Patents

Literature

404results about How to "Increase the dislocation density" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

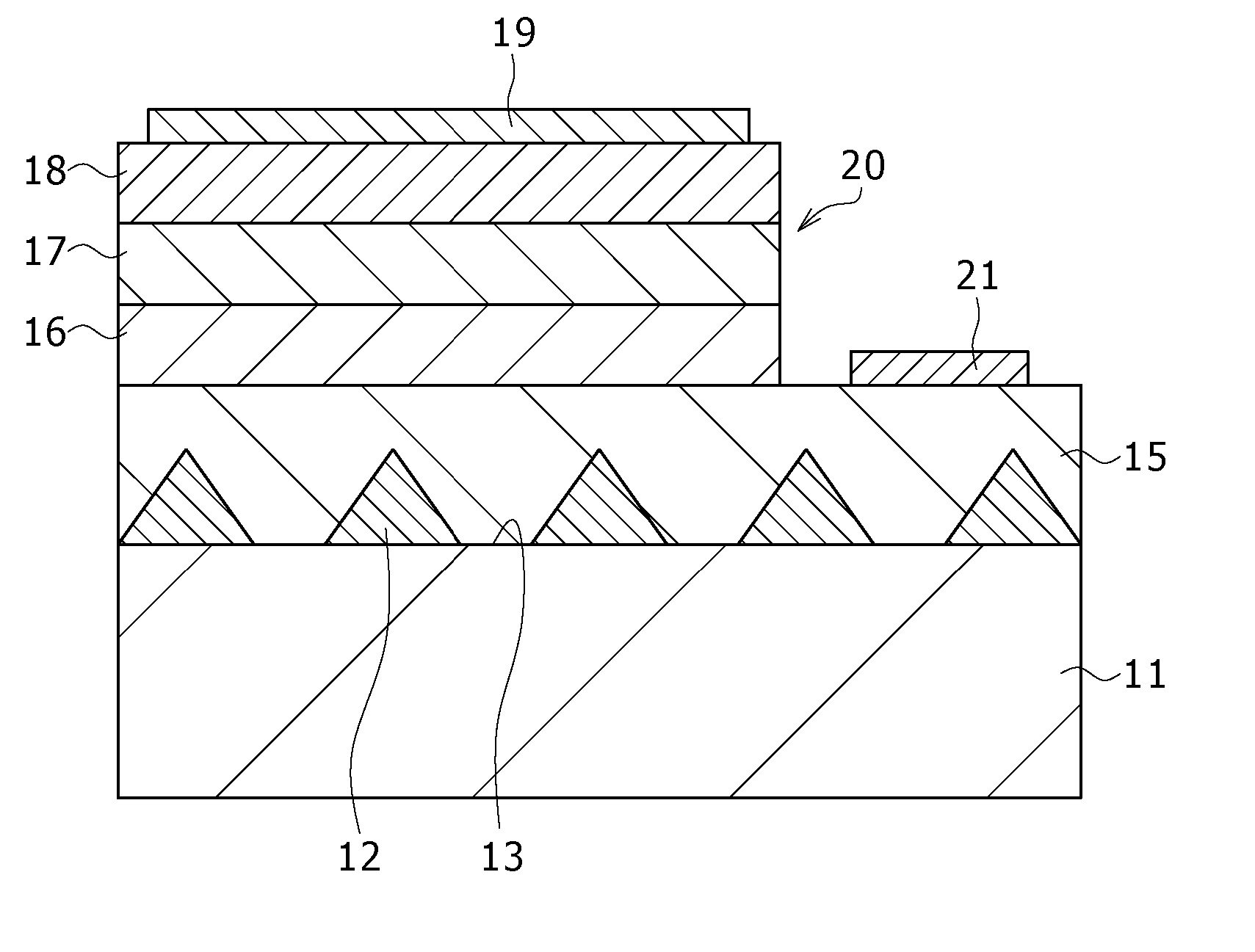

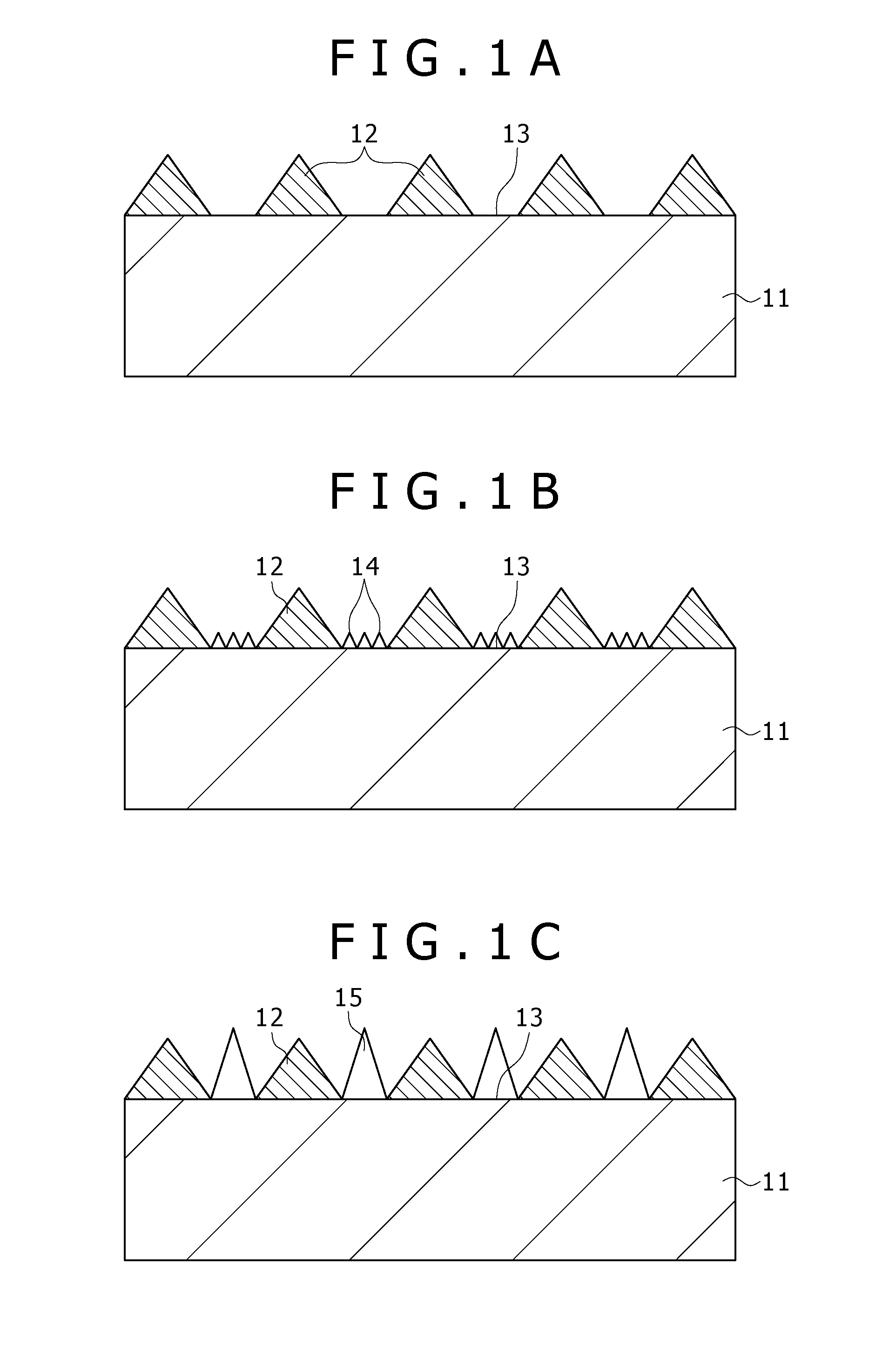

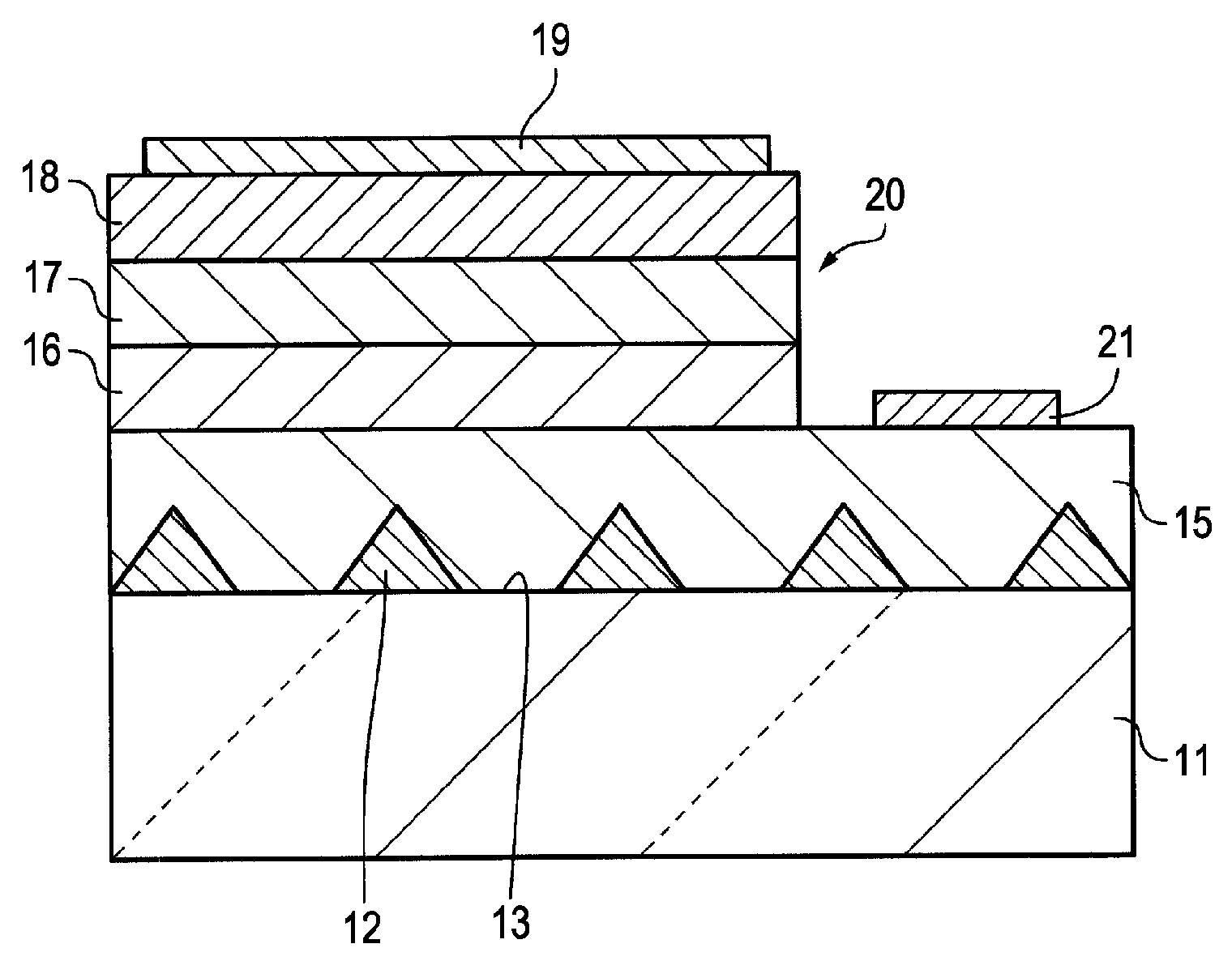

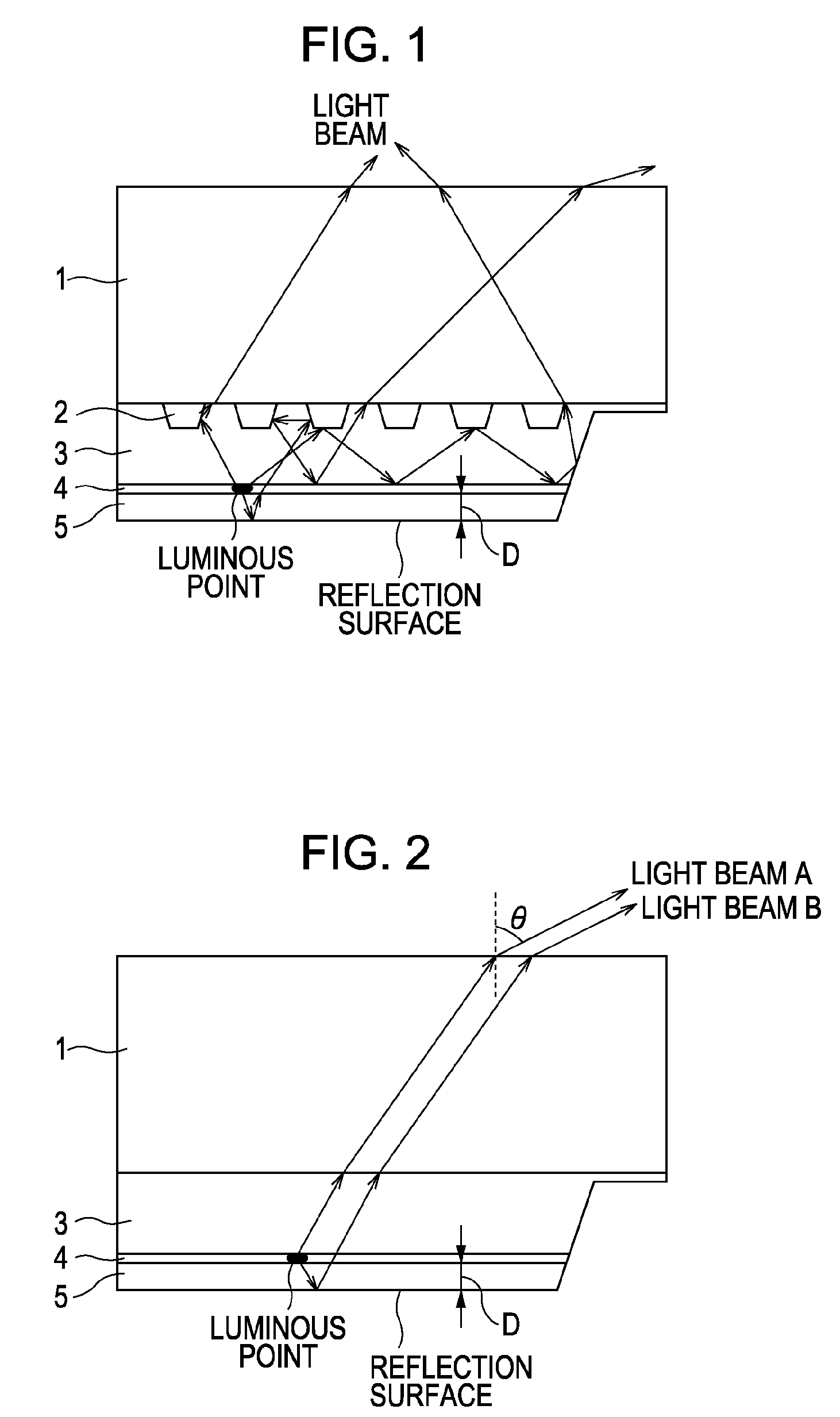

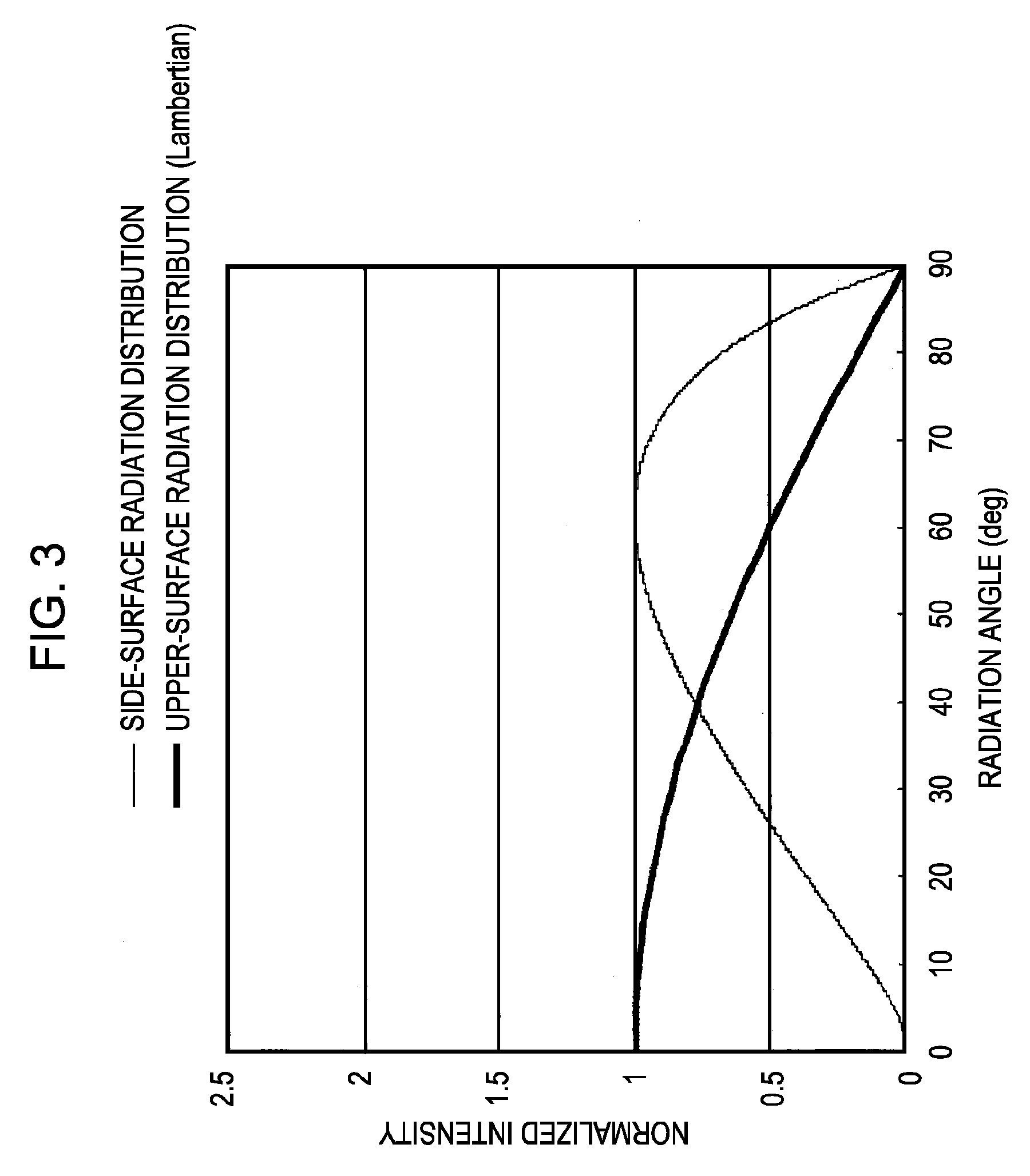

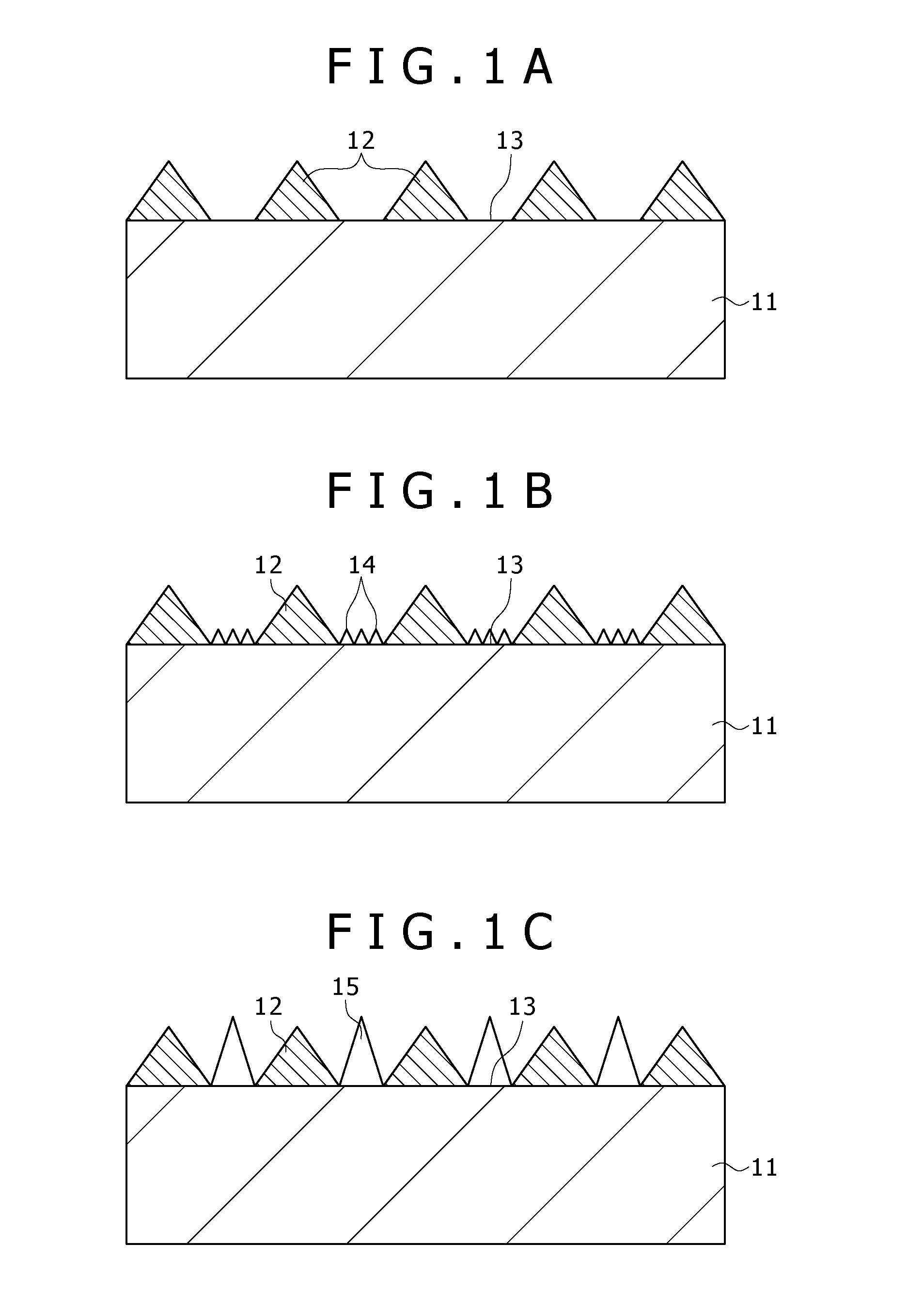

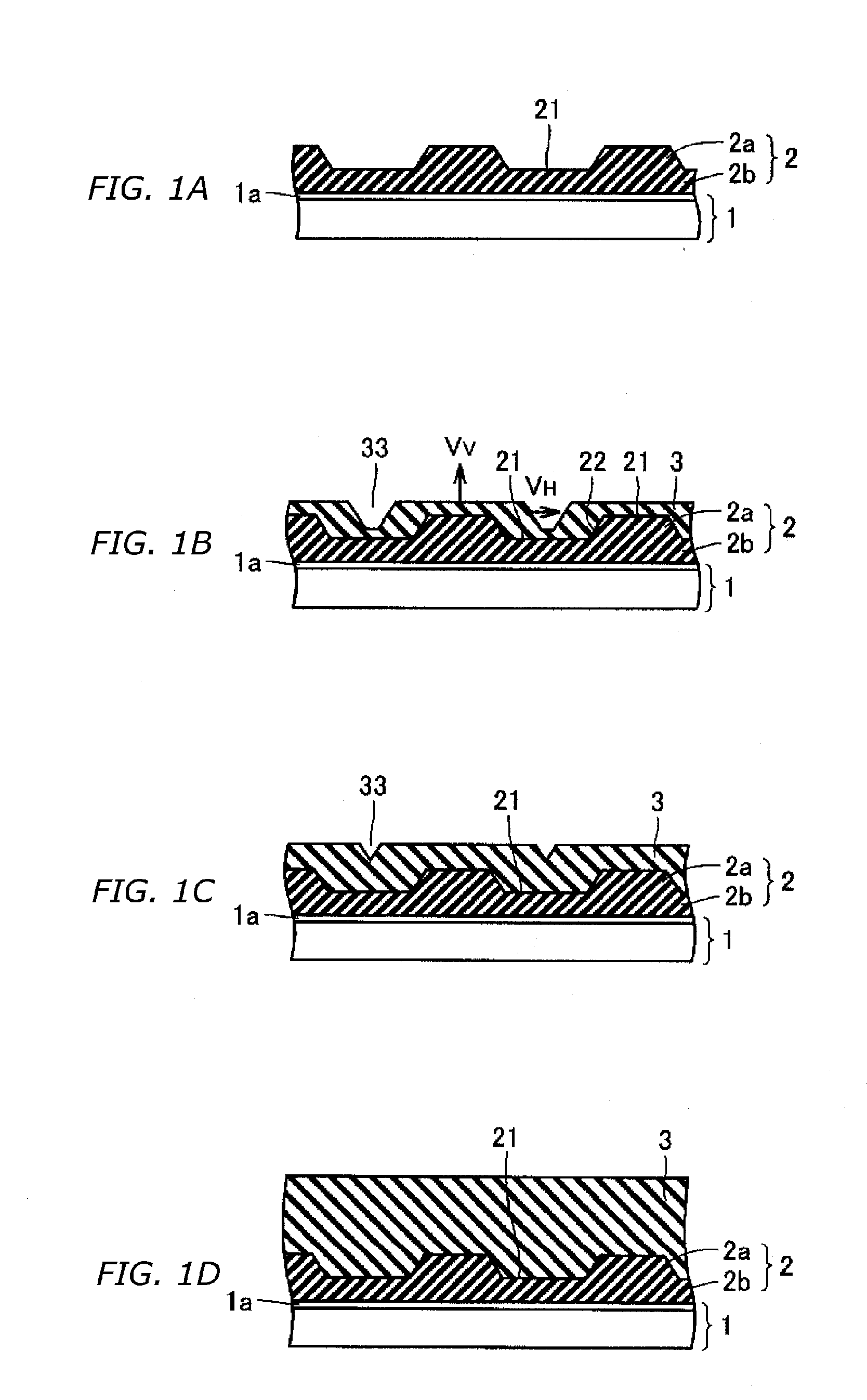

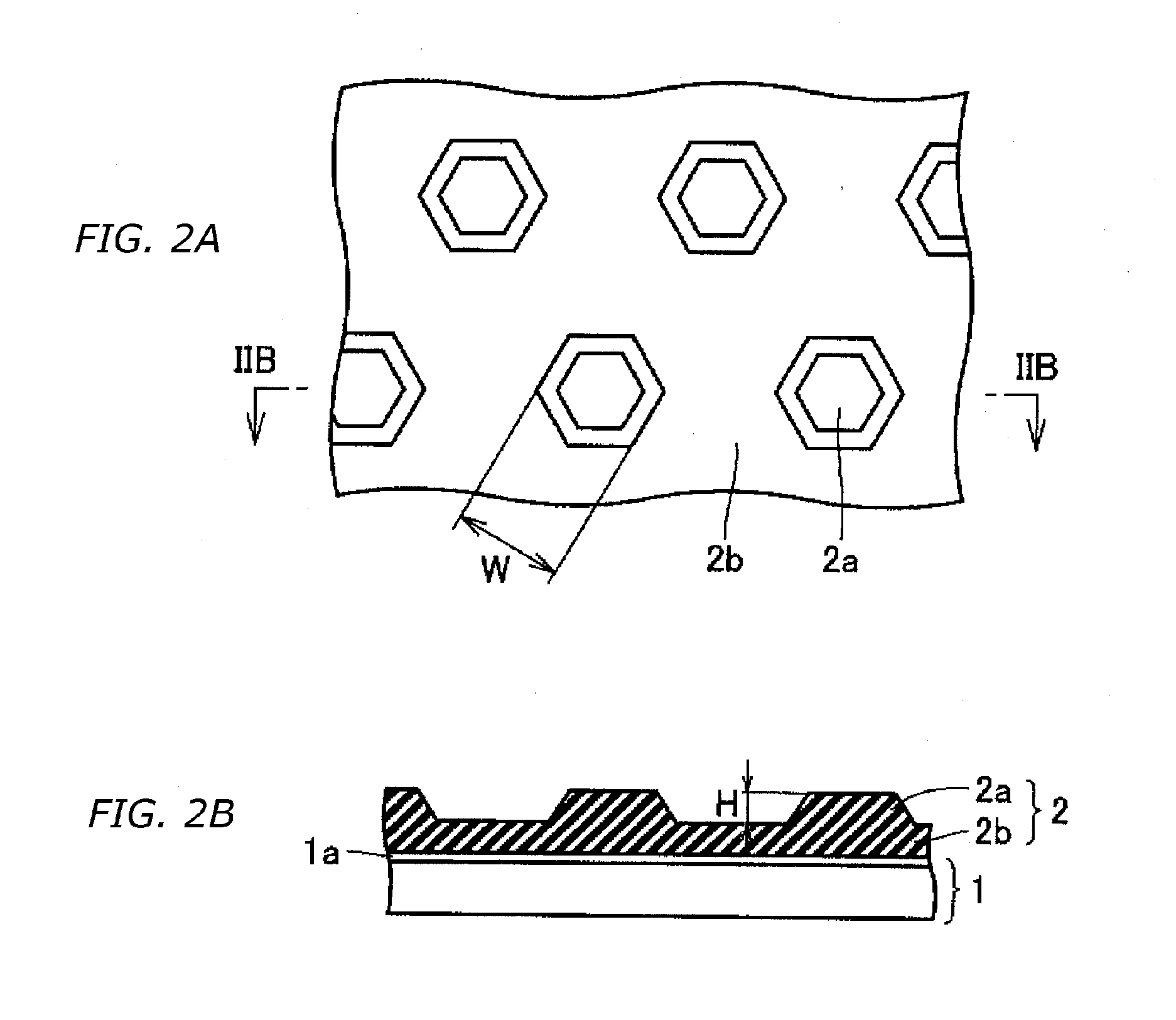

Light-emitting diode and method for manufacturing same, integrated light-emitting diode and method for manufacturing same, method for growing a nitride-based iii-v group compound semiconductor, substrate for growing a nitride-based iii-v group compound semiconductor, light source cell unit, light-emitting diode backlight, light-emitting diode illuminating device, light-emitting diode display and electronic instrument, electronic device and method for manufacturing same

InactiveUS20070085093A1Low luminous efficiencyLight extraction efficiencyPolycrystalline material growthSolid-state devicesDisplay deviceEngineering

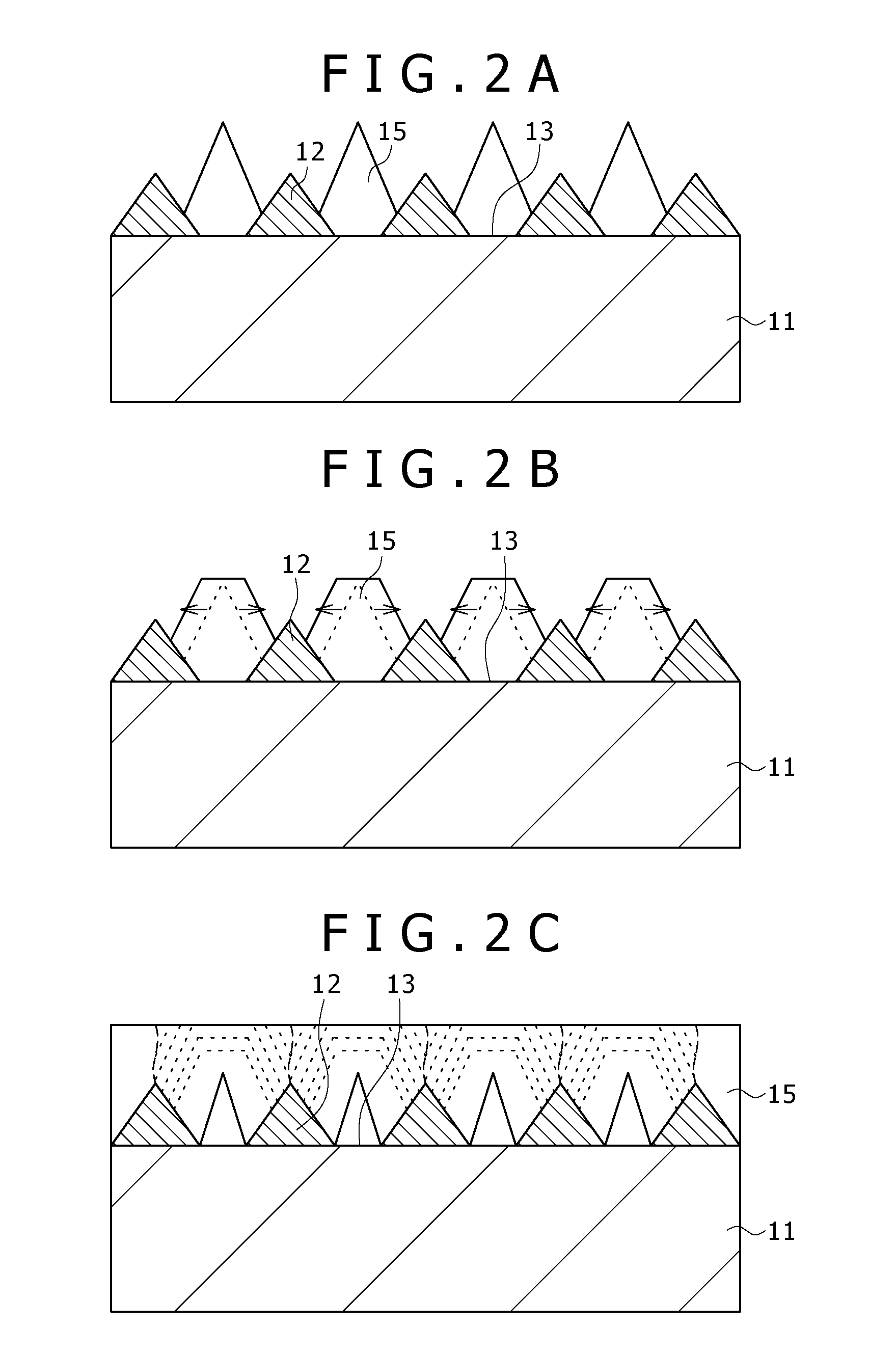

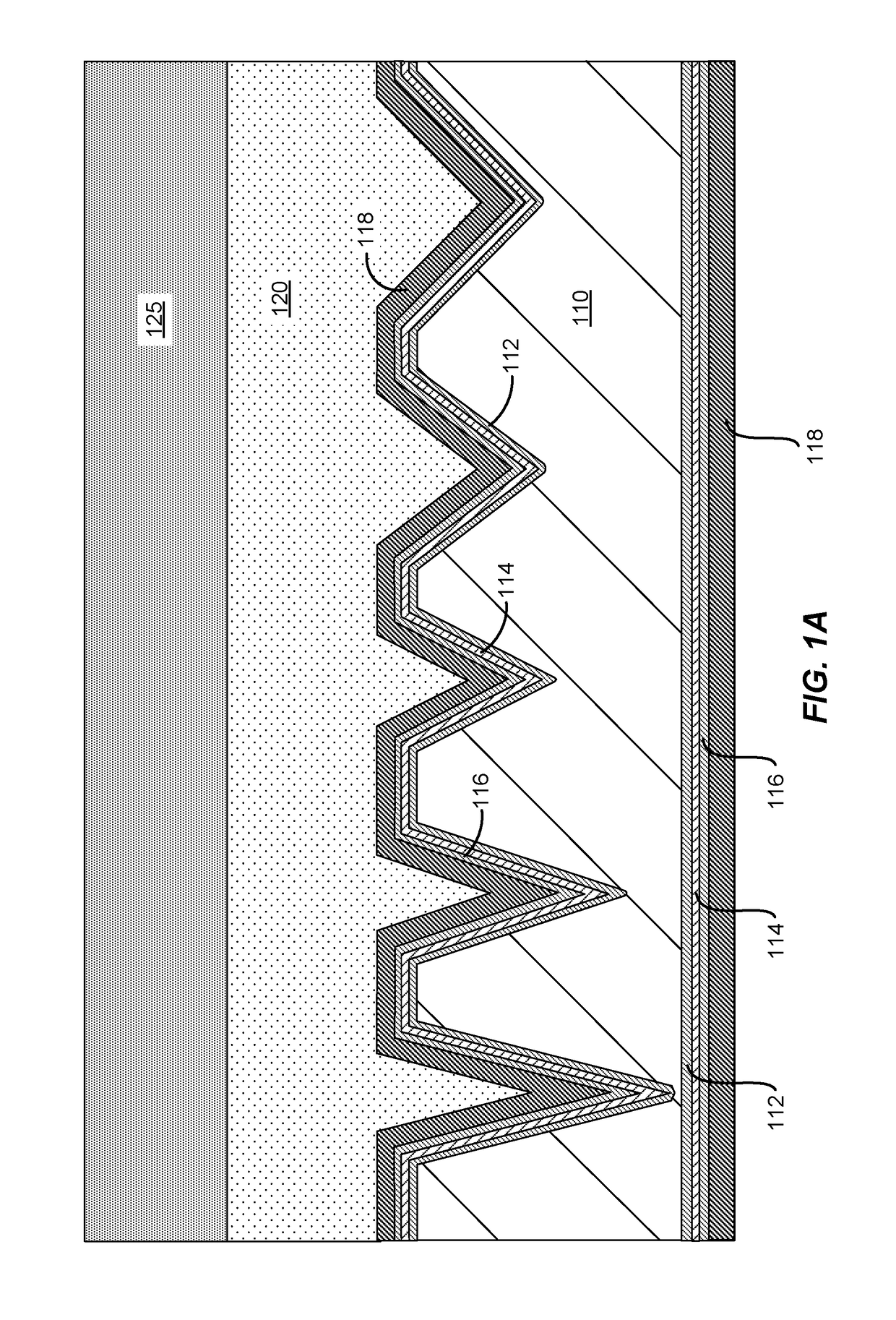

A method for manufacturing a light-emitting diode, which includes the steps of: providing a substrate having a plurality of protruded portions on one main surface thereof wherein the protruded portion is made of a material different in type from that of the substrate and growing a first nitride-based III-V Group compound semiconductor layer on each recess portion of the substrate through a state of making a triangle in section wherein a bottom surface of the recess portion becomes a base of the triangle; laterally growing a second nitride-based III-V Group compound semiconductor layer on the substrate from the first nitride-based III-V Group compound semiconductor layer; and successively growing, on the second nitride-based III-V Group compound semiconductor layer, a third nitride-based III-V Group compound semiconductor layer of a first conduction type, an active layer, and a fourth nitride-based III-V compound semiconductor layer of a second conduction type.

Owner:SONY CORP

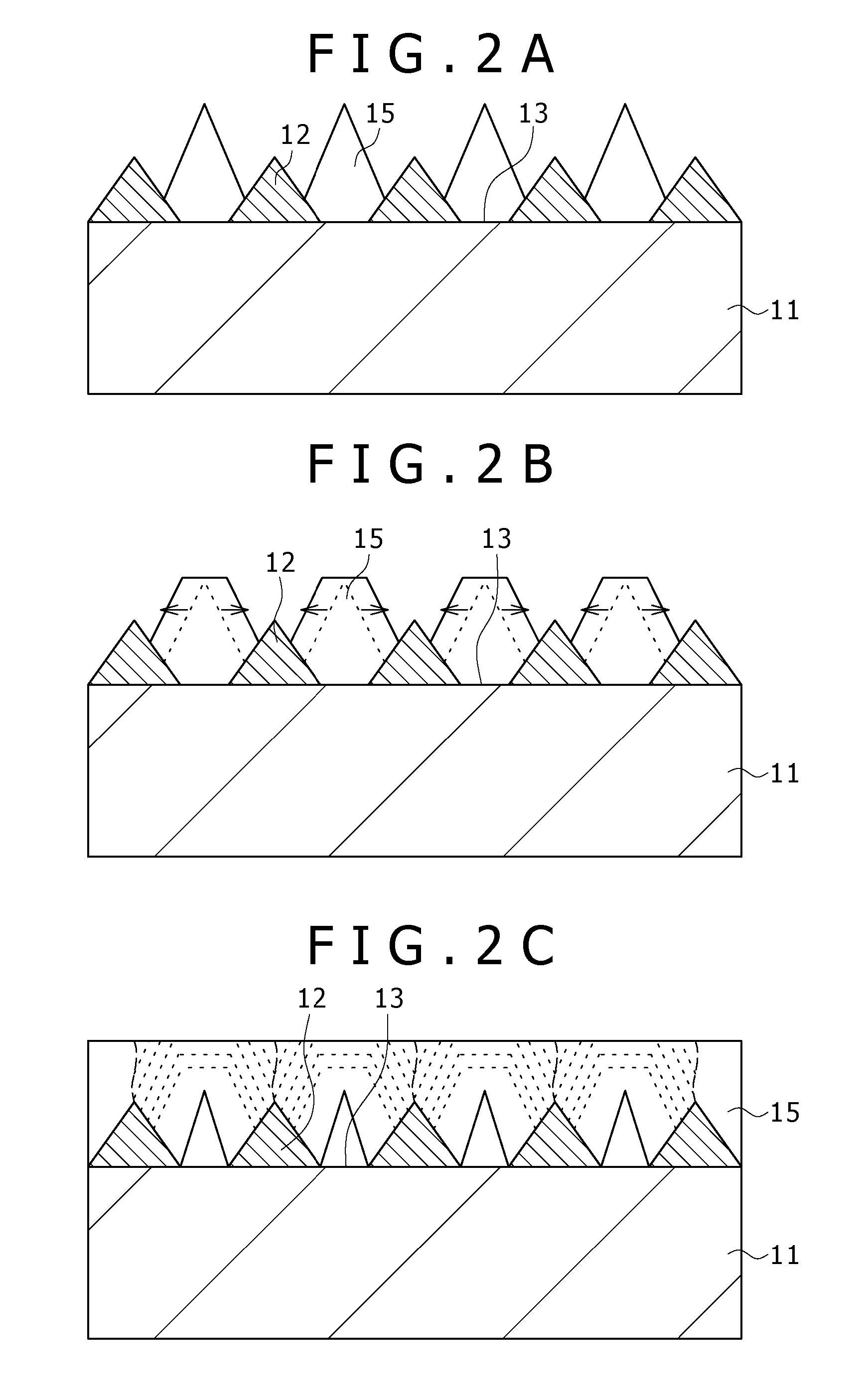

Method for manufacturing light-emitting diode, light-emitting diode, lightsource cell unit, light-emitting diode backlight, light-emitting diode illuminating device, light-emitting diode display, and electronic apparatus

InactiveUS20080121903A1Well formedImprove processing accuracySolid-state devicesSemiconductor/solid-state device manufacturingEngineeringRefractive index

