High-grafting-ratio maleic anhydride graft polypropylene material and preparation method thereof

A technology of grafting polypropylene and maleic anhydride, which is applied in the field of high grafting ratio maleic anhydride grafted polypropylene materials and its preparation, and can solve the problem of irritating odor caused by sublimation, affecting the performance of grafts, increasing processing difficulty, etc. problems, to achieve the effect of enhanced operability, reduced melt flow rate, and increased grafting rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

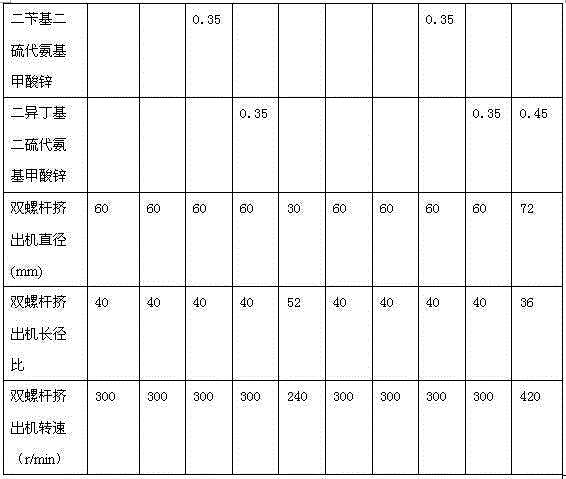

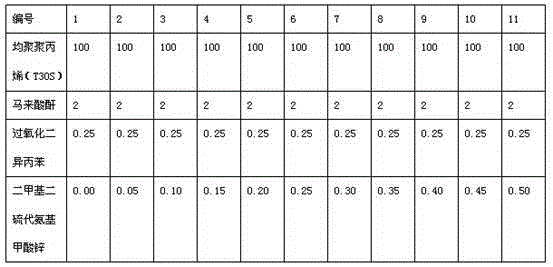

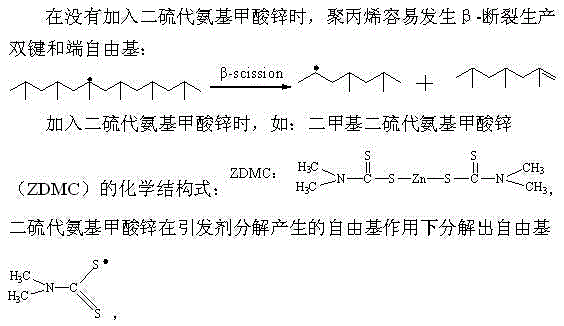

[0016] Example 1 of the present invention: high grafting rate maleic anhydride grafted polypropylene material, 11 experimental groups were established, the raw materials were calculated in parts by mass, each group included 100 parts of homopolypropylene (T30S), 2 parts Maleic anhydride and 0.25 part of dicumyl peroxide, the consumption of zinc dimethyl dithiocarbamate are as shown in table 1.

[0017]

[0018] The preparation method of maleic anhydride grafted polypropylene material with high grafting rate, according to the above-mentioned mass fraction, after fully mixing maleic anhydride, polypropylene, initiator and zinc dithiocarbamate, add it into a twin-screw extruder In the process, extrude under the condition of 160-210°C, the temperature design of the extruder is shown in Table 2, and granulate and dry to obtain the finished product; the diameter of the extruder is 60mm, the aspect ratio is 40, and the speed of the main engine is 300r / min.

[0019]

[0020] Ta...

Embodiment 2

[0022] Embodiment 2 of the present invention: the preparation of high grafting rate maleic anhydride grafted polypropylene material, set up 10 experimental groups, its preparation raw material is calculated by mass parts, each group of raw materials and preparation process are as shown in table 4:

[0023]

[0024]

[0025] The extruder temperature setting is according to Table 2; maleic anhydride, polypropylene, initiator and zinc dithiocarbamate are weighed according to the experimental formula in Table 4 and mixed uniformly in a high-speed mixer at room temperature, and then added to the twin-screw extruder In the machine, it was kneaded and extruded according to the process in Table 4, and granulated and dried.

[0026] Weigh each group of products prepared in the same amount of Example 2 respectively, measure the melt flow rate of the product, then add the product to xylene and boil to dissolve, then pour the solution into excess acetone to precipitate while it is ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com