Patents

Literature

45 results about "Electrogas welding" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Electrogas welding (EGW) is a continuous vertical position arc welding process developed in 1961, in which an arc is struck between a consumable electrode and the workpiece. A shielding gas is sometimes used, but pressure is not applied. A major difference between EGW and its cousin electroslag welding is that the arc in EGW is not extinguished, instead remains struck throughout the welding process. It is used to make square-groove welds for butt and t-joints, especially in the shipbuilding industry and in the construction of storage tanks.

Nickel-base alloy for the electro-welding of nickel alloys and steels, welding wire and use

The alloy contains, by weight, less than 0.05% of carbon, from 0.015% to 0.5% of silicon, from 0.4% to 1.4% of manganese, from 28% to 31.5% of chromium, from 8% to 12% of iron, from 2% to 7% of molybdenum, from 0% to 0.75% of aluminium, from 0% to 0.8% of titanium, from 0.6% to 2% in total of niobium and tantalum, the ratio of percentages of niobium plus tantalum and of silicon being at least 4, less than 0.04% of nitrogen, from 0.0008% to 0.0120% of zirconium, from 0.0010% to 0.0100% of boron, less than 0.01% of sulphur, less than 0.020% of phosphorus, less than 0.30% of copper, less than 0.15% of cobalt and less than 0.10% of tungsten, the remainder of the alloy, with the exception of unavoidable impurities of which the total content is at most 0.5%, consisting of nickel. The alloy is used, in particular, for the production of wires for the electro-gas welding of units or components of nuclear reactors and, more particularly, of pressurised water-cooled nuclear reactors.

Owner:FRAMSTOME ANP

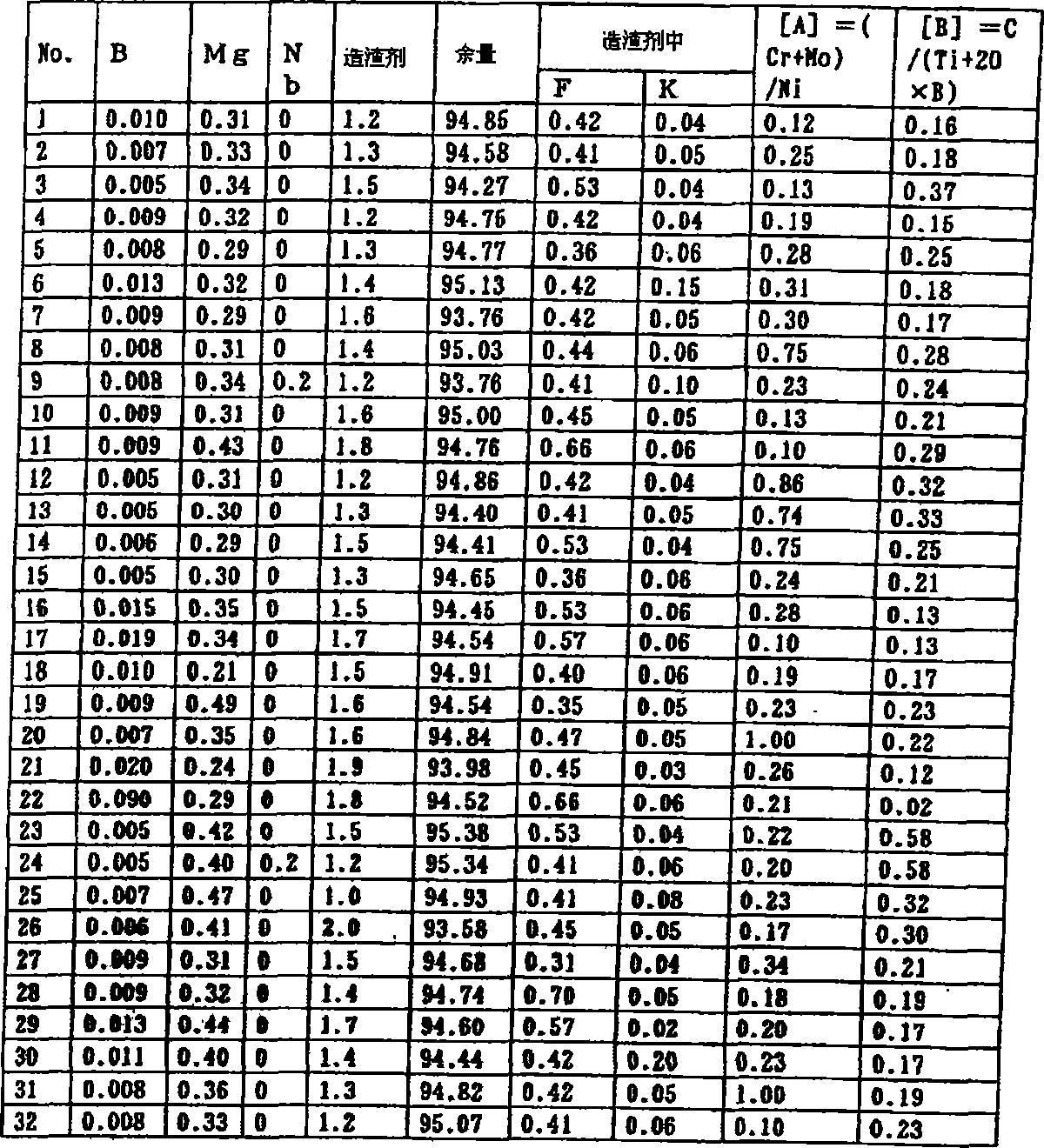

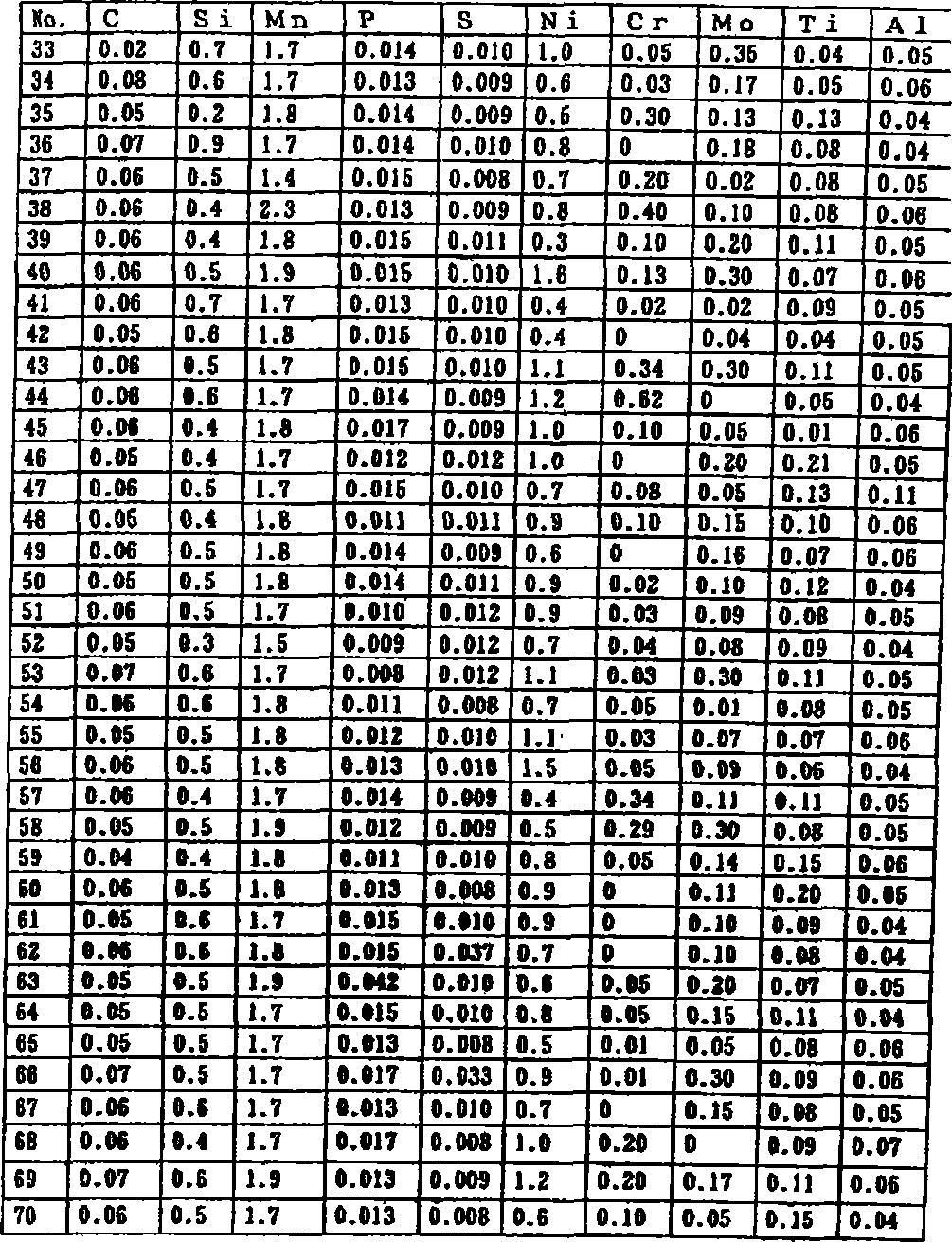

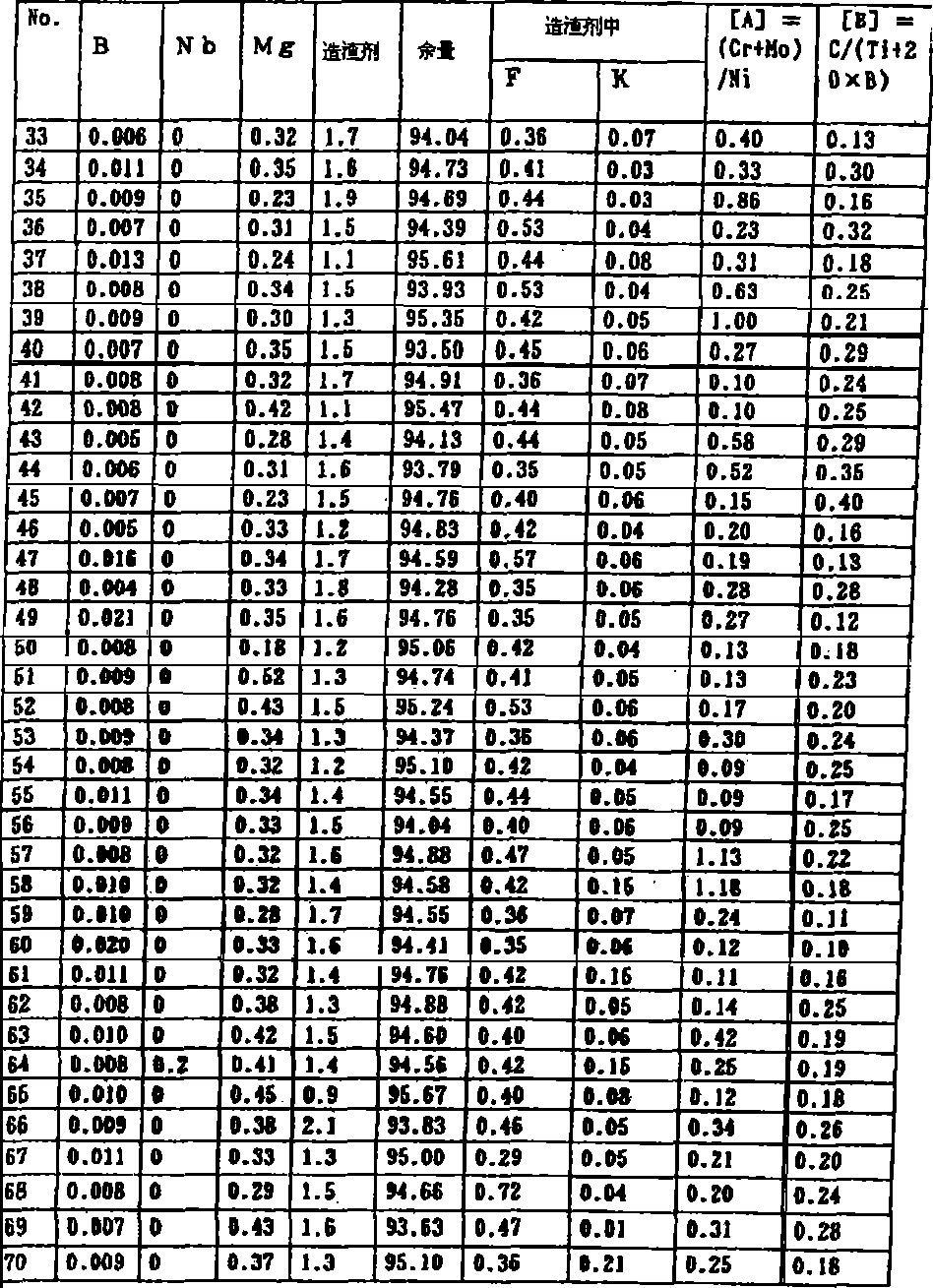

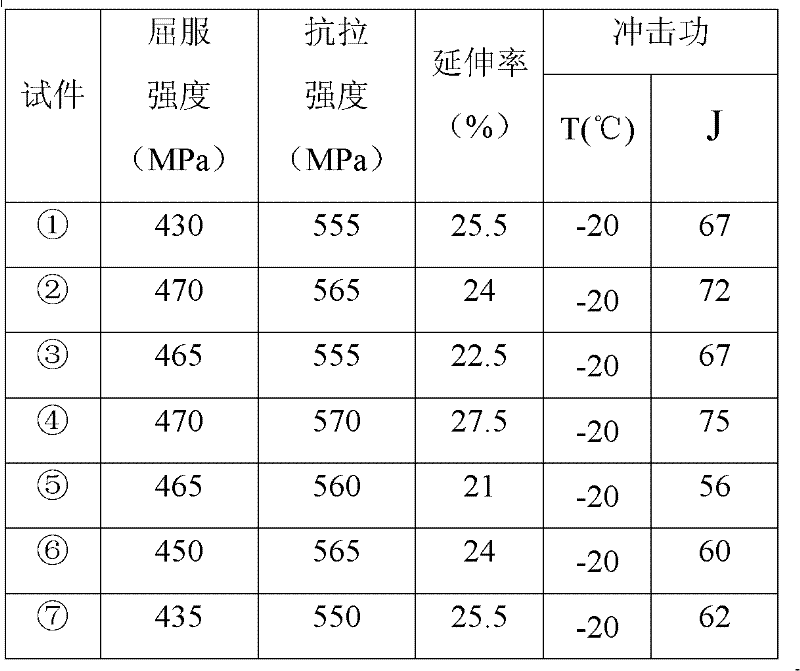

Flux-cored wire for electrogas welding and electrogas welding metal

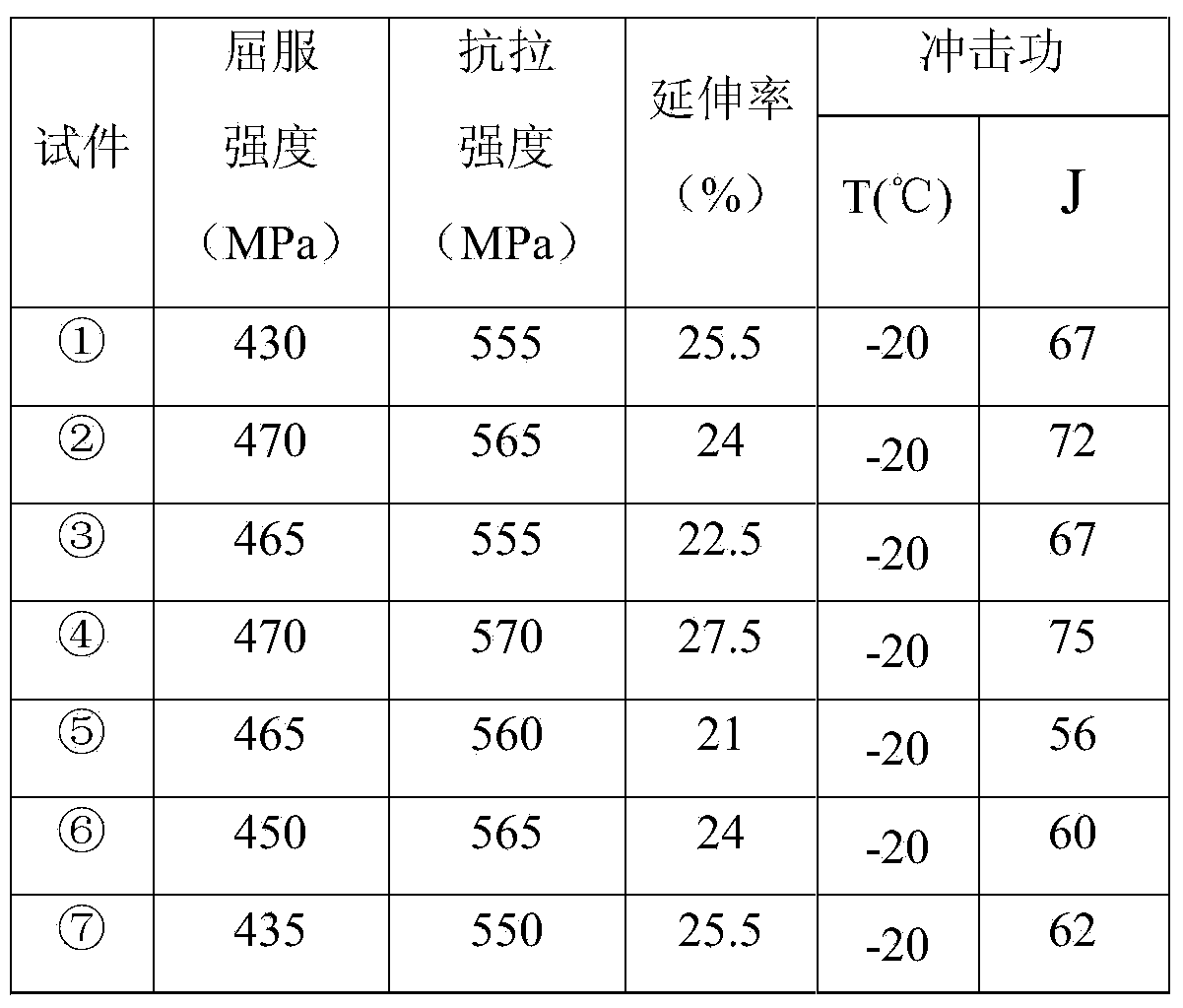

ActiveCN101185996AHigh elongationGood shock valueWelding/cutting media/materialsSoldering mediaSlagToughness

