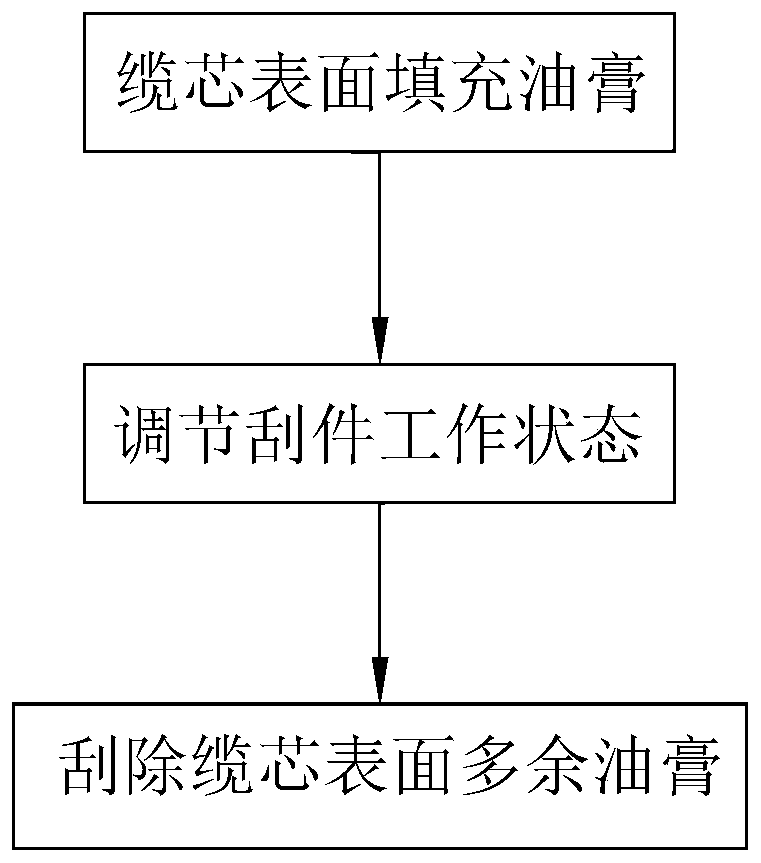

Jelly filling process

A technology of ointment and process, which is applied in the direction of light guide, optics, instruments, etc., can solve the problems of inconvenient processing and production, and achieve the effects of reducing ointment waste, slowing down the discharge efficiency, and avoiding adverse effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The present invention will be described in further detail below in conjunction with the accompanying drawings.

