Patents

Literature

957 results about "Niobium oxide" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Niobium oxide may refer to: Niobium monoxide, NbO Niobium dioxide, NbO₂ Niobium pentoxide, Nb₂O₅ In addition to the above, other distinct oxides exist general formula Nb₃ₙ₊₁O8n−2 where n ranges from 5 - 8 inclusive, e.g. Nb₈O₁₉. Nb₁₂O₂₉ and Nb₄₇O₁₁₆ Natural niobium oxide is sometimes known as niobia.

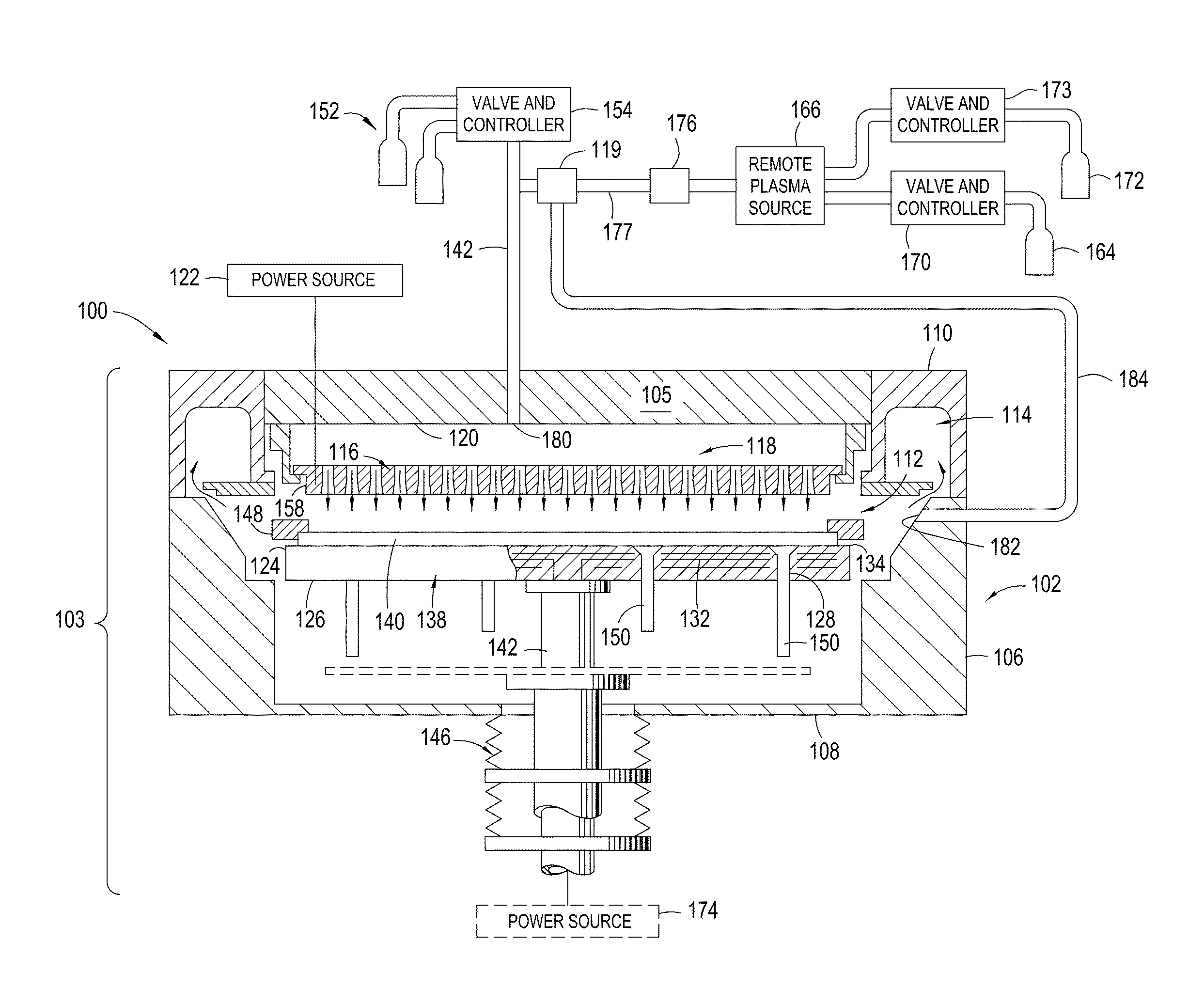

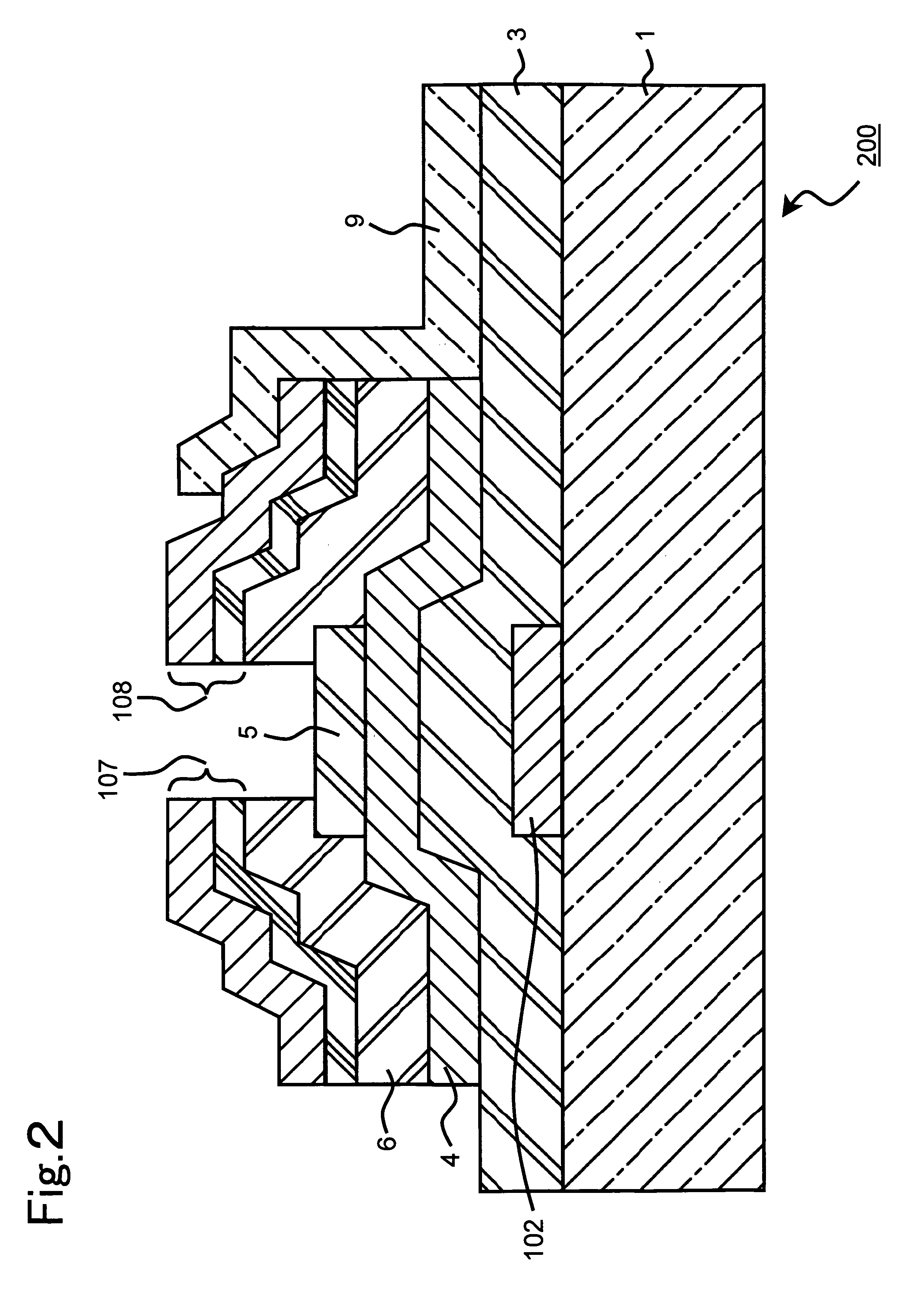

Yttria-based material coated chemical vapor deposition chamber heater

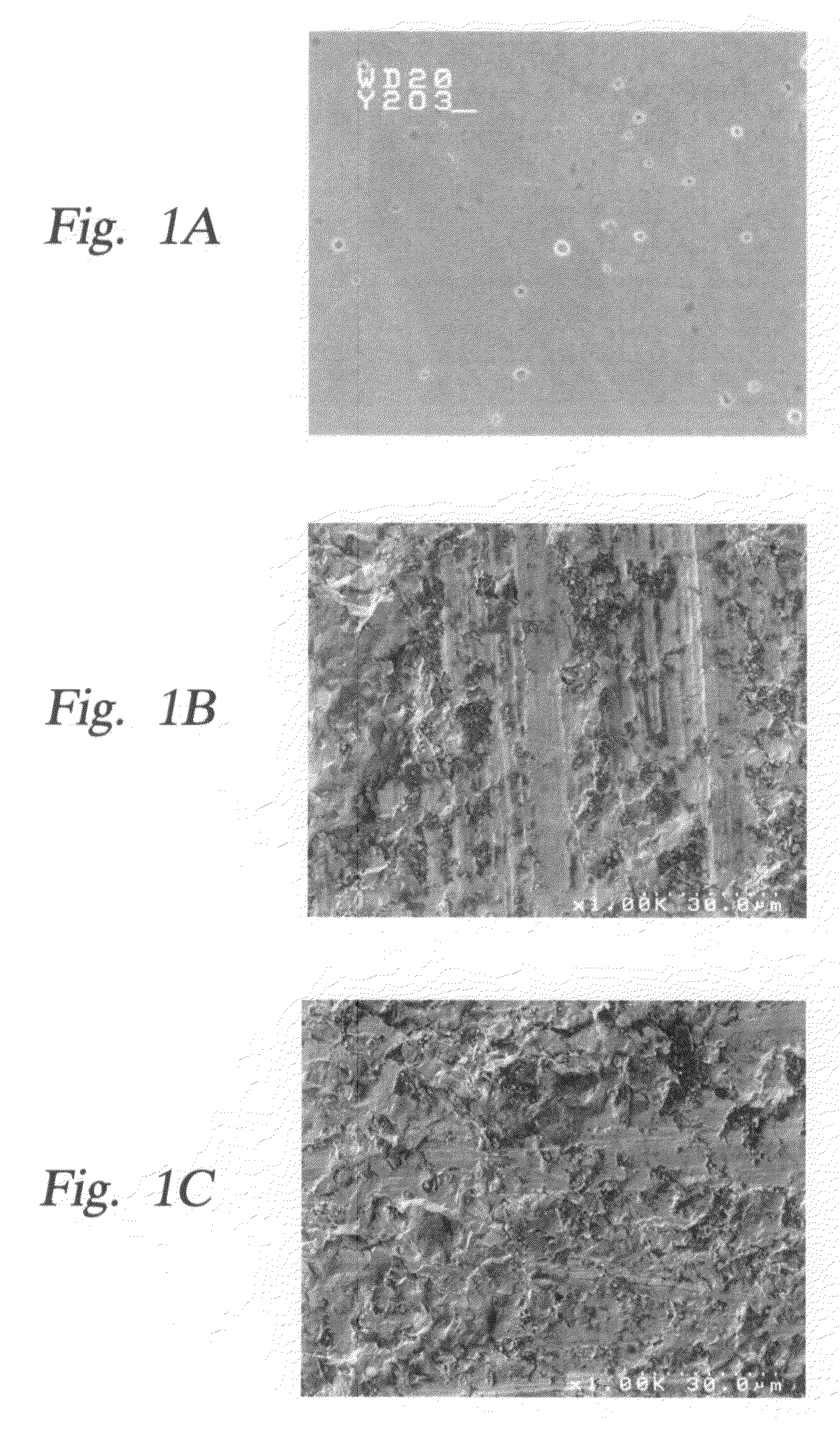

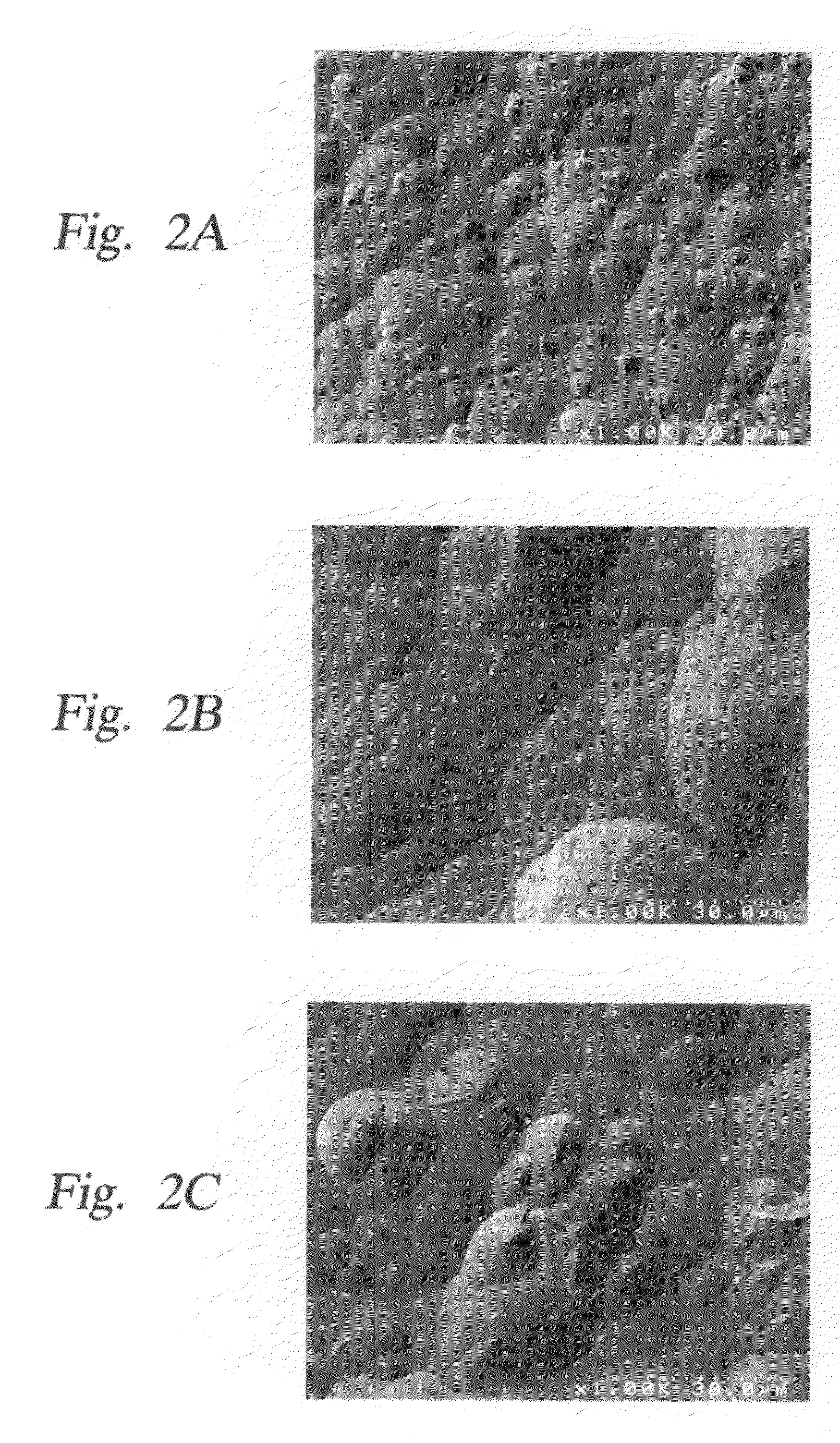

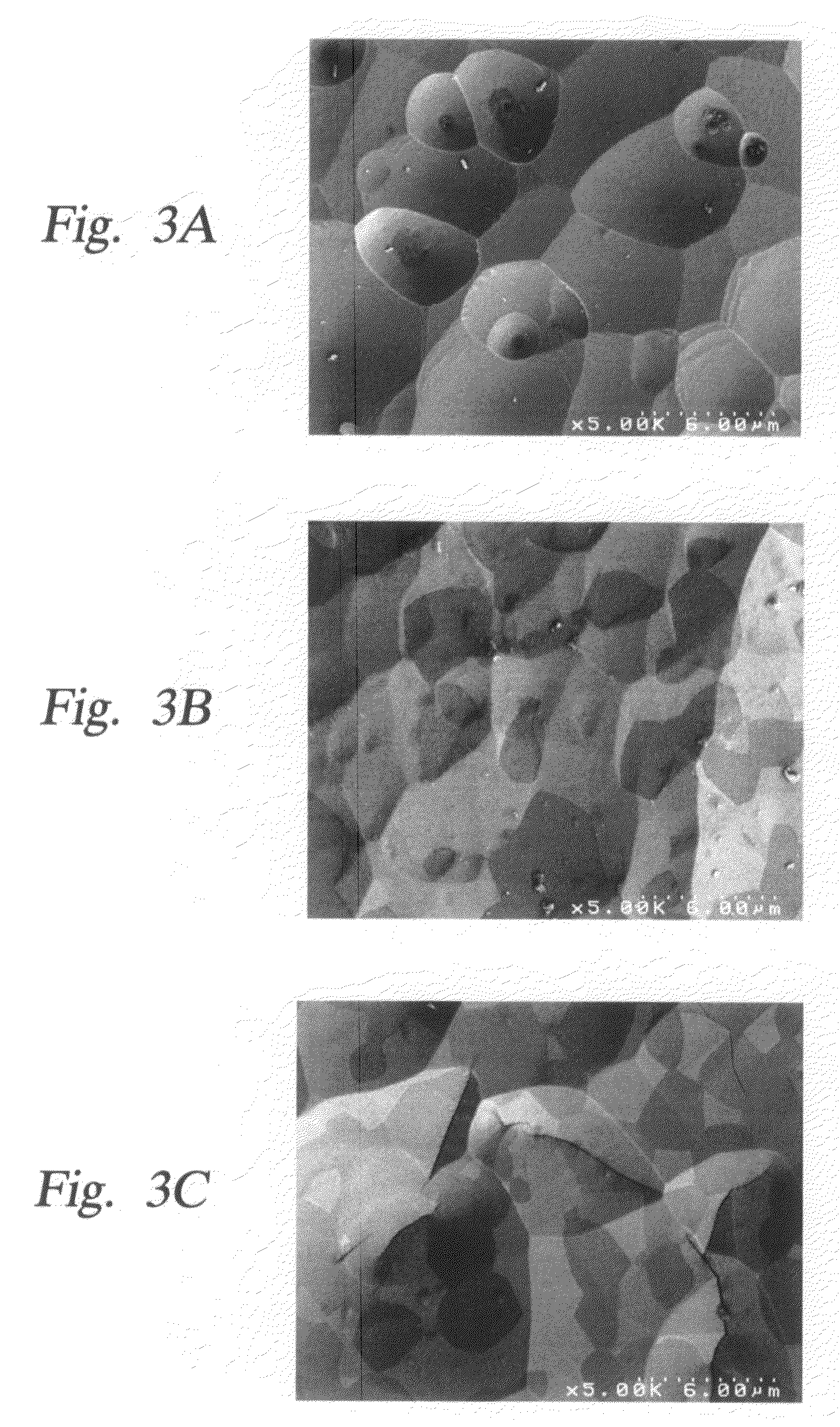

ActiveUS20140263272A1Improve wear resistanceImprove flexural strengthLiquid surface applicatorsMolten spray coatingYTTERBIUM OXIDEFlexural strength

Embodiments of the present invention generally relate to heated substrate supports having a protective coating thereon. The protective coating is formed from yttrium oxide at a molar concentration ranging from about 50 mole percent to about 75 mole percent; zirconium oxide at a molar concentration ranging from about 10 mole percent to about 30 mole percent; and at least one other component, selected from the group consisting of aluminum oxide, hafnium oxide, scandium oxide, neodymium oxide, niobium oxide, samarium oxide, ytterbium oxide, erbium oxide, cerium oxide, and combinations thereof, at a molar concentration ranging from about 10 mole percent to about 30 mole percent. The alloying of yttrium oxide with a compatible oxide improves wear resistance, flexural strength, and fracture toughness of the protective coating, relative to pure yttrium oxide.

Owner:APPLIED MATERIALS INC

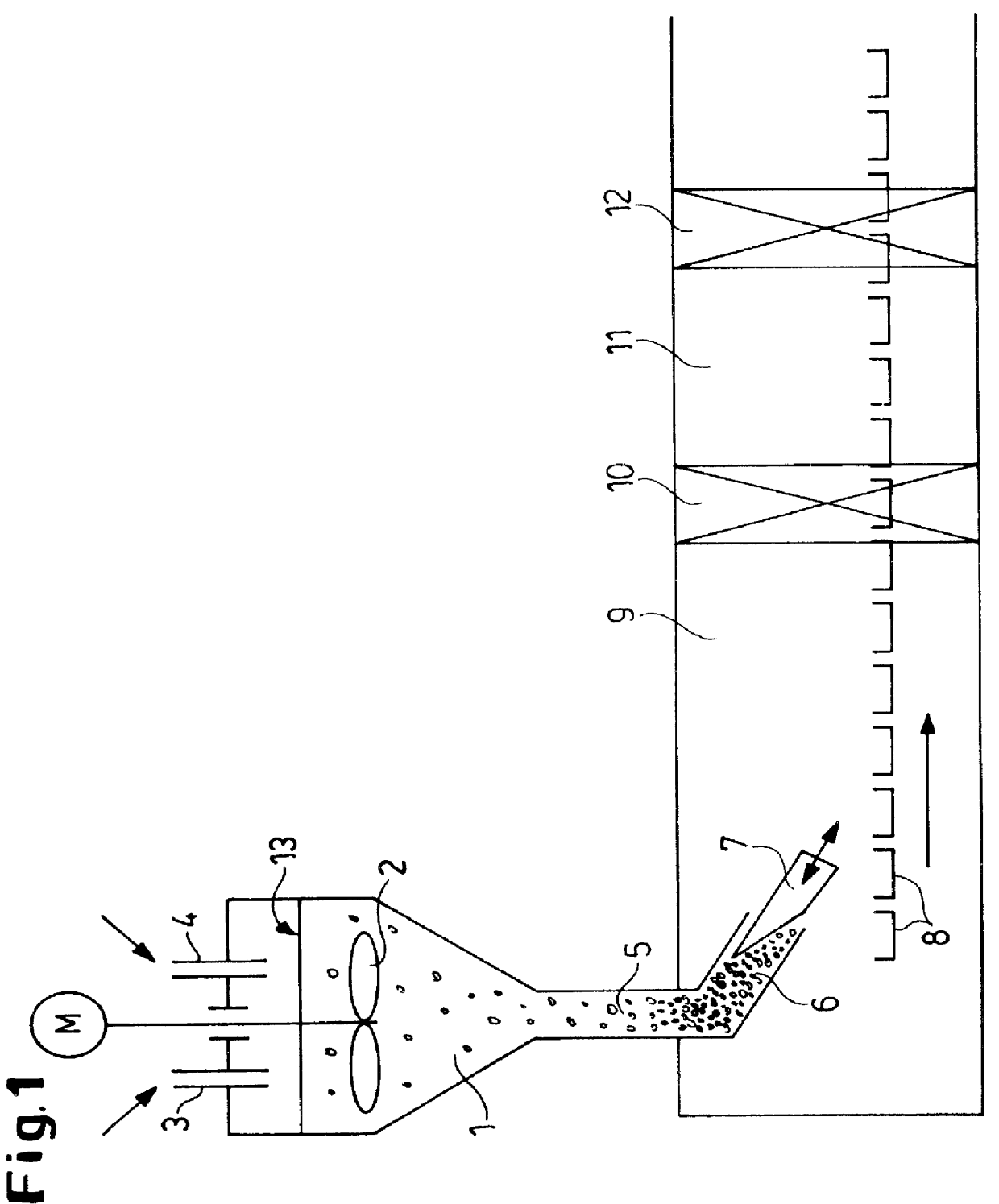

Niobium powder and a process for the production of niobium and/or tantalum powders

InactiveUS6136062APrevent local overheating effectStirring speed is fastElectrolytic capacitorsTantalum compoundsMischmetalRare earth

The process comprises the reduction of niobium and / or tantalum oxides by means of alkaline earth metals and / or rare earth metals, wherein the first reduction stage is carried out as far as an average composition corresponding to (Nb, Ta)Ox where x=0.5 to 1.5 and before the second stage the reduction product from the first stage is freed from alkaline earth oxides and / or rare earth metal oxides which are formed (and optionally from excess alkaline earth metal and / or rare earth metal) by washing with mineral acids.

Owner:H C STARCK TANTALUM & NIOBIUM GMBH

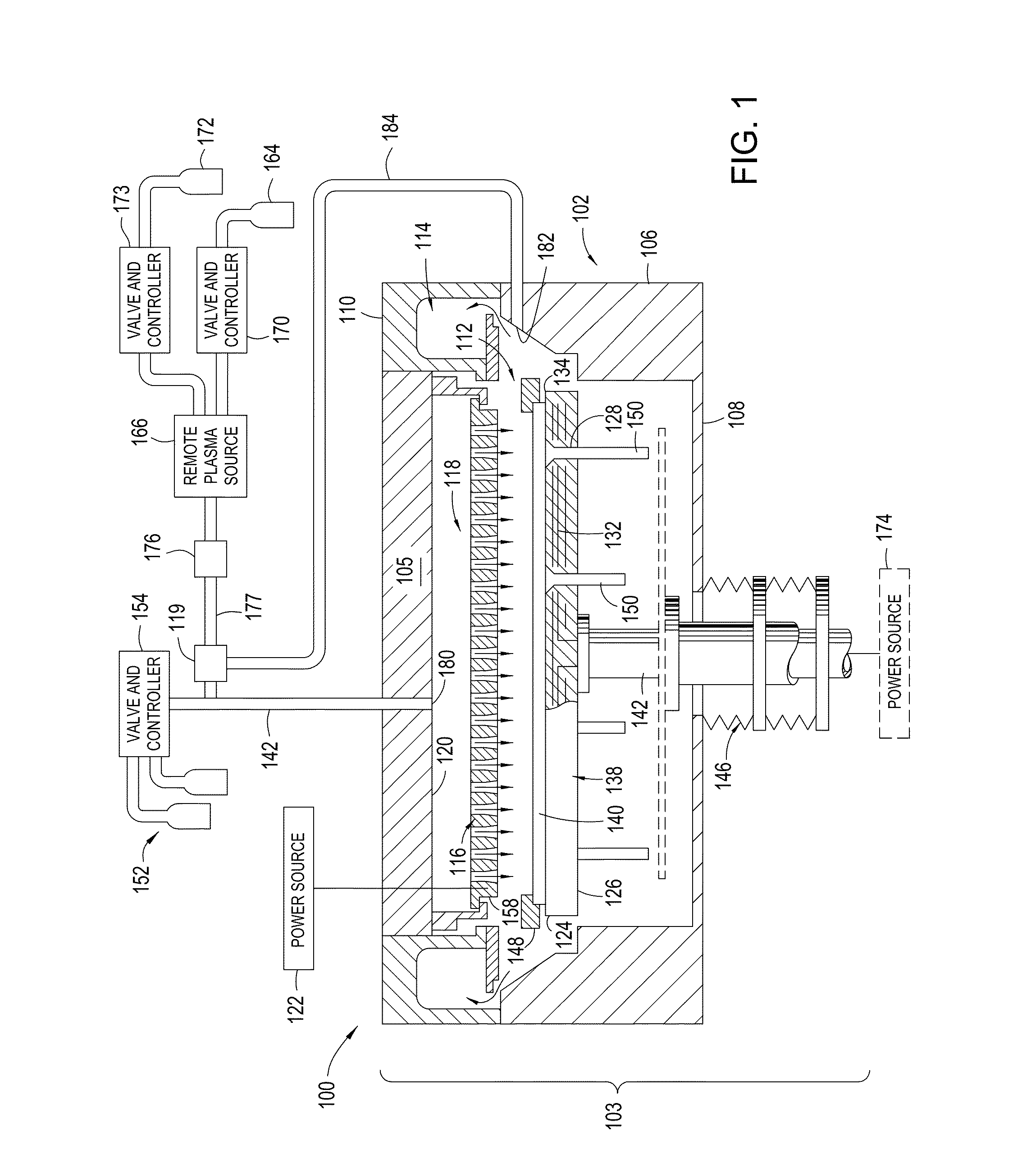

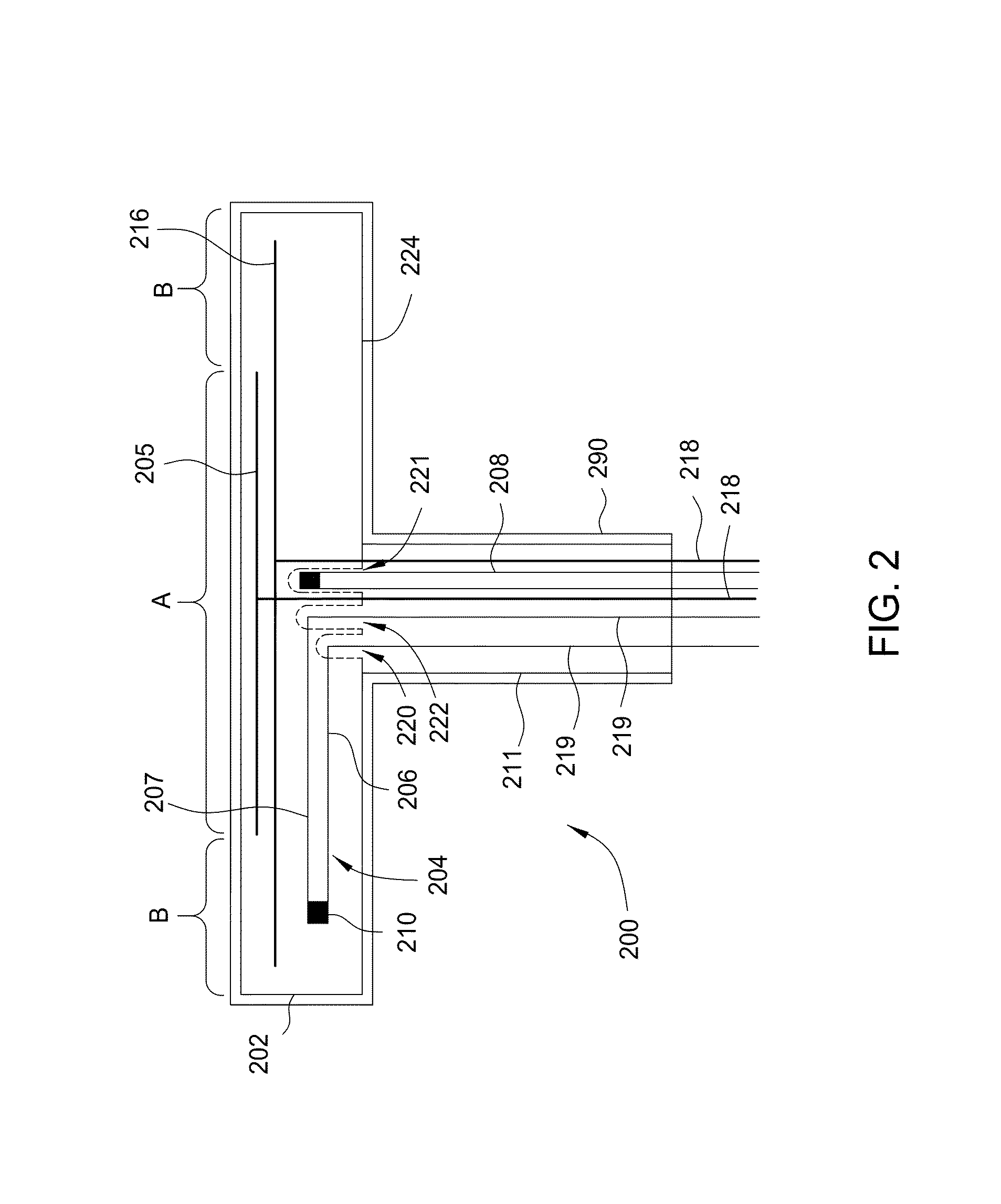

Method and apparatus which reduce the erosion rate of surfaces exposed to halogen-containing plasmas

ActiveUS20080264565A1Improve plasma resistanceImprove corrosion resistanceElectric discharge tubesSemiconductor/solid-state device manufacturingYTTERBIUM OXIDEErosion rate

A ceramic article which is resistant to erosion by halogen-containing plasmas used in semiconductor processing. The ceramic article includes ceramic which is multi-phased, typically including two phase to three phases. The ceramic is formed from yttrium oxide at a molar concentration ranging from about 50 mole % to about 75 mole %; zirconium oxide at a molar concentration ranging from about 10 mole % to about 30 mole %; and at least one other component, selected from the group consisting of aluminum oxide, hafnium oxide, scandium oxide, neodymium oxide, niobium oxide, samarium oxide, ytterbium oxide, erbium oxide, cerium oxide, and combinations thereof, at a molar concentration ranging from about 10 mole % to about 30 mole %.