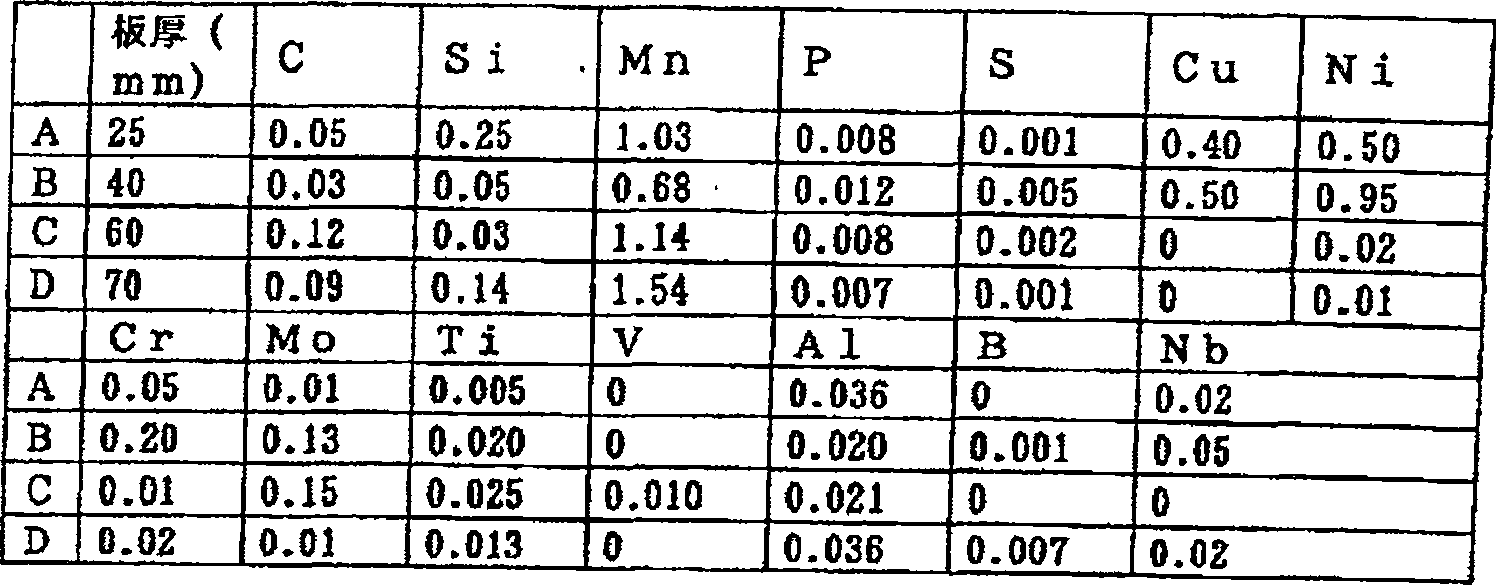

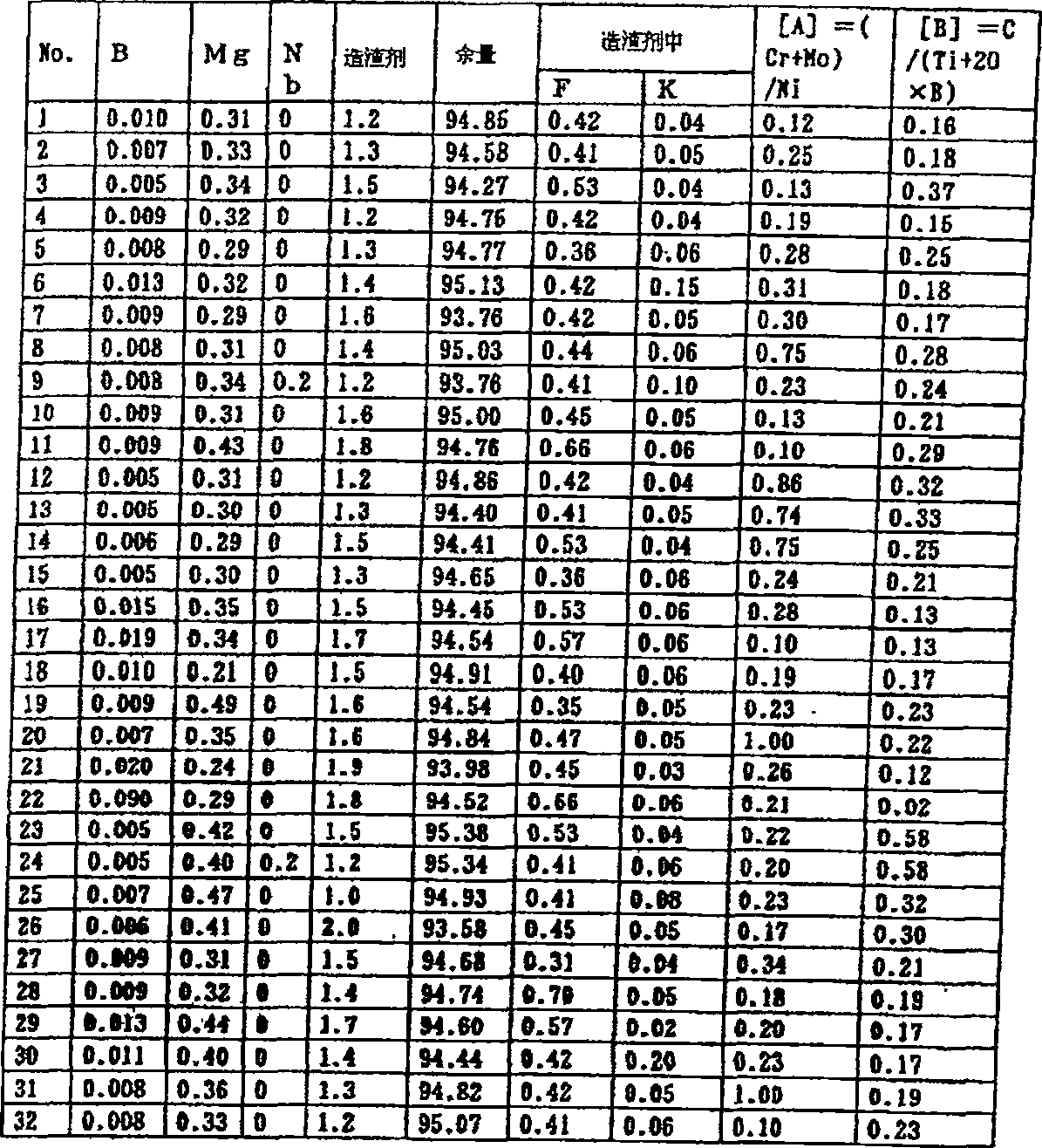

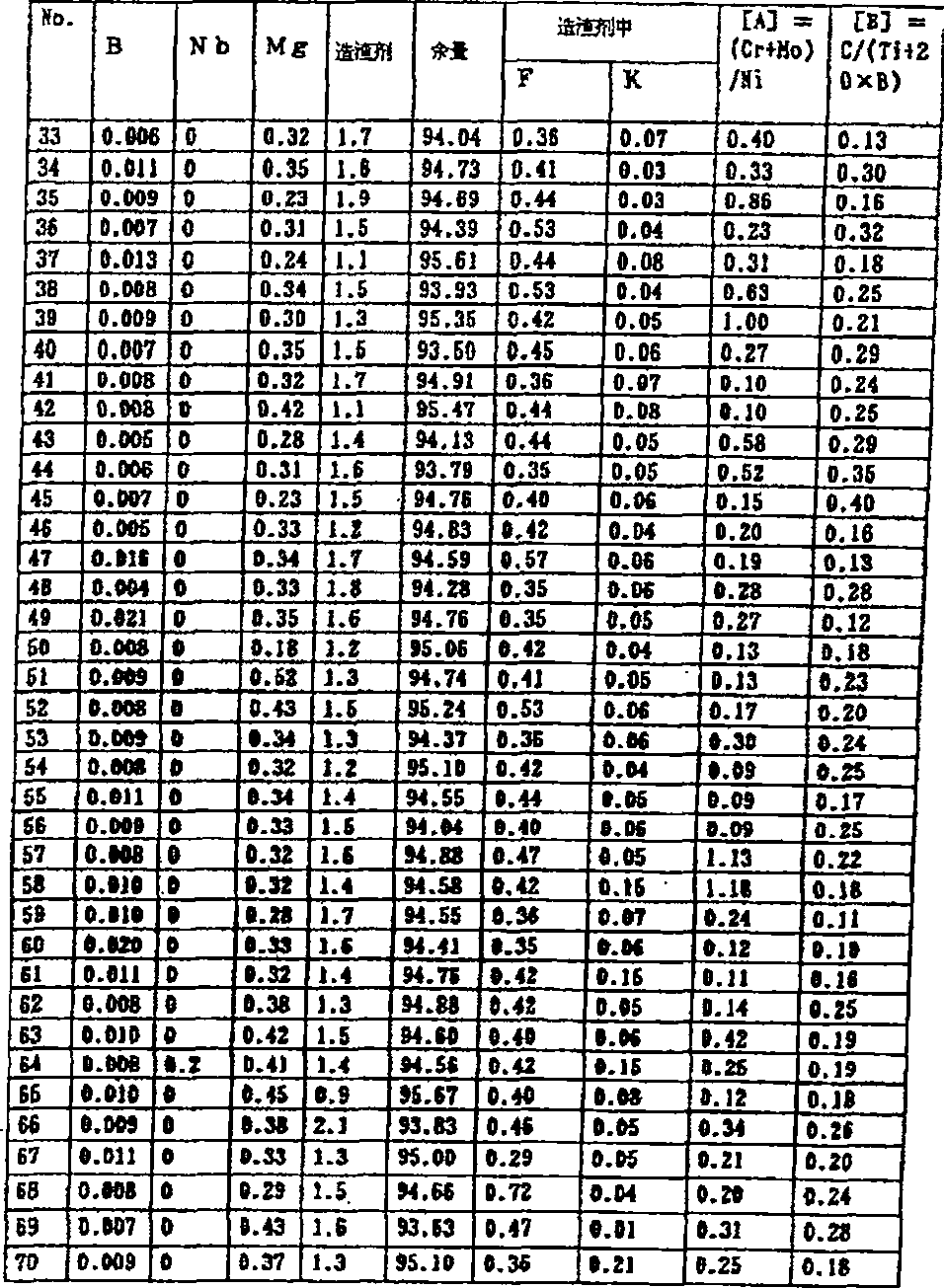

A flux-cored wire for electro gas arc welding is provided to improve strength, elongation and toughness of the weld metal and obtain excellent welding workability with respect to steel plates with a wide width and a thickness of 25 to 70 mm, and an electro gas arc weld metal manufactured using the flux-cored wire for electro gas arc welding is provided. As a flux-cored wire for electro gas arc welding formed by filling a flux in a steel sheath, the flux-cored wire for electro gas arc welding contains, per the total mass of the wire, 0.03 to 0.07 mass% of C, 0.3 to 0.8 mass% of Si, 1.5 to 2.2 mass% of Mn, 0.4 to 1.5 mass% of Ni, 0.05 to 0.60 mass% of a total of Cr and Mo, 0.02 to 0.20 mass% of Ti, 0.005 to 0.020 mass% of B, 0.20 to 0.50 mass% of Mg, controls Al to not more than 0.10 mass%, and contains 1.0 to 2.0 mass% of a slag forming agent, the slag forming agent containing, per the total wire mass, 0.30 to 0.70 mass% of F and 0.02 to 0.20 mass% of K, wherein [A] is 0.10 to 1.0 and [B] is 0.12 to 0.58 when [A] and [B] are values determined by equations [A]=(Cr+Mo) / Ni and [B]=C / (Ti+20xB) from contents of Cr, Mo, Ni, C, Ti, and B respectively.

