2-2 type cement base piezoelectric composite material

A piezoelectric composite material and composite material technology, applied in the field of smart materials, can solve the problems of poor compatibility of concrete, acoustic impedance matching, deformation coordination, stiffness and interface adhesion, false signals of smart materials, affecting sensing accuracy, etc. The effect of low cost, good durability and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Example 1: Effect of volume fraction of piezoelectric ceramics on properties of piezoelectric composites

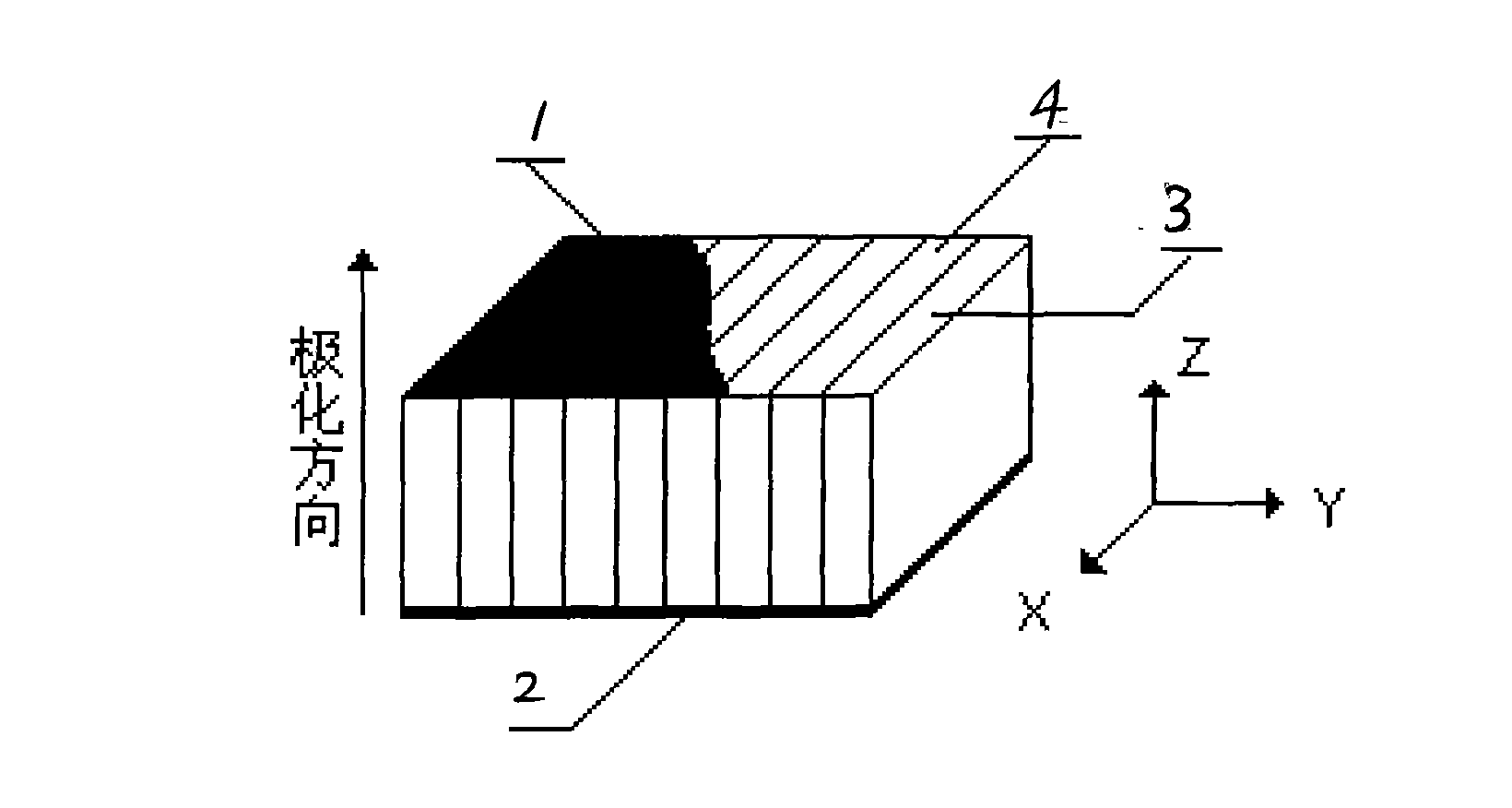

[0031] Such as figure 1 As shown (the same below), the 2-2 type cement-based piezoelectric composite material of the present invention includes alternately arranged cement layers 3 and piezoelectric ceramic sheets 4, and an upper electrode 1 on the upper surface and a lower electrode on the lower surface. Electrode 2.

[0032] It is made by the following method: polarize a cuboid piezoelectric ceramic block; use a slicer to cut out the piezoelectric ceramic pieces sequentially along the direction parallel to the polarization axis of the piezoelectric ceramic, without cutting the entire piezoelectric ceramic block during the cutting process. The ceramic block is cut through, leaving a base; the cut ceramic block is repeatedly cleaned to remove the remaining ceramic residue; the cleaned ceramic block is placed in the mold, and cement is poured according to a certain...

Embodiment 2

[0038] Example 2: The effect of water-cement ratio on the performance of piezoelectric composite materials

[0039] Using sulfoaluminate cement and polarized lead niobium magnesium zirconate titanate ceramics as raw materials, along the polarization direction of the lead niobium magnesium zirconate titanate piezoelectric ceramics, the length (X-axis direction) of 19mm, a width (Y-axis direction) of 1mm, a thickness (Z-axis direction) of 6.5mm, and the spacing of the ceramic sheets is also 1mm. After cleaning and drying, fix the ceramic block in the mold, put it on the vibrating table, fully stir the cement and water respectively according to the water-cement ratio of 0.30, 0.35, 0.40, 0.45, and 0.50, and then under the condition of constant vibration, place the Cement is poured into the mold, vacuumed and cured. The effect of water-cement ratio on the performance of piezoelectric composites is shown in Table 4.

[0040] Table 4 Properties of piezoelectric composites with dif...

Embodiment 3

[0043] Example 3: Effect of composite material thickness on the performance of piezoelectric composite materials

[0044]Using sulfoaluminate cement as the matrix and lead niobium magnesium zirconate titanate piezoelectric ceramics as the functional body, a cement-based piezoelectric composite material with a volume fraction of piezoelectric ceramics of 53.85% was prepared. The size of the ceramic sheet is as follows, the length (X-axis direction)×width (Y-axis direction) is 19mm×1mm, and the thickness (Z-axis direction) is 10.5mm, 9.7mm, 7.6mm, 6.6mm, 5.0mm respectively. The pitch of the ceramic sheets is 1mm. After cleaning and drying the cut ceramic block, fix it in the mold, place it on the vibrating table, fully mix the cement and water according to the water-cement ratio of 0.35, and pour the cement into the mold under constant vibration .

[0045] After curing for 7 days in a standard curing room (20±1°C, relative humidity ≥90%), grind and polish. Scrub the surface o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com