Forging method of high-strength heatproof magnesium alloy

A magnesium alloy, heat-resistant technology, applied in the hot deformation of heat-resistant magnesium alloy, Mg-Gd-Y series magnesium alloy high temperature forging deformation field

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

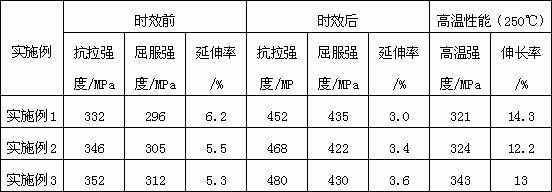

[0023] Example 1 : One-way forging

[0024] In this embodiment, a semi-continuous casting method is used to prepare a magnesium alloy ingot, which is homogenized. Heat the billet to 500°C for 2h. Heating the upper and lower flat anvils, the temperature is 520°C. One-way forging is then performed on a hydraulic press. During the forging process, evenly spread graphite powder on the surface of the upper and lower flat anvils as a lubricant. The no-load speed of the hydraulic press is 8mm / s. Depression ≥ 70%. Aging after forging, the aging process is 200 ° C for 72 hours. The mechanical properties after forging, the mechanical properties after aging and the mechanical properties at 250°C are shown in Table (1)

Embodiment 2

[0025] Example 2 : two-way forging

[0026] In this embodiment, a semi-continuous casting method is used to prepare a magnesium alloy ingot, which is homogenized. Heat the blank to 450°C for 2h. Heating the upper and lower flat anvils, the temperature is 470°C. Two-way forging is then performed on a hydraulic press. The pass reduction is 40% to 60%, annealed after 2 to 3 passes, the annealing temperature is 450°C, the annealing time is 0.5h, and the cumulative forging is 12 passes. The original size of the billet is that graphite powder is evenly sprinkled on the upper and lower flat anvil surfaces during the forging process as a lubricant, and the no-load speed of the hydraulic press is 8mm / s. Aging after forging, the aging process is 200 ° C for 72 hours. The mechanical properties after forging, the mechanical properties after aging and the mechanical properties at 250°C are shown in Table (1)

Embodiment 3

[0027] Example 3 : Three-way forging

[0028] In this embodiment, a semi-continuous casting method is used to prepare a magnesium alloy ingot, which is homogenized. Heat the billet to 530°C for 3h. Heating the upper and lower flat anvils, the temperature is 550°C. Then carry out three-way forging on the hydraulic press, the pass reduction is 40% to 60%, annealing after 2 to 3 passes, the annealing temperature is 530°C, the annealing time is 1h, and the cumulative forging is 18 passes. During the forging process, evenly spread graphite powder on the surface of the upper and lower flat anvils as a lubricant. The no-load speed of the hydraulic press is 8mm / s. Aging after forging, the aging process is 200 ° C for 72 hours. The mechanical properties after forging, the mechanical properties after aging and the mechanical properties at 250°C are shown in Table (1)

[0029] Table (1) Mechanical properties of magnesium alloy after forging

[0030]

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com