Patents

Literature

58results about How to "Low melt flow rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

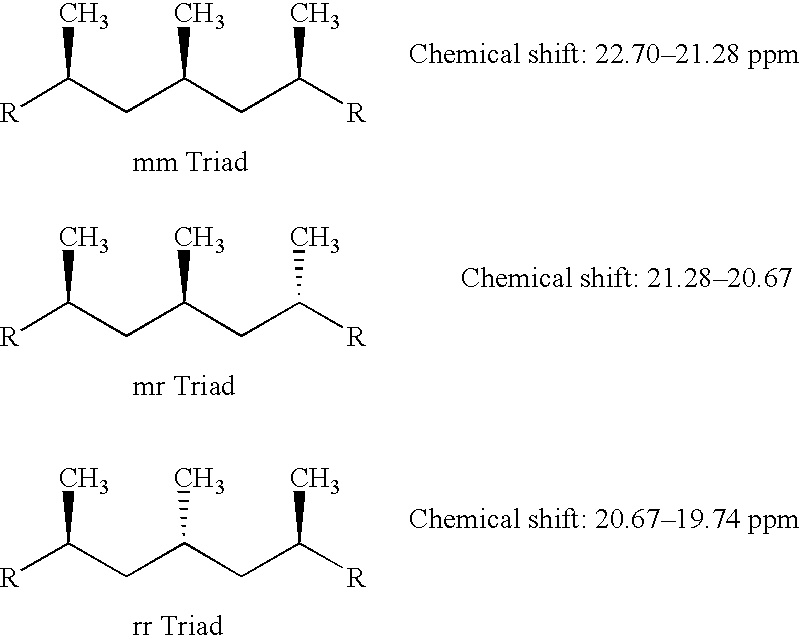

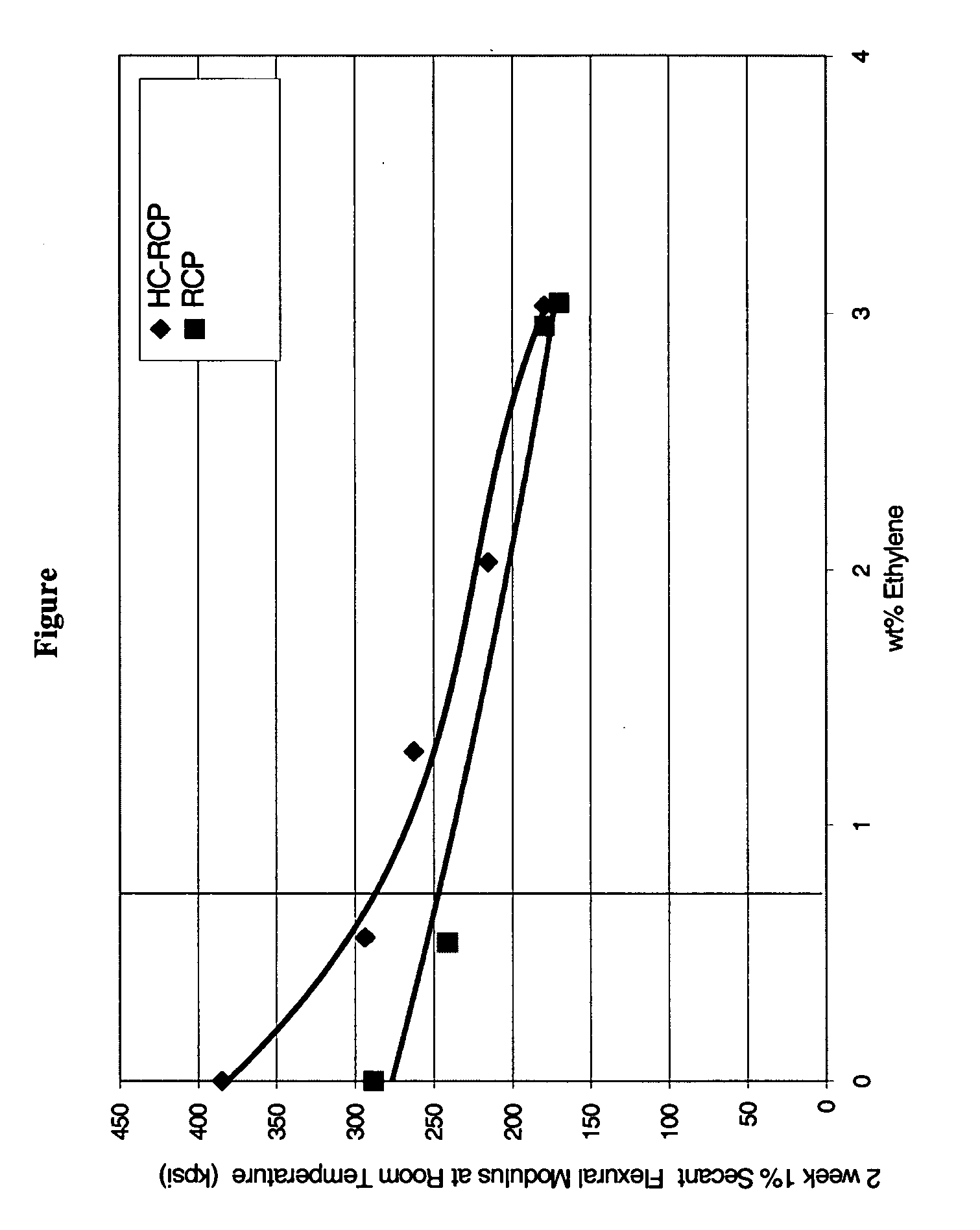

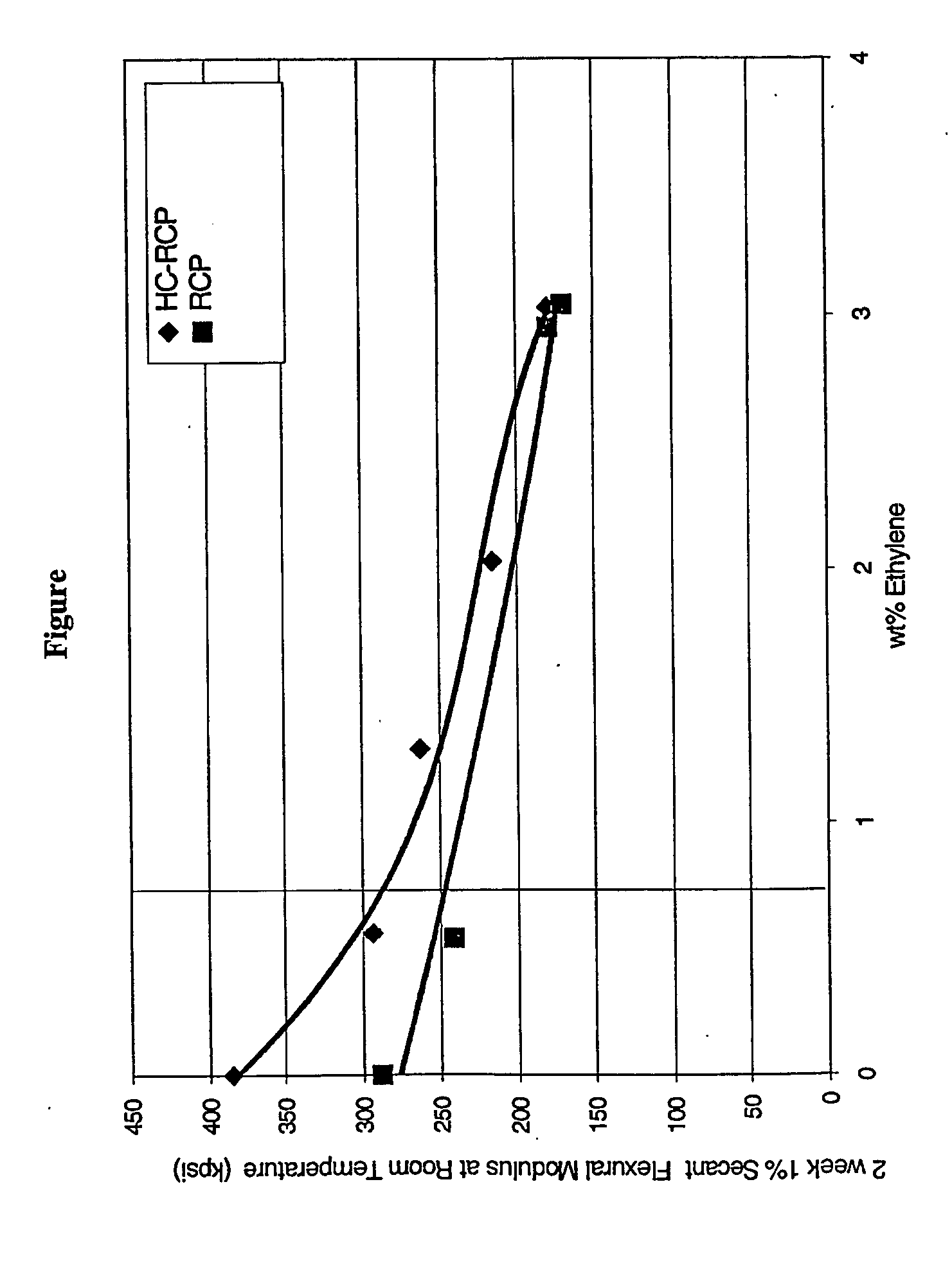

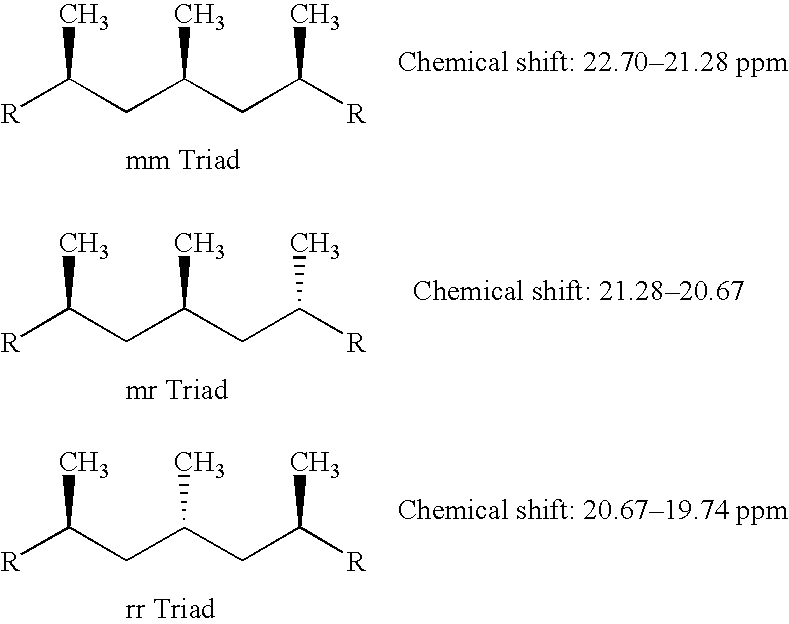

Highly crystalline polypropylene with low xylene solubles

ActiveUS20040122196A1Narrow molecular weight distributionLow melt flow rateFlexural modulusPolypropylene

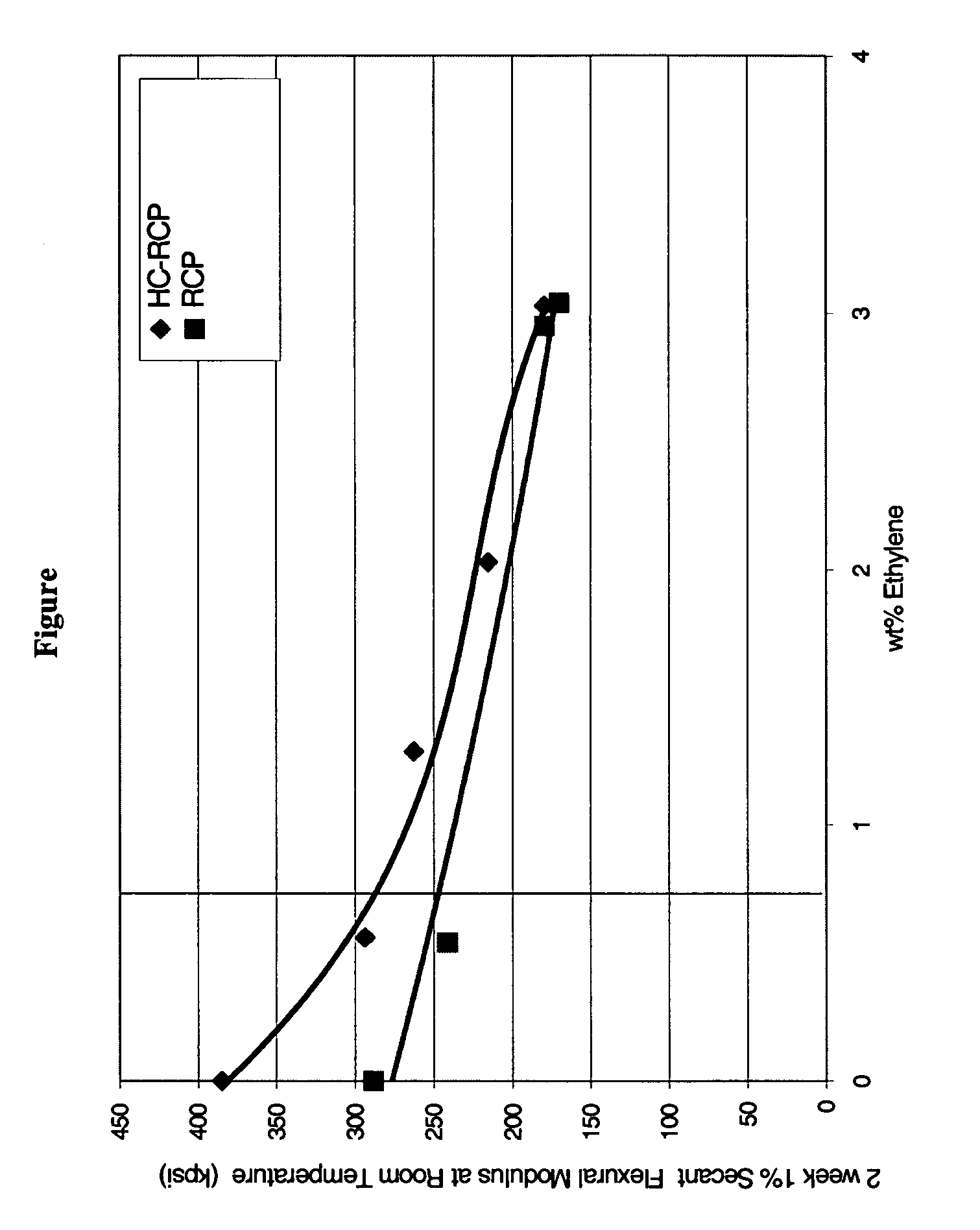

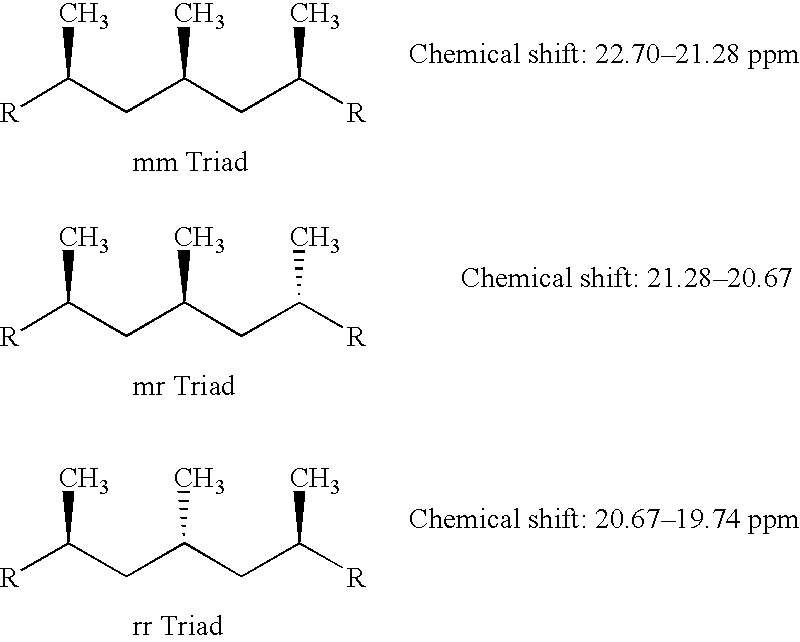

The invention is directed to a polypropylene resin which has a Mw / Mn of less than 5, a melt flow rate of less than 7 g / 10 min., a 1% secant flexural modulus of greater than 300,000 psi and less than 2 wt. % xylene solubles.