Owner:KOBE STEEL LTD

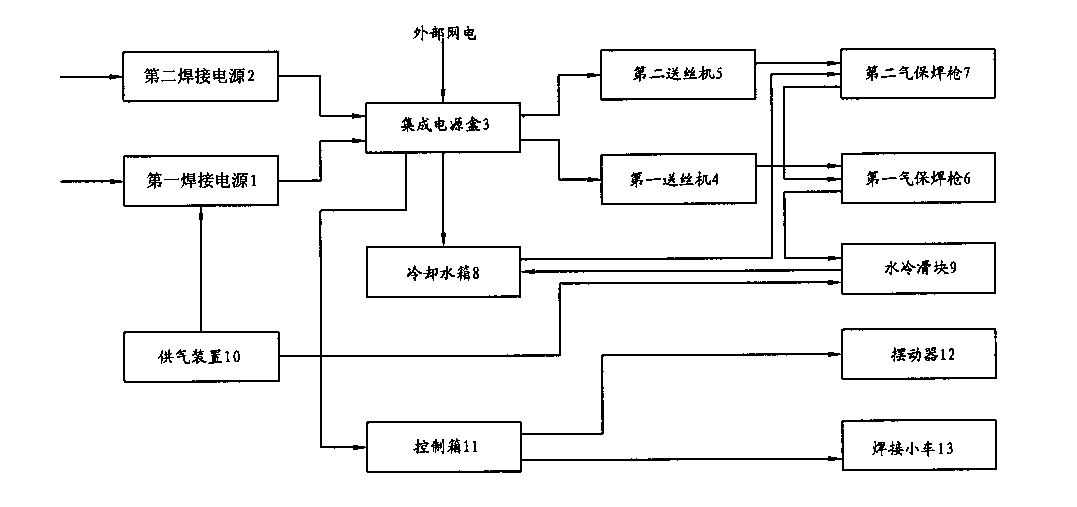

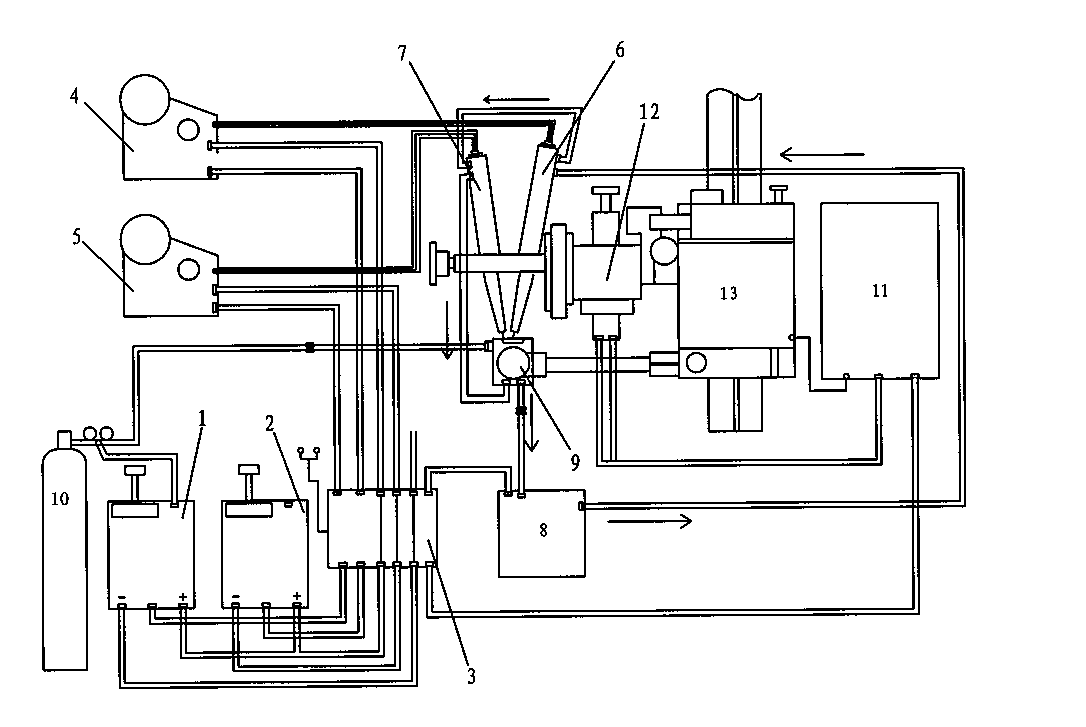

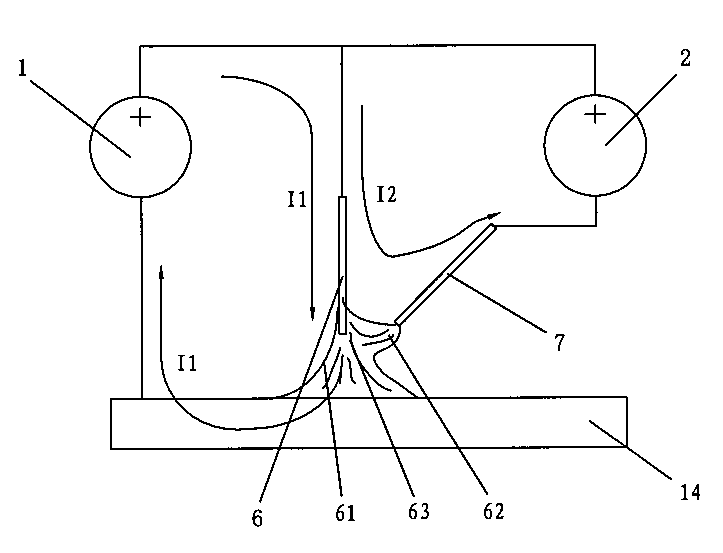

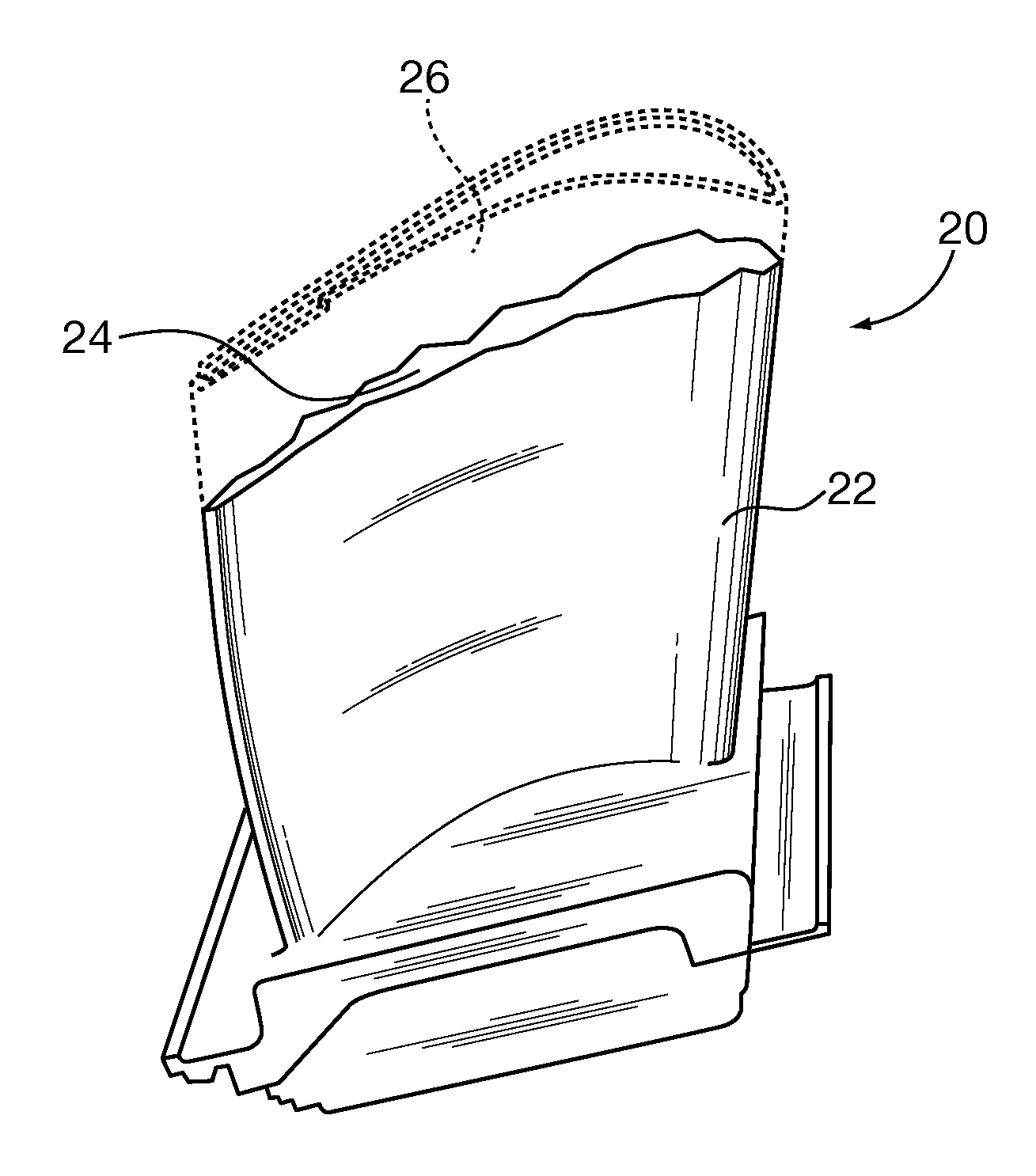

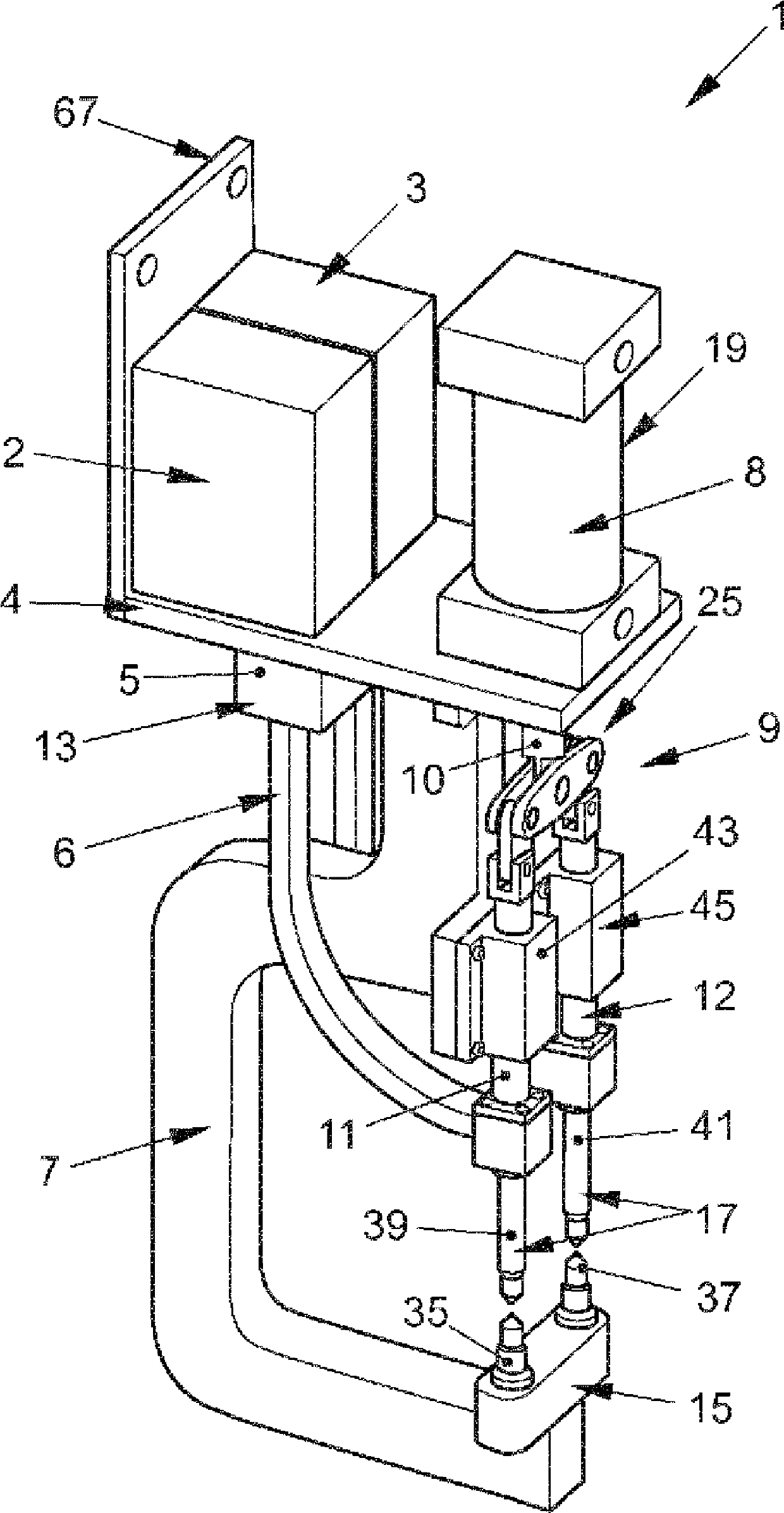

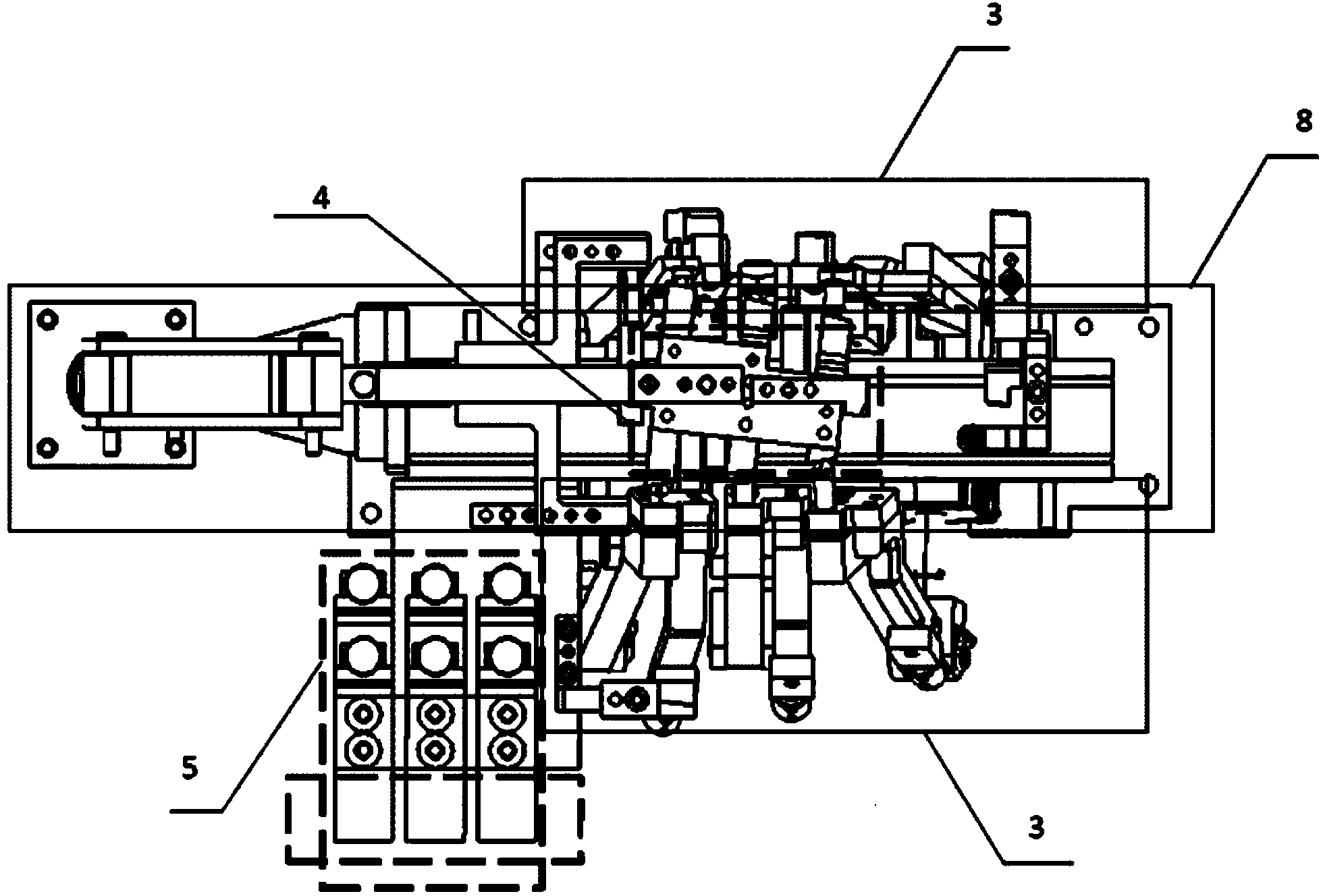

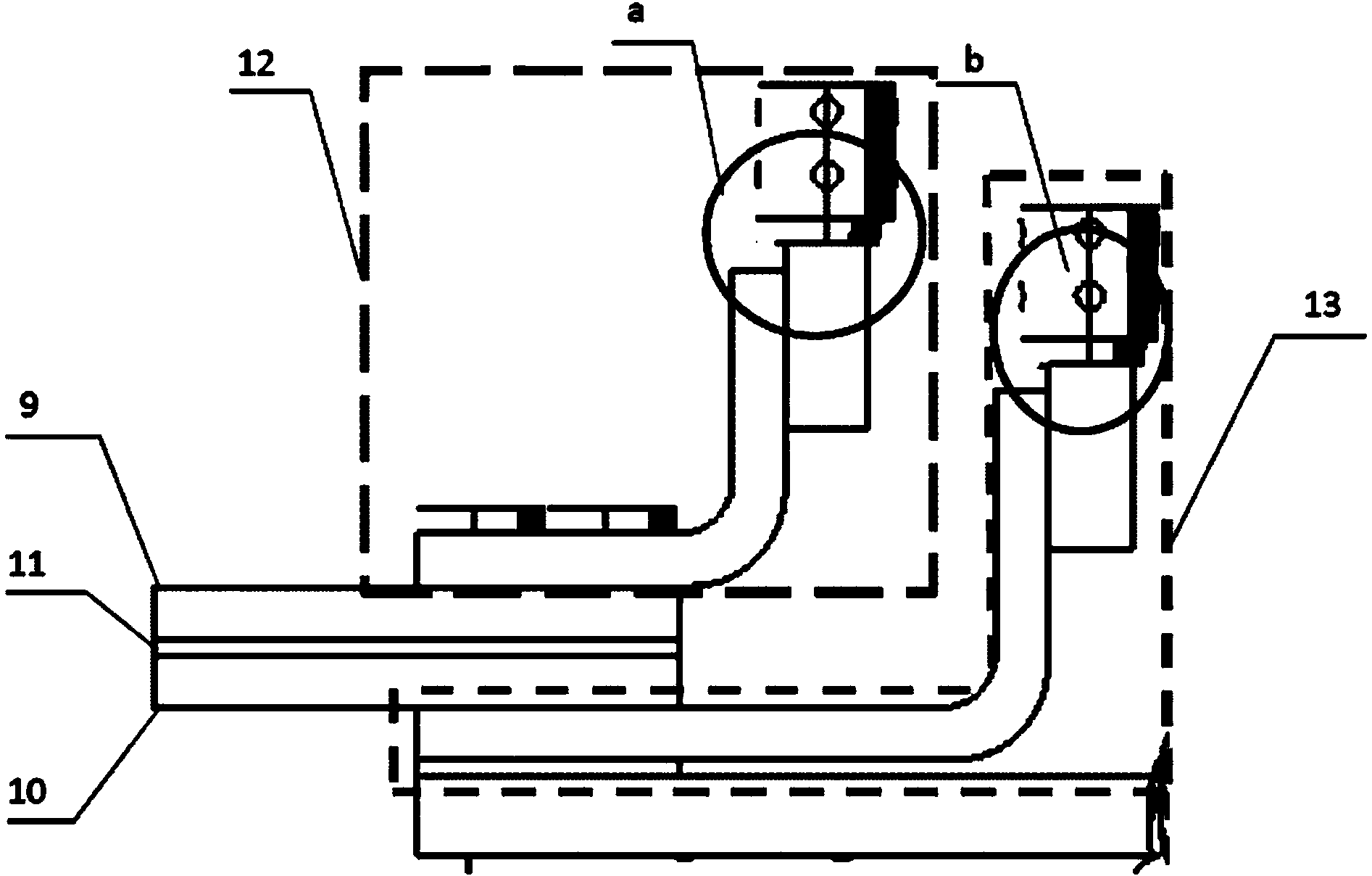

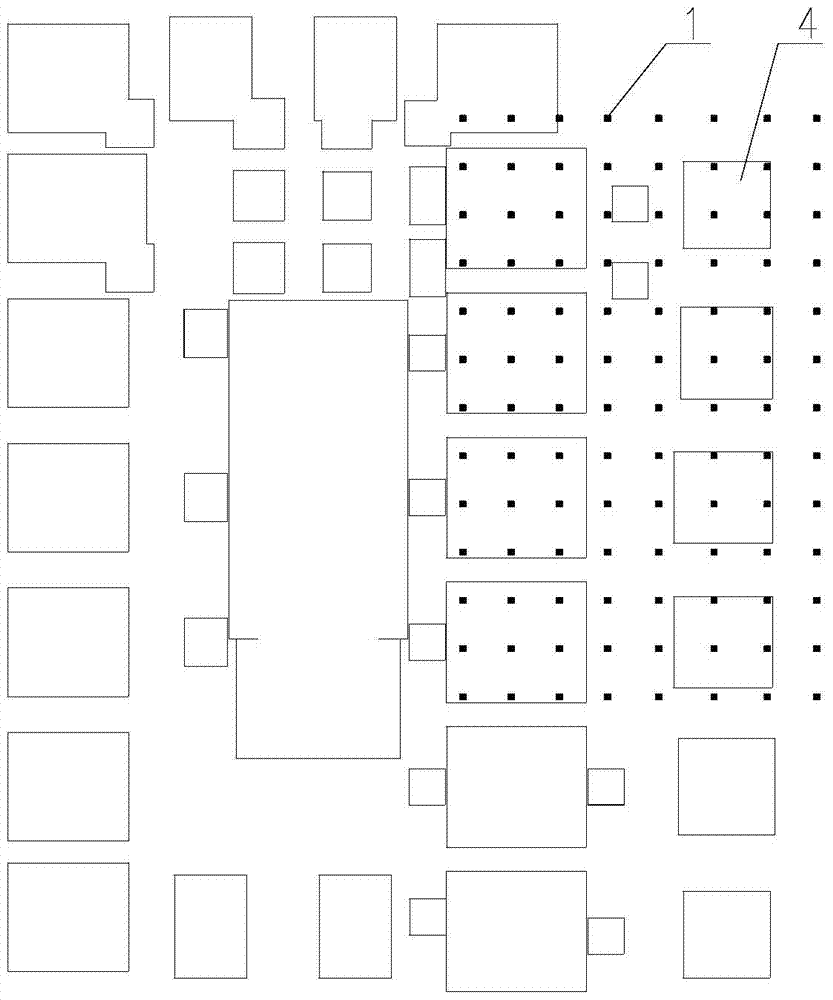

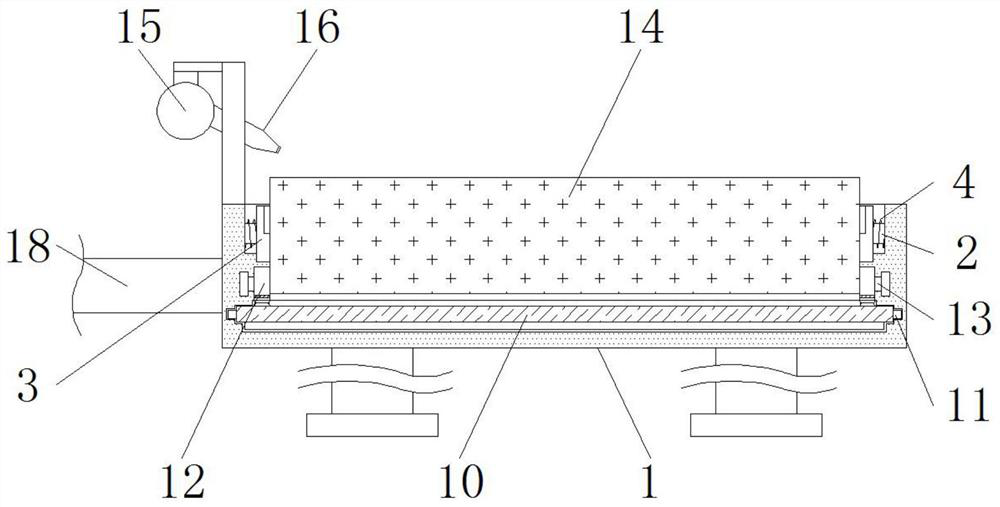

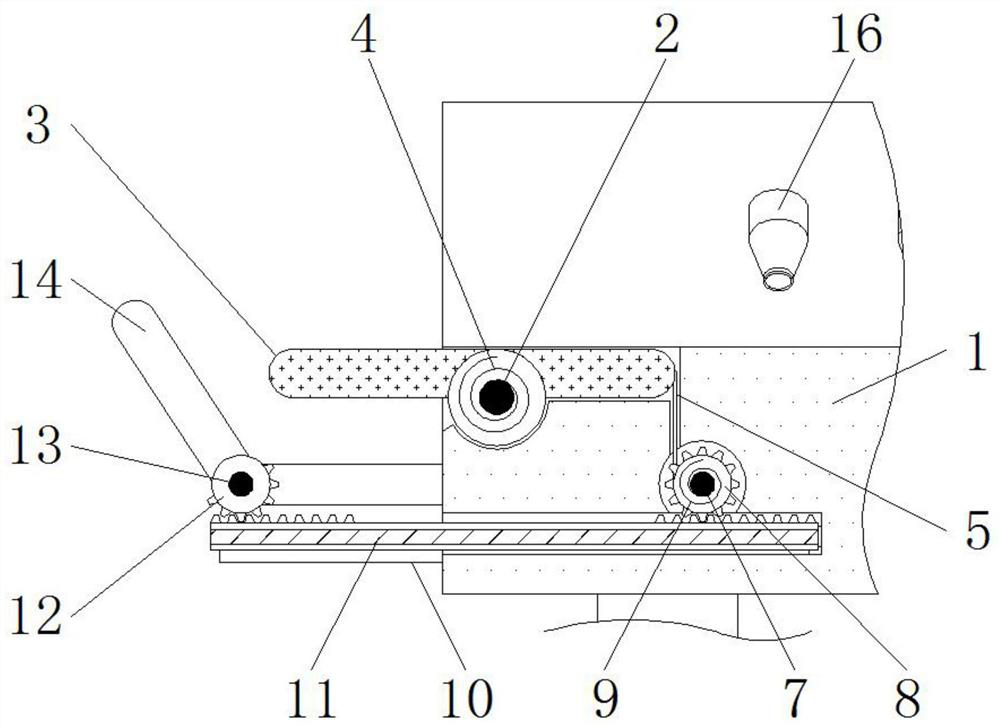

Twin-wire vertical electrogas welding system with low welding heat input and welding method

The invention provides a twin-wire vertical electrogas welding system with low welding heat input and a welding method. The system comprises a first welding power source, a second welding power source, an integrated power source box, a first wire feeder, a second wire feeder, a first gas shielded welding gun, a second gas shielded welding gun, a gas supply device, a control cabinet, an oscillator and a welding tractor, wherein homopolar output ends of the first welding power source and the second welding power source are in conductive connection with a head end of the first gas shielded welding gun, the other output end of the first welding power source is connected with a welded workpiece, and the other output end of the second welding power source is in conductive connection with a head end of the second gas shielded welding gun, so that heat input is greatly reduced while deposition rate can be increased, the system is stable and reliable, and impact toughness of a welding line is remarkably improved. Additionally, a twin-wire welding gun oscillating in the welding line can guarantee sufficient fusion of side walls of the welding line and a welding weld crater, so that mechanical properties of the welding line are remarkably enhanced.

Owner:SHENZHEN RILAND IND

Flux-cored wire for electrogas arc welding

ActiveCN101396777AImprove workabilityHigh strengthWelding/cutting media/materialsWelding/soldering/cutting articlesMetallurgySingle electrode

Owner:JFE STEEL CORP +1

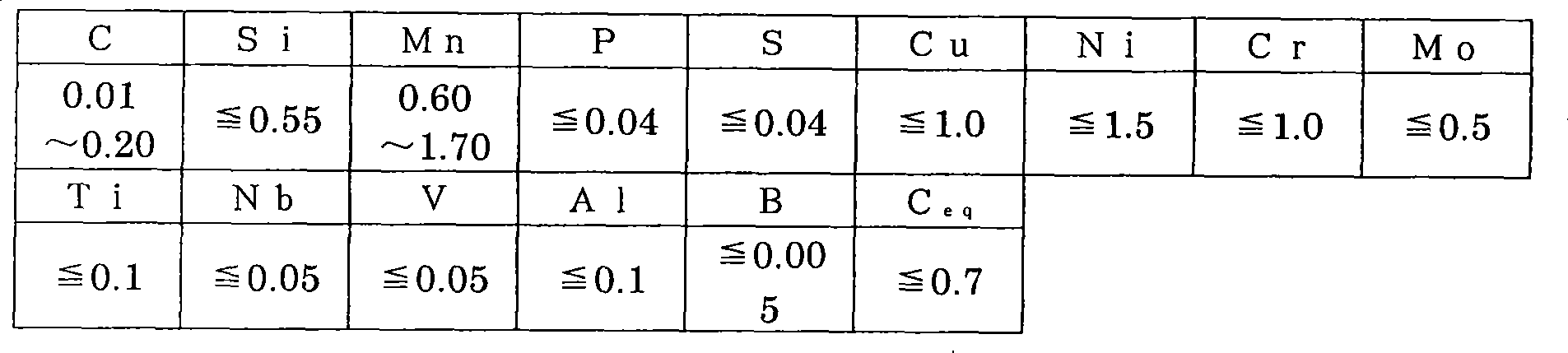

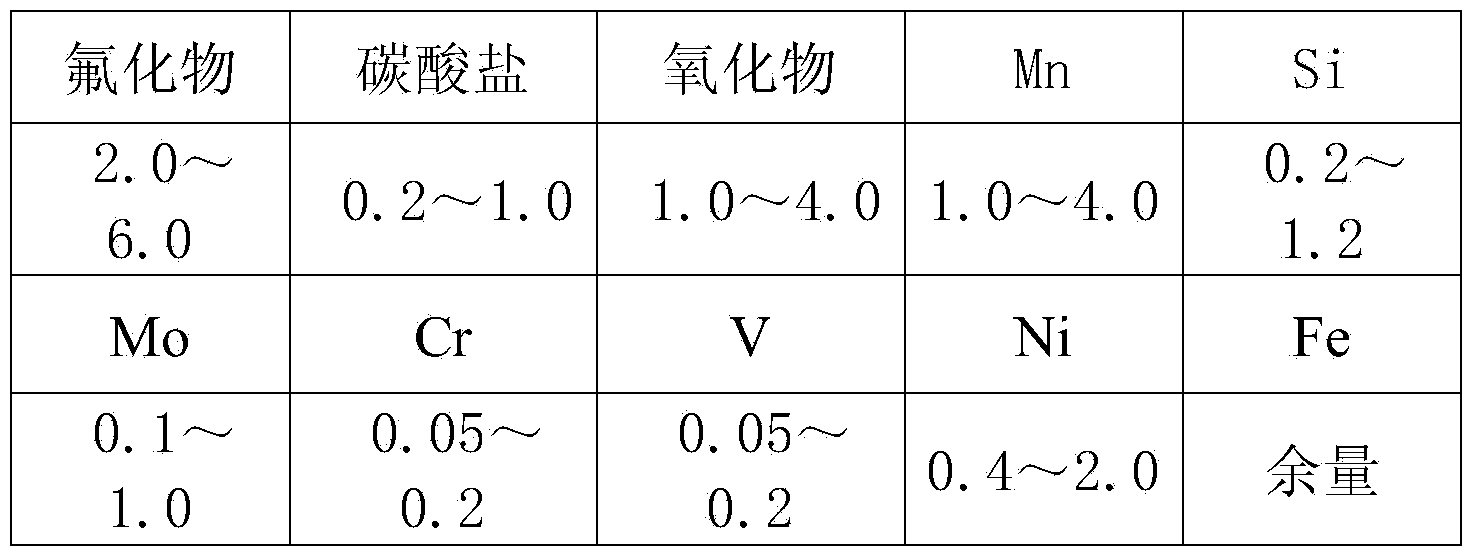

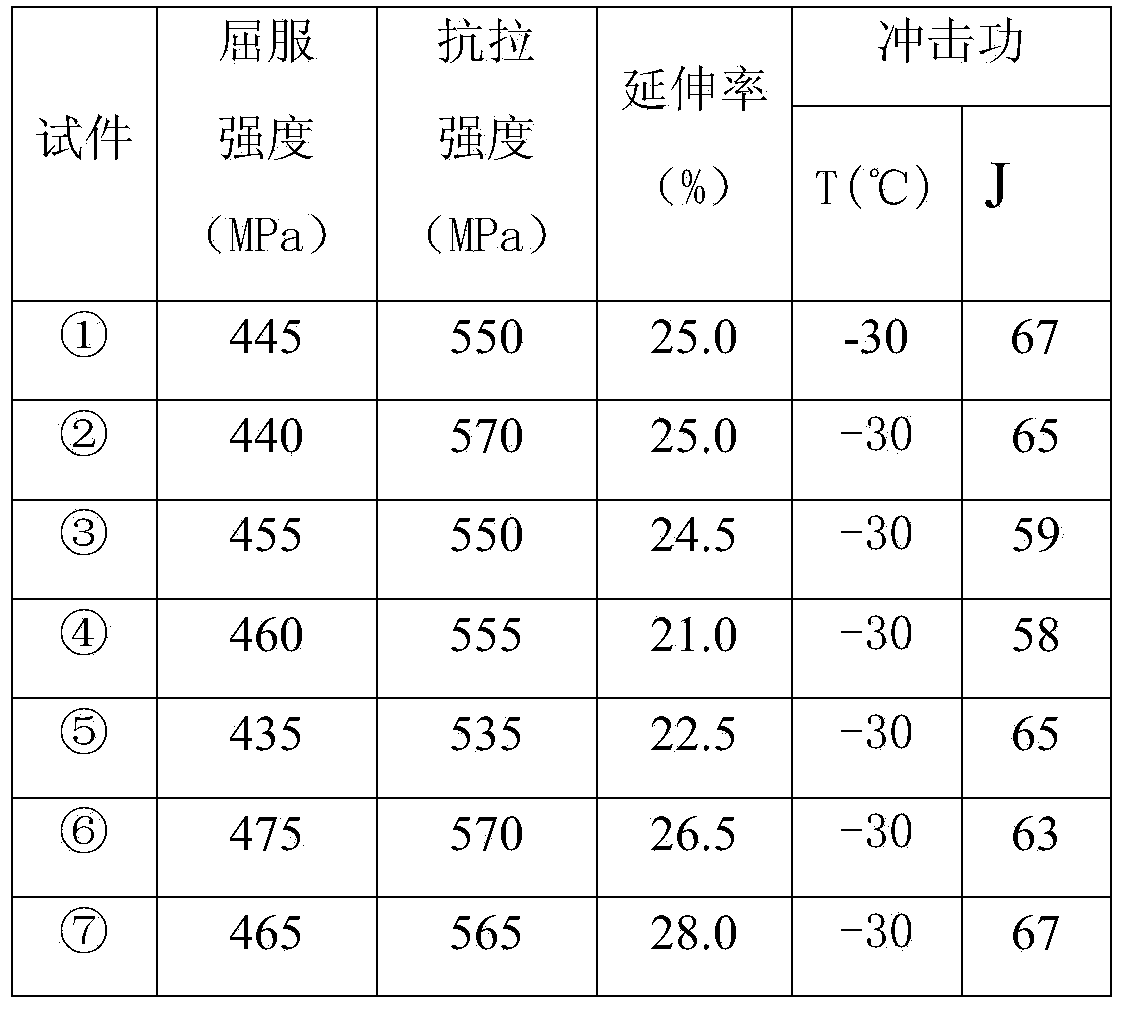

High-ductility electrogas welding self-shielded flux-cored wire

The invention discloses a high-ductility electrogas welding self-shielded flux-cored wire, which comprises a steel strip and a welding flux wrapped in the steel strip. The weight factor of the welding flux in the overall weight of the wire is 0.2-0.3, and by weight percent, the steel strip comprises 0.01-0.055% of C (carbon), 0.01-0.03% of Si (silicon), 0.10-0.30% of Mn (manganese), 0.005-0.060% of Al (aluminum), 0.007-0.015% of P (phosphorus), 0.007-0.015% of S (sulfur) and the balance Fe (ferrum). By the overall weight of the wire, the wire comprises 2.0-6.0% of fluoride, 1.0-4.0% of oxide, 0.2-1.0% of carbonate, 1.0-4.0% of Mn, 0.2-1.2% of Si, 0.4-2.0% of Ni (nickel), 0.1-1.0% of Mo (molybdenum), 0.05-0.2% of Cr (chromium), 0.05-0.2% of V (vanadium) and the balance Fe. When the wire is used for welding, weld strength is higher than 500MPa, impacting energy at the temperature of -30 DEG C is higher than 50J, and the wire is mainly applicable to occasions of heavy and rapid welding for thick plates.

Owner:KUSN GINTUNE WELDING

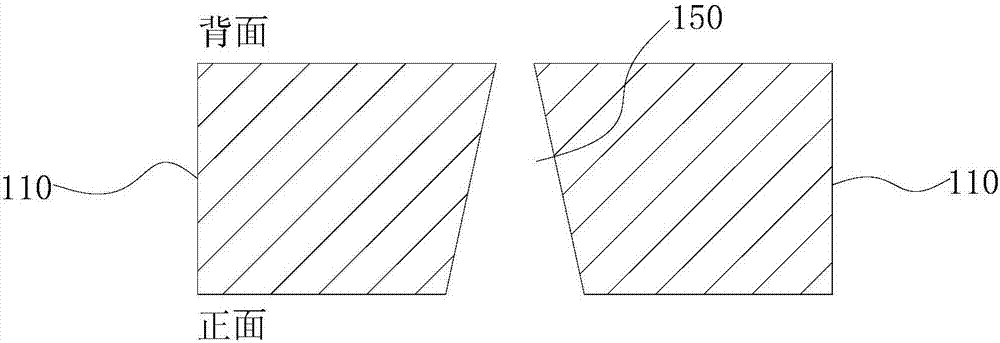

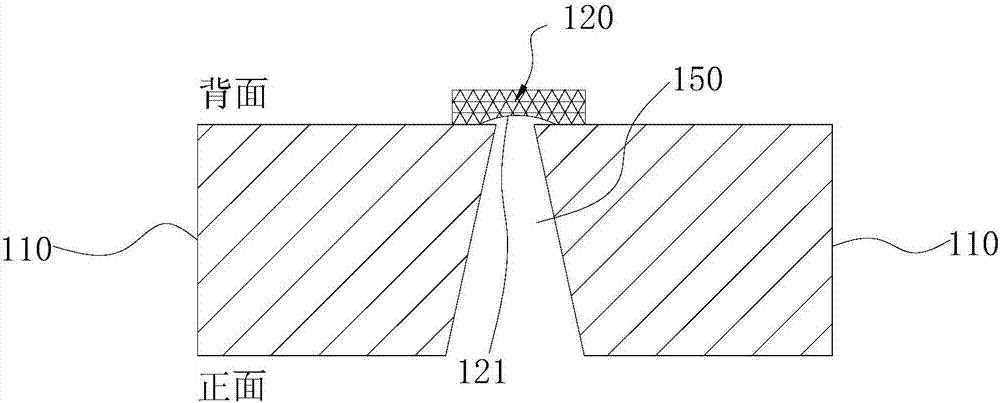

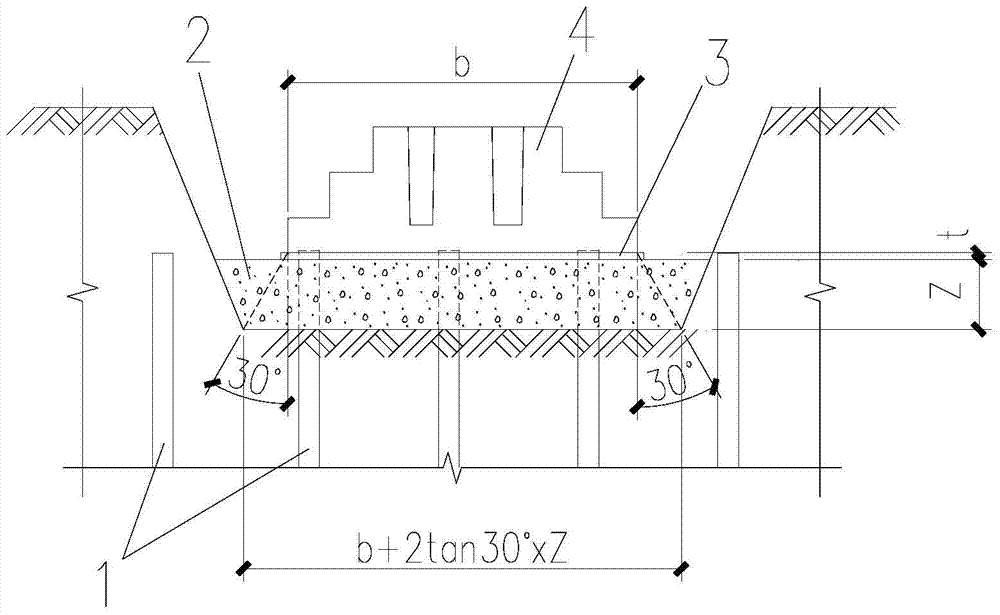

Thick plate vertical butt joint welding method

InactiveCN106862730AGuarantee welding qualityReduce the difficulty of operationArc welding apparatusThick plateButt joint

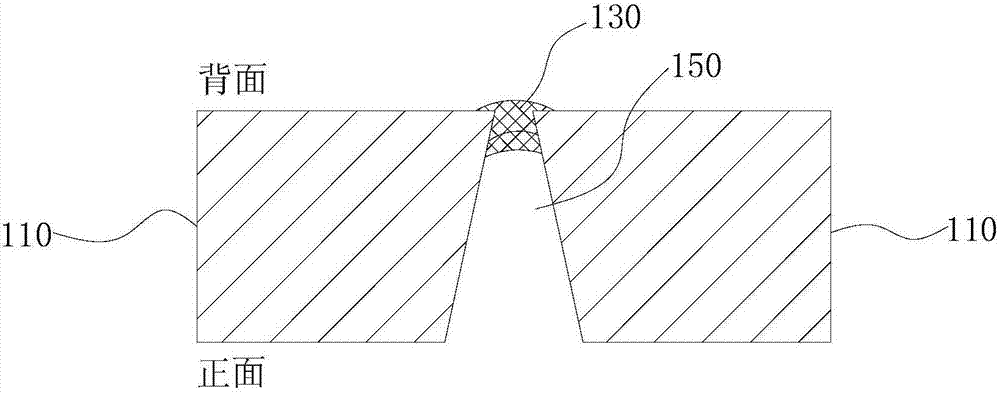

The invention discloses a thick plate vertical butt joint welding method. A butt joint welded part is provided, and is provided with a groove for welding; the CO2 gas shielded welding is adopted to weld in the groove to form a welding line bottom layer; and the vertical electrogas welding is adopted to weld on the welding line bottom layer to finish remained groove filling. The CO2 gas shielded welding is adopted to firstly weld the groove to form the welding line bottom layer difficult to thoroughly weld on the bottom or the back surface of the groove in the groove, so that the welding quality of the subsequently adopted vertical electrogas welding is guaranteed; and the two welding modes are combined to weld thicker butt joint welded part, so that the operation difficulty can be reduced, the welding quality is improved, and the welding heat input quantity also can be effectively reduced.

