Method for processing microtantalum and/or niobium powder and powder made by said method

A processing method and fine technology, which is applied in the processing of fine tantalum and/or niobium powders and the powders produced therefrom, can solve the problems of inability to be exposed for a long time, no practical value, etc., and achieve good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

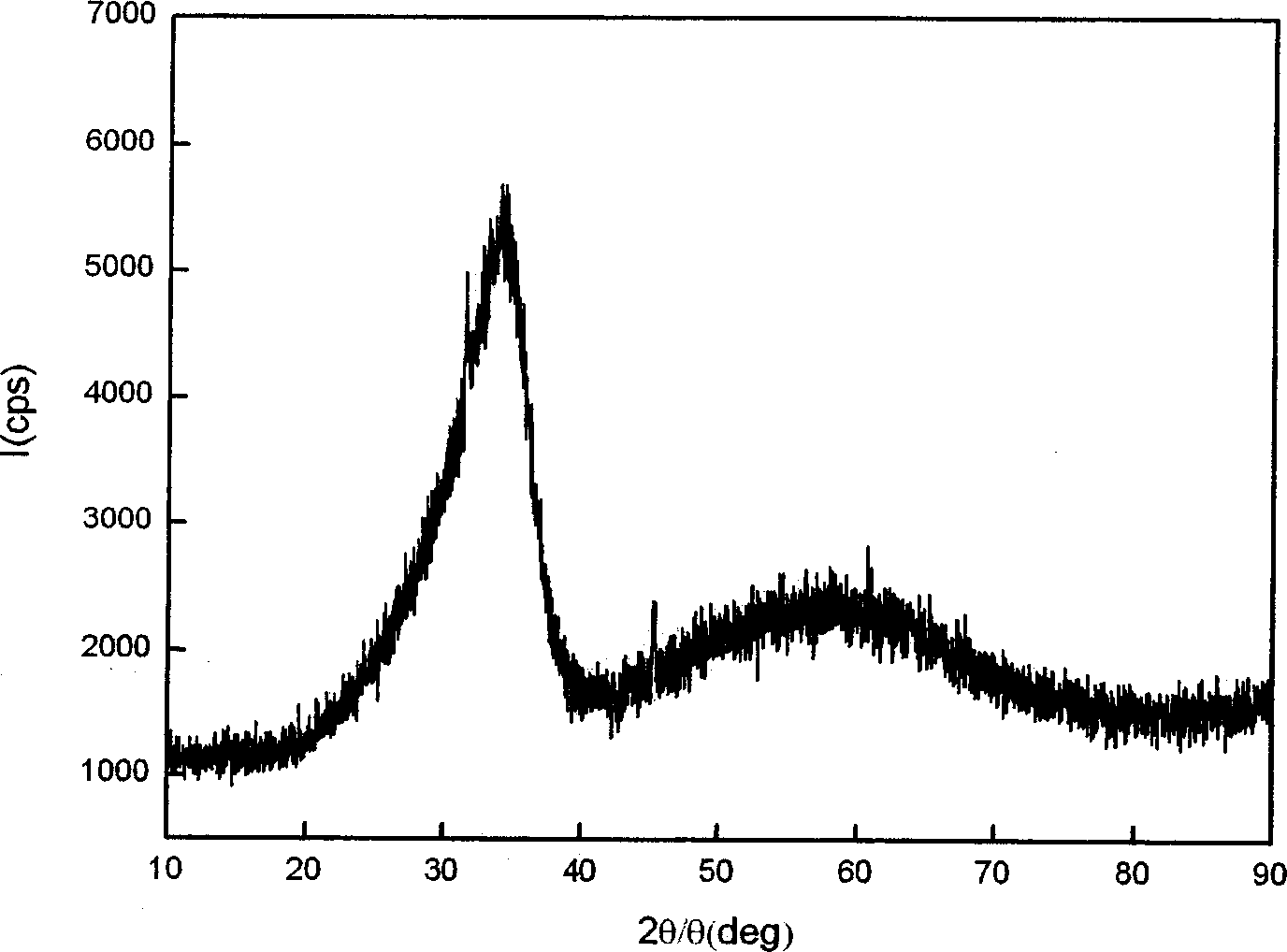

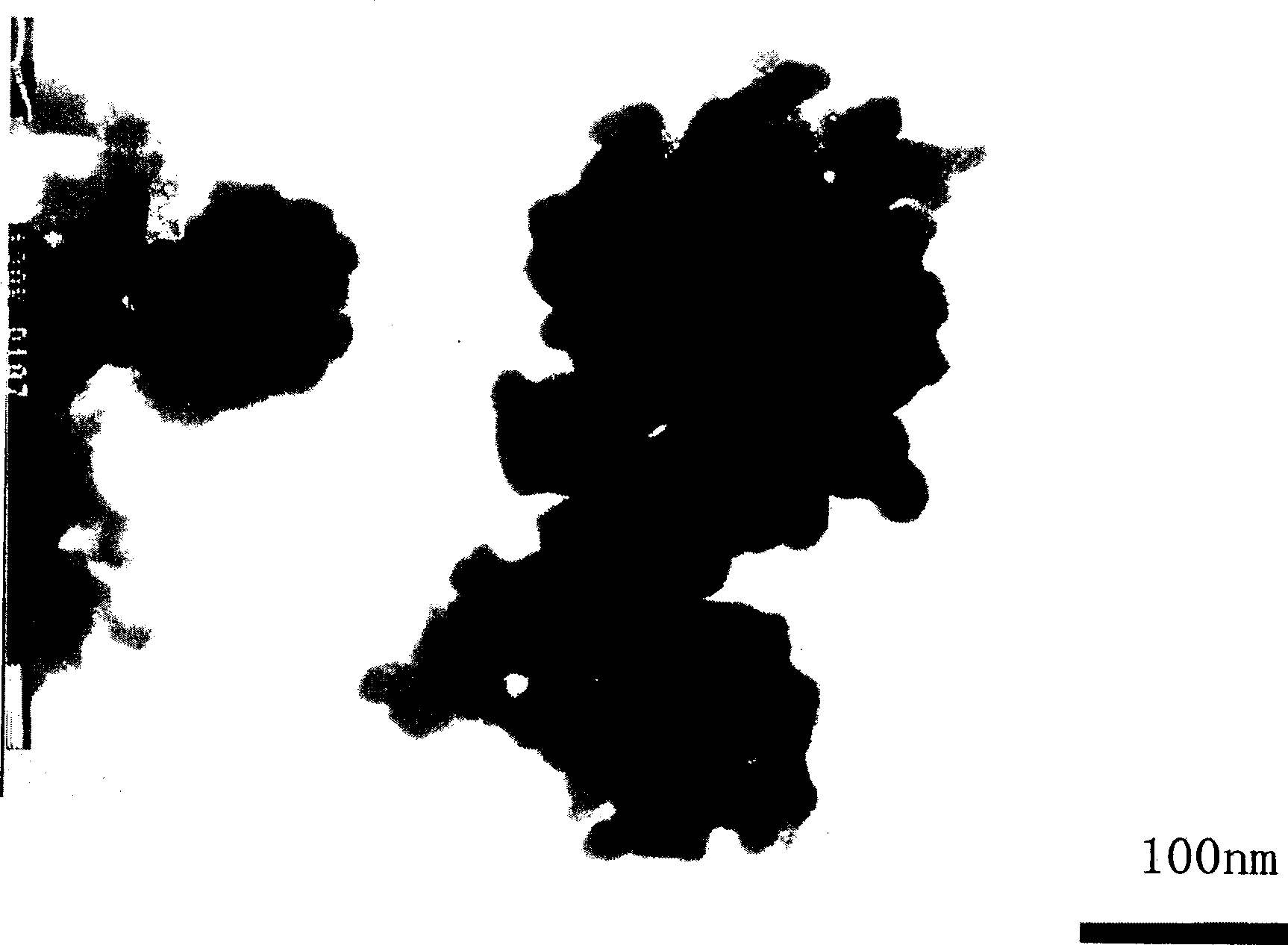

[0023] Put the fine tantalum powder obtained by the same method as the above comparative example into a tantalum crucible in a glove box filled with argon, and place the crucible with the sample above in a quartz tube container to seal, and place the quartz tube container Remove from glove box. Insert the quartz tube container into a heating furnace to evacuate. After evacuating until the pressure is lower than 1 Torr, fill it with argon to 1 atmospheric pressure, then carry out evacuation to 10-3 Torr, and raise the temperature to 500°C in 150 minutes. Maintain the pressure in the quartz tube container below 10 -3 Torr, the furnace temperature was 500° C. for 360 minutes, then cooled to room temperature, and after passivation for 20 minutes, the sample was taken out to obtain 2.2 grams of tantalum powder. The chemical composition of the tantalum powder was analyzed, and the data are listed in Table 1. The TEM image of tantalum powder is attached image 3 shown. Table 2 sh...