Owner:BRASKEM AMERICA

Highly crystalline polypropylene with low xylene solubles

InactiveUS20050272858A1Narrow molecular weight distributionLow melt flow rateGranular deliveryFlexural modulusPolypropylene

The invention is directed to a polypropylene resin which has a Mw / Mn of less than 5, a melt flow rate of less than 7 g / 10 min., a 1% secant flexural modulus of greater 5 than 300,000 psi and less than 2 wt. % xylene solubles.

Owner:BRASKEM AMERICA

Thermoplastic olefin compositions, processes and articles

A thermoplastic olefin (TPO) composition comprises (1) a major amount by weight of (a) a substantially linear homopolymer or copolymer of a C2-C10 α-olefin in major proportion to (b) a long chain branched a linear homopolymer or copolymer of a C2-C10 α-olefin, (2) a minor amount by weight of a cross linkable elastomer, and (3) at least one thermally decomposing free radical generating agent present in an amount sufficient to promote an increase in melt strength of the composition over that of the melt strength of the linear homopolymer or copolymer of a C2-C10 α-olefin alone and insufficient to substantially degrade the α-olefinic polymers. The TPO composition is prepared by melt blending the components at a temperature sufficient to melt said homopolymers or copolymers of a C2-C10 α-olefin and thermally decompose said agent. Articles are thermoformed from the thermoplastic olefin.

Owner:EXOUSIA IP LLC

Highly crystalline polypropylene with low xylene solubles

The invention is directed to a polypropylene resin which has a Mw / Mn of less than 5, a melt flow rate of less than 7 g / 10 min., a 1% secant flexural modulus of greater than 300,000 psi and less than 2 wt. % xylene solubles.

Owner:BRASKEM AMERICA

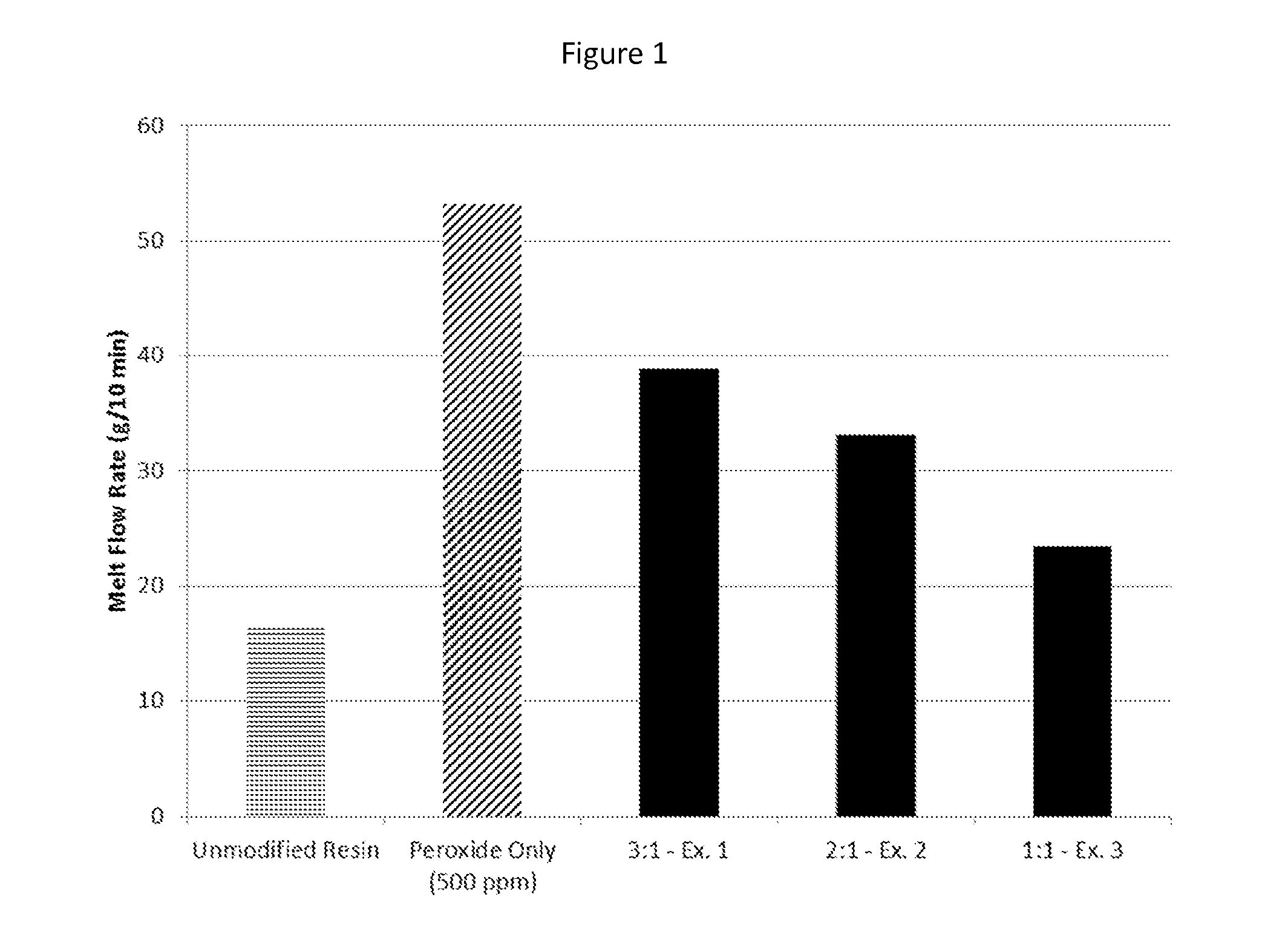

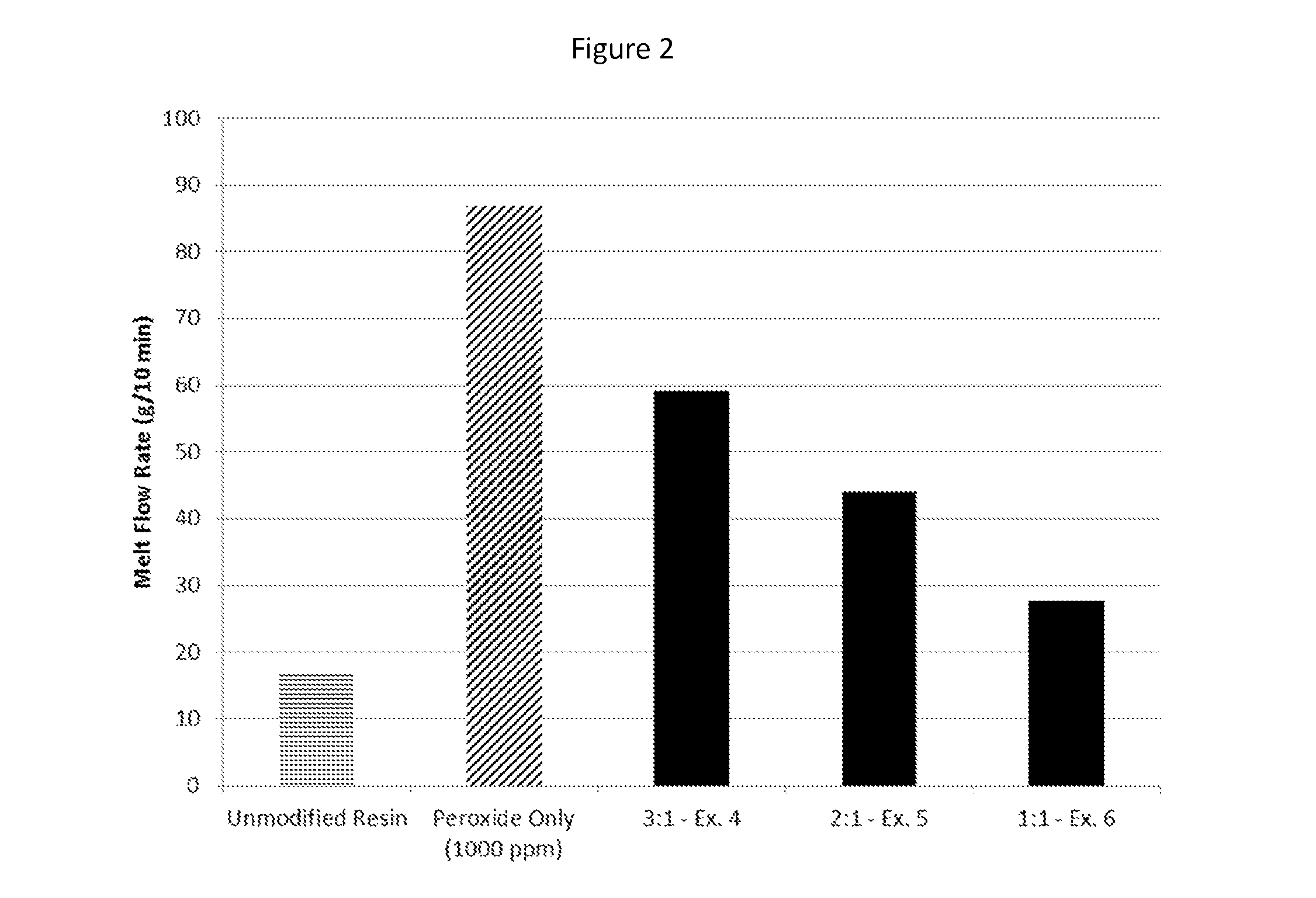

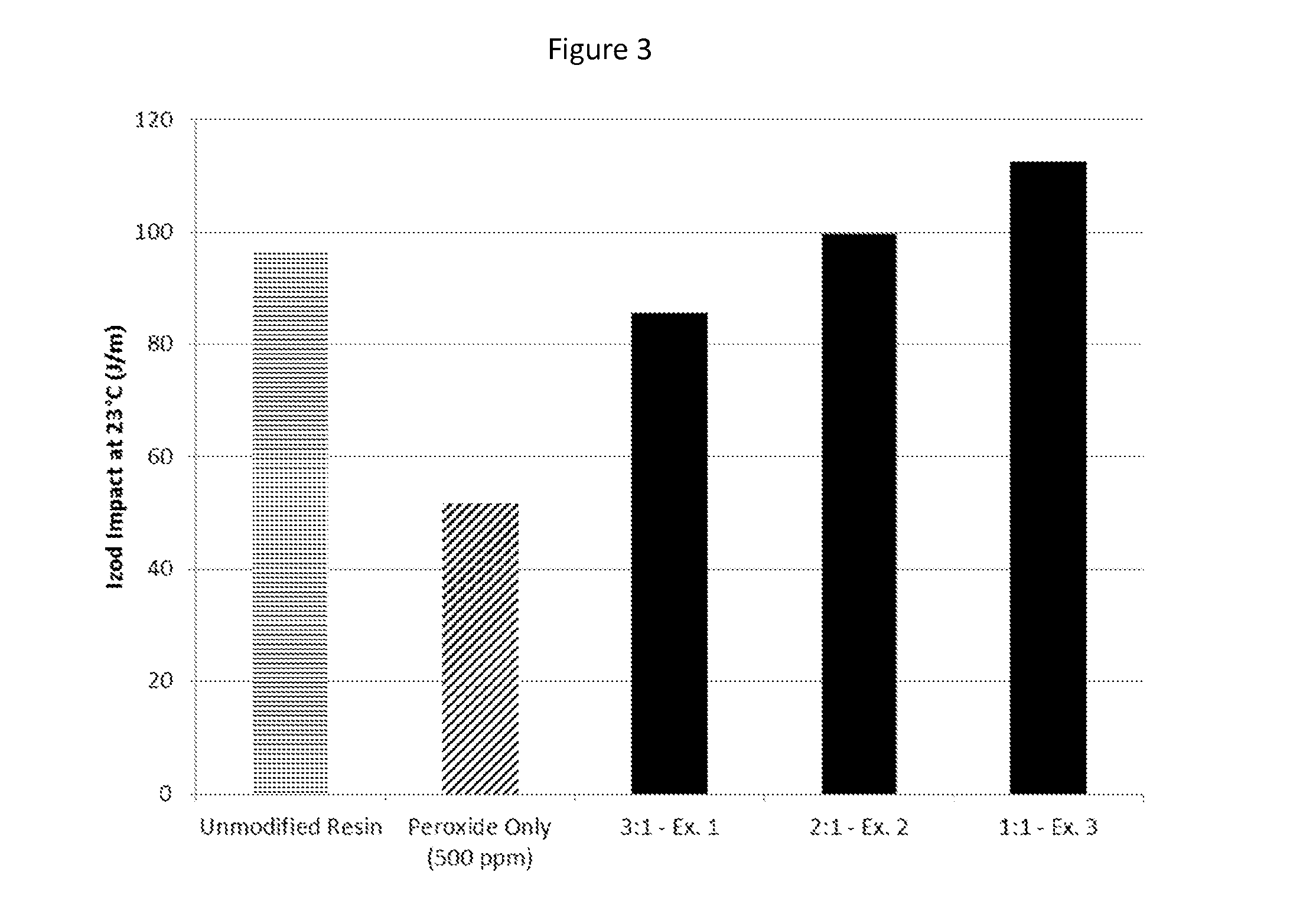

Modified heterophasic polyolefin composition

A method of creating a modified heterophasic polyolefin composition is provided, whereby a polyolefin composition having at least two phases is melt mixed with a free radical generator, such as a peroxide, and a compatibilizing agent characterized by at least one nitroxide radical and at least one unsaturated bond capable of undergoing a radical addition reaction. Modified heterophasic polyolefin compositions with increased melt flow rates, impact strength, and clarity, which incorporate the compatibilizing agent, are also included within the scope of the invention.

