Patents

Literature

46results about How to "Excellent bake hardenability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Hot rolled steel sheet for processing and method for manufacturing the same

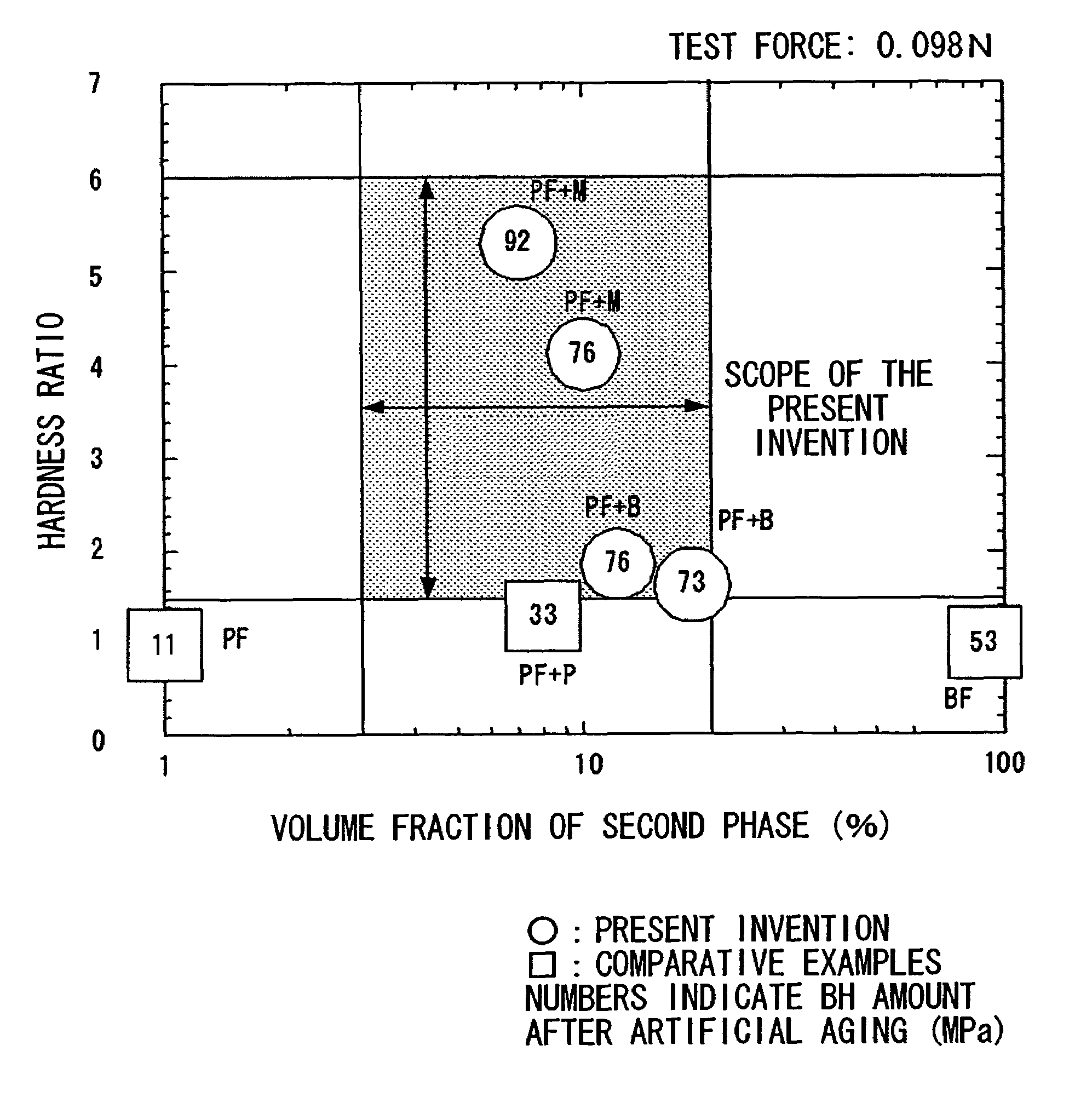

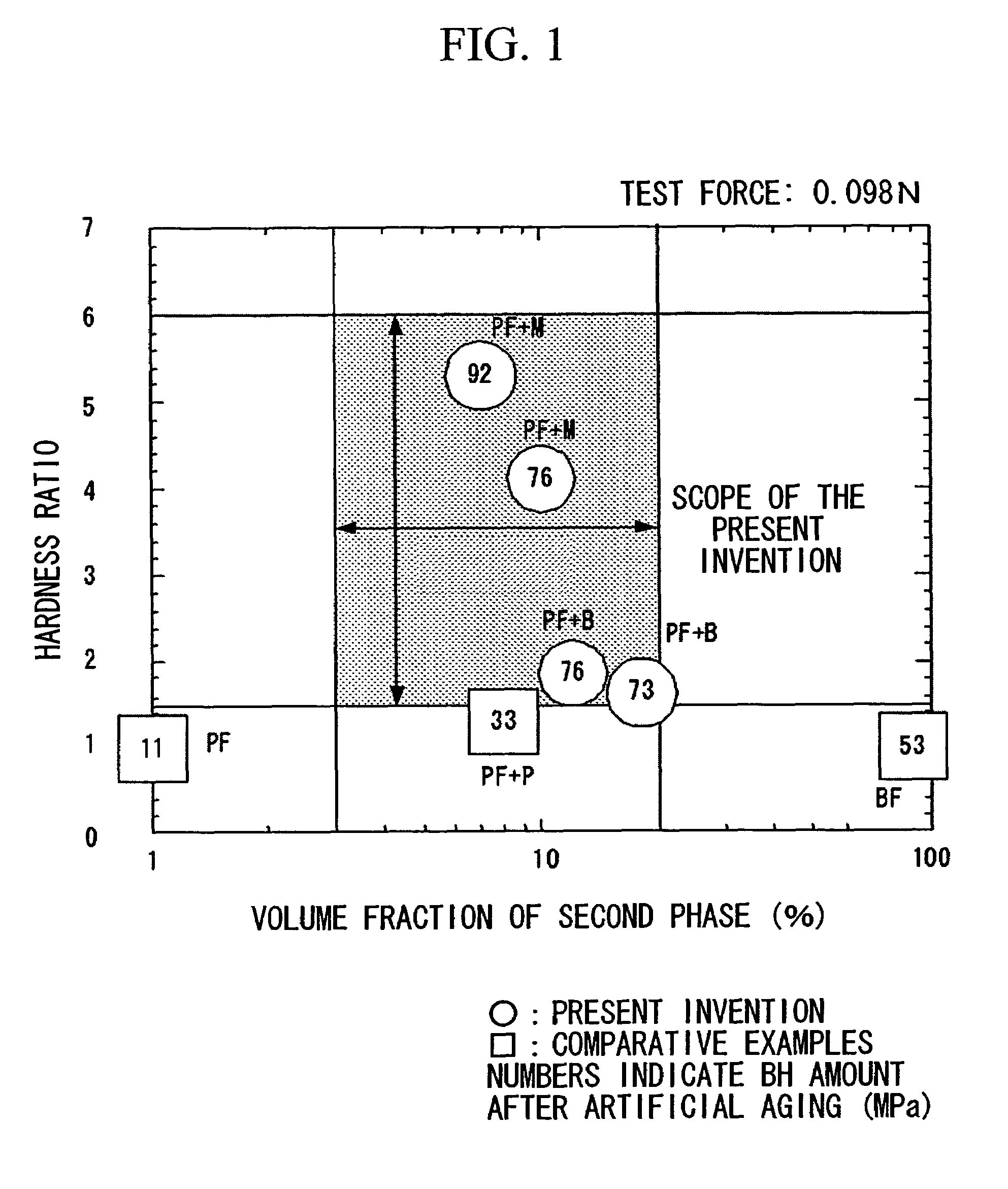

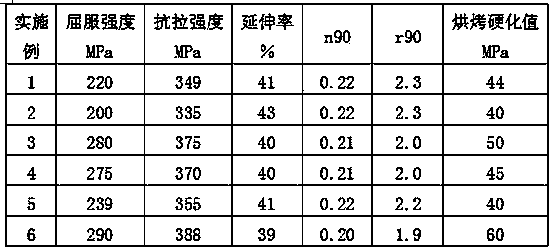

ActiveUS7381478B2Excellent bake hardenabilityLittle decrease in BH amountHot-dipping/immersion processesFurnace typesHardness ratioSheet steel

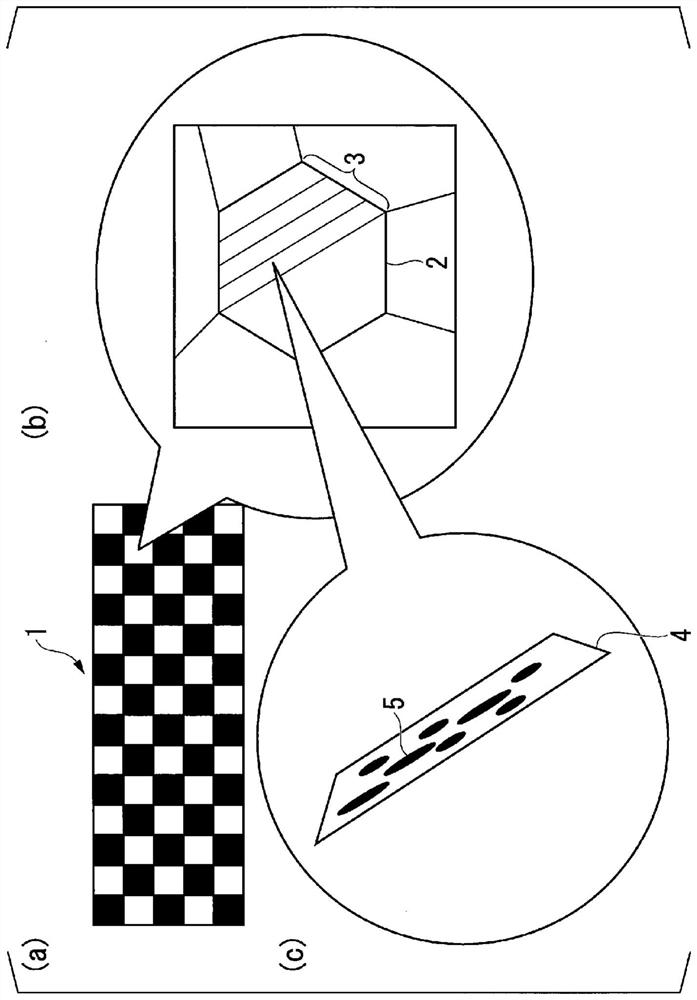

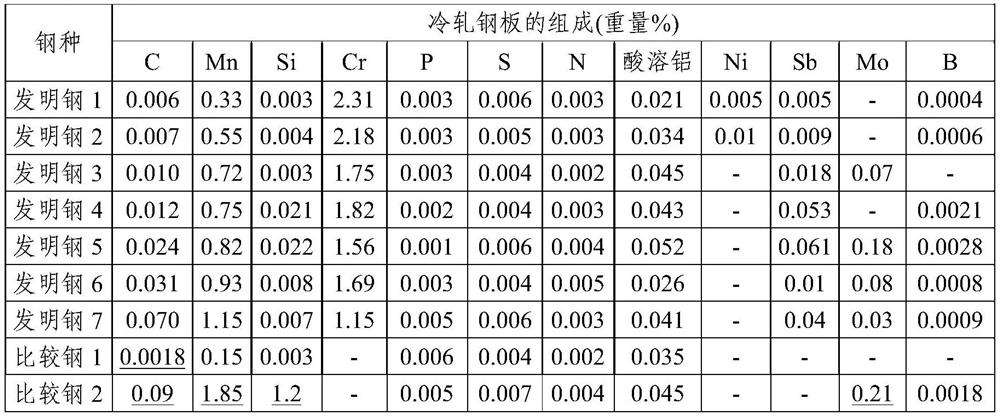

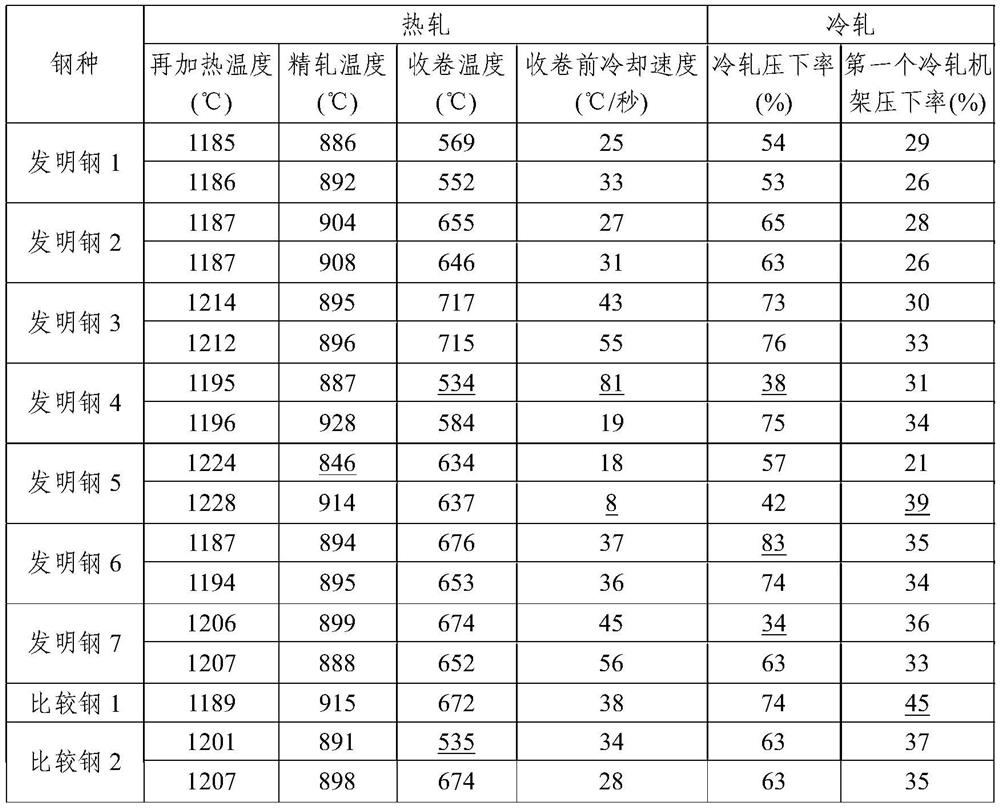

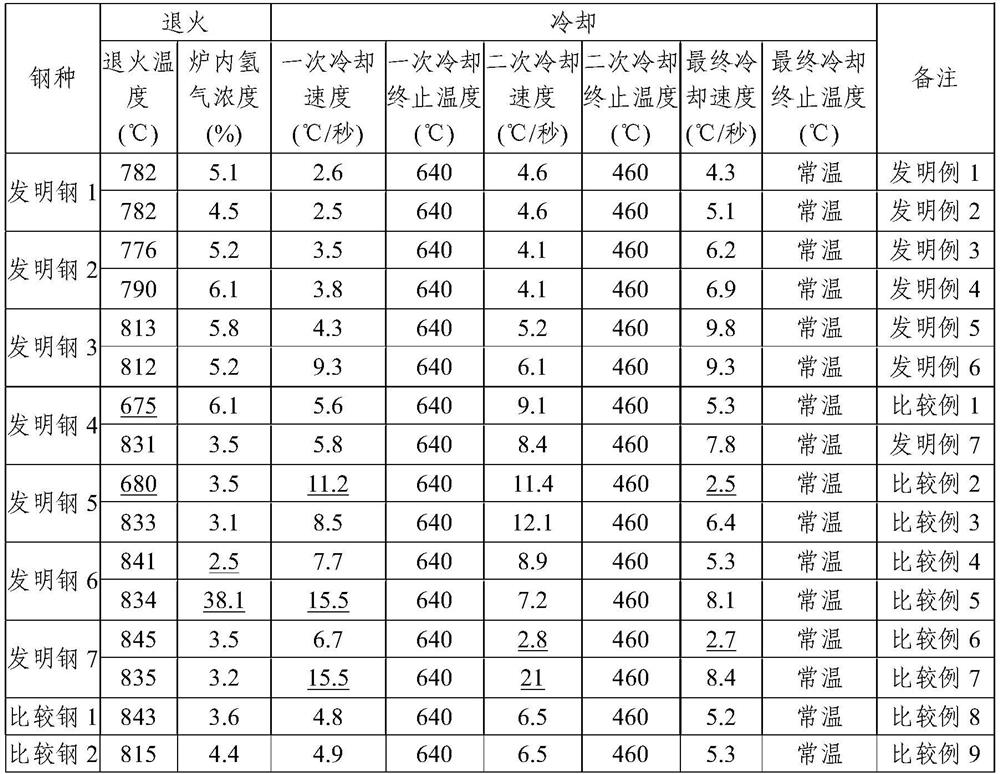

An exemplary hot rolled steel sheet for processing can include, in terms of percent by mass, C of 0.01 to 0.2%; Si of 0.01 to 0.3%; Mn of 0.1 to 1.5%; P of ≦0.1%; S of ≦0.03%; Al of 0.001 to 0.1%; N of ≦0.006%; and as a remainder, Fe and unavoidable impurities. The microstructure may include a main phase in the form of polygonal ferrite and a hard second phase, a volume fraction of the hard second phase is 3 to 20%, a hardness ratio (hardness of the hard second phase / hardness of the polygonal ferrite) is 1.5 to 6, and a grain size ratio (e.g., grain size of the polygonal ferrite / grain size of the hard second phase) is 1.5 or more.

