Patents

Literature

39results about How to "Reduce discharge efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

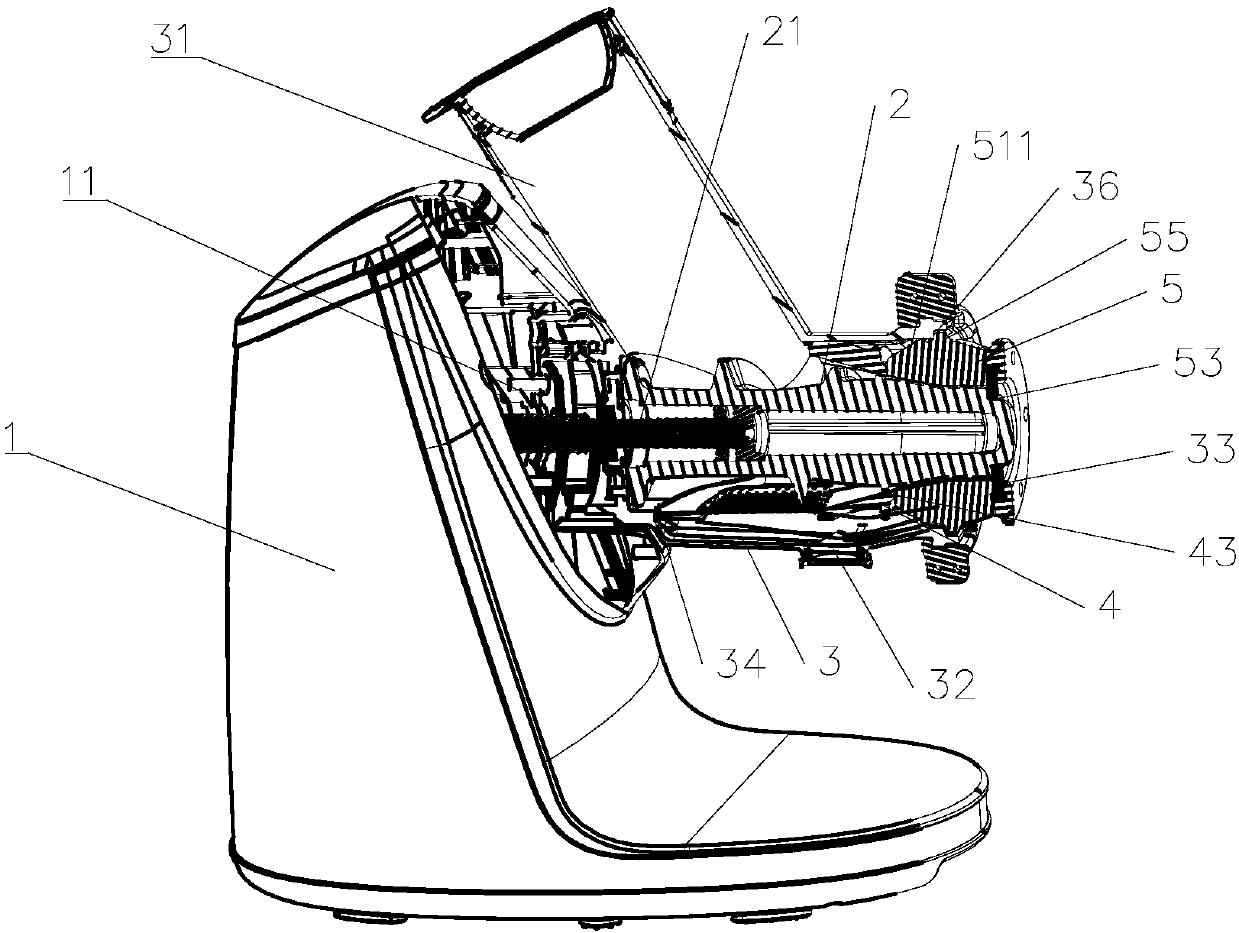

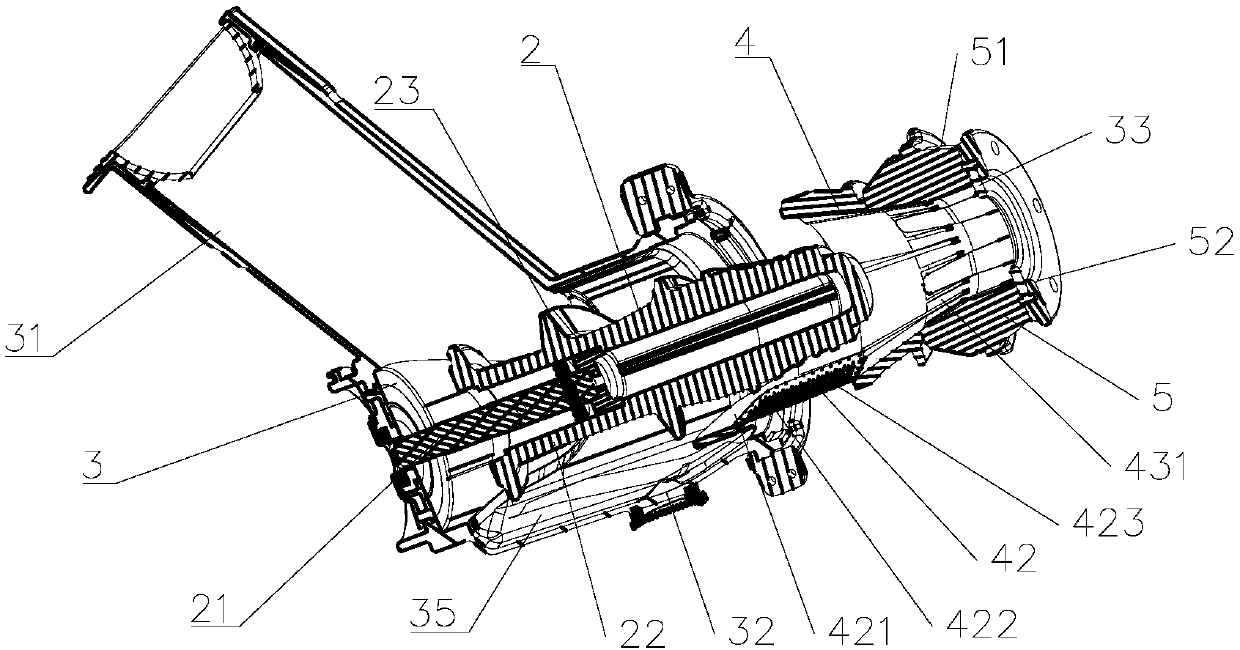

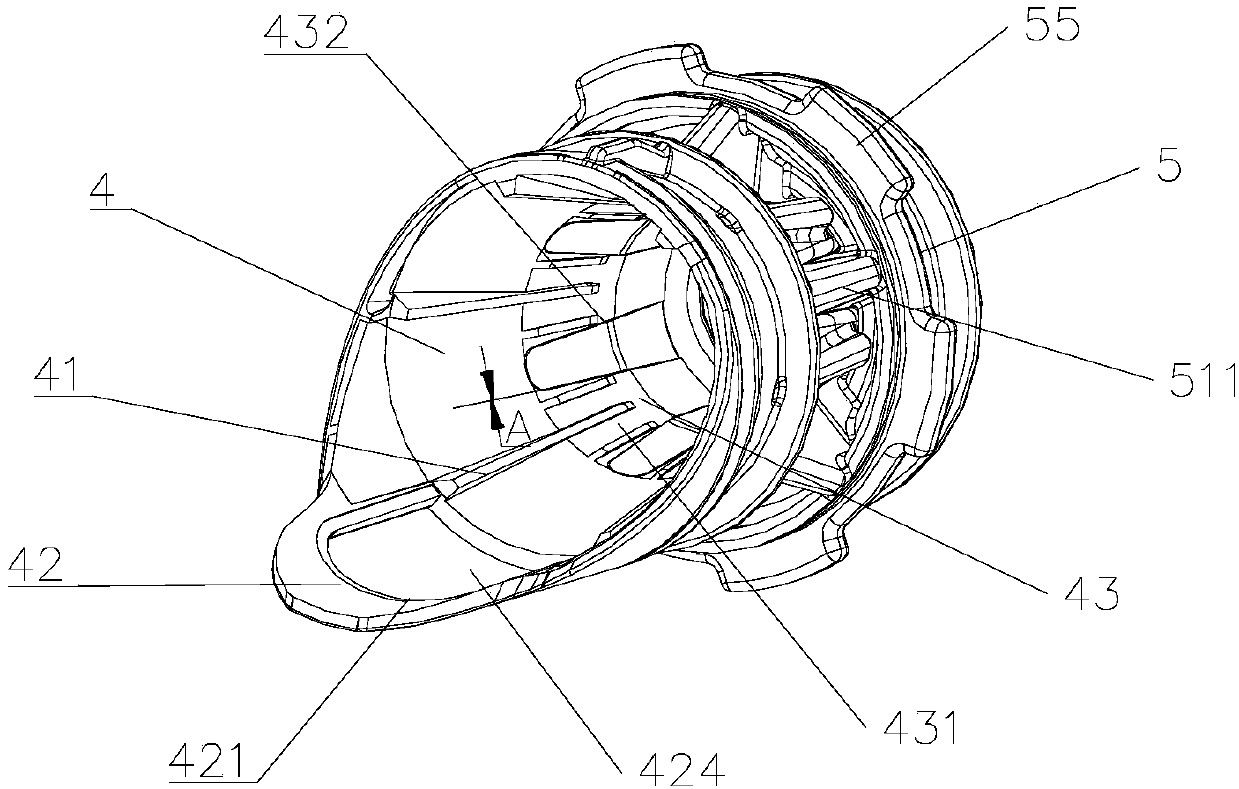

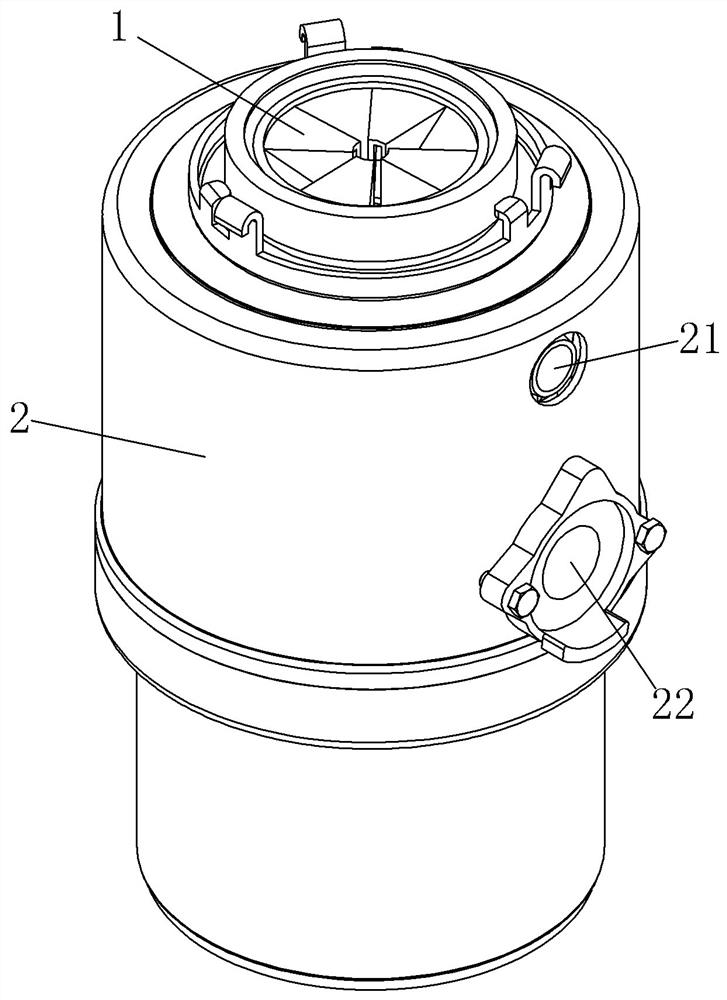

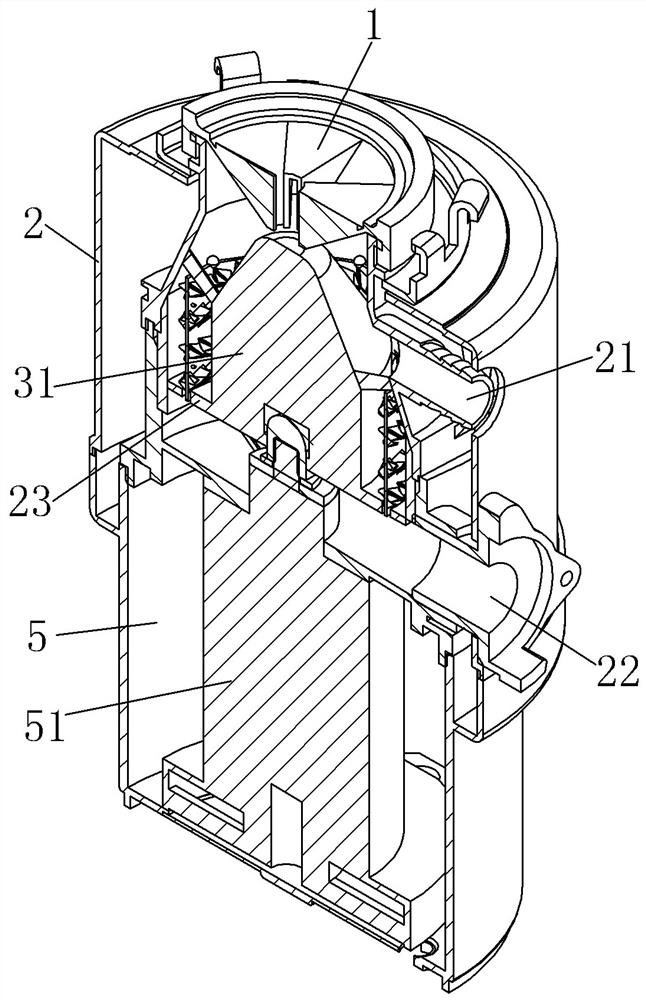

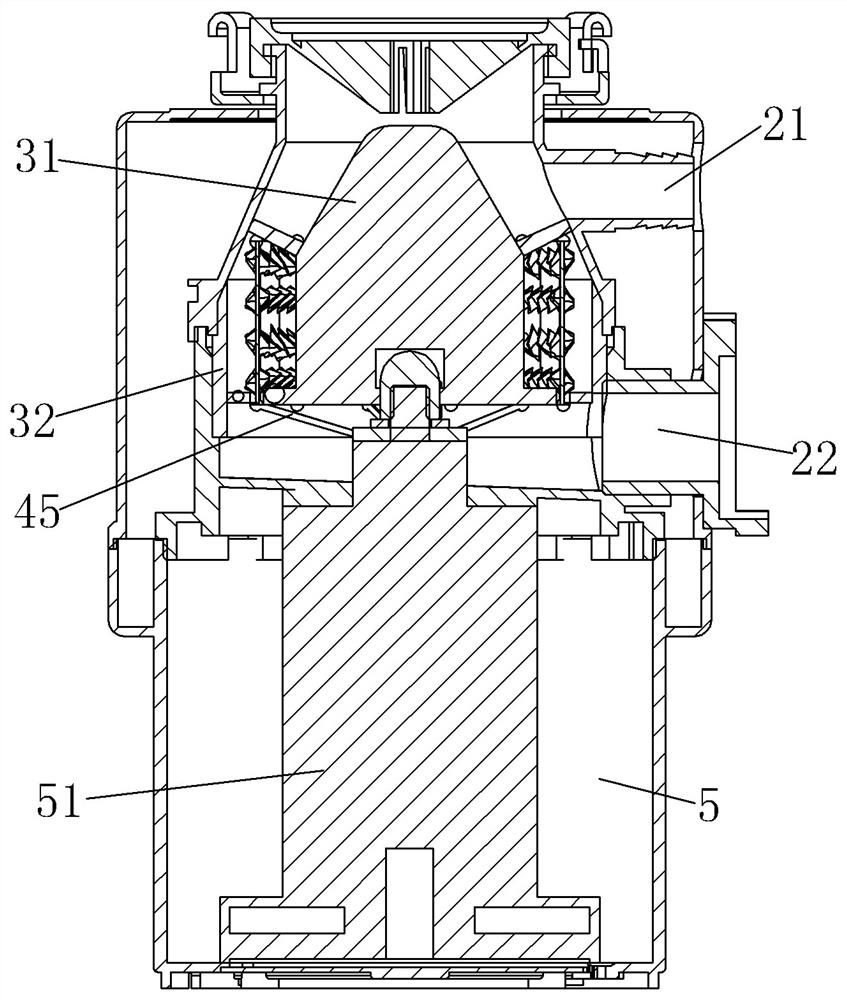

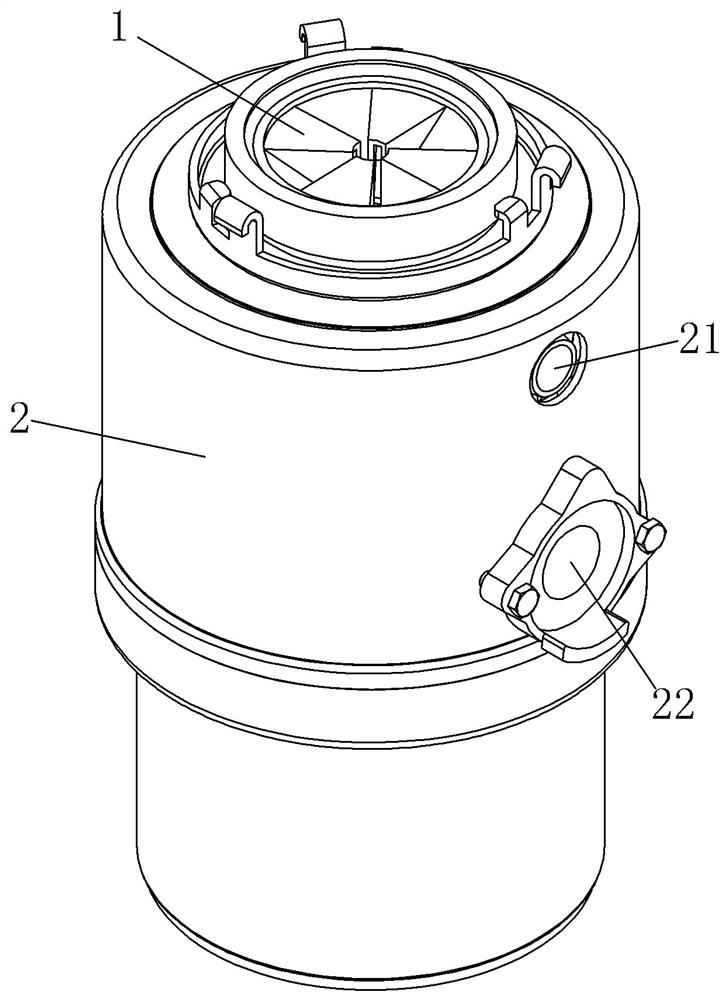

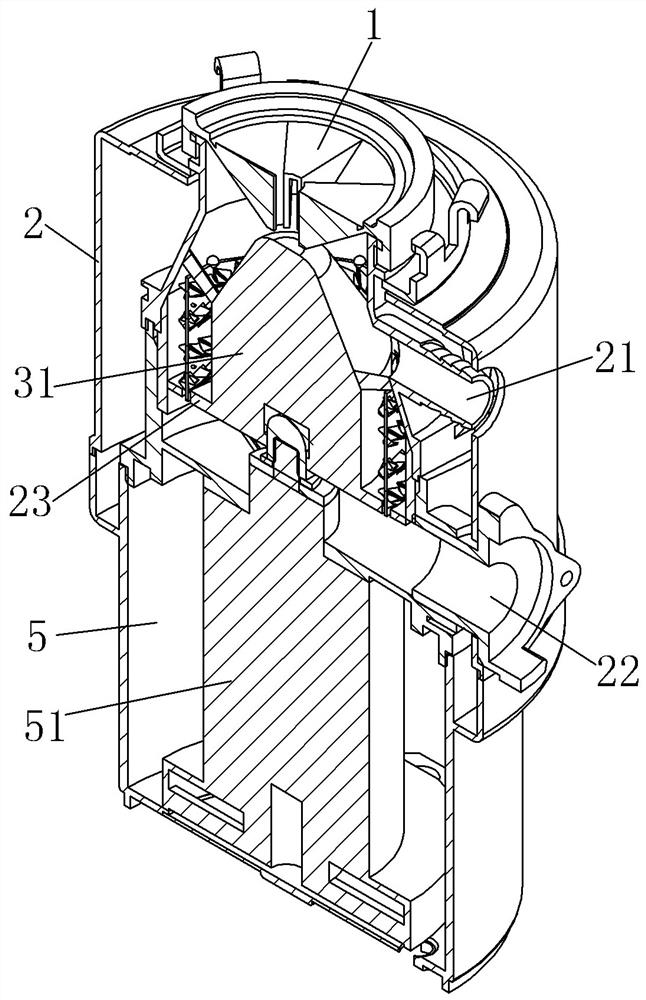

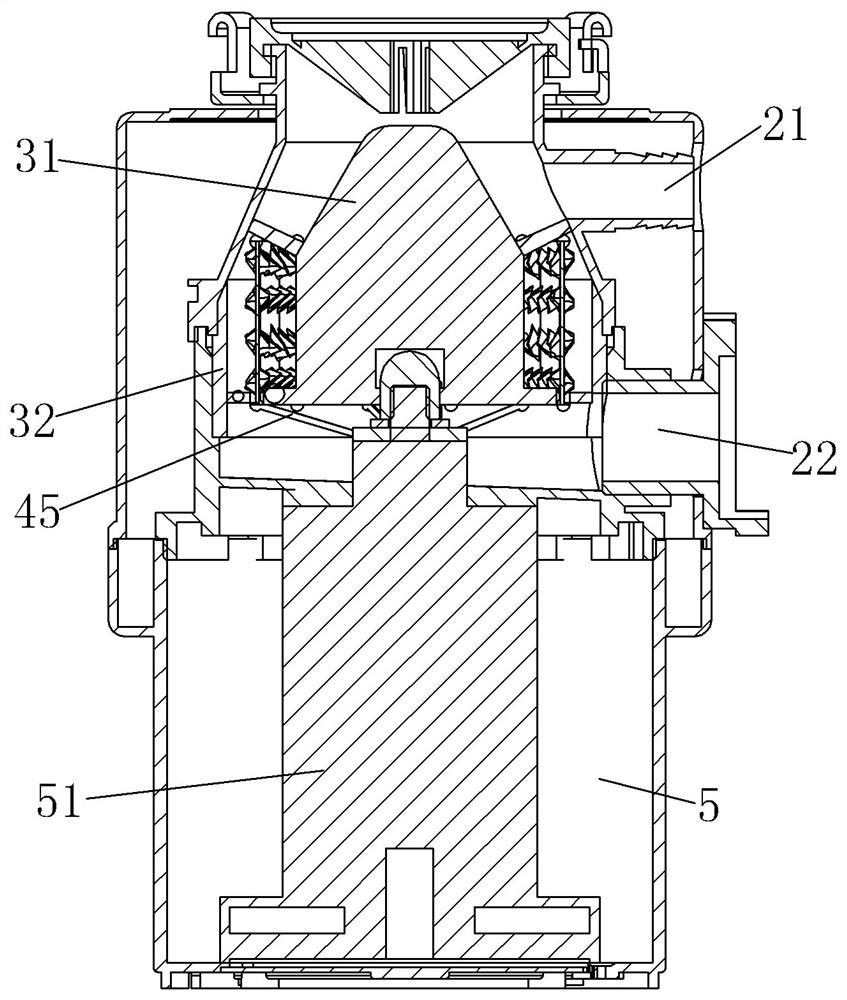

Easy cleaning screw extruding type juice extractor

ActiveCN109744842ASatisfy the adaptability of filtered juiceSqueeze evenlyStrainersEngineeringUltimate tensile strength