A light-emitting diode which has a significantly high luminous efficiency and which can be manufactured at a reasonable cost by one epitaxial growth and a manufacturing method thereof are provided. The above method includes: preparing a substrate provided with convex portions on one major surface, the convex portions being formed from a dielectric substance which is different from the substrate and which has a refractive index of 1.7 to 2.2; growing a first nitride-based III-V compound semiconductor layer in a concave portion on the substrate; growing a second nitride-based III-V compound semiconductor layer on the substrate from the first nitride-based III-V compound semiconductor layer in a lateral direction; and growing, on the second nitride-based III-V compound semiconductor layer, a first conductive type third nitride-based III-V compound semiconductor layer, an active layer, and a second conductive type fourth nitride-based III-V compound semiconductor layer.

Owner:SONY CORP

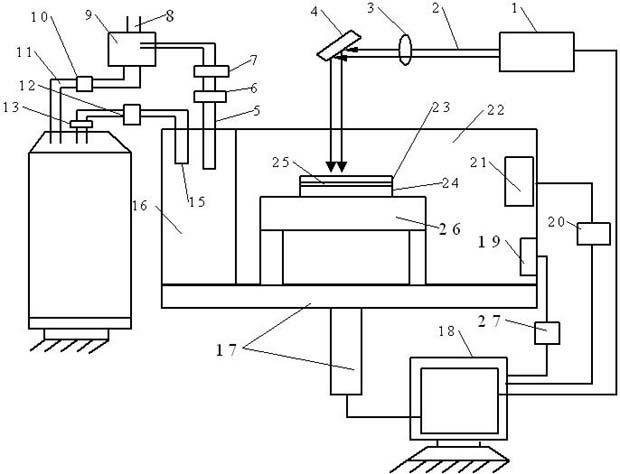

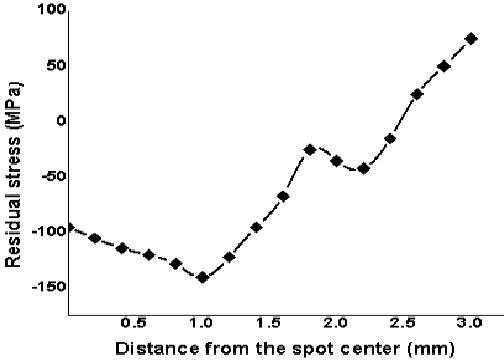

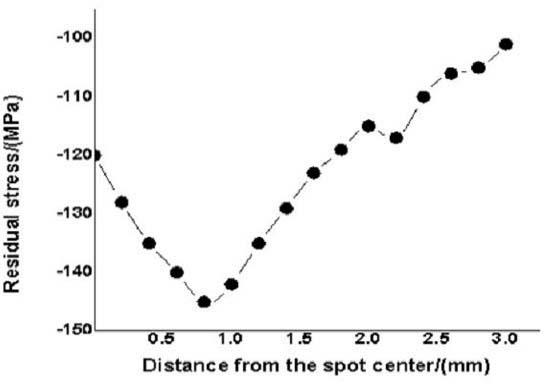

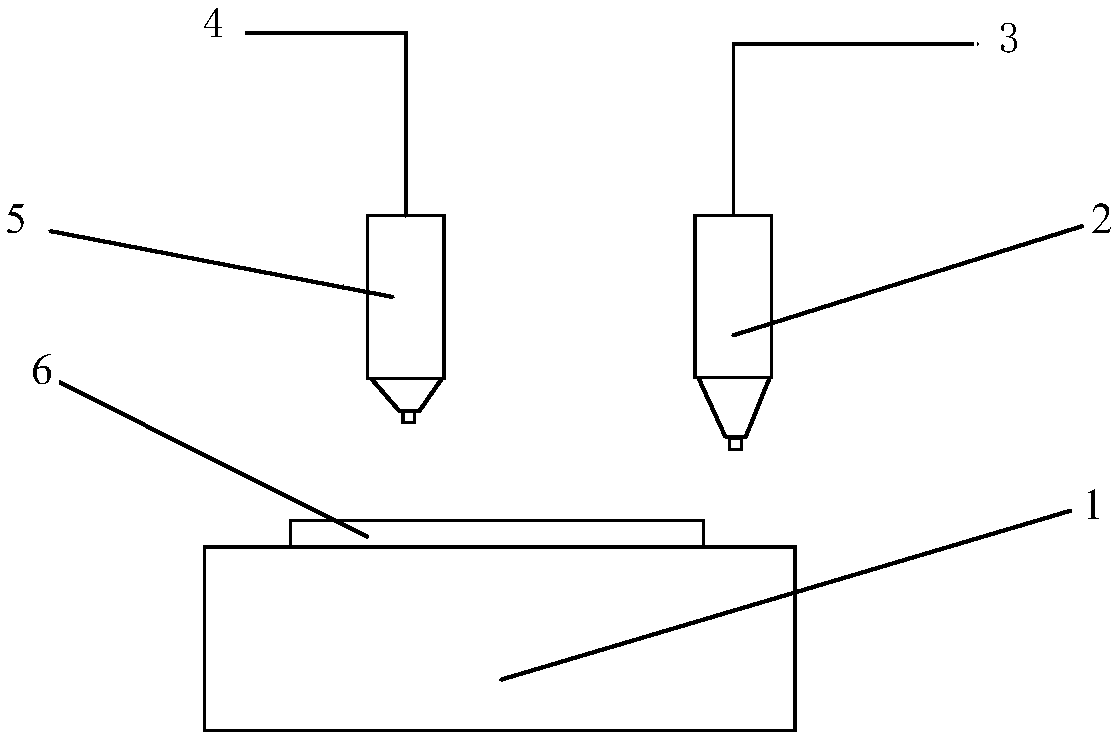

Method and device for processing metal materials with cryogenic laser shock

A method and a device for processing metal materials with cryogenic laser shock belong to the fields of laser processing and subzero treatment. The device comprises a cryogenic treatment cavity, a laser, a liquid nitrogen tank, a temperature sensor and the like. The method is used for strengthening the materials in an ultra-low temperature environment by adopting the laser shock processing technology, insulating the materials for a period after the strengthening process, and heating the materials to be as hot as the ambient temperature. In the ultra-low temperature environment, the metal materials shrink, and a large quantity of dislocation is generated in the materials; due to the instant impact effect of the laser shock processing technology, the high-density dislocation in the materials moves at a high speed, so as to induce high-density nano twin crystal, which ensures that the materials have superior tenacity as well as high intensity, and brittle failure of the metal materials in the low-temperature environment can be avoided effectively; and a large quantity of nano educt is dissolved out from the materials, and the conversion of residual austenite as well as the thinning of martensite and crystal can be promoted effectively, which remarkably improves the mechanical properties and the mechanical properties of the materials.

