High-Curie-temperature low-loss high-strength ferrite magnetic block and preparation method thereof

A ferrite magnetic, low-loss technology, applied in the direction of inductance/transformer/magnet manufacturing, permanent magnet, inorganic material magnetism, etc., can solve the problems that the open circuit magnetic core does not have, the expansion of the Curie temperature is biased, etc., to achieve the distribution than reasonable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

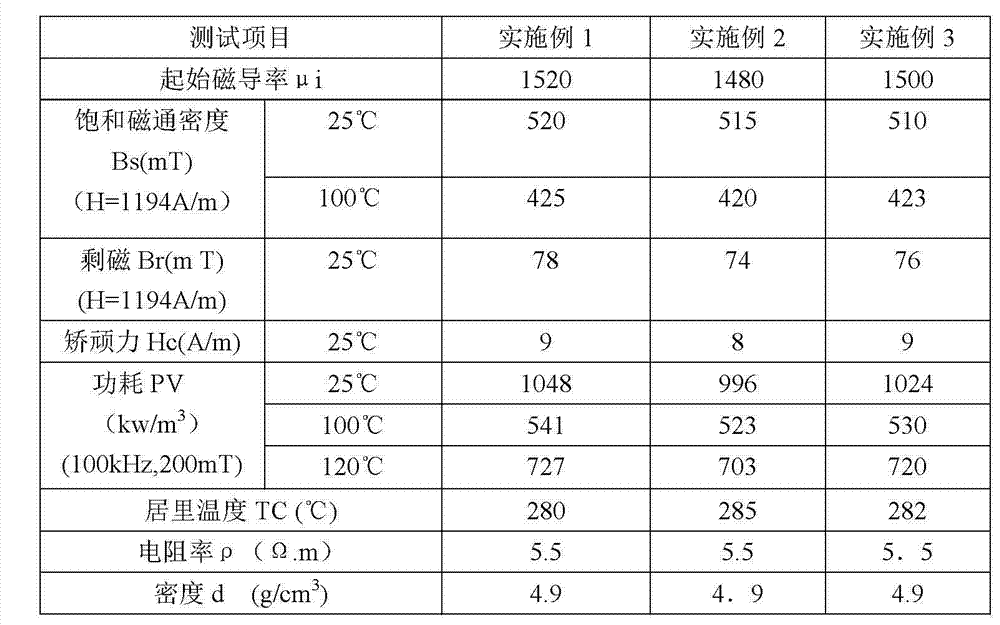

Examples

Embodiment 1

[0026] A) Ingredients, the main raw materials are weighed according to the components of iron oxide 55.4mol%, manganese oxide 38.25mol% and zinc oxide 6.35mol%, respectively, and put them into the mixer for mixing. The speed of the mixer is 40n / min, and the mixing time is 15min, obtain main raw material mixture, iron oxide described in this step is by Fe 2 o 3 Calculated iron oxide, and preferably using Fe with a purity of ≥99.3% produced and sold by Shanghai Baosteel Group Co., Ltd., China 2 o 3 , the manganese oxide is by Mn 3 o 4 Calculated manganese oxide, and preferably use Mn sold under the brand name CR-06 by Hunan Jinrui Technology Co., Ltd., Hunan Province, China 3 o 4 , the purity Mn%≥71%, the zinc oxide is zinc oxide calculated as ZnO, and ZnO produced and sold by Shanghai Jinghua Chemical Factory in China is preferably used, and its weight percentage content ZnO%≥99.7%;

[0027] B) Pre-firing and crushing, introduce the main raw material mixture obtained in s...

Embodiment 2

[0034] Only change the main raw material components in step A) as follows: iron oxide 58.35mol%, manganese oxide 34.85mol% and zinc oxide 6.8mol%, change the speed and mixing time of the mixer to 35n / min and 30min respectively; only Change the pre-burning temperature in step B) to 850°C, the pre-burning time to 70 minutes, the vibration frequency of the vibratory ball mill to 20 times / min, the vibration amplitude to 5 mm, and the average particle diameter of the crushed material to 0.95 -1.05 μm; only change the total weight of auxiliary raw materials relative to the main raw materials in step C) to: Calcium carbonate (CaCO 3 ) 3000ppm, titanium oxide (TiO 2 ) 80ppm, cobalt oxide (Co 2 o 3 ) 1200ppm, ultrafine silicon dioxide (SiO 2 ) 200ppm, chromium oxide (Cr 2 o 3 ) 800ppm, niobium oxide (Nb 2 o 5 ) 100ppm, nickel oxide (NiO) 2000ppm and copper oxide (CuO) 1300ppm, change the weight ratio of water to material to 1.9:1, change the sanding time to 80min, and change the...

Embodiment 3

[0036] Only change the main raw material components in step A) as follows: iron oxide 57mol%, manganese oxide 33mol% and zinc oxide 10mol%, change the speed and mixing time of the mixer to 37n / min and 20min respectively; only step In B), the pre-burning temperature is changed to 880°C, the pre-burning time is changed to 60 minutes, the vibration frequency of the vibration ball mill is changed to 35 times / min, the vibration amplitude is changed to 4mm, and the average particle diameter of the pulverized material is changed to 1-1.2 μm; only change the total weight of the auxiliary raw materials corresponding to the main raw materials in step C) to: calcium carbonate (CaCO 3 ) 1700ppm, titanium oxide (TiO 2 ) 3000ppm, cobalt oxide (Co 2 o 3 ) 50ppm, ultrafine silicon dioxide (SiO 2 ) 25ppm, chromium oxide (Cr 2 o 3 ) 1500ppm, niobium oxide (Nb 2 o 5 ) 1500ppm, nickel oxide (NiO) 600ppm and copper oxide (CuO) 2000ppm, change the weight ratio of water to material to 1.8:1, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Grain diameter | aaaaa | aaaaa |

| Average particle diameter | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com