Easy-to-clean floating sludge collecting device for sewage treatment tank

A technology of sewage treatment tank and collection device, which is applied in water/sludge/sewage treatment, sludge treatment, and open water surface cleaning, etc. problems, to achieve the effect of convenient discharge, strong practicability and reasonable structure design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

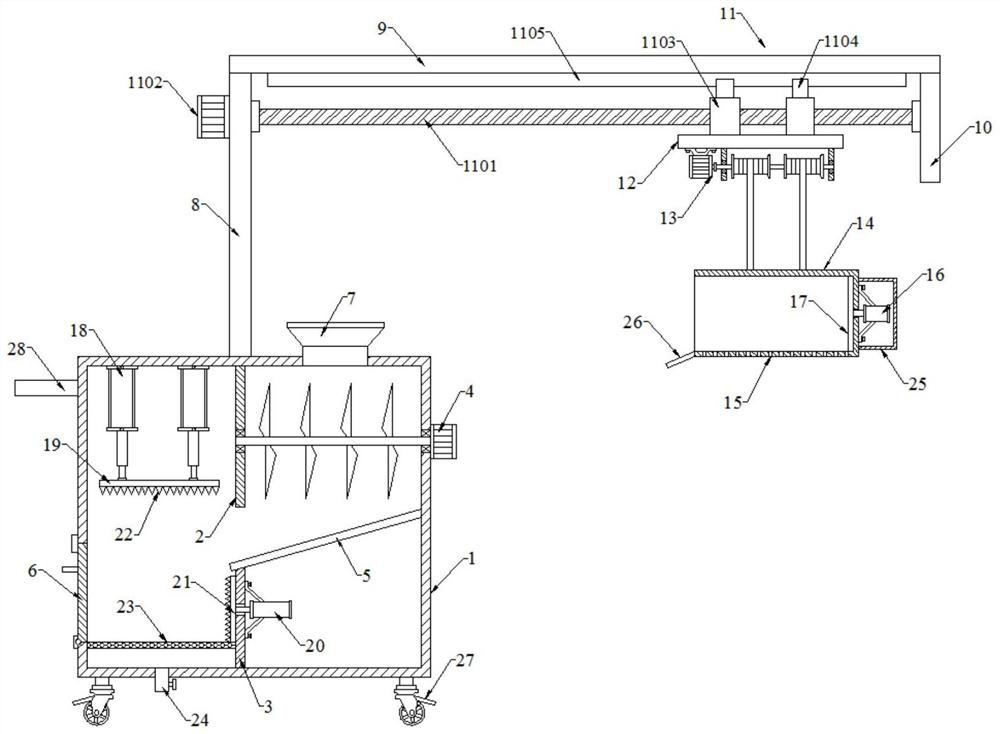

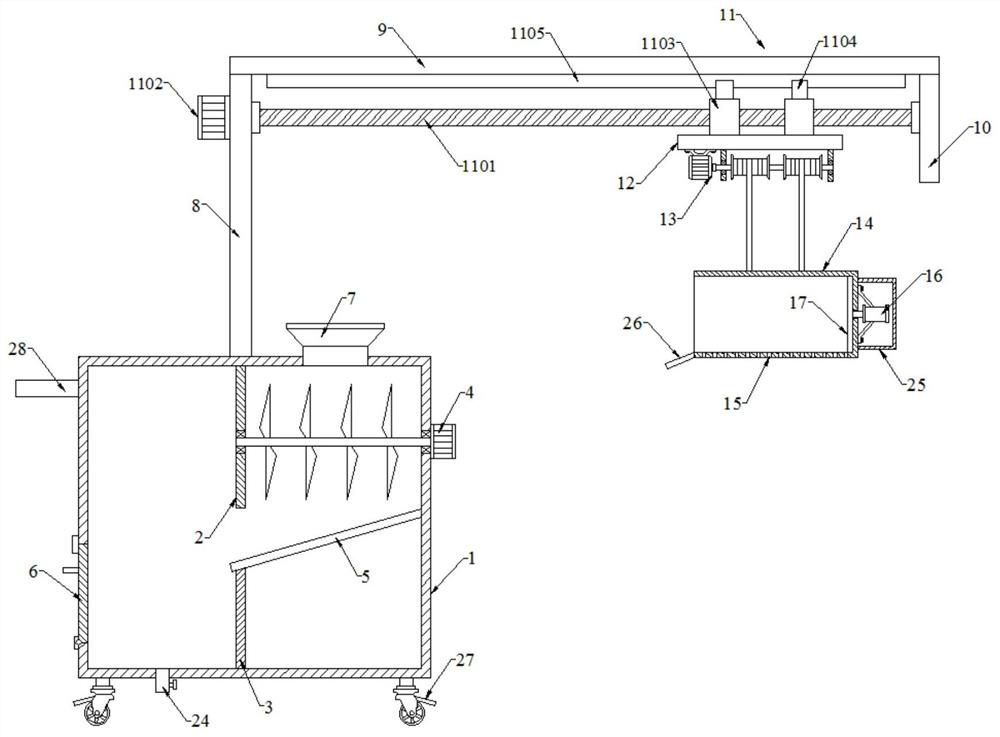

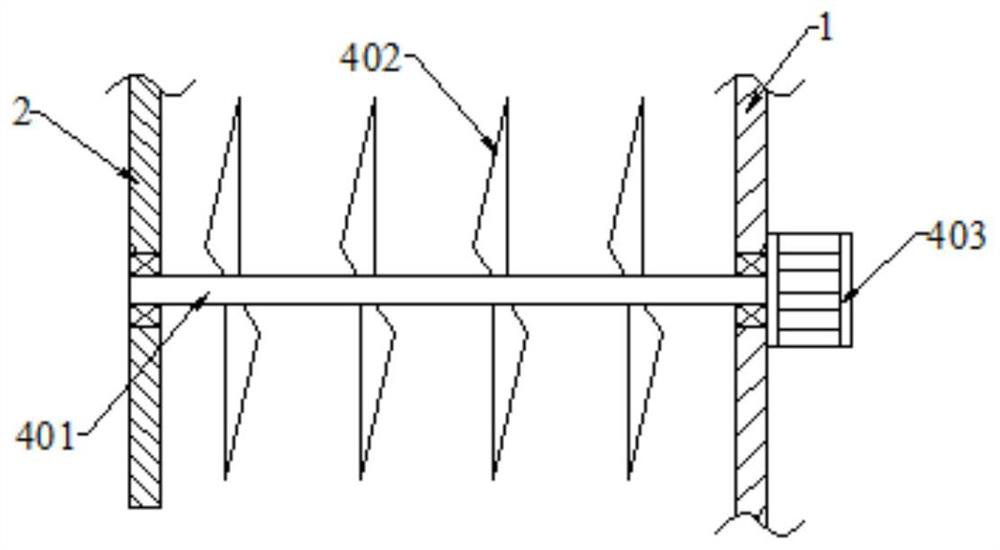

[0032] Please refer to the attached Figure 2-5 As shown, this embodiment is an easy-to-clean sewage treatment tank scum edge collection device, including a storage box 1, the upper and lower walls of the inner cavity of the storage box 1 are respectively fixed with a first partition 2 and a second partition Plate 3, a crushing assembly 4 is provided between the first partition 2 and the right wall of the storage box 1, a guide plate 5 is provided between the upper end of the second partition 3 and the right wall of the inner cavity of the storage box 1, and the left end of the storage box 1 A cleaning door 6 is hinged, the upper end of the material storage box 1 is connected to the right side with a feed hopper 7, the middle part of the upper end of the material storage box 1 is fixedly connected with a pillar 8, and the upper end of the pillar 8 is fixedly connected with a support cross bar 9, and the lower end of the support cross bar 9 is on the right side A vertical plate...

Embodiment 2

