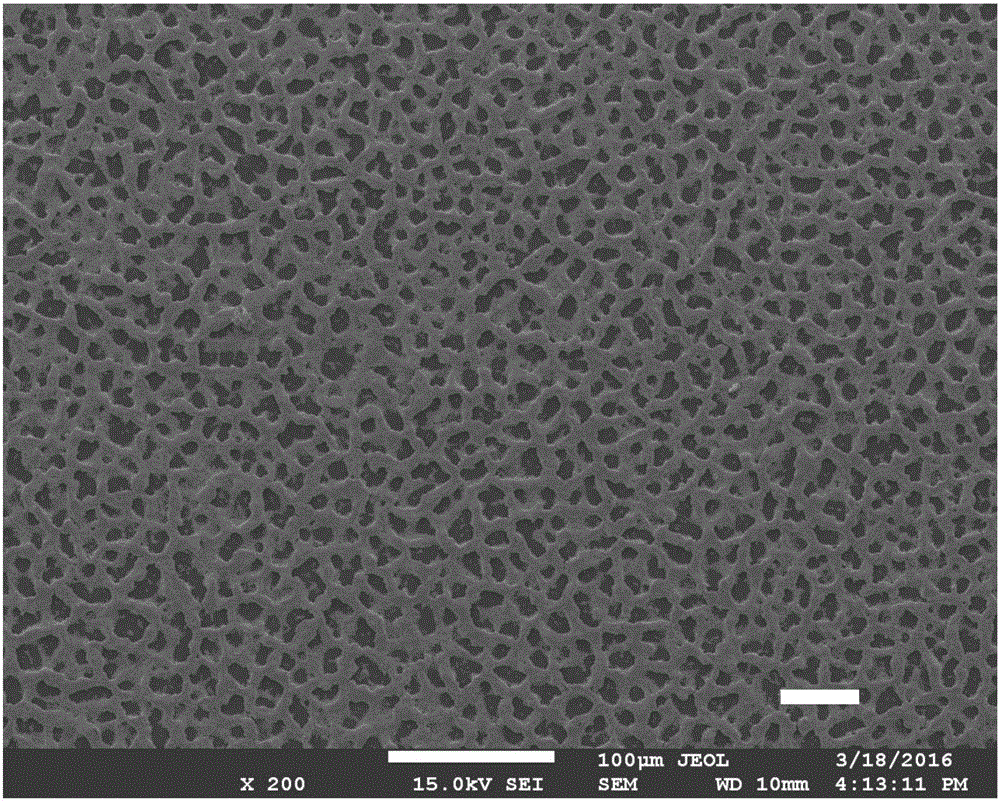

Particle-free silver ink, preparation method thereof and transparent silver conductive film and preparation method thereof

InactiveCN106752381ASimple preparation stepsSave raw materialsConductive layers on insulating-supportsInksSilver inkThin membrane

The invention discloses particle-free silver ink, a preparation method of the particle-free silver ink, a transparent silver conductive film and a preparation method of the transparent silver conductive film, and belongs to the field of transparent conductive films. The particle-free silver ink comprises the following raw materials in percentage by mass: 10 to 23% of a silver precursor, 12 to 32% of a complexing agent, 41.5 to 70% of a solvent, and 0 to 10% of an additive; the preparation method of the particle-free silver ink comprises the following steps: uniformly mixing liquid raw materials; then adding solid raw materials, stirring until being completely dissolved, and filtering. The transparent silver conductive film comprises 99.9wt % of Ag and the balance of impurities, and is of a grid structure, and the film thickness is 30nm to 2 <mu> m, the film transmittance of the transparent silver conductive film is 17 to 83%, and the square resistance of the transparent silver conductive film is 1.1 to 11.3 omega / square; the preparation method of transparent silver conductive film comprises the following steps: printing or coating the particle-free silver ink on a transparent substrate, rising temperature to 100 to 400 DEG C and carrying out heat preservation for 3 to 45min. The method has simple operation, environmental protection, low curing temperature, low cost, easy storage and easy realization of industrialization, and further can be applied to a flexible substrate and can be realized by using multiple printing and coating methods.

Owner:NORTHEASTERN UNIV

Silver ink composition

ActiveUS20140026782A1Improve stabilityImprove conductivityAntifouling/underwater paintsInksSilver inkPhysical chemistry

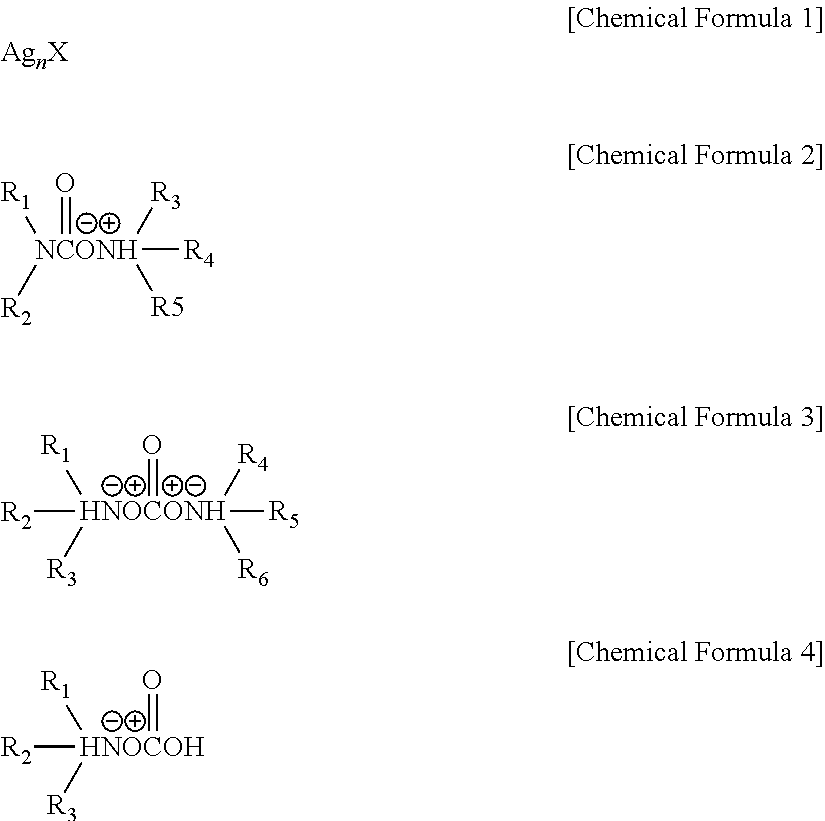

The present invention relates to a silver ink composition comprising: silver complexes obtained by reacting one or more silver compounds selected from chemical formula 1 with one or more ammonium carbamate-based compounds or ammonium carbonate-based compounds selected from chemical formula 2 to chemical formula 4; and oxime-based compounds.

