Patents

Literature

390results about "Power hammers" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

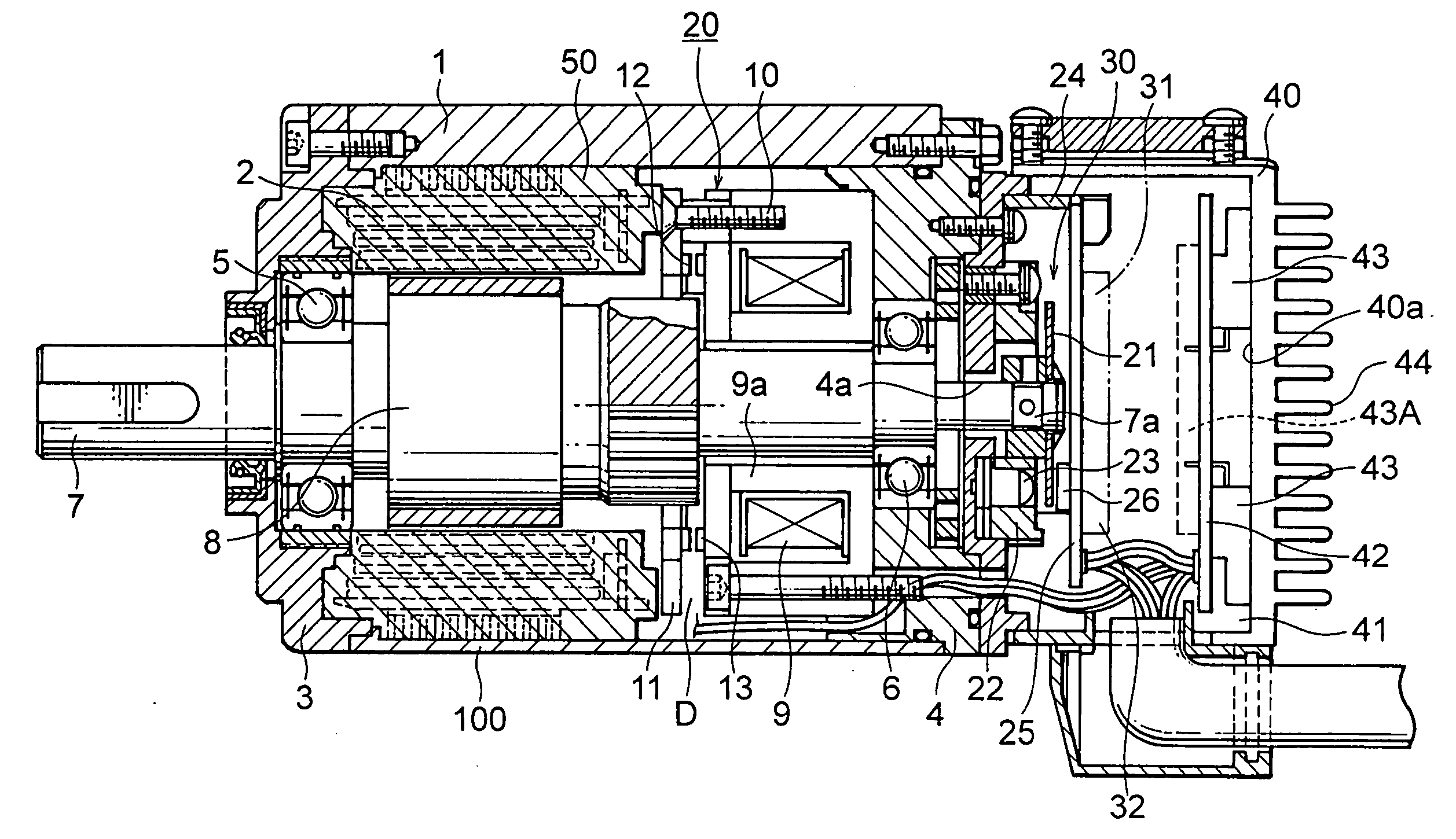

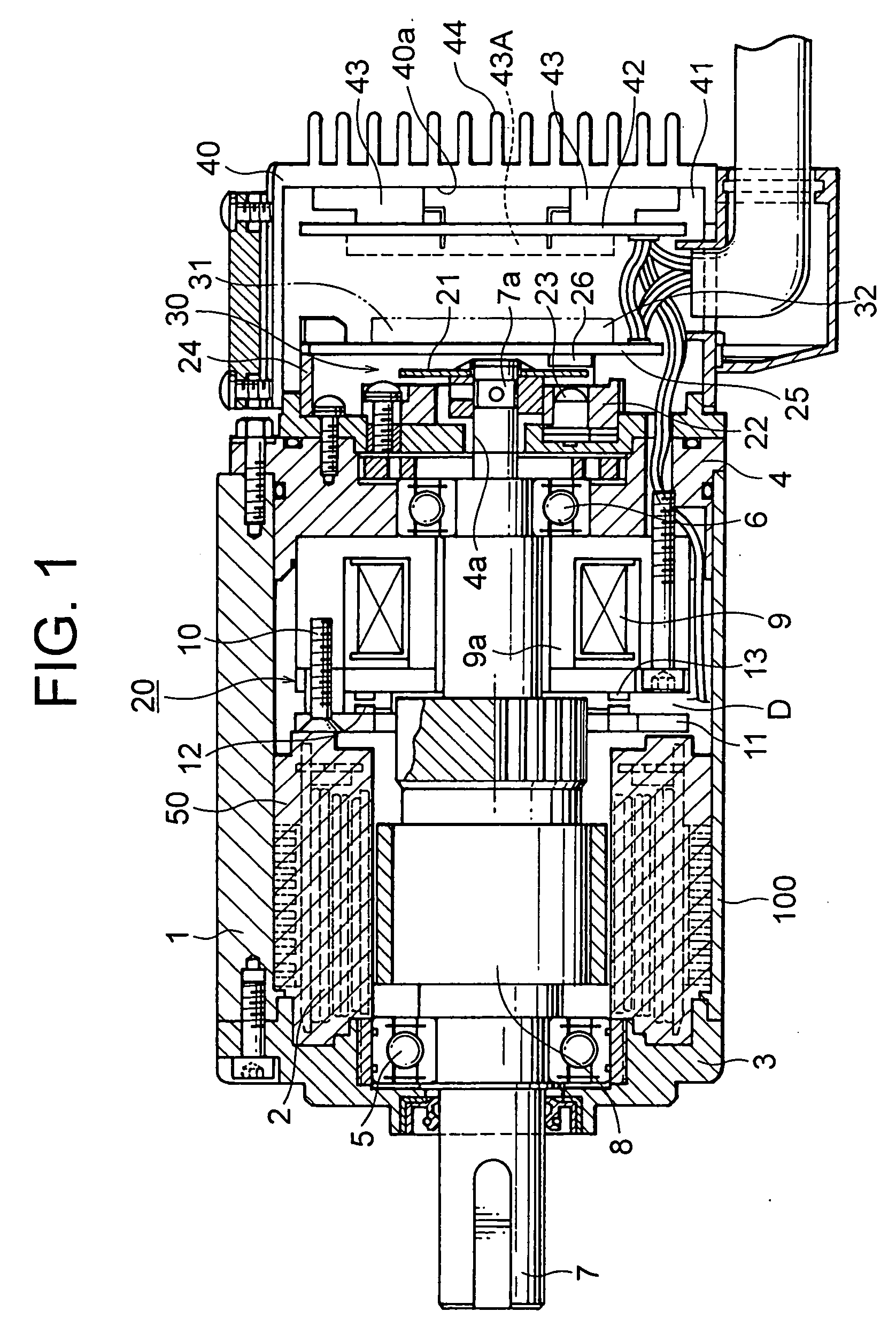

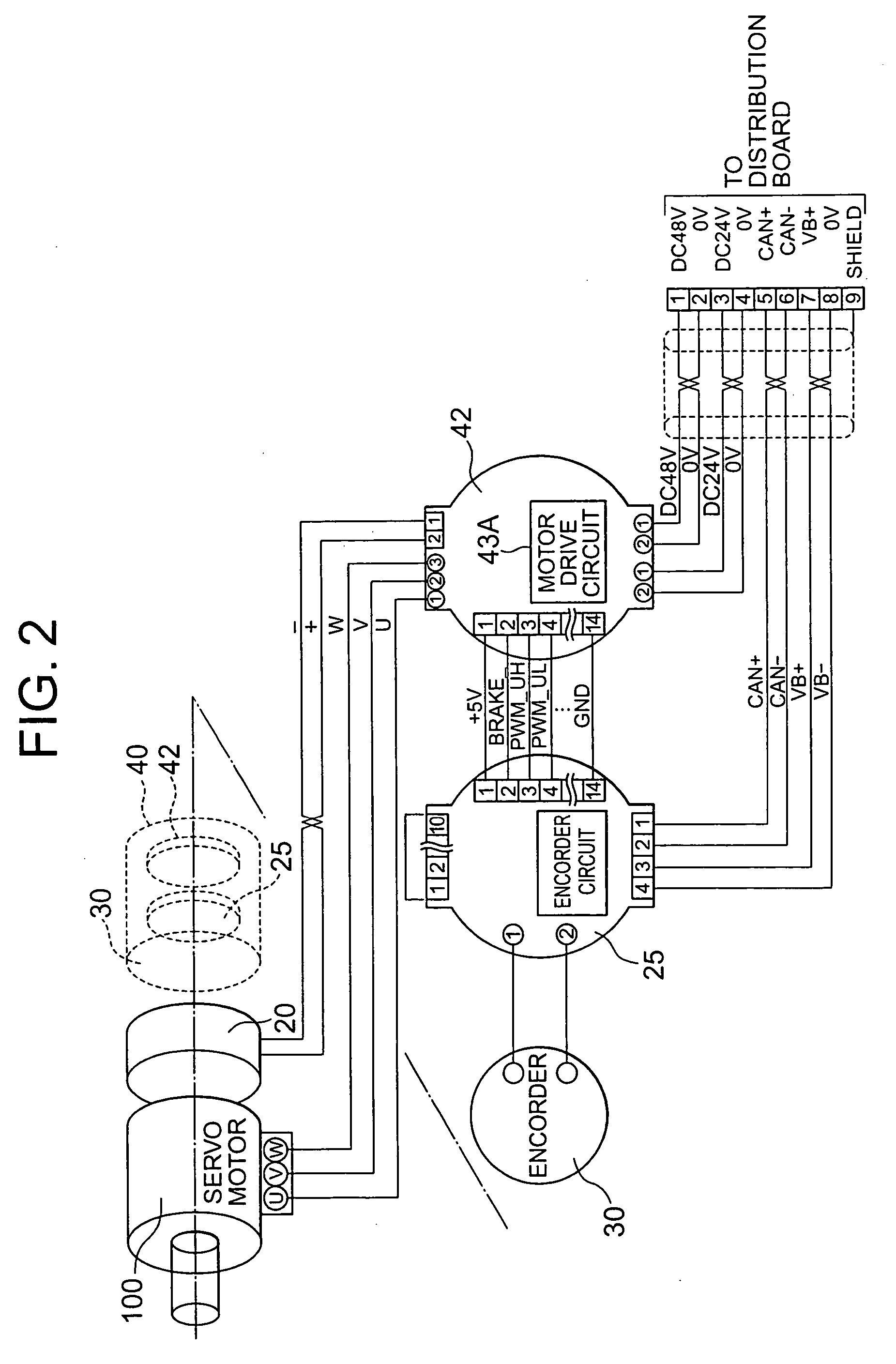

Motor with a brake

InactiveUS20040239196A1Asynchronous induction motorsMechanical energy handlingElectric machineControl theory

The present invention provides a motor with a brake in which, after an initial stage, a voltage applied to the brake is reduced to thereby restrain heat generation in the brake. In the motor with a brake, after signal drive, a voltage of a drive signal supplied to an electromagnetic drive portion of the brake is reduced, whereby heat generation in the brake during motor rotation is restrained, which makes it possible to increase a load to be applied to the motor.

Owner:TAMAGAWA SEIKI CO LTD

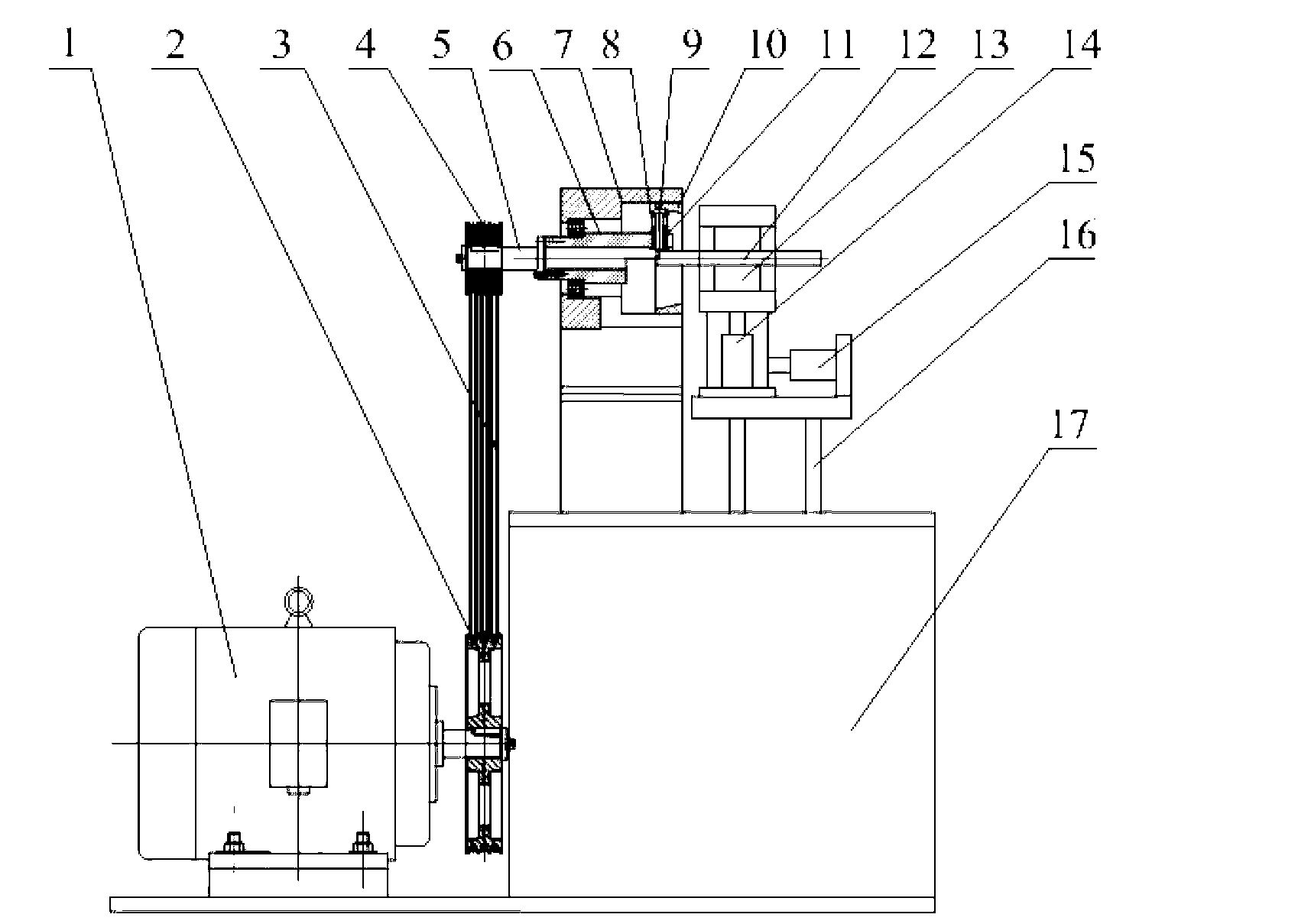

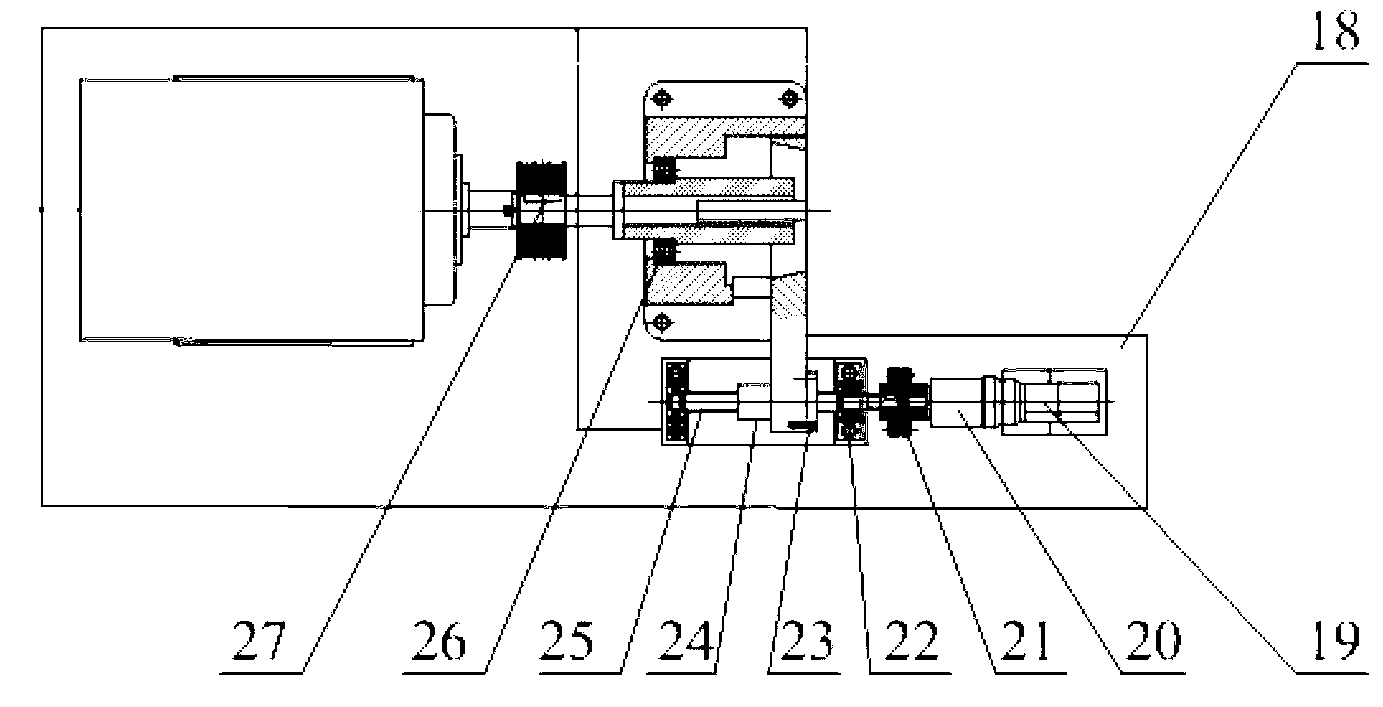

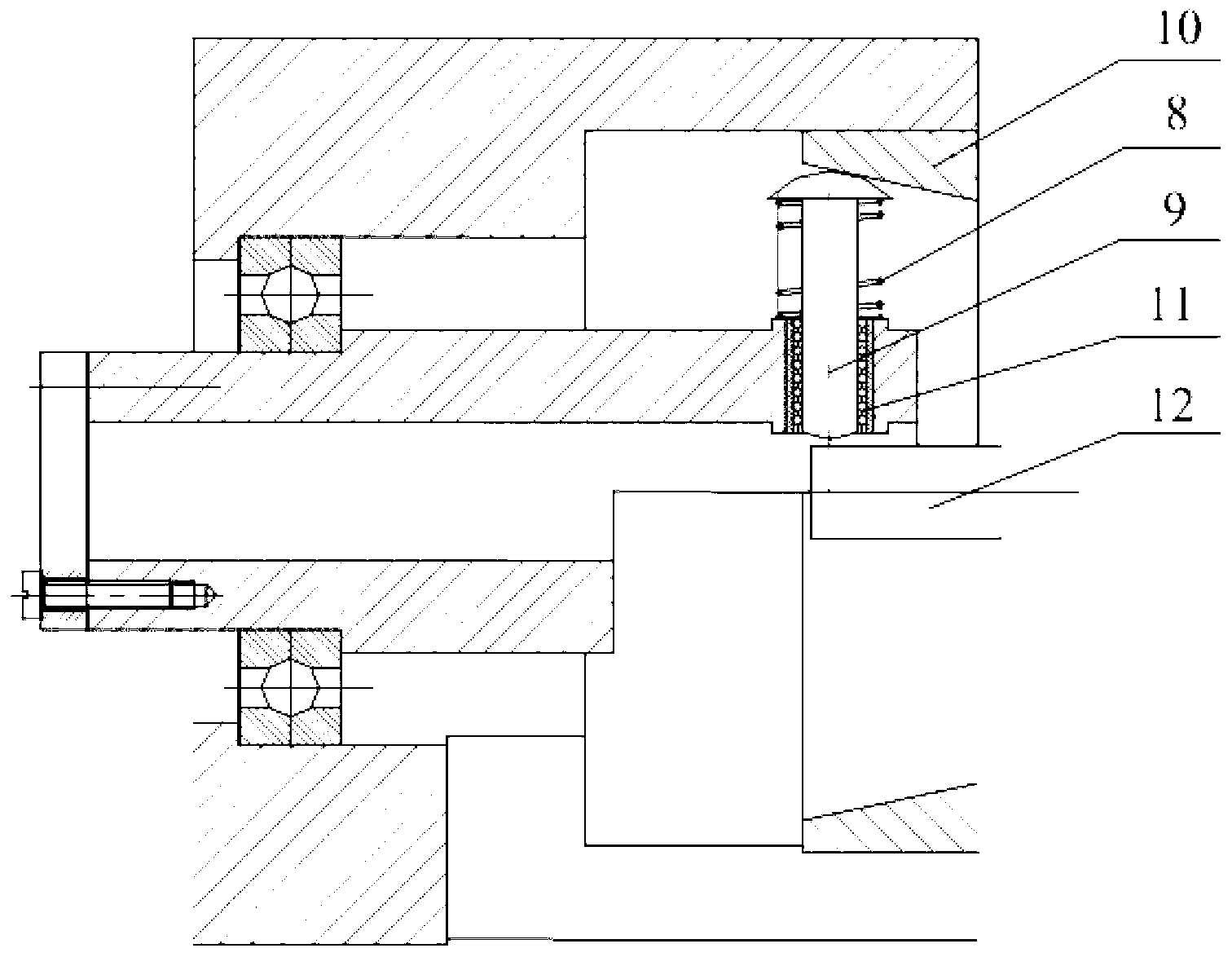

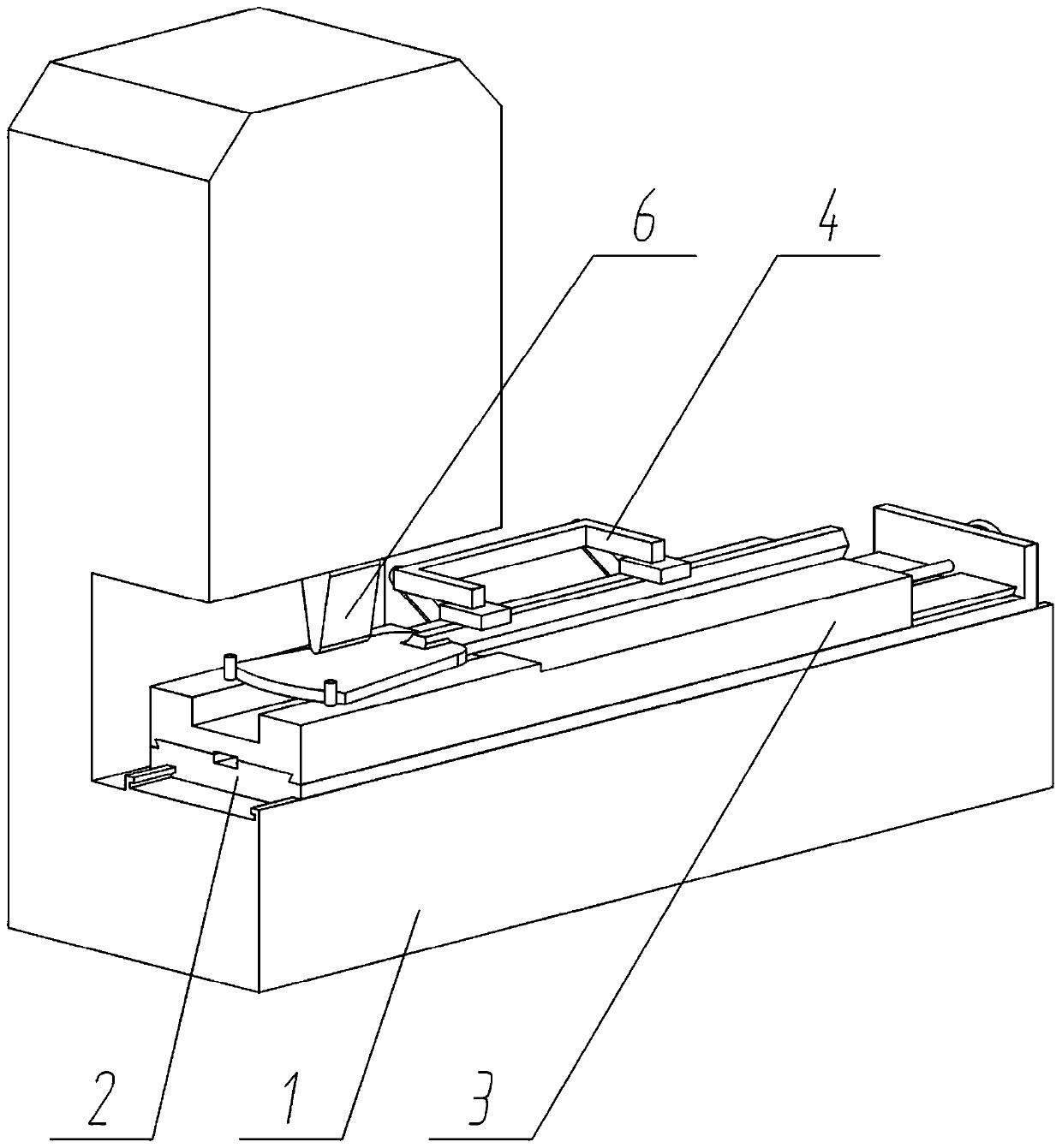

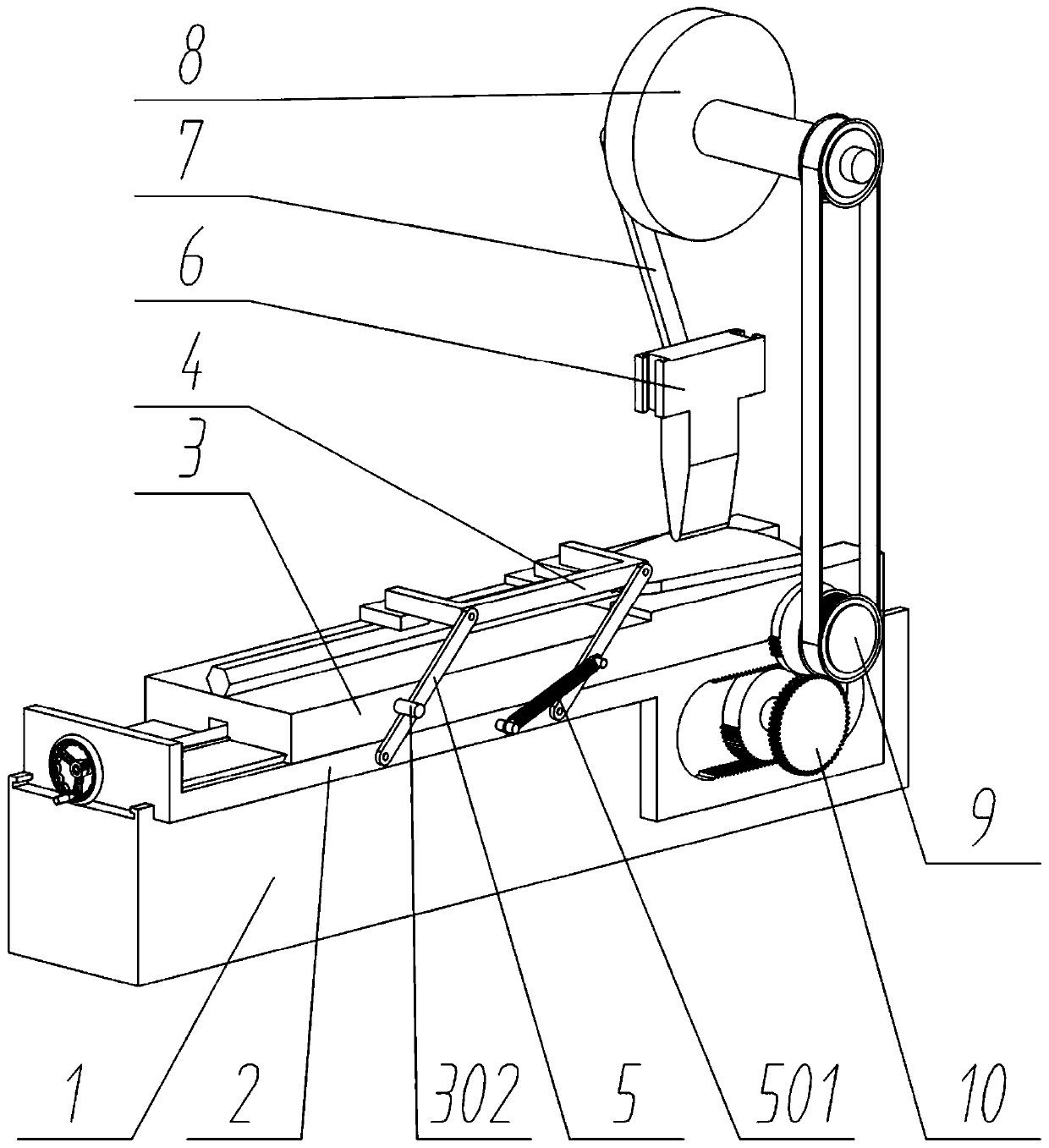

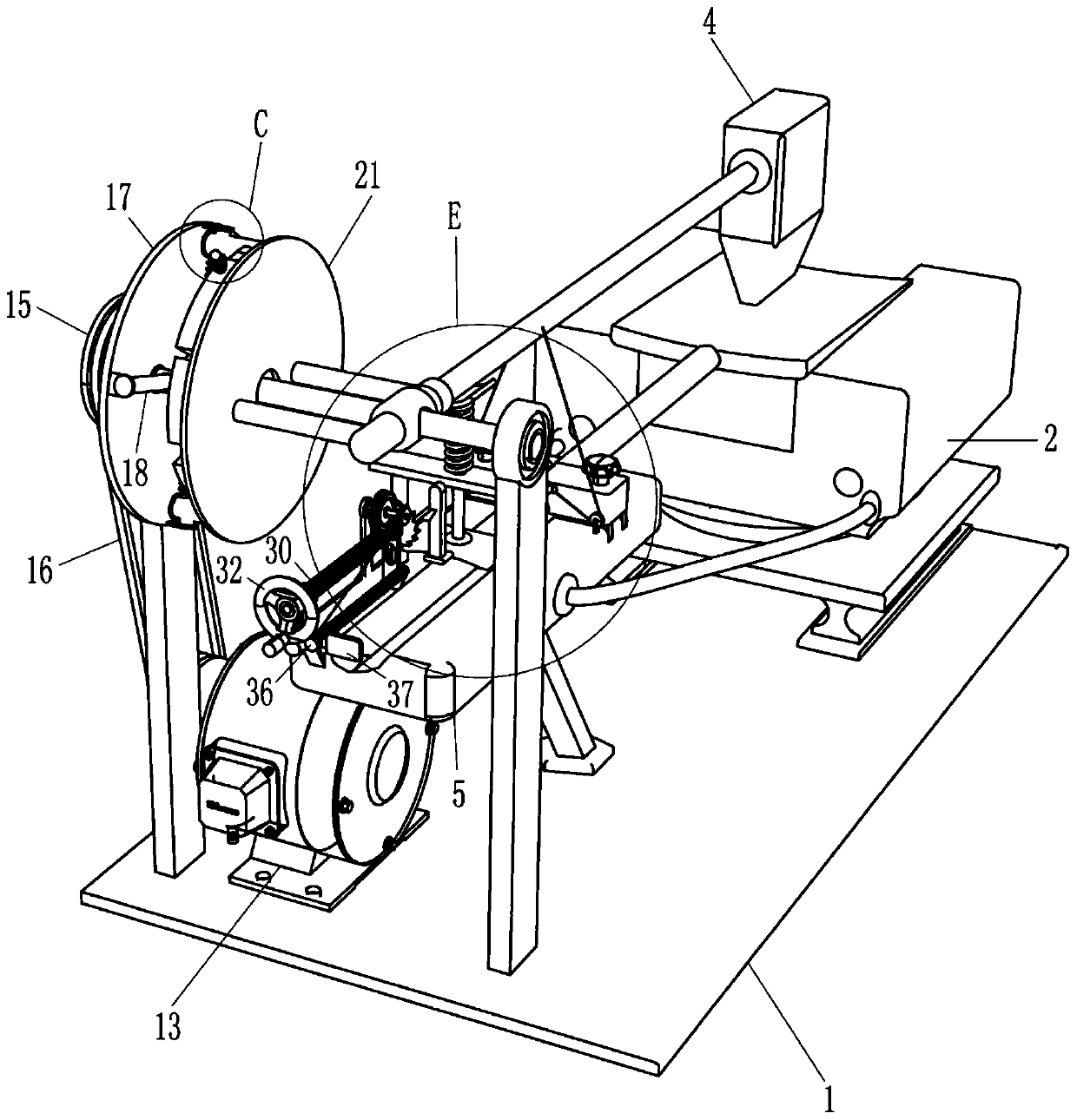

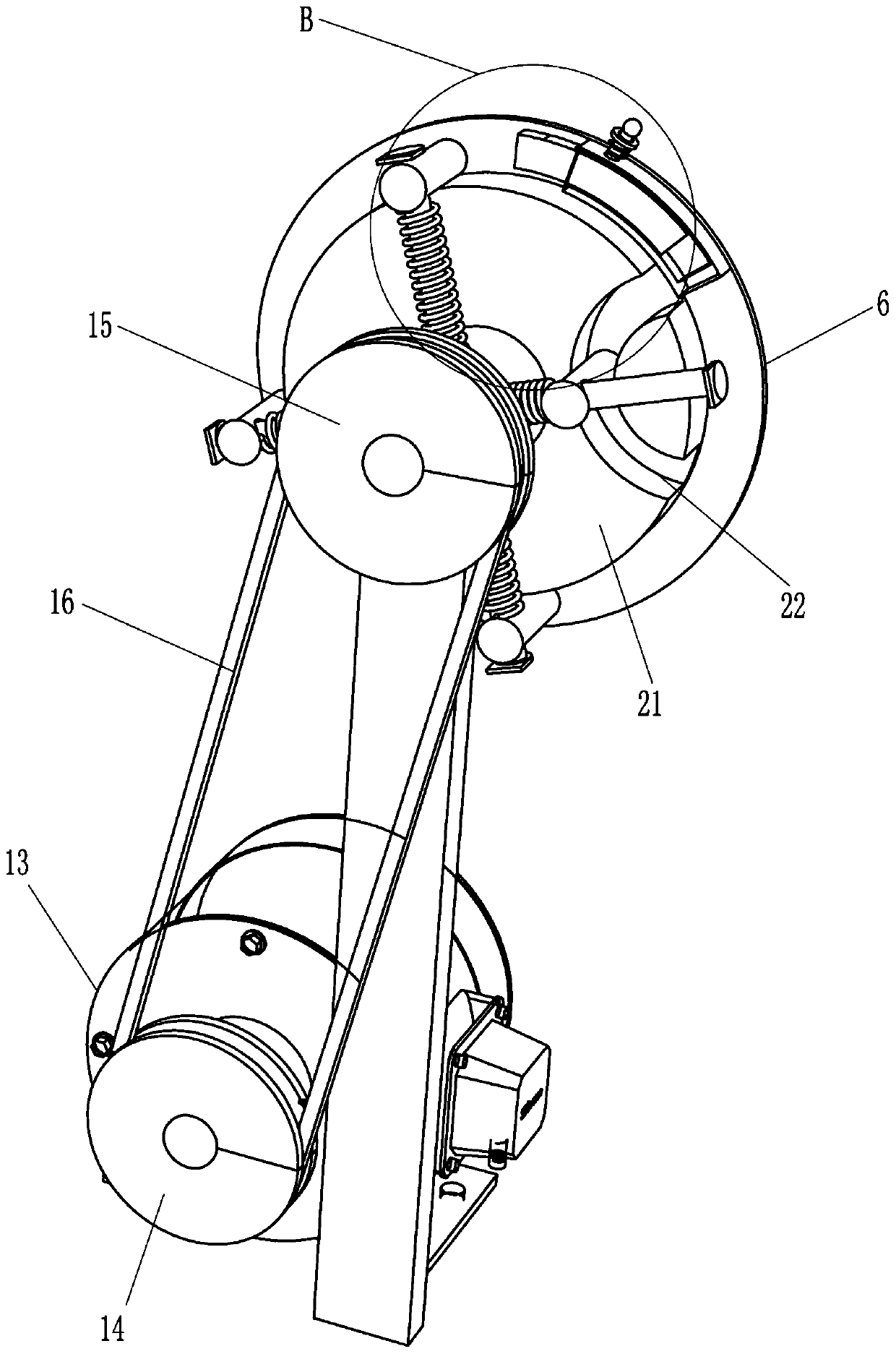

Variable-speed circumferential low-stress bending fatigue crack precise blanking machine and blanking method thereof

