Patents

Literature

524results about "Hammer drives" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Stamping system for manufacturing high tolerance parts

ActiveUS7343770B2Minimize the numberTight toleranceShaping toolsPerforating toolsMachine pressStamping press

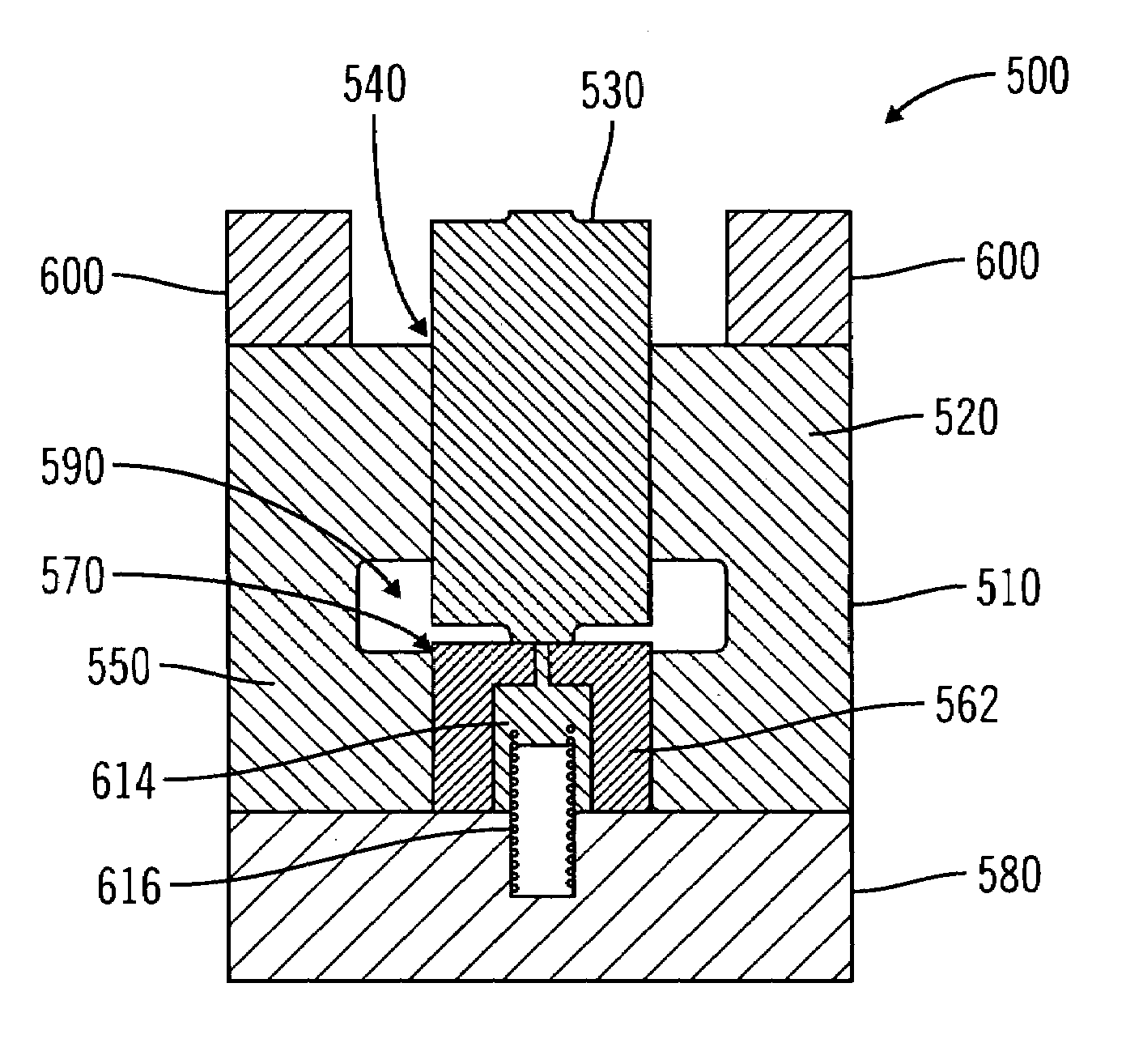

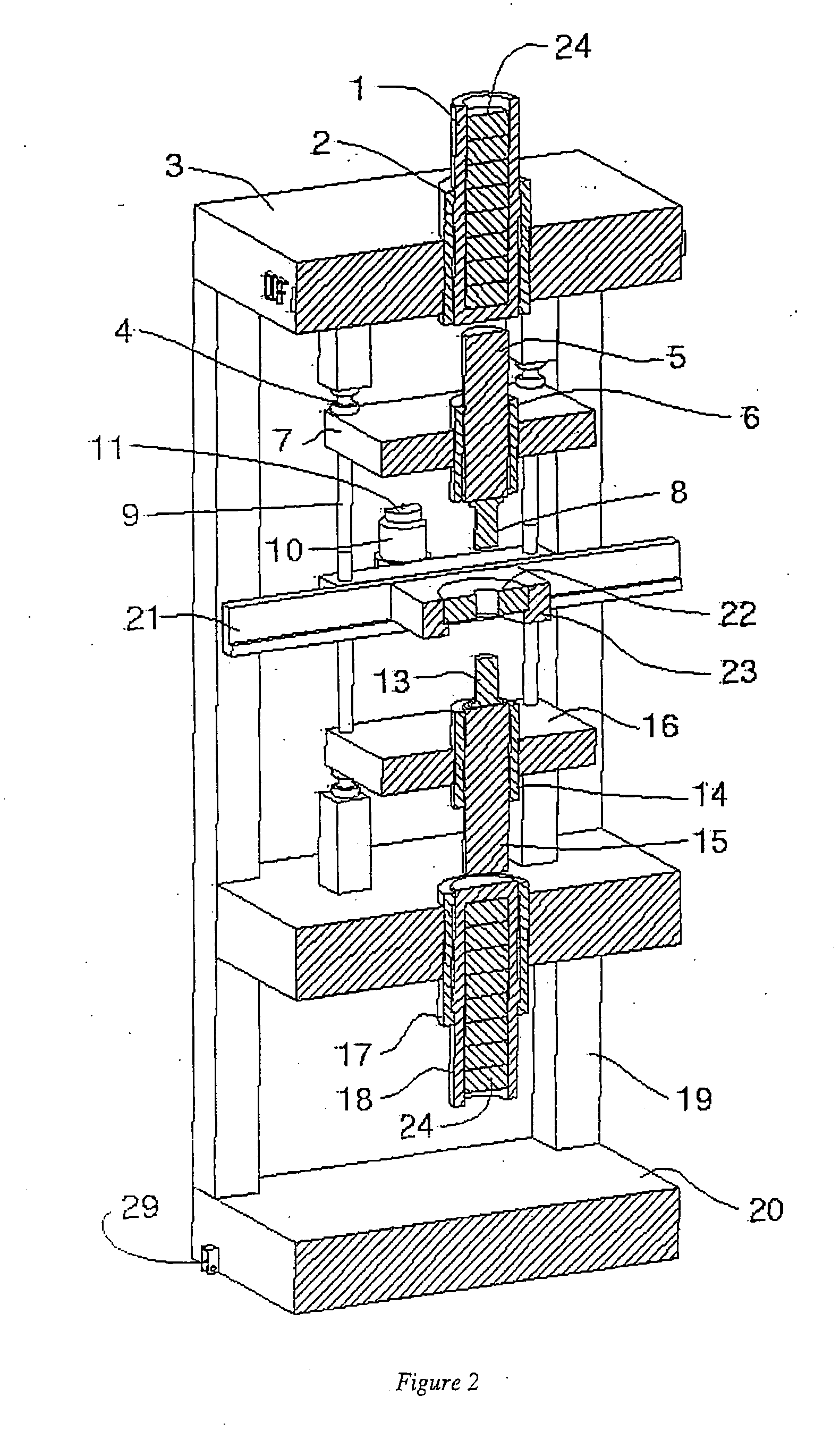

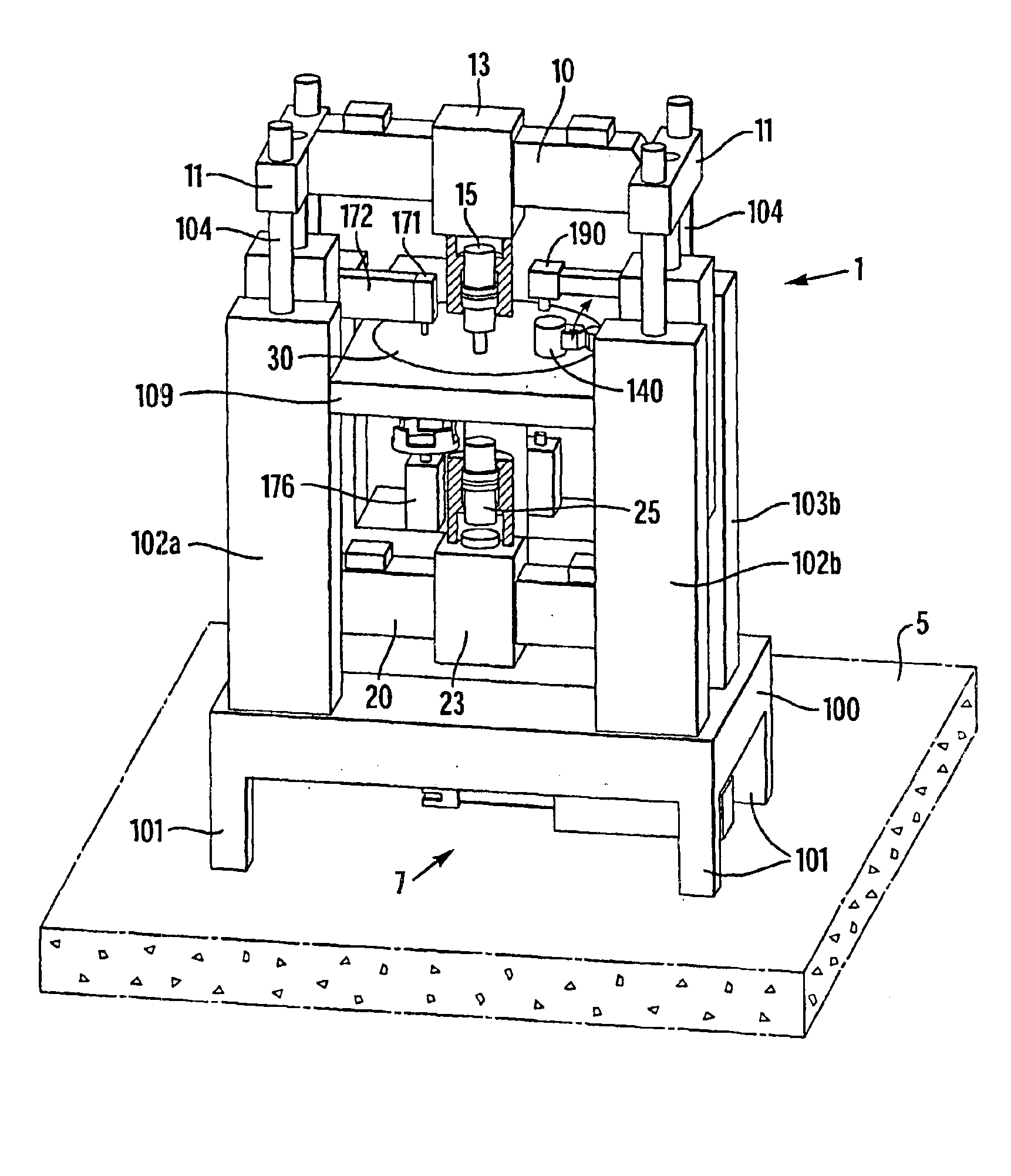

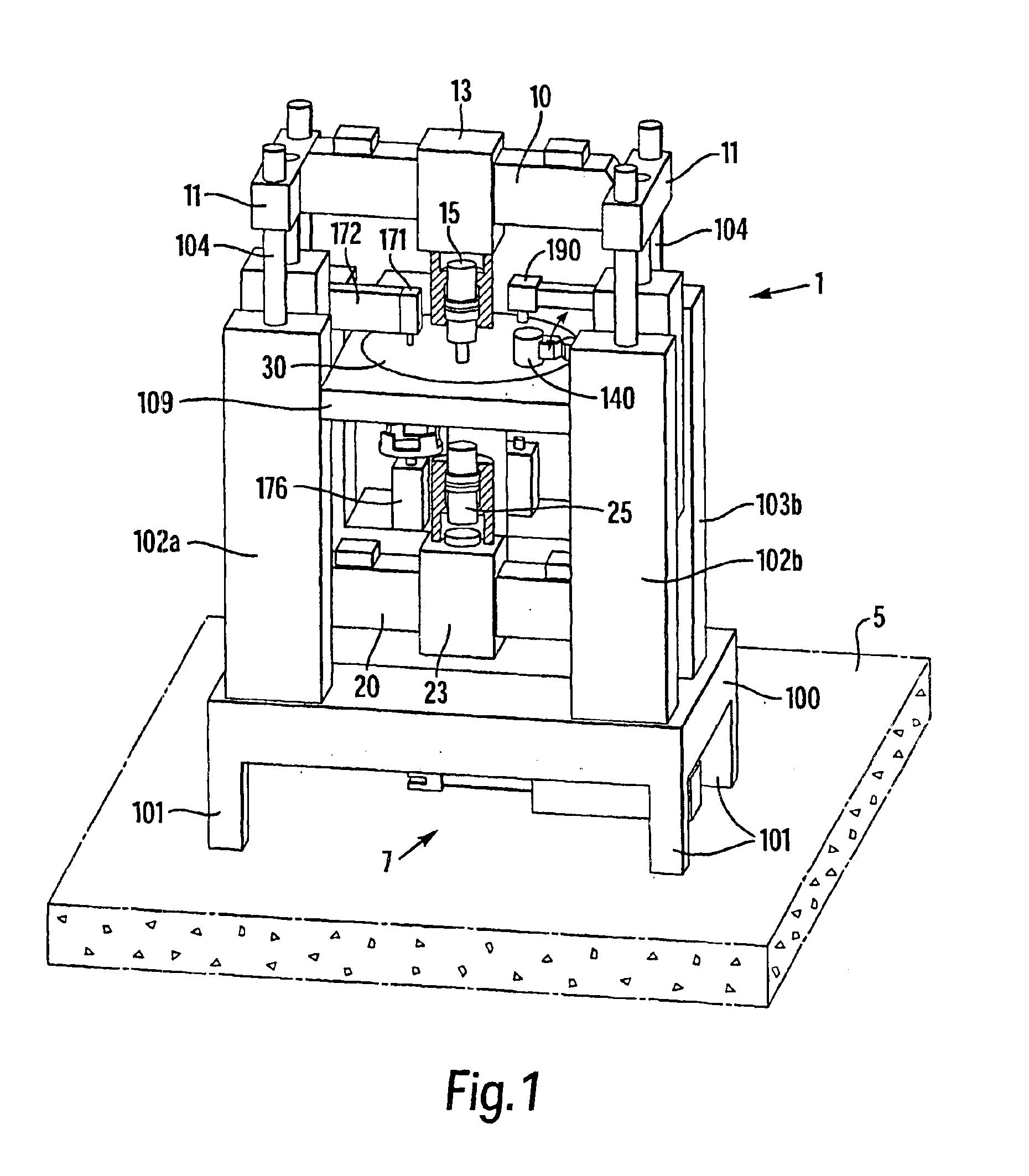

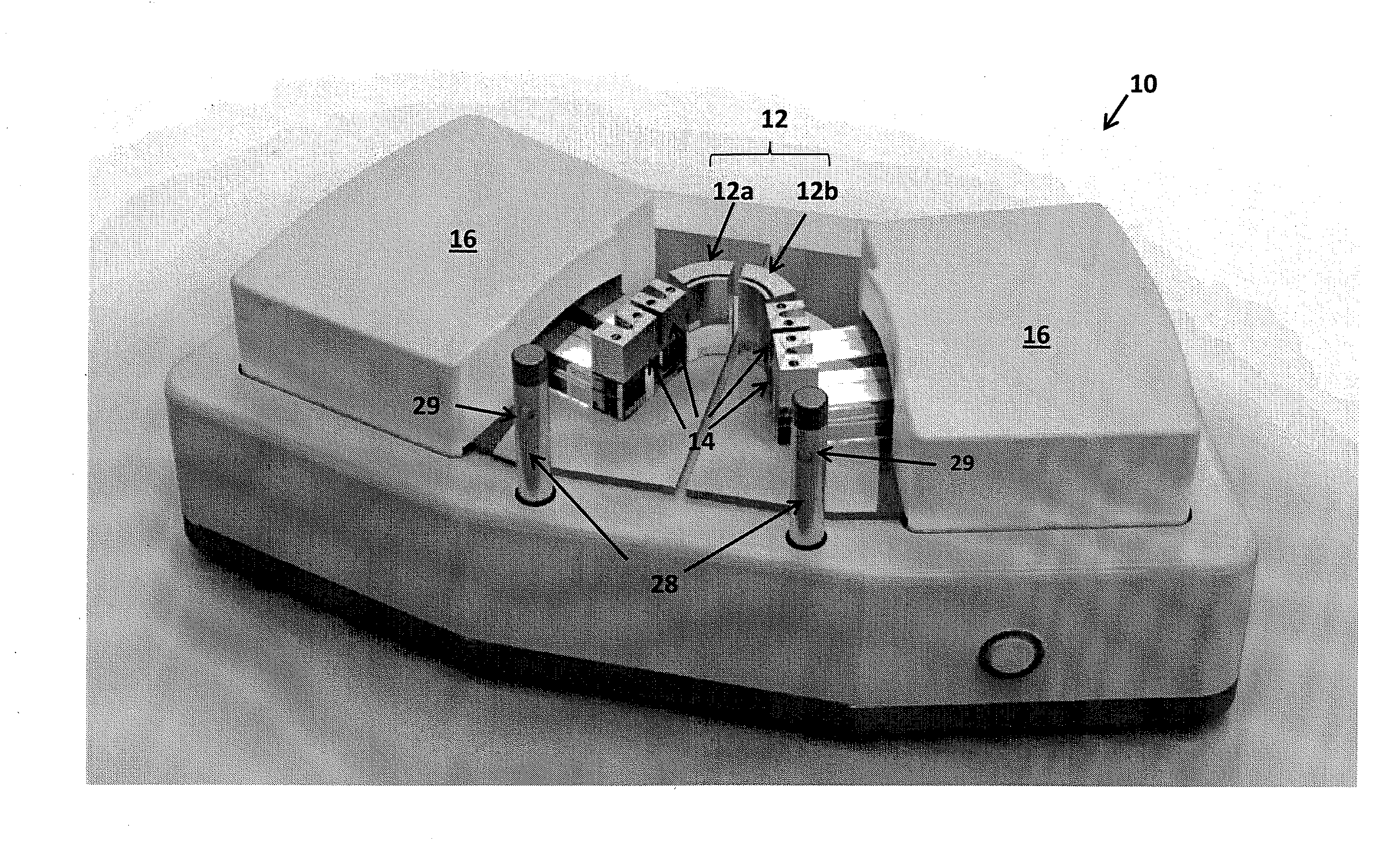

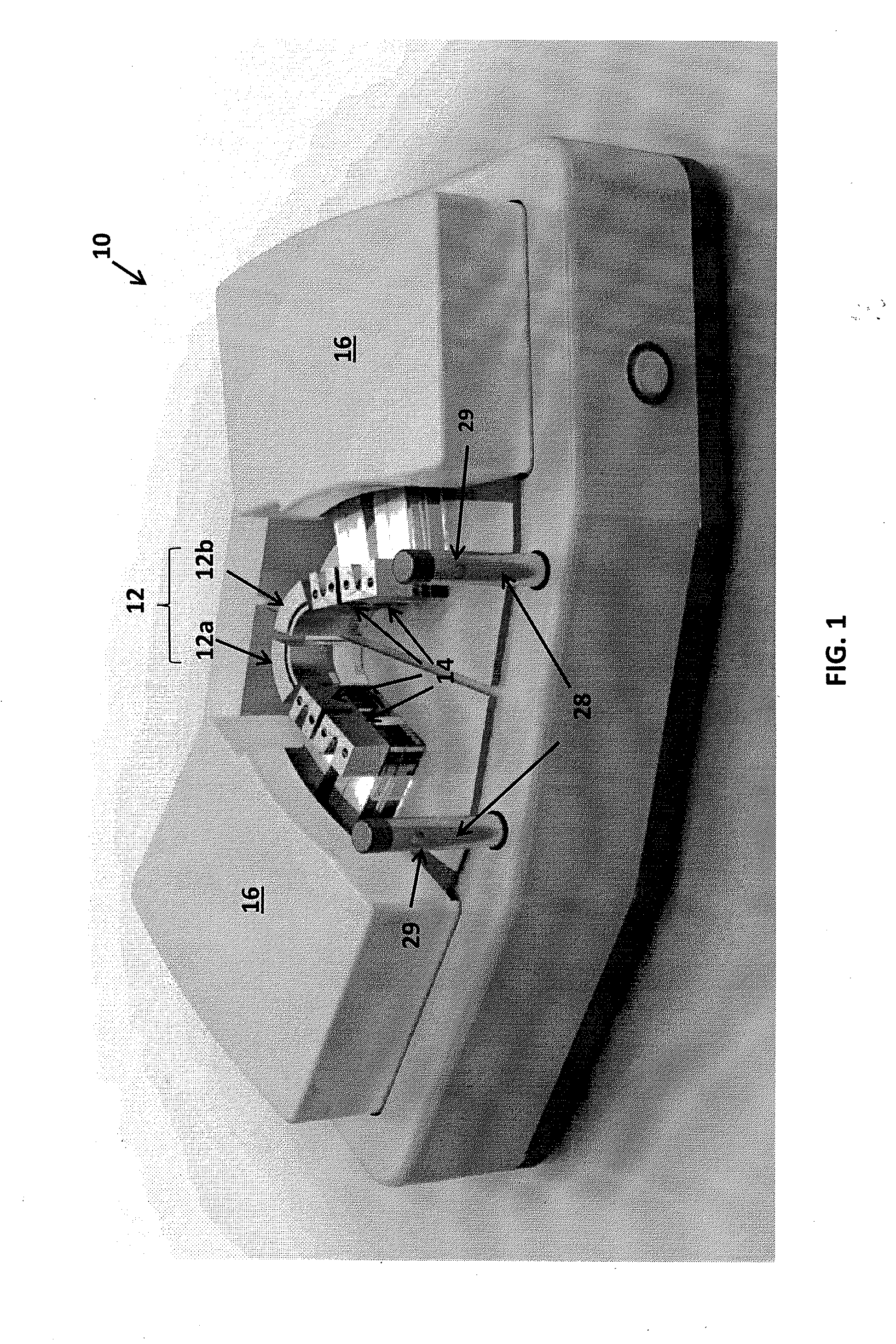

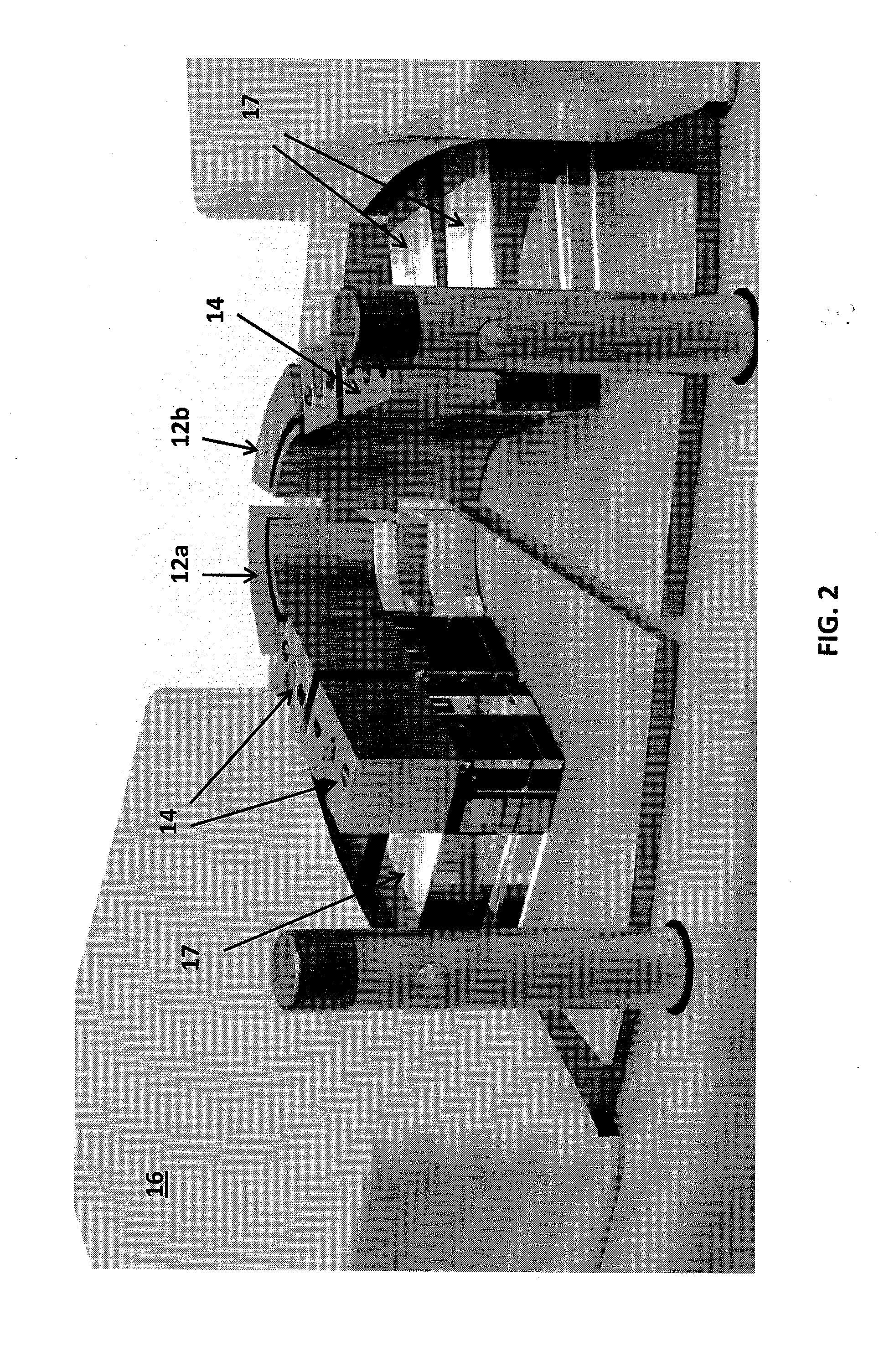

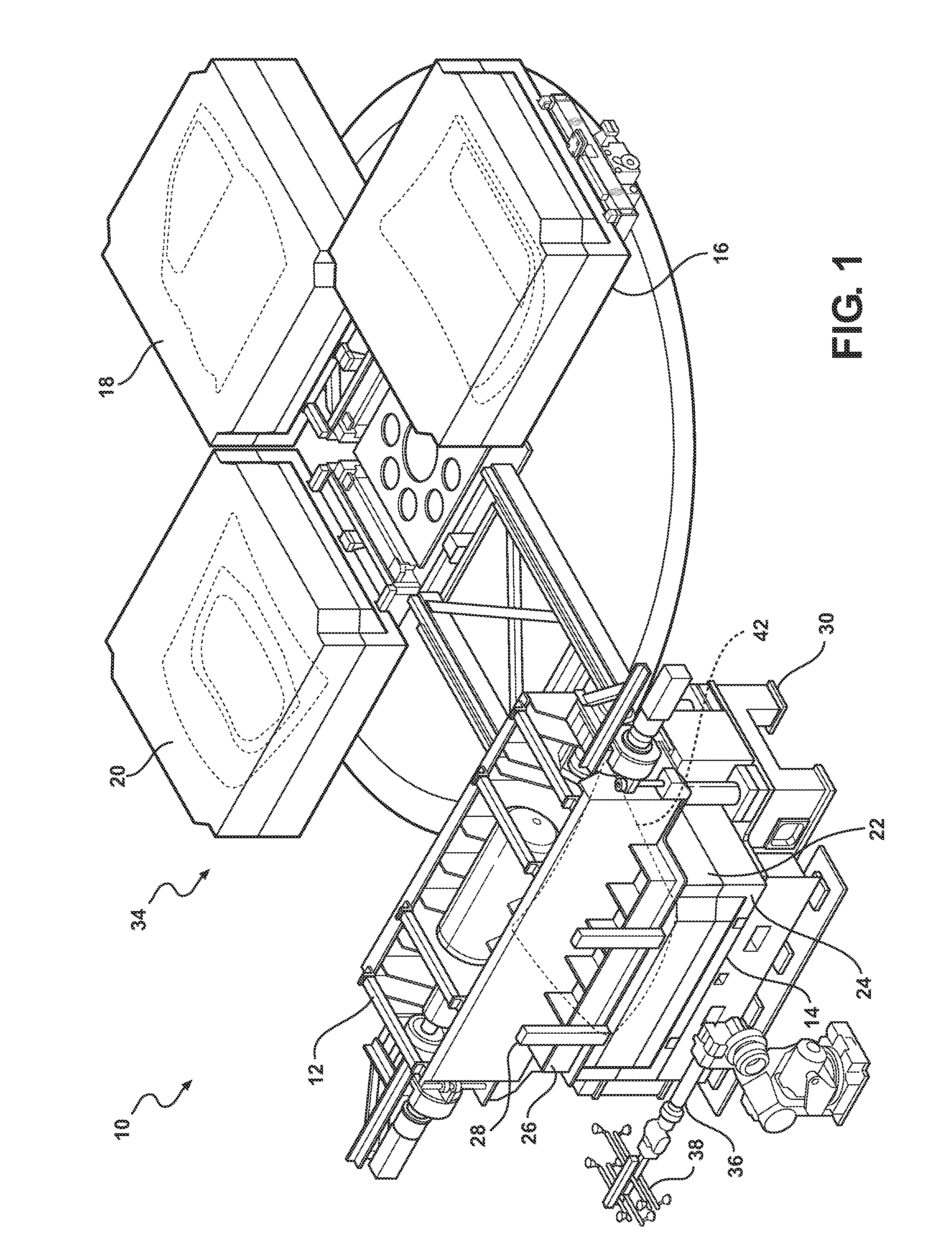

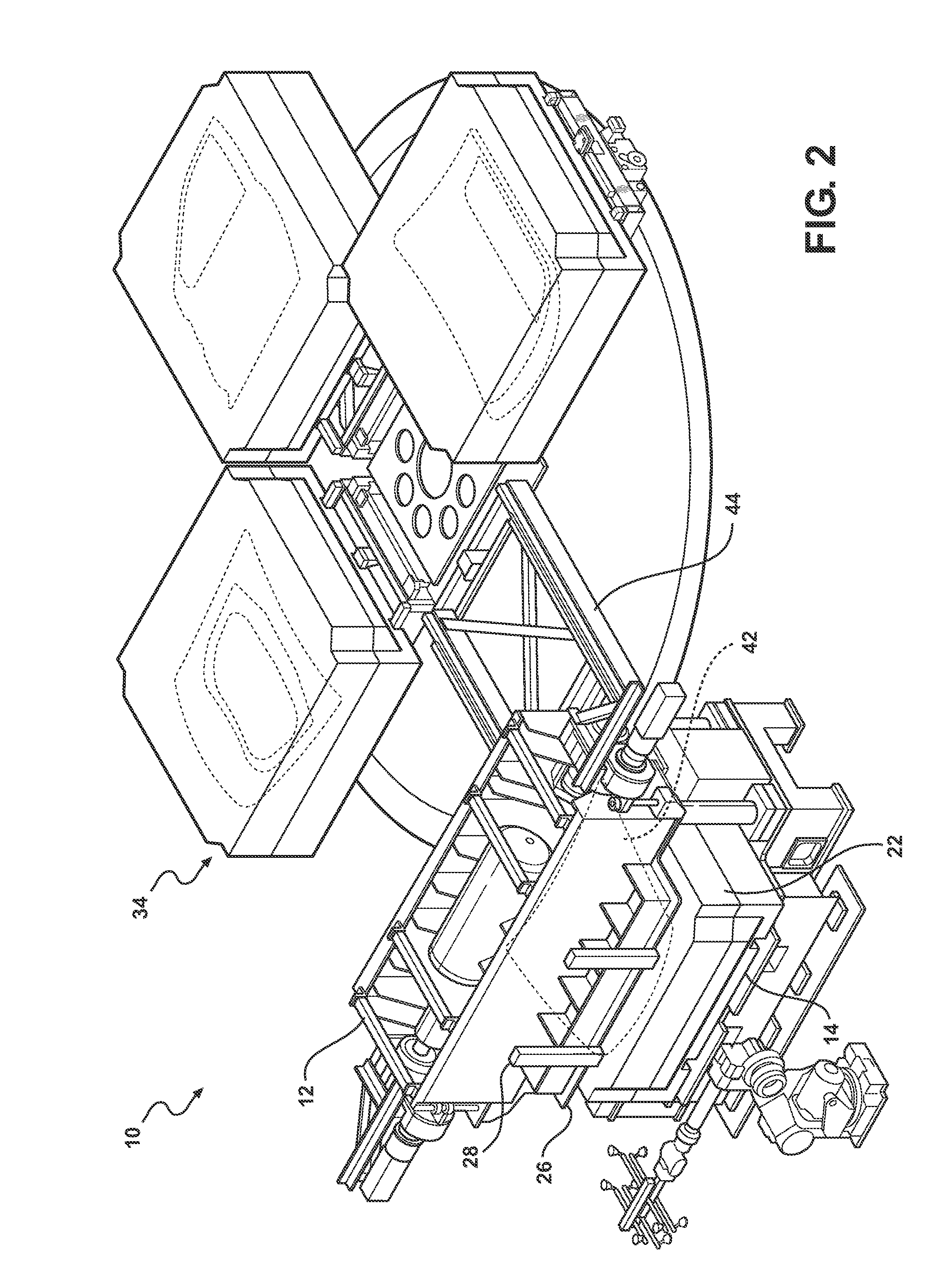

A system and process for stamping parts having tolerances below 1000 nanometers. The inventive system and process is particularly suited for producing optoelectronic parts. The system includes a stamping press and one or a progression of stamping stations for supporting a punch and die. The stamping stations are designed to maintain substantial alignment of the punch and die with minimal moving components. The stamping station includes a shaft for rigidly guiding the punch to the die. The stamping press is capable of providing the punch with the necessary force to perform the stamping operations. The system includes an interface system for interfacing the force of the press with the punch, while simultaneously structurally decoupling the press from the punch. The system also includes a locating sub-plate, for locating the stamping station in alignment relative to each other, and means for in-line machine stock material before entry into the stamping stations.