Owner:INKTEC CO LTD

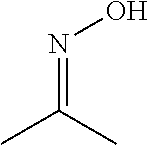

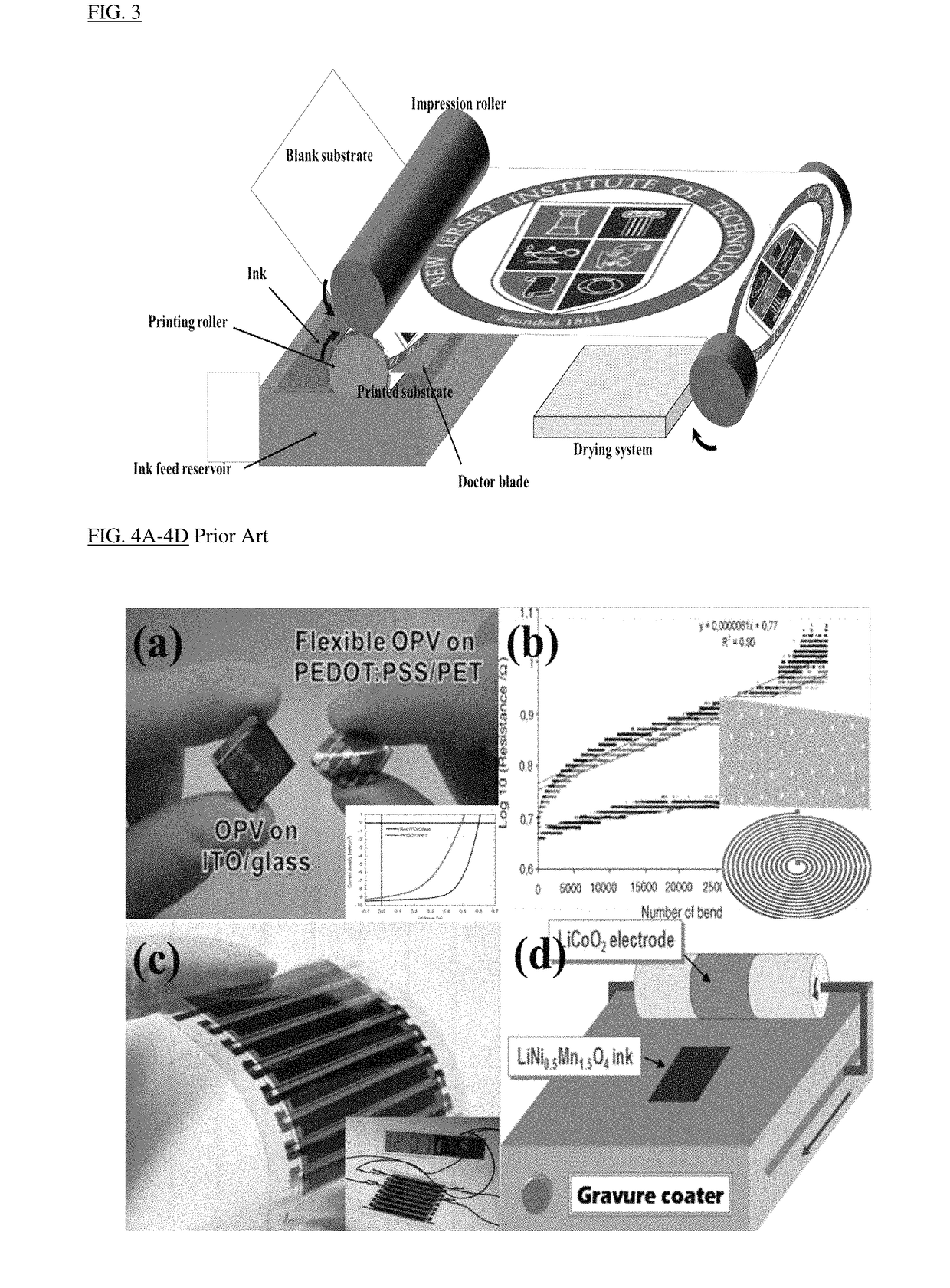

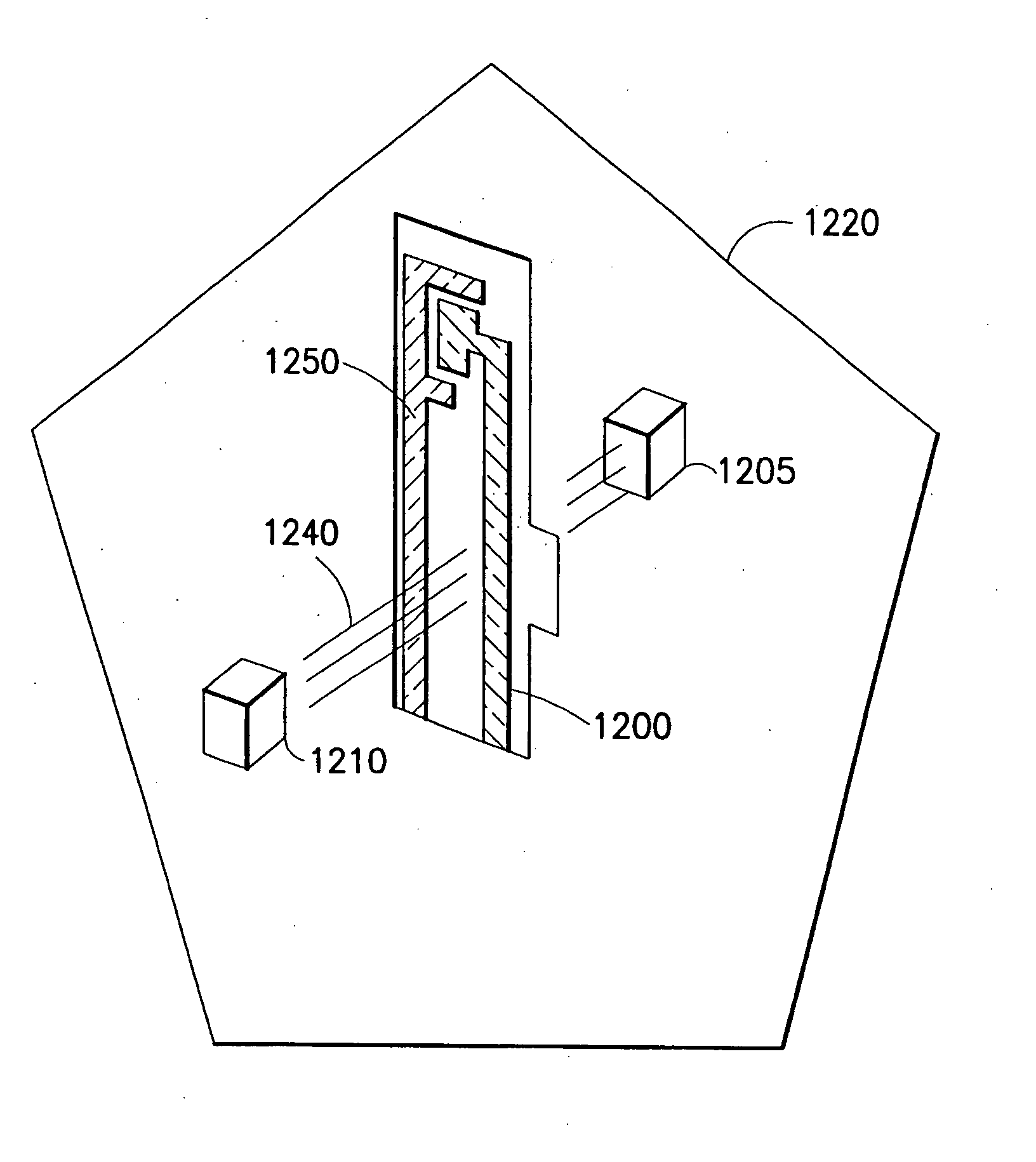

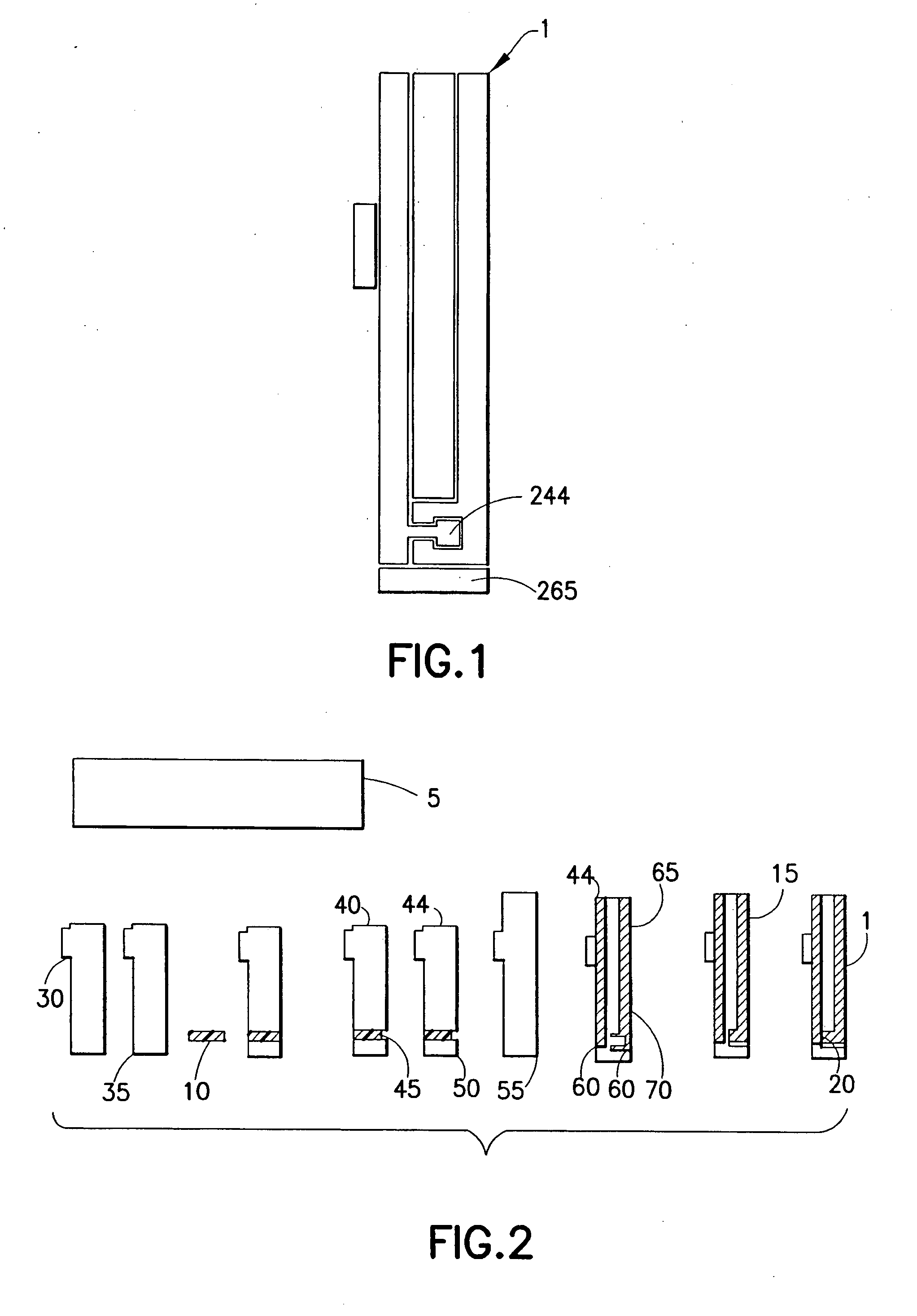

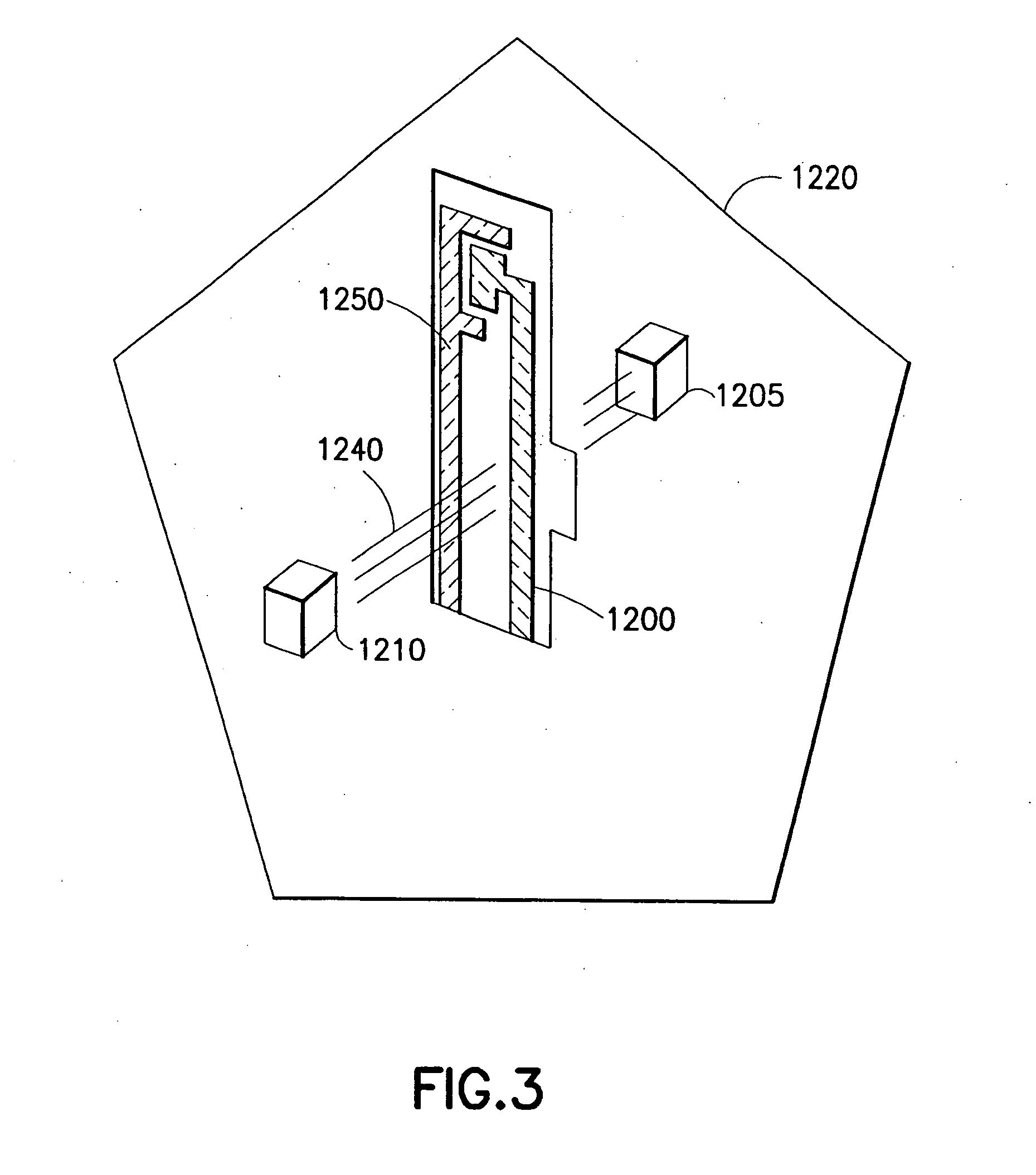

Fabrication of flexible conductive items and batteries using modified inks

ActiveUS10116000B1High resolution printingEasy to sinterAdditive manufacturing apparatusHybrid capacitor electrolytesSilver inkLithium-ion battery

A chemical process to formulate conductive ink with low sintering temperature for inkjet printing is described and shown. The application of fabricated flexible conductive film on lithium ion batteries is also described. This chemical method and composition can remove the oxidation on metallic nanoparticle surface during ink fabrication and sintering processes. Etched metallic ions in the conductive ink are reduced and particles bridged while annealing printed patterns to achieve low temperature sintering at about 350° C. The chemical process can be applied on nickel materials that are excellent current collectors for lithium ion batteries due to high chemical stability especially at high charging-discharging potential of less than 3 Volts. Thermal decomposition and chemical reduction of silver salts are two methods disclosed for particle-free silver ink. Surfactant additive further make silver film more uniform and easier to be sintered.

Owner:NEW JERSEY INSTITUTE OF TECHNOLOGY

Conductive silver ink for encapsulating LED and preparation method thereof

ActiveCN101514281AImprove protectionEasy to recycleNon-macromolecular adhesive additivesOther chemical processesSilver inkSolvent

