Forging method capable of realizing multi-surface forging forming

A technology of forging forming and dust, applied in the field of forging, can solve the problems affecting the forging quality of raw materials, achieve the effect of safe and convenient use, scientific and reasonable structure, and reduce forging quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

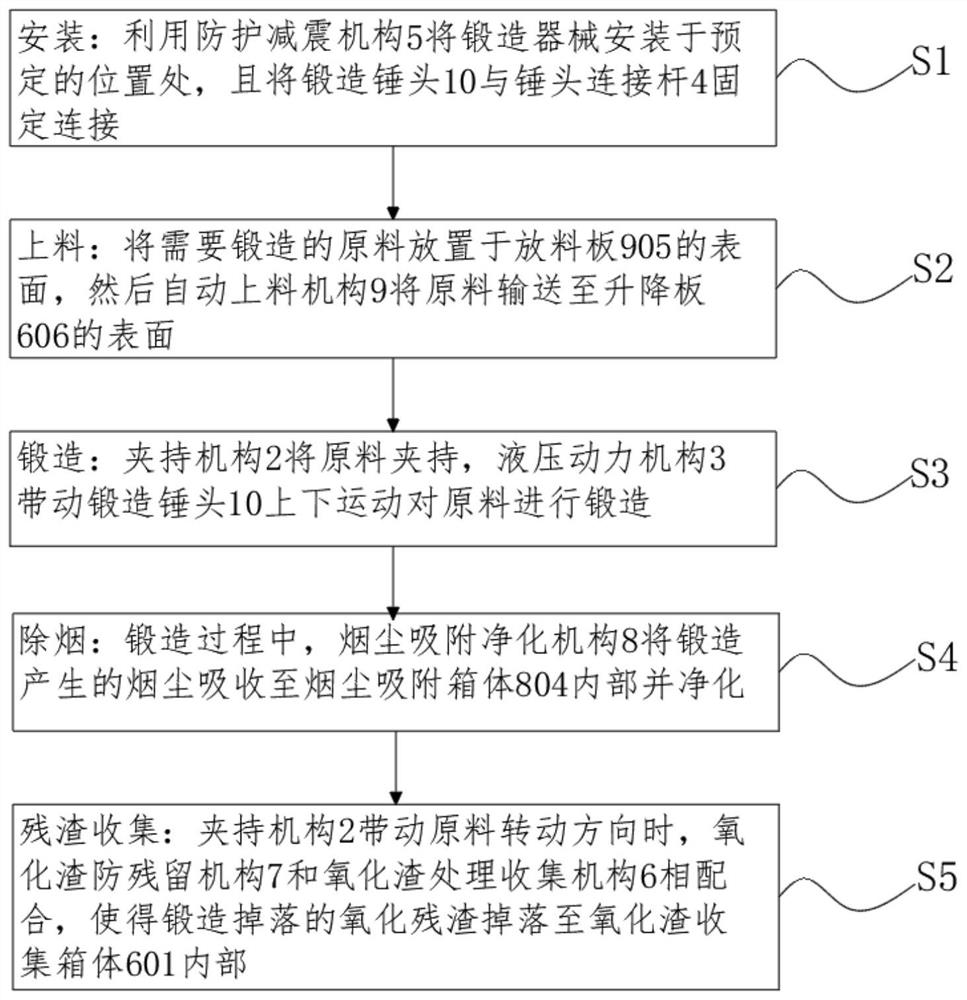

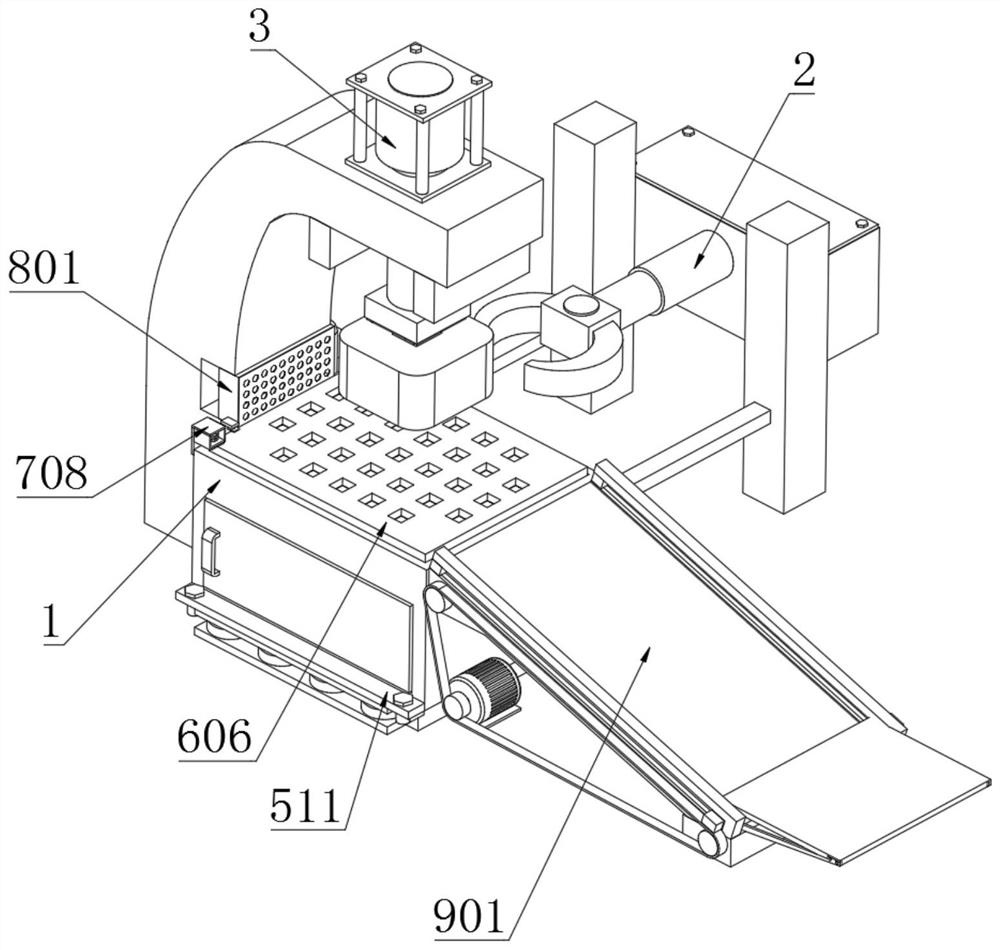

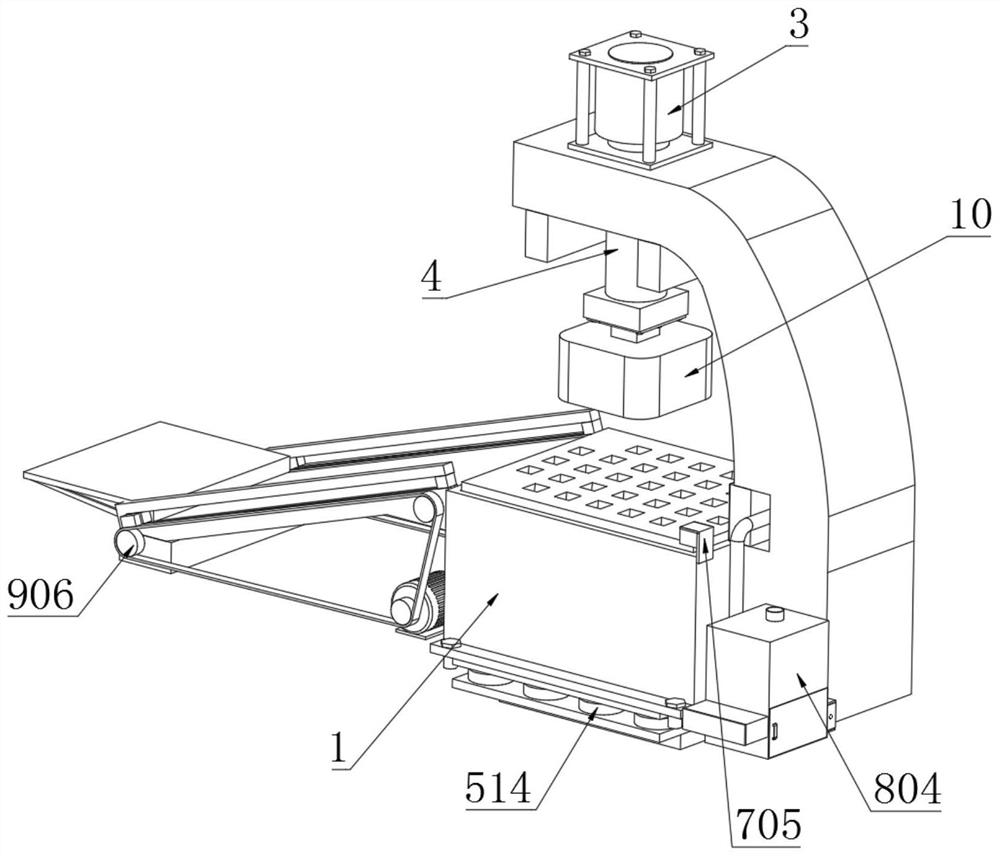

[0041] Example: such as Figure 2-9As shown, the present invention provides a technical solution, a forging method capable of multi-face forging. The forging method must be realized by a forging device. The forging device includes a processing platform 1, a clamping mechanism 2 and a hydraulic power mechanism 3. The hydraulic power mechanism The bottom end of 3 is fixedly connected with the hammer head connecting rod 4, and the bottom end of the hammer head connecting rod 4 is fixedly connected with the protection and damping mechanism 5, which plays a role in protecting the equipment during forging. The hammer head 10 and the processing platform 1 are equipped with an oxidation slag treatment and collection mechanism 6 to facilitate the cleaning of the oxidation residues dropped during forging. The slag anti-residue mechanism 7 guides the oxidation residue and prevents the residue from remaining on the surface of the processing platform 1. One end of the middle part of the pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com