Manufacturing method of circuit board taking boss as bonding pad

A manufacturing method and pad technology, which are applied in printed circuit manufacturing, printed circuits, printed circuits, etc., can solve the problems of poor solder mask thickness uniformity in the screen printing process, low rigidity of photosensitive ink materials, and low glass temperature transition point. Achieve the effect of being conducive to precision packaging, high glass temperature transition point, and small deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

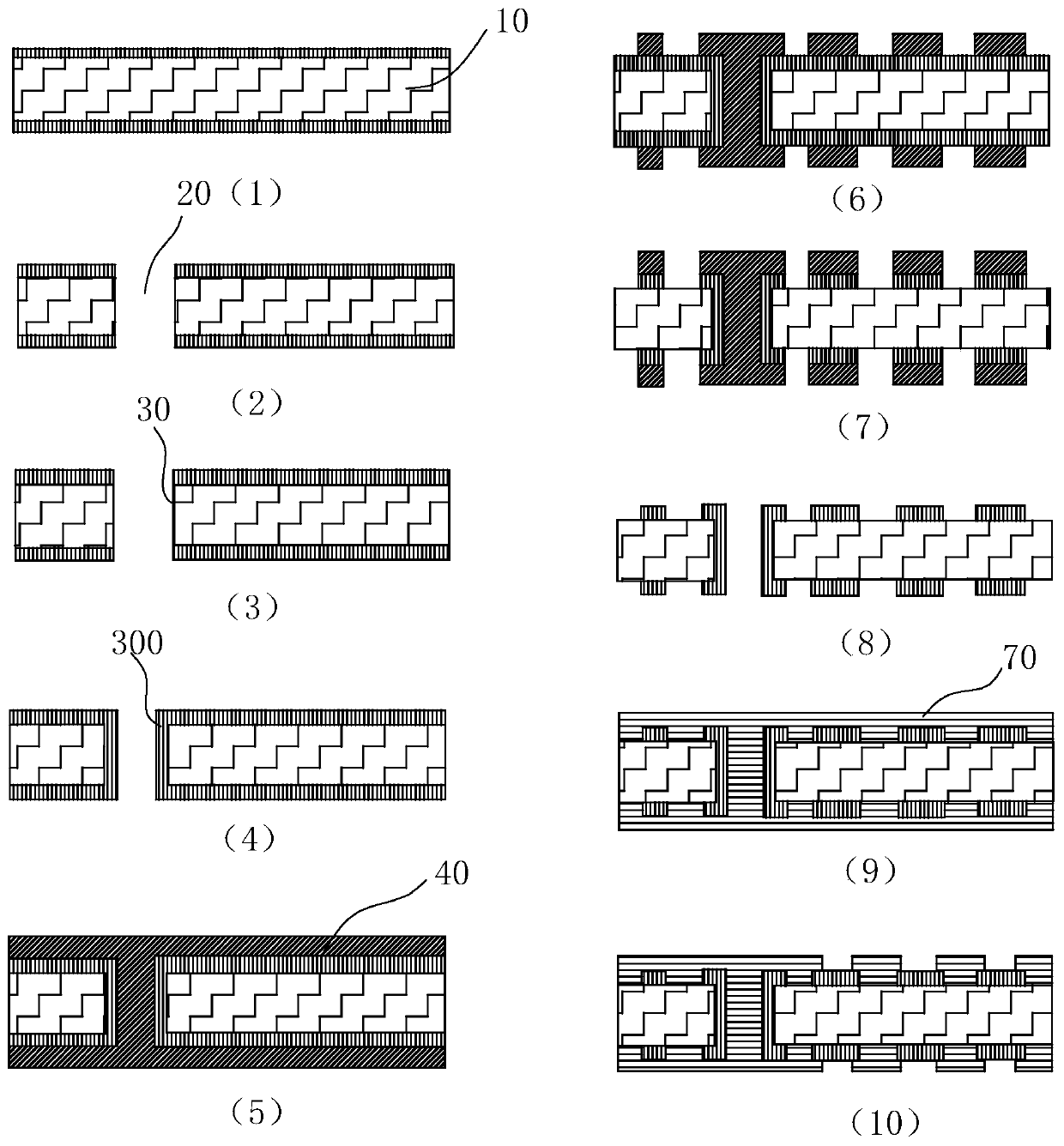

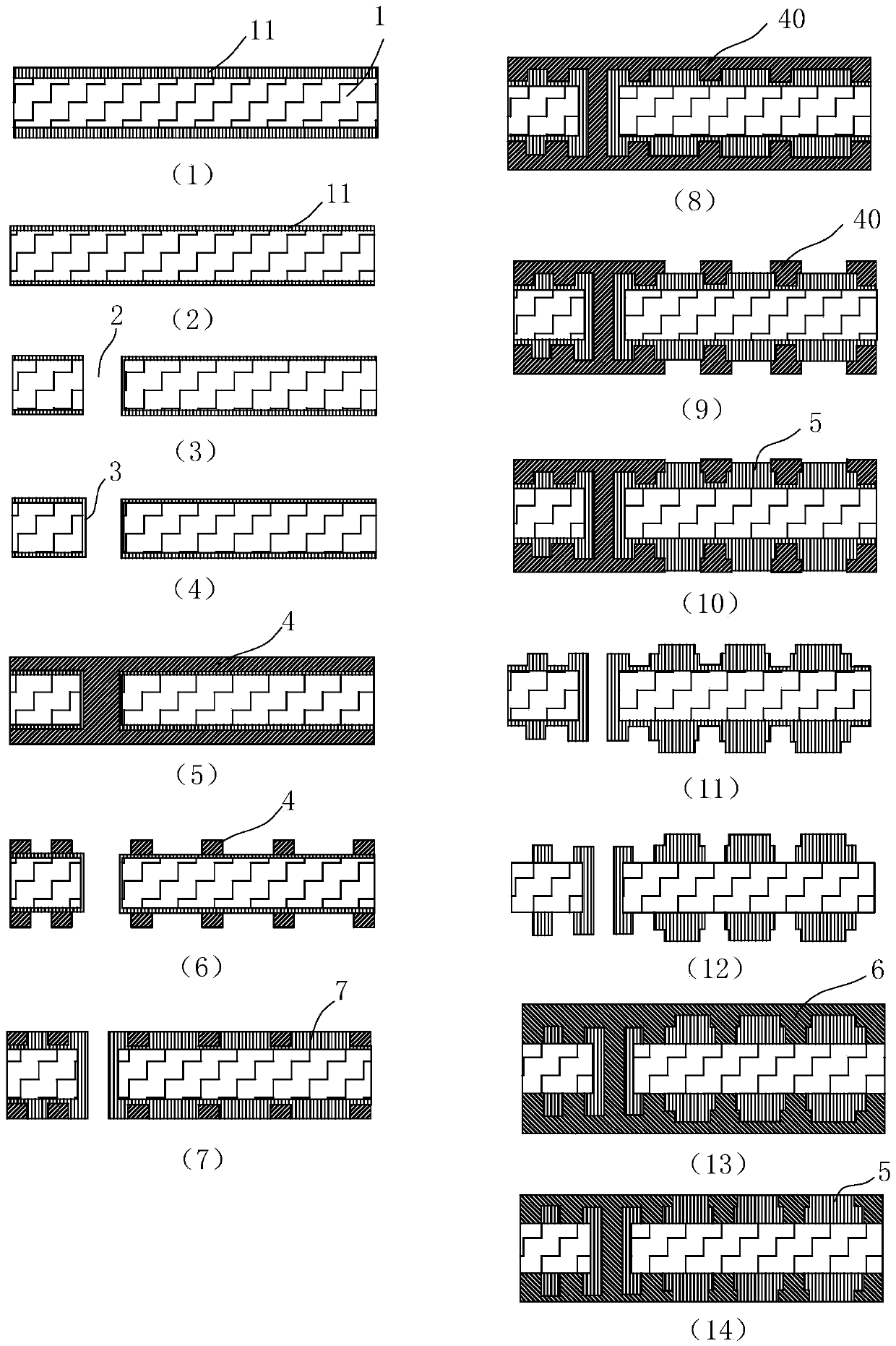

[0037] Such as figure 2 As shown, a method for making a circuit board with a boss as a pad comprises the following steps:

[0038] 1) Cutting: blanking of base material 1, base material 1 can be single-layer board, multi-layer board, soft-hard board or hard board, such as figure 2 (1);

[0039] 2) Copper reduction: thinning the copper layer 11 on the surface of the substrate 1, after the copper reduction, the thickness of the remaining copper layer 11 is 1-2 μm, such as figure 2 (2);

[0040] 3) Drilling: drill hole 3 at the position where interlayer conduction is required, such as figure 2 (3);

[0041] 4) Immersion copper: deposit a layer of conductive copper layer 3 on the insulating layer of the hole wall, with a thickness of 0.3-1.0 μm, such as figure 2 (4);

[0042] 5) Lamination: press a photosensitive dry film 4, and press ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com