Patents

Literature

660results about How to "No misalignment" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

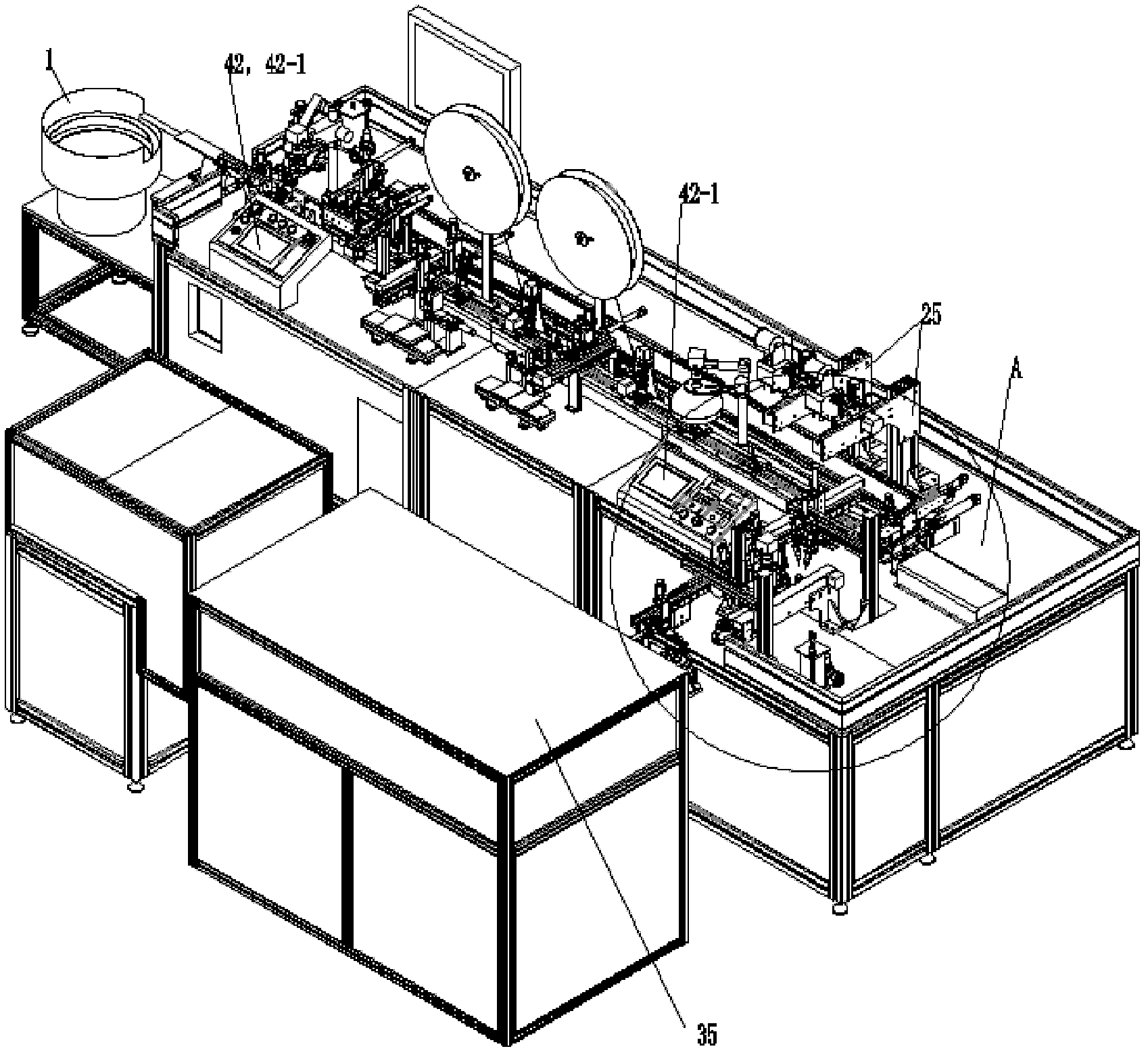

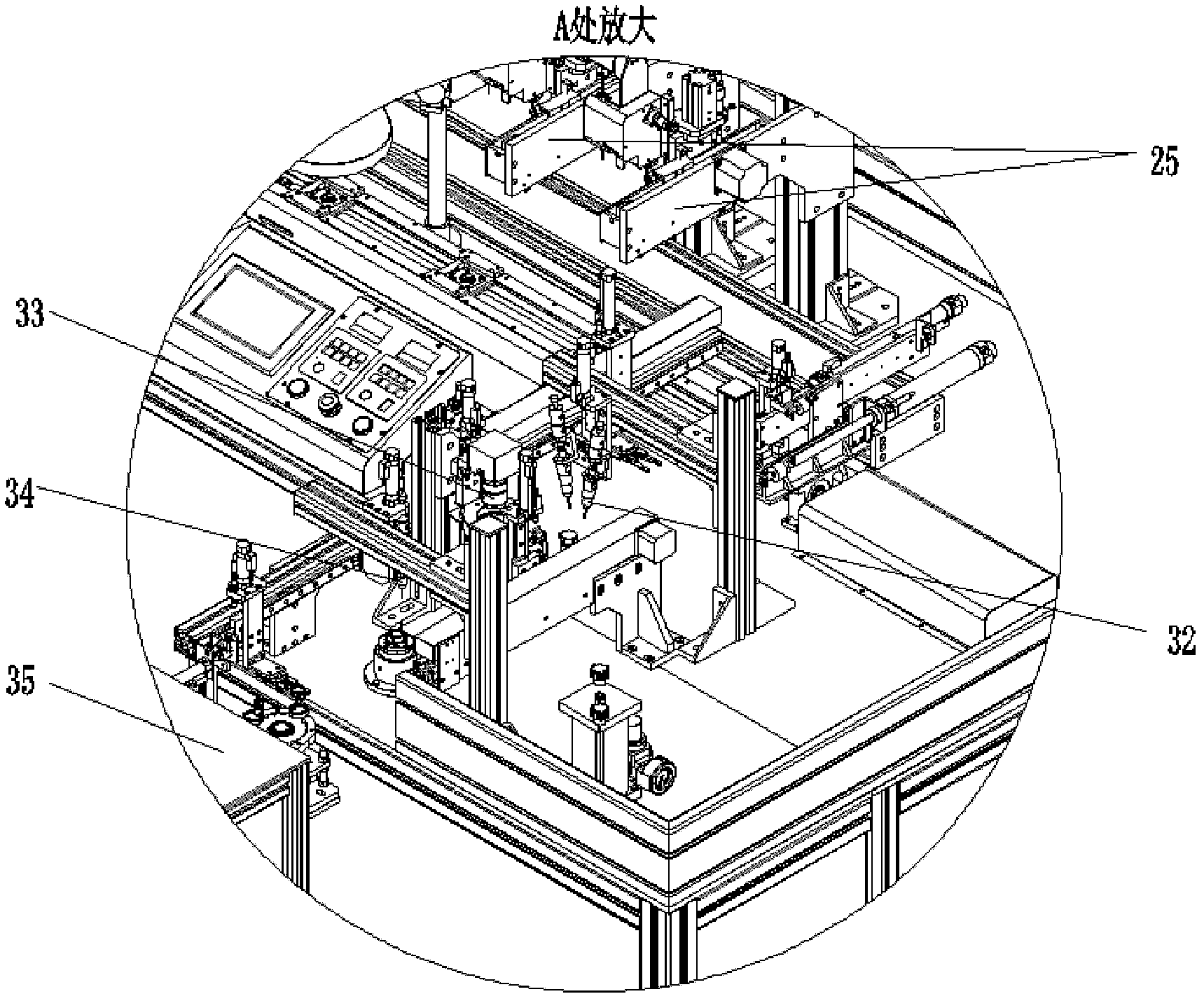

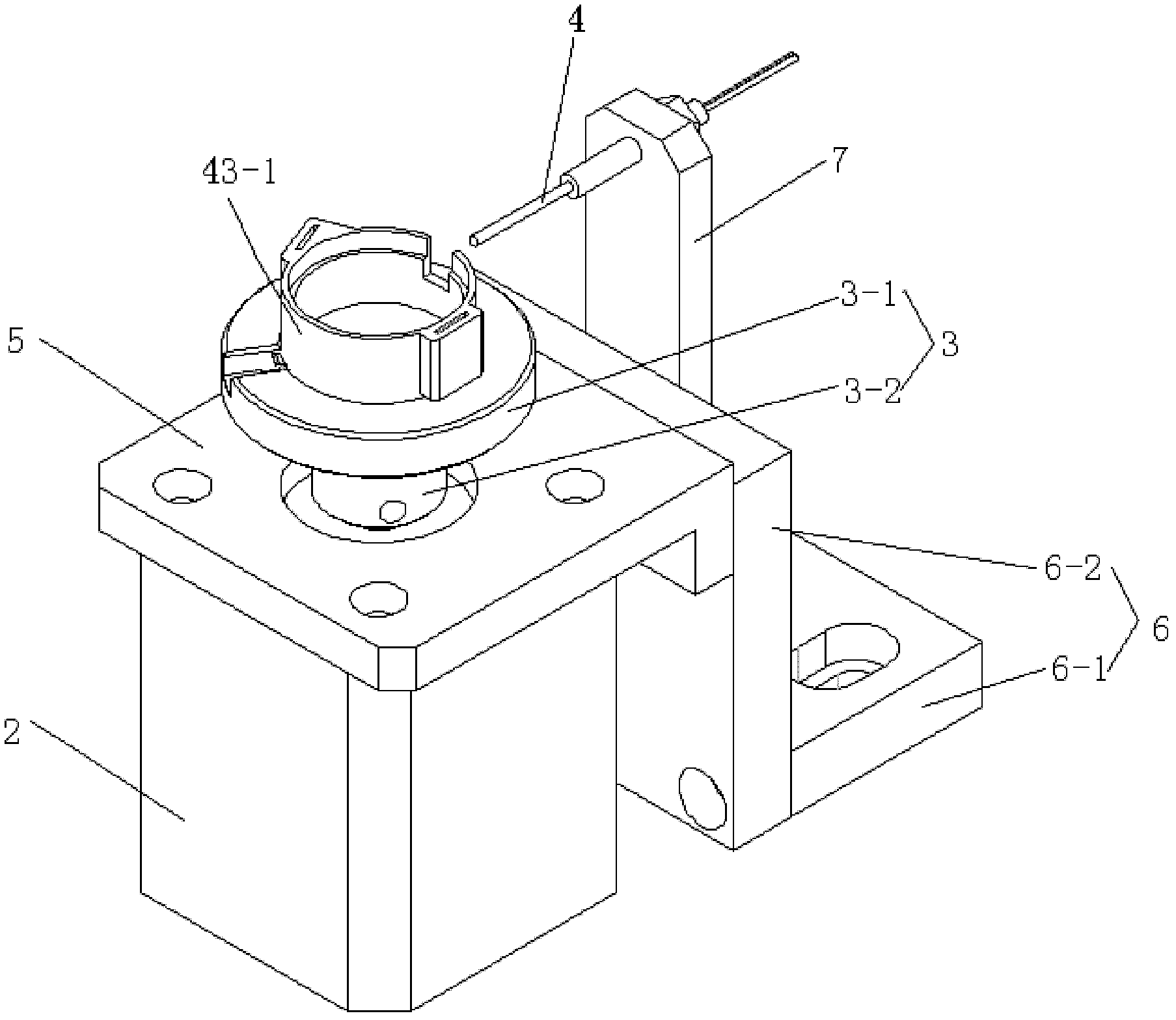

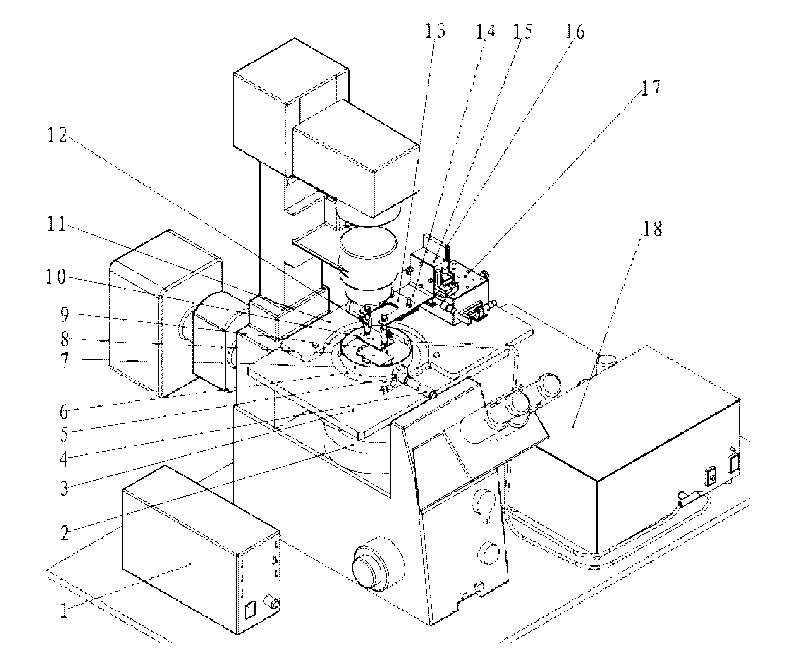

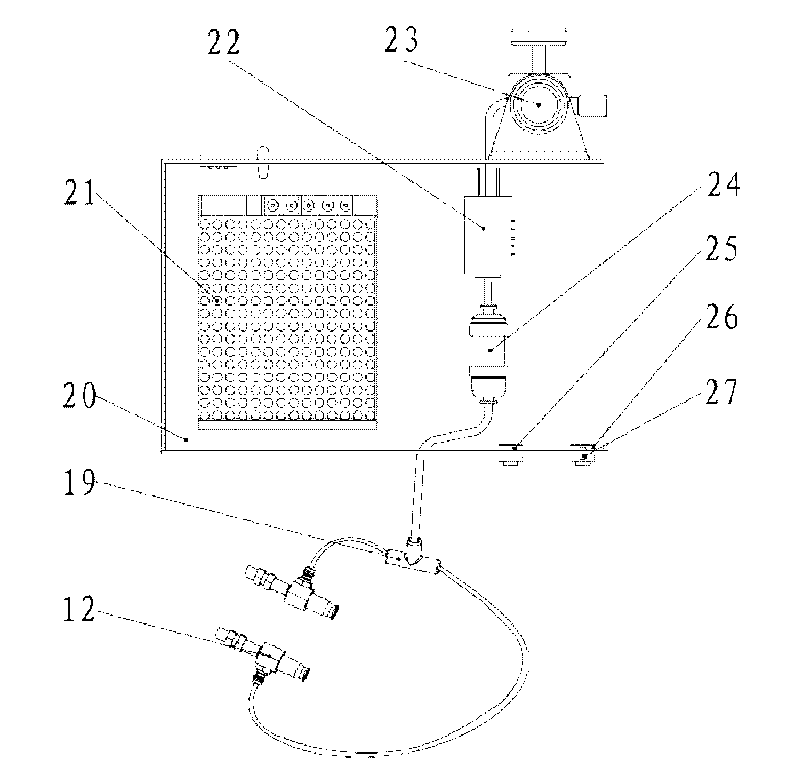

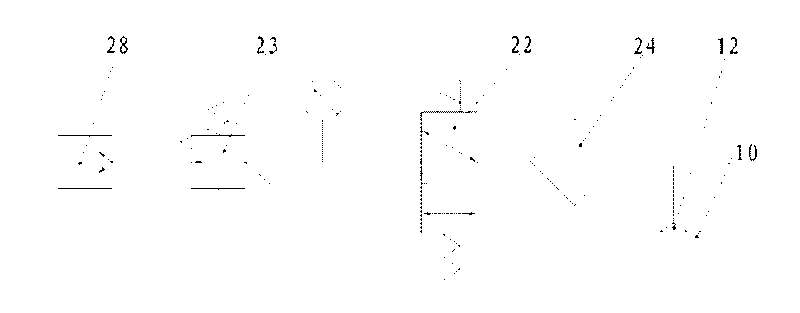

Automatic assembly production line of buzzers

ActiveCN102848187AGuaranteed accuracyRealize automatic feeding processAssembly machinesProduction lineEngineering

The invention discloses an automatic assembly production line of buzzers, which comprises a feeding mechanism, a glue coating mechanism, a buzzer piece placing mechanism, a straight contact pin placing mechanism, a first thermoplastic pipe placing mechanism, an inclined contact pin placing mechanism, a second thermoplastic pipe placing mechanism, a thermoplastic pipe heat sealing mechanism, a contact pin welding mechanism, a dispensing mechanism, a curing mechanism and a detecting and sorting mechanism, which are sequentially arranged on a work table; the glue coating mechanism comprises an automatic shell locating mechanism located behind a glue applicator, and the automatic shell locating mechanism comprises a motor, a rotating jig, an optical fiber sensor, a motor base, a supporting plate and a sensor bracket; the optical fiber sensor is a reflective optical fiber sensor and is arranged to be aligned to the shell; and the optical fiber sensor is installed on the upper part of the sensor bracket, and the lower part of the optical fiber sensor is fixed to the side plate of the supporting plate. The automatic assembly production line disclosed by the invention has the advantages of smart design and simple structure, realizes high level automation, replaces the manual operation, reduces the cost of manpower and physical resources and improves the production efficiency of the assembly line.

Owner:CHANGZHOU MINGSEAL ROBOT TECH CO LTD

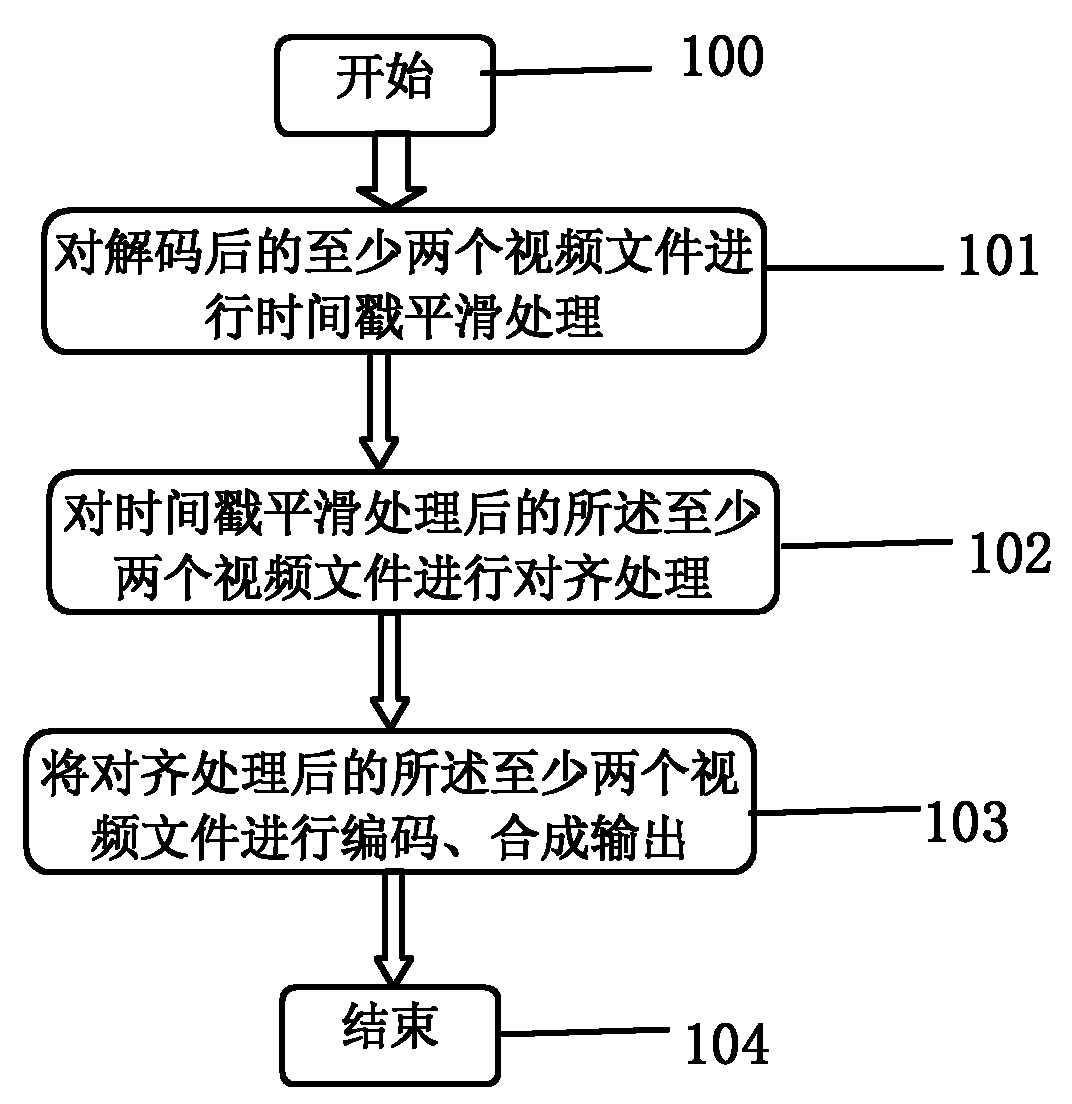

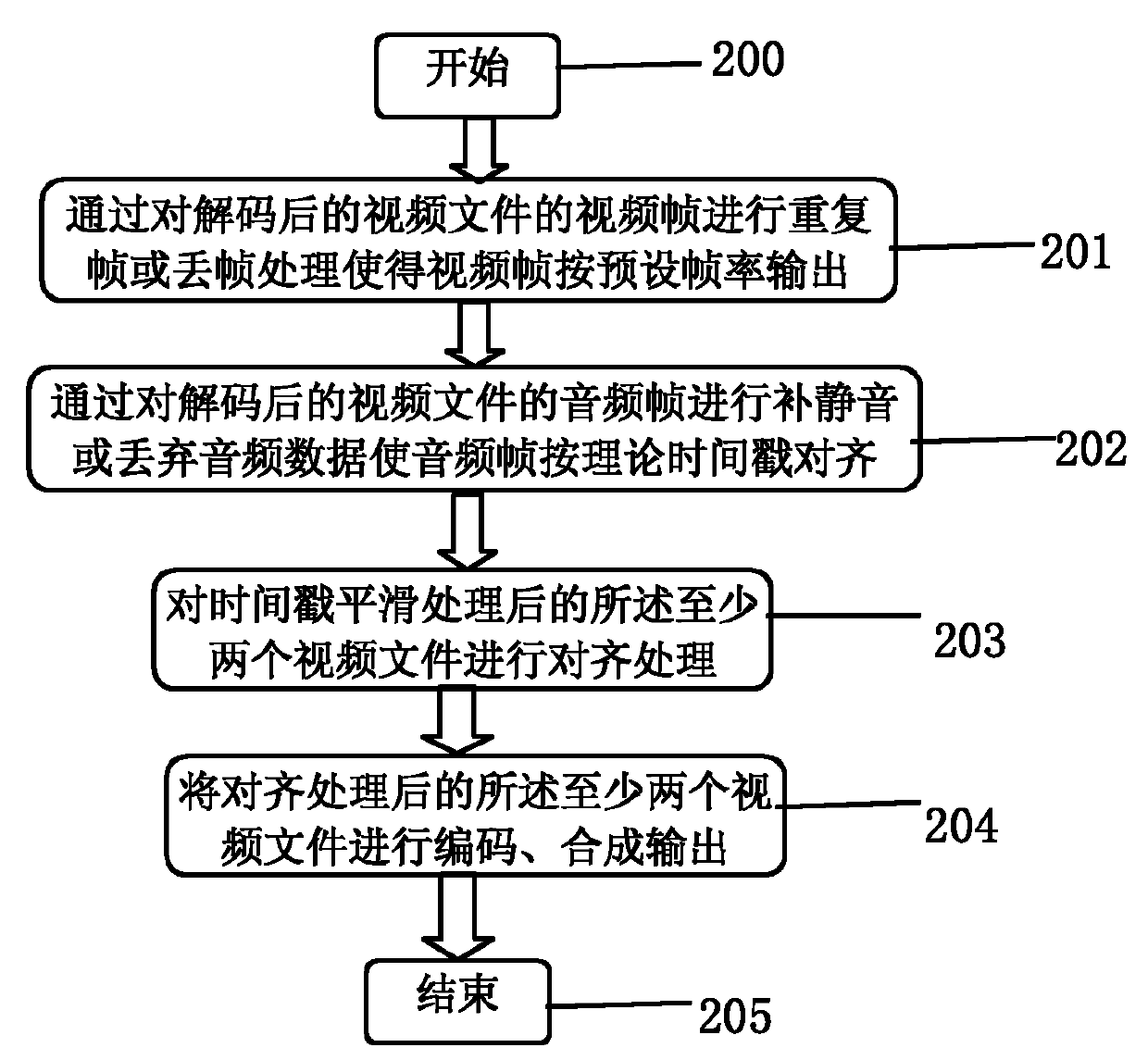

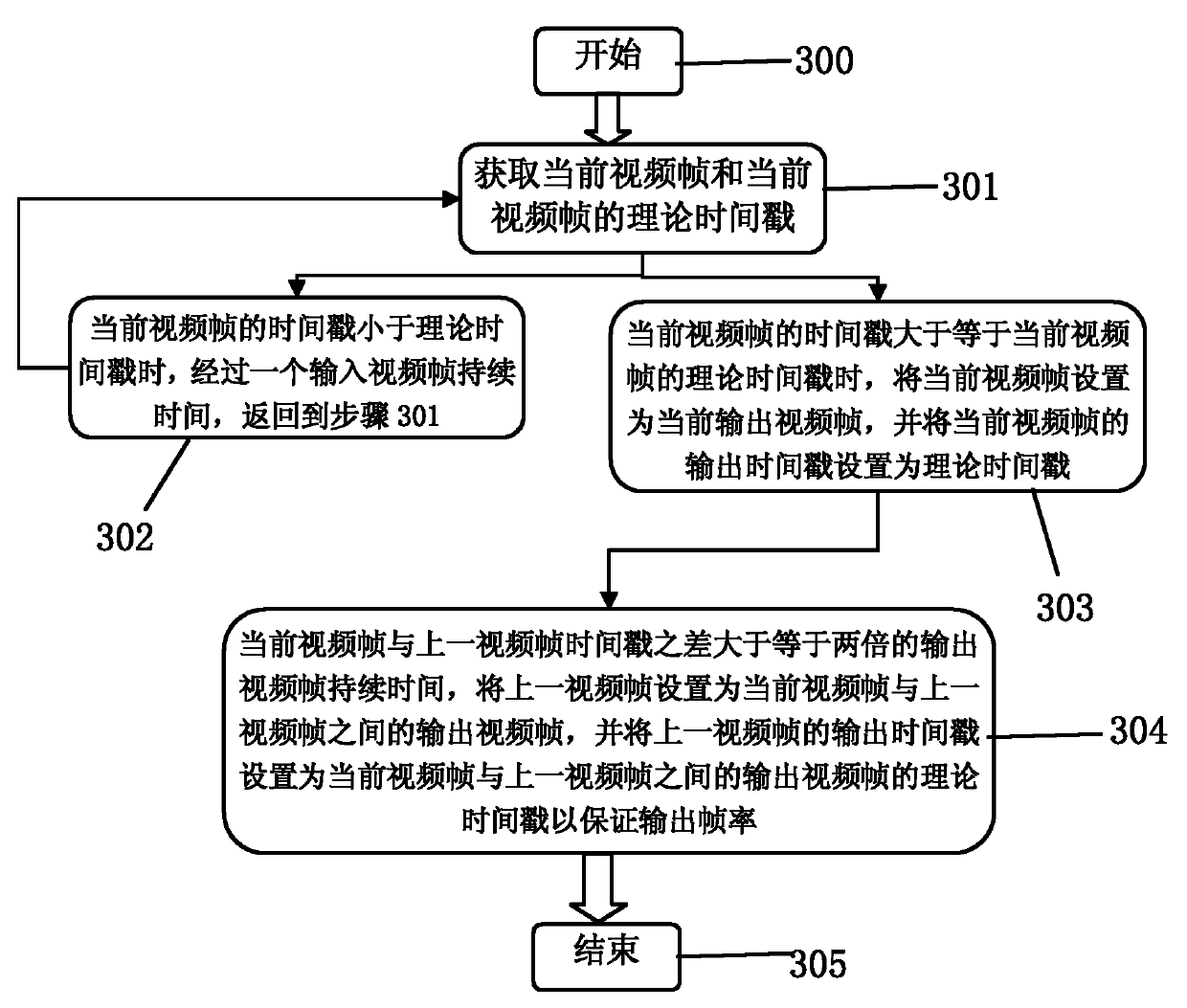

Method and device for connecting and outputting video files

ActiveCN101996662AGuaranteed rateGuaranteed completenessSelective content distributionDigital recording/reproducingTimestampOutput device

The invention relates to a method for connecting and outputting video files. The method comprises the following steps of: 1, performing timestamp smoothing processing on at least two decoded video files; 2, aligning the at least two video files after timestamp smoothing processing; and 3, encoding, synthesizing and outputting the at least two aligned video files. The step S1 comprises the following steps of: 11, repeating or losing video frames of the decoded video files to make the video frames output according to a preset frame rate; and 12, complementing silence or deleting corresponding audio data of audio frames of the decoded video files to make the audio frame aligned according to a theoretical timestamp. The invention also relates to a video file connecting and outputting device. The method and the device for connecting and outputting the video files can connect a plurality of input video files into one video file and output the video file, and can guarantee the play speed and the synchronization degree of the output video and the output audio.

Owner:WONDERSHARE TECH CO LTD

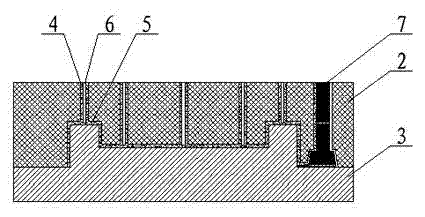

Sand-line iron mould casting process for grey cast iron flywheel housing of diesel engine

ActiveCN102728790AGood size consistencyPut an end to the phenomenon of sand swellingFoundry mouldsFoundry coresDieselingSurface roughness

The invention discloses a sand-line iron mould casting process for grey cast iron flywheel housings of diesel engines. In the invention, upper and lower sand-line iron mould processes are used, so that produced grey cast iron flywheel housing blanks have favorable geometric size precision which can be up to CT8 grade, favorable surface roughness which can be up to 12.5 microns and favorable mechanical properties, the blank processing has small allowance which can be controlled in 3mm, small flashing distortion which can be controlled in 0.5mm and small cleaning workload, so that the labor environment is improved, the environmental protection is improved, the yield is high and can be up to 95%, and the national policies of energy conservation, environmental protection and sustainable development are met.

