Patents

Literature

48results about How to "Improves drawability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

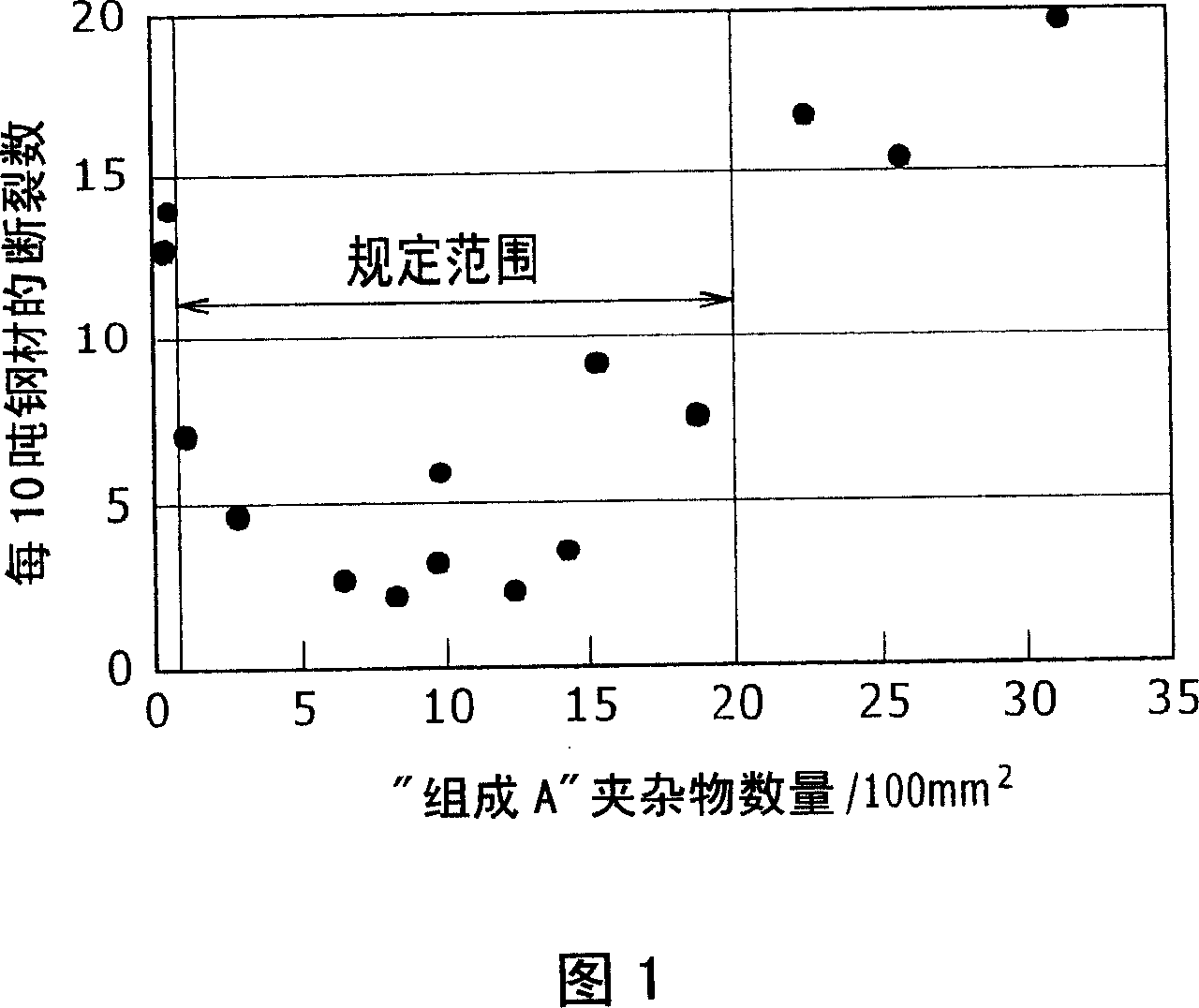

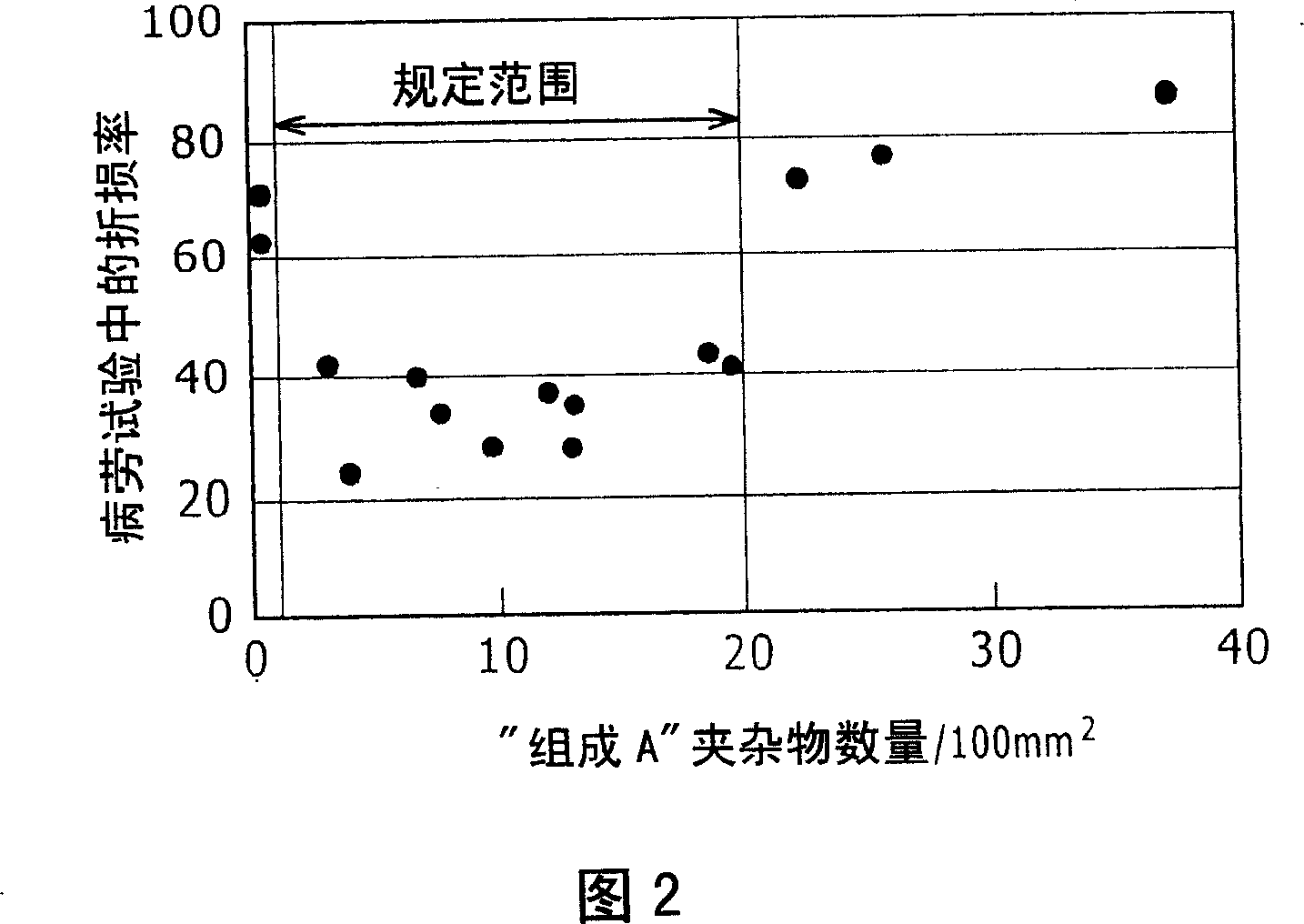

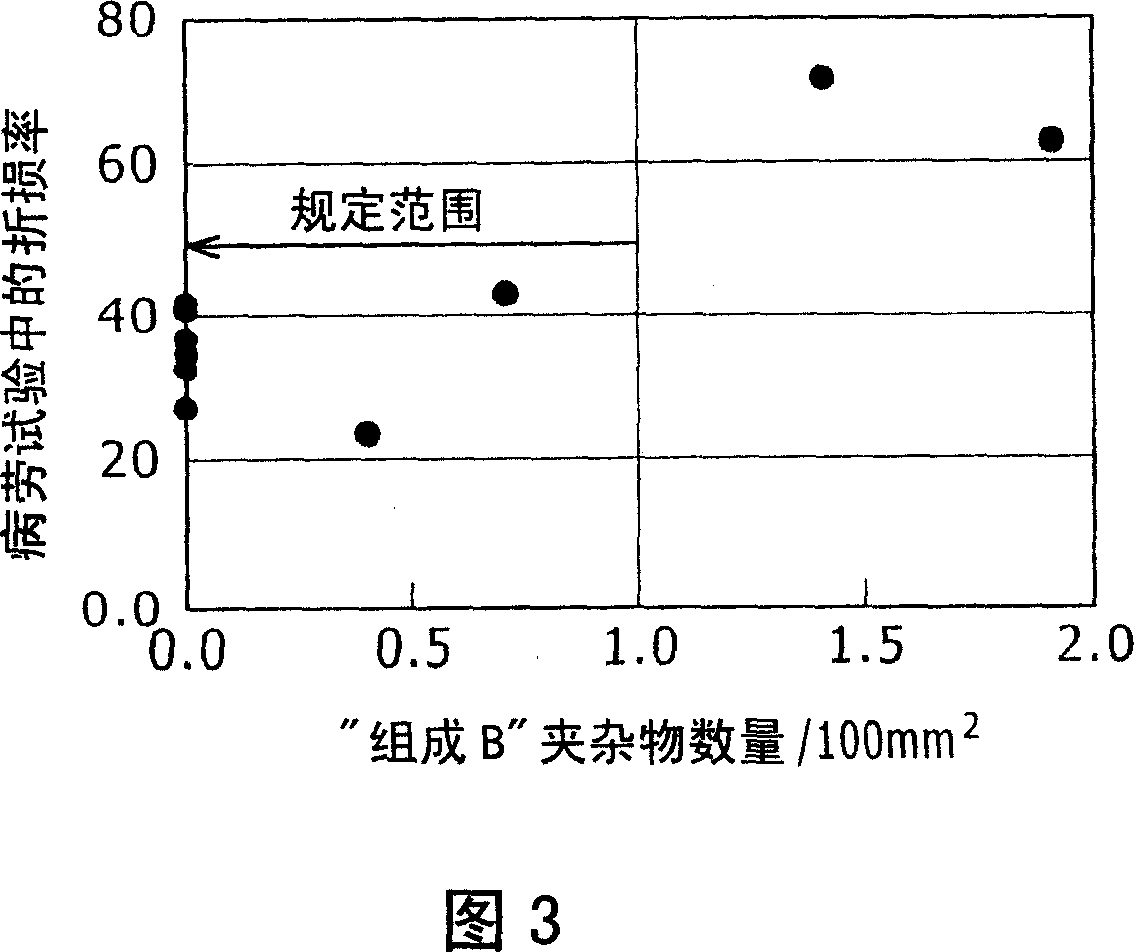

Steel wire rod having excellent drawability and fatigue properties, and manufacturing method of the same