The invention relates to LED encapsulation technology, and in particular relates to a conductive silver ink for encapsulating LED and preparation method thereof. The conductive silver ink comprises the following components of: ultrafine silver powder; an ink substrate; a solvent; a curing agent; a curing accelerator and an auxiliary agent. The manufacturing method of the conductive silver ink comprises the following steps of: 1) weighting the ink substrate, the solvent, the ultrafine silver powder, the curing agent, the curing accelerator and the auxiliary agent based on weight percentage; 2)mixing the weighted resin with the solvent, stirring at high speed and dispersing the resin in the solvent; 3) weighting the curing agent based on the weight percentage, adding the curing agent into a mixed system to be ultrasonically processed to obtain the mixed system; 4) adding the ultrafine silver powder into the mixed system for being stirred and dispersed so as to obtain preliminary conductive silver ink; 5) weighting the curing accelerator; 6) weighting the auxiliary agent; and 7) adding the well-weighted curing accelerator and the auxiliary agent into the well-prepared conductive silver adhesive, and rolling with a three-high mill to result in conductive silver ink products. The invention is simple in the preparation method, easy in operation, low in energy consumption and free from pollution.

Owner:宁波安芯美半导体有限公司

Strip electrode with conductive nano tube printing

InactiveUS20080023327A1Improve consistencyFlat surfaceImmobilised enzymesMaterial nanotechnologySilver inkCarbon nanotube

A sensor system that detects a current representative of a compound in a liquid mixture features a multi or three electrode strip adapted for releasable attachment to signal readout circuitry. The strip comprises an elongated support which is preferably flat adapted for releasable attachment to the readout circuitry; a first conductor and a second and a third conductor each extend along the support and comprise means for connection to the circuitry. The circuit is formed with single-walled or multi walled nanotubes conductive traces and may