Owner:MILLIKEN & CO

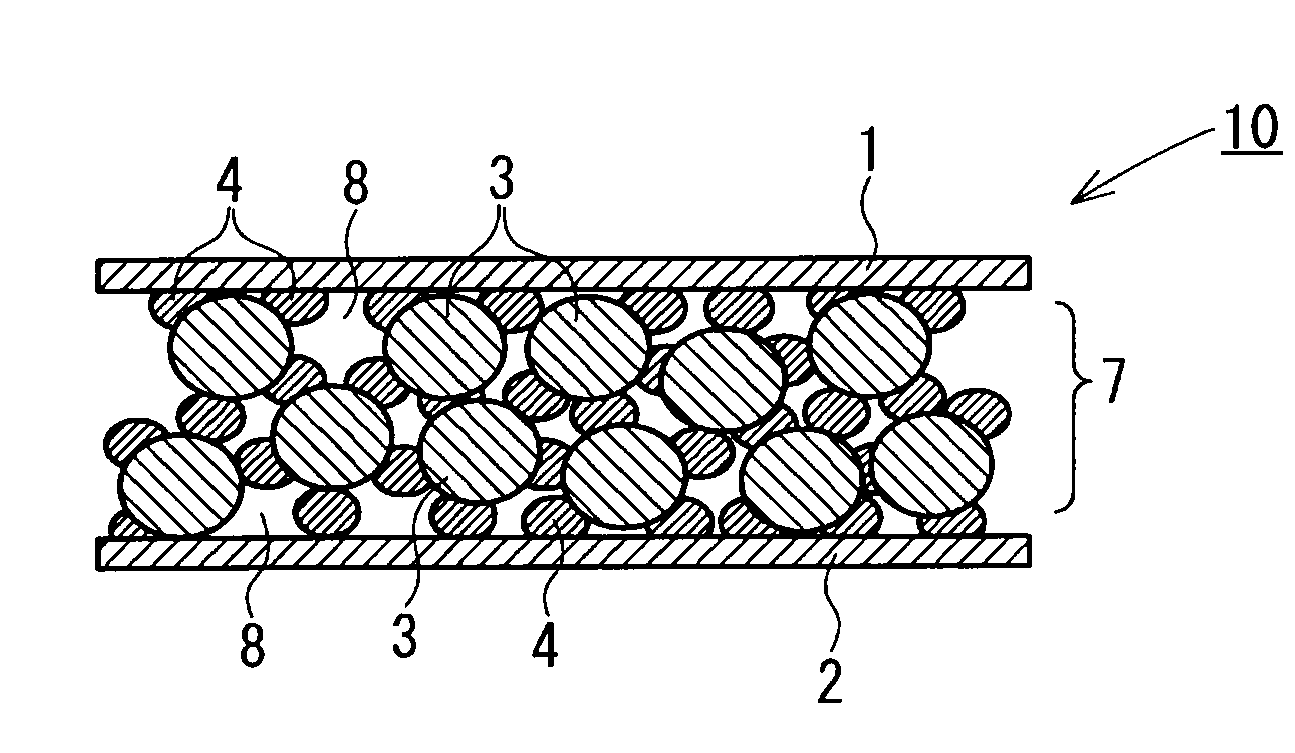

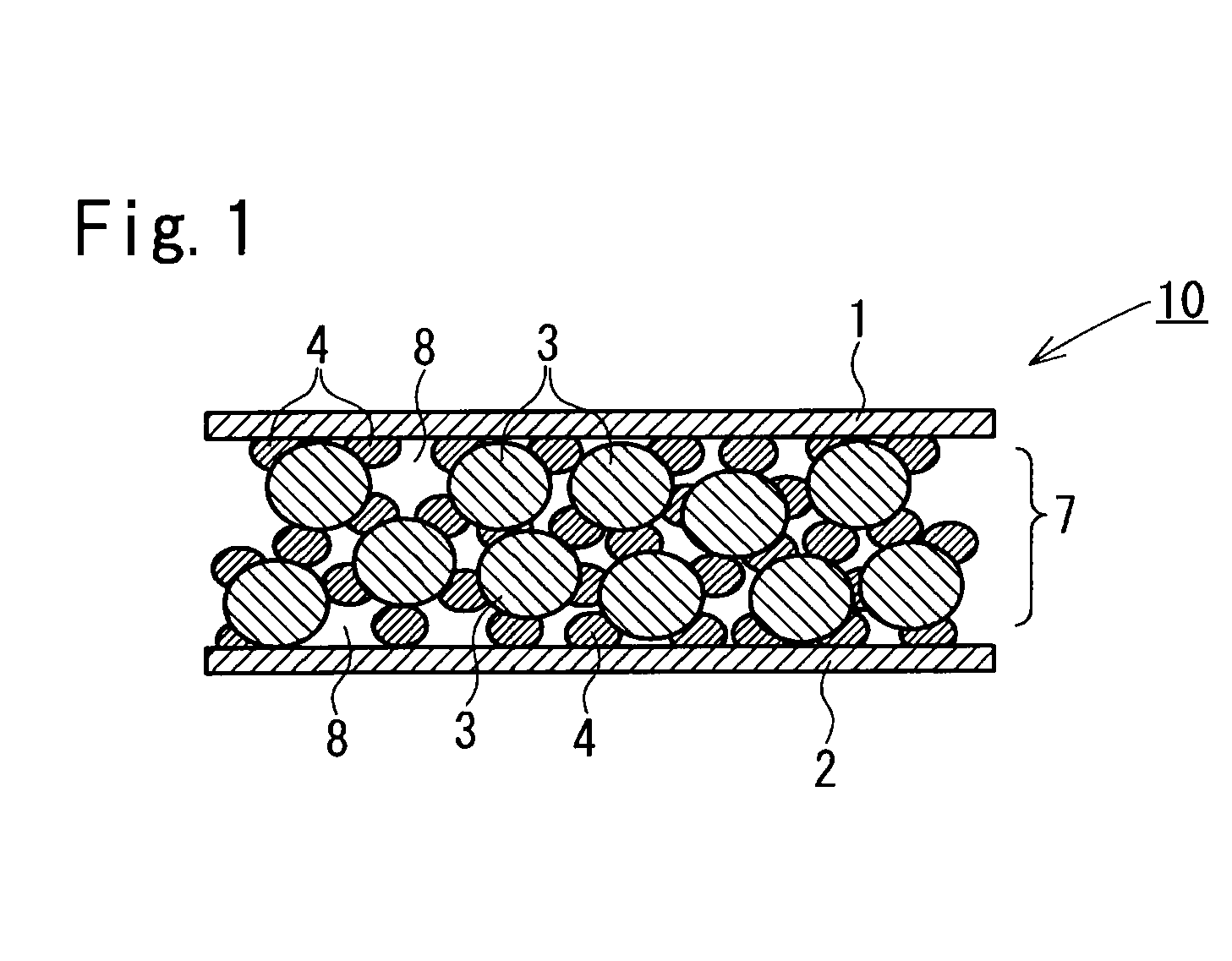

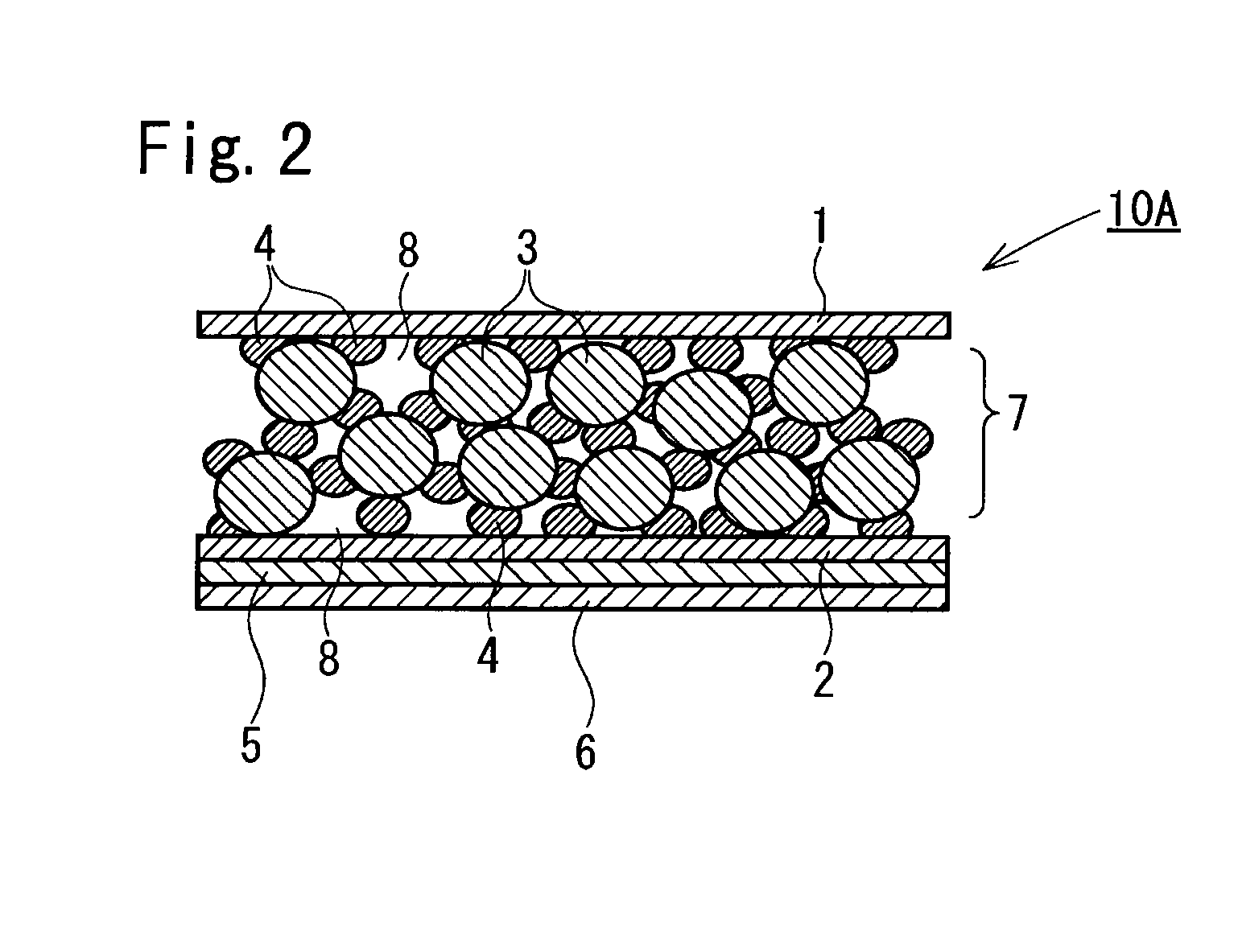

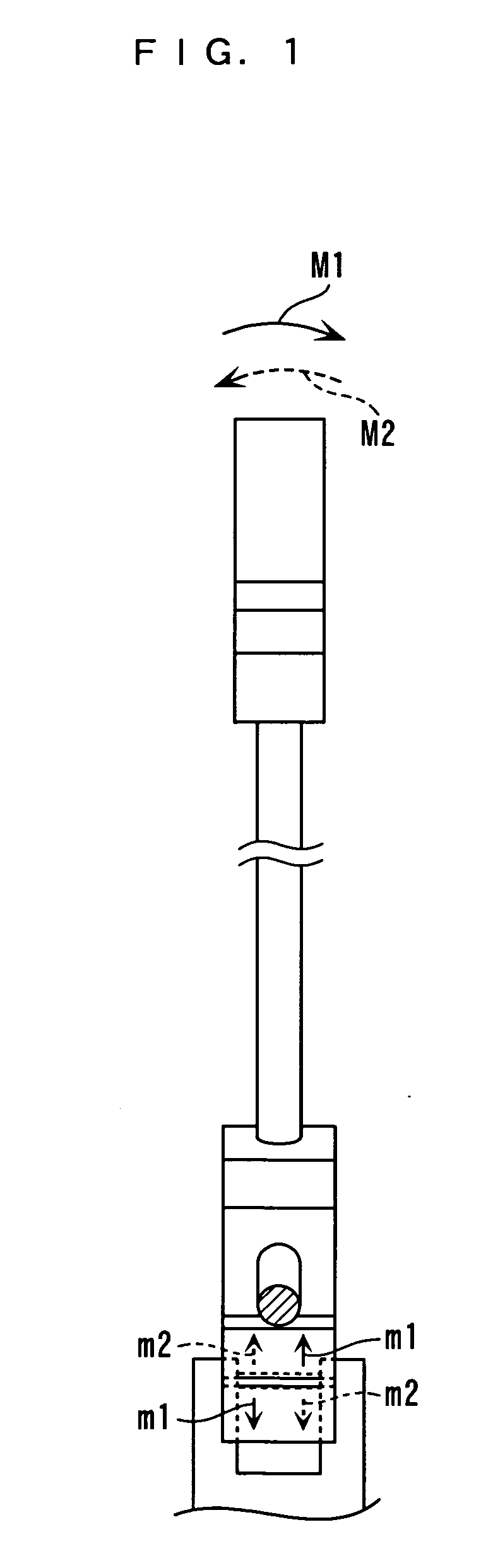

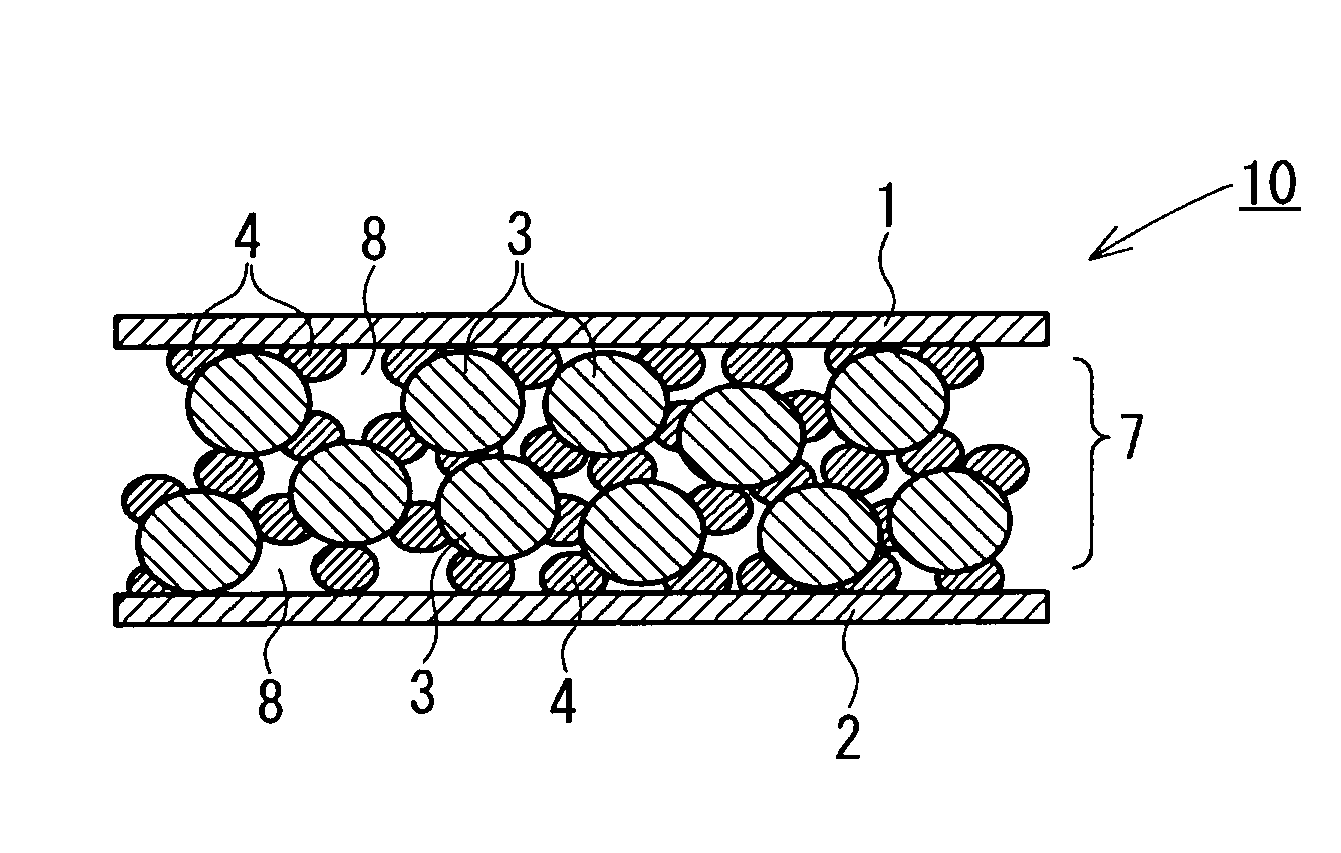

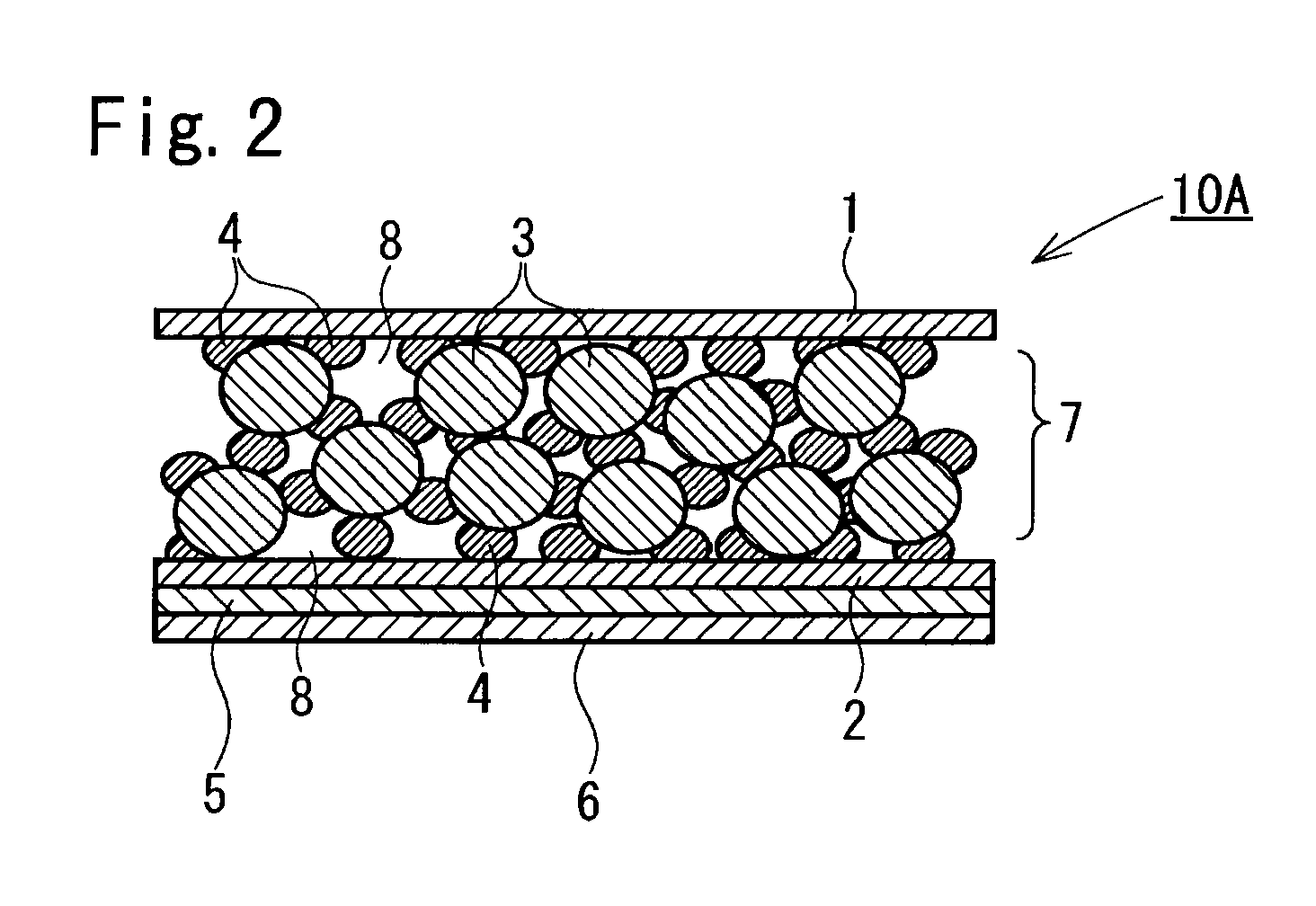

Humidity-conditioning sheet

ActiveUS20100005968A1Improve responsivenessGood reversibilityCombination devicesSynthetic resin layered productsAmbient humidityDesorption