Owner:SENKO ADVANCED COMPONENTS

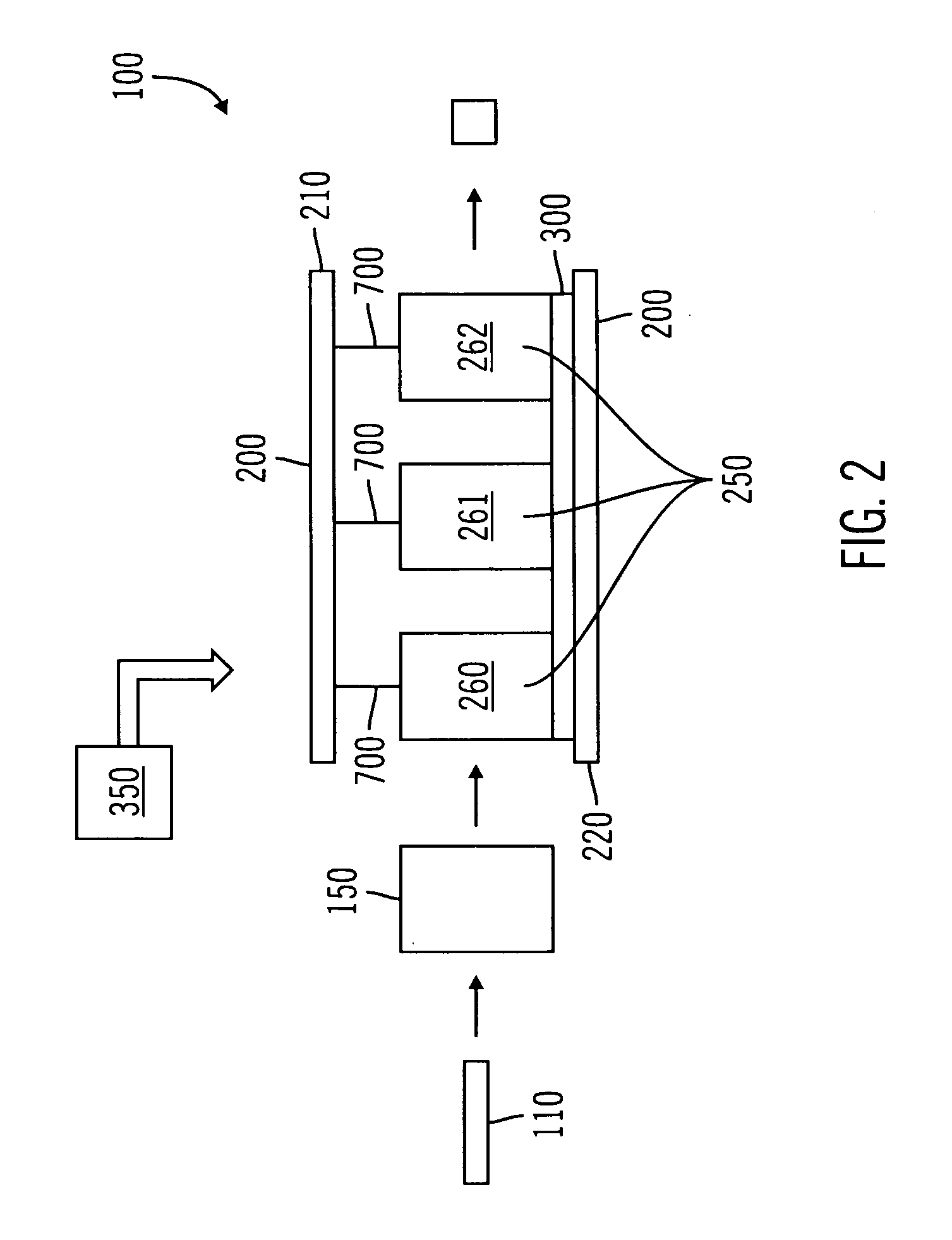

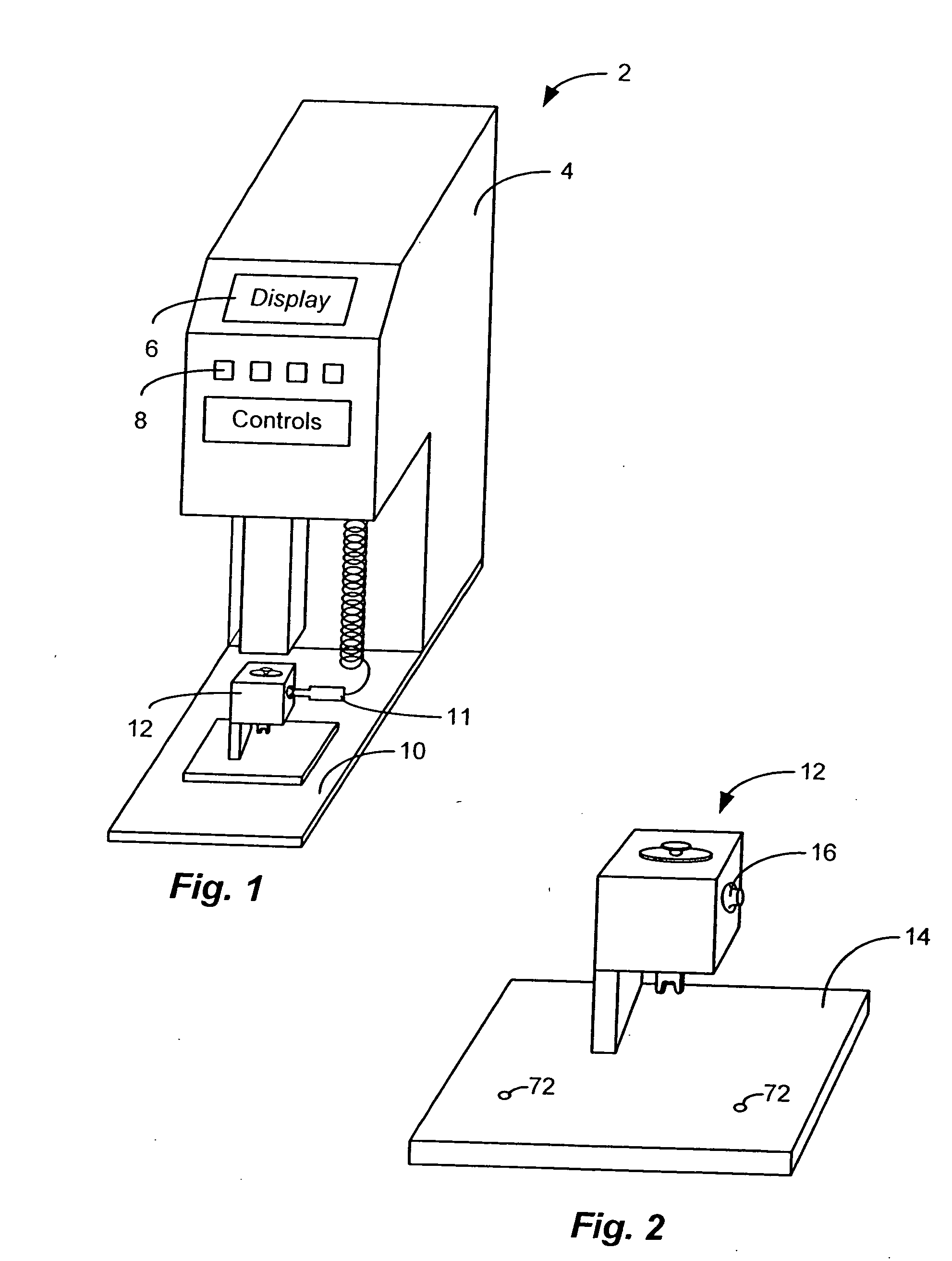

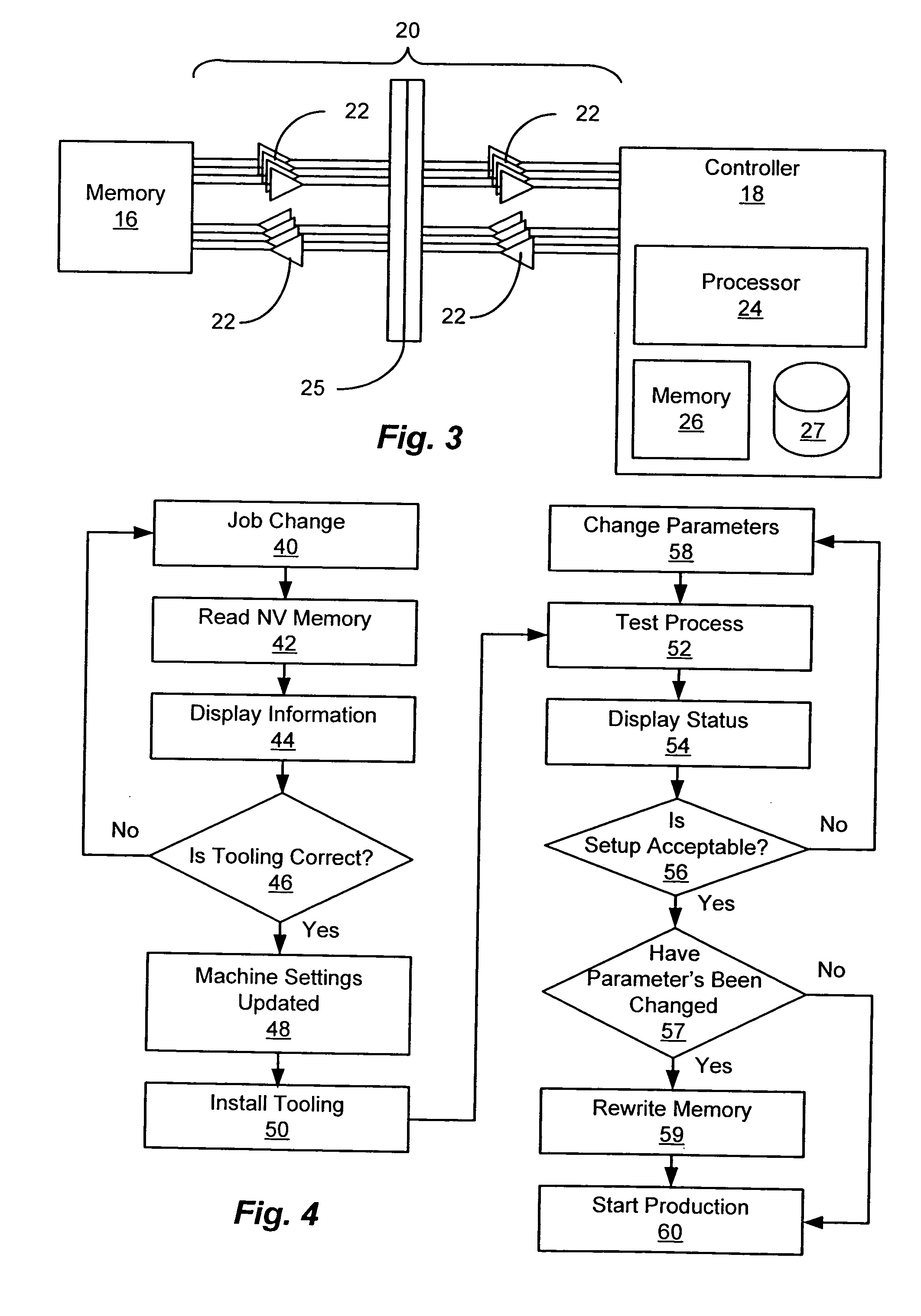

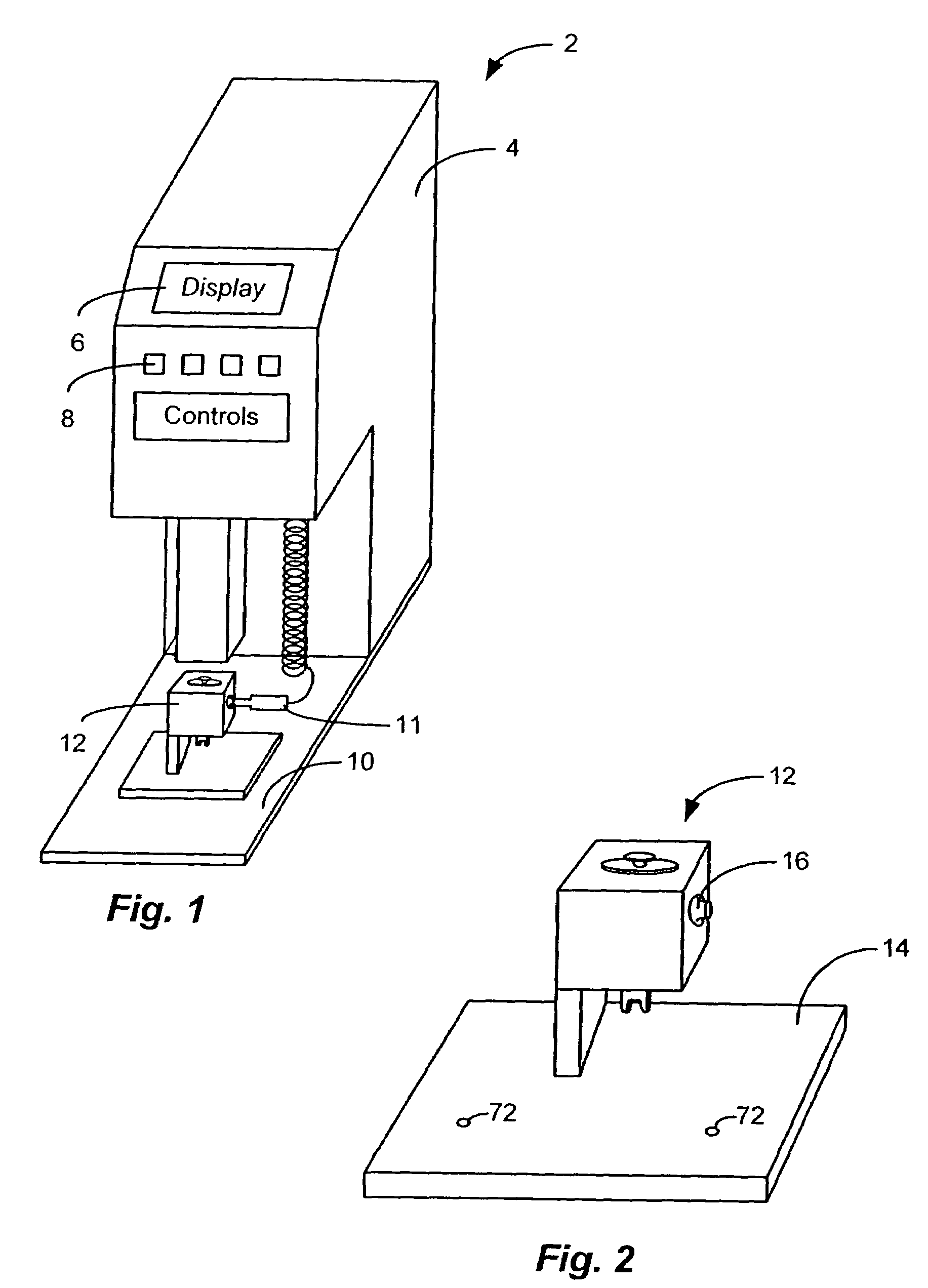

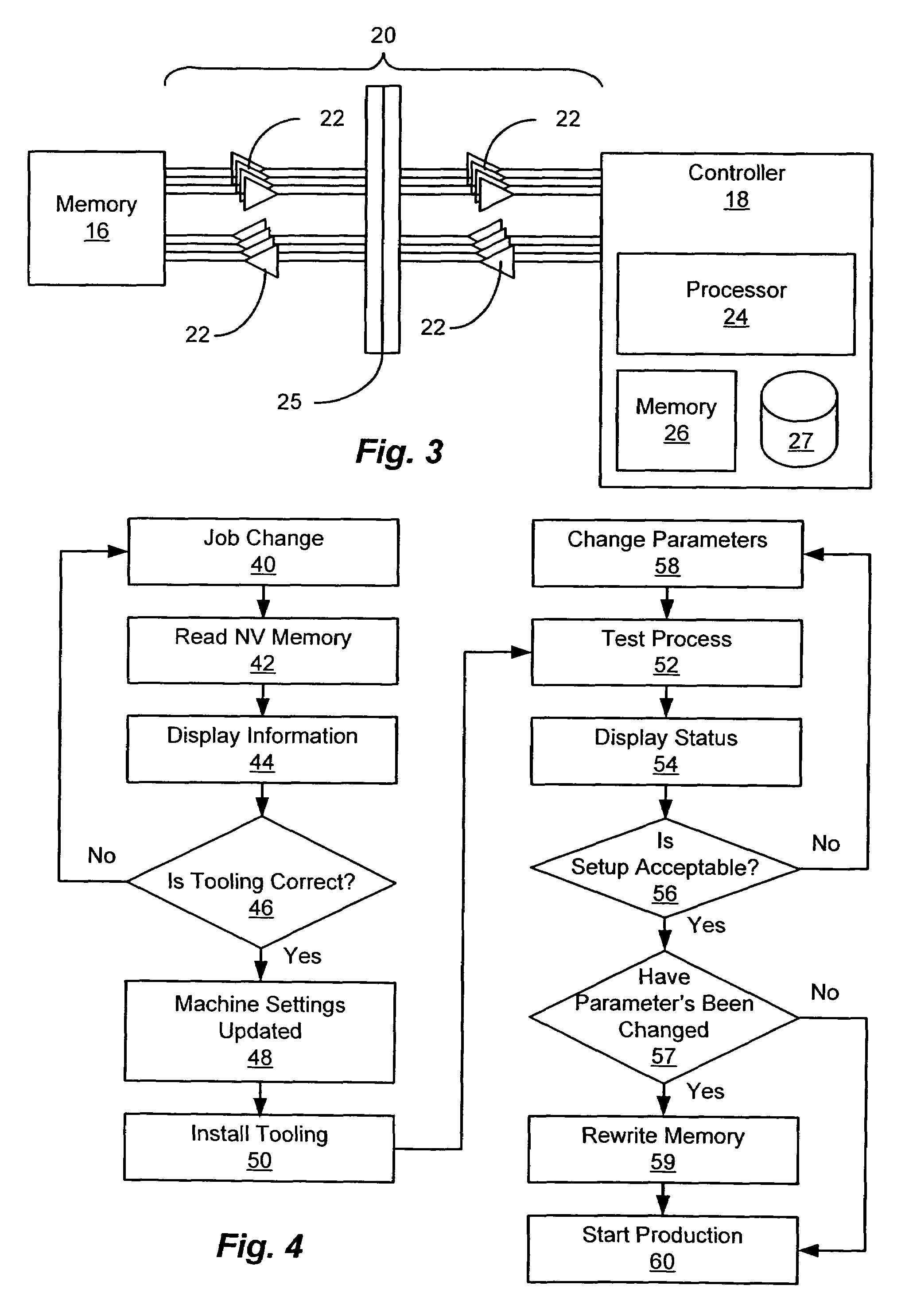

Automated machine setup with modular tooling

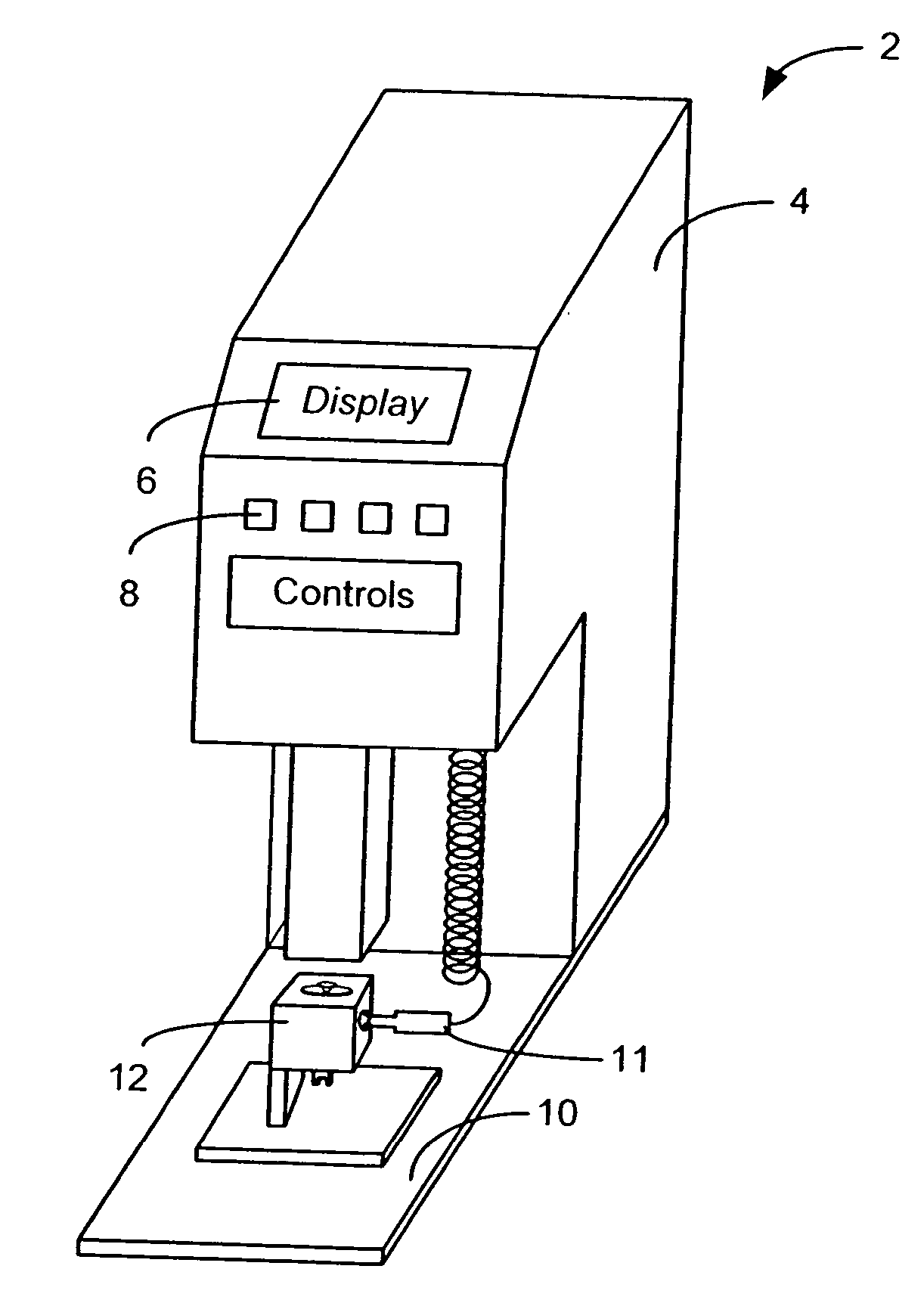

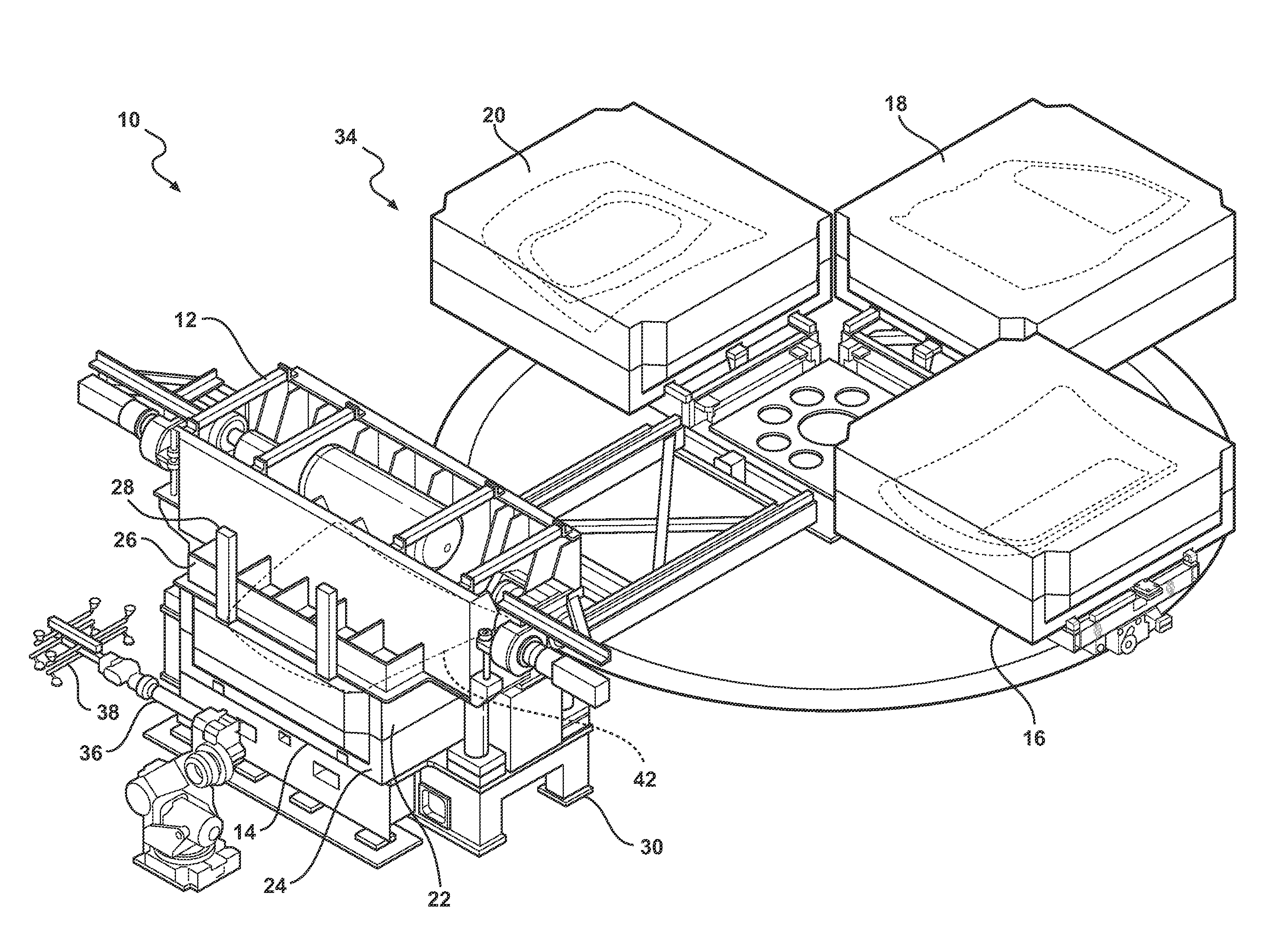

Apparatus and a method for establishing setup parameters for use in a machine. In one embodiment a tooling component is removably mountable to a host machine. The tooling component includes a memory that contains information defining setup parameters for the host machine for use with the tooling component. A controller associated with the host machine reads the information from the memory and configures the host machine based on the information read from the memory. In another embodiment, an information carrying tag, is associated with the tooling component. The information carrying tag is read and the identifying information obtained from the tag is used by a controller to select a set of setup parameters from one or more sets of setup parameters stored in a storage device accessible by the controller. A mechanism is provided to precisely position the adapter on the base plate for the host machine to minimize variations in production using the setup parameters derived from the stored information.