Owner:JIANGSU SONGLIN AUTOMOBILE PARTS

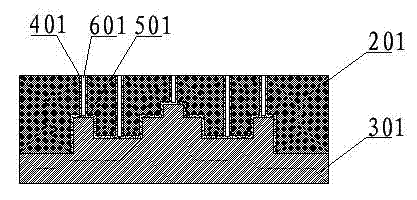

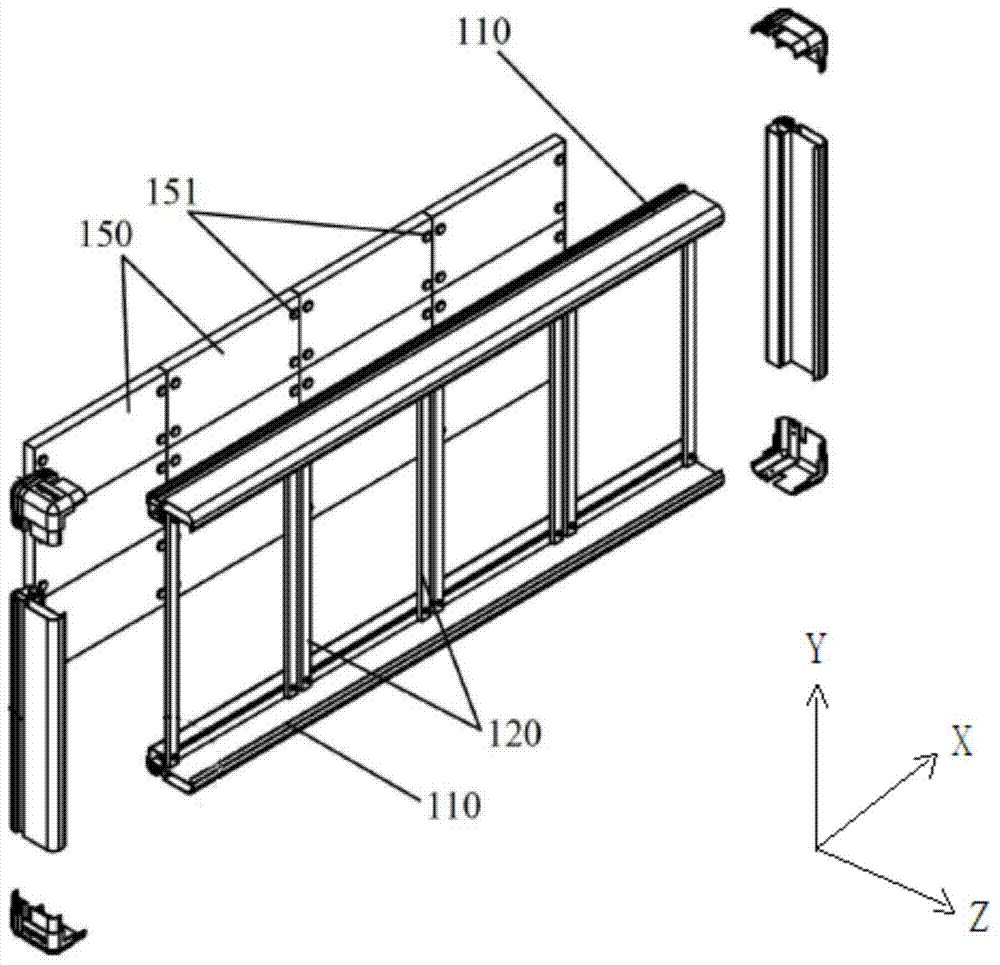

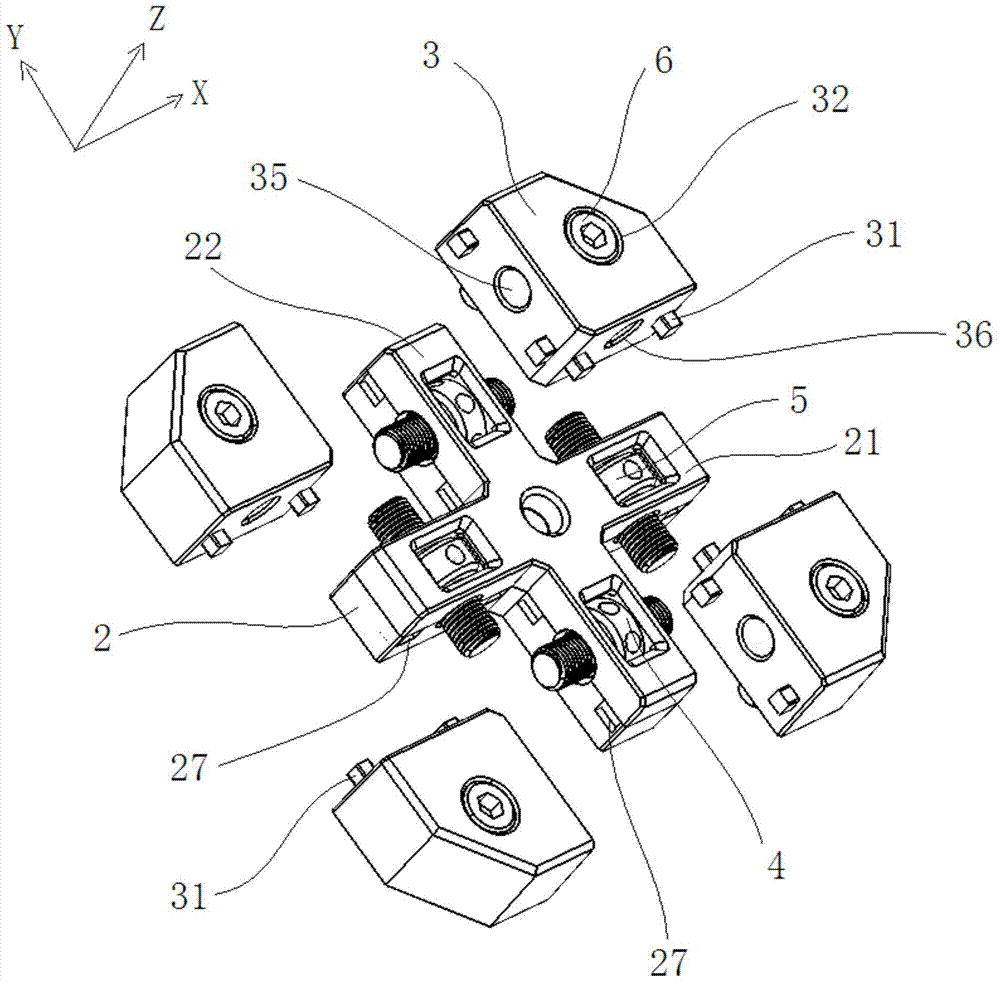

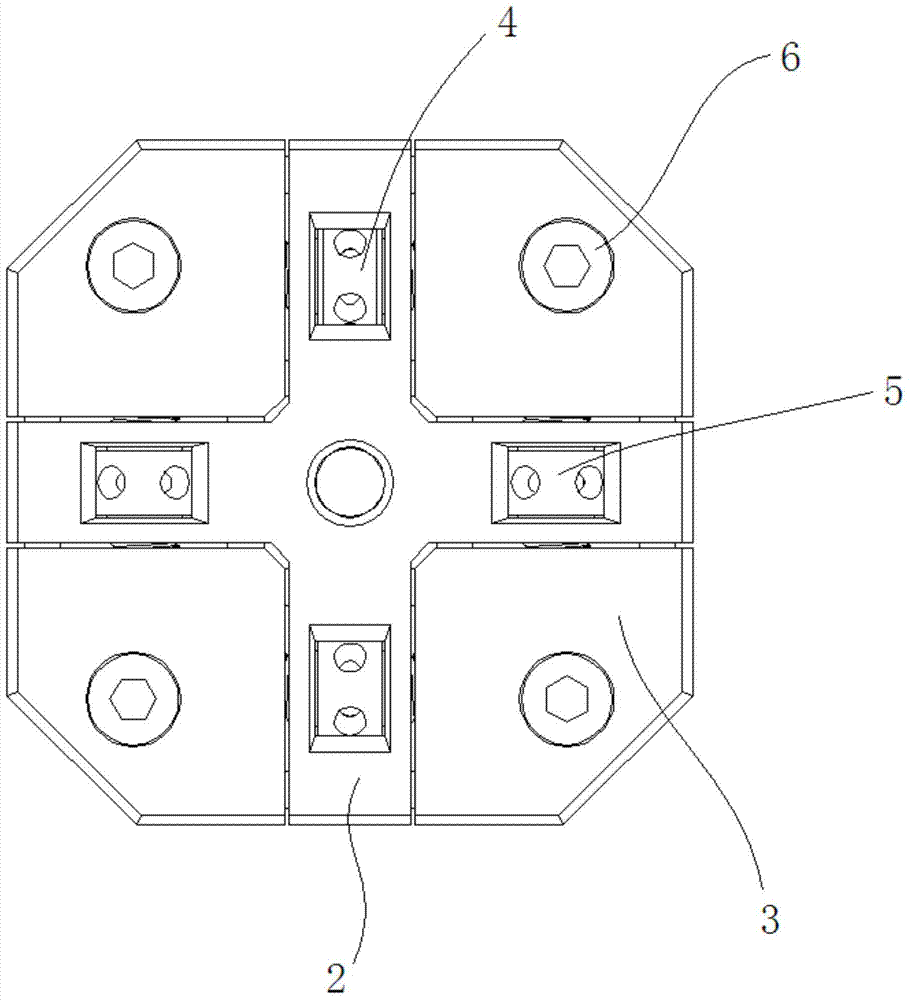

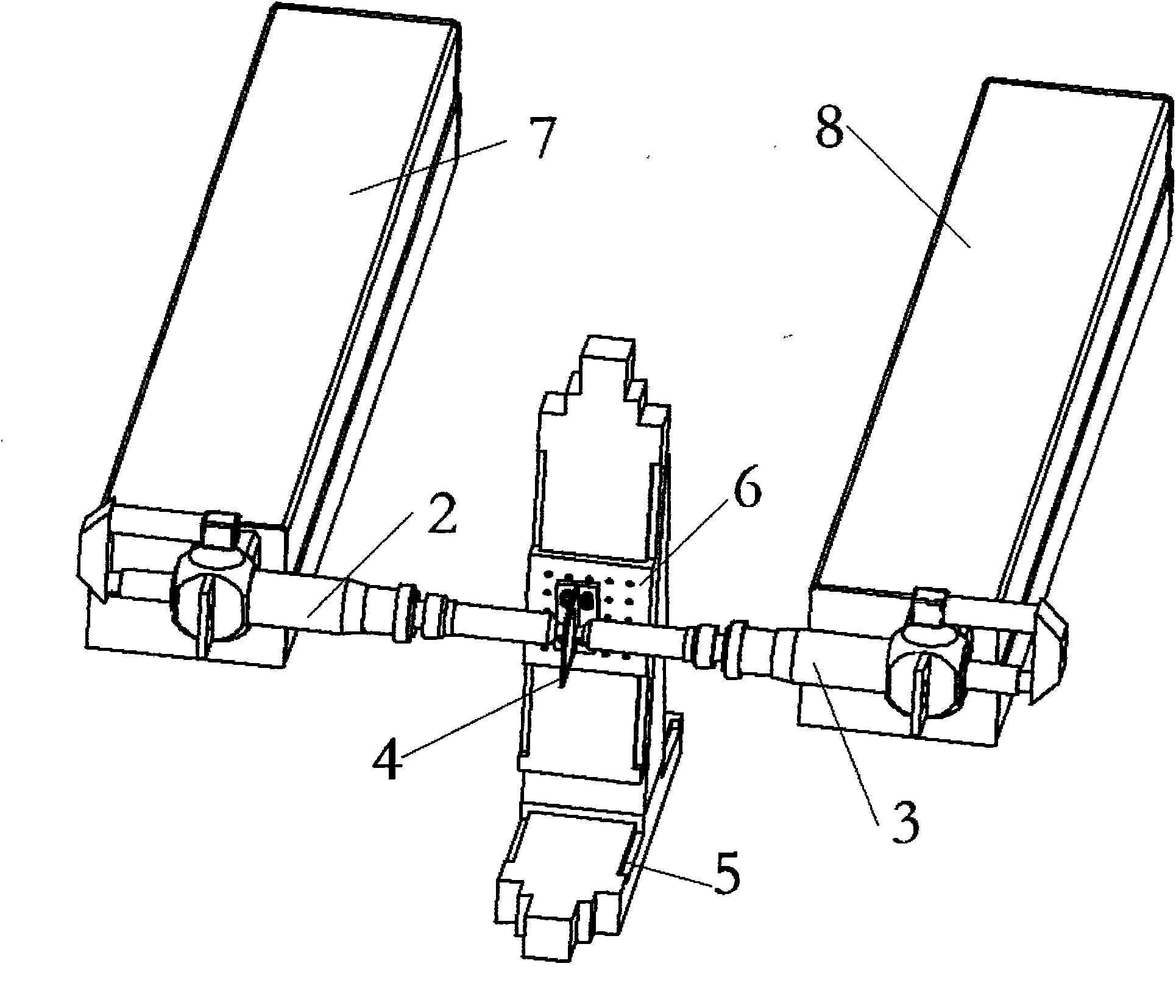

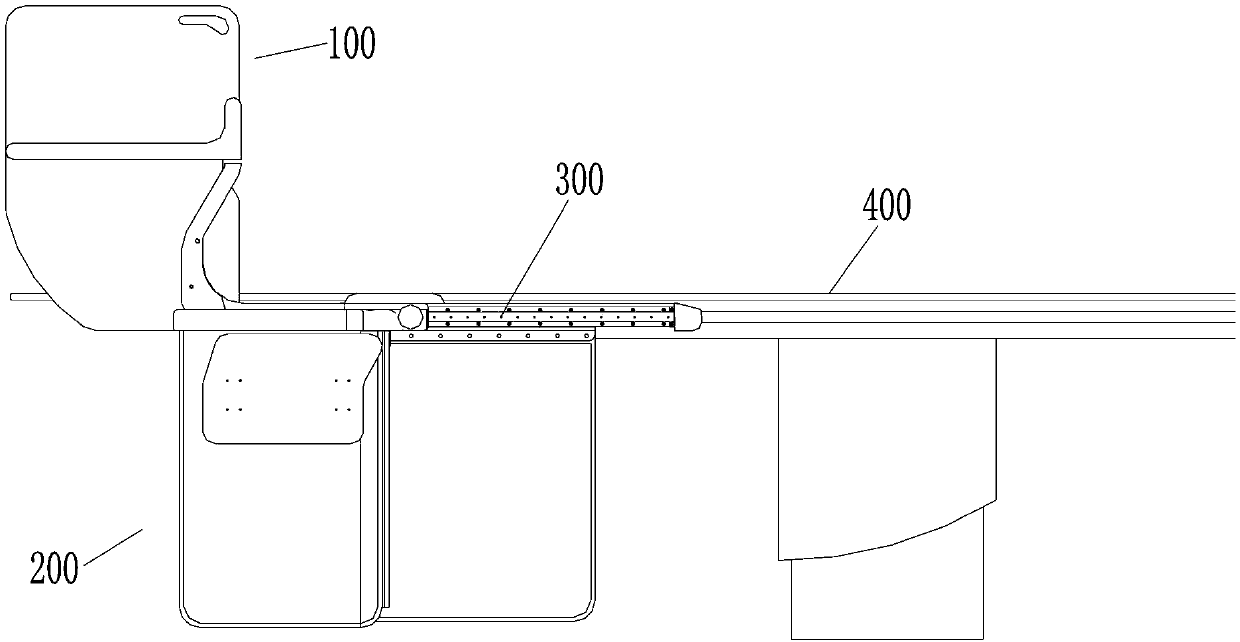

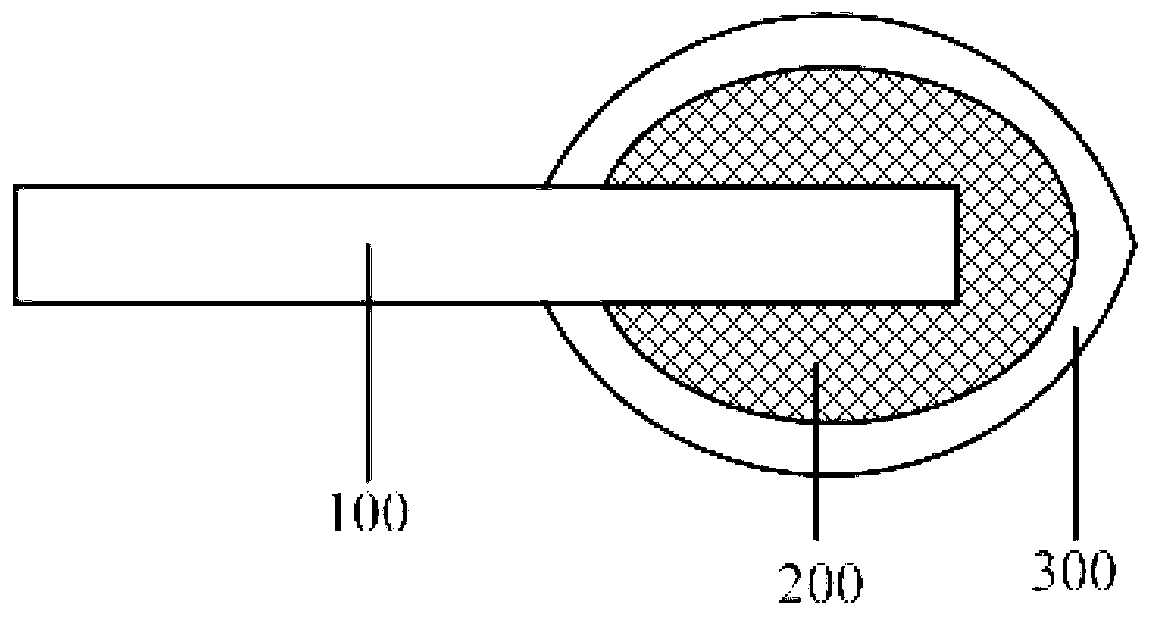

LED module installing mechanism

ActiveCN104723074AEasy to adjustSave adjustment timeCasings/cabinets/drawers detailsPrintingLED displayEngineering

The invention discloses an LED module installing mechanism. The LED module installing mechanism comprises a fixed rack (2), a gap adjusting mechanism on the fixed rack (2), and at least two moving blocks (3) movably connected with the fixed rack (2). LED modules (100) are arranged on the moving blocks (3). The two ends of the gap adjusting mechanism are connected with the moving blocks (3) respectively. By adjusting the moving block (3) on the two sides to move away or get close to each other, a gap between the LED modules (100) arranged on the moving blocks (3) is adjusted. The invention belongs to the technical field of LED modules and LED display screens. According to the LED module installing mechanism, the technical problems in the prior art that the method for adjusting the planar gap between the LED modules is complex and unstable, and the adjustment on the planeness which is perpendicular to the planar direction of the LED modules is unable to achieve are solved. The LED module installing mechanism is particularly applicable to adjusting the planeness perpendicular to the direction of the LED modules and the planar gap between the LED modules, the adjusting operation is simple, and the adjusting effect is stable.

Owner:GLUX VISUAL EFFECTS TECH (SHENZHEN) CO LTD

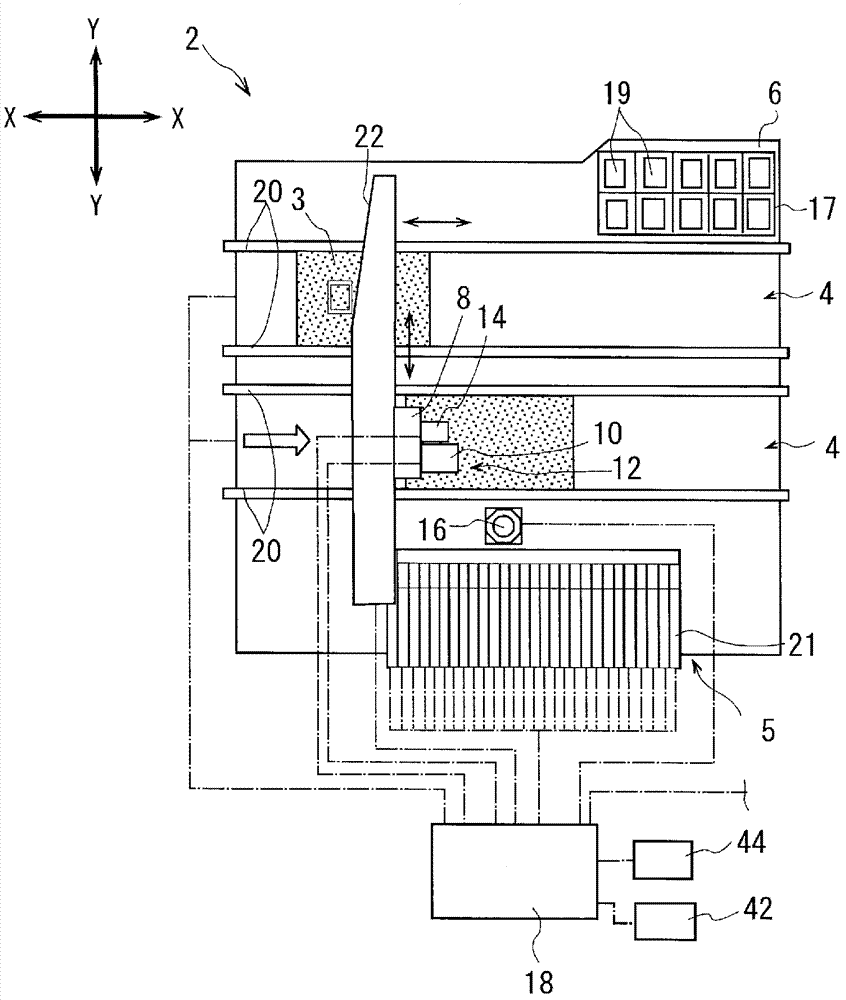

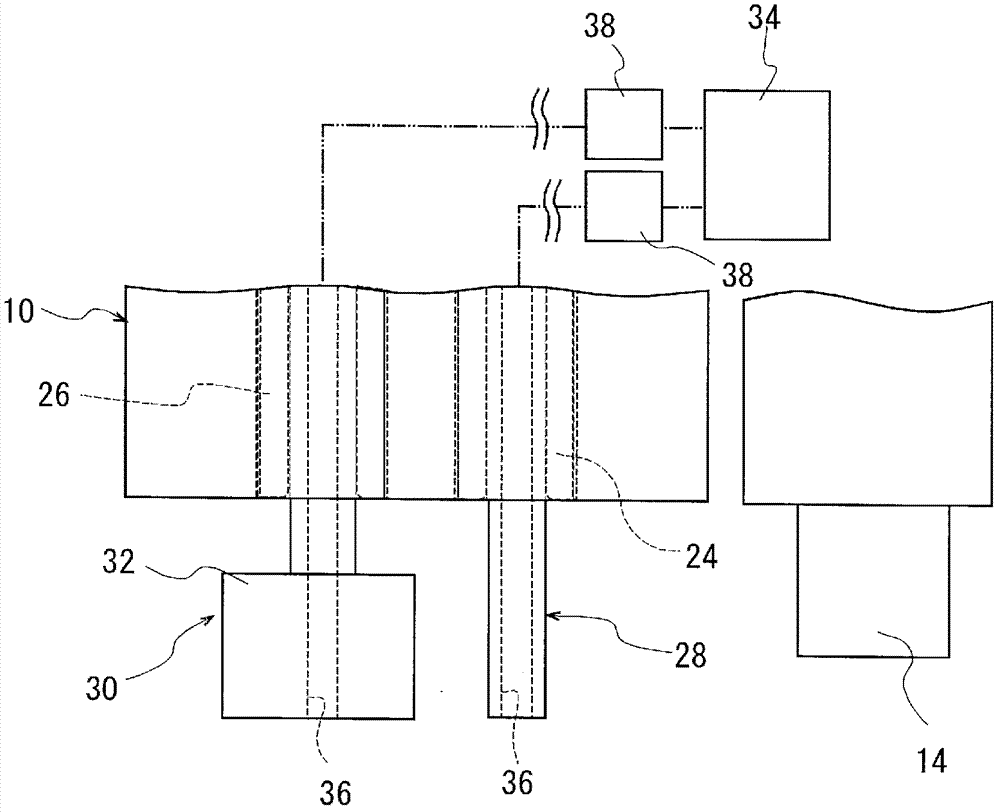

Laser double-faced synchronous machining system and machining method thereof

InactiveCN101658979ASmall thermal damage areaNarrow kerfLaser beam welding apparatusSuperhard materialBeam splitter

The invention discloses a laser double-faced synchronous machining system and a machining method thereof. The system comprises a laser, a middle displacement platform and a machined work piece. The two sides of the machined work piece are two laser beams which are respectively acted on the two side faces of the machined work piece. The laser beams at the two sides of the machined work piece are onthe same straight line or intersectant in the work piece. The two laser beams can be respectively generated by two lasers or generated by one laser with a beam splitter. The method comprises the steps: inputting cut graph into a computer, and controlling the middle displacement platform to move according to a track by software, to complete the cutting machining. By laser double-faced synchronousmachining, the machining depth at one time is more than 1 times of that of the single-faced machining. Compared with traditional double-faced machining, the invention does not need adjust a clamping tool in an overturning way, can complete the machining by clamping at one time, has balanced heat action applied to the two faces of the work piece, has low remnant stress and heat deformation after cutting, improves the cutting quality, and realizes the double-faced synchronous cutting to various superhard materials such as PDC, PCB and composite sheet thereof, ceramics, etc.

Owner:LANGFANG HAOBO DIAMOND

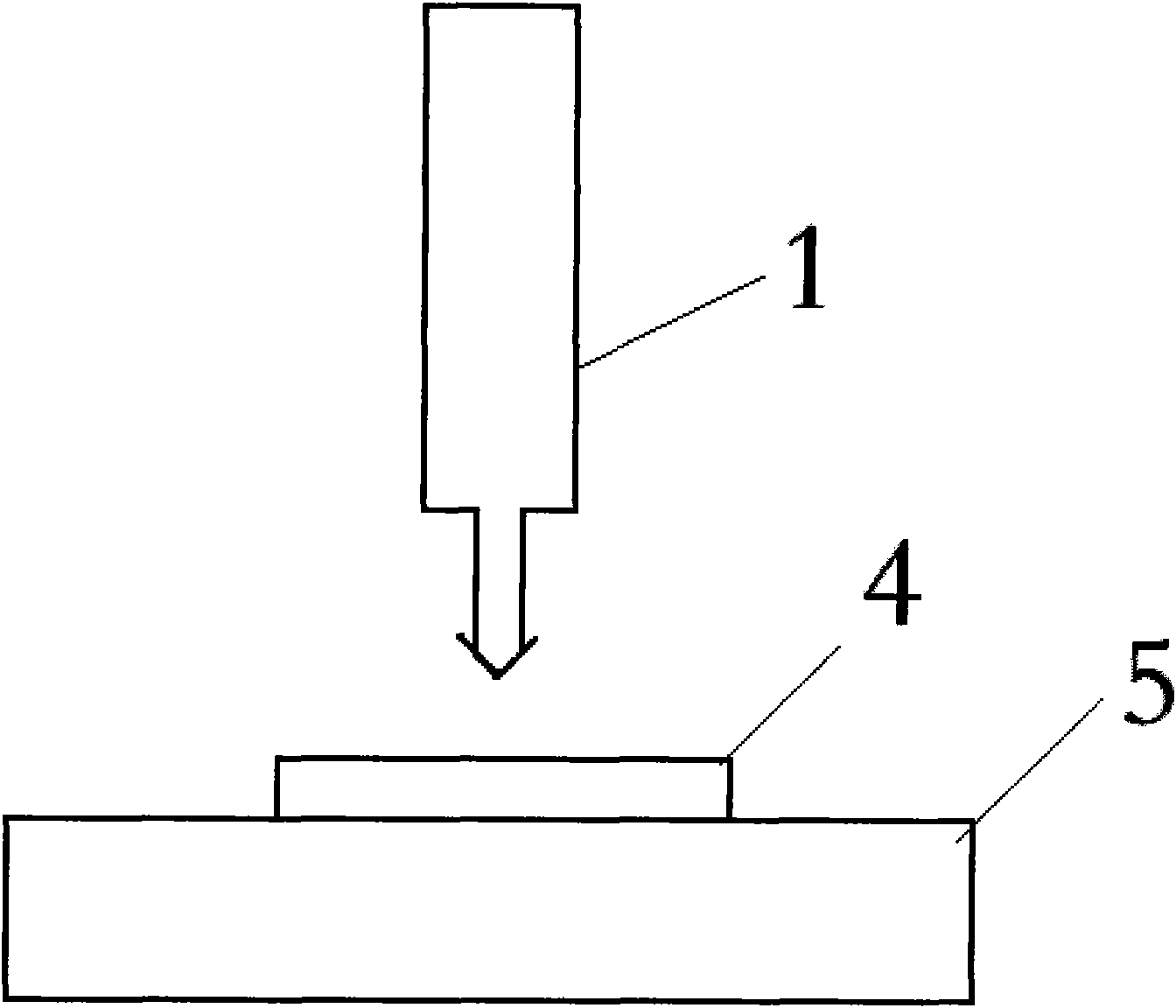

Electronic part installing method and installing device

ActiveCN102740676ARealize space savingEasy to installElectrical componentsMechanical engineeringDislocation

The invention relates to an electronic part installing method and an installing device, which can conduct positioning on cover parts and install the cover parts behind a substrate and prevent dislocation before fixing through pressing and reduce tool variety. The electronic part installing device installs upper and lower moving components having pressing parts at a part transferring device and can drive the upper and lower moving components up and down. The pressing part is pressed and positioned at a cover part of regulated position. The electronic part installing method comprises a substrate moving and positioning process which is to move the substrate by a substrate moving device and to conduct positioning on the substrate; a cover part positioning and carrying process which is to select the cover part by means of a part transferring device through absorption and to conduct positioning and carrying on the cover parts to a regulated position of the positioned substrate in the substrate moving and positioning process; a pressing and assembling process which is to immediately drive the upper and lower moving components and press the cover parts by the pressing part after the cover parts are positioned and disposed at the regulated position by means of the part transferring device, and thereby an engaging mechanism of the cover part can be engaged with an engaged mechanism disposed at the substrate.

