Magnetically-treated modified aluminum alloy automobile body panel and preparing method thereof

A technology of aluminum alloy sheet and automobile body, which is applied in the field of automobile lightweight, can solve the problems of poor formability of alloys, etc., and achieve the effects of excellent formability, good bake hardenability, and increased dislocation density.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] A method for preparing a magnetically treated modified aluminum alloy automobile body plate, comprising the following steps:

[0023] 1. Ingredients: According to the mass percentage of each element in the finished aluminum alloy plate for automobile body, Mg: 0.8%, Si: 0.5%, Fe: 0.30%, Cu: 0.20%, Mn: 0.15%, Cr: 0.13%, Zn: 0.50%, Ti: 0.07%, V: 0.60%, Bi: 0.03%, Zr: 0.20%, Be: 1.0%, Co: 0.30%, Ca: 0.60%, and the balance is Al. Pure magnesium ingots and aluminum-based master alloys corresponding to other elements involved in the above components;

[0024] 2. Melting: (1) Add the pure aluminum ingot and aluminum-based intermediate alloy weighed in step 1 into the melting furnace. The melting temperature is 780°C. When the temperature reaches 760°C, turn on the electromagnetic stirrer for stirring. After 30 minutes of electromagnetic After stirring, turn on the electromagnetic stirrer after every 15 minutes of heat preservation, and ensure that the melt temperature rises t...

Embodiment 2

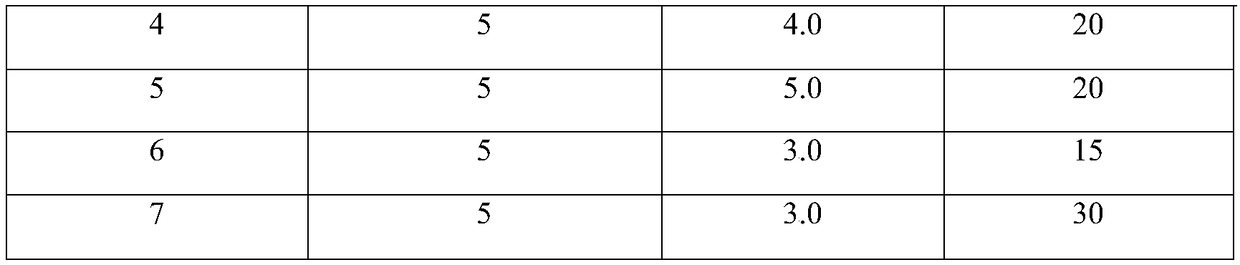

[0042] The difference between this example and Example 1 is that the composition of the aluminum alloy plate used in the experiment is different, and the specific implementation of the magnetic treatment is: the magnetic field frequency is 5 Hz, the magnetic field strength is 4.0 T, and the duration is 20 min.

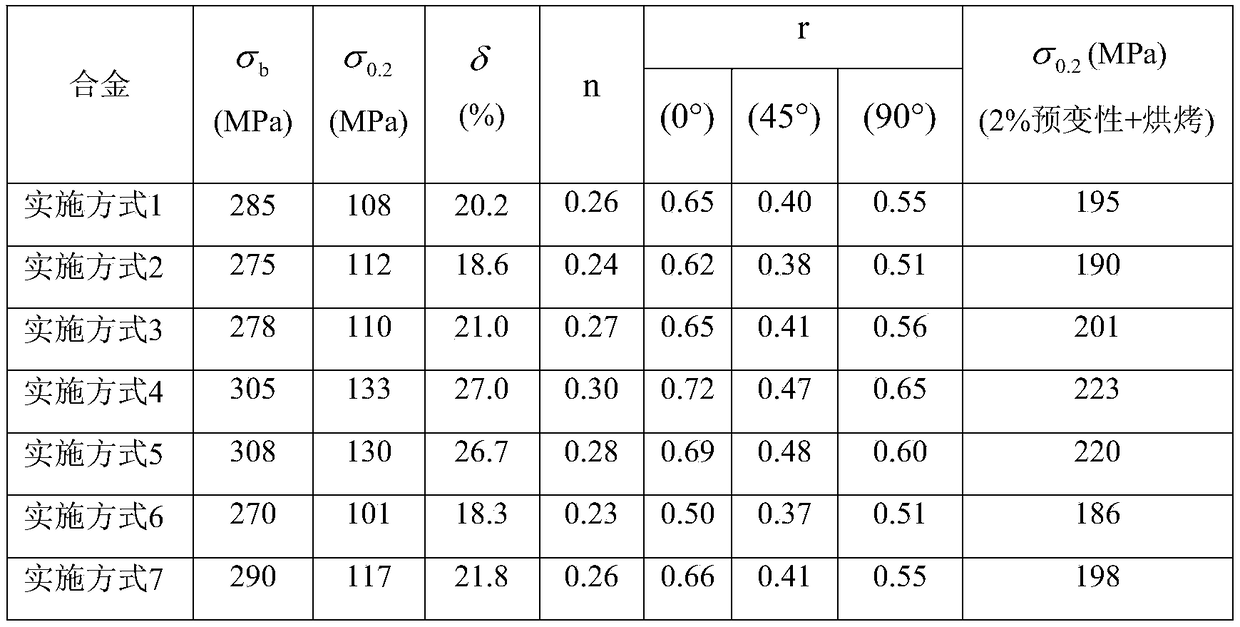

[0043] The main components of the alloy sheet are shown in Table 3, and the mechanical properties of the obtained alloy sheet at room temperature are shown in Table 4:

[0044] Table 3 Main chemical composition of plate alloys in this case (weight percent)

[0045] alloy

Mg

Si

Fe

Cu

V

Al

ingredient 1

0.80%

0.50%

0.30%

0.20%

0.60%

margin

ingredient 2

0.10%

0.40%

0.25%

0.25%

0.70%

margin

ingredient 3

0.60%

0.35%

0.20%

0.15%

0.65%

margin

ingredient 4

0.40%

0.45%

0.15%

0.10%

0.55%

margin

ingredient 5

0.70%

0.30%

0.35%

0.2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com