Owner:JIANGSU UNIV

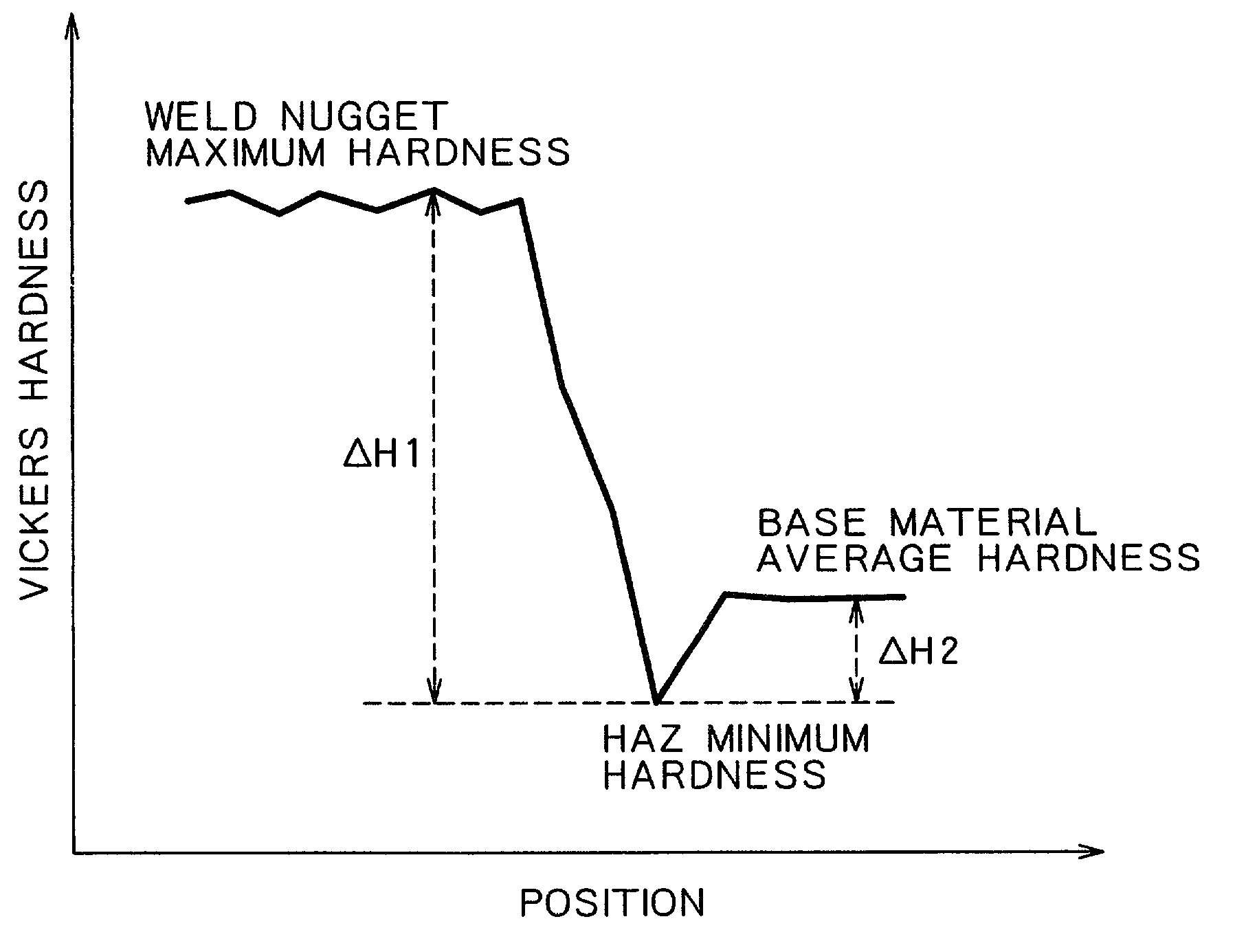

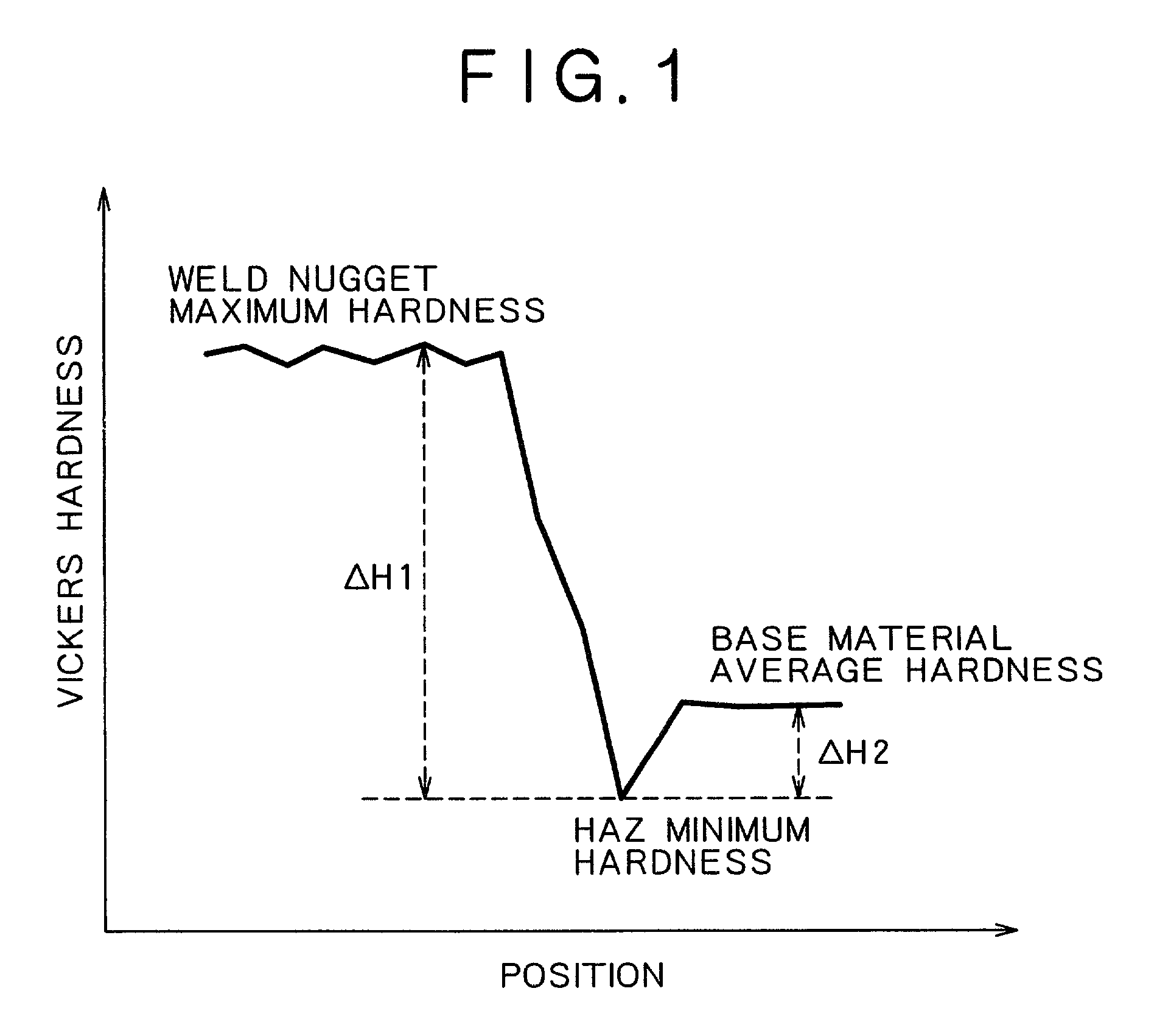

Superhigh-strength dual-phase steel sheet of excellent fatigue characteristic in a spot welded joint

InactiveUS20030221752A1Good effectIncrease volume fractionHot-dipping/immersion processesThin material handlingHardnessUltimate tensile strength

A superhigh-strength dual-phase steel sheet containing ferritic microstructure and a martensitic microstructure-containing composite-phase steel sheet containing: C: 0.08-0.20% (mass % here and hereinafter), Si: 0.5% or less (inclusive of 0%) Mn: 3.0% or less (exclusive of 0%) P: 0.02% or less (inclusive of 0%) S: 0.02% or less (inclusive of 0%), and Al: 0.001-0.15%, and further containing Mo: 0.05-1.5%, and Cr: 0.05-1.5%, and which satisfying that: the average Vickers hardness of the ferritic microstructure is 150 Hv or more and the average Vickers hardness of the martensitic microstructure is 500 Hv or more, the superhigh-strength dual-phase steel sheets being of excellent fatigue characteristic in a spot welded joint.

Owner:KOBE STEEL LTD

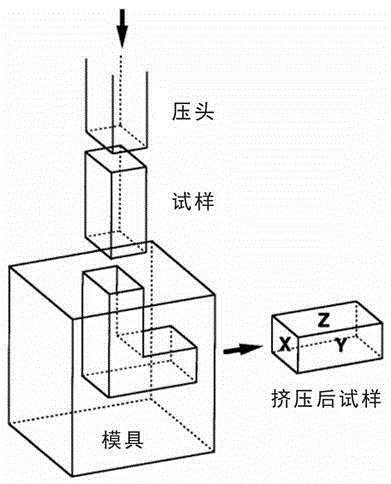

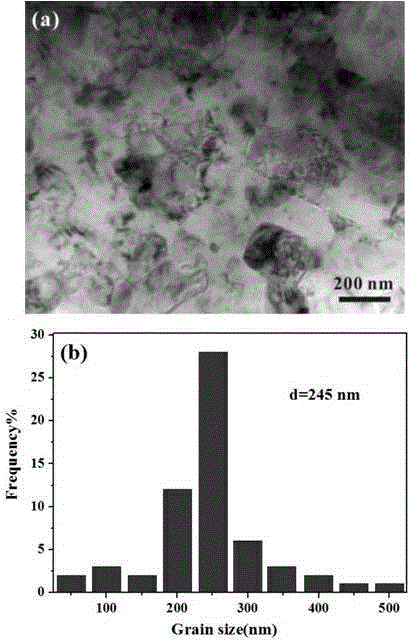

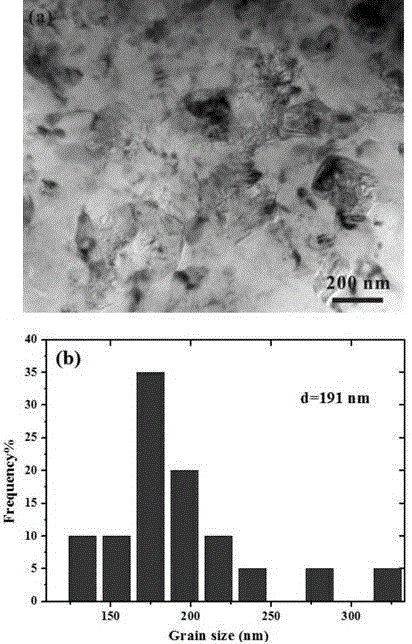

Preparation method for high-strength and high-toughness ultra-fine grain aluminium alloy

The invention belongs to the technical field of preparation of metal and alloy, and provides a preparation method for high-strength and high-toughness ultra-fine grain aluminium alloy. The preparation method comprises the steps that aluminium alloy is firstly cast to form a cast-state blank; then the cast-state blank is turned into an ECAP (Equal Channel Angular Pressing) blank, and then the ECAP blank is subjected to homogenization treatment and curing quenching treatment; and then the blank subjected to the curing quenching treatment is subjected to 1-8 passes of ECAP dynamic ageing treatment at temperatures ranging from the room temperature to 300 DEG C. According to the preparation method, through the ECAP dynamic ageing treatment at different temperatures, the grain size of the alloy is obviously refined; and the form and distribution of a nanometer ageing precipitated phase are more reasonable, so that the strength of the alloy is greatly improved, and meanwhile the alloy has excellent ductility and toughness.

Owner:JIANGSU UNIV

Aluminum alloy workpiece additive manufacturing method implemented through friction stir welding

InactiveCN109108505AImprove mechanical propertiesElimination of internal tissue for refinementWelding/soldering/cutting articlesNon-electric welding apparatusFriction weldingVolumetric Mass Density

The invention discloses an aluminum alloy workpiece additive manufacturing method implemented through friction stir welding. On the basis of an existing electric arc additive manufacturing aluminum alloy workpiece, the characteristic that aluminum alloy is soft in property is combined, after an aluminum alloy workpiece is manufactured from electric arc additives layer by layer, friction stir welding intensification treatment is conducted on each layer, and therefore, defects such as pass gaps, interlayer incomplete fusion, air holes and the like can be eliminated through friction stir weldingwhen each layer is manufactured. Compared with the pure electric arc additive manufacturing aluminum alloy workpiece, by means of the method, the structural state of the aluminum alloy workpiece obtained through additive manufacturing can be improved; the grains can be finer; second-phase grains are finer and are distributed more uniformly; and the dislocation density achieved in the aluminum alloy additive manufacturing workpiece is increased. Compared with existing friction stir welding intensification, grain refining and defect elimination are conducted on each layer of the workpiece so that the strength of the whole workpiece can be improved rather than only surface modification, namely surface intensification, is conducted.

Owner:NAT INST CORP OF ADDITIVE MFG XIAN

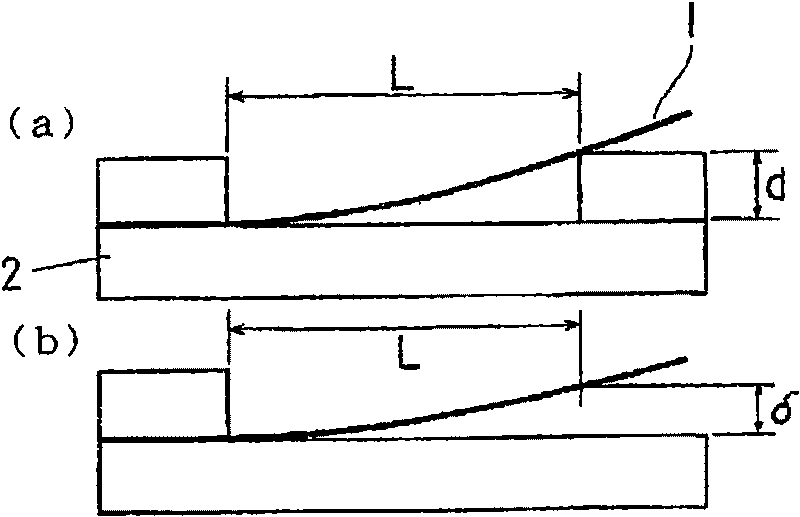

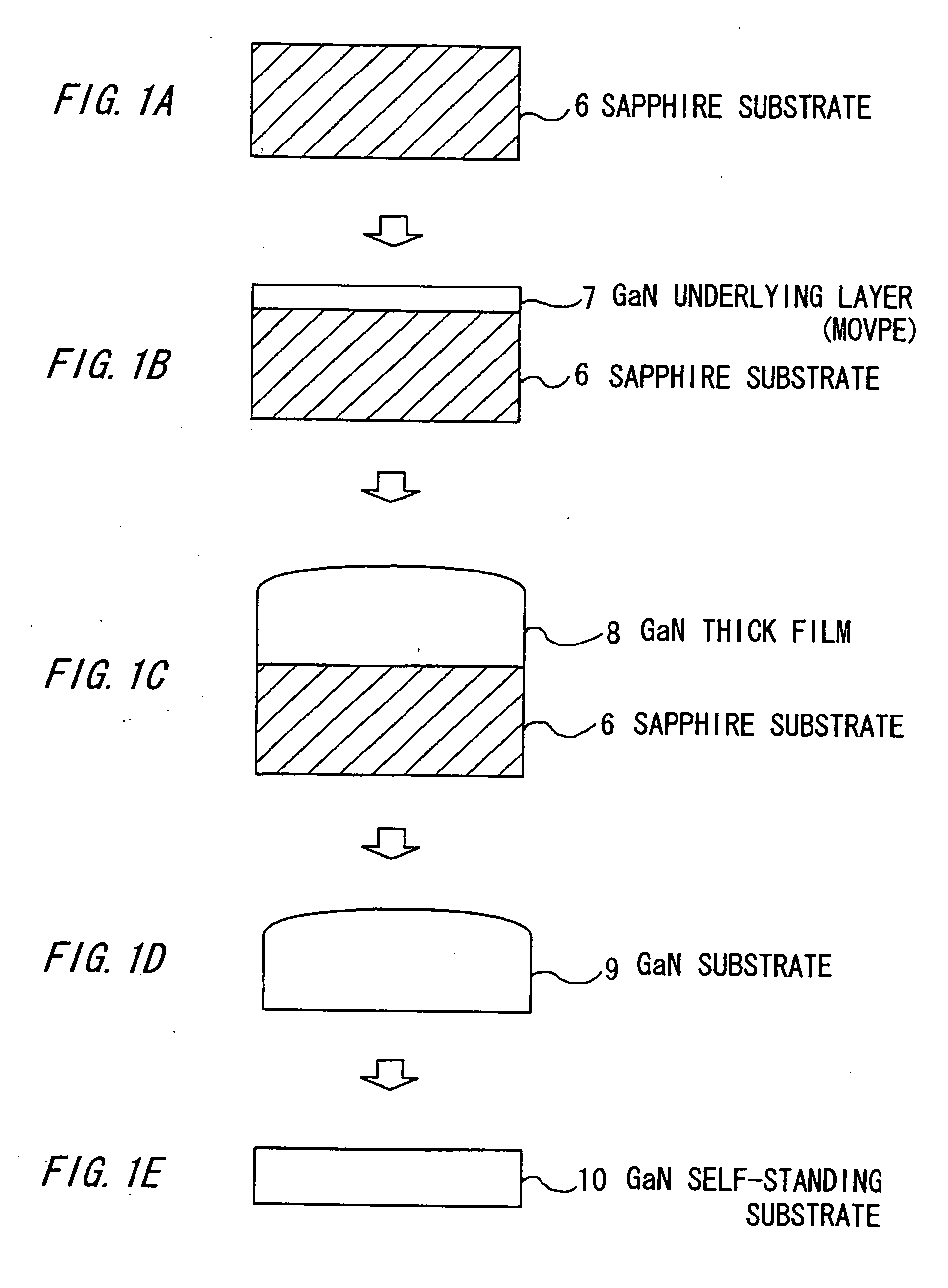

Group III-V nitride-based semiconductor substrate and method of making same

InactiveUS20060226414A1Improve uniformityUniform propertyPolycrystalline material growthSemiconductor/solid-state device manufacturingSusceptorNitride

A method of making a group III-V nitride-based semiconductor substrate has the steps of: providing a first crystal substrate; placing the first crystal substrate on a susceptor; holding down the first crystal substrate on the susceptor; and growing a first group III-V nitride-based semiconductor crystal on the first crystal substrate.