Owner:GUANGZHOU SHIPYARD INTERNATIONAL LTD

Flux-cored wire for electrogas welding

ActiveCN102528317AHigh purity of weld seamArc stabilizationArc welding apparatusWelding/cutting media/materialsWeight coefficientManganese

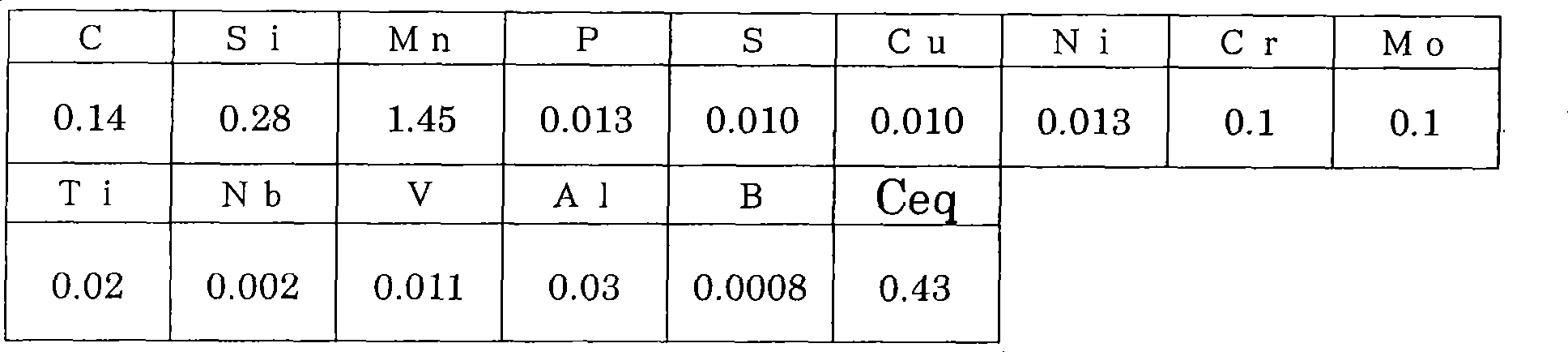

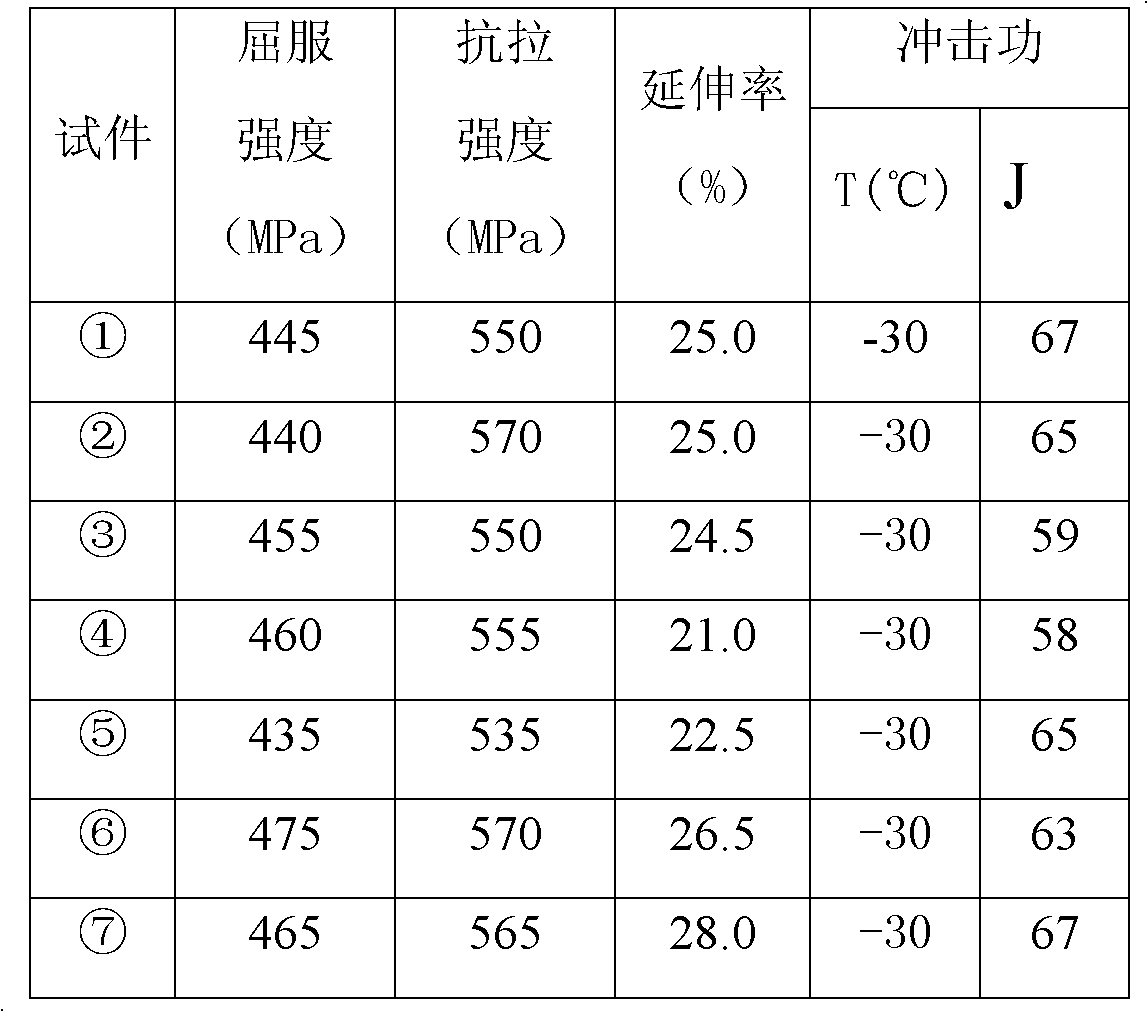

The invention discloses a flux-cored wire for electrogas welding, which comprises a steel strip and welding flux wrapped in the steel strip. The weight coefficient of the welding flux in the overall weight of the wire ranges from 0.2 to 0.3. By weight percentage, the steel strip comprises 0.010-0.055% of C (carbon), 0.01-0.03% of Si (silicon), 0.10-0.30% of Mn (manganese), 0.005-0.060% of Al (aluminum), 0.007-0.012% of P (phosphorus), 0.007-0.012% of S (sulfur) and the balance Fe (ferrum). By the overall weight of the wire, the welding flux comprises 0.2-2.0% of fluoride, 0.2-1.0% of oxide, 1.0-3.0% of Mn, 0.2-1.0% of Si, 0.4-1.2% of Ni (nickel), 0.1-1.0% of Mg (magnesium), 0.002-0.16% of Ti (titanium), 0.002-0.010% of B (boron) and the balance Fe. The flux-cored wire matched with electrogas welding is used for welding, so that welding efficiency is greatly improved, and excellent and stable mechanical performance is also obtained.

Owner:KUSN GINTUNE WELDING

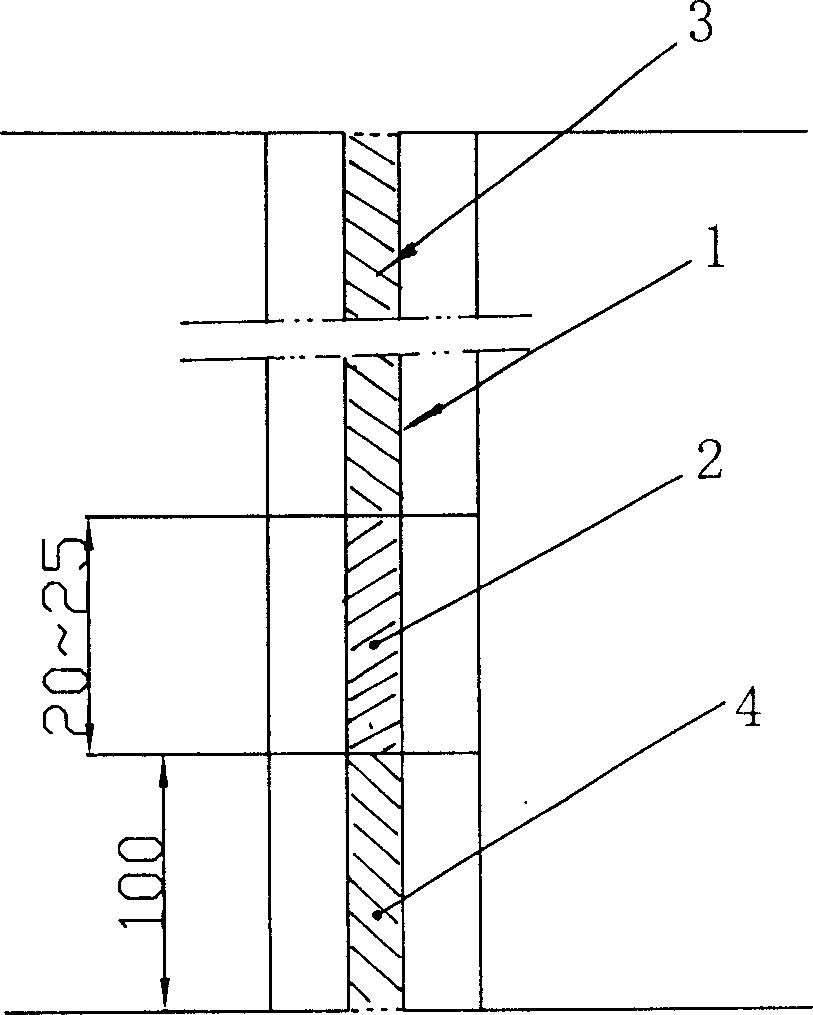

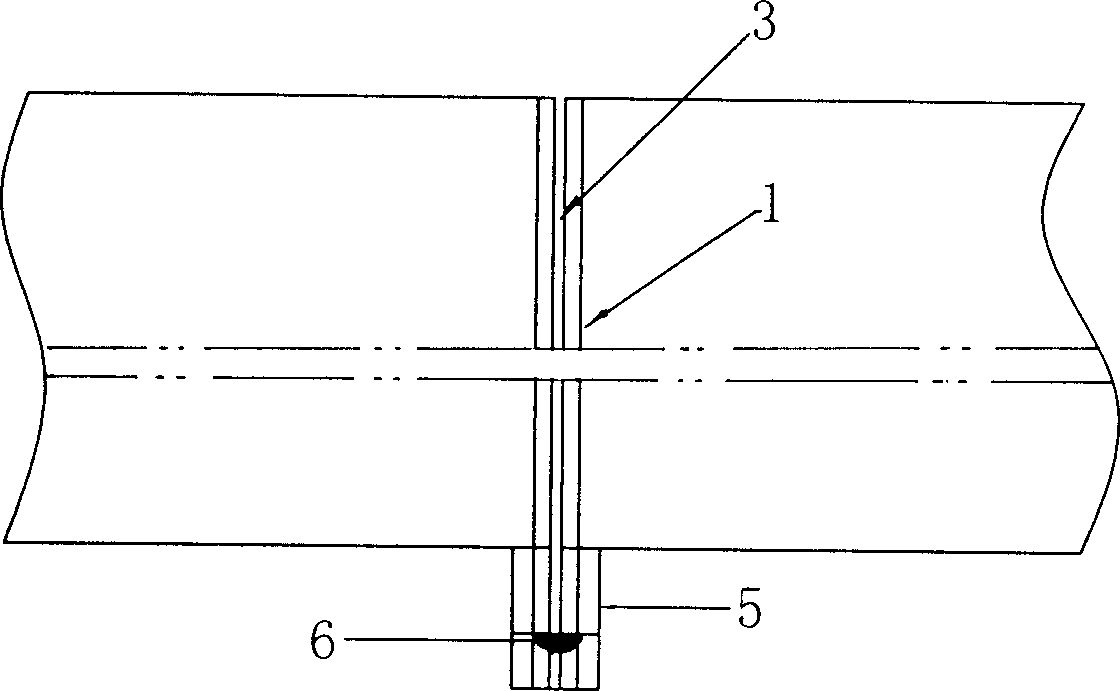

Gas electric vertical-position welding tray-free arc welding method for vertical-seam welding

InactiveCN1850414AReduce welding costsExcellent welding qualityArc welding apparatusEngineeringSeam welding

The present invention relates to an electrogas welding arc-starting welding method having no need of supporting bottom for welding vertical sea. Said method can weld the vertical seam by means of one-step welding operation and can obtain good appearance of weld, and has no need of artificially repairing welding. It is characterized by that it utilizes run-on tab or circumferential seam as supporting bottom of starting arc, and can control welding specification when the arc is started so as to attain the goal of raising welding quality.