Owner:APPLIED MATERIALS INC

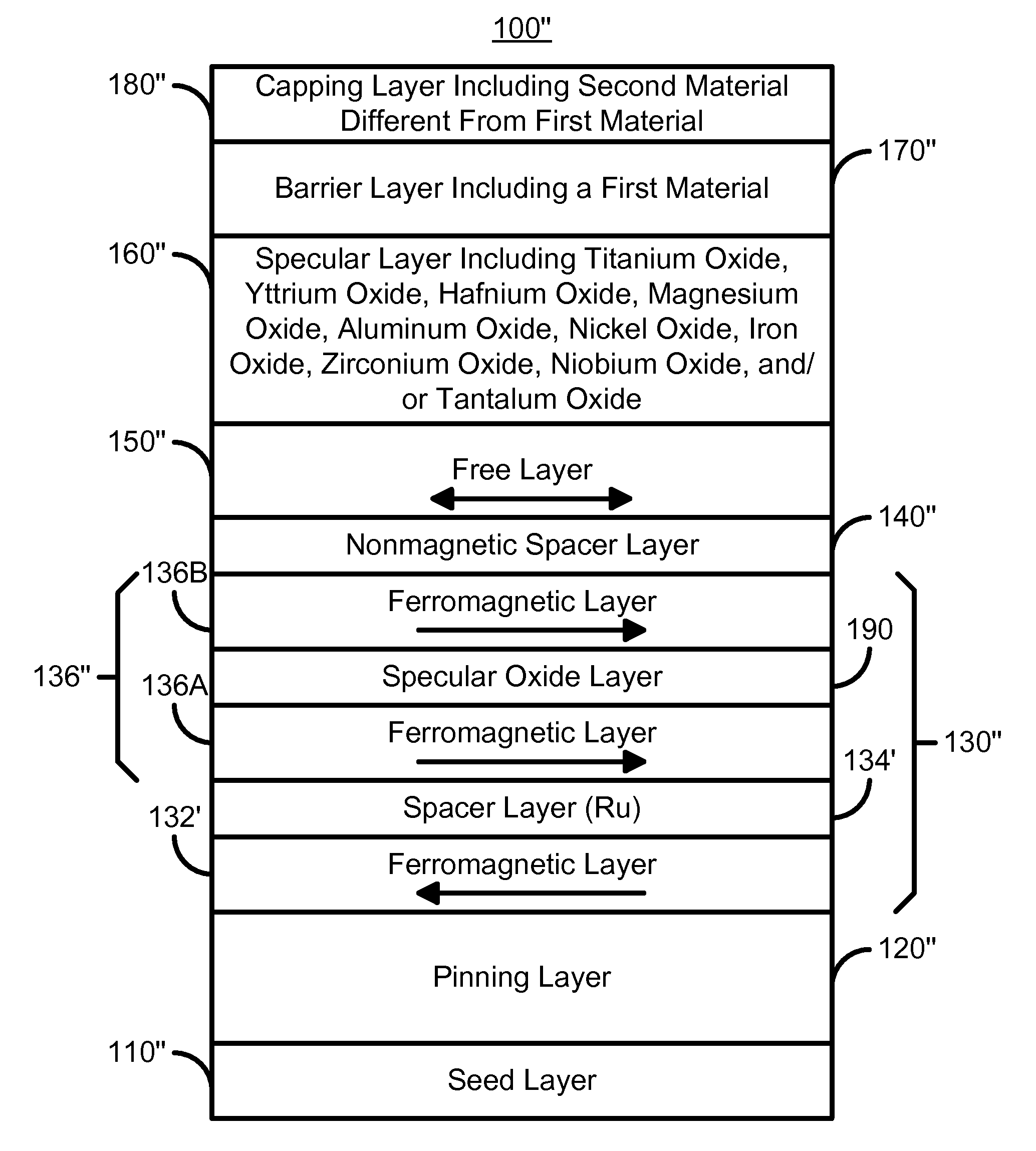

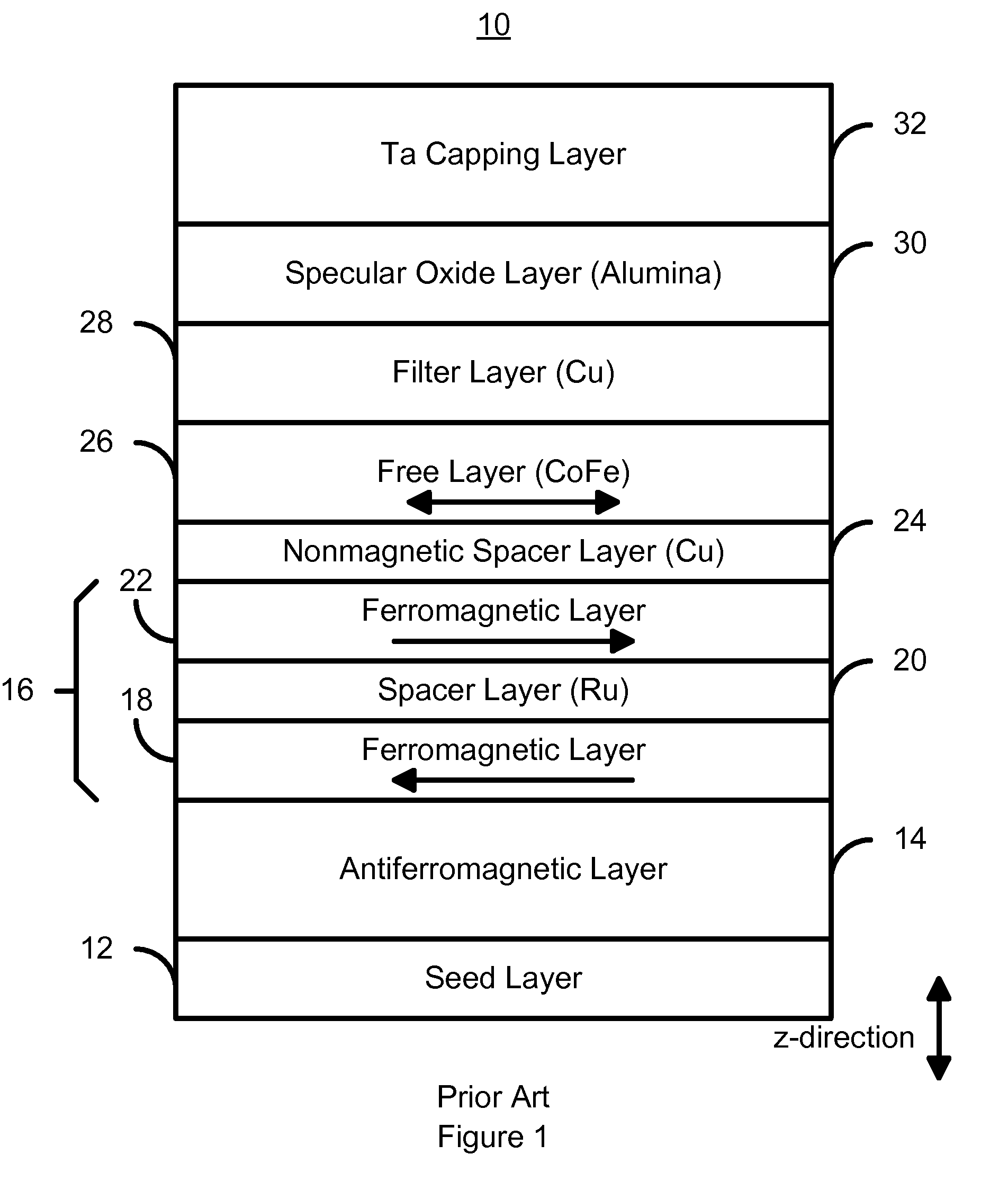

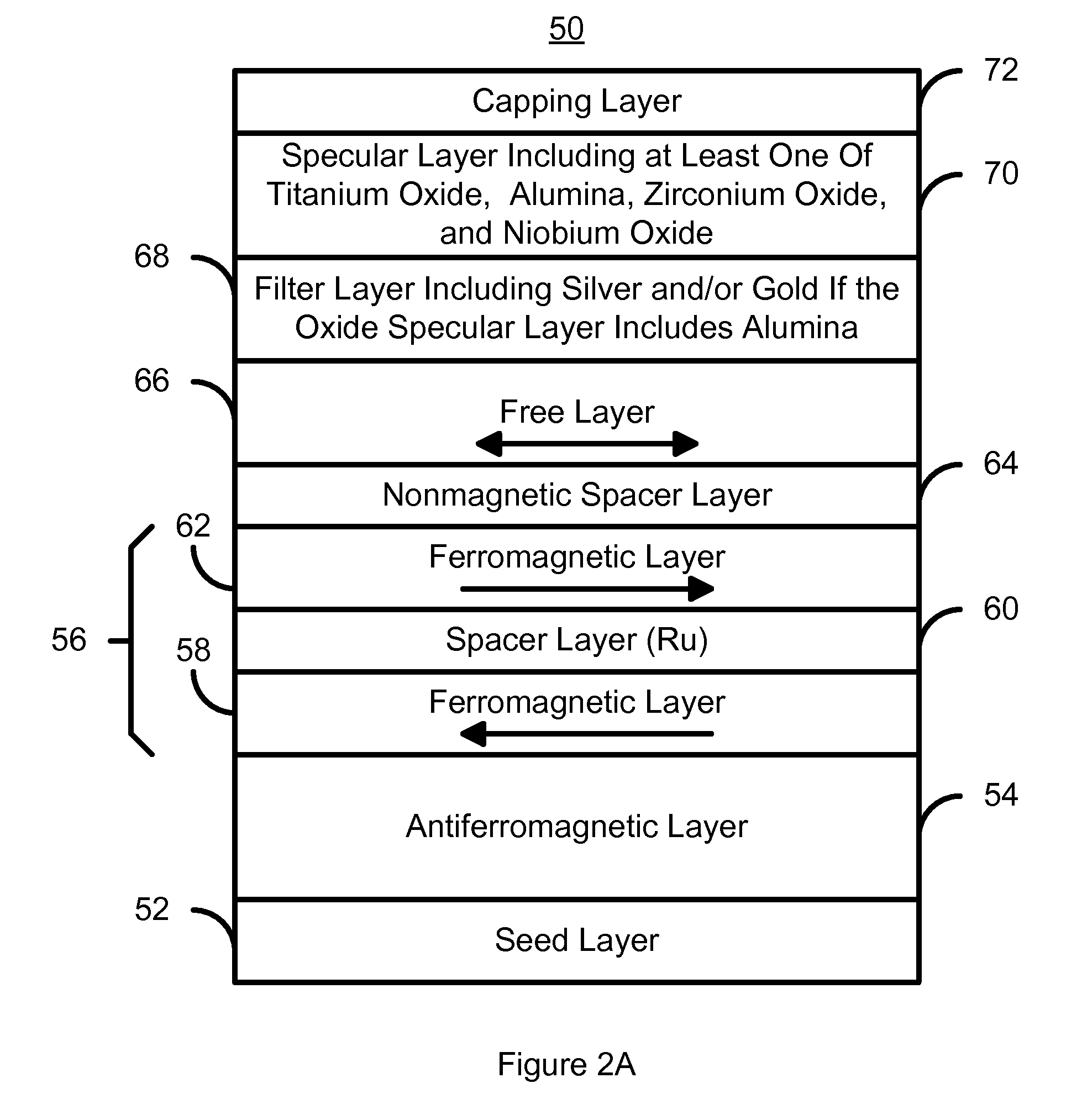

Magnetoresistive structure having a novel specular and barrier layer combination

InactiveUS7684160B1Magnetic-field-controlled resistorsConductive/insulating/magnetic material on magnetic film applicationYttriumTitanium oxide

A method and system for providing a magnetoresistive structure is disclosed. The magnetoresistive structure includes a pinned layer, a nonmagnetic spacer layer, a free layer, a specular layer, a barrier layer, and a capping layer. The spacer layer resides between the pinned layer and the free layer. The free layer is electrically conductive and resides between the specular layer and the nonmagnetic spacer layer. The specular layer is adjacent to the free layer and includes at least one of titanium oxide, yttrium oxide, hafnium oxide, magnesium oxide, aluminum oxide, nickel oxide, iron oxide, zirconium oxide, niobium oxide, and tantalum oxide. The barrier layer resides between the specular layer and the capping layer. The barrier layer is nonmagnetic and includes a first material. The capping layer includes a second material different from the first material.

Owner:WESTERN DIGITAL TECH INC

Method and apparatus which reduce the erosion rate of surfaces exposed to halogen-containing plasmas

ActiveUS7696117B2Reduce erosion rateImprove mechanical propertiesElectric discharge tubesSemiconductor/solid-state device manufacturingErosion rateYttrium

A ceramic article which is resistant to erosion by halogen-containing plasmas used in semiconductor processing. The ceramic article includes ceramic which is multi-phased, typically including two phase to three phases. The ceramic is formed from yttrium oxide at a molar concentration ranging from about 50 mole % to about 75 mole %; zirconium oxide at a molar concentration ranging from about 10 mole % to about 30 mole %; and at least one other component, selected from the group consisting of aluminum oxide, hafnium oxide, scandium oxide, neodymium oxide, niobium oxide, samarium oxide, ytterbium oxide, erbium oxide, cerium oxide, and combinations thereof, at a molar concentration ranging from about 10 mole % to about 30 mole %.

Owner:APPLIED MATERIALS INC

Capacitor

InactiveUS6115235AFixed capacitor electrodesLiquid electrolytic capacitorsOrganic semiconductorCapacitor

PCT No. PCT / JP98 / 00823 Sec. 371 Date Oct. 28, 1998 Sec. 102(e) Date Oct. 28, 1998 PCT Filed Feb. 27, 1998 PCT Pub. No. WO98 / 38660 PCT Pub. Date Sep. 3, 1998In a capacitor comprising a pair of electrodes and a dielectric substance intervening between the two electrodes, one of the electrodes is composed of sintered niobium nitride. Preferably, the dielectric substance is composed of niobium oxide and the electrode other than the electrode composed of sintered niobium nitride is composed of an ingredient selected from electrolytes, organic semiconductors and inorganic semiconductors. This capacitor has good environmental stability and good leak current characteristics.

Owner:SHOWA DENKO KK

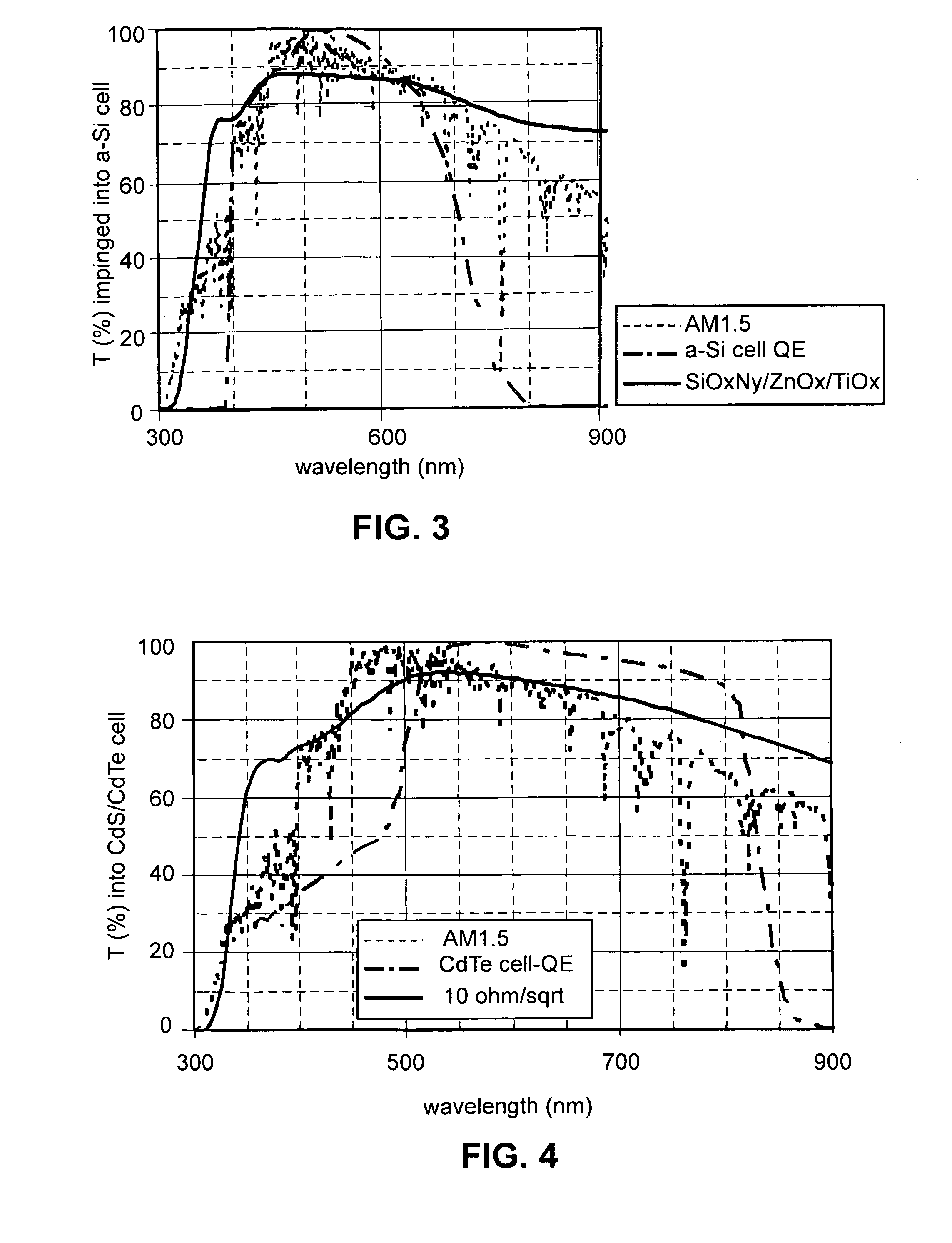

Front electrode including transparent conductive coating on patterned glass substrate for use in photovoltaic device and method of making same

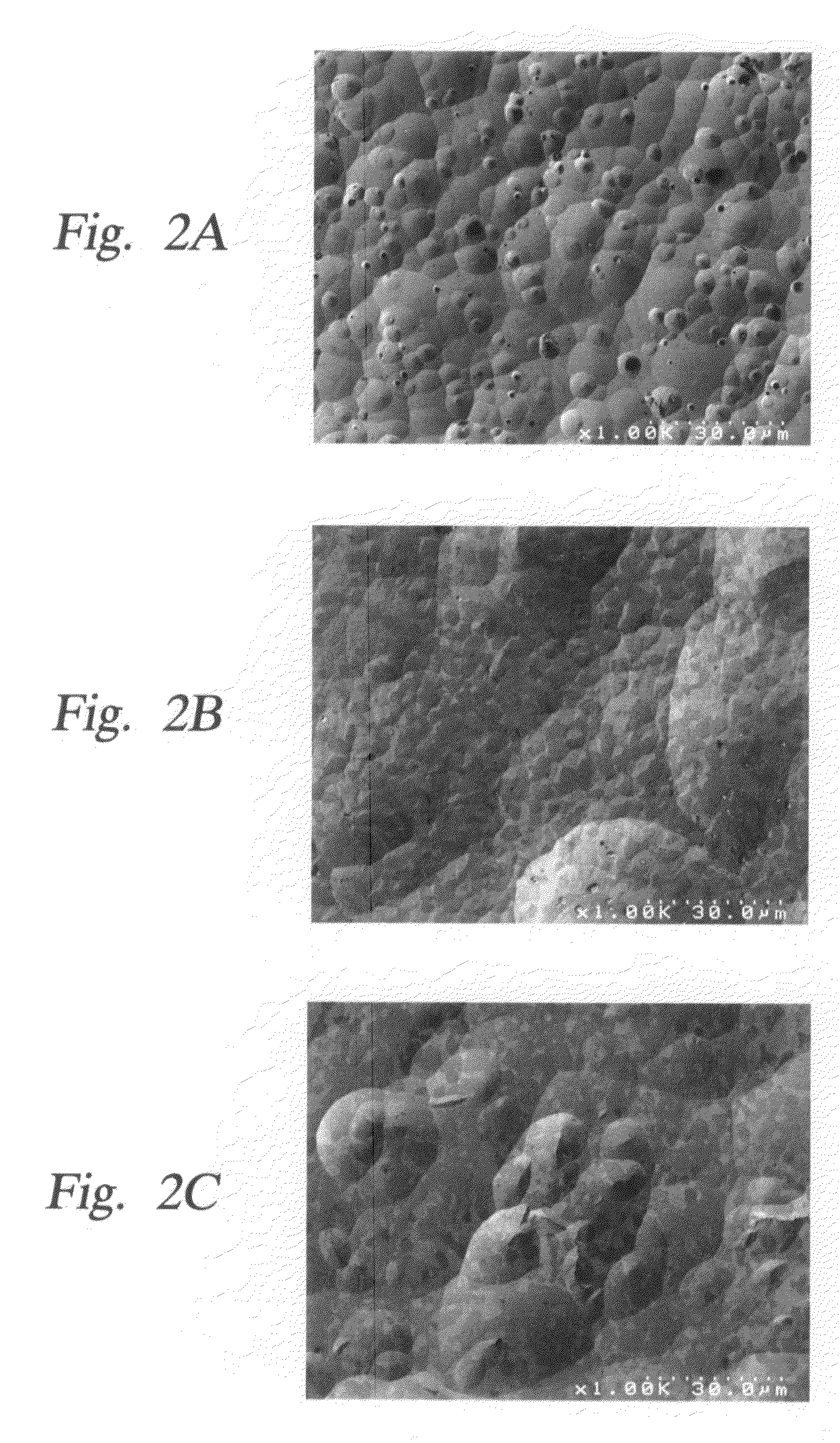

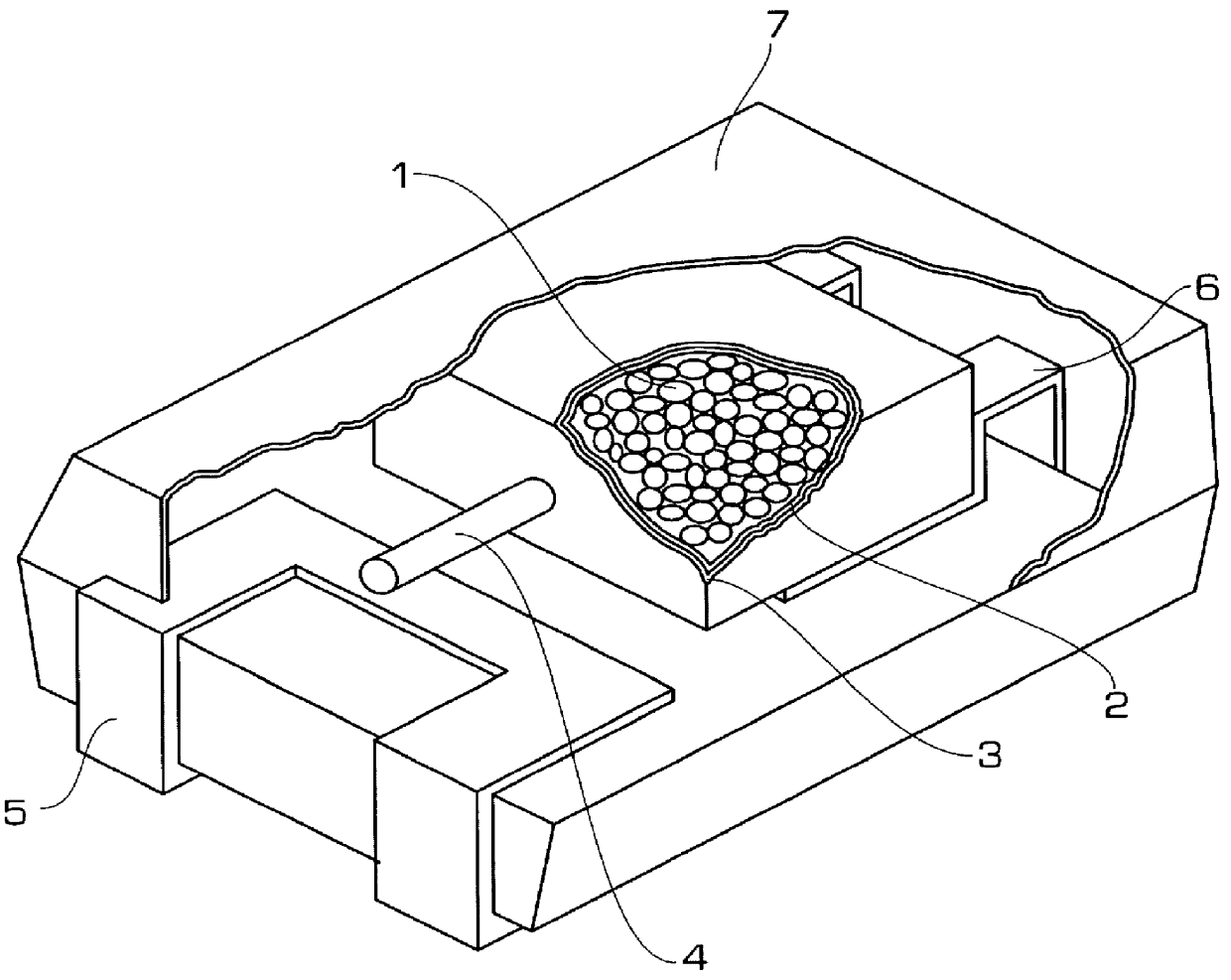

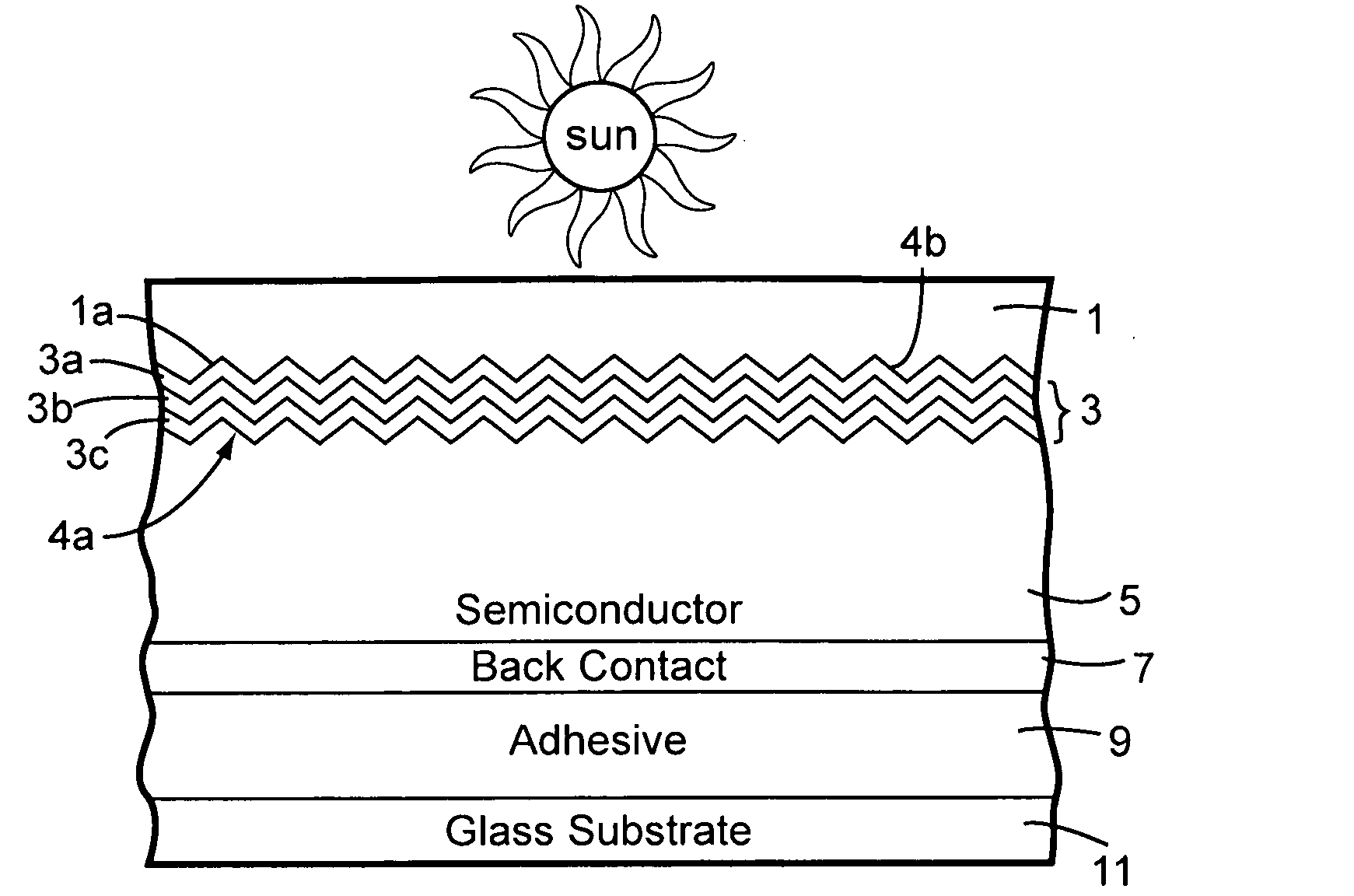

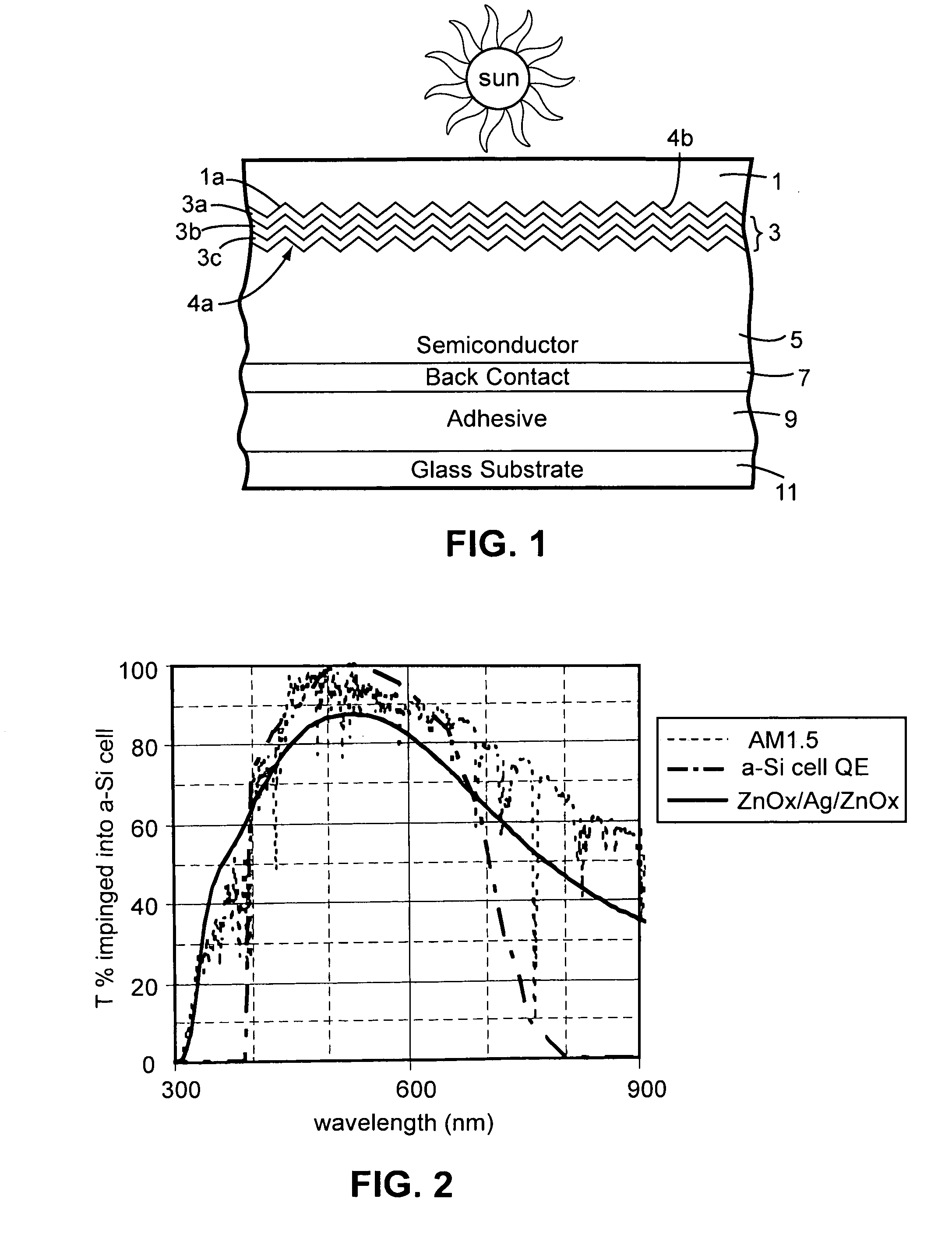

InactiveUS20080178932A1Reduced visible light reflectionImprove conductivitySemiconductor/solid-state device manufacturingPhotovoltaic energy generationPeak valuePeak area

This invention relates to a photovoltaic device including an electrode such as a front electrode / contact. In certain example embodiments, the front electrode of the photovoltaic device includes a multi-layered transparent conductive coating which is sputter-deposited on a textured surface of a patterned glass substrate. In certain example embodiments, a maximum transmission area of the substantially transparent conductive front electrode is located under a peak area of a quantum efficiency (QE) and / or QEx (photon flux of solar radiation) curve of the photovoltaic device and a light source spectrum used to power the photovoltaic device. In certain example embodiments, the front electrode includes a transparent conductive layer of or including one or more of (i) titanium zinc oxide doped with aluminum and / or niobium, and / or (ii) titanium niobium oxide.