The invention provides an easy cleaning screw extruding type juice extractor. The easy cleaning screw extruding type juice extractor comprises a machine seat, a juice collecting cavity connected withthe machine seat, a screw rod transversely arranged in the juice collecting cavity and an extruding cylinder sleeving the outside of the screw rod; one end of the juice collecting cavity is connectedwith the machine seat, the other end is provided with an end cover, the juice collecting cavity comprises a feeding hole, a juice outlet and a slag hole, and the rear end of the extruding cylinder isprovided with a filtering part; the filtering part is arranged at the periphery of the screw rod, the filtering part comprises filtering grids and filtering bulges, inserting holes are formed among the filtering grids, the filtering bulges are circumferentially arranged on the inner side of the end cover at intervals and are inserted into the inserting holes, so that the filtering grids and the filtering bulges are inserted and matched to form filtering gaps, and the filtering gap value is A, wherein A is larger than or equal to 0.05 mm and less than or equal to 0.3 mm. The gap value of the filtering gaps is accurate and stable and well consistent in the juice extracting process through the arrangement, the juice has the good taste, meanwhile, the strength of the filtering part is enhancedthrough insertion matching of the filtering grids and the filtering bulges, and the filtering grids and the filtering bugles are not prone to break.

Owner:JOYOUNG CO LTD

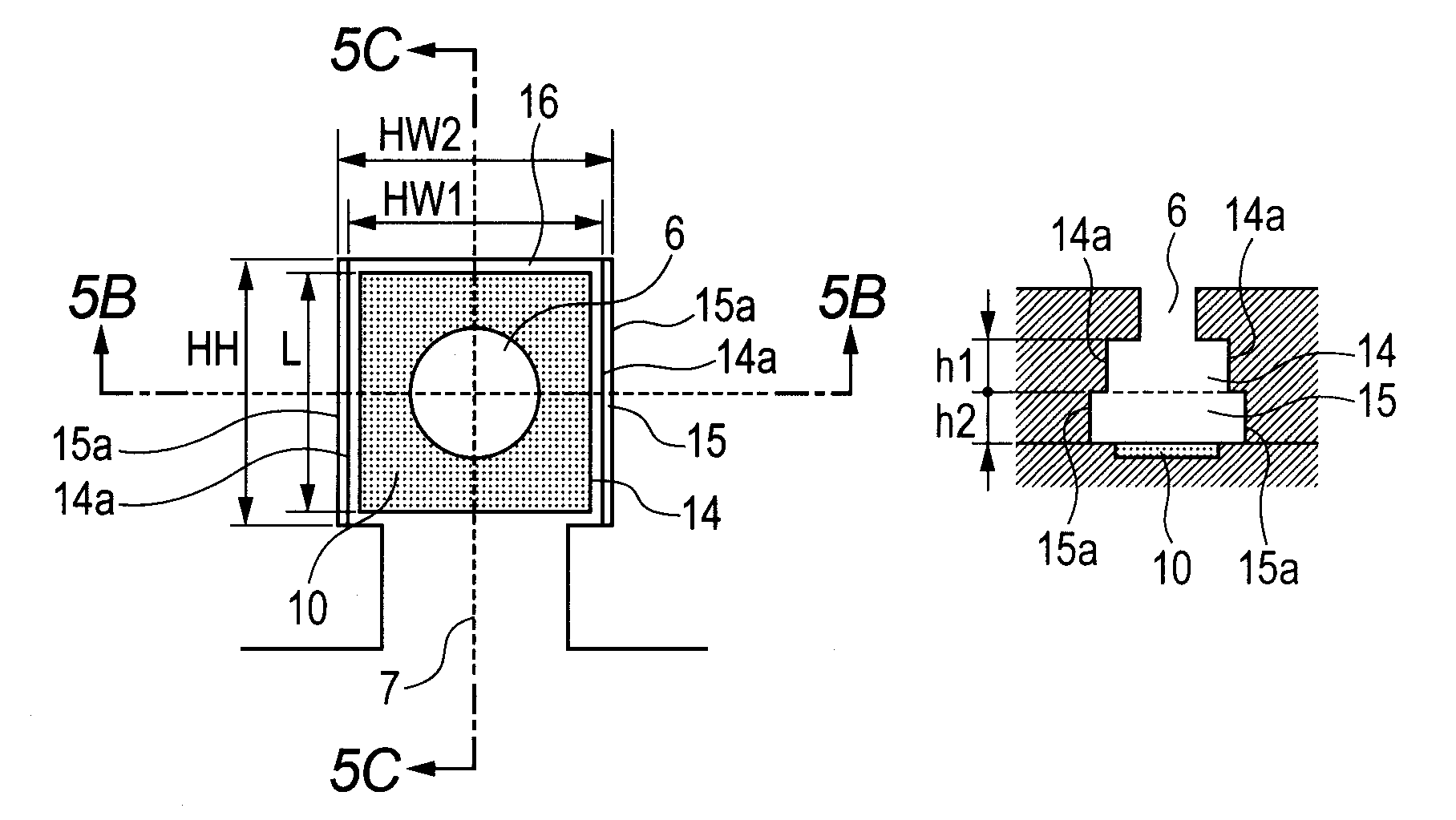

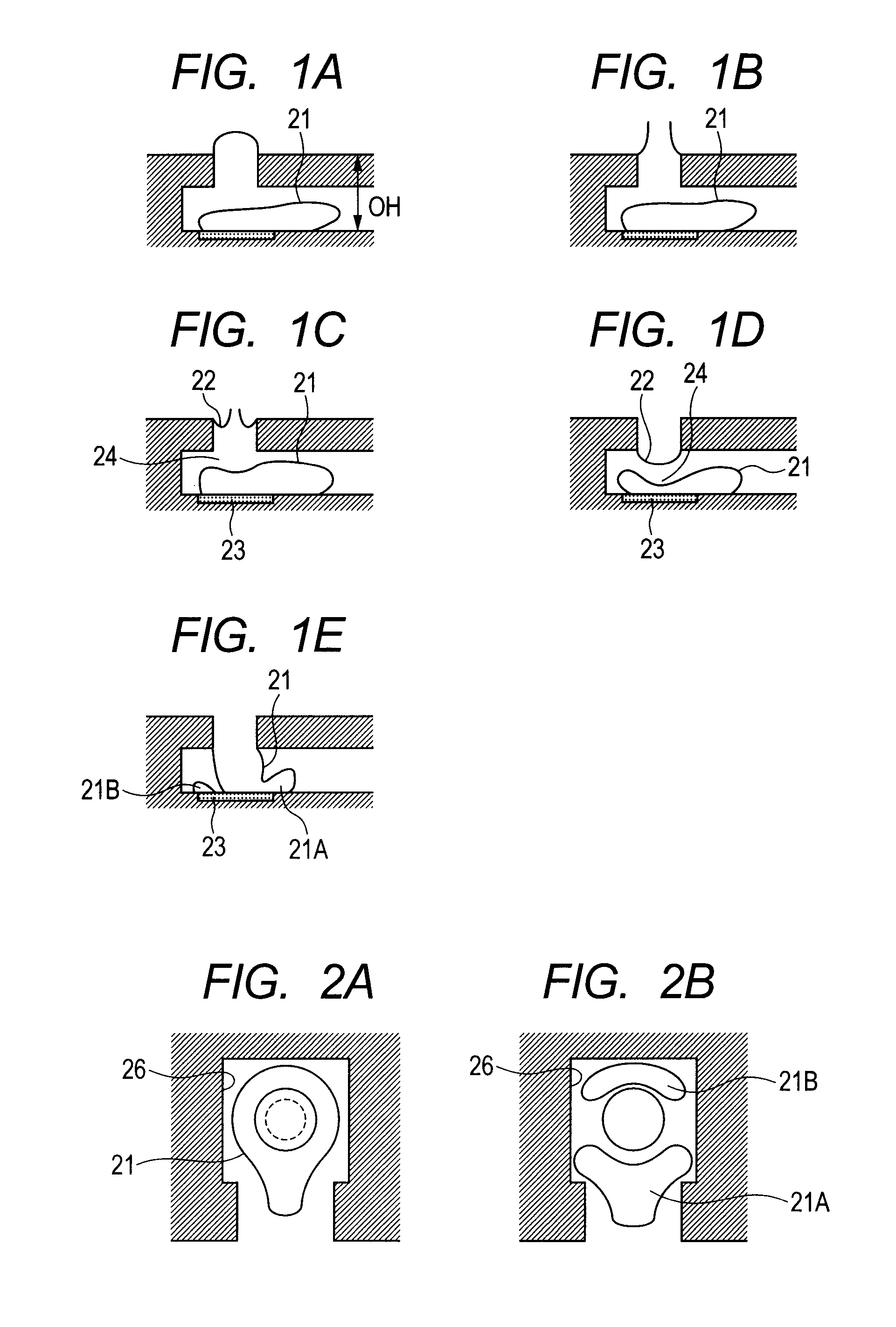

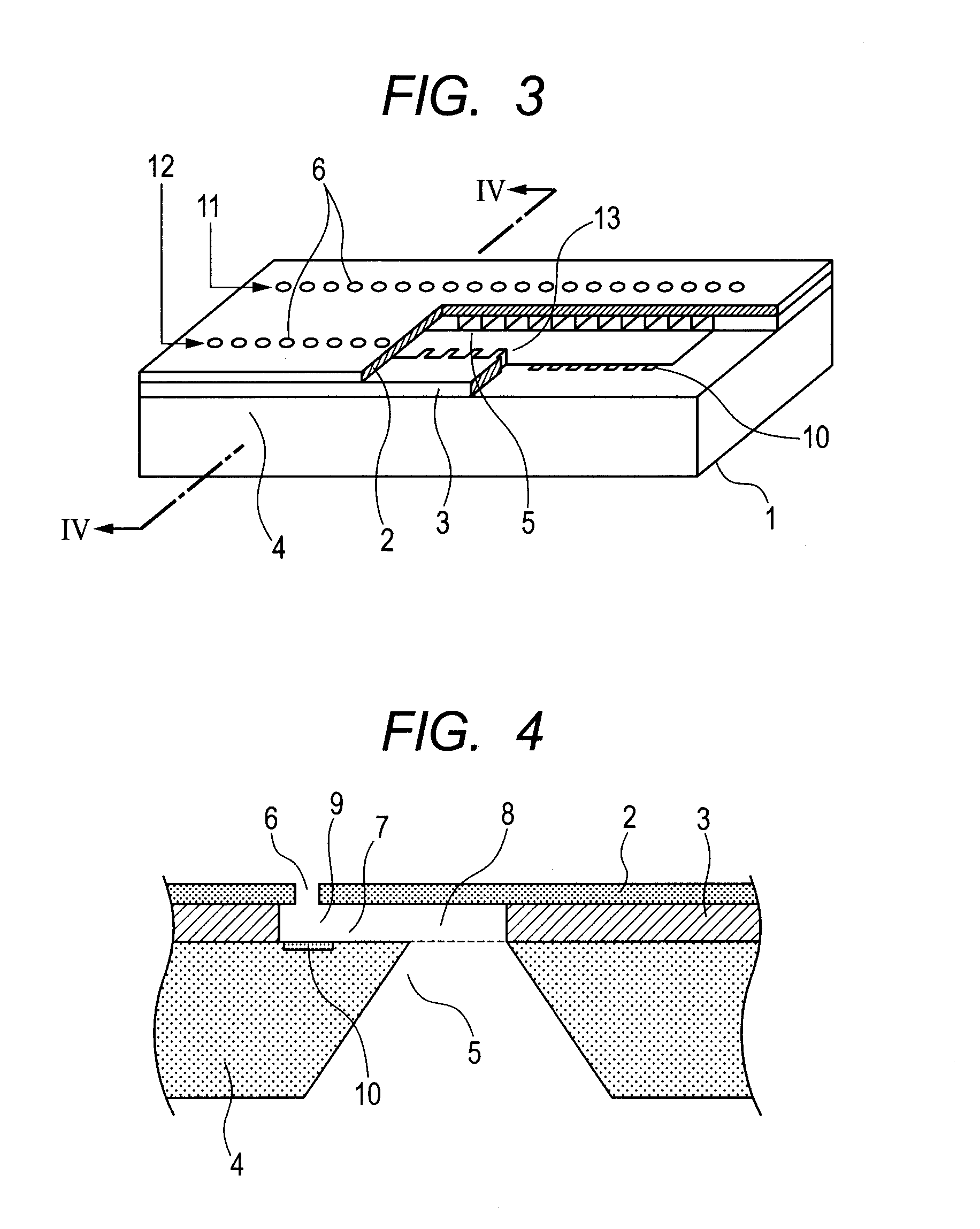

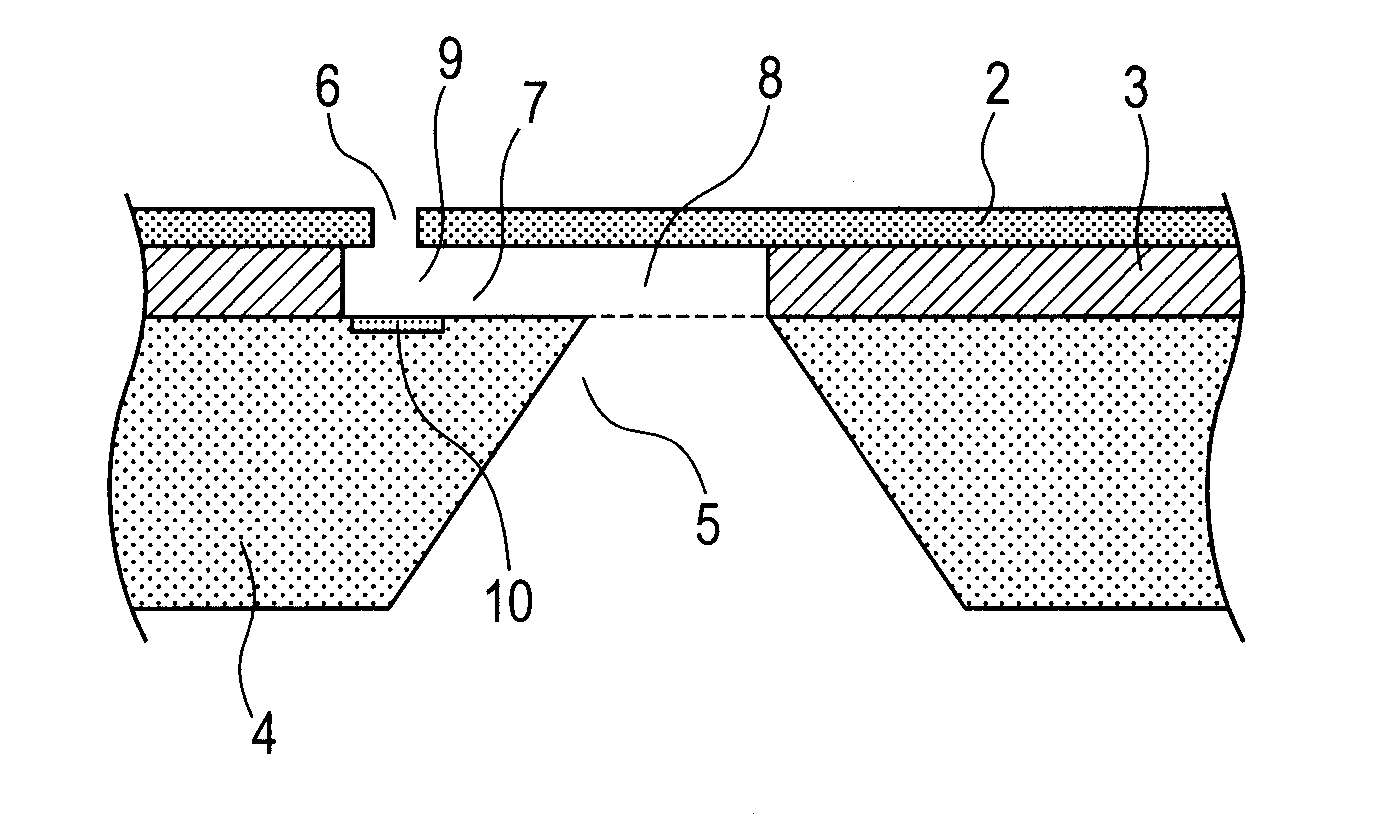

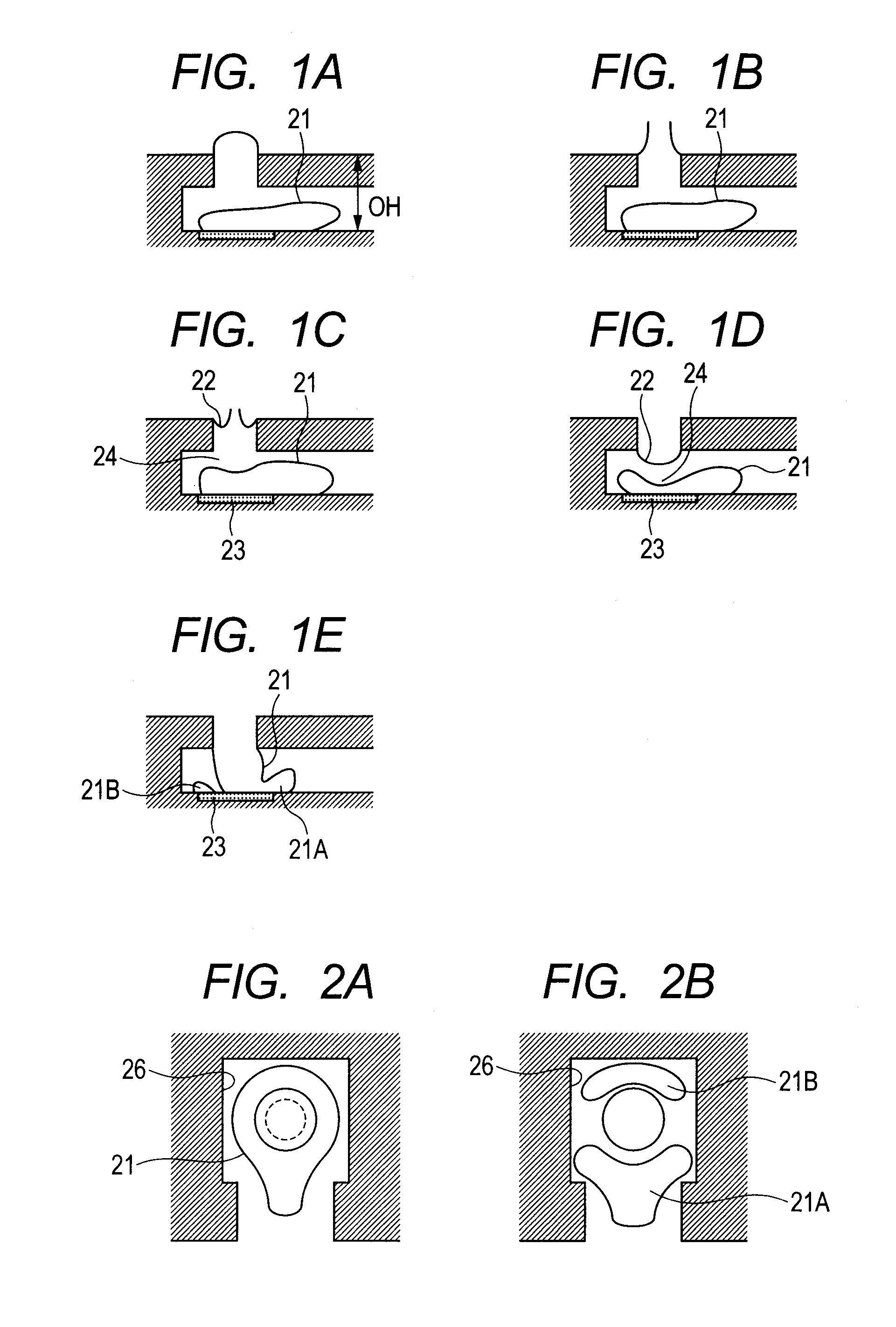

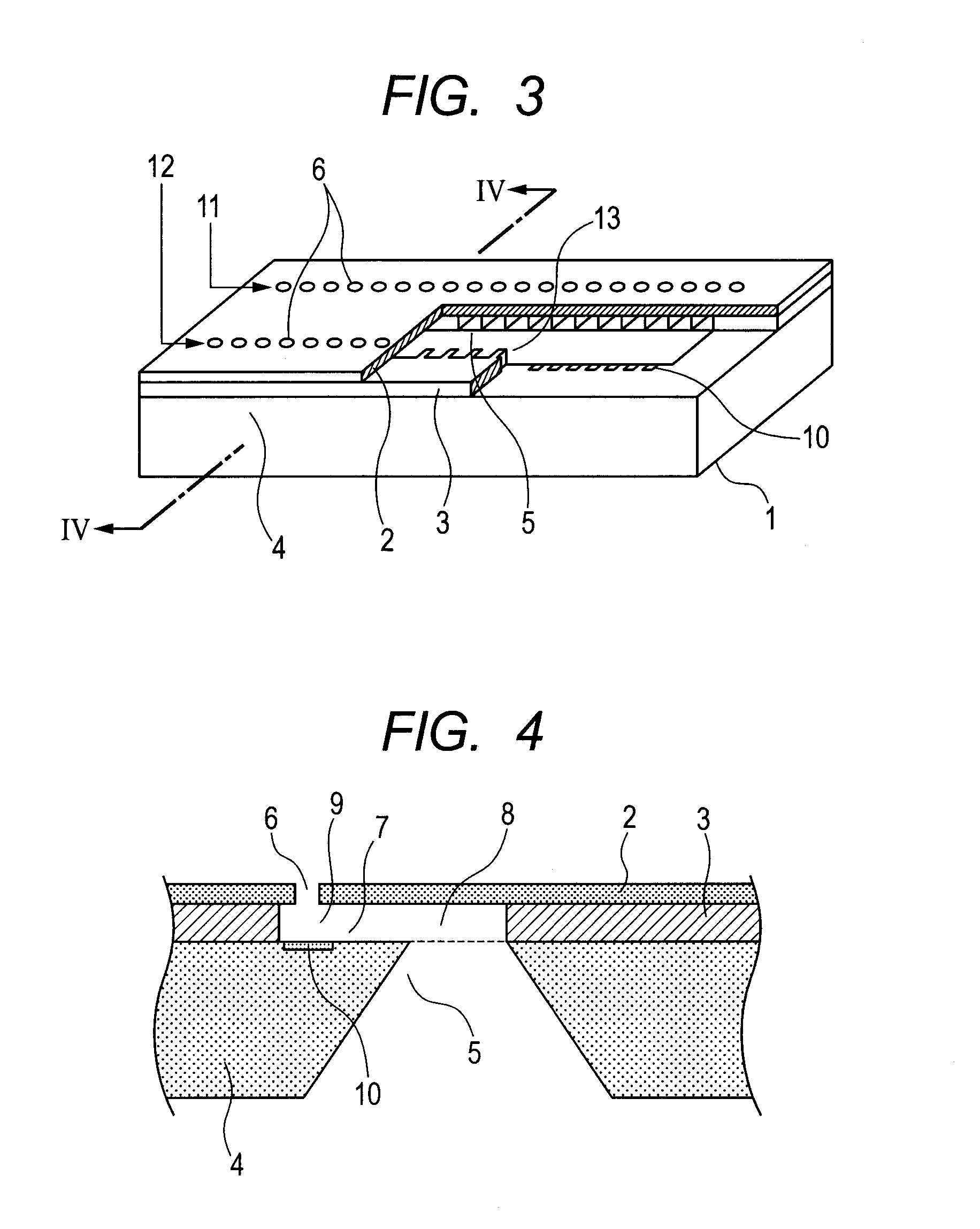

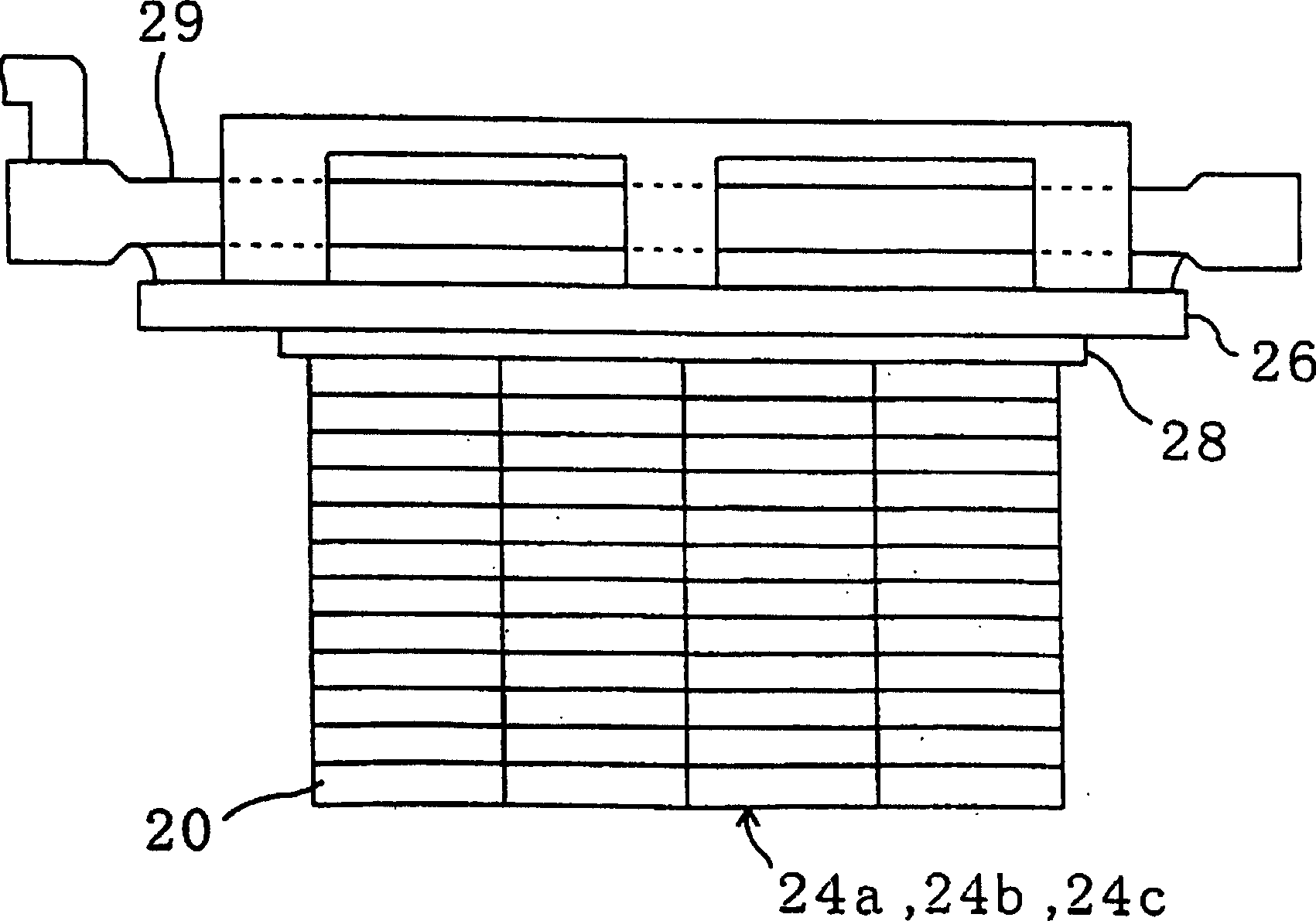

Liquid discharge head with multi-section energy application chambers