InactiveCN103286249AReduce utilizationLower the thresholdPower hammersHandling devicesStress concentrationBall bearing

The invention discloses a variable-speed circumferential low-stress bending fatigue crack precise blanking machine and a blanking method of the variable-speed circumferential low-stress bending fatigue crack precise blanking machine. The variable-speed circumferential low-stress bending fatigue crack precise blanking machine comprises a variable-frequency motor, a large belt pulley, a V-shaped belt, a small belt pulley, a two-stage gear accelerator, a high-speed main shaft, a sliding rail supporting seat, a screw compression spring, a columnar hammer head, a feeding sleeve, a ball guide bushing, metal bars, a clamping hand, a clamping cylinder, a feeding cylinder, a hydraulic clamping feeding mechanism support, a machine body, a seat plate, a servo motor, a speed reducer, a coupler, a ball screw supporting seat, a screw, a nut, a ball screw, a deep groove ball bearing and a key. The variable-speed circumferential low-stress bending fatigue crack precise blanking machine is high in geometric precision of blanking workbanks, free of corner collapse and radial deformation, perpendicular and smooth in fracture section, few in burrs, and high in use ratio of material. The stress concentration effect, the resonance effect and the bending fatigue of an annular V-shaped groove are utilized to enable the critical value of the impact speed of vibration on the metal bars to be lower than the critical value of the speed in the high-speed shearing process, and the blanking machine is applicable to precise blanking of the metal bars of different materials.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

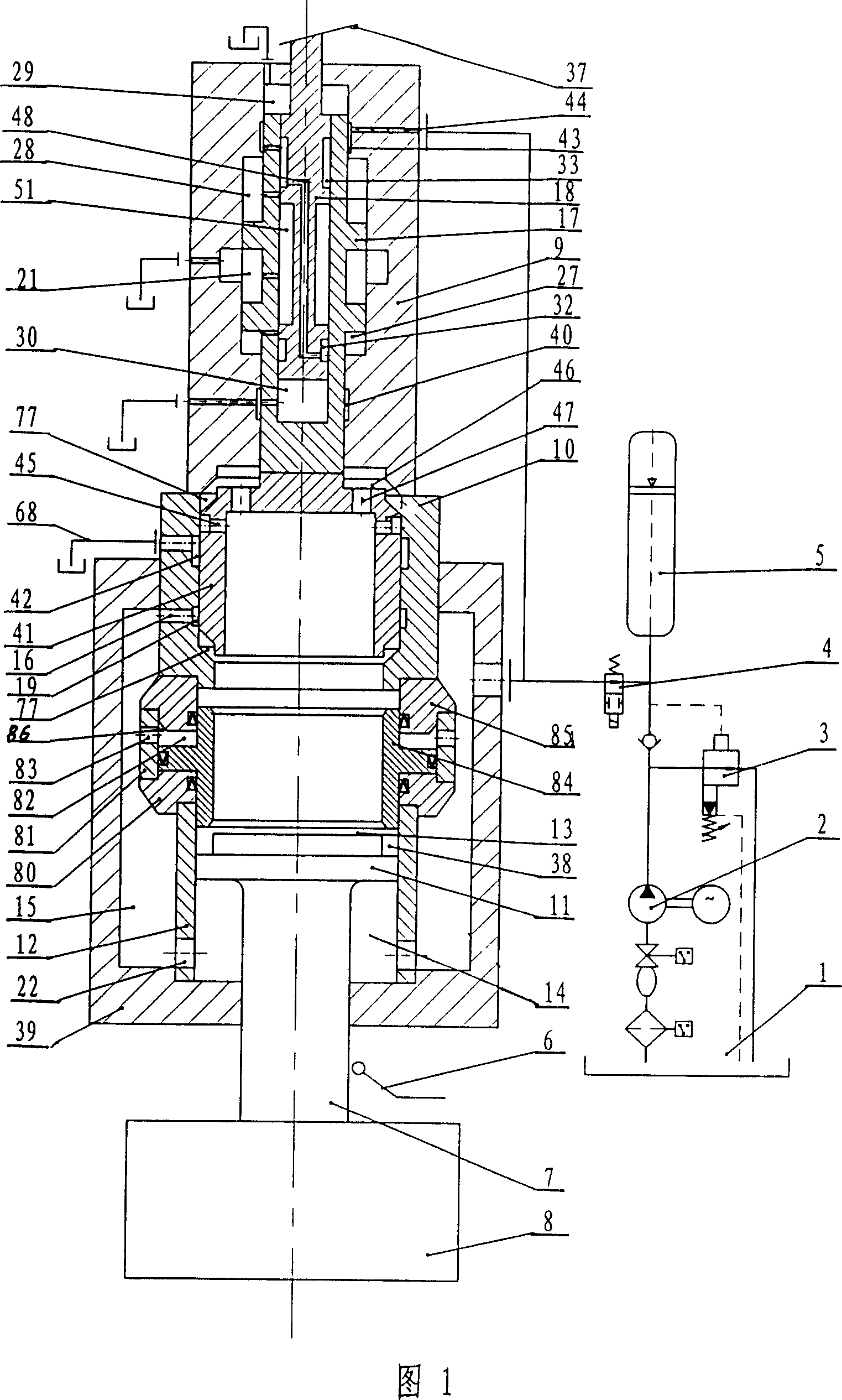

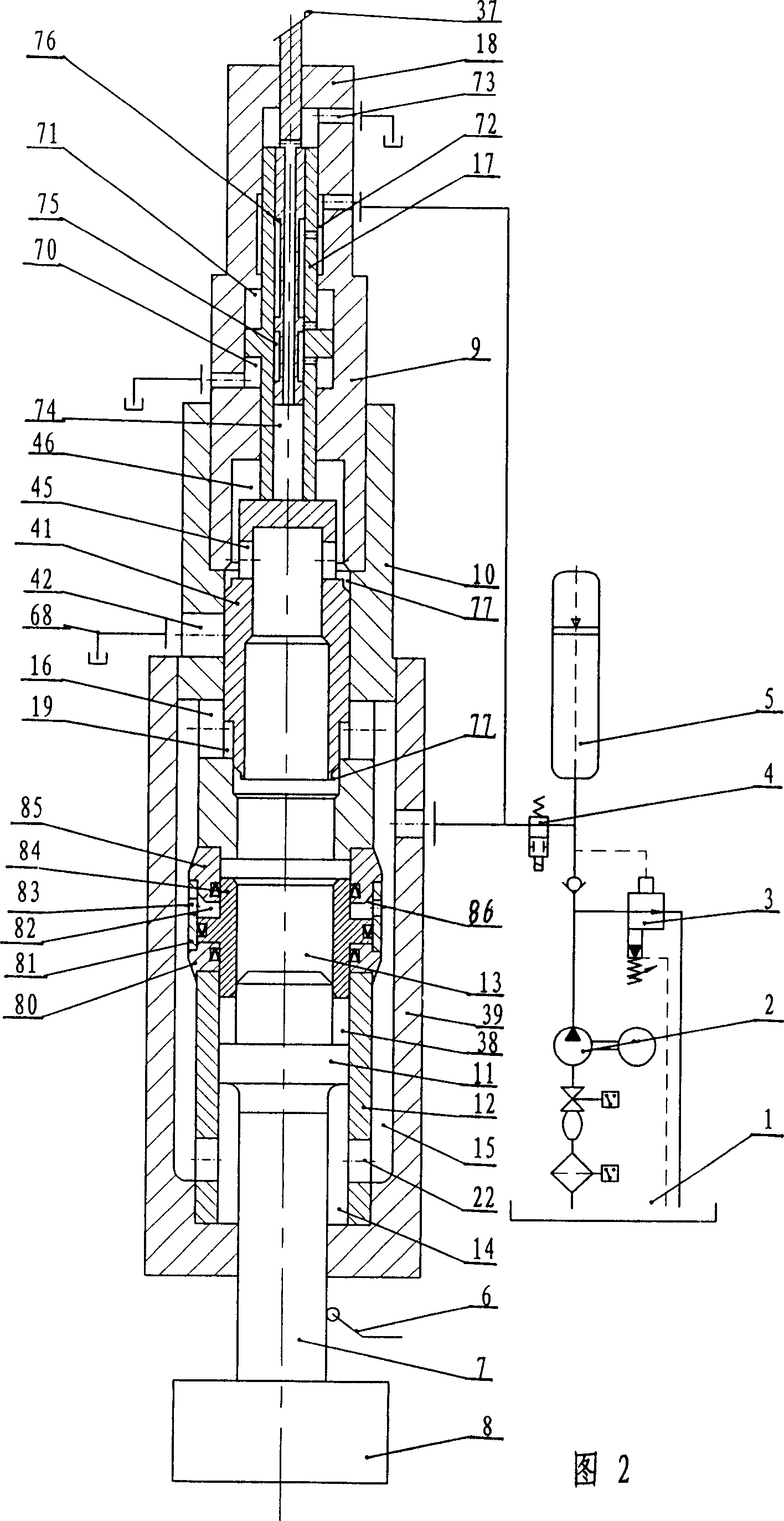

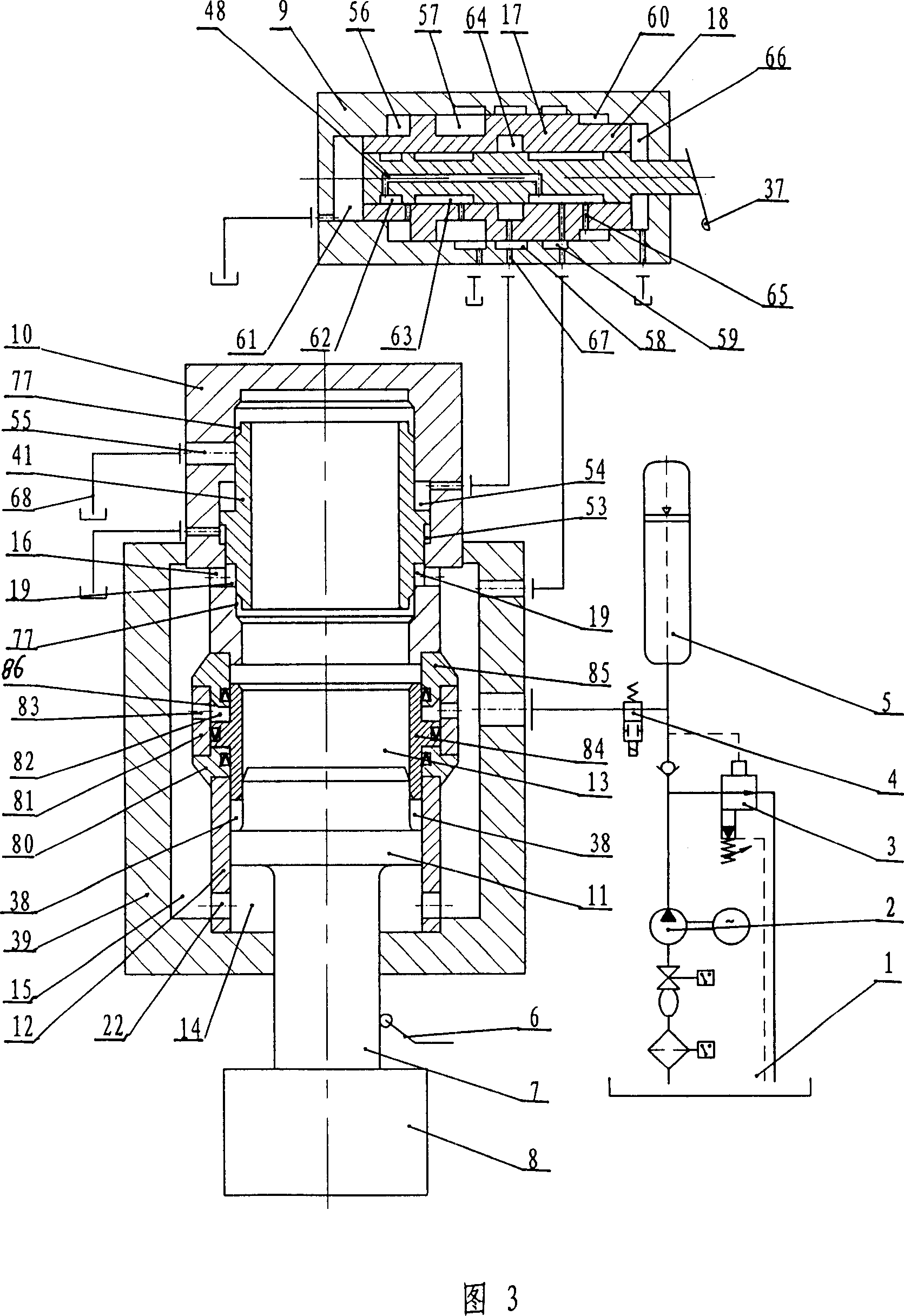

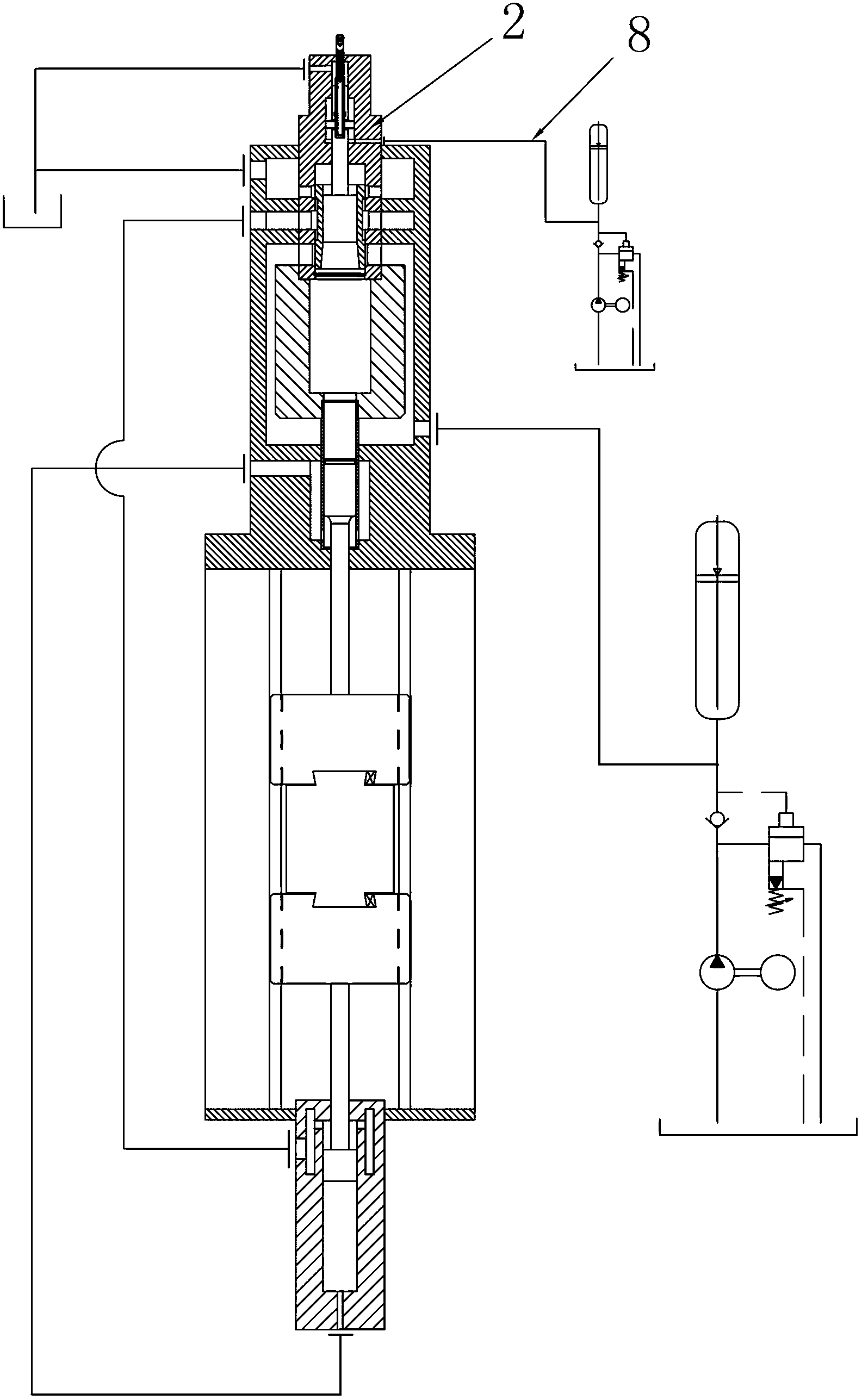

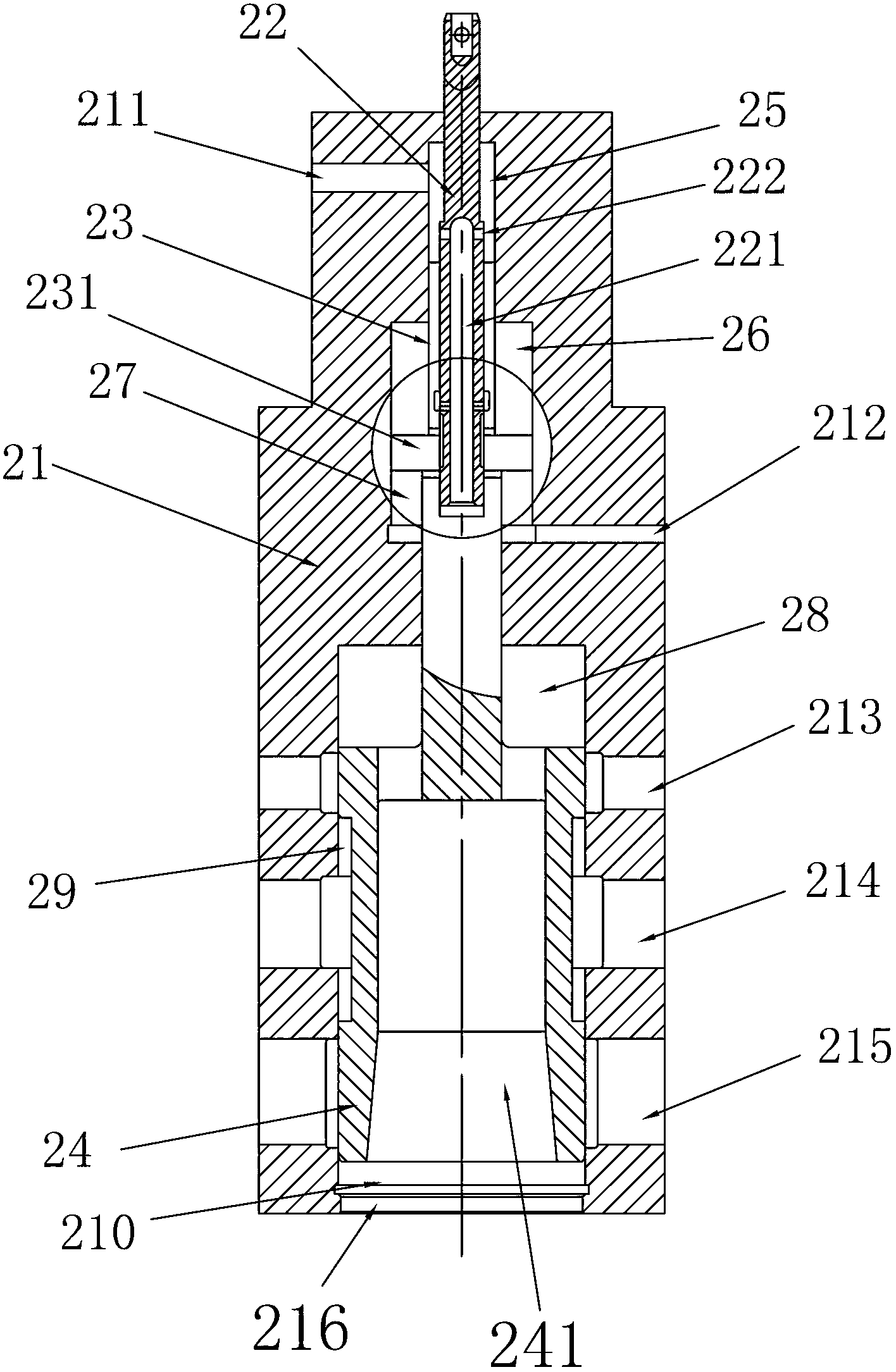

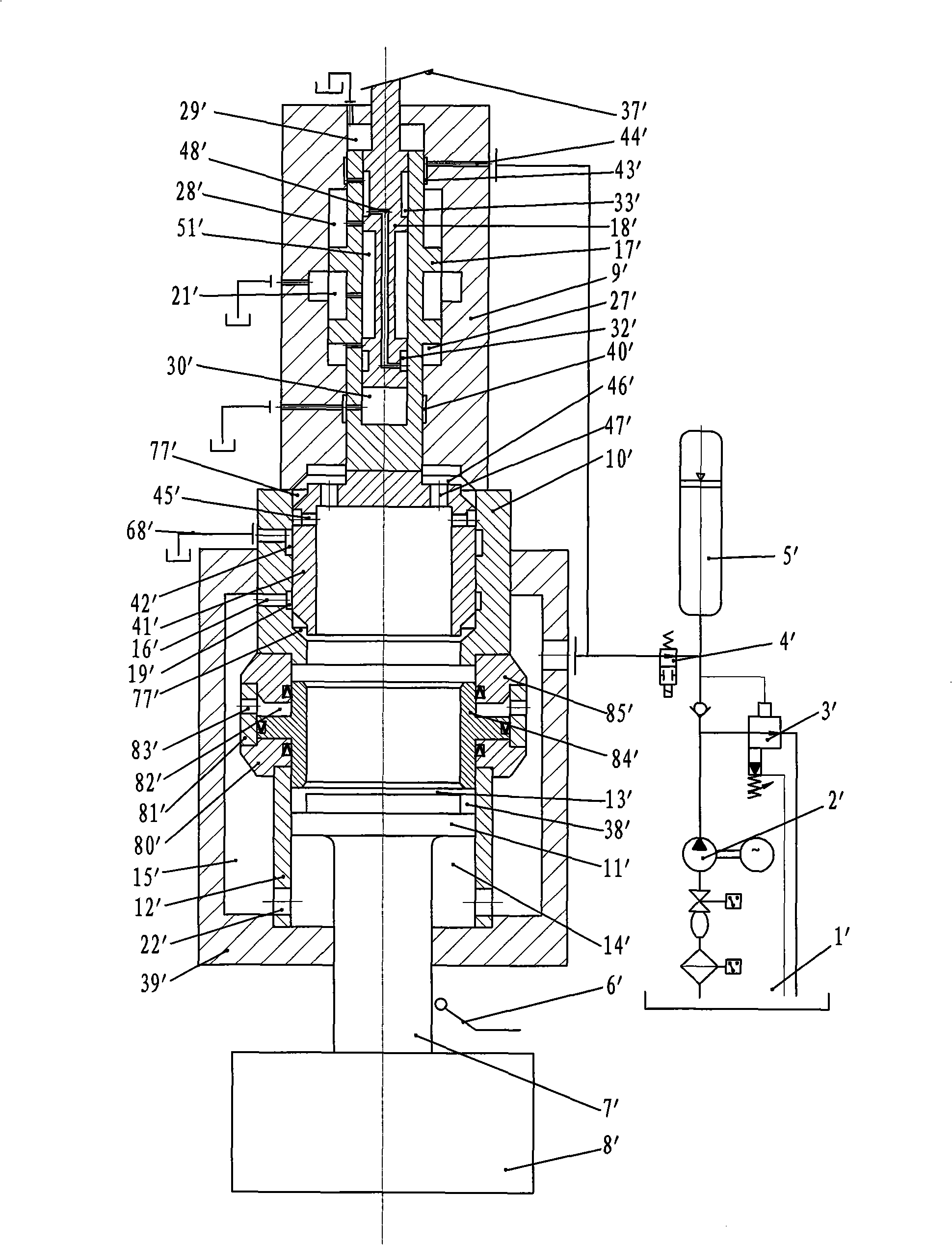

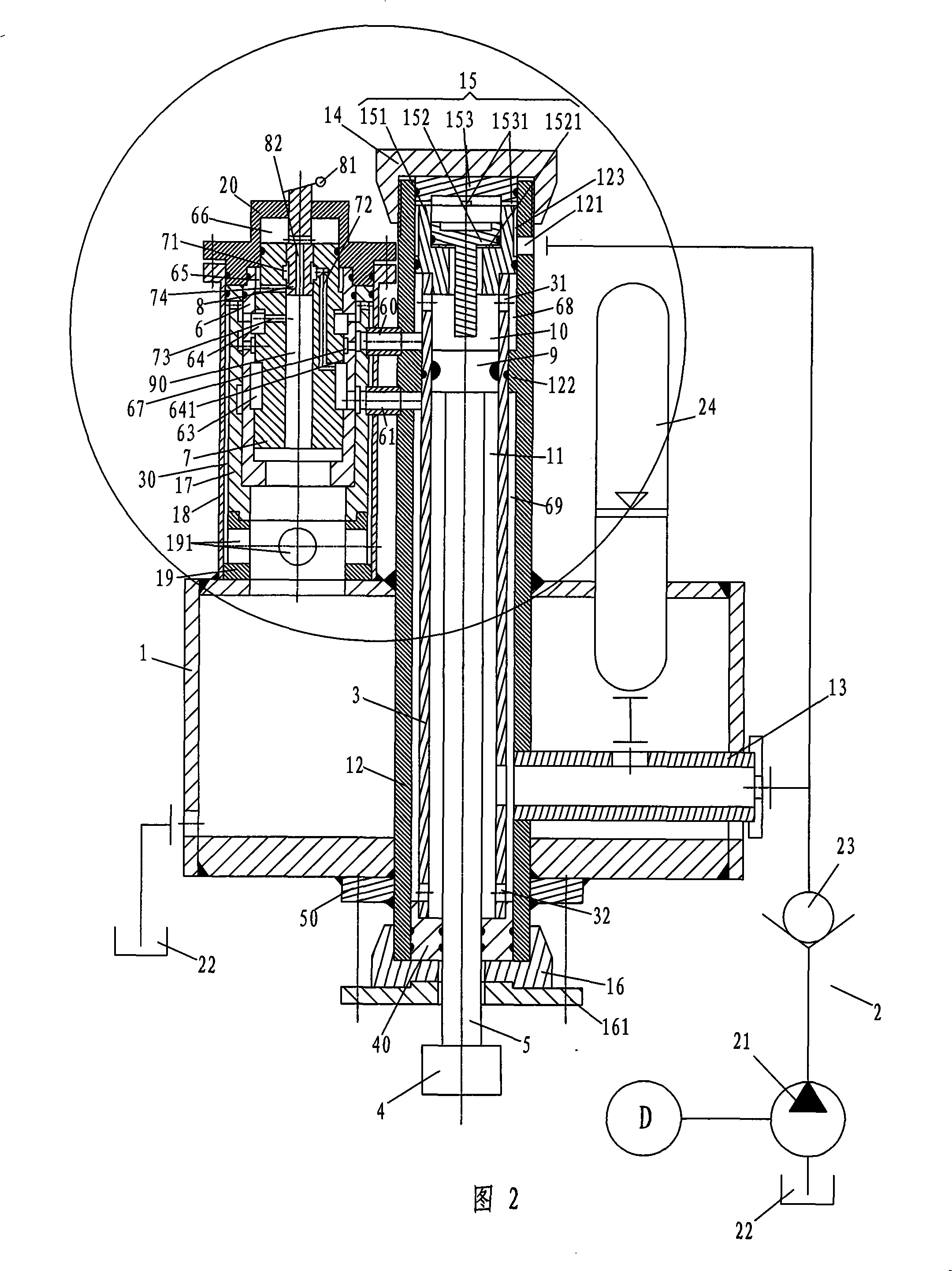

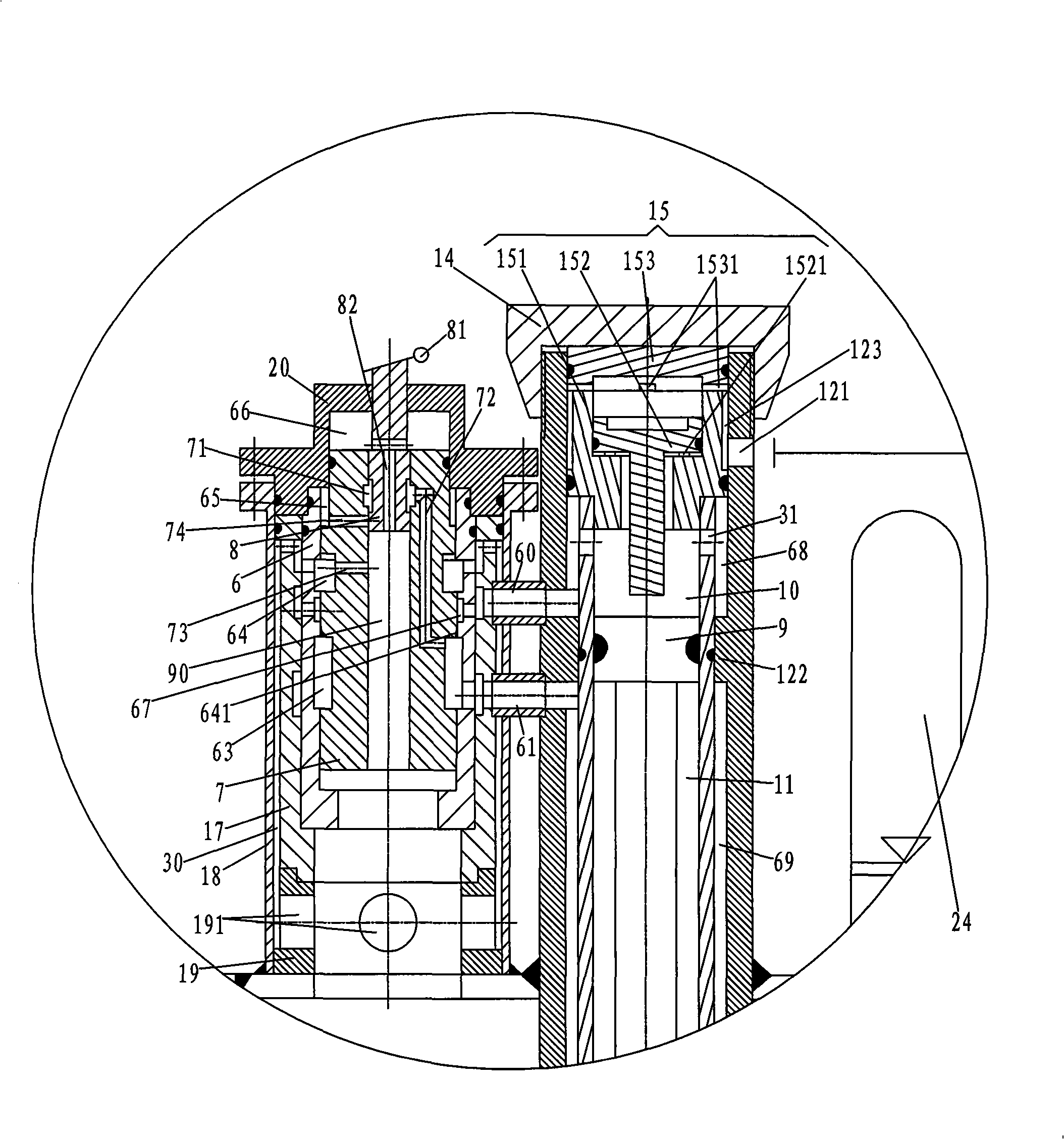

Electrohydraulic hammer

InactiveCN1986109AEasy to control speedMeet the forging hammer process requirementsPower hammersHammer drivesEngineeringMechanical engineering

The electrohydraulic hammer includes a frame, a hammer stem driving cylinder, a hydraulic source, a hammer stem with hammer head in the lower end and upper end connected to the piston inside the hammer stem driving cylinder, an upper cylinder chamber and a lower cylinder chamber in the ends of the piston, and an operating valve with valve body, a servo valve inside the valve body and valve core capable of sliding inside the servo valve. When the valve core is in different position inside the servo valve, the operating valve can close the oil inlet passage of the upper cylinder chamber, the oil exhaust passage, or both the oil inlet passage and the oil exhaust passage. Between the driving cylinder and the operating valve, there is one buffering cylinder with excellent buffering effect to avoid bumping top after the hammer head reaches the top dead point.

