Patents

Literature

211results about How to "Avoid affecting processing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

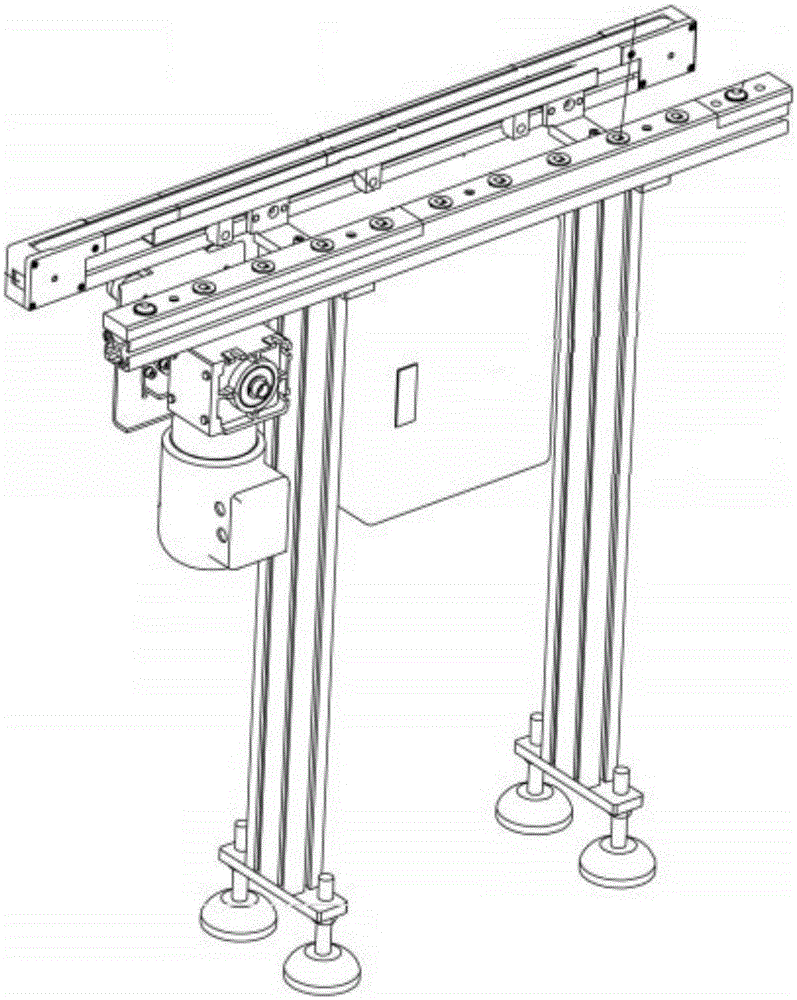

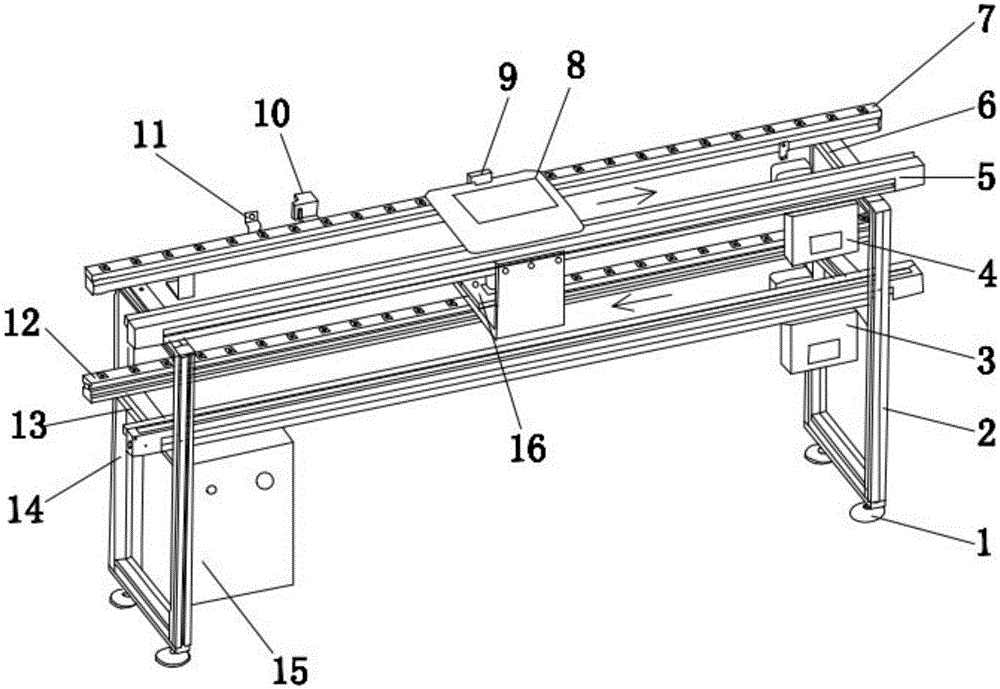

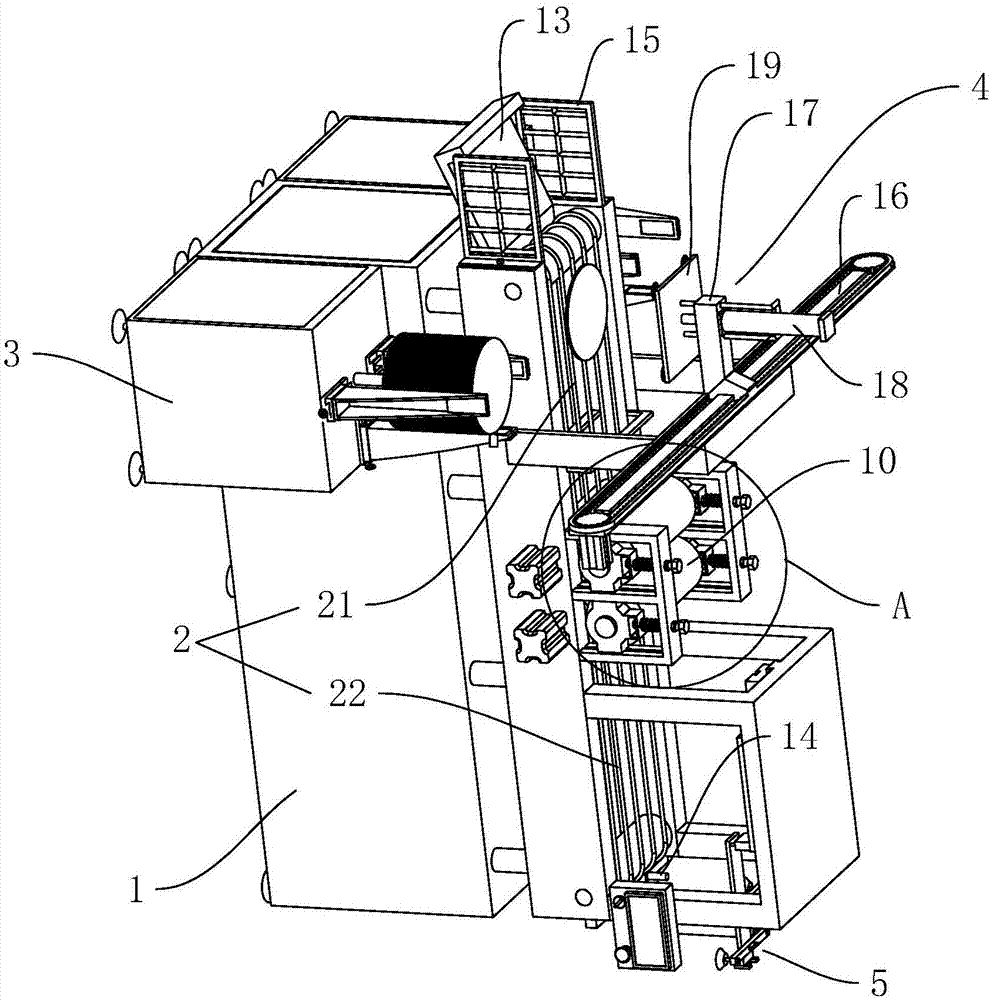

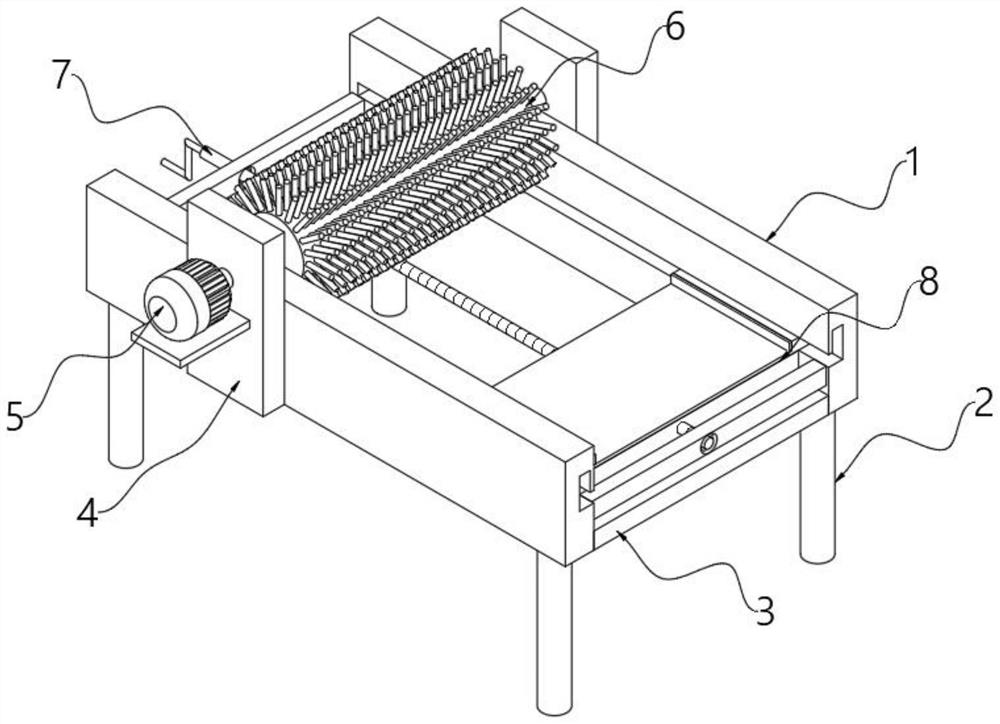

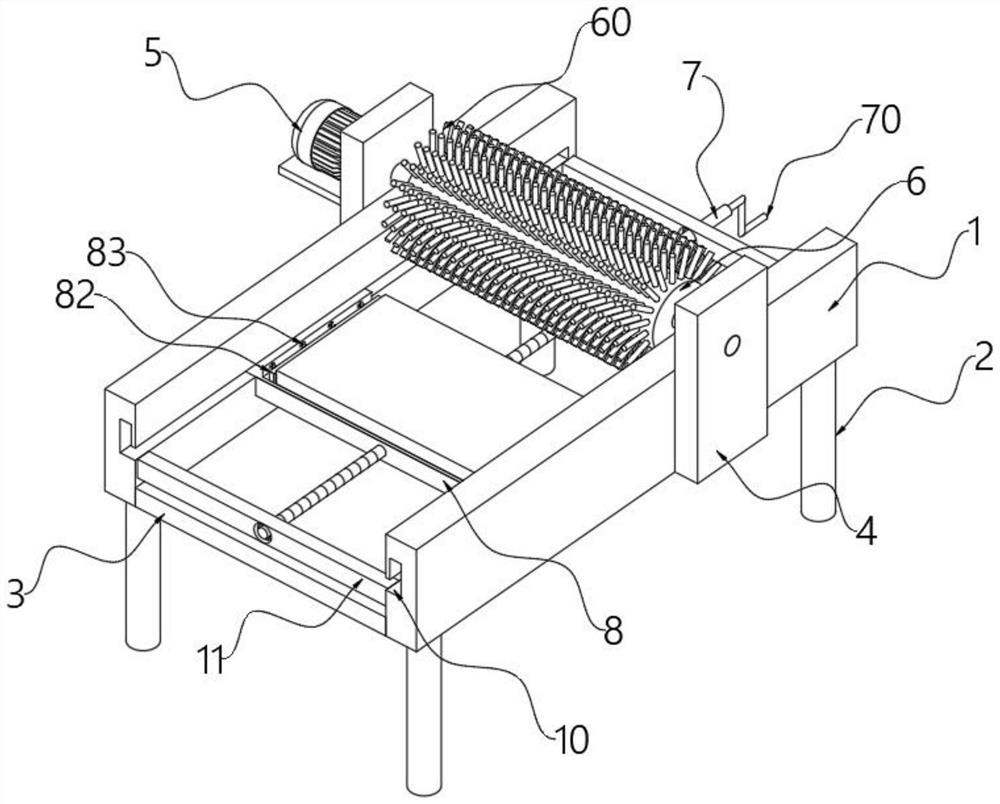

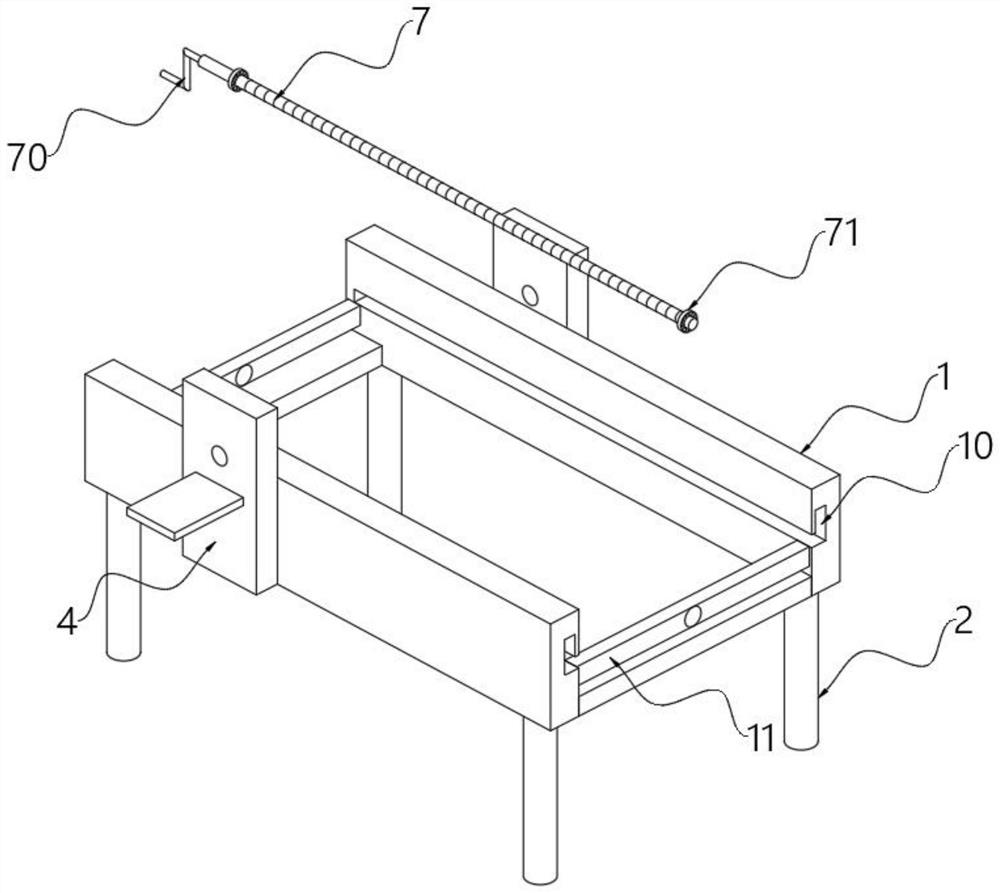

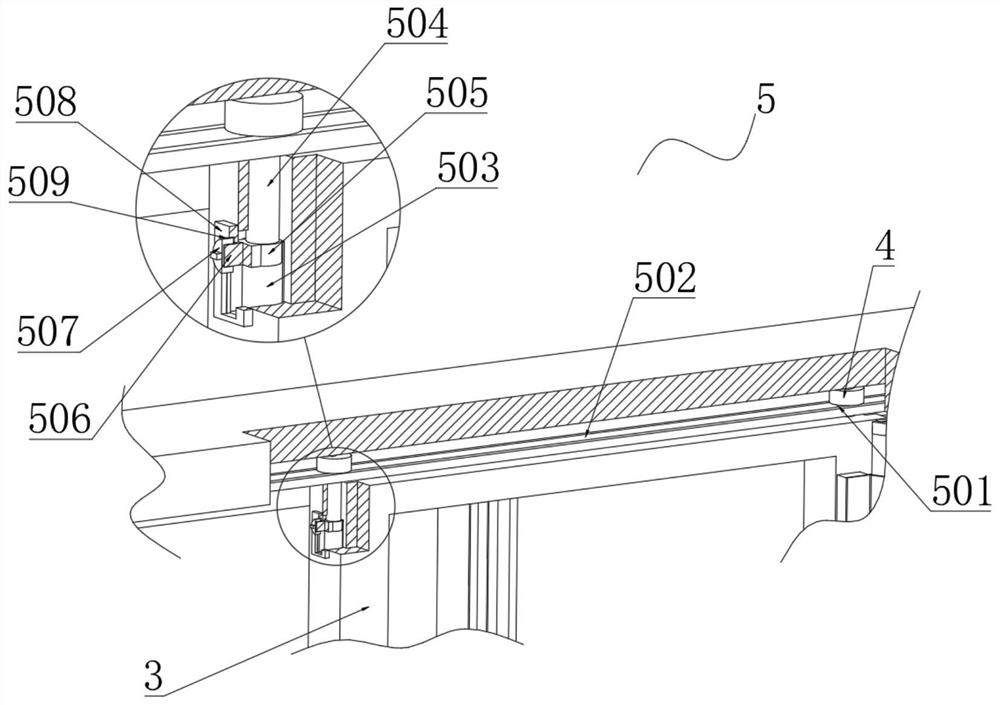

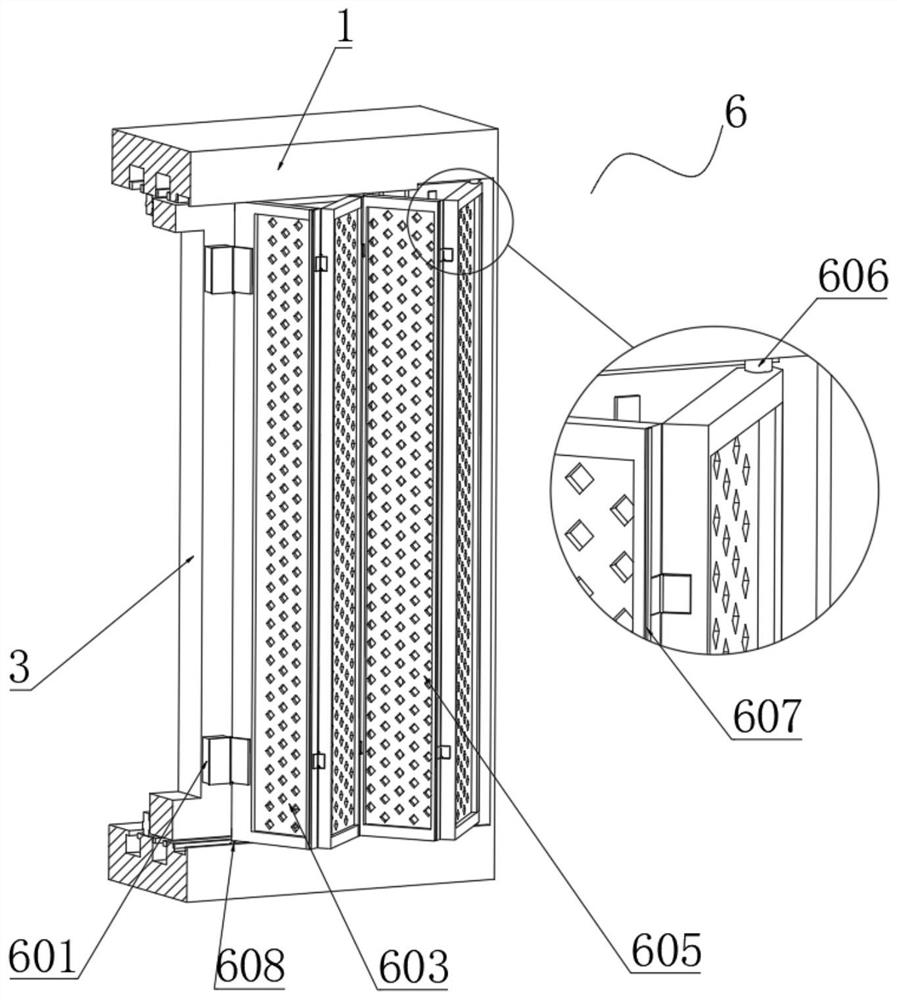

Double-layer belt line provided with jacking module and operating method thereof

InactiveCN105129358AReduced backflow spaceAchieve positioningMechanical conveyorsChinese charactersComputer module