Owner:HITACHI CABLE

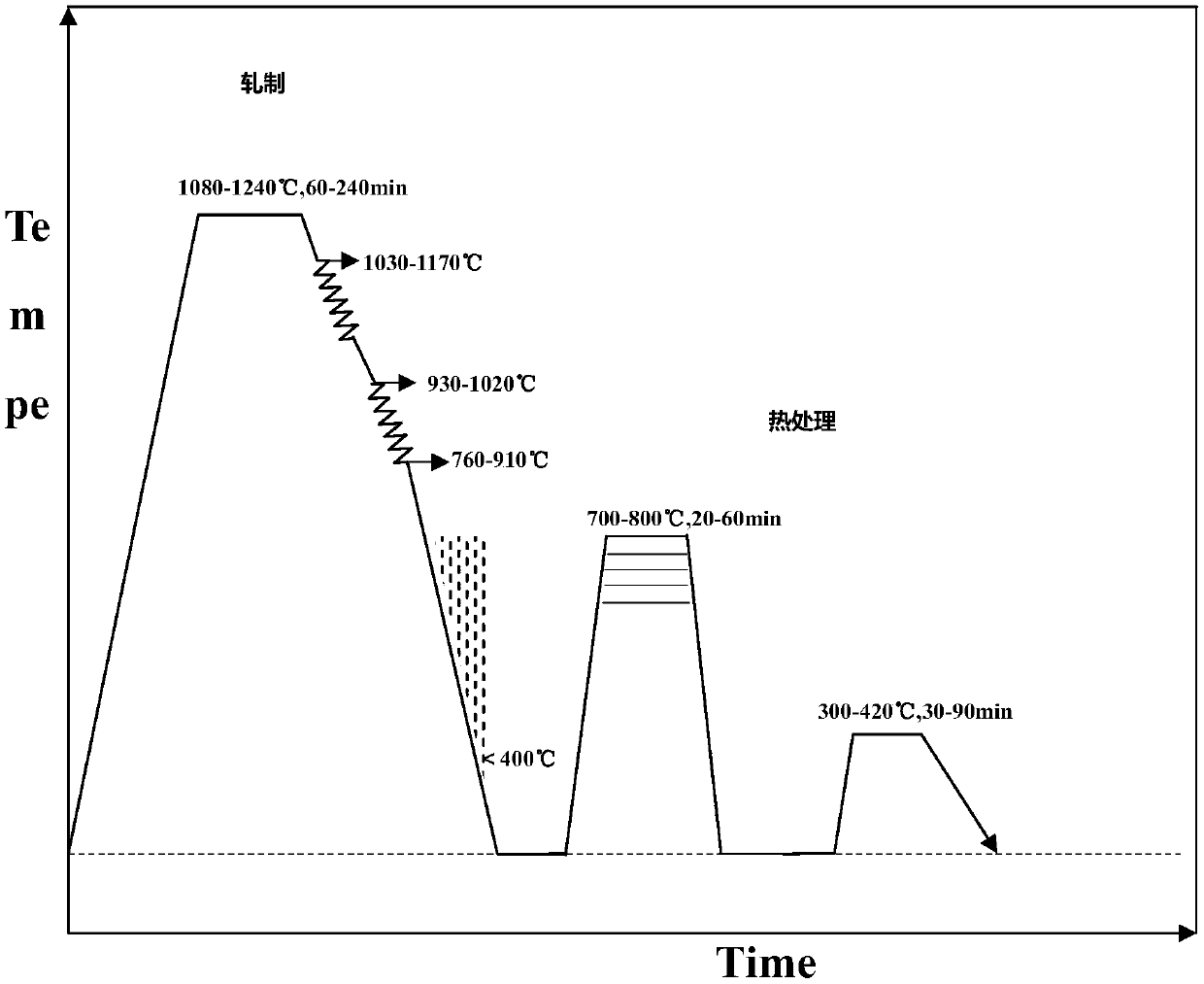

Aluminum alloy for 480 MPa-class aluminum alloy oil pipe and pipe manufacturing method thereof

The invention discloses an aluminum alloy for a 480 MPa-class aluminum alloy oil pipe. The aluminum alloy comprises the following components by weight percent: 5.10-6.90% of Zn, 1.10-1.80% of Mg, 0.05-0.20% of Cu, 0.10-0.30% of Mn, 0.10-0.30% of Cr, 0.01-0.02% of Ti, 0.15-0.2% of Zr and the balance of Al and unavoidable impurities, wherein in the unavoidable impurities, the content of the Si is not greater than 0.15 of the total weight of the aluminum alloy and the content of Fe is not greater than 0.15 of the total weight of the aluminum alloy. The manufacture method of the aluminum alloy pipe comprises the following steps: (1) smelting the raw materials according to the weight percentage, performing external refining and casting to obtain a pipe blank; (2) performing three-stage homogenization treatment; (3) squeezing under high temperature; (4) performing twin-stage solid solution treatment, quenching and cooling; (5) prestretching and deforming; and (6) performing twin-stage artificial aging treatment.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

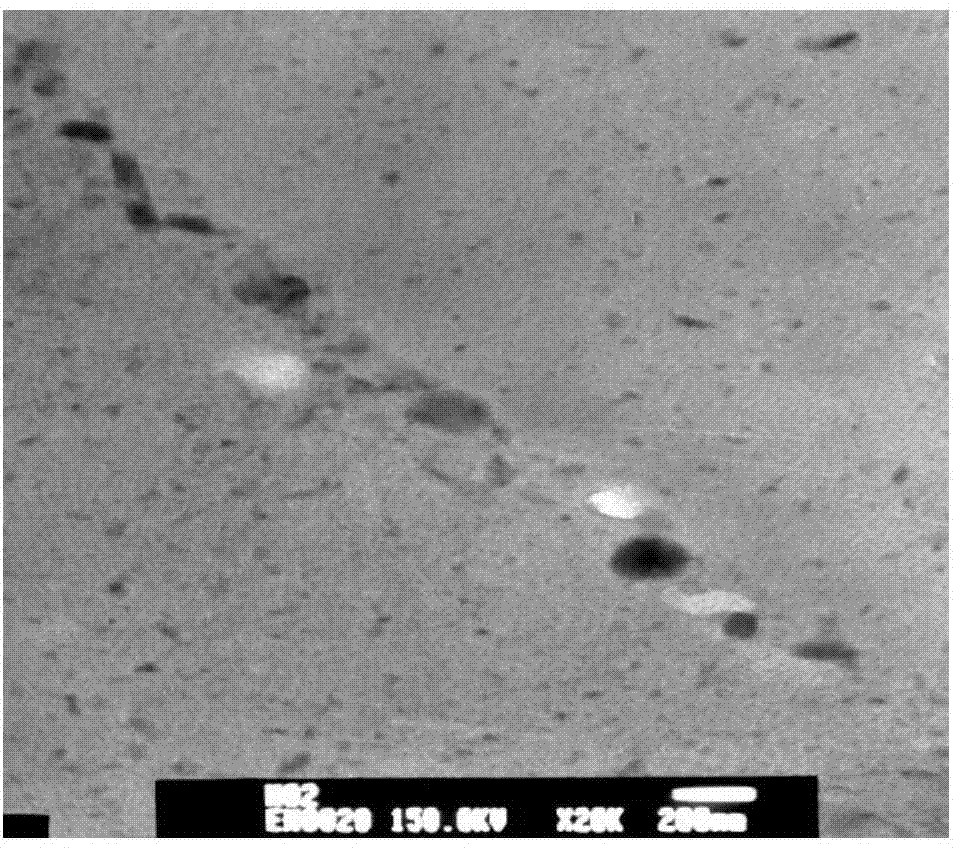

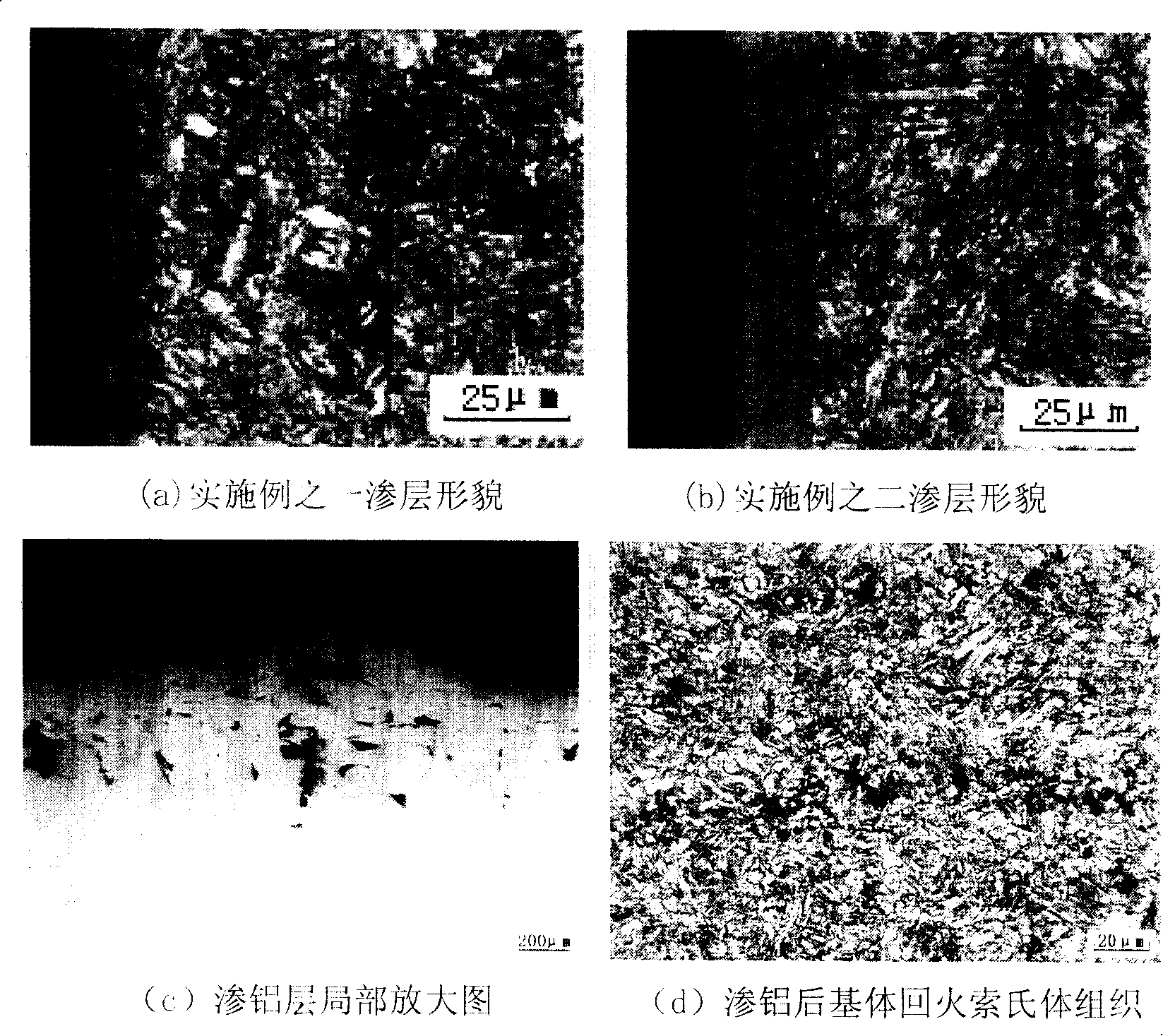

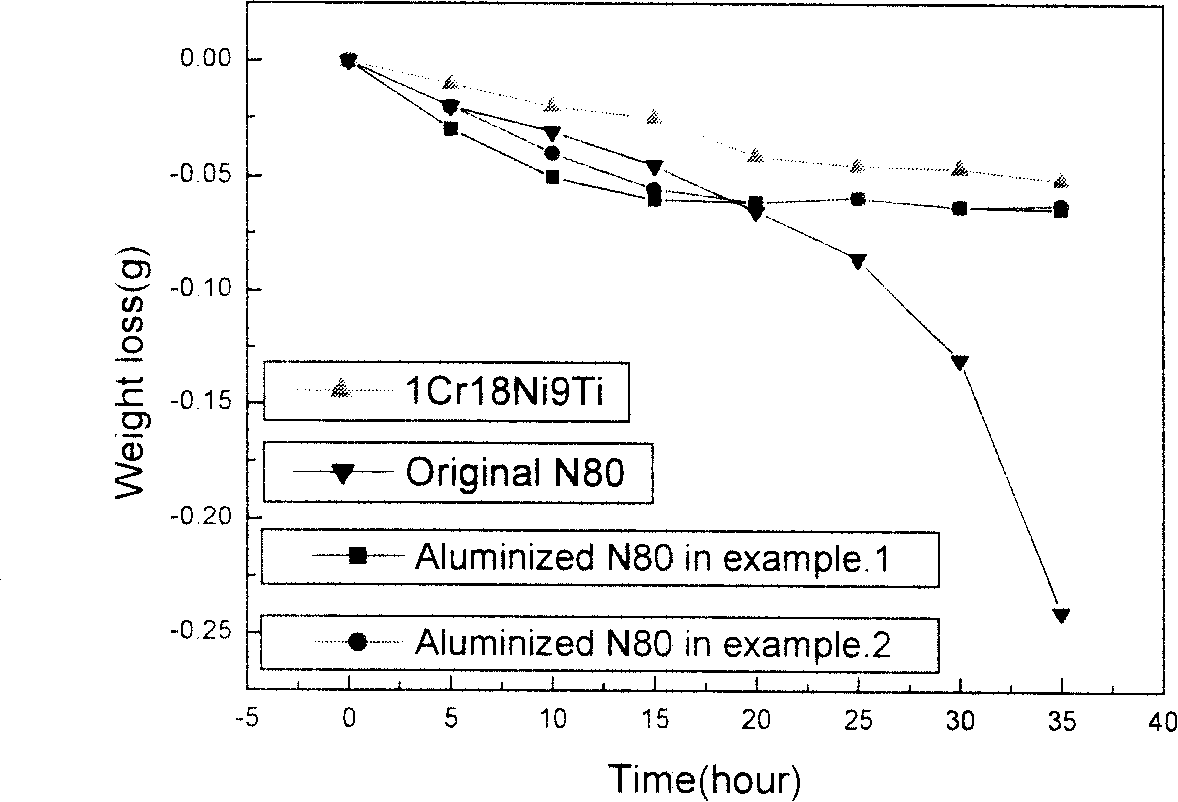

Oil and bushing low-temperature powder embedding aluminizing agent for petroleum

ActiveCN101165204AHigh bonding strengthDiffusion fastSolid state diffusion coatingAl powderSodium fluoride

The low temperature quick aluminizing agent specially for petroleum pipe and casing consists of metal source, activator, catalyst and stuffing. The metal source consists of 150-mesh Al powder in 10-20 wt% of the aluminizing agent, 120-mesh Zn powder in 10-25 wt%, 150-mesh Zn-Fe alloy powder in 10-20 wt% and / or 150-mesh Fe-Al alloy powder in 10-15 wt%. The activator consists of ammonium chloride, aluminum chloride, sodium fluoride and / or potassium bifluoride. The catalyst consists of 100-mesh Mo powder in 0-3 wt% and La and Os 0-3 wt%, with La and Os in the weight ratio of 1 to 1. The stuffing is 100-mesh alumina powder. The aluminizing agent is applied at 380-500 deg.c to obtain aluminized layer.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

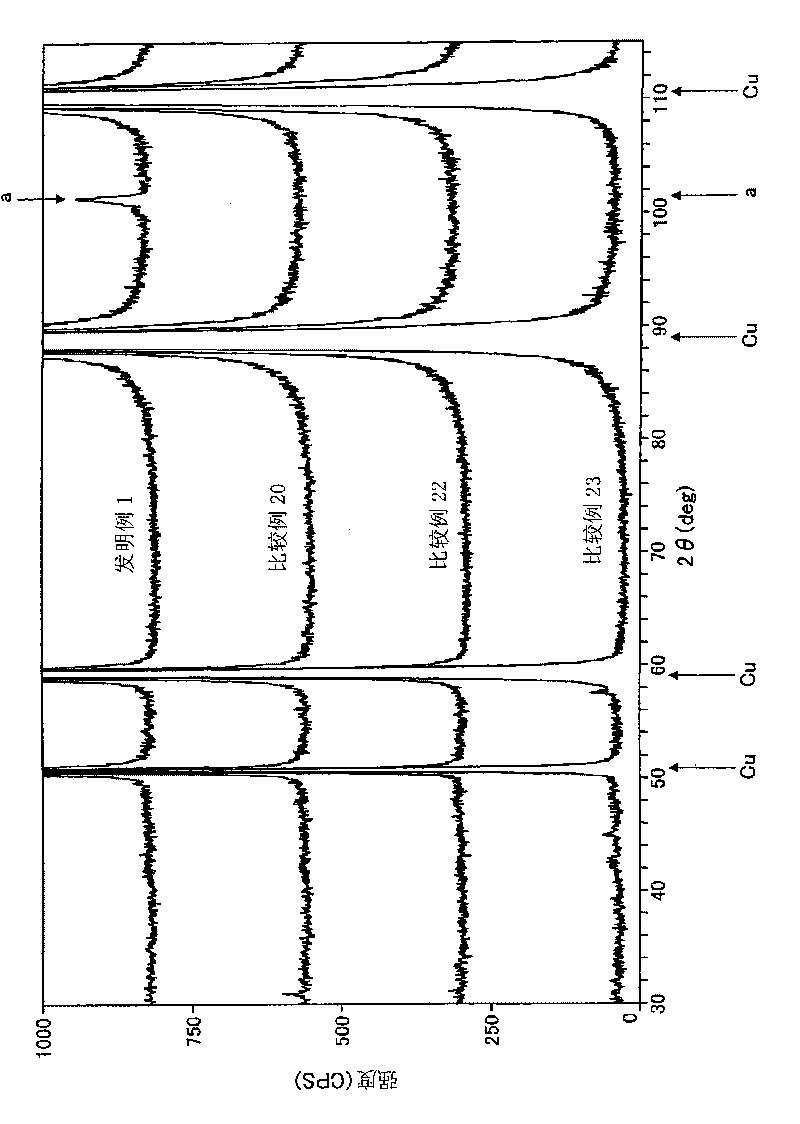

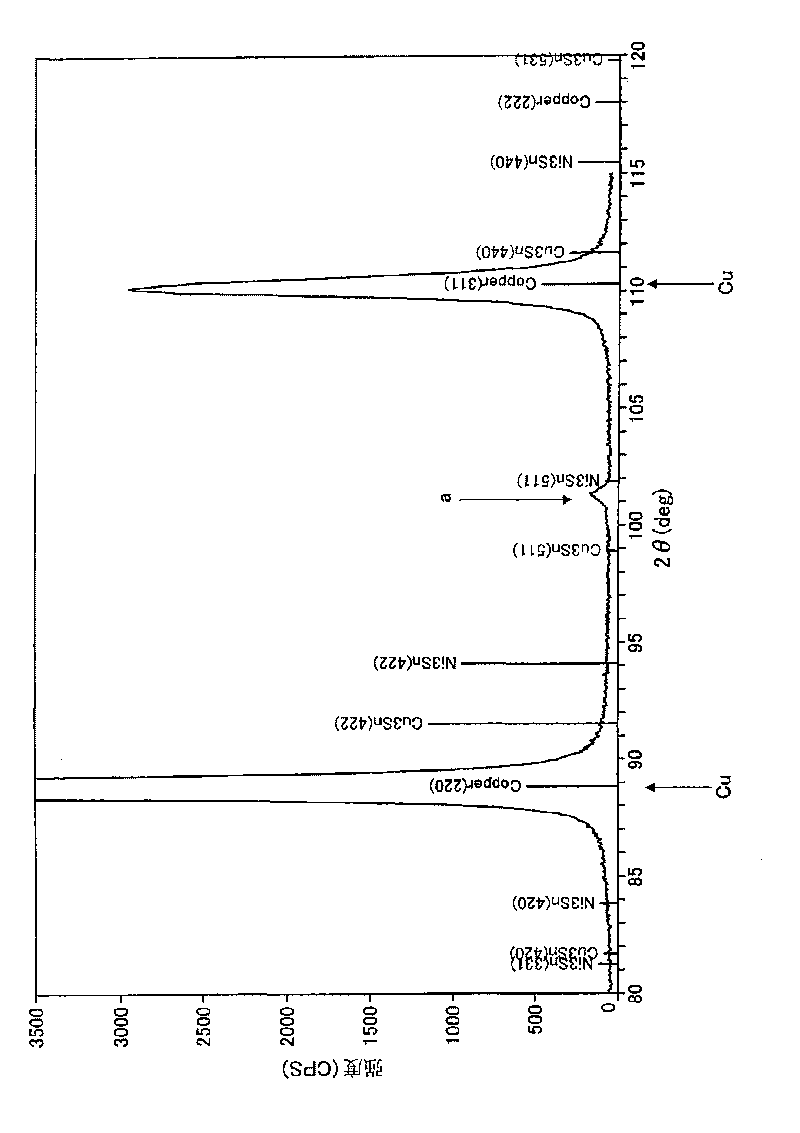

Copper alloy sheet

InactiveCN101743333AControl dislocation densityIncrease the dislocation densityContact member manufacturingCoupling contact membersX-rayStress relaxation

Owner:KOBE STEEL LTD

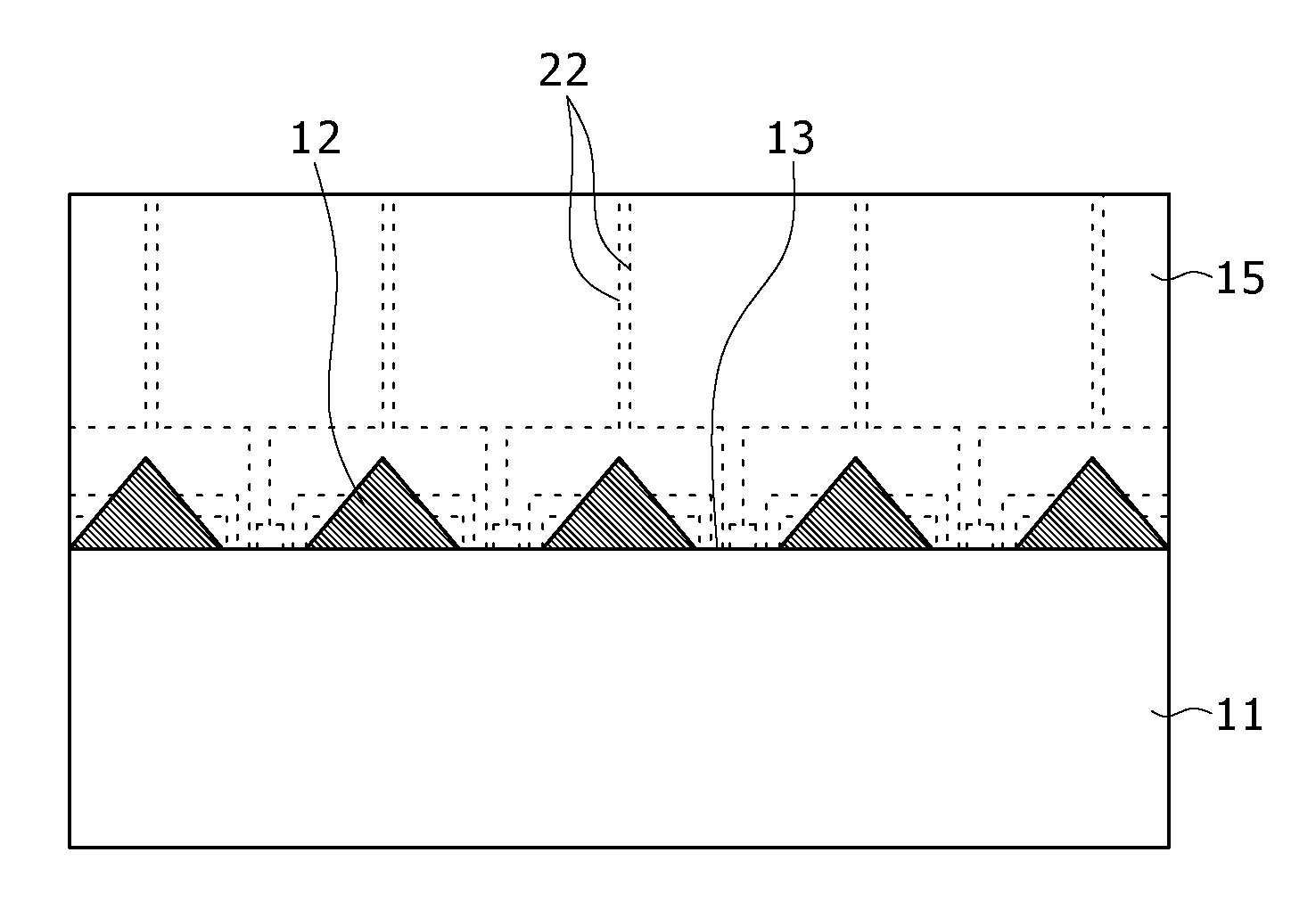

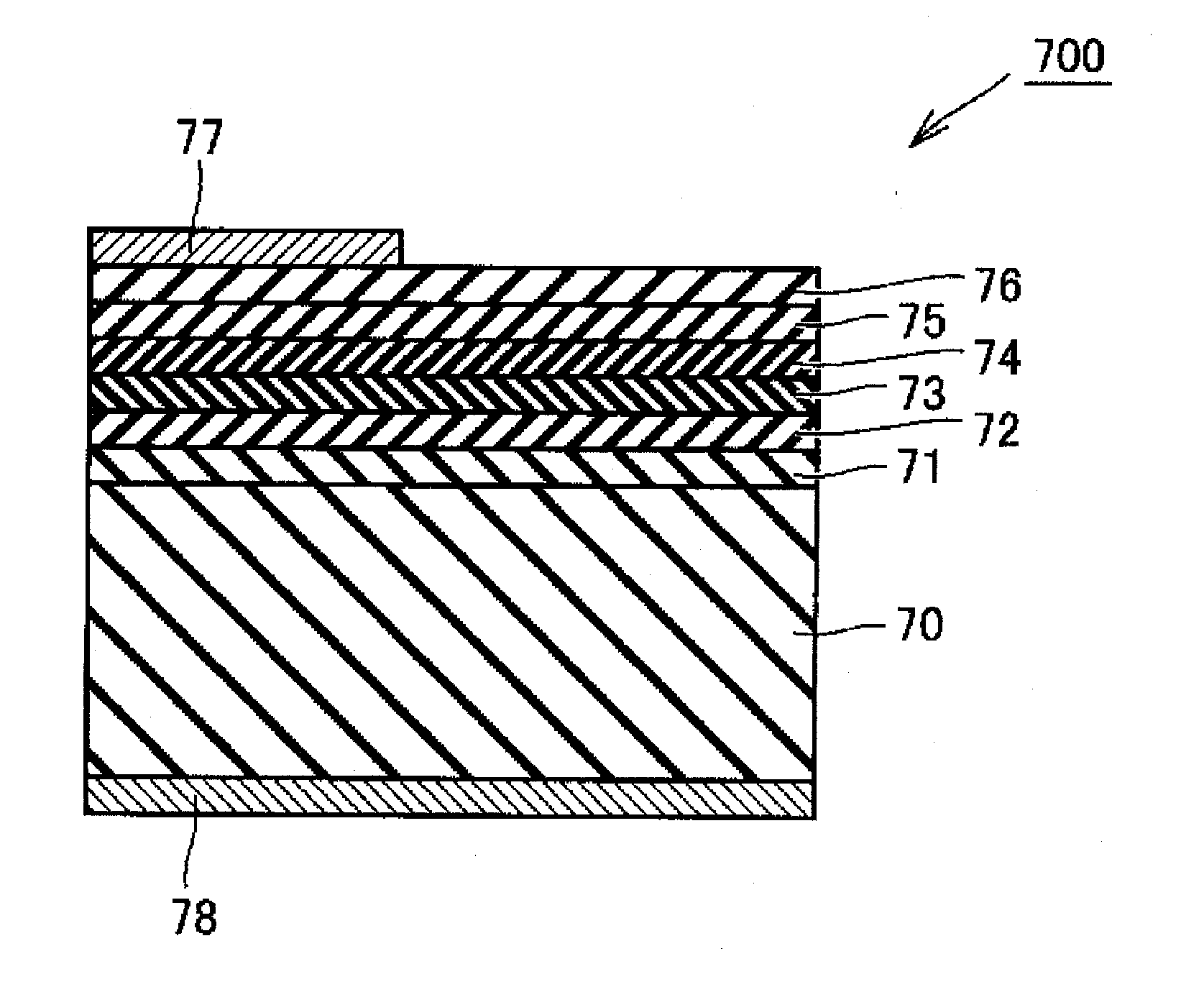

Light-emitting diode and method for manufacturing same, integrated light-emitting diode and method for manufacturing same, method for growing a nitride-based iii-v group compound semiconductor, substrate for growing a nitride-based iii-v group compound semiconductor, light source cell unit, light-emitting diode backlight, light-emitting diode illuminating device, light-emitting diode display and electronic instrument, electronic device and method for manufacturing the same