Owner:NIPPON STEEL CORP

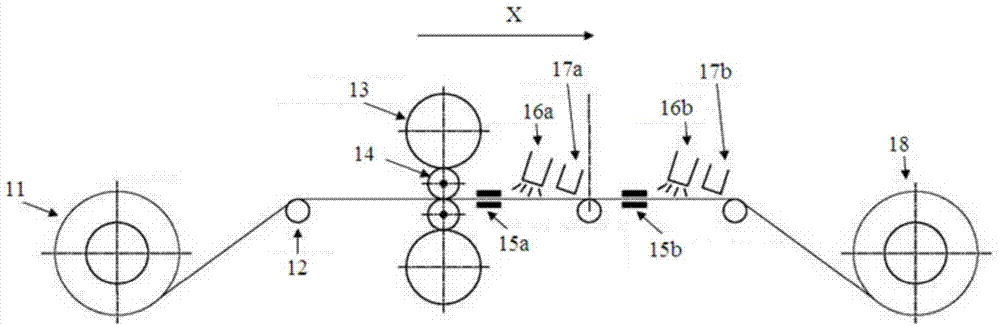

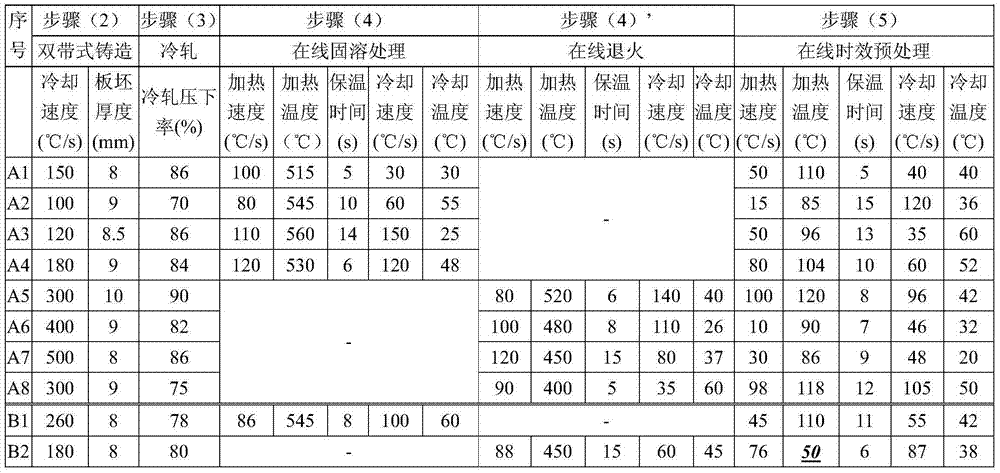

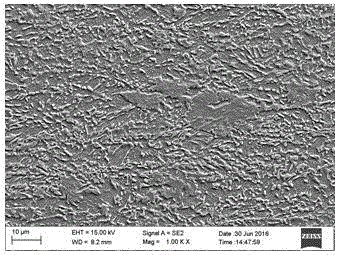

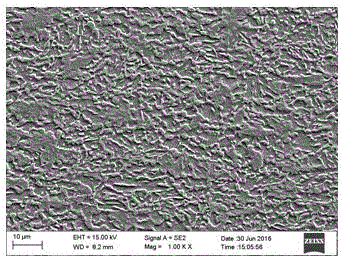

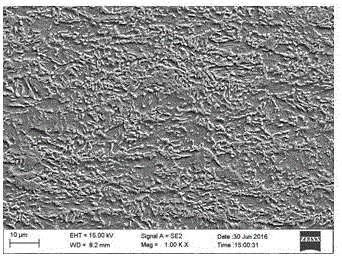

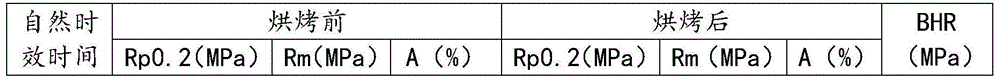

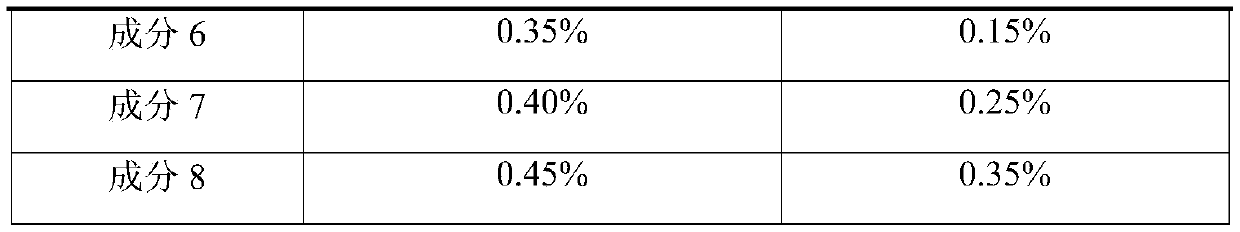

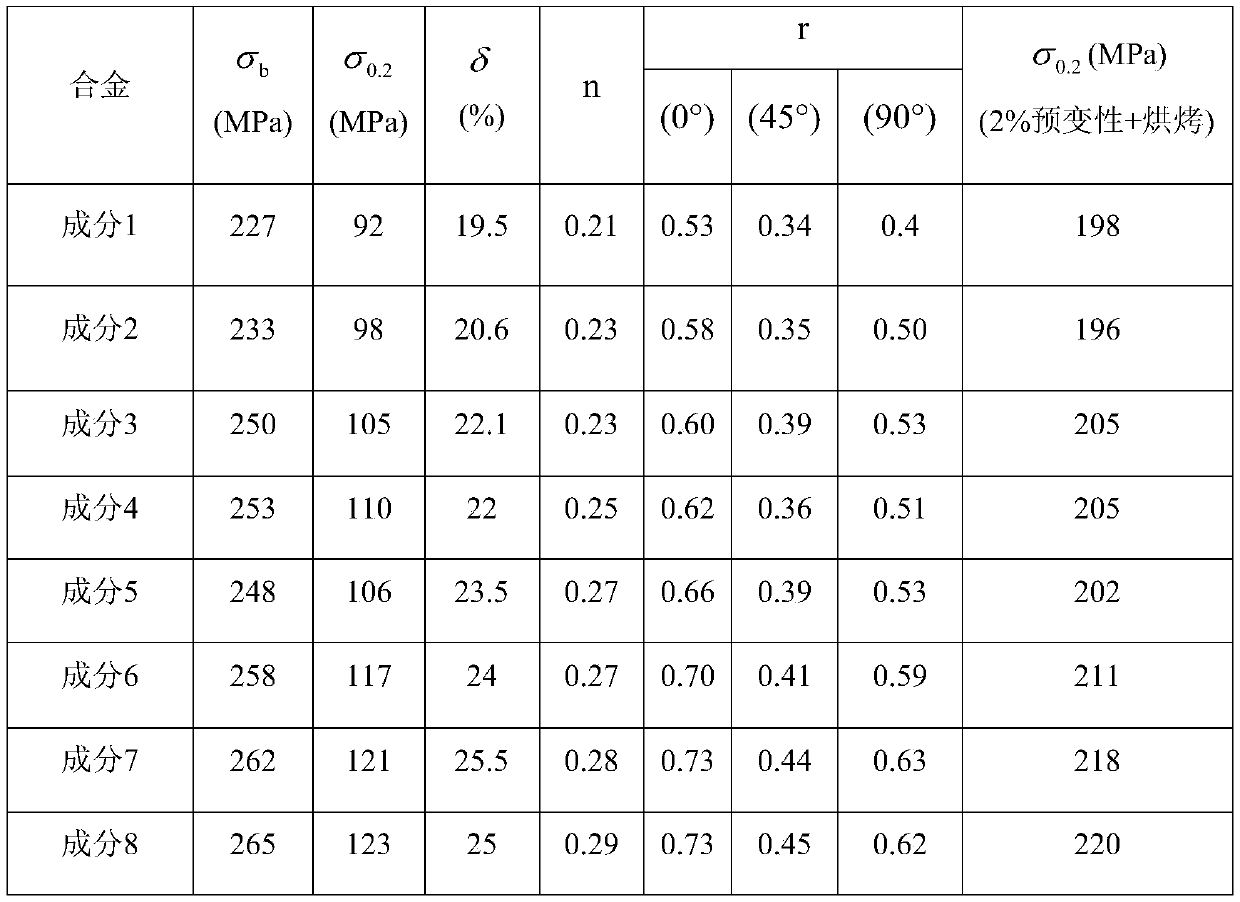

High-strength aluminum-alloy material, aluminum-alloy plate and manufacturing method thereof

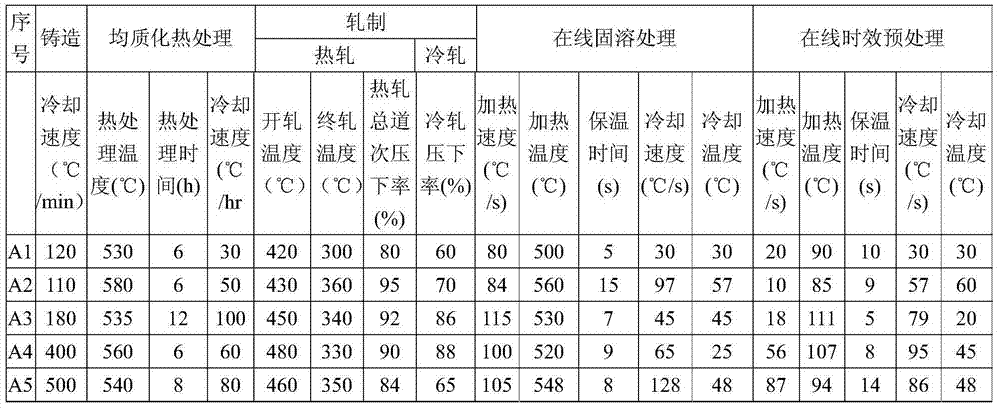

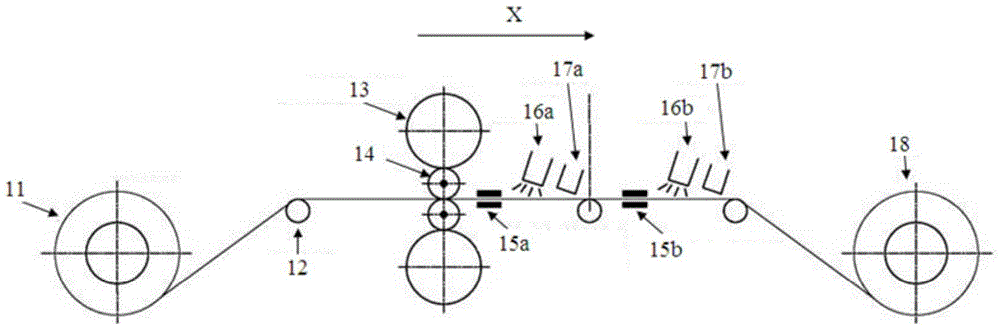

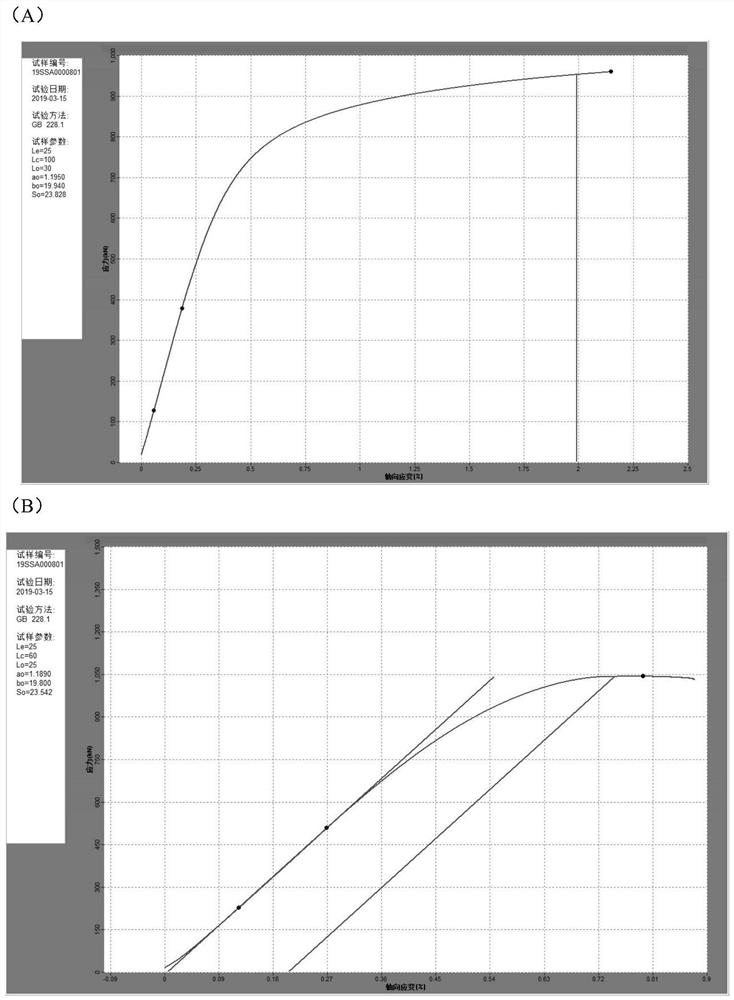

The invention discloses a high-strength aluminum-alloy material. The high-strength aluminum-alloy material contains the chemical elements in percentage by mass: not lower than 1.5% and not higher than 3.0% of Mg, not lower than 0.05% and not higher than 0.2% of Si, not lower than 0.1% and not higher than 0.2% of Mn, not lower than 0.2% and not higher than 0.4% of Fe, higher than 0 and not higher than 0.03% of Cu, higher than 0 and not higher than 0.05% of Ti, either not lower than 0.05% and not higher than 0.15% of Ca or not lower than 0.05% and not higher than 0.15% of Sr and the balance of Al and other unavoidable impurities. The invention further discloses an aluminum-alloy plate manufactured from the aluminum-alloy material. The invention further discloses a manufacturing method of the aluminum-alloy plate, wherein the method comprises the steps of carrying out double-strip casting, carrying out cold rolling, carrying out online solid solution treatment and carrying out online aging pretreatment. The high-strength aluminum-alloy material and the aluminum-alloy plate, disclosed by the invention, have relatively high strength and good natural aging stability. After painting and baking, the yield strength of the high-strength aluminum-alloy material and the aluminum-alloy plate is higher than 300Mpa.

Owner:BAOSHAN IRON & STEEL CO LTD

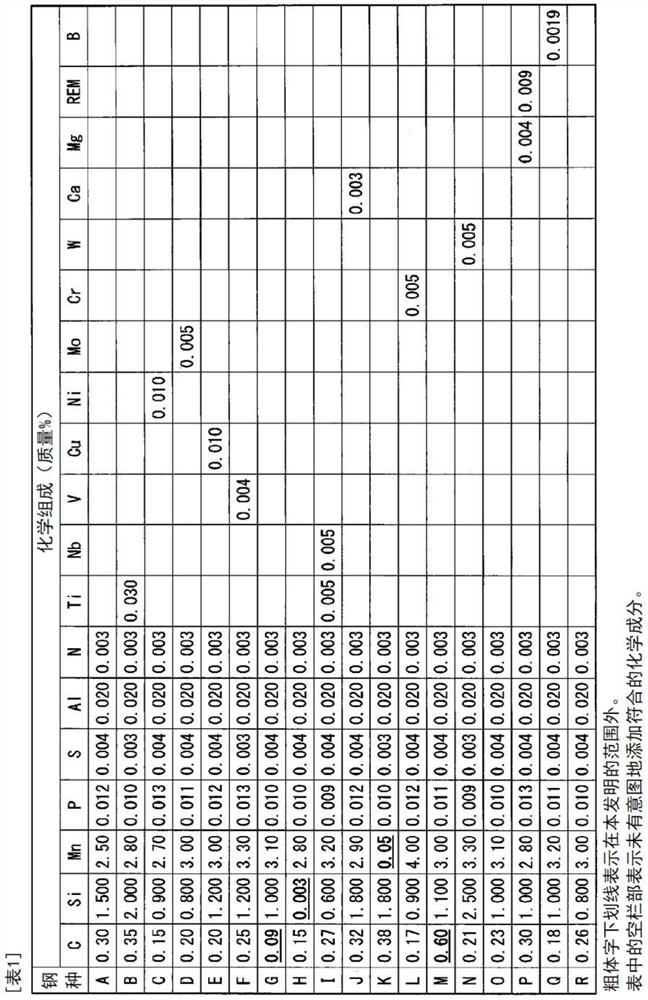

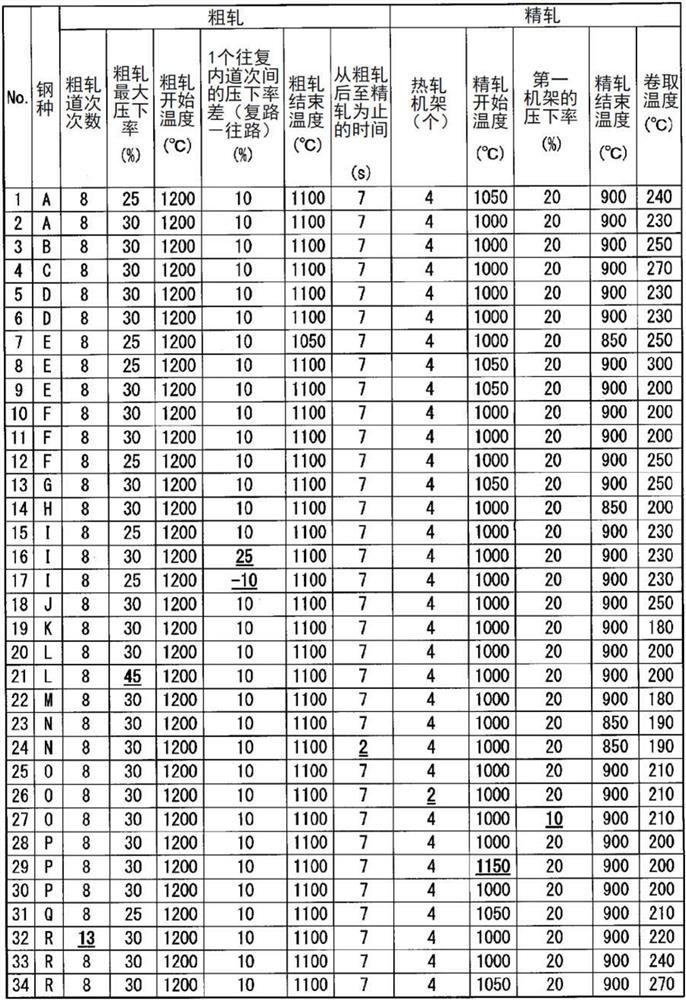

Single-steel multi-level hot-rolled complex-phase high-strength steel plate and production method thereof

The invention discloses a single-steel multi-stage hot-rolled complex-phase high-strength steel plate and a production method thereof. The production method comprises the steps of heating, hot rolling, cooling, coiling, annealing and acid pickling. The steel plate comprises, by weight percentage, 0.08-0.15% of C, 1.80-3.00% of Mn, less than or equal to 0.015% of S, less than or equal to 0.025% of P, 0.50-1.00% of Si, 0.020-0.060% of Als, 0.40-1.0% of Cr, 0.010-0.040% of Ti, 0.10-0.30% of Mo, less than or equal to 0.007% of N, and the balance Fe and inevitable impurities. According to the production method, a composition system is adopted through a reasonable composition design, complex-phase steel with different strength levels is produced by controlling different structure types in the hot rolling and annealing processes, and therefore the special requirement that a steel enterprise can meet the different performance of users by adopting one composition system can be met, the mechanical property of the whole-coil product is uniform, the baking hardening performance is good, and the requirements of the users for small-batch and different-strength-level samples can be met.

