Cutting line solidified with mixed grinding materials of diamond and cubic boron nitride and method for manufacturing cutting line

A technology of cubic boron nitride and a manufacturing method, which is applied in the field of cutting processing, can solve the problems of reducing the service life of diamond cutting wires, accelerating the wear of cubic boron nitride abrasives, poor thermal stability of diamond, etc., so as to improve cutting efficiency and high cutting efficiency , the effect of maintaining sharpness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

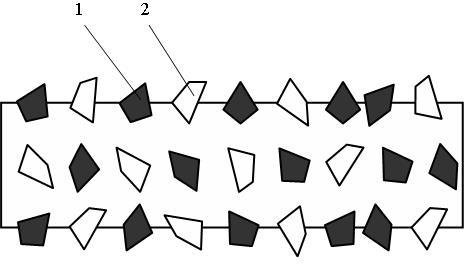

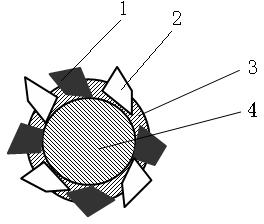

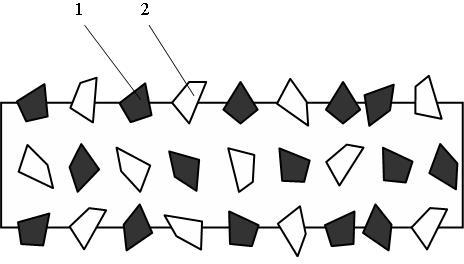

[0031] The long 10000m long 10000m of the copper-plated metal steel wire 4 of wire diameter 0.10mm degreases, derusts, and cleans up. Weigh diamond abrasive 1 and cubic boron nitride abrasive 2 with a particle size of W5-W10 in a ratio of 6:1, mix them thoroughly, soak the surface with nitric acid to activate, and form a spare diamond 1 and cubic boron nitride 2 mixed abrasive. The mixed abrasive was consolidated on the metal steel wire 4 by electroplating nickel 3 to prepare a cutting wire with a diameter of 0.12 mm of consolidated diamond 1 and cubic boron nitride 2 mixed abrasive. This kind of cutting line can be applied to the slicing process of silicon crystal.

Embodiment 2

[0033] The long 10000m long 10000m copper-plated metal steel wire 4 of wire diameter 0.20mm is degreased, derusted, cleans up. Weigh diamond abrasive 1 and cubic boron nitride abrasive 2 with a particle size of W30-W40 in a ratio of 1:6, mix them thoroughly, soak the surface in nitric acid to activate, and form a spare diamond 1 and cubic boron nitride 2 mixed abrasive. The mixed abrasive was consolidated on the metal steel wire 4 by electroplating nickel 3 to prepare a cutting wire with a diameter of 0.28 mm, a mixed abrasive of diamond 1 and cubic boron nitride 2 . This kind of cutting line can be applied to square root processing of polycrystalline silicon ingots.

Embodiment 3

[0035] The long 5000m long 5000m of the copper-plated metal steel wire 4 of wire diameter 0.20mm is degreased, derusted, cleans up. Weigh diamond abrasive 1 and cubic boron nitride abrasive 2 with a particle size of W30-W40 in a ratio of 1:1, mix them thoroughly and soak them in nitric acid to activate the surface to form a spare diamond 1 and cubic boron nitride 2 mixed abrasive. The mixed abrasive was consolidated on the metal steel wire 4 by electroplating nickel 3 to prepare a cutting wire with a diameter of 0.28 mm, a mixed abrasive of diamond 1 and cubic boron nitride 2 . This kind of cutting line can be applied to the truncation processing of monocrystalline silicon rods and the head-to-tail processing of polycrystalline silicon blocks.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com