Patents

Literature

119results about How to "Optimizing Forging Performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Manufacturing method of high-strength automobile aluminum-alloy rim material

The invention relates to a manufacturing method of a high-strength automobile aluminum-alloy rim material, which relates to a manufacturing method of automobile fitting materials. The manufacturing method comprises the following steps of: preparing materials; smelting; adding a refiner; adjusting components; refining; casting; quenching; carrying out aging treatment; and packaging to prepare the high-strength automobile aluminum-alloy rim material which comprises 0.4-0.8 percent of Si, 0.8-1.2 percent of Mg, 0.16-0.22 percent of Ti, 0.2-0.3 percent of Zn, 0.6-0.8 percent of Fe, 0.15-0.4 percent of Cu, 0.08-0.32 percent of Cr, 0.1-0.2 percent of Mn, 0.02-0.06 percent of RE rare earth, 0.02-0.06 percent of Zr, 0.02-0.06 percent of Sr and the balance of Al. The invention has reasonable process parameter and simple manufacturing method, and the manufactured aluminum-alloy rim material has the advantages of high strength, good mechanical performance and the like and is suitable for being popularized and used in small, medium and large automobiles.

Owner:卢森锴

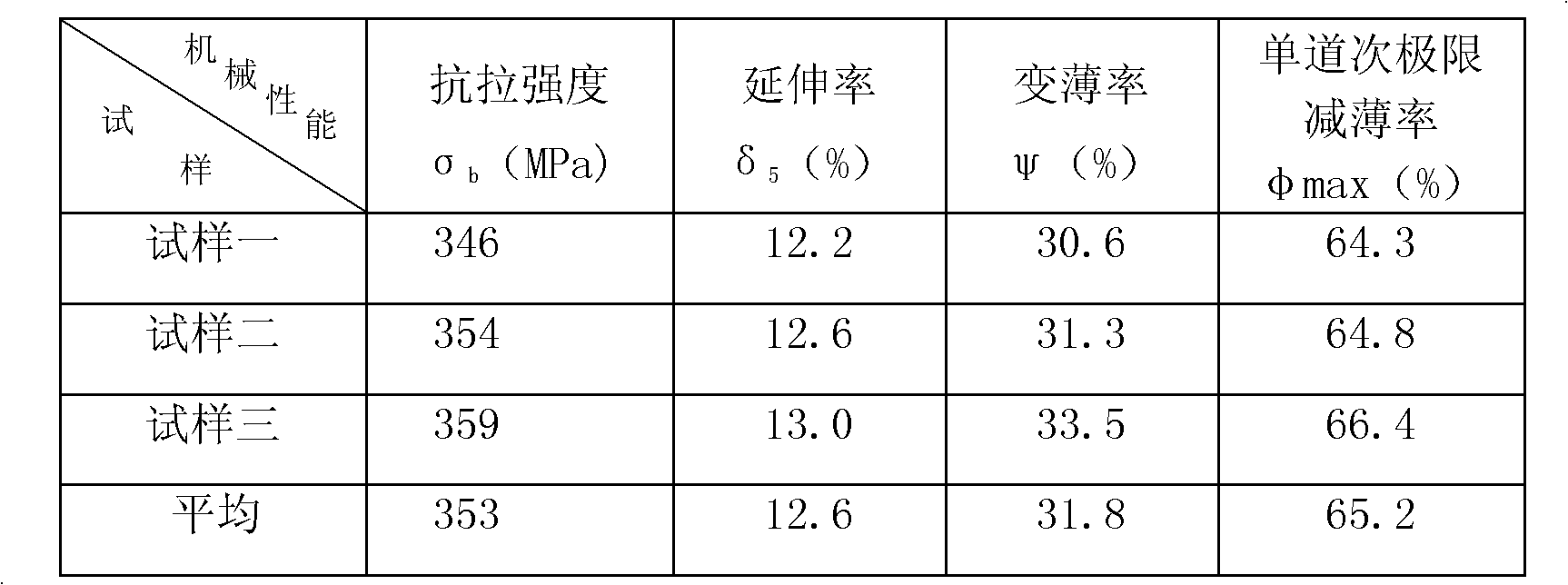

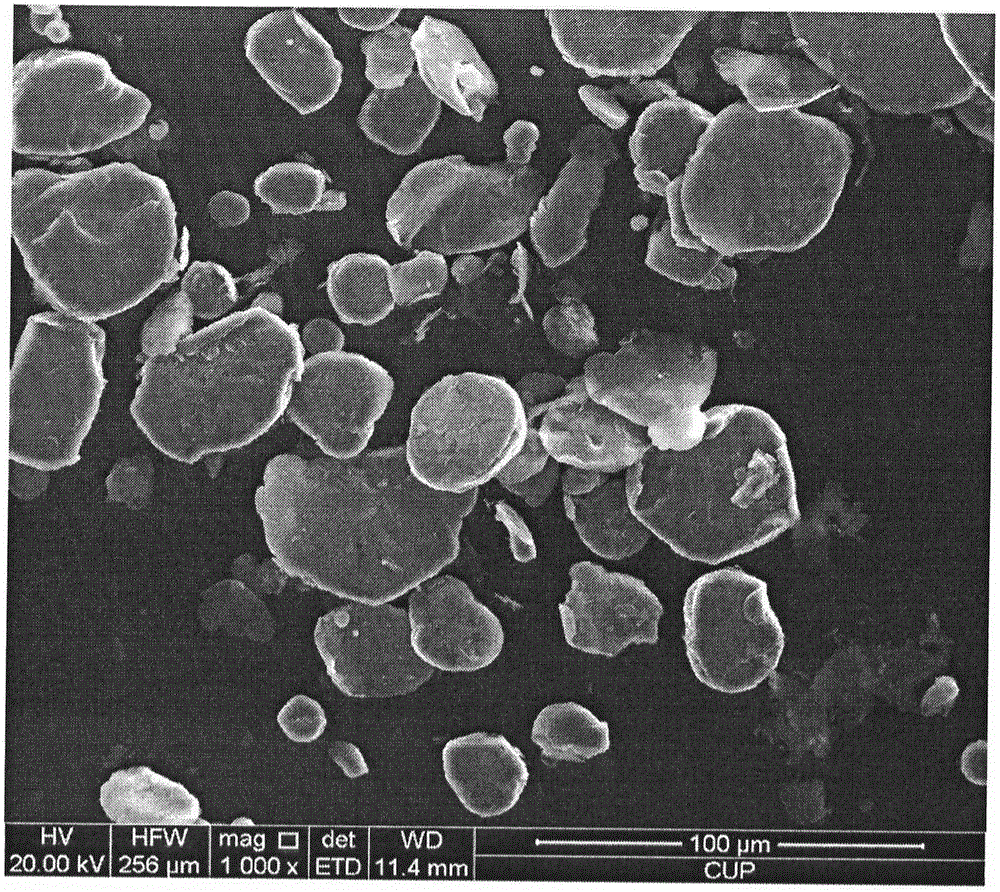

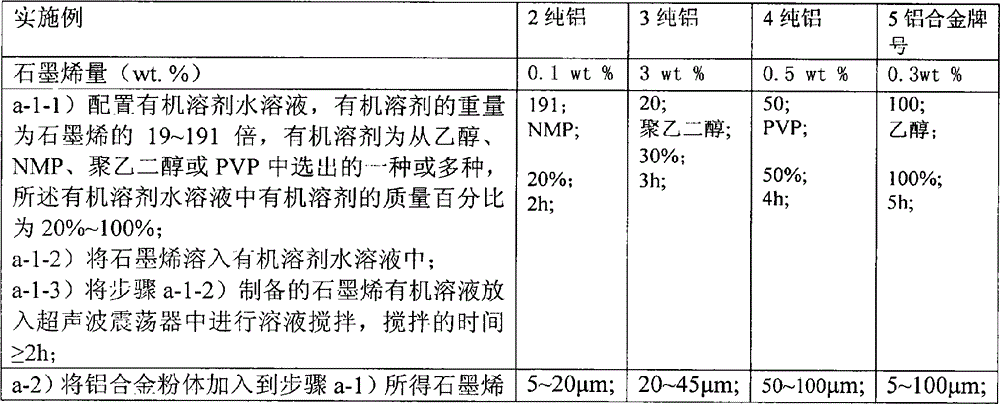

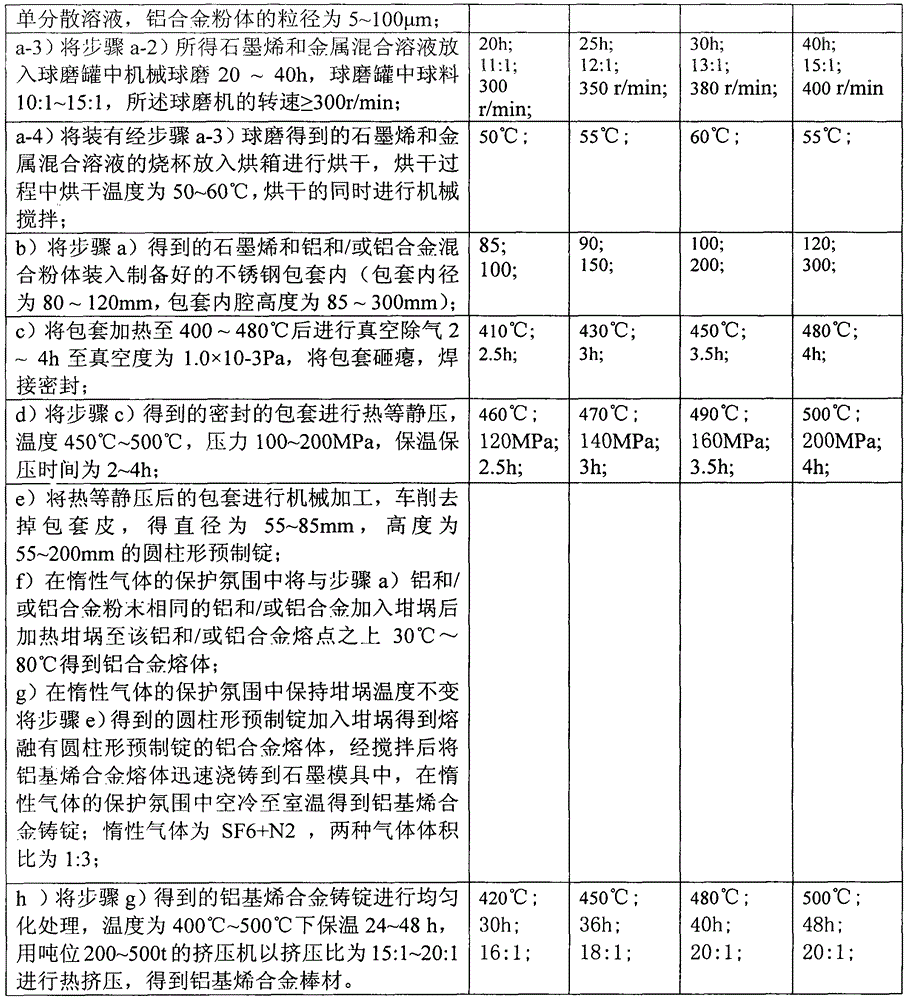

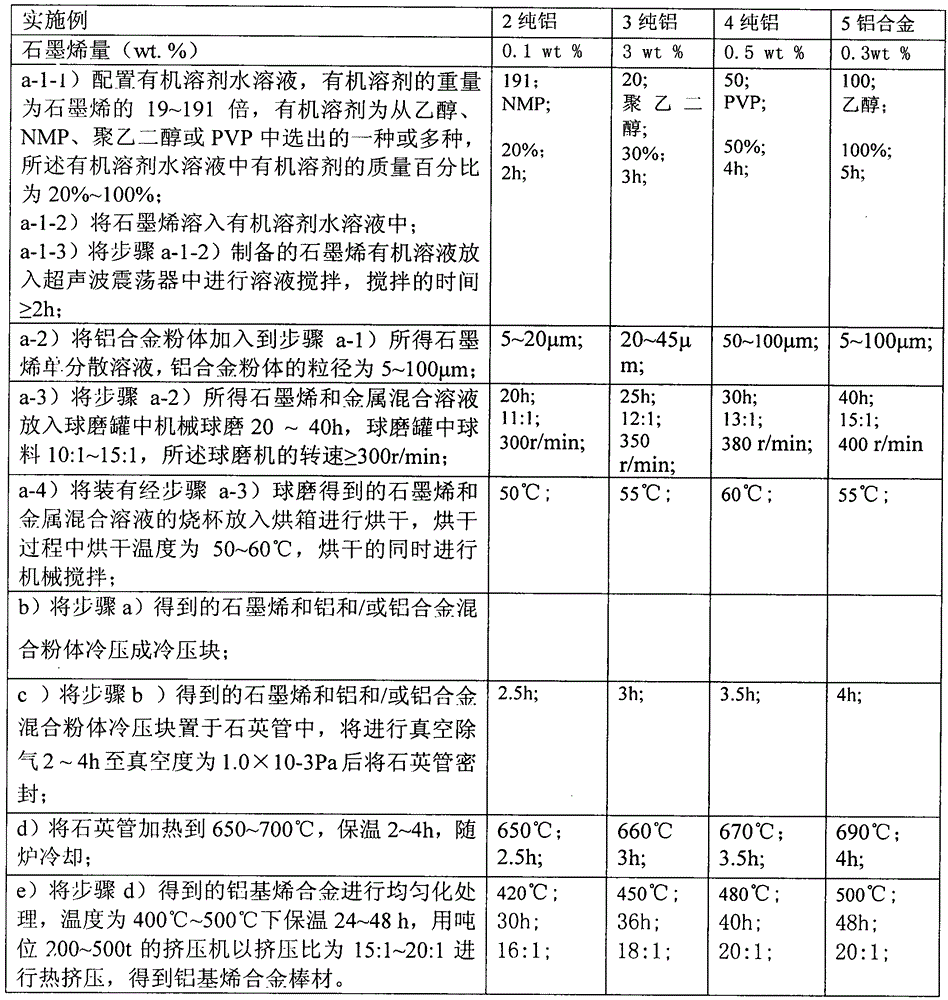

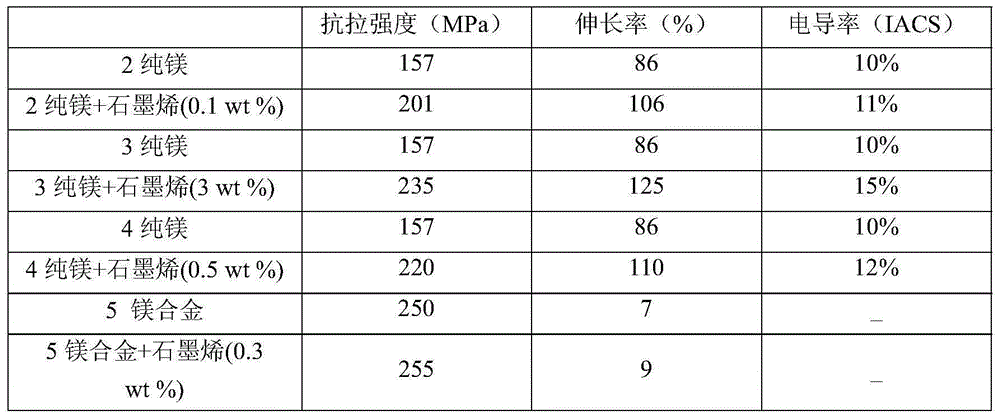

Preparation method of aluminum base graphene alloy

The invention provides a preparation method of aluminum base graphene alloy. The method comprises the following steps: preparing graphene and aluminum and / or aluminum alloy mixed powder, filling a jacket with the mixed powder, carrying out vacuum degassing, carrying out hot isostatic pressing, re-melting, and homogenizing. A certain amount of the aluminum base graphene alloy precast ingots are re-melted in aluminum alloy melt, the content of graphene in a composite material can be well controlled through calculating, and graphene cannot float, so the content of graphene in the aluminum base graphene alloy can be accurately controlled; and the preparation method is provided on the basis of semi-continuous melting casting, and has the advantages of simple operation, high production efficiency, low preparation cost, and easy realization of large scale industrialization.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