Provided is a liquid discharge head including a discharge port; an energy application chamber that includes a heat generating element, and communicates with the discharge port; and a flow path that supplies the liquid to the energy application chamber, wherein the energy application chamber includes a first energy application chamber communicating with the discharge port, and a second energy application chamber communicating with the first energy application chamber and the flow path, a distance between facing side walls of the second energy application chamber is larger than that of the first energy application chamber in a section perpendicular to a liquid supply direction from the flow path to the energy application chamber, and for side walls of the energy application chambers formed on a back side in the liquid supply direction, the first energy application chamber and the second energy application chamber share the wall.

Owner:CANON KK

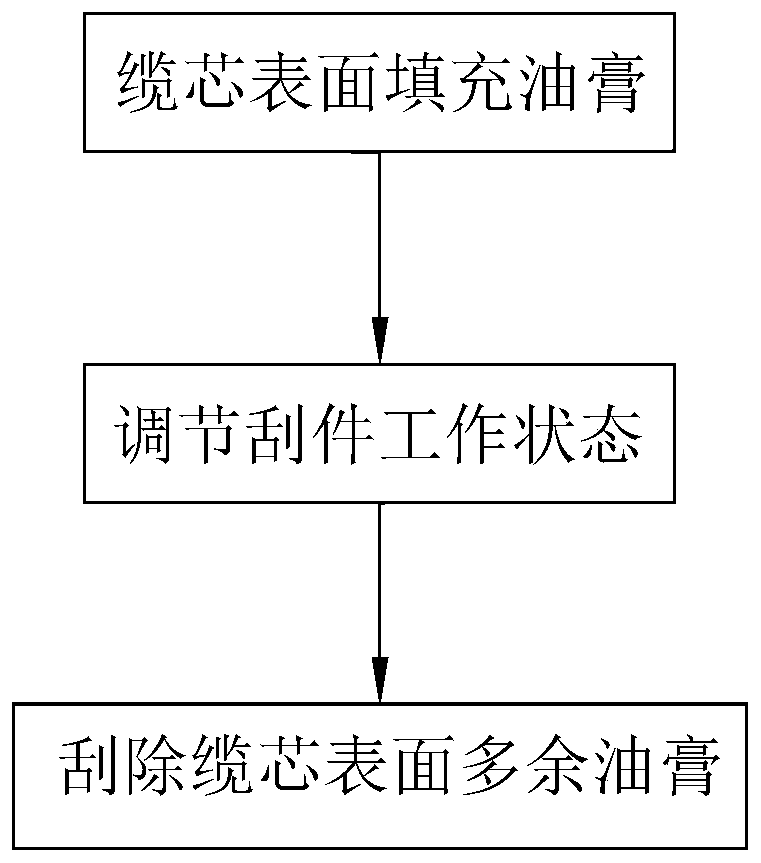

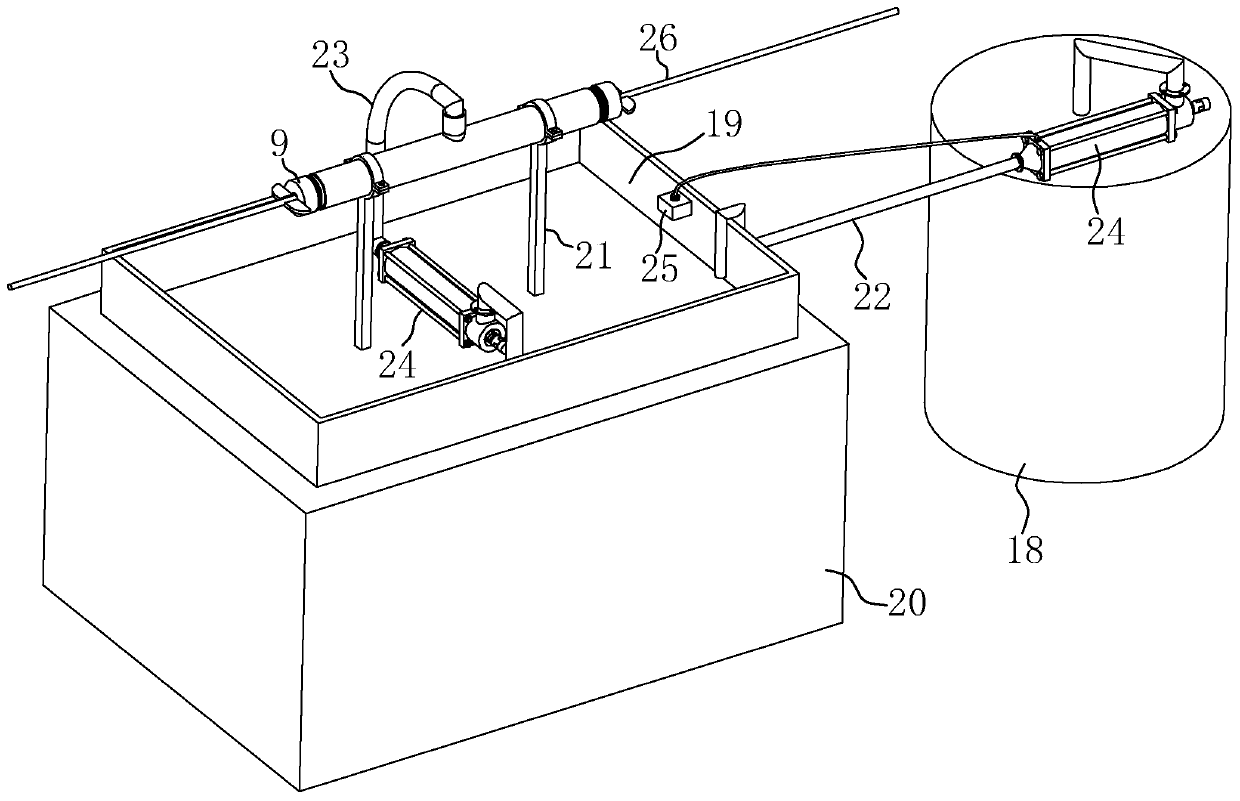

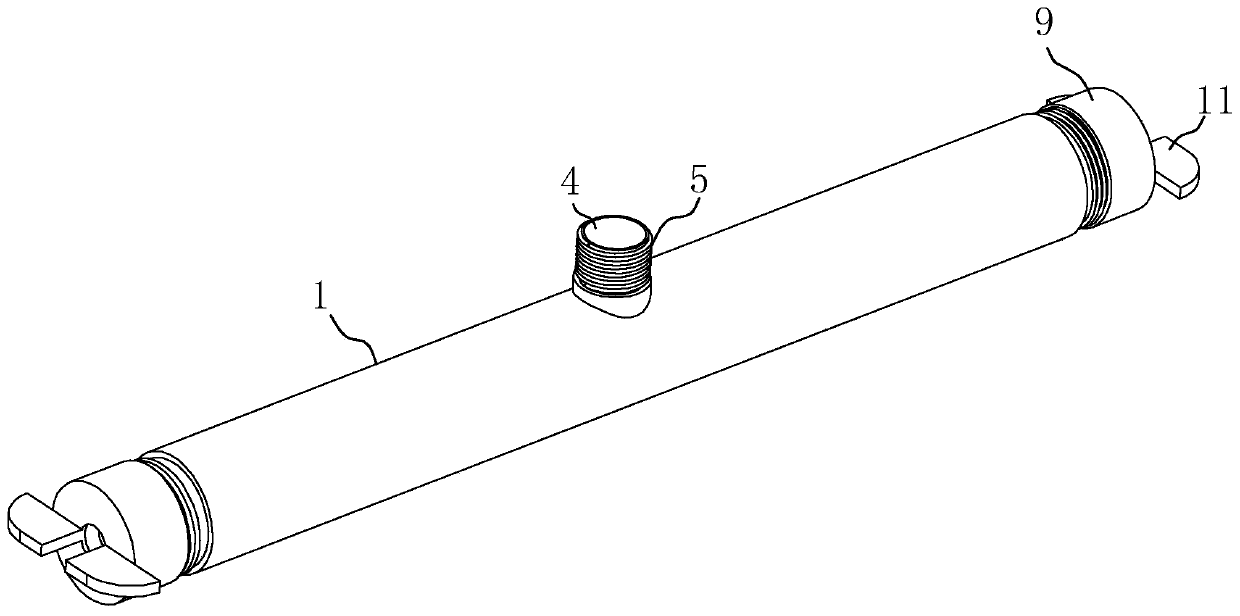

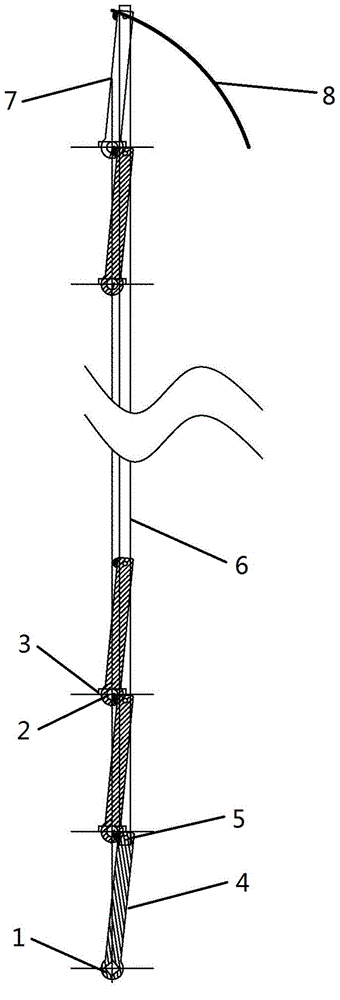

Jelly filling process

InactiveCN110673284ATake advantage ofReduce wasteFibre mechanical structuresProcess engineeringMechanical engineering

The invention discloses a jelly filling process. The jelly filling process comprises the following steps: firstly, forming a jelly layer on the surface of a cable core; then adjusting a scraping pieceto a working state of scraping the jelly; and finally making the scraping piece move relative to the cable core in order to scrape excess jelly on the surface of the cable core. After the surface ofthe cable core is filled with the jelly, a process of adjusting the scraping piece and scraping the jelly is added, so that the excess jelly can be scraped off in time after the surface of the cable core is fully filled with the jelly, thereby ensuring the normal proceeding of subsequent production and processing of the cable core, and effectively reducing the waste of the jelly at the same time.The scraped jelly can be reused in the step 1.

