Electrohydraulic hammer

An electro-hydraulic hammer and hydraulic technology, applied in the field of hydraulic electro-hydraulic hammer, can solve the problems of complexity, uncontrollable return speed, easy to hit the top, etc., and achieve obvious buffer function, good process requirements, and the effect of meeting process requirements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

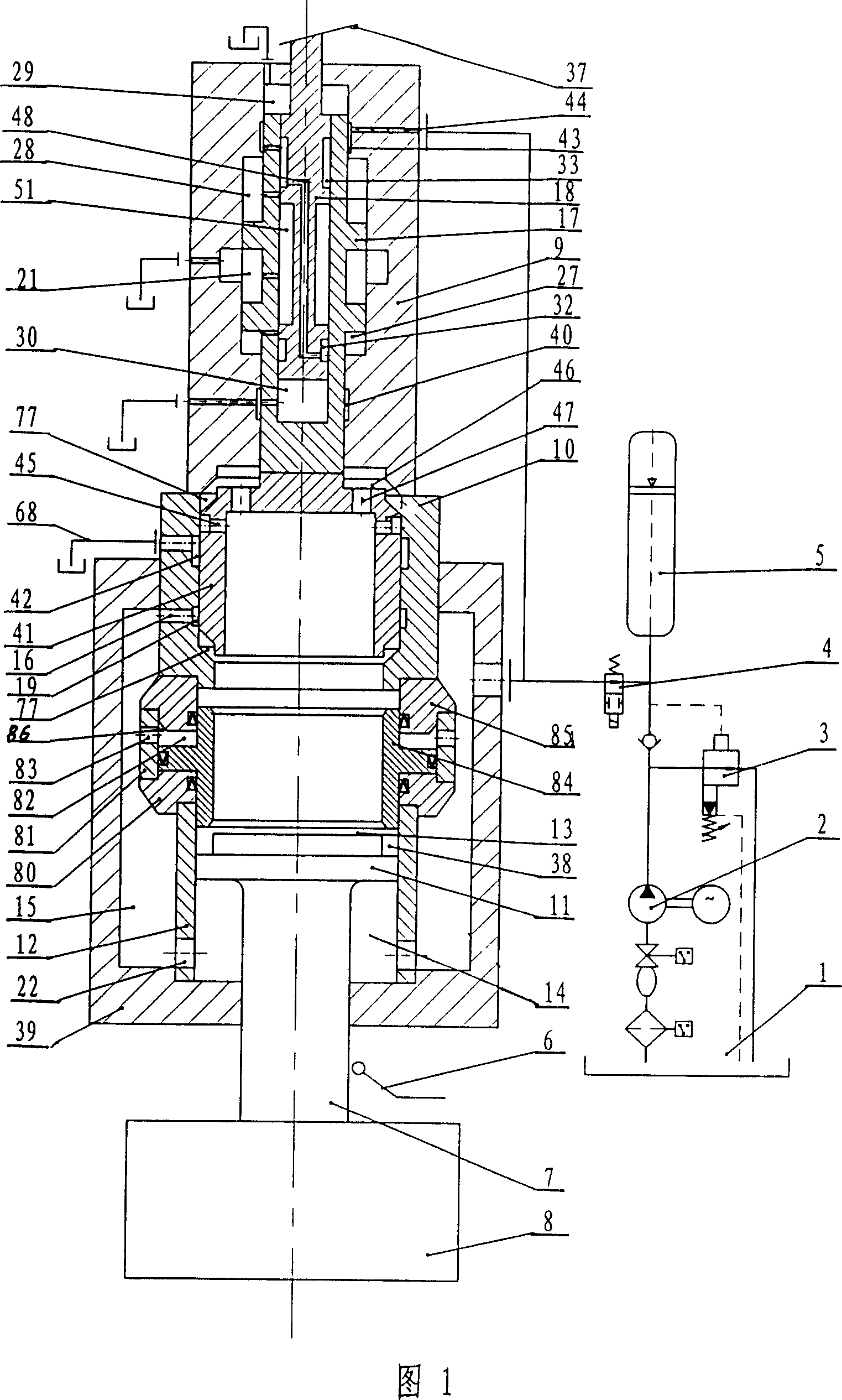

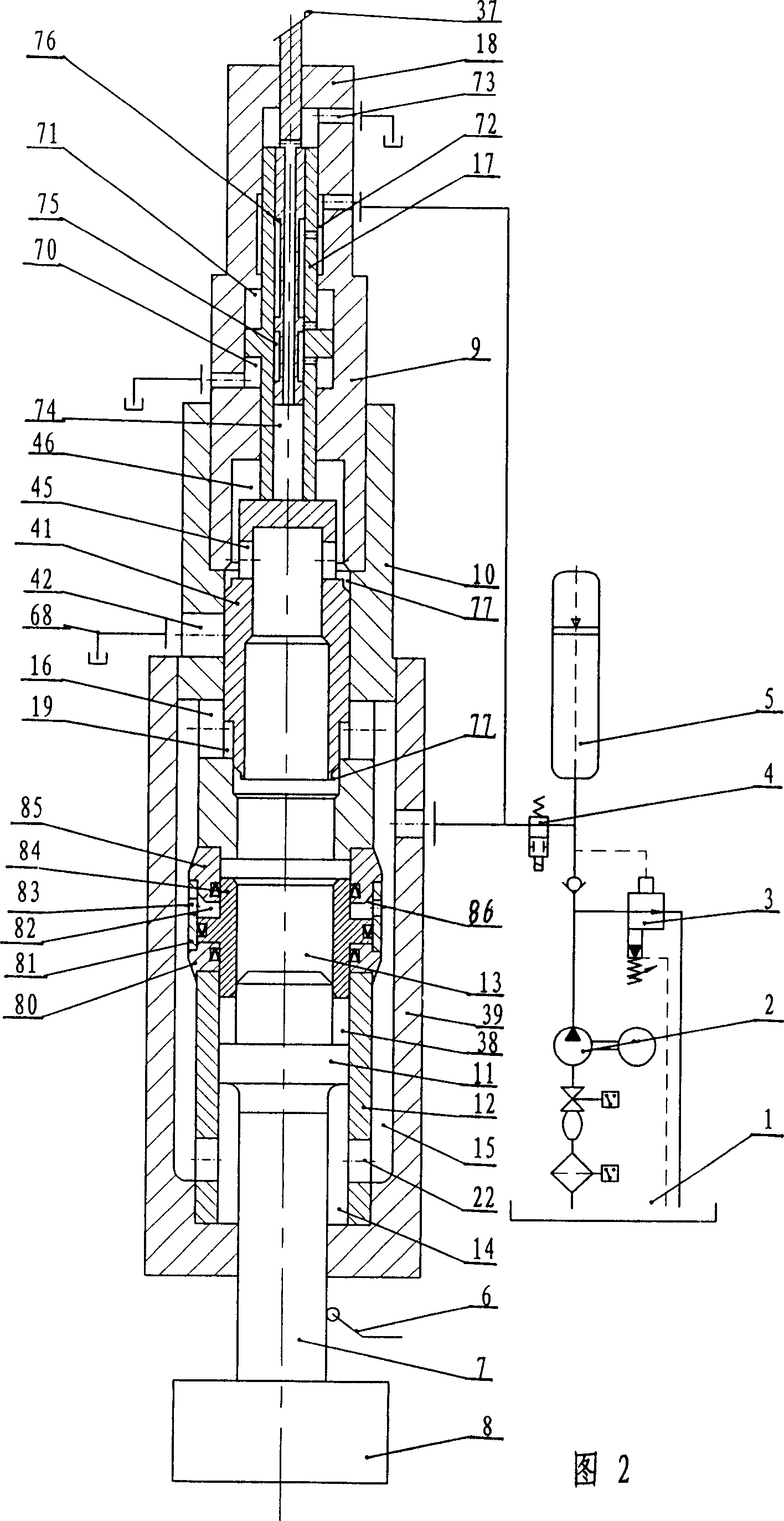

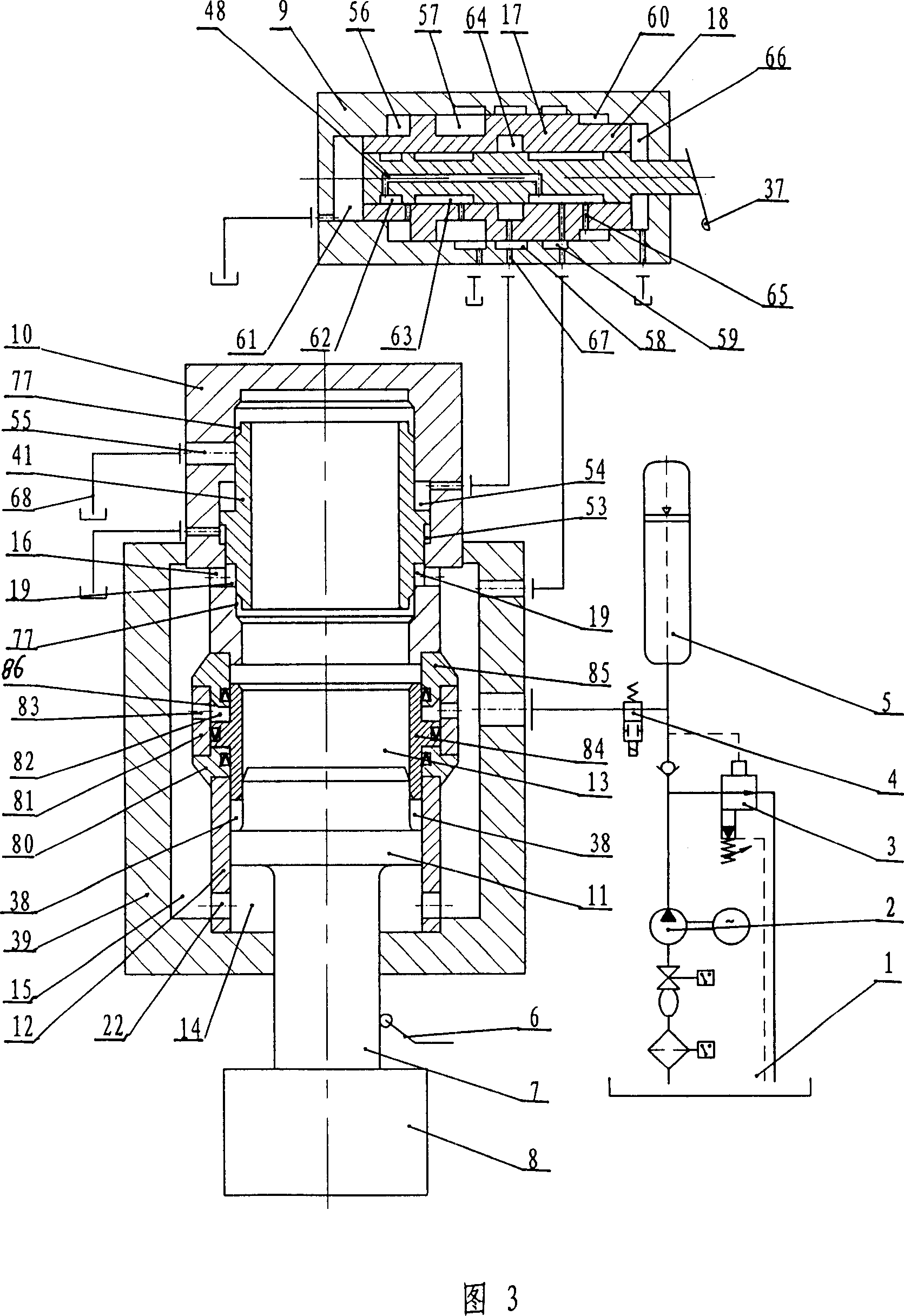

[0019] As shown in Figure 1, the anti-bump hydraulic electro-hydraulic hammer of the present invention includes a machine base 39 and a hammer rod driving oil cylinder installed in the machine base 39 along the vertical direction, and a control valve is installed above the hammer rod driving oil cylinder body 12, as shown in Fig. The control valve shown in 3 is the state when the spool 18 is at zero position, the upper end of the hammer rod 7 with the hammer head 8 at the lower end is connected with the piston 11 in the cylinder body 12 of the hammer rod driving oil cylinder, and the upper and lower two sides of the piston 11 The end has an upper cylinder chamber 13 and a lower cylinder chamber 14, the effective working area of the piston 11 in the upper cylinder chamber 13 is greater than its effective working area in the lower cylinder chamber 14, and the lower cylinder chamber 14 communicates with the high-pressure oil through at least one lower through hole 22. The channe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com