Patents

Literature

2427results about "Electrolytic coatings" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Platinum electrode and method for manufacturing the same

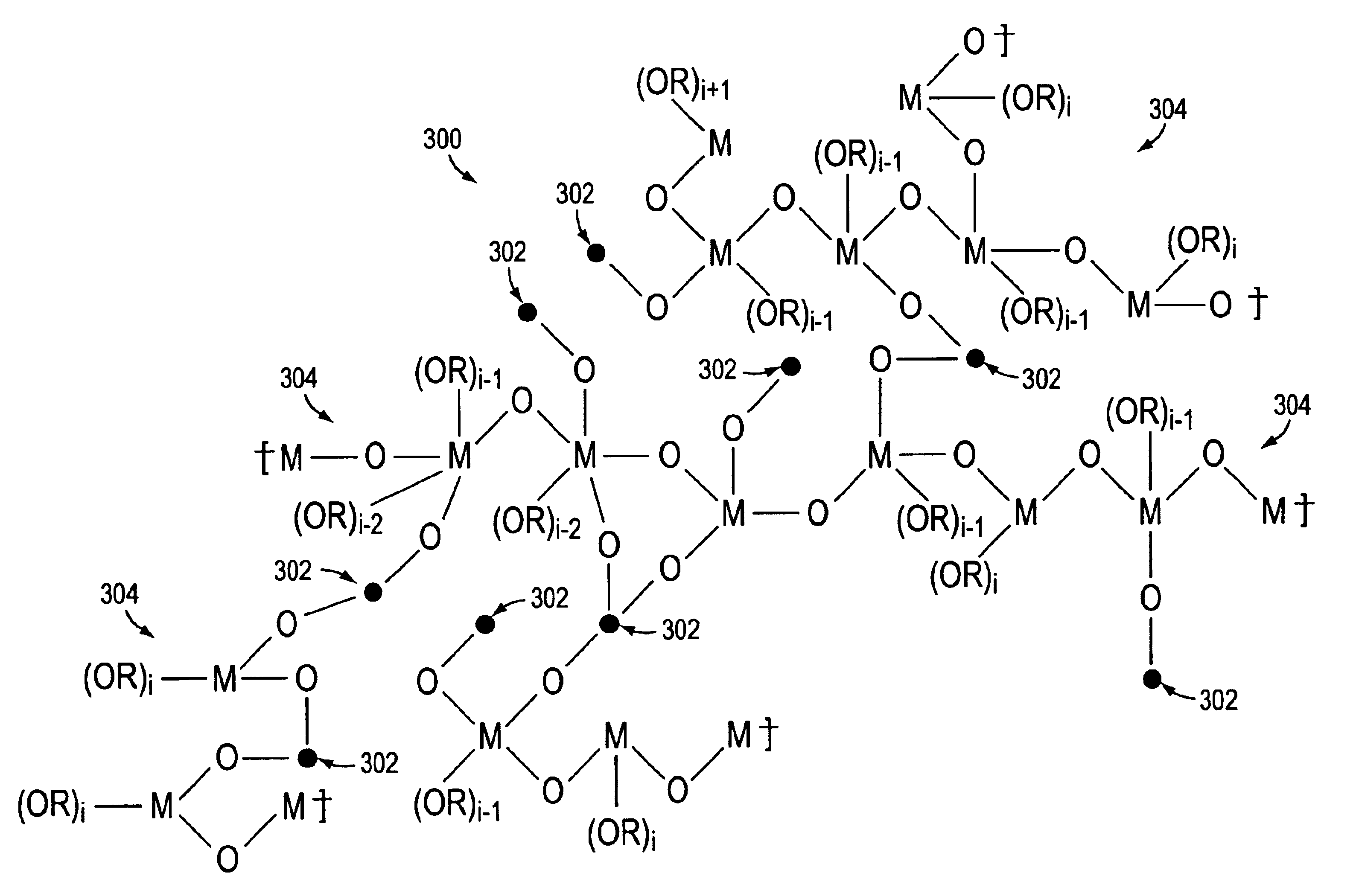

InactiveUS6974533B2Increase surface areaSufficient physical and structural strengthCellsHead electrodesMetallurgyPt element

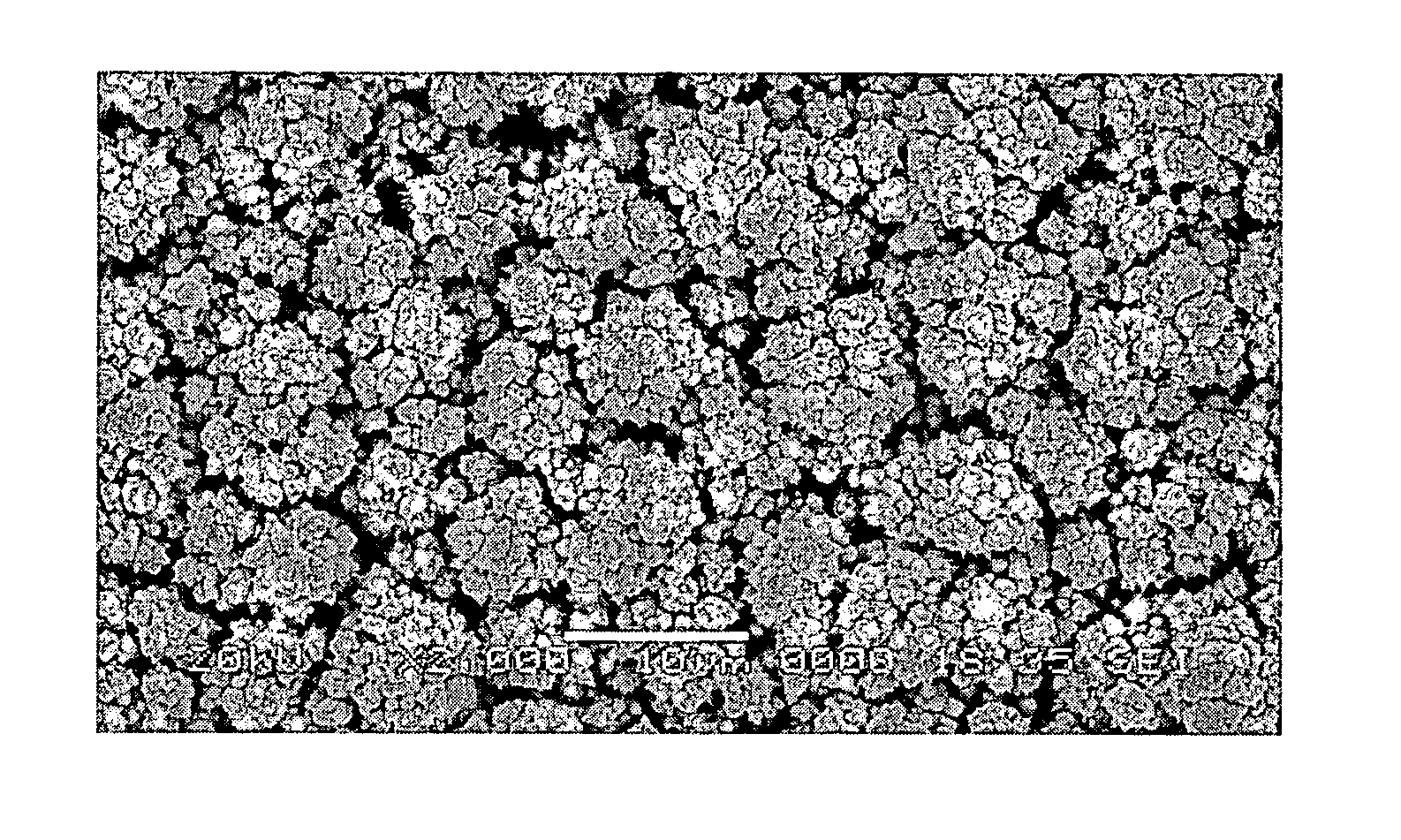

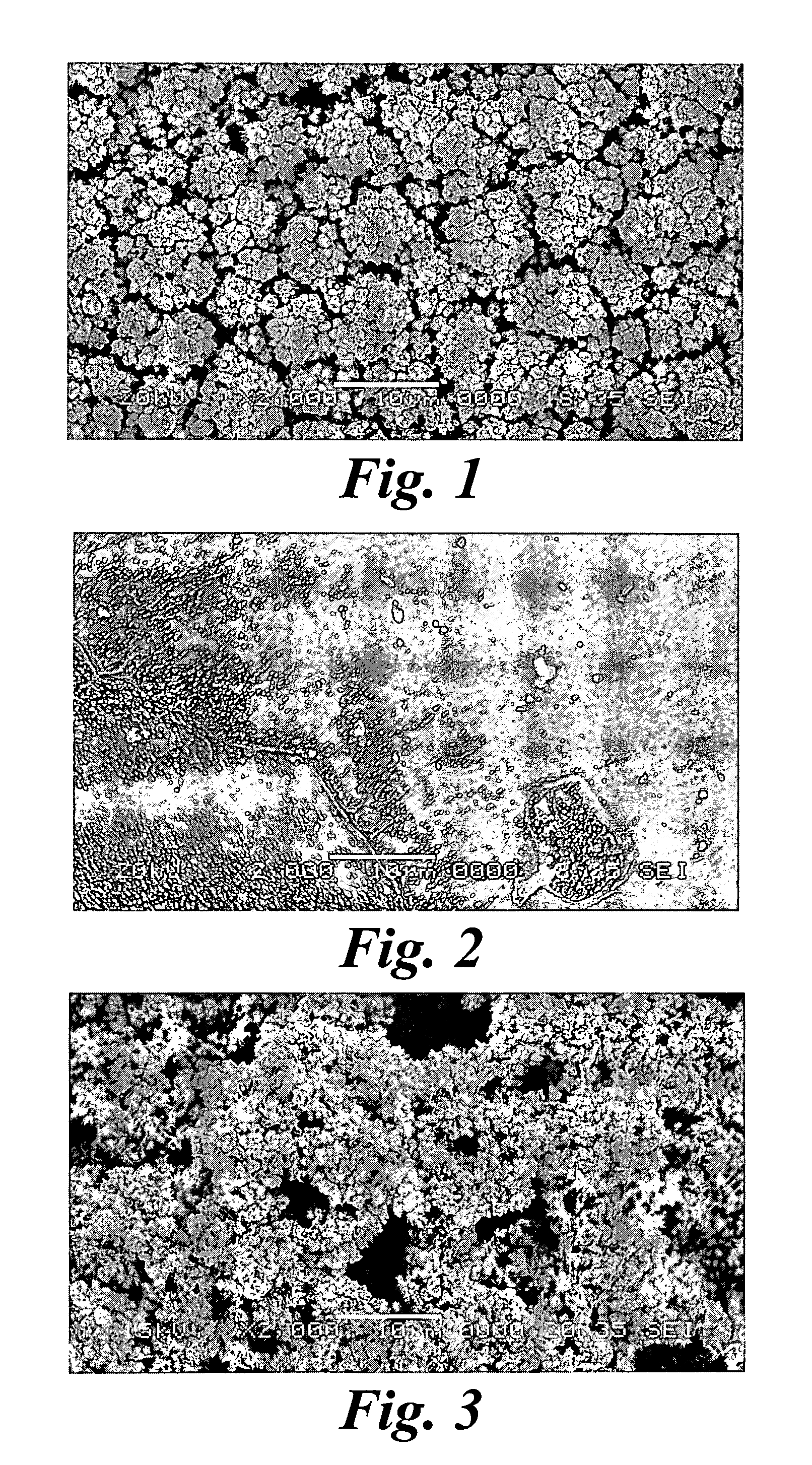

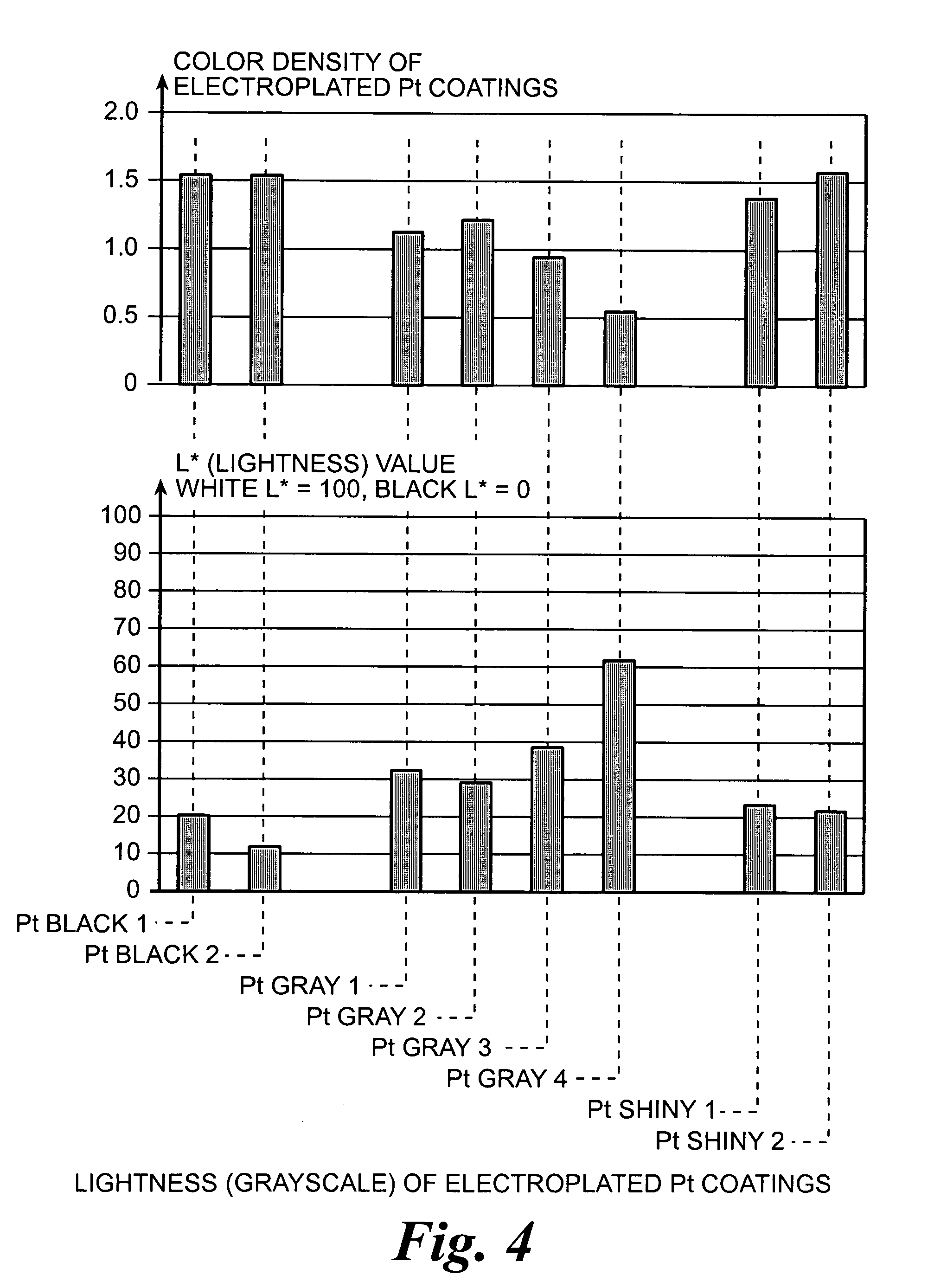

An improved electrode and method for manufacturing the improved electrode wherein the electrode having a fractal surface coating of platinum [which the present inventor refers to as “platinum gray”] with a increase in surface area of at least 5 times when compared to shiny platinum of the same geometry and also having improved resistance to physical stress when compared to platinum black having the same surface area. The process of electroplating the surface coating of platinum gray comprising plating at a moderate rate, i.e., at a rate that is faster than the rate necessary to produce shiny platinum and that is less than the rate necessary to produce platinum black.

Owner:CORTIGENT INC

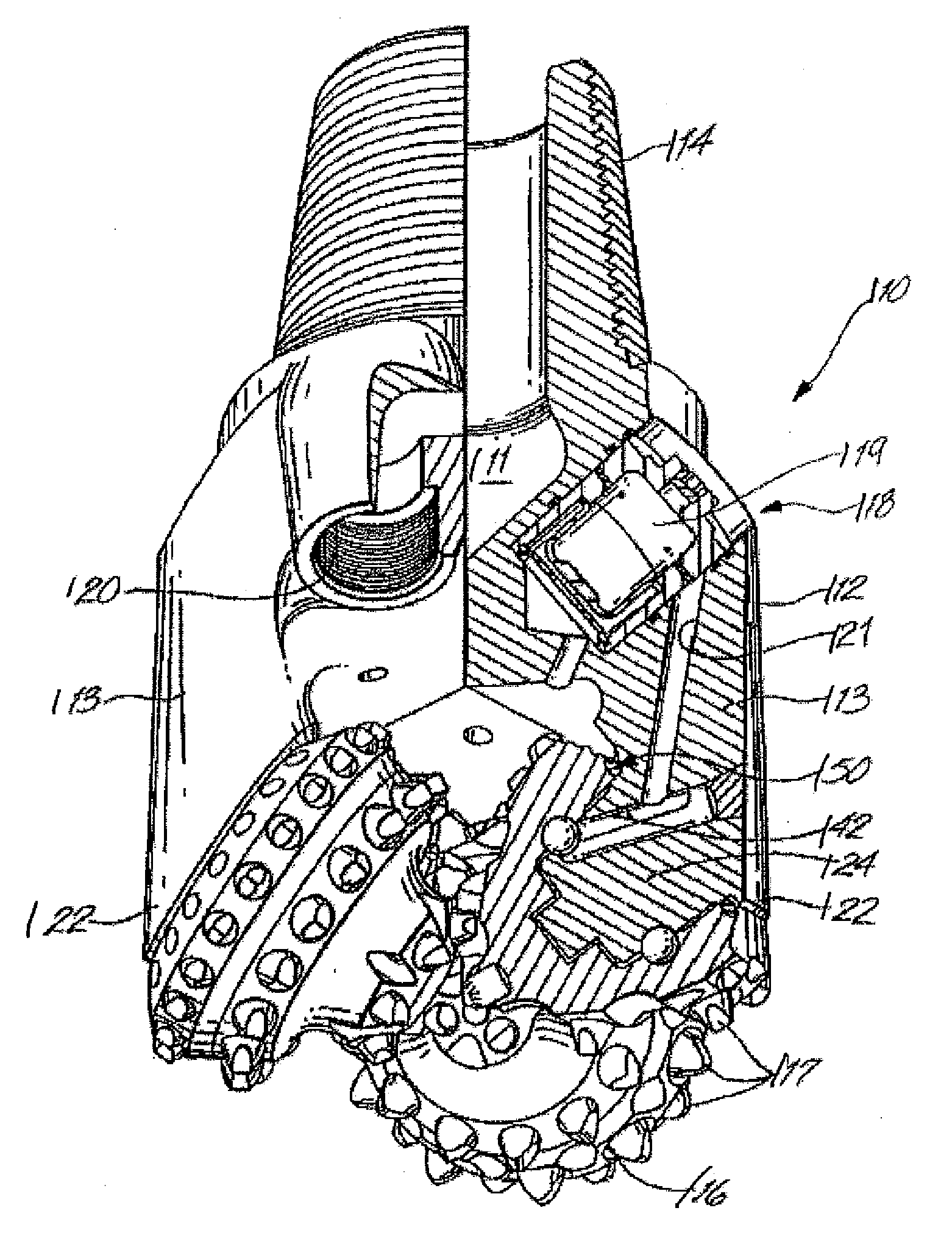

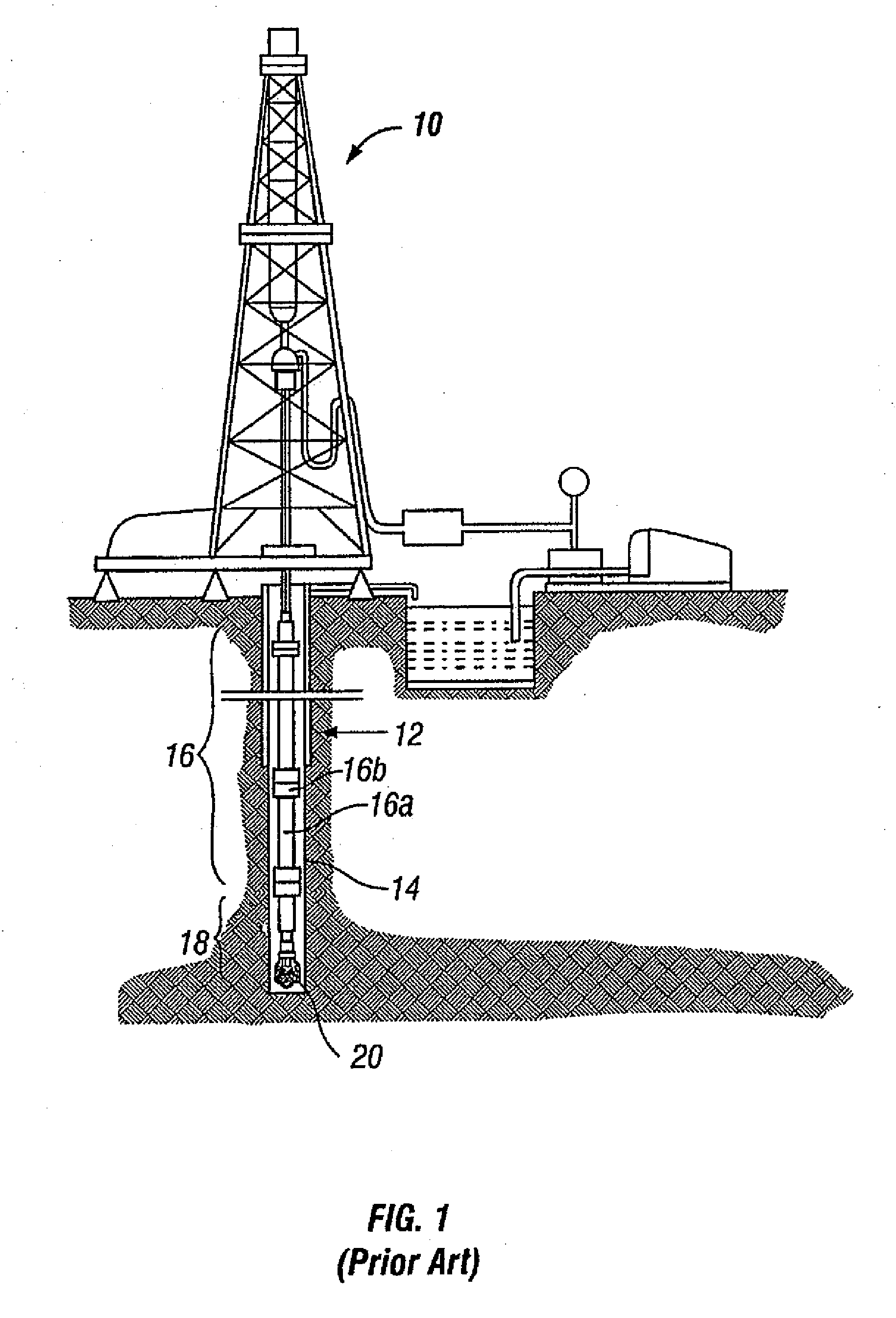

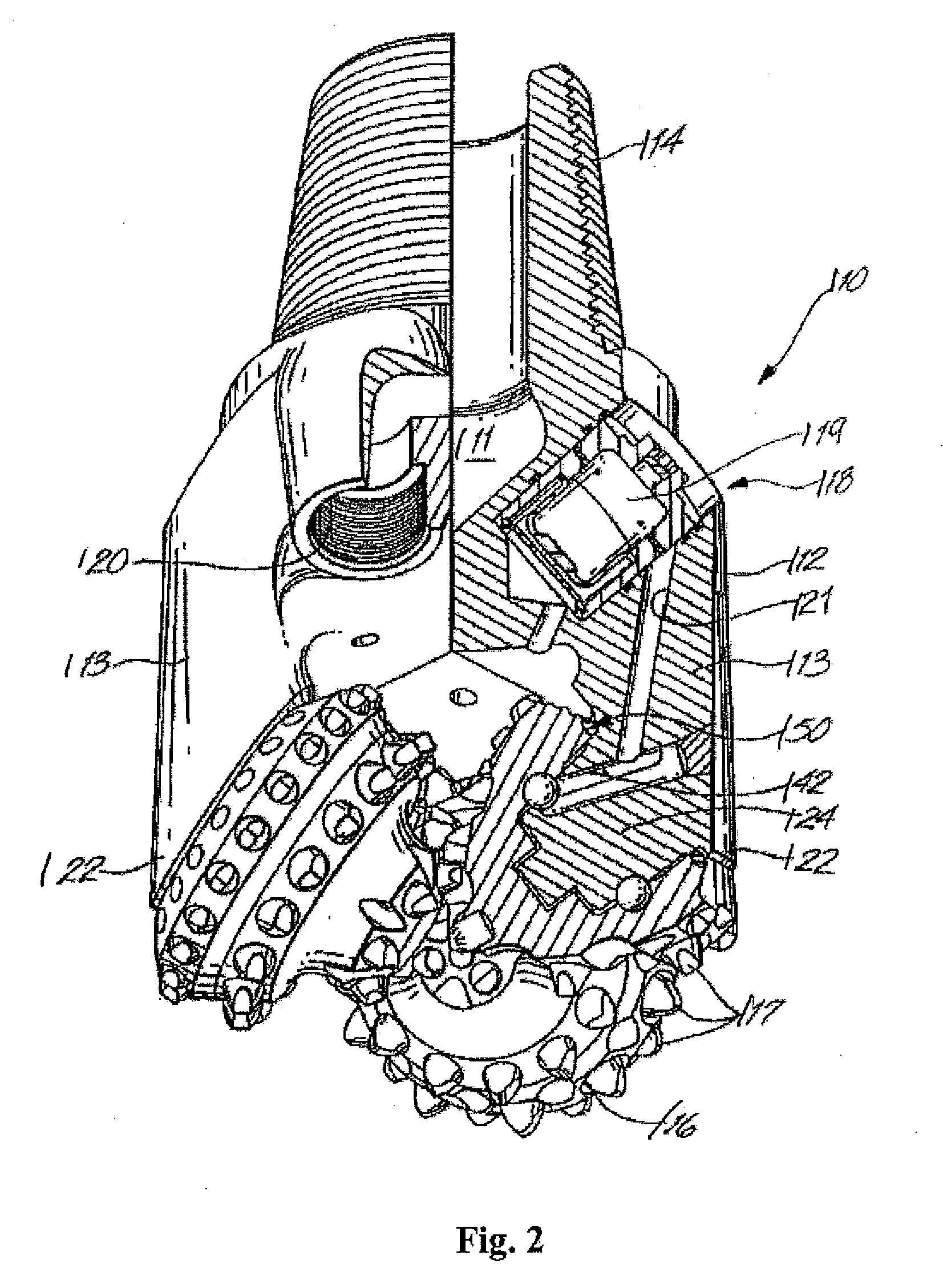

Composite coating with nanoparticles for improved wear and lubricity in down hole tools

Owner:SMITH INT INC

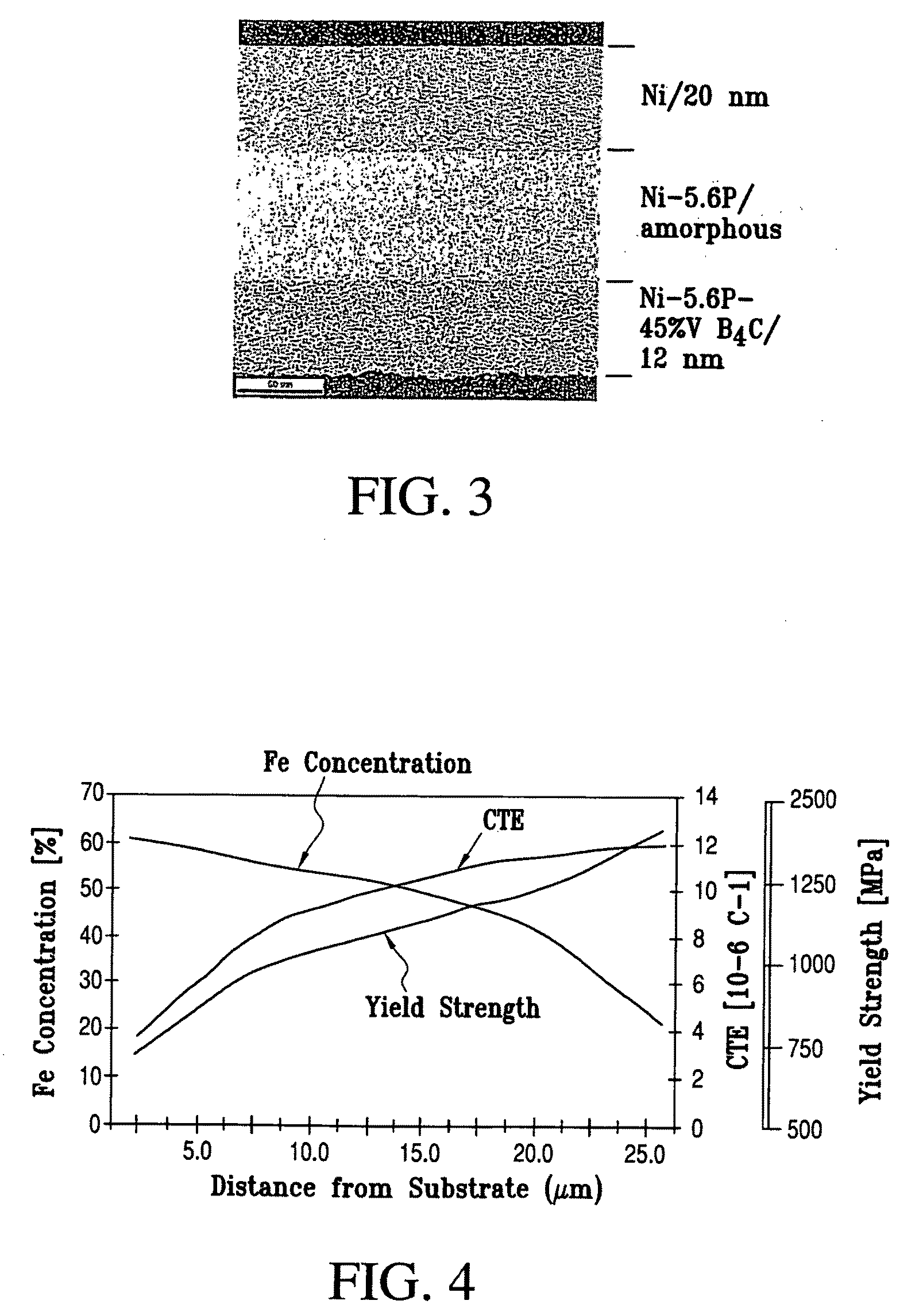

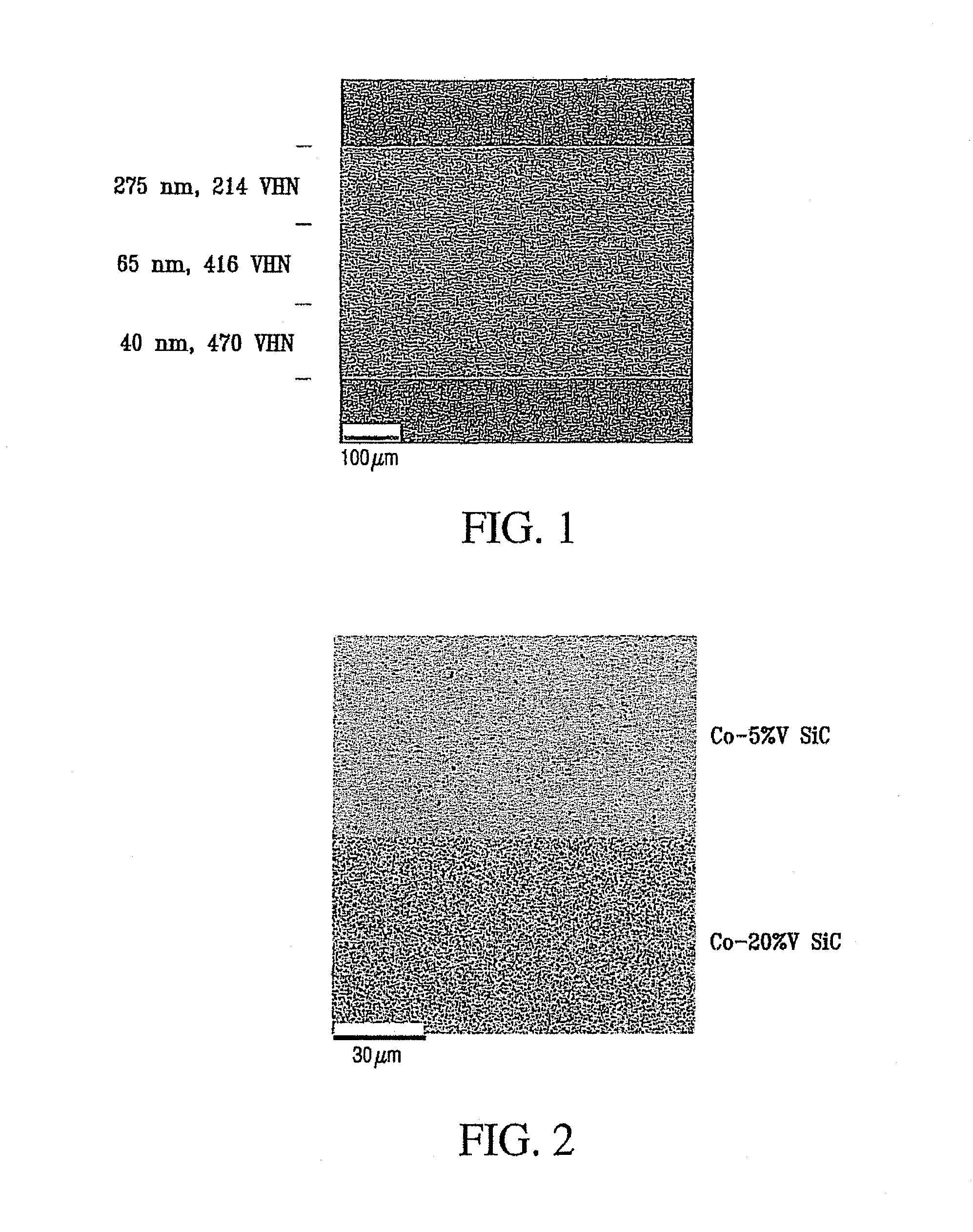

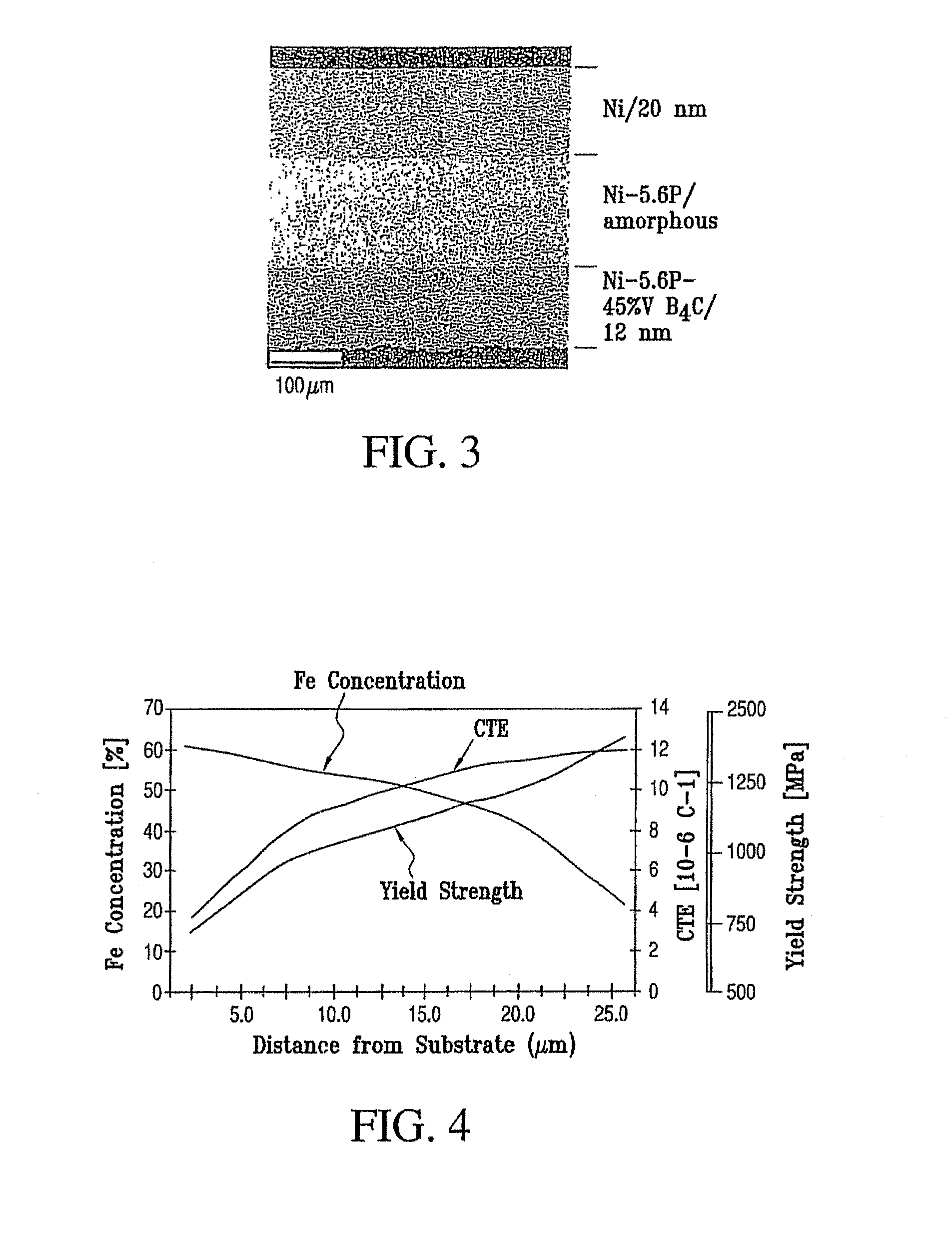

Fine-grained metallic coatings having the coefficient of thermal expansion matched to the one of the substrate