Owner:ZUSI CHRISTOPHER J

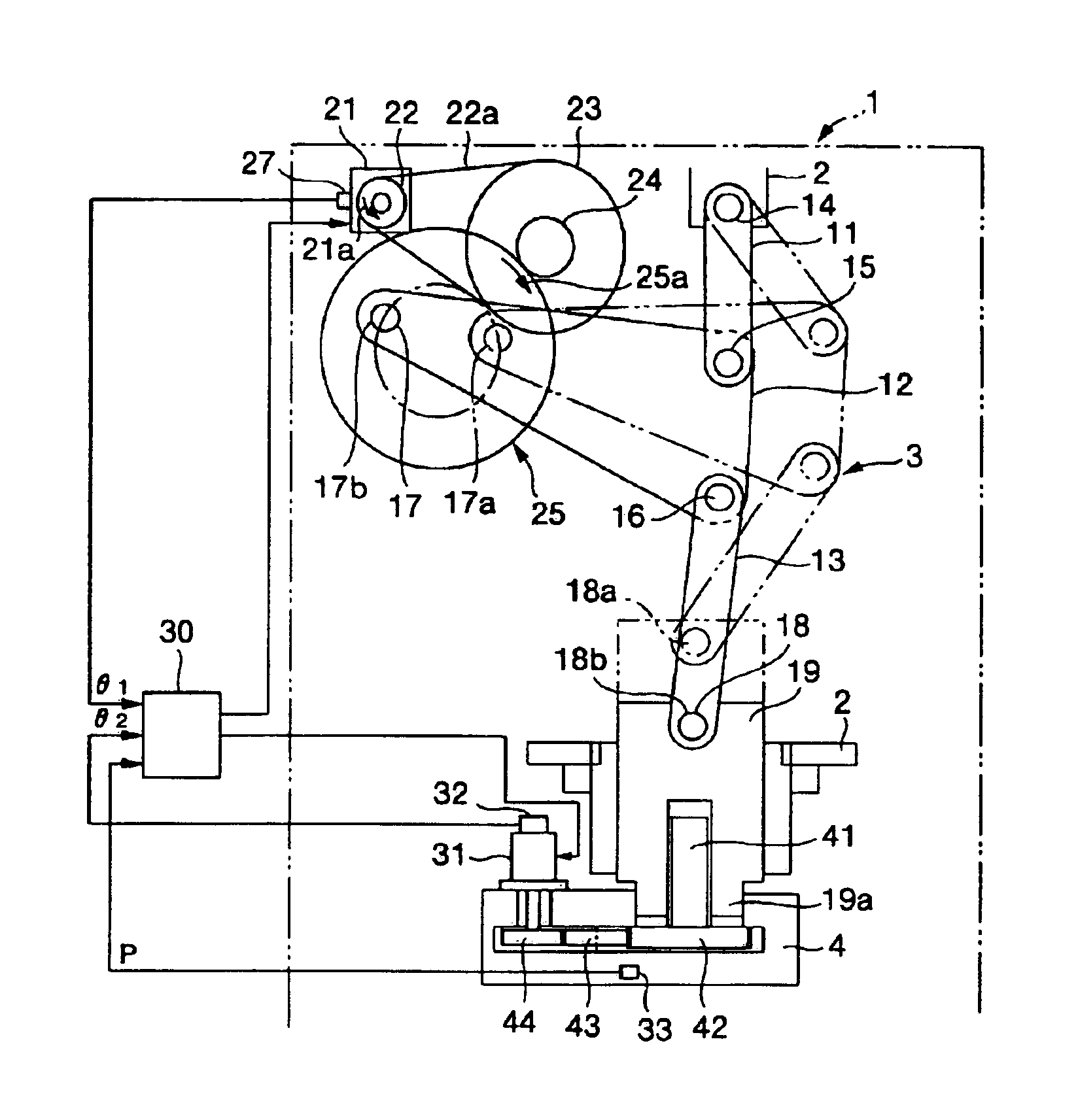

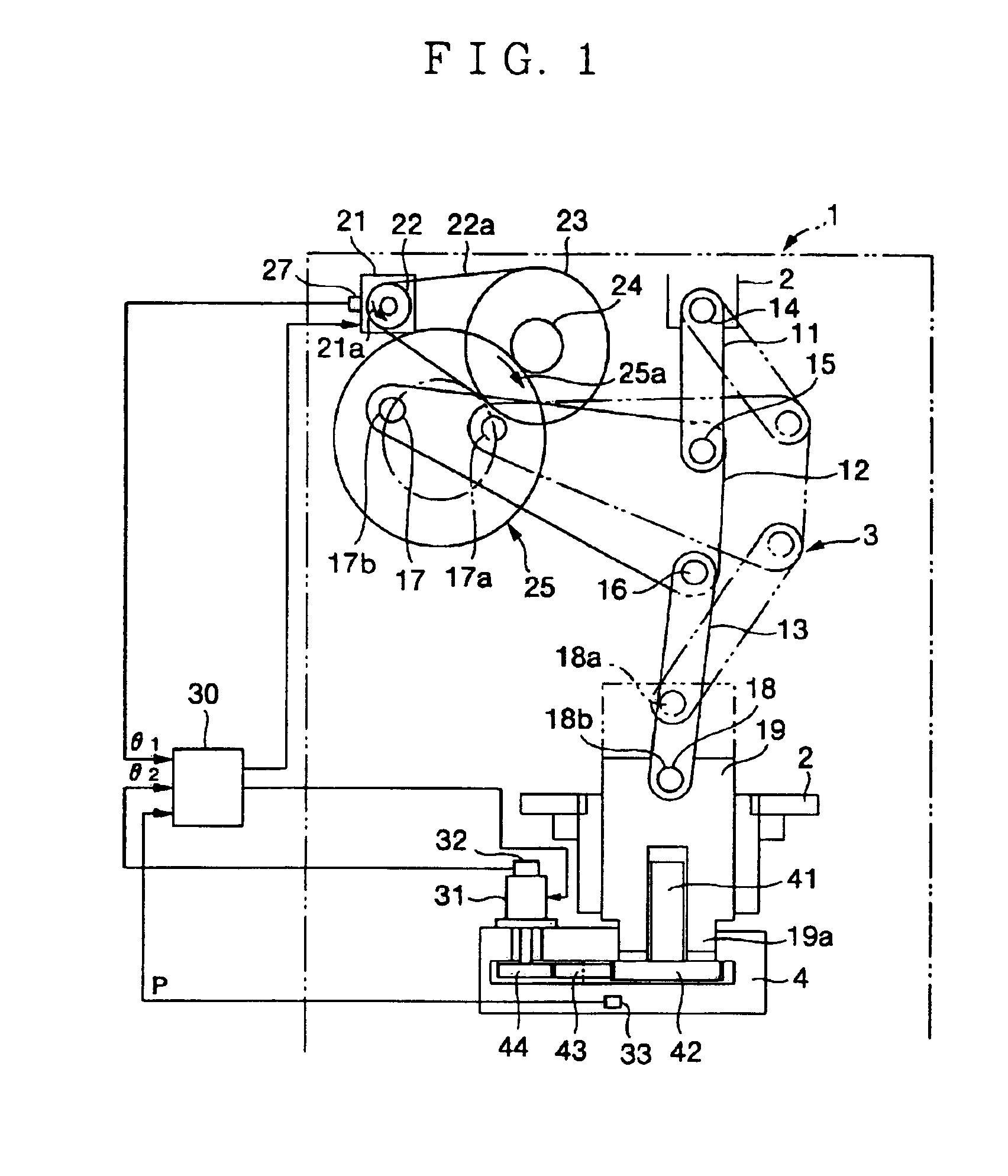

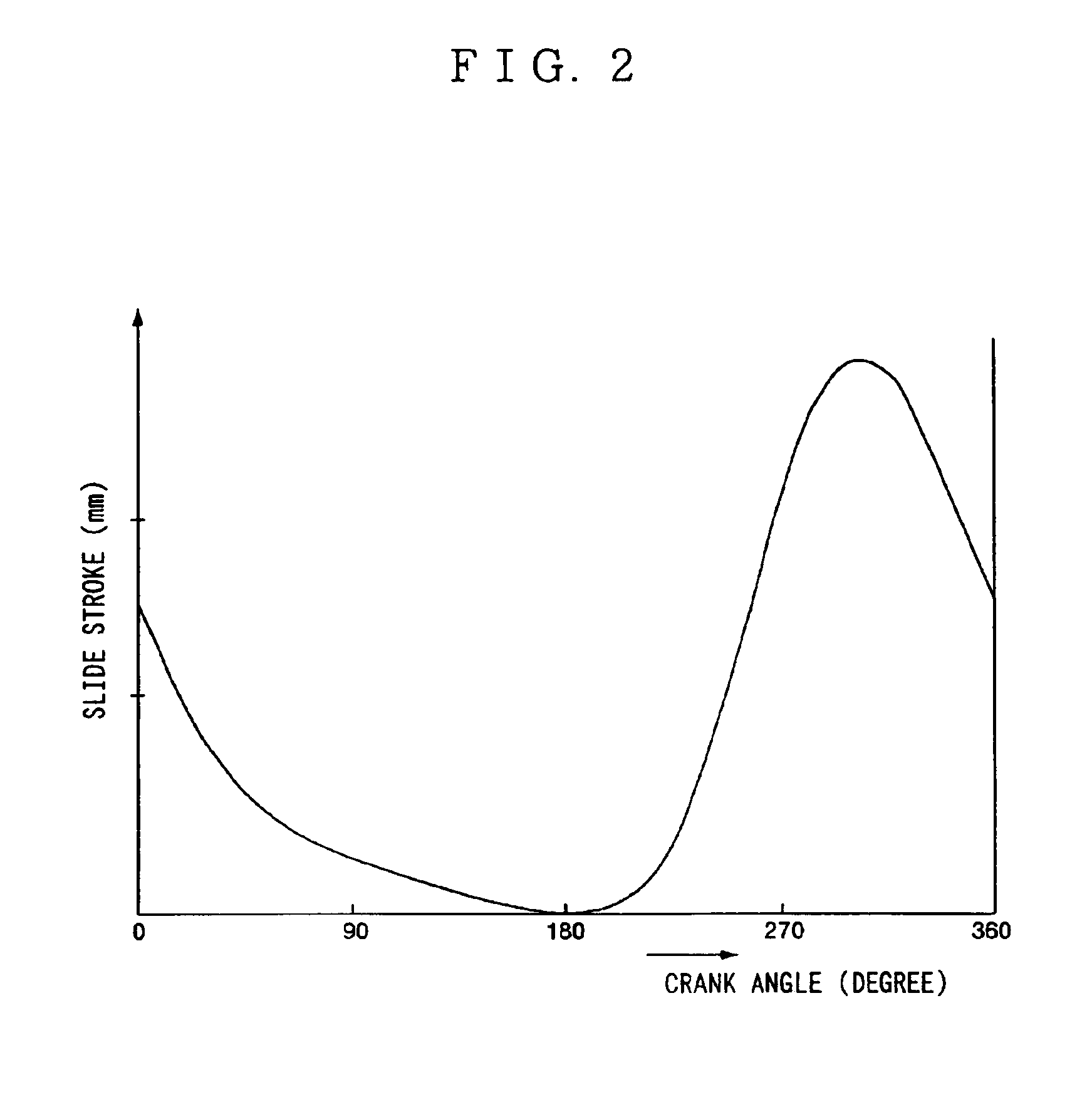

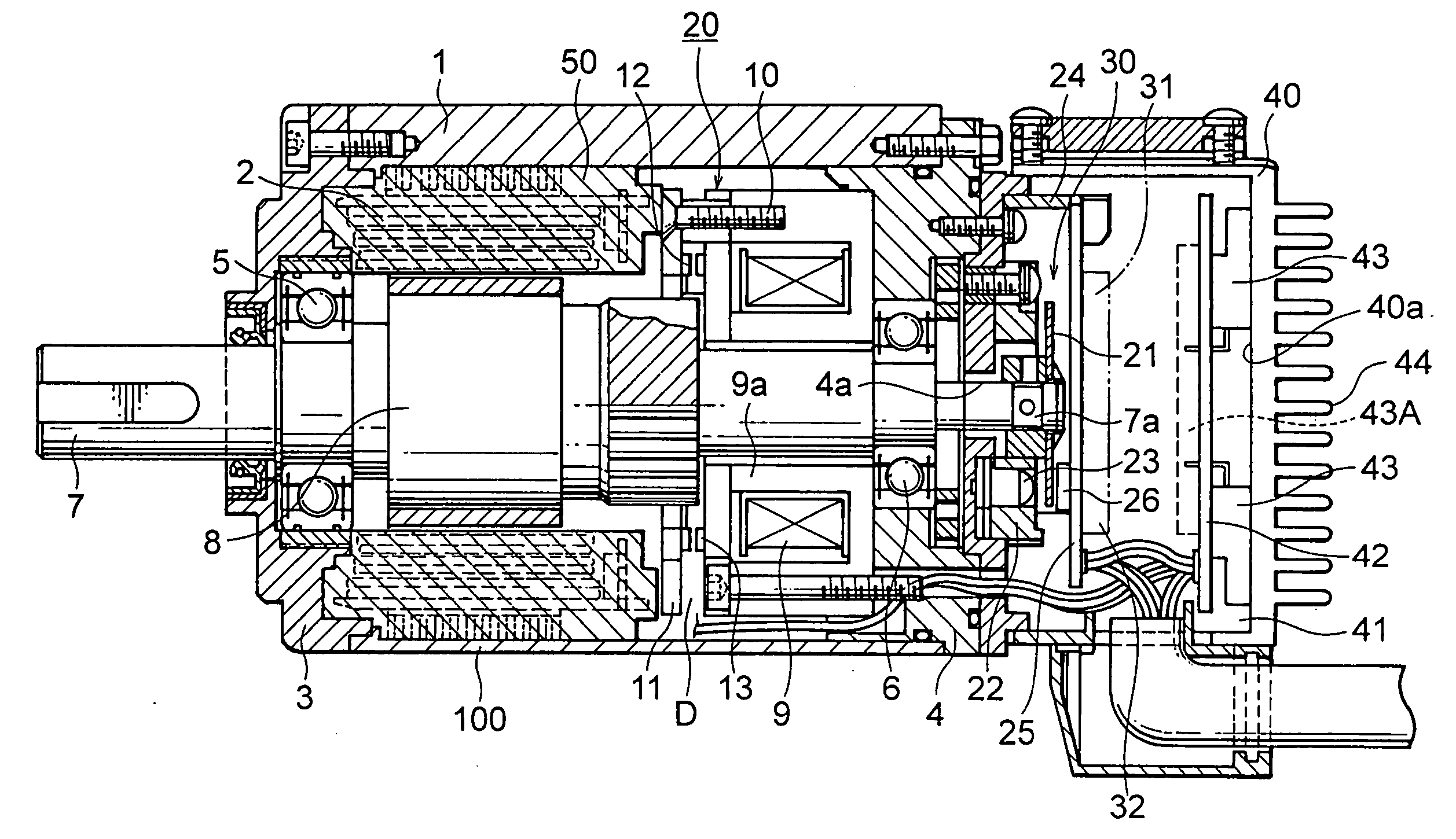

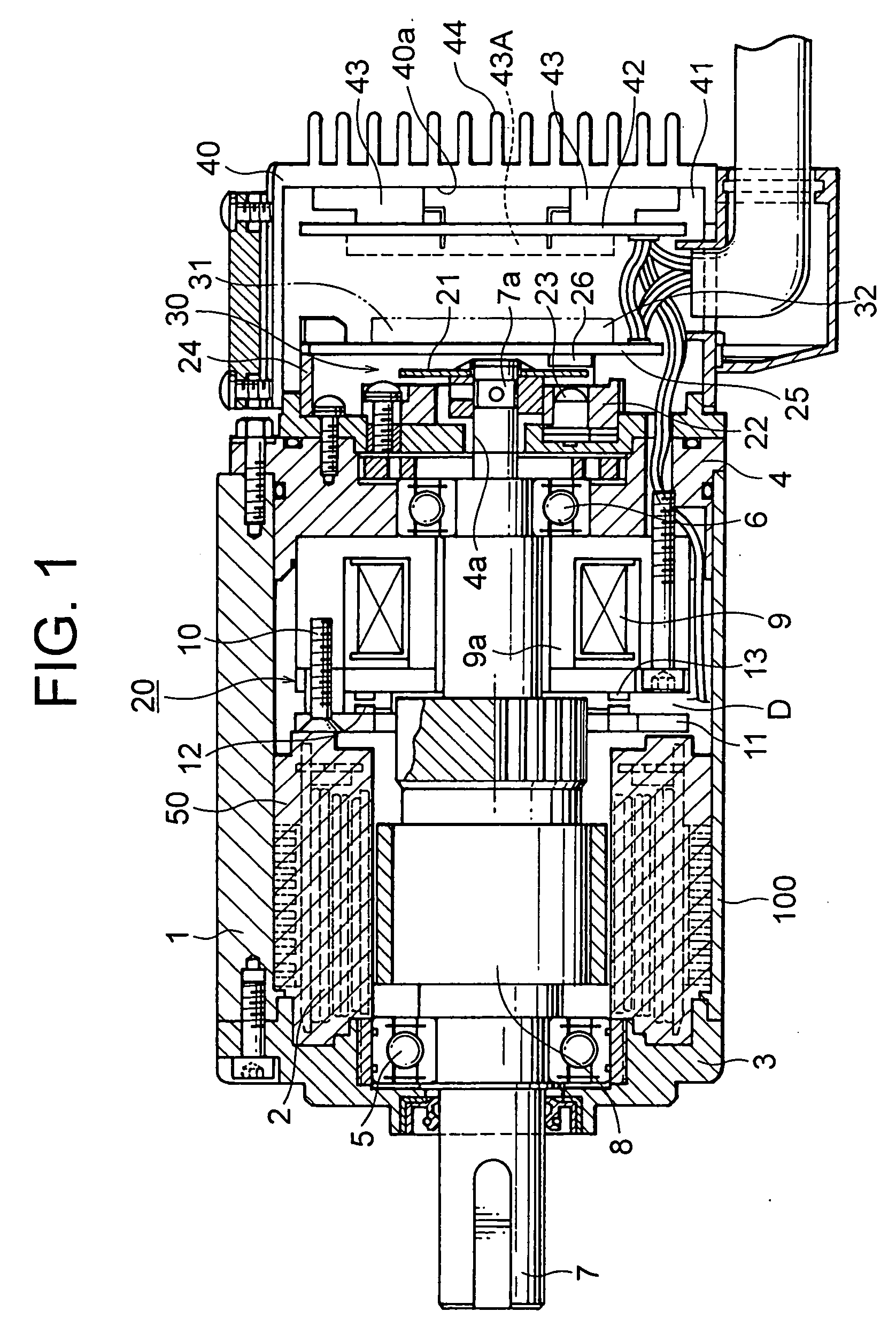

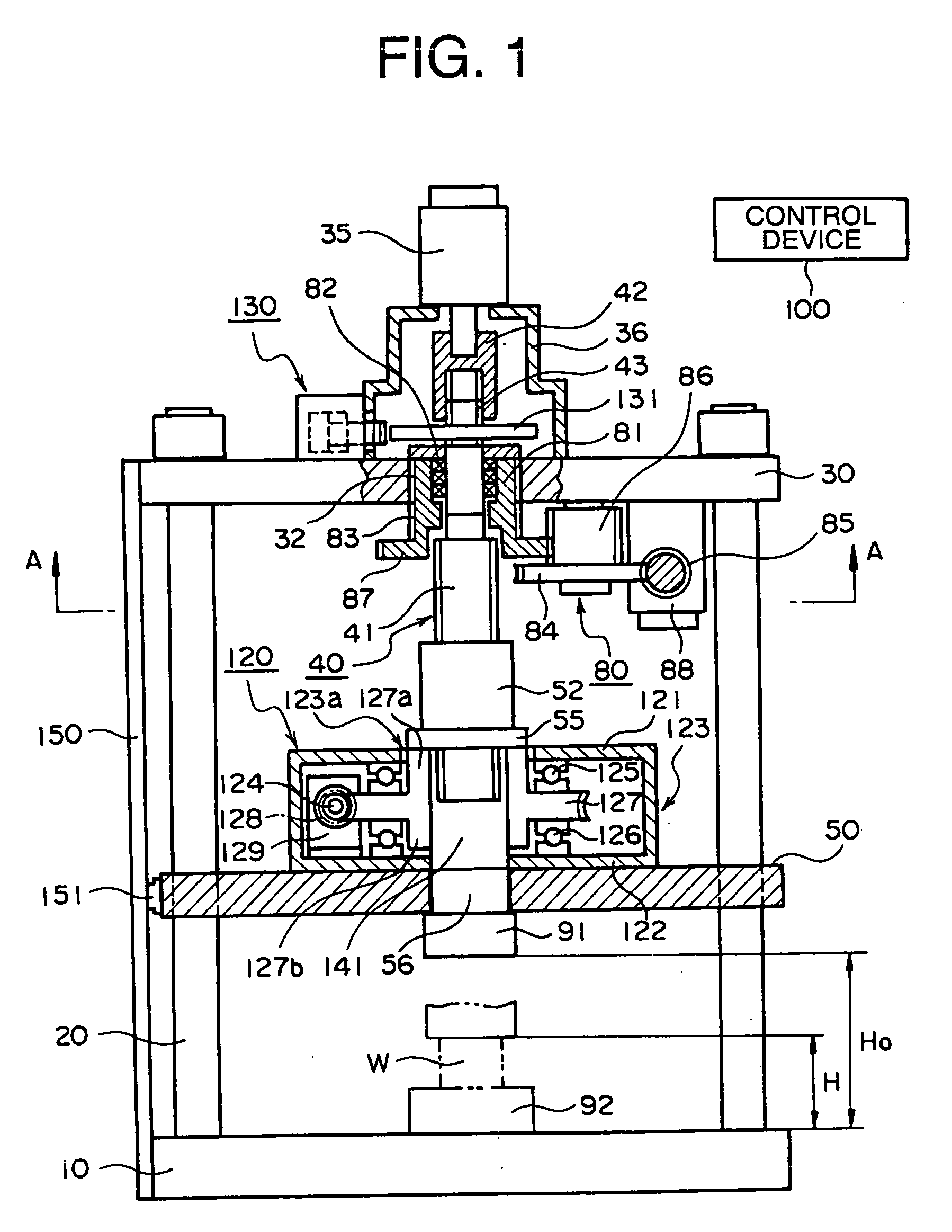

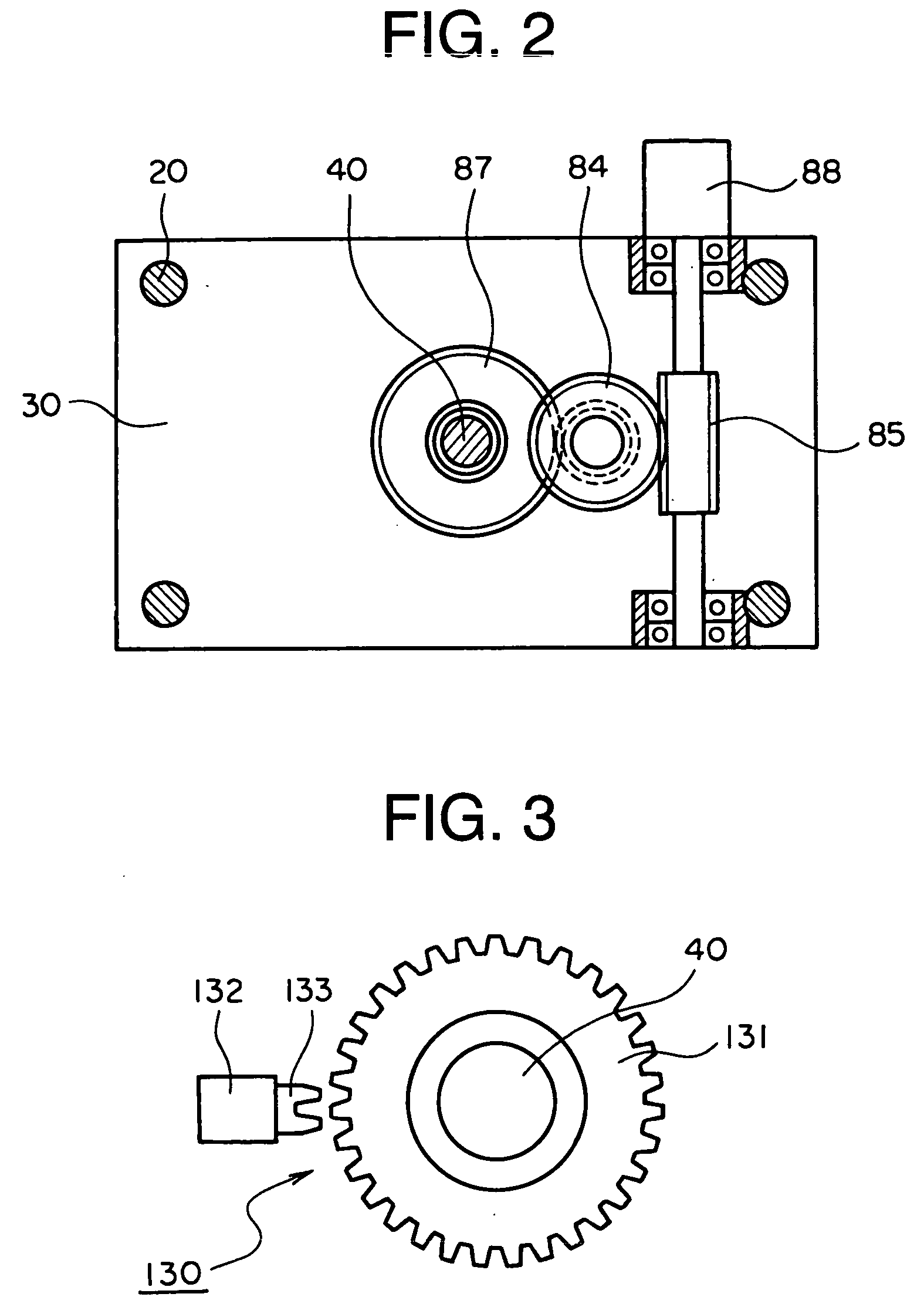

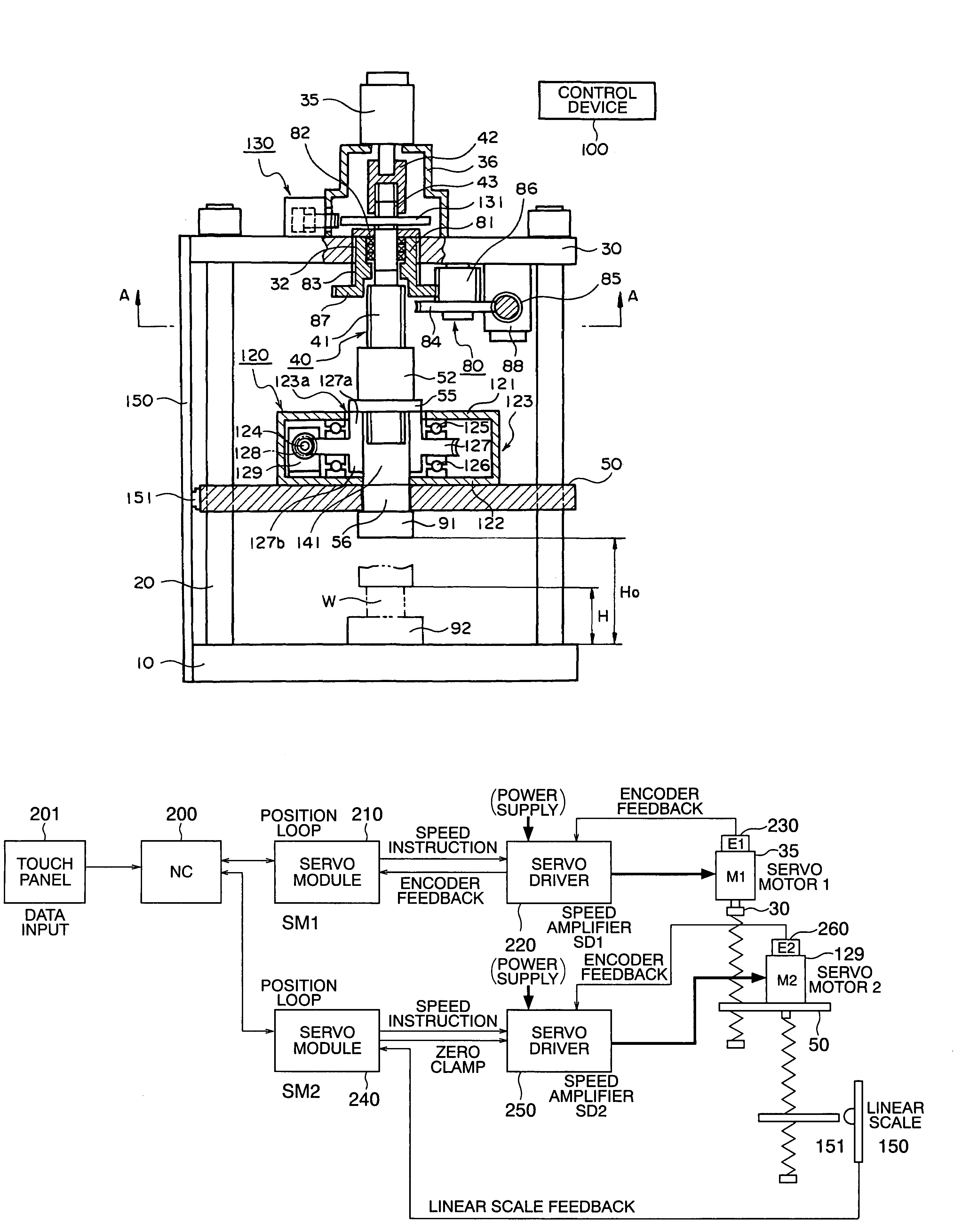

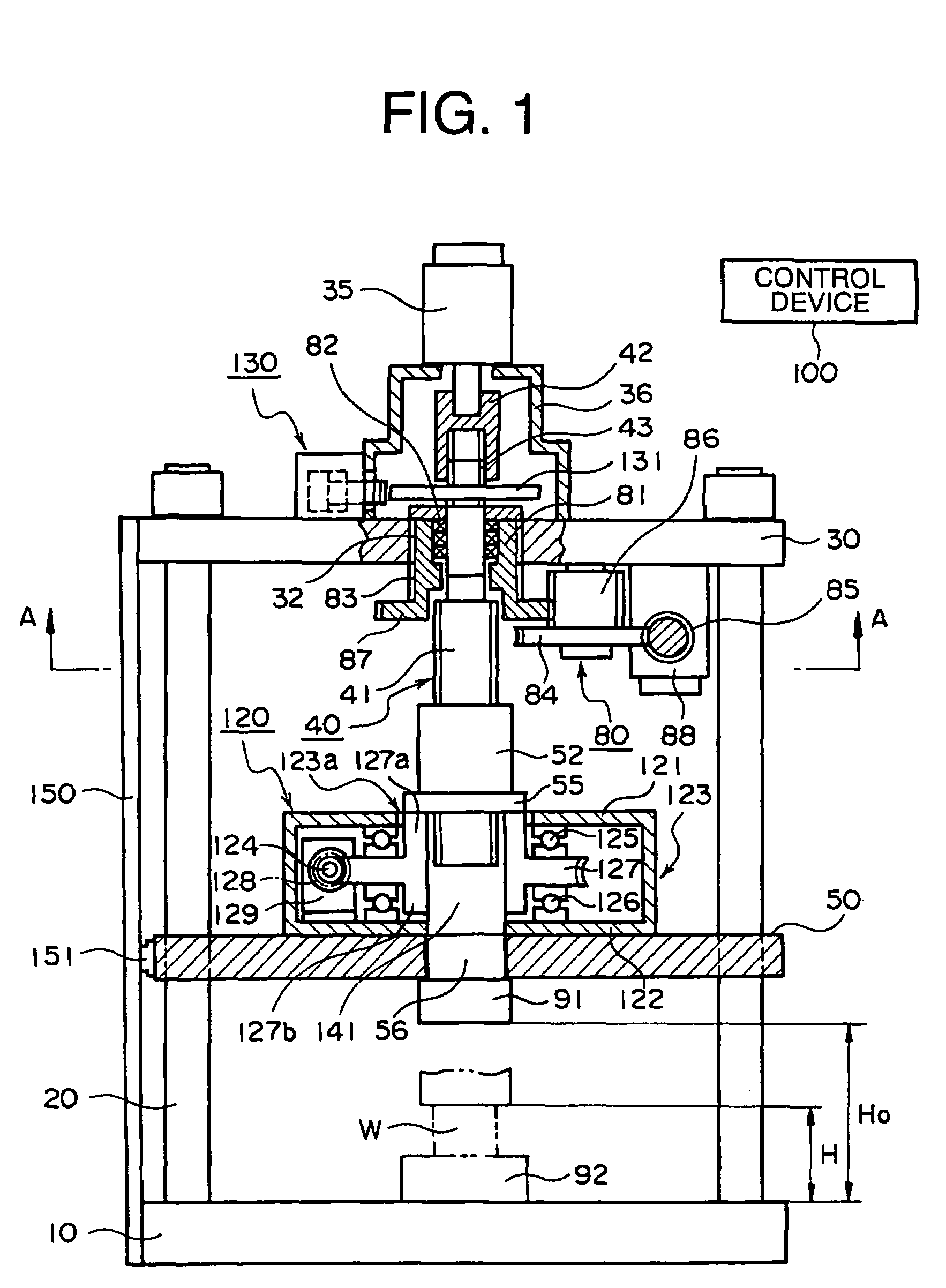

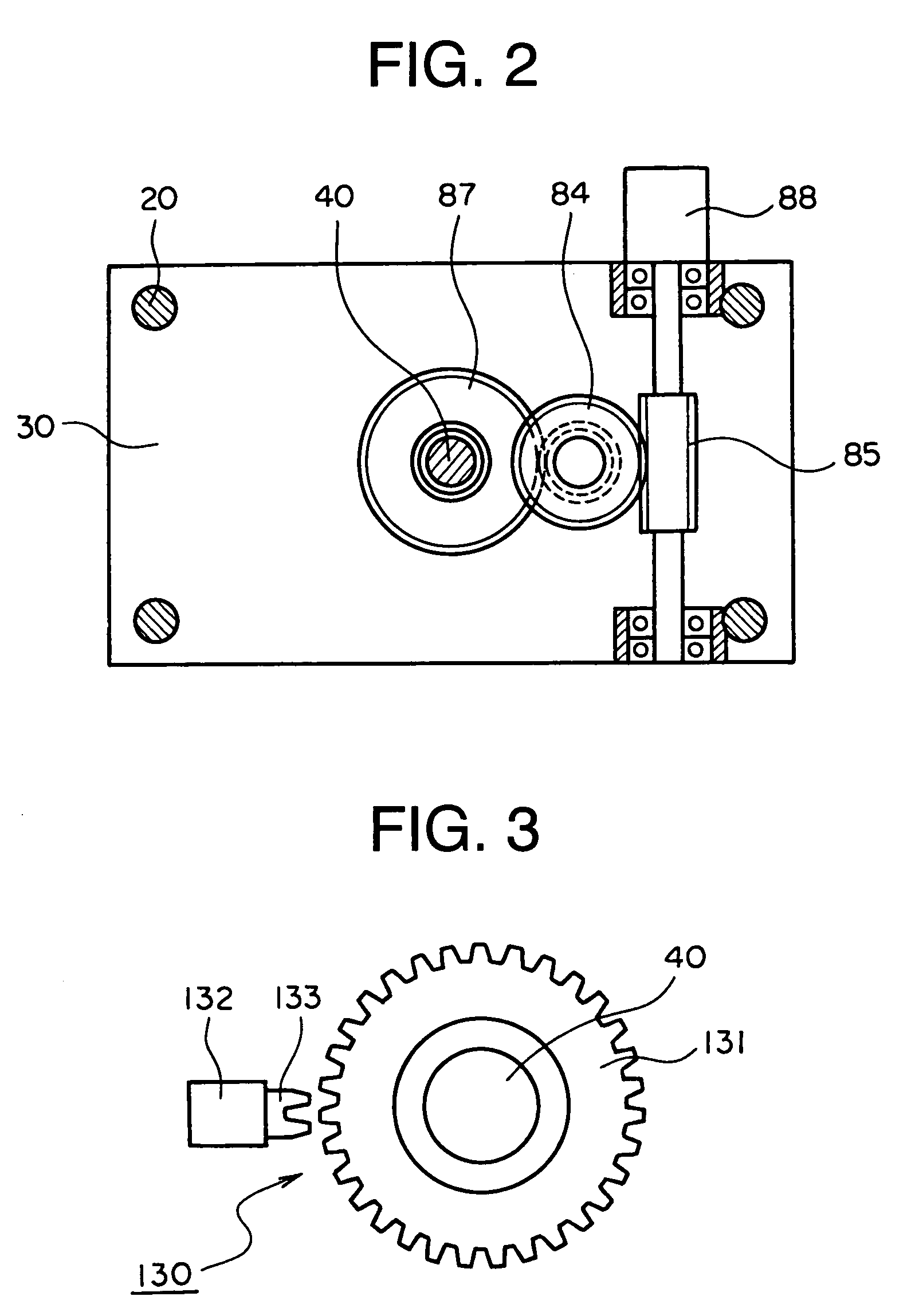

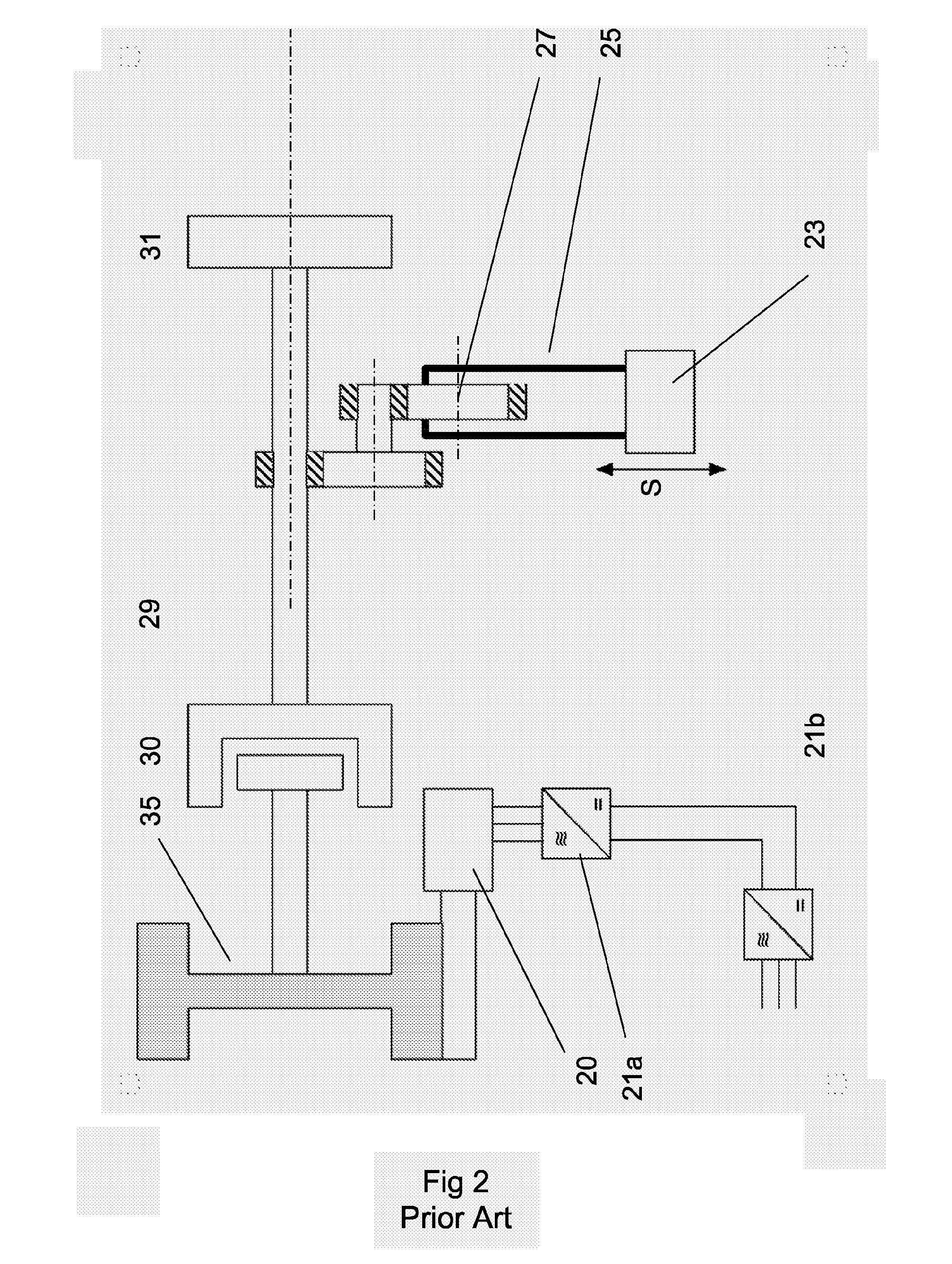

Slide drive apparatus and slide drive method for pressing machine

InactiveUS6871586B2High precisionImprove responseHammer drivesForging/hammering/pressing machinesMechanical power transmissionReciprocating motion

A slide drive apparatus and a slide drive method for a pressing machine capable of enhancing positioning precision at the time of adjustment of die height, and responding to pressing work at high stroke per minute. For this purpose, the drive apparatus includes a slide (4), a servo motor (21) for controlling slide motion, a mechanical power transmission mechanism (3, 5, 6) for converting rotational power of the servo motor for controlling slide motion into reciprocating motion of the slide, and a servo motor (31) for adjusting die height, which performs die height adjustment of the slide by a position control.

Owner:KOMATSU LTD +1

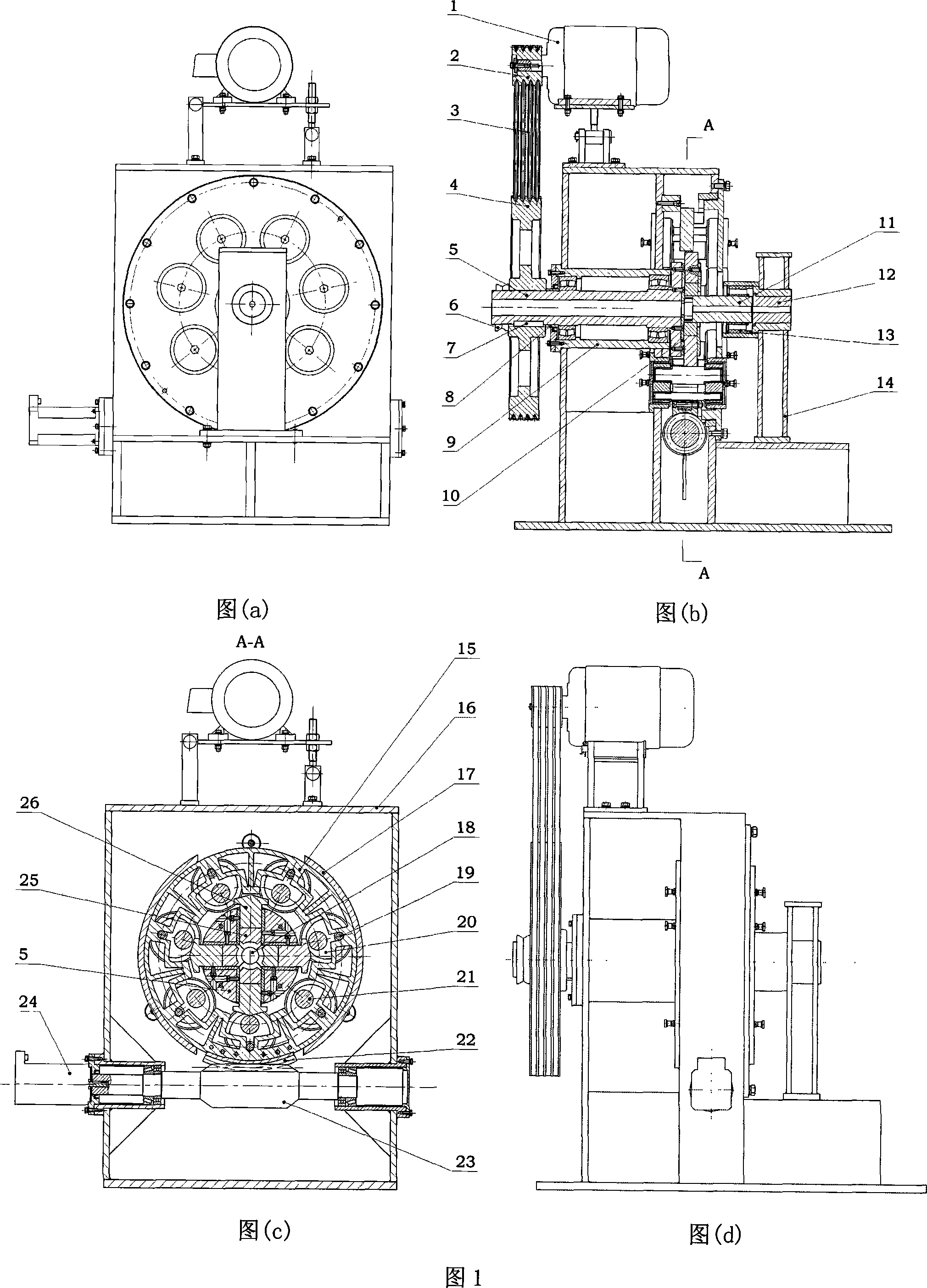

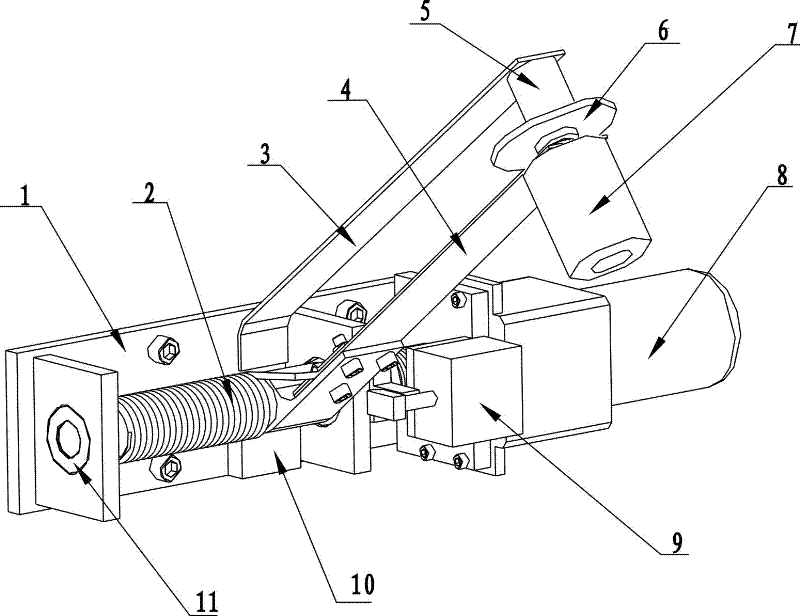

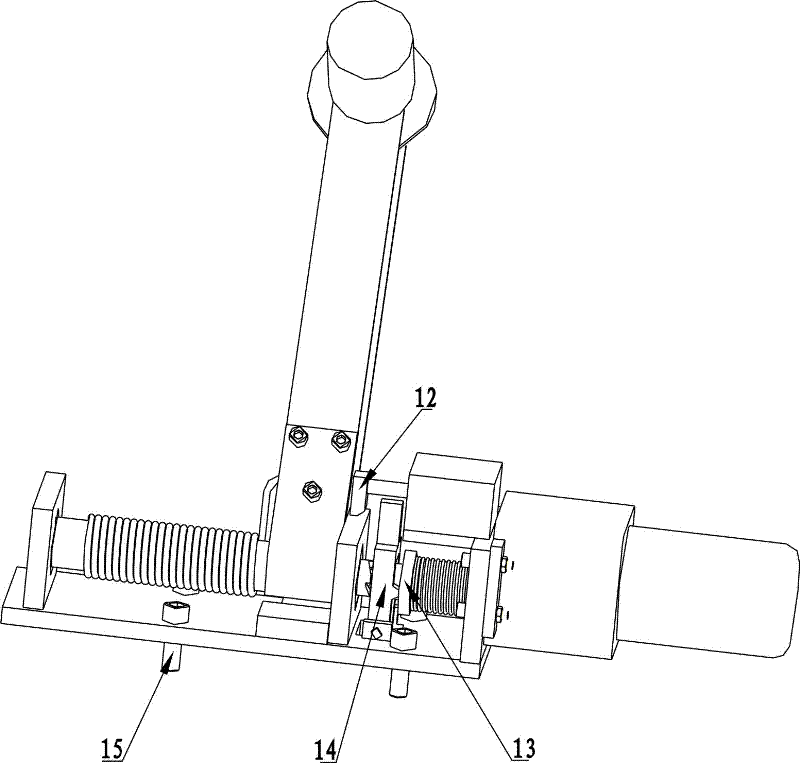

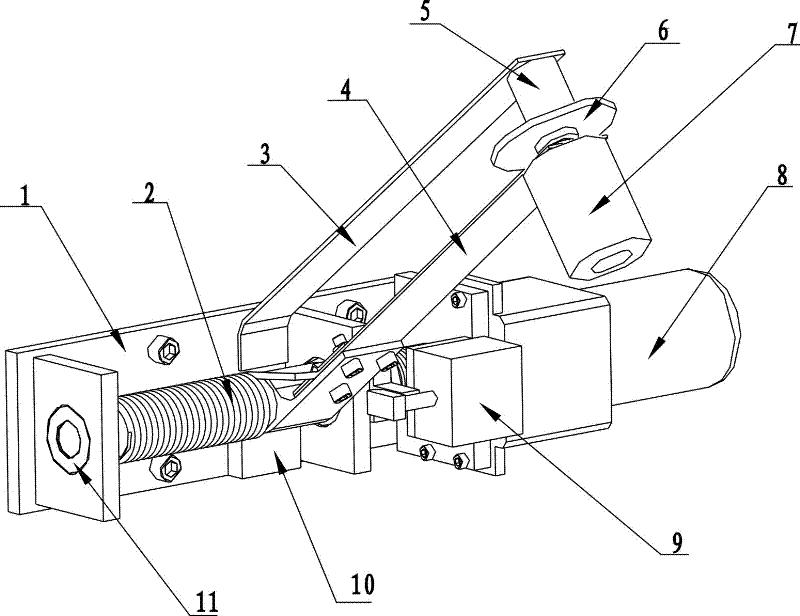

Unsymmetrical radial welding punched high performance precision blanking machine

InactiveCN101058110AEnsure stabilityGuaranteed mechanical propertiesHammer drivesForging/hammering/pressing machinesKinematicsEngineering

The invention relates to an asymmetrical radial forging highly efficient precision feeder which comprises at least the drive mechanism, radial forging feeding and stroke micro tuning structure and bar material fixture device, with the radial feeding device using hammer cycloid design, cam using cylinder roller device, without impact and stable movement. The turbine worm stroke adjusting device uses separate turbine gear structure, and be able to improve stroke adjustment structure' kinematic behavior. Through servo generator variable-frequency control function, it can make precise blank with various material and different size.

Owner:XI AN JIAOTONG UNIV

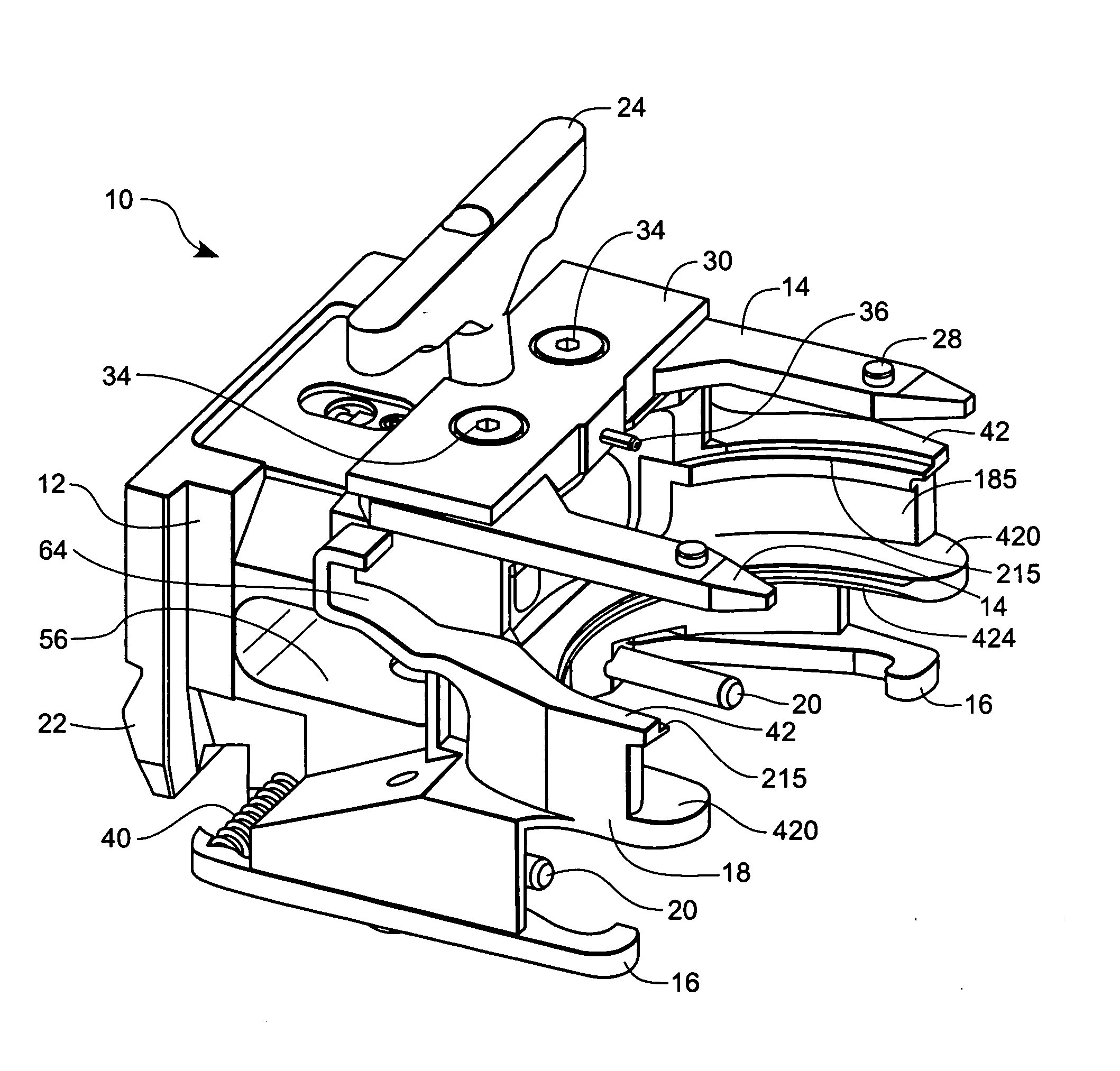

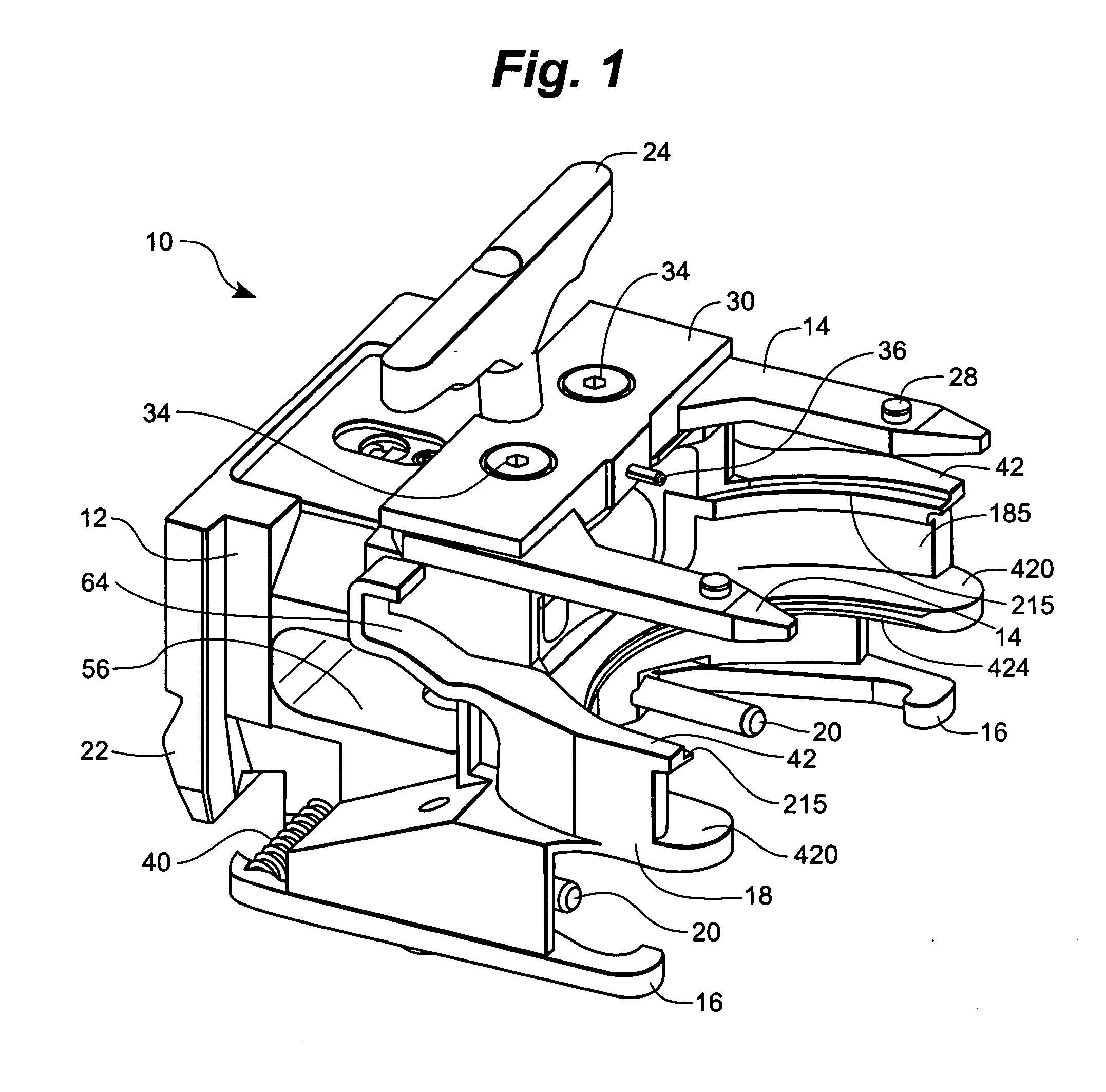

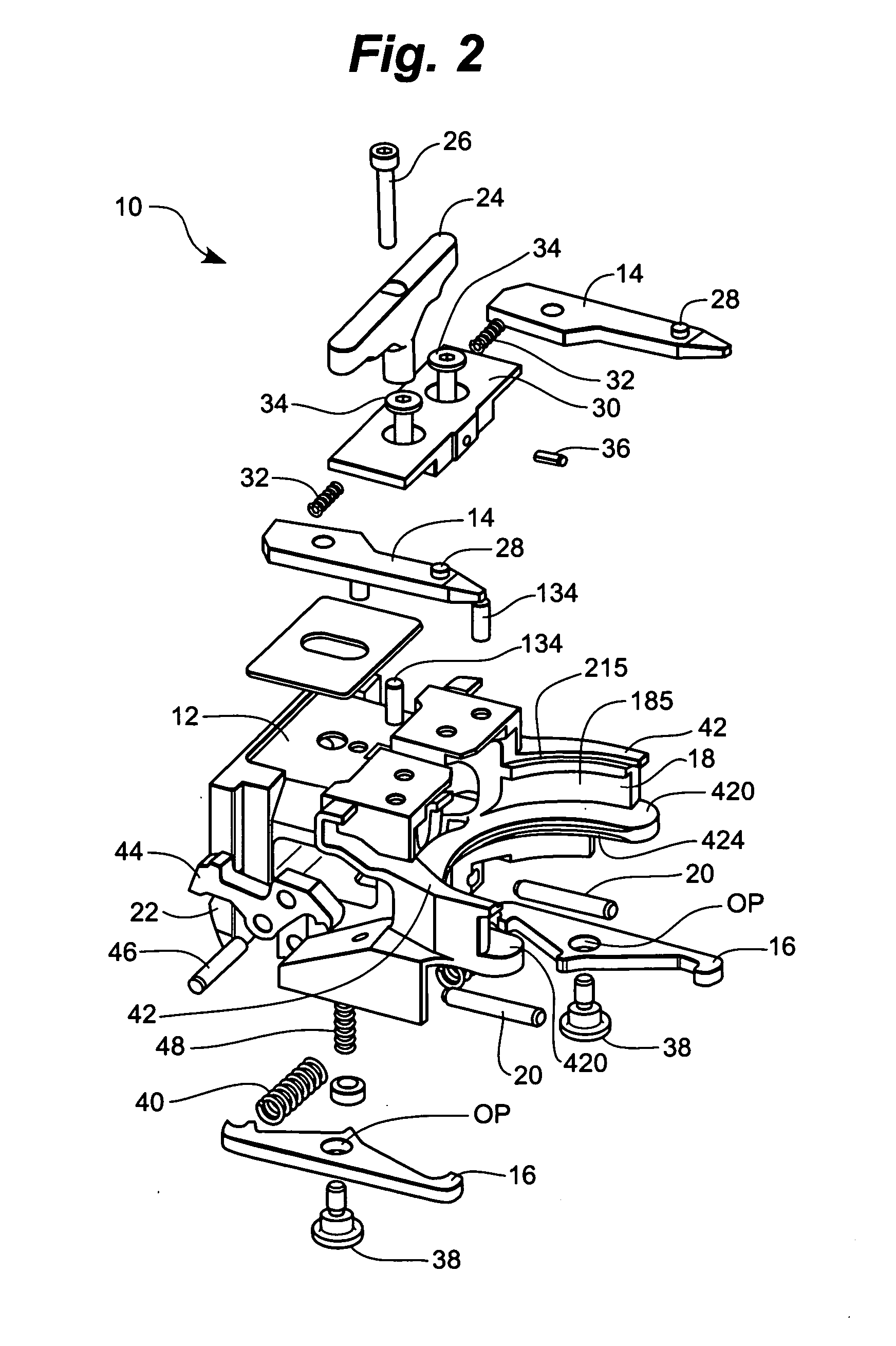

Cartridge for machine tool

A cartridge for a machine tool is provided. The cartridge has a main body, two punch-retention arms, and two die-retention arms. Preferably, the two punch-retention arms are spaced apart and at least generally parallel to each other. Likewise, the two die-retention arms preferably are spaced apart and at least generally parallel to each other. In some cases, the main body is formed of a first metal, and the punch-retention arms and die-retention arms are formed of metal(s) different than the first metal. In one group of embodiments, the invention provides a cartridge having a weight of less than 3 pounds.