Owner:SHENZHEN XIN CHANG LONG NEW MATERIALS TECH CO LTD

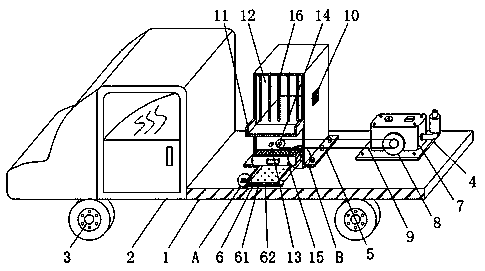

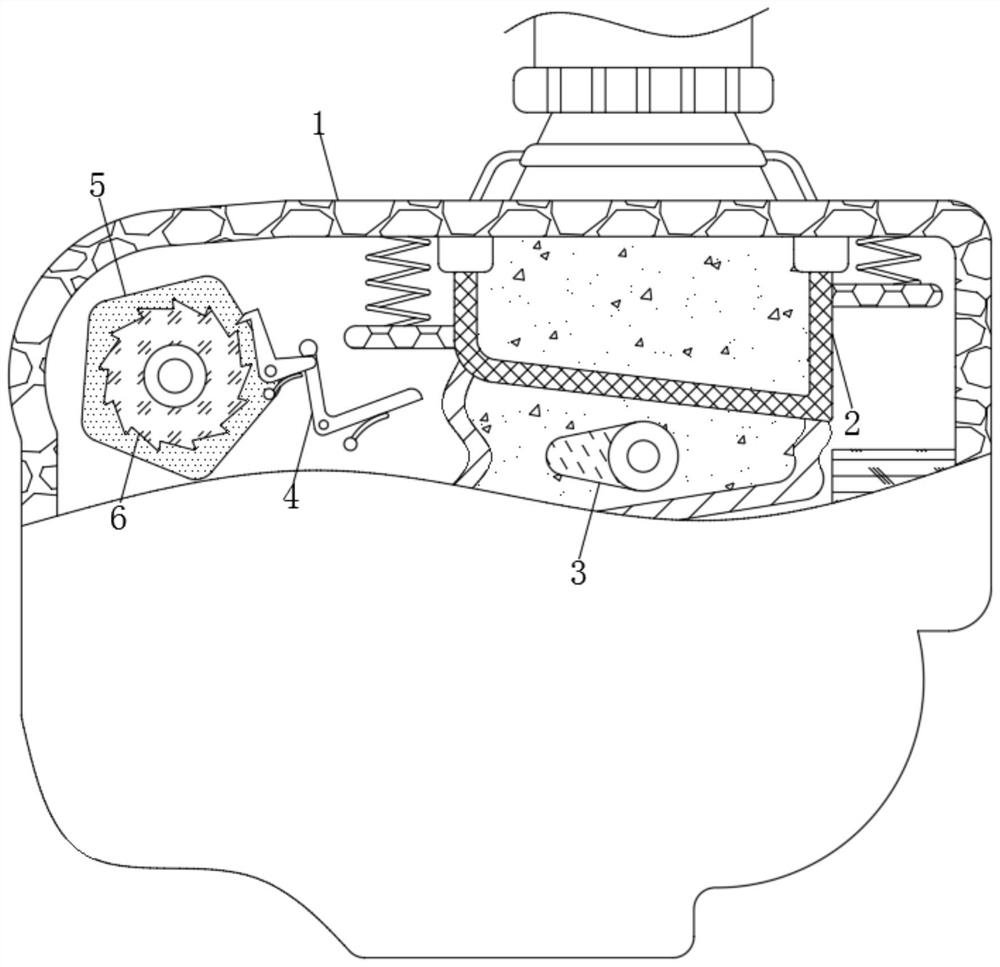

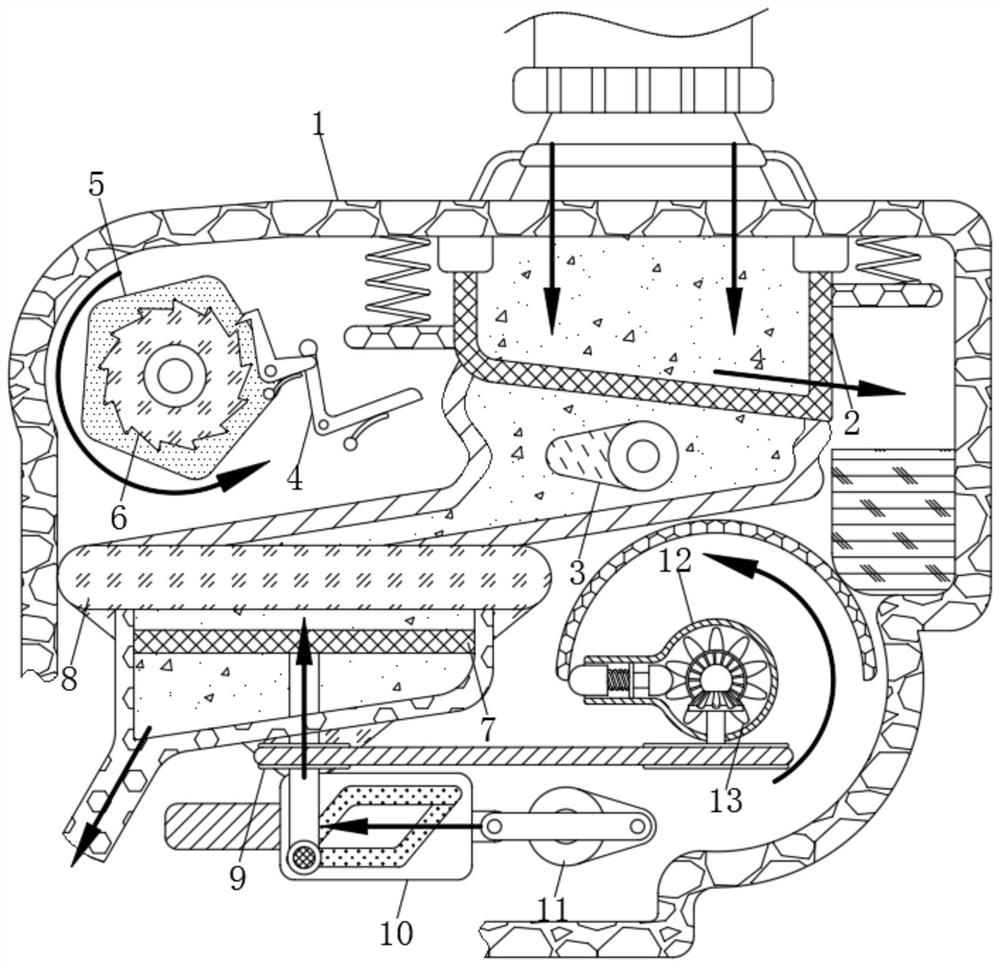

Movable type tree root crushing machine

The invention discloses a movable type tree root crushing machine. The machine comprises a vehicle body, a vehicle head is arranged at one end of the vehicle body, wheels are arranged below the vehicle body, and a diesel engine base is fixedly installed on the upper surface of the vehicle body; a rack is arranged on the portion, close to one side of the diesel engine base, of the upper surface ofthe vehicle body; a transmission mechanism is longitudinally arranged on the portion, close to the inner side of the rack, on the upper surface of the vehicle body; a diesel engine is installed on theupper surface of the diesel engine base. The cost is better reduced through the design of the diesel engine, and sequential processing is utilized, so that oil is saved while labor is saved during cutting. The working efficiency is high, the product processing speed is high, and meanwhile, finished products are very ordered. Movable processing is utilized, so that the manual material conveying cost is reduced, the cost is reduced, and no matter which position needs the machine, people can drive in the fields to arrive at the position. The tree root crushing machine is good in root crushing effect, easy to operate and high in practicality.

Owner:翁显武

Liquid discharge head

Provided is a liquid discharge head including a discharge port; an energy application chamber that includes a heat generating element, and communicates with the discharge port; and a flow path that supplies the liquid to the energy application chamber, wherein the energy application chamber includes a first energy application chamber communicating with the discharge port, and a second energy application chamber communicating with the first energy application chamber and the flow path, a distance between facing side walls of the second energy application chamber is larger than that of the first energy application chamber in a section perpendicular to a liquid supply direction from the flow path to the energy application chamber, and for side walls of the energy application chambers formed on a back side in the liquid supply direction, the first energy application chamber and the second energy application chamber share the wall.

Owner:CANON KK

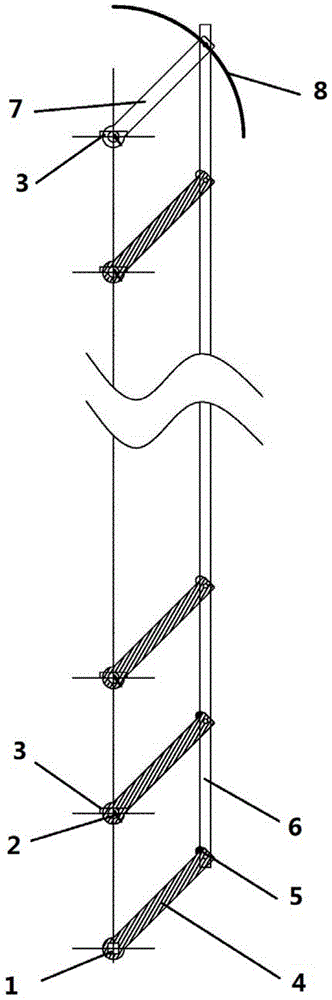

Charging switch used for improving output efficiency of impulse voltage generator

InactiveCN104377062AStable and reliable opening and closingReduce discharge efficiencySwitch power arrangementsCharge voltageCharge and discharge

The invention provides a charging switch used for improving output efficiency of an impulse voltage generator. The charging switch comprises fixing bearings and rotary conducting rods arranged on a power insulating rod at equal intervals. Each fixing bearings is mounted on a support column flange of the charging end at each level of the impulse voltage generator, and is provided with a fixed electrode. If each of contact electrodes is connected with the corresponding fixed electrode, charging voltages at all levels of the impulse voltage generator are equal, and charging nonuniformity of a traditional impulse voltage generator is eliminated; if each contact electrode is disconnected with the corresponding fixed electrode, the impulse voltage generator is disconnected at each level, and energy loss in the discharging process of a charging resistor of the traditional impulse voltage generator is eliminated. Compared with the prior art, the charging switch has the advantages that switching between charging and discharging circuit topology of the impulse voltage generator is realized effectively, and the purpose of outputting efficient long-wave front operation impulse voltage is achieved.

Owner:STATE GRID CORP OF CHINA +1

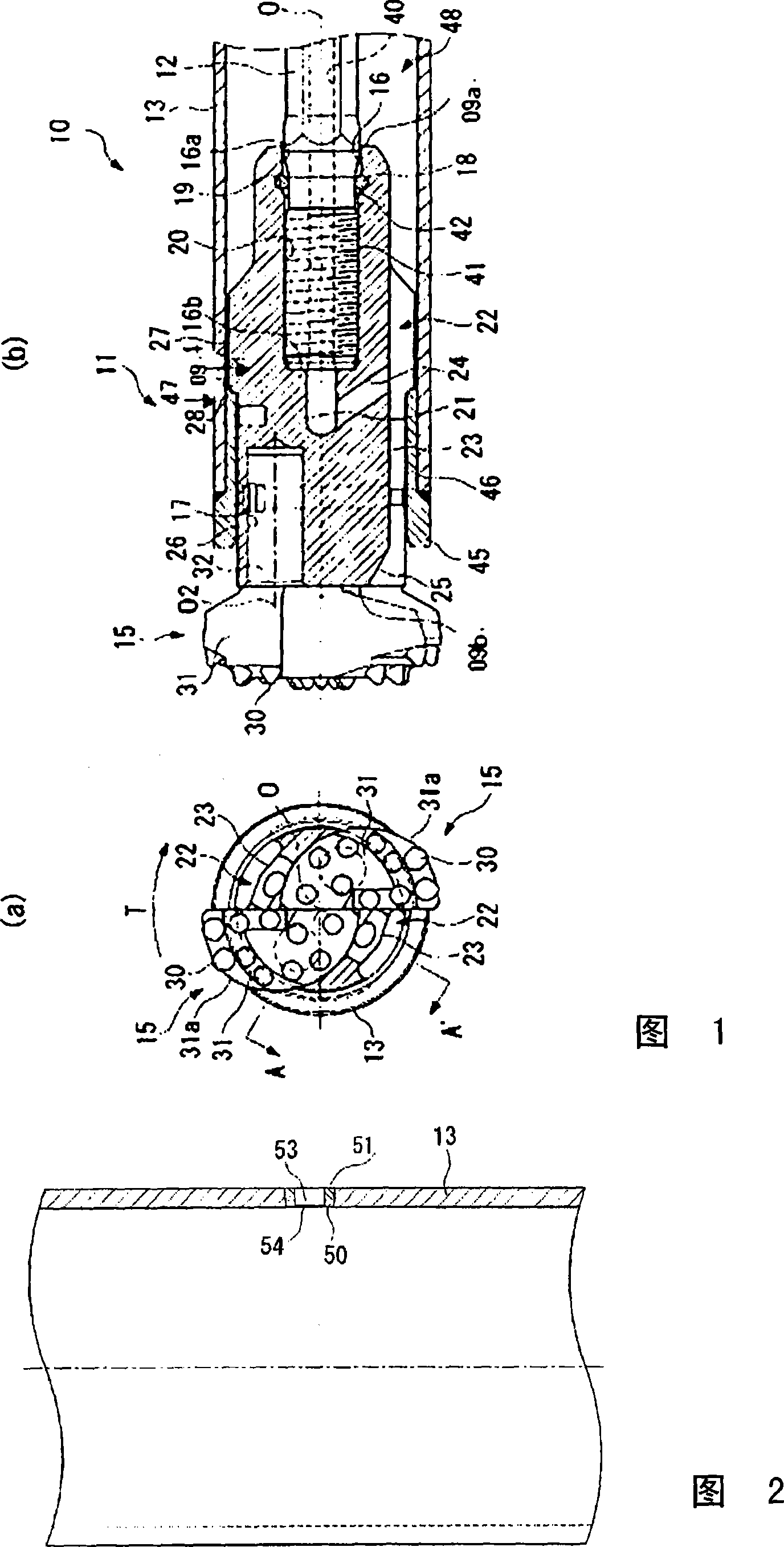

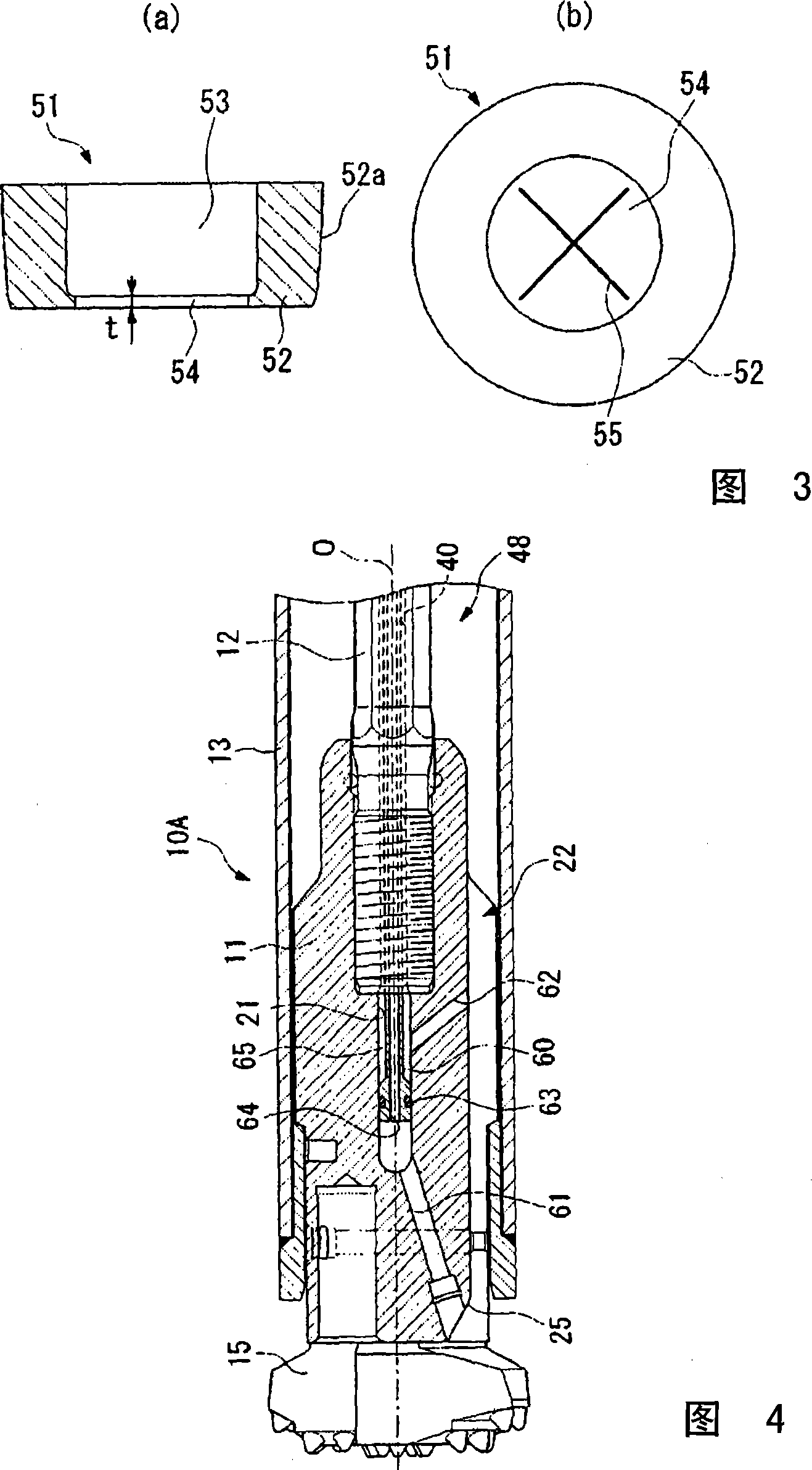

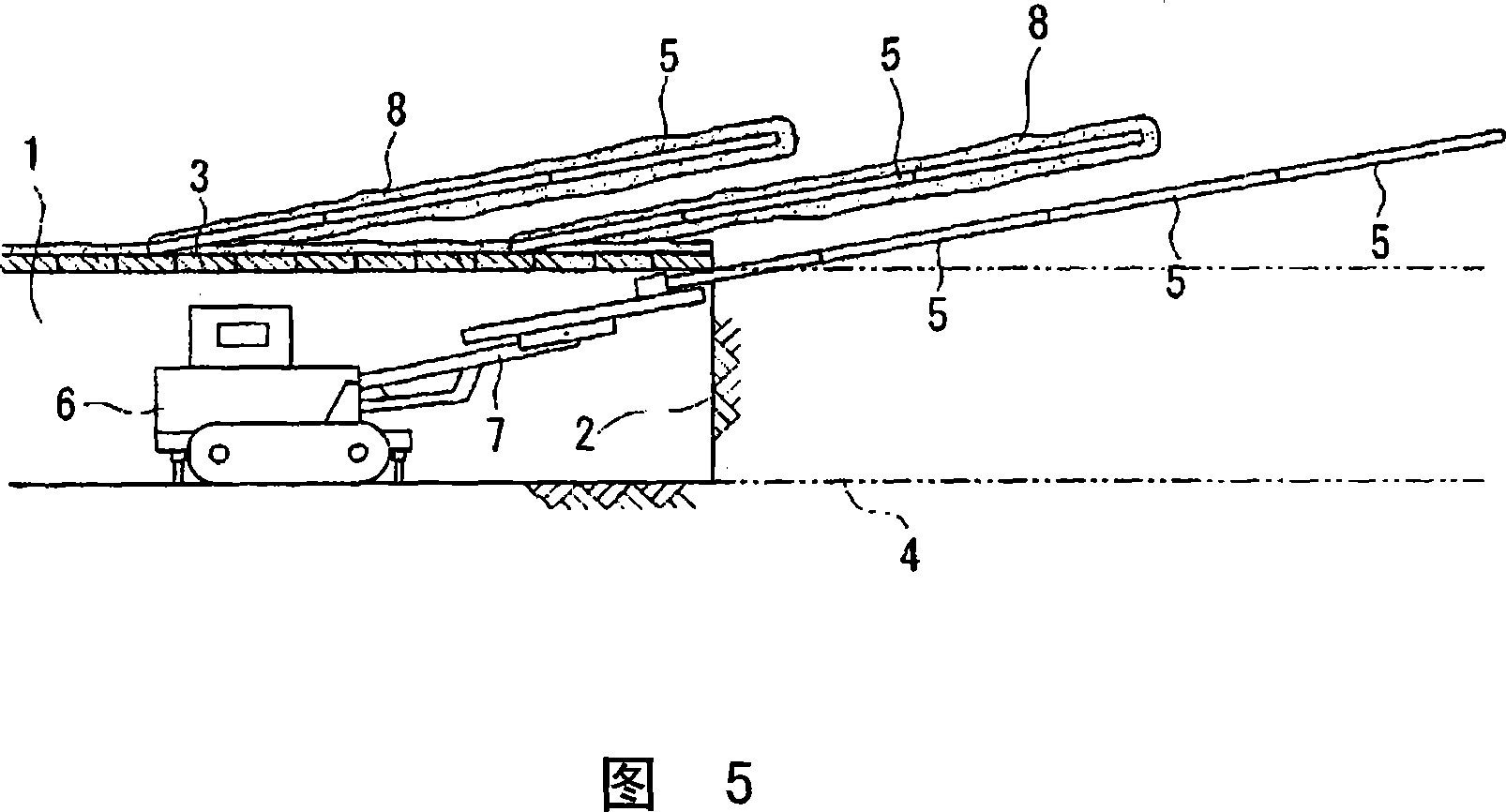

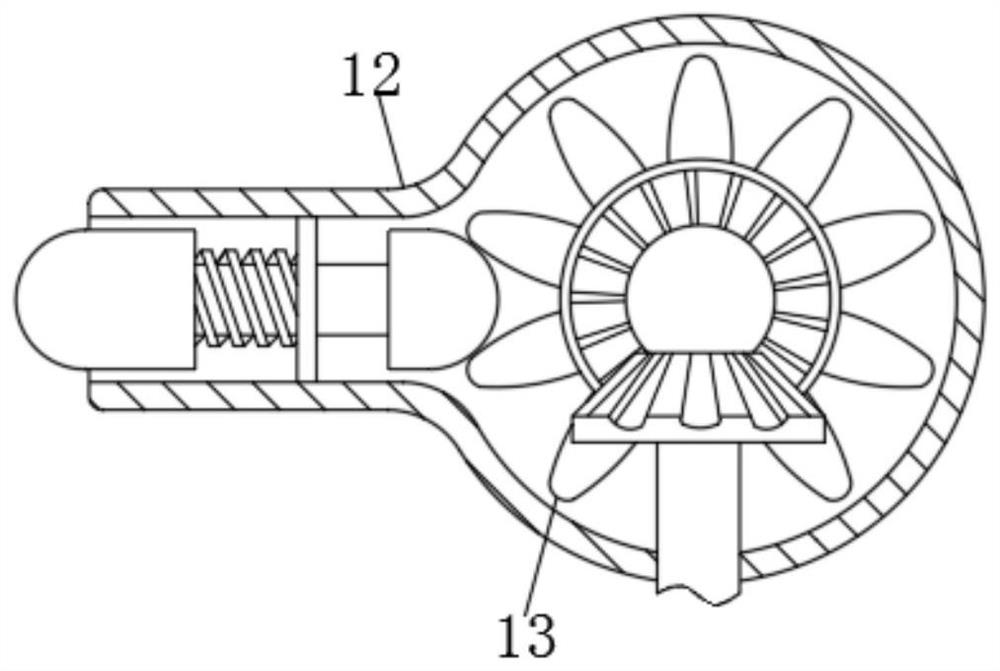

Excavating tool and steel pipe forepoling method

An excavating tool capable preventing the natural ground from being loosened by excavated water and smoothly discharging excavated chips and a steel pipe forepoling method capable of securely providing earth reinforcing effects by using the excavating tool. The excavating tool (10) comprises a boring rod (12) rotatingly drivable around an axis (0), a tool body (11) fitted to the front of the boring rod (12) in the forward excavating direction, and a cylindrical steel pipe (13) having a specified clearance relative to the boring rod (12) with the boring rod (12) inserted therein. The excavating tool is characterized in that a flow passage (21) for supplying drilling water to the axial forward direction is formed in the tool body (11), and a fluid supply port (24) communicating with the flow passage (21) and jetting the drilling water is formed only at a position on the tool body opening to the inside of the steel pipe (13) toward the rear of the tool body (11) in the forward excavating direction.