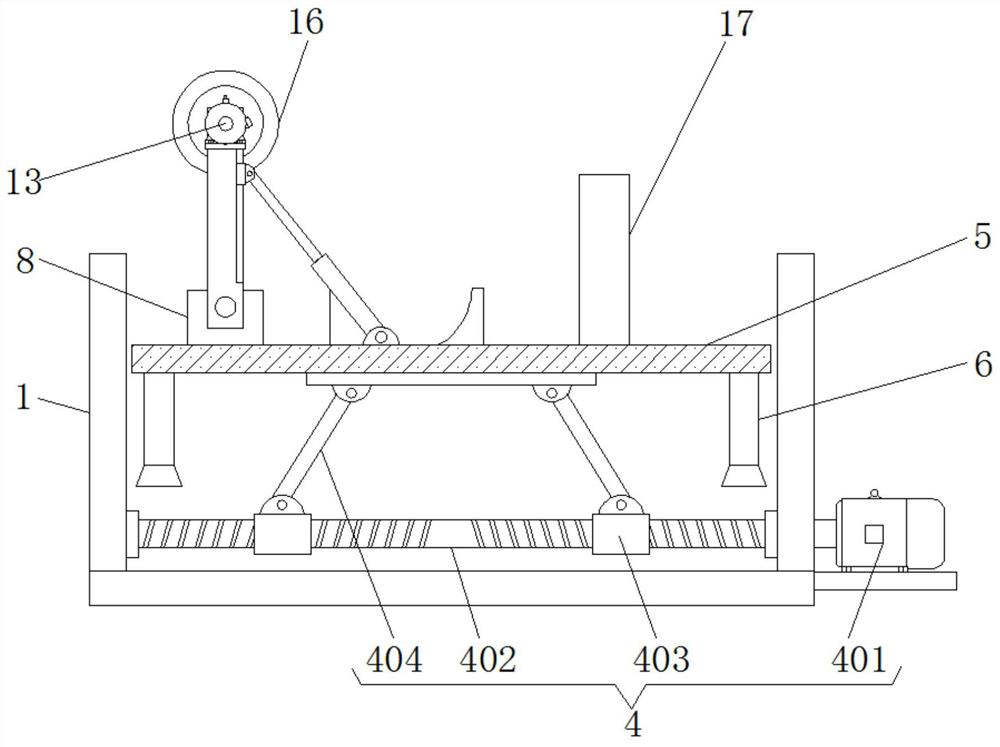

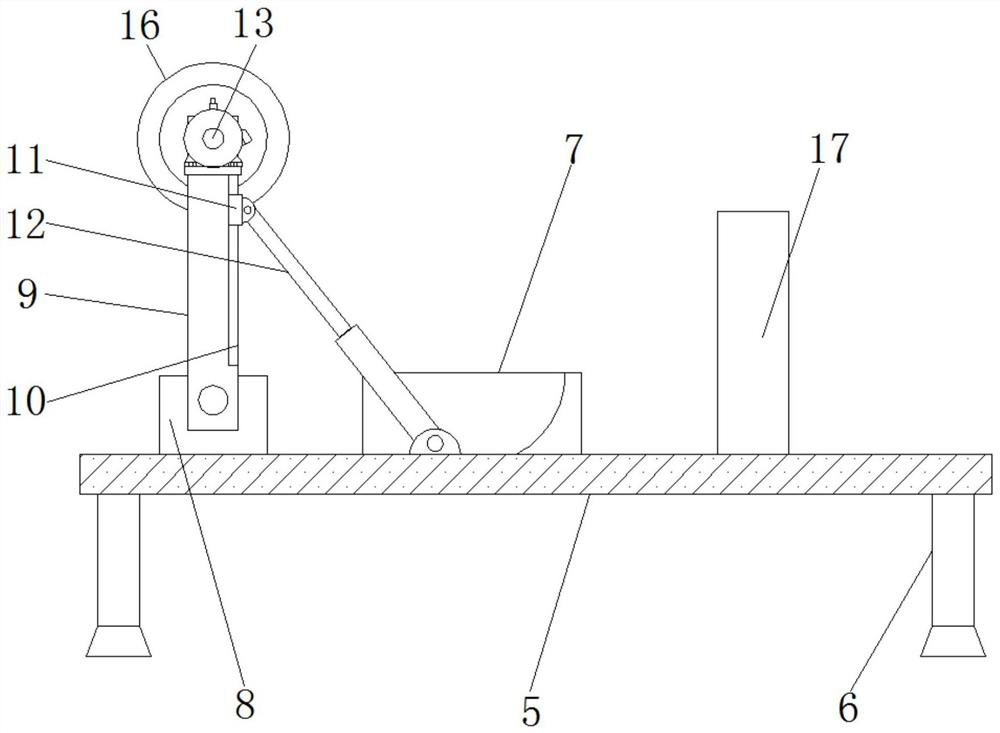

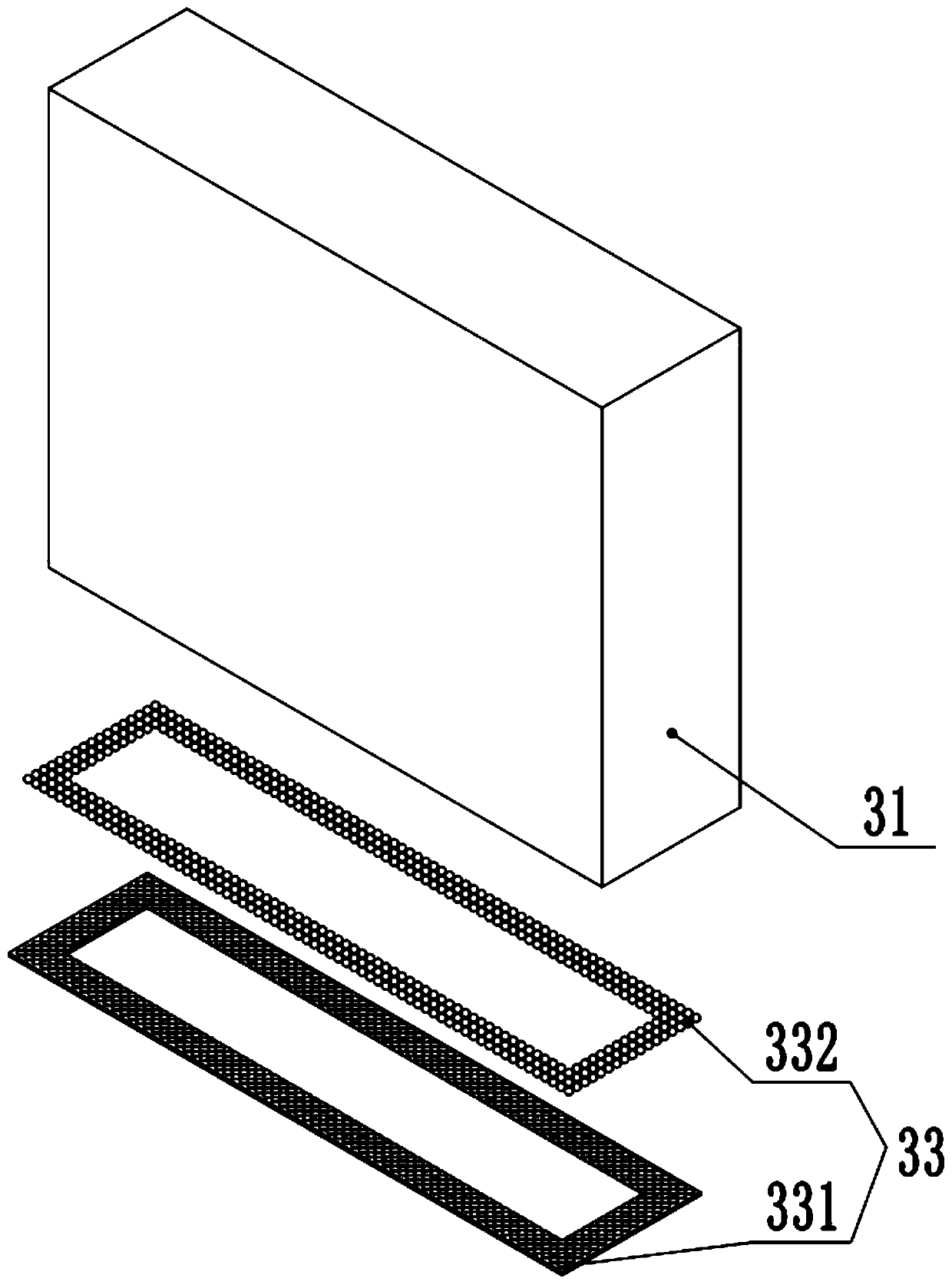

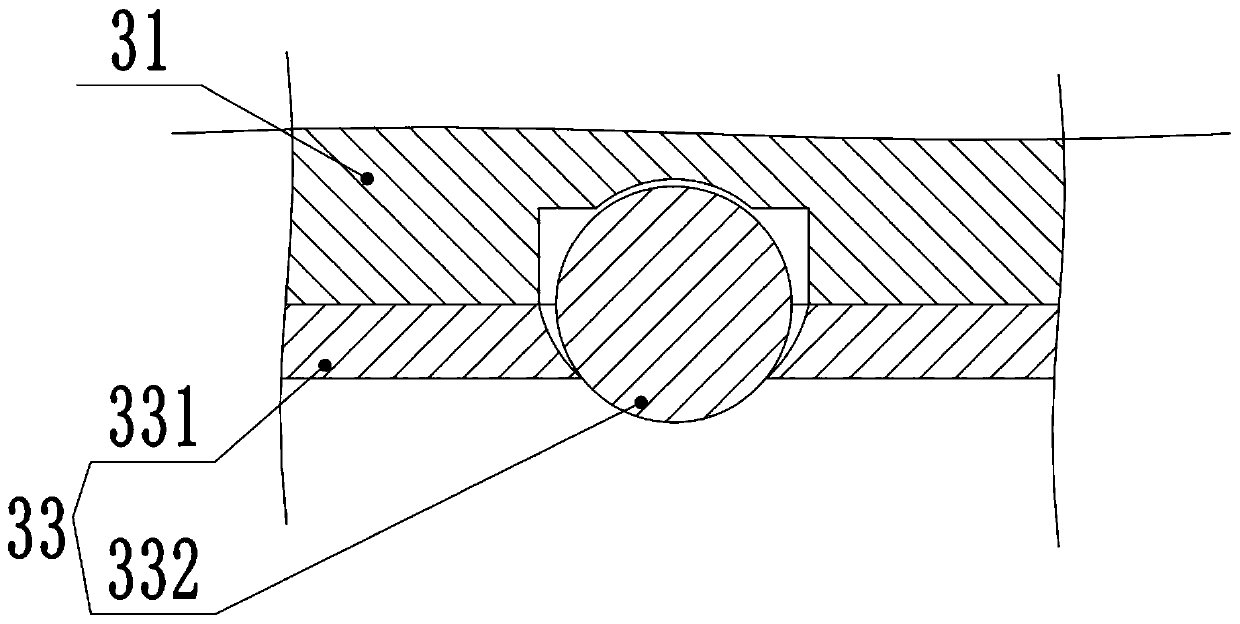

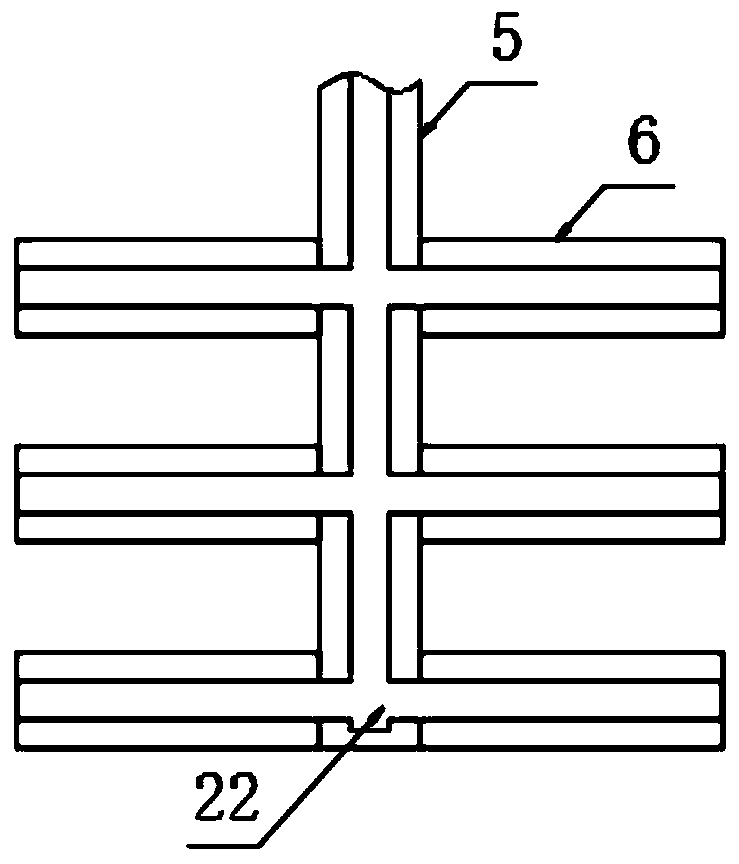

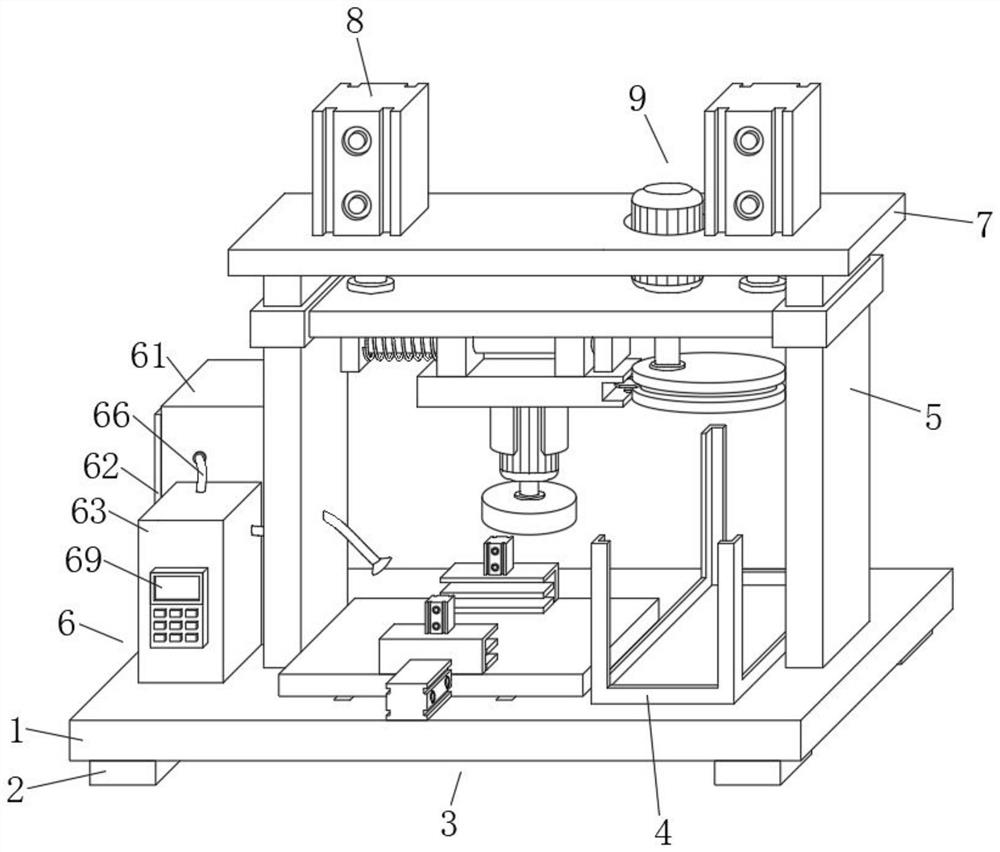

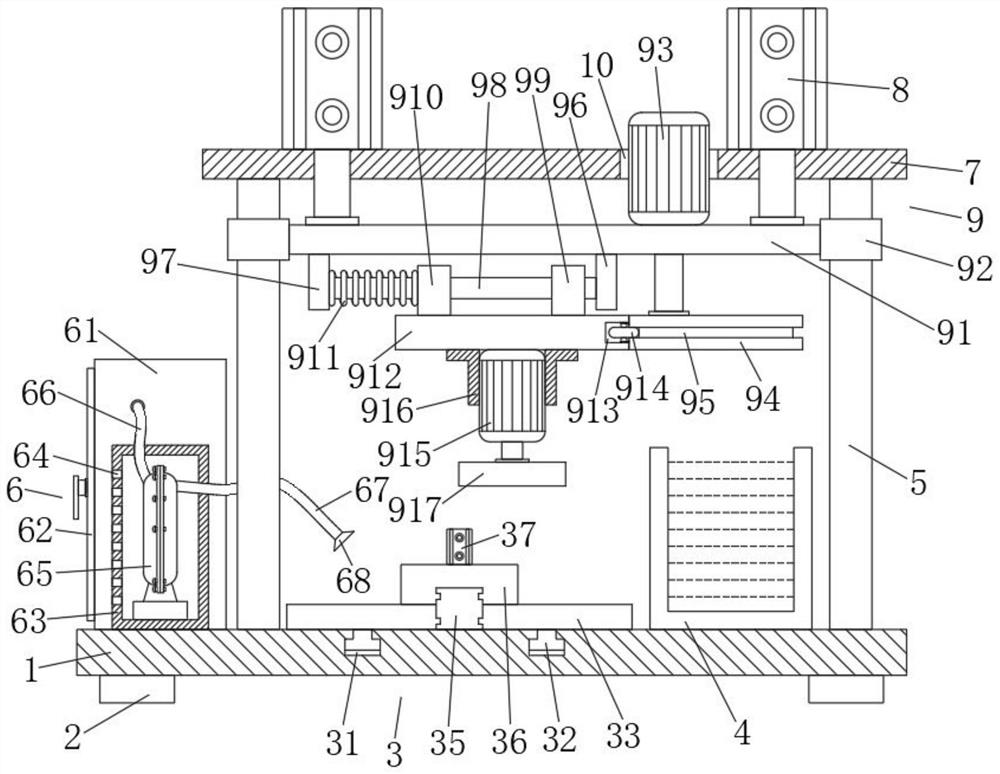

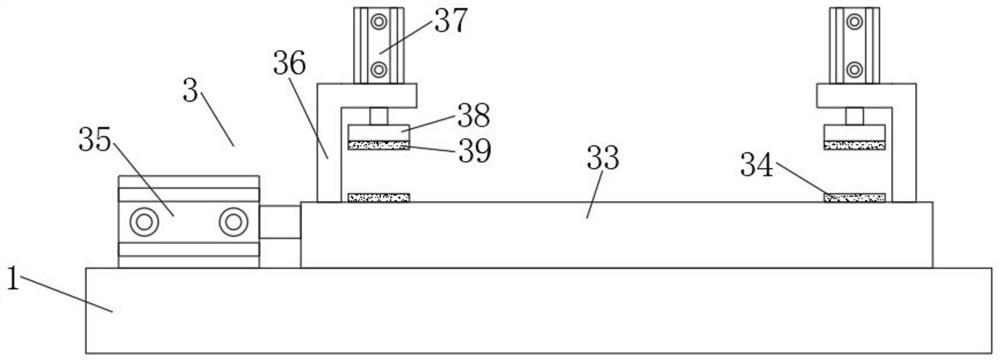

The invention discloses a double-layer belt line provided with jacking module and an operating method thereof. A support in a shape of a Chinese character 'ri' is arranged at two ends of the belt line respectively, the two supports in the shapes of the Chinese characters 'ri' are placed oppositely, and belt line bodies are erected at the positions of two cross beams connected with the upper portions of the supports in the shapes of the Chinese characters 'ri' to form a double-layer belt line structure. The double-layer belt line comprises an upper-layer belt conveying line and a lower-layer belt conveying line, wherein the upper-layer belt conveying line is used for conveying trays loaded with products and enabling the trays loaded with the products to be moved to the tail portion of the line, and the lower-layer belt conveying line is used for conveying the empty trays back to the head portion of the line. The jacking module connected with the trays is arranged under the trays, and an extensible device is arranged on the jacking module, and the trays can be upwards jacked up or put down. Two sensors and two stoppers are arranged on the upper-layer belt conveying line of the double-layer belt line, and the phenomenon that mutual bump of the trays influences product processing can be avoided. Intelligent belt line design is adopted, so that product processing is smooth, and the working efficiency of the whole belt line is improved.

Owner:SHENZHEN BORWIN PRECISION MACHINERY

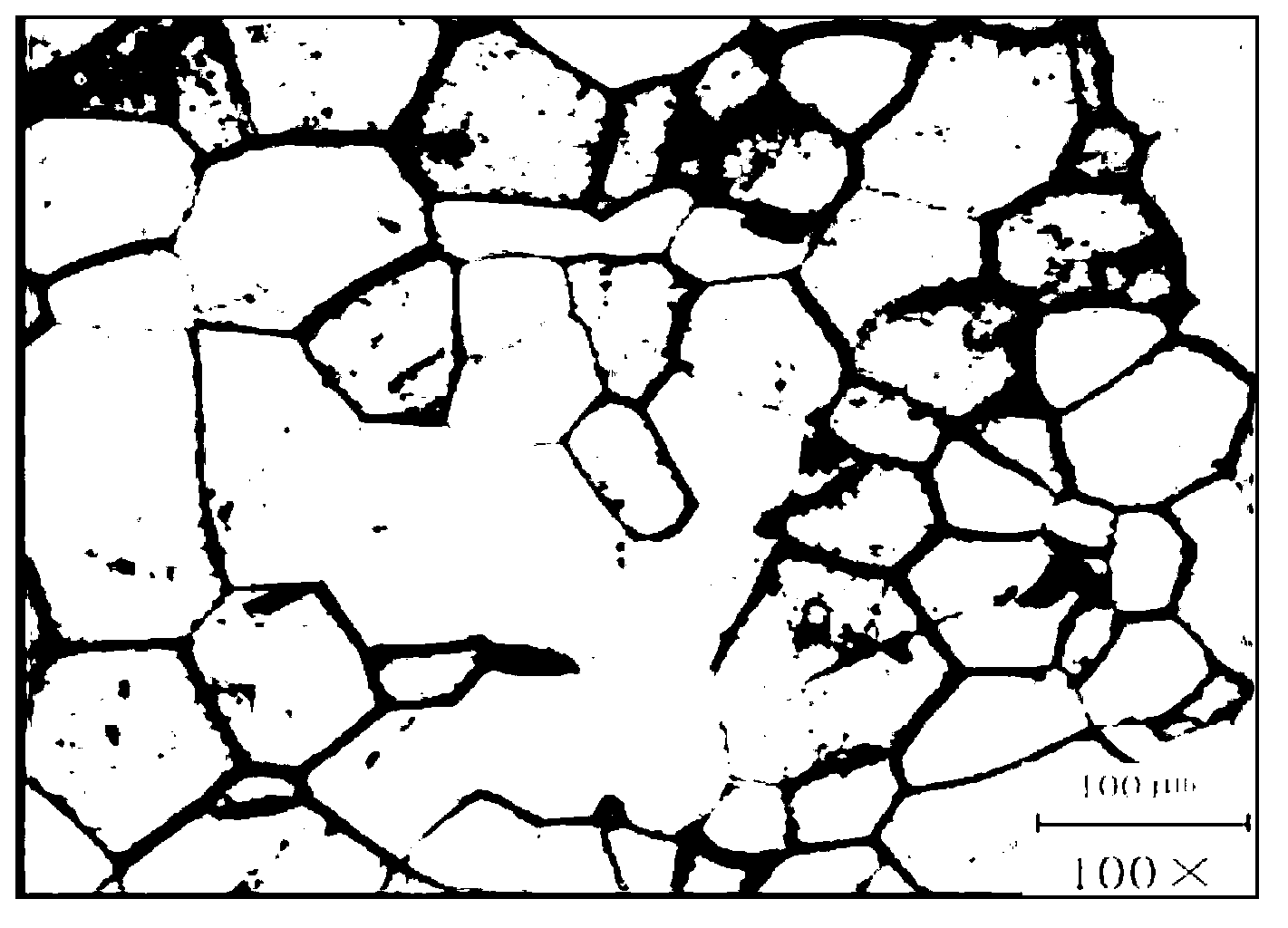

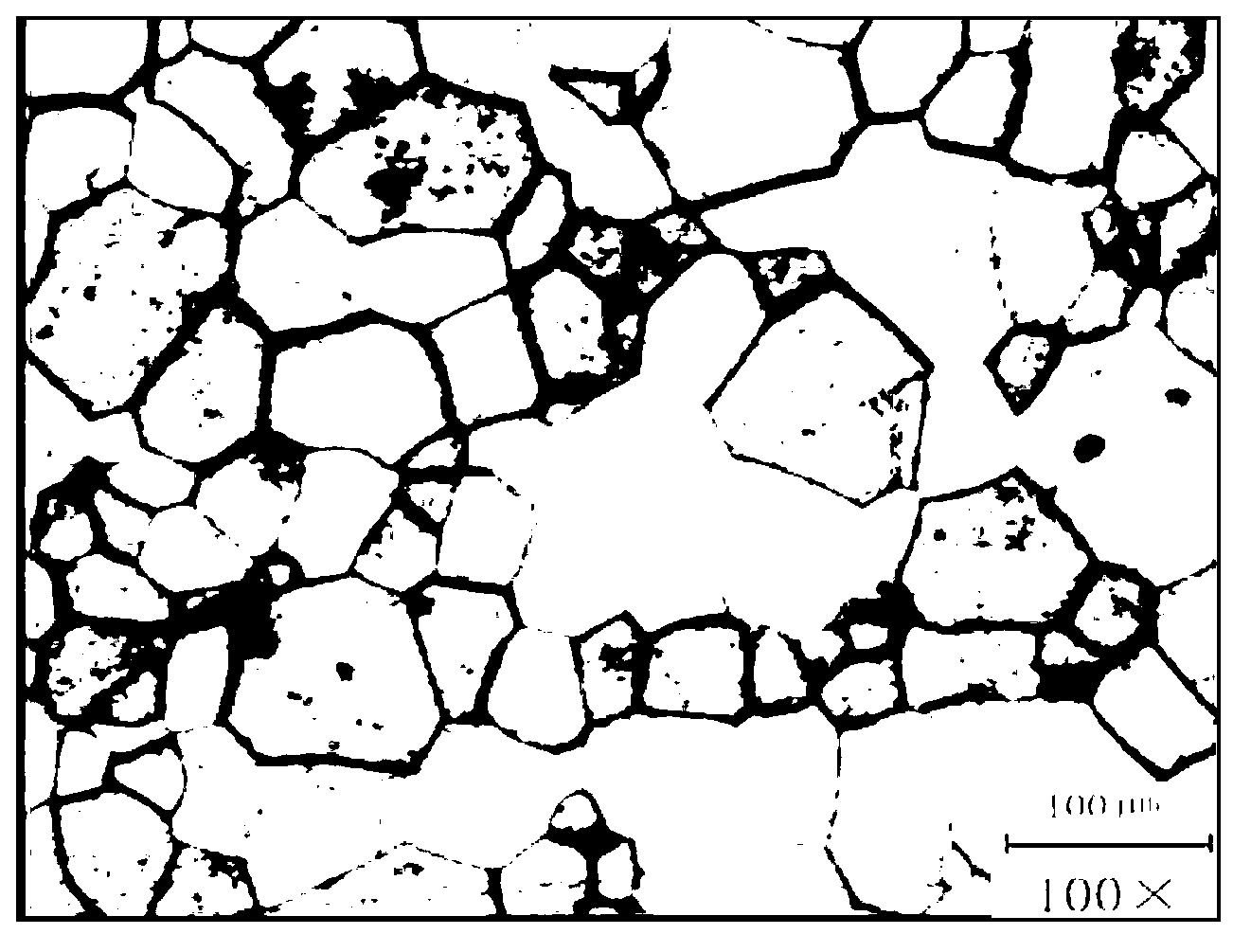

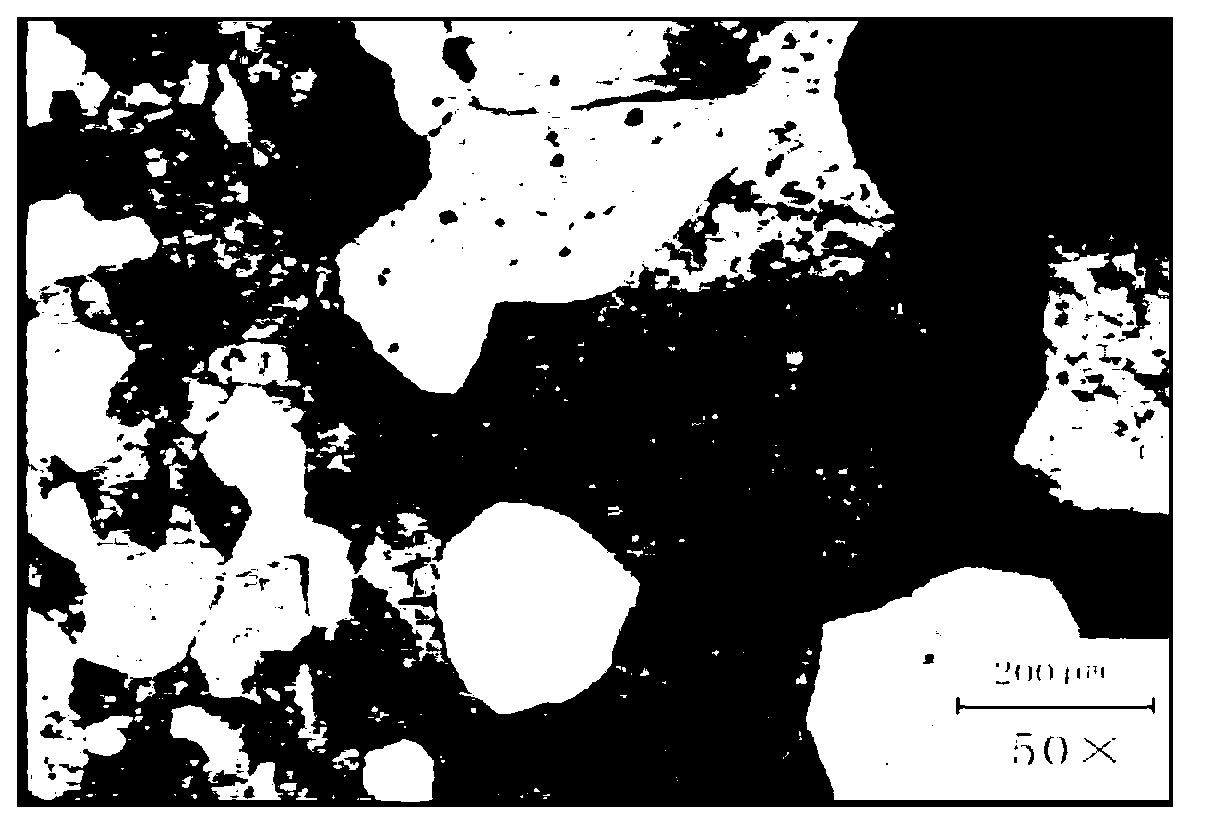

Niobium target and preparation method of niobium target

ActiveCN103009000AReduce surface roughness valueImprove surface qualityVacuum evaporation coatingSputtering coatingNiobiumSurface roughness

The invention provides a preparation method of a niobium target. According to the preparation method, firstly, a niobium pipe blank is subjected to hot extrusion, and then, the niobium pipe blank subjected to the hot extrusion is subjected to inner hole processing, so the niobium target is obtained. In the niobium target preparation process, firstly, glass powder is coated on the niobium pipe blank surface, because the niobium pipe blank surface is sprayed with the glass powder, a better lubricating effect is realized in the extrusion process, and the surface quality of the niobium pipe blank is better; the subsequent hot extrusion processing and the thermal treatment are favorable for the refining and homogenization of niobium pipe blank crystalline grains; and finally, the extruded niobium pipe blank is subjected to machining, a special tool is selected for carrying out boring and milling inner holes of the niobium pipe blank, broken chips can be continuously discharged out from the inner holes, and the problem of inner hole surface processing influence caused by the accumulation of the broken chips in the inner holes is avoided, so the niobium target with uniform inner crystalline grains and lower surface roughness value is obtained. The invention also provides the niobium target.

Owner:NINGXIA ORIENT TANTALUM IND

Old tree black tea processing method

InactiveCN106306150ASoup is gorgeousThe aroma is fresh, mellow and refreshingPre-extraction tea treatmentClimate change adaptationCooking & bakingBlack tea

The invention discloses an old tree black tea processing method. The method comprises the following specific steps: picking tea leaves, sun-drying, withering, twisting, fermenting, drying, cooling, and baking to enhance the aroma. In the method, the withering, fermenting and baking procedures are automated operations, and the operating processes are advanced; and especially the sun-drying procedure is added before withering, thus ensuring that the old tree black tea has a quality style of black tea as well as a quality charm of rock tea and achieves an unique quality flavor. After the old tea tree black tea developed by the special process is infused, the soup has a bright color, thus refreshing to the heart and pleasing to the eyes and having an unique lingering charm; the aroma is more unique, flower aroma can be inhaled at the first smell, fruit aroma can be tasted when sipping the tea soup, and honey aroma lasts in the mouth as the aftertaste; every infusion of tea soup is of a different style in the aspects of aroma, savor and soup color; and even as for the last infusion, the aroma can still last for long time. The tea sends out sufficient aroma, has a long-lasting aftertaste, and combines mellowness and sweetness, thus having an attractive charm.