Owner:GUARDIAN GLASS LLC

Niobium Oxide Compositions and Methods for Using Same

ActiveUS20120052401A1Alkaline accumulatorsElectric discharge heatingLithium-ion batteryCarbon coated

The disclosure relates a niobium oxide useful in anodes of secondary lithium ion batteries. Such niobium oxide has formula LixM1−yNbyNb2O7, wherein 0≦x≦3, 0≦y≦1, and M represents Ti or Zr. The niobium oxide may be in the form of particles, which may be carbon coated. The disclosure also relates to an electrode composition containing at least one or more niobium oxides of formula LixM1−yNbyNb2O7. The disclosure further relates to electrodes, such as anodes, and batteries containing at least one or more niobium oxides of formula LixM1−yNbyNb2O7. Furthermore, the disclosure relates to methods of forming the above.

Owner:BOARD OF RGT THE UNIV OF TEXAS SYST

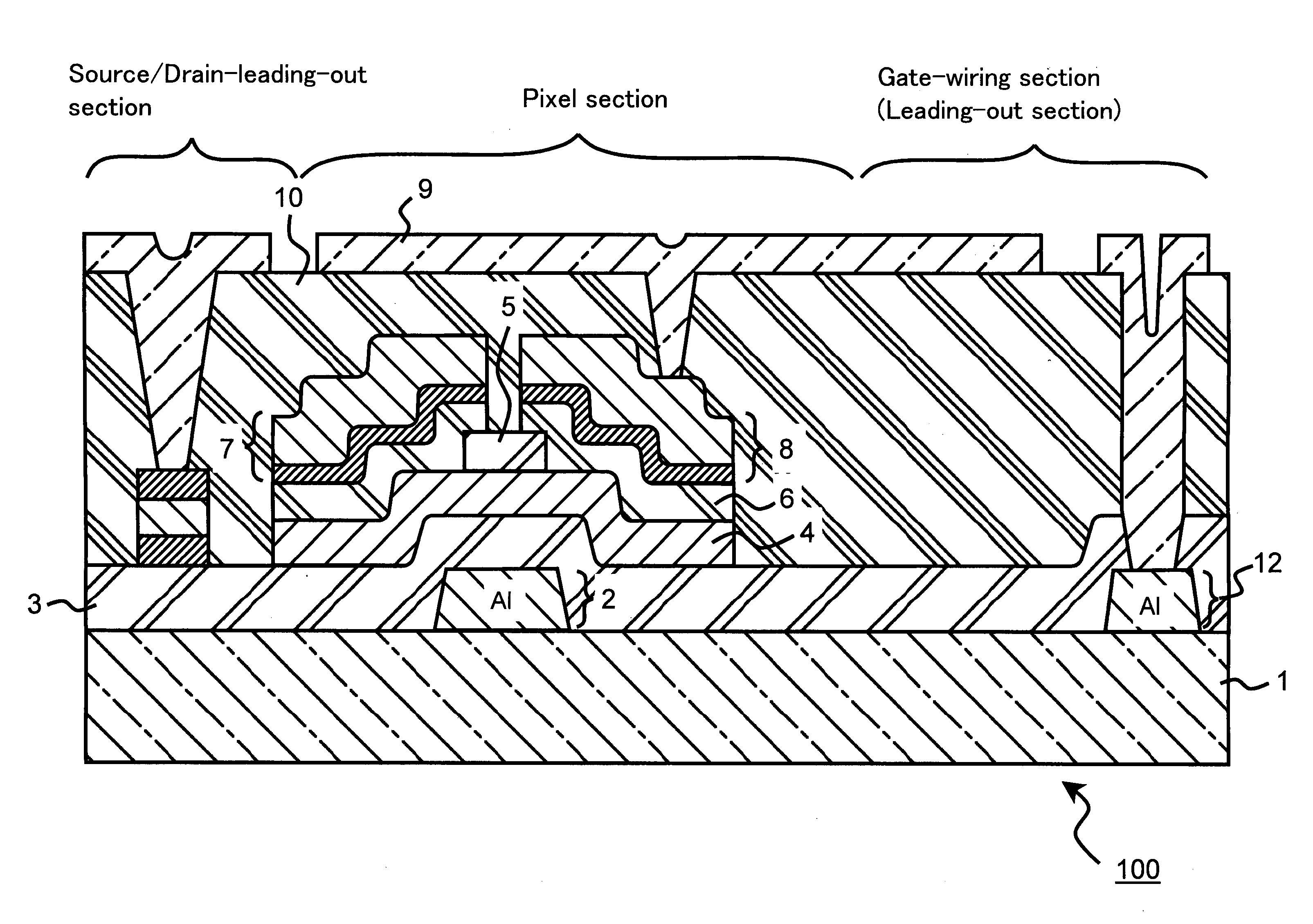

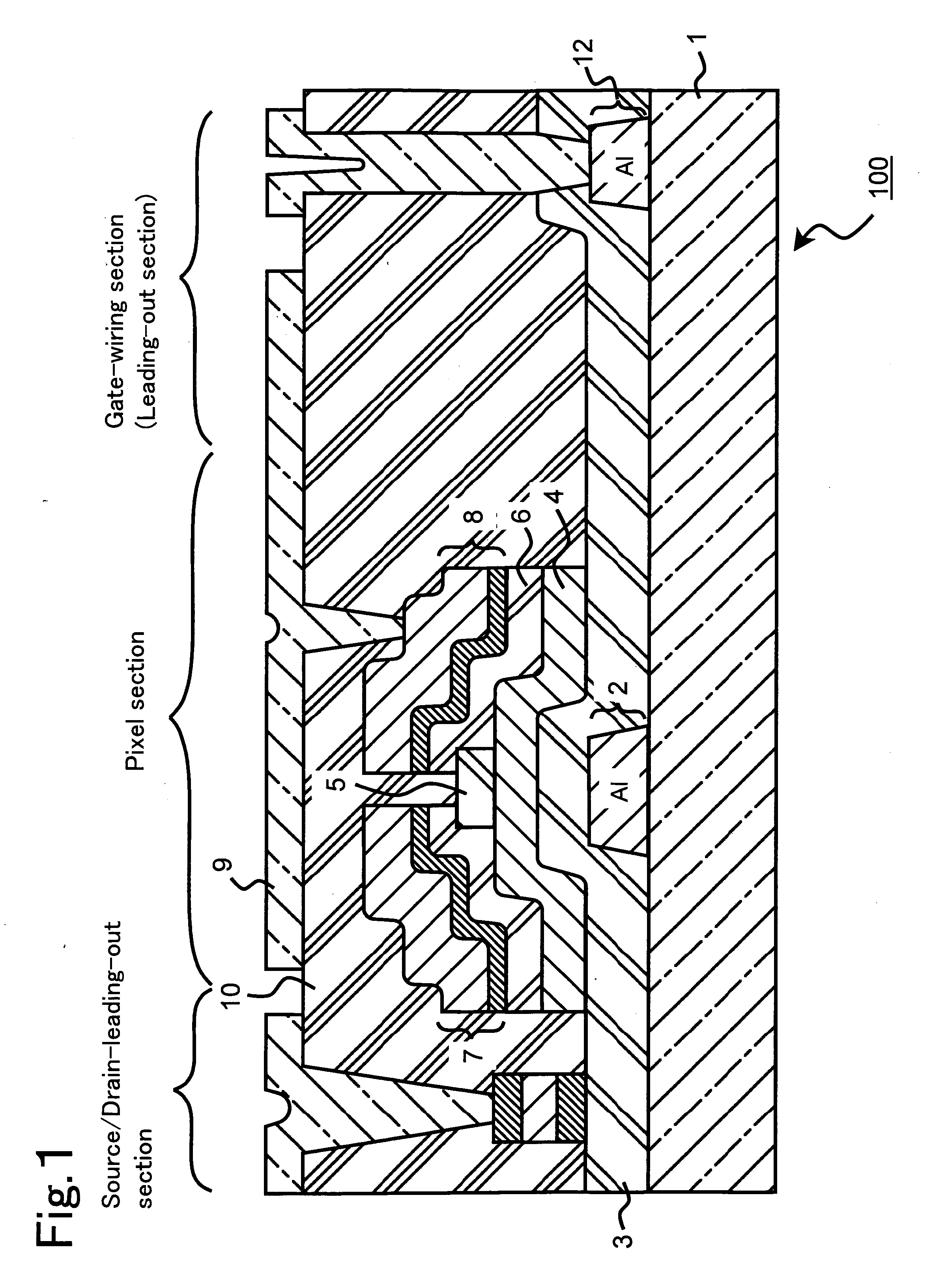

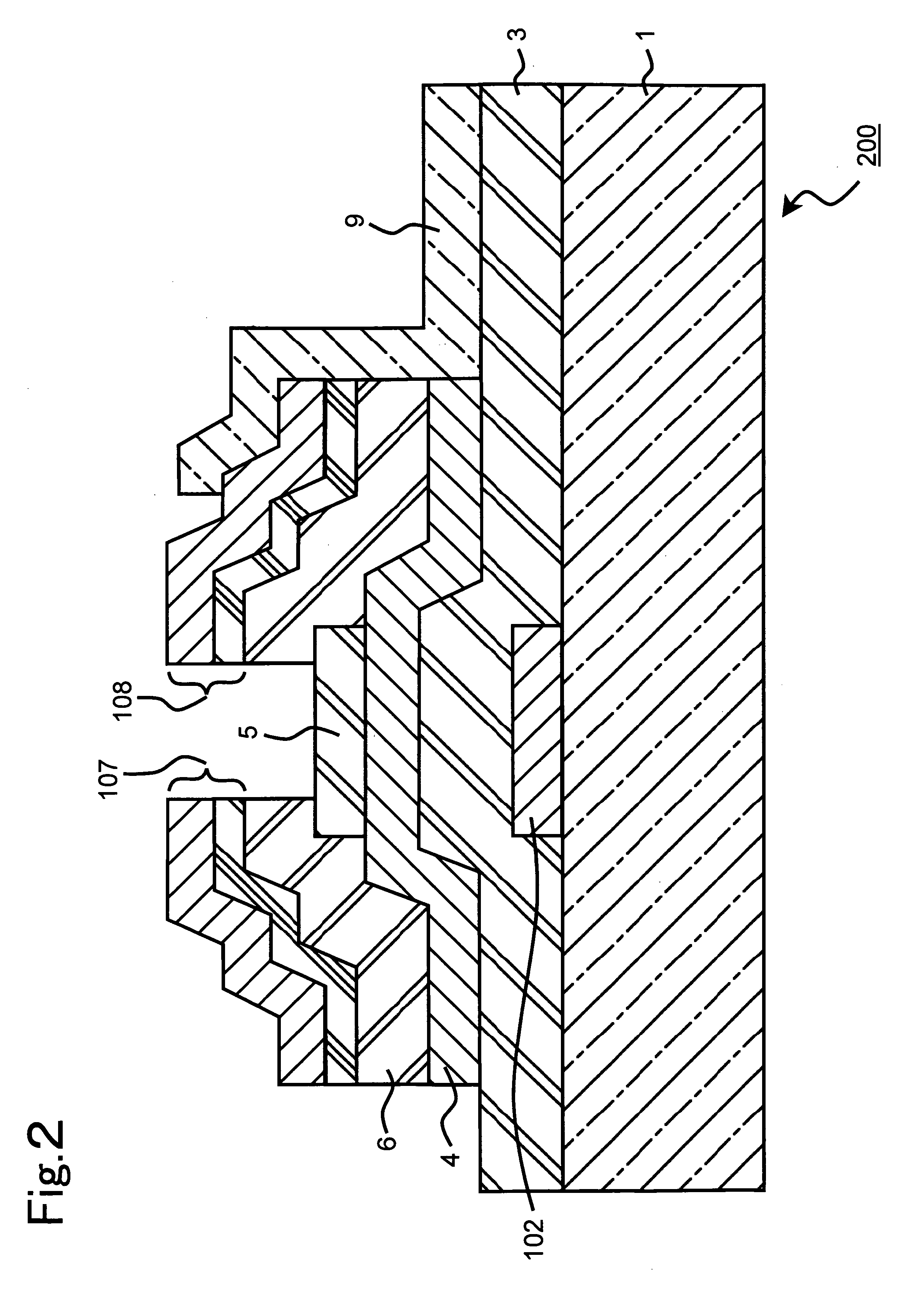

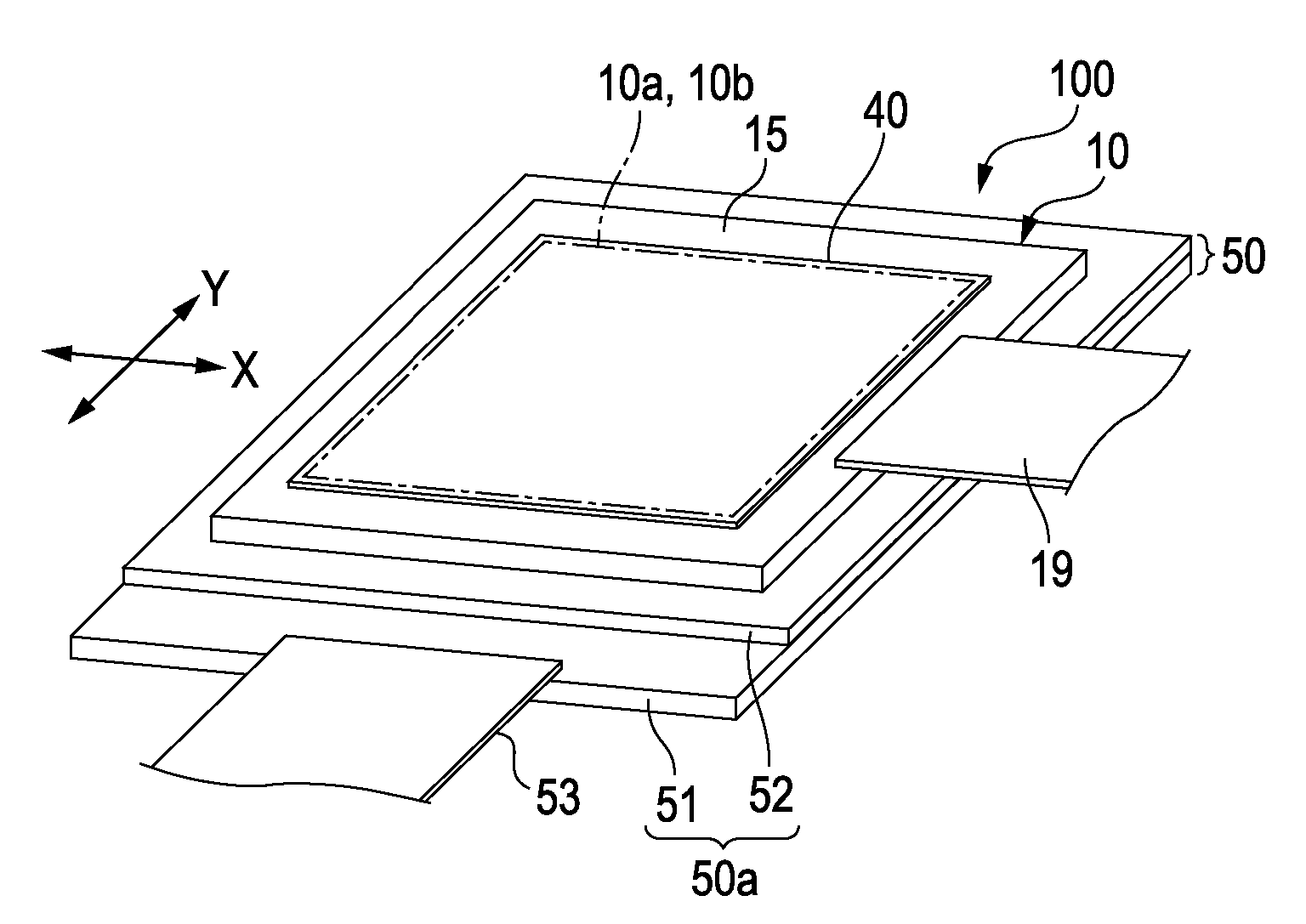

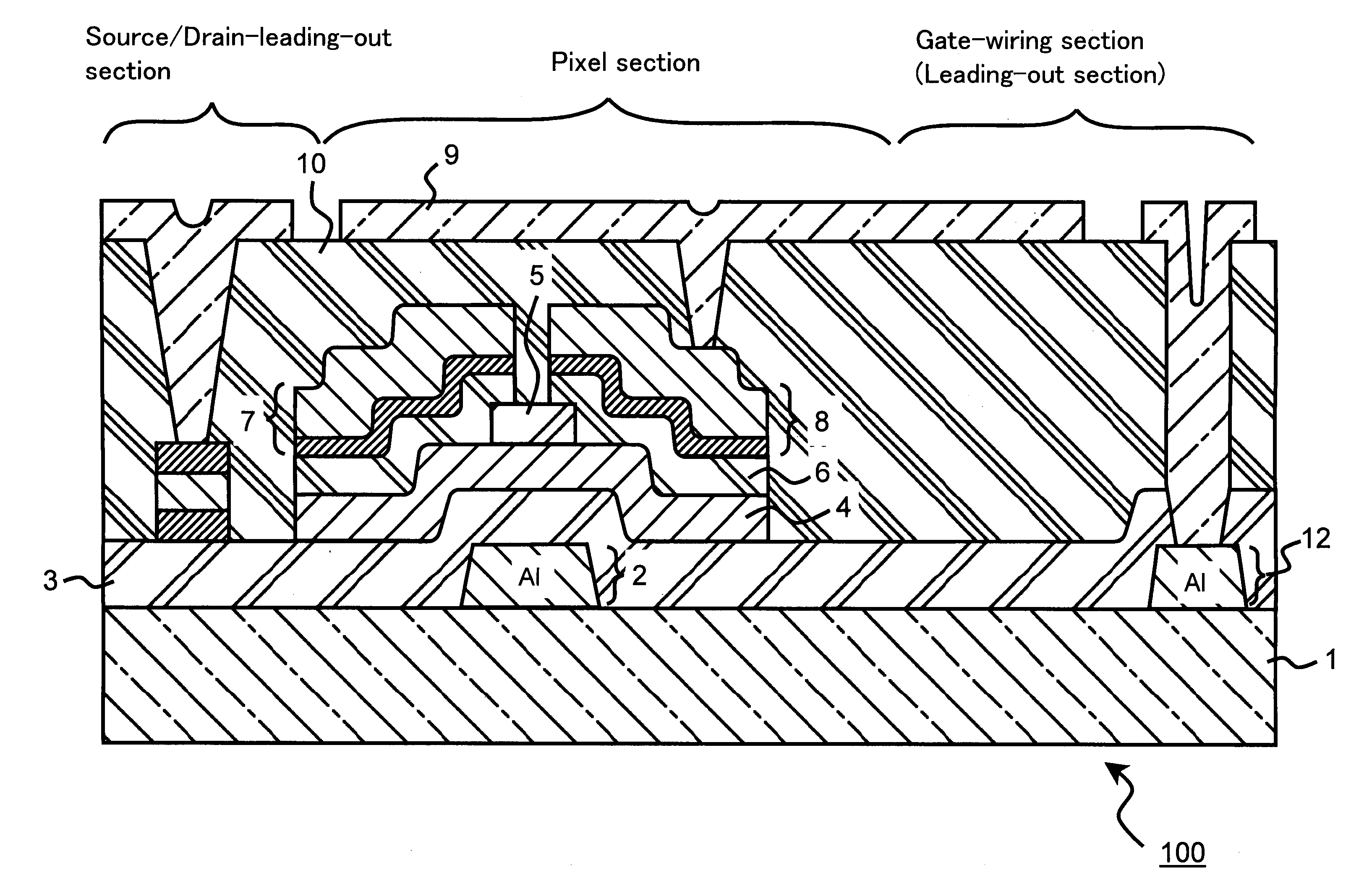

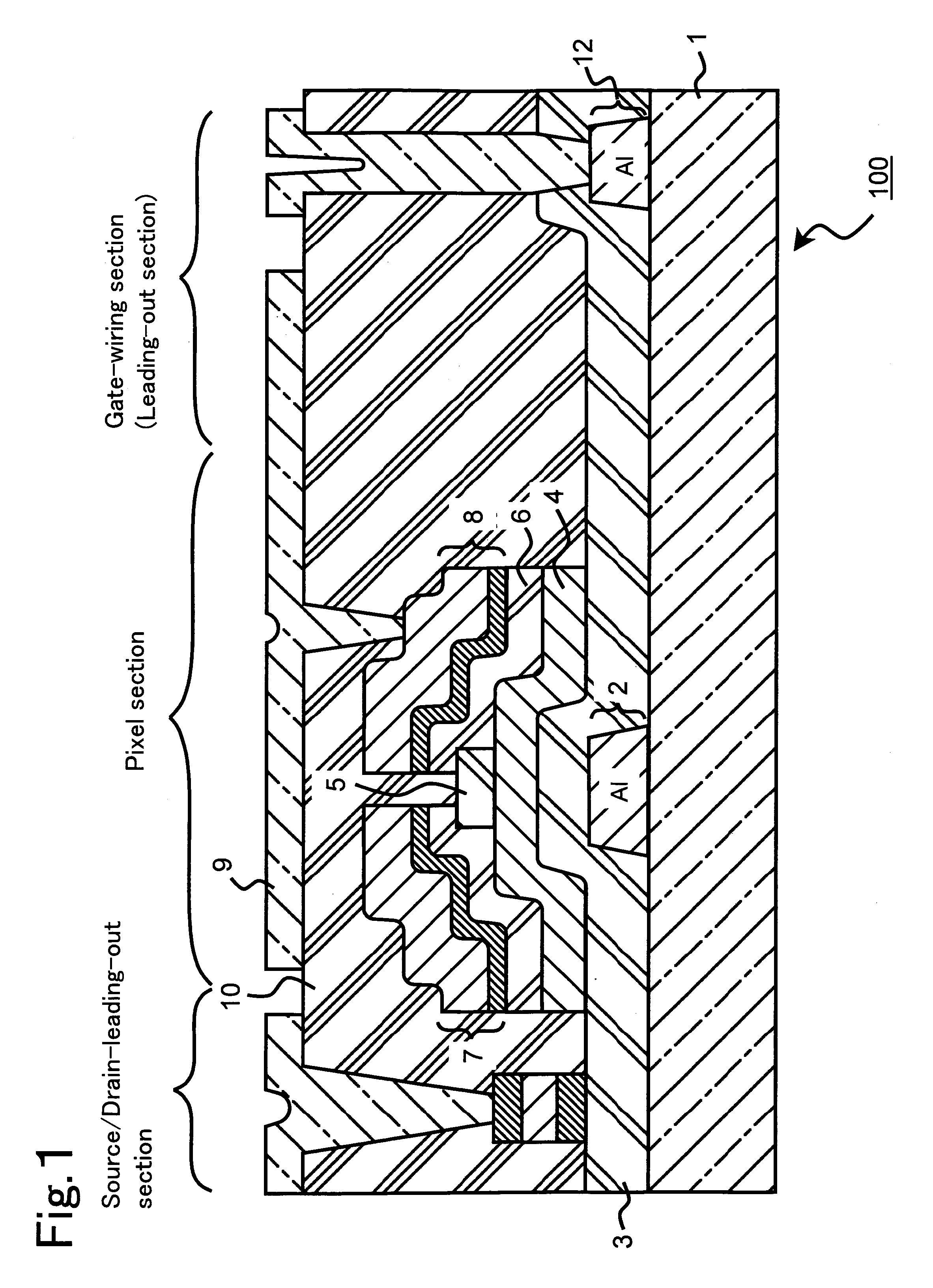

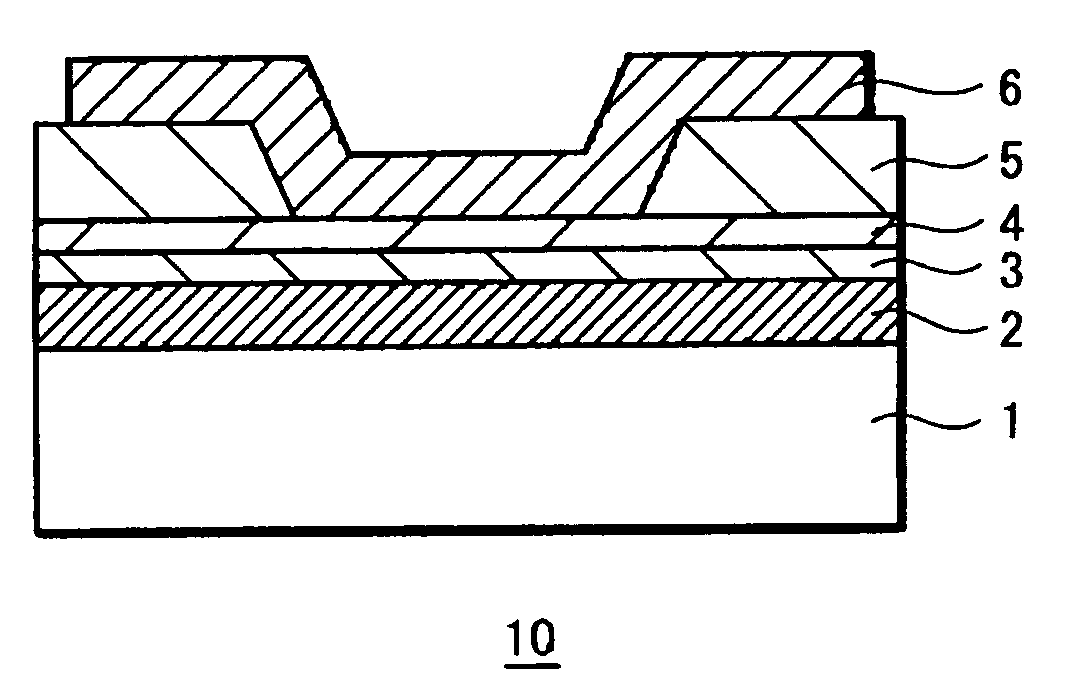

Thin film transistor, thin film transistor substrate, processes for producing the same, liquid crystal display using the same, and related devices and processes; and sputtering target, transparent electroconductive film formed by use of this,transparent electrode, and related devices and processes

InactiveUS20070170434A1Reduce light transmittanceConductive layers on insulating-supportsSemiconductor/solid-state device detailsIndiumLiquid-crystal display

Provided are a thin film transistor substrate having a transparent electroconductive film in which residues and so on resulting etching are hardly generated; a process for producing the same; and a liquid crystal display using this thin film transistor substrate. A thin film transistor substrate, comprising a transparent substrate, a source electrode formed over the transparent substrate, a drain electrode formed over the transparent substrate, and a transparent pixel electrode formed over the transparent substrate, wherein the transparent pixel electrode is a transparent electroconductive film which is made mainly of indium oxide, and further comprises one or two or more oxides selected from tungsten oxide, molybdenum oxide, nickel oxide and niobium oxide, and the transparent pixel electrode is electrically connected to the source electrode or the drain electrode; a process for producing the same; and a liquid crystal display using this thin film transistor substrate.