Owner:MITSUBISHI MATERIALS CORP

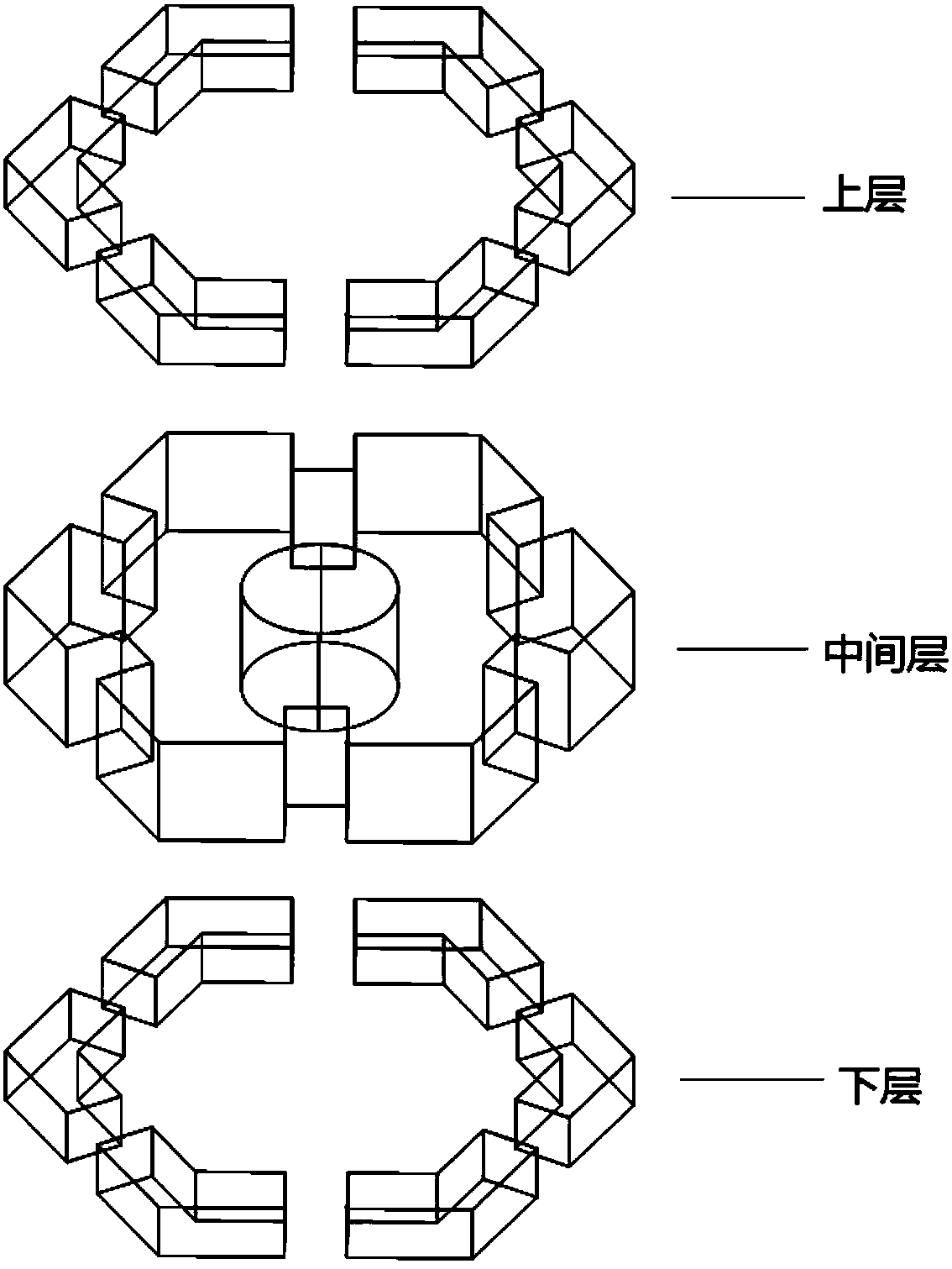

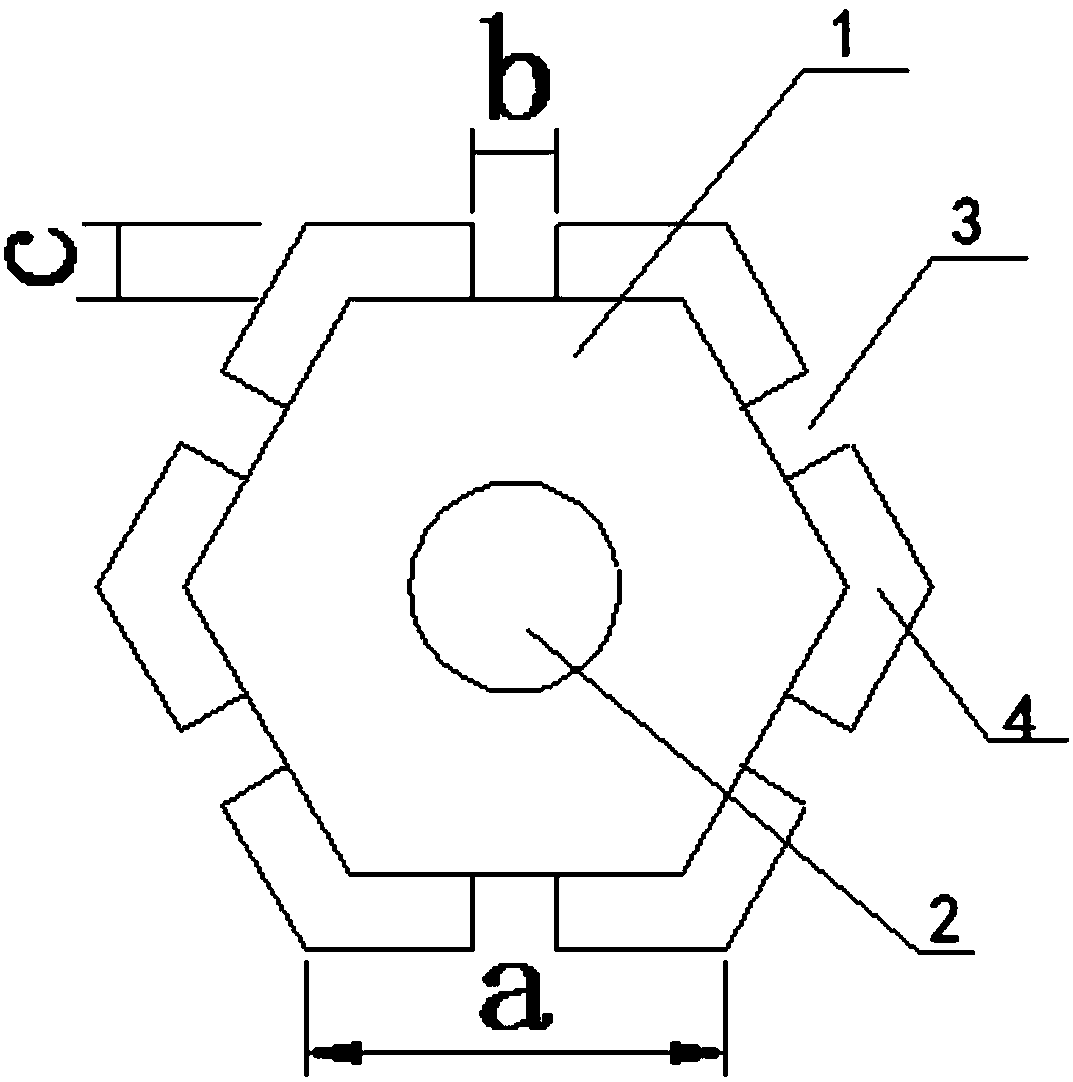

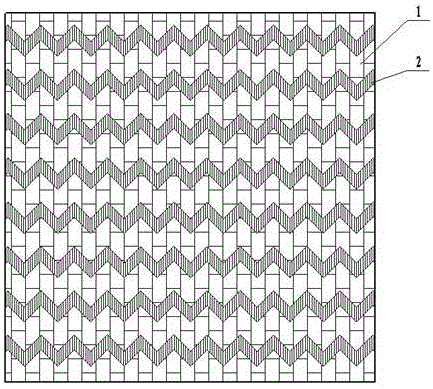

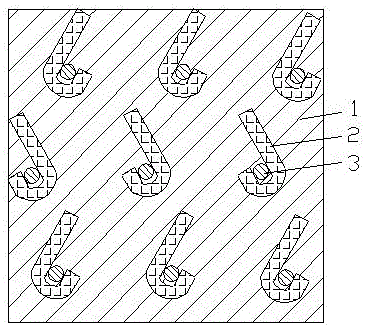

Wave dissipating prefabricated block

InactiveCN108625340AImprove connection strengthLower wave climbCoastlines protectionConvex structureEngineering

The invention discloses a wave dissipating prefabricated block. The wave dissipating prefabricated block comprises a prefabricated block body in a regular hexagon shape. A through hole is formed in the center of the prefabricated block body, each edge of the prefabricated block body is provided with a notch, the cross section of each notch is rectangular, the notches are as high as the prefabricated block body, and each notch is located in the center position of the corresponding edge of the prefabricated block body. The upper surface and the lower surface of the prefabricated block body are covered with a plurality of convex blocks. The surface, directly making contact with waves, of the wave dissipating prefabricated block is of a concave-convex structure, wave runup can be effectively reduced, the impact force of the waves can also be effectively buffered, and the wave dissipating effect is achieved. Meanwhile, the circular through hole is formed in the center portion of the wave dissipating prefabricated block as a water inlet, part of water enters the other side of the prefabricated block when the waves beat against and impact the surface of an embankment protection slope, andthus part of beating pressure of the waves can be dissipated.

Owner:HOHAI UNIV

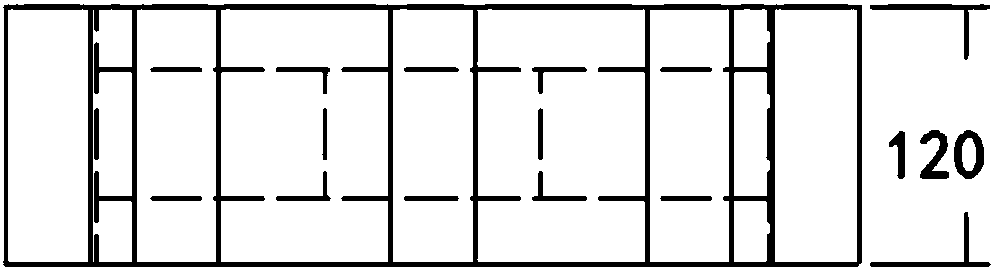

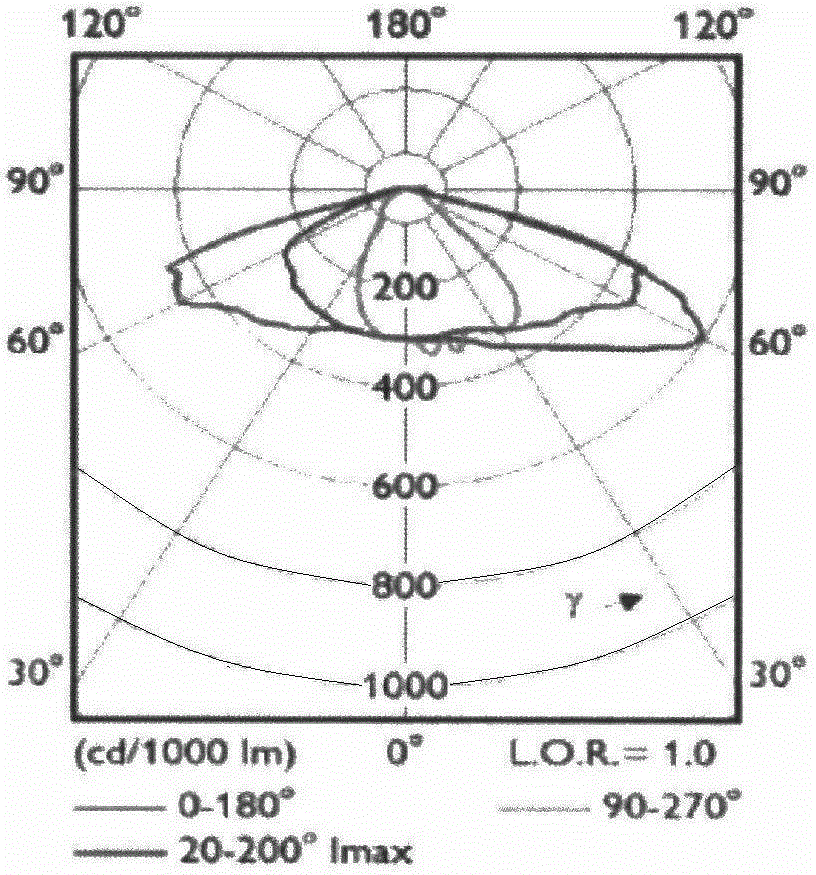

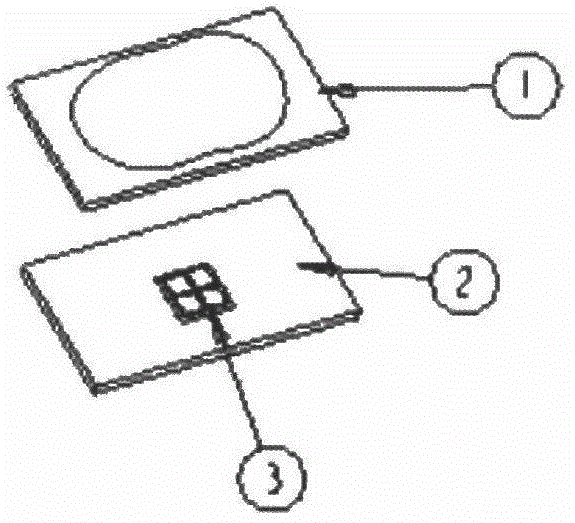

Light distribution structure of light-emitting diode (LED) lamp

InactiveCN105351892AOptimize sizeGood cooling effectLight fasteningsSemiconductor devices for light sourcesPolycarbonatePrinted circuit board

The invention discloses a light distribution structure of a light-emitting diode (LED) lamp. The light distribution structure comprises a printed circuit board (PCB) aluminum substrate provided with a lamp bead group in a welding mode and a plastic lens used for covering the lamp bead group; the lamp bead group is composed of four medium-power 3030 bicrystal lamp beads which are distributed in a square shape; the plastic lens is provided with a convex curved surface cover used for covering the lamp bead group; the plastic lens is made of an ultraviolet-proof polycarbonate (PC) material. The light distribution structure of the LED lamp is compact and reasonable in structure and good in heat dissipation effect, and the size, lighting effect and cost performance ratio can be optimized when compared with the prior art.

Owner:苏州艾莱科光电科技有限公司

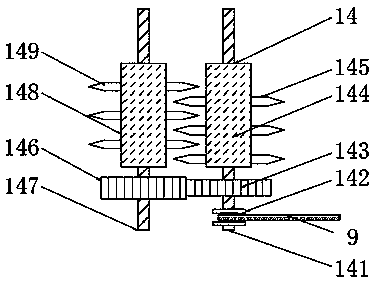

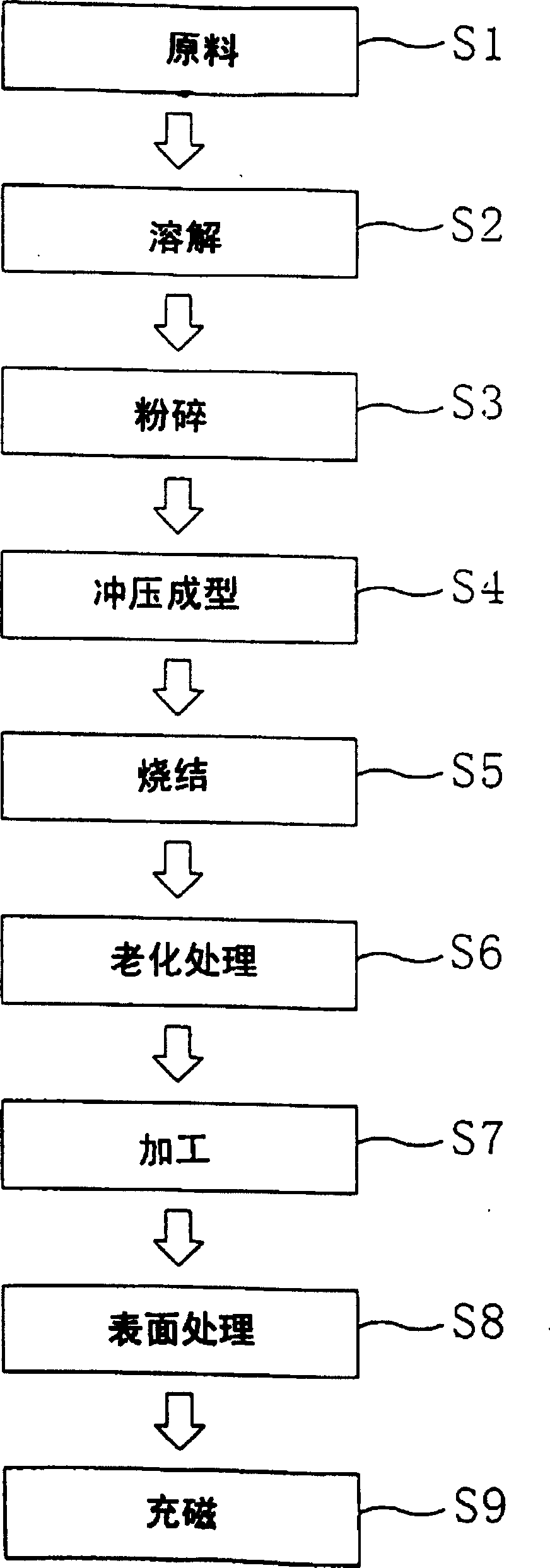

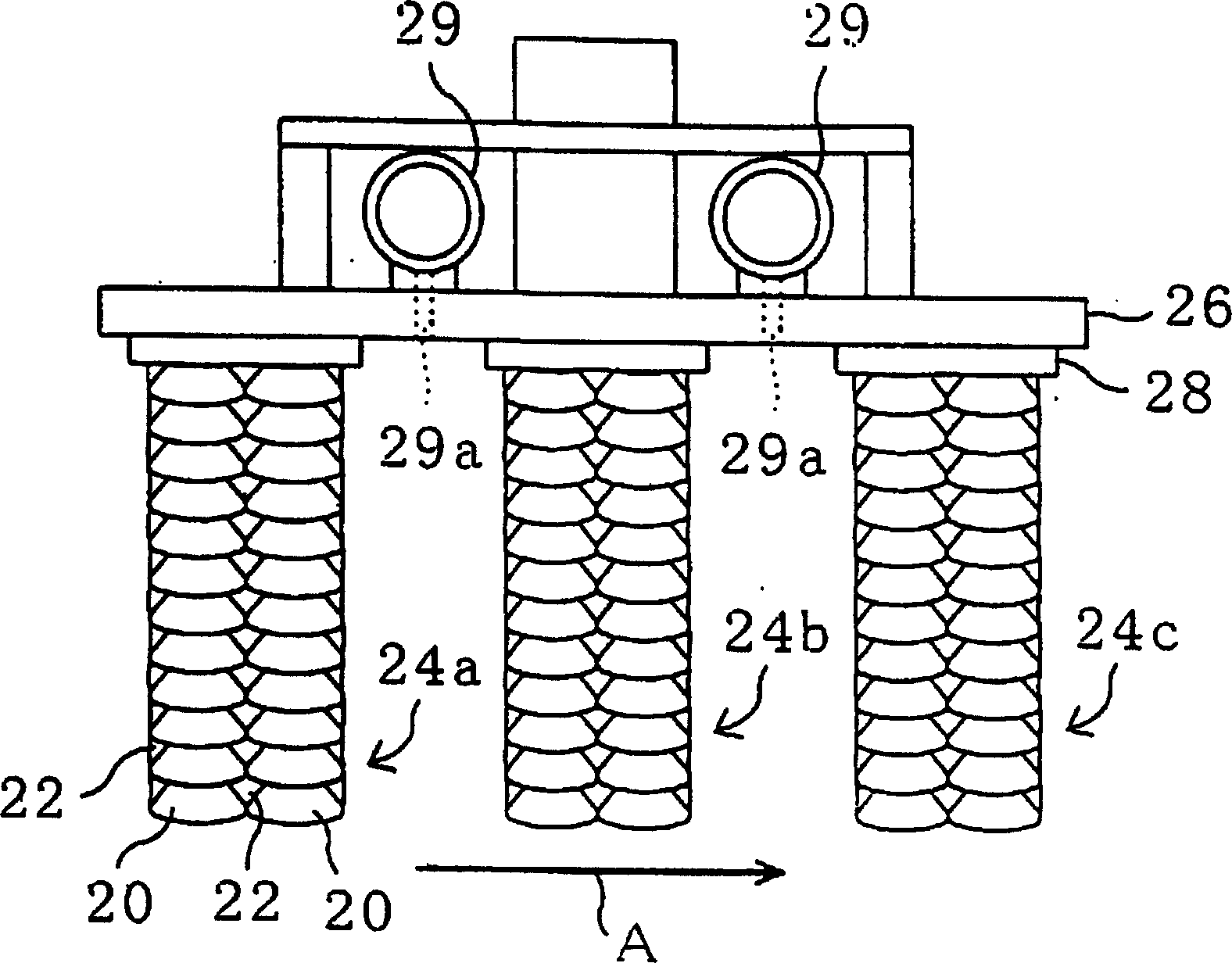

Method for cutting rare earth alloy with scroll saw and method for producing rare earth alloy plate

InactiveCN1118837CFully effective separationAvoid breakingMetal sawing devicesInductances/transformers/magnets manufactureRare earthSlurry

A method for cutting a rare earth alloy according to the present invention includes the steps of: a) supplying slurry containing abrasive grains onto a wire; and b) machining the rare earth alloy with the abrasive grains, interposed between the wire and the rare earth alloy, by running and pressing the wire against the rare earth alloy. The slurry contains, as a main component, oil in which the abrasive grains are dispersed, and the viscosity of the slurry at 25 DEG C is in the range from 92 to 175 mPa . sec.