Owner:中国石化集团第二建设有限公司

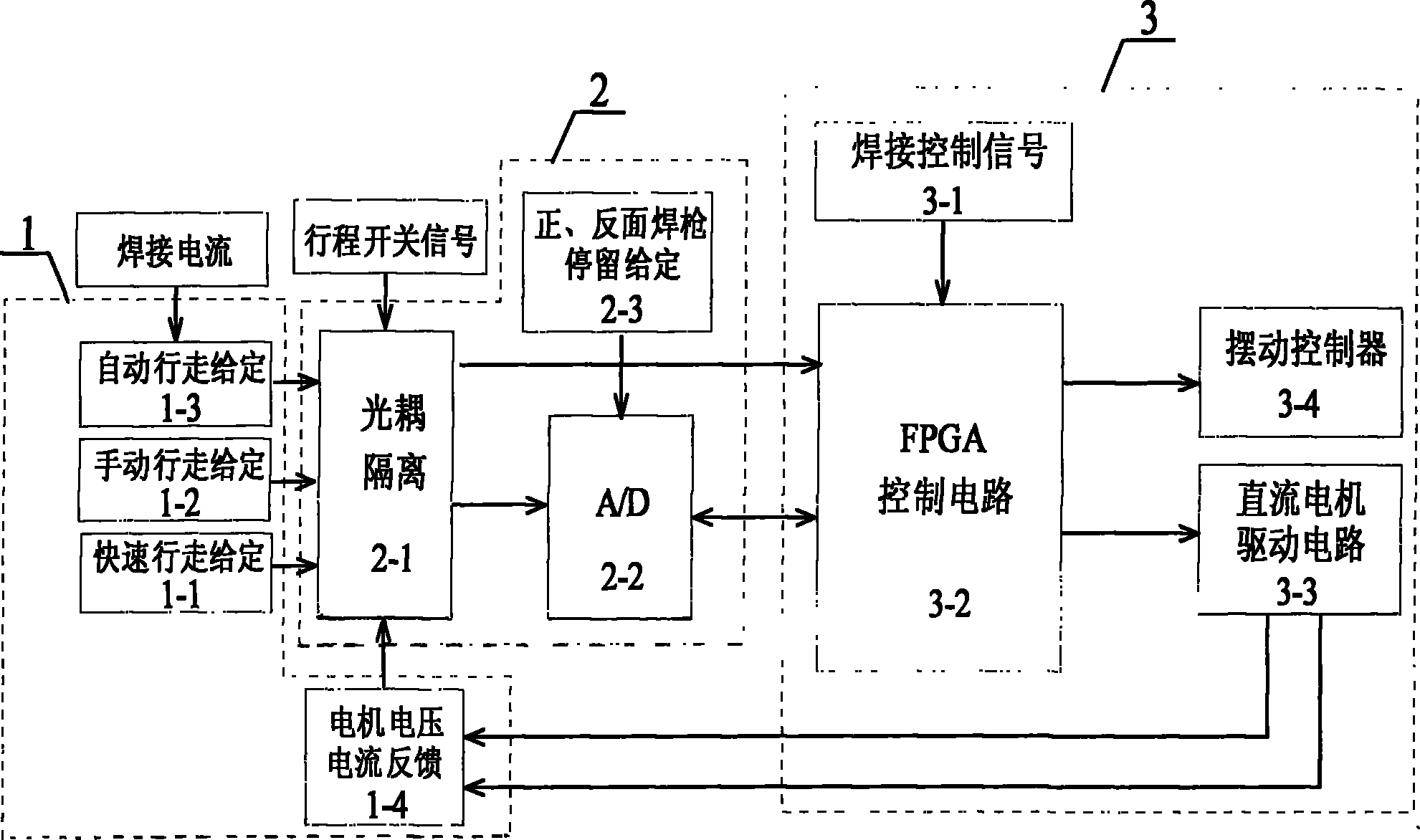

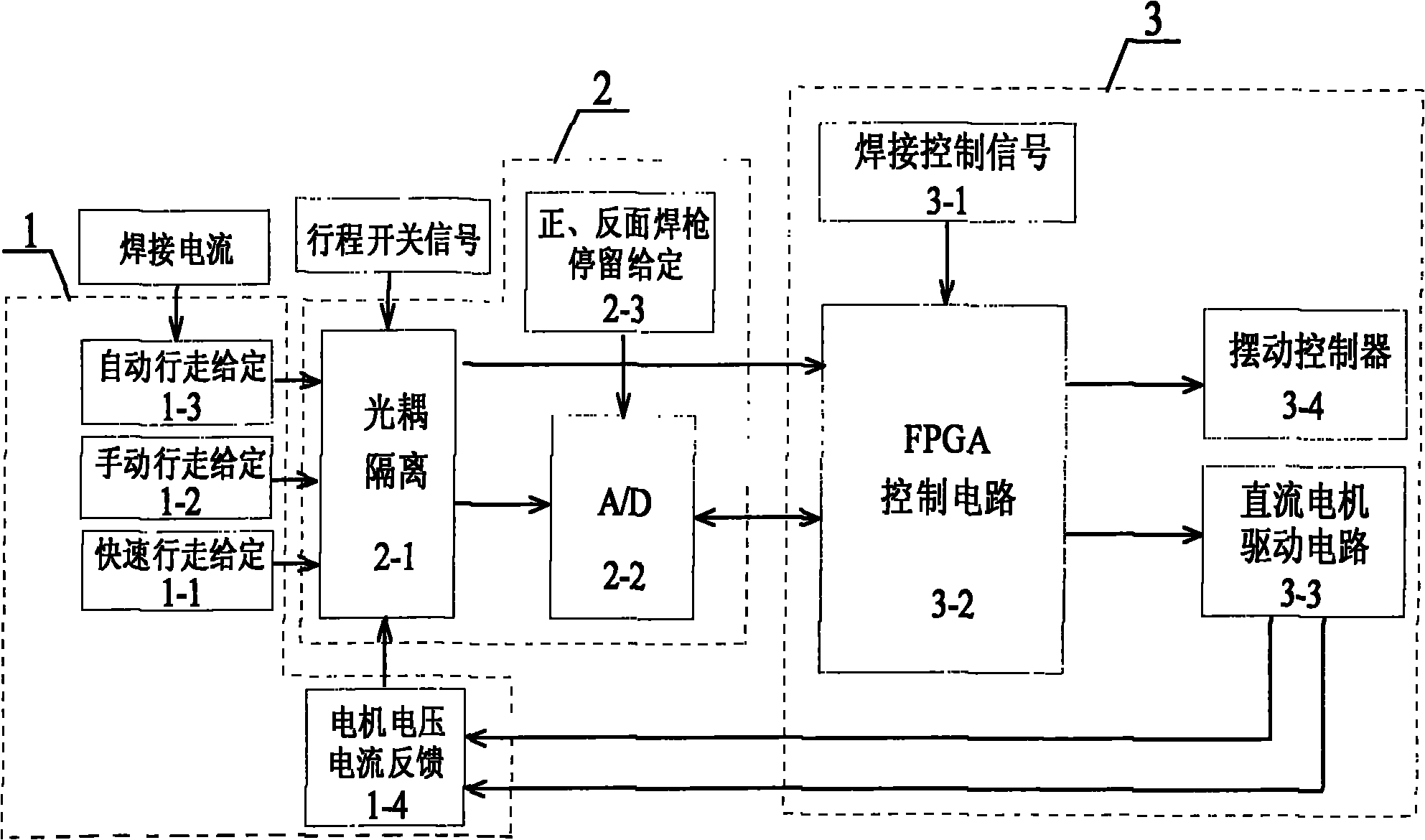

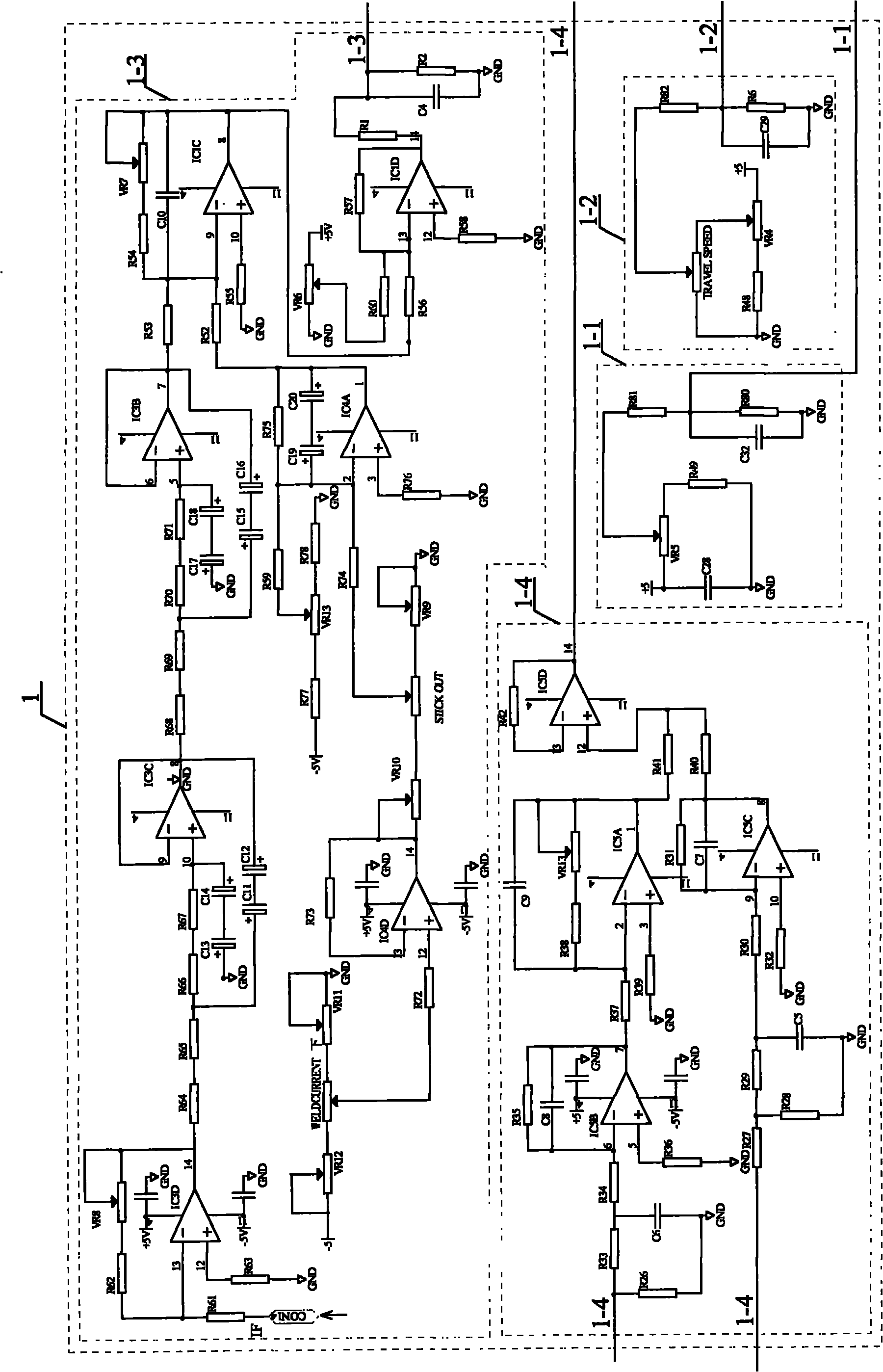

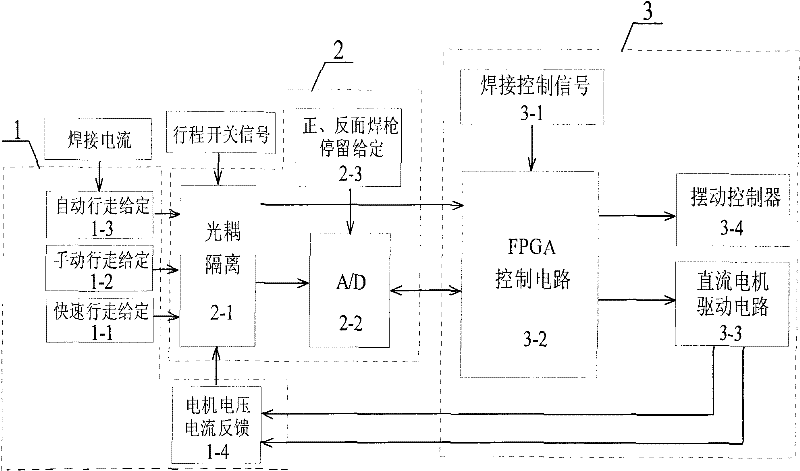

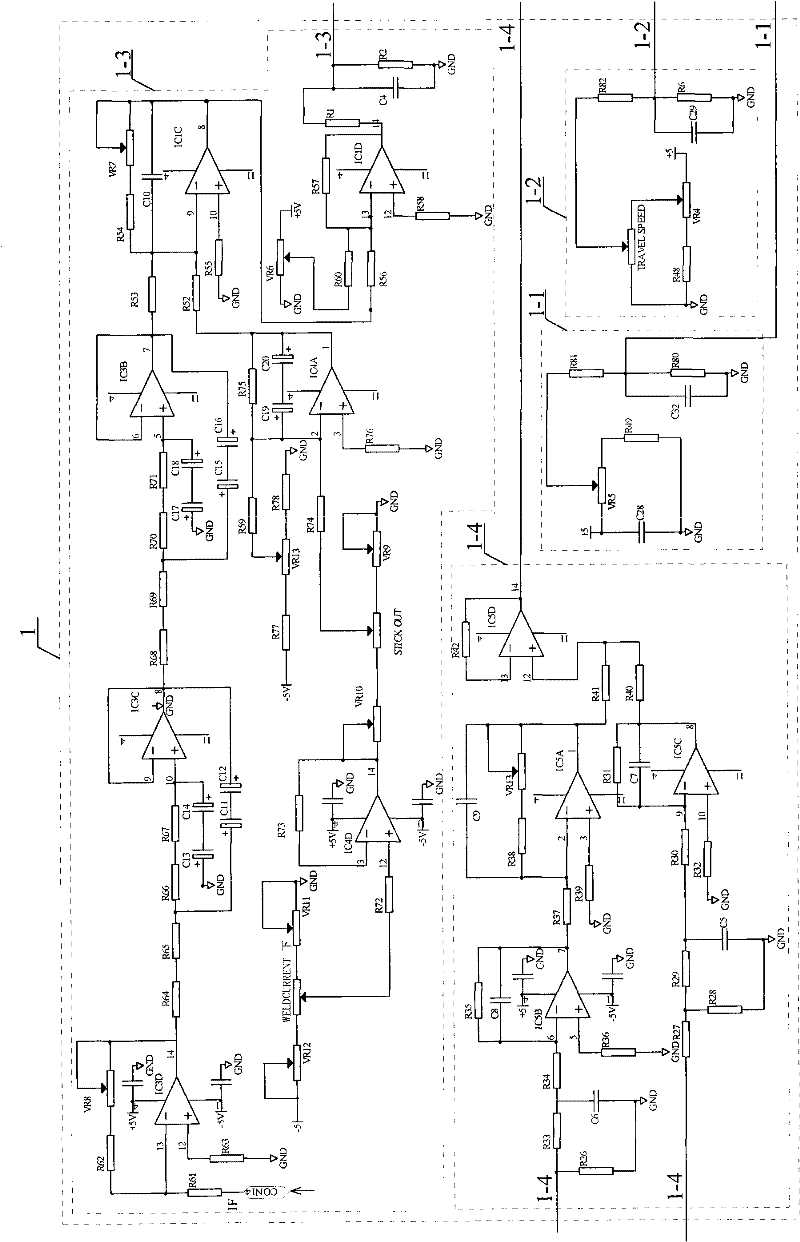

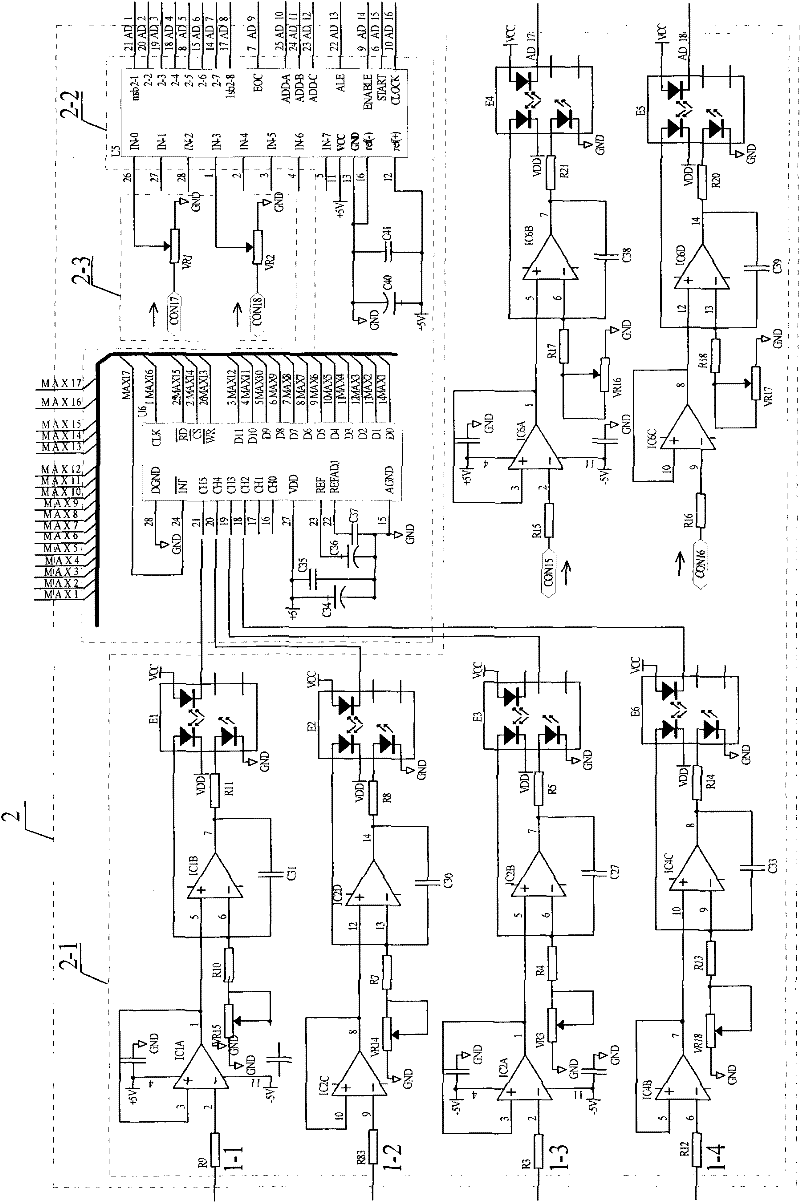

Electrogas welding arc length controller based on FPGA (Field Programmable Gate Array)

The invention discloses an electrogas welding arc length controller based on FPGA (Field Programmable Gate Array), comprising three trolley walking given circuits, a motor voltage negative feedback and current positive feedback circuit, an isolation optocoupler circuit, an AD conversion circuit, a positive and negative welding gun retaining and given circuit, a welding control signal circuit, an FPGA control circuit, a direct current motor driving circuit and a welding gun swinging control circuit. The invention has the advantages of wire feeding with equal speed and climbing of the trolley with variable speed, and can better control the stability of arc during welding.

Owner:JIANGSU UNIV OF SCI & TECH

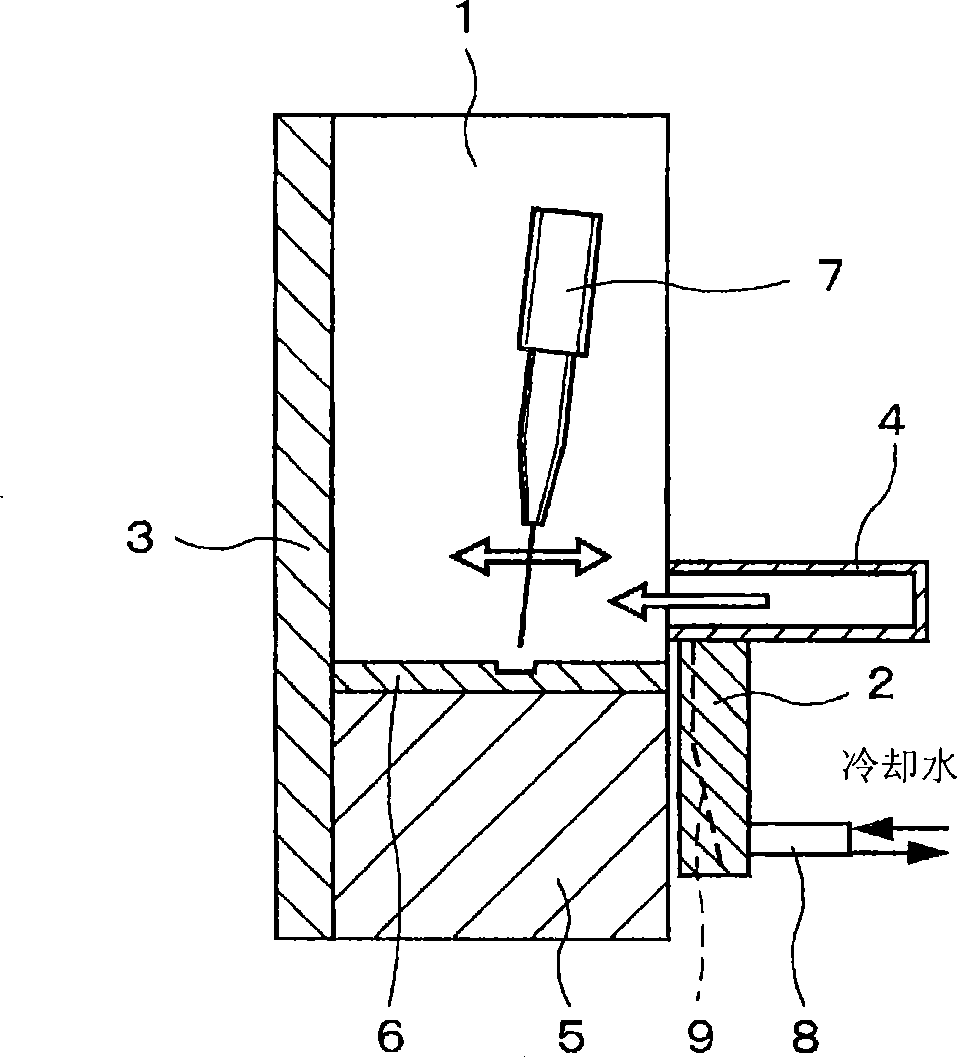

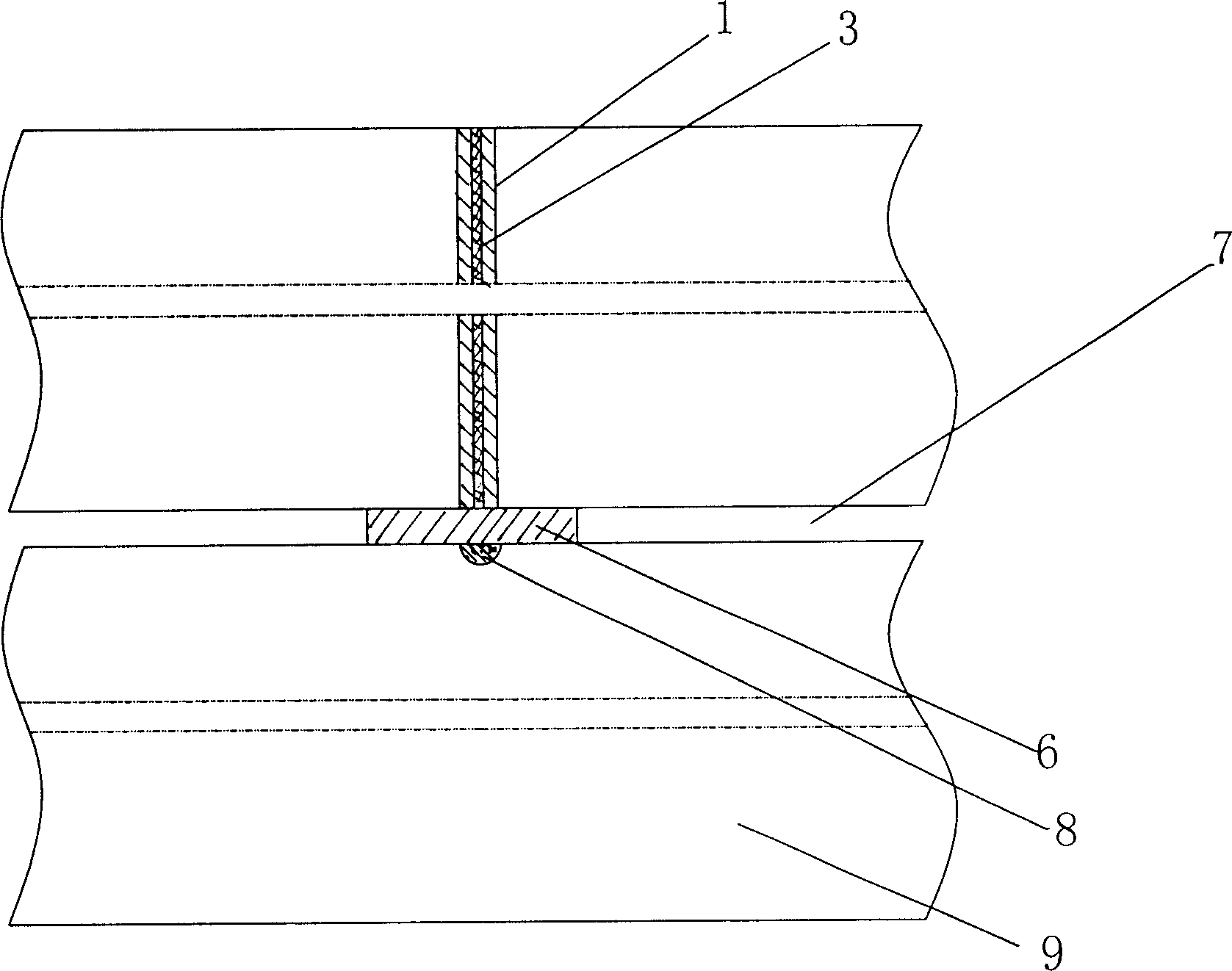

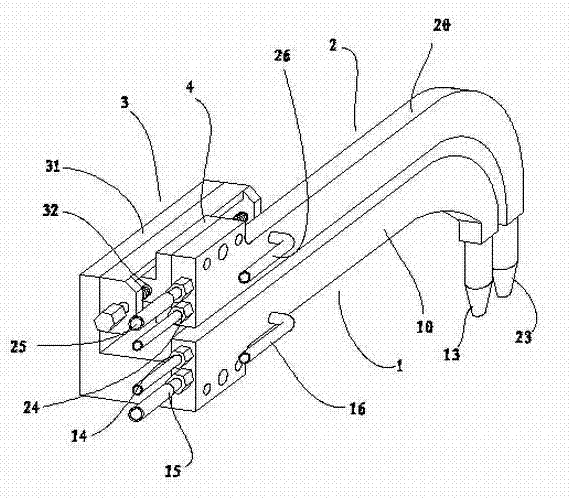

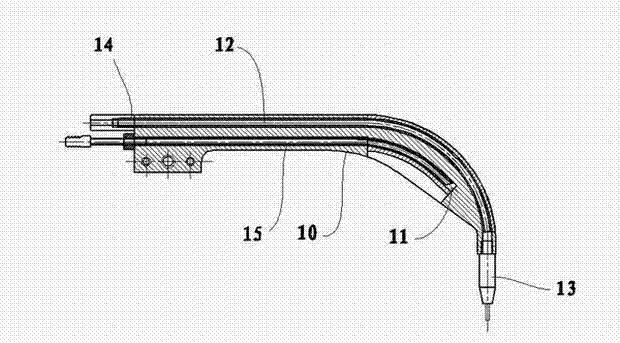

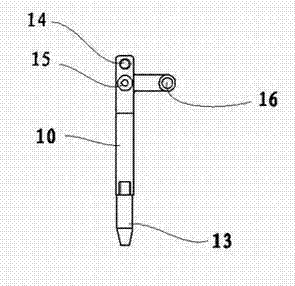

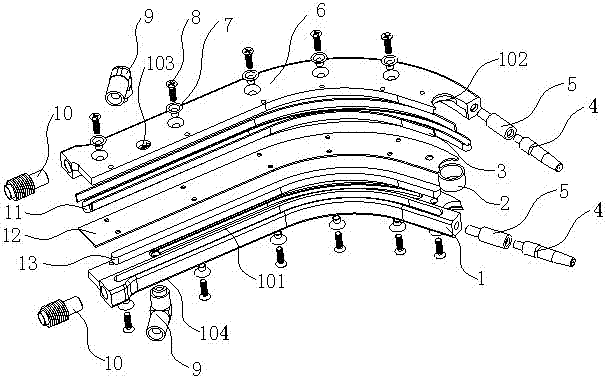

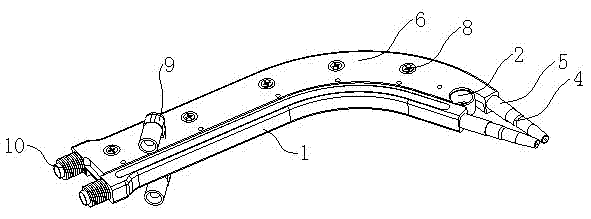

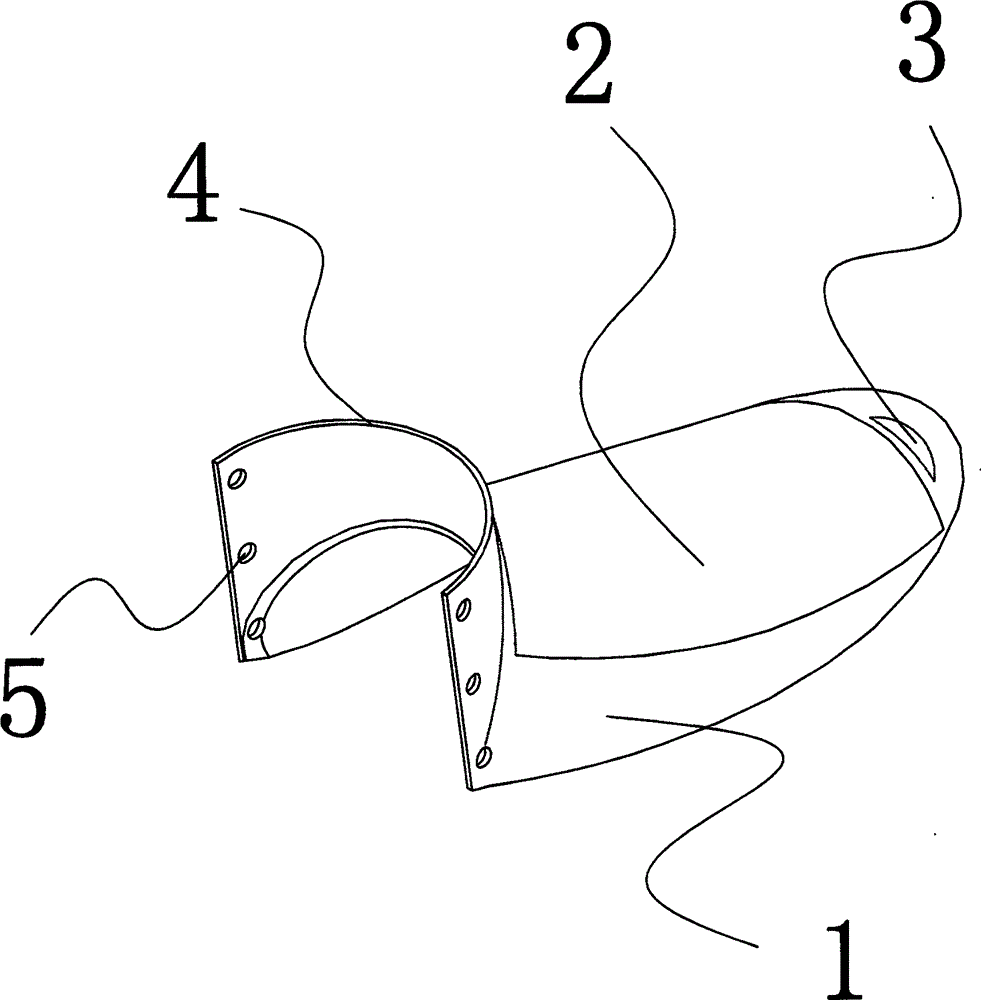

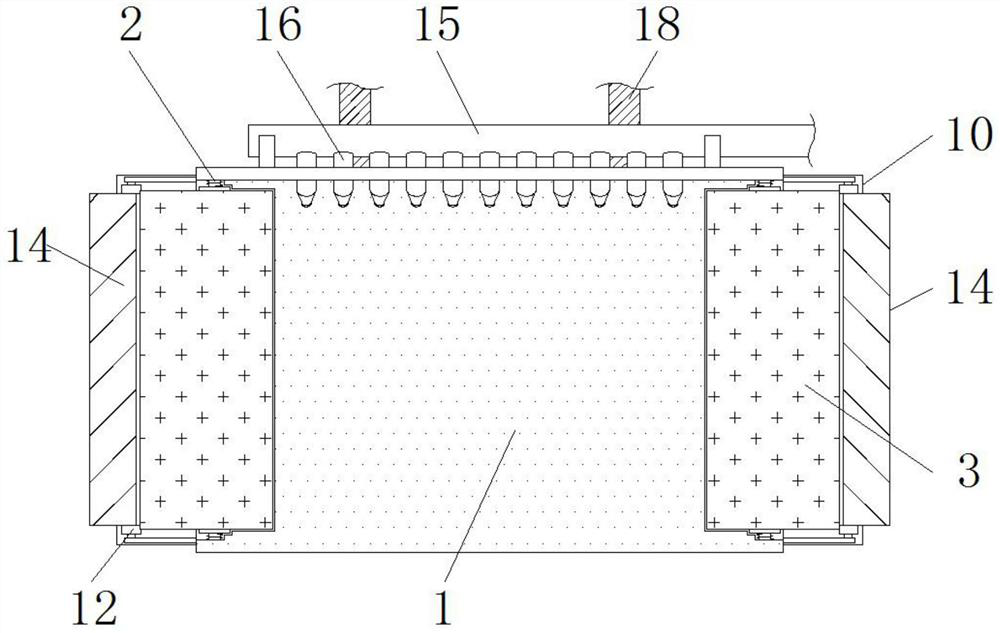

Twin-wire electrogas welding water-cooled welding torch

InactiveCN103071899ASimple structureReduce manufacturing costElectrode supporting devicesWater coolingElectrogas welding

The invention relates to a welding torch for arc welding, in particular to a twin-wire electrogas welding water-cooled welding torch, which comprises a first water-cooled welding torch and a second water-cooled welding torch which are mutually insulated, and an adjusting device for a distance between welding wires. The twin-wire electrogas welding water-cooled welding torch is characterized in that the adjusting device for the distance between the welding wires comprises a substrate and a feed screw nut mechanism arranged on the substrate; the first welding torch is fixed with the substrate; the second welding torch is fixed with a nut of the feed screw nut mechanism through a fixing plate; and the second welding torch is positioned above the first welding torch. The distance between the two welding torches is adjustable, an adjusting range for a welding condition is widened, proper current, voltage, welding speed and distance between the welding wires can be selected according to the thickness and materials of plates to be welded, and high quality welding lines are efficiently completed.