Owner:TANGSHAN IRON & STEEL GROUP +1

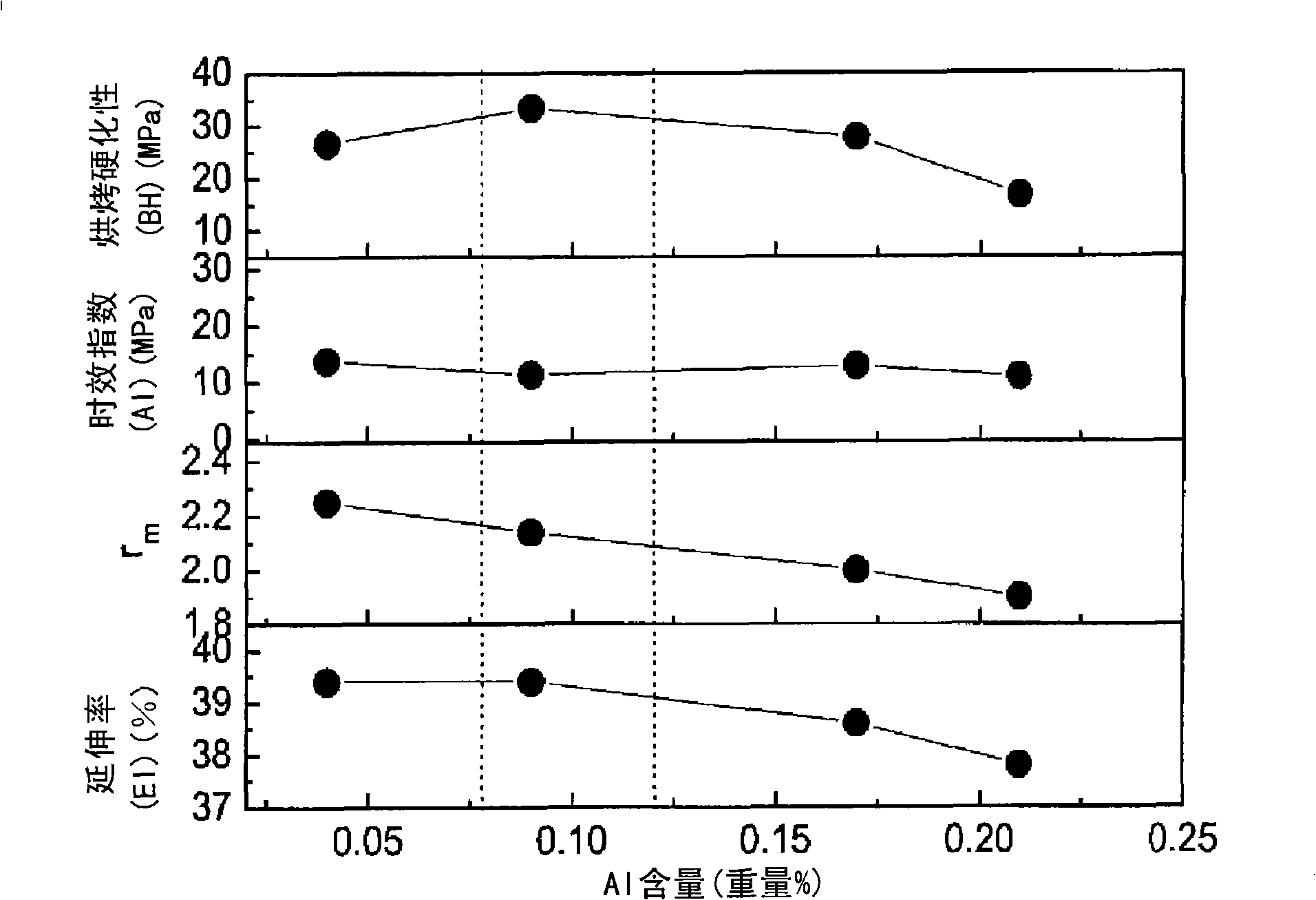

Bake-hardenable high-strength cold-rolled steel sheet and method of manufacturing the same

ActiveUS20130240094A1Excellent bake hardenabilityReduced planar anisotropyFurnace typesHeat treatment process controlHardenabilityAging resistance

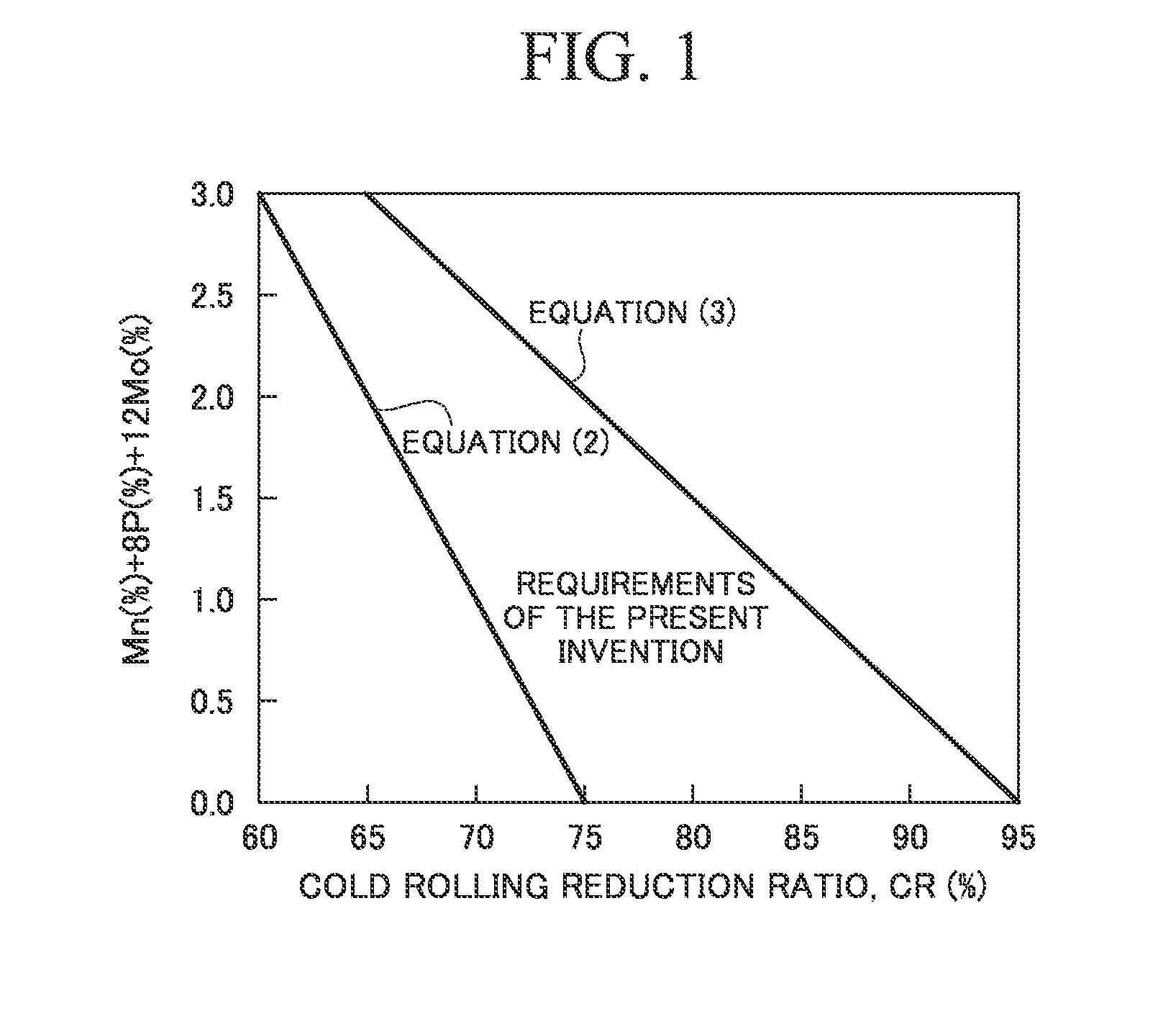

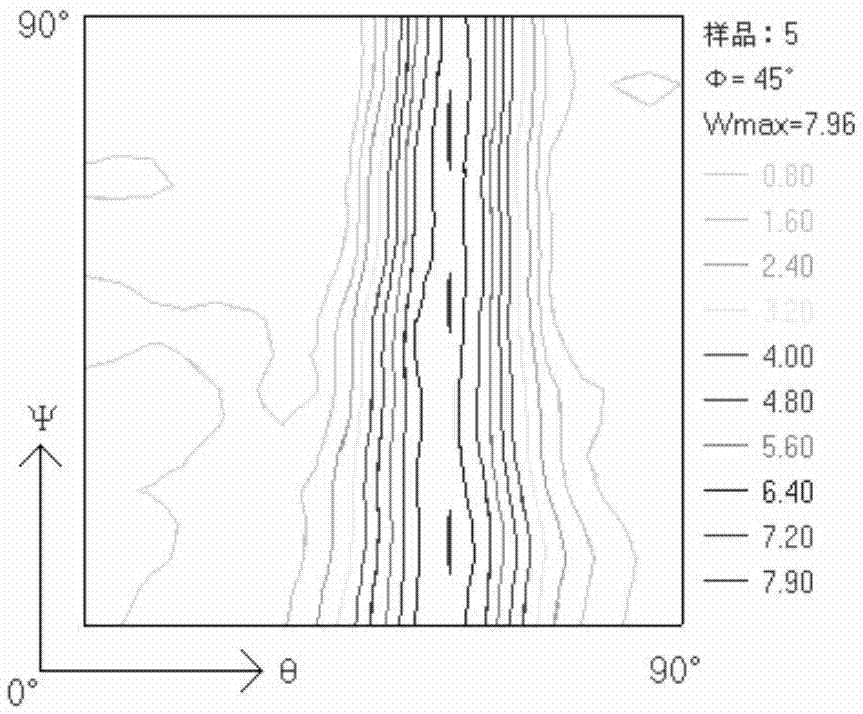

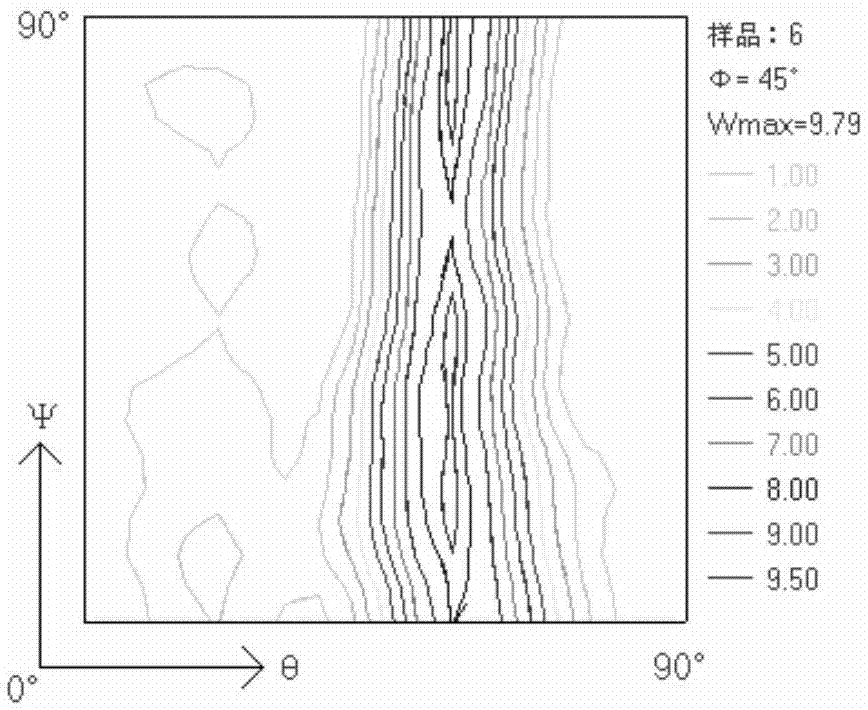

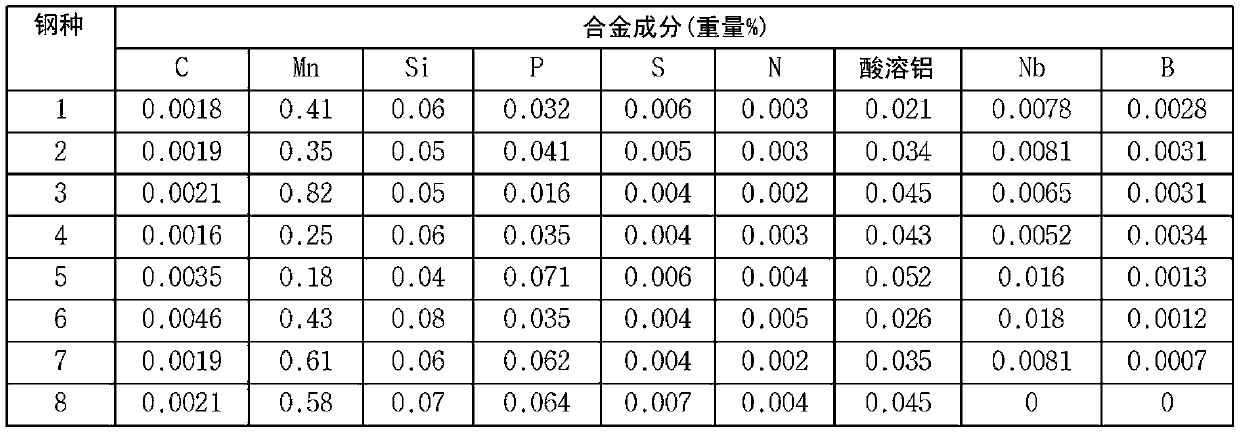

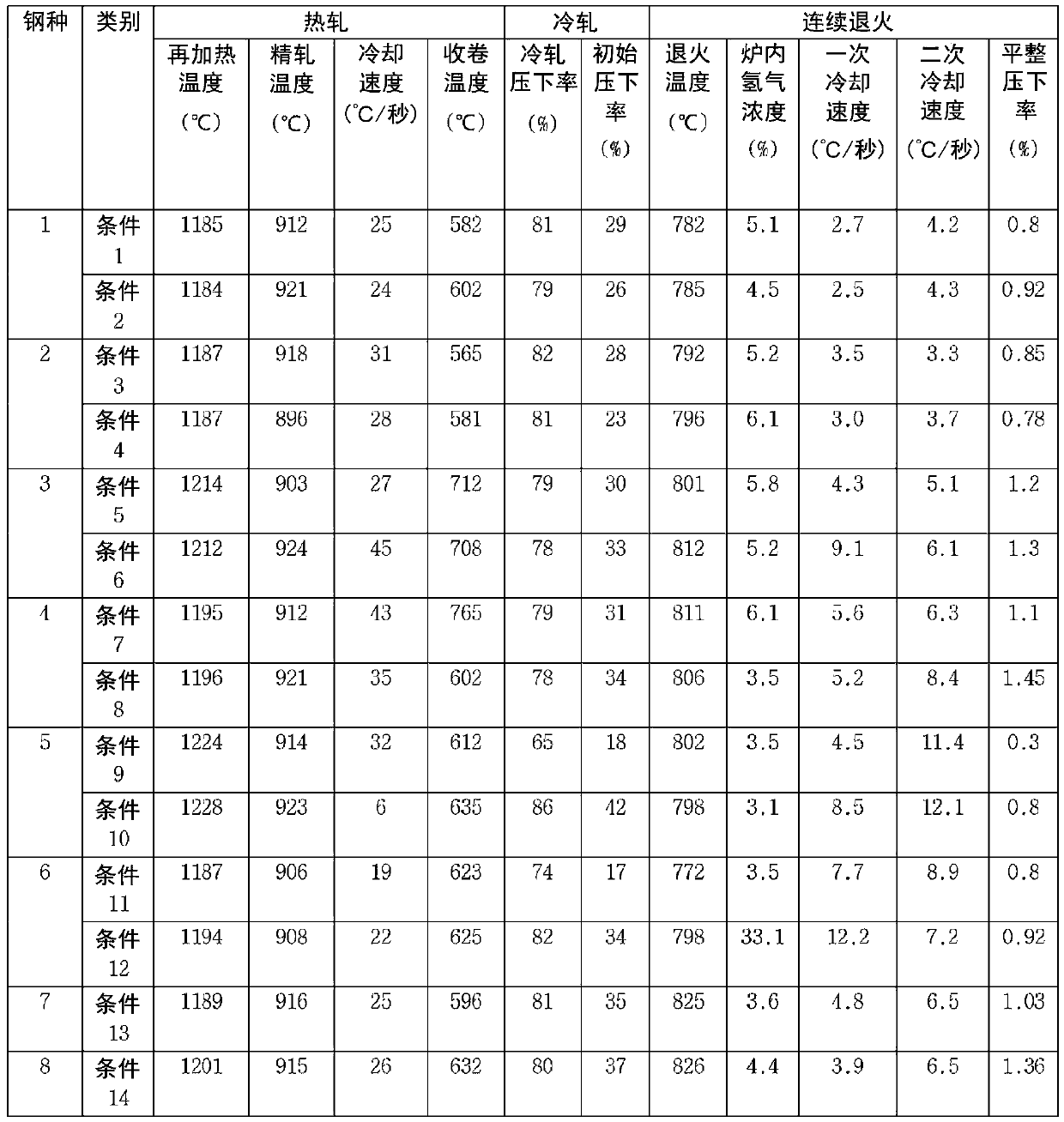

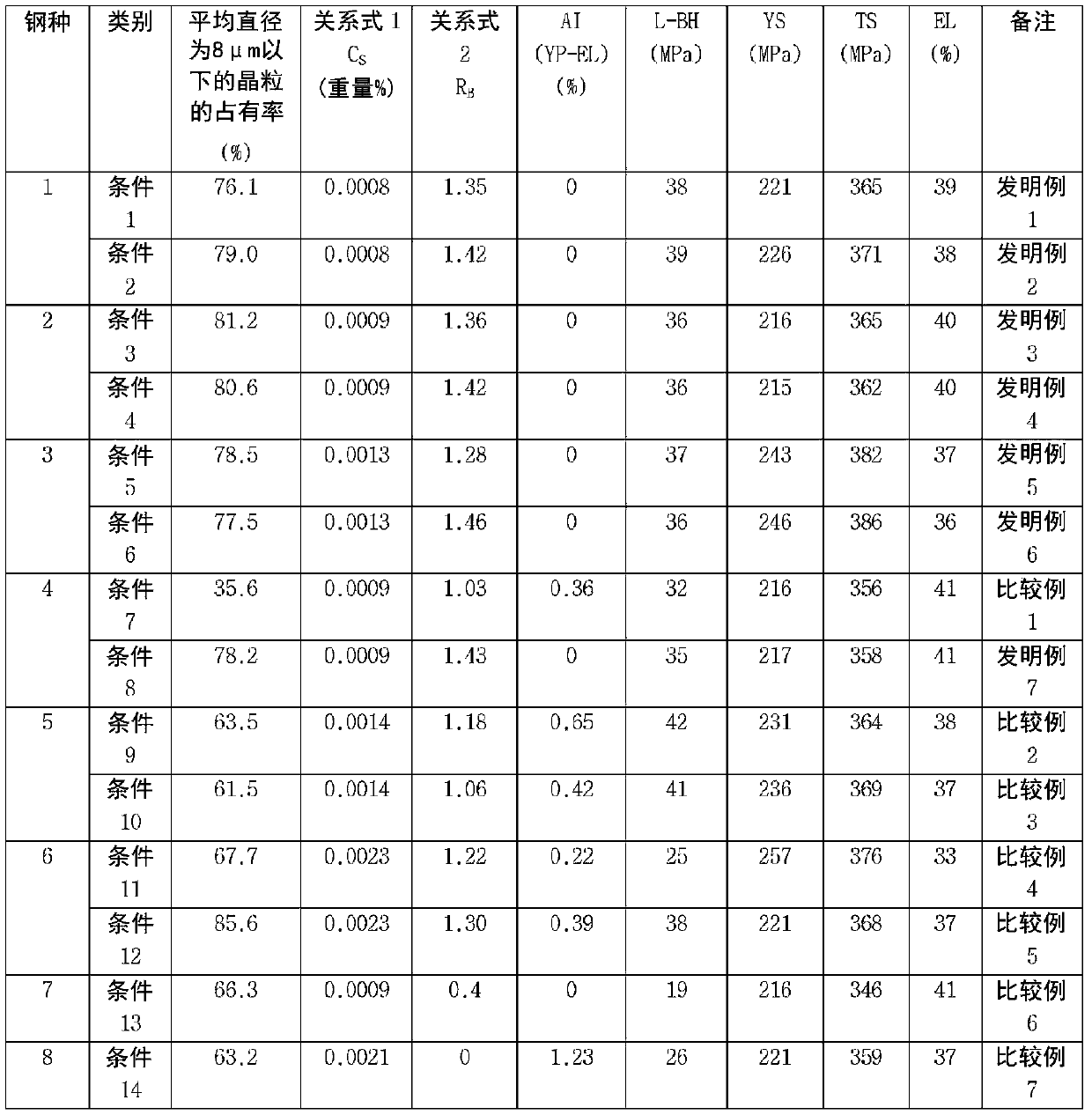

The present invention provides a bake-hardenable high-strength cold-rolled steel sheet having excellent bake hardenability, cold aging resistance, and deep-drawability, and reduced planar anisotropy, containing chemical components in % by mass of: C: 0.0010% to 0.0040%, Si: 0.005% to 0.05%, Mn: 0.1% to 0.8%, P: 0.01% to 0.07%, S: 0.001% to 0.01%, Al: 0.01% to 0.08%, N: 0.0010% to 0.0050%, Nb: 0.002% to 0.020%, and Mo: 0.005% to 0.050%, a value of [Mn %] / [P %] being in the range of 1.6 to 45, where [Mn %] is an amount of Mn and [P %] is an amount of P, an amount of C in solid solution obtained from [C %]−(12 / 93)×[Nb %] being in the range of 0.0005% to 0.0025%, where [C %] is an amount of C and [Nb %] is an amount of Nb, with a balance including Fe and inevitable impurities, wherein the bake-hardenable high-strength cold-rolled steel sheet satisfies the following Equation (1), where X(222), X(110), and X(200) represent ratios of integrated intensity of X-ray diffraction of {222} plane, {110} plane, and {200} plane, respectively, being parallel to a plane located at a depth of ¼ plate thickness measured from the surface of the steel sheet, and the bake-hardenable high-strength cold-rolled steel sheet has tensile strength in the range of 300 MPa to 450 MPa.X(222) / {X(110)+X(200)}≧3.0 Equation (1)