A humidity-conditioning sheet 10 excellent in reversibility and responsiveness of a moisture adsorbing / desorbing ability of rapidly adsorbing moisture at high ambient humidity and conversely rapidly desorbing adsorbed moisture at low ambient humidity includes a sheet-shaped humidity-conditioning layer 7 formed by bonding together, with a thermoplastic resin powder 4, humidity-conditioning particles 3 which reversibly adsorb and desorb water vapor. The void ratio of the humidity-conditioning layer 7 is 5% or more. Since a ratio of voids 8 formed between the humidity-conditioning particles 3 is high, the voids 8 between the humidity-conditioning particles 3 can be used as water retention spaces for moisture adsorption and desorption, thereby achieving the high reversible moisture adsorbing / desorbing ability and excellent moisture adsorption / desorption responsiveness with the aid of not only the moisture adsorbing / desorbing ability inherent in the humidity-conditioning particles but also the moisture adsorbing / desorbing ability of the voids between the humidity-conditioning particles.

Owner:MITSUBISHI CHEM CORP

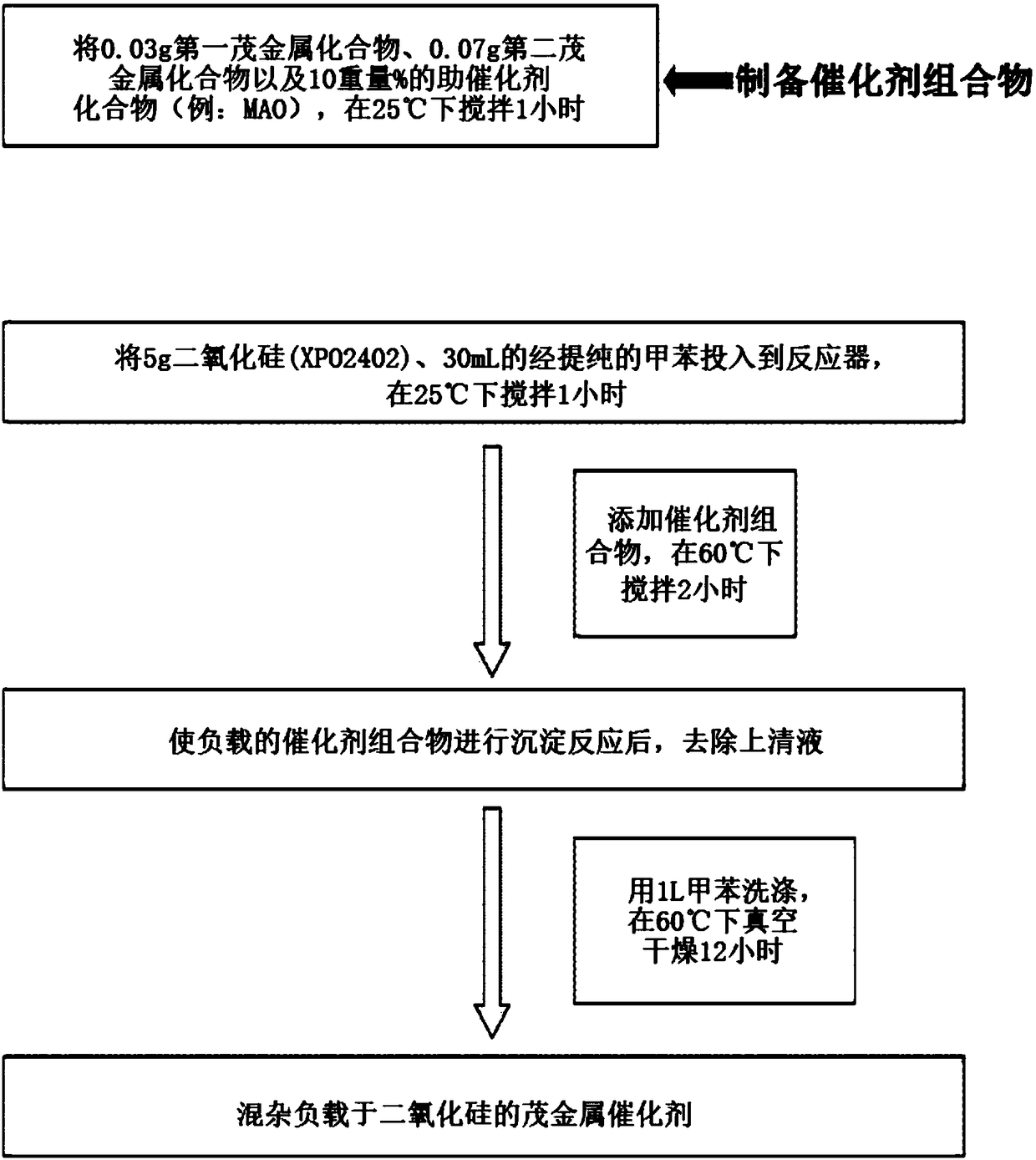

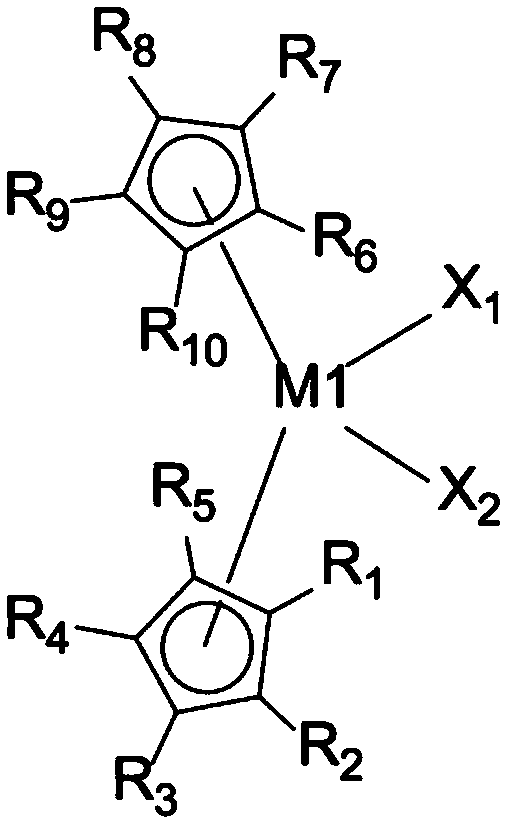

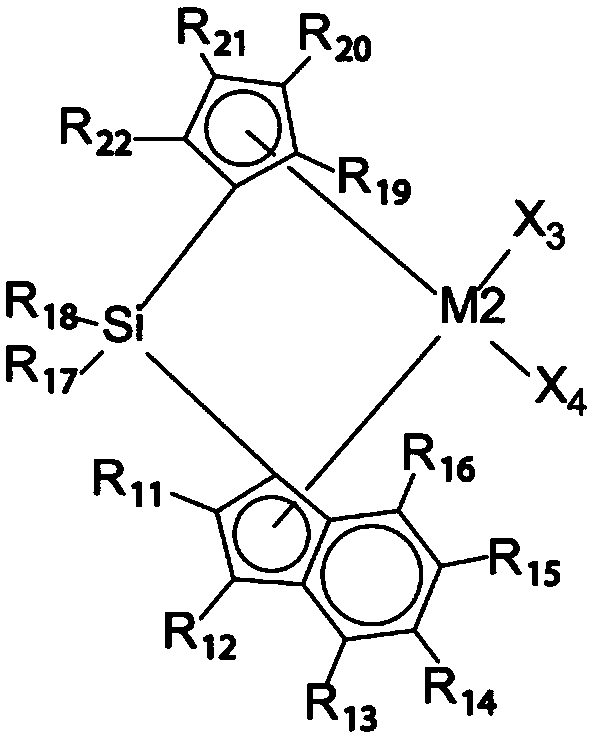

Hybrid supported metallocene catalyst, and polyolefin resin having excellent processability and using same

The present invention relates to: a hybrid supported metallocene catalyst comprising one or more first metallocene compounds, one or more second metallocene compounds, one or more co-catalyst compounds, and a support; a preparation method therefor; and a polyolefin resin polymerized in the presence of the catalyst, wherein the second metallocene compound is a compound of a bridged structure havinga ligand of an asymmetric structure, and the polyolefin resin has a density of 0.910-0.960 g / cm3, has a molecular weight density in a unimodal distribution of 3-5, and has a melt index of 0.05-100 at2.16 kg and a melt flow index of 20-40.

Owner:HANWHA CHEMICAL CORPORATION

Highly weather-proof PBT (polybutylene terephthalate)/ASA (acrylonitrile styrene acrylate) wire for 3D printing and preparation method of PBT/ASA wire

ActiveCN105440596AReduce thermo-oxidative degradationAvoid damageAdditive manufacturing apparatusASA-polymerWeather resistance

The invention discloses a highly weather-proof PBT (polybutylene terephthalate) / ASA (acrylonitrile styrene acrylate) wire for 3D printing and a preparation method of the PBT / ASA wire, relates to a printing material and aims to provide a 3D printing polymer material with better toughness and higher weather resistance. The technical scheme is that the formula comprises components in percentage by weight as follows: 50%-93% of PBT, 4%-90% of ASA, 0.5%-10% of a compatilizer, 0.1%-2% of a heat stabilizer, 0.1%-1% of an ultraviolet absorber, 0.1%-5% of an ultraviolet screening agent, 0.01%-0.1% of an antioxidant and 0.1%-1% of while oil. The weather-proof ASA is adopted to serve as a toughener of PBT, other weather-proof assistants are added, and the printing wire applied to a 3D printing product and used in outdoor intensive ultraviolet, damp, rain and light environments is provided.

Owner:FUJIAN NORMAL UNIV

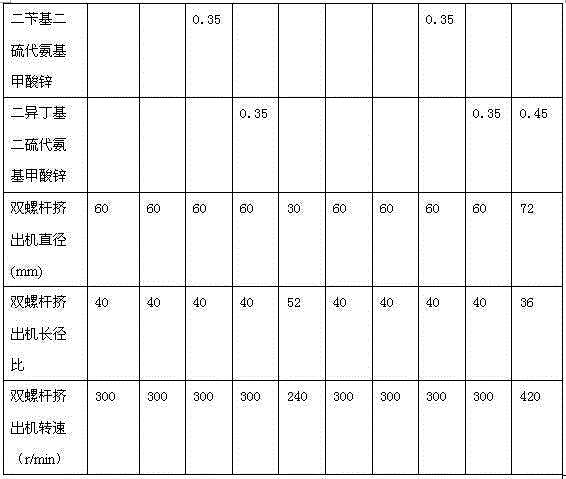

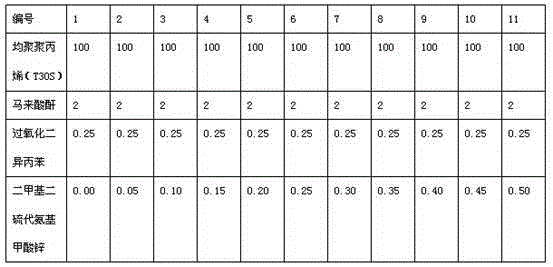

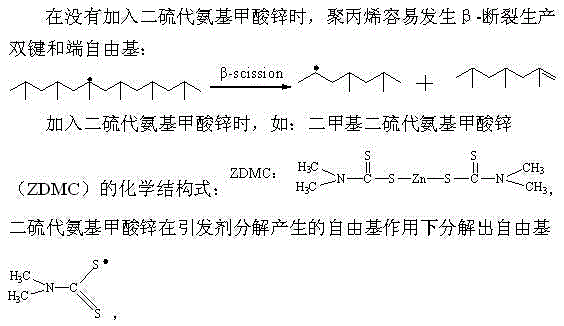

High-grafting-ratio maleic anhydride graft polypropylene material and preparation method thereof

The invention discloses a high-grafting-ratio maleic anhydride graft polypropylene material and a preparation method thereof. By adopting zinc dithiocarbamate as a stabilizer for macromolecular free radicals, the stability of the macromolecular free radicals is increased, the decomposition of the macromolecular free radicals is inhibited and thus the chain degradation is decreased and meanwhile, the reaction time of the macromolecular free radicals and graft monomer is prolonged so that the grafting ratio is increased, the maleic anhydride graft polypropylene material with high grafting ratio and low degradation is prepared and the grafting ratio can be doubled compared to that of the general grafting modification scheme; the degradation of polypropylene is inhibited, the flow rate of a melt is greatly reduced so that the operability of the production process is enhanced.