Owner:FUJI KK

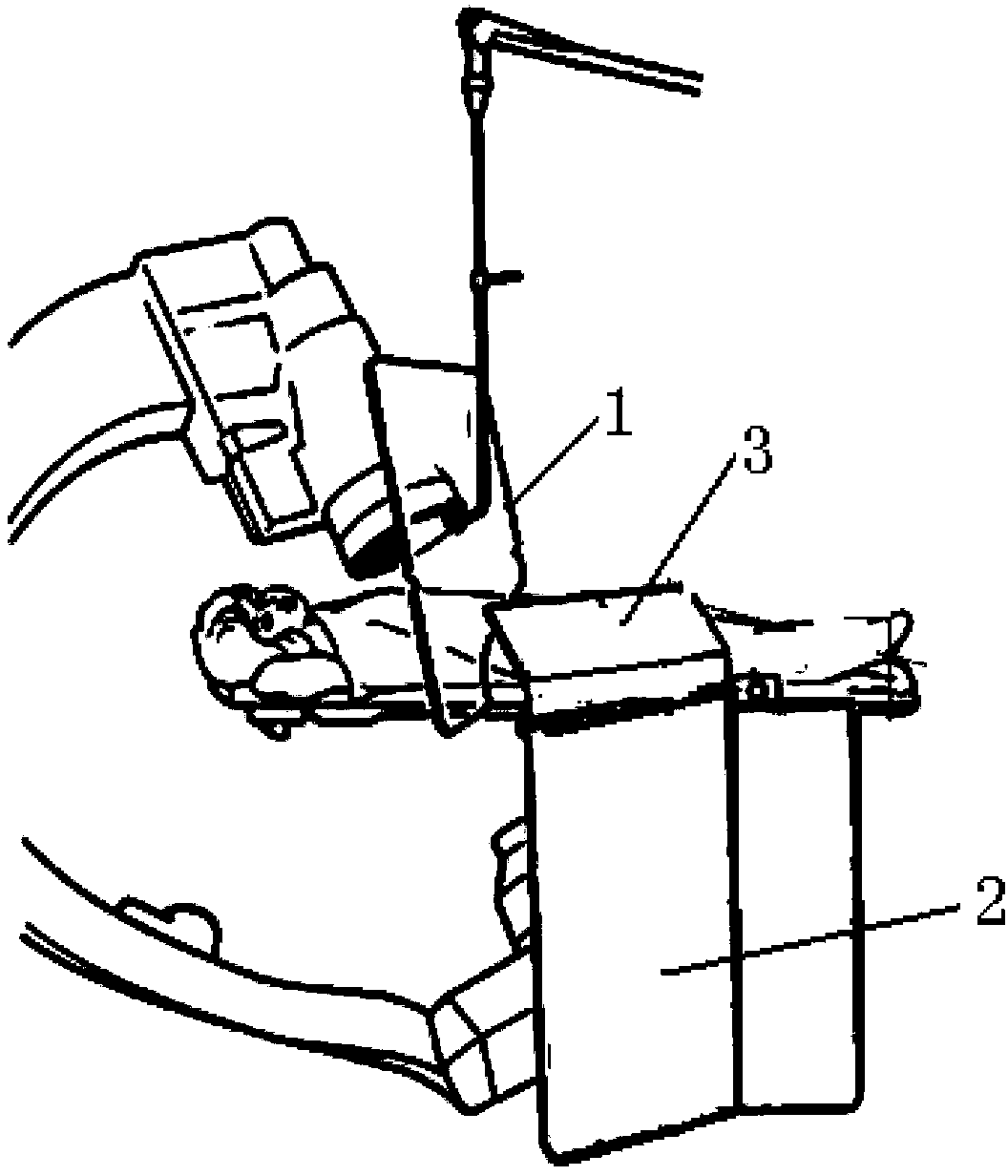

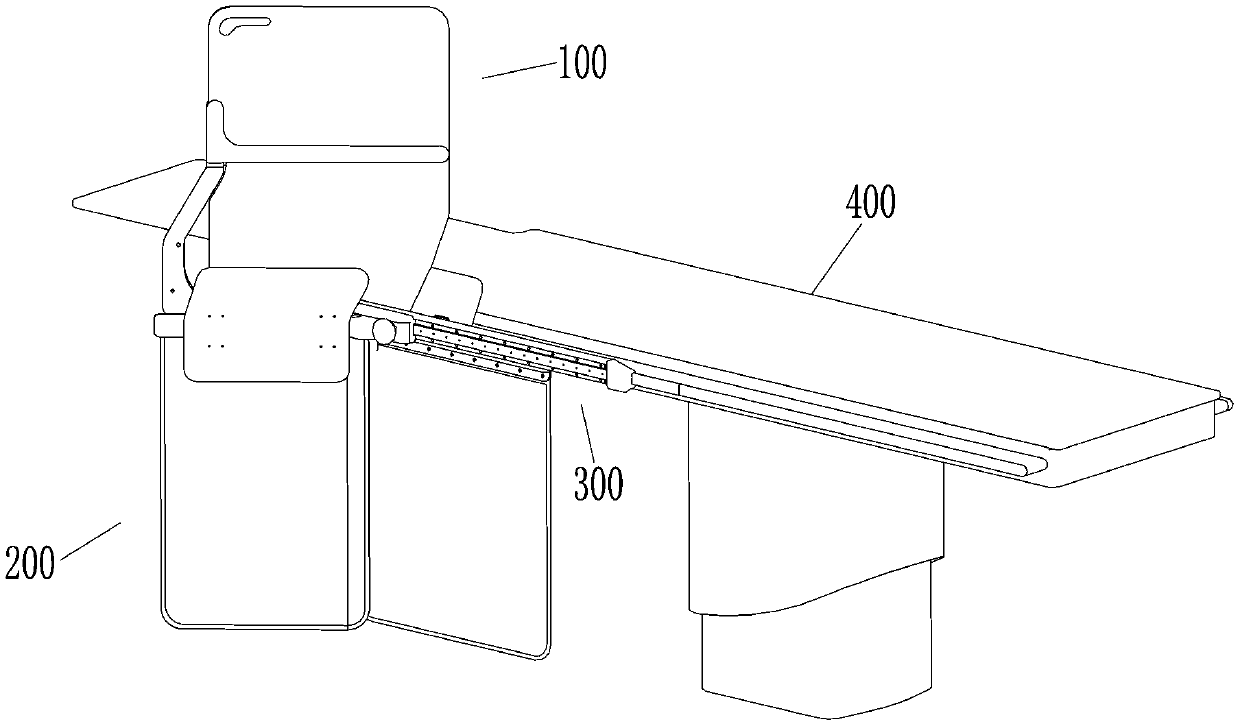

Integrated X-ray protection device on angiography machine

ActiveCN103385733ARealize simultaneous movement with the bedRealize synchronized movementRadiation safety meansAngiographyX-rayEngineering

The invention relates to the field of medical instruments, in particular to an X-ray protection device with an integrated structure for an angiography machine. The device comprises a protection screen unit, a protection curtain unit and a bedside sliding rail unit, wherein the protection screen unit is arranged on the protection curtain unit, and the protection curtain unit is fixed on the bedside sliding rail unit so as to enable the protection curtain unit and the protection screen unit to synchronously and horizontally move along a bedside. The protection device can synchronously move along with a bed, and in a moving process, the protection device is always in the best protecting state and close to a patient, so that the problem that the radiation, especially the secondary stray radiation caused by the rays reflected by the patient, can not be effectively shielded due to the movement of the bed surface of a conduit bed is effectively solved, and meanwhile, the problems of prolonged surgery time, increased surgery risk and the like that are caused by adjusting the protection screen unit during surgery in the prior art are effectively avoided.

Owner:BEIJING ORIENTAL E T MEDICAL EQUIP

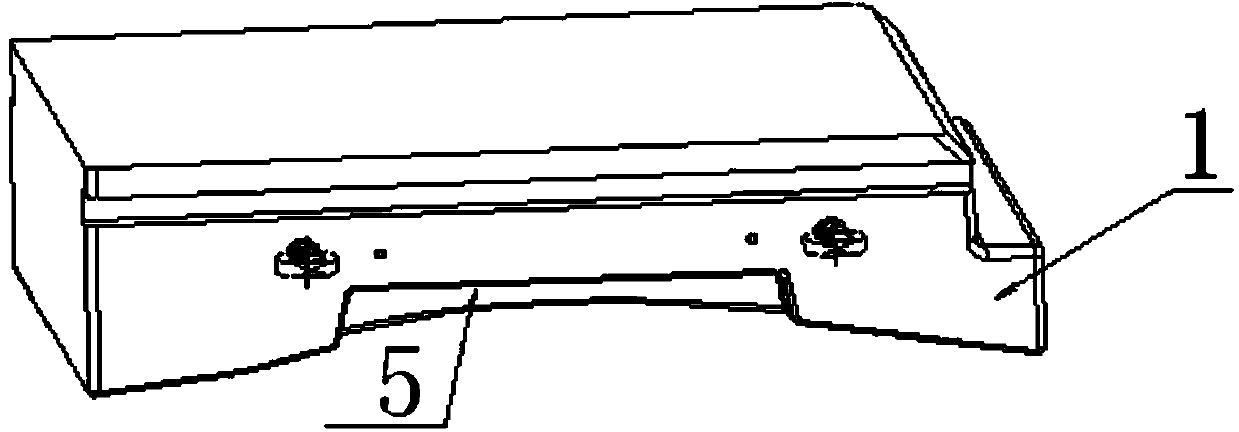

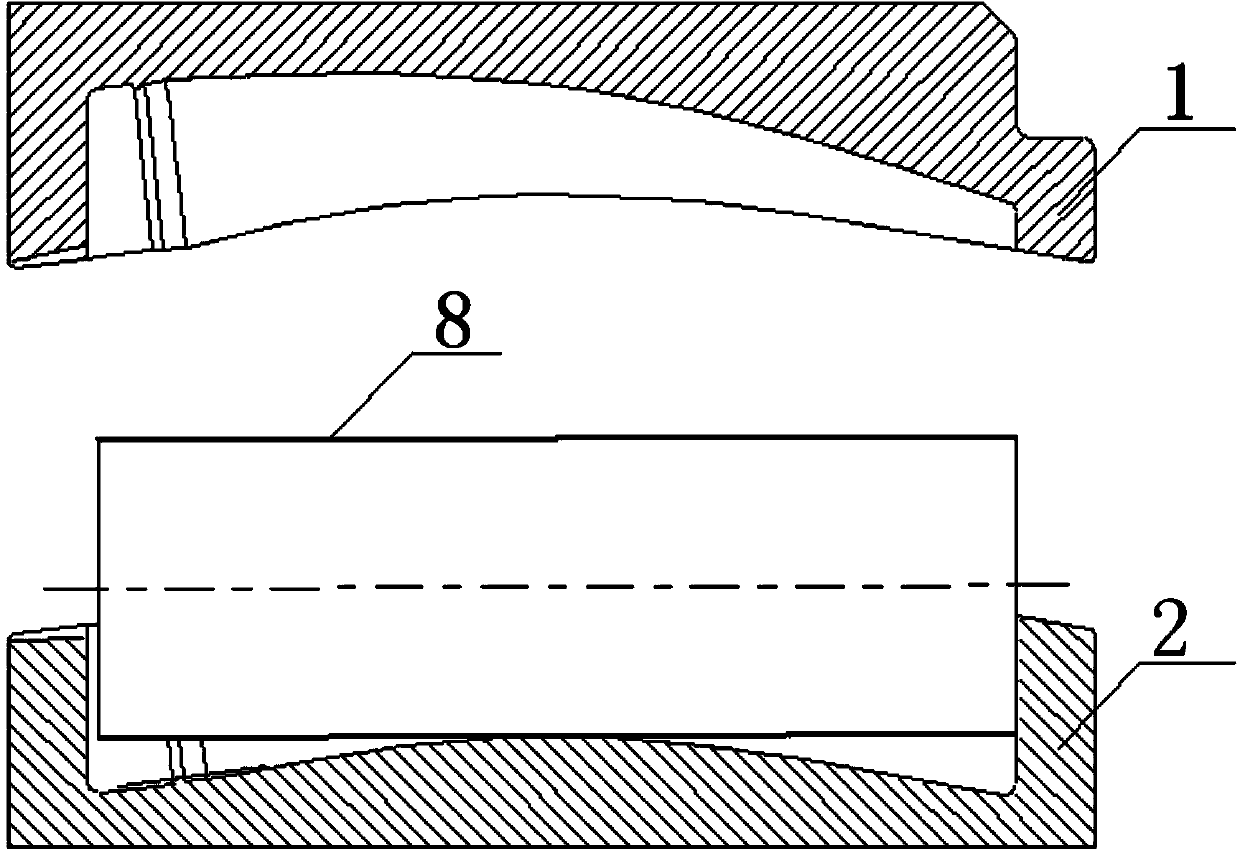

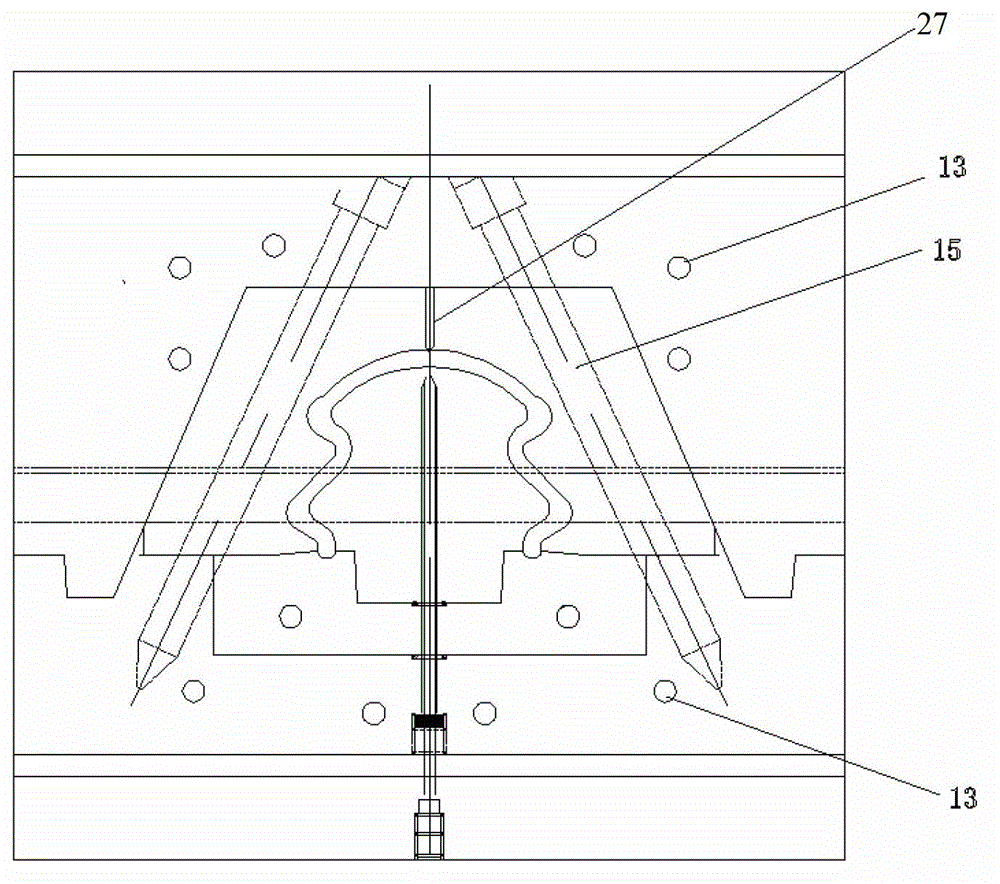

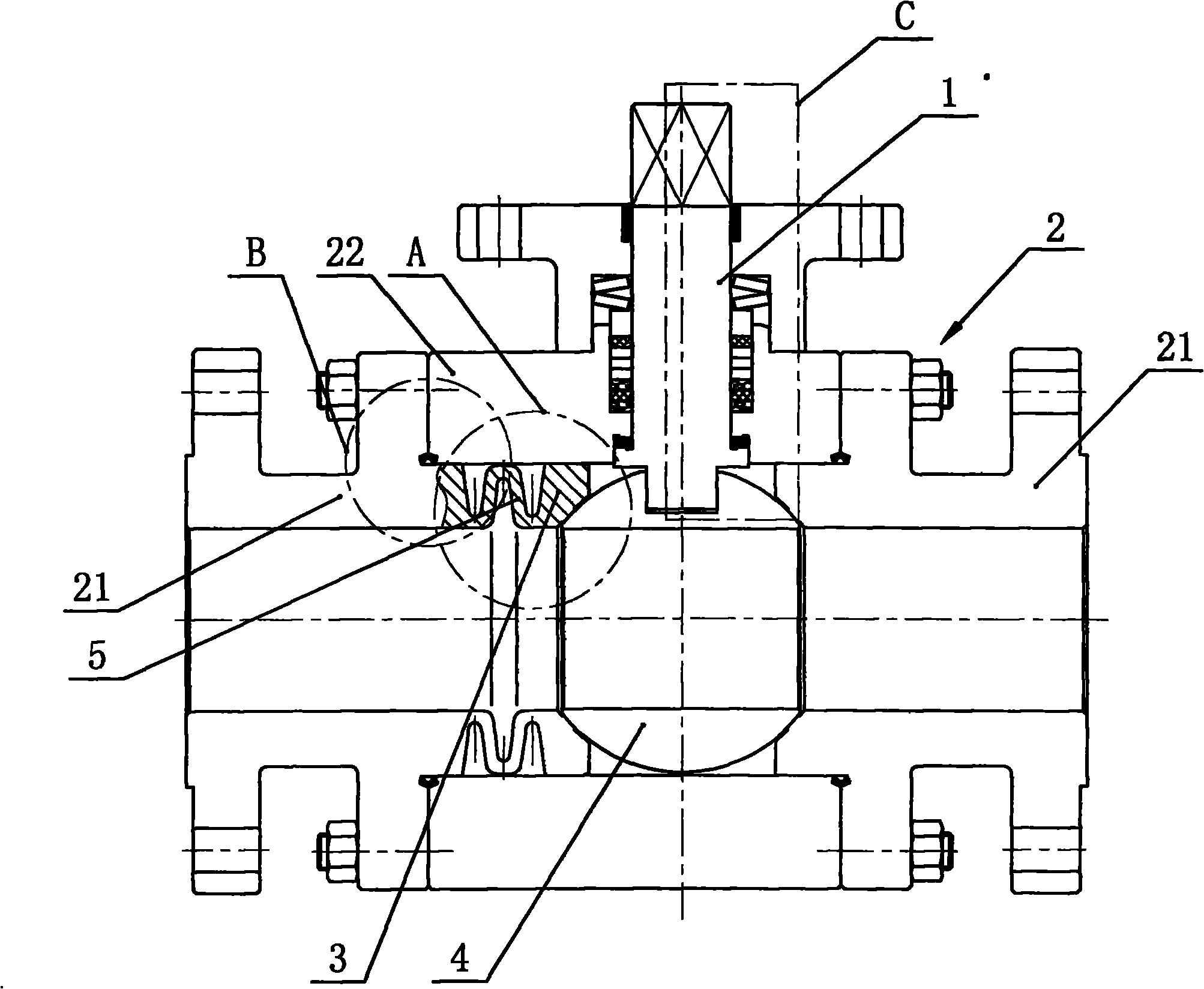

Global shaping mould and method of titanium alloy air inlet part

ActiveCN103769482AReduce cavity depthGood for stable placement and shapingShaping toolsRoundingTitanium alloy

The invention belongs to the field of sheet metal and hot processing and in particular relates to a global shaping mould and method of a titanium alloy air inlet part. The mould comprises an upper mould and a lower mould, wherein two lifting screws are arranged on each of the upper and lower moulds. The method comprises the following steps: fixing the mould in a hot forming press, heating, putting a round blank after the rounding process into a lower mould cavity, and pre-shaping; performing seal welding on the pre-shaped blank, welding an air inlet pipeline on the end surface of the pre-shaped blank, and opening the mould to take out a formed part as a qualified part meeting the size requirement. The method has the advantages that the process position of the part during global shaping is reasonably determined, so that the mould parting surface is selected at an irregular arc surface tangent line and is an irregular curved surface, the mould cavity depth is reduced, the blank can be stably arranged and formed, and the part can be conveniently taken out after the mould is opened.

Owner:BEIJING HANGXING MACHINERY MFG CO LTD

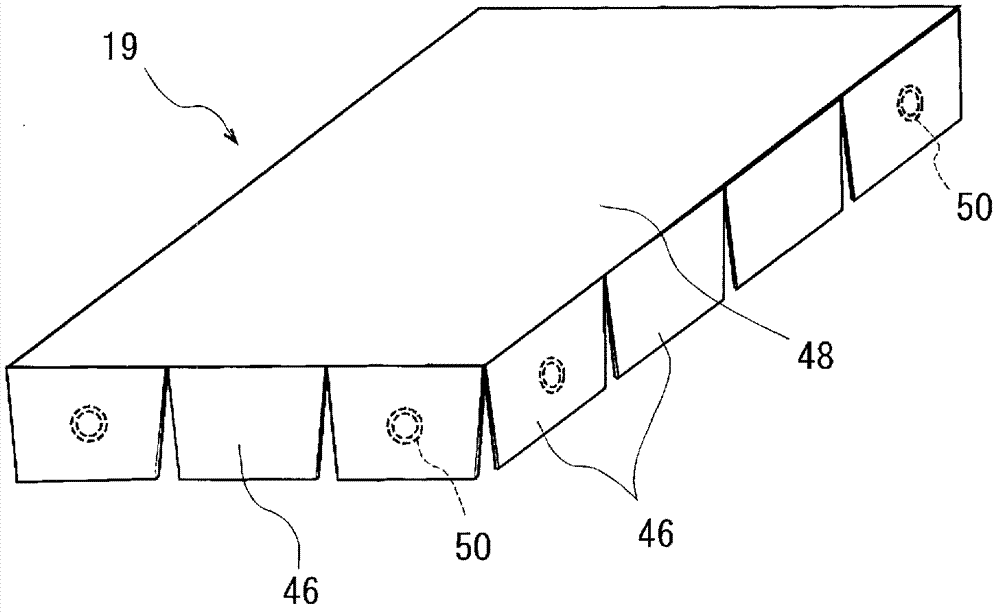

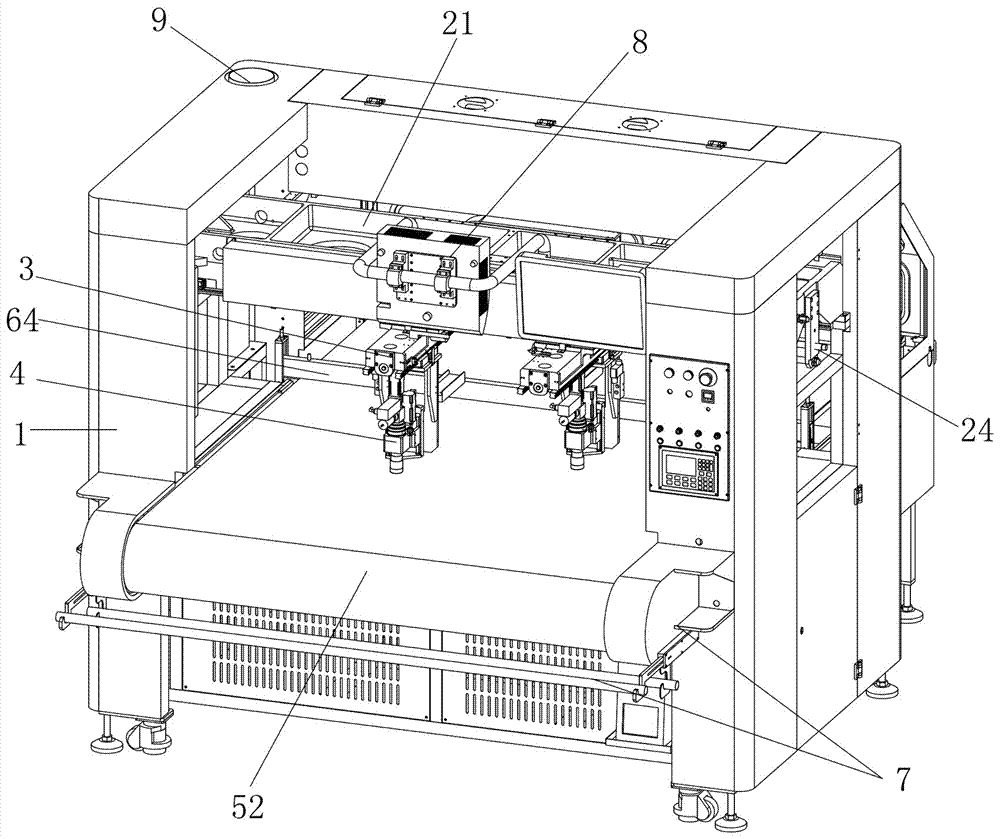

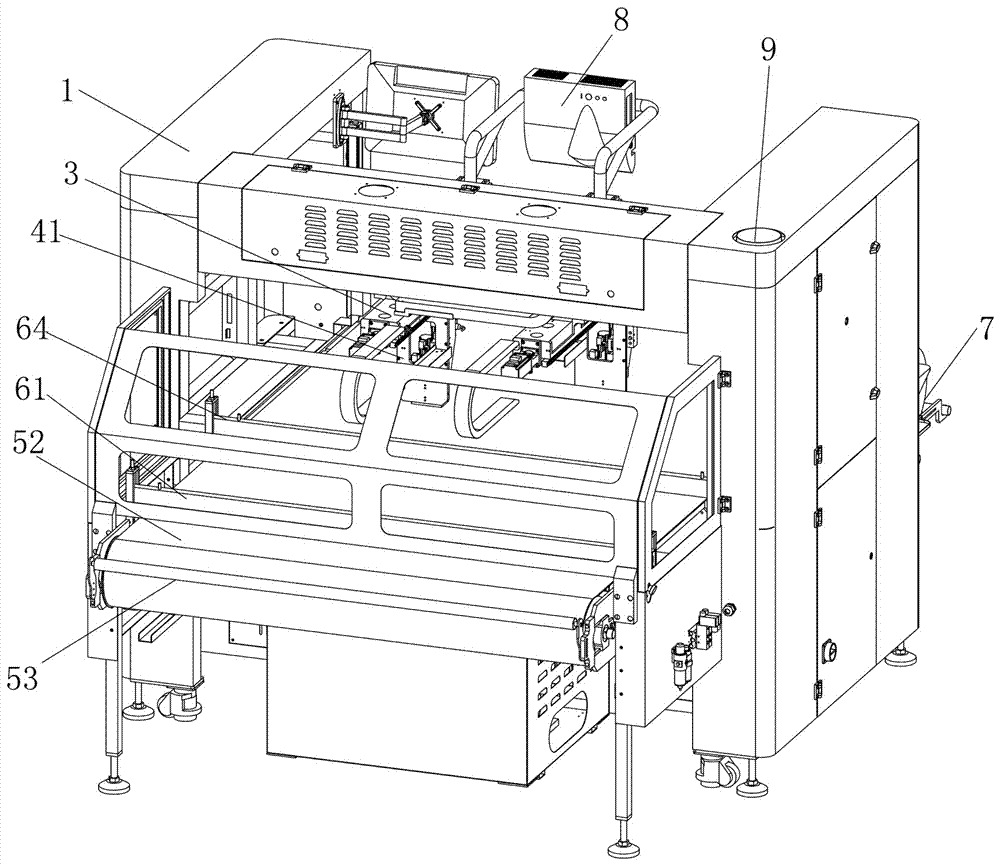

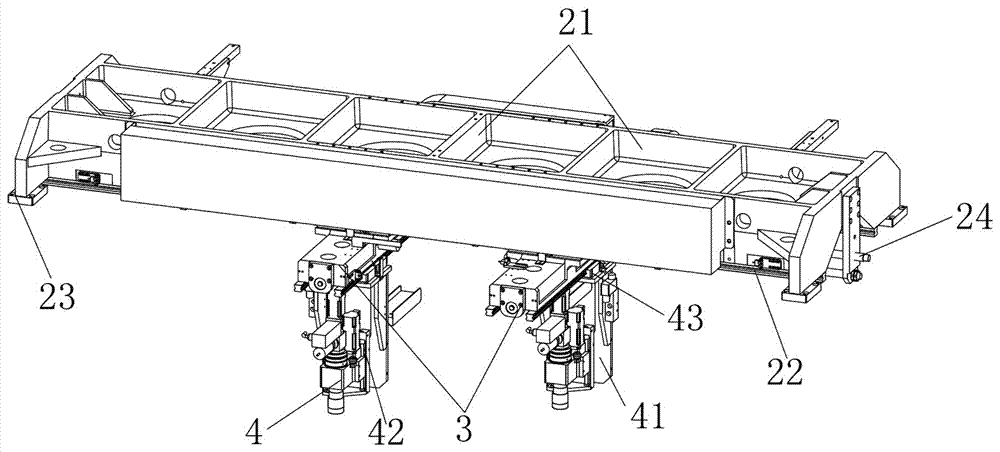

Cutting machine

InactiveCN106930092ANo misalignmentEnsure consistencySevering textilesThree-dimensional spaceEngineering

The invention discloses a cutting machine. The cutting machine comprises a frame and a feeding device which is arranged on the frame, wherein a feed inlet, a cutting station and a product collecting station are successively arranged on the frame along the feeding direction of the feeding device; a portal frame is arranged above the cutting station of the frame, the portal frame hoists at least one tool apron for mounting a tool, a mobile device which drives the tool apron to move in a three-dimensional space is arranged between the portal frame and the tool apron, and a traction material pressing device and a fixed pressing device are successively arranged along the feeding direction between the feed inlet and the cutting station. Cloth and a conveyor belt are clamped together and moved through the traction pressing device, so that the cloth in the transfer process is not staggered, and meanwhile, the cloth is tightly pressed to the conveyor belt through the fixed pressing device, so that the cloth cutting consistency and precision are guaranteed, and the problem that the cloth which is cut is easy to be staggered is solved.