Owner:IDEMITSU KOSAN CO LTD

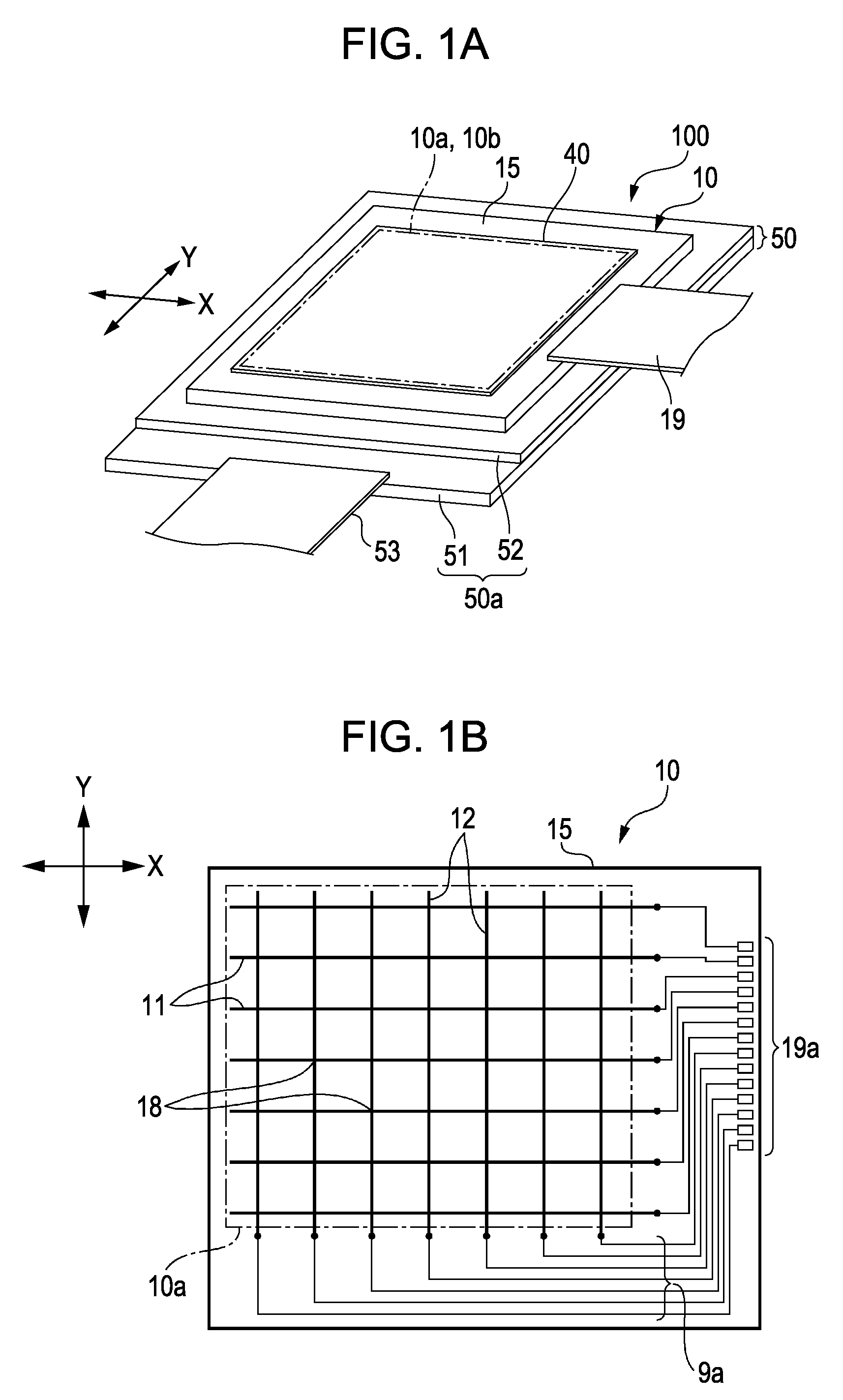

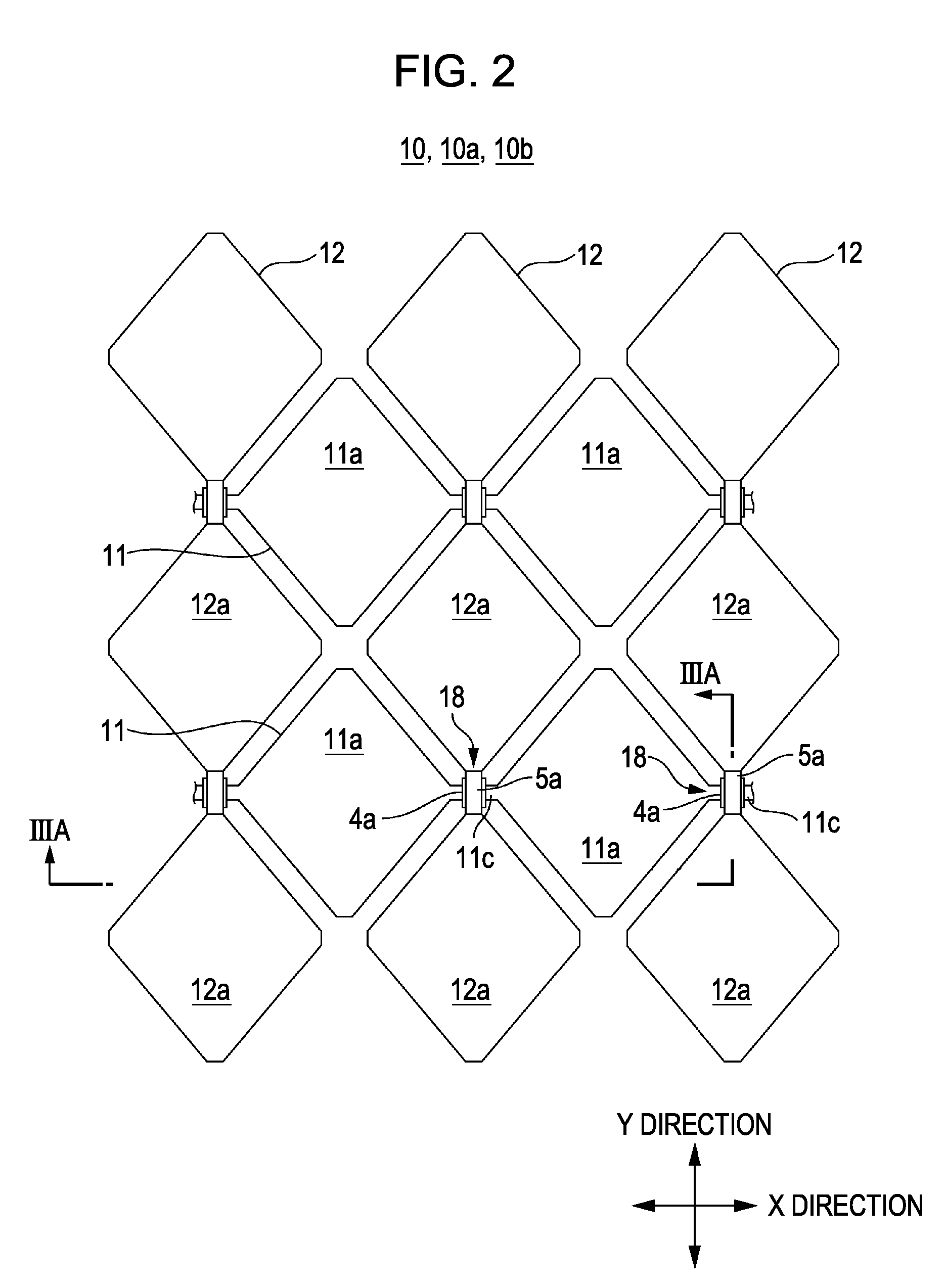

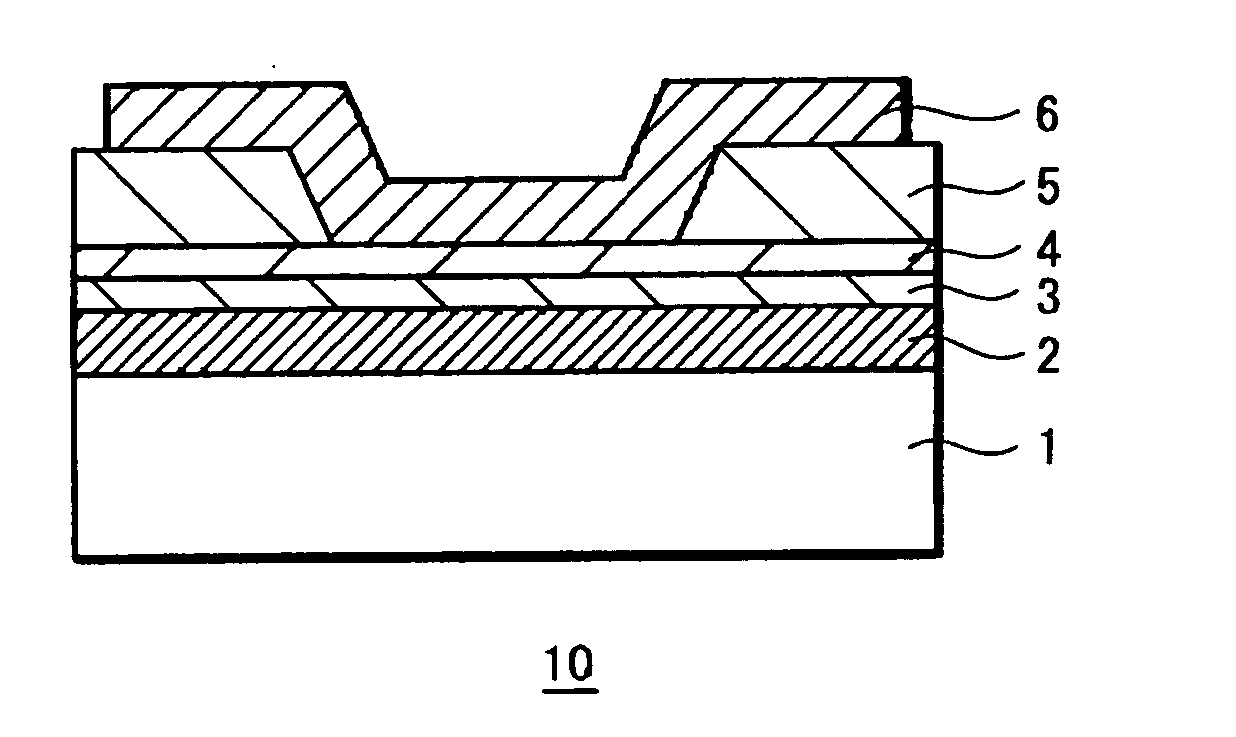

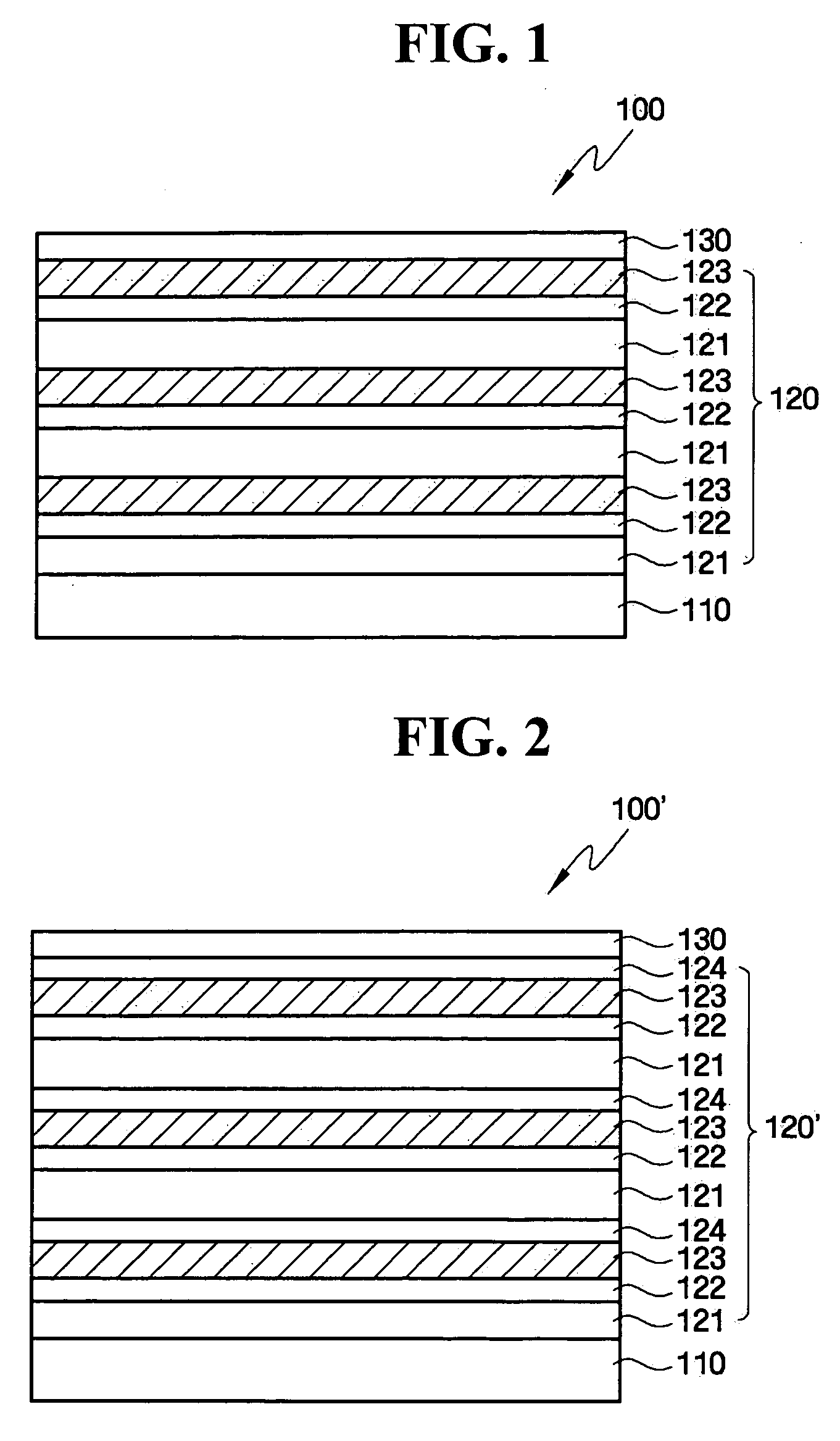

Capacitive input device, display device with input function, and electronic apparatus

ActiveUS20090244028A1Simple manufacturing processSimple processInput/output processes for data processingOptical elementsCapacitanceRefractive index

A capacitive input device includes a light-transmitting substrate, a multilayer film formed on one of the surfaces of the light-transmitting substrate and including a plurality of light-transmitting thin films which have different refractive indexes and one of which is a niobium oxide film, a plurality of first light-transmitting electrodes formed on the multilayer film in an input region of the light-transmitting substrate to extend in a first direction, and a plurality of second light-transmitting electrodes formed on the multilayer film in the input region of the light-transmitting substrate to extend in a second direction crossing the first direction.

Owner:JAPAN DISPLAY WEST

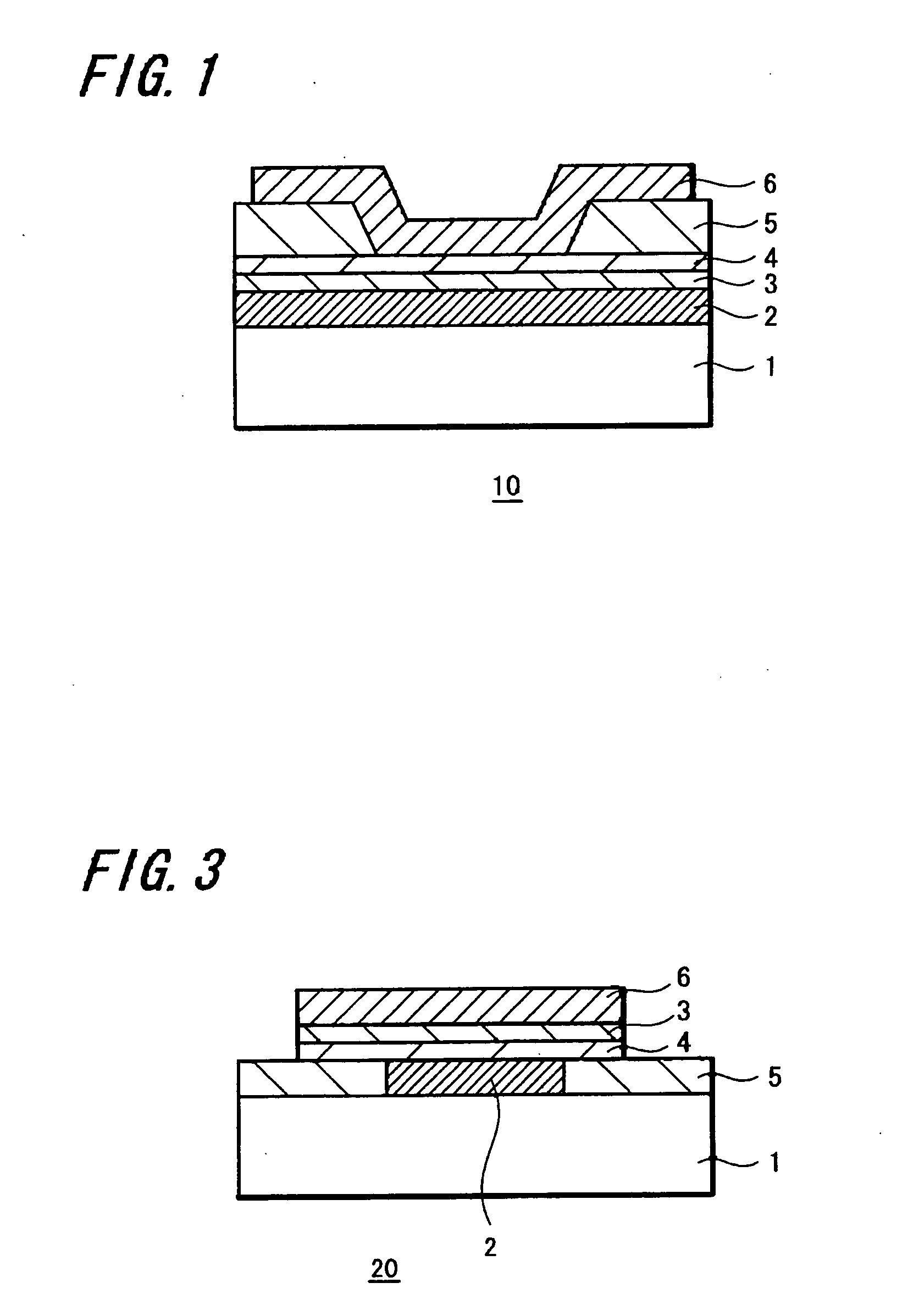

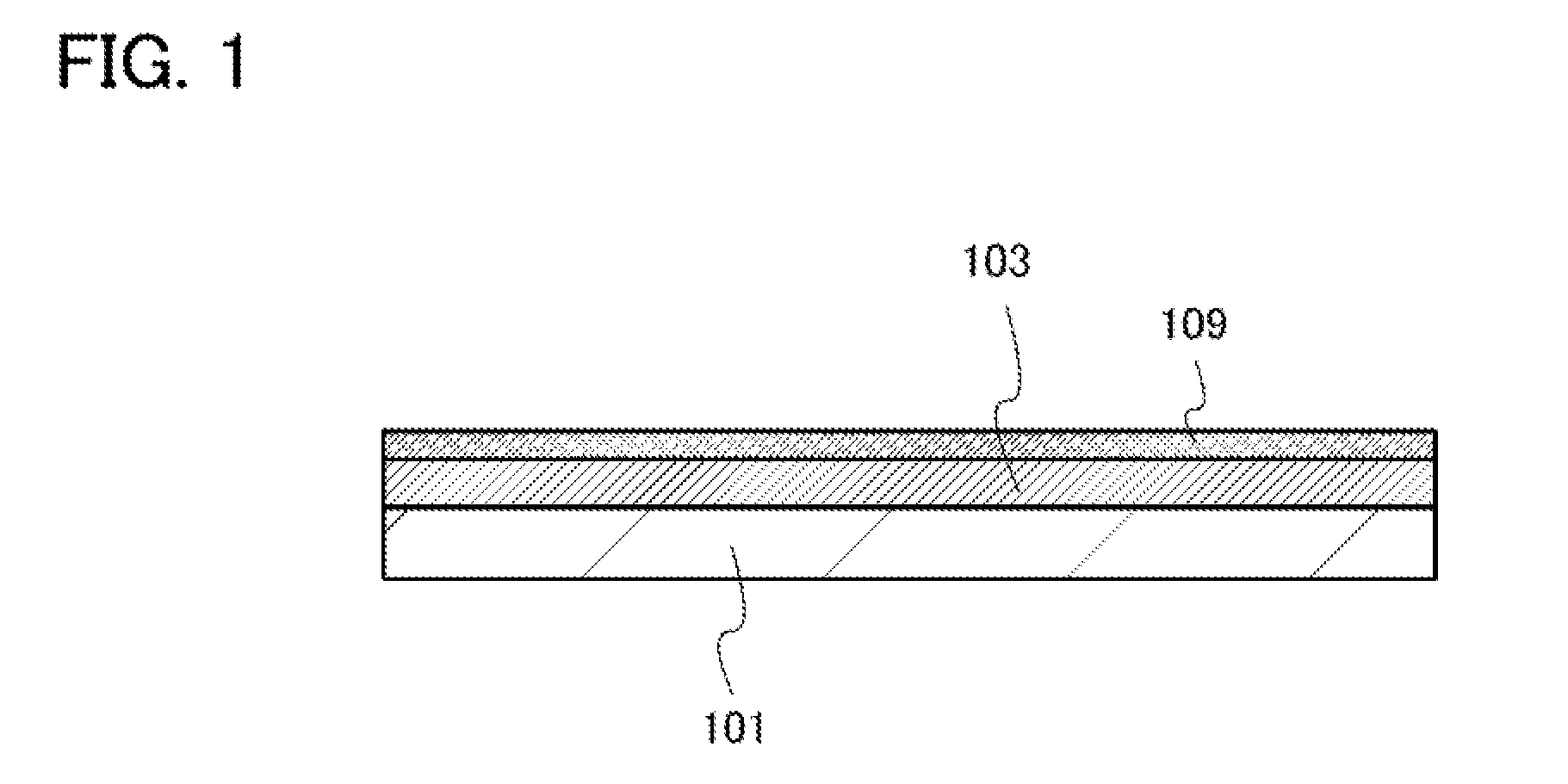

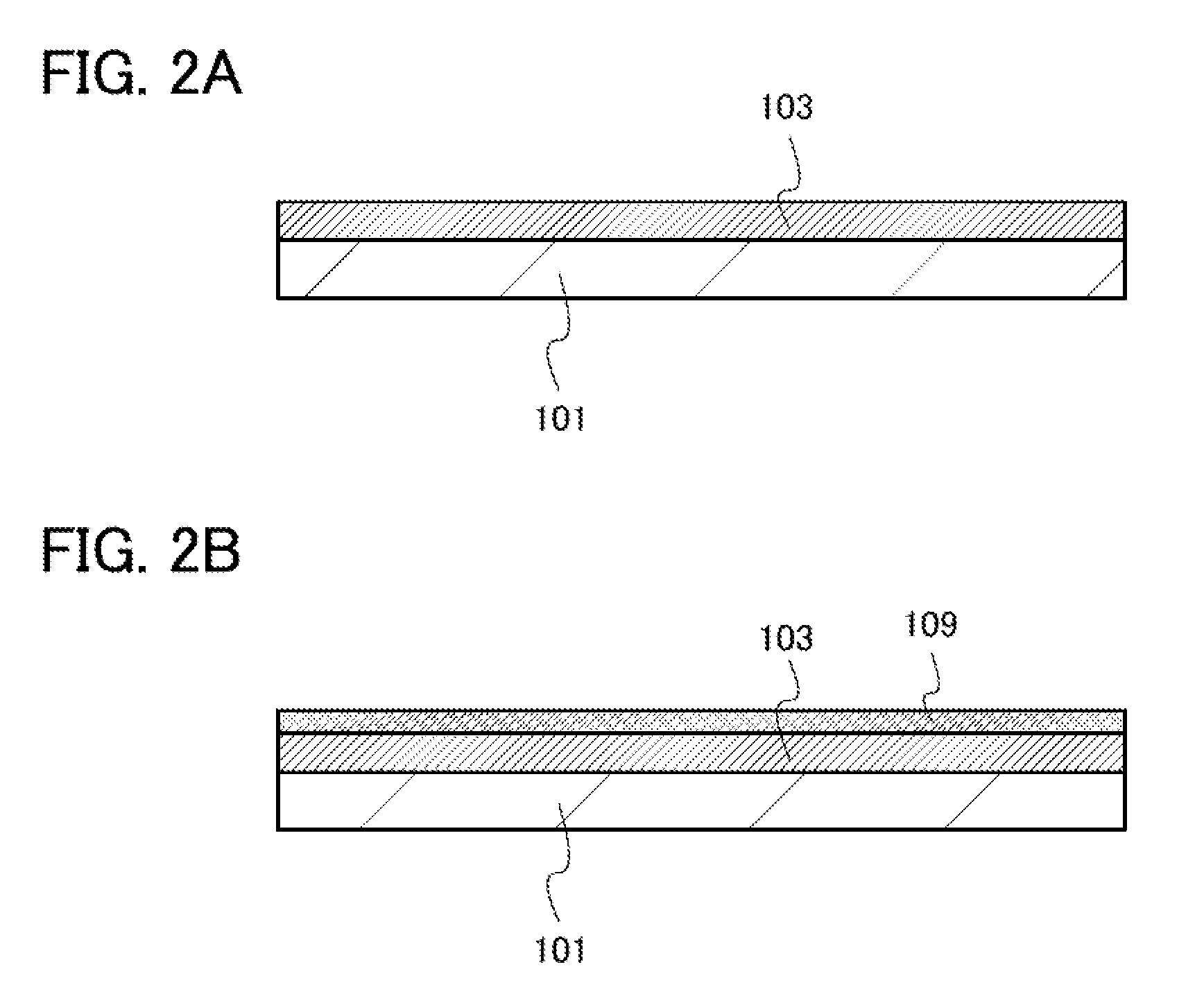

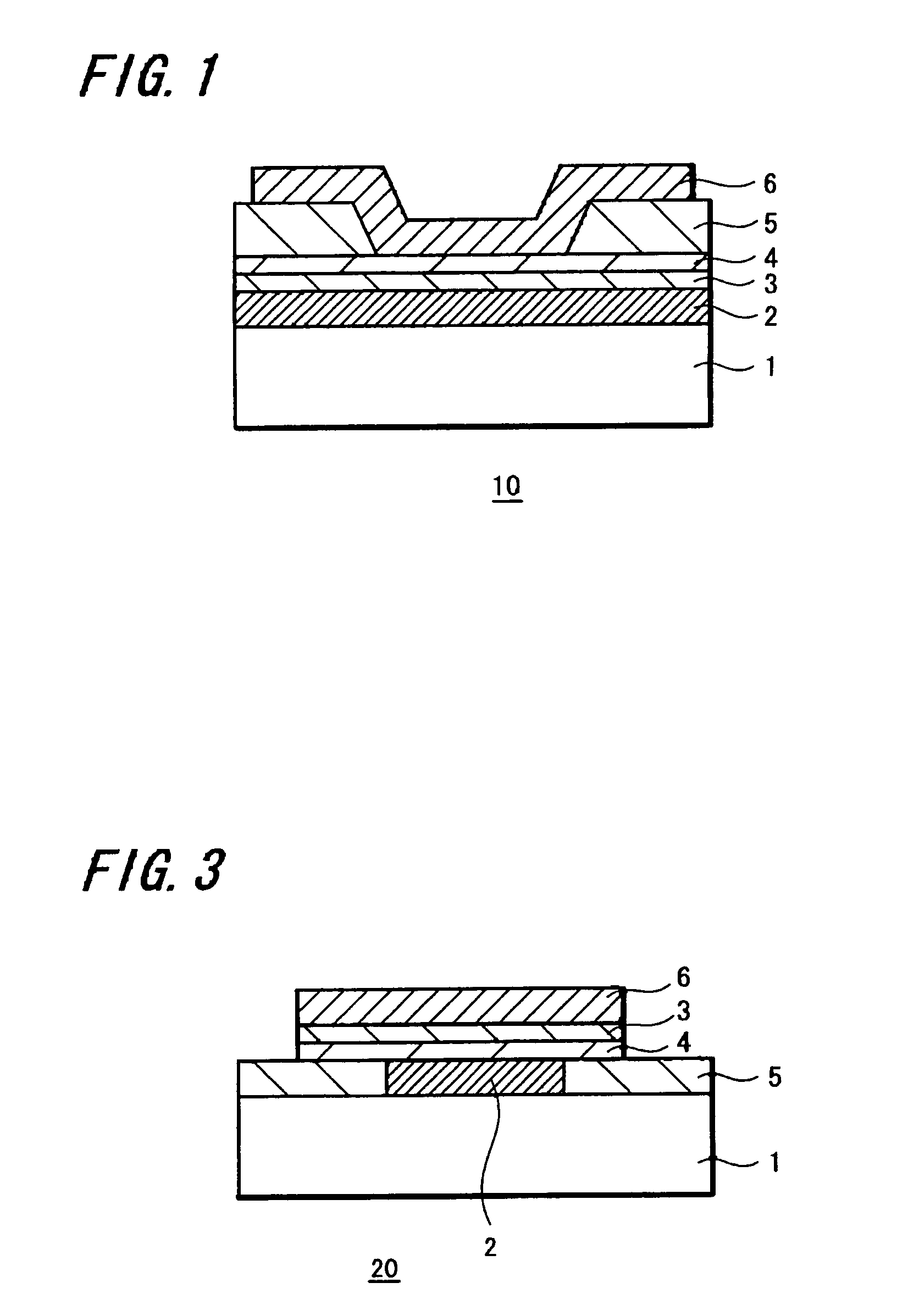

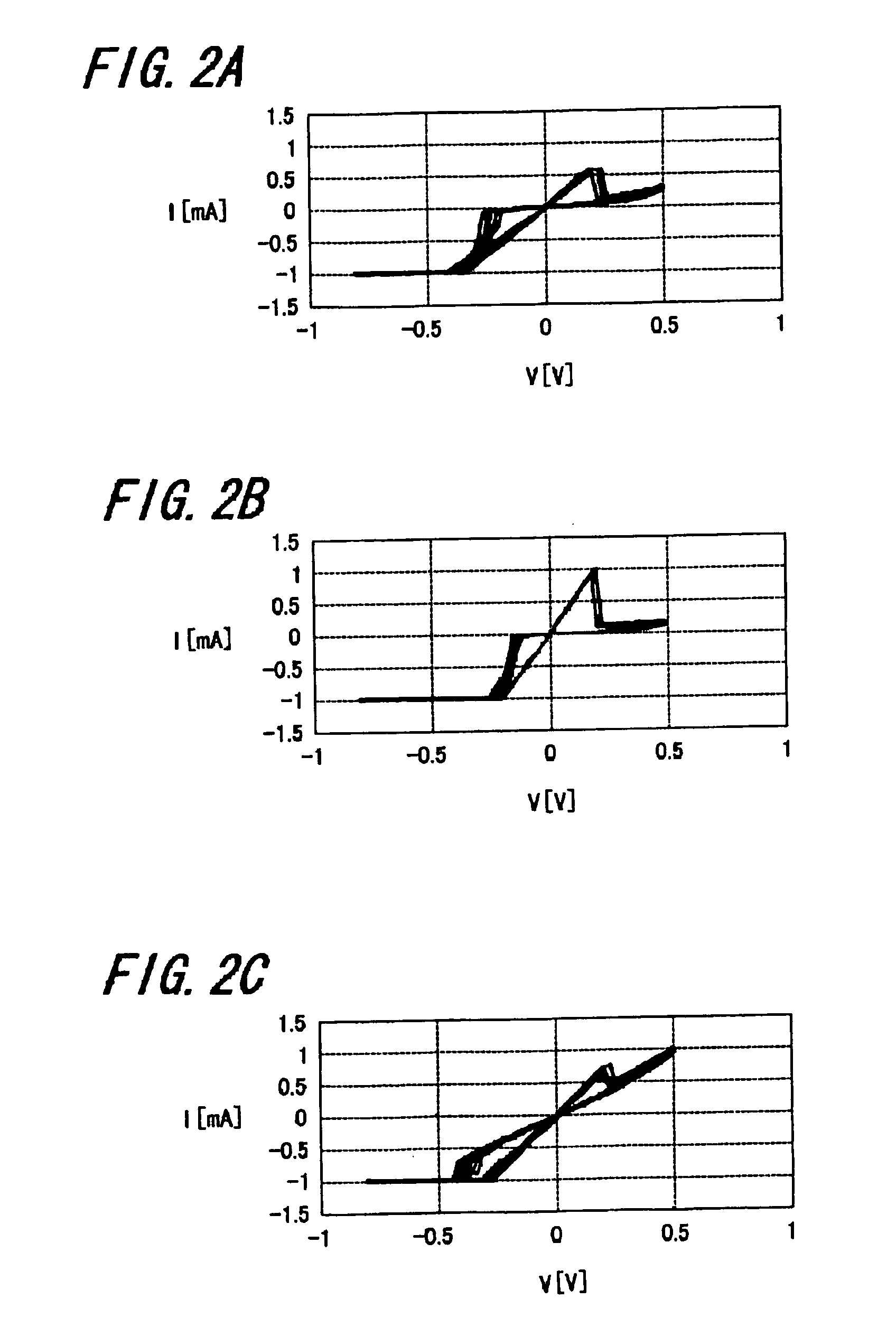

Memory element and memory device

ActiveUS20060126423A1Deterioration of characteristic can be preventedDeterioration of characteristicSolid-state devicesDigital storageData recordingNiobium oxide

A memory element which stably performs operations such as data recording and which has a stable structure with respect to heat is provided. A memory element 10 includes a memory layer 4 and an ion source layer 3 positioned between the first electrode 2 and second electrode 6, in which the ion source layer 3 contains any of elements selected from Cu, Ag and Zn, and any of elements selected from Te, S and Se, and the memory layer 4 is made of any of tantalum oxide, niobium oxide, aluminum oxide, hafnium oxide and zirconium oxide, or is made of mixed materials thereof.

Owner:SONY CORP

Solid electrolytic capacitor and manufacturing method thereof

InactiveUS6215652B1Avoid volatilityIncrease capacitanceLiquid electrolytic capacitorsFixed capacitor dielectricElectrolysisMetal powder

A solid electrolytic capacitor is here disclosed in which a dielectric layer formed on the surface of an anode obtained by molding and then sintering a niobium metal powder which includes a niobium oxide layer and a niobium nitride region, and a method for manufacturing the solid electrolytic capacitor is also disclosed.

