Negative electrode for nonaqueous secondary battery, process of producing the negative electrode, and nonaqueous secondary battery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1-1

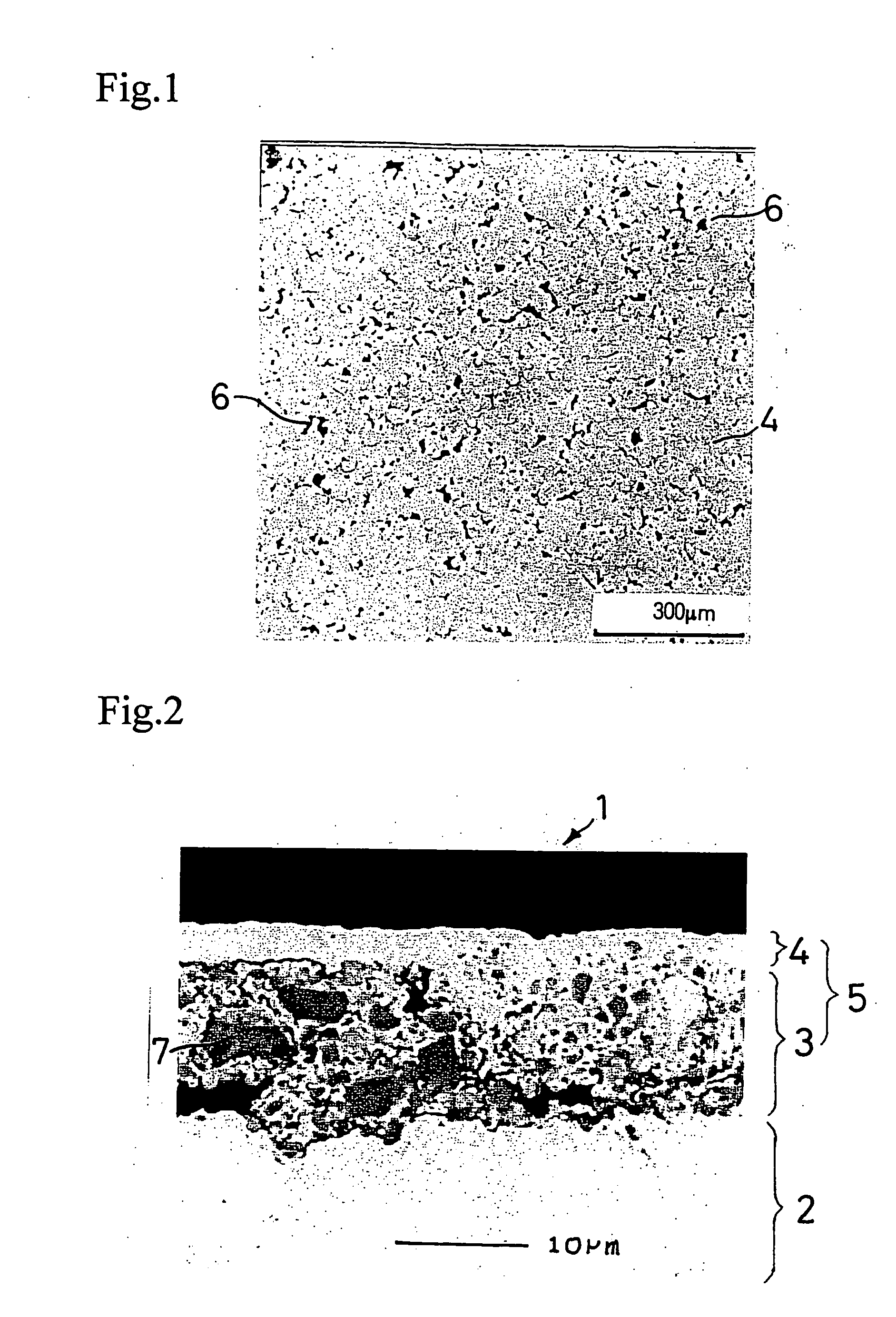

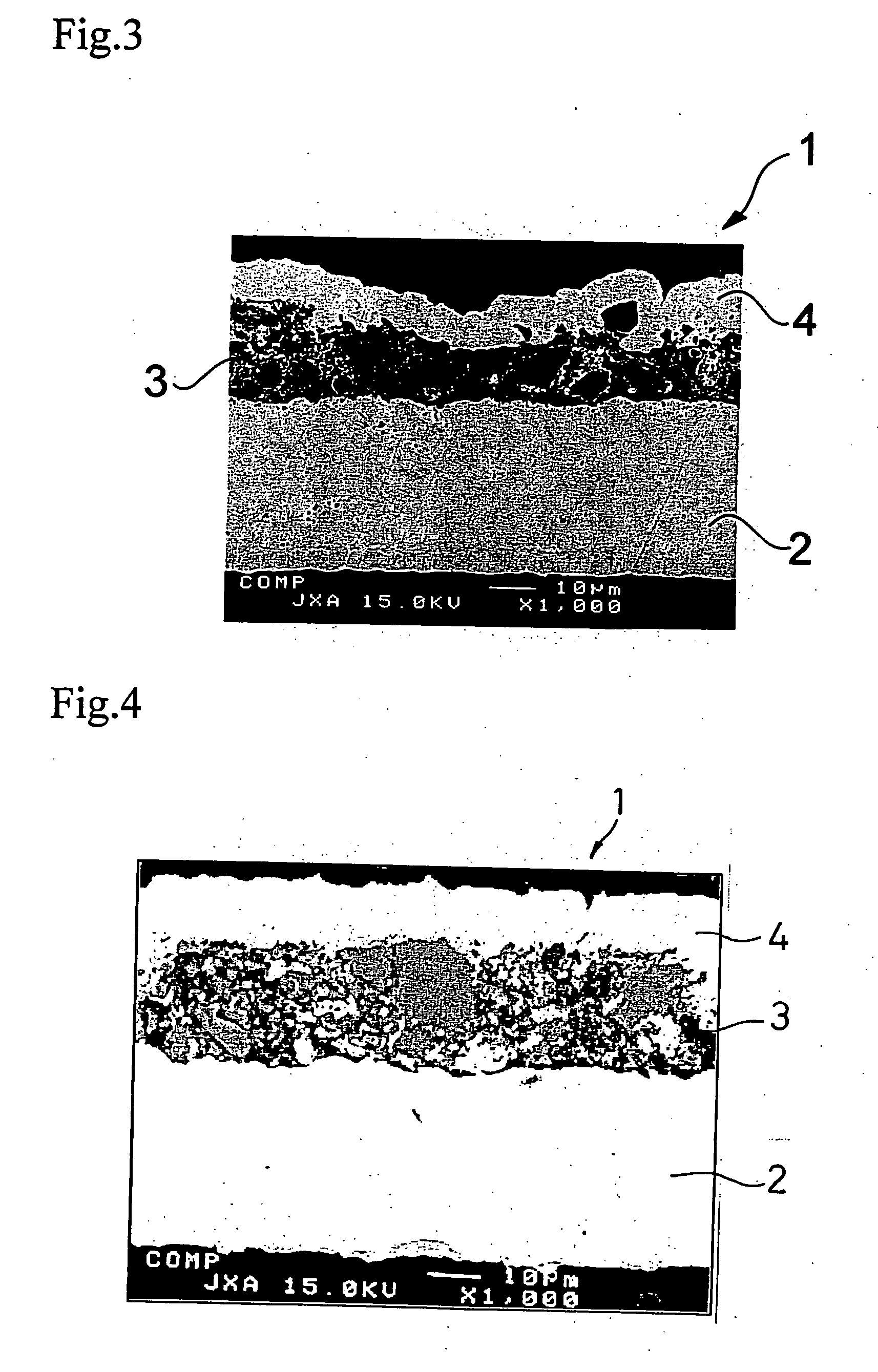

(1) Preparation of Active Material Particles

[0102] A molten metal at 1400° C. containing 90% of silicon and 10% of nickel was cast into a copper-made mold and quenched to obtain an ingot of a silicon-nickel alloy. The ingot was pulverized and sieved to obtain silicon-nickel alloy particles having particle sizes of 0.1 to 10 μm. The silicon-nickel alloy particles and nickel particles (particle size: 30 μm) were blended at a rate of 80%:20% and mixed and pulverized simultaneously in an attritor to obtain uniformly mixed particles of silicon-nickel particles and nickel. The mixed particles had the maximum particle size of 1 μm and a D50 value of 0.8 μm.

(2) Preparation of Slurry

[0103] A slurry having the following composition was prepared.

Mixed particles obtained in (1) above16%Acetylene black (particle size: 0.1 μm) 2%Binder (polyvinylidene fluoride) 2%Diluting solvent (N-methylpyrrolidone)80%

(3) Formation of Active Material Layer

[0104] The above prepared slurry was applied to...

examples 1-2 to 1-4

[0107] A negative electrode was produced in the same manner as in Example 1-1, except for using the active material particles shown in Table 1-1 below. The same electron microscopic observation as in Example 1-1 revealed presence of micropores in the resulting negative electrode.

example 1-5

[0108] A 35 μm thick copper foil was plated with nickel to a deposit thickness of 2 μm to prepare a current collector. An active material layer and a surface coating layer were formed on the nickel layer in the same manner as in Example 1-1, except for using the active material particles shown in Table 1-1 in the active material layer. The same electron microscopic observation as in Example 1-1 revealed presence of micropores in the resulting negative electrode.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fraction | aaaaa | aaaaa |

| Percent by mass | aaaaa | aaaaa |

| Percent by mass | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com