be formed from multiple layers or dispersions containing, carbon nanotubes, carbon nanotubes / antimony tin oxide, carbon nanotubes / platinum, or carbon nanotubes / silver or carbon nanotubes / silver-chloride. An active electrode formed from a separate conductive carbon nanotubes layer or suitable dispersion, positioned to contact the liquid mixture and the first conductor, comprises a deposit of an enzyme capable of catalyzing a reaction involving the compound and preferably an electron mediator, capable of transferring electrons between the enzyme-catalyzed reaction and the first conductor. A reference electrode also formed from a conductive carbon nanotube layer or suitable dispersion is positioned to contact the mixture and the second conductor. The system includes circuitry adapted to provide an electrical signal representative of the current which is formed from printing conductive inks made with nano size particles such as conductive carbon or carbon / platinum or carbon / silver, or carbon nanotubes / antimony tin oxide to form a conductive carbon nanotube layers. The multiple-electrode strip is manufactured, by then applying the enzyme and preferably the mediator onto the electrode. Alternatively the electrode can have a carbon nanotubes / antimony tin oxide, carbon nanotubes / platinum, or carbon nanotubes / silver or carbon nanotubes / silver-chloride surface and or a conductive carbon or silver ink surface connecting leg. The carbon nanotube solution is first coated and patterned into electro shapes and the conductive carbon nanotubes, carbon or silver ink can be attached by printing the ink to interface with the carbon nanotube electro surface. A platinum electrode test strip is also disclosed that is formed from either nano platinum distributed in the carbon nanotube layer or by application or incorporation of platinum to the carbon nanotube conductive ink.

