Unsymmetrical radial welding punched high performance precision blanking machine

A precision blanking and radial forging technology, applied in the driving device of forging press, forging/pressing/hammering machinery, forging/pressing/hammer device, etc. Inertia, cost reduction, safety and self-locking effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

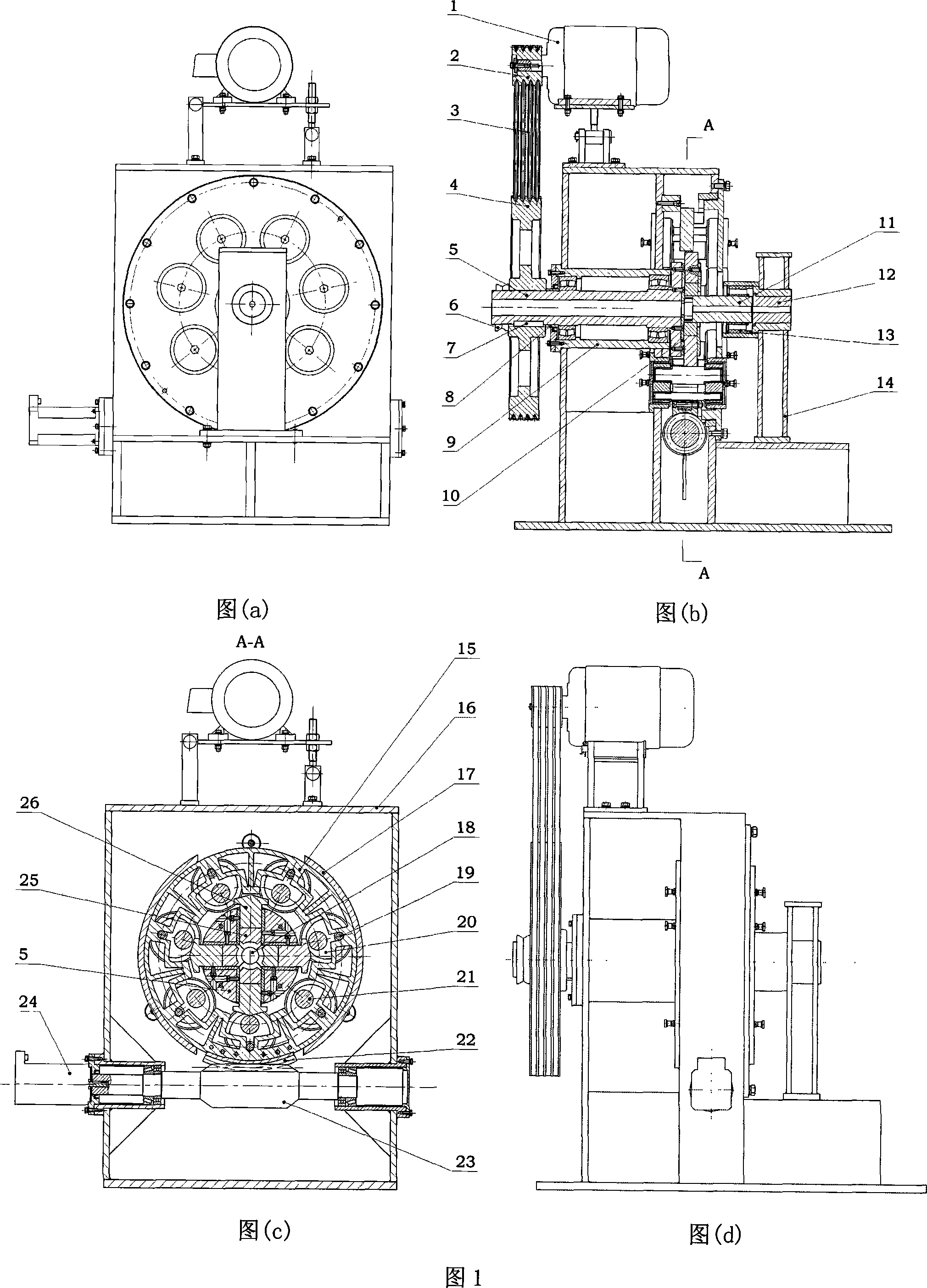

[0024] The structure of the high-efficiency precision blanking machine for asymmetric radial forging punching of the present invention is shown in FIG. 1 . The blanking system is mainly composed of the transmission system part, the radial forging blanking part, the stroke fine-tuning part, the bar fixing bracket part and other main components. The above four parts are described in detail below.

[0025] The transmission mechanism of the blanking machine of this invention is mainly composed of a main motor 1, a driving pulley 2, a transmission belt 3, a driven pulley 4, a transmission spindle 5, a lock nut 6, a connecting key 7, an adjustment sleeve 8 and a spindle fixing sleeve. 9 and other components.

[0026] The main motor 1 drives the driving pulley 2 keyed to the motor transmission shaft to rotate, and the driven pulley 4 is driven by the transmission belt 3 to rotate, and the transmission ratio of the transmission mechanism is 5:1.

[0027] Driven pulley 4 is connected...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com