ActiveUS7320832B2Good thermal cycle performanceHigh strengthMaterial nanotechnologyRodsParticulatesChemical composition

Owner:INTEGRAN TECH

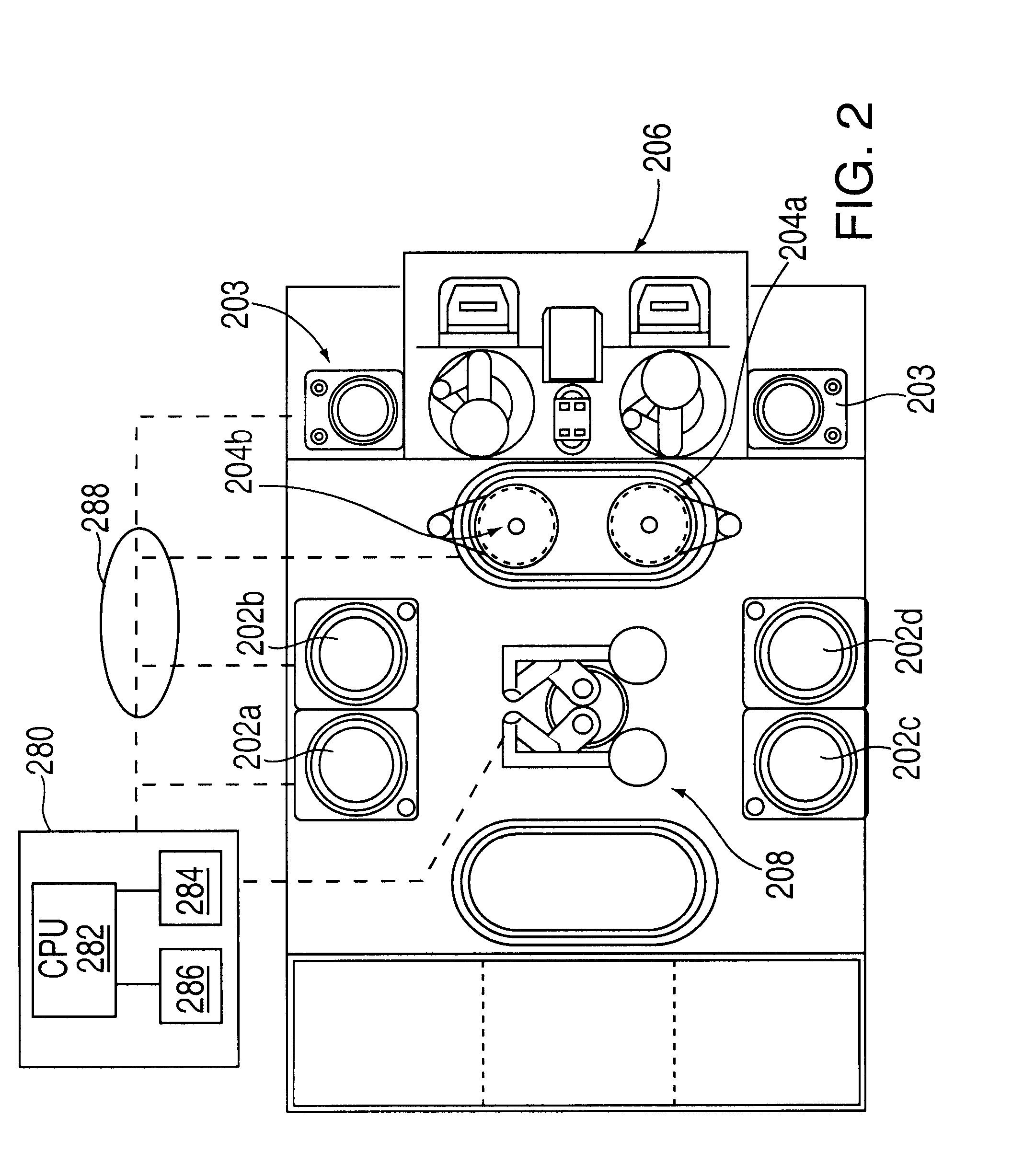

Variable property electrodepositing of metallic structures

ActiveUS20090159451A1Increase floor spaceAdd equipmentCellsElectrolytic coatingsParticulatesMetallic materials

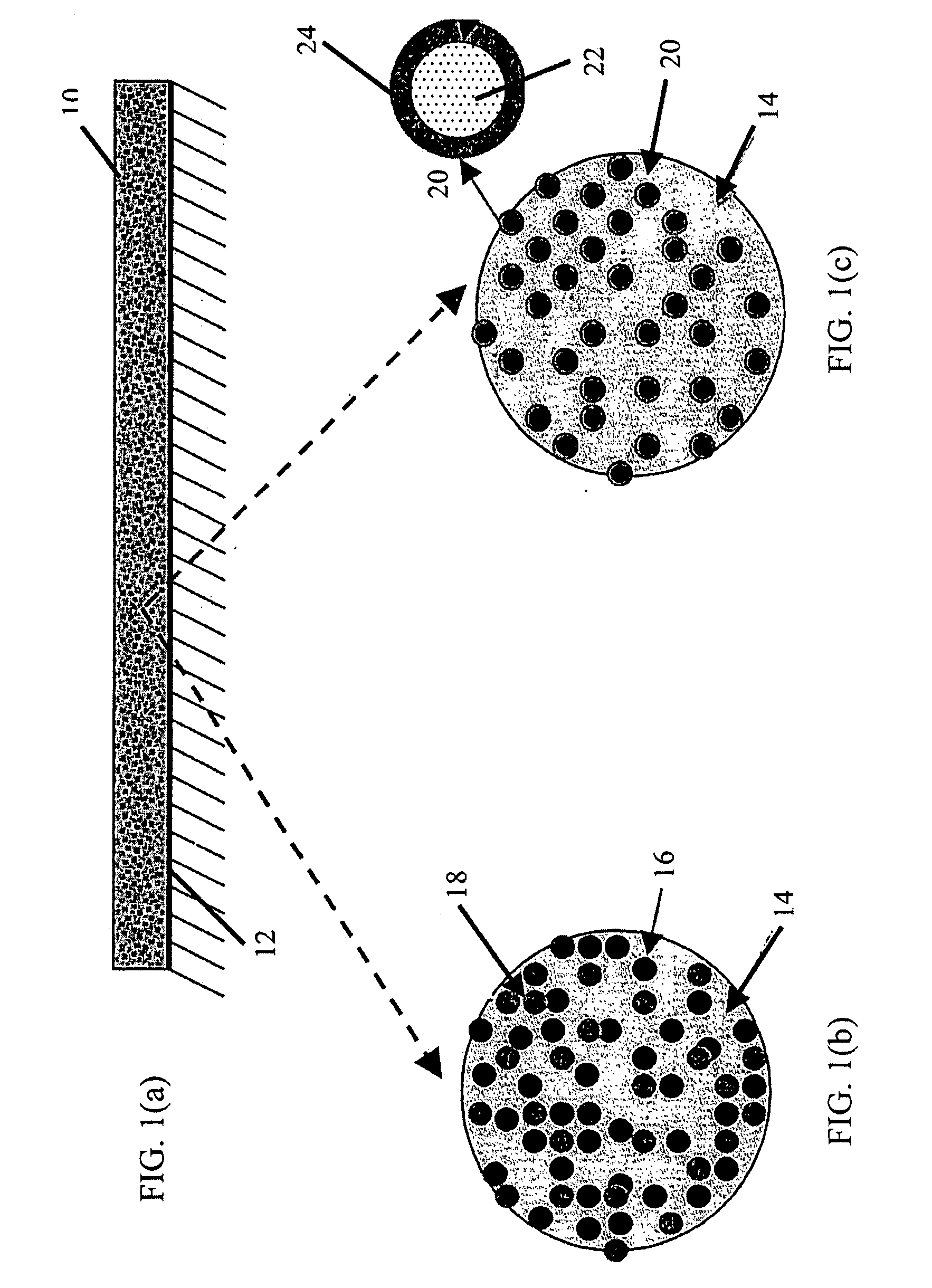

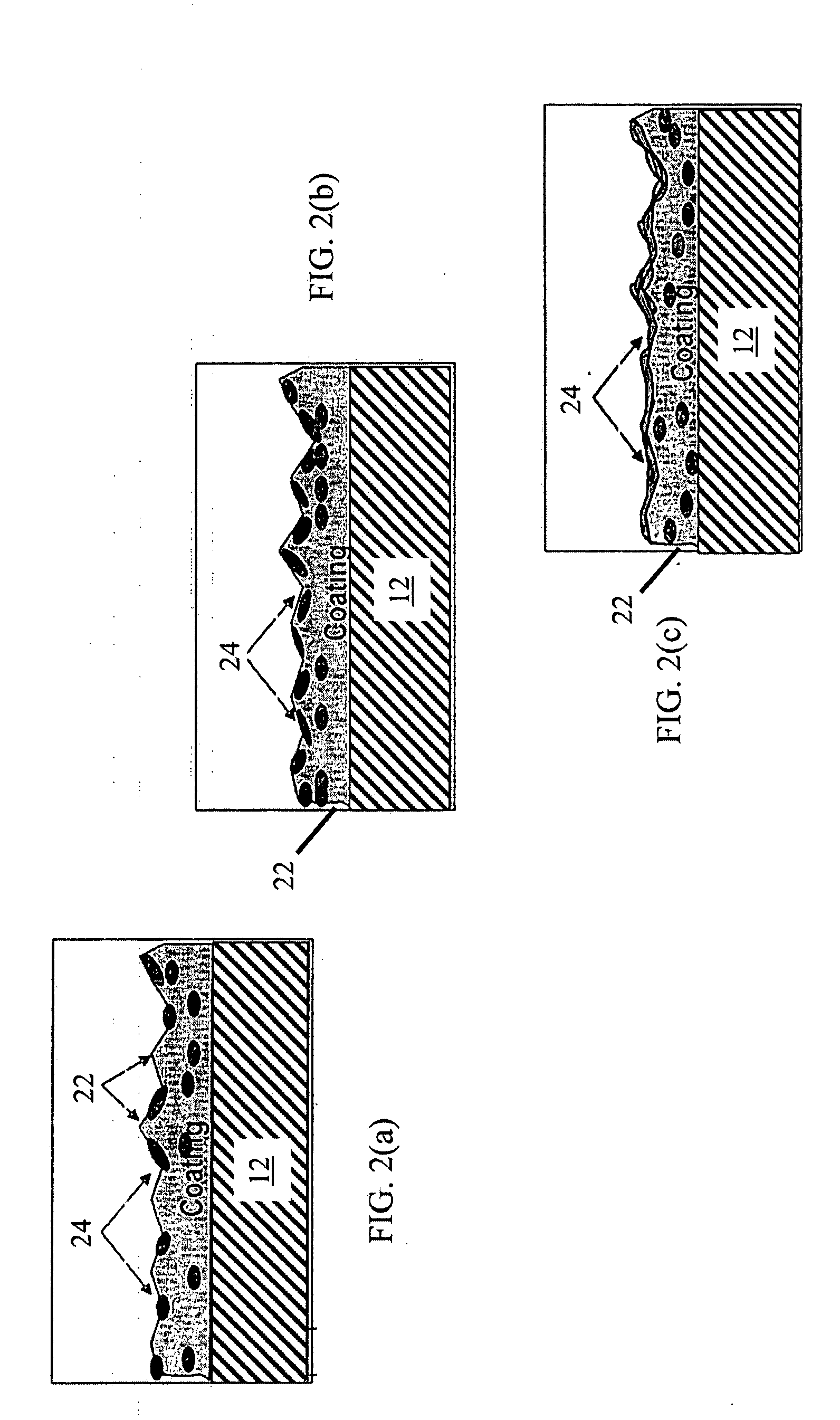

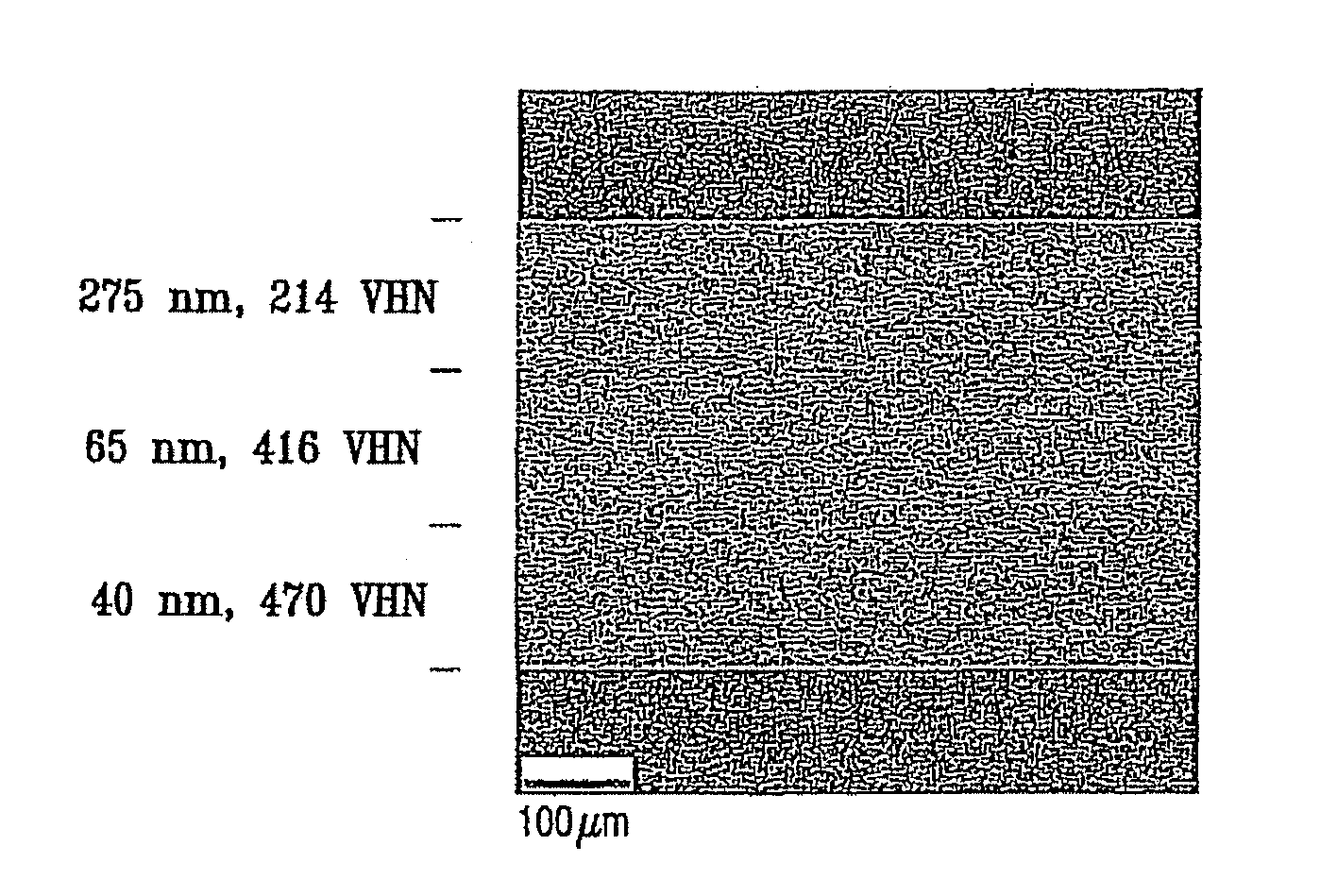

Variable property deposit, at least partially of fine-grained metallic material, optionally containing solid particulates dispersed therein, is disclosed. The electrodeposition conditions in a single plating cell are suitably adjusted to once or repeatedly vary at least one property in the deposit direction. In one embodiment denoted multidimension grading, property variation along the length and / or width of the deposit is also provided. Variable property metallic material deposits containing at least in part a fine-grained microstructure and variable property in the deposit direction and optionally multidimensionally, provide superior overall mechanical properties compared to monolithic fine-grained (average grain size: 2 nm-5 micron), entirely coarse-grained (average grain size: >20 micron) or entirely amorphous metallic material deposits.

Owner:INTEGRAN TECH

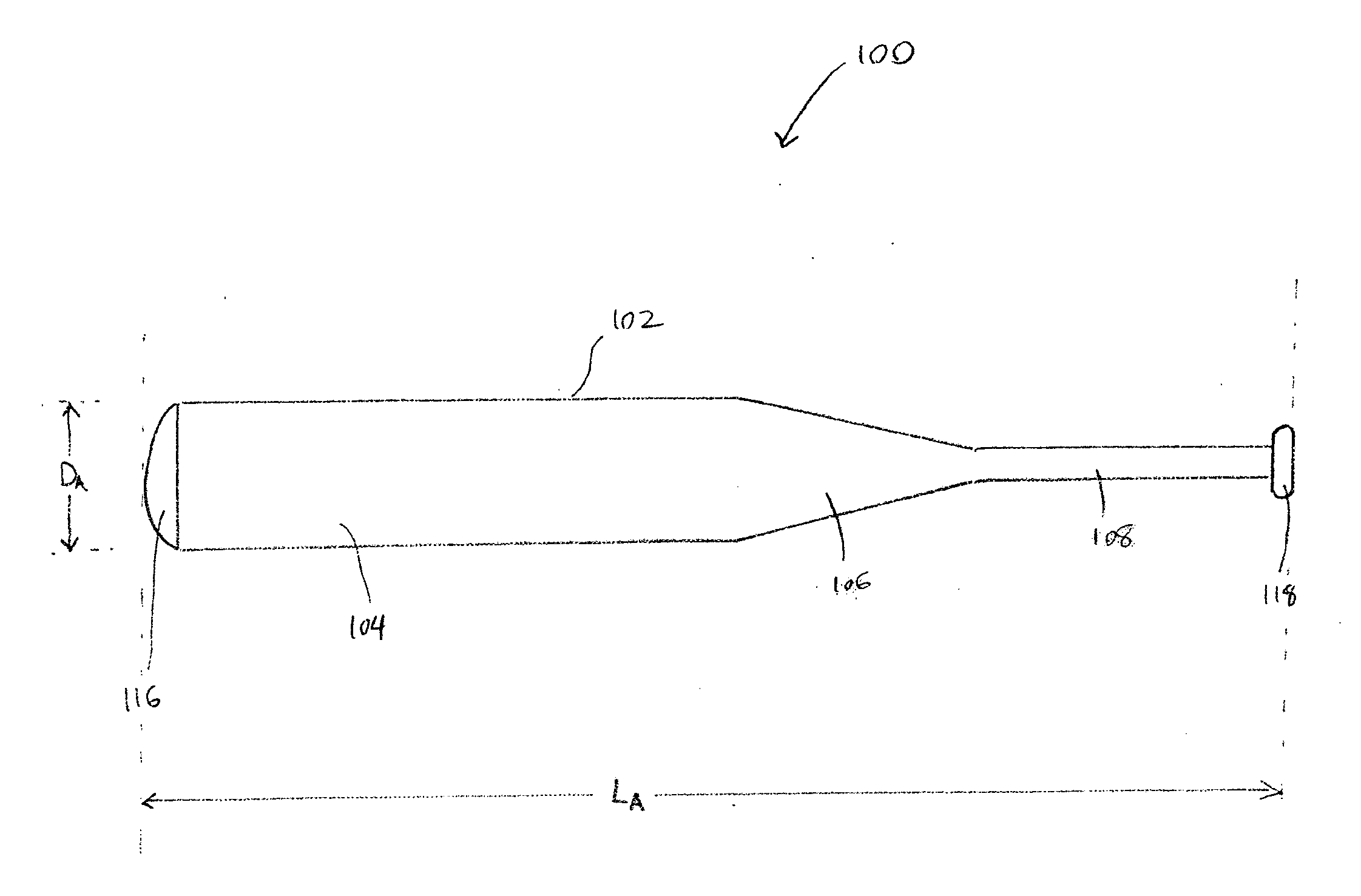

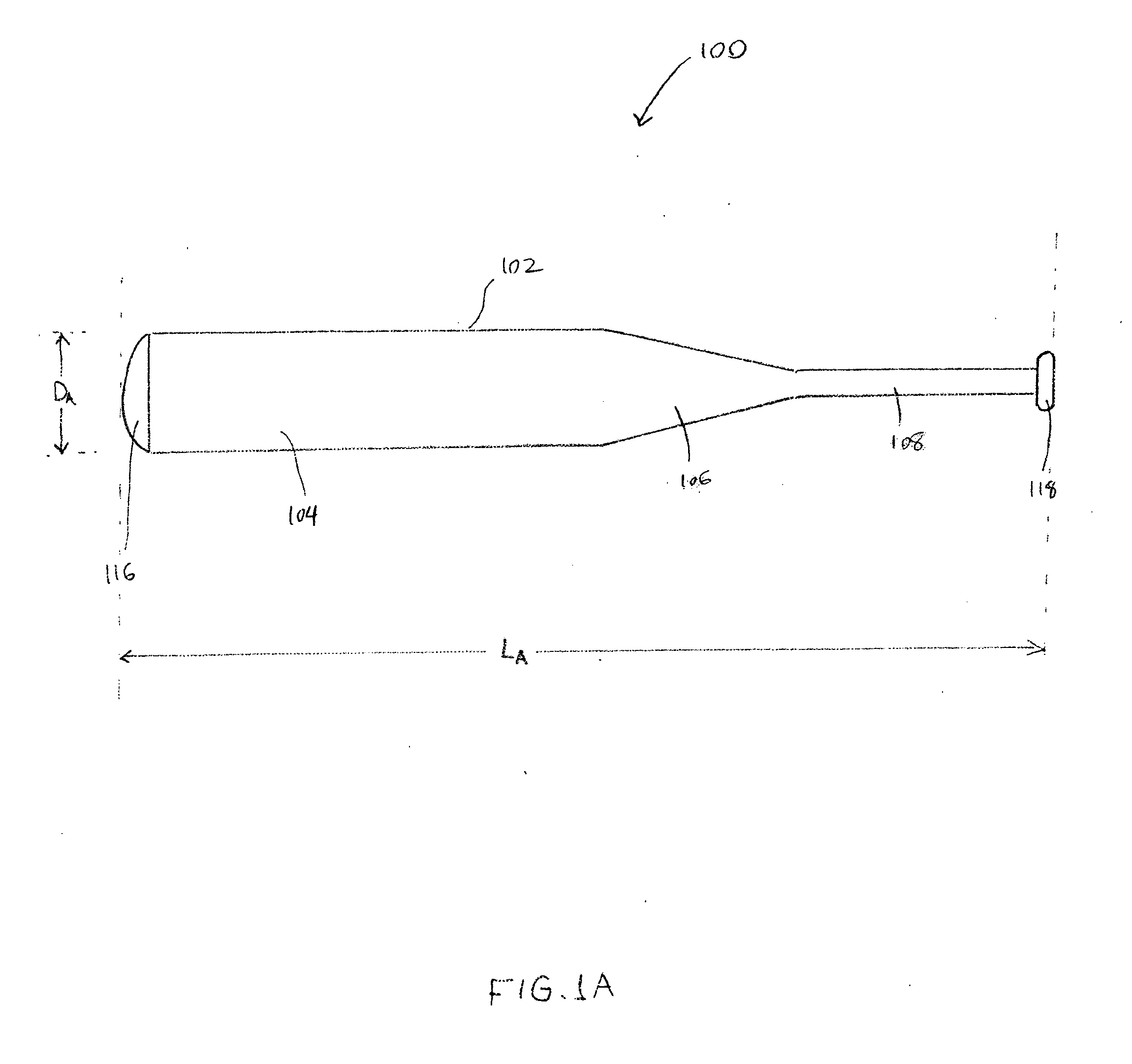

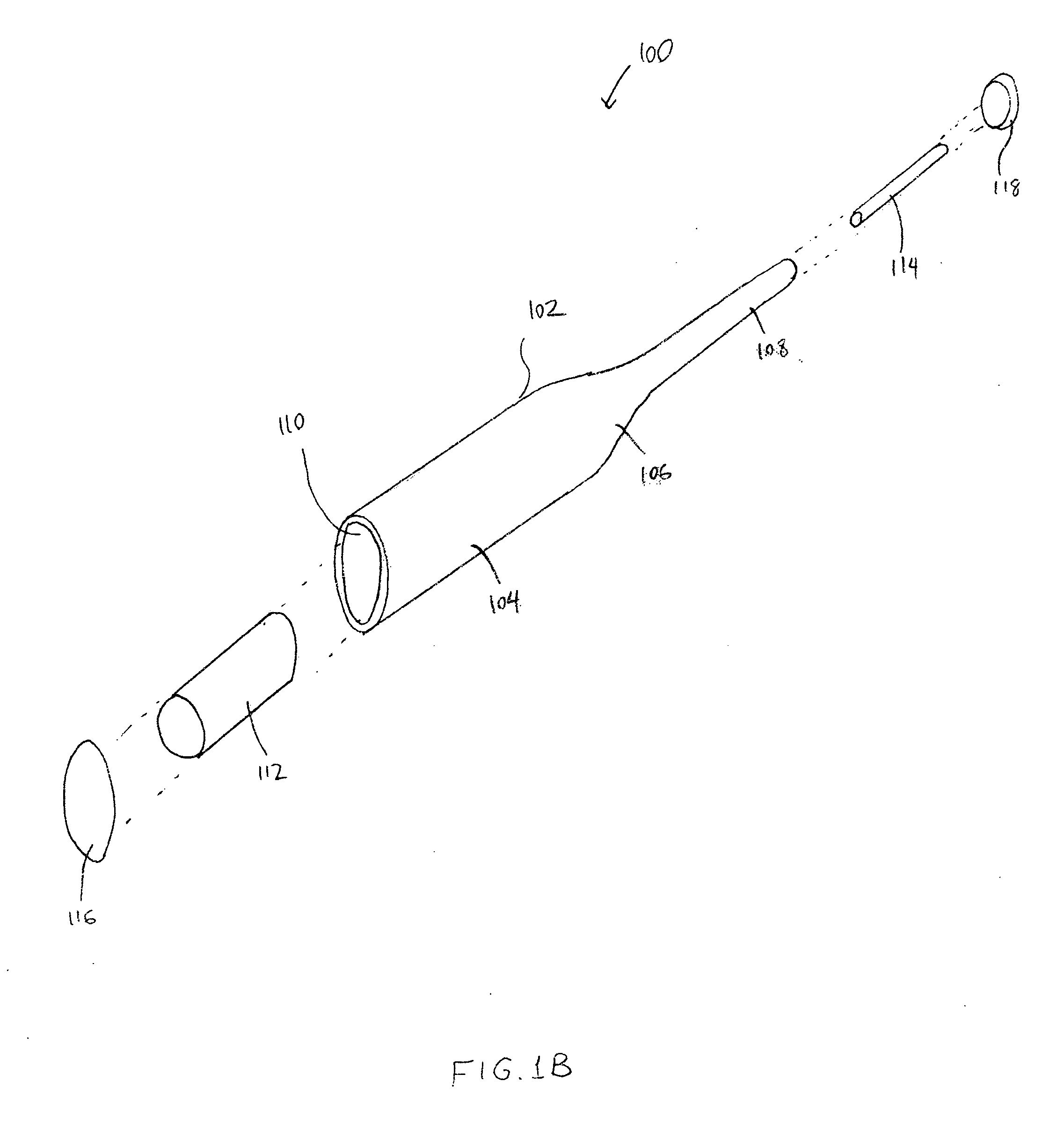

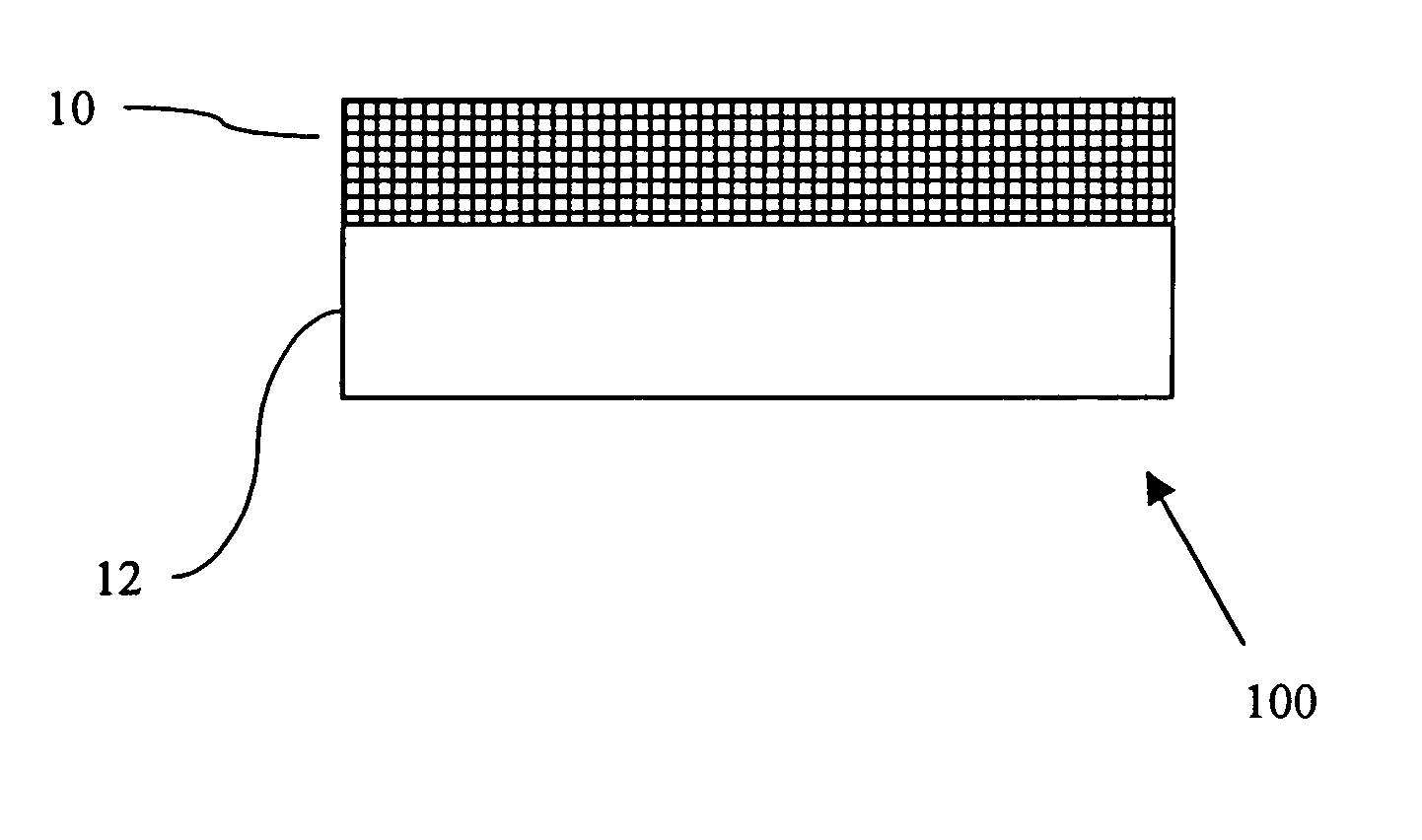

Article comprising a fine-grained metallic material and a polymeric material

InactiveUS20060135282A1Strength-to-weight ratio can be improvedGood damping propertiesWalking sticksMaterial nanotechnologyPolymer scienceHigh stiffness

Lightweight articles comprising a polymeric material at least partially coated with a fine-grained metallic material are disclosed. The fine-grained metallic material has an average grain size of 2 nm to 5,000 nm, a thickness between 25 micron and 5 cm, and a hardness between 200 VHN and 3,000 VHN. The lightweight articles are strong and ductile and exhibit high coefficients of restitution and a high stiffness and are particularly suitable for a variety of applications including aerospace and automotive parts, sporting goods, and the like.