Owner:HITACHI METALS LTD

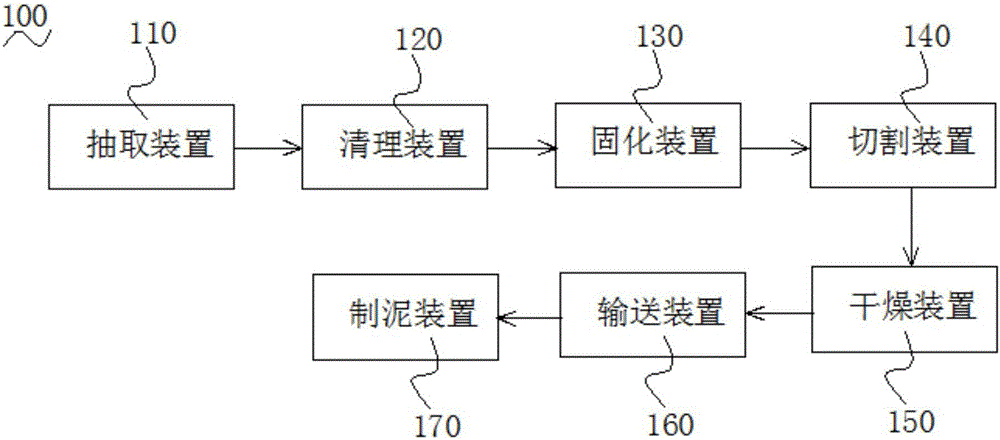

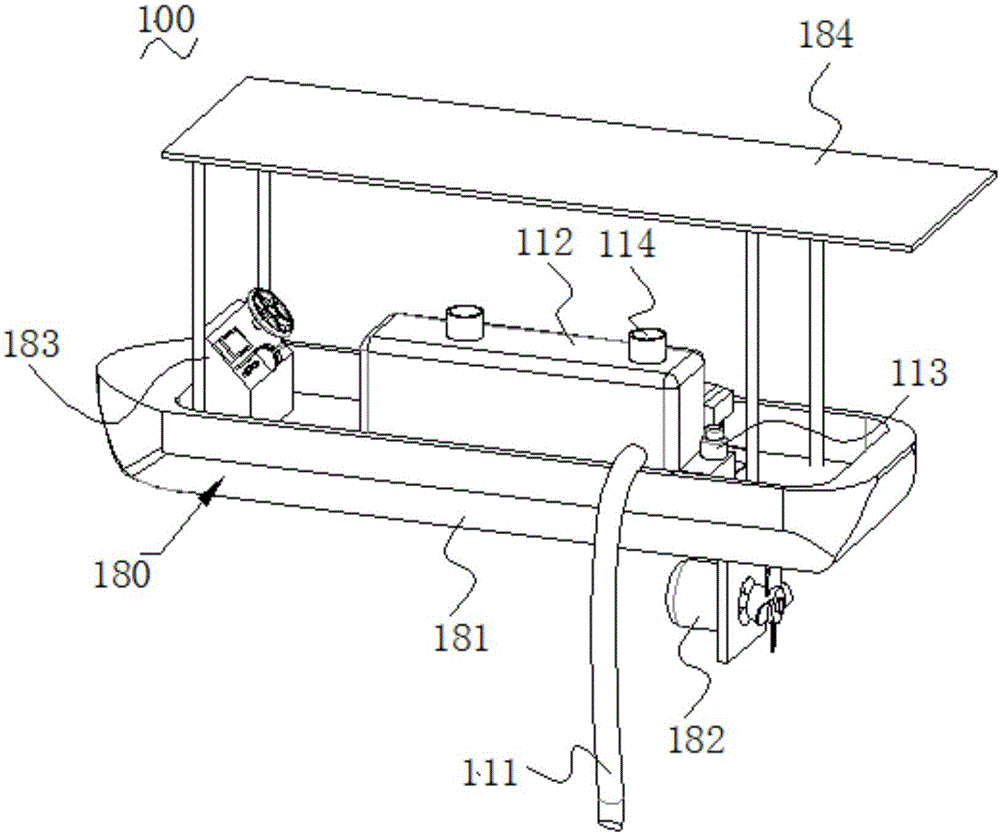

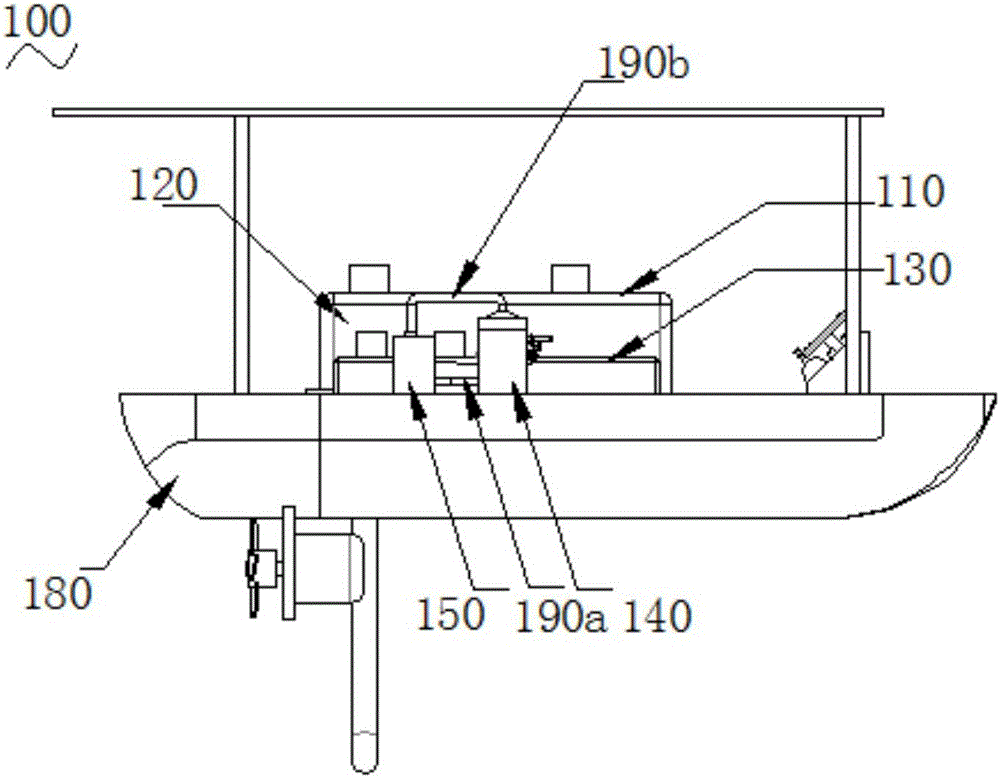

River channel sludge recycling system

PendingCN106145581ARealize resourcesRealize resource utilizationSludge treatment by de-watering/drying/thickeningSpecific water treatment objectivesSiltSludge

The invention relates to the technical field of river channel cleanout and particularly relates to a river channel sludge recycling system. The river channel sludge recycling system comprises an extraction device, a cleaning device, a solidifying device, a cutting device, a drying device, a conveying device and a cement producing device, wherein the extracting device is used for extracting sludge, the cleaning device is used for removing waste from the sludge, the solidifying device is used for solidifying the sludge into blocky sludge, the cutting device is used for cutting the blocky sludge into powdery sludge, the drying device is used for drying the powdery sludge, the conveying device is used for conveying the powdery sludge, and the cement producing device is used for producing cement from the powdery sludge. The river channel sludge recycling system is used for recycling the sludge, so that the wasting of resources is avoided, and secondary pollution is prevented.

