Tungsten electrode-consuming electrode indirect electric arc welding device and its welding method

A welding method and melting electrode welding technology, applied in arc welding equipment, welding equipment, manufacturing tools, etc., can solve the problems of high dilution rate, large heat input of workpiece base material, low weld deposition rate, etc., and achieve improved Effects of melting speed, reducing weld dilution rate, and increasing deposition rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

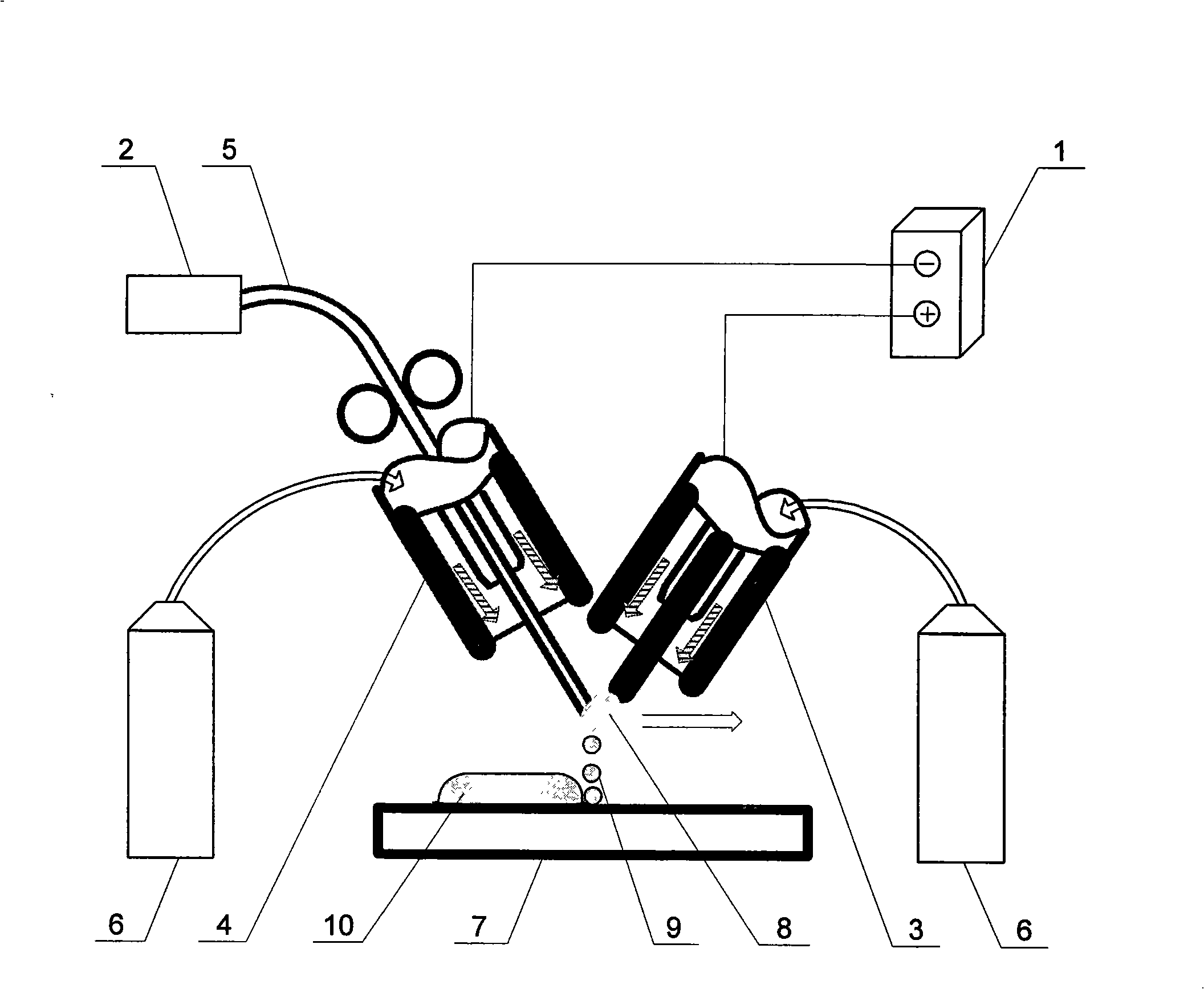

[0019] Specific implementation mode one: the following combination figure 1 Describe this embodiment, this embodiment is made up of GTAW power supply 1, wire feeder 2, tungsten electrode welding torch 3, melting pole welding torch 4, welding wire 5 and shielding gas cylinder 6, and wire feeder 2 is connected with one end of welding wire 5, and welding wire 5 The other end of the tungsten electrode welding torch 3 and the melting electrode welding torch 4 are connected to the positive and negative terminals of the GTAW power supply 1 respectively. The intersection of the axes of the tungsten electrode welding torch 3 and the melting electrode welding torch 4 is located above the workpiece to be welded, and the gas output ends of the two shielding gas cylinders 6 communicate with the shielding gas inlets of the tungsten electrode welding torch 3 and the melting electrode welding torch 4 respectively.