Owner:刘振英

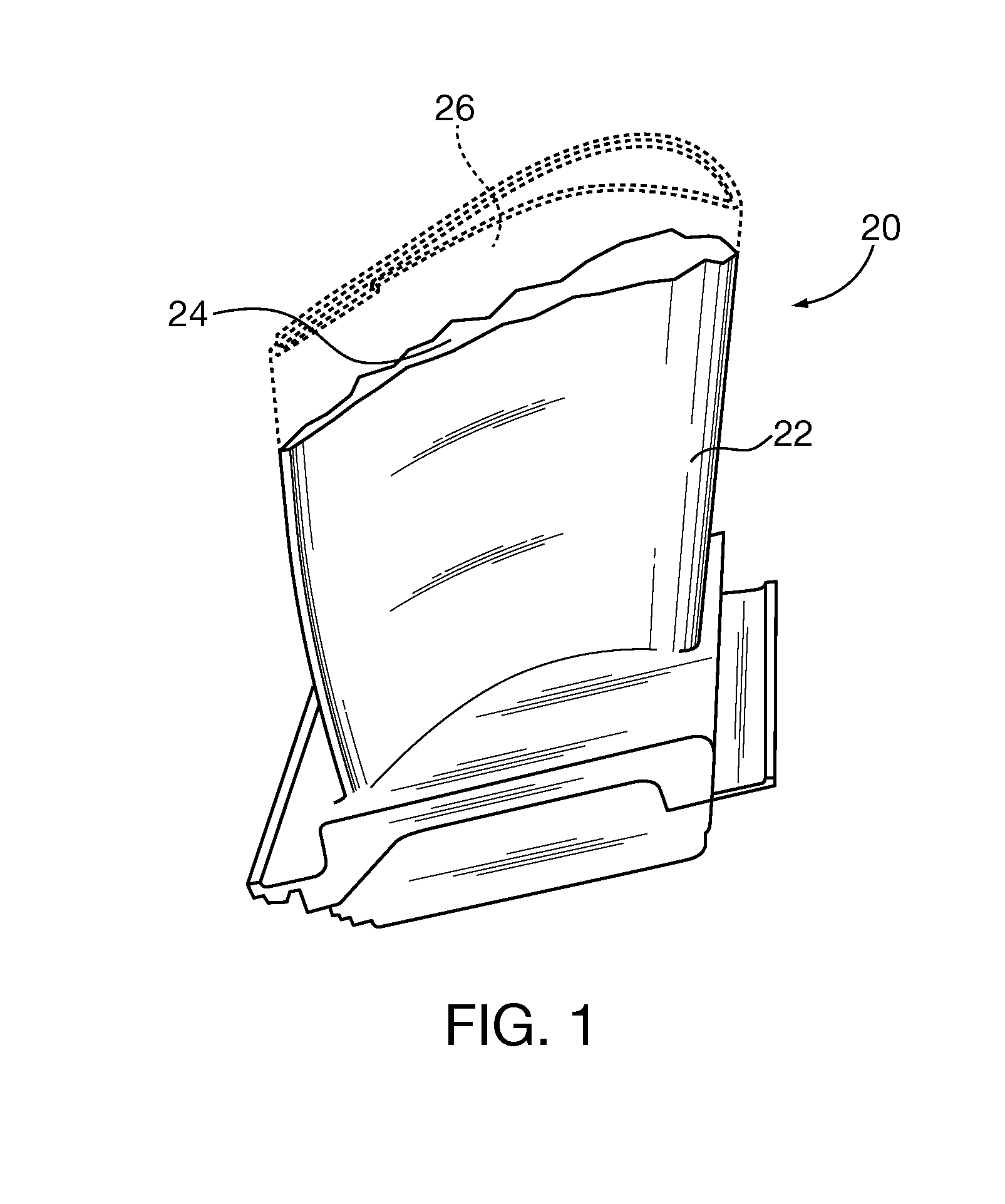

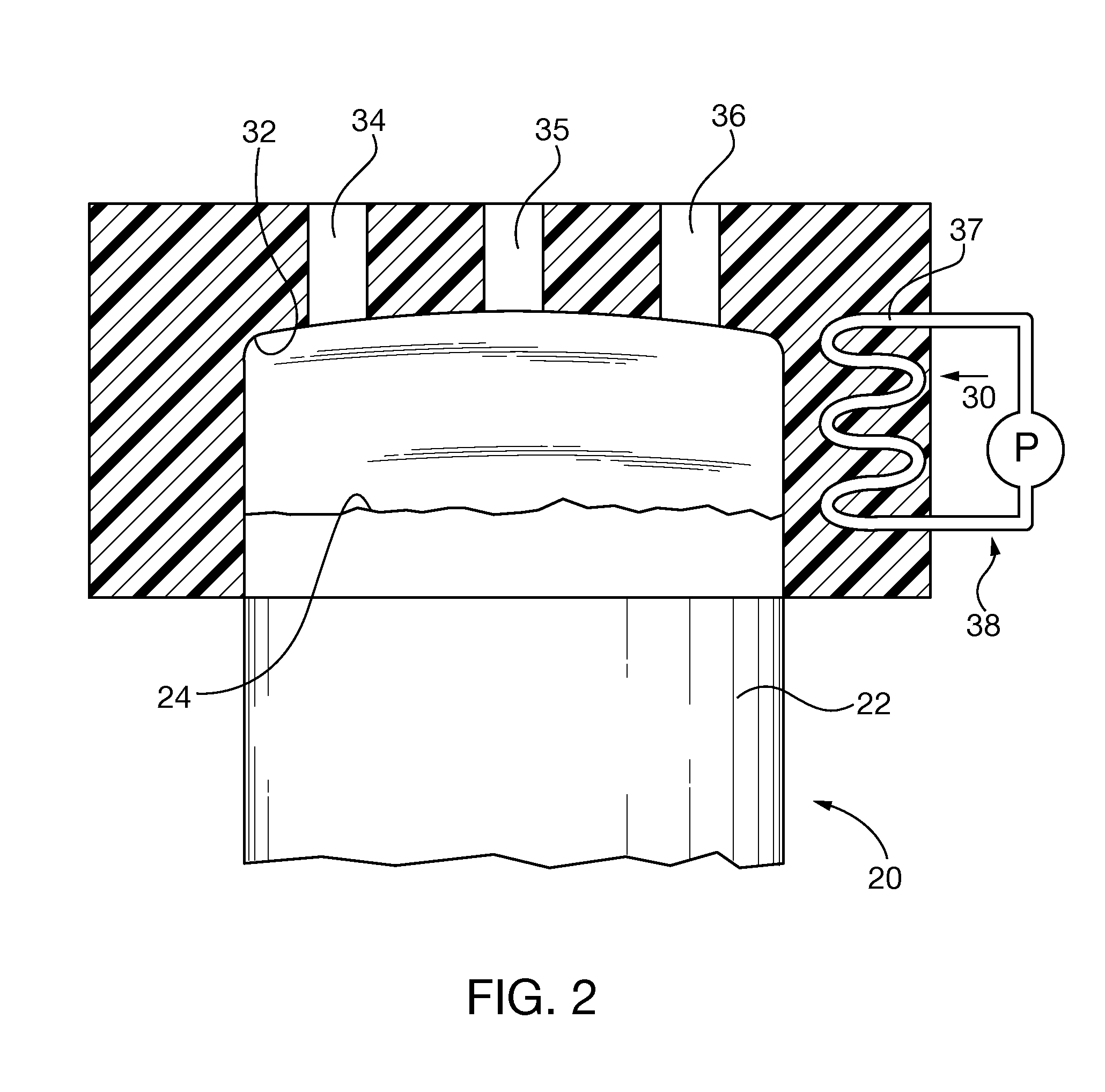

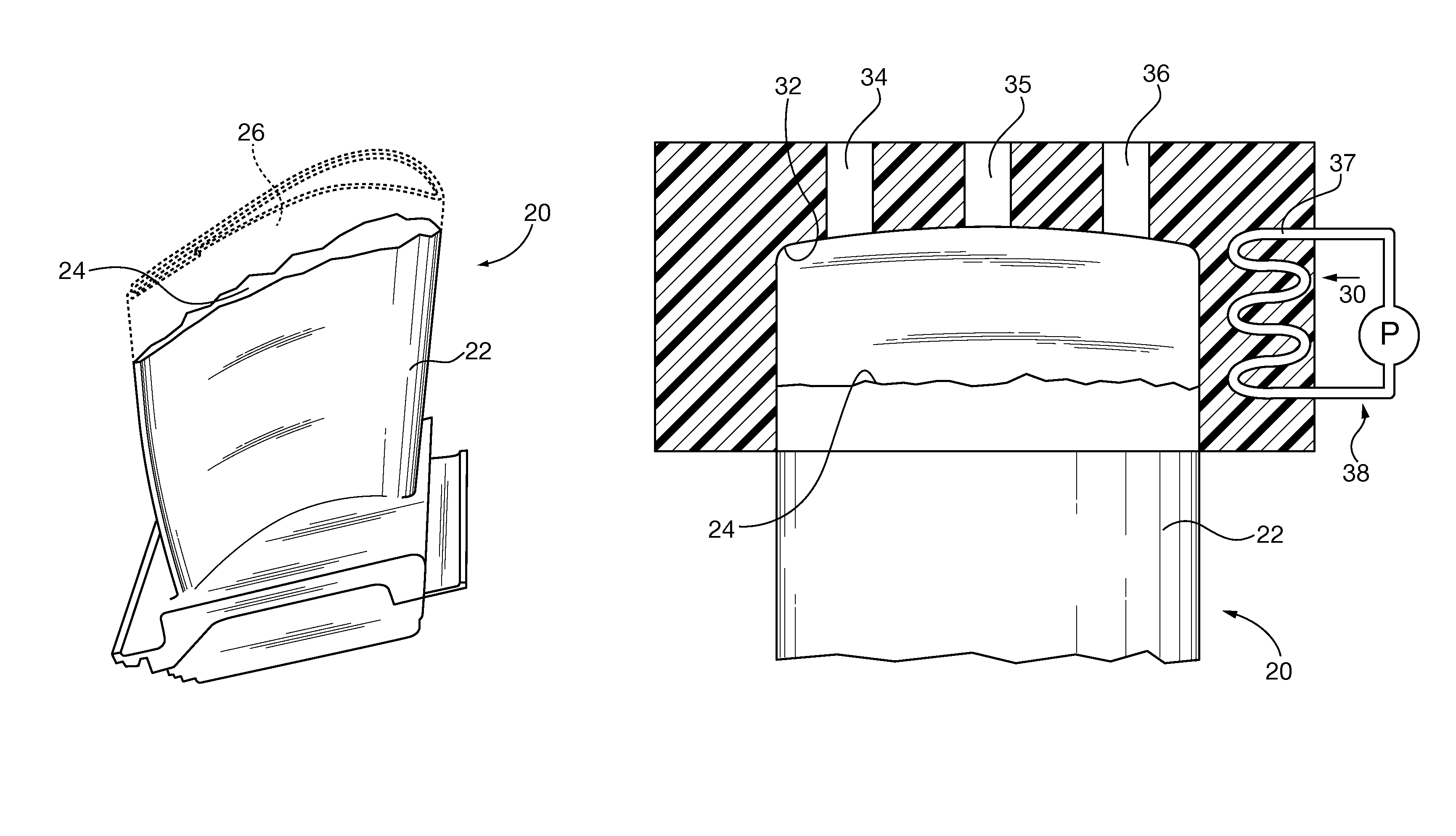

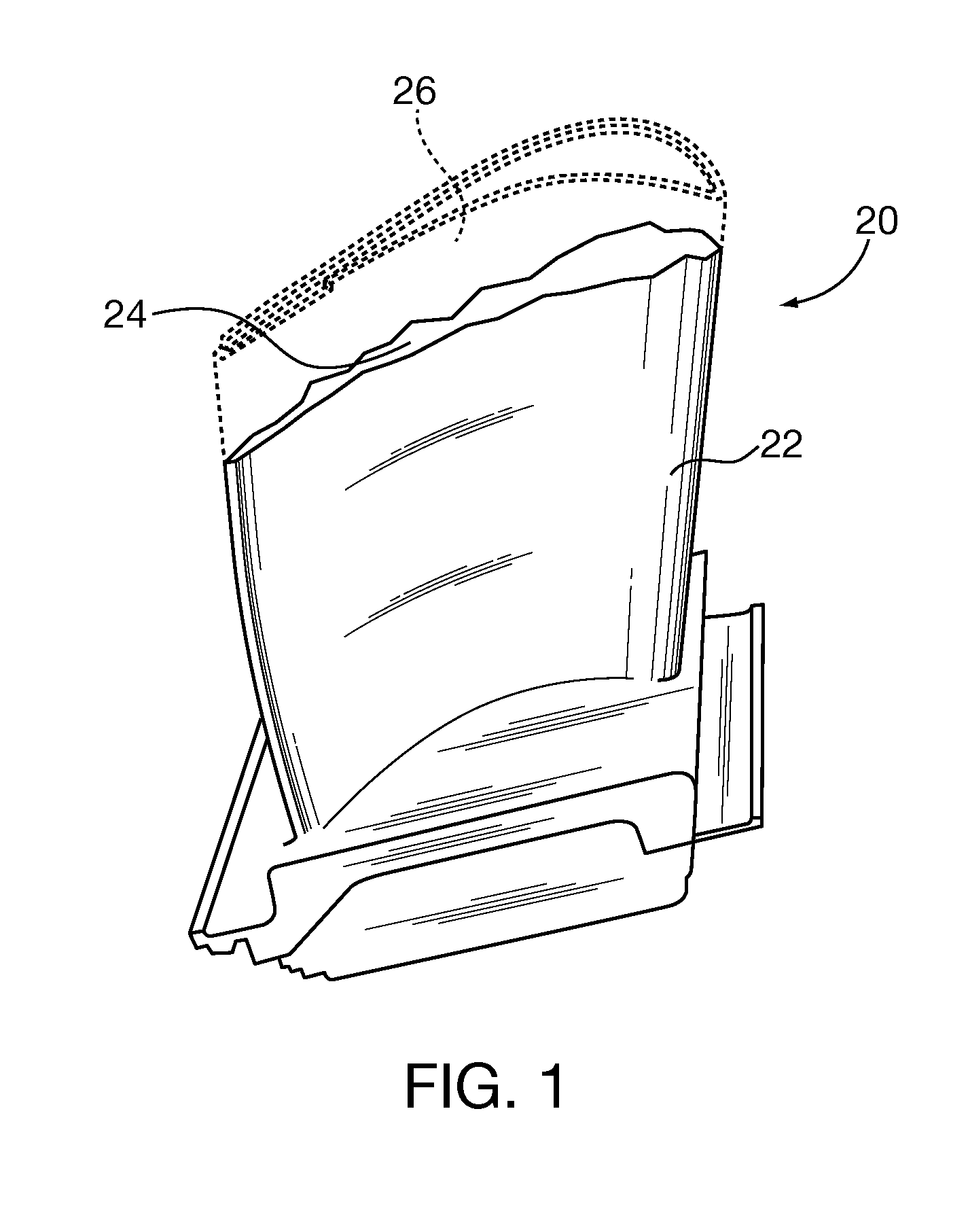

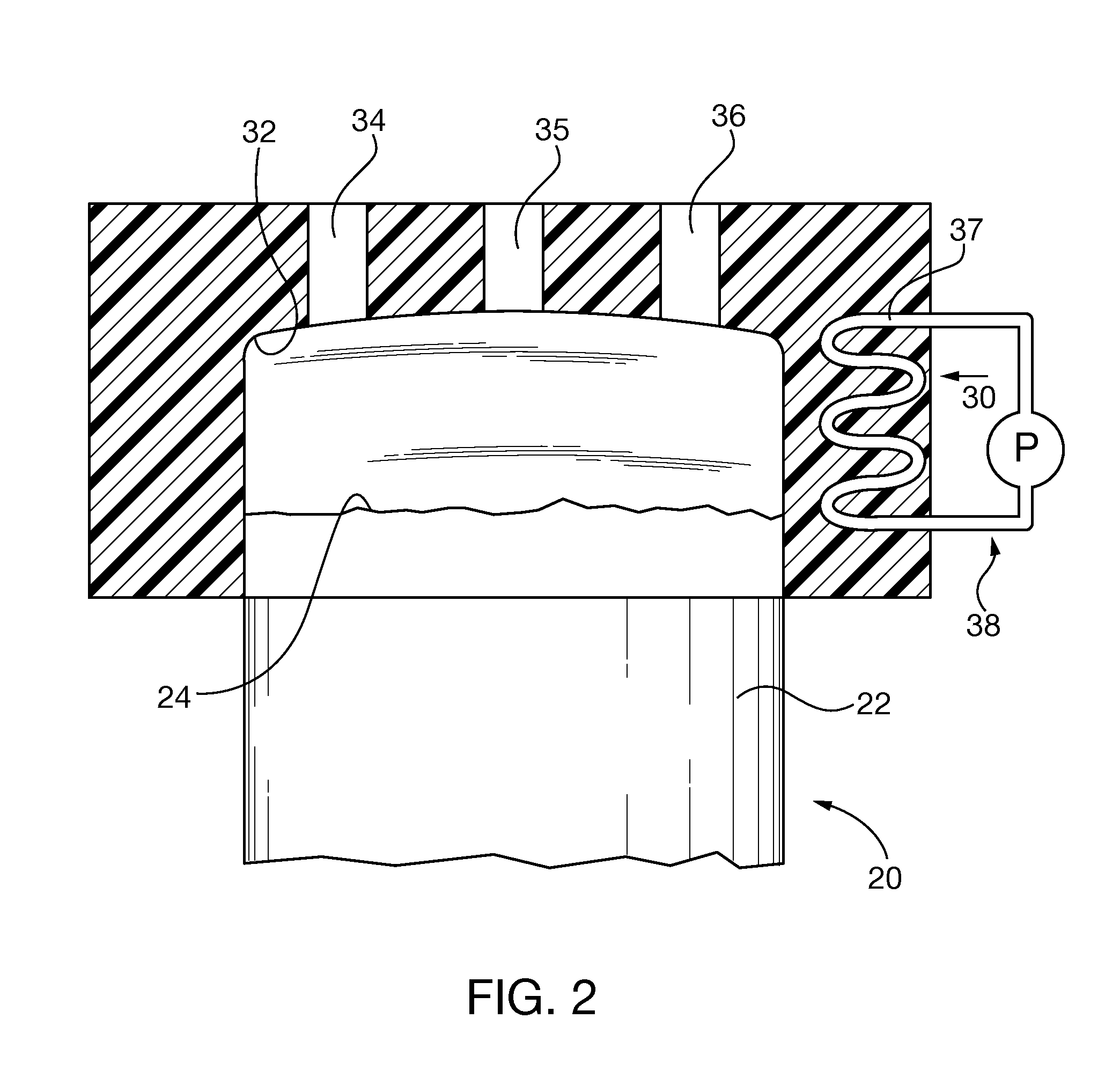

Electroslag and electrogas repair of superalloy components

ActiveUS20140044991A1Raise the possibilityDamaged component scrap rates can be reducedTurbinesPropellersTurbine bladeFilling materials

Superalloy component castings, such as turbine blades and vanes, are fabricated or repaired by an electroslag or electrogas welding process that at least partially replicates the crystal structure of the original cast substrate in a cast-in-place substrate extension. The process re-melts the base substrate surface and grows it with new molten filler material. As the base substrate and the filler material solidify, the newly formed “re-cast” component has a directionally solidified uniaxial substrate extension portion that at least in part replicates the crystalline structure of the base substrate. The “re-cast” component can be fabricated with a unified single crystal structure, including the extension portion. In other applications, a substrate extension can replicate a directionally solidified uniaxial crystal structure of an original base substrate casting. Polycrystalline substrate base structures can be re-cast with a substrate extension that replicates base substrate crystals that are most parallel to the uniaxial casting direction.

Owner:SIEMENS ENERGY INC

Double-wire efficient perpendicular water-cooling electrogas welding gun

InactiveCN102773597AImprove mechanical propertiesThe overall thickness is thinElectrode supporting devicesElectrode accessoriesEngineeringMechanical property

The invention relates to a double-wire efficient perpendicular water-cooling electrogas welding gun which is good in radiating effect in a welding process and is high in quality of weld joints. The double-wire efficient perpendicular water-cooling electrogas welding gun comprises a first welding gun and a second welding gun which are integrated, and a cooling circuit is arranged on the double-wire efficient perpendicular water-cooling electrogas welding gun. The double-wire efficient perpendicular water-cooling electrogas welding gun is provided with the cooling circuit, and the cooling circuit, an external water-cooling slider and a water tank can form a welding circulating water cooling system, so that the service life of the double-wire efficient perpendicular water-cooling electrogas welding gun is longer. In addition, owing to the integral structural design, a gun body is thin and is compact in structure, welding efficiency is improved, economical benefit is greatly increased, and mechanical properties of the molded weld joint are high.

Owner:KUSN RUILING WELDING TECH

High-ductility electrogas welding self-shielded flux-cored wire

The invention discloses a high-ductility electrogas welding self-shielded flux-cored wire, which comprises a steel strip and a welding flux wrapped in the steel strip. The weight factor of the welding flux in the overall weight of the wire is 0.2-0.3, and by weight percent, the steel strip comprises 0.01-0.055% of C (carbon), 0.01-0.03% of Si (silicon), 0.10-0.30% of Mn (manganese), 0.005-0.060% of Al (aluminum), 0.007-0.015% of P (phosphorus), 0.007-0.015% of S (sulfur) and the balance Fe (ferrum). By the overall weight of the wire, the wire comprises 2.0-6.0% of fluoride, 1.0-4.0% of oxide, 0.2-1.0% of carbonate, 1.0-4.0% of Mn, 0.2-1.2% of Si, 0.4-2.0% of Ni (nickel), 0.1-1.0% of Mo (molybdenum), 0.05-0.2% of Cr (chromium), 0.05-0.2% of V (vanadium) and the balance Fe. When the wire is used for welding, weld strength is higher than 500MPa, impacting energy at the temperature of -30 DEG C is higher than 50J, and the wire is mainly applicable to occasions of heavy and rapid welding for thick plates.