Owner:WILSON TOOL INT

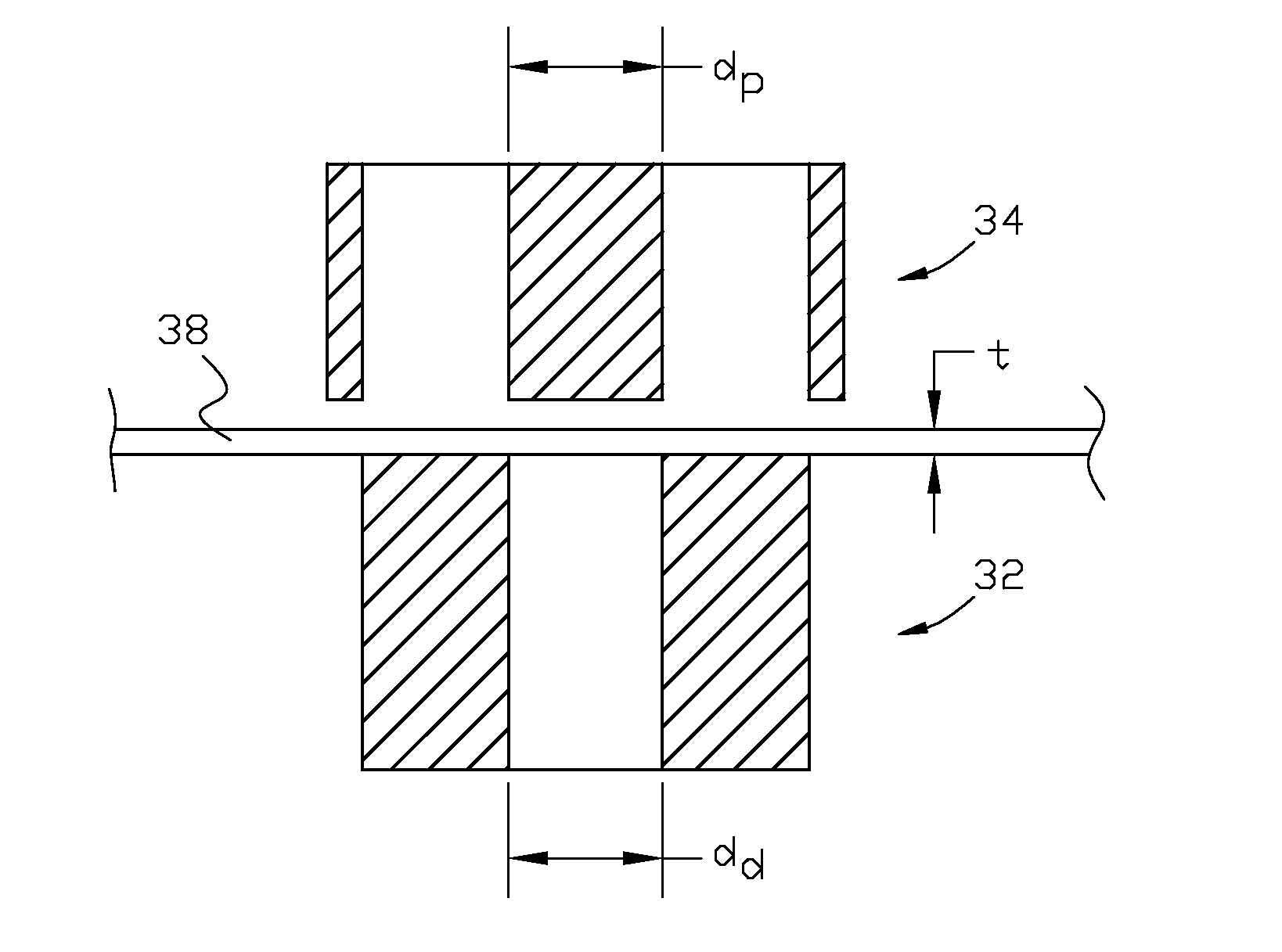

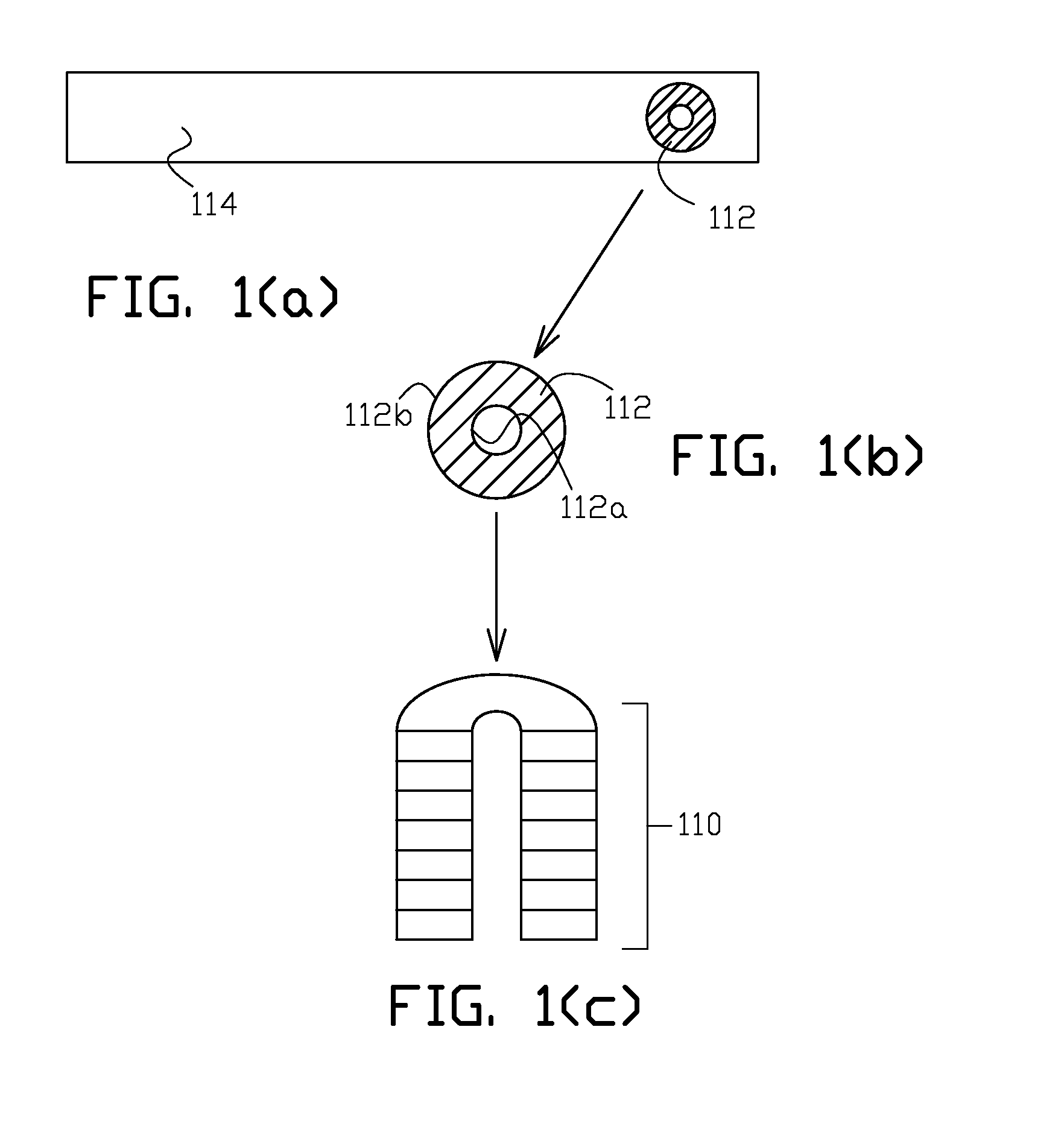

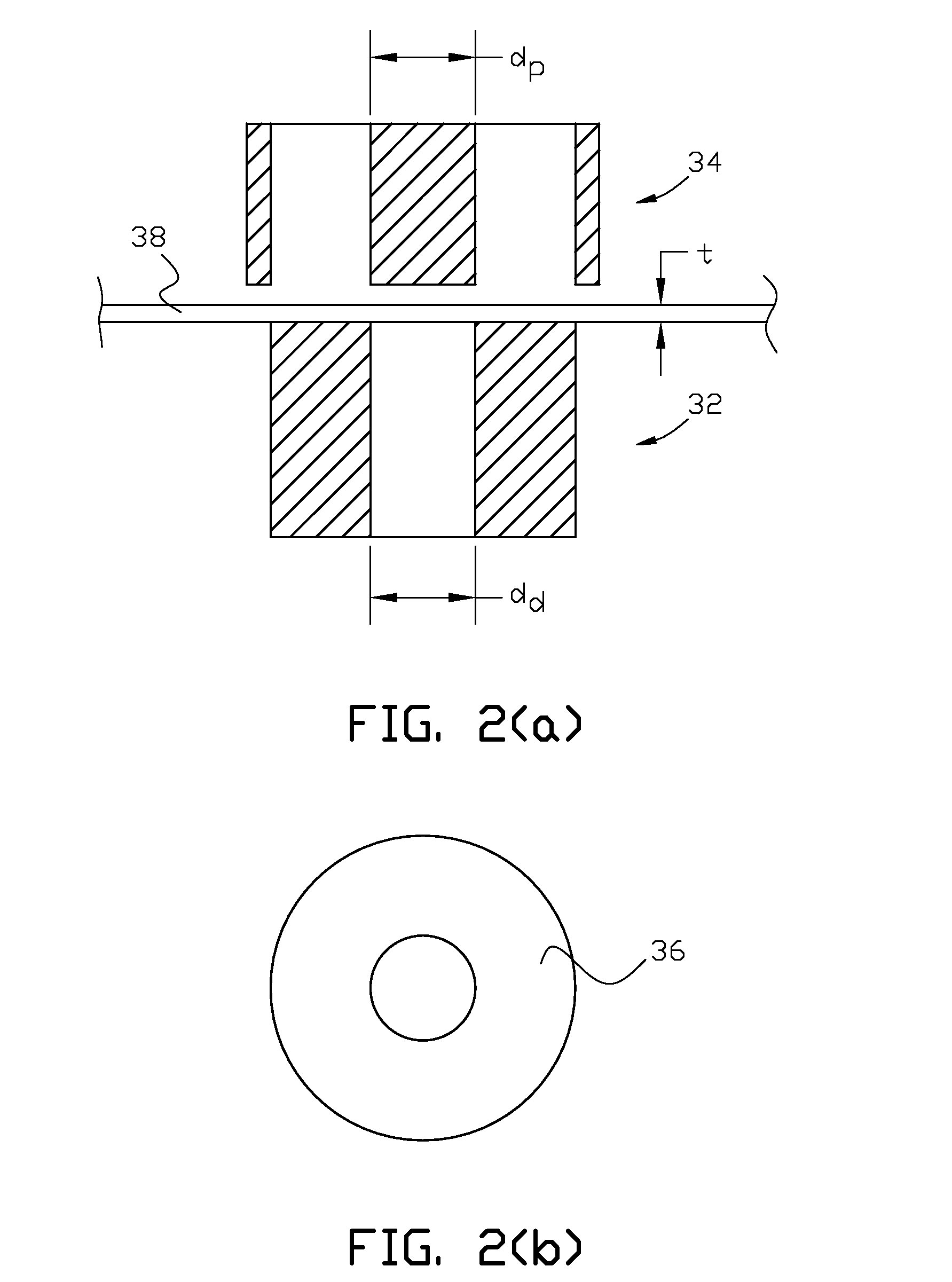

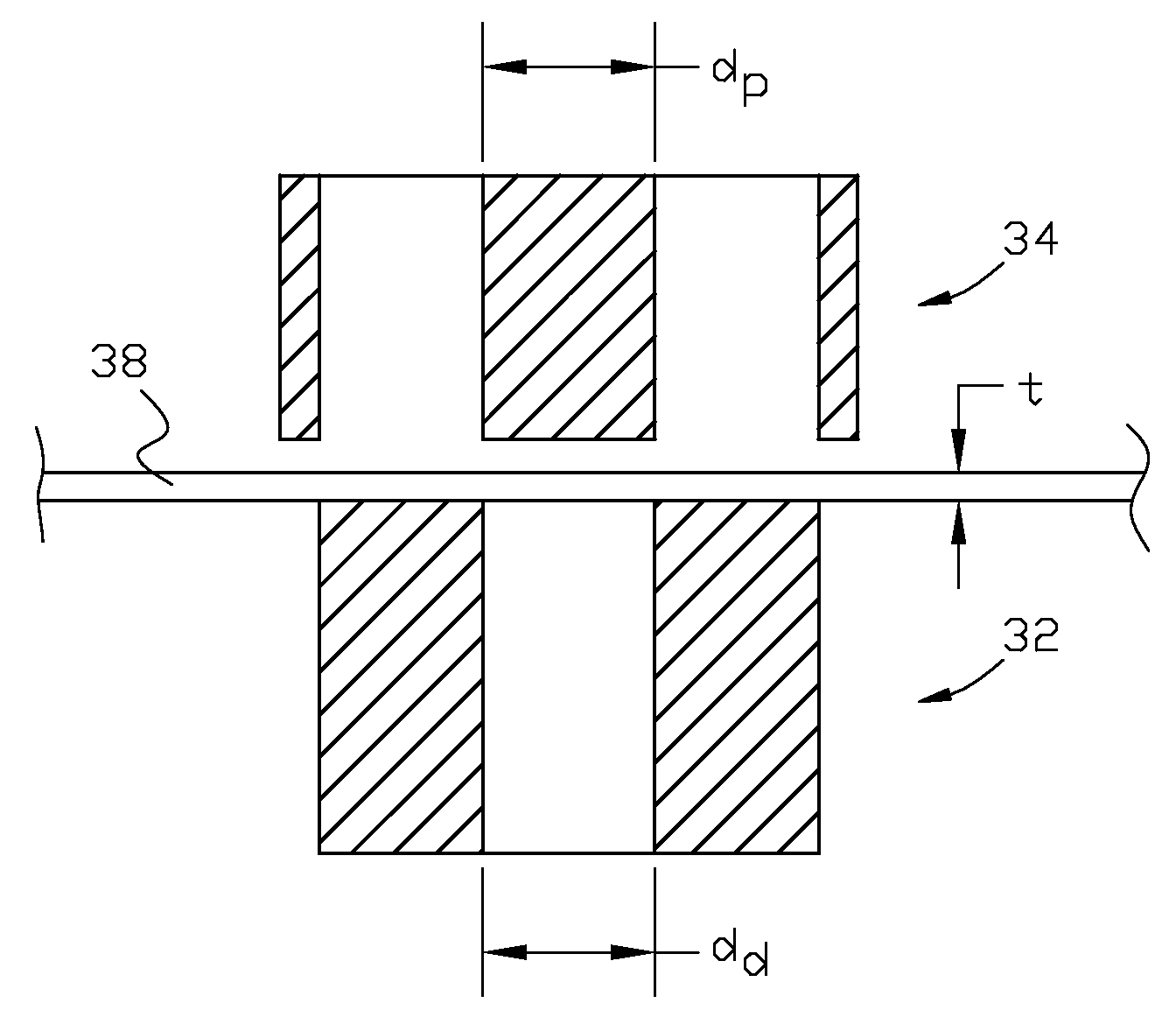

Laminated magnetic cores

InactiveUS8276426B2Deformation MinimizationHammer drivesInductances/transformers/magnets manufacturePunch pressEngineering

Laminations to be stacked as magnetic cores are produced from a very thin amorphous metal strip, using a punch press with accurate punch / die clearance. The laminations are collected on conveyor spindles or a transport rod or pipe, in either case being arranged without the need for substantial handling. Heat annealing and anti-vibration treatments can be applied along a conveying path. The laminations are grouped in a stack to define a core and are packaged or encapsulated in electrically nonconductive coverings. The finished core has advantageous electrical characteristics and low cost.

Owner:MAGNETIC METALS CO

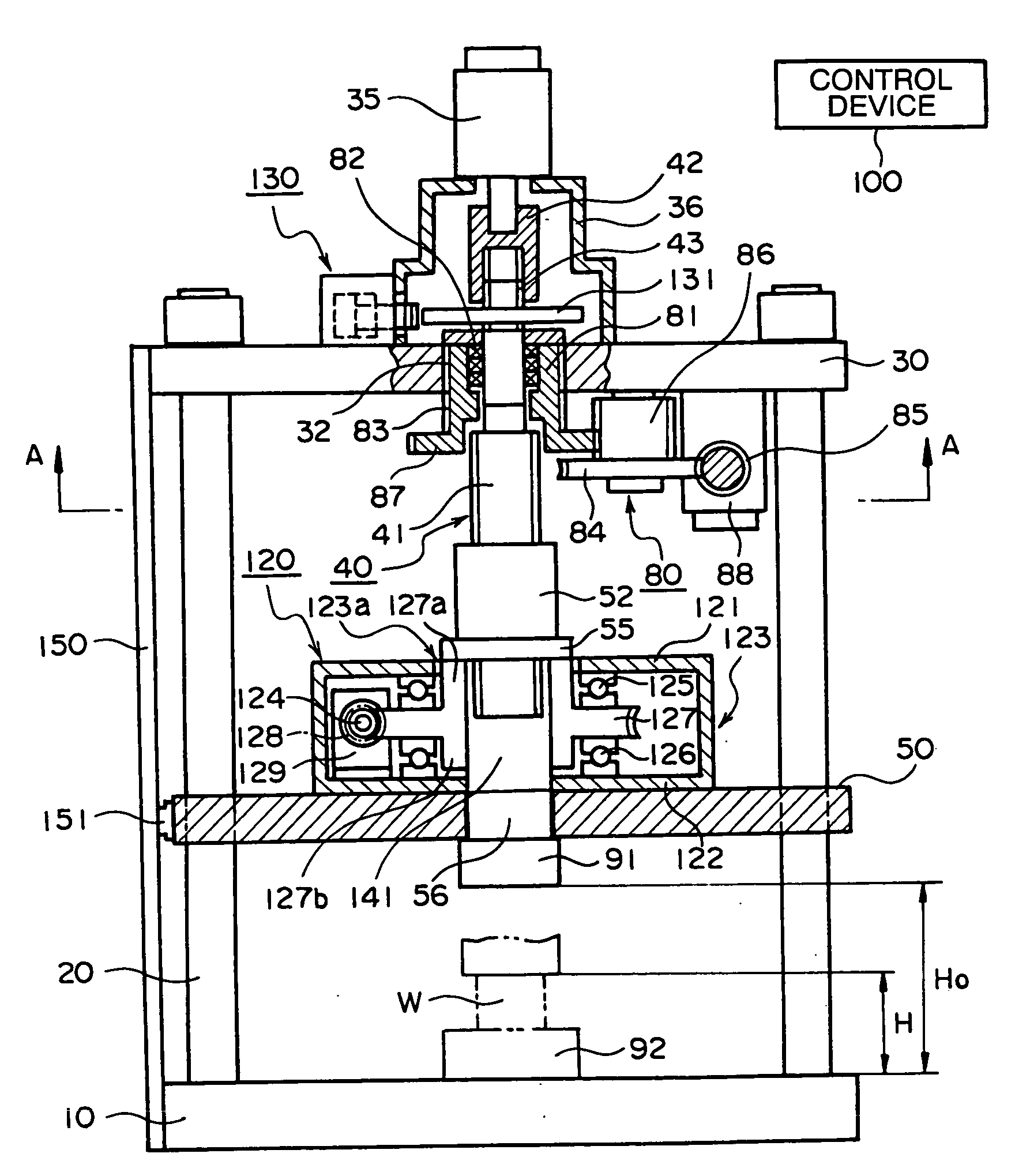

Motor with a brake

InactiveUS20040239196A1Asynchronous induction motorsMechanical energy handlingElectric machineControl theory

The present invention provides a motor with a brake in which, after an initial stage, a voltage applied to the brake is reduced to thereby restrain heat generation in the brake. In the motor with a brake, after signal drive, a voltage of a drive signal supplied to an electromagnetic drive portion of the brake is reduced, whereby heat generation in the brake during motor rotation is restrained, which makes it possible to increase a load to be applied to the motor.

Owner:TAMAGAWA SEIKI CO LTD

Press

InactiveUS20060283229A1Shorten the timeShaping safety devicesHammer drivesControl theoryPosition detector

The invention provides a pressing apparatus using a motor, in which driving means for fast feed, which lowers a upper die to a position immediately before pressing, and a motor for pressing, which performs a pressing operation, are used to cause the driving means for fast feed and the motor for pressing to operate cooperatively, and only one position detector, which detects a present position of a slider, is provided for a set of the driving means for fast feed and the motor for pressing.

Owner:HODEN SEIMITSU KAKO KENKYUSHO CO LTD

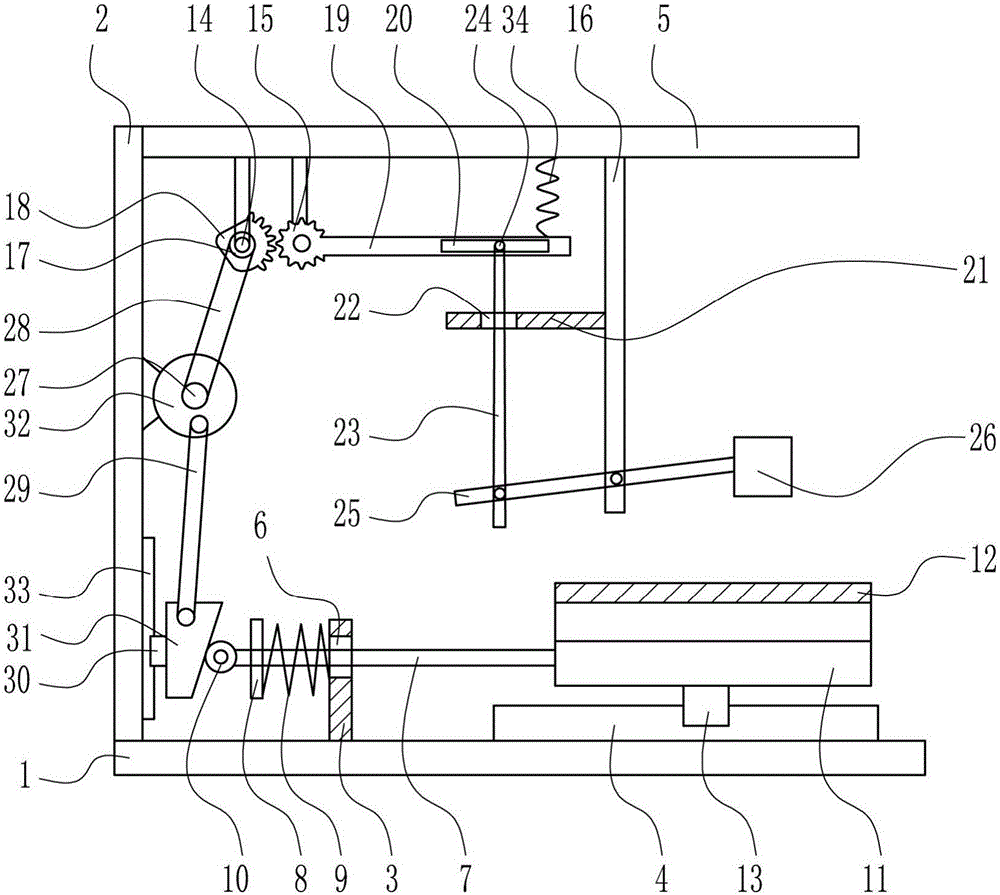

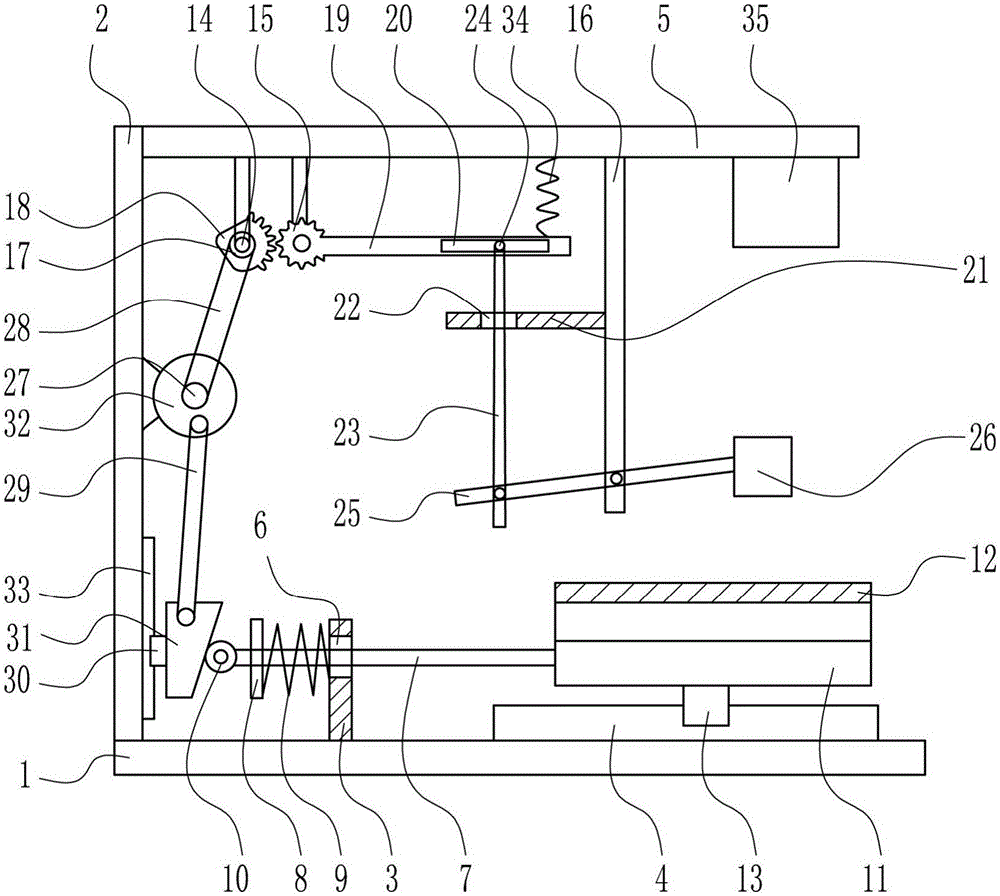

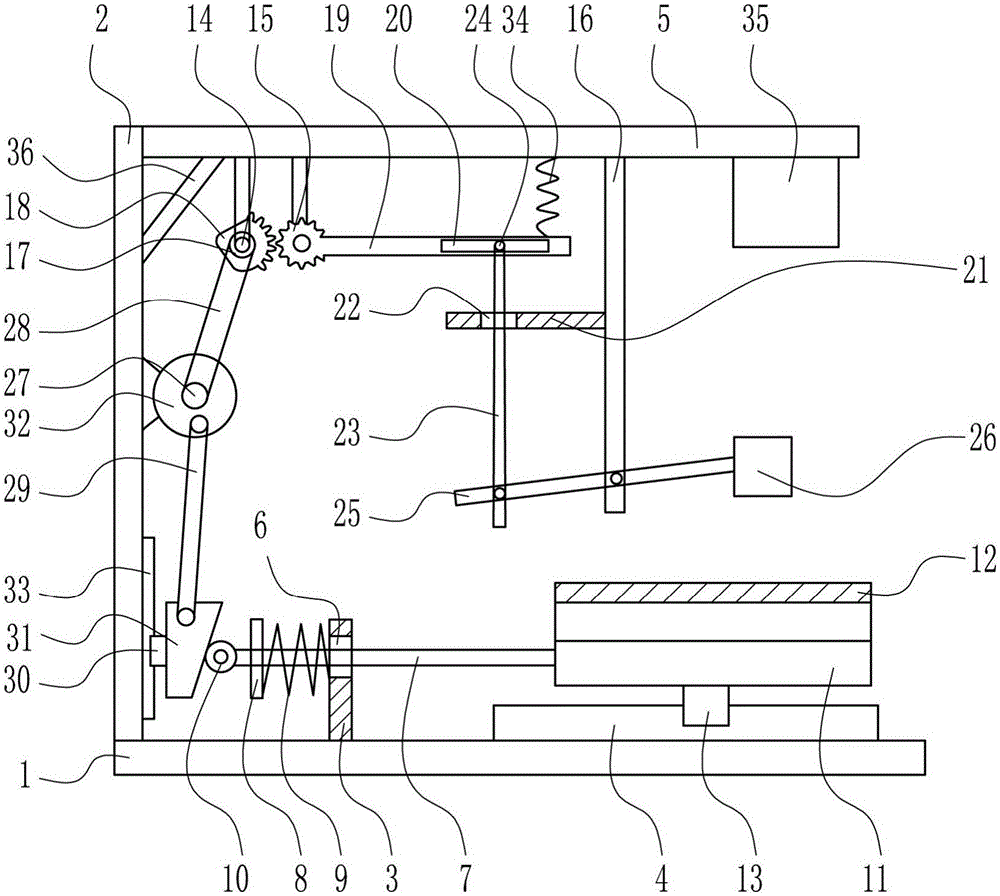

Rapid iron sheet forging device for hardware

ActiveCN106111865AOptimizing Forging PerformanceImprove stabilityDrop hammersHammer drivesMaterials sciencePulley

The invention relates to an iron sheet forging device, and particularly relates to a rapid iron sheet forging device for hardware. The invention aims to solve the technical problem of providing the rapid iron sheet forging device for hardware, which has the advantages of good forging effect, simplicity in operation and high stability. In order to solve the technical problem, the invention provides the rapid iron sheet forging device for hardware. The rapid iron sheet forging device comprises a bottom plate, a left side plate, a first guide rod, a first sliding rail, a top plate, a push rod, a fixed stop block, a carbon fire box, an electromagnet, a first sliding block, a motor, a gear, a vertical plate, a transverse plate, a second guide rod, a lifting rod, a rolling shaft, a first connecting rod, a hammer, a second belt pulley and the like, wherein the left side plate, the first guide rod and the first sliding rail are arranged on the bottom plate in sequence from left to right, and the top plate and the like are arranged on the right side of the left side plate in sequence from top to bottom. The invention provides the rapid iron sheet forging device for hardware, the effects of good forging effect and high stability are achieved by utilizing a water tank and an inclined plate, and the rapid iron sheet forging device is operated only by controlling the motor.