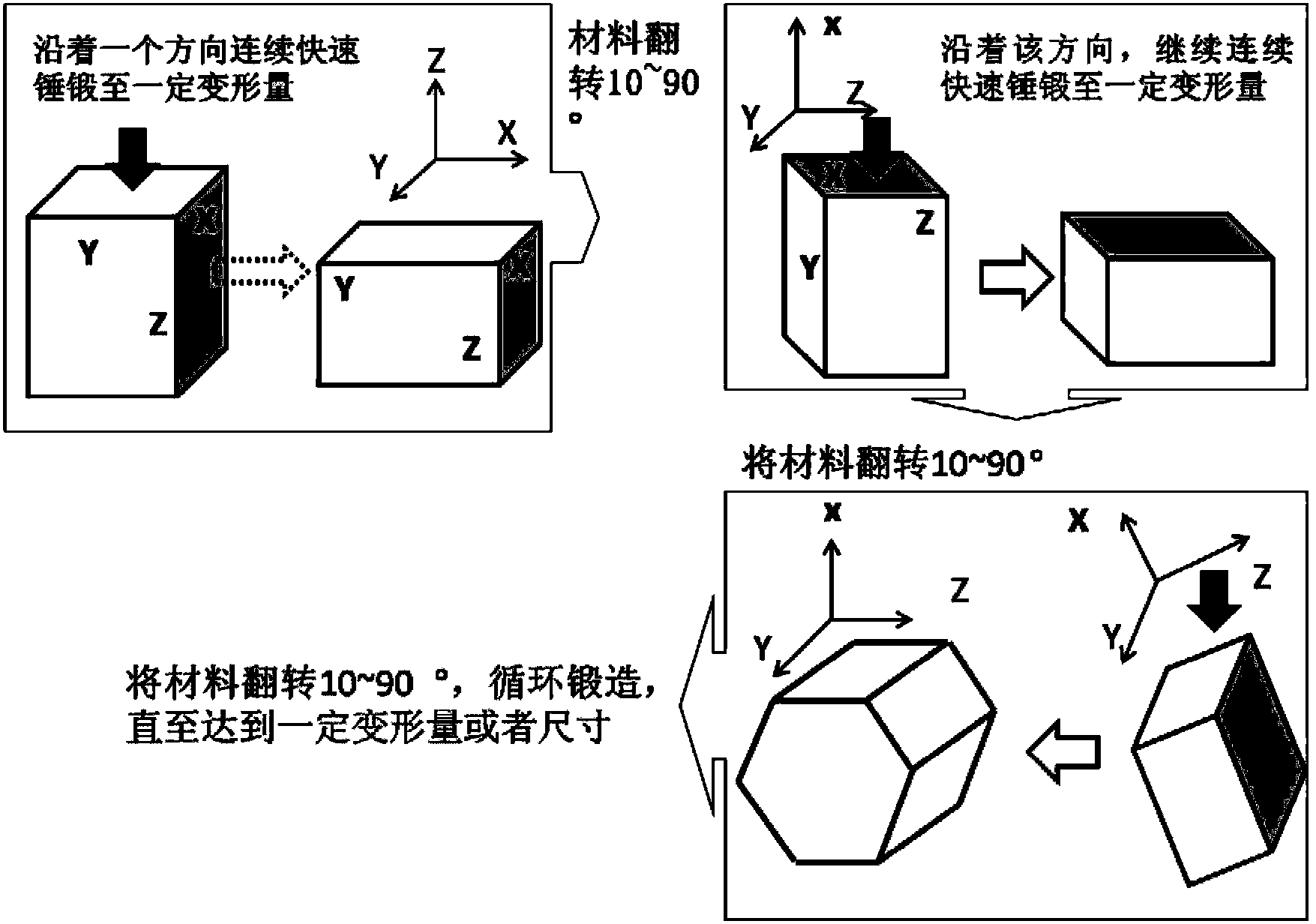

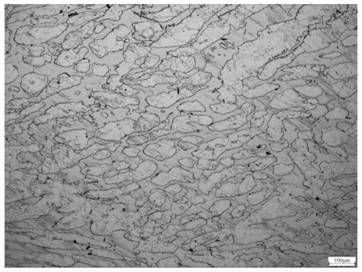

Forging method for multi-direction, circulatory and high-speed hammer forging of magnesium alloy

ActiveCN103805923AOvercome the shortcomings of poor plastic processing performanceLess slipHigh velocityHeat treated

The invention relates to a magnesium alloy plastic processing technology, and relates to a forging method for multi-direction, circulatory and high-speed hammer forging of a magnesium alloy. The method comprises the specific steps: after carrying out homogenization annealing of a casting-state or deformation-state magnesium alloy, carrying out continuous high-speed hammer forging along one direction of the bulk material at a certain temperature; after a certain deformation amount is reached, overturning the material, and continuing to carry out continuous high-speed hammer forging along another direction to reach a certain deformation amount; then overturning the material to another direction, and carrying out such circulatory hammer forging until the material reaches a predetermined deformation amount and size; and finally, carrying out heat treatment on the material. The method utilizes the textured micostructure formed during the processes of high-speed hammer forging of the magnesium alloy to be combined to change the hammer forging direction, thereby improving the ultimate deformation amount that the magnesium alloy can withstand and is not cracked during forging, and improving the plastic processing performance of the magnesium alloy. The method is suitable for magnesium and the alloy material thereof, and improves the forging processing production efficiency of magnesium and the alloy material thereof.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

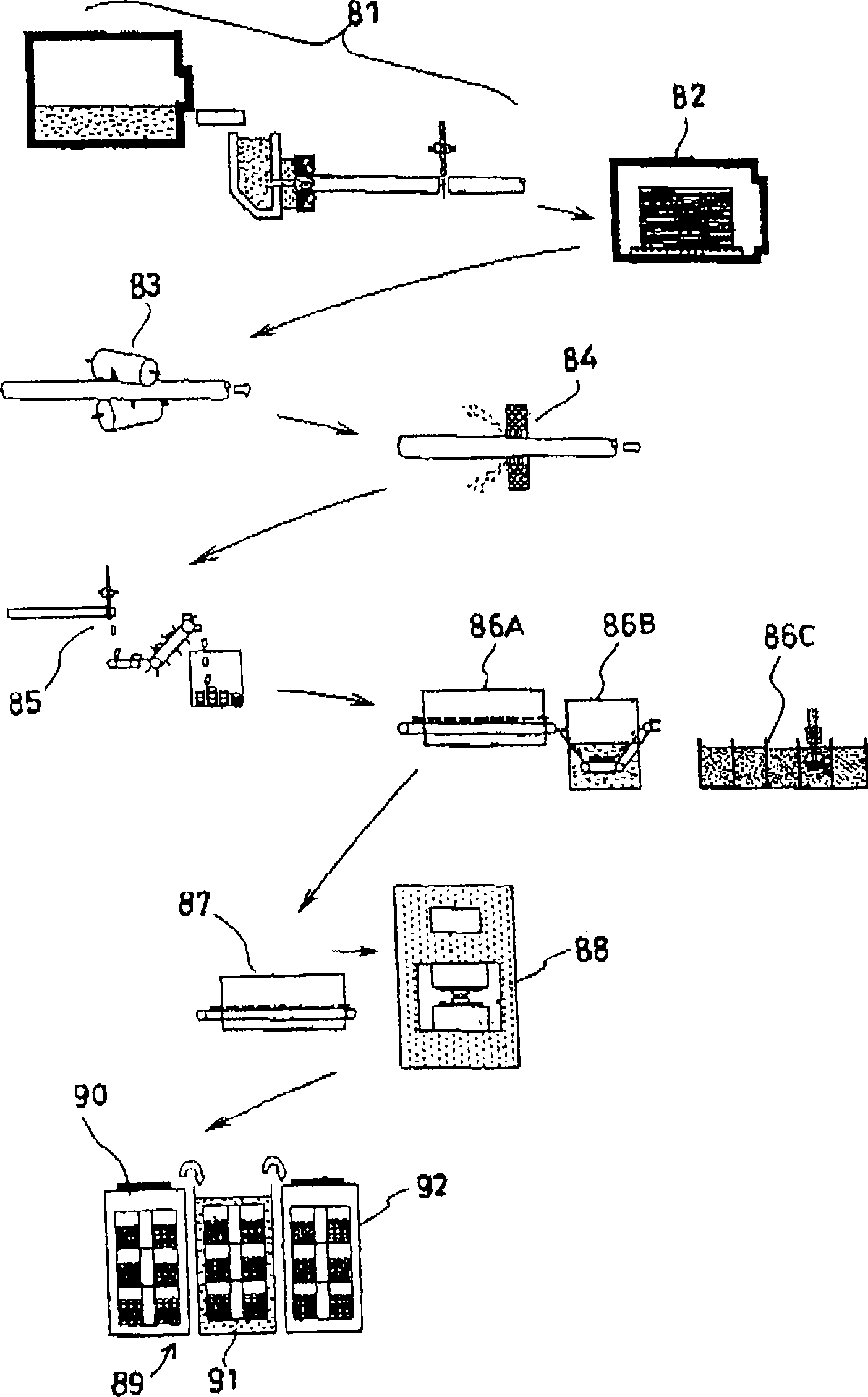

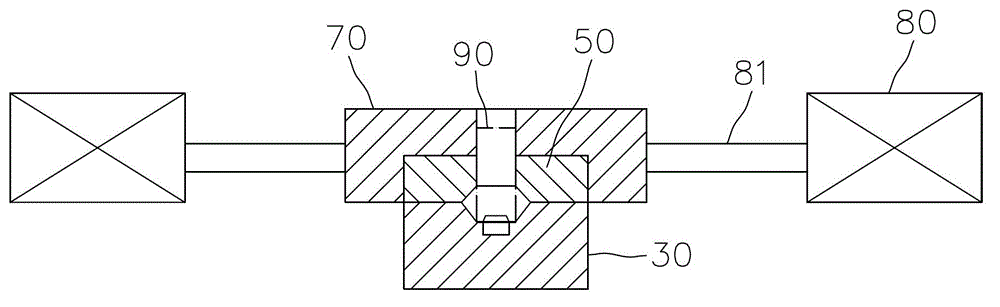

Process for production of aluminum alloy formings, aluminum alloy formings and production system

InactiveCN101522935ABoth ductilityToughnessMetal-working apparatusMachines/enginesUltimate tensile strengthMaterials science

The invention provides a process for production of aluminum alloy formings superior to conventional aluminum alloy forgings in mechanical strength at high temperature. A process for production of aluminum alloy formings by forging a stock consisting of a continuously cast rod made of an aluminum alloy, in which the aluminum alloy contains 10.5 to 13.5% by mass of Si, 2.5 to 6% by mass of Cu, 0.3 to 1.5% by mass of Mg, and 0.8 to 4% by mass of Ni and satisfies the relationship: Ni (% by mass) = [-0.68 OECu(% by mass) + 4.2(% by mass)] and which comprises the step (82) of preheat treatment of the stock, the heating step (87) of forging the stock, and the step (89) of postheat treatment of an aluminum alloy forming as the heat treatment / heating steps, with the step (82) involving the treatment of keeping the stock at -10 DEG C to 480 DEG C for 2 to 6 hours.

Owner:SHOWA DENKO KK

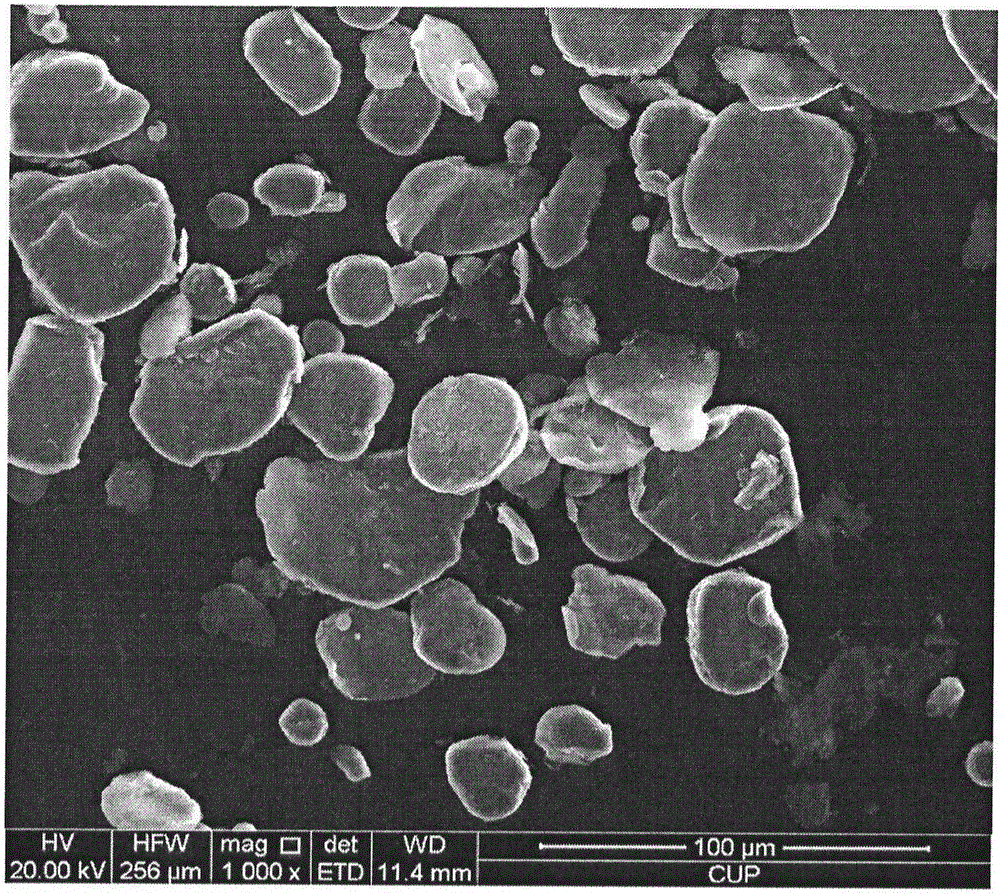

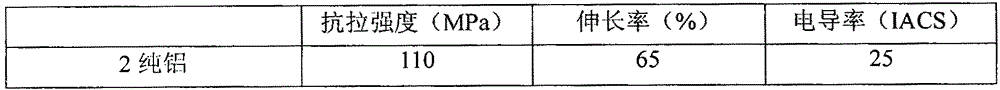

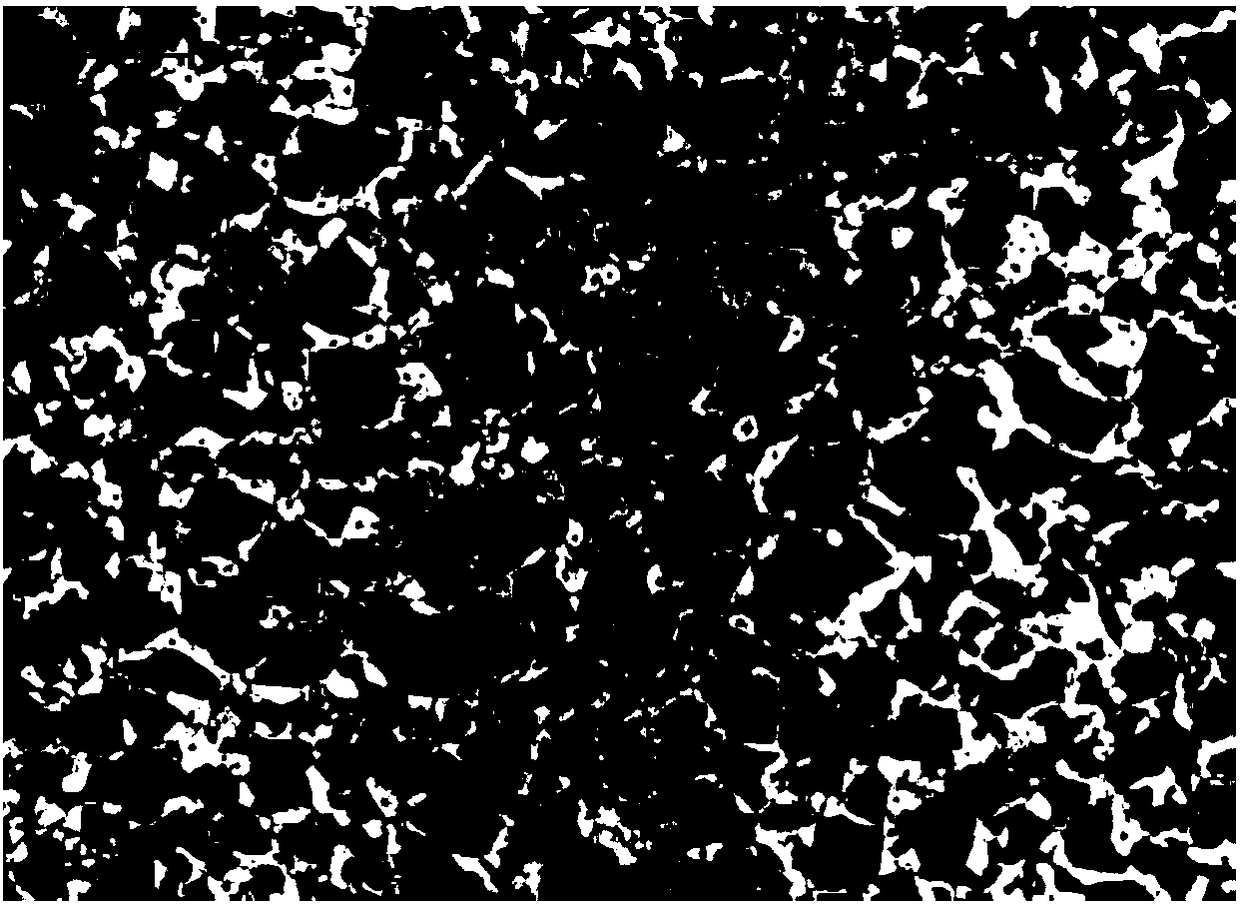

Preparation method of aluminum base graphene alloy

InactiveCN105063402AEvenly dispersedSolve the problem of easy reunion and difficult dispersionCvd grapheneProcess operation

The invention provides a preparation method of aluminum base graphene alloy. The method comprises the following steps: preparing graphene and aluminum and / or aluminum alloy mixed powder, carrying out cold pressing, and carrying out sintering molding. The method improves an original preparation technology of the aluminum base graphene alloy, and has the advantages of production period and cost reduction, simple process operation, simple required device, high production efficiency, low preparation cost, and easy realization of large-scale industrialization.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

High-hardenability gear steel and manufacturing method thereof

The invention discloses high-hardenability gear steel. The high-hardenability gear steel comprises the chemical elements of, by mass, 0.19-0.25% of C, 0.15-0.35% of Si, 0.70-1.05% of Mn, 0.70-0.80% ofCr, 0.40-0.65% of Ni, larger than 0 and less than or equal to 0.20% of Cu, 0.33-0.40% of Mo, 0.020-0.050% of Al, 0.003-0.010% of Ti, 0.05-0.08% of b, 0.0001-0.0003% of B, 0.0080-0.0150% of N, and thebalance Fe and other inevitable impurities. The invention further discloses a gear which is obtained through the high-hardenability gear steel. In addition, the invention further discloses a manufacturing method of the high-hardenability gear steel. The high-hardenability gear steel is high in strength and good in toughness.