Owner:GUIZHOU UNIV

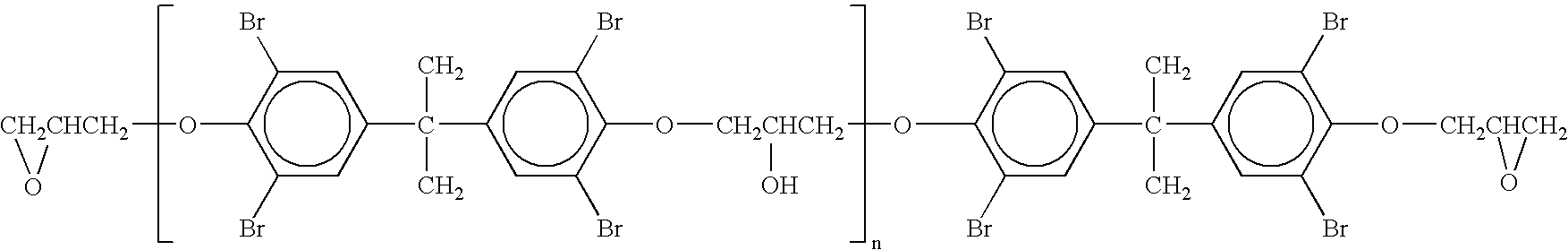

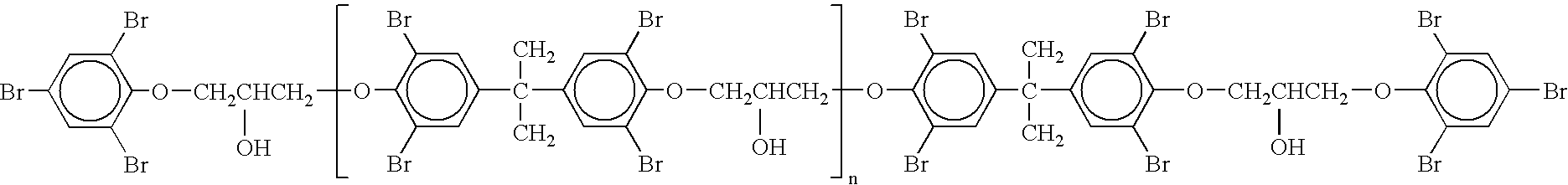

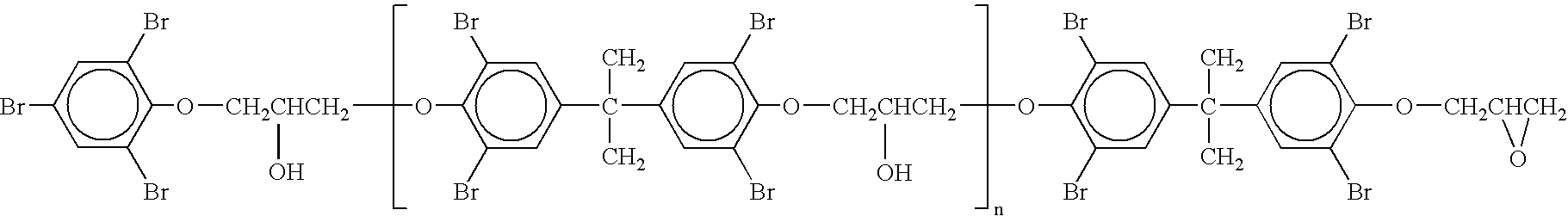

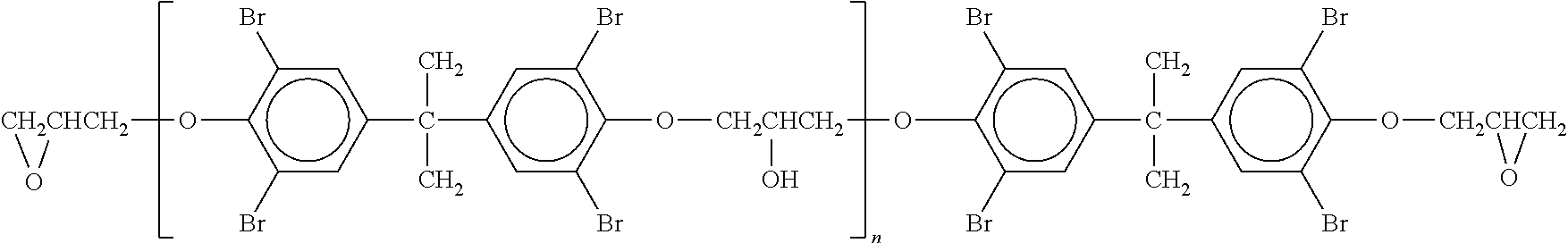

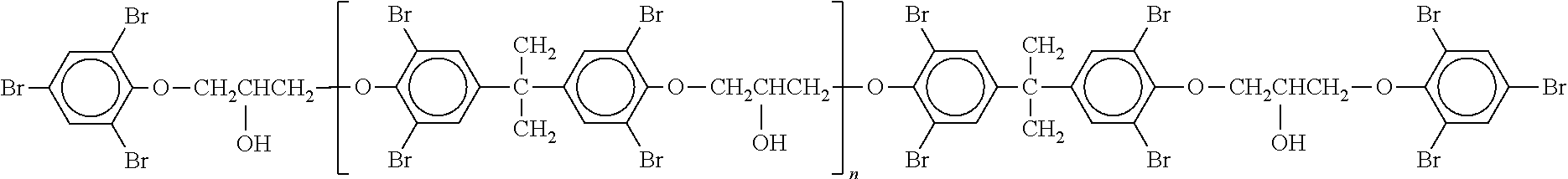

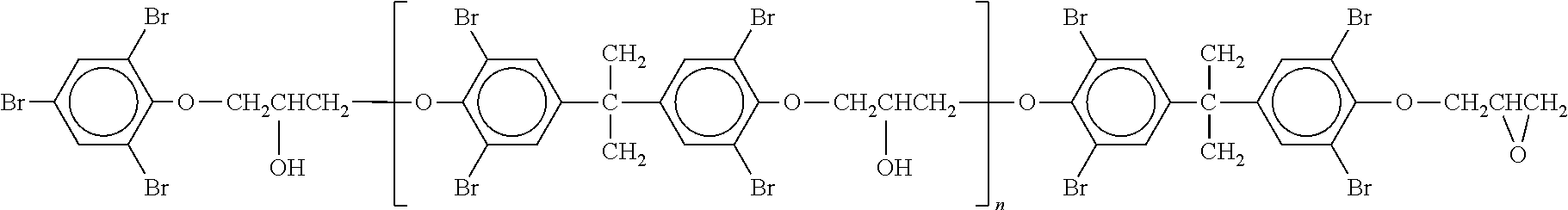

Flame-retardant for engineering thermoplastic applications

InactiveUS20060148948A1Corrosion minimizationShorten the timeDyeing processTextile shapingThermoplasticOrganic solvent

This invention provides a flame retardant for polymeric compositions which is a mixture consisting of high molecular weight brominated epoxides modified with tribromophenol, having a low content of organic solvents. The invention further relates to a method for the preparation of the retardant, and to its use in flame retarded engineering thermoplastics having good chemical, thermal, and mechanical properties.

Owner:BROMINE COMPOUNDS

Thermoplastic olefin compositions and articles

A thermoplastic olefin (TPO) composition comprises (1) a major amount by weight of (a) a substantially linear homopolymer or copolymer of a C2–C10 α-olefin in major proportion to (b) a long chain branched a linear homopolymer or copolymer of a C2–C10 α-olefin, (2) a minor amount by weight of a cross linkable elastomer, and (3) at least one thermally decomposing free radical generating agent present in an amount sufficient to promote an increase in melt strength of the composition over that of the melt strength of the linear homopolymer or copolymer of a C2–C10 α-olefin alone and insufficient to substantially degrade the α-olefinic polymers. The TPO composition is prepared by melt blending the components at a temperature sufficient to melt said homopolymers or copolymers of a C2–C10 α-olefin and thermally decompose said agent. Articles are thermoformed from the thermoplastic olefin.

Owner:EXOUSIA IP LLC

Method of preparing polystyrene extrusion molding cystosepiment by polystyrene recovery material

The invention relates to a method for using foam polyphenylacetylene to produce polyphenylacetylene extruded plastic foam plate, which comprises: (1), classifying the foam polyphenylacetylene material via colors; (2) breaking said material, and making particle in the particle maker, while the temperature is 160-200Deg. C; (3), collecting the particles, adding agent, mixing, while the ratio between the particles and the agent is 100:0-10; (4) mixing and fusing said particles in plastic extruder, adding carbon dioxide foaming agent, to foam, while the mass ratio between the particle and the foaming agent is 100:4-15, to be extruded from mould, to obtain the foam plastic plate.