Owner:CN PRECISION CASING (SHENZHEN) CO LTD

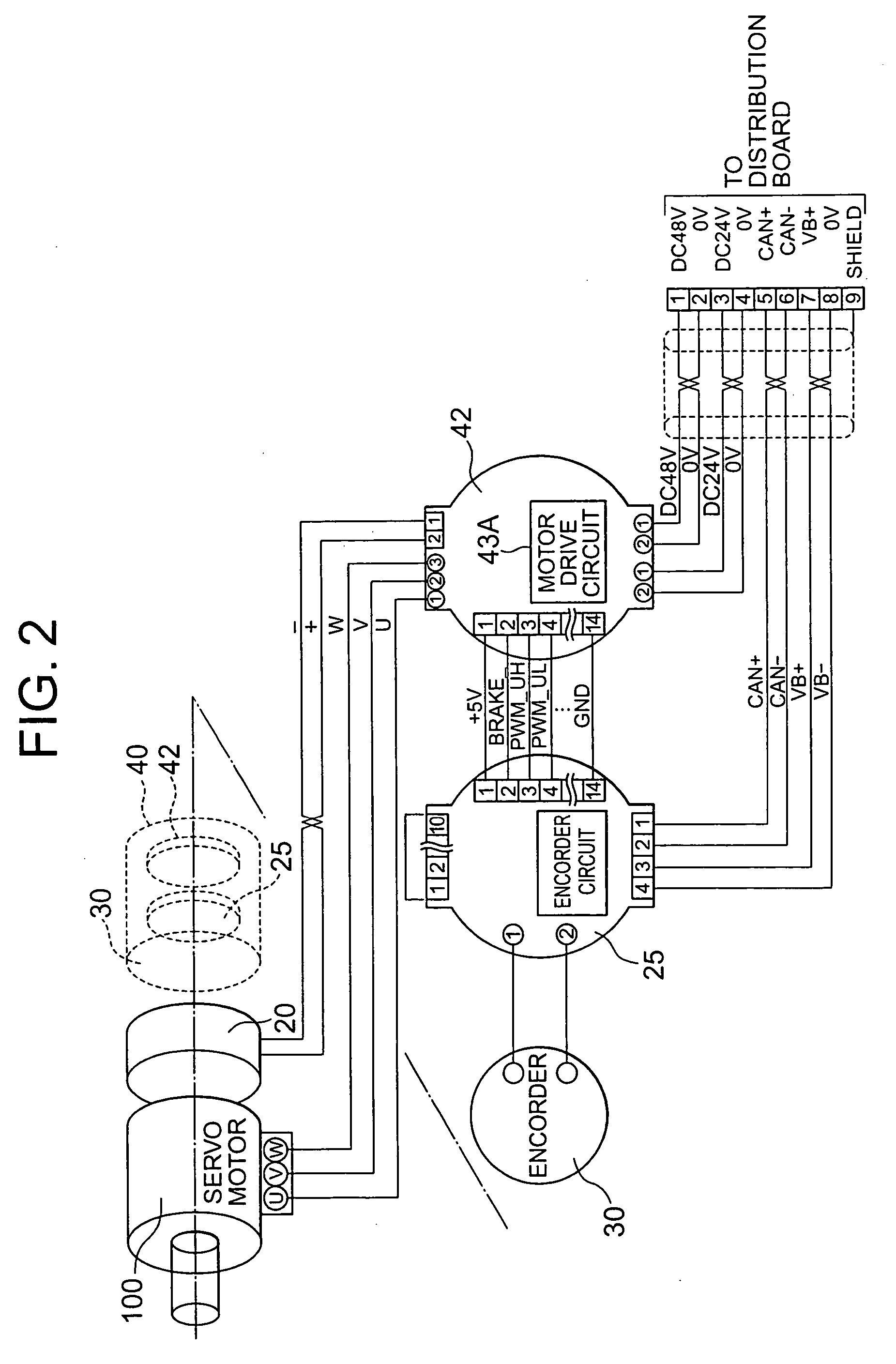

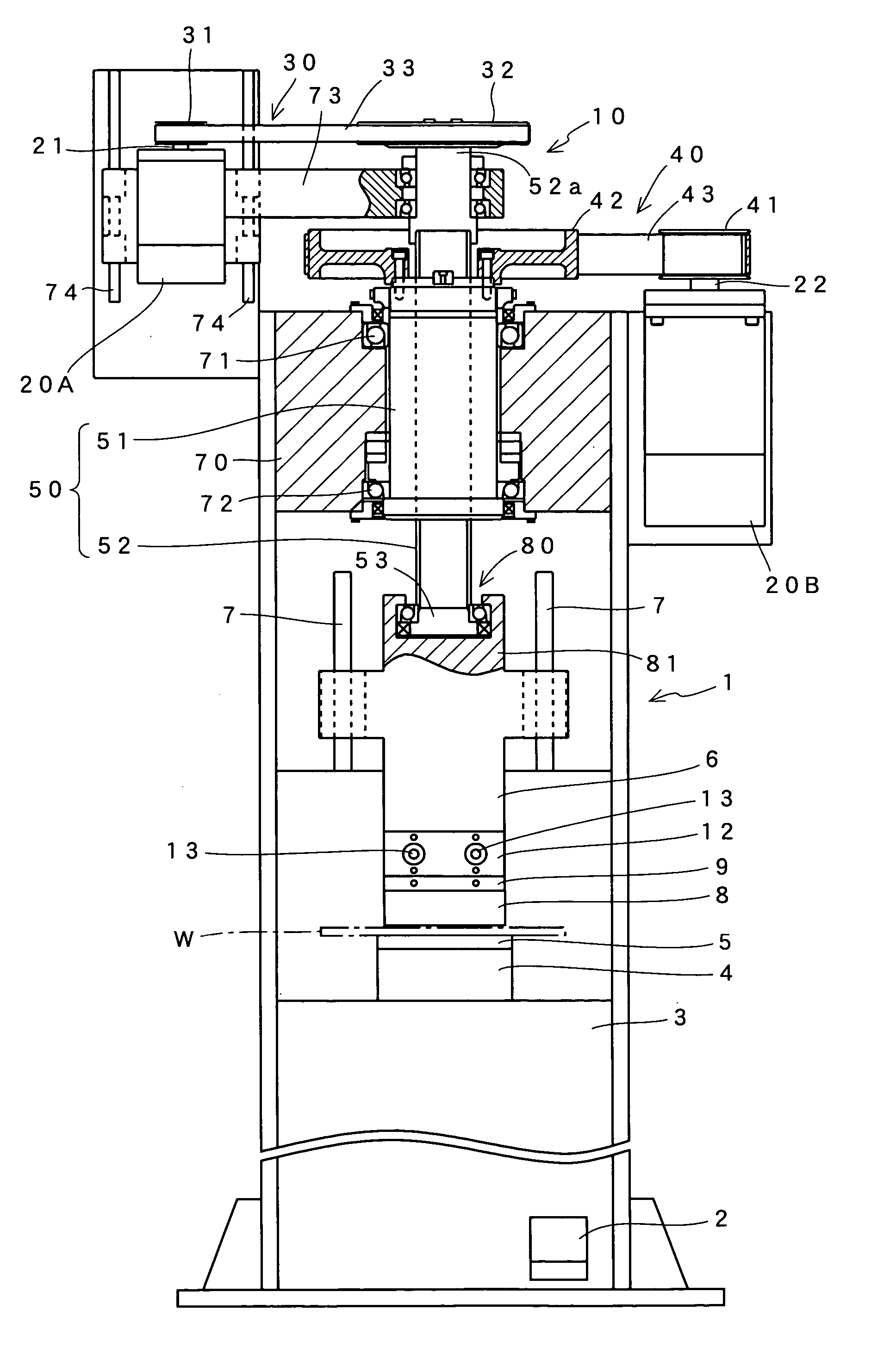

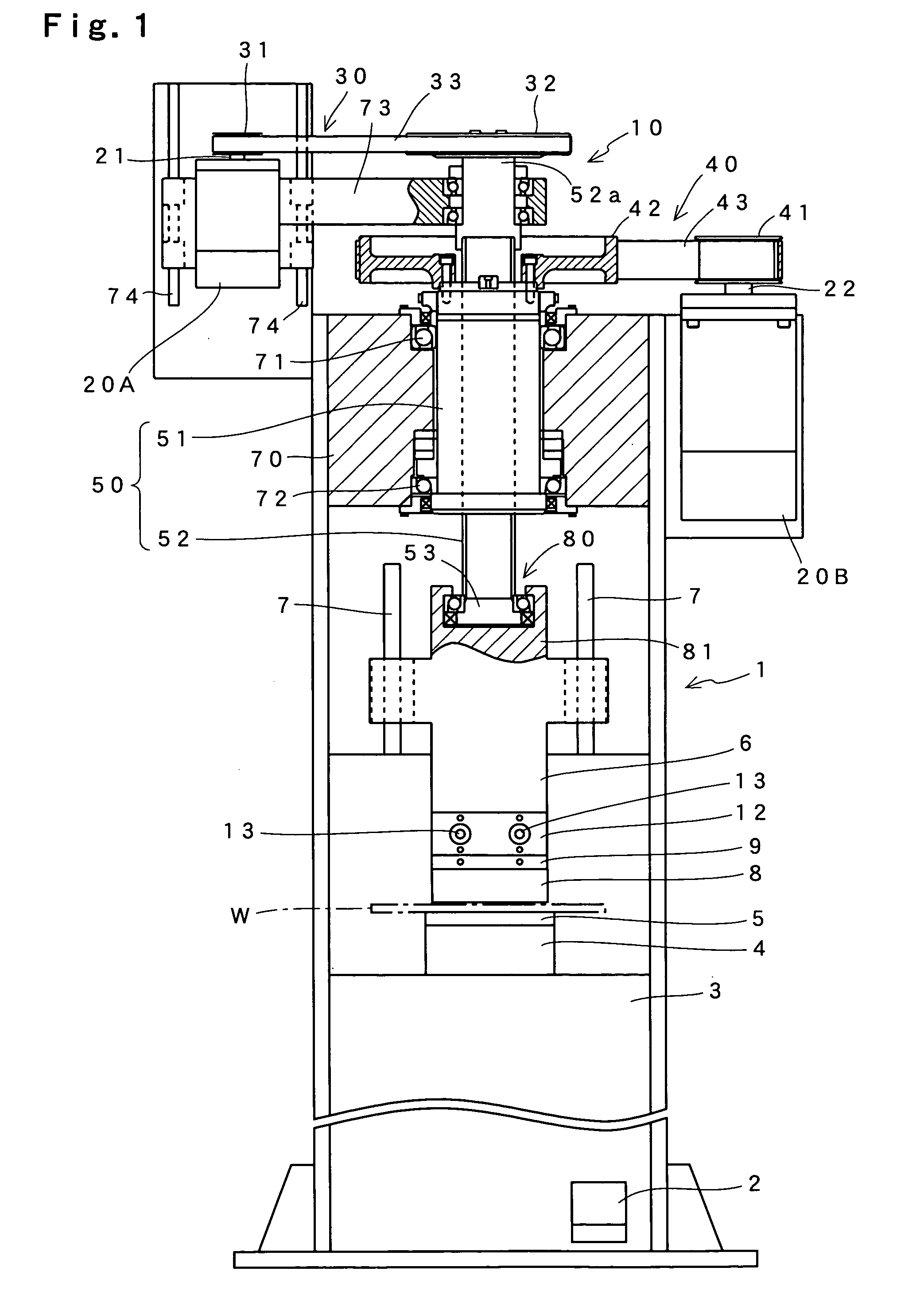

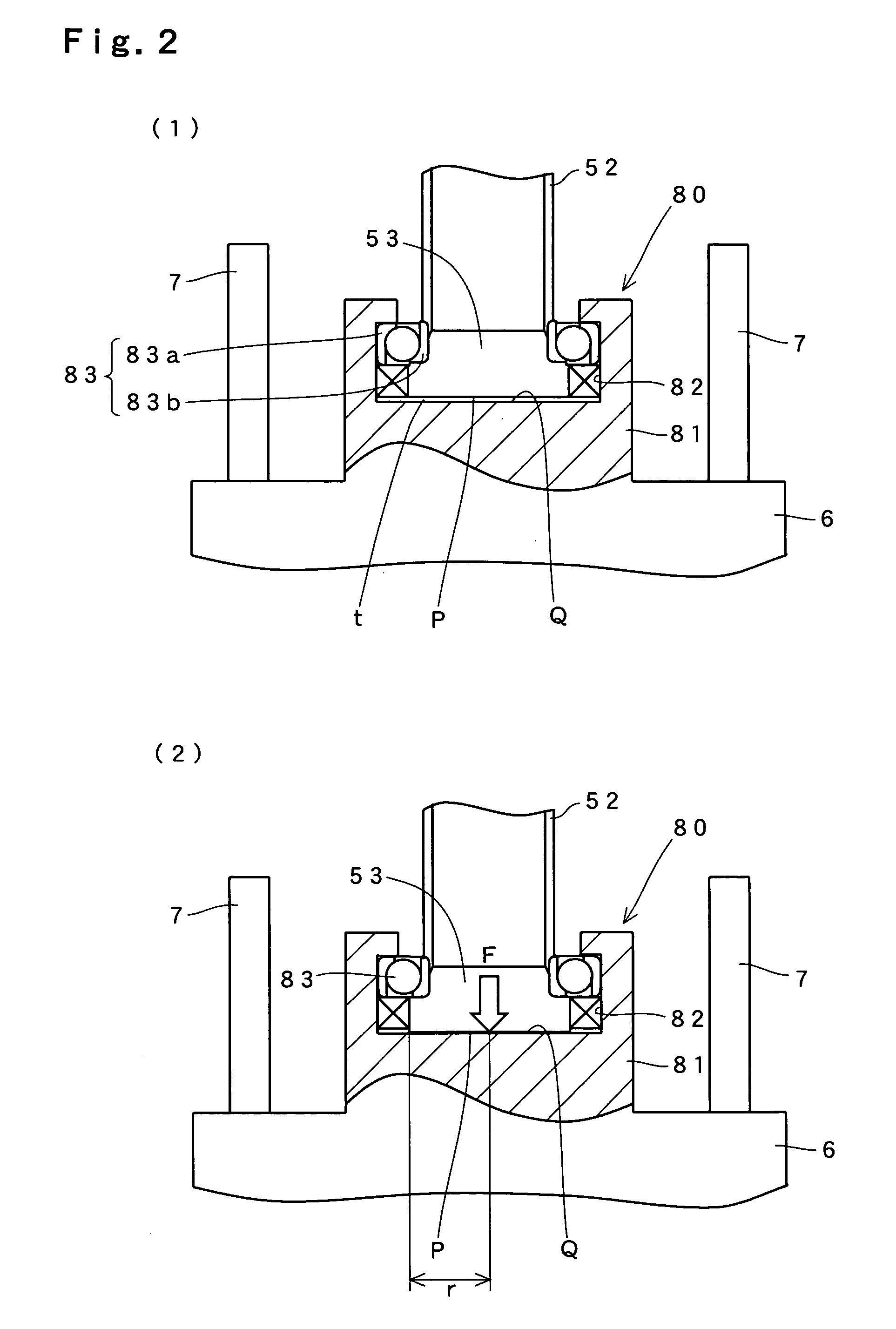

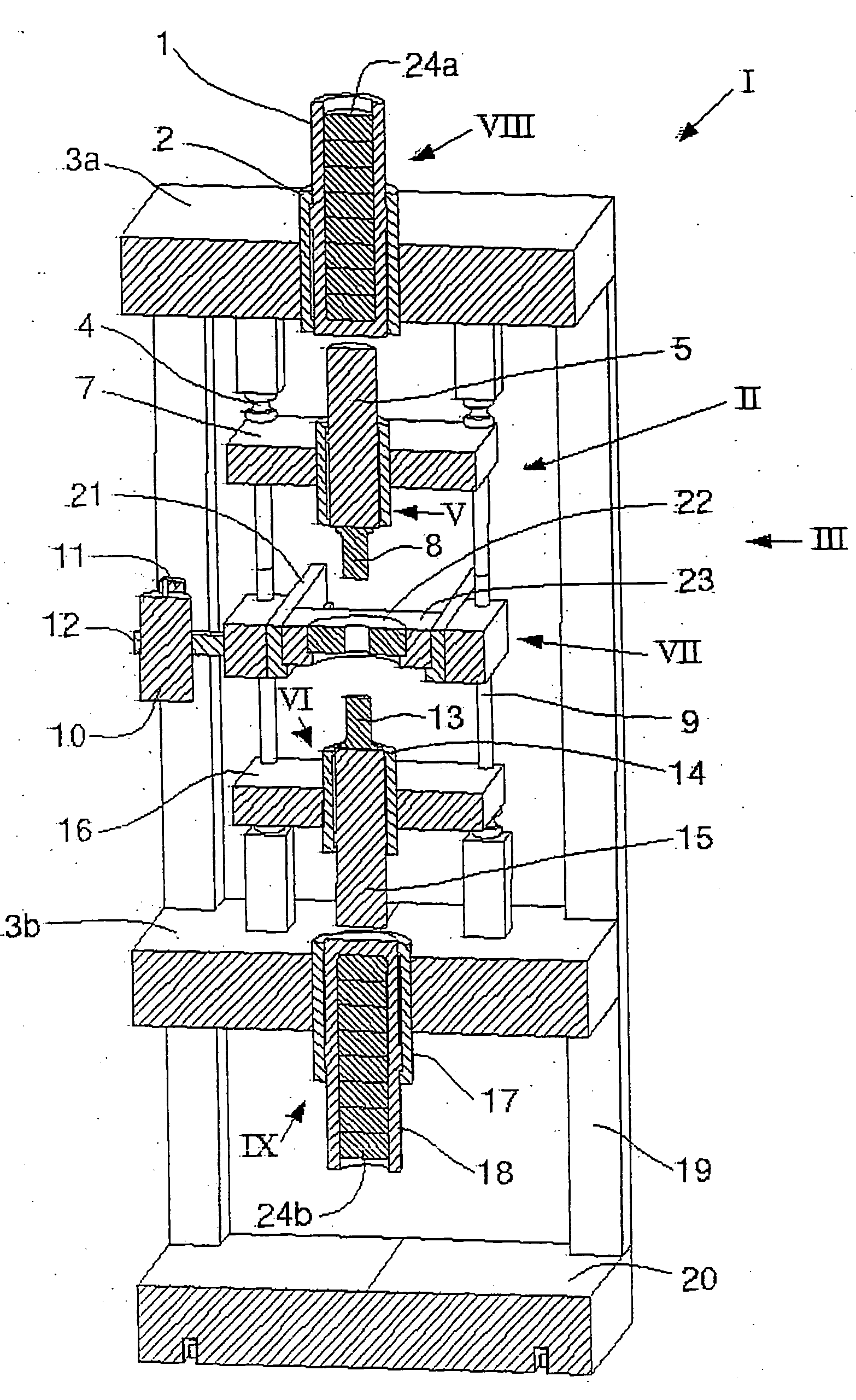

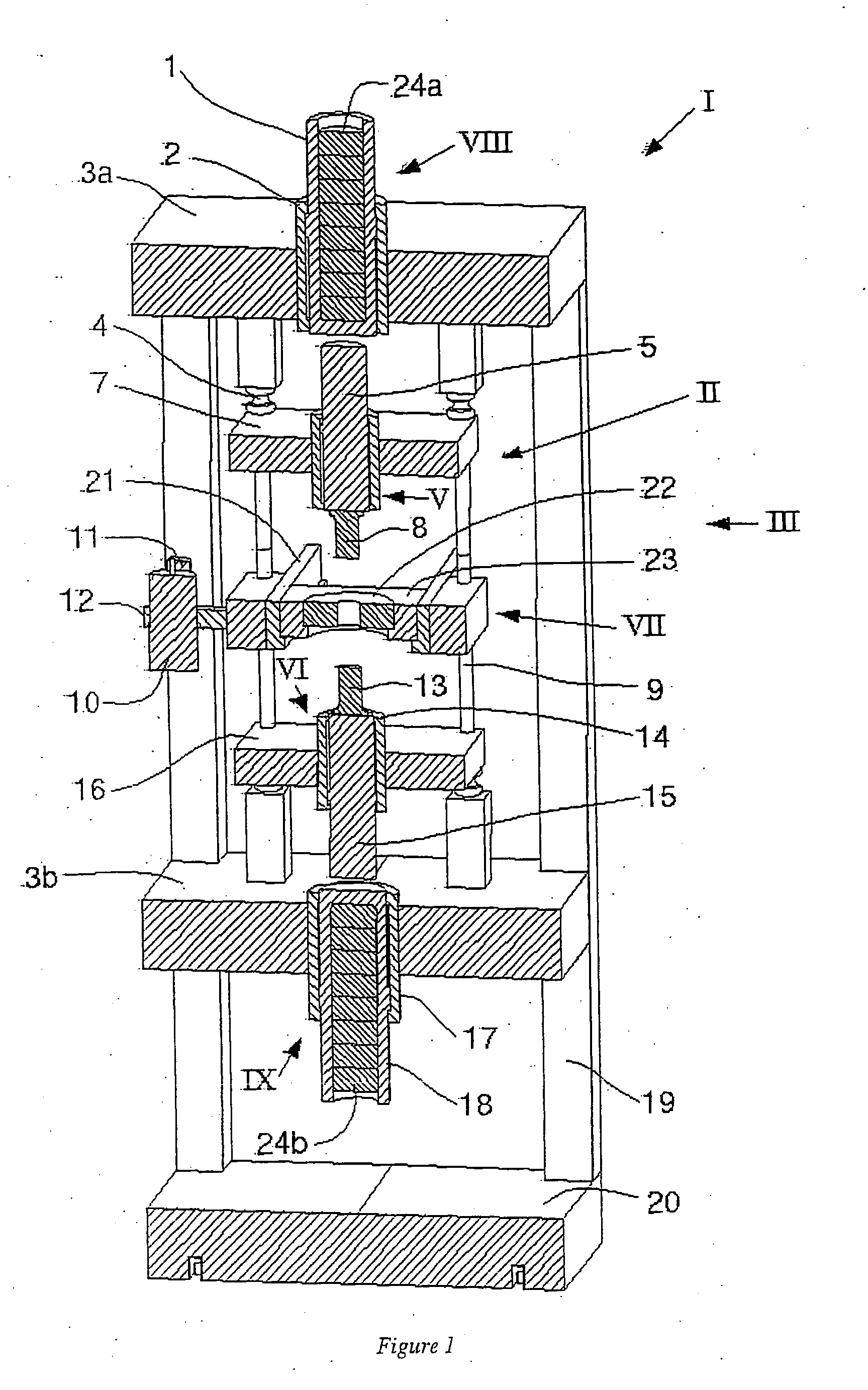

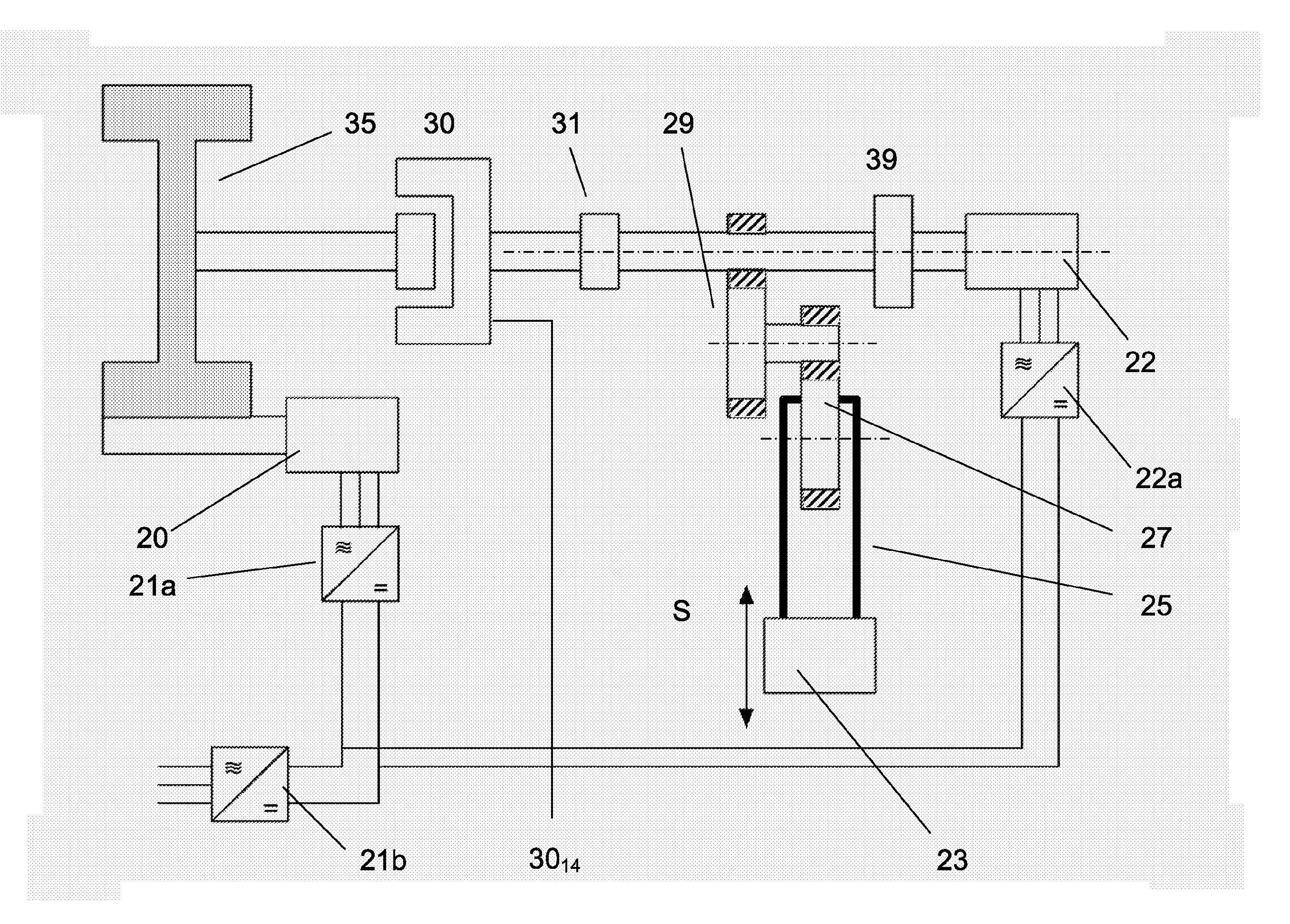

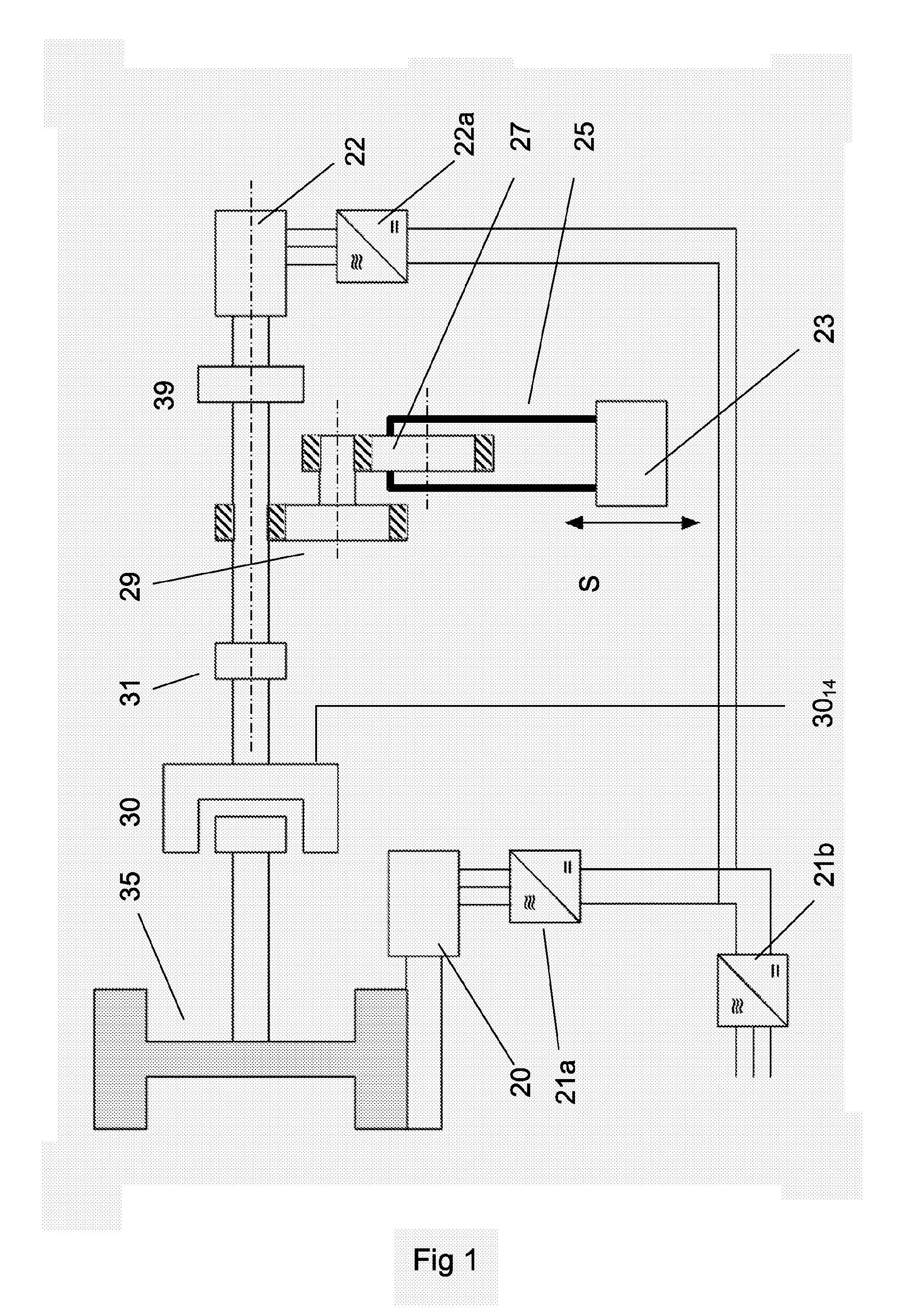

Reciprocating drive mechanism and press using the same

ActiveUS20050204798A1Sufficiently-high maximum pressing torqueSimple configurationGearingHammer drivesLinear motionBall screw

A reciprocating drive mechanism for converting motor rotation into linear motions to produce a reciprocating drive force, and a press machine using the mechanism. The rotation of a first motor (20A) out of two motors (20A) and (20B) is converted into a high-speed low-torque rotational output and transmitted to a ball screw mechanism (50) by a first power transmission mechanism (30). The rotation of the second motor (20B) is converted into a low-speed high-torque rotational output and transmitted to the ball screw mechanism (50) by a second power transmission mechanism (40). The ball screw mechanism (50) is made of a feed screw (52) supported in a screw hole of a nut member (51) so as to be capable of screw-fed rotation. The feed screw (52) and the nut member (51) are coupled with the first power transmission mechanism (30) and the second power transmission mechanism (40), respectively. A corotation prevention mechanism (80) prevents the feed screw (52) from rotating together with the rotation of the nut member (51).

Owner:AMADA CO LTD

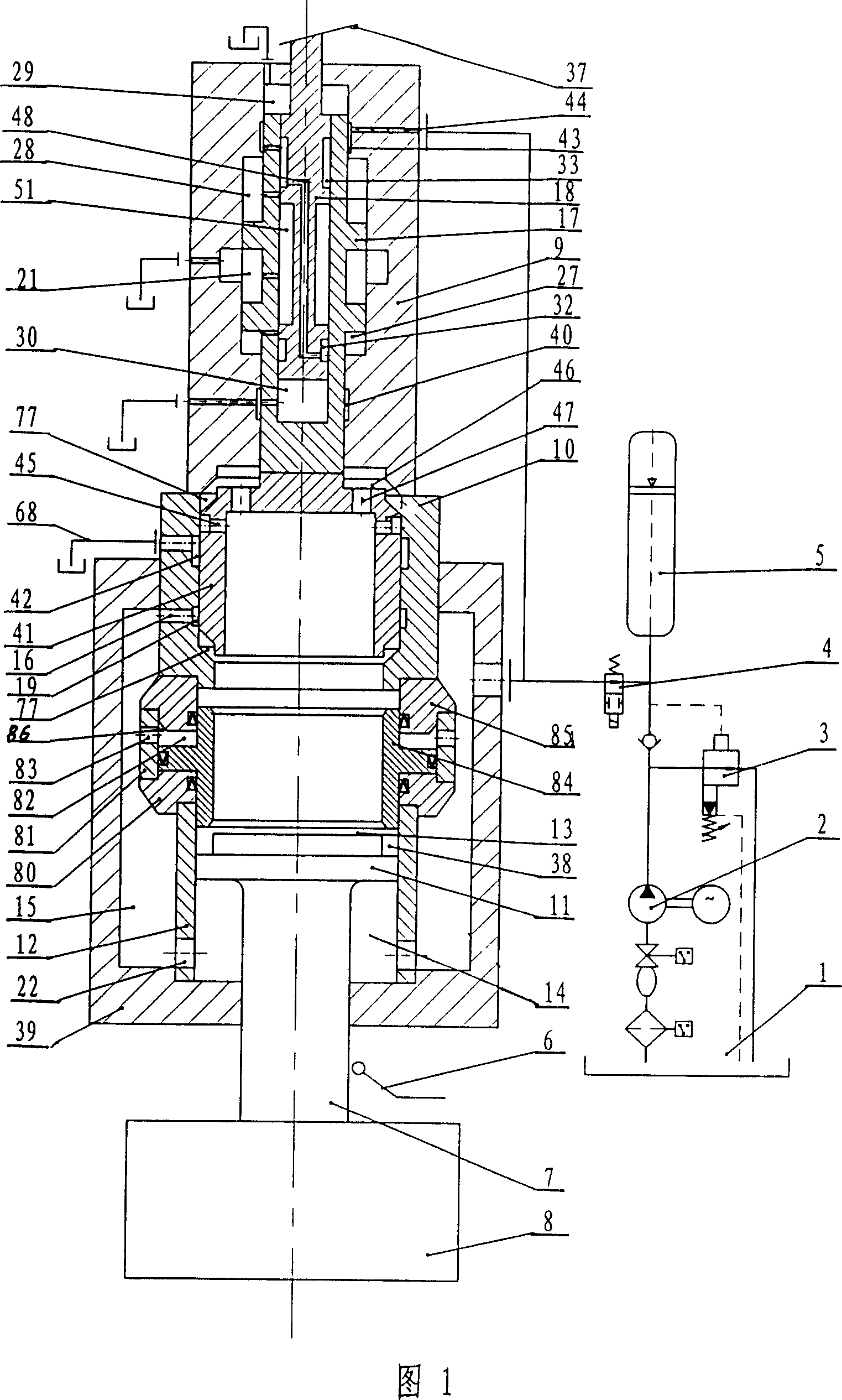

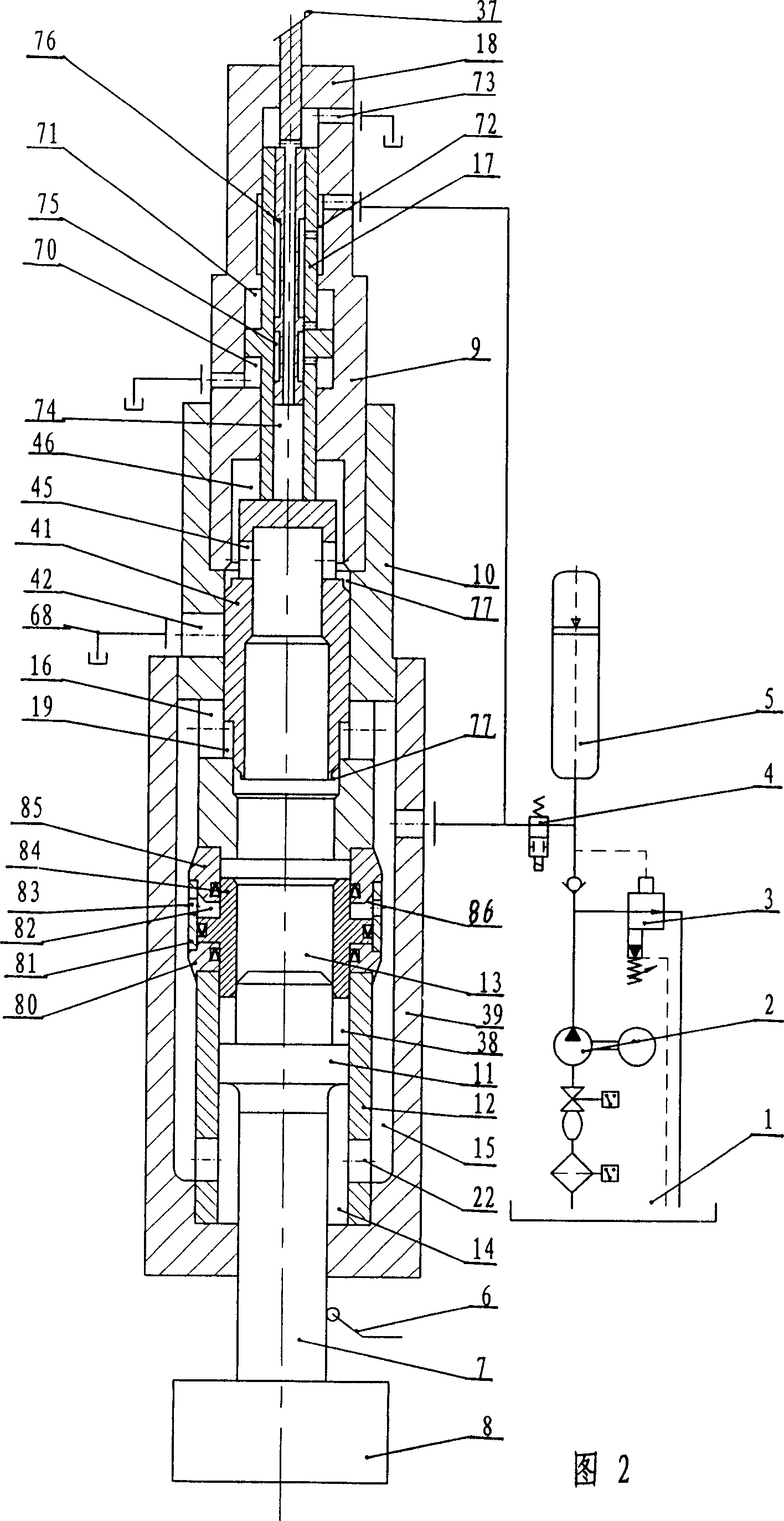

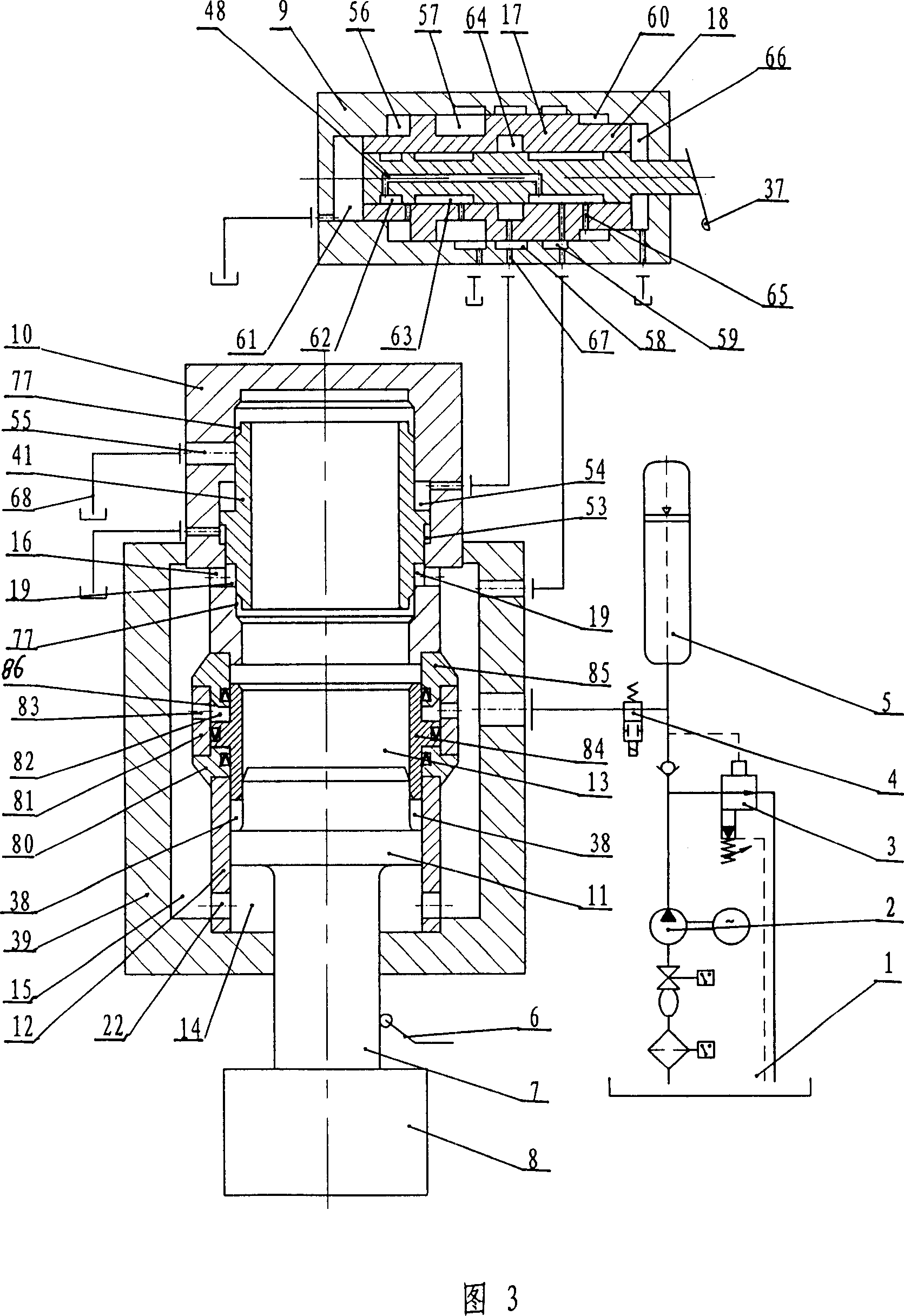

Electrohydraulic hammer

InactiveCN1986109AEasy to control speedMeet the forging hammer process requirementsPower hammersHammer drivesEngineeringMechanical engineering

The electrohydraulic hammer includes a frame, a hammer stem driving cylinder, a hydraulic source, a hammer stem with hammer head in the lower end and upper end connected to the piston inside the hammer stem driving cylinder, an upper cylinder chamber and a lower cylinder chamber in the ends of the piston, and an operating valve with valve body, a servo valve inside the valve body and valve core capable of sliding inside the servo valve. When the valve core is in different position inside the servo valve, the operating valve can close the oil inlet passage of the upper cylinder chamber, the oil exhaust passage, or both the oil inlet passage and the oil exhaust passage. Between the driving cylinder and the operating valve, there is one buffering cylinder with excellent buffering effect to avoid bumping top after the hammer head reaches the top dead point.

Owner:ANYANG FORGING PRESS MACHINERY IND

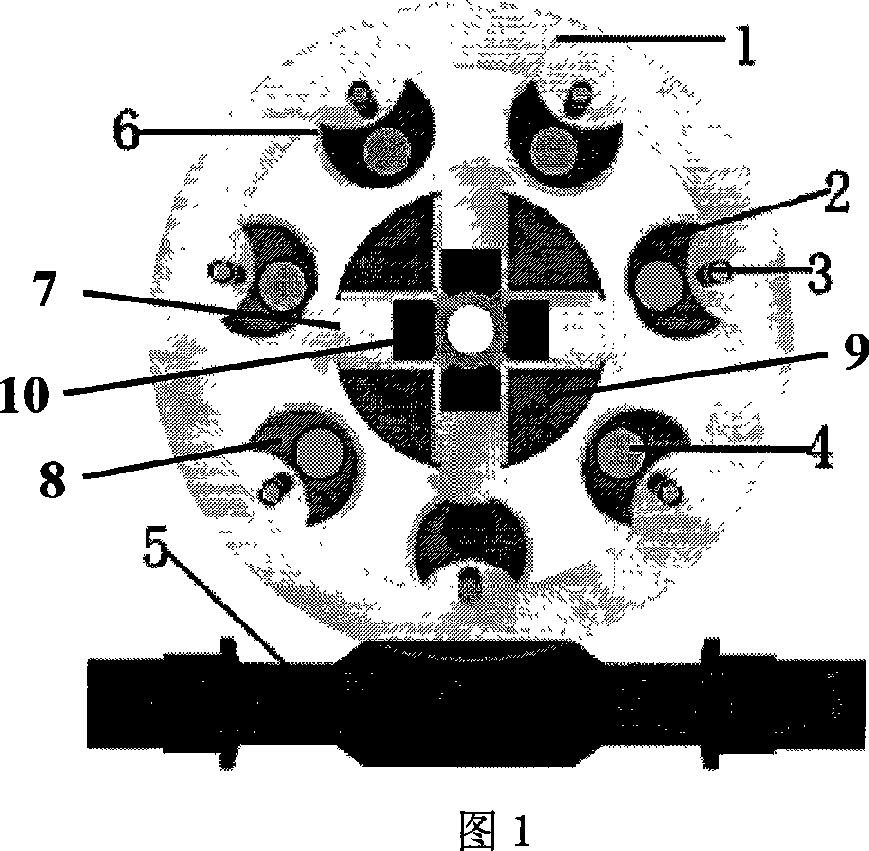

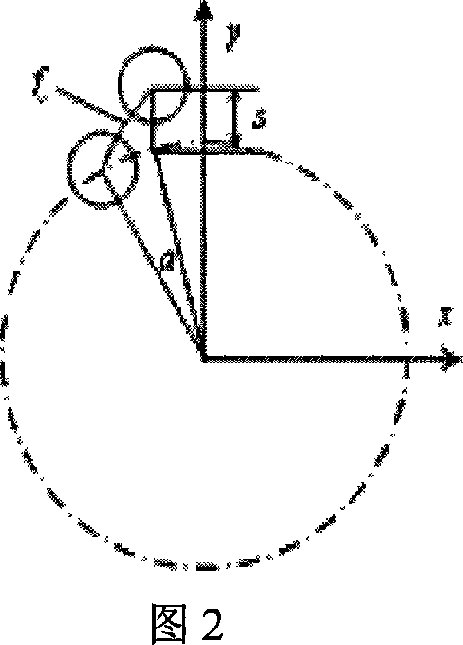

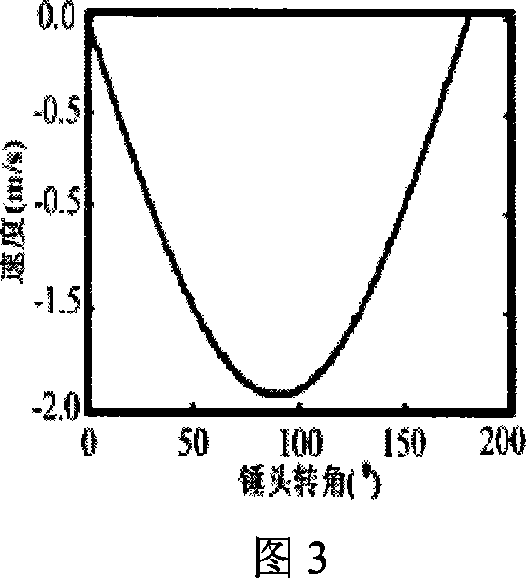

Bars and tubes material unsymmetrical radial welding punched high performance precision blanking method

The invention relates to a feeding method with the bar tube set on the asymmetrical radial impact forging precision feeding device which mainly comprises the micro tuning turbine, micro tuning base, micro tuning lever, hammer feeding cylinder, micro tuning worm, micro tuning base shaft sleeve, hammer pole, feeding cam, main shaft, hammer, with the micro tuning worm driven by the exchange servo generator, controlling the rotation angle of the micro tuning turbine, hammer lever being able to slide inside the main shaft slide slot, working curvature of the hammer lever matching with the feeding cam, pushing the radial down of the hammer lever, with one hammer pushed down one time, 4 hammers in even distribution, 7 cams forming into roller structure. When the main shaft drive hammer lever working in circumference movement, it drives the cam loading, using the bar fatigue broken principle, fostering the fissure expanding along the radial circumference, to finish feeding and get fine cross section quality.

