Patents

Literature

112 results about "Uniaxial crystal" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

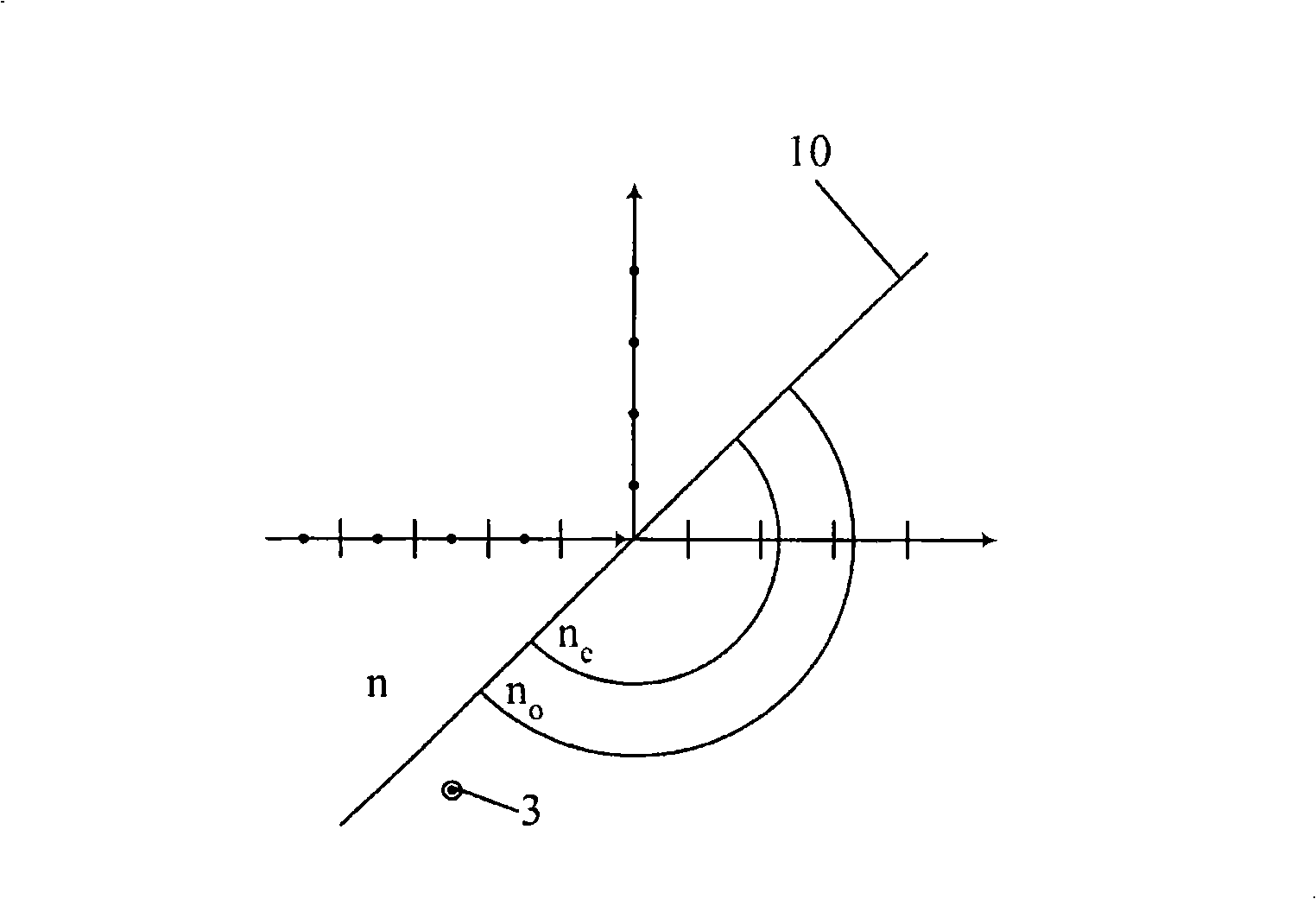

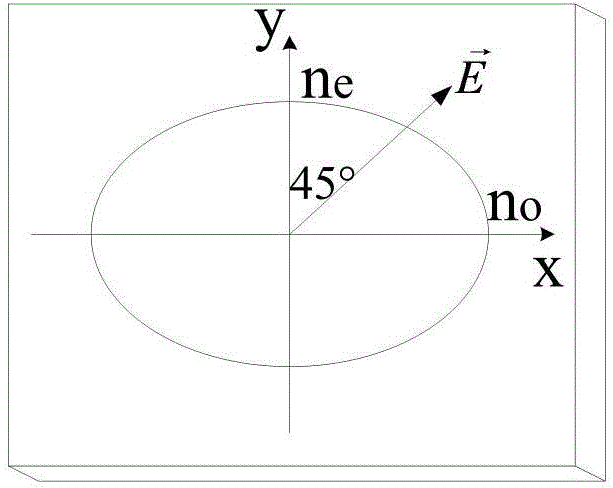

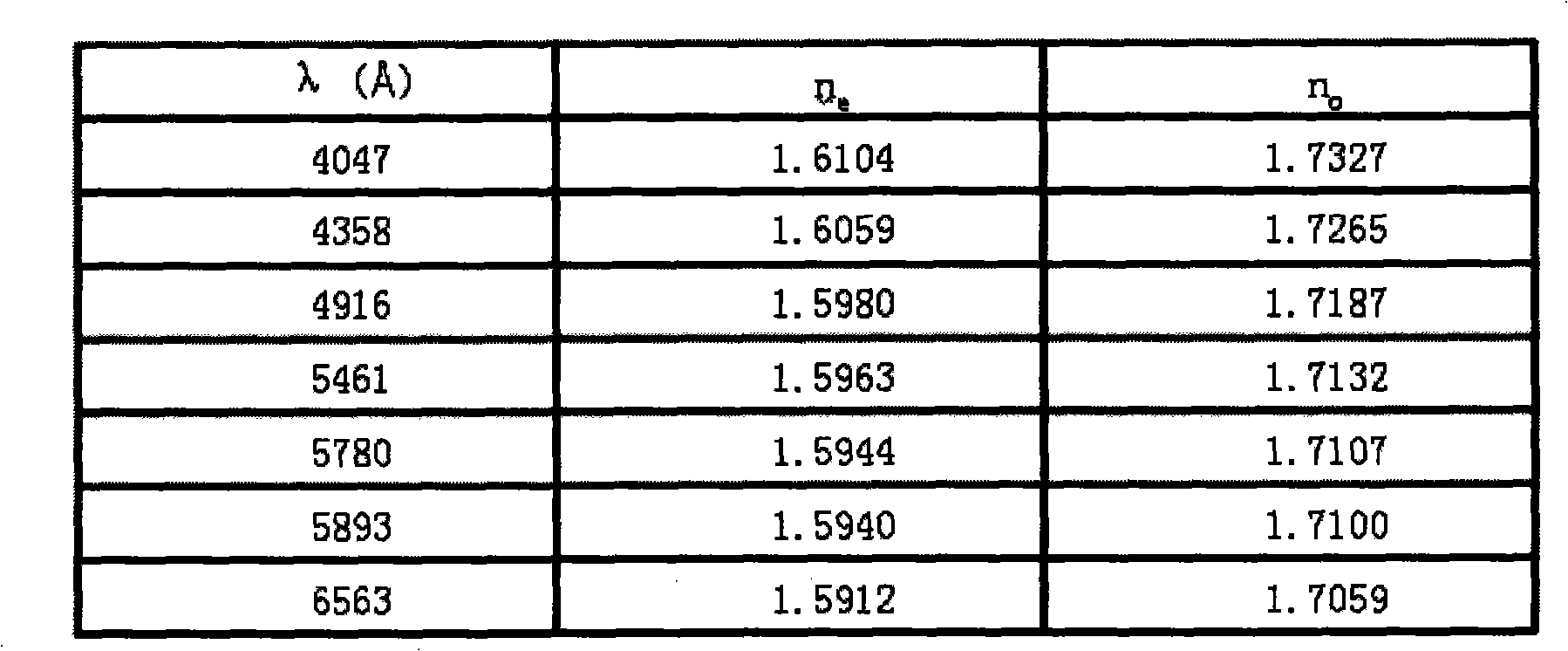

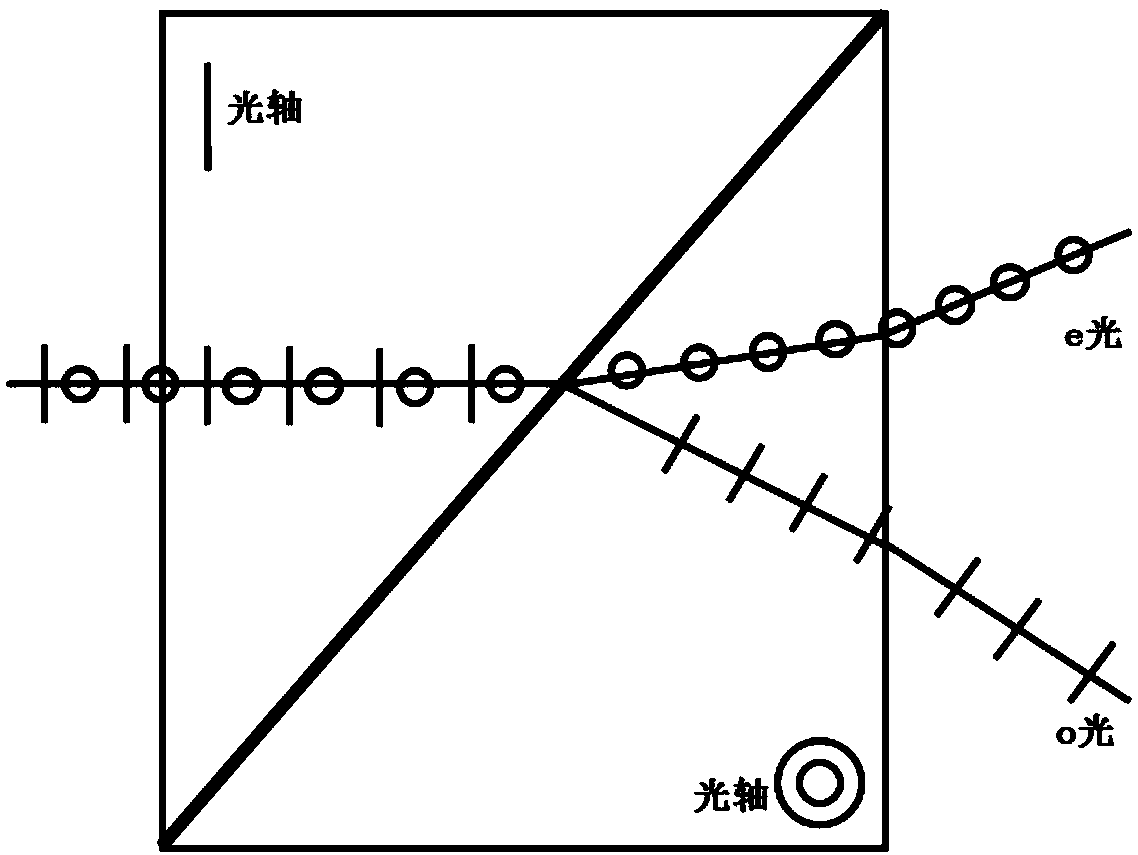

Uniaxial crystals are transmissive optical elements in which the refractive index of one crystal axis is different from the other two crystal axes (i.e. nᵢ ≠ nⱼ = nₖ). This unique axis is called the extraordinary axis and is also referred to as the optic axis. Light travels with a higher phase velocity through an axis that has the smallest refractive index and this axis is called the fast axis. Similarly, an axis which has the highest refractive index is called a slow axis since the phase velocity of light is the lowest along this axis. The optic axis can be the fast or the slow axis for the crystal depending upon the material. Negative uniaxial crystals (e.g. calcite CaCO₃, ruby Al₂O₃) have nₑ < nₒ so for these crystals, the extraordinary axis (optic axis) is the fast axis whereas for positive uniaxial crystals (e.g. quartz SiO₂, sellaite (magnesium fluoride) MgF₂, rutile TiO₂), nₑ > n ₒ and thus the extraordinary axis (optic axis) is the slow axis. These crystals show birefringent property.

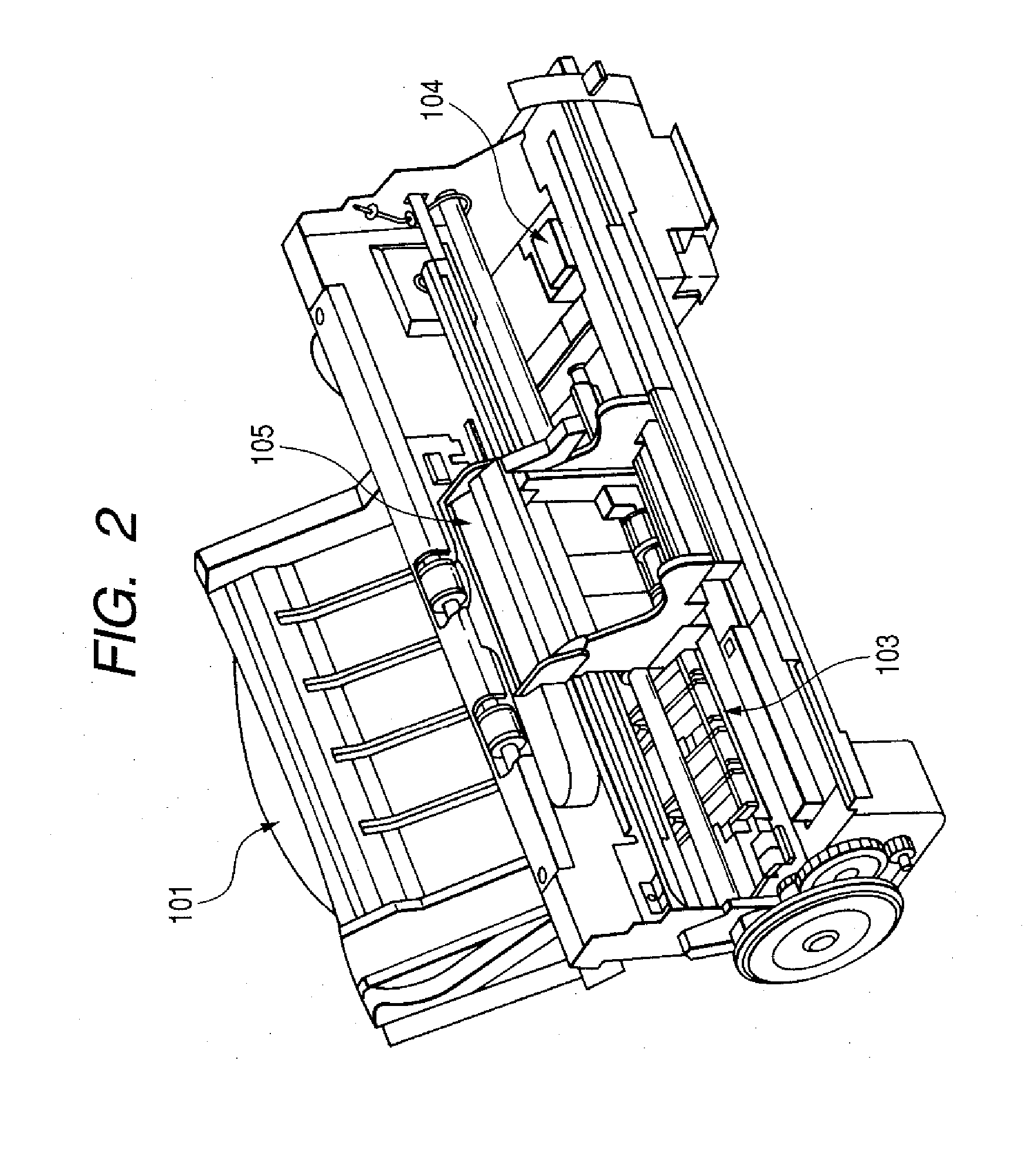

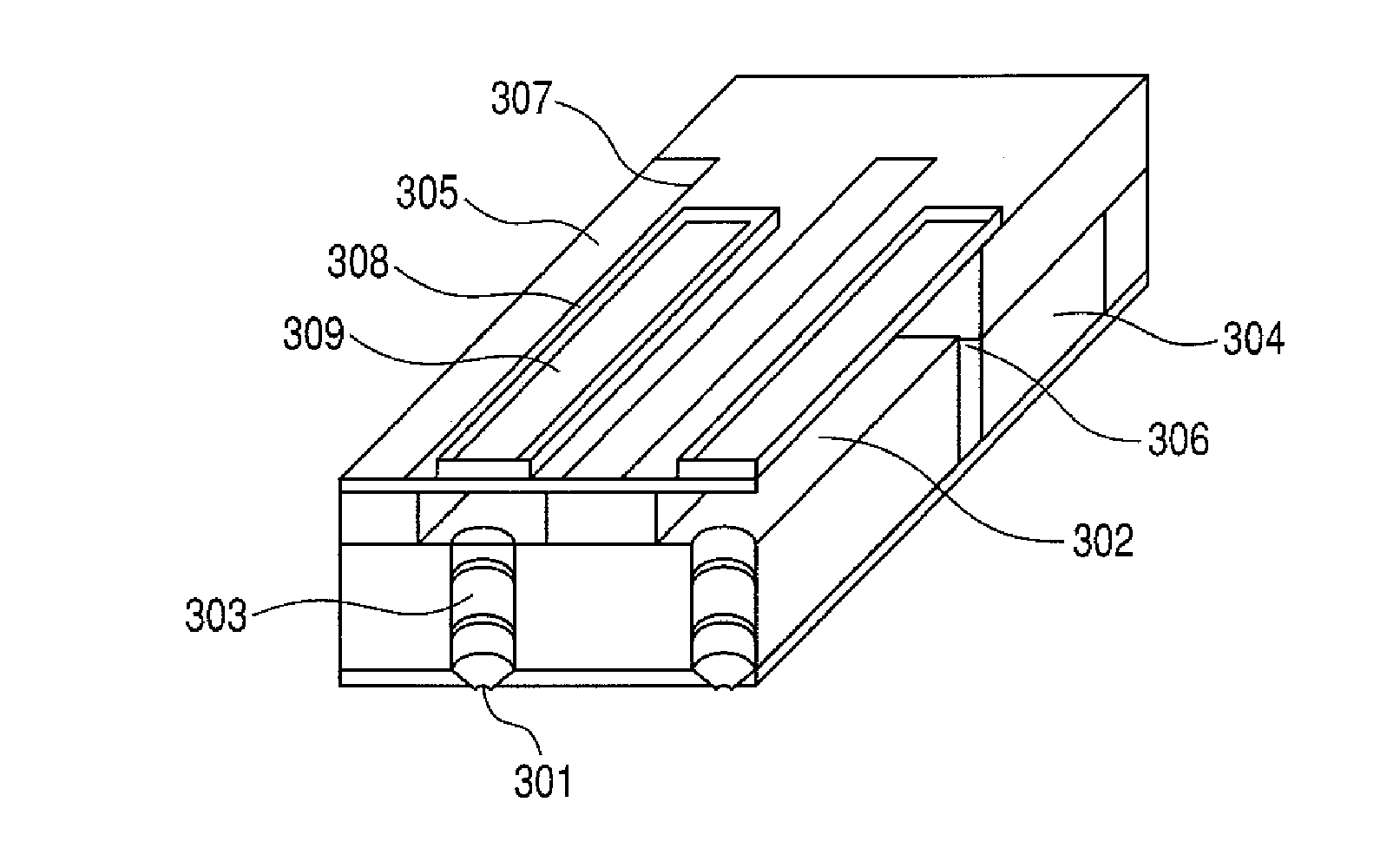

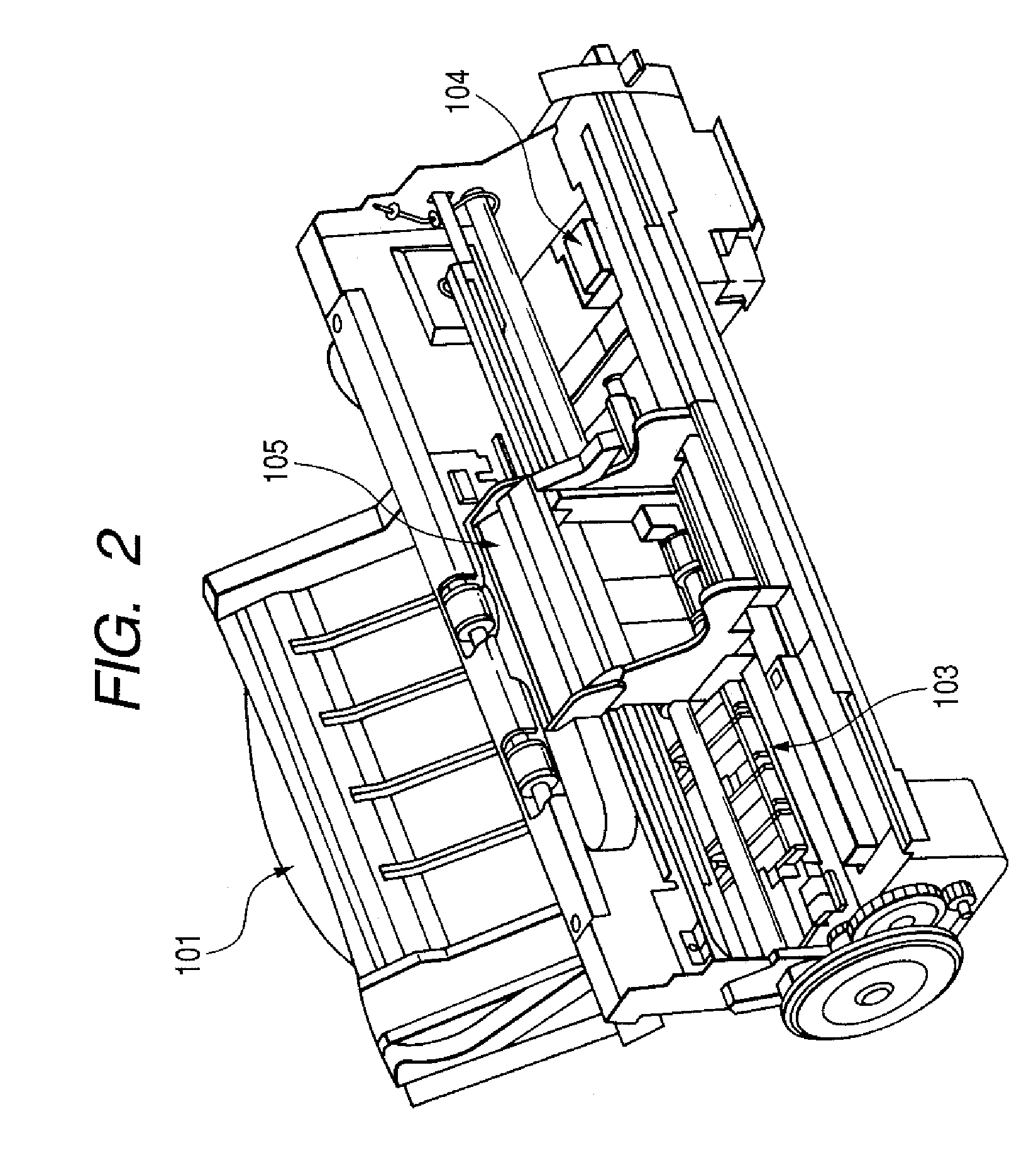

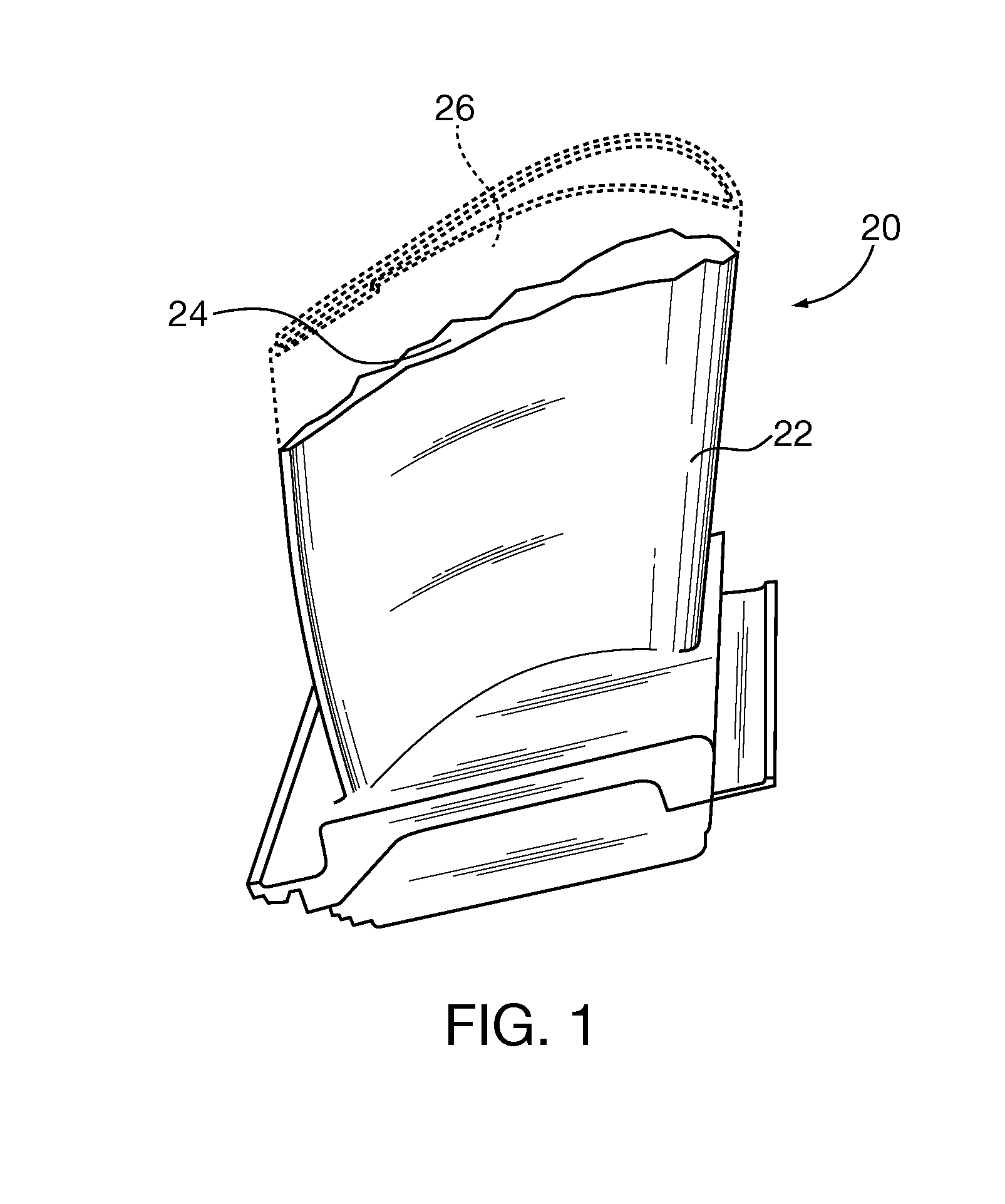

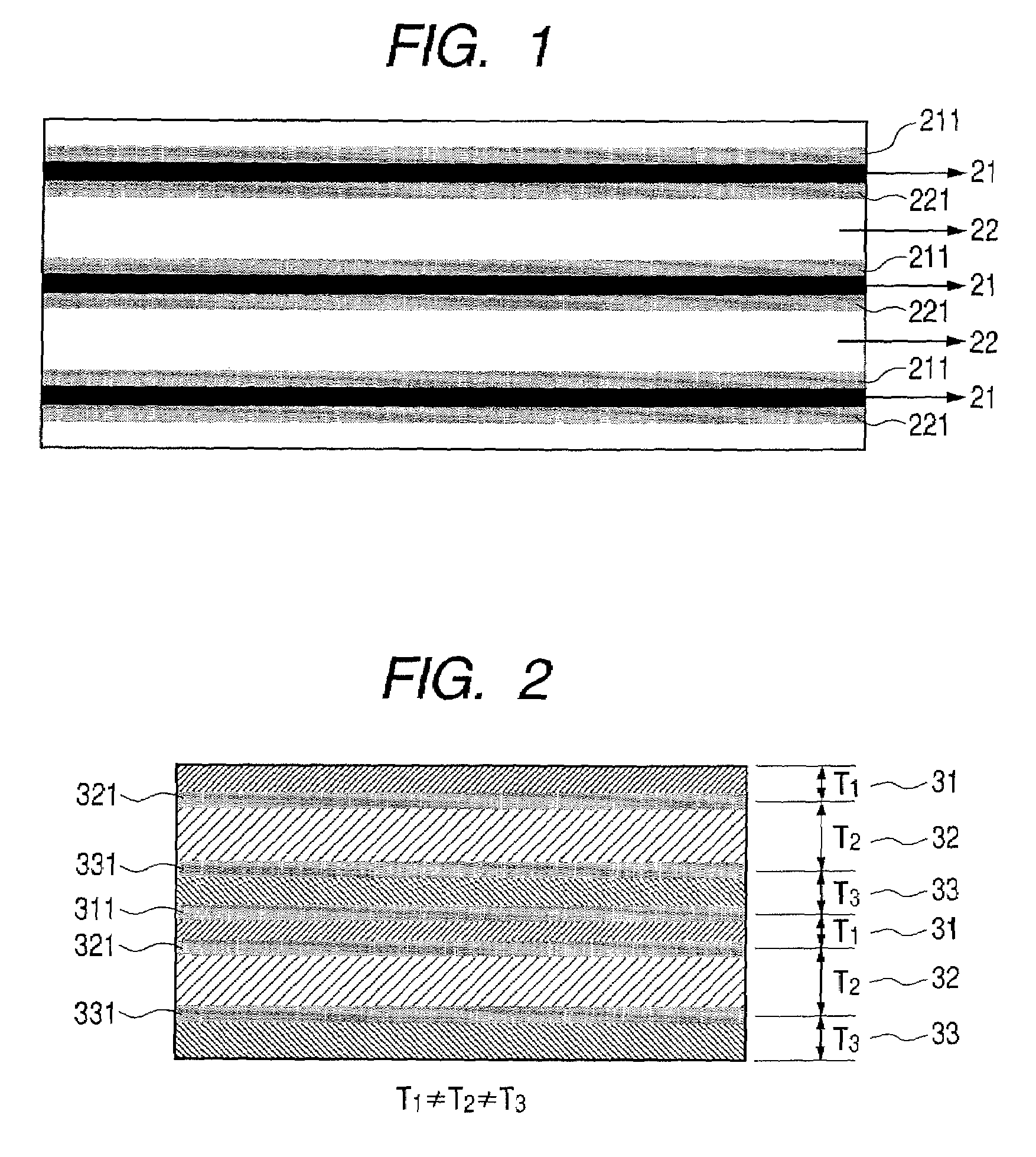

Piezoelectric substrate, piezoelectric element, liquid discharge head and liquid discharge apparatus

InactiveUS20070046153A1Reduce crystallinityEnhanced levelInking apparatusPiezoelectric/electrostriction/magnetostriction machinesCrystal structureSingle crystal