Owner:BAOSHAN IRON & STEEL CO LTD

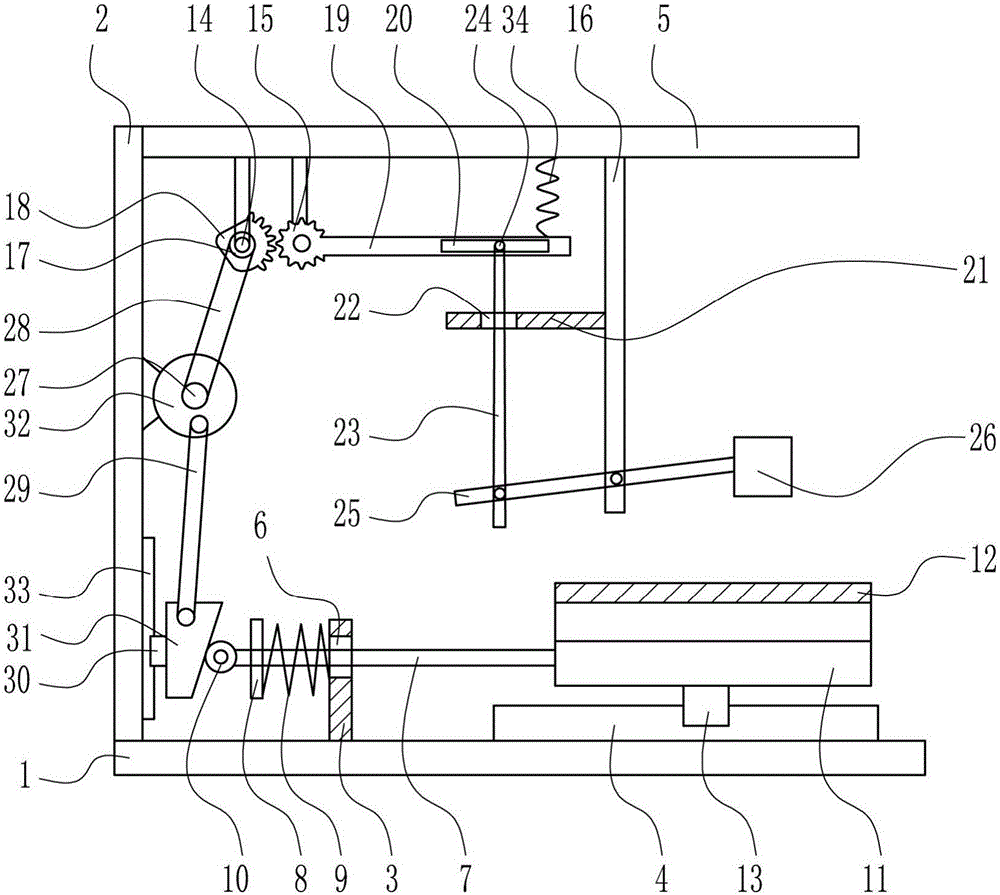

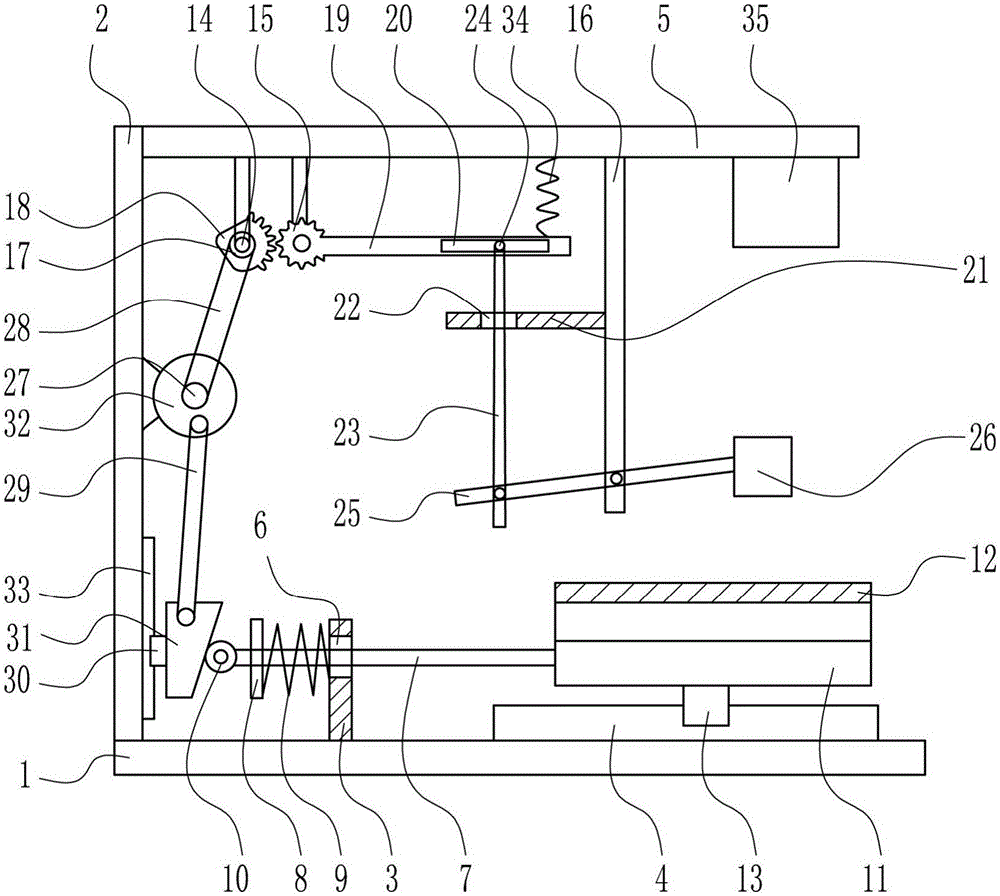

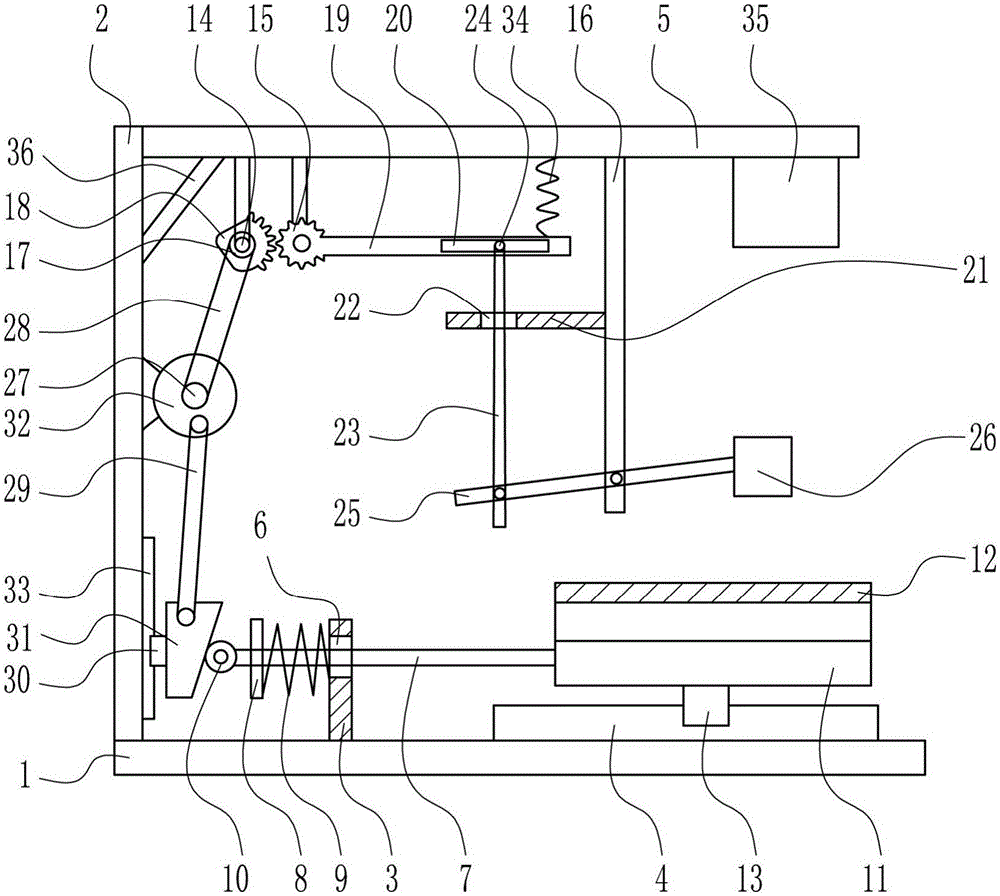

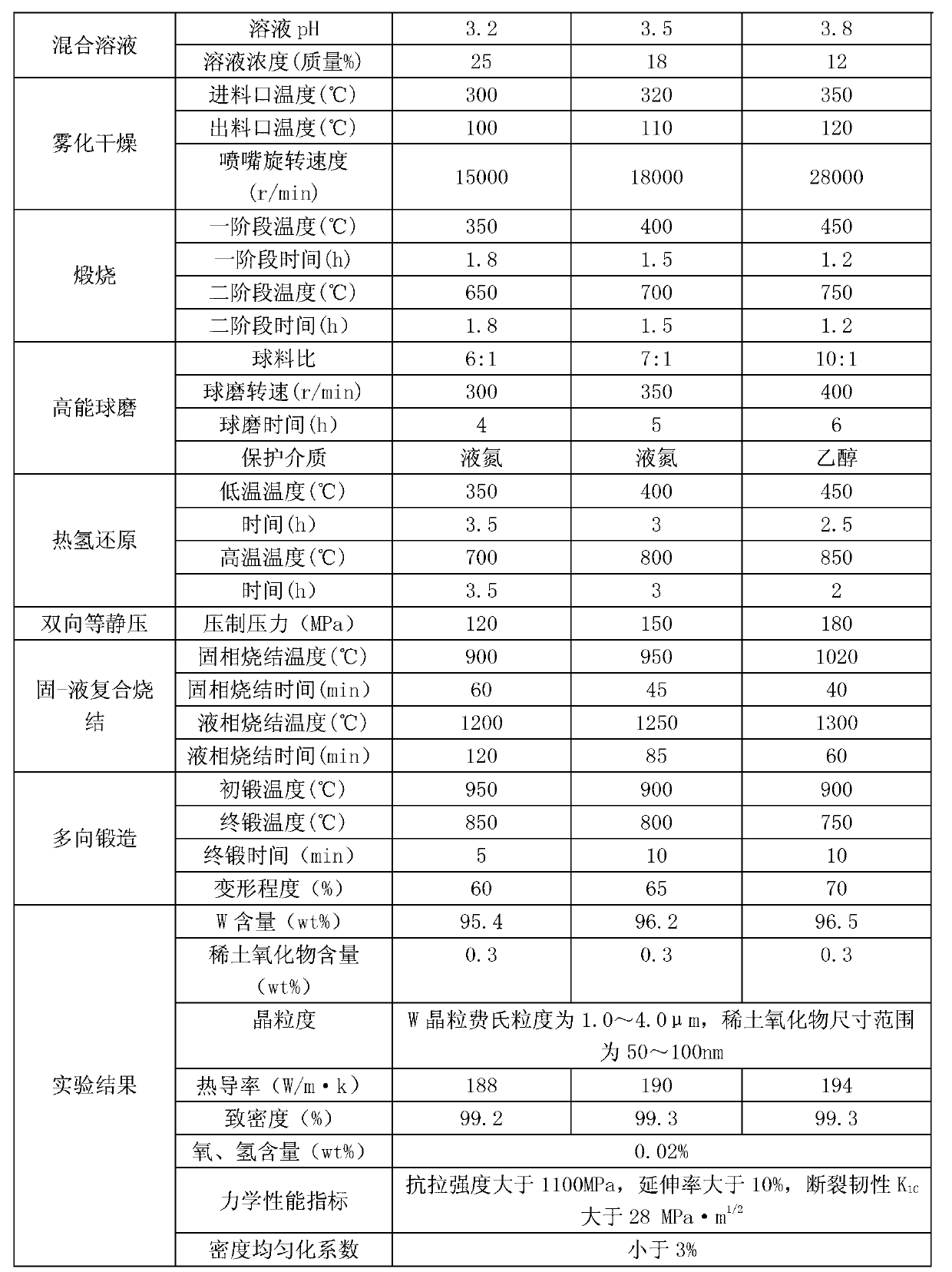

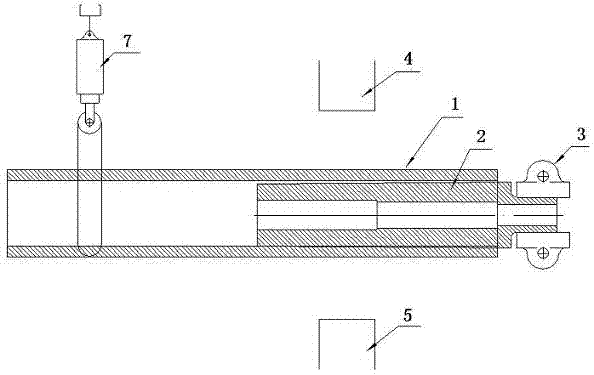

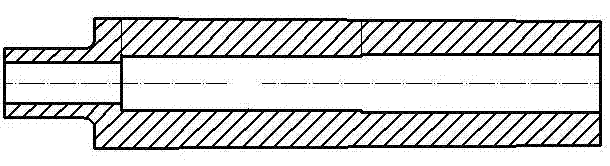

Rapid iron sheet forging device for hardware

ActiveCN106111865AOptimizing Forging PerformanceImprove stabilityDrop hammersHammer drivesMaterials sciencePulley

The invention relates to an iron sheet forging device, and particularly relates to a rapid iron sheet forging device for hardware. The invention aims to solve the technical problem of providing the rapid iron sheet forging device for hardware, which has the advantages of good forging effect, simplicity in operation and high stability. In order to solve the technical problem, the invention provides the rapid iron sheet forging device for hardware. The rapid iron sheet forging device comprises a bottom plate, a left side plate, a first guide rod, a first sliding rail, a top plate, a push rod, a fixed stop block, a carbon fire box, an electromagnet, a first sliding block, a motor, a gear, a vertical plate, a transverse plate, a second guide rod, a lifting rod, a rolling shaft, a first connecting rod, a hammer, a second belt pulley and the like, wherein the left side plate, the first guide rod and the first sliding rail are arranged on the bottom plate in sequence from left to right, and the top plate and the like are arranged on the right side of the left side plate in sequence from top to bottom. The invention provides the rapid iron sheet forging device for hardware, the effects of good forging effect and high stability are achieved by utilizing a water tank and an inclined plate, and the rapid iron sheet forging device is operated only by controlling the motor.

