Niobium oxide electrolytic capacitor cathode and producing method thereof

A technology of electrolytic capacitors and niobium monoxide, which is applied in the manufacture of capacitors, capacitors, circuits, etc., and can solve the problem of the limited application range of aluminum electrolytic capacitors, the inability to meet the requirements of miniaturization, high speed and large capacity of mobile phones and computers, and high prices. problem, to achieve the effect of small leakage current, stable anode performance and stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

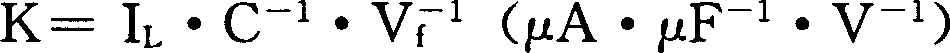

Embodiment 1

[0033] To manufacture niobium monoxide electrolytic capacitor anodes, first weigh 200g of niobium monoxide with a particle size of 1.0μm, press 200mg each into blanks, and the pressed density is 3.4g cm -3 ; Then put it into a vacuum furnace, the vacuum pressure is 3 PO 4 , enabling voltage V f 50V, the enabling temperature is 90°C, and the enabling current density is 60mA·g -1 , The constant voltage time is 2h, and the anode of the niobium monoxide electrolytic capacitor is obtained, and the test results are listed in Table 1.

Embodiment 2

[0035] Manufacture doped niobium monoxide To manufacture electrolytic capacitor anode, first weigh 79wt% niobium monoxide and 21wt% niobium and mix them into 200g of doped niobium monoxide powder with an average particle size of 1.3μm, and press each 200mg into blanks, and the pressing density is 3.4g cm -3 ; Then put it into a vacuum furnace, the vacuum pressure is 3 PO 4 , enabling voltage V f 50V, the enabling temperature is 90°C, and the enabling current density is 60mA·g -1 , The constant voltage time is 2h, and the anode of the niobium monoxide electrolytic capacitor is obtained, and the test results are listed in Table 1.

Embodiment 3

[0037] To manufacture doped niobium monoxide electrolytic capacitor anodes, first weigh 79wt% niobium monoxide and 21wt% tantalum and mix them into 200g of doped niobium monoxide powder with an average particle size of 1.8μm, and press each 200mg into blanks with a pressing density of 3.4 g cm -3 ; Then put it into a vacuum furnace, the vacuum pressure is 3 PO 4 , enabling voltage V f 50V, the enabling temperature is 90°C, and the enabling current density is 60mA·g -1 , The constant voltage time is 2h, and the anode of the niobium monoxide electrolytic capacitor is obtained, and the test results are listed in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average particle size | aaaaa | aaaaa |

| Average particle size | aaaaa | aaaaa |

| Pressed density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com