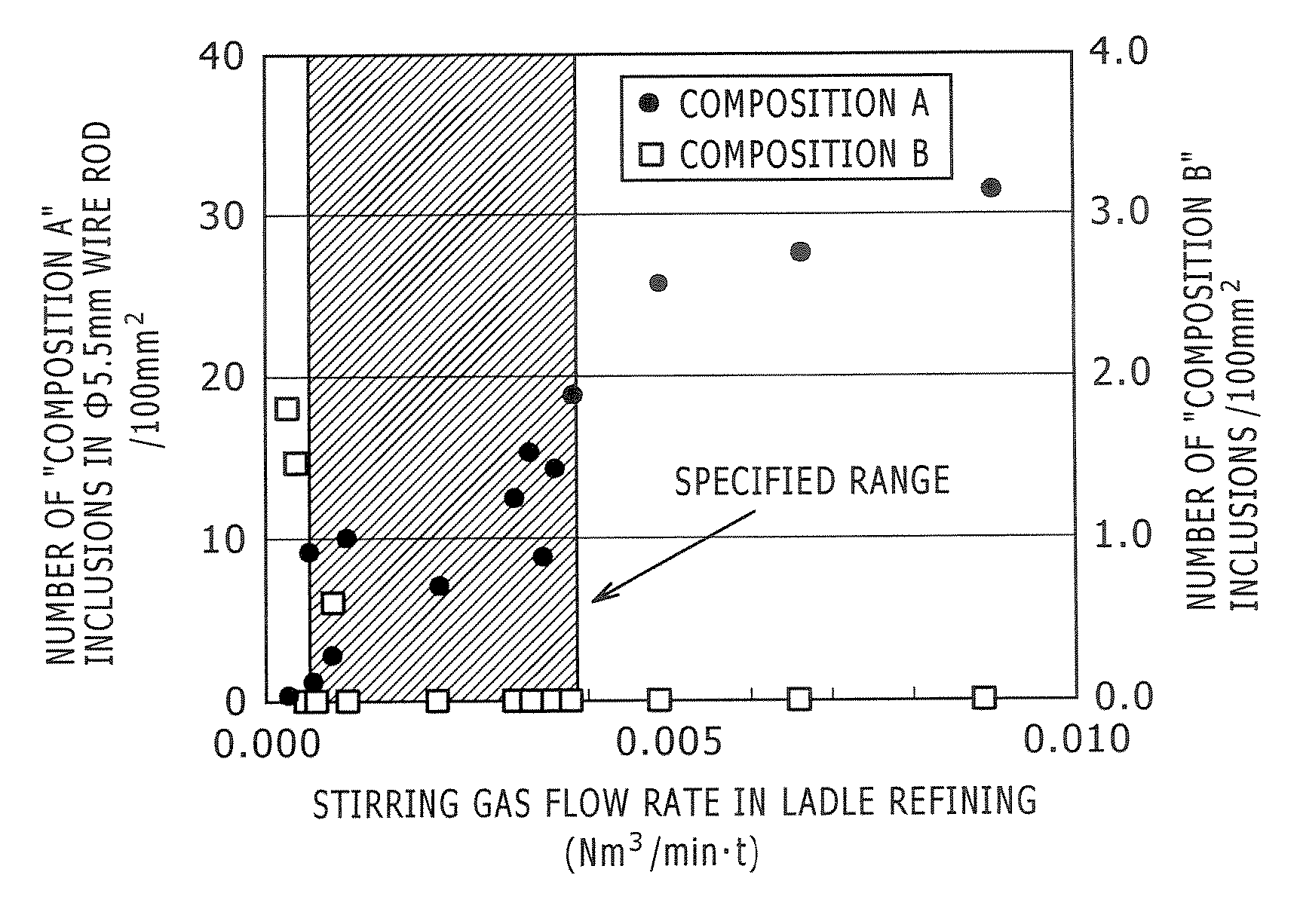

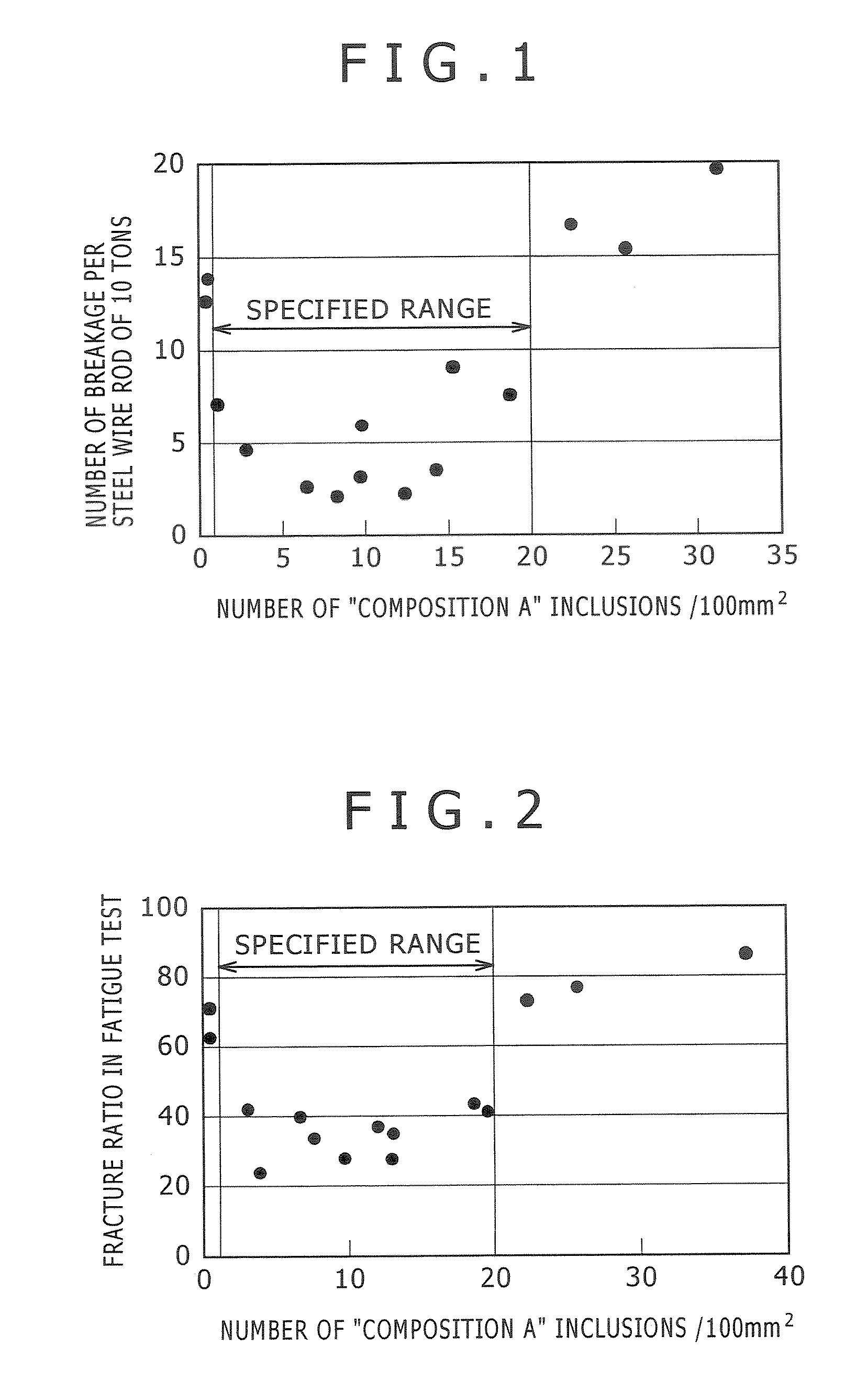

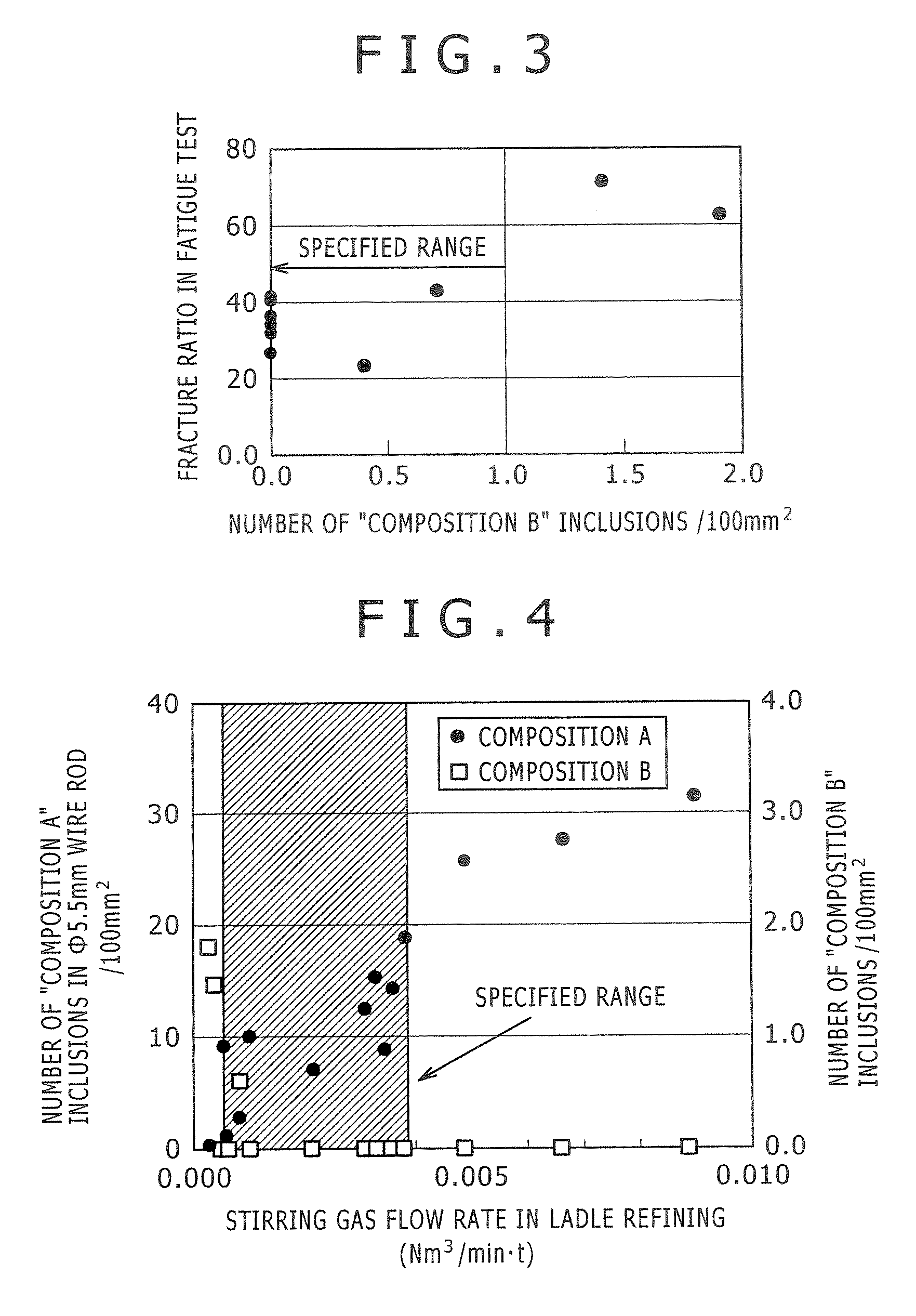

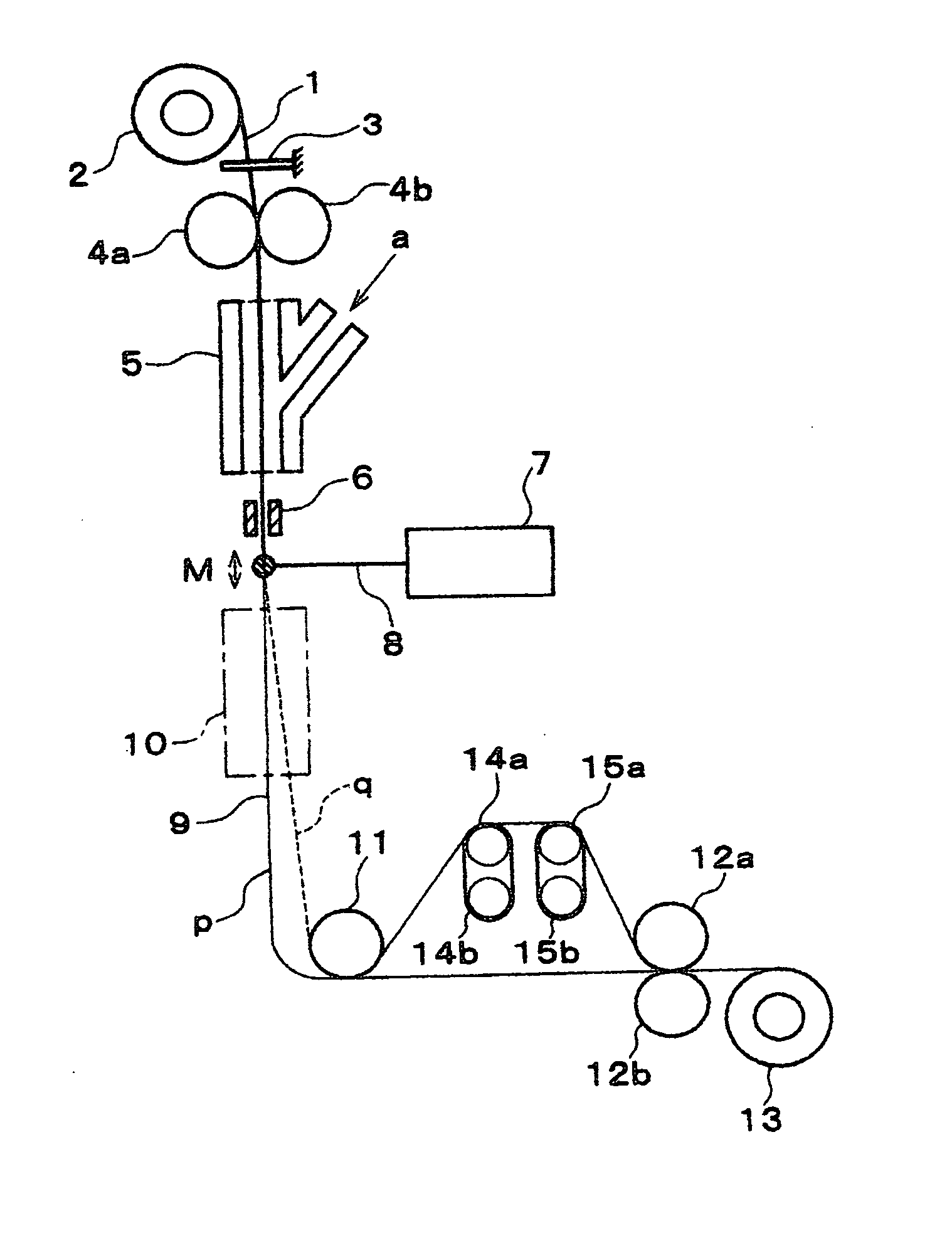

A steel wire rod is obtained, in which a gas flow rate during gas stirring in molten steel treatment is controlled to be 0.0005 Nm3 / min to 0.004 Nm3 / min per molten steel of 1 ton, thereby the rod satisfies a specified composition, and oxide base inclusions in any section including an axis line of the steel wire rod satisfy the following composition X, the inclusions having width of 2 Am or more perpendicular to a rolling direction, wherein the number of the oxide base inclusions of the following composition A is 1 to 20, and the number of the oxide base inclusions of the following composition B is less than 1: composition X: when composition of inclusions is converted to Al2O3+MgO+CaO+SiO2+MnO=100%, Al2O3+CaO+SiO2≧70% is given. composition A: when composition of inclusions is converted to Al2O3+CaO+SiO2=100%, 20%≦CaO≦50% and Al2O3≦30% are given; and composition B: when composition of inclusions is converted to Al2O3+CaO+SiO2=100%, CaO>50% is given. In the steel wire rod, drawability and fatigue properties are improved to the utmost.

Owner:KOBE STEEL LTD

Highly oriented super microfilaments

InactiveUS20060006585A1Improve heat resistanceUse in some applicationFilament handlingArc welding apparatusThermosetting polymerInfrared beam

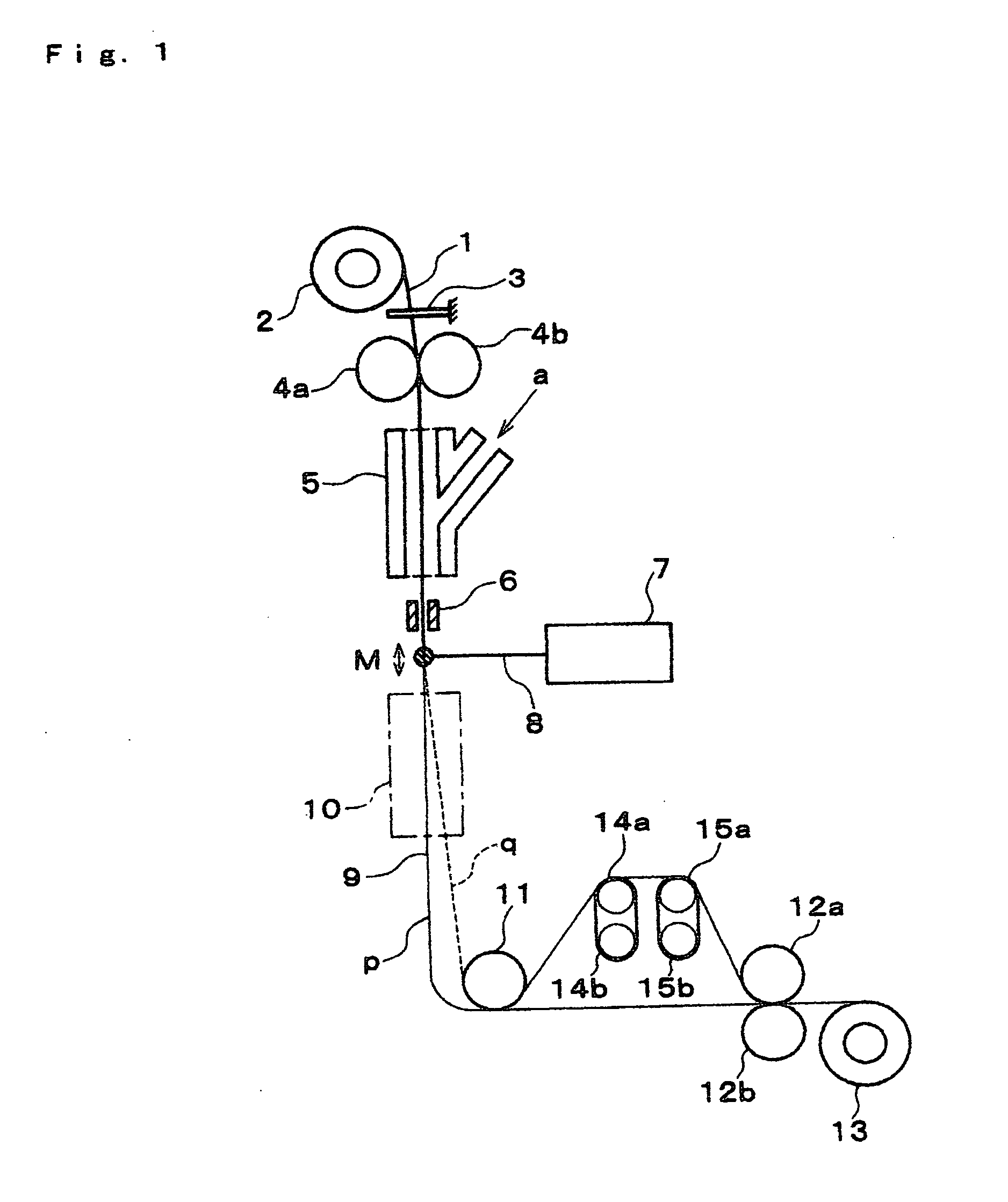

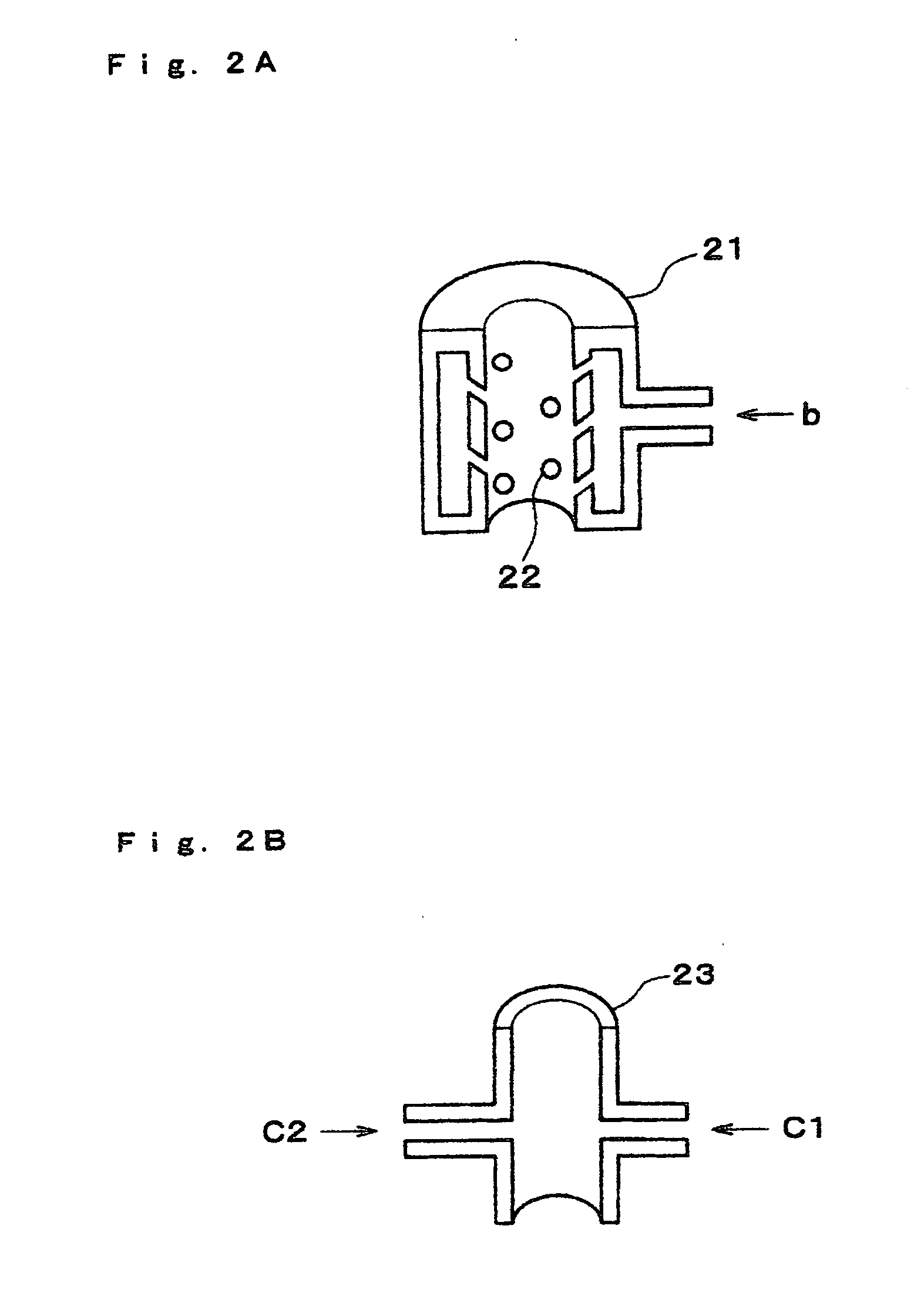

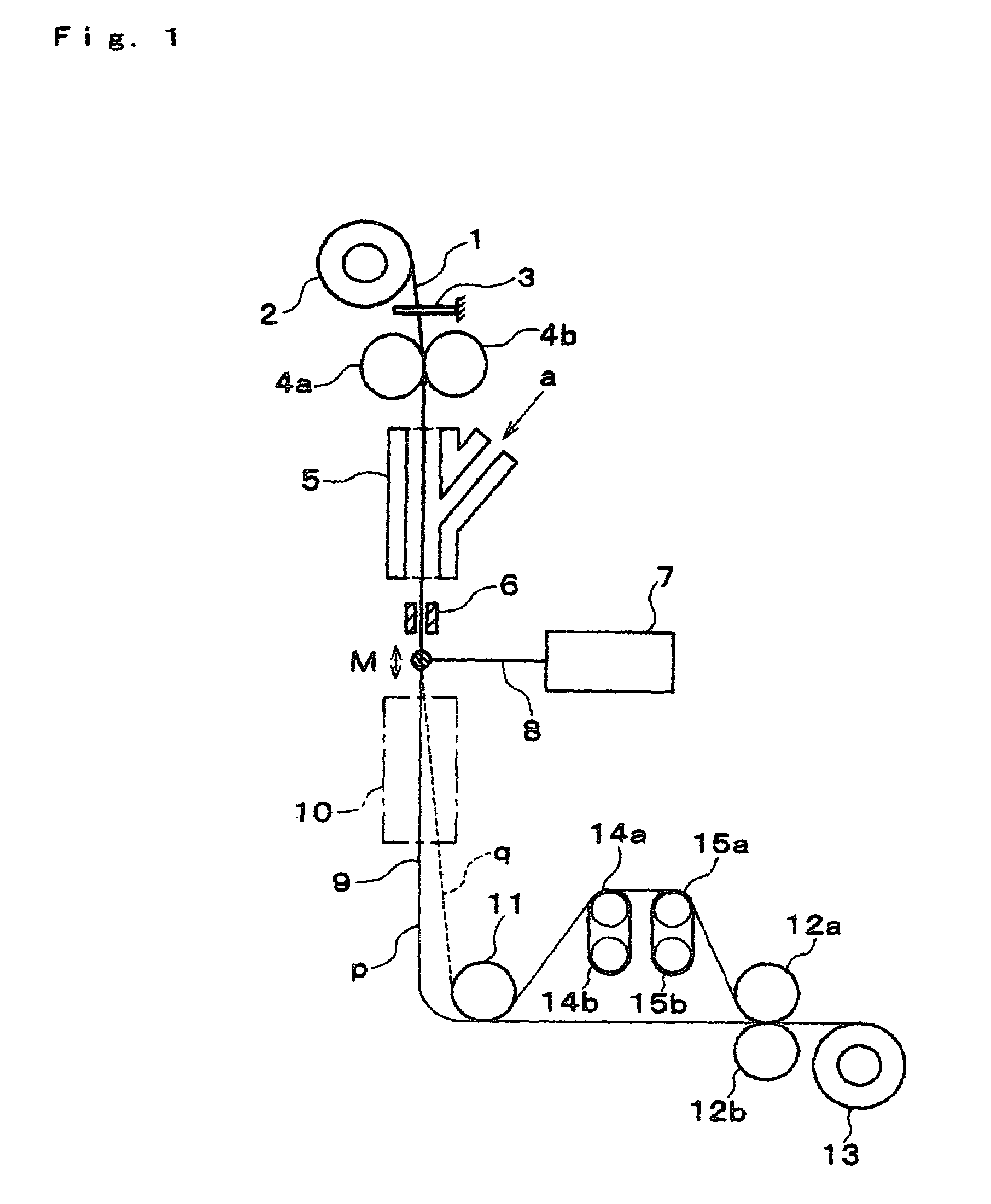

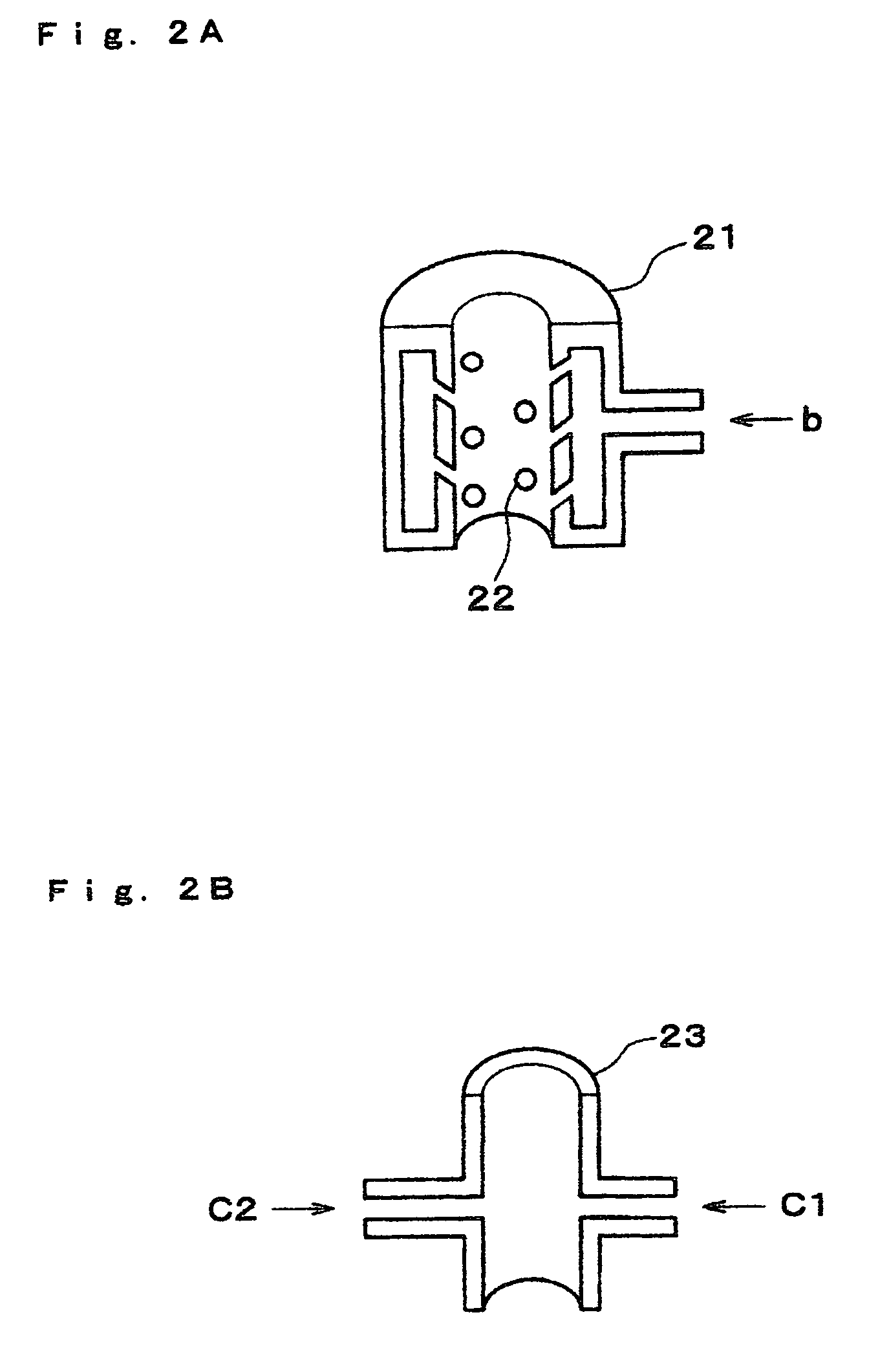

Method of and apparatus for continuously manufacturing highly oriented super micro filaments with a diameter of 5 μm or less from most of thermoplastic polymers stably by a simple and convenient means without requiring any special apparatus of high accuracy and high level, characterized in original filaments supplied from a filament supply means are heated by infrared beams and the heated filaments are drawn by tension provided by their own weight or under an applied tension of 1 MPa or less, and are drawn to 1000 times or more.