Owner:NIPPON STEEL CORP

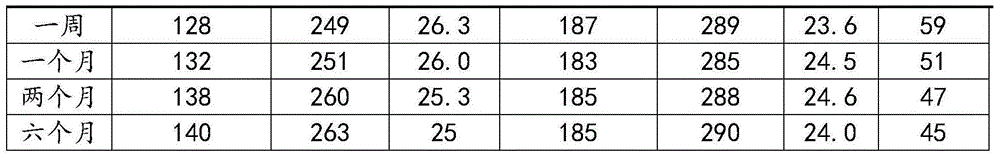

Aluminum alloy sheet and production method thereof

InactiveCN105925858AExcellent formability and mechanical propertiesImproved coiling performanceChemical compositionHardness

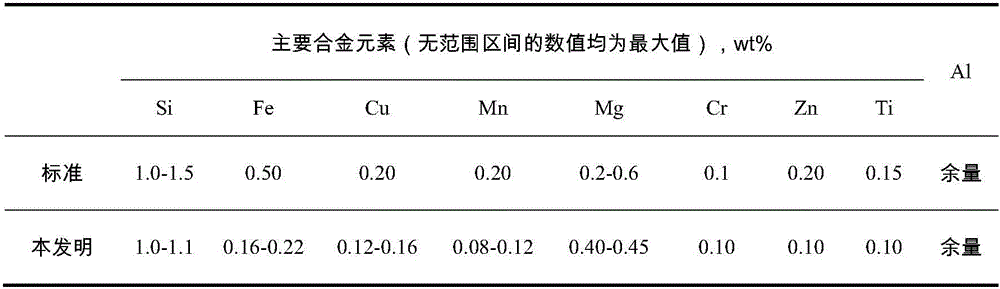

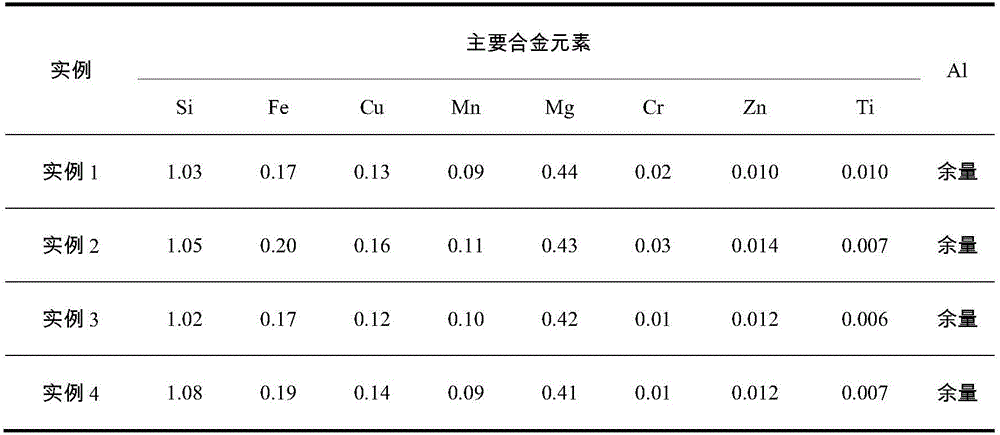

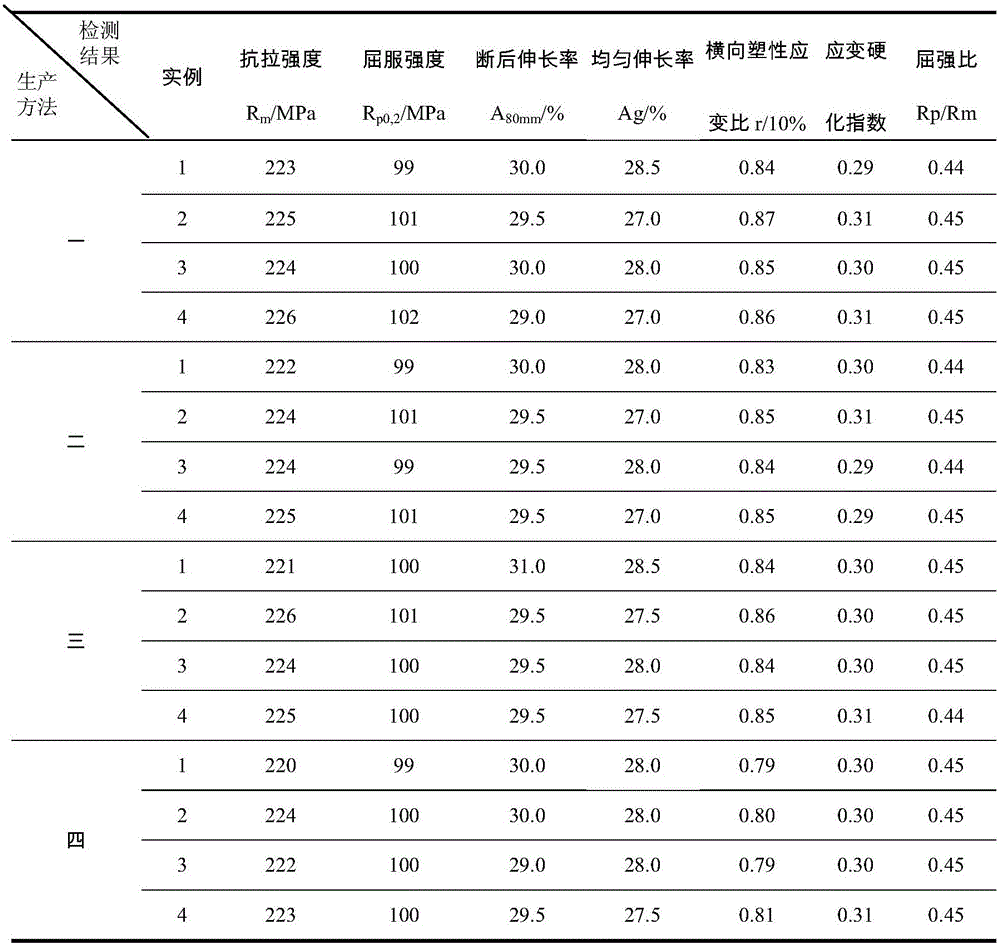

The invention discloses a 6016-series aluminum alloy sheet for a vehicle body and a production method thereof. The aluminum alloy sheet comprises the following chemical components in percentage by mass: 1.0-1.5% of Si, 0-0.50% of Fe, 0-0.20% of Cu, 0-0.20% of Mn, 0.25-0.60% of Mg, 0-0.10% of Cr, 0-0.10% of Zn, 0-0.10% of Ti, and the balance of Al. The production method comprises the steps of batching-smelting-converter-furnace side refining-standing-casting-sawing-surface milling-ingot homogenization-hot rolling-intermediate annealing-cold rolling-electrospark frosting-finished product cold rolling-solid solution quenching-drawing correction-Ti / Zr passivation-preageing-finished product coiling. The aluminum alloy sheet can provide a high-grade vehicle body sheet to users, improves the yield in punching, reduces the vehicle manufacturer cost, improves the formability and the baking hardness of aluminum alloy sheets, and is broad in market prospect and prominent in economic benefit.

Owner:SHANDONG NANSHAN ALUMINUM +1

Pretreatment process for automobile deformed aluminum alloy plate

The invention relates to a technique of processing low-copper vehicle wrought aluminium alloy boards such as 6022, 6016 and the like, especially relates to a preprocessing technique for assuring baking hardenability and formability of vehicle wrought aluminium alloy boards.The preprocessing technique of vehicle wrought aluminium alloy boards is characterized by placing aluminum alloy boards into a furnace for solid solution treatment, 30 minutes after the solid solution heating and heat preserving under a temperature of 520 DEG C-550 DEG C, placing them into a polyether water-soluble medium of 5-10% for quenching, putting them in a room temperature for 2-3 days after being cooled, putting them into an aging treatment furnace for being treated for 10-15 minutes under a temperature of 140-170 DEG C. The invention which is a simple technique improves the yield strength, tensile strength and specific elongation of aluminum alloy boards, therefore, improving the formability, aging -resisting stability and baking hardenability of aluminum alloy boards, can achieve an satisfactory baking and overhardening effect on the existing oil paint line, improves rate of final products formed by pressing, reduces the pressing cost and promotes the application of aluminum boards in the lighteningof vehicles.