Owner:南京法宁格节能科技股份有限公司

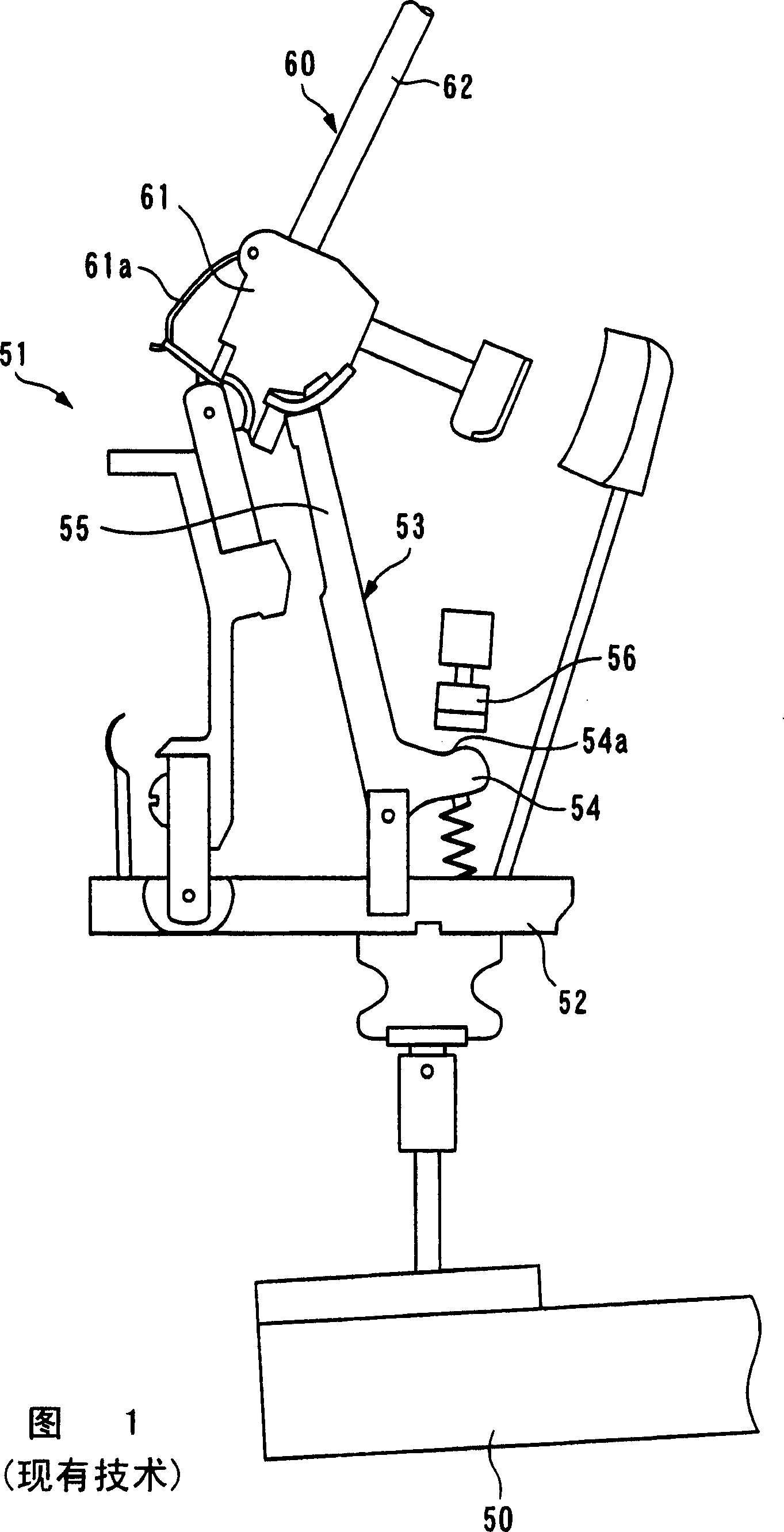

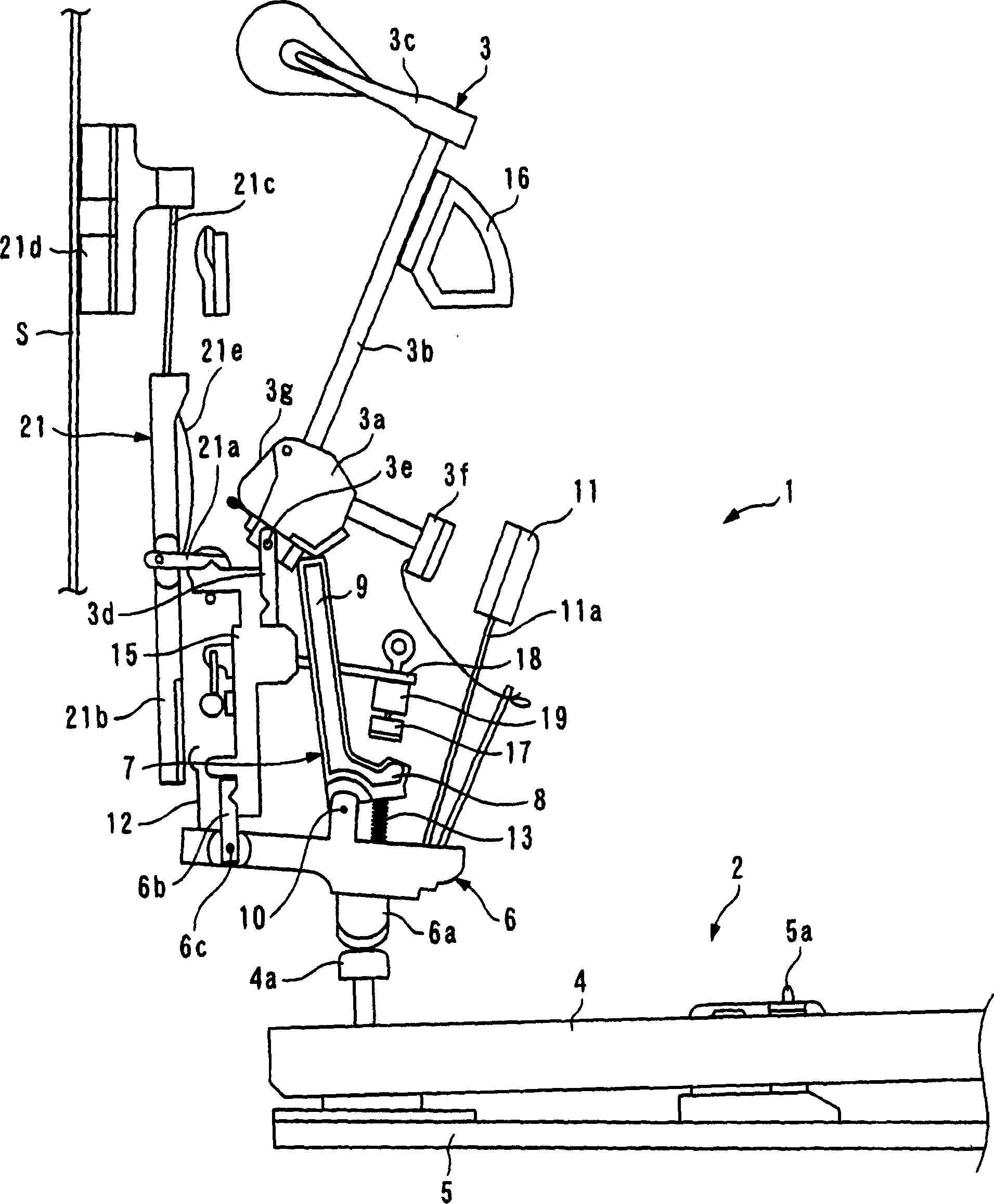

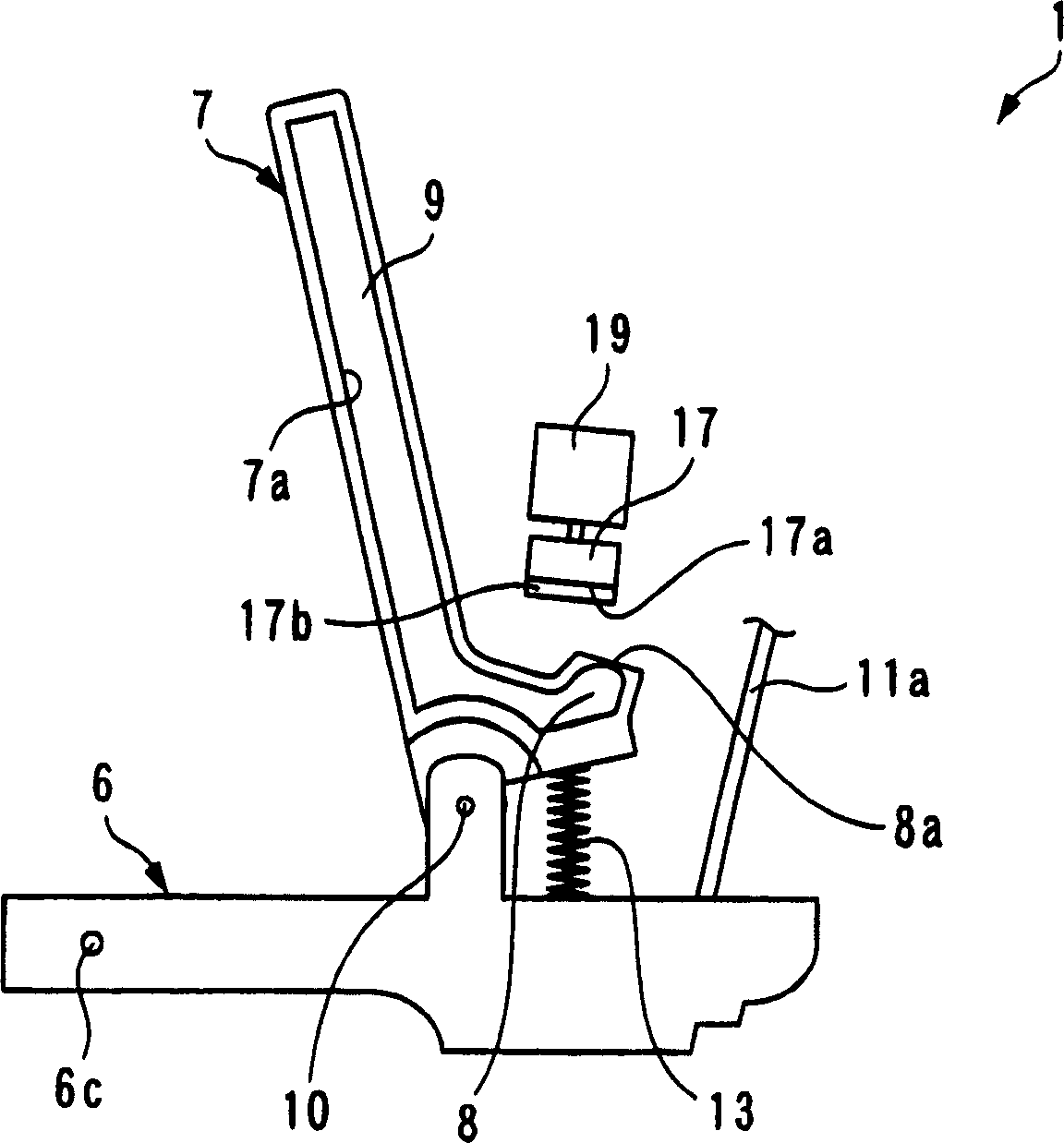

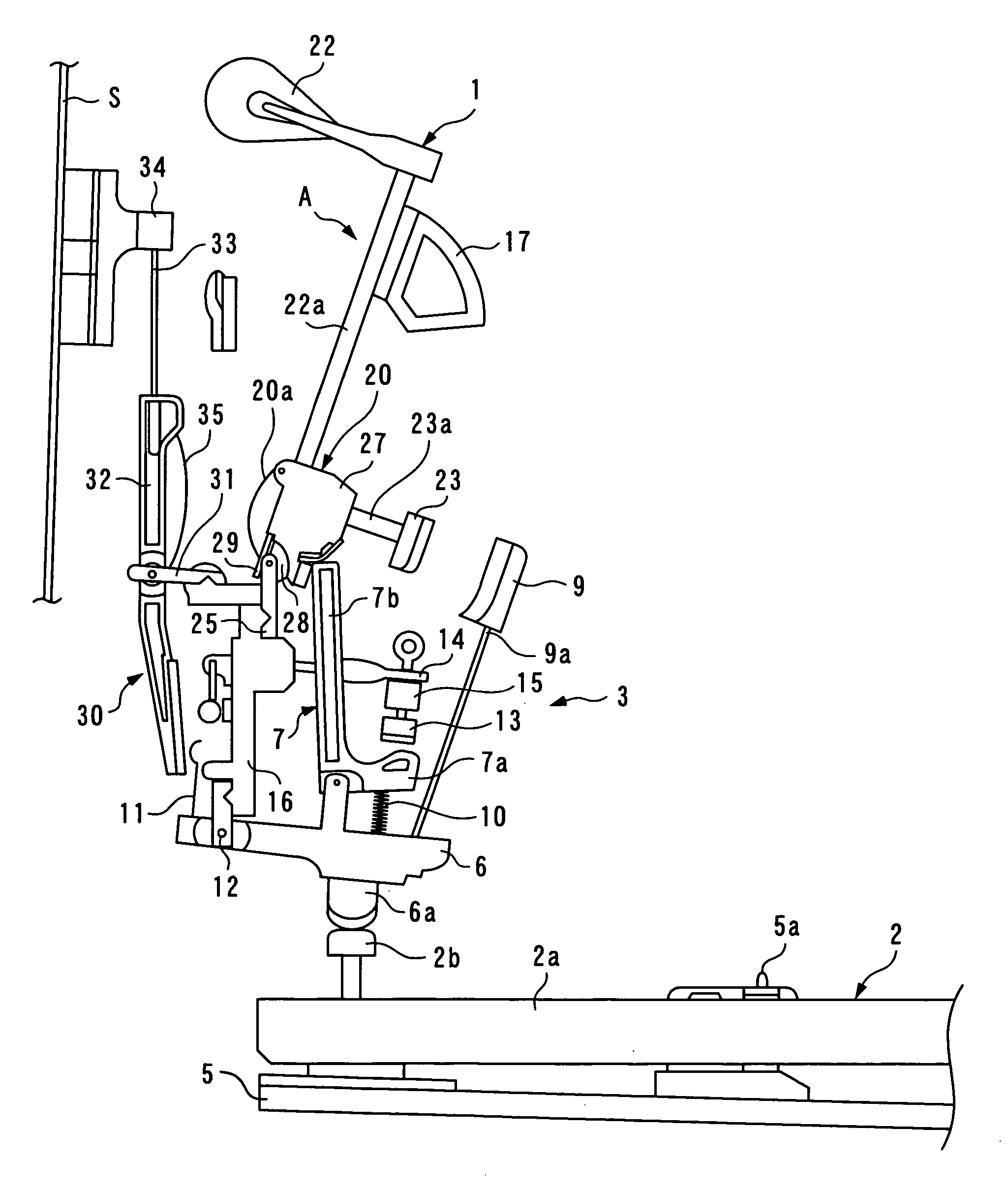

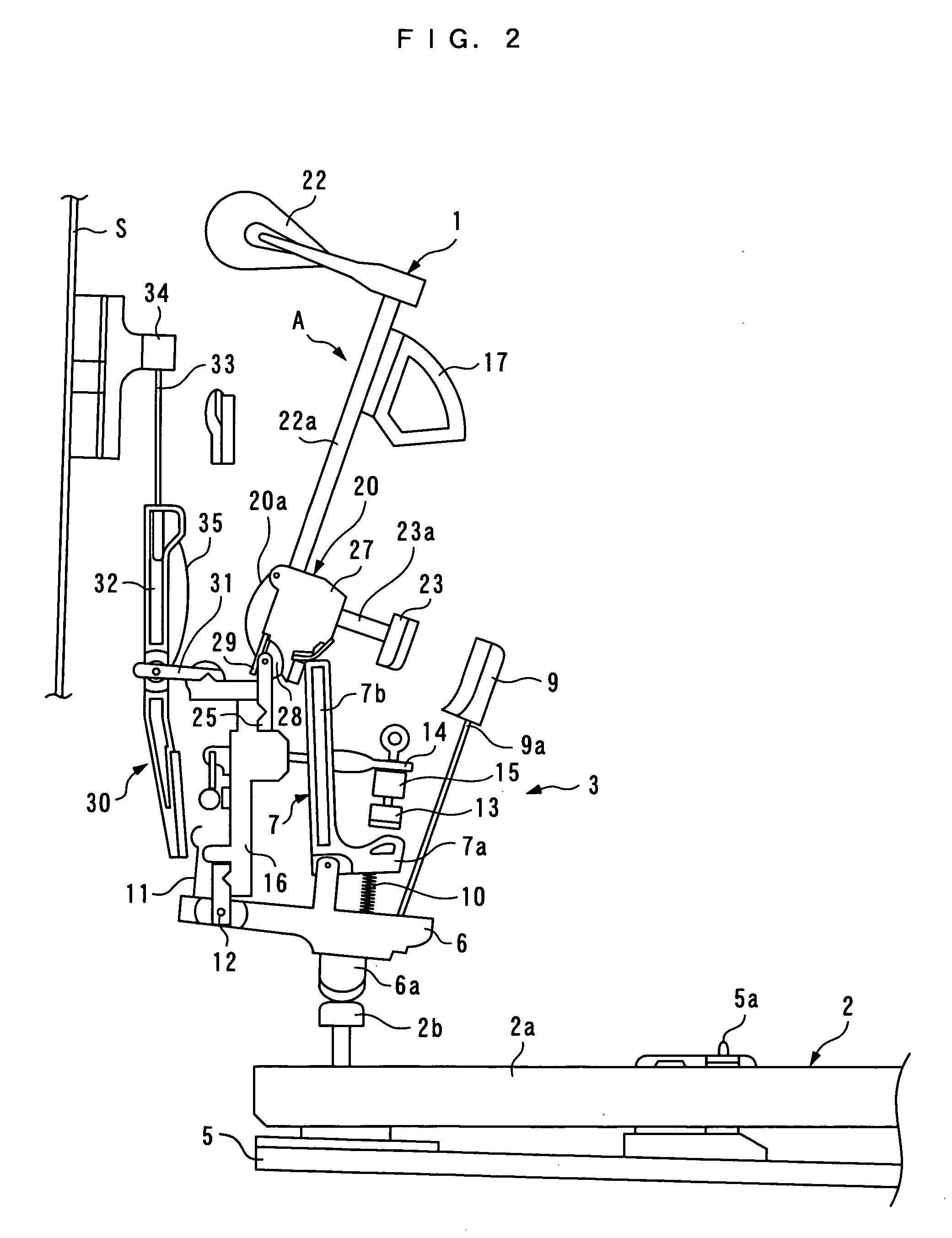

Mechanical device for piano

An action for a piano is provided for clarifying a timing of let-off, improving the sequential touching capabilities, and consequently realizing high playing performance excellent in expressive power in a simple structure without adversely affecting the key touch feeling. The action for a piano swings a hammer in response to a touch on a key, and comprises a wippen pushed up by the key to pivotally move, a regulating button having a flat jack contact surface on the lower end, and a jack having a flat regulating button contact surface which comes into contact with the jack contact surface as the key is depressed. The jack comprises a molding made of a thermoplastic resin containing long fibers for reinforcement.

Owner:KAWAI MUSICAL INSTR MFG CO

Tackifying polyamide 6 composition

The present invention relates to a combination of tackified polyamide 6, which is made up of materials having following weight percentages: 6 60-94.7 percent of nylon, 0.1-35 percent of tackifier, 5-20 percent of compatilizer, 0.1-5 percent of silicon dioxide of nanometer scale and 0.1-1 percent of antioxidant. The combination of tackified nylon 6 of the present invention has simple manufacturing method, the present invention has the advantages that the impact toughness is improved, the intension of the fused mass is high, various thin wall shaping articles can be made by extruding or blow molding, and in particular the present invention can be used in polymer tubular of good high performance in medical operation due to the good compliance, high tenacity and low friction factor of the material.

Owner:SHANGHAI SUNNY

Polypropylene resin suitable for manufacturing medical infusion bottle by using injection stretch blow moulding process

InactiveCN101724203AImproved resistance to thermal degradationLow melt flow ratePropanoic acidBottle

The invention relates to polypropylene resin which is suitable for manufacturing a medical infusion bottle by using an injection stretch blow moulding process. The polypropylene resin is a composition, comprises the following ingredients of resin base material, acid neutralizer and antioxidant and is formed by melting and mixing, wherein the resin base material is propylene and ethylene random copolymer with the fusion temperature of 140 to 165 DEG C and the melt flow rate of 5.0 to 10.0g / 10min; the antioxidant is a mixture of hindered phenol antioxidant and phosphite ester antioxidant, and the weight ratio of the former to the latter is 1: 0.2 to 10; wherein the hindered phenol antioxidant is selected from one of 1,3,5-trimethyl-2,4,6-tri(3,5-tertiary dibutyl-4 hydroxy benzyl) benzene, bi-(3,3-bi-(3-tertiary butyl-4-hydroxy phenyl)-butyrate) glycol ester or tetra(Beta-(3,5-tertiary dibutyl-4- hydroxy phenyl) propionic acid) pentaerythritol ester; and the phosphite ester antioxidant is diphosphorous acid bi(2,4-teritiary dibutyl) pentaerythritol ester.

Owner:SINOPEC SHANGHAI PETROCHEMICAL CO LTD

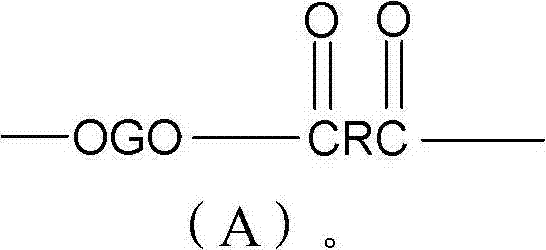

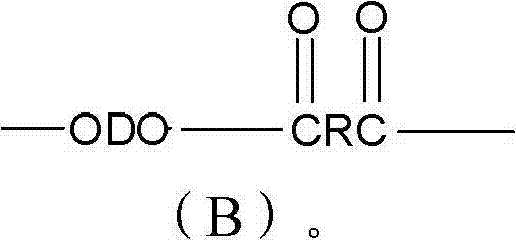

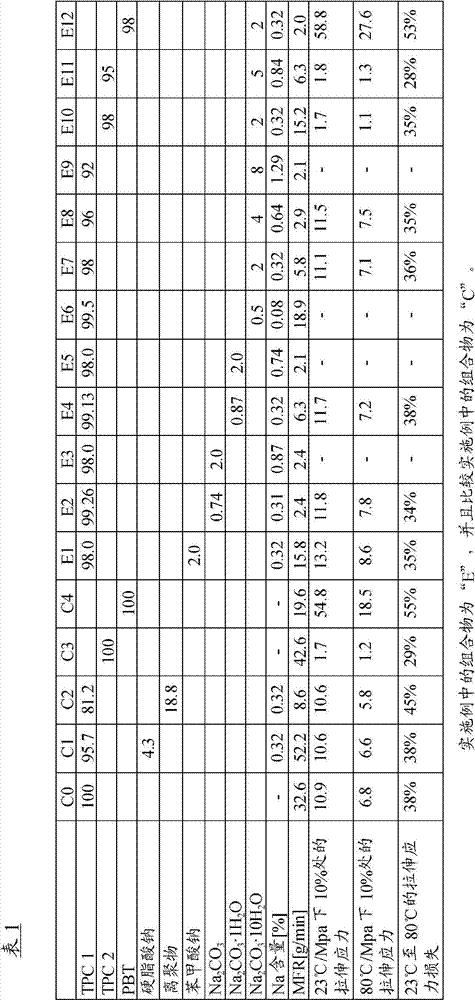

High melt viscosity polyester or co-polyester compositions

Processes of decreasing the melt flow rate of a polyester selected from the group consisting of polyesters derived from one or more dicarboxylic acids and one or more diols having more than two carbon atoms, copolyester thermoplastic elastomers, and mixtures of these, by melt mixing with the polyester an alkali metal salt having a molecular weight less than 300 to provide a melt mixed composition. Processes of making a melt extruded article from such melt mixed compositions and the articles made therefrom.

