Self-compacting concrete topping pouring construction method for tubular column

A technology of self-compacting concrete and construction method, which is applied in the direction of columns, buildings, pillars, etc., can solve the problems of difficult discharge of air bubbles, reduction of cross-section, unfavorable force and force transmission of steel columns, etc., and achieve faster discharge speed and concrete The effect of strengthening strength and improving mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

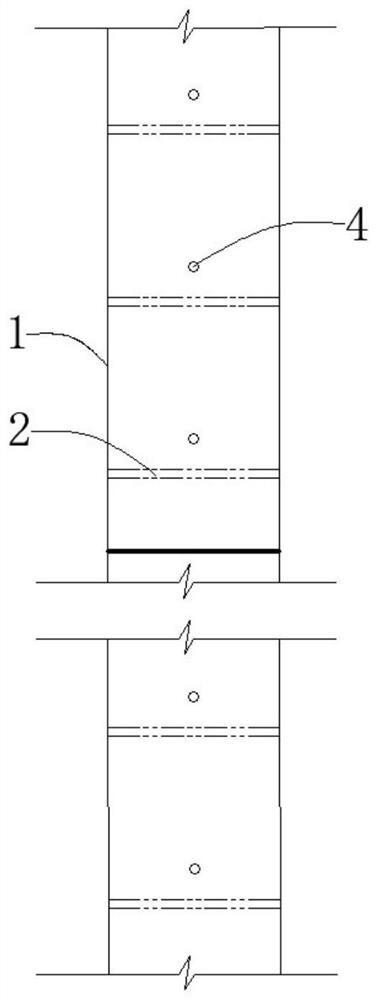

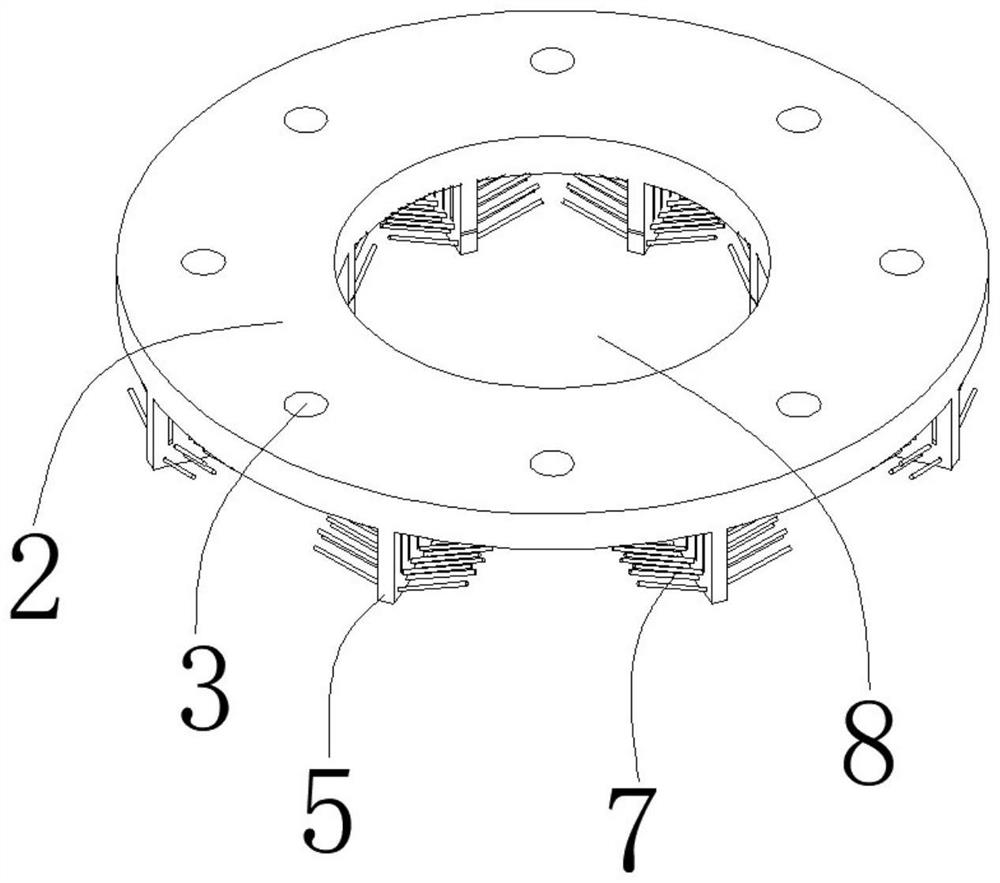

[0061] Such as Figure 1 to Figure 6 Shown:

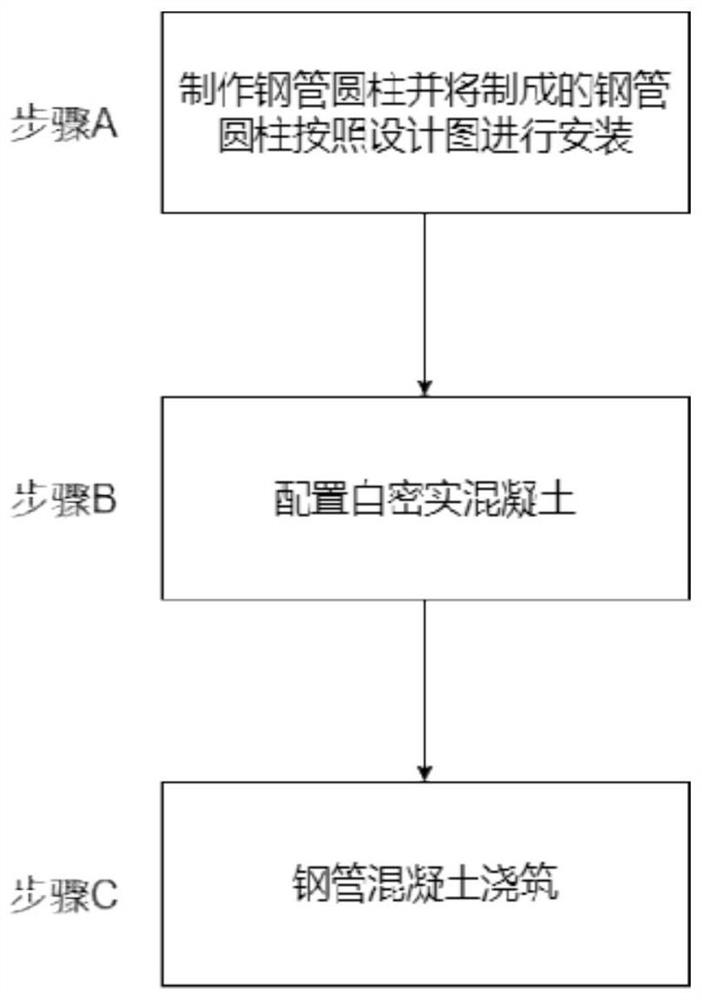

[0062] A construction method for self-compacting concrete roofing of round pipe steel columns, comprising the following steps:

[0063] A. Make a steel pipe cylinder and install the steel pipe cylinder according to the design drawing: make a steel pipe cylinder that can discharge air bubbles generated inside the concrete, and install the steel pipe cylinder according to the design drawing to form a steel pipe round steel skeleton.

[0064] B. Configure self-compacting concrete: make a concrete mixture whose self-compacting performance meets the design requirements.

[0065] C. Concrete-filled steel pipe pouring: pour the self-compacting concrete prepared in step B into the steel pipe cylinder to form a steel pipe concrete structure.

[0066] Adopting a construction method for self-compacting concrete roofing of round pipe steel columns according to the present invention, by setting a steel pipe cylinder that can discharge air bub...

Embodiment 2

[0092] Such as Figure 1 to Figure 6 As shown in the present invention, a construction method for self-compacting concrete roofing of round pipe steel columns, in the step B, the mix ratio of self-compacting concrete should be based on the characteristics of the applied structure, construction technology and environmental factors Design the technical requirements of self-compacting concrete. On the basis of comprehensive consideration of concrete self-compacting performance, strength, durability and other necessary performance requirements, the initial mix ratio is proposed, and the benchmark that meets the workability requirements is obtained through laboratory trial adjustment. Mixing ratio, and further check the strength and durability to obtain the production mixing ratio.

[0093] As a preferred embodiment, on the basis of the above method, further, the self-compacting concrete mix design adopts the absolute volume method; the water-cement ratio of self-compacting concret...

Embodiment 3

[0121] Such as Figure 1 to Figure 6 As shown in the present invention, a construction method for self-compacting concrete roofing of round pipe steel columns, in the step C, the high-throwing method is used for pouring below the third floor of the building slab structure, and the third floor of the building slab The above is poured by jacking method.

[0122] The technical principle of high-throw concrete pouring is to adopt a reasonable mix ratio to make the concrete mixture have high fluidity, no segregation and no bleeding during high-altitude throwing, and use pouring without vibration or less vibration. During the process, the kinetic energy generated when throwing down from a high place meets the requirement of self-compacting. The high throw pouring method is mature, the construction is simple and fast, and the overall construction cost is low.

[0123] The jacking method is in the lower part of the steel column, the height is suitable for construction, and a hole sl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com