Owner:HENAN SUDA ELECTRIC AUTOMOBILE TECH

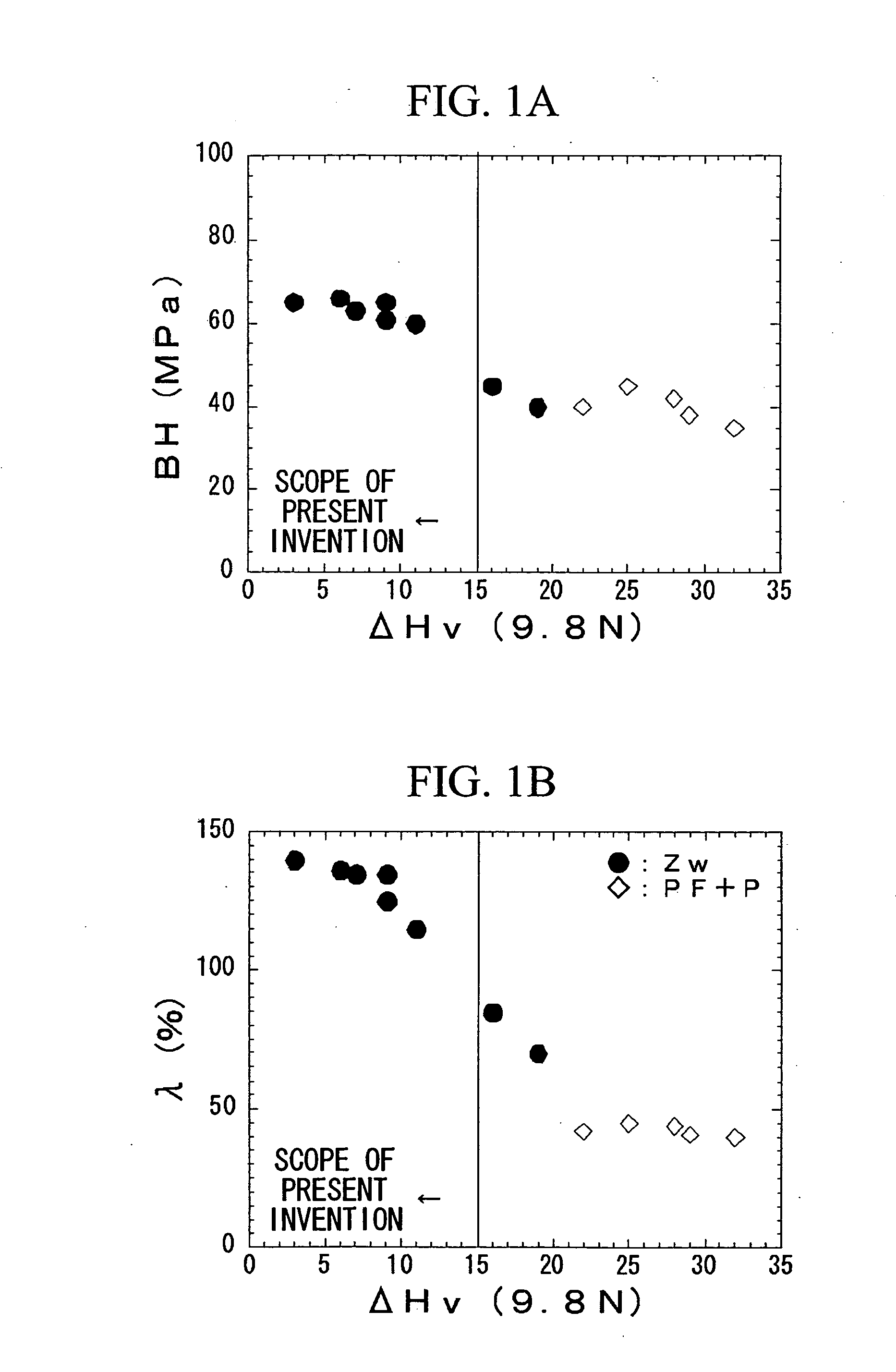

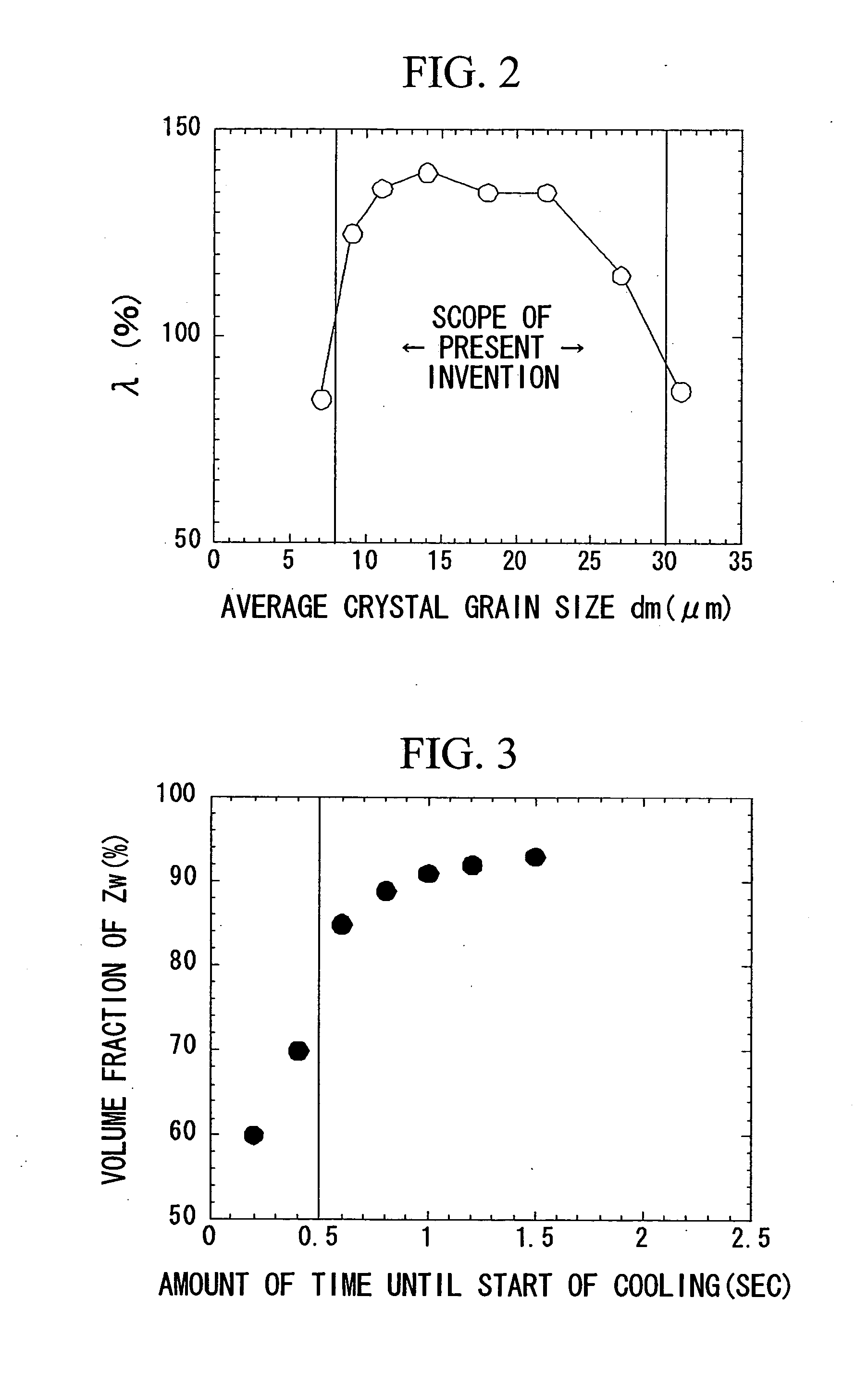

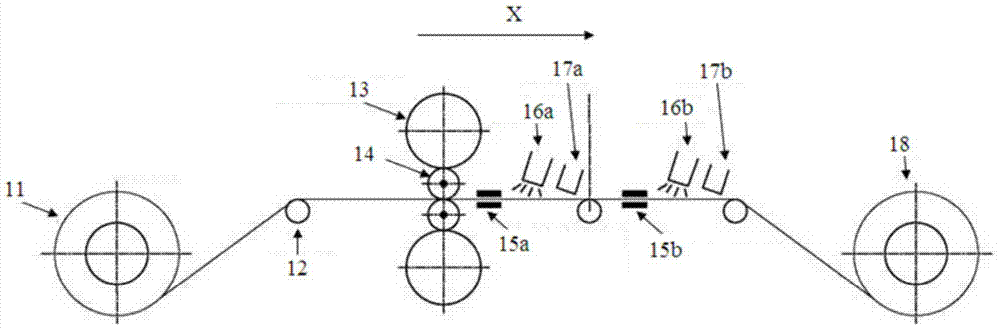

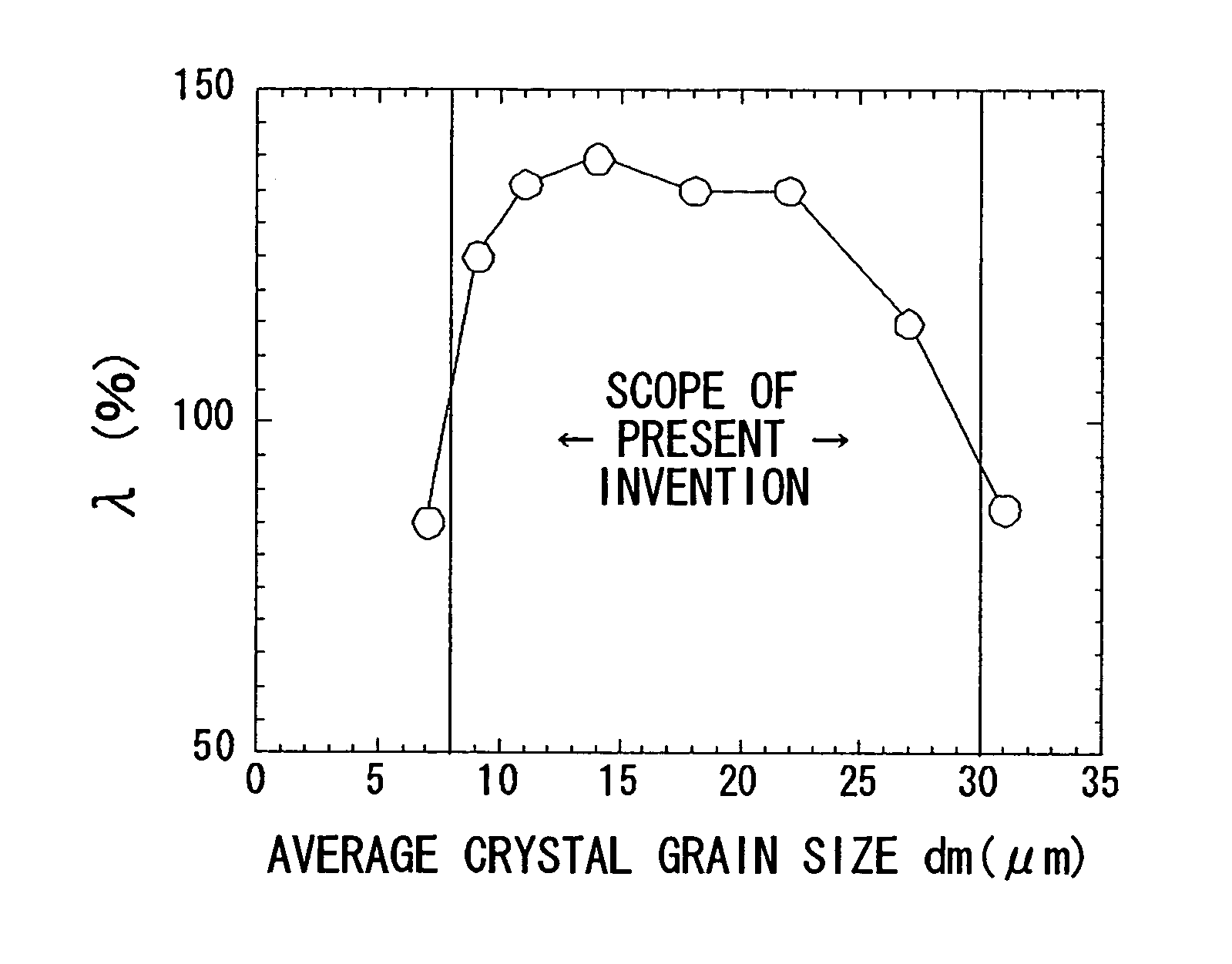

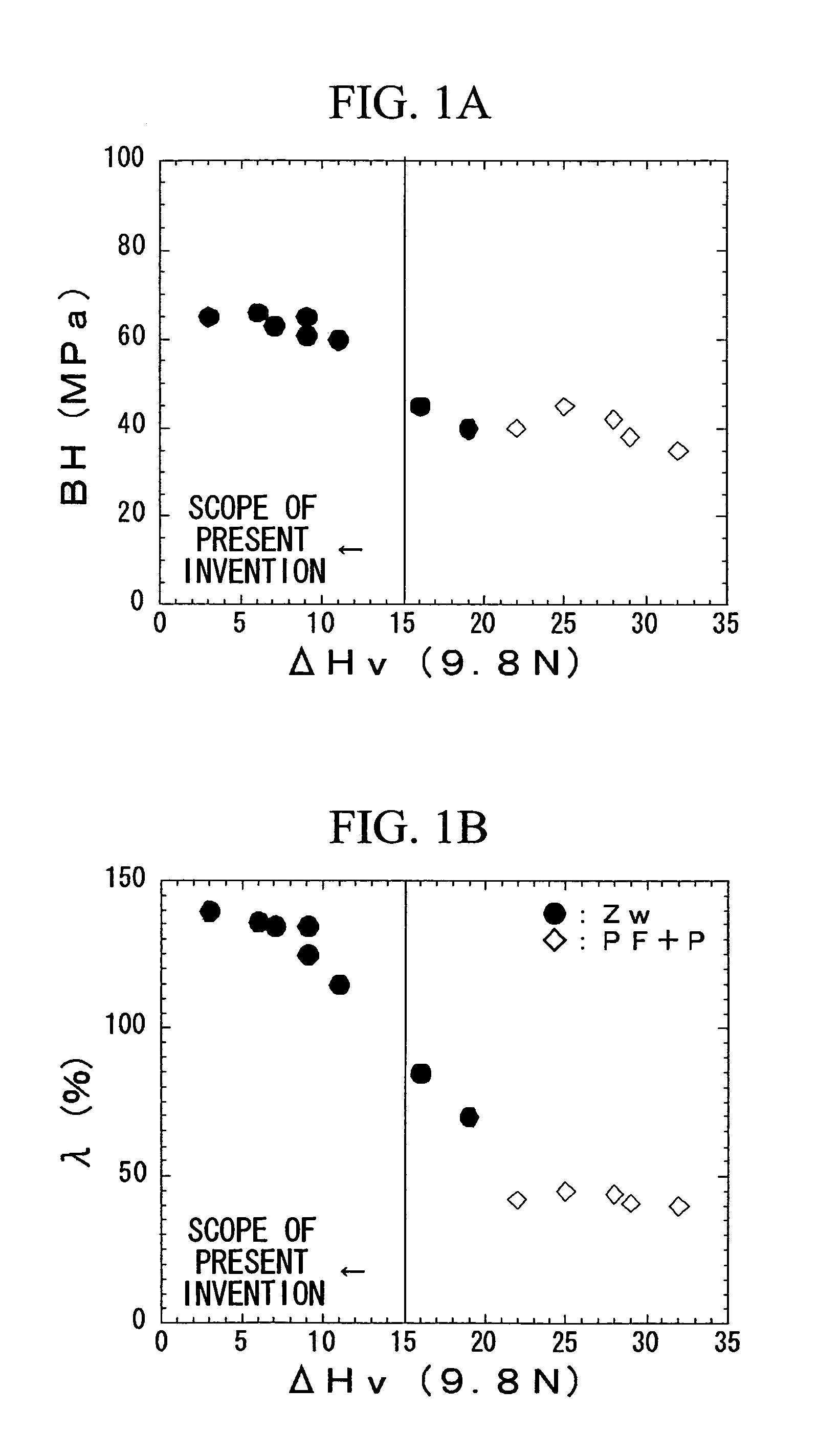

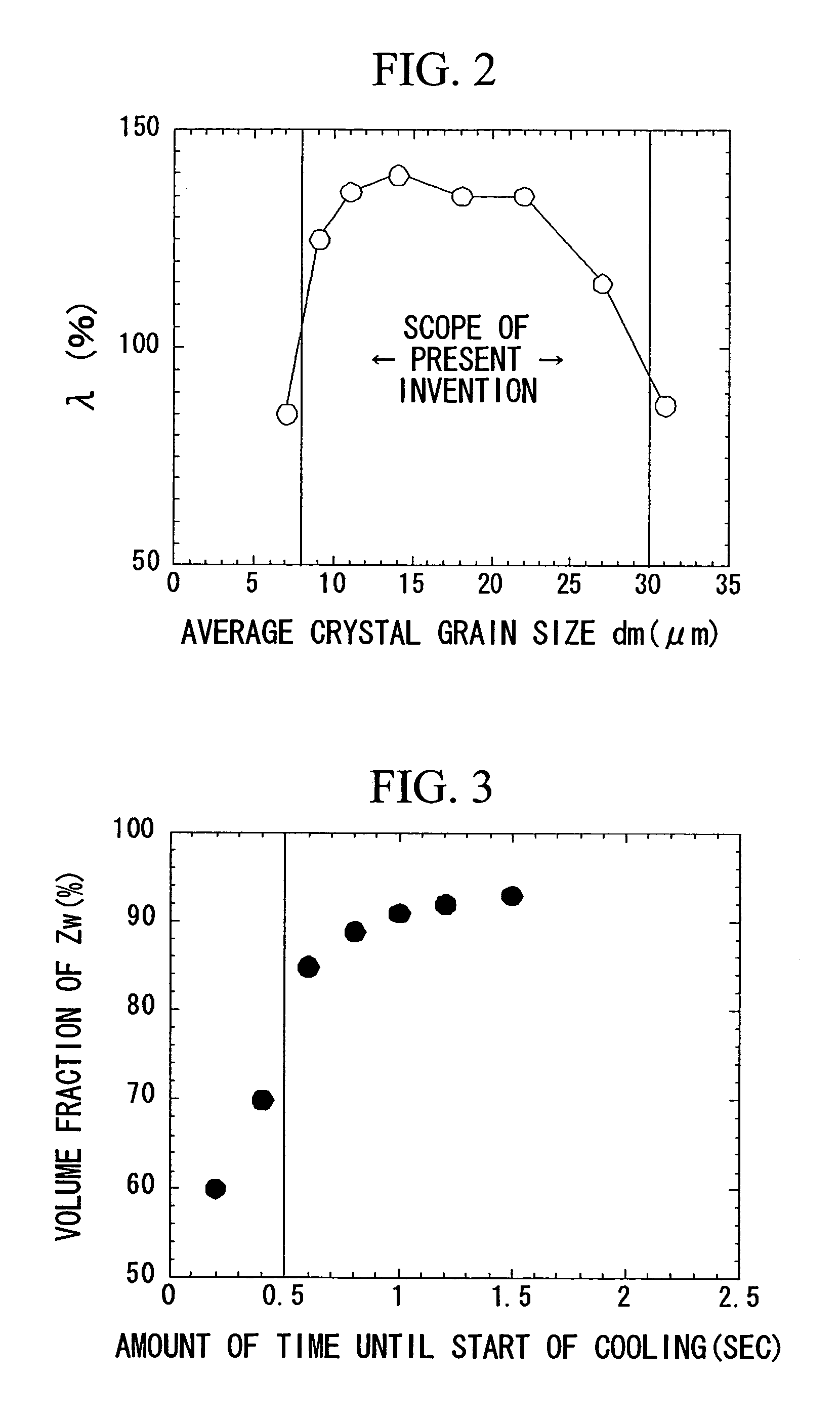

Hot rolled steel sheet and method for production thereof

InactiveUS20060266445A1Stable BH amountSuperior stretch flangabilityHot-dipping/immersion processesFurnace typesImpurityHot rolled

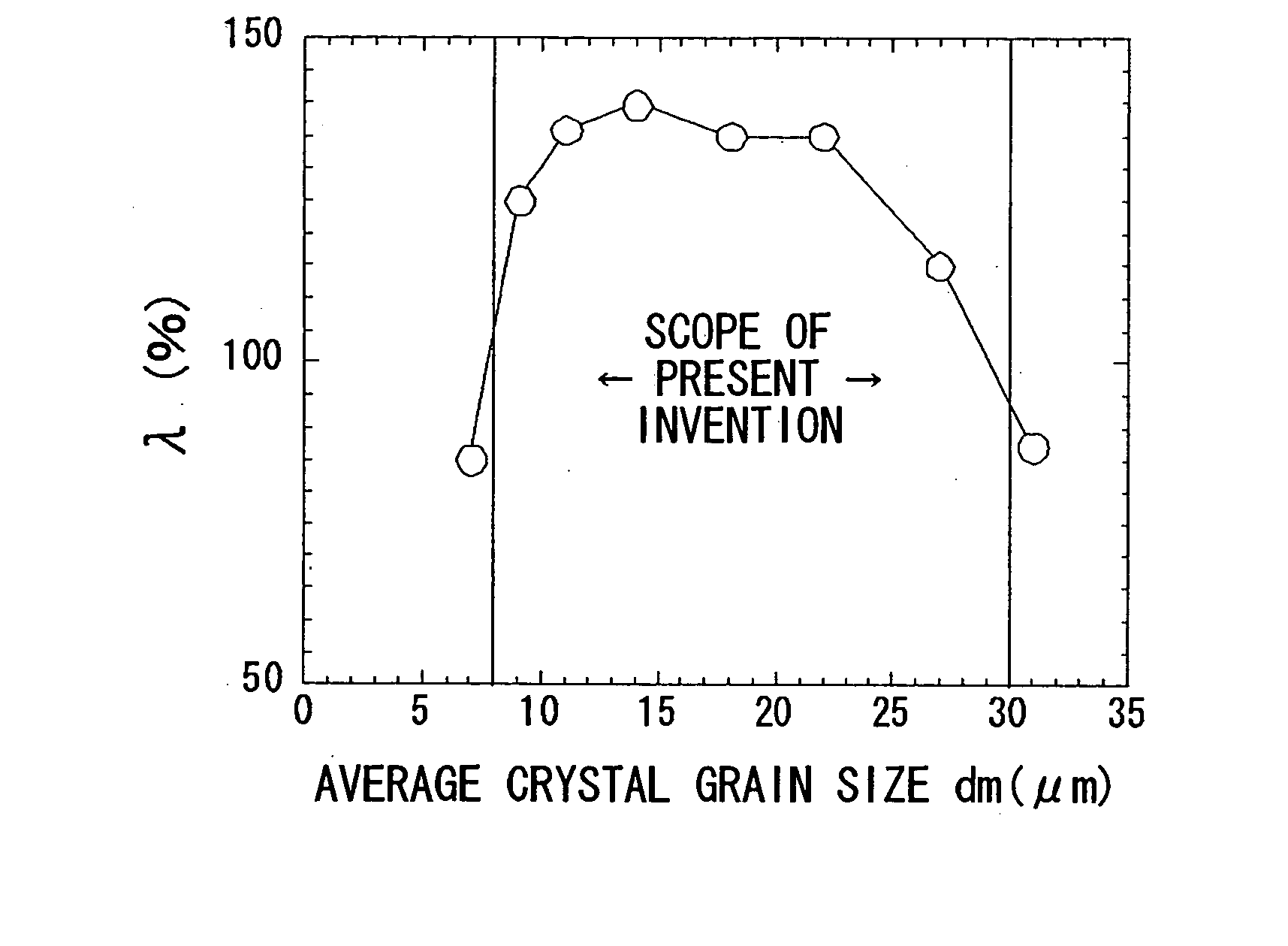

An exemplary hot rolled steel sheet can included, in terms of percent by mass, C of 0.01 to 0.2%; Si of 0.01 to 2%; Mn of 0.1 to 2%; P of ≦0.1%; S of ≦0.03%; Al of 0.001 to 0.1%; N of ≦0.01%; and as a remainder, Fe and unavoidable impurities. For example, a microstructure can be substantially a homogeneous continuous-cooled microstructure, and an average grain size of the microstructure may be more than 8 mm and 30 mm or less. An exemplary method for manufacturing a hot rolled steel sheet can include subjecting a slab having the above composition to a rough rolling so as to obtain a rough rolled bar, subjecting the rough rolled bar to a finish rolling so as to obtain a rolled steel under conditions in which a finishing temperature is (Ar3 transformation point +50° C.) or more; and starting cooling the rolled steel after 0.5 seconds or more pass from the end of the finish rolling at a temperature of the Ar3 transformation point or more. At least in the temperature range from the Ar3 transformation point can be cooled to 500° C. at a cooling rate of 80° C. / sec or more, a further cooling can be effectuated until the temperature is 500° C. or less to obtain a hot rolled steel sheet and coiling the hot rolled steel sheet.

Owner:NIPPON STEEL CORP

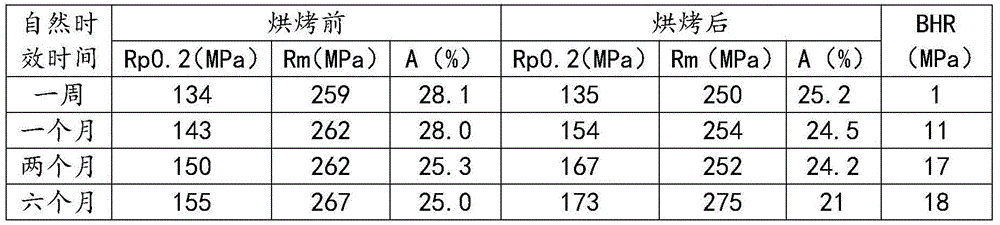

Al-Mg-Si series aluminum-alloy material with long-time natural aging stability, aluminum-alloy plate and manufacturing method thereof

The invention discloses an Al-Mg-Si series aluminum-alloy material with long-time natural aging stability. The Al-Mg-Si series aluminum-alloy material contains the chemical elements in percentage by mass: not lower than 0.3% and not higher than 0.6% of Mg, not lower than 0.8% and not higher than 1.2% of Si, not lower than 0.05% and not higher than 0.15% of Mn, higher than 0 and not higher than 0.03% of Cu, higher than 0 and not higher than 0.12% of Fe, higher than 0 and not higher than 0.05% of Ti, either not lower than 0.05% and not higher than 0.15% of Ca or not lower than 0.05% and not higher than 0.15% of Sr and the balance of Al and other unavoidable impurities. The invention further discloses an aluminum-alloy plate manufactured from the aluminum-alloy material. The invention further discloses a manufacturing method of the aluminum-alloy plate, wherein the method comprises the steps of smelting, casting, carrying out homogenizing heat treatment, carrying out face milling, rolling, carrying out online solid solution treatment and carrying out online aging pretreatment. The aluminum-alloy material and the aluminum-alloy plate, disclosed by the invention, are high in strength and good in natural aging stability.

Owner:BAOSHAN IRON & STEEL CO LTD

Galvanized bake hardening steel and production method thereof

InactiveCN104213020AImprove stamping effectImprove the baking effectHot-dipping/immersion processesChemical compositionEconomic benefits

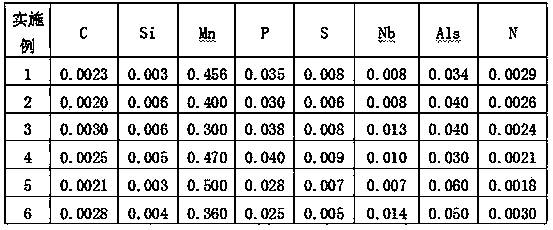

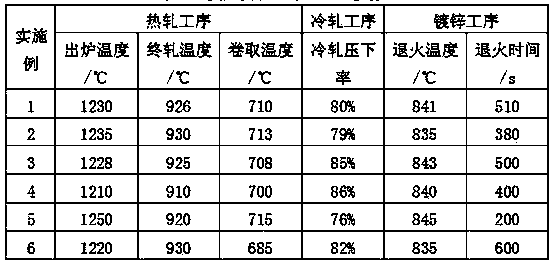

The invention discloses galvanized bake hardening steel and a production method thereof. The production method comprises procedures of hot rolling, cold rolling and galvanizing; a substrate comprises the following chemical components in percentage by weight: 0.002-0.003% of C, Si not higher than 0.006%, 0.3-0.5% of Mn, 0.025-0.040% of P, S not higher than 0.009%, 0.007-0.014% of Nb, 0.030-0.060% of Als, N not higher than 0.0030%, and the balance of Fe. The chemical components are designed, and the technological parameters of the hot rolling, cold rolling and galvanizing procedures are adjusted and optimized, so that the Nb-contained bake hardening steel for deep drawing with excellent comprehensive performance can be successfully produced without adding other alloy elements; the substrate produced by the method is easily galvanized; and the galvanized bake hardening steel with excellent surface quality can be produced. A galvanized plate produced by the method has such characteristics as proper yield strength, high n value (strain hardening index) and r value (plastic strain ratio) and good bake hardenability; and meanwhile, the alloy content is reasonably matched, the production cost is reduced, and the considerable economic benefit is brought to enterprises.

Owner:HBIS COMPANY LIMITED HANDAN BRANCH COMPANY

Hot rolled steel sheet

InactiveUS7662243B2Uniform microstructureSuperior stretch flangabilityHot-dipping/immersion processesFurnace typesSheet steelImpurity

Owner:NIPPON STEEL CORP

Thermal treatment method for improving bake-hardening performance and natural aging stability of 6xxx-series aluminum alloys

The invention discloses a thermal treatment method for improving bake-hardening performance and natural aging stability of 6xxx-series aluminum alloy, and belongs to the technical field of aluminum alloy processing. The thermal treatment method comprises the following steps: within 20 minutes after performing solution treatment on 6xxx-series aluminum alloy plates and quenching to the room temperature, entering a furnace at 50-150 DEG C, and cooling to be lower than 40 DEG C at the cooling rate of 3-20 DEG C / h within 20 minutes after keeping the temperature. The thermal treatment method disclosed by the invention is simple in process, high in production efficiency, and capable of effectively improving the natural ageing stability and the bake-hardening performance of the 6xxx-series aluminum alloy car plates, so that the 6xxx-series aluminum alloy car plates can be applicable to automotive body aluminum alloy plates.