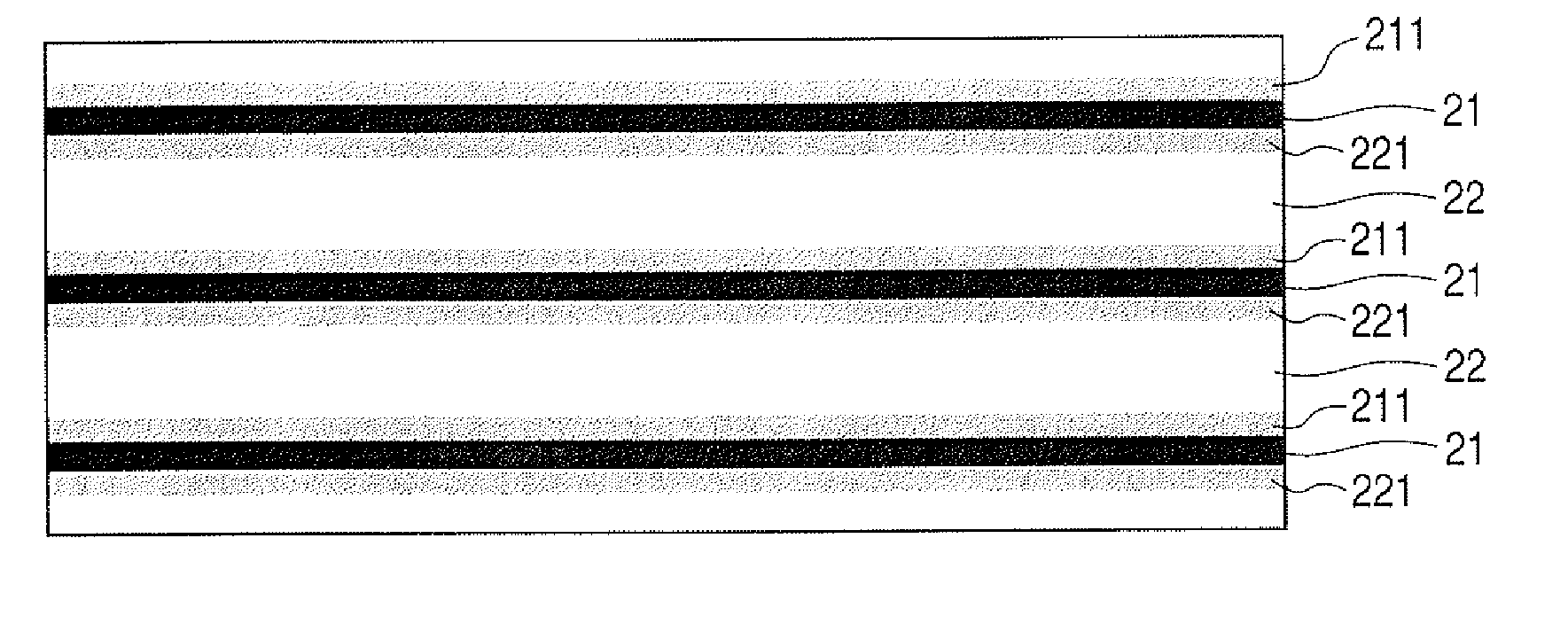

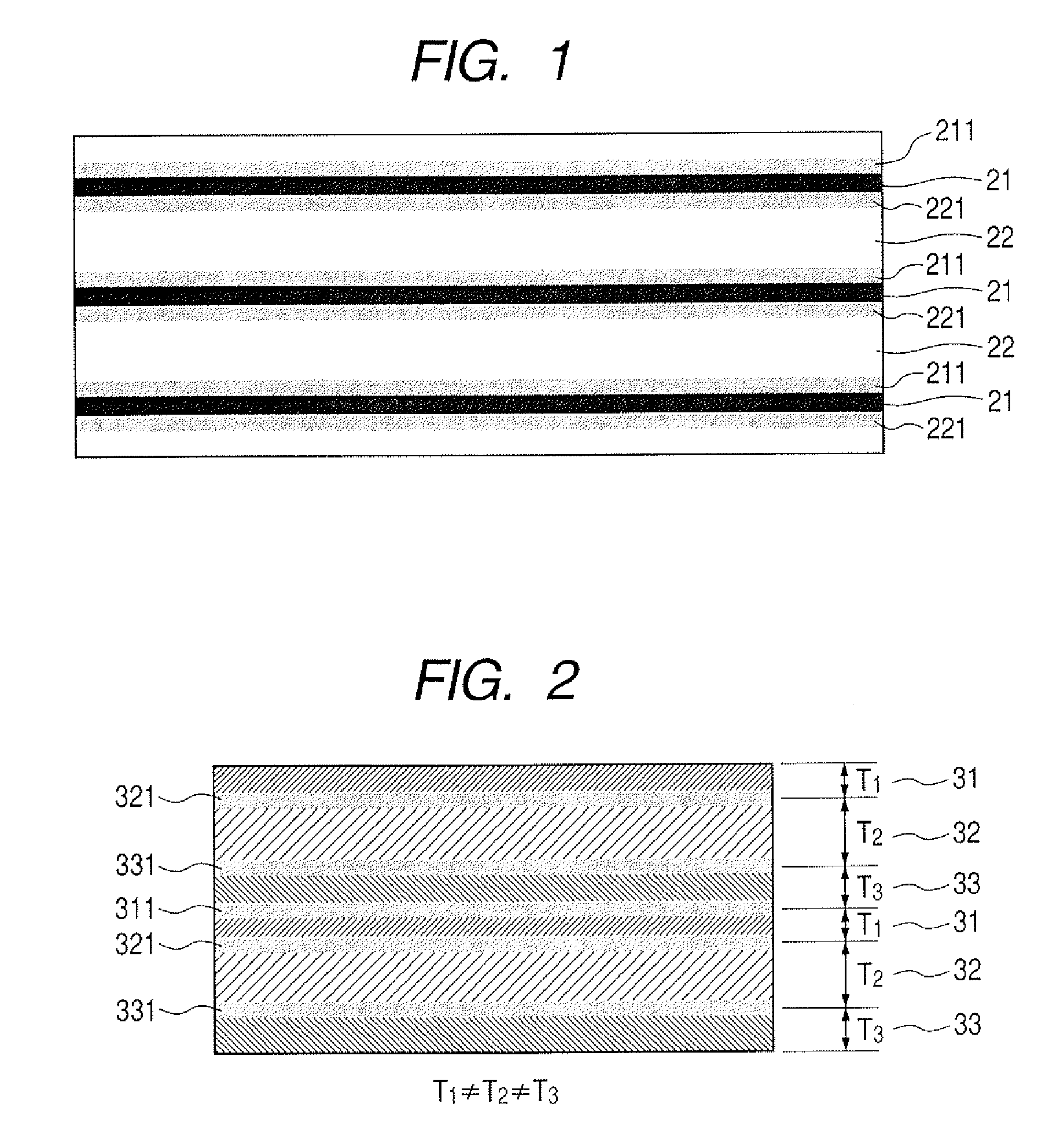

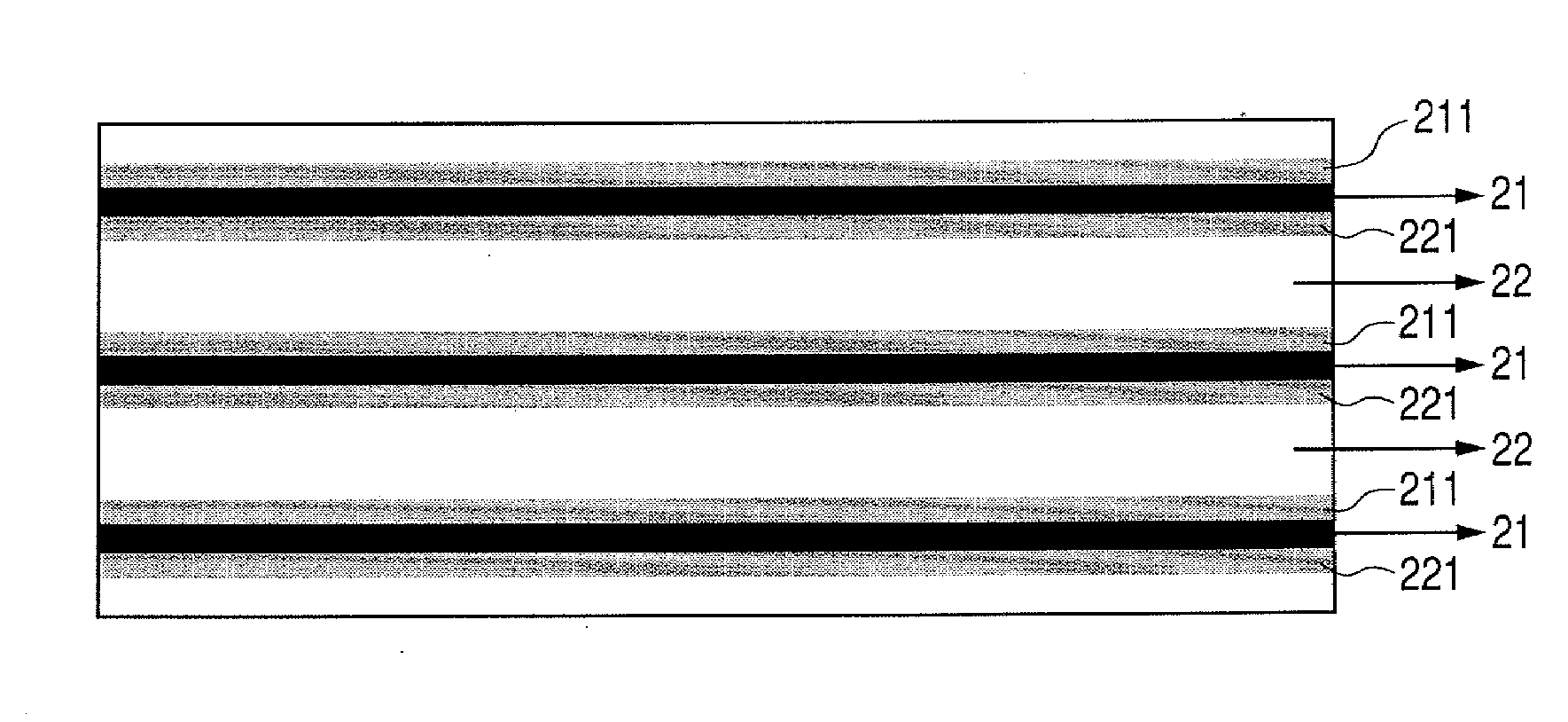

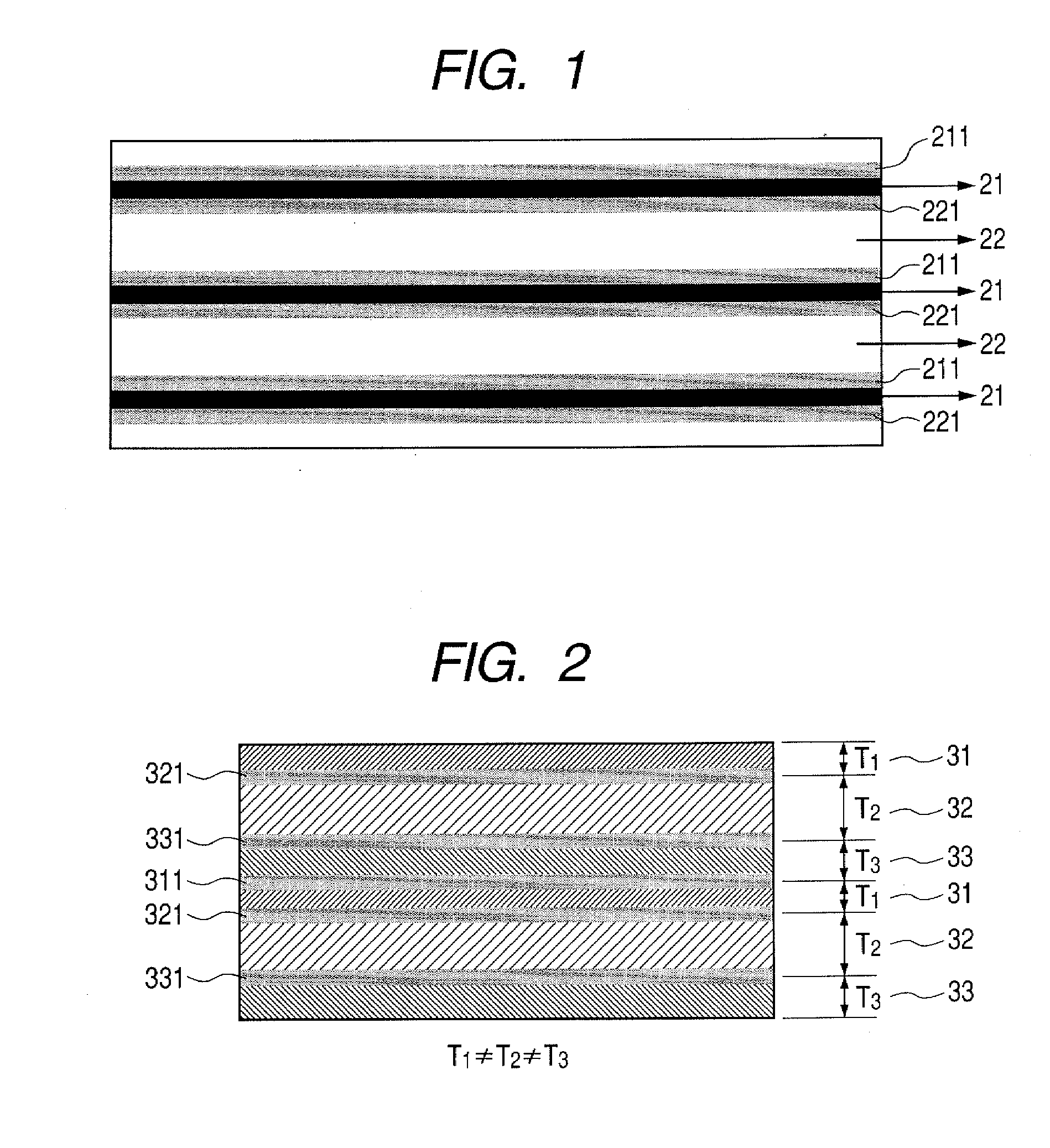

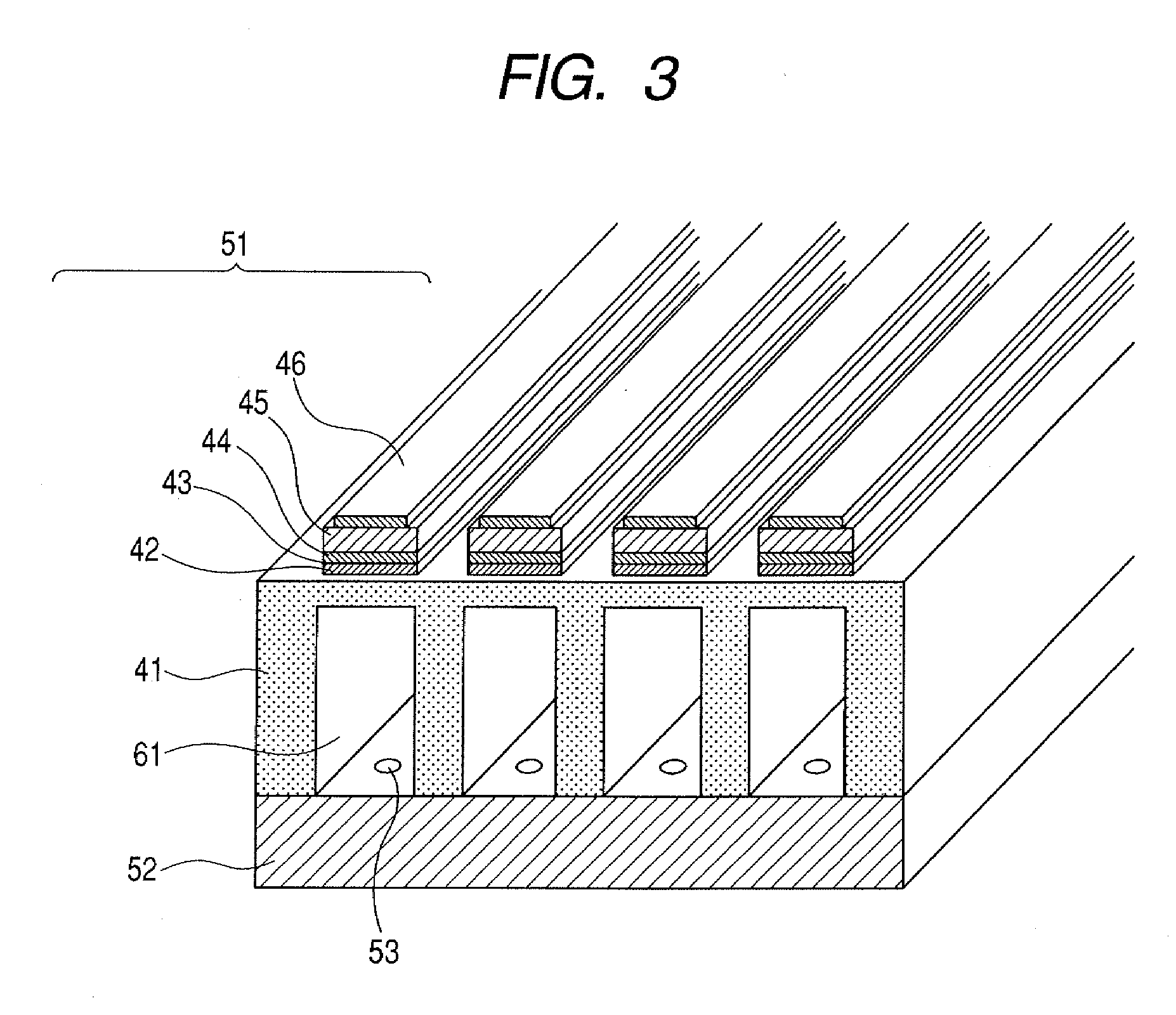

A piezoelectric substrate of a perovskite-type oxide is expressed by a general formula of ABO3 having a laminate structure of a single crystal structure or a uniaxial crystal structure expressed by (Pb1-xMx)xm(ZryTi1-y)O3 (where M represents an element selected from La, Ca, Ba, Sr, Bi, Sb and W) and the laminate structure has a layered first crystal phase having a crystal structure selected from the tetragonal structure, the rhombohedral structure, the pseudocubic structure and the monoclinic structure, a layered second crystal phase having a crystal structure different from the crystal structure of said first crystal phase and a boundary layer arranged between said first crystal phase and said second crystal phase with a crystal structure gradually changing in a width direction of layer.

Owner:CANON KK

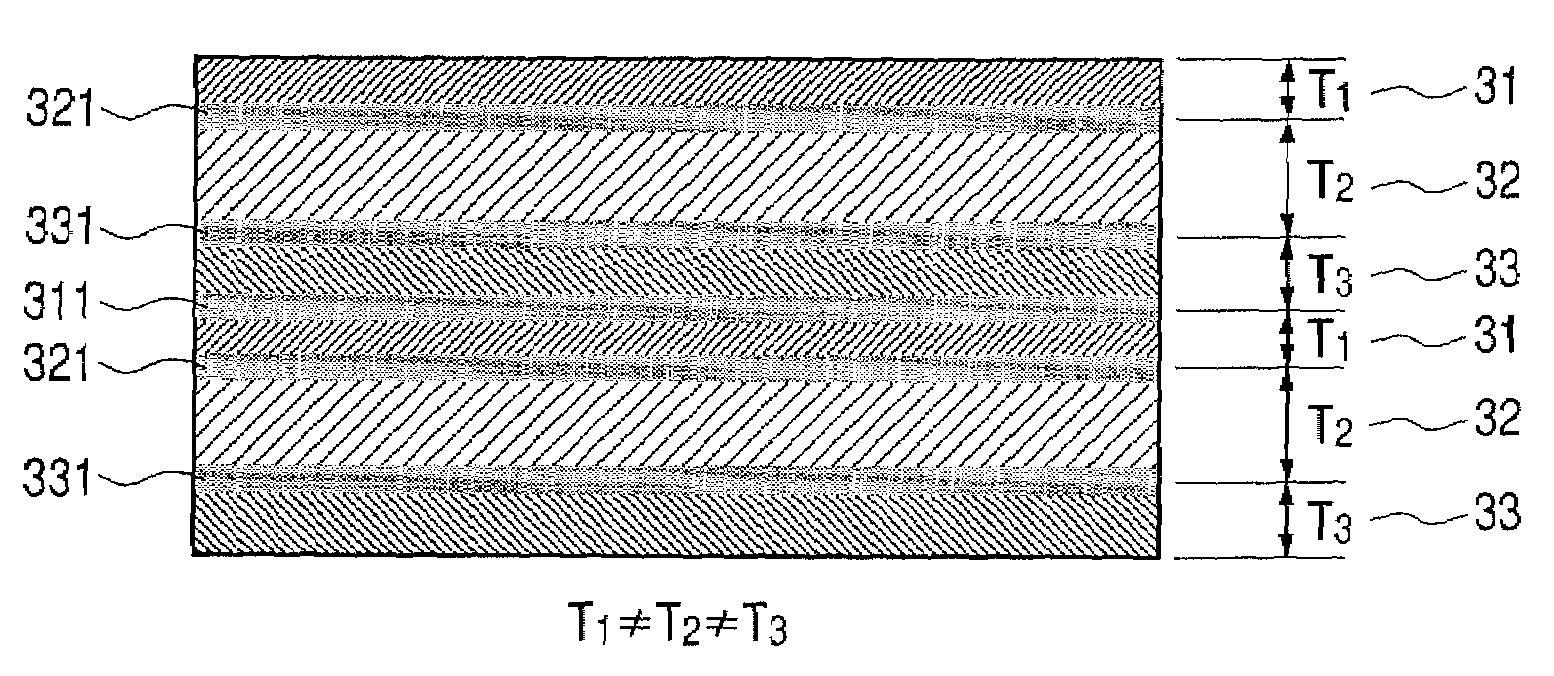

Piezoelectric substance, piezoelectric substance element, liquid discharge head, liquid discharge device and method for producing piezoelectric substance

InactiveUS20070090728A1Excellent piezoelectric propertiesEasy to controlInking apparatusPiezoelectric/electrostriction/magnetostriction machinesCrystal structureSingle crystal

A piezoelectric substance has a multi-layer structure consisting of single crystal layers or uniaxial crystal layers of a perovskite oxide expressed by the general formula of ABO3 in which a main component at the site (A) is Pb, and a main component at the site (B) includes at least three elements selected from the group consisting of Mg, Zn, Sc, In, Yb, Ni, Nb, Ti and Ta, wherein the multi-layer structure comprises: a first layer crystal phase having any crystal structure selected from the group consisting of tetragonal, rhombohedral, pseudocubis, orthorhombic and monoclinic crystals; a second layer crystal phase having a different crystal structure from the crystal structure of the first crystal phase; and a boundary layer between the first crystal phase and the second crystal phase, and having a crystal structure gradually changing in a thickness direction of the layer.

Owner:CANON KK

Piezoelectric member, piezoelectric member element, liquid discharge head in use thereof, liquid discharge apparatus and method of manufacturing piezoelectric member

InactiveUS20070046734A1Good driving responseStable characteristicsPiezoelectric/electrostrictive device material selectionPrintingCurie temperatureUniaxial crystal

A piezoelectric member of uniaxial crystal or uniaxial crystal and the piezoelectric member has perovskite type oxide described to be ABO3 in a general formula with a main component of the A being Pb and a main component of the B containing at least three kinds of elements selected from the group consisting of Mg, Zn, Sc, In, Yb, Ni, Nb, Ti and Ta and film thickness of the piezoelectric member is not less than 1 μm and not more than 10 μm and the piezoelectric member fulfills a predetermined conditions on relative dielectric constant or Curie temperature.

Owner:CANON KK

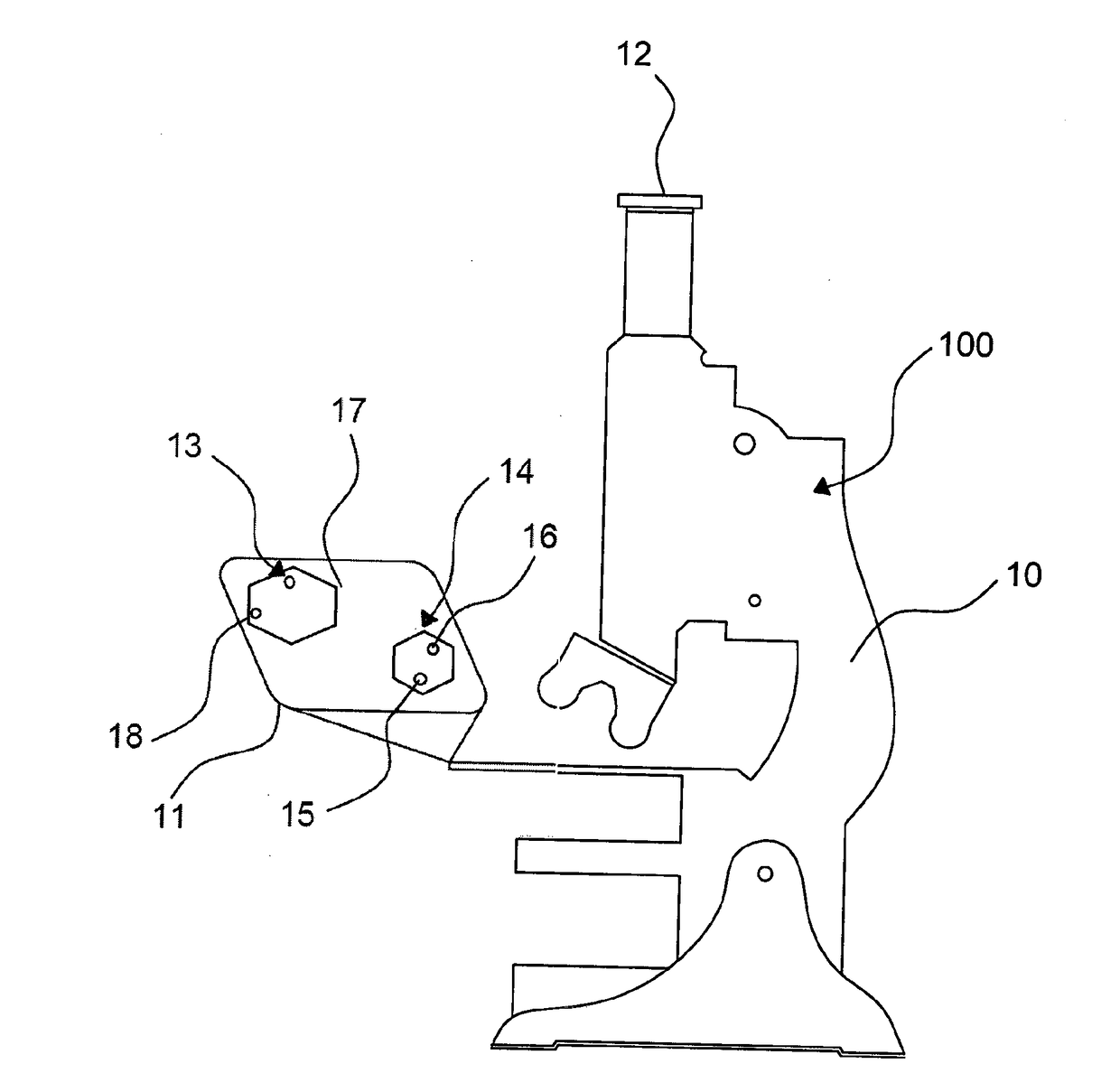

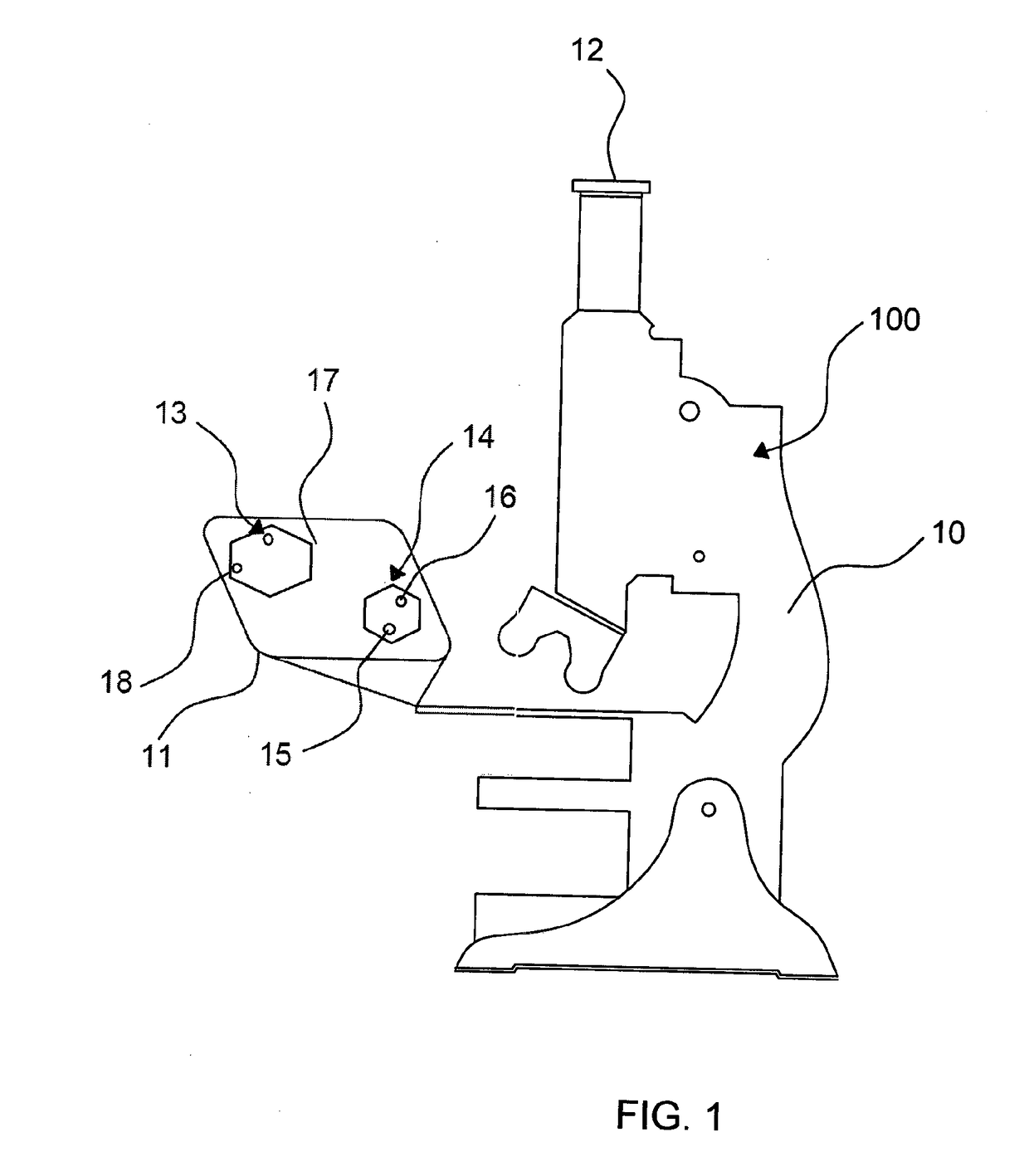

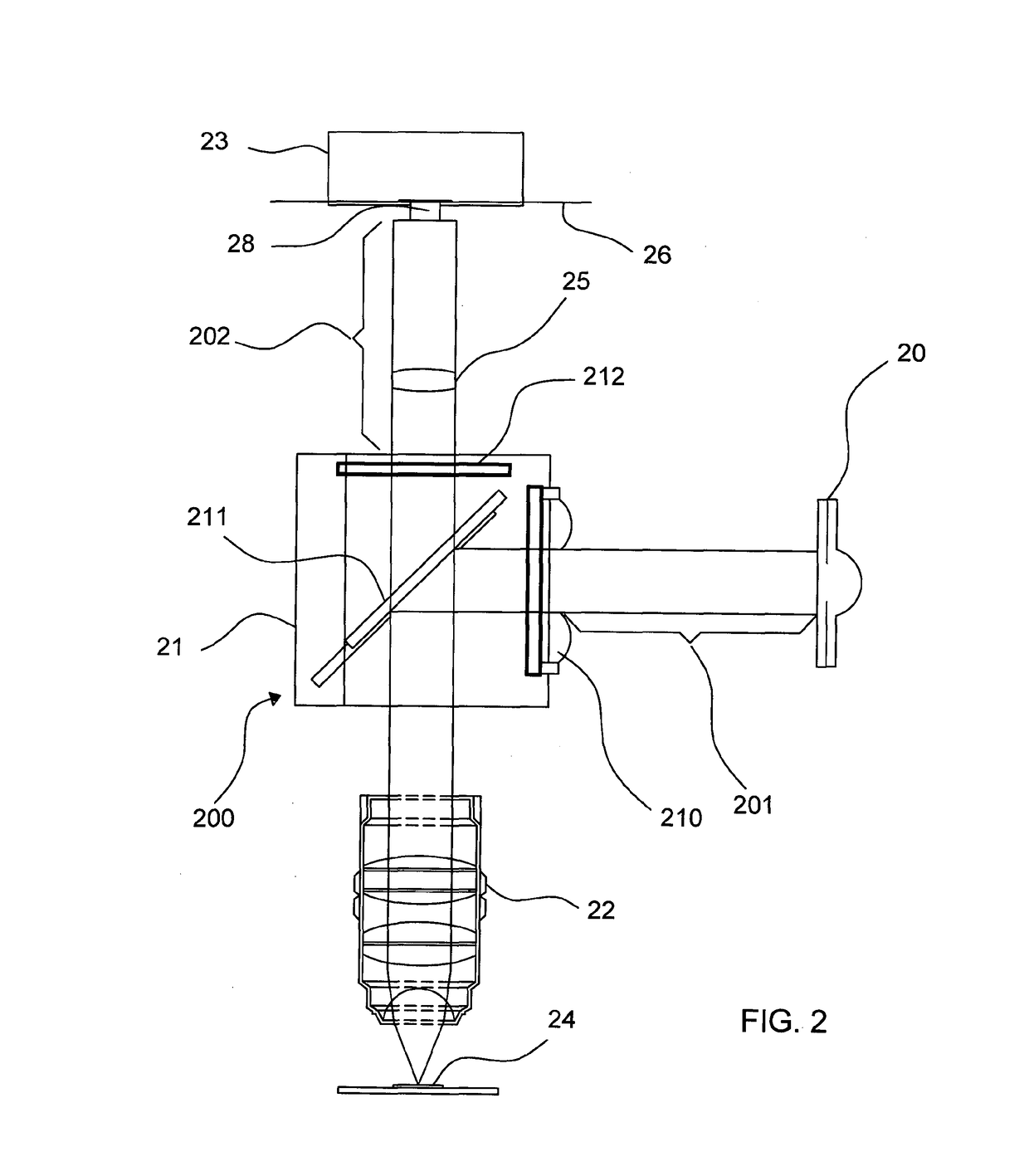

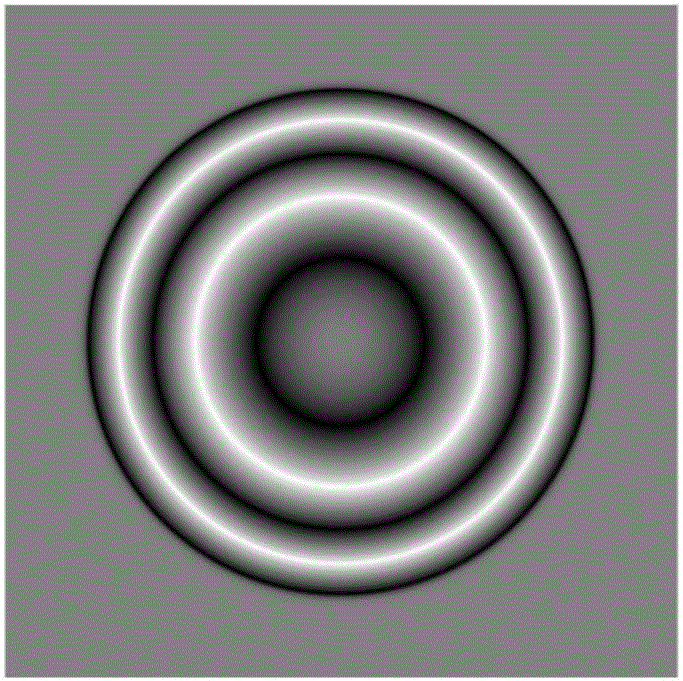

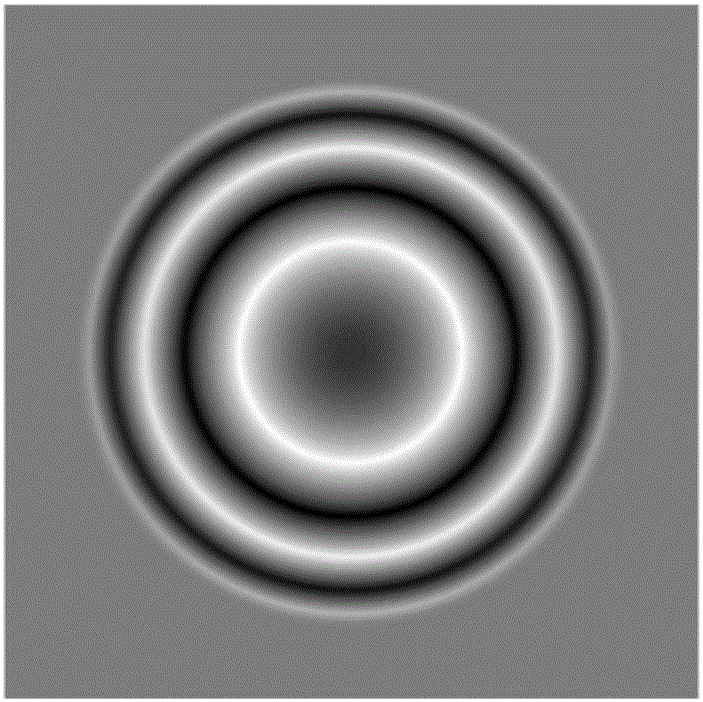

Optical Measuring Device and Process

ActiveUS20170336326A1Quick scanReduced functionalityMicroscopesFluorescence/phosphorescenceDiffraction effectOptical measurements

An achromatic 3D STED measuring optical process and optical method, based on a conical diffraction effect or an effect of propagation of light in uniaxial crystals, including a cascade of at least two uniaxial or conical diffraction crystals creating, from a laser source, all of the light propagating along substantially the same optical path, from the output of an optical bank to the objective of a microscope. A spatial position of at least one luminous nano-emitter, structured object or a continuous distribution in a sample is determined.Reconstruction of the sample and its spatial and / or temporal and / or spectral properties is treated as an inverse Bayesian problem leading to the definition of an a posteriori distribution, and a posteriori relationship combining, by virtue of the Bayes law, the probabilistic formulation of a noise model, and possible priors on a distribution of light created in the sample by projection.

Owner:BIOAXIAL

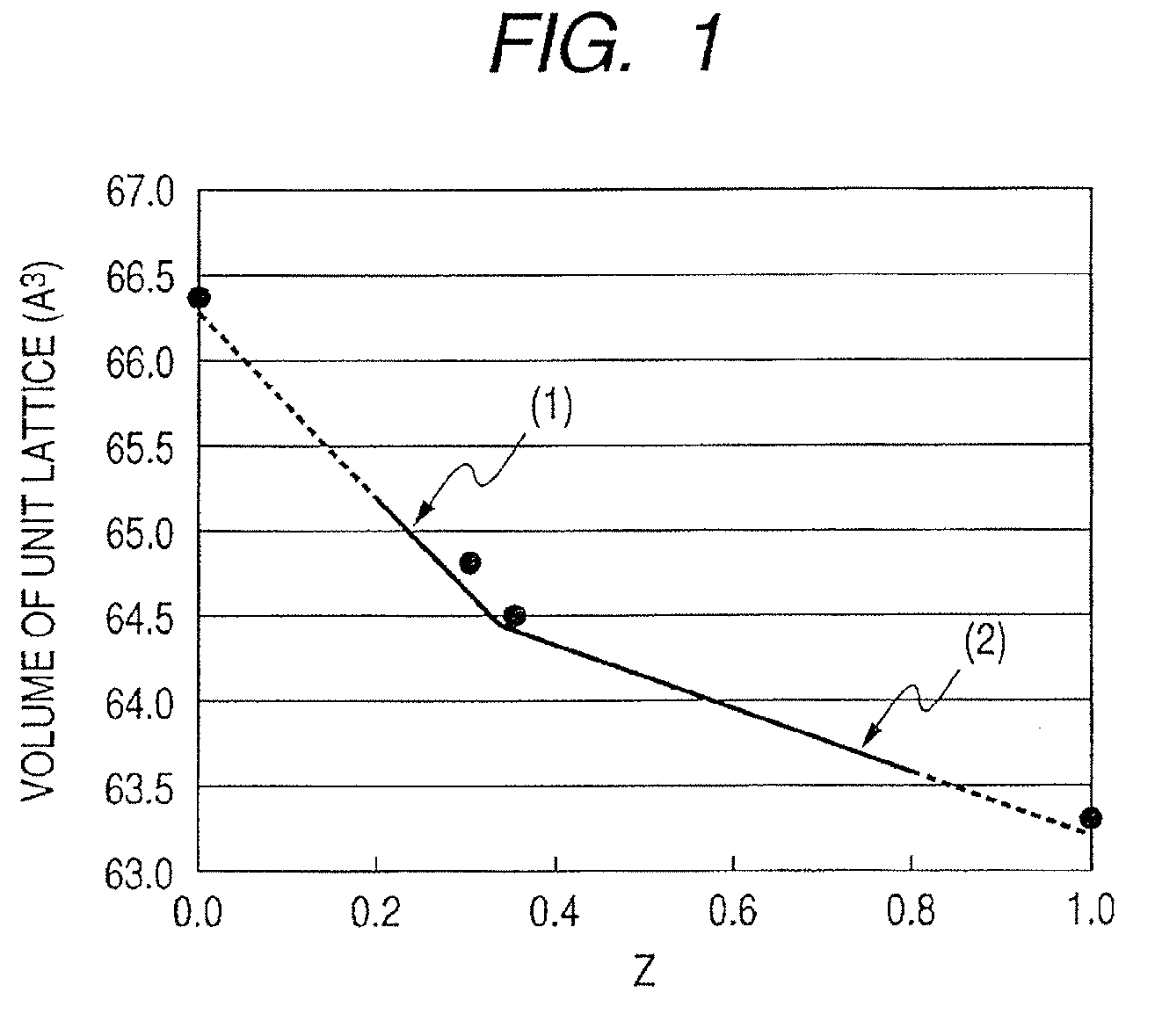

Piezoelectric substance and manufacturing method thereof, piezoelectric element and liquid discharge head using such piezoelectric element and liquid discharge apparatus

InactiveUS20070046154A1Excellent piezoelectric propertiesImprove discharge performancePiezoelectric/electrostriction/magnetostriction machinesPiezoelectric/electrostrictive/magnetostrictive devicesSingle crystalUniaxial crystal

The present invention provides a piezoelectric substance of single crystal or uniaxial crystal type in which three lattice lengths a, b and c of a unit lattice of the piezoelectric substance are smaller than lattice length a0, b0 and c0 of a unit lattice of a bulk state of single crystal having the same temperature and same composition, respectively, and a volume of the unit lattice of the piezoelectric substance is smaller than a volume of the unit lattice of the bulk state of single crystal having the same temperature and same composition.