Owner:GBOS LASER INC

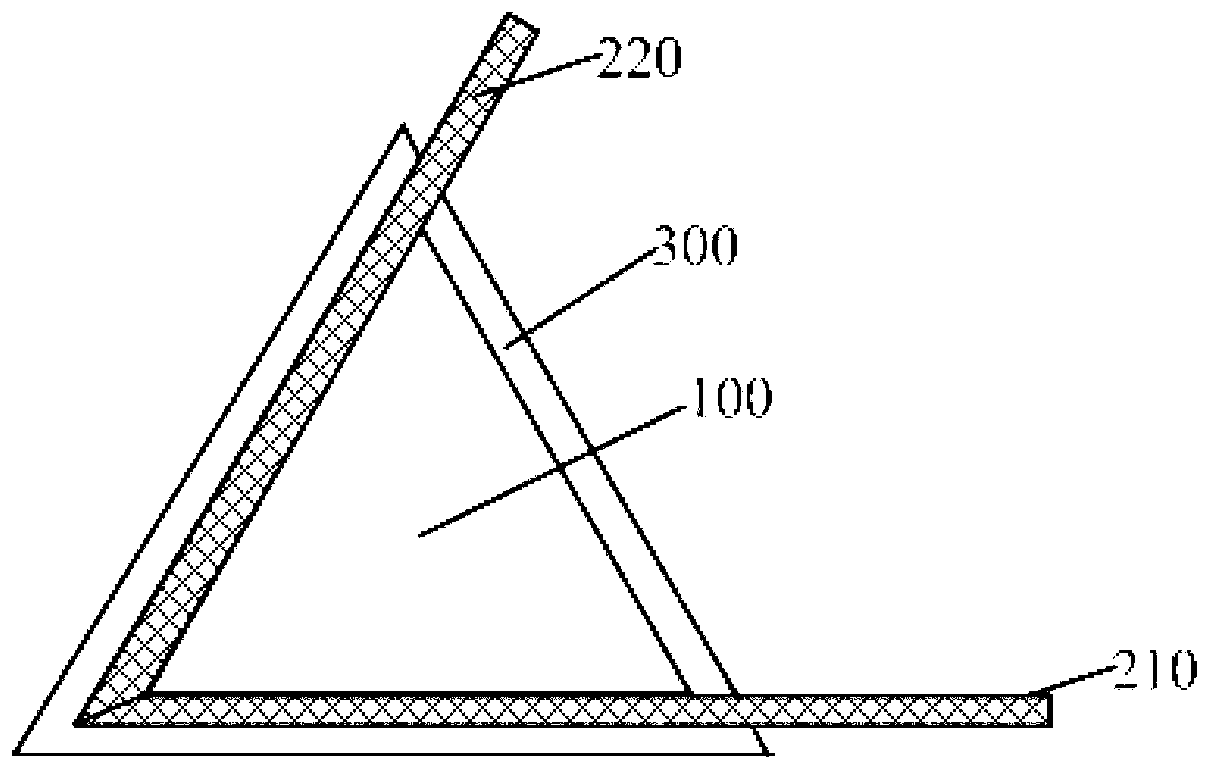

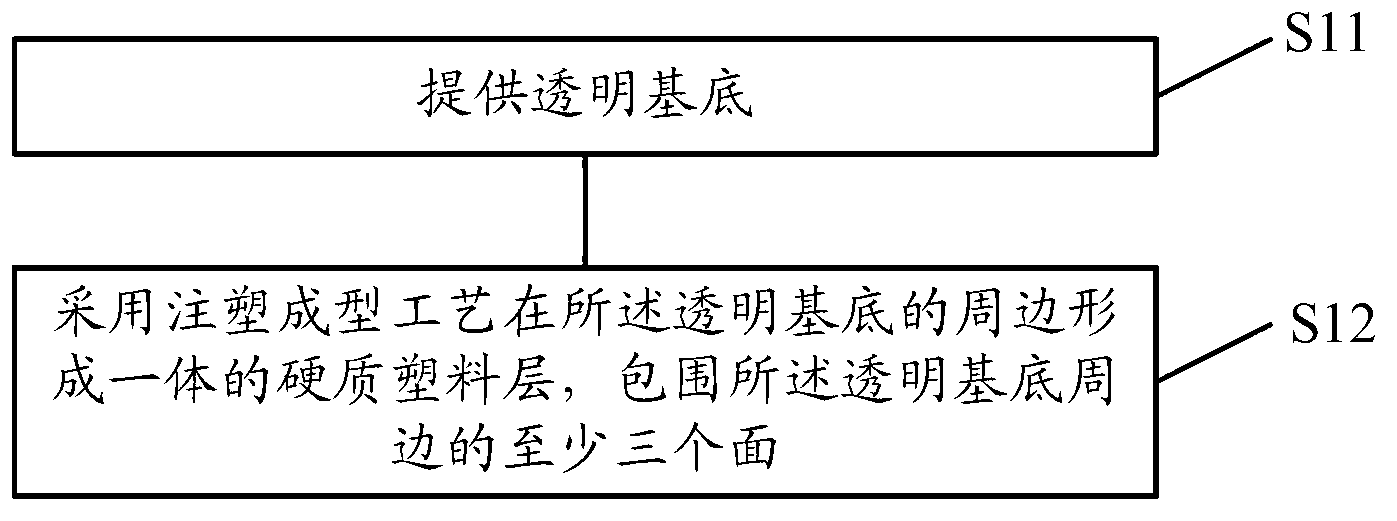

Car window assembly and binding method thereof

ActiveCN103057384AImprove adhesionImprove hemming efficiencyWindowsWindscreensEngineeringInjection moulding

Disclosed are a car window assembly and a binding method thereof. The car window assembly comprises a transparent base and an integrated hard plastic layer covering at least three peripheral sides of the transparent base. The binding method of the car window assembly includes: providing the transparent base; forming the integrated hard plastic layer on the periphery of the transparent base by injection molding to cover at least three peripheral sides of the transparent base. Bond between the plastic layer and glass in the car window assembly is higher, no dislocation occurs, binding efficiency is higher, and production cost is lowered.

Owner:SAINT-GOBAIN GLASS FRANCE

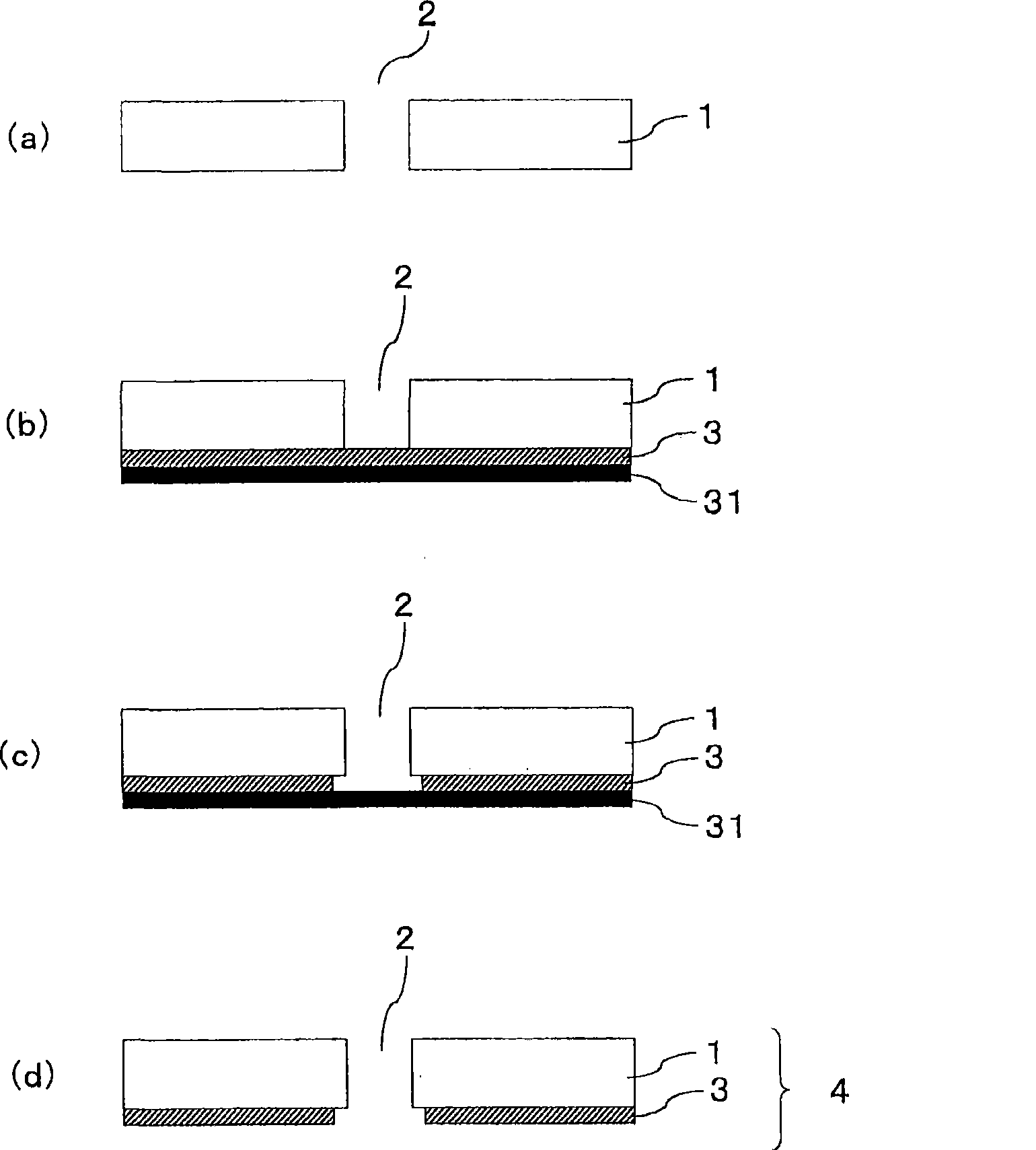

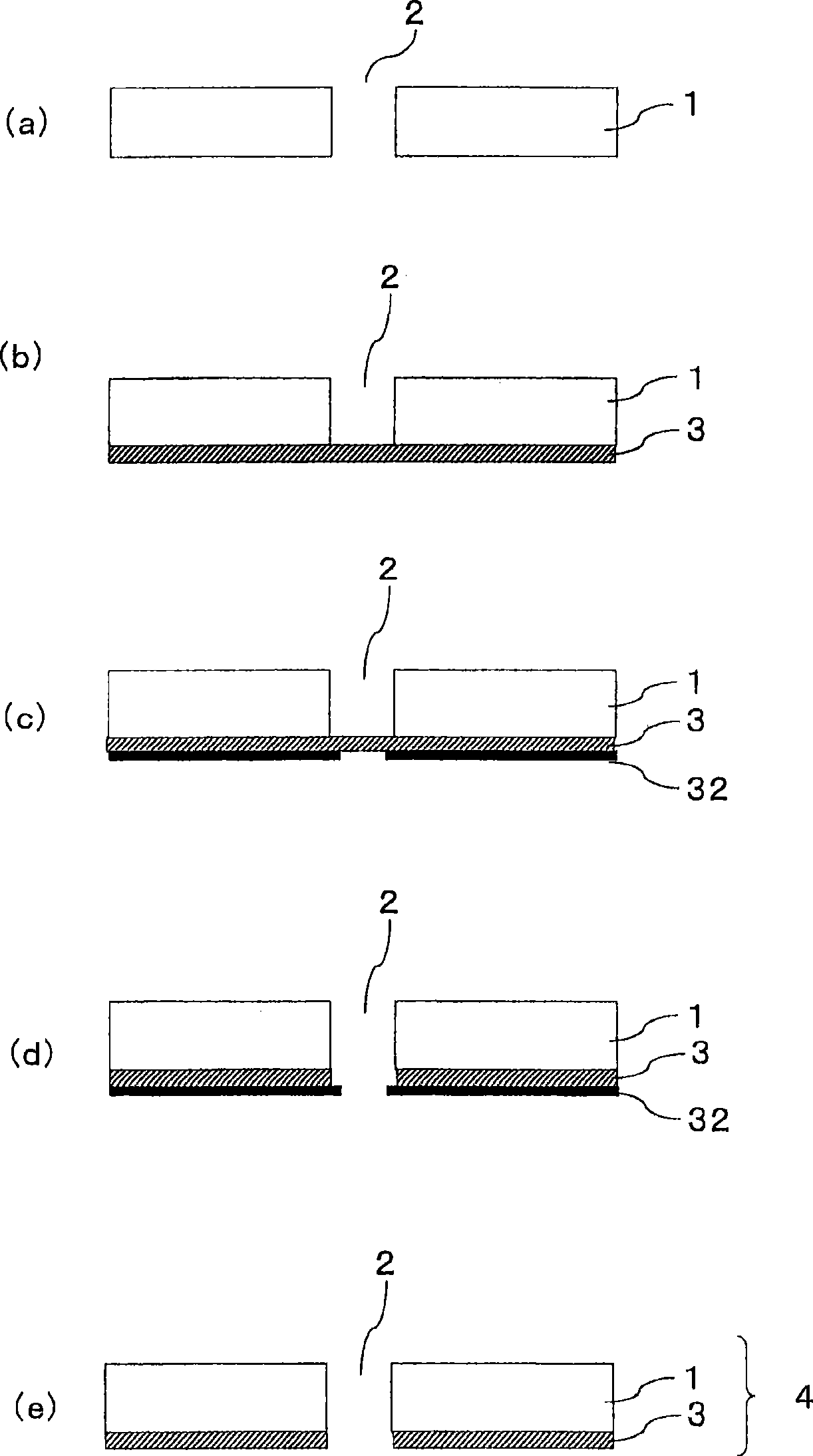

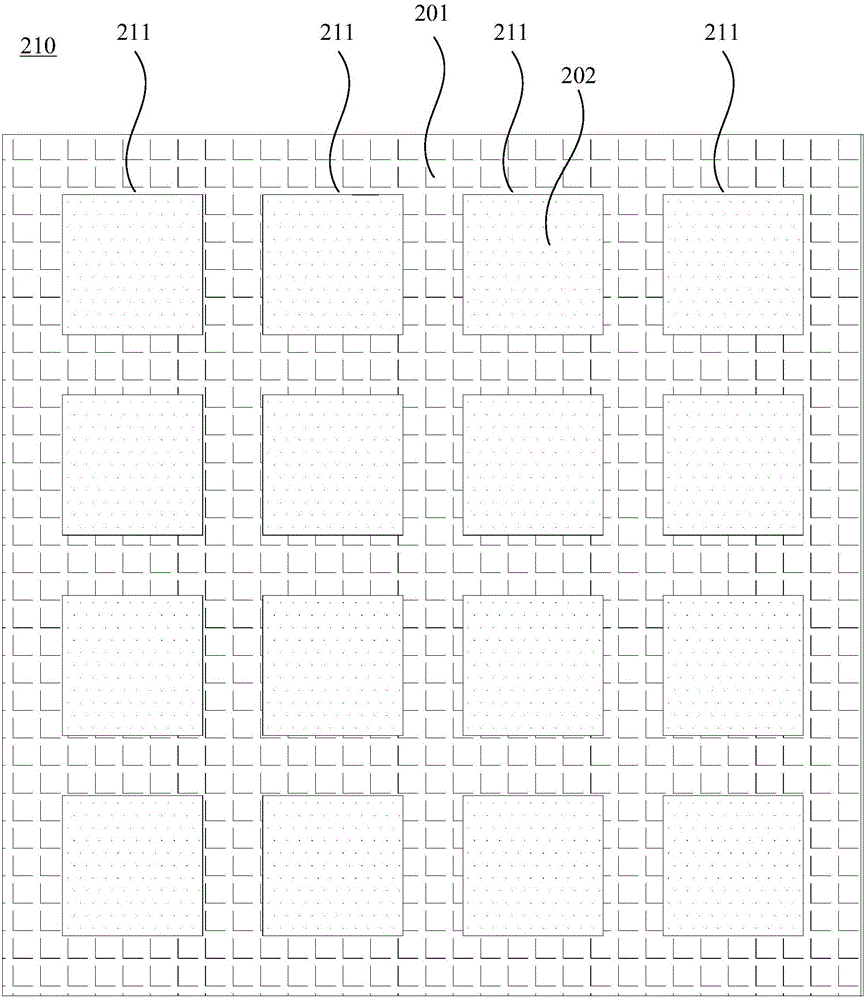

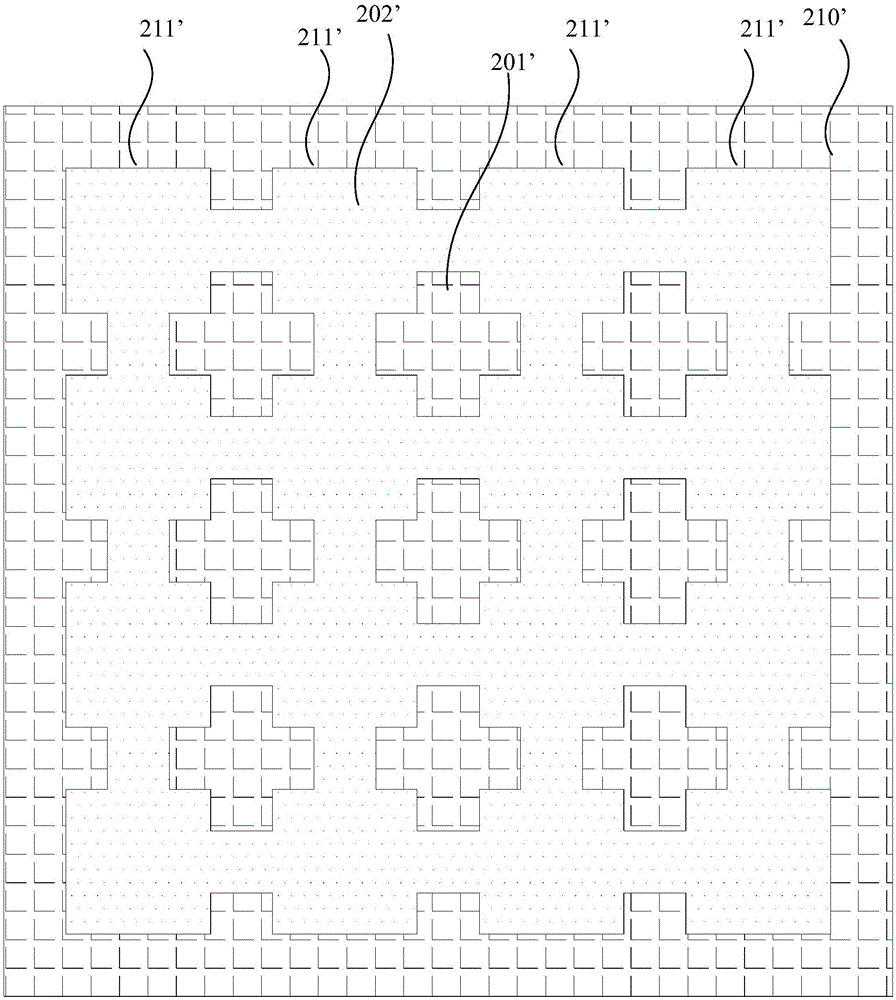

Method for manufacturing screen printing mask with resin, and screen printing mask with resin

InactiveCN101466555ANo misalignmentUniform thickness and free settingPrinted circuit assemblingScreen printersScreen printingSelf alignment

This invention provides a method for manufacturing a screen printing mask with a resin, comprising a screen printing mask having an opening part and a resin layer provided on one main surface of the screen printing mask and having an opening part at a position substantially identical to the position of the above opening part. The method is characterized by comprising the steps of covering a resin layer by lamination on one main surface of the screen printing mask and removing the resin layer in its part located at a position substantially identical to the position of the opening part of the screen printing mask in a self-alignment manner to form an opening part in the resin layer.

Owner:MITSUBISHI PAPER MILLS LTD

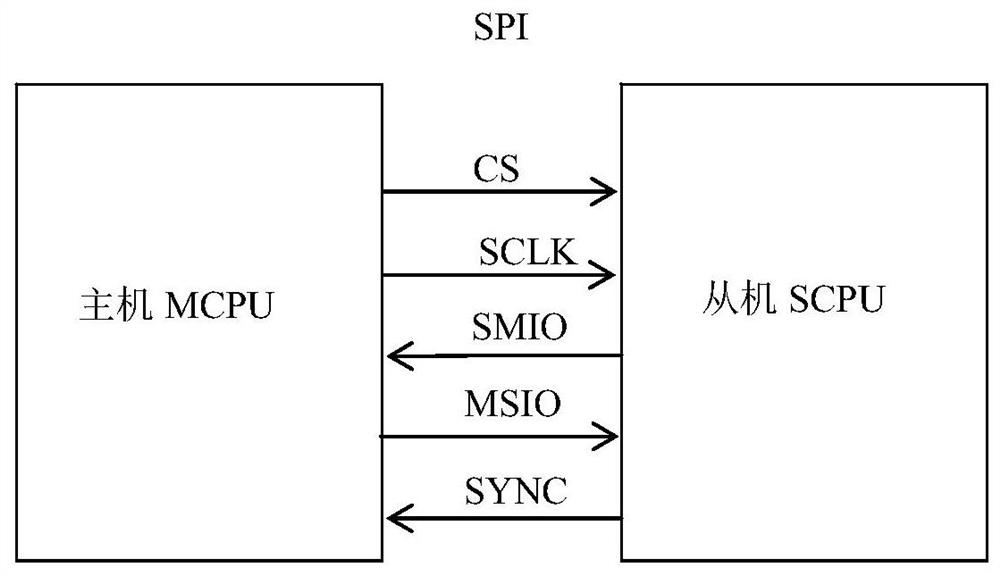

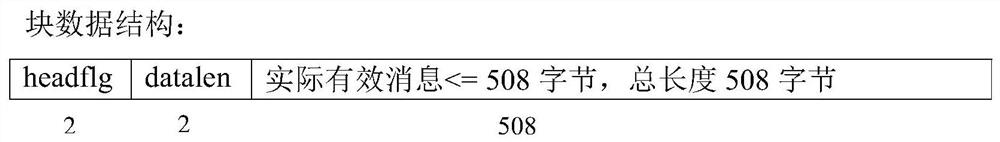

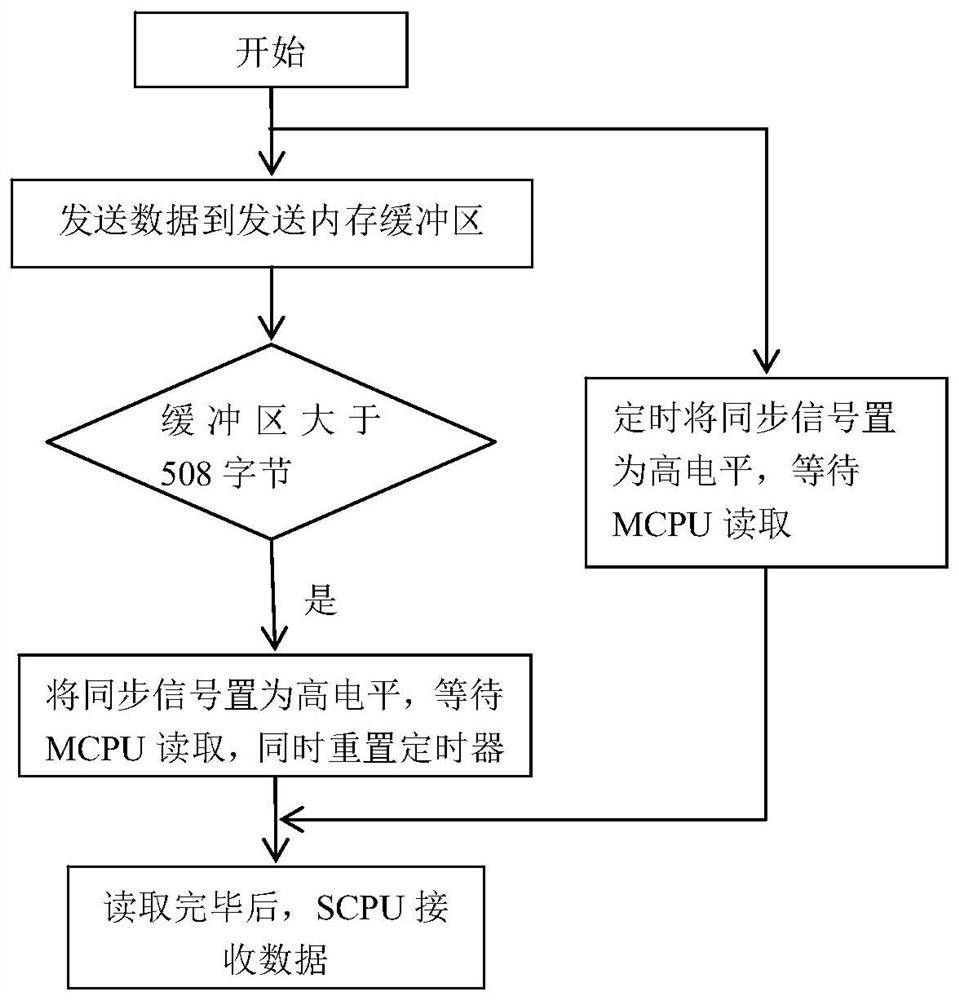

High-speed SPI master-slave communication method, terminal equipment and storage medium

ActiveCN111737175ASynchronized data exchange timeNo misalignmentElectric digital data processingData packTerminal equipment

The invention relates to a high-speed SPI master-slave communication method, terminal equipment and a storage medium, and the method comprises the following steps: S1, enabling a master to be connected with a slave through a five-wire SPI bus; S2, limiting that a block communication form is adopted between a master and a slave, wherein each block data comprises an information header identifier ofa fixed byte and effective information data; S3, sending and receiving slave data, and setting a synchronization signal to be at a high level when the slave sends the data; and S4, sending and receiving host data, wherein the host detects a synchronization signal at regular time, when the synchronization signal is detected to be at a high level, the host starts to read and send data, and when thehost finishes reading a block of data, DMA sending completion interruption and DMA receiving completion interruption are generated from an opportunity and a corresponding interruption processing program is carried out. According to the invention, the problem of dislocation generated in the existing high-speed SPI master-slave communication can be solved.

Owner:明见(厦门)技术有限公司

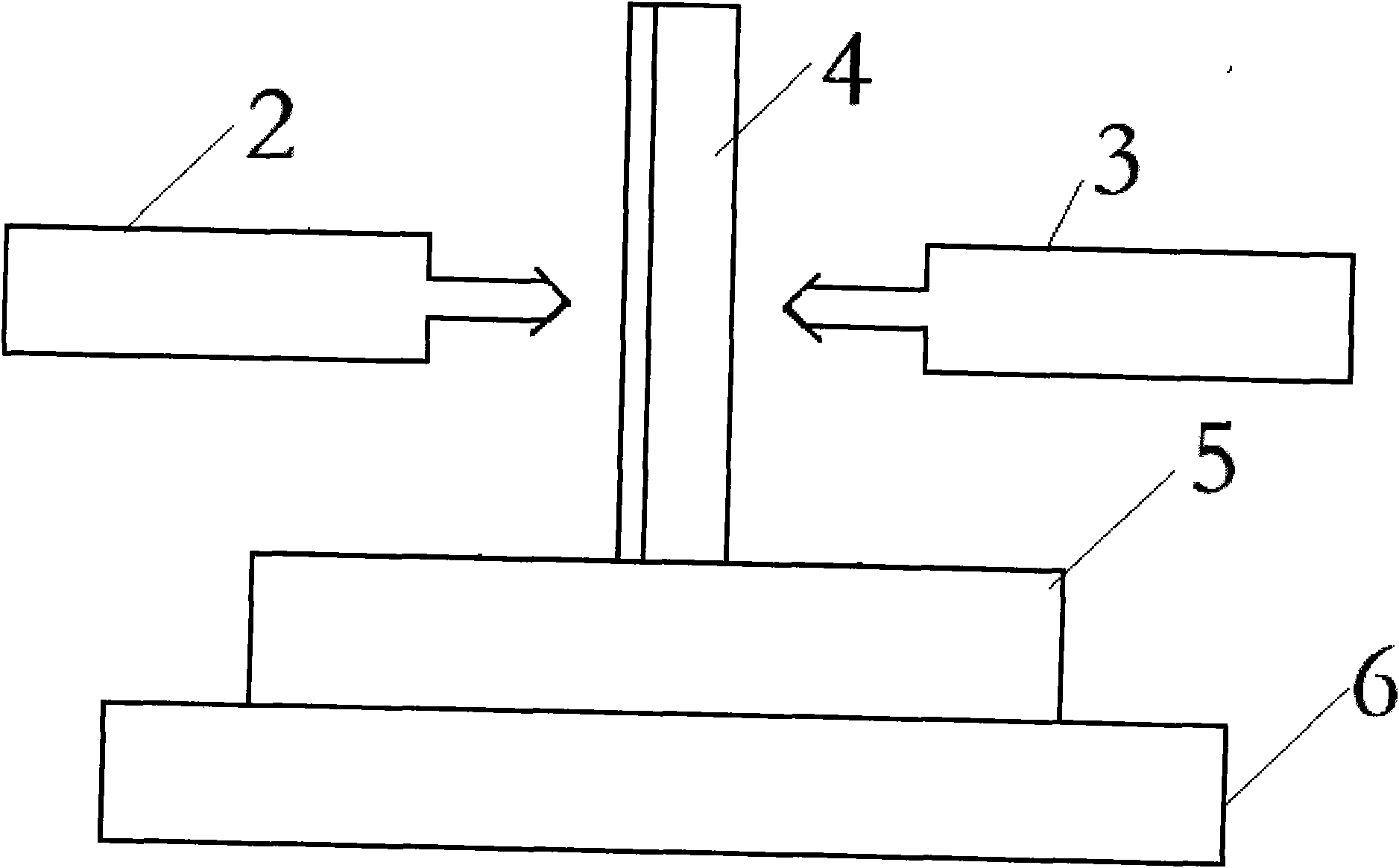

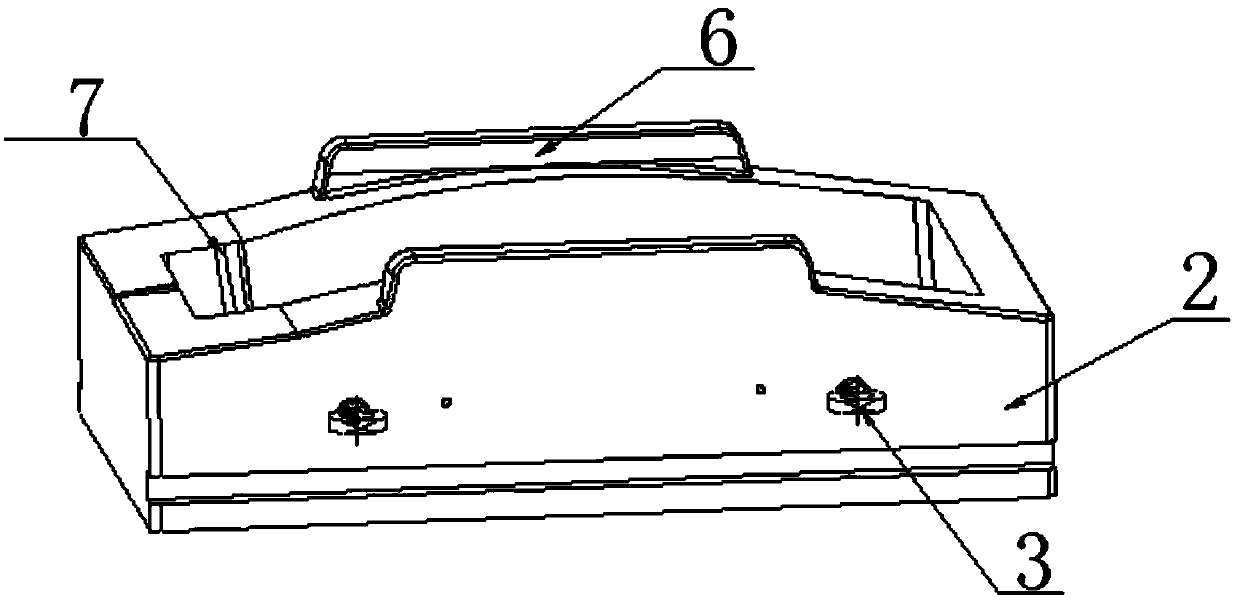

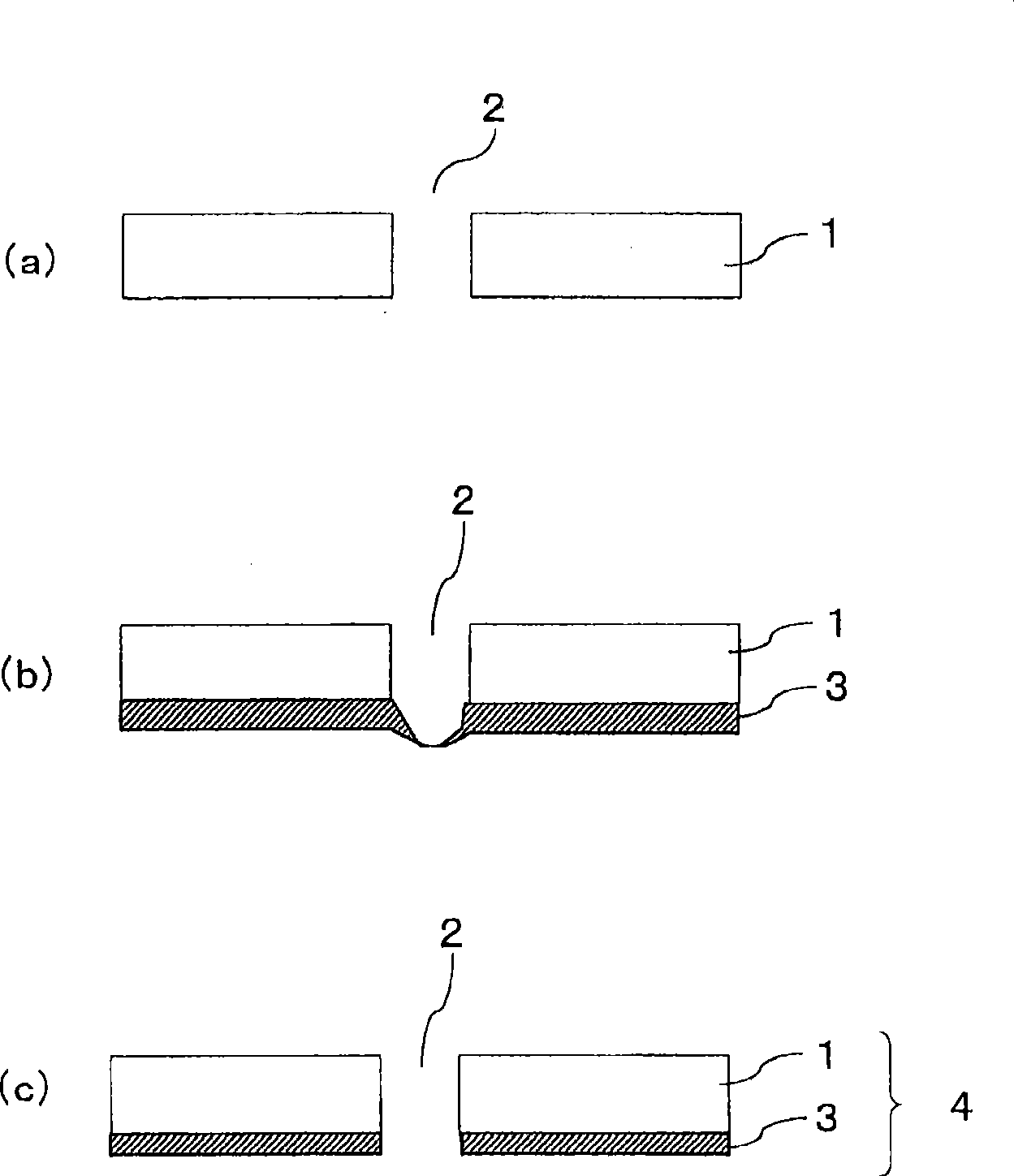

Method and device for alignment and assembly of glass micro nanofluidic chip

InactiveCN101691203APrecise and Fast AlignmentEasy to operateNanostructure manufacturePrecision positioning equipmentMicro motionBiomedical engineering