Owner:CN PRECISION CASING (SHENZHEN) CO LTD

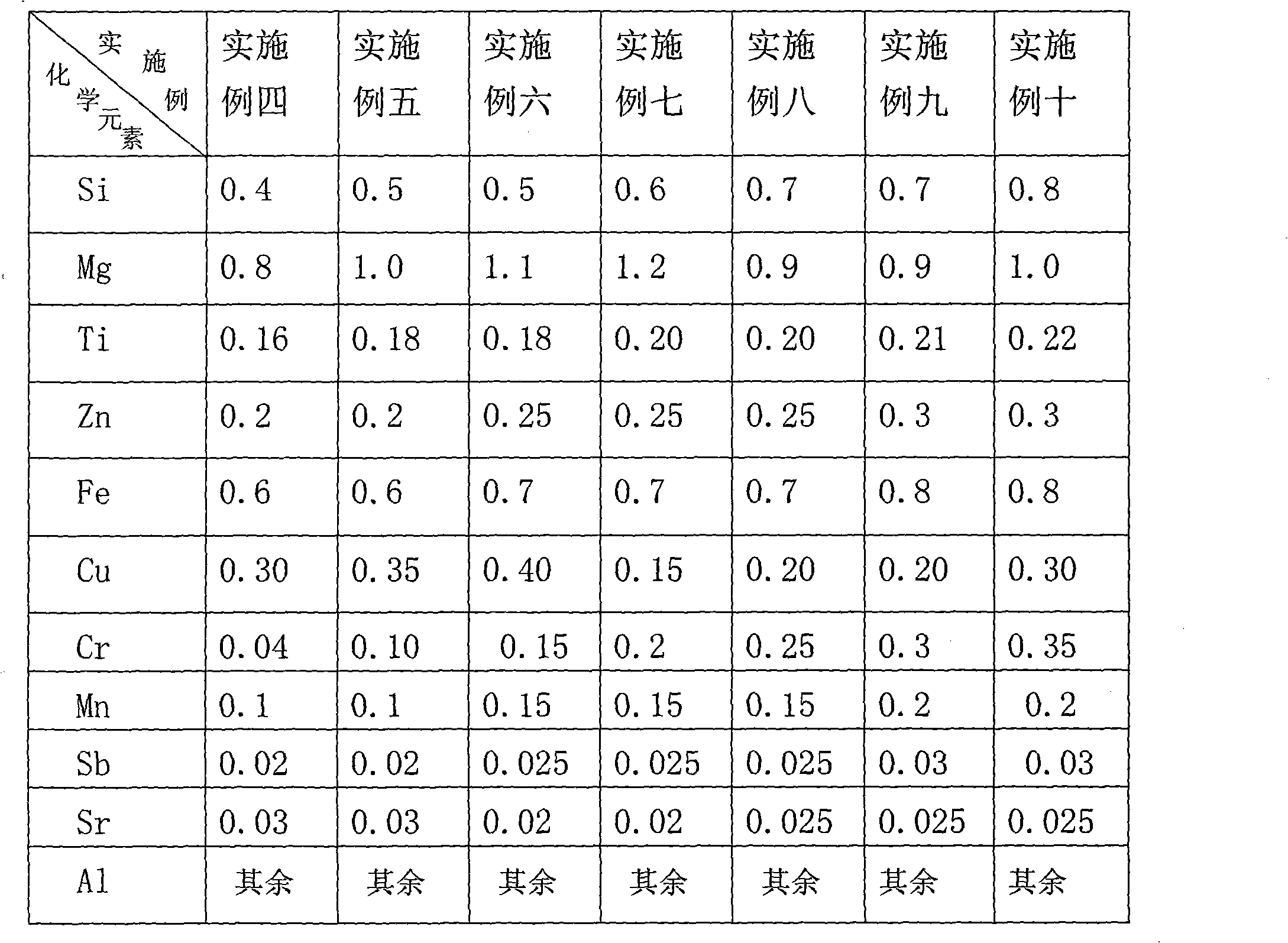

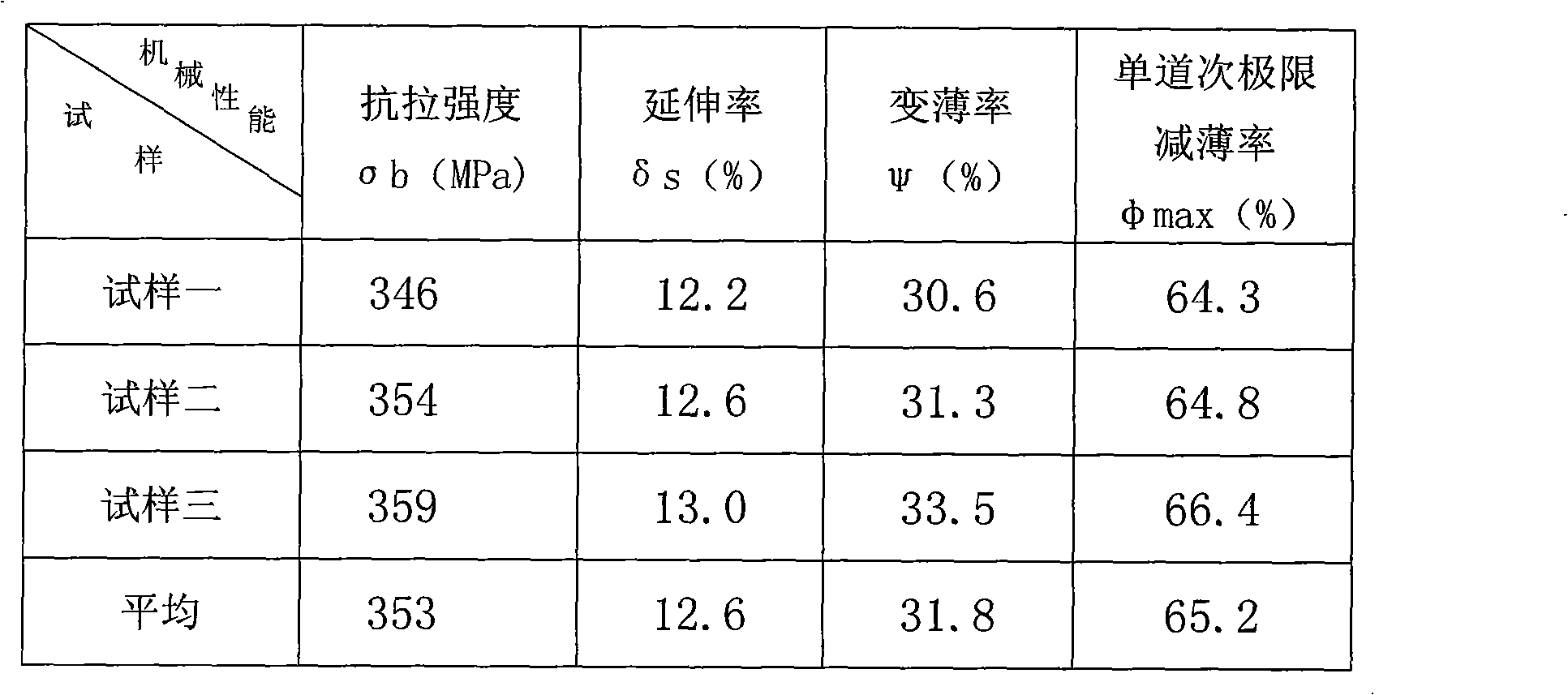

High strength automobile aluminium alloy wheel rim

The invention relates to a high strength automobile aluminium alloy wheel rim, in particular to an automobile wheel rim matched with oversize vehicles. The high strength automobile aluminium alloy wheel rim is made of high strength aluminium alloy material which comprises main chemical elements with the mass percent: 0.4-0.8% of Si, 0.8-1.2% of Mg, 0.16-0.22% of Ti, 0.2-0.3% of Zn, 0.6-0.8% of Fe,0.15-0.4% of Cu, 0.04-0.35% of Cr, 0.1-0.2% of Mn, 0.02-0.03% of Sb, 0.02-0.03% of Sr and the rest of Al. The automobile aluminium alloy wheel rim has high tensile strength which is 10% higher than that of the existing aluminium alloy wheel rim produced by 6061-T6, is good in mechanical property, enhances the rotatable performance of alloy when the structure is refined, and has the advantages ofwide application scope, low production cost and easy popularization and use.

Owner:HECHI UNIV

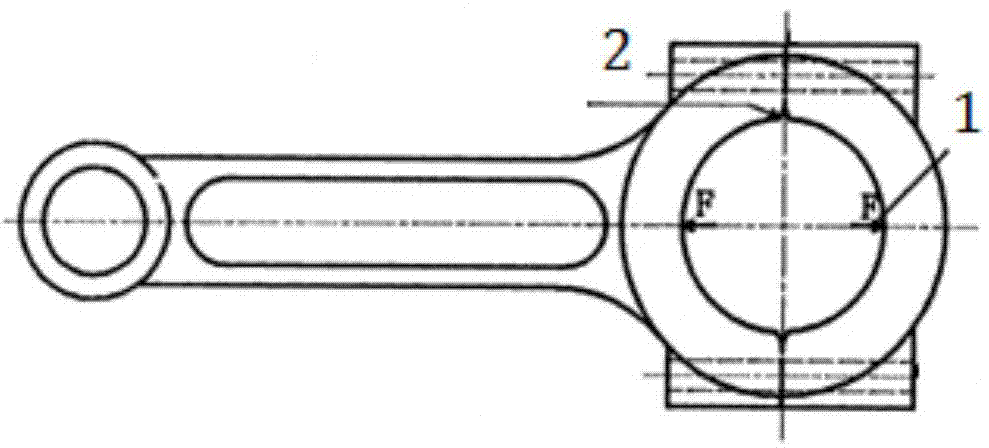

High-carbon non-tempered steel for breaking connecting rod and manufacturing method thereof

InactiveCN104775081ANo obvious plastic deformationMeet breakout requirementsHigh carbonChemical element

The invention discloses high-carbon non-tempered steel for breaking a connecting rod and a manufacturing method thereof. The high-carbon non-tempered steel comprises the following chemical elements in percentage by weight: 0.65%-0.85% of C, 0.15%-0.25% of Si, 0.50%-0.60% of Mn, 0.010%-0.045% of P, 0.060%-0.070% of S, 0.10%-0.20% of Cr, 0.55%-0.80% of Ni, 0.03%-0.04% of V, 010%-0.20% of W, 0.0120%-0.0160% of N, 0.0001%-0.0004% of Re and the balance of Fe and inevitable impurities. The manufacturing method comprises the following steps: electric furnace primary smelting; ladle refining and vacuum degassing; die casting or continuous casting; and steel bar rolling. The high-carbon non-tempered steel has relatively high strength and good breaking performance.

Owner:BAOSHAN IRON & STEEL CO LTD

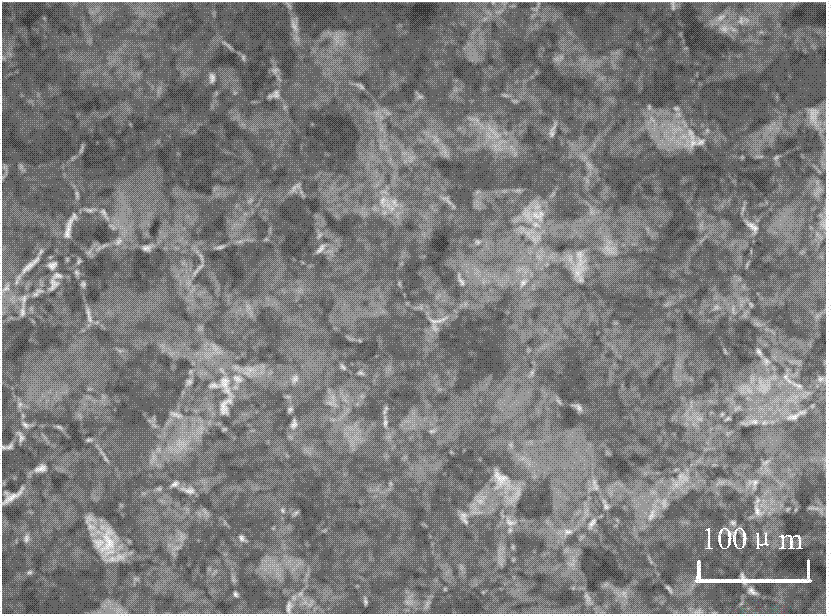

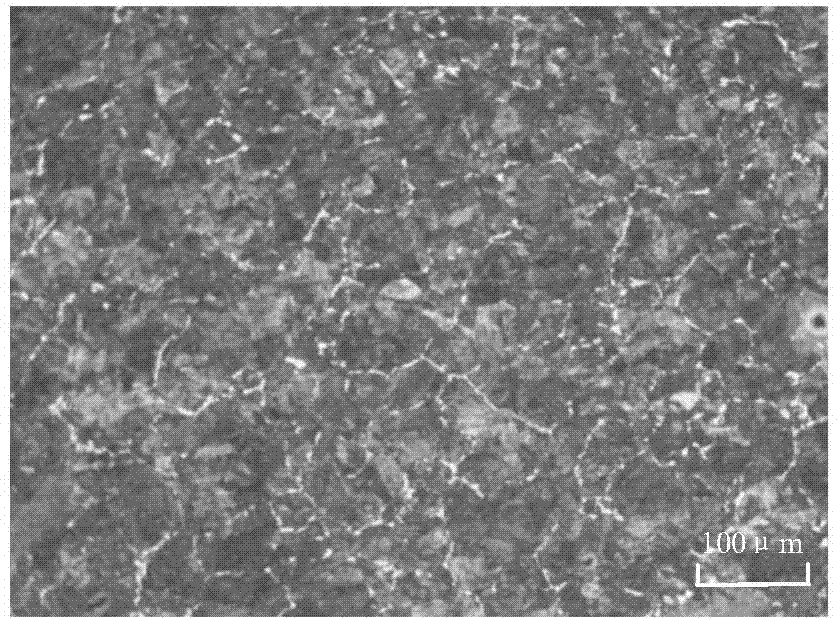

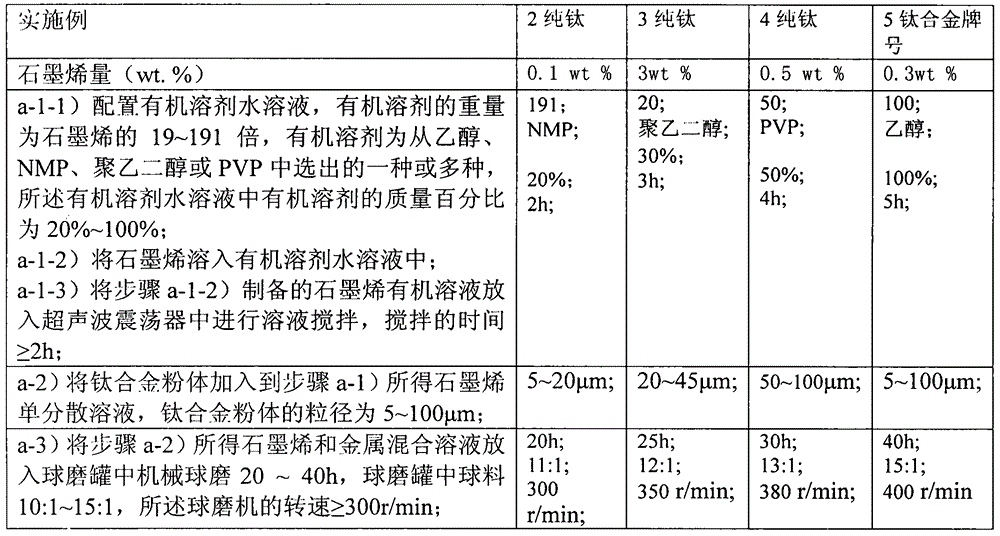

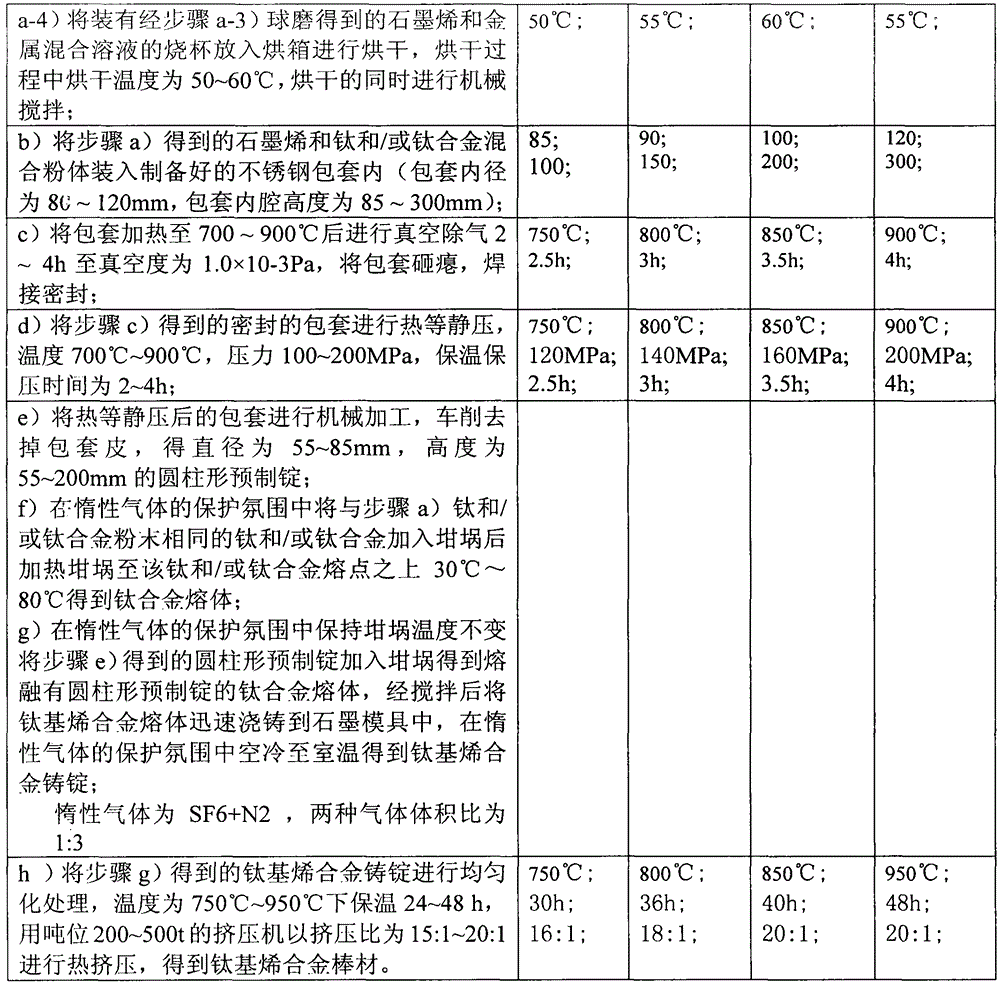

Preparation method of titanium matrix graphene alloy

The invention provides a preparation method of titanium matrix graphene alloy. The method comprises the following steps: preparing graphene and titanium and / or titanium alloy mixed powder, filling a jacket with the mixed powder, carrying out vacuum degassing, carrying out hot isostatic pressing, re-melting, and homogenizing. A certain amount of the titanium matrix graphene alloy precast ingots are re-melted in titanium alloy melt, the content of graphene in a composite material can be well controlled through calculating, and graphene cannot float, so the content of graphene in the titanium matrix graphene alloy can be accurately controlled; and the preparation method is provided on the basis of semi-continuous melting casting, and has the advantages of simple operation, high production efficiency, low preparation cost, and easy realization of large scale industrialization.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

Steel for case hardening which has excellent cold workability and machinability and which exhibits excellent fatigue characteristics after carburizing and quenching, and process for production of same

ActiveCN102378822AOptimizing Forging PerformanceExcellent machinabilitySolid state diffusion coatingSulfideCase hardening

Provided is a steel for case hardening, which is to be subjected to cold working, machining, and carburizing and quenching, and in which the occurrence of coarse particles is prevented. The steel for case hardening has excellent cold workability and machinability and further exhibits excellent fatigue characteristics after carburizing and quenching. The steel for case hardening is characterized by: containing, by mass, 0.001 to 0.15% of S, 0.05 to 0.2% of Ti, at most 0.04% of Al, at most 0.0050% of N, and specific amounts of other specific components, and further containing at most 0.003% of Mg, and / or at most 0.01% of Zr, and / or at most 0.005% of Ca; having a content of precipitated AlN of 0.01% or less; and satisfying the relationship: d = 1700[S]+20 [wherein d is the density (particles / mm2) of sulfides which have equivalent circle diameters exceeding 20[mu]m and aspect ratios exceeding 3; and [S] is the content (mass%) of S].