Owner:贵州怡壶春生态茶业有限公司

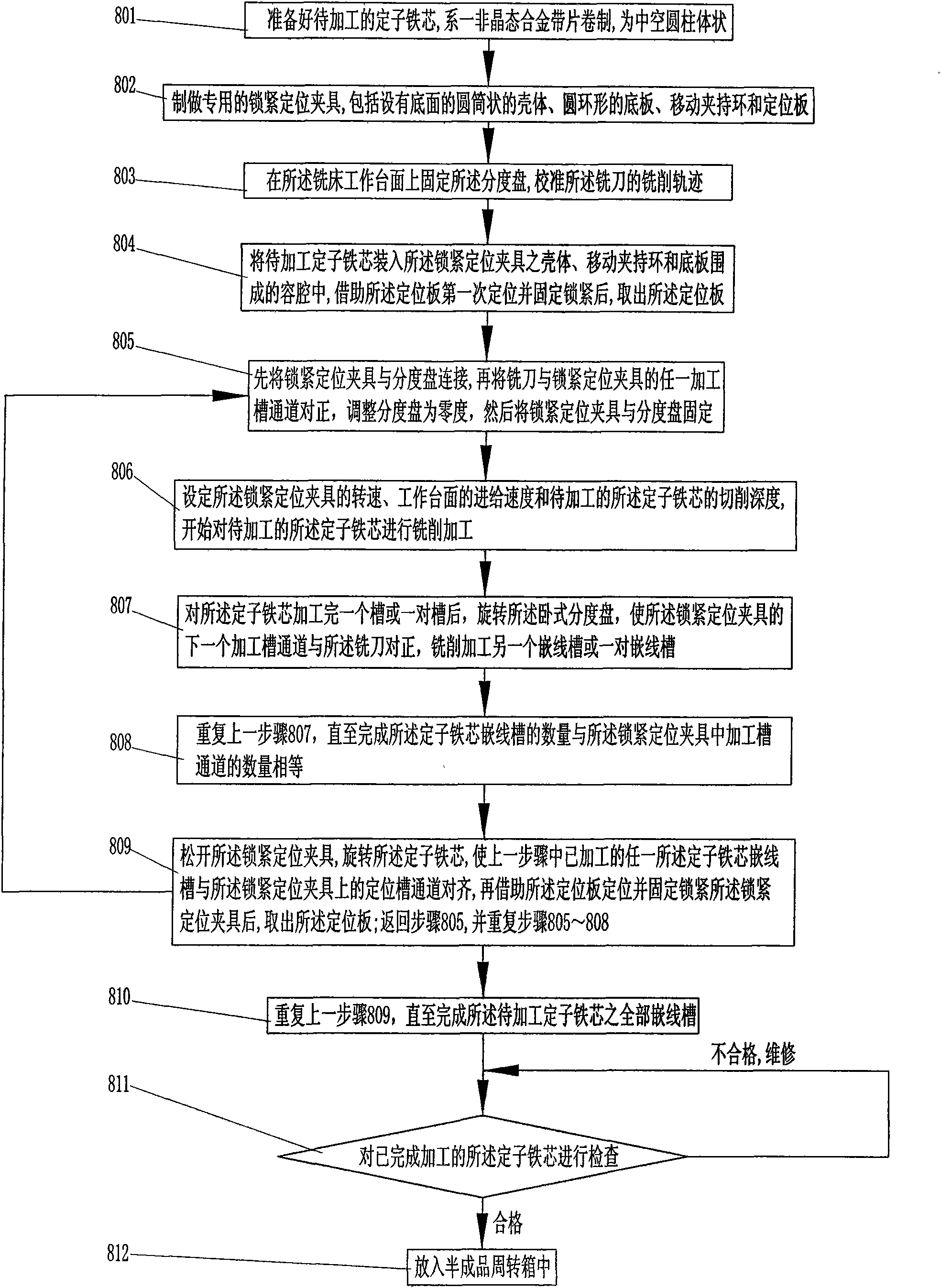

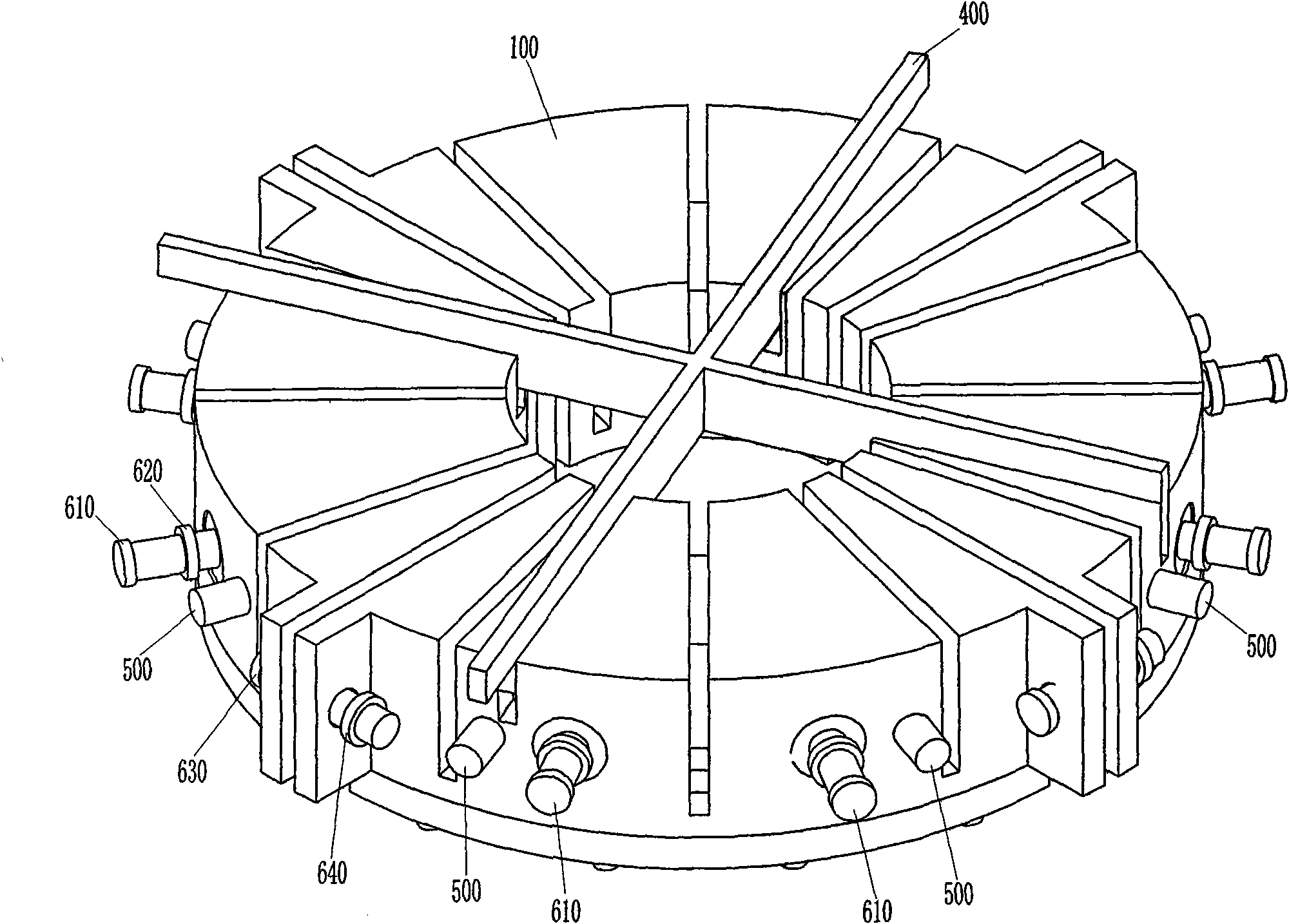

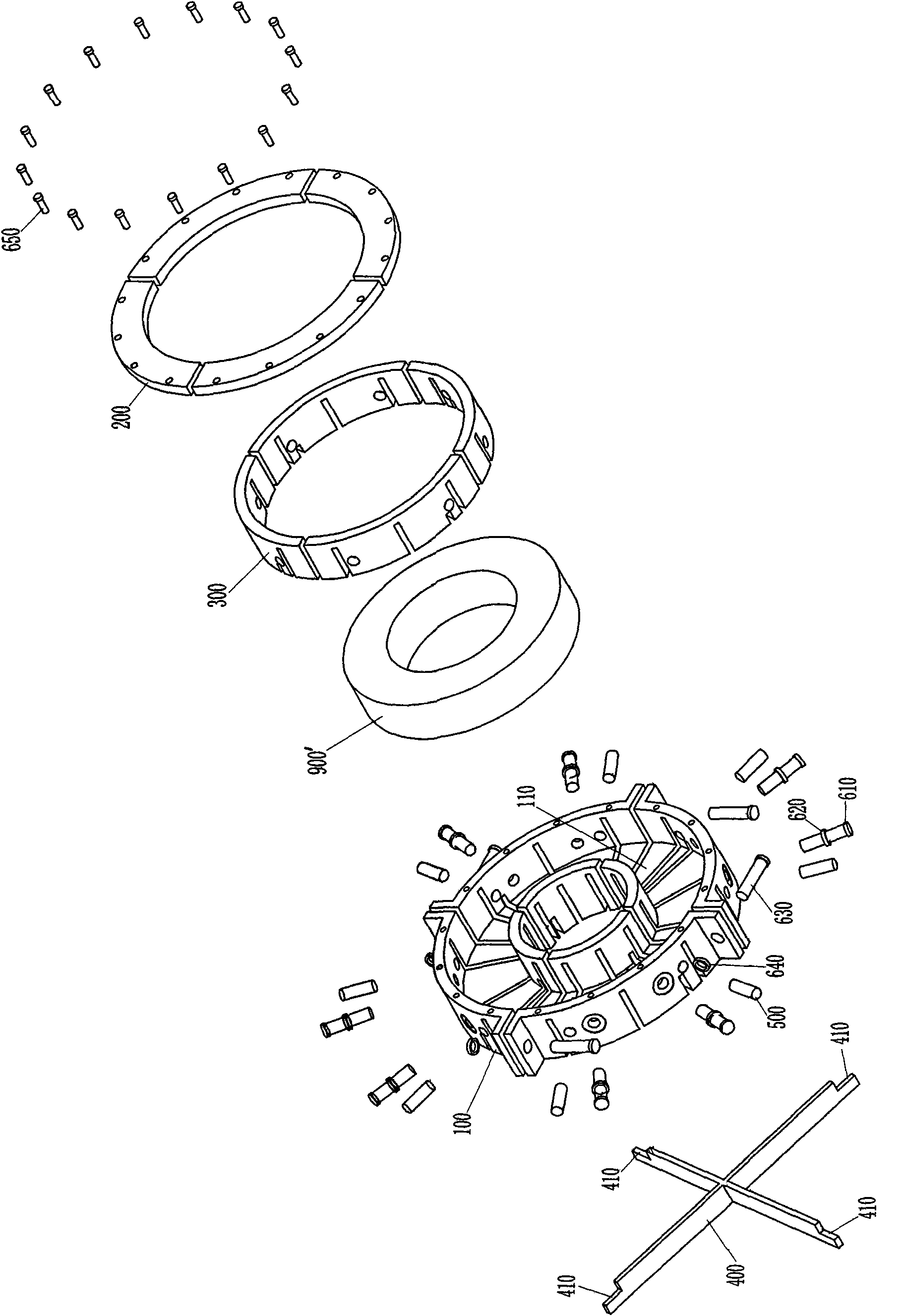

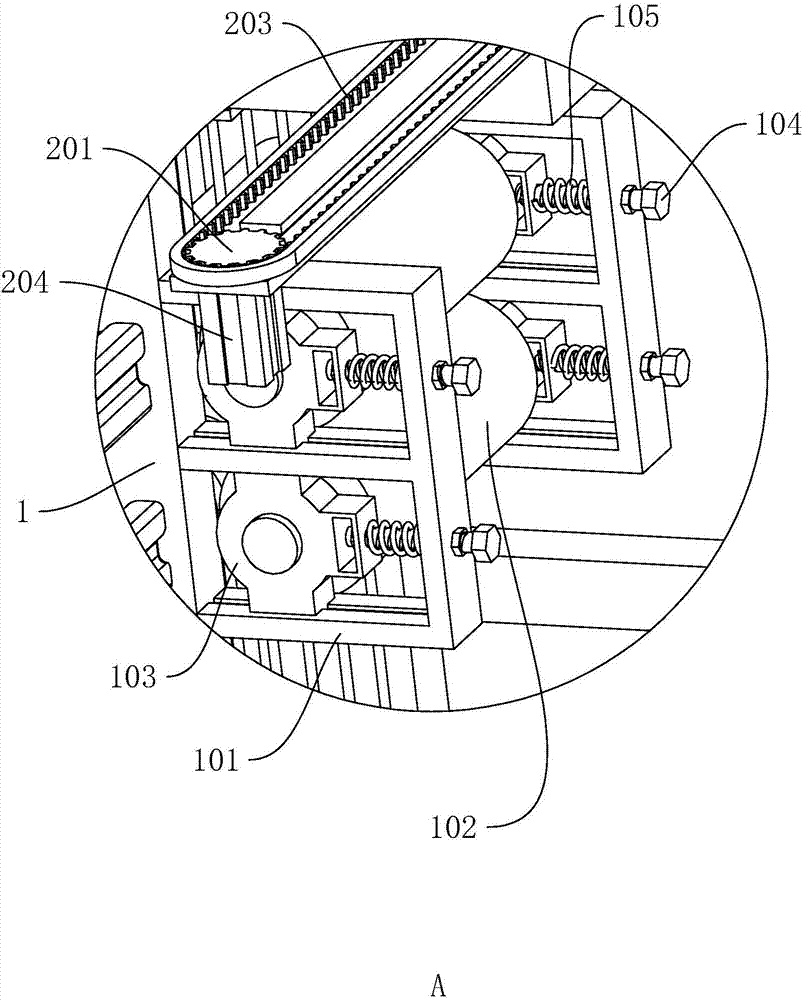

Processing method of amorphous alloy stator core slot and locking and positioning clamp thereof

ActiveCN101954507AImprove efficiencyQuality improvementMilling equipment detailsPositioning apparatusMetallurgyAdhesive

The invention relates to a processing method of an amorphous alloy stator core slot, which comprises the steps of: making a special locking and positioning clamp used for processing the amorphous alloy stator core slot; packing a stator core to be processed into the locking and positioning clamp for repeatedly positioning and fixedly locking the stator core; and milling a batch of stator core cable embedding trays after each time of positioning and fixedly locking until finishing all the cable embedding trays of the stator core to be processed. The processing method of the invention has the advantages of high efficiency, stable quality, low cost and the like, eliminates the problems of cracking and falling-off of the edge of the amorphous alloy stator core, caused by the impact of cutting force in a traditional mechanical processing method, and also avoids the problem on affecting processing due to nonconductive phenomenon caused by insulation of an adhesive in wire cutting. The invention also relates to the locking and positioning clamp used for processing the amorphous alloy stator core slot.

Owner:DONGMING MOTOR ELECTRICSHENZHEN CO LTD

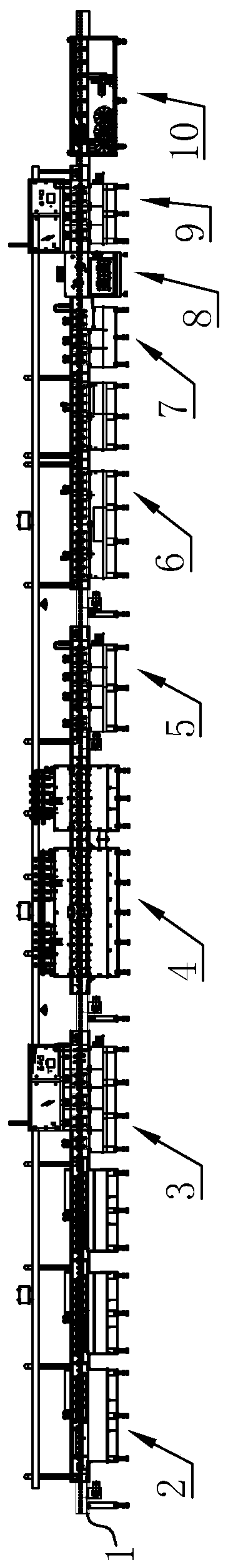

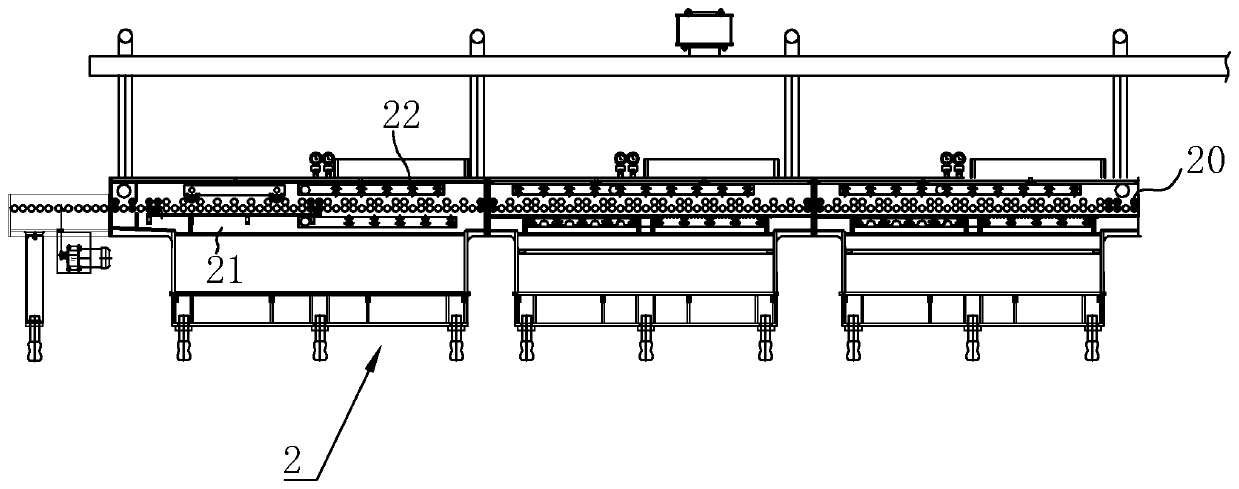

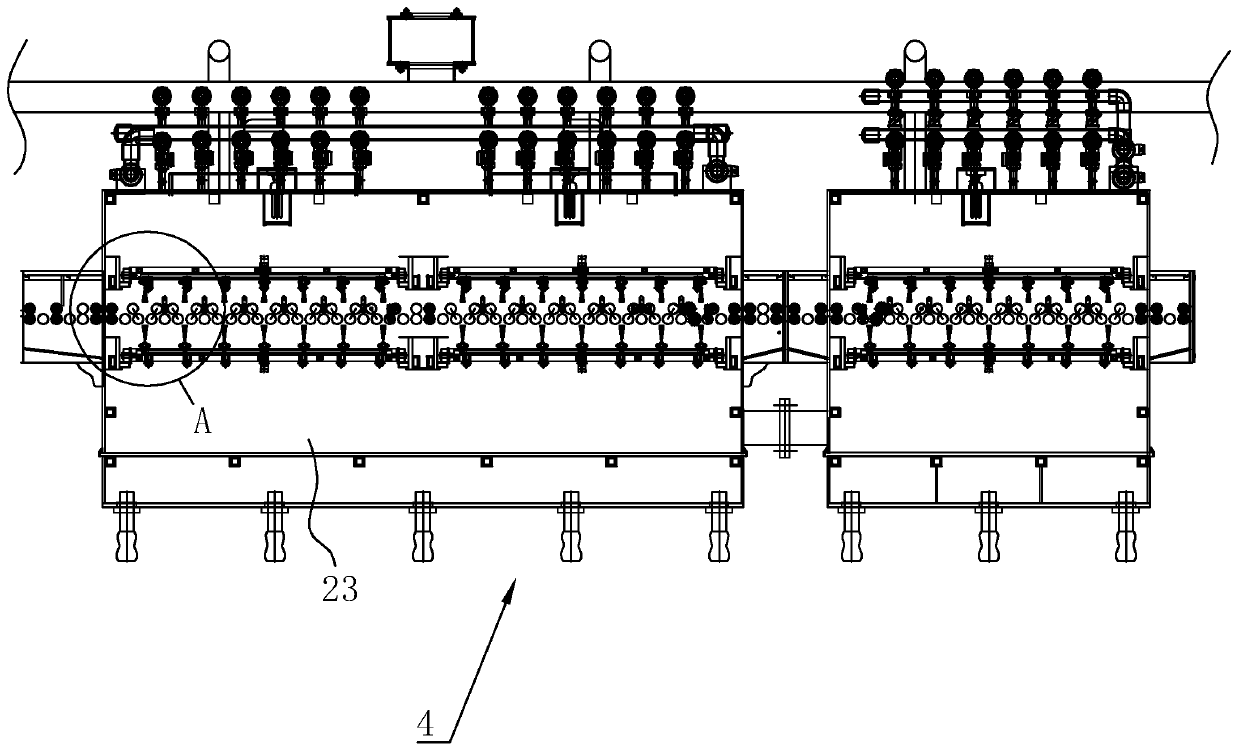

SES production line

ActiveCN110035620AAchieve recyclingGuaranteed cleanlinessConductive material chemical/electrolytical removalProduction lineEtching

The invention discloses an SES production line. The SES production line comprises a conveying table, a demoulding device, an etching device and a solder stripping device, wherein the demoulding device, the etching device and the solder stripping device are sequentially arranged in the conveying direction; the etching device comprises a vacuum etching chamber; first spraying heads used for sprayingan etching liquid is arranged in the vacuum etching chamber; the first spraying heads are located on the upper side and the lower side of a PCB respectively and are arranged at intervals in the conveying direction; a liquid sucking head used for sucking the etching liquid accumulated on the upper surface of the PCB is arranged between the adjacent first spraying heads in the conveying direction,so that the PCB is continuously conveyed forwrads on the conveying table, and the processing of demoulding, etching and solder stripping is gradually realized; and the etching liquid is sprayed to thesurface of the PCB from the upper side and the lower side through the first spraying heads in the etching process, and the etching liquid accumulated on the upper surface of the PCB is sucked away under the action of a suction force of the liquid suction head, so that the situation that an etching reaction is weakened due to the accumulated liquid on the upper surface of the PCB is effectively avoided, and the purpose of more uniform etching is achieved.

Owner:CIRCUIT TECH MACHINERY

Folding pay-off equipment for cable processing

PendingCN112047203AEasy to adjustEasy to store and transportFilament handlingElectric machineryScrew thread

The invention discloses folding pay-off equipment for cable processing. The equipment comprises a body, a tensioning mechanism and a pay-off mechanism, a mounting plate is fixed to a lifting mechanism, a second hydraulic rod is fixed to the right side of the interior of a pay-off reel, movable blocks are fixed to the second hydraulic rod, a movable plate is mounted in the pay-off reel, and arc-shaped plates are fixed to the outer side of the movable plate. The folding pay-off equipment for cable processing is provided with a first motor, the movable blocks and a supporting frame, a lead screwis driven by the first motor on the outer side of the body to rotate, the lead screw enables the movable blocks in threaded connection with the outer side of the lead screw to rotate at the same time,the two sets of movable blocks move to the middle point of the lead screw on the lead screw to cooperate with the rotatably-connected supporting frame to support and lift the mounting plate and the pay-off reel on the mounting plate so that the height can be conveniently adjusted according to field conditions during processing, meanwhile, the mounting plate and the pay-off reel can conveniently descend into the body to facilitate storage and transportation, the structure is compact, space is saved, and practicability is improved.

Owner:镇江市滨江电子有限公司

Processing method of Gongfu black tea

InactiveCN106359693AUnique aromaFresh and smooth tastePre-extraction tea treatmentClimate change adaptationBlack teaSweetness

The invention provides a processing method of Gongfu black tea. The method comprises the following steps: picking tea leaves, sun-drying, stirring, withering, twisting, mixing, fermenting, drying, cooling, baking to enhance the aroma, and packaging. The operating method is unique. The stirring step is added before withering, so that the Gongfu black tea has a quality style of black tea as well as a quality charm of rock tea and achieves a unique quality flavor. After the black tea developed by the special process is infused, the soup has a bright color, thus refreshing to the heart, pleasing to the eyes and having an unique lingering charm; the aroma is more unique, and the tea soup has the flower aroma, honey aroma and fruit aroma; every infusion of tea soup is of a different style in the aspects of aroma, savor and soup color; and even as for the last infusion, the aroma can still last for long time. The tea sends out sufficient aroma, has a long-lasting aftertaste, and combines mellowness and sweetness, thus having an attractive charm.

Owner:贵州怡壶春生态茶业有限公司

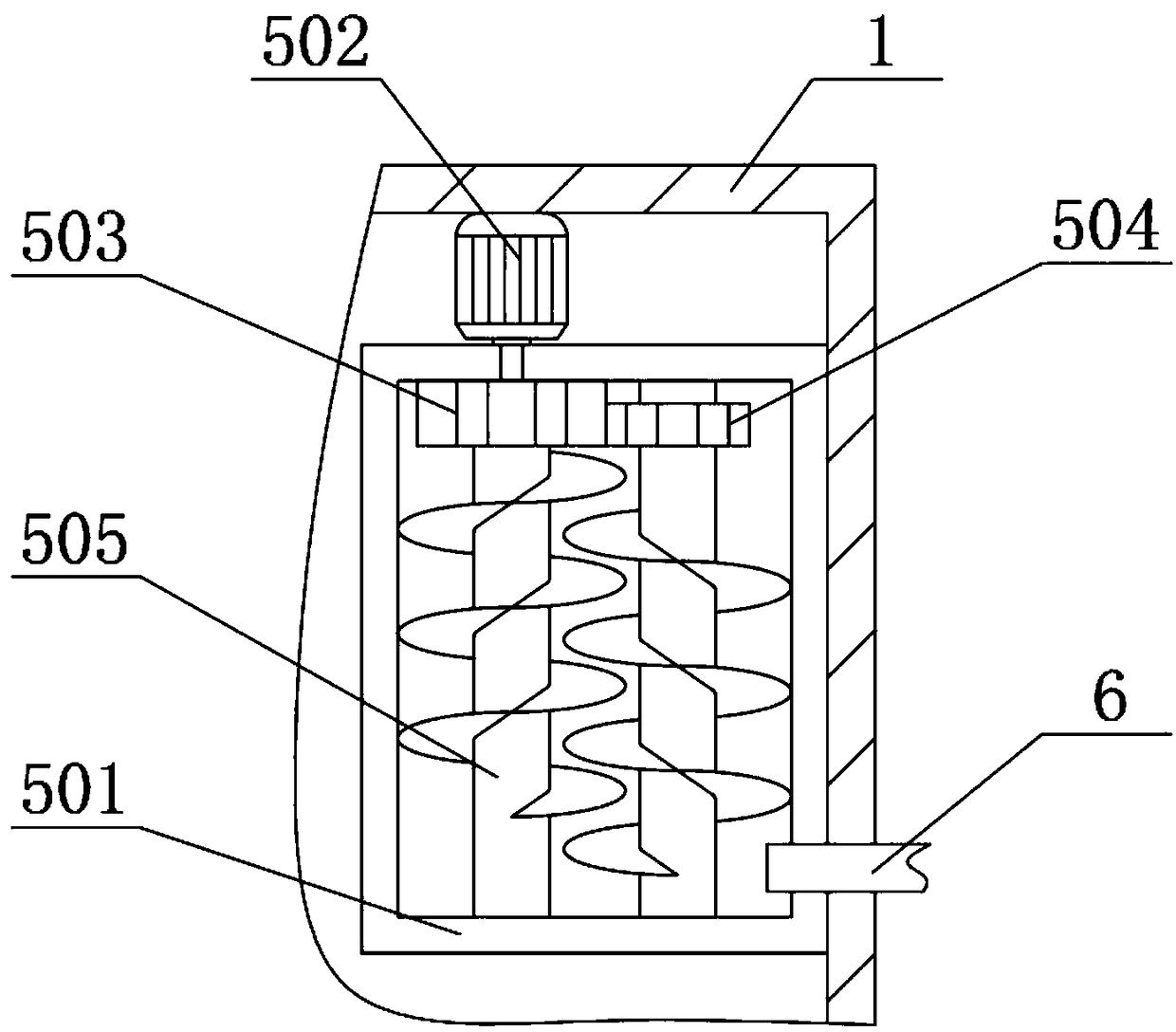

Grinding device for production and manufacture of panax notoginseng powder

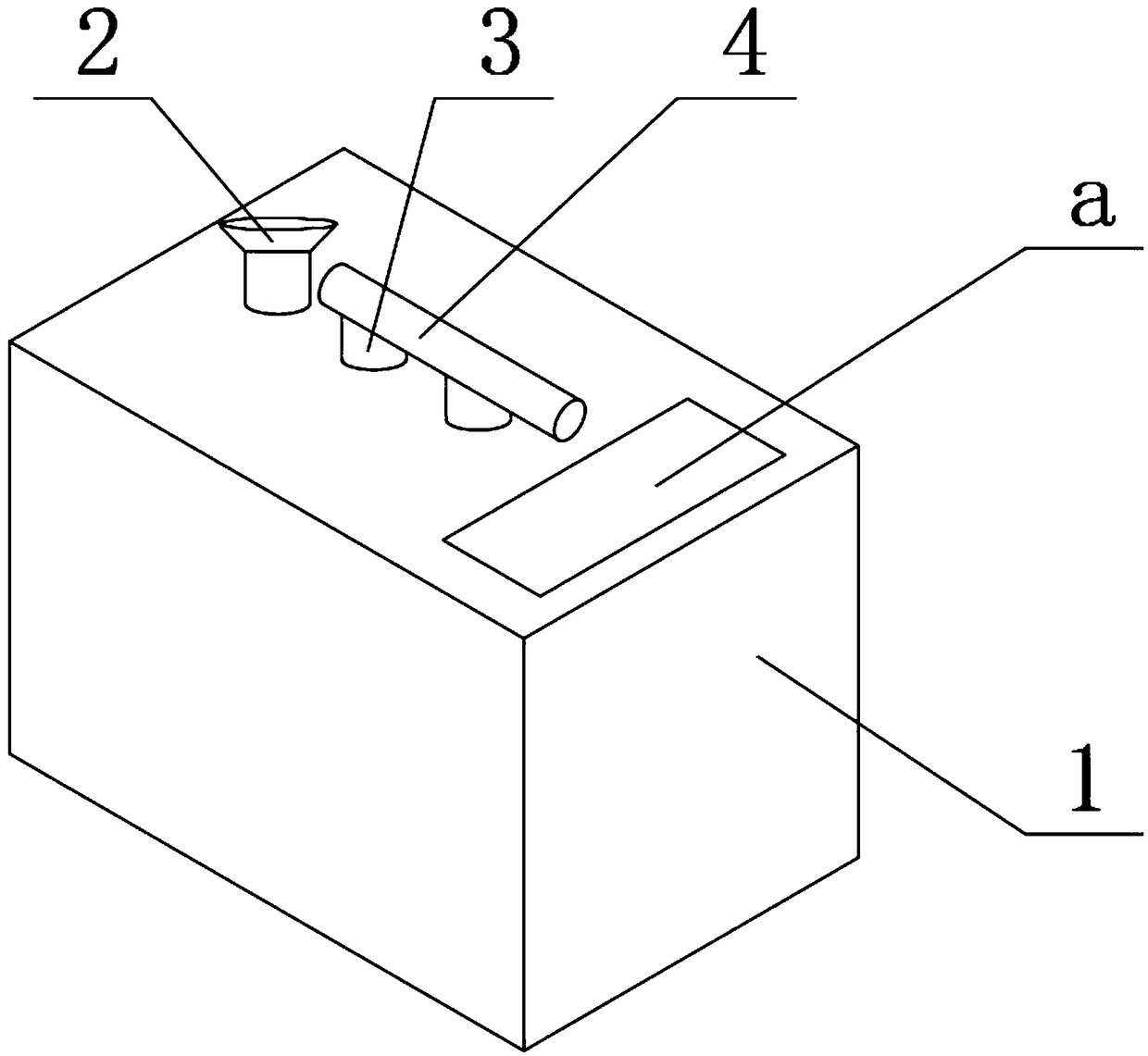

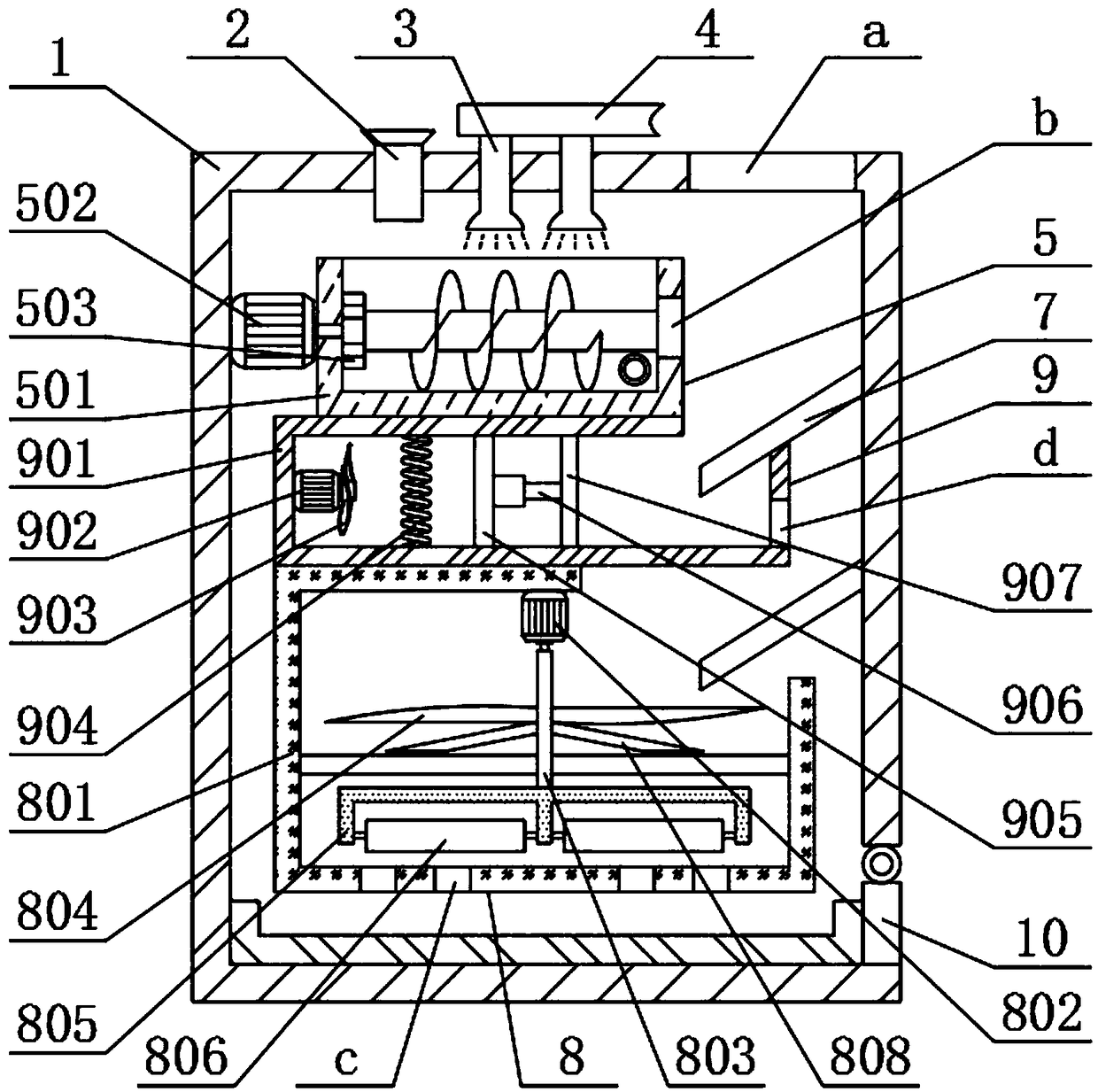

InactiveCN109317288AEasy to cleanImprove work efficiencySievingScreeningPANAX NOTOGINSENG ROOTEngineering

The invention relates to the technical field of medicine manufacture and especially relates to a grinding device for production and manufacture of panax notoginseng powder. The device provided by theinvention comprises a box body and a feeding hopper, wherein the top end of the box body communicates with the feeding hopper; a washing device, a drying device and a grinding device are firmly connected in succession on the inner side of the box body from top to bottom; the washing device comprises a first washing box and a first electric motor; the first washing box is firmly connected on the inner side of the rear end face of the box body; the first electric motor is firmly connected to the left end of the first washing box; a first gear is firmly connected to the tail end of a main shaft of the first electric motor; and a second gear is in engaged connection with the rear end of the first gear. According to the invention, with spiral cleaning blades, the first gear and the second geardisposed in the device, less dirty panax notoginseng can be effectively cleaned; the spiral cleaning blades not only can be used to convey the panax notoginseng, but can also be used to wash the panaxnotoginseng; and the washing effect is good and the working efficiency is high.