The invention discloses a method and a device for the alignment and assembly of a glass micro nanofluidic chip and belongs to the field of microelement assembly. In the method for the alignment and assembly of the glass micro nanofluidic chip, a microscope is adopted to observe the alignment condition of the glass micro nanofluidic chip, and a method of a fixed substrate and a movable cover plate is adopted to realize the micro nanochannel alignment between the cover plate and the substrate. The device observes the alignment condition of the glass micro nanofluidic chip by the inverted high-power microscope and drives a vacuum sucker absorbing the cover plate to move by a three-dimensional micro motion table, thereby realizing the three-dimensional micro motion of the cover plate. The device consists of the three-dimensional micro motion table, the vacuum absorption device, the inverted microscope and a micro hot plate. The method and the device can reduce the manufacturing period of the chip, reduce the manufacturing cost and difficulty of the chip and meet the increasing complex inter-channel alignment requirements.

Owner:DALIAN UNIV OF TECH

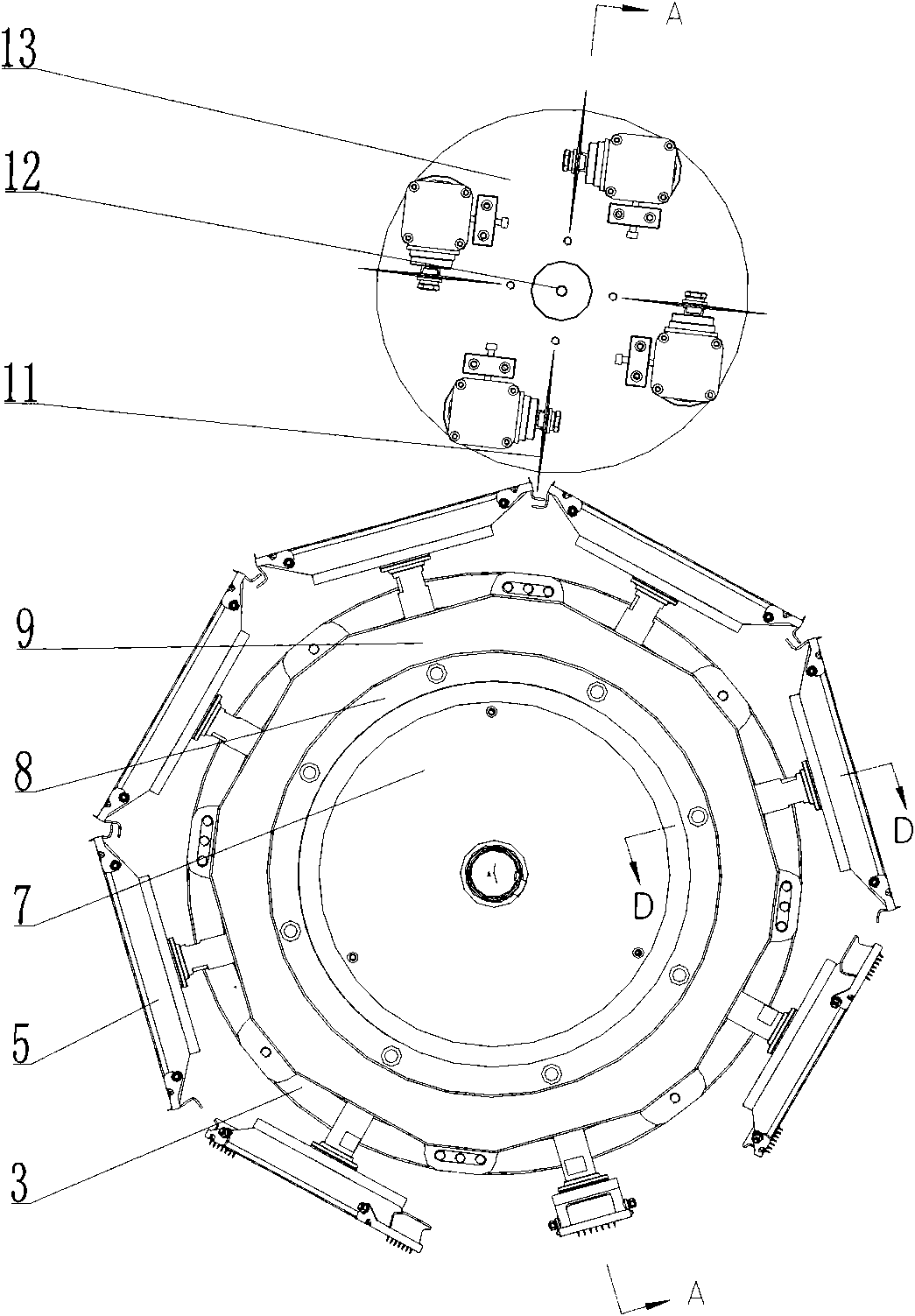

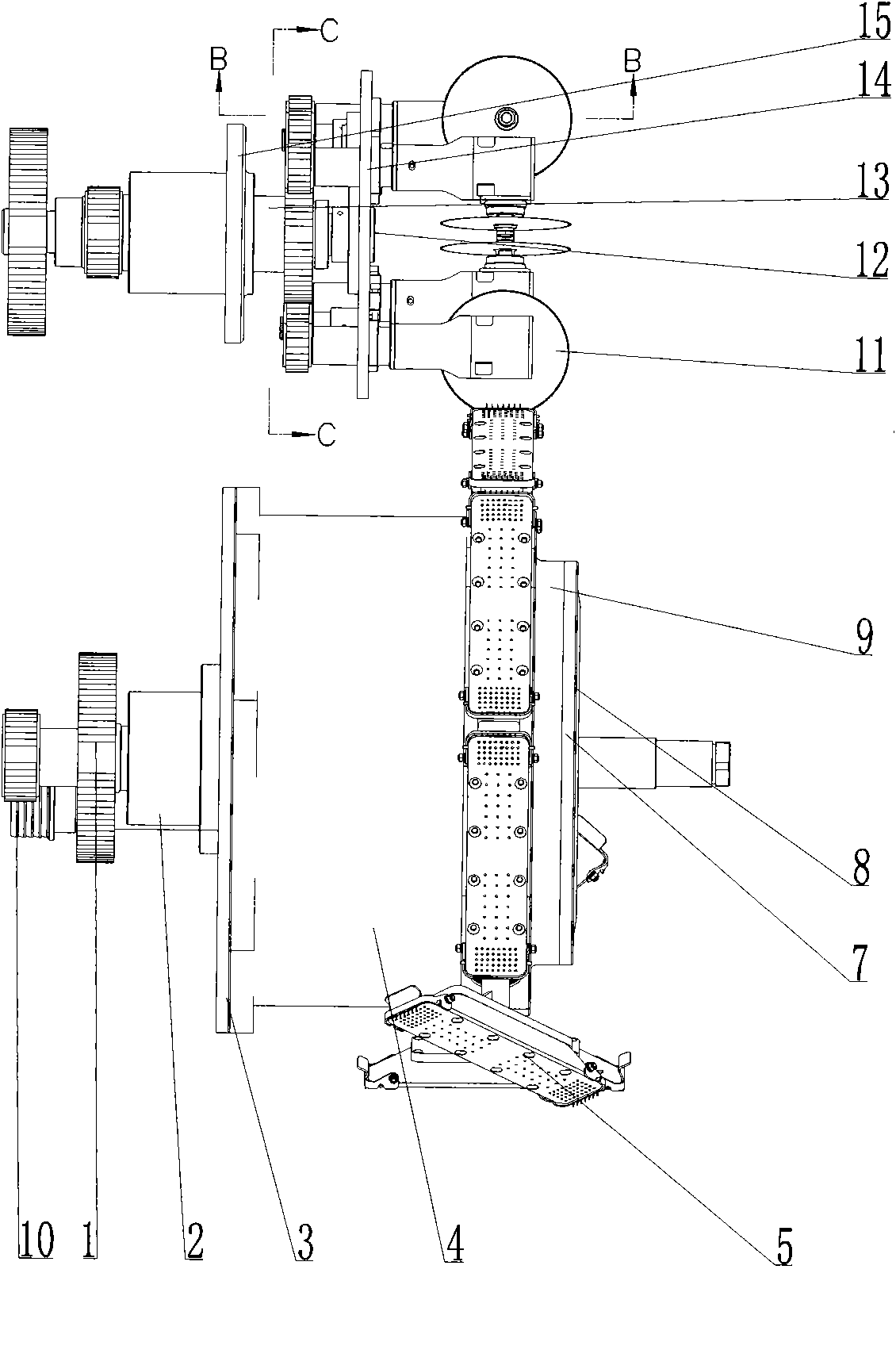

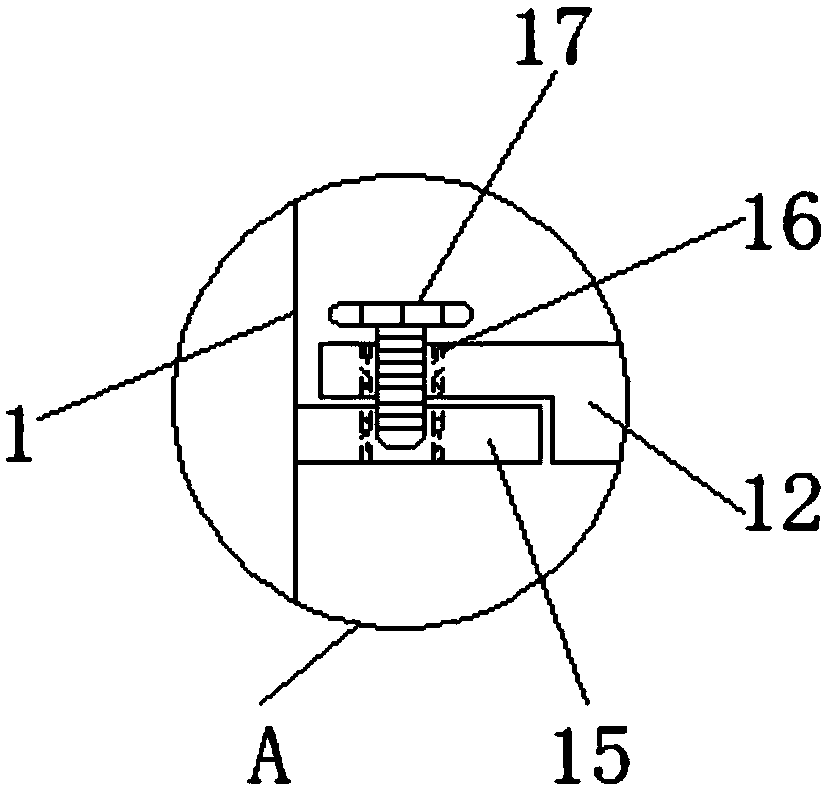

Elastic material cutting transverse state converter on production line of disposable sanitary articles

The invention relates to an elastic material cutting transverse state converter on a production line of disposable sanitary articles, which comprises a suction disc mechanism and a cutting mechanism, wherein the suction disc mechanism comprises a transverse state conversation main shaft, a positioning disc, an air suction ring, a rotating disc support seat and a rotating disc, eight suction discs are uniformly distributed in the radial direction of the rotating disc through bearings and hollow suction disc shafts, the cutting mechanism comprises a rotating cutting main shaft, a rotating cutting middle bearing seat, a rotating cutting fixed bearing seat and a cutter assembly fixing plate, four groups of cutter assemblies are uniformly distributed on the outer side surface of the cutter assembly fixing plate, and a belt transmission mechanism is arranged on the inner side surface of the cutter assembly fixing plate. The device of the invention has the advantages of compact structure and reasonable design, and realizes full-automatic operation.

Owner:ANQING HENG CHANG MACHINERY

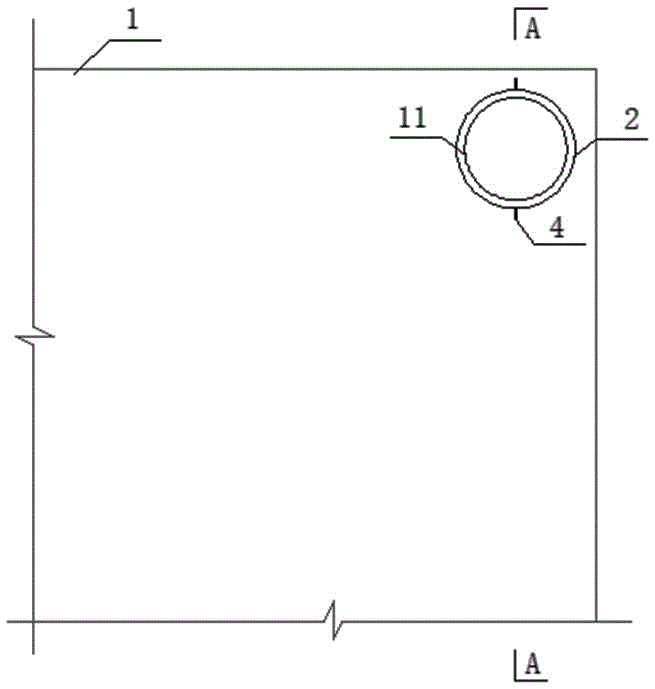

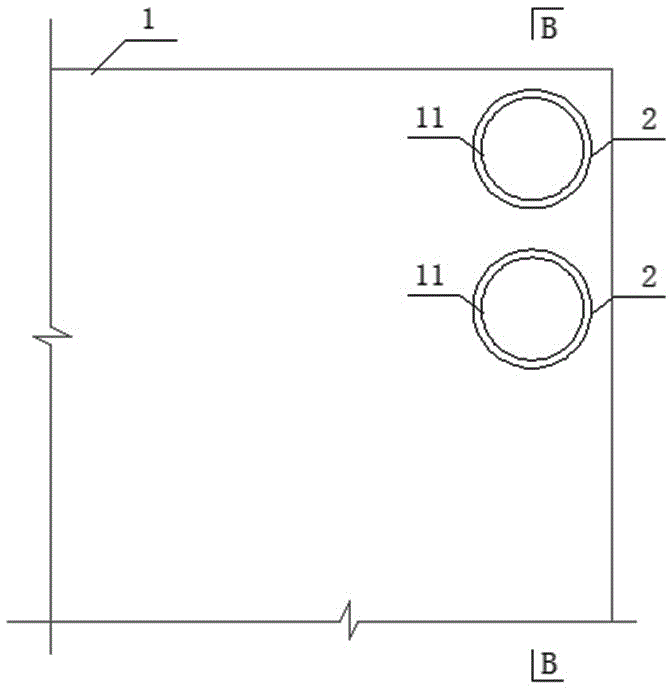

Accurately embedded water supply or water drainage casing pipe based on BIM and aluminum alloy formwork and construction method

ActiveCN106481880AGuarantee the verticality of the installationGuaranteed one-time successful installationPipe laying and repairPipesStructure of the EarthProduction drawing

Provided is a construction method for accurately embedding a water supply or water drainage casing pipe based on BIM and an aluminum alloy formwork. The construction method comprises the operation steps that 1, a model is built through the BIM technology, position collision checking of the water supply or water drainage casing pipe is conducted, and a water supply or water drainage casing pipe production drawing is deeply optimized and designed; 2, the aluminum alloy formwork of a floor or a wall or a beam where a pipeline passes through is designed through the BIM technology, and pipeline position information data are recorded and stored through a two-dimensional code; 3, the aluminum alloy formwork with a positioning clamp ring is produced according to the information model; 4, the aluminum alloy formwork of the floor or the wall or the beam is installed; and 5, concrete is poured into the floor or the wall or the beam, when the concrete strength meets the requirement, the aluminum alloy formwork is dismounted, and the water supply or water drainage casing pipe is accurately embedded in the concrete structure. The effect that pipelines on the floor are on the same straight line is ensured, and perpendicularity of later pipeline installation is ensured; pipelines on the beam or the wall can be on the same proper slope line, and gradient of later pipeline installation is ensured; and the pipelines can be installed at a time successfully, and rework caused by dimensional deviation is avoided.

Owner:CHINA RAILWAY SHANGHAI ENGINEERING BUREAU GROUP CO LTD +1

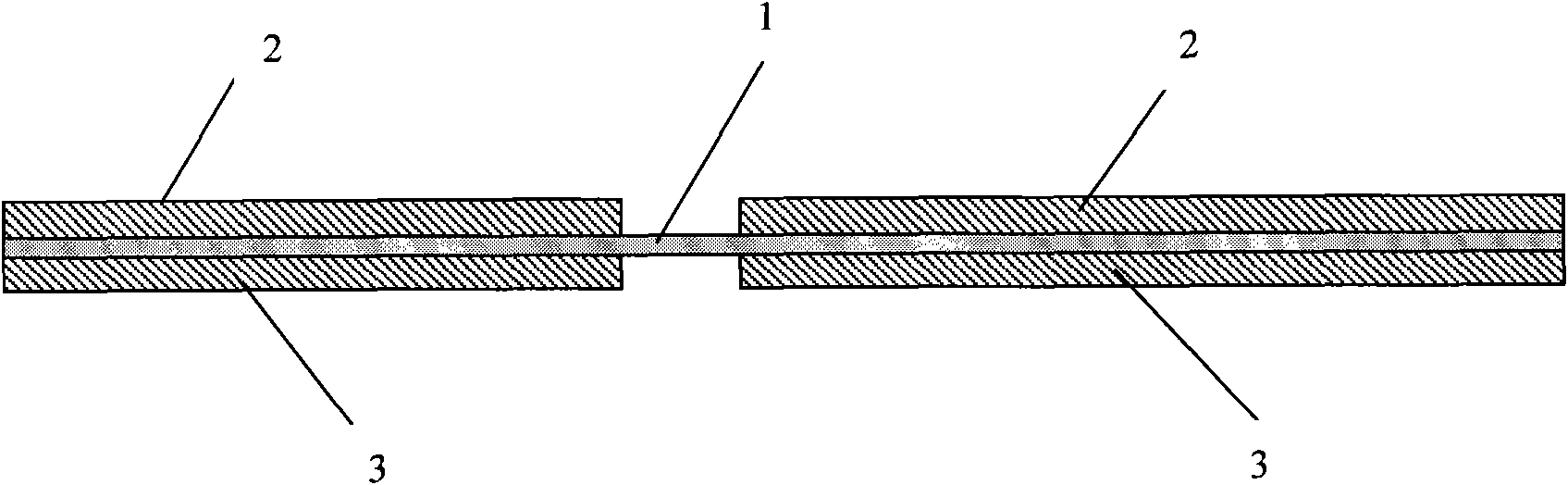

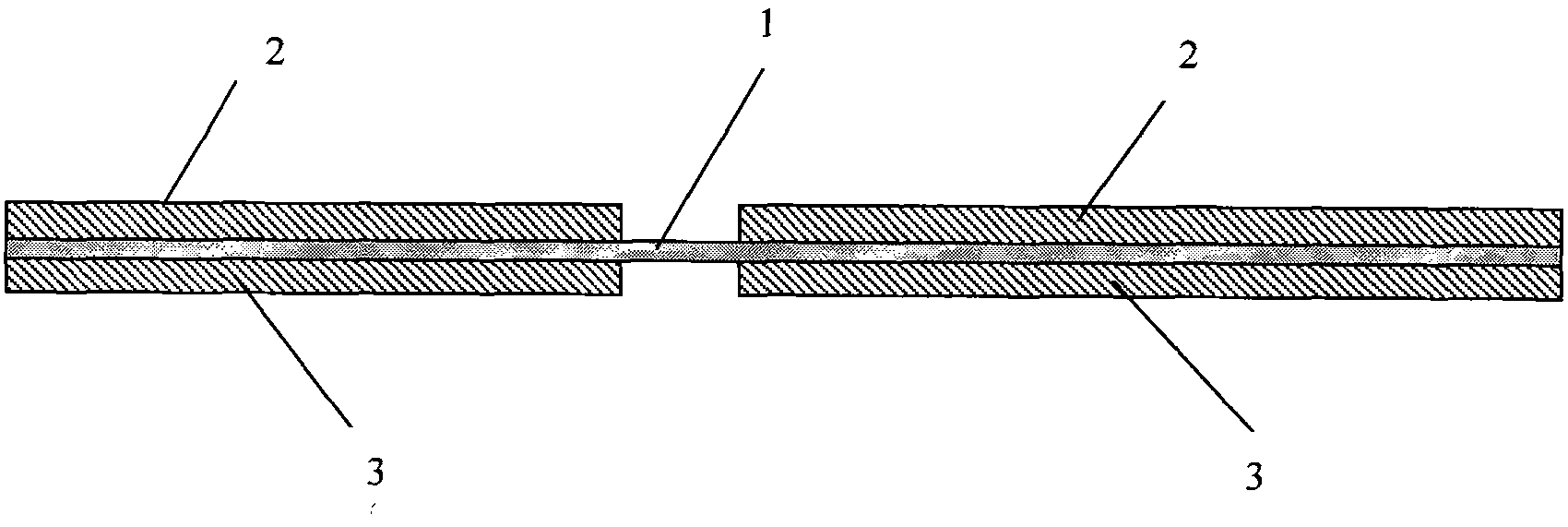

Method for intermittently coating battery pole piece

InactiveCN101985118AU-shape fragment improvementQuality improvementLiquid surface applicatorsCell electrodesPole pieceSlurry

The invention relates to a method for intermittently coating a battery pole piece. The method comprises the following steps of: firstly, performing single-sided intermittent coating by using slurry according to a normal coating operation process, and drying, and rolling to form a single-sided pole piece; secondly, placing the single-sided pole piece on the head of a coating machine to pass through an empty tape for one time; and finally, performing intermittent coating on the second surface of the single-sided pole piece after passing through the empty tape, and drying to obtain a product. By the method, the coating uniformity is effectively controlled; the difference between single-sided thickness and double-sided thickness is reduced; and the misplacement of the pole piece and U-shaped fragments are improved certainly.

Owner:BALEAF XIAMEN NEW ENERGY TECH

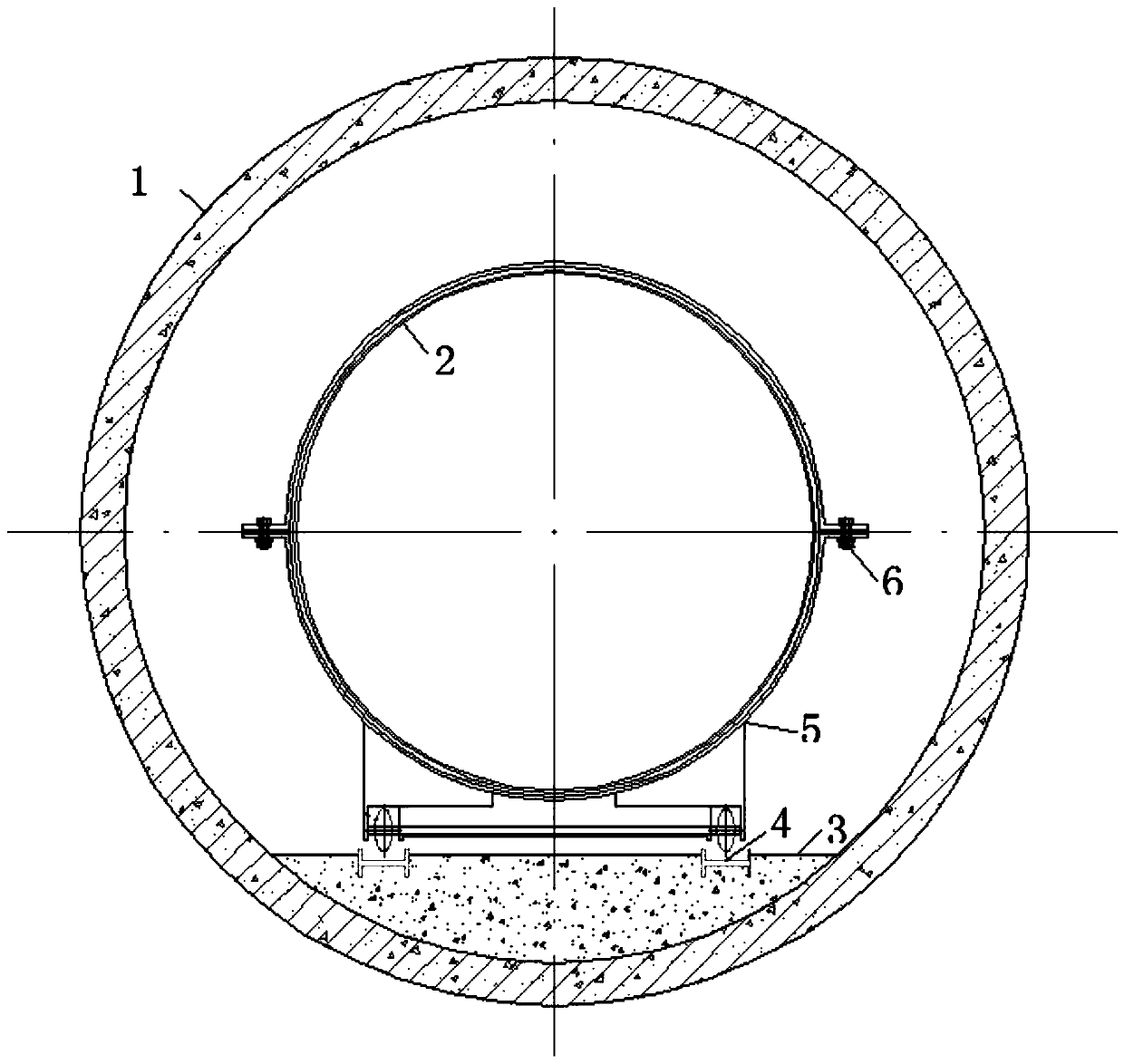

Pipe laying construction method and system inside sleeve pipe based on wheel-rail type pipe hoop

The invention relates to a pipe laying construction method and system inside a sleeve pipe based on a wheel-rail type pipe hoop. The method comprises the following steps that the sleeve pipe is constructed; after constructing of the sleeve pipe is completed, a concrete cushion layer is constructed inside the sleeve pipe; after constructing of the concrete cushion layer is completed, sliding railsare symmetrically arranged on set positions of the two sides of the central axis of the concrete cushion layer; the two ends of a steel pipe are correspondingly and fixedly provided with pre-machinedpipe hoops with pulleys; and the steel pipe is lifted to an inlet of one end of the sleeve pipe so as to be laid, the pulleys of the pipe hoops are connected to the sliding rails on the concrete cushion layer in a sliding mode, the sliding rails are used for providing a fixed advancing route for the pipe hoops, and therefore the steel pipe penetrates into the sleeve pipe. According to the method,aiming at the problems that the advancing track of the pulleys of a traditional steel pulley bracket method is difficult to be unified, and the matching degree and the stability of the steel pipe on the bracket are poor, the pipe laying construction method inside the sleeve pipe based on the wheel-rail type pipe hoop is provided, the sliding rails are utilized for providing the fixed advancing route for the pulleys, and it is ensured that the advancing tracks of the pulleys for conveying all the steel pipes are kept consistent, the steel pipes are free of dislocation, and the directions of thesteel pipes are free of deviation.