Owner:INTEGRAN TECH

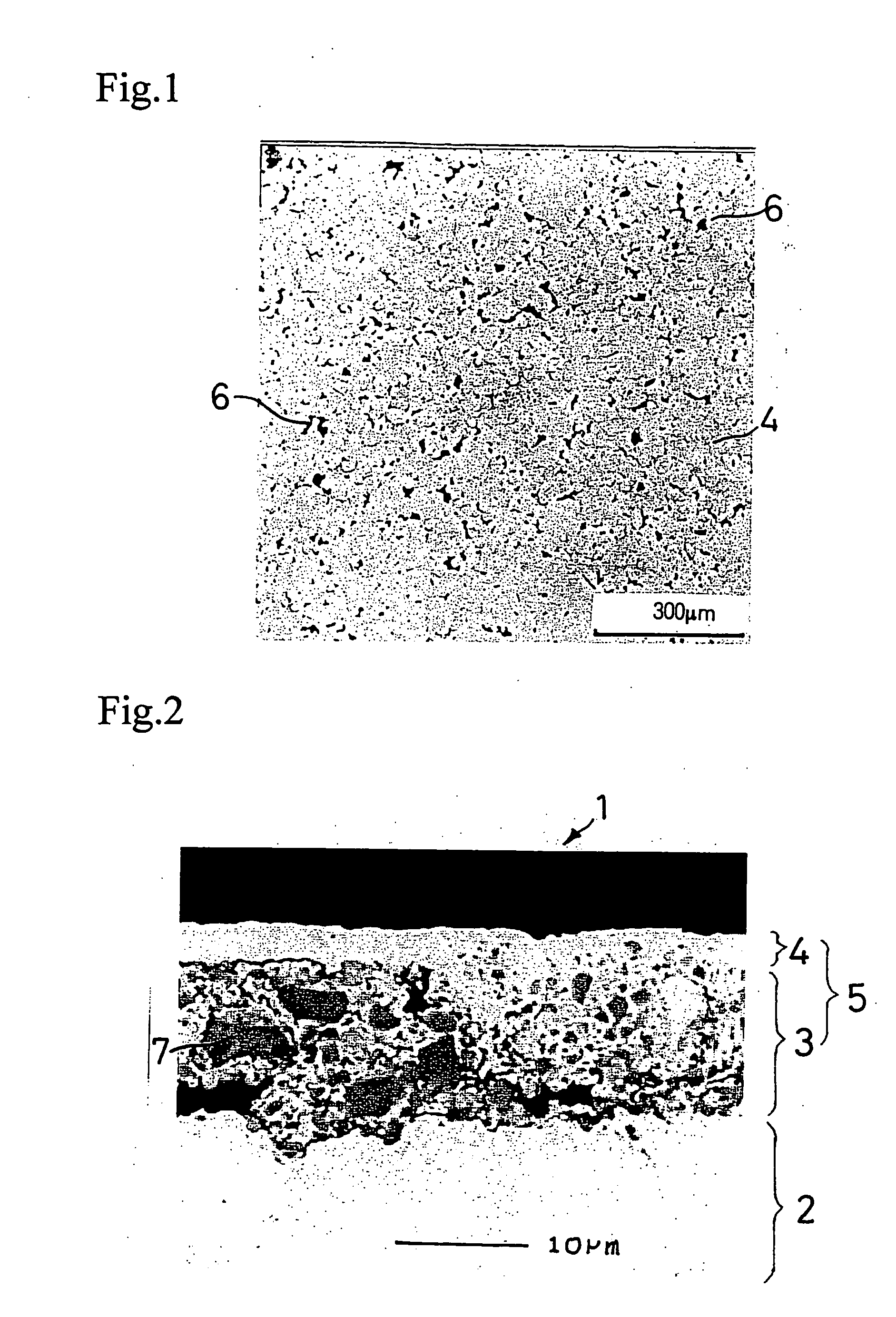

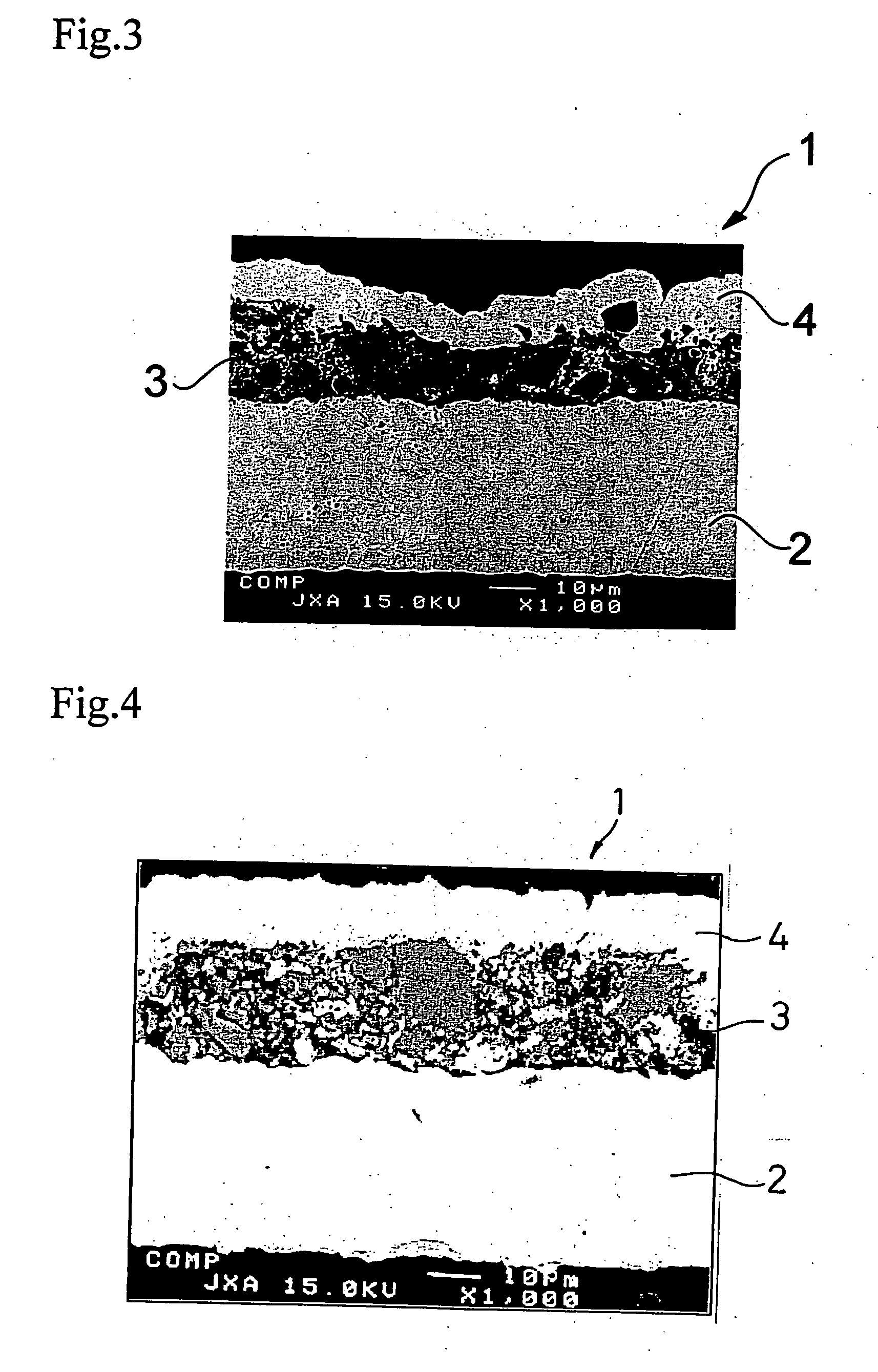

Anode for nonaqueous secondary battery, process of producing the anode, and nonaqueous secondary battery

InactiveUS20060147802A1Simple materialRaise the ratioCellsElectrochemical processing of electrodesSurface layerLithium compound

A negative electrode for nonaqueous secondary batteries is disclosed. The negative electrode has a pair of current collecting surface layers of which the surfaces are adapted to be brought into contact with an electrolyte and at least one active material layer interposed between the surface layers. The active material layer contains particles of an active material having high capability of forming a lithium compound. The material constituting the surfaces is preferably present over the whole thickness of the active material layer to electrically connect the surfaces so that the electrode exhibits a current collecting function as a whole. The surface layers each preferably have a thickness of 0.3 to 10 μm.

Owner:MITSUI MINING & SMELTING CO LTD

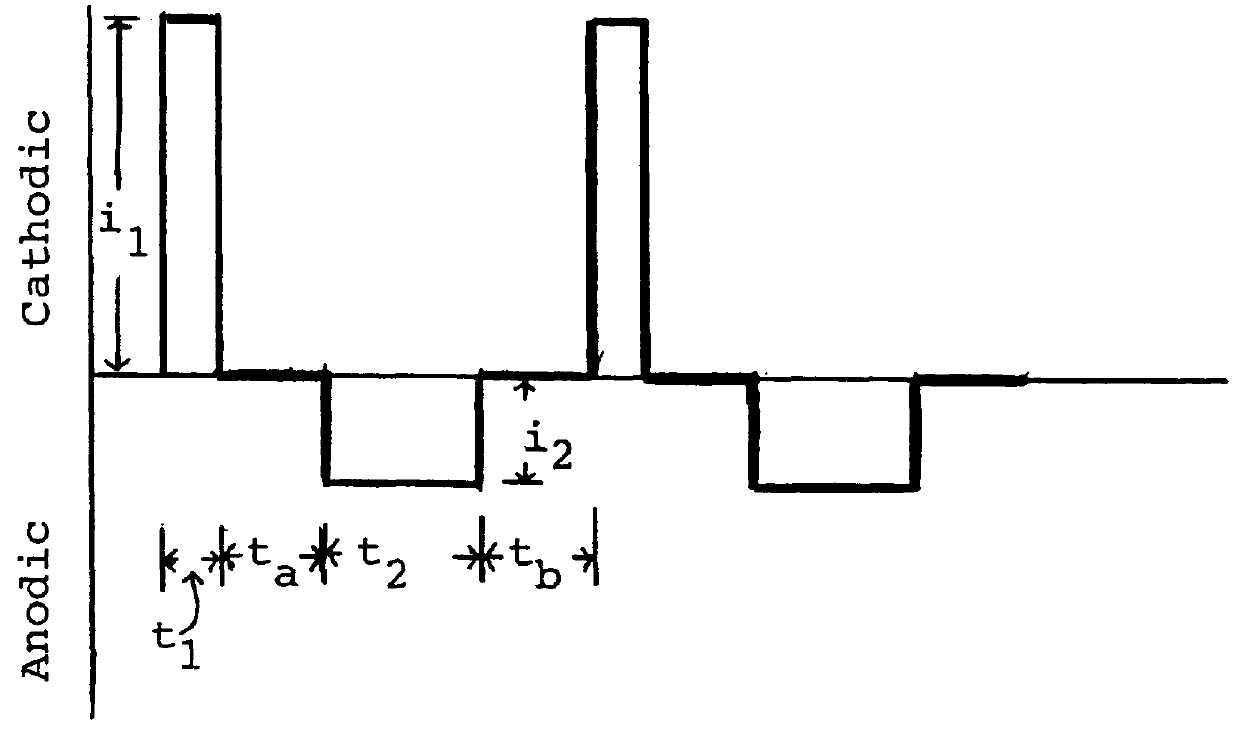

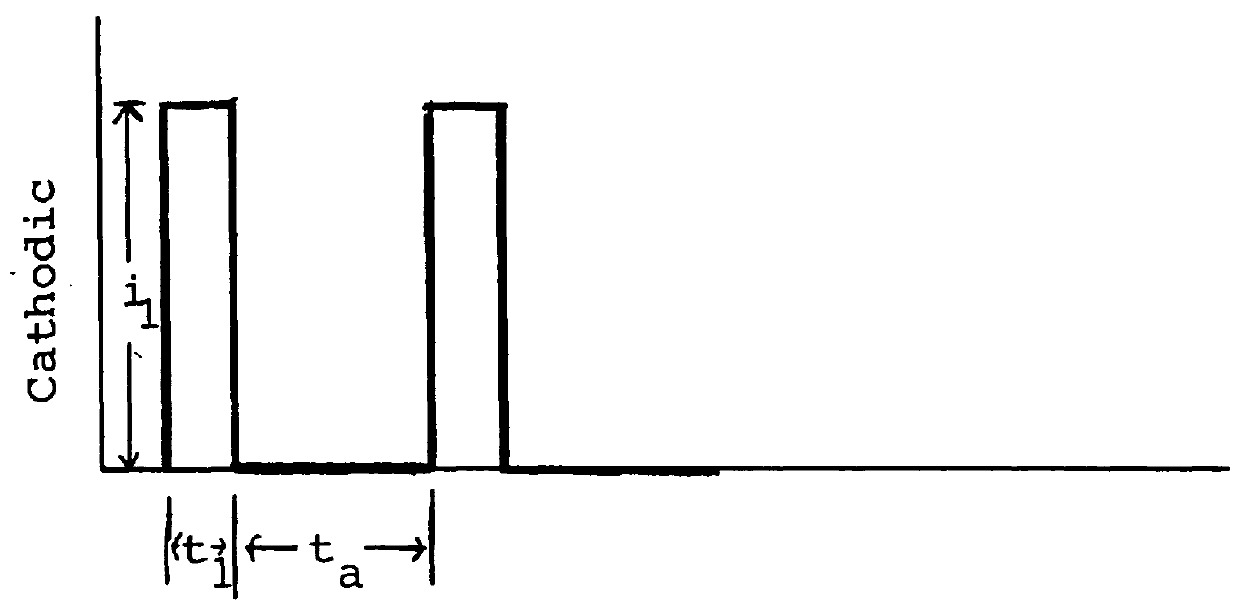

Electrodeposition of catalytic metals using pulsed electric fields

InactiveUS6080504AAdequate power densityEconomical catalyst loadingSolid electrolytesElectrolytic coatingsHertzPulse electric field

A gas diffusion electrode for a proton exchange membrane fuel cell is prepared by electrodeposition of a catalytic metal in nanocrystalline form on a substrate by contacting an electrically conductive substrate and a counterelectrode with a plating bath containing ions of a metal to be deposited on the substrate and passing a pulsed electric current between the substrate and counterelectrode having pulses that are cathodic with respect to the substrate and have a short on-time and / or a short duty cycle with a frequency from about 10 hertz to about 5000 hertz. In a preferred embodiment the electric current is a modulated reversing electric current having pulses that are cathodic with respect to the substrate and pulses that are anodic with respect to the substrate, the cathodic pulses having a short on-time and / or short duty cycle, the charge transfer ratio of the cathodic pulses to the anodic pulses being greater than one, and the frequency of the pulses ranging from about 10 hertz to about 5 kilohertz.

Owner:FARADAY TECH INC

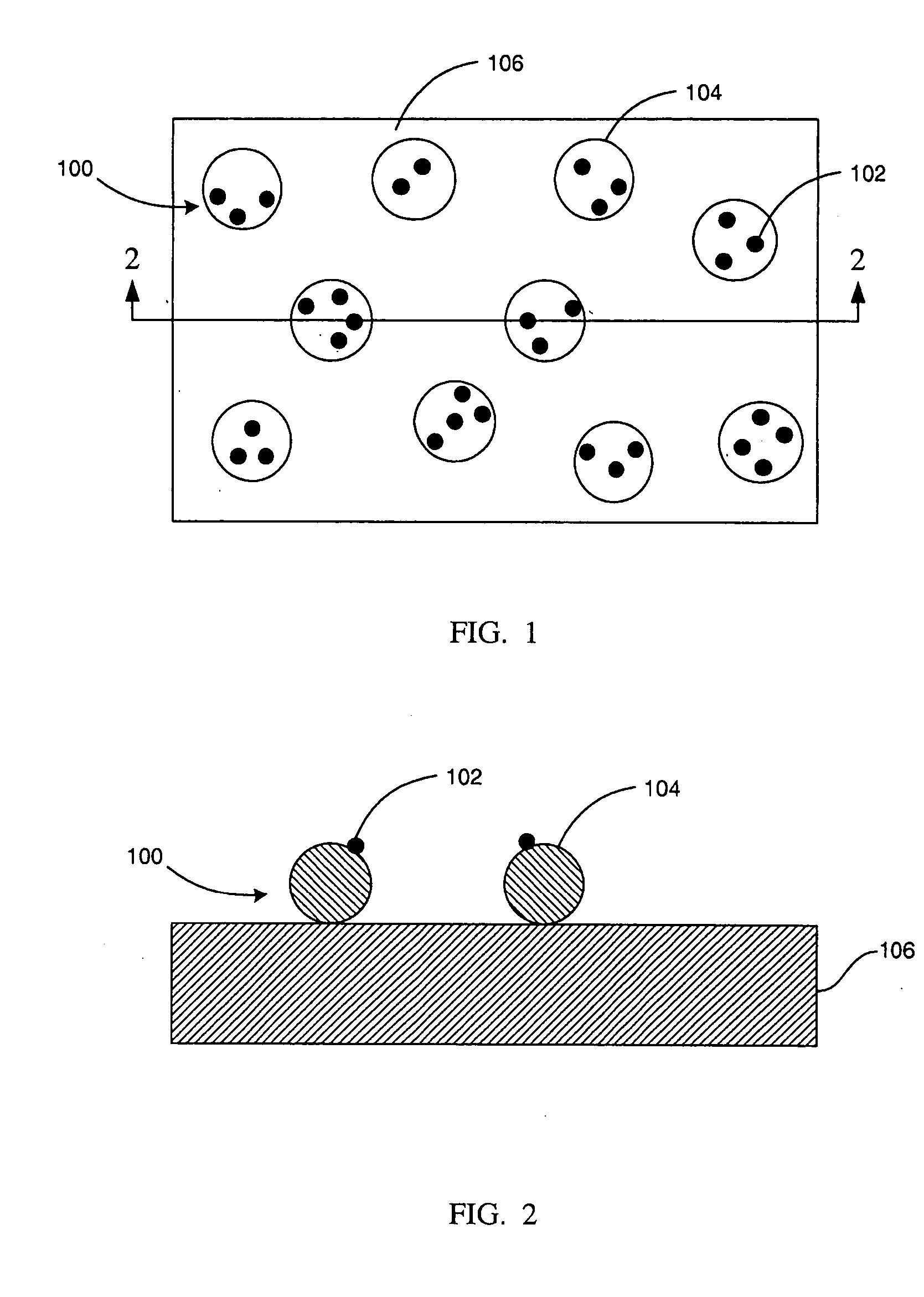

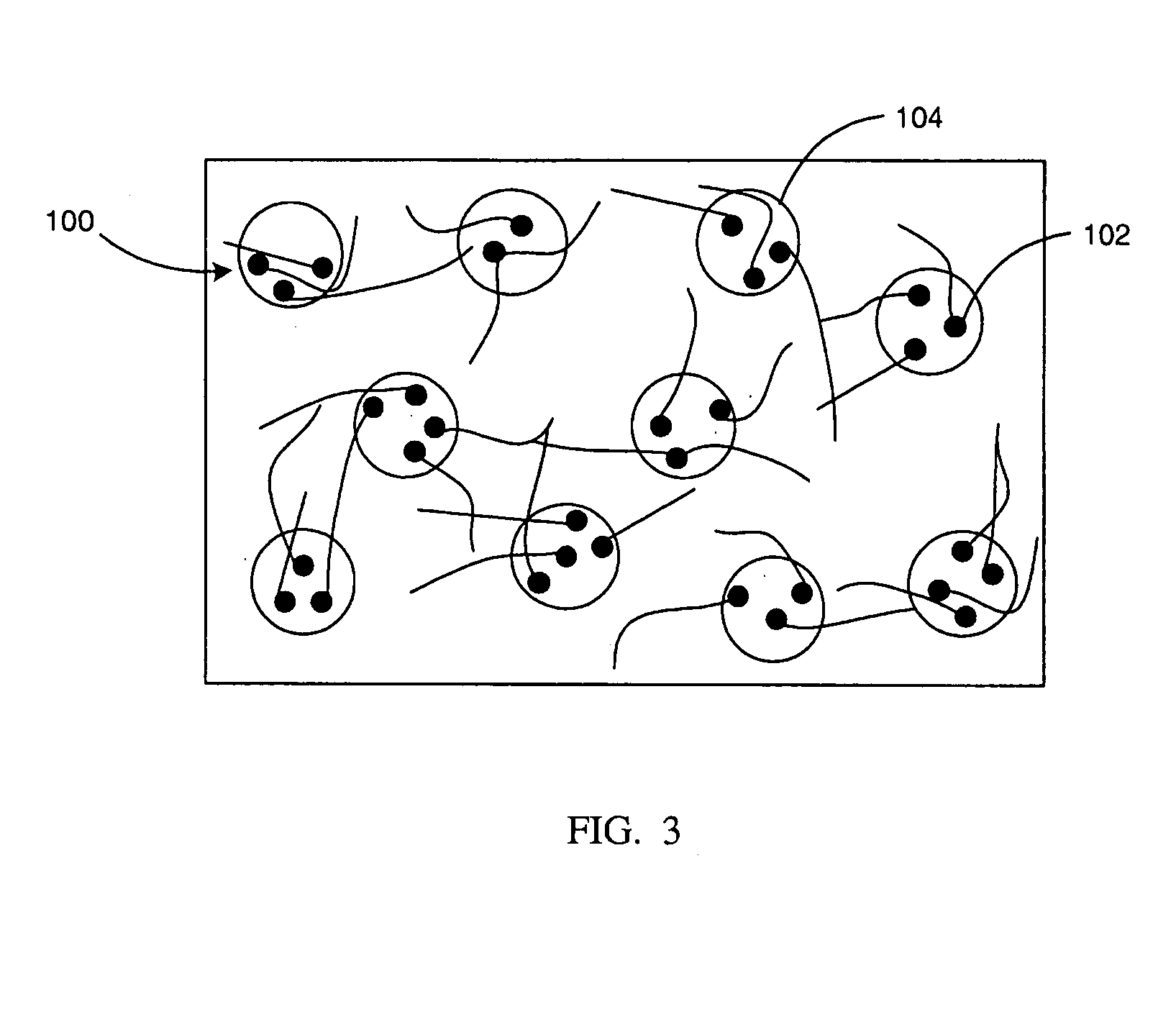

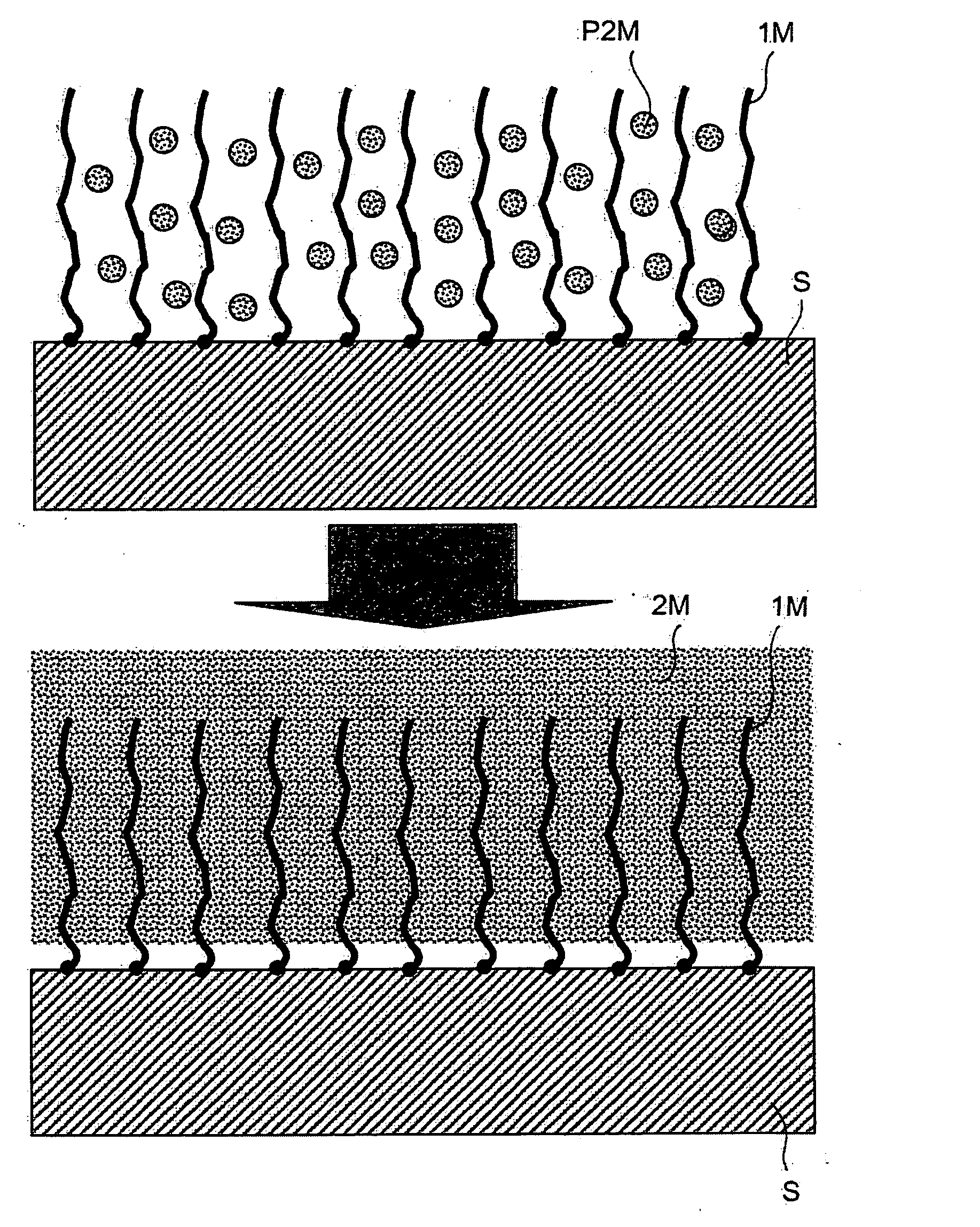

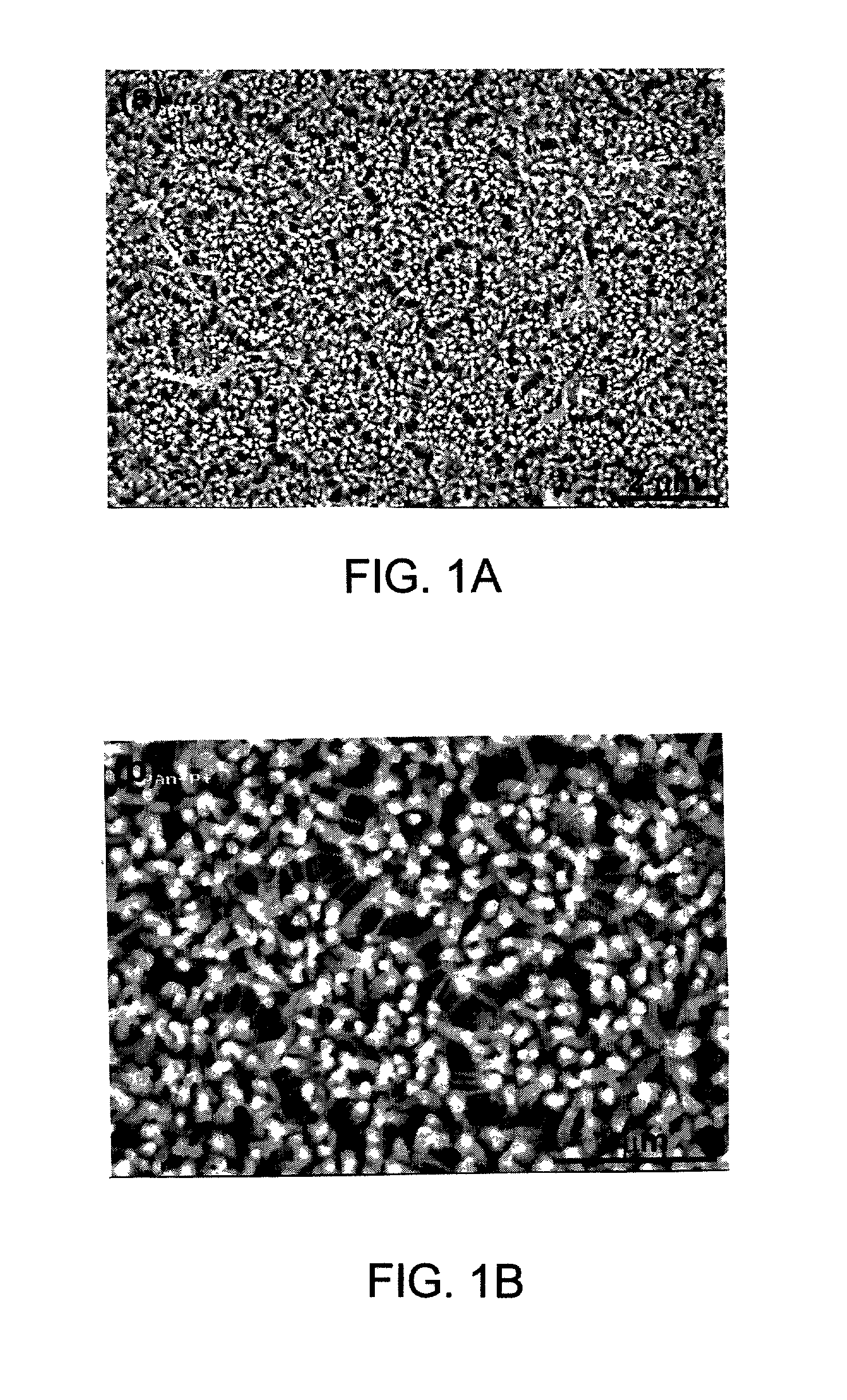

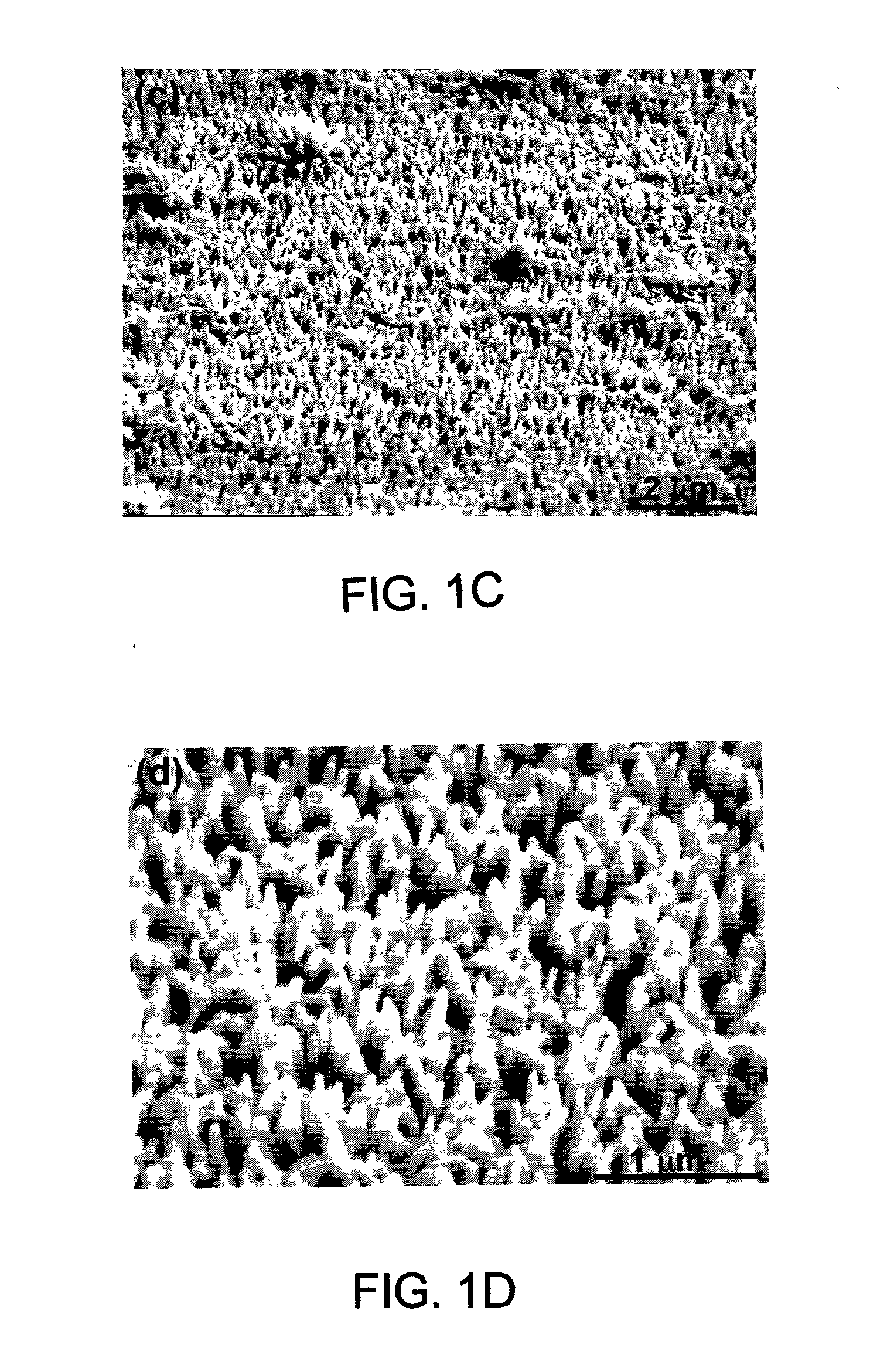

Methods for producing and using catalytic substrates for carbon nanotube growth

InactiveUS20050112052A1Efficient CatalysisMaterial nanotechnologyElectric discharge heatingNucleationCatalyst nanoparticles

A catalyst material for carbon nanotube synthesis includes a uniform dispersion of host particles on a substrate. The host particles themselves include catalyst nanoparticles that are effective to catalyze nanotube syntheses reactions and provide nucleation sites. Methods for preparing catalyst materials include co-sputtering a catalytic species and a host species to form a precursor thin film on a substrate, followed by an oxidation reaction of the precursor thin film in air. The precursor thin film can be patterned on the substrate to limit the locations of the catalyst material to well-defined areas. Methods for nanotube synthesis employ CVD in conjunction with the catalyst materials of the invention. During the synthesis, the catalyst nanoparticles catalyze carbon nanotubes to grown from a carbon-containing gas.