specific Embodiment approach 2

[0020] Specific embodiment two: this embodiment is a welding method implemented based on the device of embodiment one, and the welding steps are as follows:

[0021] Step 1: Process the part to be welded of the workpiece 7 into grooves, curls or no processing as required;

[0022] Step 2: Fix the workpiece 7 on the fixture to be welded;

[0023] Step 3: Keep the included angle between the tungsten welding torch 3 and the melting electrode torch 4 between 30°-90°; the distance between the tip end of the tungsten electrode of the tungsten welding torch 3 and the end of the welding wire 5 is between 2mm-5mm ; The distance between the intersection of the axes of the two welding torches and the surface of the workpiece 7 is 5mm-16mm;

[0024] Step 4: Set the process parameters, the welding current is between 20A-180A; the wire feeding speed is between 2.0m / min-12m / min; the gas flow rate of the tungsten welding torch 3 is between 10L / min-20L / min; The gas flow rate of the melting e...

specific Embodiment approach 3

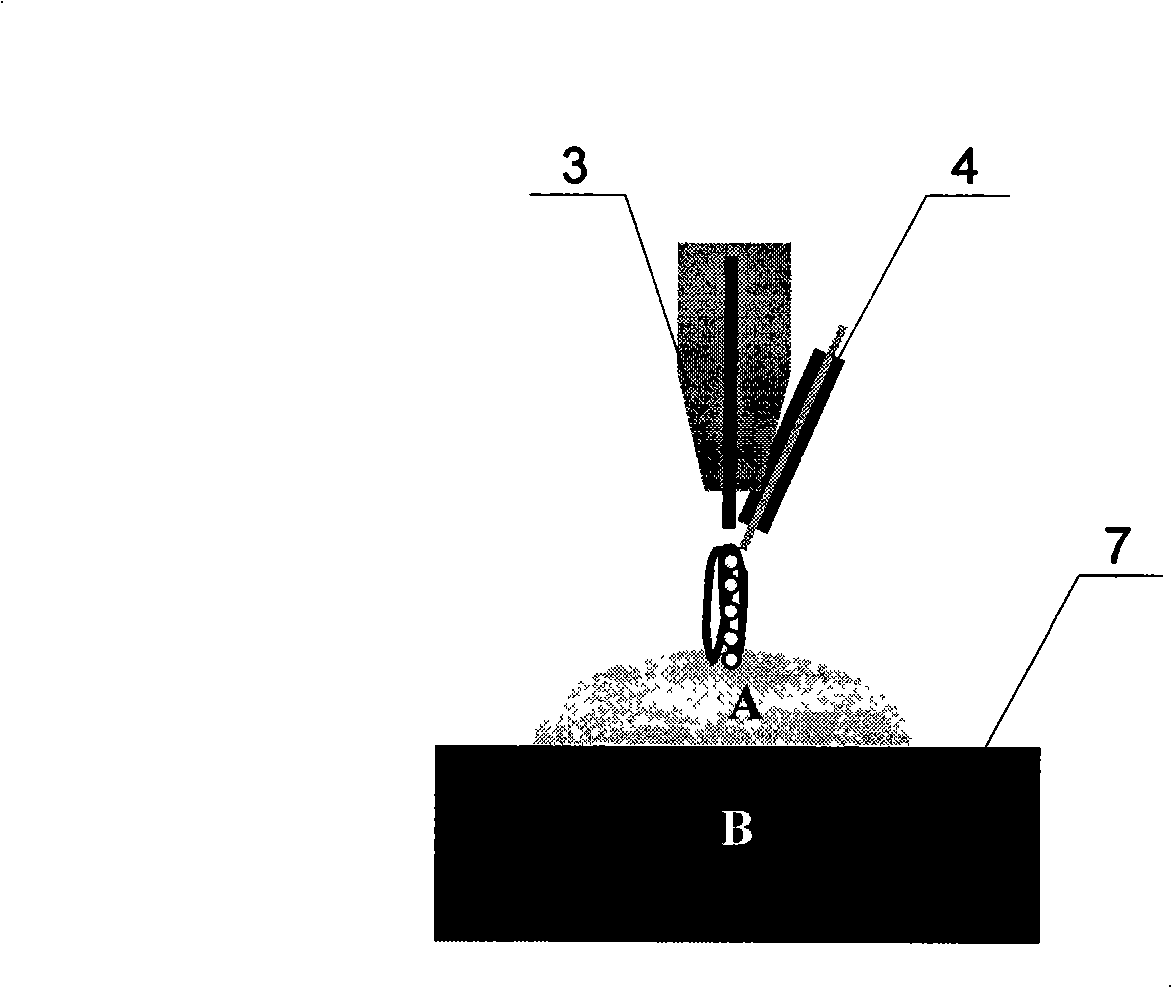