Owner:TOKIN CORP

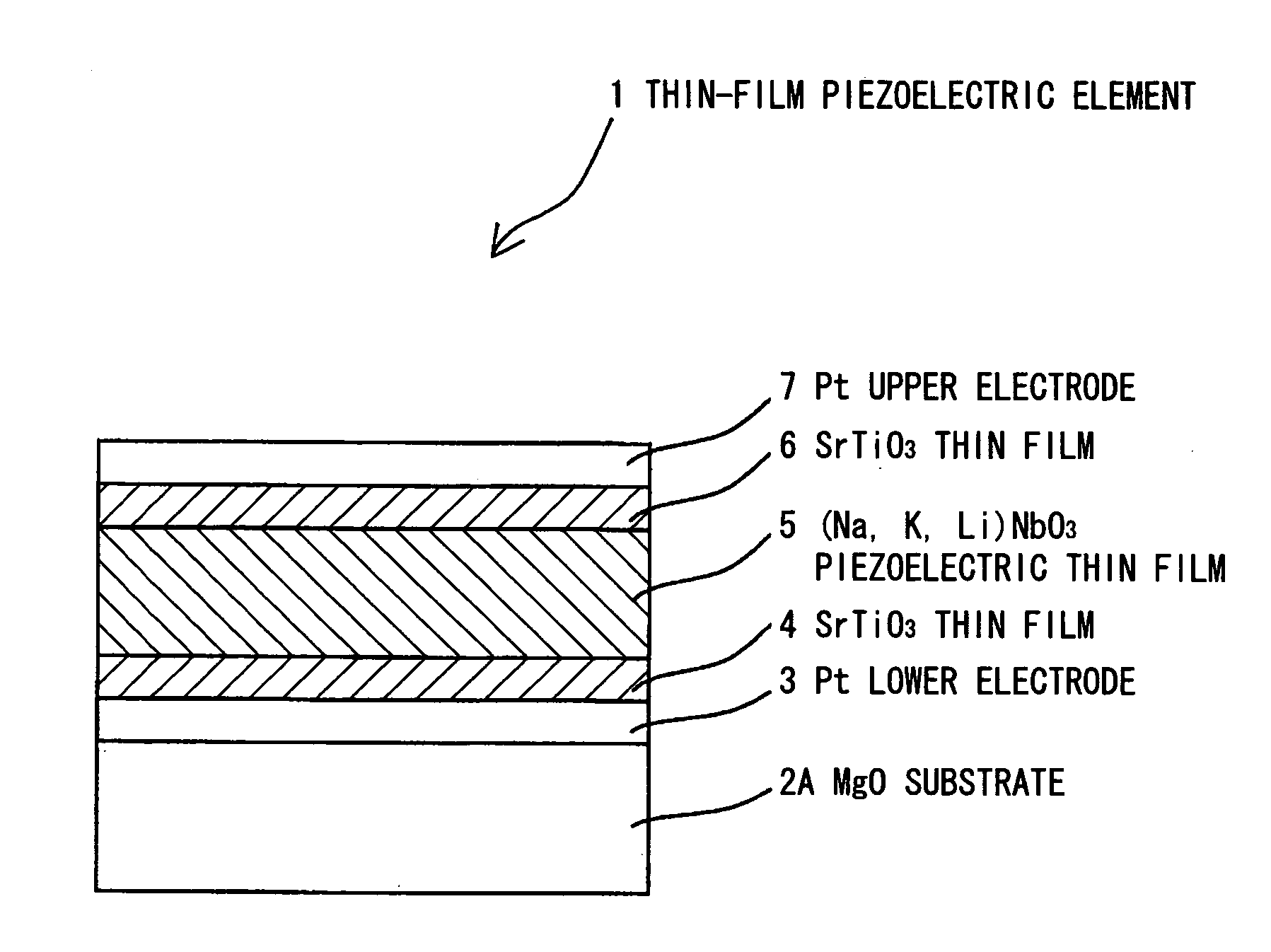

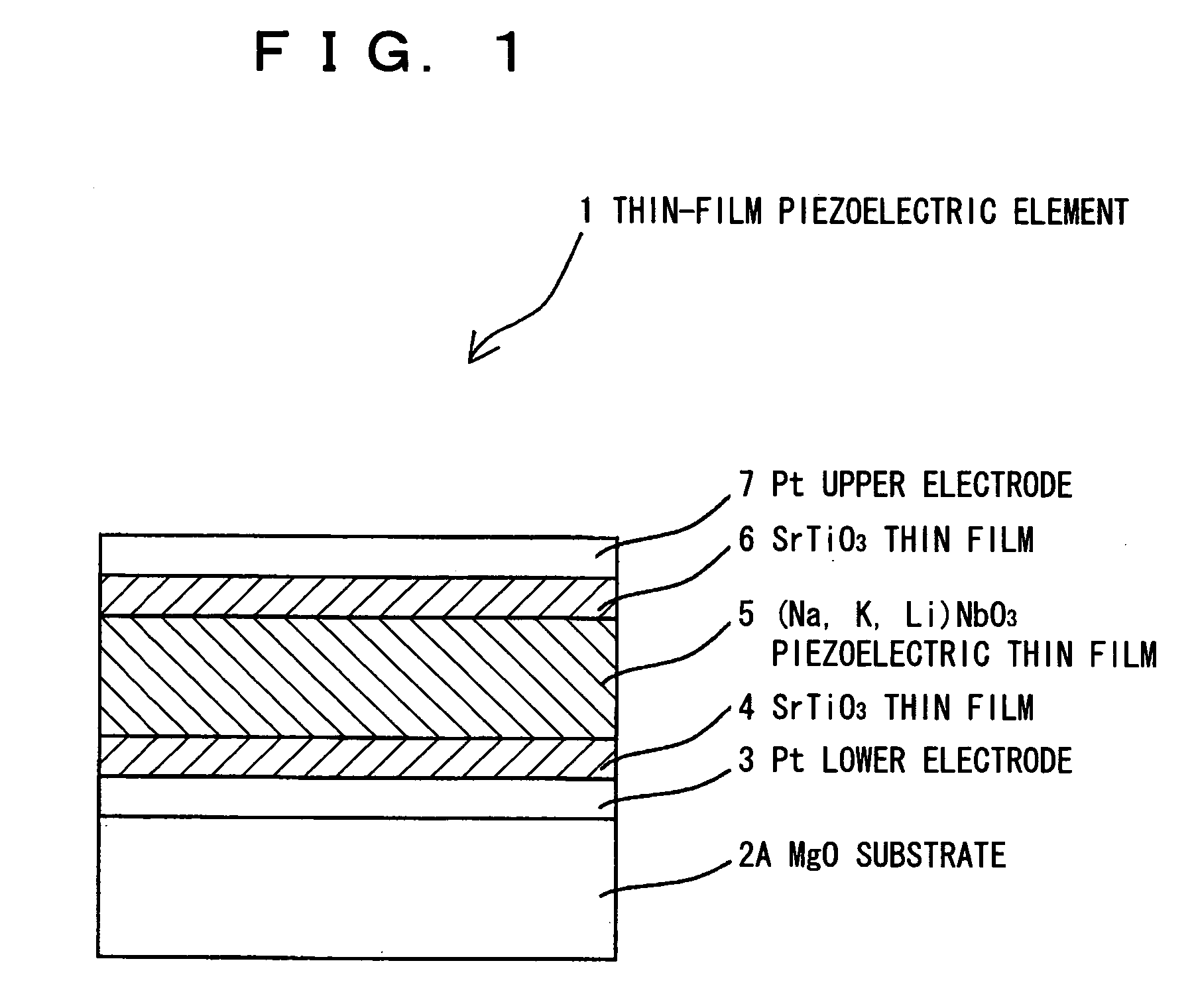

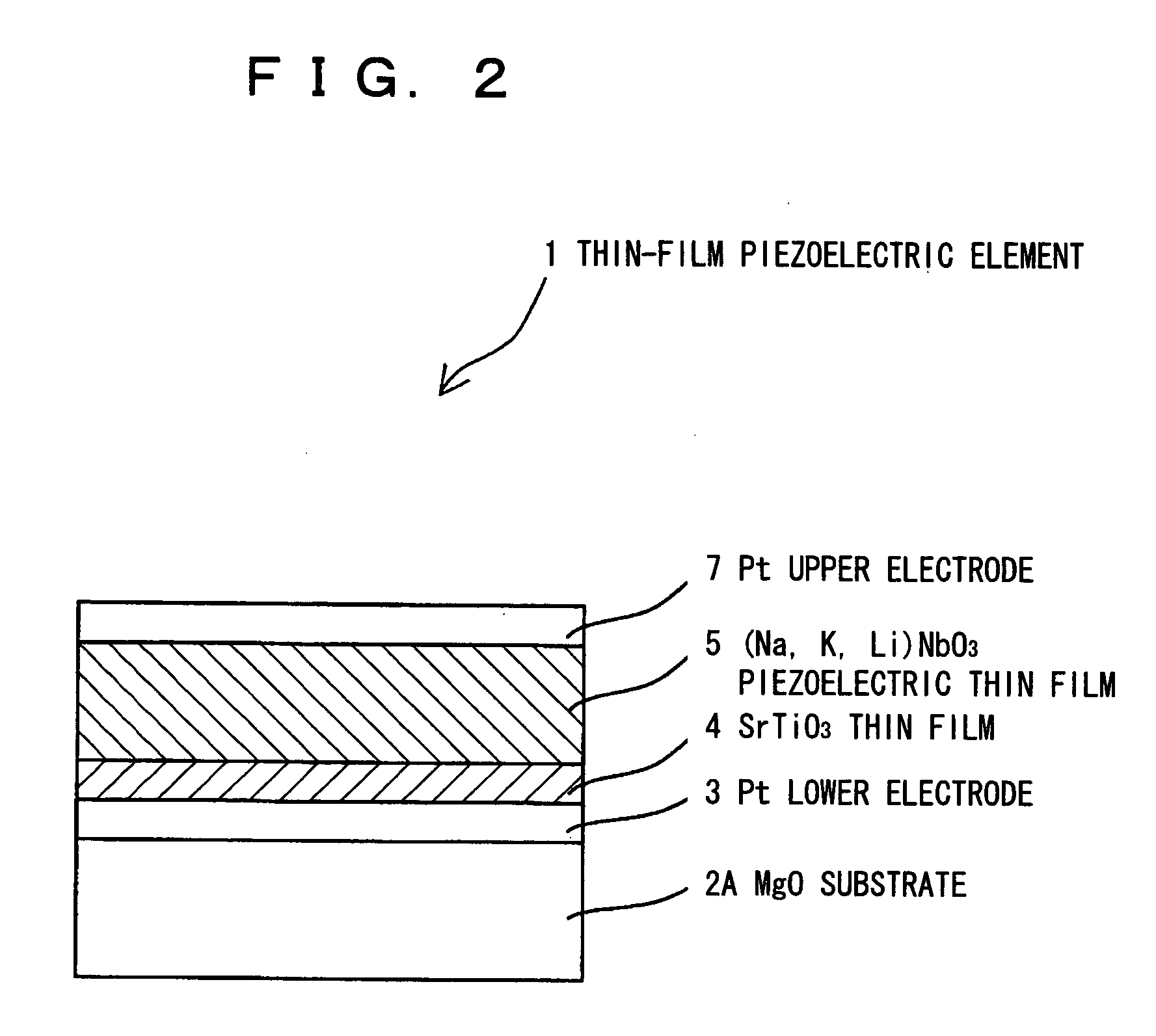

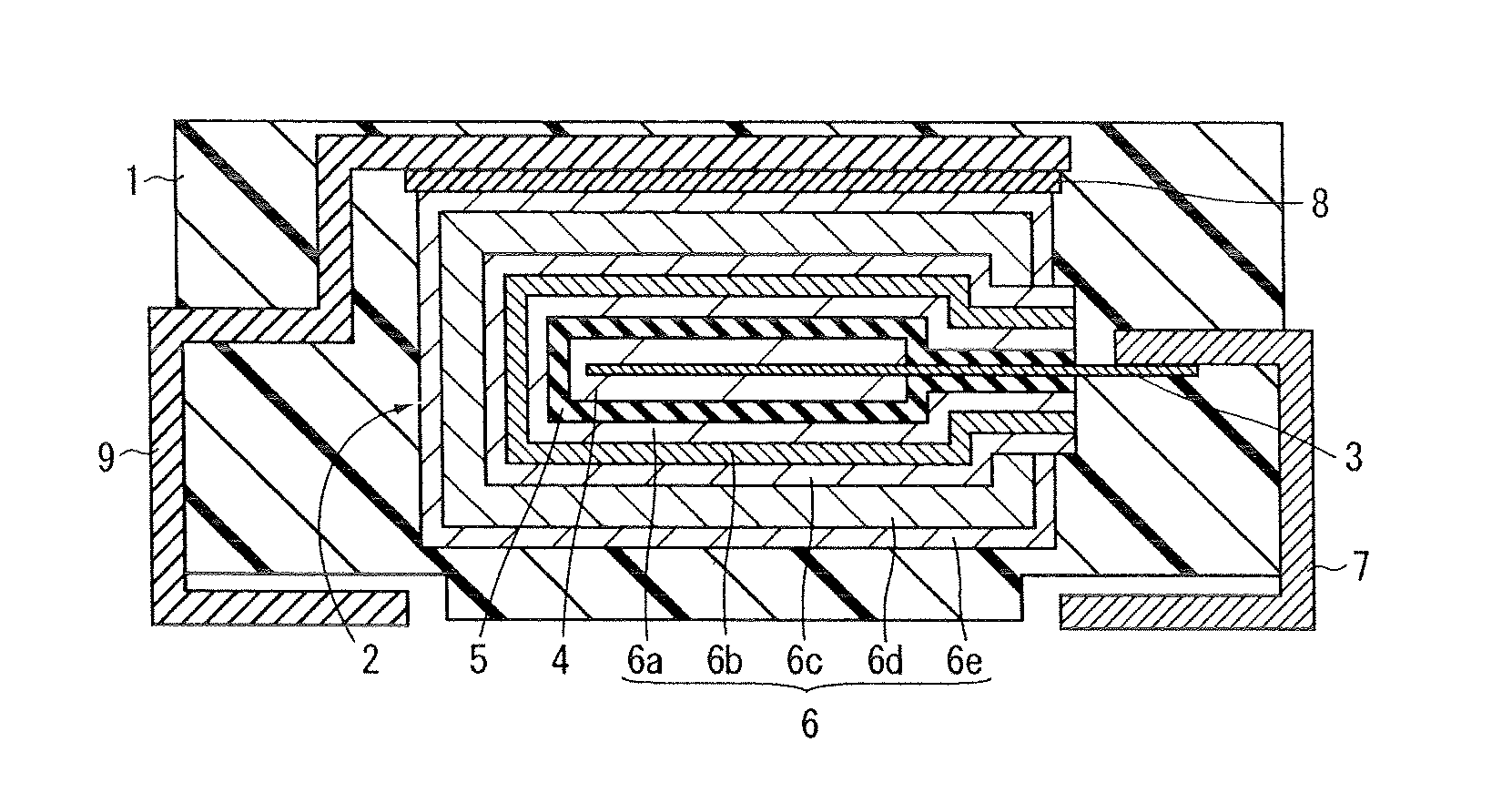

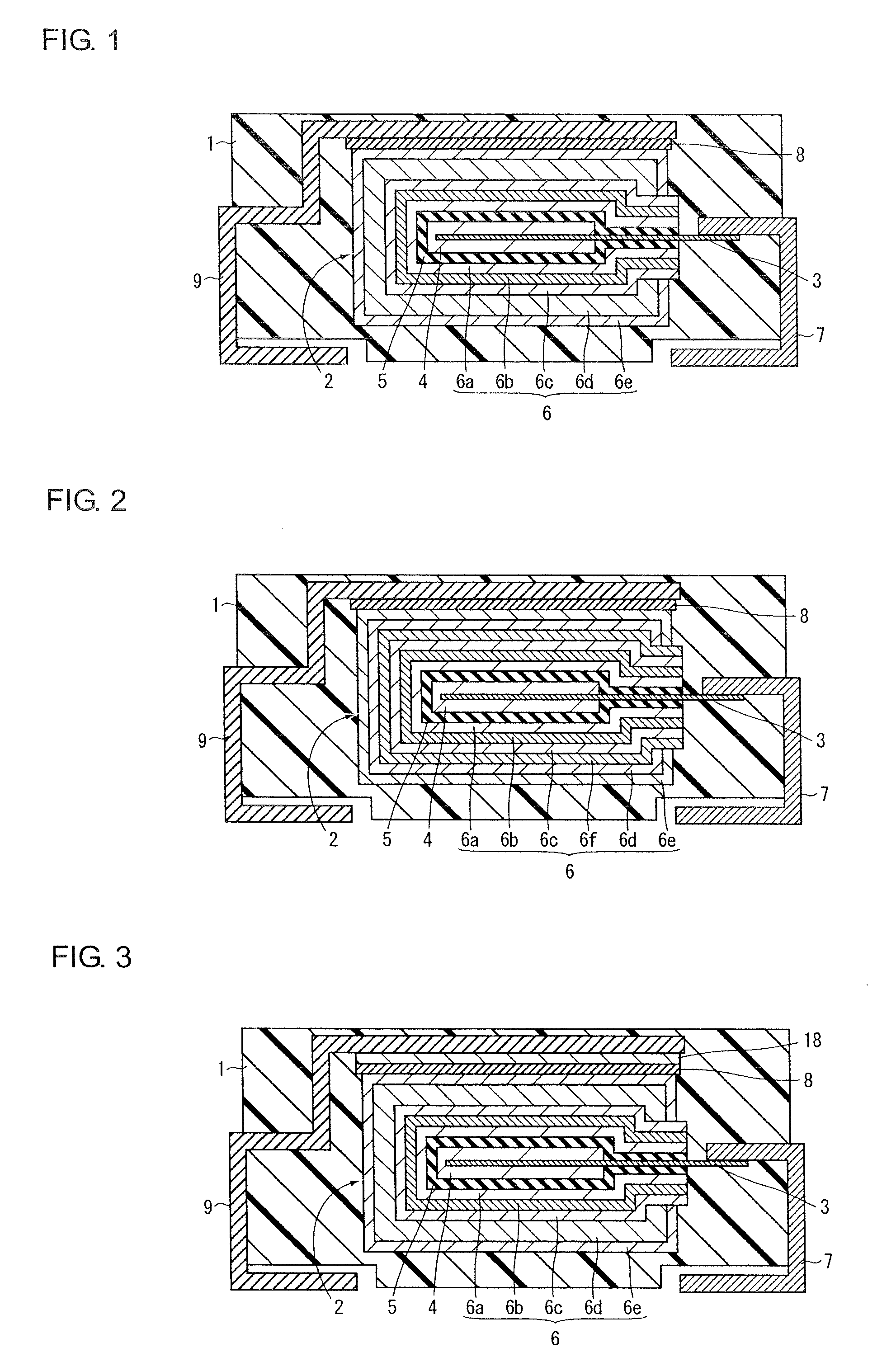

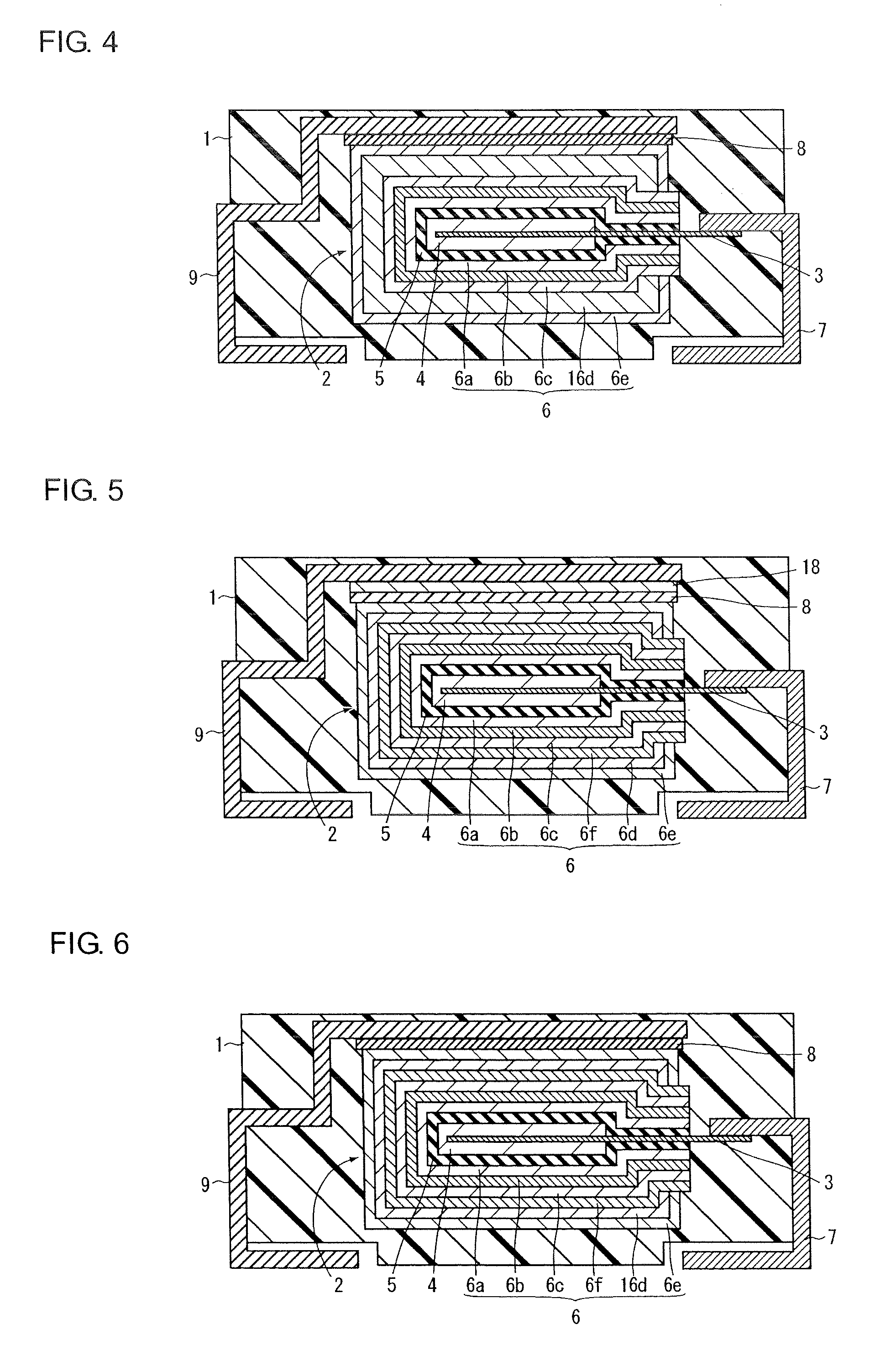

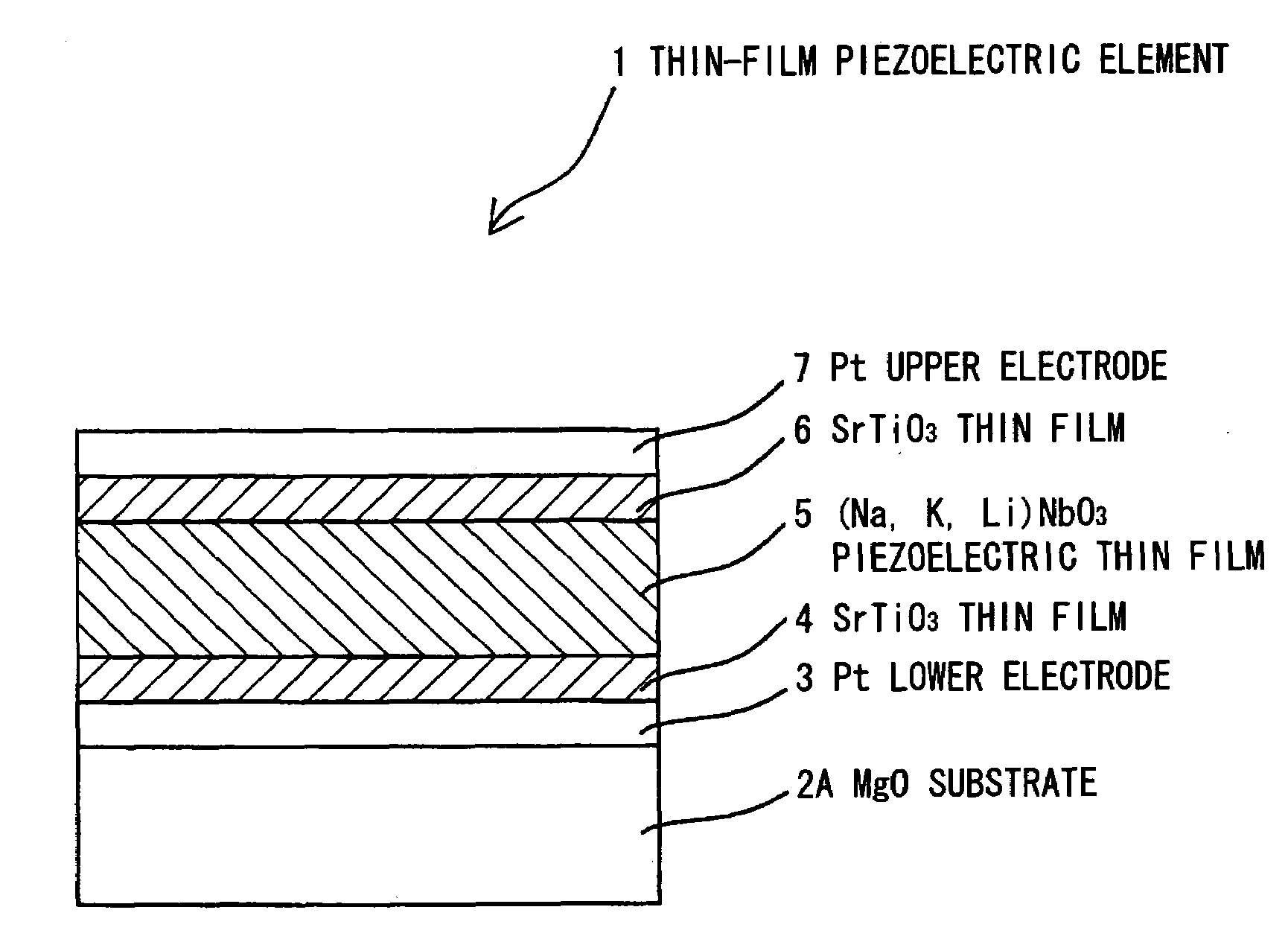

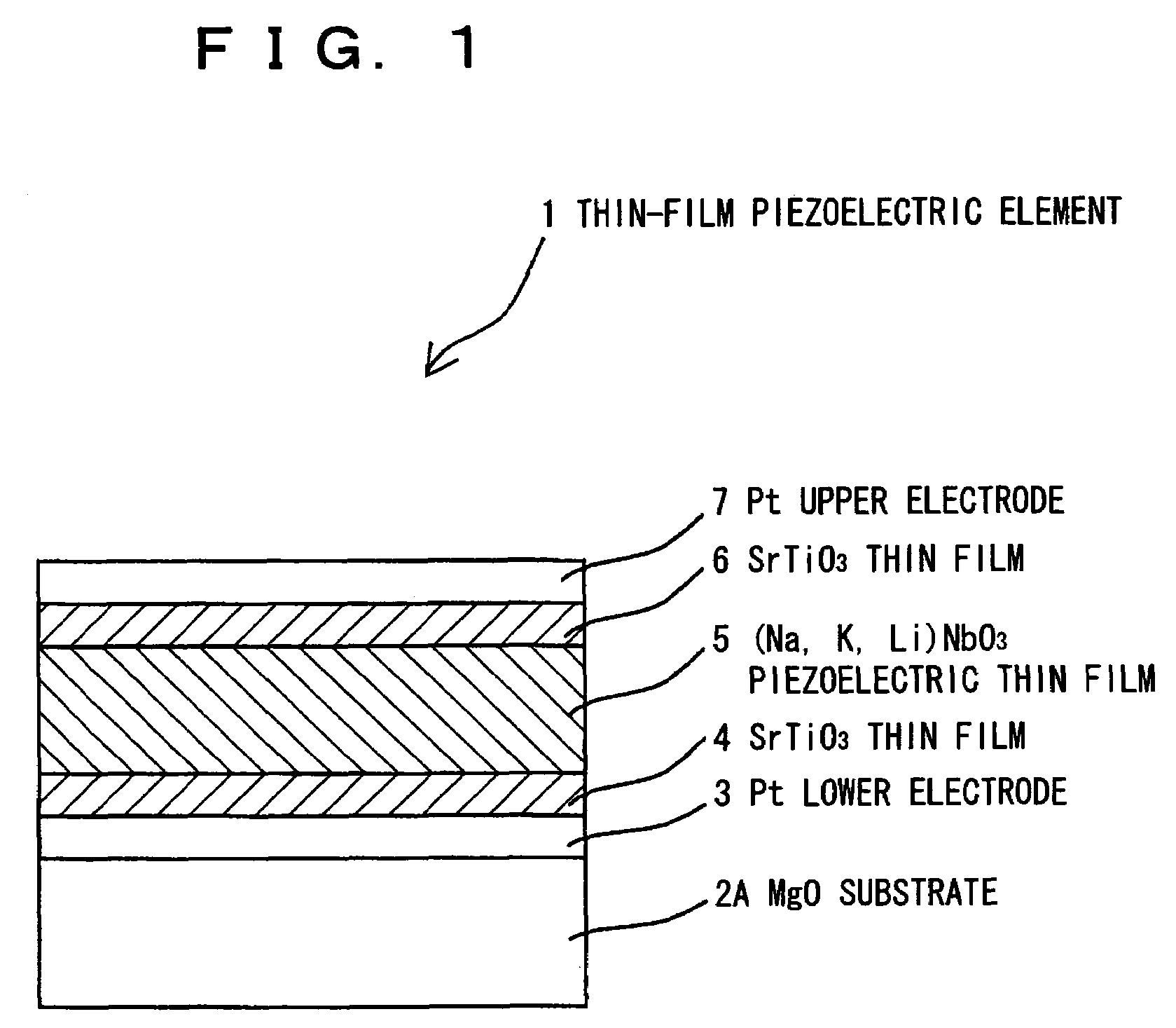

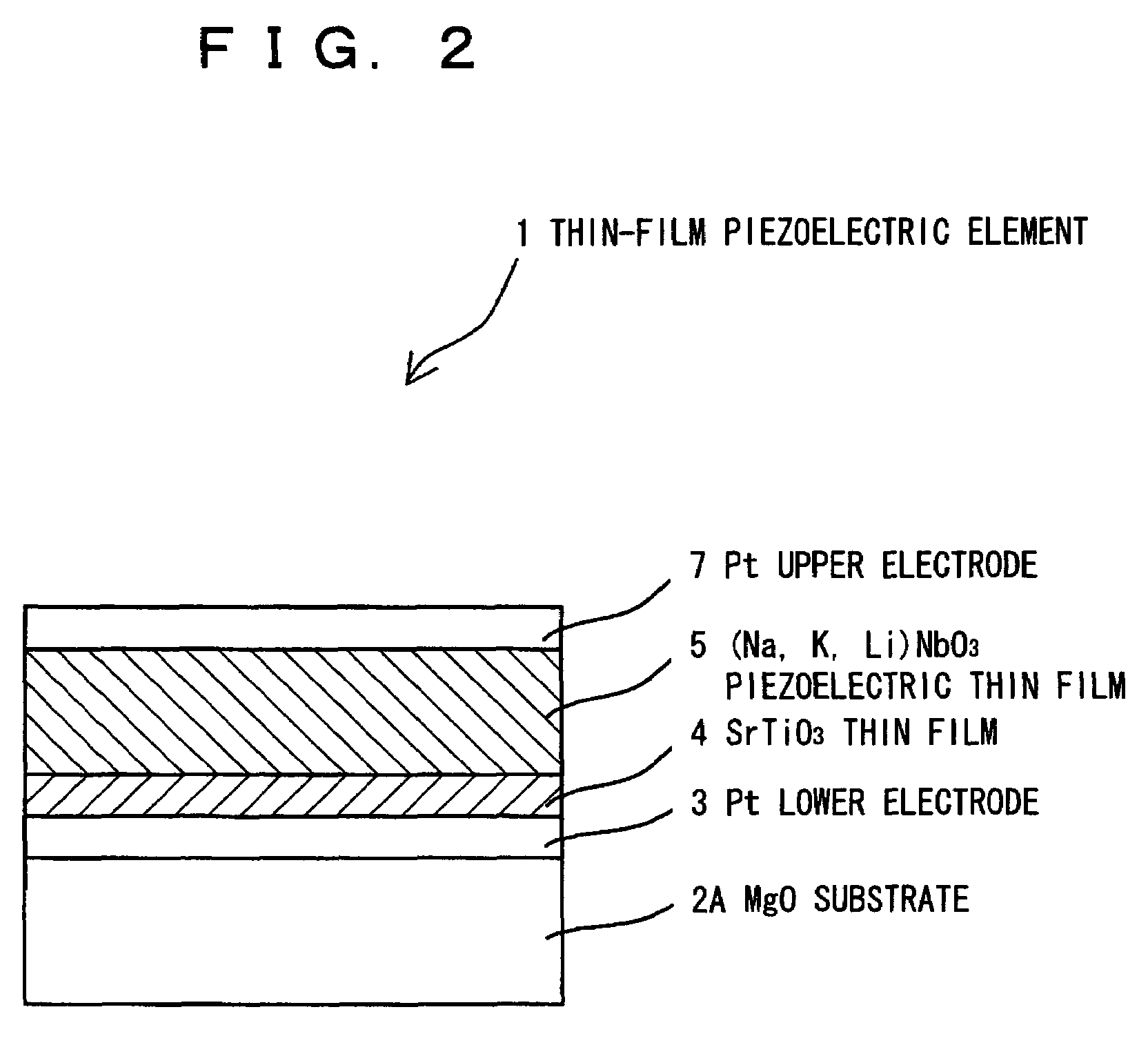

Piezoelectric thin film element

InactiveUS20070024162A1Excellent dielectric strength voltageExcellent piezoelectric propertiesPiezoelectric/electrostrictive device manufacture/assemblyPiezoelectric/electrostriction/magnetostriction machinesDielectric strengthDielectric thin films

A thin-film piezoelectric element has a substrate, a lower electrode, a piezoelectric portion, and an upper electrode that are sequentially formed on the substrate. The piezoelectric portion has a dielectric thin film that has an alkali niobium oxide-based perovskite structure expressed by general formula (NaxKyLiz)NbO3 (0<x<1, 0<y<1, 0≦z<1, x+y+z=1), and a high voltage-withstand dielectric that has a dielectric strength voltage greater than that of the dielectric thin film.