Owner:MOLECULAR NANOSYST

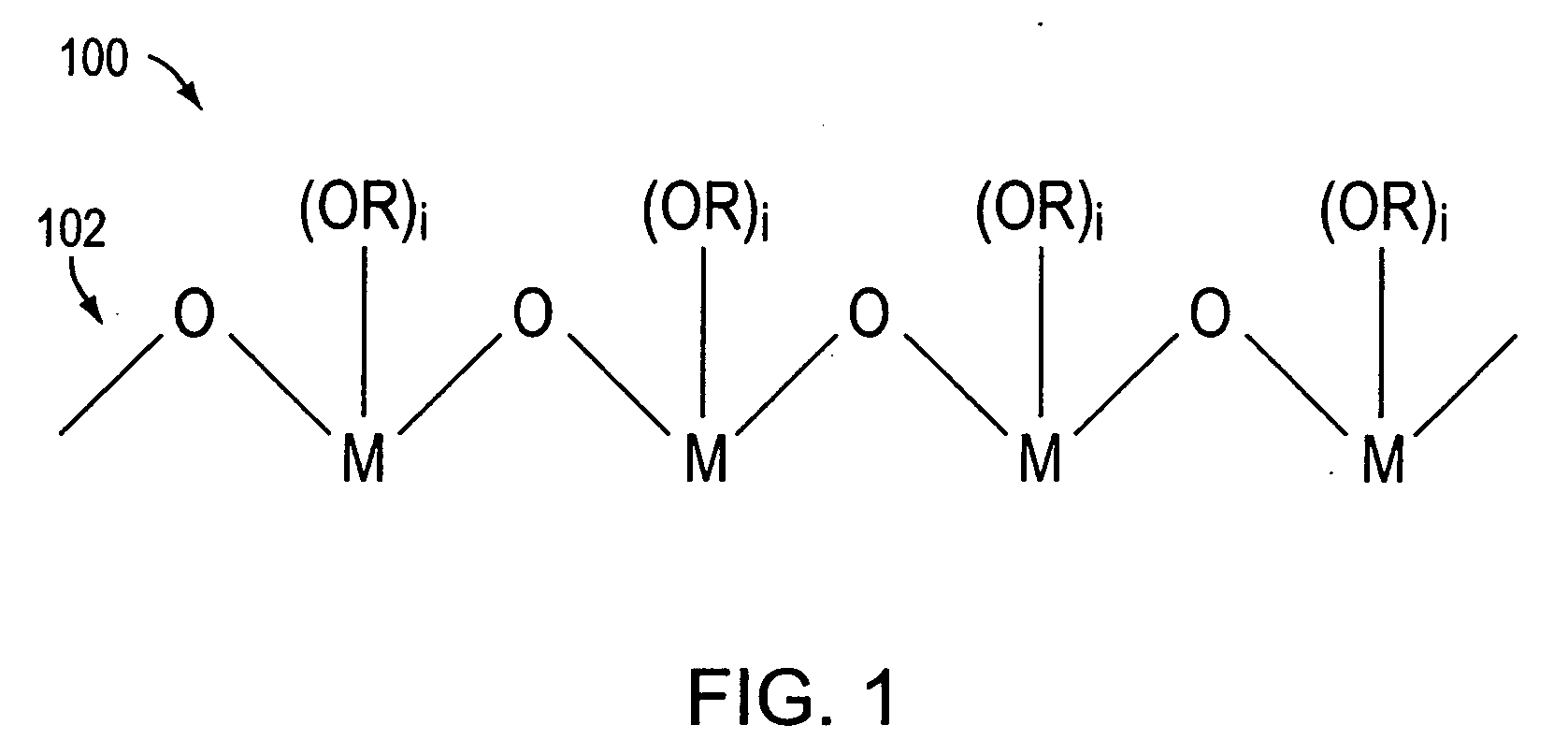

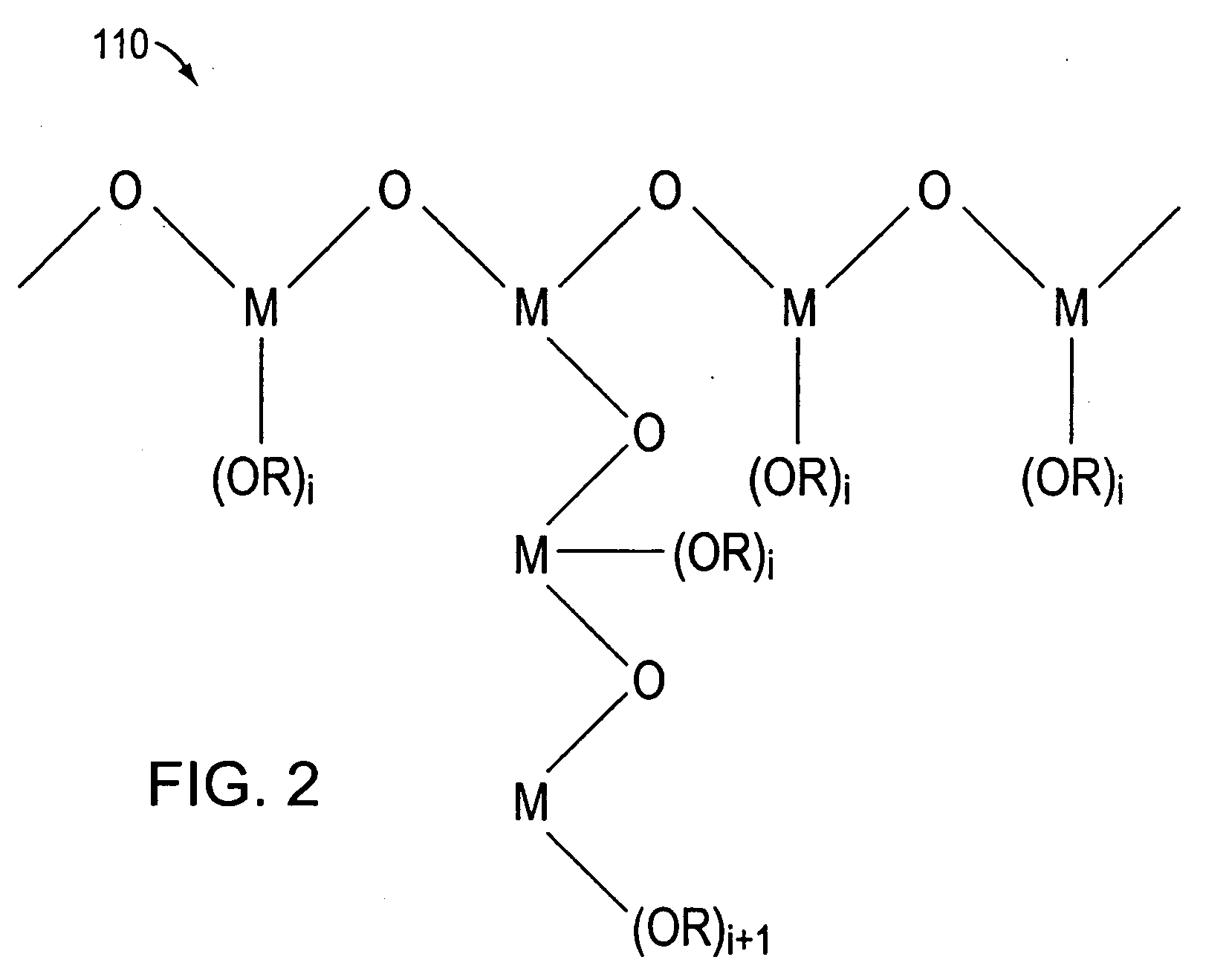

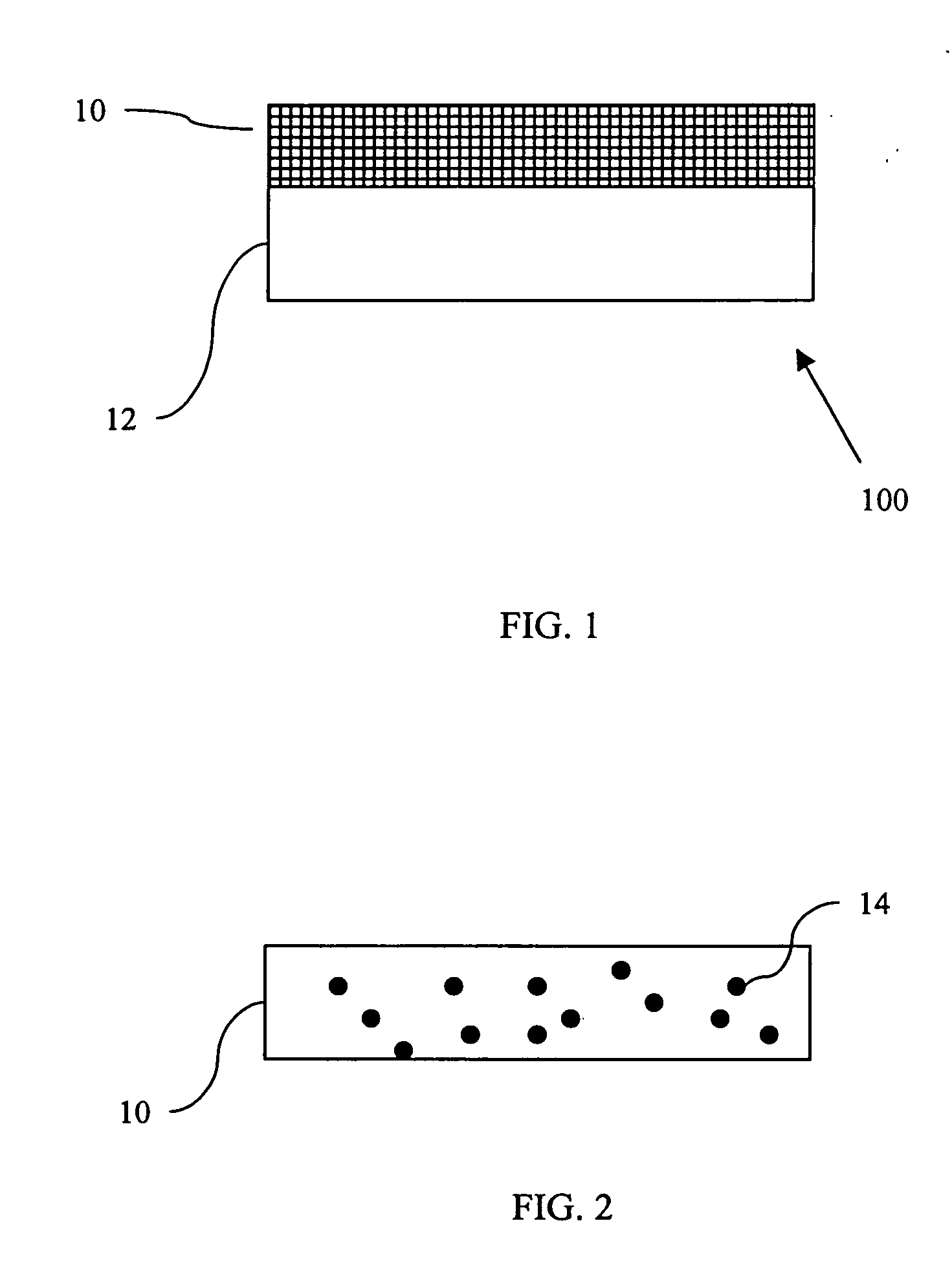

Low temperature interconnection of nanoparticles

A polymeric linking agent enables the manufacture of photovoltaic cells on flexible substrates, including, for example, polymeric substrates. Photovoltaic cells may be fabricated by a relatively simple continuous manufacturing process, for example, a roll-to-roll process, instead of a batch process.

Owner:MERCK PATENT GMBH

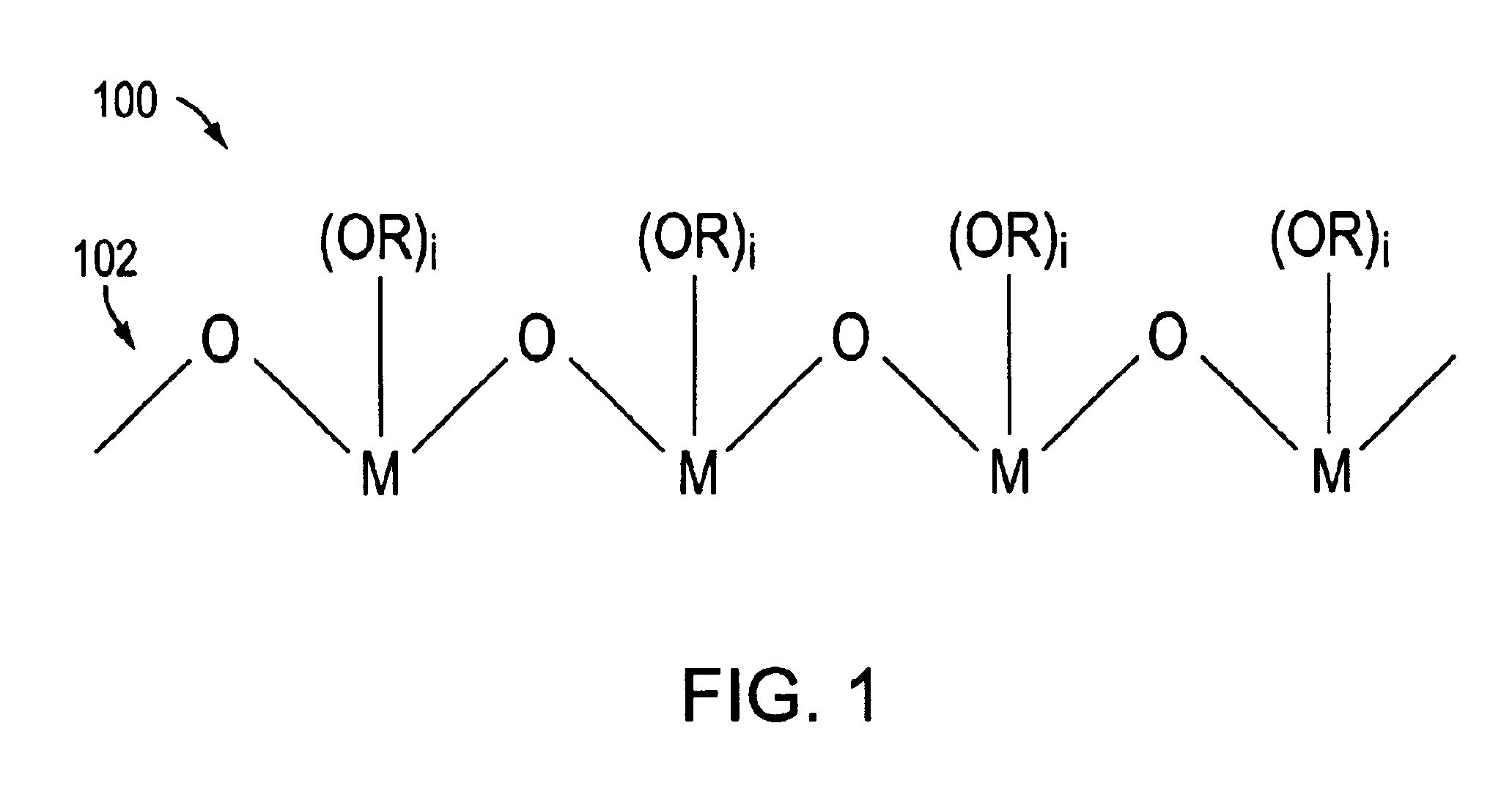

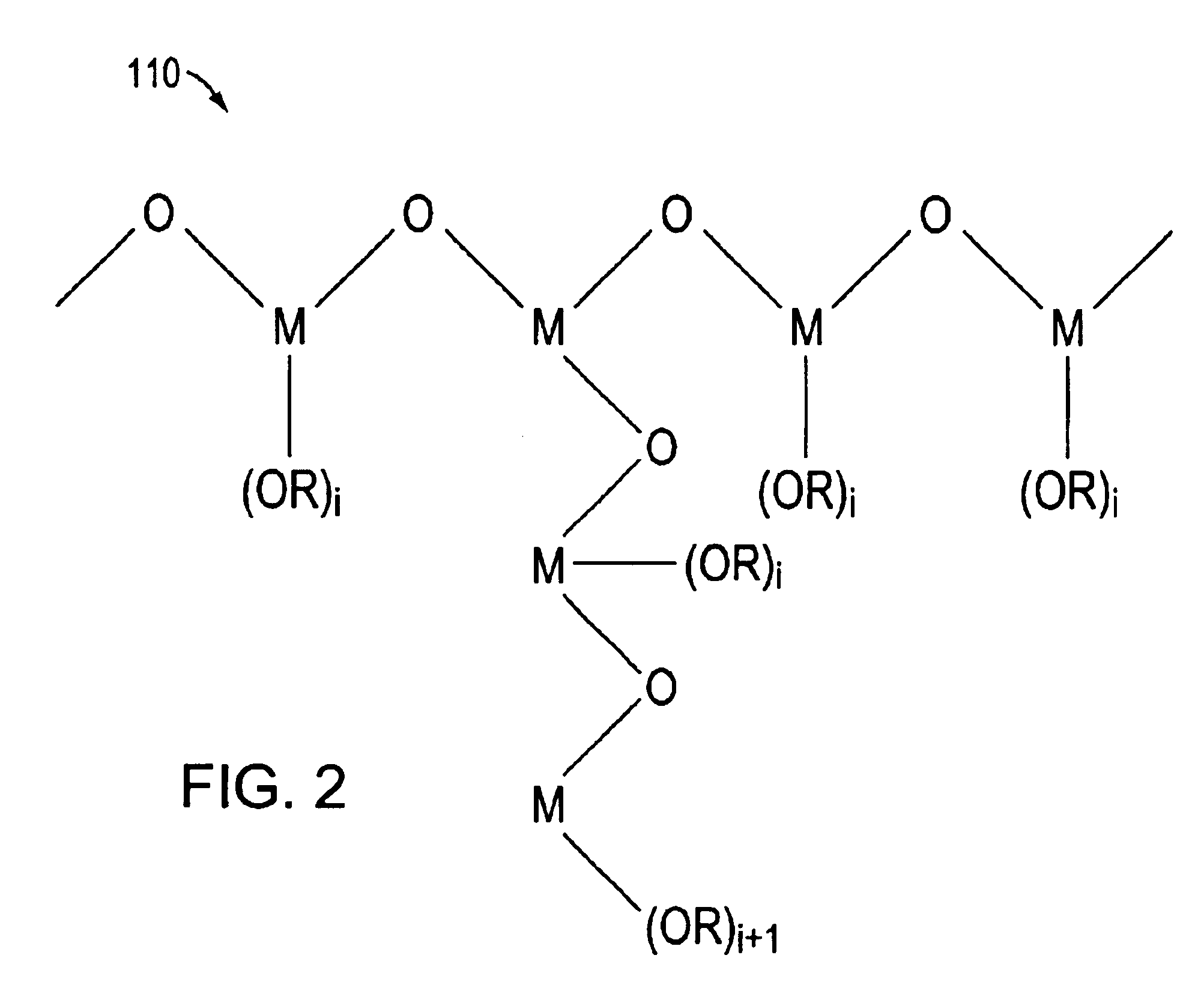

Low temperature interconnection of nanoparticles

InactiveUS20050011550A1From normal temperature solutionsLight-sensitive devicesNanoparticleEngineering

A polymeric linking agent enables the manufacture of photovoltaic cells on flexible substrates, including, for example, polymeric substrates. Photovoltaic cells may be fabricated by a relatively simple continuous manufacturing process, for example, a roll-to-roll process, instead of a batch process.

Owner:MERCK PATENT GMBH

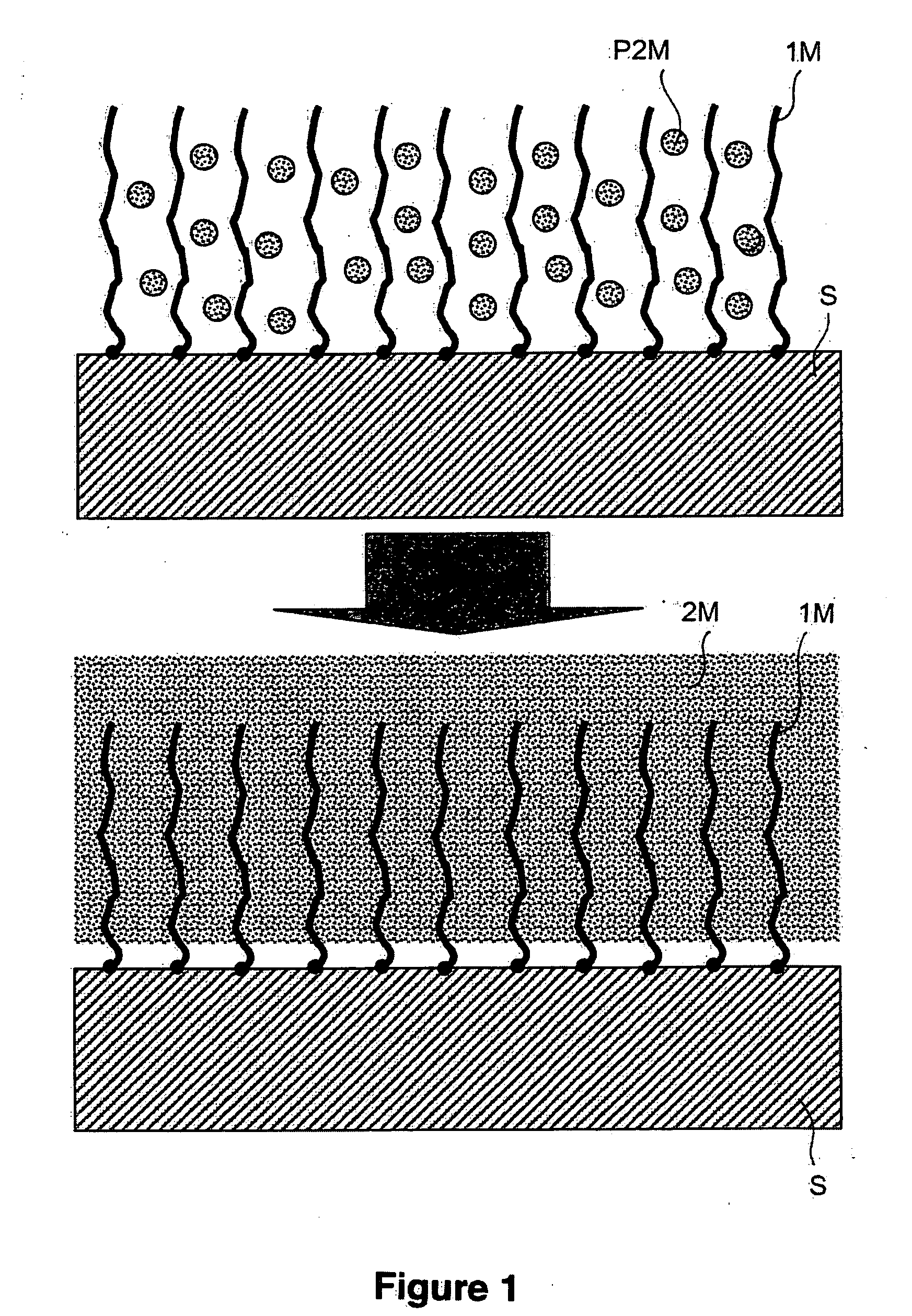

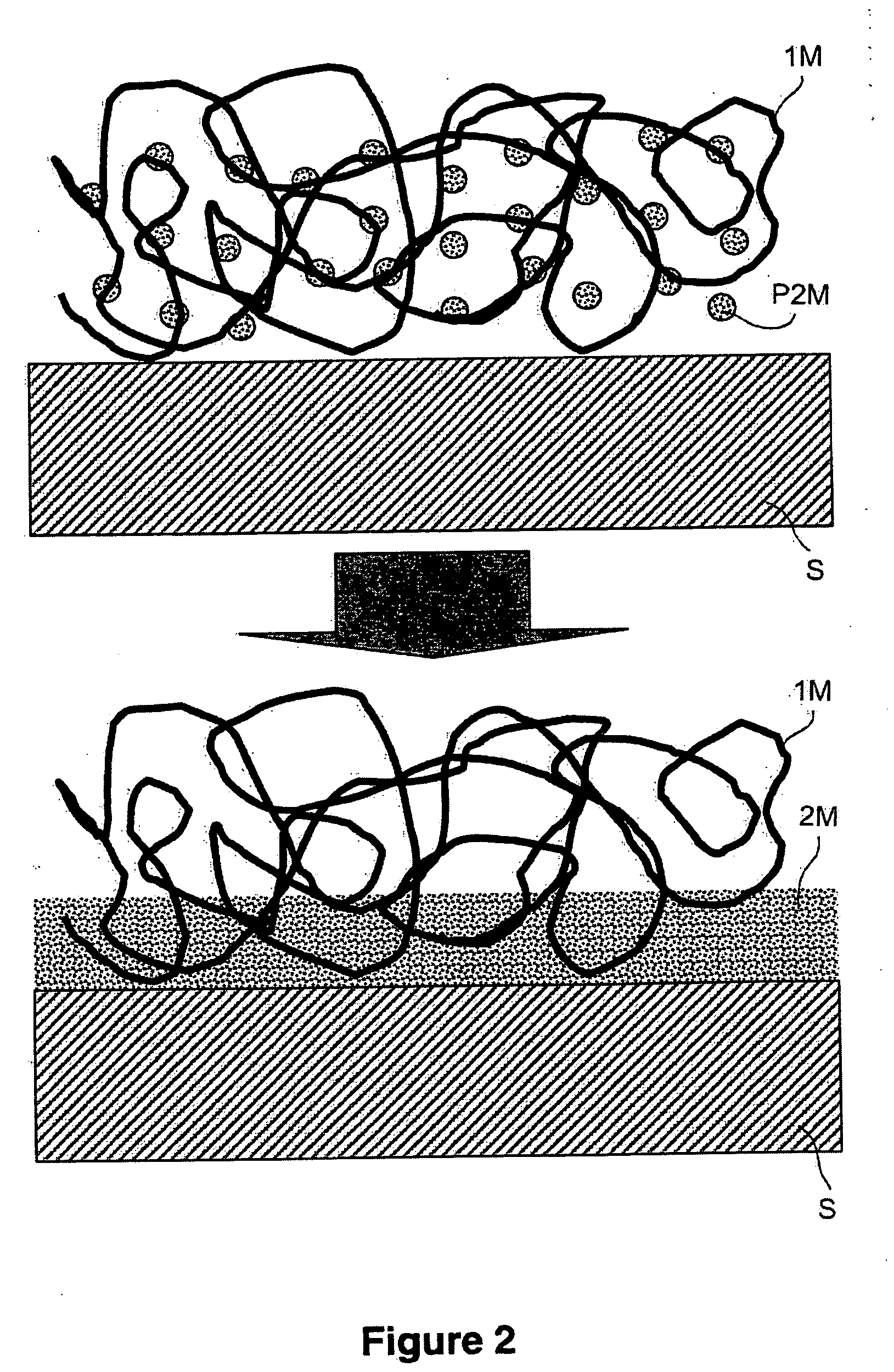

Surface-coating method

ActiveUS20060141156A1Improve adhesionShorten the timePhotography auxillary processesElectrolysis componentsMaterials scienceSurface coating

The invention relates to the deposition or attachment of materials to surfaces. It relates to a process for coating a surface with a first material and a second material, comprising the following steps: placing the first material on the said surface, inserting into the first material placed on the said surface precursor molecules of the second material, converting the said precursor molecules of the second material inserted into the first material into the said second material such that this second material becomes formed on the said surface to be coated and within the said first material placed on the said surface. The object of the process of the invention is to allow the deposition of materials of any type onto surfaces of any type.

Owner:COMMISSARIAT A LENERGIE ATOMIQUE ET AUX ENERGIES ALTERNATIVES

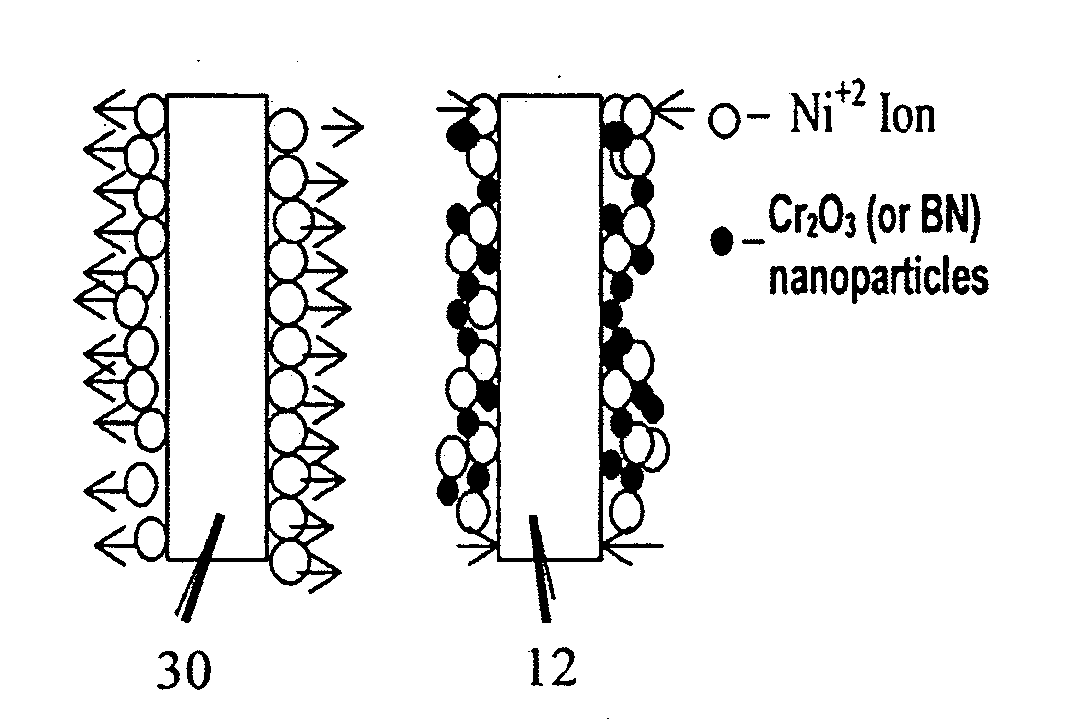

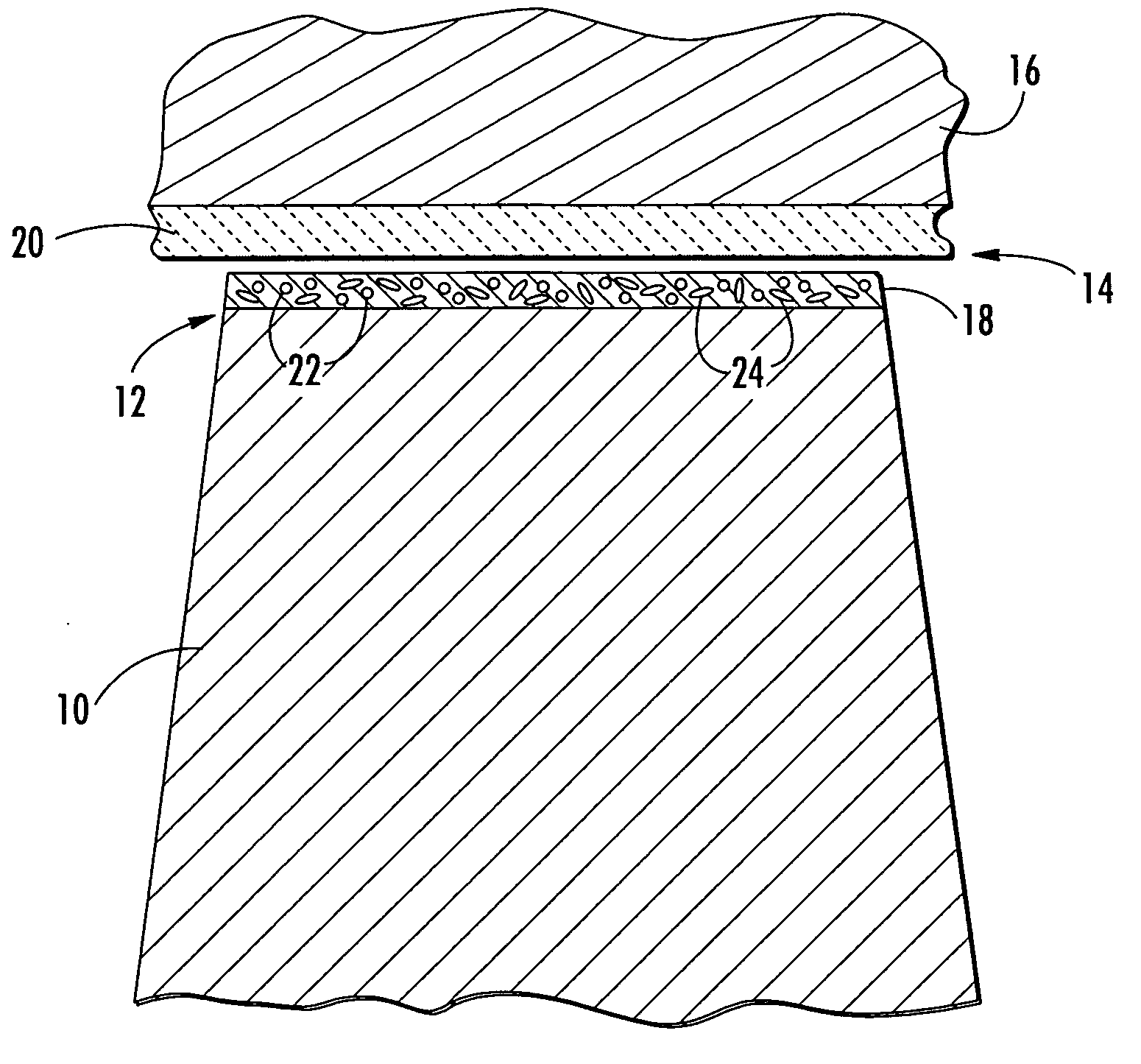

Process equipment wear surfaces of extended resistance and methods for their manufacture

A method for producing process equipment having a wear surface having extended resistance to one or more of abrasion, erosion, or corrosion, associated with fillers or solids processed by said process equipment includes applying to said process equipment wear surface a metal matrix coating filled with superabrasive particles. Diamond and cubic boron nitride superabrasive particles can fill the metal matrix, which can be a nickel coating.