Owner:CANON KK

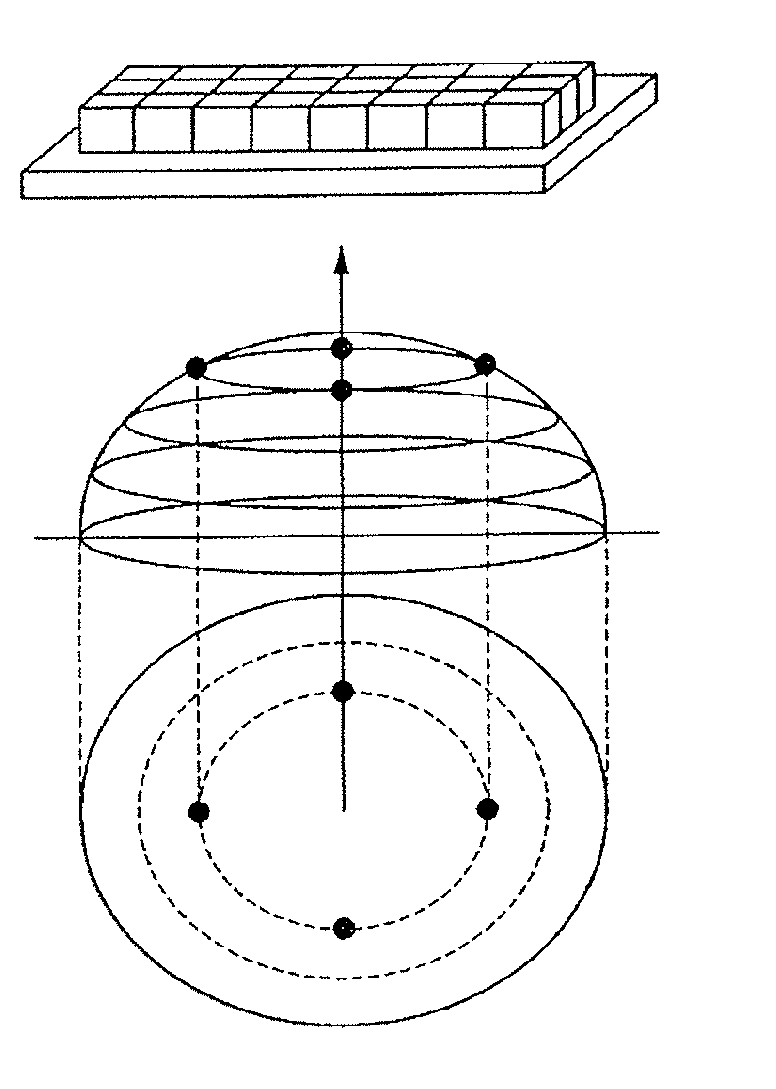

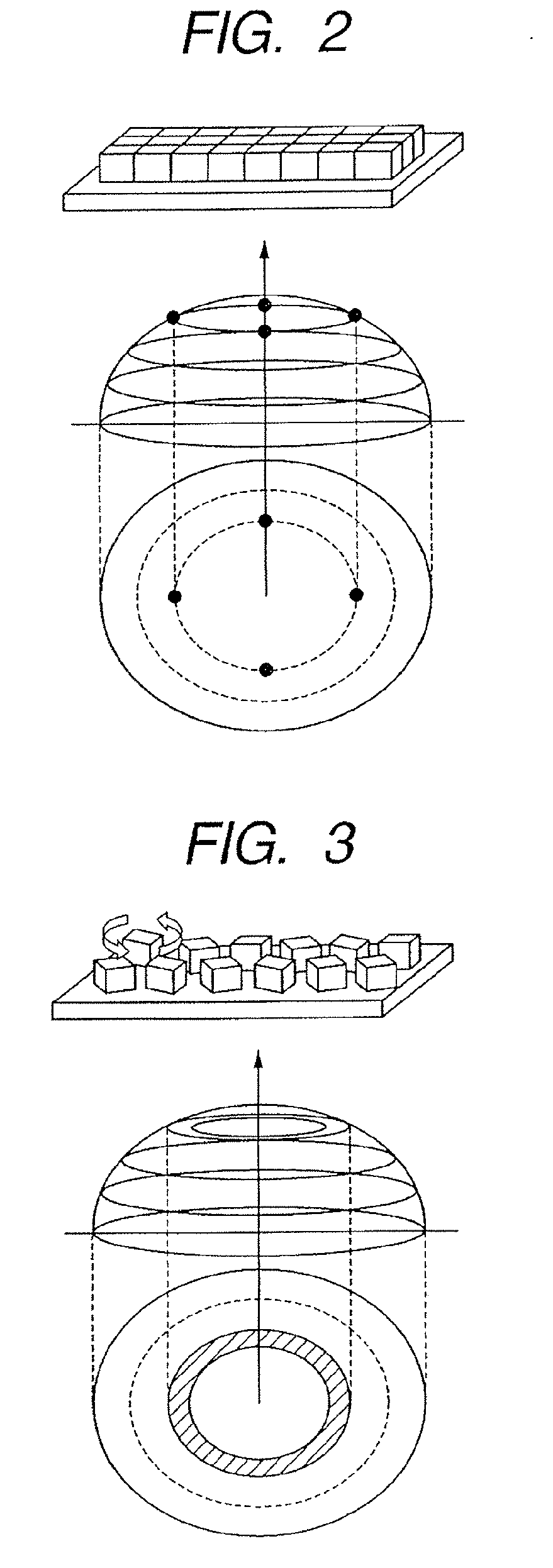

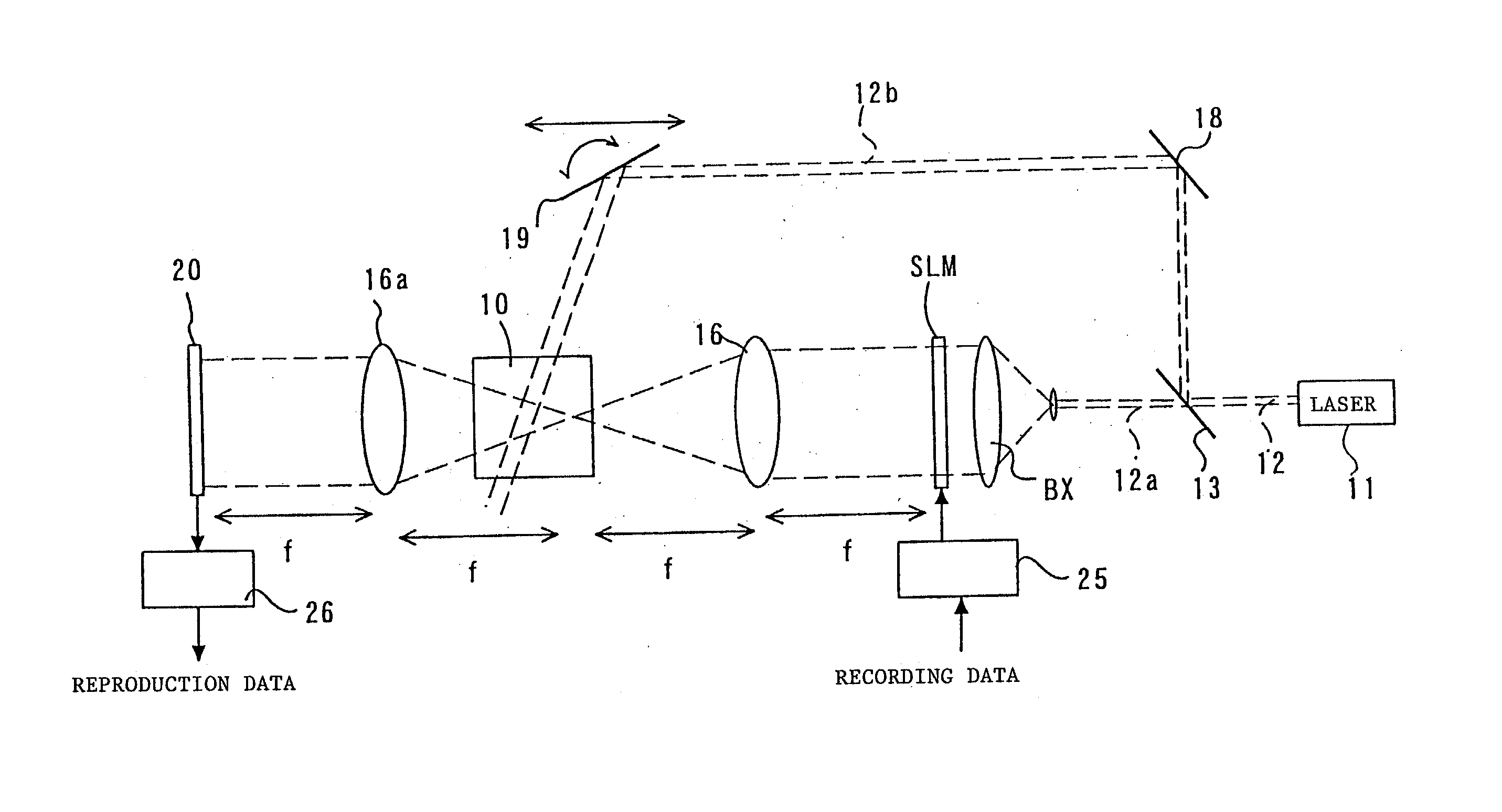

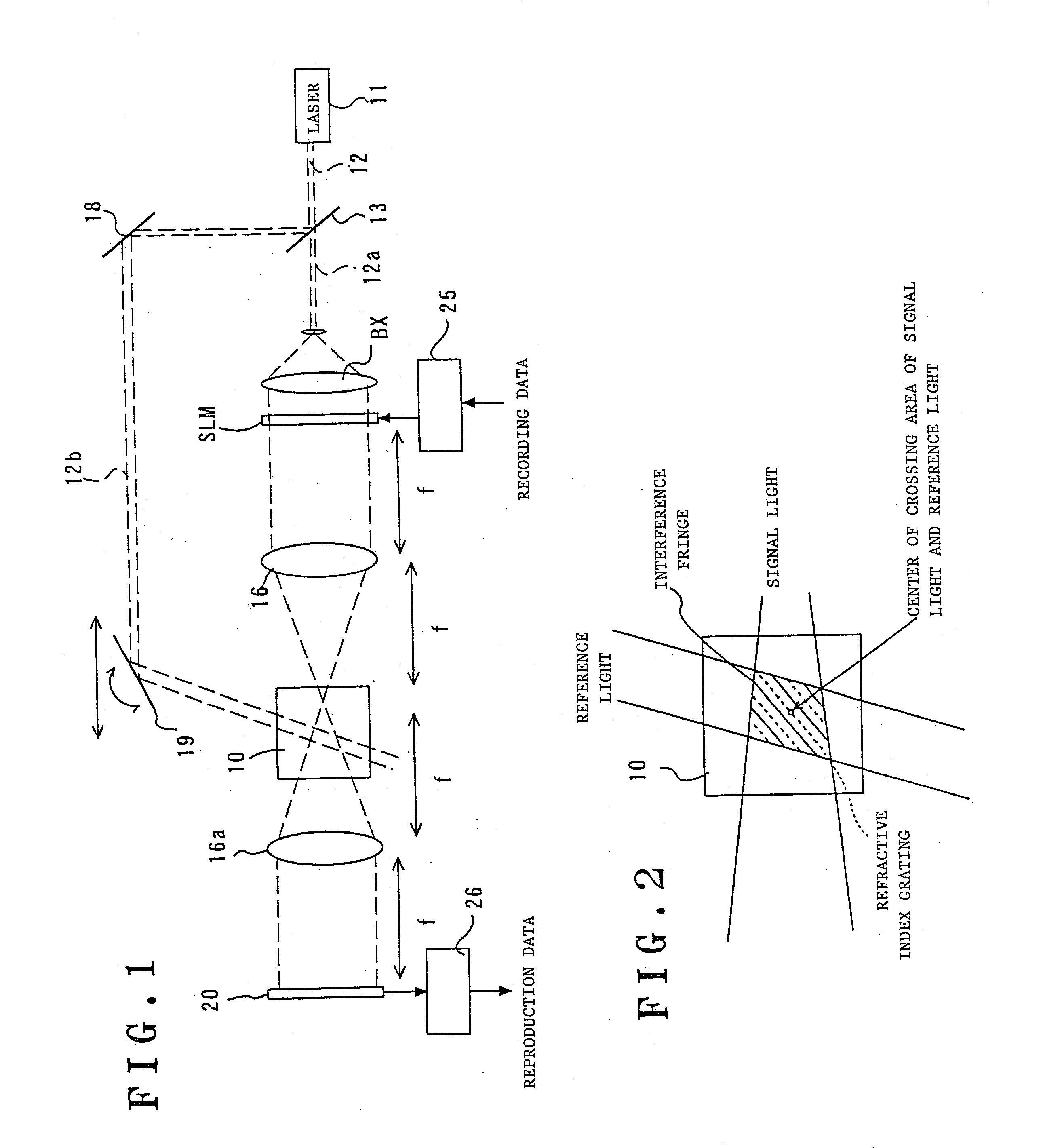

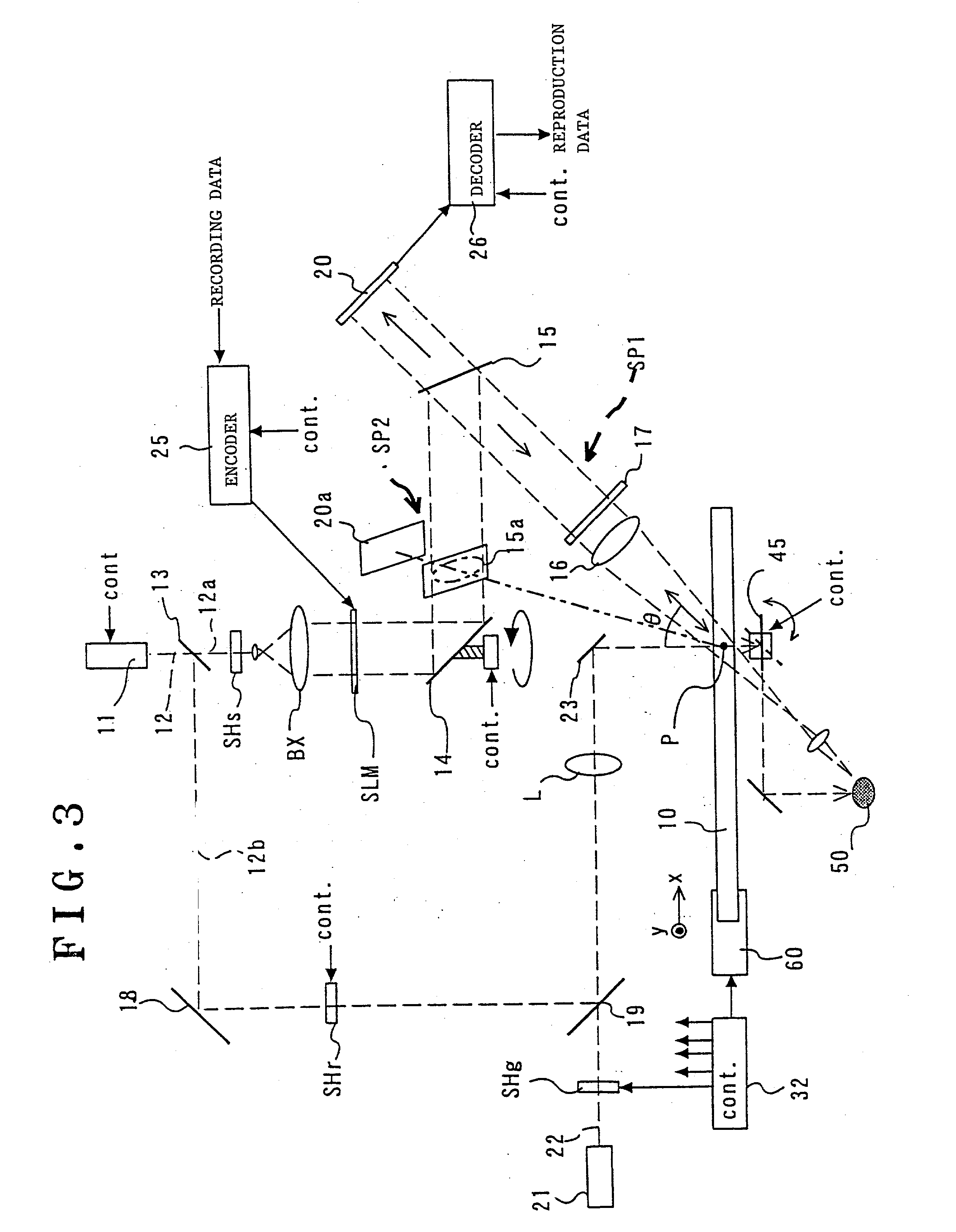

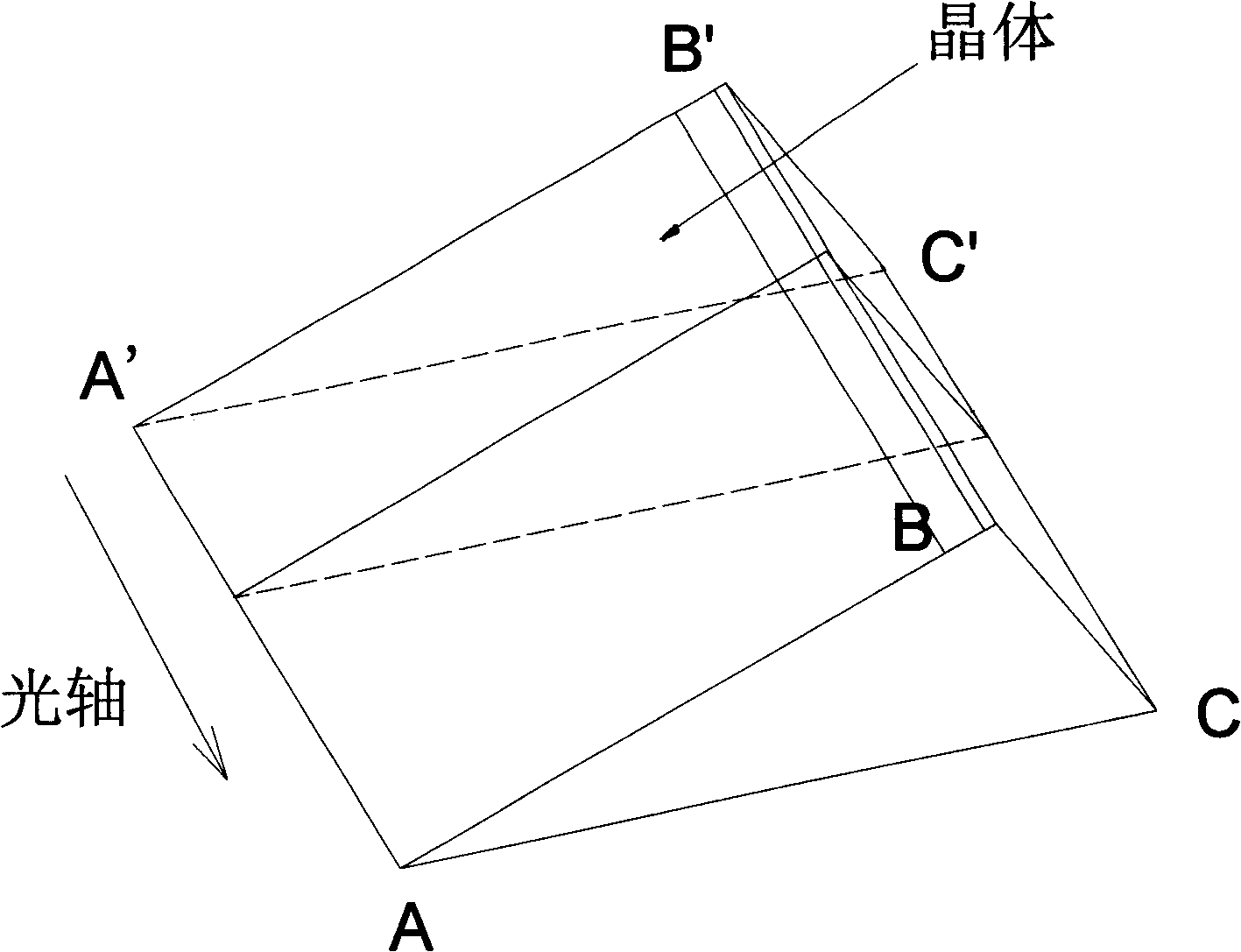

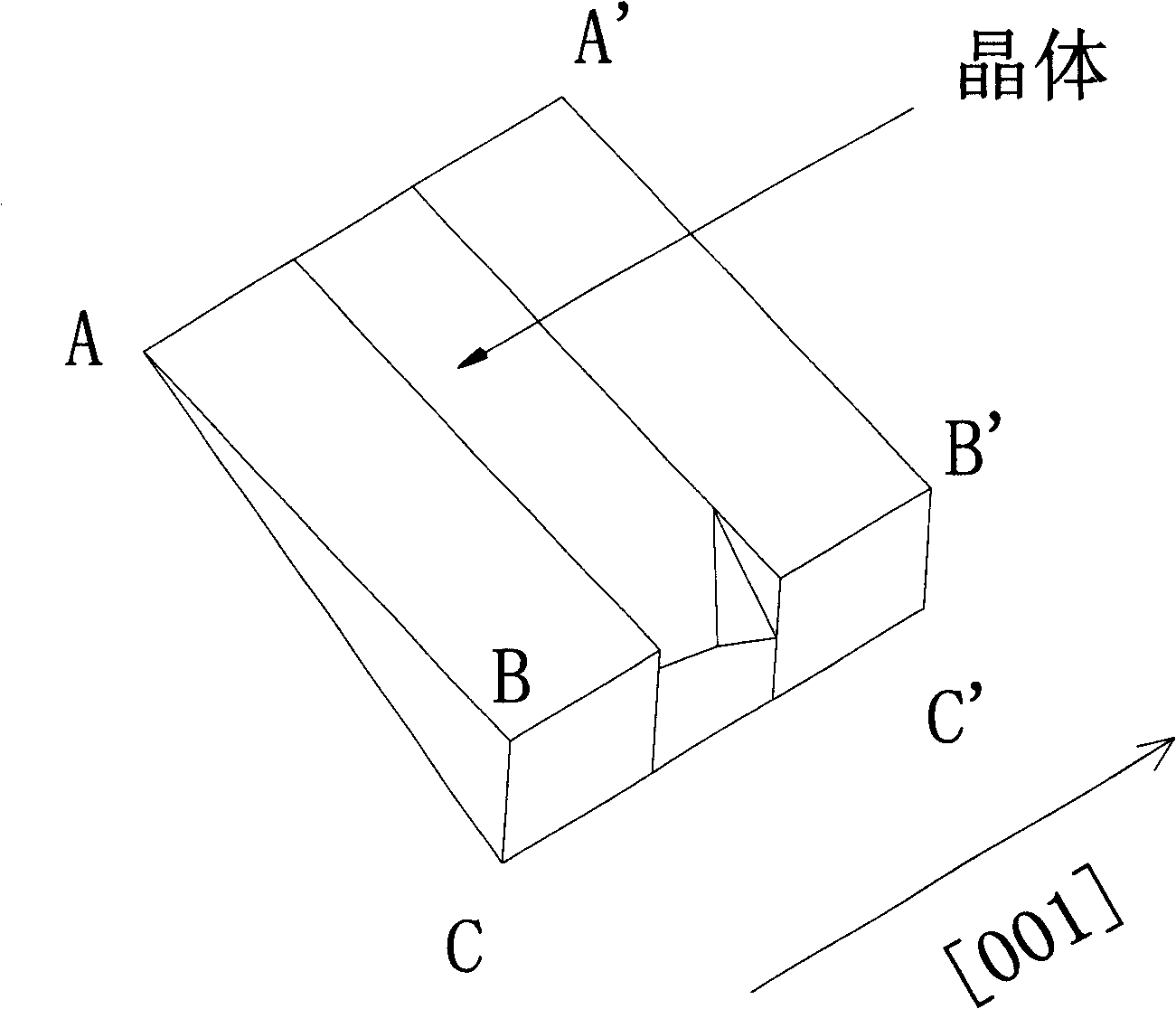

Hologram recording medium, hologram recording-reproducing method, and horogram recording-reproducing apparatus

A hologram recording medium can record an interference pattern to a volume holographic memory at high density. Therefore, the hologram recording medium is made of a photo refractive crystal of a uniaxial crystal having a shape of parallel flat plates, and has a plurality of areas of a refractive index grating corresponding to one portion of a three-dimensional light interference pattern of a coherent signal light beam and coherent reference light of a first wavelength modulated in accordance with information data, wherein the areas of the refractive index grating respectively have a spatially independent columnar shape and are juxtaposed in parallel with each other, and lattice vectors of the refractive index grating in the adjacent areas of the refractive index grating exist in directions different from each other.

Owner:PIONEER CORP

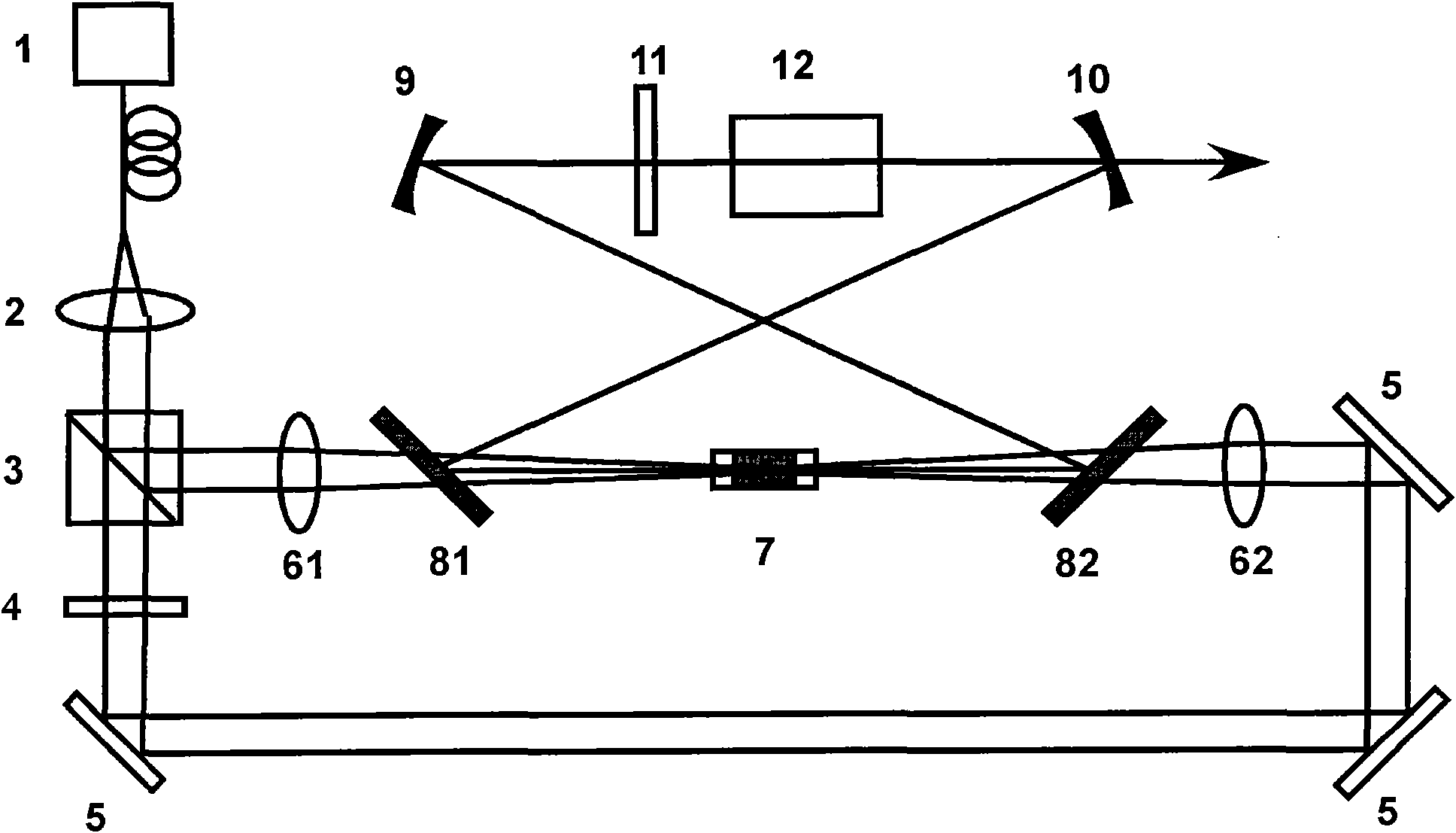

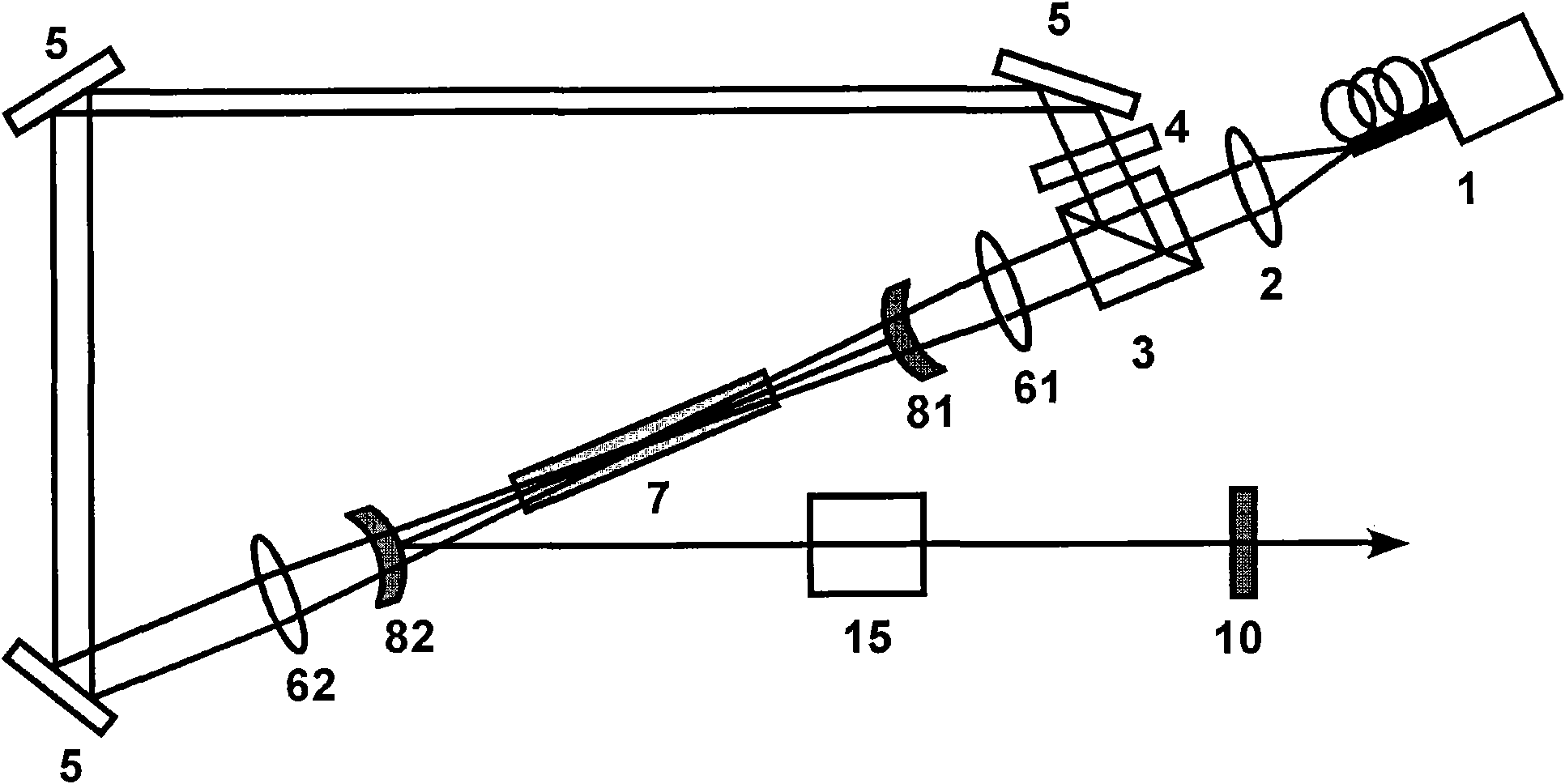

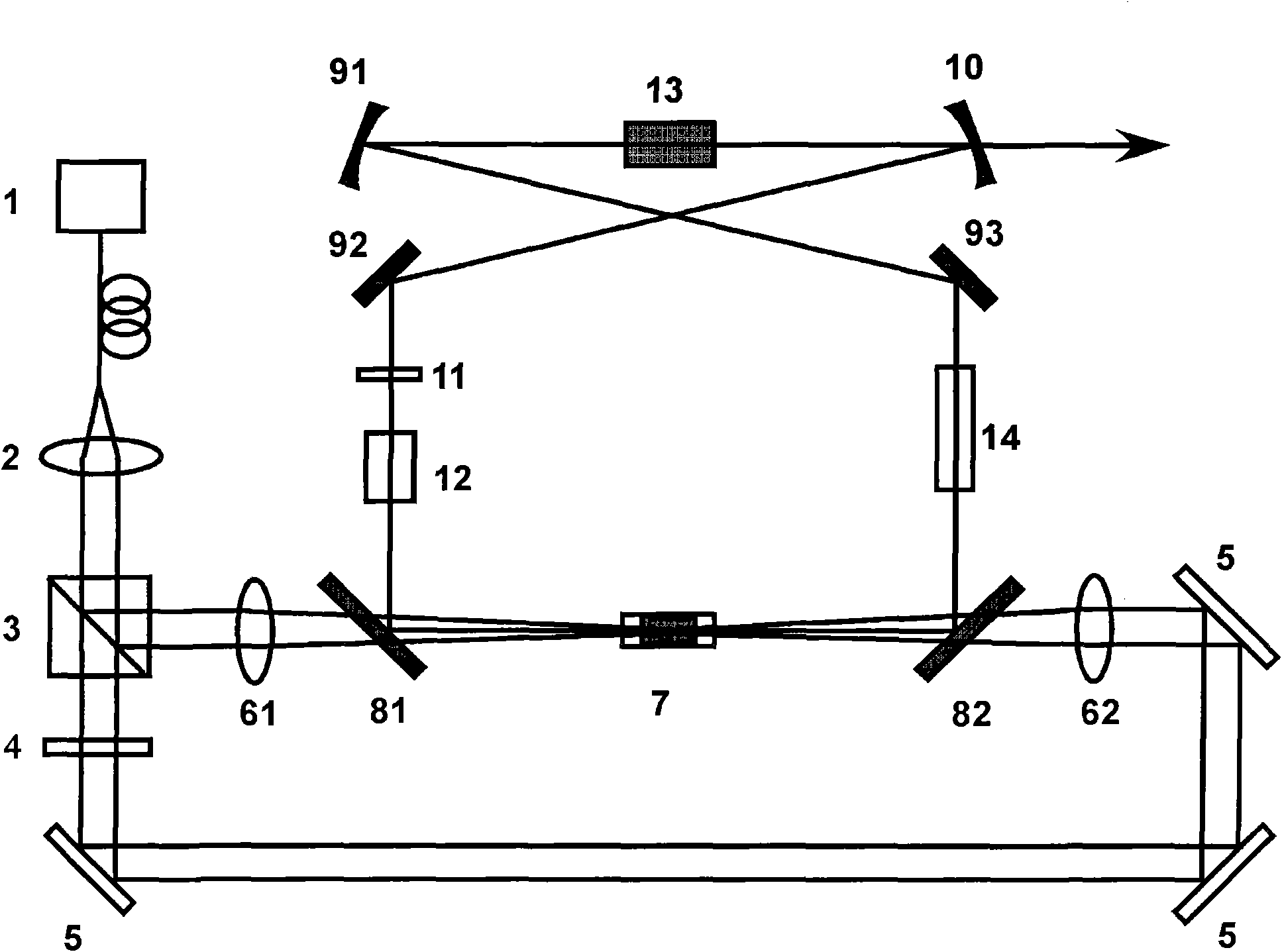

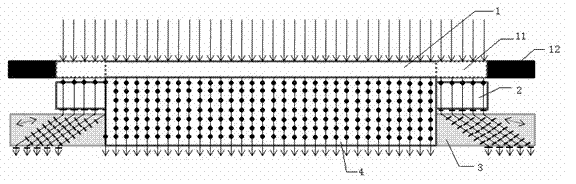

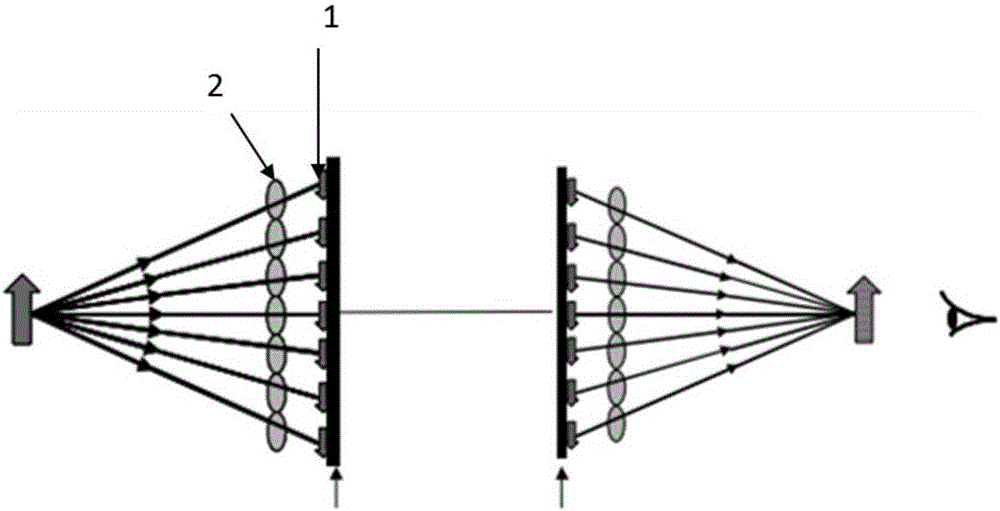

Double-end end-pumped solid laser based on polarization coupling

InactiveCN102136670AAvoid influenceOvercome parallel toActive medium materialResonant cavityBeam splitter

The invention provides a double-end end-pumped solid laser based on polarization coupling, comprising a pumping source (1), a collimating lens (2), a polarization splitting prism (3), a one-half wave plate (4), a reflector (5), a focusing lens, a laser gain medium (7) and a laser resonant cavity. The pumping source (1) is a filter coupling output laser diode and outputs non-polarized laser; and the laser gain medium (7) is an anisotropic uniaxial crystal. The non-polarized laser output by the fiber coupling output laser diode is decomposed into two beams of polarized laser through a polarized beam splitter prism, respectively coupled into the gain medium from both end surfaces of the gain medium through an optical system so that the polarization direction of the pumping laser entering the gain medium is parallel to a certain optical axis in the laser gain medium, and double-end polarized laser end-pumping is realized. The invention can overcome the problems of thermal load distribution unevenness, and the like caused by non-polarized one-end end-pumping so as to improve the output power, the beam quality and the operation stability of the laser.