Owner:广西南南铝加工有限公司

Preheating method for improving bake-hardening performance and forming performance of 6022 aluminum alloy

InactiveCN101985728AExcellent bake hardenabilityGuaranteed forming effectSolution treatmentQuenching

The invention provides a preheating method for improving the bake-hardening performance and the forming performance of a 6022 aluminum alloy, comprising the following steps: performing solution treatment on the 6022 aluminum alloy sheet for 10-20 min at the temperature of 530-555 DEG C, and performing water quenching; and preheating the aluminum alloy sheet after water quenching within one day for 20-60s at the temperature of 180-250 DEG C by implementing the preheating process, the bake-hardening performance of the 6022 aluminum alloy can be obviously improved, and the forming performance of the 6022 aluminum alloy can be improved to some extent at the same time.

Owner:苏州有色金属研究院有限公司

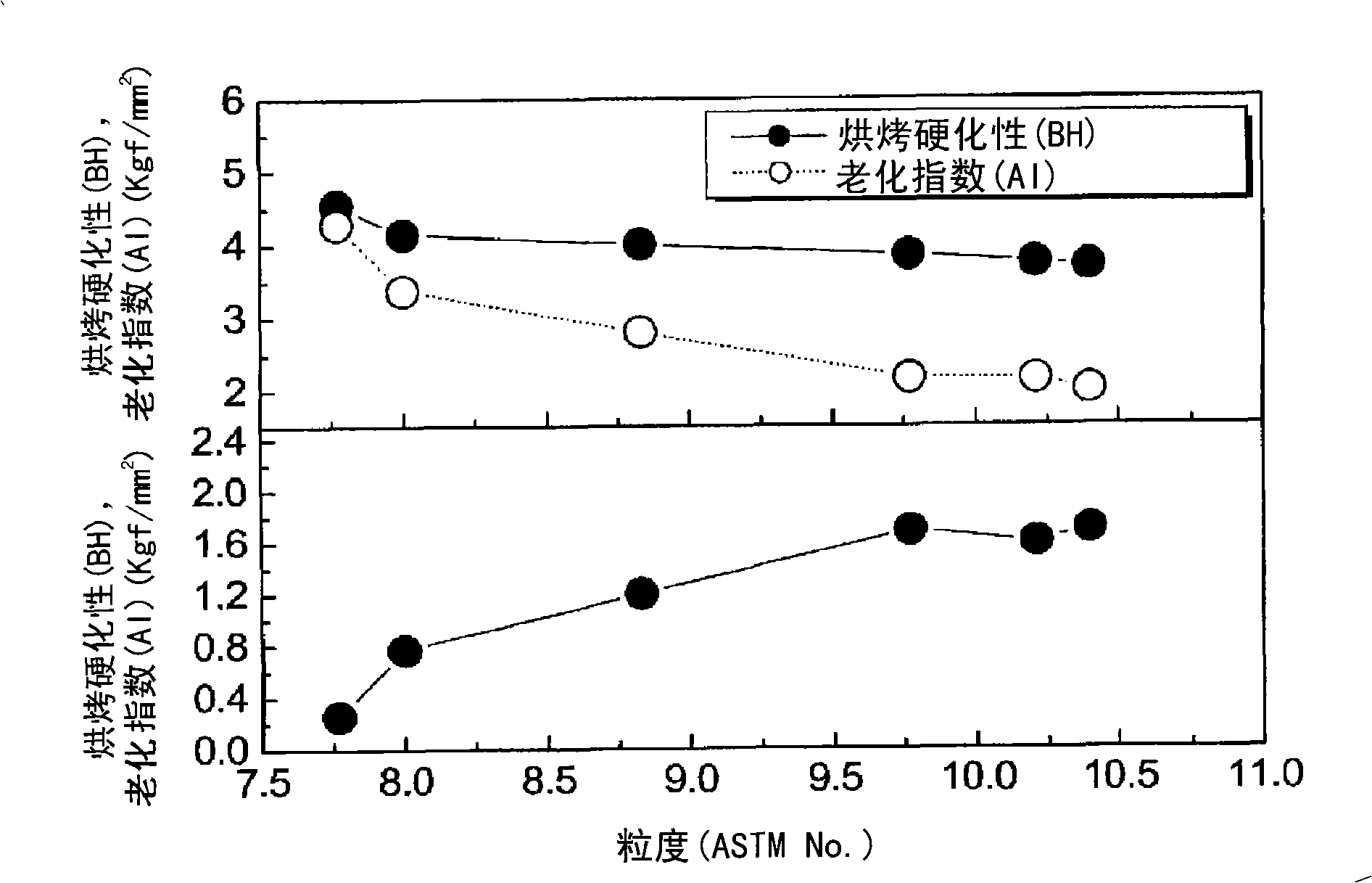

Bake-hardenable cold rolled steel sheet with superior strength, galvannealed steel sheet using the cold rolled steel sheet and method for manufacturing the cold rolled steel sheet

ActiveCN101310032AUniform heat treatmentExcellent bake hardenabilityFurnace typesHeat treatment furnacesSheet steelRoom temperature

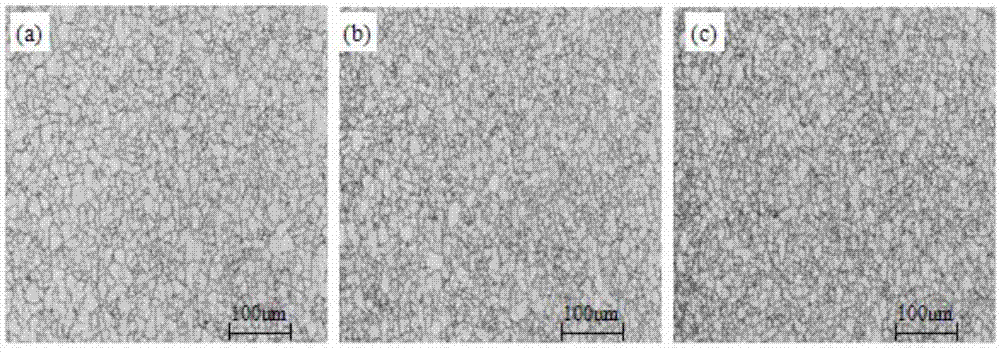

A cold-rolled steel sheet for outer panels and the like of an automobile body, a galvannealed steel sheet using the cold-rolled steel sheet, and a method for manufacturing the same are disclosed. It is an object of the present invention to provide a high strength cold-rolled steel sheet, which has superior bake hardenability, aging resistance at room temperature and secondary work embrittlement resistance, and a method for manufacturing the same. The steel sheet has a grain size of ASTM No. of 9 or more after annealing, a BH of 30 MPa or more, an AI of 30 MPa or less, and a tensile strength of 340-390 MPa through appropriate control of solute elements in steel by addition of a small amount of Ti, addition of Al and Mo, and control of manufacturing conditions, and refinement of crystal grains after annealing. The cold-rolled steel sheet and the galvannealed steel sheet produced using the cold-rolled steel sheet have the superior bake hardenability, aging resistance at room temperature, and secondary work embrittlement resistance.

Owner:浦项股份有限公司

Machining method of 180BH cold-rolled baked hardened high-strength steel for automobiles

InactiveCN106906418AGuaranteed stable mechanical propertiesGuaranteed aging resistance at room temperatureChemical compositionRoom temperature

The invention relates to the field of metallurgical materials, in particular to a machining method of 180BH cold-rolled baked hardened high-strength steel for automobiles and belongs to the field of advanced high-strength steel for the automobiles. The chemical components of the steel include, by mass, 0.0015-0.0025% of C, 0-0.05% of Si, 0.15-0.30% of Mn, 0.030-0.050% of P, 0-0.015% of S, 0.02-0.06% of Als, 0.008-0.020% of Nb, 0.05-0.10% of Cr, 0-0.05% of Mo and the balance Fe. In the hot rolling process, the heating temperature of a plate blank ranges from 1150 DEG C to1220 DEG C, the finish rolling temperature is 900 DEG C, and the coiling temperature ranges from 680 DEG C to 720 DEG C; and in the cold rolling process, the cold-rolling reduction ratio is larger than or equal to 70%. A continuous annealing process is adopted as follows: heat preservation is performed at the temperature of 840 DEG C to 860 DEG C for 60-120 minutes; and furnace cooling is performed till the temperature reaches 700 DEG C to 750 DEG C, quick cooling is performed at the cooling speed of 25 DEG C to 50 DEG C per second till the temperature reaches 400 DEG C, heat preservation is performed for 1-3 h, and then furnace cooling is performed till the temperature reaches the indoor temperature. The chemical components of the cold-rolled baked hardened high-strength steel 180BH product produced through the method are stable, and the stable forming property, good BH property and room temperature ageing resistance are achieved.

Owner:BENGANG STEEL PLATES

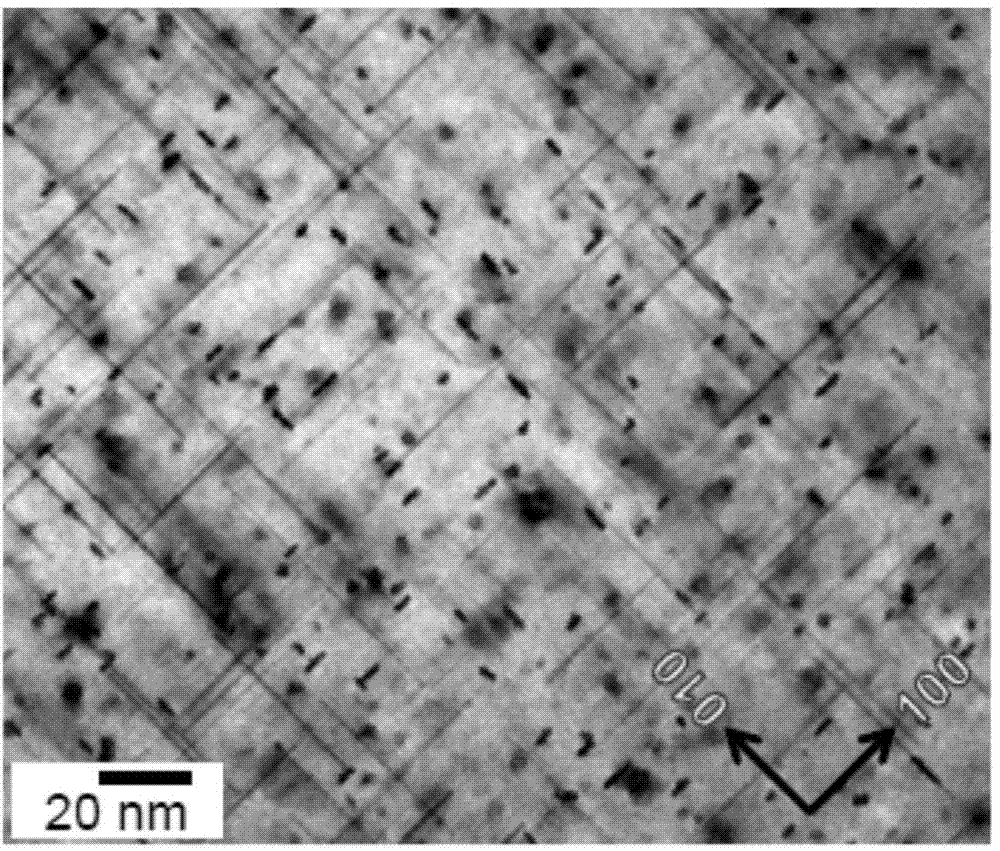

High-strength aluminum alloy plate

InactiveUS20180363113A1Excellent bake hardenabilityHigh yield strengthChemical compositionRoom temperature

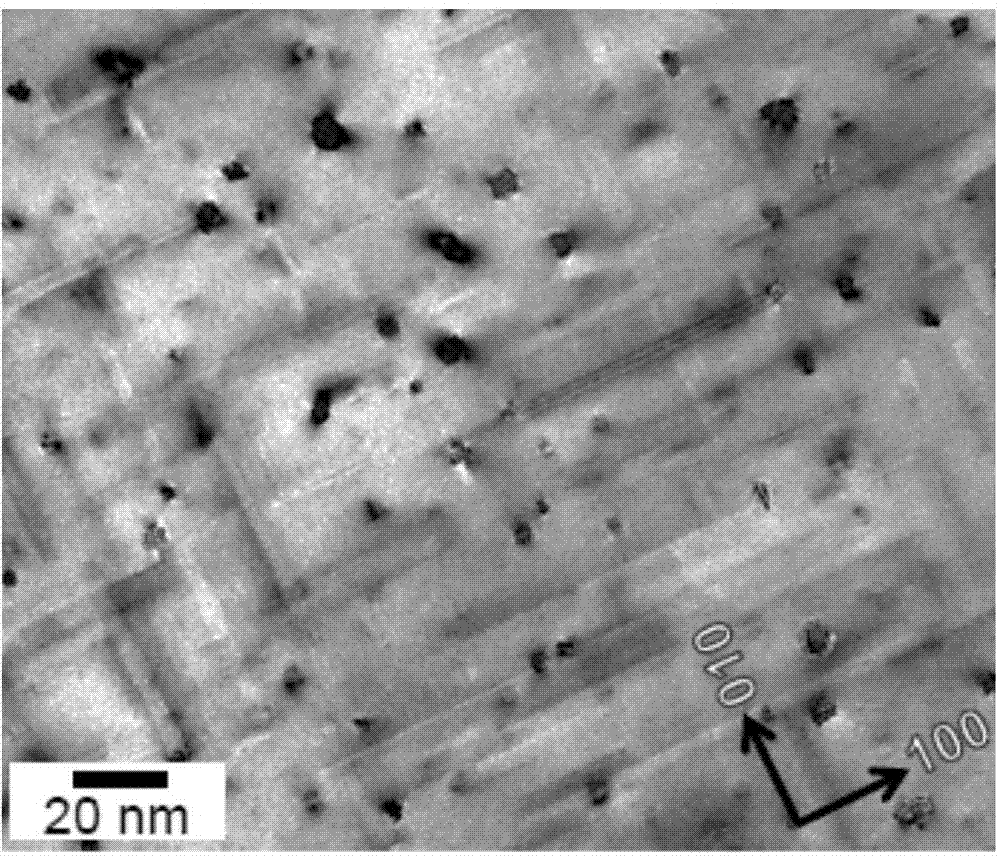

Provided is an Al—Mg—Si aluminum alloy sheet having a specific chemical composition including a transition element. The microstructure of the sheet includes grains refined to have a smaller average grain size, and includes nanometer-level fine transition-element-dispersed particles. This allows the aluminum alloy sheet to have higher strength during work hardening in forming into a structural component and, synergistically with this, to have better bake hardenability. The resulting aluminum alloy sheet, when formed into an automobile structural component, offers higher strength after bake hardening without deterioration in formability, even after natural aging at room temperature.

Owner:KOBE STEEL LTD

High-strength hot-rolled steel sheet having excellent baking hardenability and low temperature toughness with maximum tensile strength of 980 MPa or more

ActiveUS10196726B2Excellent bake hardenabilityLow toughnessHot-dipping/immersion processesFurnace typesCarbideToughness

Provided is a high-strength hot-rolled steel sheet consisting of, in mass %, C: 0.01% to 0.2%, Si: 0% to 2.5%, Mn: 0% to 4.0%, Al: 0% to 2.0%, N: 0% to 0.01%, Cu: 0% to 2.0%, Ni: 0% to 2.0%, Mo: 0% to 1.0%, V: 0% to 0.3%, Cr: 0% to 2.0%, Mg: 0% to 0.01%, Ca: 0% to 0.01%, REM: 0% to 0.1%, B: 0% to 0.01%, P: less than or equal to 0.10%, S: less than or equal to 0.03%, O: less than or equal to 0.01%, one or both of Ti and Nb: 0.01% to 0.30% in total, and the balance being Fe and inevitable impurities. The steel sheet has a structure in which a total volume fraction of tempered martensite or lower bainite is 90% or more, a dislocation density thereof is greater than or equal to 5×1013 (1 / m2) and less than or equal to 1×1016 (1 / m2) and 1×106 (numbers / mm2) or more iron-based carbides are included therein.

Owner:NIPPON STEEL CORP

Processing method for 220BH cold-rolled bake-hardened high-strength steel used for automobiles

InactiveCN106906417AStable mechanical propertiesImprove stamping formabilityAging propertyChemical composition

The invention relates to the field of metallurgical materials, also belongs to the field of advanced high-strength steel used for automobiles, and particularly provides a processing method for 220BH cold-rolled bake-hardened high-strength steel used for automobiles. The 220BH cold-rolled bake-hardened high-strength steel used for the automobiles comprises, by mass, 0.0015%-0.0025% of C, 0-0.05% of Si, 0.40%-0.60% of Mn, 0.040%-0.065% of P, 0-0.015% of S, 0.02%-0.06% of Als, 0.008%-0.020% of Nb, 0.05%-0.10% of Cr, 0-0.05% of Mo, and the balance Fe. In the hot rolling process, the slab heating temperature is 1150-1220 DEG C, the final rolling temperature is 900 DEG C, and the coiling temperature is 680-720 DEG C; in the cold rolling process, the cold rolling reduction ratio is larger than or equal to 70%; and a continuous annealing process is adopted and comprises the following steps that heat preservation is conducted for 60-120 min at the temperature of 840-860 DEG C; and the steel is cooled to 700-750 DEG C along with a furnace and is rapidly cooled to 400 DEG C at the cooling rate of 25-50 DEG C / second, heat preservation is conducted for 1-3 h, and then the steel is cooled to the room temperature along with the furnace. The 220BH cold-rolled bake-hardened high-strength steel product produced by the processing method is stable in chemical component, and has the stable forming property, the excellent BH property and the normal temperature resisting aging property.

Owner:BENGANG STEEL PLATES

High-strength aluminum alloy sheet

InactiveUS20180105900A1Excellent bake hardenabilityIncreasing grain aspect ratioChemical compositionHigh intensity

An Al—Mg—Si aluminum alloy sheet has a chemical composition which includes at least one element selected from the group consisting of Mn, Cr, and Zr and which meets the condition: 0.6≤([Mg] / [Si]-0.15[Mn]-0.3[Cr]-0.1[Zr]≤1.8. The aluminum alloy sheet is controlled to have a higher aspect ratio of grains, thereby has significantly higher strength after artificial aging such as paint bake (after bake hardening), and satisfactorily has strength necessary for automobile structural components, without deterioration in bendability.