Owner:CHINA RAILWAY SIYUAN SURVEY & DESIGN GRP

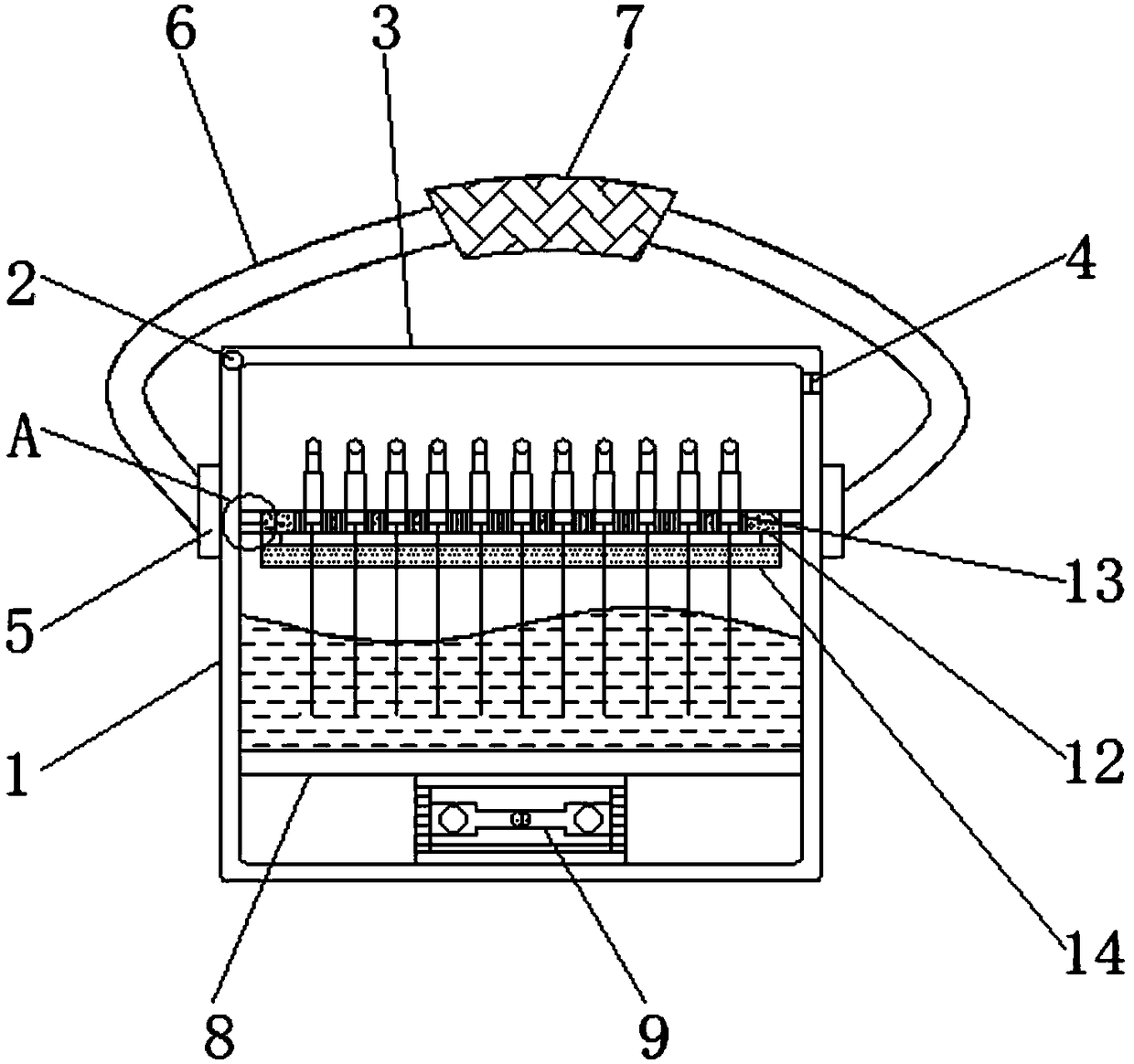

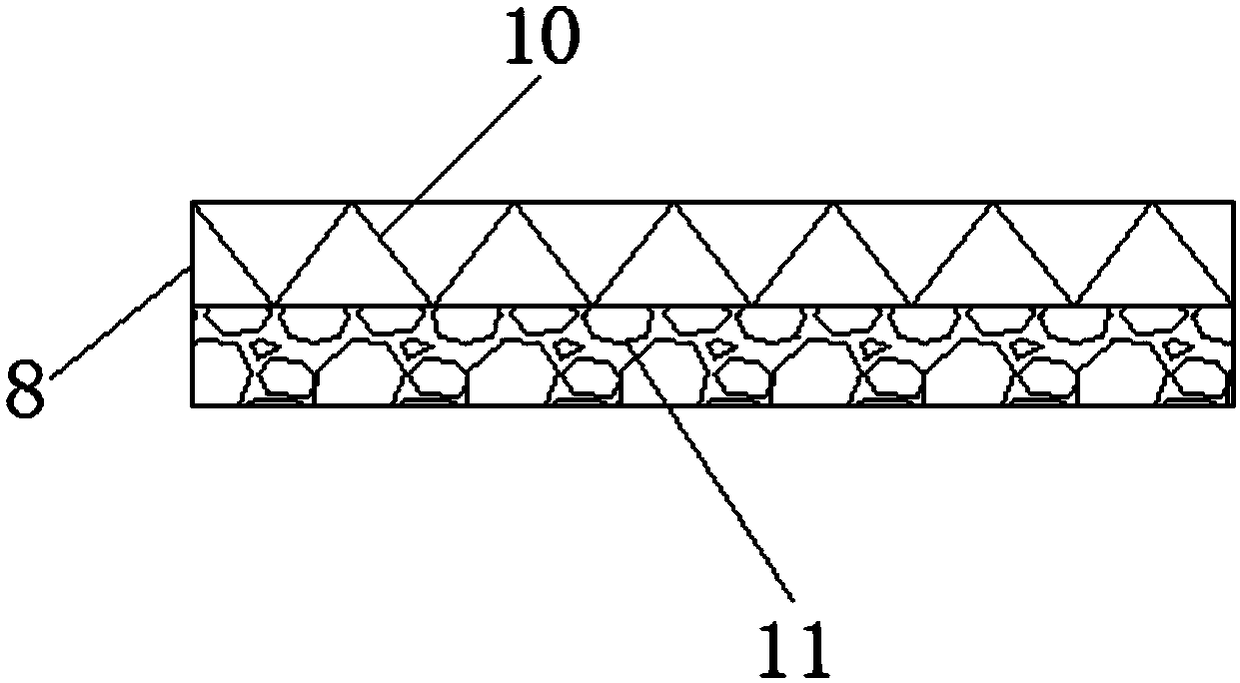

Acupuncture disinfection storage box for doctor of traditional Chinese medicine

The invention relates to an acupuncture disinfection storage box for a doctor of traditional Chinese medicine. The storage box comprises a tank body, connecting parts, a heating plate, a heating wire,a placing plate, a sponge placing rack, a support plate, a sleeve and an upper fixing sleeve; a rotary shaft is embedded and connected to the upper end of the tank body, a cover plate is fixedly connected with the rotary shaft, a lock latch is arranged at the right end of the cover plate, the connecting parts are fixedly at the left side wall and the right side wall of the tank body, and a handstrap is connected with the connecting parts; the tail end of a connecting spring is connected with a connecting column, and a clamping plate is fixed at the tail end of the connecting column; an antiskid pad is arranged on the surface of the clamping plate, the upper fixing sleeve is arranged above a fixing hole, and a lower fixing sleeve is arranged below the fixing hole. The acupuncture disinfection storage box for the doctor of traditional Chinese medicine is designed for storing silver needles; the fixing hole is formed in the device, and the connecting spring is arranged in a body wall ofthe fixing hole, so that the silver needles can be well fixed under the effect of the elasticity of the connecting spring, and the malposition is avoided.

Owner:魏江

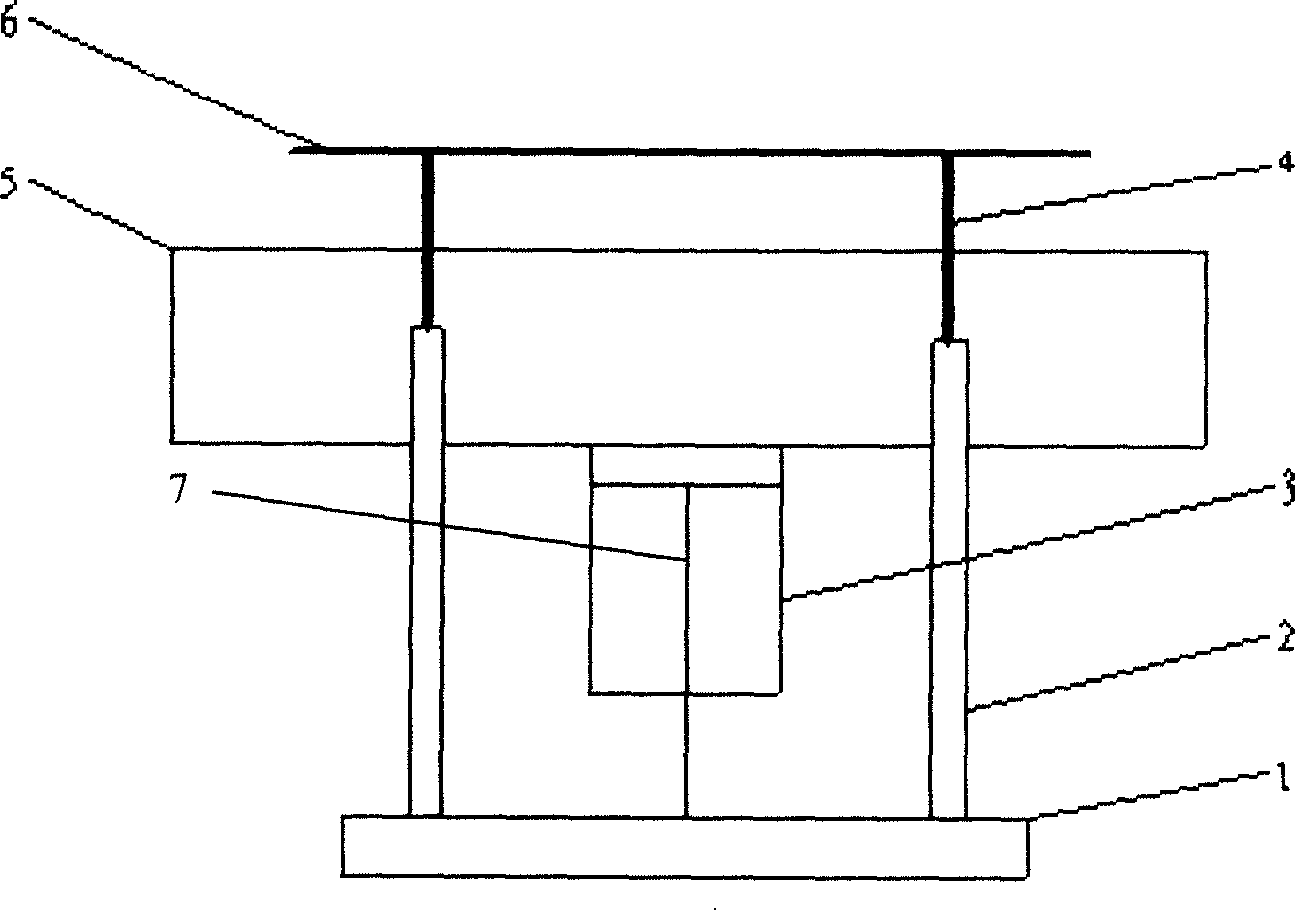

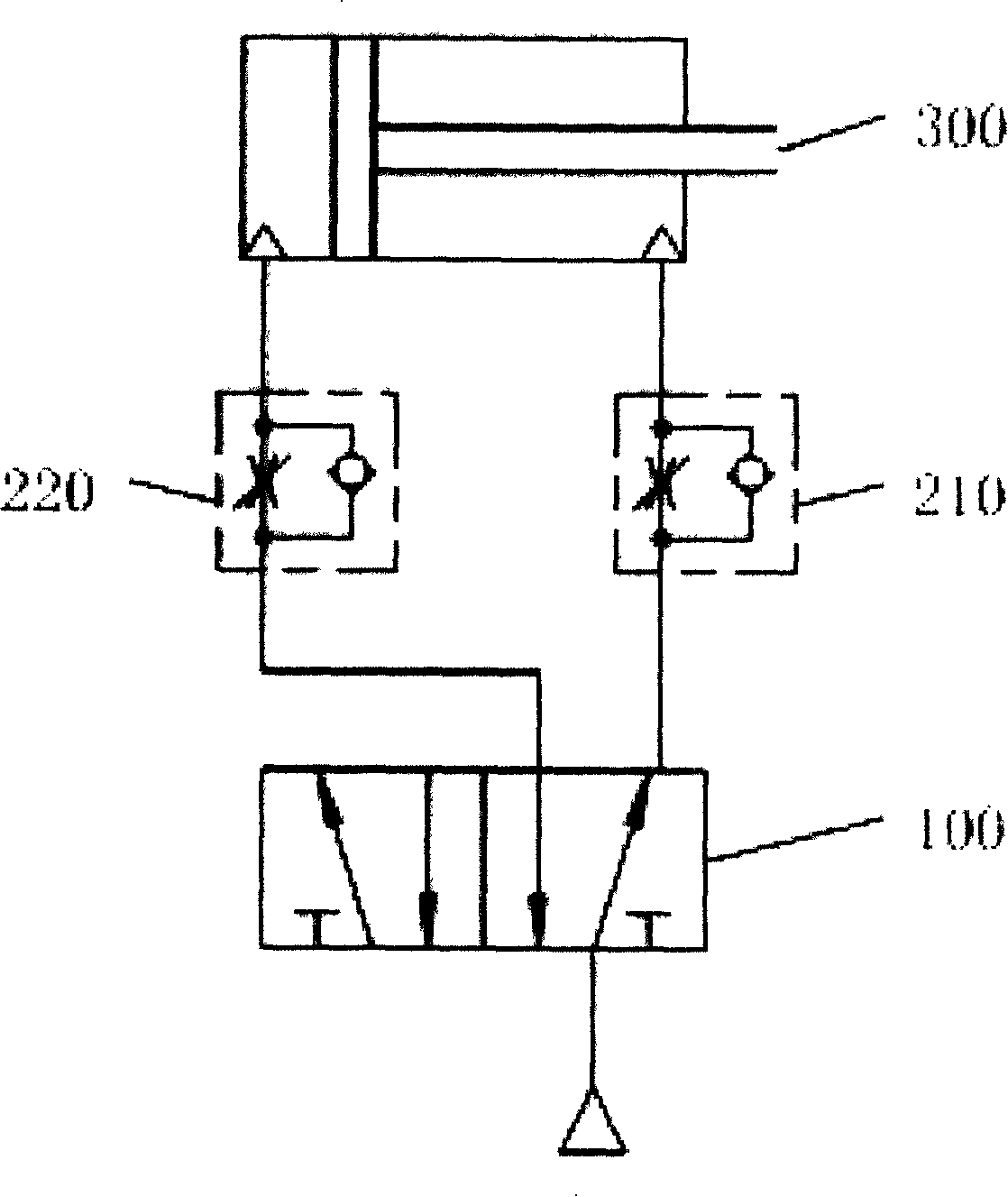

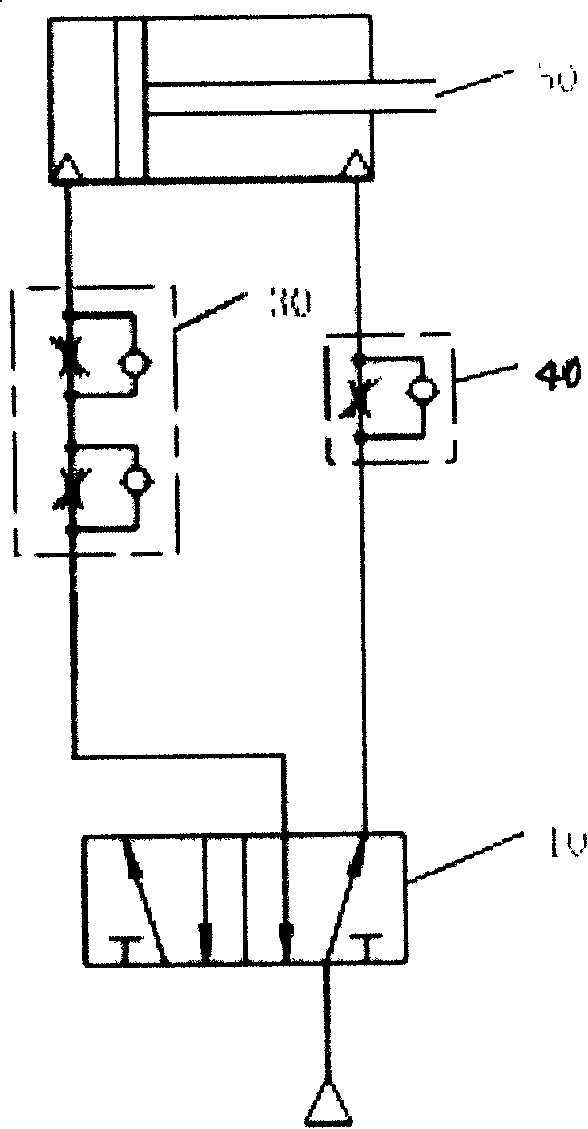

Control apparatus for eliminating reversing shake of dbl act gas cylinder

ActiveCN101201074AGuaranteed uptimeImprove stabilityServomotor componentsSemiconductor/solid-state device manufacturingAutomatic controlGas cylinder

The invention discloses a control device for eliminating the reverse judder of a double-acting air cylinder. The device is connected with the two air inlet ends of the double-acting air cylinder to control the movement of the cylinder. The device comprises a reversing valve, a bidirectional governing valve and a throttle valve. The inlet opening of the reversing valve is connected with air supply. One outlet of the reversing valve is connected with one air inlet end of the double-acting air cylinder by the bidirectional governing valve. The other outlet of the reversing valve is connected with the other air inlet end of the double-acting air cylinder by the throttle valve. In addition, the control device includes a detecting unit and an automatic control unit which are used for detecting the operation situation of the double-acting air cylinder and controlling the operation of the double-acting air cylinder. When the air cylinder is started, the rapid extension of a cylinder rod, namely the reverse judder of the double-acting air cylinder, can be eliminated by the control device. The invention can improve the stability and the reliability of the air cylinder and can not effect the running time requirement of the double-acting air cylinder at the same time.

Owner:BEIJING NAURA MICROELECTRONICS EQUIP CO LTD

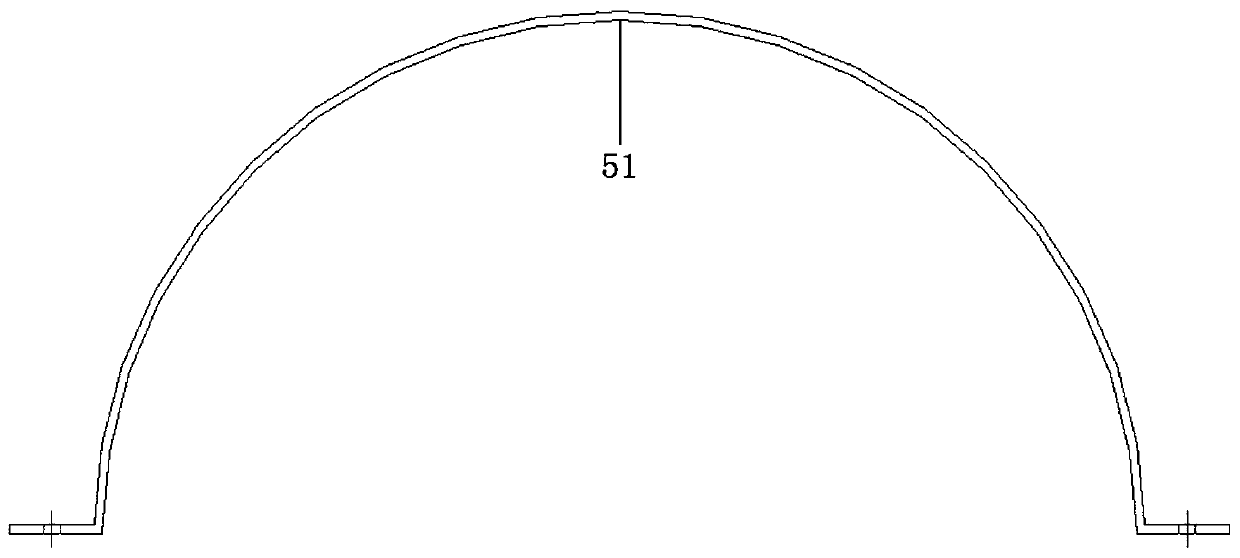

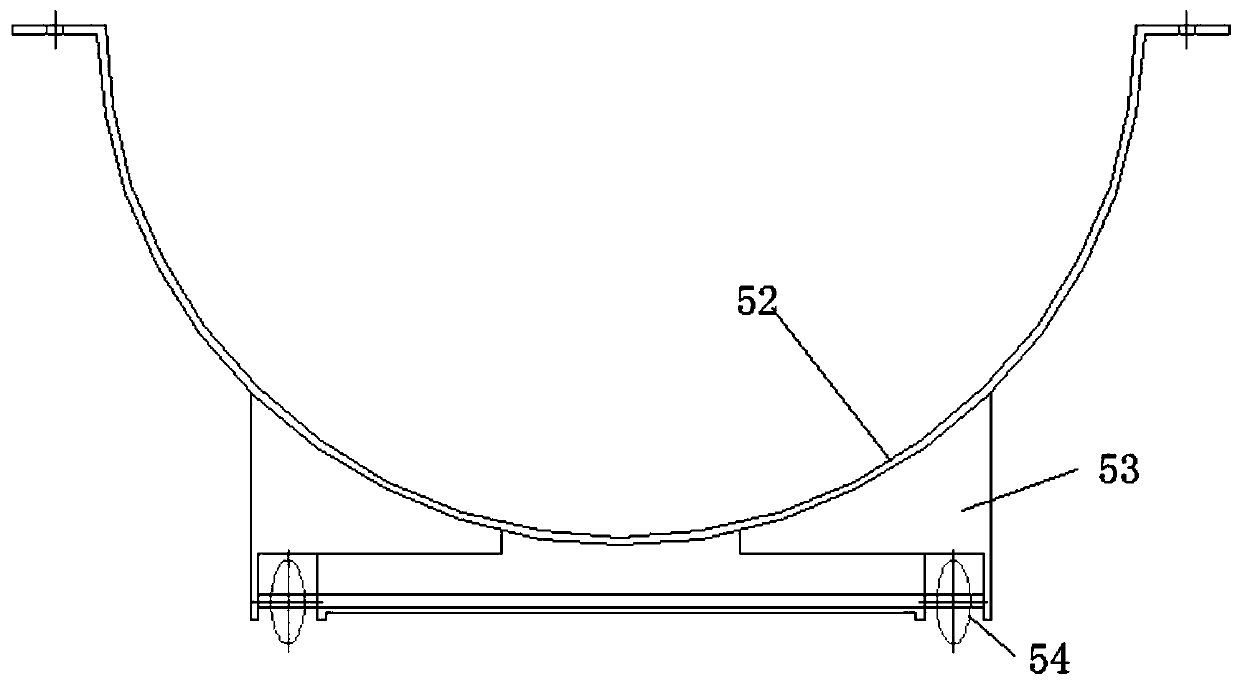

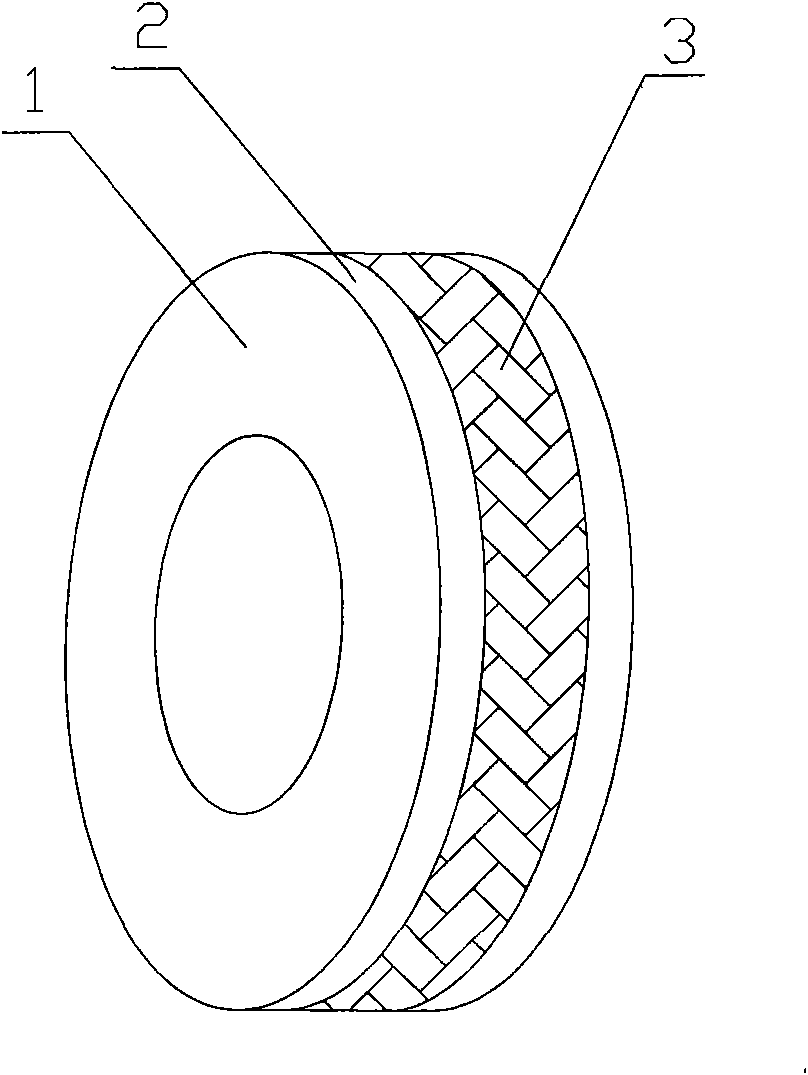

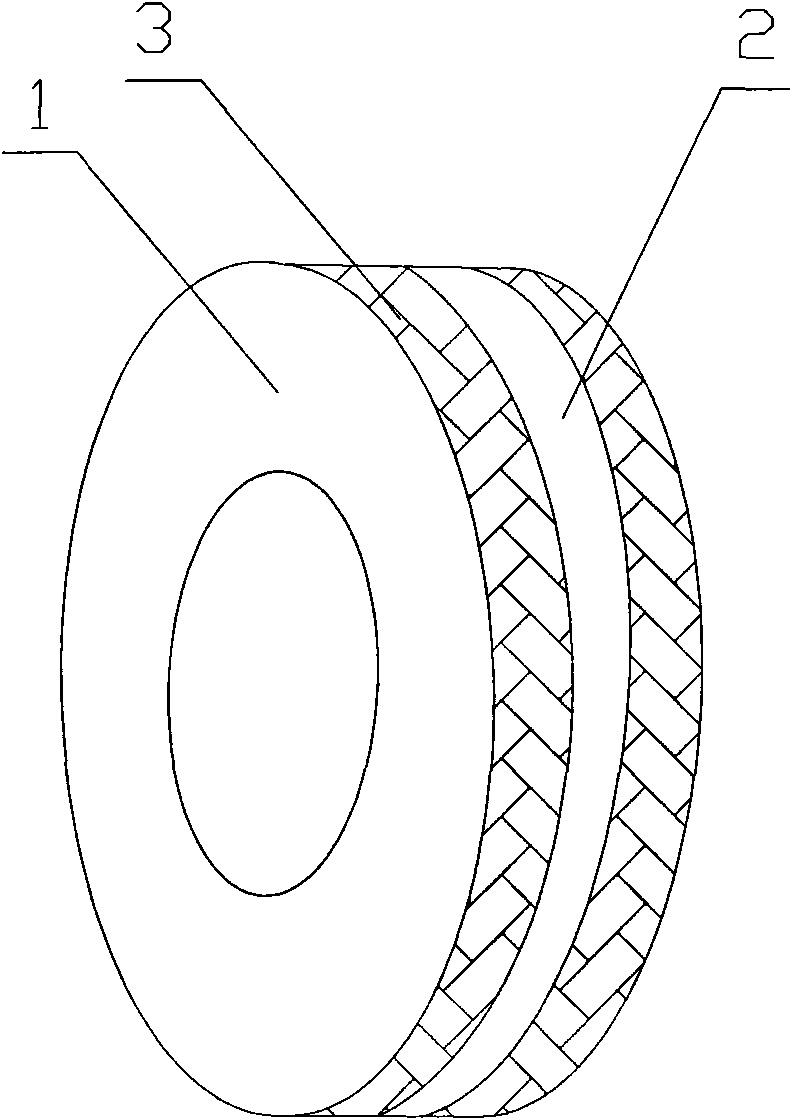

Method of retreading tyre

InactiveCN101549565AWithout breaking the balanceImprove handling comfortTyresMechanical engineeringTread

The invention relates to a method of retreading the old and useless full steel wire tyre by the meridian, comprising the steps as follow: milling the tyre surface, removing the vitiated tyre face and roughening the surface of the steel wire tyre by milling; gluing by coating the plasmagel on surface of the tyre; winding the new glued steel wire curtain cloth on the tread of tyre and adhering with the middle pad glue; adhering the matched type face glue on the tread of tyre, which wound by the glued steel wire curtain cloth, after the tyre face is adhered with glue; then sulphrizing in the tank that is sulphrizing the reinforced tread bracing layer into the sulphrizing tank. The invention will not damage the equilibrium of tyre, improve the controlling amenity, increase the anti-piercing and anti-explosion capability of the tread of tyre, prevent the skeleton of tyre from deforming and improve the retreading rate of tyre. The thickness of glue steel wire curtain cloth installed with the middle pad glue increase the cementation effect between tyre body and the tyre face, improve the anti-tearing capacity of tread block, decrease chunking and improve the bearing and buffer capacity of the tyre.