Owner:KUSN GINTUNE WELDING

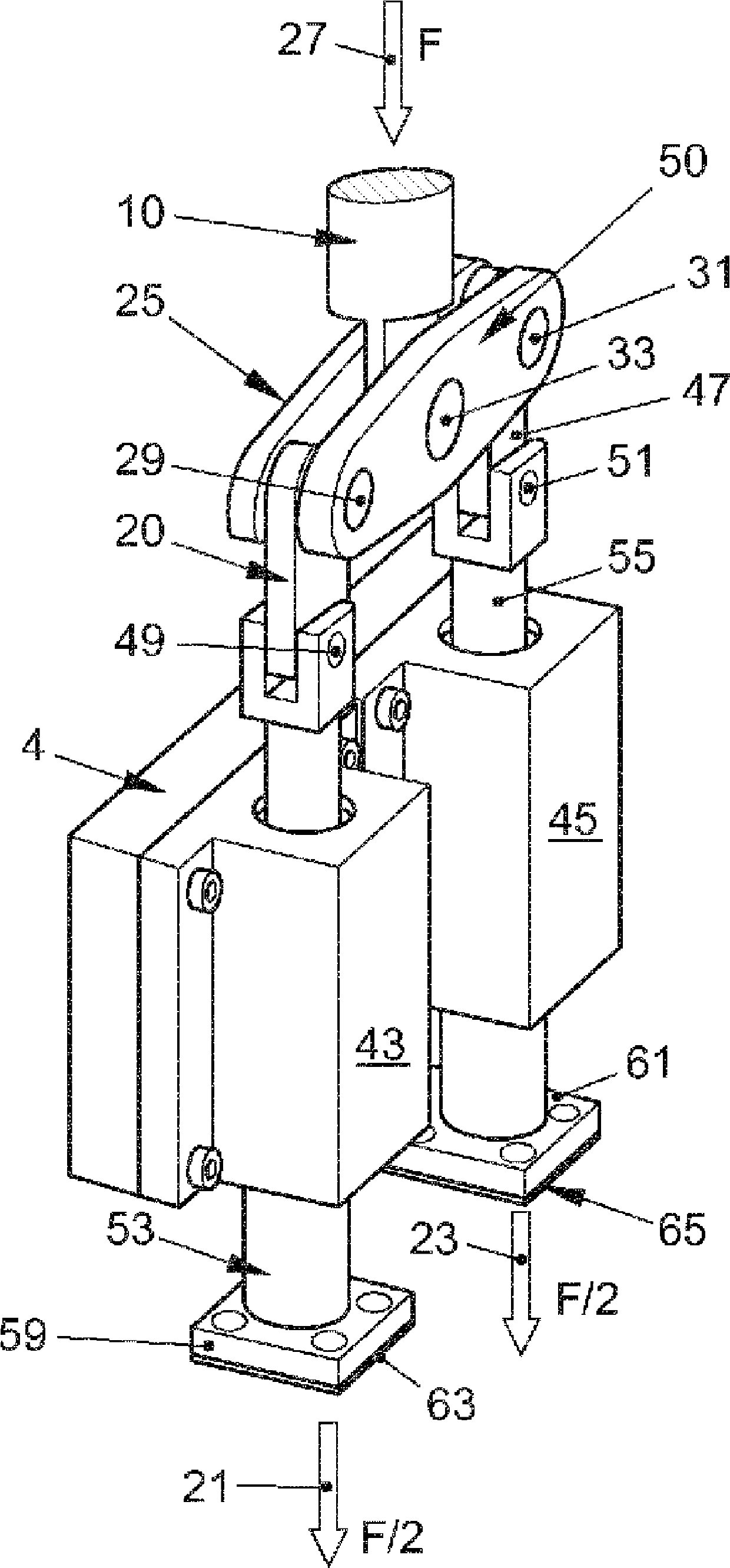

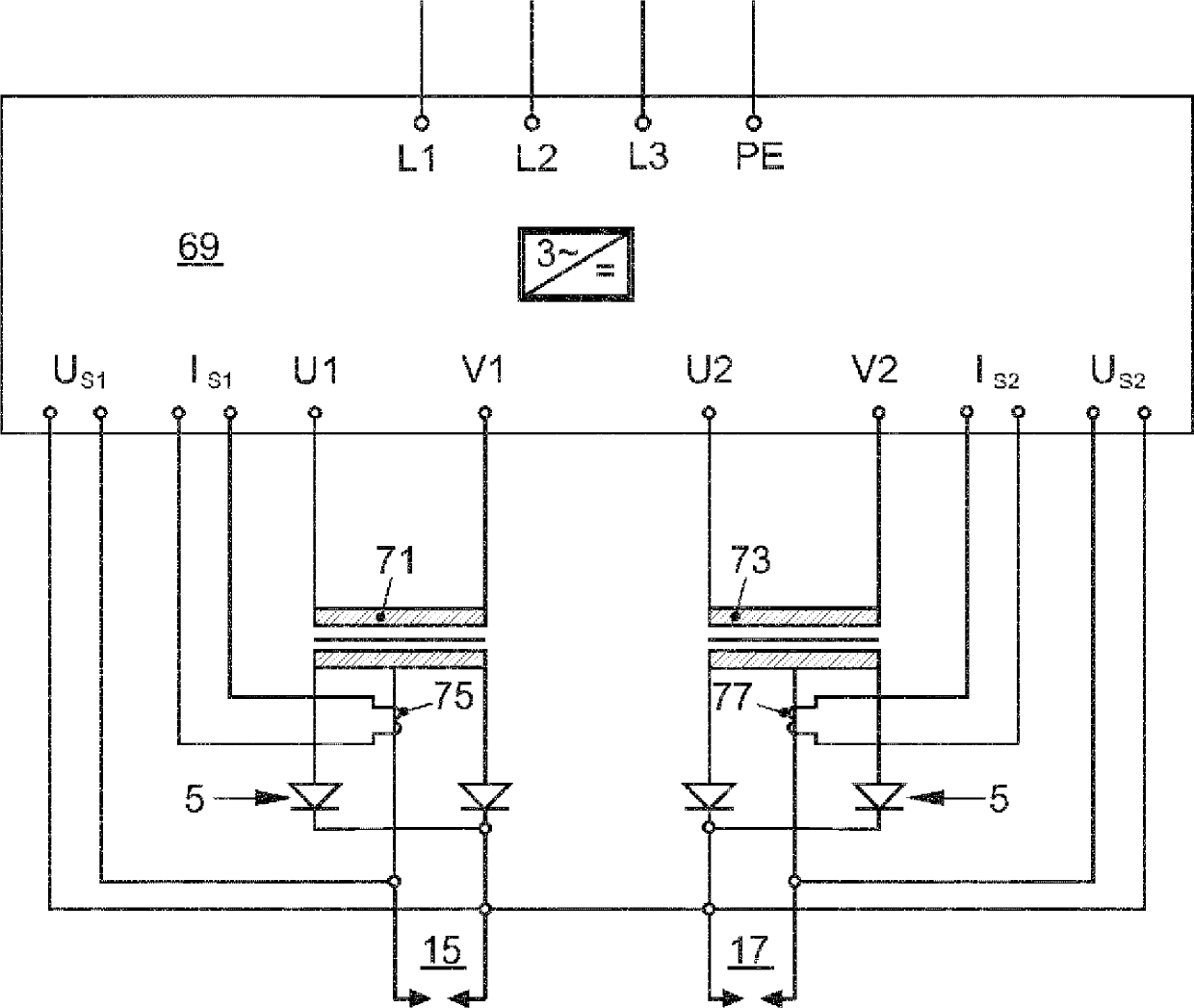

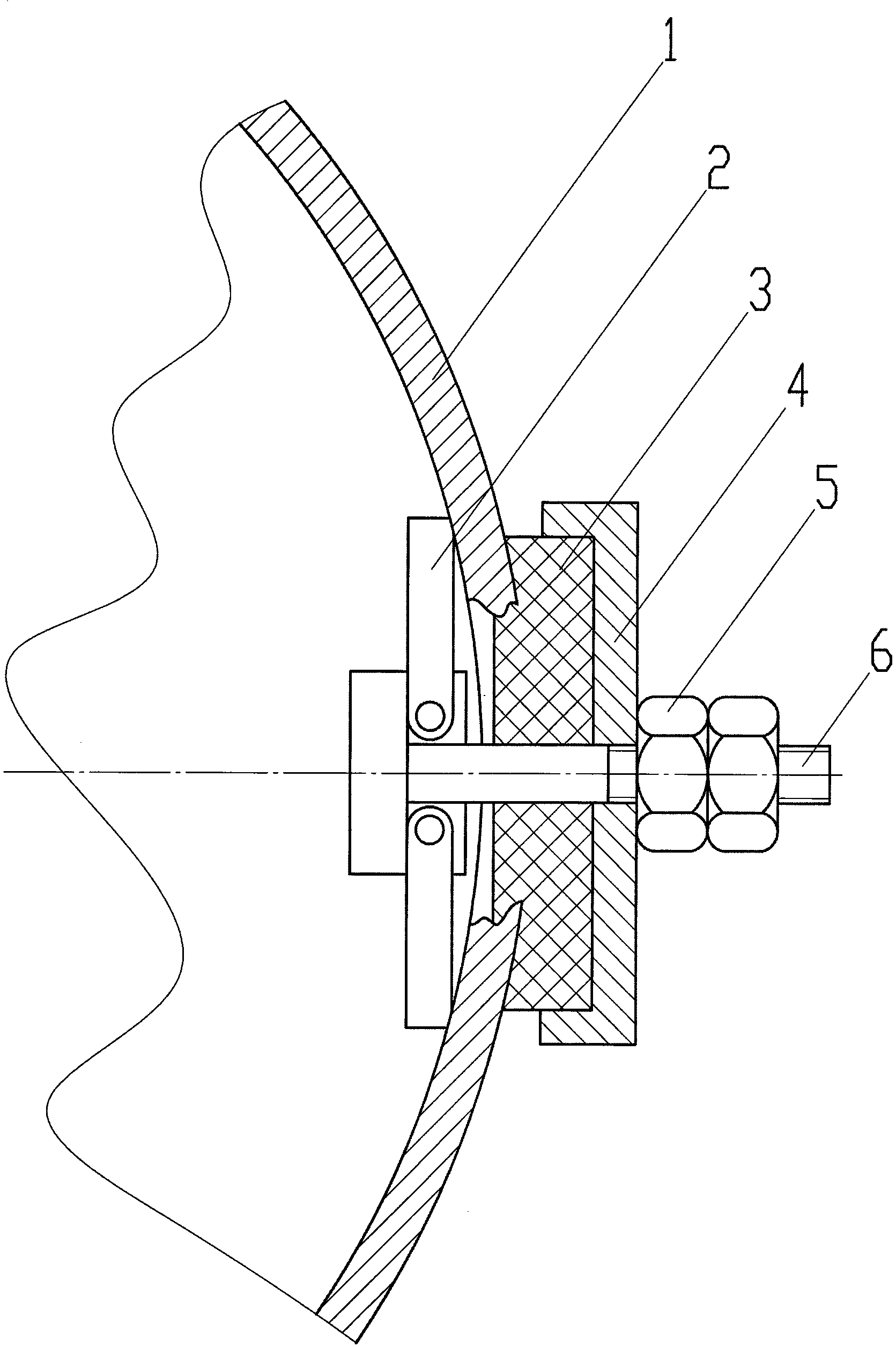

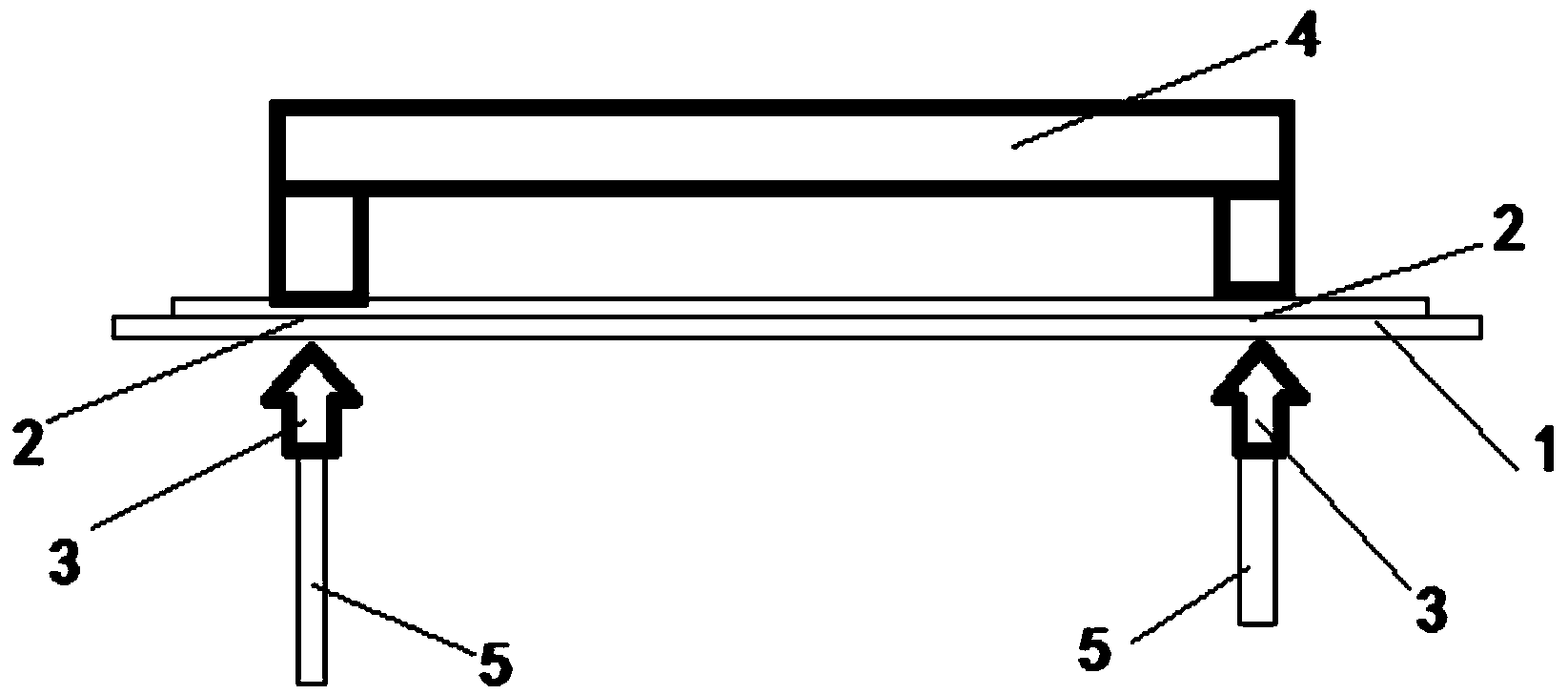

Joining components by means of resistance welding

A welding device (1) for joining components by means of resistance welding is proposed, comprising: - a pair of electrodes (15), by means of which an electrode force (21) and an electrical welding current IS1 can be introduced into the components, - at least one further pair of electrodes (17), by means of which an electrode force (23) and a further electrical welding current IS2 can be introduced into the components, - a power source (19), by means of which the electrode forces (21, 23) can be generated, - a coupling link (35), which is mechanically connected between the power source (19) and the pairs of electrodes (15, 17) and by means of which a total electrode force (27) that can be generated by the power source (19) can be divided into the electrode force (21) and the further electrode force (23).

Owner:VOLKSWAGEN AG

Method for welding thick steel plates through single-wire electrogas welding machine

InactiveCN104985283AThe overall shape is smooth and beautifulFusion transition without defectsWelding/soldering/cutting articlesMetal working apparatusFurnace temperatureHeat-affected zone

The invention discloses a method for welding thick steel plates through a single-wire electrogas welding machine. The method is characterized by including the following steps of pre-welding preparation, welding and post-welding heat treatment. The post-welding heat treatment method includes the steps of placing workpieces in a furnace with the furnace temperature not higher than 300 DEG C, heating the workpieces to the temperature of 625+ / -20 DEG C at the heating rate of 65 DEG C / h, keeping the temperature of 625+ / -20 DEG C for six hours, then cooling the workpieces to below 300 DEG C at the rate of 65 DEG C / h, discharging the workpieces out of the furnace and cooling the workpieces in still air. At the macroscopic level, arc breaking does not occur in the welding process, smooth and attractive surfaces of weld joints are formed, and follow-up fusion transition of weld metal of the weld joints and wood has not defect except for incomplete fusion at arc striking ends. Cutting and sampling analysis on weld joints of test pieces for welding shows that mechanical properties of the weld joints are higher than those of parent metal, the hardness of the part, in the heat affected zone, of the parent metal is lower than that of the weld joints and slightly higher than that of the part, outside the heat affected zone, of the parent metal; the front weld joints and the back weld joints have the same forming width.

Owner:SUZHOU HUARI JINLING MACHINERY

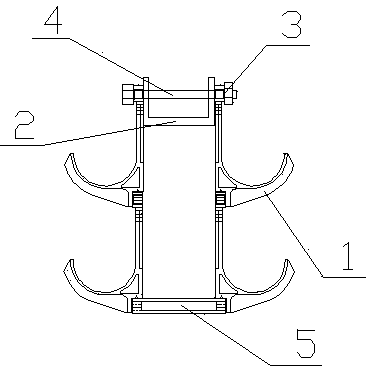

Wall-mounted leaking stoppage device

InactiveCN104176398ARapid productionImprove blockageLarge containersMechanical engineeringMaterial Perforation

Provided is a wall-mounted leaking stoppage device. Folding supporting legs are in hinged connection with heads of bolts, the folding supporting legs can rotate on the heads of the bolts to enable the folding supporting legs to be folded and unfolded, rotating angles of the folding supporting legs can be limited through the heads of the bolts, and the folding supporting legs do not rotate after being unfolded to be in a working state and are put into a perforated tank through the perforated positions of the perforated tank after being folded on the bolts. The folding supporting legs are unfolded, the boundary dimension of each unfolded folding supporting leg is larger than the perforation size of the perforated tank, the outer ends of the folding supporting legs are clamped on the inner wall of the perforated tank, the connecting ends of the folding supporting legs and the bolts are limited by the bolts and cannot move, sealing plates and supporting cover plates are installed on the bolts in a sleeved mode, the boundary dimension of each sealing plate is larger than the perforation size of the perforated tank, the supporting cover plates cover the sealing plates, nuts are screwed on the bolts and can conveniently and quickly block penetrating holes in the overhead tank, various penetrating holes different in shape and size can be blocked, electrogas welding is not needed, and construction is safe.

Owner:东营市鸿祥石油技术开发有限公司

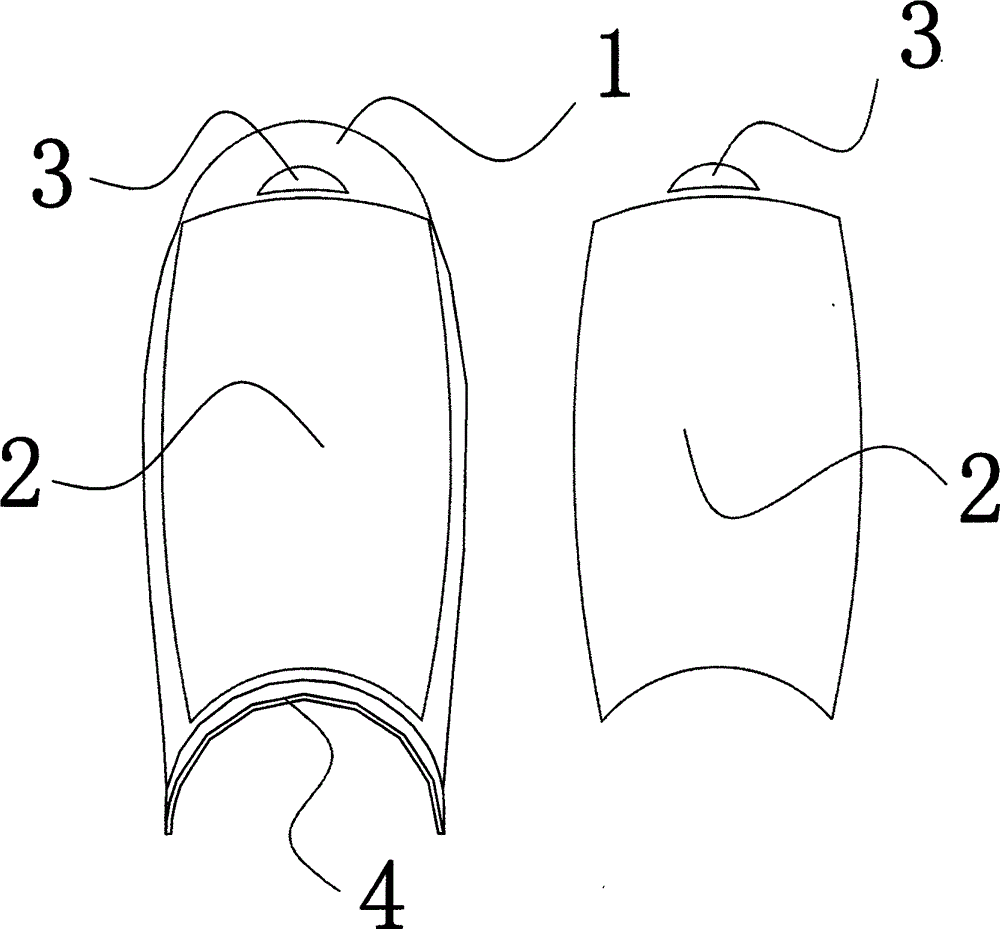

Labor protection shoe electric welding protective covers

The invention discloses such a pair of labor protection shoe electric welding protective covers that belongs to the technical field of labor protection shoes for electric welding, in order to solve the problems of existing electric welding labor protection shoes that shoelaces are easily burned out and shoe tongues are easily burned through due to electrogas welding slags and sparks generated in an electric welding process, and subsequently two feet of an electric welder get burned. The invention aims at solving the technical problem of providing the protective covers which can cover tiptoes up to calves and the entire labor protection shoes including vamps, shoelaces, shoe tongues, uppers, ankles and the like. In the electric welding process of a worker, the pair of labor protection shoe electric welding protective covers can effectively protect the labor protection shoes; and moreover, the pair of labor protection shoe electric welding protective covers can effectively protect two feet of the electric welding operator from getting burned.

Owner:张云轩

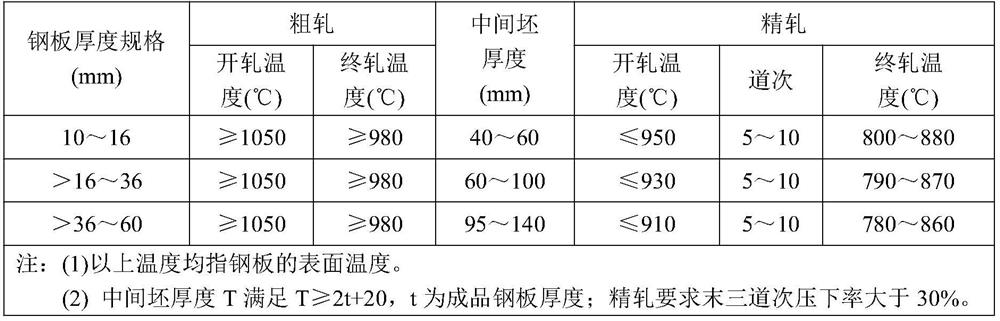

800MPa-grade high heat input welding resistant pressure vessel steel and preparation method thereof

ActiveCN113637911AImprove low temperature toughnessGood resistance to large heat input welding performanceTemperature control deviceHeat treatment process controlElectroslag weldingPetrochemical

The invention relates to 800MPa-grade high heat input welding resistant pressure vessel steel and a preparation method thereof. The steel comprises the following elements in percentage by mass: 0.05%-0.10% of C, less than or equal to 0.10% of Si, 1.50%-2.00% of Mn, less than or equal to 0.008% of P, less than or equal to 0.002% of S, 0.10%-0.50% of Cu, 0.10%-0.60% of Mo, 1.00%-2.00% of Ni, 0.010%-0.050% of Nb, 0.015%-0.030% of Ti, 0.001%-0.002% of B, 0.010%-0.030% of Ce, 0.015%-0.045% of Als, 0.0050%-0.0080% of N, 0.002%-0.006% of Ca and the balance Fe and inevitable impurities, in addition, Ti / N is more than or equal to 3 and less than or equal to 4, Ca / S is more than or equal to 2, fB is more than or equal to 1.4 and less than or equal to 1.6, fB=1+1.5(0.9-Ceq), Pcm is less than or equal to 0.25,Ceq is less than or equal to 0.57, and Psr is less than or equal to 0. The steel is high in strength and toughness, is suitable for submerged arc welding, gas shielded welding, electrogas welding, electroslag welding and other welding with different linear energy inputs, and can be used for manufacturing various large petrochemical engineering pressure-bearing equipment.