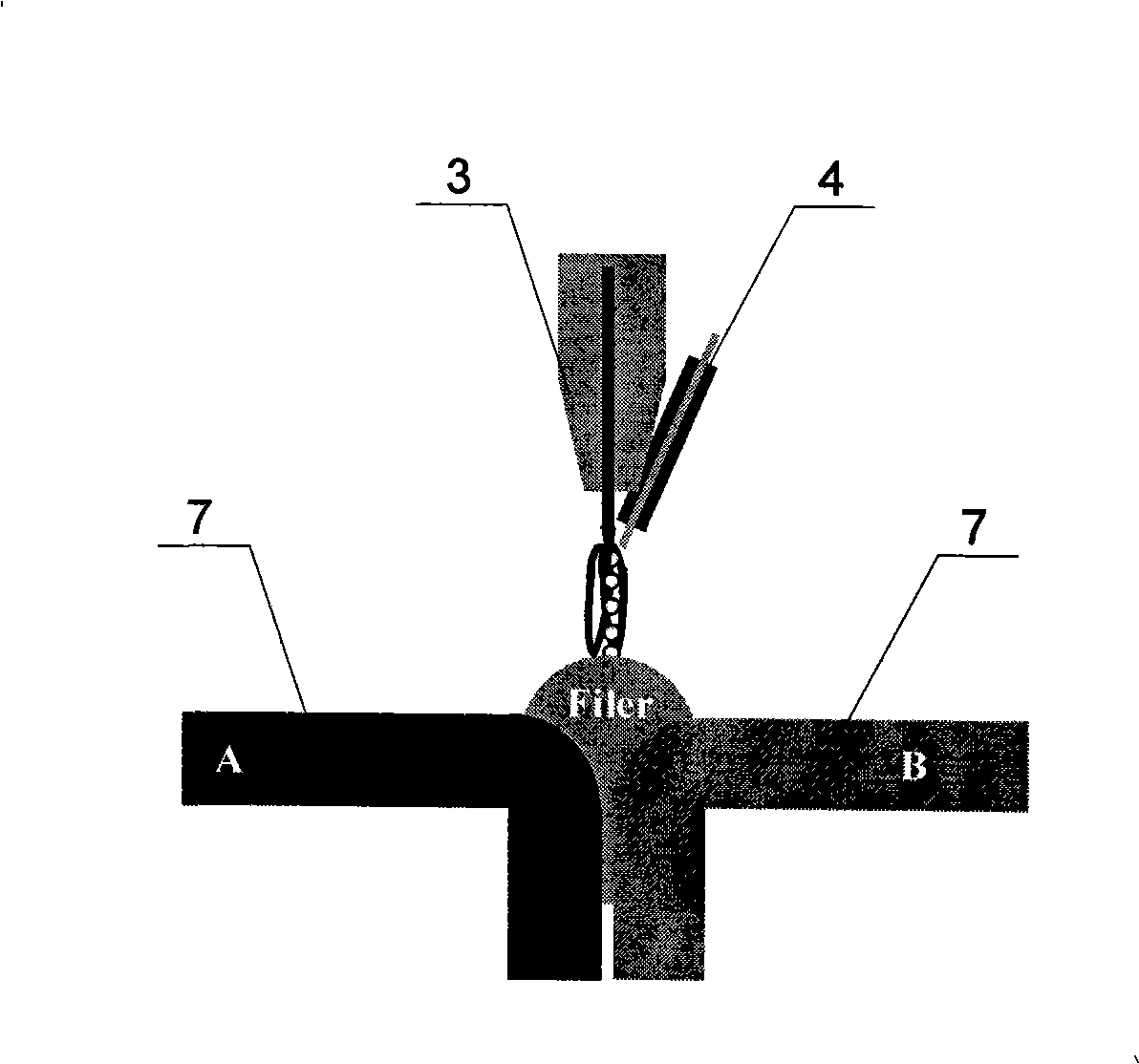

[0026] Specific embodiment three: provide a specific embodiment, weld with the method of the present invention, as figure 2 shown. The process is as follows: the workpiece 7 used is 30CrMnSi structural steel with a thickness of 3 mm, the composition of the welding wire 5 is CuSi3Mn, and the diameter of the welding wire 5 is 1.0 mm. Use a stainless steel brush to polish the surface of the part to be welded of the workpiece 7 to remove rust. A special fixture is used to position the workpiece 7 . Use acetone to clean the workpiece 7, remove oil stains and impurities, and wait for welding after drying. Connect the tungsten electrode welding torch 3 and the melting electrode welding torch 4 to the positive and negative poles of the GTAW power supply 1 respectively, keep the angle between the two welding torches at 45°, the distance between the tip of the tungsten electrode welding torch 3 and the welding wire 5 is 4mm, and the intersection point of the axes of the two welding t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com