Owner:ANYANG FORGING PRESS MACHINERY IND

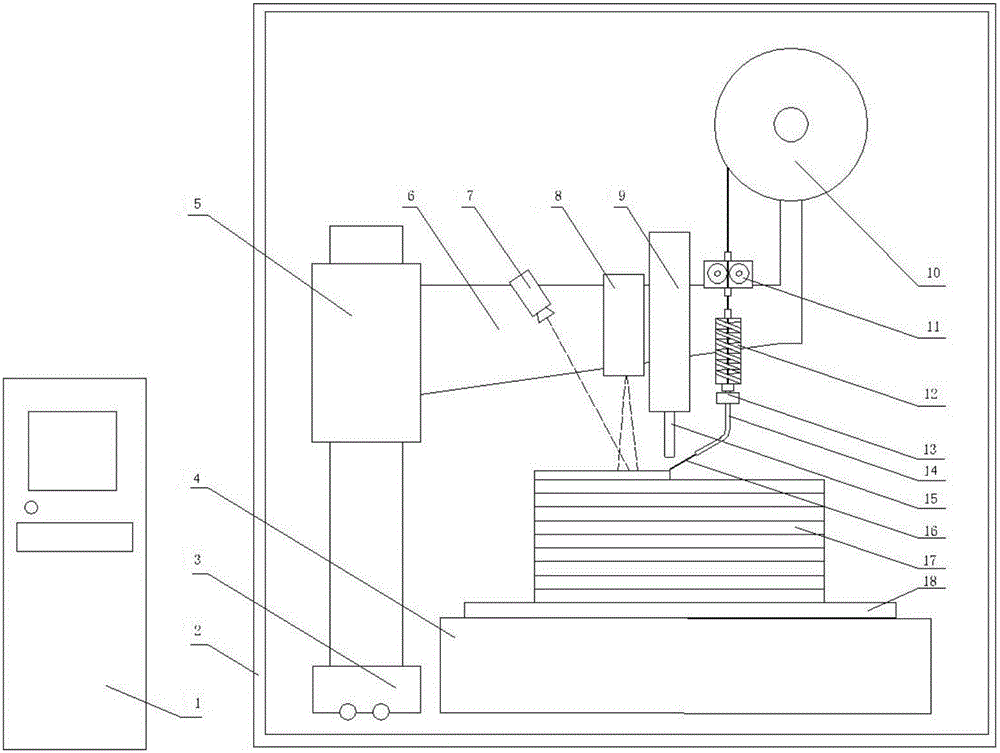

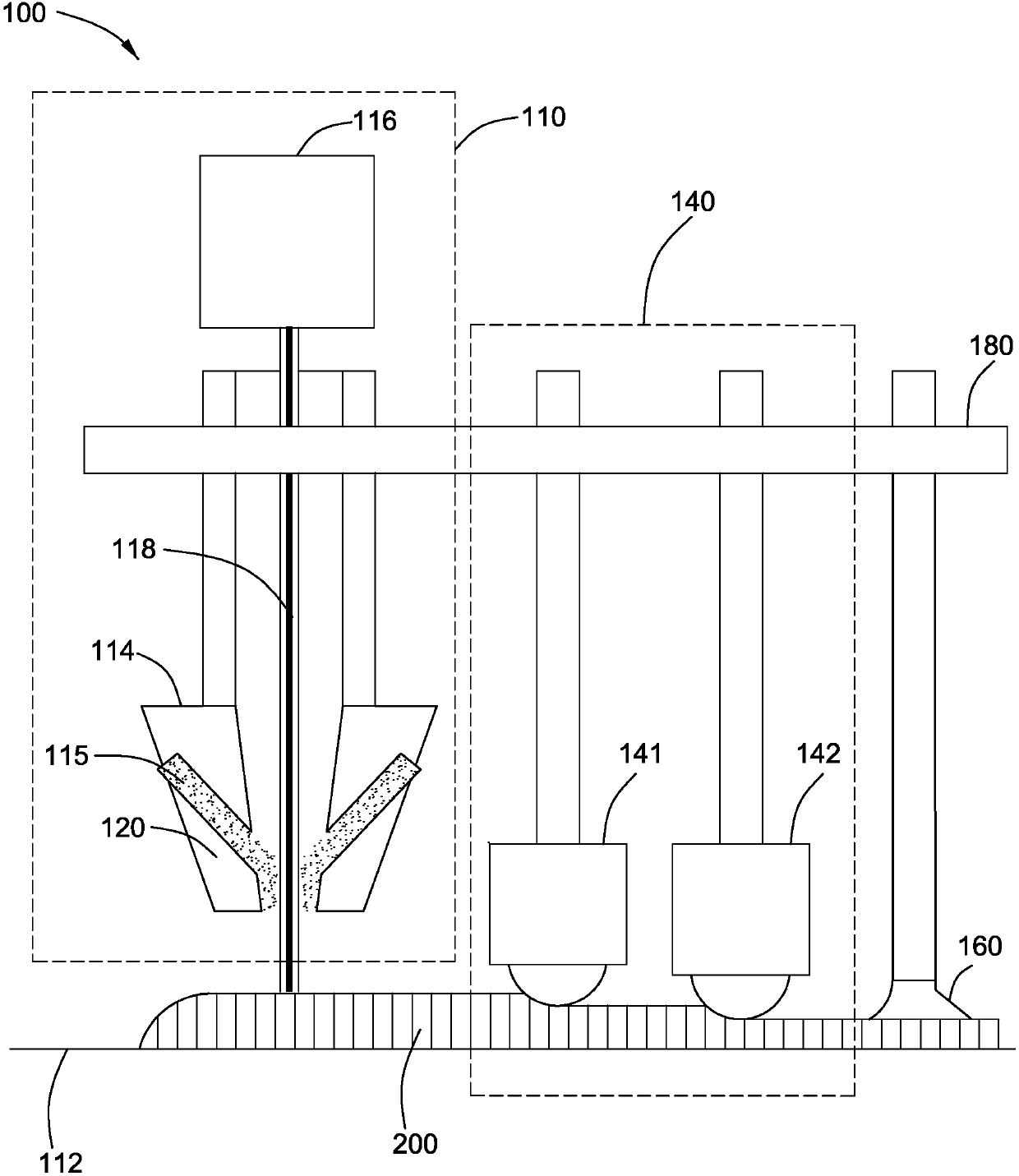

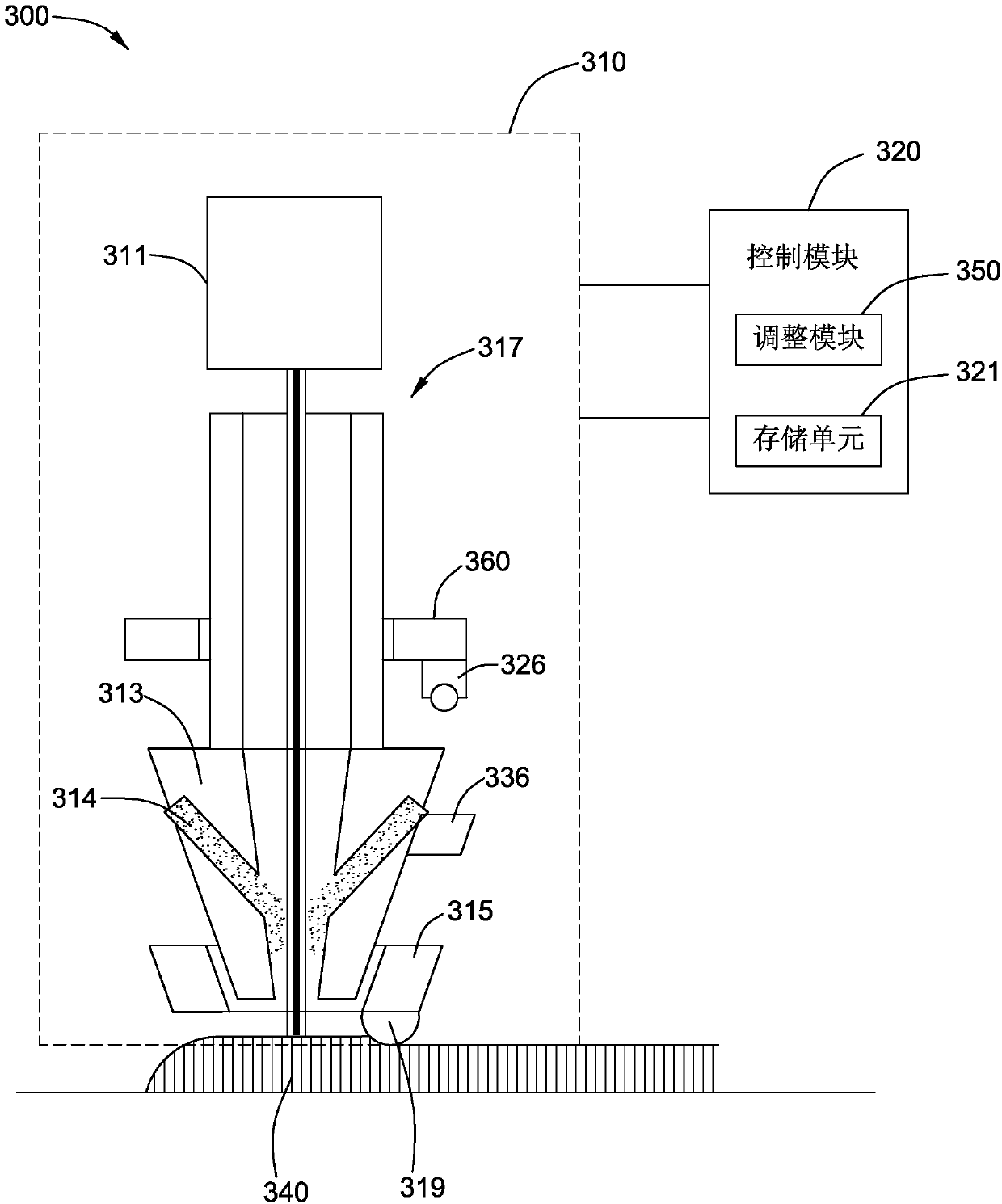

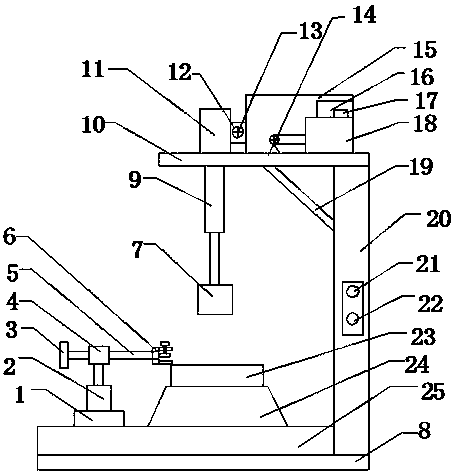

Metal forge welding additional material manufacturing device and forging method

ActiveCN106825348AImprove reliabilityImprove consistencyAdditive manufacturing apparatusPower hammersReciprocating motionManufactured material

The invention provides a metal forge welding additional material manufacturing device and a forging method. The metal forge welding additional material manufacturing device comprises a work bin and a control unit connected with the work bin. The work bin is internally provided with a forging base plate, a machining unit and a moving unit. The moving unit is arranged at the side portion of the forging base plate. The machining unit is located on one side of the moving unit. The machining unit is located above the forging base plate when machining a workpiece. The machining unit comprises a preheating unit, a forging unit, a wire feeder and a wire storage device, all of which are sequentially arranged in the direction from the moving unit to the forging base plate. The forging unit comprises a forging hammer capable of reciprocating up and down, a forging area is formed between the lower portion of the forging hammer and the surface of the workpiece, the forging hammer reciprocates in the forging area, and accordingly the workpiece and a metal wire can be continuously forged. An inner microscopic structure in the manufactured material is a forging structure, grain is fine, the mechanical performance s good, air holes and other common welding metallurgical defects cannot occur, and the reliability and consistency of the metal additional material manufacturing component performance can be greatly improved.

Owner:青岛卓思三维智造技术有限公司

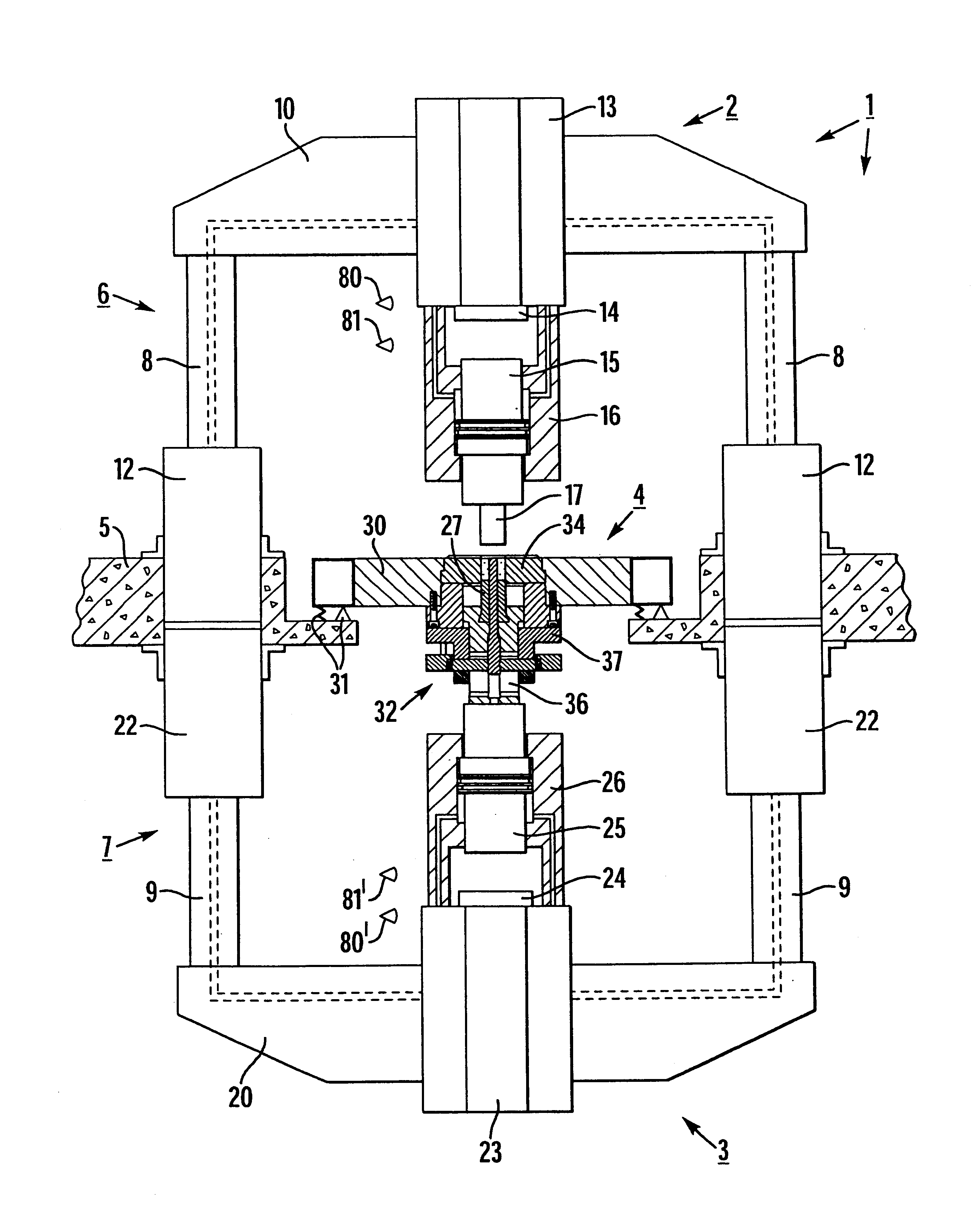

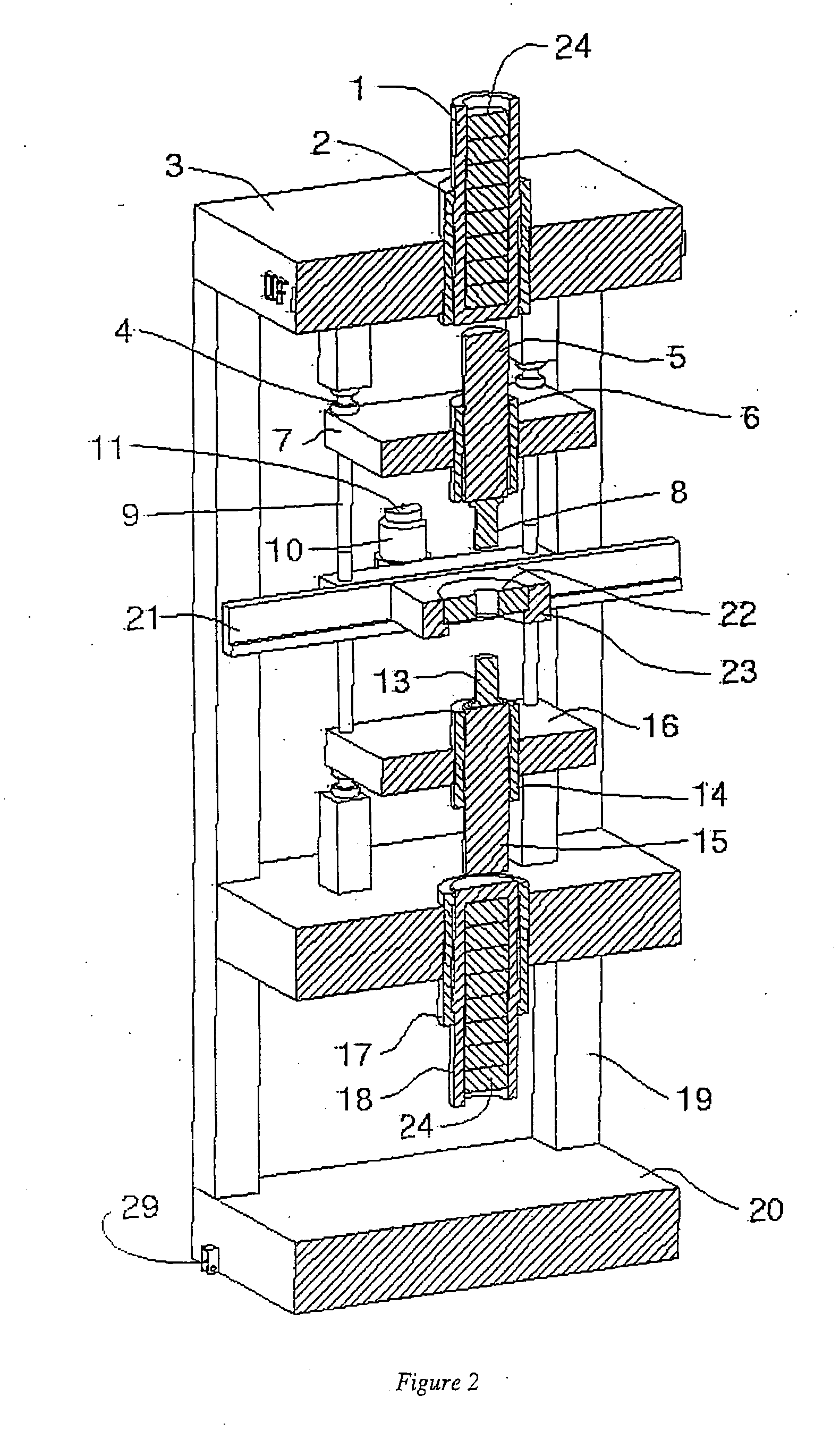

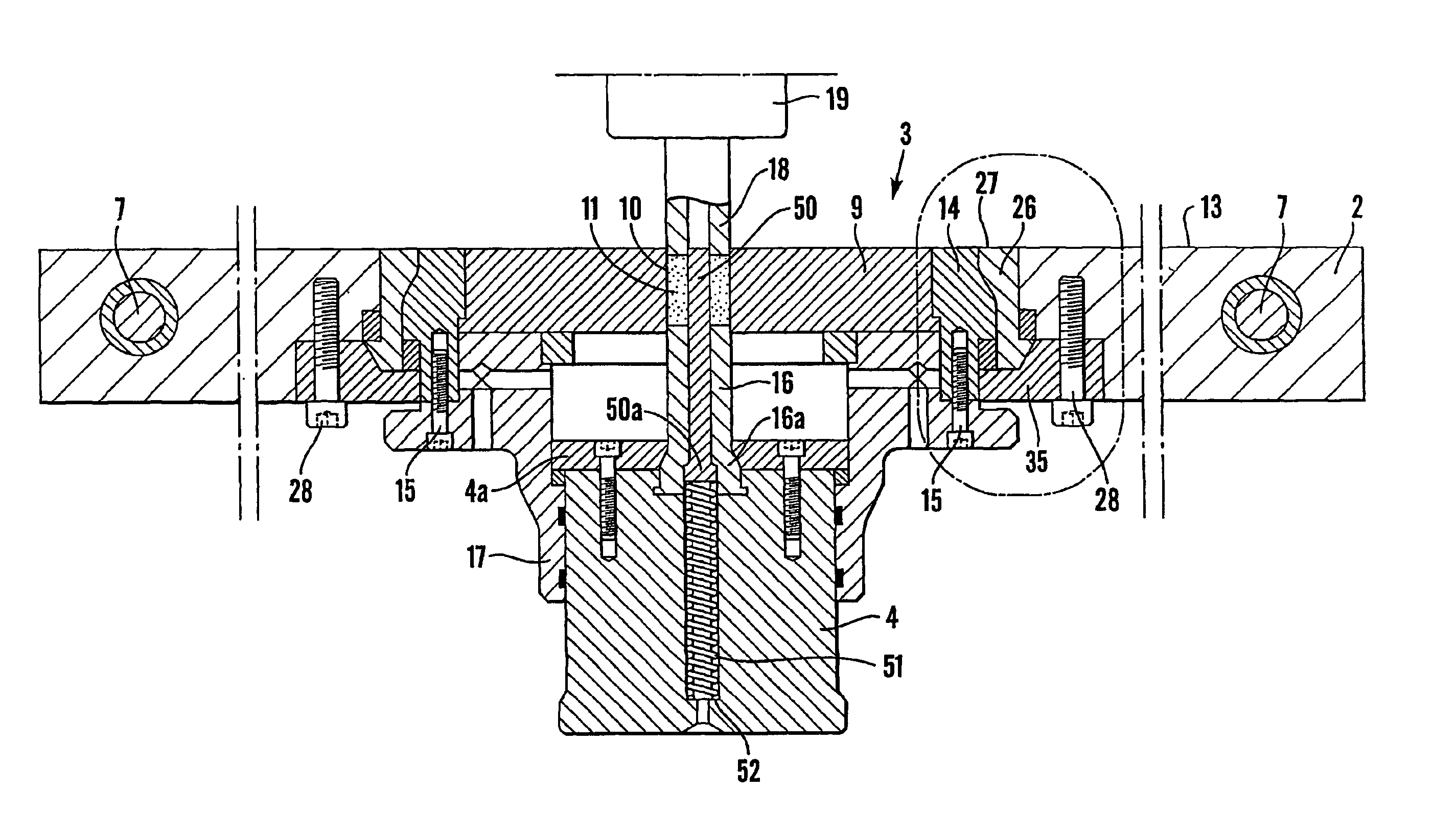

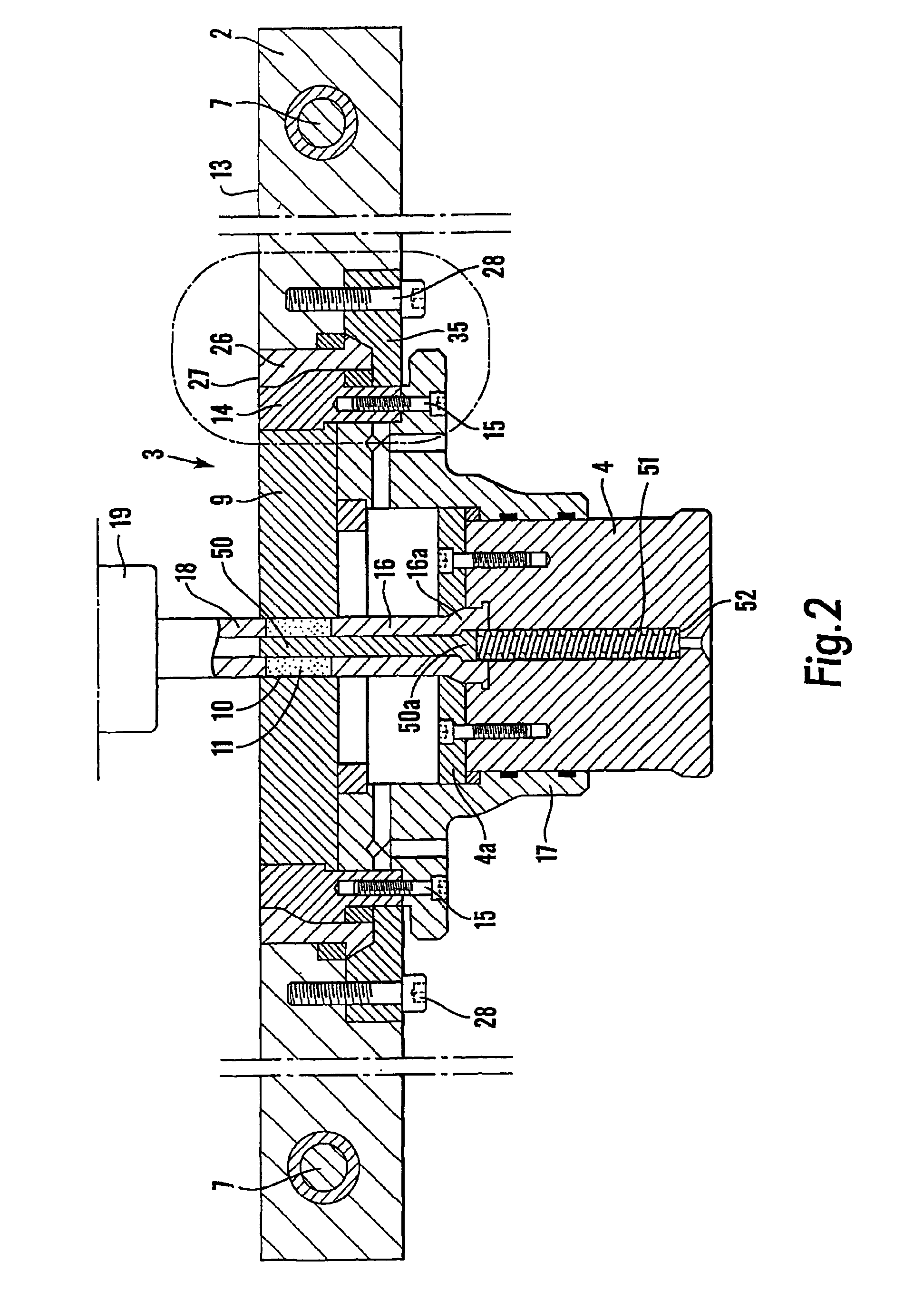

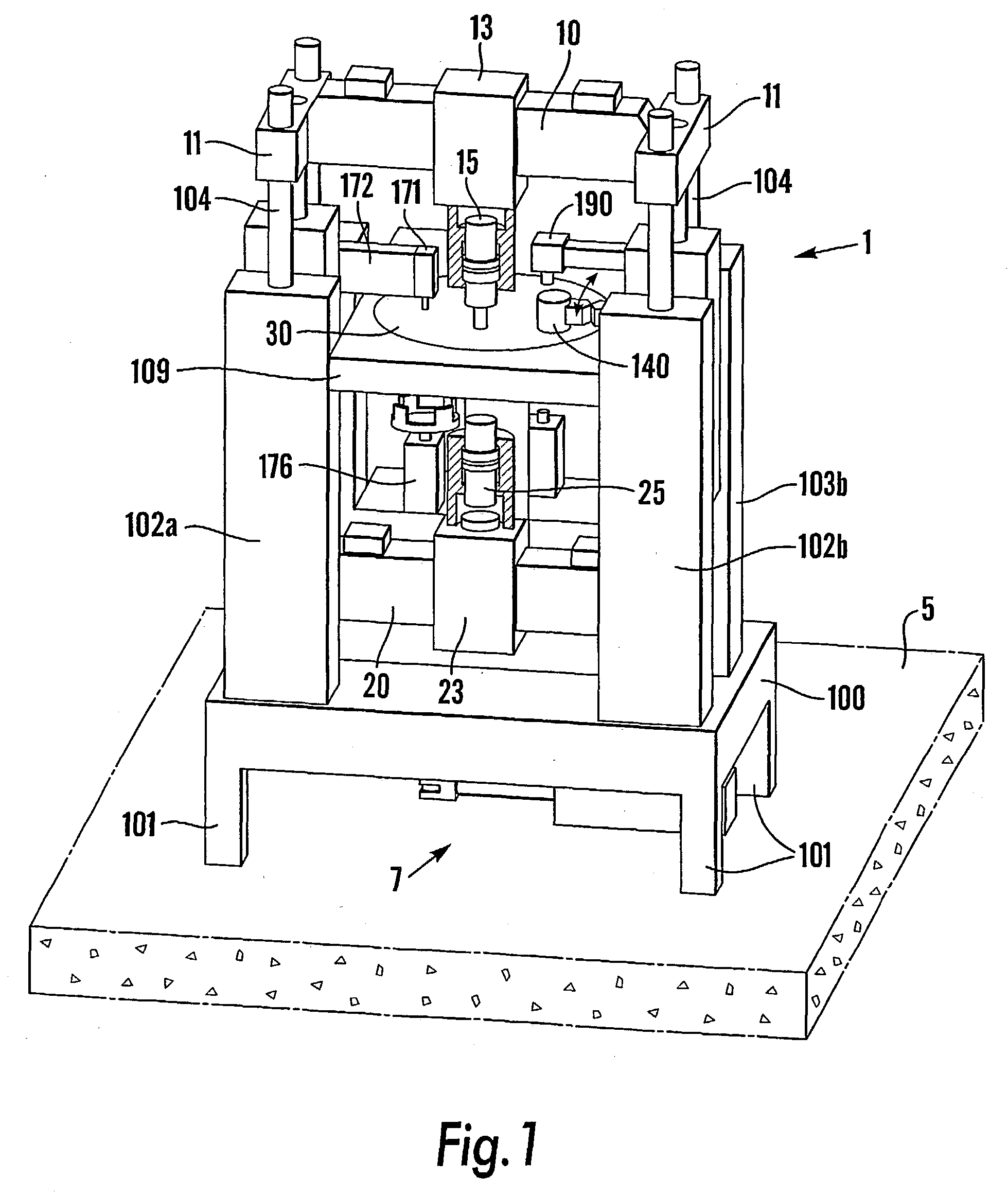

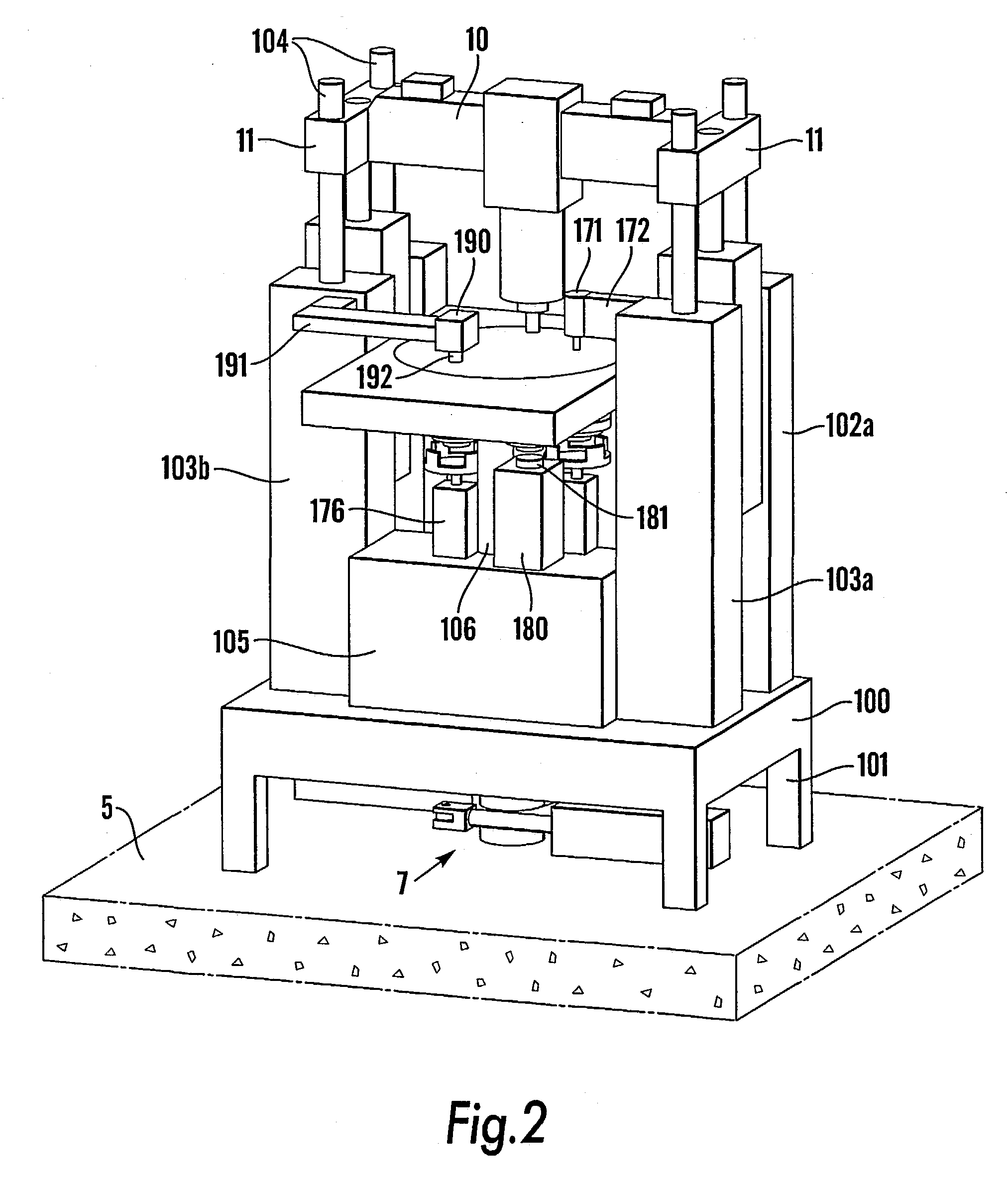

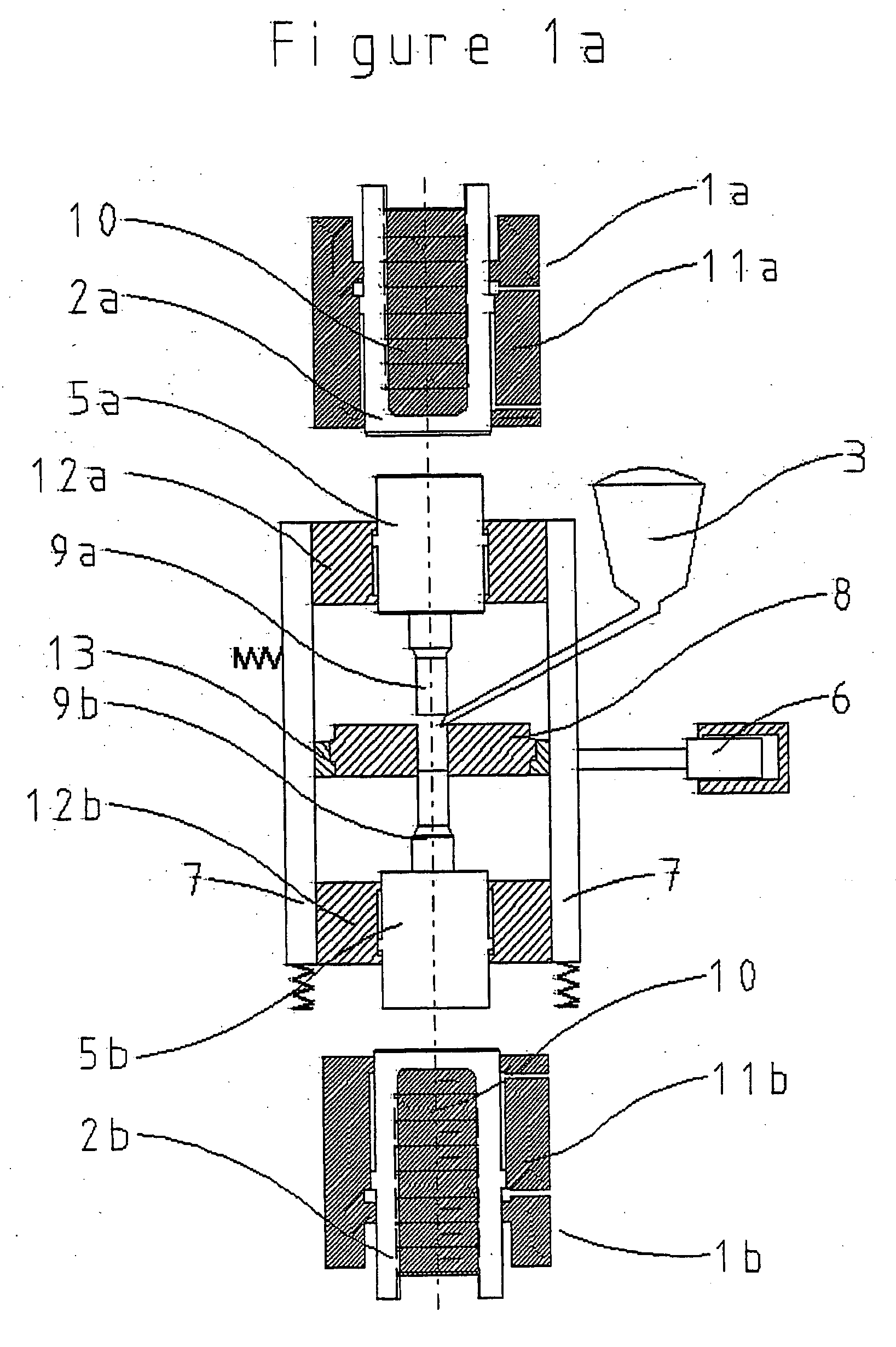

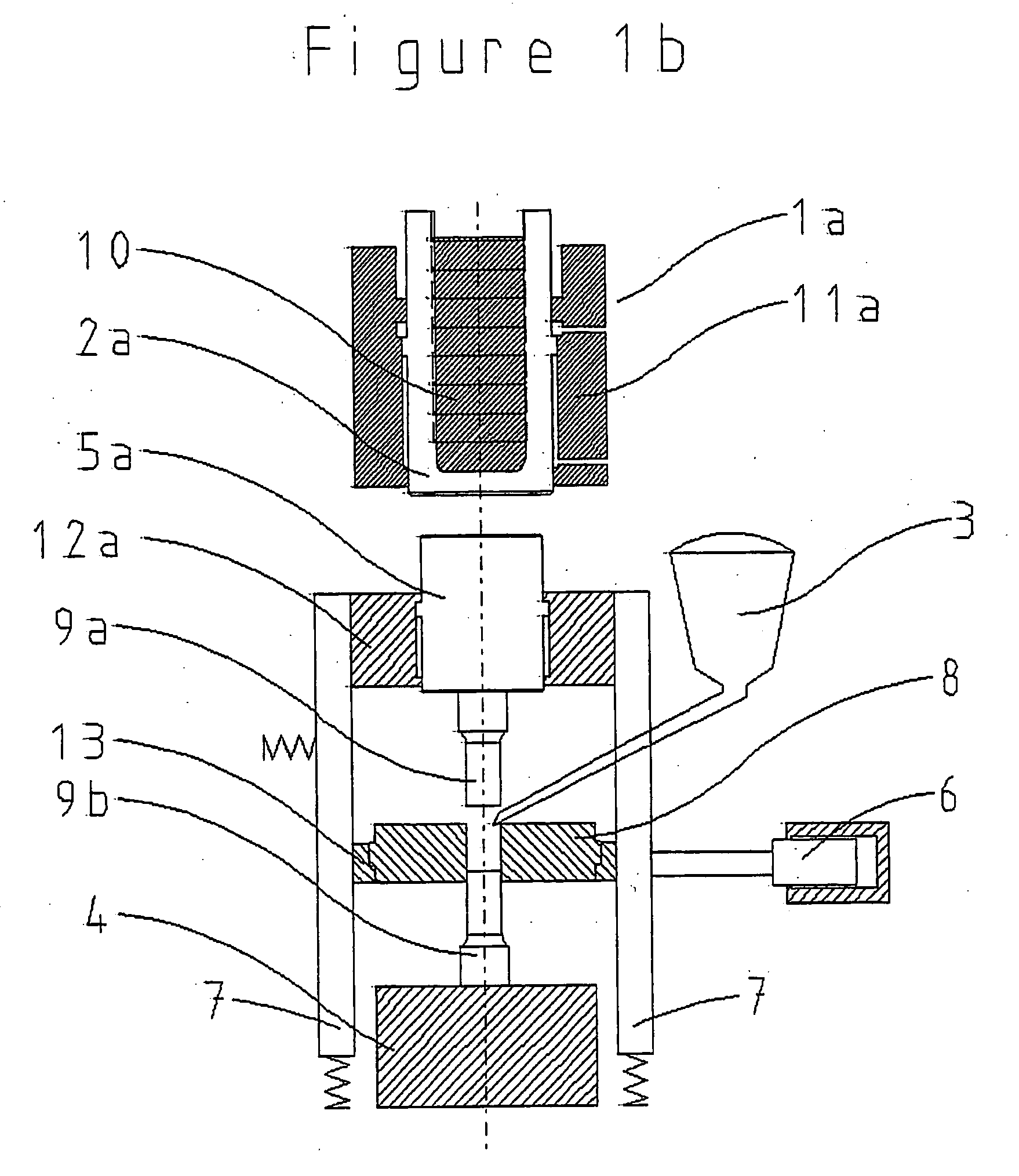

Method and impact machine for forming a body

A method of forming a body of a formable working material in an impact machine, which comprises an upper impact unit (29 with an upper ram (14), an upper punch (17), a lower impact unit (3) with a lower ram (24), a lower punch (27), and mould cavity for the working material between the punches when the punches are brought towards one another, is characterized in that downwards movable masses, which comprise at least the mass of the upper ram and the mass of the upper punch, and upwards movable masses, which include at least the mass of the lower ram and the mass of the lower punch, are caused to move towards one another and towards the working material in the mould cavity, that the masses which move downwards, including the upper punch (17) obtain a downwards directed velocity (v1) and those masses which move upwards, including the lower punch (27), obtain an upwards directed velocity (v2), wherein the movable parts have such masses and the velocities are so high that the momentums of the downwards movable masses and the upwards movable masses become essentially equally large, i.e. so that the following condition applies.where m1 is the total mass of the downwards movable masses during the stroke, and m2 is the total mass of the upwards movable masses during the stroke.