Owner:WUHAN IRON & STEEL GRP ECHENG IRON & STEEL CO LTD

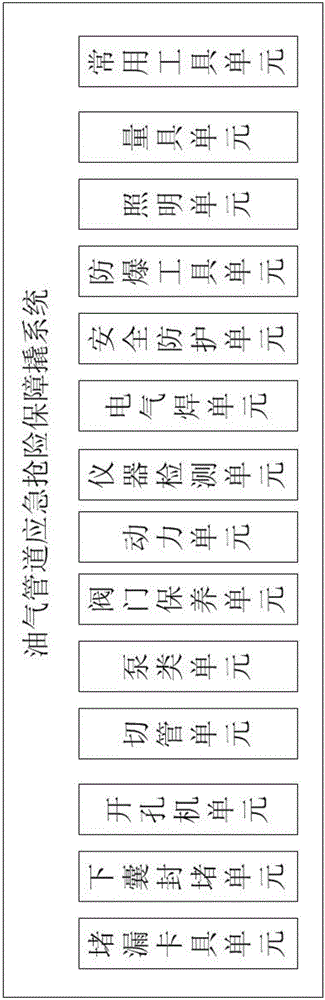

Emergency rush repair guarantee pry system for oil and gas pipeline

InactiveCN105003789AEasy to useTimely and effective emergency repairPipe elementsPower unitElectrogas welding

The invention provides an emergency rush repair guarantee pry system for an oil and gas pipeline. The emergency rush repair guarantee pry system comprises a leakage stopping fixture unit, a lower bag blocking unit, a tapping machine unit, a pipe cutting unit, a pump unit, a valve maintaining unit, a power unit, an instrument detecting unit, an electrogas welding unit, a safety protection unit, an anti-explosion tool unit, an illumination unit, a measuring tool unit and a common tool unit. The emergency rush repair guarantee pry system for the oil and gas pipeline is convenient to use, and rush repair staff can quickly find corresponding tools and effectively complete rush repairing in time at oil and gas pipeline leakage sites no matter what condition happens.

Owner:TIANJIN ZHUODA PIPELINE MACHINERY MFG

Double-wire electrogas welding machine

InactiveCN104985284AImprove fusion qualityAvoid poor fusionElectrode holder supportersWelding/soldering/cutting articlesElectricityThick plate

The invention discloses a double-wire electrogas welding machine. The double-wire electrogas welding machine comprises two welding power supplies, two wire feeders, a double-wire water-cooled welding gun, a welding tractor, a water cooling system, a carbon dioxide supply system and a welding operation box which is electrically connected with the other components. One welding power supply is connected with one wire feeder. The wire feeders, the water cooling system and the carbon dioxide supply system are connected with the double-wire water-cooled welding gun. The double-wire water-cooled welding gun is arranged on the welding tractor. By the adoption of two welding systems composed of the two welding power supplies and by the adoption of the double wire feeders, the double-wire electrogas welding machine is especially suitable for welding thick steel plates and can achieve thermal input needed for weld joint fusion when the thick plates are welded. In addition, the filling quantity of welding wires for vertical welding of the thick plates is much larger than that of welding wires for vertical welding of thin plates, a single wire feeder cannot meet the requirement for welding wire filling, but the filling speed and total quantity of welding wires can be increased manyfold by the adoption of double wire feeding, and thus welding efficiency can be increased manyfold.

Owner:SUZHOU HUARI JINLING MACHINERY

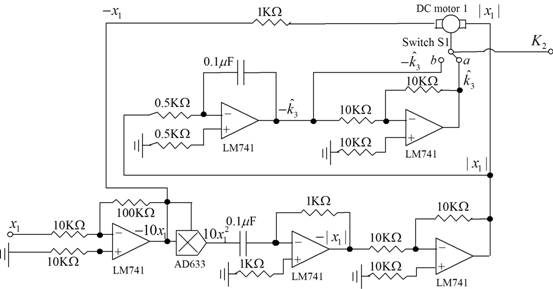

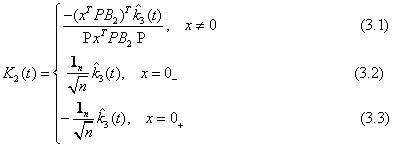

Self-adaptation anti-interference control system for electrogas welding automatic welder

InactiveCN102248256AGuaranteed uptimeGuaranteed welding effectWelding electric supplyArc welding apparatusCapacitanceElectrical resistance and conductance

The invention discloses a self-adaptation anti-interference control system for an electrogas welding automatic welder. The self-adaptation anti-interference control system is characterized in that: in a control box of the electrogas welding automatic welder, according to a current signal x1 of the system, a self-adaptation anti-interference circuit is designed as follows: LM741 is an operational amplifier, AD633 is an multiplying unit with an output factor of 0.1, resistance values are respectively 0.5 kilohm, 1 kilohm, 10 kilohms and 100 kilohms, and the capacitance value is 0.1muF; and a motor adopts a Z2 series direct current motor. The self-adaptation anti-interference control system is easy to realize in the control box of the electrogas welding automatic welder, can be used for automatically adjusting control parameters under the conditions of unknown interference and even signal fluctuation due to faults of certain elements and has a better economic value and social significance; and the welding precision is improved and the welding effect is ensured.

Owner:SHENYANG UNIV

Electrogas welding arc length controller based on FPGA (Field Programmable Gate Array)

Owner:JIANGSU UNIV OF SCI & TECH

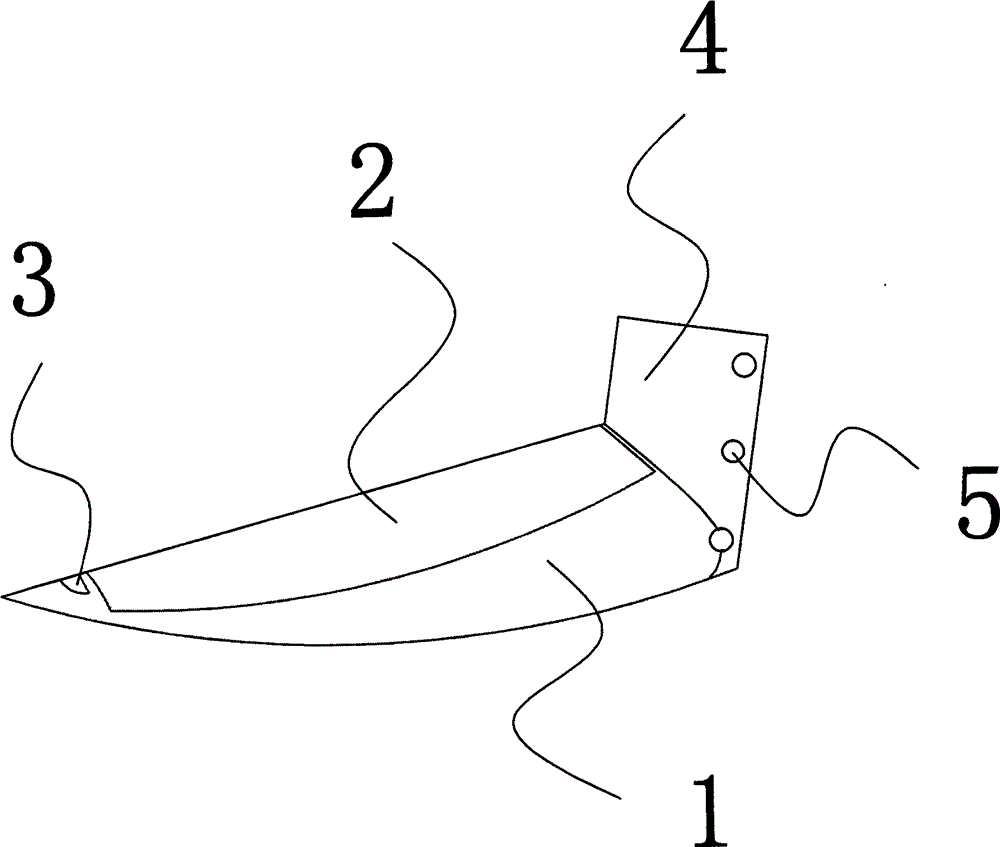

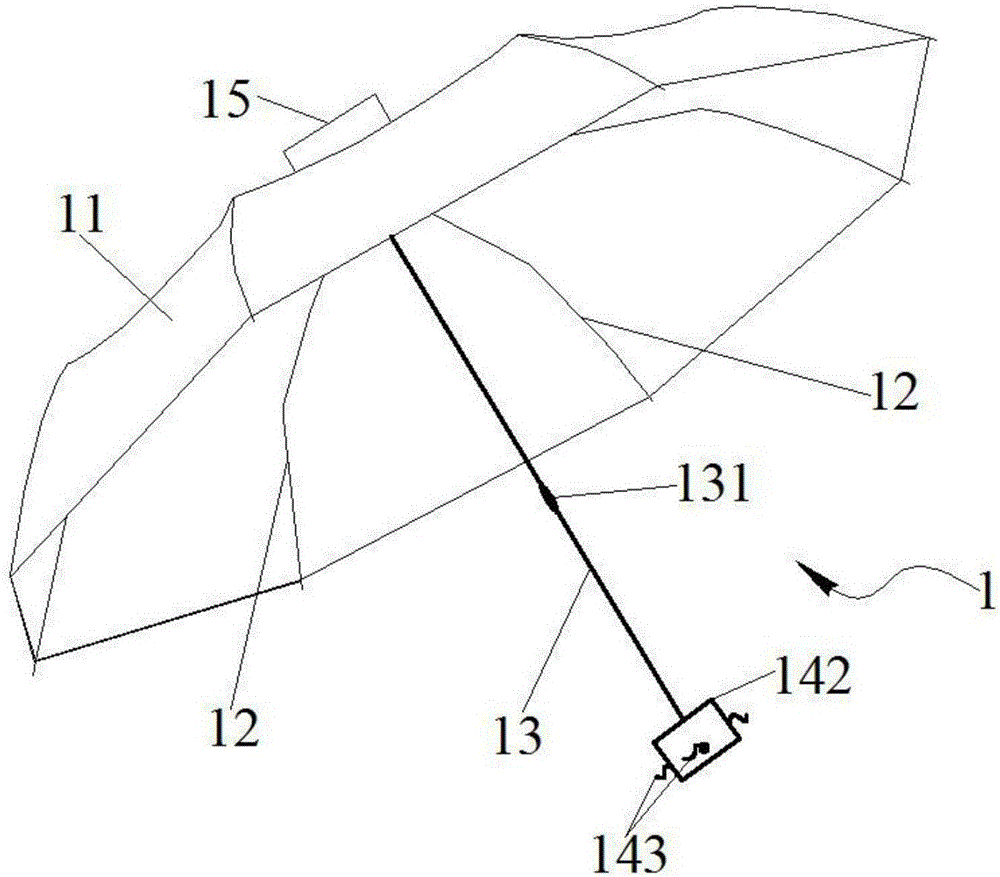

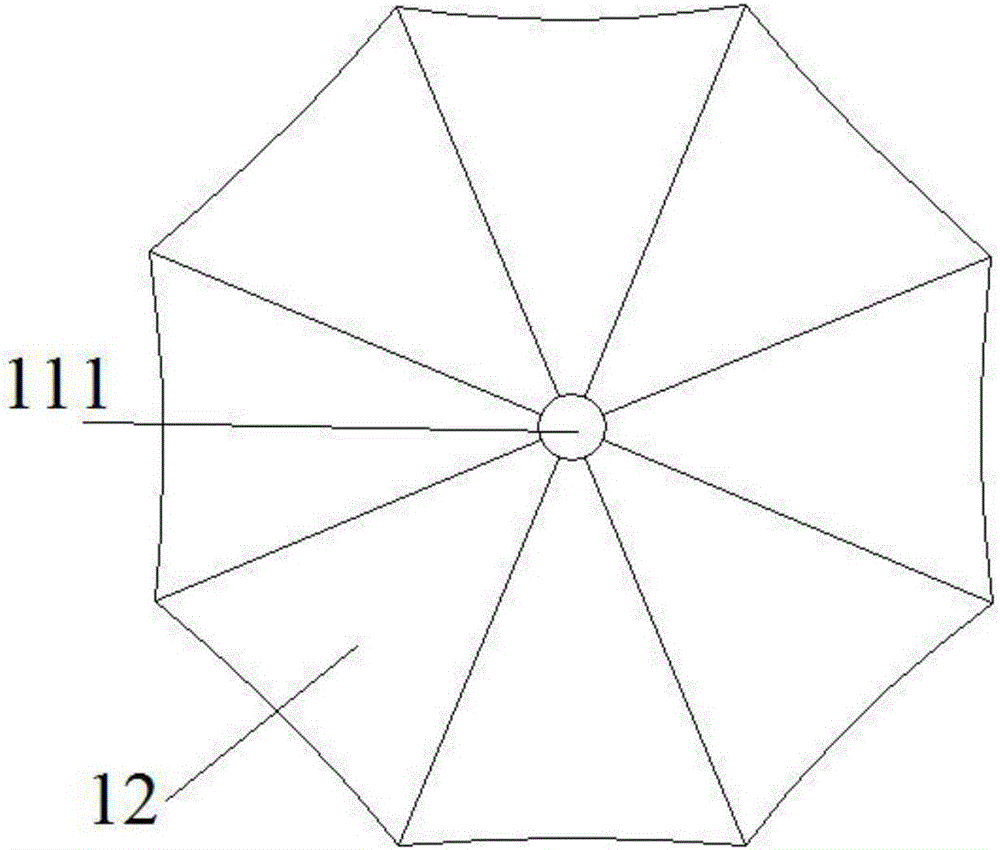

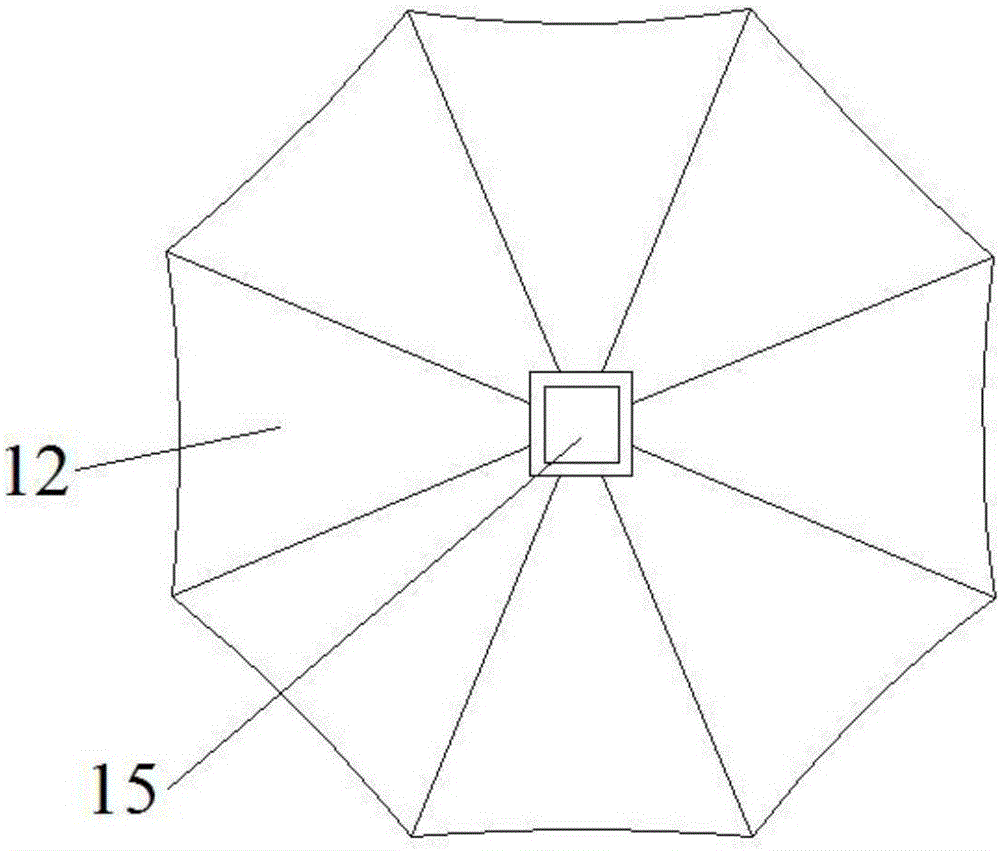

Portable fire-receiving hopper

ActiveCN106174931AEasy to carryEasy to install hookWalking sticksUmbrellasEngineeringElectrogas welding

The invention relates to the technical field of corollary equipment in design engineering construction, in particular to a portable fire-receiving hopper. The hopper comprises a folding umbrella body. The folding umbrella body is of a double-layer covering structure and composed of an umbrella surface, an umbrella framework and a support rod used for supporting the umbrella framework and the umbrella surface covers the inner surface and the outer surface of the umbrella framework. The folding part of the umbrella framework is coated with fire-proof material. The portable fire-receiving hopper has following beneficial effects: the portable fire-receiving hopper is convenient to carry and to install and hung, low in weight and broad in application; and the hopper can be extensively used in electrogas welding.

Owner:郝飞

Electroslag and electrogas repair of superalloy components

ActiveUS9186724B2Raise the possibilityDamaged component scrap rates can be reducedTurbinesBlade accessoriesFilling materialsCrystal structure

Superalloy component castings, such as turbine blades and vanes, are fabricated or repaired by an electroslag or electrogas welding process that at least partially replicates the crystal structure of the original cast substrate in a cast-in-place substrate extension. The process re-melts the base substrate surface and grows it with new molten filler material. As the base substrate and the filler material solidify, the newly formed “re-cast” component has a directionally solidified uniaxial substrate extension portion that at least in part replicates the crystalline structure of the base substrate. The “re-cast” component can be fabricated with a unified single crystal structure, including the extension portion. In other applications, a substrate extension can replicate a directionally solidified uniaxial crystal structure of an original base substrate casting. Polycrystalline substrate base structures can be re-cast with a substrate extension that replicates base substrate crystals that are most parallel to the uniaxial casting direction.

Owner:SIEMENS ENERGY INC

Trunk lid welding structure and method

ActiveCN103817476APrecise positioningPrecise contact fitResistance electrode holdersWelding/cutting auxillary devicesElectrical connectionEngineering

Disclosed is a trunk lid welding structure. According to the trunk lid welding structure, a welding tongs part, a clamping part and a copper bar part are installed on a clamp body, the clamping part is electrically connected with the welding tongs part through a clamped portion of a plate to be welded, a welding point is formed on the clamped portion through electrical connection to achieve welding connection of the plate to be welded, the clamping part also serves as a contact for electrical welding, and accurate positioning and accurate contact matching are guaranteed during welding.

Owner:ANHUI JIANGHUAI AUTOMOBILE GRP CORP LTD

Double-layer cable erecting method

InactiveCN103791162AShorten the lengthImprove securityPipe supportsMining devicesEngineeringElectrogas welding

The invention relates to mine underground powder distribution equipment erecting methods, particularly to a double-layer cable erecting method. The method comprises fixing a pylon and two rows of cable hooks on the pylon, wherein every row of cable hooks is composed of more than one single cable hook, the hook heads of the two rows of cable hooks face outwards and are connected on both sides of the pylon, a support unit is arranged between the lower ends of the two rows of cable hooks, and the length of the support unit is identical to the width of the pylon. The double-layer cable erecting method shortens the length of a single row of cable hooks, omits electrogas welding fixation and improves the underground construction safety of high-gas mines.

Owner:神华神东保德煤矿

Flux-cored wire for electrogas welding and electrogas welding metal

ActiveCN100525990CHigh elongationGood shock valueWelding/cutting media/materialsSoldering mediaElectrogas weldingWeld metal

The invention relates to a flux-cored wire for electrogas welding, in the total quality of wire, including 0.03 to 0.07 quality % of C, 0.3 to 0.8 quality % of Si, 1.5 to 2.2 quality % of Mn, 0.4 to 1.5 quality % of Ni, 0.05 to 0.60 quality % of Cr and Mo, 0.02 to 0.20 quality % of Ti, 0.005 to 0.020 quality % of B, and 0.20 to 0.50 quality % of Mg, wherein, the Al is equal to or less than 0.10%, with 1.0 to 2.0% of slagging agent. The slagging agent, in the total quality of the wire, includes 0.30 to 0.70 quality % of F and 0.02 to 0.20 quality % of K, wherein, the [A]=(Cr+Mo) / Ni is equal to 0.10 to1.0 and [B]=C / (Ti+20*B) is equal to 0.12 to 0.58. With the components, the invention can increase the intensity, extension rate and the flexibility of the welded metal, with more excellent welding operation.

Owner:KOBE STEEL LTD

Ground treatment method when there is residual old pile foundation during building construction

ActiveCN105484227BAvoid uneven settlementReduce construction difficultySoil preservationArchitectural engineeringCrushed stone

The invention relates to a foundation treatment method adopted when an old residual pile foundation exists during building construction. The method comprises the steps that 1, a newly-built foundation bottom face is adopted as a base, and overexcavation is carried out towards the lower portion and the two sides; 2, the old pile foundation exposed after overexcavation is chiseled away through a concrete chiseling machine, and exposed steel bars in an old pile are cut away through electrical welding; 3, after the ground obtained after overexcavation is leveled, gravel refilling is carried out, graded gravel with the maximum particle size of 50 mm is adopted for refilling, refilling gravel layers are ground by a vibrating roller layer by layer, the thickness of each layer is 200-300 mm, and the degree of compaction of the refilling gravel layers is not smaller than 0.97; 4, foundation pad layers are laid on the refilling gravel layers, and the strength grade of concrete is not lower than C10; and 5, newly-built foundation construction is carried out above the foundation pad layers. Under the condition of meeting foundation bearing capacity, the functions of adjusting the foundation bearing state and preventing differential settlement through an artificial mattress formed by the refilling gravel layers are achieved; and by means of the structure, construction difficulty can be greatly lowered, the construction progress can be accelerated, and a large amount of project investment can be saved.

Owner:鞍钢集团工程技术有限公司

A workbench for electrical spot welding capable of rapid cooling and preventing components from falling

The invention discloses a workbench for electrical spot welding capable of rapid cooling and preventing components from falling, comprising a workbench body, nylon blocking cloth, an air duct, a waterproof sealed bearing and a horizontal shaft, the inside of the side of the workbench body The installation shaft is fixed, the air duct is fixed on the top of the workbench body, and the side of the workbench body is provided with cooling holes, the horizontal shaft is connected to the inner side of the waterproof sealed bearing, and the horizontal shaft is located in the inner part of the circulating water pipe. A water flow fan is fixed at the middle position, and a cooling fan is fixed at the part where the horizontal axis is located outside the circulating water pipe. The workbench for electric spot welding, which can cool quickly and prevent components from falling, adopts a new structural design, so that the device can quickly dissipate the heat generated during the electric welding process, ensuring that the workbench and the workbench being welded on the workbench The temperature of the device will not be too high, which plays a certain protective role. At the same time, a structure to prevent the device from falling is designed to effectively protect the device.

Owner:东莞市威立特焊接设备有限公司

Flux-cored wire for electrogas welding

ActiveCN102528317BHigh purity of weld seamArc stabilizationArc welding apparatusWelding/cutting media/materialsWeight coefficientManganese

The invention discloses a flux-cored wire for electrogas welding, which comprises a steel strip and welding flux wrapped in the steel strip. The weight coefficient of the welding flux in the overall weight of the wire ranges from 0.2 to 0.3. By weight percentage, the steel strip comprises 0.010-0.055% of C (carbon), 0.01-0.03% of Si (silicon), 0.10-0.30% of Mn (manganese), 0.005-0.060% of Al (aluminum), 0.007-0.012% of P (phosphorus), 0.007-0.012% of S (sulfur) and the balance Fe (ferrum). By the overall weight of the wire, the welding flux comprises 0.2-2.0% of fluoride, 0.2-1.0% of oxide, 1.0-3.0% of Mn, 0.2-1.0% of Si, 0.4-1.2% of Ni (nickel), 0.1-1.0% of Mg (magnesium), 0.002-0.16% of Ti (titanium), 0.002-0.010% of B (boron) and the balance Fe. The flux-cored wire matched with electrogas welding is used for welding, so that welding efficiency is greatly improved, and excellent and stable mechanical performance is also obtained.

Owner:KUSN GINTUNE WELDING

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com