Owner:XI AN JIAOTONG UNIV

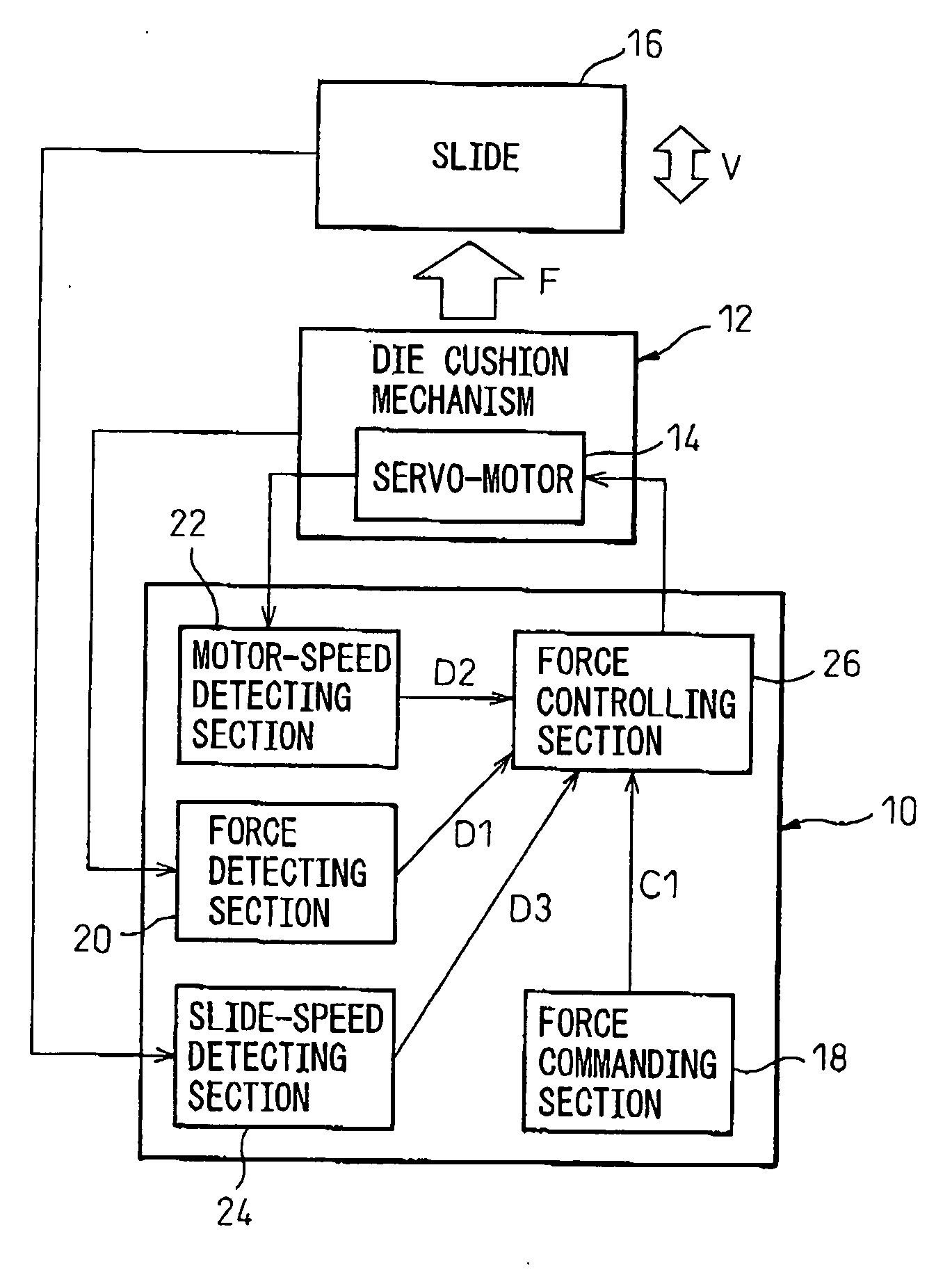

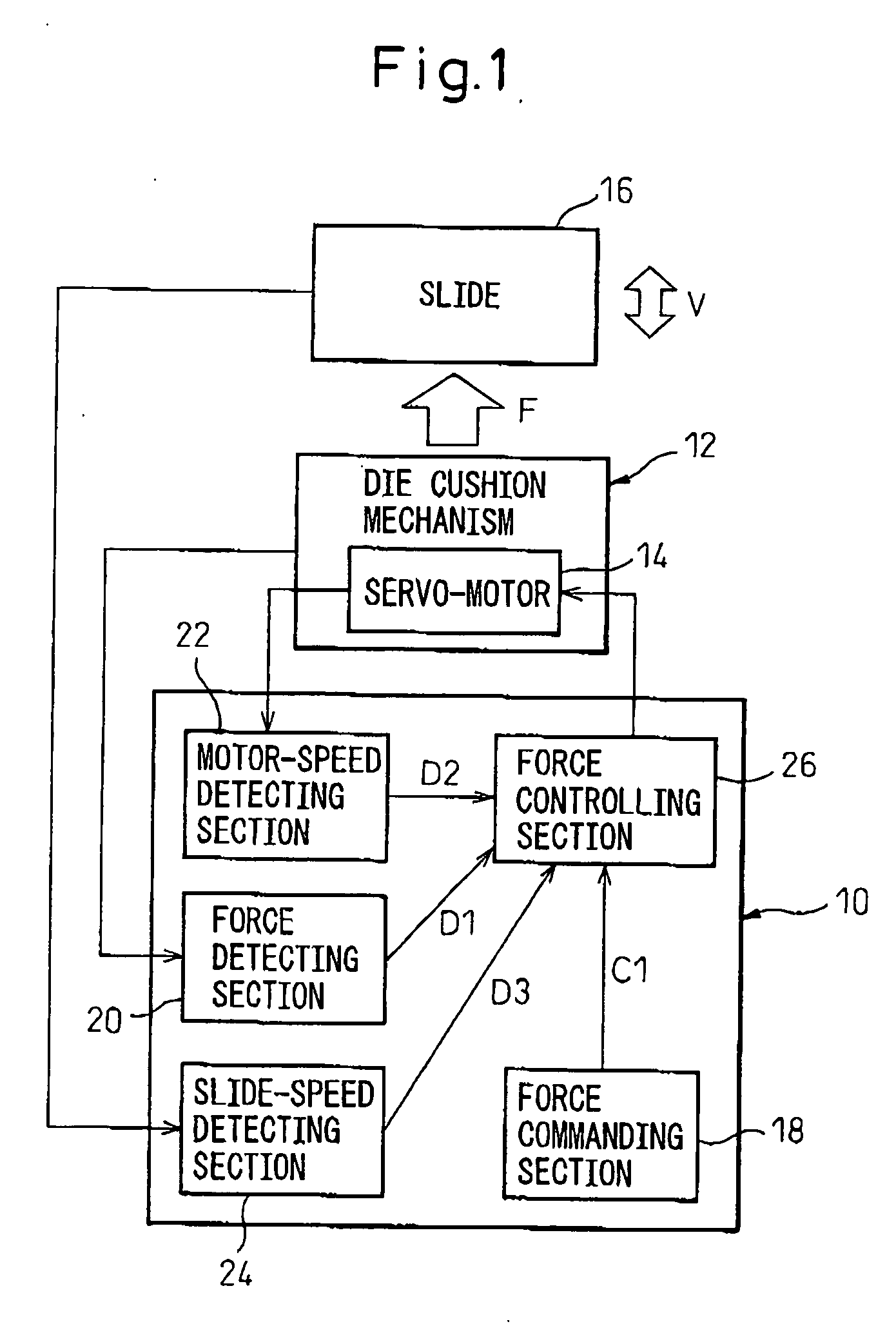

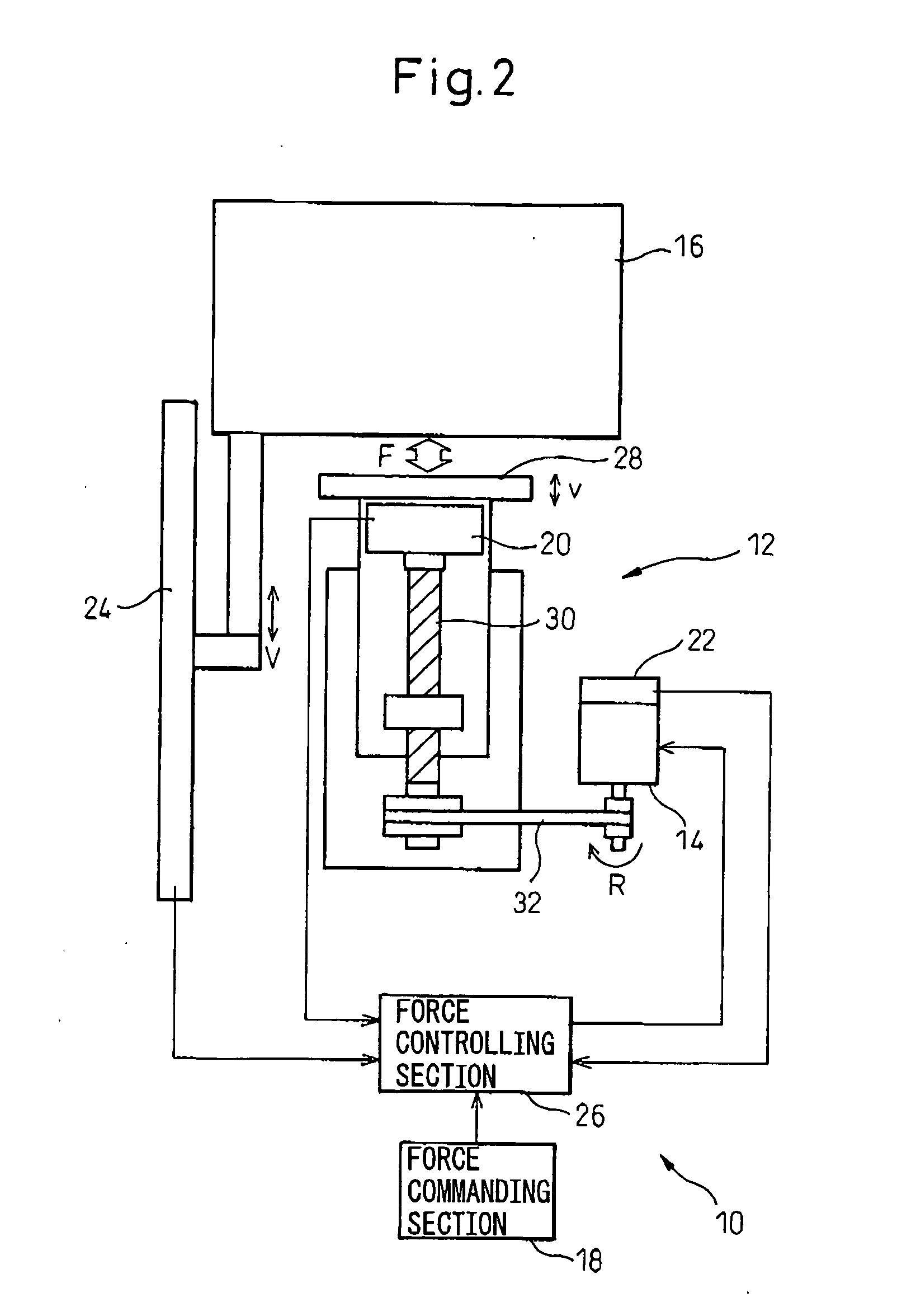

Die cushion mechanism, and apparatus and method for controlling the same

ActiveUS20060090656A1Improve performancePrecision productionShaping safety devicesHammer drivesMotor speedEngineering

A control apparatus for controlling a die cushion mechanism including a servo-motor as a drive source and producing a force adapted to be applied to a slide in a press machine. The control apparatus includes a force commanding section for commanding a force to be produced by the die cushion mechanism; a force detecting section for detecting the force produced by the die cushion mechanism; a motor-speed detecting section for detecting an operating speed of the servo-motor; a slide-speed detecting section for detecting a moving speed of the slide; and a force controlling section for executing a force control on the servo-motor, based on a force command value commanded by the force commanding section, a force detected value detected by the force detecting section, a motor-speed detected value detected by the motor-speed detecting section and a slide-speed detected value detected by the slide-speed detecting section.

Owner:FANUC LTD

Laminated magnetic cores

InactiveUS20080229799A1Deformation MinimizationHammer drivesInductances/transformers/magnets manufacturePunch pressEngineering

Laminations to be stacked as magnetic cores are produced from a very thin amorphous metal strip, using a punch press with accurate punch / die clearance. The laminations are collected on conveyor spindles or a transport rod or pipe, in either case being arranged without the need for substantial handling. Heat annealing and anti-vibration treatments can be applied along a conveying path. The laminations are grouped in a stack to define a core and are packaged or encapsulated in electrically nonconductive coverings. The finished core has advantageous electrical characteristics and low cost.

Owner:MAGNETIC METALS

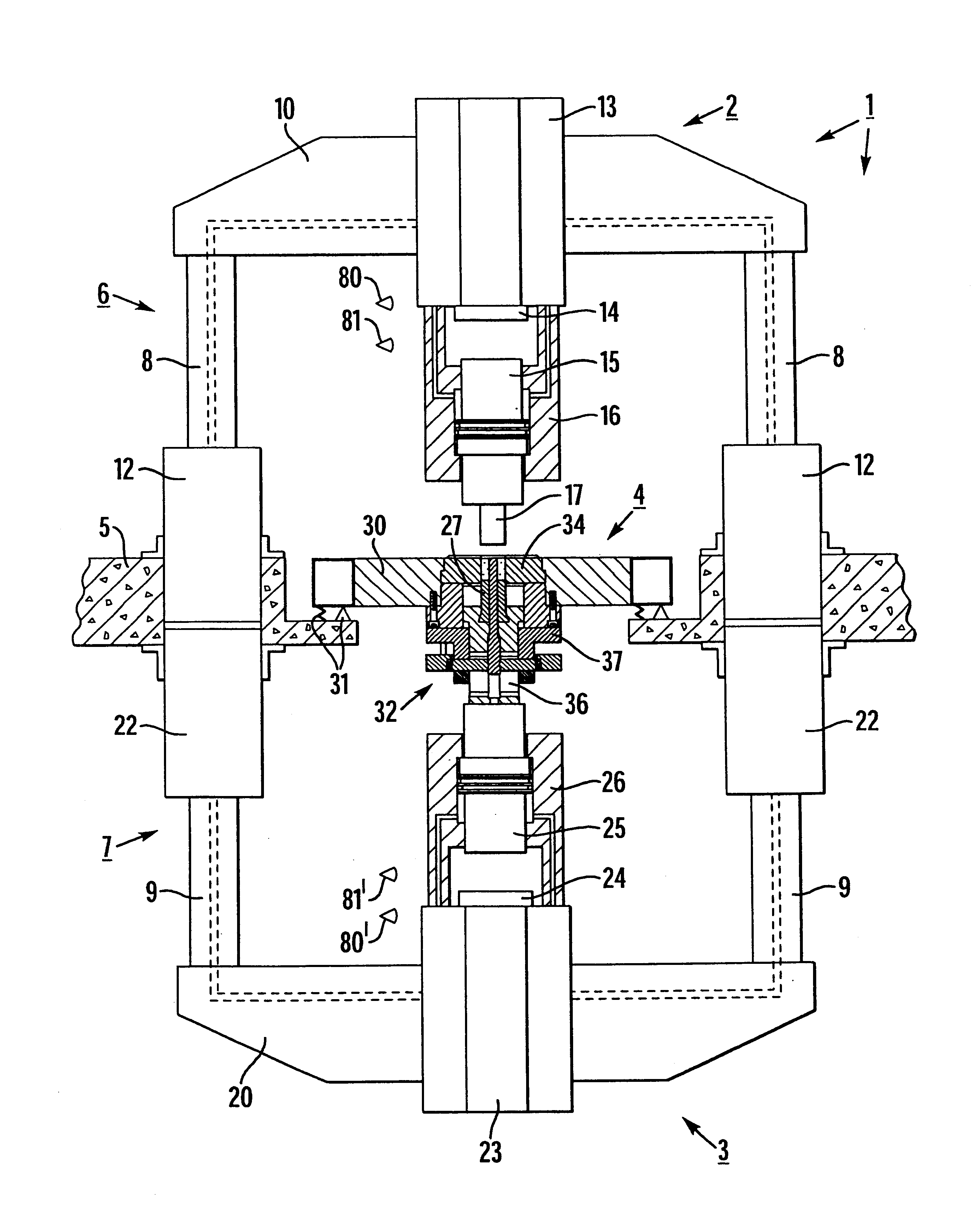

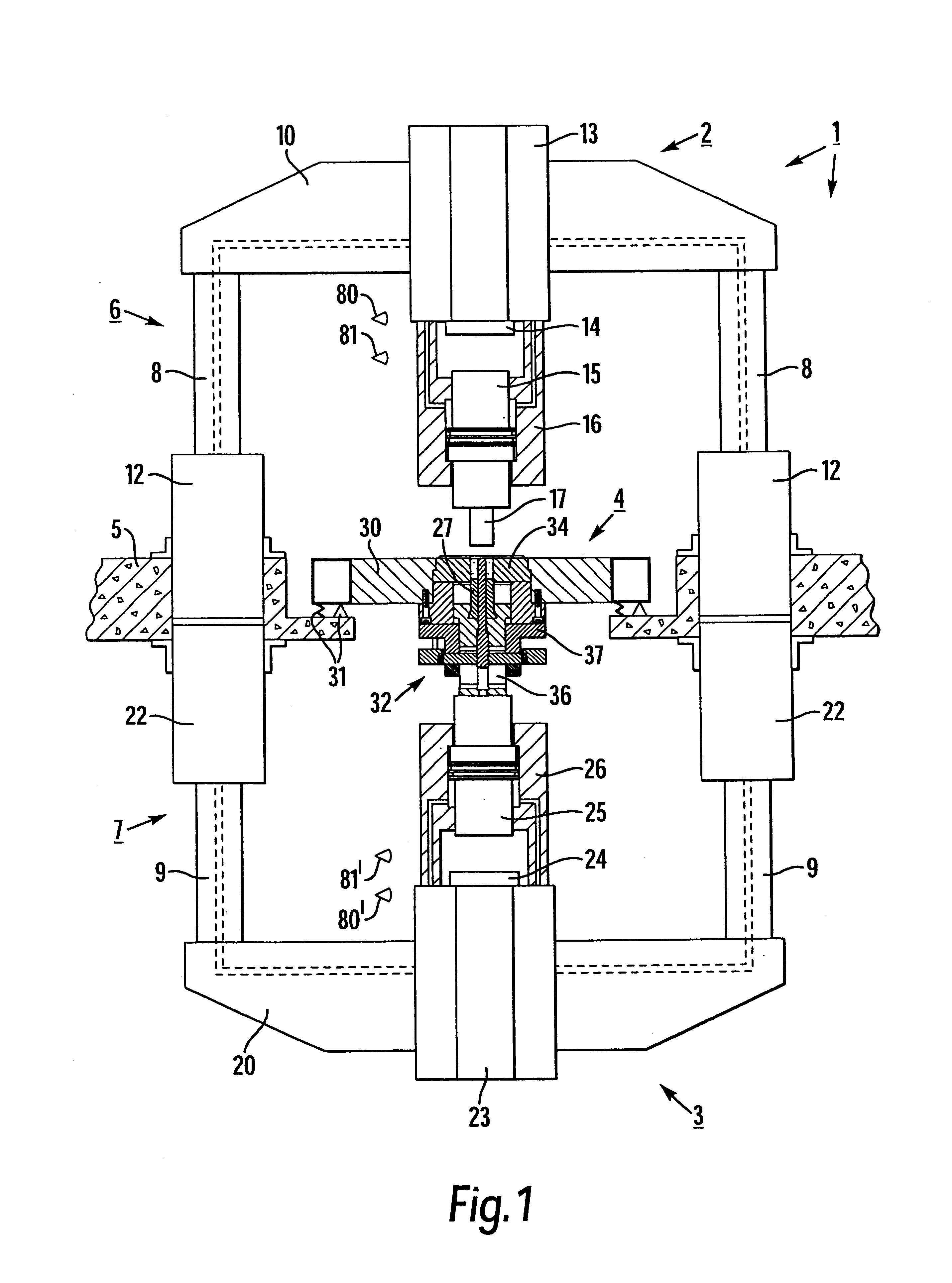

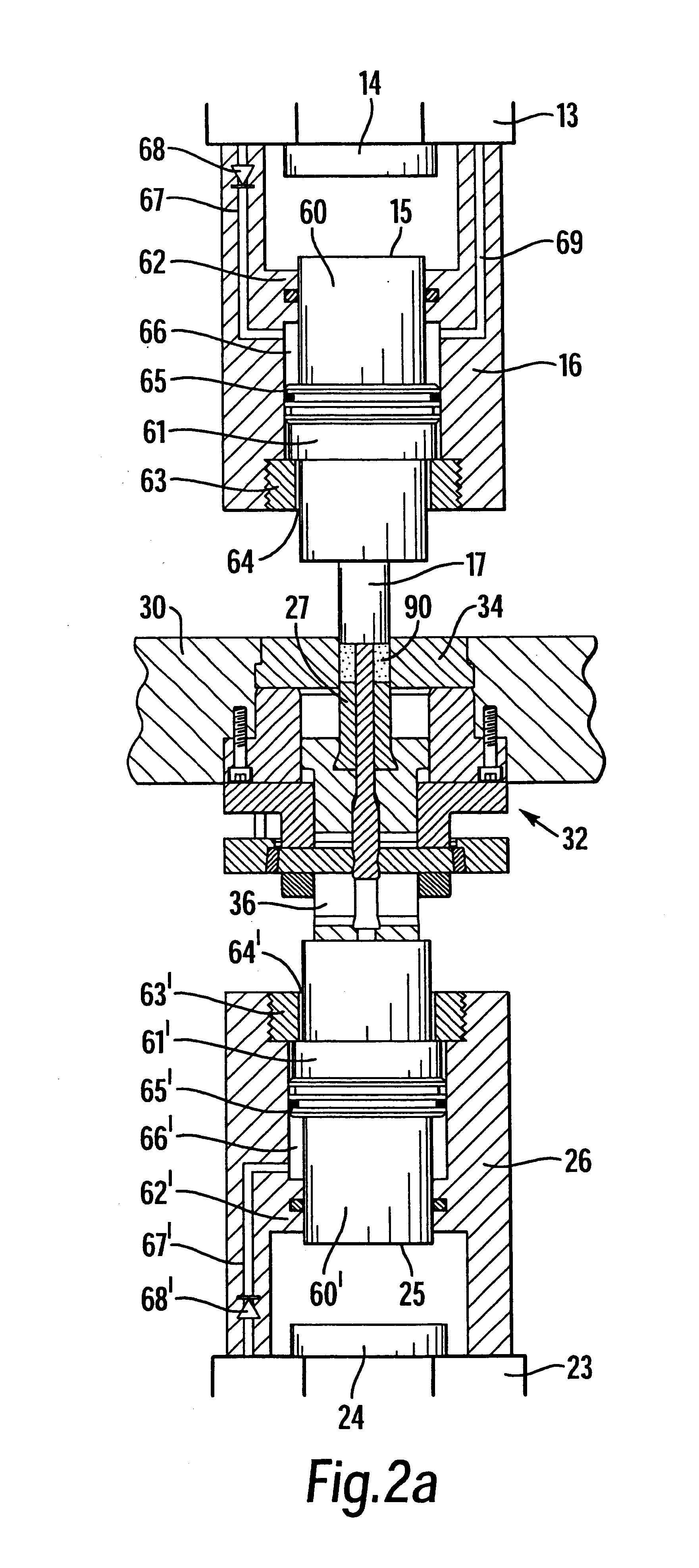

Method and impact machine for forming a body

A method of forming a body of a formable working material in an impact machine, which comprises an upper impact unit (29 with an upper ram (14), an upper punch (17), a lower impact unit (3) with a lower ram (24), a lower punch (27), and mould cavity for the working material between the punches when the punches are brought towards one another, is characterized in that downwards movable masses, which comprise at least the mass of the upper ram and the mass of the upper punch, and upwards movable masses, which include at least the mass of the lower ram and the mass of the lower punch, are caused to move towards one another and towards the working material in the mould cavity, that the masses which move downwards, including the upper punch (17) obtain a downwards directed velocity (v1) and those masses which move upwards, including the lower punch (27), obtain an upwards directed velocity (v2), wherein the movable parts have such masses and the velocities are so high that the momentums of the downwards movable masses and the upwards movable masses become essentially equally large, i.e. so that the following condition applies.where m1 is the total mass of the downwards movable masses during the stroke, and m2 is the total mass of the upwards movable masses during the stroke.

Owner:MORPHIC TECH

Press

Owner:HODEN SEIMITSU KAKO KENKYUSHO CO LTD

Dynamic forging impact energy retention machine

InactiveUS20050220921A1Low costEfficient productionPower hammersConfectioneryShock waveImpact system

A machine for producing a body with desired shape of a workable material through dynamic forging under impact and finally with energy retention while the shock wave fades out. The machine includes a machine stand, a dynamic outer impact system having an upper unit, and a lower impact unit, which includes a counter-impact device, and possibly one or more dynamic side impact units, and a static inner press system having an upper unit and a lower unit, possibly with additional one or more static side compacting units, with a central unit in between. The lower units of the outer and inner systems can be exchanged with a common stationary anvil for a single direction machine instead of a counter-acting machine.

Owner:OLSSON KENT

Servo-press with energy management

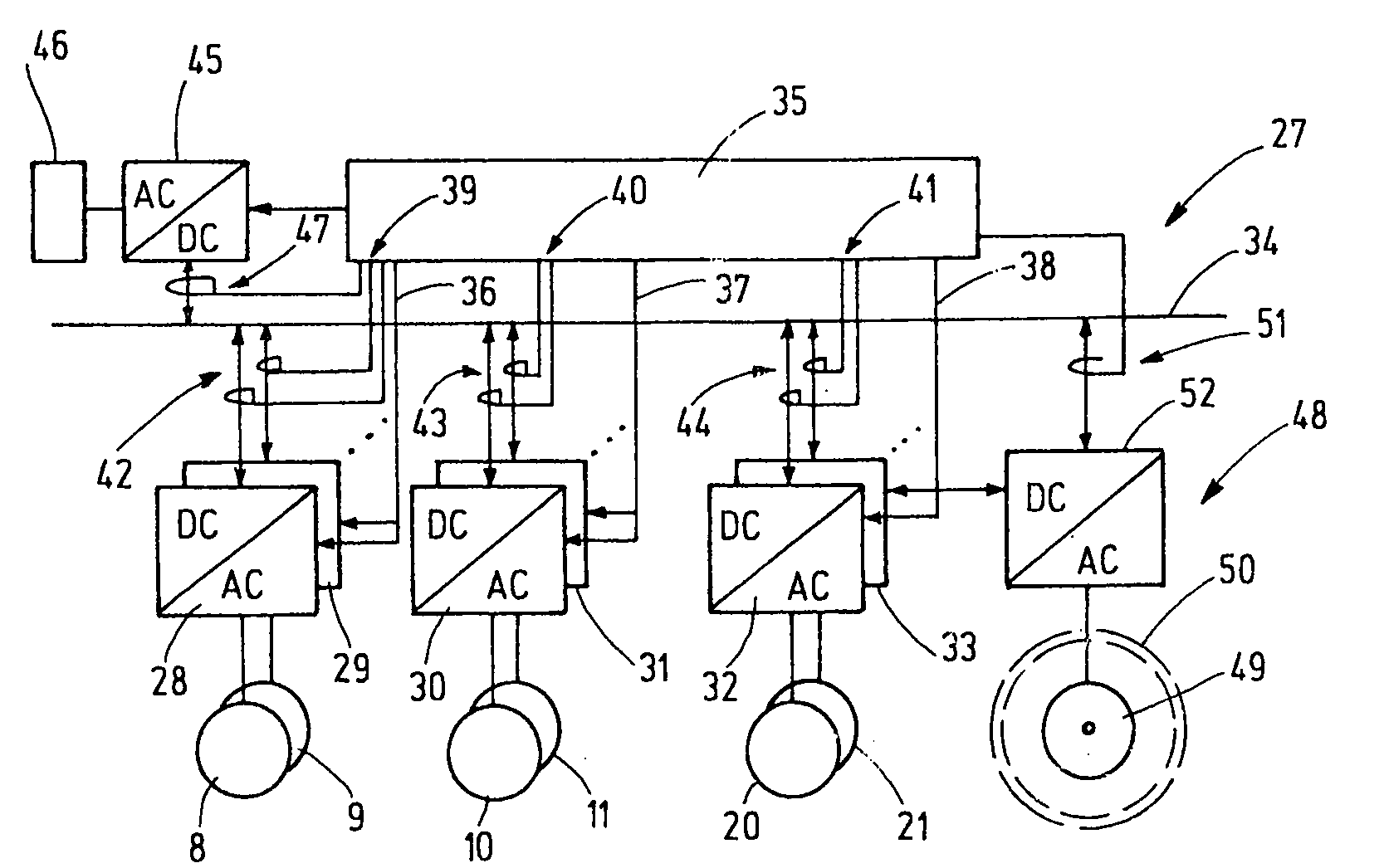

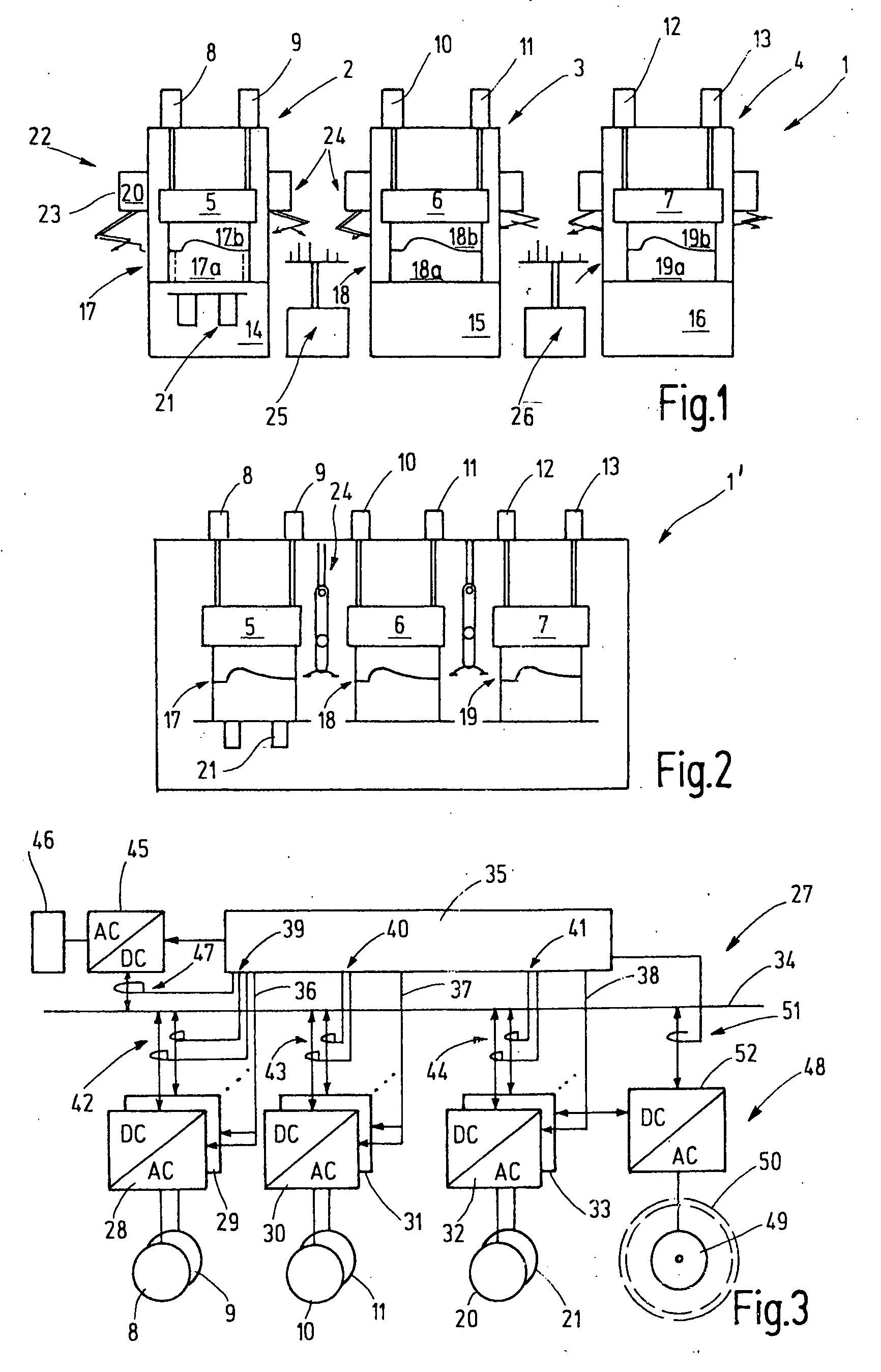

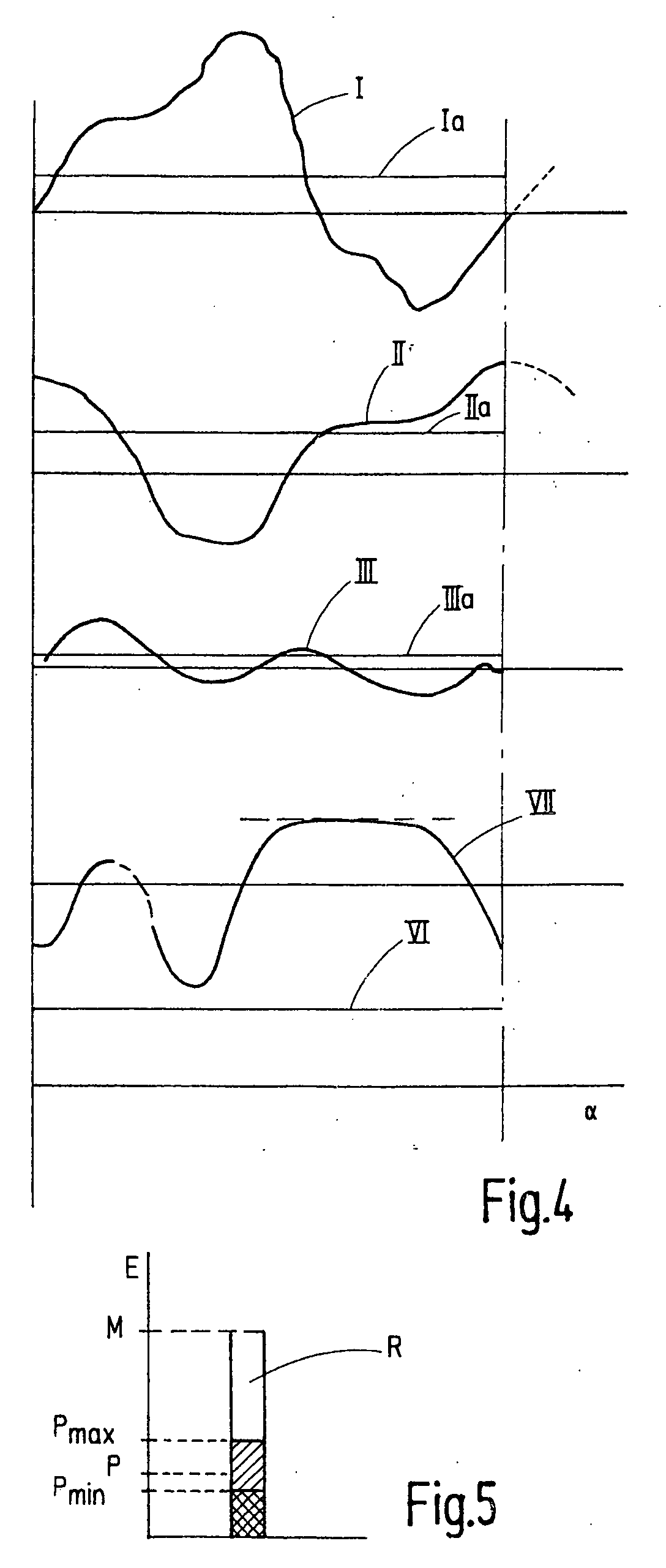

InactiveUS20080016940A1Arrangement be smallLow costDrop hammersMetal-working feeding devicesServo pressEnergy management system

In a press installation including a number of presses with servo-drives for operating the presses and auxiliary equipment such as workpiece handling devices wherein an energy management system is provided including a DC voltage intermediate circuit connected to a power supply grid via an AC / DC converter and to the servo-drives via servo-converters, a fly-wheel storage device is connected to the intermediate circuit for supplying energy thereto and recapturing energy therefrom under the control of a control arrangement which controls the flow of power between the intermediate circuit, the servo-drives, the fly-wheel storage device and the power supply grid.

Owner:SCHULER PRESSEN GMBH & CO KG

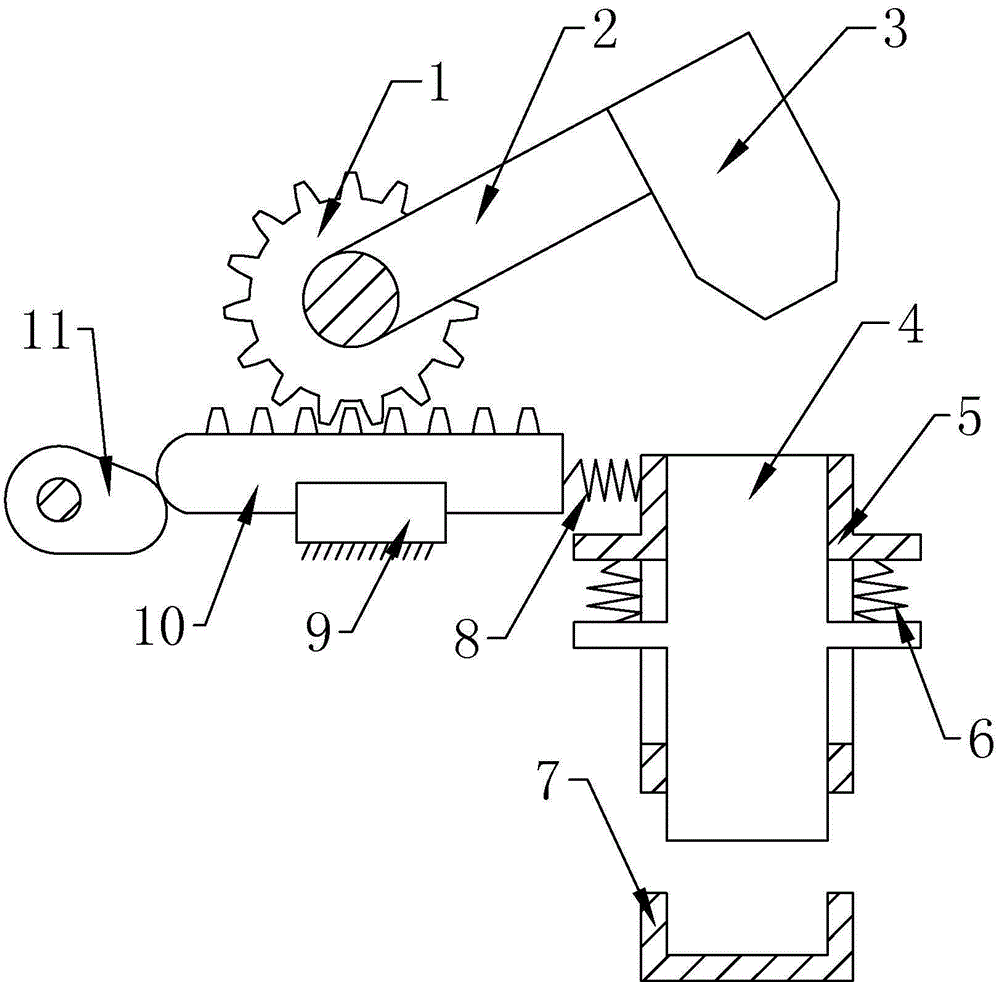

Mechanical double energy storage impact mechanism and impact method

InactiveCN102357634AReduce contact stressProtect working facePower hammersHammer drivesElectric driveEngineering

The invention discloses a mechanical double energy storage impact mechanism and a mechanical double energy storage impact method. The mechanism comprises a frame, a rotating shaft is arranged on the frame, the rotating shaft is fixedly connected with a swinging arm, the swinging arm is connected with a hammer head, a torsion spring is arranged coaxial with the rotating shaft, the swinging arm is fixedly connect to one end of the torsion spring, and the other end of the torsion spring is fixed on the frame. An electric driving mechanism and a first electromagnet are arranged on the frame, the first electromagnet is connected with a drag hook, a gear clutch is arranged on the electric driving mechanism, and a lever is movably connected to the frame and movably matched with the drag hook; and a second electromagnet is arranged on the frame through a mounting arm. The mechanism has two energy storage links, namely deformation energy storage of the torsion spring and elastic bending energystorage of the swinging arm, so that the contact stress during impacting can be effectively reduced and the working surface of a workpiece is well protected. By using the mechanism and the method, conventional heavy manual hammering can be replaced, and the labor intensity is lightened; and the mechanism can also be used for replacing the conventional starting pneumatic striker in the powder conveying process to prevent blockage.