Owner:MYSTICMD

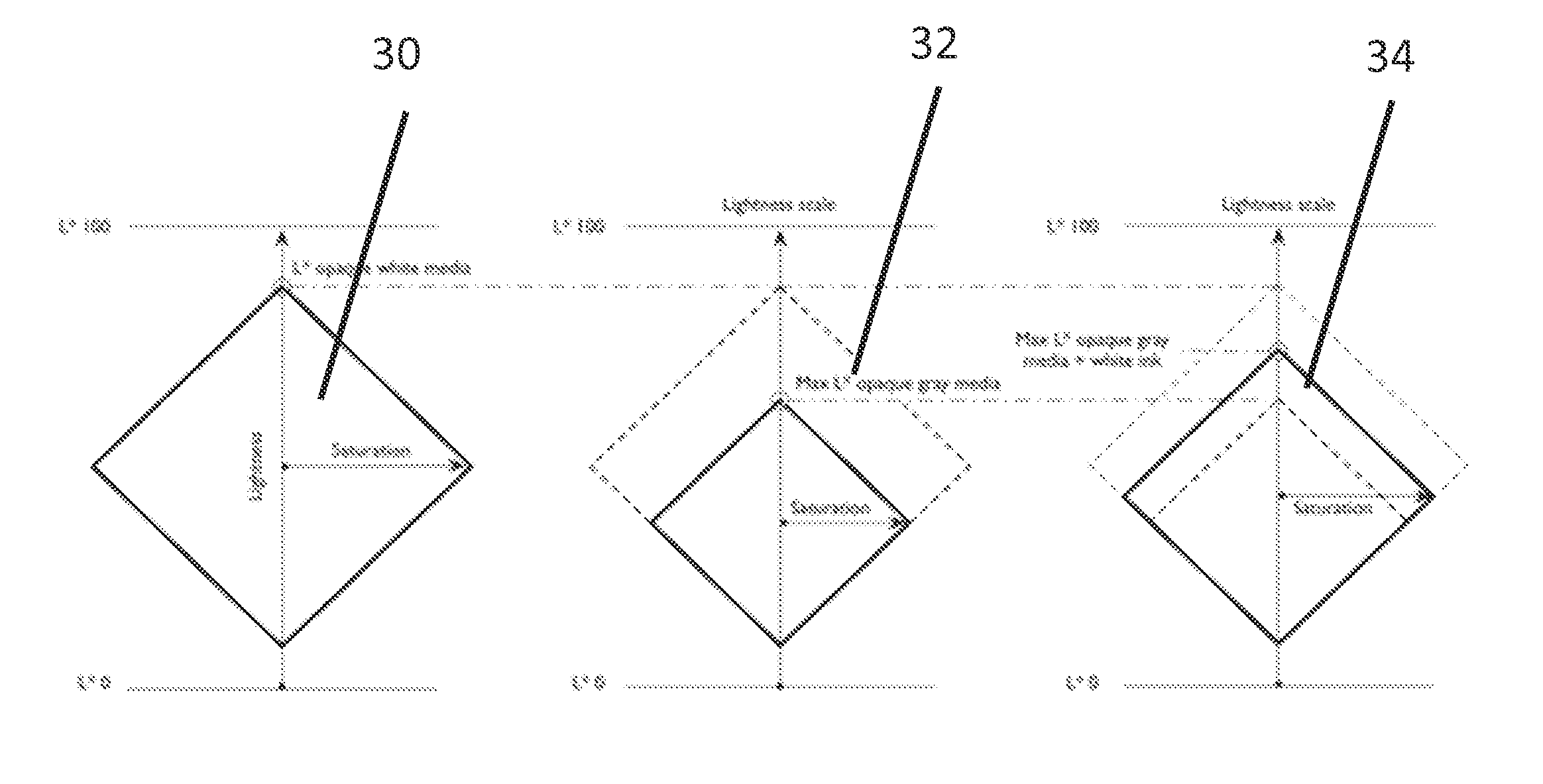

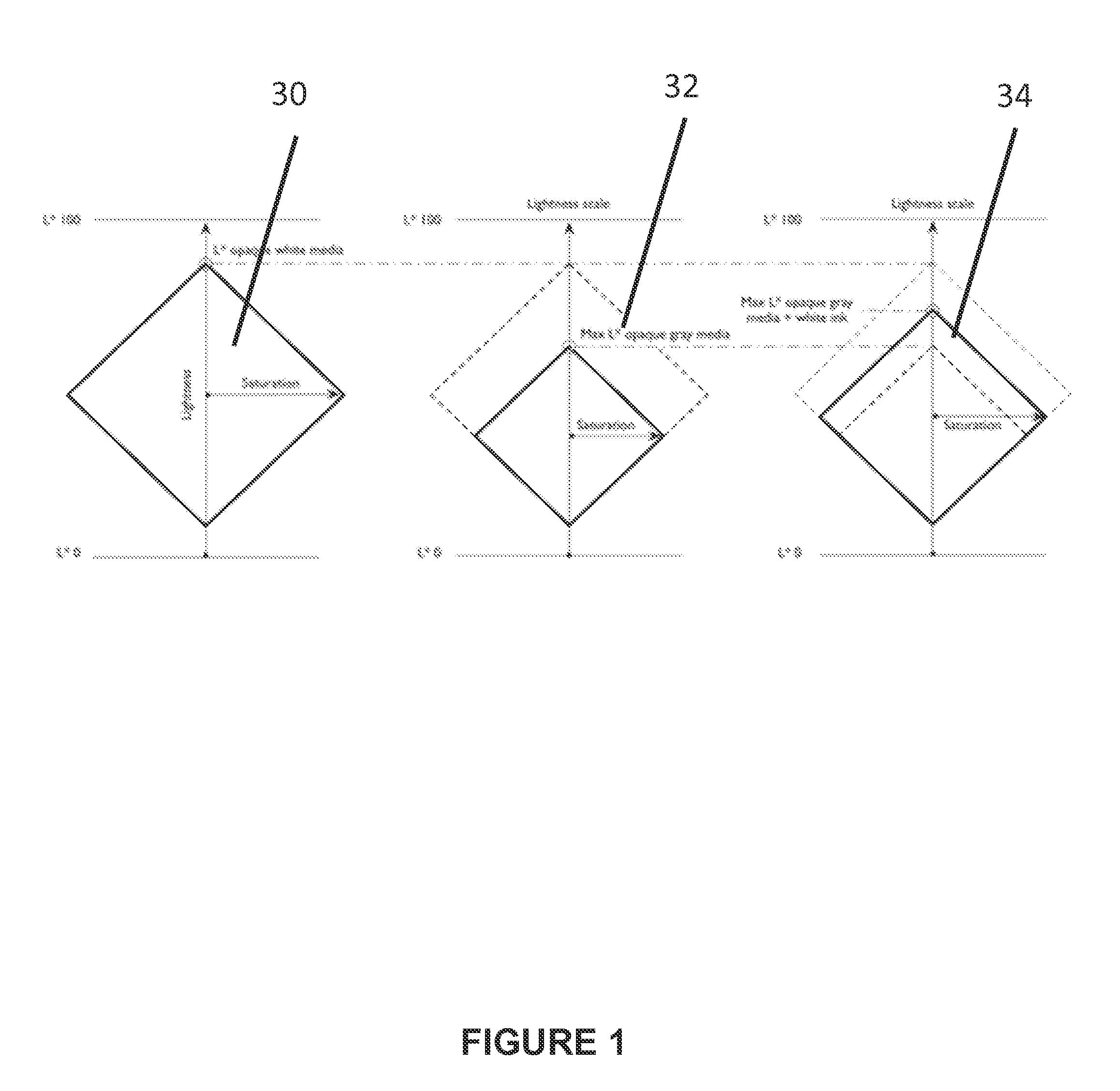

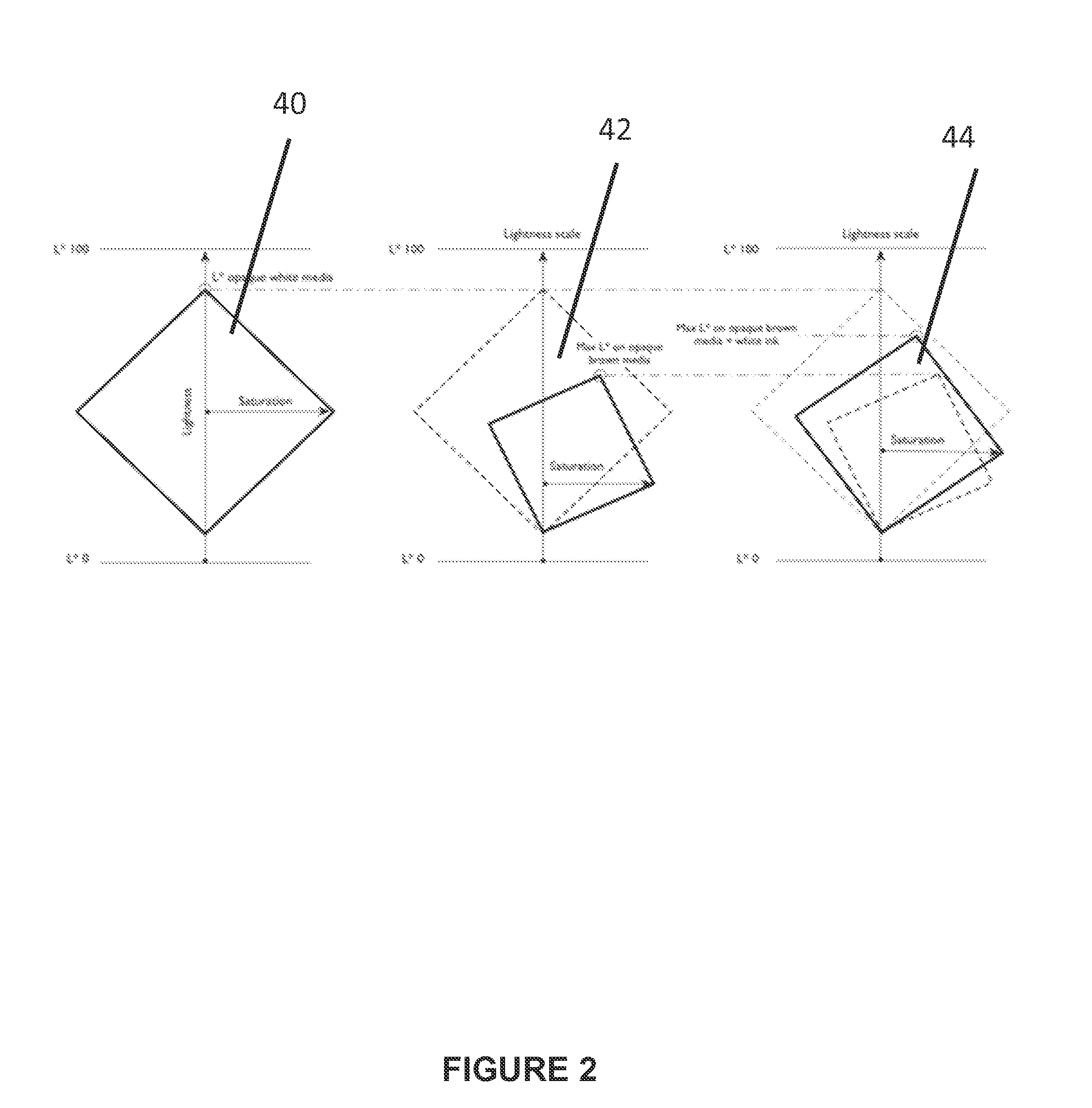

Method and apparatus for effecting color separation, color variation, color characterization, and gamut mapping in color printing

ActiveUS20150022832A1Reduce contrastDigitally marking record carriersVisual presentation using printersSilver inkVariable thickness

Embodiments of the invention concern automatic color separation with a white ink for colored and / or transparent substrate, automatic color separation with a silver ink for a natural rendering, automatic color separation with a varnish which has a gloss scale different from that of the printed sample for all shades of gloss that are possible between high glossy to high matte for a false third rendering, automatic color variation with variable thickness under the inks, and variable gamut mapping for a low contrast space.

Owner:FIERY LLC

Solvent-based conductive ink, preparation method and application

The invention relates to a solvent-based conductive silver ink, a preparation method and an application. The solvent-based metal conductive ink for ink jet printing is characterized by being preparedfrom 10%-30% metal salt, 1%-10% of a reducing agent, 10%-30% of a complex stabilizer, 40%-60% of a solvent and 0.1%-0.5% of an additive, wherein the sum of mass percentage of the components is 100%. The preparation method comprises the following steps: firstly, dissolving the metal salt in a stabilizer and a solvent, then adding the reducing agent, performing stirring at room temperature, then leaving the mixture to stand overnight, performing filtering to obtain a clear solution, and then adding the additive to obtain the conductive ink. A complex precursor solution is formed with the preparation method of the ink, the conductive ink is printed on a flexible substrate by a 3D ink jet printer in an additive manufacturing mode, and a conductive film is obtained by heating. The preparation method is simple, low in cost and low in post-treatment temperature. The prepared solvent-based conductive ink is suitable for ink jet printing and spray holes are prevented from being blocked; the conductive ink is suitable for preparing electrode circuits of various flexible electronic devices such as solar cells, field effect transistors, RFID and the like.

Owner:SHANGHAI MI FANG ELECTRONICS LTD

Silver ink with good metal printing effect and printing process using silver ink

ActiveCN104403407AGood metal effectImprove surface smoothnessInksOther printing apparatusCardboardSilver ink