Owner:张乐平

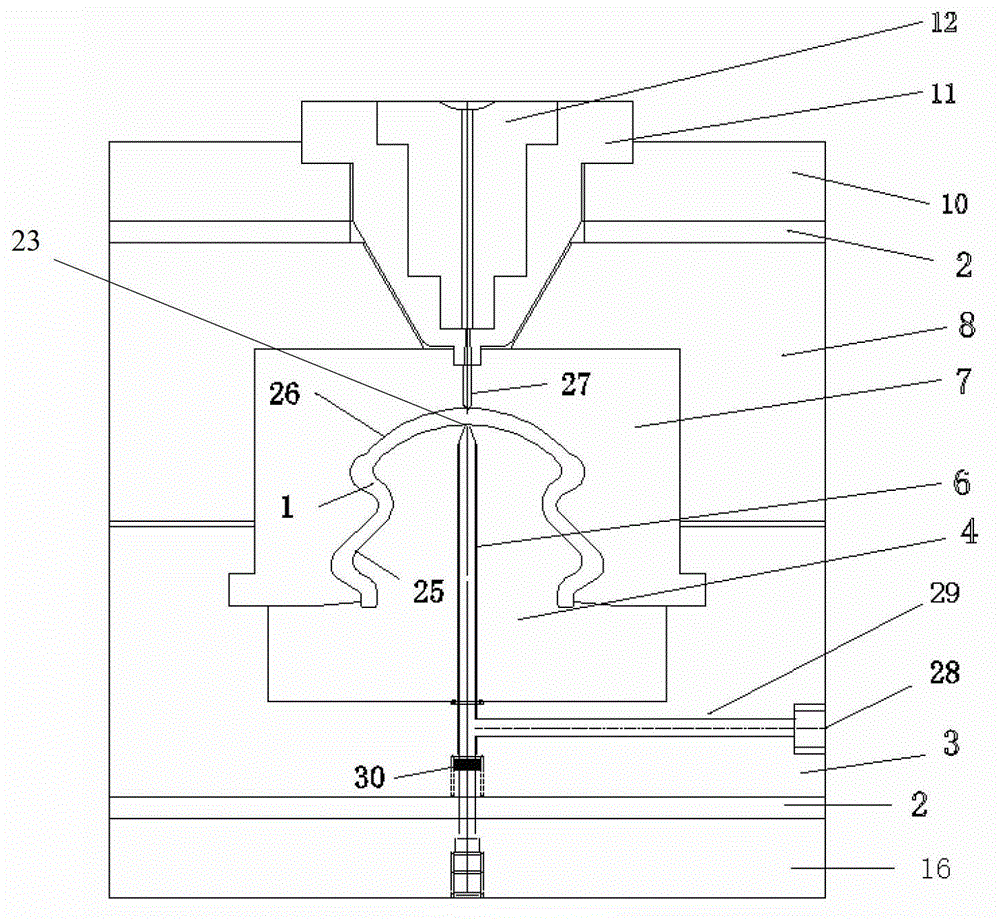

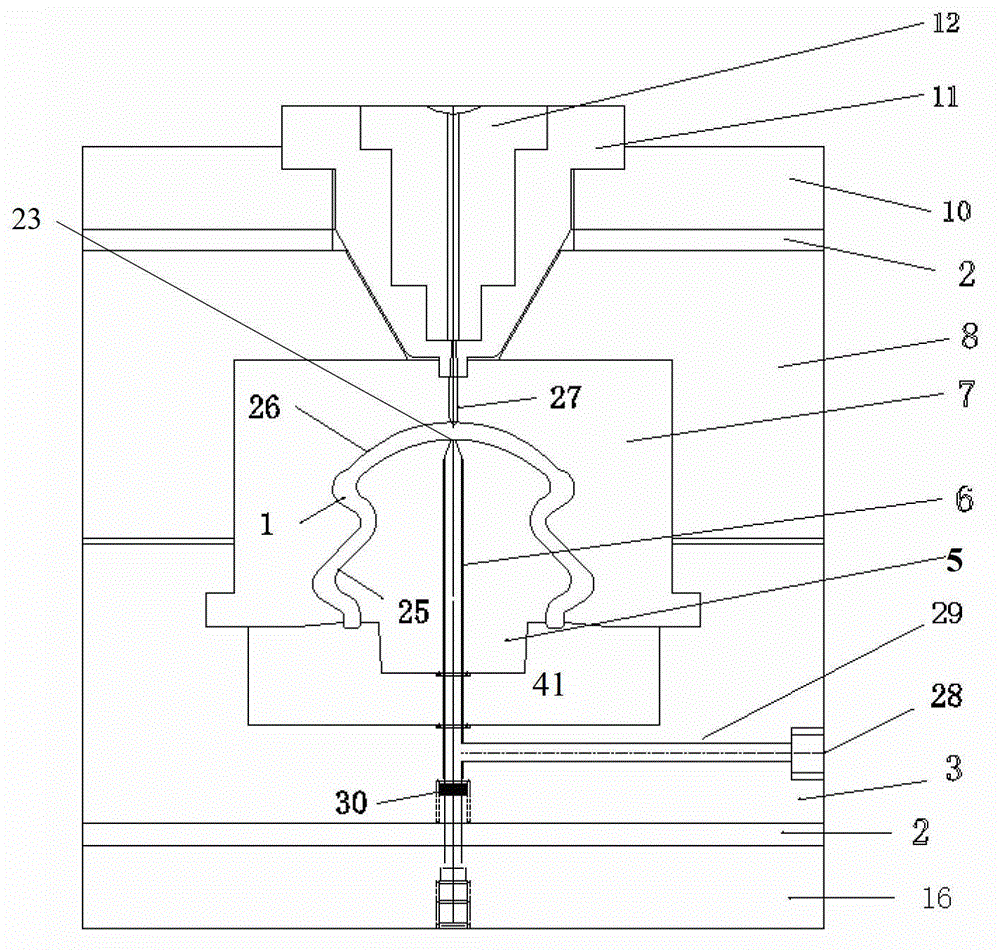

Method and device for manufacturing silicon rubber fire-cupping tool

InactiveCN103182763AIncrease productivityEasy and quick demouldingPneumatic massageDomestic articlesLiquid siliconNozzle

The invention discloses a method and a device for manufacturing a silicon rubber fire-cupping tool. The device comprises a nozzle, an internal mold core, a separable slide and a blowing and demolding device, wherein the slide comprises at least two separable slide blocks; a mold cavity for forming the silicon rubber fire-cupping tool is formed between the slide and the internal mold core; one end of the nozzle is connected with a channel for feeding the liquid silicon rubber raw material, while the other end is communicated with the mold cavity; and the blowing and demolding device is communicated with the mold cavity through a blowing hole opening which is arranged at the junction of the internal mold core and the mold cavity. The method takes the liquid silicon rubber as a raw material, and adopts the injected silicon rubber vulcanization molding technology to manufacture the silicon rubber fire-cupping tool with high elasticity, high transparency and complicated shape. The working procedures are simple and automated. The production efficiency is high, the demolding is simple and quick, and the device is not required to be dismantled or cleaned during the demolding process.

Owner:东莞市绿洲医疗器械有限公司

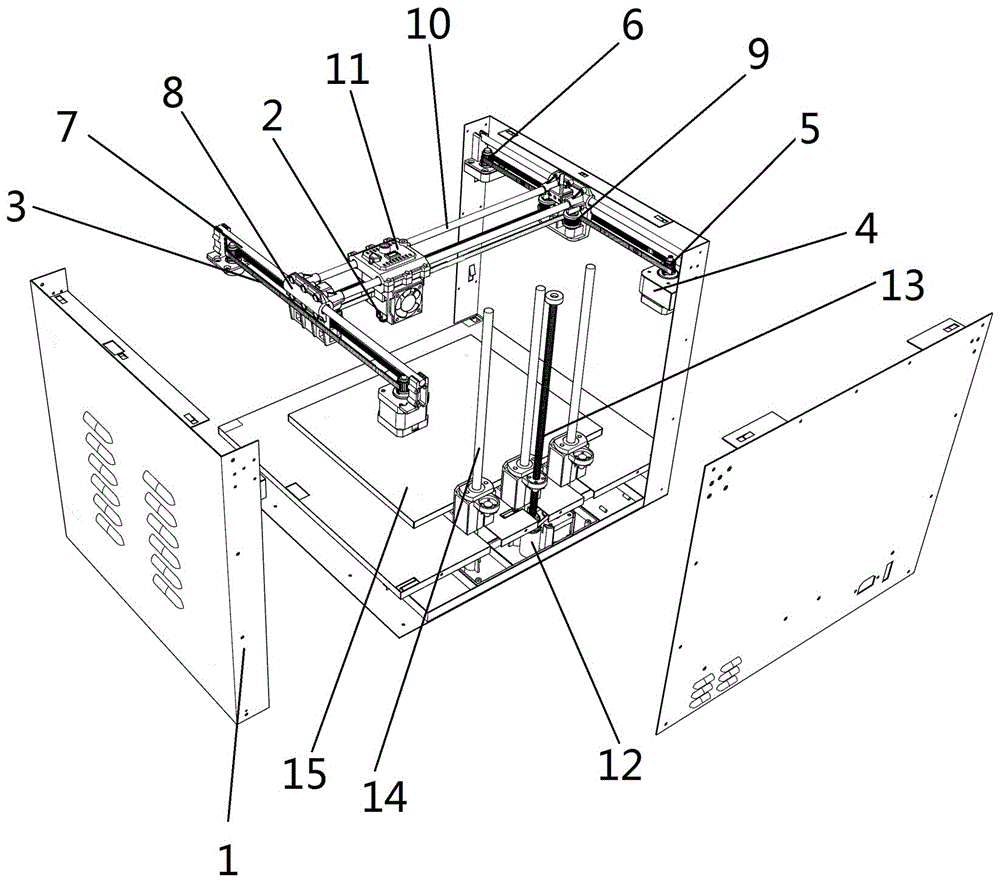

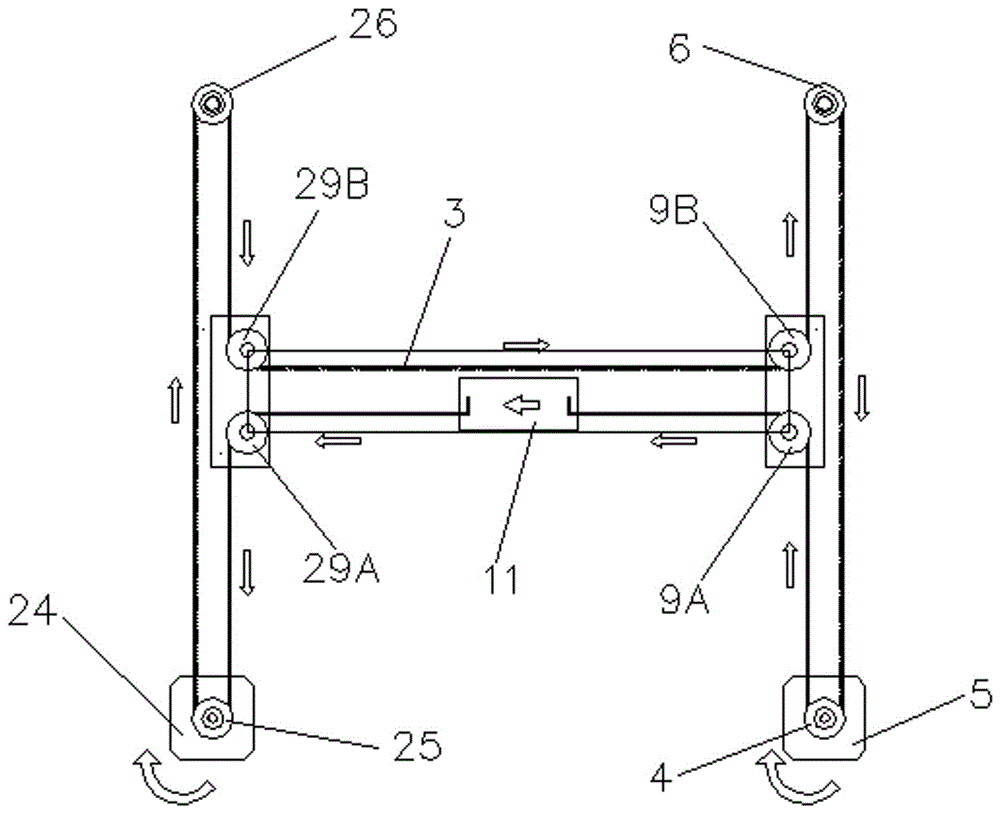

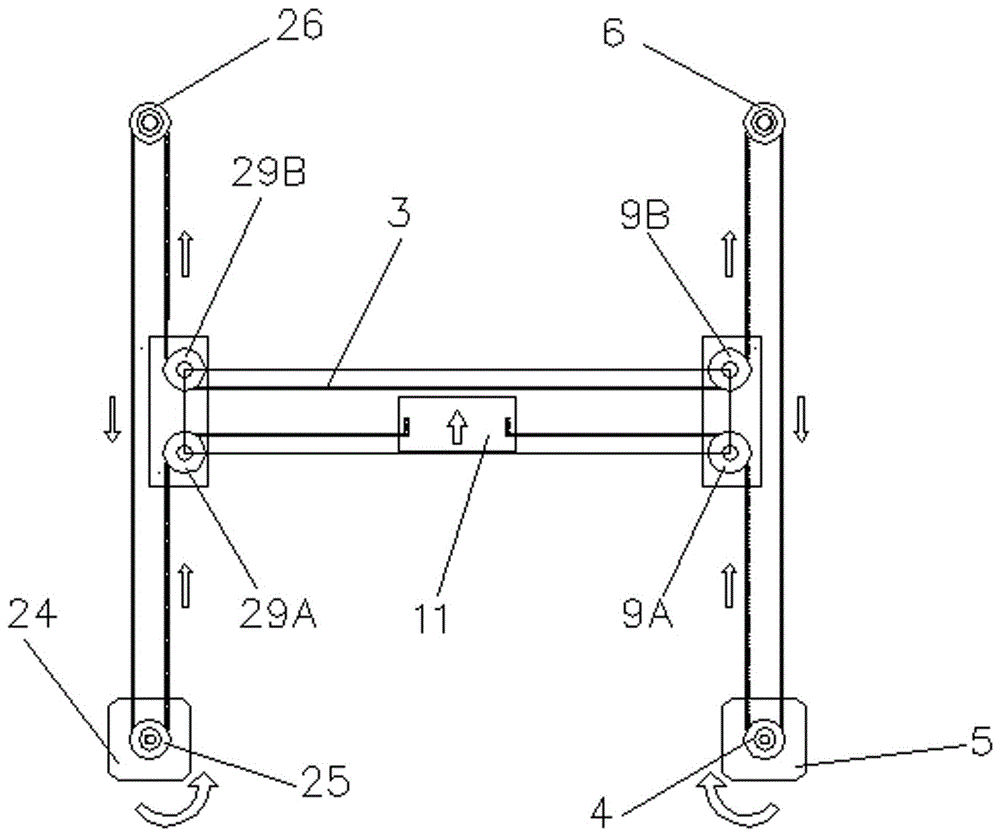

3D printer, special horizontal movement mechanism and horizontal movement method of 3D printer

InactiveCN105922599ASimple structureEasy to installAdditive manufacturing apparatusEngineering3d printer

Owner:HEBEI DAAI INTELLIGENT TECH CO LTD

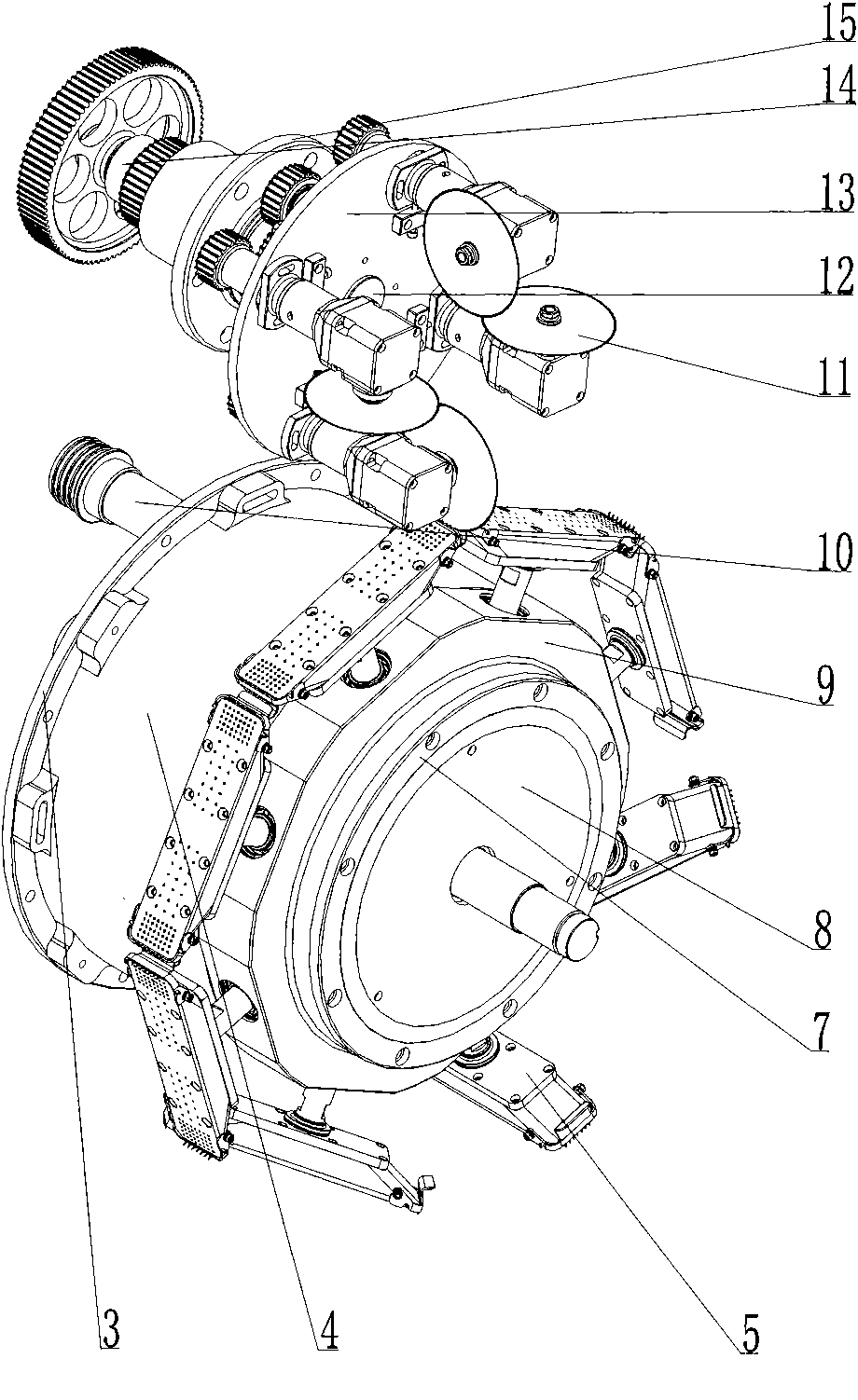

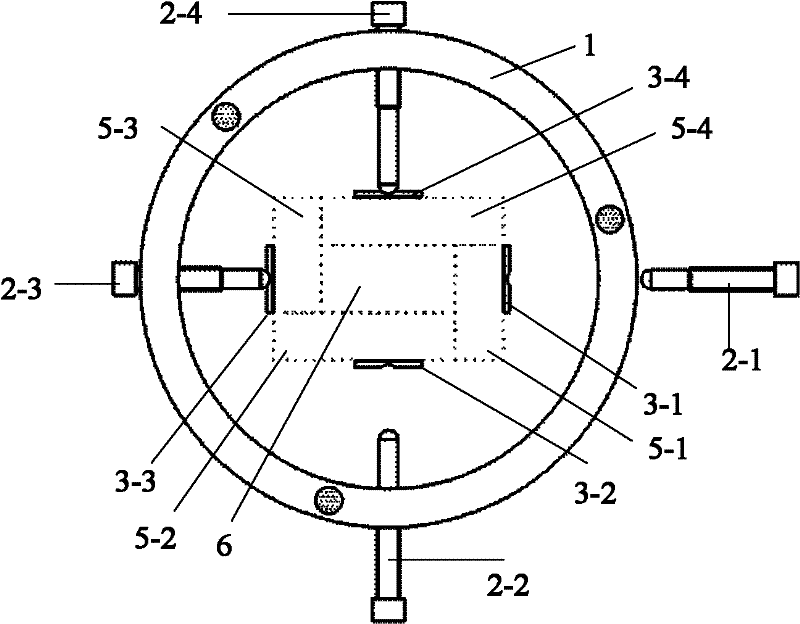

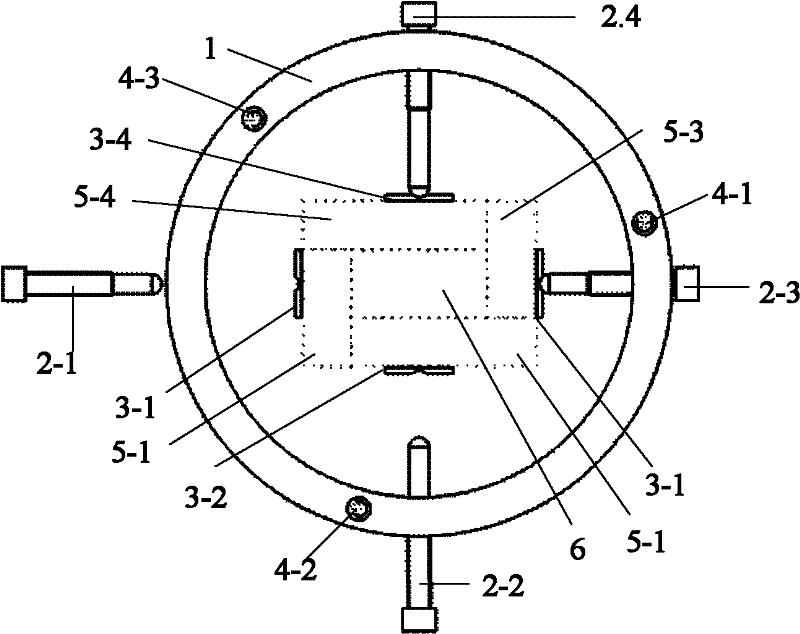

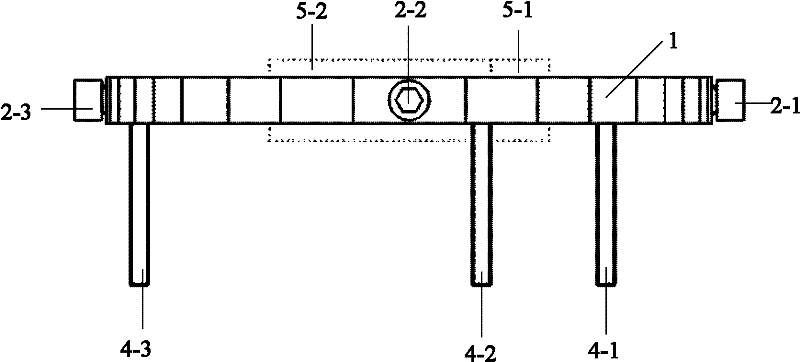

Device for assembling rock samples in true triaxial test

InactiveCN102252892AThe test results are in line with the actualImprove assembly efficiencyPreparing sample for investigationTriaxial shear testEngineering

The invention discloses a device for assembling rock samples in a true triaxial test. The device comprises an annular framework, locking screw bolts, disc-shaped gaskets and supporting threaded rods. Two pairs of orthogonal threaded openings are arranged on the annular framework in the horizontal direction; a central axis of each pair of the orthogonal threaded openings penetrates through the center of the annular framework; the locking screw bolts are respectively screwed in the horizontal threaded openings of the annular framework; end parts of the locking screw bolts are in contact with the disc-shaped gaskets; and the other faces of the disc-shaped gaskets are directly in contact with bearing cushion blocks. The heads of the locking screw bolts are designed into a hemispherical shape, and a spherical hole with the same radius of curvature as that of the hemispherical shape is arranged at the center of one face of each of the disc-shaped gaskets. The contact faces of the locking screw bolts and the disc-shaped gaskets are spherical surfaces. Three non-penetrating threaded openings which form angles of 120 DEG mutually are arranged on the lower surface of the annular framework and are used for being screwed by the supporting threaded rods. Three non-penetrating circular holes which form angles of 120 DEG mutually are arranged on the upper surface of the annular framework. The device for assembling the rock samples in the true triaxial test has a simple structure, and is simple and convenient to operate, the difficulty in assembling a sample due to daubing of silica gel is eliminated, the misplacement of the rock samples is avoided, and a plurality of rock samples can be simultaneously dried in a drying oven conveniently.

Owner:INST OF ROCK & SOIL MECHANICS CHINESE ACAD OF SCI

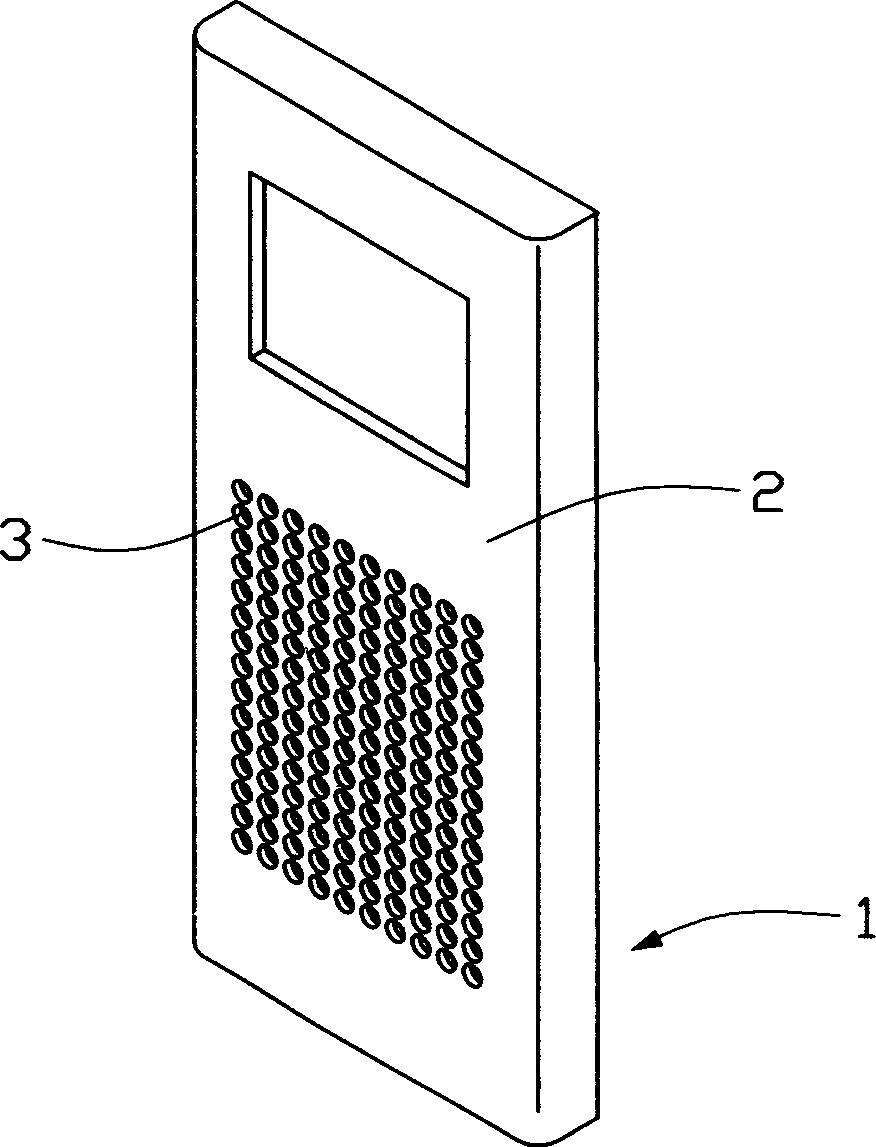

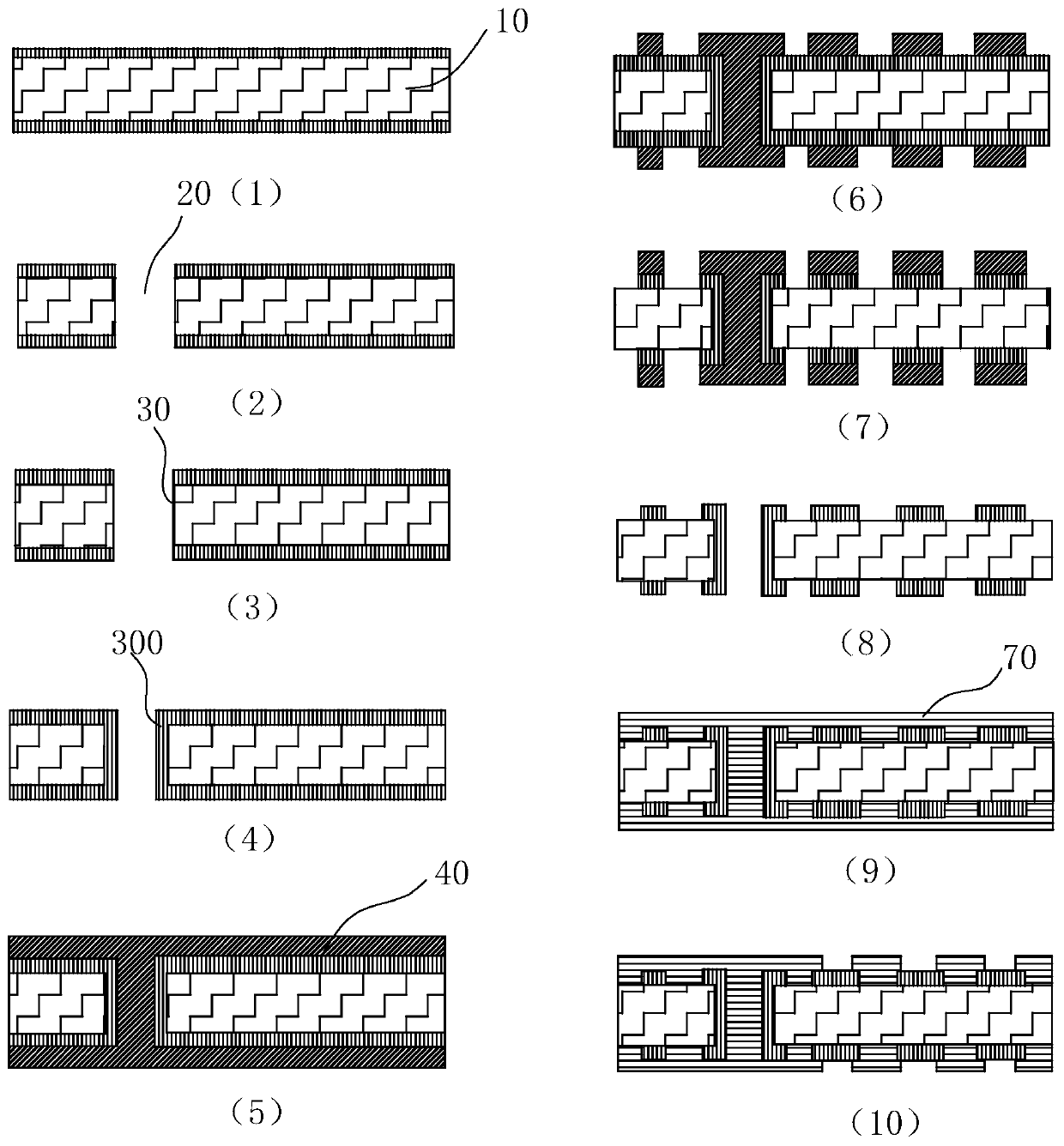

Production method of porous shell

InactiveCN1504279AImprove wear resistanceImprove corrosion resistanceAnodisationPunch pressAnodic oxidation

A method of making porous casing body comprising the steps of , perforating, forming by punching, grinding and anodic oxidation. The method provided by the invention can be applied onto the manufacture of porous housings for miscellaneous installations.