Owner:MORPHIC TECH

Dynamic forging impact energy retention machine

InactiveUS20050220921A1Low costEfficient productionPower hammersConfectioneryShock waveImpact system

A machine for producing a body with desired shape of a workable material through dynamic forging under impact and finally with energy retention while the shock wave fades out. The machine includes a machine stand, a dynamic outer impact system having an upper unit, and a lower impact unit, which includes a counter-impact device, and possibly one or more dynamic side impact units, and a static inner press system having an upper unit and a lower unit, possibly with additional one or more static side compacting units, with a central unit in between. The lower units of the outer and inner systems can be exchanged with a common stationary anvil for a single direction machine instead of a counter-acting machine.

Owner:OLSSON KENT

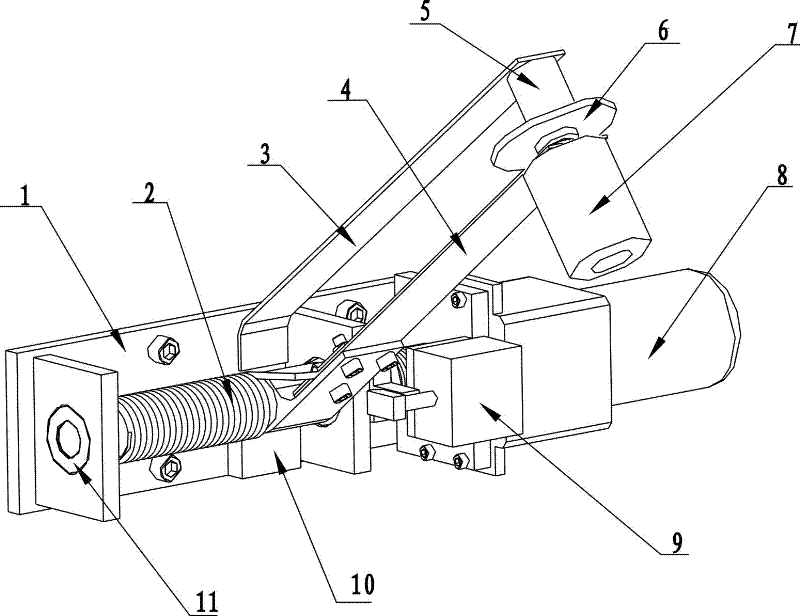

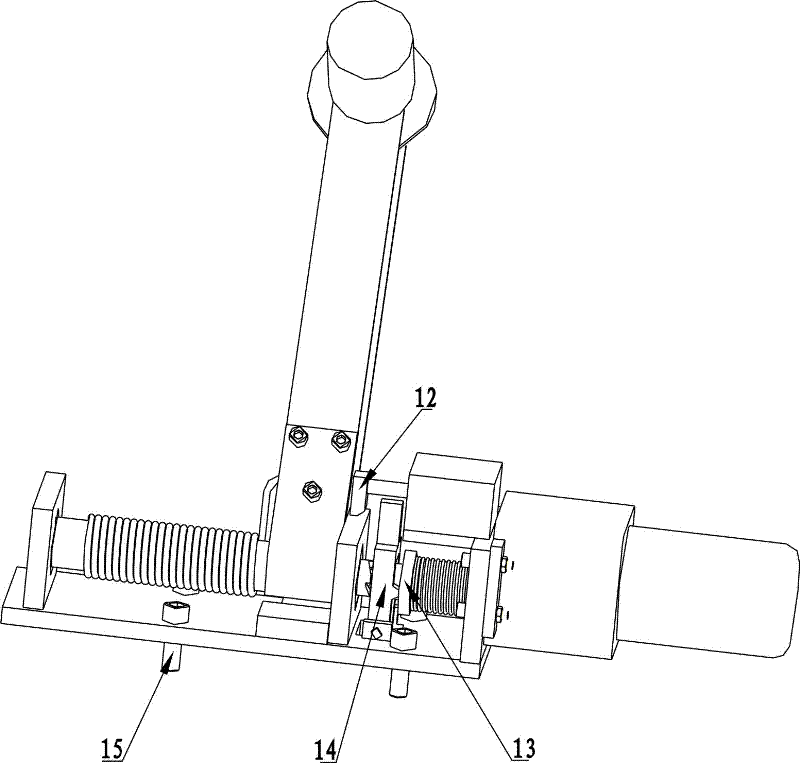

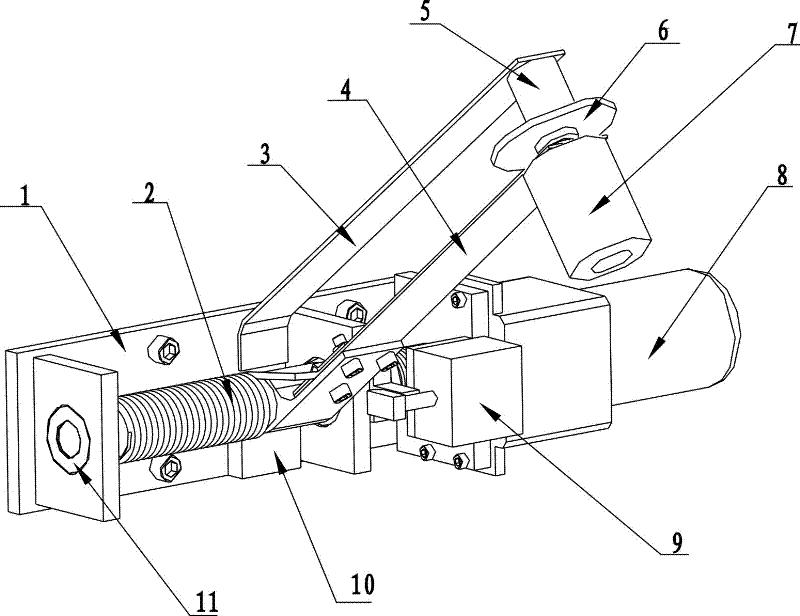

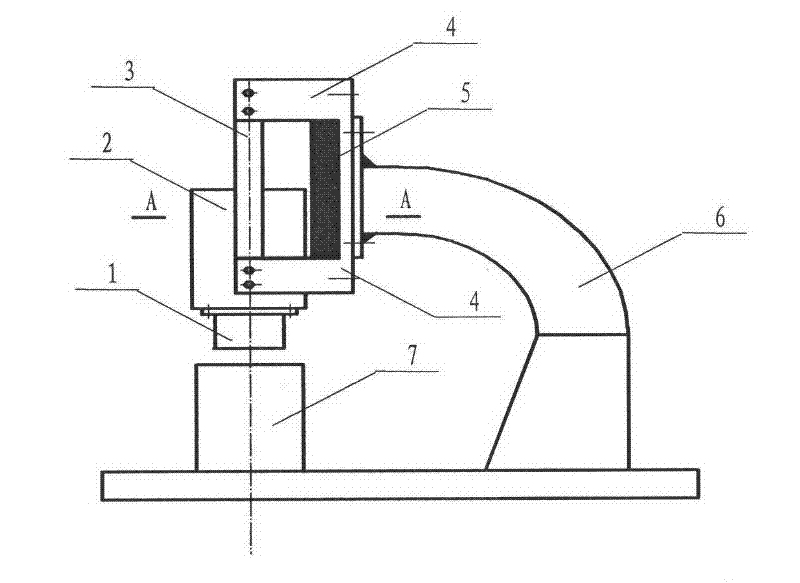

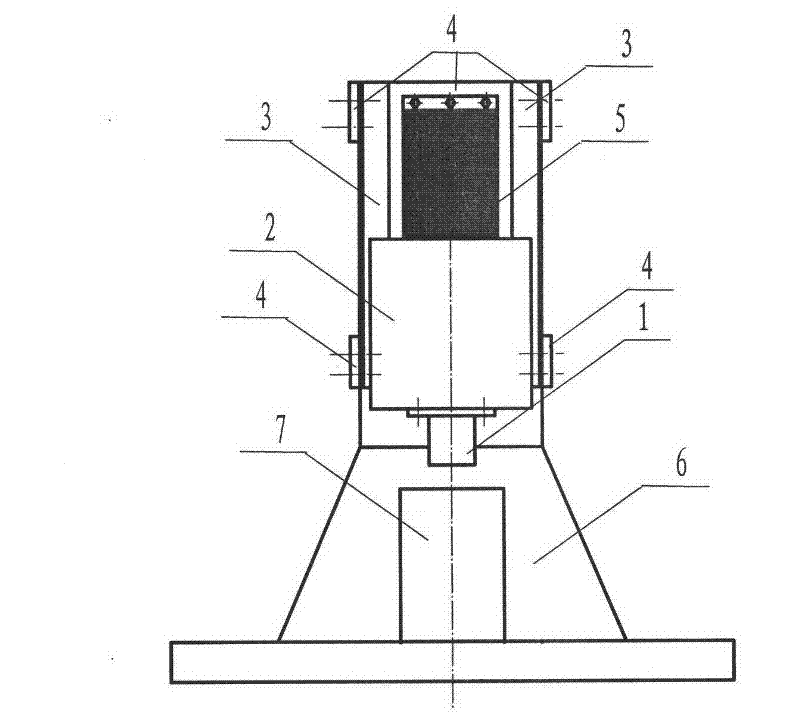

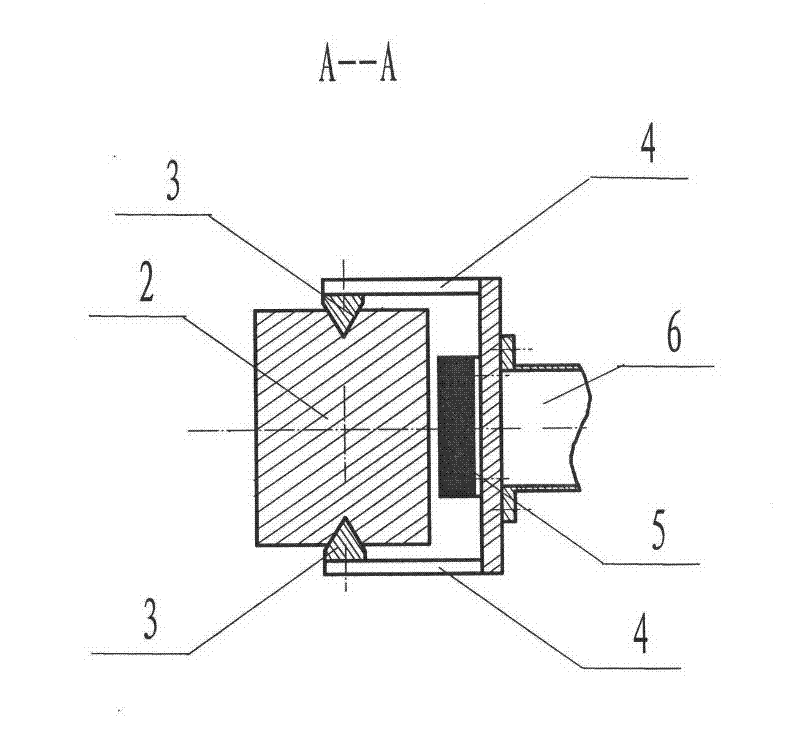

Mechanical double energy storage impact mechanism and impact method

InactiveCN102357634AReduce contact stressProtect working facePower hammersHammer drivesElectric driveEngineering

The invention discloses a mechanical double energy storage impact mechanism and a mechanical double energy storage impact method. The mechanism comprises a frame, a rotating shaft is arranged on the frame, the rotating shaft is fixedly connected with a swinging arm, the swinging arm is connected with a hammer head, a torsion spring is arranged coaxial with the rotating shaft, the swinging arm is fixedly connect to one end of the torsion spring, and the other end of the torsion spring is fixed on the frame. An electric driving mechanism and a first electromagnet are arranged on the frame, the first electromagnet is connected with a drag hook, a gear clutch is arranged on the electric driving mechanism, and a lever is movably connected to the frame and movably matched with the drag hook; and a second electromagnet is arranged on the frame through a mounting arm. The mechanism has two energy storage links, namely deformation energy storage of the torsion spring and elastic bending energystorage of the swinging arm, so that the contact stress during impacting can be effectively reduced and the working surface of a workpiece is well protected. By using the mechanism and the method, conventional heavy manual hammering can be replaced, and the labor intensity is lightened; and the mechanism can also be used for replacing the conventional starting pneumatic striker in the powder conveying process to prevent blockage.

Owner:CHINA THREE GORGES UNIV

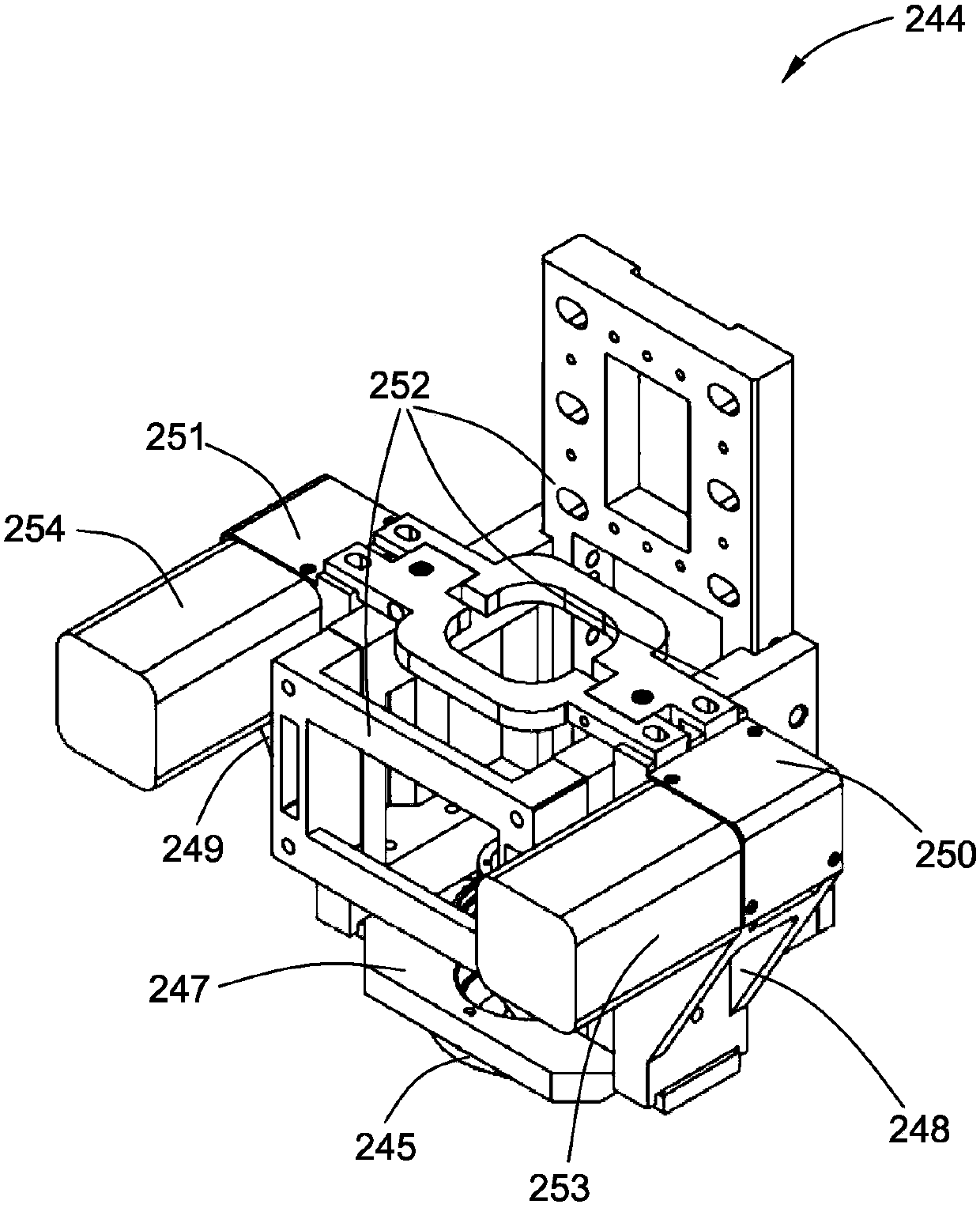

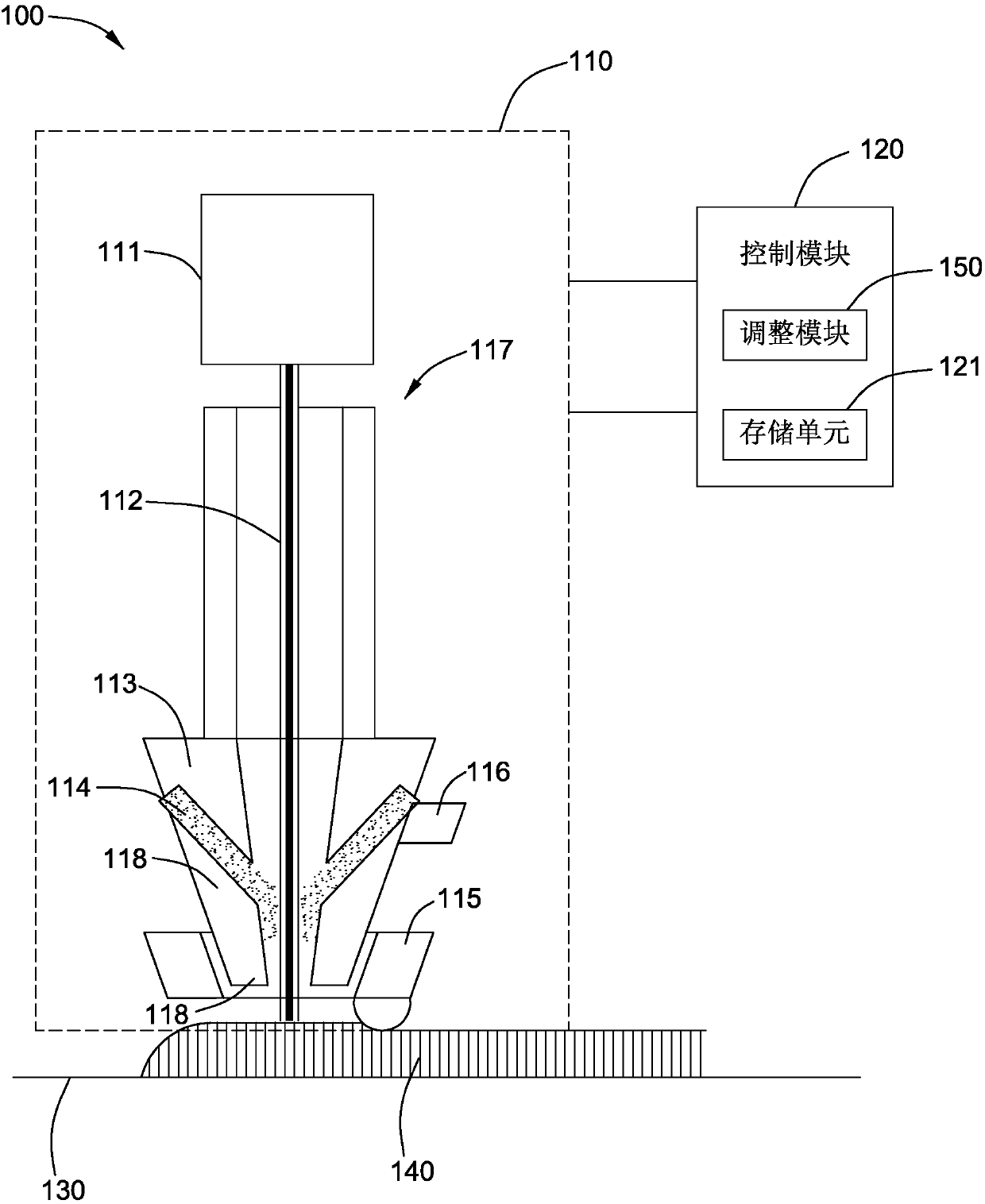

Added material manufacturing and forging combined compound forming system and method

ActiveCN109702127AArc welding apparatusFlexible-parts wheelsManufacturing systemsAdditive layer manufacturing

The invention relates to an added material manufacturing system and method. The system comprises a material conveyor, an energy source and a micro forging device. The material conveyor is provided forconveying materials. The energy source is provided for enabling energy beams to point to the materials, and melts at least part of the materials to form cured parts. The micro forging device can movewith the material conveyor to forge the cured parts, and comprises a first forging hammerhead and a second forging hammerhead; the first forging hammerhead is provided for hammering the cured parts to generate a first deformation quantity; the second forging hammerhead is provided for hammering the cured parts to generate a second deformation quantity; and the second deformation quantity is higher than the first deformation quantity.

Owner:GENERAL ELECTRIC CO

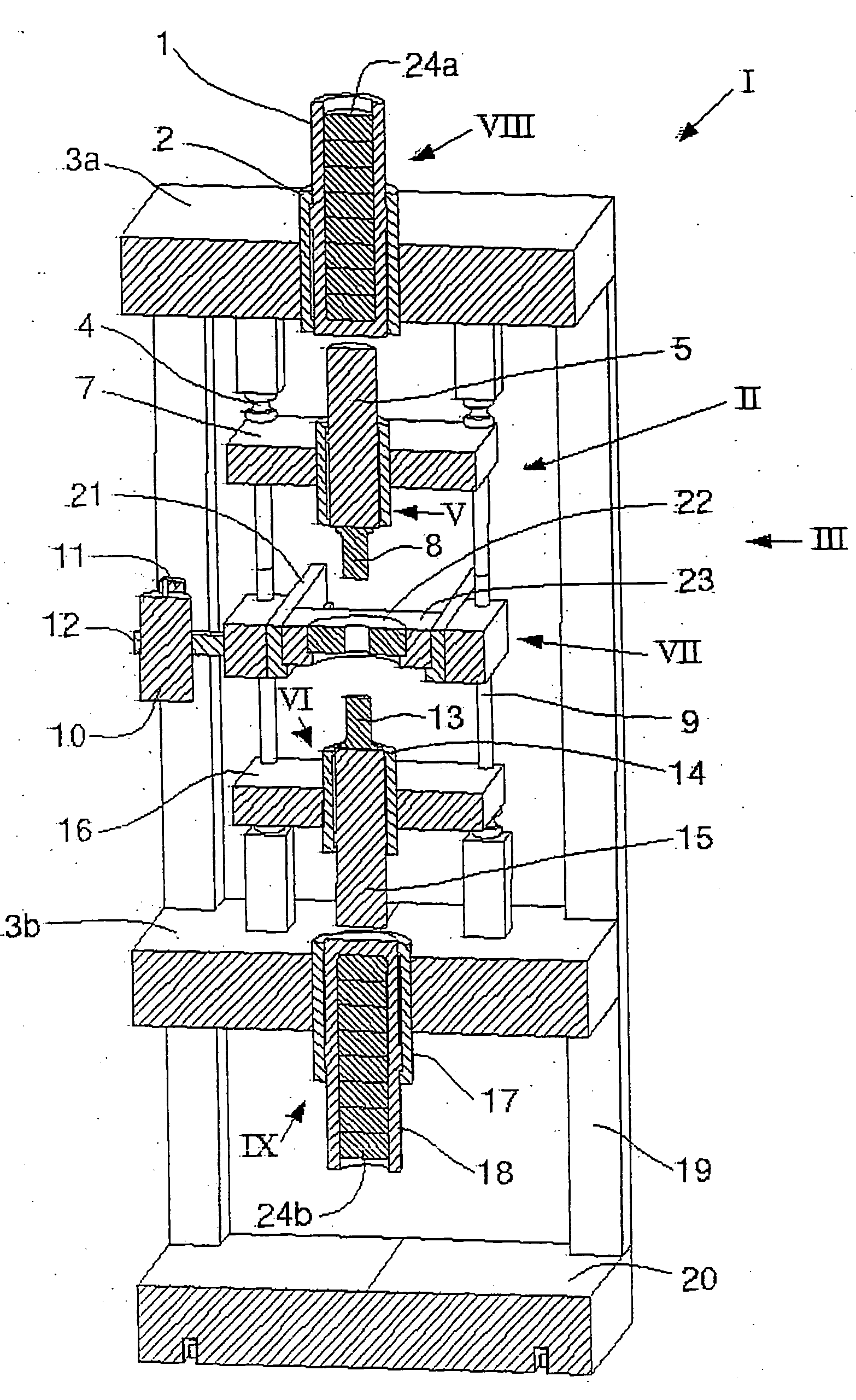

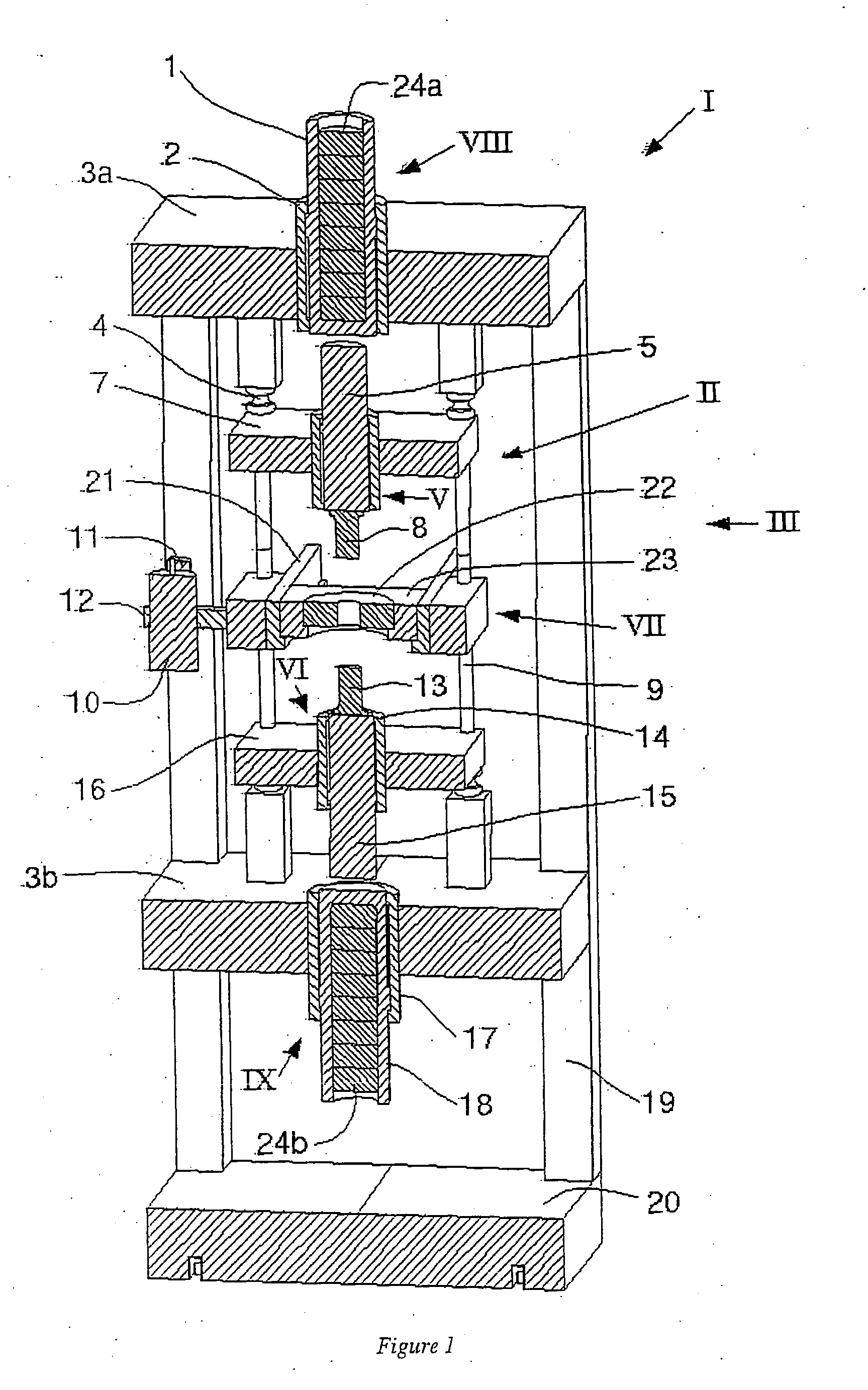

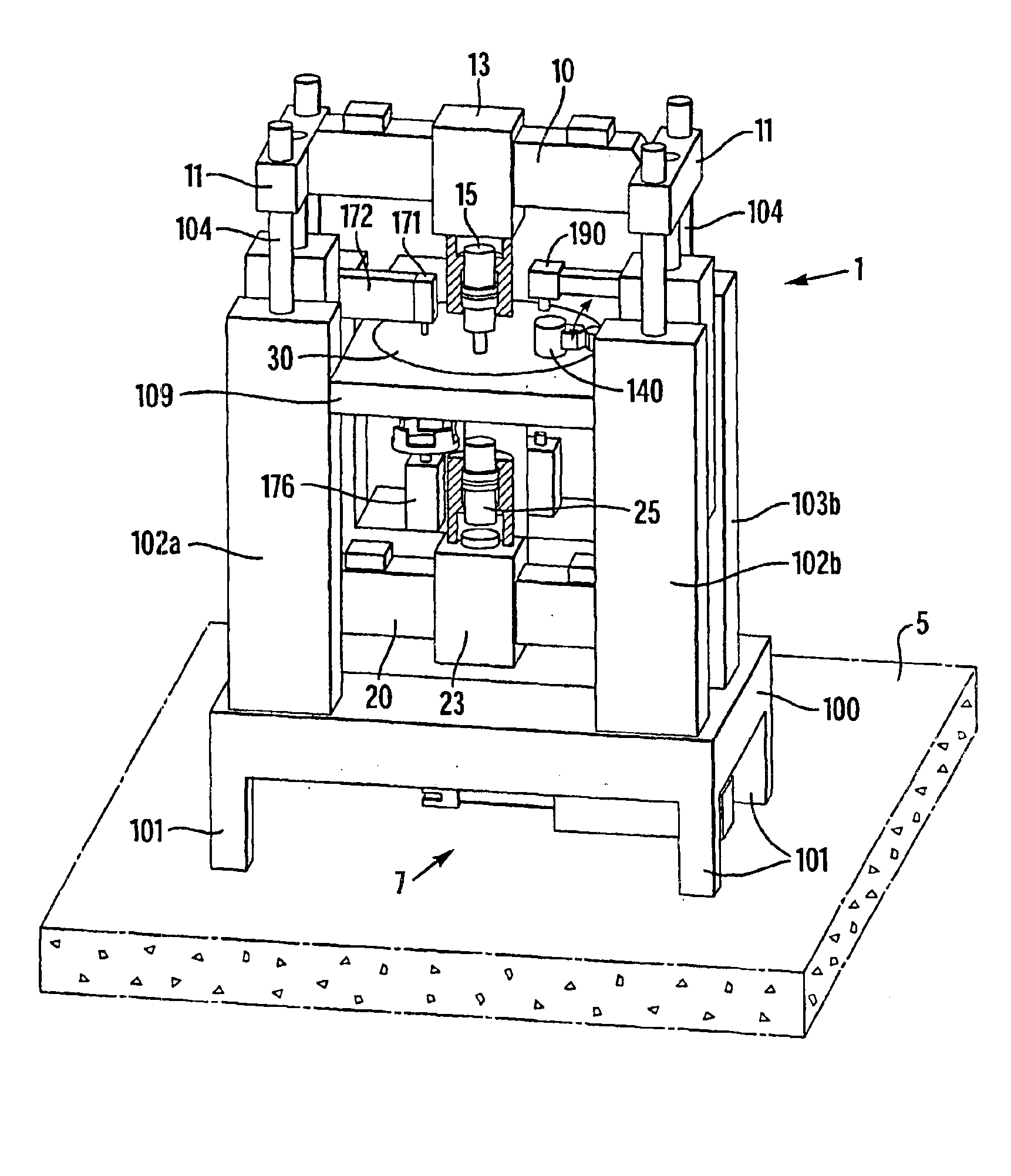

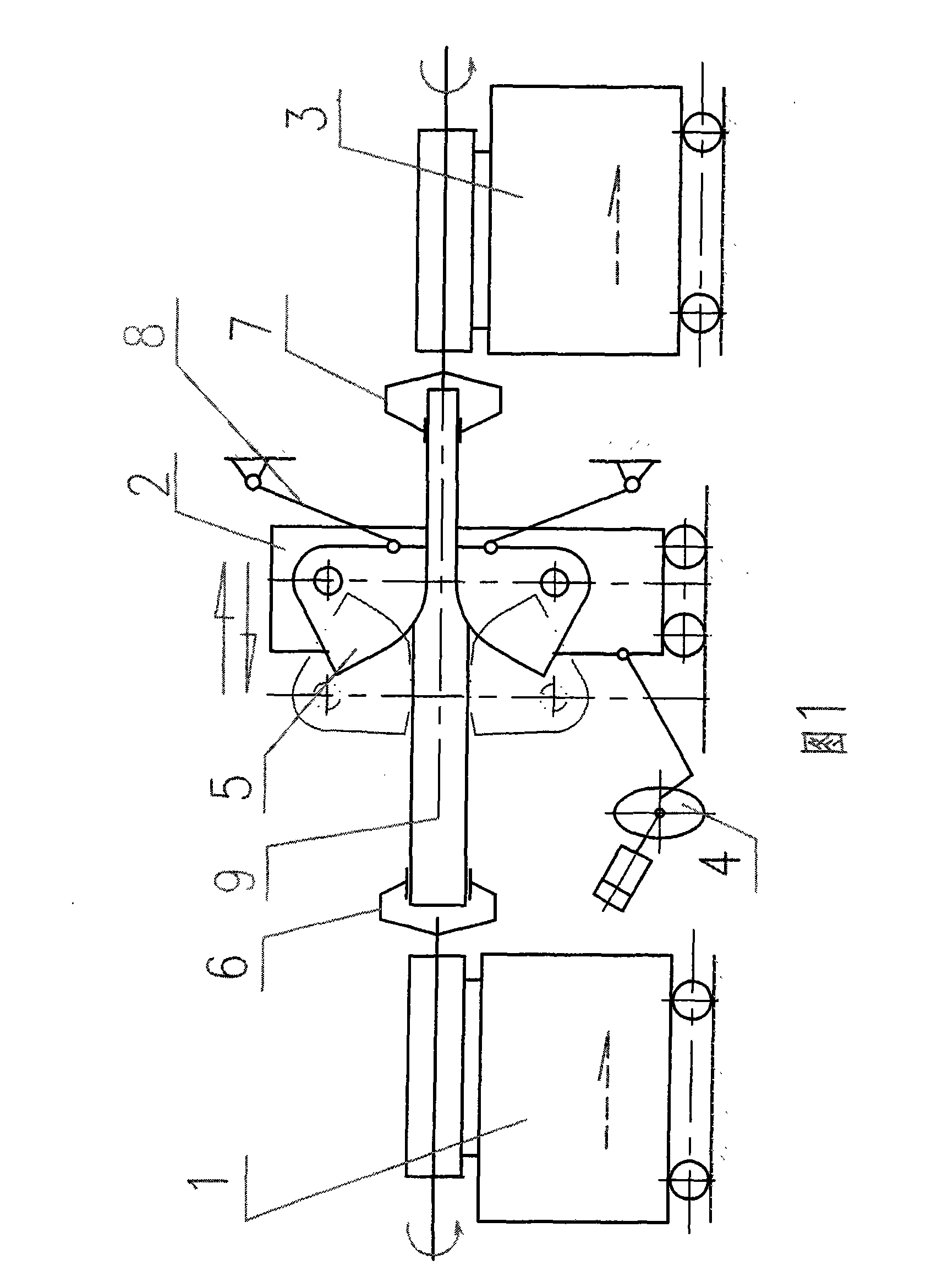

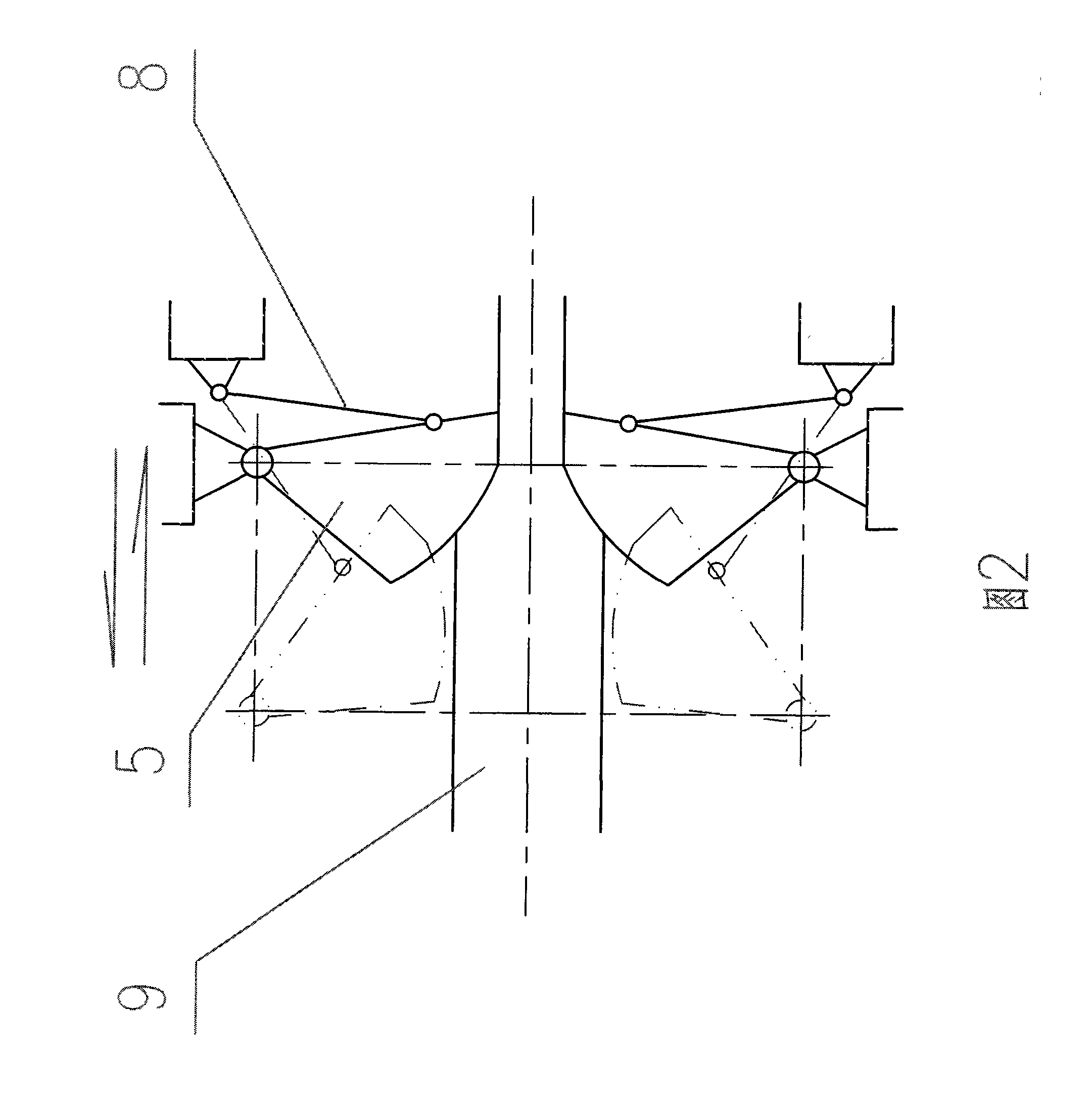

Method, impact machine, and equipment included in an impact machine

InactiveUS6871524B2High strengthReasonably preparedDrop hammersPower hammersHigh velocityMaterials science

The invention relates to a method for the manufacture of an annular article, which substantially consists of metal, ceramic material, and / or polymer. A cavity in a die is filled with a formable working material, which shall form said article. A tubular, upper punch (17) is introduced into the upper mouth of a hole in a die (34), so that a closed mould cavity is formed. The upper punch and a lower punch (27) are simultaneously struck towards one another at such a high velocity that the working material is plasticized and flows out and fills the mould cavity, and thereafter the upper punch is removed. Then, a mandrel (35) in the lower punch is driven out of the annular body by means of a mandrel expulsor (170), which is pressed against the mandrel from above, and thereafter the annular body is from below pushed out of the die by mean of the lower punch. The invention also relates to an equipment for the carrying out of the method.