InactiveUS20110212559A1Low luminous efficiencyLight extraction efficiencyPolycrystalline material growthSolid-state devicesDisplay deviceEngineering

A method for manufacturing a light-emitting diode, which includes the steps of: providing a substrate having a plurality of protruded portions on one main surface thereof wherein the protruded portion is made of a material different in type from that of the substrate and growing a first nitride-based III-V Group compound semiconductor layer on each recess portion of the substrate through a state of making a triangle in section wherein a bottom surface of the recess portion becomes a base of the triangle; laterally growing a second nitride-based III-V Group compound semiconductor layer on the substrate from the first nitride-based III-V Group compound semiconductor layer; and successively growing, on the second nitride-based III-V Group compound semiconductor layer, a third nitride-based III-V Group compound semiconductor layer of a first conduction type, an active layer, and a fourth nitride-based III-V compound semiconductor layer of a second conduction type.

Owner:SONY CORP

High-strength, high-conductivity and heat-resisting aluminum alloy bus and production method thereof

InactiveCN102978490AHigh strengthImprove heat resistanceSingle bars/rods/wires/strips conductorsMetal/alloy conductorsRare earthThermal deformation

The invention discloses a high-strength, high-conductivity and heat-resisting aluminum alloy bus and a production method thereof. The high-strength, high-conductivity and heat-resisting aluminum alloy bus comprises the following components in percentage by mass: 0.4-1.1 percent of magnesium (Mg), 0.3-0.9 percent of silicon (Si), 0.85-2.1 percent of copper (Cu), 0.03-0.3 percent of zirconium (Zr), 0.05-0.38 percent of rare earth (La), less than 0.4 percent of Ferrum (Fe), less than 0.01 percent of manganese (Mn) and the balance of aluminum (Al), wherein the ratio of Cu to Mg is 1.9-2.3. The production method comprises the steps of: uniformly annealing a cast ingot obtained through smelting and casting for 10-20h at a temperature of 470-550 DEG C, furnace-cooling; controlling the temperature of the cast ingot to be 480-540 DEG C for thermally deforming, wherein the final temperature of the thermal deformation is not less than 380 DEG C, the total deformation rate of the thermal deformation reaches 80-94 percent; then carrying out cold deformation on a thermally deformed blank at the total deformation rate of 80-90 percent; annealing the deformed product, wherein the annealing temperature is 330-350 DEG C, the insulation time is 2h; carrying out solution treatment for 1-3h at a temperature of 490-525 DEG C; and carrying out artificial ageing treatment for 24-36h at a temperature of 175-200 DEG C.

Owner:BAOTOU JI TAI RARE EARTH ALUMINUM CO LTD

High-strength corrosion-resistant aluminum alloy profile and preparation method thereof

The invention discloses a high-strength corrosion-resistant aluminum alloy profile and a preparation method thereof. The aluminum alloy profile comprises an aluminum alloy base body and a ceramic coating. The aluminum alloy base body is prepared from Cu, Si, Fe, Cr, Mg, Mn, Zn, Ti, Li, Ni, Zr, Y, W, V and the balance Al. The ceramic coating is prepared from SiC, Cr2O3, NiO, Cr3C2, Al2O3 and Si3N4. According to the high-strength corrosion-resistant aluminum alloy profile, ceramic powder is arranged on the surface of the aluminum alloy base body through plasma cladding, and then laser remelting is conducted, so that the obtained aluminum alloy profile has good mechanical performance such as strength, hardness and impact toughness; and meanwhile, the high-strength corrosion-resistant aluminum alloy profile has the beneficial effects of being resistant to corrosion, good in abrasion resistance, long in service life and the like.

Owner:安徽省煜灿新型材料科技有限公司

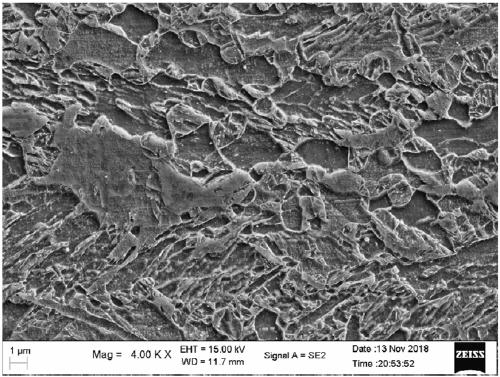

Anti-seismic and fireproof steel for high-strength building structure and preparation method thereof

The invention provides anti-seismic and fireproof steel for a high-strength building structure and a preparation method thereof, and belongs to the field of building steel. The preparation method comprises, 0.04-0.08% of C, 1.0-1.5% of Mn, 0.15-0.60% of Si, 0.2-0.7% of Cr, 0.10-0.60% of Mo, less than or equal to 0.35 of Ti+V+Nb, 0.01-0.05% of Al, 0.1-0.6% of Cu, 0.1-0.6% of Ni, less than or equalto 0.008% of P, less than or equal to 0.002% of S, and the balance iron and inevitable trace chemical elements. Continuous casting is adopted for smelting through a converter or an electric furnace, amedium-thickness plate rolling machine is adopted for rolling, and after rolling is carried out, a steel plate is subjected to heat preservation, quenching and tempering heat treatment processes in an alpha+gamma phase region, and the strength and the yield ratio of a material are controlled by regulating the tissue proportion of bainite, martensite and ferrite; the yield strength is larger thanor equal to 690 MPa, the tensile strength is 850-950 MPa, the elongation at break is larger than or equal to 85%, the percentage elongation after fracture is larger than or equal to 20%, -40 DEG C KV2larger than or equal to 150 J, and the yield strength after heat preservation at 600 DEG C for 3 hours is greater two thirds than the yield strength at room temperature. The preparation method can bewidely applied to high-rise and super-high-rise building steel simultaneously with high-strength, anti-seismic and fireproof requirements and the like.

Owner:UNIV OF SCI & TECH BEIJING

Group III Nitride Crystal Substrate, Method of Its Manufacture, and Group-III Nitride Semiconductor Device

ActiveUS20050164419A1Reduce dislocation densityReduce manufacturing costPolycrystalline material growthFrom normal temperature solutionsVolumetric Mass DensityVapor phase

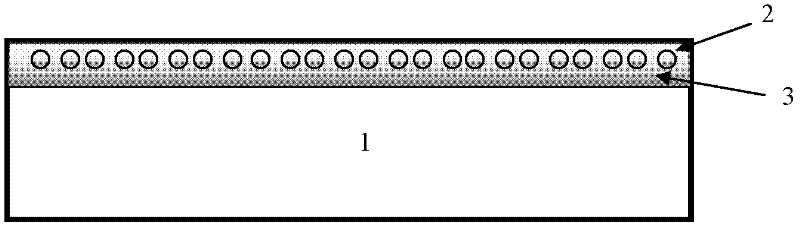

Affords a Group-III nitride crystal substrate that is of low dislocation density and is inexpensive to manufacture, a method of manufacturing such a substrate, and Group-III nitride semiconductor devices that incorporate the Group-III nitride crystal substrate. The Group-III nitride crystal substrate manufacturing method includes: a step of growing, by liquid-phase epitaxy, a first Group-III nitride crystal (2) onto a base substrate (1); and a step of growing, by vapor-phase epitaxy, a second Group-III nitride crystal (3) onto the first Group-III nitride crystal (2). The Group-III nitride crystal substrate, produced by such a manufacturing method, has a dislocation density of 1×107 dislocations / cm2.

Owner:SUMITOMO ELECTRIC IND LTD

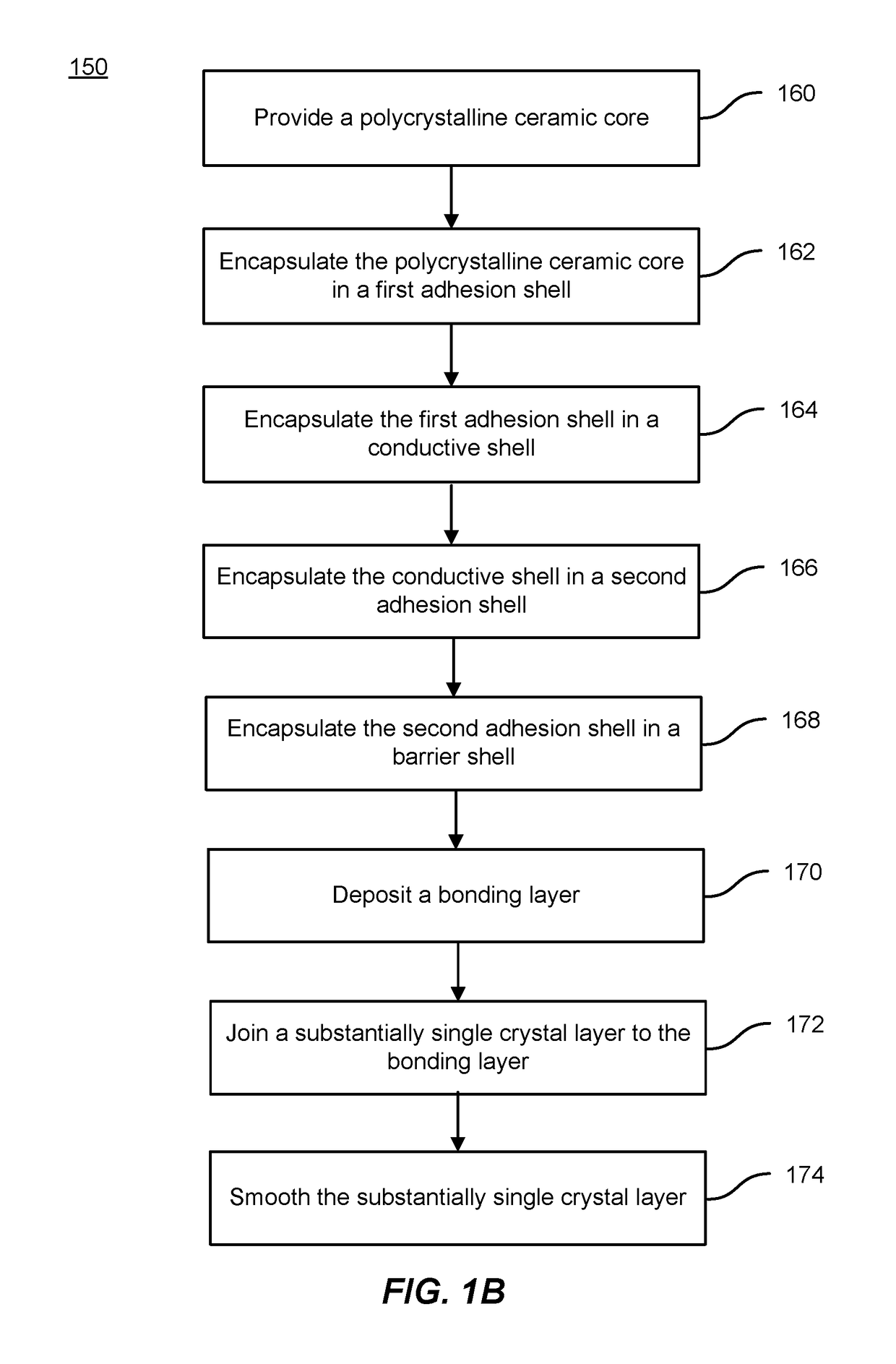

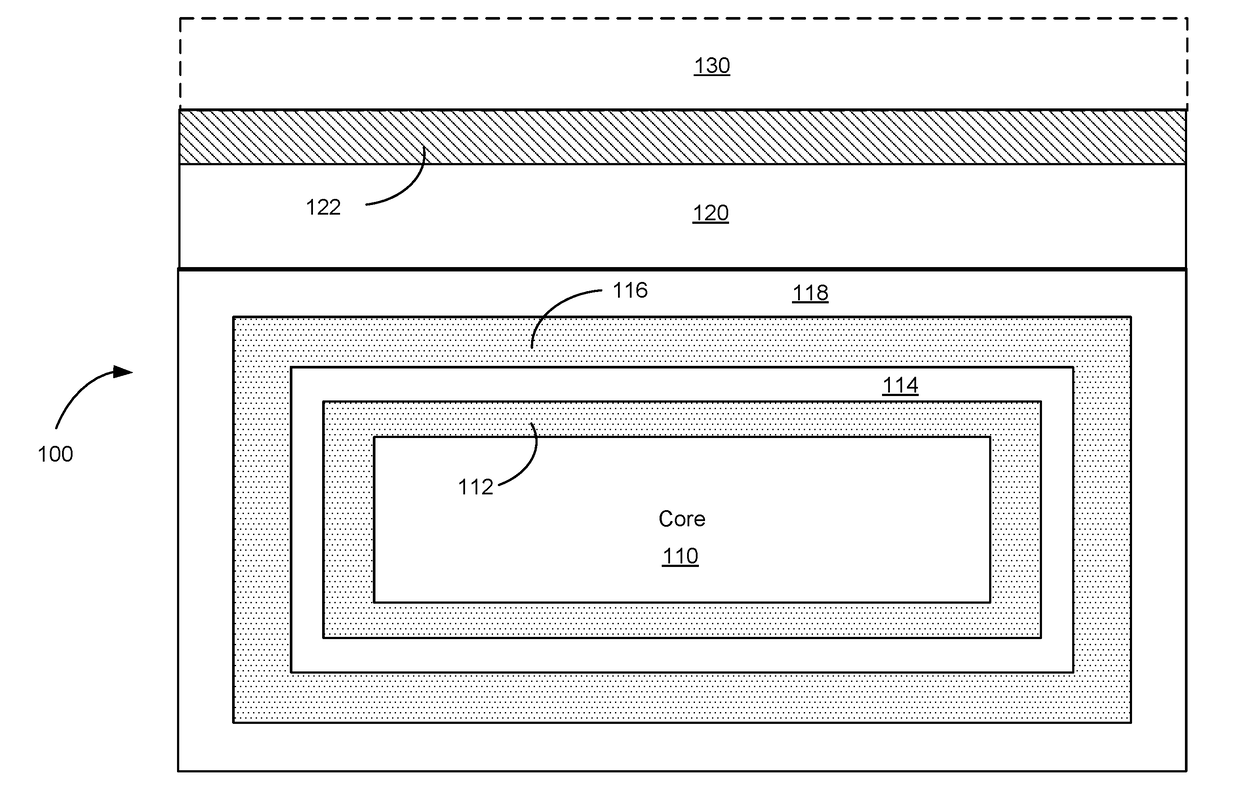

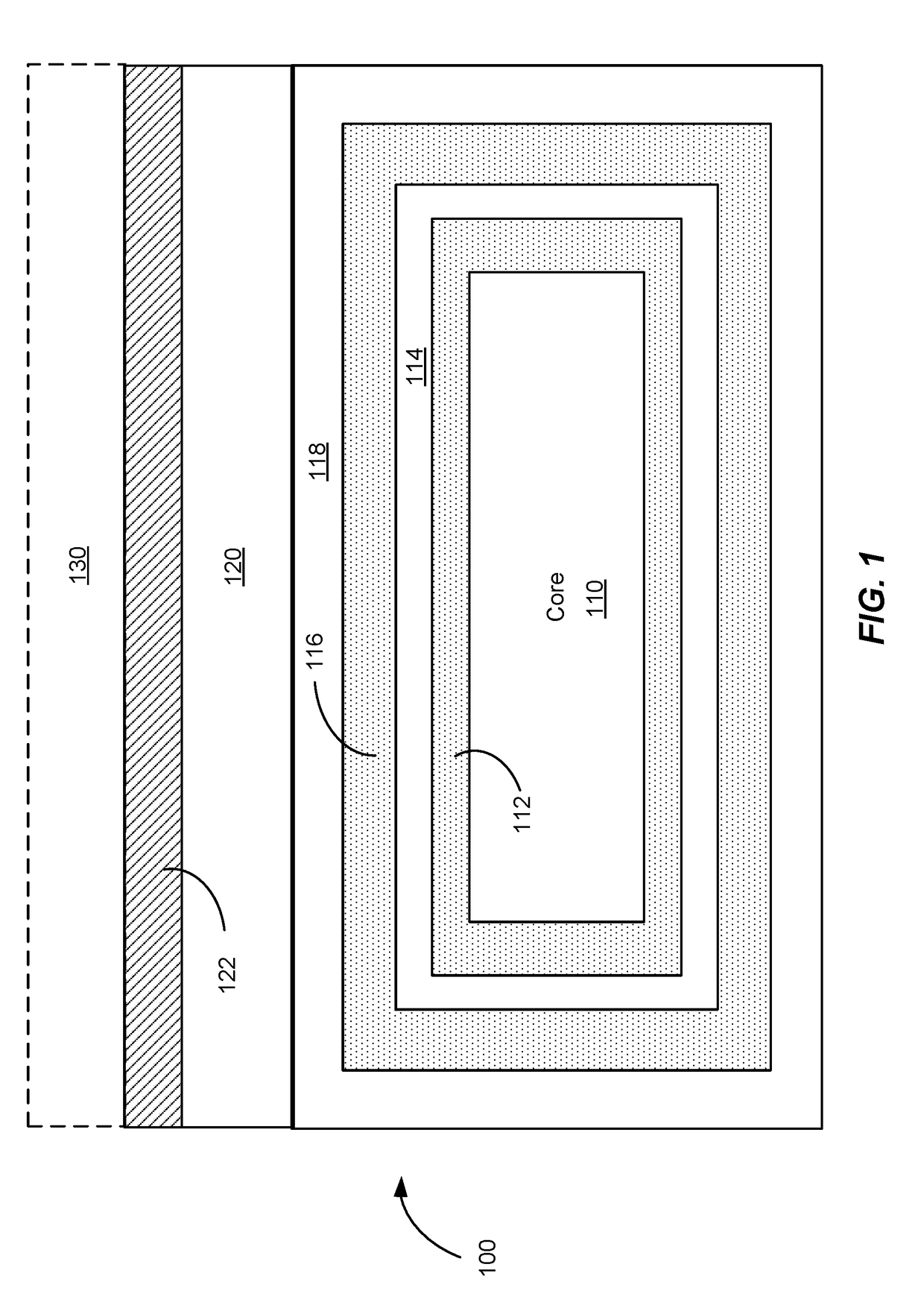

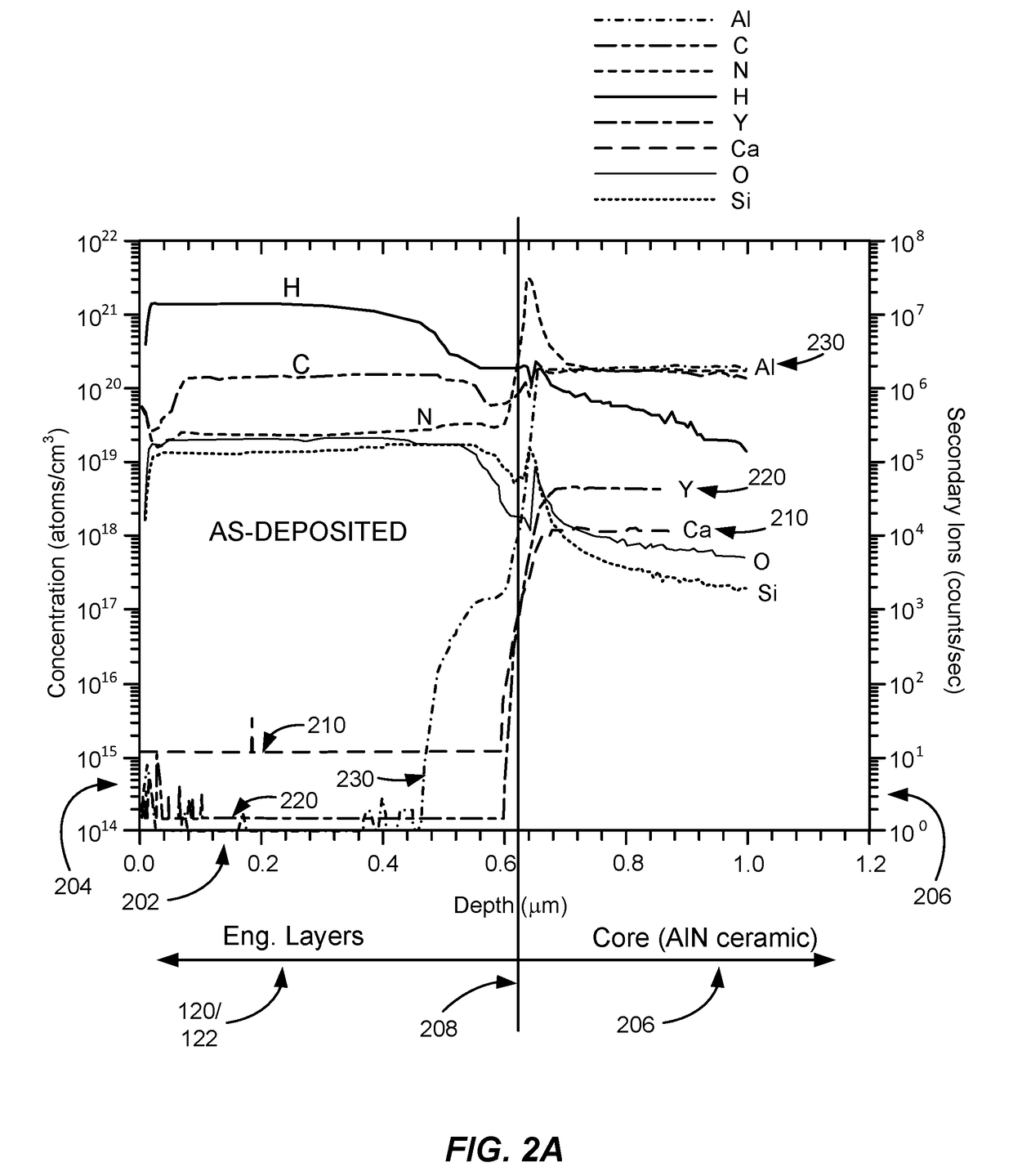

Polycrystalline ceramic substrate and method of manufacture

ActiveUS20180047557A1Relieve pressureIncrease the dislocation densityPolycrystalline material growthSolid-state devicesMetallurgyCeramic substrate

A method of fabricating a ceramic substrate structure includes providing a ceramic substrate, encapsulating the ceramic substrate in a barrier layer, and forming a bonding layer coupled to the barrier layer. The method further includes removing a portion of the bonding layer to expose at least a portion of the barrier layer and define fill regions, and depositing a second bonding layer on the at least a portion of the exposed barrier layer and the fill regions.