Owner:湖南龟寿堂健康产业发展有限公司

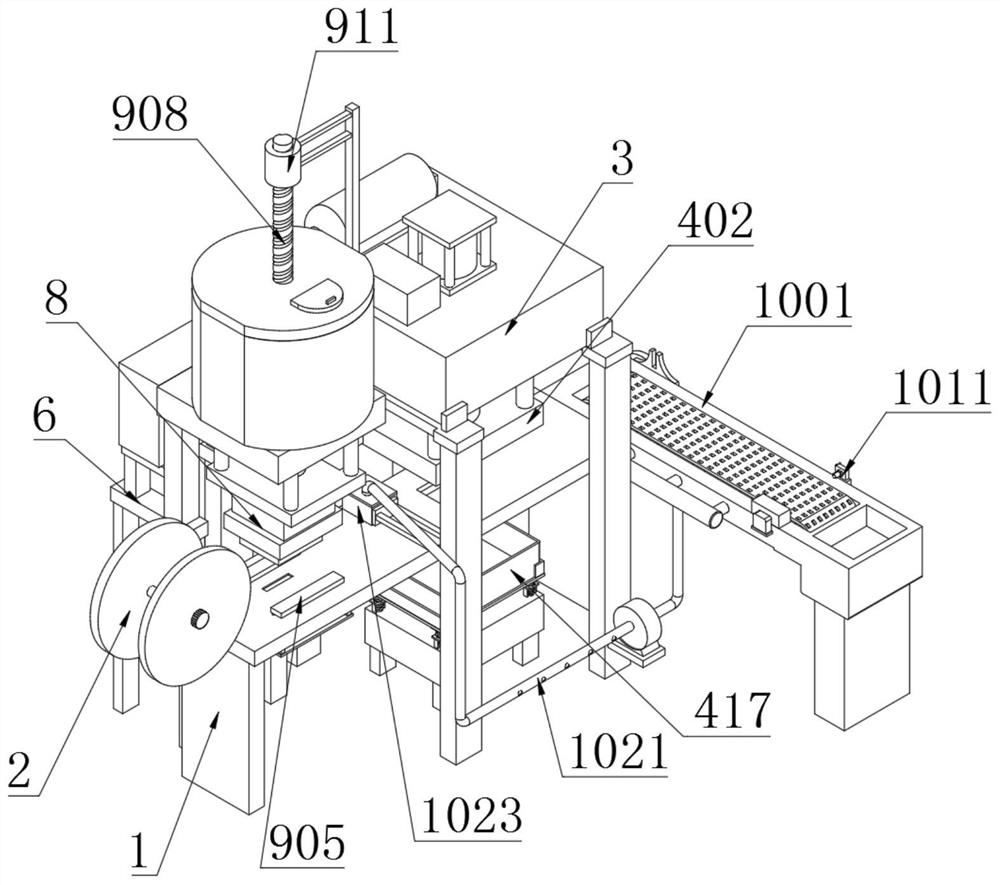

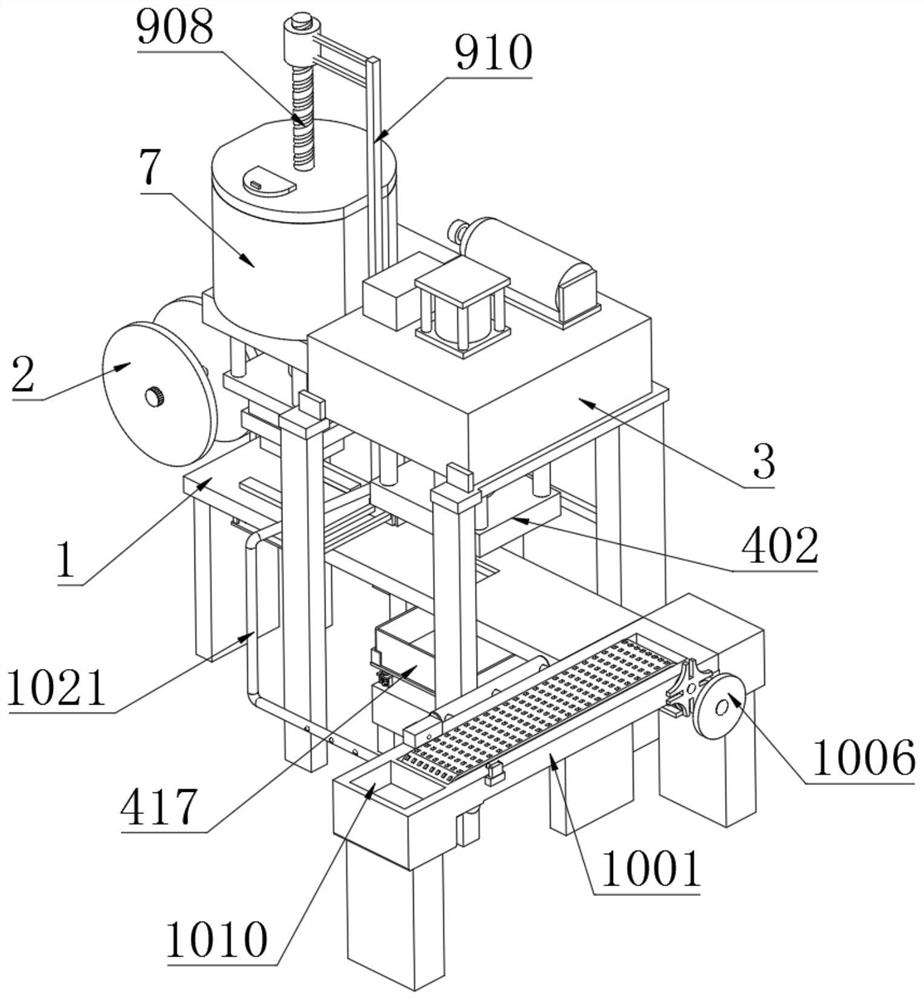

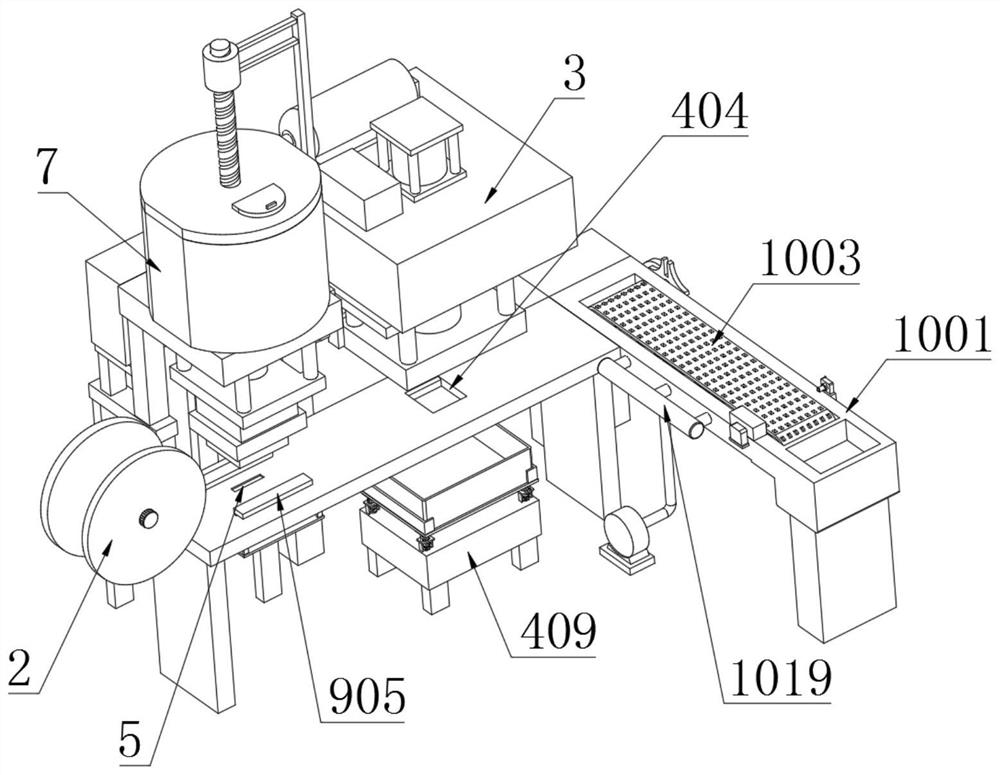

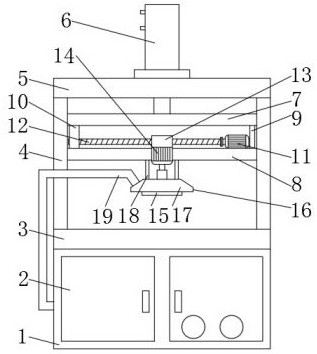

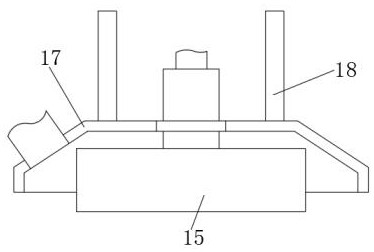

Double-station feeding device and oil press with same

ActiveCN107244094AHigh degree of automationAvoid safety accidentsMetal-working feeding devicesPositioning devicesEngineeringFuselage

The invention discloses a double-station feeding device and an oil press with the same. The double-station feeding device is technically characterized in that the double-station feeding device comprises a machine base; a conveying mechanism is arranged on the machine seat in the length direction; a loading mechanism for loading workpieces to be machined is arranged at the front end of the machine base; a material fetching robot is arranged at the front end of the machine base and used for grabbing the workpieces in the loading mechanism to the conveying mechanism to be conveyed; a feeding robot is arranged at the rear end of the machine base and used for grabbing the workpieces at the tail end of the conveying mechanism to the next procedure; and the loading mechanism comprises a machine body arranged at the front end of the machine base, and at least two baffles vertically arranged on the upper end face of the machine body, the baffles form a feeding station matched with the workpieces, and the feeding station is provided with a lifting assembly which is used for guaranteeing the effect that the workpieces on the uppermost layer are located at the same height all the time. According to the double-station feeding device and the oil press with the same, the automation degree can be improved, and the labor cost is reduced.

Owner:浙江佶福智能科技有限公司

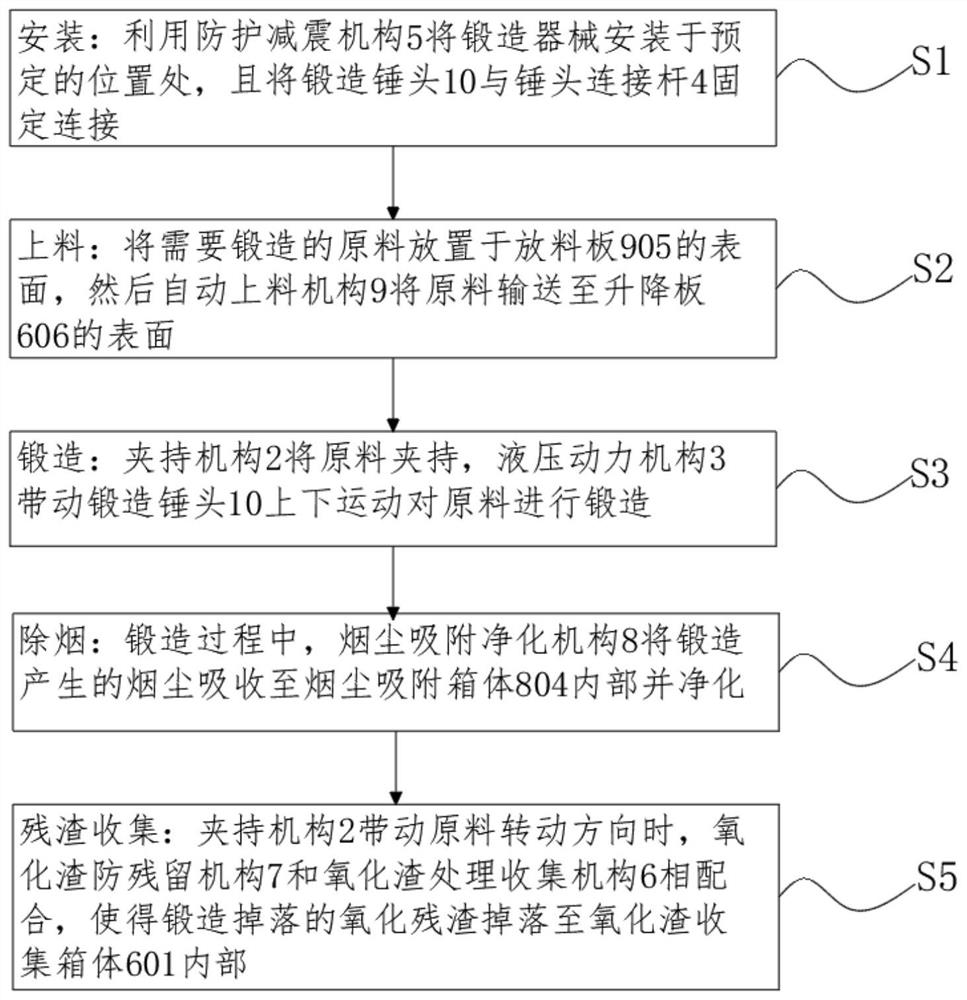

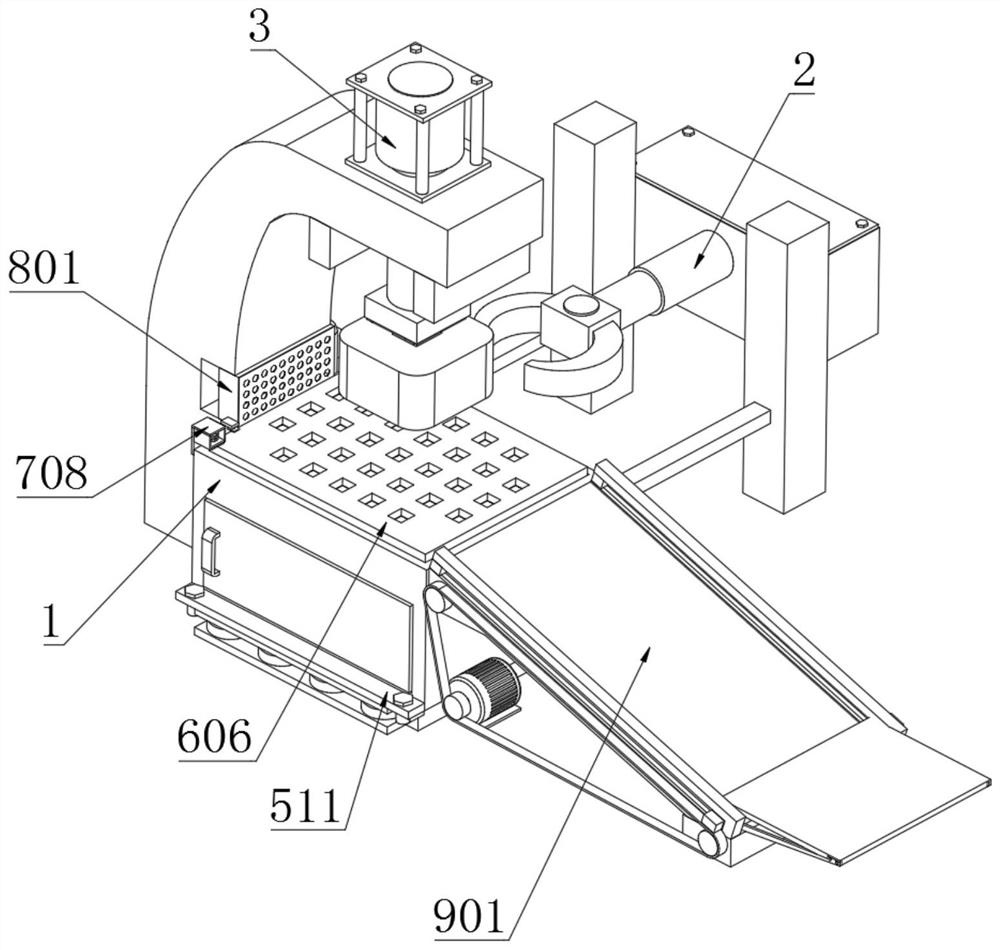

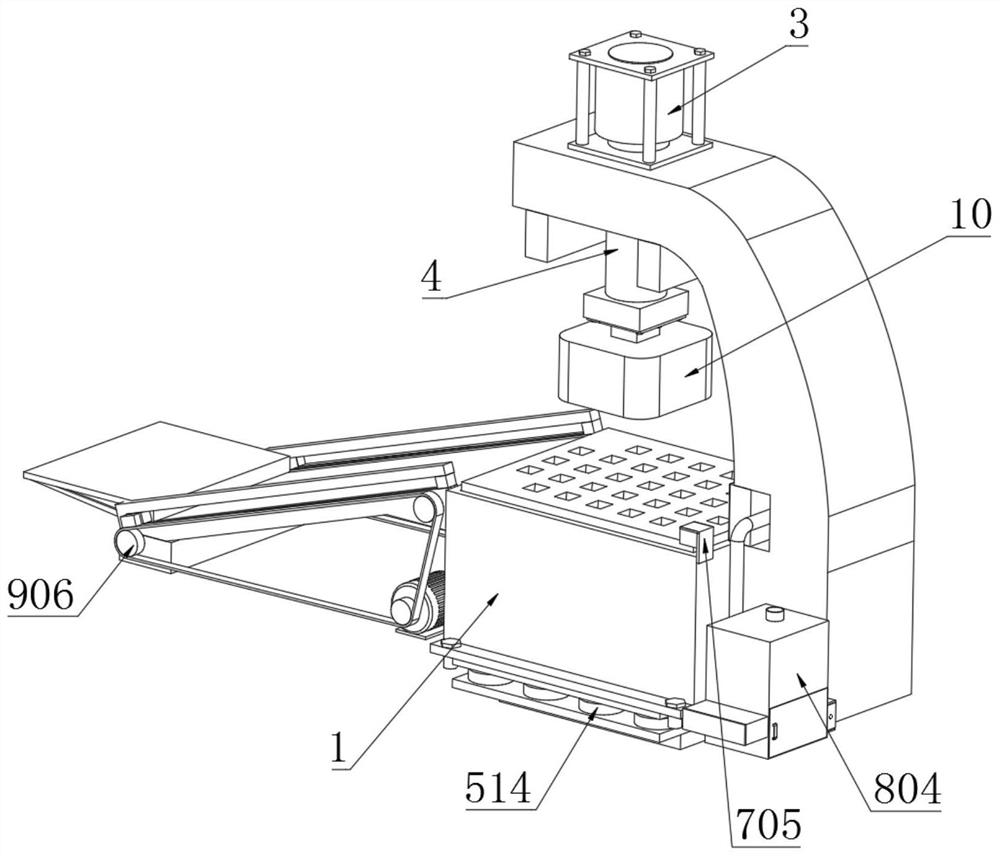

Forging method capable of realizing multi-surface forging forming

InactiveCN111822636AScientific and reasonable structureEasy to useCombination devicesNon-rotating vibration suppressionSlagStructural engineering

The invention discloses a forging method capable of realizing multi-surface forging forming. According to the forging method, a fixed sleeve is fixedly installed in a circular groove, the surface of the fixed sleeve is sleeved with a reset spring, the top end of the reset spring is fixedly connected with a lifting plate, and movable columns are fixedly connected to the four corners of the bottom end of the lifting plate correspondingly; and conical discharging holes are formed in the middle of the lifting plate at equal intervals, cross beams are symmetrically and fixedly installed at the topend of an oxidation slag collecting box body, and conical clamping blocks are fixedly connected to the top ends of the cross beams at equal intervals. Through cooperative use of the reset spring and the conical discharging holes, oxidation residues generated by forging can fall down when the lifting plate is jacked up, the situation that oxidation residues are accumulated on the surface of the lifting plate to affect the normal forging process, a raw material is forged on the accumulated residues, pits are formed in the surface of the raw material, and the surface of the raw material is uneven, so that the forging quality of a subsequent raw material is reduced is avoided, the surface of a machining platform can be kept clean without manual cleaning, and the qualified rate of forging is increased.