Embodiment 2

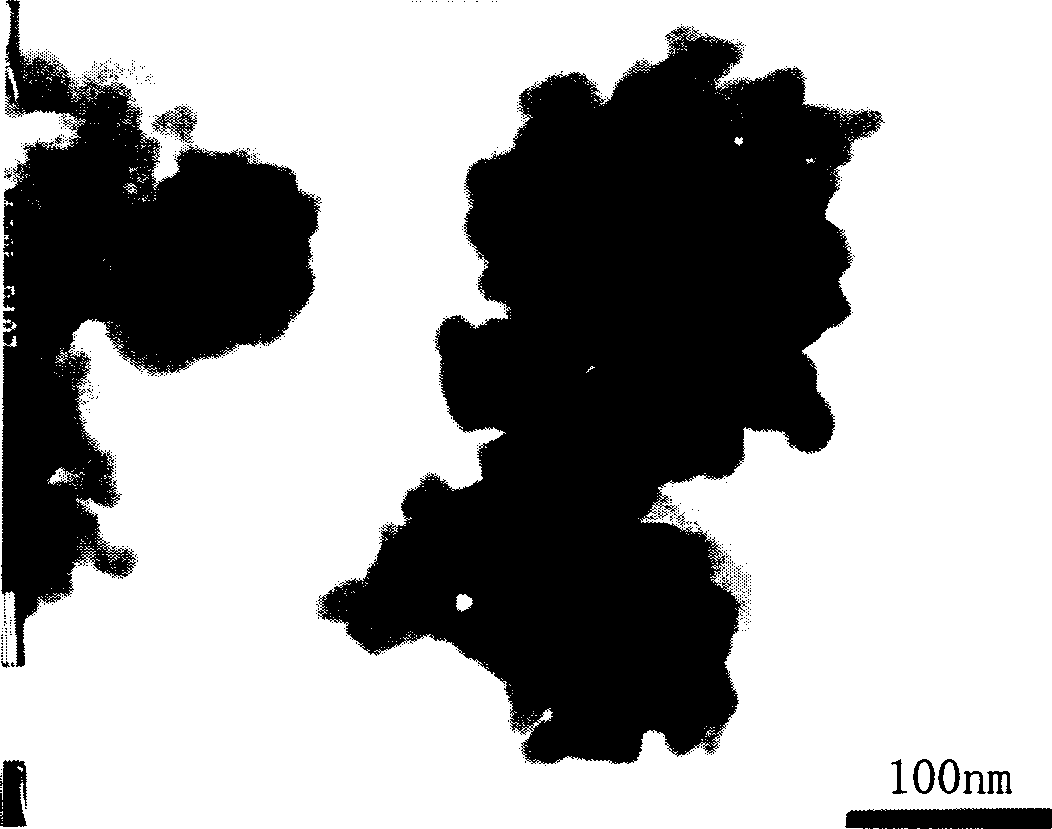

[0025] With 4.0 g NbCl 5 and 1.8 grams of Na are respectively dissolved in liquid ammonia at -40°C, and black niobium powder is formed after mixing and reacting, and then the above niobium powder is mixed with NaCl, NH 3 , Na to separate to obtain fine niobium powder. Above-mentioned fine niobium powder is carried out heat treatment the same as embodiment 1, is kept at 700 ℃ for 300 minutes and keeps the pressure in the quartz tube container always about 10 -2 Torr, and then cooled to room temperature, after 20 minutes of passivation, the sample was taken out, washed with deionized water and then vacuum-dried at 50°C to obtain 1.2 g of niobium powder. The chemical composition of niobium powder was analyzed, and the data are listed in Table 1. The TEM image of niobium powder is attached Figure 4 shown.

Embodiment 3

[0027] Same as embodiment 1, vacuumize to 10 -3Torr, the temperature was raised to 300° C. and filled with argon gas, and then the argon gas was kept flowing. Then, the temperature was raised to 900° C. and kept for 240 minutes to obtain 2.1 grams of tantalum powder. The chemical composition of the tantalum powder was analyzed, and the data are listed in Table 1. The TEM image of tantalum powder is attached Figure 5 shown. Table 2 shows the changes in oxygen content of tantalum powder exposed to air at a temperature of 20-35°C and a relative humidity of 30%-80% for 48 hours.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com