Owner:QROMIS INC

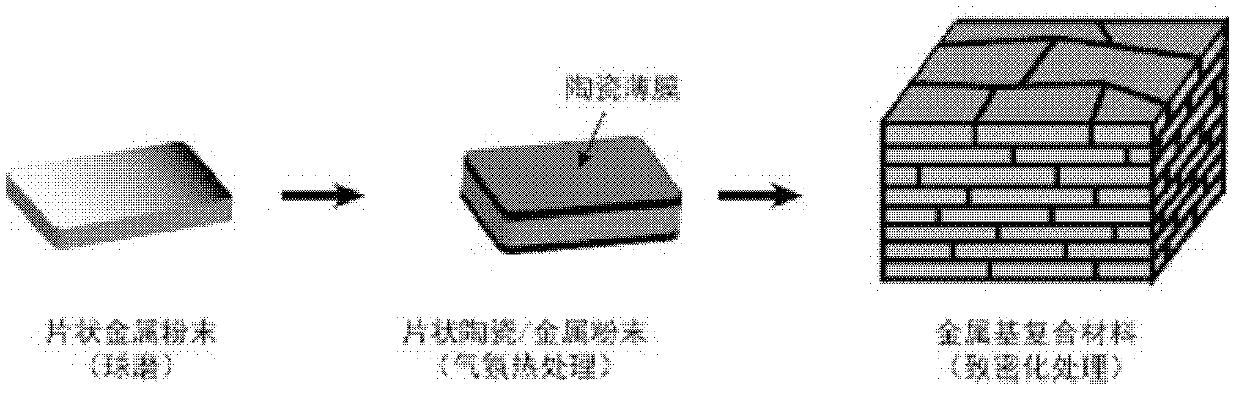

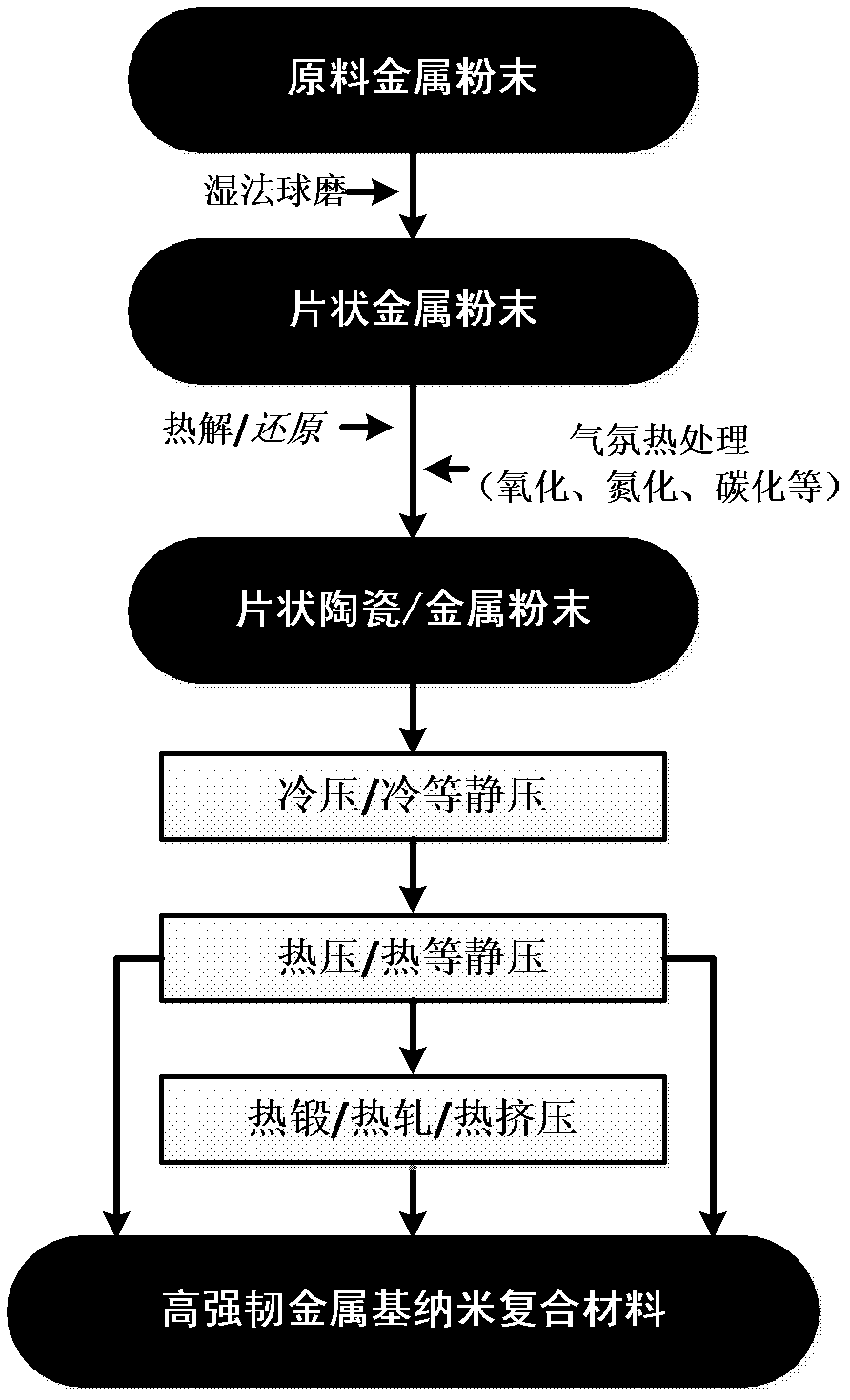

Preparation method of high-toughness metal-based nanometer composite material

The invention provides a preparation method of a high-toughness metal-based nanometer composite material and belongs to the technical field of composite materials. The preparation method provided by the invention comprises the following steps of: firstly, using an atmosphere heat treatment process, generating a layer of a nanometer ceramic thin film on the sheet-shaped metal powder through reaction in-situ; and then carrying out densifying treatment by using a powder metallurgical process, so as to obtain the large compact metal-based composite material. The metal-based composite material prepared by the invention has a metal / ceramic alternative laminated structure, wherein a ceramic layer can be used for effectively restraining the reply of a metal layer and the crystal grain growth, improving the high-position wrong storage capability, keeping a nanometer crystal matrix structure, and causing the rotation and inactivation of fissures, so as to realize mechanical properties matched with the high toughness. The preparation method provided by the invention is simple, convenient and practicable, can be used for realizing the macro-quantized preparation of the large-size composite material, and is good for prompting engineering applications of the metal-based nanometer composite material.

Owner:SHANGHAI JIAO TONG UNIV

A method for obtaining low bit discrepancy density extension thin film via using neck down extension

InactiveCN101150054AGood surface roughnessIncrease concentrationSemiconductor/solid-state device manufacturingDislocationOptoelectronics

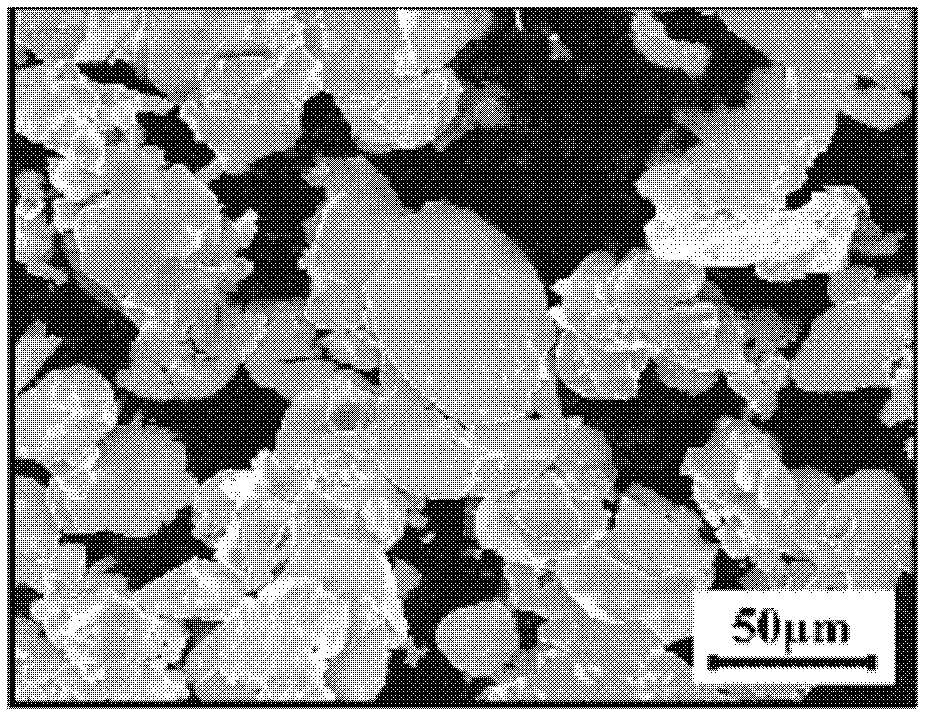

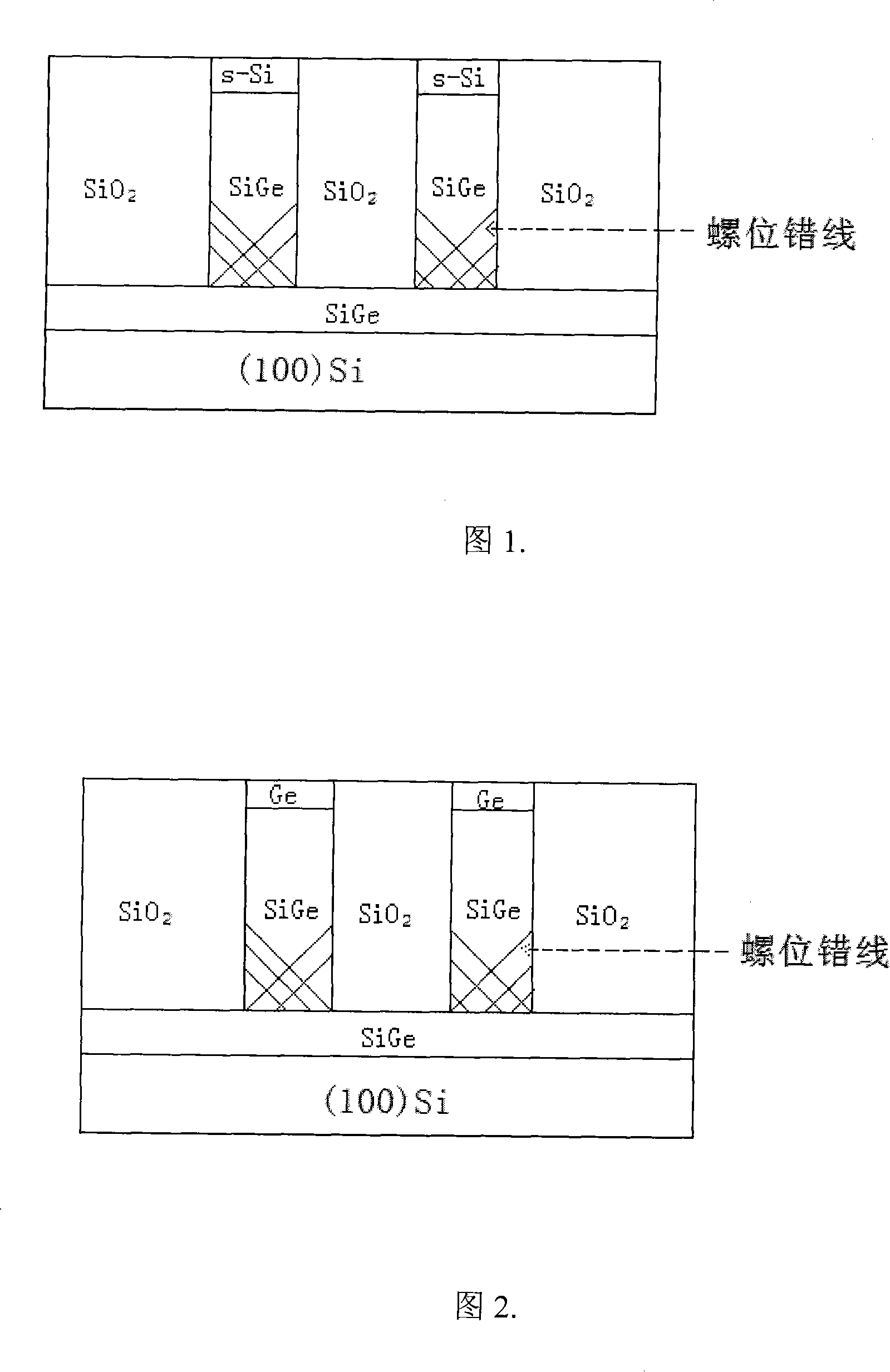

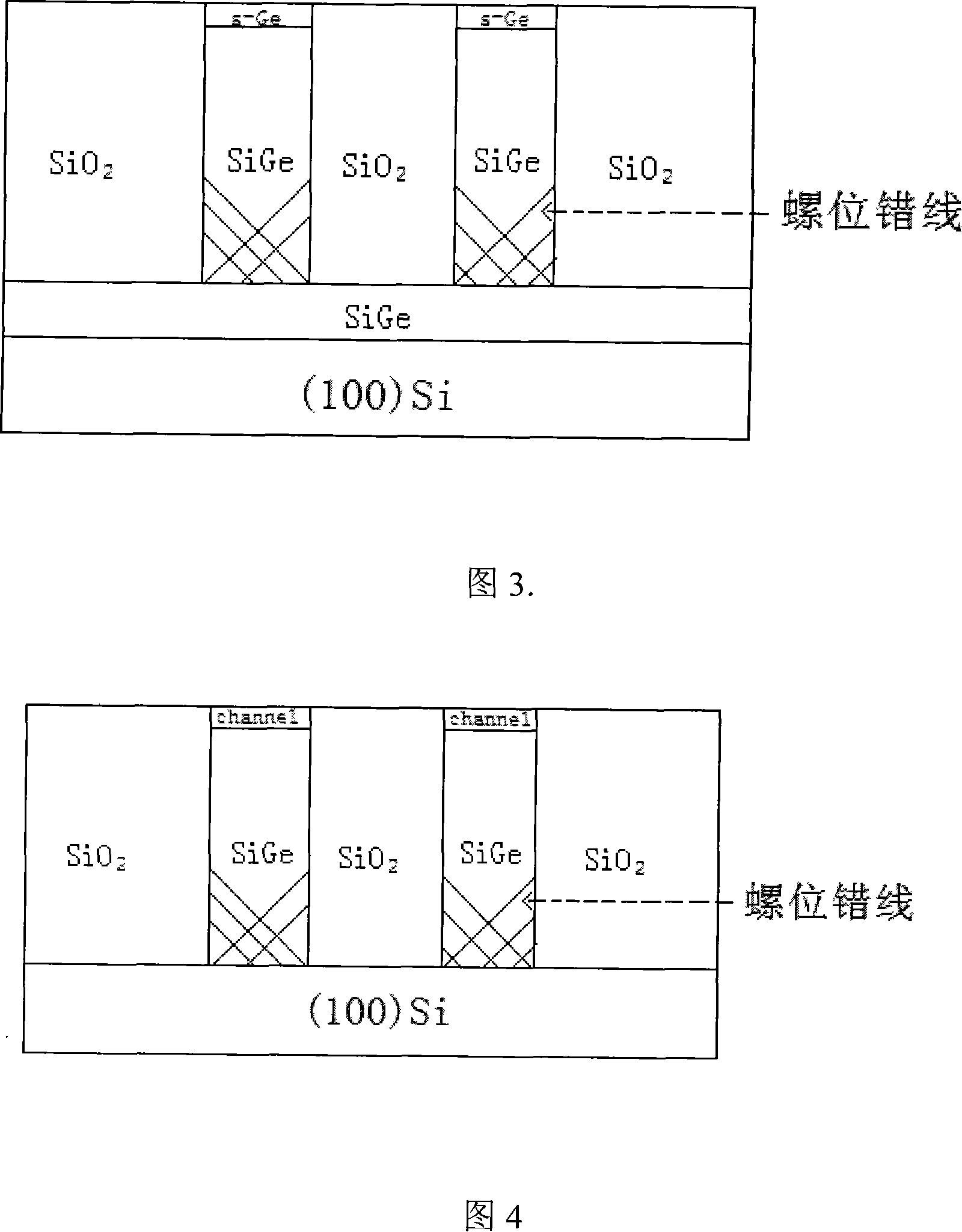

This invention discloses a method for using necking extension to get extension films of low dislocation density, which utilizes deposition, selective extension and thermal oxidation to prepare GeSi substrates of low dislocation density and channels of high migration rate and gets films of exremely low dislocation density on a silicon wafer meeting the requirement of MOS devices or luminescent devices.