Owner:SUMITOMO CHEM CO LTD

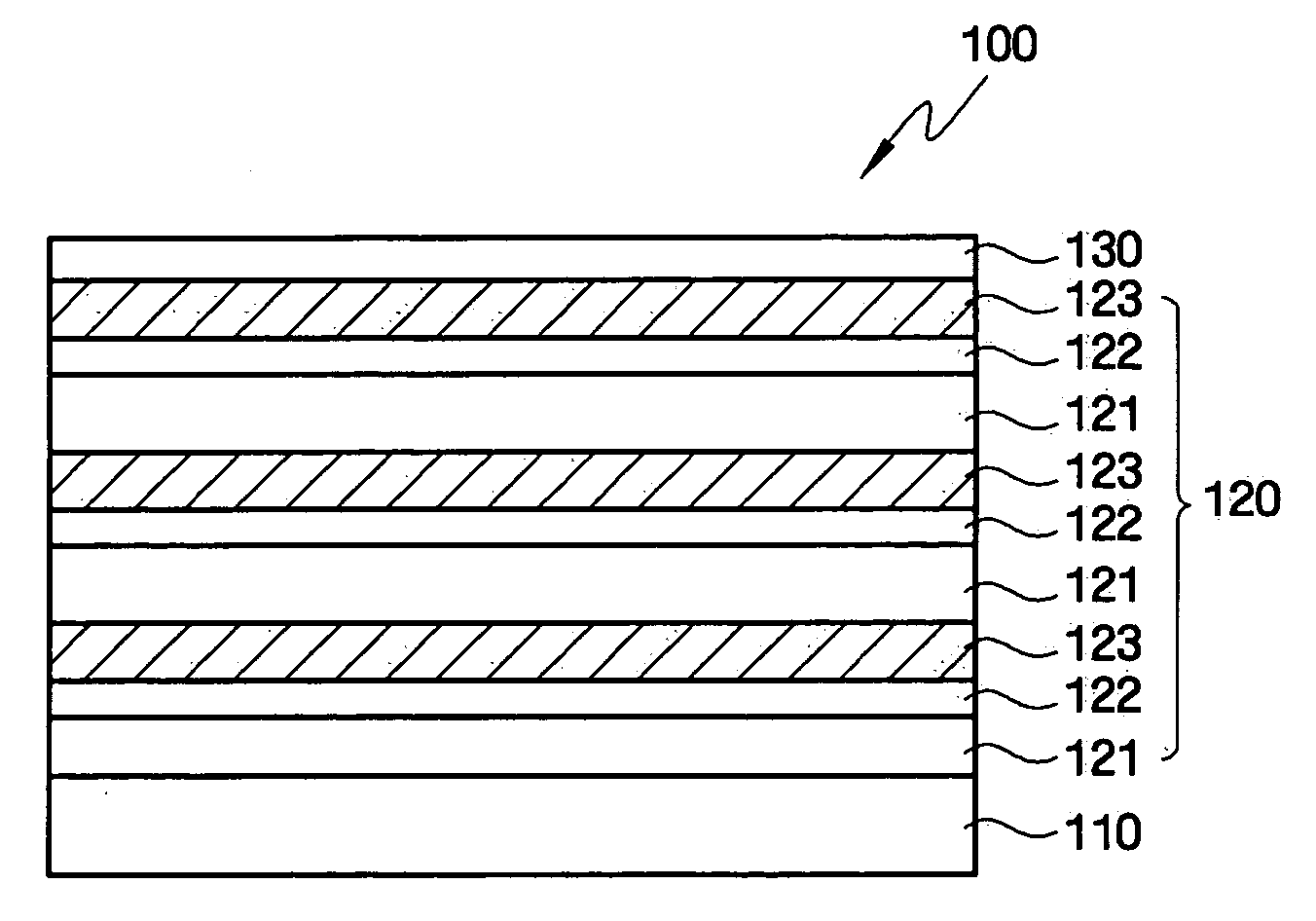

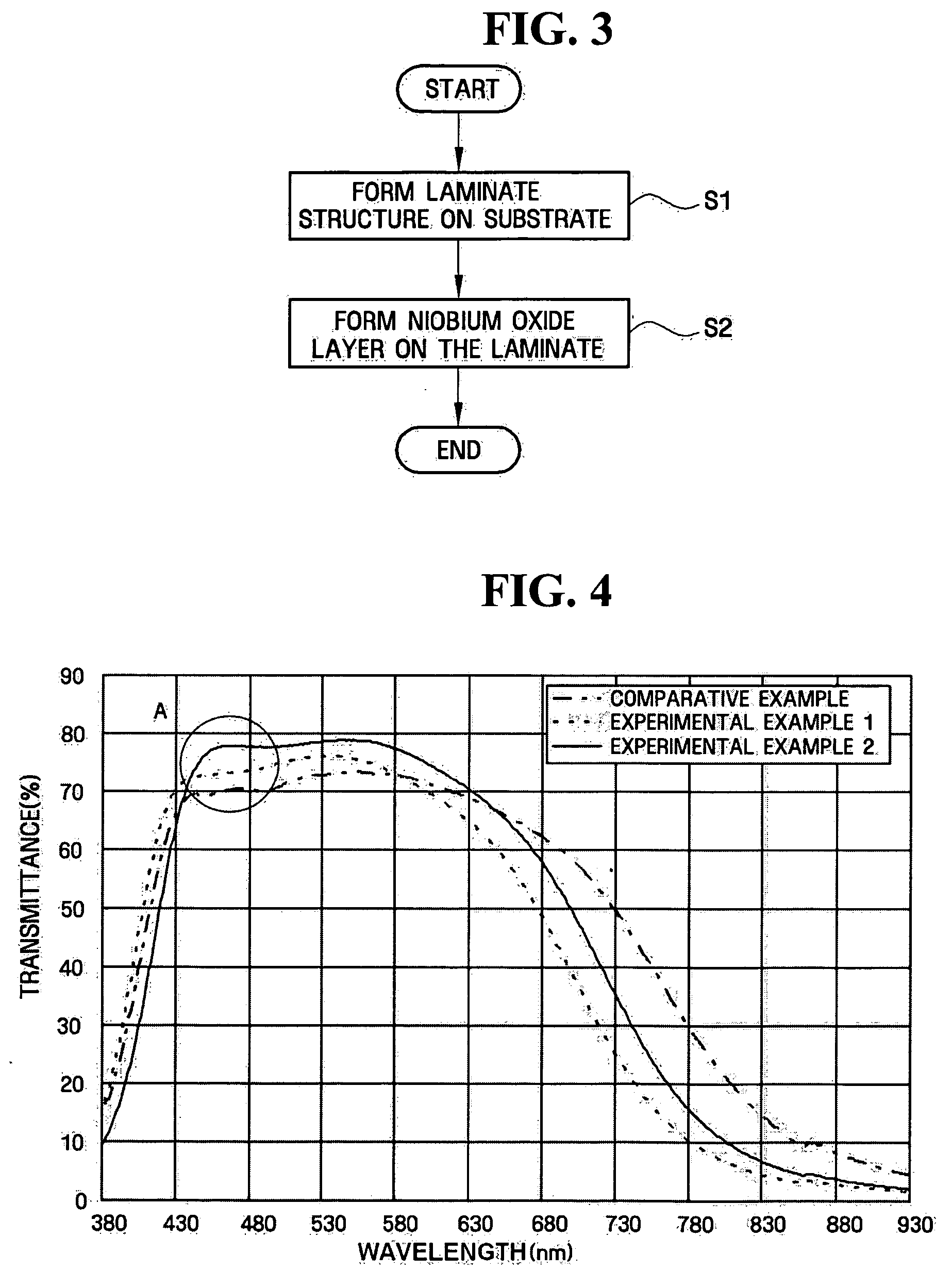

Electromagnetic wave shielding filter, method of manufacturing the same, PDP apparatus including the same filter

InactiveUS20060083938A1Low conductivityHigh visible light transmittance rayMagnetic/electric field screeningCathode ray/electron stream lampsTransmittanceElectromagnetic shielding

An electromagnetic wave shielding filter that has low electric conductivity, high visible light transmittance and good durability, a method of manufacturing the electromagnetic wave shielding filter, and a PDP apparatus including the electromagnetic wave shielding filter. The electromagnetic wave shielding filter includes a laminate structure including multiple stacks each consisting of a niobium oxide layer, a first protective layer having a ZnO as a main component, and a metal layer sequentially laminated in that order, the multiple stacks formed by repeatedly laminating the respective layers at least three times, and a niobium oxide layer formed on the laminate structure.

Owner:SAMSUNG CORNING PRECISION MATERIALS CO LTD

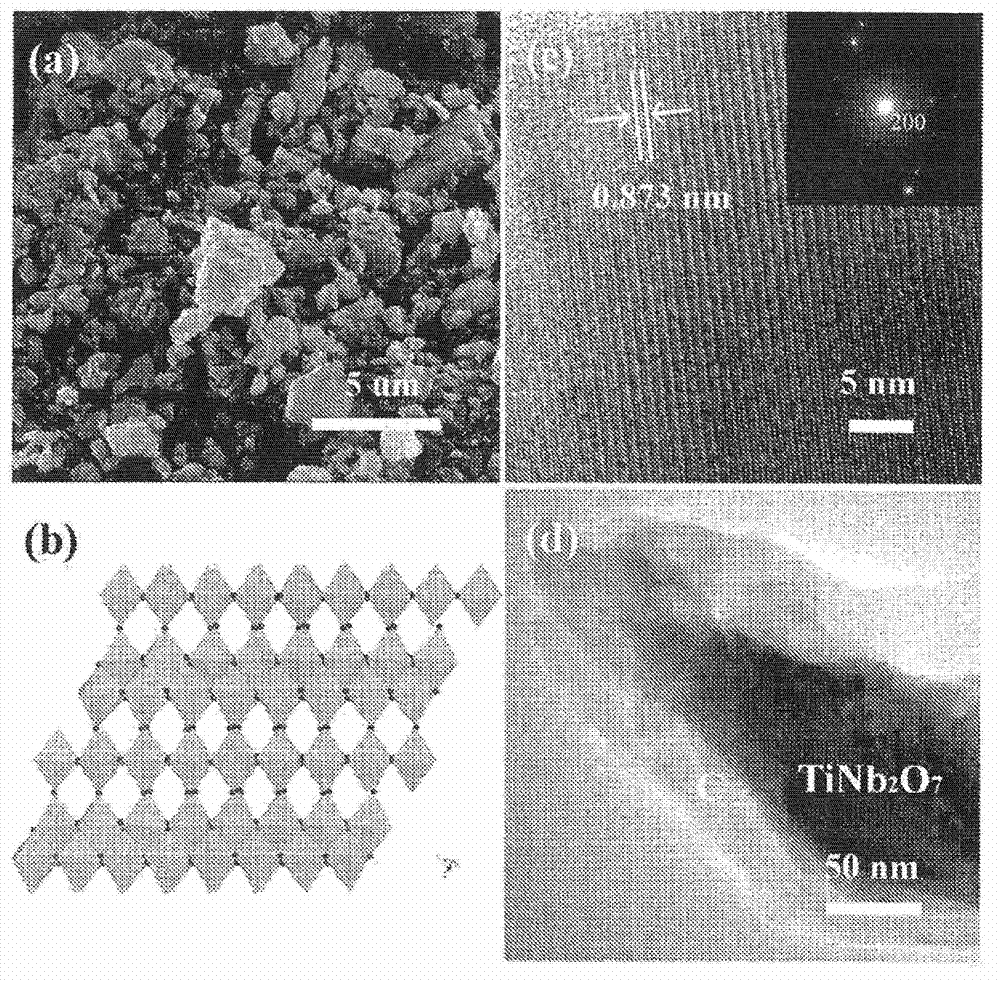

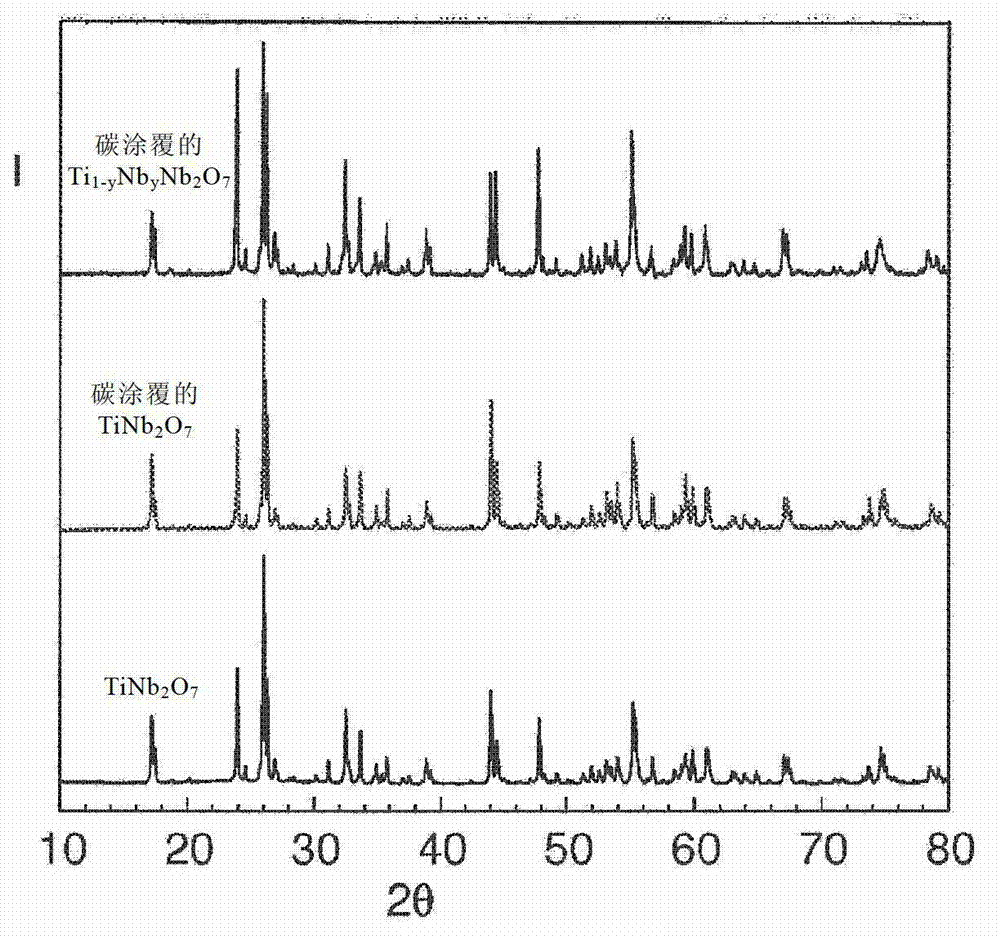

Niobium oxide compositions and methods for using same

InactiveCN103081187ALi-accumulatorsNon-aqueous electrolyte accumulator electrodesLithium-ion batteryCarbon coated

Owner:BOARD OF RGT THE UNIV OF TEXAS SYST

Hydrated Niobium Oxide Nanoparticle Containing Catalysts for Olefin Hydration

An olefin hydration catalyst and method for producing same is provided. The olefin hydration catalyst can be prepared by contacting a niobium containing compound with a strong Bronsted acid, such as sulfuric or phosphoric acid, to produce niobium oxo sulfate or niobium oxo phosphate nanoparticles. The nanoparticles can be separated, dried and utilized in a reactor for the hydration of olefins to their corresponding alcohols.

Owner:SAUDI ARABIAN OIL CO

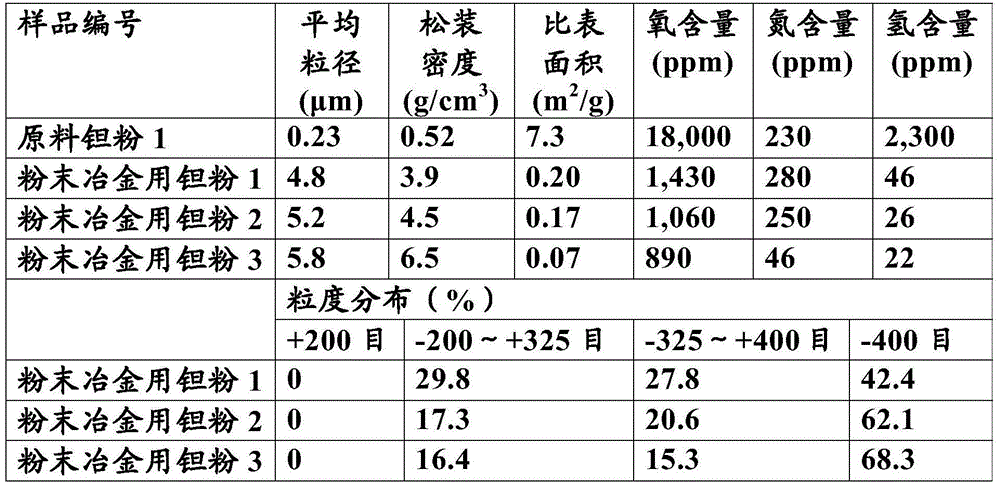

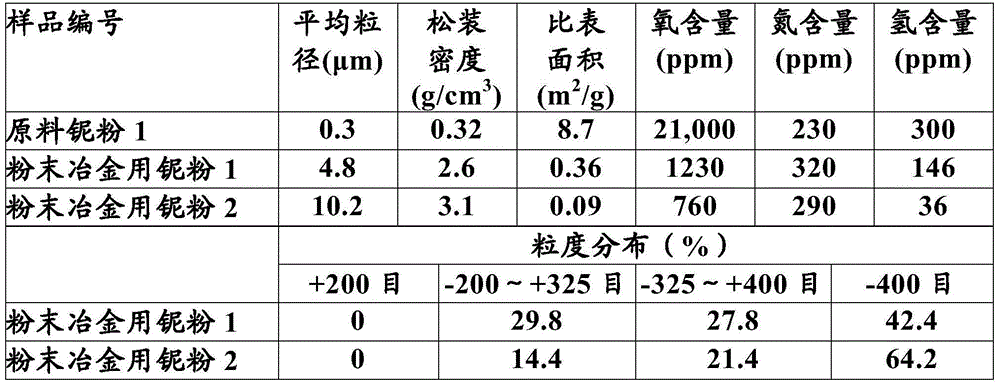

Powder metallurgy tantalum powder and/or niobium powder and preparing method thereof

The invention provides a preparing method of powder metallurgy tantalum powder and / or niobium powder. The method comprises the steps that (1) heat treatment sintering is conducted, wherein heat treatment sintering is conducted on raw tantalum powder and / or the niobium powder and after sintering is accomplished, cooling is conducted and then passivation is conducted so that a sintered block can be obtained; (2) hydrogenation and powder preparation are conducted, wherein the sintered block obtained through heat treatment is hydrogenated and powder is prepared so that the hydrogenated tantalum powder and / or the hydrogenated niobium powder can be obtained; (3) dehydrogenation and oxygen reduction are conducted, wherein reducibility metal is added to the hydrogenated tantalum powder and / or the niobium powder so that dehydrogenating and deoxygenating heat treatment can be conducted, and therefore a mixture of reducibility metallic oxide, residue reducibility metal, dehydrogenated and deoxidized tantalum powder and / or the niobium powder can be obtained; (4) acid pickling and impurity removal are conducted, wherein acid pickling and drying are conducted on a mixture obtained through dehydrogenation and oxygen reduction so that the tantalum powder and / or the niobium powder suitable for powder metallurgy can be obtained. The method is suitable for recycling and treating the waste tantalum powder and / or the niobium powder generated in the process of production of the high-specific-volume tantalum powder and / or the niobium powder for a capacitor so that the tantalum powder and / or the niobium powder suitable for powder metallurgy can be prepared, investment of needed devices is small, the adaptive capacity to raw materials is strong, the technological process is short, and the safety coefficient of the treatment process is high.

Owner:NINGXIA ORIENT TANTALUM IND

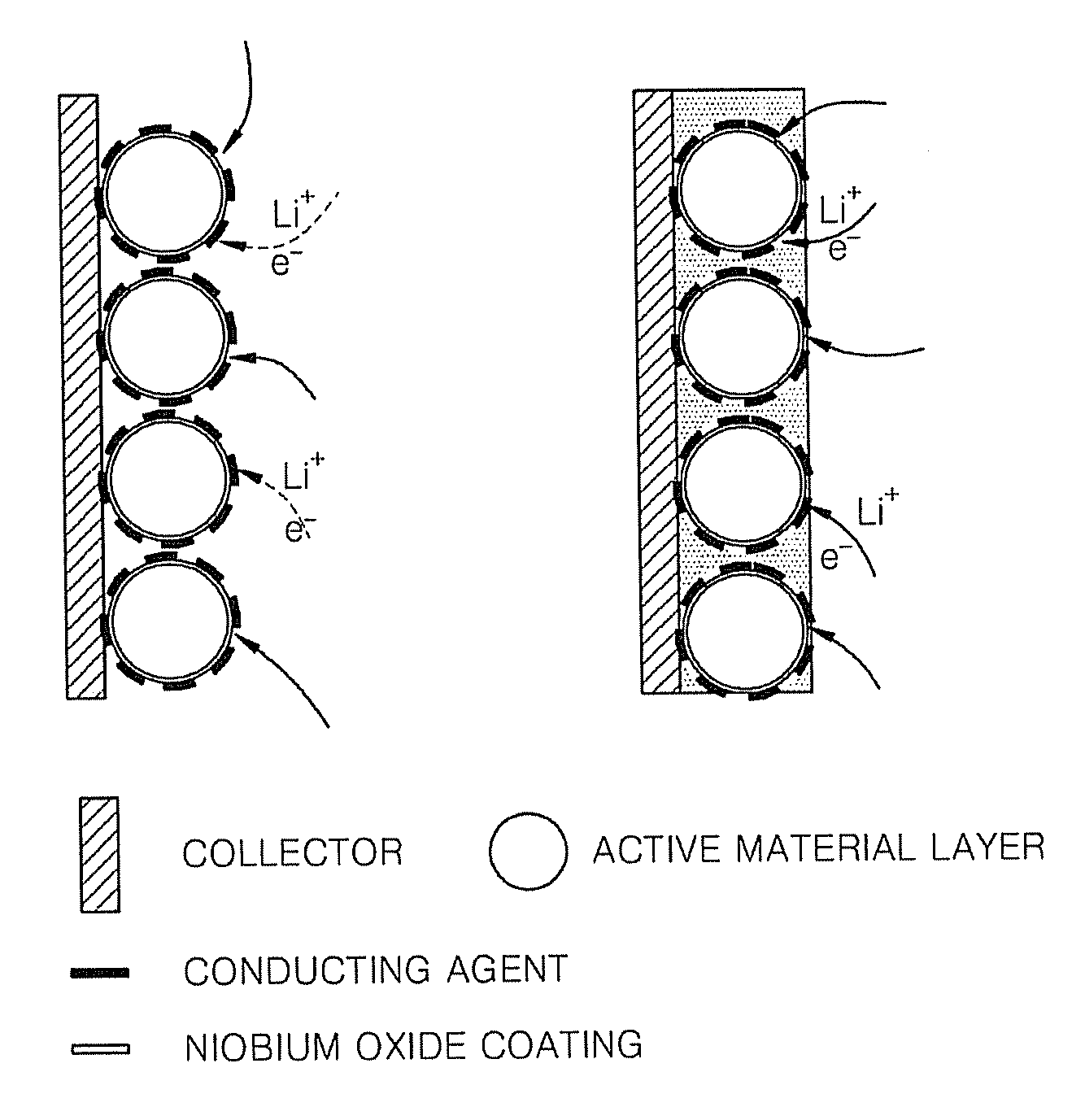

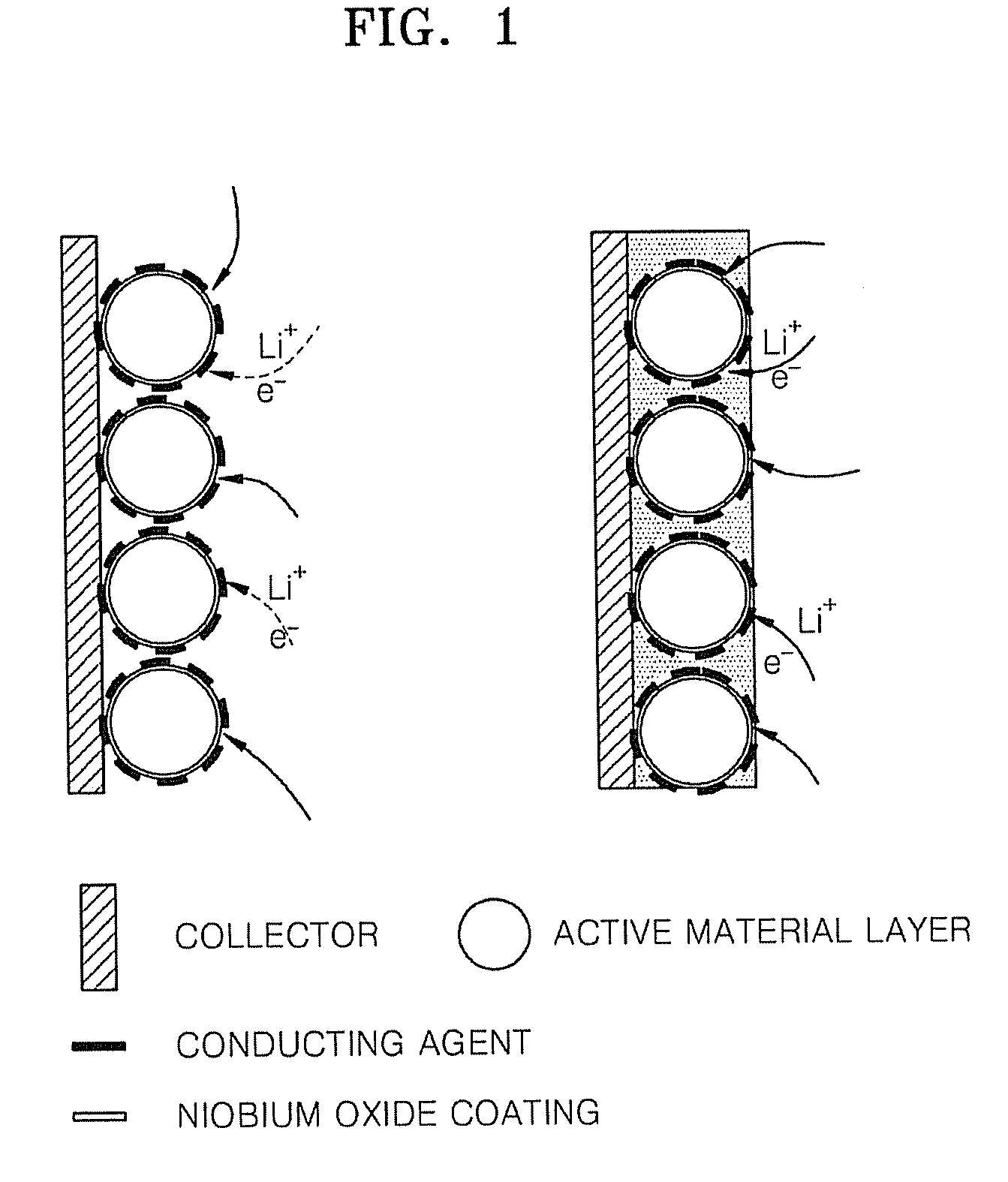

Niobium oxide-containing electrode and lithium battery including the same

InactiveUS20090214958A1Excellent characteristicsImprove efficiencyOrganic electrolyte cellsActive material electrodesMaterials scienceNiobium oxide

