Method and device for processing metal materials with cryogenic laser shock

A technology of laser shock strengthening and metal materials, applied in the fields of laser processing and cold treatment, it can solve the problems of inability to solve the toughness characteristics of materials, uneven distribution of residual compressive stress, and inability to significantly improve the toughness of materials, so as to improve the stability and various Mechanical properties, effect of promoting transformation, preventing brittle failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

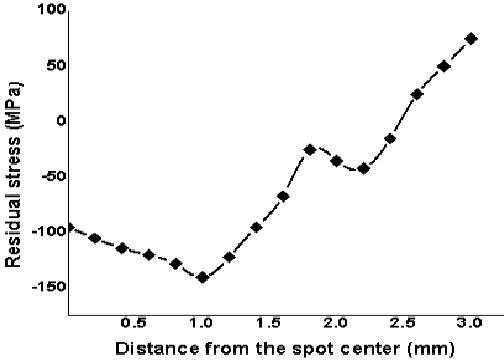

[0037] Room temperature laser impact enhanced zk60 magnesium alloy

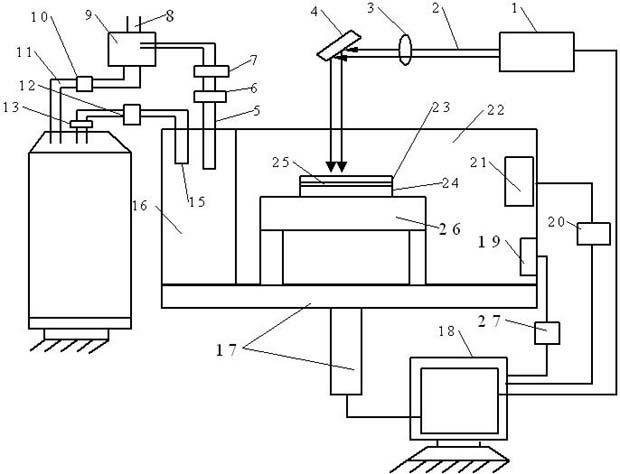

[0038] Place ZK60 magnesium alloy 24 with a size of 10mm × 10mm × 5mm on the sample placement platform 26, start the computer system 18 issued instructions, control the movement of ND: YAG solid lasers 1 and CNC five -axis workbench, ND: YAG: YAG: YAGSolid laser 1 emits laser beam 2 through optical lens 3, and the effect of reflective 4 makes the laser beam 2 vertically illuminate to the K9 glass 23 for laser impact reinforcement.The overlap rate is 75%, with organic silica gel as the absorption layer 25 and K9 glass as the constraint layer 23.

[0039] After the corresponding instrument detection: the hardness increased from 105HV to 139HV, the yield strength increased from 198MPa to 269MPa, and the extension rate increased from 20.5%to 23.4%.The shock toughness is 28.4j.cm 3 Fall to 23,1 j.cm 3 The corrosion resistance has increased by 37%, and the abrasion resistance is increased by 57%.The metal material was ...

Embodiment 2

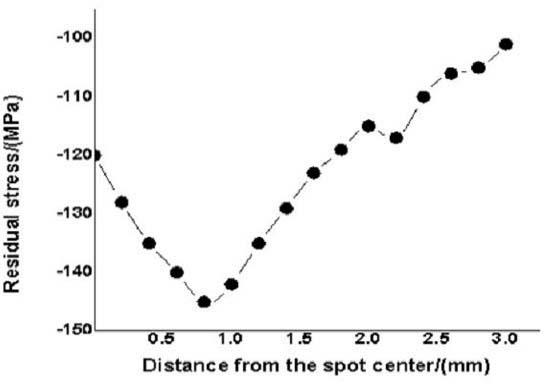

[0042] Deep cold laser shock strengthening ZK60 magnesium alloy

[0043] There are liquid nitrogen storage cavity 16 and sample placement platform 26 in the deep -cold treatment cavity 22, the deep -cold treatment cavity 22 will be placed on the five -axis workbench 17, the five -axis workbench 17 connects the computer system 18 through the wire;On the sample placement platform 26, there is a temperature sensor 21 in the deep cold treatment cavity 22, and the temperature sensor 21, A / D converter 20 and computer system 18 are connected with a wire;Device 19, micro heater 19 connects the electronic switch 27 with the computer system 18 through the wire; the liquid nitrogen tank 14 is connected to the liquid nitrogen storage cavity 16 with liquid nitrogen transportation tube 15, and 15There is a flow control valve 12 on the top; at the same time, the liquid nitrogen return pipe 11 is used to connect the liquid inlet of liquid nitrogen tank 23 with the nitrogen liquefied device 9, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Yield strength | aaaaa | aaaaa |

| Grain size | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com