Owner:EI DU PONT DE NEMOURS & CO

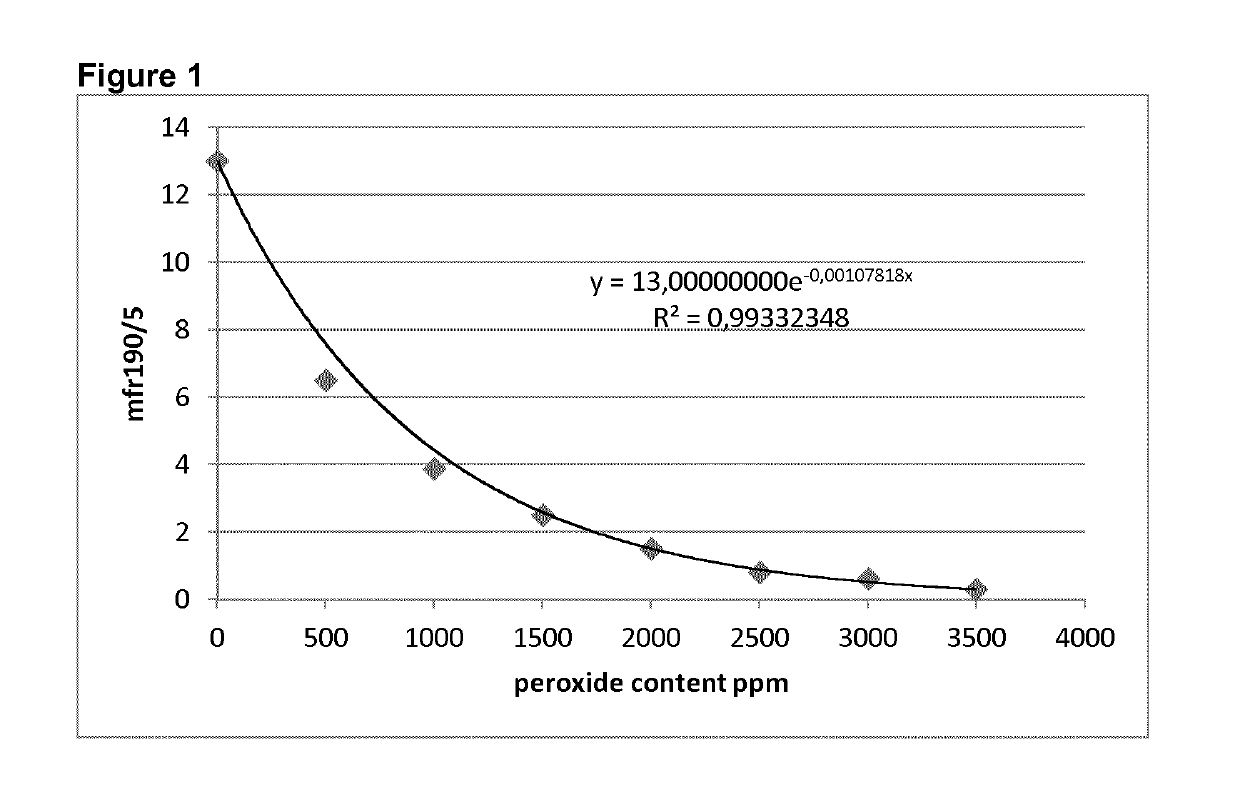

Molecular modification of polyethylene resin

ActiveUS20190177448A1MFR is also loweredLow melt flow ratePlastic recyclingPolymer scienceControl manner

The invention is related to a process for producing modified polyethylene having decreased melt flow rate (5 kg, 190° C.) (MFR). In particular, the present invention is directed to a process in a controlled manner for producing modified polyethylene recyclates having low MFR and low gel content directly by reactive extrusion processing.

Owner:BOREALIS AG

Tackifying polyamide 66 composition

The invention relates to a tackifying polyamide 66 combination, which is made from raw materials of the following percentage by weight: 70 percent to 94.7 percent of nylon 66, 0.1 percent to 35 percent of tackifier, 4 percent to 20 percent of compatilizer, 0.1 percent to 5 percent of nanometer silicon dioxide and 0.1 percent to 1 percent of antioxidant. The invention has the advantages that: the method of making is simple and the impact toughness of the made material is substantially improved while maintaining original excellent properties of nylon 66; the strength of fused mass is high, thereby the fused mass can be extruded or made into various thin-wall shaping articles through blow molding; particularly, due to possessing ideal compliance, high tenacity, low friction coefficient, the material can be used in high performance polymer pipe for surgery.

Owner:SHANGHAI SUNNY

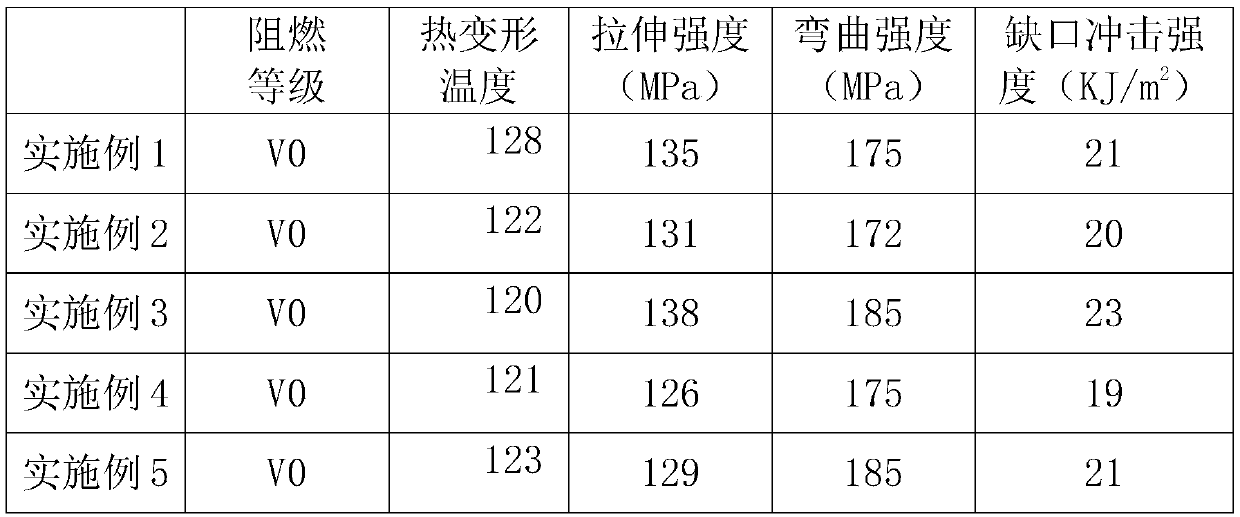

Flame-retardant reinforced heat stable ABS composite material and preparation method thereof

The invention relates to a flame-retardant reinforced heat stable ABS composite material and a preparation method thereof. The ABS composite material comprises 75-85 parts of ABS resin, 15-25 parts ofthermosetting resin, 5-10 parts of triazine boron flame retardants, 1-5 parts of sulfonate flame retardants, 5-10 parts of Kevlar chopped fiber, 2-3 parts of cellulose dispersants, 0.5-1 part of hyperbranched polyester and 1-5 parts of heat stabilizers. The flame-retardant reinforced heat stable ABS composite material has good flame retardant performance, heat stability and excellent mechanical properties.

Owner:滁州斯英铂聚合材料有限公司

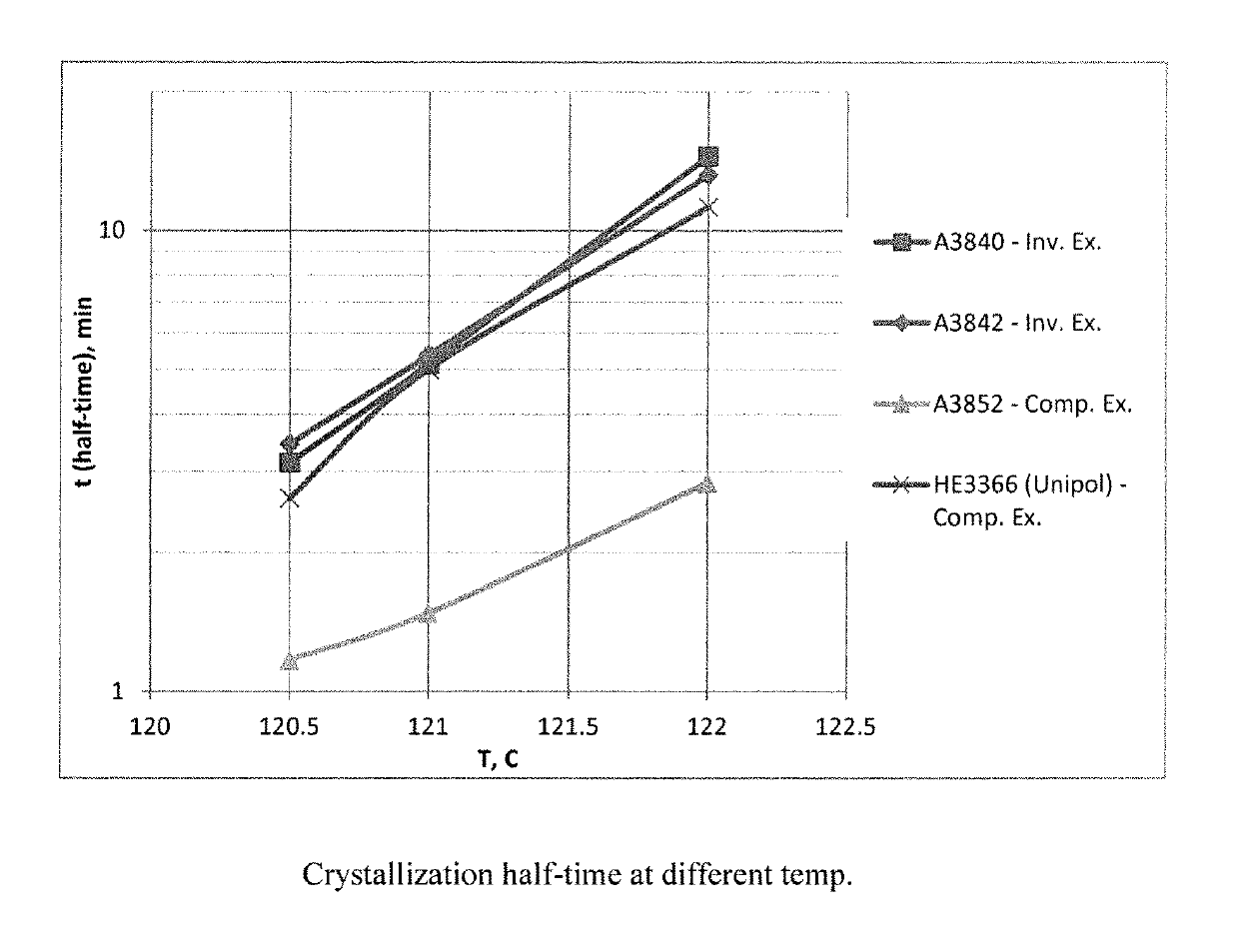

Multimodal polyethylene

ActiveUS10435493B2Reduce speedEasy to processCoaxial cables/analogue cablesPlastic/resin/waxes insulatorsAlpha-olefinEthylene

A multimodal polyethylene copolymer suitable for use in cable insulation comprising:(III) 45 to 55 wt % of a lower molecular weight component which is an ethylene copolymer of ethylene and at least one C3-12 alpha olefin comonomer, said LMW component having a density of 940 to 962 kg / m3 and an MFR2 of 50 to 500 g / 10 min;(IV) 55 to 45 wt % of a higher molecular weight ethylene copolymer component of ethylene and at least one C3-12 alpha olefin comonomer;wherein said multimodal polyethylene copolymer has a density of 940 to 950 kg / m3, an MFR2 of 0.05 to 2.0 g / 10 min and preferably at least one of crystallization half time>3.0 mins at 120.5° C., a crystallization half time>5.0 mins at 121° C. or a crystallization half time>10.0 mins at 122° C.

Owner:BOREALIS AG +1

Flame-retardant for engineering thermoplastic applications

InactiveUS8067497B2Shorten the timeReduce melt viscosityDyeing processTextile shapingThermoplasticOrganic solvent

This invention provides a flame retardant for polymeric compositions which is a mixture consisting of high molecular weight brominated epoxides modified with tribromophenol, having a low content of organic solvents. The invention further relates to a method for the preparation of the retardant, and to its use in flame retarded engineering thermoplastics having good chemical, thermal, and mechanical properties.

Owner:BROMINE COMPOUNDS

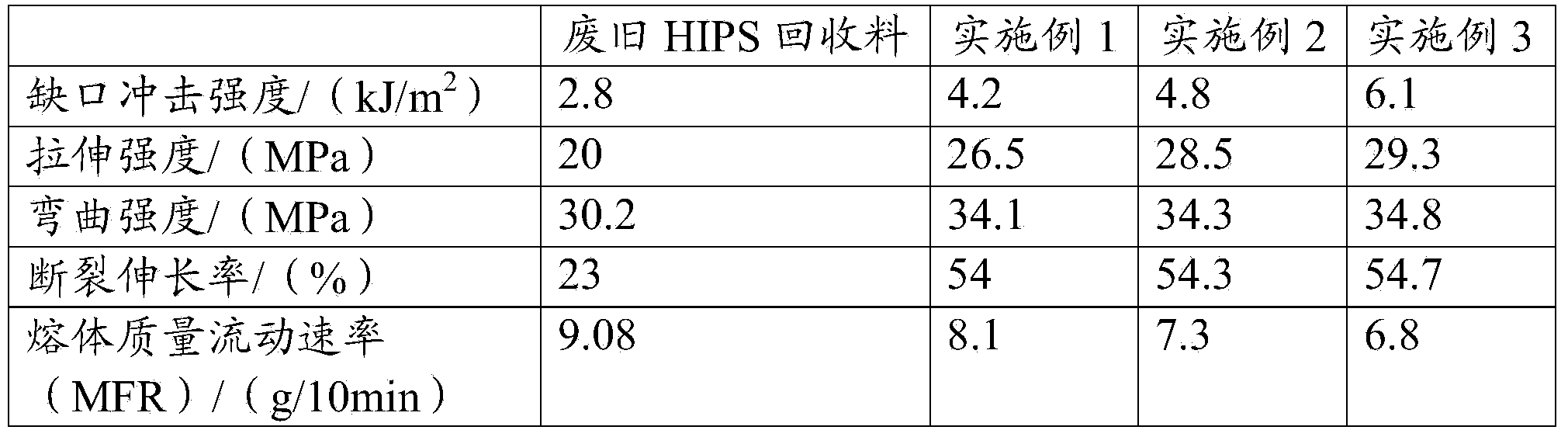

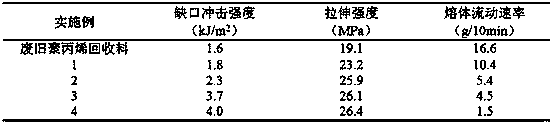

Waste high impact polystyrene modified material and preparation method thereof

InactiveCN104327402AImprove mechanical propertiesHigh tensile strengthPolymer scienceFlexural strength

The invention belongs to the field of high polymer materials and in particular relates to a waste high impact polystyrene modified material and a preparation method thereof. The waste high impact polystyrene modified material provided by the invention is prepared by performing melt blending on materials, wherein the materials comprise the following components in parts by weight: 100 parts of waste high impact polystyrene and 0.3-1.5 parts of bi-oxazoline compound; the notch impact strength of the waste high impact polystyrene is lower than 4kJ / m<2>. The waste high impact polystyrene modified material provided by the invention has good mechanical property. The experimental result proves that the notch impact strength of the waste high impact polystyrene modified material provided by the invention is higher than 4kJ / m<2>, the tensile strength is higher than 25MPa, the bending strength is higher than 34MPa, the elongation at break is higher than 50 percent, and the melt mass-flow rate is lower than 8.5g / 10 minutes.