Owner:林璋

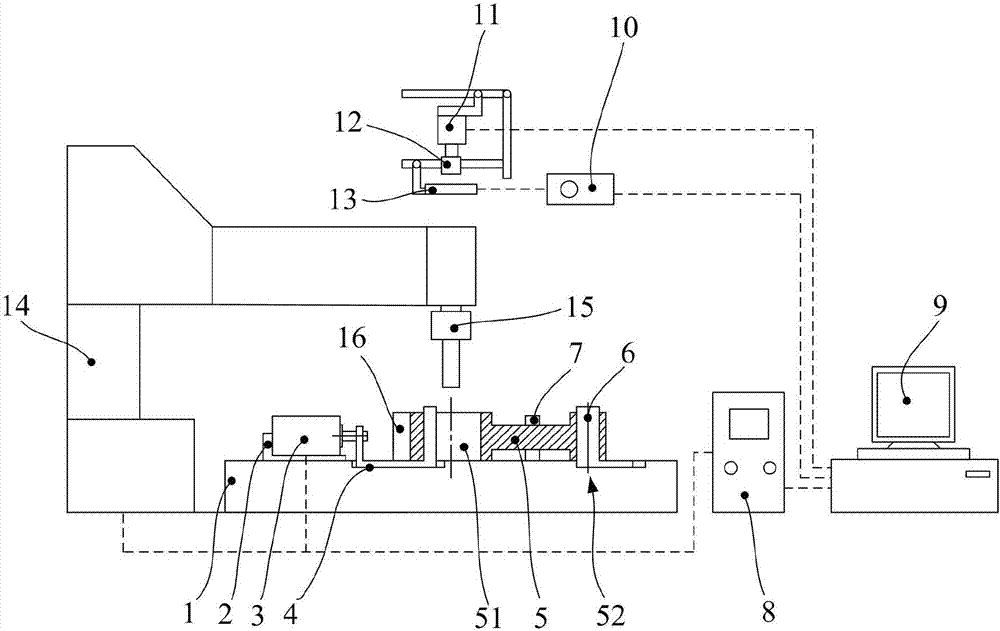

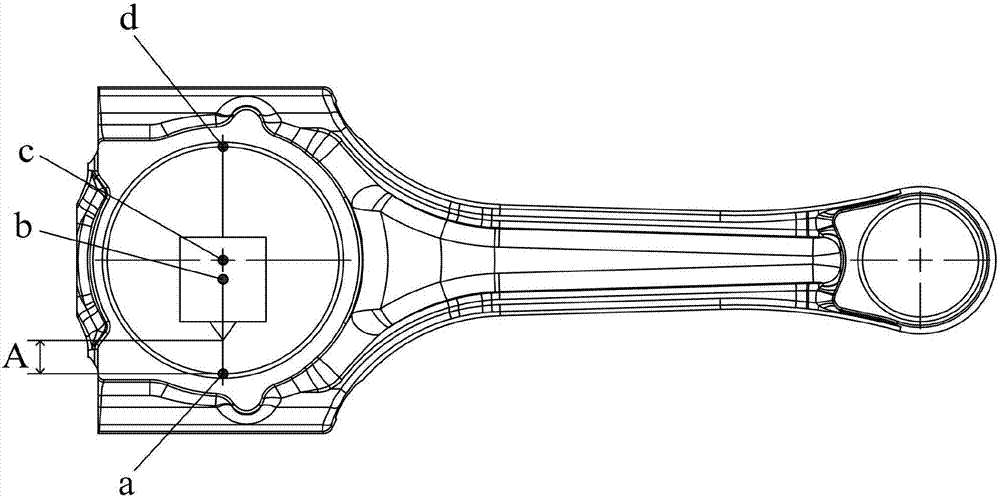

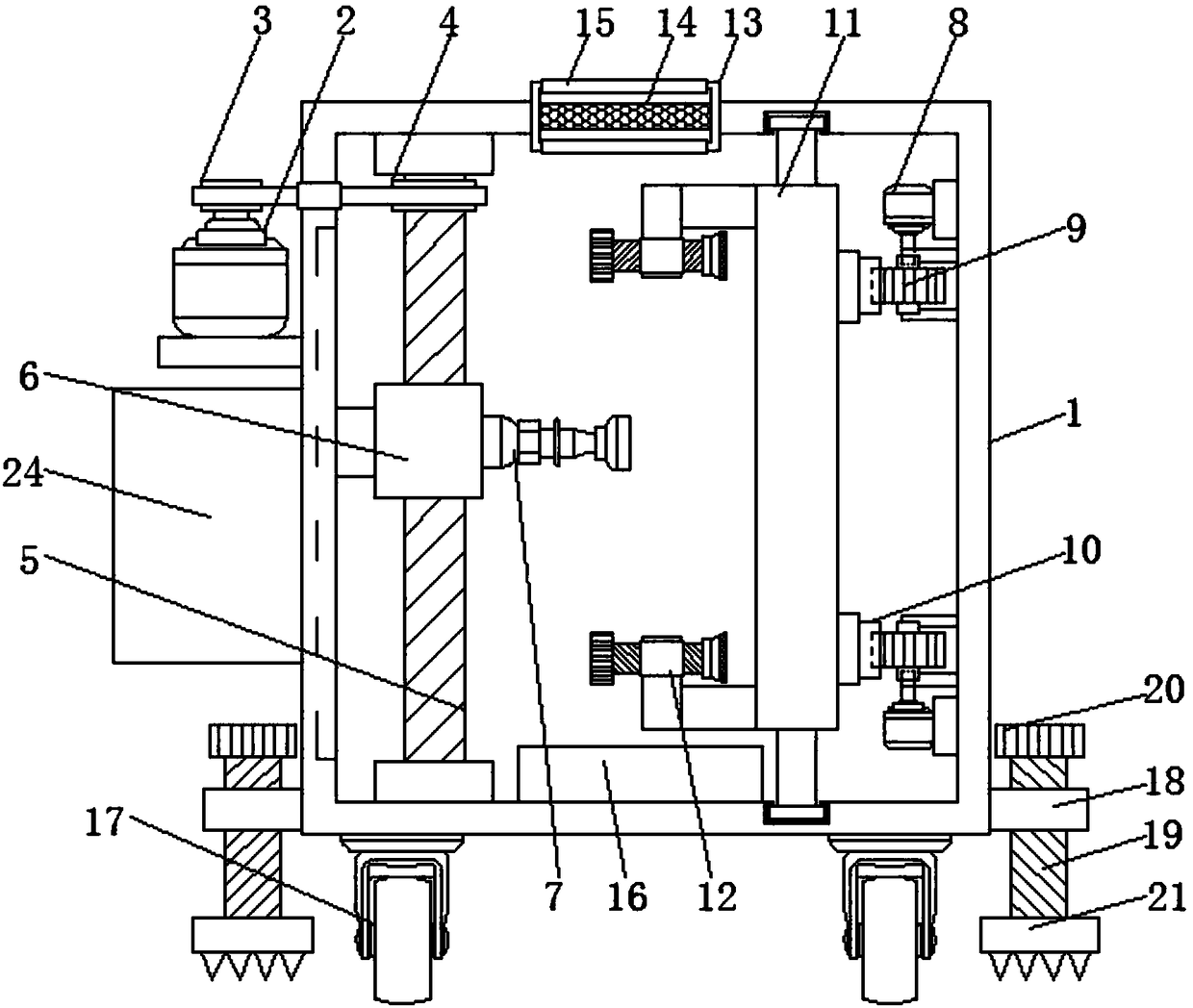

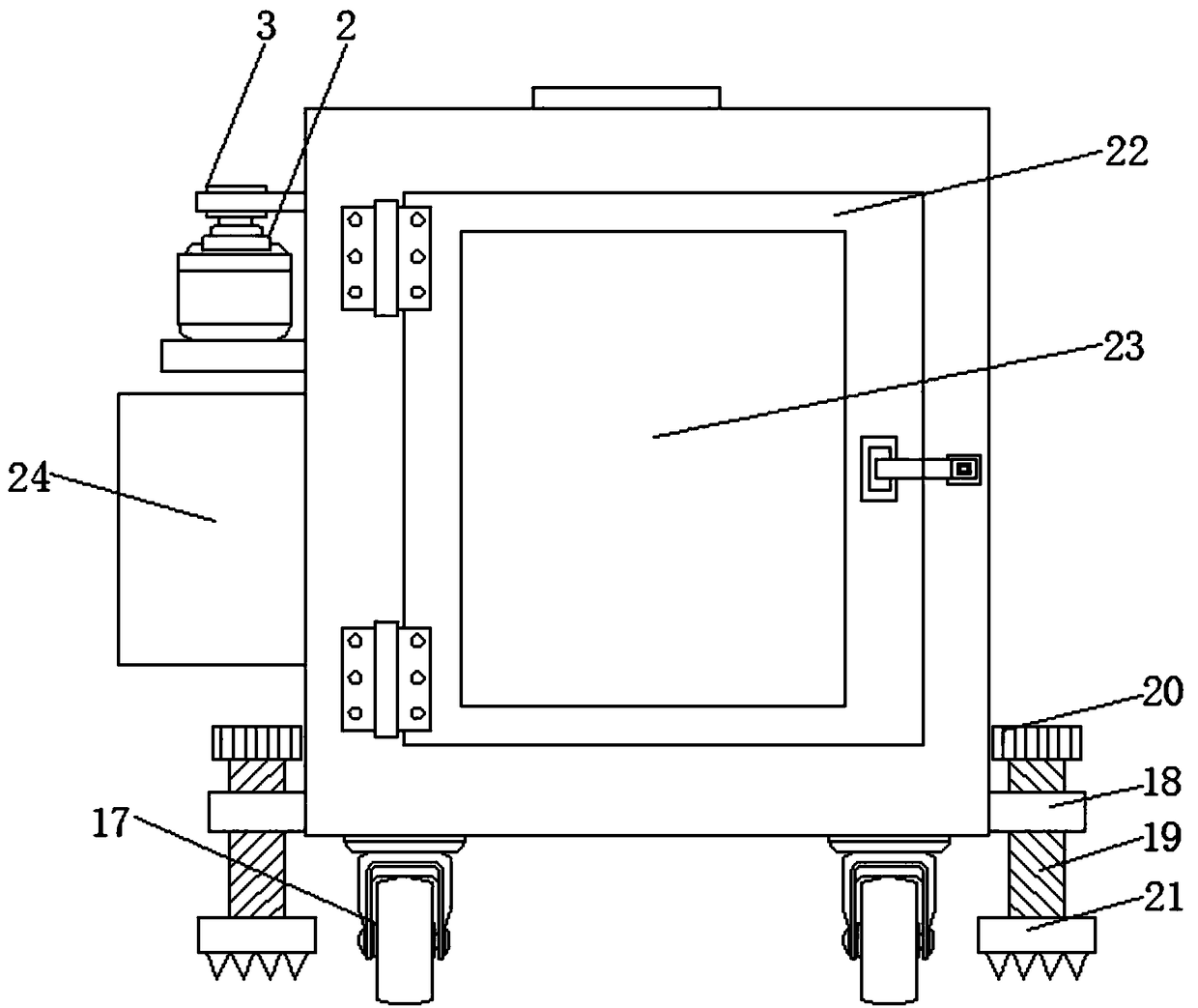

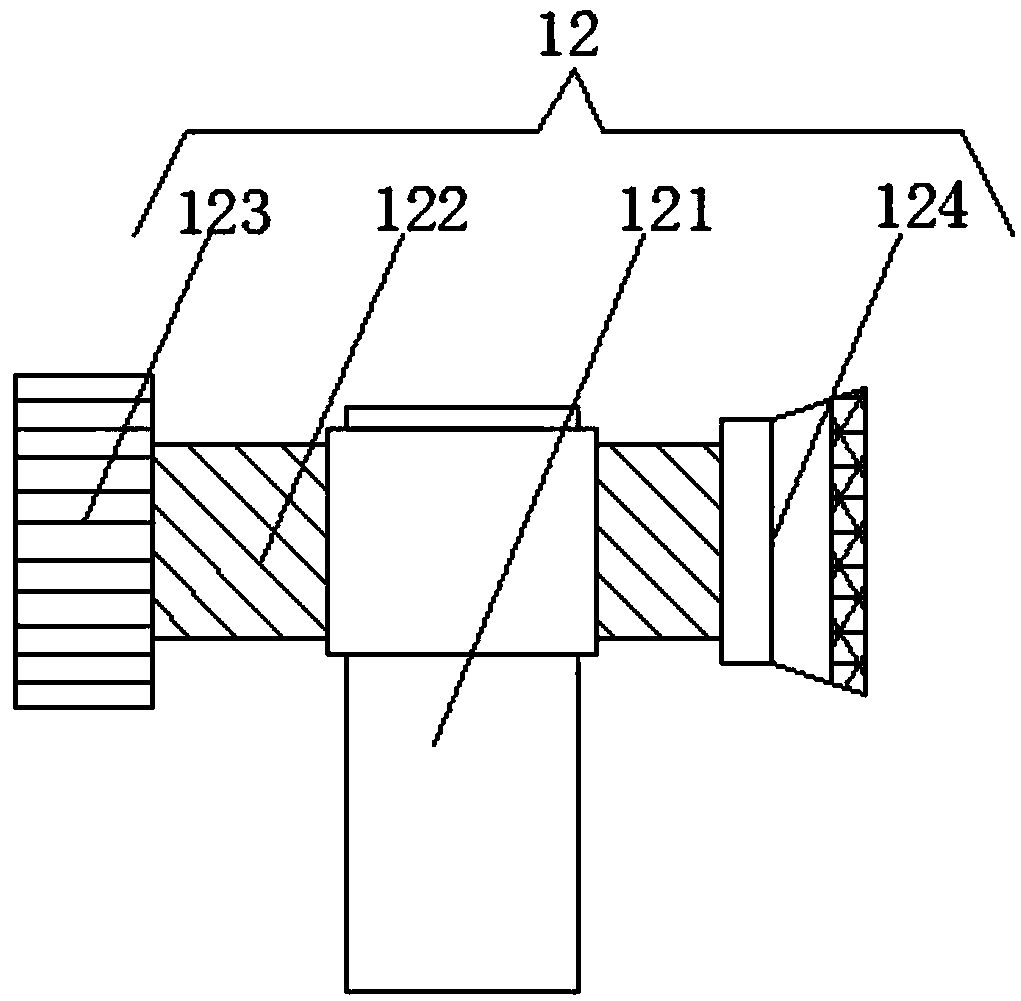

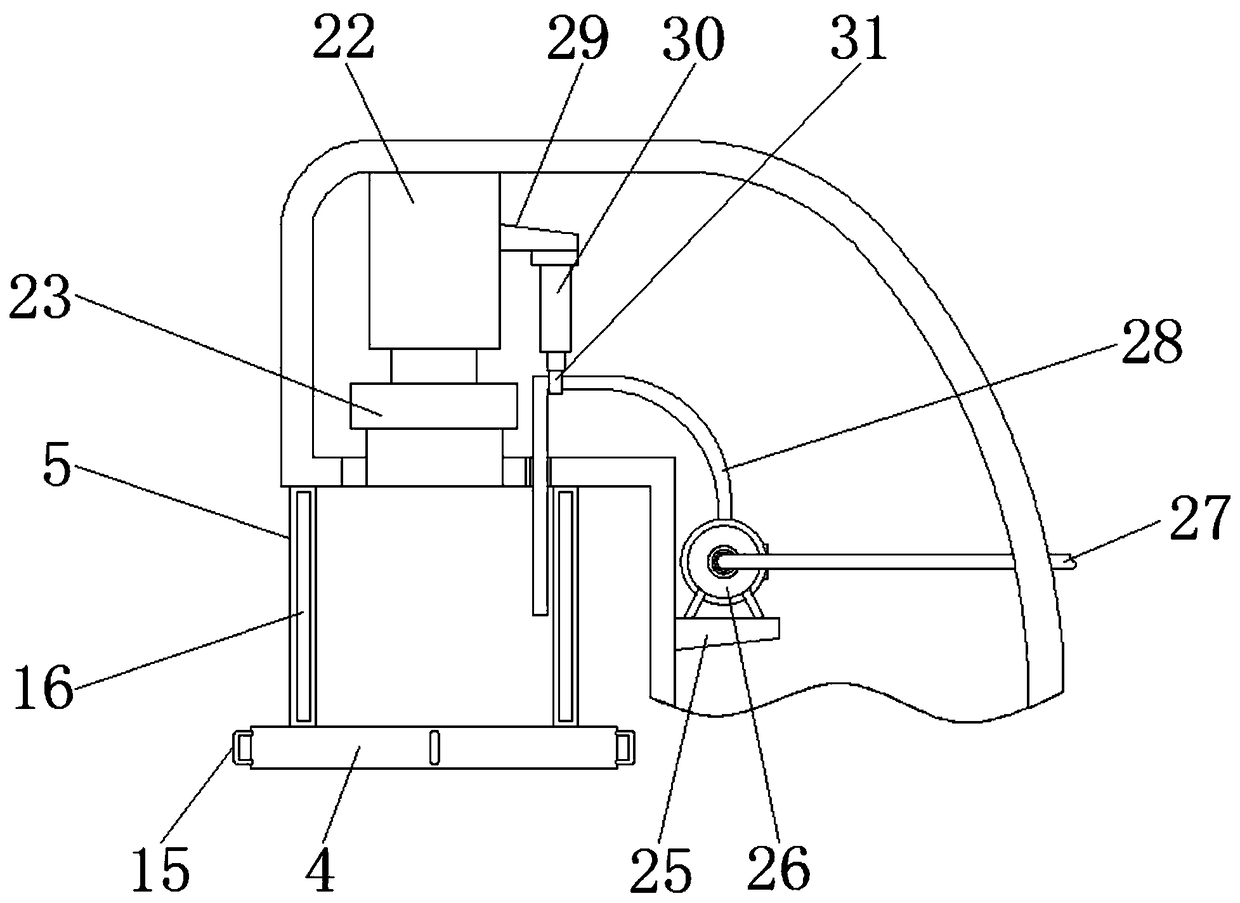

Connecting rod visual auxiliary locating laser groove cutting device and control method

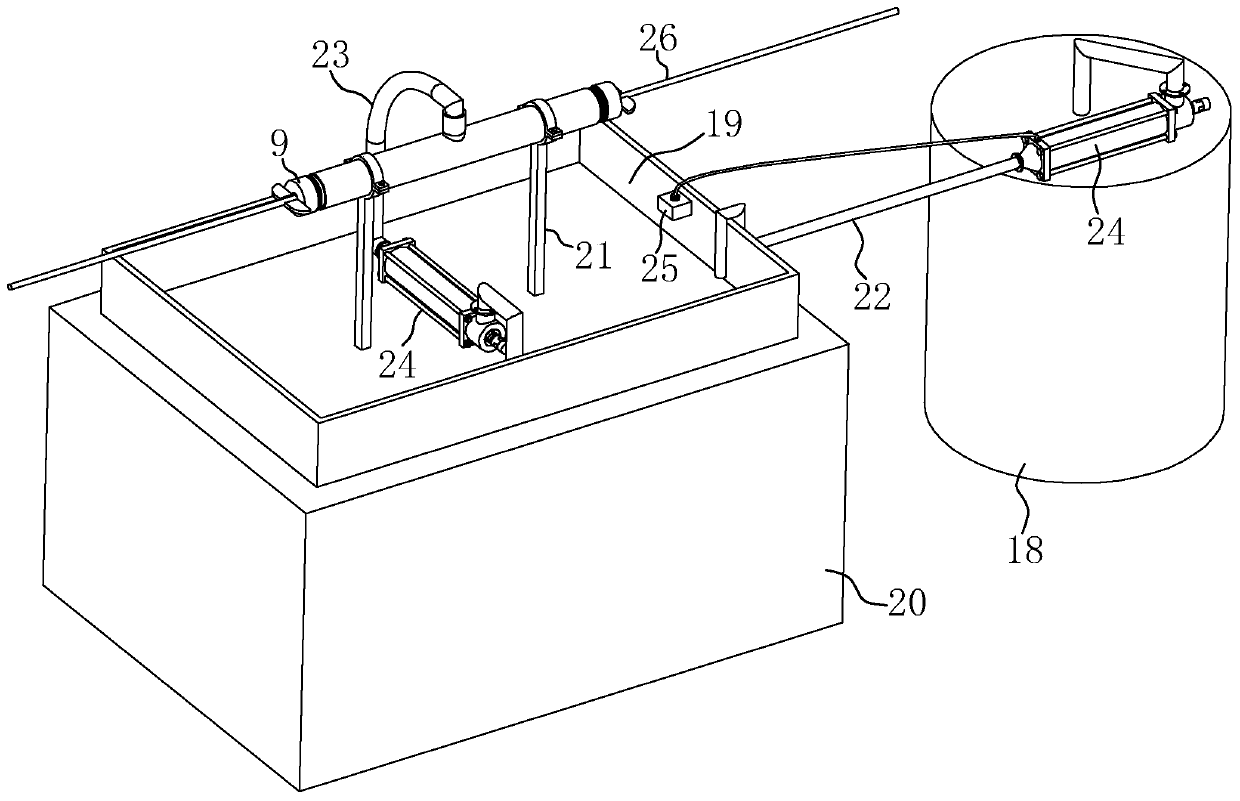

The invention discloses a connecting rod visual auxiliary locating laser groove cutting device which comprises a work platform. A drive cylinder base is fixed to one side of the top face of the work platform. A drive cylinder is fixed to the top face of the drive cylinder base. The power output end of the drive cylinder is connected with a connecting rod large end hole tensioning rod. The other end of the connecting rod large end hole tensioning rod is connected to the inner circumferential face of a connecting rod large end hole in an abutting manner. The top face of the work platform is further connected with a connecting rod small end hole tensioning rod penetrating into a connecting rod small end hole. An industrial camera is arranged above the center of the connecting rod large end hole to be electrically connected with a computer processor. The computer processor is further electrically connected with a laser movement platform through a controller. A laser device is arranged at the top of the laser movement platform and can move to the position above the connecting rod large end hole to carry out connecting rod cracking groove laser cutting on the inner circumferential face of the connecting rod large end hole. The invention further provides a control method of the connecting rod visual auxiliary locating laser groove cutting device. Compared with the prior art, according to the technical scheme, the connecting rod visual auxiliary locating laser groove cutting device has the beneficial effects of being simple in structure, low in cost, efficient in operating, mature, reliable, convenient to demount, mount and maintain and the like.

Owner:GUANGDONG UNIV OF TECH

Paint spraying device for new energy automobile door production

The invention discloses a paint spraying device for new energy automobile door production. The paint spraying device comprises a box body. The top of the left side of the box body is fixedly connectedwith a first motor through a motor base, and an output shaft of the first motor is fixedly connected with a first belt wheel. The surface of the first belt wheel is in transmission connection with asecond belt wheel through a belt, and the axis of the second belt wheel is fixedly connected with a lead screw. The two ends of the lead screw are rotationally connected with the top and the bottom ofthe inner wall of the box body correspondingly, and the surface of the lead screw is in threaded connection with a thread block. The invention relates to the technical field of automobile door processing equipment. According to the paint spraying device for new energy automobile door production, a paint spraying gun can be driven to do reciprocating motion, uniform paint spraying treatment is carried out on the surface of an automobile door, a paint spraying table can be moved out of the box body, a worker can take and place the automobile door conveniently, the work efficiency is improved, and the workloads of the worker are reduced; and peculiar smells in the box body can be subjected to filter treatment, and the comfort during work of the worker is improved.

Owner:滨州高新高端装备制造产业园有限公司

Insert high-precision stamping and bending die

ActiveCN113696408AAct as a barrierPlay a cleaning roleDirt cleaningCleaning using toolsStructural engineeringBrush

The invention discloses an insert high-precision stamping and bending die. A hydraulic driving rod is fixedly installed at the bottom of a stamping machine, wherein the bottom end of the hydraulic driving rod is fixedly connected with a lifting plate, a stamping block is arranged at the middle portion of the bottom end of the lifting plate, and a stamping die cavity is formed in the position, corresponding to the stamping block, of the top of a machining platform. According to the insert high-precision stamping and bending die, the hydraulic driving rod is used for driving the lifting plate and the stamping block to move downwards, then the stamping block can stamp and cut workpieces so that the workpieces can enter the stamping die cavity, metal contact pins at one sides of the workpieces are bent, part of sweeps can fall off in the stamping processes, a movable baffle plays a role in blocking the bent workpieces, thus sweeps and the workpieces all stay in the stamping die cavity, after the workpieces are taken away, an electric telescopic rod drives the movable baffle to slide towards the interior of a movable groove, and a cleaning brush plays a cleaning role on the surface of the movable baffle, so that the surface of the movable baffle is kept clean, and the sweeps remaining on the surface of the movable baffle can be swept and fall into a collecting box to be stored.

Owner:福益柯汽车系统(上海)有限公司

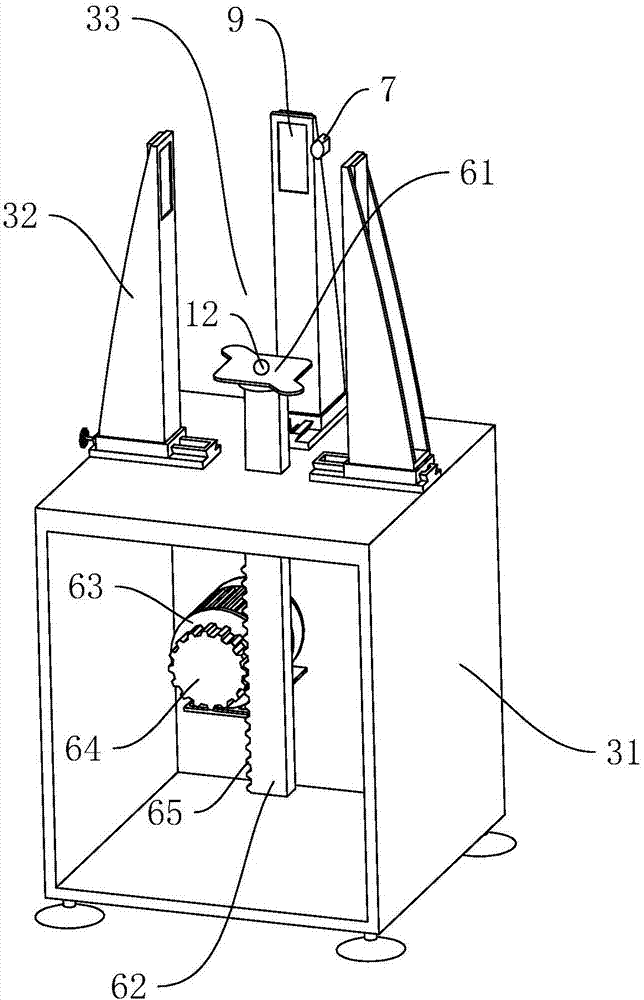

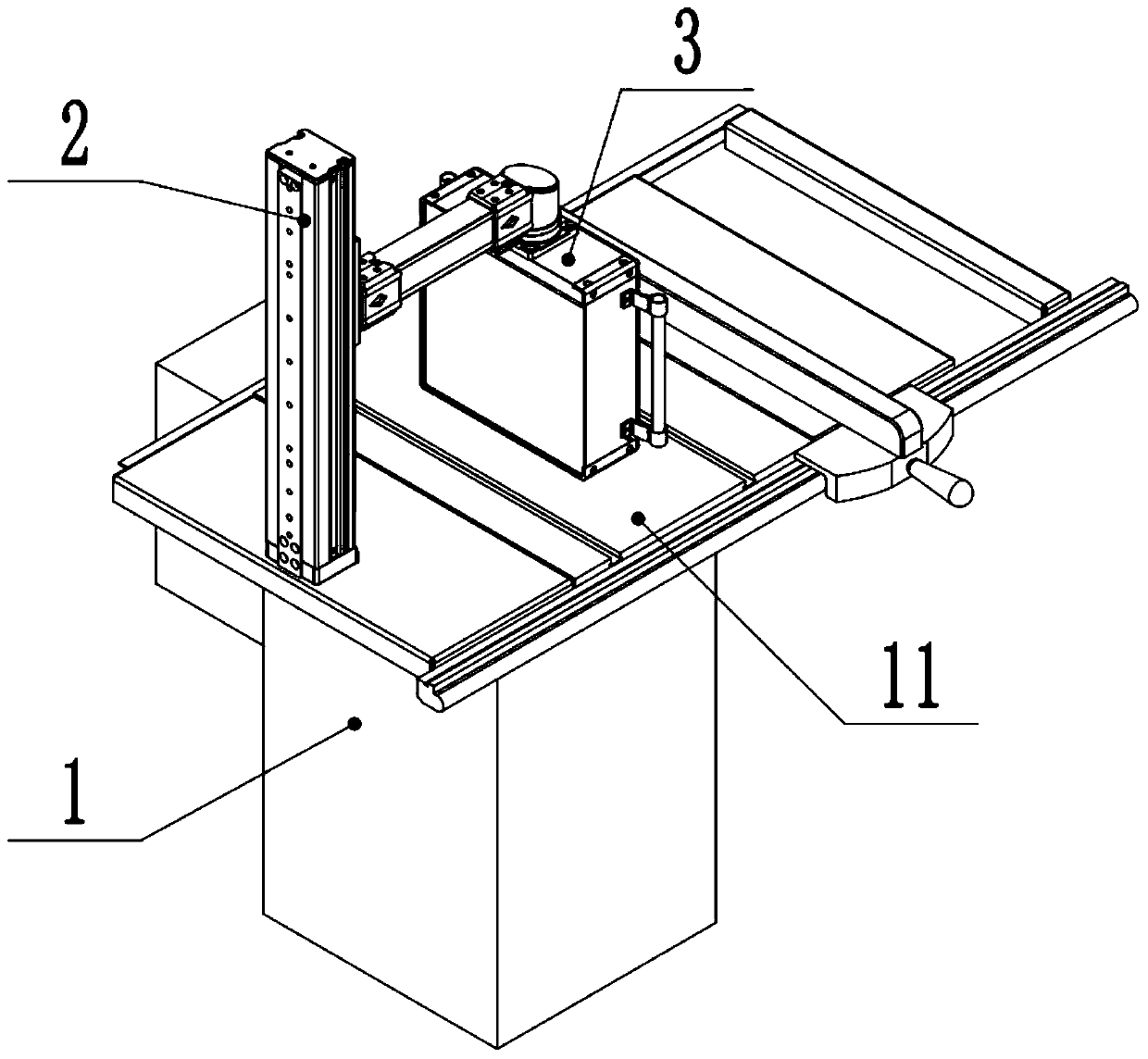

Safe-to-use sliding table saw and safety use method

PendingCN111113565ACause some damagesPrevent mildewCleaning using gasesCircular sawsWoodworking machineryStructural engineering

The invention discloses a safe-to-use sliding table saw and a safety use method, and belongs to the field of woodworking machinery. The safe-to-use sliding table saw comprises a sliding table saw body, a lifting assembly and a saw blade shield, wherein the sliding table saw body comprises a processing table for placing wood, a rotary saw blade fixedly connected with the processing table and a sawdust collecting assembly fixedly arranged at one end of the rotary saw blade; the lifting assembly performs up-and-down linear motion on one side of the rotary saw blade; the saw blade shield comprisesa shield body, an elastic assembly and a rolling assembly; the shield body is fixedly connected with the lifting assembly through the elastic assembly; the shield body abuts against timber through the rolling assembly; and a humidifying assembly is arranged in the shield body. According to the safe-to-use sliding table saw and the safety use method, an existing sawdust recycling function is reserved, the resistance generated when the shield body abuts against the timber is reduced through the rolling assembly, the abutting between the shield body and the timber is achieved, the safety of workers in misoperation is improved, and the probability of fire is reduced by humidifying the timber and the rotary saw blade through the humidifying assembly.

Owner:南京天悦家具有限公司

Extruding device for thermosetting powder coating production

ActiveCN110013792AIncrease air pressureResidue reductionRotary stirring mixersTransportation and packagingWinding machineEngineering

The invention discloses an extruding device for thermosetting powder coating production. The device comprises a shell; a scraping plate is arranged in the shell, the edge of the scraping plate is attached to the shell, the scraping plate is provided with a through hole in a pass-through manner, and the top of the scraping plate is fixedly provided with steel wire ropes; a stirring rod is fixedly arranged in the inner side of the through hole, stirring plates sleeve the outer side of the stirring rod, and the stirring plates are matched with the through hole; the top of the stirring rod is fixedly provided with an air cylinder, the bottom of the air cylinder is fixedly provided with a top plate, the bottom of the top plate is fixedly provided with installation rods, and the installation rods are fixedly arranged at the top of the shell; and the top of the shell is fixedly provided with winding machines, each winding machine is provided with a winding wheel, and each steel wire rope is fixedly arranged at the outer side of the corresponding winding wheel. According to the device provided by the invention, the scraping plate and the stirring plates cooperate to form a sealed plate shape, so that residues of the thermosetting powder coating is effectively reduced, waste of the thermosetting powder coating can be avoided, and influence on a next coating processing process can be prevented.

Owner:ANHUI SUNROAD ENVIRONMENT PROTECTIVE NEW MATERIALS

Plate-shaped part polishing device for hardware tool processing and using method thereof

InactiveCN112296848AGuaranteed cleanlinessFast clamping and fixingGrinding carriagesPolishing machinesGas cylinderPolishing

The invention discloses a plate-shaped part polishing device for hardware tool processing and a using method thereof. The plate-shaped part polishing device comprises a bottom plate, wherein the fourcorners of the bottom of the bottom plate are fixedly connected to supporting cushions; the top of the bottom plate is fixedly connected to a placing frame; and the position, at one side of the placing frame, on the top of the bottom plate is equipped with a fixing mechanism. The plate-shaped part polishing device is compact in structure, is simple and convenient in operation and is high in practicability; the fixing mechanism can be arranged for quickly clamping and fixing the plate-shaped part to be processed, so that follow-up polishing operation is normally performed; meanwhile, a drive gas cylinder is arranged at one side of the fixing mechanism, and can be matched with a polishing mechanism capable of transversely moving, so that all-around polishing operation on the plate-shaped part to be processed can be achieved, and thus, a polishing range is greatly increased; beside, a cleaning mechanism can be arranged for cleaning the polished plate-shaped part, so that cleanliness of the processed plate-shaped part can be guaranteed, and follow-up processing can be avoided.

Owner:湖南精专自动化技术有限公司

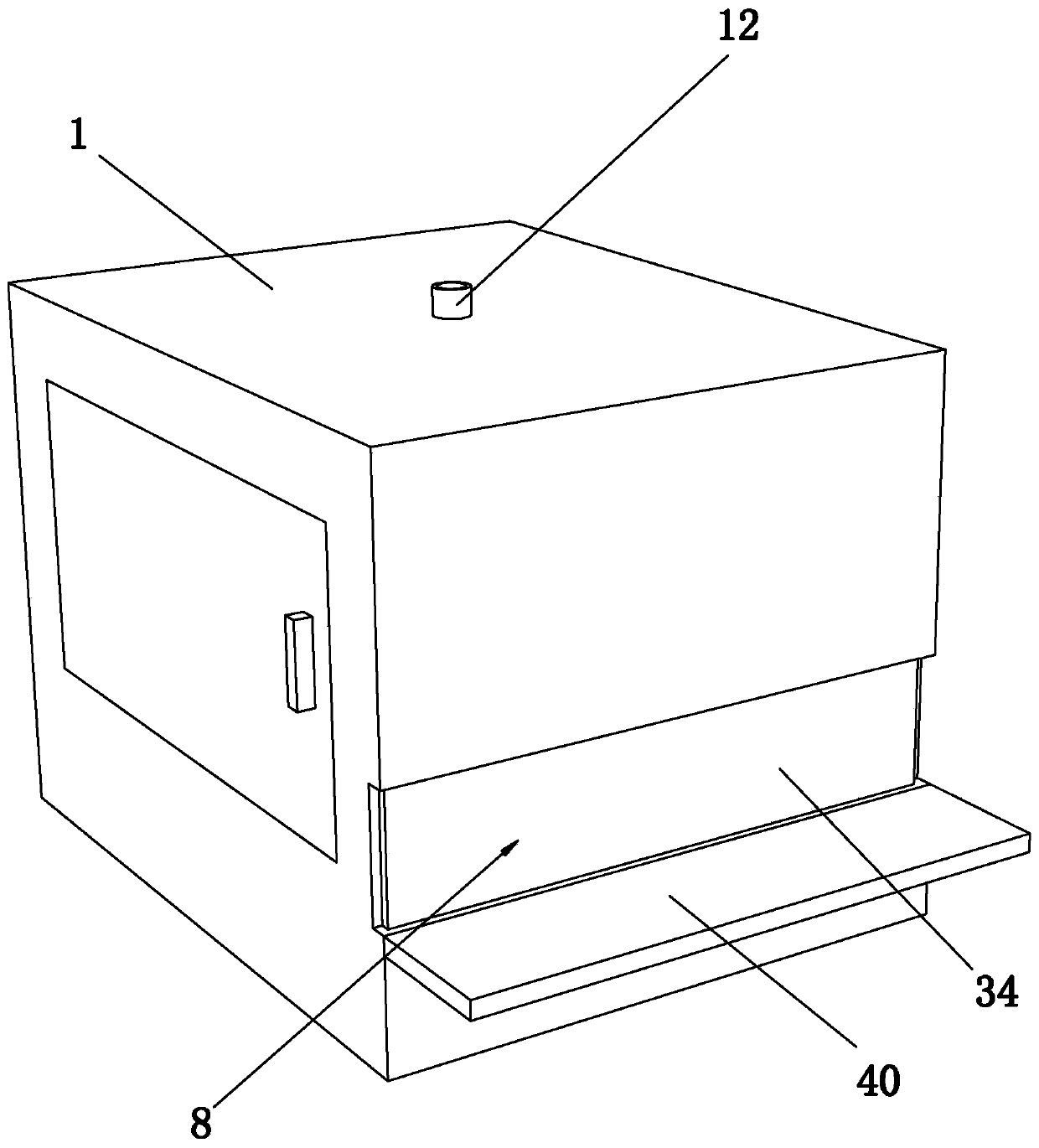

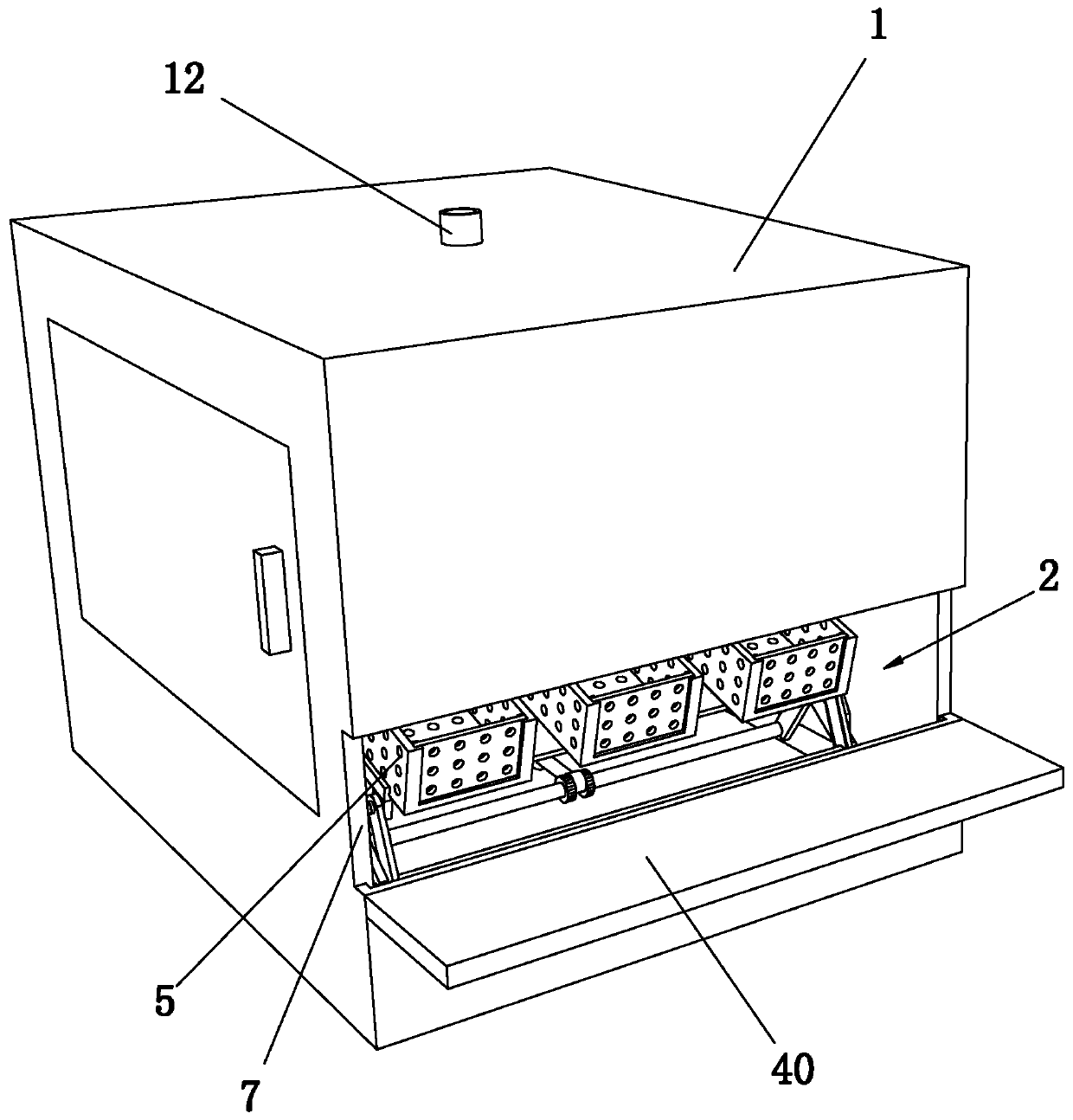

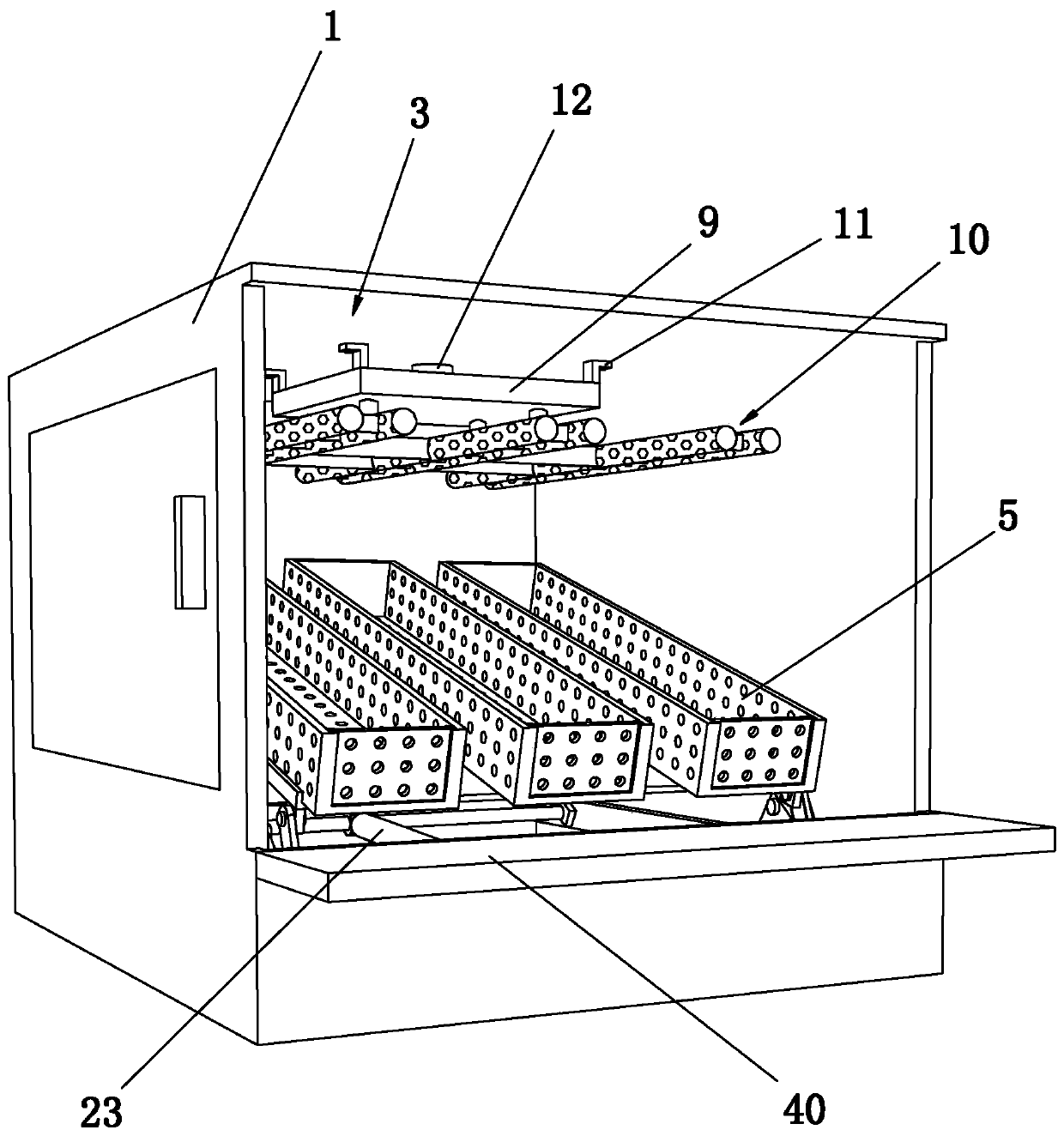

Cleaning device used for hardware accessory machining

ActiveCN111014138AImprove cleaning effectImprove cleaning qualityCleaning using liquidsEngineeringStructural engineering

The invention discloses a cleaning device used for hardware accessory machining. The cleaning device comprises a cleaning box. A carrying frame and a cleaning spray head are arranged in the cleaning box. The carrying frame comprises a swing frame and at least two carrying boxes, wherein the carrying boxes are located on the swing frame. Water leaking holes are evenly formed in the surfaces of thecarrying boxes. A part taking opening is formed in the end face of one side of the cleaning box, a movable door assembly is arranged at the position of the part taking opening, and the cleaning sprayhead is located above the carrying frame. The cleaning device is ingenious and reasonable in structural design, due to the design of at least two carrying boxes, classified and synchronous cleaning ofhardware accessories is achieved, the phenomenon that different types of hardware accessories are stacked to be cleaned is avoided, scientific cleaning work is achieved, in addition, sewage seeps downwards and is discharged continuously from the water leaking holes in the cleaning process so that the carrying boxes can have the double effects of cleaning and airing; and meanwhile due to the design of the part taking opening in the cleaning box and with the combination of practicability of the swing frame, after the cleaning work is over, the carrying boxes are rotated by a certain angle towards the part taking opening, and therefore the cleaned hardware accessories can be collected conveniently.