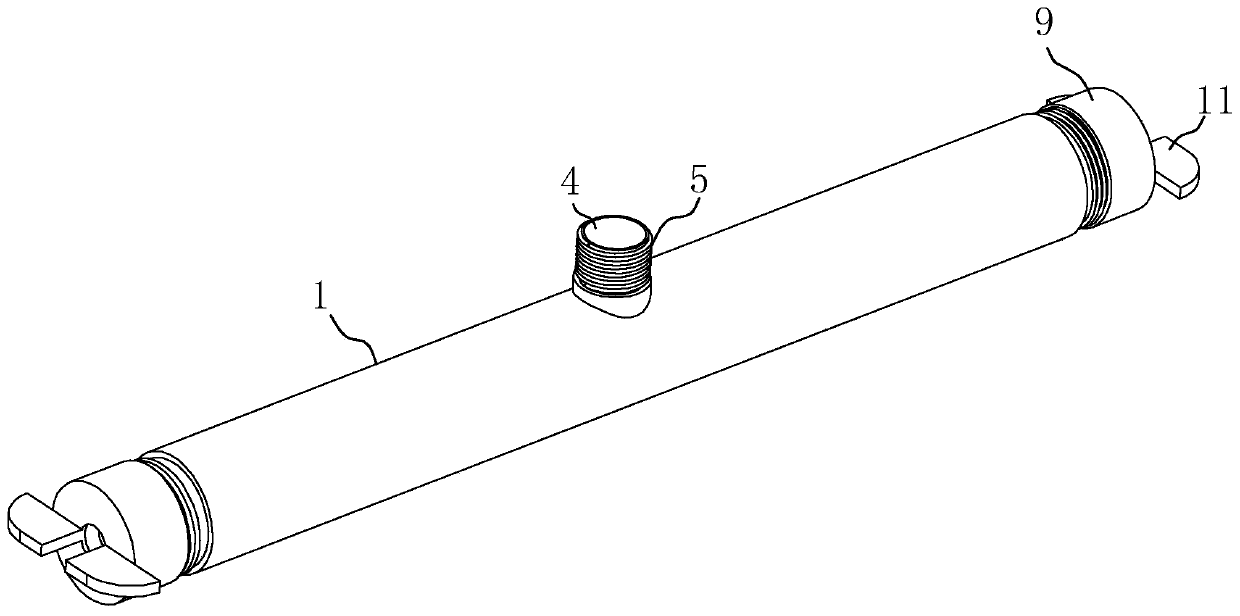

[0047] An ointment filling process such as figure 1 As shown, at first the cable core 26 is passed through the filling pipe filled with grease to realize the grease filling on the surface of the cable core 26; The working state of scraping; Finally, by driving the cable core 26 to move linearly relative to the scraper, the excess grease on the surface of the cable core 26 is finally scraped off to ensure the normal progress of the subsequent production and processing of the cable core 26, and it is also effective Reduce the waste of grease, the scraped grease can be used in the filling tube for recycling.

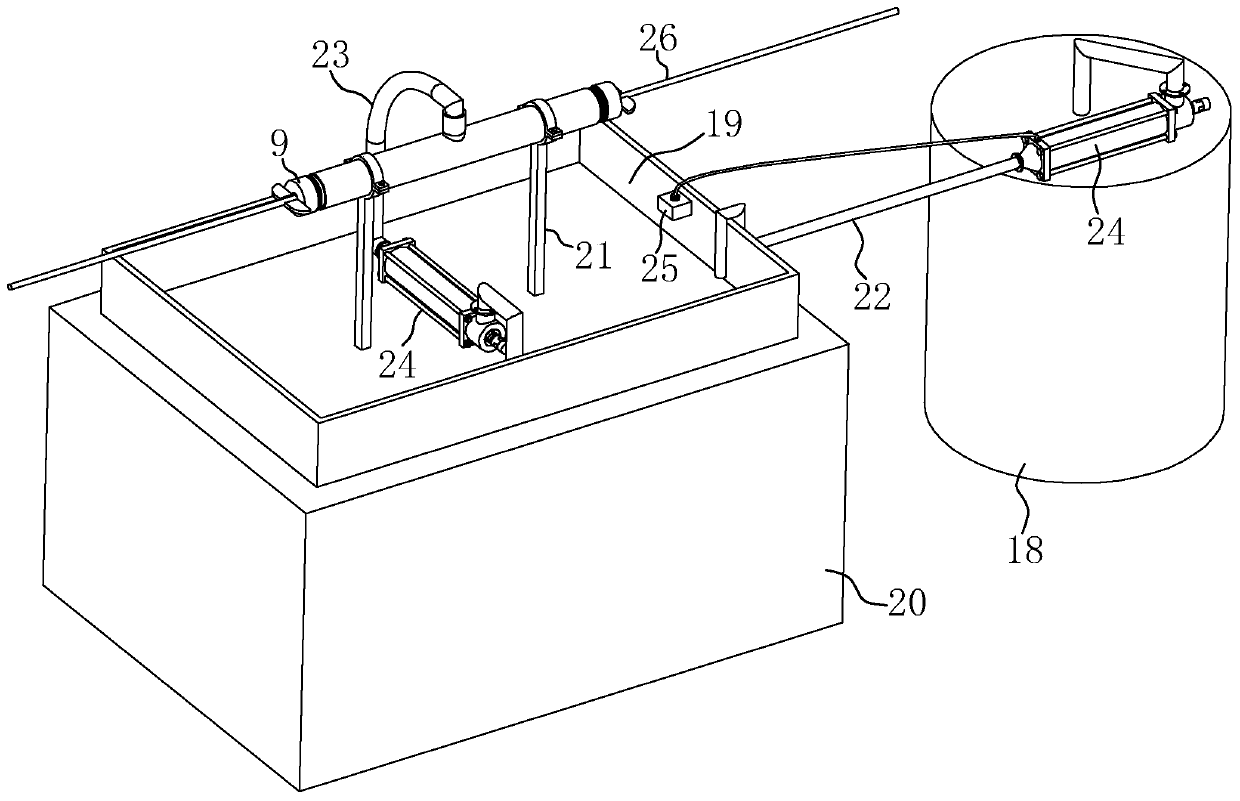

[0048] Such as figure 2Shown is the grease filling system A used for the grease filling process, including a filling device, a storage tank 18 for storing the grease, and a grease tank 19, wherein the filling device includes a body 20 and embodiment 1, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com