Owner:YAMANASHI UNIV OF

Multimodal high strength devices and composites

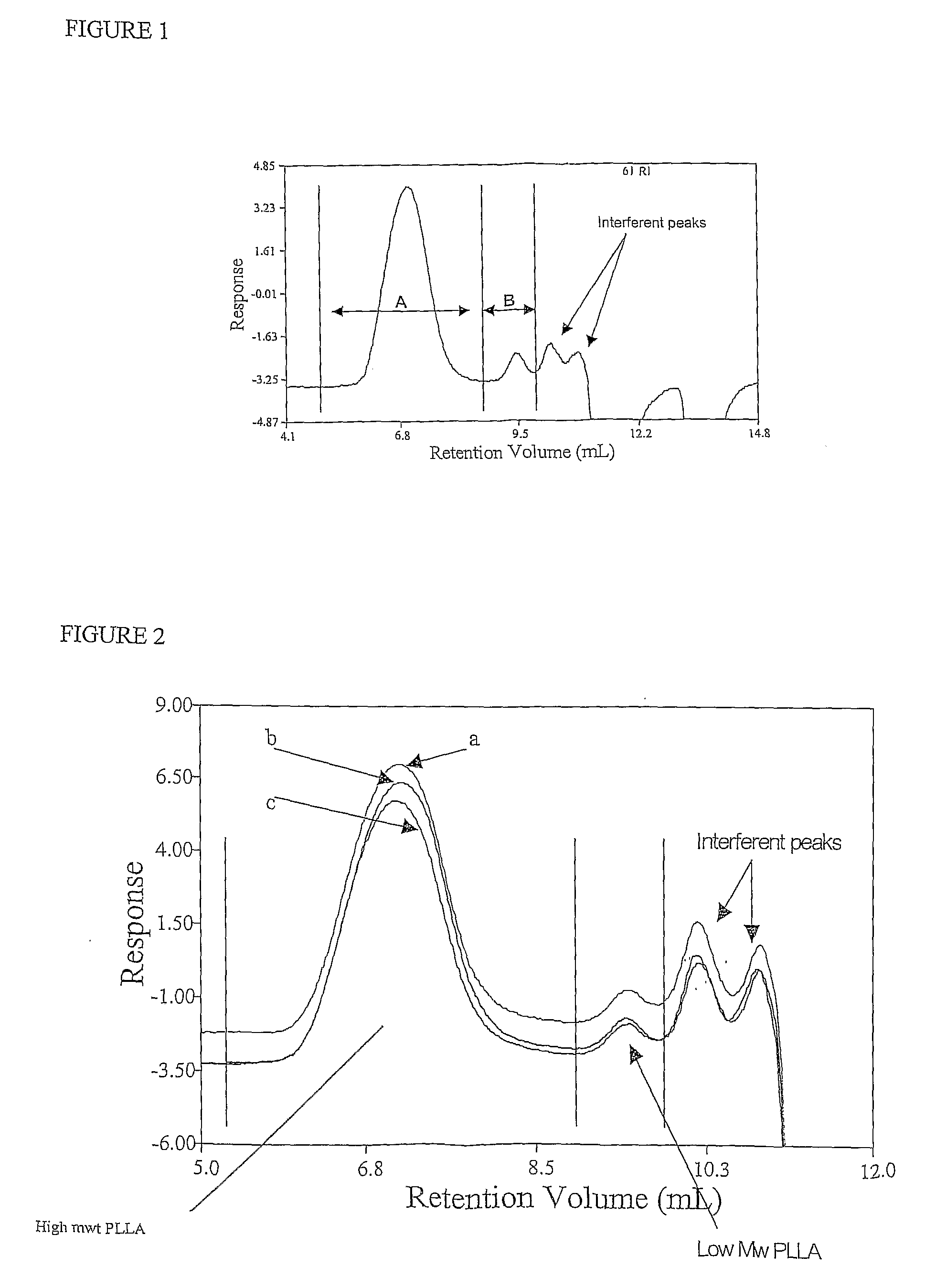

InactiveUS20090274742A1Reduce the possibilityPromote degradationBiocideSurgical adhesivesHuman bodyPolymer science

An oriented implantable biodegradable multimodal device is disclosed. The orientated implantable biodegradable multimodal device includes a blend of a first polymer component having a first molecular weight (mwt) together with at least a second polymer component having a mwt which is less than that of the first component. The polymer within the blend may be in a uniaxial, biaxial or triaxial orientation. Also disclosed is a composite thereof with matrix polymer, processes for the preparation thereof and the use thereof as an implantable biodegradable device such as a high strength trauma fixation device suitable for implantation into the human or animal body. As examples the high strength trauma device may take the form of plates, screws, pins, rods, anchors or scaffolds.

Owner:SMITH & NEPHEW INC

Highly oriented super microfilaments

InactiveUS7101504B2Improves drawabilityImprove mobilityFilament handlingArc welding apparatusThermosetting polymerInfrared beam

Owner:YAMANASHI UNIV OF

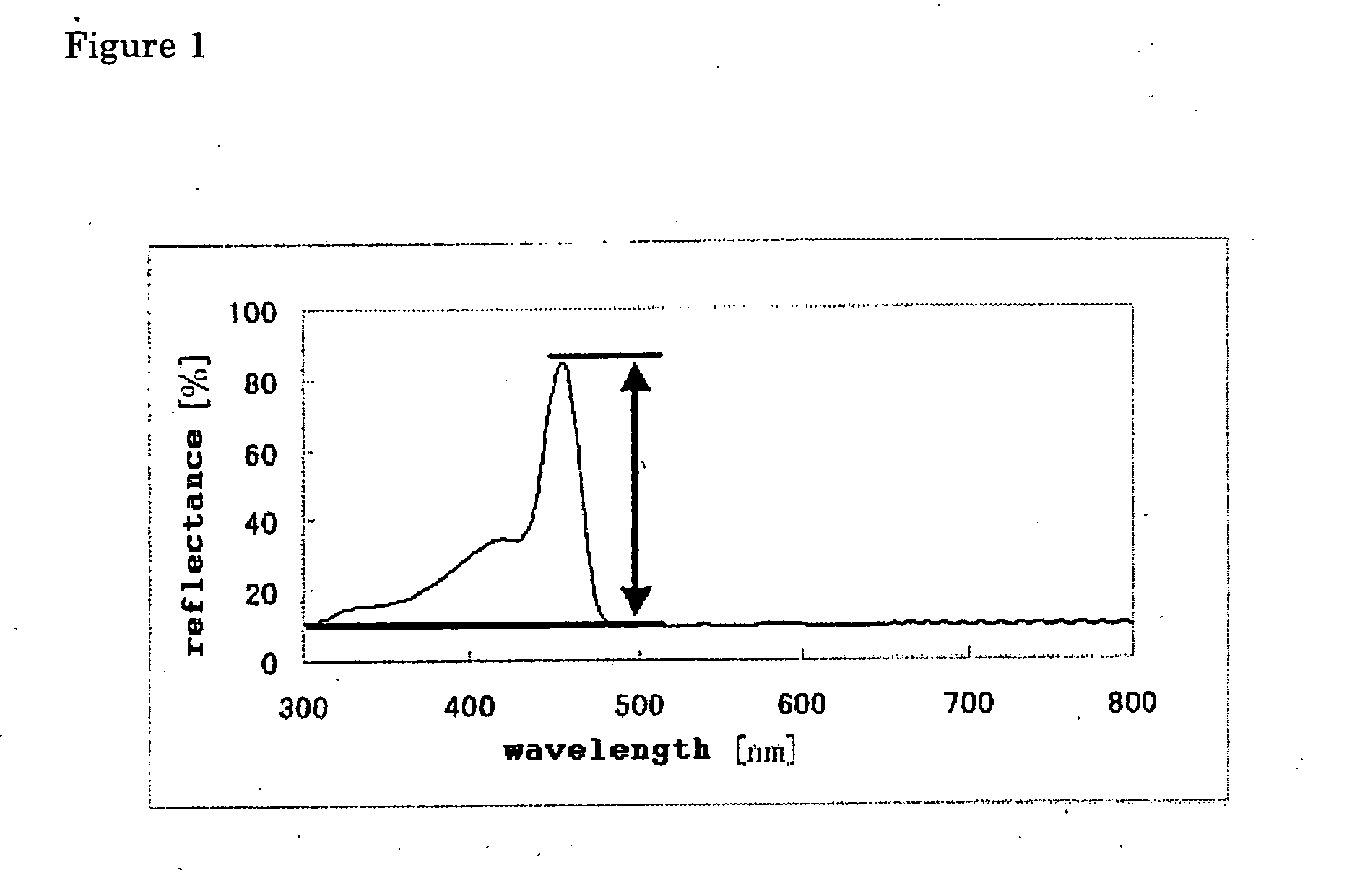

Biaxially oriented multi-layer laminated film and method for manufacture thereof

InactiveUS20050014011A1Improve adhesionIncrease resistanceLamination ancillary operationsSynthetic resin layered productsOptical propertyRefractive index

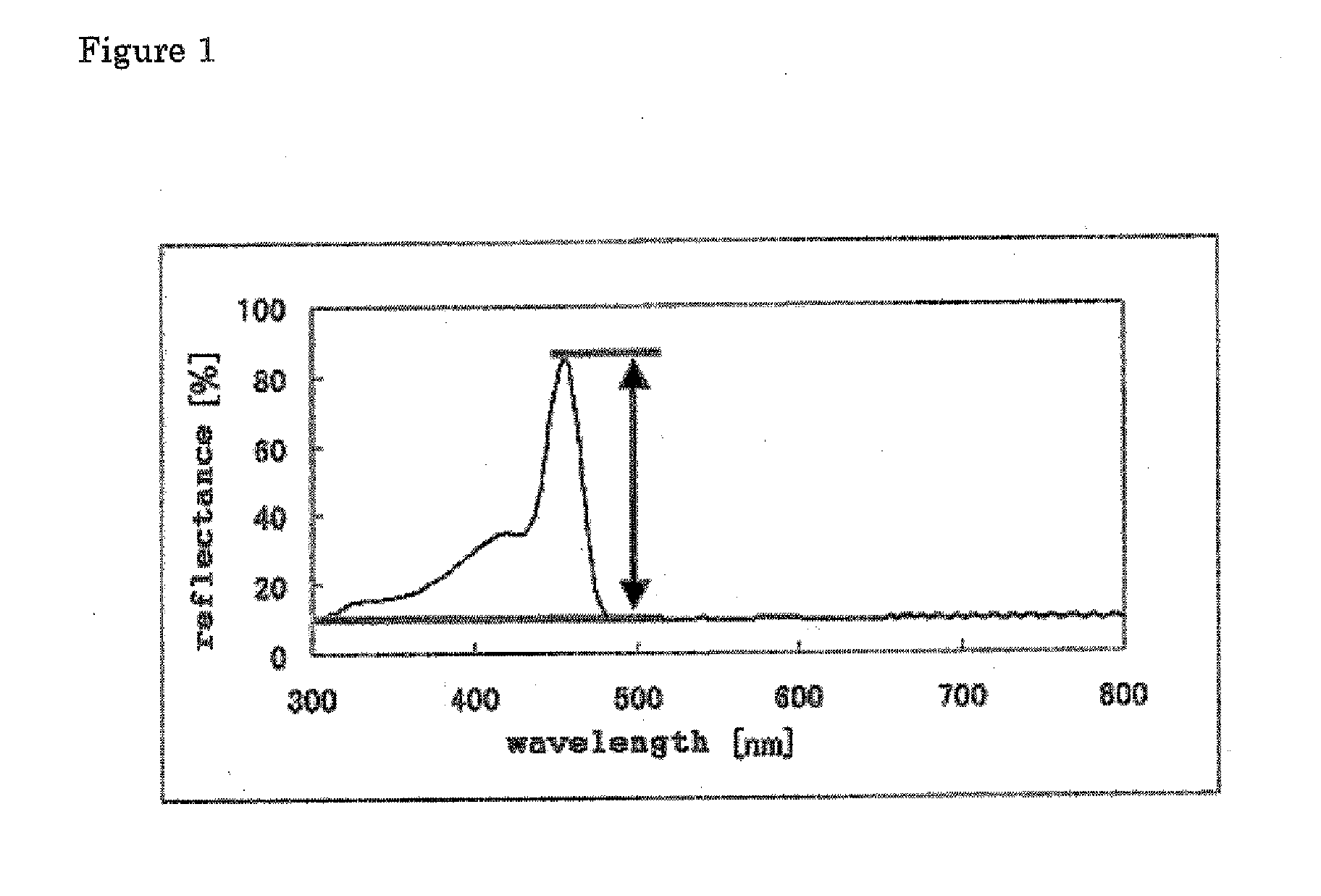

A film composed of a number of layers having different refractive indices and alternately laminated one upon another has characteristic optical properties by light interference. Conventional films having such structure have problems of poor interlaminar adhesivity and low tear strength. The problems are solved by a film having the following constitution. A biaxially drawn multilayer laminated film composed of alternately laminated 1st layers and 2nd layers at a total layer number of 11 or more. Each layer has a thickness of 0.05 to 0.5 μm. The 1st layer is made of a crystalline thermoplastic resin and the 2nd layer is made of a crystalline thermoplastic resin having a composition different from that of the resin constituting the 1st layer. The maximum light reflectance of the film within the wavelength range of 350 to 2,000 nm is higher than the base line reflectance obtained from a light reflectance curve within the wavelength range of 350 to 2,000 nm by 20% or over.