Owner:NIPPON STEEL CORP

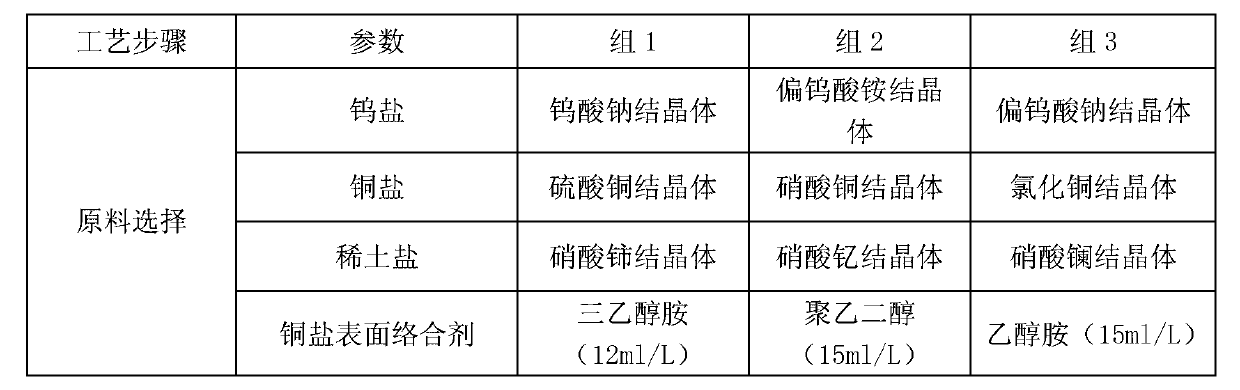

W-Cu composite material with high Cu content and preparation method of W-Cu composite material

The invention relates to a W-Cu composite material with high Cu content and the preparation method of the W-Cu composite material. The W-Cu composite material is characterized in that due to the improvement of raw materials and a technology, the prepared composite material has high Cu content reaching up to more than 70% and has the characteristics of uniform structure and high compactness.

Owner:NO 59 RES INST OF CHINA ORDNANCE IND

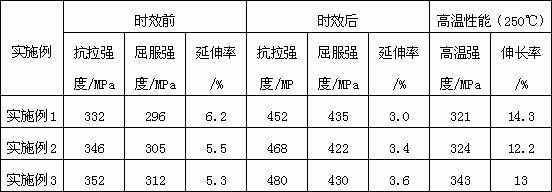

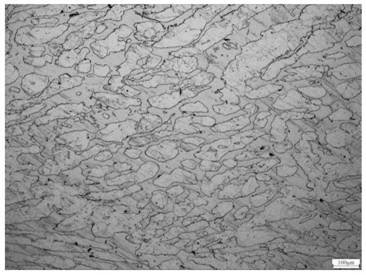

Forging method of high-strength heatproof magnesium alloy

The patent discloses a forging method of a high-strength heatproof magnesium alloy, specifically comprising the following steps of: preparing a blank material; heating the blank material and keeping warm; heating upper and lower flat anvils; carrying out multiple forging treatments on a hydraulic press with the cooperation of an intermediate annealing process; and carrying out aging treatment after forging. The forged magnesium alloy has advantages of uniform microstructure, fine crystal grains and excellent mechanical properties. After aging treatment, the tensile strength at normal temperature is greater than or equal to 450 MPa, the yield strength is greater than or equal to 410 MPa, and the elongation percentage is greater than or equal to 3%; at the temperature of 250 DEG C, the tensile strength is greater than or equal to 320 MPa and the elongation percentage is greater than or equal to 12%. By the adoption of the method provided by the invention, high temperature plasticity of the magnesium alloy is fully performed, and the service performance of the magnesium alloy is remarkably improved.

Owner:CENT SOUTH UNIV

Forging method of valve

InactiveCN105397416AGuaranteed pass rateHigh precisionValve arrangementsProcessing costMachining time

The invention relates to a forging method of a valve. The method specifically comprises the following steps: (1) preparing a sample; (2) testing; (3) blanking; (4) heating a blank; (5) preparing a blank; (6) pre-forging; (7) refining; (8) thermally cutting edges; (9) inspecting for the first time; (10) thermally treating; (11) performing shot blasting; (12) inspecting for the last time. With the adoption of the forging method, an A105 steel forging of the valve can be uniformly forged, the processing costs a little time, and the forging accuracy is high.

Owner:WENZHOU YANZHI VALVE FACTORY

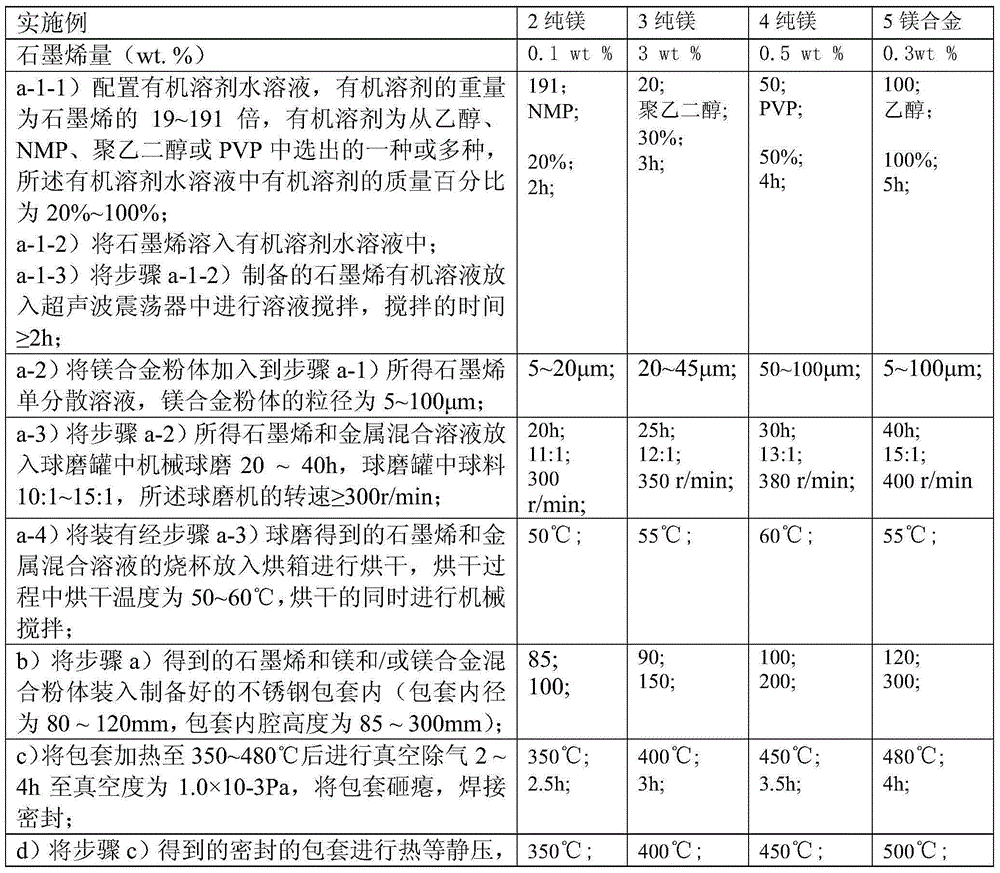

Preparation method of magnesium base graphene alloy

The invention provides a preparation method of a magnesium base graphene alloy. The method comprises the steps of: preparing mixed powder of graphene and magnesium and / or magnesium alloy, putting the mixed powder into a cover for vacuum degassing, performing hot isostatic pressing, remelting and performing homogenization treatment. According to the method, a certain quantity of magnesium base graphene alloy prefabricated ingot is remelted into magnesium alloy molten liquid; the content of graphene in a composite material is preferably controlled through calculation; as the graphene does not float out, the content in the magnesium base graphene alloy can be accurately controlled; and the preparation method is provided based on semi-continuous casting, and is simple in process operation, high in production efficiency, low in manufacturing cost and easy for realizing large-scale industrialization.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

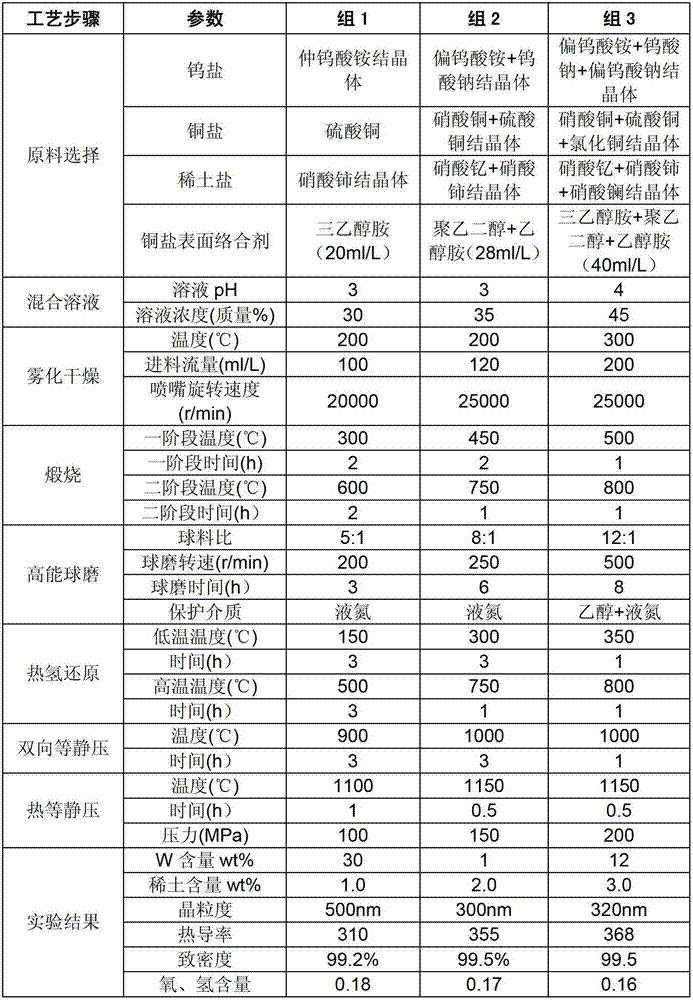

Rare-earth-oxide-doped W-Cu composite material and preparation method thereof

The invention provides a W-Cu composite material which is characterized by comprising the following components in percentage by mass: 5-30 wt% of Cu, 0.5-2 wt% of rare-earth oxide and the balance of W. The invention also provides a preparation method of the W-Cu composite material. The density of the composite material is up to 99.2%, the density uniformized coefficient of different positions is less than 5%, the room temperature tensile strength is greater than 900 MPa, the elongation percentage is greater than 10%, and the fracture toughness K1C is greater than 28 MPa.m<1 / 2>; and thus, the composite material satisfies the performance requirements of electric contact materials and liner materials for complete density, structure uniformity, ablation resistance and the like of the W-Cu alloy.

Owner:NO 59 RES INST OF CHINA ORDNANCE IND

Method for forging super-long hollow part from short core rod through free forging press

ActiveCN102357625ASolve the clamping torque problemIncrease tonnageMetal-working apparatusPunchingTempering

The invention belongs to the technical field of forging and in particular relates to a method for forging a super-long hollow part through an oil pressing and forging machine. The method comprises the steps of heating a steel ingot, cutting and blanking through an oil press, upsetting, punching, chambering, drawing a core shaft, forging to form a finished product, annealing, roughly processing, tempering and finely processing to form the finished product. On the premise of not increasing equipment, the clamping moment problem of a free forging oil press and an operation machine can be solved by using a specific tooling and a unique forging method. According to the method disclosed by the invention, the tonnage for the free forging press to forge the steel ingot can be greatly increased; by using the method, a pipe casting die blank beyond the clamping moment of the free forging press can be successively forged; furthermore, the free forging operation machine cannot operate in overloading the forging process; and the forging capability of the equipment is greatly increased.

Owner:HENAN ZHONGYUAN SPECIAL STEEL EQUIP MFG CO LTD

Manufacturing method of low-oxygen low-inclusion bearing steel

The invention discloses a manufacturing method of low-oxygen low-inclusion bearing steel. The manufacturing method comprises the steps of preparing of raw materials, converter smelting and alloying, LF+VD refining, continuous casting, rolling and slow cooling, wherein the mass percent of chemical components of the bearing steel in content is controlled to reach the standards of 1.06-1.1% of C, 0.7-0.75% of Si, 1.30-1.35% of Mn, 0.02-0.05% of Mo, 0.06-0.08% of Ni, 1.85-1.9% of Cr, 0.02-0.04% of Co, 0.02-0.03% of V, 0.01-0.03% of Als, 0.02-0.03% of Hf, 0.01-0.02% of Ta, 0.005-0.008% of Te, 0.05-0.1% of Cu, less than or equal to 0.025% of S, less than or equal to 0.025 of P, less than or equal to 10*10<-6> of O, less than or equal to 2*10<-6> of H and the balance Fe and inevitable impurities.According to the manufacturing method of the low-oxygen low-inclusion bearing steel smelting, the raw materials, the refining process, refining slag, crystallizer casting powder and the continuous casting process are controlled, so that the content of the obtained non-metal impurities of the bearing steel is low, and the content of the Ti is low; the phenomenon of nozzle nodulation is avoided inthe continuous casting process of square billets, blank throwing is smooth, the solidification speed of a blank shell is high, and safety of continuous casting is ensured, so that a final product is uniform in component, stable in performance and good in strength; and after heat treatment, the yield strength reaches 700 MPa, the tensile strength reaches 910 MPa, and the elongation at the cross section reaches 35%.

Owner:温州市赢创新材料技术有限公司

Manufacturing method for automobile transmission gear

The invention discloses a manufacturing method for an automobile transmission gear, and relates to the field of manufacturing of automobile parts. The method comprises the following steps: (1) blank forging, (2) spheroidizing annealing, (3) turning machining, (4) hobbing, (5) gear shaving, (6) carburization, (7) quenching and tempering and (8) grinding machining. According to the method, spheroidizing annealing treatment is adopted, so that the cutting performance of the gear is improved, a structure with spheroidized or granular carbide uniformly distributed on a ferrite substrate is obtained for preparation for subsequent heat treatment; a gas carburization method is adopted, and volatile kerosene is used as a carburizer, so that carburization effects are effectively improved, the thickness of a carburized layer is increased, the surface of the gear is hard and wear-proof, and high toughness of the core of the gear is maintained; quenching and tempering heat treatment is adopted after carburization, so that the carburization effects are further consolidated, and the mechanical performance of the gear is improved.