Owner:佛山市臻朗五金制品有限公司

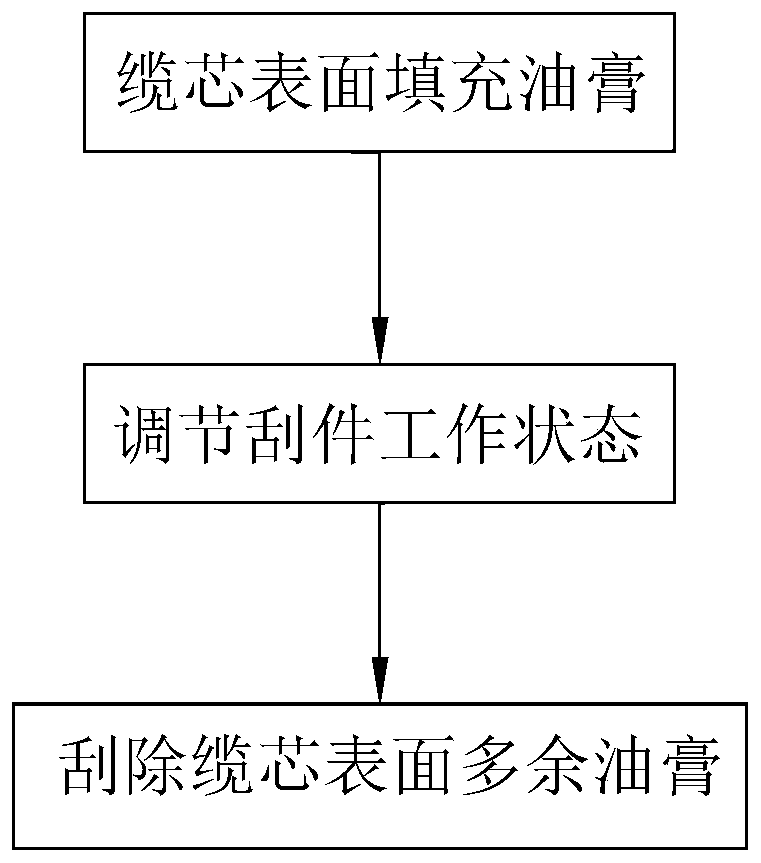

Jelly filling process

InactiveCN110673284ATake advantage ofReduce wasteFibre mechanical structuresProcess engineeringMechanical engineering

The invention discloses a jelly filling process. The jelly filling process comprises the following steps: firstly, forming a jelly layer on the surface of a cable core; then adjusting a scraping pieceto a working state of scraping the jelly; and finally making the scraping piece move relative to the cable core in order to scrape excess jelly on the surface of the cable core. After the surface ofthe cable core is filled with the jelly, a process of adjusting the scraping piece and scraping the jelly is added, so that the excess jelly can be scraped off in time after the surface of the cable core is fully filled with the jelly, thereby ensuring the normal proceeding of subsequent production and processing of the cable core, and effectively reducing the waste of the jelly at the same time.The scraped jelly can be reused in the step 1.

Owner:SHENZHEN XIN CHANG LONG NEW MATERIALS TECH CO LTD

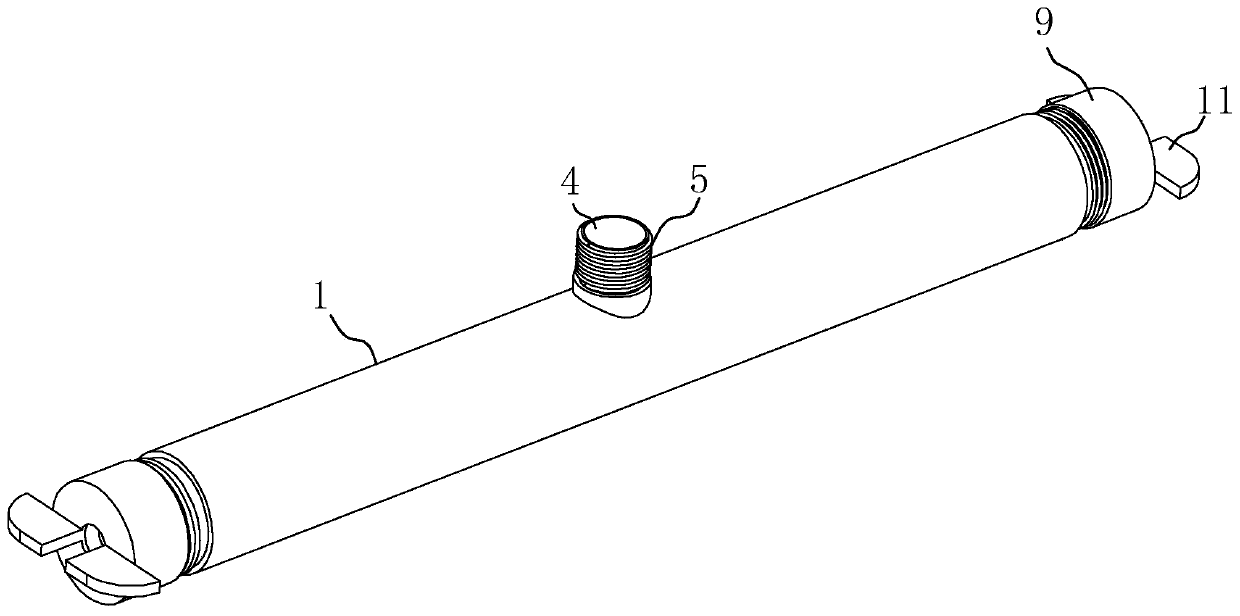

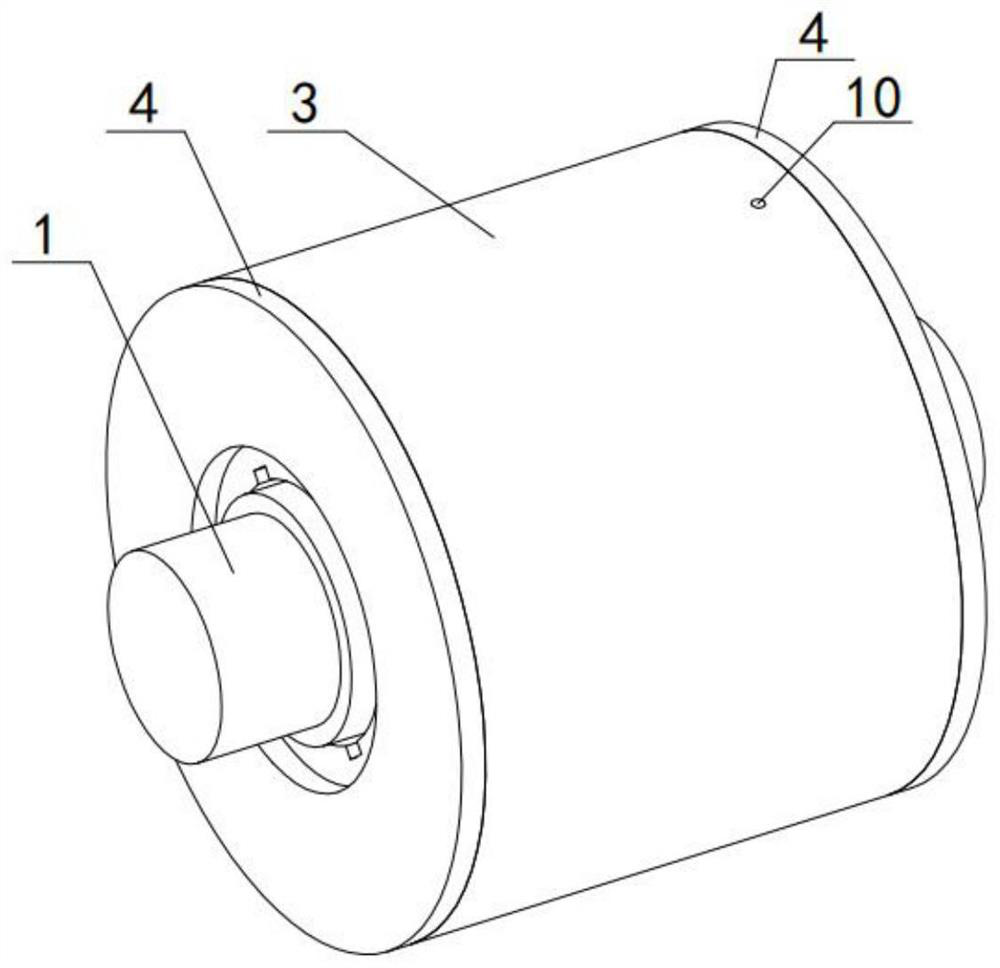

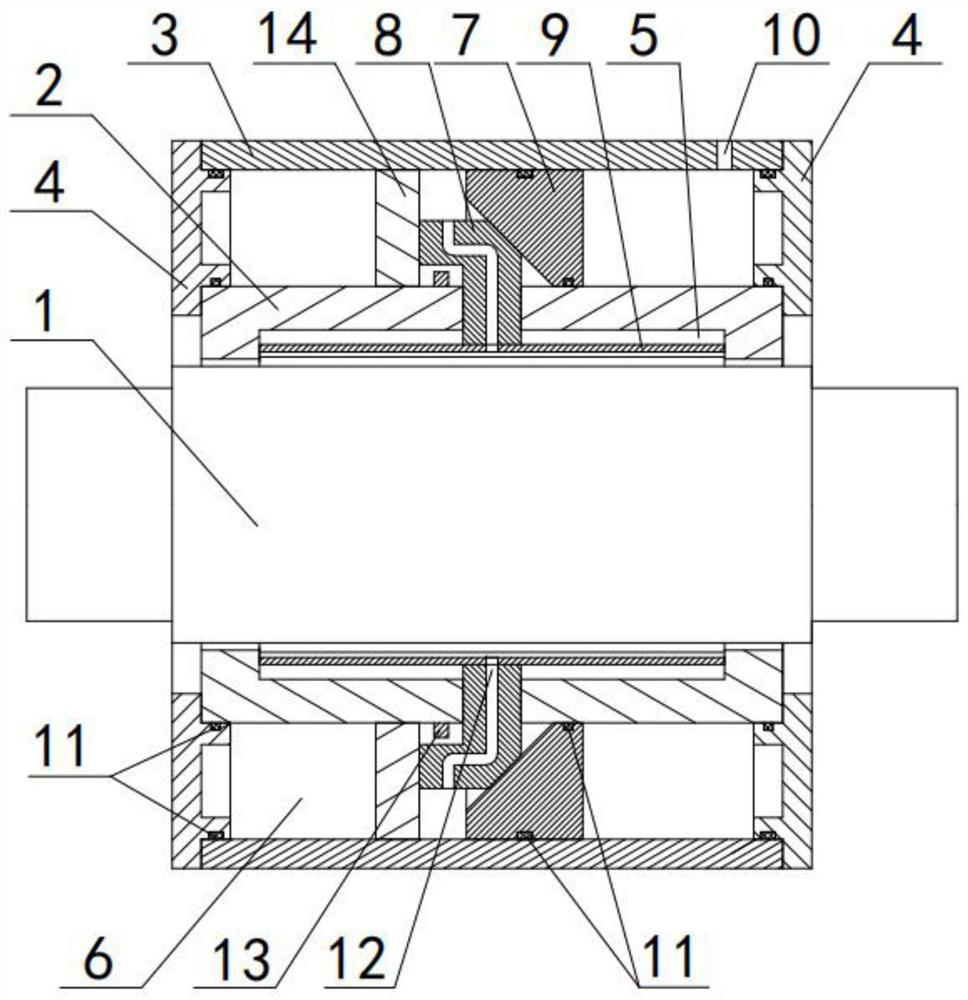

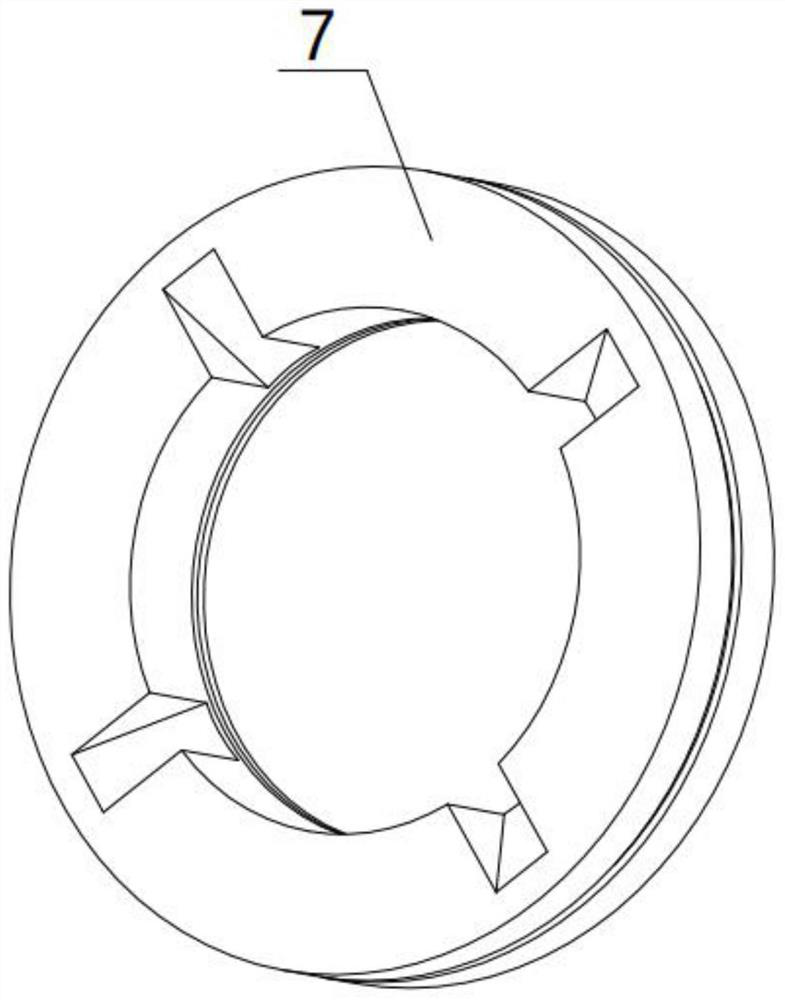

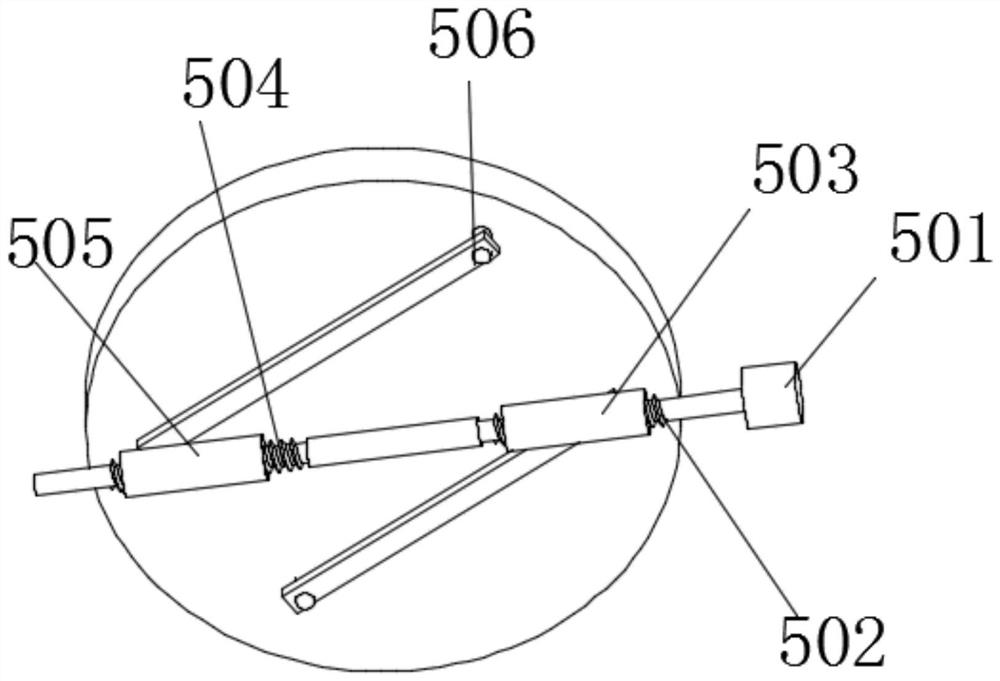

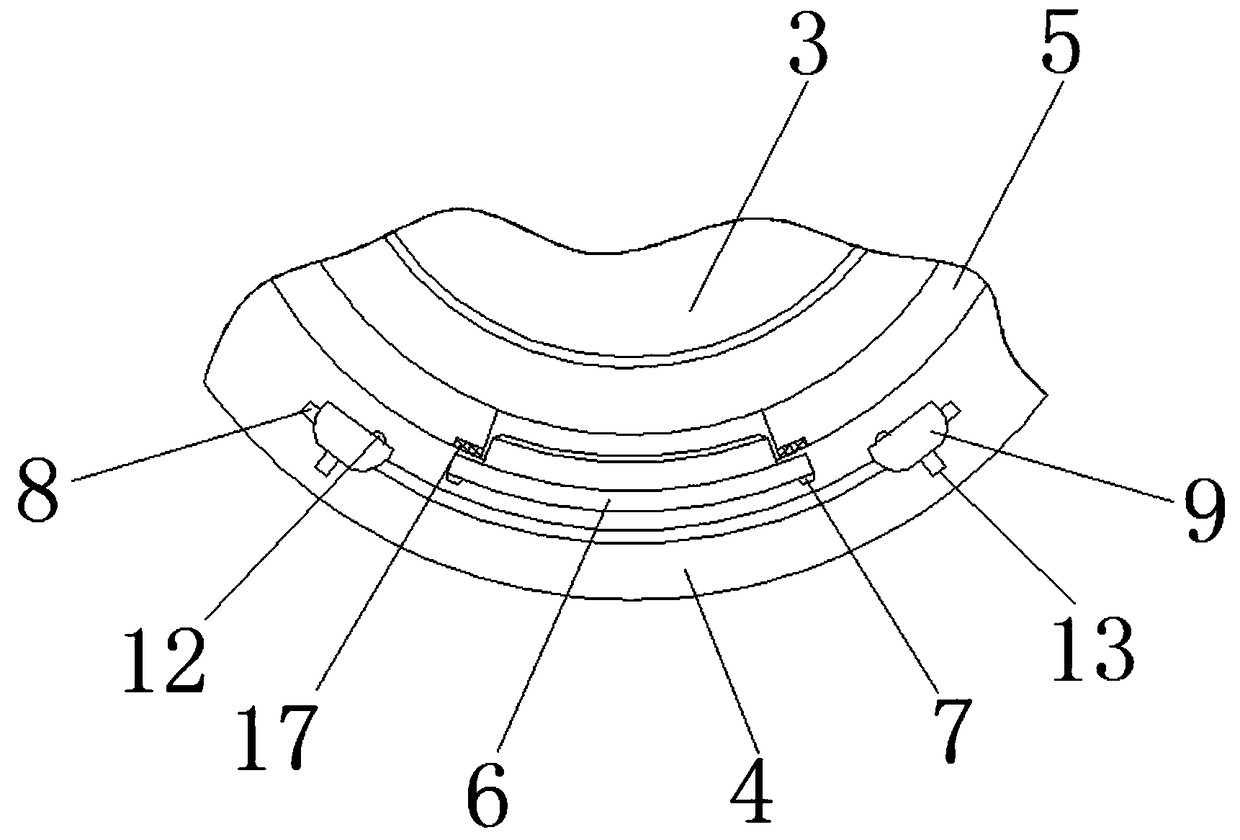

Hydrodynamic journal bearing

PendingCN113833764AAvoid affecting processingImprove the smoothness of movementLiquid cushion bearingsHydrostatic bearingsReciprocating motionProcessing accuracy

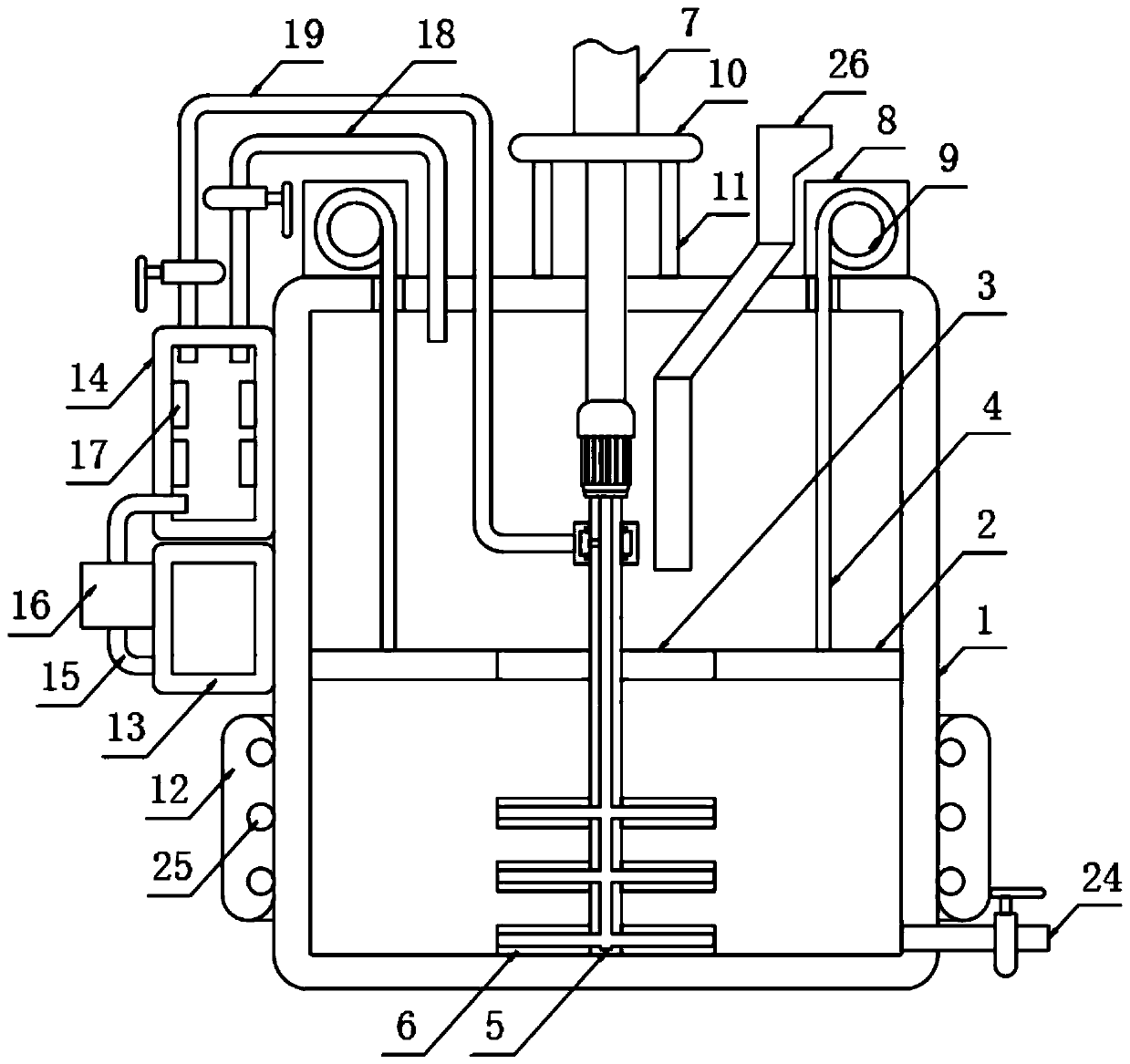

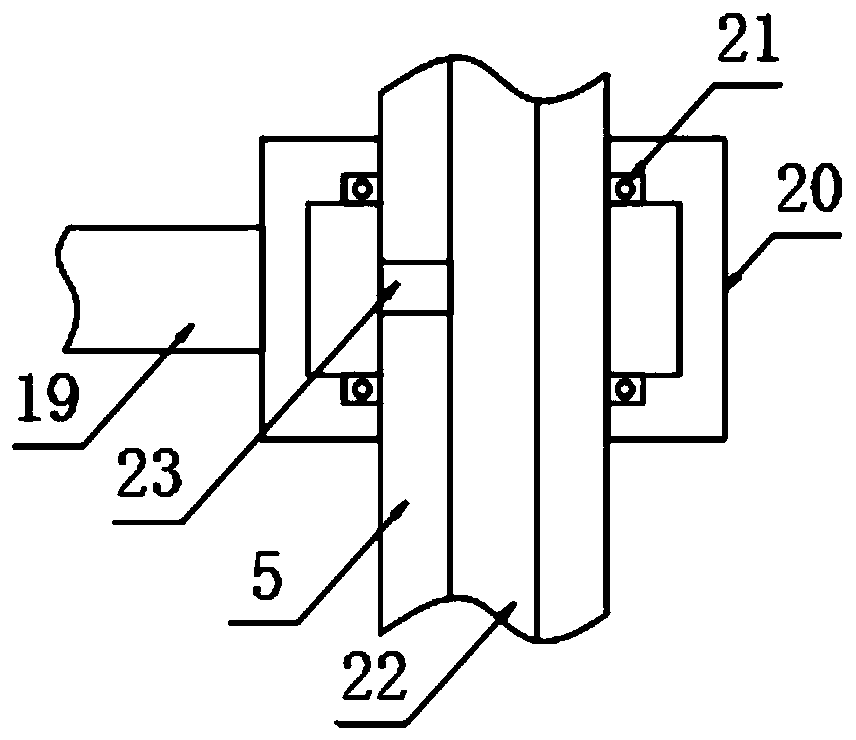

The invention discloses a hydrodynamic journal bearing which comprises a main shaft, a shaft sleeve, a bearing outer shell and two sealing end covers. A plurality of oil cavities are evenly distributed in the inner wall of the shaft sleeve, the main shaft is arranged in the middle of the shaft sleeve in a penetrating mode, the bearing outer shell is arranged on the outer side of the shaft sleeve in a sleeving mode, a working cavity is formed between the bearing outer shell and the shaft sleeve, a driving disc is arranged in the working cavity, a plurality of driving blocks are arranged on one side of the driving disc in a sliding mode, and an adjusting plate is arranged at the end, penetrating through a preformed hole in the shaft sleeve, of each driving block. According to the hydrodynamic journal bearing provided by the invention, the pressure of compressed air injected into air holes is adjusted. The driving disc can be controlled to reciprocate in the horizontal direction, so that all the driving blocks are driven to synchronously contract inwards or expand outwards in the direction perpendicular to the main shaft, the adjusting plate is driven to reciprocate, a gap between each oil cavity and the main shaft is changed, the thickness of an oil film is adjusted, the machining requirements of different products are met, the machining precision is improved, and the service life is prolonged.