Owner:东莞市众源环境投资有限公司

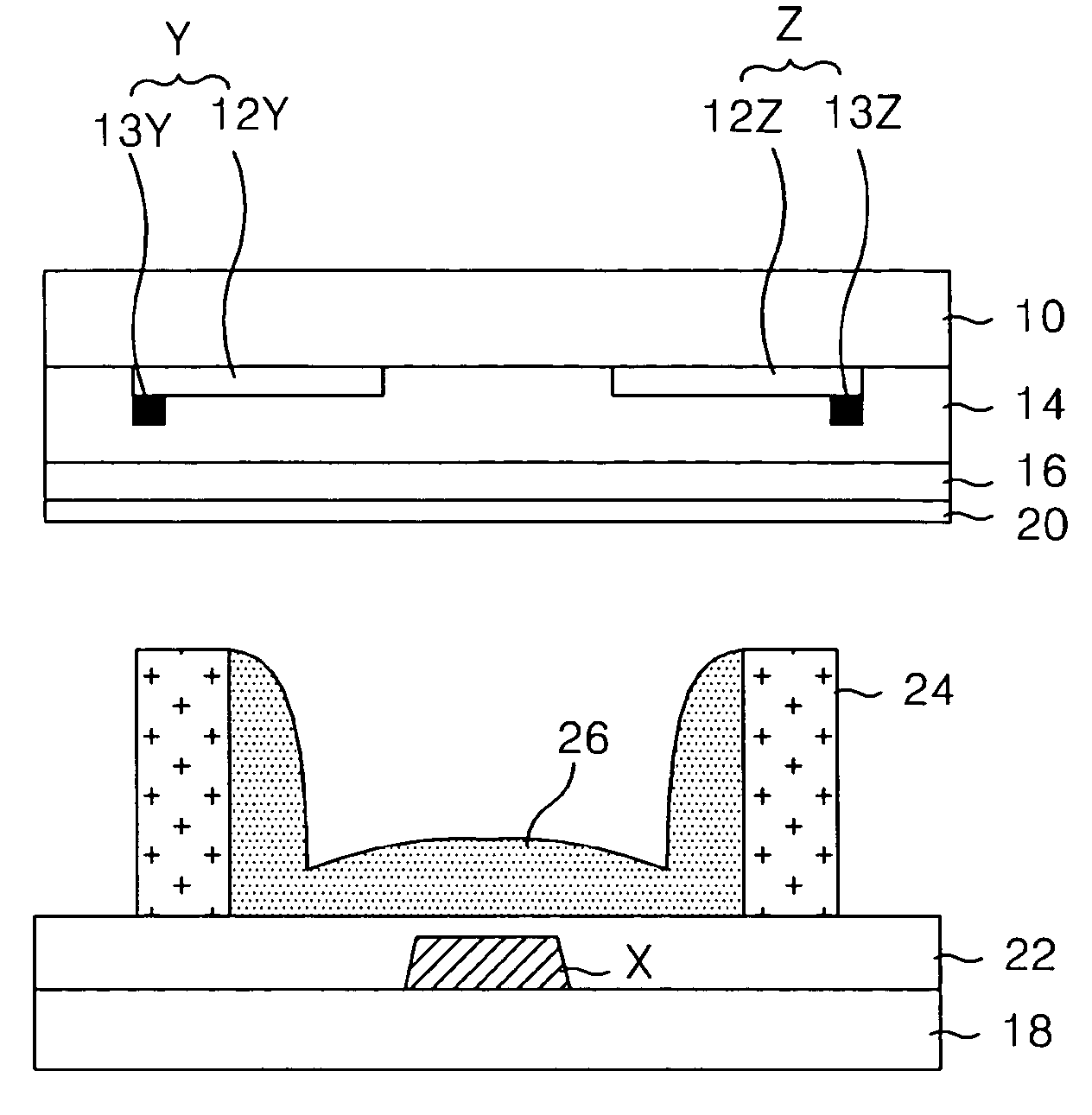

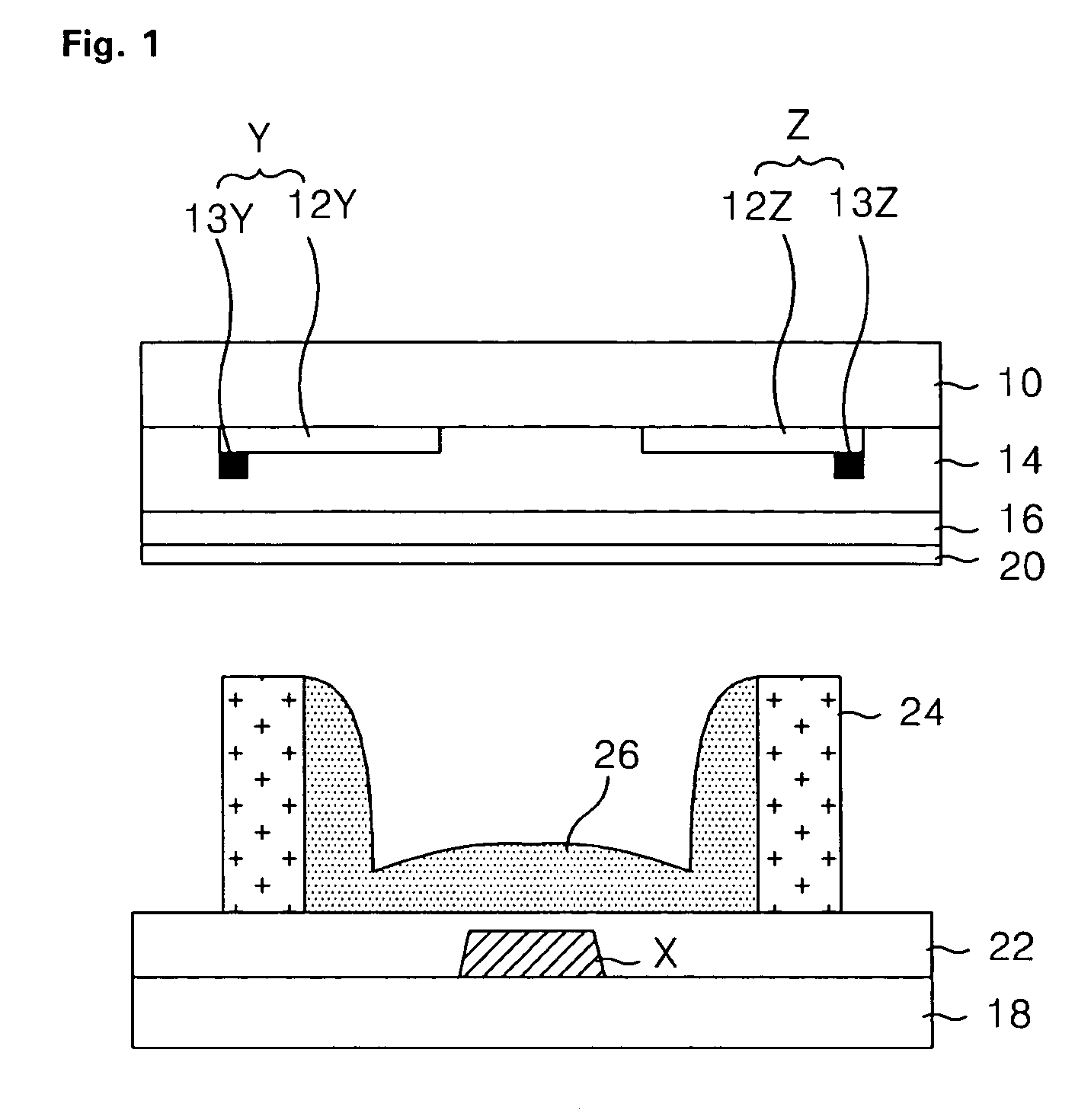

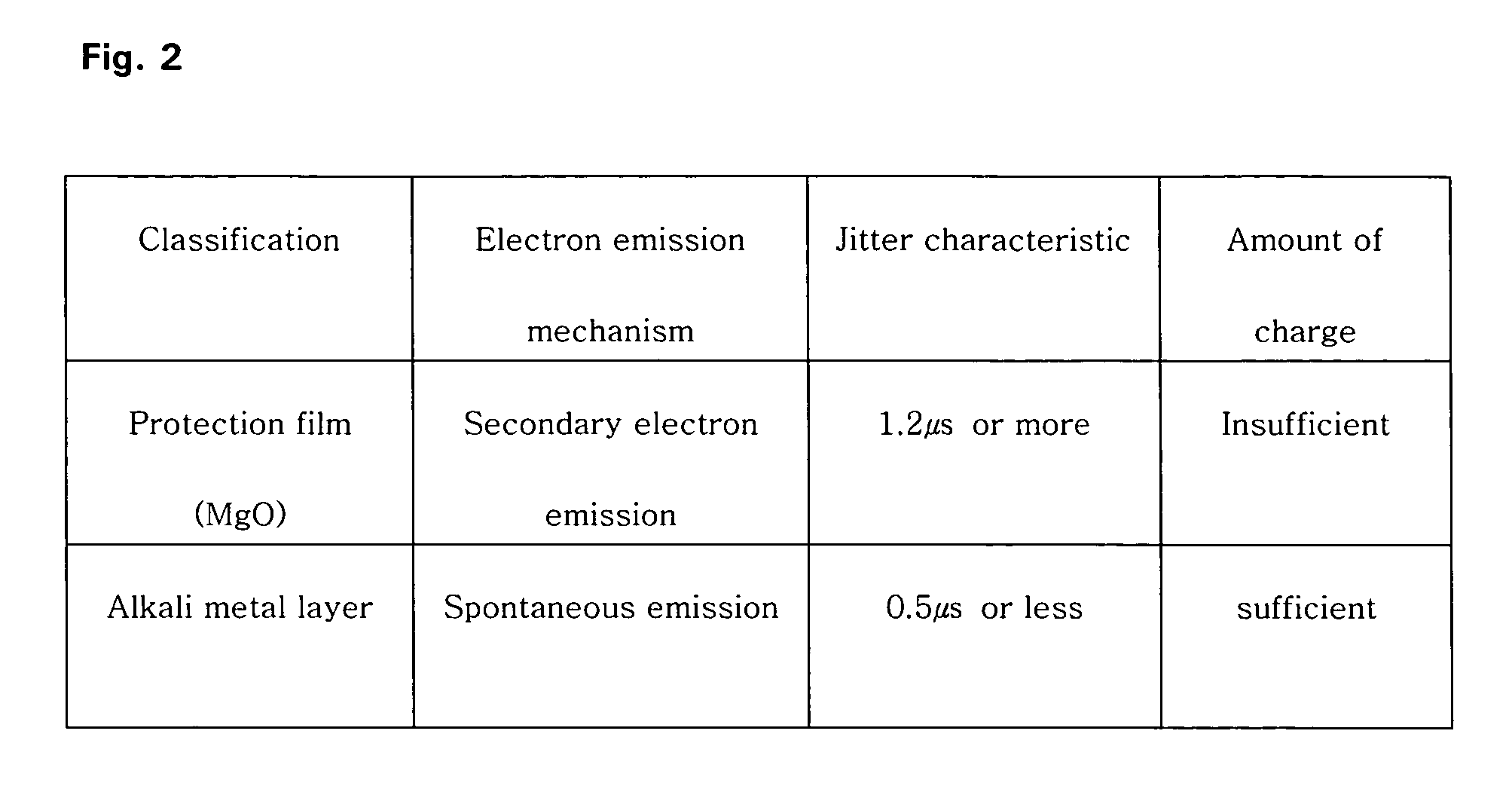

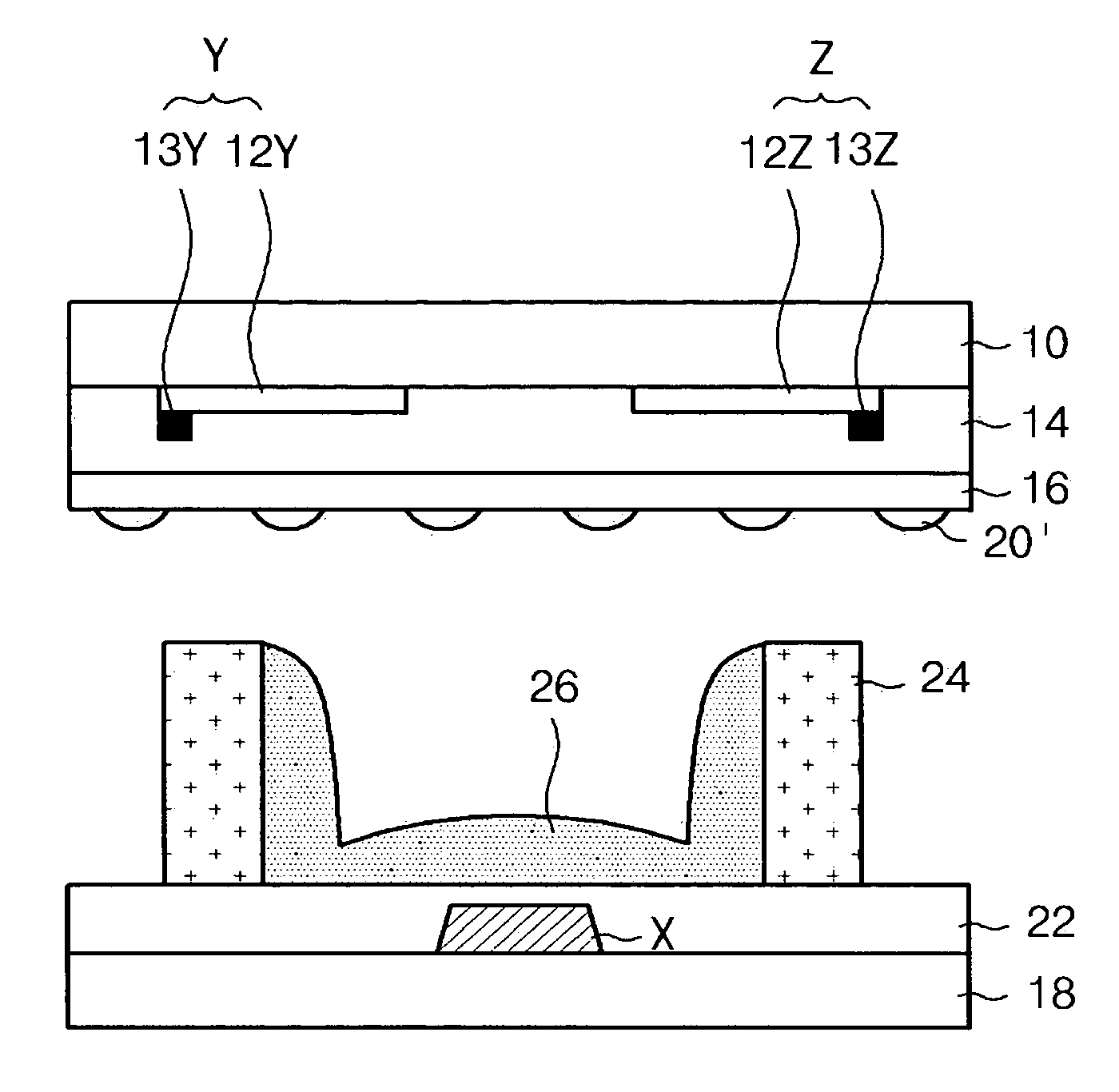

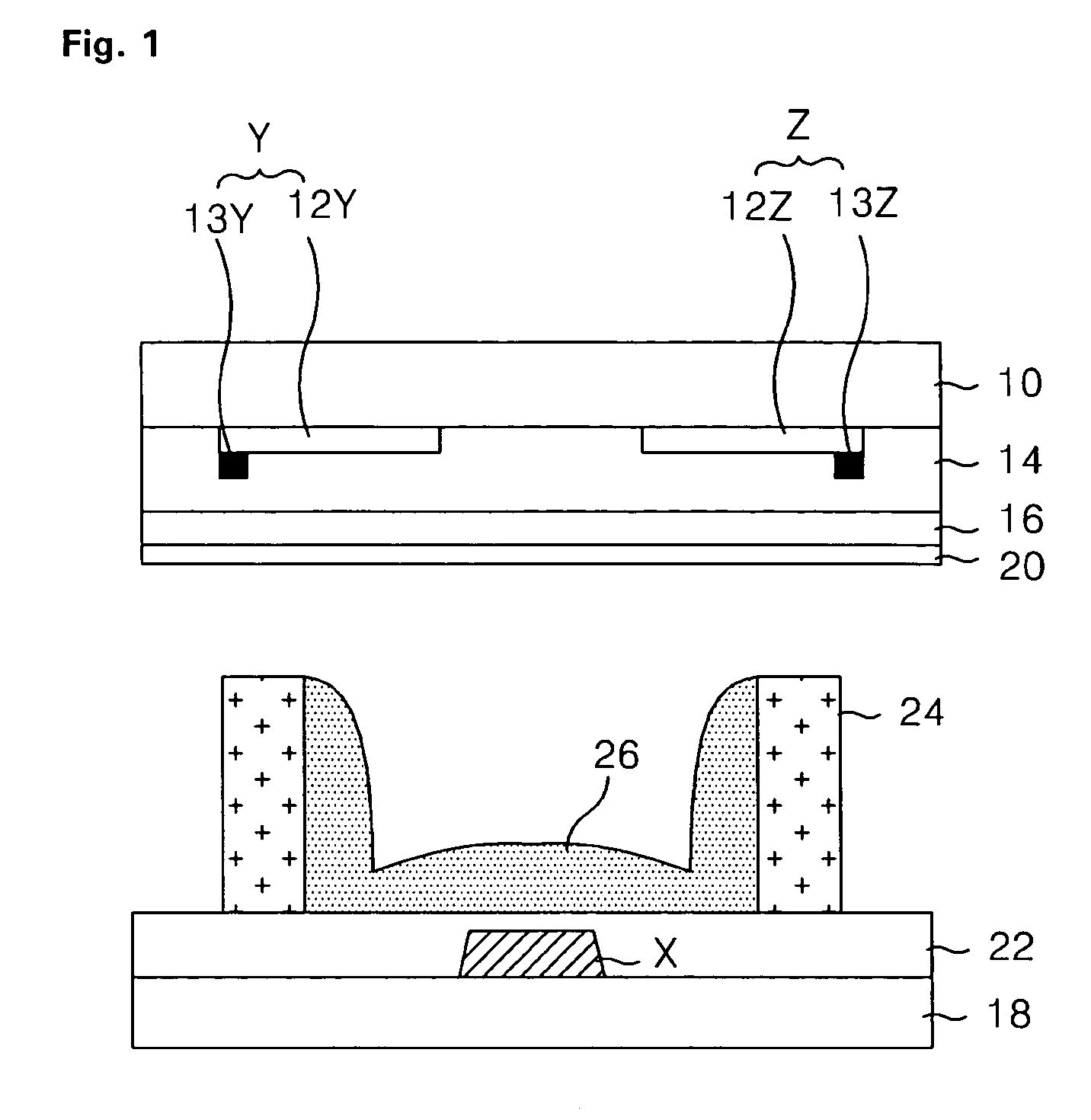

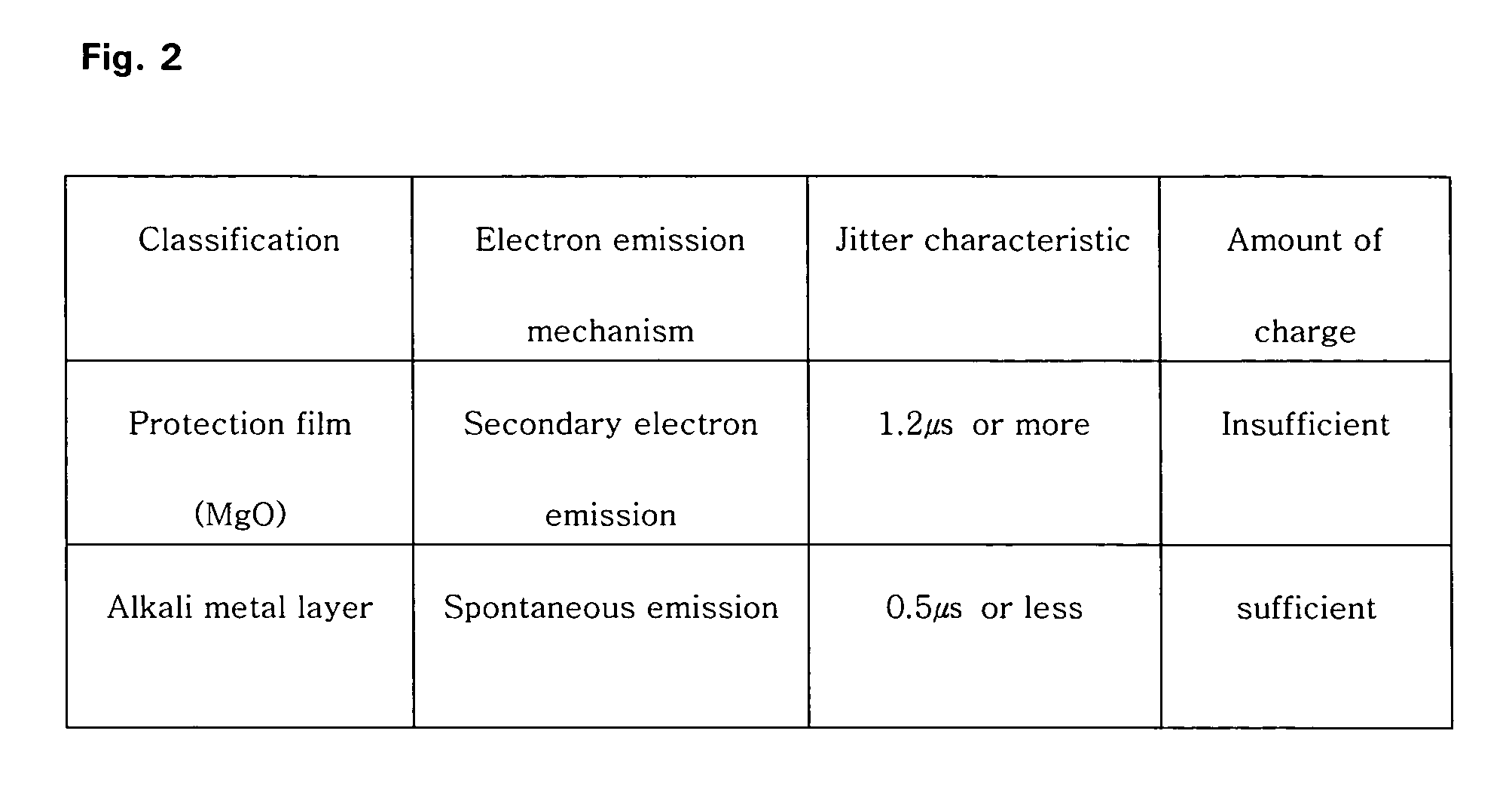

Plasma display panel and method for manufacturing the same

InactiveUS20050062419A1Improve featuresVoltage marginAddress electrodesSustain/scan electrodesDisplay deviceEngineering

The present invention relates to a plasma display panel and method for manufacturing the same in which electron discharge characteristic is improved and a voltage margin can be secured. According to a first embodiment of the present invention, a plasma display panel including a plurality of a pair of display electrodes formed and arranged parallely on an upper plate, a plurality of address electrodes formed on a lower plate and arranged to be crossed to the display electrodes, a barrier rib defined a discharge space on the lower plate, and fluorescent body formed between the barrier ribs, includes further: a number of discharge cells having the discharge space; and an alkali metal layer formed in the discharge cells for supplying electrons to the discharge space.

Owner:LG ELECTRONICS INC

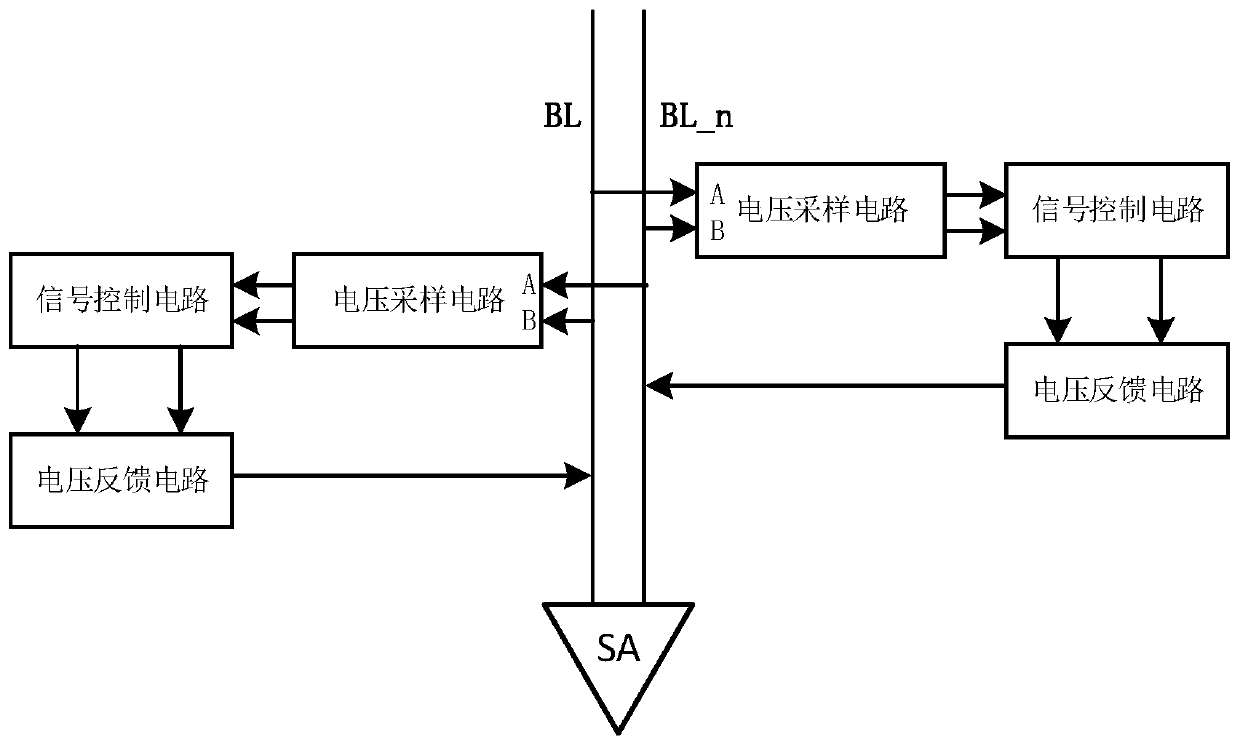

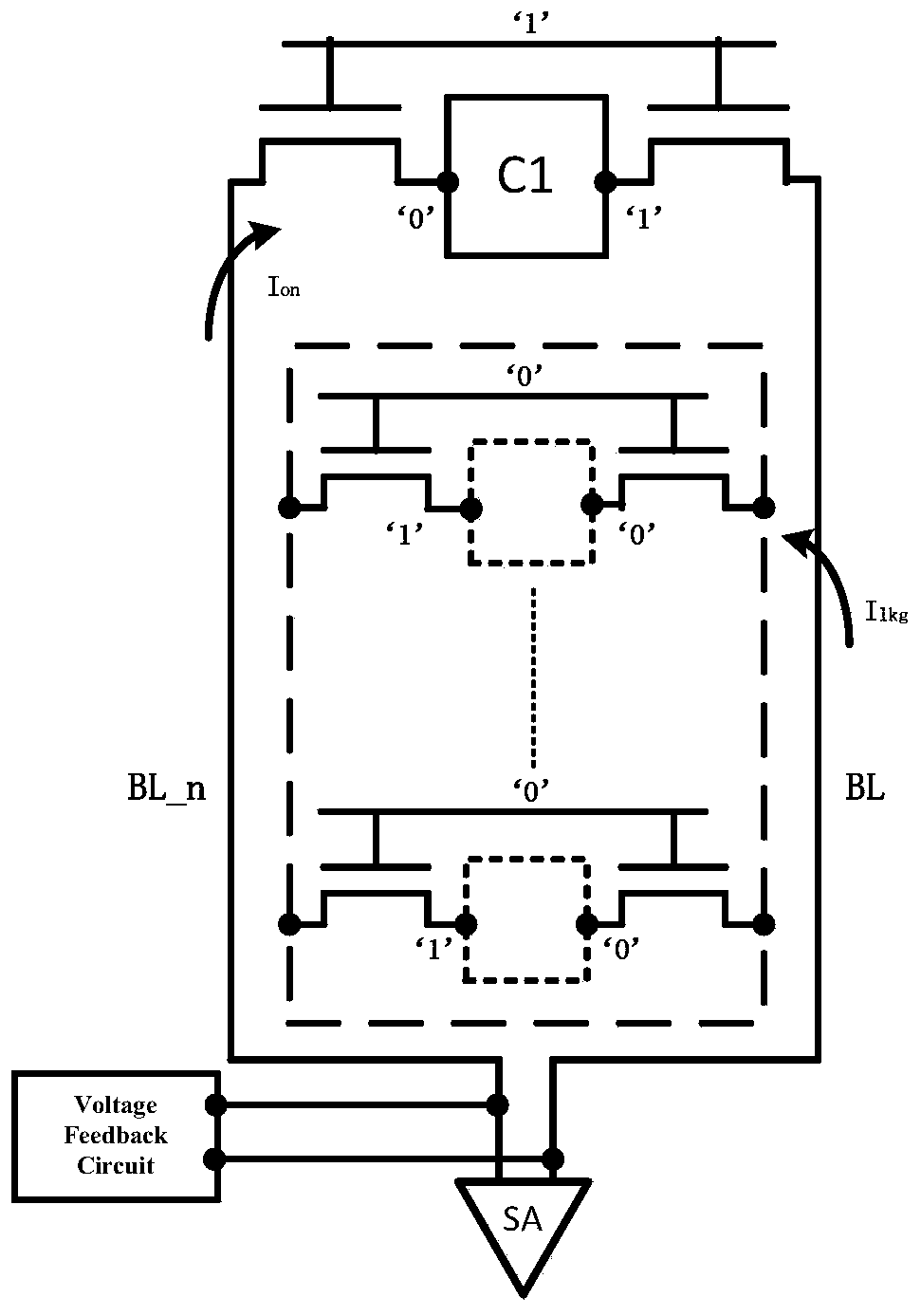

Compensation method and device for bit line leakage current of static random access memory

InactiveCN111312303AImprove performanceImprove yieldDigital storageBit lineStatic random-access memory

The invention provides a compensation method for bit line leakage current of a static random access memory. The compensation method comprises the following steps: collecting discharge current of two adjacent bit lines; and controlling the voltage of the bit line with relatively large discharge current in the two adjacent bit lines to be reduced, and / or controlling the voltage of the bit line withrelatively small discharge current in the two adjacent bit lines to be increased. According to the compensation method for the bit line leakage current of the static random access memory, less time isneeded when the SA can detect the voltage, the read working time is shortened, and the working speed of the circuit is increased. In the same read clock window, the SA can detect a larger voltage difference.

Owner:SHENZHEN PANGO MICROSYST CO LTD

Plasma display panel and method for manufacturing the same

InactiveUS7466079B2Voltage marginImprove featuresAddress electrodesSustain/scan electrodesDisplay deviceEngineering

The present invention relates to a plasma display panel and method for manufacturing the same in which electron discharge characteristic is improved and a voltage margin can be secured. According to a first embodiment of the present invention, a plasma display panel including a plurality of a pair of display electrodes formed and arranged parallely on an upper plate, a plurality of address electrodes formed on a lower plate and arranged to be crossed to the display electrodes, a barrier rib defined a discharge space on the lower plate, and fluorescent body formed between the barrier ribs, includes further: a number of discharge cells having the discharge space; and an alkali metal layer formed in the discharge cells for supplying electrons to the discharge space.

Owner:LG ELECTRONICS INC

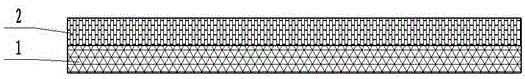

Cotton cloth drape chiffon fabric for preventing evaporative heat loss

InactiveCN106217965AImprove aestheticsSimple processSynthetic resin layered productsTextile decorationPolyesterCotton cloth

The invention discloses a cotton cloth drape chiffon fabric for preventing evaporative heat loss. The fabric comprises a drape layer (1) and an inner layer (1). The drape layer is fixed to the inner layer. The drape layer is subjected to hot pressing to be in a drape shape. Drapes (2-1) are evenly distributed. A lining fabric layer is arranged on the back face of the inner layer and is a composite fabric composed of a lining, a blocking layer and a fabric layer not likely to be wetted by water. The blocking layer is prepared from one of polyethylene, nylon, polyester, ethyl urethane and polytetrafluoroethylene. According to the cotton cloth drape chiffon fabric, the wearing comfort is achieved, the aesthetic feeling of the drape layer is improved, and evaporative heat loss is prevented.

Owner:JIANGYIN BETTER TEXTILE

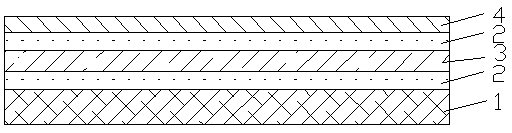

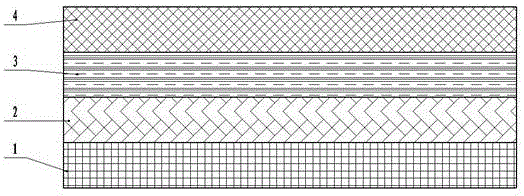

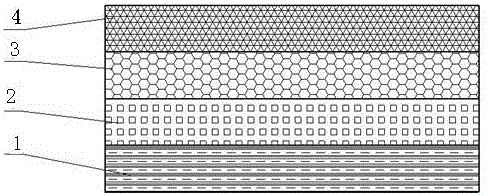

Artificial leather capable of preventing evaporation heat loss and with tensile strength

InactiveCN107650476AImprove tensile propertiesIncrease elasticitySynthetic resin layered productsPolyesterSurface layer

The invention relates to a tensile artificial leather for preventing evaporative heat loss, which consists of base layer (1), adhesive layer (2), reinforcement layer (3), adhesive layer (2) and surface layer (4) from bottom to top composition. The back of the base layer is compounded with a lining fabric layer, and the lining fabric layer is a composite fabric consisting of a lining, a barrier layer and a fabric layer that is not easily wetted by water. The barrier layer is made of polyethylene, nylon, polyester, Made of either urethane or polytetrafluoroethylene. The invention achieves good elasticity and tension. The present invention prevents evaporation heat loss.

Owner:JIANGYIN YONGTAI PLASTICS CO LTD

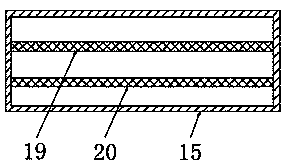

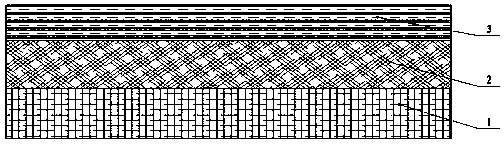

Thermal-insulation antibacterial fabric capable of preventing evaporation and heat loss

InactiveCN107685499AReduce discharge efficiencyImprove insulation effectSynthetic resin layered productsPolyesterThermal insulation

The invention relates to a warm-keeping and antibacterial fabric for preventing evaporative heat loss, which comprises an inner layer (1), a thermal insulation layer (2) and an outer layer (3). The back of the inner layer is provided with a lining fabric layer. The lining fabric layer is a composite fabric consisting of a lining, a barrier layer and a fabric layer that is not easily wetted by water. The barrier layer is made of polyethylene, nylon, polyester, Made of either urethane or polytetrafluoroethylene. The invention has good flexibility, good heat-retaining performance, remarkable effect of sterilization and deodorization, soft and wear-resistant texture. The present invention prevents evaporation heat loss.

