Composite microalloyed high-strength steel forge piece with tensile strength of 700 MPa and production method thereof

A micro-alloying and tensile strength technology, applied in the field of high-strength low-alloy steel production, can solve the problems of poor plasticity and low-temperature toughness, low elongation, poor low-temperature toughness, etc. Effect of carbon content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

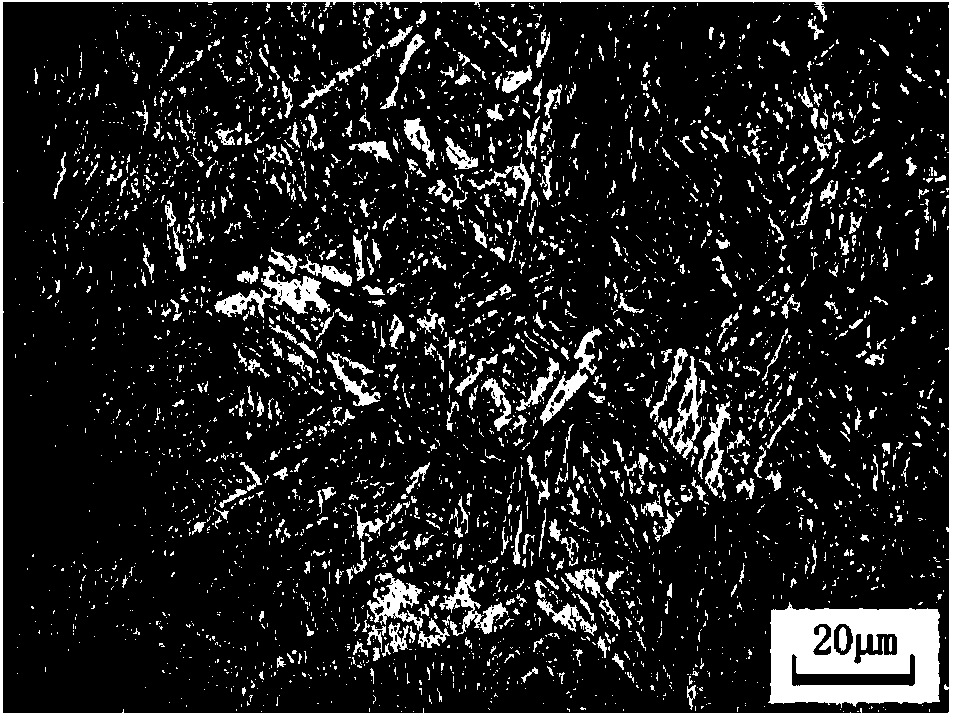

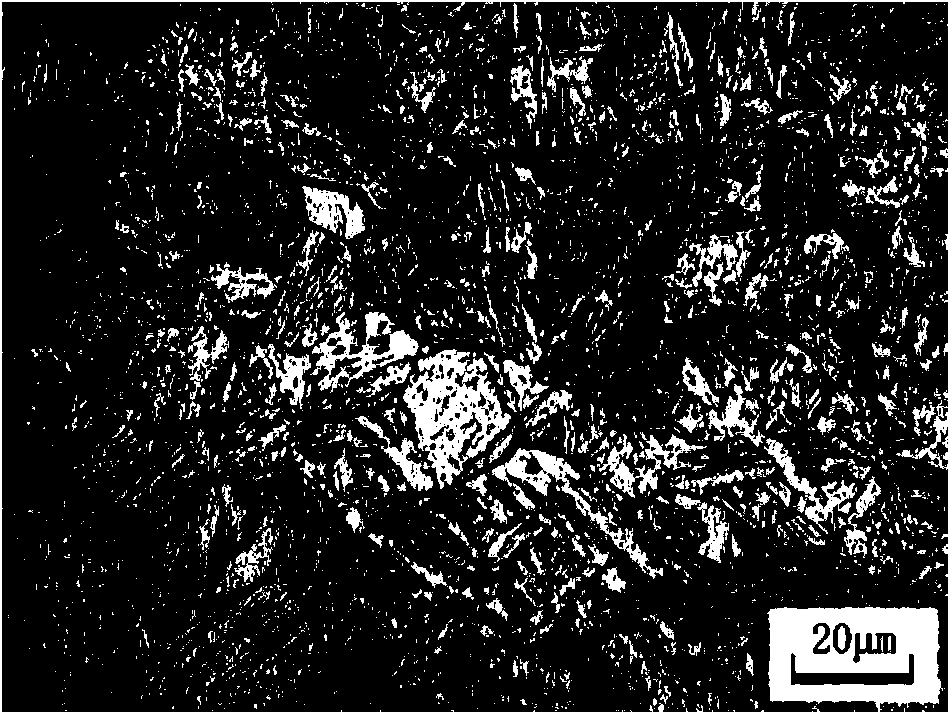

Image

Examples

Embodiment Construction

[0040] In order to achieve the above purpose, the present invention designs a brand-new vanadium-niobium-titanium composite microalloyed high-strength steel forging with a tensile strength of 700MPa. The forging is composed of the following chemical components: C: 0.07-0.12%; Mn: 1.2-1.8%; Si: 0.2~0.4%; S≤0.006%; P≤0.015%; Ni: 1.3~1.8%; Cr: 0.15~0.3%; Mo: 0.2~0.4%; Nb: 0.02~0.1%; V≤0.1%; Ti: ≤0.02%; Cu≤0.25%; B: ≤0.001%, the rest is Fe and unavoidable impurities; at the same time, the welding crack sensitivity index of forgings is P cm ≦0.26%.

[0041] Weld crack sensitivity index P cm Determine according to the following formula:

[0042] P cm =C+Si / 30+Ni / 60+(Mn+Cr+Cu) / 20+Mo / 15+V / 10+5B (%).

[0043] The added alloy elements of the present invention are based on the following principles:

[0044] C: 0.07 to 0.12%. C is the most effective element to improve the strength of steel. With the increase of carbon content, the amount of Fe3C in steel increases, and the tensile s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com