Owner:SHANXI UNIV +1

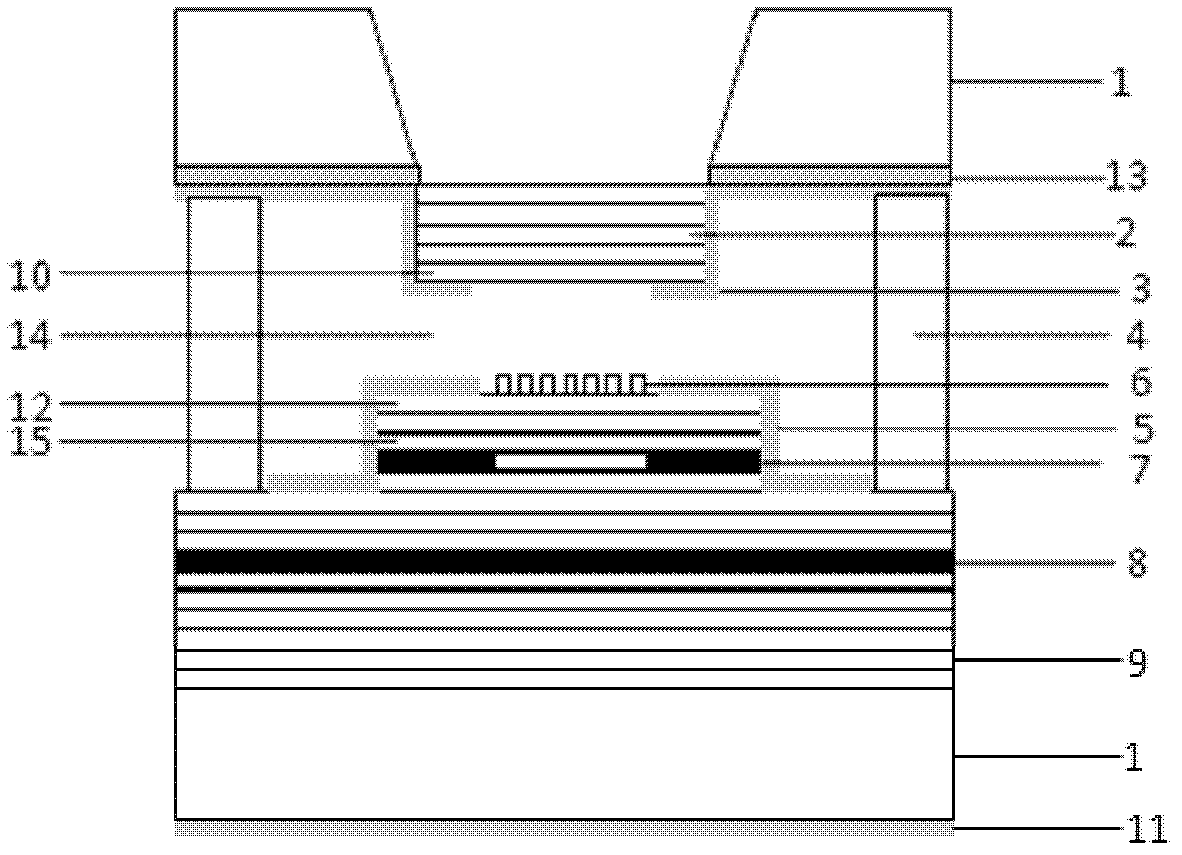

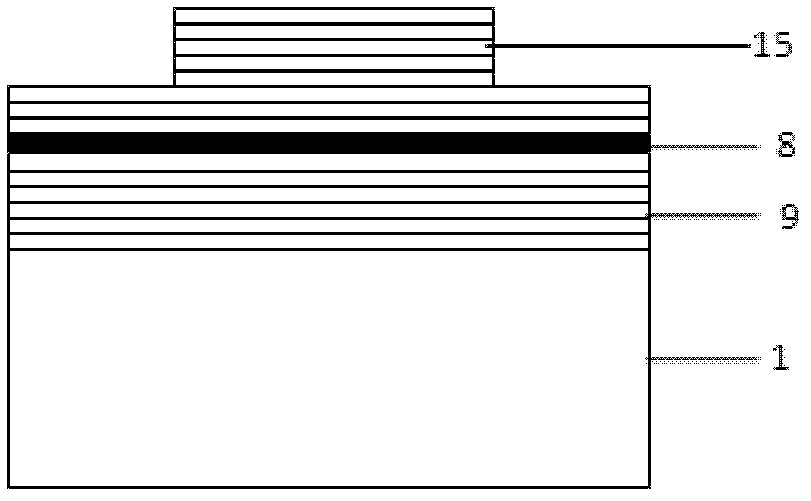

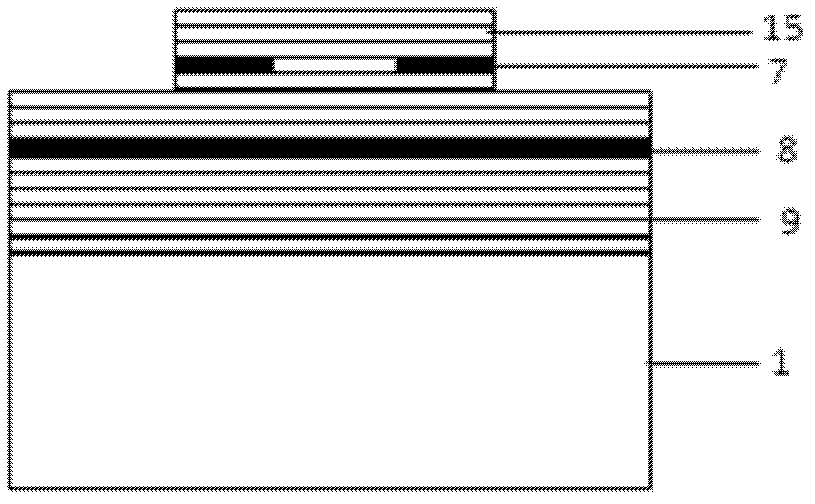

Tunable polarization wavelength vertical-cavity surface-emitting laser and preparation method thereof

InactiveCN102570302ALow threshold gainPolarization wavelength stableOptical wave guidanceLaser detailsMicro nanoVertical-cavity surface-emitting laser

Owner:BEIJING UNIV OF TECH

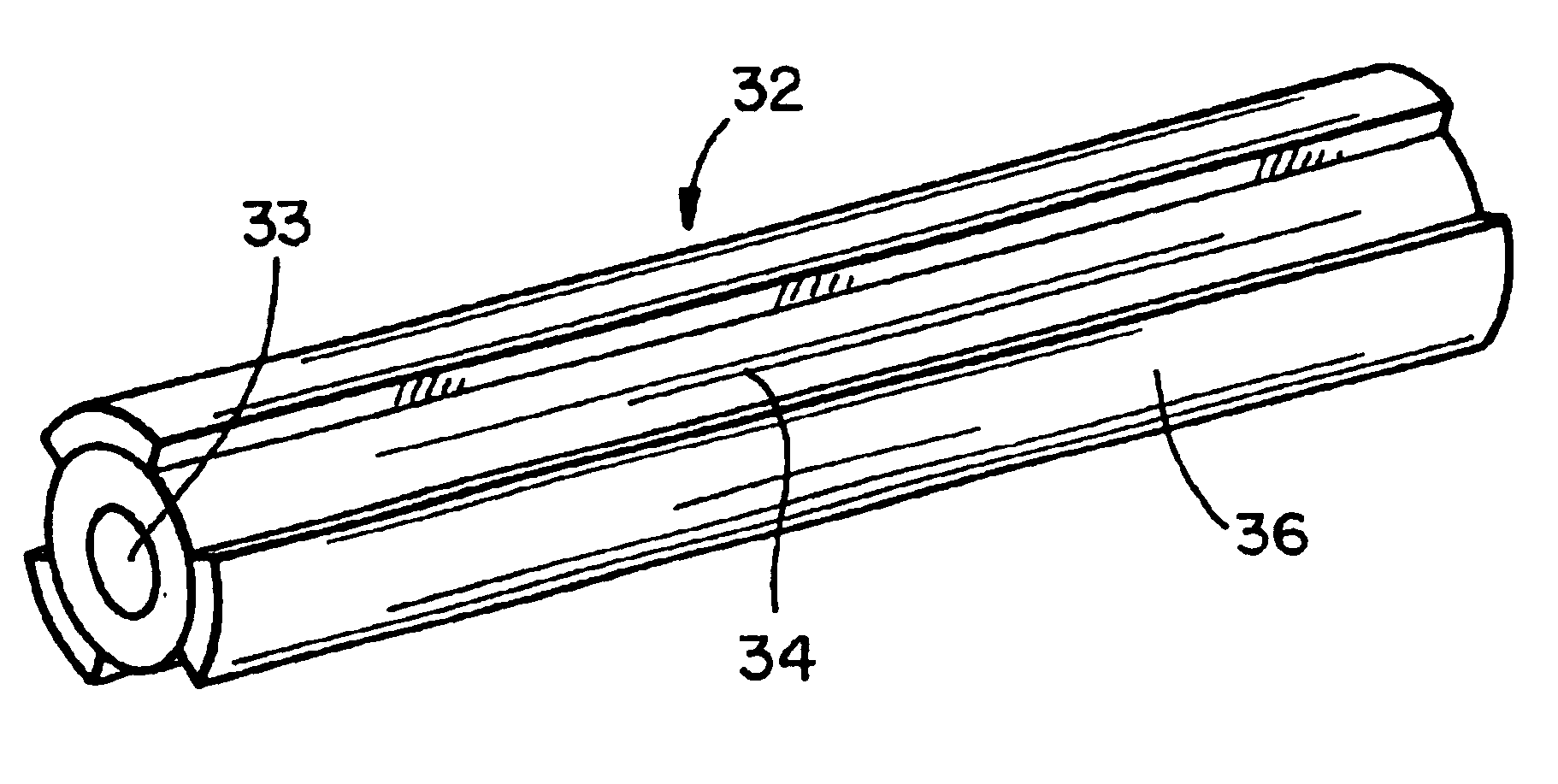

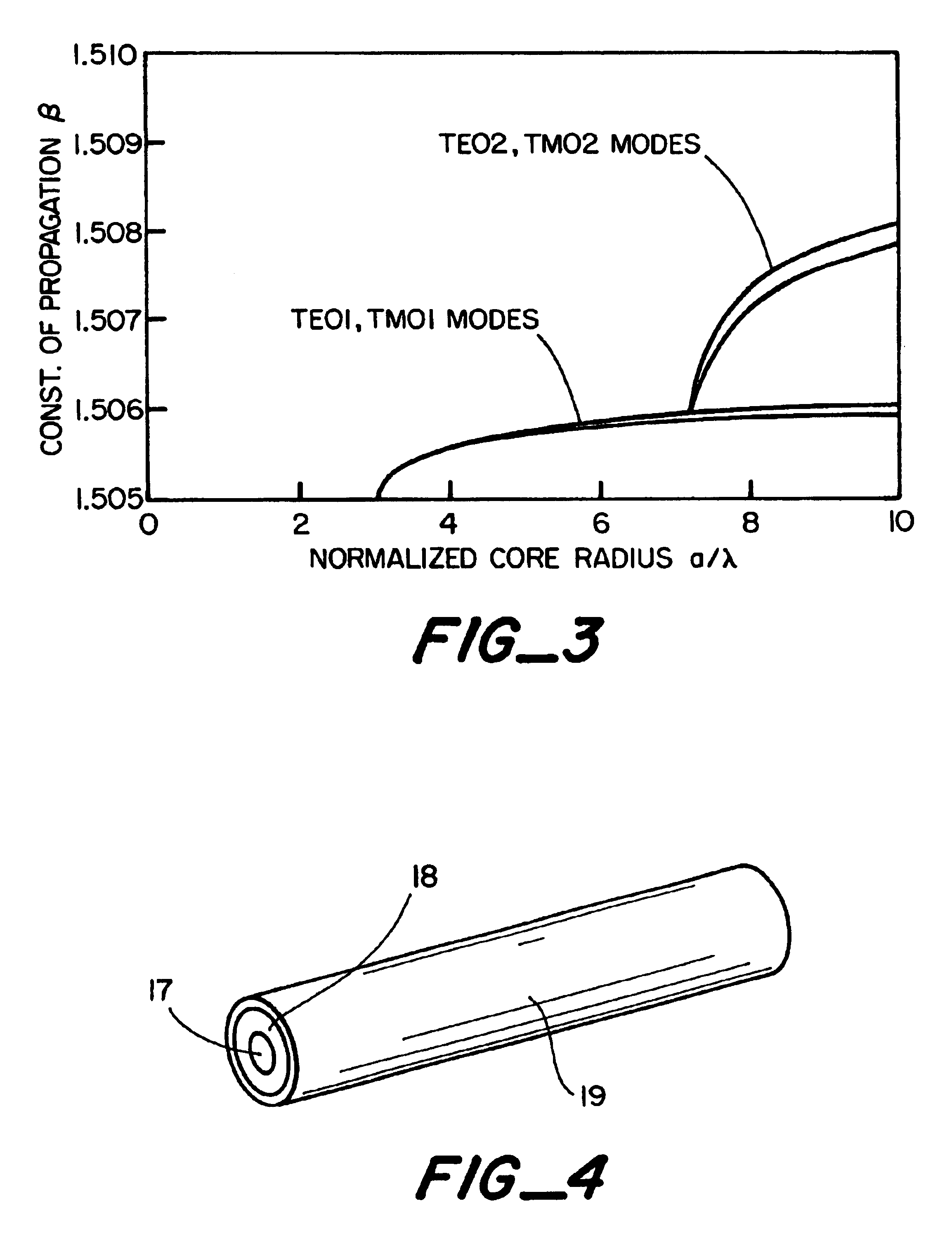

Optical waveguides and method of fabrication thereof

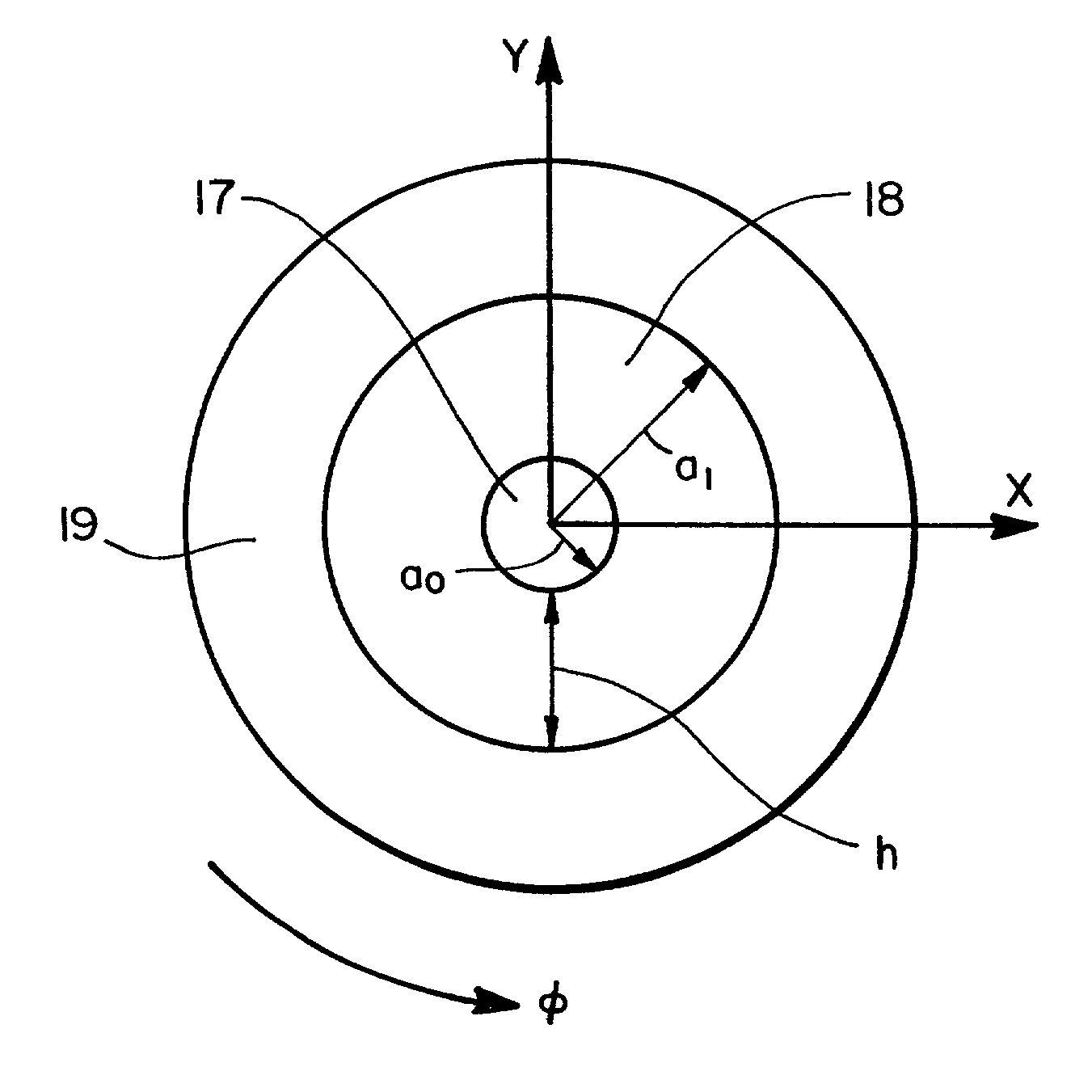

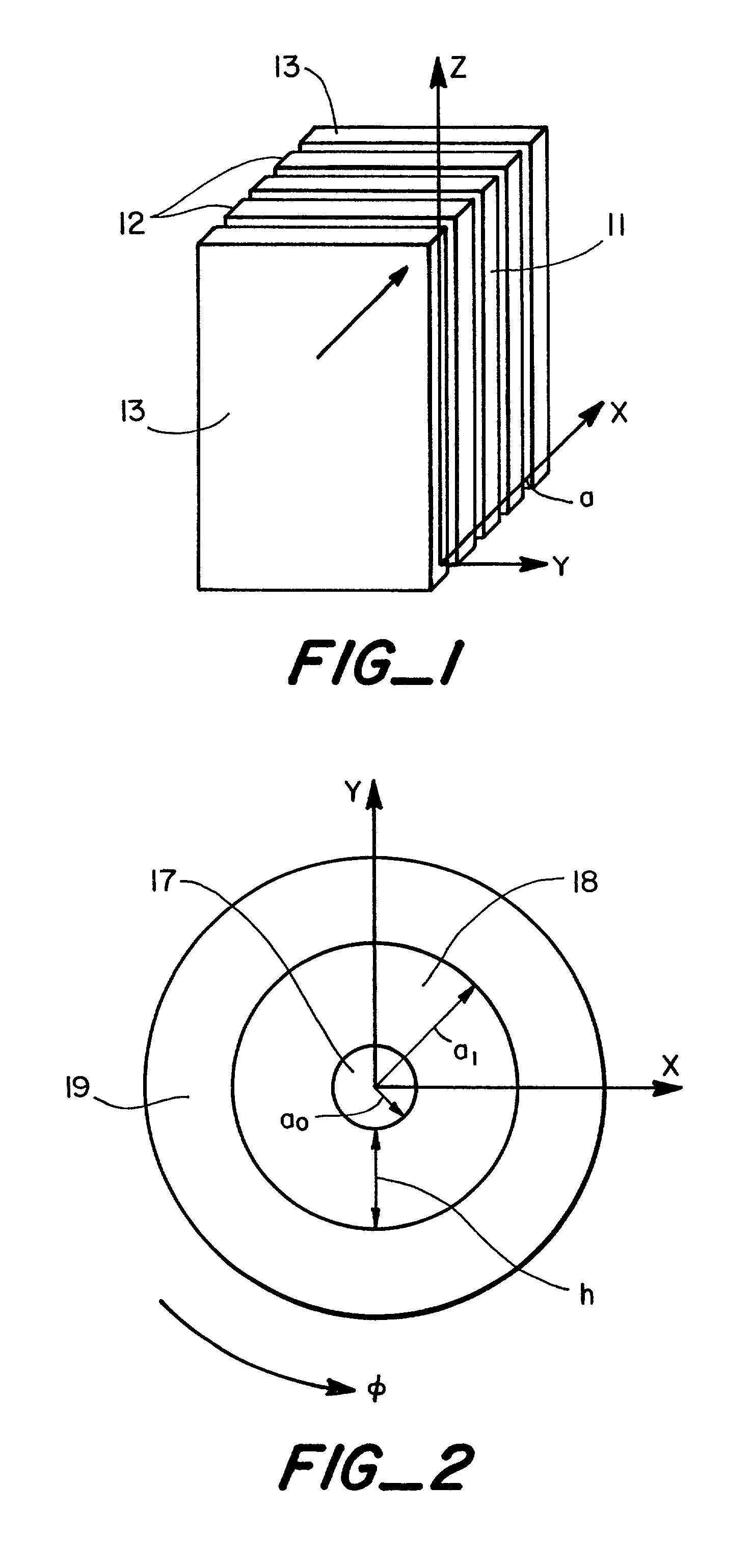

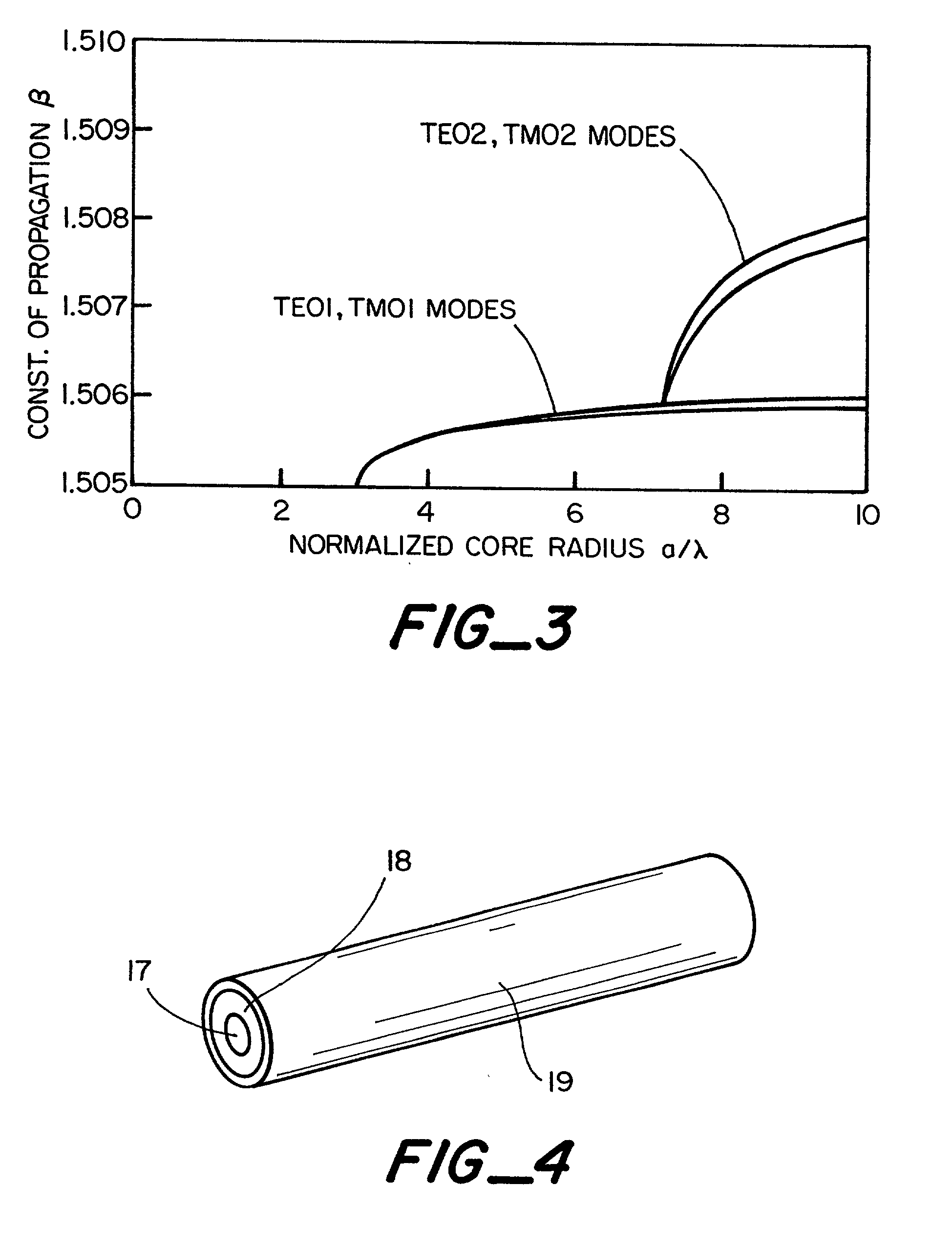

InactiveUS20020090188A1Easy to controlOptical fibre with polarisationOptical fibre with multilayer core/claddingRefractive indexCrystalline materials

Optical waveguides of the type which include a light-transmitting core and a cladding layer in said core. The optical waveguide can be planar or cylindrical such as an optical fiber. The optical waveguide is provided with an additional coating of highly biaxial or uniaxial crystalline material with different refraction indices in different directions.

Owner:NITTO DENKO CORP

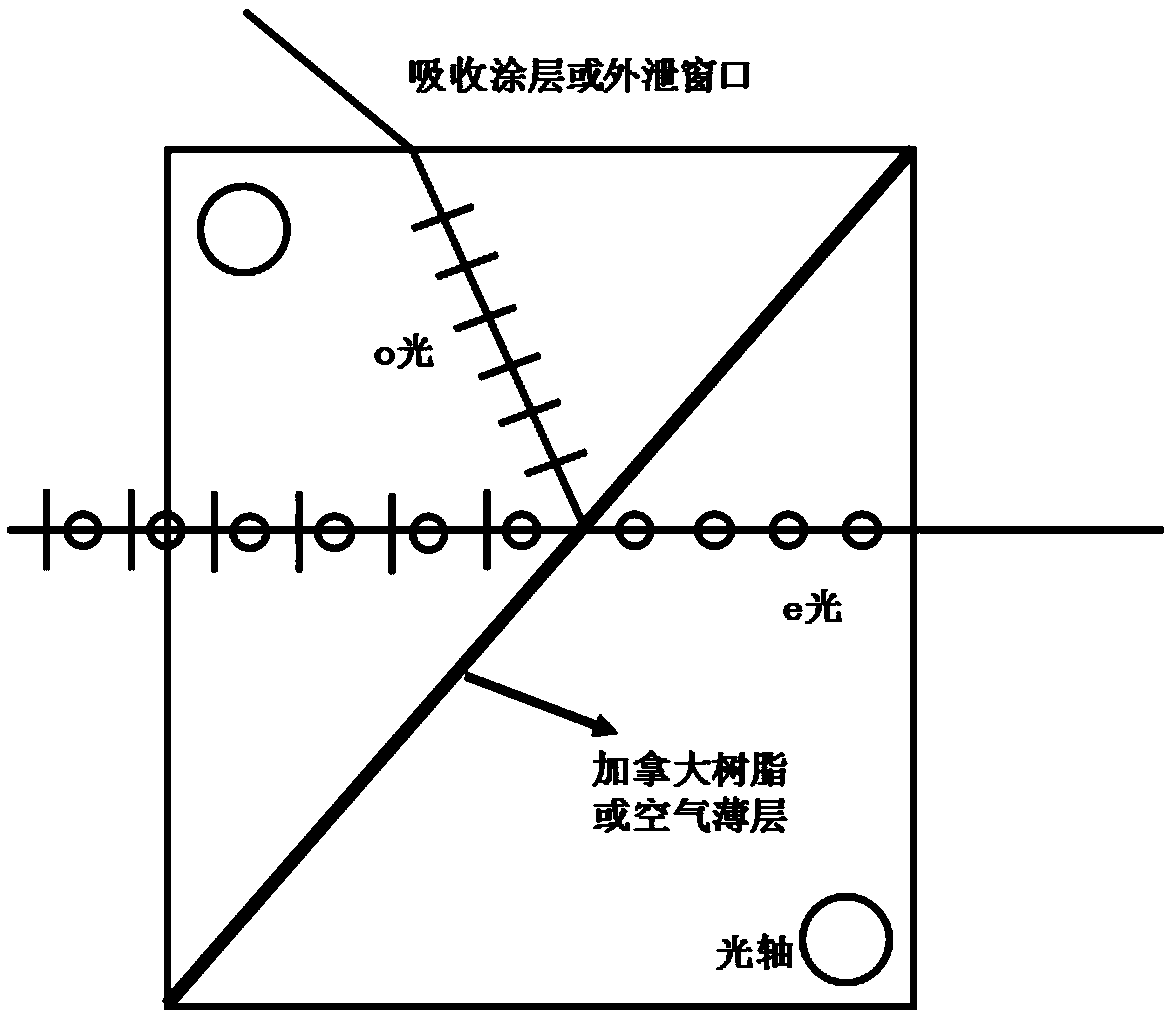

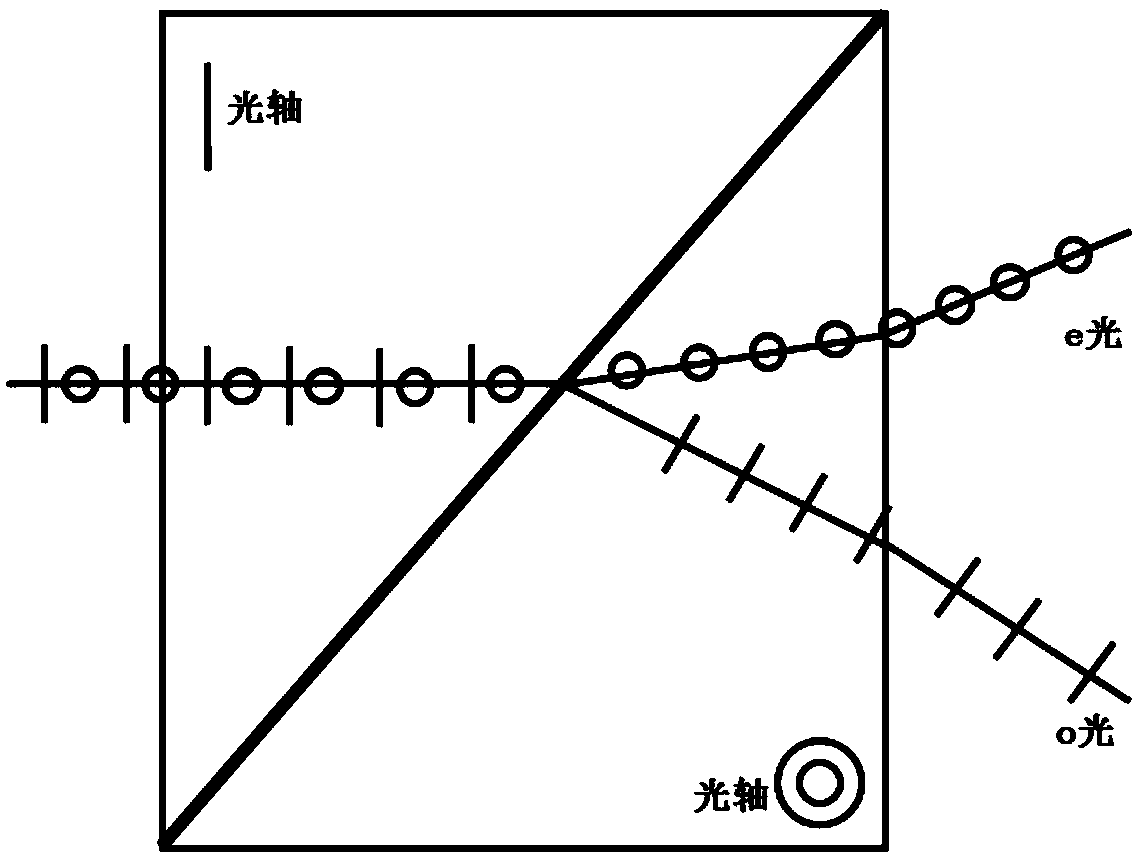

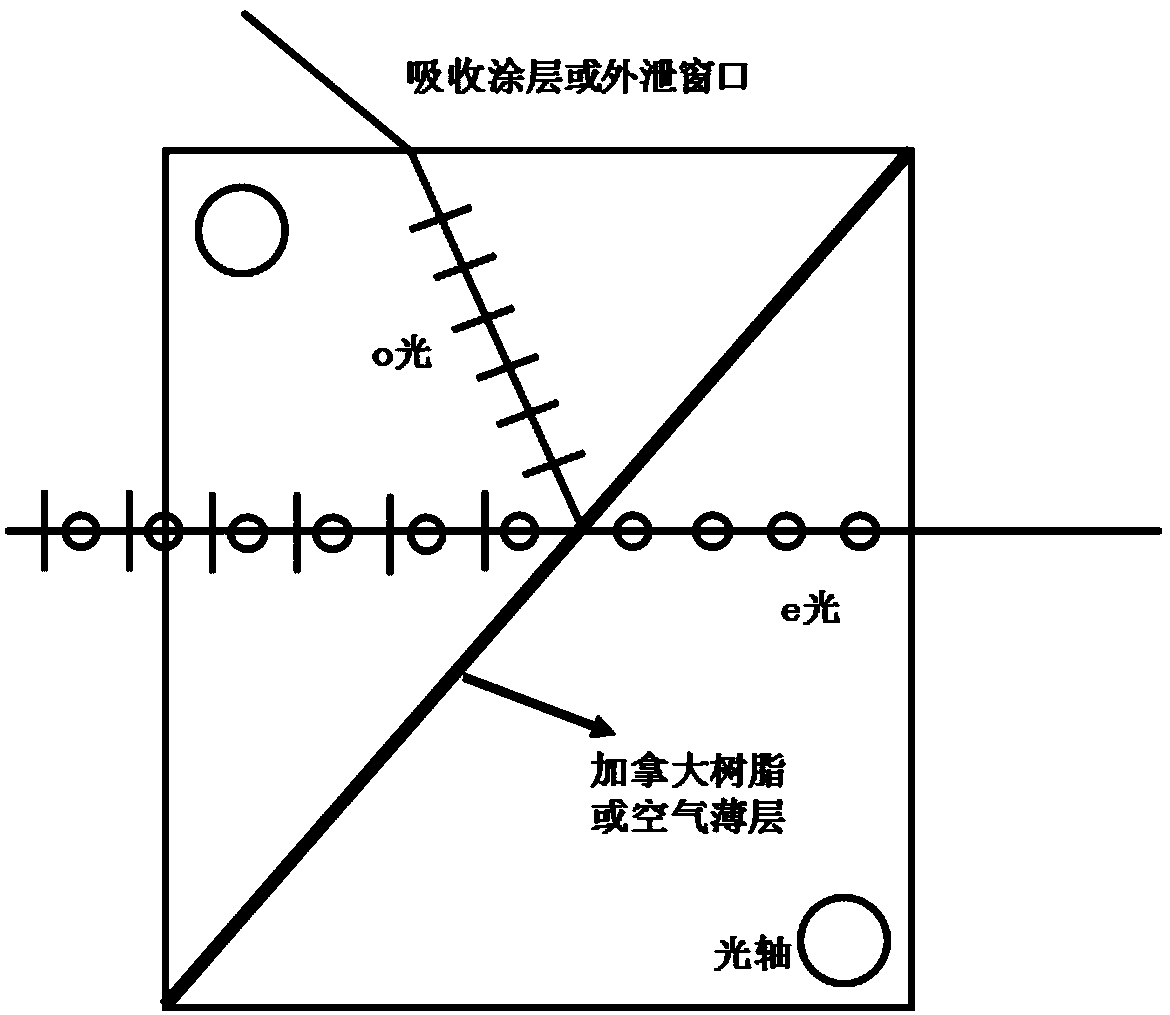

Polarization spectroscopic device and projection display device using the same

The invention discloses a polarization spectrometer which comprises at least one sub-wavelength grating and two optical prisms, and the sub-wavelength grating is clamped between the two optical prisms. The sub-wavelength grating can be equivalent to a uniaxial crystal and respectively has different refractive indexes for two linearly polarized lights (o light and e light) which are mutually orthogonal, thus leading the light in one of the polarization directions to satisfy the total reflection condition and be totally reflected out when a beam of light passes through the optical prisms and irradiates on the sub-wavelength grating by a certain angle; while the other light of the orthogonal polarization direction can just satisfy the refractive index matching and be totally transmitted out almost without loss, thus achieving the aim of separating the lights of two polarization directions. The invention also discloses a liquid crystal on silicon (LCoS) projection display device adopting the polarization spectrometer.