[0043] Please refer to the attached figure 1 As shown, on the basis of Embodiment 1, two first hydraulic cylinders 18 are provided on the top of the inner chamber of the material storage box 1, and the telescopic end of the first hydraulic cylinder 18 is provided with a pressure plate 19, and the right end of the second partition 3 is provided with a second The hydraulic cylinder 20 and the telescopic end of the second hydraulic cylinder 20 move through the second partition plate 3 and are fixedly connected with a second push plate 21 , and a plurality of crushing teeth 22 are fixedly connected with the left end of the second push plate 21 and the lower end of the pressure plate 19 .

[0044] Start the first hydraulic cylinder 18 to drive the pressure plate 19 down to squeeze the floating mud and floating objects in the vertical direction, which can reduce its volume, not only reduce the occupied space, but also facilitate subsequent processing, and then pass the second hydraul...

Embodiment 3

[0046] Please refer to the attached figure 1 As shown, on the basis of Embodiment 1, a filter plate 23 is provided between the second partition 3 and the left wall of the inner cavity of the material storage box 1 , and a drain pipe 24 is communicated with the lower wall of the material storage box 1 .

[0047] The floating mud and floating matter will fall on the filter plate 23 for storage, and the residual sewage and waste liquid in the floating mud and floating matter will fall through the filtering plate 23, and then be discharged through the liquid discharge pipe 24, realizing the cleaning of the floating mud and floating matter. The solid-liquid separation of objects is beneficial to the subsequent treatment of floating sludge and floating objects.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com