Owner:ZHONGBEI UNIV +1

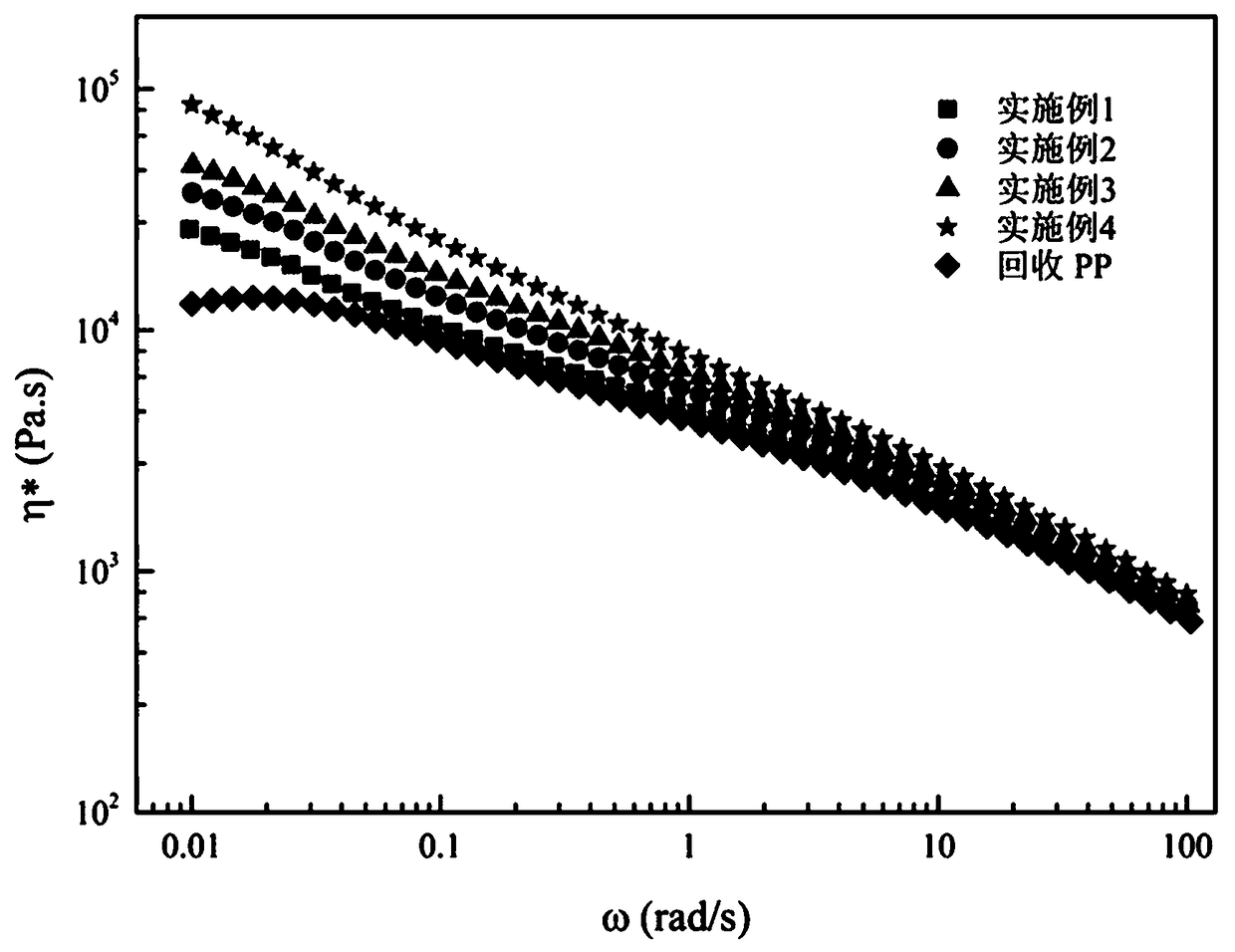

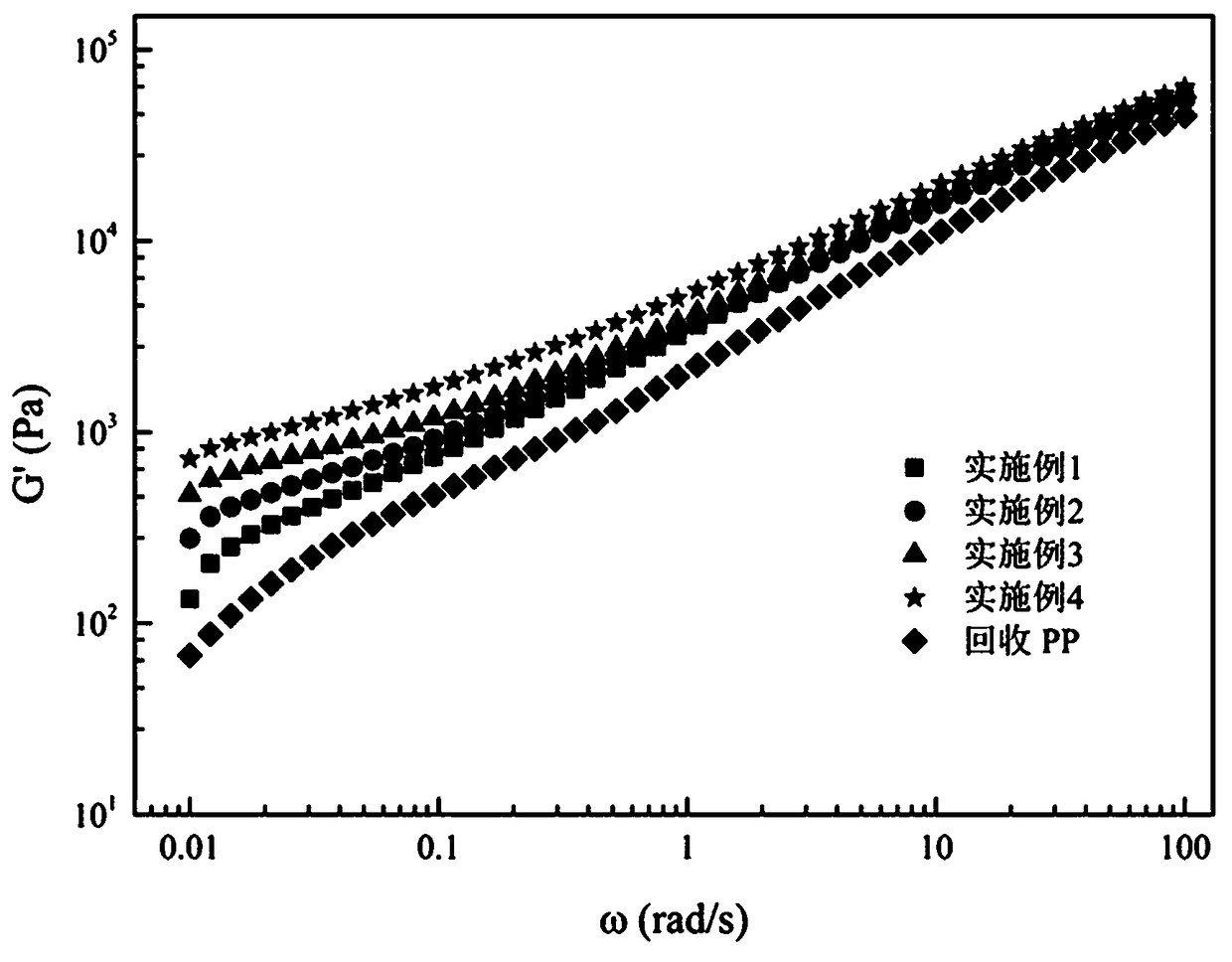

Waste polypropylene long branched chain material and preparation method thereof

Belonging to the field of polymer material science, the invention in particular relates to a waste polypropylene long branched chain material and a preparation method thereof. The waste polypropylenelong branched chain material provided by the invention is prepared by melt blending modification of raw materials. The raw materials include, by weight, 100 parts of waste household appliance polypropylene; 0.1-10 parts of an epoxy functional monomer; 0.1-2 parts of an organic peroxide; 0-5 parts of an anhydride functional monomer; 0.1-10 parts of styrene; and 0.1-2 parts of other additives. The waste household appliance polypropylene has tensile strength of less than 22MPa and notched impact strength of lower than 3kJ / m<2>. The waste household appliance polypropylene long branched chain material has provided by the invention has good mechanical properties. The experimental result shows that the waste household appliance polypropylene long branched chain material has tensile strength higher than 22MPa, notched impact strength higher than 3kJ / m<2> and a melt mass flow rate of less than 12g / 10min.

Owner:ZHONGBEI UNIV

Polyamide 66 composite material for extruding thin-walled section bar

The invention relates to a polyamide 66 composite material used for extruding thin-wall shaping articles, which is made from raw materials of the following percentage by weight: 70 percent to 94.8 percent of nylon 66, 0.1 percent to 24 percent of tackifier, 5 percent to 20 percent of compatilizer and 0.1 percent to 1 percent of antioxidant. The invention has the advantages that: the method of making is simple and the impact toughness of the made material is substantially improved while maintaining original excellent properties of nylon 66; the strength of fused mass is high, thereby the fused mass can be extruded or made into various thin-wall shaping articles through blow molding; particularly, due to possessing ideal compliance, high tenacity, low friction coefficient, the material can be used in high performance polymer pipe for surgery.

Owner:SHANGHAI SUNNY

Bat for upright piano

A bat for an upright piano is provided for ensuring stable swinging movements of a hammer to generate a proper piano sound even if a hammer assembly has the centroid which is laterally asymmetric about a center pin. The bat for an upright piano is supported by the center pin having a circular cross section and arranged horizontally in a bat flange, in order to swing a hammer to cause the same to strike a string. The bat comprises a bat body integrally formed with the hammer, and having a linear pin holding groove in a back surface thereof, and a metal plate having a linear pin retaining groove in one side thereof, and attached to a back surface of the bat body such that the pin retaining groove extends in parallel with the pin holding groove, wherein the bat is pivotally supported by the center pin while the center pin is in engagement with the pin holding groove and the pin retaining groove, and the center pin is sandwiched between the bat body and the metal plate.

Owner:KAWAI MUSICAL INSTR MFG CO

Polypropylene resin used for manufacturing medical infusion bottle by injection stretch blow moulding

ActiveCN101724200AImproved resistance to thermal degradationLow melt flow rateResin matrixOxidation resistant

A polypropylene resin used for manufacturing medical infusion bottle by injection stretch blow moulding is composition, comprises the components of resin matrix, acid-acceptor and antioxidant and is formed by melting and mixing. The resin matrix is propene ethane random copolymer, melting temperature is 140-165 DEG C, and melt flowing speed is 5.0-10.0g / 10min. The antioxidant is mixture of hindered phenol type antioxidant and phosphite ester type antioxidant, and the weight ratio of the two is 1: 0.3-10.0. The hindered phenol type antioxidant is 1, 1, 3-tri(2-methyl-4-hydroxy-5-tert-butyl phenyl) butane; and the phosphite ester type antioxidant is tri(2, 4-ditertiary butyl phenyl) phosphite ester or bis(2, 4-di-tert-butyl phenyl) pentaerythritol phosphite ester. Resin has more continuous and stable oxidation resistant capability and is applicable to injection stretch blow moulding bottle-making process.

Owner:SINOPEC SHANGHAI PETROCHEMICAL CO LTD

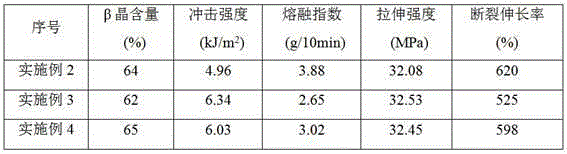

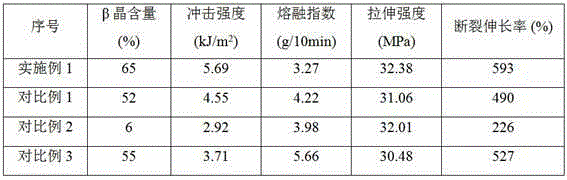

Long chain branching polypropylene random copolymer and preparation method thereof

The invention discloses long chain branching polypropylene random copolymer and a preparation method thereof. The method includes the steps of dispersing a beta nucleating agent in solvent to form first dispersion liquid, evenly mixing the first dispersion liquid with polypropylene random copolymer to form a mixture, obtaining a beta material batch through melting extrusion after the solvent is evaporated, dispersing long chain branching monomers and free radical initiator in solvent to form second dispersion liquid, evenly mixing the second dispersion liquid with the beta material batch and polypropylene random copolymer, and preparing the long chain branching polypropylene random copolymer with the beta crystal content larger than or equal to 60% through a melting reaction and extrusion after solvent is evaporated. The long chain branching polypropylene random copolymer has the low melt flow rate and high impact strength, tensile strength and elongation at break, is excellent in both processing performance and mechanical property, and is suitable for the application fields of foaming, thermal forming, thin film blow molding, extrusion coating, and the like.

Owner:FUZHOU UNIV

Humidity-conditioning sheet

ActiveUS8404032B2Improve responsivenessGood reversibilityCombination devicesSynthetic resin layered productsAmbient humidityDesorption

Owner:MITSUBISHI CHEM CORP

Preparing method of bamboo powder reinforced high density polyethylene material

The invention discloses a preparing method of a bamboo powder reinforced high density polyethylene material. The preparing method comprises a bamboo powder coupling step and a composite material preparing step. The interaction between bamboo powder obtained after treatment of an aluminate coupling agent and HDPE is enhanced, bamboo powder is evenly dispersed, and impact performance and tensile performance are obviously improved. The section of the composite material is more flat, fine and smooth, and the flowing rate of polymeric material melt is reduced.

Owner:林建君

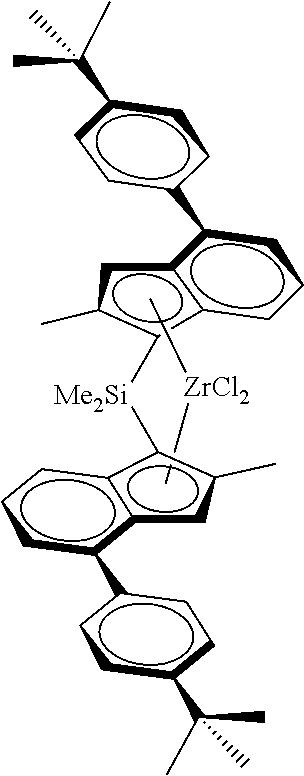

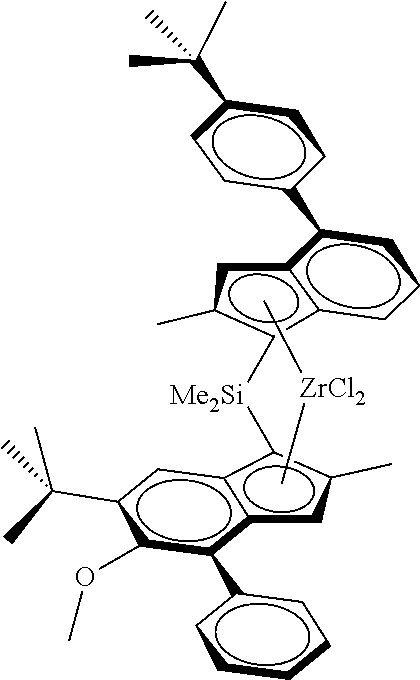

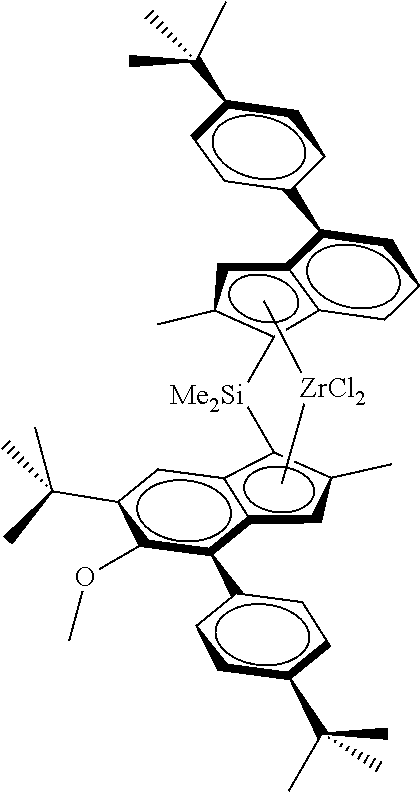

Catalysts for olefin polymerization

ActiveUS20210017307A1High selectivityImprove purification effectMetallocenesBulk chemical productionOlefin polymerizationPolypropylene

New bisindenyl ligand complexes and catalysts comprising those complexes. The invention is directed to improving the manufacturing of specific C1-symmetric bisindenyl complexes by modifying one of the indenyl ligands in order to improve the selectivity of the complex synthesis towards the desired anti-isomer, increase the yield and simplify the purification of the complex. The invention also relates to the use of the new bisindenyl metallocene catalysts for the production of polypropylene homopolymers or propylene copolymers.

Owner:BOREALIS AG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com