Owner:JINGYING OPTICS

Piezoelectric member, piezoelectric member element, liquid discharge head in use thereof, liquid discharge apparatus and method of manufacturing piezoelectric member

InactiveUS7591543B2Improve responseStable characteristicsPiezoelectric/electrostriction/magnetostriction machinesPiezoelectric/electrostrictive device material selectionSingle crystalUniaxial crystal

Owner:CANON KK

Optical waveguides and method of fabrication thereof

InactiveUS6876806B2Easy to controlOptical fibre with polarisationOptical fibre with multilayer core/claddingRefractive indexCrystalline materials

Optical waveguides of the type which include a light-transmitting core and a cladding layer on said core. The optical waveguide can be planar or cylindrical such as an optical fiber. The optical waveguide is provided with an additional coating of highly biaxial or uniaxial crystalline material with different refraction indices in different directions.

Owner:NITTO DENKO CORP

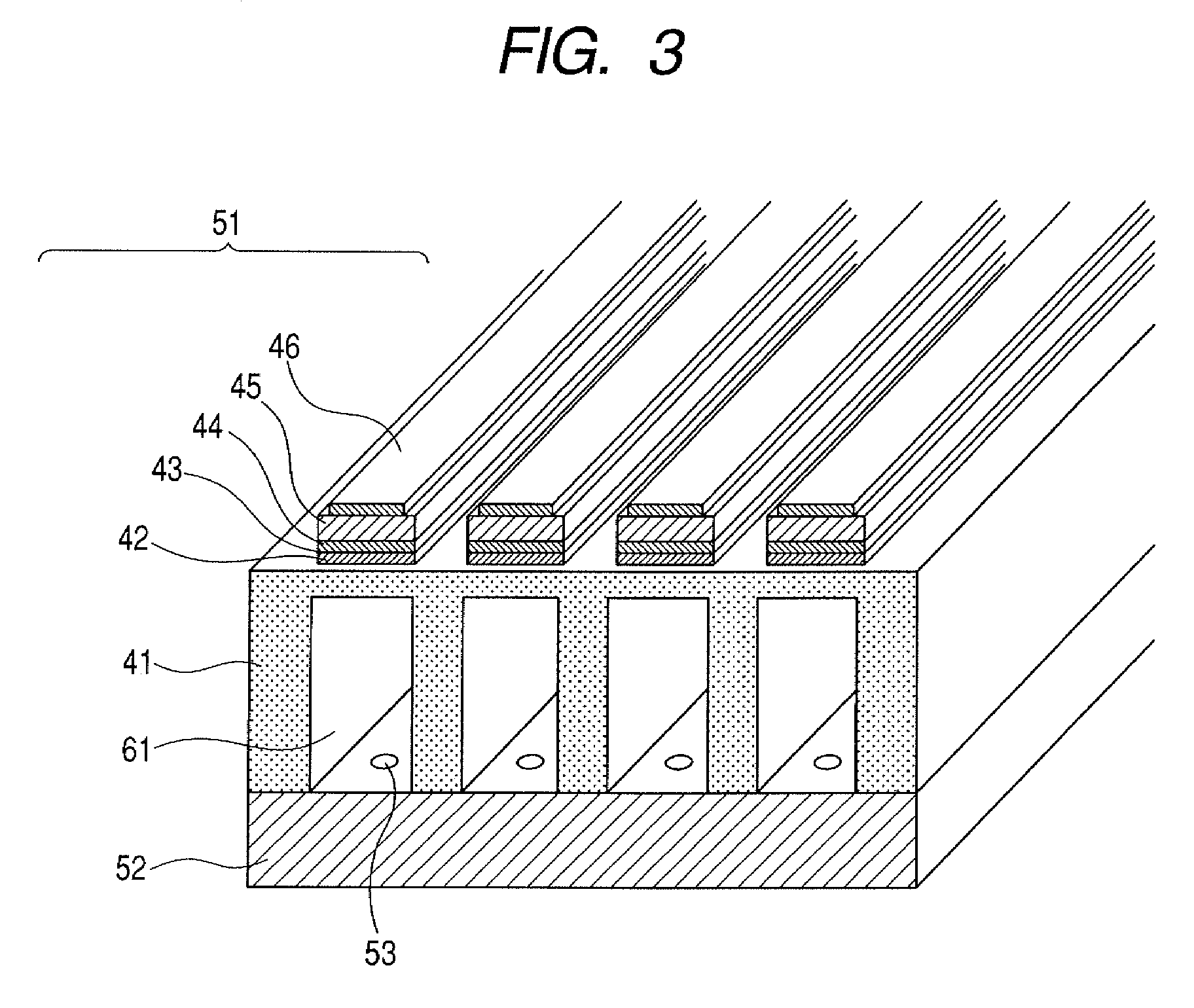

Liquid crystal projector

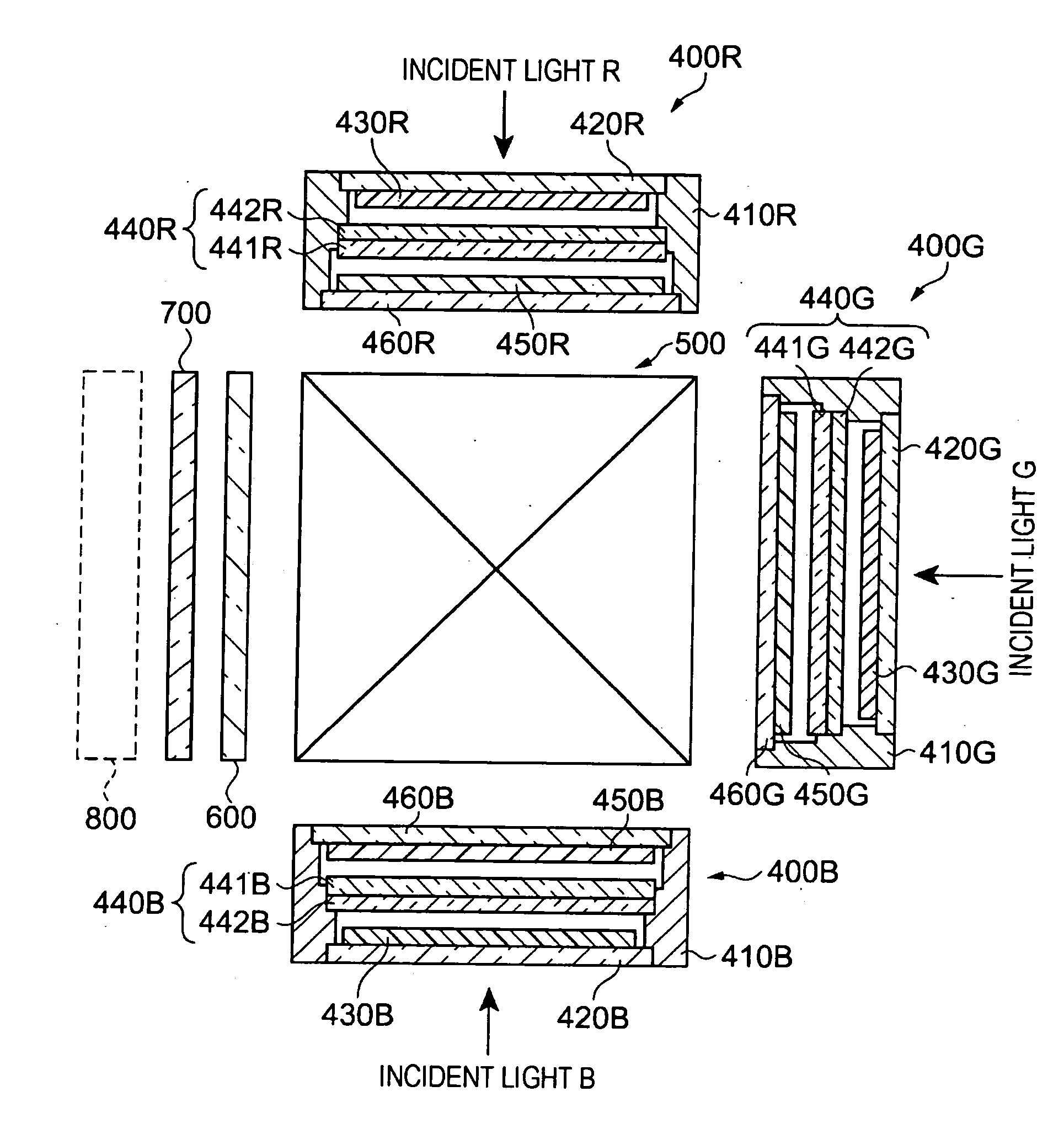

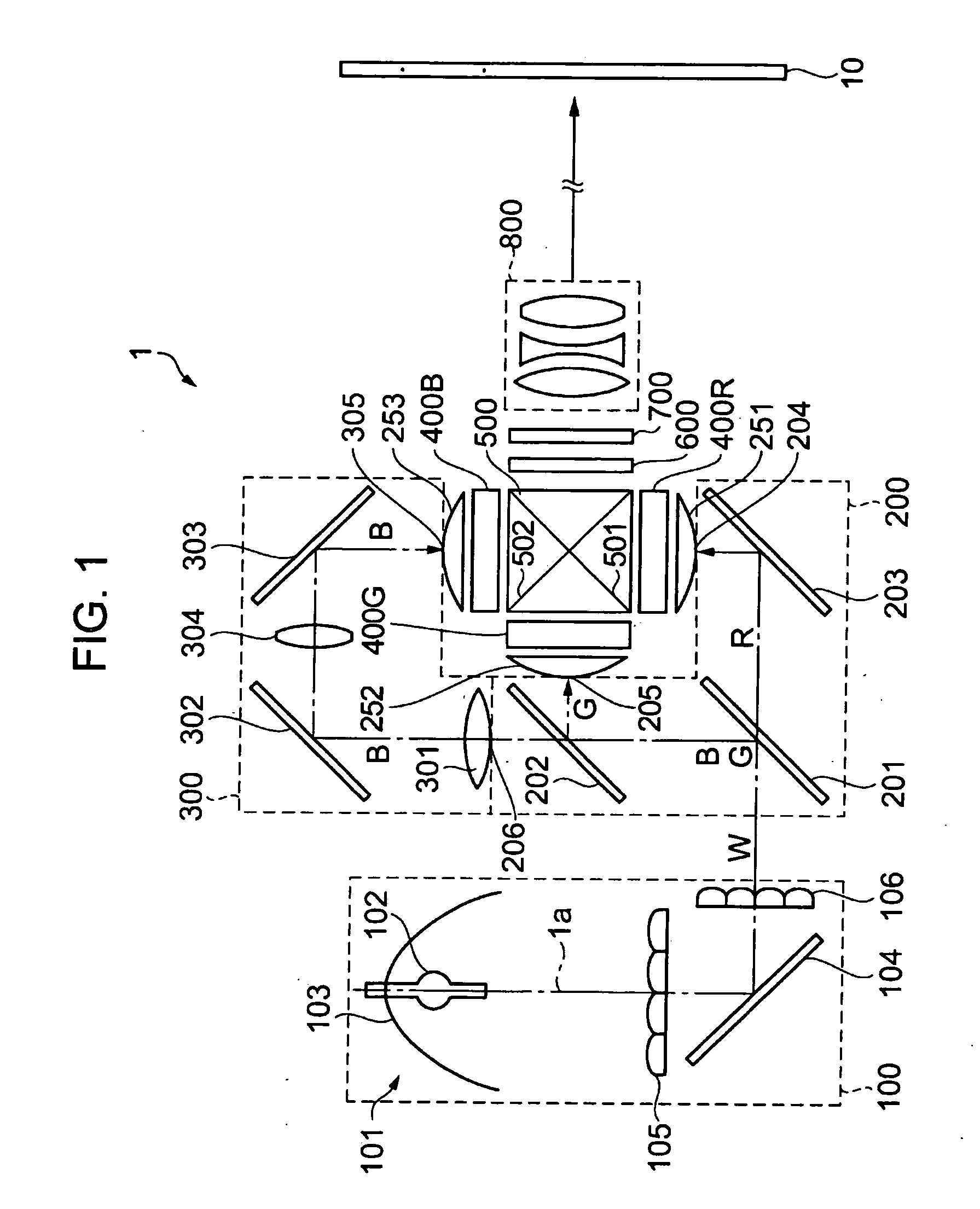

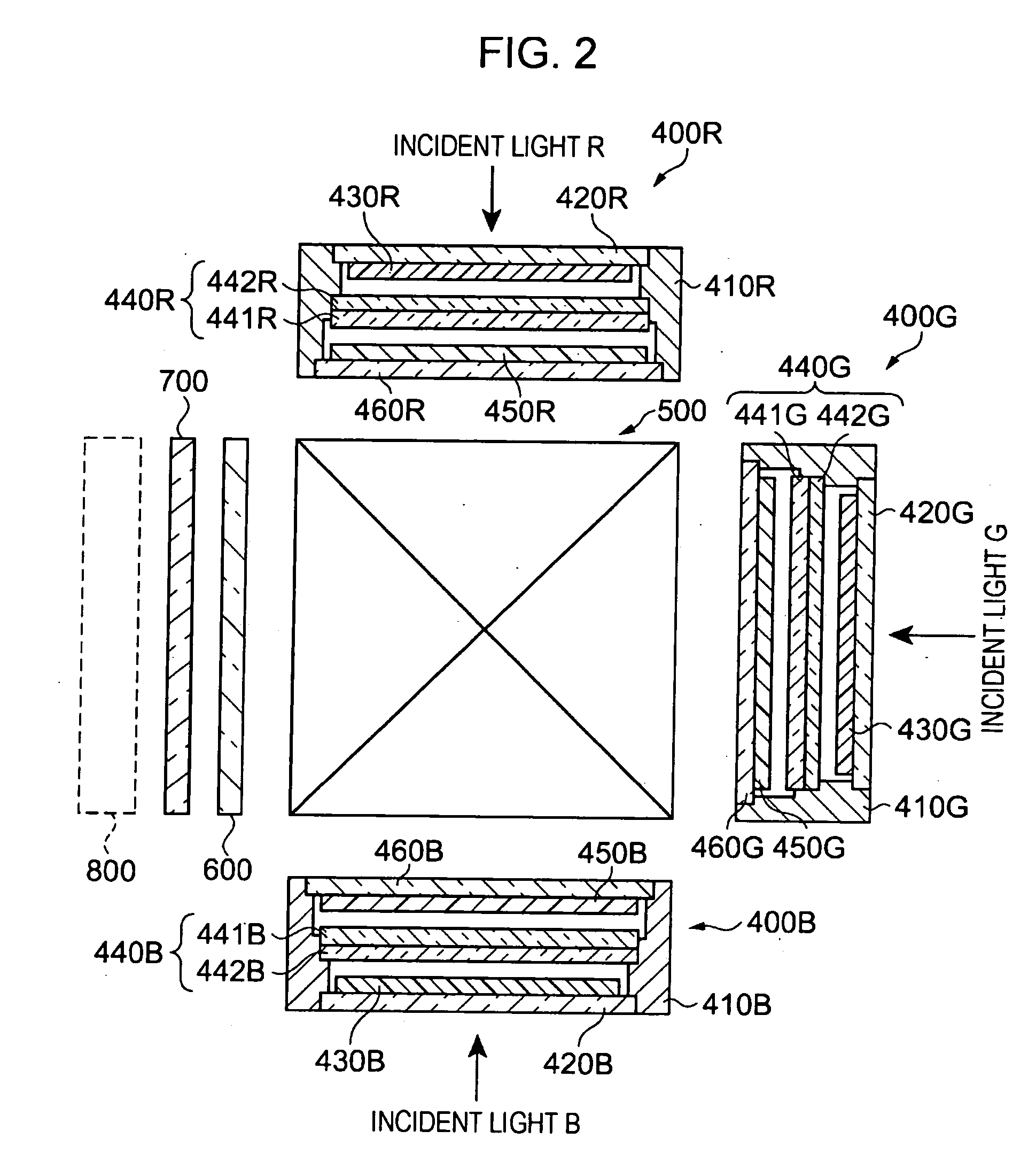

InactiveUS20060262233A1Increase heat radiationAvoid dustTelevision system detailsProjectorsLiquid crystal light valveLCD projector

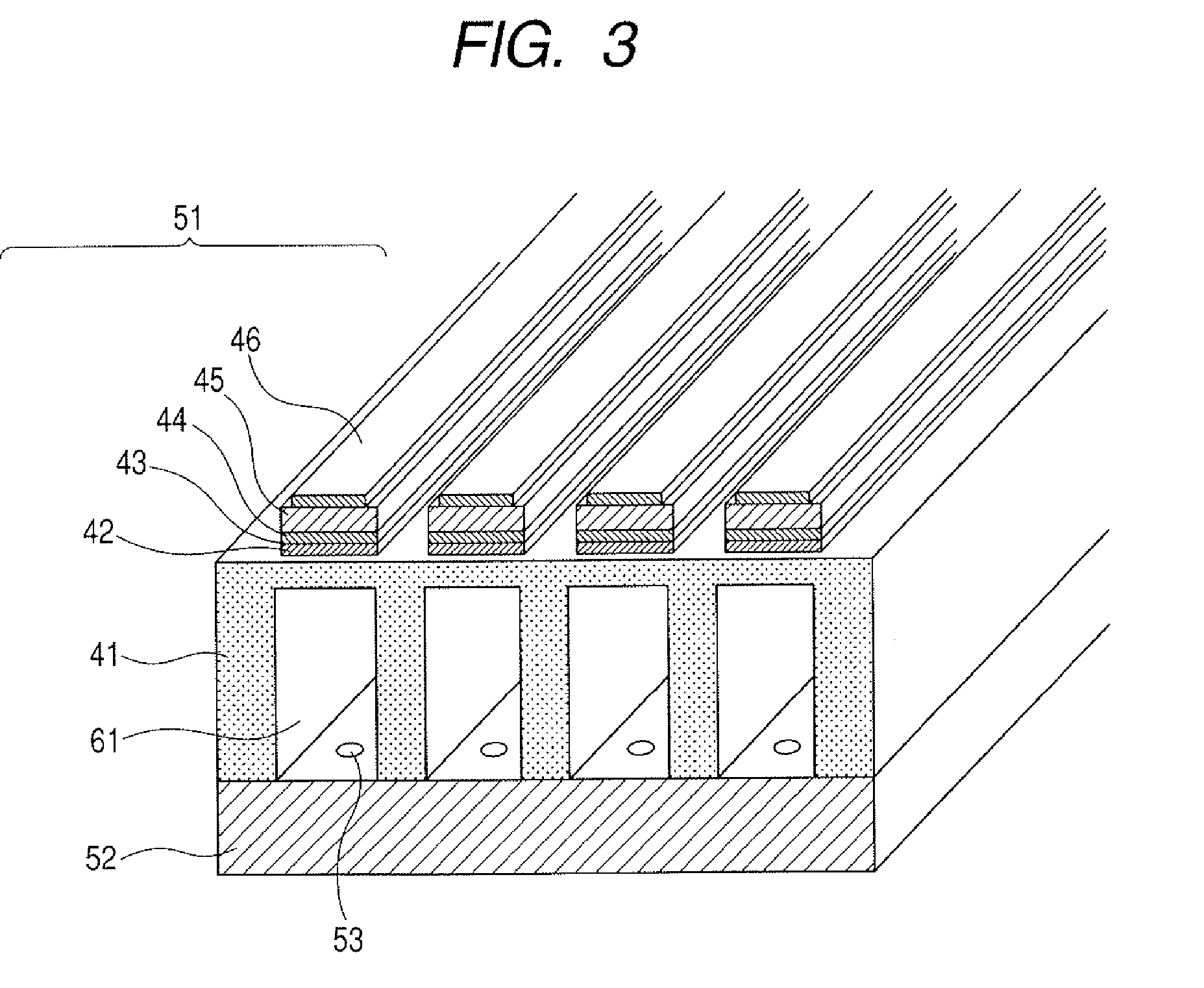

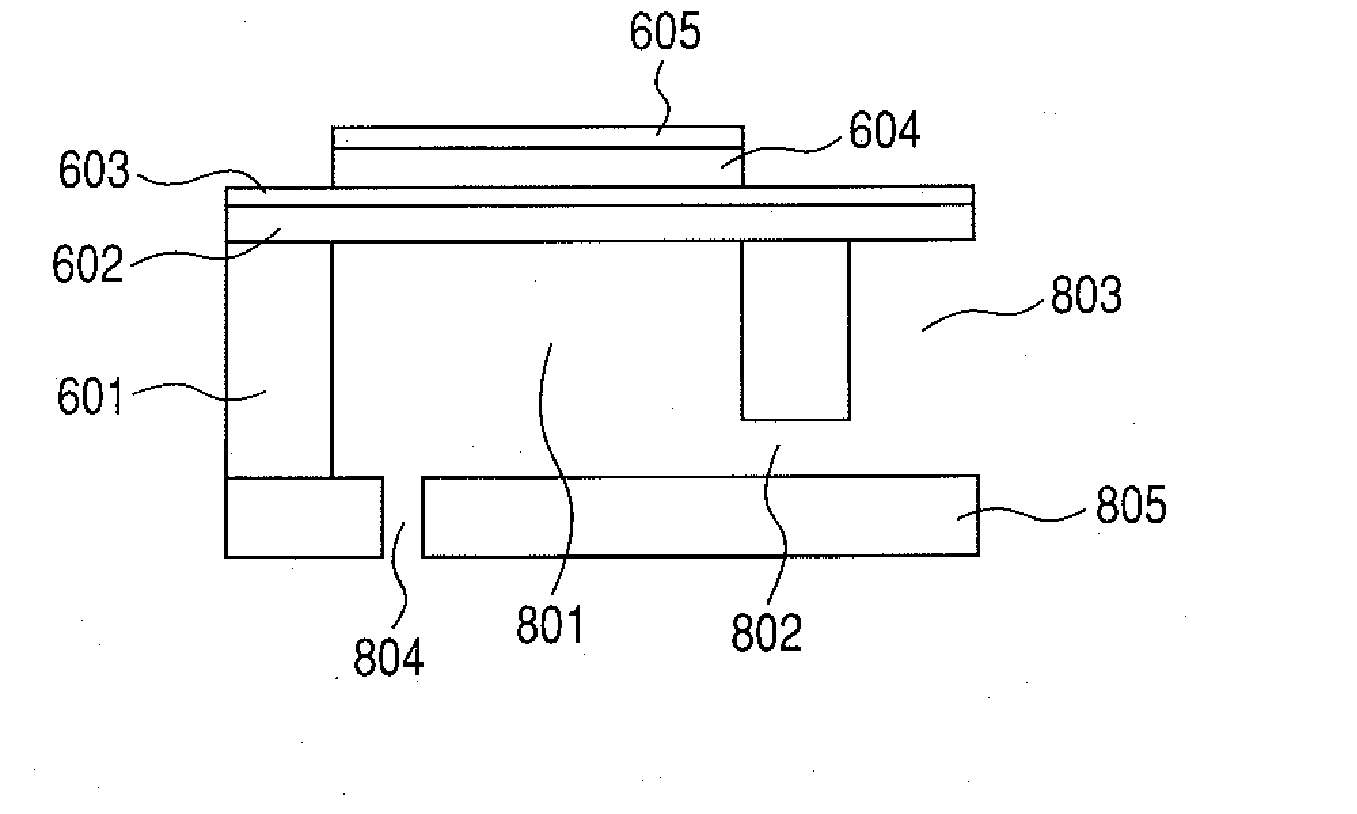

There is provided a liquid crystal projector capable of enhancing heat radiation of light modulating means including a liquid crystal light valve, preventing dust or the like from being attached to the surface of the liquid crystal light valve, and making black matrixes formed between pixels in the liquid crystal light valve invisible. The liquid crystal projector includes a light source unit, colored-ray dividing means for dividing light emitted from the light source unit into three colored rays, light modulating means for serving to modulate the three colored rays on the basis of a given image signal and to emit the modulated rays which are predetermined linear polarized rays, colored-ray synthesizing means for synthesizing the modulated rays, and optical projection means for enlarging and projecting the synthesized rays synthesized by the colored-ray synthesizing means onto a screen. The light modulating means includes entrance dust-proof glasses 420R, 420G, and 420B made of crystallized quartz or sapphire having a uniaxial crystal structure and disposed on entrance sides of liquid crystal light valves 440R, 440G, and 440B of the light modulating means, respectively, and exit dust-proof glasses 460R, 460G, and 460B made of crystallized quartz or sapphire having birefringence and disposed on exit sides thereof, respectively.

Owner:SEIKO EPSON CORP

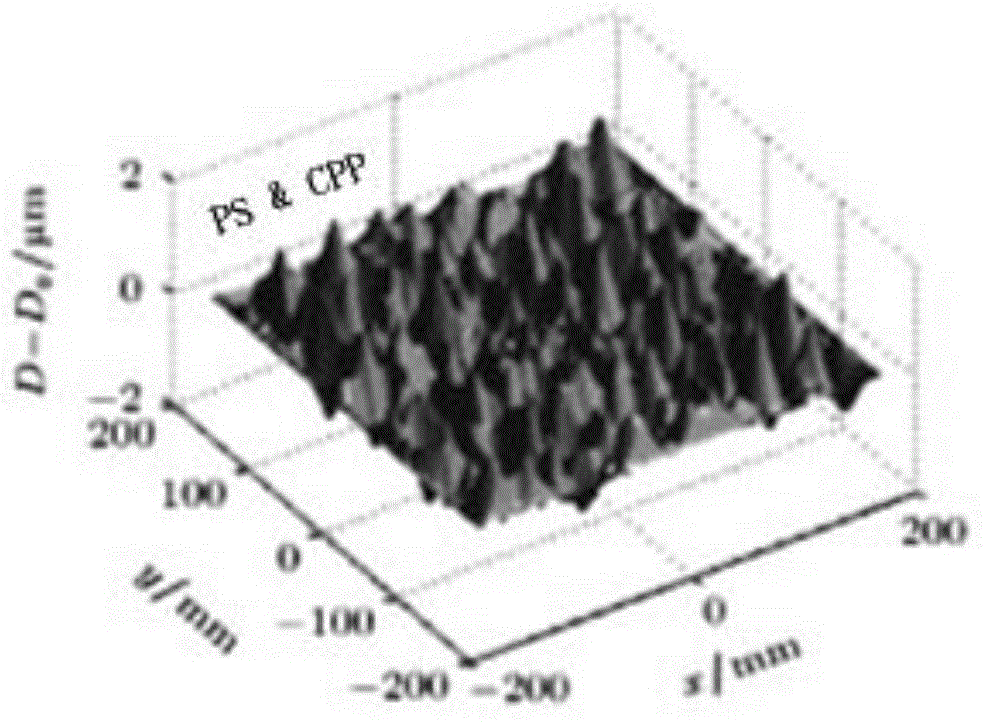

Laser optical path used for target focal spot shaping and beam smoothing

InactiveCN104102009AReduce thicknessReduce the risk of injuryOptical elementsTarget surfaceLight beam

The invention discloses a laser optical path used for target focal spot shaping and beam smoothing. The laser optical path is characterized in that the laser optical path comprises an incident laser beam, a convex lens, a phase plate and a target surface; the phase plate is composed of a uniaxial crystal; front and rear surfaces of the phase plate are parallel to the optical axis of the uniaxial crystal; continuous phase plate surface shapes are etched on one of front and rear surfaces through the existing technology; when the incident laser beam comes into the optical path, the incident laser beam is perpendicular to the surface of the convex lens, and the polarization direction and the optical axis of the uniaxial crystal form an angle of 45 degrees; the phase plate is located between the lens and the target surface, and is near the side of the lens; and the surface, which is etched with the continuous phase plate surface shapes, of the phase plate is relative to the target surface. According to the invention, without reducing the performance of a laser driver, the functions of focal spot shaping and polarization smoothing are reserved; the combination of continuous phase plates and a polarization smoothing crystal plate is replaced; compared with the previous method, the laser optical path is more concise; the total thickness of the beam passing through an optical element is reduced; and the damage risk of the optical element can be effectively reduced.

Owner:LASER FUSION RES CENT CHINA ACAD OF ENG PHYSICS

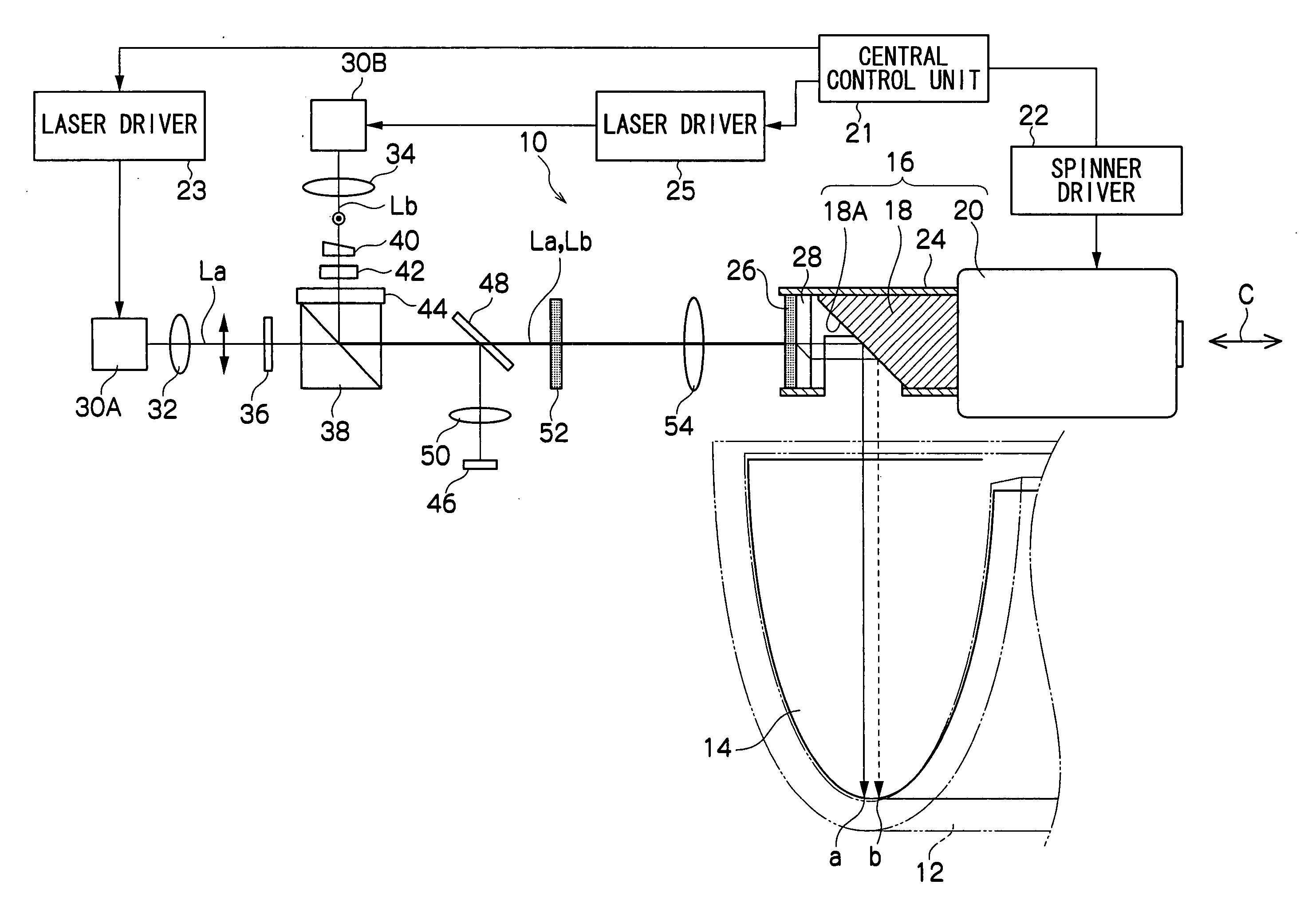

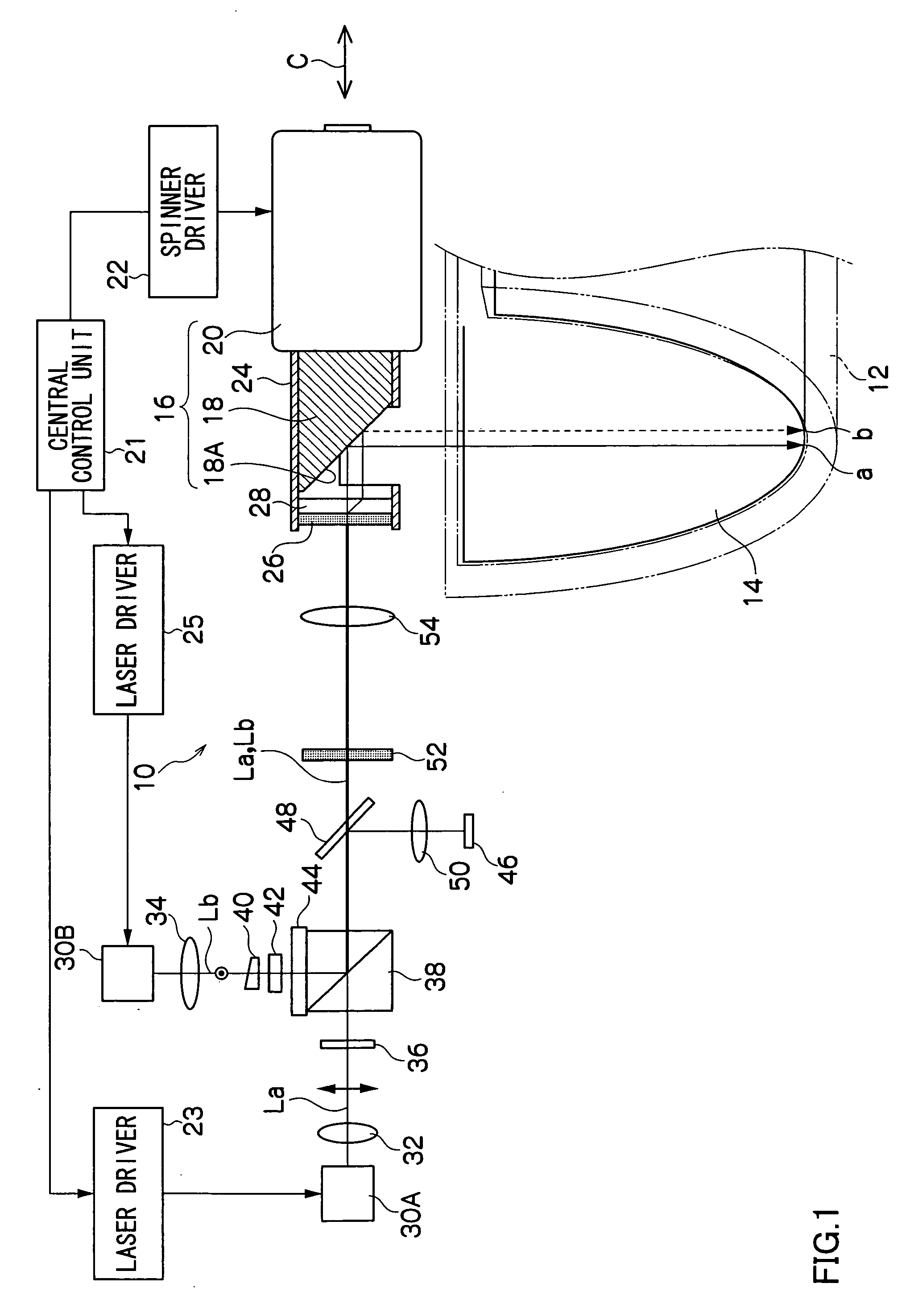

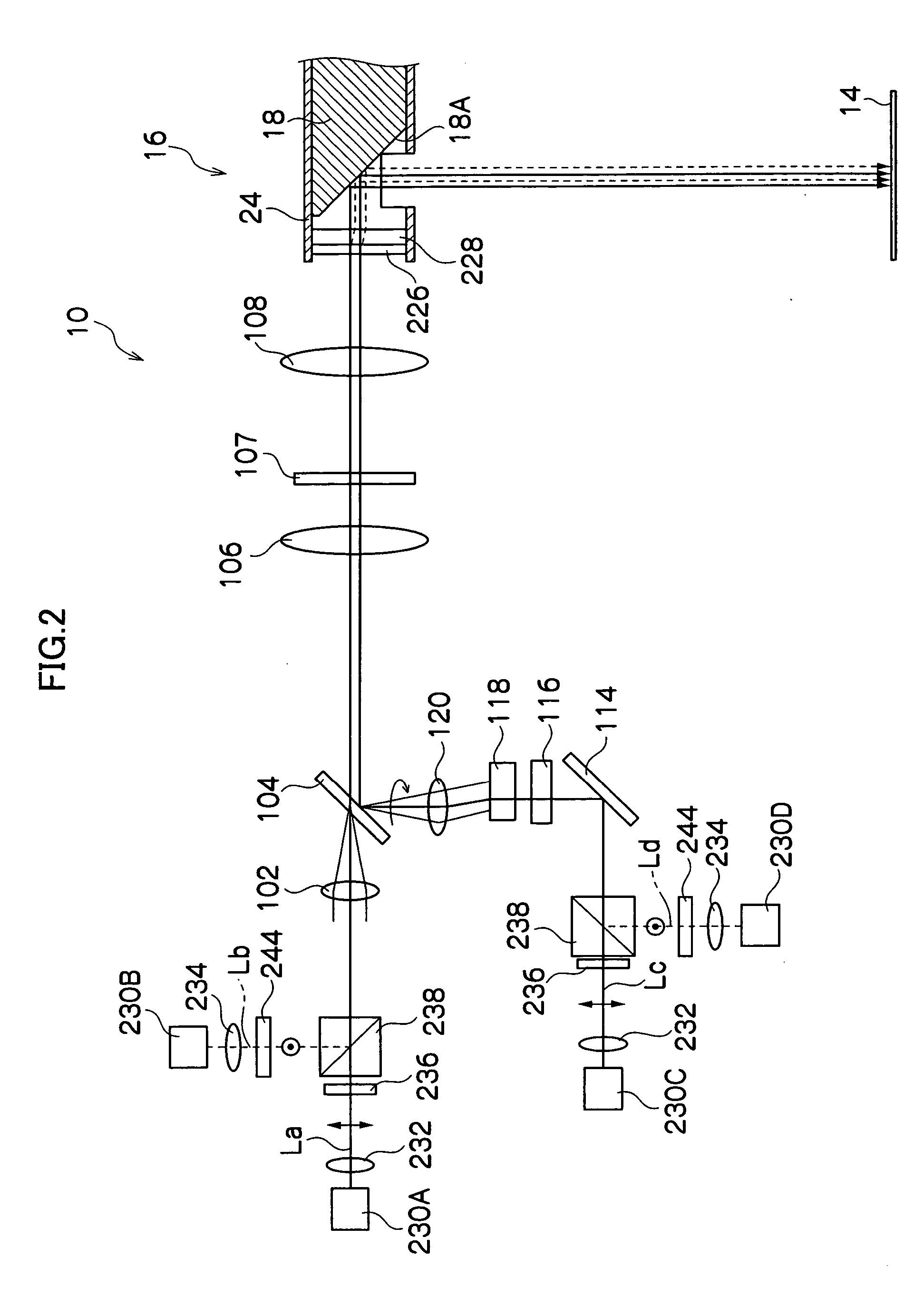

Inner drum exposure apparatus

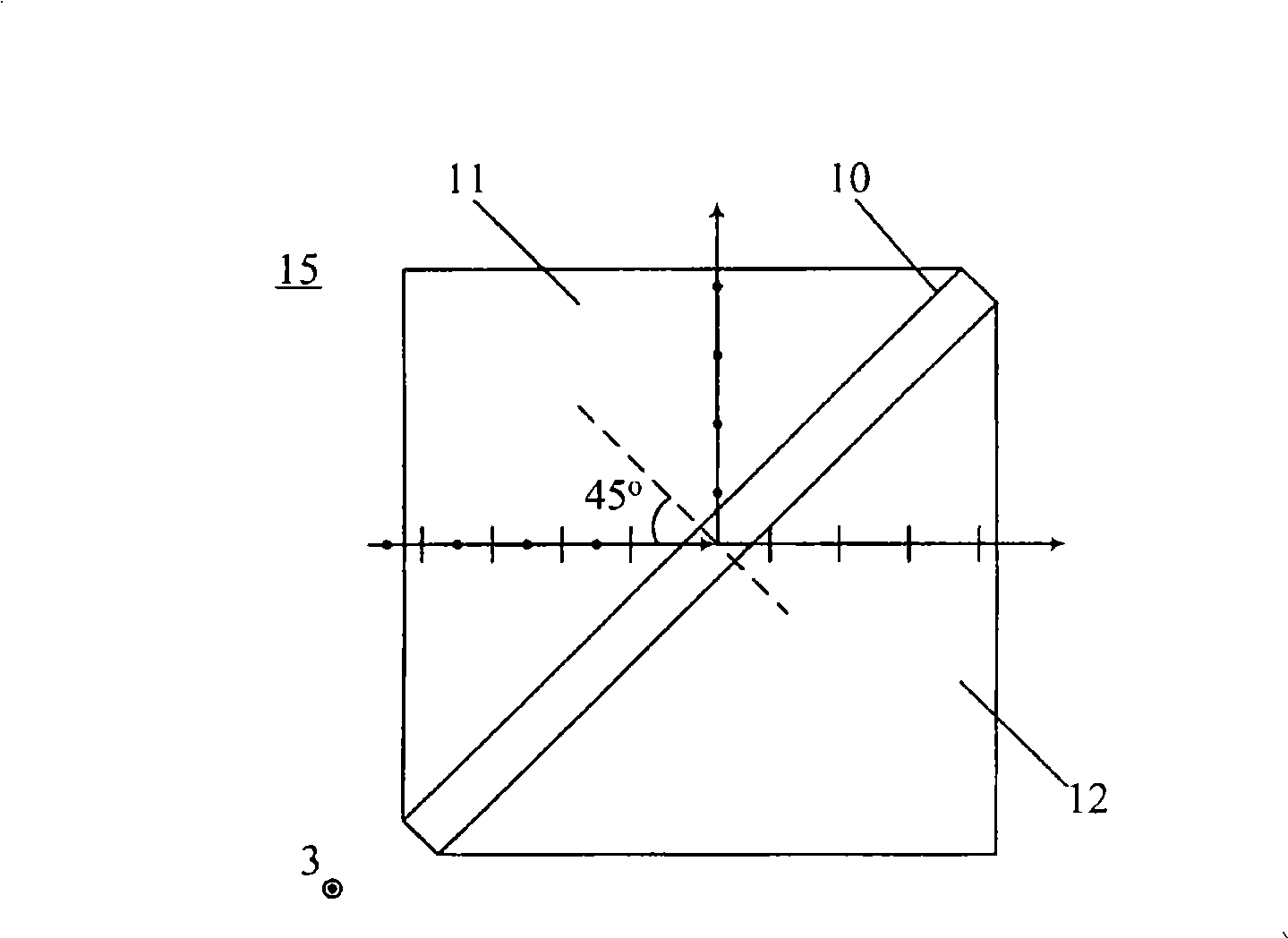

InactiveUS20060139717A1Quality improvementKeep widthRecording apparatusPolarising elementsOptoelectronicsUniaxial crystal

