Thick plate vertical butt joint welding method

A welding method and butt welding technology, applied in welding equipment, arc welding equipment, manufacturing tools, etc., can solve problems such as high operational difficulty, poor welding quality stability, and reduced welding efficiency, so as to reduce operational difficulty and heat input , Improve the effect of welding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

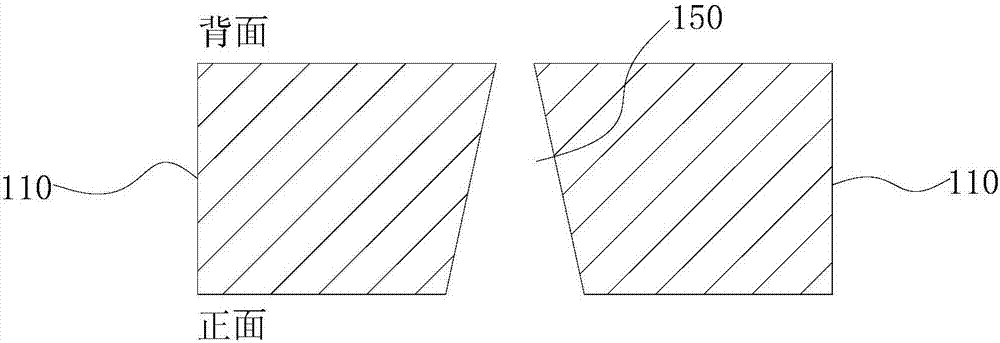

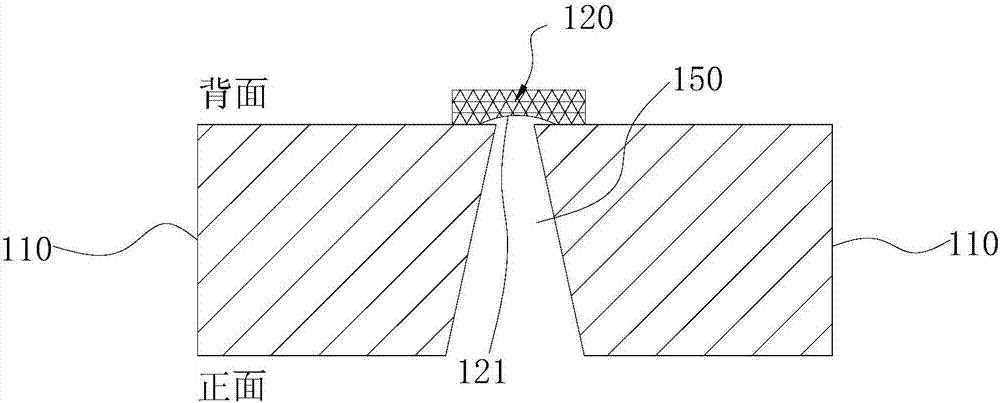

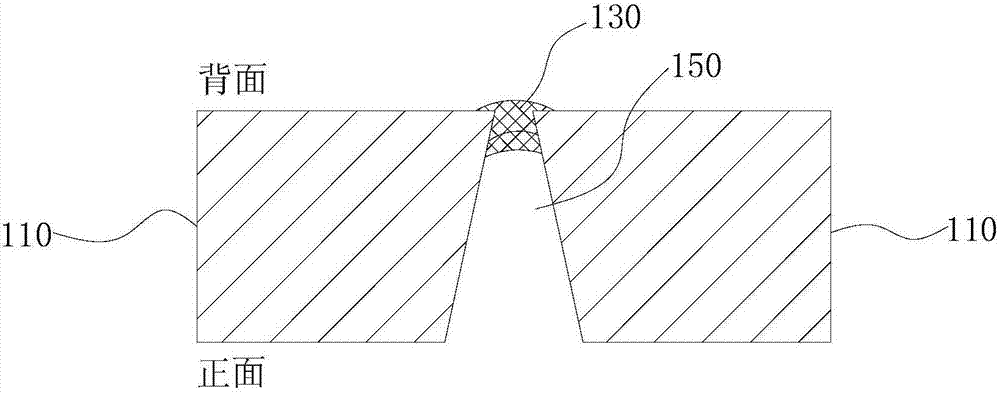

[0051] like Figures 1 to 4 As shown, in this embodiment, a vertical butt welding method for thick plates is provided. Specifically, a butt weldment 110 is provided, a groove for welding is provided on the butt weldment 110, and CO2 gas shielded welding is used to weld in the groove to form The weld primer layer 130 is welded on the weld primer layer 130 by vertical gas electric welding to complete the remaining groove filling to form the weld seam cover layer 140 . Using CO2 gas shielded welding to weld the groove first can form a weld base layer 130 that is difficult to weld through in the groove and at the bottom of the groove, thereby ensuring the welding quality of the subsequent vertical gas-electric welding. The combination of the two welding methods is thicker Welding the butt weldment 110 can not only reduce the operation difficulty, improve the welding quality, but also effectively reduce the heat input of welding.

[0052] The specific operation steps are as follow...

Embodiment 2

[0063] like Figures 5 to 8 As shown, in this embodiment, a vertical butt welding method for thick plates is provided. Specifically, a butt weldment 210 is provided, a groove for welding is provided on the butt weldment 210, and CO2 gas shielded welding is used to weld in the groove to form The weld primer 230 is welded on the weld primer by vertical gas electric welding to complete the remaining groove filling, so as to form the weld cover 240 . CO2 gas shielded welding is used to weld the groove first, which can form a weld base layer 230 that is difficult to weld through in the groove and at the bottom of the groove, thereby ensuring the welding quality of the subsequent vertical gas-electric welding. The combination of the two welding methods is thicker Welding the butt weldment 210 can not only reduce the operation difficulty, improve the welding quality, but also effectively reduce the heat input of welding.

[0064] The specific operation steps are as follows:

[0065...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com