Vertical type forging machine

A forging machine and vertical technology, which is applied in the field of forging machines, can solve the problems of increasing equipment cost, not meeting the economic cost, and the large shape of the forming machine, so as to achieve the effect of improving the punching and forging force and making full use of the workshop space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Below in conjunction with accompanying drawing and embodiment the present invention is described in detail:

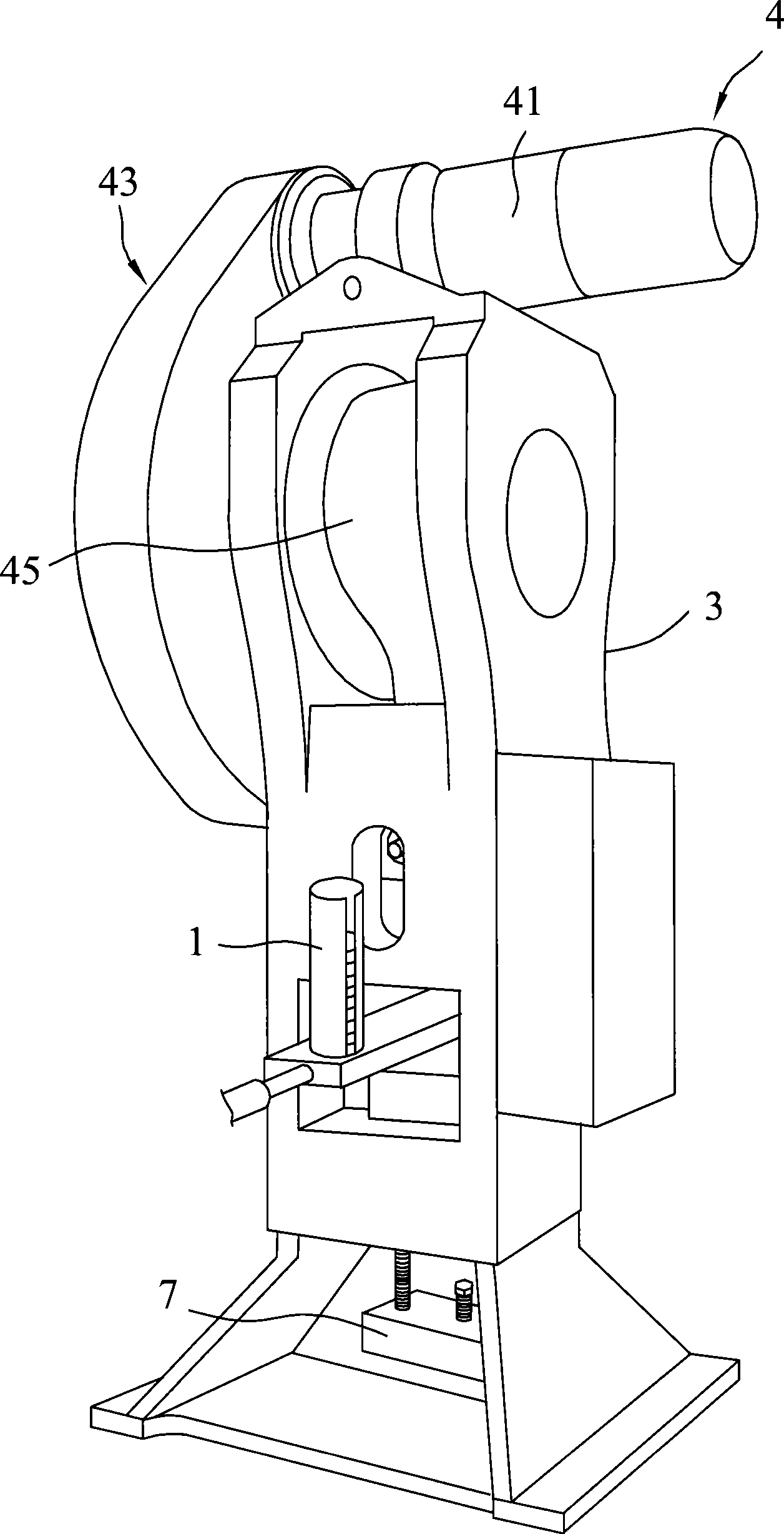

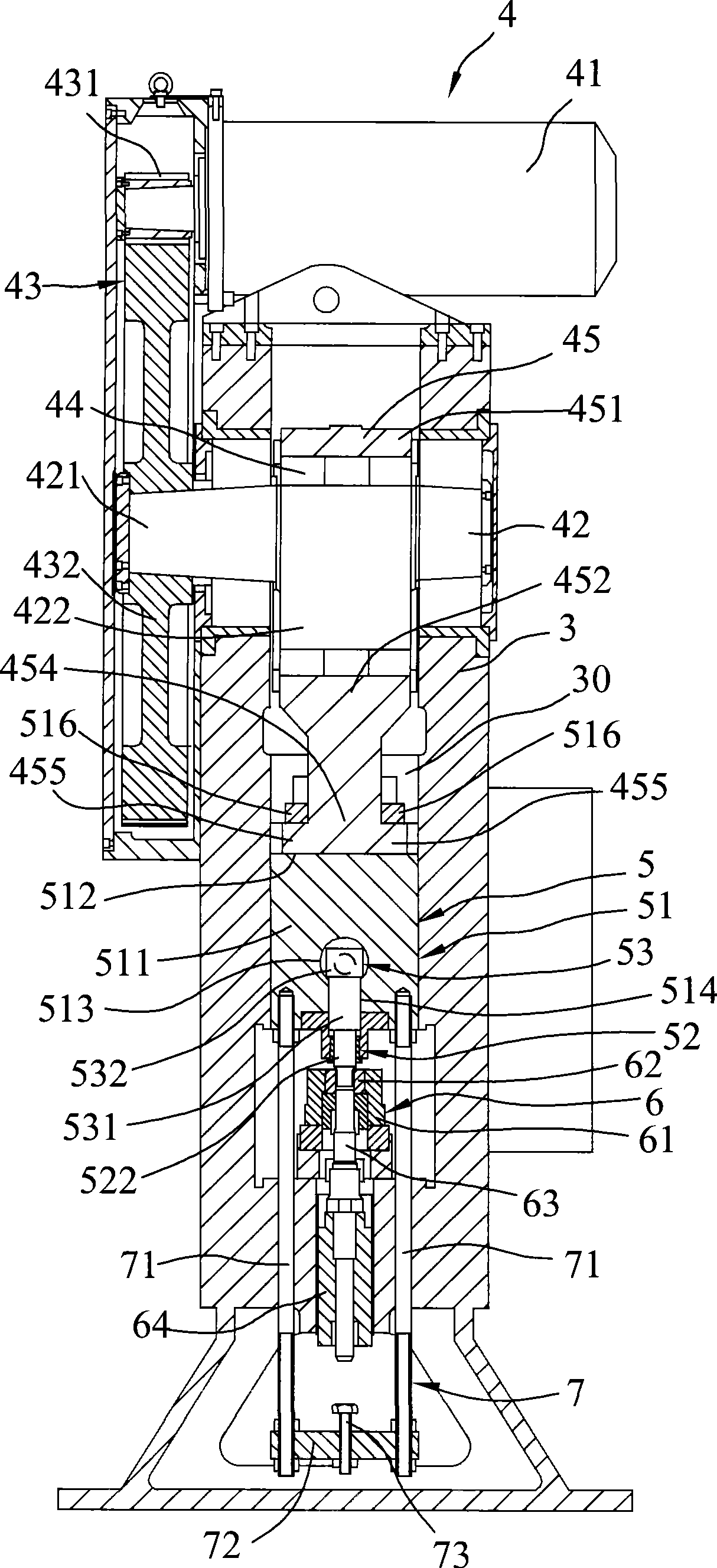

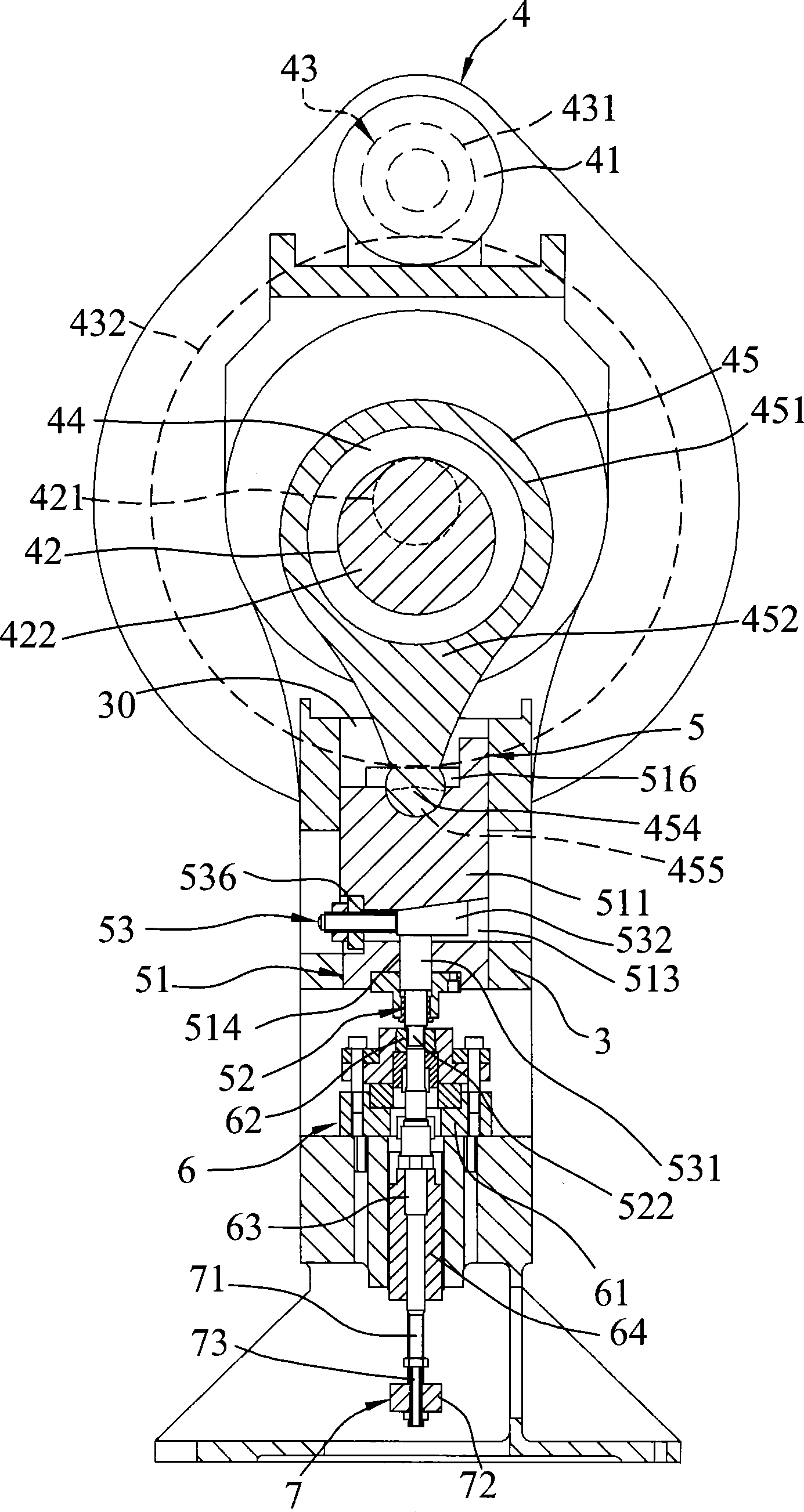

[0020] Such as figure 1 , 2 As shown, the embodiment of the vertical forging machine of the present invention is suitable for punching and forging a blank into a part with a predetermined shape. In this embodiment, a block-shaped blank is punched and forged into a cup-shaped part, but during implementation, Part shape is not limited to this. The forging machine includes: an upright machine platform 3, a transmission mechanism 4 installed in the machine platform 3, a punching forging mechanism 5 installed in the machine platform 3 and installed with the transmission mechanism 4, and a transmission mechanism 5 installed in the machine platform 3 A die mechanism 6 located in the middle and below the stamping mechanism 5, and a push mechanism 7 installed in the machine table 3.

[0021] Such as Figure 2-4 As shown, the machine table 3 has a sliding space 30 ext...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com