Owner:MORPHIC TECH

Hammer type forging device

InactiveCN105328099ADimensions conform to standardImprove pass ratePower hammersHammer drivesHorizontal forceEngineering

The invention relates to a forging device and discloses a hammer type forging device. The hammer type forging device comprises a main shaft, wherein the main shaft is fixedly connected with a heavy hammer; a vertical sliding chute is formed in the lower part of the heavy hammer; a heavy block is connected in the sliding chute in a sliding manner; a concave die is arranged at the lower part of the heavy block; a support lug is arranged on the peripheral surface of the heavy block and is located in a vertical strip-shaped hole of the sliding chute; a first elastic part is connected between the top surface of the support lug and the sliding chute; the main shaft is also fixedly connected with a gear; the gear is meshed with a rack; a fixed sliding chute is formed in the lower part of the rack; a second elastic part is arranged between the rack and the sliding chute; a cam presses against one side, far from the second elastic part, of the rack. Compared with the prior art, the heavy block of the device can transmit the force of the heavy hammer to blanks; the heavy block can dissolve the component of the horizontal force of the heavy hammer and only generate the vertical downward pressure, so that the size of the forged parts is more in line with the standard; the qualified rate of products is increased.

Owner:CHONGQING YUXI FLOUR PROD

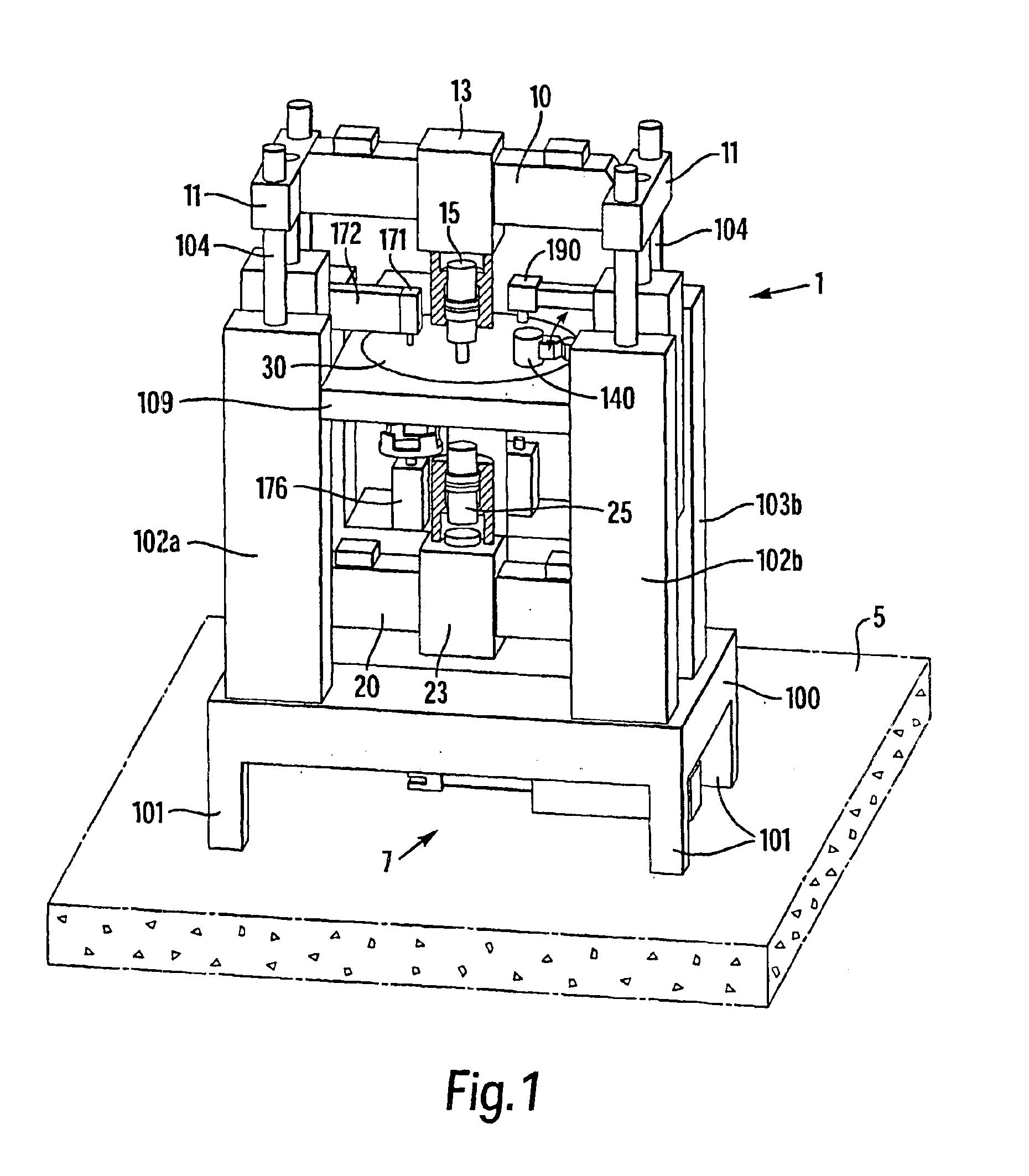

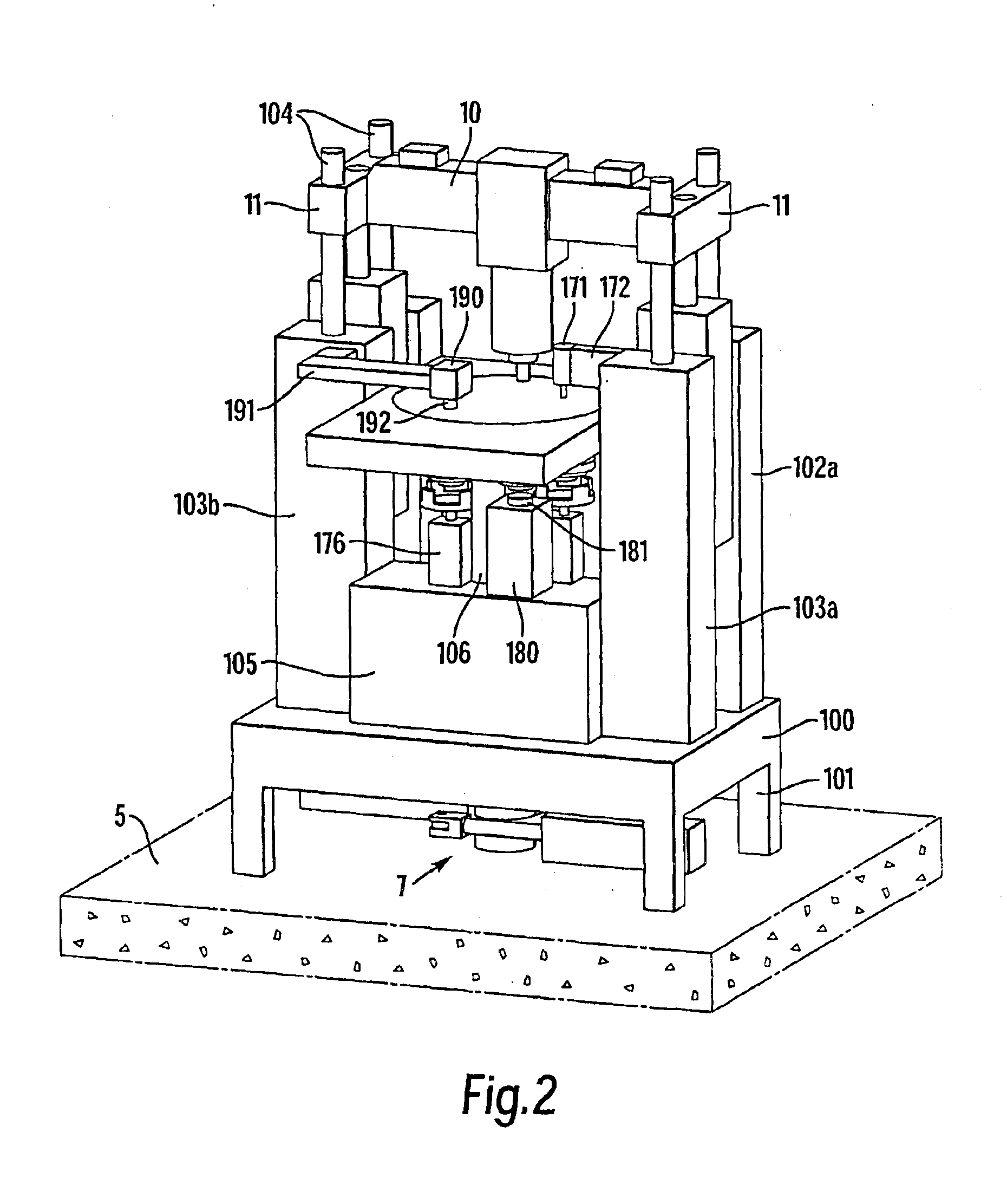

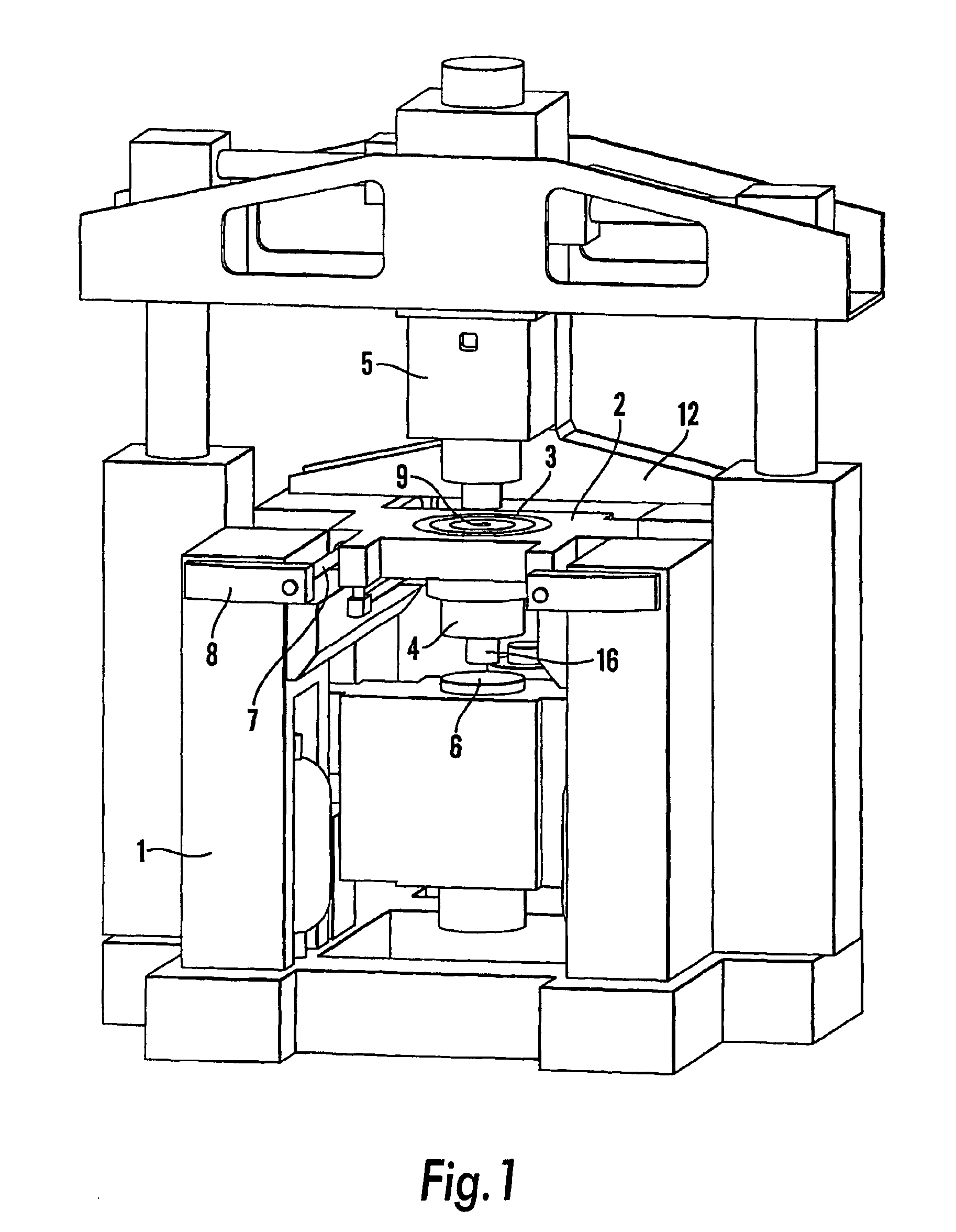

Impact machine

The invention concerns an impact machine for forming, cutting, or punching a working material in a mould die by impact action during an impact operation carried out by means of impact devices, preferably from two opposite directions, said impact devices being provided to strike the working material or impact members which transfer the impact energy of the impact devices to the working material, said die (9) being carried by a carrier (2) included in the impact machine. According to the invention, the die is resiliently mounted in the carrier, which e.g. may consist of a stationary or moveable table.

Owner:MORPHIC TECH

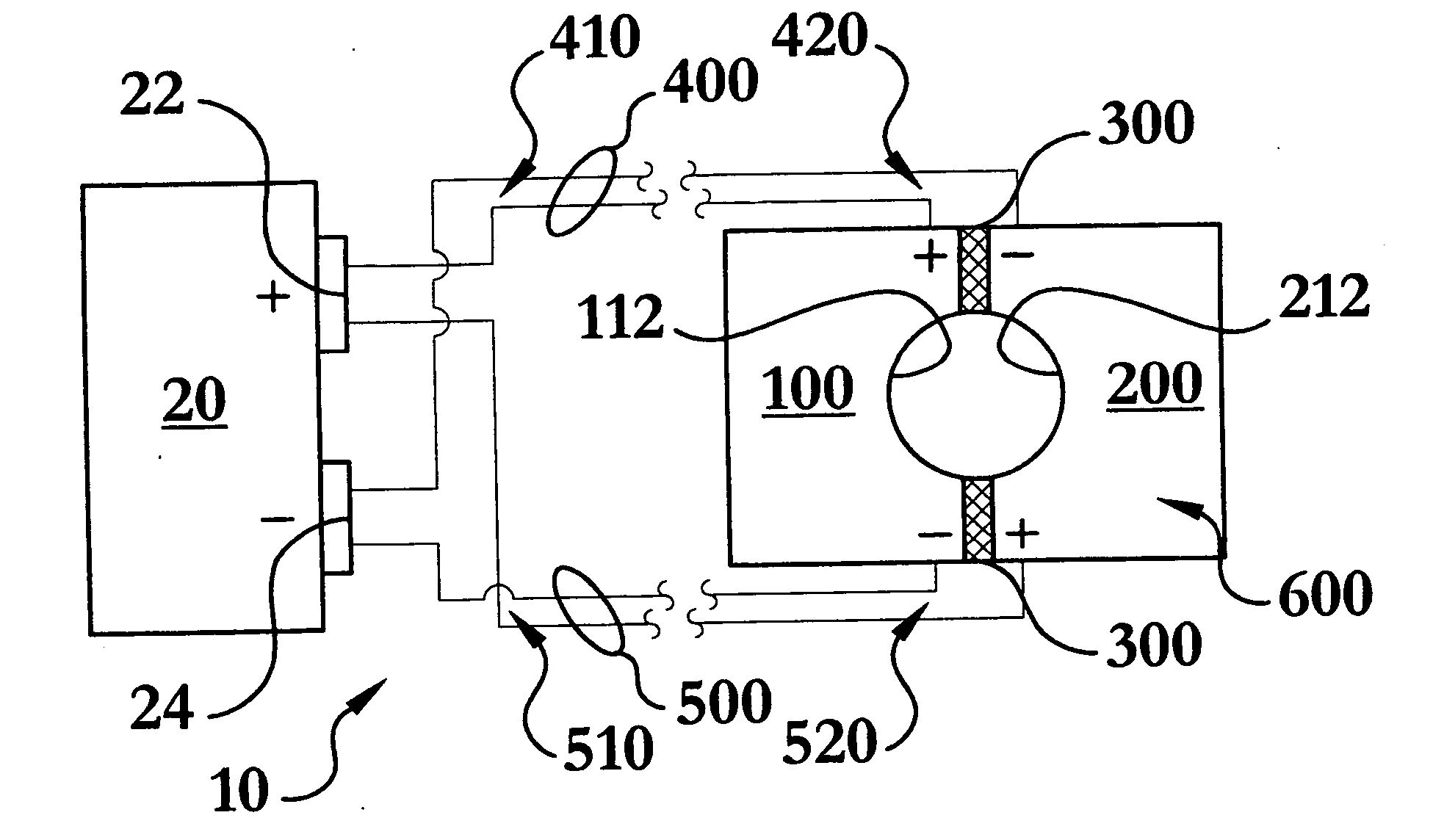

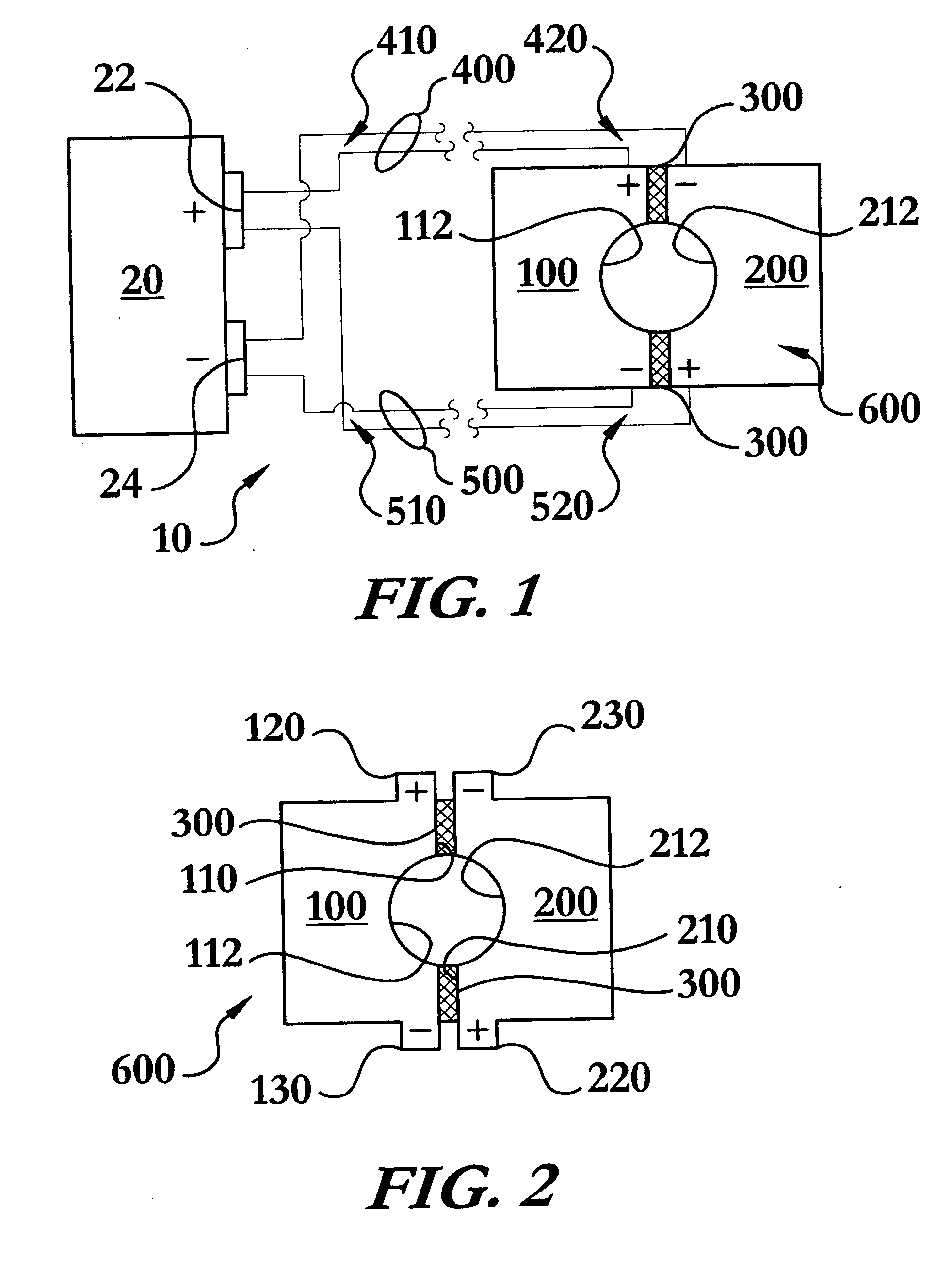

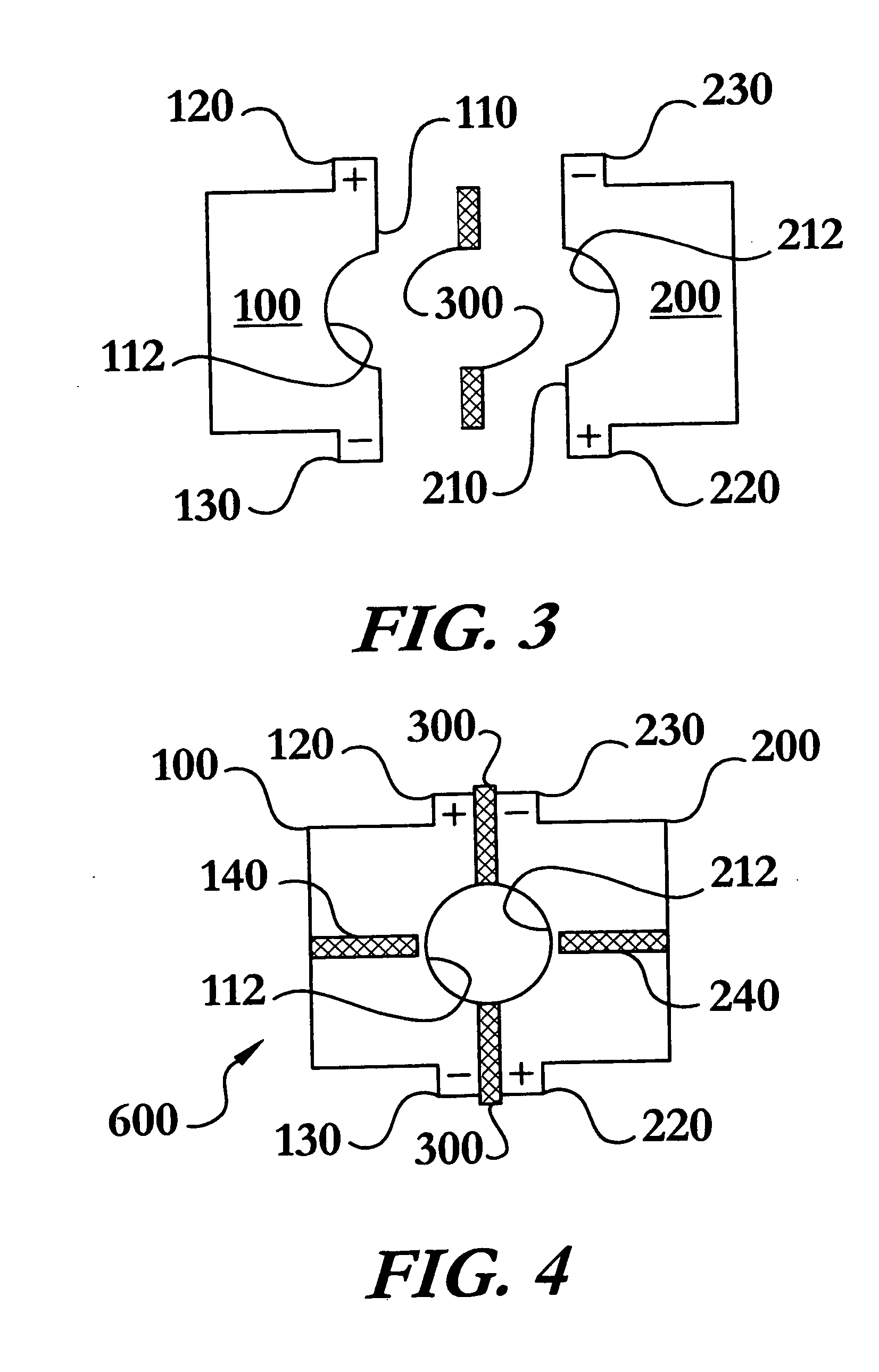

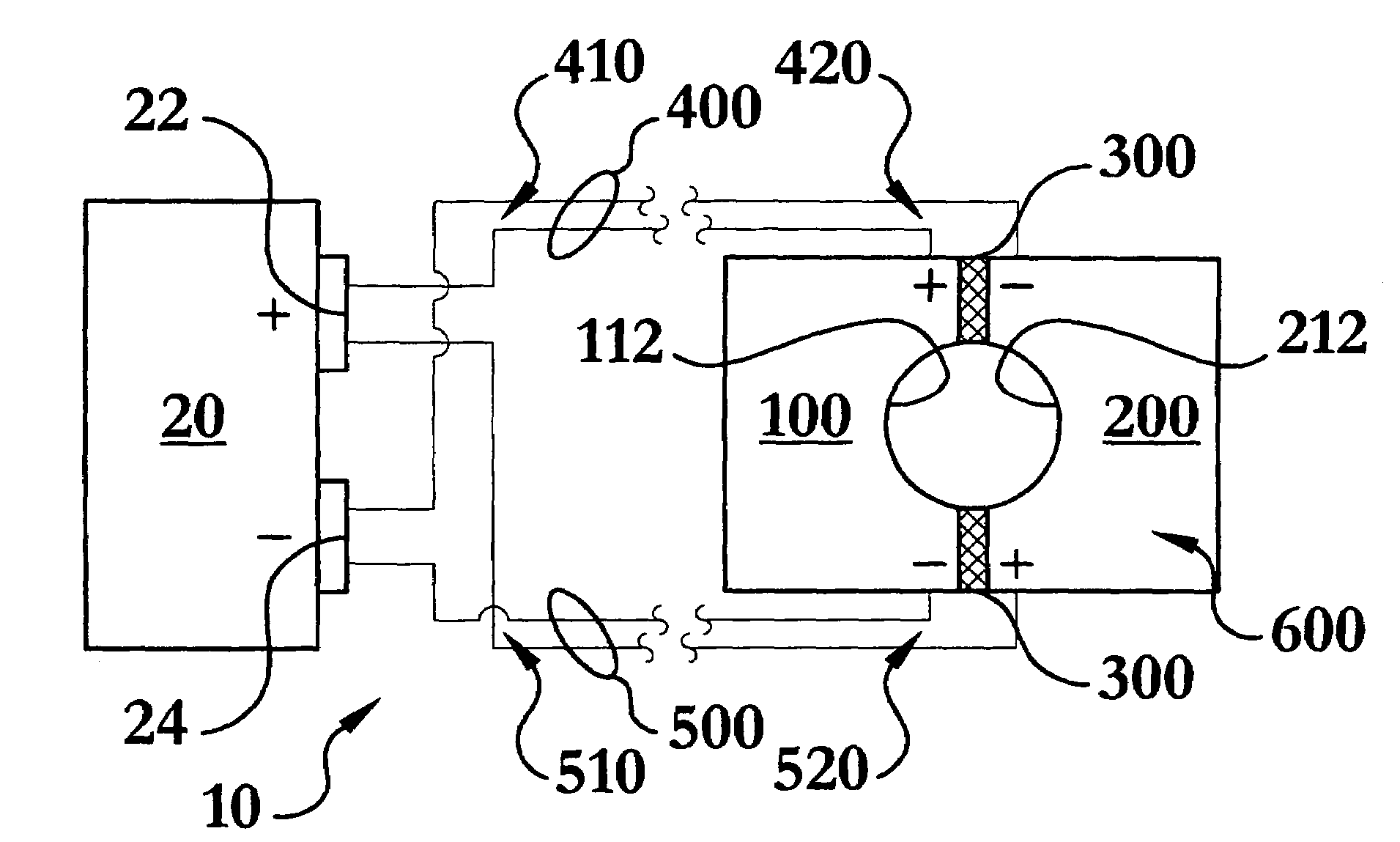

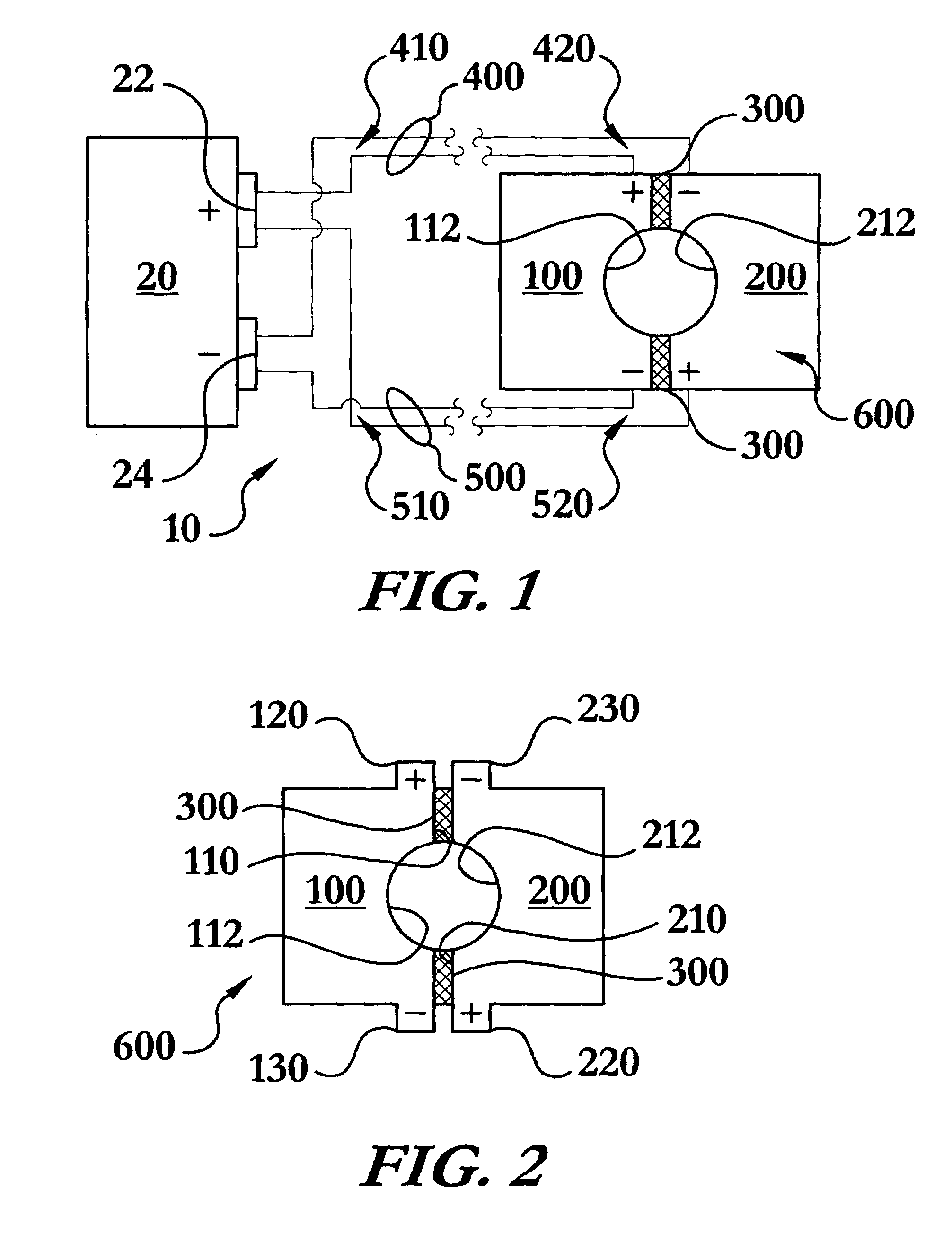

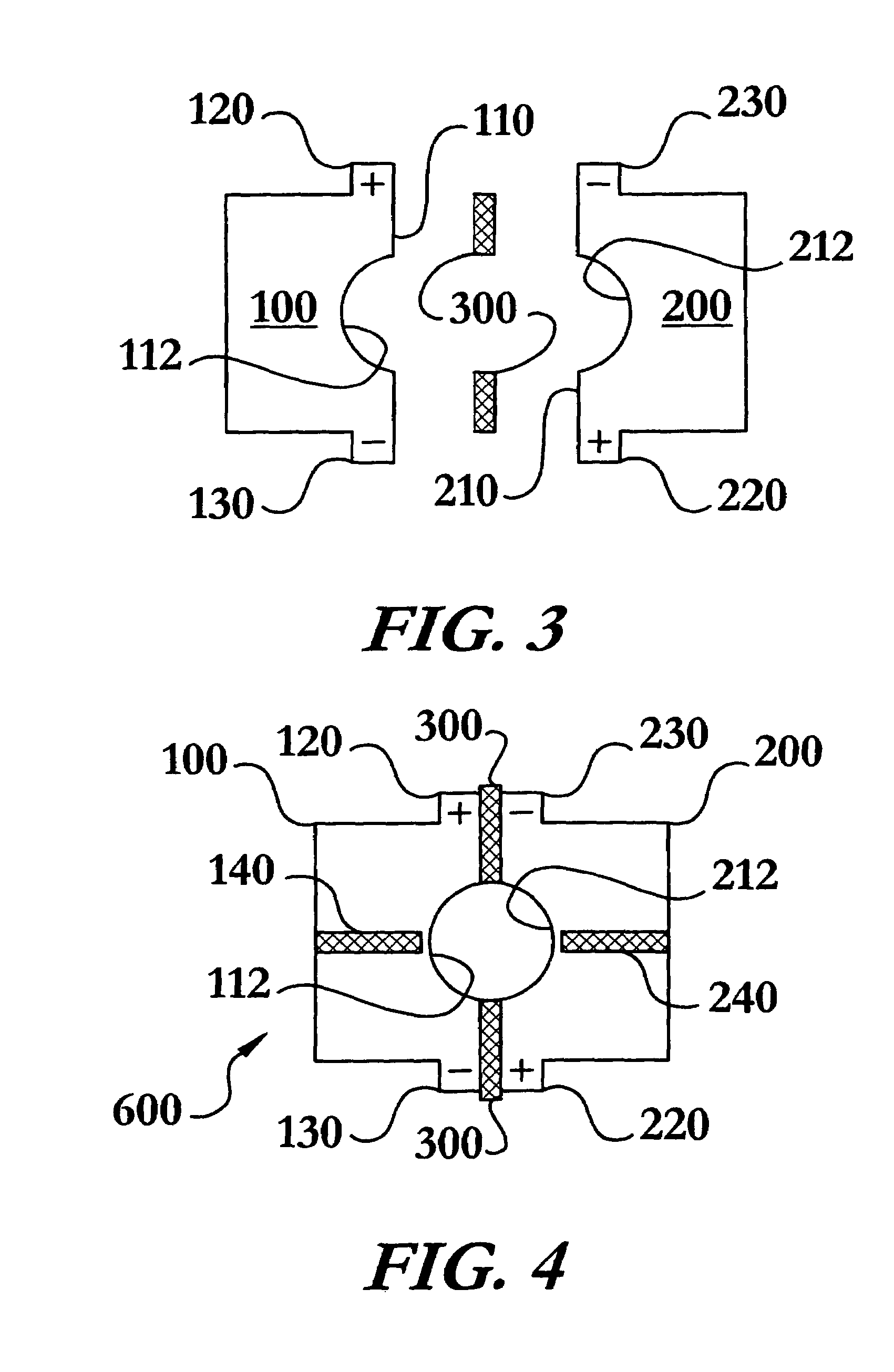

Opposed current flow magnetic pulse forming and joining system

ActiveUS20060185412A1Reduce inductanceMinimize their inductancePower hammersHammer drivesElectricityElectrical conductor

An opposed current flow magnetic pulse forming and joining system in electrical communication with a magnetic pulse power supply having a positive connection and a negative connection. The system may be used in forming individual workpieces or joining multiple workpieces, including joining by magnetic pulse welding. The system includes a first section, a second section, an insulator, and a first and a second pair of conductors. The first and second sections cooperate to enclose the workpiece(s) and function to create an electromagnetic force similar to that produced by a single closed coil. The system is configured to achieve desirable current flow by minimizing inductance, inductive reactance, and impedance in the conductors. The pairs of conductors may incorporate closely spaced individual conductors, braided conductors, and coaxial conductors. The current flow in the individual conductors of each pair of conductors is opposed, as is the current flow through the sections.