Owner:JIANGXI UNIV OF TECH

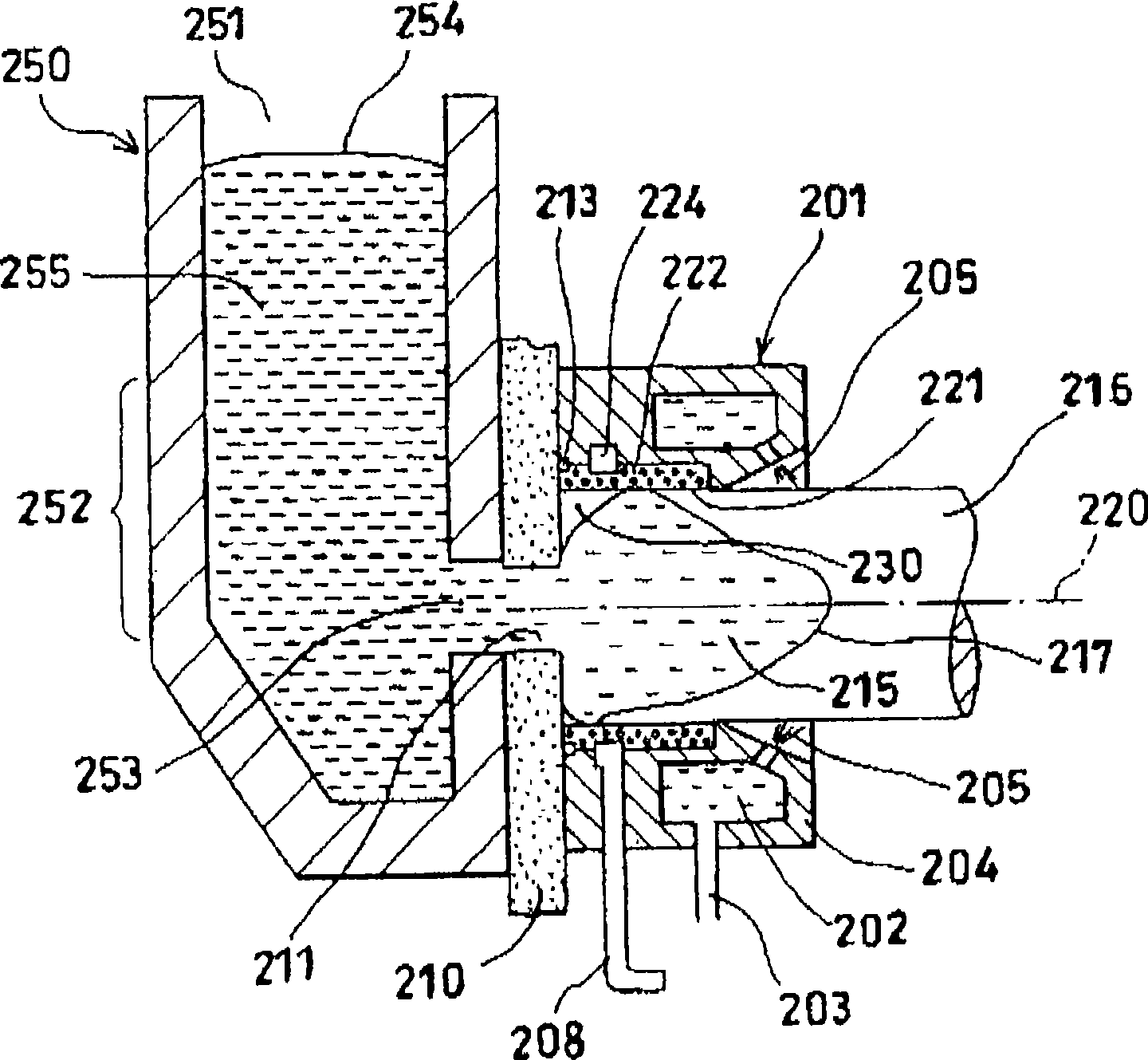

Swash plate of automobile air-condition compressor and production method of swash plate

ActiveCN104831133AImprove cutting performanceLow costPositive displacement pump componentsPositive-displacement liquid enginesPre treatment5005 aluminium alloy

The invention discloses a swash plate of an automobile air-condition compressor. The swash plate is prepared from an aluminium alloy comprising the following components in percentage by weight: 13-15% of Si, 4-5% of Cu, 0.2-0.3% of Mg, 0.8-1.5% of Ni, 0-0.1% of Mn, 0-0.5% of Fe, 0-0.1% of Zn, 0-0.2% of Ti, 0.1-0.3% of C, 0.1-0.3% of RE and the balance of Al. The invention further provides a production method of the swash plate of the automobile air-condition compressor. According to the production method provided by the invention, the high-temperature strength and the high-temperature hardness of the swash plate are improved, the cutting properties and the plasticity are improved, and low-cost production is realized by choosing and controlling elements in the aluminium alloy for the swash plate, and then replacing casting by forging, optimizing the pre-treatment and the post-treatment of the forging, and optimizing process parameters during the various treatment processes.

Owner:SHANDONG HUICHUAN AUTO PARTS

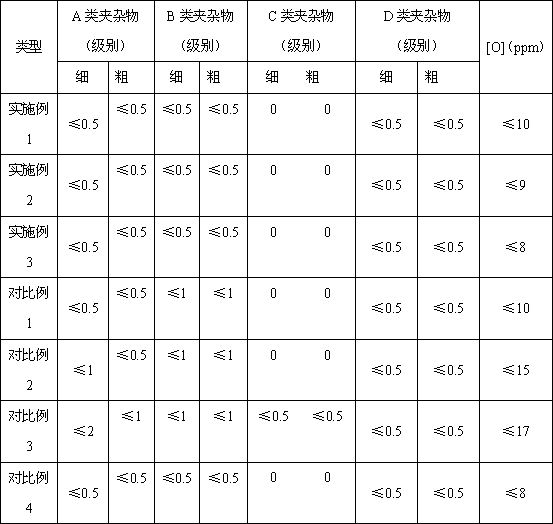

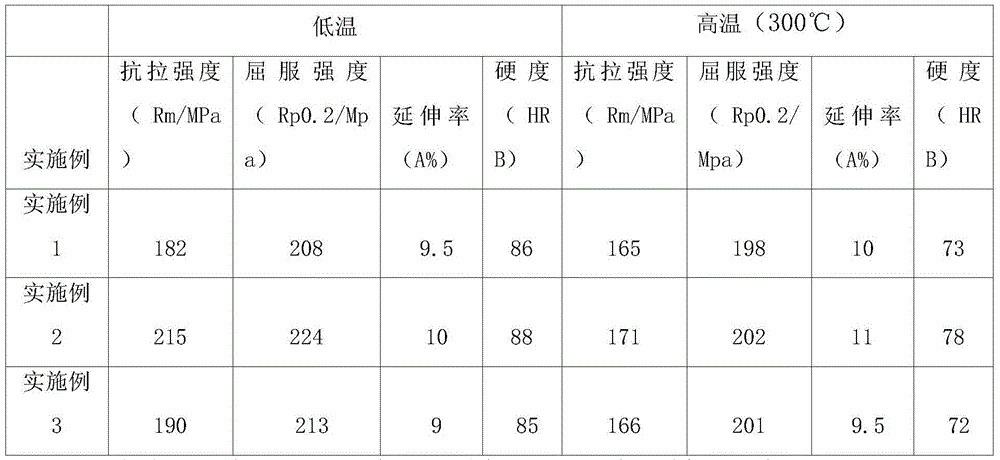

Smelting technique and production method of bearing steel and bearing steel

The invention relates to a smelting technique and production method of bearing steel and the bearing steel. Impurities in the bearing steel are controlled through the smelting technique. Low-titanium ferrochromium with the Cr content being equal to or higher than 75% serves as raw materials, and Al is added at one time for deoxidation before smelting and tapping of an electric furnace. High-purity silicon carbide with the purity being larger than 95% is adopted for deoxidation. After degassing of a vacuum furnace is conducted, the standing time of molten steel is not shorter than 10 minutes. By the adoption of a tundish current regulator, a covering agent with the calcium oxide content being not smaller than 50% serving as a tundish covering agent, and casting powder with the calcium oxide content being not smaller than 34% serving as tundish casting powder, the bearing steel is obtained, wherein the A type coarse impurity content of the beating steel is smaller than or equal to 1.0%, the A type fine impurity content of the beating steel is smaller than or equal to 1.0%, the B type coarse impurity content of the beating steel is smaller than or equal to 0.5%, the B type fine impurity content of the beating steel is smaller than or equal to 0.5%, the D type coarse impurity content of the beating steel is smaller than or equal to 0.5%, the D type fine impurity content of the beating steel is smaller than or equal to 0.5%, the C type coarse impurity content of the beating steel is 0, the C type fine impurity content of the beating steel is 0, and the DS type impurity content of the bearing steel is smaller than or equal to 1.0%. By the adoption of the smelting technique, the content of all the impurities is greatly reduced.

Owner:SUZHOU SUXIN SPECIAL STEEL +2

Tetrapod-shaped zinc oxide whisker reinforced aluminum alloy hub and preparing method thereof

InactiveCN105671463AUniform crystallizationHigh strengthTurbinesOther manufacturing equipments/toolsManganeseBall mill

The invention discloses a tetrapod-shaped zinc oxide whisker reinforced aluminum alloy hub and preparing method thereof. The aluminum alloy hub is made of compositions including, by weight percent, 8% to 14% of tetrapod-shaped zinc oxide whiskers, 12% to 16% of silicon, 1.0% to 1.5% of strontium, 0.12% to 0.18% of tantalum, 2.0% to 2.8% of magnesium, 1.8% to 2.4% of manganese, 0.40% to 0.56% of chromium and the balance aluminum. The preparing method comprises the steps of burdening, smelting, atomizing and obtaining aluminum alloy powder; performing ball mill mixing, performing cold isostatic pressing, demolding, performing sleeving coating treatment, performing warming pressure maintaining treatment and obtaining a blank; heating, rolling, forging, and spinning forming to obtain a hub workblank; and performing heat treatment, machining and surface treatment, and obtaining a hub finished product. After-casting treatment temperature is reasonably controlled, and the alloy is uniform in crystallization, high in strength, resistant in corrosion and impact, good in heat resistance, free of bubbles and good in casing and forging performance.

Owner:DONGGUAN PINPAI IND INVESTMENT

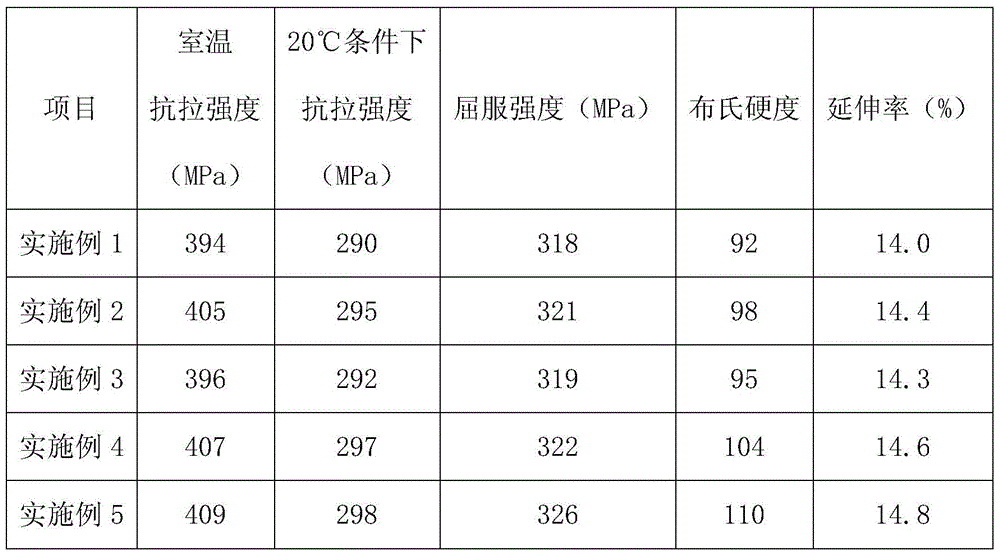

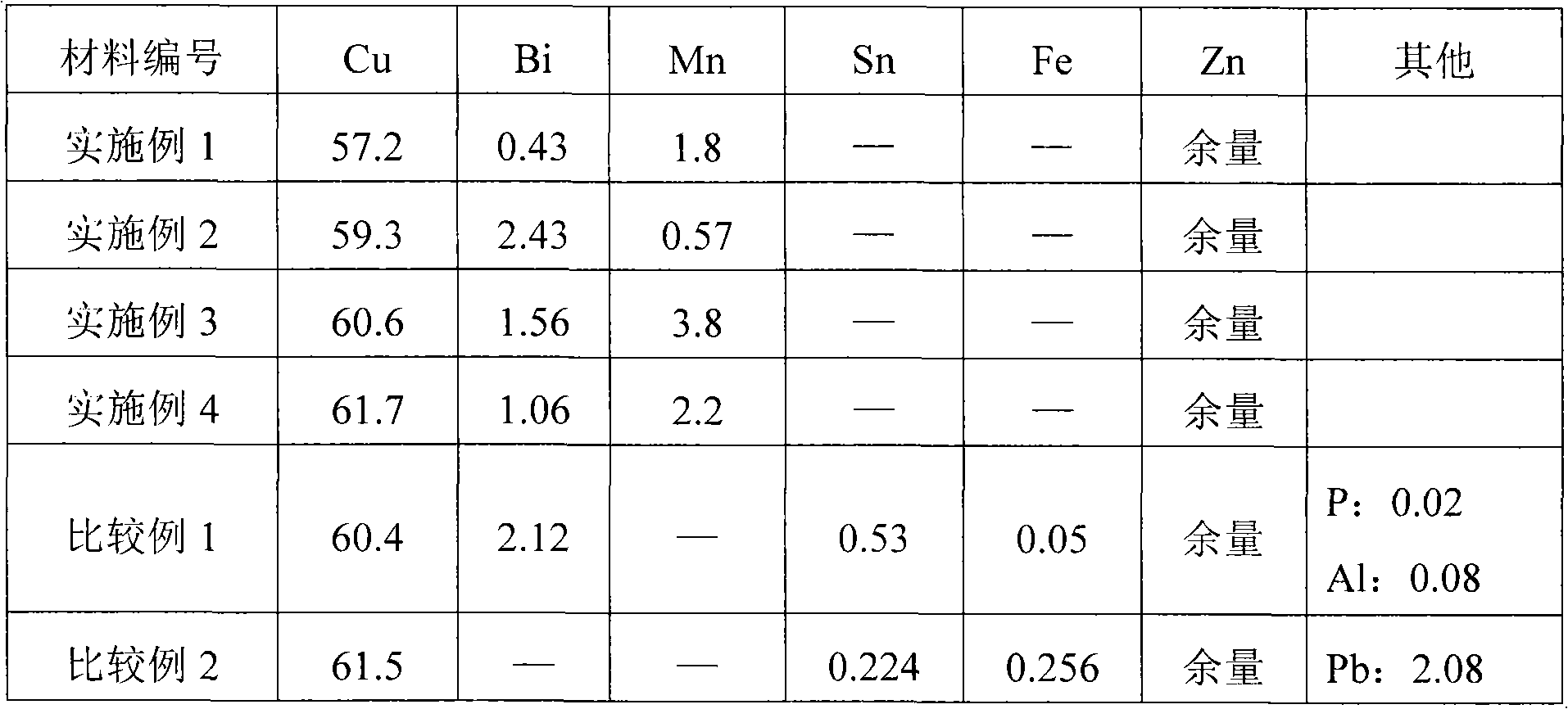

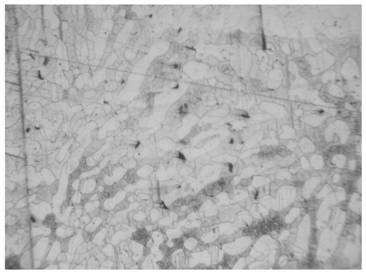

Manganiferous lead-free forgeable easy-cutting brass and preparation method thereof

InactiveCN102383004AImprove cutting performanceOptimizing Forging PerformanceManganeseInduction furnace

The invention discloses manganiferous lead-free forgeable easy-cutting brass and a preparation method thereof. The manganiferous lead-free forgeable easy-cutting brass is characterized by comprising the following components in percentage by weight: 57-62 wt% of copper, 0.3-2.5wt% of bismuth, 0.5-4.0 wt% of manganese, less than or equal to 0.2wt% of impurities and the balance of zinc. The preparation method comprises the following steps of: firstly preparing copper-bismuth intermediate alloy, then adding electrolytic copper, electrolytic manganese, the copper-bismuth intermediate alloy and electrolytic zinc into an electric induction furnace in sequence for smelting at the smelting temperature of 1030-1080 DEG C, and after all the metals are melted, maintaining the temperature for 5-30 minutes; carrying out casting of a copper-alloy ingot at the casting temperature of 1030-1050 DEG C; then heating a copper-alloy casting ingot to 570-700 DEG C for hot extrusion; and finally carrying out acid cleaning, scalping, drawing, straightening and stress relieving annealing on an extruded semi-finished product to obtain a finished product. In the manganiferous lead-free forgeable easy-cutting brass disclosed by the invention, the chemical component is simple, the recovery and reutilization are easy, the cutting performance, the forging performance, the mechanical performance and cold-hot forming performance are good, the production process is simple, and the manganiferous lead-free forgeable easy-cutting brass can be manufactured by utilizing the existing lead-brass production equipment without adding new equipment.

Owner:JINTIAN COPPER GROUP CORP NINGBO

Low-lead brass alloy and preparation method thereof

InactiveCN104087782AExcellent machinabilityImprove dezincification corrosion resistanceManganeseAlloy

The invention discloses a low-lead brass alloy. The low-lead brass alloy comprises 61.5-63.5% of copper and 0.02-0.15% of arsenic and also comprises less than or equal to 0.3% of nickel, less than or equal to 0.1% of aluminum, less than or equal to 0.2% of lead, less than or equal to 0.1% of manganese, iron and tin and the balance Fe and unavoidable impurities, wherein the content of the unavoidable impurities is less than or equal to 0.2%. The low-lead brass alloy reduces an alloy manufacturing cost, improves cutting ability and improves dezincification resistance.