An exposure process is executed by multi-beams divided by polarizing and combining laser beams (La, Lb) modulated based on an image signal so as to be emitted by a light source side optical system by using a polarized light beam splitter, and by converting the laser beams (La, Lb) emitted as right circular polarized light and left circular polarized light into mutually orthogonal linear polarized light by using a quarter wave plate arranged on a light path of a scanning portion, and thereafter transmitting through an optical element of uniaxial crystal. An appropriate image can be formed by setting a division width of beam spots on a scanning surface set by the optical element of uniaxial crystal such that scanning unevenness of an image formed on a scanning surface is within an allowable range even when changing resolution of the inner drum exposure apparatus.

Owner:FUJIFILM CORP +1

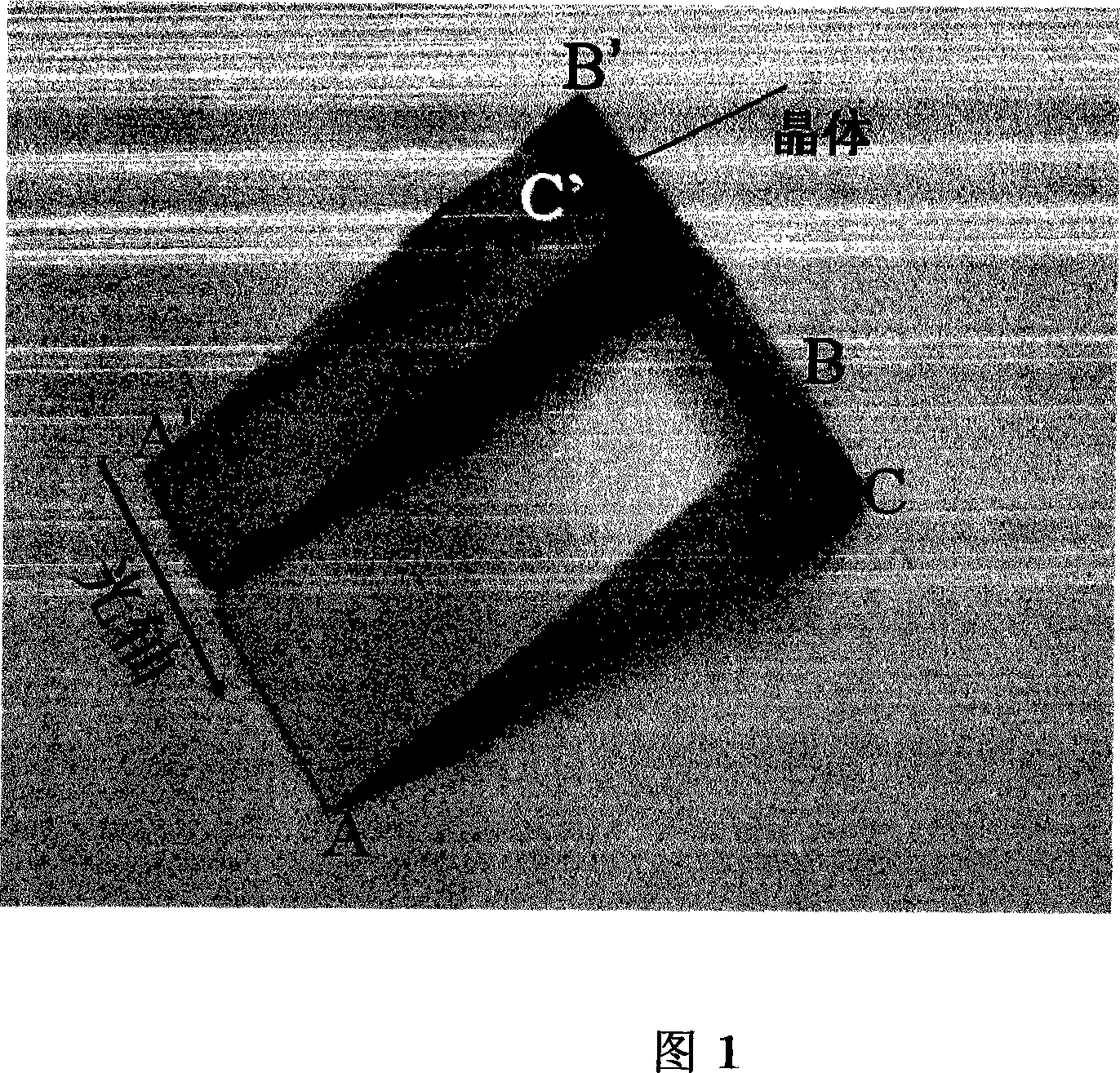

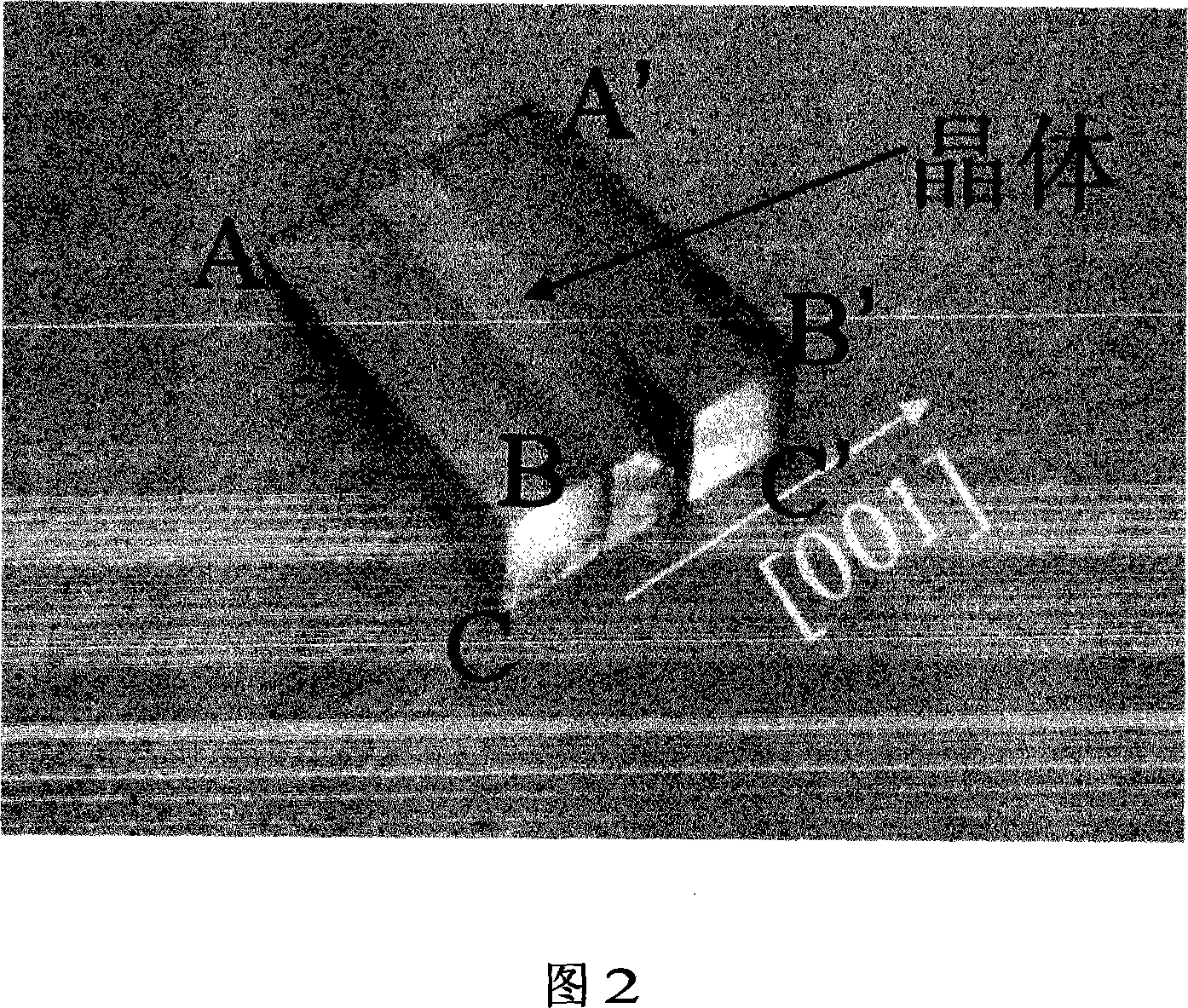

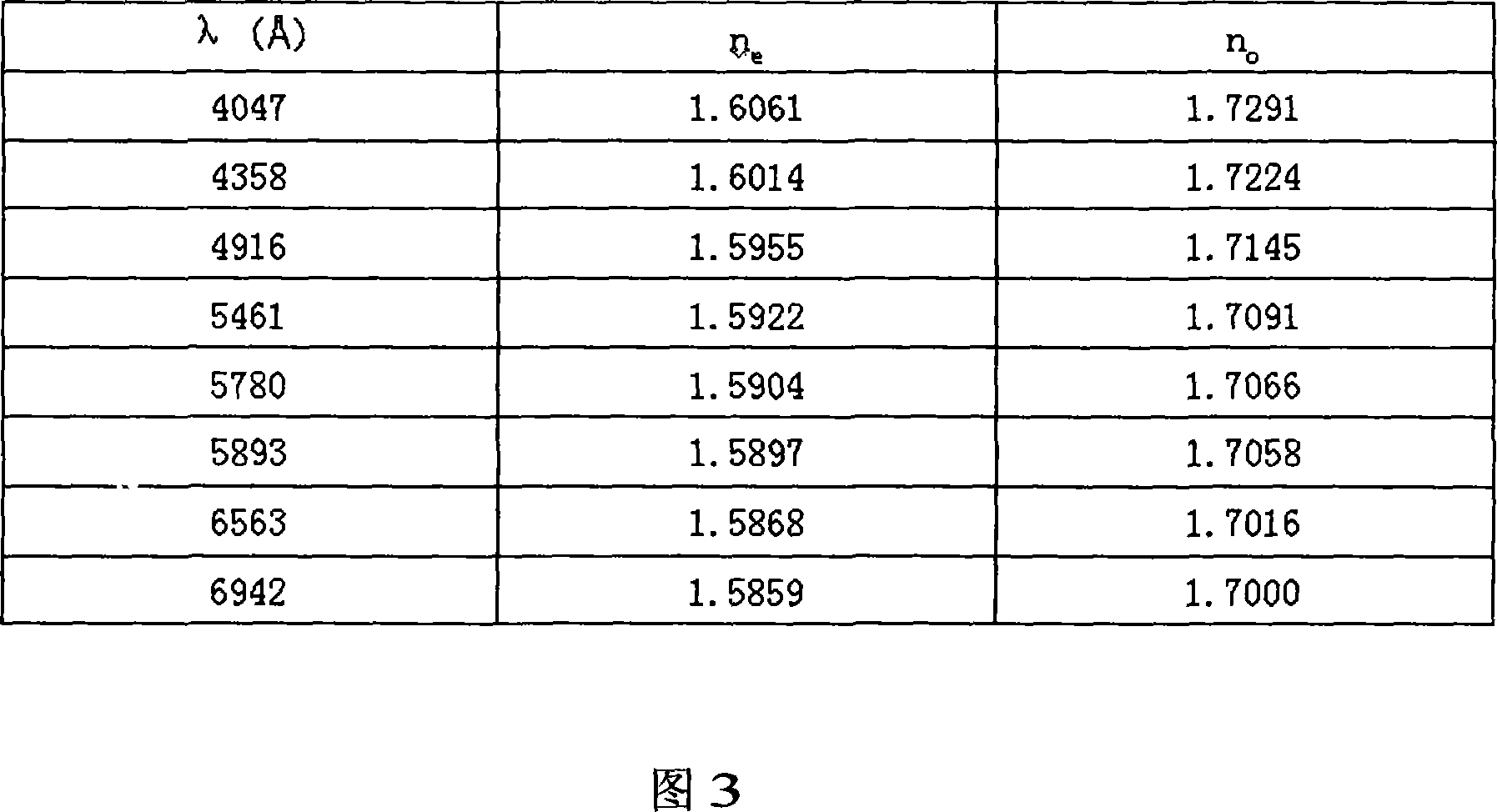

Use of birefraction borate crystal

ActiveCN101323981ACut wellGood groundingPolycrystalline material growthSingle crystal growth detailsBirefringent crystalRefractive index

The invention relates to an optical borate-series crystal with double refraction and application thereof. The borate-series crystal with double refraction has the chemical formula of ReBa3B9O18 (Re equals to Y, Pr, Nd, Sm, Eu, Gd, Tb, Er, Dy, Ho, Tm, Yb and / or Lu). The crystals are all uniaxial negative crystals, which have the birefringence of about 0.08 to 0.15 in the visible light band. The crystals in the series are easy to be incised, ground, polished and stored, are water immiscible, non-deliquescent and stable in air, and are suitable for being used for producing optical communication elements such as optoisolators, circulators, light beam shifters, optical polarizers and optical modulators, etc., in particular for producing polarizing prisms, phase delaying devices and electro-optical modulators with various purposes. The devices utilize the refraction index property of the optical borate-series crystal, particularly the larger birefringence (ne-no) thereof.

Owner:INST OF PHYSICS - CHINESE ACAD OF SCI

Calcium barium cyanurate double-refraction crystal for UV visible band and preparation method and application

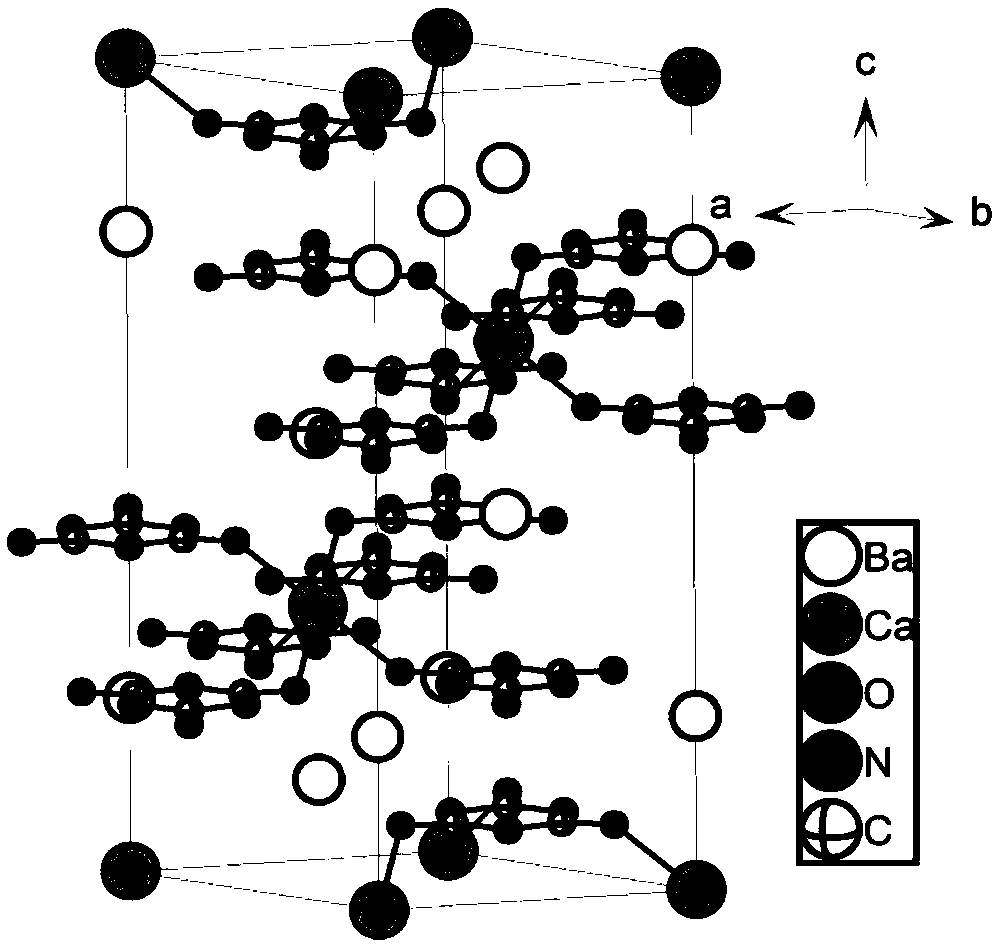

InactiveCN109161959APromote growthCut wellPolycrystalline material growthFrom frozen solutionsSpace groupRefractive index

The invention discloses a calcium barium cyanurate double-refraction crystal for UV visible band and a preparation method and application thereof. The chemical formula is Ba2Ca(C3N3O3)2 and belongs totrigonal system; the space group is as shown in the description; the cell parameters are as shown in the description, wherein Z is 3; the crystal grows through a high-temperature melt spontaneous crystallization method or a crucible lowering method. The calcium barium cyanurate double-refraction crystal prepared by the method is a negative single-axis crystal; the transmittance range is 240-5000nm; the refractivity calculation value under gamma of 532nm is that no equals to 2.008, ne equals to1.641, and delta n equals to 0.367. The crystal is easy to grow, easy to cut, easy to polish, stablein air, and not dissolved in water; the crystal can be used for preparing polarization beam splitters such as a Glan prism, a Wollaston prism, a Rochon prism or a beam-separated polarizer; and the crystal has an important application in the optical and communication fields.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

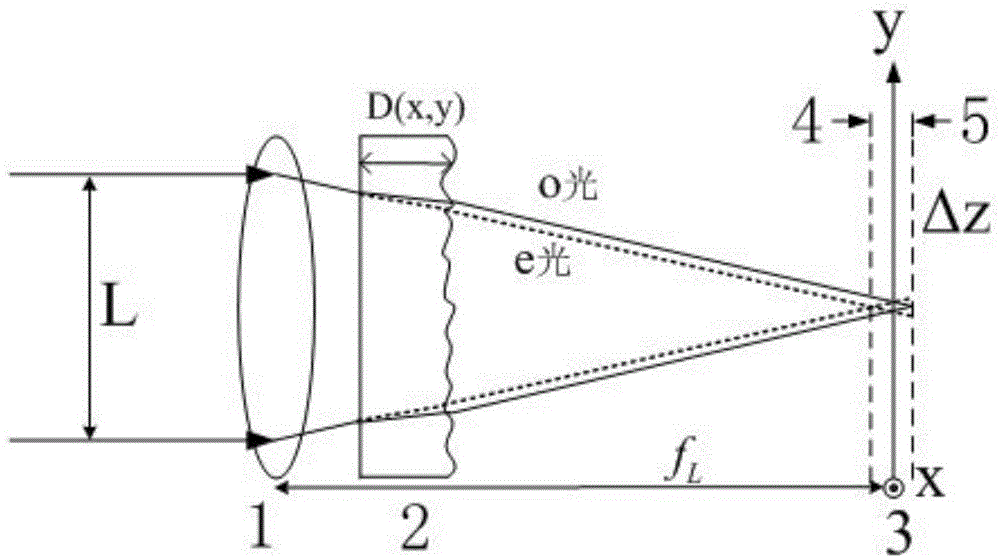

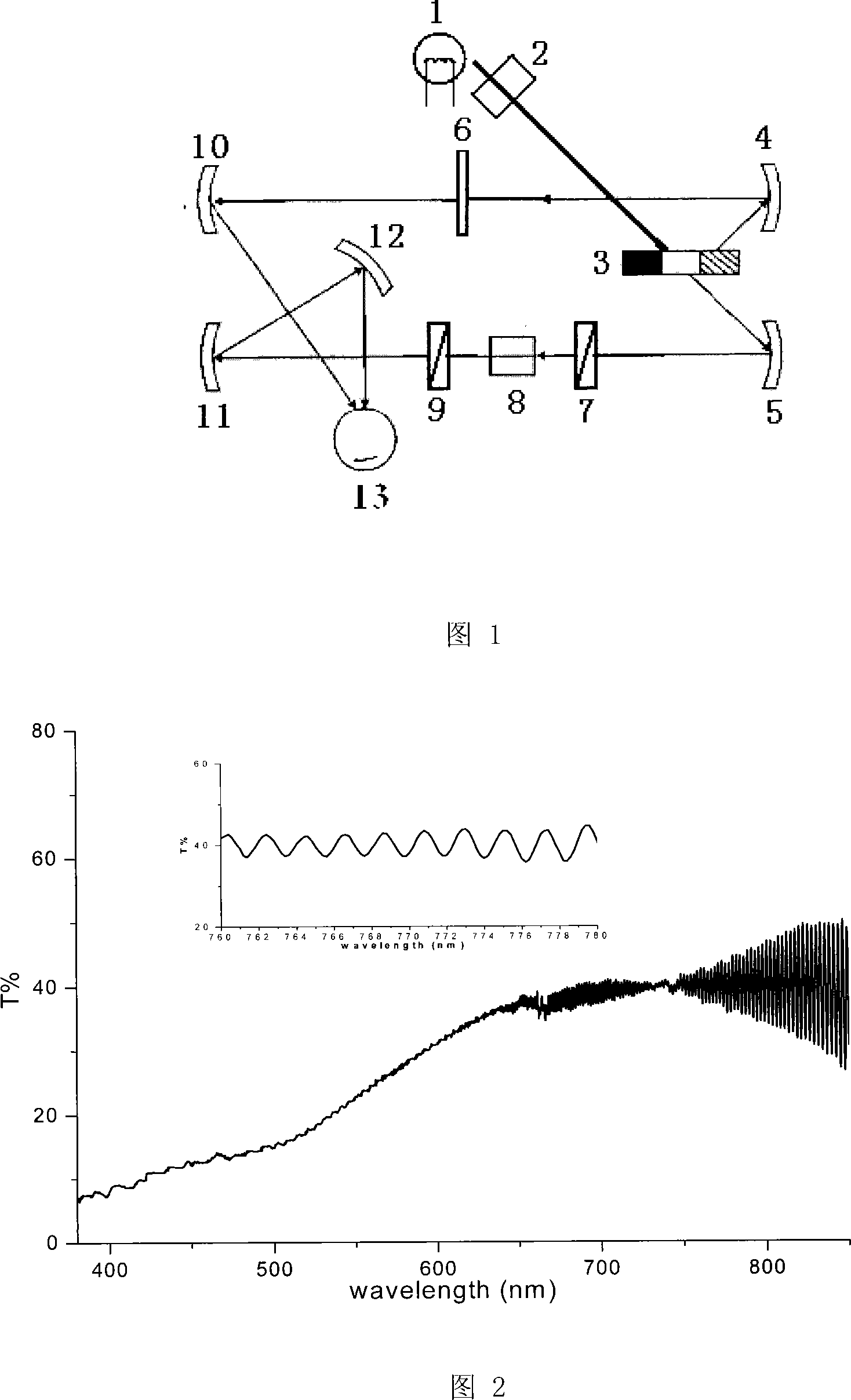

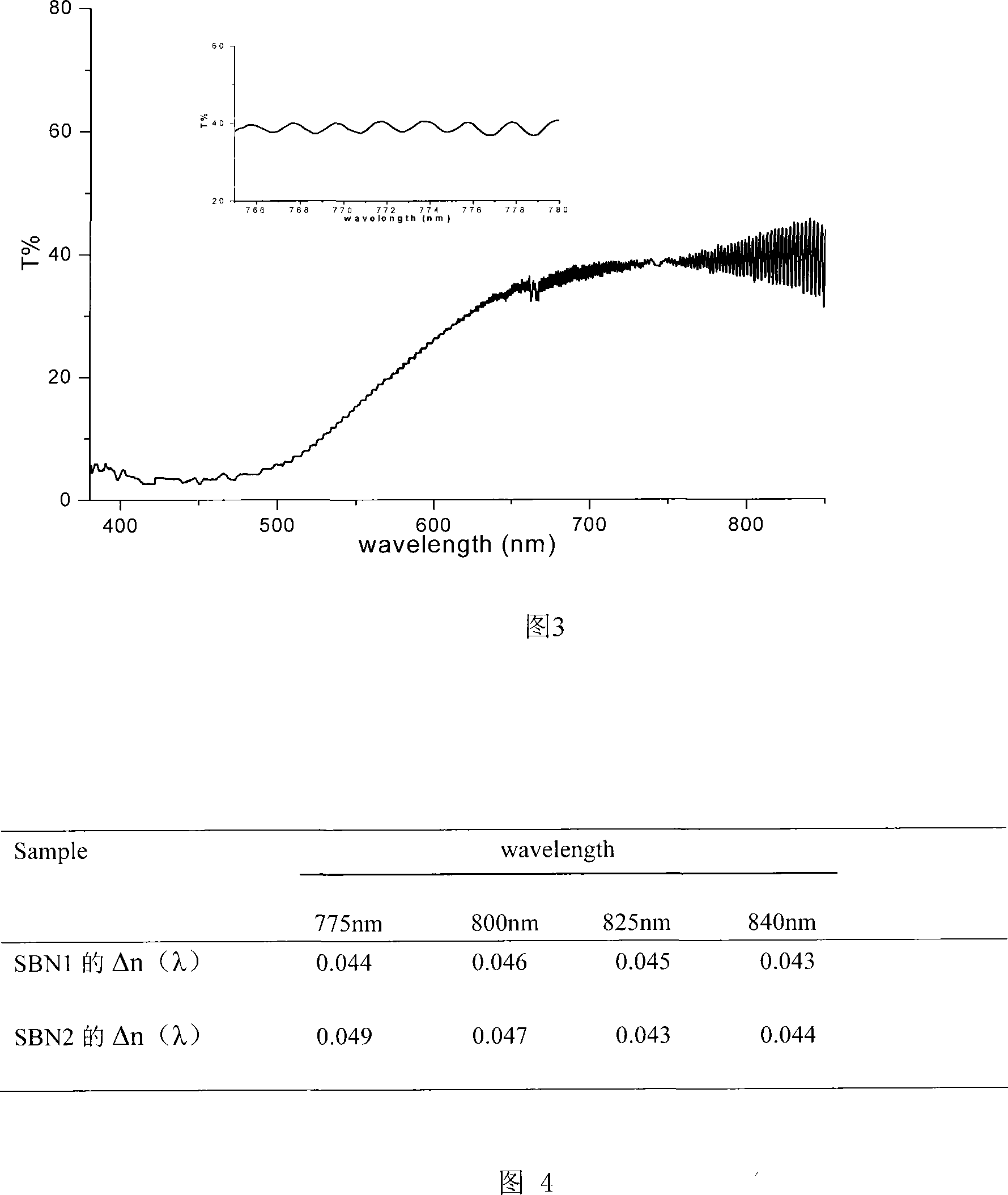

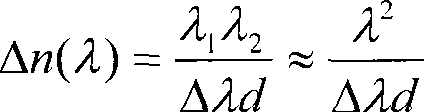

Uniaxial crystal birefringence measuring method

InactiveCN101187631AEasy to operateEnables multi-wavelength measurementsTransmissivity measurementsComplex mathematical operationsRefractive indexLight beam

The invention discloses a method for measuring uniaxial crystal birefringence rates and belongs to the crystal material measuring technology, which comprises adopting a double-beam spectrophotometer and a polarizing and polaroid analyzer, using a bromine lamp which can emit ultraviolet and visible light as a light source, measuring out continuously transmission spectrums of the uniaxial crystal, obtaining corresponding wave lengths according to the transmission spectrums of the uniaxial crystal, and thereby obtaining the uniaxial crystal birefringence rate. The measuring method has simple operation, simple employing instrument and equipment, the uniaxial crystal birefringence rate can be rapidly calculated out through the transmission spectrums, and the invention is easy to be realized in a lab. On the other side, the uniaxial crystal birefringence rate value in a certain spectrum range can be obtained through the transmission spectrums, and multi-wavelength measurements of uniaxial crystal birefringence rate value can be realized.

Owner:SHANDONG UNIV

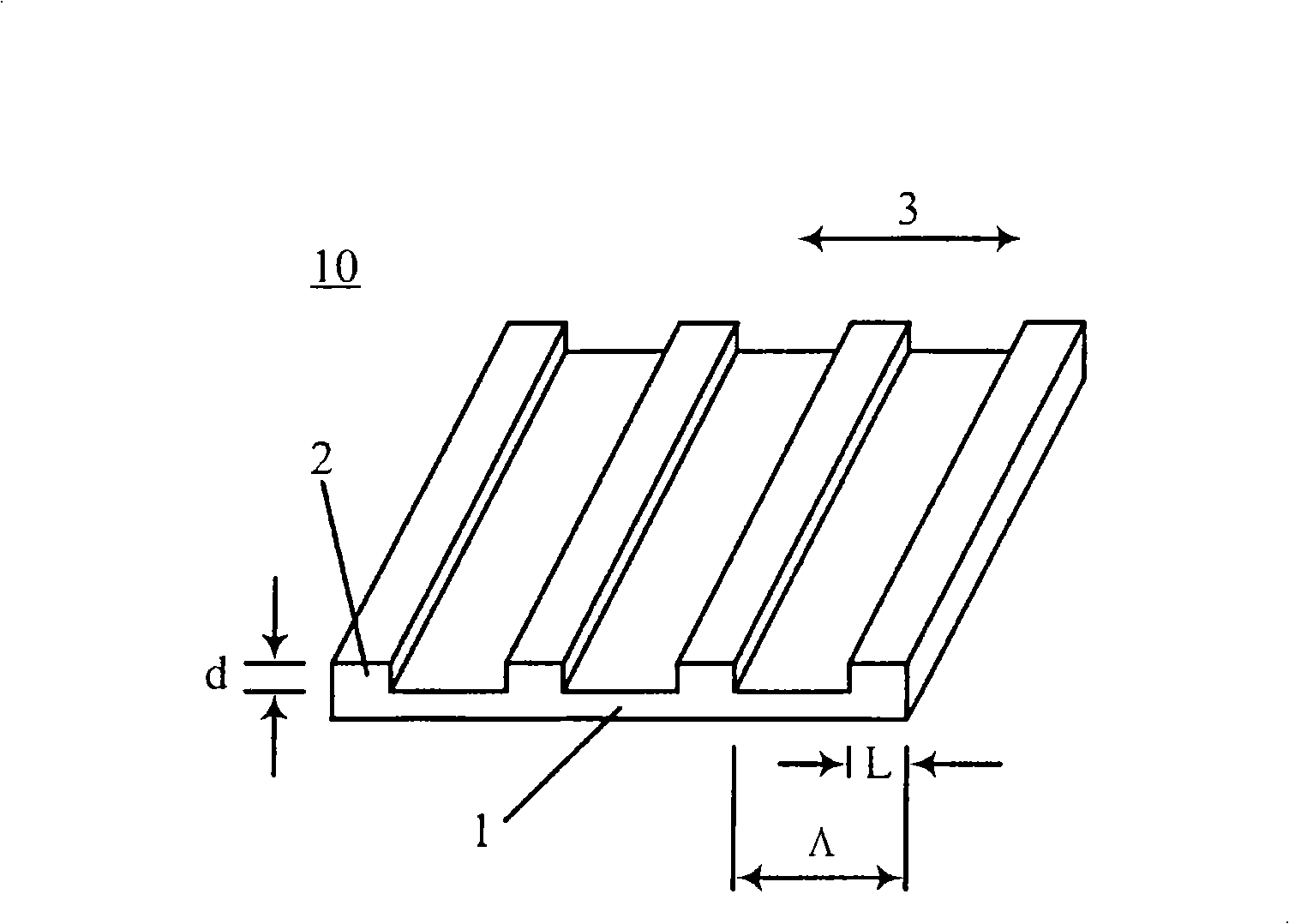

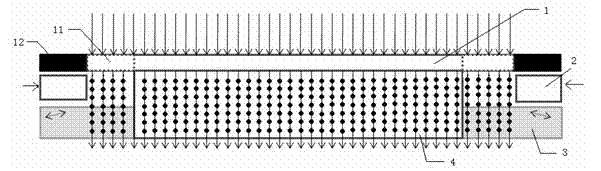

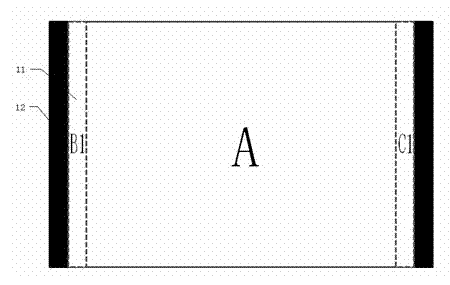

Device for eliminating splicing seam of light crystal display (LCD) screen and application method of device

ActiveCN102364563AEliminate seamsEasy to viewIdentification meansUniaxial crystalSwitching frequency

The invention belongs to the technical field of image display and in particular relates to a device for eliminating a splicing seam of a light crystal display (LCD) screen and an application method of the device. The device comprises an LCD panel, wherein the LCD panel comprises a display area and a non-display area; a selected area is arranged at the edge of the display area of the LCD panel; the selected area switches display images according to image switching frequency, displays the own display image at a1 moment and displays an image, which is required to be displayed by the non-display area but cannot be displayed by the non-display area, at a t2 moment; the selected area is as wide as and as long as the non-display area; an optical device which does not change the polarization direction of a linear polarized light from the selected area at the t1 moment according to the image switching frequency and rotates the polarization direction of the linear polarized light from the selected area by 90 DEG at the t2 moment is arranged in front of the LCD panel; a uniaxial crystal is arranged in front of the optical device; an optical axis of the uniaxial crystal is in a light incidence plane, and an inclined angle is formed between the optical axis and a crystal plane; according to the polarization direction of a signal light, the deflection of the signal light is determined; and the splicing seam of the screen is covered and eliminated by using an image signal which is subjected to image deflection. By the invention, the splicing seam of the screen can be completely eliminated, and the problems of incompleteness and discontinuity of splicing images of the screen are solved.