Owner:DIAMOND INNOVATIONS INC

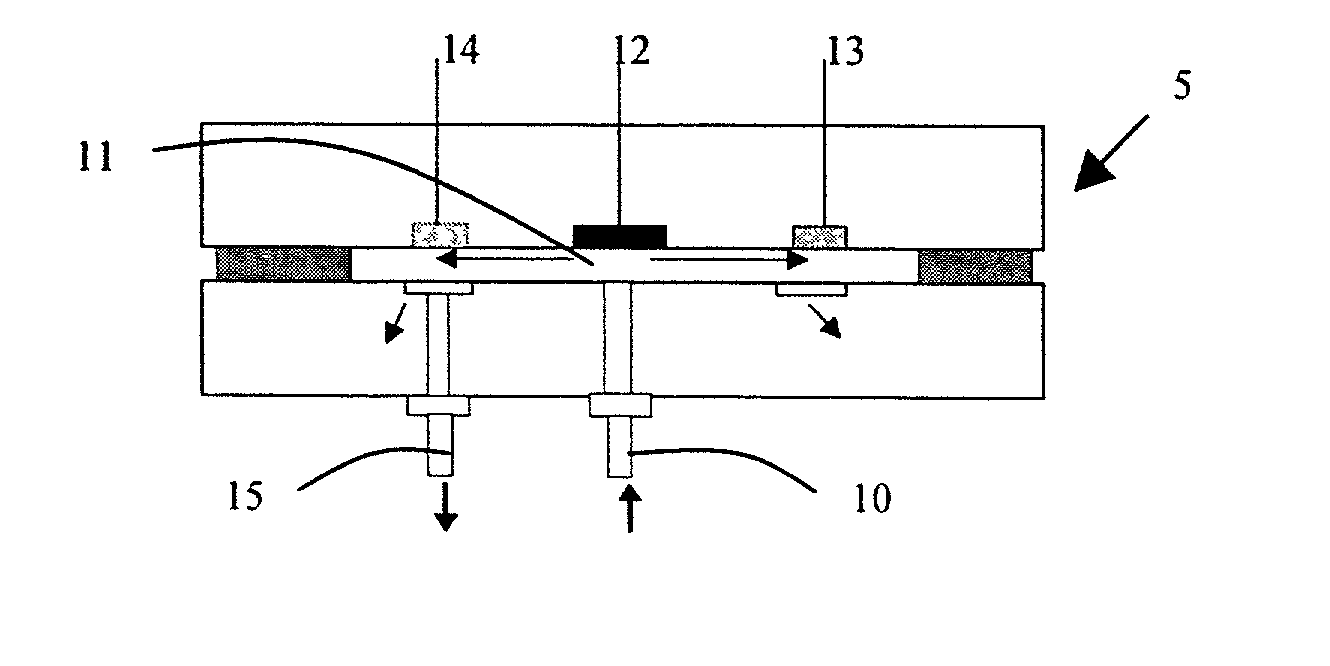

Electrosynthesis of nanofibers and nano-composite films

A method for producing an array of oriented nanofibers that involves forming a solution that includes at least one electroactive species. An electrode substrate is brought into contact with the solution. A current density is applied to the electrode substrate that includes at least a first step of applying a first substantially constant current density for a first time period and a second step of applying a second substantially constant current density for a second time period. The first and second time periods are of sufficient duration to electrically deposit on the electrode substrate an array of oriented nanofibers produced from the electroactive species. Also disclosed are films that include arrays or networks of oriented nanofibers and a method for amperometrically detecting or measuring at least one analyte in a sample.

Owner:BATTELLE MEMORIAL INST

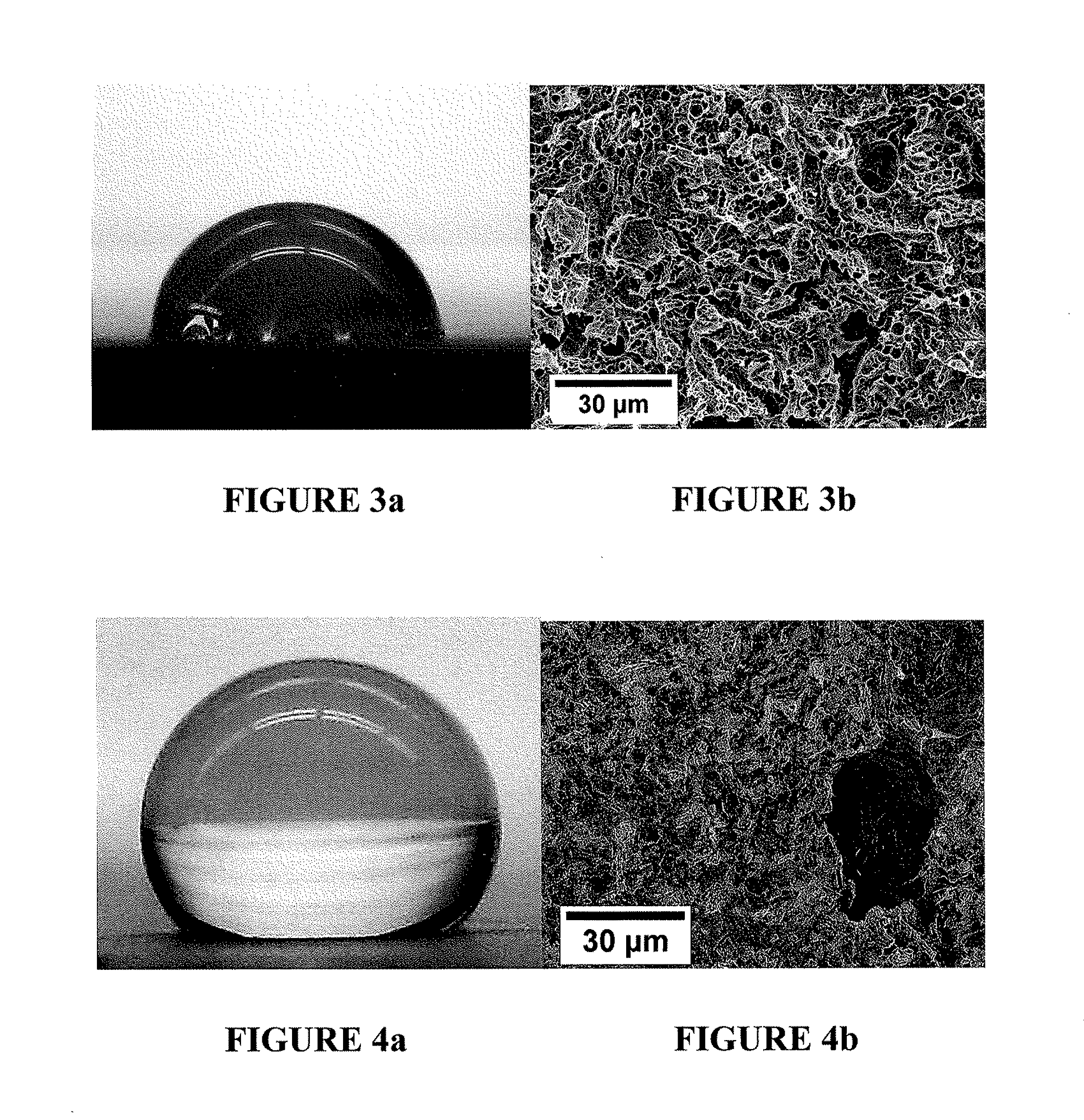

Metallic articles with hydrophobic surfaces

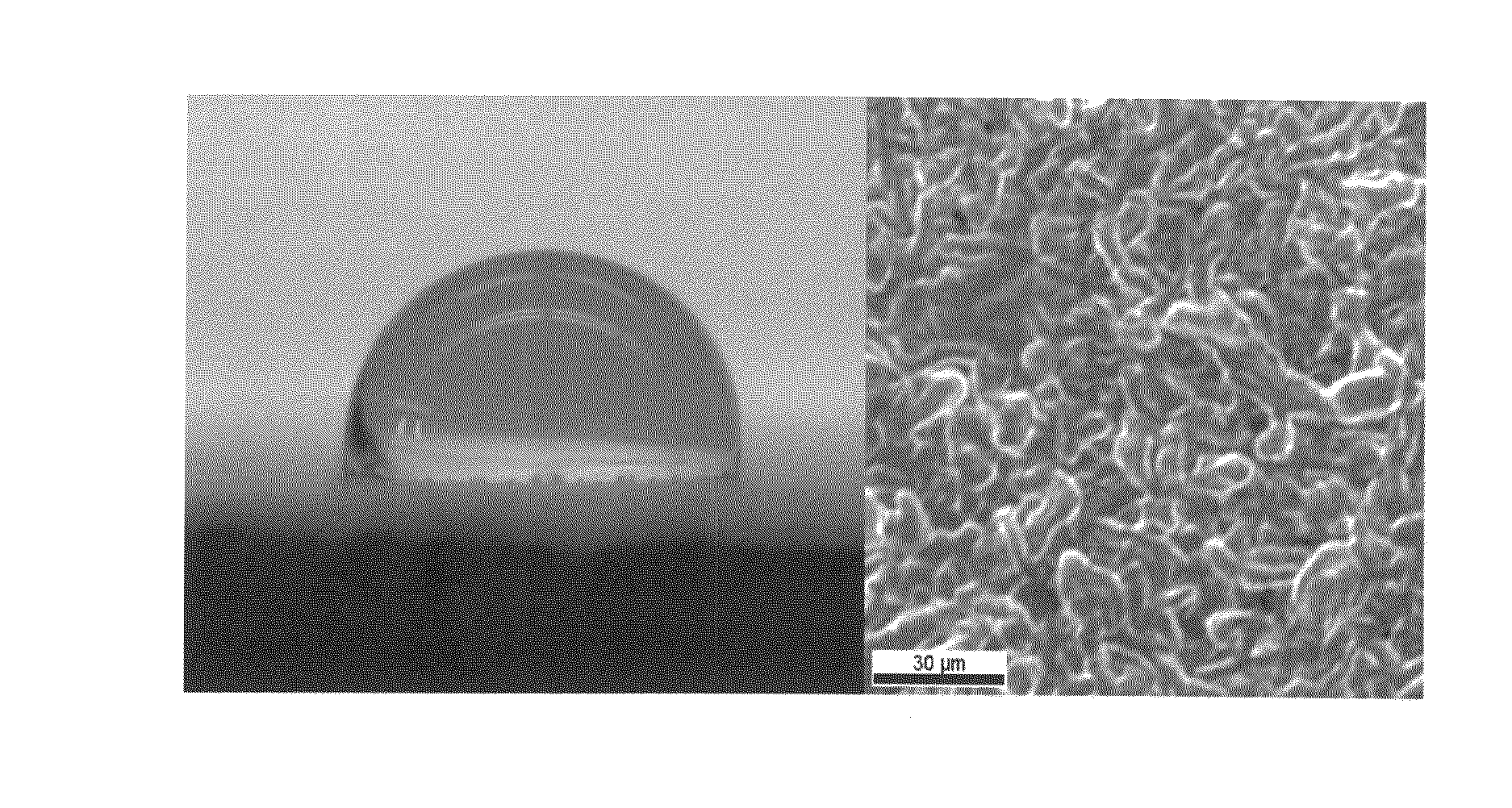

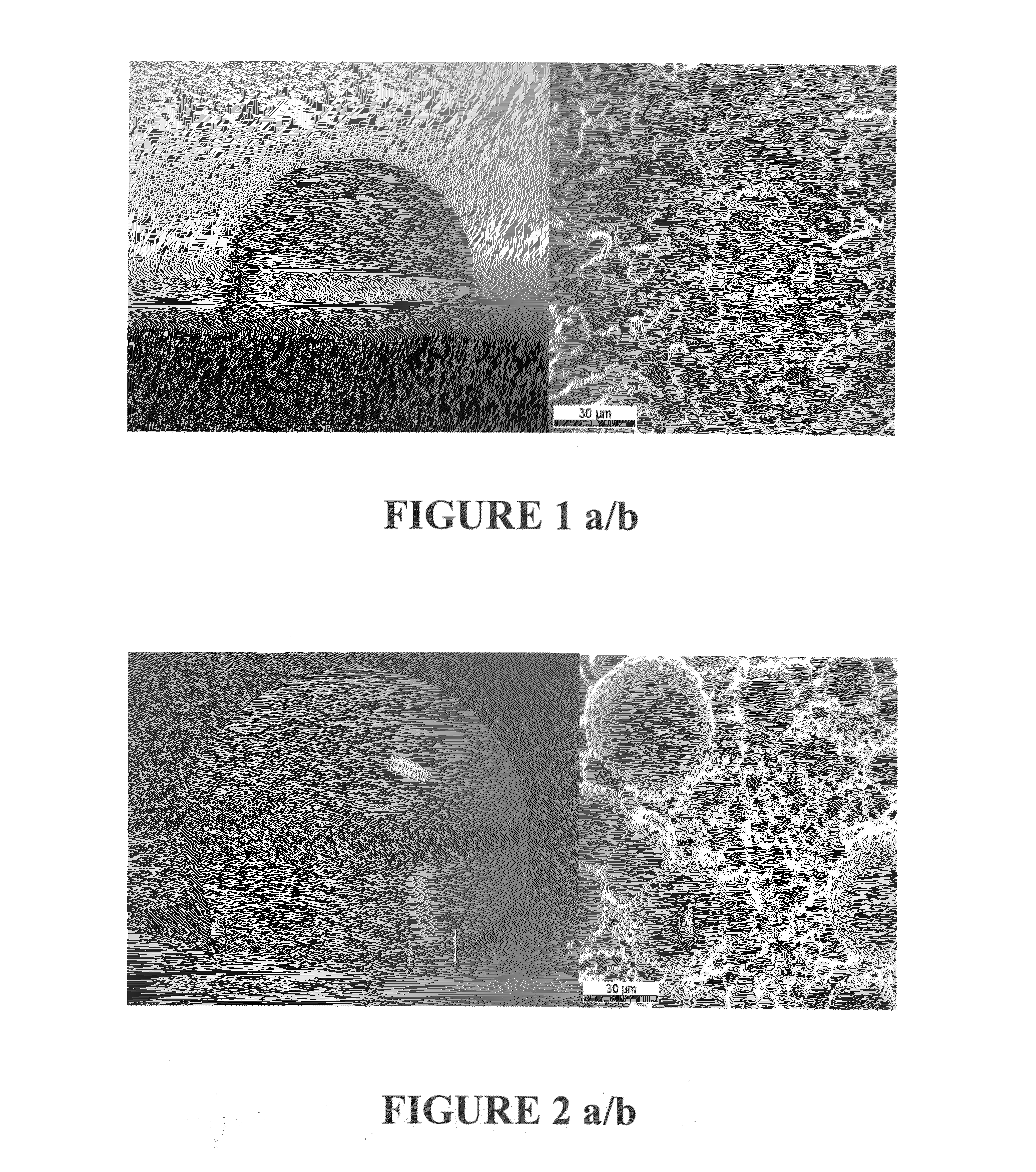

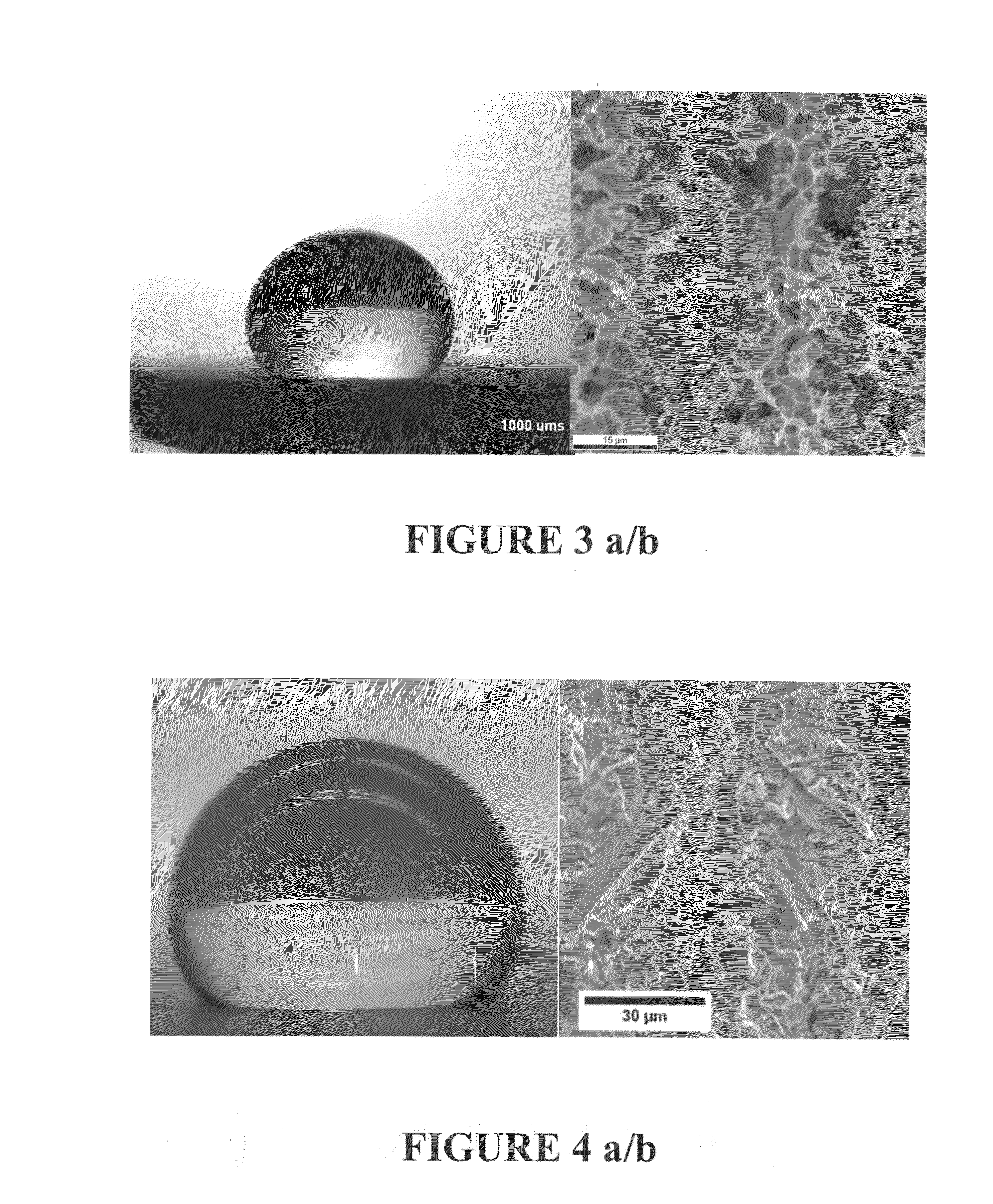

ActiveUS20110287223A1Lower contact angleLarge scaleElectrolysis componentsPretreated surfacesMetal coatingMetallic materials

Articles containing fine-grained and / or amorphous metallic coatings / layers on at least part of their exposed surfaces are imprinted with surface structures to raise the contact angle for water in the imprinted areas at room temperature by equal to or greater than 10°, when compared to the flat and smooth metallic material surface of the same composition.

Owner:INTEGRAN TECH

Metallic structures incorporating bioactive materials and methods for creating the same

ActiveUS20060062820A1Reduce riskStructuredMaterial nanotechnologySurgeryInsertion stentElectroless deposition

Disclosed herein are methods to create medical devices and medical devices including bioactive composite structures. The methods include using template-assisted electro- or electroless deposition or codeposition methods for providing implantable medical devices coated with bioactive composite structures and also include layering deposited or codeposited metal layers with layers of bioactive materials. In one use, the implantable medical devices of the present invention include stents with bioactive composite structure coatings.

Owner:CELONOVA BIOSCIENCES INC

Lubricant-hard-ductile nanocomposite coatings and methods of making

InactiveUS20090155479A1Liquid surface applicatorsMolten spray coatingNanocomposite coatingWear resistance

Lubricant-hard-ductile composite coating compositions and methods of making the same are provided. In embodiment, a composite coating composition comprises: a lubricant phase for providing lubrication to a surface; a hard ceramic phase for providing structural integrity and wear resistance to the surface; and a ductile metal phase for providing ductility to the surface.

Owner:INFRAMAT CORPORATION

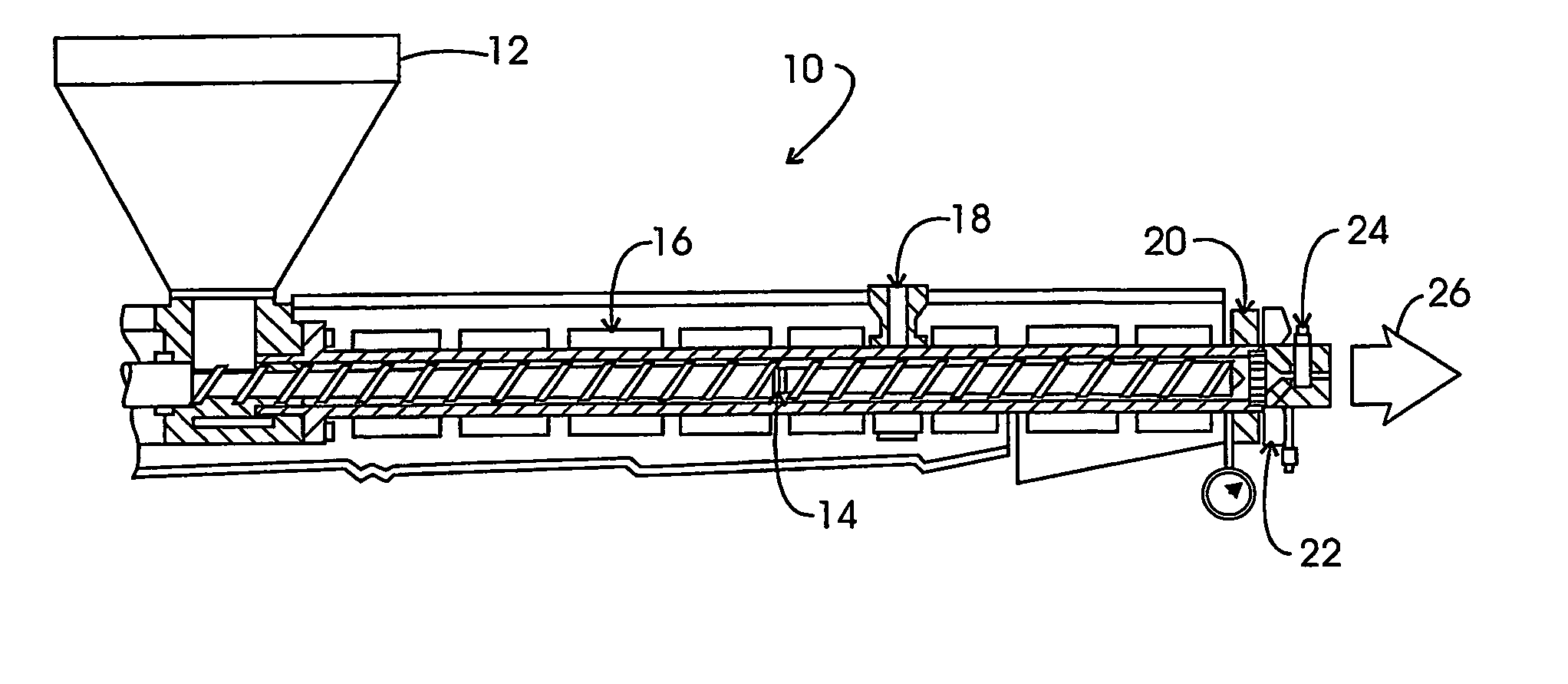

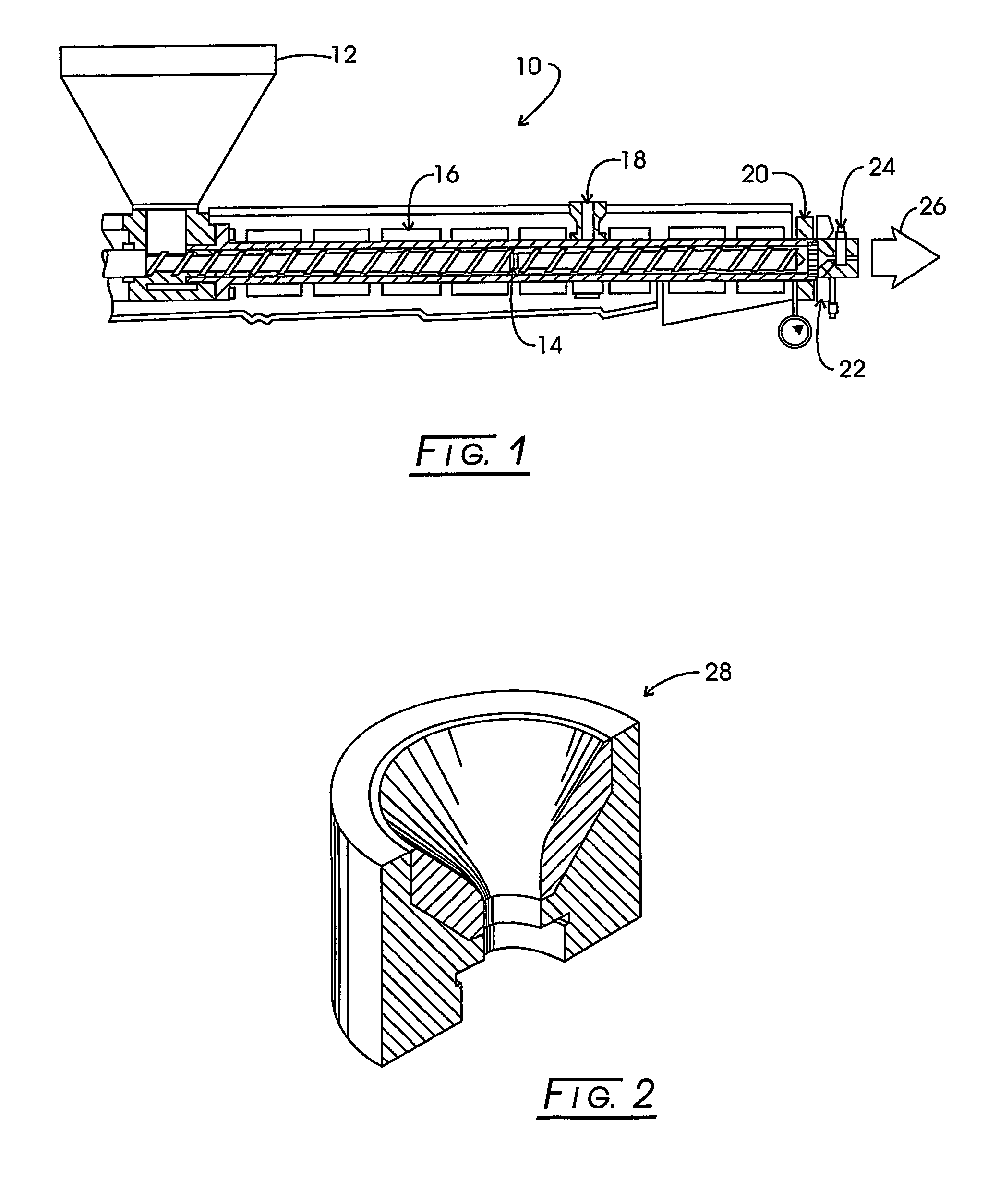

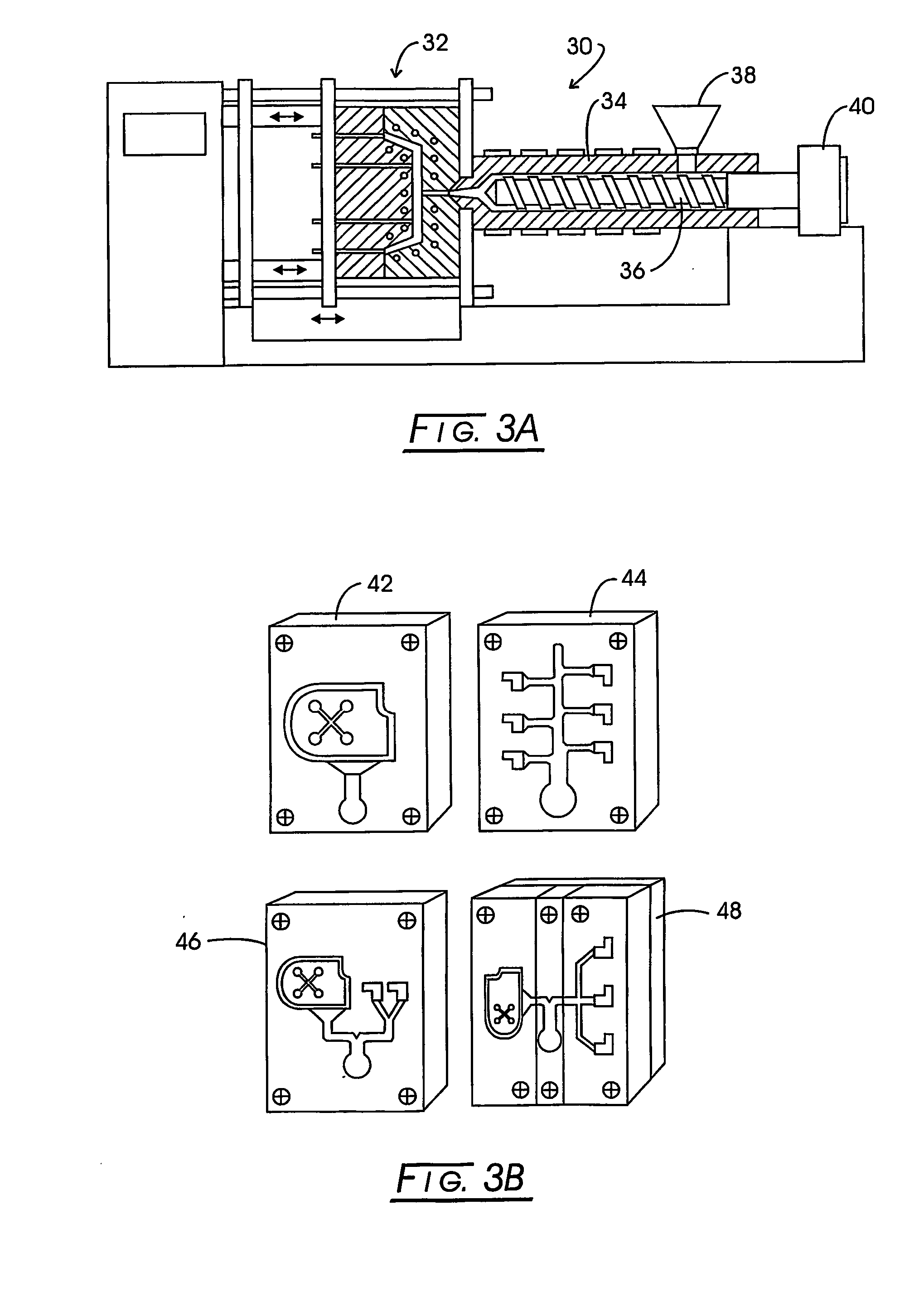

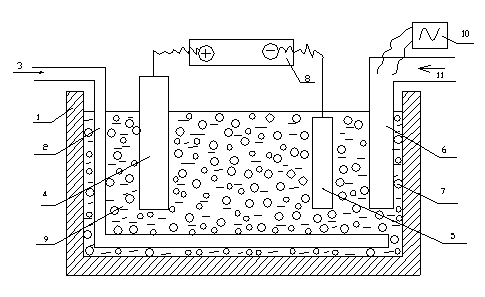

Wearable compound layer material for machine parts and manufacturing method and equipment thereof

The invention relates to a wearable compound layer material for machine parts and a manufacturing method and equipment thereof. The wearable compound layer material is a metal-based wearable compound layer material which is composed of a matrix metal and lots of particles or fibers dispersed and distributed in the matrix metal, thereby having a multi-phase structure. The wearable compound layer material is manufactured by a direct-current electroplating or pulse electroplating method. The direct-current electroplating or pulse electroplating equipment is composed of parts such as an electroplating power source, an electroplating tank, a metal anode or a metal alloy anode, a machine part substrate cathode, a stirring device, a solution circulating device, a heating and temperature control device, an additive supplementing device and the like. The wearable compound layer material for machine parts provided by the invention is obviously superior in performance to good-quality cast iron wearable parts, good-quality cast steel wearable parts and wearable parts for surface heat treatment of common steel and good-quality steel commonly employed in the present product. The wearable compound layer also has high-temperature abrasive resistance and excellent corrosion resistance while having excellent abrasive performance; and the internal stress of the coating is very low.