Owner:EDISON WELDING INSTITUTE INC

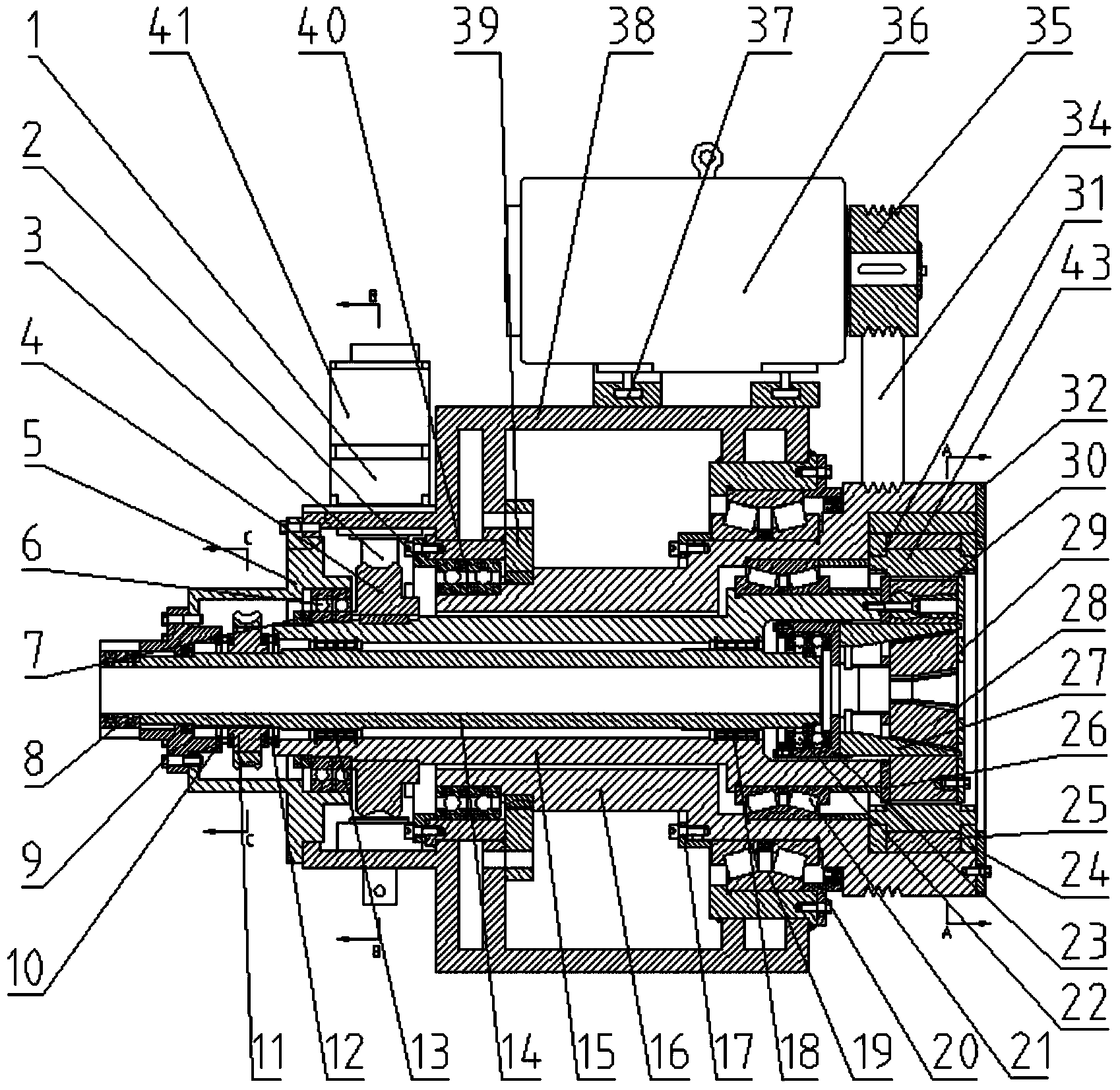

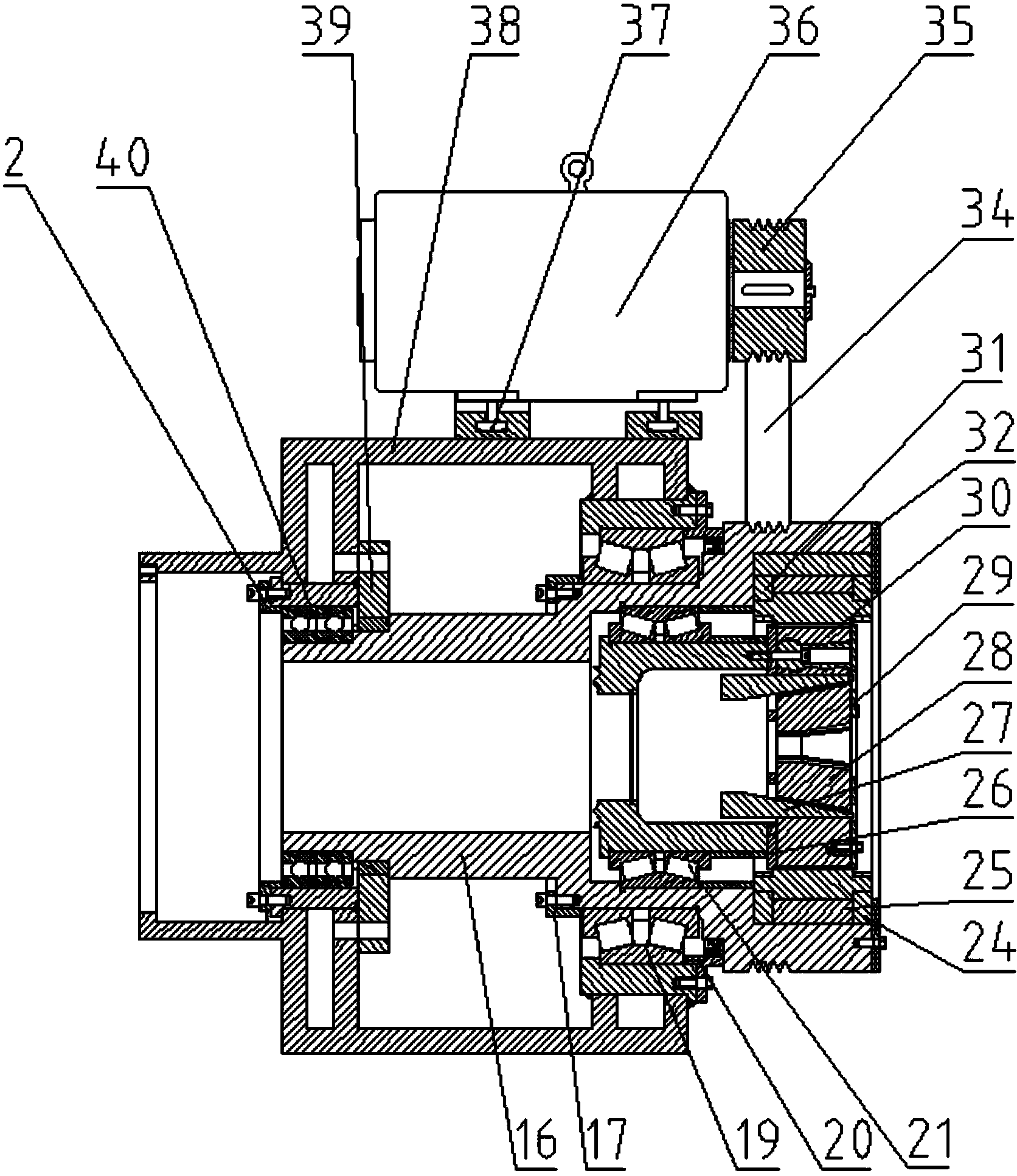

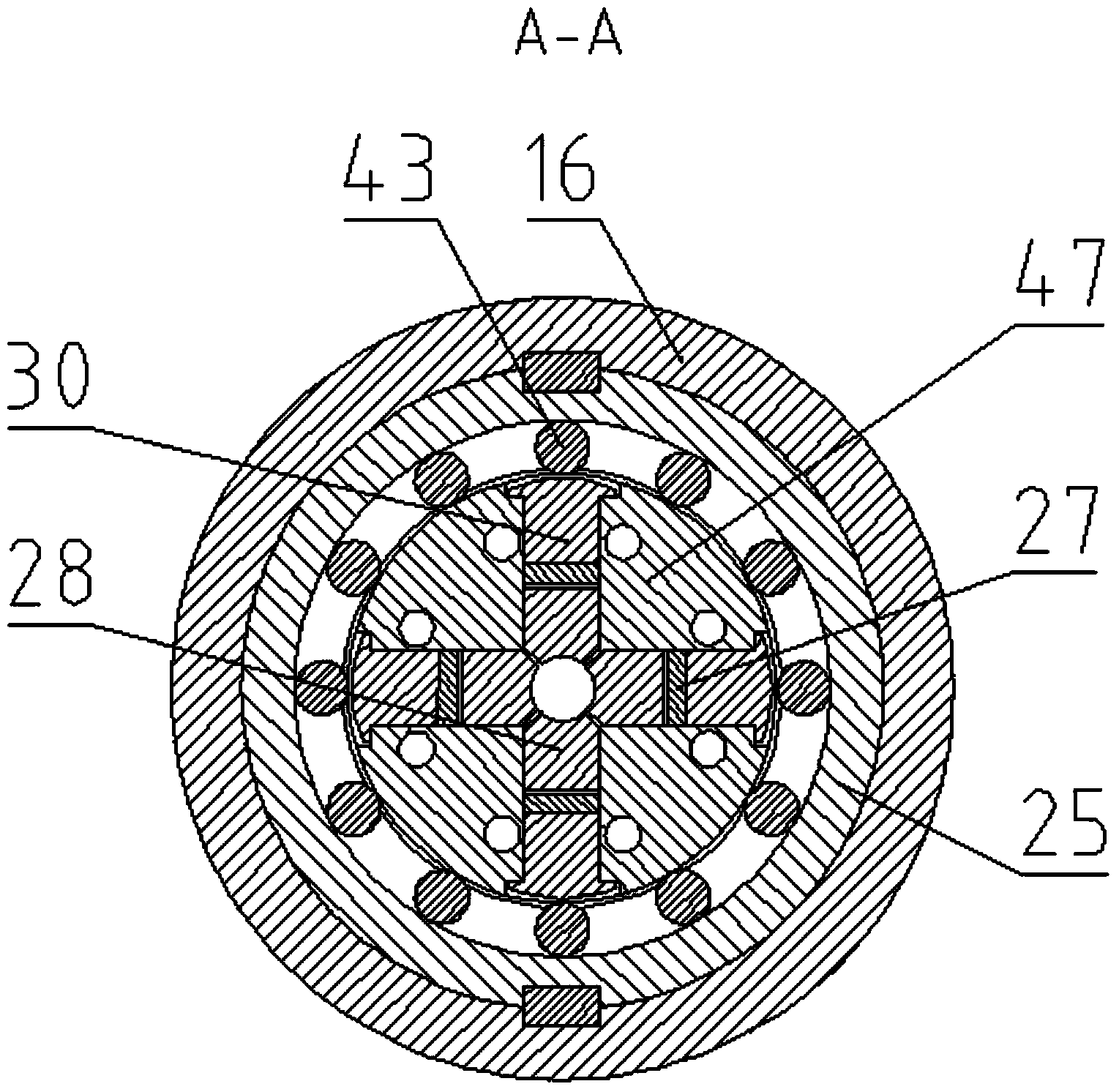

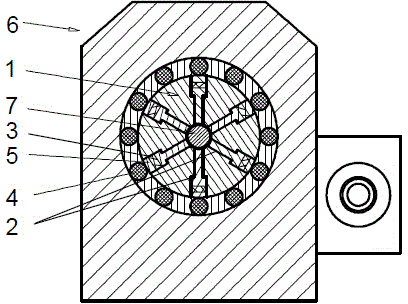

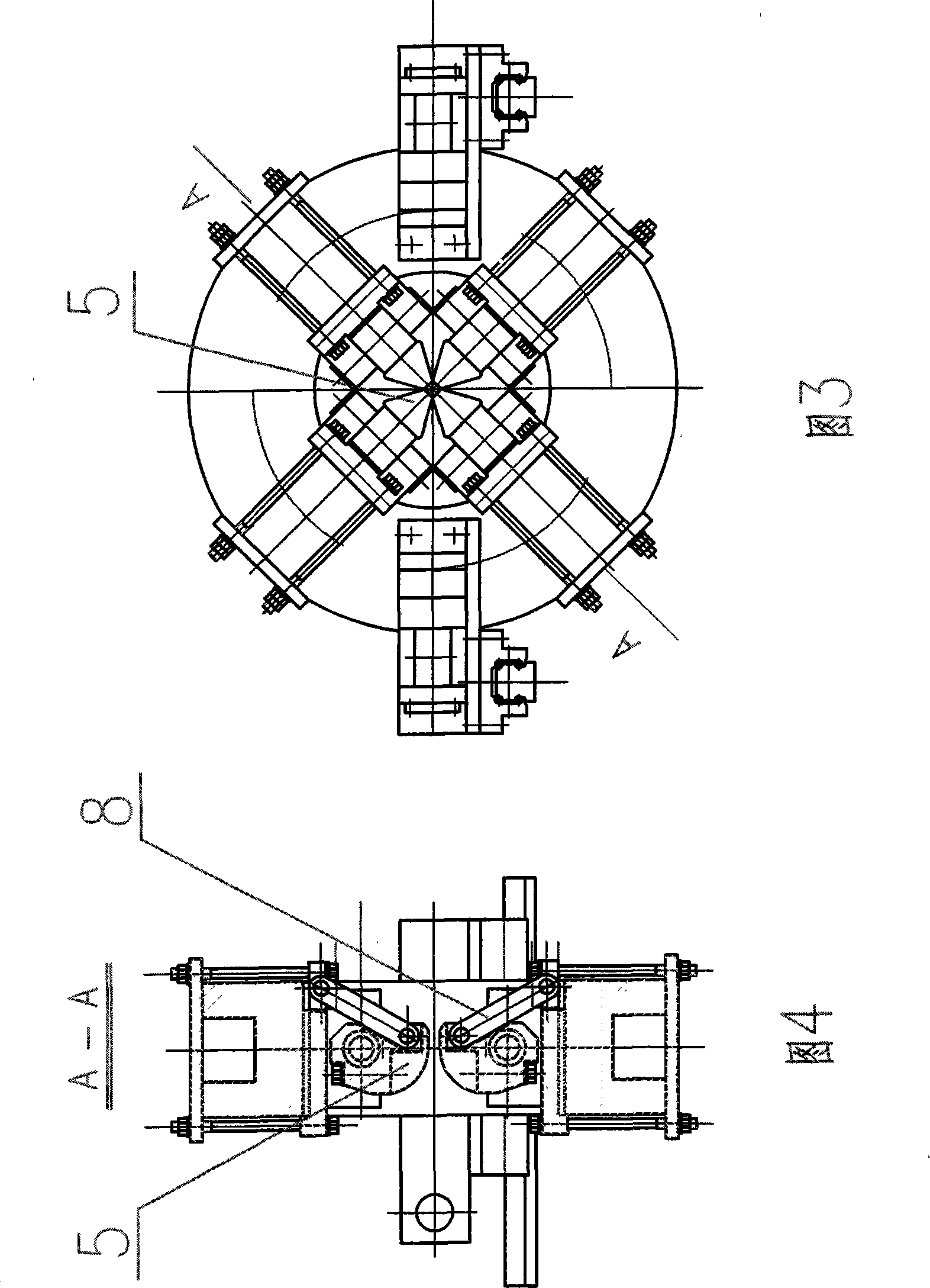

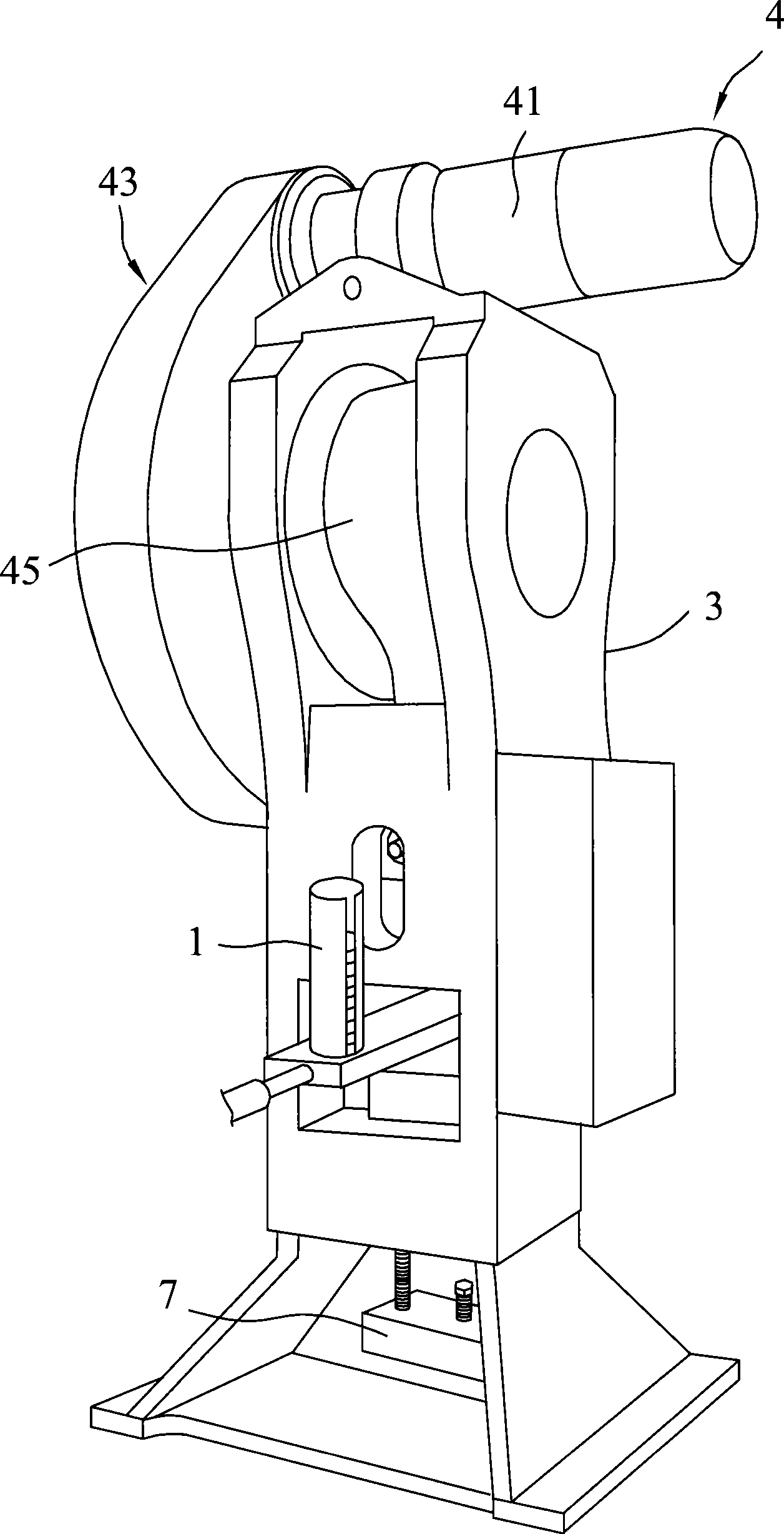

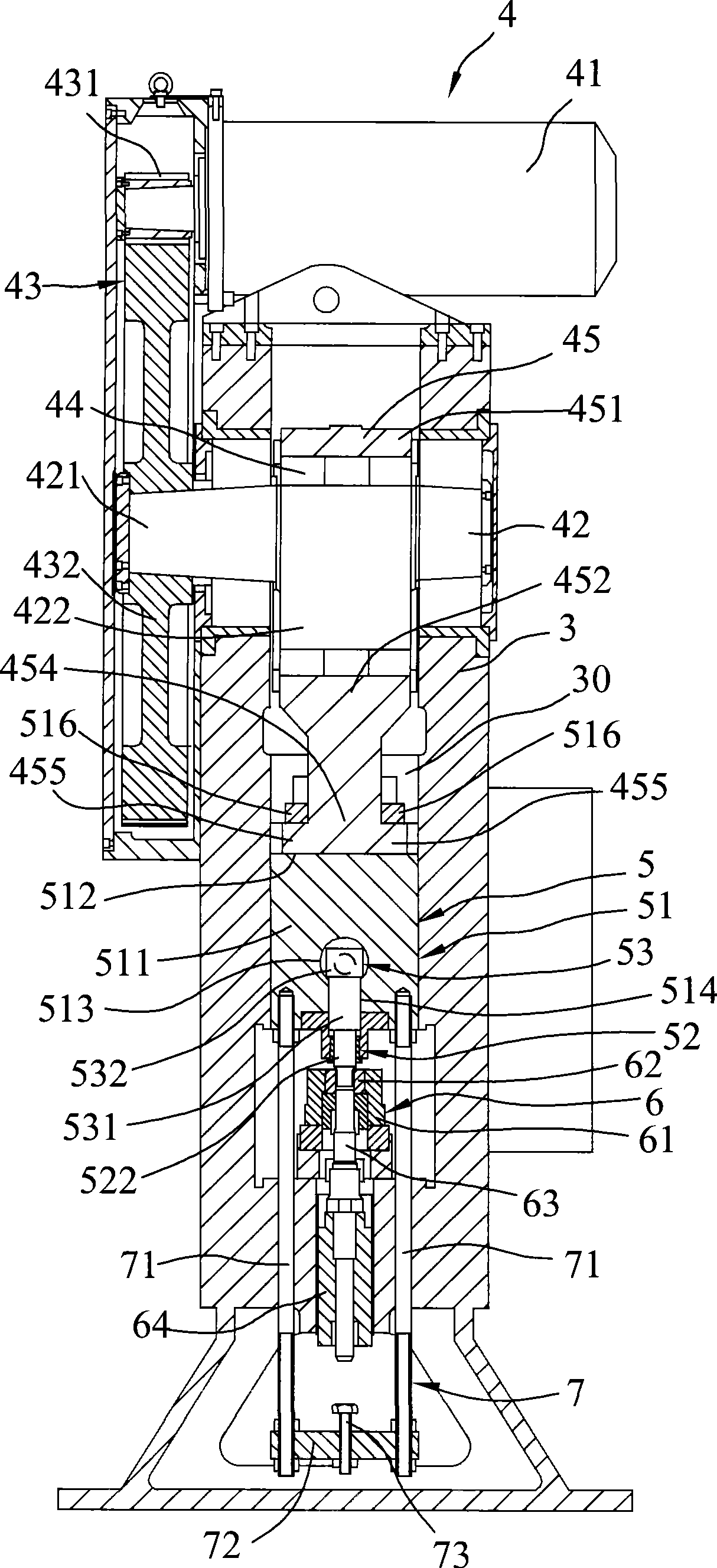

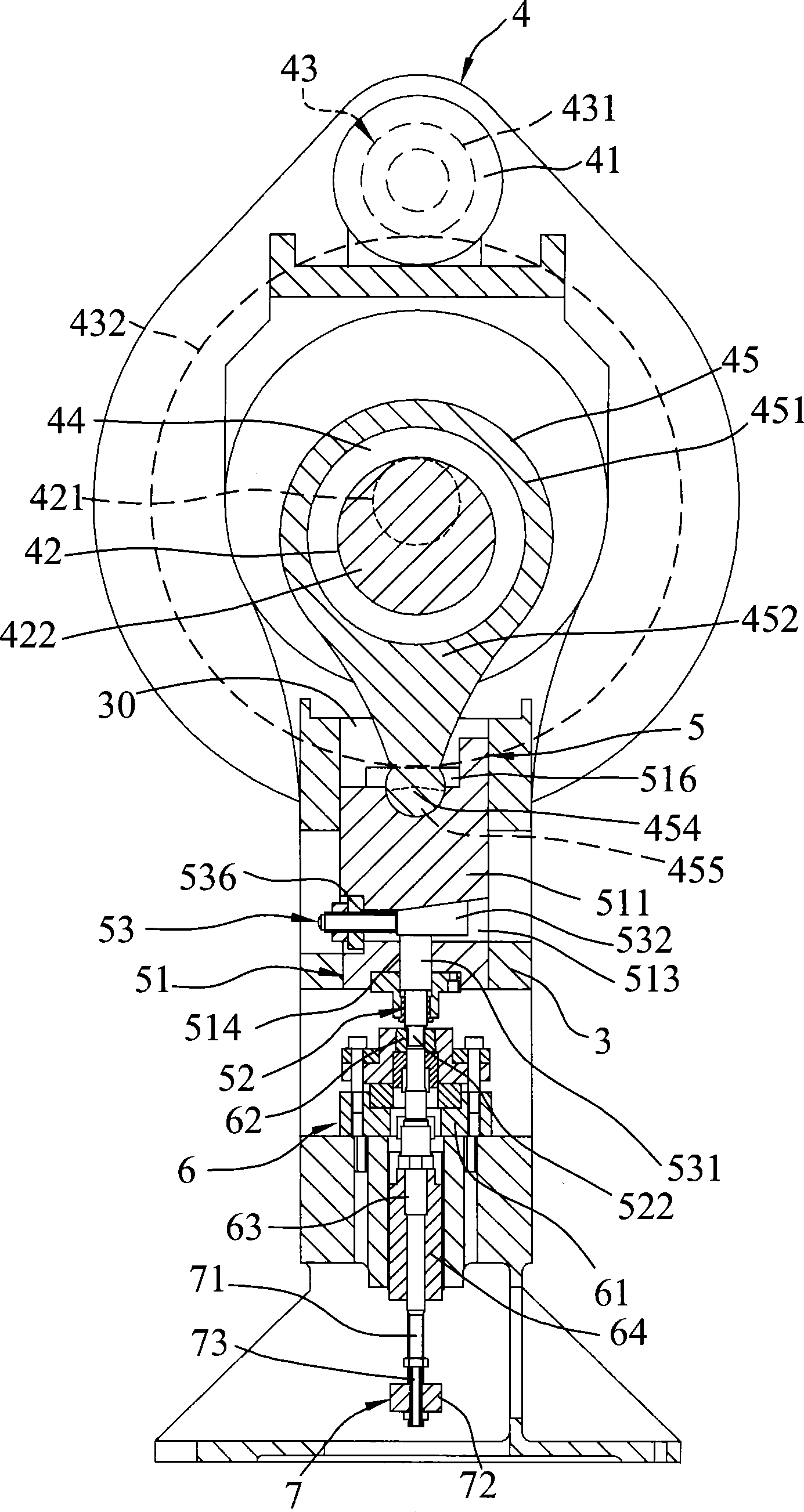

Multifunctional precision alternating-current servo swaging machine

InactiveCN103894528ARealize functionRealize variable diameter processingPower hammersHammer drivesEngineeringAlternating current

A multifunctional precision alternating-current servo swaging machine comprises a swaging head, a die rotation system, a variable diameter system and a body portion. The swaging head is a forming part. The die rotation system drives a die portion to rotate, so that a hammerhead can rotate by 360 degrees to swage a tubular bar part. The variable diameter system is used for variable diameter machining of a tubular bar. The body portion is used for supporting a whole operating mechanism of the swaging machine. The multifunctional precision alternating-current servo swaging machine has the functions of a spindle rotary forging machine, a rim rotary forming machine and a drum rotary forming machine, and has the advantages of flexibility and controllability, good stability, wide machining range and the like.

Owner:XI AN JIAOTONG UNIV

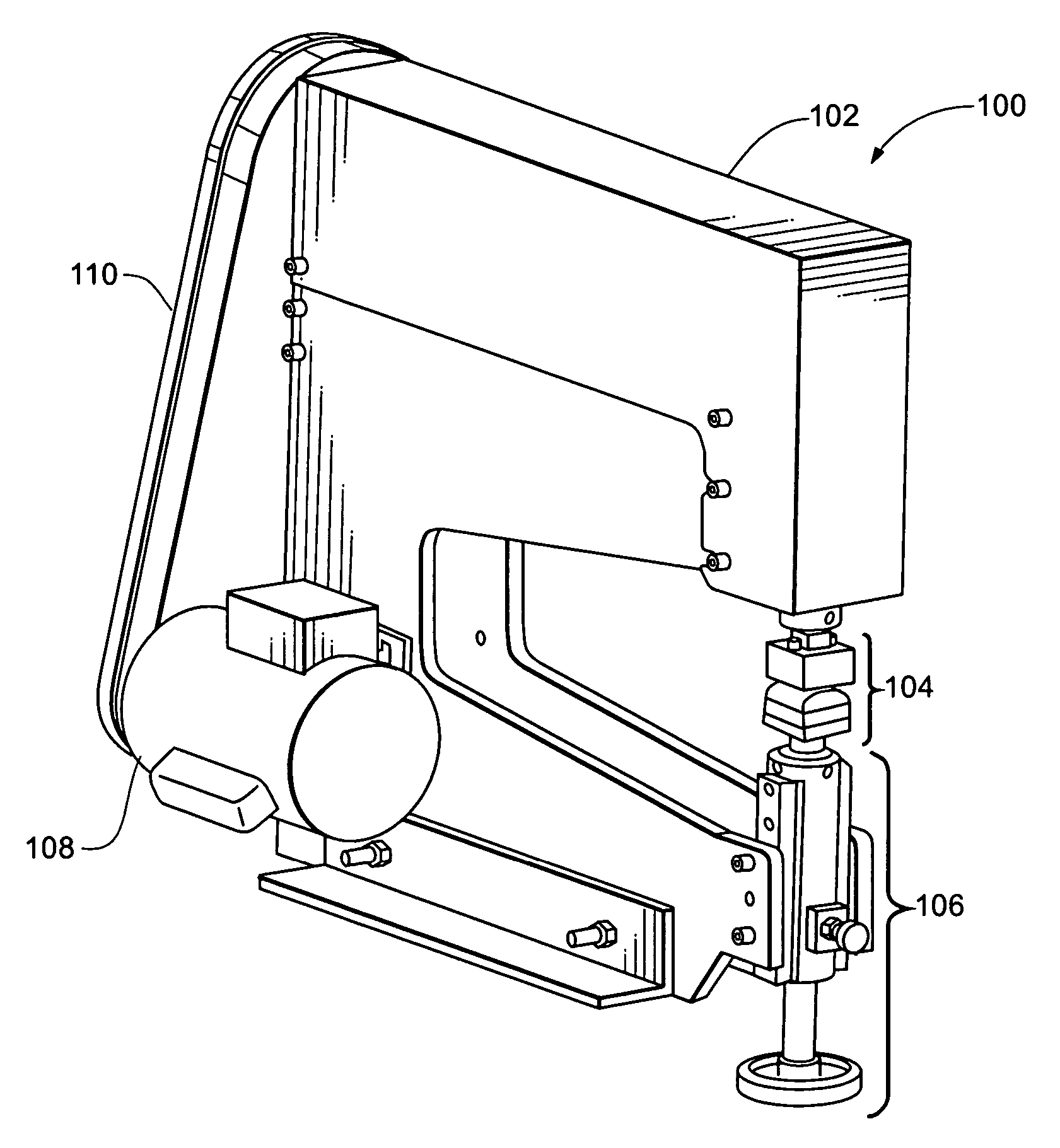

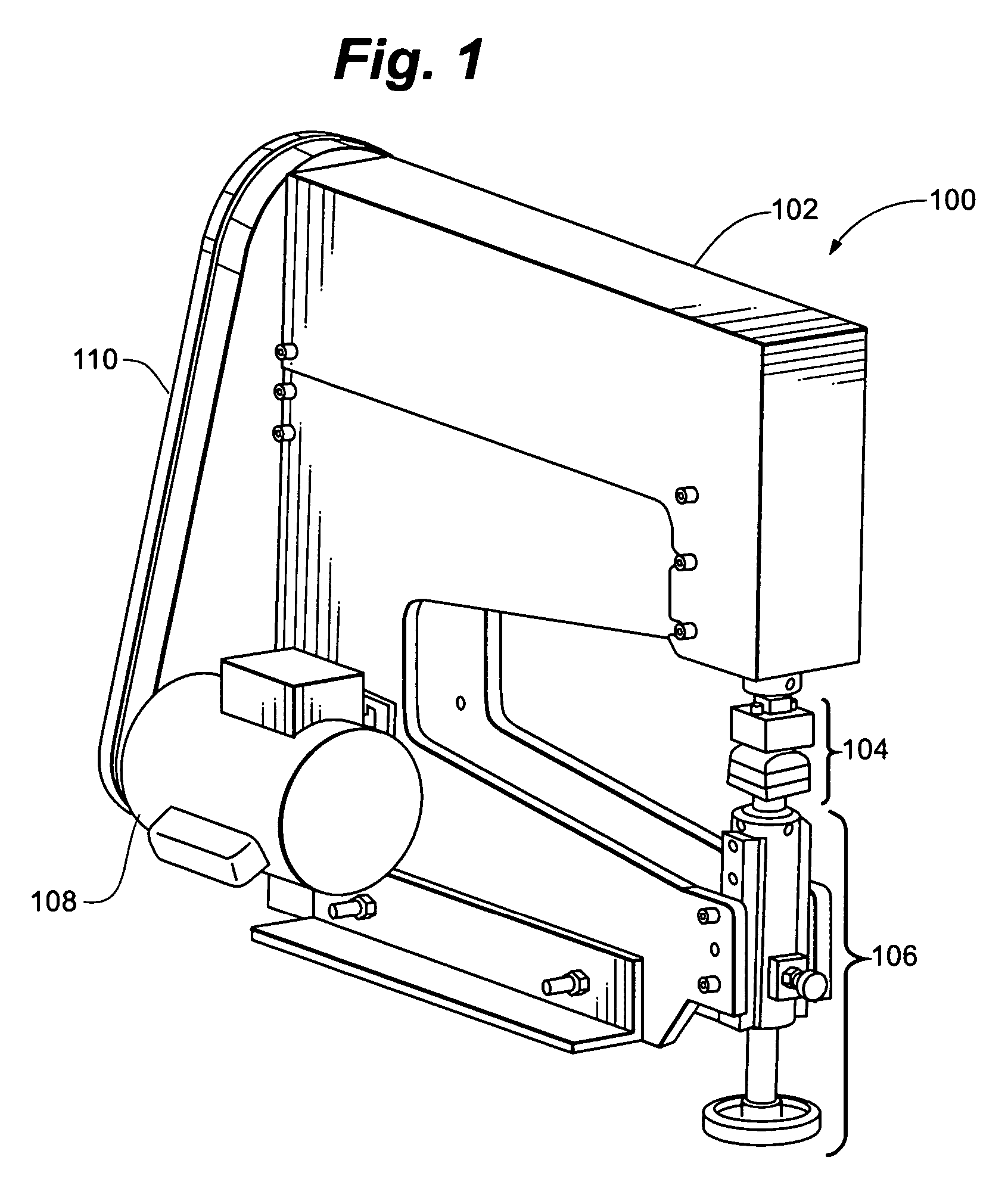

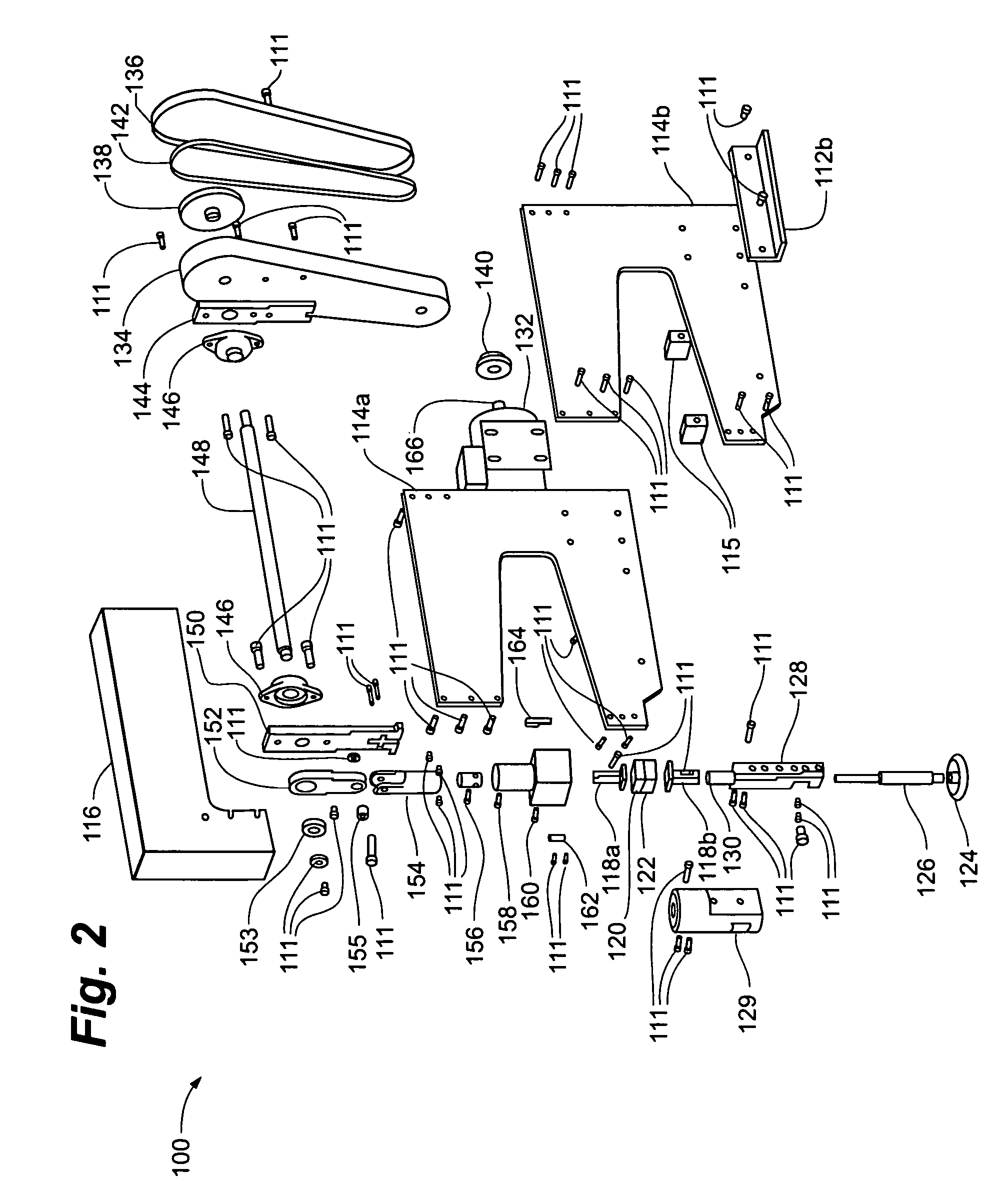

Metal shaping apparatus

A power hammer assembly providing forming capabilities while remaining economical with respect to performance, vibration, footprint size and acquisition costs. The power hammer assembly can provide for a single stroke speed and / or a single set stroke with respect to the striking of die assemblies against a piece of metal. The power hammer assembly can provide for a large throat area and / or a larger die gap for ease of use. The power hammer assembly can include adjustment features allowing for the use of die sets of varying configurations such as, for example, shank size, shank length or alternatively, die sets fabricated for use with other machinery. In addition, the power hammer assembly can include a belt transmission assembly designed to slip in the event of die interference during set-up or operation so as to avoid damaging the power hammer assembly.