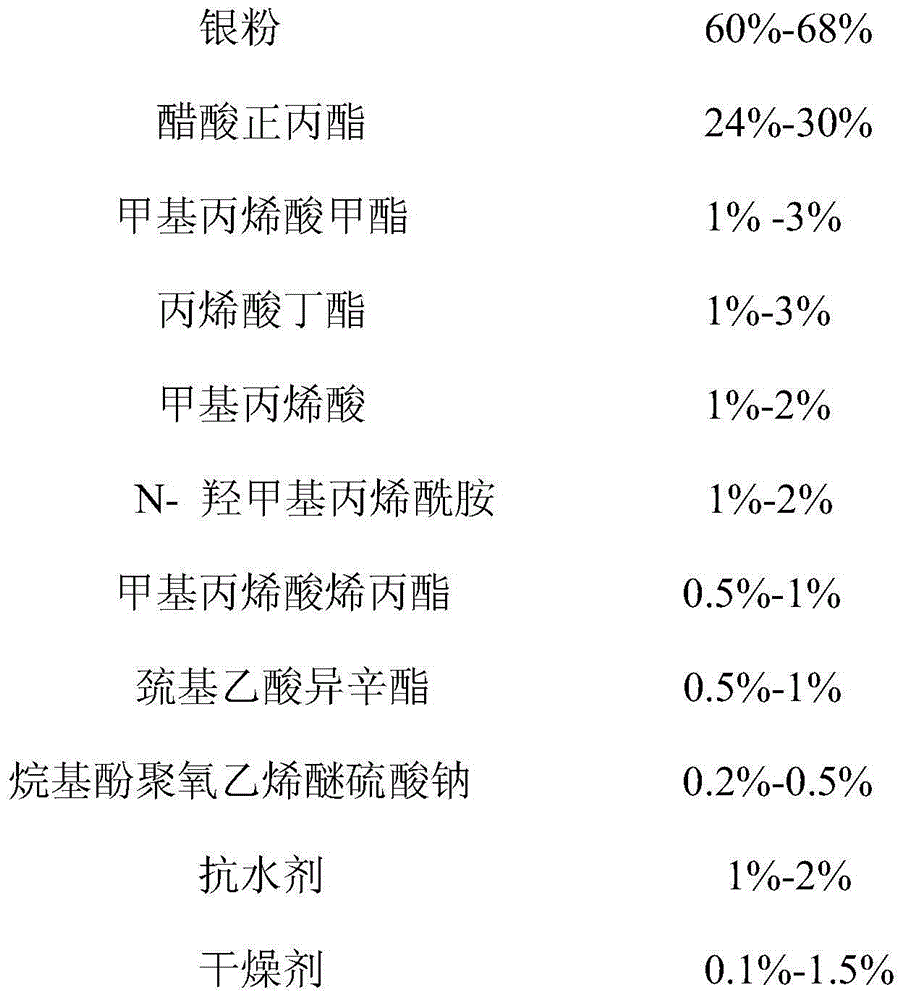

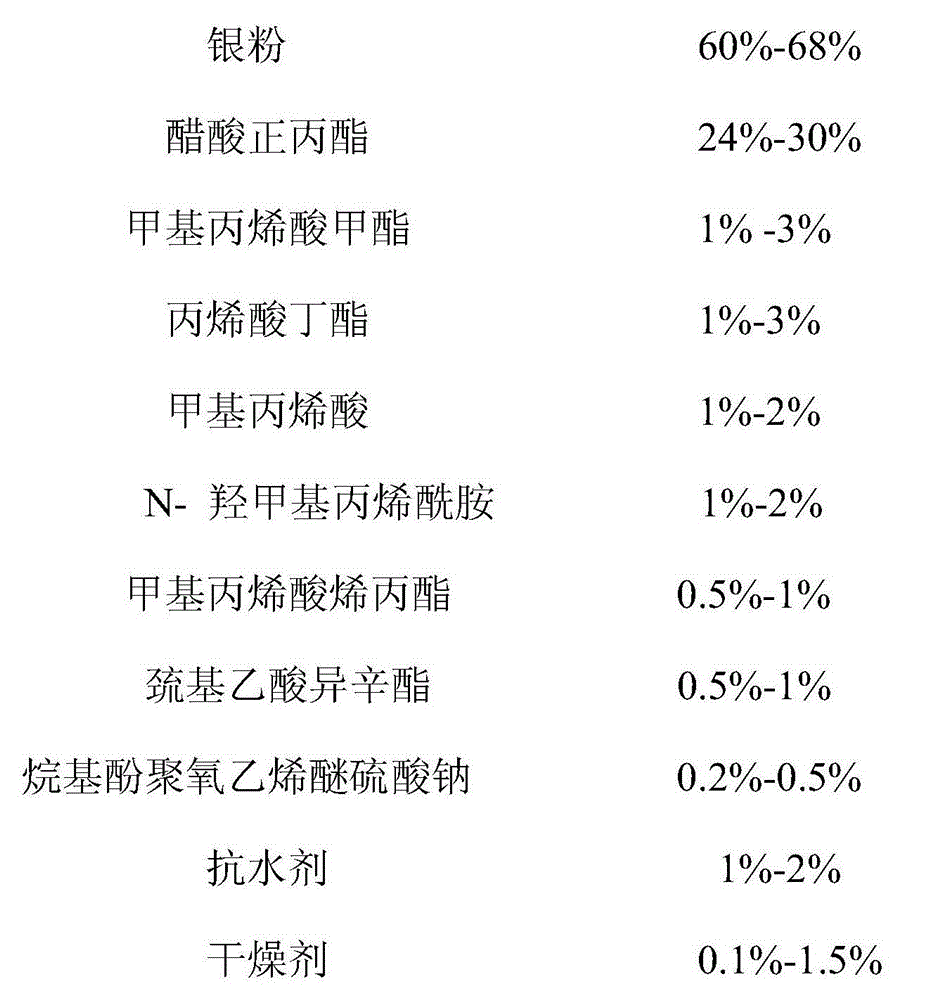

The invention provides silver ink with a good metal printing effect and a printing process using the silver ink. The printing process comprises the steps that first, a coated surface of a white cardboard with a single side coated is coated with water-soluble varnish or UV (ultraviolet) varnish, images and texts are printed with well mixed gravure silver ink in a gravure manner, and finally, a layer of water-soluble varnish or UV varnish is printed on an image and text area with the gravure silver ink. The gravure silver ink is formed by blending the following materials in percentage by weight: 60-68% of silver powder, 24-30% of n-propyl acetate, 1-3% of methyl methacylate, 1-3% of butyl acrylate, 1-2% of methacrylic acid, 1-2% of N-hydroxymethyl acrylamide, 0.5-1% of allyl methacrylate, 0.5-1% of isooctyl thioglycolate, 0.2-0.5% of alkylphenol ethoxylates sodium sulfate, 1-2% of water-resistant agents and 0.1-0.5% of drying agents. By means of the silver ink and the printing process, a metal ink layer has a refraction effect, the metal effect is more obvious and an optimal metal effect is achieved.

Owner:WUHAN HONGZHICAI PACKAGING PRINTING

Preparation method for crystalline silicon solar cell nanometer transparent buried gate electrode

ActiveCN102983212AReduce light reflectivityReduce manufacturing costFinal product manufactureSemiconductor devicesSilver inkEtching