Owner:TEIJIN LTD

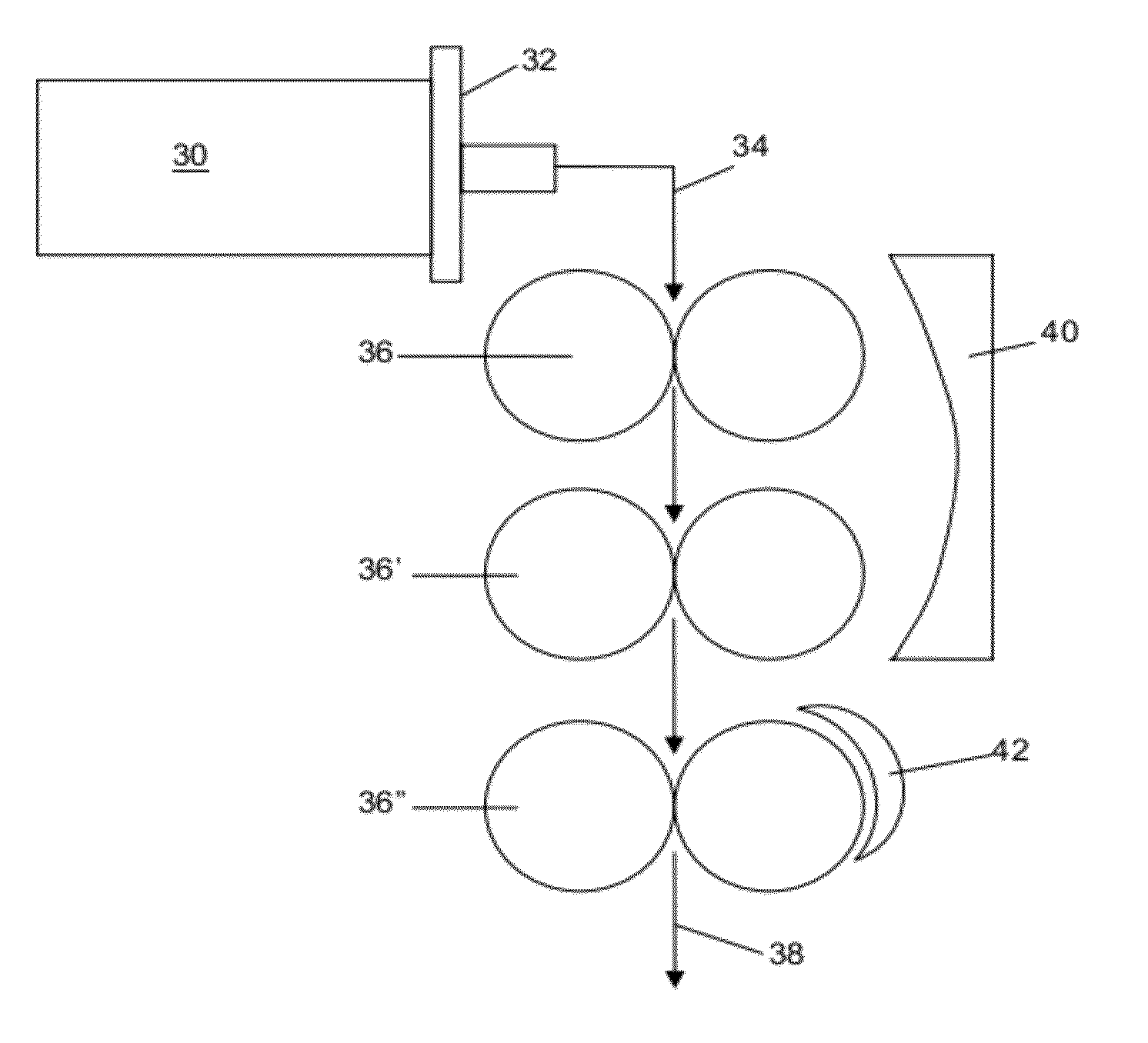

Dynamically Vulcanized Thermoplastic Elastomer Film

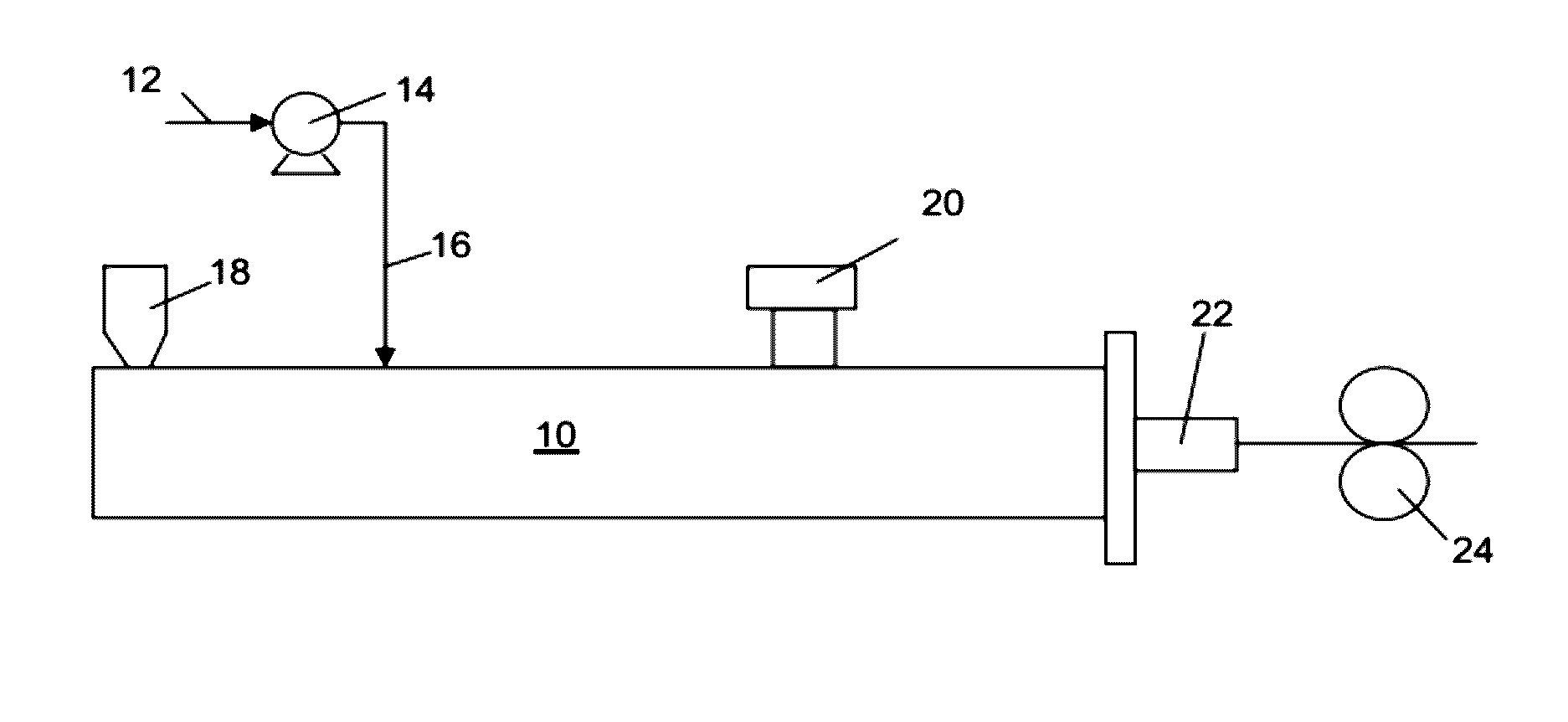

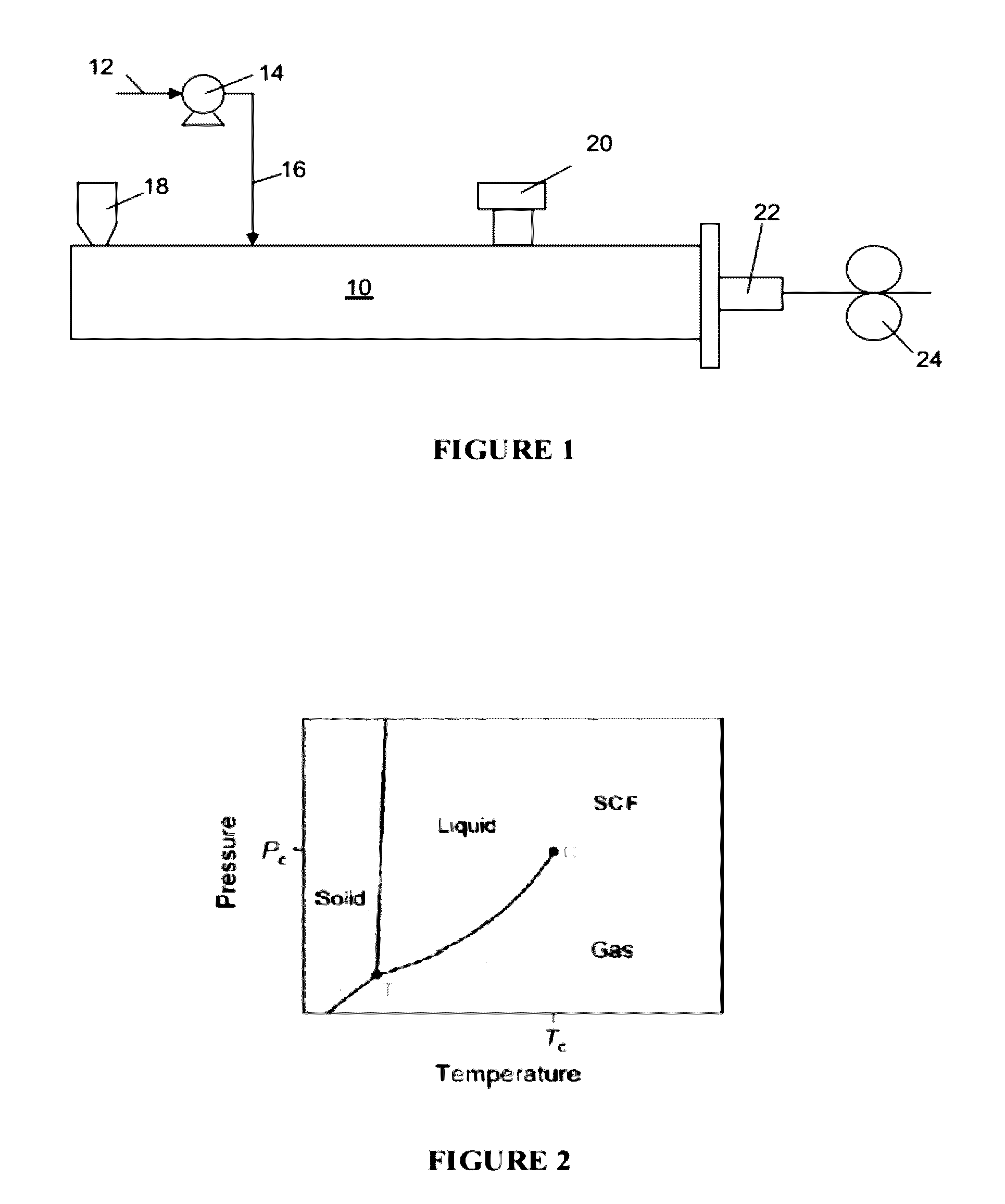

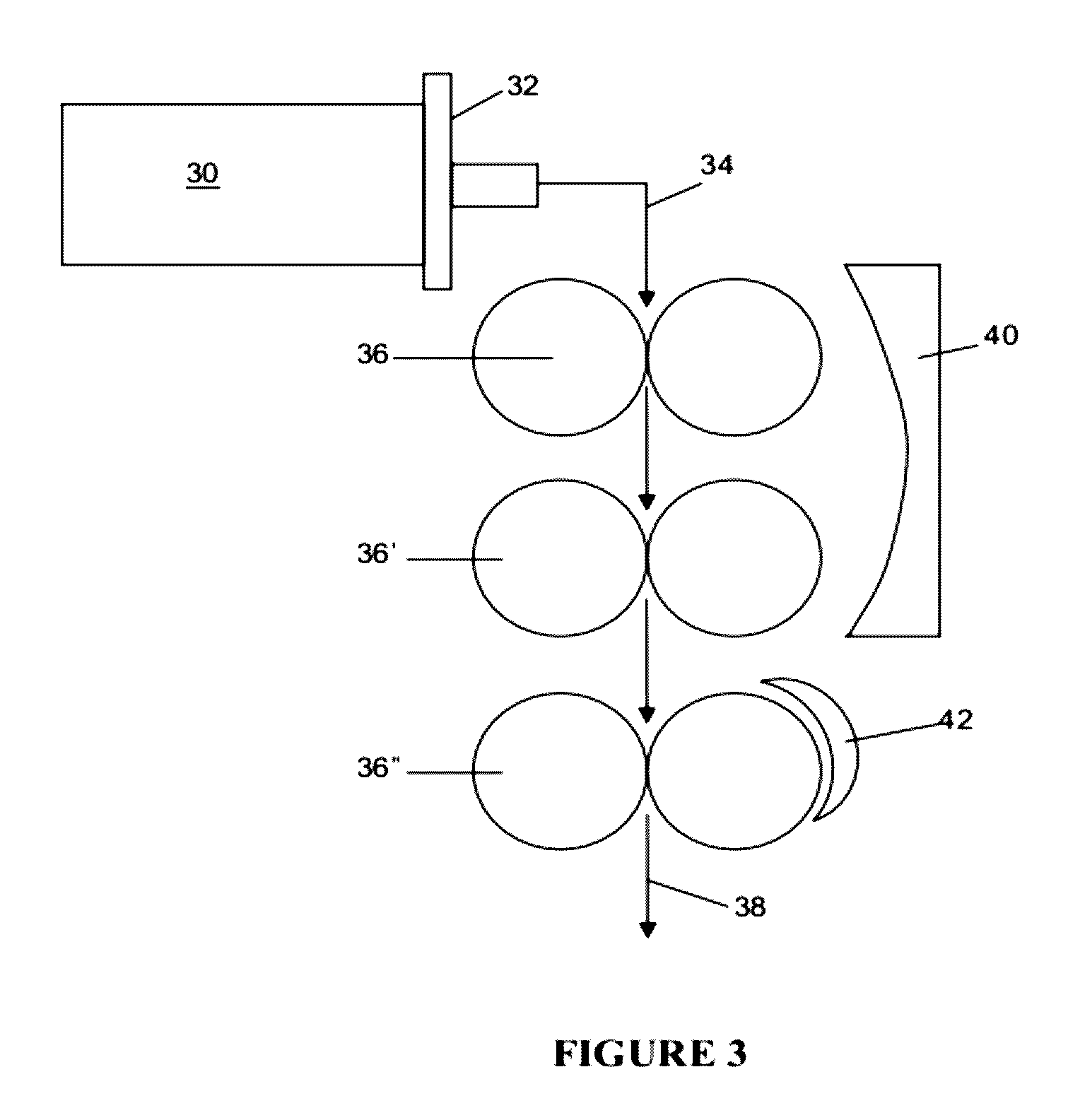

ActiveUS20120232210A1Easy to processImproves drawabilitySpecial tyresCoatingsElastomerThermoplastic elastomer

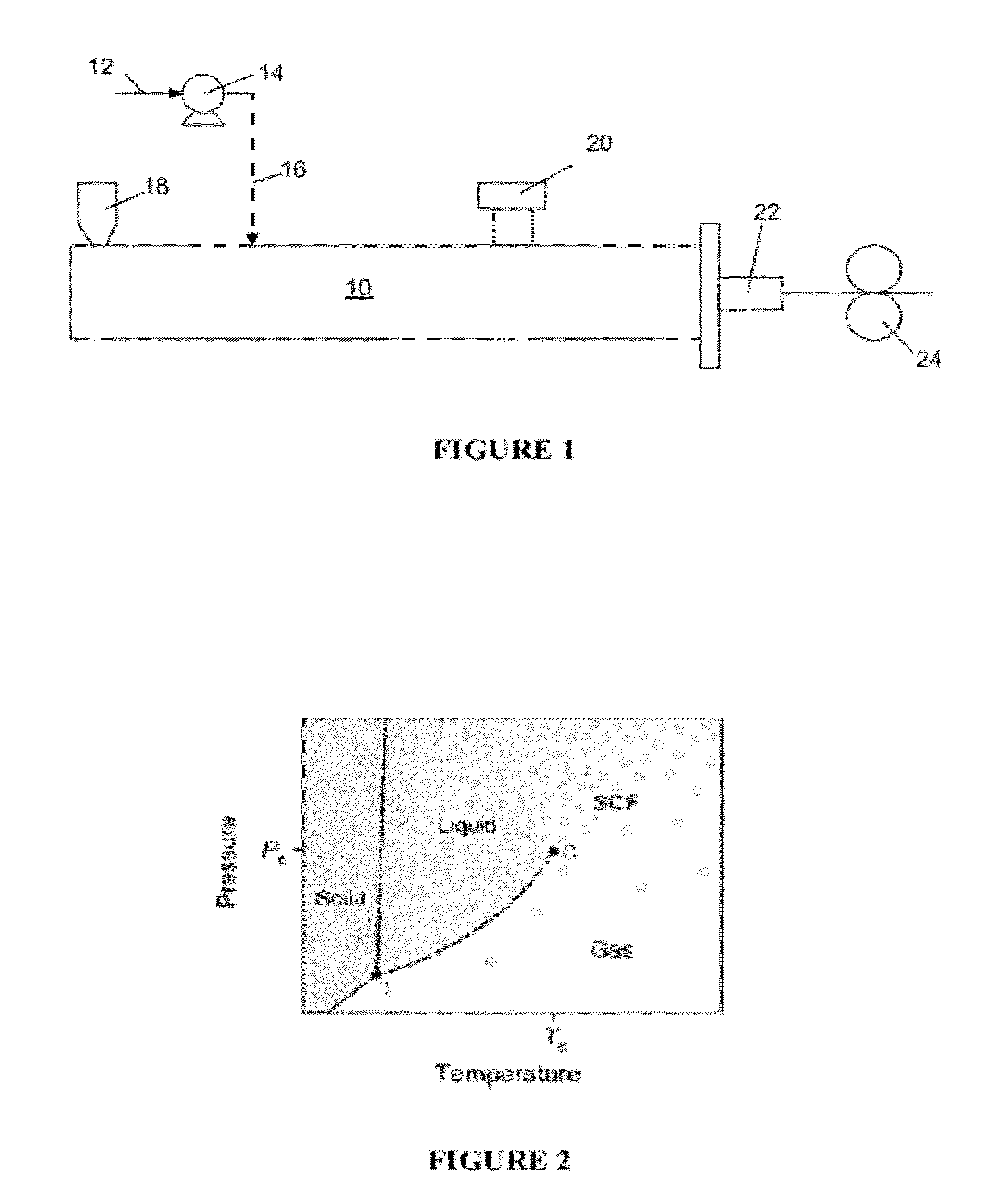

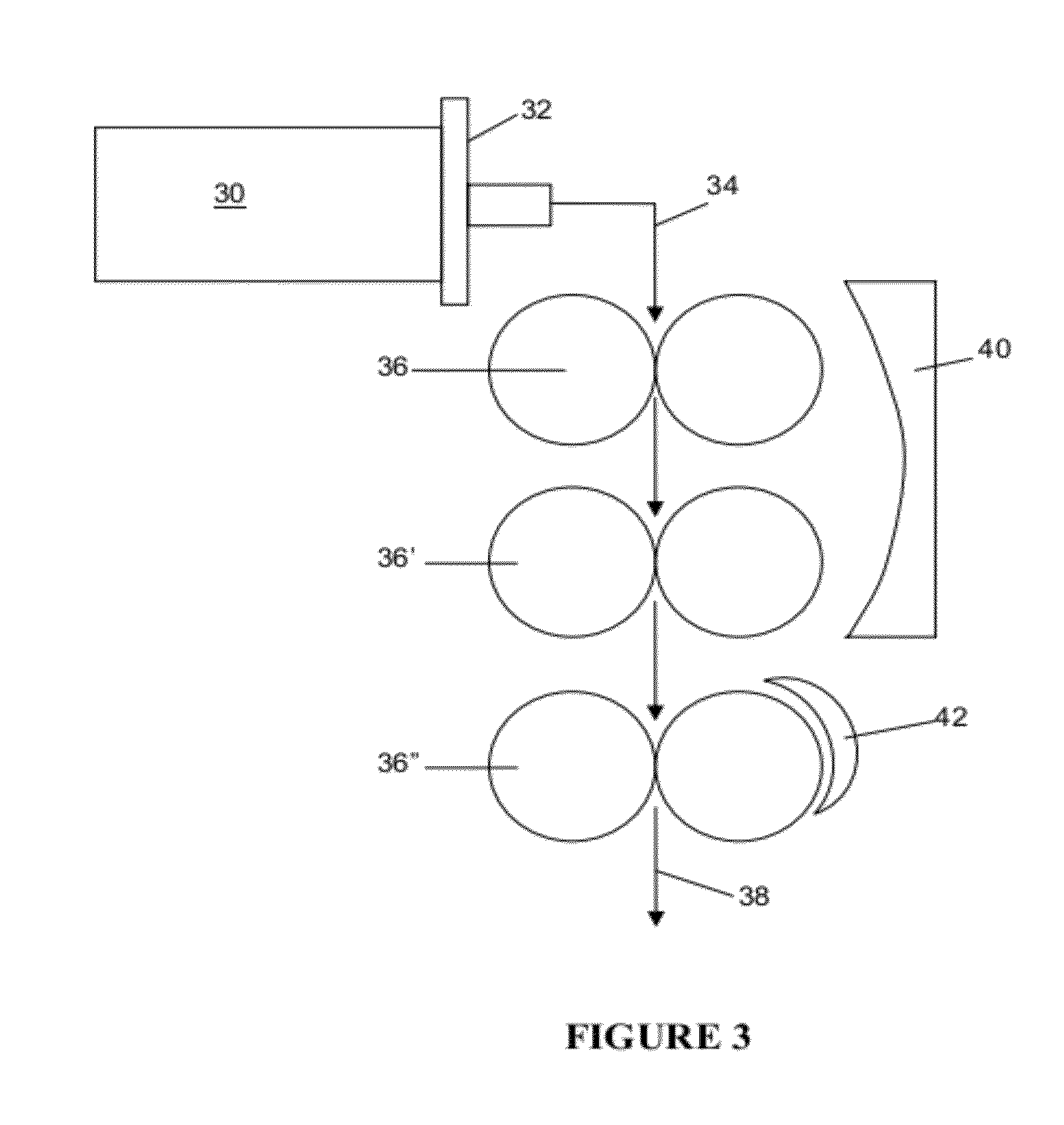

A dynamically vulcanized alloy containing an elastomer and a thermoplastic resin is prepared by a process wherein supercritical fluid is injected into the thermoplastic elastomeric material as the material is mixed in an extruder. The material is mixed under conditions such that the thermoplastic elastomeric material is dynamically vulcanized wherein the elastomer forms a discontinuous dispersed of small particles in a continuous phase of the thermoplastic resin. The DVA material may then be directly formed into film or sheets by the use of at least one set of rolls located adjacent to the extruder outlet.