Owner:JIANGXI SORNID HI TECH

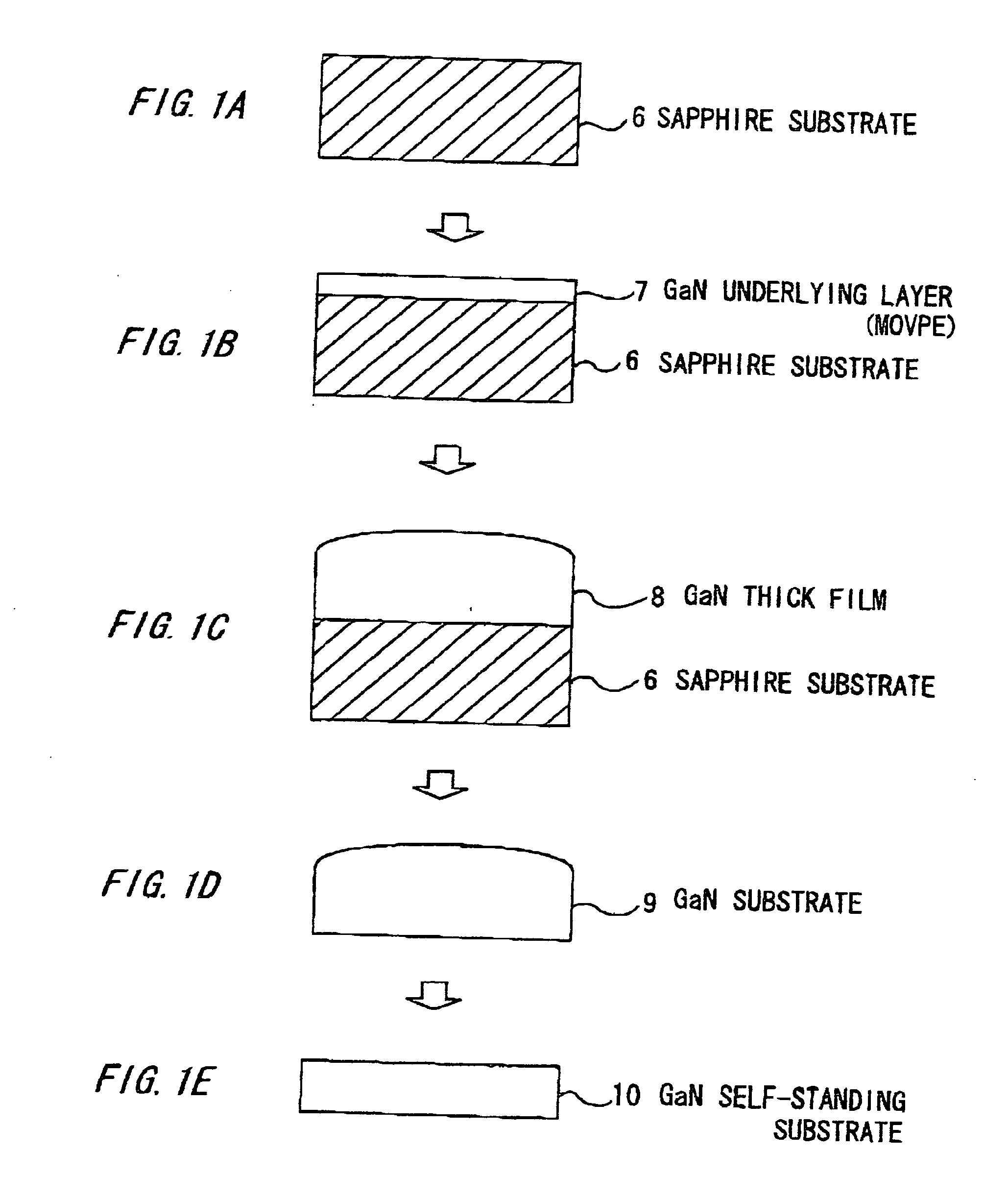

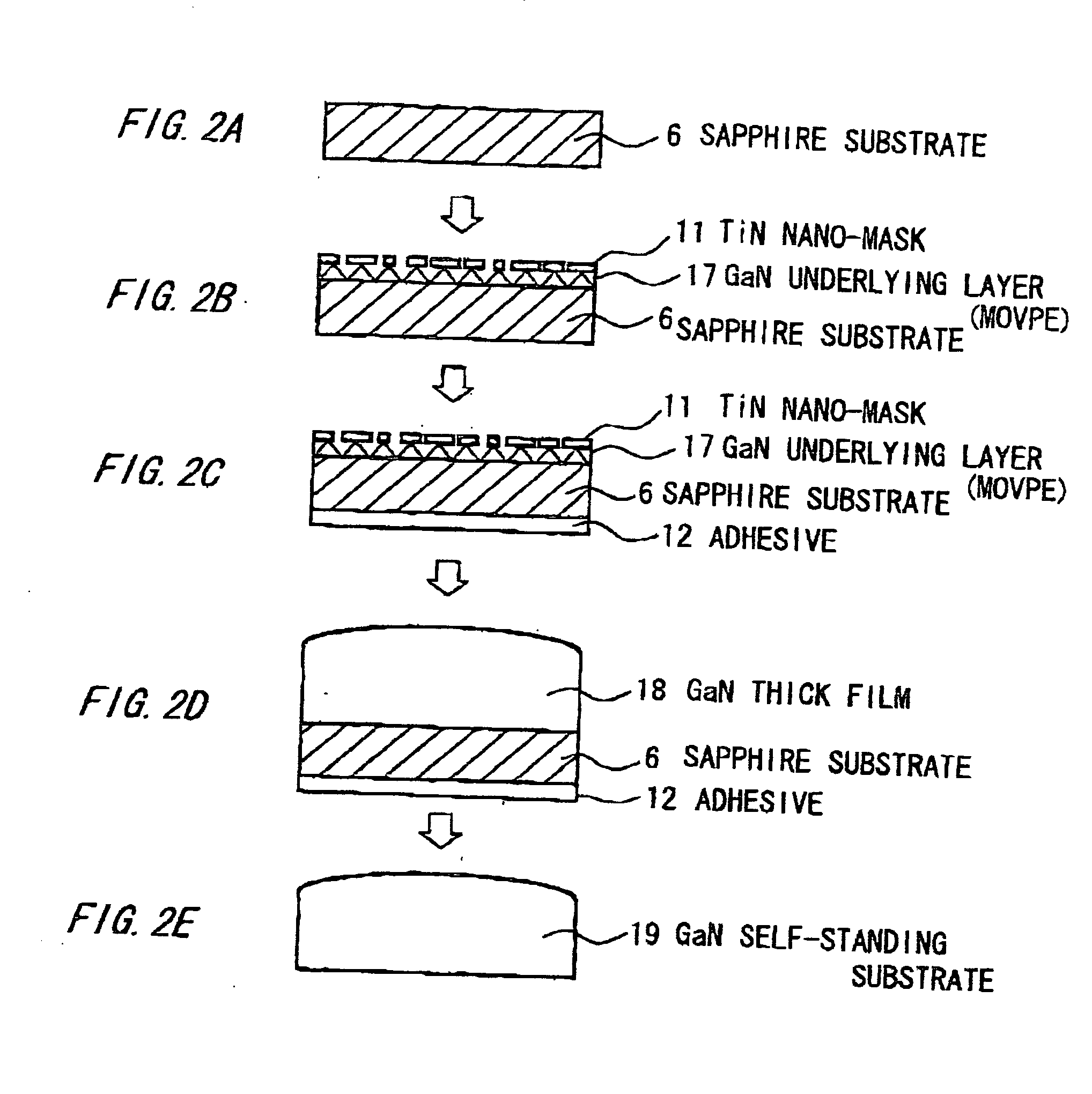

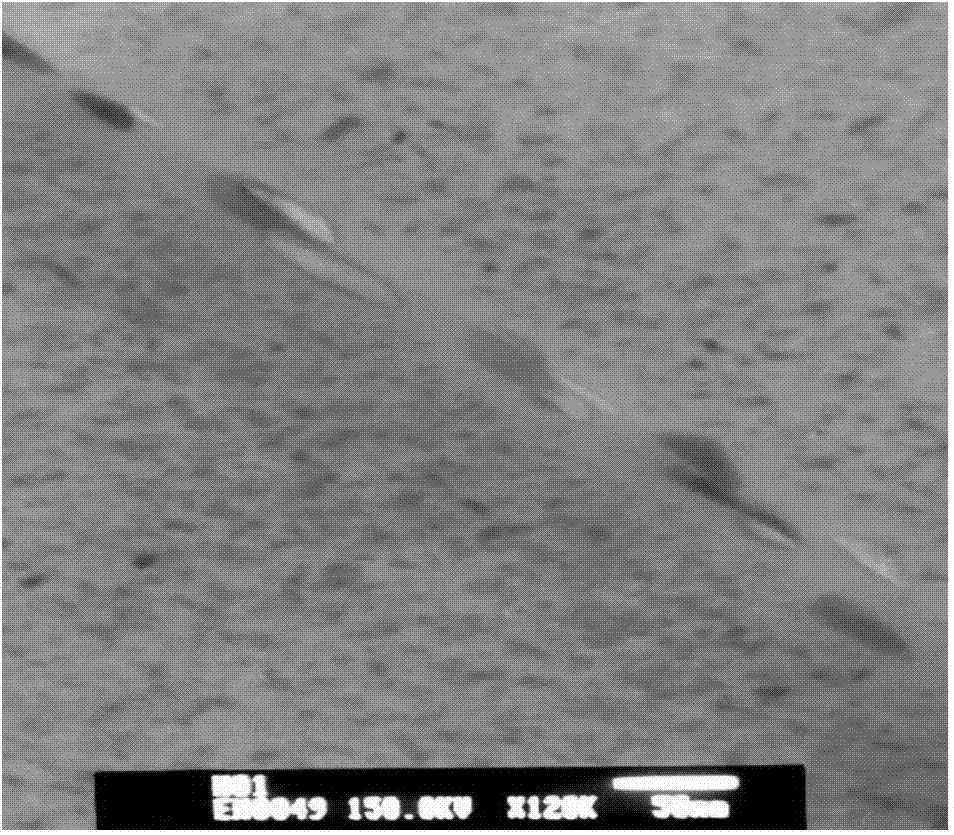

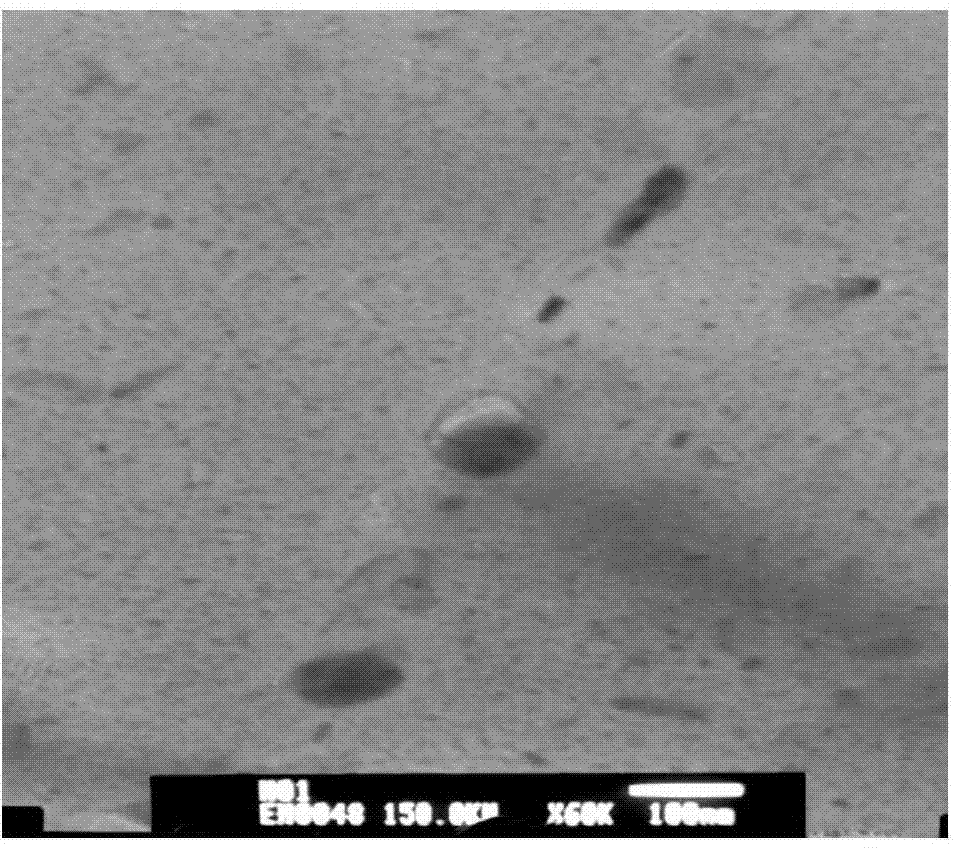

Technology for obtaining large-area high-quality GaN self-supporting substrate

InactiveCN1381870AQuality improvementIncrease the dislocation densitySemiconductor/solid-state device manufacturingGas phaseLaser scanning

A process for preparing large-area high-quality self-supporting GaN substrate includes such steps as firstly transversely expitaxying on a sapphire substrate to obtain low-dislocation-density GaN film, then gas-phase epitaxying of hybride on ELO GaN film to obtain low-dislocation-density large-area thick GaN film, stripping the thick GaN film without damage by laser scan and radiation, and polishing the surface.

Owner:NANJING UNIV

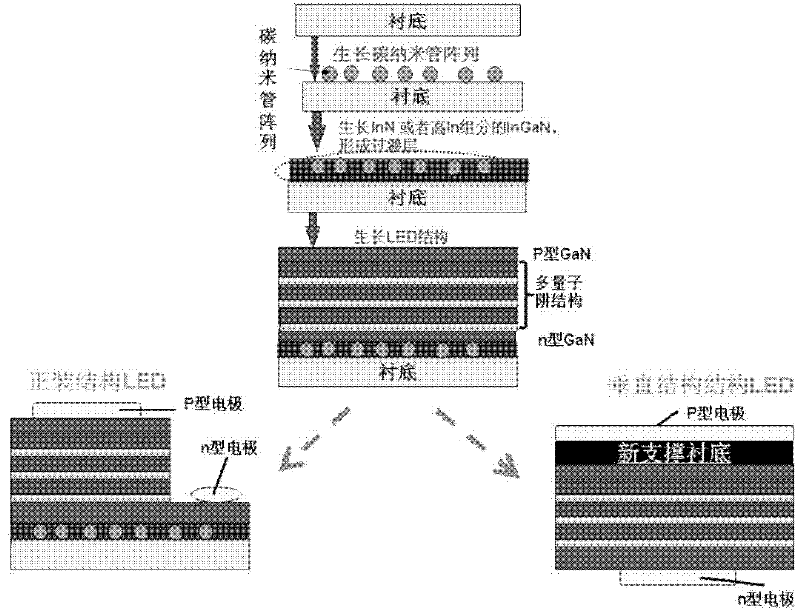

Method for preparing light emitting diode

InactiveCN102244162AQuality improvementImprove luminous efficiencySemiconductor devicesCarbon nanotubeLight-emitting diode

The invention provides a method for preparing an LED (light emitting diode) and belongs to the field of preparation of a photoelectronic device. The method comprises the following steps of: forming a transition layer consisting of a carbon nano tube and InN or a high In component InGaN epitaxial layer material on a substrate; growing an LED epitaxial wafer on the transition layer; carrying out photoetching, etching, electrode deposition and packaging process on the LED epitaxial wafer to prepare the LED with a positively assembled structure; or transferring the substrate, carrying out laser stripping and separation on the substrate and then carrying out photoetching, etching, electrode deposition and packaging process to prepare the LED with a vertical structure. According to the method, the crystal quality can be improved, but also the stress regulation and control can be realized.

Owner:北京燕园中镓半导体工程研发中心有限公司

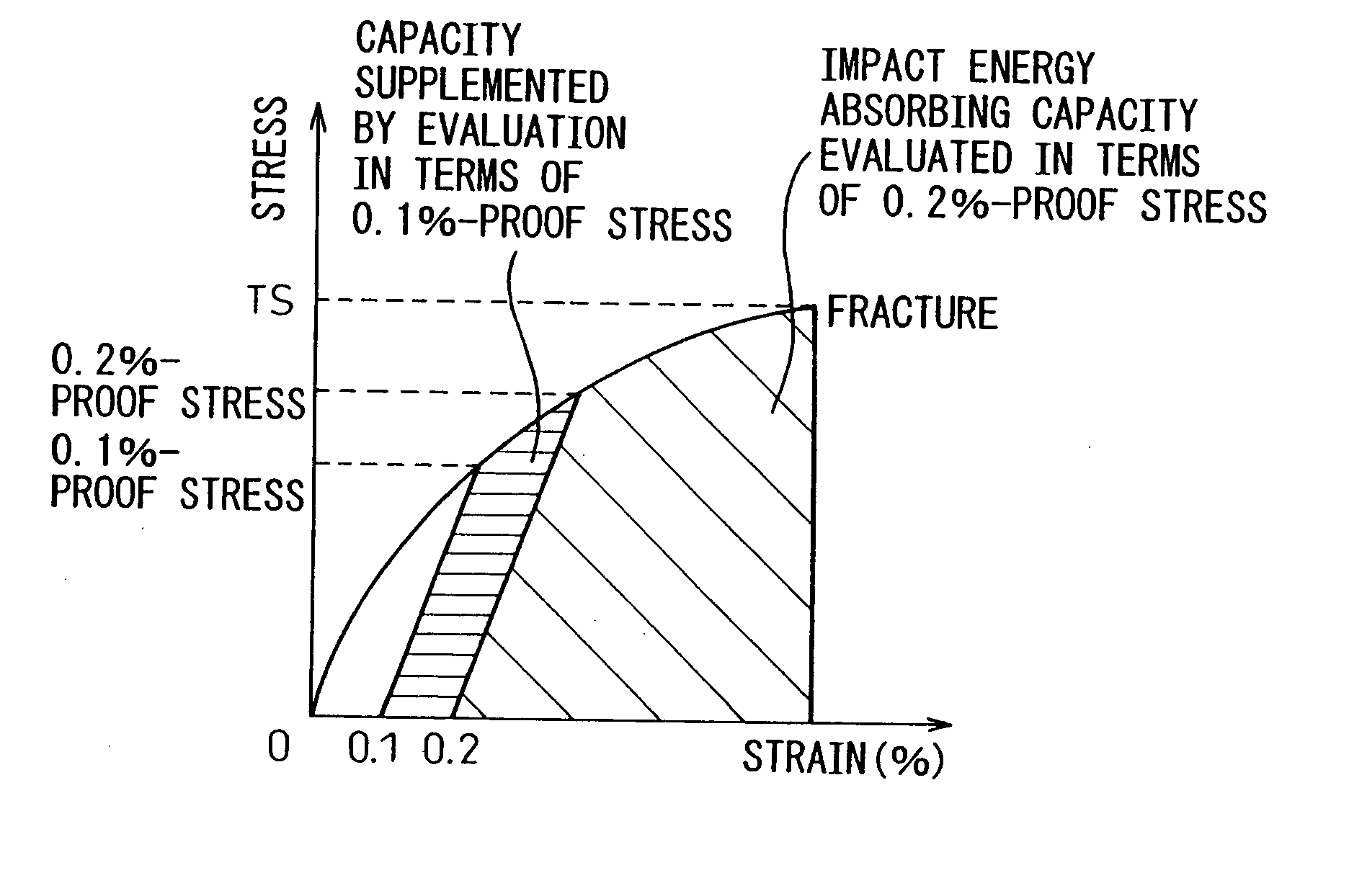

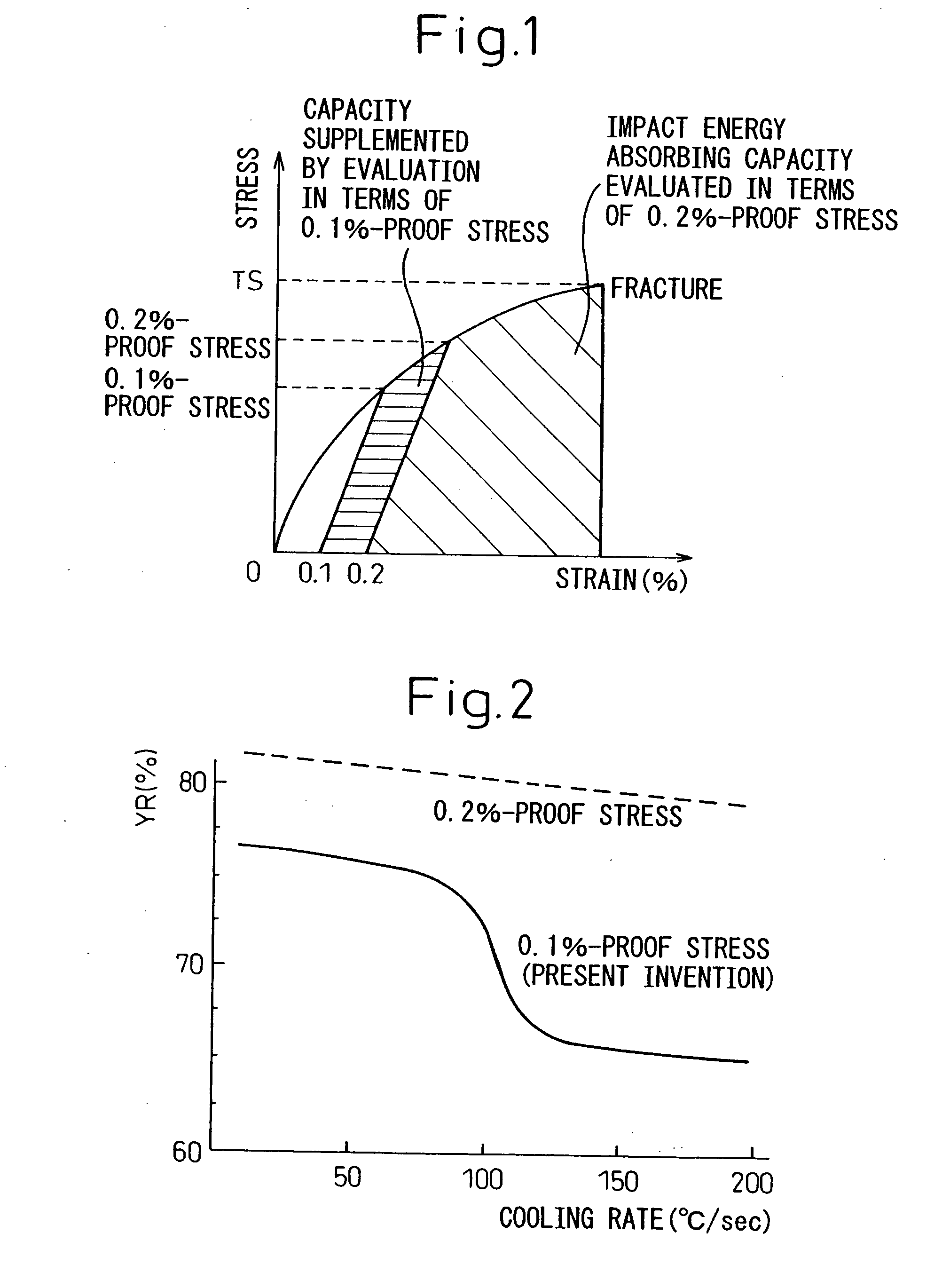

Highly impact-resistant steel pipe and method for producing the same

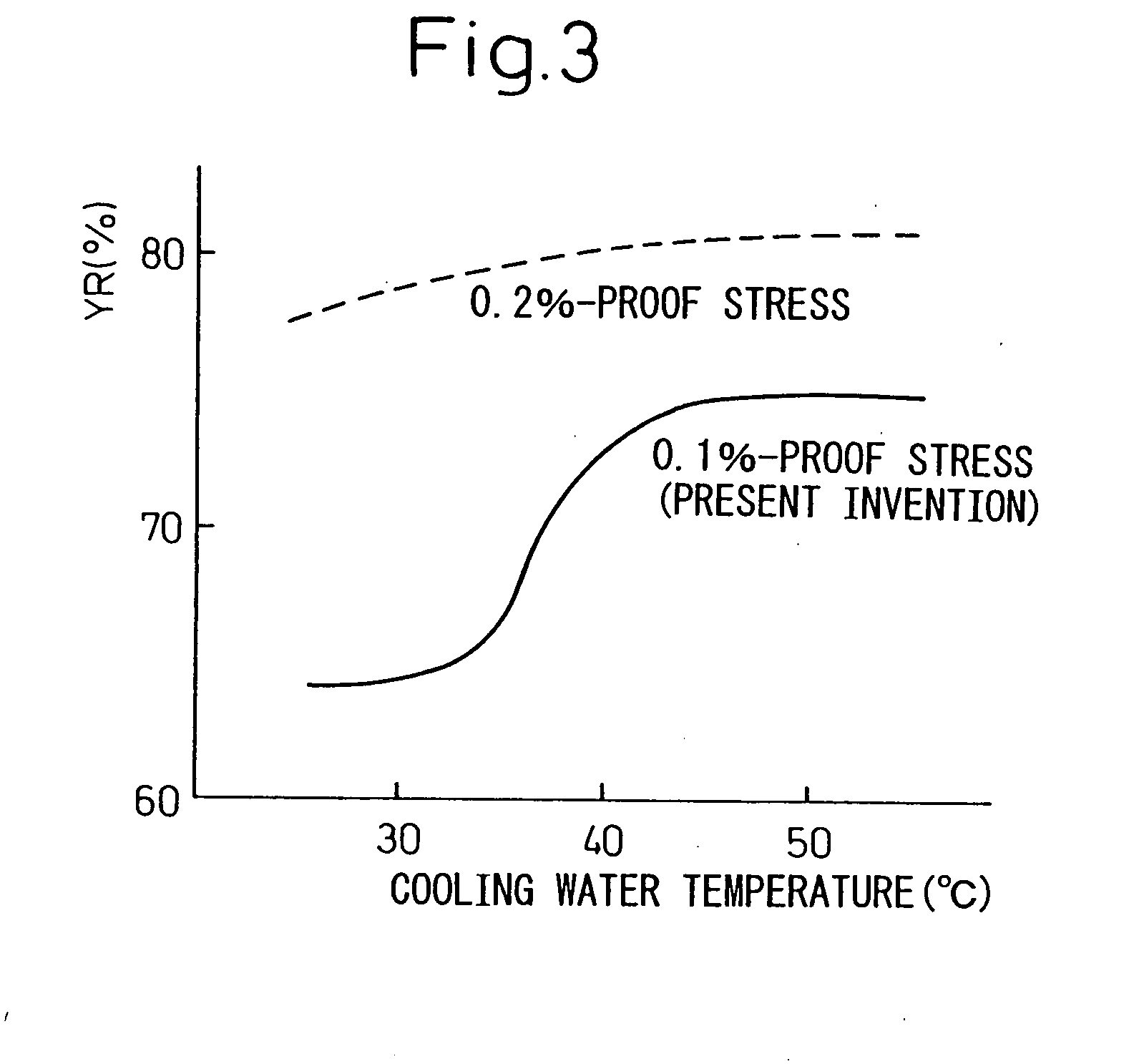

InactiveUS20050034795A1High strengthReduce the ratioIncreasing energy efficiencyFurnace typesYield ratioToughness

A highly impact-resistant member has a round or square sectional shape, that is excellent in strength and toughness, does not undergo the deterioration of toughness in the vicinity of the welded portion, and a highly impact-resistant steel pipe has a tensile strength TS of 1,700 MPa or more and a yield ratio YR of 72% or less, the yield ratio being the ratio of a 0.1%-proof stress YS to a tensile strength TS (YS / TS). The toughness of the welded portion of the steel pipe is enhanced by controlling the Si amount in the steel of the steel pipe in the range from Mn / 8−0.07 to Mn / 8+0.07. The steel contains, in mass, 0.19 to 0.35% C, 0.10 to 0.30% Si, 0.5 to 1.60% Mn, not more than 0.025% P, not more than 0.01% S, 0.010 to 0.050% Al, 2 to 35 ppm B and 0.005 to 0.05% Ti as indispensable components.