Owner:SAMSUNG SDI CO LTD

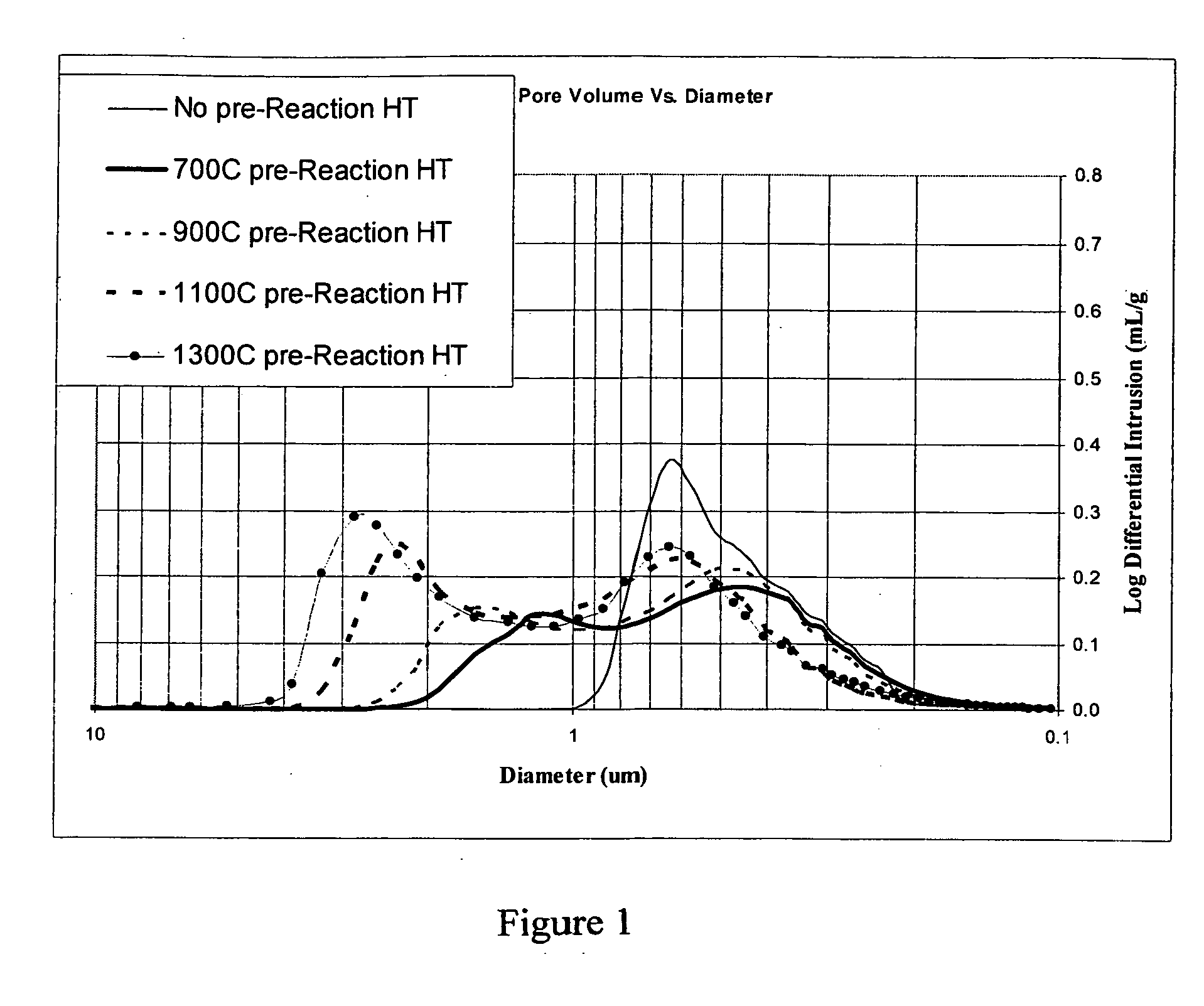

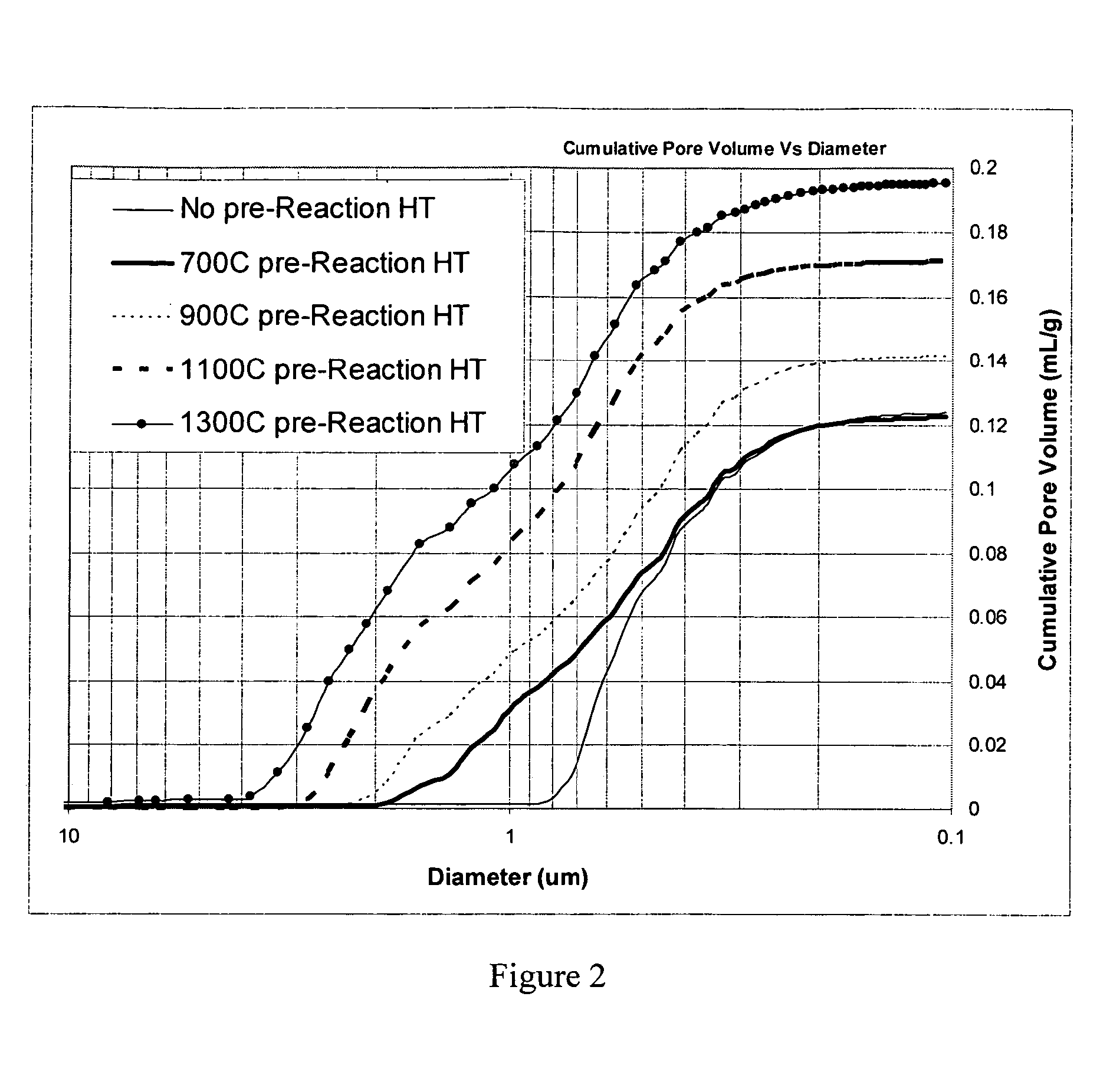

Methods of making a niobium metal oxide and oxygen reduced niobium oxides

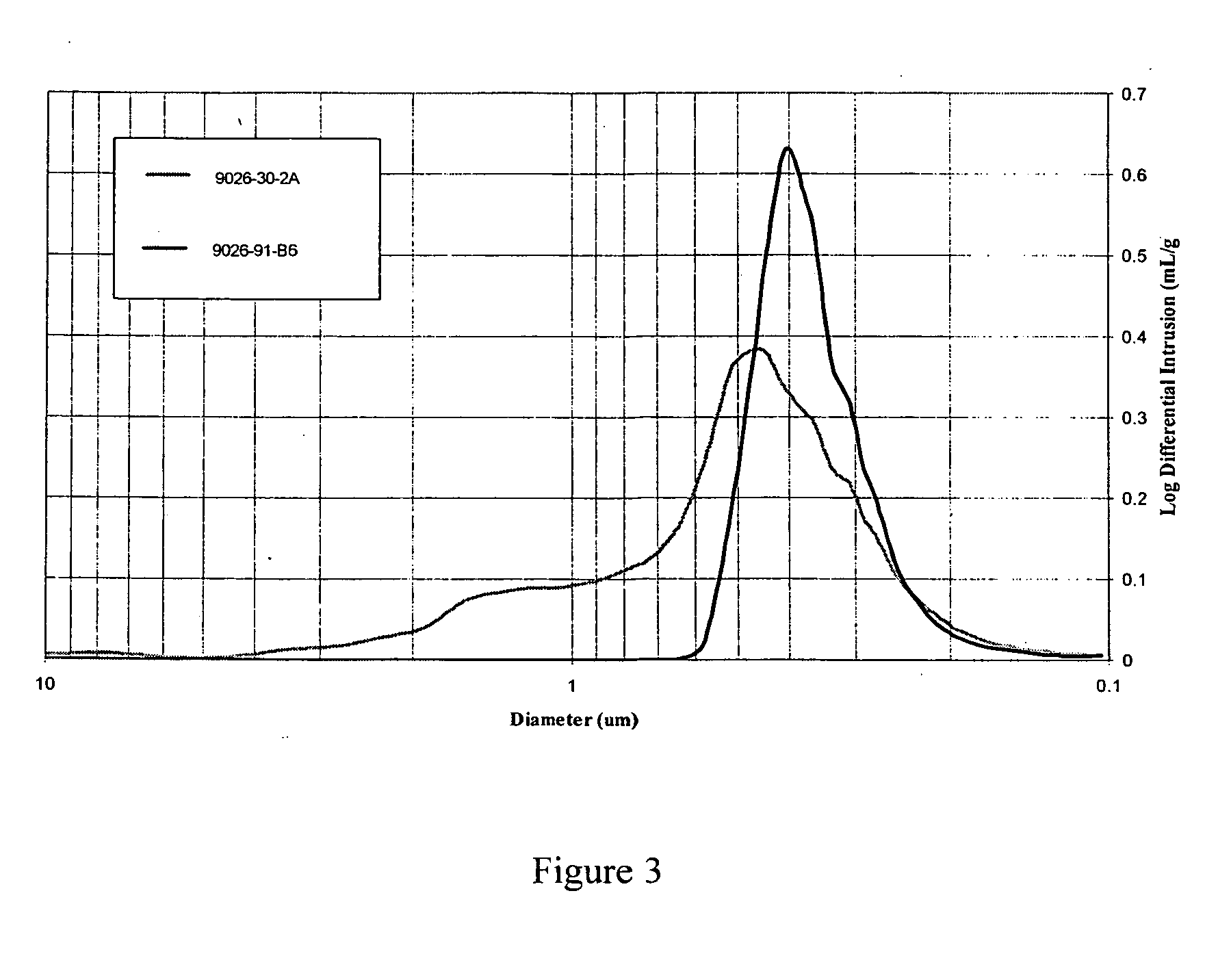

ActiveUS20050025699A1Increase capacitanceReduce leakageLiquid electrolytic capacitorsTantalum compoundsPorosityPowder mixture

Methods to at least partially reduce a niobium oxide are described wherein the process includes mixing the niobium oxide and niobium powder to form a powder mixture that is then heat treated to form heat treated particles which then undergo reacting in an atmosphere which permits the transfer of oxygen atoms from the niobium oxide to the niobium powder, and at a temperature and for a time sufficient to form an oxygen reduced niobium oxide. Oxygen reduced niobium oxides having high porosity are also described as well as capacitors containing anodes made from the oxygen reduced niobium oxides.

Owner:GLOBAL ADVANCED METALS USA

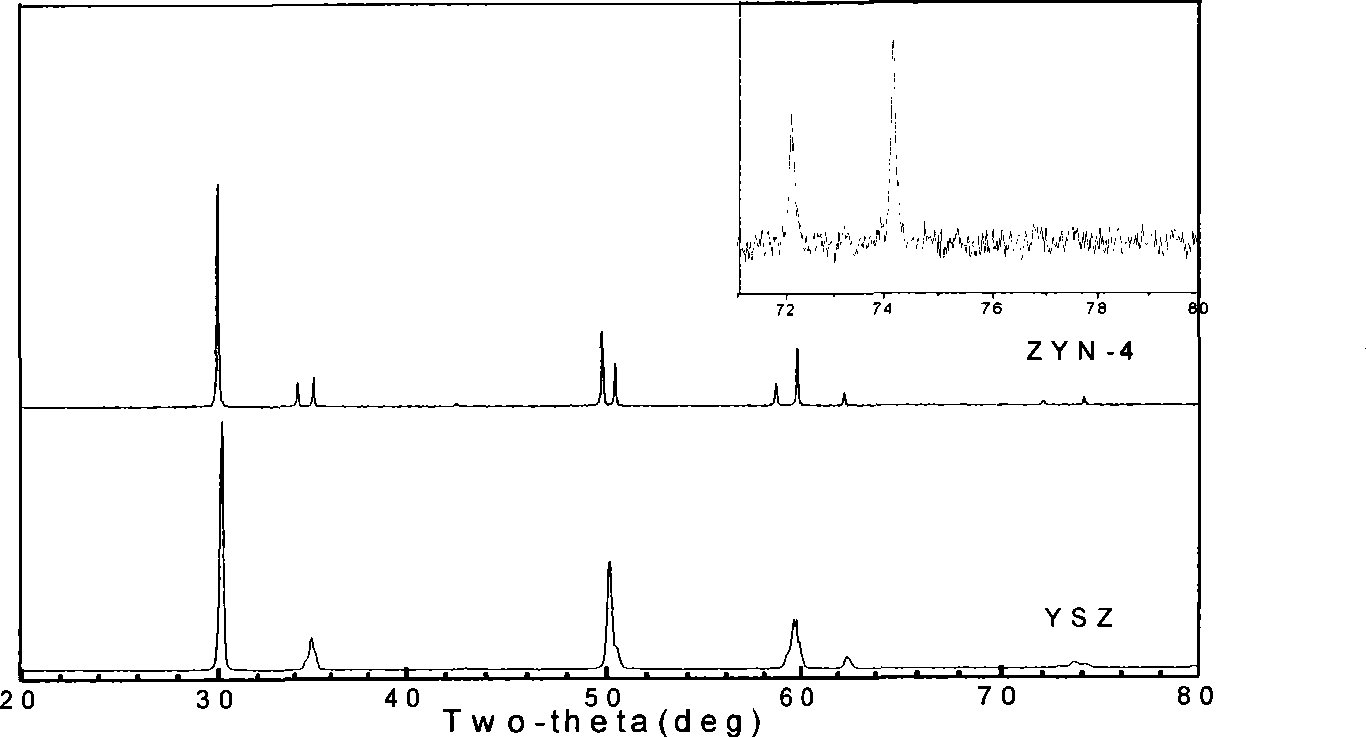

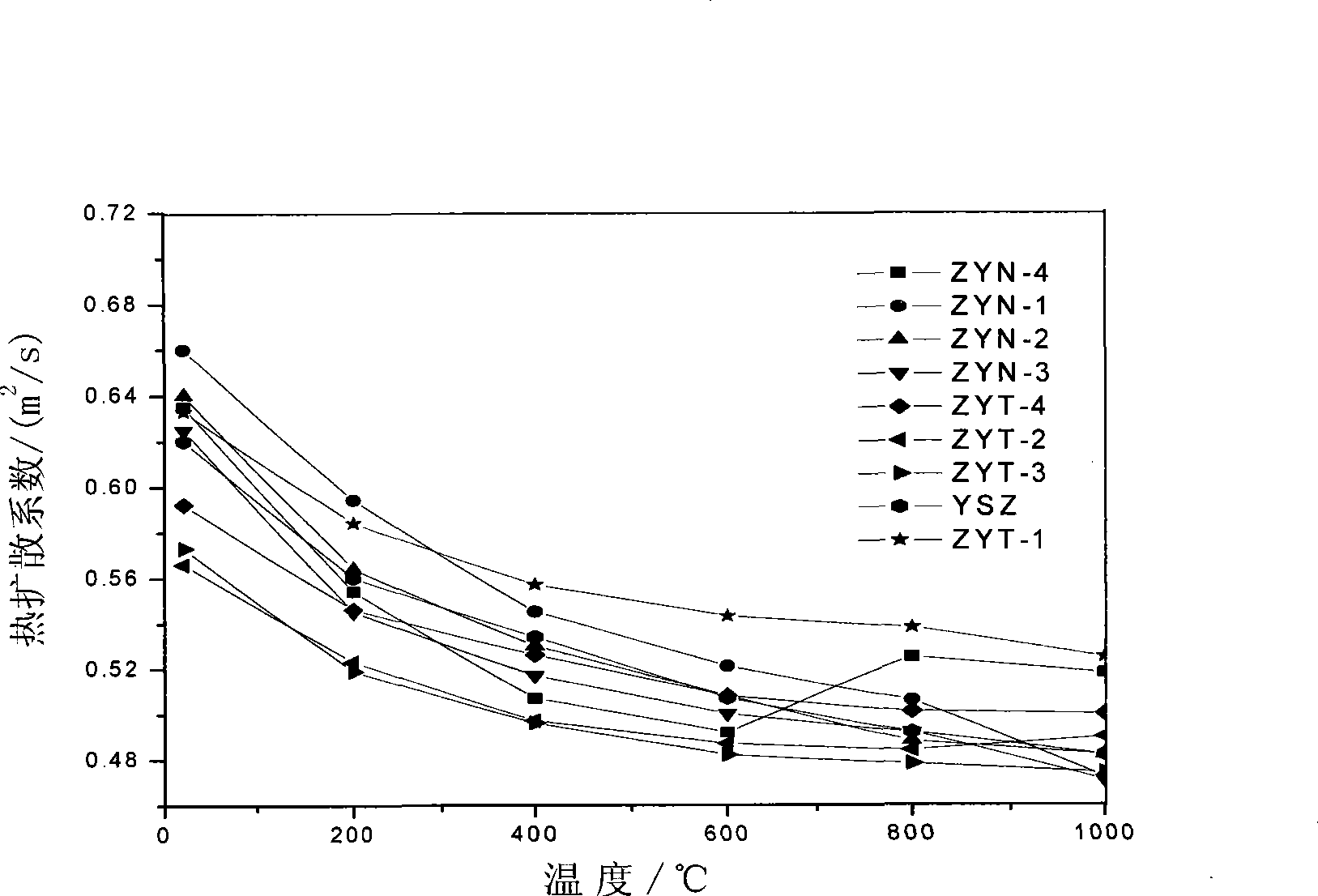

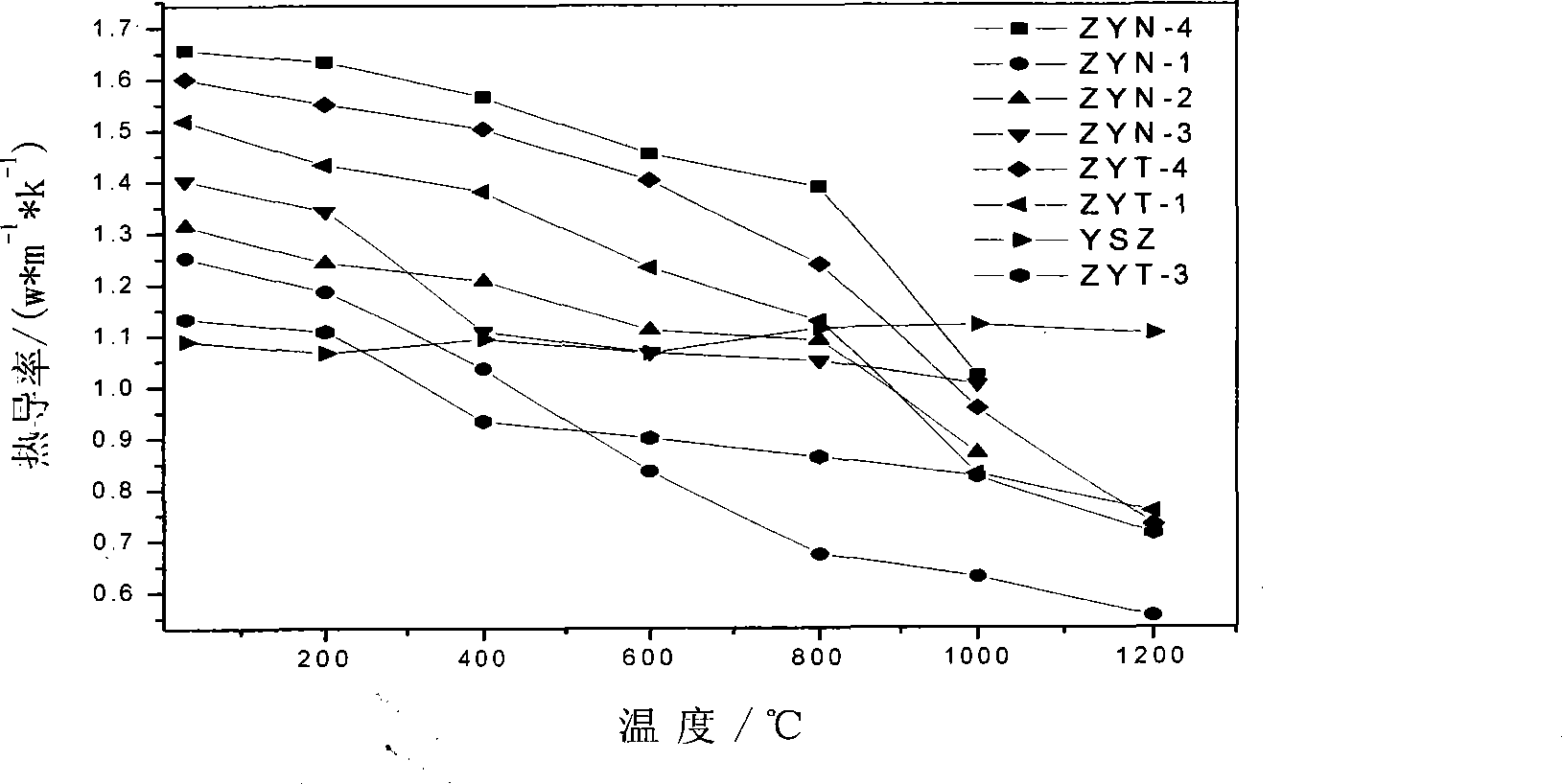

Multi-element co-stabilizing zirconia of heat barrier coat material and preparation method

The invention relates to a multivariant co-stable zirconia thermal barrier coating material and a preparation method which belong to the field of materials. The multivariant co-stable zirconia thermal barrier coating material is characterized by consisting of the following materials according to mole fractions: zirconia, yttria, niobium oxide or tantalum oxide and rare earth oxide. The preparation method comprises the following steps: a zirconia ball is ground by wet process, dried and molded; a pre-burnt block is obtained by pre-burning; the pre-burnt block is smashed and further carried out with the wet ball milling to obtain slurry; the slurry is dried, granulated and mould pressed to obtain a green body, the green body is sintered to obtain the multivariant co-stable zirconia thermal barrier coating material; the ceramic material can be used as a target material for preparing a thermal barrier coating by using the EB-PVD method. A third phase of Nb2O5 / Ta2O5 is introduced in YSZ to develop the stable existence interval of t-ZrO2 to further obtain non-transition t'-ZrO2, and the rare earth oxide is added to increase the defects to further improve the phonon or photon scattering on the basis, thereby improving the using temperature of the ZrO2 thermal barrier coating and reducing the thermal conductivity of the material.

Owner:INNER MONGOLIA UNIV OF SCI & TECH

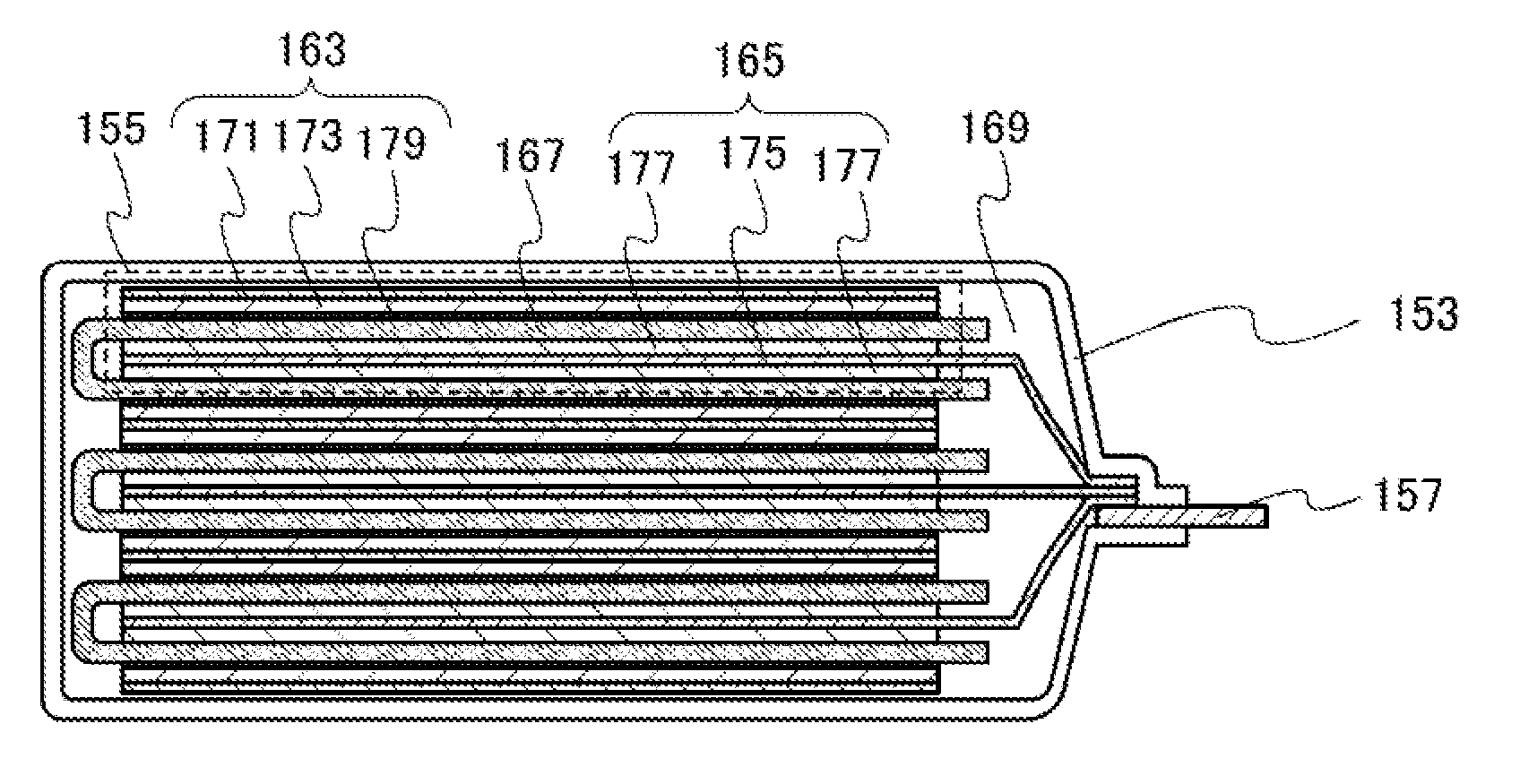

Solid electrolytic capacitor and method for producing the same

ActiveUS7800887B2Improve adhesionReduce contact resistanceHybrid capacitor electrolytesHybrid capacitor electrodesEpoxyElectrolysis

A solid electrolytic capacitor, having a small equivalent series resistance, is formed by burying a capacitor element inside an epoxy resin outer package. The capacitor element includes an anode, having part of an anode lead buried therein, a dielectric layer formed on the anode and containing a niobium oxide, and a cathode formed on the dielectric layer. The cathode includes a first electrolyte layer containing a conductive polymer and formed on the dielectric layer, an intermediate layer containing an organic silane and formed on the first electrolyte layer, a second electrolyte layer containing a conductive polymer and formed on the intermediate layer, a first conductive layer containing carbon particles and formed on the second electrolyte layer, and a second conductive layer containing silver particles and formed on the first conductive layer.

Owner:SANYO ELECTRIC CO LTD

Piezoelectric thin film element

InactiveUS7323806B2Excellent dielectric strength voltageExcellent piezoelectric propertiesPiezoelectric/electrostrictive device manufacture/assemblyPiezoelectric/electrostriction/magnetostriction machinesDielectric thin filmsDielectric strength

A thin-film piezoelectric element has a substrate, a lower electrode, a piezoelectric portion, and an upper electrode that are sequentially formed on the substrate. The piezoelectric portion has a dielectric thin film that has an alkali niobium oxide-based perovskite structure expressed by general formula (NaxKyLiz)NbO3 (0<x<1, 0<y<1, 0≦z<1, x+y+z=1), and a high voltage-withstand dielectric that has a dielectric strength voltage greater than that of the dielectric thin film.

Owner:SUMITOMO CHEM CO LTD

Thin film transistor, thin film transistor substrate, processes for producing the same, liquid crystal display using the same, and related devices and processes; and sputtering target, transparent electroconductive film formed by use of this, transparent electrode, and related devices and processes

InactiveUS8038857B2Reduce light transmittanceConductive layers on insulating-supportsSemiconductor/solid-state device detailsIndiumLiquid-crystal display

Provided are a thin film transistor substrate having a transparent electroconductive film in which residues and so on resulting etching are hardly generated; a process for producing the same; and a liquid crystal display using this thin film transistor substrate.A thin film transistor substrate, comprising a transparent substrate,a source electrode formed over the transparent substrate, a drain electrode formed over the transparent substrate, and a transparent pixel electrode formed over the transparent substrate, wherein the transparent pixel electrode is a transparent electroconductive film which is made mainly of indium oxide, and further comprises one or two or more oxides selected from tungsten oxide, molybdenum oxide, nickel oxide and niobium oxide, and the transparent pixel electrode is electrically connected to the source electrode or the drain electrode; a process for producing the same; and a liquid crystal display using this thin film transistor substrate.