Owner:JSJ CORP

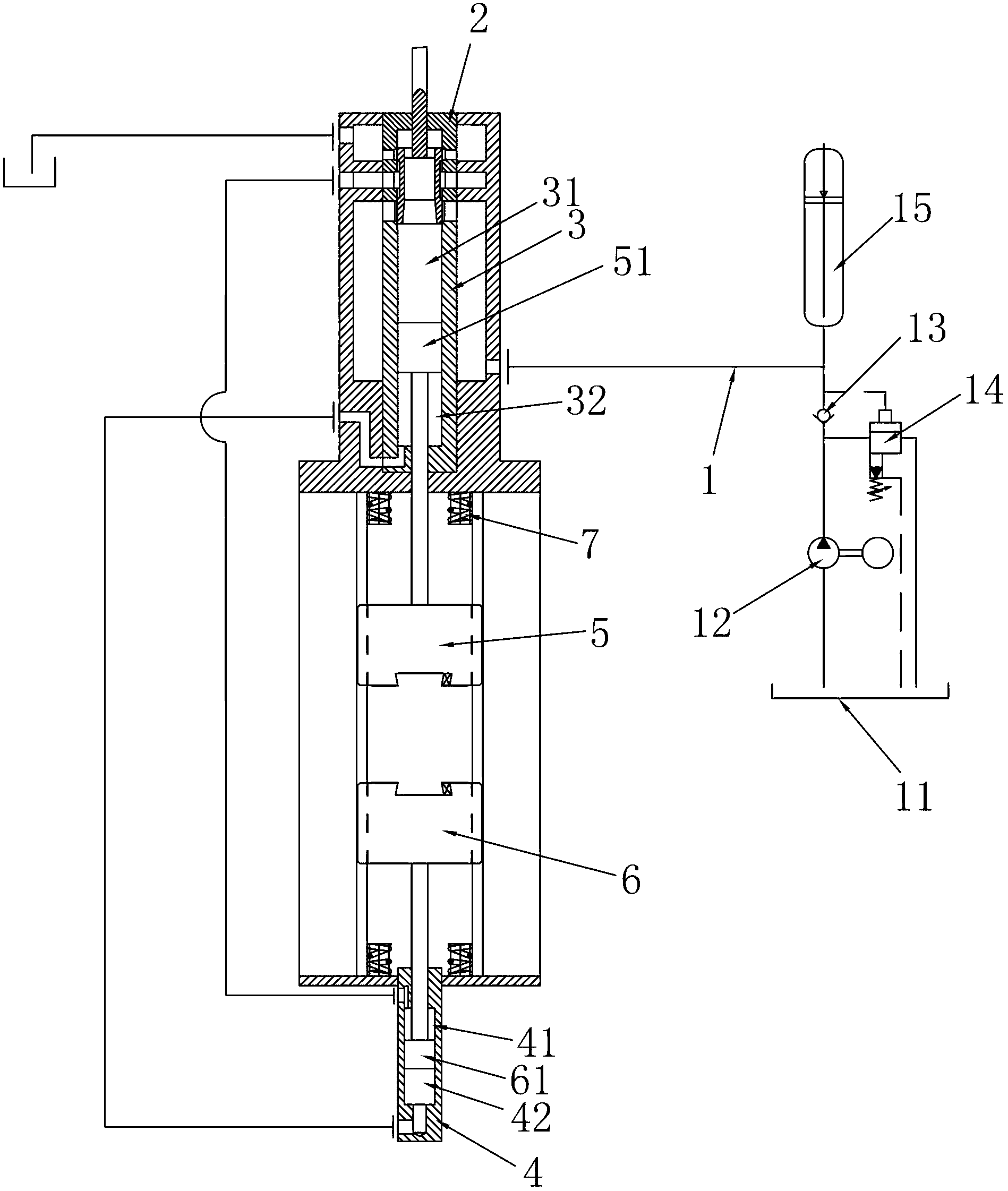

Fully-hydraulic counter-blow hammer

InactiveCN102794379ASimple structureFewer sliding seal failuresPower hammersHammer drivesControl valvesEquipment use

The invention discloses a fully-hydraulic counter-blow hammer, relates to forging and pressing equipment used in the forging industry, particularly relates to a counter-blow hammer driven hydraulically and provides a fully-hydraulic counter-blow hammer which is simpler in linkage structure and fewer in linkage fault. The fully-hydraulic counter-blow hammer provided by the invention comprises a hydraulic source (1), a control valve (2), an upper drive cylinder (3), a lower drive cylinder (4), an upper hammerhead (5), and a lower hammerhead (6), wherein the upper drive cylinder is divided into an upper drive upper cavity (31) and an upper drive lower cavity (32) via an upper hammer-rod piston (51); the lower drive cylinder is divided into a lower drive upper cavity (41) and a lower drive lower cavity (42) via a lower hammer-rod piston (61); the upper drive lower cavity (32) is hermetically connected to the lower drive lower cavity (42) to form an airtight accommodating cavity, and a liquid with a constant volume is fully filled in the airtight accommodating cavity; and the upper drive upper cavity (31) and the lower drive upper cavity (41) are switchably communicated with the hydraulic source (1) and an oil drainage channel respectively under the control of the control valve (2).

Owner:胡大勇

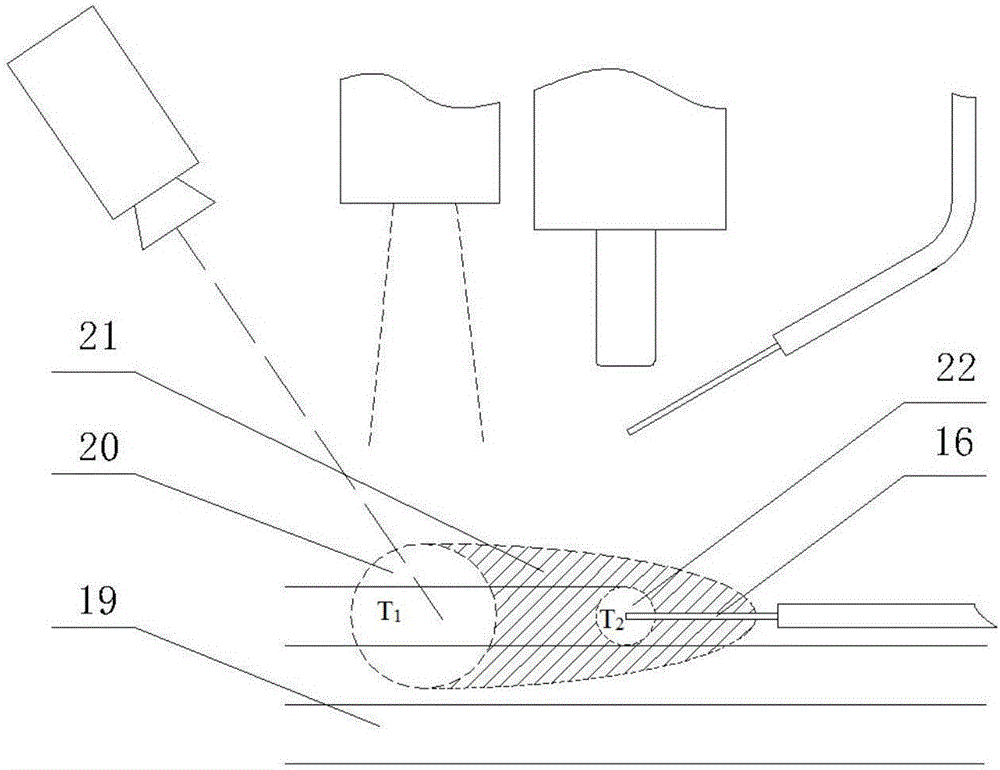

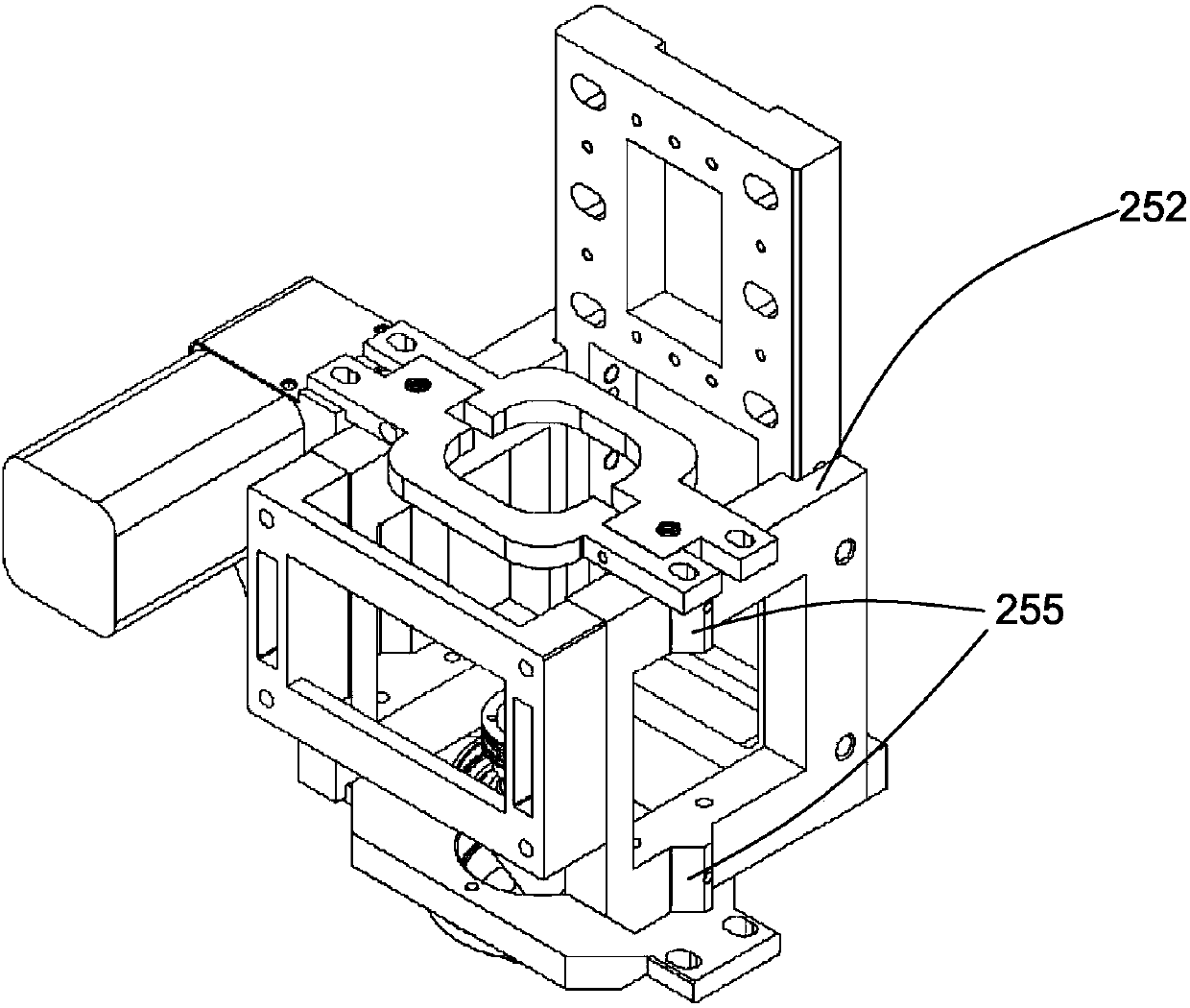

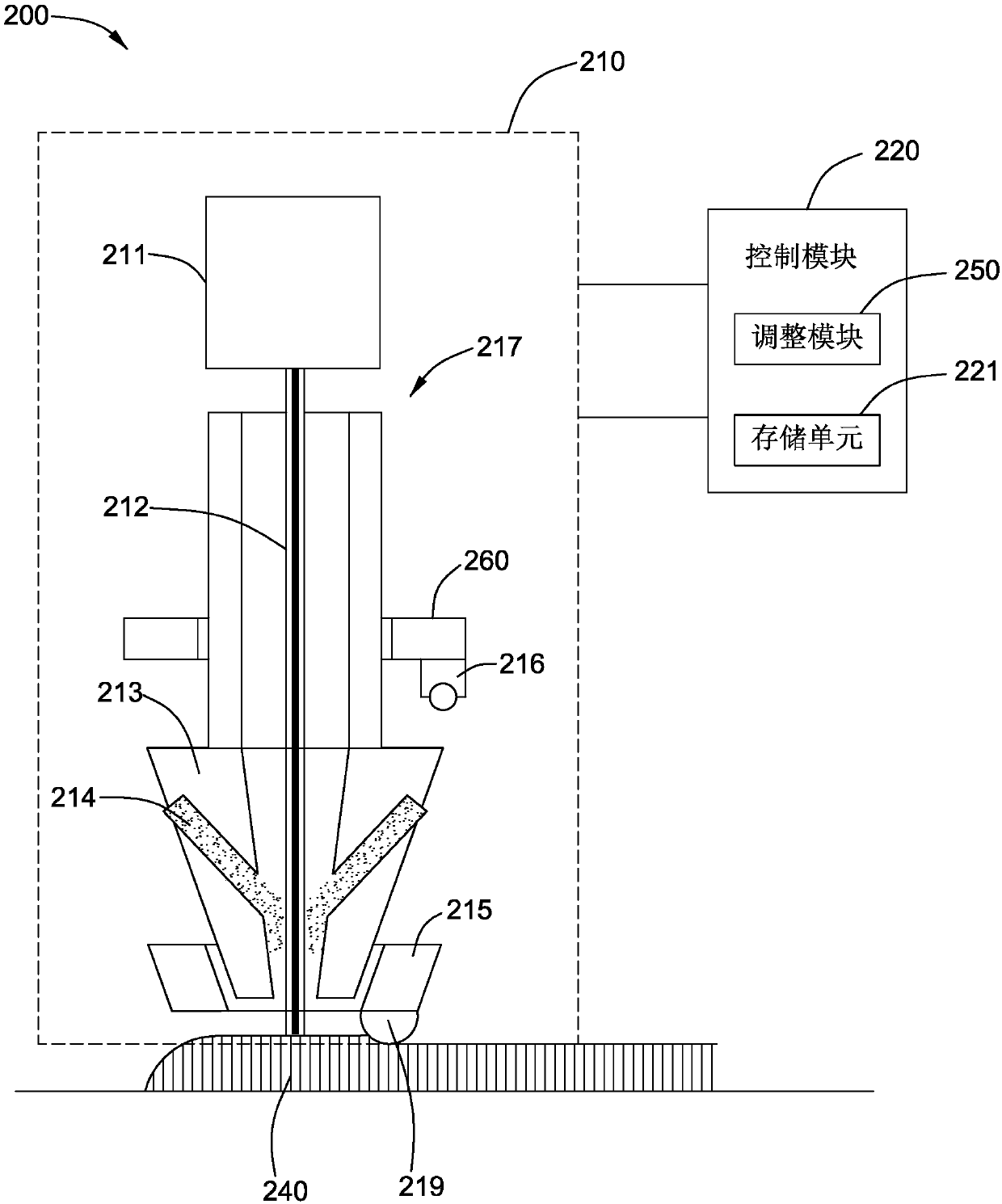

Temperature controlling system and method for additive manufacturing

The invention relates to a temperature controlling system and method for additive manufacturing. The temperature controlling system comprises a fused cladding device, a micro-forging device, a detection device, a controlling module and an adjustment device, wherein the fused cladding device is used for fusing materials to form a fused cladding layer; the fused cladding device comprises a first energy source which is configured to enable energy beams to point to the materials so as to fuse at least a part of materials and form the fused cladding layer; the micro-forging device is coupled with the fused cladding device and is used for forging the fused cladding layer; the detection device is used for detecting first internal effect parameters of a forging position of the fused cladding layerunder a forging effect of the micro-forging device; the control module is used for receiving the first internal effect parameters detected by the detection device and calculating a first calculationtemperature value of the forging position based on the first internal effect parameters; and the adjustment device is coupled with at least one of the first energy source and the micro-forging device,and is used for receiving the first calculation temperature value and adjusting at least one of the first energy source and the micro-forging device to ensure that the first calculation temperature value is located in an expected temperature range when the first calculation temperature value of the forging position is not located in the expected temperature range.

Owner:GENERAL ELECTRIC CO

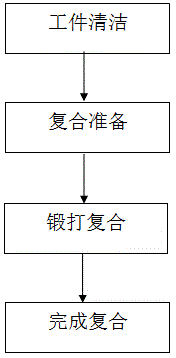

High-frequency rotary precision-forging compounding method for metal composite tube and rod manufacturing

ActiveCN104646579AReduce power consumptionLow site requirementsPower hammersHammer drivesIndustrial engineeringSurface flatness

The invention discloses a high-frequency rotary precision-forging compounding method for metal composite tube and rod manufacturing. The high-frequency rotary precision-forging compounding method comprises the following main process steps: (1) cleaning workpieces; (2) preparing for compounding; (3) forging and compounding: putting to-be-compounded metal composite tubes / rods on a feeding rack of a high-frequency rotary precision-forging machine, introducing the to-be-compounded metal composite tubes / rods into the high-frequency rotary precision-forging machine to forge under the pushing of a feeding system of the high-frequency rotary precision-forging machine, and forging until inner and outer layers of composite metal tubes / rods are tightly compounded; (4) completing the compounding: if lining tubes at the inner layer are metal tubes, dropping out core rods. The high-frequency rotary precision-forging compounding method has the advantages of low power consumption, easy operation, high product manufacturing efficiency, high bonding strength, high product surface flatness, short process flow and safe production. Compared with an existing process, the cost of the equipment is greatly reduced, the maintenance cost is relatively low and the requirements on field are relatively low; a plurality of layers of different metal tube rods can also be compounded in a multi-layer mode.

Owner:李富申 +1

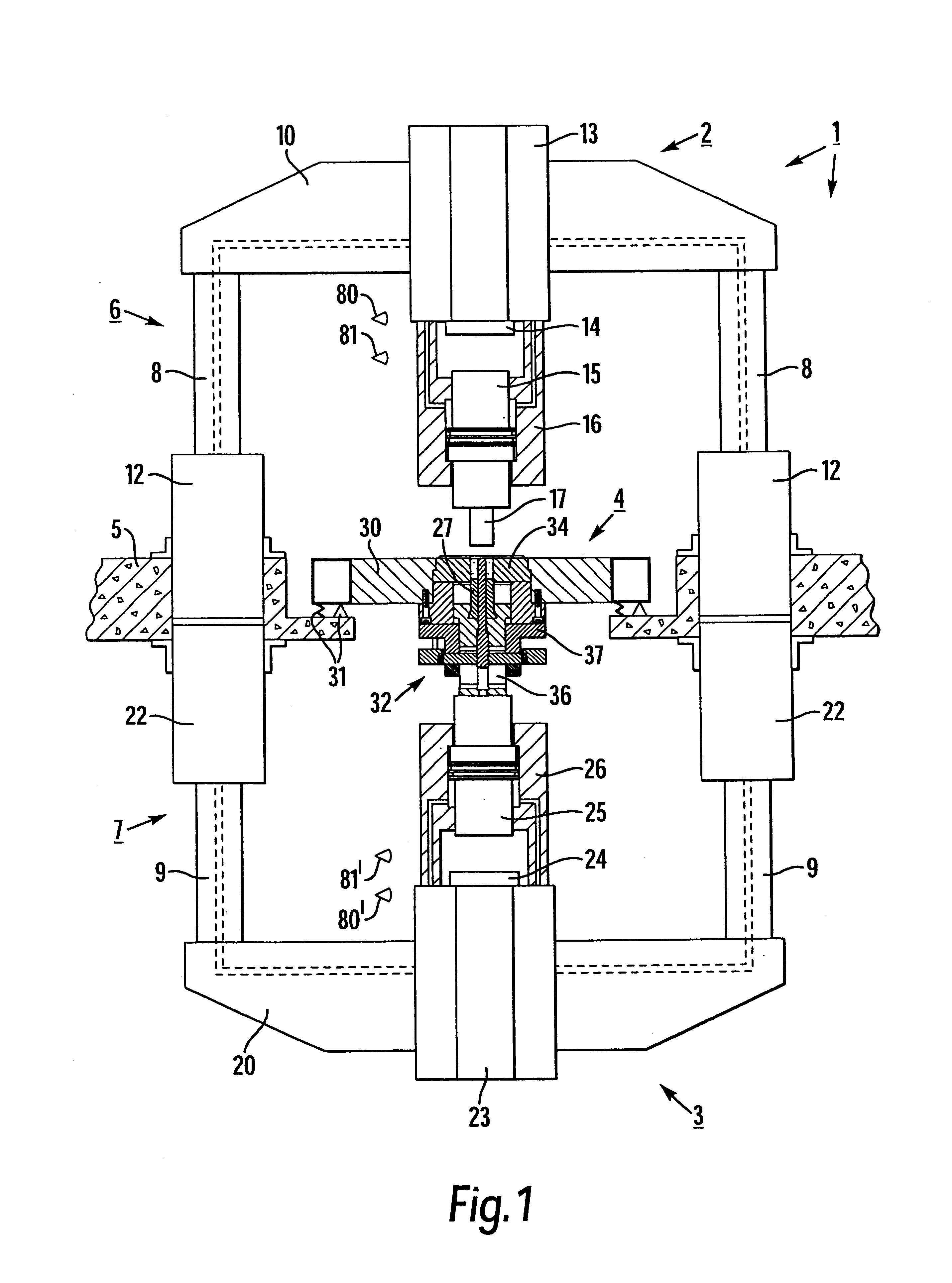

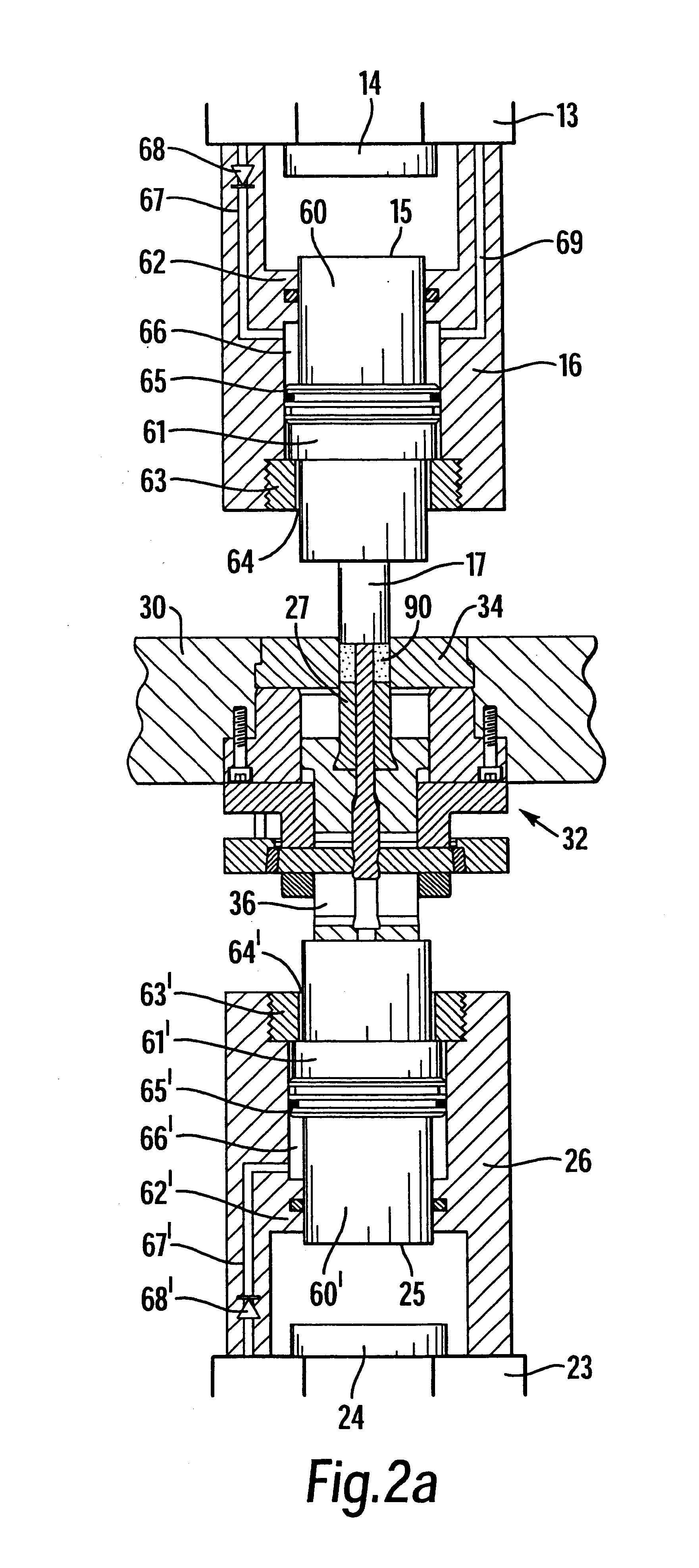

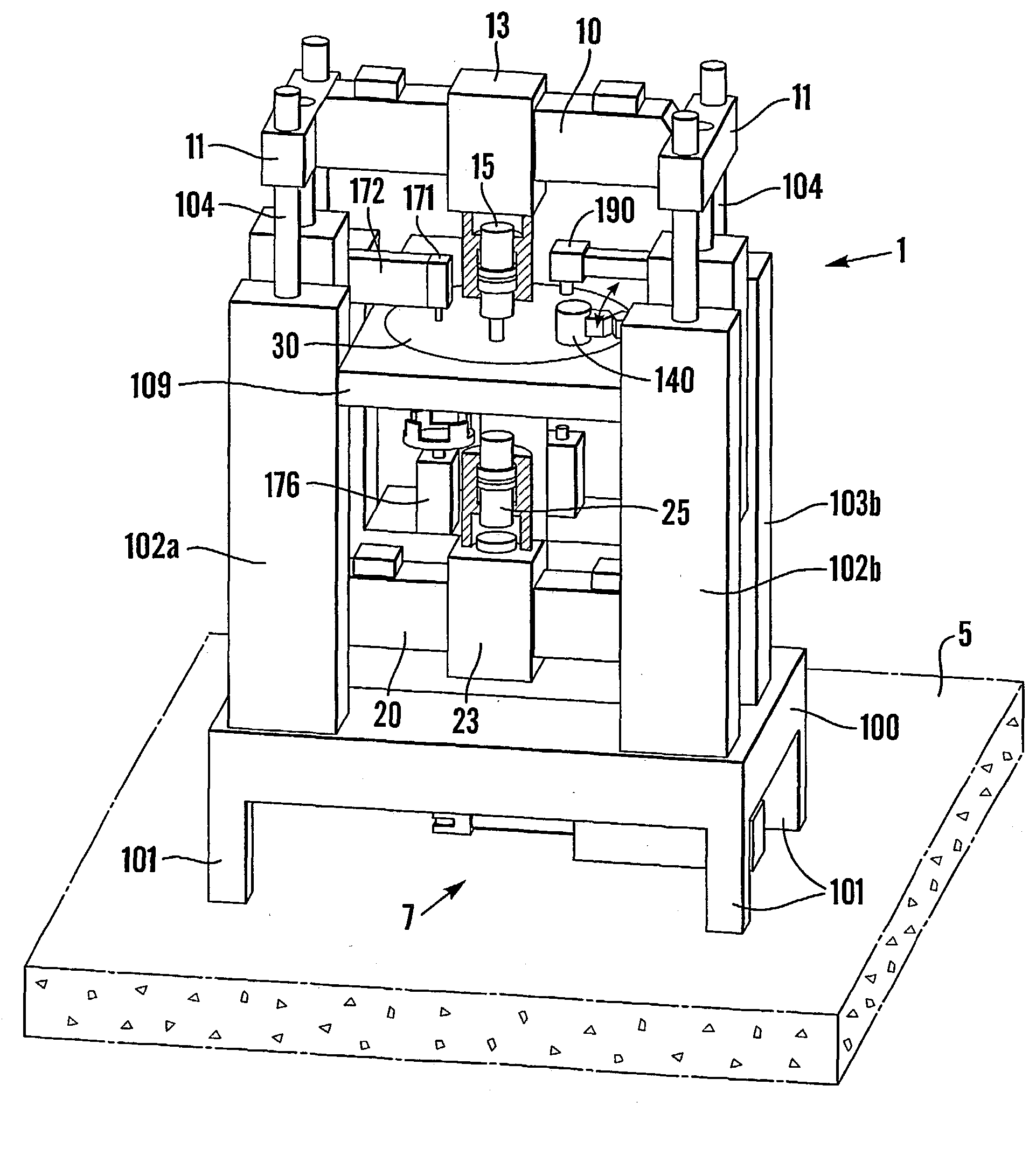

Impact machine and a method of forming a body

The invention concerns an impact machine for forming a body with desired shape of a formable working material through impact action in a forming operation, said impact machine comprising a machine stand (6), an upper unit which comprises either a lower impact unit (3), which comprises a counter-impact device, or a stationary anvil, and a central unit between the upper and the lower units. The central unit (4) comprises one or more carriers (30), each of which containing and carrying one or a plurality of identically equal tool units (32), each of which comprising a die (34) with a mould cavity (46) for the working material (90) intended to be formed, said carriers including at least one carrier which is stationary during the forming operation and which contains at least one such tool unit, and that motion devices (7) are provided for indexing the carrier or carriers in a horizontal plane for positioning the tool units in different function stations (I-V), comprising a forming station (II) and at least one more station.

Owner:MORPHIC TECH

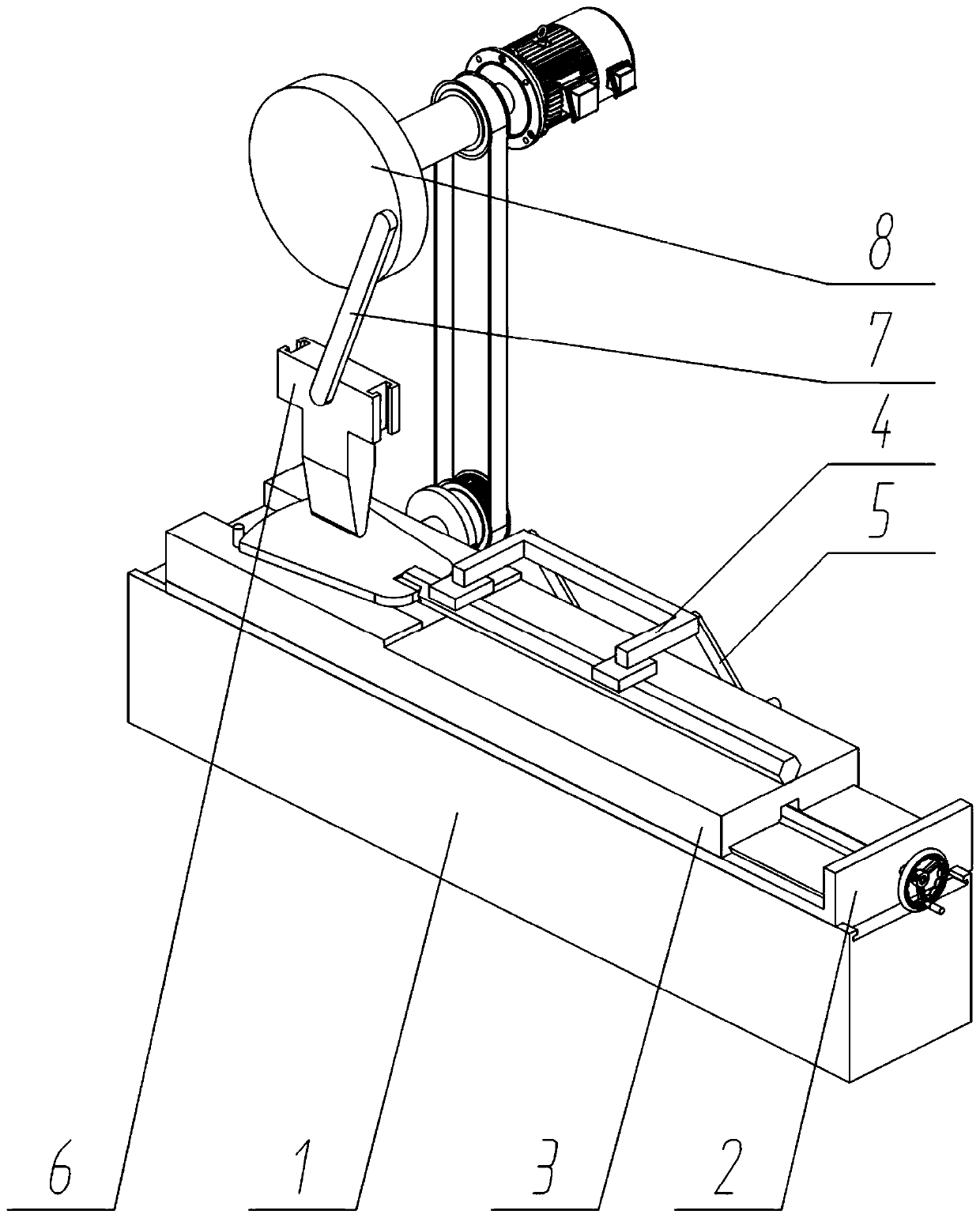

Roll forming integrated technique of high intensity high-hardness alloy and roll forming equipment

InactiveCN101249603AInternal crystal structure is goodUniform surfacePower hammersRollsNiobiumTitanium alloy

The invention relates to a roll forging integrated process of high-strength and high-hardness alloy and a piece of roll forging device thereof. The process mainly comprises the following processing steps: a main frame and an eccentric roller arranged on the main frame make an advance and return movement along the axial direction of the blank; the eccentric roller is continuously and repeatedly separated from the blank during the advance and return process, then falls down to forge, and rolls the blank until the processing is completed. The device for roll forging high-strength and high-hardness alloy consists of four parts, namely a feeding device, a main frame, a discharging device and a drive mechanism of the main frame. The process is simple, practical and efficient. The structure of the device is simple and compact. The process can save the material in the processing of the high-strength, high-hardness and refractory alloy materials with more than 200 HB, such as the refractory metal such as tool steel, roll steel, tungsten, molybdenum, tantalum, niobium, and alloy thereof, and titanium alloy, and improves the mechanical property of products.