Owner:EXXONMOBIL CHEM PAT INC

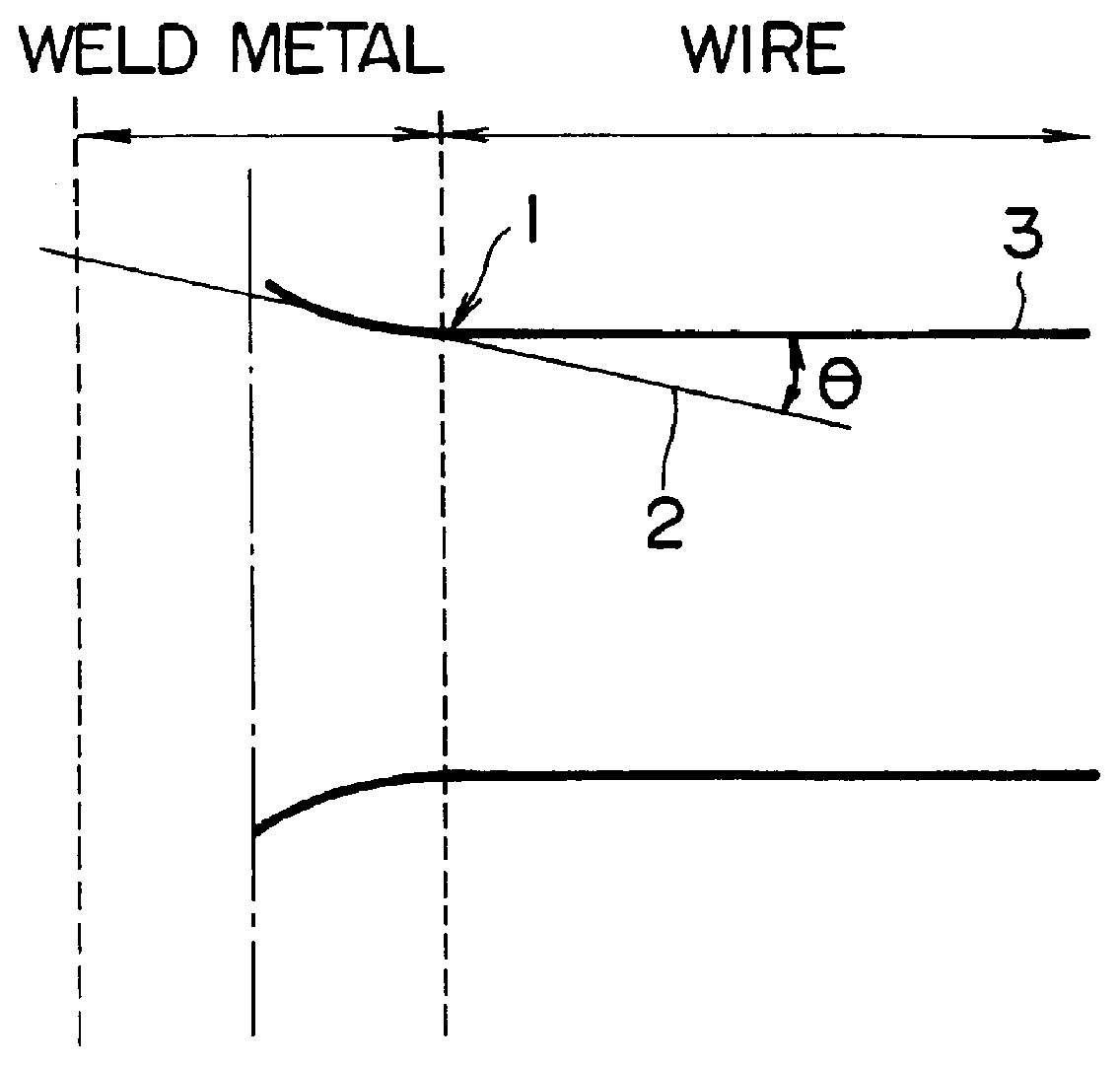

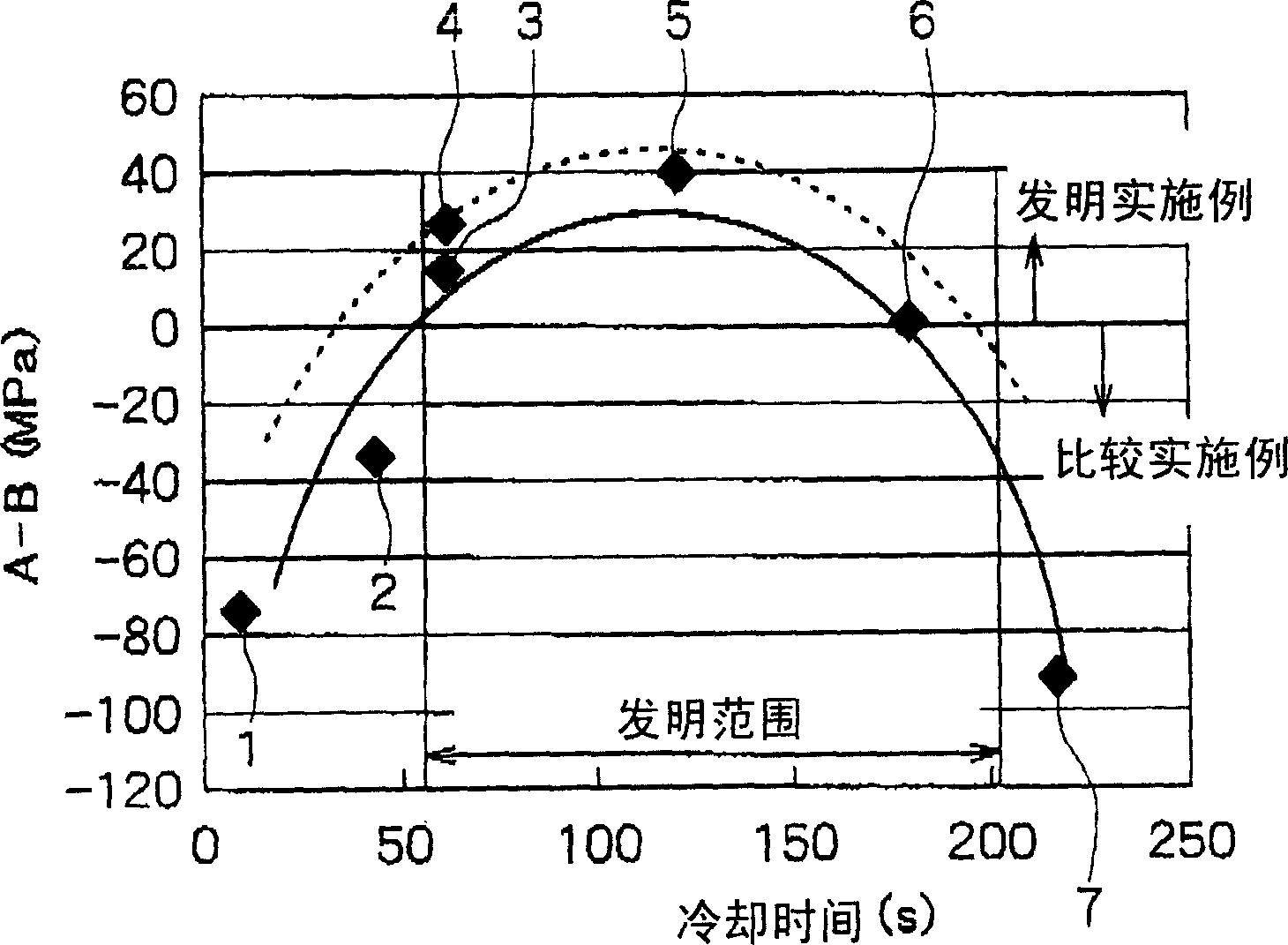

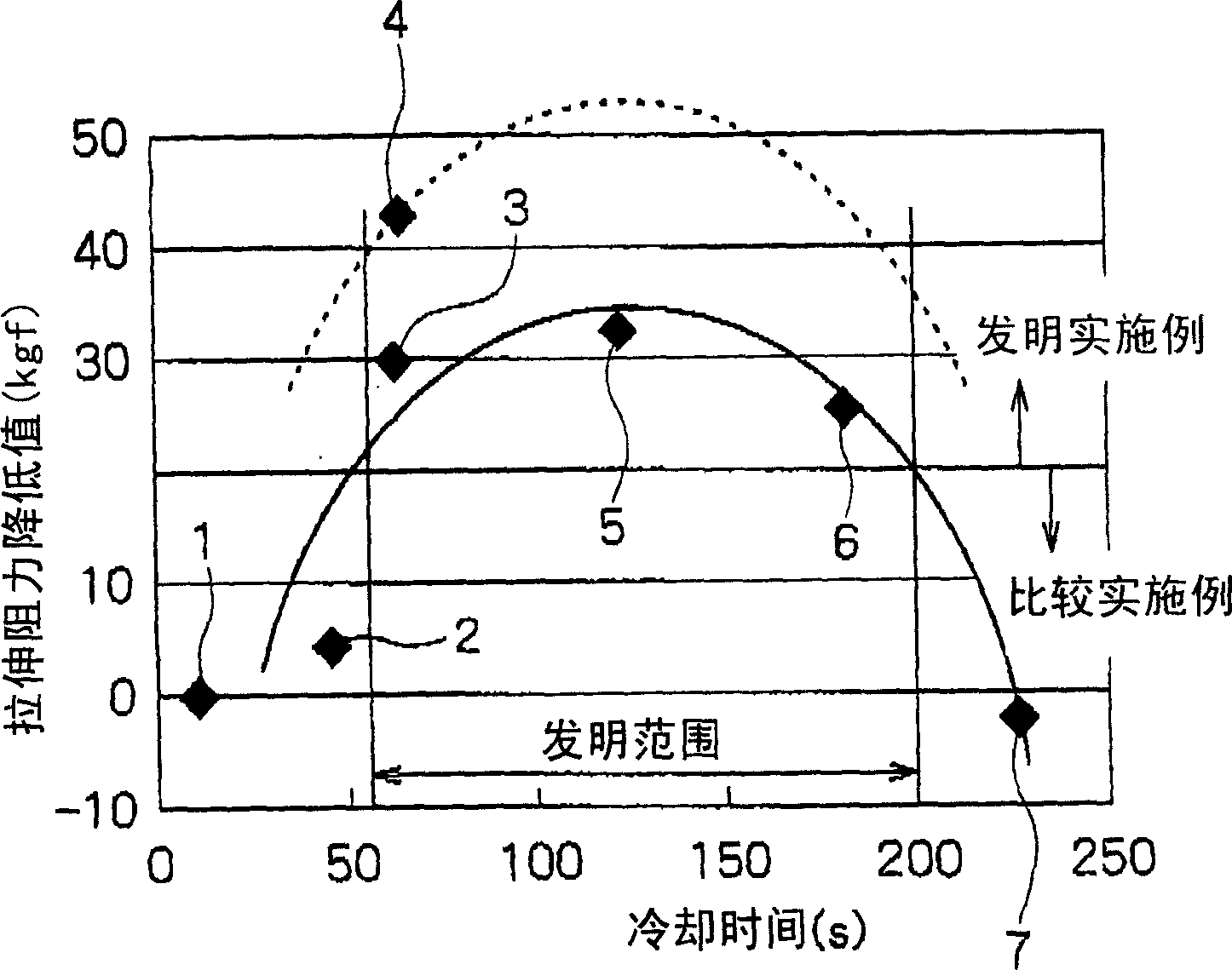

Welding wire

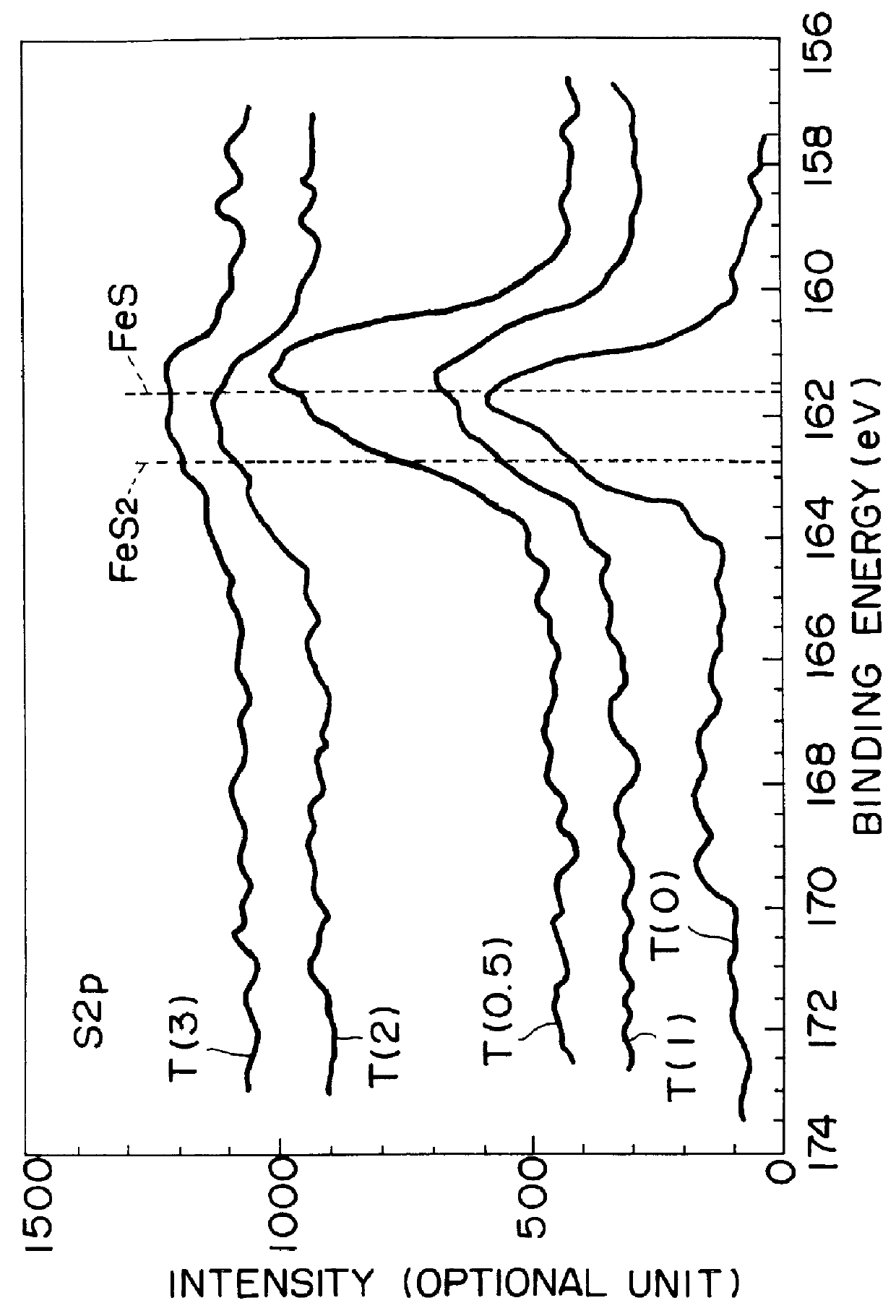

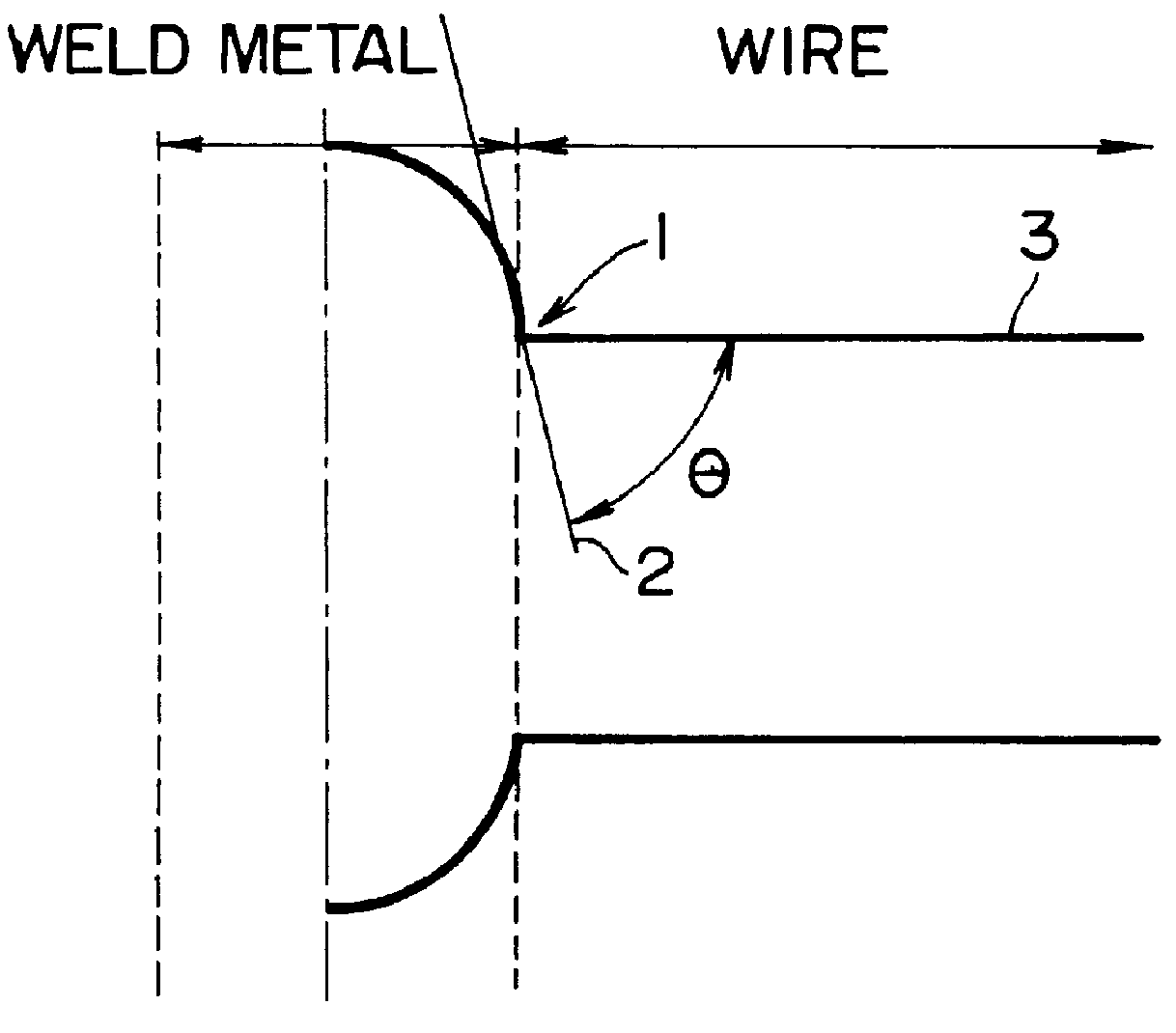

InactiveUS6146768AImprove wettabilityImproves drawabilityWelding/cutting media/materialsNatural mineral layered productsAmmonium sulfideIron sulfide

A welding wire capable of improving wettability between weld metal and wire surface, thereby providing excellent drawability and weldability in resistance welding of wires is provided. A wire is dipped in an aqueous solution of a sulfide of alkali metal or ammonium sulfide to generate iron sulfide (FeS2 or FeS) on the surface, whereby the wettability of weld metal to wire surface is improved in the resistance welding of the resulting wires. The S in the iron sulfide is preferably present in an amount of 0.1-20 atomic % as measured by X-ray photoelectron spectroscopy. At least one sulfide of S with an element of Mn, Ti, Cu, Cr, Ni, Al or Zn can be used instead of or in addition to the iron sulfide.

Owner:KOBE STEEL LTD

High carbon steel wires excellent in spinnability and method for producing same

InactiveCN1840729ALow tensile strengthSoftening mechanical propertiesMetal rolling arrangementsPearliteCarbon steel

The invention relates to high-carbon steel wires comprises 0.65-1.20% of C, 0.05-1.2% of Si, 0.2-1.0% of Mn, 0-0.35% of Cr, 0-0.02% of P and S, wherein over 80% of the metallic structure comprises pearlite structure.