Owner:NINGBO IDC INT TRADE +1

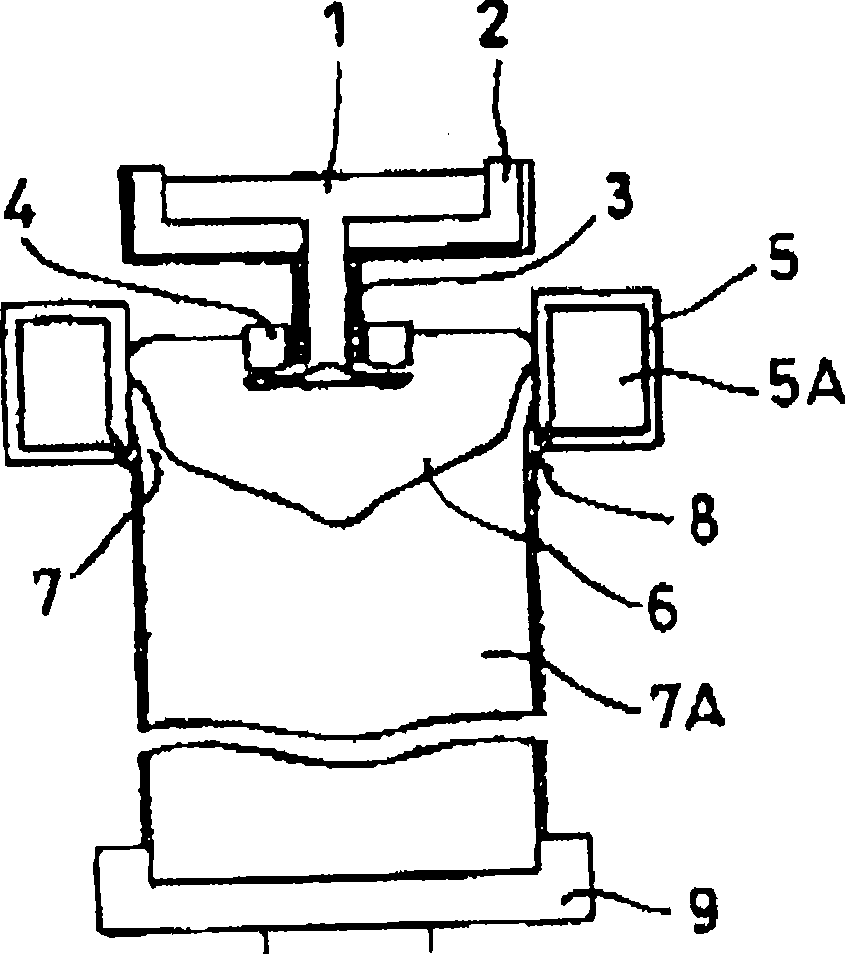

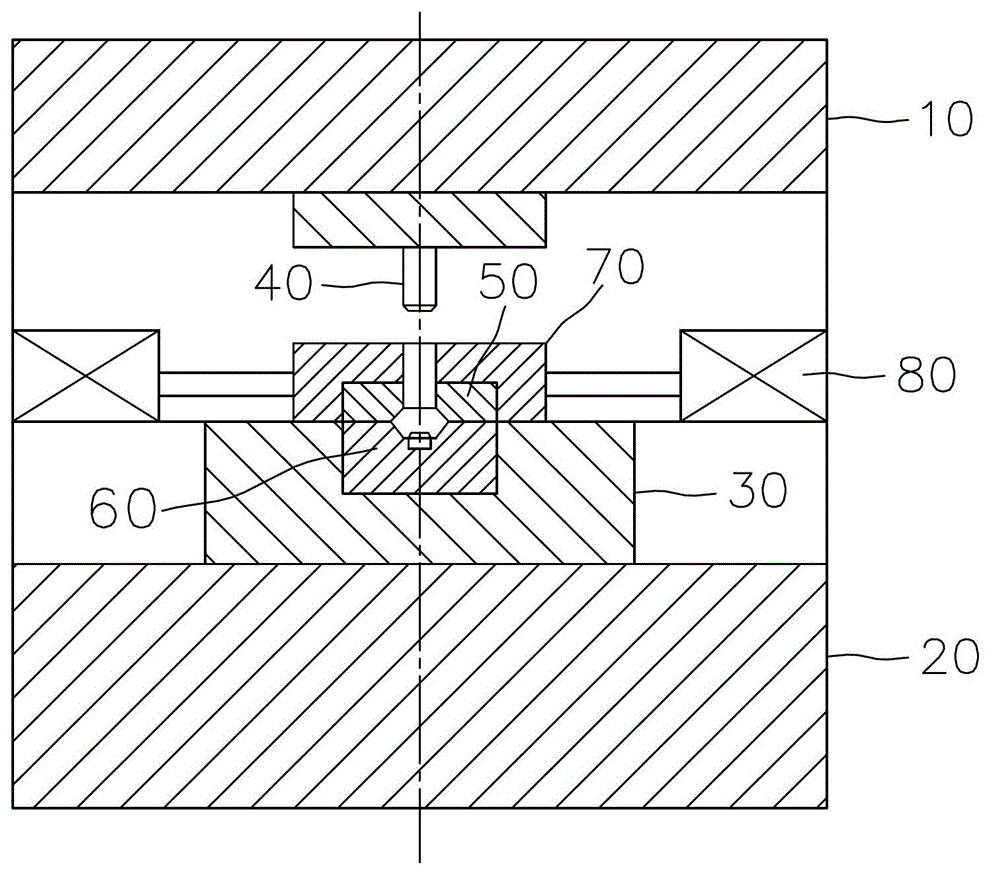

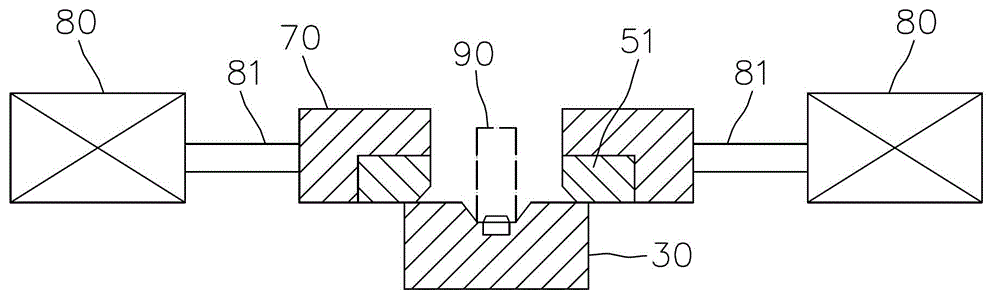

Closed cold-temperature precision forging die for straight-tooth bevel gear

ActiveCN103056264AEasy to controlIncreased precision and strengthForging/hammering/pressing machinesForgingBevel gear

The invention relates to the technical field of dies, in particular to a closed cold-temperature precision forging die for a straight-tooth bevel gear. The closed cold-temperature precision forging die for the straight-tooth bevel gear comprises a precision forging upper die, a precision forging lower die and an upper punch. The precision forging upper die is formed by combining a plurality of upper die units, each upper die unit is provided with a corresponding driving mechanism, the upper die units are mutually connected under driving of the driving mechanisms and are enclosed to form the precision forging upper die or the upper die units can be separated in scattering mode to facilitate forge piece taking out, and a channel used for the upper punch to pass through is arranged at the mutually connected upper ends of all the upper die units. The precision forging die is not provided with a lower punch so that manufacture cost is reduced, die assembling errors are reduced and forging accuracy is improved. The precision forging die can be form parts with complex shapes in once forming mode and accordingly is high in production efficiency. Simultaneously, metal flow lines are continuously distributed along the appearance of the forge pieces during forging so that the forge pieces are good in mechanical property.

Owner:周卫星

High wear resistant ultra-high carbon steel and preparation method for same

The invention relates to high wear resistant ultra-high carbon steel, which mainly contains alloy element chromium and comprises the chemical components: (according to weight percentage): 1.25-1.35% of C (carbon), 3.2-4.2% of Cr (chromium), 0.5-1.2% of Si+Al (silicon and aluminum), 0.85-1.25% of Mn (manganese), 0.08-0.15% of V (vanadium), 0.3% of Mo (molybdenum) or less than 0.3% of Mo, 0.025% of S (sulphur) or less than 0.025% of S, 0.025% of P (phosphorus) or less than 0.025% of P and the rest of Fe (ferrum) and inevitable impurities. The preparation method for the high wear resistant ultra-high carbon steel includes that after being refined, the components are heated at the temperature of 900-920 DEG C and are in salt bath at the constant temperature of 300-320 DEG C for 30min, and then the components are placed into a 320-340 DEG C box-type resistance furnace and insulated for 120-240min prior to air cooling. The high wear resistant ultra-high carbon steel can be produced by the aid of a medium frequency induction furnace, a vacuum induction furnace and an arc furnace with LF (low frequency) refining process. Compared with high manganese steel and high-chromium iron wear-resistant materials, the high wear resistant ultra-high carbon steel is remarkably lower in production cost. The high wear resistant ultra-high carbon steel with high hardness (55-57HRC (Rockwell hardness)) and fine impact flexibility (higher than or equal to 40J / cm2) can be used for manufacturing wear resistant parts such as hammerheads of crushers, liners for ball mills and the like requiring high wear resistance.

Owner:天津职业大学

Forging and heat treatment process of marine anticorrosion pull rod duplex stainless steel forge piece

ActiveCN112893510AOptimizing Forging PerformanceSmall tissueFurnace typesProcess efficiency improvementSolution treatmentSS - Stainless steel

The invention discloses a forging and heat treatment process of a marine anticorrosion pull rod duplex stainless steel forge piece, and belongs to the technical field of stainless steel forging treatment. The forging and heat treatment process is characterized by comprising the following steps that S1, smelting raw materials to obtain a steel ingot; S2, forging and heating the steel ingot; S3, forging the steel ingot to obtain a forge piece, specifically, the forging comprises three heating numbers, 1, in the first heating number, the forging temperature of the steel ingot is 1140-1160 DEG C; in the second heating number, the forging temperature of the steel ingot is 1120-1140 DEG C; in the third heating number, the forging temperature of the steel ingot is 1070-1100 DEG C; S4, the forge piece heat treatment, specifically, the forge piece heat treatment comprises the following steps of 1, water cooling treatment of the forge piece after forging; 2, forging rough machining; 3, the forge piece solution treatment; and S5, the forge piece finish machining. The method has the advantages that the uniform refining degree of crystal grains is improved, and the service life of the forge piece is greatly prolonged.

Owner:无锡继平新材料科技有限公司

A kind of environment-friendly silicon-tin brass suitable for forging and its manufacturing method

The invention relates to an environment-friendly silicon tin brass suitable for forging. The environment-friendly silicon tin brass comprises the following components in percentages by weight: 66-72% of copper, 0.4-3.0% of silicon, 0.03-1.0% of tin, 0.001-0.1% of titanium, not more than 0.2% of lead and the balance of zinc and unavoidable impurities, wherein the total amount of the unavoidable impurities is not more 0.2%. A preparation method comprises the following steps of: firstly, preparing copper silicon and copper titanium intermediate alloys; then sequentially adding electrolytic copper, the copper silicon intermediate alloy, electrolytic zinc and a tin ingot into an induction electric furnace to smelt; adding the copper titanium intermediate alloy after all metals are melted; thenpouring a copper alloy ingot, wherein a copper alloy cast ingot is heated to 650-750 DEG C and thermally extruded; uniformly annealing an extruded semifinished product; and then carrying out acid washing, stretching, straightening and stress relief annealing to obtain a finished product. In the invention, lead is replaced with silicone to improve the cutting property and the forging property of the alloy, tin is used for improving the cutting property and the dezincification and corrosive resistances of the alloy, and the titanium is used for refining crystal grains. Comparative experiments show that the environment-friendly silicon tin brass suitable for forging has better forging property, cutting property and dezincification and corrosive resistances.

Owner:JINTIAN COPPER GROUP CORP NINGBO

High-magnesium aluminum alloy material for wheel hubs and preparation method thereof

InactiveCN103774007AQuality improvementHigh magnesium aluminum alloy has light weightPorosityManganese

The invention relates to a high-magnesium aluminum alloy material for wheel hubs, which contains the following chemical components in percentage by mass: 12-15% of magnesium, 3.2-3.5% of silicon, 0.2-0.5% of calcium, 0.12-0.17% of molybdenum, 0.1-0.15% of copper, 0.04-0.06% of manganese, 0.2-0.25% of titanium, 0.04-0.06% of nickel, 0.12-0.15% of strontium, 0.12-0.16% of Ta and the balance of aluminum. The high-magnesium aluminum alloy has the characteristics of light weight and corrosion resistance; and the titanium, strontium, nickel and other elements are added to refine the crystal grain and enhance the strength and wear resistance of the alloy, so that the alloy quality is more stable and uniform. When being used for manufacturing wheel hubs, the aluminum alloy has the advantages of favorable casting and forging property, favorable thermal conductivity, light weight and fuel cost saving. When the refining agent is used for casting production, the porosity in the casting can be lowered by 1-2 degrees, the oxide inclusion content is Grade 2 or so, and the yield is high.

