Biaxially oriented multi-layer laminated film and method for manufacture thereof

a laminated film, biaxial orientation technology, applied in the direction of synthetic resin layered products, instruments, other domestic objects, etc., can solve the problems of resins, insufficient strength, uniform drawing, delamination defects, etc., to achieve high interlayer adhesion and high tearing resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

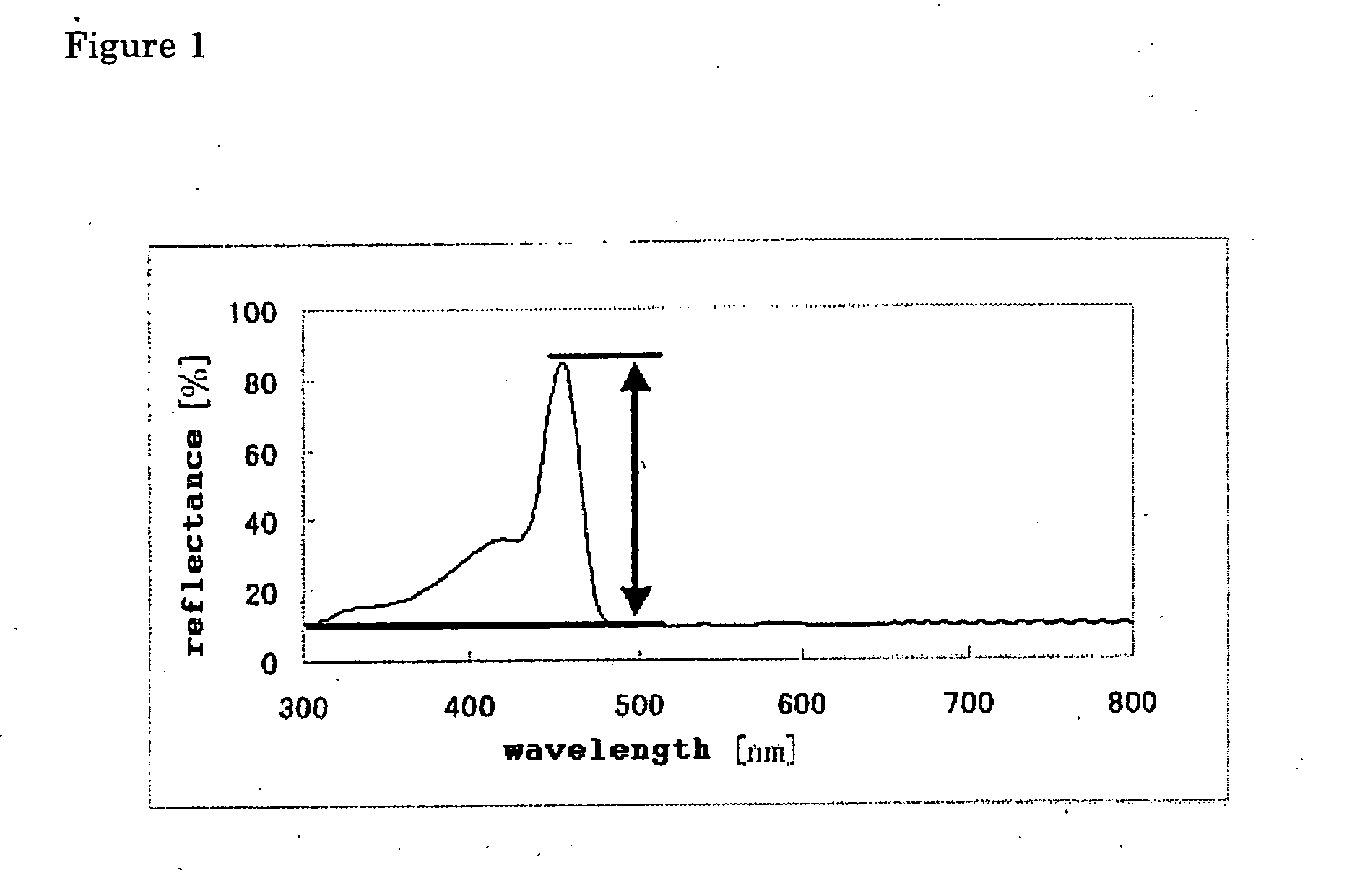

Image

Examples

example 1

A polyethylene terephthalate having an intrinsic viscosity of 0.63 (in o-chlorophenol at 35° C.) (described as “PET” in the Table 1) was used as the polyester for the 1st layer and a copolymerized polyethylene terephthalate copolymerized with 12 mol % isophthalic acid and having an intrinsic viscosity of 0.61 (in o-chlorophenol at 35° C.) (described as “IA12PET” in the Table 1) was incorporated with 0.10 wt. % truly spherical silica particles (average particle diameter: 1.5 μm, major diameter to minor diameter ratio: 1.02, average deviation of particle diameter: 0.1) (described as “a” in the Table 1.) and the product was used as the polyester for the 2nd layer. The polyester for the 1st layer and the polyester for the 2nd layer were dried at 170° C. for 3 hours, supplied to respective extruders and melted by heating at 280° C. The polyester for the 1st layer was branched to 101 layers and the polyester for the 2nd layer was branched to 100 layers, the branched 1st layers and 2nd la...

examples 2 , 3 and 5 to 7

EXAMPLES 2, 3 and 5 to 7

The operations of the Example 1 were repeated except for the change of the polyester for the 2nd layer and the production conditions to those described in the Table 1. The term “IA8PET” described in the Table 1 as the kind of the resin of each layer is a polyethylene terephthalate copolymerized with 8 mol % isophthalic acid and having an intrinsic viscosity of 0.65 (in o-chlorophenol at 35° C.) and “IA20PET” is a polyethylene terephthalate copolymerized with 20 mol % isophthalic acid and having an intrinsic viscosity of 0.58 (in o-chlorophenol at 35° C.). The term “b” described in the Table 1 as the kind of the inert particle is bulk calcium carbonate (average particle diameter: 1.5 μm, major diameter to minor diameter ratio: 1.30, average deviation of particle diameter: 0.3) and the term (c) is truly spherical silicone particles (average particle diameter: 0.1 μm, major diameter to minor diameter ratio: 1.10, average deviation of particle diameter: 0.2).

T...

example 4

A polyethylene terephthalate having an intrinsic viscosity of 0.63 (in o-chlorophenol at 35° C.) (PET) was used as the polyester for the 1st layer and a copolymerized polyethylene terephthalate copolymerized with 10 mol % 2,6-naphthalenedicarboxylic acid and having an intrinsic viscosity of 0.70 (in o-chlorophenol at 35° C.) (described as “NDC10PET” in the Table 1) was prepared as the polyester for the 2nd layer. The polyester for the 1st layer and the polyester for the 2nd layer were dried at 170° C. for 3 hours, supplied to respective extruders and melted by heating at 280° C. The polyester for the 1st layer was branched to 101 layers and the polyester for the 2nd layer was branched to 100 layers, the branched 1st layers and 2nd layers were alternately laminated by using a multilayer feed block apparatus, guided to a die while keeping the laminated state, and cast on a casting drum to obtain an undrawn multilayer laminated film having a total layer number of 201 and composed of a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com