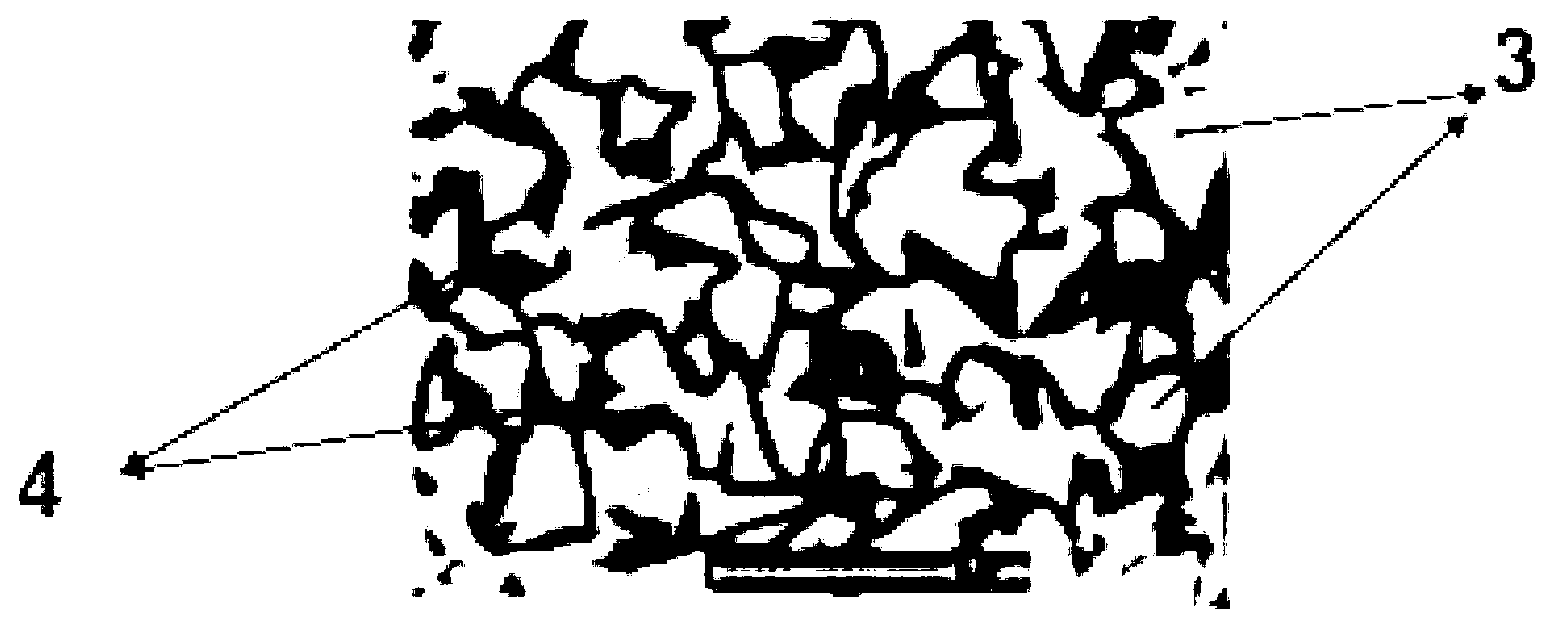

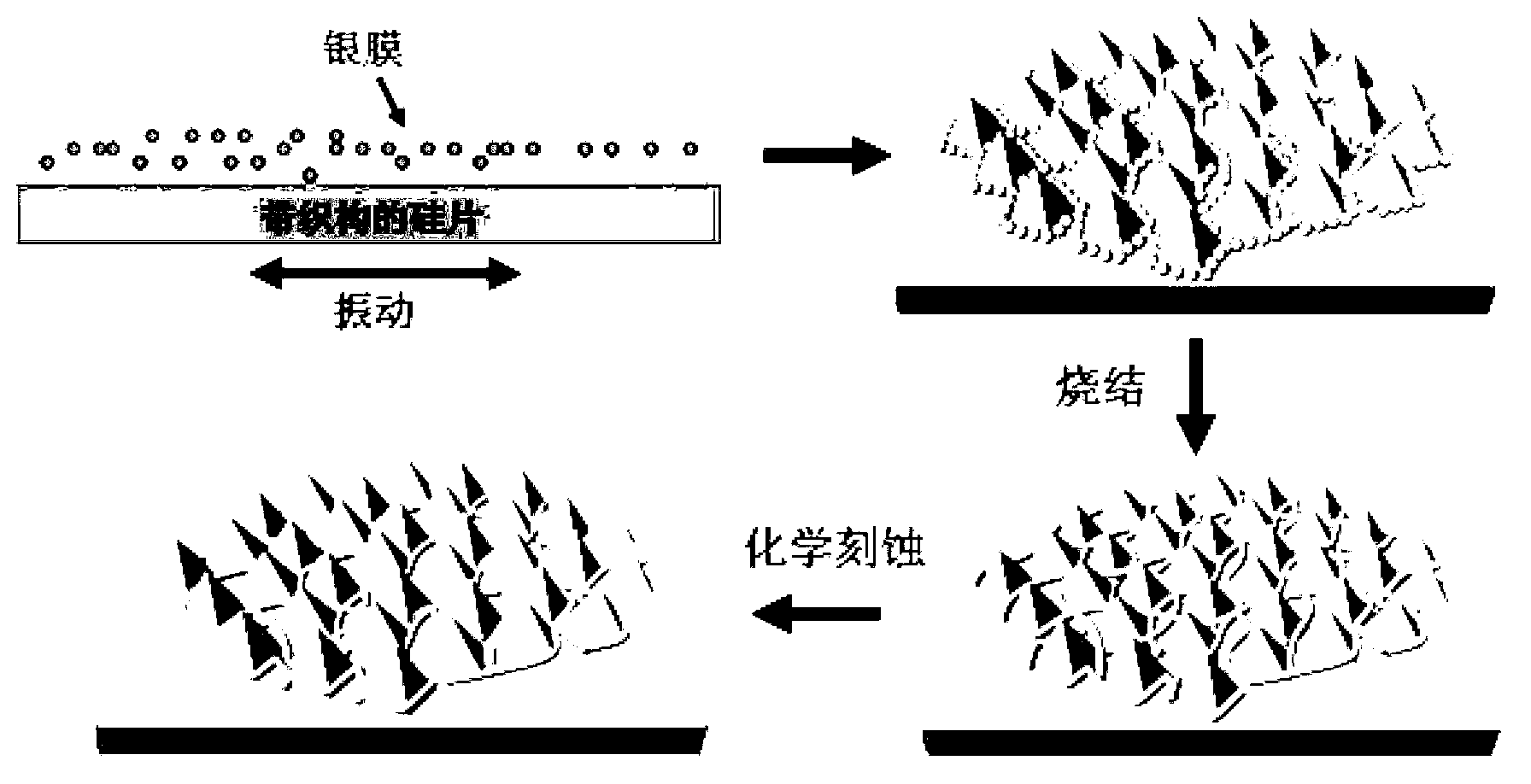

The invention relates to a preparation method for a crystalline silicon solar cell nanometer transparent buried gate electrode. The preparation of an electrode sample includes a first step of dripping silver ink solutions to the surface of a silicon wafer with a pyramid suede structure, exerting vibration in the horizontal direction on the silicon wafer, and enabling the whole surface of the silicon wafer to form an aggregate structure with evenly distributed nanometer silver particles, a second step of sintering the electrode sample, heating the electrode sample through microwave radiation and enabling the nanometer silver particles to be mutually fused to form mutually connected metal nanometer line or bar network structures, a third step of carrying out metal auxiliary chemical etching to the electrode sample, carrying out metal auxiliary etching process to the sample after being sintered in mixed solutions of hydrofluoric acid, hydrogen peroxide and ethanol, and enabling the metal nanometer line or bar network electrode to be inserted into the silicon wafer to form the nanometer transparent buried gate electrode. After the metal auxiliary chemical etching, antireflection effects of the metal nanometer line or bar networks inserting into the silicon wafer are remarkably optimized, contact resistance of the metal nanometer line or bar network electrode and the silicon wafer is remarkably decreased, and the electrode has a function of an antireflection layer and potential excellent carrier collection efficiency.

Owner:SOUTH CHINA NORMAL UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com