Owner:JIANGSU JITRI JINGKAI HIGH VALUE MFG CO LTD

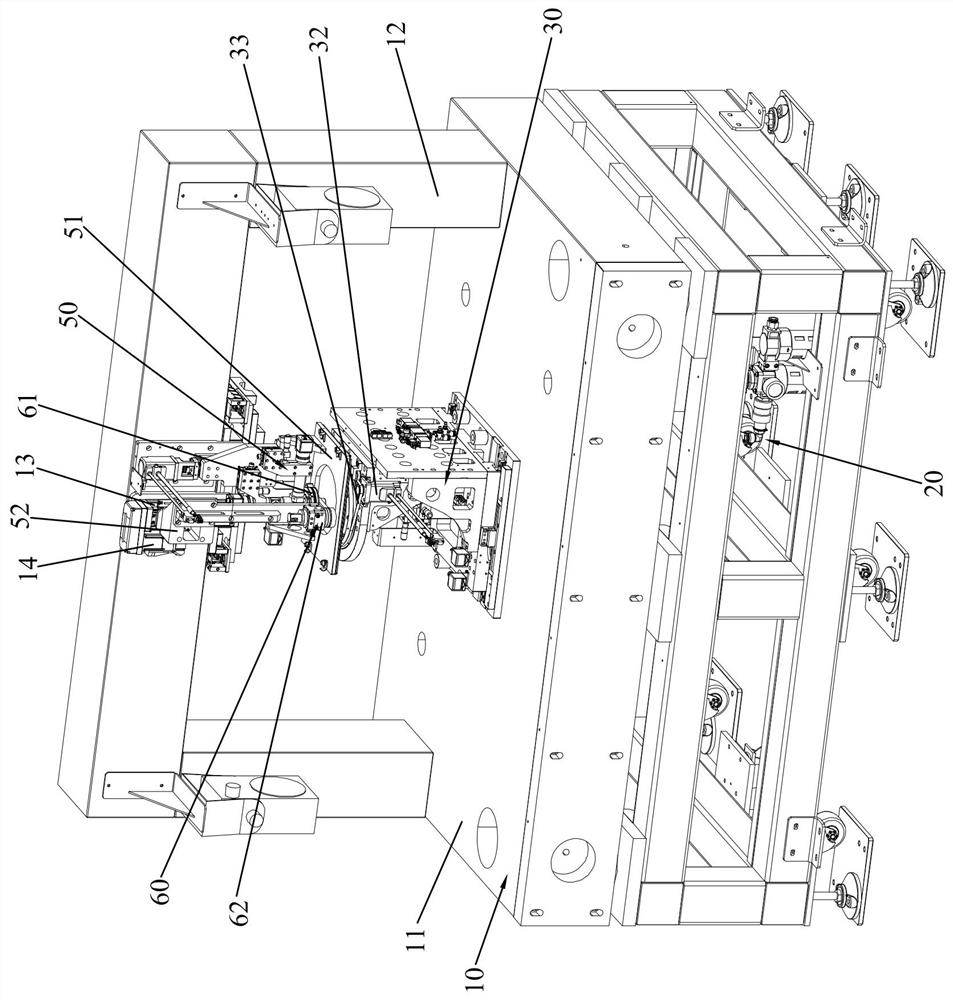

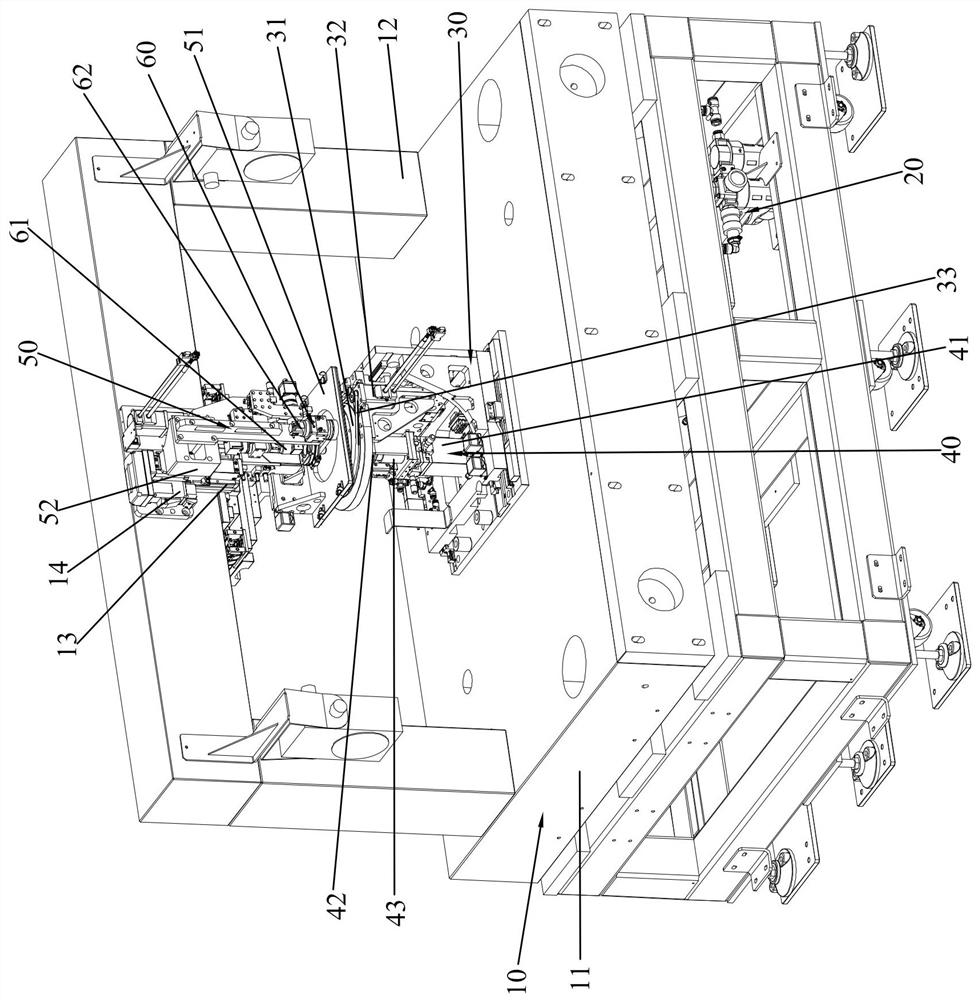

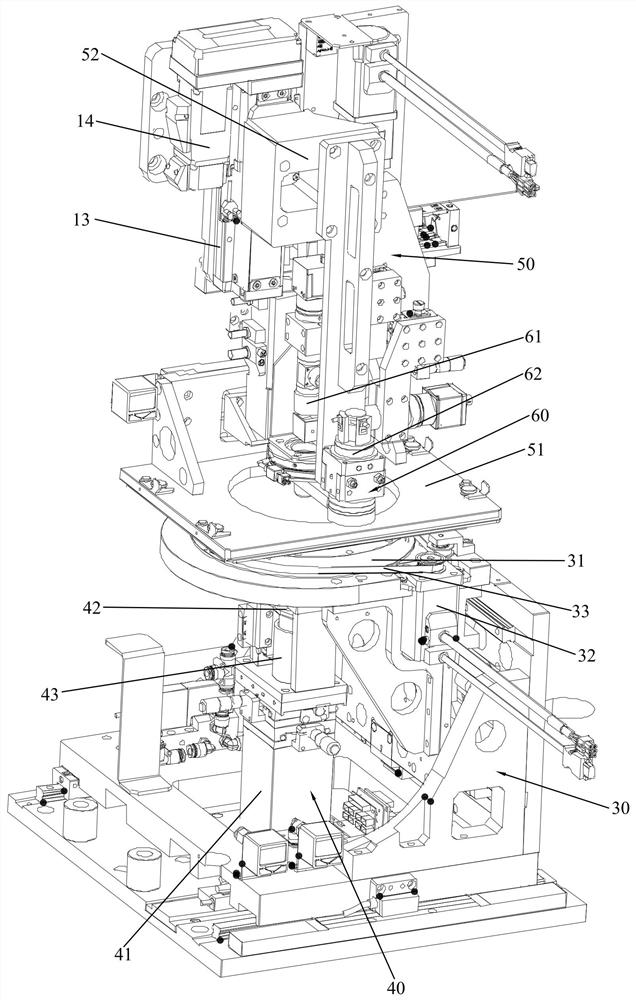

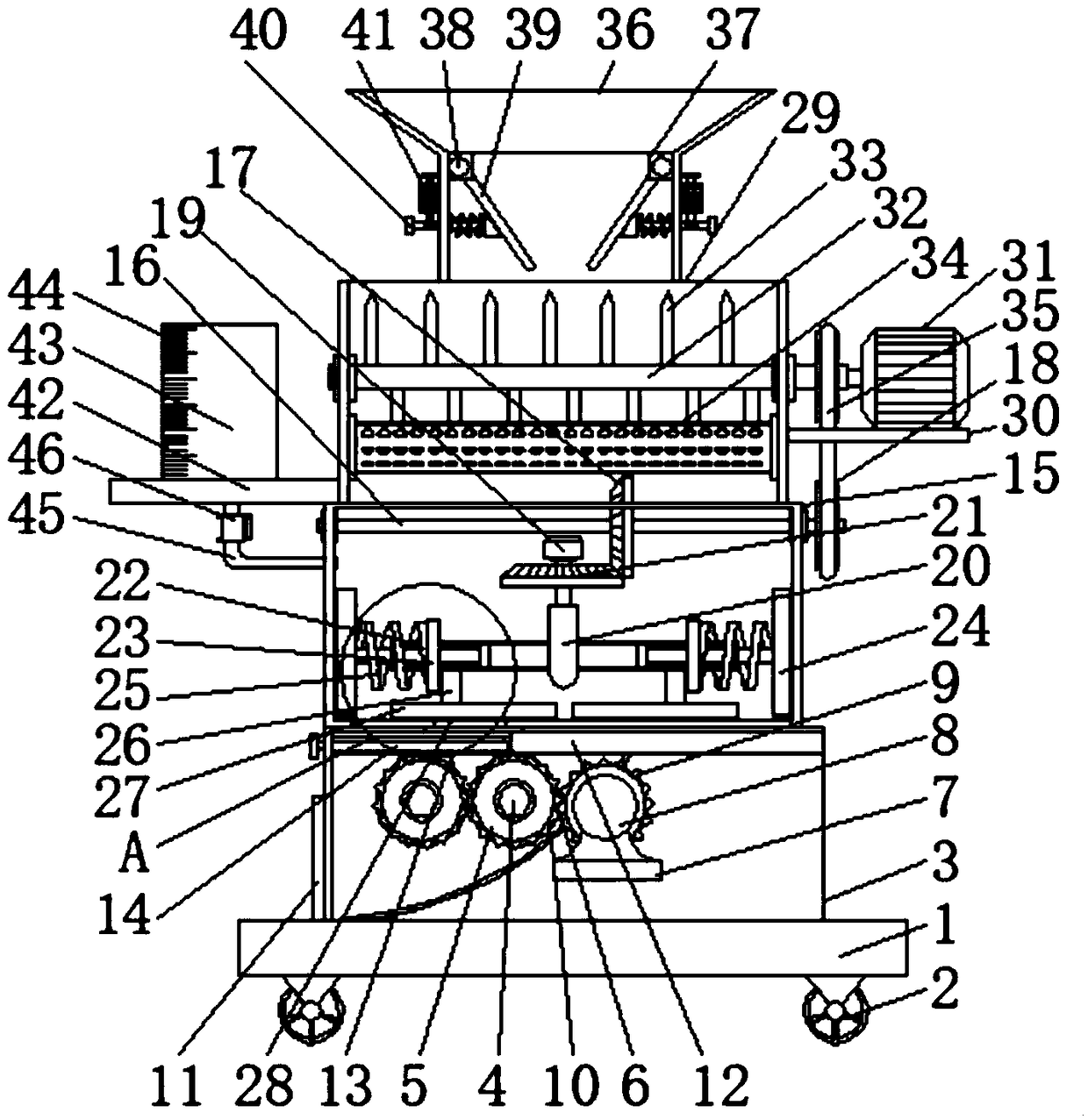

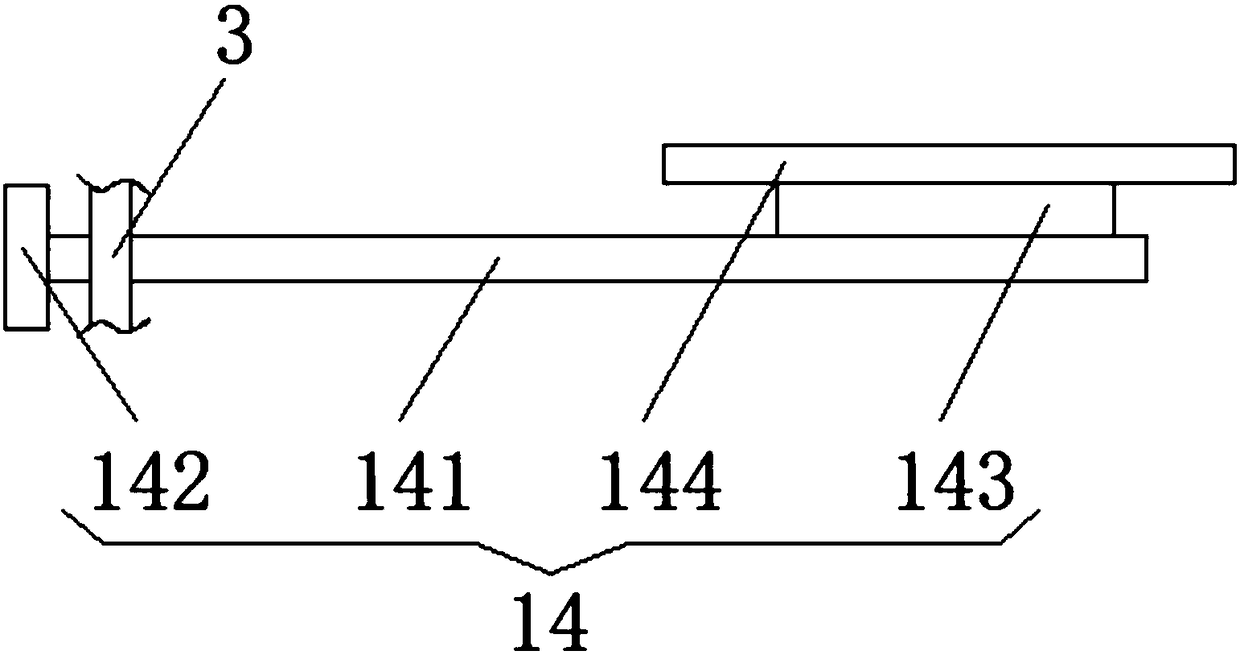

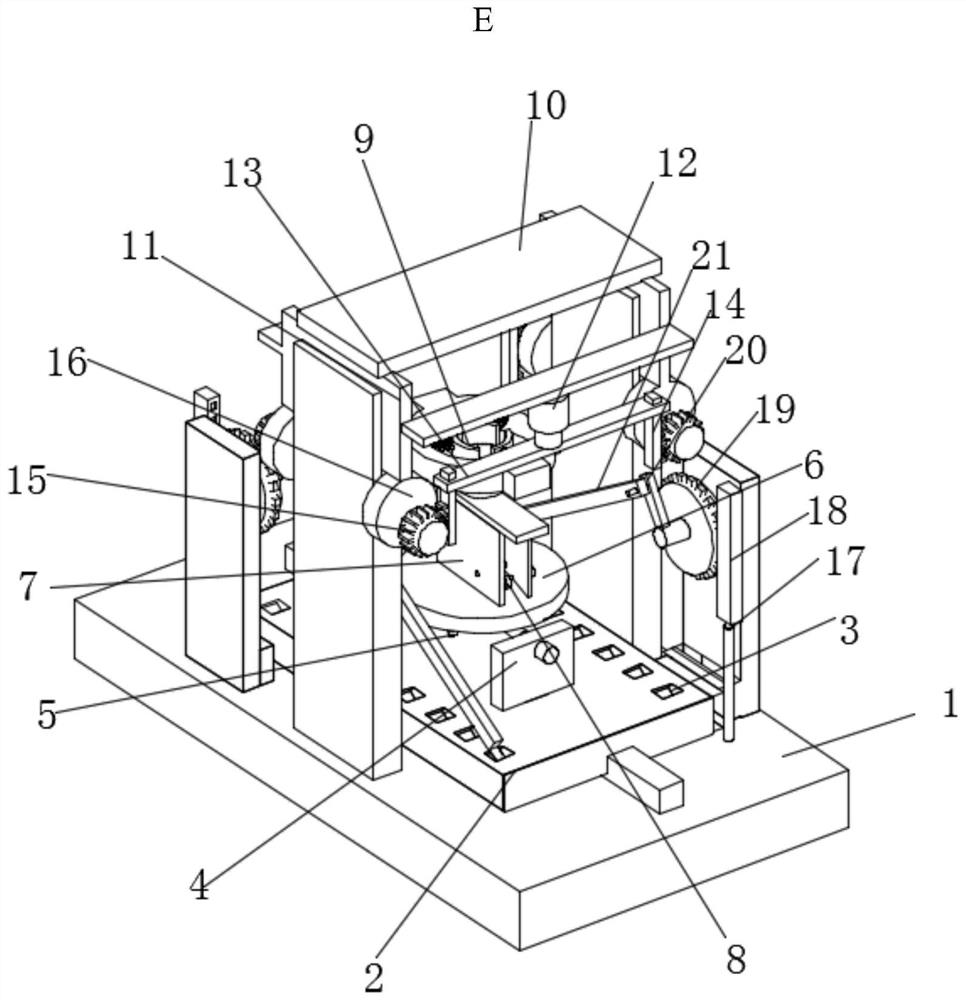

Full-automatic needling crystal grain sorting equipment

PendingCN113828545AAvoid affecting processingRemove in timeSemiconductor/solid-state device manufacturingSortingPhysical chemistryEngineering

The invention discloses full-automatic needling crystal grain sorting equipment. The equipment comprises a rack, a controller, a lower blue film fixing mechanism, an ejector pin mechanism, an upper blue film fixing mechanism and a CCD visual mechanism, wherein the controller is arranged on the rack. Through the arrangement of the lower blue film fixing mechanism, the ejector pin mechanism, the upper blue film fixing mechanism and the CCD visual mechanism, crystal grains of a lower blue film can be directly ejected to a new blue film through the ejector pin mechanism when the blue film is sorted; compared with an existing swing arm type vacuum adsorption mode, the working efficiency is greatly improved, and the requirement for subsequent productivity can be met; and meanwhile, when the crystal grains are sorted, the crystal grains on the blue film can be monitored through the CCD visual mechanism, incomplete and bad crystal grains are removed in time, the quality of the crystal grains on the new blue film is guaranteed, and the influence on the subsequent process of the blue film is avoided.

Owner:东莞市德镌精密设备有限公司

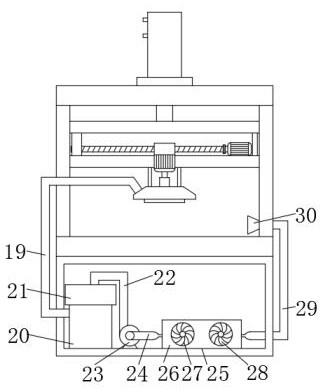

Multi-process numerical control gated processing device

InactiveCN111604293AImprove cleanlinessEasy to installWork holdersCleaning using toolsNumerical controlElectric machinery

The invention relates to the technical field of gated processing, in particular to a multi-process numerical control gated processing device. The multi-process numerical control gated processing device includes two symmetrical horizontal plates; the two horizontal plates are provided with sliding grooves on the opposite sides; a supporting plate is arranged in the middle of each horizontal plate,and one of the supporting plates is equipped with a motor; a sweeping roller is arranged between the two supporting plates; sliding blocks are arranged at both ends of a movable plate; a spring is arranged on the back end surface of a clamping plate; a threaded hole is arranged in the center of the movable plate; a threaded rod is arranged in the middle of a connecting plate; and a bearing is arranged on the threaded rod. According to the multi-process numerical control gated processing device, the sweeping roller is cooperated with a brush, which is convenient for cleaning the decorated gateddevice arranged below; the sliding blocks on the movable plate cooperate with the sliding grooves, which is convenient for the movement of the entire movable plate; the clamping plate cooperates withthe spring, which is convenient for stable clamping of door controls of different widths; and the threaded rod is matched with a rocking handle, which is convenient for the user to manually control the movement of the movable plate under the action of the bearing, and is convenient for the processing use of the corresponding multi-process numerical control gated.

Owner:浙江香乡门业有限公司

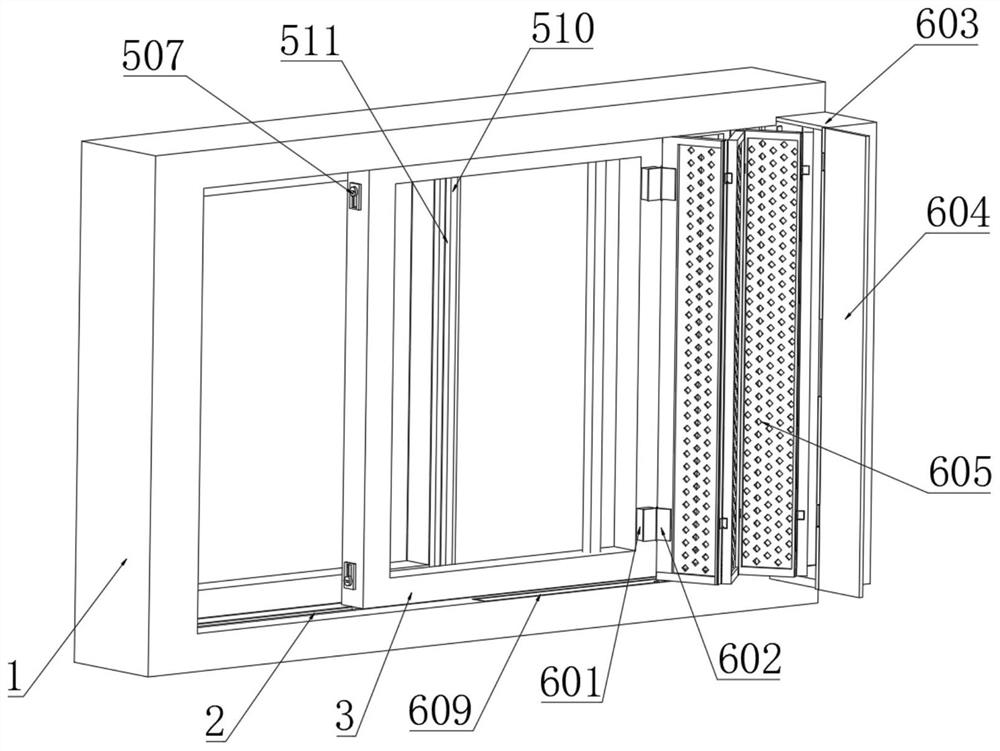

Decorative aluminum alloy door window

PendingCN111827842AScientific and reasonable structureEasy to useWrapping material feeding apparatusInsect protectionEngineeringStructural engineering

The invention discloses a decorative aluminum alloy door window. A rotating shaft is fixedly mounted at one end of a window frame, a connecting rod is fixedly connected between two window frame pulleys, movable grooves are symmetrically formed in the end, which is away from the rotating shaft, of the middle of the window frame, a movable column is movably mounted in each movable groove, a connecting block is fixedly connected to the bottom end of each movable column, a connecting rod is fixedly mounted at one end of the middle of each connecting block, and a fastening knob is connected to oneend of each connecting rod. Through cooperative use of the movable columns and the connecting blocks, one end of the window frame is separated from the window frame pulleys; through use of the rotating shaft, it is ensured that the window frame and an aluminum alloy window body can rotate, the window frame is conveniently turned over, great convenience is provided for cleaning the window frame andglass, the circumstances that the outward face of the glass of the window frame is inconvenient to clean, consequently, dust is gathered on the surface of the glass, and normal sunlight irradiation is affected are avoided, cleaning personnel can clean the glass without standing outside the window, and the safety is improved.

Owner:林兰根

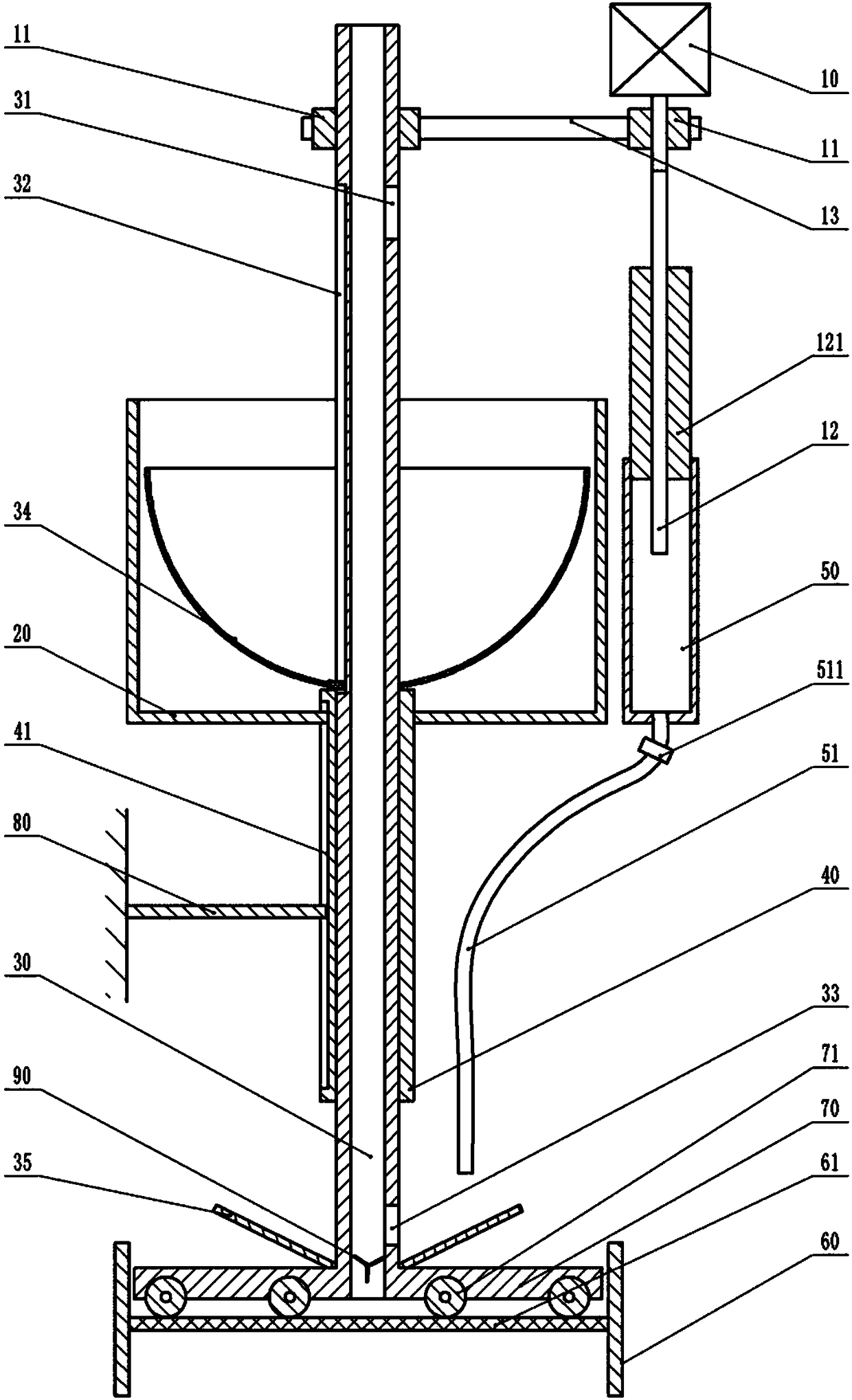

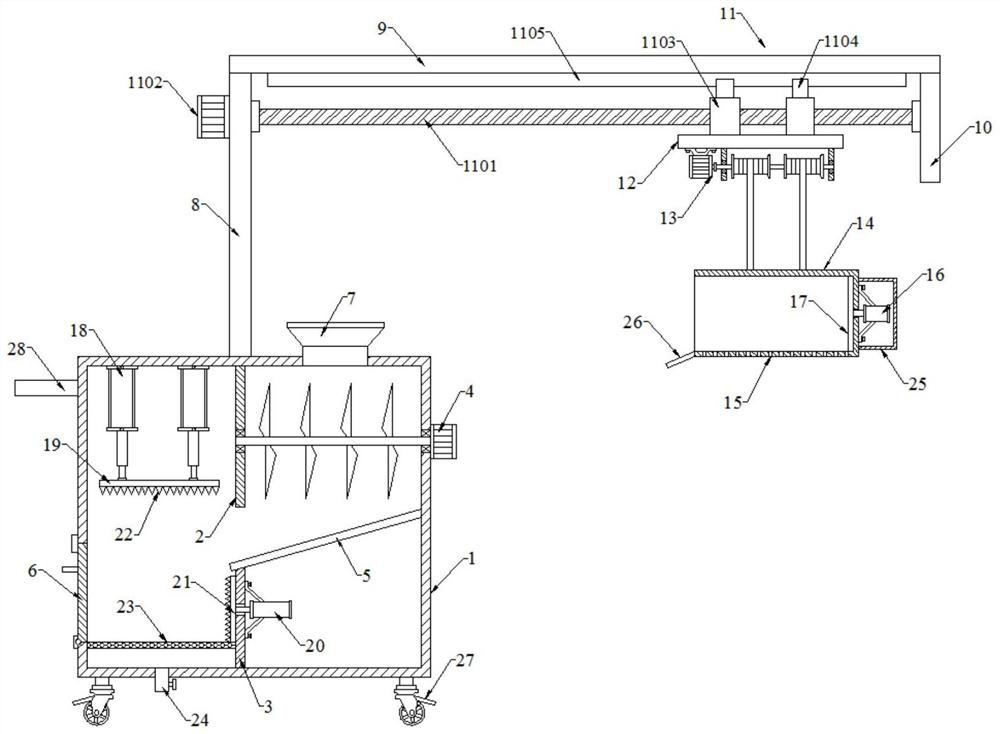

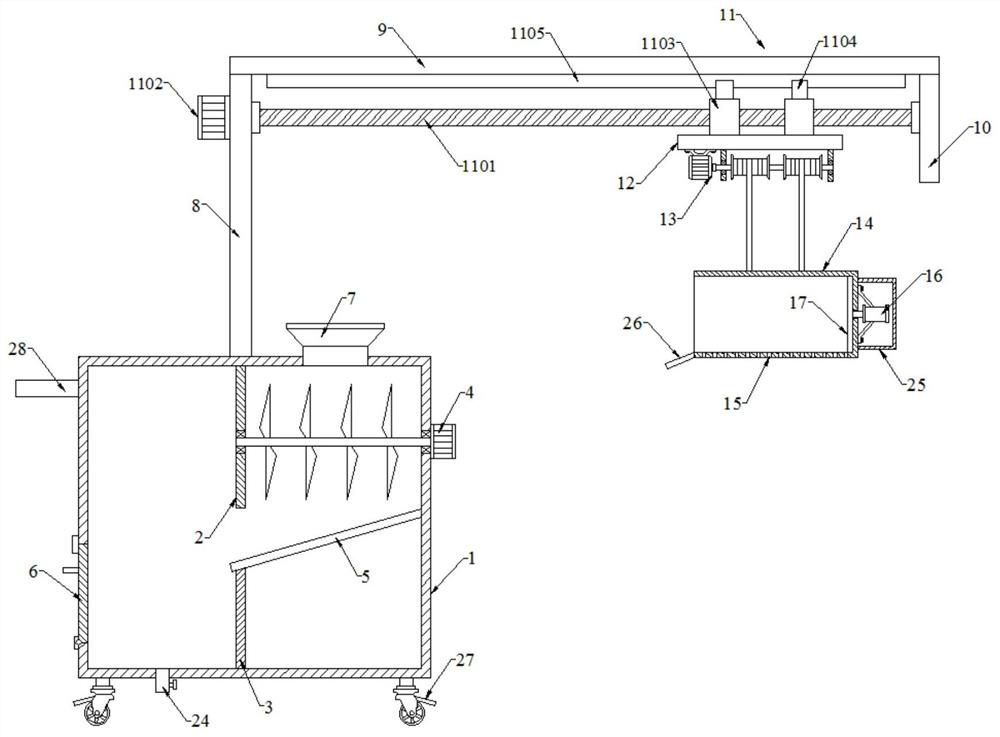

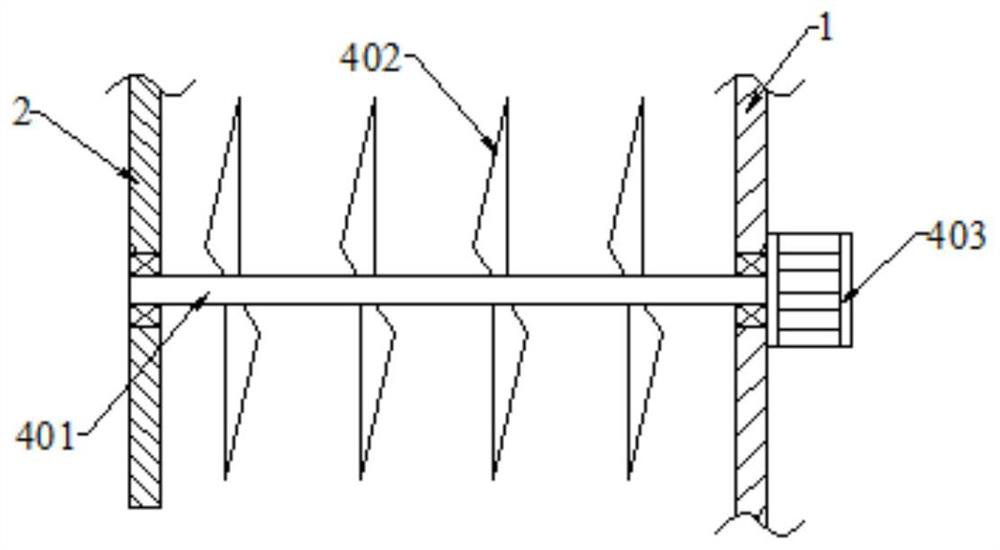

Feed granulating machine capable of granulating mixed feed

The invention relates to the technical field of feed granulating equipment, and discloses a feed granulating machine capable of granulating a mixed feed. The granulating machine comprises a bottom plate, wherein universal wheels are respectively and fixedly mounted on two sides of the bottom of the bottom plate; a granulating tank is fixedly mounted at the top of the bottom plate; two granule pressing rods are fixedly mounted on one side of the front surface of the granulating tank in a sleeving manner; driven gears are respectively and fixedly mounted at one ends outside the granulating tank,of the two granule pressing rods, in a sleeving manner; a granule pressing disk located in the granulating tank is fixedly mounted on each of the two granule pressing rods in a sleeving manner; a motor supporting seat is fixedly mounted at the middle part of the front surface of the bottom plate; and a driving motor is fixedly mounted at the top of the motor supporting seat. According to the feedgranulating machine capable of granulating a mixed feed disclosed by the invention, the driven gears, the granule pressing disks and the driving motor cooperate for use, so that granule pressing is convenient to perform on a feed which is uniformly mixed; and through the equidirectional movement of the two granule pressing disks, the uniformity of granule pressing is guaranteed, so that the efficiency of granule pressing of the feed granulating machine is higher, and time of a user is saved.