Owner:SHENZHEN FUTAIHONG PRECISION IND CO LTD

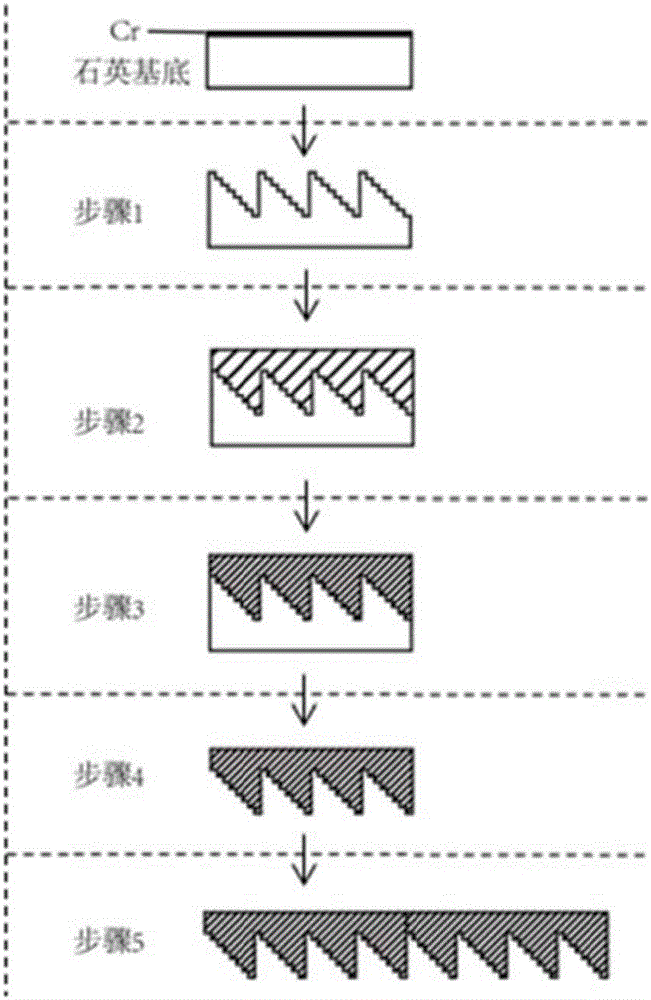

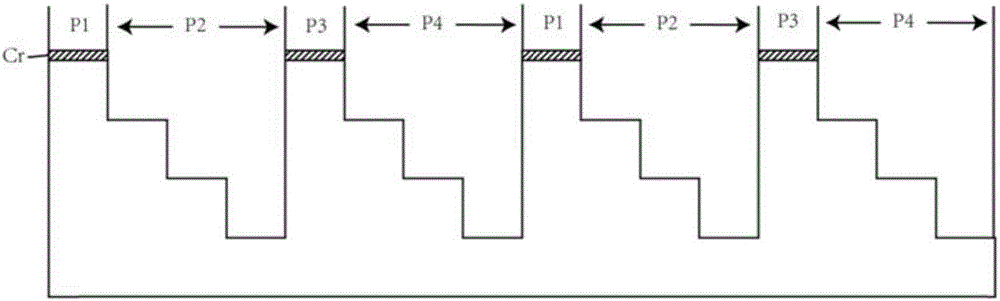

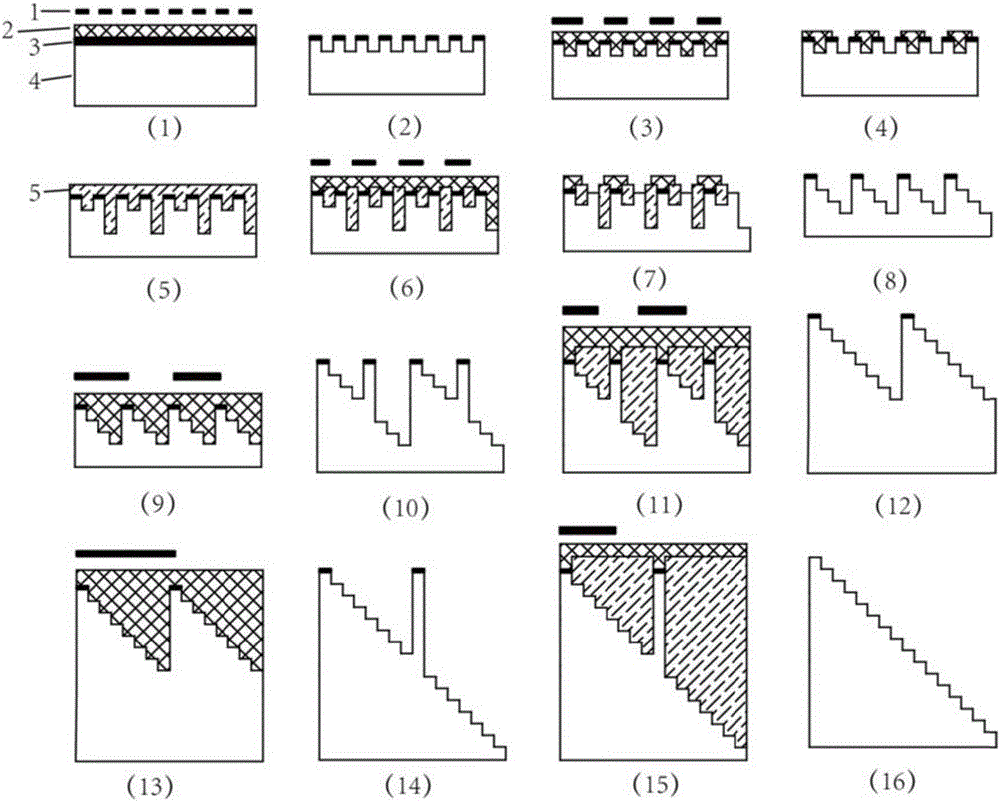

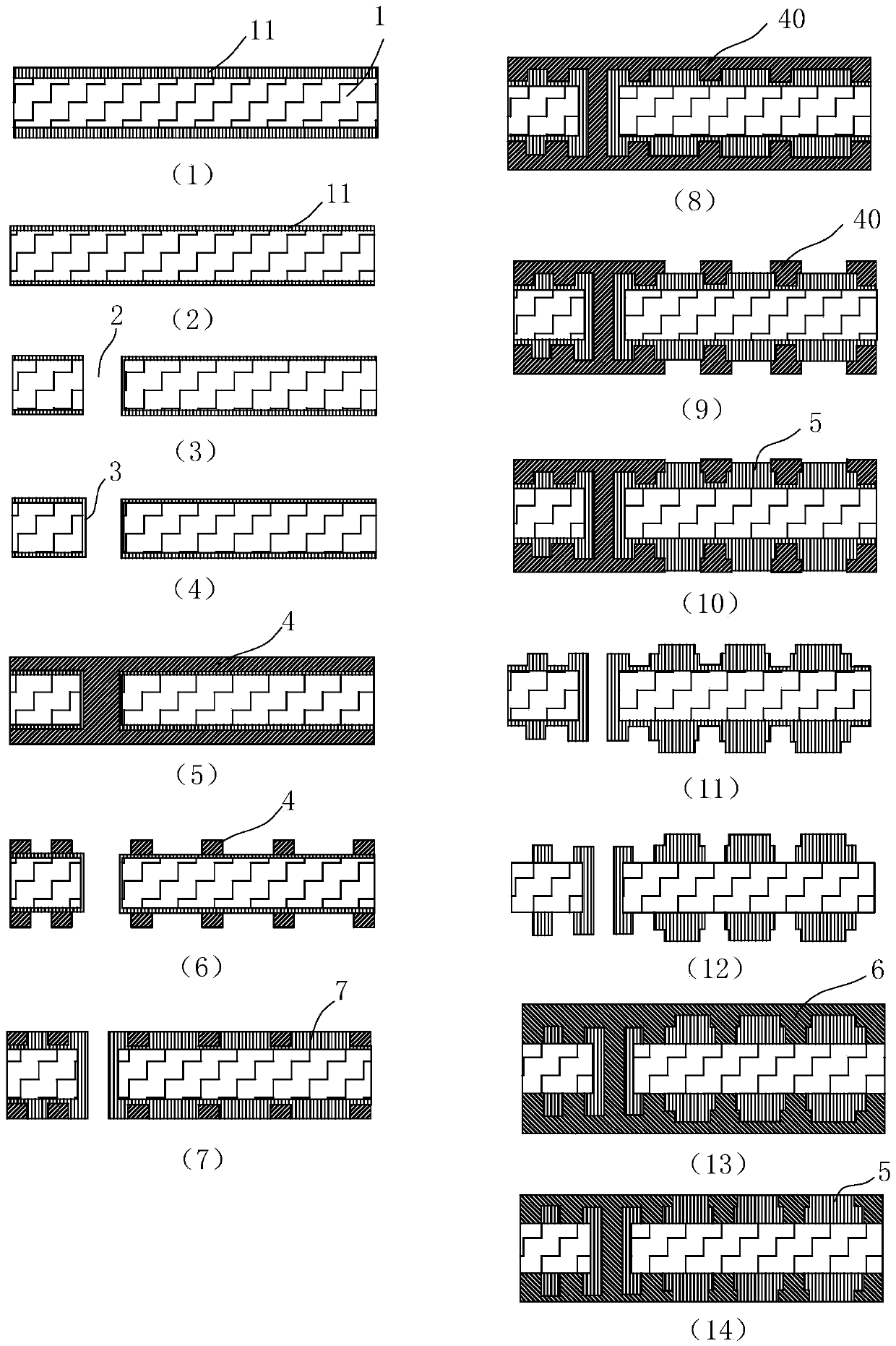

Making method of large-caliber film diffraction element with high diffraction efficiency

ActiveCN106154382AReduce alignment accuracy requirementsGood repeatabilityDiffraction gratingsChemistryCaliber

The invention provides a making method of a large-caliber film diffraction element with high diffraction efficiency to solve technical problems existing in a present preparing process of large-caliber film diffraction elements. The method includes the first step of making of a multi-step relief structure quartz substrate, the second step of polymer solution coating, the third step of polymer solution curing and film forming, the fourth step of film and substrate separating, and the fifth step of film splicing. The method has the advantages of being low in cost, high in repeatability, simple and efficient. The diffraction efficiency of the element made with the method is not lower than 7%.

Owner:UNIV OF SCI & TECH OF CHINA

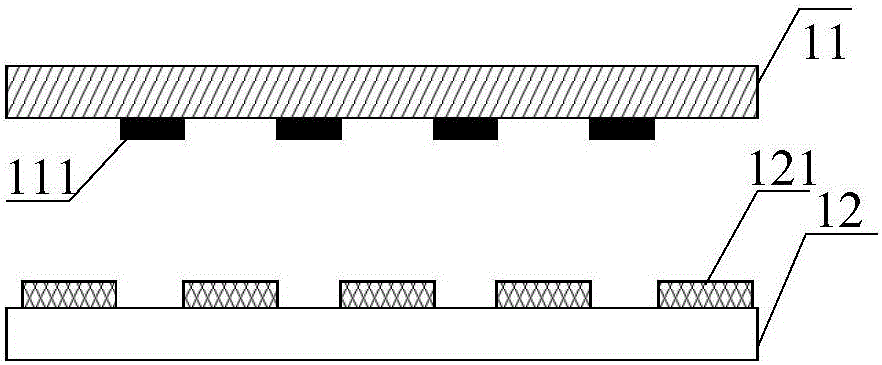

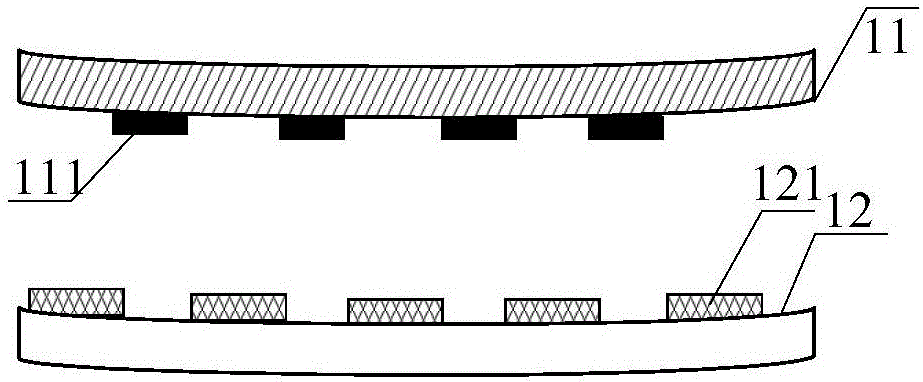

Display panel and manufacturing method thereof, as well as curved-surface display panel and curved-surface display device

InactiveCN106019756AHas a light-transmitting effectNo misalignmentNon-linear opticsSurface plateSurface display

The invention discloses a display panel and a manufacturing method thereof, as well as a curved-surface display panel and a curved-surface display device, which are used for avoiding phenomena including light leak, colour mixture and aperture ratio reduction caused in a curving process of the display panel. The display panel comprises a first substrate, a second substrate, a pixel structure, an electrochromic material layer, first transparent electrodes and second transparent electrodes, wherein the pixel structure is distributed to form an array, and is arranged on one side, away from the second substrate, of the first substrate; the electrochromic material layer is arranged between the first substrate and the second substrate; the first transparent electrodes are arranged between the electrochromic material layer and the pixel structure, and have the same shapes as opening areas of the pixel structure; the second transparent electrodes are arranged between the electrochromic material layer and the second substrate, and at least part of orthographic projections of the second transparent electrodes on the first substrate or the second substrate are overlapped with orthographic projections of the first transparent electrodes on the first substrate or the second substrate.

Owner:BOE TECH GRP CO LTD

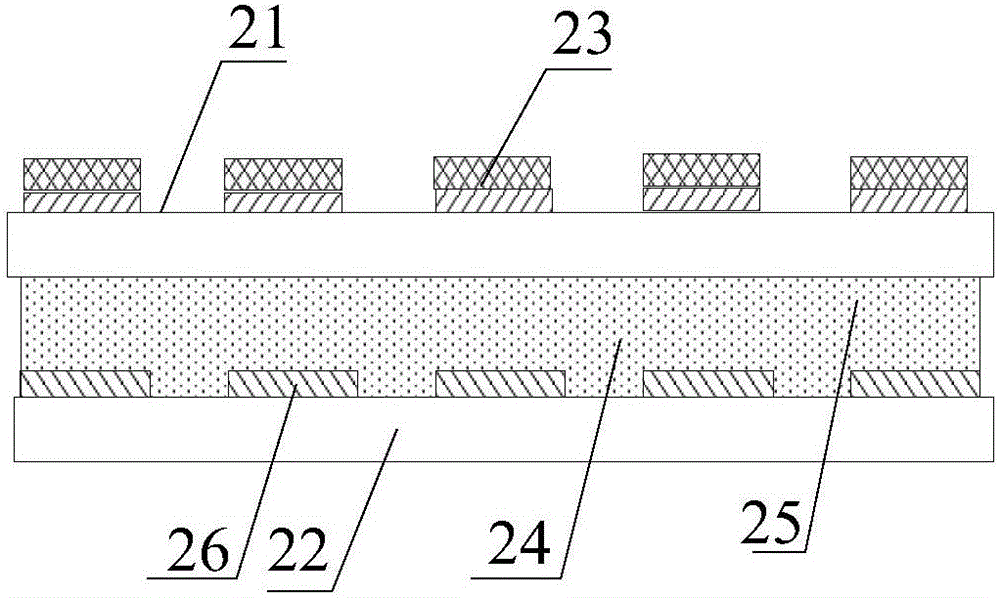

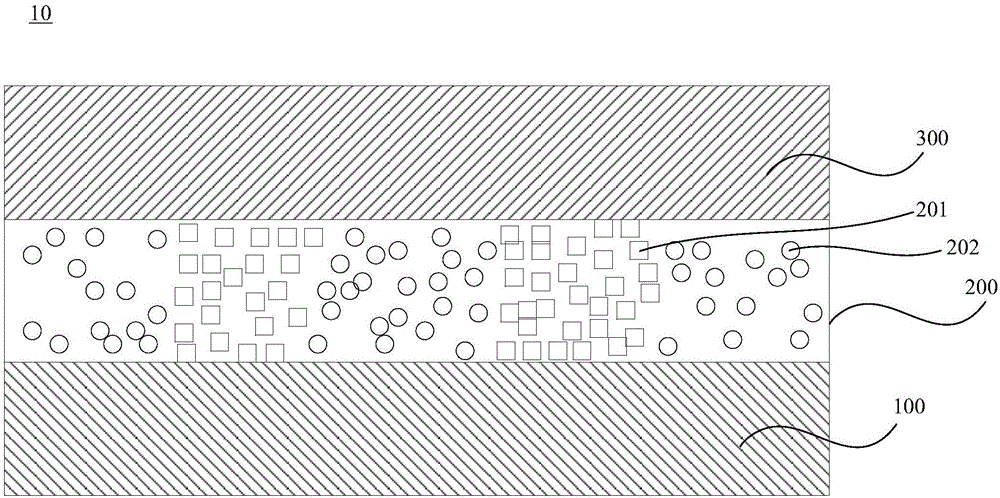

Preparation method of electronic device and flexible display device

PendingCN106448463AReduce internal stressNo misalignmentIdentification meansUltraviolet lightsIrradiation

The invention relates to an electronic device and a flexible display device and the preparation method of the same. The flexible display device comprises a flexible display screen, a glue layer and a protective cover plate. The glue material is coated on the surface of the flexible display screen to form the glue layer. The glue layer comprises a colloidal component which can be cured by ultraviolet light and a non-colloidal component which cannot be cured by ultraviolet light. The glue layer is exposed by ultraviolet light through a patterned mask in the upper portion of the protective cover plate. The colloidal component is gathered in the ultraviolet light irradiation area, and the non-colloidal component is excluded from the ultraviolet light irradiation area. The colloidal component in the glue layer is cured to form a colloidal grid, and the non-colloidal component in the glue layer is filled in the colloidal grid. When the flexible display device is bent or curved, the colloidal grid in the glue layer has space to extend, which can effectively reduce the internal stress during bending. Therefore, the electronic device and a flexible display device and the preparation method of the same cannot cause the occurrence of staggered layers and can prolong the life of the flexible display device.

Owner:ANHUI JINGZHUO OPTICAL DISPLAY TECH CO LTD

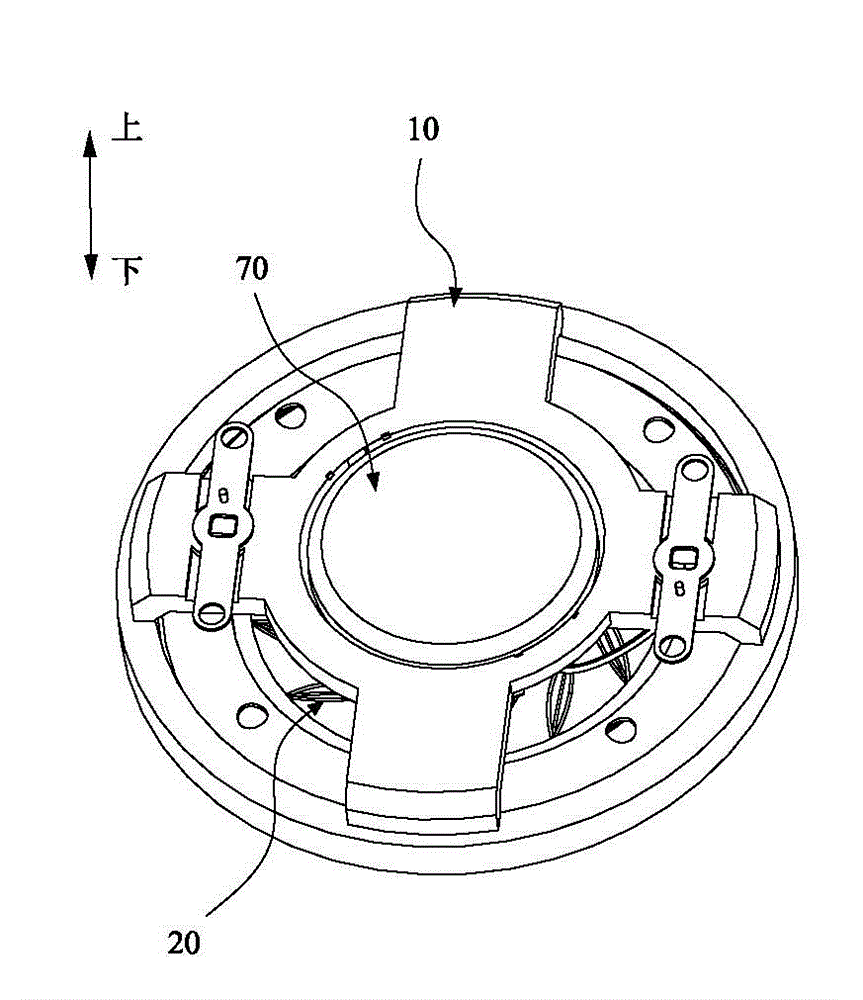

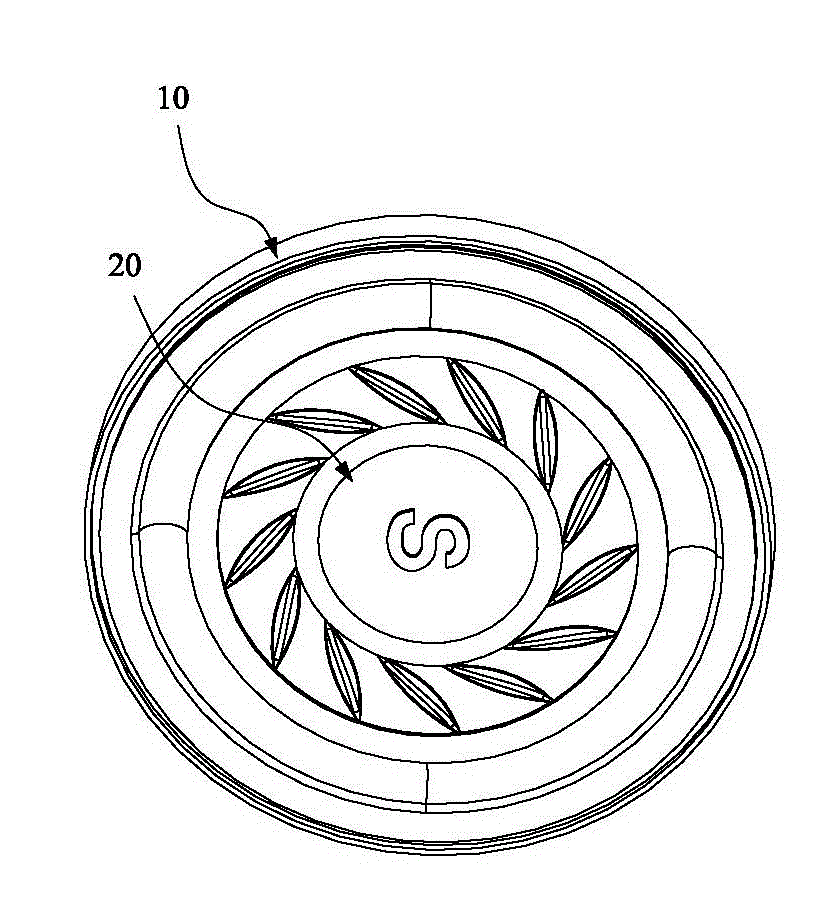

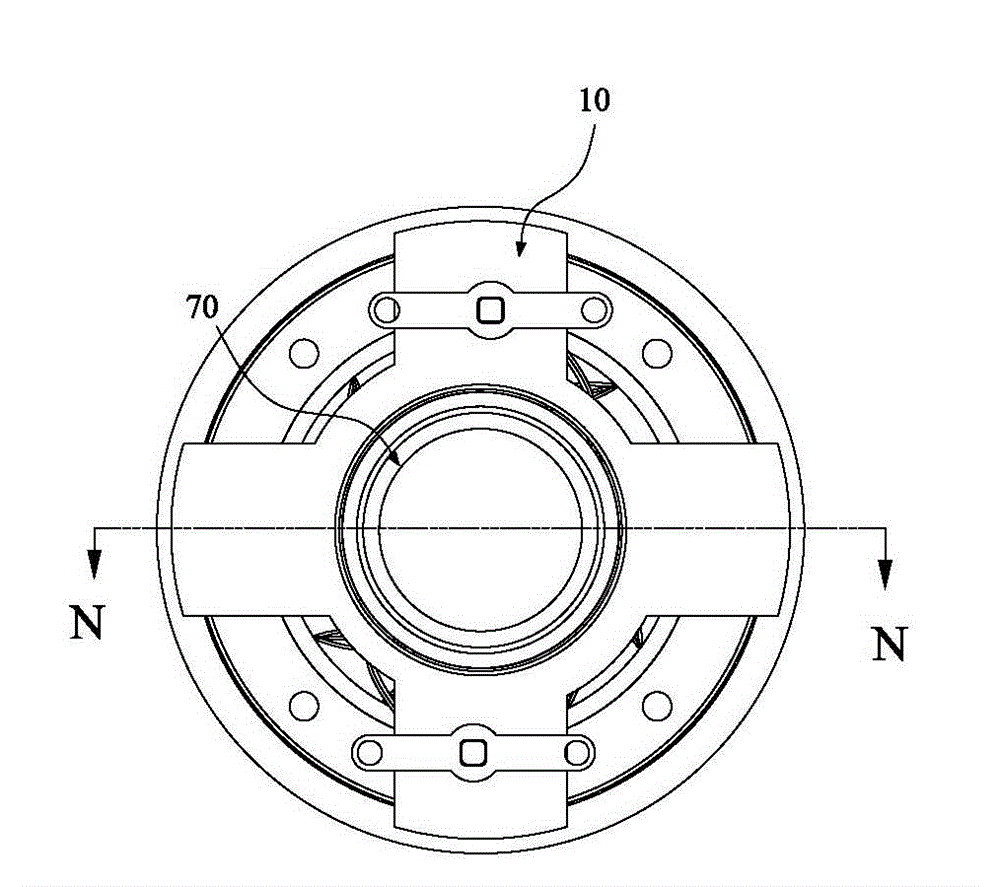

Horn basin frame for improving voice coil concentricity and manufacture method for horn

The invention discloses a horn basin frame for improving voice coil concentricity and a manufacture method for the horn. The horn basin frame comprises an inner ring, an outer ring and a skeleton which is connected between the inner ring and the outer ring in an overlapping mode. A through hole is formed in the center of the inner ring. A circular locating ring is arranged inside the through hole. The locating ring and the inner ring are arranged in a concentric mode. An interval is kept between the locating ring and the wall face of the inner ring. The locating ring is connected to the inner ring through a connecting part. The manufacture method for the horn comprises the steps of selecting and using the basin frame, when the horn is assembled, pasting a voice coil and drum paper, locating the voice coil, removing the locating ring in a cutting mode, and installing a magnetic assembly. After a combined body of the drum paper and the voice coil is firmly pasted with the basin frame, the locating ring connected with the basin frame is removed in the cutting mode. According to the locating ring, location of the voice coil is rapidly and accurately achieved, the concentricity among various elements of a product is greatly improved, and therefore acoustic and yield of the product are improved.

Owner:东星电声科技(东莞)有限公司

Integrated high-temperature high-pressure metal seal ball valve

InactiveCN101813201AReasonable structureFlexible opening and closingSpindle sealingsPlug valvesHigh pressureMetal

The invention relates to a valve, in particular to an integrated high-temperature high-pressure metal seal ball valve. The invention adopts the following scheme that: the integrated high-temperature high-pressure metal seal ball valve comprises a valve rod, a valve body, a valve seat and a valve core ball. The valve is characterized in that the valve seat and the valve body are integrally arranged, and a transversal ripple structure is formed at the integral joint of the valve seat and the valve body. By adopting the scheme, the invention overcomes the defects of the prior art and provides a novel integrated high-temperature high-pressure metal seal ball valve with reasonable structure, flexible opening and closing, high efficiency and good seal effect.

Owner:浙江宏明阀门有限公司

Manufacturing method of circuit board taking boss as bonding pad

ActiveCN110536564AHigh modulusHigh glass transition pointPrinted circuit aspectsElectrical connection printed elementsEngineeringElectroplating

The invention discloses a manufacturing method of a circuit board taking a boss as a bonding pad. The manufacturing method comprises the following steps of cutting and reducing copper; drilling a hole; carrying out copper deposition; pressing a film; exposing and developing; carrying out circuit electroplating; pressing the film; exposing and developing; electroplating the bonding pad; demouldingand removing copper; laminating an insulating layer; and grinding: grinding a surface of the insulating layer till that the bonding pad is exposed, and forming a top layer / bottom layer bonding pad through windowing. A thermosetting insulating material is adopted, cost is low, silk-screen is not needed, green and environmental protection performance is achieved, and simultaneously, a manufacturingprocess is simple, operation is easy, the bonding pad is directly manufactured through grinding, the bonding pad with a small area and a large density can be conveniently manufactured, a manufacturedcircuit board is smooth in surface, precise packaging is facilitated, circuit attachment is firm, and quality is good.

Owner:NINGBO HUAYUAN ELECTRONICS TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com