Owner:NIPPON STEEL CORP

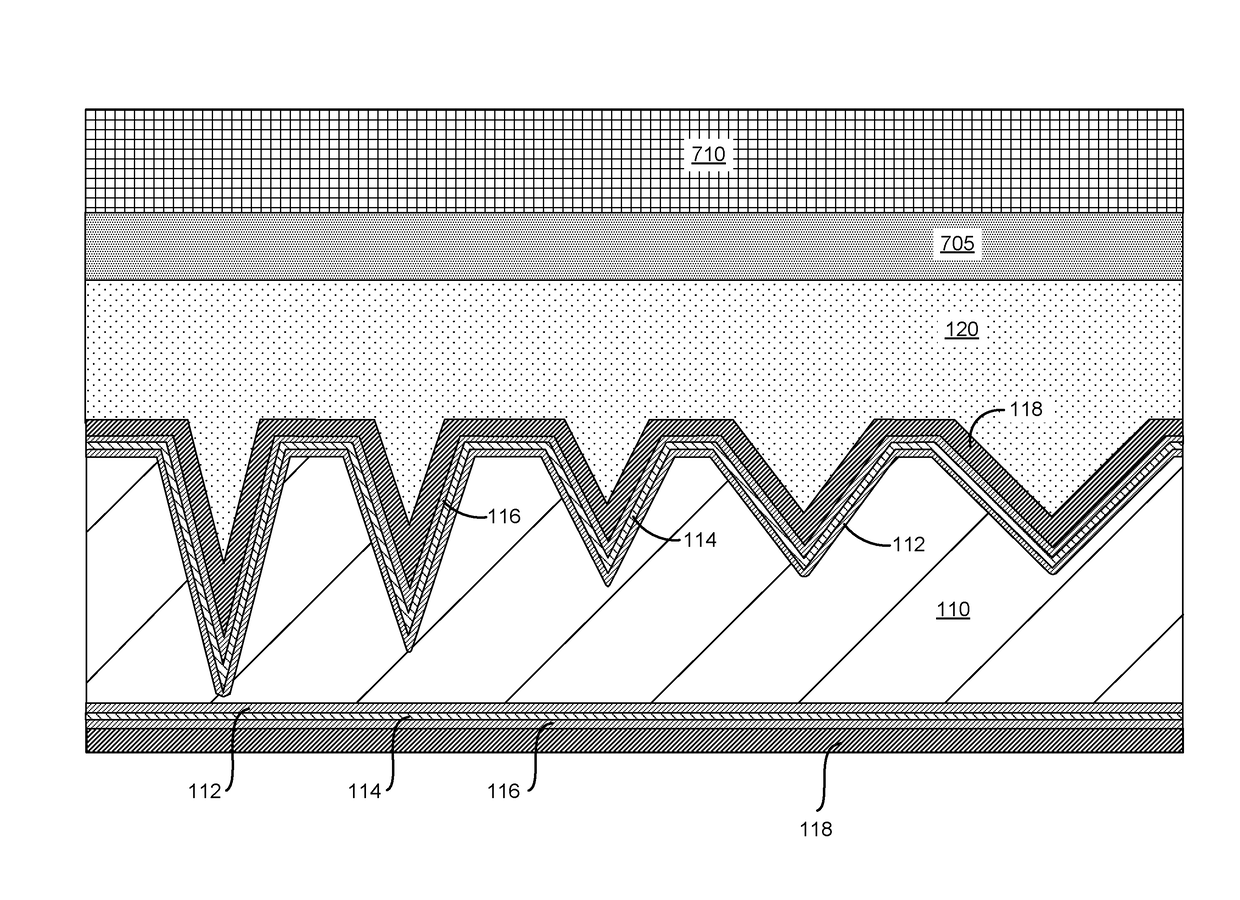

Vertical semiconductor diode manufactured with an engineered substrate

ActiveUS20180061630A1Relieve pressureIncrease the dislocation densityPolycrystalline material growthSolid-state devicesSingle crystalGallium nitride

A semiconductor diode includes an engineered substrate including a substantially single crystal layer, a buffer layer coupled to the substantially single crystal layer, and a semi-insulating layer coupled to the buffer layer. The semiconductor diode also includes a first N-type gallium nitride layer coupled to the semi-insulating layer and a second N-type gallium nitride layer coupled to the first N-type gallium nitride layer. The first N-type gallium nitride layer has a first doping concentration and the second N-type gallium nitride layer has a second doping concentration less than the first doping concentration. The semiconductor diode further includes a P-type gallium nitride layer coupled to the second N-type gallium nitride layer, an anode contact coupled to the P-type gallium nitride layer, and a cathode contact coupled to a portion of the first N-type gallium nitride layer.

Owner:QROMIS INC

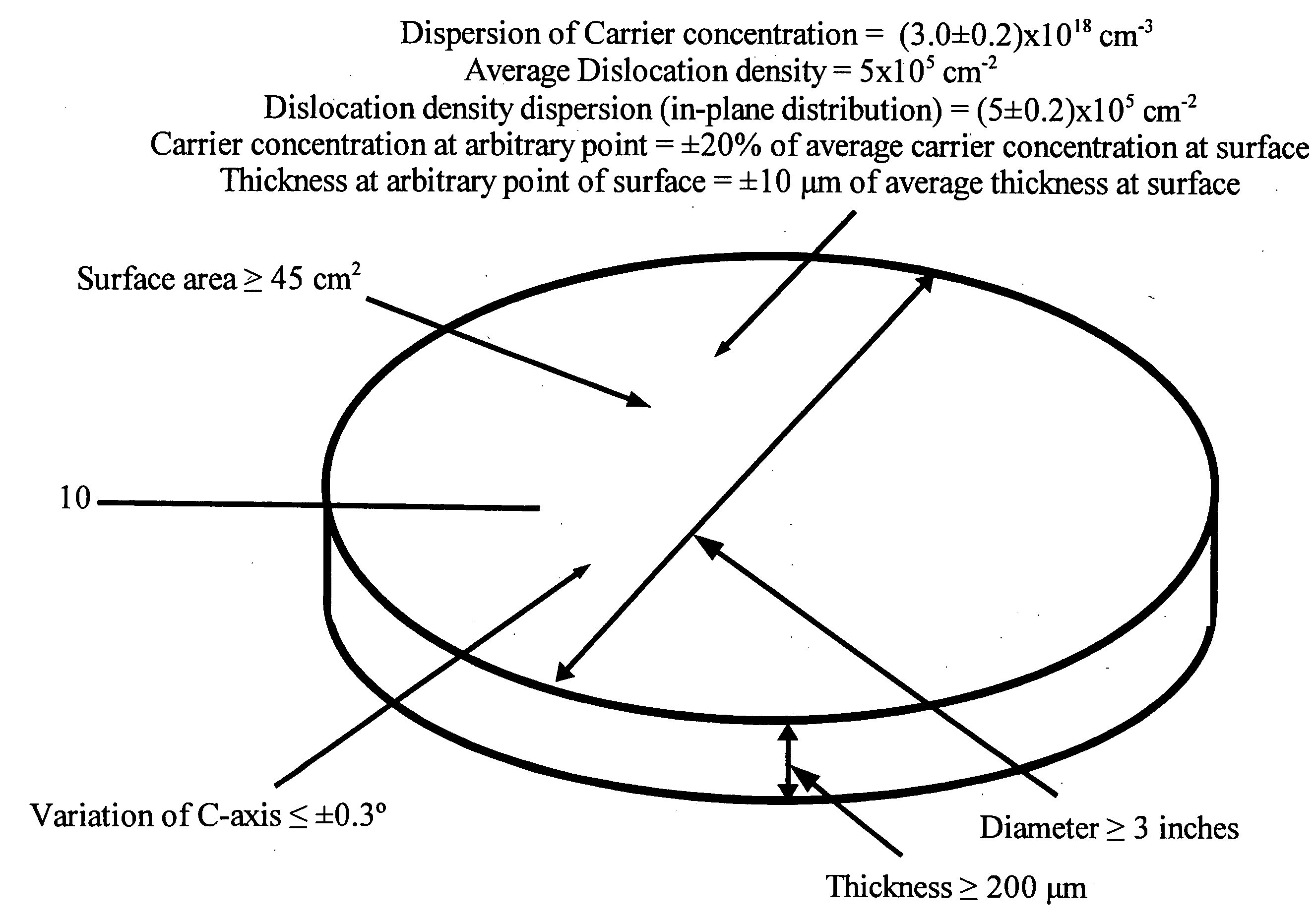

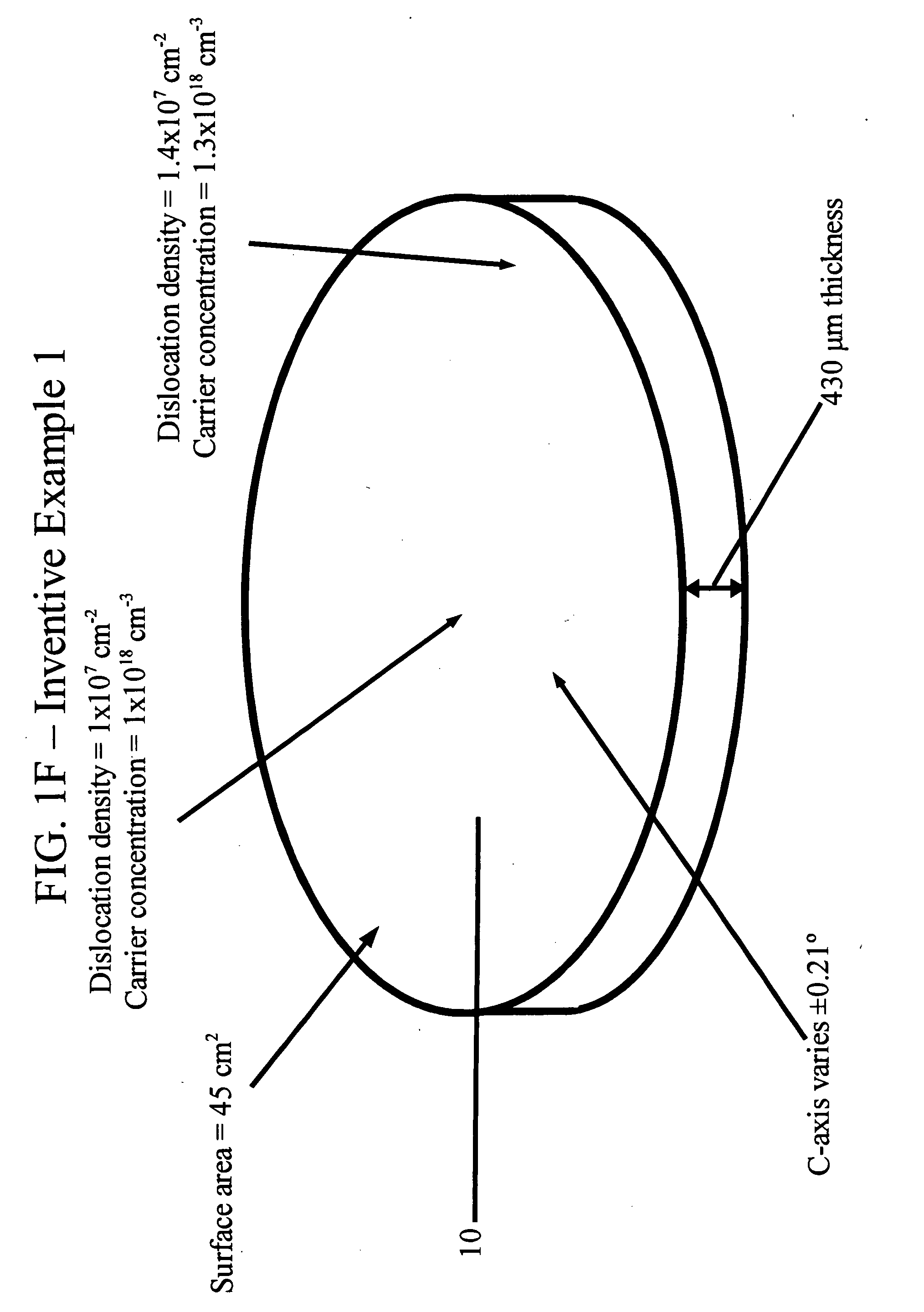

Group III-V nitride based semiconductor substrate and method of making same

ActiveUS20100200955A1Uniform propertyImpurities increasePolycrystalline material growthSemiconductor/solid-state device manufacturingIn planeDislocation

A group III-V nitride-based semiconductor substrate includes a group III-V nitride-based semiconductor crystal. A surface area of the substrate is greater than or equal to 45 cm2. A thickness of the substrate is greater than or equal to 200 μm. An in-plane dislocation density of the substrate is less than or equal to 2×107 cm−2 in average. The in-plane dislocation density of the substrate is less than or equal to 150% of the average at maximum.

Owner:SUMITOMO CHEM CO LTD

Manufacturing process of high-strength aluminum alloy ring forge

ActiveCN106363352AImprove the problem of low mechanical propertiesAchieve productionNumerical controlHigh intensity

The invention relates to a manufacturing process of a high-strength aluminum alloy ring forge. The manufacturing process comprises the following operation steps of blank purchasing, blank cut-off, heating of the forge, blank forming, machining of an inner hole, heating, broaching of a mandrel supporter, return heating, ring milling, cooling, curing, cold deformation, aging and machining to the required dimension. Through combination of the multiway improving forging technology, the mandrel supporter broaching technology, the lubricating technology, the numerical control ring-milling technology, the high-intensity thermal treatment technology and the cold deformation technology, the problems that an existing aluminum alloy ring forge is low in overall performance, nonuniform in mechanical property, obvious in anisotropism and the like.

Owner:WUXI PAIKE HEAVY CASTING & FORGING

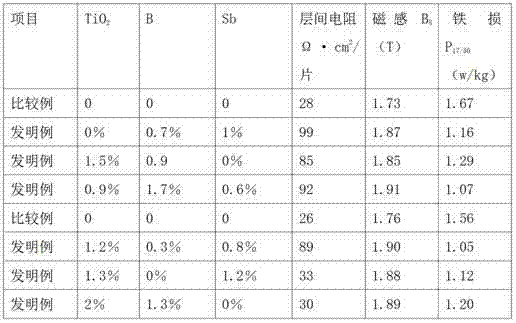

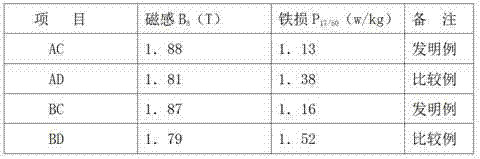

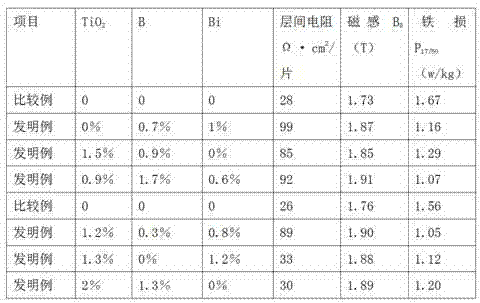

Production method for improving insulating property by adding trace elements in oriented silicon steel barrier-coat

The invention discloses a production method for improving the insulating property by adding trace elements in an oriented silicon steel barrier-coat. The production method comprises the following steps of smelting, processing in vacuum, refining and continuously casting into a blank; carrying out hot rolling; normalizing and acid pickling; carrying out once cold rolling, wherein the reduction rate is greater than or equal to 82%; decarbonizing and annealing, wherein the temperature is 750-890 DEG C, the atmosphere dew-point temperature is 25-75 DEG C, the decarbonization time is 90-350 seconds, and the total oxygen [O] of the surface of a steel belt is greater than or equal to 170 / t and less than or equal to 315 / t; coating a magnesium oxide coating added with trace elements on the surface of the steel belt; carrying out high temperature annealing, wherein the atmosphere dew-point temperature is less than or equal to 30 DEG C, two low thermal insulation steps and one high thermal insulation step are arranged, and the nitridation amount of nitrogen is greater than or equal to 16ppm; stretching and smoothing and annealing, namely, coating, annealing and smoothing. In high temperature annealing stage, silicon dioxide and magnesium oxide on the surface of the steel belt carry out chemical reaction so as to generate a magnesium silicate bottom layer, and additives are added into the magnesium oxide coating so as to help to obtain excellent finished product magnetism and good magnesium silicate bottom layer.

Owner:新万鑫(福建)精密薄板有限公司

Treatment method for improving alloy material strength, toughness, and anti-fatigue life

The invention discloses a treatment method for improving alloy material strength, toughness, and anti-fatigue life. The method comprises solid solution and aging treatments. The method also comprises cryogenic cooling, tempering, and laser impact treatments. The cryogenic cooling treatment comprises the steps that: from room temperature, the alloy is cooled to -196 DEG C with a cooling speed of 1-10 DEG C / min, and the temperature is maintained for 10-40h. According to the tempering treatment, the alloy is heated to 100-150 DEG C, and the temperature is maintained for 2-3h. Laser impact parameters comprise laser impact spot diameter of 1-10mm, pulse energy of 1-10J, laser wavelength of 900-1200nm, repetition rate of 0.1-1HZ, pulse width of 15-40ns, and output laser pulse energy fluctuation no higher than + / -5%. The alloy material is preferably aluminum, magnesium, and titanium alloy. With the method, alloy material tissue can be compact, residue stress is low, and refined grains exist. With the method, yield strength, tensile strength, impact toughness, and anti-fatigue life of the alloy material can be greatly and simultaneously improved.

Owner:CHANGZHOU RUNYUAN WARP KNITTING ENG TECH RES CENT

High-strength Cu-Ni-Si alloy and preparation method thereof

The invention relates to a high-strength Cu-Ni-Si alloy and preparation method thereof. The alloy comprises 2.0-6.0% of Ni, 0.5-1.5% Si, 0.5-1.0% of Ti, 0.5-1.0% of Mn, 0.5-1.0% of Ag and the balance of copper and unavoidable impurity elements. The preparation method sequentially comprises the following steps of smelting; casting; homogenization treatment; hot rolling and solution treatment; pre-cold rolling and aging treatment; and cold-rolling deformation. A Ni2Si non-oxide reinforcing phase is generated in the alloy disclosed by the invention; after the rolling is carried out repeatedly, the nucleation positions of precipitated phases can be increased, the more the broken grains, the more grain boundaries, the more nucleation positions of the precipitated phases and the more the precipitated phases; and under the condition that aging treatment is carried out repeatedly, the more precipitated phases are precipitated and thus the comprehensive performance of the alloy is dramatically increased, the strength, the elongation property at a high temperature and the electric conductivity are improved and the bending workability of the alloy is also improved.

Owner:HENAN UNIV OF SCI & TECH

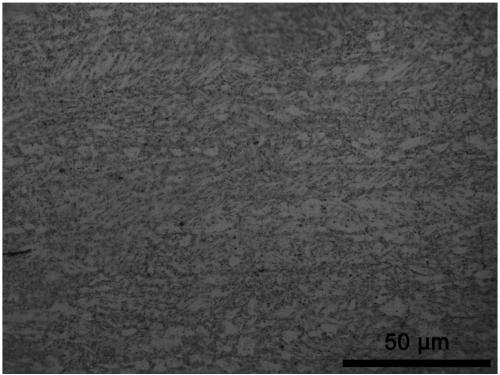

Non-oriented electrical steel for variable frequency motor and production method thereof

InactiveCN101876028AStorage capacity declineRich in componentsManufacturing stator/rotor bodiesElectrical steelFree cooling

The invention relates to non-oriented electrical steel for a variable frequency motor and a production method thereof, aiming to overcome the defects of traditional non-oriented electrical steel which has high strength and poor toughness and can not meet the requirement of the variable frequency motor and complex process. The non-oriented electrical steel comprises the flowing chemical components in percentage by weight: 0.001-0.015 percent of C, 0.3-0.9 percent of Mn, 0.4-1.6 percent of Cr, 0.1-1.2 percent of Al, 0.9-1.6 percent of Si, no more than 0.08 percent of P, no more than 0.015 percent of S, no more than 0.008 percent of N and the balance of Fe and residue, wherein the sum of the weight percent of Si and Al is 1.4-2.2 percent, the sum of the weight percent of Cr and Mn is 0.7-2.5 percent, and Cr / Mn is 0.9-2.0. The production method comprises the following steps of: smelting by using a clean steel process and continuously casting to form a billet; heating the billet; roughly rolling; finish rolling, and controlling the accumulated percentage of reduction of former four passes to be 80-95 percent; reeling; naturally cooling to the room temperature; washing with acid; cold rolling; decarbonizing; soaking; cooling according to conventional method, coating and finishing. The invention has the advantages of simple process, low iron loss at low frequency and power frequency, lower iron loss at high frequency, higher magnetic induction as well as good corrosion resistance and stamping property.

Owner:WUHAN IRON & STEEL (GROUP) CORP

Production method for manufacturing cold-rolled oriented silicon steel with high magnetic strength by using generally oriented steel raw material

The invention discloses a production method for manufacturing cold-rolled oriented silicon steel with high magnetic strength by using a generally oriented steel raw material. The method comprises the following steps: (1) smelting, carrying out vacuum treatment, refining and continuously casting into a billet; (2) carrying out hot rolling; (3) normalizing and pickling; (4) wherein the single cold rolling pressure ratio is greater than or equal to 82%; (5) decarburizing annealing temperature; (6) annealing at high temperature, setting low thermal insulation of two steps, and high thermal insulation of one step, wherein the nitriding amount of an N gas is greater than or equal to 16ppm; (7) stretching, leveling and annealing, namely, pickling, coating, annealing and leveling. Gauss texture and nucleation are formed by the big pressure rate by cold rolling one time or twice, inclusions with enough quantity are formed by nitriding at an earlier stage of high-temperature annealing, development, stabilization and perfection of gaussian grains are recrystallized for the second time by using the enhanced inhibiting effect. By adopting the process, the magnetic property and the orientation degree of the product are improved when the silicon steel is produced by using the generally oriented silicon steel material, so that the property of the oriented silicon steel is improved, and high grade of cold-rolled oriented silicon steel 27Q105 is produced.

Owner:新万鑫(福建)精密薄板有限公司

Composite microalloyed high-strength steel forge piece with tensile strength of 700 MPa and production method thereof

The invention discloses a composite microalloyed high-strength steel forge piece with tensile strength of 700 MPa and a production method thereof, and relates to a low-welding crack sensitivity high-strength steel forge piece with tensile strength of 700 MPa and a production method thereof. The forge piece comprises the following chemical components in percentage by weight: 0.07-0.12% of C, 1.2-1.8% of Mn, 0.2-0.4% of Si, not more than 0.006% of S, not more than 0.015% of P, 1.3-1.8% of Ni, 0.15-0.3% of Cr, 0.2-0.4% of Mo, 0.02-0.1% of Nb, not more than 0.1% of V, not more than 0.02% of Ti, not more than 0.25% of Cu, and not more than 0.001% of B, the balance being Fe and inevitable impurities; and Pcm is not more than 0.26%. The plate thickness of the forge piece can reach up to 200 mm; and the mechanical performance of the force piece satisfies the following conditions: the yield strength is not less than 560 MPa; the tensile strength is not less than 700 MPa; the elongation is not less than 17%; and KV2 (-40 DEG C) is not less than 80 J.

Owner:HEFEI GENERAL MACHINERY RES INST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com