Owner:KOBE STEEL LTD

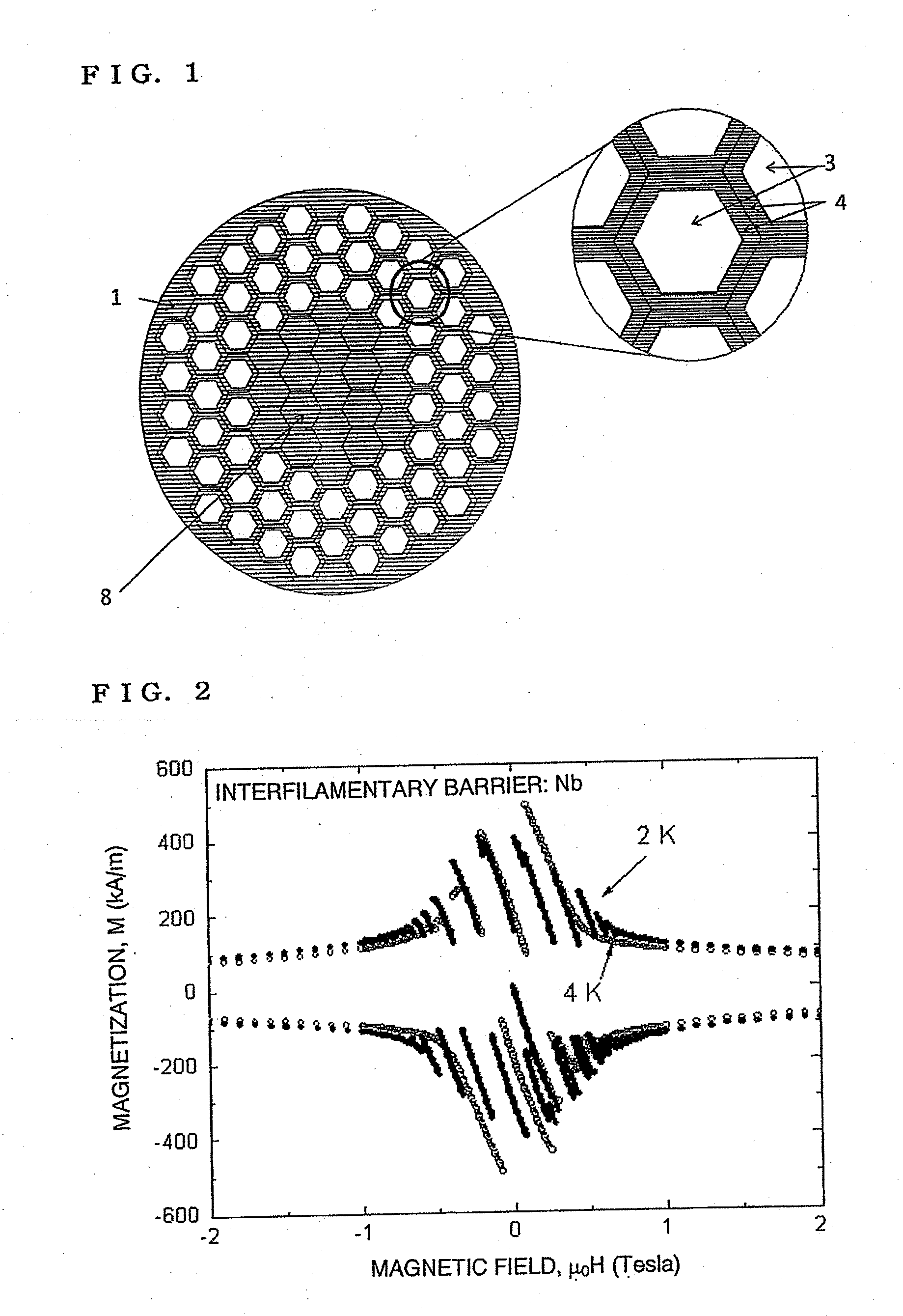

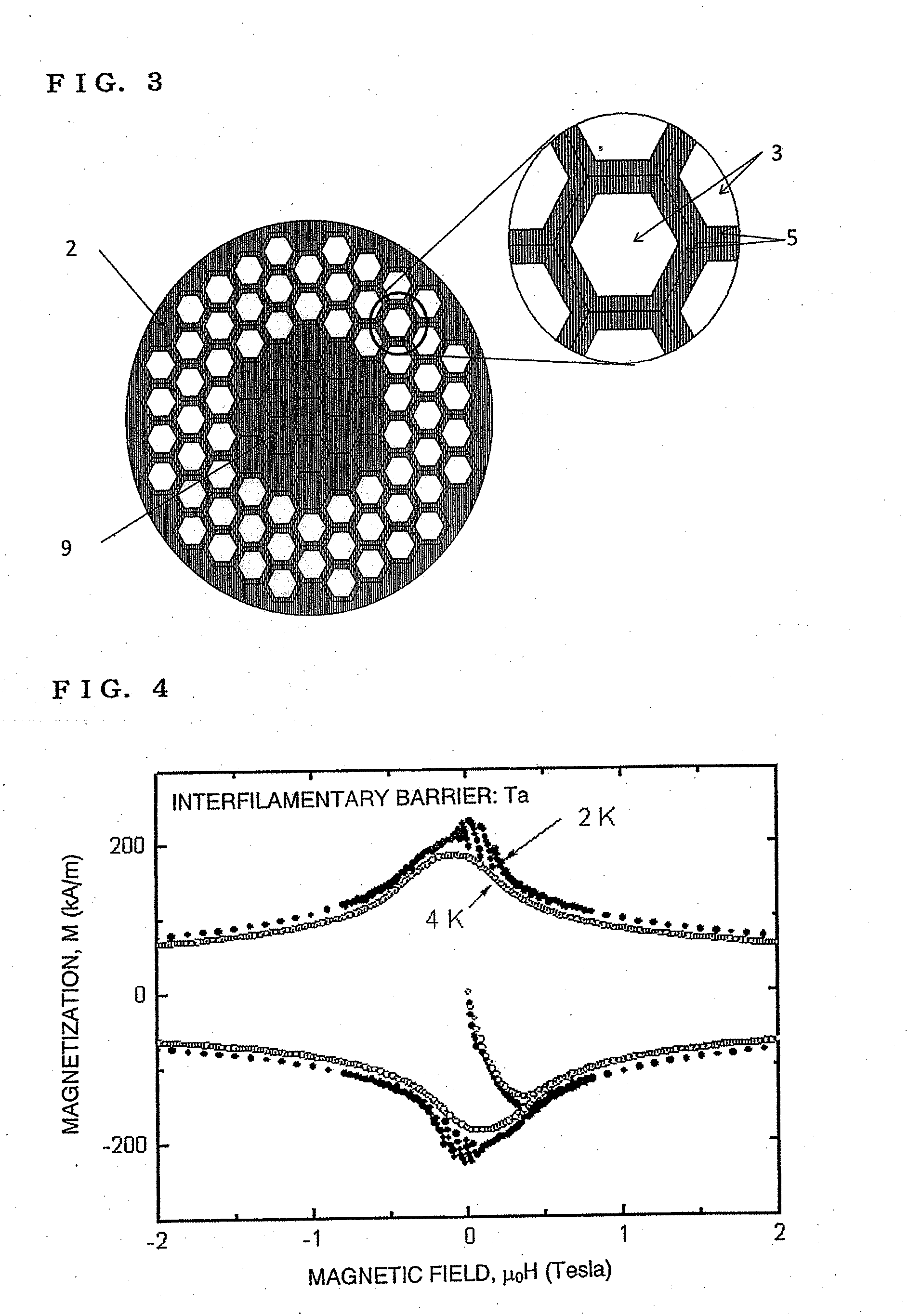

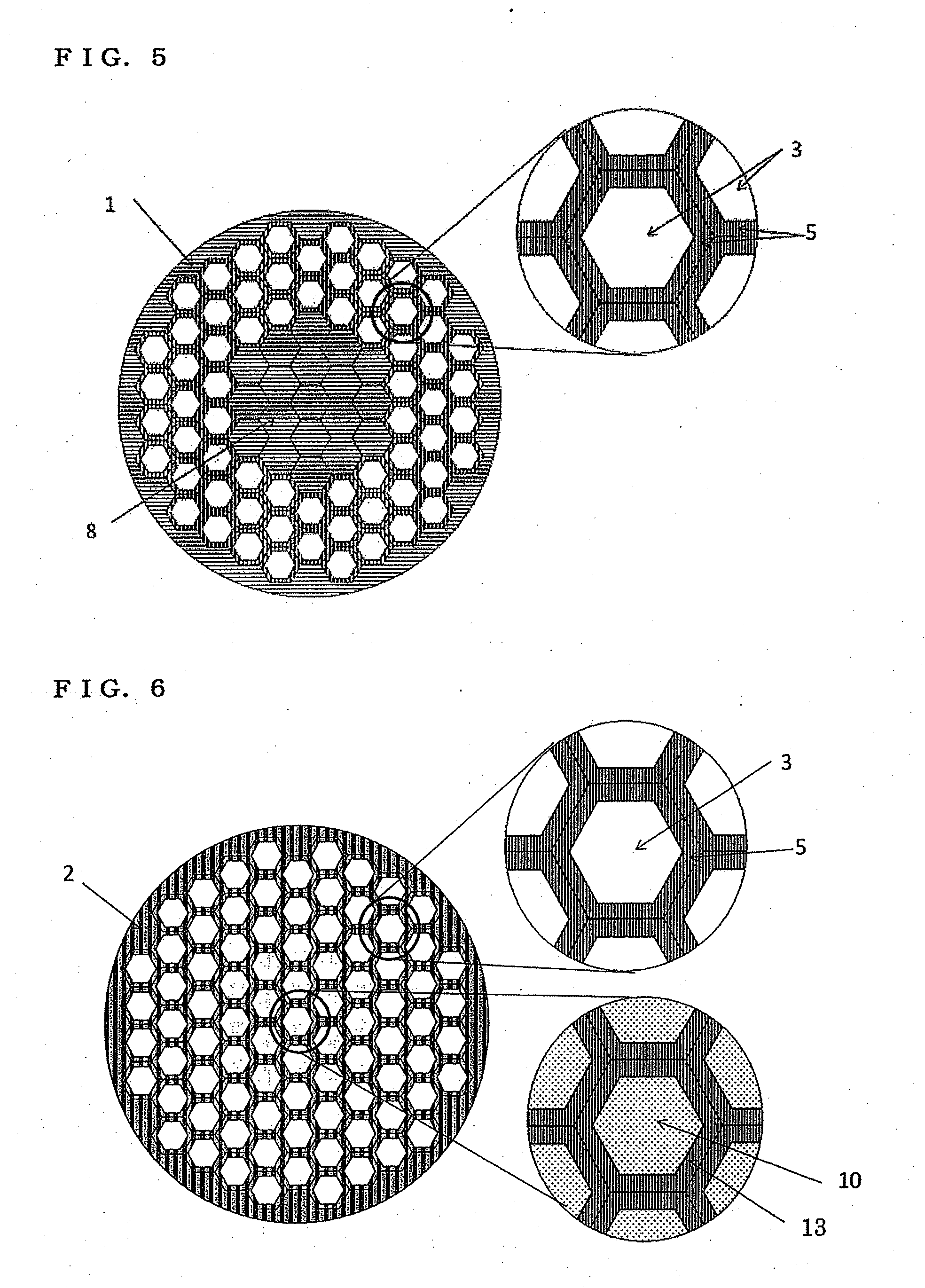

Precursor wire for nb3al superconducting wire, nb3al superconducting wire, method for producing precursor wire for nb3al superconducting wire, and method for producing nb3al superconducting wire

InactiveUS20150348679A1Improvement of wire drawability of wireSuppression of low magnetic-field instabilitySuperconductors/hyperconductorsSuperconductor detailsInstabilityHeat treated

ProblemThere is proposed an innovative cross-sectional structure, with an idea contrary to the conventional one, utilizing the non-reactivity between Cu and Ta (or between Ag and Nb, Ta) in a high-temperature short-time heat treatment, thus achieving (1) the suppression of the low magnetic-field instability, (2) excellent wire drawability of a precursor wire, and (3) the reduction of the cost required for the incorporation of a stabilizer.Means for ResolutionThere is proposed a structure having an assembly of a plurality of single wires, wherein the assembly is covered with an outer cover (skin) formed from Nb or Ta, wherein each of the single wires has an Nb / Al composite filament region which is formed from a composite of Nb and Al mixed in an Nb:Al molar ratio of 3:1, and which is covered with a partition formed from Nb or Ta, and further covered with an interfilamentary barrier formed from Cu or Ag disposed around the partition.

Owner:NAT INST FOR MATERIALS SCI +1

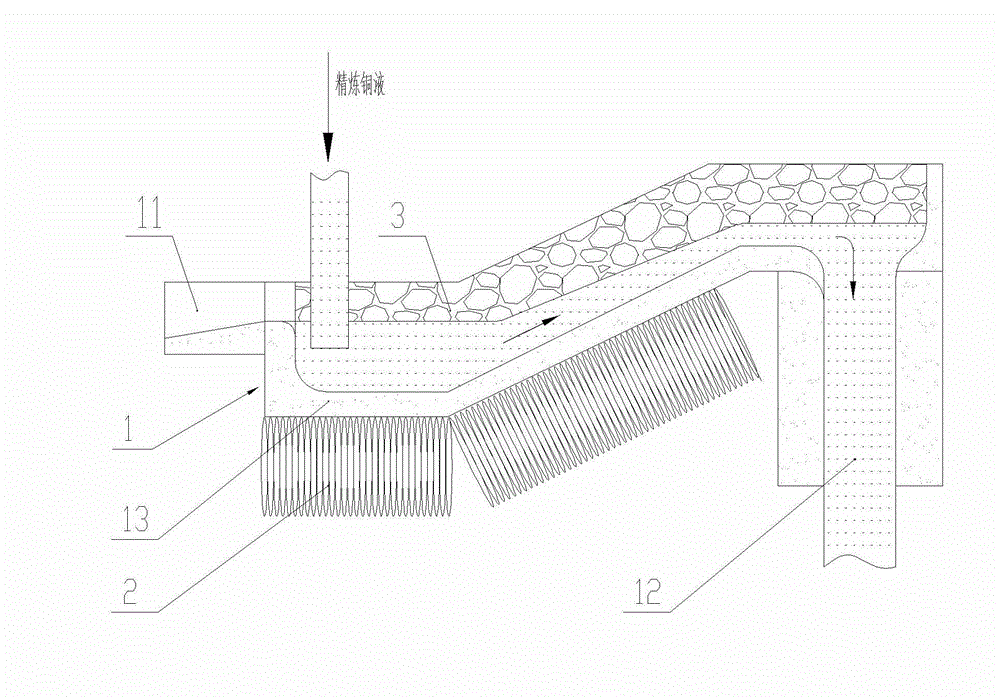

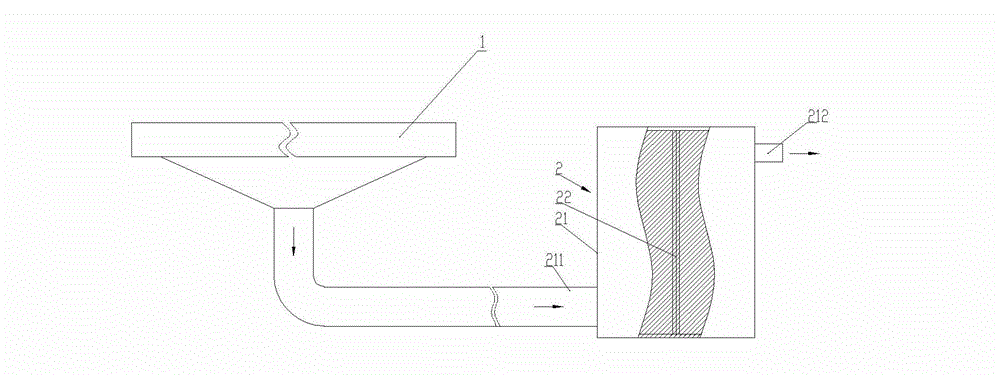

Device and process adopted for rod-making by continuous casting and continuous rolling of red impure copper

InactiveCN102744257AImprove performanceReduce the amount of iron powderMetal rolling arrangementsCopperOxygen content

The invention provides a device and a process adopted for rod-making by continuous casting and continuous rolling of red impure copper. The device adopted for rod-making by continuous casting and continuous rolling of red impure copper comprises a launder which tilts upwards and is provided with an electromagnetic field, and deoxidizer is contained in an inner wall of the launder. According to the process for the rod-making by the continuous casting and continuous rolling of red impure copper, on the basis of a prior rod-making process by continuous casting and continuous rolling of red impure copper, after steps of melting, oxidization and restoring, impurities are removed and oxygen content is lowered by further refining, and casting is carried out to increase surface quality, conductivity, plasticity and tensibility of a copper rod. The surface quality, conductivity, plasticity and tensibility of the copper rod manufactured by the device and the process provided by the invention are more excellent, and manufacturing cost is low.

Owner:湖南金龙国际铜业有限公司

Ultra-low carbon wire rod with high conductivity and production method of wire rod

The invention discloses an ultra-low carbon wire rod with high conductivity and a production method of the wire rod. The ultra-low carbon wire rod comprises main chemical components including, by mass percent, not larger than 0.012% of C, not larger than 0.012% of Si, not larger than 0.08% of Mn, not larger than 0.015% of P, not larger than 0.010% of S, not larger than 0.080% of Sieq, and the balance iron and inevitable impurities. The production method comprises smelting, casting, wire rolling and wire cooling. The specification of the ultra-low carbon wire rod is phi5.5 to 9.0mm, the conductivity is larger than or equal to 16.3%, and due to the high conductivity, the good pulling and drawing and good comprehensive mechanics property of the wire rod, the thickness of the copper layer coated on the surface of the wire during downstream customer machining can be effectively reduced, and therefore the production cost is reduced.

Owner:XINGTAI IRON & STEEL

Manufacturing method of ternary ammonification modified T400-stage 12K carbon fiber

ActiveCN103184592AImproved hydrophilicity and stretchabilityIncreased orientation and crystallinityArtificial filament washing/dryingArtificial filament heat treatmentChemistryItaconic acid

The invention relates to a manufacturing method of ternary ammonification modified T400-stage 12K carbon fiber. Acrylonitrile, itaconic acid and 2-acrylamido-2-methylpropanesulfonic acid are taken as copolymerization monomers for performing polymerization of a ternary free radical solution, ammonification modification is performed on an obtained spinning solution and then spinning is performed through a 12K spinning nozzle. 12K raw yarn is prepared by performing solidification, water washing, hot water drafting, oiling and drying on a tow, and then performing steam drafting and heat setting treatment. Pre-oxidation and carbonization treatment are further performed on the obtained raw yarn to prepare the carbon fiber. According to the manufacturing method disclosed by the invention, the non-toxic solid powder raw materials are taken as the copolymerization monomers, the ammonification modification treatment is performed on the spinning solution, the hydrophilicity and the draftability of the spinning solution obtained by the method are obviously improved, and the compactness, the orientation degree and the crystallinity of the obtained raw yarn after the spinning process are also obviously improved. After the pre-oxidation treatment of the raw yarn, gradient carbonization is performed in a low-temperature carbonization furnace at the temperature of 400-750 DEG C, drafting treatment is further performed, and the prepared carbon fiber has the advantages of high mechanical properties and strong binding force.

Owner:XIAN KANGBEN MATERIAL

Ultralow carbon coil rod for blasting fuse and production method thereof

ActiveCN105779870AImproves drawabilityImprove mechanical propertiesWire rodElectrical resistance and conductance

The invention provides an ultralow carbon coil rod for a blasting fuse and a production method thereof and belongs to the technical field of steel smelting and high-speed wire rolling. The ultralow carbon coil rod comprises the following chemical components in a percent by mass: smaller than or equal to 0.012% of C, smaller than or equal to 0.012% of Si, 0.15-0.30% of Mn, smaller than or equal to 0.015% of P, smaller than or equal to 0.010% of S and the balance of iron and unavoidable impurities. The production method comprises the following specific production procedures: manufacturing a casting blank of optimized components, heating a steel blank, rolling a wire material, cooling the wire material and slowly cooling. The production method ensures that the tensile strength of the coil rod is smaller than or equal to 310MPa, the elongation rate is larger than or equal to 45%, and electric conductivity is stably controlled between 14.5% and 15.0%. After drawing and thermal treatment, a blasting fuse finished product has a resilience angle which is smaller than 58 degrees and resistance being between 0.50 omega / m and 0.60 omega / m under the condition that the diameter is between 0.52mm and 0.54mm, and the processing requirements and the technical index requirements of the blasting fuse are met.

Owner:XINGTAI IRON & STEEL

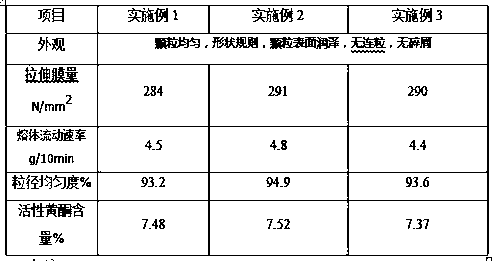

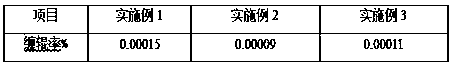

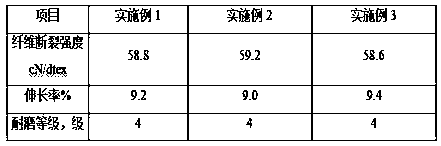

Plant-derived PE masterbatch and preparation method thereof

InactiveCN110437519AUniform particlesImprove spinnabilityMonocomponent polyolefin artificial filamentArtifical filament manufactureMotherwortLeonurus cardiaca extract

The invention provides a plant-derived PE masterbatch. The plant-derived PE masterbatch is mainly prepared by blending and fusing a PE masterbatch and a modified motherwort extract, wherein a mass ratio of the PE masterbatch to the modified motherwort extract is 99: 21. The invention also provides a preparation method for the above cellulosic fiber. The plant-derived PE masterbatch prepared in theinvention is regular in shape and free of connected granules and chippings and has particle size uniformity of 93.2-94.9%, melt flow rate of 4.4-4.8 g / 10min and tensile modulus of 284-291 N / mm<2>; and a prepared fiber has breaking tenacity of 58.6-59.2 cN / dtex, elongation of 9.0-9.4% and a wear resistance level of level 4.

Owner:ZHONGKE TEXTILE RES INST QINGDAO CO LTD

Ferromagnetic alloy for induction cooking

ActiveUS20060192181A1Improve corrosion resistanceGood cutabilityCooking-vessel materialsConductive materialChemical compositionAlloy

The invention concerns a ferromagnetic alloy whereof the chemical composition comprises, in wt. %: 32.5% ≦Ni ≦72.5%; 5% ≦Cr≦18%; 0.01% ≦Mn≦4%, C≦1%; optionally one or more elements selected among Mo, V, Co, Cu, Si, W, Nb and Al, the total contents of said elements being not more than 10%, the remainder being iron and impurities resulting from preparation, the chemical composition further satisfying the following relationships: Cr−1.1Ni+23.25≦0%; 45Cr+11Ni≦1360 ;Ni+3Cr≧60% if Ni≧37.5; Cr≧7.5 if Ni≦37.5. The invention also concerns the use of said alloy for making heating elements for induction heated cooking appliances.

Owner:IMPHY ALLOYS

High-strength cold rolled steel sheet having excellent deep drawability and bake hardenability and method for manufacturing the same

InactiveUS20130213529A1Excellent bake hardenabilityGood deep drawabilityHeat treatment process controlSheet steelChemical composition

A high-strength cold rolled steel sheet having excellent deep drawability and bake hardenability, with a tensile strength ≧440 MPa, an average r-value ≧1.20 and a bake hardening value ≧40 MPa, is obtained by subjecting a steel raw material having a chemical composition including C: 0.010-0.06 mass %, Si: more than 0C:\Users\ejensen\Desktop\!TEMP\.5 mass % but not more than 1.5 mass %, Mn: 1.0-3.0 mass %, Nb: 0.010-0.090 mass %, Ti: 0.015-0.15 mass % and satisfying(Nb / 93) / (C / 12)<0.20 to hot rolling, cold rolling and then to annealing including steps of heating to a temperature of 800-900° C. while a temperature region of 700-800° C. is an average heating rate <3° C. / s, and soaking and thereafter cooling at a rate ≧5° C. / s from the soaking temperature to a cooling stop temperature ≦500° C. to thereby form a microstructure including ferrite phase with an area ratio ≧70% and martensite phase with an area ratio ≧3%.

Owner:JFE STEEL CORP

Preparation method of high-strength high-conductivity copper-silver alloy micro-wire

The invention relates to a preparation method of a high-strength high-conductivity copper-silver alloy micro-wire, and belongs to the technical fields of copper alloy material preparation, non-ferrouswire processing forming and electromagnetic wire manufacturing. The preparation method comprises the following steps that high-purity electrolytic copper plates and high-purity silver plates are putin a vacuum induction furnace according to the mass percent of a copper-silver alloy for smelting; smelting, solidification, purification and impurity removal are conducted on cast ingots by adoptinga vacuum electron beam to prepare high-purity copper-silver alloy ingots; the copper-silver alloy ingots are machined, and sheathing vacuum extrusion is conducted; surface defects of an extruded bar material are removed, and cold rolling is conducted; multi-pass drawing is conducted on the cold rolled bar material on a multi-mold drawing machine to obtain a wire blank; and after vacuum heat treatment is conducted on the wire blank, and multi-mold drawing is conducted on the micro wires. According to the preparation method, the drawing micro-process is stable, and is free of broken ends duringdrawing, the yield is high, the production efficiency is high, the industrialized, large-scale and stable volume production is achieved, the micro-wire of 0.015mm-0.05 mm is prepared, and the method has good engineering application on micro-electromagnetic wires.

Owner:GRIMAT ENG INST CO LTD

Bio-based terpolymers and process of making the same

InactiveUS20120301659A1High viscosityExcellent characteristicsNon-fibrous pulp additionLayered productsMonomer compositionColour fastness

Polyamide terpolymer compositions, which contain biobased monomers and are suitable for making shaped articles, are disclosed. Comprised of three monomeric species polymerized randomly, including hexamethylene diamine, adipic acid and a bio-based monomer, the compositions are easier to process and have better dye uniformity than polyamides formed from melt-blended biobased components, and are comparable in dyeability, color fastnessand appearance retention performance to non-biobased polyamide copolymers.

Owner:INVISTA NORTH AMERICA R L

High-carbon steel wire excellent in wire drawability and fatigue property after wiredrawing

ActiveUS20130022491A1Excellent in wire drawability and fatigue propertyImproves drawabilityPearliteCarbon steel

Provided is a high-carbon steel wire which gives steel wires having high strength and has excellent suitability for wiredrawing and which after being wiredrawn, has excellent fatigue properties. The high-carbon steel wire has an adequately regulated chemical composition and has a pearlite structure in an areal proportion of 90% or more. In 2,000 μm2 of the pearlite structure, the number of BN compound grains having an equivalent-circle diameter of 100 nm or more but less than 1,000 nm is 100 or less (including 0) and the number of BN compound grains having an equivalent-circle diameter of 1,000 nm or more is 10 or less (including 0).