Owner:MAANSHAN HENGYI MACHINERY MFG

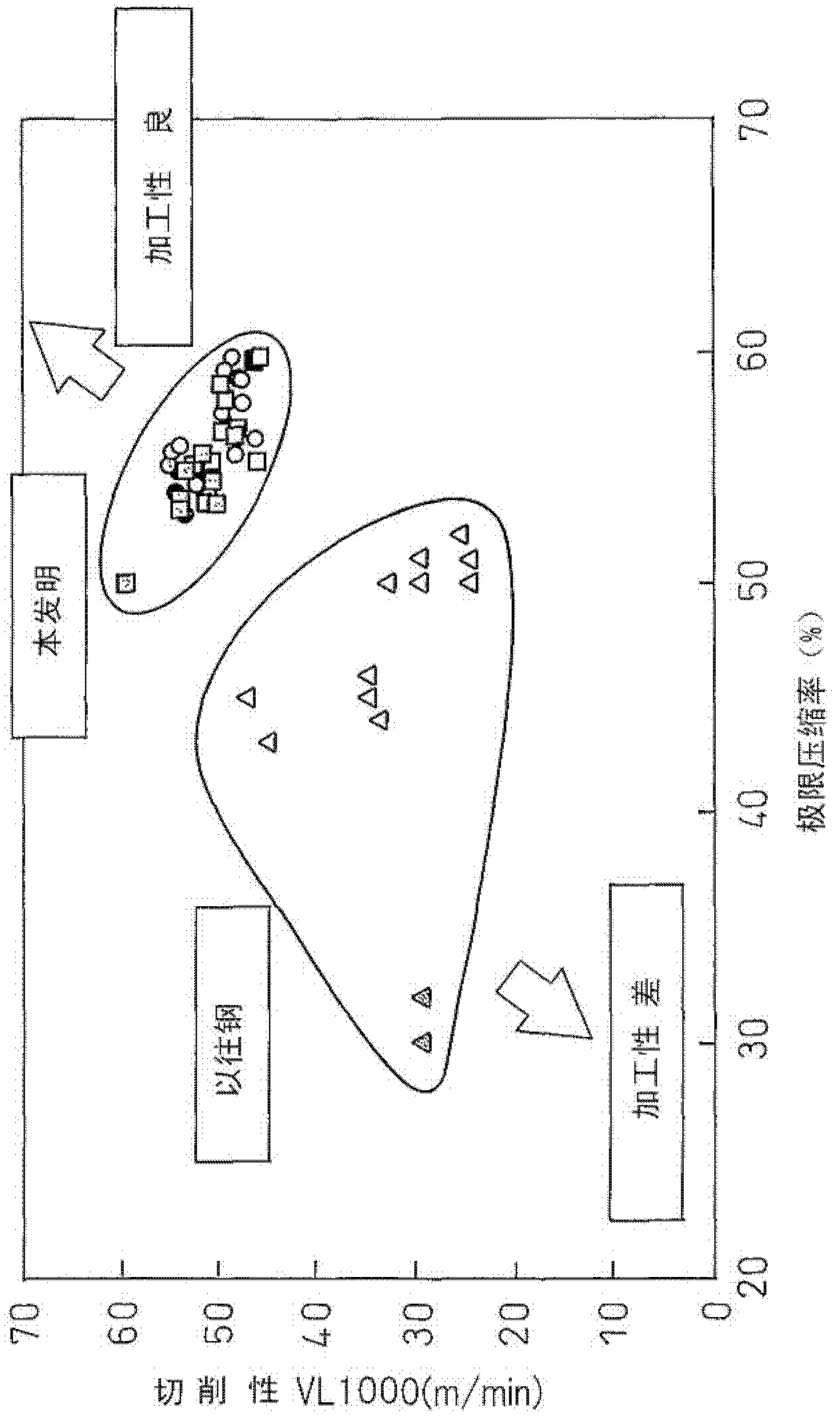

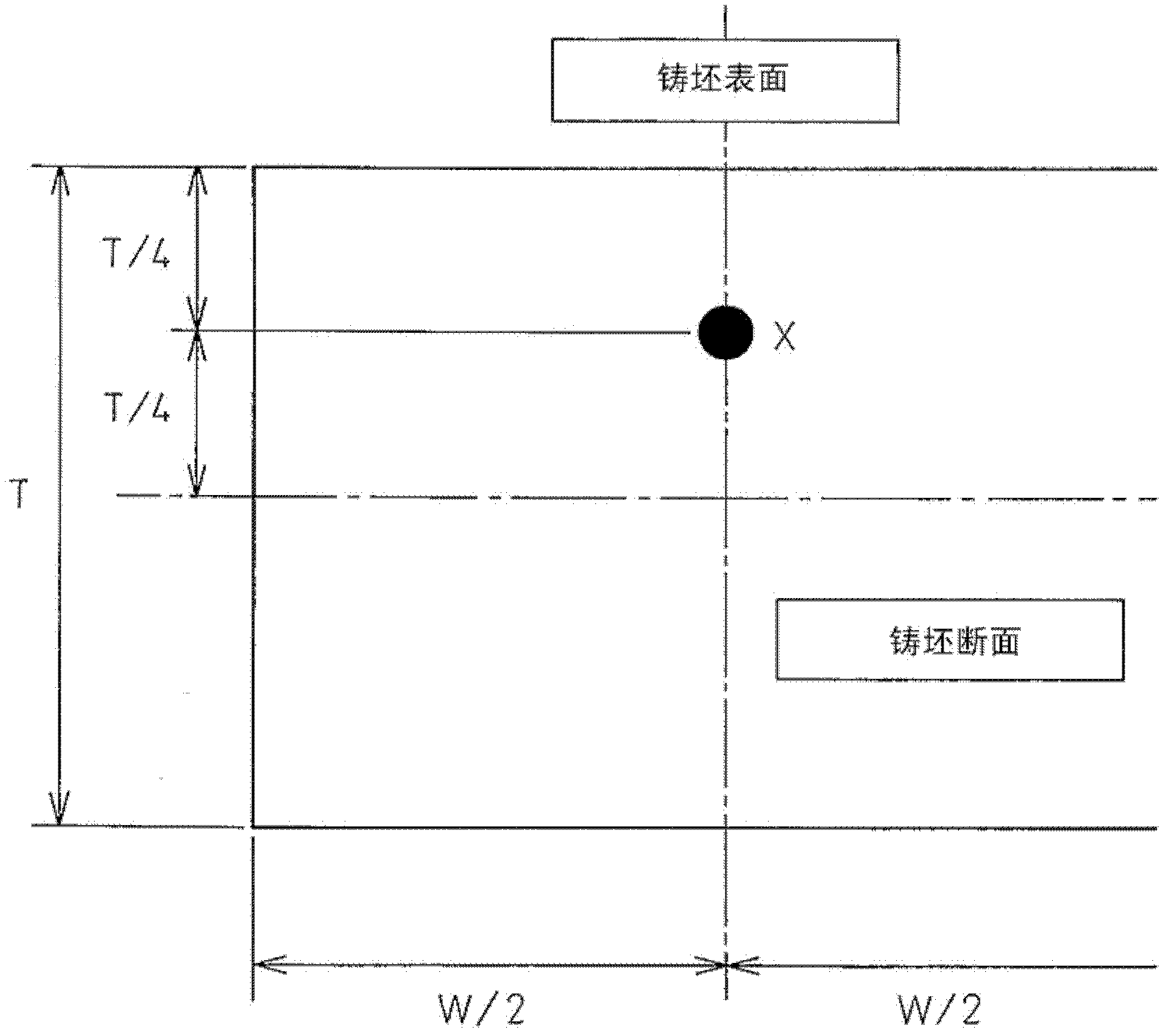

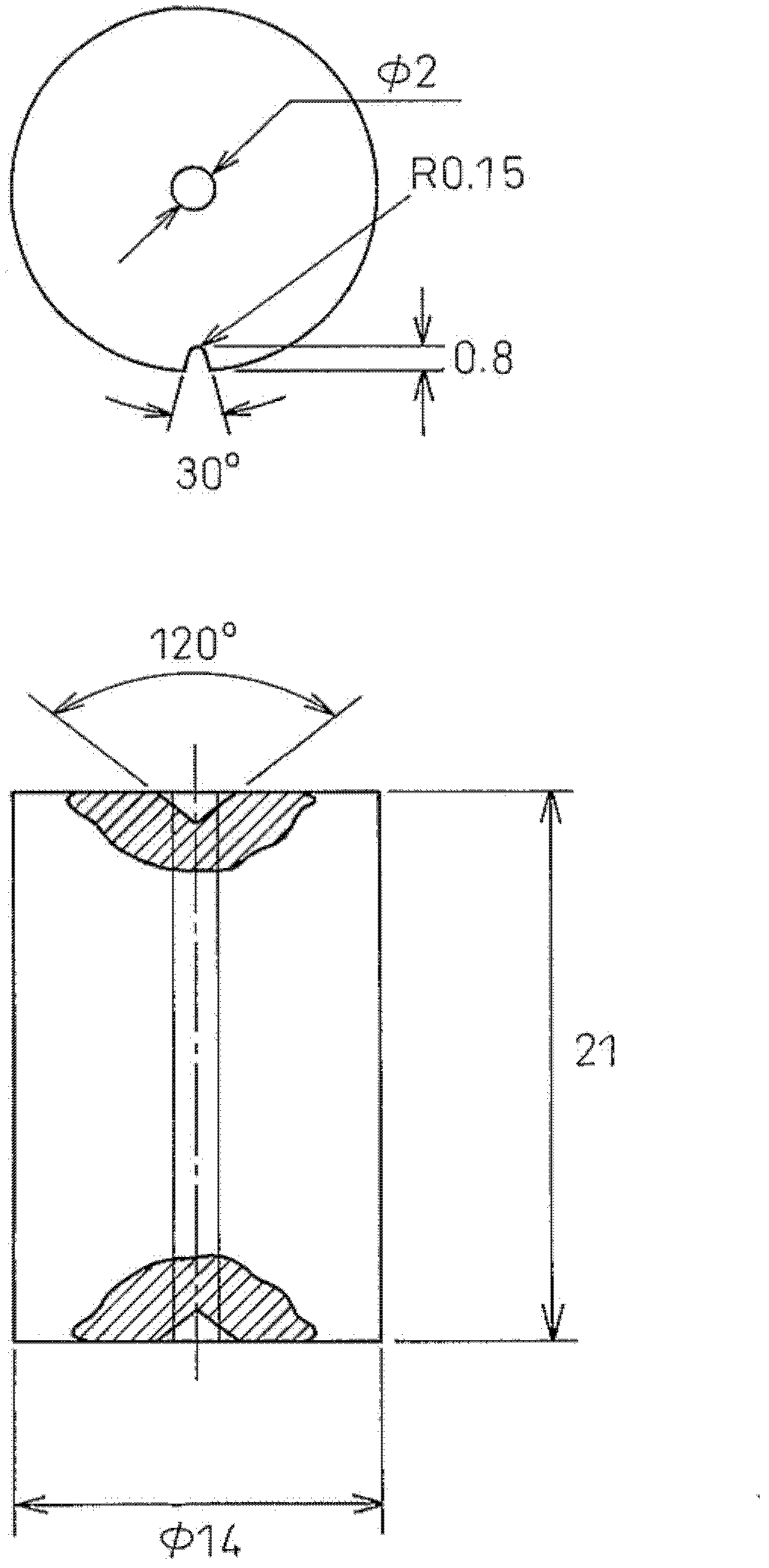

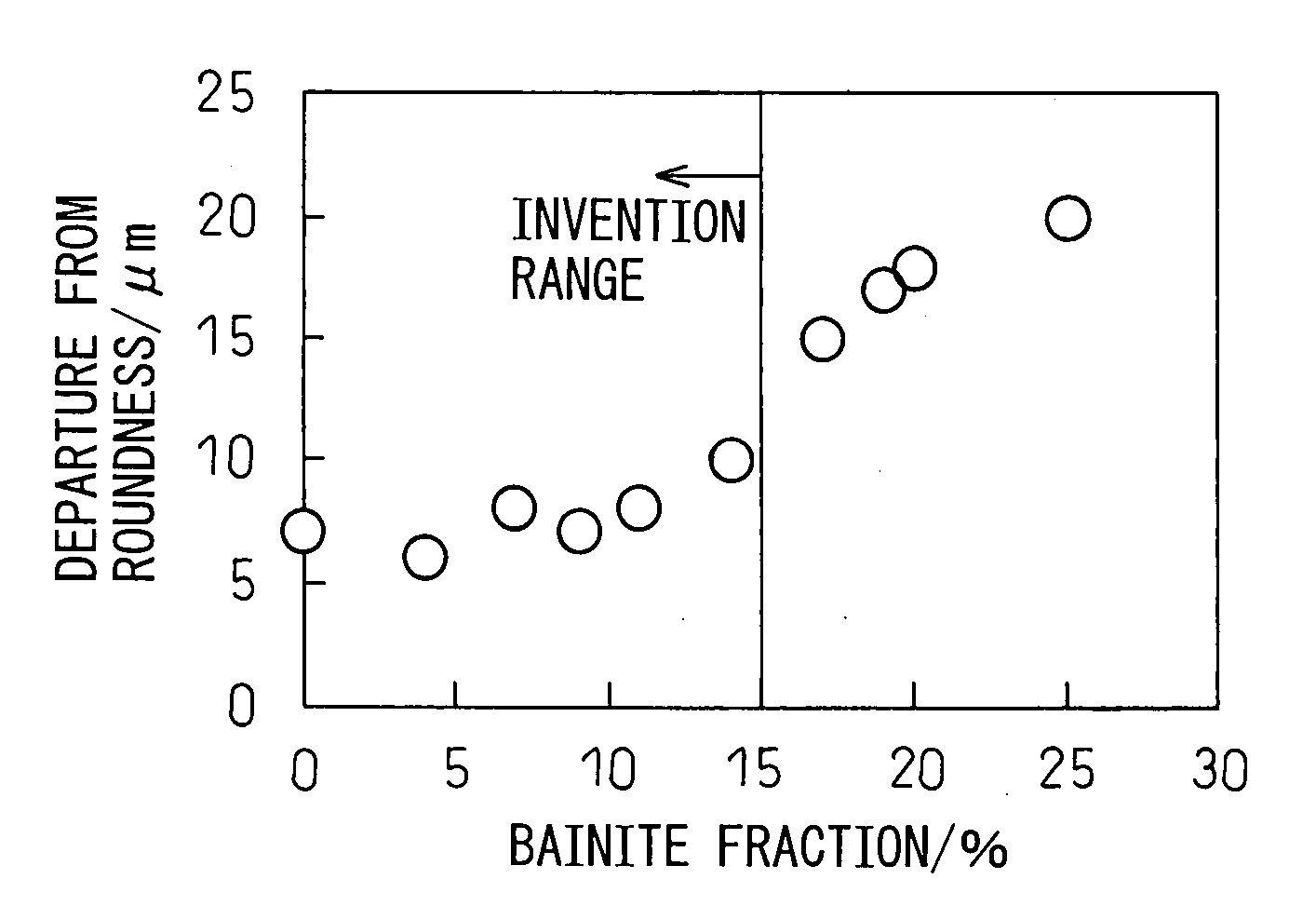

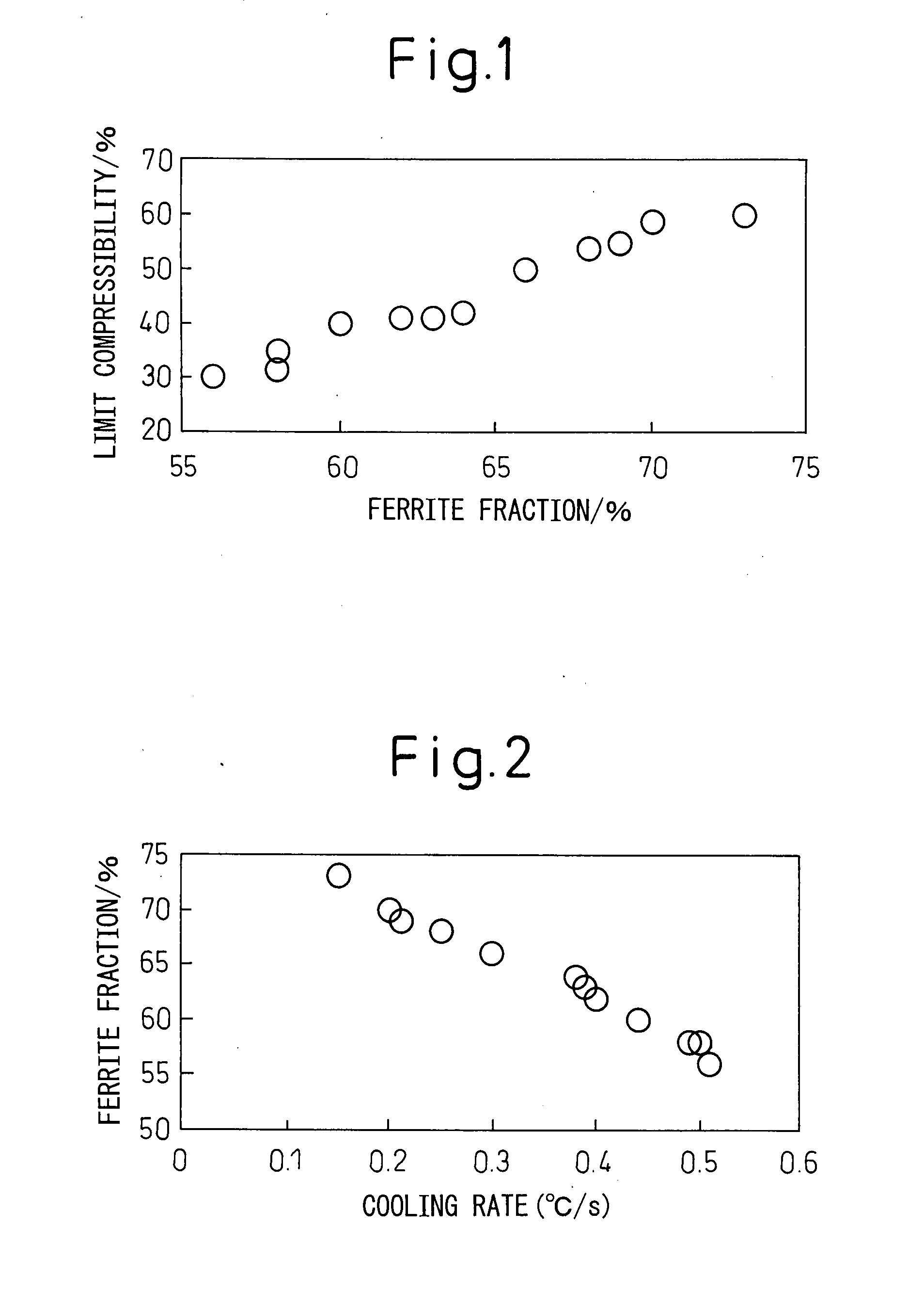

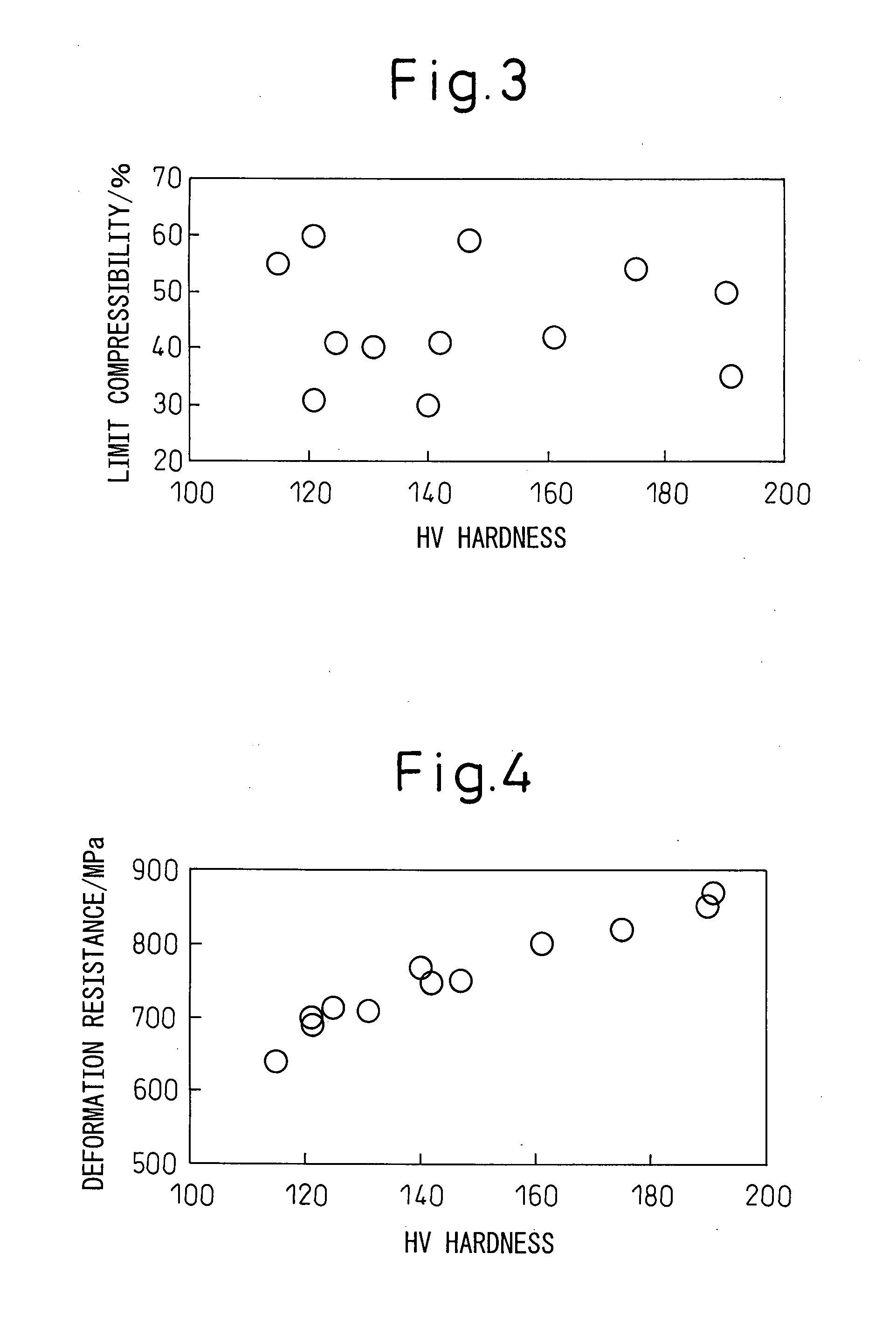

Case-hardening steel excellent in cold forgeability and low carburization distortion property

This invention provides a case-hardening steel excellent in cold forgeability and low carburization distortion property that exhibits low deformation resistance and high limit compressibility when cold, namely, a case-hardening steel excellent in cold forgeability and low carburization distortion property comprising, in mass %, C: 0.07% to 0.3%, Si: 0.01% to 0.15%, Mn: 0.1% to 0.7%, P: 0.03% or less, S: 0.002% to 0.10%, Al: 0.01% to 0.08%, Cr: 0.7% to 1.5%, Ti: 0.01% to 0.15%, B: 0.0005% to 0.005%, N: 0.008% or less, and the balance of Fe and unavoidable impurities, and having a metallographic structure comprising 65% or greater of ferrite and 15% or less of bainite.

Owner:NIPPON STEEL CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com