Owner:周珏伟

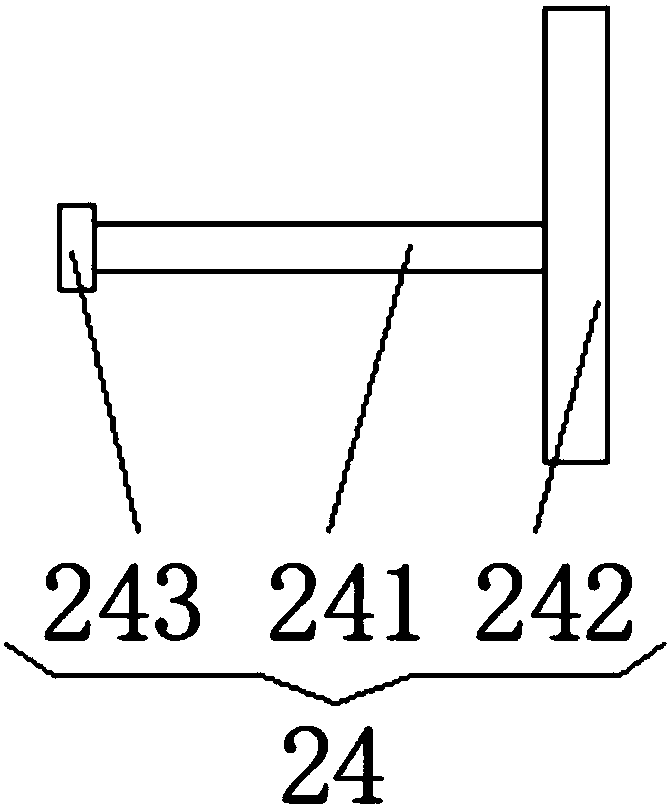

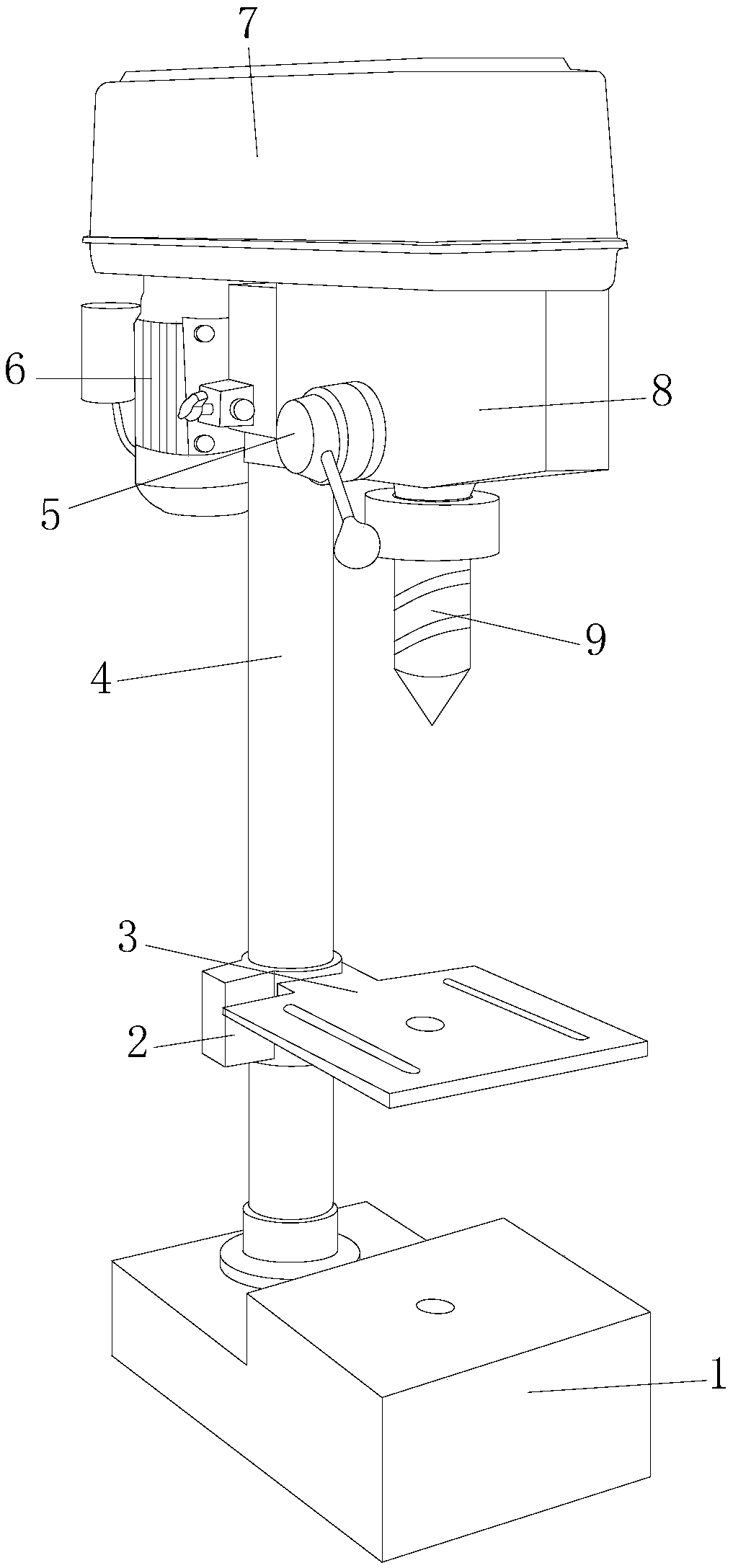

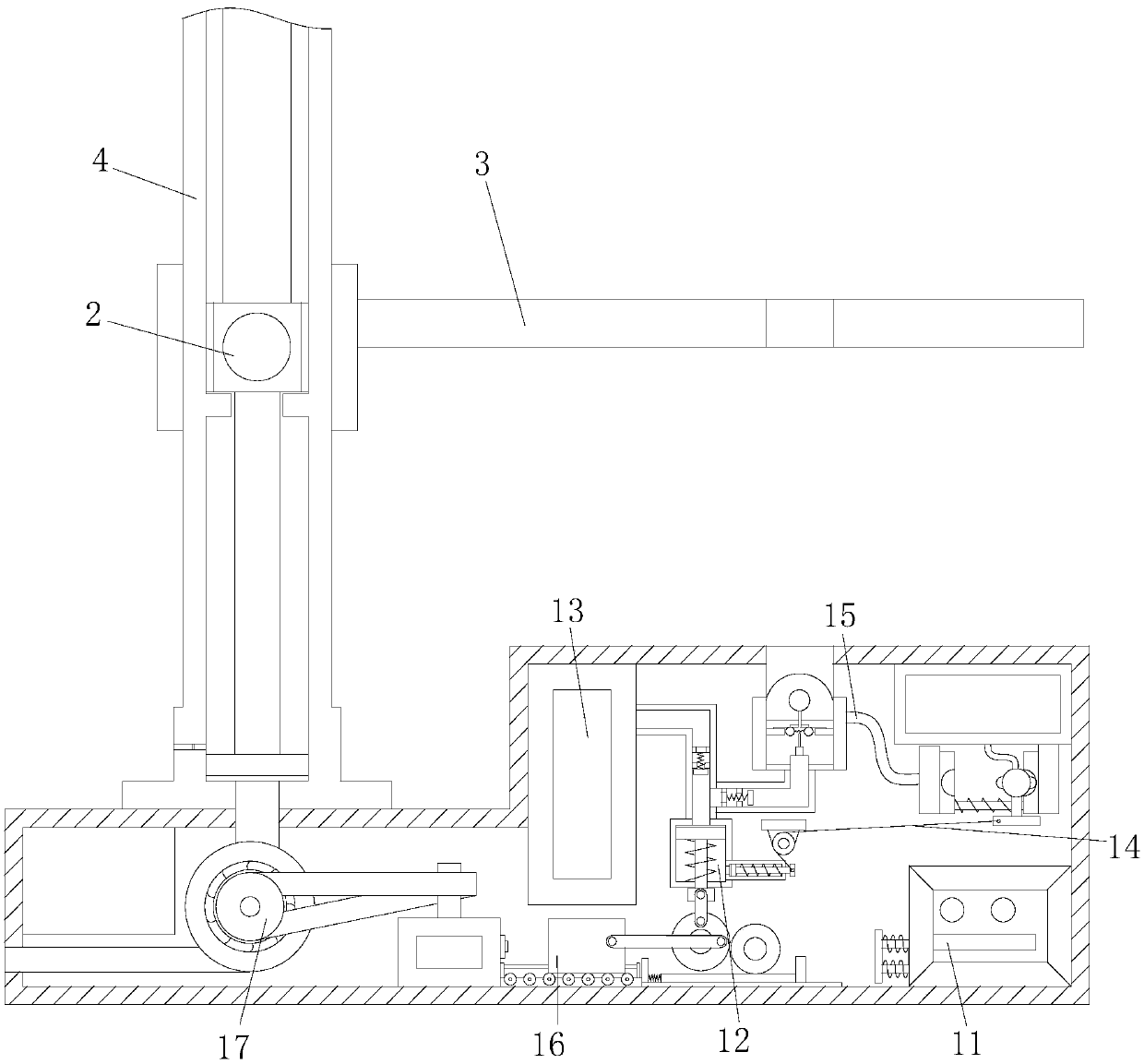

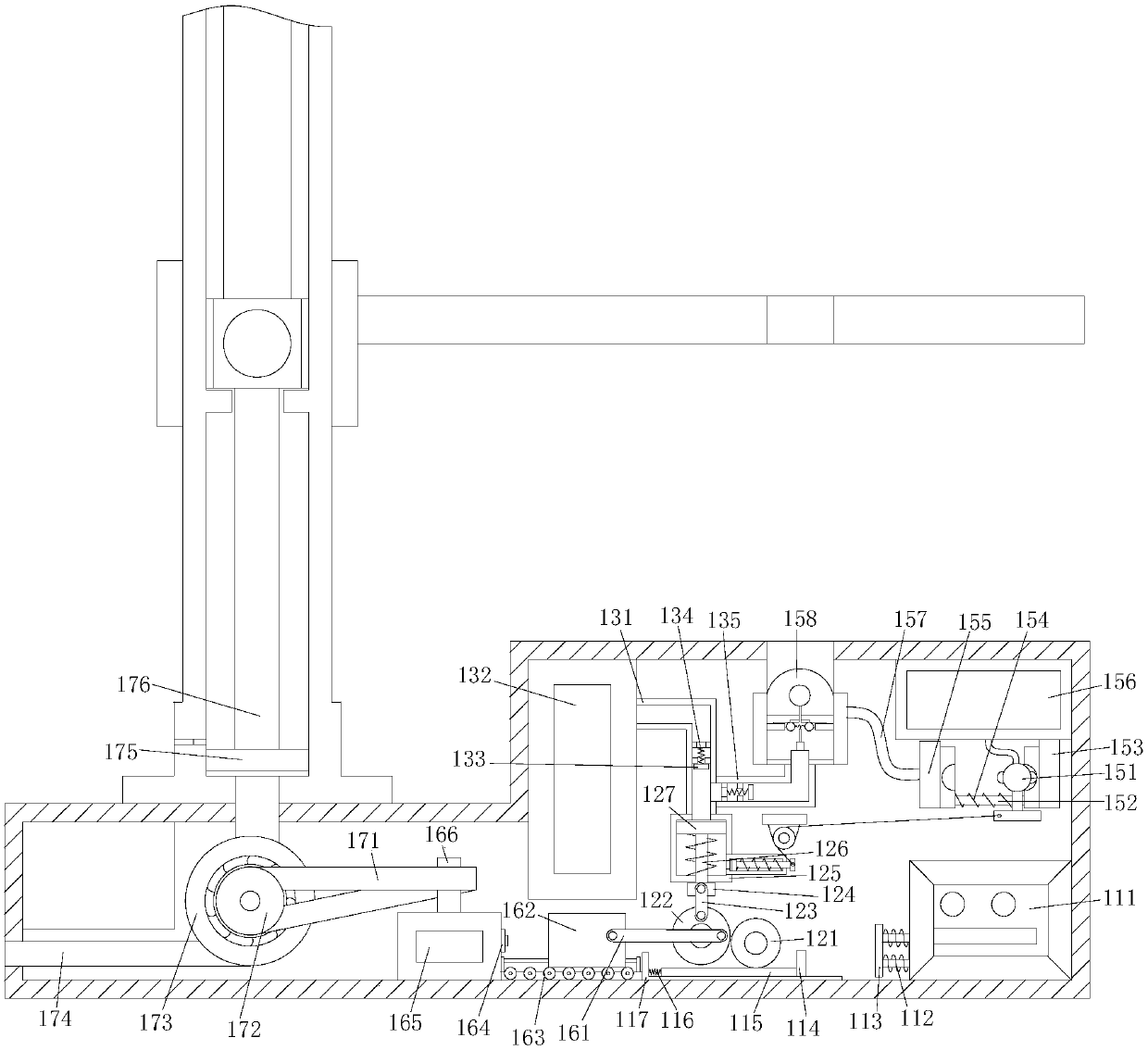

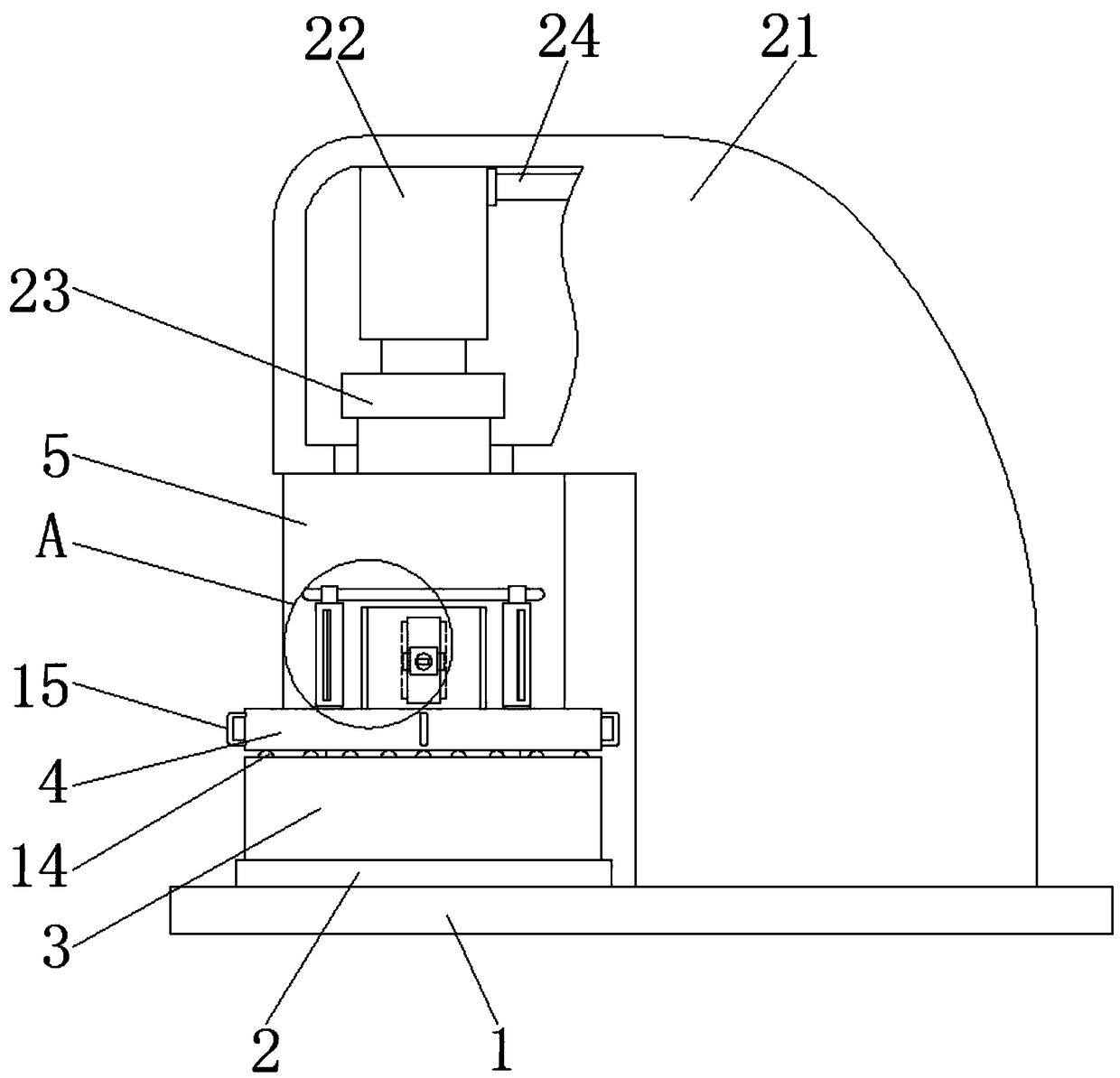

Intelligent automatic photoelectric sensing drilling machine

InactiveCN108673170AReduce frictionAvoid affecting processingMeasurement/indication equipmentsLarge fixed membersElectric machineEngineering

The invention discloses an intelligent automatic photoelectric sensing drilling machine. The intelligent automatic photoelectric sensing drilling machine structurally comprises an automatic supplementing neon base, a connecting lifting device, a drilling machine machining workbench, a pneumatic supporting rod, a manual adjusting device, a driving main motor, an electric machine cover, an electricbox, a mechanical machining drill bit, the upper surface of the automatic supplementing neon base is provided with a pneumatic supporting rod, moreover, the pneumatic supporting rods are vertically connected with each other in an electric welding mode, the inner side of the connecting lifting device is connected with the outer side of the pneumatic supporting rod in a fitting mode, and the top endof the pneumatic supporting rod is connected with the lower surface of the electric box through an electric welding mode. According to the drilling machine, when the LED lamp works, the electromagnet is used for driving the lamp to charge the lamp, and meanwhile, the power supply is connected to conduct discharging and light emitting to form the light source for detection, so that the direct brightness of the lamplight is prevented from affecting the machining, and meanwhile, the lamp is cooled and reduced by virtue of the on-off and power-off, and then the drilling machine machining workbench is controlled to be lifted up and down so as to finish high-precision drilling machining.

Owner:黄红兵

Valve body forging process

ActiveCN110538951AImprove finished product qualityImprove forging effectValve arrangementsMetal-working apparatusPre treatmentEngineering

The invention discloses a valve body forging process which comprises the following steps: S1, band saw blanking: first, checking and confirming quantity and boundary dimension of round bars for processing, carrying out blanking by using a horizontal band saw, wherein the maximum cross section width and height of the horizontal band saw are ranged at 400*350 mm, and then adjusting a carrier rack tobe consistent with the height of a worktable, wherein the blanking dimension precision is improved; S2, surface cleaning: first polishing and derusting the surfaces of cut round bars by means of a milling machine for primary surface treatment to remove rust on the surfaces, and then pickling the round bars for secondary surface treatment to remove oxide skin left on the surfaces of the round bars; S3, electric furnace heating: heating the round bars in stages by using an oven type electric furnace at a rated temperature of 1300 DEG C; and S4, upsetting pre-treatment: upsetting the round barsby using an air hammer, the weight of the falling part of which is 750 kg, to change the shapes of the round bars. The valve body forging process is relatively good in cleaning effect to surfaces of the round bars, improves the forging quality of a valve body and is better in forging effect by way of staged heating.

Owner:WENZHOU ZHONGHAI VALVE FORGING CO LTD

Recycling device of waste plastic

ActiveCN108297308AReduce labor intensitySmall footprintPlastic recyclingCleaning using liquidsEngineeringPower unit

The invention belongs to the technical field of plastic recycling, and particularly discloses a recycling device of waste plastic. The recycling device comprises a cleaning unit, a power unit, a crushing unit and a feeding unit, wherein the cleaning unit comprises a cleaning tank, a hollow rotating shaft, a hemispherical screen, a jacking column and a limiting rod, the hemispherical screen is located above the cleaning tank and on the jacking column, and the jacking column penetrates through the bottom of the cleaning tank and is slidably connected in the cleaning tank; a strip-shaped groove is formed in the surface of the hollow rotating shaft, a feeding hole located above the cleaning groove is formed in the surface of the hollow rotating shaft, and a convex block which is connected to the strip-shaped groove in a sliding mode is arranged on the hemispherical screen; the power unit is used for driving the hollow rotating shaft to rotate; the crushing unit comprises a pressing plate and a grinding cylinder with openings at two ends, wherein the pressing plate is fixed at the lower part of the hollow rotating shaft and communicates with the hollow rotating shaft, and a pressing roller is rotationally connected to the bottom surface of the pressing plate; a rigid screen plate capable of being in contact with the pressing roller is arranged in the grinding cylinder; and the feeding unit is used for conveying an auxiliary agent to the upper part of the rigid screen plate. By means of the device, the waste plastic can be cleaned, dried and crushed, so that processing efficiencyis greatly improved.

Owner:宁波鑫神泽汽车零部件有限公司

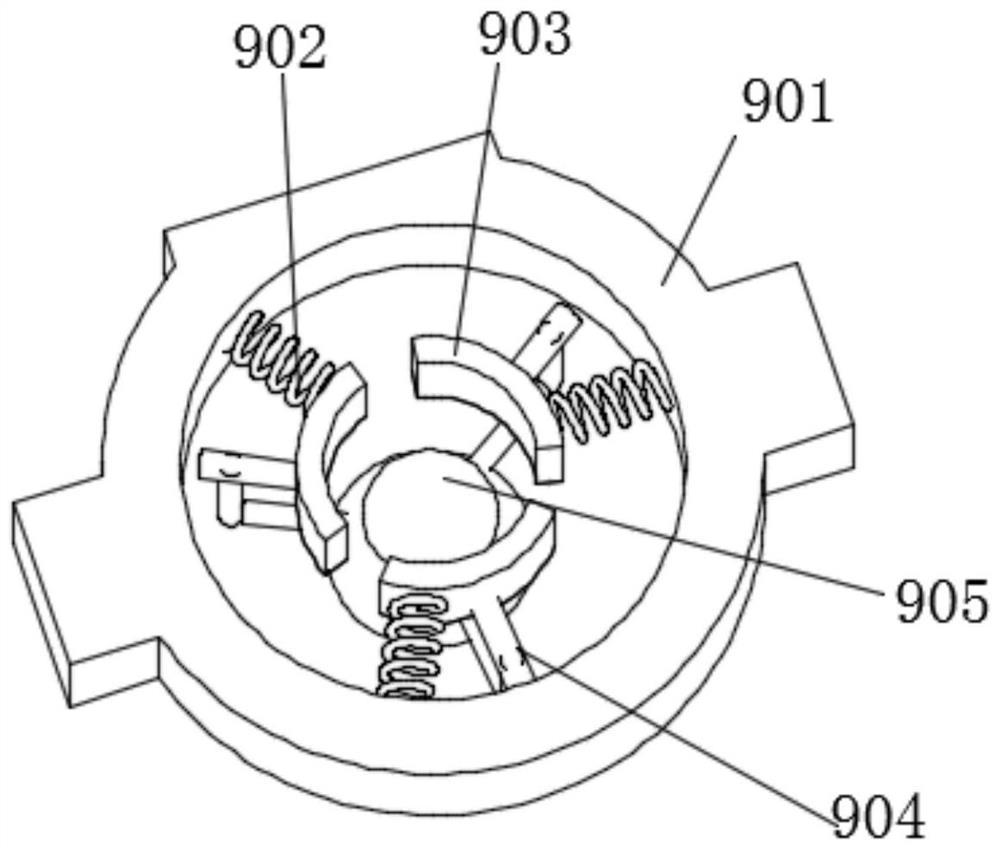

Clamp for hemispherical valve automatic surfacing equipment and technology thereof

ActiveCN112643277APlay a limiting roleAvoid affecting processingWelding/cutting auxillary devicesAuxillary welding devicesElectric machineryEngineering

The invention discloses a clamp for hemispherical valve automatic surfacing equipment and a technology of the clamp. The clamp comprises a base, wherein a first connecting plate is connected to the top of the base in a sliding mode, grooves are formed in the surface of the first connecting plate, supporting plates are installed on the top of the first connecting plate and located on the side faces of the grooves, and a rotating mechanism is installed on the side faces of the supporting plates. A rotating disc is installed on the top of the rotating mechanism, baffles are installed on the top of the rotating disc, and a lifting mechanism is installed on the inner walls of the baffles. Due to the arrangement of the rotating mechanism, when a first motor drives a first lead screw to rotate, the first lead screw can drive a second lead screw to rotate, and the second lead screw is fixedly connected with the the first lead screw. Due to the fact that threaded grooves which are matched with the corresponding lead screws are formed inside a first sleeve and a second sleeve, when the two lead screws rotate, the two sleeves can be driven to form opposite sliding structures, the two sleeves can drive the rotating disc to form a rotating structure through stress rods in the sliding process, and the rotating disc is rotationally connected with the stress rods.

Owner:星球阀门有限公司

Easy-to-clean floating sludge collecting device for sewage treatment tank

PendingCN113152405AReasonable structural designIncrease flexibilityWater cleaningSludge treatmentSludgeTreatment pond

The invention relates to an easy-to-clean floating sludge collecting device for a sewage treatment tank. The easy-to-clean floating sludge collecting device comprises a storage box, wherein a crushing assembly is arranged between a first partition plate and the right wall of the storage box, a moving assembly is arranged between a vertical plate and a supporting column, a lifting assembly is arranged at the lower end of a connecting plate, and a collecting frame is connected to the lower end of the lifting assembly. The collecting frame is driven by the moving assembly to move rightwards to the designated collecting distance, the floating sludge collecting distance can be adjusted according to the actual situation, the collecting frame is driven by the lifting assembly to descend to a certain distance in a pond, the descending height of the collecting frame can be adjusted according to treatment ponds with different depths, manual cleaning and fishing are not needed, and the collecting efficiency is improved. Floating sludge and floaters are crushed into small-particle waste through the crushing assembly, follow-up treatment is facilitated, a pressing plate can vertically extrude the floating sludge and the floaters, follow-up treatment is facilitated while occupied space is reduced, then a second push plate transversely extrudes the floating sludge and the floaters, the size is further reduced, the floating sludge and the floaters can be pushed out through the second push plate, and time and labor are saved.

Owner:RIZHAO POLYTECHNIC

Stamping die production structure

InactiveCN111843734ASpeed up circulationAvoid overheatingGrinding machinesGrinding/polishing safety devicesElectric machineryPortal frame

The invention discloses a stamping die production structure. The stamping die production structure comprises a supporting box, a movable door is movably installed on the front portion of the supporting box, a machining table is fixedly installed on the upper portion of the supporting box, a portal frame is fixedly installed on the upper portion of the machining table, a top plate is fixedly installed on the top of the portal frame, an air cylinder is fixedly installed in the middle position of the upper portion of the top plate, a first cantilever and a second cantilever are slidably connectedinto the portal frame, the first cantilever is located above the second cantilever, a first connecting column and a second connecting column are fixedly connected to the two ends between the first cantilever and the second cantilever, and a driving motor is fixedly installed at a position, close to one end, of the upper part of the second cantilever. According to the stamping die production structure, waste chips generated during grinding machining can be collected, machining is prevented from being influenced by the waste chips, a ground die can be cooled as well, the phenomenon that takingout of the die is influenced due to the fact that the temperature is too high is avoided, and use is more facilitated.

Owner:孝感德客电子科技有限公司

Copper and aluminum forging and pressing mechanical device with protective performance

ActiveCN108620521AExtend functional lifeGuaranteed protective effectForging/hammering/pressing machinesForging press drivesEngineeringMechanical devices

The invention discloses a copper and aluminum forging and pressing mechanical device with protective performance, and relates to the field of technology forging and pressing mechanical devices. A baseis included; the left side of the top of the base is fixedly connected with a shock absorbing pad, and the top of the shock absorbing pad is fixedly connected with a fixed base; the top of the surface of the fixed base is sleeved with a forging and pressing base, and the top of the forging and pressing base is fixedly connected with an anti-explosion glass cylinder; and the front side of the anti-explosion glass cylinder is connected with a movable cover in a clamped manner. According to the copper and aluminum forging and pressing mechanical device with the protective performance, the anti-explosion glass cylinder is matched with the movable cover, the top of the forging and pressing base can form a closed space, it is avoided that during forging and pressing, high-temperature oxidization layer fragments are scattered everywhere and consequently people are scalded or clothing and other articles for daily use are damaged, and a safety protection effect is achieved; a slide groove is matched with a slide rod frame, a clamping plate can rotate to press the movable cover, and it is avoided that in work, the movable cover gets loose; and a vacuum noise lowering cavity is formed in theanti-explosion glass cylinder, noise during forging and pressing can be greatly lowered, and therefore the work environment is improved.

Owner:徐州众工精密模锻有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com