Owner:CHINA THREE GORGES UNIV

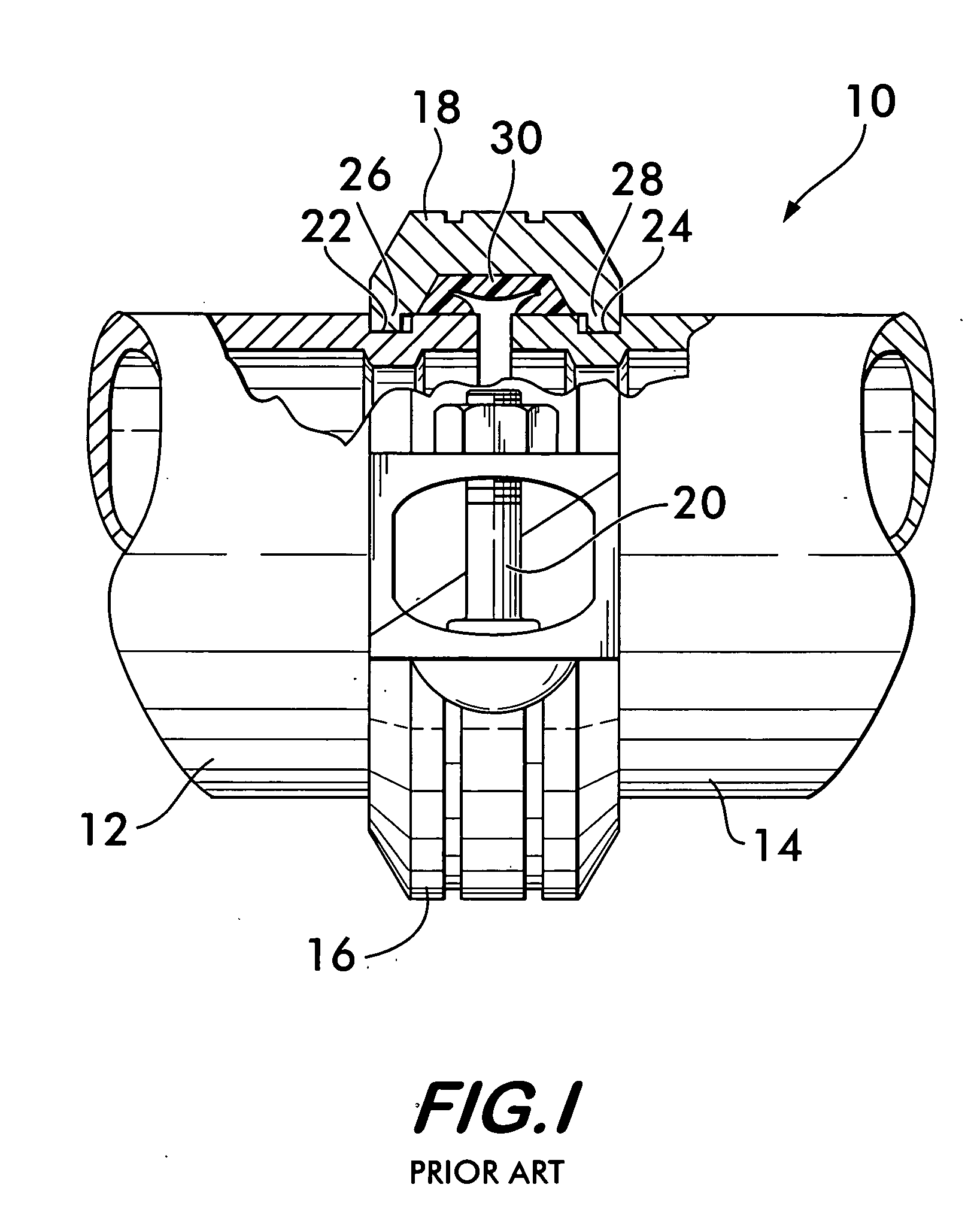

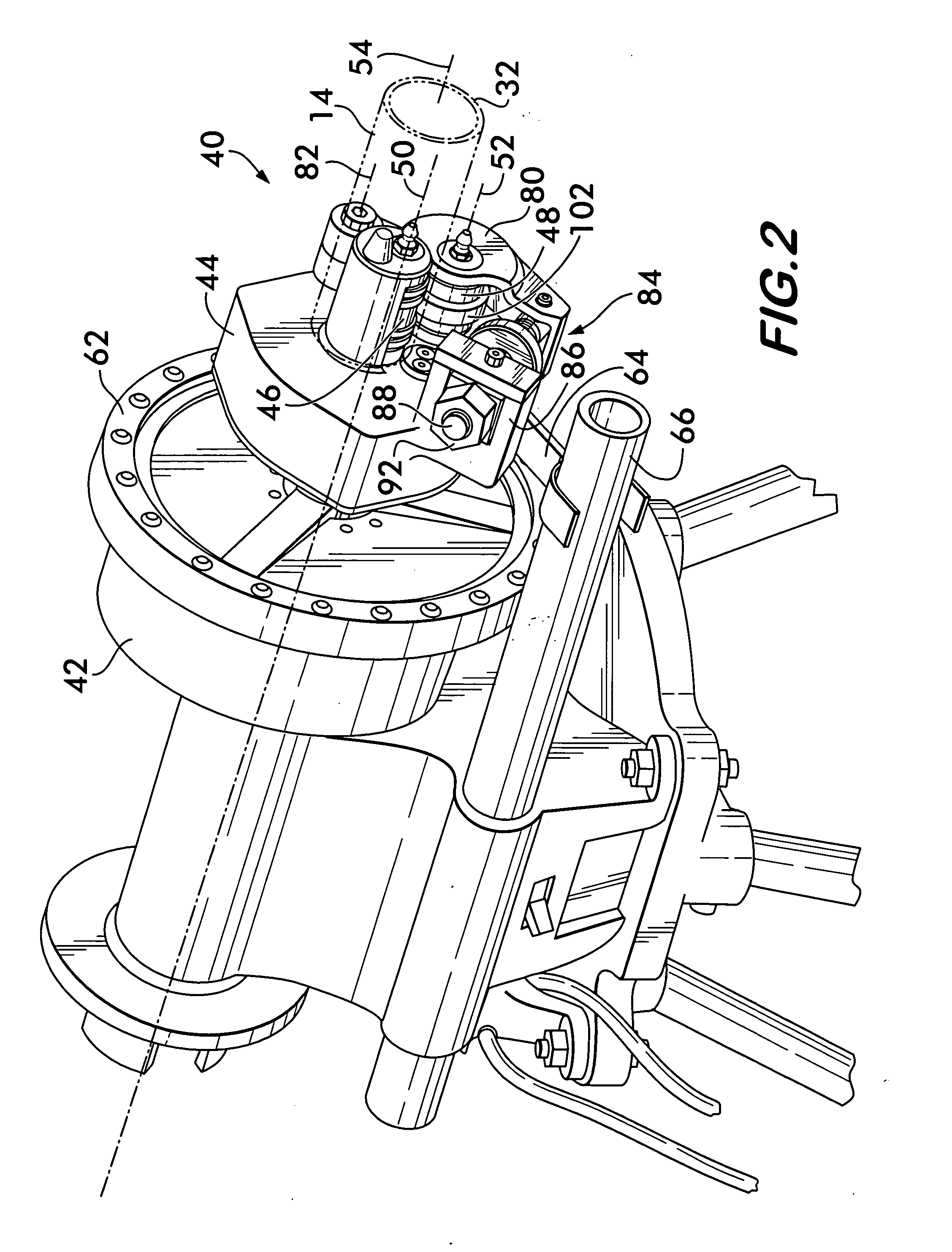

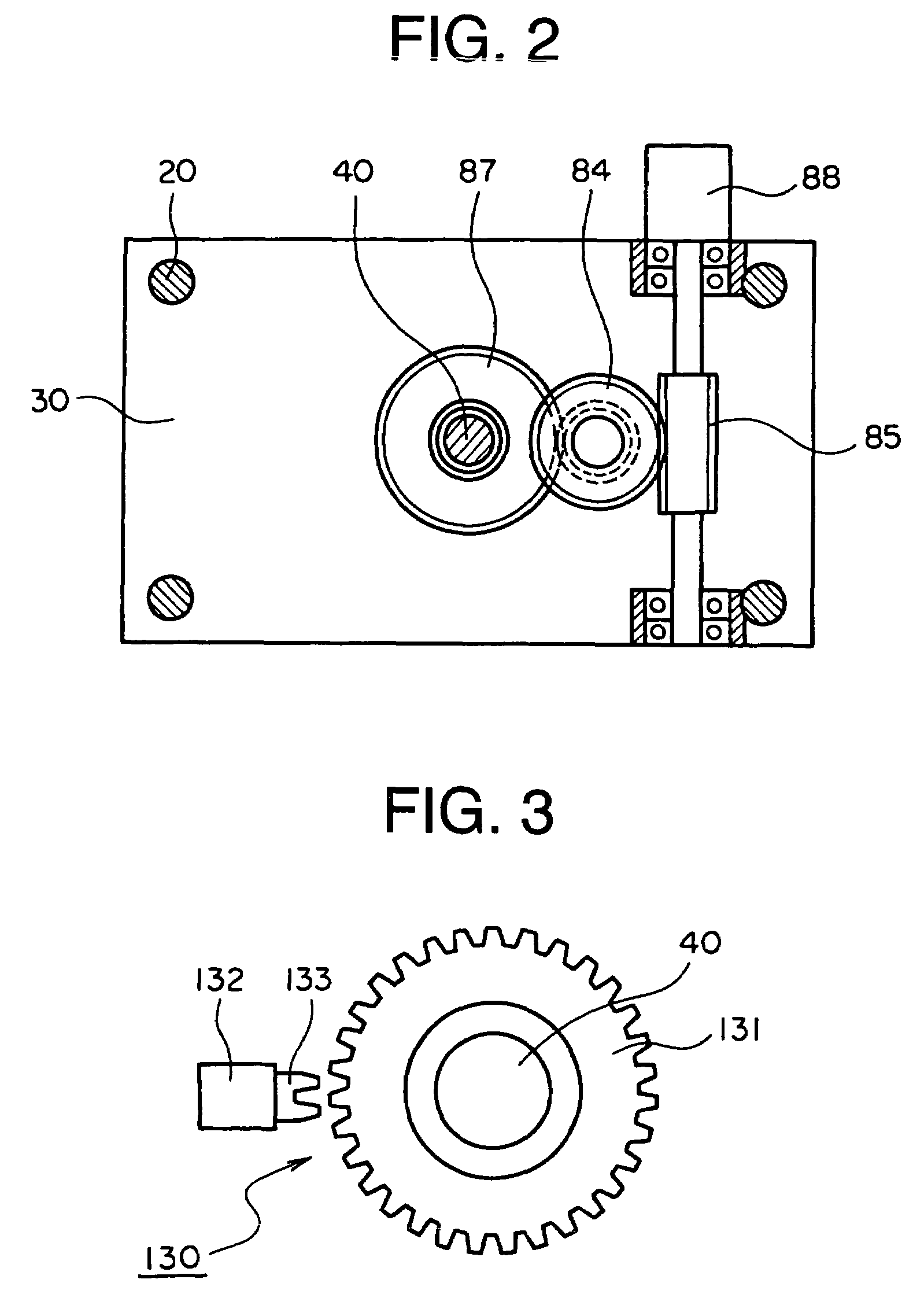

Power or manually operated pipe grooving tool

A pipe grooving tool is disclosed having a housing on which a back-up roller and a grooving roller are rotatably mounted. The grooving roller is pivotably movable toward the back-up roller and has a raised tool surface engageable with the outer surface of the pipe. The pipe is positioned with its sidewall between the rollers, and the back-up roller is rotated while the grooving roller is forcibly moved toward the back-up roller. A circumferential groove is formed around the pipe as the rollers traverse its circumference. A power drive shaft connected directly to the back-up roller is provided, the power drive shaft engaging a power drive unit on which the tool is mounted operated under power. A manual drive shaft is connected to the back-up roller through a torque multiplying gear and pinion transmission for manual operation of the tool.

Owner:VICTAULIC

Mechanical press drive system

InactiveUS20090217724A1Improve controllabilityShorten cycle timeShaping safety devicesHammer drivesFreewheelLinear motion

A method for operating a mechanical press including an electric drive motor, a drive control for controlling the motor, a ram, a flywheel, a clutch and a member for translating rotational motion of the flywheel in a first rotation direction into a linear motion of the ram arranged to be lowered and raised along a linear path for operating the press to carry out a press production cycle. The press cycle includes a pressing part and one or more non-pressing parts. The press includes a second drive motor or actuator arranged connected to the ram and by providing a control output to the drive control means, the speed of the second drive motor is made variable during at least one part of the press production cycle. The press may be reversed between production cycles. A press and system including such a press.

Owner:ABB RES LTD

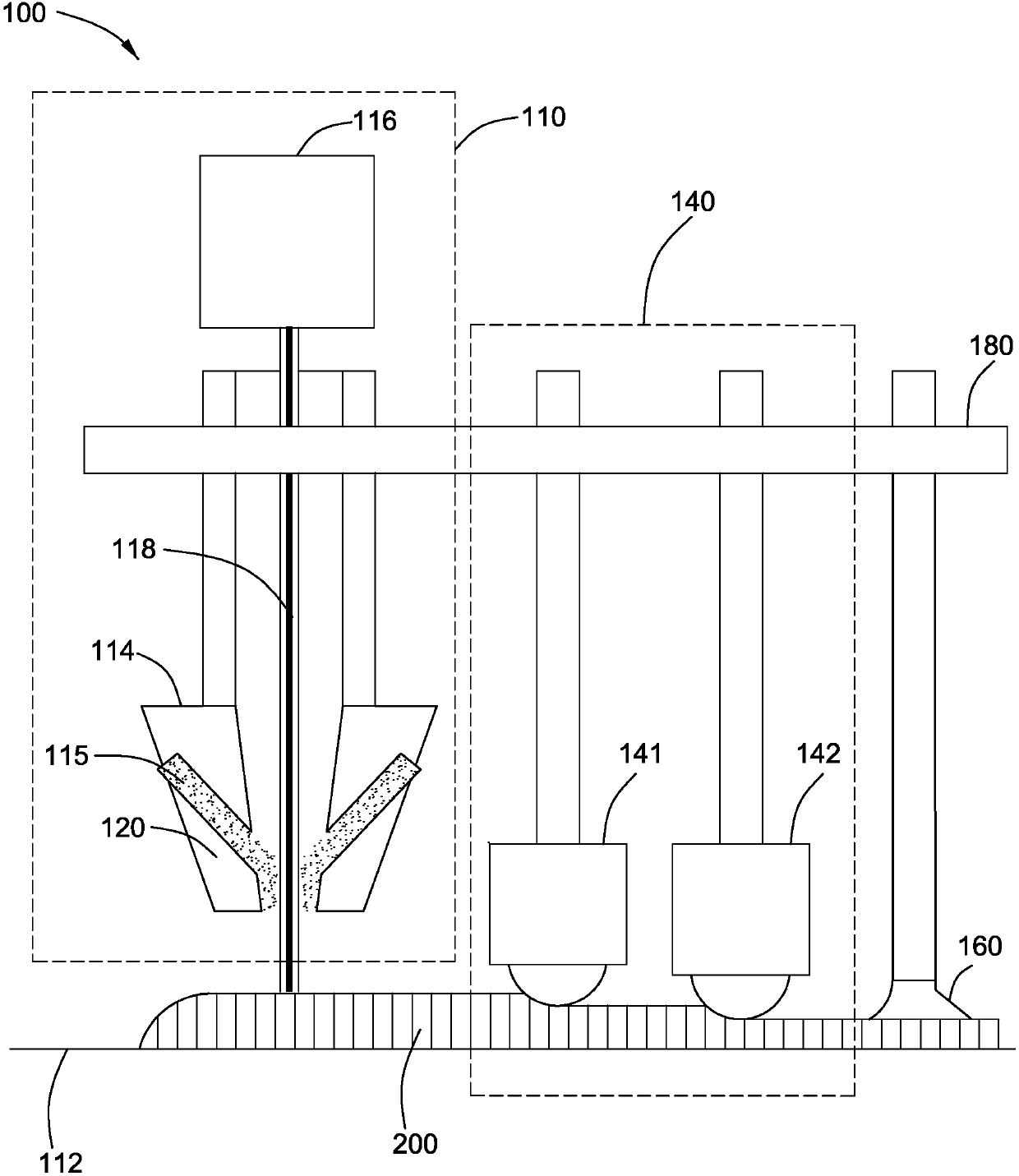

Added material manufacturing and forging combined compound forming system and method

ActiveCN109702127AArc welding apparatusFlexible-parts wheelsManufacturing systemsAdditive layer manufacturing

The invention relates to an added material manufacturing system and method. The system comprises a material conveyor, an energy source and a micro forging device. The material conveyor is provided forconveying materials. The energy source is provided for enabling energy beams to point to the materials, and melts at least part of the materials to form cured parts. The micro forging device can movewith the material conveyor to forge the cured parts, and comprises a first forging hammerhead and a second forging hammerhead; the first forging hammerhead is provided for hammering the cured parts to generate a first deformation quantity; the second forging hammerhead is provided for hammering the cured parts to generate a second deformation quantity; and the second deformation quantity is higher than the first deformation quantity.

Owner:GENERAL ELECTRIC CO

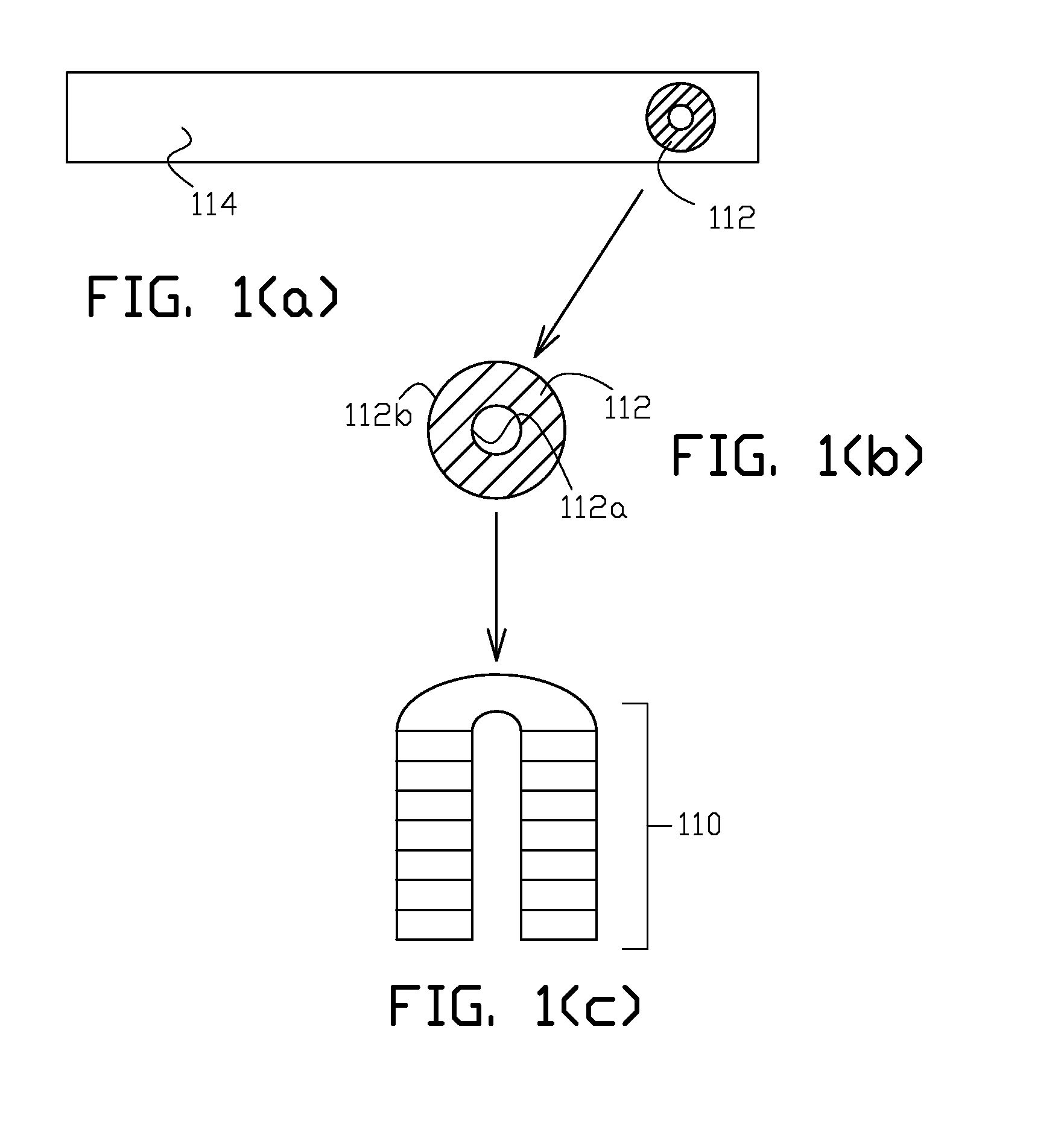

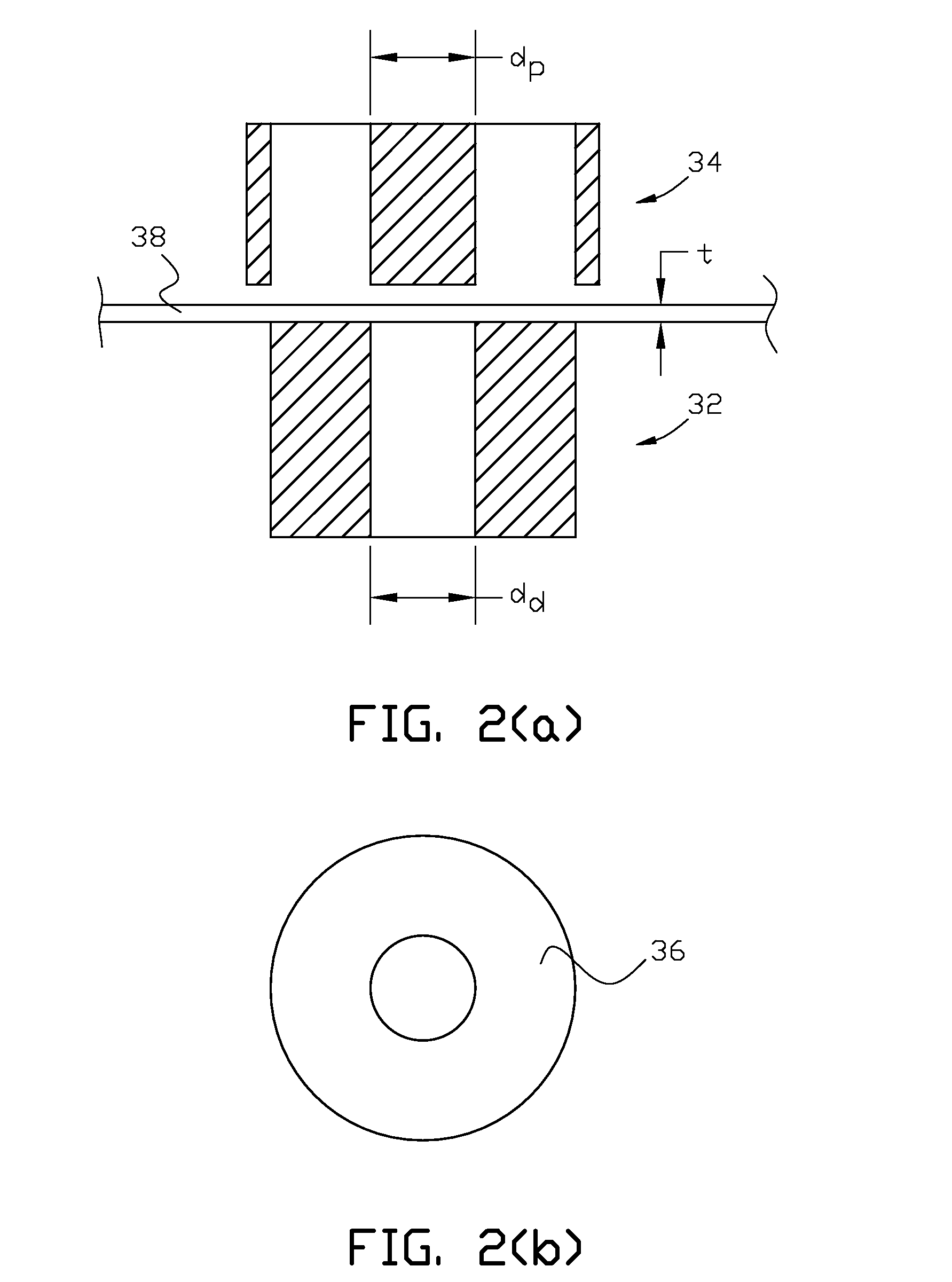

Method, impact machine, and equipment included in an impact machine

InactiveUS6871524B2High strengthReasonably preparedDrop hammersPower hammersHigh velocityMaterials science

The invention relates to a method for the manufacture of an annular article, which substantially consists of metal, ceramic material, and / or polymer. A cavity in a die is filled with a formable working material, which shall form said article. A tubular, upper punch (17) is introduced into the upper mouth of a hole in a die (34), so that a closed mould cavity is formed. The upper punch and a lower punch (27) are simultaneously struck towards one another at such a high velocity that the working material is plasticized and flows out and fills the mould cavity, and thereafter the upper punch is removed. Then, a mandrel (35) in the lower punch is driven out of the annular body by means of a mandrel expulsor (170), which is pressed against the mandrel from above, and thereafter the annular body is from below pushed out of the die by mean of the lower punch. The invention also relates to an equipment for the carrying out of the method.

Owner:MORPHIC TECH

Hammer type forging device

InactiveCN105328099ADimensions conform to standardImprove pass ratePower hammersHammer drivesHorizontal forceEngineering

The invention relates to a forging device and discloses a hammer type forging device. The hammer type forging device comprises a main shaft, wherein the main shaft is fixedly connected with a heavy hammer; a vertical sliding chute is formed in the lower part of the heavy hammer; a heavy block is connected in the sliding chute in a sliding manner; a concave die is arranged at the lower part of the heavy block; a support lug is arranged on the peripheral surface of the heavy block and is located in a vertical strip-shaped hole of the sliding chute; a first elastic part is connected between the top surface of the support lug and the sliding chute; the main shaft is also fixedly connected with a gear; the gear is meshed with a rack; a fixed sliding chute is formed in the lower part of the rack; a second elastic part is arranged between the rack and the sliding chute; a cam presses against one side, far from the second elastic part, of the rack. Compared with the prior art, the heavy block of the device can transmit the force of the heavy hammer to blanks; the heavy block can dissolve the component of the horizontal force of the heavy hammer and only generate the vertical downward pressure, so that the size of the forged parts is more in line with the standard; the qualified rate of products is increased.