Owner:黄磊

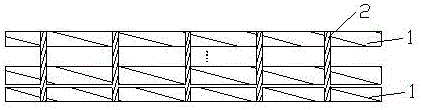

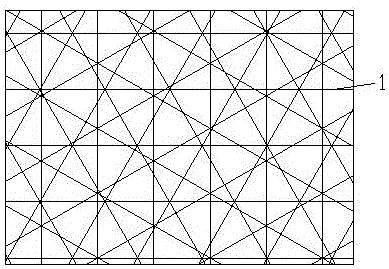

Multi-layer meshed fabric capable of preventing evaporation heat loss

InactiveCN106217989AReduce discharge efficiencyImprove insulation effectSynthetic resin layered productsTextile decorationPolyesterEvaporation

The invention relates to a multi-layer meshed fabric capable of preventing the evaporation heat loss, and belongs to the field of textile fabrics. The multi-layer meshed fabric comprises a plurality of meshed layers (1), the mesh layers (1) are rotated in an angle in sequence and then vertically connected through bright silks (2). The back of each meshed layer is provided with a lining fabric layer. The lining fabric layer is a composite fabric composed of a lining, a baffle layer, and a fabric layer that cannot be wetted easily by water, wherein the baffle layer is made of one of polyethylene, nylon, polyester, ethyl carbamate, and polytetrafluoroethylene. The provided fabric has a bright color and is capable of preventing evaporation heat loss.

Owner:JIANGYIN CHUNZHILAN SPECIAL YARN

Crushing and recycling equipment for optical cable waste

ActiveCN113427674ACrushing works smoothly and efficientlyImprove nesting efficiencyPlastic recyclingMechanical material recoveryFiberStructural engineering

The invention relates to the technical field of optical cable recycling, in particular to crushing and recycling equipment for optical cable waste. The crushing and recycling equipment for the optical cable waste comprises a shell, a plurality of grinding plates, a driving device and a plurality of grinding parts, wherein the grinding parts are rotatably arranged between two vertically adjacent material passing openings; each grinding part comprises two cutters which are located on the inner sides and outer sides of the grinding plates and can synchronously rotate; and each cutter is provided with structures such as a grinding face, a mounting face, a sharp edge end, a first transition face, a material gathering face, a blunt edge end and a material raising face. According to the crushing and recycling equipment for the optical cable waste, when the resistance borne by a first-stage grinding cavity or a second-stage grinding cavity is increased, the cutters deflect, the angles of the sharp edge ends and the blunt edge ends relative to the movement direction of the light-guide fiber are changed, so that the cutting strength of light-guide fibers is changed; and the positions of the material raising faces and the material gathering faces relative to the material passing openings are changed, the flow guide direction of the light-guide fibers is changed, and then the grinding force of the first-stage grinding cavity and the second-stage grinding cavity is automatically adjusted according to the change of the resistance of the grinding cavities, so that the stacking and jamming are avoided, and the grinding efficiency is improved.

Owner:南通安广美术图案设计有限公司

Stain-proof fabric capable of preventing evaporative heat loss

InactiveCN106273734AReduce discharge efficiencyImprove insulation effectSynthetic resin layered productsClothingsBlock layerBlocking layer

The invention relates to a stain-proof fabric capable of preventing evaporative heat loss. The fabric comprises an inner layer (1), wherein a ventilation layer (2), an outer layer (3) and a stain-proof layer (4) are sequentially arranged outside the inner layer; the stain-proof layer is a fluorine monomer waterborne polyurethane paint layer; the back side of the inner layer is provided with a lining fabric layer; the lining fabric layer is a composite fabric, and consists of a lining, a blocking layer and a fabric layer which cannot get water by water; the blocking layer is made of one material from polyethylene, nylon, polyester, ethyl carbamate or polyfluortetraethylene. The stain-proof fabric has the advantages that the ventilation can be favorably achieved; the outer layer of the fabric is enabled to be smooth; the fabric cannot be easily stained; in addition, the waterproof and ventilation effects are achieved. The fabric has the advantage that the evaporative heat loss is prevented.

Owner:JIANGYIN HANXIN TEXTILE

Kitchen sewage treatment device for solving problems of incomplete separation and low convenience

InactiveCN112588001ASolve the convenienceIncrease linkageFatty/oily/floating substances removal devicesTreatment involving filtrationOil and greaseOil water

The invention relates to the technical field of sewage treatment, and discloses a kitchen sewage treatment device for solving the problems of incomplete separation and low convenience. The kitchen sewage treatment device comprises a shell, and the interior of the shell is movably connected with a screen frame. Vibration operation and oil-water separation operation are triggered through the gravityeffect of sewage, the linkage between structures is increased, and the device has high automation degree. The screen frame vibrates, separation of oil, water and impurities is promoted, the impurities are vibrated and transferred out of the screen frame, cleaning and collection of the impurities are achieved, screen holes are prevented from being blocked by excessive accumulation of the impurities, sewage discharge efficiency is reduced, hands are liberated, frequent manual cleaning and collecting operation is omitted, operation is convenient, and actual use requirements are better met. Condensed grease is automatically retained on the surface of a filter plate, water smoothly passes through the filter plate, the grease is thrown out of the filter plate under the centrifugal action generated by rotation of the filter plate and moves into an oil collecting tank to be collected in a centralized mode, grease is prevented from flowing into a sewer along with water to cause blockage, and the device has high practicability.

Owner:范翠华

A crushing and recycling equipment for optical cable waste

ActiveCN113427674BCrushing works smoothly and efficientlyImprove nesting efficiencyPlastic recyclingMechanical material recoveryFiberStructural engineering

The invention relates to the technical field of optical cable recovery, in particular to equipment for crushing and recycling optical cable waste. It includes a shell, several grinding plates, a driving device and several grinding parts. The grinding part is rotatably arranged between the two upper and lower adjacent feed ports. Each grinding part includes two grinding parts located on both sides of the grinding plate. And the tool that can rotate synchronously has structures such as a grinding surface, a mounting surface, a sharp edge end, a first transition surface, a gathering surface, a blunt edge edge, and a lifting surface. In the present invention, when the resistance of the primary grinding cavity or the secondary grinding cavity increases, the tool deflects, and the angle between the sharp blade end and the blunt blade end relative to the moving direction of the optical fiber changes, so as to change the cutting force on the optical fiber and lift the material. The position of the surface and the aggregate surface relative to the material opening is changed to change the guiding direction of the optical fiber, so as to adjust the grinding force of the primary grinding chamber and the secondary grinding chamber according to the change of the resistance of the grinding chamber to avoid material stacking Jamming, improve grinding efficiency.

Owner:南通安广美术图案设计有限公司

Evaporation heat loss prevention easy-drying easy-care fabric

InactiveCN106218112AReduce discharge efficiencyImprove insulation effectSynthetic resin layered productsWoven fabricsPolyesterEvaporation

The invention relates to an evaporation heat loss prevention easy-drying easy-care fabric which comprises a base layer (1), and a quick-drying layer (2) is arranged on the outer side of the base layer. A lining fabric layer is disposed on the back side of the base layer, is a compound fabric and is composed of a lining, a barrier layer and a fabric layer which cannot be wetted by water easily. The barrier layer is made from one of polyethylene, nylon, polyester, ethyl carbamate and polytetrafluoroethylene. The fabric can be quickly dewatered, is natural and straight after being washed with water and does not need to be ironed, the fabric is stiff and smooth, and the inner layer is comfortable and cool.

Owner:JIANGYIN HULIAN DYEING & FINISHING

Clothing capable of charging up mobile phones and preventing evaporation heat loss

InactiveCN106263123AReduce discharge efficiencyImprove insulation effectGarment special featuresBatteries circuit arrangementsPolyesterPolytetrafluoroethylene

The invention relates to clothing capable of charging up mobile phones and preventing evaporation heat loss. The clothing comprises a clothing main body (1), wherein small power generating devices (2) are arranged on cuffs of the clothing main body; a lithium battery (3) is arranged on the front side of the clothing main body; and a USB interface (4) is connected to the terminal of the lithium battery (3). A lining fabric layer is arranged on the back side of the clothing main body; the lining fabric layer, as a composite fabric, is composed of a lining, a barrier layer and a fabric layer which is not easily wet by water; and the barrier layer is made from one of the following materials: polyethylene, nylon, polyester, ethyl carbamate and polytetrafluoroethylene. The clothing disclosed by the invention is capable of charging up the mobile phones. The clothing disclosed by the invention is capable of preventing the evaporation heat loss.

Owner:江苏红柳床单有限公司

Neck massage clothes with function of preventing evaporative heat loss

InactiveCN106263079ARelax neck musclesPrevent cervical spondylosisGarment special featuresDevices for pressing relfex pointsPolyesterCervical spondylosis

The invention relates to neck massage clothes with a function of preventing evaporative heat loss. The neck massage clothes comprise a clothes body (1), wherein a latex massage strip (2) provided with convex points is arranged at the neck part of the clothes body and connected with a control module (3), and the control module is connected with a power supply module. A lining fabric layer is arranged on the back of the clothes body, adopts composite fabric and comprises a lining, a blocking layer and a fabric layer which is not wetted by water easily, and the blocking layer is made of one of polyethylene, nylon, polyester, ethyl carbamate or polytetrafluoroethylene. With the adoption of the neck massage clothes, the effect of relaxing neck muscles can be realized, cervical spondylosis is prevented, and the evaporative heat loss is prevented.

Owner:JIANGYIN DONGFA GARMENT MAKING

Double-functional manual biogas liquid residue discharge pump

InactiveCN101487459BEasy to diluteEasy loadingPiston pumpsPositive-displacement liquid enginesDischarge efficiencyEngineering

A manual double-function marsh dregs and marsh liquid discharging pump relates to a manual marsh dregs and marsh liquid discharging pump. The discharging pump helps solve the problems of small discharging pressure, slow discharging speed and low discharging efficiency and the like of the existing methane pool discharging pump. In the discharging pump, a big diameter end of a reducer is connected with an upper end screw thread of a sheathing support tube of a cylinder sleeve, the lower end of a draw bar passes an inner bore of the reducer to be arranged inside a piston work tube of the cylinder sleeve, a piston is arranged on the lower end surface of the draw bar, the upper end of the draw bar is hinged with one end of a hand pressing bar and one end of a hinged element, two switches are respectively positioned on the inner wall of a first elbow close to one end of the cylinder sleeve and the inner wall of a connecting tube of the cylinder sleeve, the lower end of a back-washing tube is connected with the upper end of the elbow by a second connecting part, and a discharging tube is connected with the back-washing tube by a second elbow. The discharging pump has the advantages of large discharging pressure, fast discharging speed and high discharging efficiency. The discharging pump also has the advantages of strong practicability, and being easy to dilute the marsh liquid, being easy for popularization and application and the like.

Owner:HARBIN DEGUANG NEW ENERGY

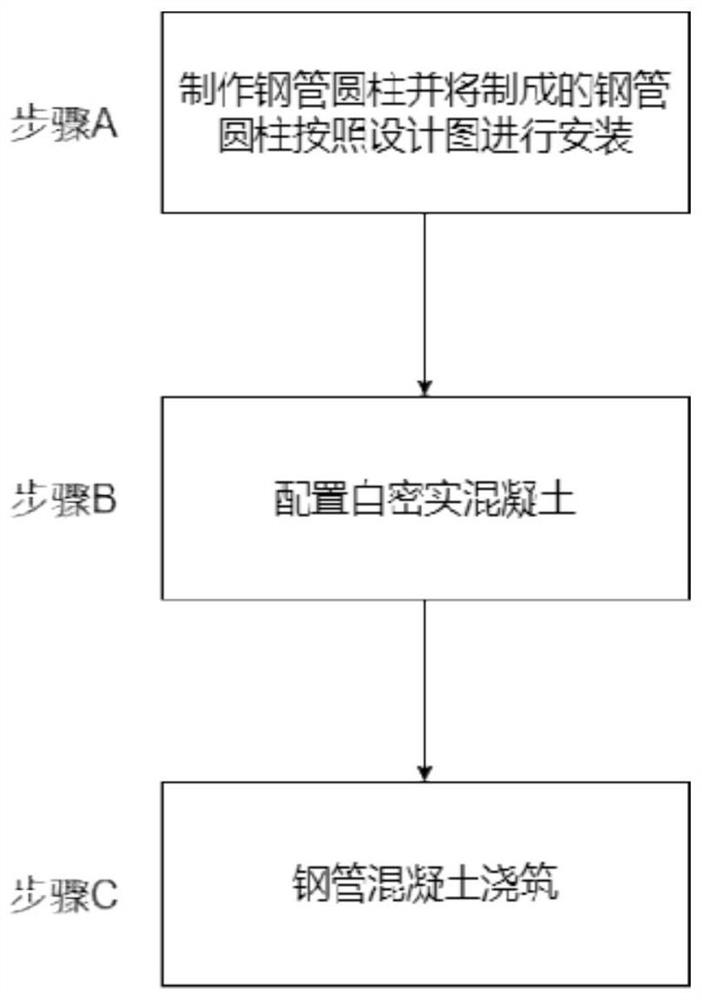

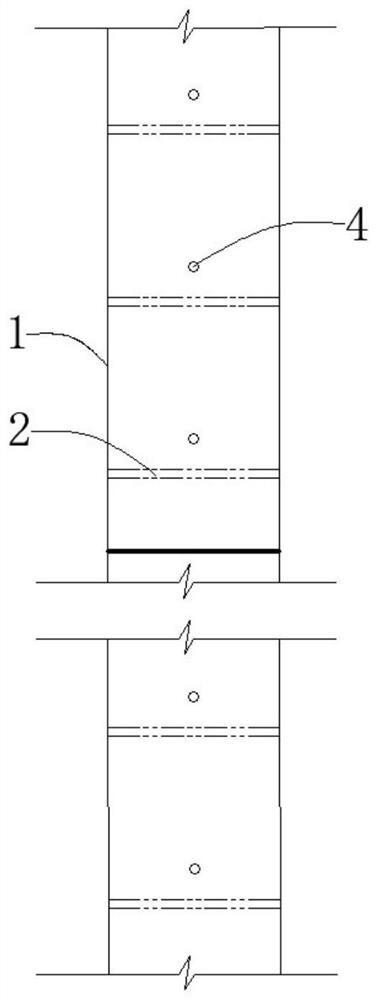

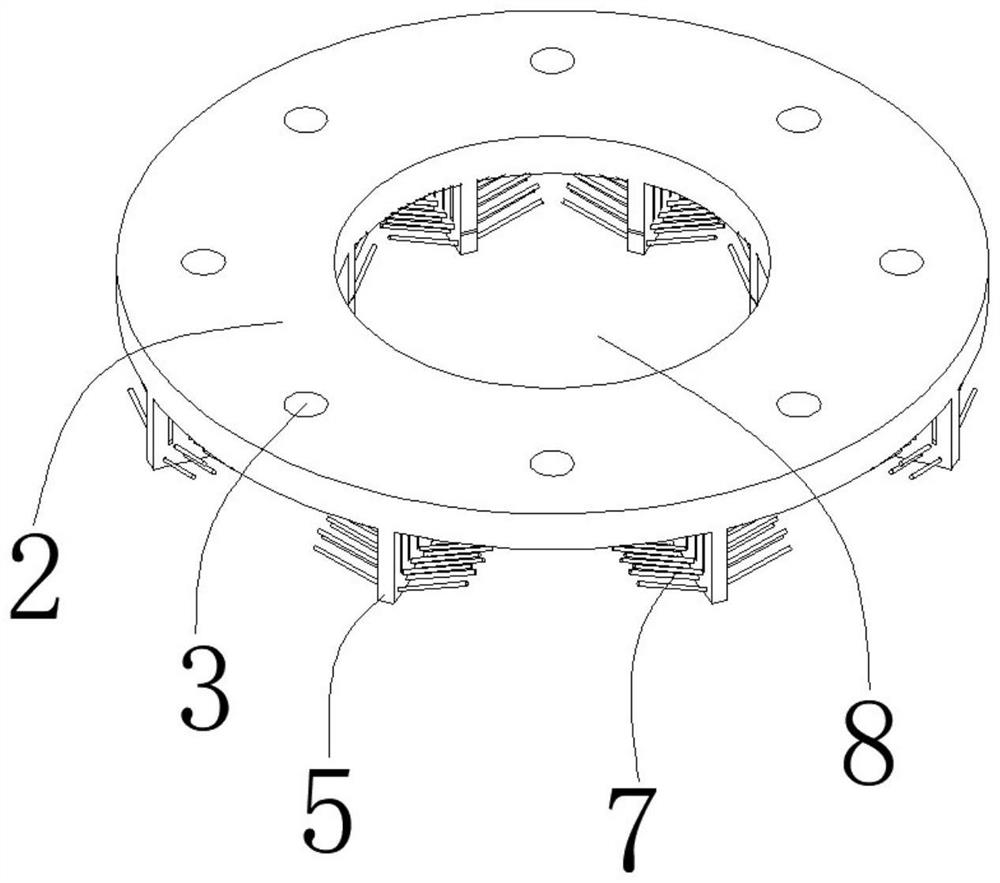

Self-compacting concrete topping pouring construction method for tubular column

ActiveCN114482409AImprove mechanical propertiesImprove concrete strengthStrutsBuilding material handlingSteel tubeSteel columns

The invention relates to the field of building construction, in particular to a self-compacting concrete topping construction method for a circular pipe steel column, which comprises the following steps: A, manufacturing a steel pipe cylinder and installing the manufactured steel pipe cylinder according to a design drawing; B, preparing self-compacting concrete; and C, pouring the steel pipe concrete. According to the self-compacting concrete topping construction method for the circular pipe steel column, the steel pipe cylinder capable of discharging the bubbles generated in the concrete is arranged, and the situation that when the concrete is poured, the bubbles generated in the concrete are accumulated in the steel pipe cylinder, and consequently the concrete in the steel pipe cylinder is hollow is avoided. Meanwhile, a corresponding pouring construction method is arranged to be matched with the steel pipe cylinder structure, hollowing of the concrete in the steel pipe cylinder is further avoided, and therefore the mechanical property of the steel pipe concrete structure is improved.

Owner:CHINA CONSTR FIRST BUILDING GRP CORP LTD

Evaporation heat loss preventive high-elasticity mercerized cotton fabric

InactiveCN106218022AReduce discharge efficiencyImprove insulation effectSynthetic resin layered productsWoven fabricsPolyesterEvaporation

The invention relates to an evaporation heat loss preventive high-elasticity mercerized cotton fabric, comprising a bottom layer (1), a breathable layer (2), an elastic layer (3) and a mercerized layer (4); the back of the bottom layer is provided with a lining fabric layer that is composite fabric composed of a lining, a barrier layer and a fabric layer rarely wetted by water, and the barrier layer is made from one of polyethylene, nylon, polyester and ethyl carbamate or polytetrafluoroethylene. The evaporation heat loss preventive high-elasticity mercerized cotton fabric is breathable and comfortable to wear, has good warmth retention, can avoid underlying dampness and stuffiness, is highly elasticity with mercerized and attractive surface, and is comfortable to touch; the fabric of the invention can prevent evaporation heat loss.

Owner:JIANGYIN FANRONG YARN DYE FABRIC

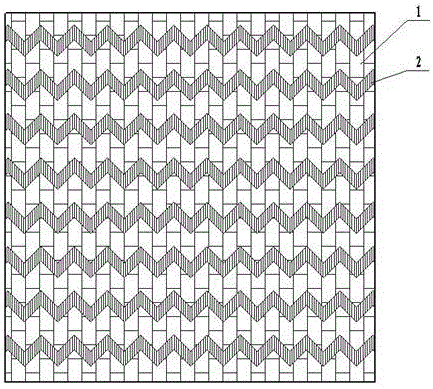

Passementerie fabric preventing evaporation heat loss

InactiveCN106217991AReduce discharge efficiencyImprove insulation effectSynthetic resin layered productsPolyesterEvaporation

The invention relates to passementerie fabric preventing evaporation heat loss. The passementerie fabric comprise a fabric body (1), multiple mesh openings (2) are formed in the fabric body and in a hook shape, a bead (3) is arranged in the center of the hook of each mesh opening. A lining layer is arranged on the back face of the fabric body, is a composite fabric and is formed by a lining, a blocking layer and a fabric layer not prone to being bedewed by water, the blocking layer is made of one of polyethylene, nylon, polyester, ethyl carbamate and polytetrafluoroethylene. The stereoscopic impression of the passementerie fabric is improved, and evaporation heat loss can be prevented.

Owner:JIANGYIN DONGFA GARMENT MAKING

Crossed raised grain fabric capable of preventing evaporative heat loss

InactiveCN106273716AAdd dimensionFeel goodSynthetic resin layered productsClothingsPolyesterWave shape

The invention relates to a crossed raised grain fabric capable of preventing evaporative heat loss. The fabric comprises a fabric body (1), wherein the outer surface of the fabric body is provided with a plurality of bulges (2), wherein the bulges (2) are in a wave shape; the bulges are inclined in a way of forming 90-degree angles with the fabric body, and are in parallel arrangement; a lining fabric layer is arranged on the inner surface of the fabric body; the lining fabric layer is a composite fabric, and consists of a lining, a blocking layer and a fabric layer which cannot get wet by water; the blocking layer is made of one material from polyethylene, nylon, polyester, ethyl carbamate or polyfluortetraethylene. The crossed raised grain fabric has the advantages that the three-dimensional feeling and the handfeel of the fabric are enhanced; the cold-proof effect of the fabric is good. The evaporative heat loss is prevented by the crossed raised grain fabric.

Owner:JIANGSU HAIPENG SPECIAL VEHICLES

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com