Owner:KOBE STEEL LTD

Steel wire rod having excellent drawability and fatigue properties, and manufacturing method of the same

A steel wire rod is obtained, in which a gas flow rate during gas stirring in molten steel treatment is controlled to be 0.0005 Nm<3> / min to 0.004 Nm<3> / min per molten steel of 1 ton, thereby the rod satisfies a specified composition, and oxide base inclusions in any section including an axis line of the steel wire rod satisfy the following composition X, the inclusions having width of 2 Am or more perpendicular to a rolling direction, wherein the number of the oxide base inclusions of the following composition A is 1 to 20, and the number of the oxide base inclusions of the following composition B is less than 1. The composition X: when the compound of the inclusions is converted to Al<2>O<3>+MgO+CaO+SiO<2>+MnO=100%, Al<2>O<3>+CaO+SiO<2>>=70% is achieved. The composition A: when the compound of the inclusions is converted to Al<2>O<3>+CaO+SiO<2>=100%, 20%<=CaO<=50% and Al<2>O<3><=30% is achieved. And the composition B: when the compound of the inclusions is converted to Al<2>O<3>+CaO+SiO<2>=100%, CaO>50% is achieved. In the steel wire rod, the drawability and fatigue is largely improved.

Owner:KOBE STEEL LTD

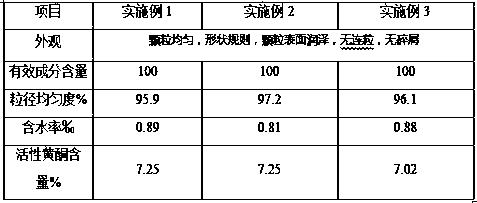

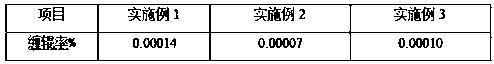

Plant-derived nylon master batch and preparation method thereof

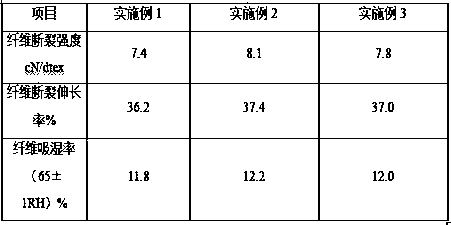

The invention provides a plant-derived nylon master batch. The plant-derived nylon master batch is mainly prepared by blending and melting nylon master batch and modified sarcandra glabra extract; themass ratio of the nylon master batch to the modified sarcandra glabra extract is 84:16. The invention further provides a preparation method of the cellulose fiber. The plant-derived nylon master batch prepared by the preparation method is regular in shape and free of continuous particles, no debris is generated, the particle size uniformity is 95.9-97.2%, and the water content is 0.081-0.089%; for the prepared fiber, the fiber breaking strength is 7.4-8.1 cN / dtex, the elongation at break is 36.2-37.4%, the fiber moisture absorption rate is 11.8-12.2%, and the moisture absorption performance is durable after multiple times of washing.

Owner:ZHONGKE TEXTILE RES INST QINGDAO CO LTD

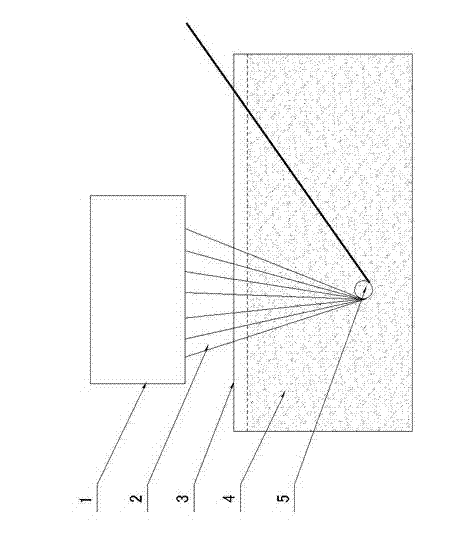

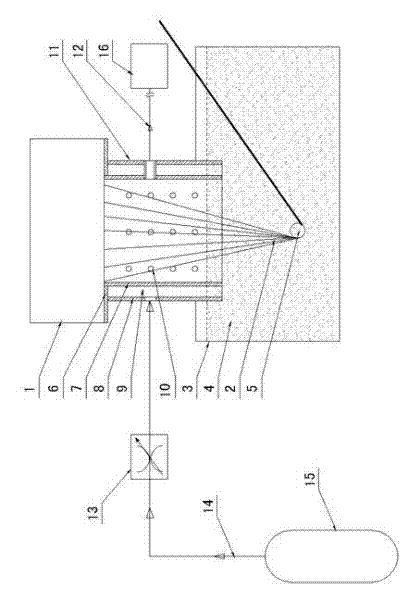

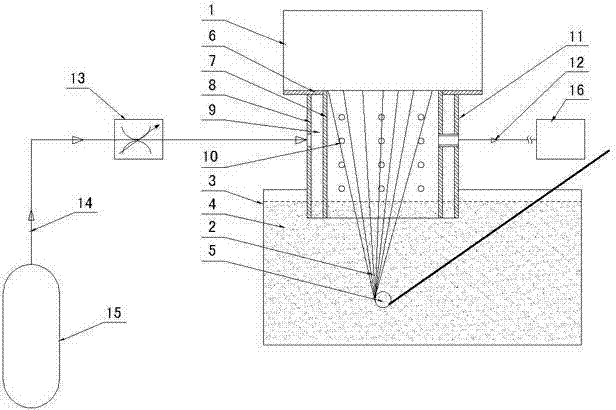

High-strength high-modulus polyethylene fiber circular-blow cooling device

InactiveCN102534825AIncrease distanceLittle influence of temperatureFilament/thread formingFiberEngineering

The invention creatively discloses a high-strength high-modulus polyethylene fiber circular-blow cooling device, which comprises a gas storage tank (15) for storing cooling gas, a throttling valve (13) and a cooler (11), wherein the cooler (11) comprises a fixed seat (6) fixed on a spinning pack (1), and an inner barrel body (7) and an outer barrel body (8) which are correspondingly fixed on the fixed seat (6), the inner barrel body (7) is provided with a tow (2) passage, an annular pressure equalization chamber (9) with a sealed upper port and an opened lower port is formed between the inner barrel body (7) and the outer barrel body (8), the lower port of the annular pressure equalization chamber (9) is soaked in coolant (4) of a freezing water tank (3), multiple gas inlet holes (10) for cooling the tow (2) are uniformly distributed on the barrel wall of the inner barrel body (7), at least one gas inlet is arranged on the outer barrel body (8), and at least one exhaust port is arranged on the inner barrel body (7). After the structure is adopted, the cooling device has the advantages of simple and reasonable structure, high circulating rate, high cooling efficiency, good spinning quality and the like.

Owner:ZHEJIANG QIANXILONG SPECIAL FIBER

Ferromagnetic alloy for induction cooking

ActiveUS7575712B2Good cutabilityImproves drawabilityCooking-vessel materialsMagnetic materialsChemical compositionAlloy

The invention concerns a ferromagnetic alloy whereof the chemical composition comprises, in wt. %: 32.5%≦Ni≦72.5%; 5%≦Cr≦18%; 0.01%≦Mn≦4%; C≦1%; optionally one or more elements selected among Mo, V, Co, Cu, Si, W, Nb and Al, the total contents of said elements being not more than 10%, the remainder being iron and impurities resulting from preparation, the chemical composition further satisfying the following relationships: Cr−1.1Ni+23.25≦0%; 45Cr+11Ni≦1360; Ni+3Cr≧60% if Ni≧37.5; Cr≧7.5 if Ni≦37.5. The invention also concerns the use of said alloy for making heating elements for induction heated cooking appliances.

Owner:IMPHY ALLOYS

Biaxially drawn multilayer laminated film and method for producing the same

InactiveUS20070090557A1Improve adhesionIncrease resistanceLamination ancillary operationsSynthetic resin layered productsOptical propertyRefractive index

A film composed of a number of layers having different refractive indices and alternately laminated one upon another has characteristic optical properties by light interference. Conventional films having such structure have problems of poor interlaminar adhesivity and low tear strength. The problems are solved by a film having the following constitution. A biaxially drawn multilayer laminated film composed of alternately laminated 1st layers and 2nd layers at a total layer number of 11 or more. Each layer has a thickness of 0.05 to 0.5 μm. The 1st layer is made of a crystalline thermoplastic resin and the 2nd layer is made of a crystalline thermoplastic resin having a composition different from that of the resin constituting the 1st layer. The maximum light reflectance of the film within the wavelength range of 350 to 2,000 nm is higher than the base line reflectance obtained from a light reflectance curve within the wavelength range of 350 to 2,000 nm by 20% or over.

Owner:TEIJIN LTD

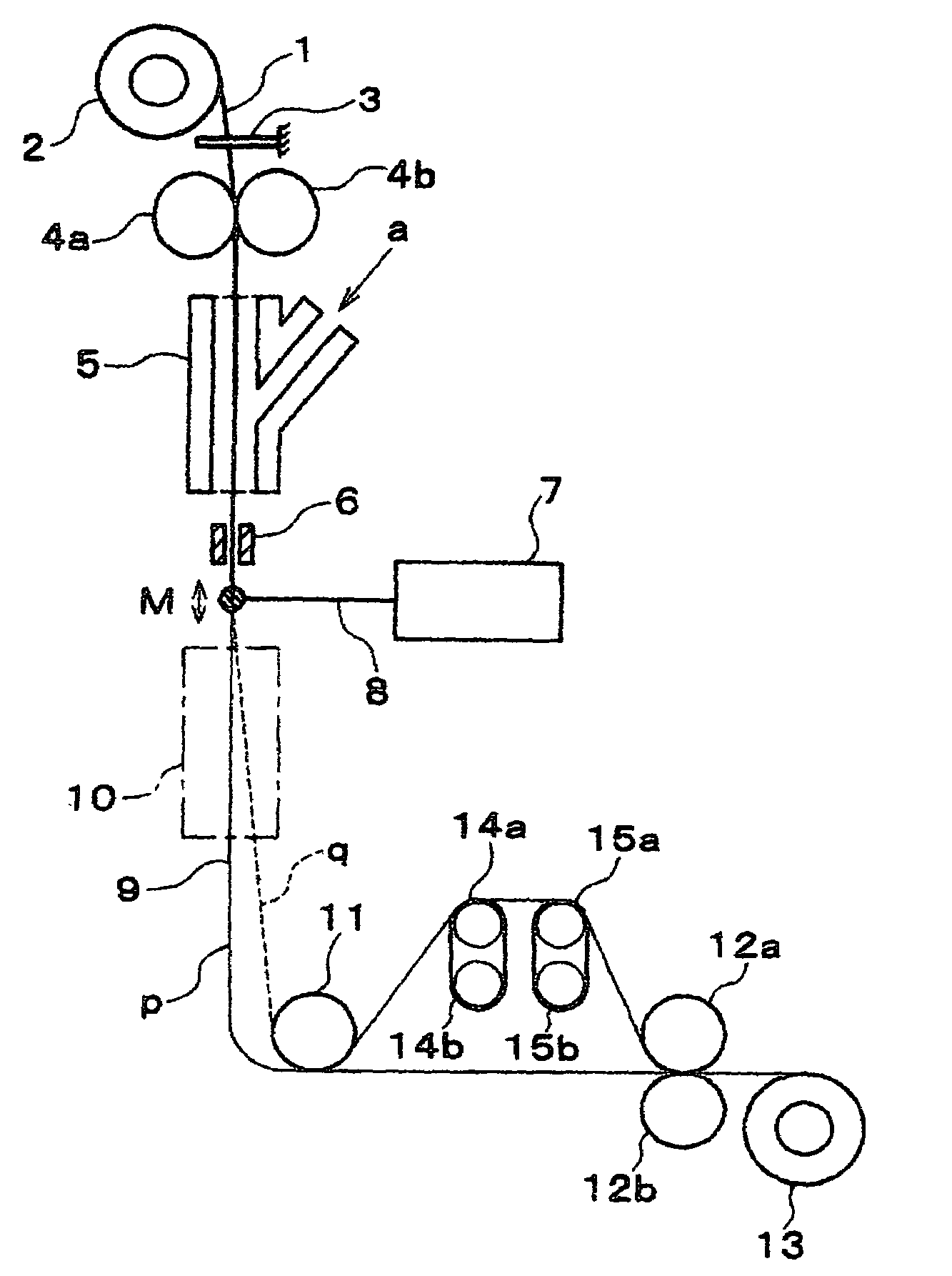

Dynamically vulcanized thermoplastic elastomer film

ActiveUS9586355B2Easy to processImproves drawabilitySpecial tyresTyresElastomerThermoplastic elastomer

A dynamically vulcanized alloy containing an elastomer and a thermoplastic resin is prepared by a process wherein supercritical fluid is injected into the thermoplastic elastomeric material as the material is mixed in an extruder. The material is mixed under conditions such that the thermoplastic elastomeric material is dynamically vulcanized wherein the elastomer forms a discontinuous dispersed of small particles in a continuous phase of the thermoplastic resin. The DVA material may then be directly formed into film or sheets by the use of at least one set of rolls located adjacent to the extruder outlet.

Owner:EXXONMOBIL CHEM PAT INC

Method for adding bubbles in EDC water tank to produce lead-bath-free wire

InactiveCN108396127ASpeed up coolingUniform tissueFurnace typesHeat treatment furnacesEngineeringWater tanks

The invention relates to a method for adding bubbles in an EDC water tank to produce a lead-bath-free wire. The method comprises the steps that firstly, water cooling and spinning are conducted aftersteel blank rolling; secondly, a wire ring is subjected to temperature reset and then enters an EDC system to be subjected to phase change treatment; thirdly, a bubble generator is arranged in the EDCwater tank, hot water in the EDC water tank is in a steam-water mixing state, a steam film is broken through the bubbles at the cooling earlier stage, the earlier stage cooling speed is increased, the bubbles are used for isolating the wire from the hot water part in the cooling later period, and the cooling speed is reduced; and fourthly, the wire cooled through the EDC water tank can be directly drawn into a steel wire without lead bath. According to the method, the lead bath cooling effect can be reached or approached, and the wire drawability and steel wire performance are improved by improving the cooling condition and the wire structure performance; and the method can be adopted for replacing the lead bath, energy can be better saved, and the steel wire production cost is reduced.