Owner:KOBE STEEL LTD

Zinc-based plated steel sheet having excellent room temperature aging resistance and bake hardenability, and method for producing same

ActiveCN111492079AExcellent bake hardenabilityBest practiceHot-dipping/immersion processesFurnace typesZincBake hardening

Owner:浦项股份有限公司

A high-strength aluminum alloy material, aluminum alloy plate and manufacturing method thereof

Owner:BAOSHAN IRON & STEEL CO LTD

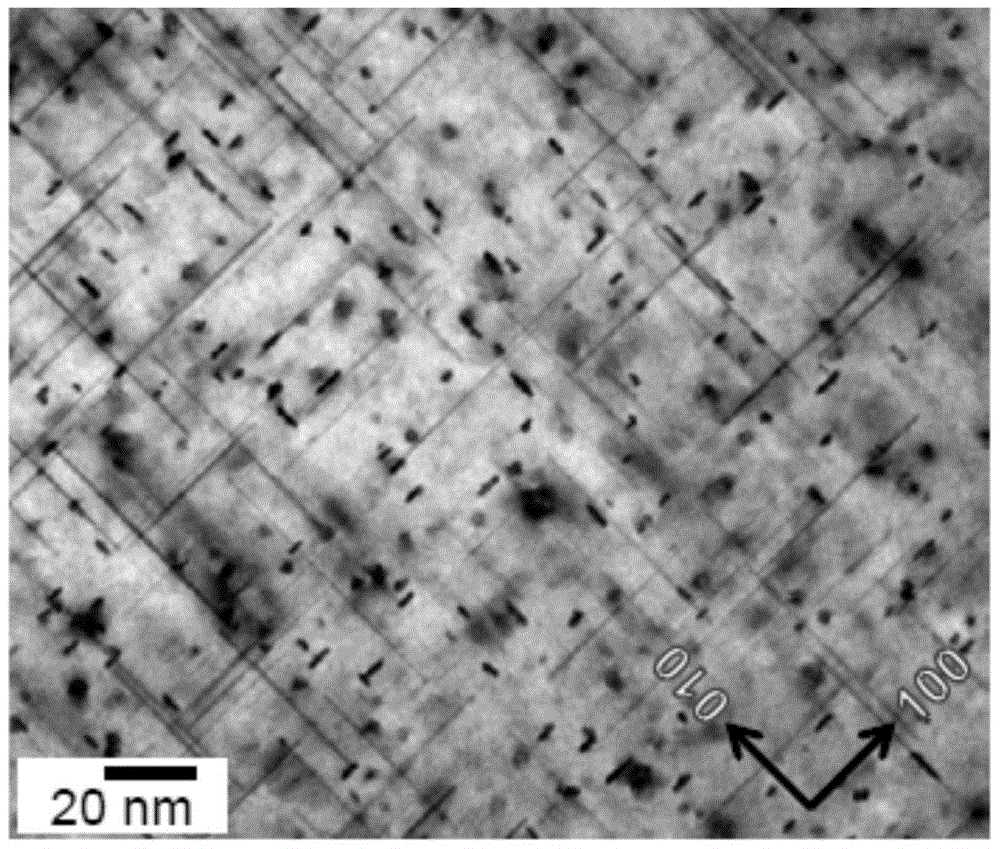

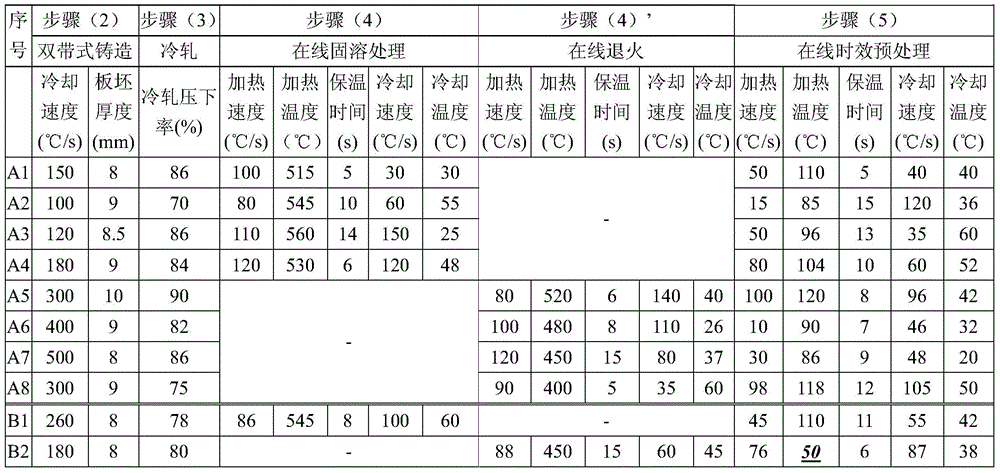

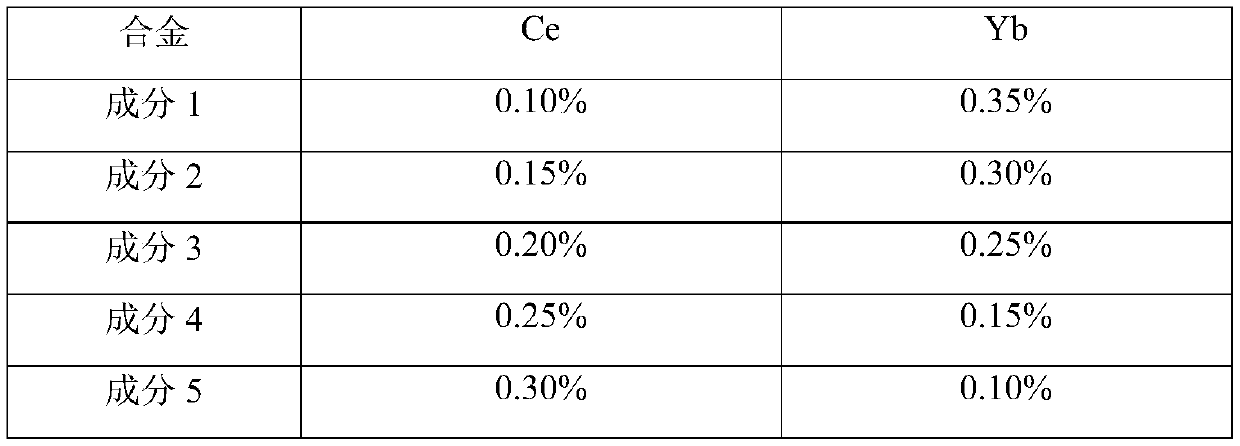

A kind of rare earth modified aluminum alloy automobile body plate and preparation method thereof

ActiveCN108950316BImprove forming qualityExcellent bake hardenabilitySolution treatmentSilicon alloy

The invention provides a rare earth modified aluminum alloy automotive body plate and a preparation method thereof. The preparation method comprises the steps of firstly, material preparing, secondly,smelting, thirdly, casting, fourthly, homogenizing annealing, fifthly, hot rolling, sixthly, cold rolling, seventhly, finished product sawing, eighthly, solution treatment and ninthly, pre-aging, andthe rare earth modified automotive body aluminum alloy plate containingcerium and ytterbium is obtained. According to the prepared automotive body aluminum alloy plate, it is guaranteed that a general aluminum-magnesium-silicon alloy has various properties, meanwhile, the forming property and the mechanical property are improved, the good anti-aging stability and baking hardening property are achieved, the alloy can meet the material requirement of the automotive body plate, and the alloy is applied to the field of automobile lightweight aluminum alloy preparation.

Owner:WUHAN UNIV OF TECH

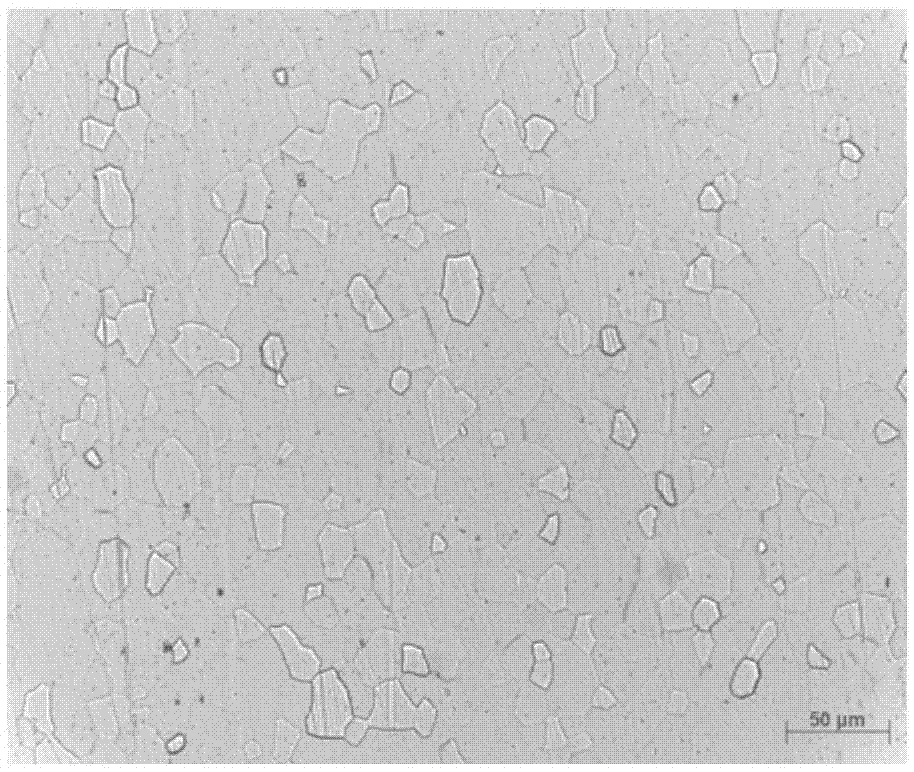

High-strength steel sheet

ActiveUS20210164082A1Excellent bake hardenabilityInhibition formationFurnace typesHeat treatment furnacesMartensiteUltimate tensile strength

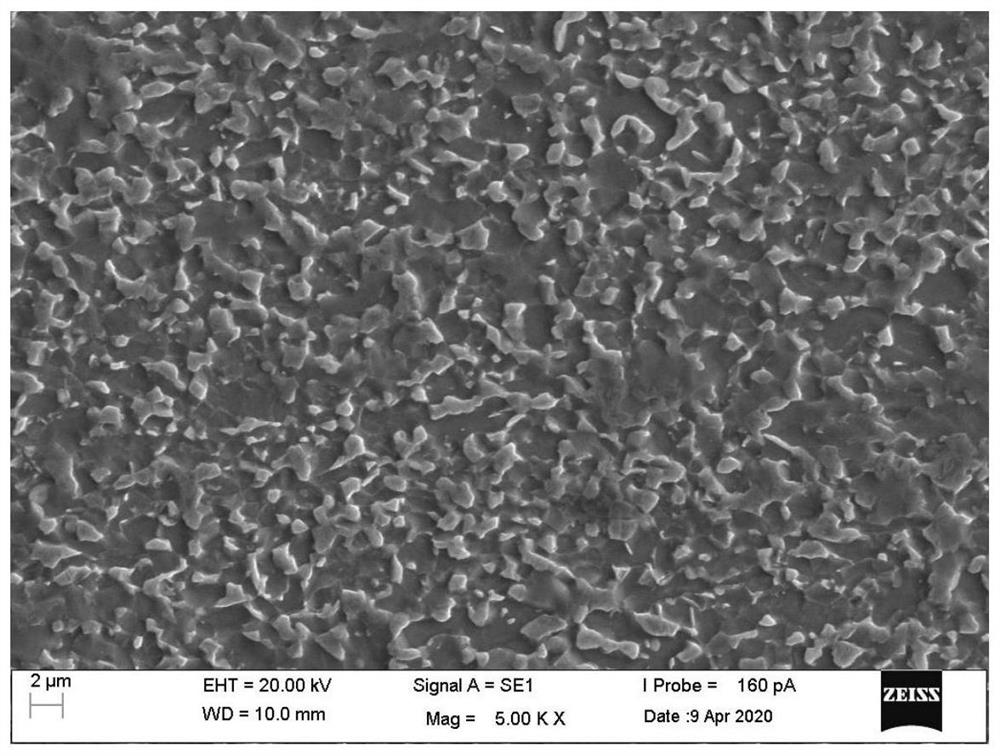

What is provided is a high-strength steel sheet having a large bake hardening amount and a uniform bake hardenability is provided according to the present invention, the high-strength steel sheet comprising, by mass %: C: 0.13% to 0.40%; Si: 0.500% to 3.000%; Mn: 2.50% to 5.00%; P: 0.100% or less; S: 0.010% or less; Al: 0.001% to 2.000%; N: 0.010% or less; and a remainder consisting of Fe and impurities, wherein martensite is 95% or more in an area ratio, and residual structure is 5% or less in an area ratio, a ratio C1 / C2 of an upper limit C1 (mass %) of Si concentrations to a lower limit C2 (mass %) of the Si concentrations in a cross section in a thickness direction is 1.25 or less, precipitates having a major axis of 0.05 μm or more and 1.00 μm or less and an aspect ratio of 1:3 or more are included in a number density of 30 / μm2 or more, and a tensile strength is 1300 MPa or more.

Owner:NIPPON STEEL CORP

Magnetically-treated modified aluminum alloy automobile body panel and preparing method thereof

ActiveCN109022930AIncreased dislocation strain energyIncrease the dislocation densityMagnesiumHardness

The invention provides a magnetically-treated modified aluminum alloy automobile body panel and a preparing method thereof. The preparing method comprises the first step of burdening, the second stepof smelting, the third step of casting, the fourth step of homogenizing annealing, the fifth step of hot rolling, the sixth step of cold rolling, the seventh step of finished product saw cutting, theeighth step of solid solution treatment, the ninth step of pre-aging and the tenth step of magnetic treatment, and then the aluminum alloy panel for an automobile body is obtained. According to the prepared aluminum alloy panel for the automobile body, various properties of common aluminum-magnesium-silicon alloys are guaranteed, meanwhile, the forming performance and mechanical performance are improved, good anti-aging stability and baking hardness are achieved, the alloy can meet the automobile body panel material requirement, and the alloy is applied to the field of automobile lightweight aluminum alloy preparing.

Owner:WUHAN UNIV OF TECH

Aging-resistant bake-hardened steel plate and galvanized plate and production method of aging-resistant bake-hardened steel plate

InactiveCN112048662AGood mechanical propertiesGood bake hardenability and aging resistanceHot-dipping/immersion processesSteel platesHardened steel

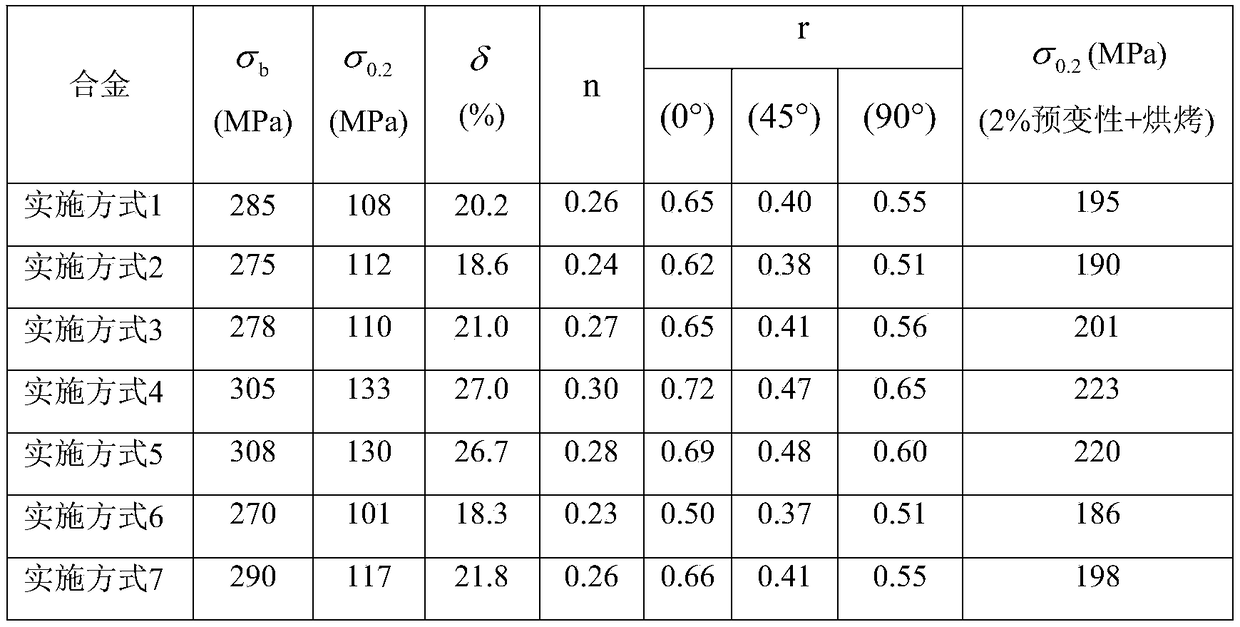

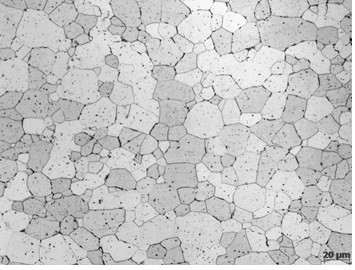

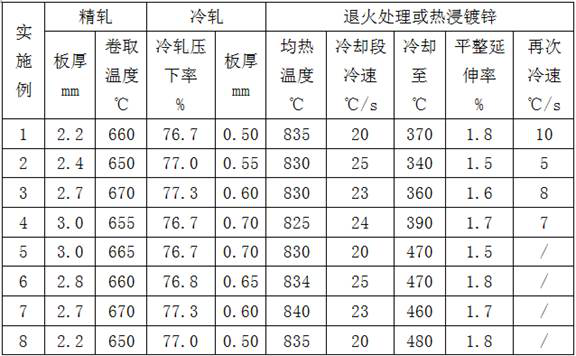

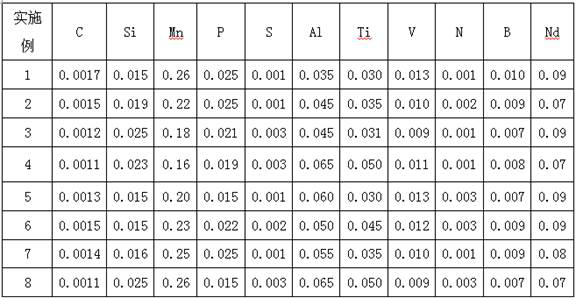

The invention discloses an aging-resistant bake-hardened steel plate and a galvanized plate and a production method of the aging-resistant bake-hardened steel plate. The aging-resistant bake-hardenedsteel plate comprises the following chemical components of, in percentage by mass, 0.0011%-0.0017% of C, 0.015%-0.025% of Si, 0.16%-0.26% of Mn, 0.015%-0.025% of P, less than or equal to 0.003% of S,0.035%-0.065% of Al, 0.030%-0.050% of Ti, 0.009%-0.013% of V, less than or equal to 0.0030% of N, 0.007%-0.010% of B, 0.07%-0.09% of Nd and the balance Fe and inevitable impurities. Through reasonablechemical component design, the steel plate has good mechanical properties and good bake hardenability and aging resistance, meanwhile, parts manufactured by utilizing the characteristics of magnetizers formed in the components have good closeness, and the steel plate can be used for manufacturing car door inner and outer plates, engine hood inner and outer plates and other parts. Particularly, the structure of the steel plate is ultra-low carbon ferrite, and in the forming process, the high plastic strain ratio and the high strain hardening index ensure that the formability is good, and the cracking phenomenon is avoided; and meanwhile the size of the deformed part is kept stable.

Owner:HEBEI IRON AND STEEL

High-strength steel plate

ActiveCN112204162APrevent cellularizationExcellent bake hardenabilityFurnace typesHeat treatment furnacesMartensiteBake hardening

Provided is a high-strength steel plate which exhibits a large amount of bake-hardening and highly uniform bake-hardening properties, and contains, in mass%, C in the amount of 0.13-0.40%, Si in the amount of 0.500-3.000%, Mn in the amount of 2.50-5.00%, P in the amount of 0.100% or less, S in the amount of 0.010% or less, Al in the amount of 0.001-2.000%, and N in the amount of 0.010% or less, with the remainder constituting Fe and impurities, wherein: the martensite content by area ratio is at least 95%, and remaining structures occupy an area ratio of 5% or less; the ratio C1 / C2 of the upper-limit value C1 (mass%) of the Si concentration in a thickness direction cross-section to the lower-limit value C2 (mass%) thereof is 1.25 or less; the number density of precipitates exhibiting a major axis dimension of 0.05-1.00[mu]m, inclusive, and an aspect ratio of at least 1:3 is 30 per um2 or higher; and the tensile strength of the plate is 1,300 MPa or higher.