Owner:HUAWEI TEHCHNOLOGIES CO LTD

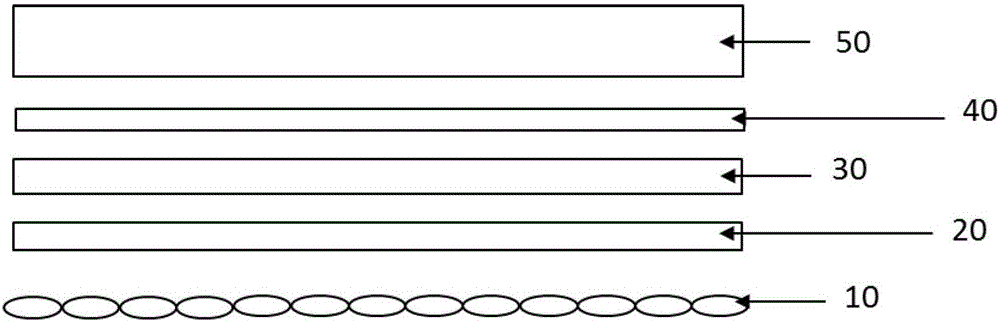

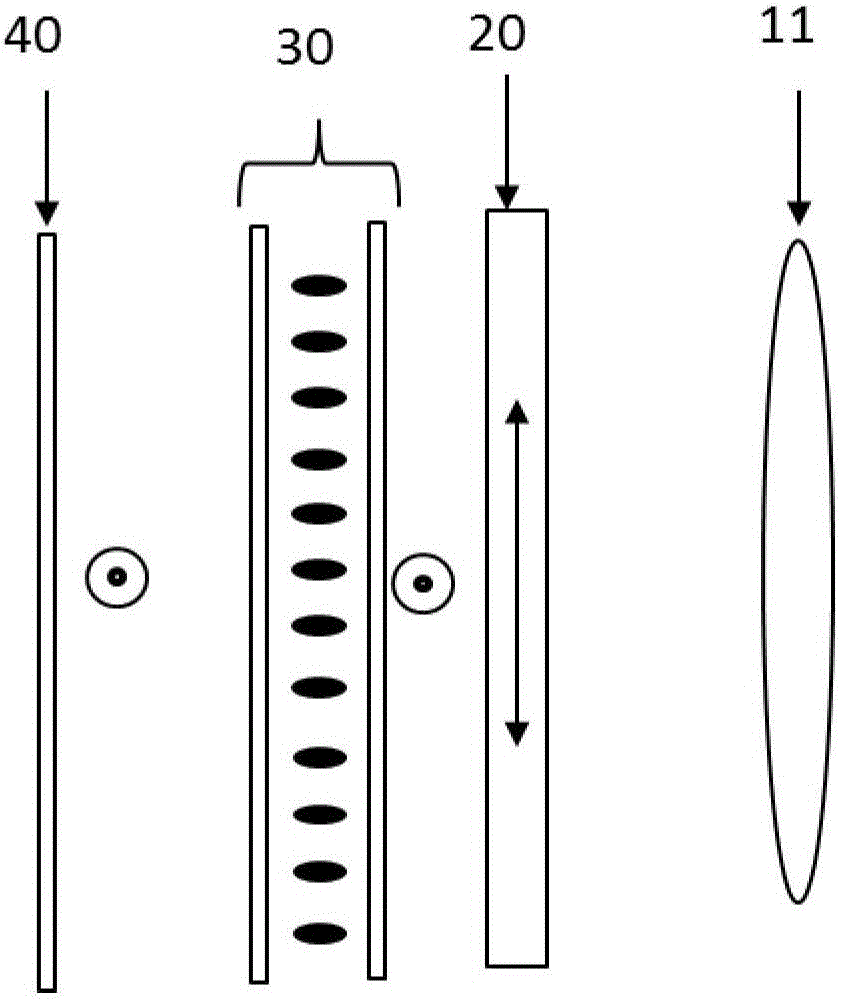

Integral imaging three dimensional display apparatus and method

The invention provides an integral imaging three dimensional display apparatus and method. The integral imaging three dimensional display apparatus successively includes a microlens array, a single shaft crystal slab, a TN box, a lower polaroid, a display panel, a first center depth plane and a second center depth plane, wherein when the TN box is in the open state, emergent light passes through the single shaft crystal slab; as the light emitted from an image primitive of the display panel passes through the microlens array, an image distance is formed and is lo; the first center depth plane is located at the image distance lo; when the TN box is the closed state, after the emergent linearly polarized light passes through the TN box, the polarization direction of the emergent linearly polarized light changes, and the polarization direction of the emergent linearly polarized light is parallel to the optical axis direction of the single shaft crystal slab; when the emergent light passes through the single shaft crystal slab, the light emitted from the image primitive of the display panel passes through the microlens array and then an image distance le is formed; and the second center depth plane is located at the image distance le. For the integral imaging three dimensional display apparatus and method, by means of formation of the two center depth planes, the center depth plane are the focusing image planes that the image primitive array on the display panel are imaged through the lens array, and the three dimensional image depth can be enhanced.

Owner:NANJING CEC PANDA LCD TECH

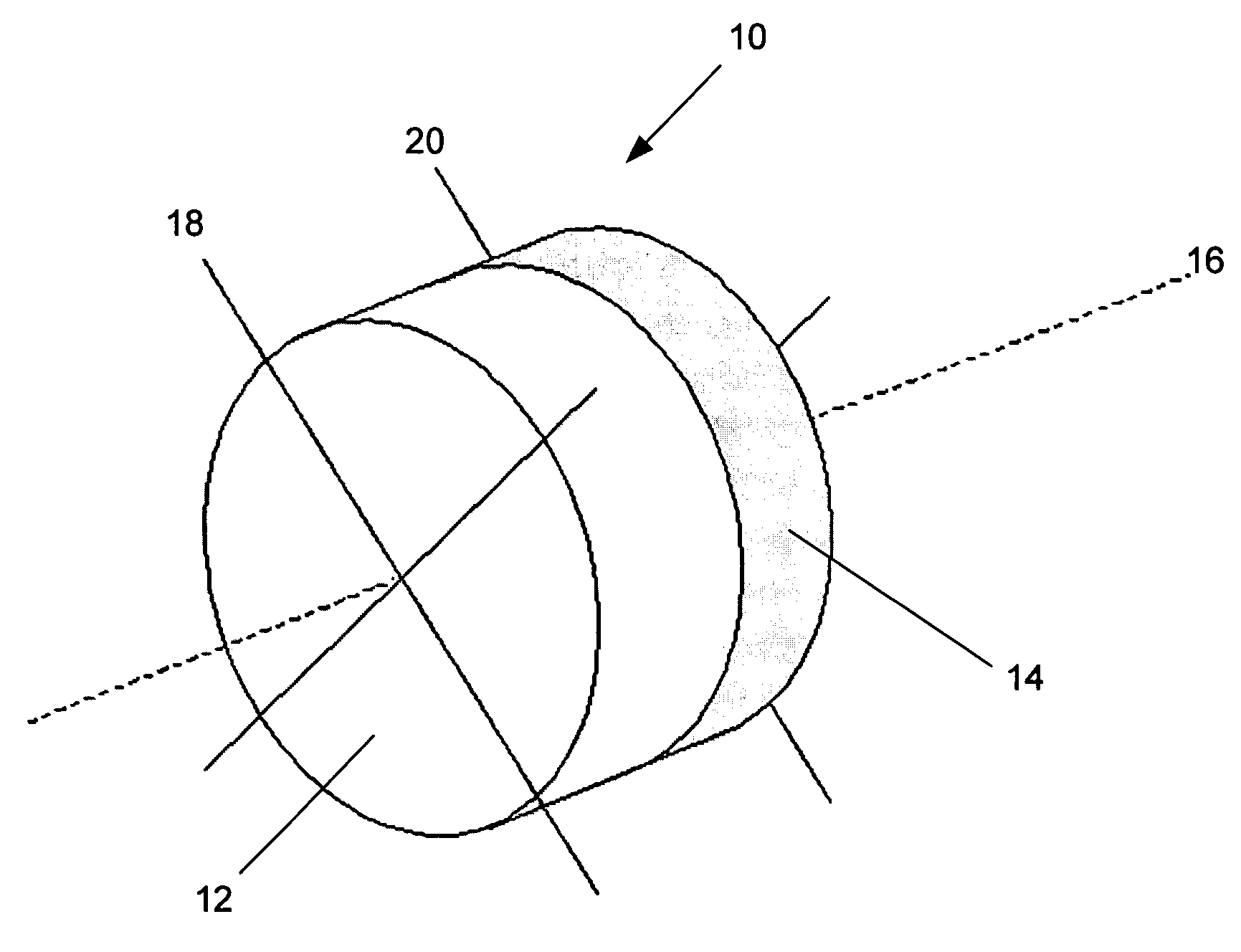

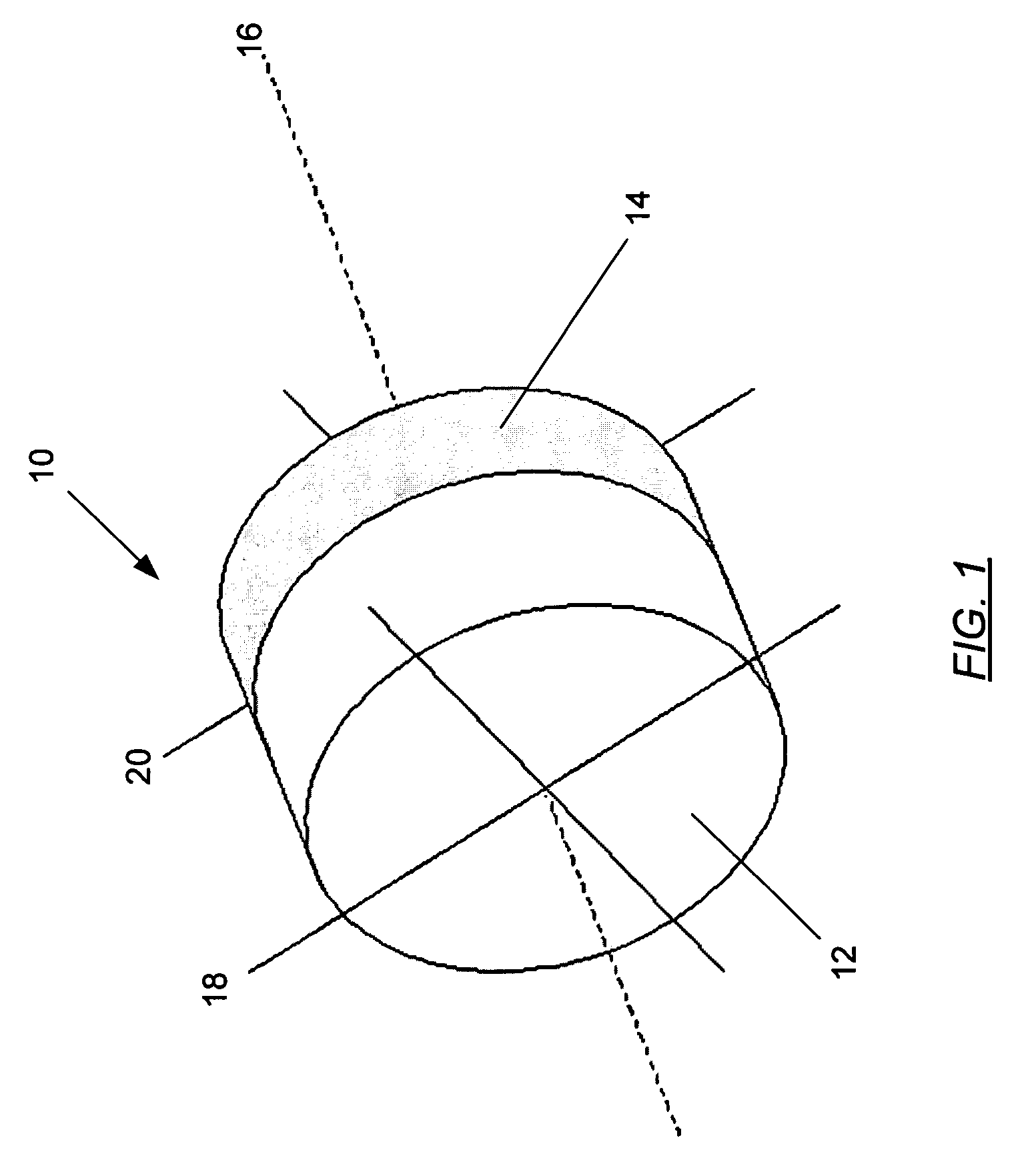

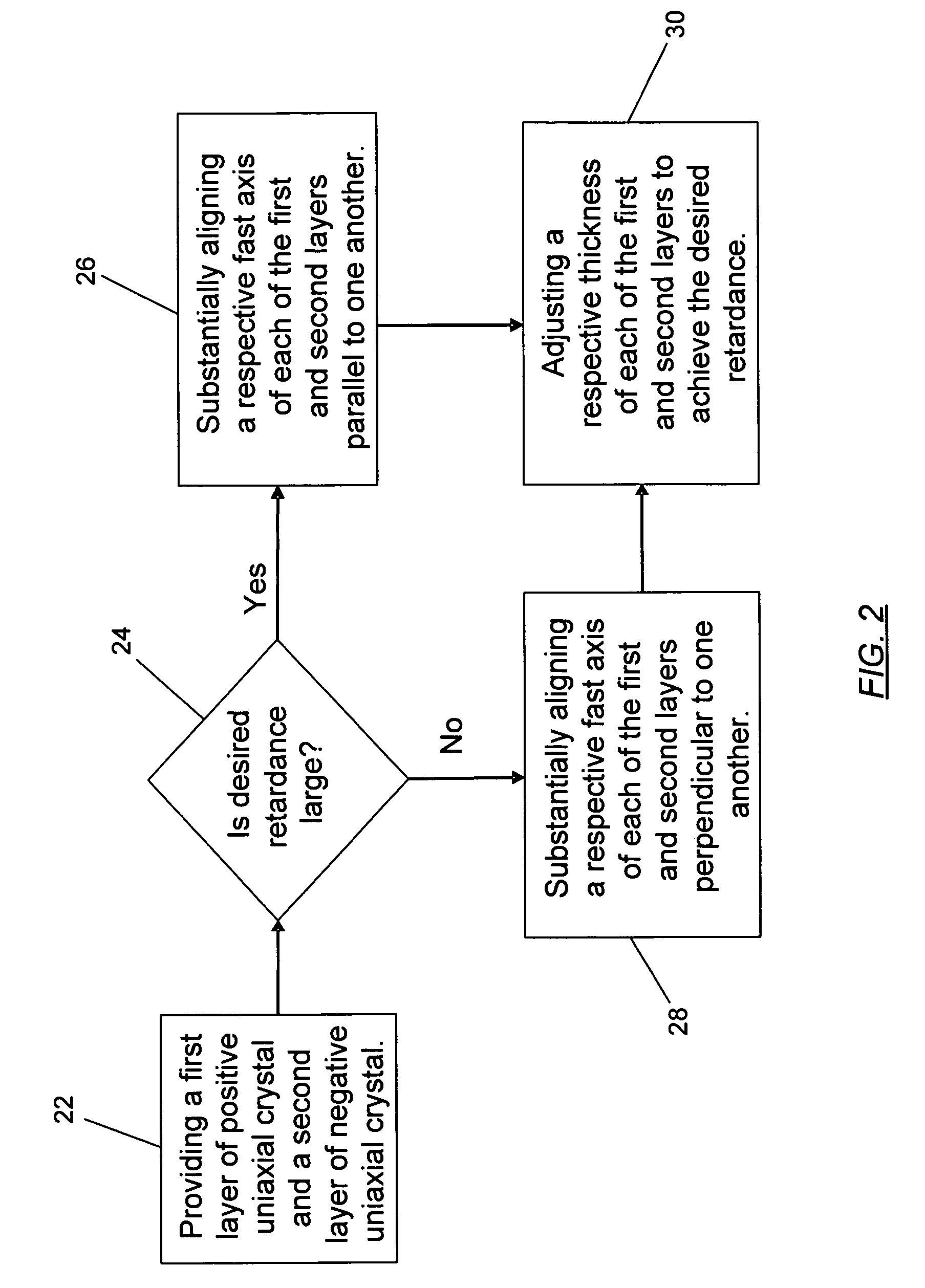

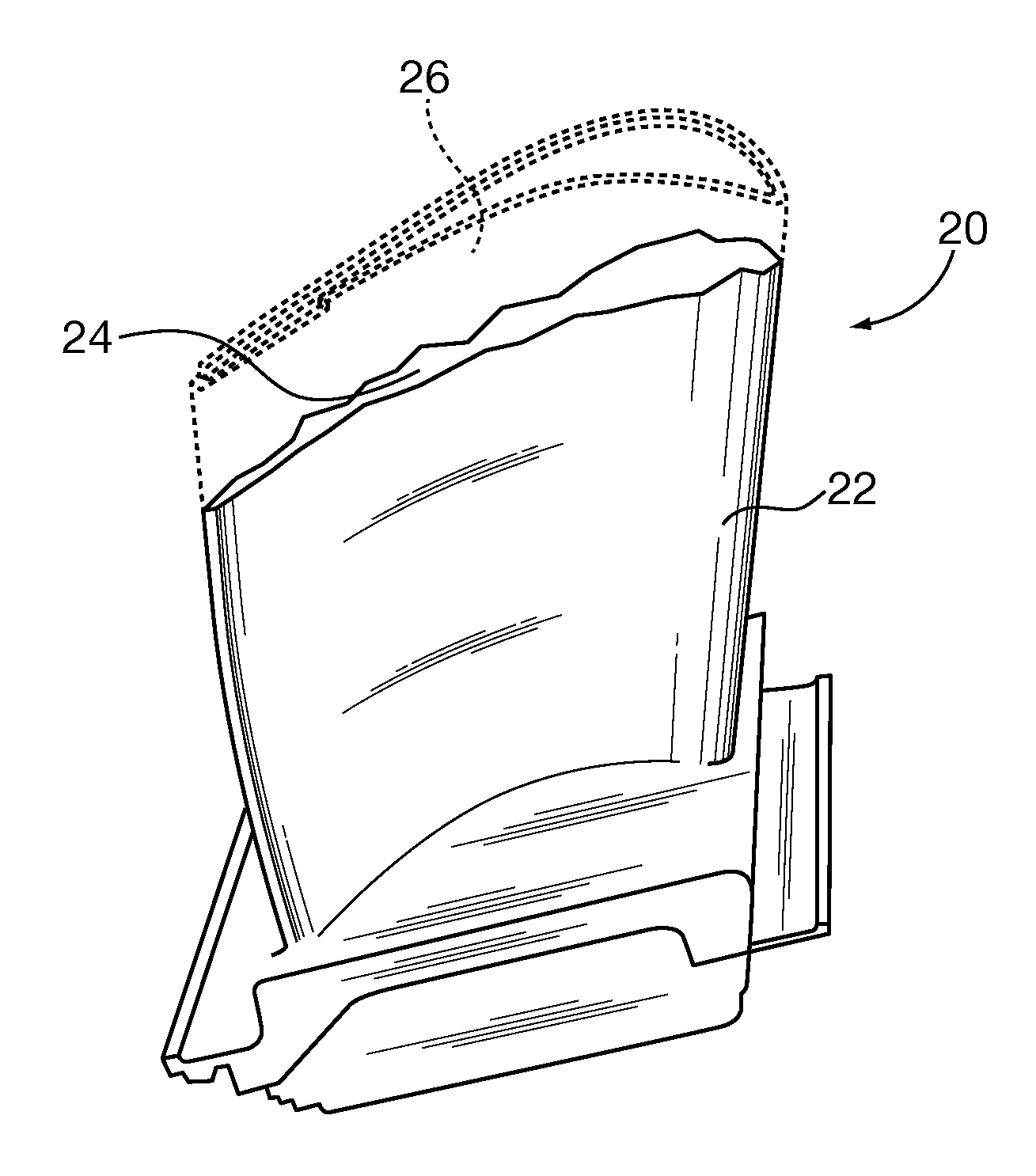

Wave plate and associated method

ActiveUS7382535B2Reduce sensitivityReduce and eliminate angular sensitivityPolarising elementsNon-linear opticsAngle of incidenceClassical mechanics

Owner:THE BOEING CO

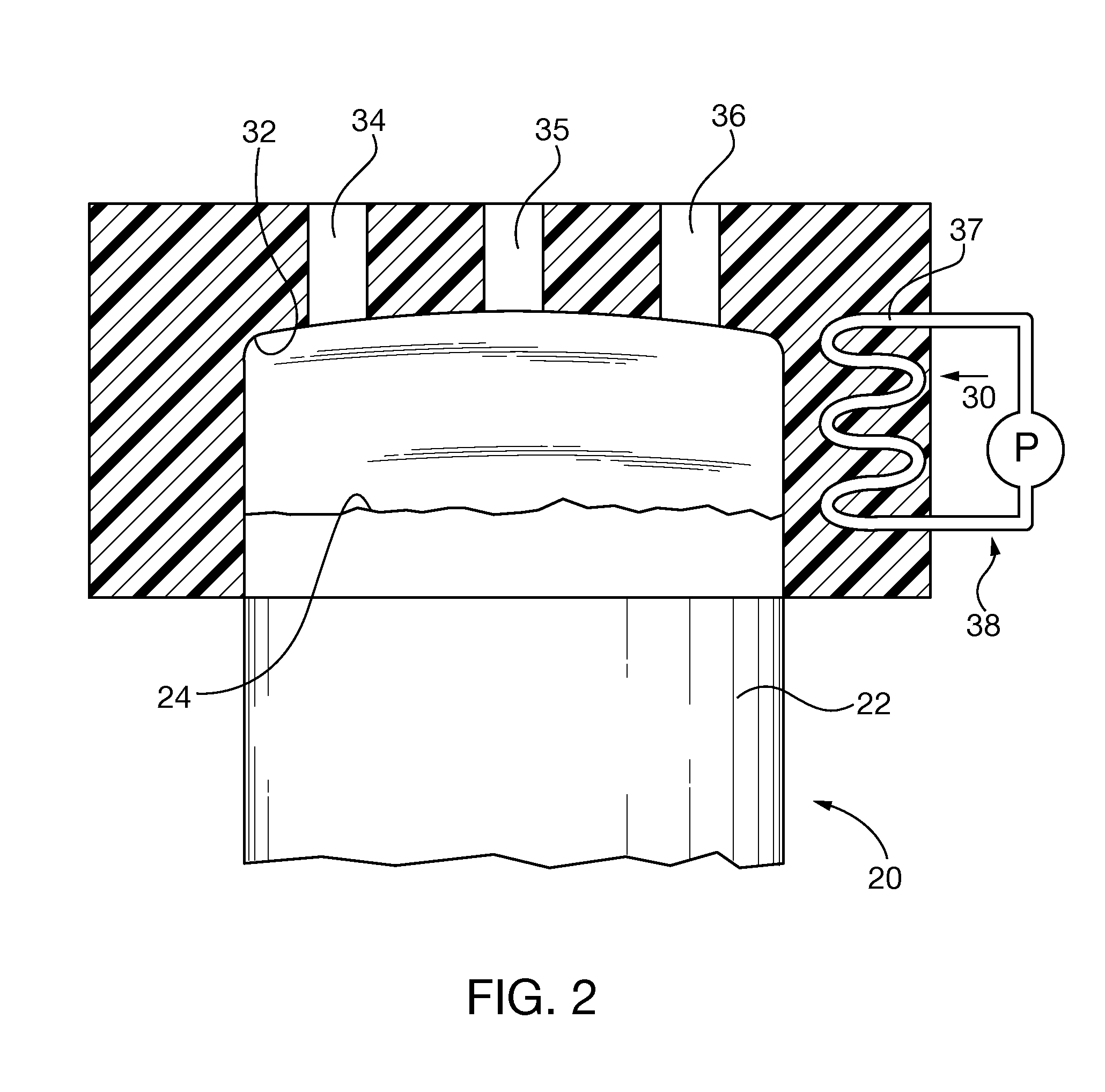

Electroslag and electrogas repair of superalloy components

ActiveUS20140044991A1Raise the possibilityDamaged component scrap rates can be reducedTurbinesPropellersTurbine bladeFilling materials

Superalloy component castings, such as turbine blades and vanes, are fabricated or repaired by an electroslag or electrogas welding process that at least partially replicates the crystal structure of the original cast substrate in a cast-in-place substrate extension. The process re-melts the base substrate surface and grows it with new molten filler material. As the base substrate and the filler material solidify, the newly formed “re-cast” component has a directionally solidified uniaxial substrate extension portion that at least in part replicates the crystalline structure of the base substrate. The “re-cast” component can be fabricated with a unified single crystal structure, including the extension portion. In other applications, a substrate extension can replicate a directionally solidified uniaxial crystal structure of an original base substrate casting. Polycrystalline substrate base structures can be re-cast with a substrate extension that replicates base substrate crystals that are most parallel to the uniaxial casting direction.

Owner:SIEMENS ENERGY INC

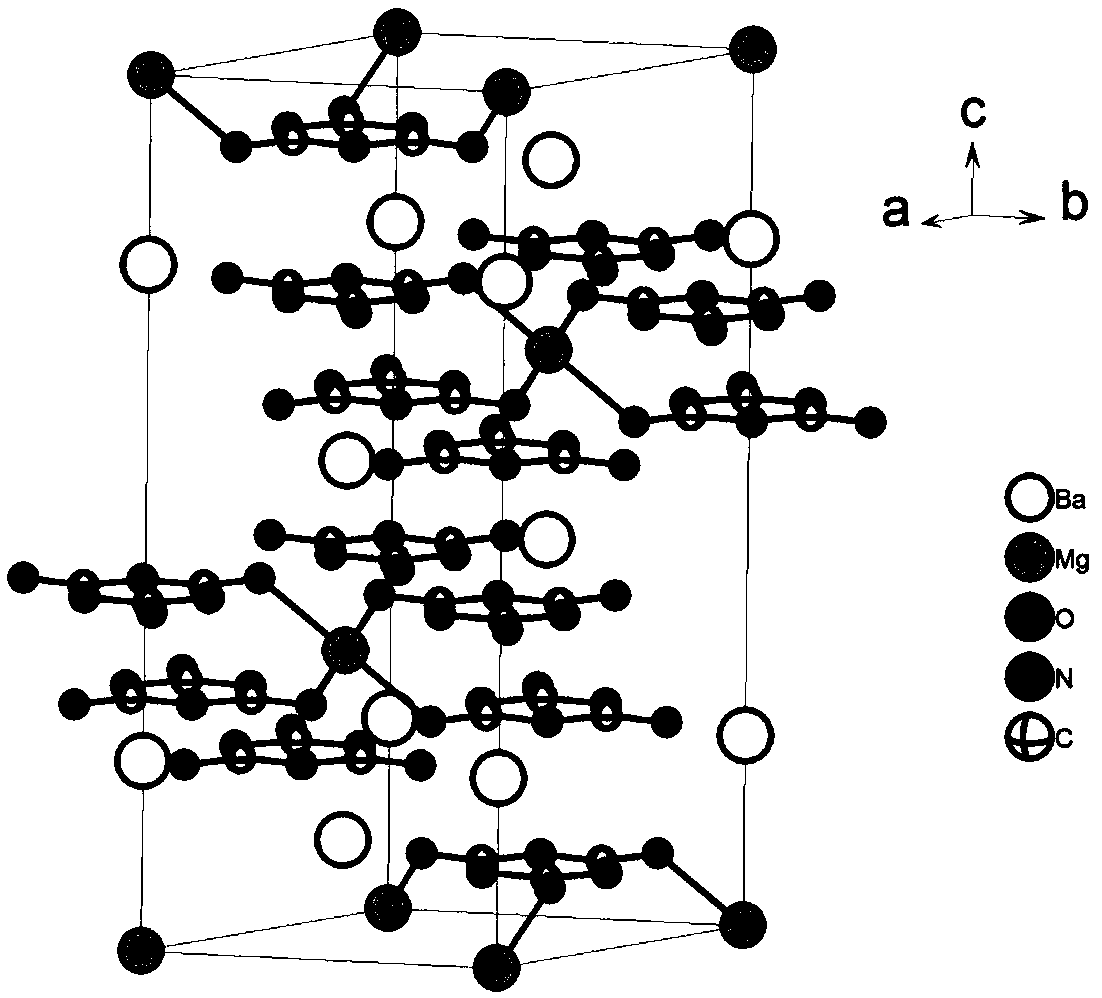

Barium magnesium cyanurate birefringent crystals for ultraviolet visible wavebands and preparation method and application of crystals

InactiveCN109137071APromote growthEasy to processPolycrystalline material growthFrom frozen solutionsSpace groupBeam splitting

The invention discloses barium magnesium cyanurate birefringent crystals for ultraviolet visible wavebands and a preparation method and application of the crystals. The chemical formula is Ba2Mg(C3N3O3)2 and belongs to a trigonal system, and the space group and unit-cell parameters are shown in the descriptions. The crystals grow by means of a high-temperature melt spontaneous crystallization method or a Bridgman-Stockbarger method. The barium magnesium cyanurate birefringent crystals obtained by means of the method are uniaxial negative crystals, the transmission range is 230-3,000 nm, and the calculation values of the refractive indexes at the place where lambda is equal to 800 nm are as follow:no is equal to 2.00, ne is equal to 1.649, and deltan is equal to 0.351. The crystals easily grow and are easy to cut, grind, polish and store, stable in air, uneasy to deliquesce and insoluble in water; the crystals can be used for manufacturing Glan prisms, Wollaston prisms, Rochon prisms orbeam splitting polarization device or other polarization beam splitting prisms and have important application in the field of optics and communications.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

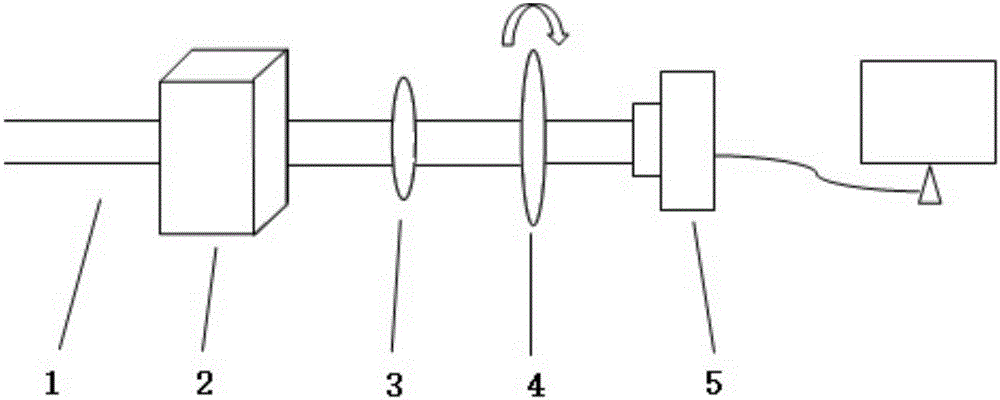

Two-dimensional coding device and method for spin angular momentum of light field

ActiveCN107526179ARealize two-dimensional controlGeneration technology is matureOptical elementsSpin angular momentum of lightMomentum

The invention discloses a two-dimensional coding device and method for the spin angular momentum of a light field, and the method comprises the steps: achieving the different two-dimensional distribution of the photon spin angular momentum on a cross section of a radial change hybrid polarization vector light field through an uniaxial crystal; and achieving the coding from the photon spin angular momentum to digital logic '0'and '1'. The method provided by the invention is provided with the uniaxial crystal, a quarter-wave plate, a polaroid and a CCD sensor, wherein the uniaxial crystal, the quarter-wave plate, the polaroid and the CCD sensor are sequentially set from the left side to the right side in the propagation direction of a light beam. Compared with other common coding methods, the method is simple in optical path, is convenient and reliable, is easy for adjustment, and has the potential application perspective in the technical field of light field communication.

Owner:SOUTHEAST UNIV

Use of double refraction crystal of borate system

This invention relates to a birefringent optical crystal of borate series and its use: the chemical formula of this birefringent crystal of borate series is: ReBa3B9O18(Re=Y, Pr, Nd, Sm, Eu, Gd, Tb, Er, Dy, Ho, Tm, Yb and / or Lu).These crystals are negative uniaxial crystal, and its refractive index on Dual-band visible light in the numerical size of about 0.08-0.15. This series of crystal easy cutting, grinding, polishing and preservation, do not dissolve in water, not deliquescence, be stability in the air, suitable for production of optical communications components, such as optical isolator, toroid, beam displacement, optical polarizer and optical modulators, etc. Particularly for the production of the various used for polarizing prisms, phase delay devices and electro-optical modulation devices, and so on. These devices use of the refractive index is crystal characteristics, in particular the larger dual refractive index.