Owner:肖云捷

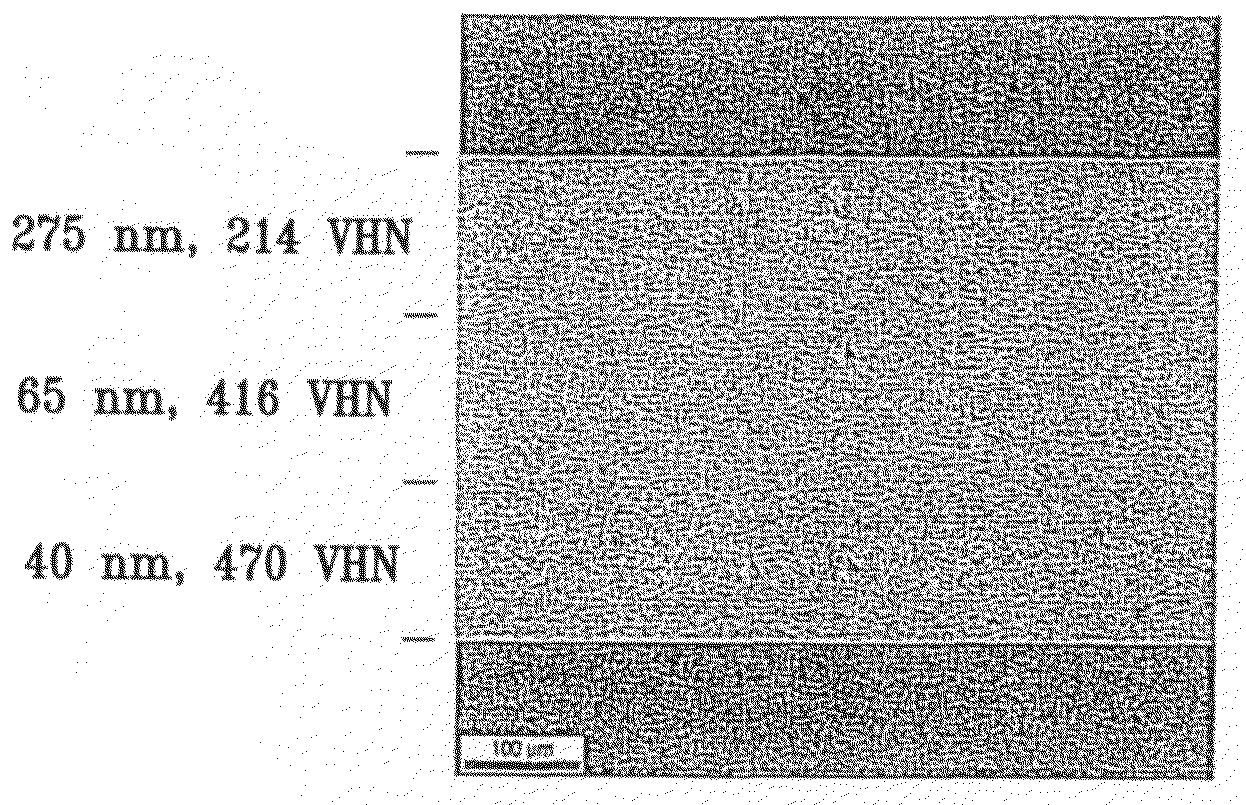

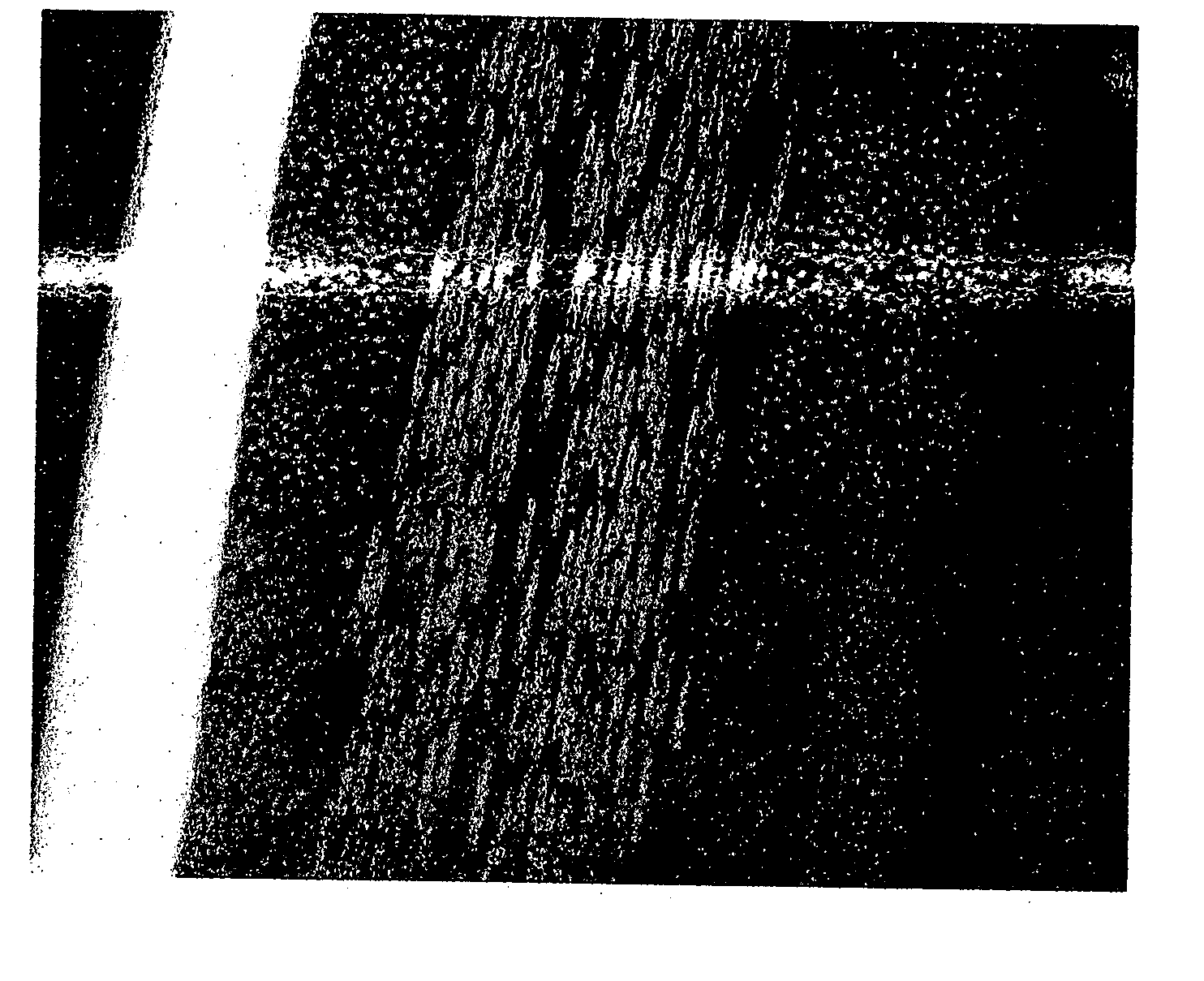

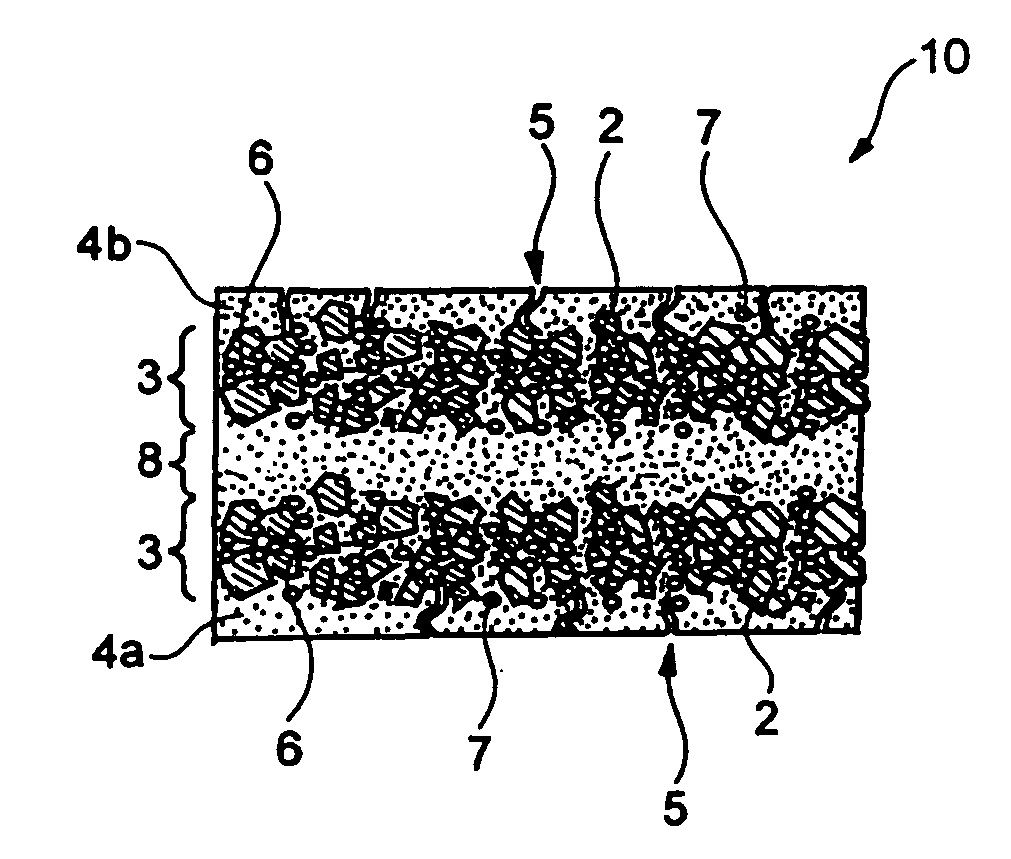

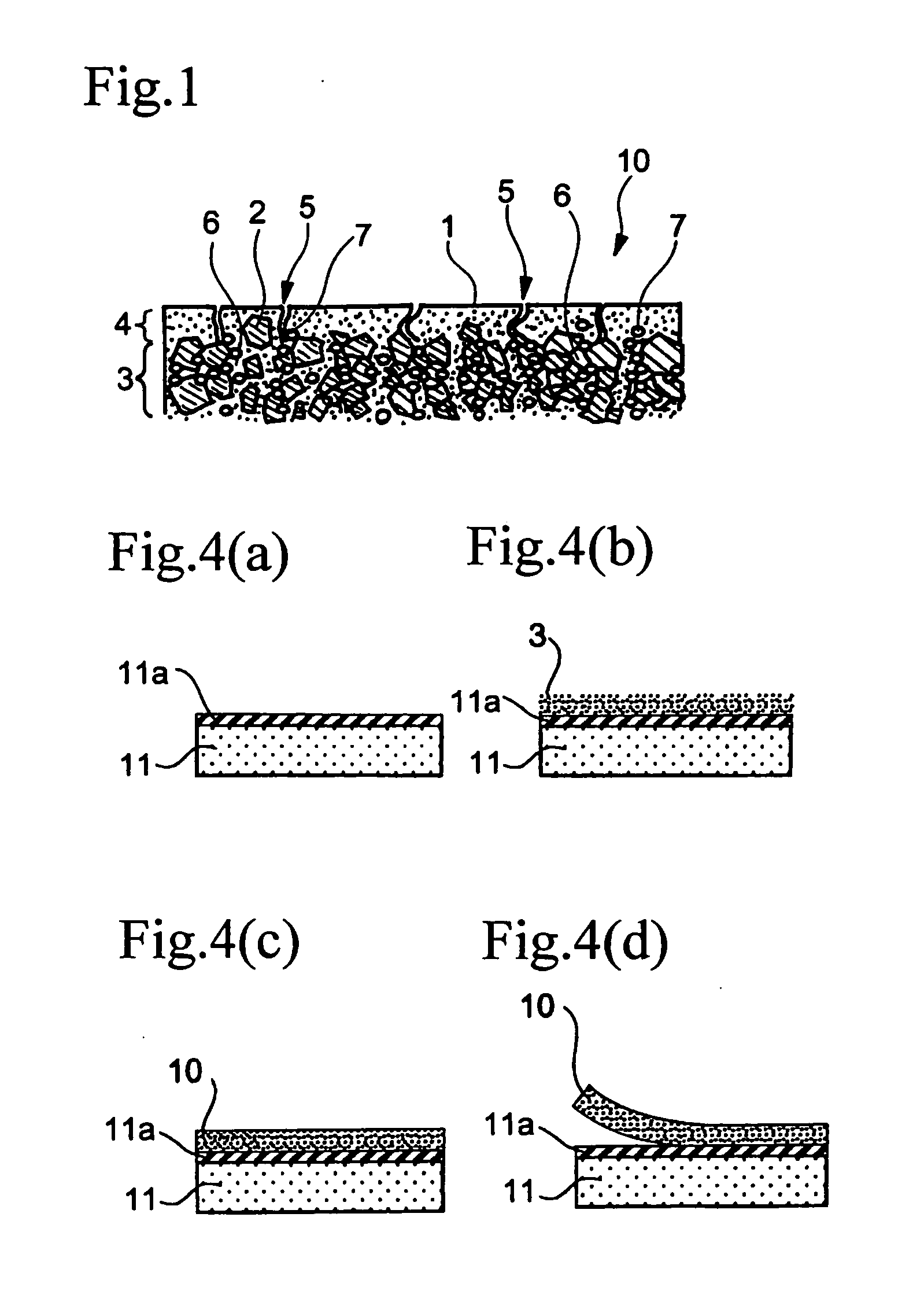

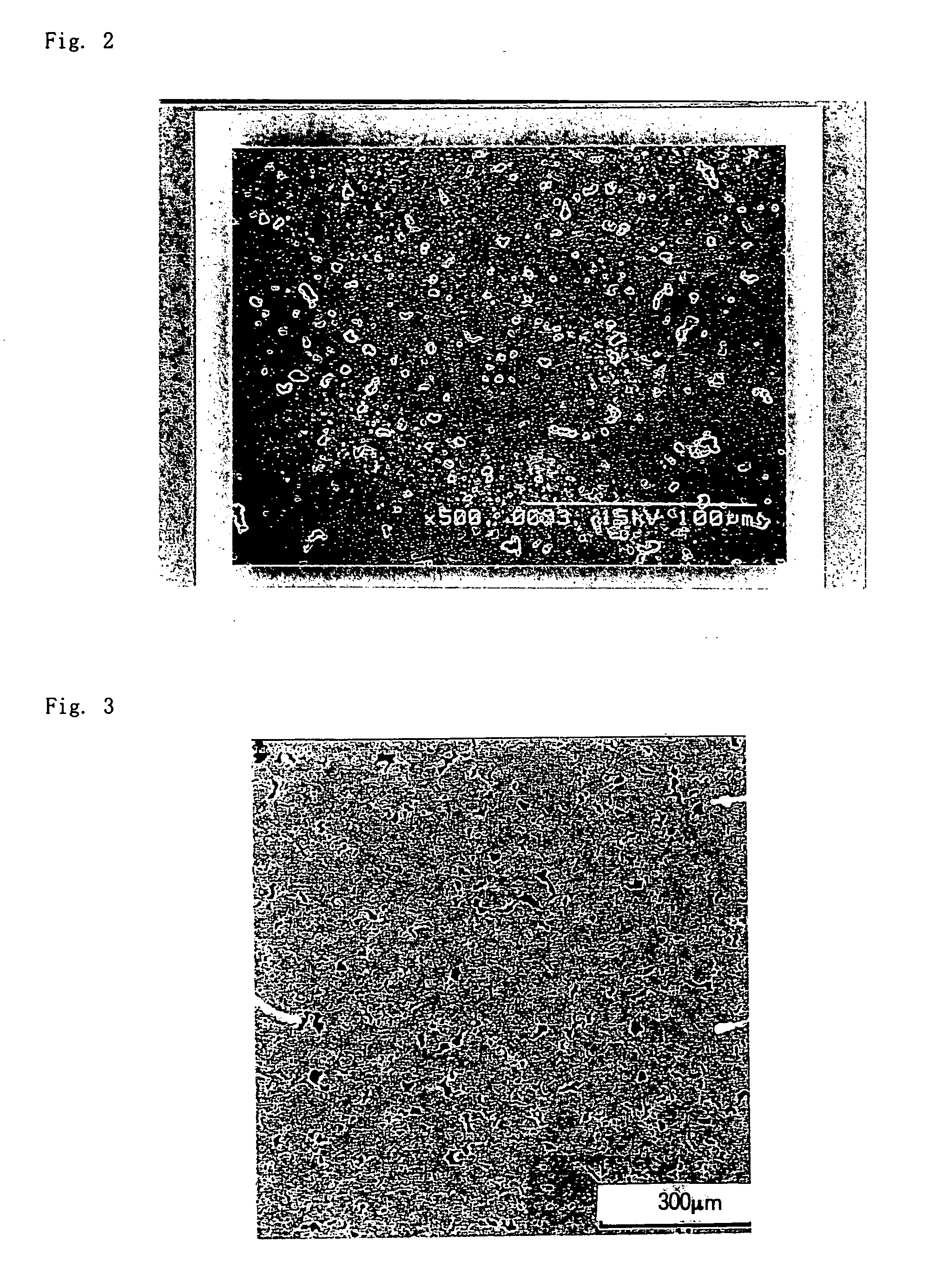

Metallic Structures with Variable Properties

InactiveUS20110256356A1Increased durabilityIncrease floor spaceVacuum evaporation coatingSputtering coatingParticulatesMetallic materials

Variable property deposit, at least partially of fine-grained metallic material, optionally containing solid particulates dispersed therein, is disclosed. The electrodeposition conditions in a single plating cell are suitably adjusted to once or repeatedly vary at least one property in the deposit direction. In one embodiment denoted multidimension grading, property variation along the length and / or width of the deposit is also provided. Variable property metallic material deposits containing at least in part a fine-grained microstructure and variable property in the deposit direction and optionally multidimensionally, provide superior overall mechanical properties compared to monolithic fine-grained (average grain size: >20 micron) or entirely amorphous metallic material deposits.

Owner:INTEGRAN TECH

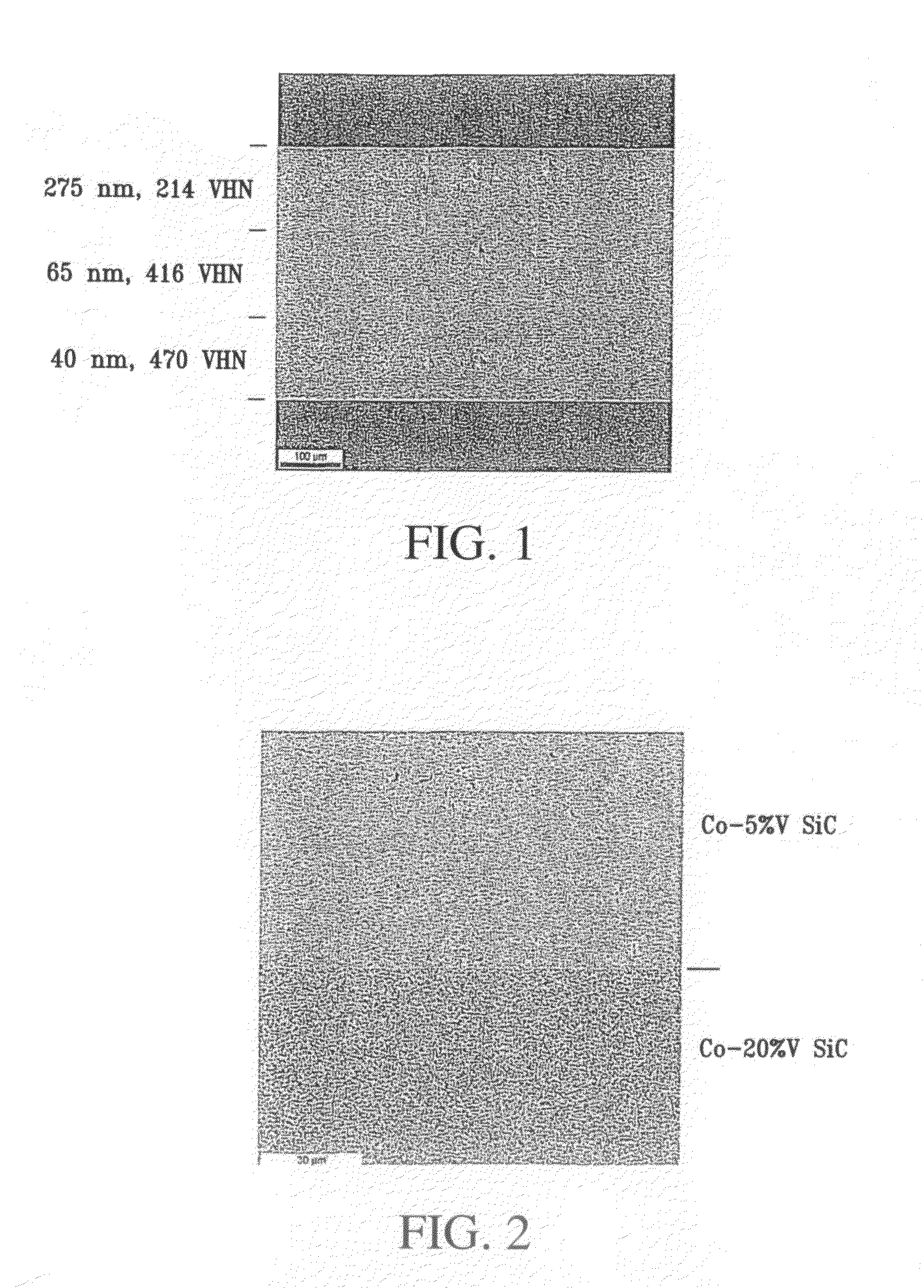

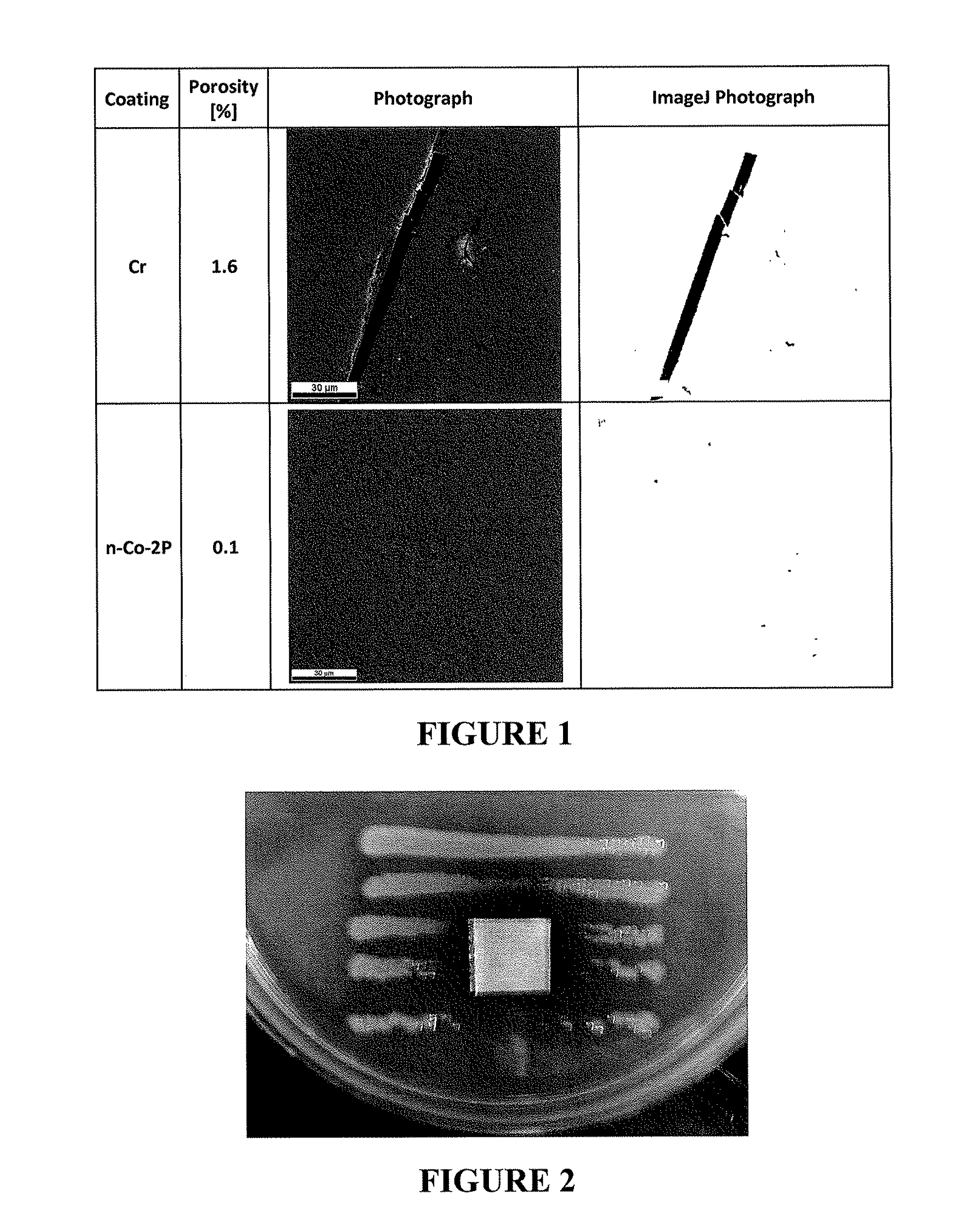

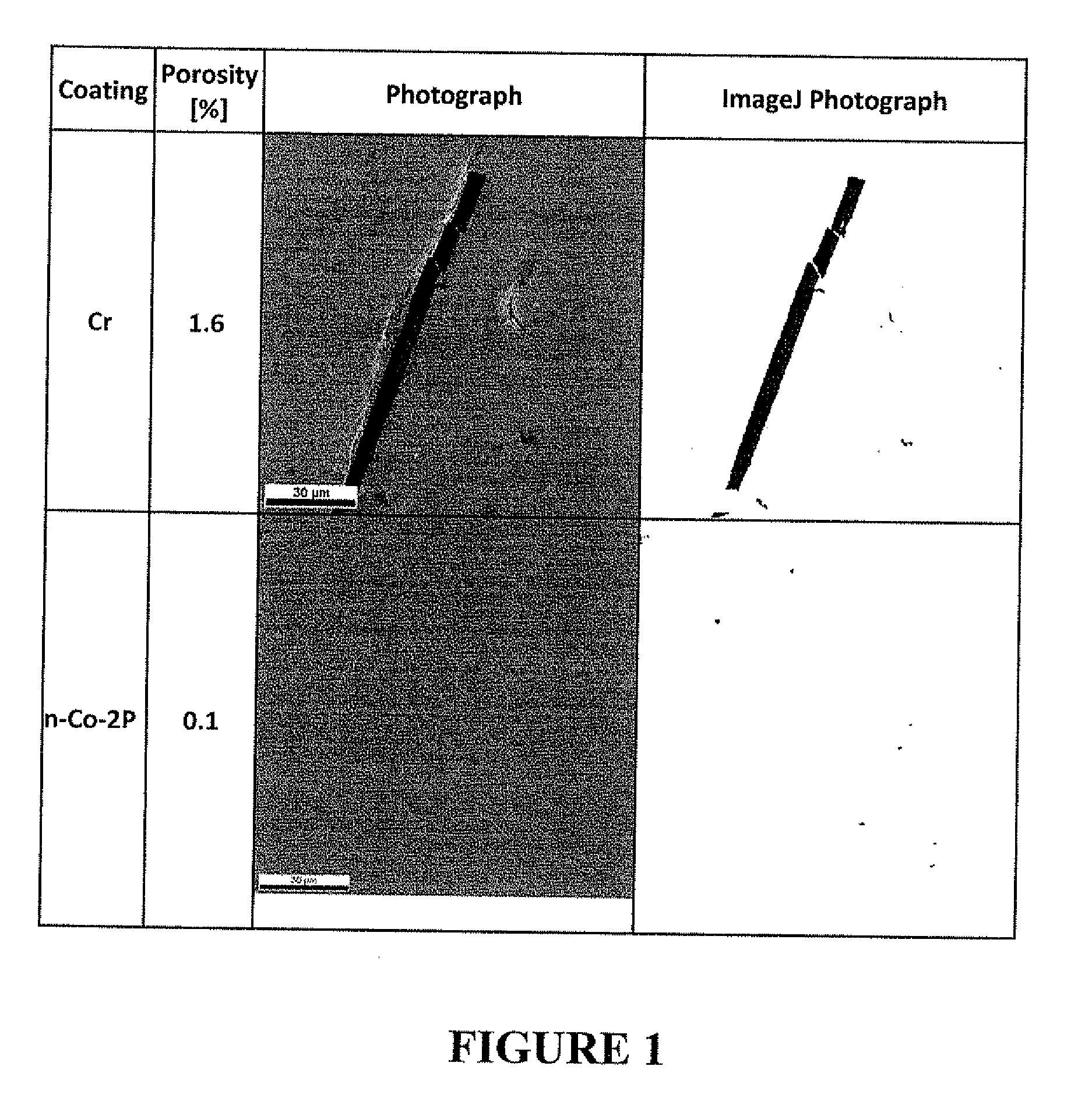

Electrodeposited metallic materials comprising cobalt

ActiveUS20100304179A1Reduce resistanceEliminate security concernsPig casting plantsElectrolytic coatingsMetal coatingMetallic materials

Free standing articles or articles at least partially coated with substantially porosity free, fine-grained and / or amorphous Co-bearing metallic materials optionally containing solid particulates dispersed therein, are disclosed. The electrodeposited metallic layers and / or patches comprising Co provide, enhance or restore strength, wear and / or lubricity of substrates without reducing the fatigue performance compared to either uncoated or equivalent thickness Cr coated substrate. The fine-grained and / or amorphous metallic coatings comprising Co are particularly suited for articles exposed to thermal cycling, fatigue and other stresses and / or in applications requiring anti-microbial and hydrophobic properties.

Owner:INTEGRAN TECH

Electrodeposited metallic-materials comprising cobalt

ActiveUS20100304182A1Reduce resistanceEliminate security concernsEnvelopes/bags making machineryRecord information storageParticulatesPorosity

Free standing articles or articles at least partially coated with substantially porosity free, fine-grained and / or amorphous Co-bearing metallic materials optionally containing solid particulates dispersed therein, are disclosed. The electrodeposited metallic layers and / or patches comprising Co provide, enhance or restore strength, wear and / or lubricity of substrates without reducing the fatigue performance compared to either uncoated or equivalent thickness chromium coated substrate. The fine-grained and / or amorphous metallic coatings comprising Co are particularly suited for articles exposed to thermal cycling, fatigue and other stresses and / or in applications requiring anti-microbial properties.

Owner:INTEGRAN TECH

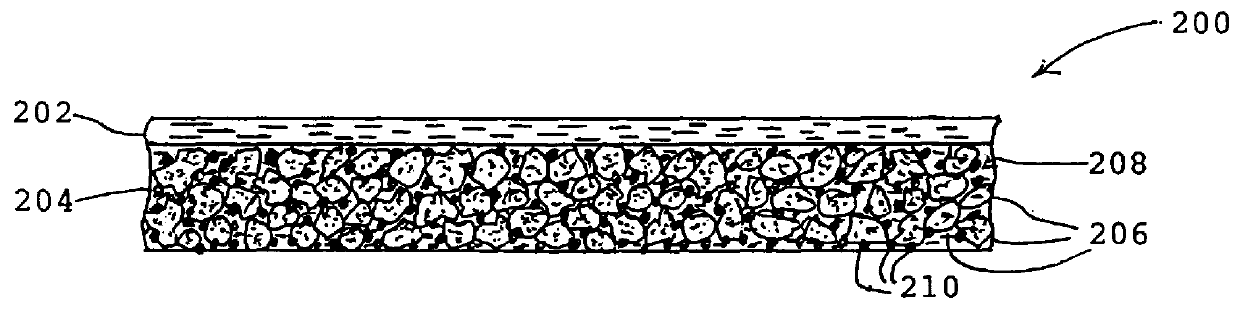

Negative electrode for nonaqueous secondary battery, process of producing the negative electrode, and nonaqueous secondary battery

InactiveUS20050208379A1Relaxation stressImprove electronic conductivityElectrolytic coatingsVacuum evaporation coatingLithium compoundCurrent collector

Disclosed is a negative electrode for a nonaqueous secondary battery comprised of a current collector and an active material structure containing an electro-conductive material having low capability of forming a lithium compound on at least one side of the current collector, the active material structure containing 5 to 80% by weight of active material particles containing a material having high capability of forming a lithium compound. The active material structure preferably has an active material layer containing the active material particles and a surface coating layer formed on the active material layer.

Owner:MITSUI MINING & SMELTING CO LTD

Sports articles formed using nanostructured materials

InactiveUS20060160636A1Increases weight of unitWeight increaseWalking sticksMaterial nanotechnologyMicrochiropteraSports equipment

A sports article includes a portion that includes a nanostructured material. The nanostructured material includes a metal, and the nanostructured material has an average grain size that is in the range of 2 nm to 5,000 nm, a yield strength that is in the range of 200 MPa to 2,750 MPa, and a hardness that is in the range of 100 Vickers to 2,000 Vickers. The sports article can be any of a variety of sports equipment and associated components, such as a golf club, a baseball bat, a softball bat, a lacrosse stick, or a hockey stick.