Owner:NIPPON STEEL CORP

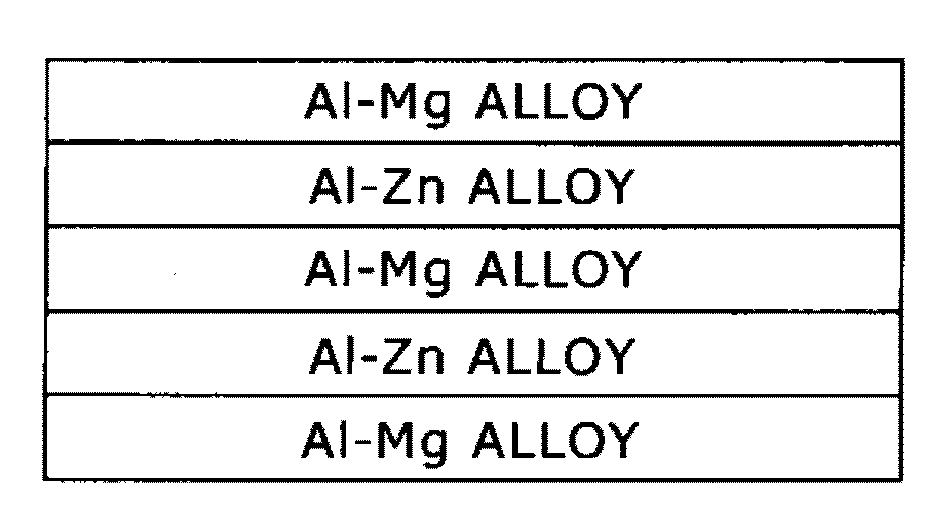

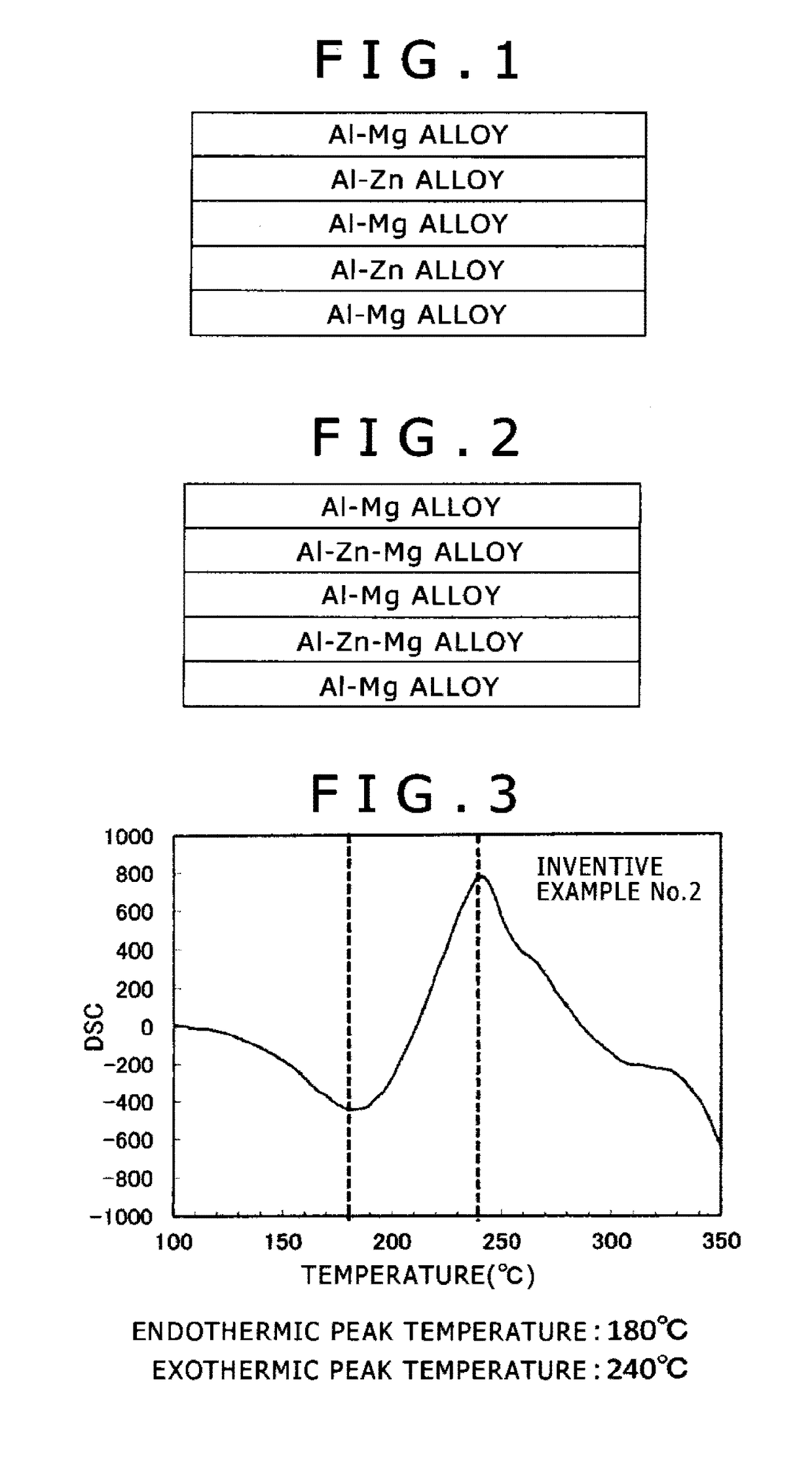

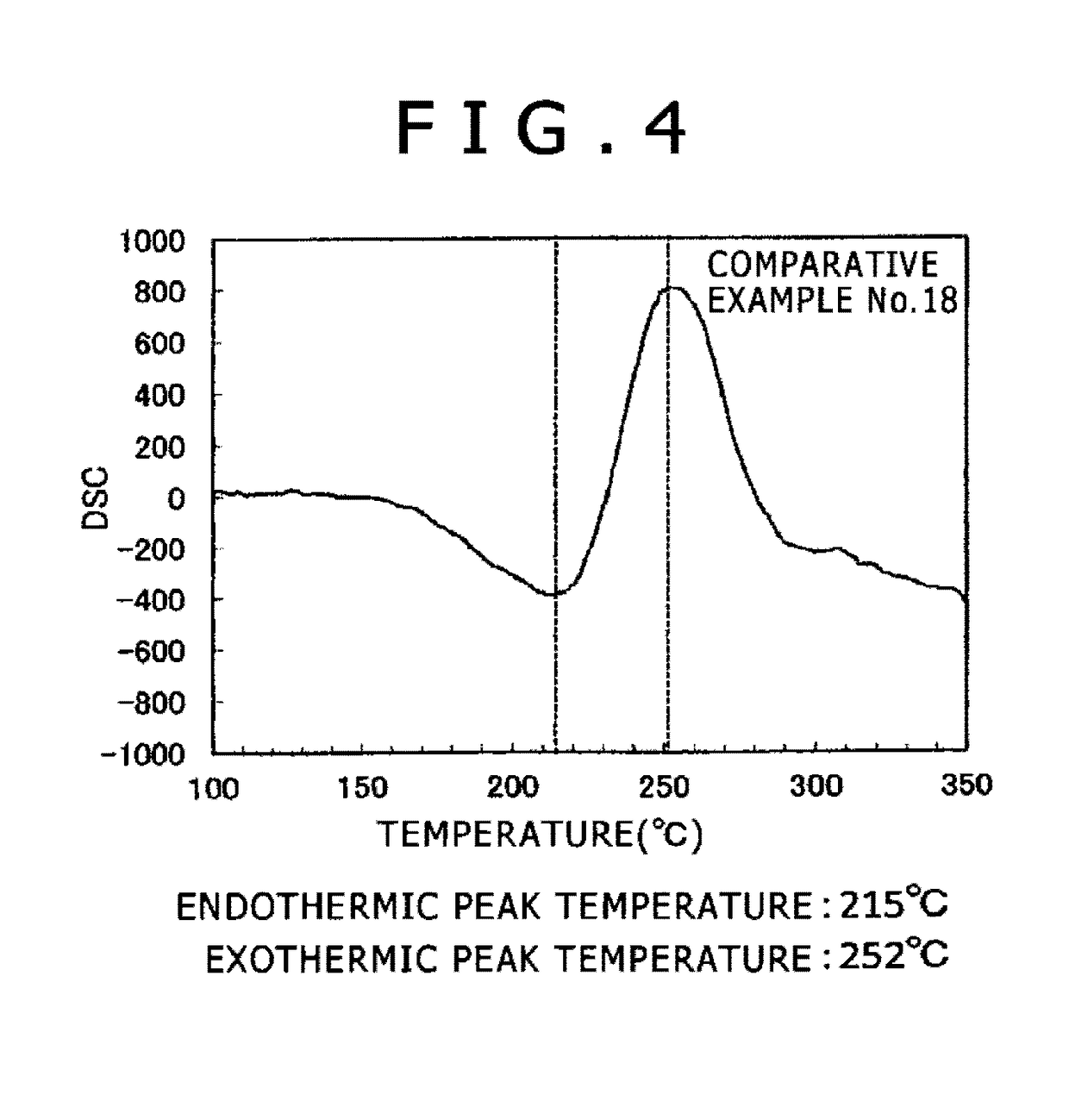

Aluminum-alloy-clad plate and aluminum-alloy-clad structural member

ActiveUS20180022067A1High strengthGood molding effectThin material handlingMetal layered productsUltimate tensile strengthHeat treating

An aluminum-alloy-clad plate which includes a plurality of superposed aluminum alloy layers and which has undergone a diffusion heat treatment. Aluminum alloy layers having specific compositions are superposed so that any adjoining two of these differ in the content of Mg or Zn, and are subjected to a diffusion heat treatment to give a structure which has fine crystal grain diameters and Mg / Zn mutual diffusion regions and which has specific DSC properties. Thus, both higher strength and high formability are imparted.

Owner:KOBE STEEL LTD

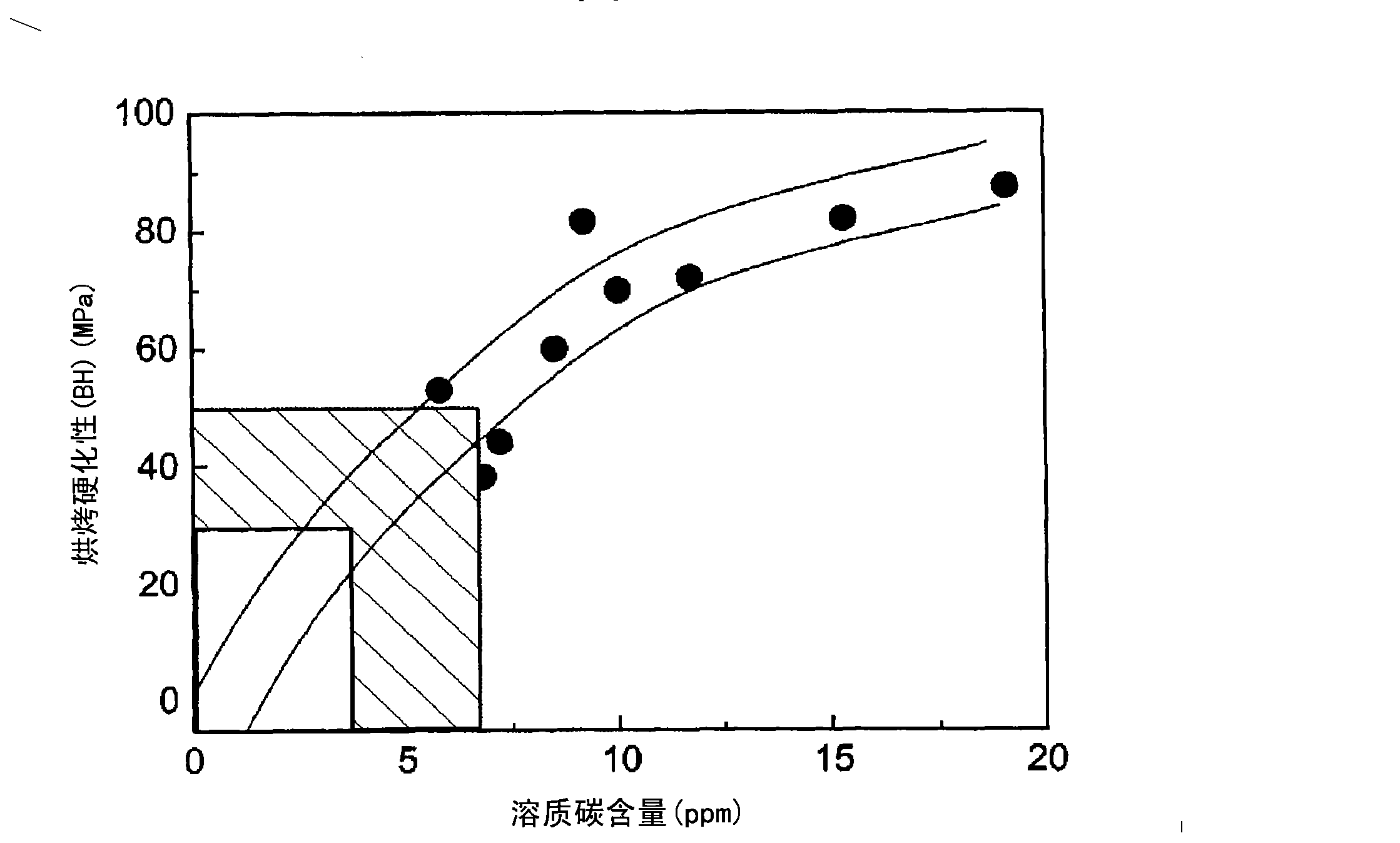

Hot-dip galvanized dual-phase steel with good bake hardening performance and preparation method thereof

The invention discloses a hot-dip galvanized dual-phase steel with good baking hardening performance and a preparation method thereof. The chemical composition of the steel is calculated by mass fraction: C: 0.08%-0.12%, Si: 0.1%-0.4% , Mn: 1.8%~2.6%, Cr: 0.2%~0.7%, Mo: 0.1%~0.4%, P: ≤0.010%, S: ≤0.006%, Ti: 0.01%~0.04%, Al: 0.1%~ 0.4%, the balance is iron and other unavoidable impurities; the metallographic structure of the steel is: ferrite, martensite and bainite, and the carbon content in the ferrite reaches above 20ppm. The invention ensures that the carbon content dissolved in the ferrite reaches more than 20ppm, suppresses the surface decarburization of the steel plate during the heating process, and has no obvious decarburization layer between the finished plate substrate and the coating layer, thereby obtaining good bake hardening performance BH2 ≥80MPa.

Owner:SHOUGANG CORPORATION

Hot-dip galvanized steel sheet with superior bake hardenability and aging resistance, and manufacturing method thereof

InactiveCN108779537AExcellent bake hardenabilityImprove aging resistanceHot-dipping/immersion processesFurnace typesManganeseMartensite

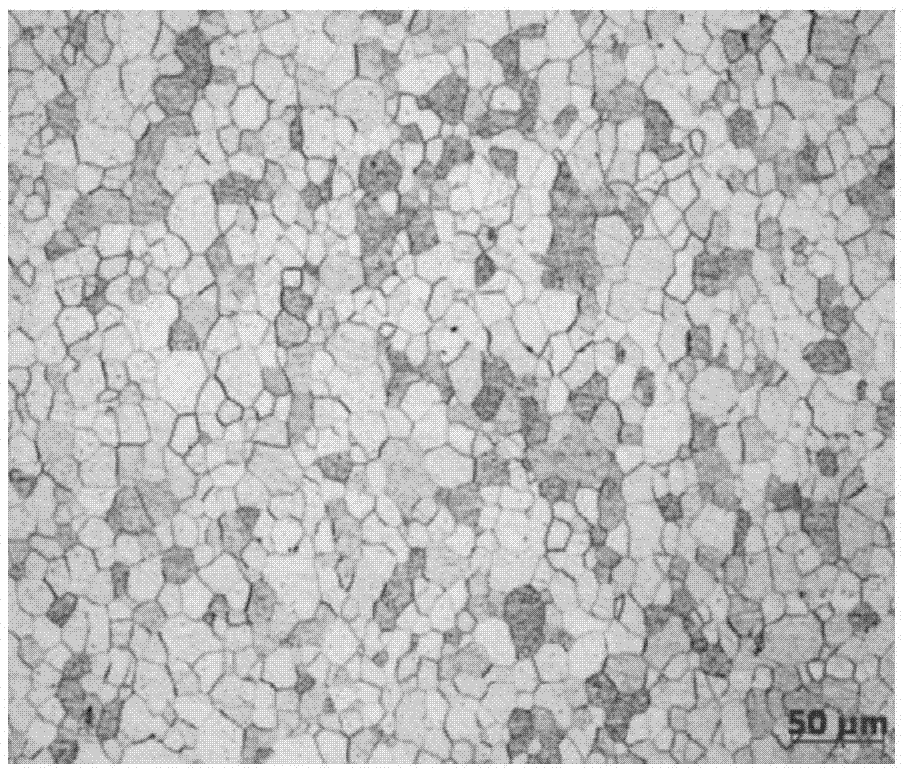

Disclosed are a cold-rolled steel sheet having excellent bake hardenability and aging resistance, and a manufacturing method thereof. The cold-rolled steel sheet comprises, by weight %, 0.02-0.08% ofC; 1.3-2.1% of Mn; 0.3% or less (excluding 0%) of Si; 1.0% or less (excluding 0%) of Cr; 0.1% or less (excluding 0%) of P; 0.01% or less (excluding 0%) of S; 0.01% or less (excluding 0%) of N; and 0.01-0.06% of sol.Al; at least one selected from the group consisting of 0.2% or less (excluding 0%) of Mo and 0.003% or less (excluding 0%) of B; and the balance being Fe and other inevitable impurities, wherein the steel sheet contains, as a microstructure thereof, 90-99% of ferrite and 1-10% of martensite in an area fraction,wherein a ratio (a / b) of an average carbon concentration a in the martensite and an average carbon concentration b in the ferrite located in an imaginary circle having a major axis of the martensite as a diameter, at a point of the sheet thickness of 1 / 4 t is 1.4 or less,and a ratio (d / c) of an average manganese concentration c in the martensite and an average manganese concentration d in the ferrite located in an imaginary circle having a major axis of the martensiteas a diameter, at a point of a sheet thickness of 1 / 4 t is 0.9 or less.

Owner:POHANG IRON & STEEL CO LTD

Steel sheet

ActiveUS20200332397A1Excellent bake hardenabilityImprove stamping formabilityFurnace typesThin material handlingRare-earth elementChemical composition

A steel sheet includes, as a chemical composition, by mass %: C: 0.05% to 0.30%; Si: 0.2% to 2.0%; Mn: 2.0% to 4.0%; Al: 0.001% to 2.000%; P: 0.100% or less; S: 0.010% or less; N: 0.010% or less; Ti: 0% to 0.100%; Nb: 0% to 0.100%; V: 0% to 0.100%; Cu: 0% to 1.00%; Ni: 0% to 1.00%; Mo: 0% to 1.00%; Cr: 0% to 1.00%; W: 0% to 0.005%; Ca: 0% to 0.005%; Mg: 0% to 0.005%; a rare earth element (REM): 0% to 0.010%; B: 0% to 0.0030%; and a remainder of Fe and impurities, in which a metallographic structure contains, by area ratio, 95% or more of a hard structure and 0% to 5% of residual austenite, by mass % in a cross section in a thickness direction, C1 / C2 which is a ratio of an upper limit C1 of a Mn content to a lower limit C2 of the Mn content is 1.5 or less, and a bake-hardening amount BH is 150 MPa or less.

Owner:NIPPON STEEL CORP

Steel sheet excellent in bake hardenability and corrosion resistance and method for producing the same

ActiveCN111479943BExcellent bake hardenabilityImprove corrosion resistanceHot-dipping/immersion processesFurnace typesBake hardeningCorrosion

The present invention relates to a steel sheet used as a material for automobile outer panels, etc., and a manufacturing method thereof, and more particularly, to a cold-rolled steel sheet having excellent bake hardenability, corrosion resistance, and aging resistance, and a hot-dipped steel sheet Zinc-based steel sheet and its manufacturing method.

Owner:POSCO CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com