Owner:INST OF PHYSICS - CHINESE ACAD OF SCI

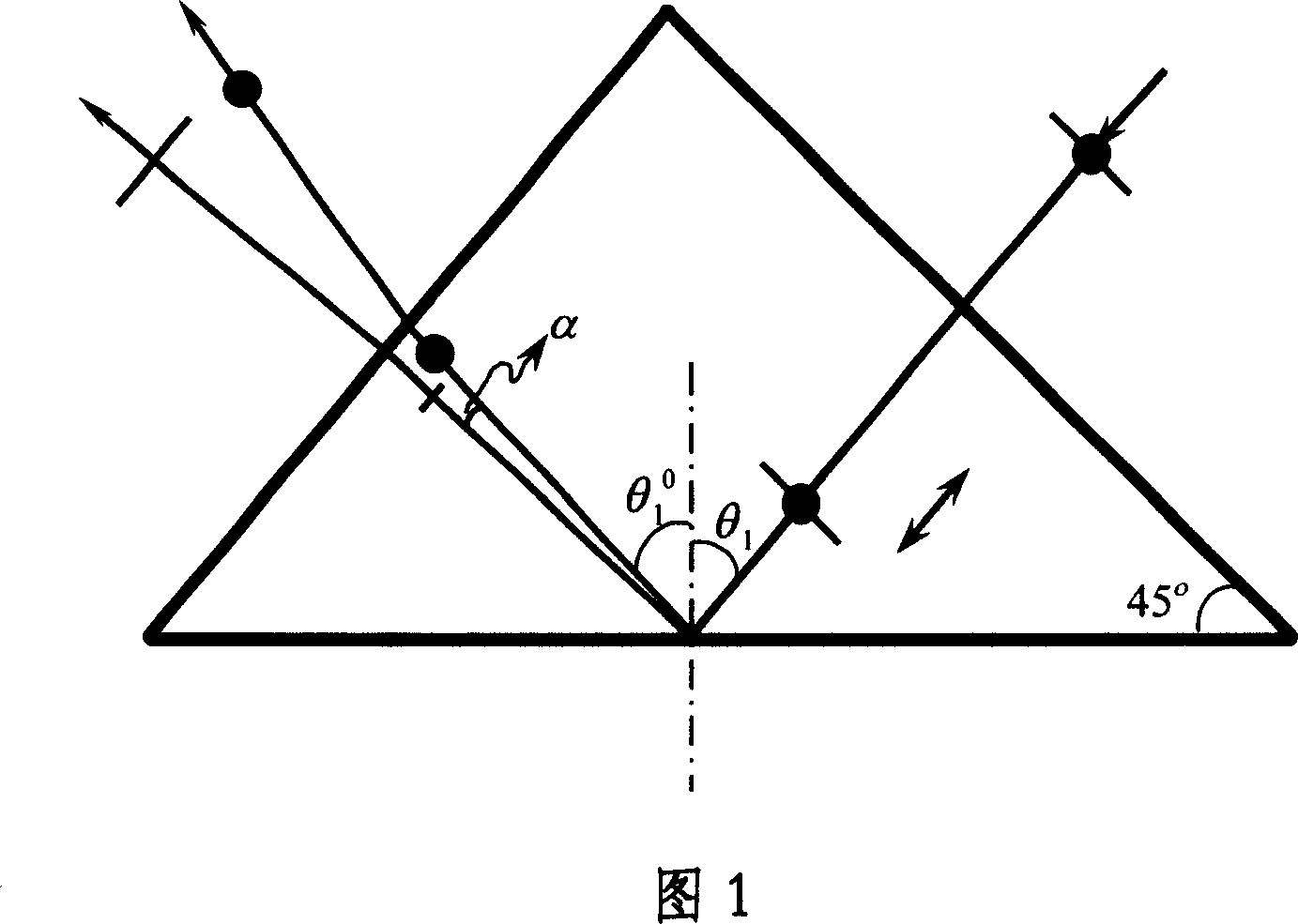

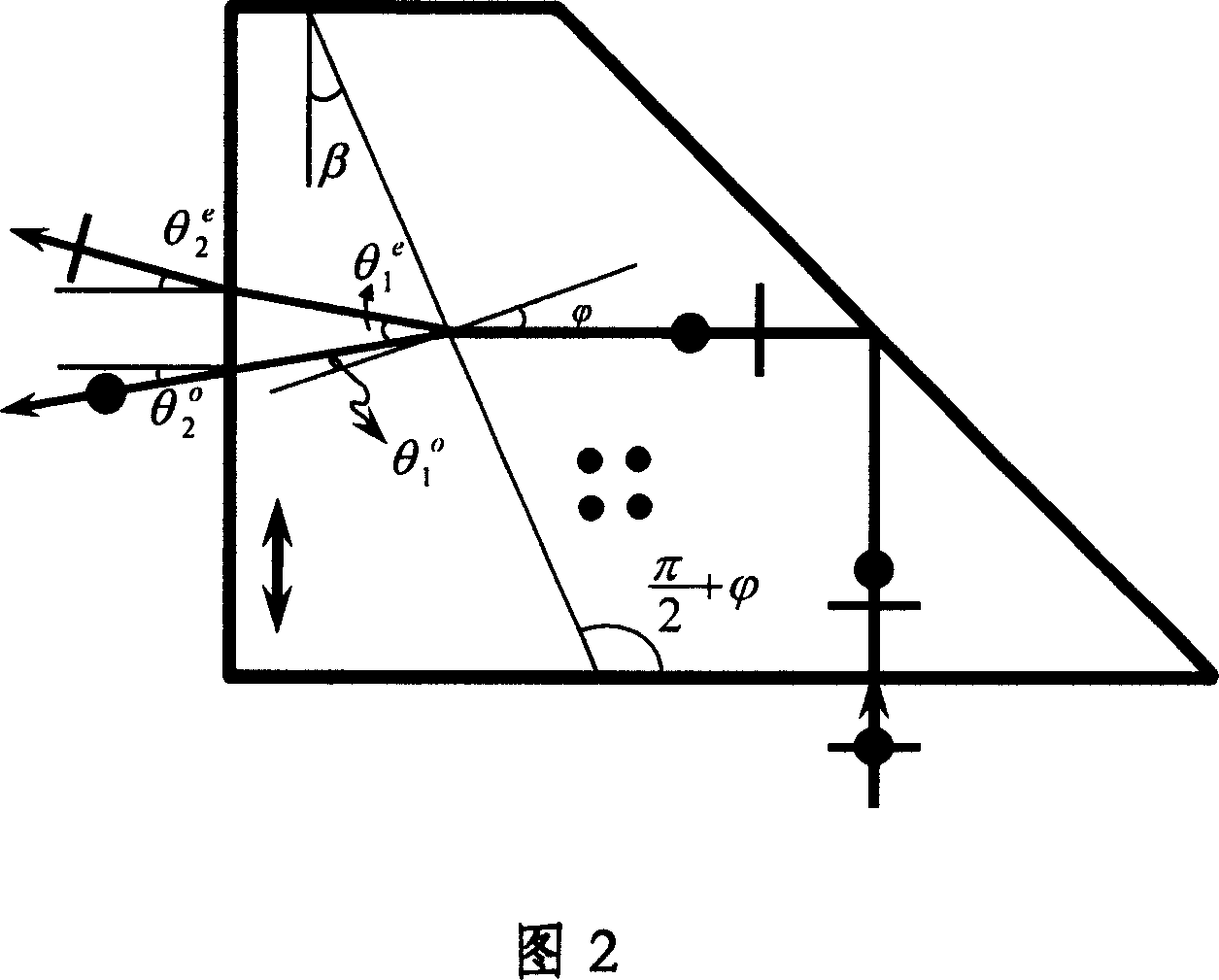

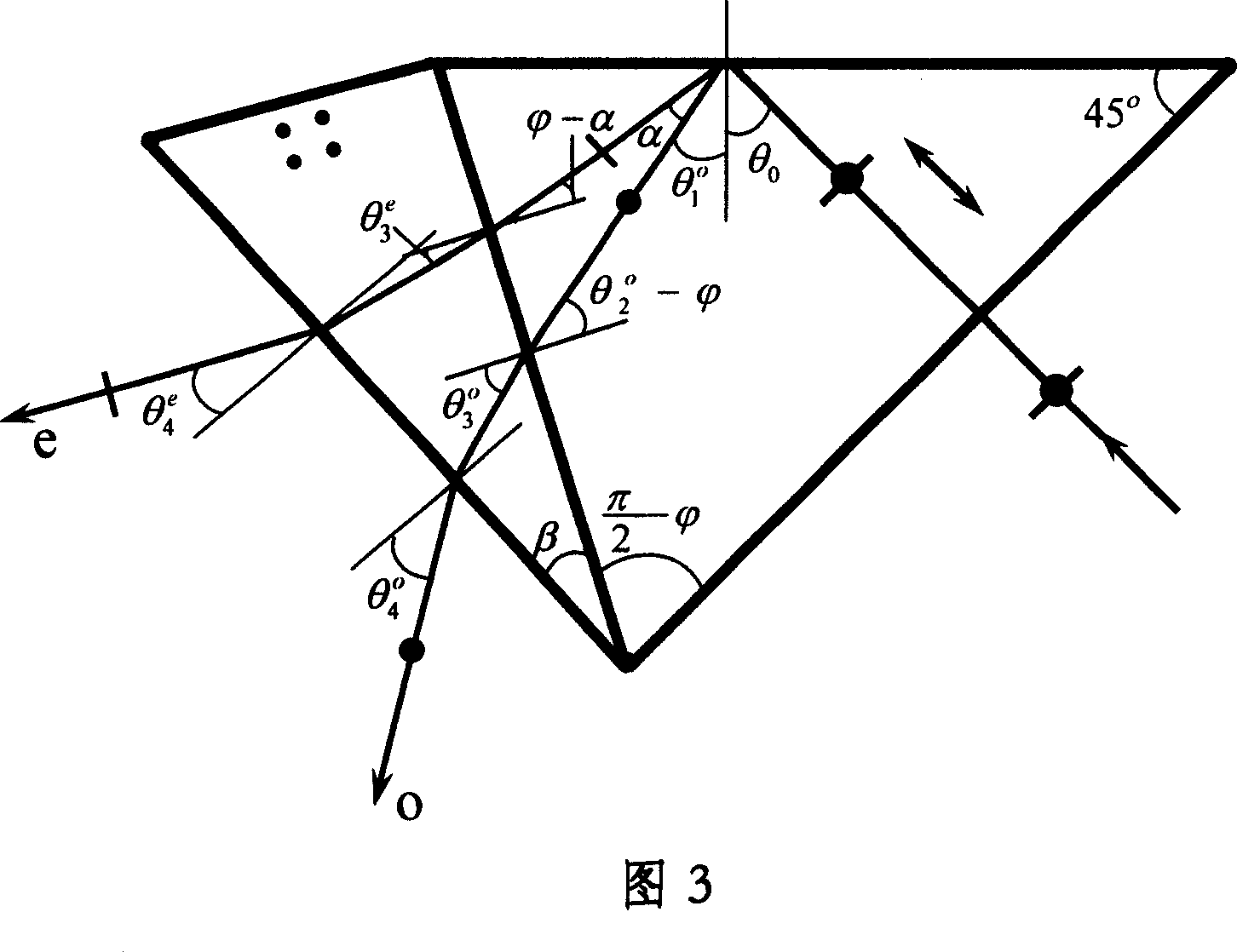

Polarized light beam splitting double reflection method and polarized light beam splitting prism

InactiveCN101046555ASolve the single functionGuaranteed Extinction RatioPrismsPolarising elementsLaser technologyOptical test

The present invention discloses polarized light beam splitting double reflection method and polarized light beam splitting prism, and belongs to the field of optical device technology. The present invention features that light beam is radiated to crystal interface and bireflected to split into two planar light beams with perpendicular vibration directions before being emitted from the outgoing plane. The polarized light beam splitting prism consists of one prism of one single uniaxial crystal and one prism of two uniaxial crystals, and has optical axis perpendicular to the incident plane and angle between the incident plane and the reflecting plane of 45 and 90 deg. It has the functions of several devices and important application in laser technology, optical test, optical modulation, etc.

Owner:LASER INST QUFU NORMAL UNIV

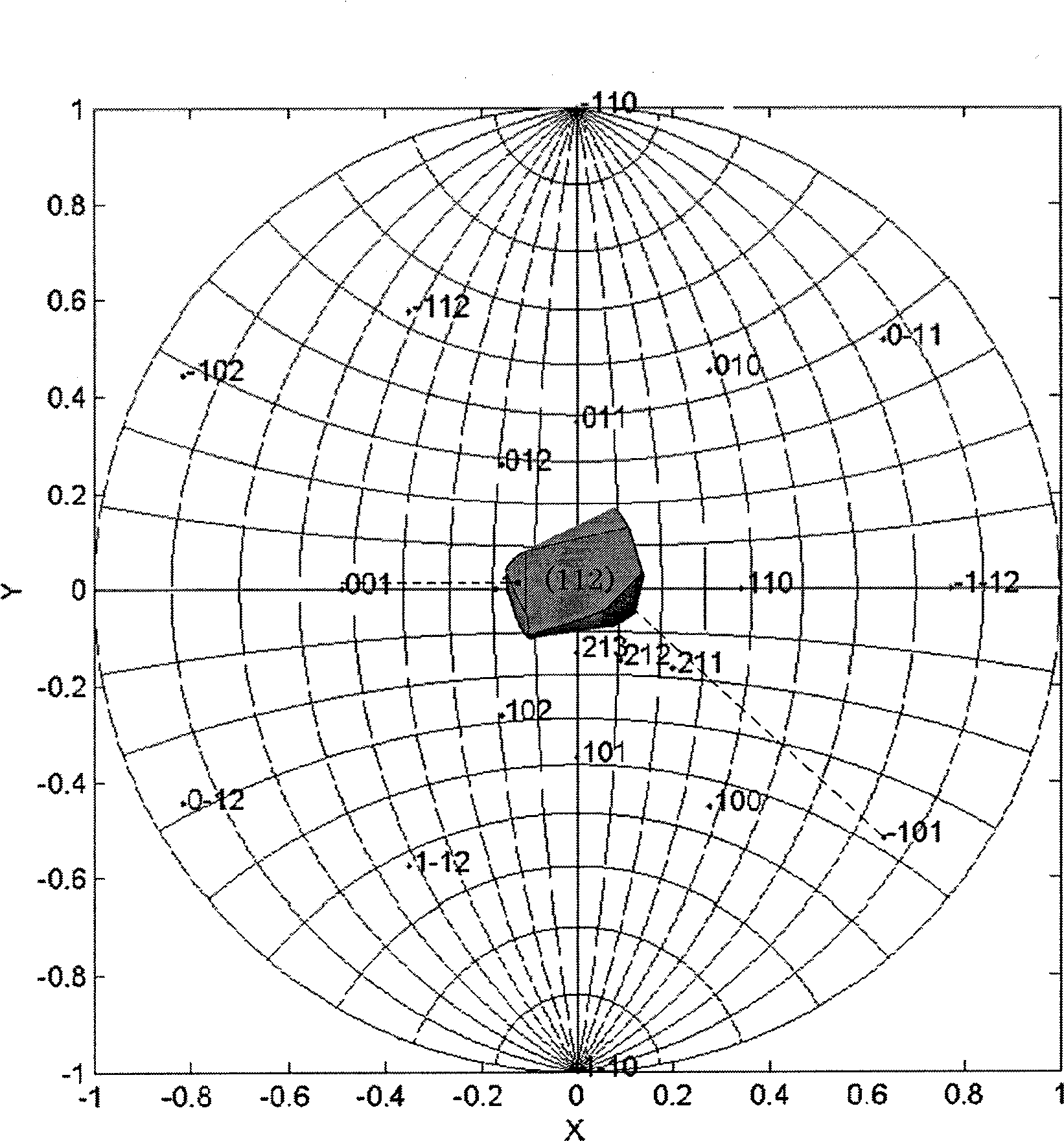

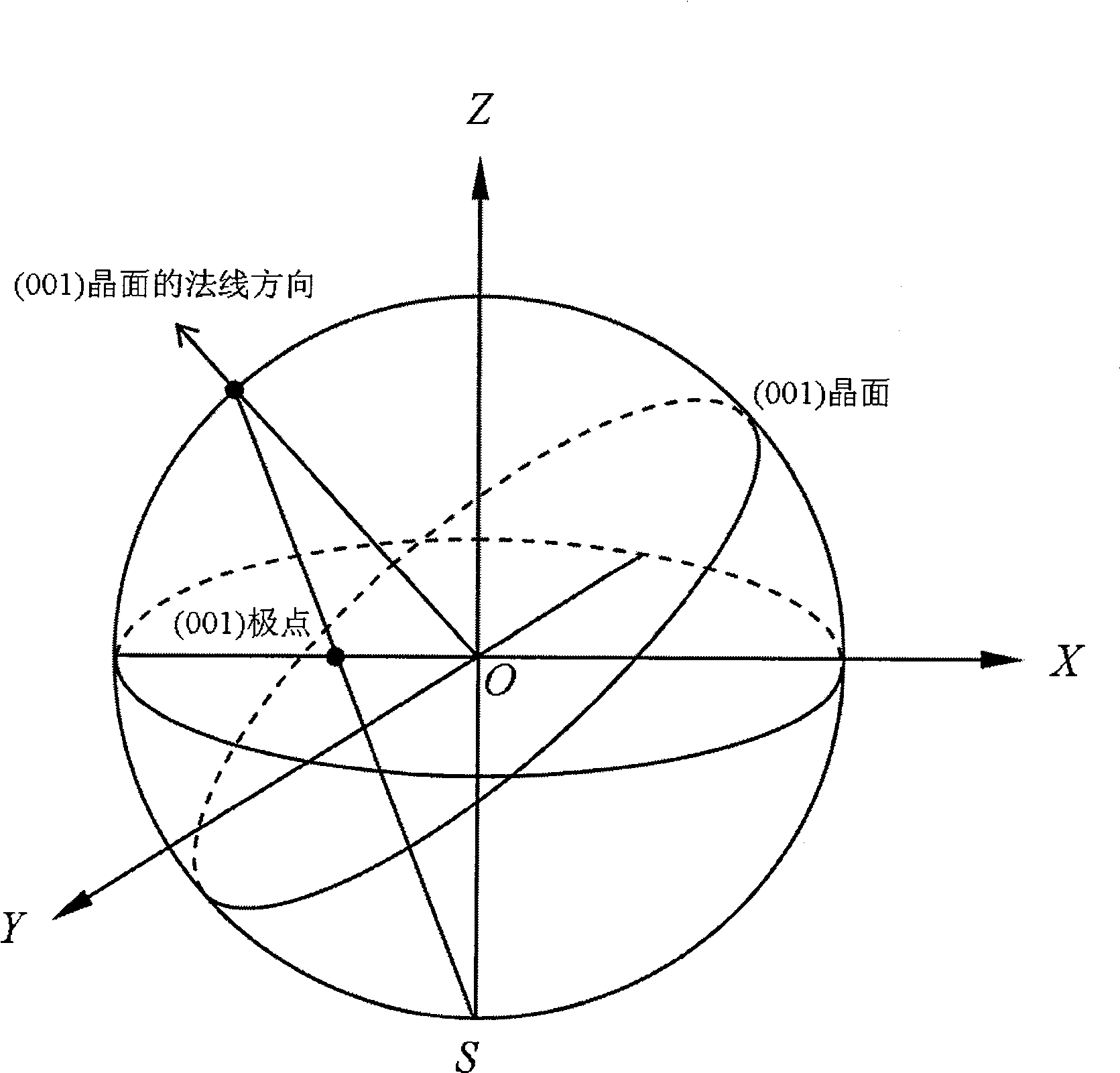

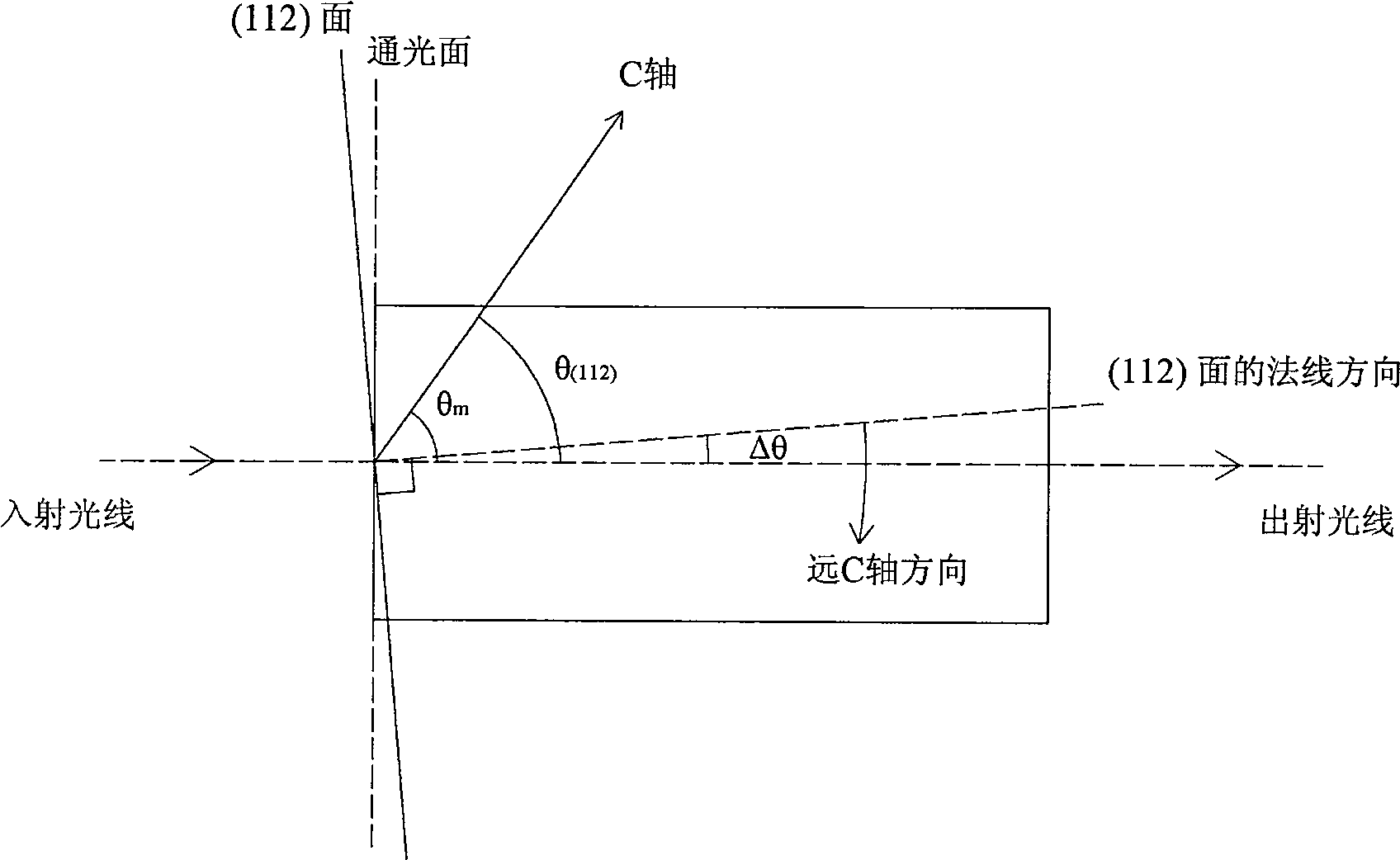

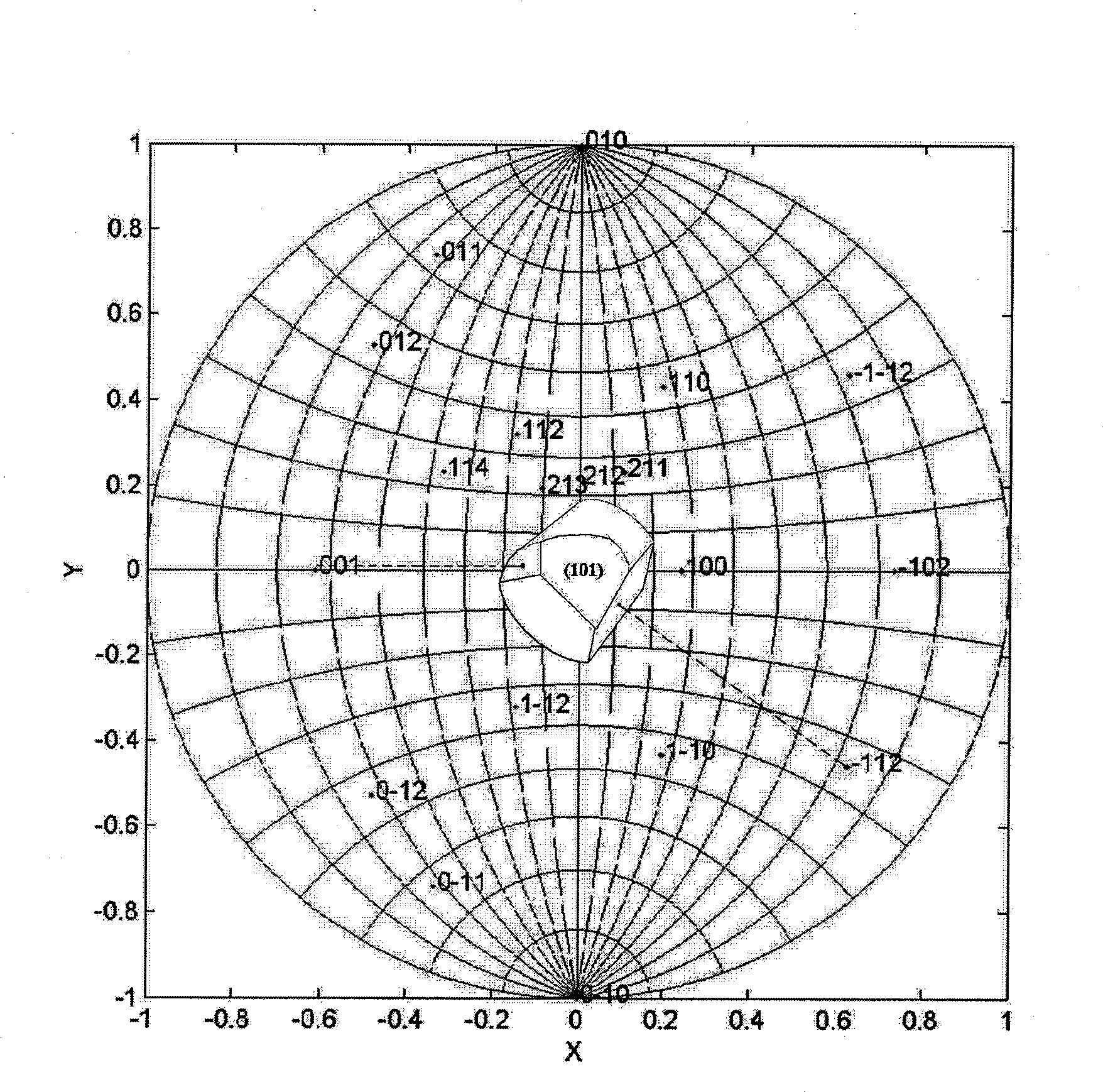

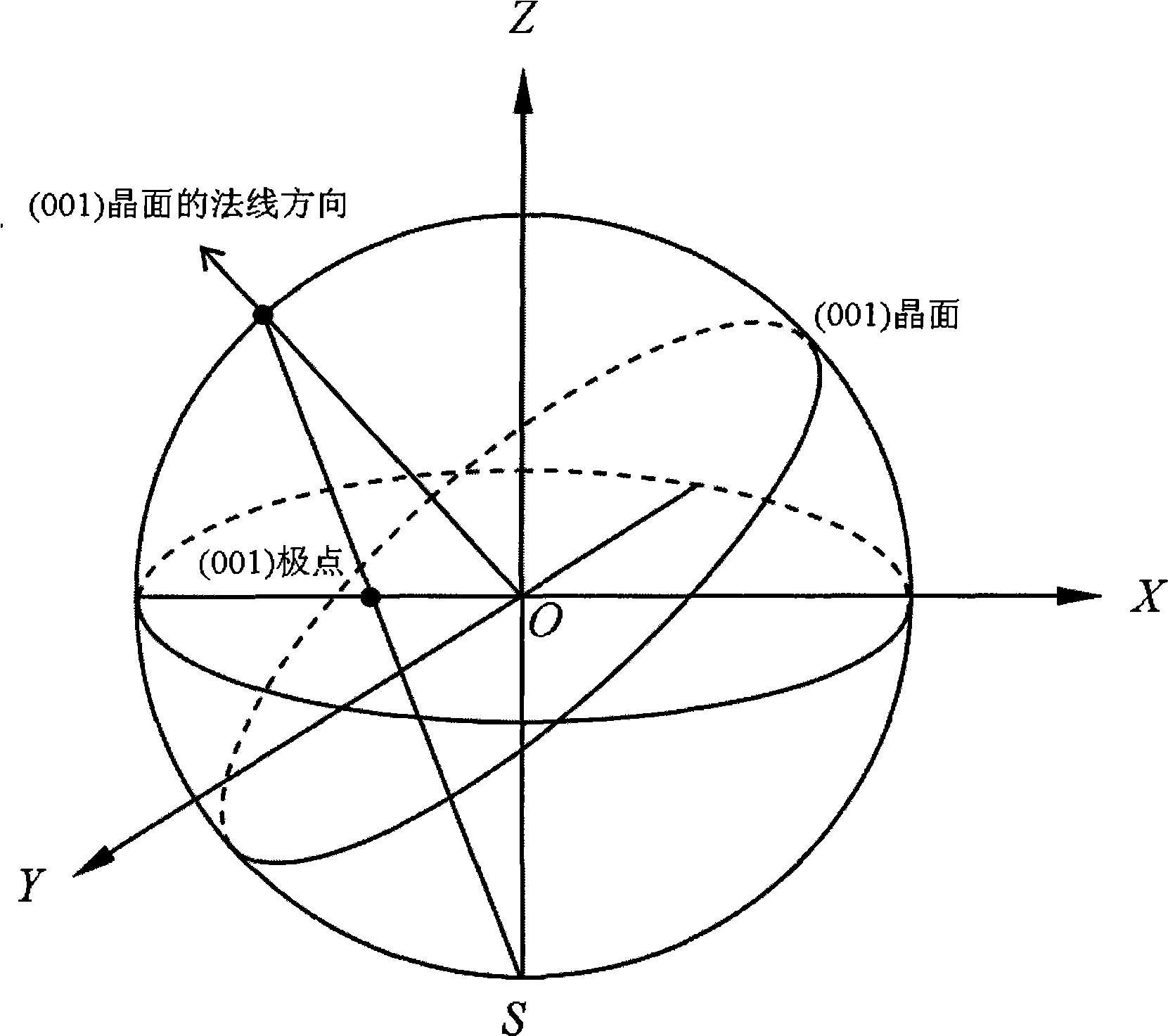

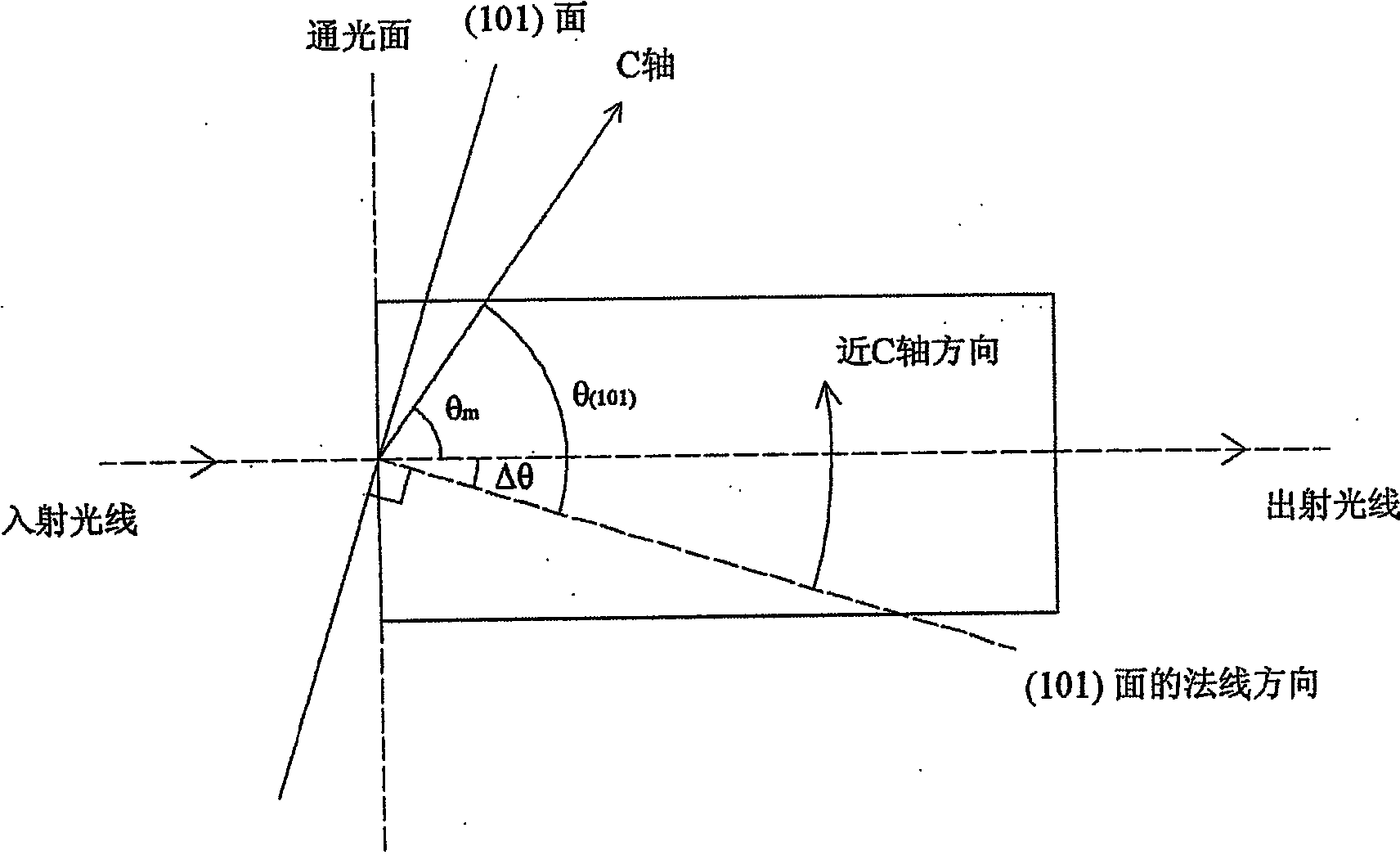

Oriented cutting method for preparing infrared non-linear optics element from yellow copper uniaxial negative crystal

InactiveCN101486231AEasy to operateQuick orientationFine working devicesContinuous scanningDiffractometer

The invention relates to a directional cutting method for preparing infrared nonlinear optical elements from a chalcopyrite uniaxial negative crystal, which comprises the following steps: (1) according to cleavage surfaces {112} and {101} of the chalcopyrite uniaxial negative crystal, utilizing a crystal standard pole figure with Wuwov's intersection ruler and an X-ray diffractometer to determine the direction of a C axis of the crystal through theta-2theta continuous scanning; (2) putting the crystal of which the direction of the C axis is determined on a cutting machine, rotating a sample stage for delta theta far away from the direction of the C axis according to a phase matching angle theta m required by an optical element, and cutting the crystal to obtain an original sample of the optical element, wherein the delta theta= theta m - theta (112); (3) putting the original sample of the optical element on the sample stage of the X-ray diffractometer, determining an oscillation photograph of a cutting surface of the original sample of the optical element, and obtaining a diffraction peak place value theta' and delta theta', wherein the delta theta'=absolute (theta'- theta'(112)); and (4) finishing the optical element, and correcting the cutting surface of the original sample of the optical element until the delta theta'=the delta theta.

Owner:SICHUAN UNIV

Piezoelectric substance, piezoelectric substance element, liquid discharge head, liquid discharge device and method for producing piezoelectric substance

InactiveUS7528530B2Excellent piezoelectric propertiesEasy to controlInking apparatusPiezoelectric/electrostriction/magnetostriction machinesTetragonal crystal systemUniaxial crystal

Owner:CANON KK

Oriented cutting method for preparing infrared non-linear optics element from yellow copper positive uni-axial crystal

InactiveCN101486232AEasy to operateQuick orientationFine working devicesContinuous scanningDiffractometer

The invention relates to a directional cutting method for preparing infrared nonlinear optical elements from a chalcopyrite uniaxial positive crystal, which comprises the following steps: (1) according to cleavage surfaces {112} and {101} of the chalcopyrite uniaxial positive crystal, utilizing a crystal standard pole figure with Wuwov's intersection ruler and an X-ray diffractometer to determine the direction of a C axis of the crystal through theta-2theta continuous scanning; (2) putting the crystal of which the direction of the C axis is determined on a cutting machine, rotating a sample stage for delta theta toward the direction of the C axis according to a phase matching angle theta m required by an optical element, and cutting the crystal to obtain an original sample of the optical element, wherein the delta theta= theta (101) - the theta m; (3) putting the original sample of the optical element on the sample stage of the X-ray diffractometer, determining an oscillation photograph of a cutting surface of the original sample of the optical element, and obtaining a diffraction peak place value theta' and delta theta', wherein the delta theta'=absolute (theta'- theta'(101)); and (4) finishing the optical element, and correcting the cutting surface of the original sample of the optical element until the delta theta'=the delta theta.

Owner:SICHUAN UNIV

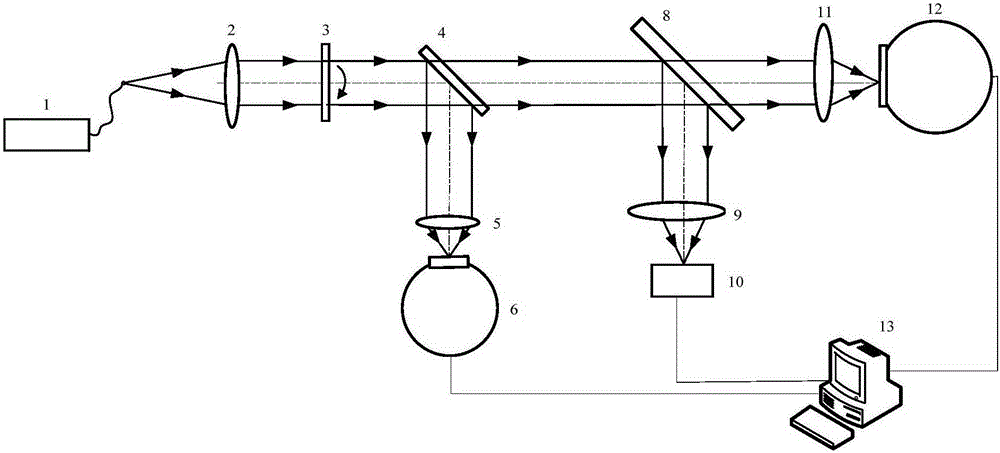

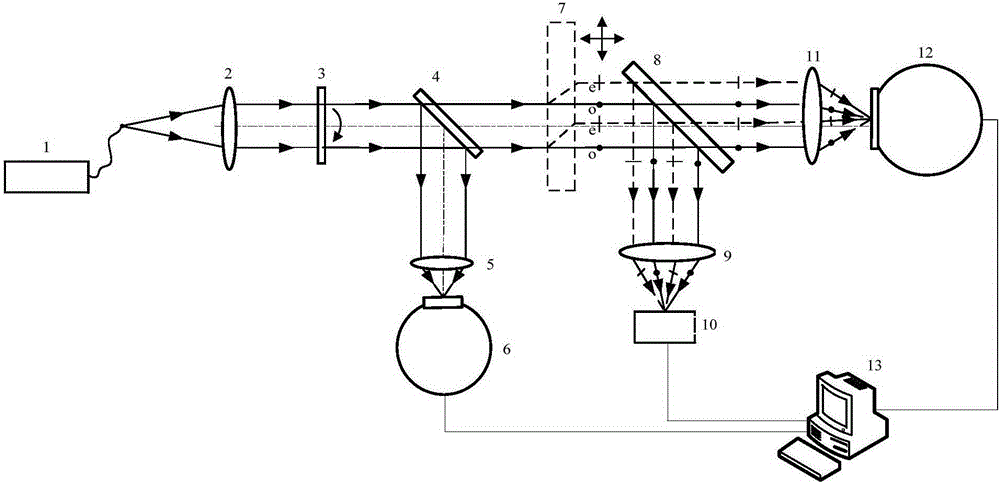

Large aperture uniaxial crystal light absorption coefficient measurement apparatus and method thereof

InactiveCN105158163AConfidenceSimple structureMaterial analysis by optical meansMeasurement deviceOptoelectronics

The invention relates to a large aperture uniaxial crystal light absorption coefficient measurement apparatus and a method thereof. A collimating mirror, a polarizer and a semitransparent mirror A are sequentially arranged in the emitting light path of a laser; the semitransparent mirror A makes incident light form reflected light A and transmitted light A; a convergent mirror A is arranged in the path of the reflected light A and converges the reflected light A into a supervision integrating sphere power meter; a semitransparent mirror B is arranged in the path of the transmitted light A and makes the transmitted light A form reflected light B and transmitted light B; a convergent mirror B is arranged in the path of the reflected light B and converges the reflected light B into a supervision CCD; a convergent mirror C is arranged in the path of the reflected light B and converges the reflected light B into a measurement integrating sphere power meter; a large aperture uniaxial crystal to be measured is placed between the semitransparent mirror A and the semitransparent mirror B; and a computer is respectively connected with the large aperture uniaxial crystal to be measured, the supervision integrating sphere power meter, the supervision CCD and the measurement integrating sphere power meter. The apparatus and the method can be used to measure the P light and S light absorption coefficients of the large aperture uniaxial crystal, and guarantee the measurement precision.

Owner:XI'AN INST OF OPTICS & FINE MECHANICS - CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com