Owner:ANGANG STEEL CO LTD

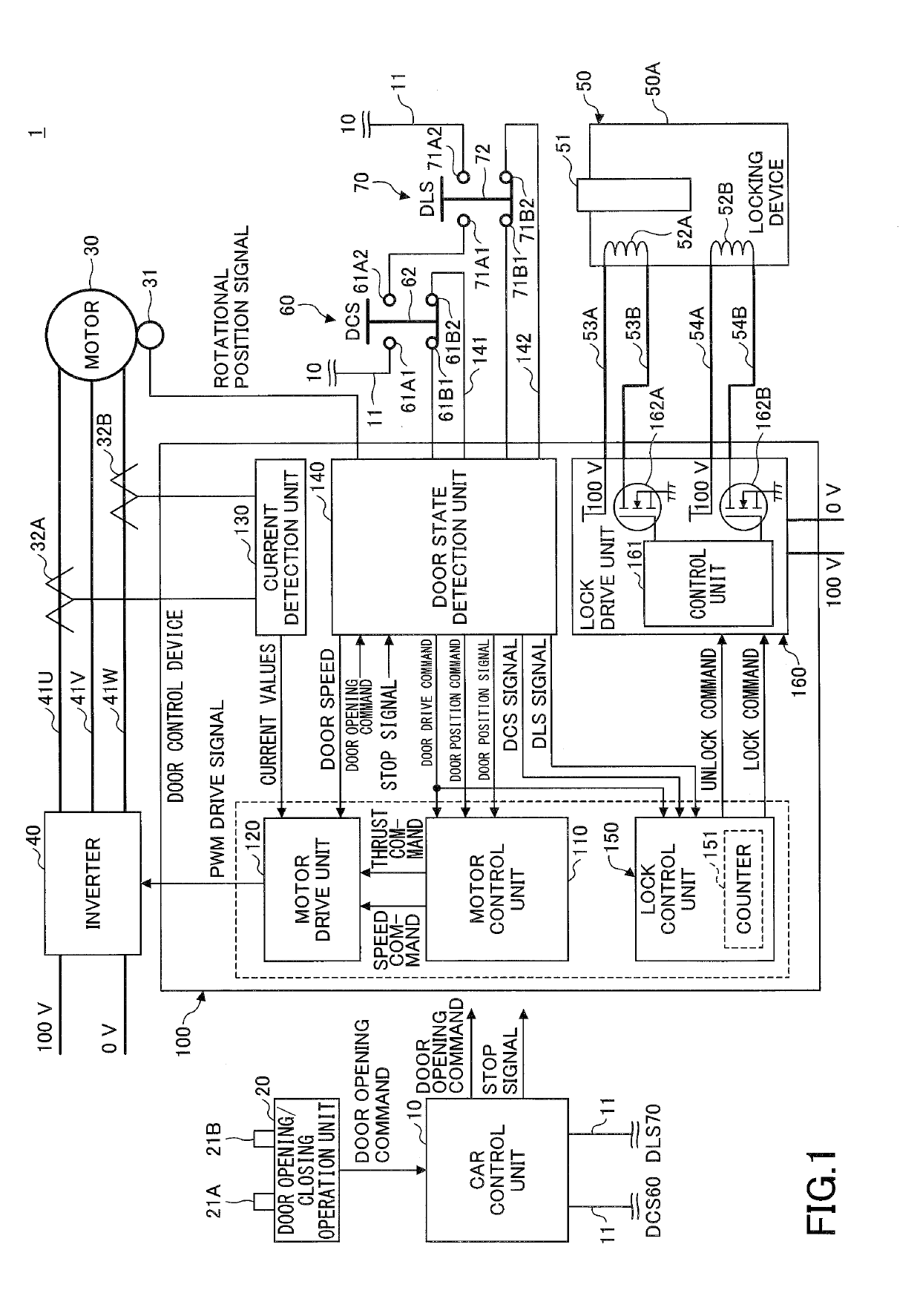

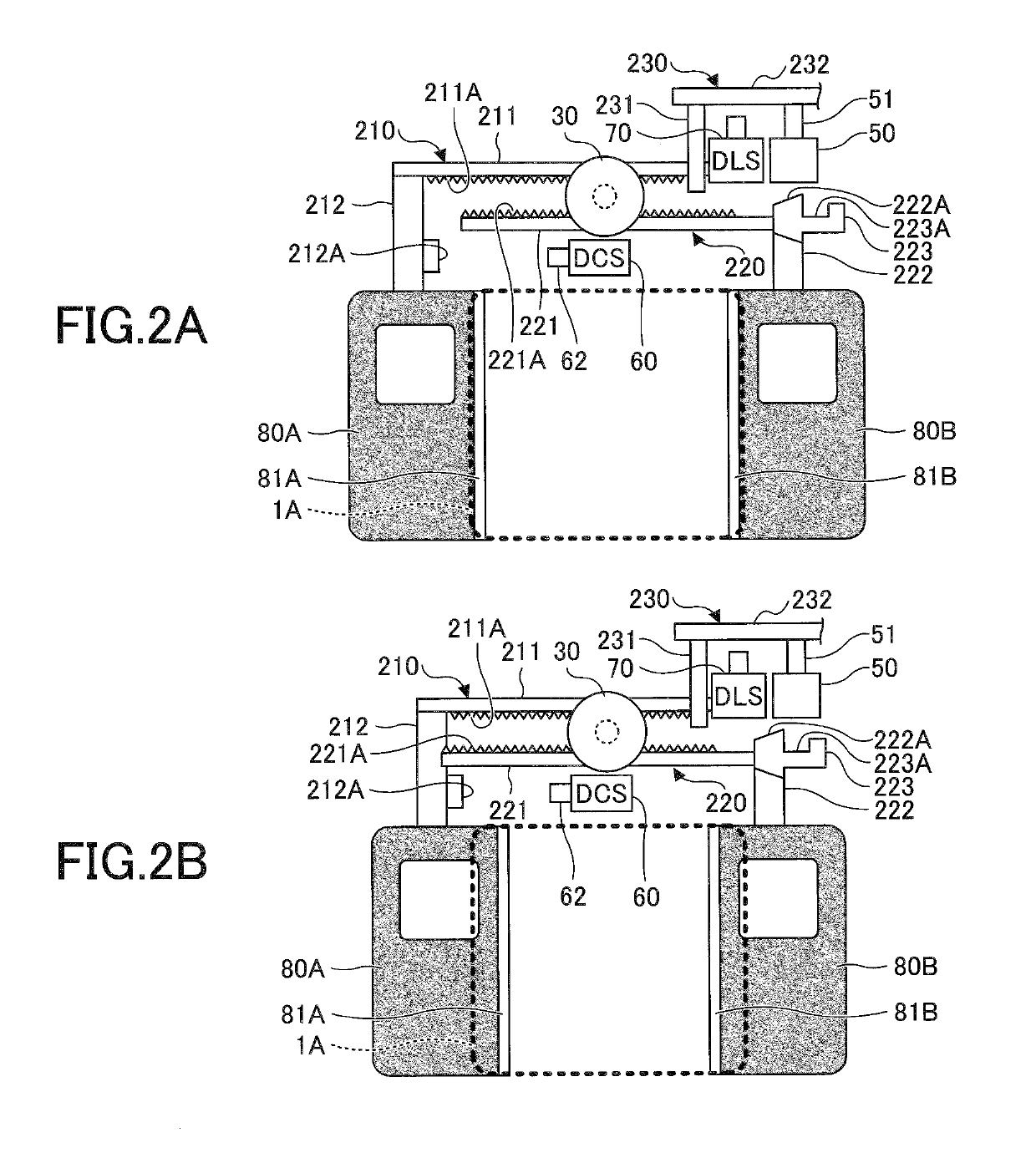

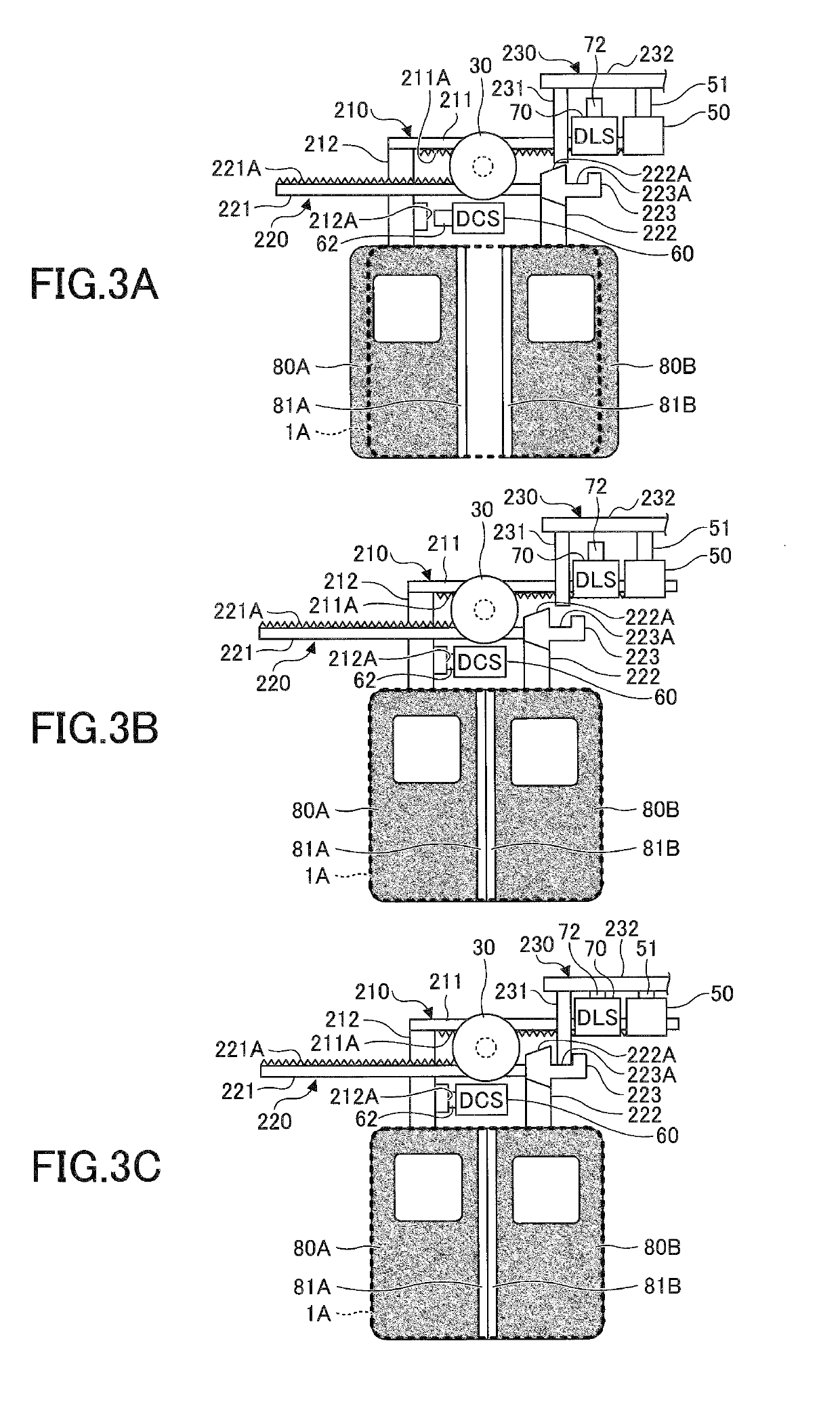

Door control device

ActiveUS20190218848A1Improves drawabilityVehicle locksPower-operated mechanismEmbedded systemWaiting time

A door control device includes: an electric motor control unit configured to drive, in response to a closing command for closing a door that is driven to be opened and closed by an electric motor, the electric motor; a door closed state detection unit configured to detect a closed state of the door; and a lock command output unit configured to output a lock command to lock a locking device of the door, upon the closed state being detected when a predetermined waiting time has passed after the electric motor was driven by the electric motor control unit in response to the closing command and the closed state was detected by the door closed state detection unit.

Owner:FUJI ELECTRIC CO LTD

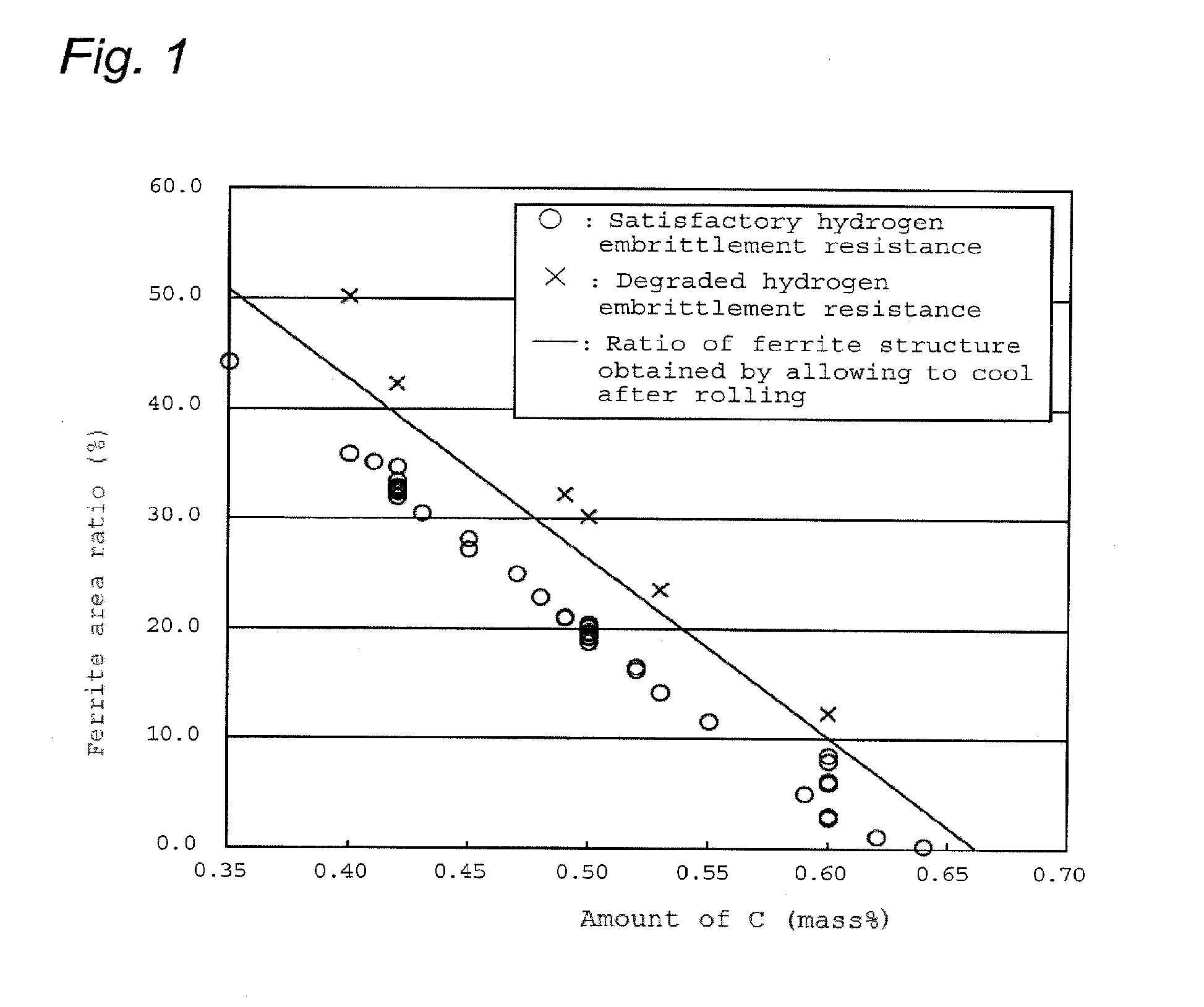

Rolled material for high strength spring, and wire for high strength spring using the same

InactiveUS20160319393A1Good drawing effectExcellent fatigue propertiesFurnace typesHeat treatment furnacesWire rodHydrogen

An object of the present invention is to provide a rolled material for high strength spring, which has excellent wire drawability even when suppressing the addition amount of an alloying element, and which can exhibit corrosion fatigue properties after quenching and tempering.The present invention provides a rolled material for high strength spring, including C, Si, Mn, P, S, Al, Cu and Ni, wherein an amount of nondiffusible hydrogen is 0.40 ppm by mass or less, and an area ratio of ferrite expressed as a percentage satisfies an inequality expression (1) below, and a total area ratio of bainite and martensite is 2% or less:Ferrite area ratio<{(0.77−[C]) / 0.77−[C] / 3+0.08}×100 (1)where [name of element] in the above inequality expression (1) means a content expressed in % by mass of each element.

Owner:KOBE STEEL LTD

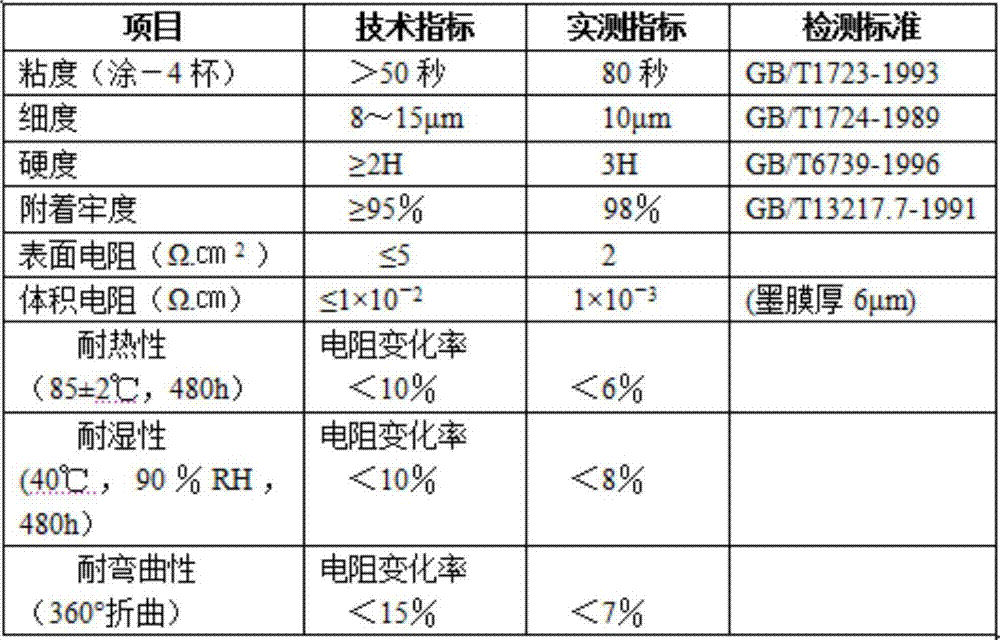

Inductive percussion instrument based on wood grain style printing and conductive ink

InactiveCN107221315ASimple processLow costElectrophonic musical instrumentsInksCapacitanceManufacturing technology

The invention provides an inductive percussion instrument based on wood grain style printing and color conductive ink. The inductive percussion instrument comprises a percussion panel. Conductive color ink blocks are coated on the upper surface of the percussion panel. Sound generating speakers powered by a power supply module are arranged on the lower surface of the percussion panel. The sound generating speakers are connected with the conductive color ink blocks on the upper surface of the percussion panel through conductive color ink lines. According to the inductive percussion instrument based on wood grain style printing and the color conductive ink, vibration and sound generation of the conventional percussion instrument depend on physical percussion, the multipart mode of the capacitive touch percussion instrument is eliminated, and on / off of the sound generating device is realized by using the capacitive induced conductivity of the color conductive ink so that the manufacturing technology is simple, parts are less and the percussion instrument is safe and stable and suitable for children in comparison with the conventional capacitive touch percussion instrument.

Owner:武汉鸥易光电科技有限公司

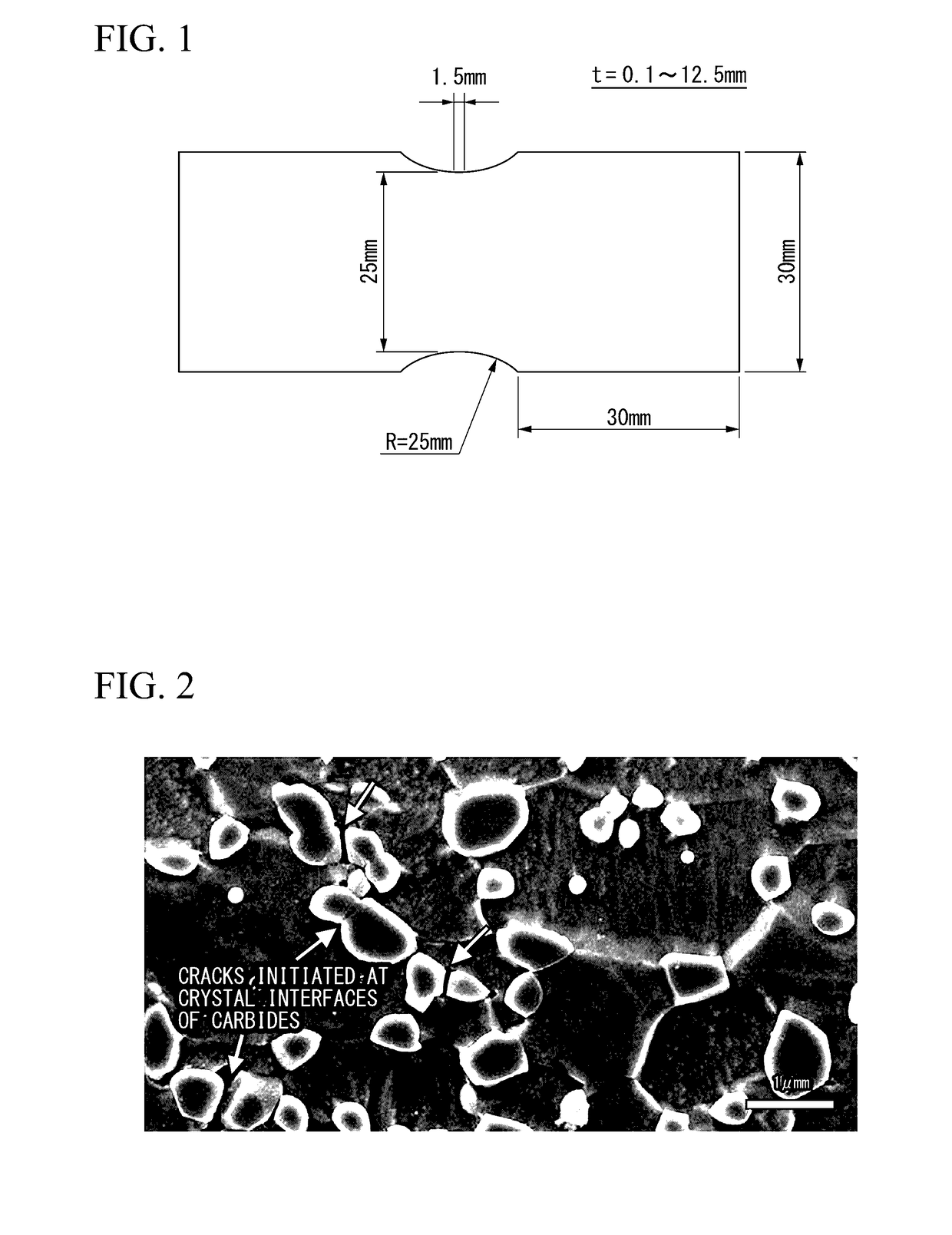

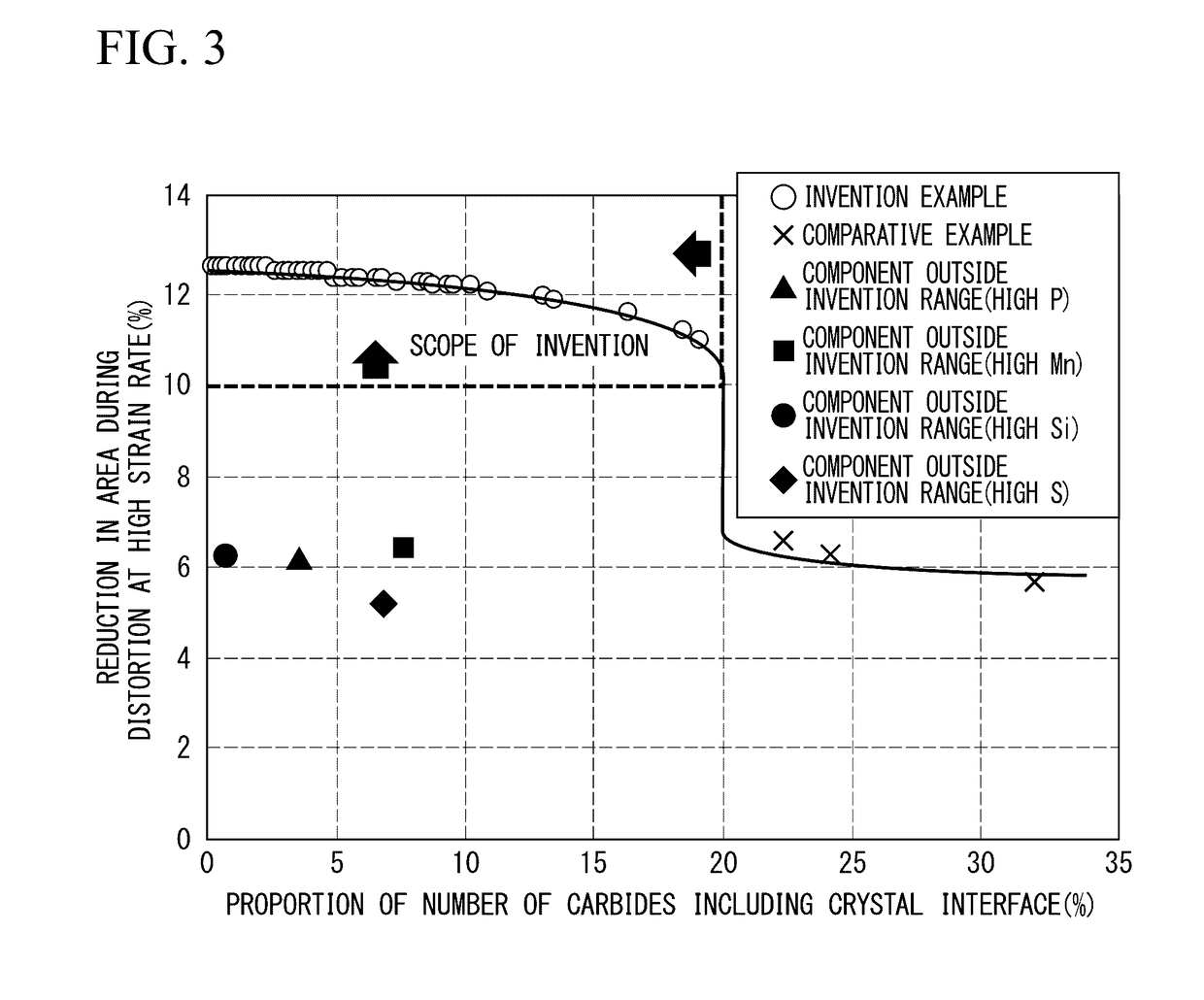

Middle/high carbon steel sheet and method for manufacturing same

InactiveUS20170067132A1Improve machinabilityExcellent reduction in sizeFurnace typesHeat treatment furnacesHigh carbonCarbide

A middle / high carbon steel sheet according to an aspect of the present invention is a steel sheet, in which composition thereof contains, by mass %, C: 0.10% to 1.50%, Si: 0.01% to 1.00%, Mn: 0.01% to 3.00%, P: 0.0001% to 0.1000%, and S: 0.0001% to 0.1000%, and a remainder consisting of Fe and impurities, in which the steel sheet has a structure in which a total volume percentage of a martensite, a bainite, a pearlite, and a residual austenite is equal to or lower than 5.0%, and a remainder thereof is a ferrite and carbides, in which a spheroidizing ratio of carbide particles is 70% to 99%, and in which a proportion of a number of the carbide particles including a crystal interface at which an orientation difference is equal to or greater than 5° in the carbide particles is equal to or lower than 20% of a total number of the carbide particles.

Owner:NIPPON STEEL CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com