Owner:INTEGRAN TECH

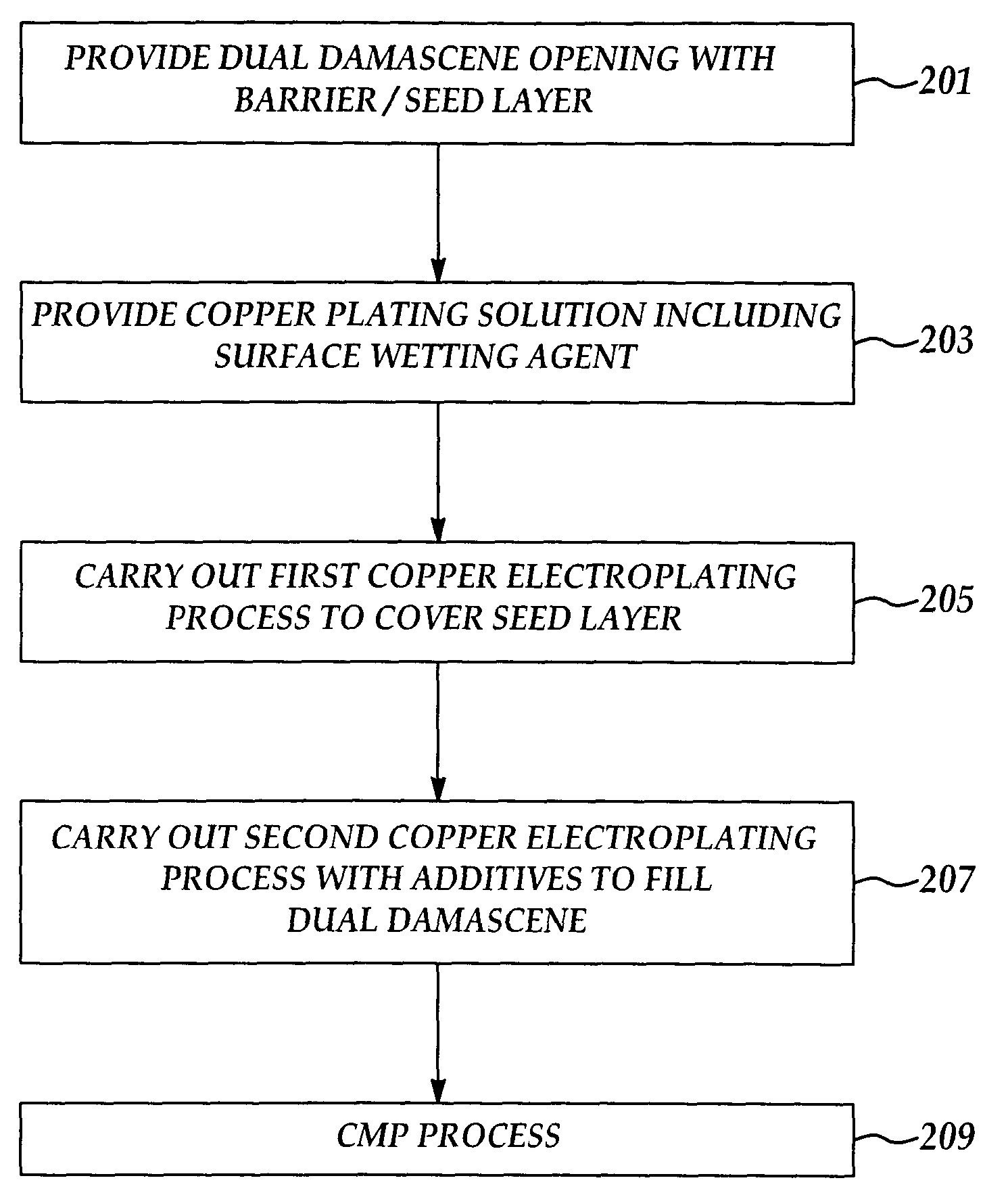

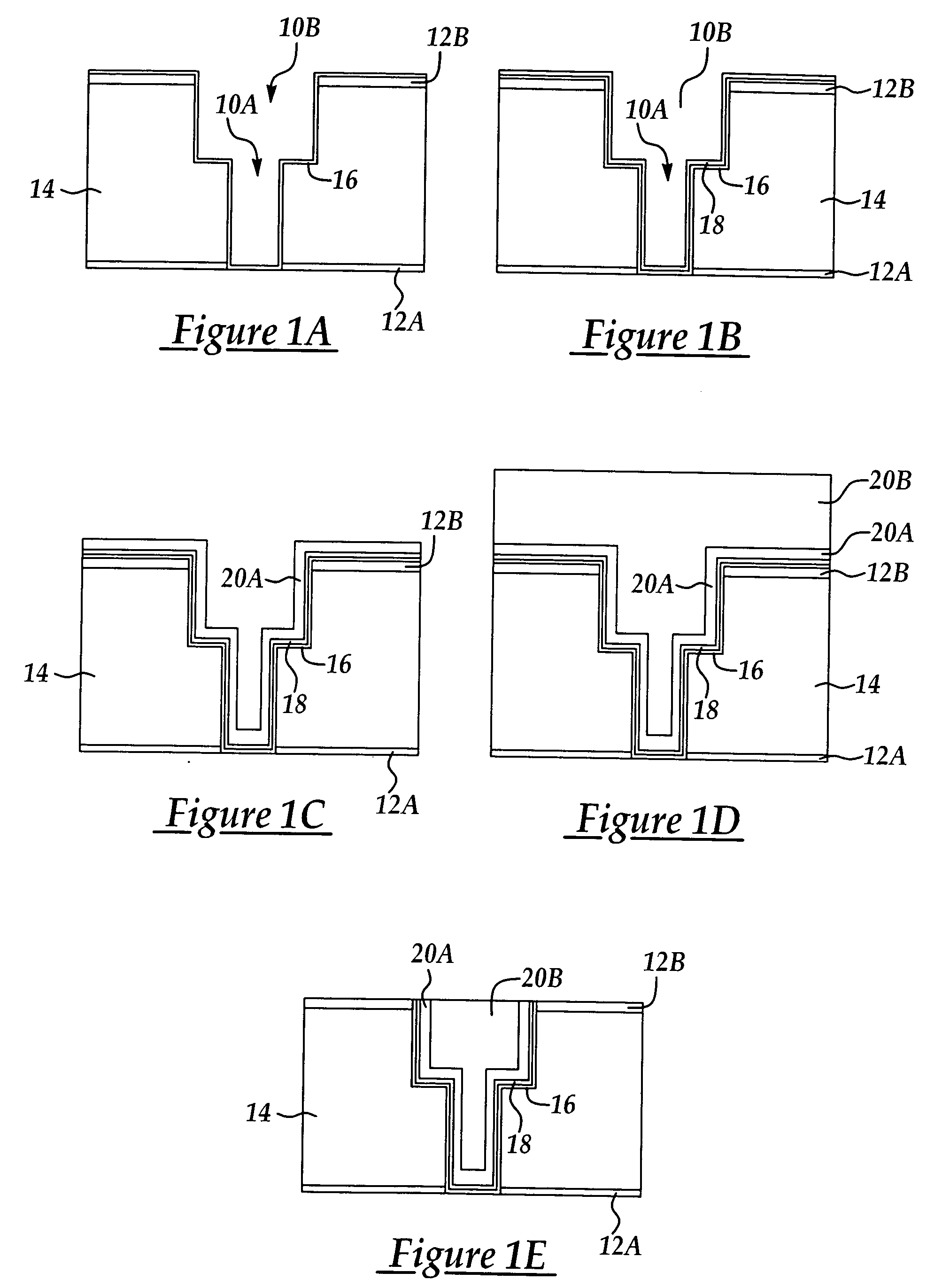

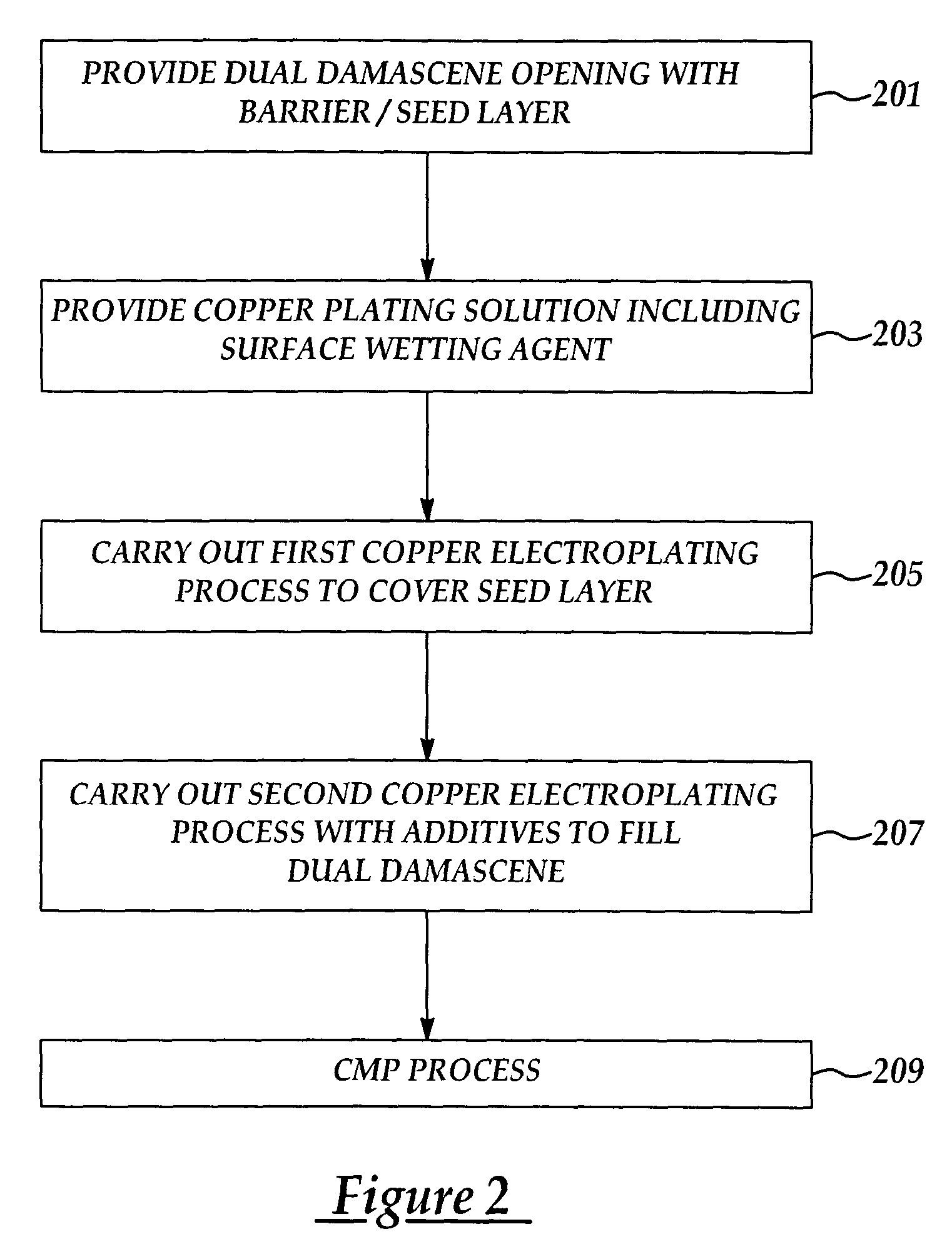

Method to improve copper electrochemical deposition

InactiveUS20050045485A1Improving deposit uniformityReducing or avoiding copper layer pittingElectrolytic coatingsSemiconductor/solid-state device manufacturingDeposition processCopper

A method for reducing or avoiding copper layer pitting in a copper electrochemical deposition process to improve deposition uniformity including providing a substrate for carrying out at least a first copper electroplating process; providing a copper electroplating solution including a deforming (antiforming) agent wherein the antiforming (deforming) agent includes at least one alkylene monomer; and, carrying out at least a first copper electroplating process to deposit at least a first copper layer.

Owner:TAIWAN SEMICON MFG CO LTD

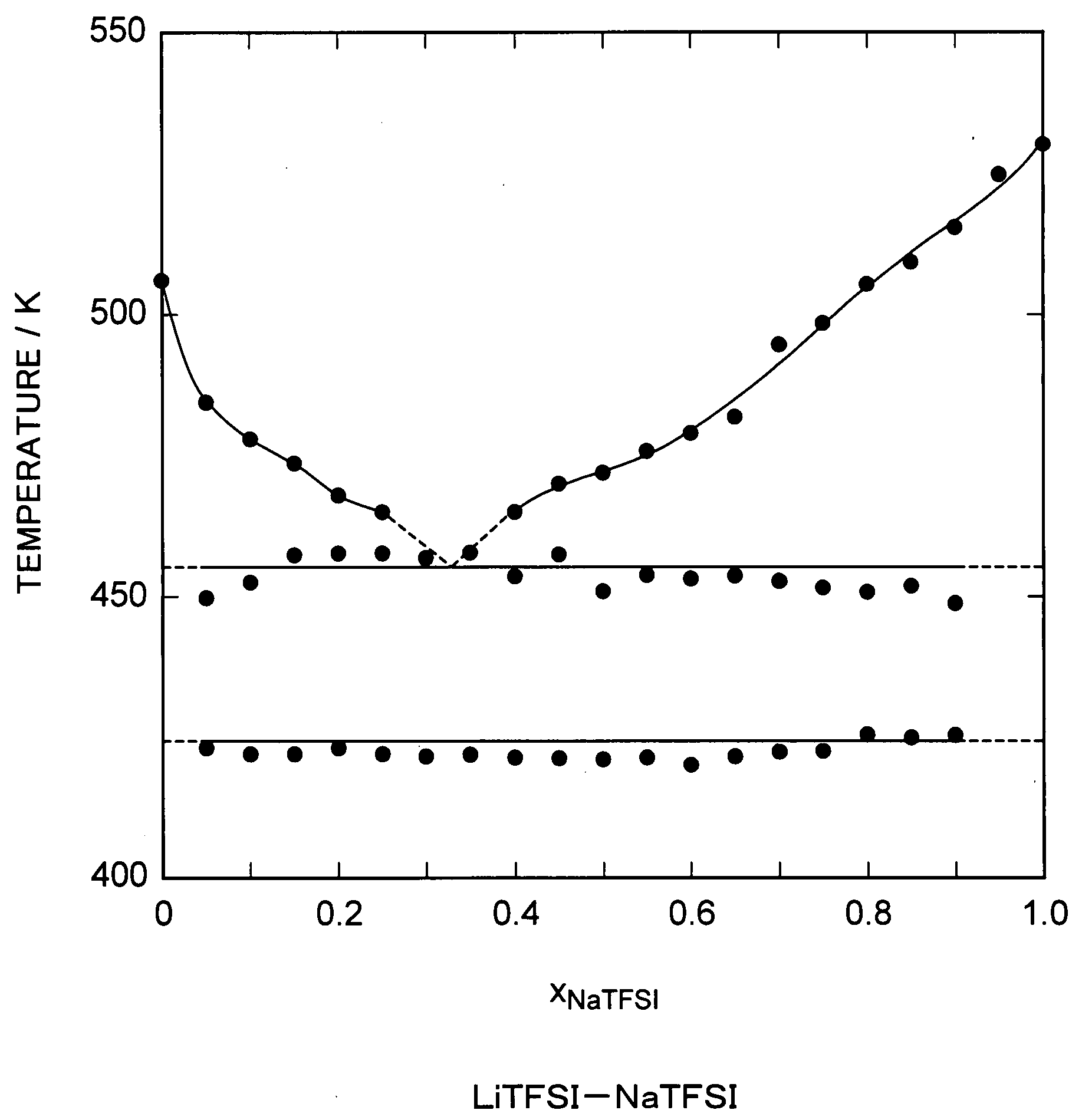

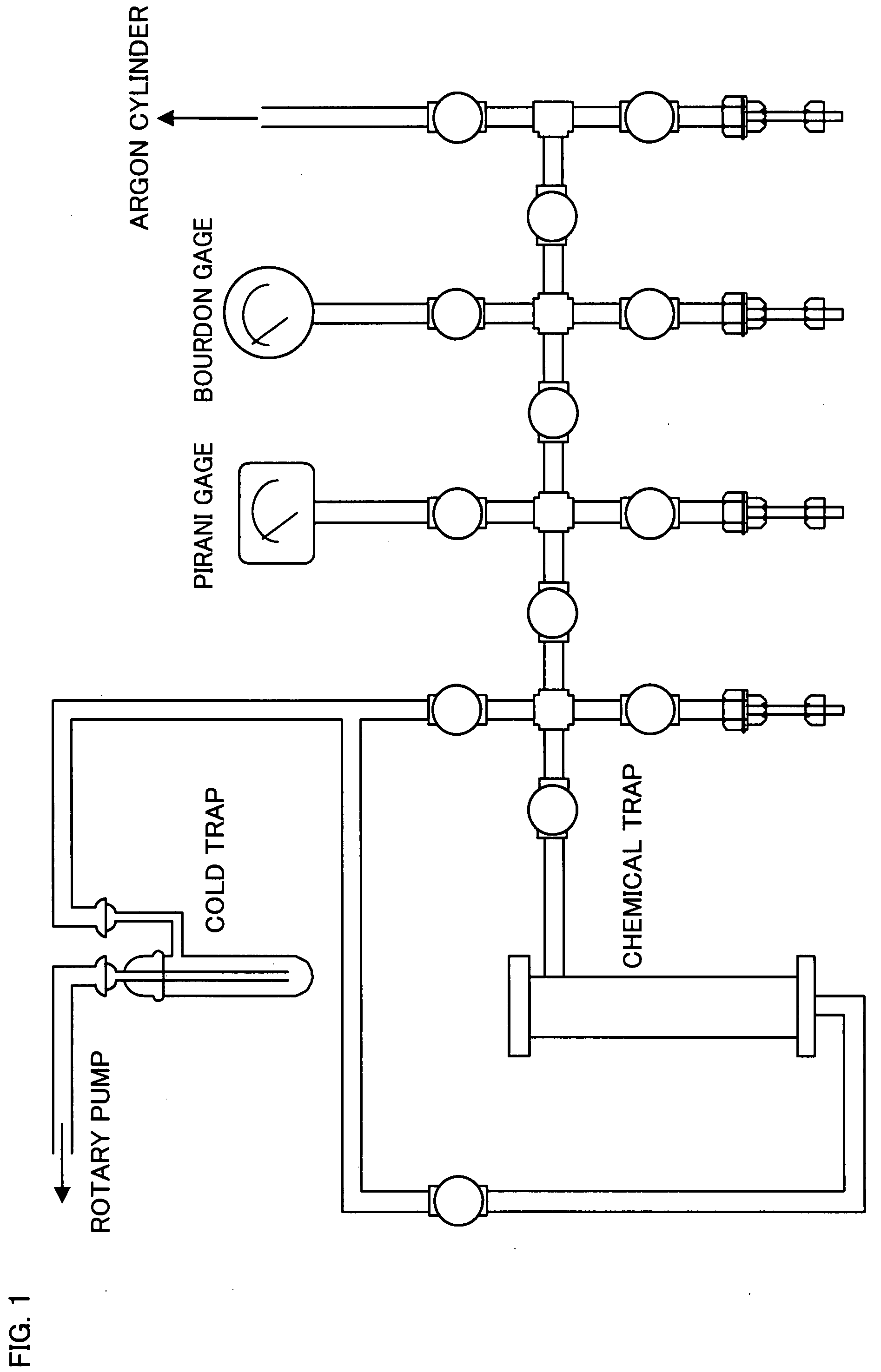

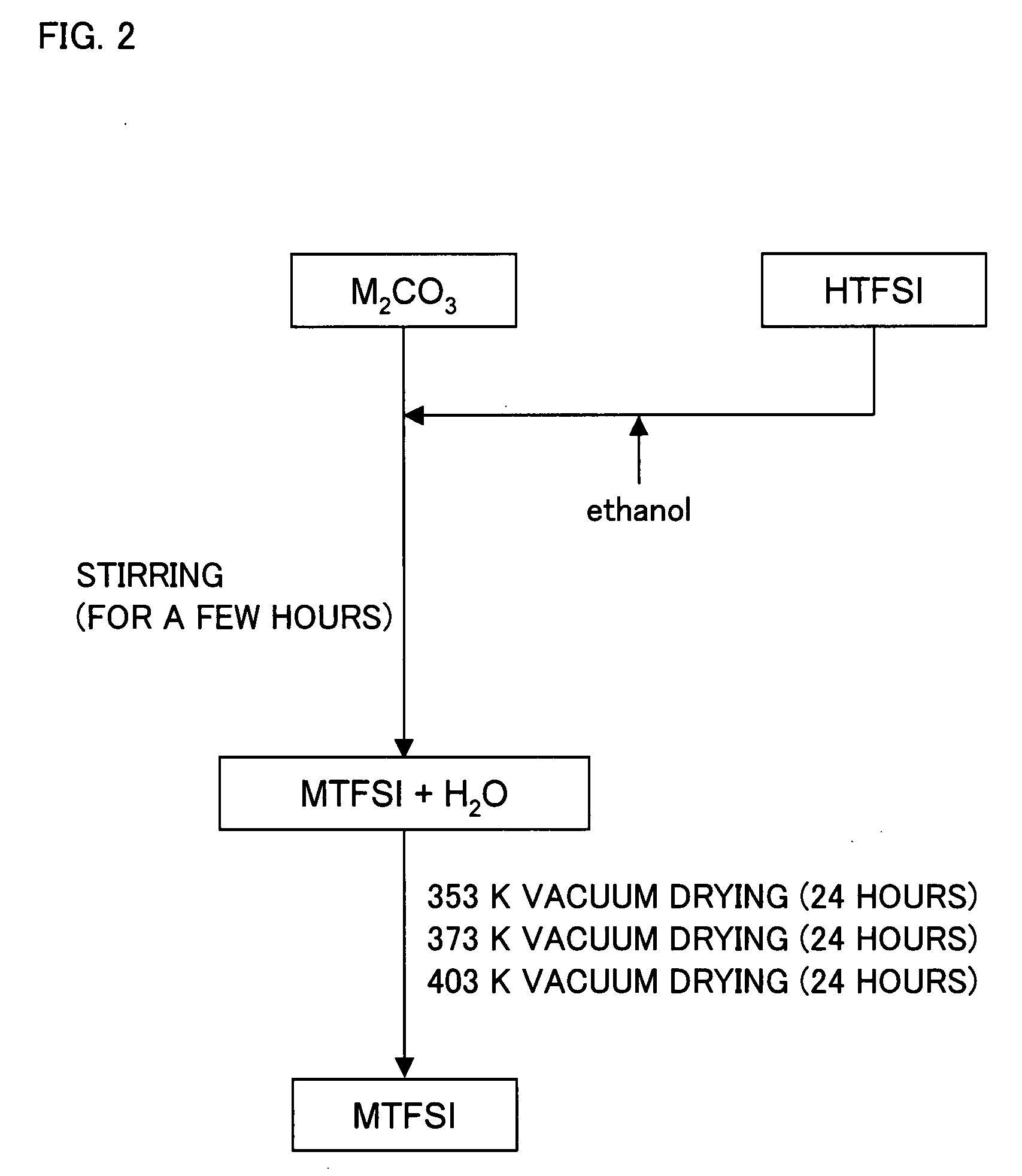

Molten Salt Composition and Use Thereof

ActiveUS20090212743A1High surface finishUniform platingNon-metal conductorsBatteries circuit arrangementsImideMolten salt

A molten salt composition is disclosed containing two or more types of molten salt MTFSI whose anion is an imide anion TFSI and whose cation is an alkali metal M exhibits a lower electrolyte melting point and a wider operating temperature range than a simple salt does. This brings about various advantages such as a wider range of materials that are chosen for use in batteries and the like.

Owner:KYOTO UNIV

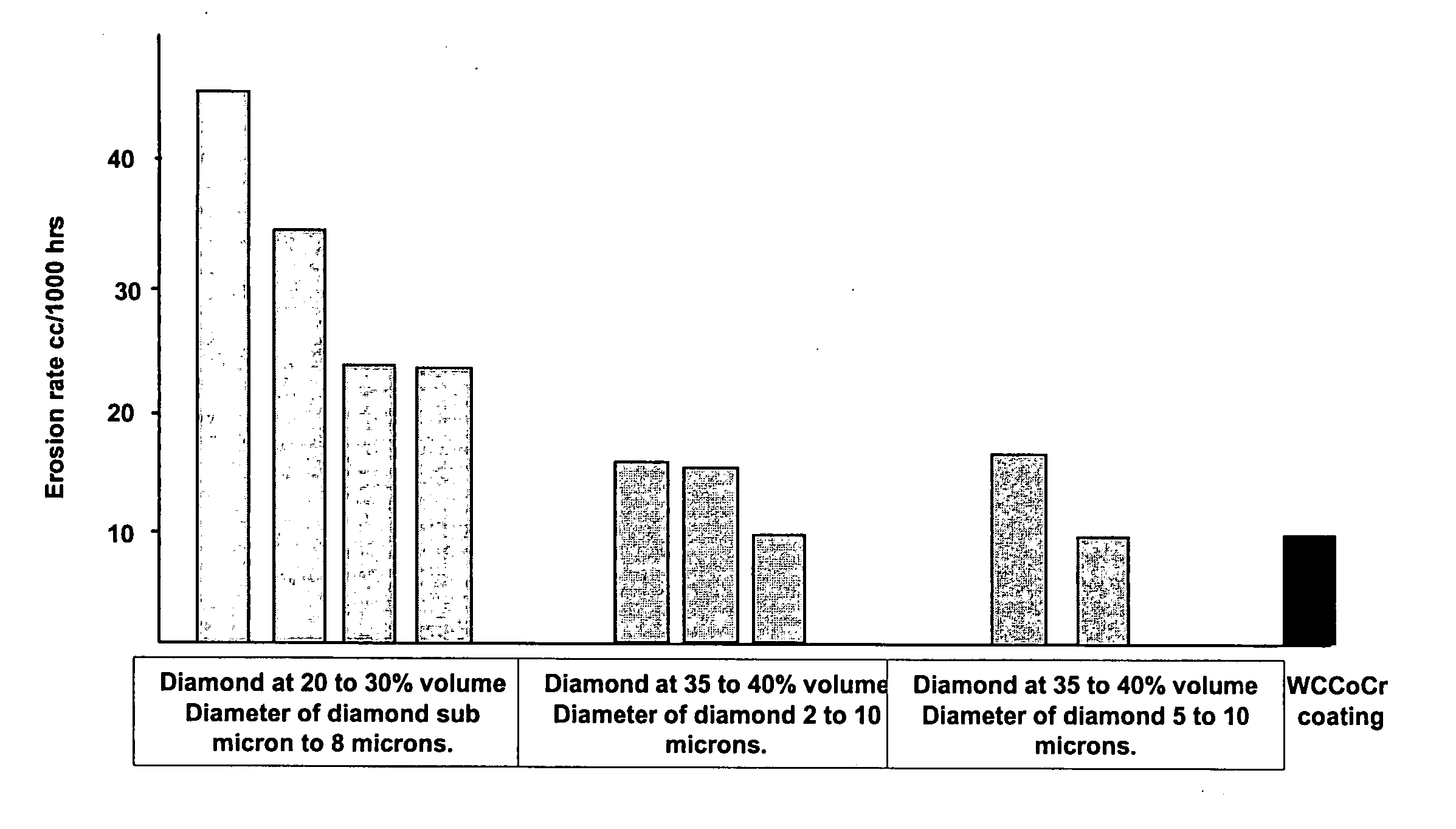

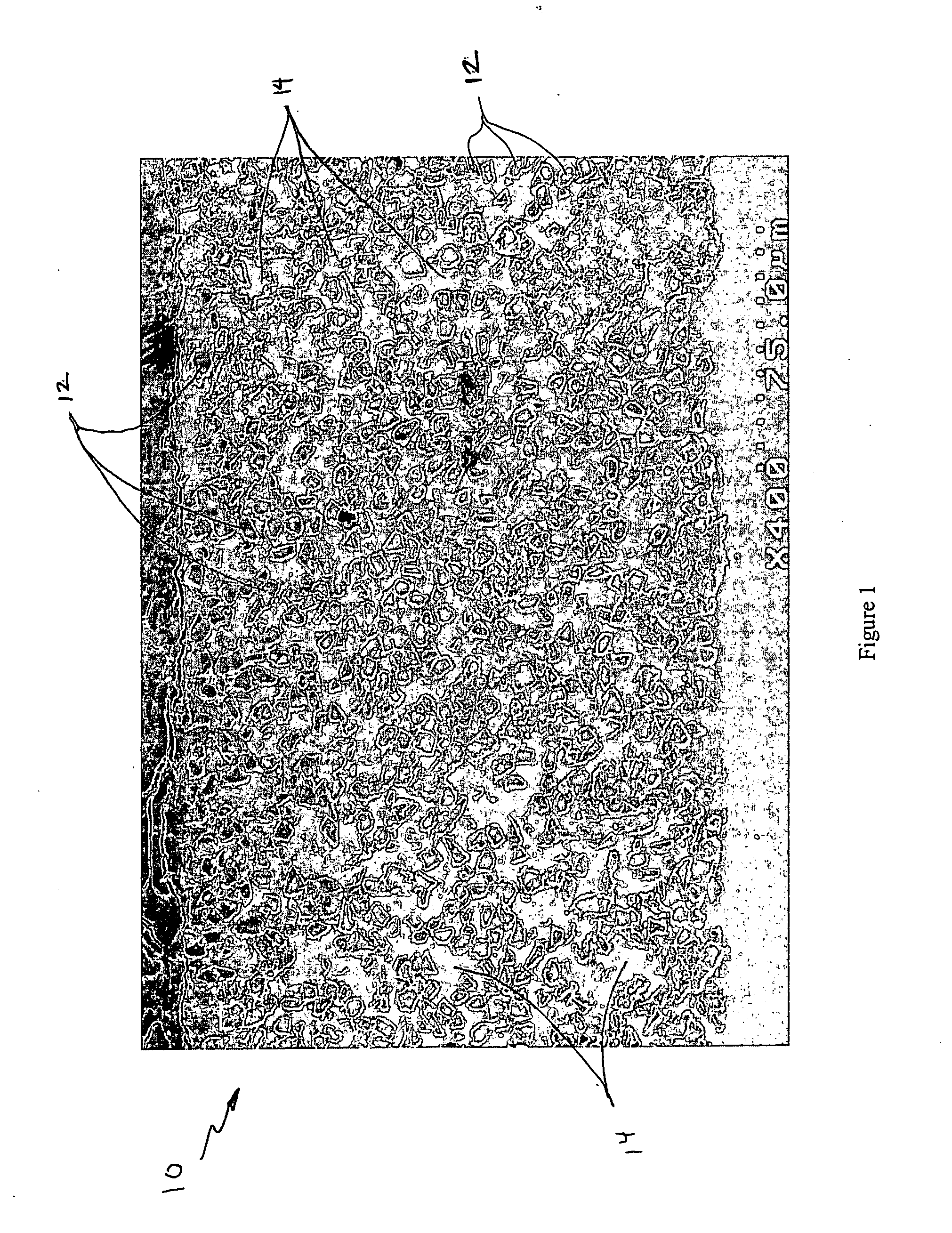

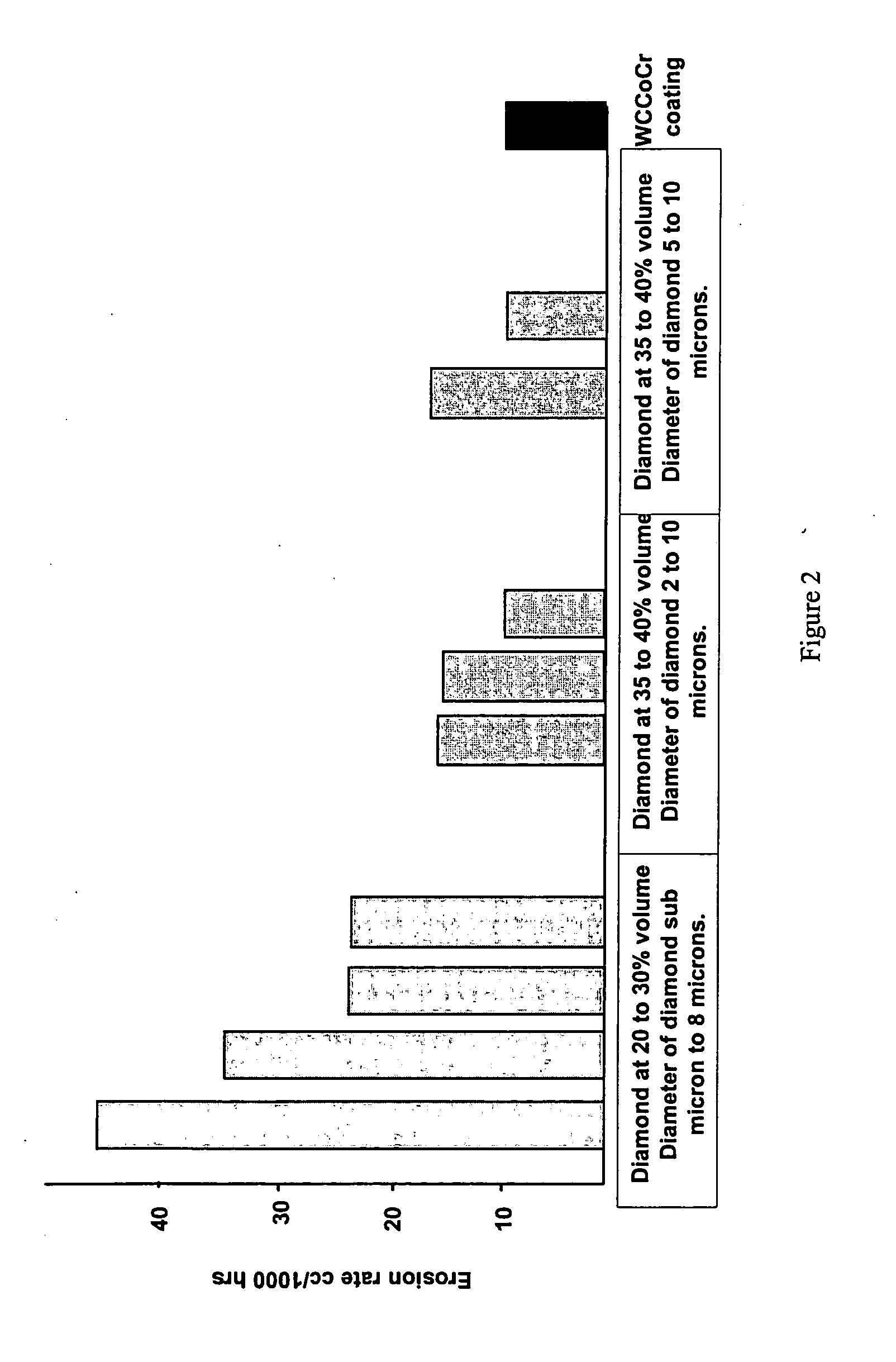

Erosion resistant coatings and methods thereof

Erosion resistant coating compositions include hard particles in a metal matrix such as nickel-based, cobalt-based and iron-based matrices applied by a plating process for complex geometry or hard to access component surfaces or by thermal spray processes for line of sight applications. These materials and processes are especially suited for providing erosion resistance to hydroelectric turbine components.