Owner:宝鸡市浩源特种材料有限公司

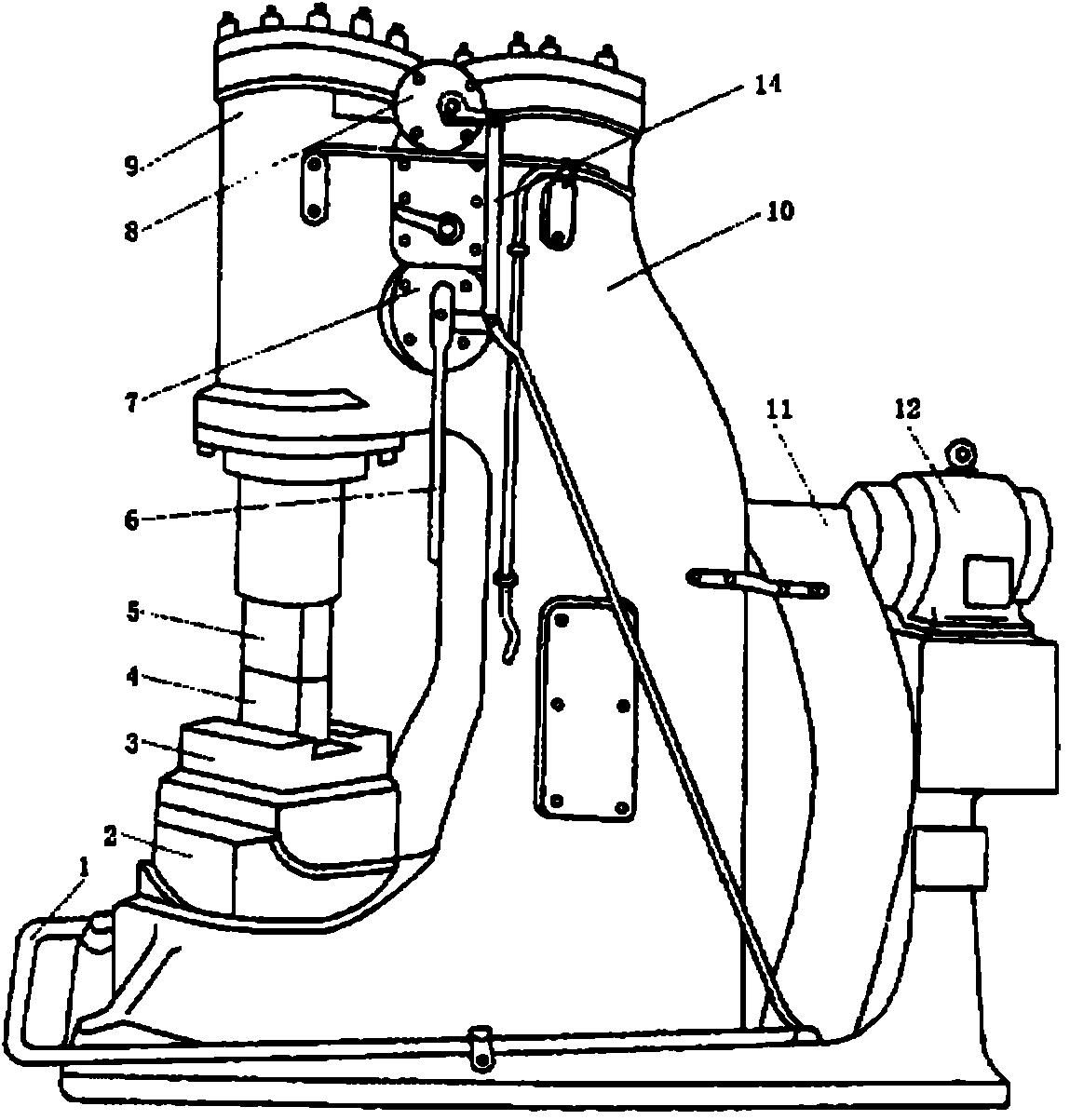

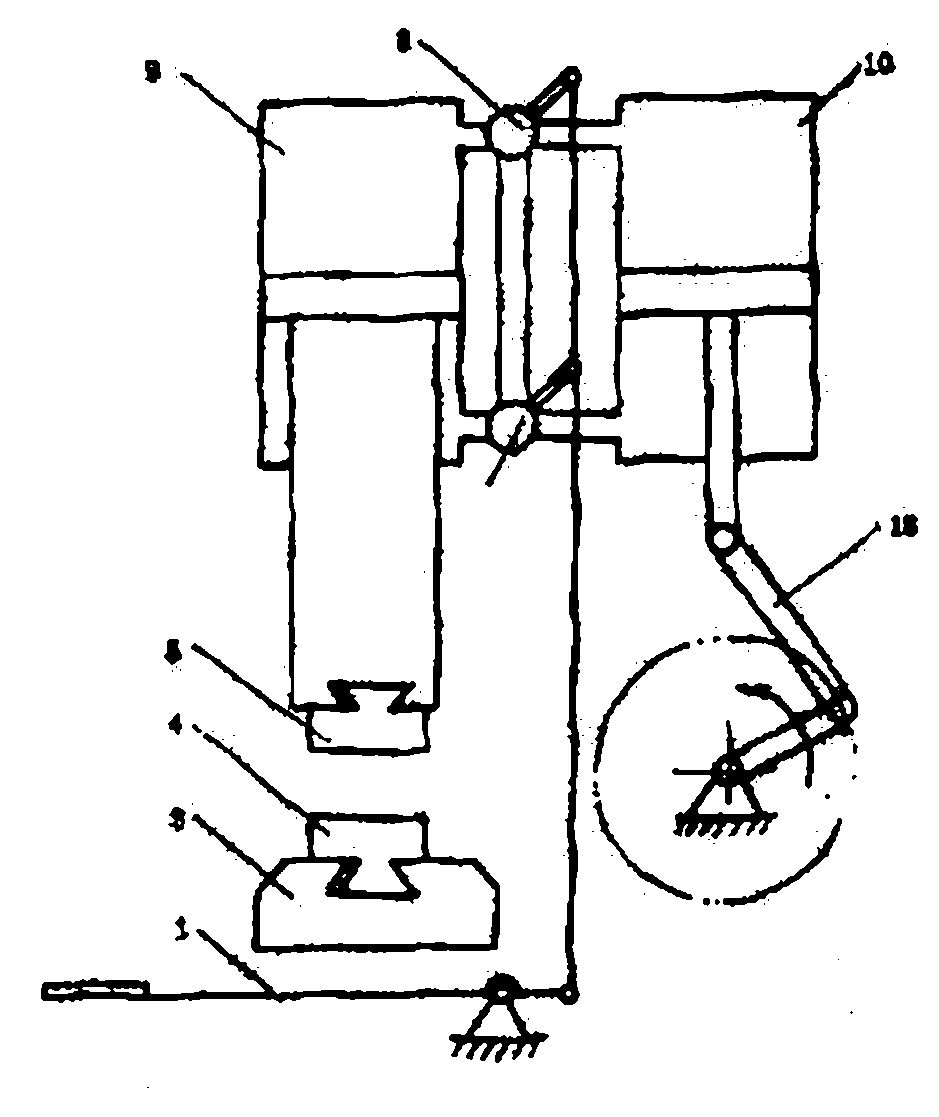

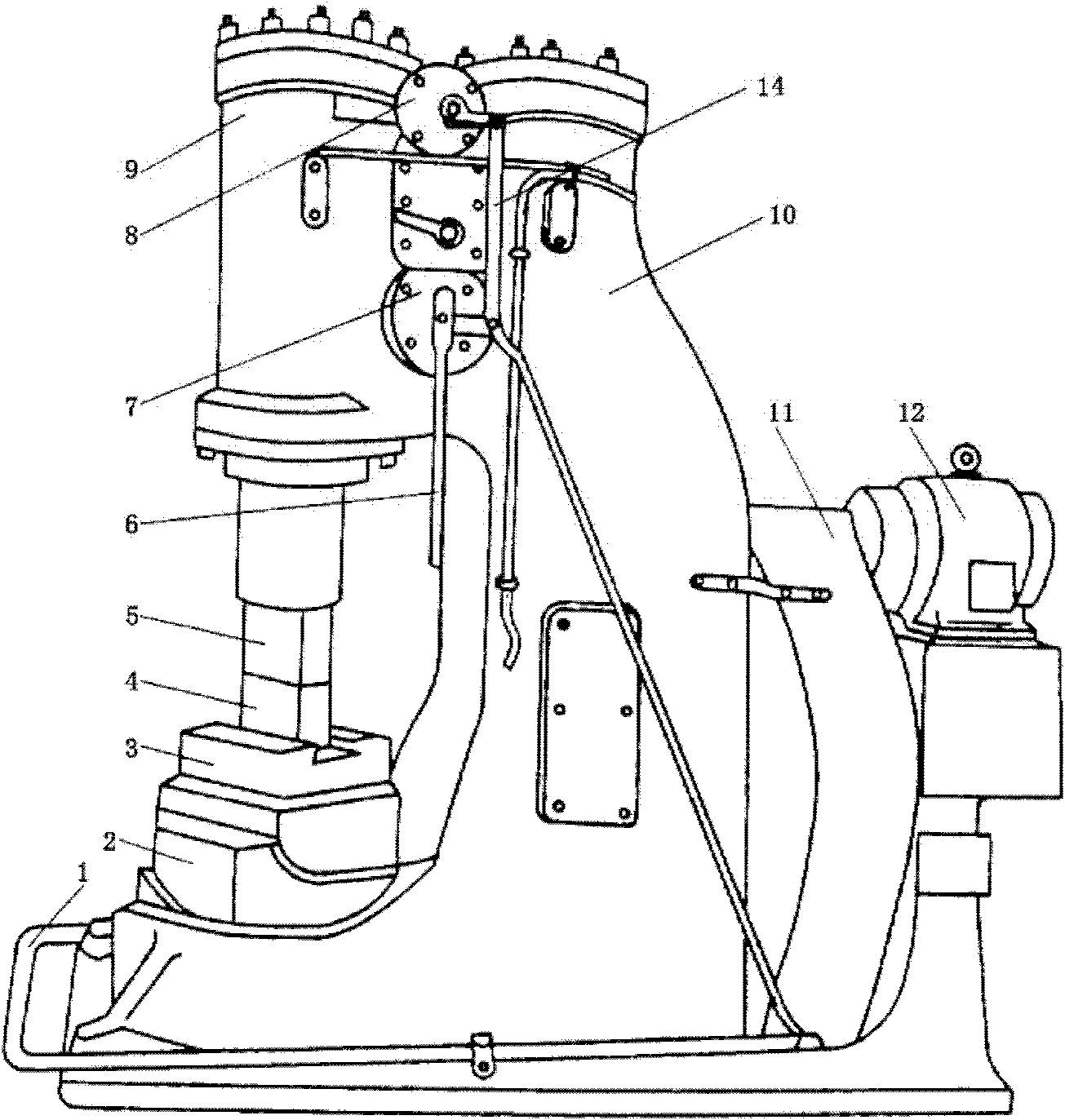

Air hammer

The invention discloses an air hammer. The air hammer comprises a motor, a reducer, a connection rod mechanism, a compression air cylinder, a working air cylinder and an anvil block; the output end of the motor is connected with the reducer; the reducer is connected to one end of the connection rod mechanism; the other end of the connection rod mechanism is connected with a piston rod of the compression air cylinder; the compression air cylinder is connected with the working air cylinder through a first air transmission pipe and a second air transmission pipe; the piston rod of the working air cylinder is provided with upper pressing iron; the anvil block is positioned below the upper pressing iron, and is provided with lower pressing iron; the air hammer also comprises a switching device which can switch compressed air between the compression air cylinder and the working air cylinder; and the switching device is arranged on the first air transmission pipe and the second air transmission pipe respectively. The air hammer can suspend, continuously hammer, and press a workpiece and can also hammer the workpiece once. The air hammer can fully process the workpiece.

Owner:常州市新特力工具有限公司

Electric direct driving type impact forging hammer

InactiveCN102335705ALow failure rateSimple structurePower hammersHammer drivesFailure rateMechanical energy

The invention relates to an electric direct driving type impact forging hammer and belongs to the technical field of forging equipment. The electric direct driving type impact forging hammer is an impact forging hammer driven by a linear electric motor and is characterized in that the hammer head of the electric direct driving type impact forging hammer is directly driven by a three-phase alternated current linear electric motor, and the three-phase alternated current linear electric motor can be applied to a maglev train and the take-off of an aircraft carrier airplane and can directly convert electric energy into mechanical energy in the form of linear motion without a middle switching mechanism. The electric direct driving type impact forging hammer has the advantages of simple structure, small mechanical abrasion, low failure rate, small maintenance work load, durability, and the like. No middle switching process is adopted, the hammer head is directly driven by a three-phase alternated current linear electric motor, the three-phase alternated current linear electric motor is powered off when the hammer head has no action, the energy-saving efficiency is high and the noise is low. With a compact structure and a more scientific and reasonable driving principle, the electric direct driving type impact forging hammer is an ideal updated product of a traditional air hammer.

Owner:TAIYUAN UNIV OF TECH

Convenient hydraulic electrohydraulic hammer

InactiveCN101347814ALower the altitudeSimple structurePower hammersHammer drivesElectro hydraulicEngineering

Owner:ANYANG FORGING PRESS MACHINERY IND

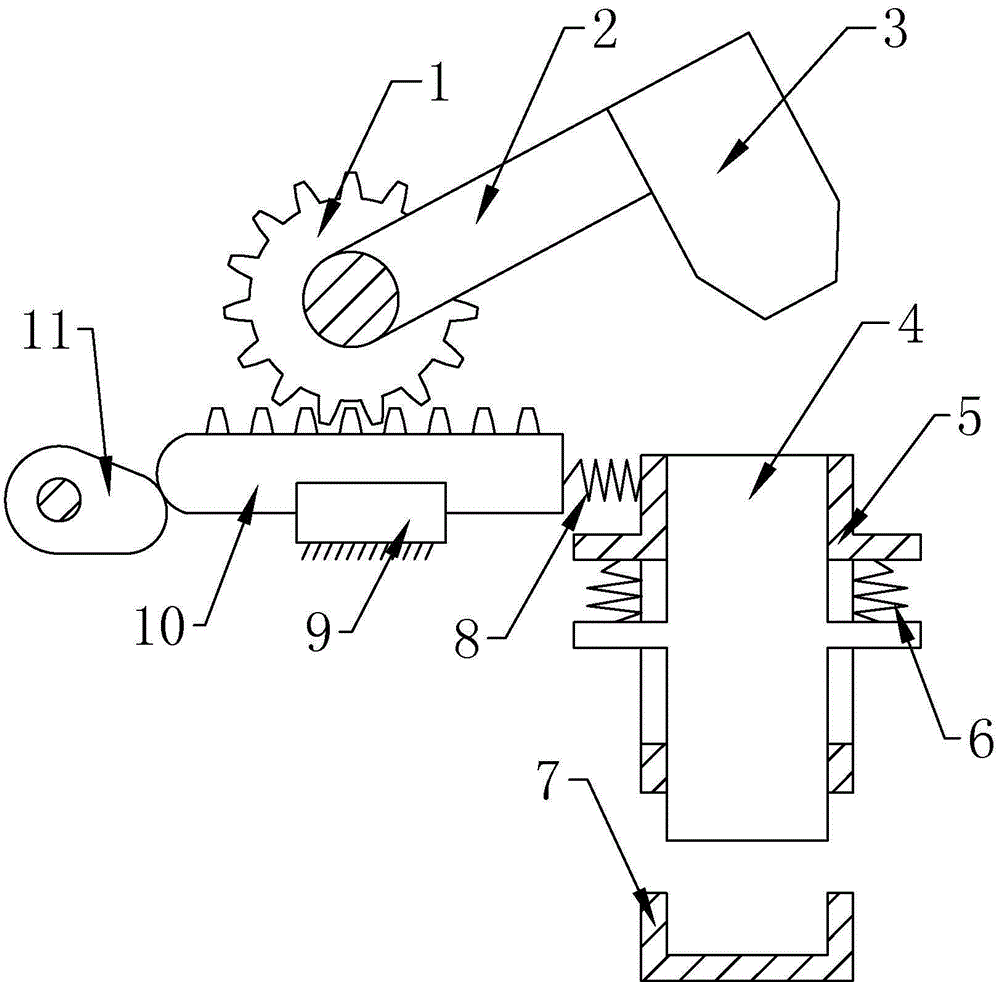

Middle hammering device for forging Luoyang shovel

InactiveCN110744003ARealize repeated beatingReduce labor intensityPower hammersHammer drivesGear wheelElectric machinery

The invention discloses a middle hammering device for forging a Luoyang shovel and relates to the technical field of production and machining of Luoyang shovels. The middle hammering device for forging the Luoyang shovel solves the problems that in the using process of an existing hammering device for a Luoyang shovel, the labor intensity of workers is large, the control difficulty of products ishigh, and meanwhile the production efficiency is low. The middle hammering device for forging the Luoyang shovel comprises a body. A set of sliding table is connected to the top of the body in a sliding mode. A set of feeding table is connected to the top of the sliding table in a sliding mode. A set of flywheel is connected to the inner side of the upper portion of the body in a shaft mode. A setof driven belt wheel and a set of middle gear are connected to the inner side of the rear end face of the body in a shafting mode. The rear end face of the flywheel is coaxially and fixedly connectedwith a motor. By means of the device, automatic pressing in the feeding process can be achieved, repeated hammering to workpieces can be achieved, feeding operation by workers is not needed, manpoweris saved, the dependence on the technical ability of workers is removed, the yield can be better ensured, the working efficiency is greatly improved, and the middle hammering device is easy to operate and convenient to use.

Owner:肖亚凡

Vertical type forging machine

InactiveCN101412068AImprove punching strengthTake advantage ofPower hammersHammer drivesGear wheelEngineering

The invention provides a vertical type forging machine. The machine comprises a transmission mechanism and an impact forging mechanism, wherein the transmission mechanism comprises a motor, an eccentric rotary shaft, a gear unit which is driven by the motor and can drive the eccentric rotary shaft to rotate and an impact connecting rod which is eccentrically and pivotally sleeved on the eccentric rotary shaft and can be driven by the eccentric rotary shaft to swing up and down. The gear unit is provided with a transmission gear which can be driven to rotate by the motor and a reduction gear which is pivotally arranged on one shaft rod part of the eccentric rotary shaft and meshed with the transmission gear and has an external diameter larger than that of the transmission gear. The impact connecting rod is sheathed with the outer part of one eccentric deflecting part of the eccentric rotary shaft. Because of big gear ratio between the transmission gear and the reduction gear, and the structural design of the impact unit which is eccentrically and pivotally arranged on the eccentric rotary shaft and used to drive the forging mechanism, the forging force generated by the motor transmission is increased.

Owner:运通工业股份有限公司

Safety automatic forging and pressing machine

InactiveCN108526367ARealize multi-angle forgingImprove processing efficiencyPower hammersHammer drivesHydraulic cylinderCoupling

The invention relates to a safety automatic forging and pressing machine. The machine comprises a clamping mechanism and a base; the base is arranged to be of a rectangular plate-shaped structure, a vertical beam is vertically riveted to the right end of the base, the left end of the vertical beam is transversely and fixedly provided with a cross beam, an oil tank is arranged on one side of the cross beam, an electric motor, a transmission and an oil pump are arranged in the oil tank, the electric motor is rotatably connected with the oil pump through a coupler, and is electrically connected with the transmission, a speed controller is arranged in the transmission, the oil pump is communicated with a hydraulic cylinder through an electromagnetic valve liquid supply end, the bottom of the hydraulic cylinder is fixedly connected with a telescopic rod through a connecting rod, and the top end of the telescopic rod is connected with a forging hammer. Through control over the rotating speedof the electric motor by the transmission, according to needs, the pressure of the forging hammer can be changed, machining efficiency is improved, a clamp is arranged, a machined workpiece can be conveniently clamped, and through the rotating disc which rotates, multi-angle forging and pressing of the workpiece can be achieved.

Owner:成都鹏派科技有限公司

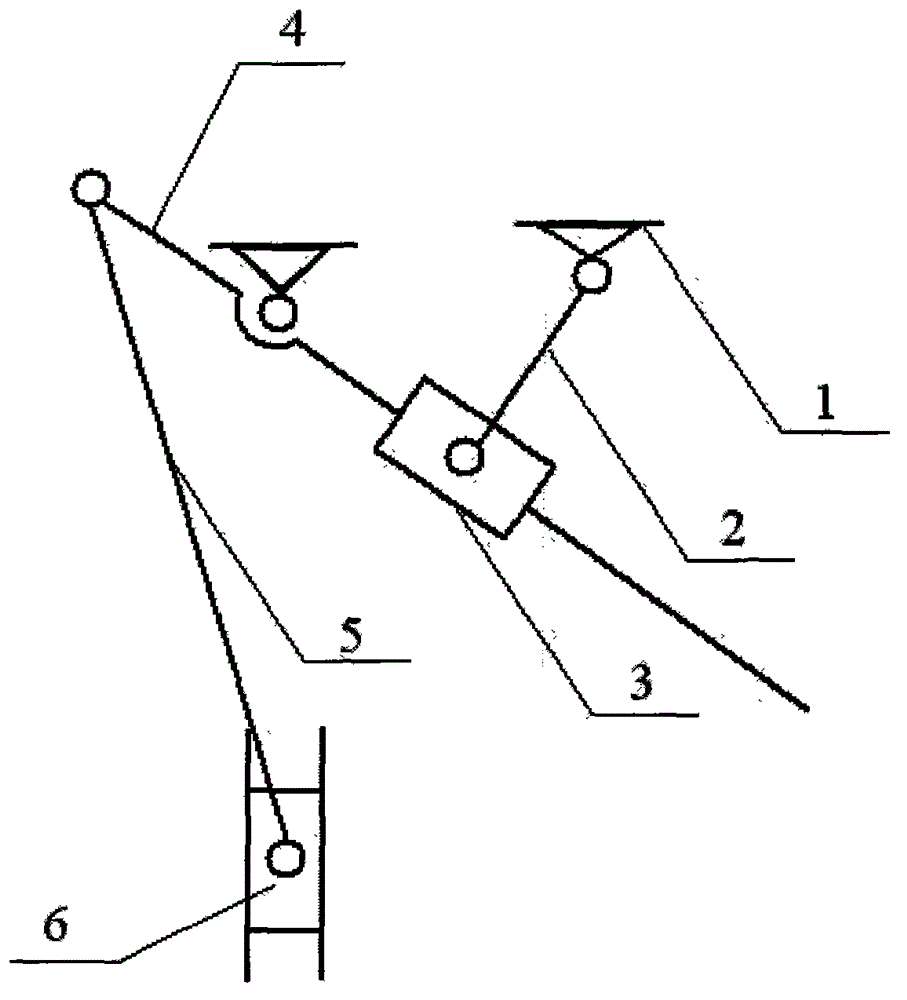

Connecting rod press machine with swinging guide rod

The invention relates to a connecting rod press machine with a swinging guide rod. The press machine comprises a swinging guide rod mechanism, a punching hammer connecting rod and a punching hammer, wherein the swinging guide rod mechanism consists of a machine frame, a crank, a slide block and a swinging rod, the crank is respectively connected with the machine frame and the slide block through a rotating pair, the slide block is connected with the swinging rod through a moving pair, the swinging rod is respectively connected with the machine frame and the punching hammer connecting rod through a rotating pair, the tail end of the punching hammer connecting rod is connected with the punching hammer through a rotating pair, and the punching hammer is fixedly arranged in a fixed guide rail. An ordinary constant-speed motor is utilized for driving a combination mechanism with the swinging guide rod, good low-speed forging punching fast return characteristics can be realized, in addition, the structure of the press machine is simple and compact, and the manufacture cost is low.

Owner:SHANDONG UNIV OF SCI & TECH

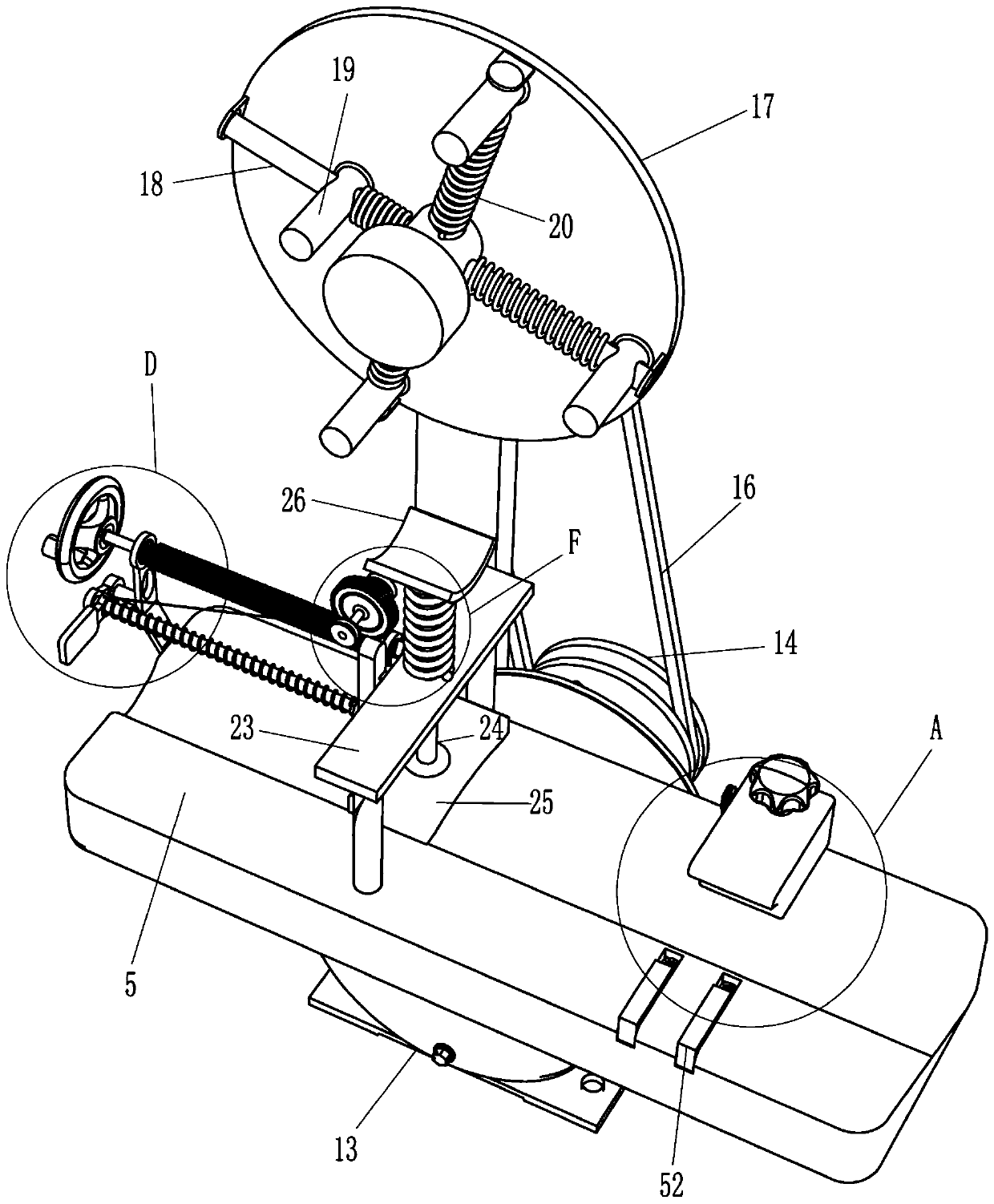

Luoyang shovel middle hammering device

InactiveCN110918852AQuality assuranceSave human effortPower hammersHammer drivesStructural engineeringWorkbench

The invention relates to a hammering device, in particular to a Luoyang shovel middle hammering device. The Luoyang shovel middle hammering device can automatically hammer the Luoyang shovel, adjust the hammer force and improve the working efficiency. The Luoyang shovel middle hammering device comprises a mounting bottom plate, a workbench, a rotating shaft, a hammer, a limiting part, a force adjusting part, a power assembly and the like; the workbench is arranged on the right side of the top of the mounting bottom plate, the rotating shaft is arranged on the left side of the top of the mounting bottom plate, the hammer is arranged on the rotating shaft, and the limiting part for fixing a handle of a Luoyang shovel through a sliding mode is arranged on the left side of the top of the mounting bottom plate. According to the Luoyang shovel middle hammering device, through the matching of the power assembly and the force adjusting part, the hammer can be driven to swing up indirectly to hammer the Luoyang shovel continuously, manpower is saved, meanwhile the hammer force of each time is same, and the quality of the Luoyang shovel is ensured.

Owner:肖亚凡

Opposed current flow magnetic pulse forming and joining system

ActiveUS7395597B2Quality improvementImprove reliabilityPower hammersHammer drivesElectricityElectrical conductor

An opposed current flow magnetic pulse forming and joining system in electrical communication with a magnetic pulse power supply having a positive connection and a negative connection. The system may be used in forming individual workpieces or joining multiple workpieces, including joining by magnetic pulse welding. The system includes a first section, a second section, an insulator, and a first and a second pair of conductors. The first and second sections cooperate to enclose the workpiece(s) and function to create an electromagnetic force similar to that produced by a single closed coil. The system is configured to achieve desirable current flow by minimizing inductance, inductive reactance, and impedance in the conductors. The pairs of conductors may incorporate closely spaced individual conductors, braided conductors, and coaxial conductors. The current flow in the individual conductors of each pair of conductors is opposed, as is the current flow through the sections.

Owner:EDISON WELDING INSTITUTE INC

Forging method for reducing proportion of tiny crack defects of bearing

InactiveCN105215258AThe effect of streamline changesIncreased streamline variationPower hammersHammer drivesCrazingMaterials science

The invention relates to a forging method for reducing the proportion of tiny crack defects of a bearing. The forging method aims at solving the problems that a die used in an existing high-performance bearing forging technology influences changes of a streamline of a material section, and defects are likely to occur in a forged part. The forging method specifically comprises the following steps that firstly, the material section is upset, wherein the material section is thumped by a 450Kg air hammer, and the number of thumping times ranges from 10 to 22; secondly, single-face stamping expansion is carried out, wherein the thumped forged piece is subjected to single-face stamping expansion; thirdly, stamping expansion is carried out repeatedly, wherein the corresponding face of the forced piece obtained through single-face stamping expansion in the second step is subjected to stamping expansion, and the operation in the second step and the operation in the third step are repeated 2-3 times; fourthly, rolling expansion is carried out, wherein before rolling expansion is carried out, a rolling expansion wheel is preheated, and the forged piece obtained after repeated stamping expansion is subjected to rolling expansion after the temperature of the rolling expansion wheel reaches 150-200 DEG C. The forging method is used for the field of bearings.

Owner:AVIC HARBIN BEARING

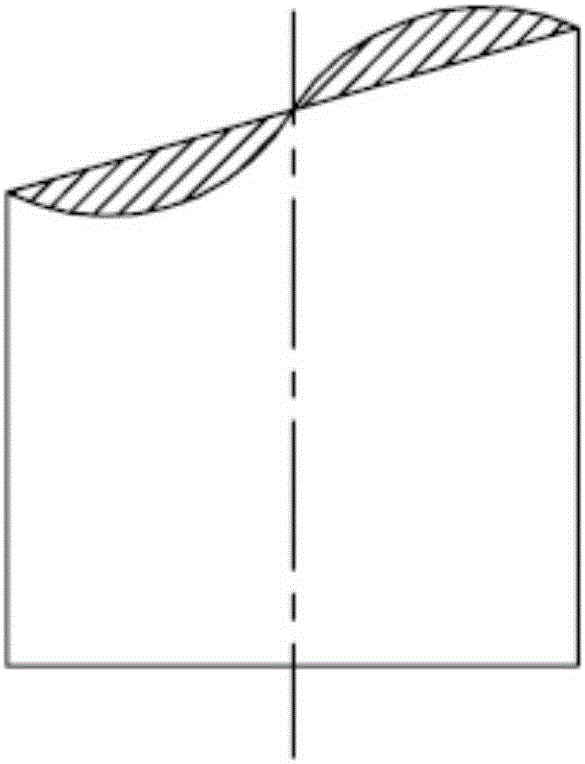

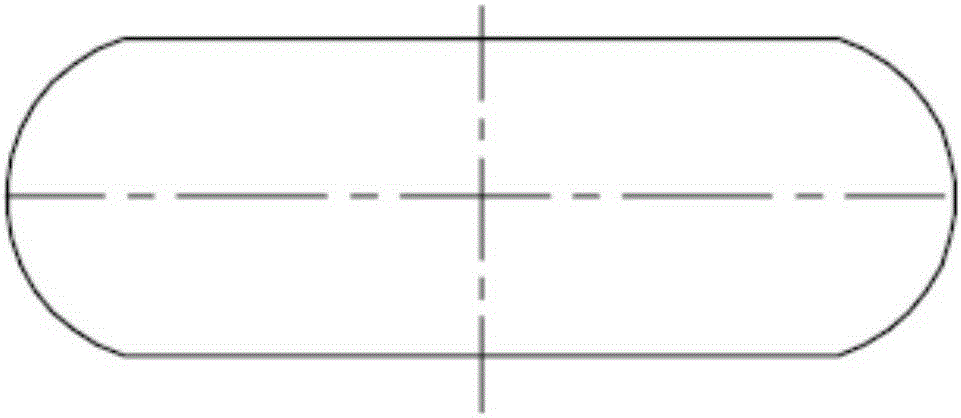

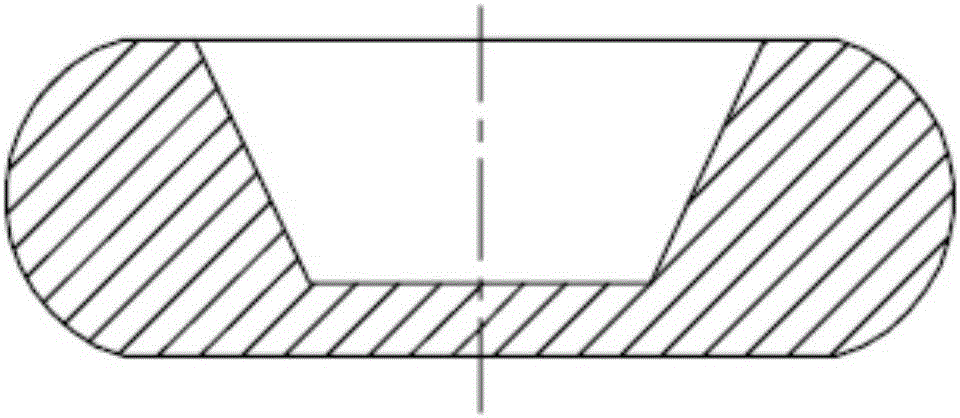

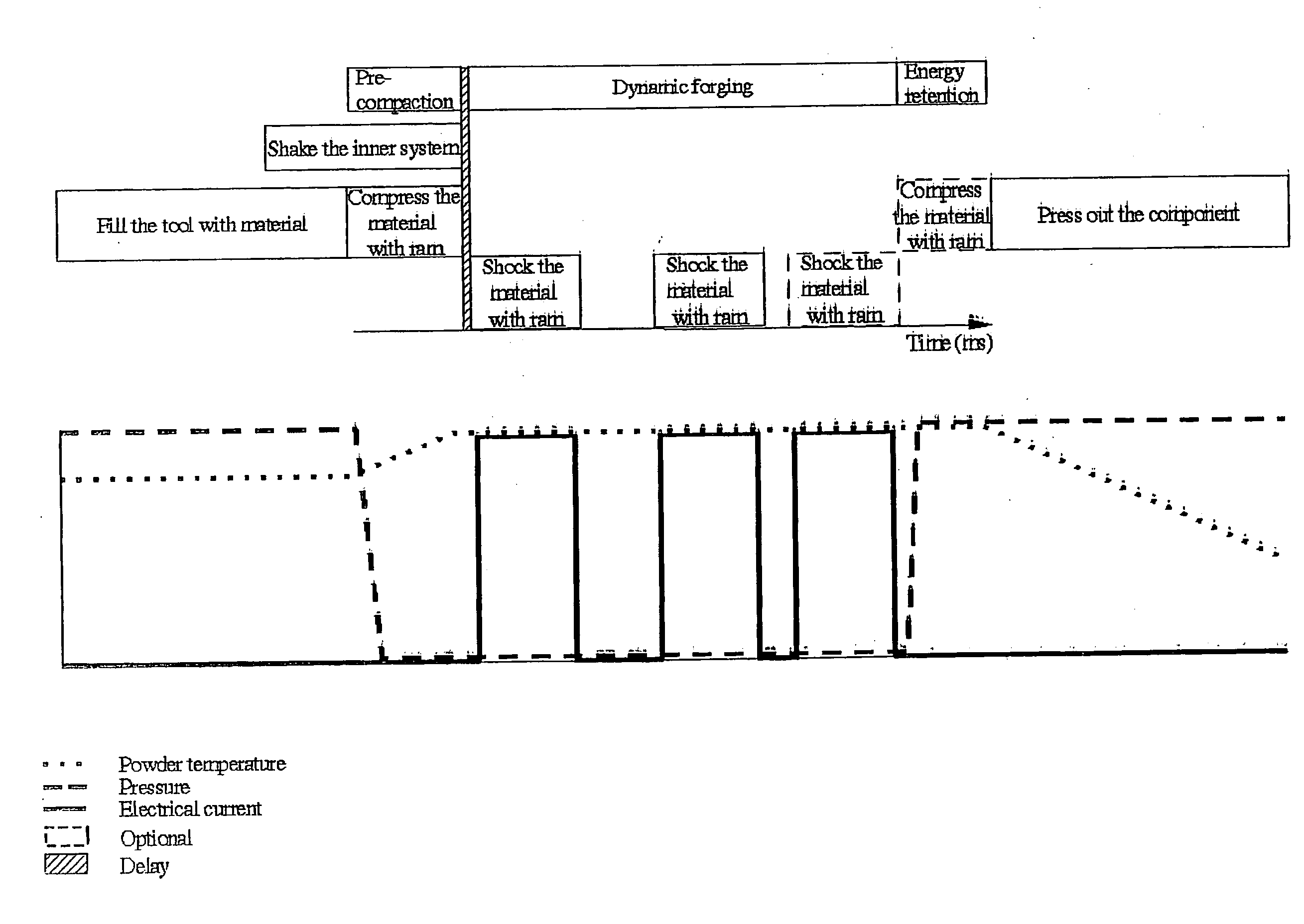

Process for producing a high density by high velocity compacting

InactiveUS20050220658A1Good sequence controlLow running costPower hammersHammer drivesParticulatesHigh density

A method of producing a body from a particulate or solid material comprises filling a precompacting mould with the material, optionally vibrating the mould, pre-compacting the material and compressing it by at least one stroke with high kinetic energy in order to cause coalescence or high density of the material.

Owner:OLSSON KENT +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com