Owner:CHONGQING YUXI FLOUR PROD

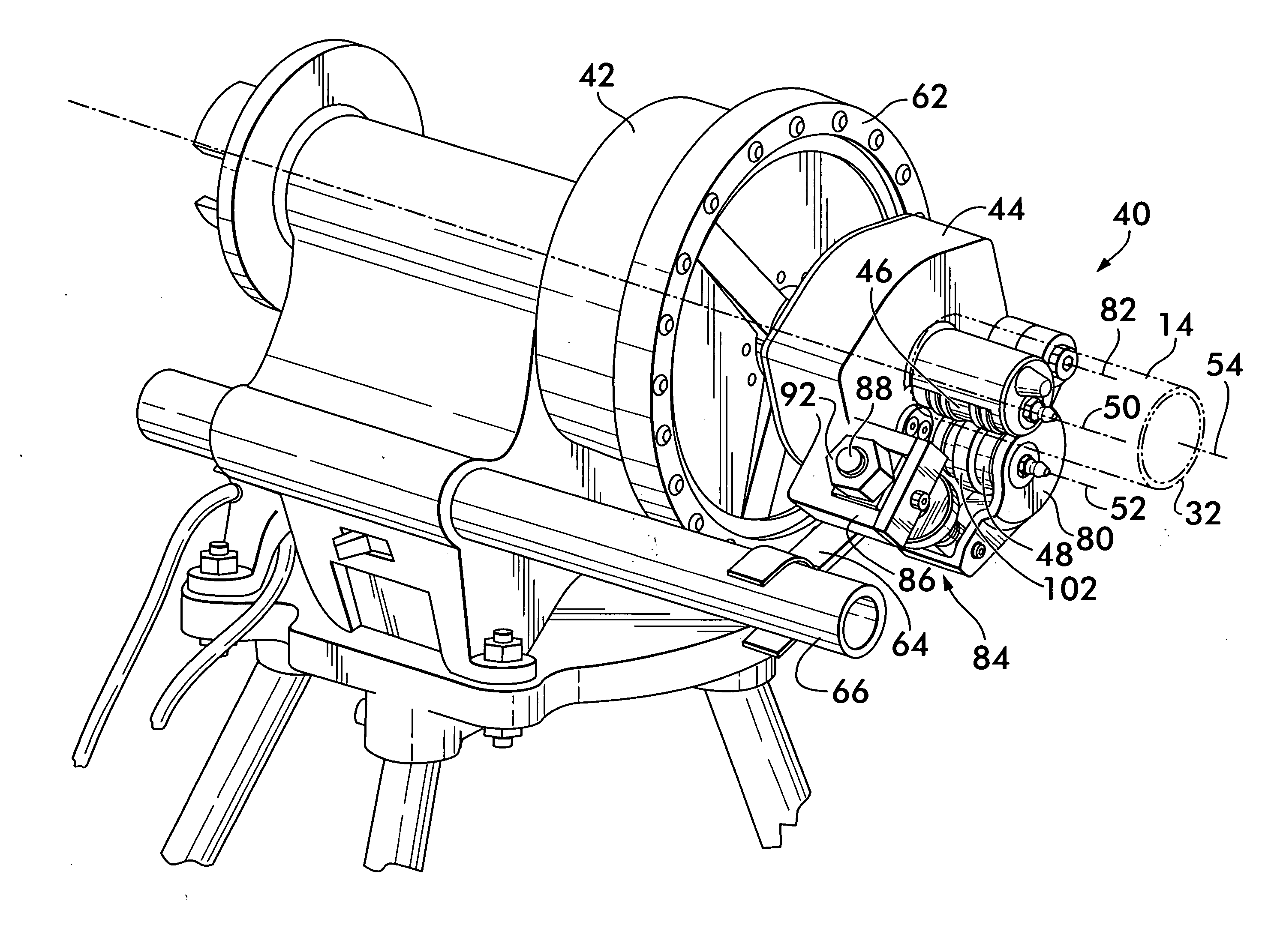

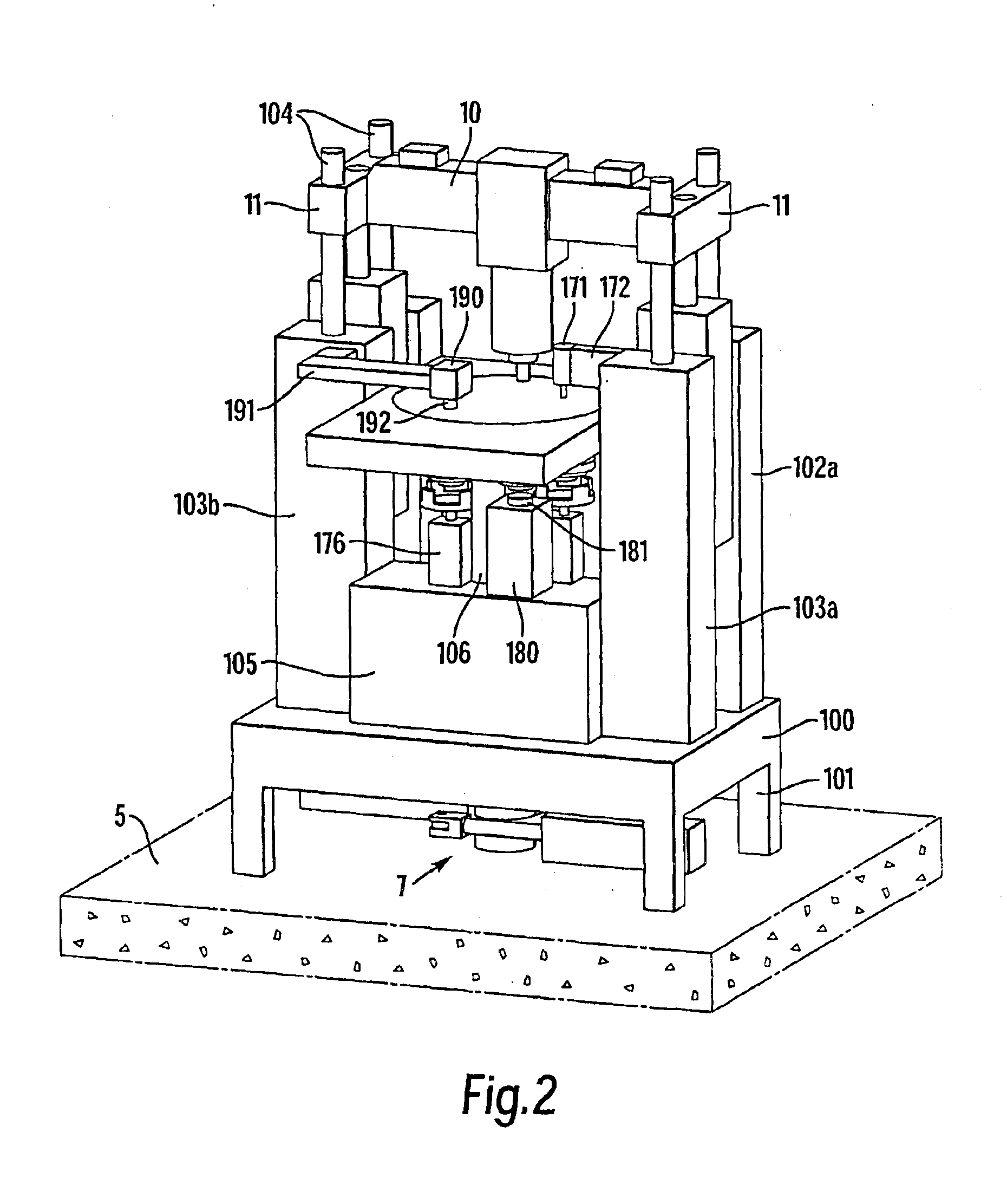

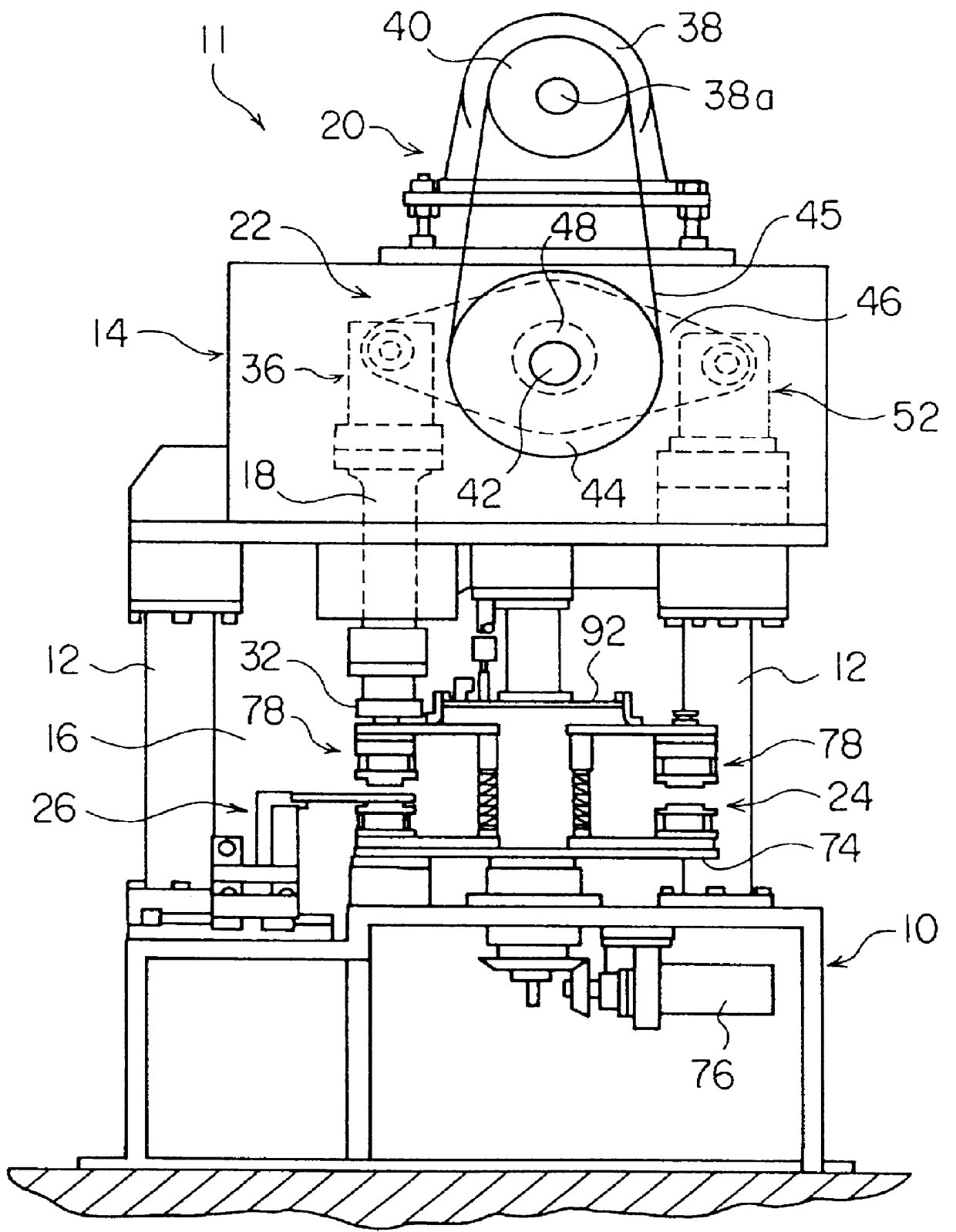

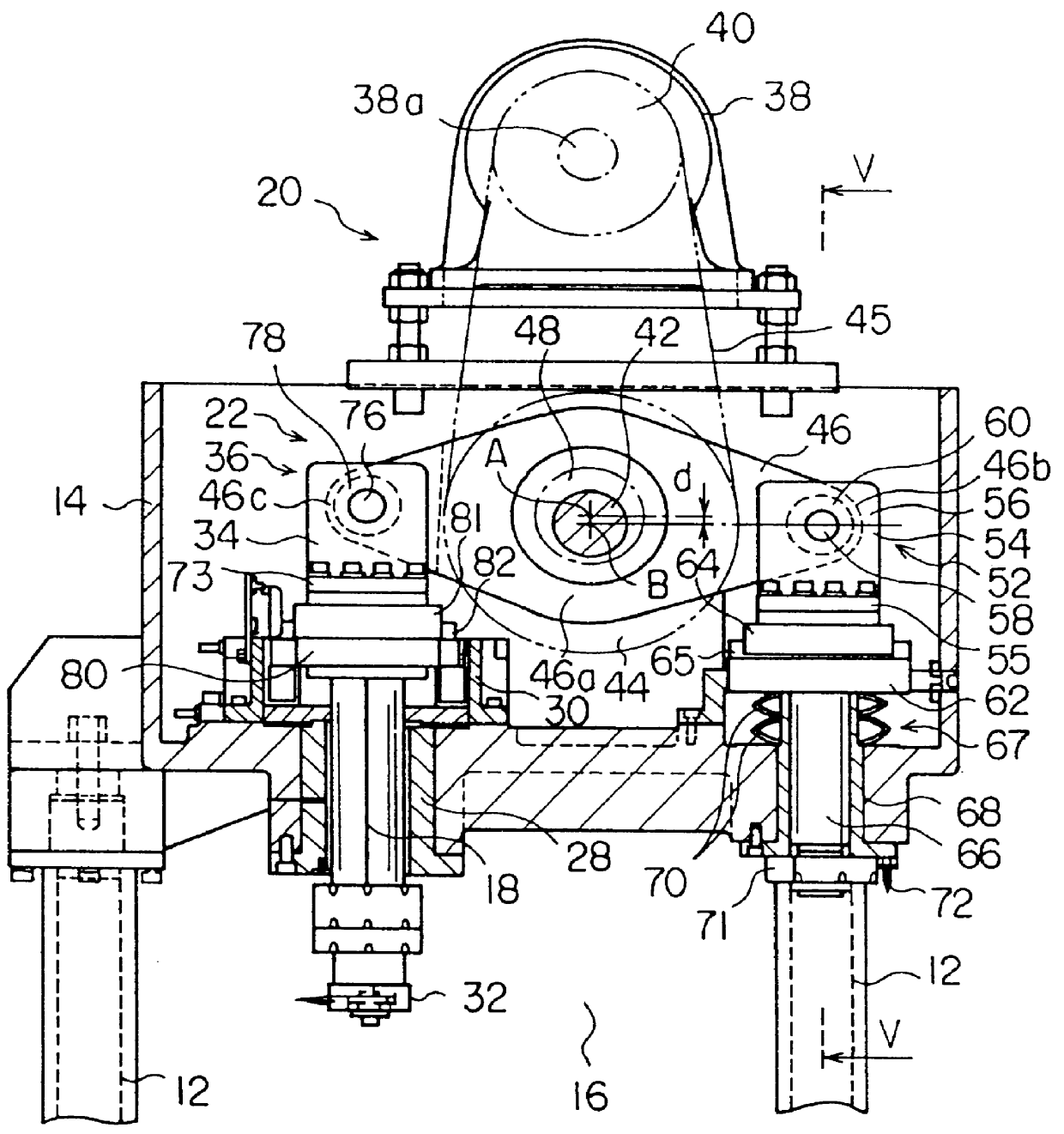

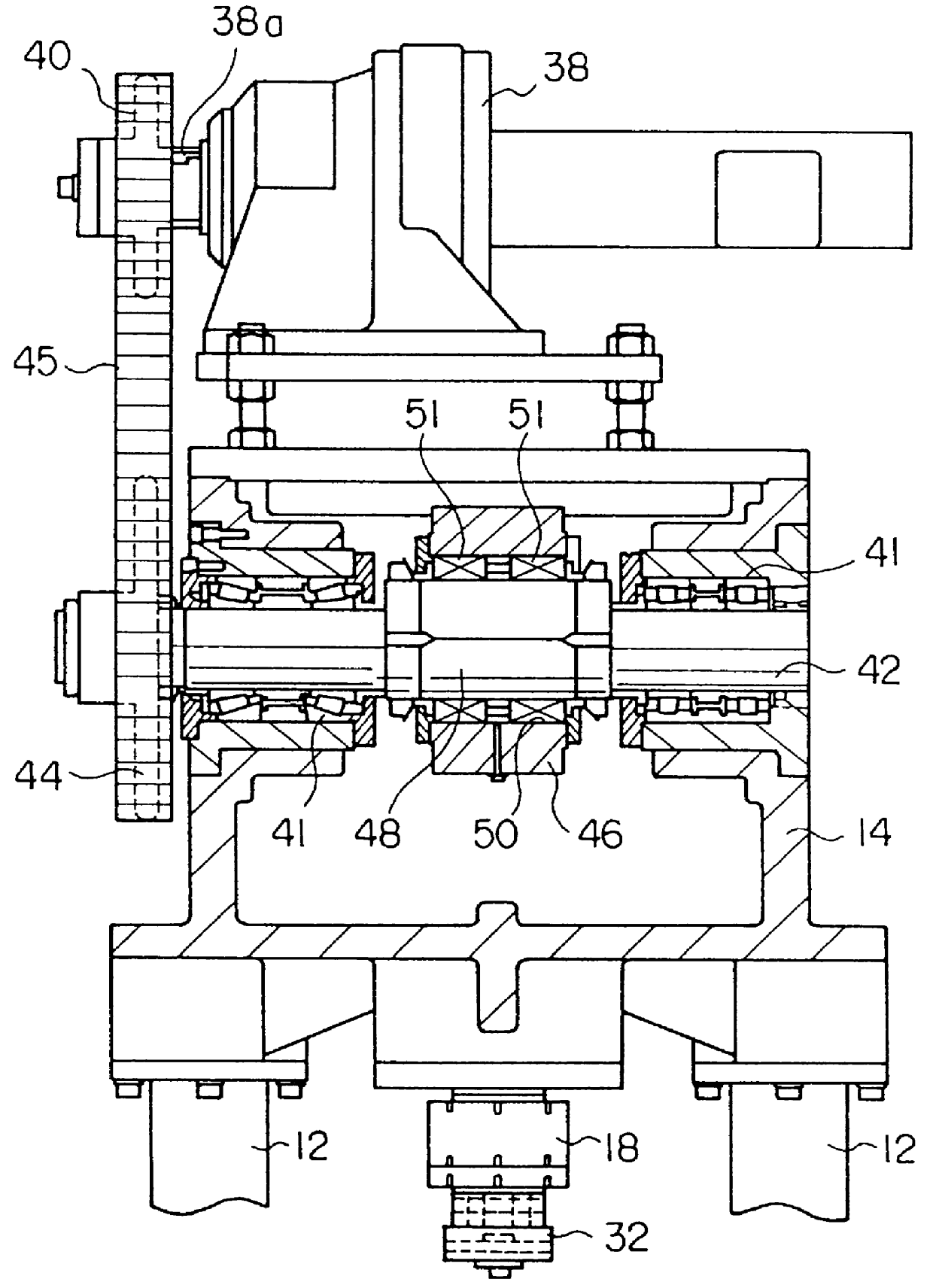

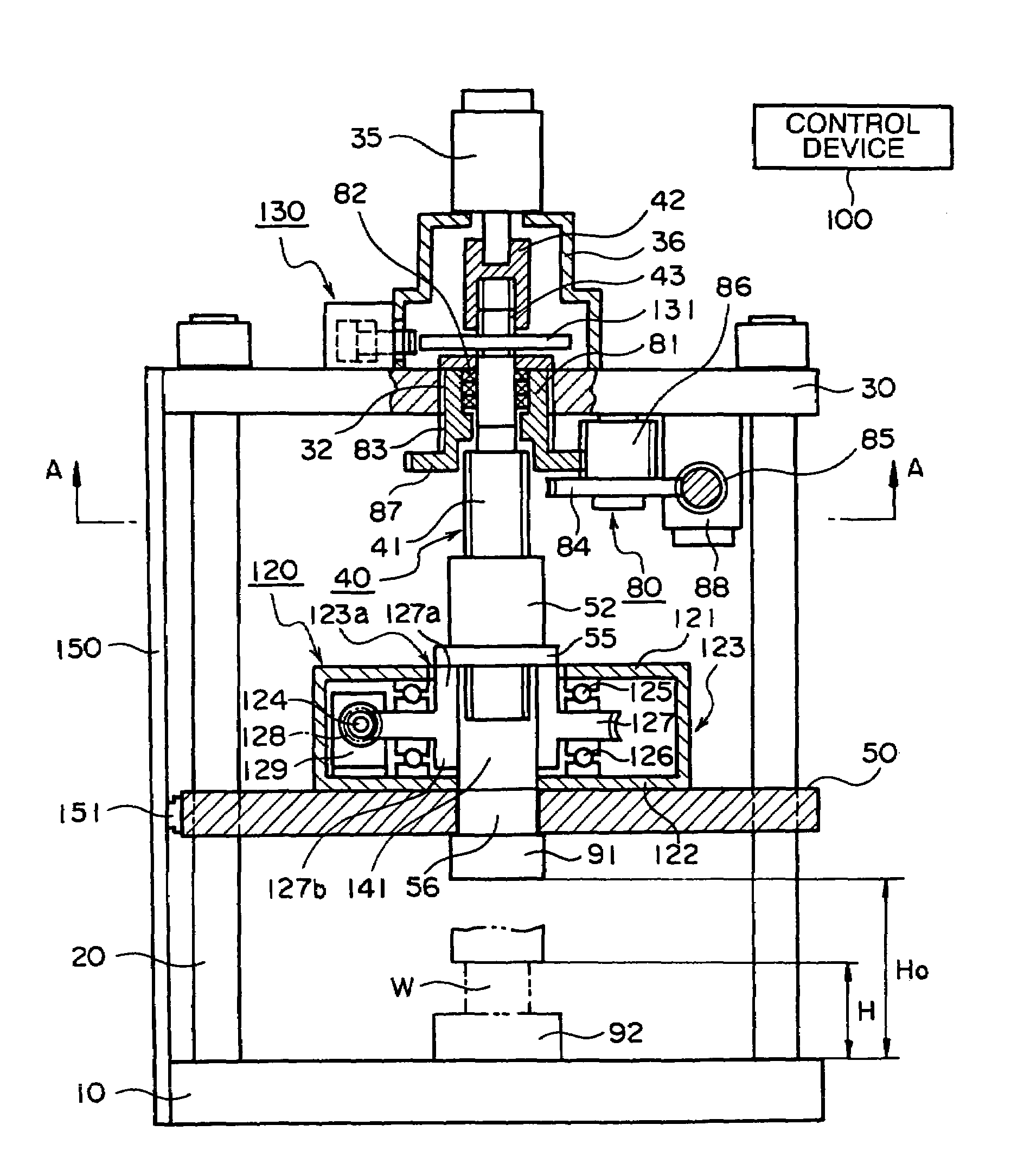

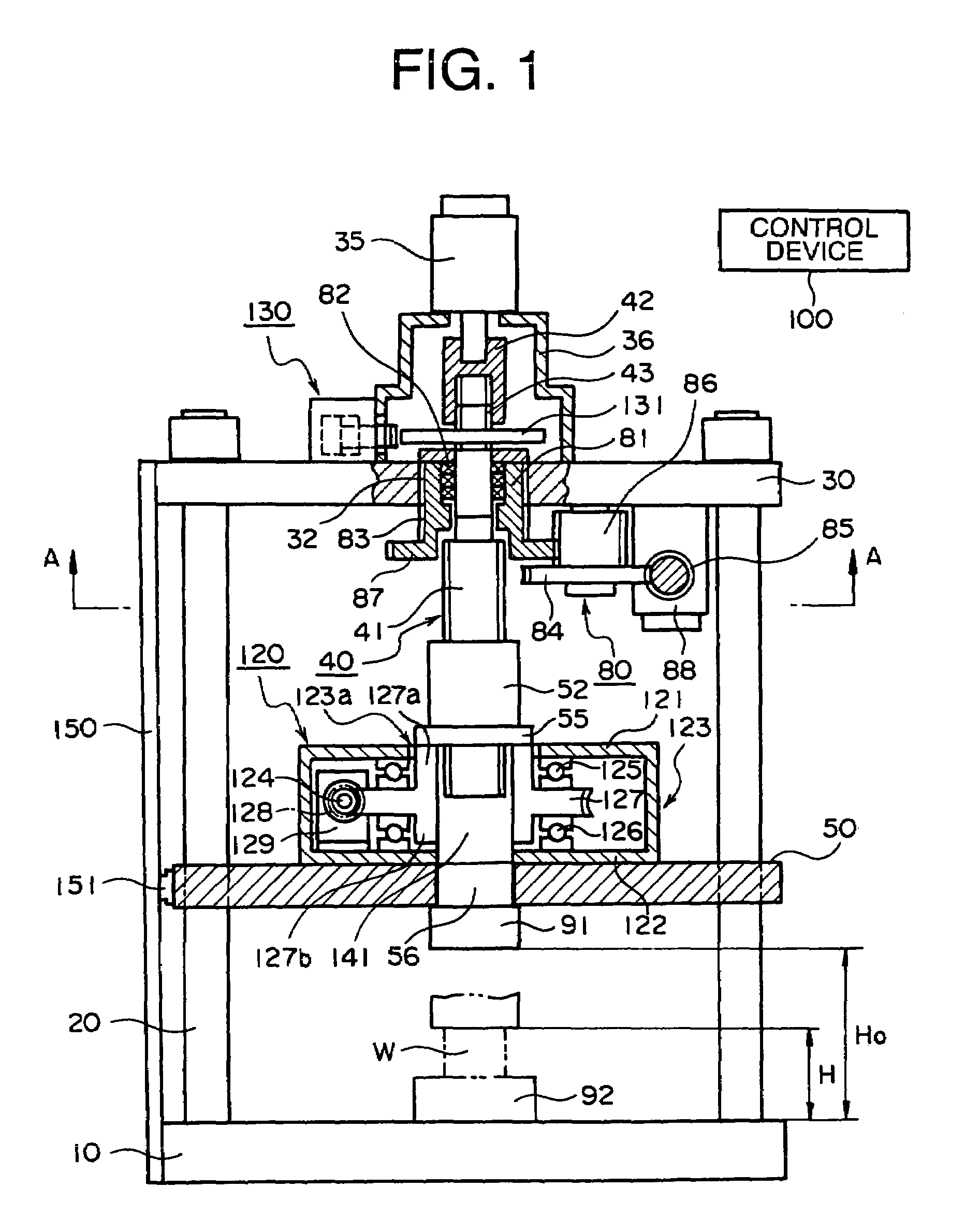

Press apparatus and press system

PCT No. PCT / JP97 / 04308 Sec. 371 Date Sep. 1, 1998 Sec. 102(e) Date Sep. 1, 1998 PCT Filed Nov. 26, 1997 PCT Pub. No. WO98 / 23438 PCT Pub. Date Jun. 4, 1998A support frame (14) is provided above a base (10), defining a working space (16) together with the support frame. An automatic die-replacing mechanism (24) is provided in the working space, for moving a selected one of a plurality of die units (78) to a predetermined working position. A support base table is provided with an elevating axle (18) for opening and closing the die unit located at the working position, and a drive mechanism section for moving the elevating axle up and down. The drive mechanism section has a pulse servomotor (38) and an oscillating-fulcrum mechanism (22) for transmitting a drive force to the elevating axle. The oscillating arm (46) of the oscillating-fulcrum mechanism has a fulcrum section supported by the support table, a power-point section supported by a shaft which is rotated by the pulse servomotor, and an application-point section coupled to the elevating axle.

Owner:ITRIX CORP

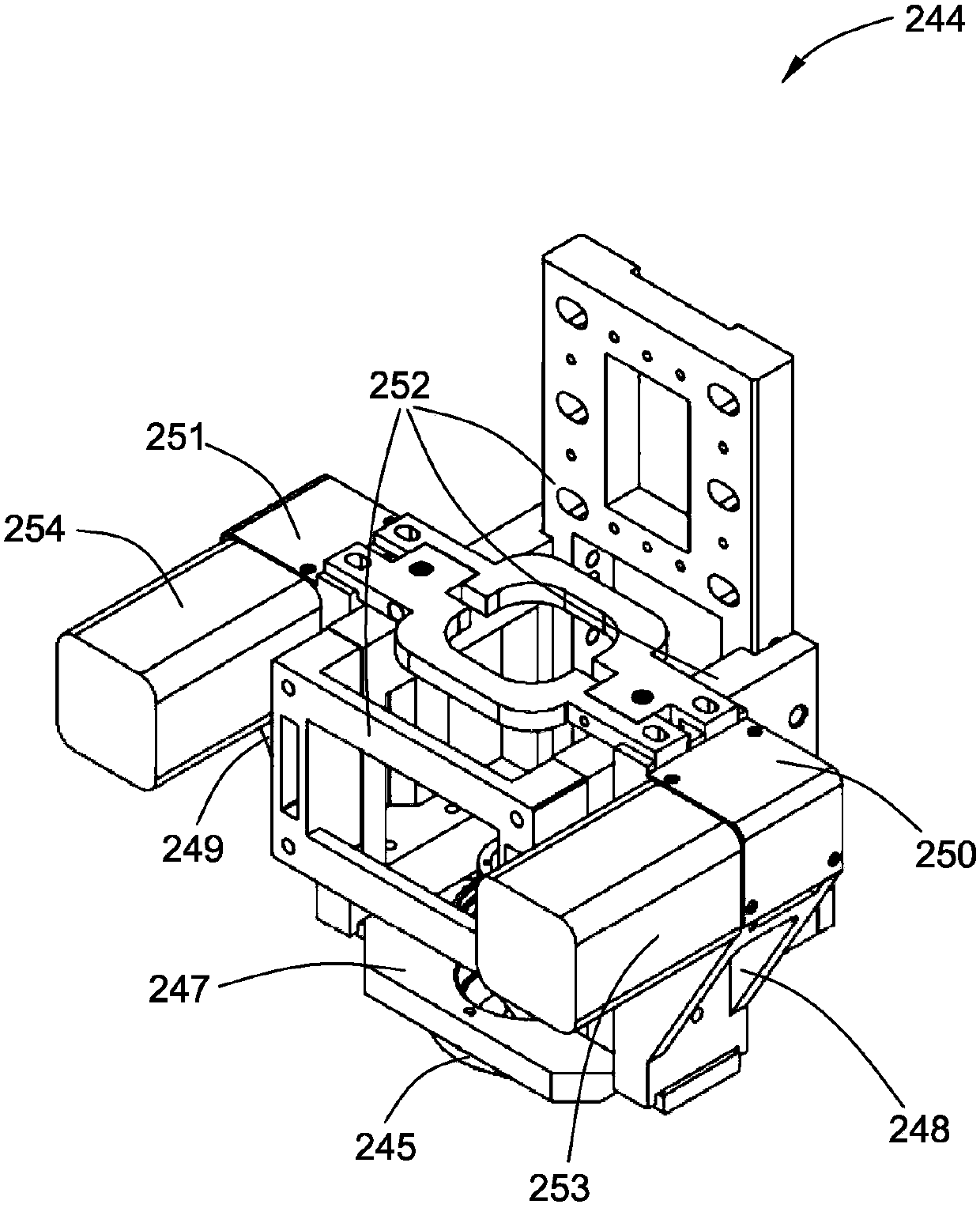

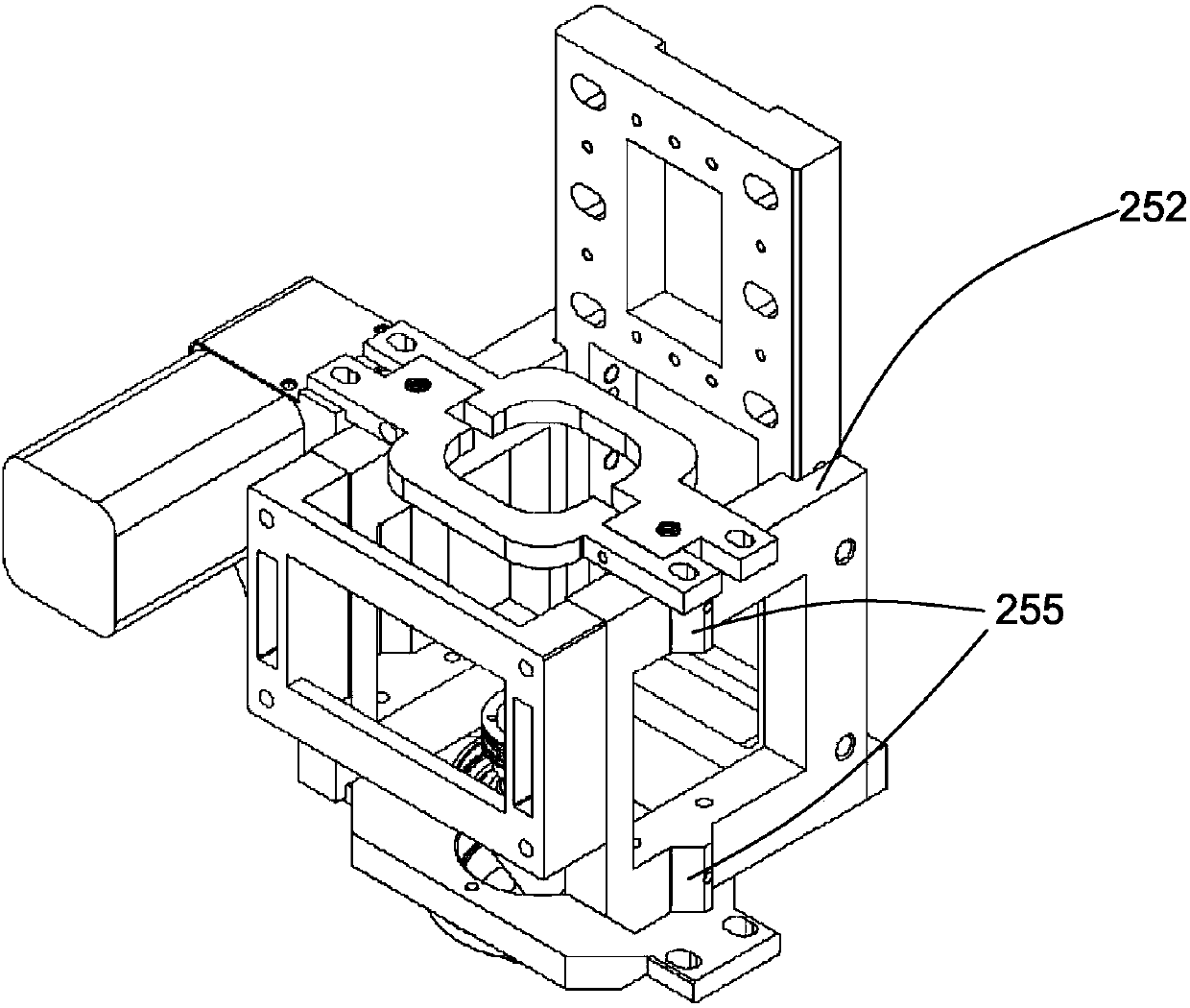

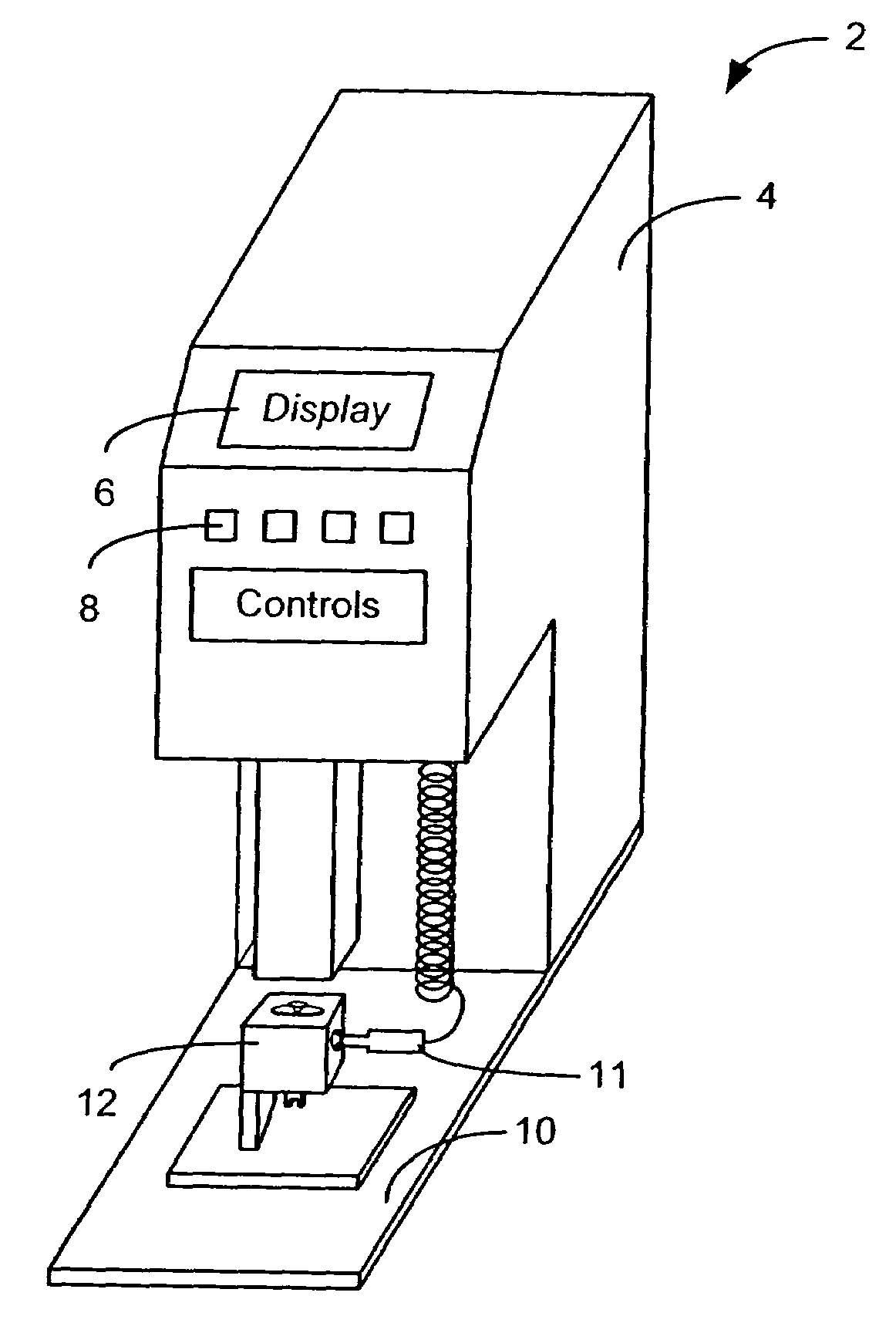

Automated machine setup with modular tooling

Apparatus and a method for establishing setup parameters for use in a machine. In one embodiment a tooling component is removably mountable to a host machine. The tooling component includes a memory that contains information defining setup parameters for the host machine for use with the tooling component. A controller associated with the host machine reads the information from the memory and configures the host machine based on the information read from the memory. In another embodiment, an information carrying tag, is associated with the tooling component. The information carrying tag is read and the identifying information obtained from the tag is used by a controller to select a set of setup parameters from one or more sets of setup parameters stored in a storage device accessible by the controller. A mechanism is provided to precisely position the adapter on the base plate for the host machine to minimize variations in production using the setup parameters derived from the stored information.

Owner:ZUSI CHRISTOPHER J

Press

InactiveUS7574891B2Shorten the timeShaping safety devicesHammer drivesPosition detectorElectric motor

A pressing apparatus using a motor, in which a driving device for fast feed, which lowers a upper die to a position immediately before pressing, and a motor for pressing, which performs a pressing operation, are used to cause the driving device for fast feed and the motor for pressing to operate cooperatively, and only one position detector, which detects a present position of a slider, is provided for a set of the driving device for fast feed and the motor for pressing. A lock device is provided so as to lock the slider and the screw shaft while the motor for pressing is operating for pressing a work piece.

Owner:HODEN SEIMITSU KAKO KENKYUSHO CO LTD

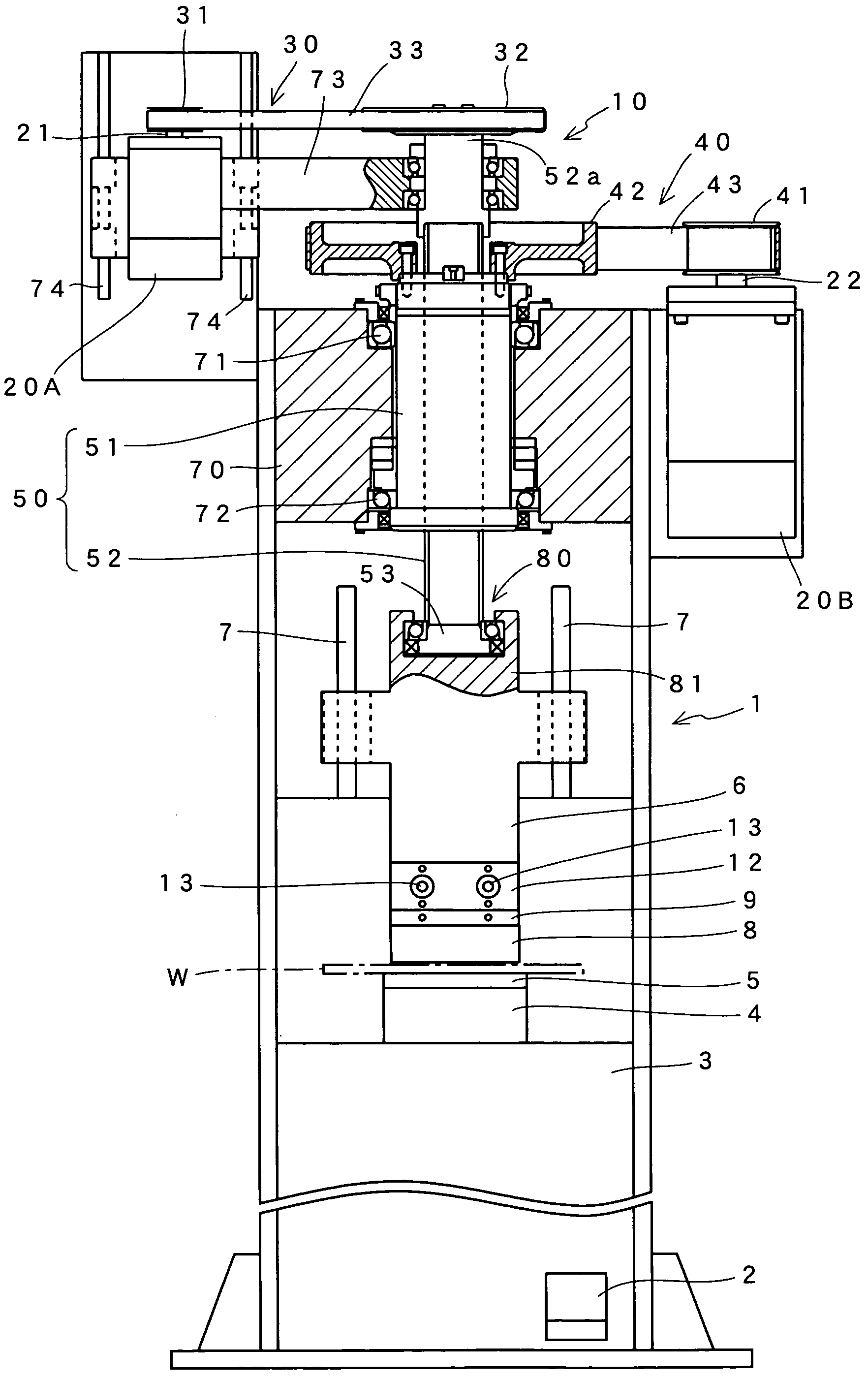

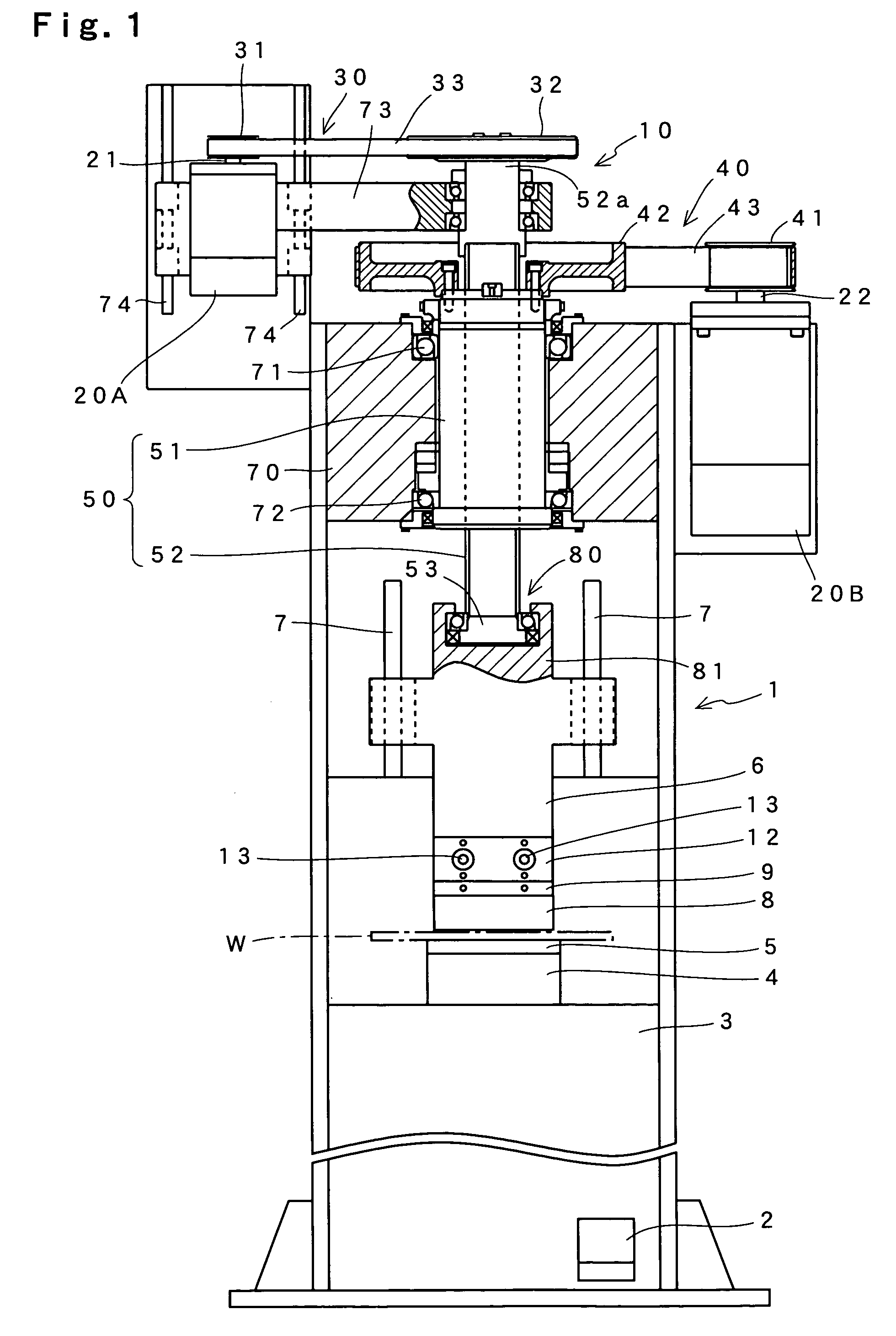

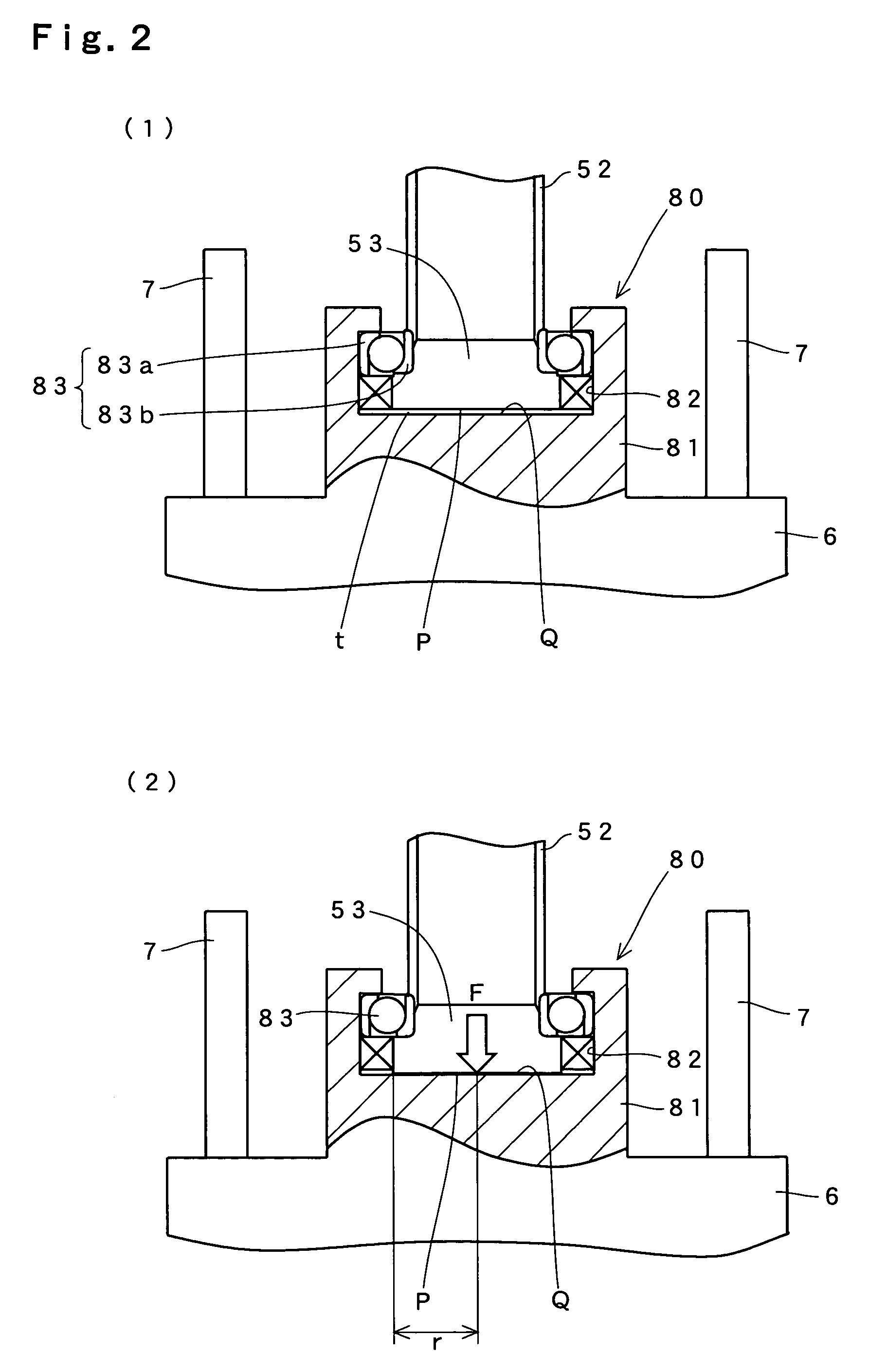

Reciprocating drive mechanism and press using the same

A reciprocating drive mechanism for converting motor rotation into linear motions to produce a reciprocating drive force, and a press machine using the mechanism. The rotation of a first motor (20A) out of two motors (20A) and (20B) is converted into a high-speed low-torque rotational output and transmitted to a ball screw mechanism (50) by a first power transmission mechanism (30). The rotation of the second motor (20B) is converted into a low-speed high-torque rotational output and transmitted to the ball screw mechanism (50) by a second power transmission mechanism (40). The ball screw mechanism (50) is made of a feed screw (52) supported in a screw hole of a nut member (51) so as to be capable of screw-fed rotation. The feed screw (52) and the nut member (51) are coupled with the first power transmission mechanism (30) and the second power transmission mechanism (40), respectively. A corotation prevention mechanism (80) prevents the feed screw (52) from rotating together with the rotation of the nut member (51).

Owner:AMADA CO LTD

Robot for the elaboration of lingual archwires

A robot for the shaping of lingual archwires, including an anterior plate arced according to an anterior portion of a patient's teeth, wherein the anterior plate is capable of accepting an anterior portion of a lingual wire; a plurality of movable posterior bending units positioned posterior to the anterior plate, each bending unit capable of accepting a posterior portion of the lingual wire; a plurality of motors capable of selectively actuating each of the posterior bending units independently along at least one axis to bend the lingual wire along the at least one axis at a plurality of positions; a mother board in electrical communication with the plurality of motors and capable of receiving and executing instructions for desired dimensions of a lingual archwire; and a power source.

Owner:GILBERT ALFREDO

Part in die, die change process

InactiveUS20090126452A1Reduce amountIncrease chanceShaping toolsHammer drivesEngineeringMinimum distance

A die change method includes providing a press apparatus having a base and a ram, and a first die set including an upper die member and a lower die member. The lower die member is supported on the base and the upper die member is mounted on the ram. The ram is lowered into a closed, home position to mate the upper and lower die members and to perform an operation on a workpiece disposed between the die members. The ram is released from the upper die member. The ram is raised a minimum distance to provide minimal clearance for removing the upper and lower die members from the press. The mated upper and lower die members are moved out of the press with the workpiece held between the upper and lower die members.

Owner:HIROTEC AMERICA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com