Owner:GENERAL ELECTRIC CO

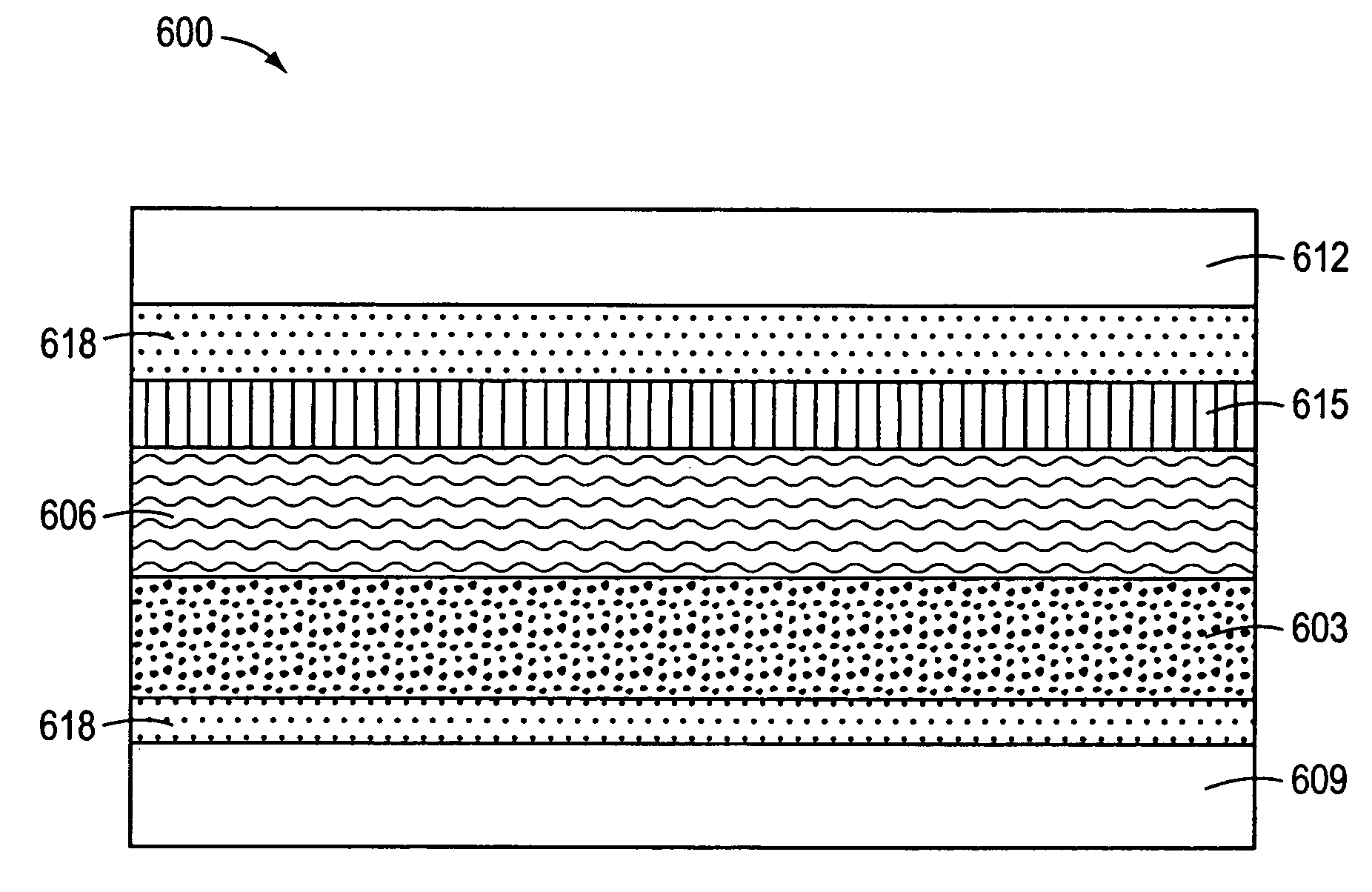

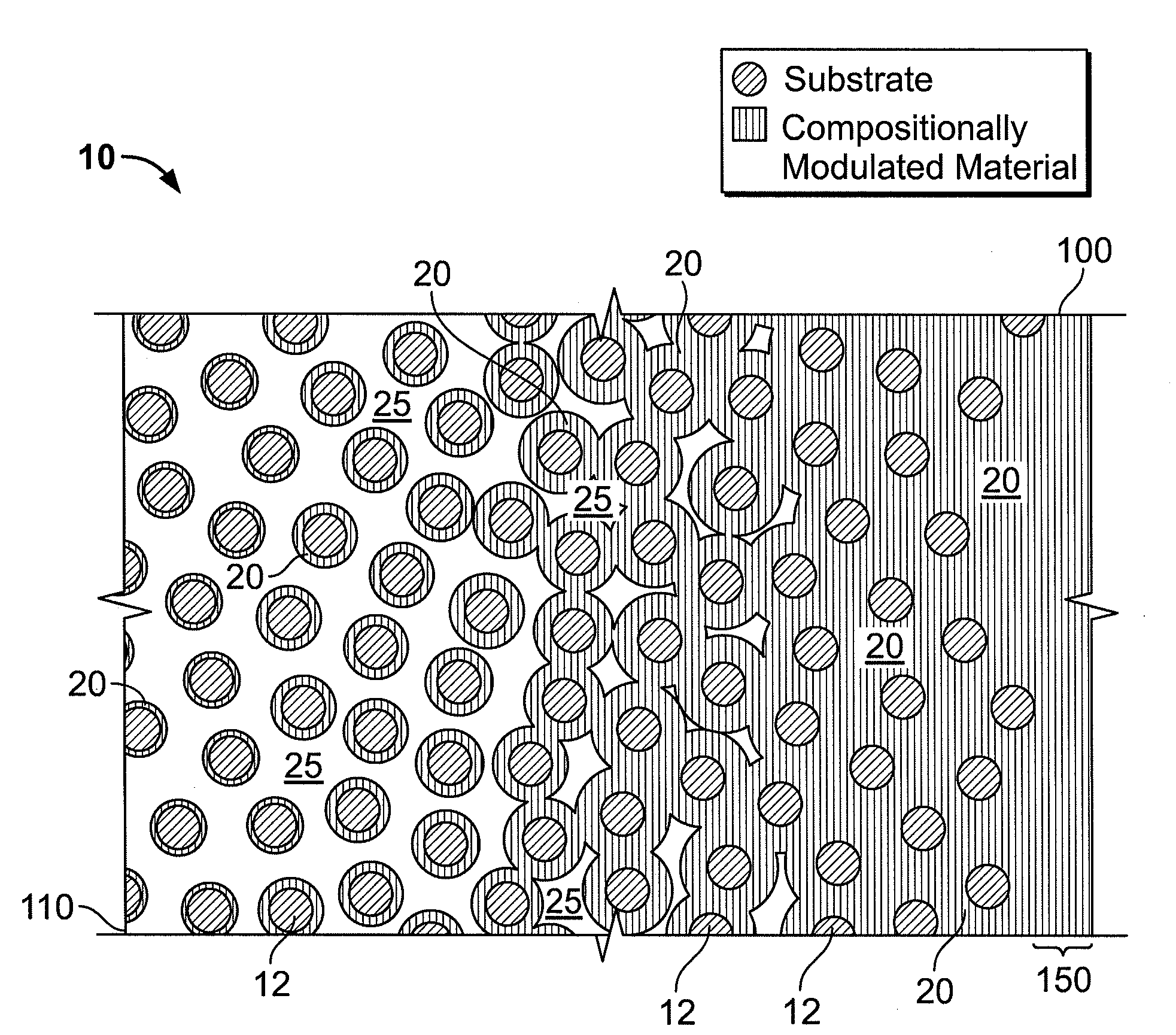

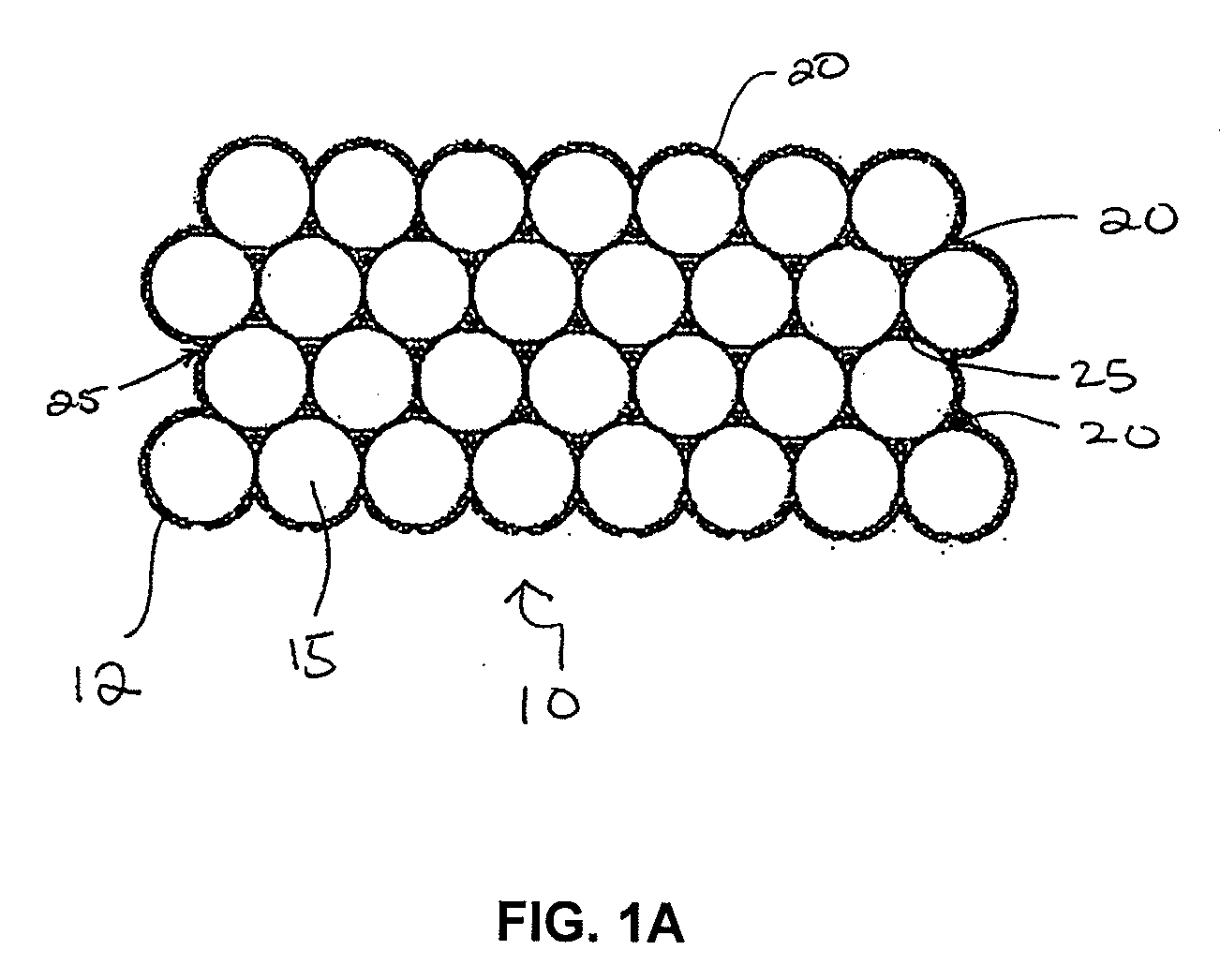

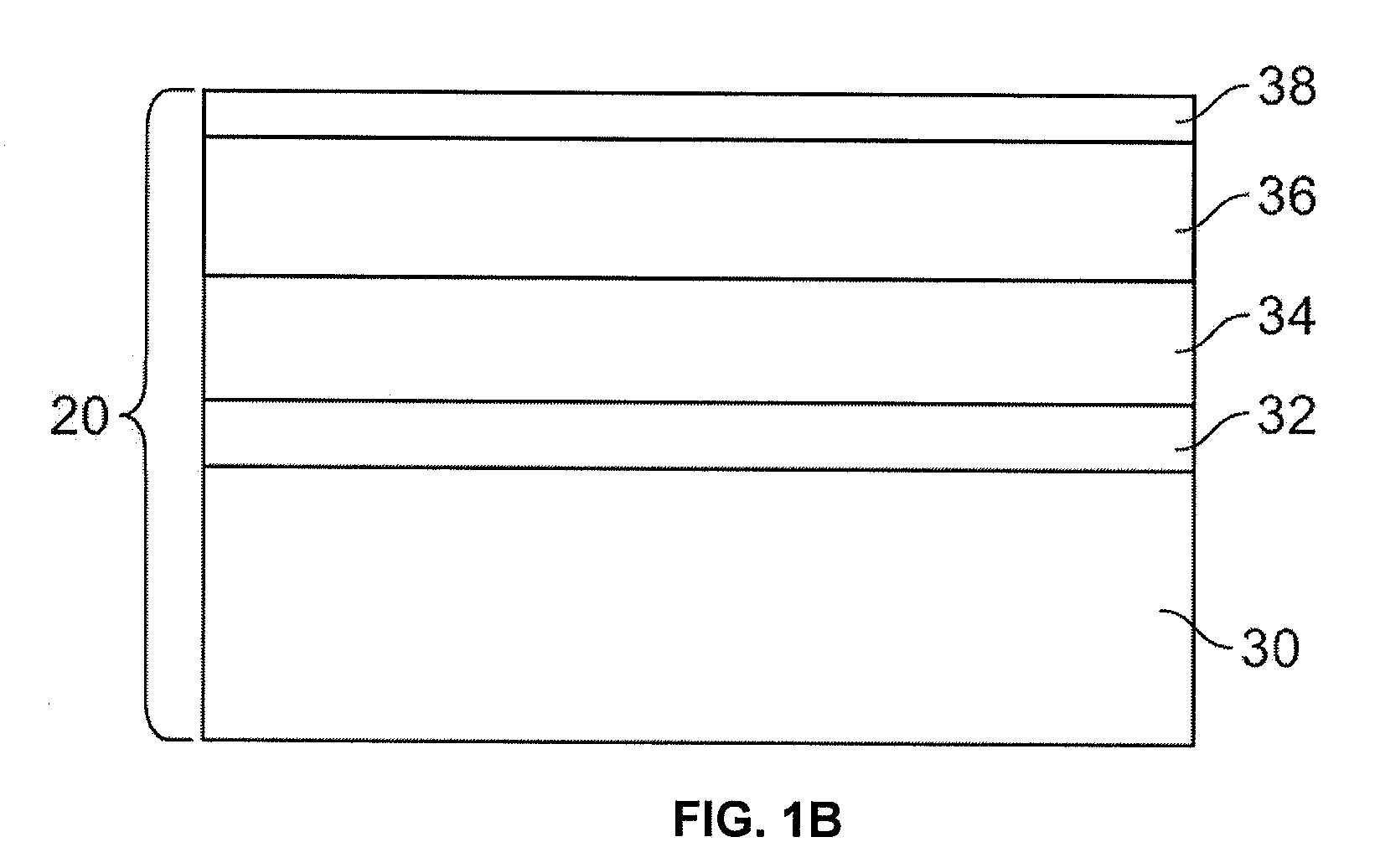

Compositionally modulated composite materials and methods for making the same

ActiveUS20090130425A1Easy to depositImprove material performanceArmourElectrolytic coatingsPorous substrateSports equipment

A light-weight composite material with enhanced structural characteristics includes, in one embodiment, a compositionally modulated nanolaminate coating electrically deposited into an open, accessible void structure of a porous substrate. As a result of including a nanolaminate within the void structure, the composite can include a greater amount of nanolaminate material per unit volume than can be achieved by depositing a nanolaminate material solely on a two-dimensional surface. In addition, the nanolaminate material as well as other material electrodeposited to form the composite is compositionally modulated so that discontinuities between layers are minimized and potentially eliminated. The light-weight but structurally enhanced composite material can be used in a number of different applications including, but not limited to, ballistic applications (e.g., armor panels or tank panels), automotive protection applications (e.g., car door panels, racing shells) and sporting equipment applications (e.g., golf club shafts and tennis racket frames).

Owner:MODUMETAL LLC

Metallic structures incorporating bioactive materials and methods for creating the same

One embodiment of the invention is directed to a method comprising providing an electrochemical solution comprising metal ions and a bioactive material such as bioactive molecules, and then contacting the electrochemical solution and a substrate. A bioactive composite structure is formed on the substrate using an electrochemical process, where the bioactive composite structure includes a metal matrix and the bioactive material within the metal matrix.

Owner:MEDLOGICS DEVICE CORP

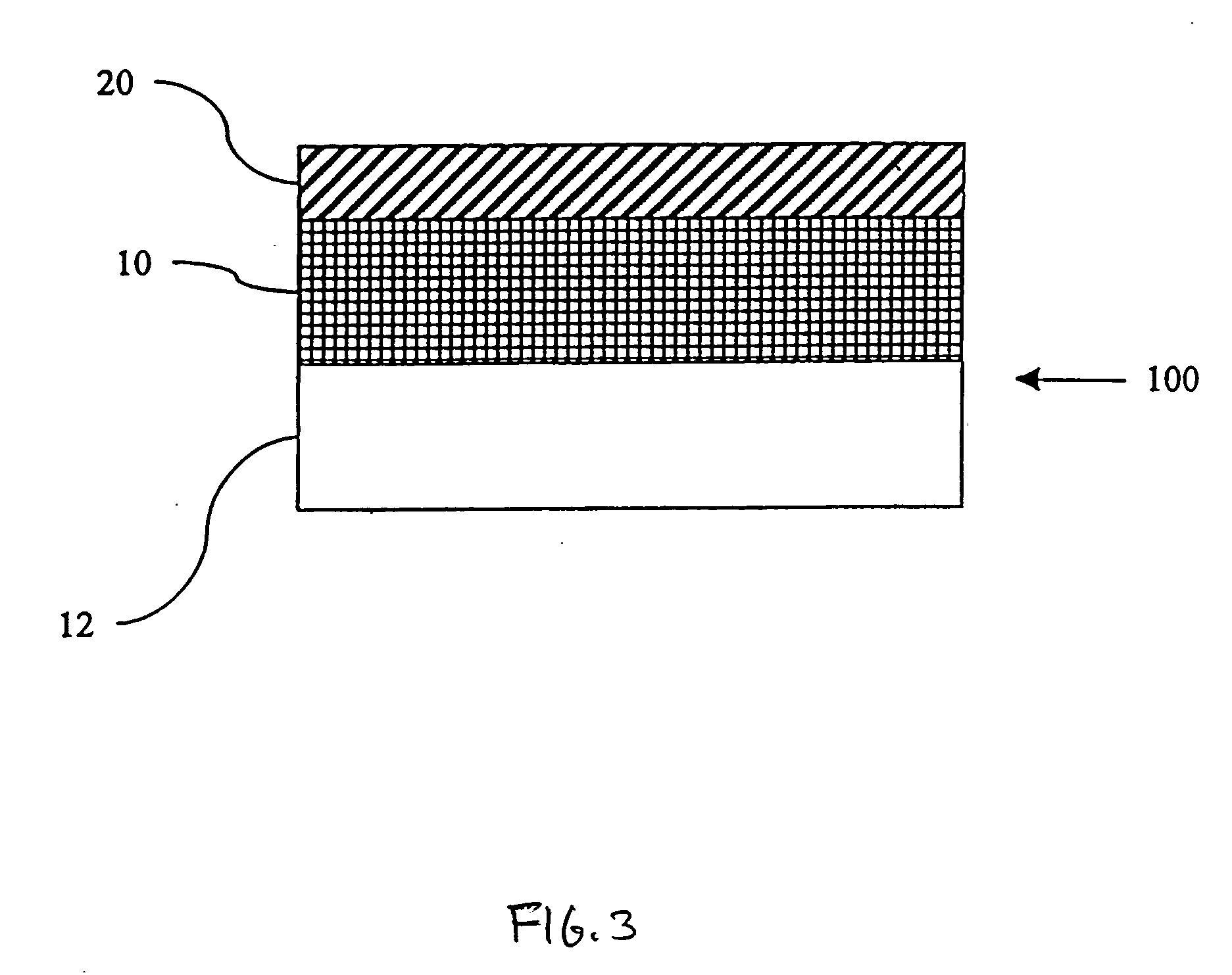

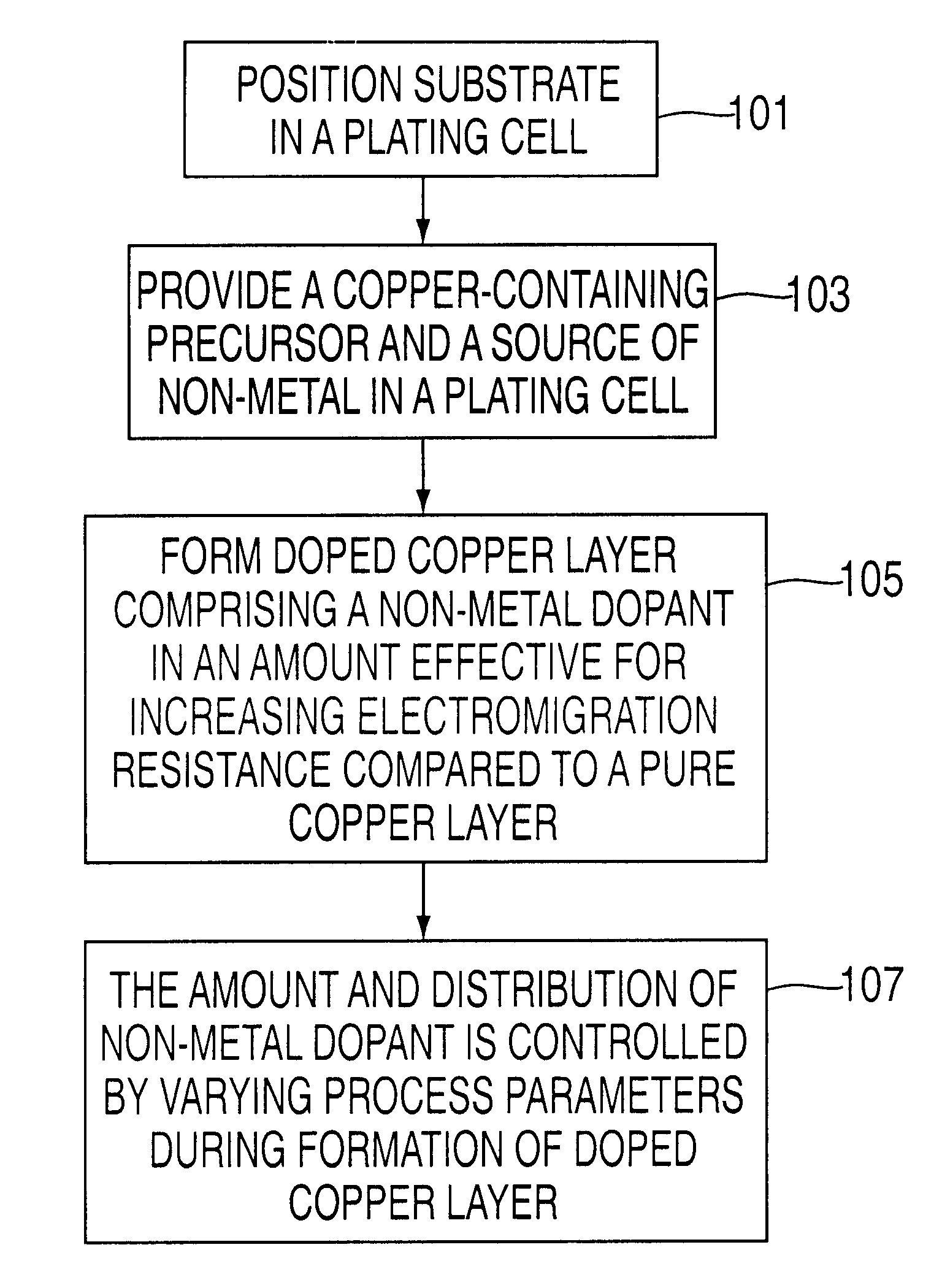

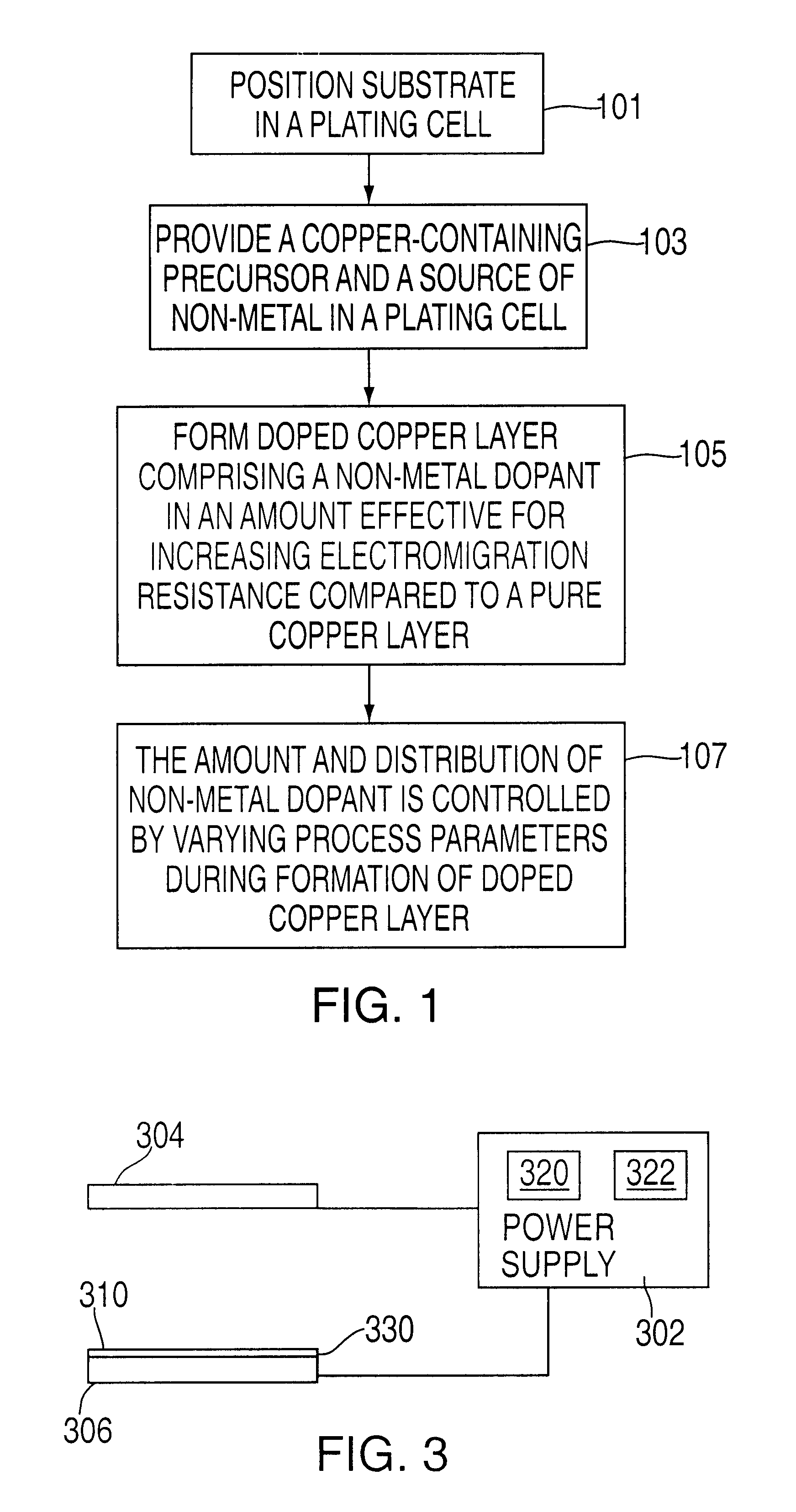

Method of forming copper interconnects

A method of forming a copper layer with increased electromigration resistance. A doped copper layer is formed by controlling the incorporation of a non-metallic dopant during copper electroplating.

Owner:APPLIED MATERIALS INC

Turbine blade tip with optimized abrasive

InactiveUS20050129511A1Improved blade tip clearance controlImprove engine efficiencyElectrolytic coatingsPump componentsIndustrial gasTurbine blade

A new abrasive blade tip treatment is disclosed with the potential to provide improved blade tip clearance control in the turbine section of modern industrial gas turbines (IGT's). This blade tip treatment is composed of a unique combination of abrasive compounds that result in improved resistance to thermal degradation while retaining desirable initial cutting capacity.

Owner:SIEMENS ENERGY INC

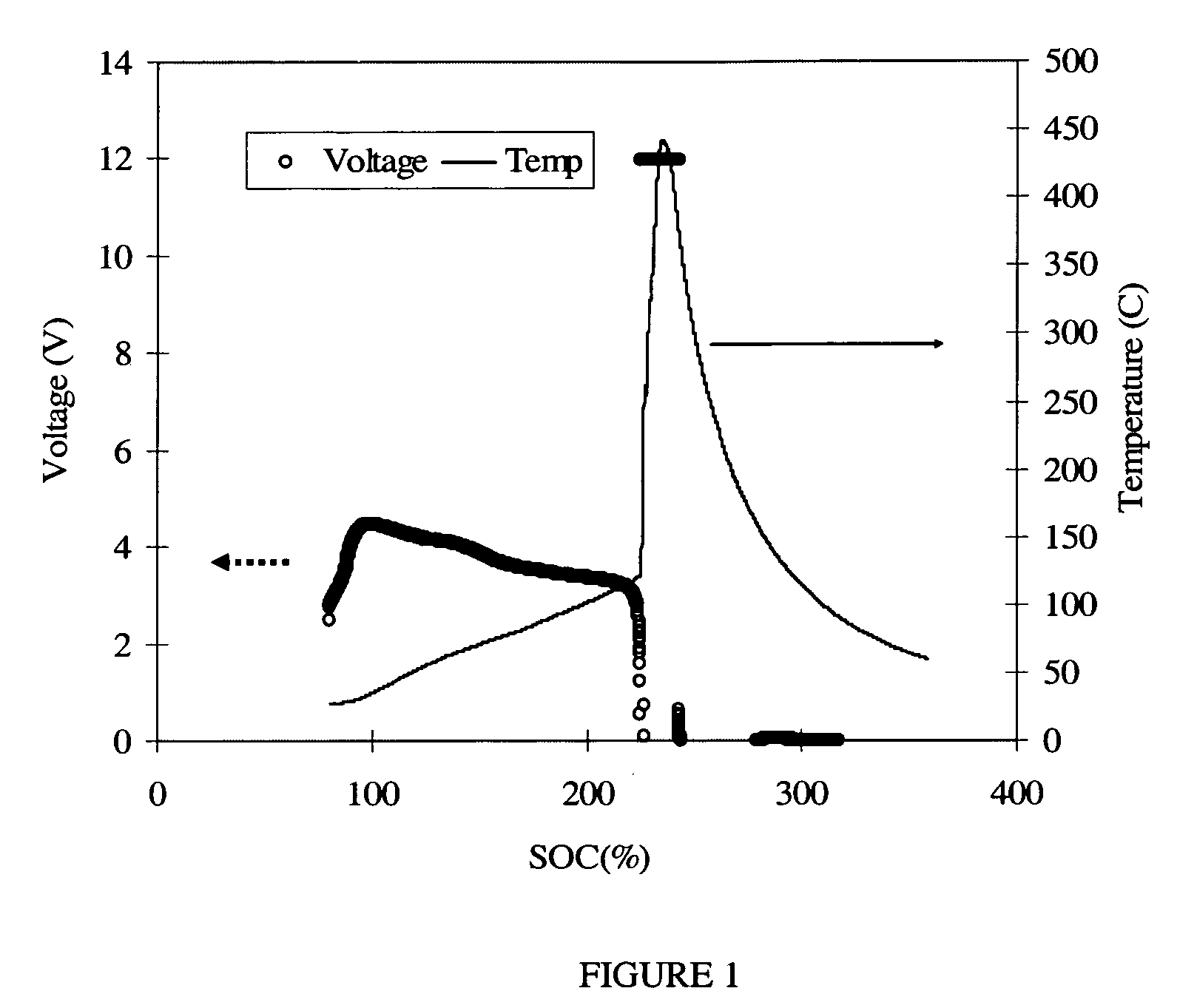

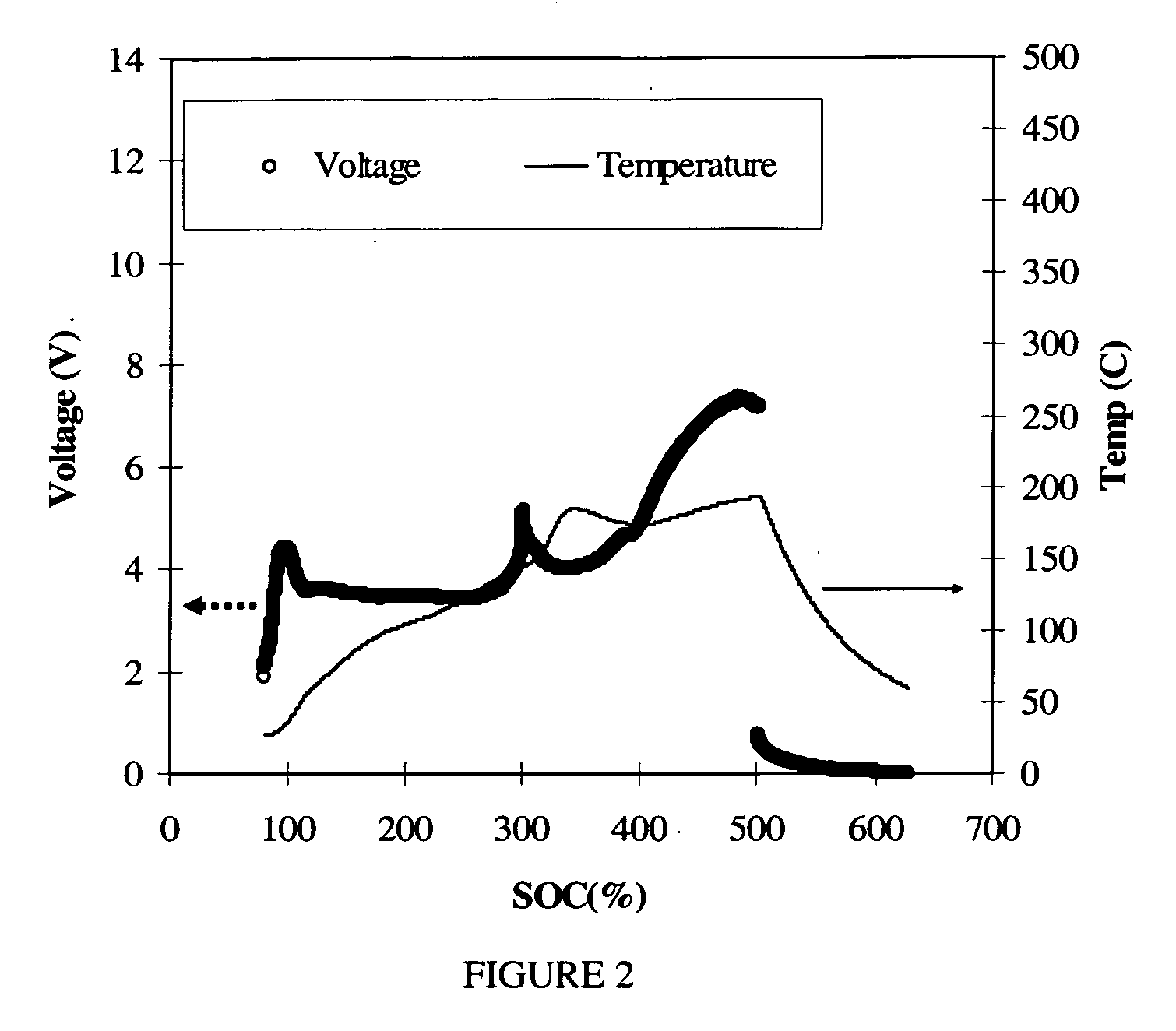

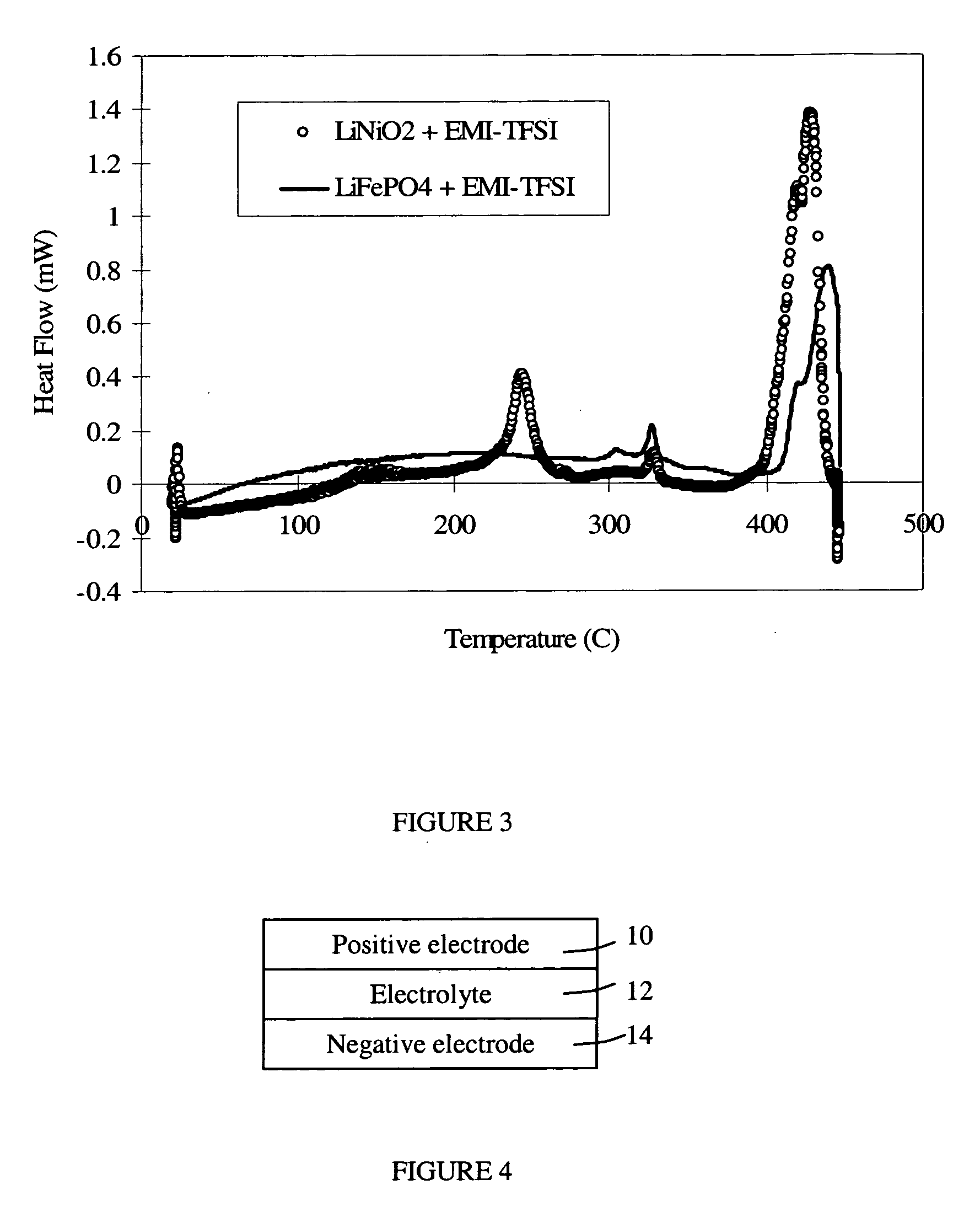

Battery with molten salt electrolyte and phosphorus-containing cathode

A lithium-ion battery comprises a negative electrode, a positive electrode, and an electrolyte including a molten salt. The positive electrode comprises an electroactive compound including phosphorus, oxygen, lithium, and at least one other metal or semi-metal. The combination of such electrode compositions and a molten salt electrolyte provides a battery with very high thermal stability. Other ions, such as alkal metal ions, may be used in place of lithium ions for applications in other battery technologies.

Owner:TOYOTA MOTOR CO LTD +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com