Owner:IDEMITSU KOSAN CO LTD

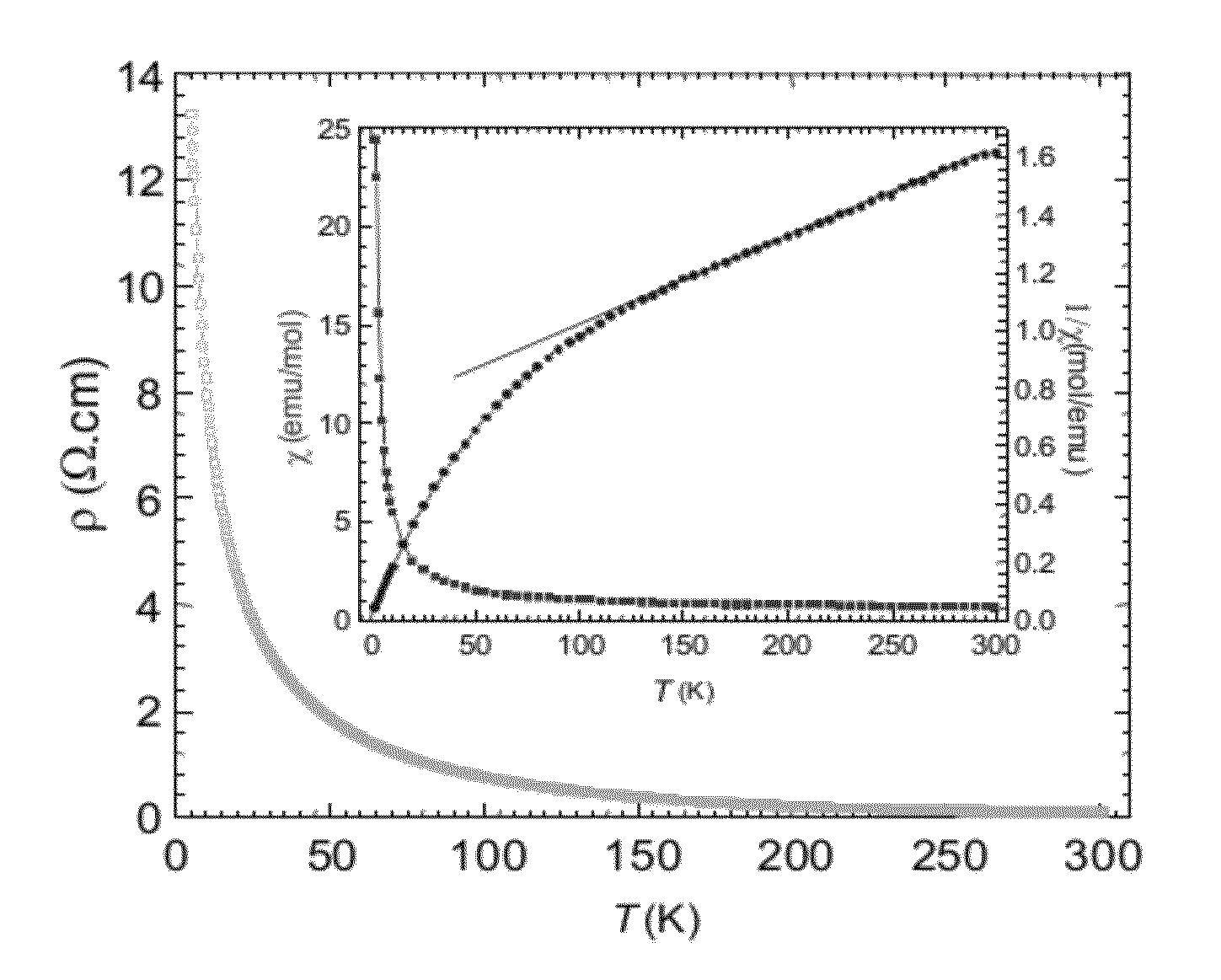

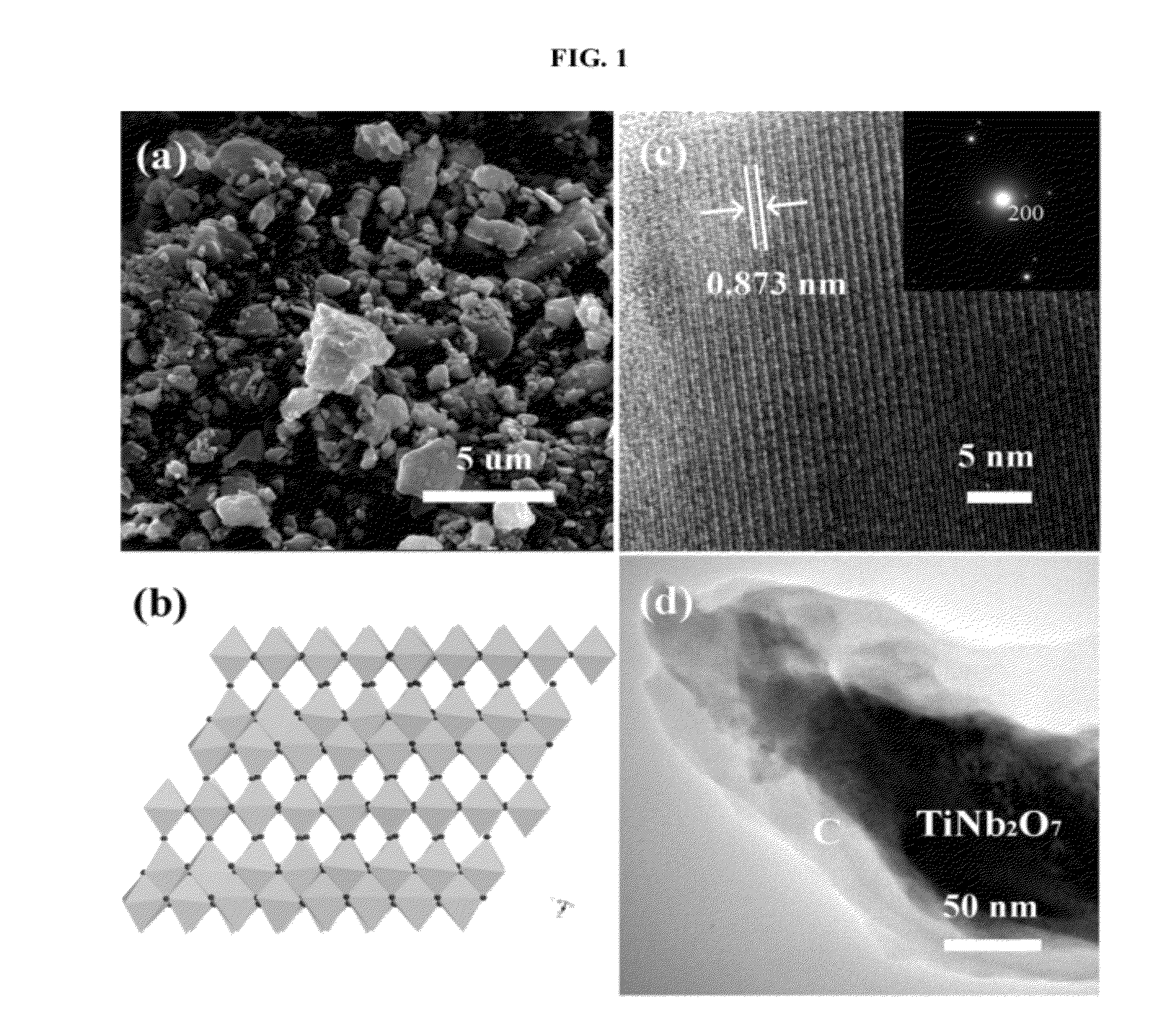

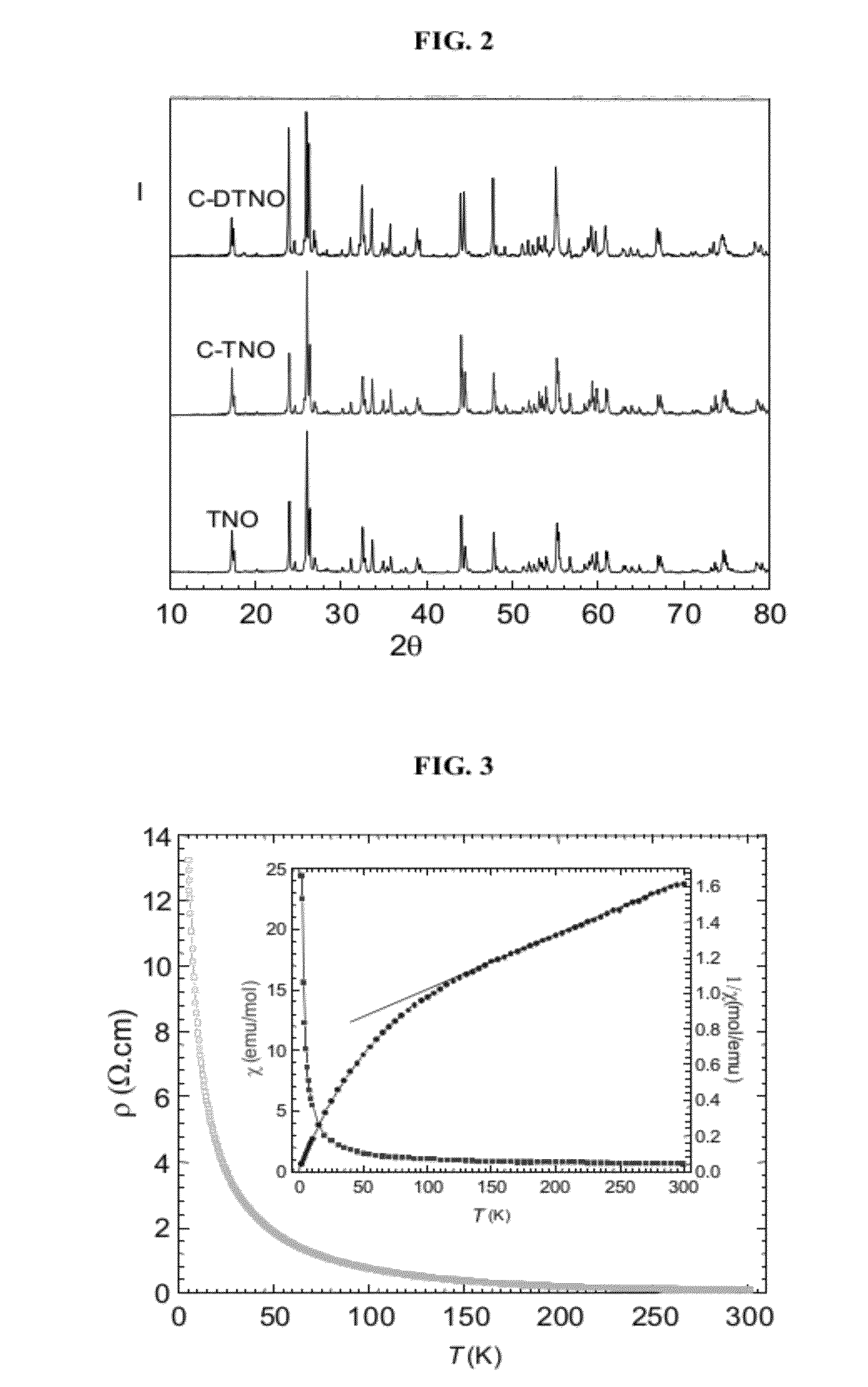

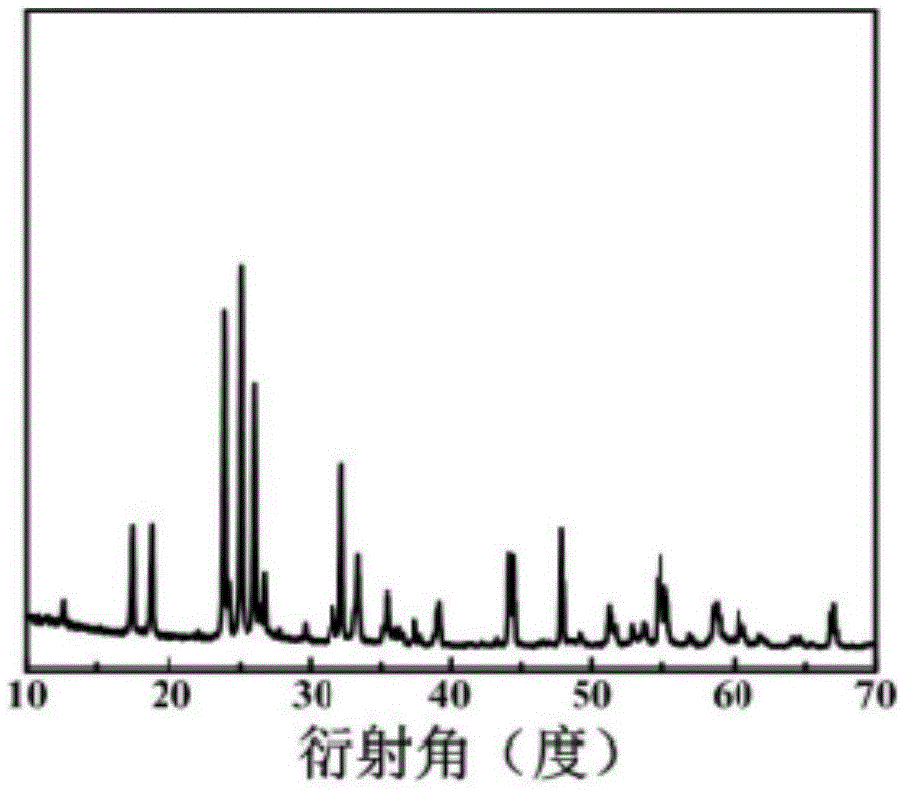

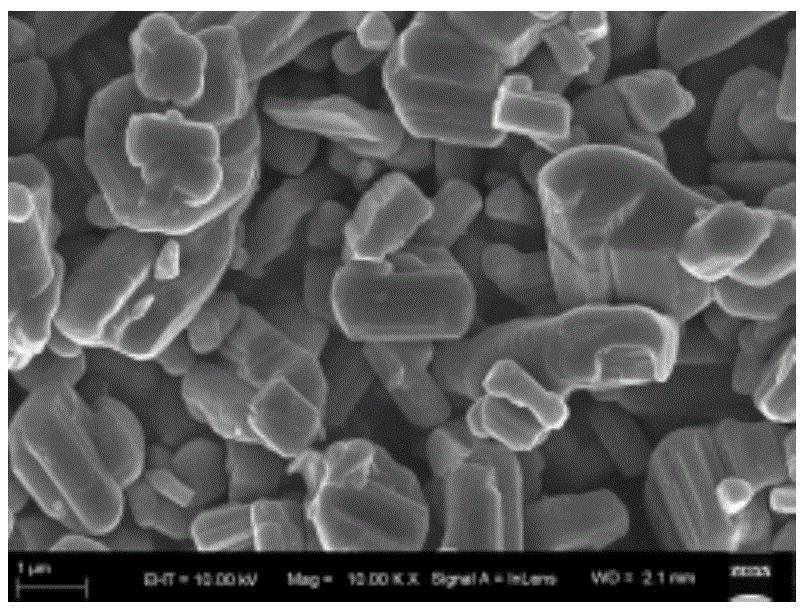

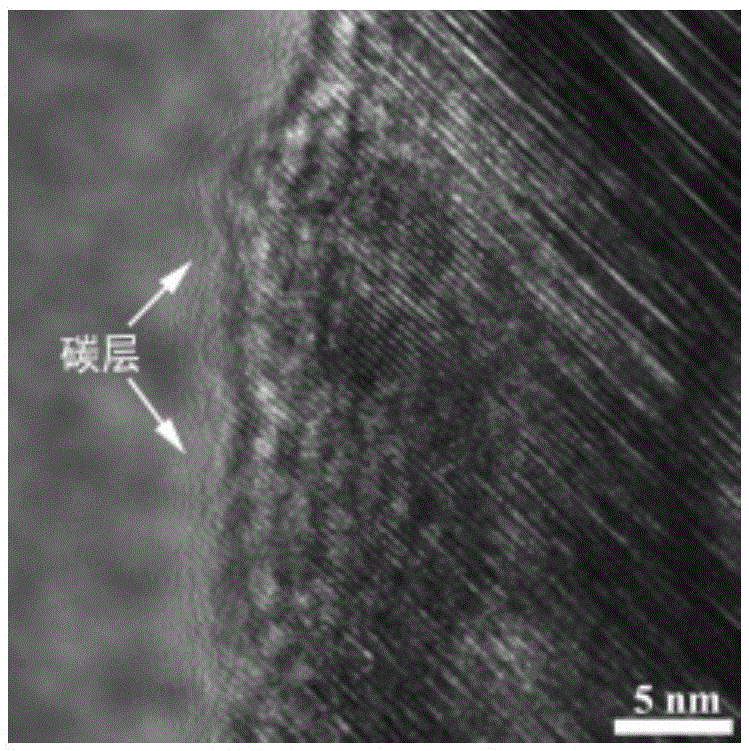

Titanium niobate/carbon composite electrode material and preparation method thereof

InactiveCN105552346AImprove conductivitySimple preparation processCell electrodesSecondary cellsCarbon compositesLithium niobate

The invention discloses a preparation method of a titanium niobate / carbon composite electrode material belonging to the lithium ion battery material technical field. According to the method, ball mill mixing is carried out to titanium dioxide, niobium oxide and carbon source according to a certain proportion; the dried mixture is calcined under the protection of an inert gas, thus obtaining the titanium niobate / carbon composite electrode material. The invention also discloses the titanium niobate / carbon composite electrode material prepared by the preparation method. According to the invention, the conductivity of the material is improved through carbon coverage; meanwhile, a certain inhibiting effect on the particle size increasing phenomenon of the titanium niobate is realized through carbon coverage; the material shows excellent rate capability and cycle performance when being used as the lithium ion battery anode material; in addition, the material and the preparation method of the invention are featured by simple preparation technology, convenient operation and low production cost and are easy in large-scale industrial production.

Owner:NANYANG NORMAL UNIV

Method for processing microtantalum and/or niobium powder and powder made by said method

The present invention relates to a new treatment method for preparing microfine tantalum and / or niobium powder, specially, it relates to a method capable of making halide of tantalum and / or niobium mix with reduced metal in the liquid ammonia and produce reaction to produce microfine tantalum and / or niobium powder and making them undergo the processes of heat treatment and subsequent treatment at high-temp. in the non-oxidation atmosphere. The tantalum and / or niobium powder prepared according to the invented method is a kind of relatively-stable microfine nano-grade powder.

Owner:NINGXIA ORIENT TANTALUM IND

Toughened low-radiation coated glass with double-silver composite structure and technique thereof

InactiveCN101531471AQuality is not affectedControl and barrier infiltrationDielectric layerTitanium oxide

The invention provides a membranous layer composite structure of toughened low-radiation coated glass with a double-silver composite structure; toughening processing technique can be carried out after coating without influence on quality of products; silicon nitride (Si3N4) + ZnO is used as a composite dielectric layer of a base layer; one or more of tin oxide (SnO2), titanium oxide (TiO2), silicon nitride (Si3N4), and an absorbing layer of niobium oxide (Kb2O5) with ZnO are selected to form a composite dielectric layer of a middle layer; and the thicknesses and membranous components of other layers are reasonably selected, so as to prepare the toughened low-radiation coated glass with the double-silver composite structure which can undergo high-temperature heat processing.

Owner:SHANGHAI YAOHUA PILKINGTON GLASS GROUP +3

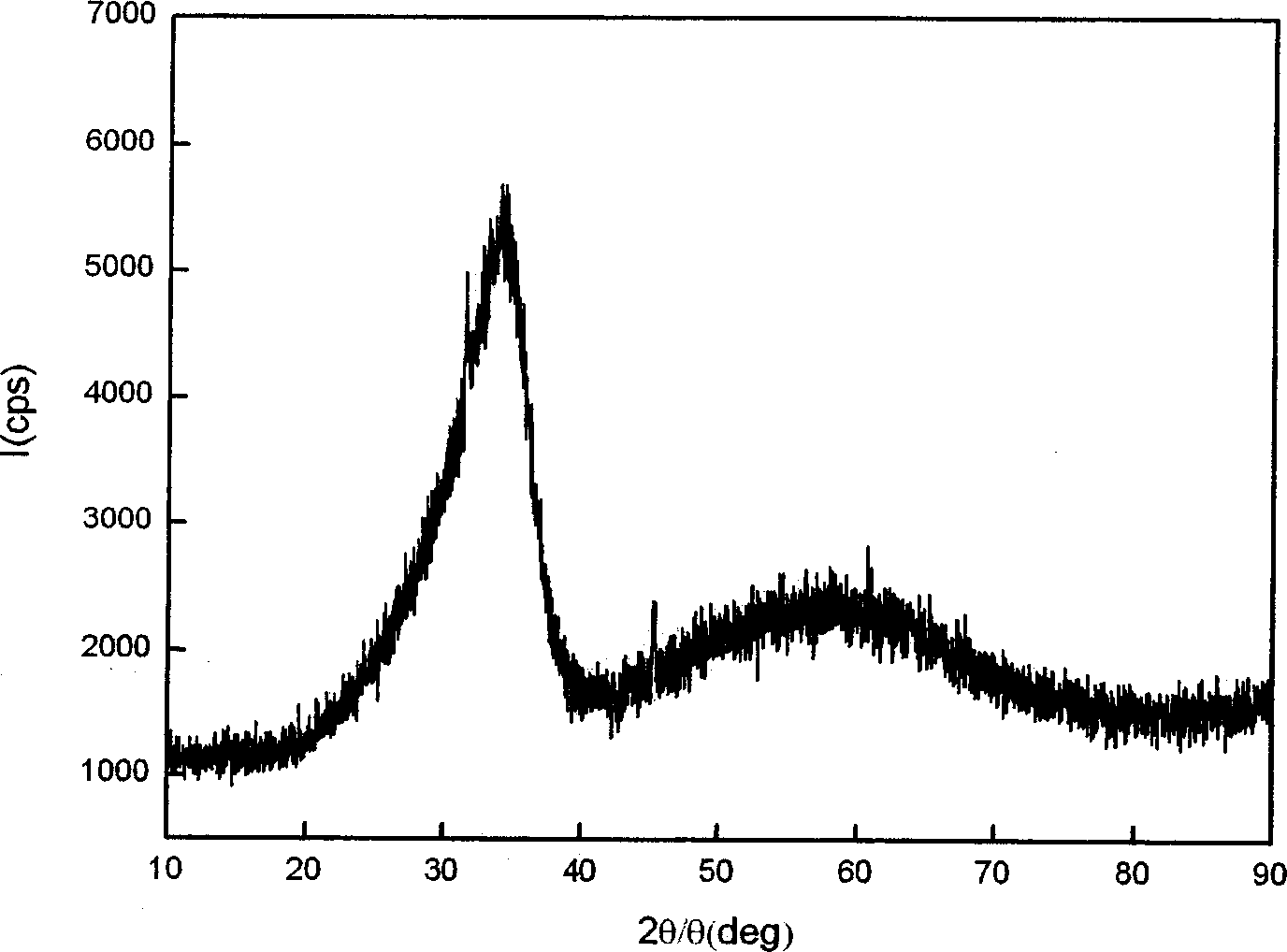

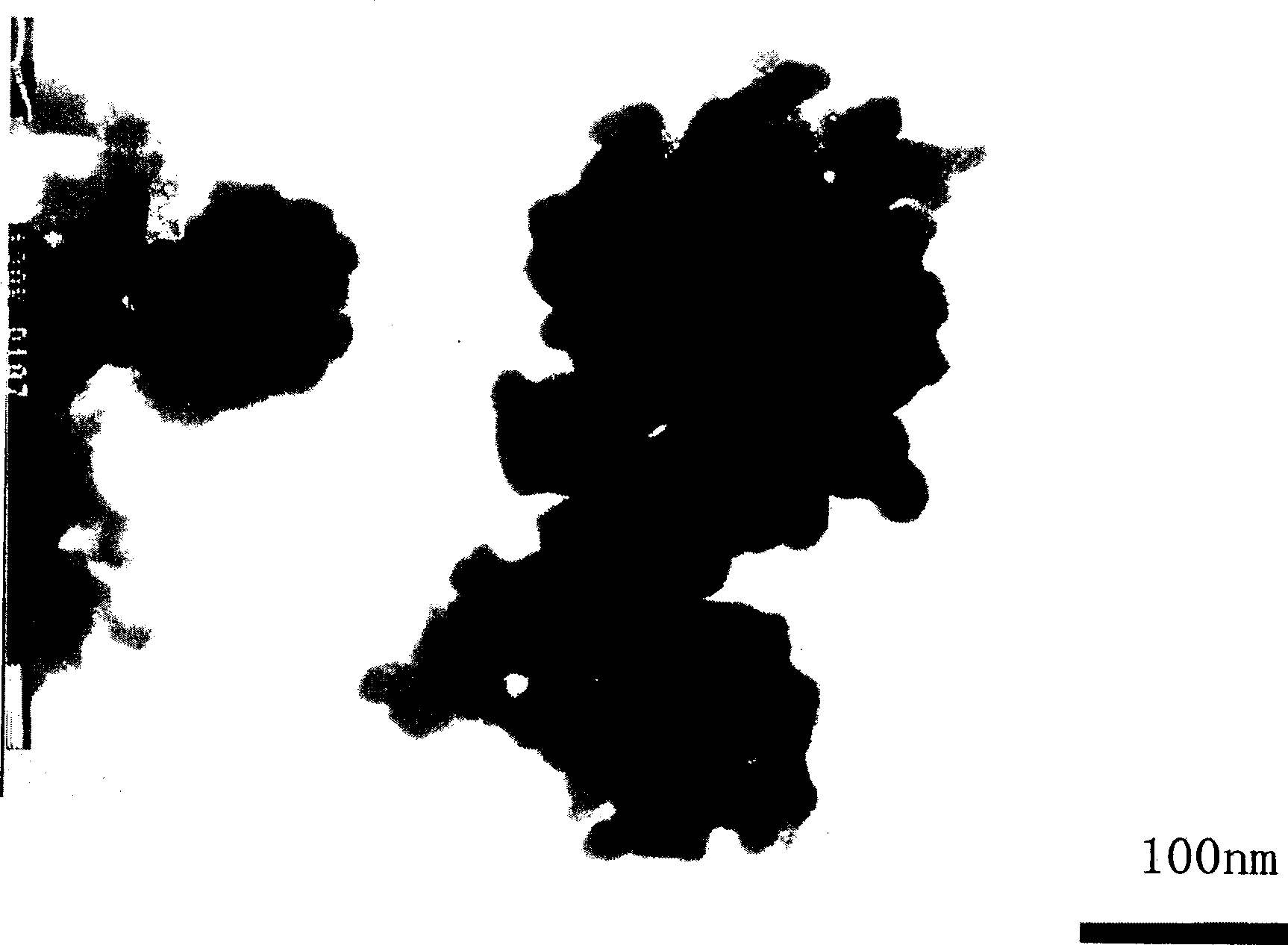

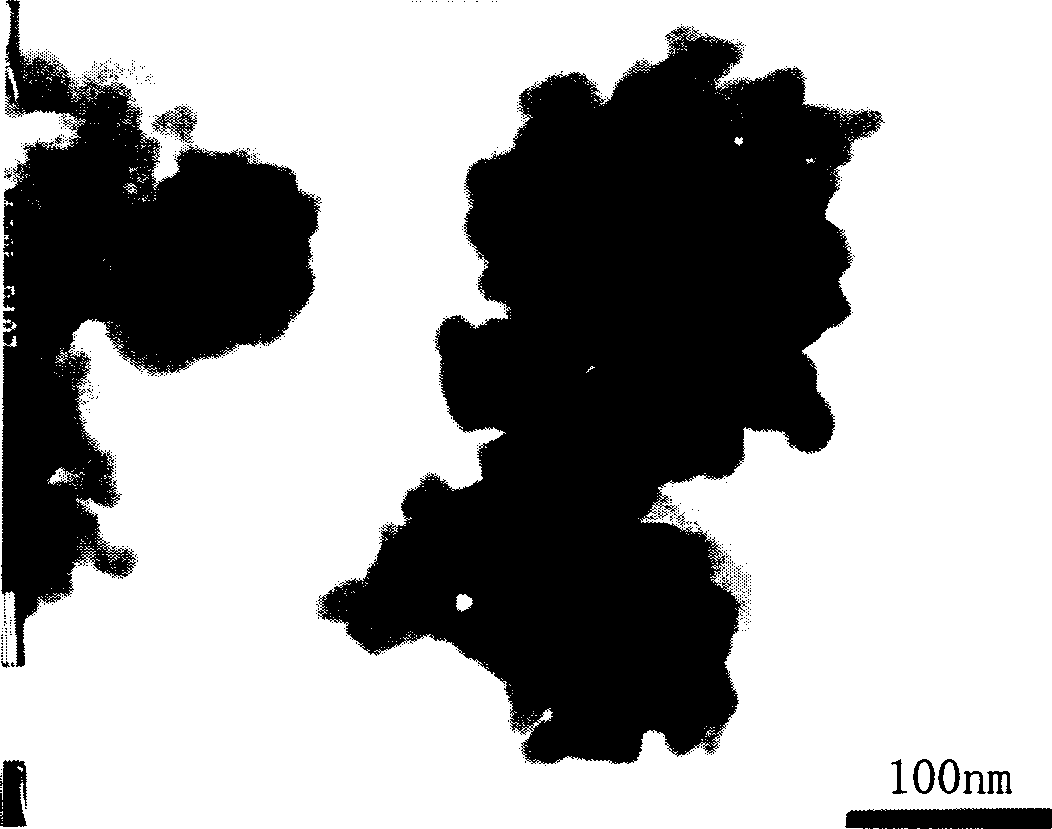

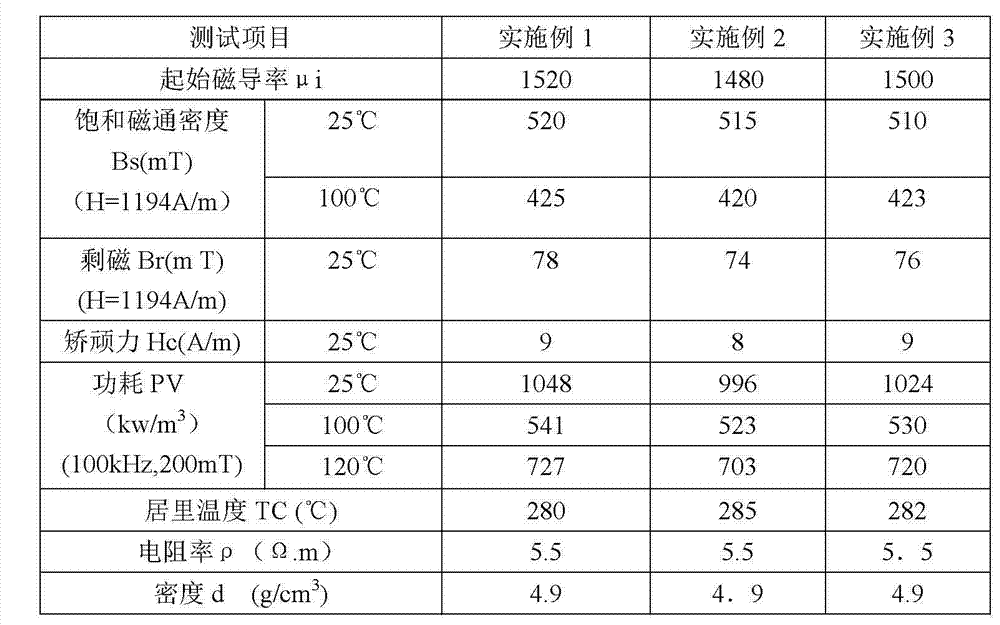

High-Curie-temperature low-loss high-strength ferrite magnetic block and preparation method thereof

InactiveCN103117146AReasonable choiceReasonable ratioPermanent magnetsInorganic material magnetismSilicon oxideCopper oxide

The invention discloses a high-Curie-temperature low-loss high-strength ferrite magnetic block and a preparation method thereof and belongs to the technical field of Mn-Zn serial ferrite. Main raw materials include ferric oxide, manganese oxide and zinc oxide, auxiliary raw materials include calcium carbonate, titanium oxide, cobalt oxide, silicon oxide, chromium oxide, niobium oxide, nickle oxide and copper oxide, the ferrite magnetic block is composed of the main raw materials, 55-61mol% of ferric oxide calculated according to Fe2O3, 33-40mol% of manganese oxide calculated according to MnO and 5-10% of zinc oxide calculated according to ZnO, and the adding amount of the auxiliary raw materials relative to the total weight of the main raw materials is 500-3000ppm of CaCO3, 80-3000ppm of TiO2, 50-1200ppm of Co2O3, 20-200ppm of superfine SiO2, 100-1500ppm of Cr2O3, 100-1500ppm of Nb2O5, 600-2000ppm of NiO and 600-2000ppm of CuO. The high-Curie-temperature low-loss high-strength ferrite magnetic block has the advantages that initial magnetic permeability can be lowered to be maintained at 1400+ / -25%, power consumption is lower than 550kw / m3 under the condition of 100KHz200mT and at the temperature of 100 DEG C, saturation magnetic flux density at 100 DEG C is larger than 410mT, the Curie temperature is larger than 275 DEG C, and strength of the magnetic block can meet the strength detection standard (F)40N).

Owner:SUZHOU GUANDA MAGNET

Rear-earth-rich, niobium-rich and cand-rich rear sorted tail-ore microcrystal glass and mfg. method

The invention relates to a rare earth enriched, niobium, fluorite rare selecting tail mine micro-crystal glass and manufacture method. The feature is that the manufacture raw material of the glass is rare selecting tail mine and quartz sand. The chemical constituent includes SiO2 30-70wt%, CaO 5-20wt%, Al2O3 5-15wt%, CaF 3-15wt%, ReO 3-15wt%, Nb2O5 0-5wt%, and TiO2 0-10wt%. The advantages of the invention are that it has more refined micro-crystal, and the fracture toughness is obviously improved.

Owner:内蒙古科韵环保材料股份公司

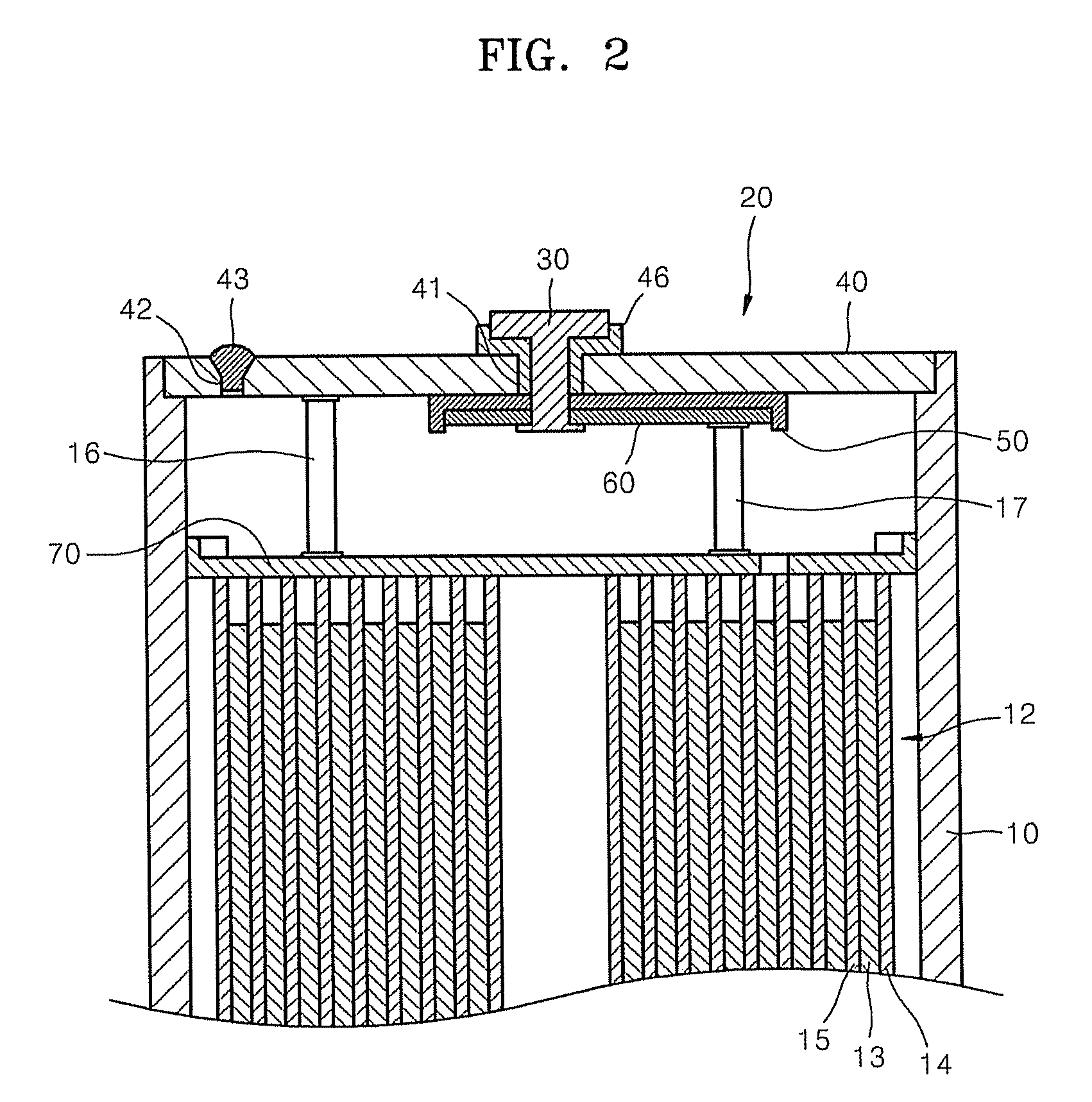

Power storage device

ActiveUS20120141866A1Charge-discharge efficiency can be improvedShorten charging timeNon-aqueous electrolyte accumulatorsHybrid capacitor electrodesLithiumAmorphous silicon

A power storage device which has improved performance such as higher discharge capacity and in which deterioration due to peeling or the like of an active material layer is less likely to be caused is provided. In an electrode for the power storage device, phosphorus-doped amorphous silicon is used for the active material layer over a current collector as a material that can be alloyed with lithium, and niobium oxide is deposited over the active material layer as a layer containing niobium. Accordingly, the capacity of the power storage device can be increased and the cycle characteristics and the charge-discharge efficiency can be improved.

Owner:SEMICON ENERGY LAB CO LTD

Memory element and memory device

ActiveUS7307270B2Sufficient resistance changeImprove reliabilitySolid-state devicesDigital storageMixed materialsData recording

A memory element which stably performs operations such as data recording and which has a stable structure with respect to heat is provided.A memory element 10 includes a memory layer 4 and an ion source layer 3 positioned between the first electrode 2 and second electrode 6, in which the ion source layer 3 contains any of elements selected from Cu, Ag and Zn, and any of elements selected from Te, S and Se, and the memory layer 4 is made of any of tantalum oxide, niobium oxide, aluminum oxide, hafnium oxide and zirconium oxide, or is made of mixed materials thereof.

Owner:SONY CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com